Patents

Literature

1253 results about "Liquid resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital mask-image-projection-based additive manufacturing that applies shearing force to detach each added layer

ActiveUS20130295212A1Additive manufacturing apparatusAuxillary shaping apparatusComputer graphics (images)Projection system

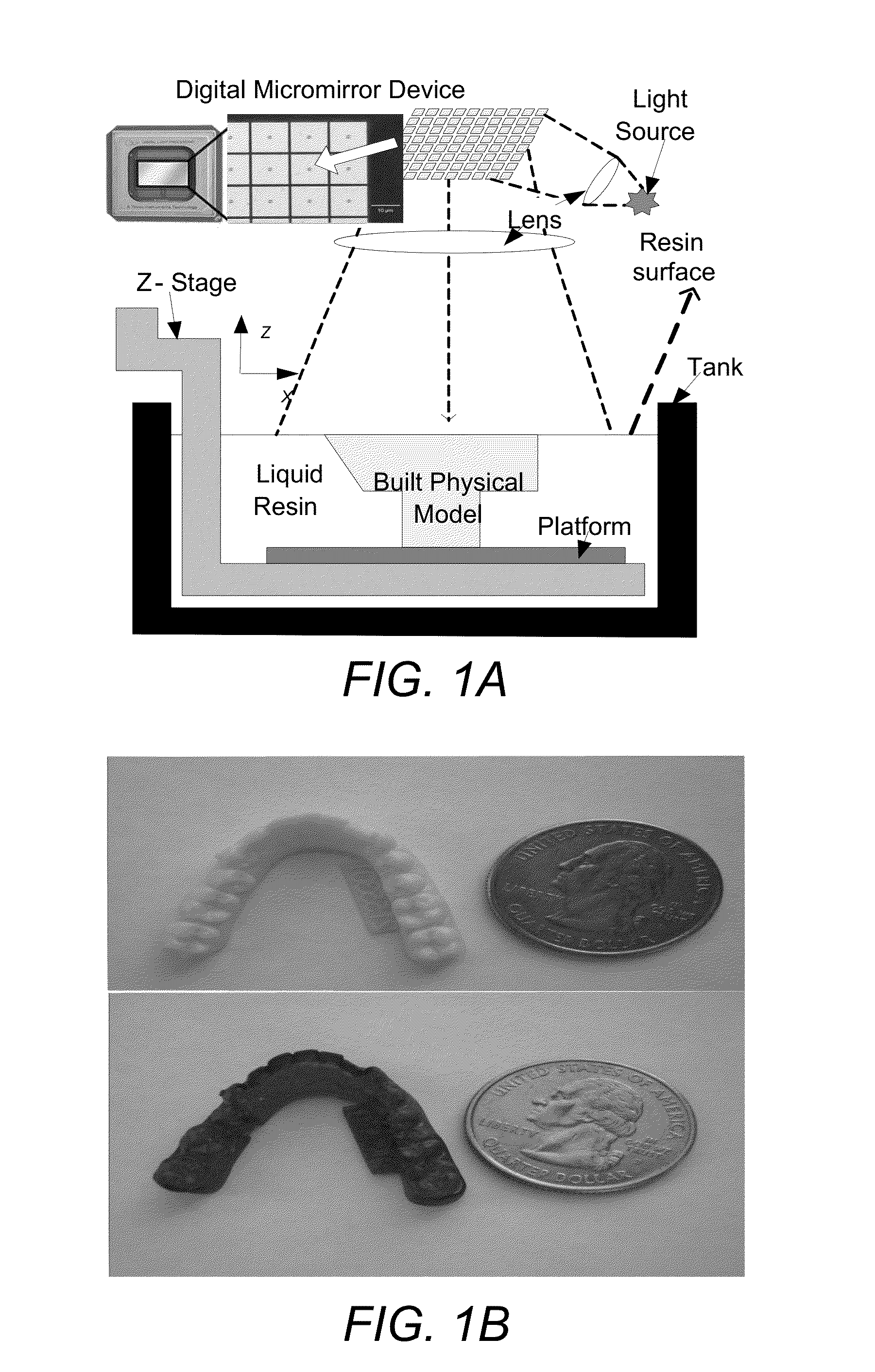

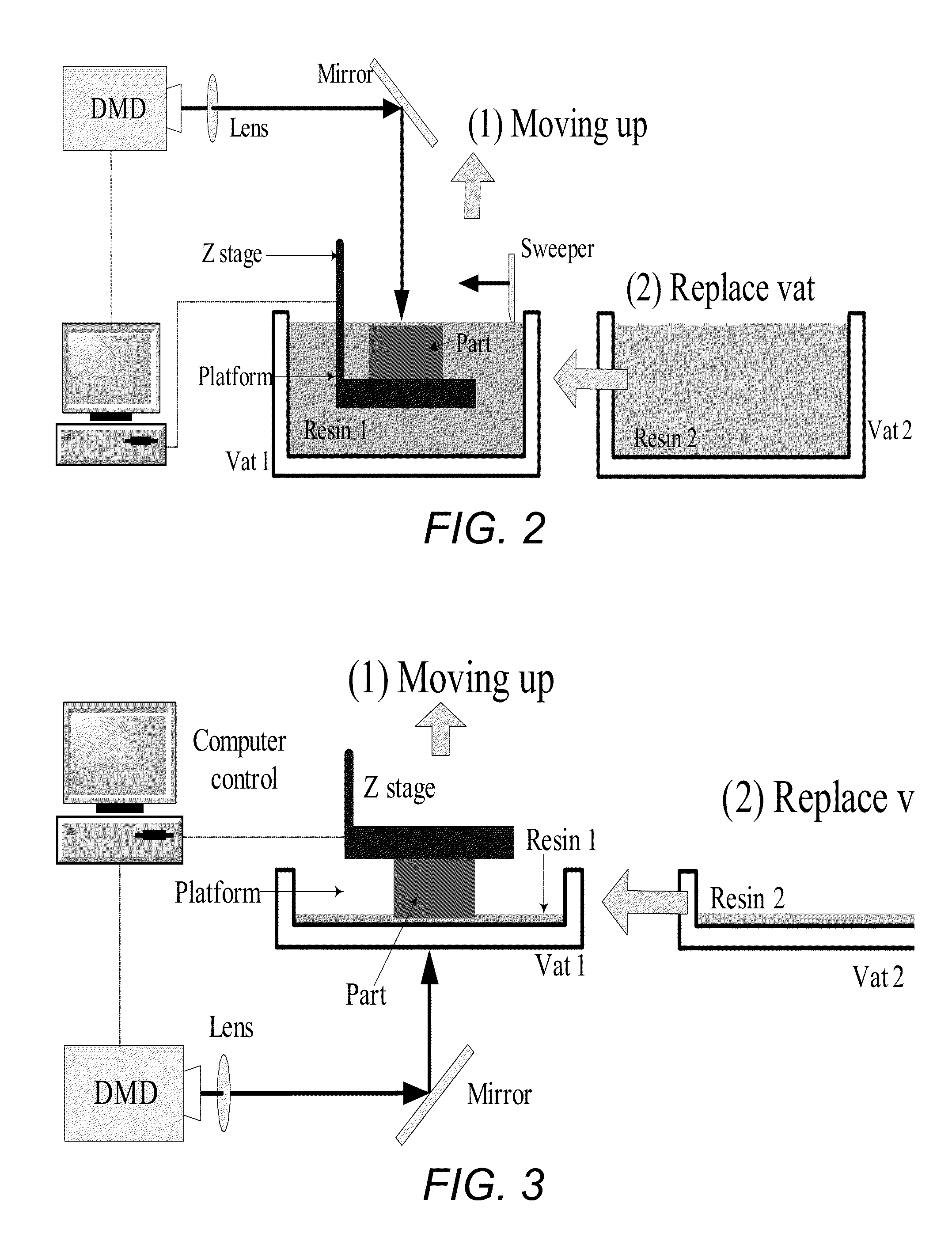

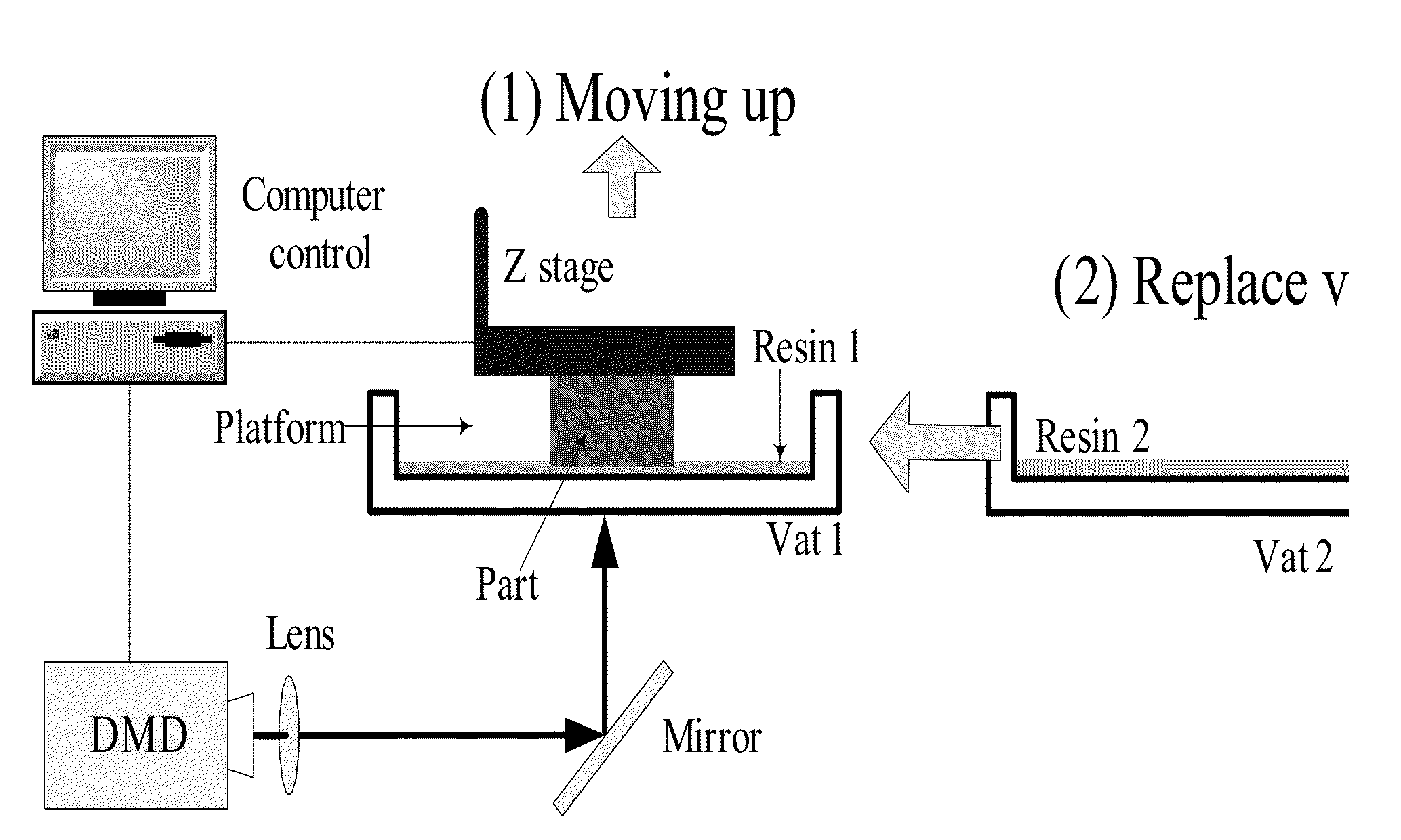

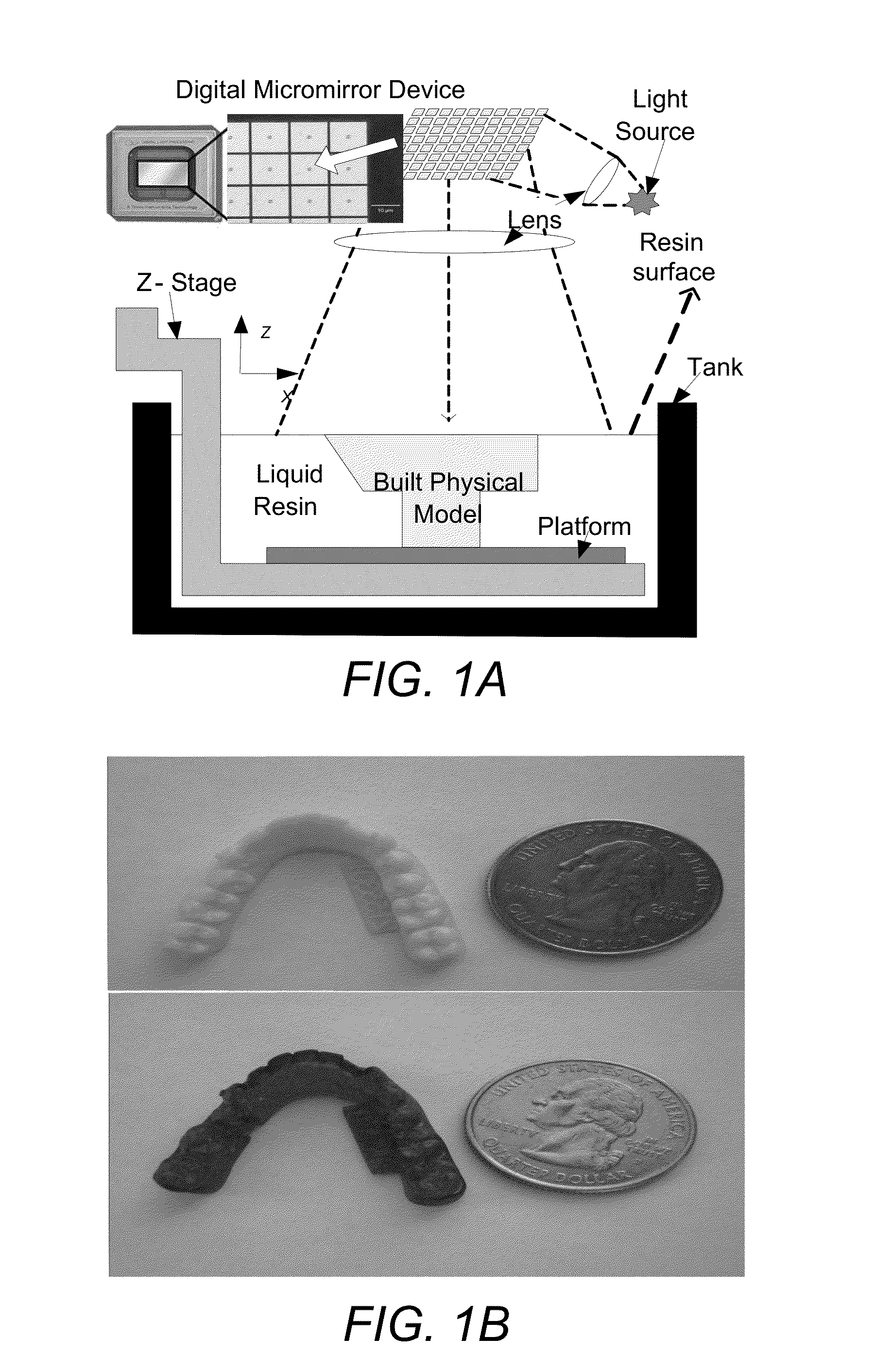

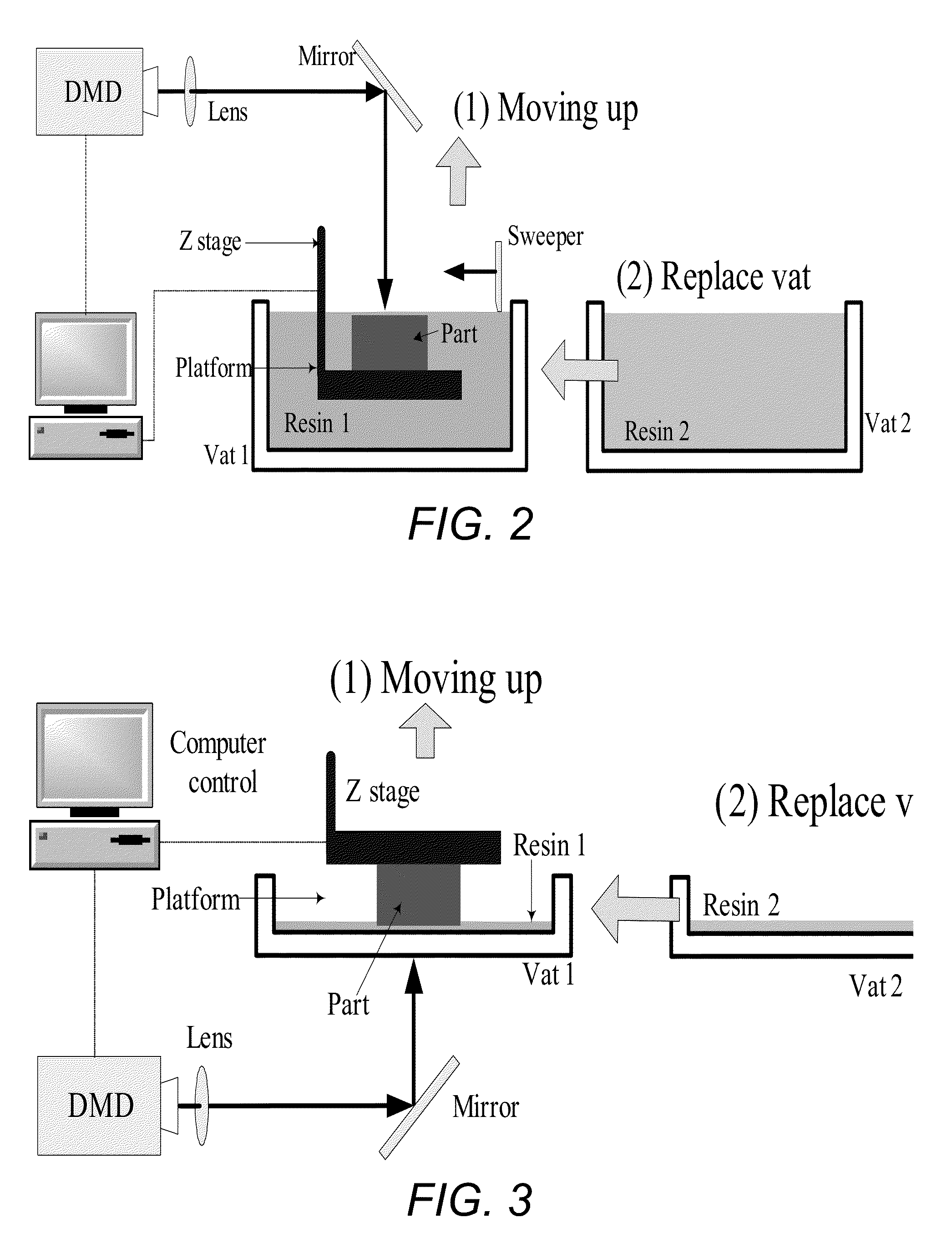

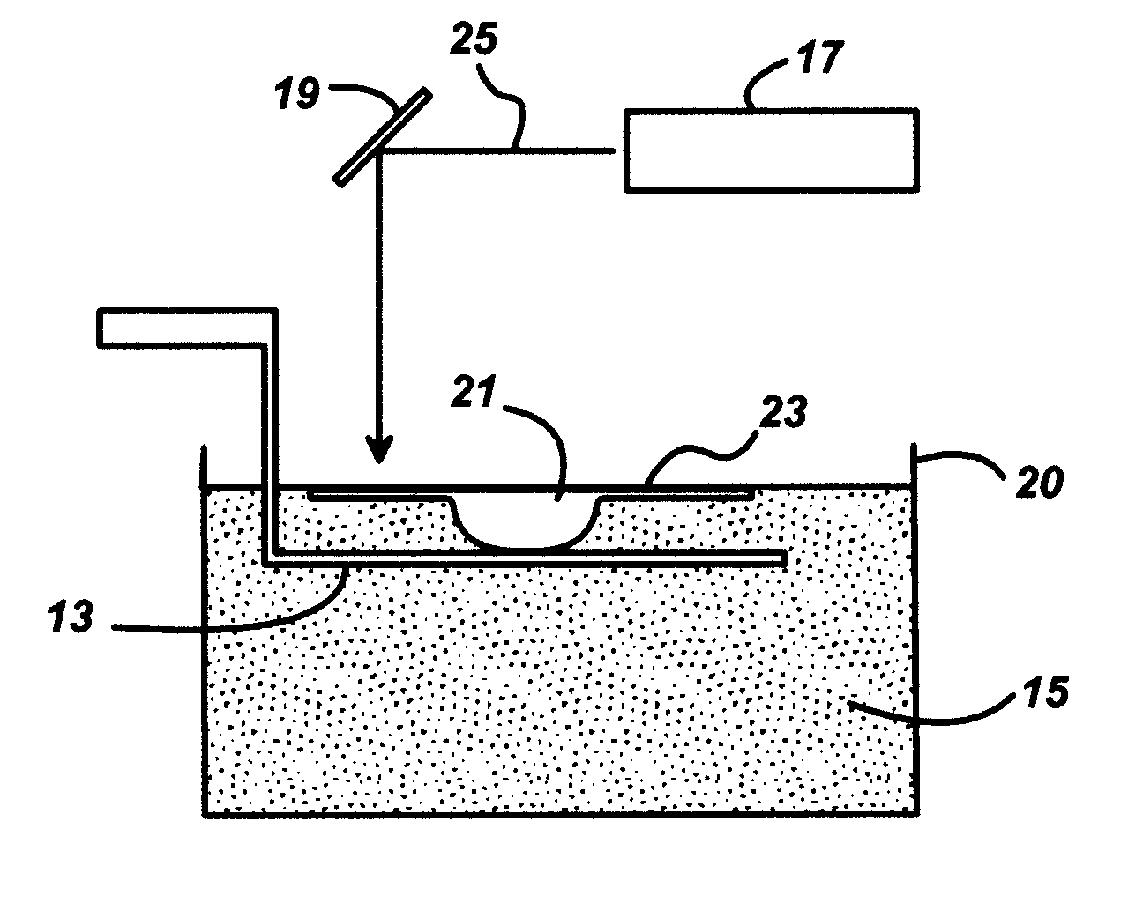

A three-dimensional object may be produced in cascaded layers from a liquid resin that solidifies upon exposure to light. A translation stage may be positioned relative to a vat that is suitable for solidifying the highest un-solidified layer of the three-dimensional object directly beneath any existing, solidified layers of the three-dimensional object. A mask image projection system may project a two-dimensional image of the highest un-solidified layer through a transparent bottom of the vat and into the liquid resin. This may cause at least a portion of the liquid resin to solidify in the shape of the two-dimensional image and to adhere to the bottom of a surface beneath the solidified layer. A shearing force may be applied between the bottom surface of the solidified layer and the surface beneath that is great enough to detach the solidified layer from the surface beneath.

