Temperature-resistant thickening light-cured epoxy vinyl ester resin and preparation method thereof

A technology of epoxy vinyl ester and epoxy resin, which is applied in the field of polymers, can solve the problems of reducing the corrosion resistance of vinyl ester resins, being unable to be used for simultaneous temperature resistance, corrosion resistance, and material thermal deformation temperature drop, etc., to achieve The effect of high double bond content, fast photocuring speed and slow thickening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

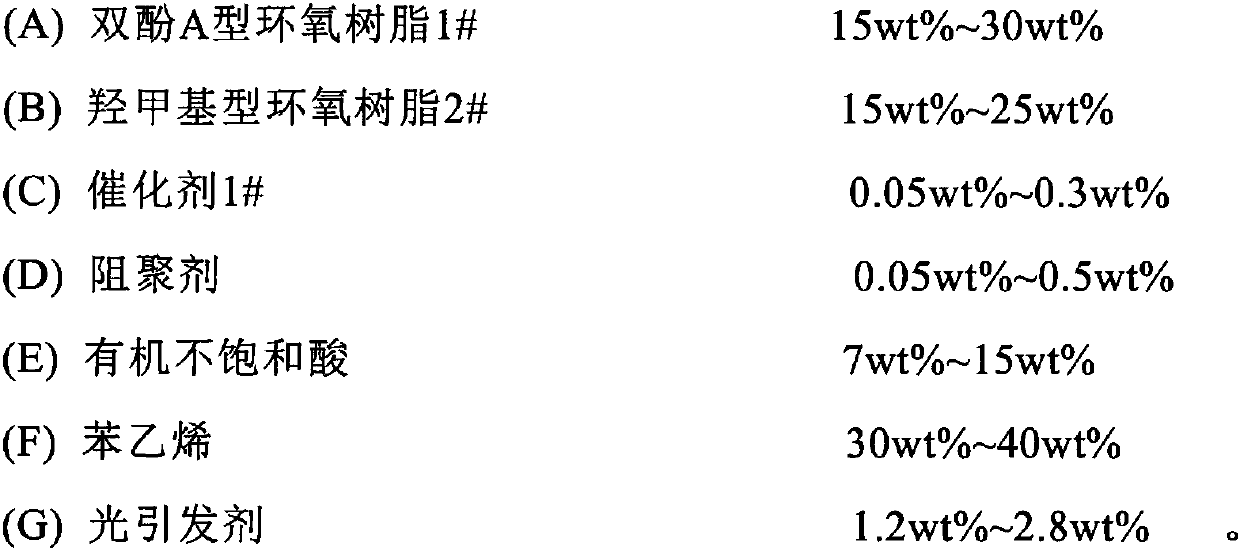

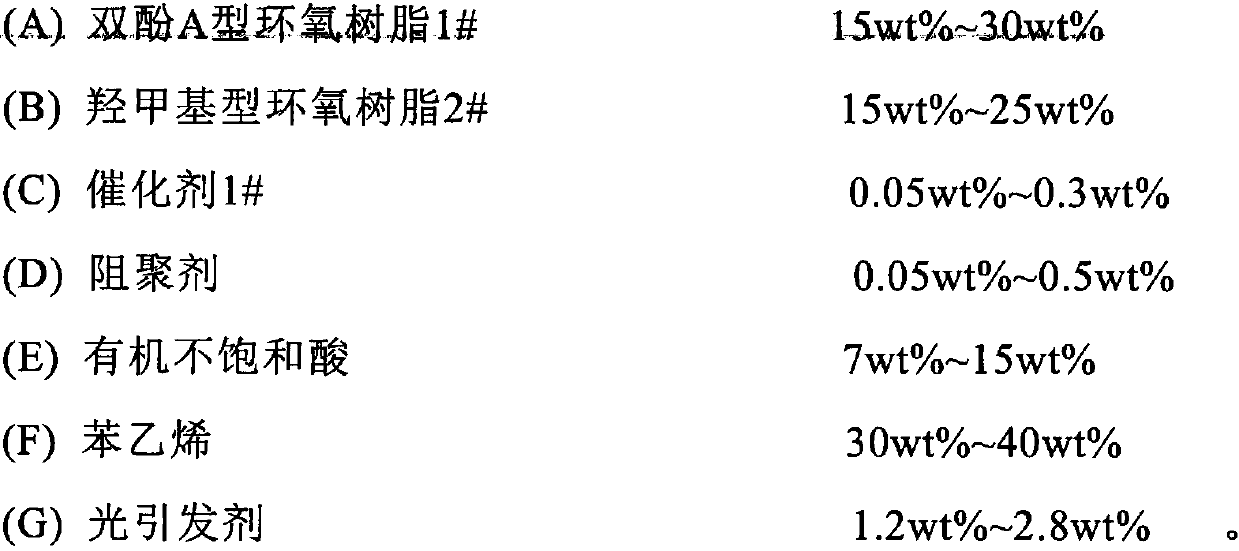

Method used

Image

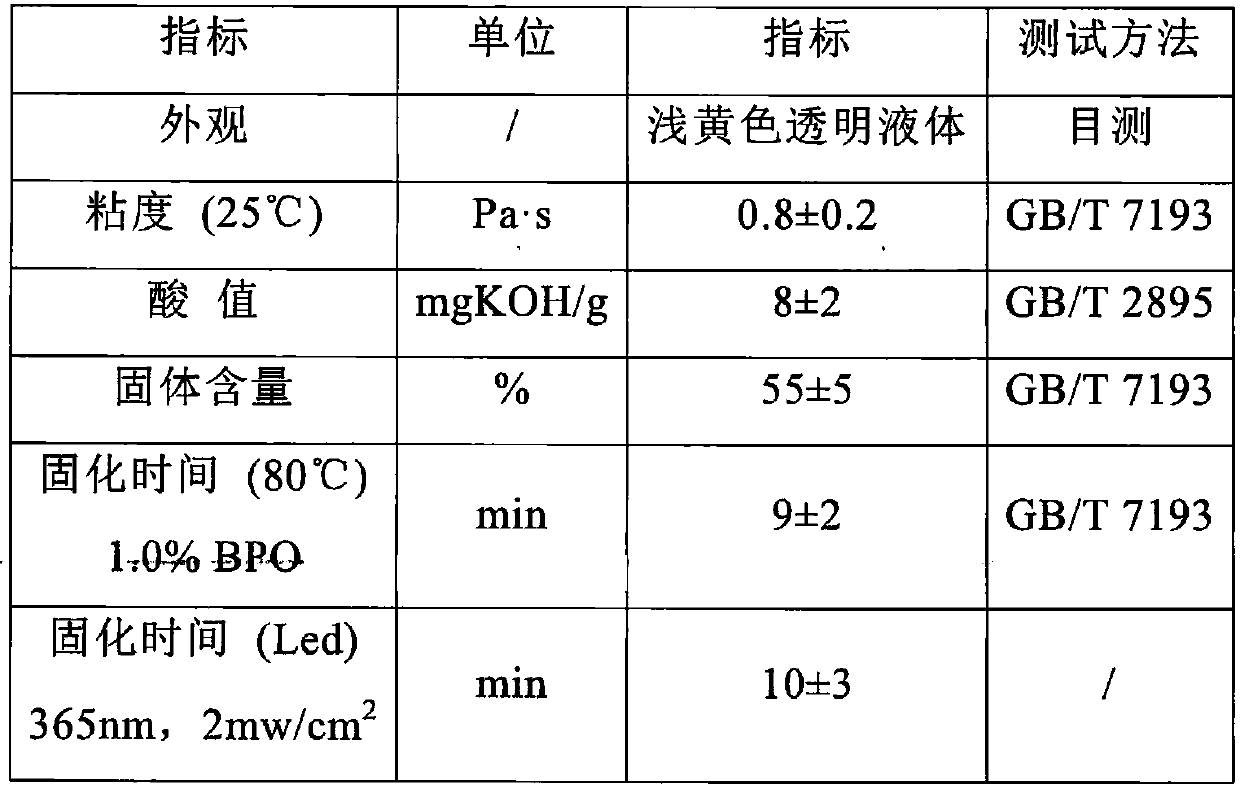

Examples

Embodiment 1

[0048] Put 180.0g of bisphenol A type epoxy resin E12 and 250.0g of hydroxymethyl bisphenol A type epoxy resin EL-50 into the reactor, heat up to 105°C, stir evenly, add 2.0g of p-tert-butylcatechol, Stir for 10 minutes, add 114.4g of methacrylic acid, control the temperature to stabilize at 90°C, slowly add 1.2g of benzyltrimethylammonium chloride and 0.4g of 2-ethyl-4-methylimidazole in 3 times within 30 minutes , keep warm at 115-120°C, react for 1.5-2.5 hours, the acid value is less than 12mgKOH / g, cool the mixture