Model area change rate-based adaptive hierarchical processing method

A technology of area change rate and processing method, which is applied in the field of self-adaptive layering processing, can solve the problems of increased model forming time, increased number of printing layers, and unguaranteed accuracy, so as to increase the forming speed, save printing materials, improve The effect of the time it takes to print

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

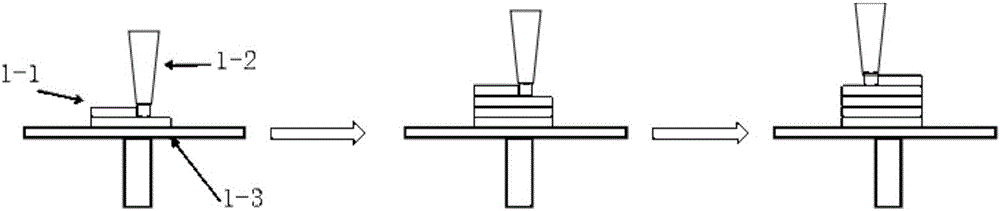

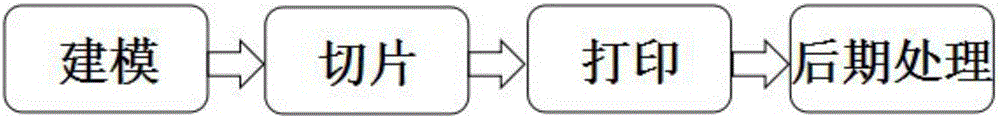

[0052] see Figure 4 , the implementation steps are as follows: A1: Obtain a 3D model in stl format by modeling, scanning, etc., obtain the vertices and surface normal vector information of the triangular surface of the model, and establish its topology.

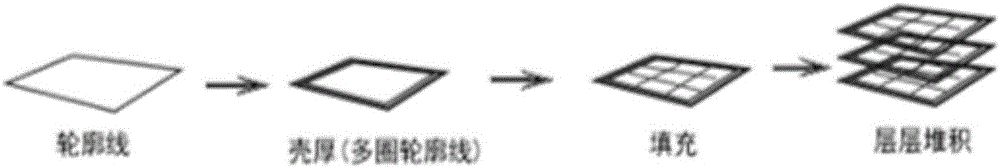

[0053] A2: Slice the model uniformly without filling, without support, and without offset with the highest precision to obtain a closed two-dimensional polygonal contour layer, and calculate the area of each layer of polygons after slicing, such as Figure 5 Shown is the area curve of the model of this embodiment.

[0054] A3: Obtain the area of each layer of polygons, and derive the area change rate of the model, such as Figure 6 Shown is the area change rate curve of the model of this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com