Owner:UNIV OF SOUTHERN CALIFORNIA

Methods of consolidating subterranean zones and compositions therefor

Methods of consolidating subterranean zones and hardenable resin compositions are provided. A hardenable resin composition of the invention basically comprises a furan liquid resin mixture comprising a 2-furanmethanol homopolymer and furfuryl alcohol, an organosilane coupling agent and an acid catalyst.

Owner:HALLIBURTON ENERGY SERVICES INC

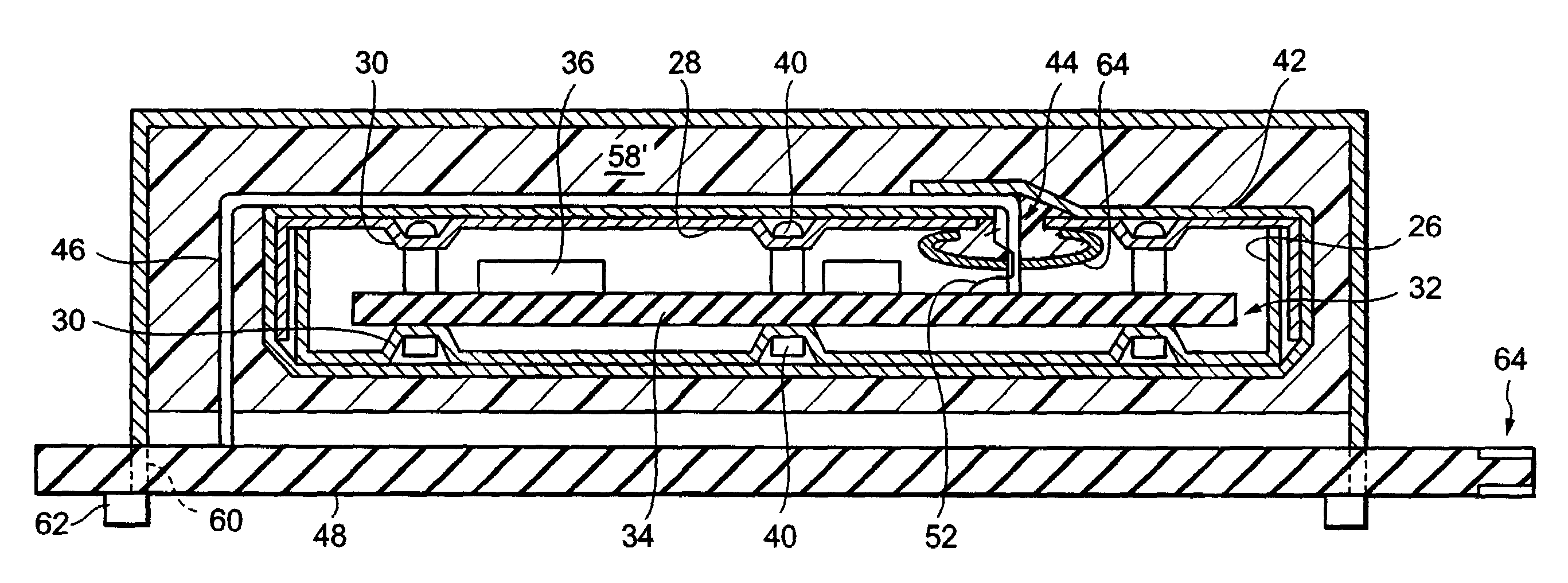

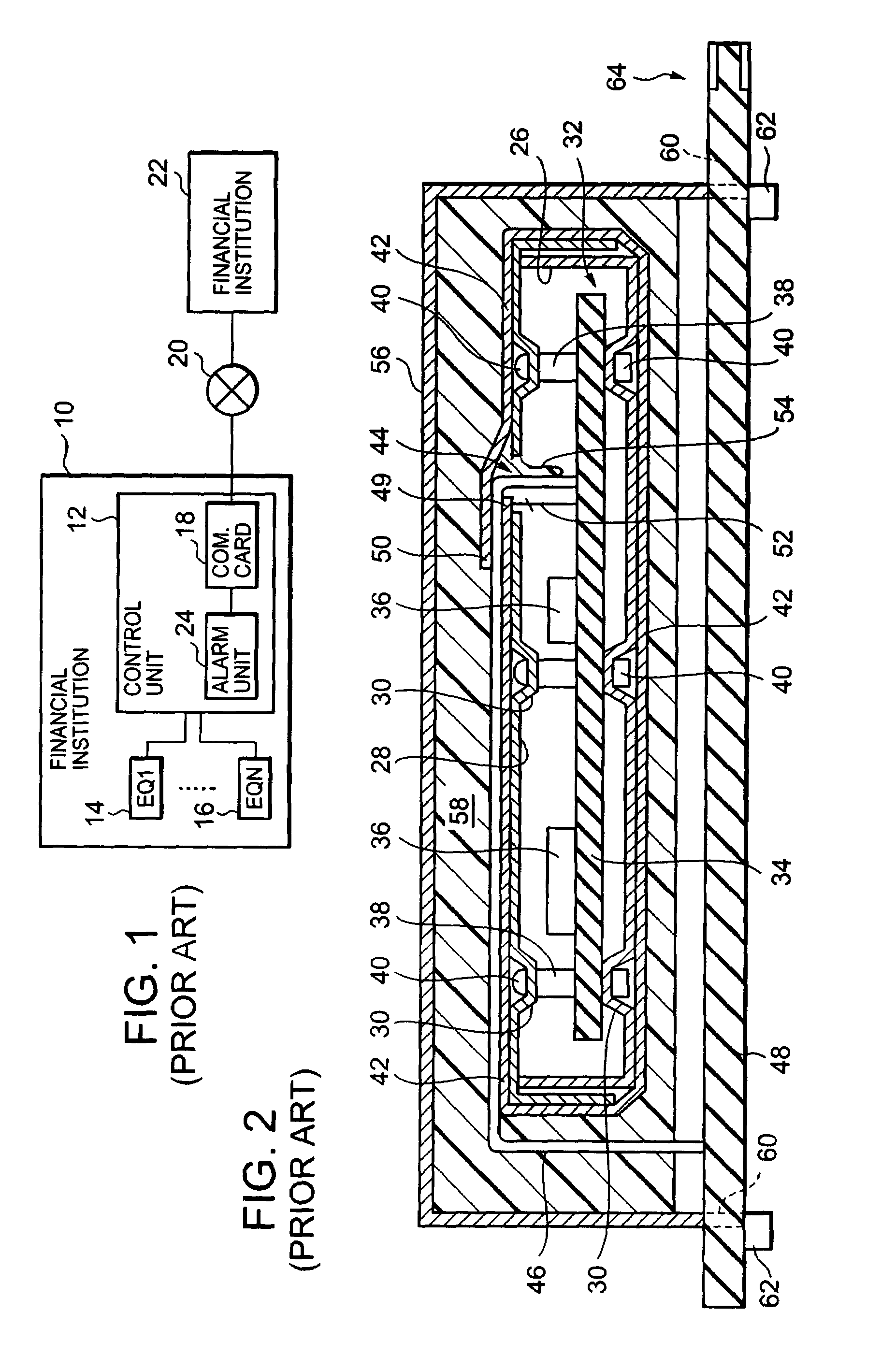

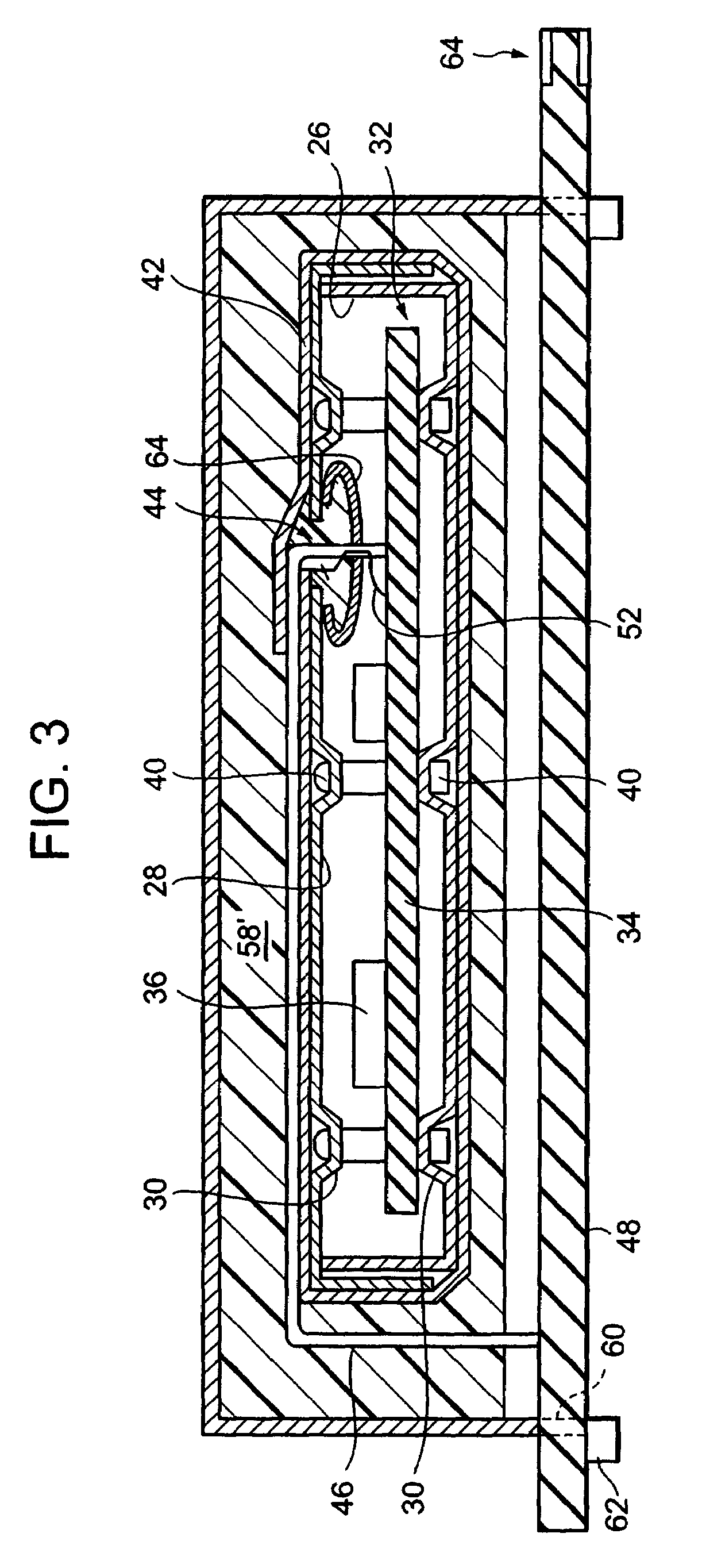

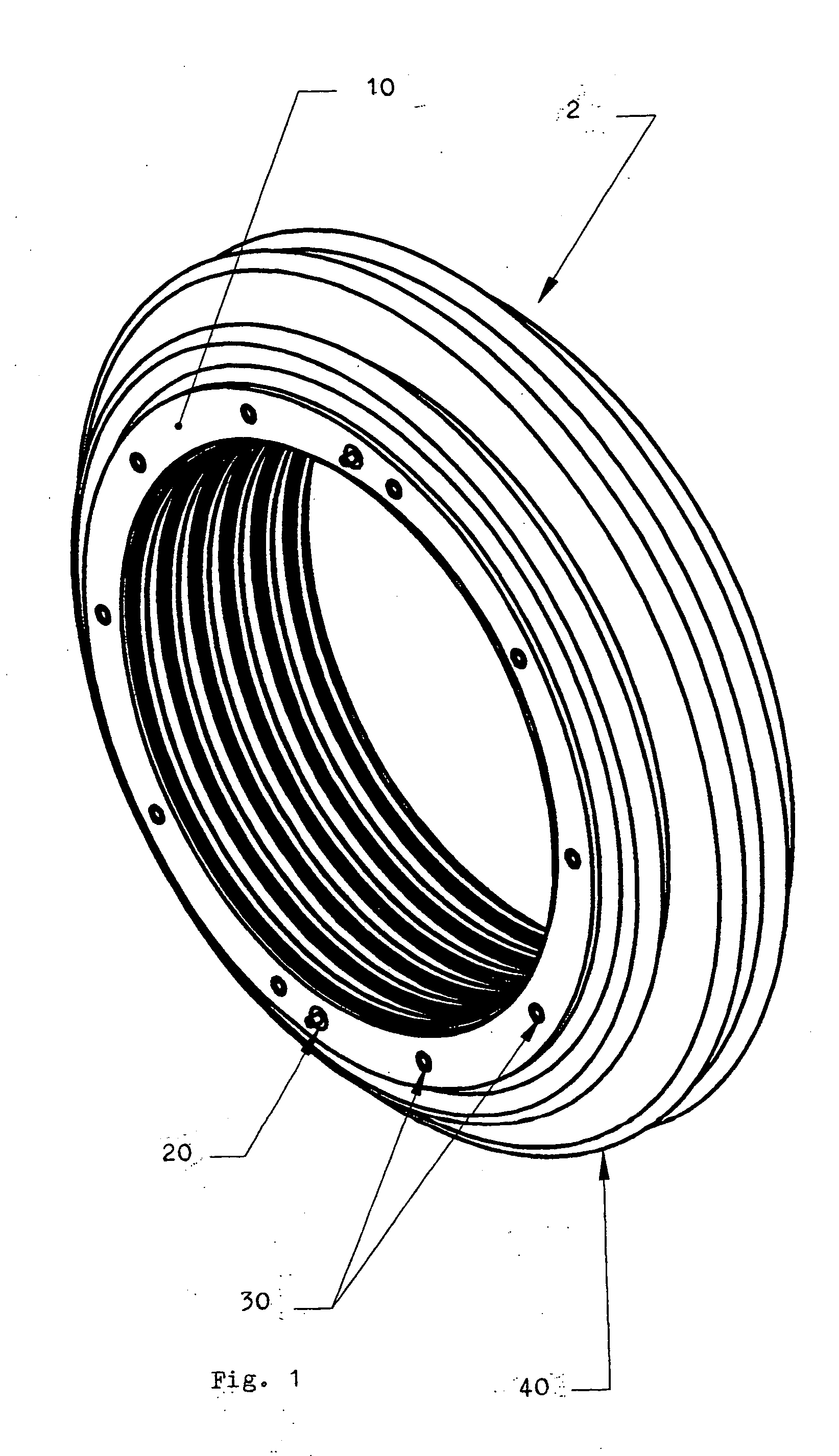

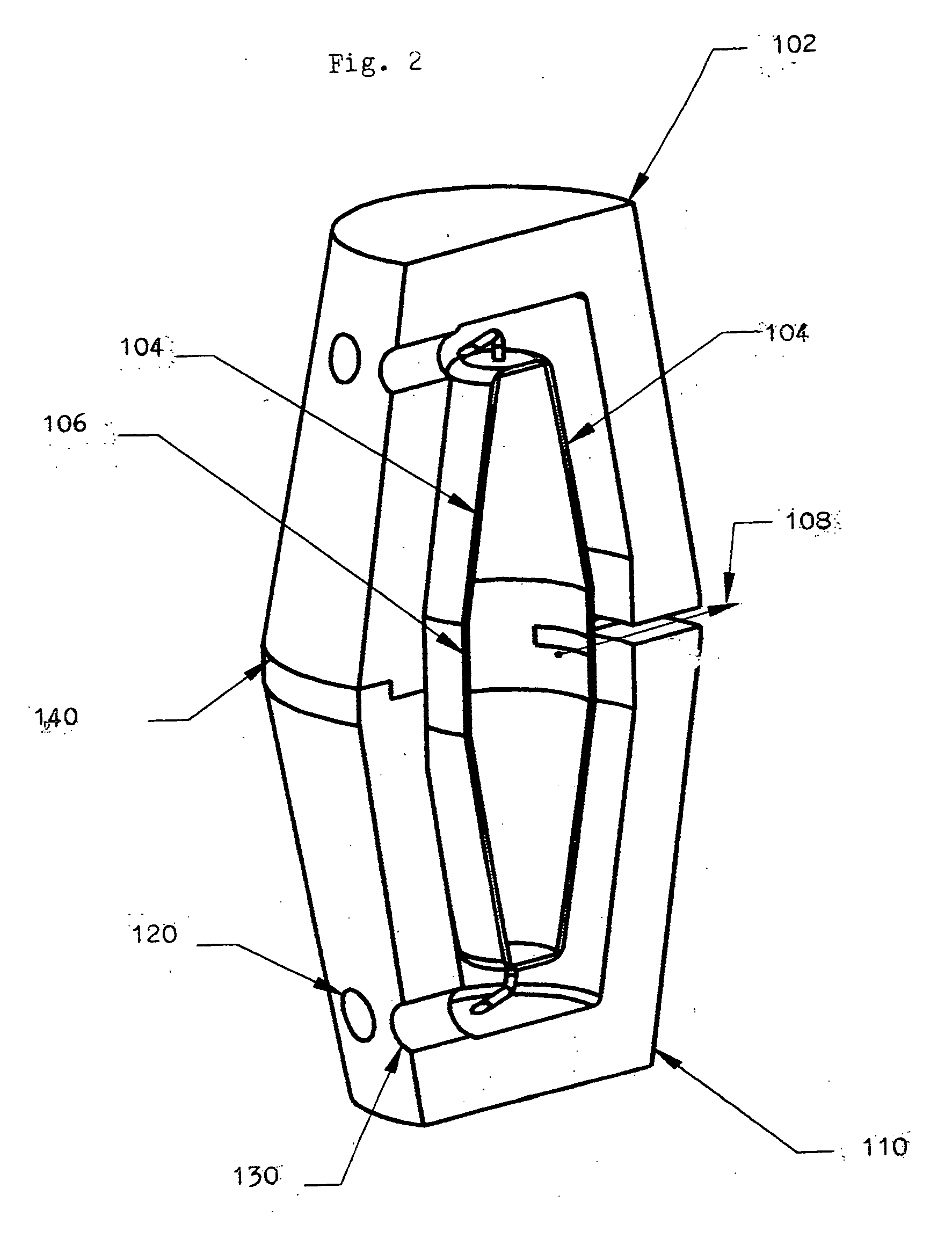

Tamper-proof enclosure for a circuit card

InactiveUS6970360B2Improve reliabilityImprove securitySemiconductor/solid-state device detailsSolid-state devicesInternal pressureTamper resistance

A tamper-proof enclosure for an electrical card, such as a high speed communications card, includes an enclosure in which the card is mounted. The enclosure has a wall with an opening, and a cup member is attached to the wall at the opening. A bus that is connected to the card extends through a passage in the cup member and through the opening in the wall. A security mesh is wrapped around the enclosure. The cup member is filled with liquid resin, which is also coated onto the security mesh. After the resin is cured, the resin in the cup member forms a plug that seals the security mesh from inner pressure when the enclosure is heated to an elevated temperature. The resin is preferably polyamide.