below 90°C, add 432.0g of styrene, stir for 30 minutes, when the temperature of the mixture is lower than 50°C, add diethoxy 15 g of methyl benzophenone and 5 g of diethyl 2,4,6-tricresylbenzoyl phosphonate were stirred for 30 minutes to obtain a light yellow transparent liquid resin, which was stored away from light.

[0049] Add 100 g of the above-mentioned light yellow transparent liquid resin, 30 g of calcium carbonate, 5.1 g of methylene bis(4-phenylisocyan...

Embodiment 2

[0051] Put 190g of bisphenol A type epoxy resin E20 and 200.0g of hydroxymethyl bisphenol A type epoxy resin CEQ-45 into the reactor, raise the temperature to 105°C, stir evenly, add 2-tert-butylhydroquinone 3.0 g, stirred for 10 minutes, added 112.5g of methacrylic acid, controlled the temperature to stabilize at 90°C, slowly added 0.8g of benzyltriethylammonium chloride and 1.6g of 1-methylimidazole in 3 times within 30 minutes, and kept warm for 115 -120°C, react for 1.5-2.5 hours, the acid value is less than 12mgKOH / g, cool the mixture below 90°C, add 471.1g of styrene, stir for 30 minutes, when the temperature of the mixture is lower than 50°C, add 2-hydroxy-2- 18 g of methyl-1-phenylacetone and 3 g of 2,4,6-tricresylbenzoyldiphenylphosphine oxide were stirred for 30 minutes to obtain a light yellow transparent liquid resin, which was stored away from light.

