Non-contact fluid infusion photocuring device and working method thereof

A non-contact, light-curing technology, applied in the direction of metal processing equipment, manufacturing tools, additive processing, etc., can solve the problems of poor precision, quality and mechanical properties of light-cured products, and achieve the improvement of molding speed, molding accuracy and surface Effects of quality improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

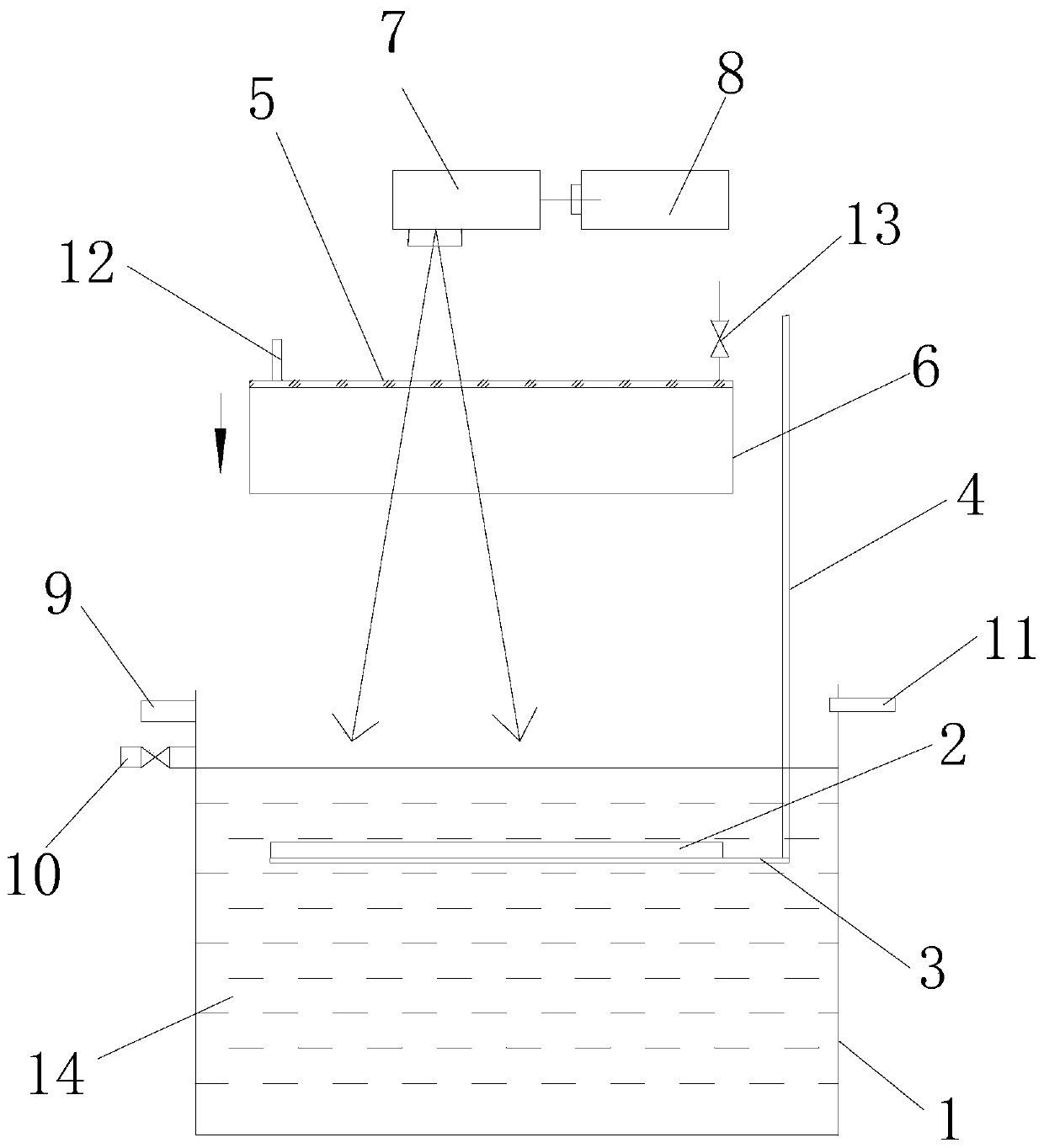

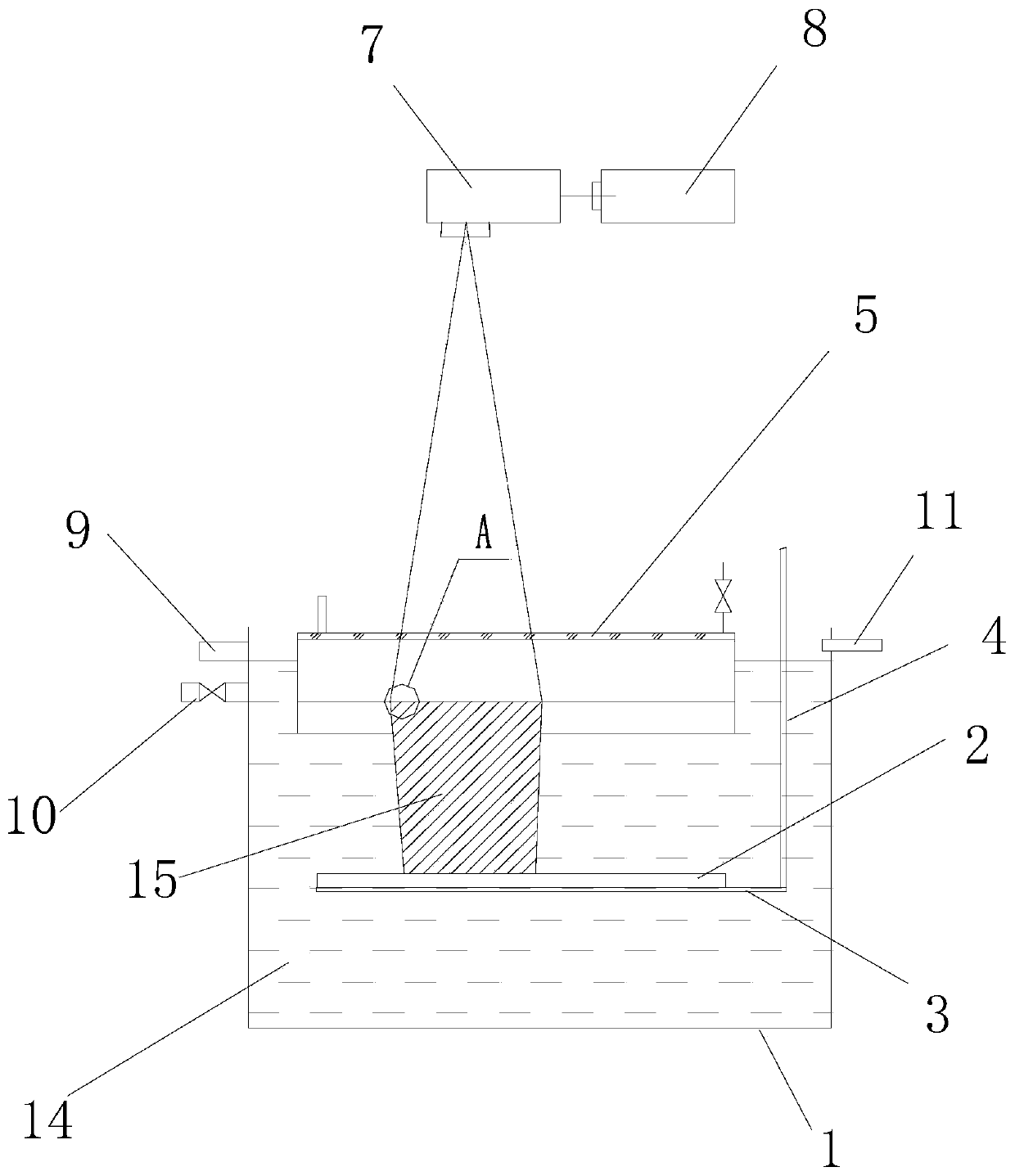

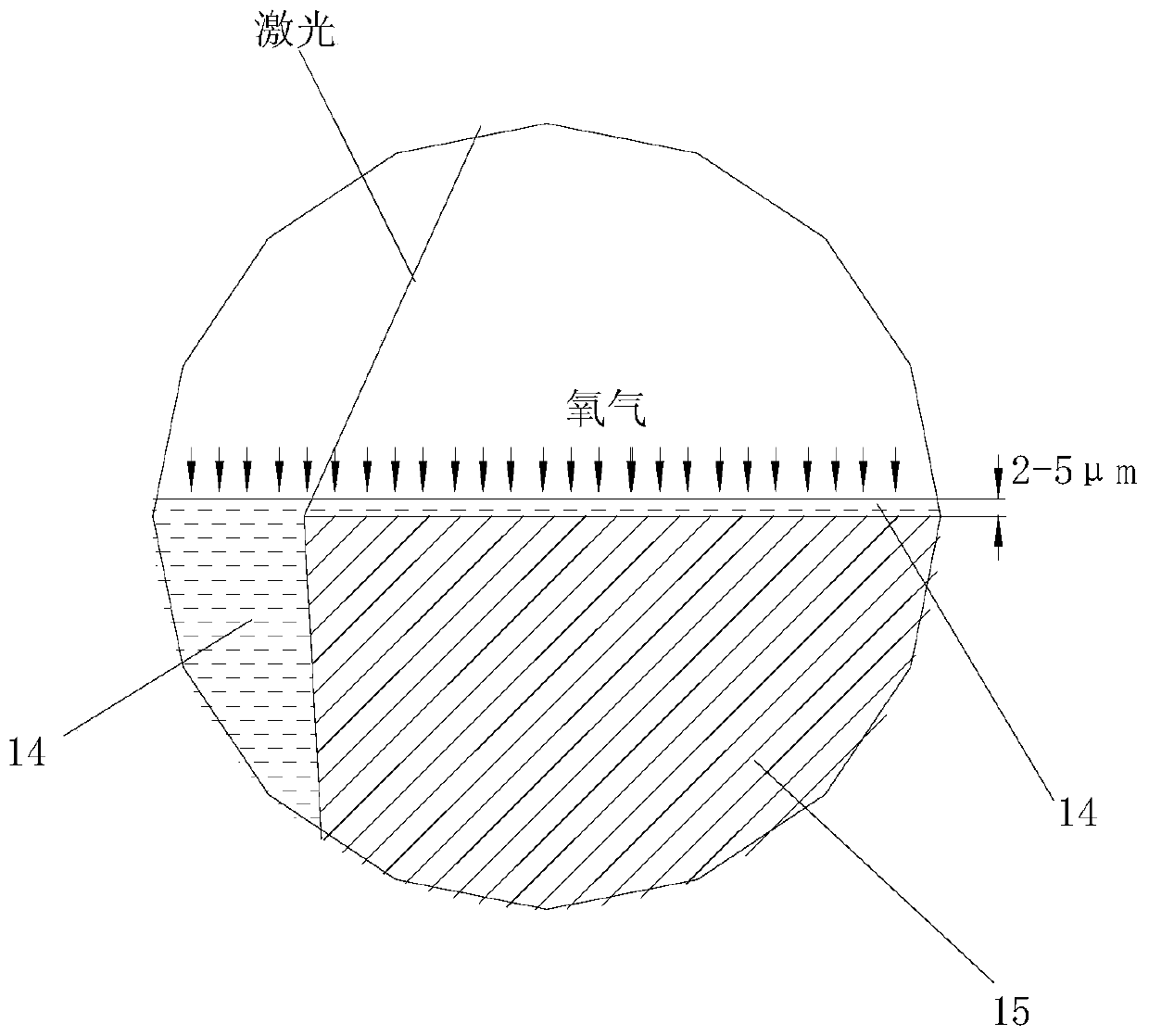

[0029] Such as figure 1 and 2 As shown, on the one hand, the present invention provides a light-curing device for non-contact liquid replenishment, including a storage tank 1, a forming platform 2 is arranged in the storage tank 1, and the bottom of the forming platform 2 is fixedly connected to a supporting plate 3, The side of the supporting plate 3 is fixedly connected to the connecting rod 4, and the connecting rod 4 is connected to an external drive device 1 to drive the supporting plate 3 to move up and down. A quartz glass 5 is arranged dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com