Owner:INT BUSINESS MASCH CORP

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS20100065271A1Lower cost of capitalEconomical and fastLiquid surface applicatorsLayered productsLiquid resinPhenol formaldehyde resin

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including a curable liquid resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include one or more of a resole phenolic-formaldehyde resin, a novolak phenolic-formaldehyde resin, a polyester resin, an acrylic polymer resin, a urethane resin or an epoxy resin. A method including applying a coating including the continuous phase including the curable resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

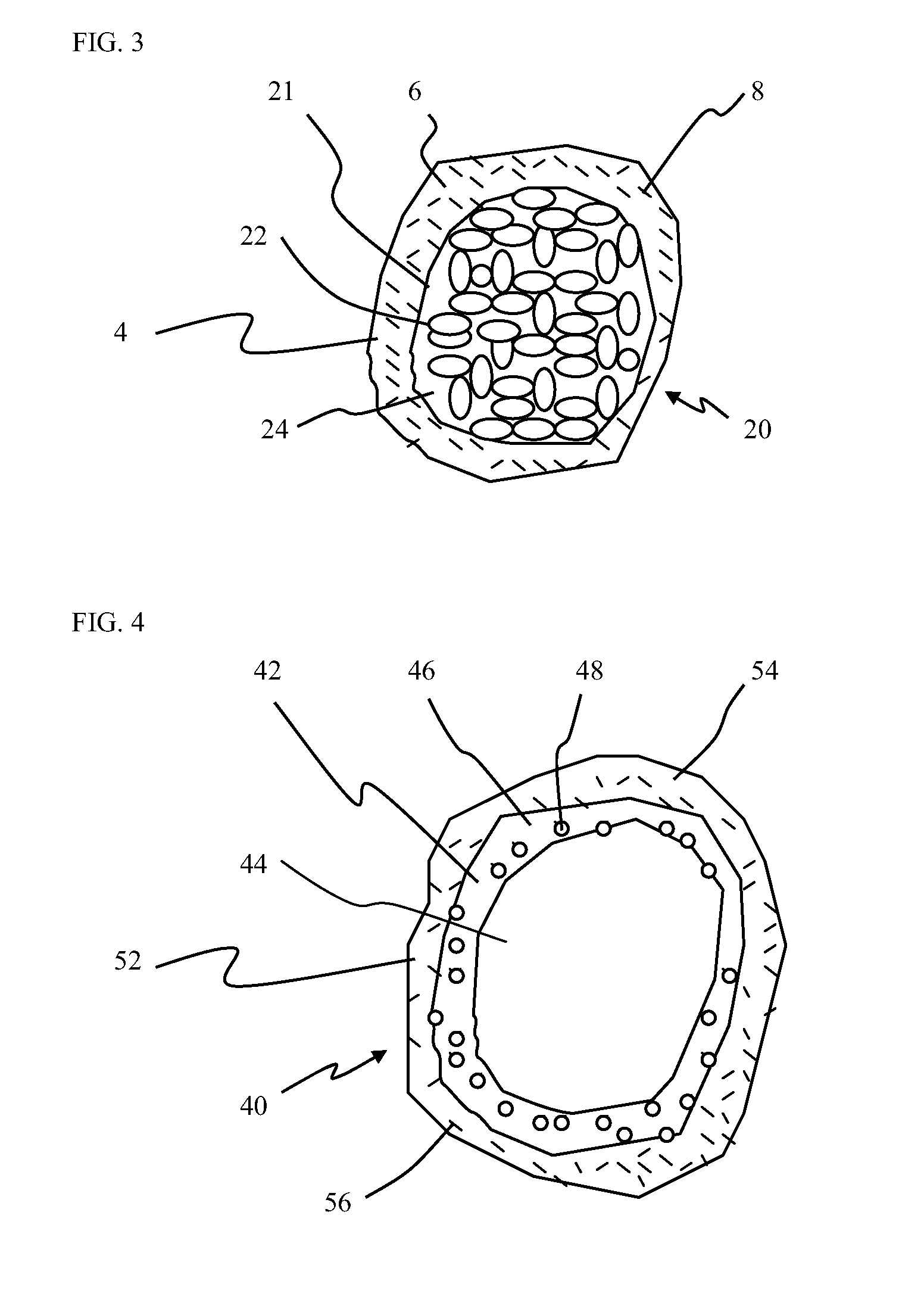

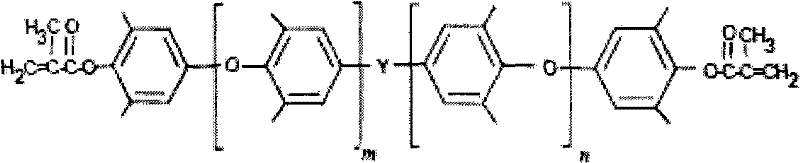

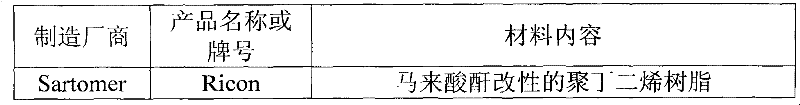

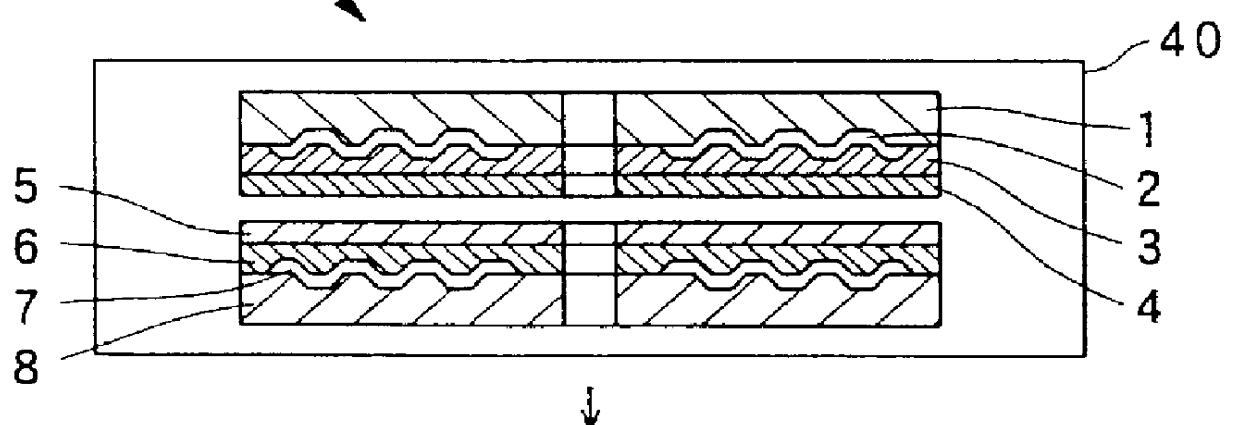

Composite material, high-frequency circuit substrate therefrom and manufacture method thereof

ActiveCN102161823AHigh peel strengthImprove the sticky problemPrinted circuit manufactureCircuit susbtrate materialsDouble bondCopper foil

The invention relates to a composite material, a high-frequency circuit substrate therefrom and a manufacture method thereof. The composite material comprises thermoset mixture, glass fiber cloth, power filler, a fire retardant and a curing initiator, wherein the thermoset mixture comprises more than one kind of vinyl liquid resin and polyphenyl ether resin; the molecular weight of the vinyl liquid resin is below 10000, and the vinyl liquid resin is provided with a polar functional group; the molecular weight of the polyphenyl ether resin is less than 5000, and the molecular tail end of the polyphenyl ether resin is provided with unsaturated double bonds. The high-frequency circuit substrate manufactured with the composite material comprises multiple layers of semi-solidified sheets and copper foils, wherein the semi-solidified sheets are mutually overlaid, and the copper foils are respectively pressed on two sides. The composite material disclosed by the invention causes the semi-solidified sheets to be easily manufactured and have high adhesive bonding force with the copper foils. The high-frequency circuit substrate manufactured by the material has the advantages of low dielectric constant, low dielectric loss angle tangent, good heat resistance and simple technical operation. Thus, the composite material disclosed by the invention is suitable for manufacturing the circuit substrate of the high-frequency electronic equipment.

Owner:GUANGDONG SHENGYI SCI TECH

Digital mask-image-projection-based additive manufacturing that applies shearing force to detach each added layer

ActiveUS9120270B2Additive manufacturing apparatusAuxillary shaping apparatusComputer graphics (images)Projection system

A three-dimensional object may be produced in cascaded layers from a liquid resin that solidifies upon exposure to light. A translation stage may be positioned relative to a vat that is suitable for solidifying the highest un-solidified layer of the three-dimensional object directly beneath any existing, solidified layers of the three-dimensional object. A mask image projection system may project a two-dimensional image of the highest un-solidified layer through a transparent bottom of the vat and into the liquid resin. This may cause at least a portion of the liquid resin to solidify in the shape of the two-dimensional image and to adhere to the bottom of a surface beneath the solidified layer. A shearing force may be applied between the bottom surface of the solidified layer and the surface beneath that is great enough to detach the solidified layer from the surface beneath.