[0052] Add 100g of the above-mentioned light yellow transparent liquid resin, 20g of aluminum hydroxide, 4.2g of ...

Embodiment 3

[0054] Put 241.6g of bisphenol A type epoxy resin E14 and 160g of hydroxymethyl bisphenol A type epoxy resin Apogen101 into the reactor, heat up to 105°C, stir evenly, add 3.5g of di-tert-butyl p-cresol, stir for 10 Minutes, add 95.1g of methacrylic acid, control the temperature to stabilize to 90°C, slowly add 0.9g of benzyldimethylamine and 1.5g of 2-phenyl-4-methyl-5-hydroxymethylimidazole in 3 times within 30 minutes, Keep warm at 115-120°C, react for 1.5-2.5 hours, the acid value is less than 12mgKOH / g, cool the mixture below 90°C, add 480g of styrene, stir for 30 minutes, when the temperature of the mixture is lower than 50°C, add α-aminoalkyl 15 g of benzophenone and 2.8 g of 2,4,6-tricresylbenzoyldiphenylphosphine oxide were stirred for 30 minutes to obtain a light yellow transparent liquid resin, which was stored away from light.

[0055] Add 100 g of the above-mentioned light yellow transparent liquid resin, 10 g of aluminum hydroxide, 4.0 g of methylene bis(4-phenyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com