Owner:UNIV OF SOUTHERN CALIFORNIA

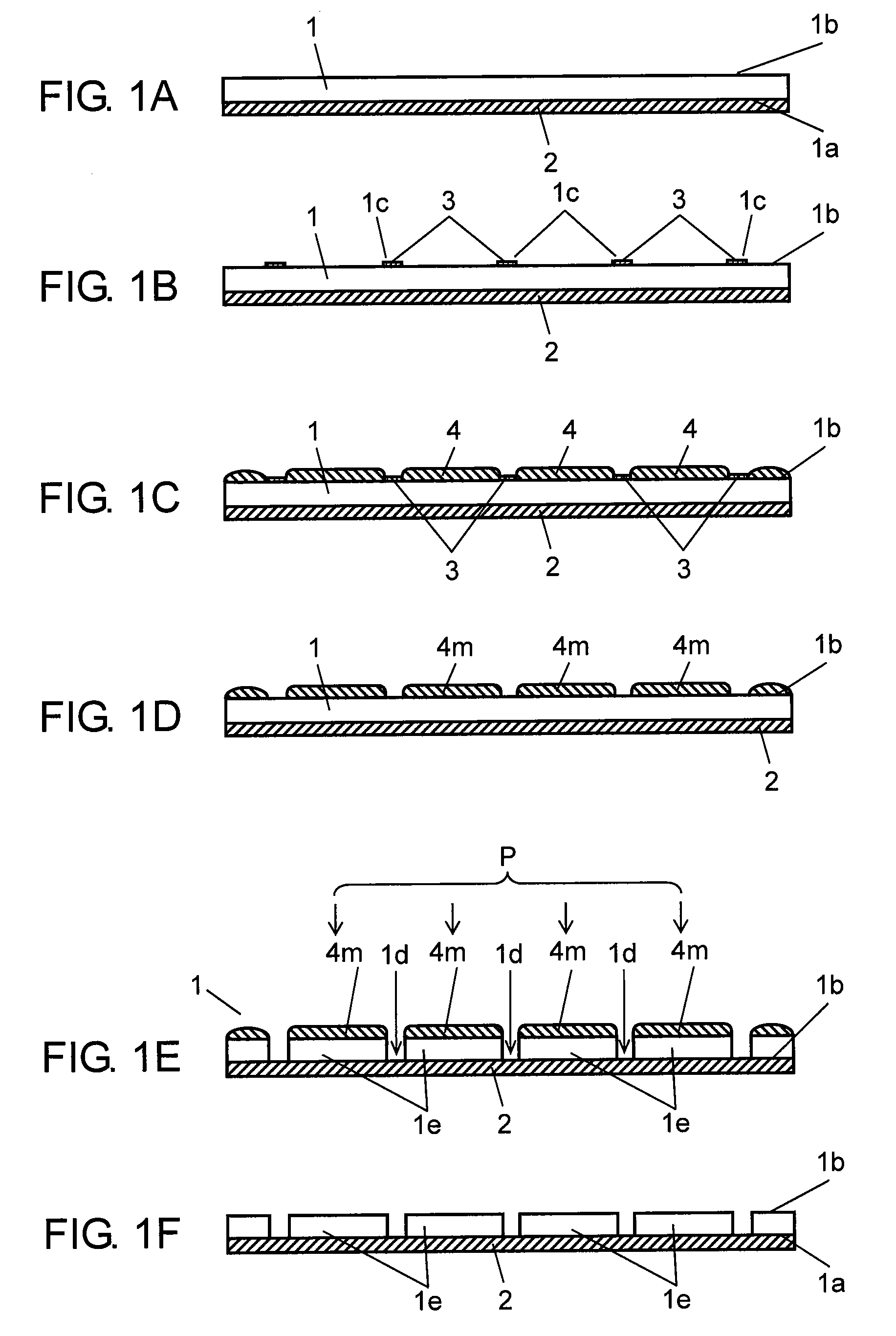

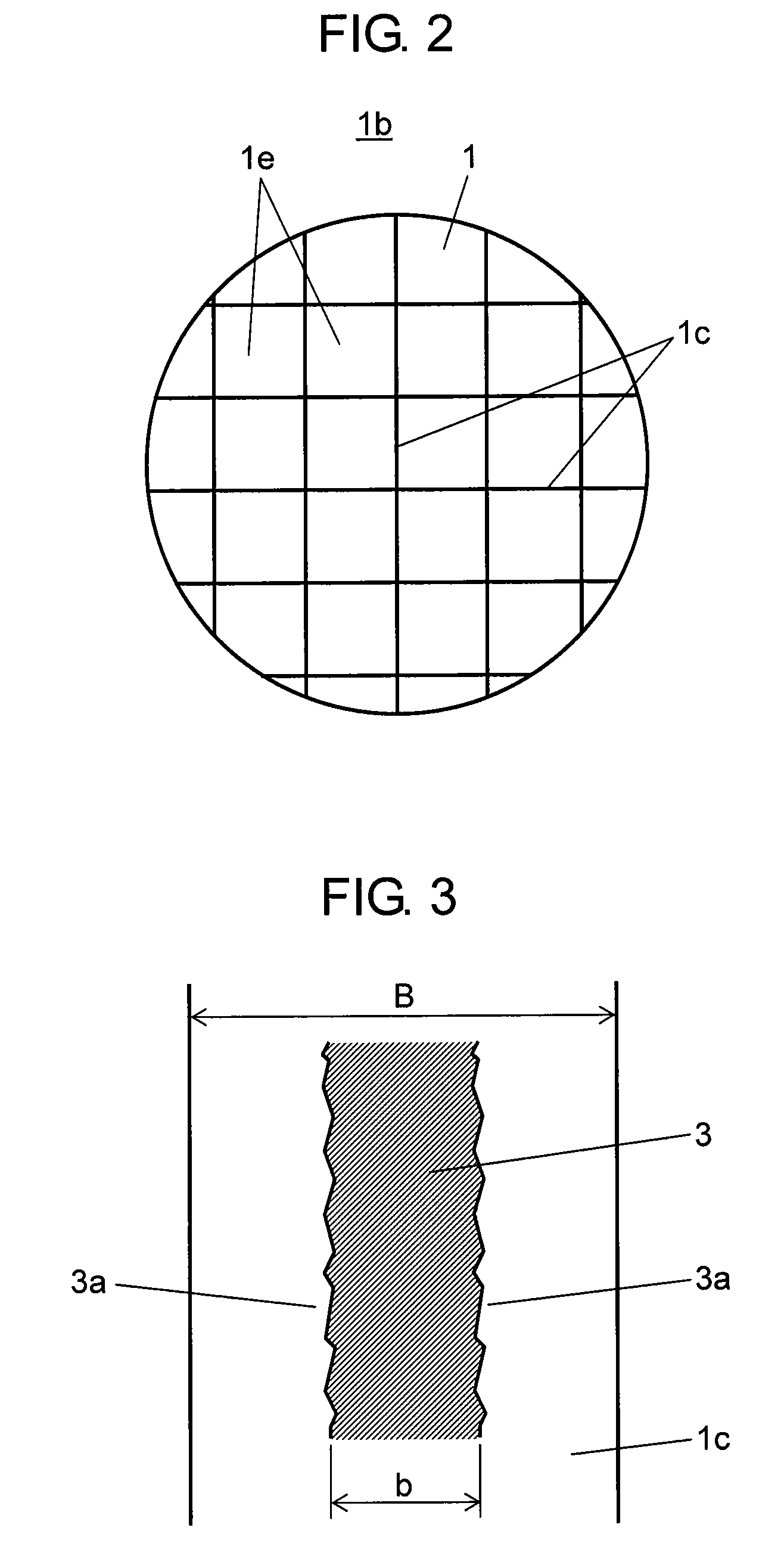

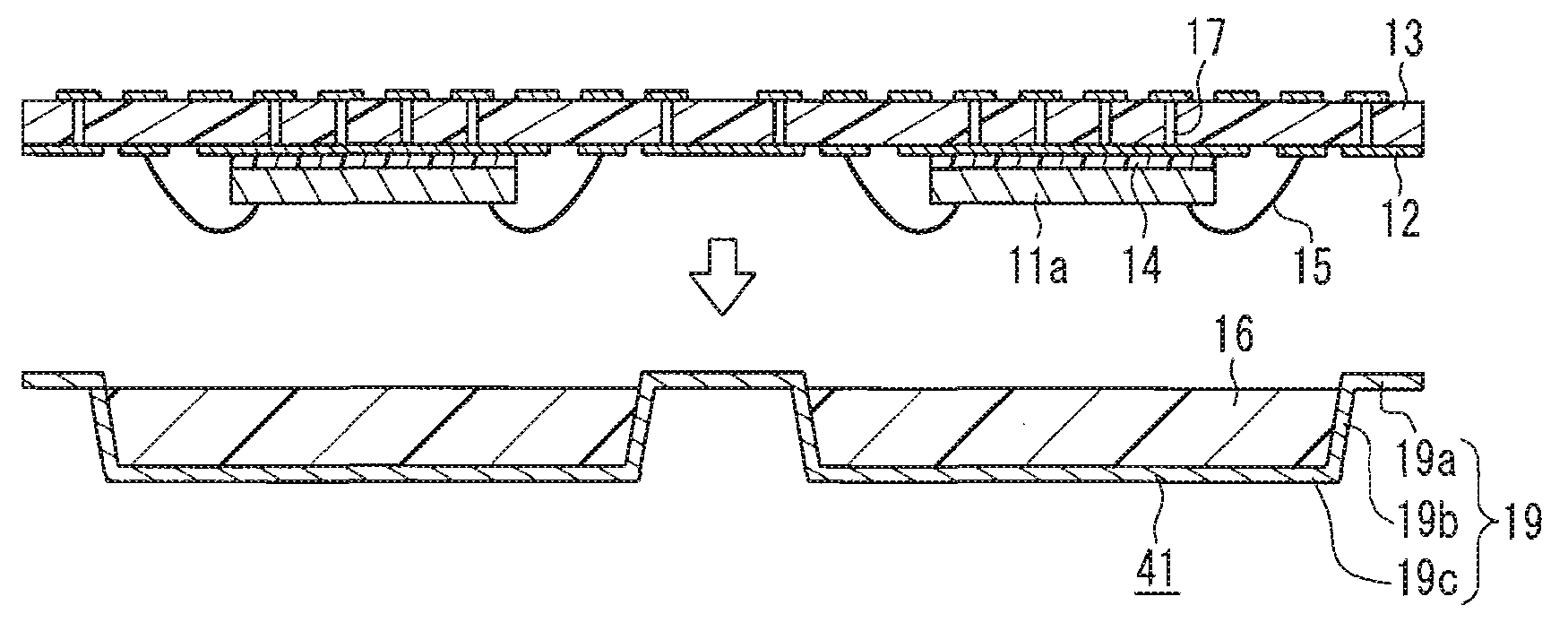

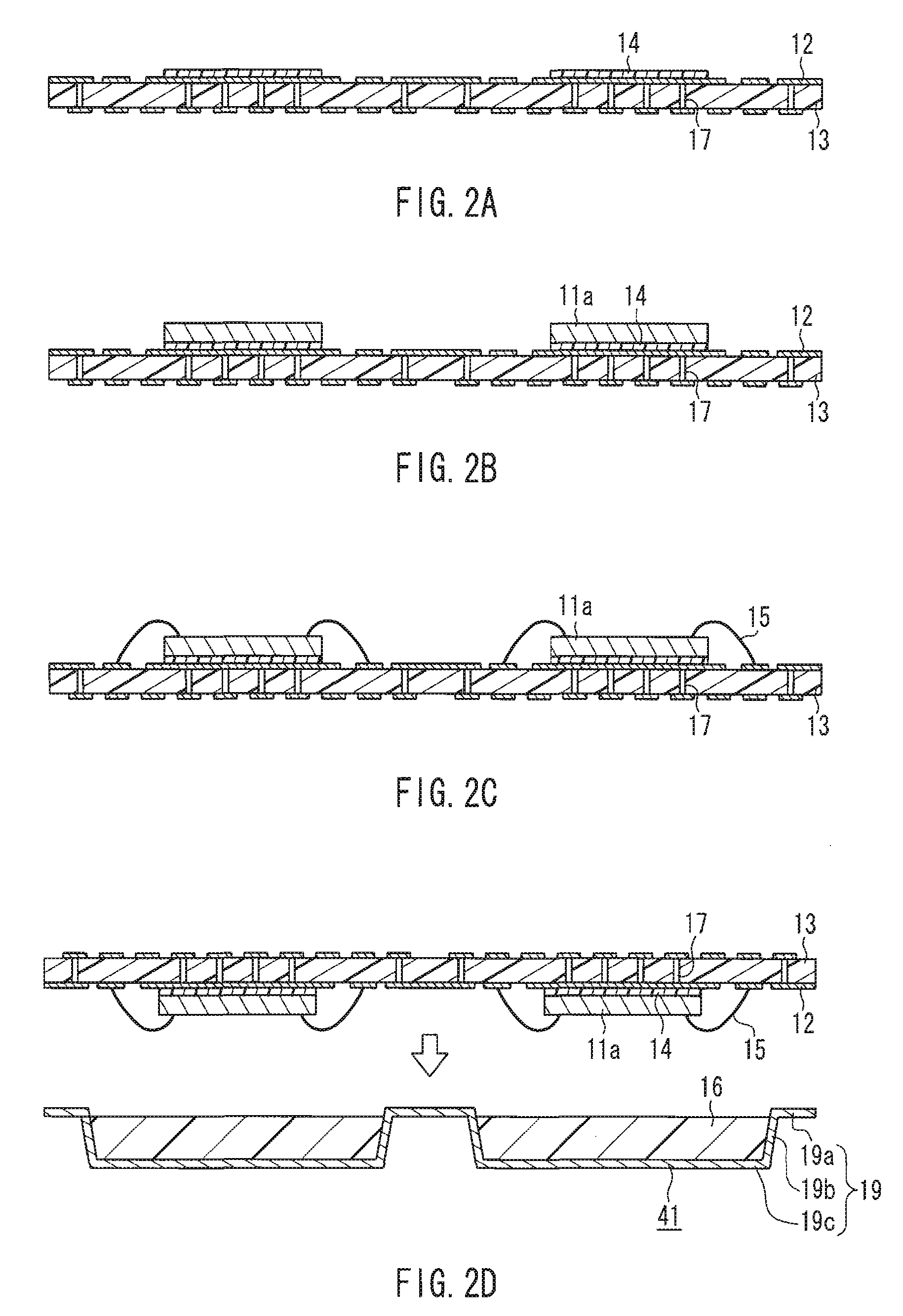

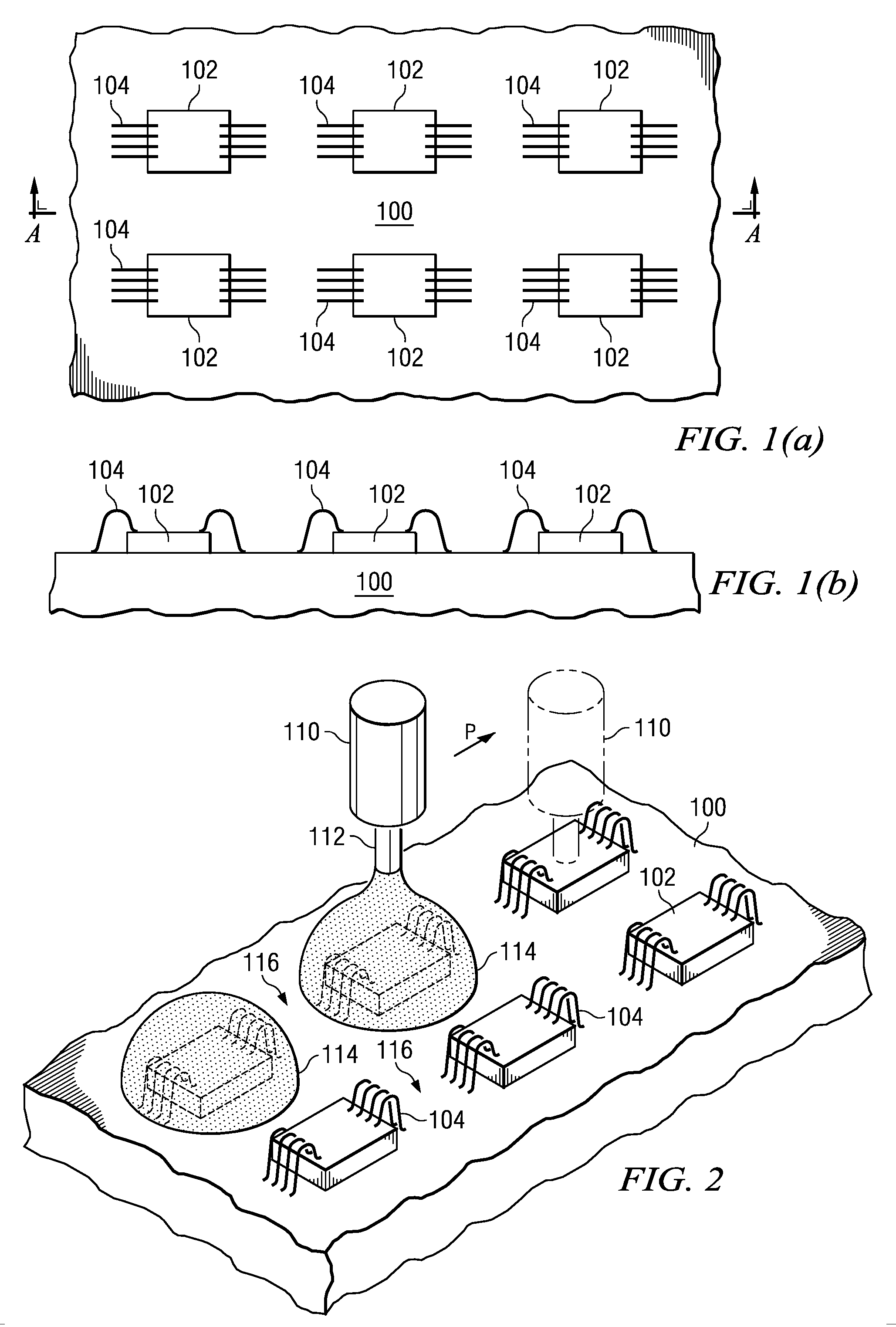

Method for processing a substrate, method for manufacturing a semiconductor chip, and method for manufacturing a semiconductor chip having a resin adhesive layer

ActiveUS20110014777A1Low costLow cost manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

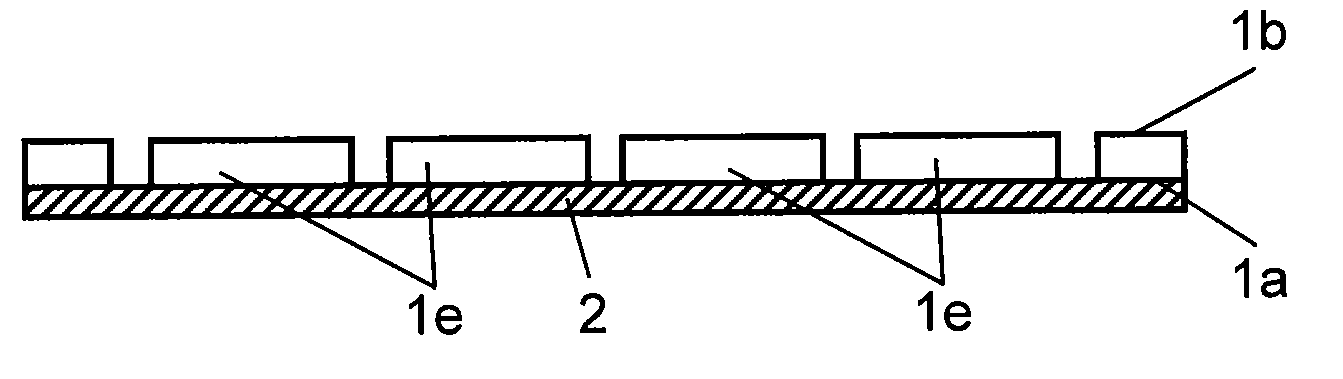

A mask used when a semiconductor wafer is diced into individual semiconductor chips by plasma etching is formed as follows. First, a pattern of a liquid-repellent film is formed by printing a liquid-repellent liquid on the area to be etched on the rear surface of the semiconductor wafer. Next, a resin film thicker than the liquid-repellent film is formed in the area not having the liquid-repellent film by supplying a liquid resin to the rear surface on which the liquid-repellent pattern has been formed. Then, the resin film is cured to form the mask covering the area other than the area to be removed by the etching. This method allows the formation of an etching mask without using a high-cost method such as photolithography.

Owner:PANASONIC CORP

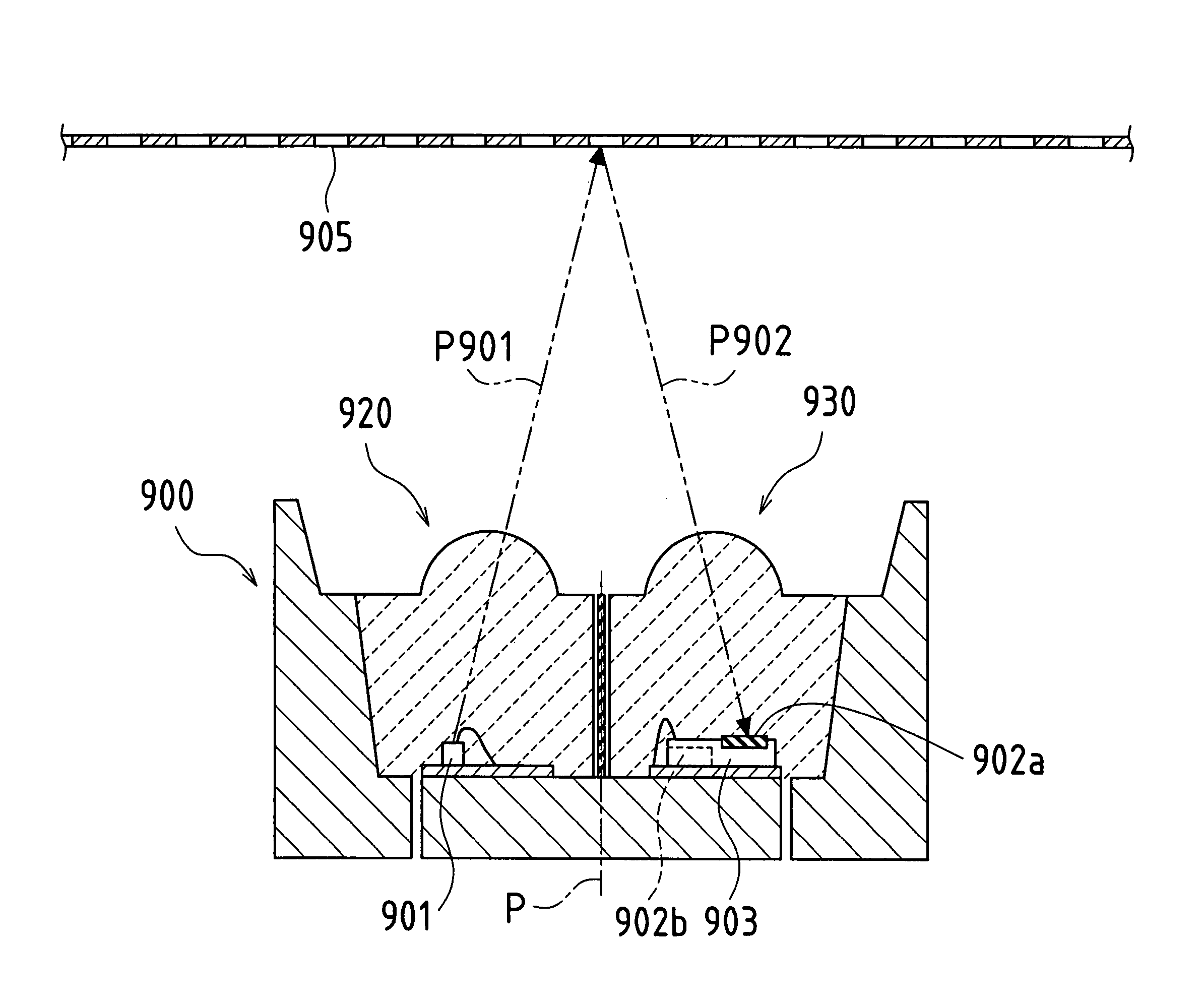

Reflective encoder with light shield and electronic device using such reflective encoder

InactiveUS7309855B2Good optical performanceElimination of signalSolid-state devicesMaterial analysis by optical meansLens hoodElectron

A reflection encoder is disclosed having a light emitting element in a light receiving element that are separated by a light shielding body that prevents unwanted light from entering the light receiving element. In variations of the invention, the light shielding body may be integrally formed with a mold resin portion that holds the light emitting element and light receiving element, formed by a sheet or plate, or formed using an opaque liquid resin that is poured between transparent resin bodies that encapsulate the light emitter and receiver. In operation, light radiated from the light emitting element is reflected by a code wheel and then received by a light receiving element. Other variations include varying the height at which the light receiving and detecting elements are disposed relative to the code wheel and tilting these elements towards each other so as to increase light efficiency.

Owner:SHARP KK

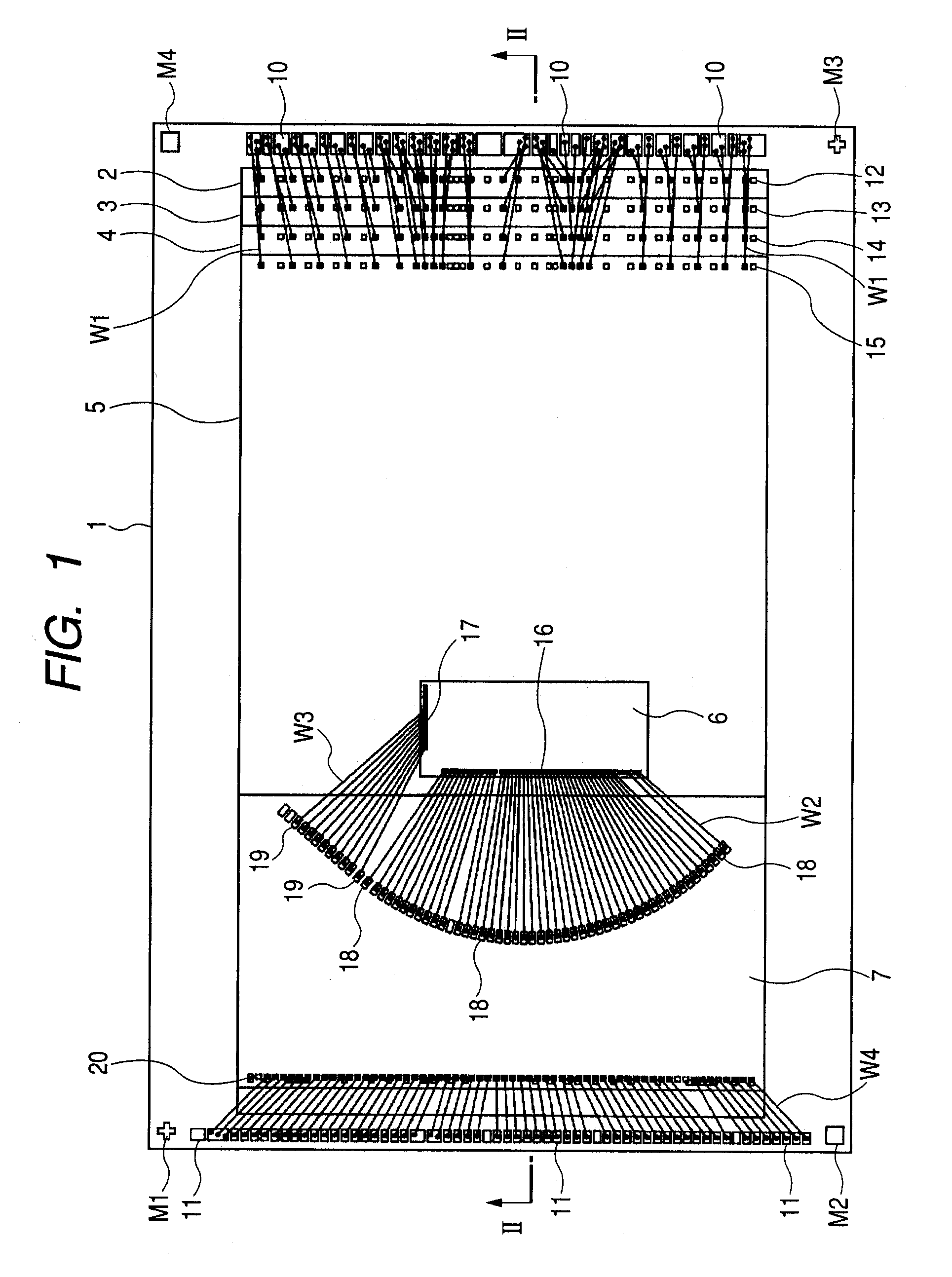

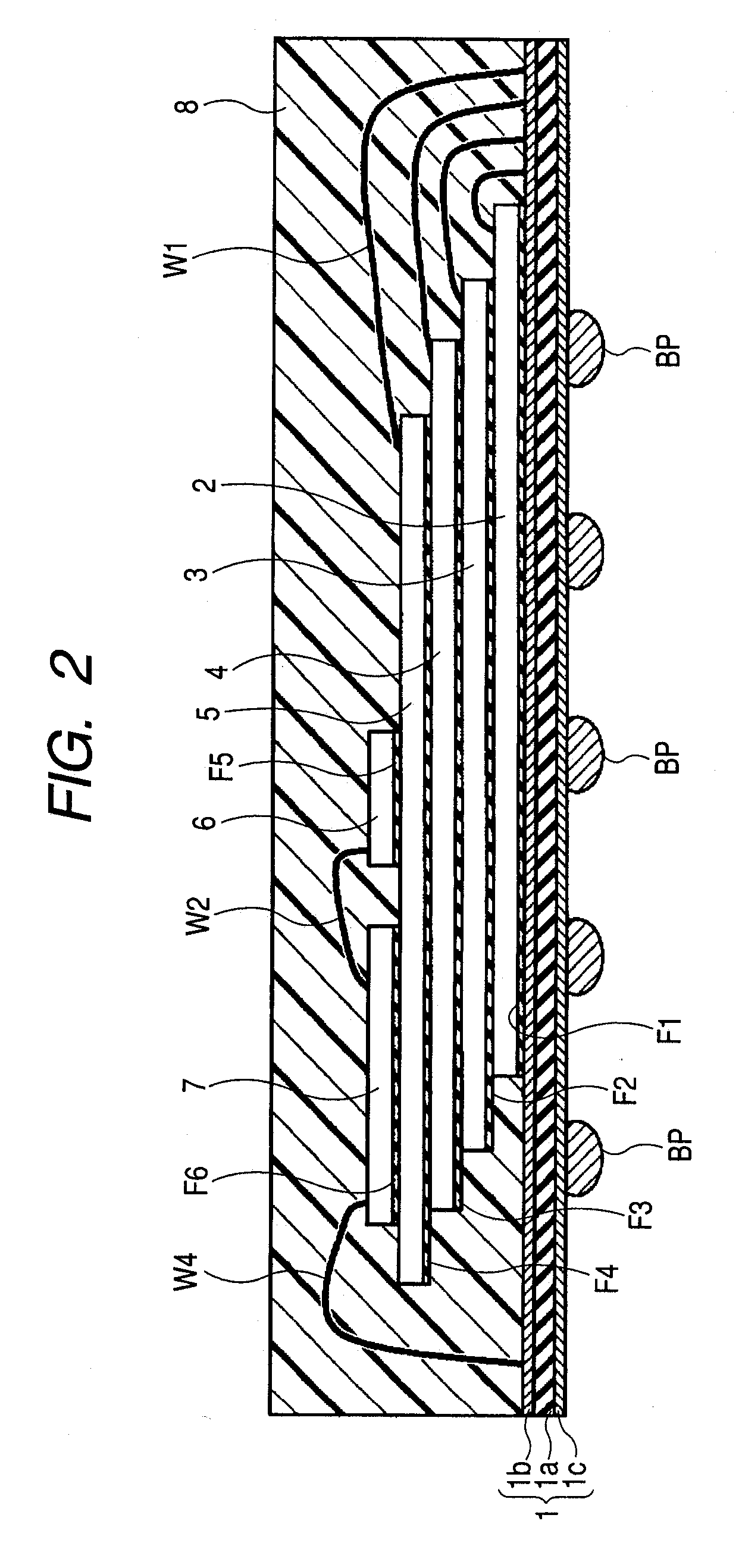

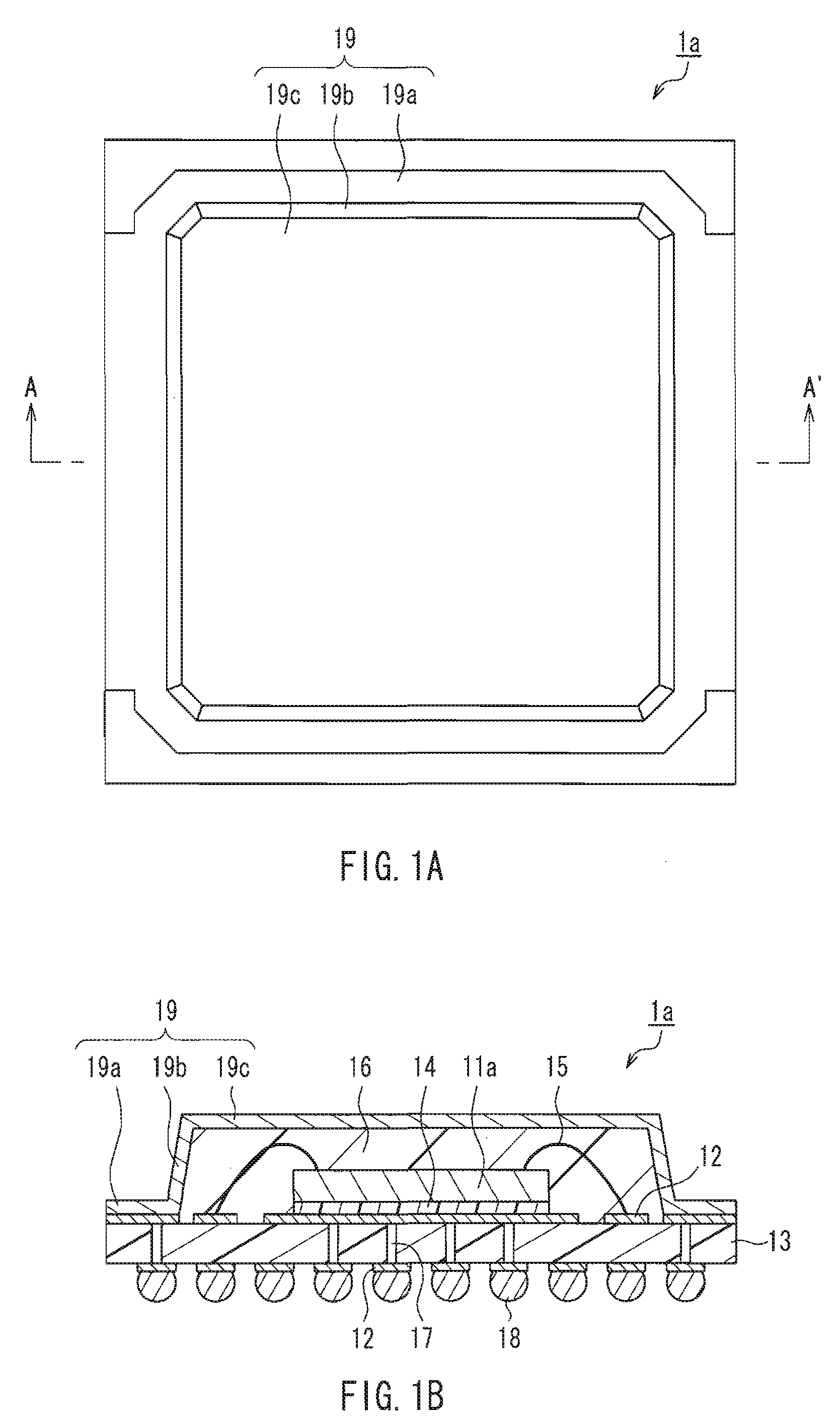

Semiconductor device, interposer chip and manufacturing method of semiconductor device

ActiveUS20070170573A1Avoid makingImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMicrocomputerMemory chip

The semiconductor device with which bonding wires cannot contact easily is offered.In this semiconductor device, memory chips are stacked on the surface of a wiring substrate, a microcomputer chip and an interposer chip are arranged on the surface of the memory chip, and the pad of a microcomputer chip and the pad of an interposer chip arranged almost circularly are connected by a bonding wire. Therefore, since the transfer pressure of liquid resin for sealing can be weakened with a wire, contact of the wires by deformation of a wire can be prevented.

Owner:RENESAS ELECTRONICS CORP

Curable liquid resin composition

PCT No. PCT / JP97 / 01871 Sec. 371 Date Feb. 3, 1998 Sec. 102(e) Date Feb. 3, 1998 PCT Filed Jun. 2, 1997 PCT Pub. No. WO97 / 46601 PCT Pub. Date Dec. 11, 1997A curable liquid resin composition containing 100 parts by weight of the following (meth)acrylic liquid resin (A) and 1 to 1,000 parts by weight of a (meth)acrylic monomer (B) having an unsaturated double bond in its molecule and having a number average molecular weight of 1,000 or less, the (meth)acrylic liquid resin (A) being a liquid resin which is obtained by polymerizing monomers containing an alkyl (meth)acrylate monomer (a-1-1) of the formula (1),CH2 C(R1)COO-R2(1)wherein R1 is a hydrogen atom or CH3 and R2 is an alkyl group, and / or an alkylene glycol (meth)acrylate monomer (a-1-2) of the formula (2),CH2=C(R1)COO(CnH2nO)mR3(2)wherein R1 is a hydrogen atom or CH3, R3 is an alkyl group or a phenyl group, n is an integer of 1 to 3, and m is an integer of 3 to 25, and other polymerizable vinyl monomer (a-2), an average of molecular weights of all the monomers being 100 to 1,500, the liquid resin having a number average molecular weight of 10,000 to 200,000 and a viscosity of 1 to 10,000 poise (measured at 50 DEG C.), or a modified product of the above liquid resin, the curable liquid resin composition can form a film as a film-forming material or as a resin for an adhesive without using a solvent and give a cured film.

Owner:TOYO INK SC HOLD CO LTD

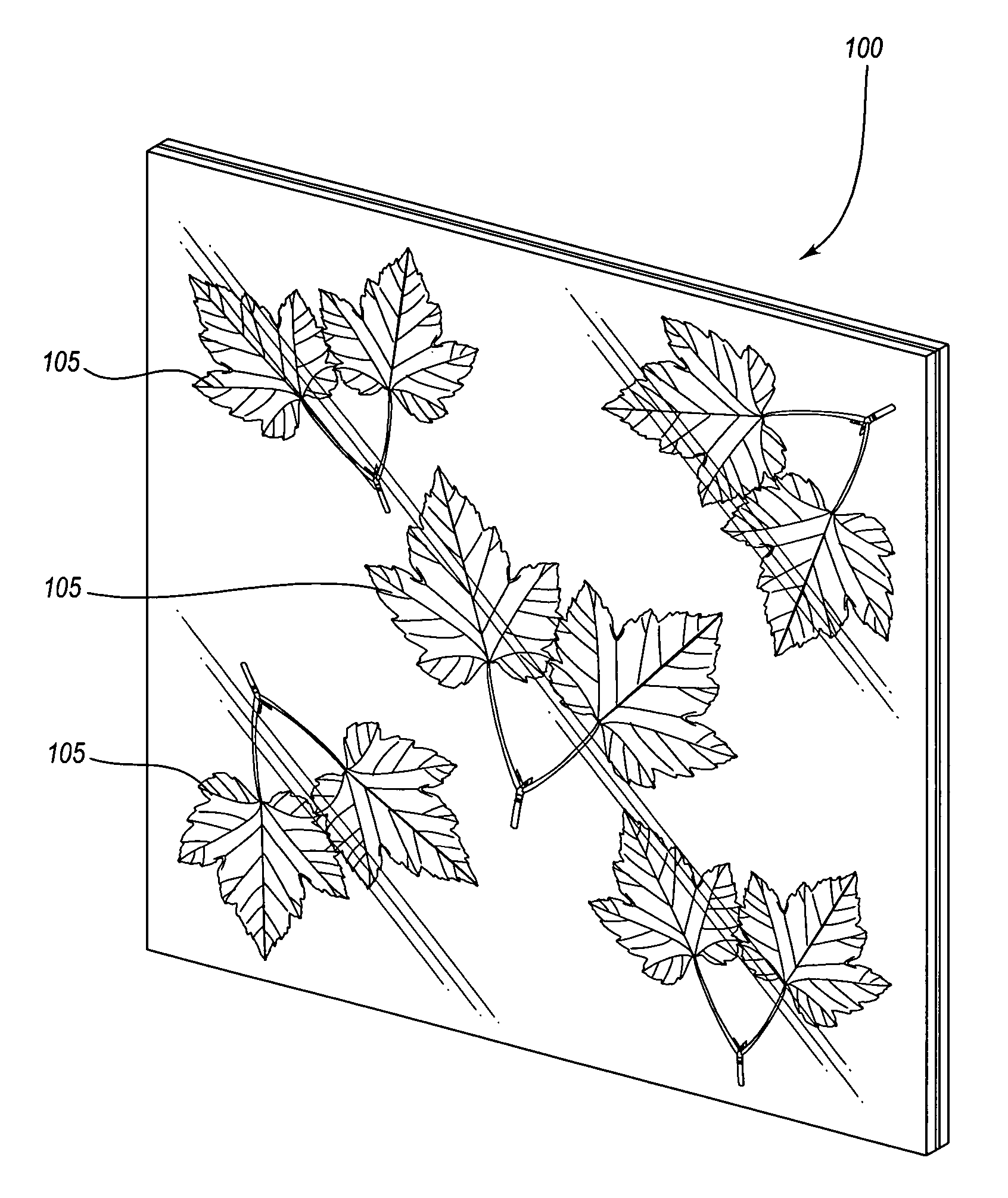

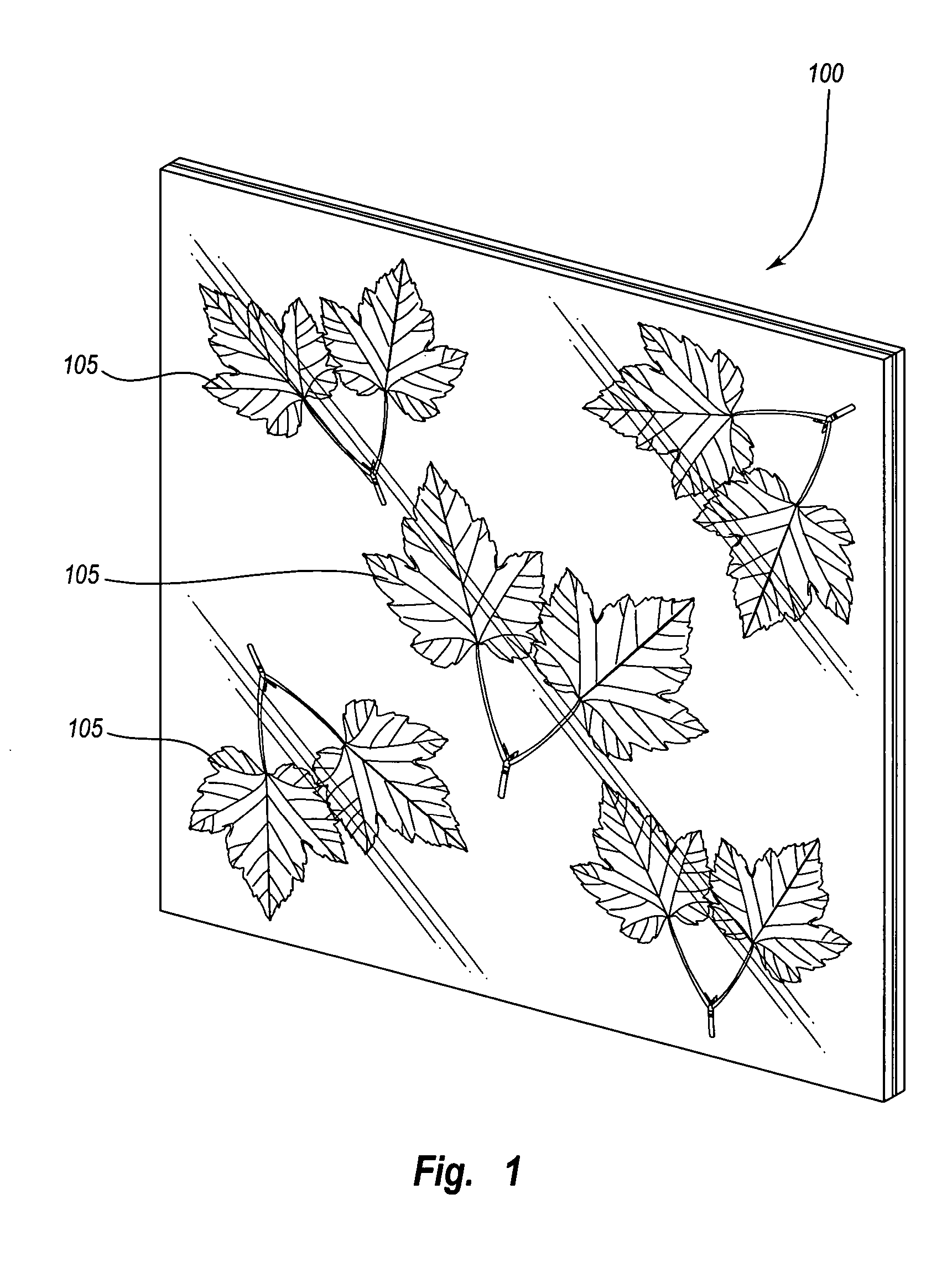

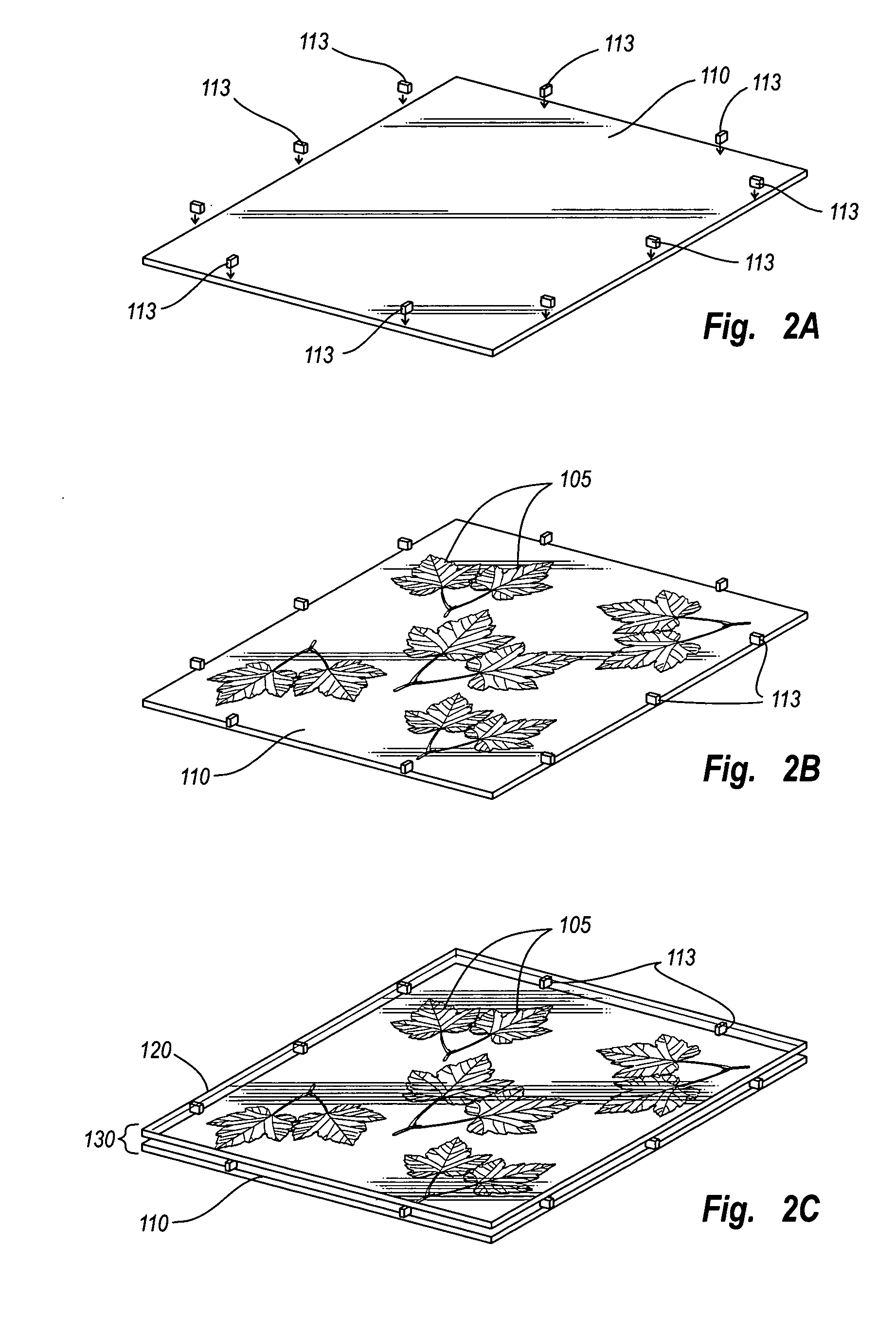

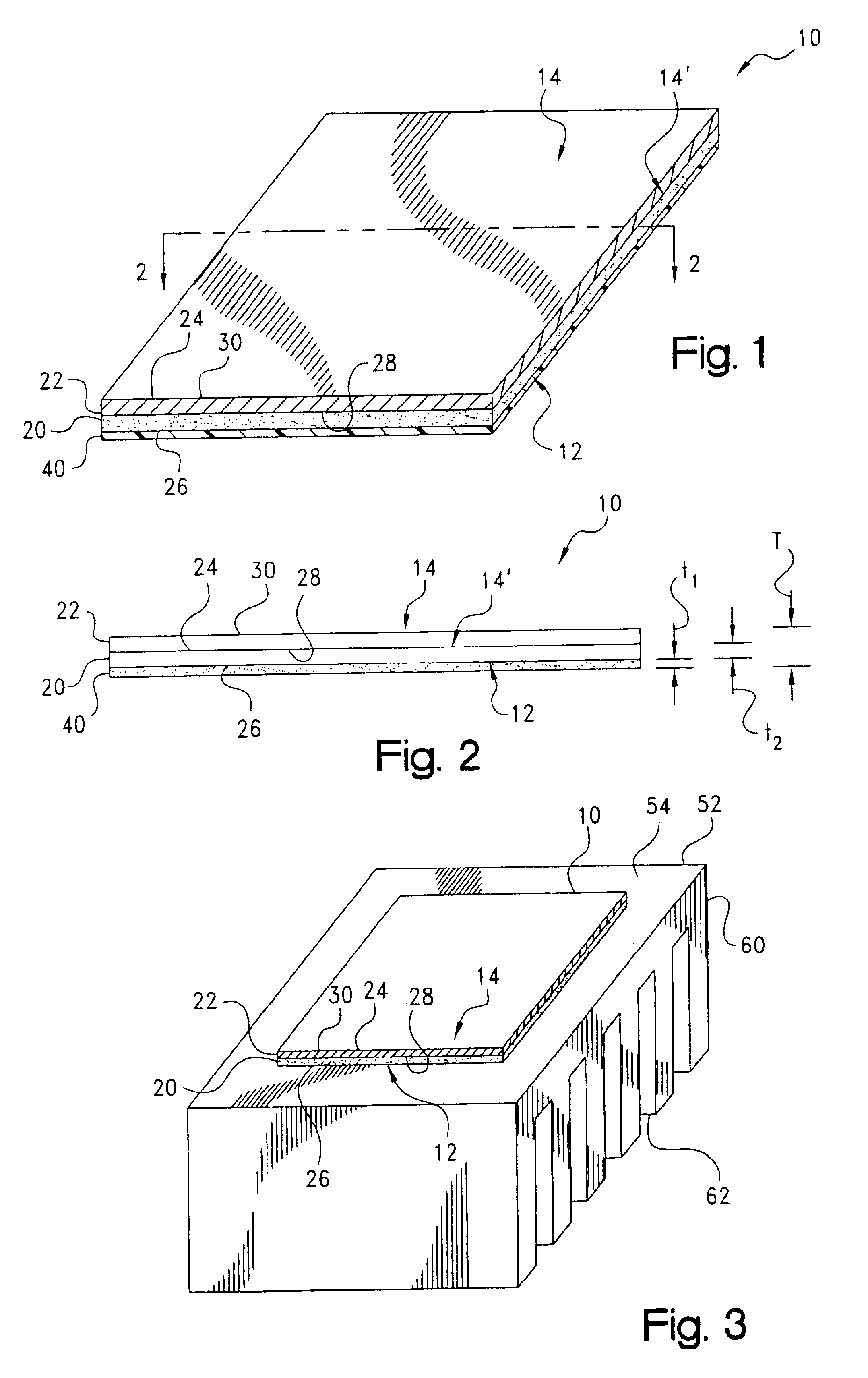

Architectural glass panels with embedded objects and methods for making the same

InactiveUS20060046017A1Decorative surface effectsOrnamental structuresArchitectural glassEngineering

A decorative architectural glass panel comprises a two or more glass sheets separated by a resin in which one or more decorative objects are suspended. A method of making the glass panel comprises positioning one or more spacers and one or more decorative objects on a first glass sheet, placing a second glass sheet about the first glass sheet, sealing the edges of the first glass sheet and second glass sheet, and filling the space between the first and second glass sheets with a curable liquid resin. The resin can be poured using a substantially horizontal pour in order to keep the decorative objects from substantially shifting when pouring the liquid resin. The resin can also be poured in combination with a vacuum force. In some implementations, the glass panel may also be substituted with a resin panel using polymeric resin sheets.

Owner:3FORM

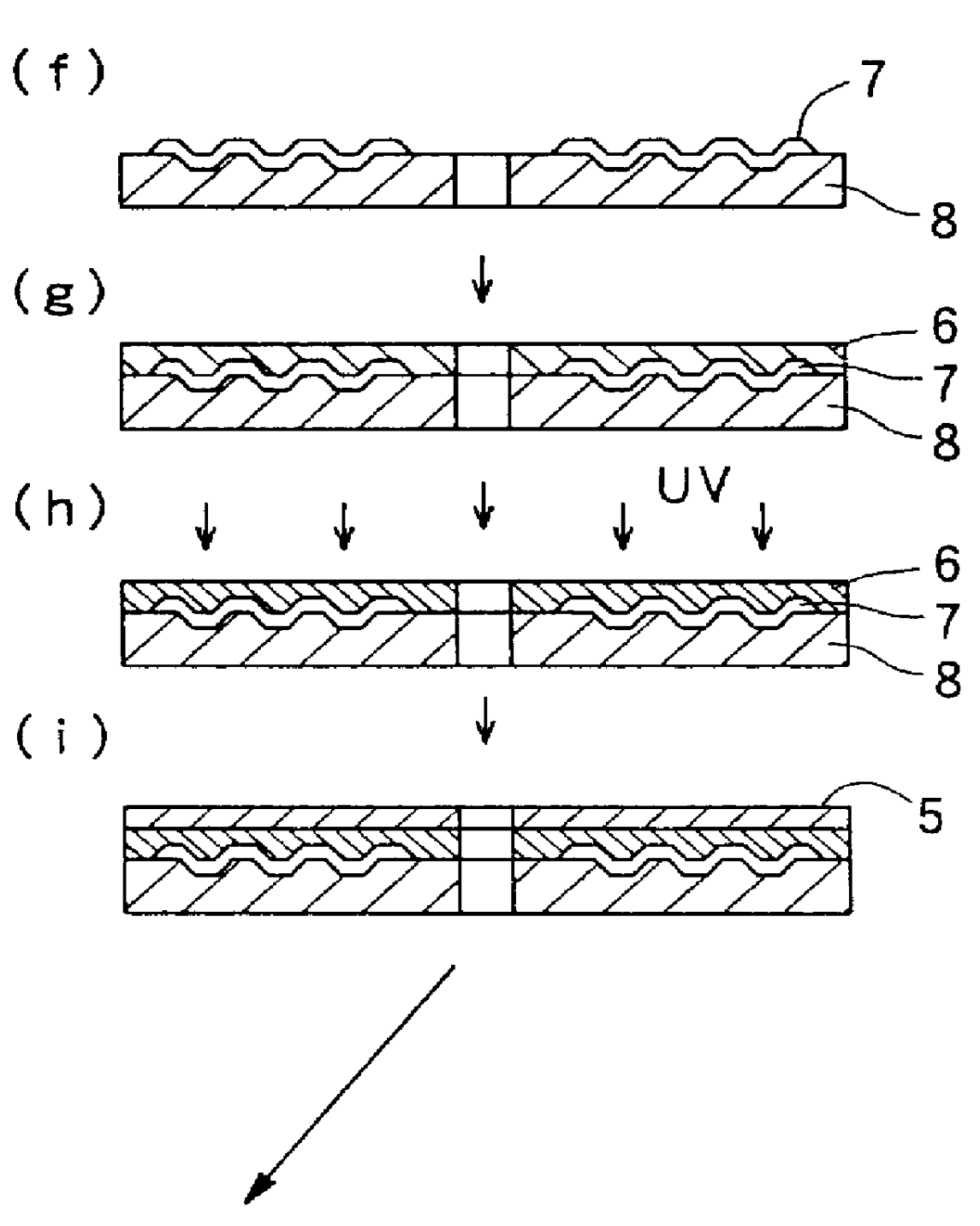

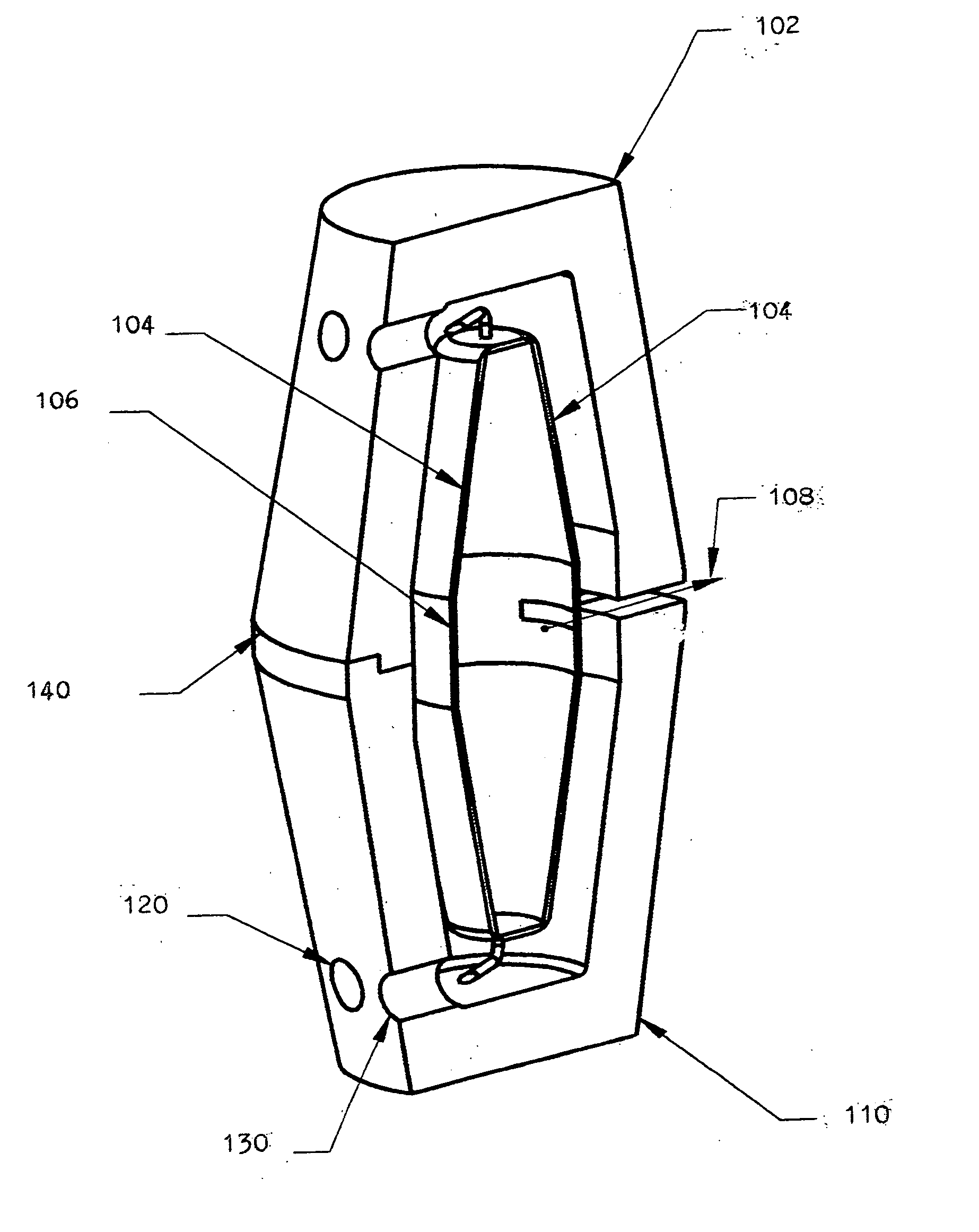

Method of producing optical disc of bonded type

InactiveUS6136133AUniform and constant thicknessEfficiently obtainedRecord carriersLamination ancillary operationsUltravioletPartial reflection

A method of producing an optical disc of bonded type includes the processes of: (A) forming a first reflection film, which is half transparent for partially reflecting and partially transmitting an incident light, on a first information record surface of a first transparent substrate; (B) forming a second reflection film, which has a reflective index higher than that of the first reflection film, on a second information record surface of a second transparent substrate; (C) dripping a liquid resin of ultraviolet hardening type onto one of the first and second reflection films by a spin coating method to form a first resin layer in a non-hardened condition; (D) dripping a liquid resin of ultraviolet hardening type onto the other of the first and second reflection films by a spin coating method; (E) emitting ultraviolet onto the liquid resin dripped by the process (D) to form a second resin layer of ultraviolet hardening type in a hardened condition; (F) provisionally bonding the first and second transparent substrates together in a pressure reduced environment; and (G) hardening the first resin layer by emitting ultraviolet from a side of the first transparent substrate.

Owner:PIONEER CORP +1

Desalting adjunct chemistry

InactiveUS6120678AImproves separation of waterReduce decreaseDewatering/demulsification with chemical meansLiquid separation by electricityChemical treatmentMeth-

Improved performance in the phase separation of aqueous brines from hydrocarbons within an electrostatic desalter operation is obtained by the addition to the crude oil emulsions entering the desalter of an effective asphaltene dispersing amount of an alkyl phenol-formaldehyde liquid resin polymer, optionally in the presence of a lipophilic / hydrophilic vinylic polymer. The preferred resin is a nonyl phenol-formaldehyde resin having a molecular weight of from 1,000-20,000, and the preferred vinylic polymer is a copolymer of lauryl (meth)acrylate and hydroxyethyl (meth)acrylate. Best results from the electrostatic desalter are obtained when also using a demulsifier chemical treatment along with the asphaltene dispersing treatments. Desalter efficiency is increased and desalter brine effluent quality is greatly increased.

Owner:ECOLAB USA INC +1

Carbon-carbon composite article manufactured with needled fibers

InactiveUS20060177663A1Manufacturing EaseReduce layeringLayered productsTextiles and paperCarbon compositesCarbon fibers

Method of making a carbon-carbon composite article such as an aircraft brake disc. The method includes: selecting carbon fiber precursors, having limited shrinkage in the axial direction when carbonized, in the form of individualized chopped or cut fibers; placing the selected chopped or cut carbon fiber precursors into a preform mold configured in the form of a brake disc to form a fibrous matrix; and then needling the molded fibrous matrix to provide it with three-dimensional structural integrity and to reduce layering. The carbon fiber precursor matrix may subsequently be infused with liquid carbon matrix precursor, the impregnated matrix may be carbonized; e.g., at 600-1800° C. for 1-10 hours to provide a preform having a density of at least about 1.1 g / cc, and the carbonized preform may be further densified to a density of at least about 1.6 g / cc by known liquid resin infiltration techniques and / or by conventional CVI / CVD processing.

Owner:HONEYWELL INT INC

Bismuth compounds composite

InactiveUS20050258404A1High glossSimilar surface material propertyDiffusing elementsNuclear engineering problemsBismuth compoundCompound (substance)

A bismuth compound composite having a polymer matrix and a bismuth compound therein. The bismuth compound may be bismuth oxide, or other bismuth compounds. The polymer may be any of a very wide range of materials or combinations thereof. Binder, secondary fillers or other third components may be added. By means of use of various bismuth compounds, polymers, and third components, the physical, radiological and electrical properties of the finished products may be tailored to achieve desired properties. In addition, the invention teaches that radiation shielding, insulators, and combined radiation shield / insulators may be fashioned from the composite. A wide range of production methods may be employed, including but not limited to liquid resin casting.

Owner:MCCORD STUART JAMES

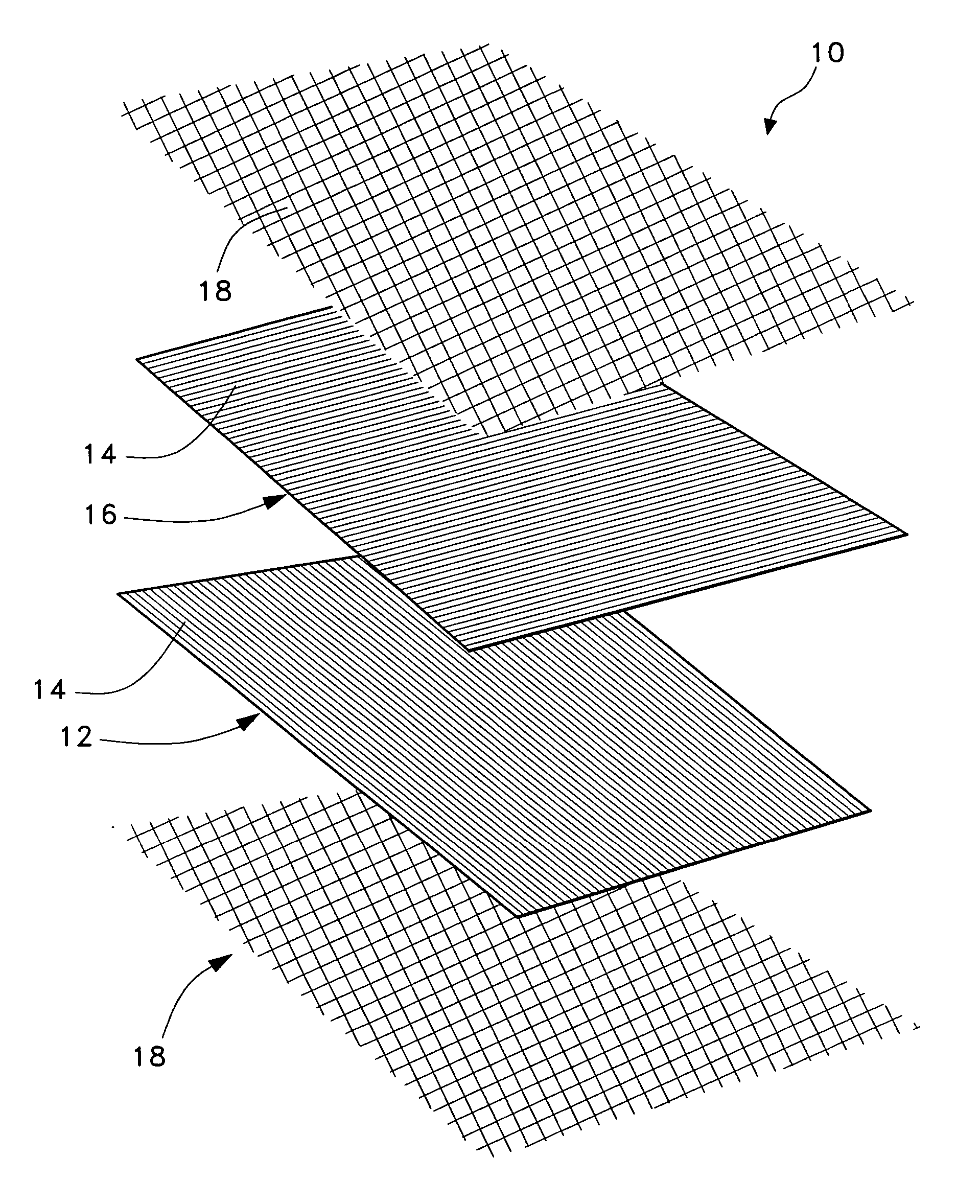

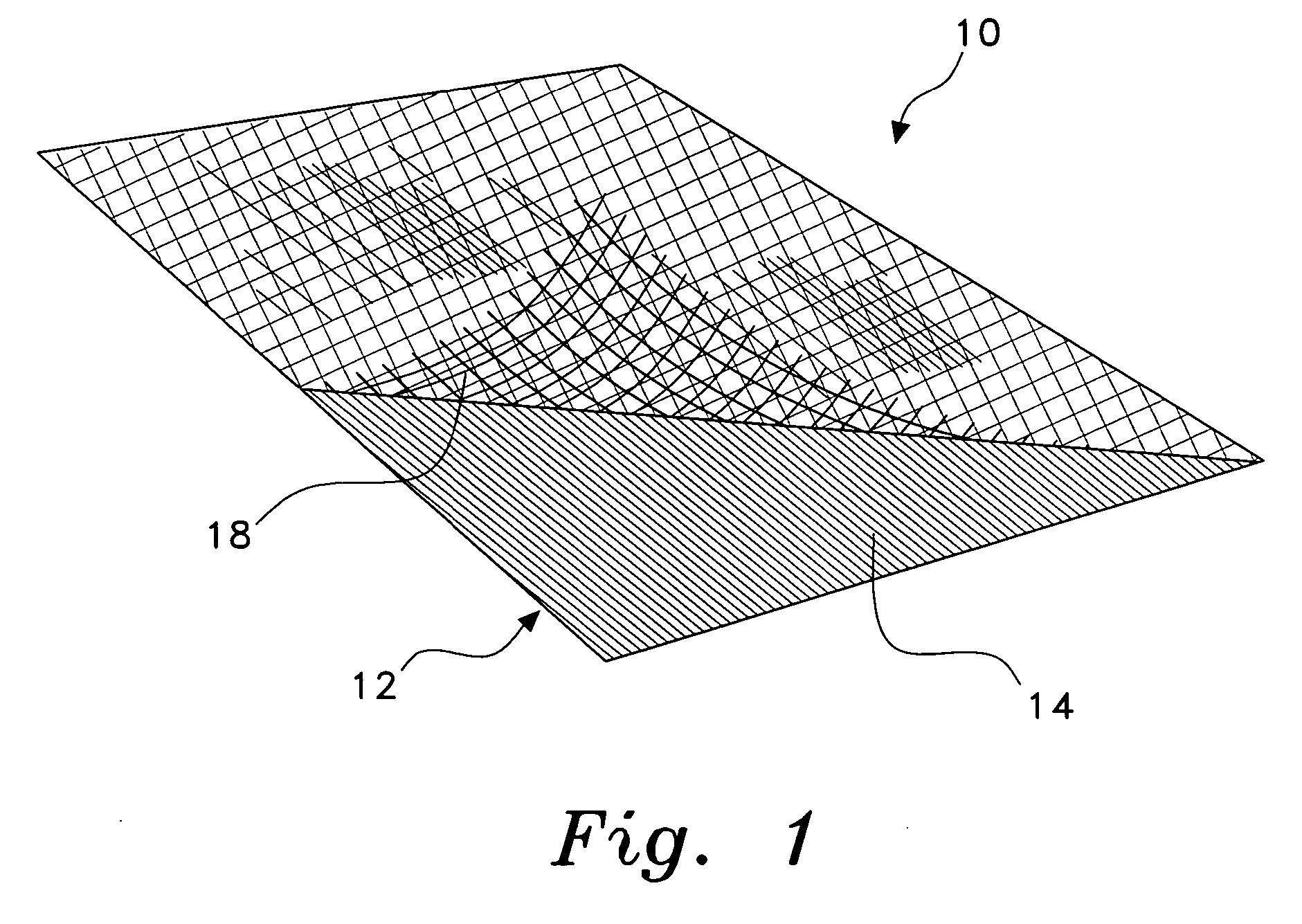

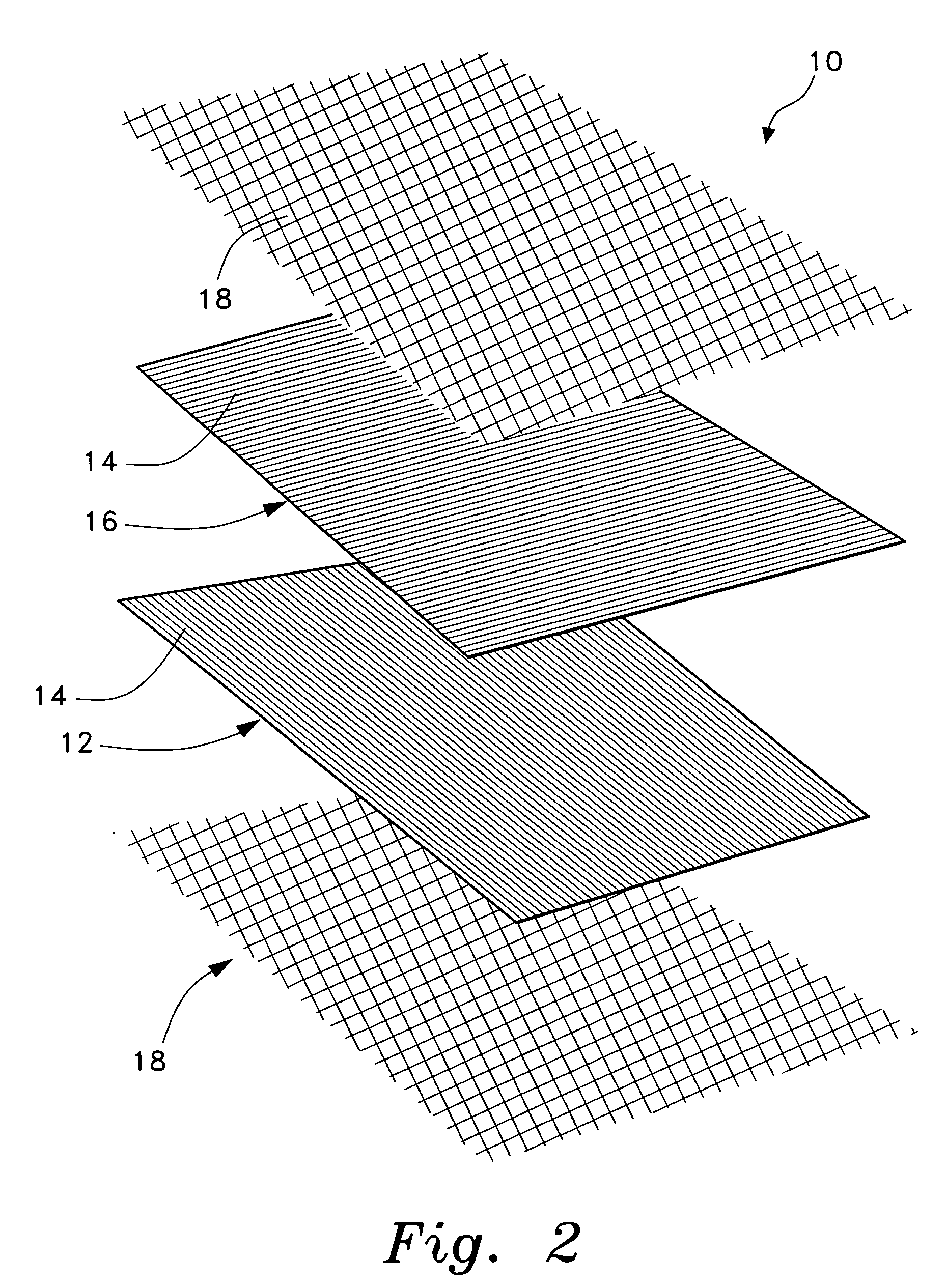

Non-woven, uni-directional multi-axial reinforcement fabric and composite article

InactiveUS20060121805A1Negligible effectInexpensive, dependableAdhesive processes with surface pretreatmentSynthetic resin layered productsAdhesiveNonwoven fabric

A non-woven, unidirectional, multi-axial layered fabric for reinforcement of composite structures provides for holding the non-woven yarns as laid-out by adhesion of polymeric adhesive applied to the non-woven yarns. The adhesive layer on the yarns, dissolves as liquid resin is applied to form a composite structure, the polymeric coating dissolving in the liquid resin. The polymeric adhesive dissolves to allow liquid resin to wet the yarns. Curing creates the desired composite structure. Filament yarns useful in the present invention include but are not limited to those made of aramid, boron, carbon, fiberglass, nylon, PBO, PEN, polyester, and polyethylene. A preferred adhesive is low molecular weight polyester and a preferred liquid resin is polyester resin. A web of netting material is applied in a similar manner for added physical stability of the inventive reinforcement fabric.

Owner:KRULIC CHARLIE B

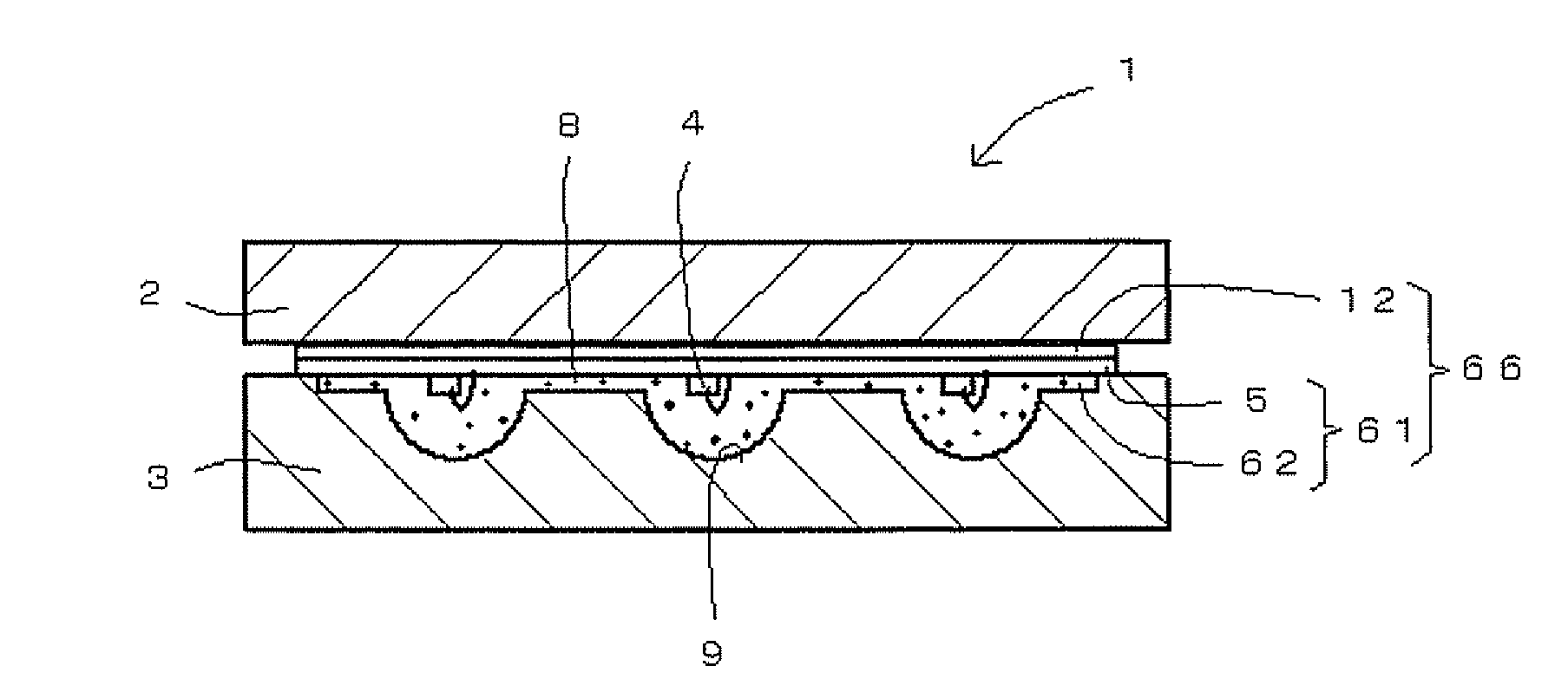

Semiconductor device and method for manufacturing the same

ActiveUS20090140402A1Quality improvementSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

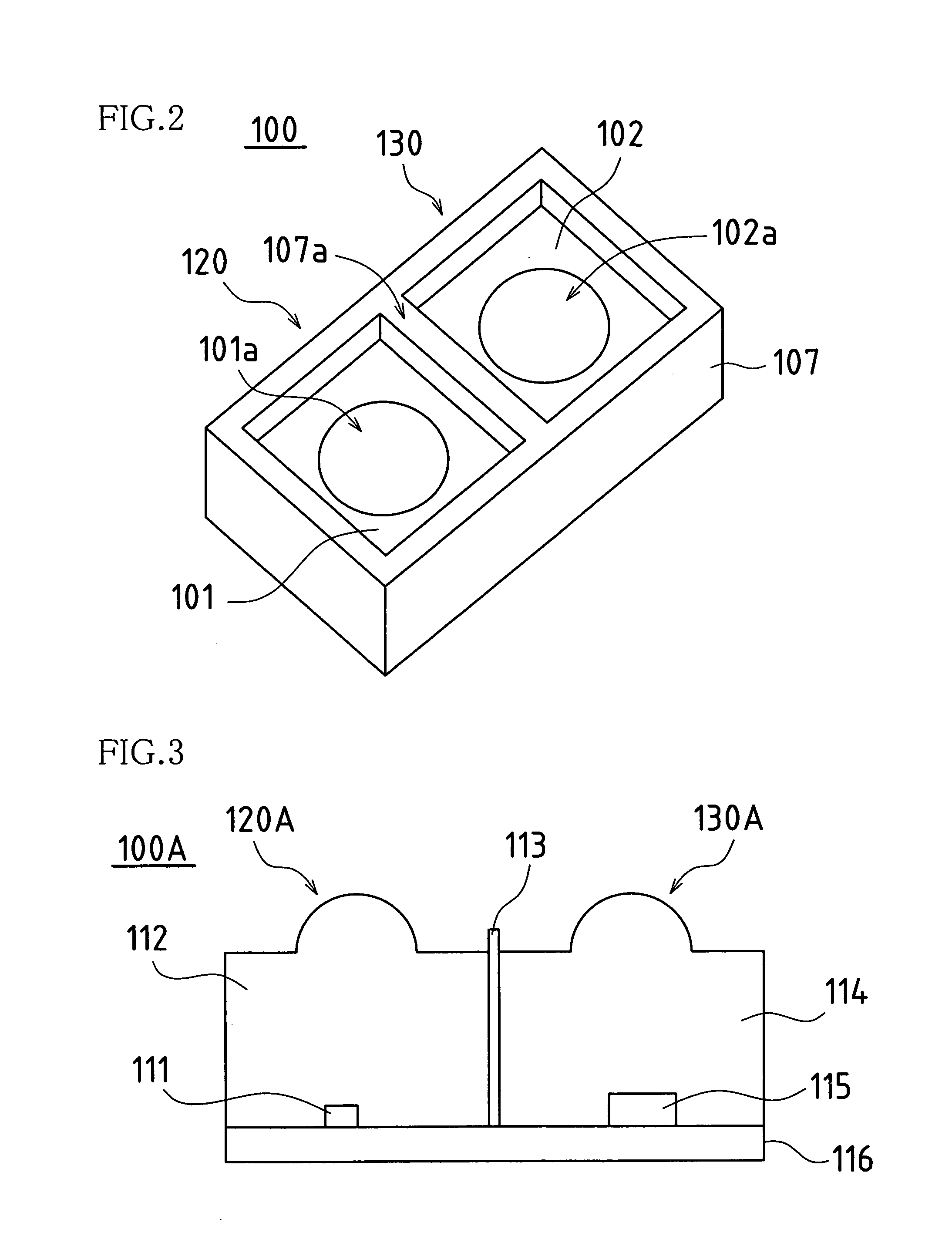

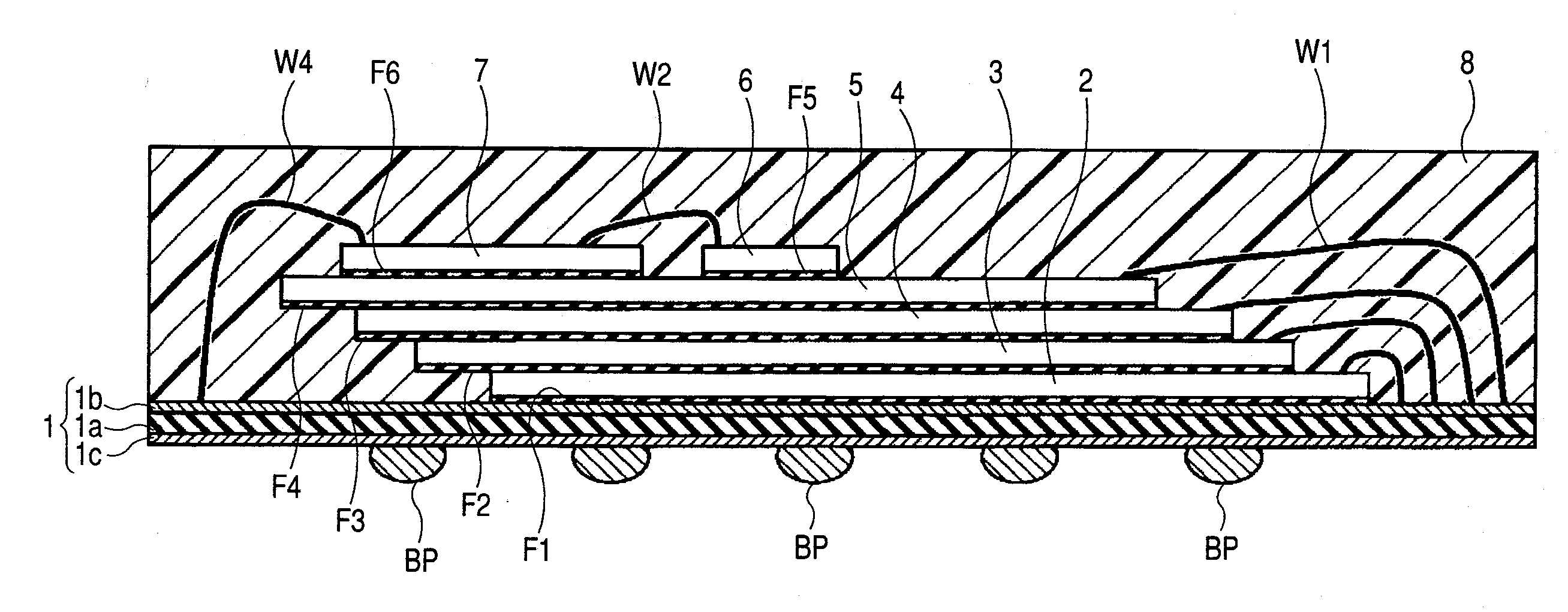

A method includes: mounting a plurality of semiconductor elements on a substrate having wirings; connecting electrically electrodes of the semiconductor elements and the wirings; sealing the semiconductor elements with a resin, which is carried out by bringing a thermal conductor having a concavity and the substrate to be in contact with each other so that the semiconductor elements are positioned within the concavity and by filling the concavity with the resin; and separating respective semiconductor elements 1. In the resin-sealing step, in a state where the thermal conductor is arranged with its concavity facing up and the concavity of the thermal conductor is filled with a liquid resin, the semiconductor elements are dipped in the liquid resin in the concavity and the liquid resin is solidified. Due to these steps, a semiconductor device can be manufactured without experiencing troubles such as short circuit of the metal thin wires or imperfect filling of resin during the manufacturing steps, and thus semiconductor devices with stable quality can be manufactured.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

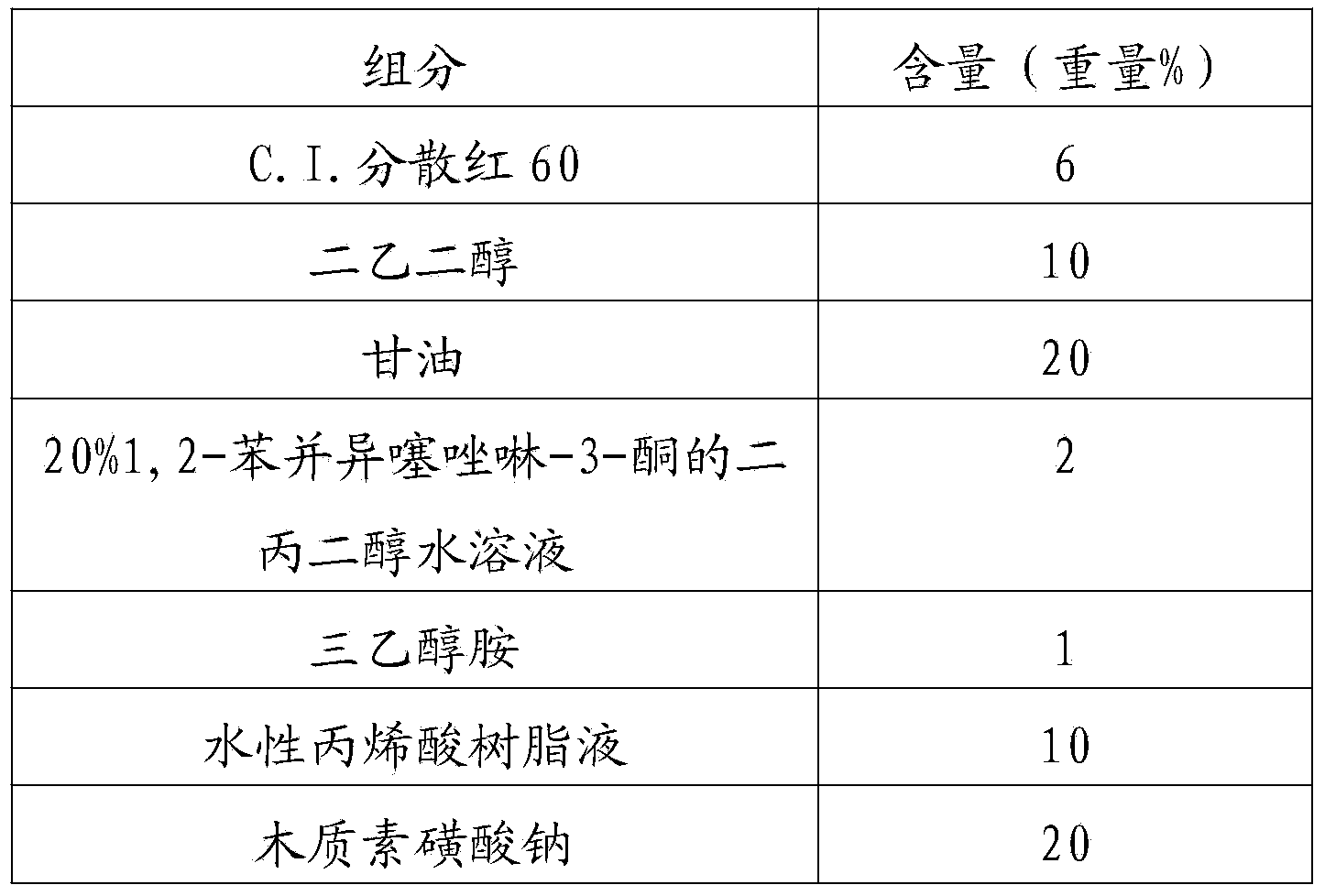

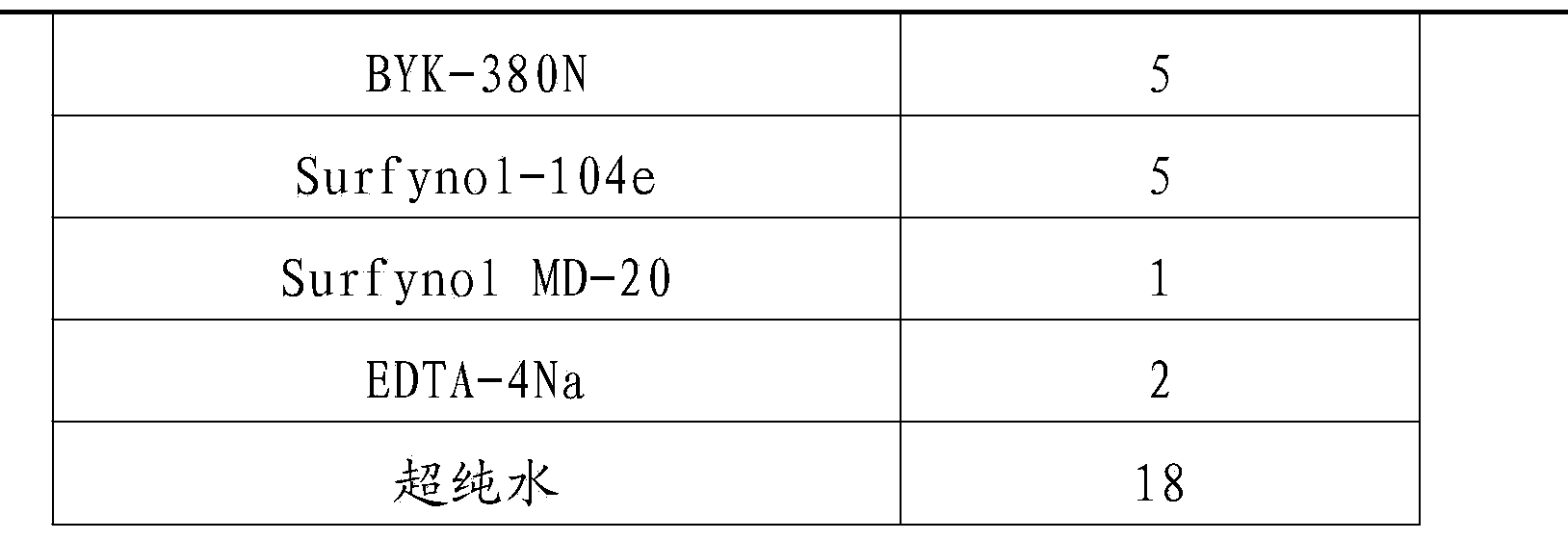

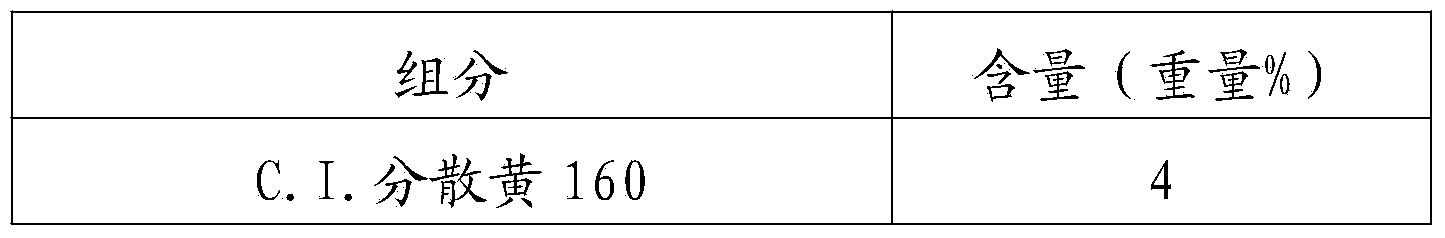

Sublimation ink-jetting ink used for industrial nozzle and manufacturing method thereof

The invention relates to an ink-jetting ink, in particular to a sublimation ink-jetting ink used for an industrial nozzle and a manufacturing method thereof. The sublimation ink-jetting ink comprises, by weight, 1-6% of disperse dyes, 10-14% of wetting agents, 5-20% of viscosity adjusting agents, 0.1-2% of bactericides, 0.01-1% of pH buffering agent, 1-10% of liquid resin, 0.1-40% of disperse agents, 0.01-5% of antifoaming agents, 0.1-5% of surface active agents, 0.01-2% of metal ion chelating agents and 10-80% of purified water. The manufacturing method of the sublimation ink-jetting ink used for the industrial nozzle includes color paste manufacturing and finished product manufacturing. The sublimation ink-jetting ink used for the industrial nozzle is simple in manufacturing method, smooth in ink jetting, free of blocking the nozzle, good in dispersion stability, free of going bad or denaturing even if being stored for a long time and low in cost, and diameters of dispersed ink points are even.

Owner:山东力美喷墨科技有限公司

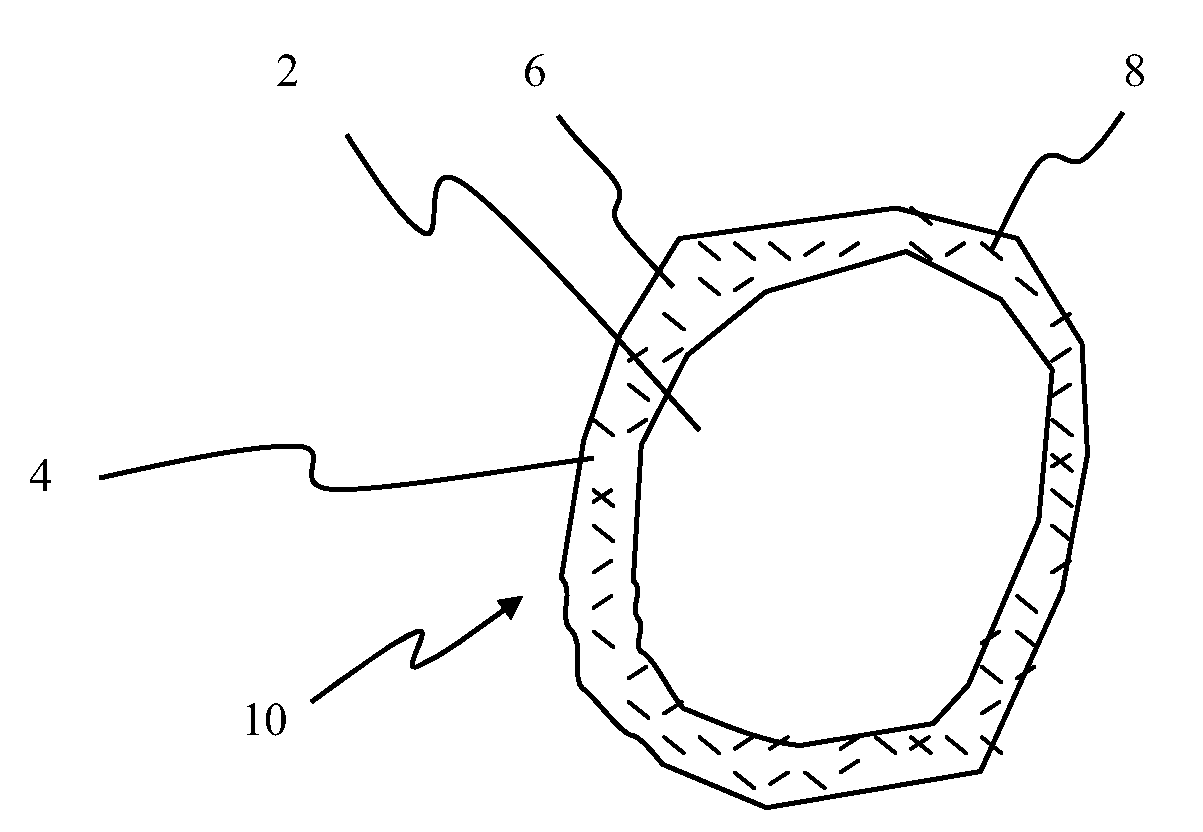

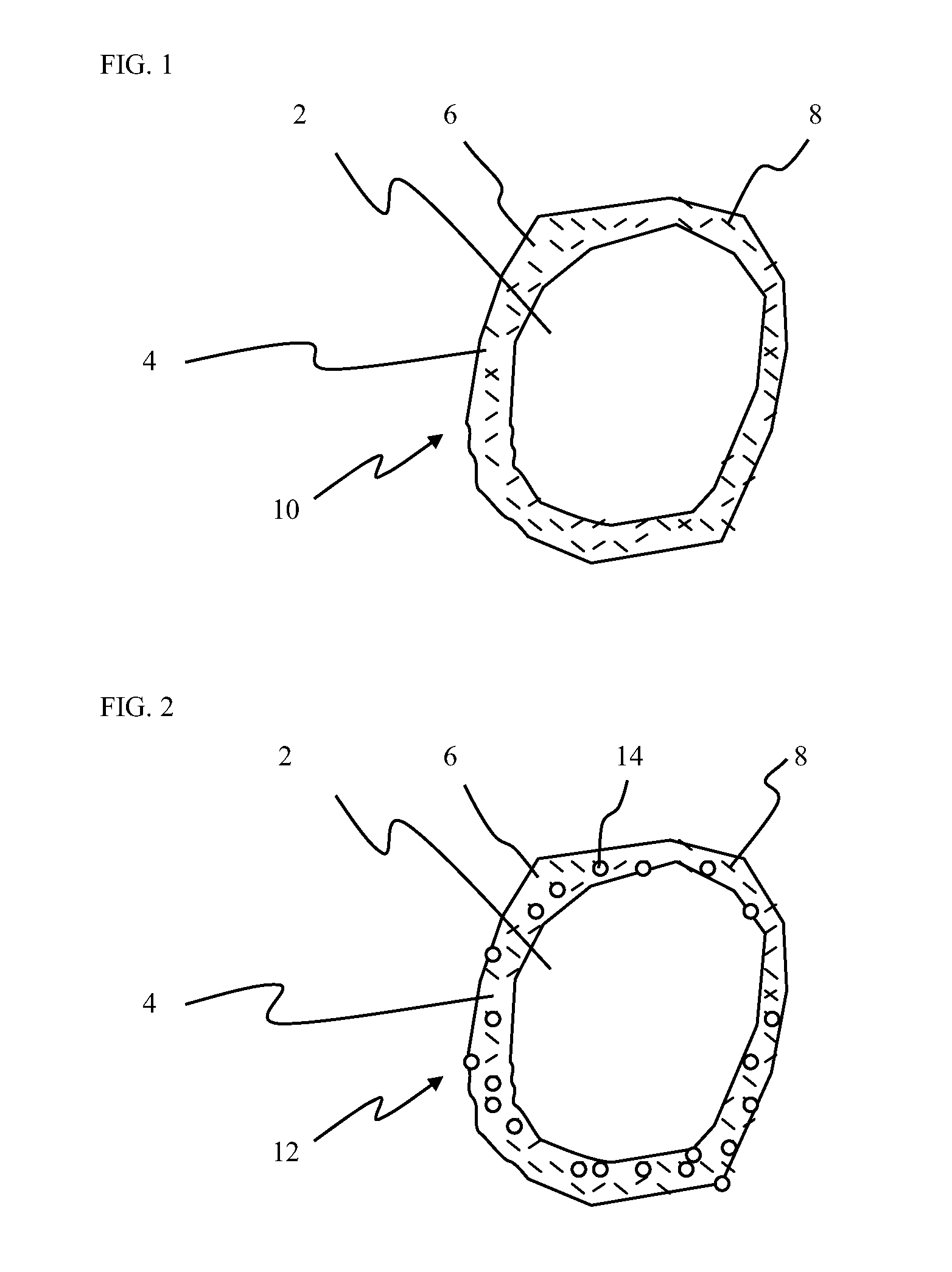

Preform for composite material and composite material

InactiveUS6828016B2High strengthMaintain good propertiesSynthetic resin layered productsAbsorbent padsTransfer moldingFiber-reinforced composite

A preform can be molded by resin transfer molding and yields a composite material having excellent strength and excellent interlaminar debonding resistance. The preform, which is for producing a fiber-reinforced composite, comprises layers of laminated structure of a reinforcing material comprising reinforcement fibers and has, between these layers, a layer comprising a thermoplastic resin and having space so as not to inhibit a liquid resin from flowing therethrough. The preform is molded to yield a fiber-reinforced composite material.

Owner:MITSUBISHI CHEM CORP

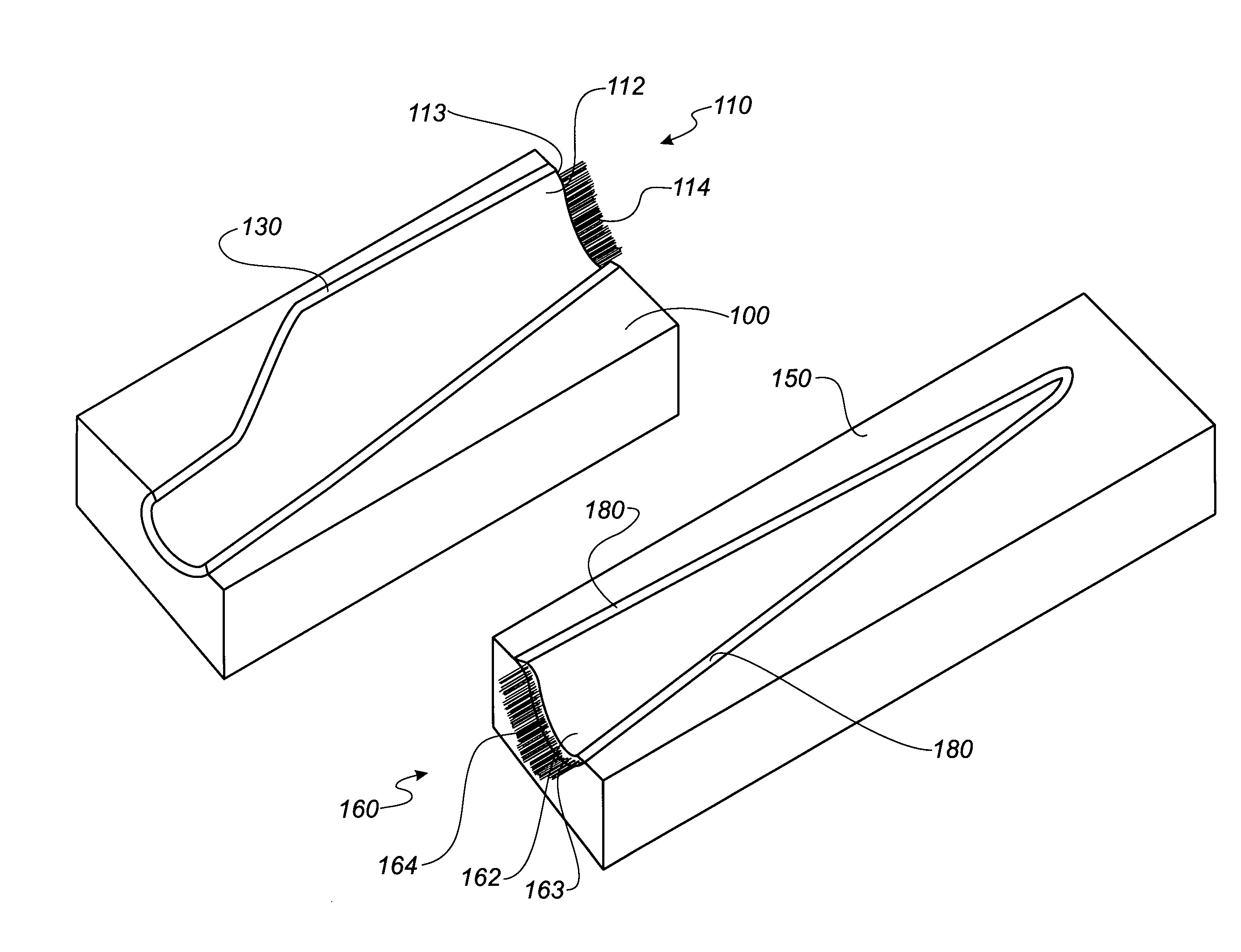

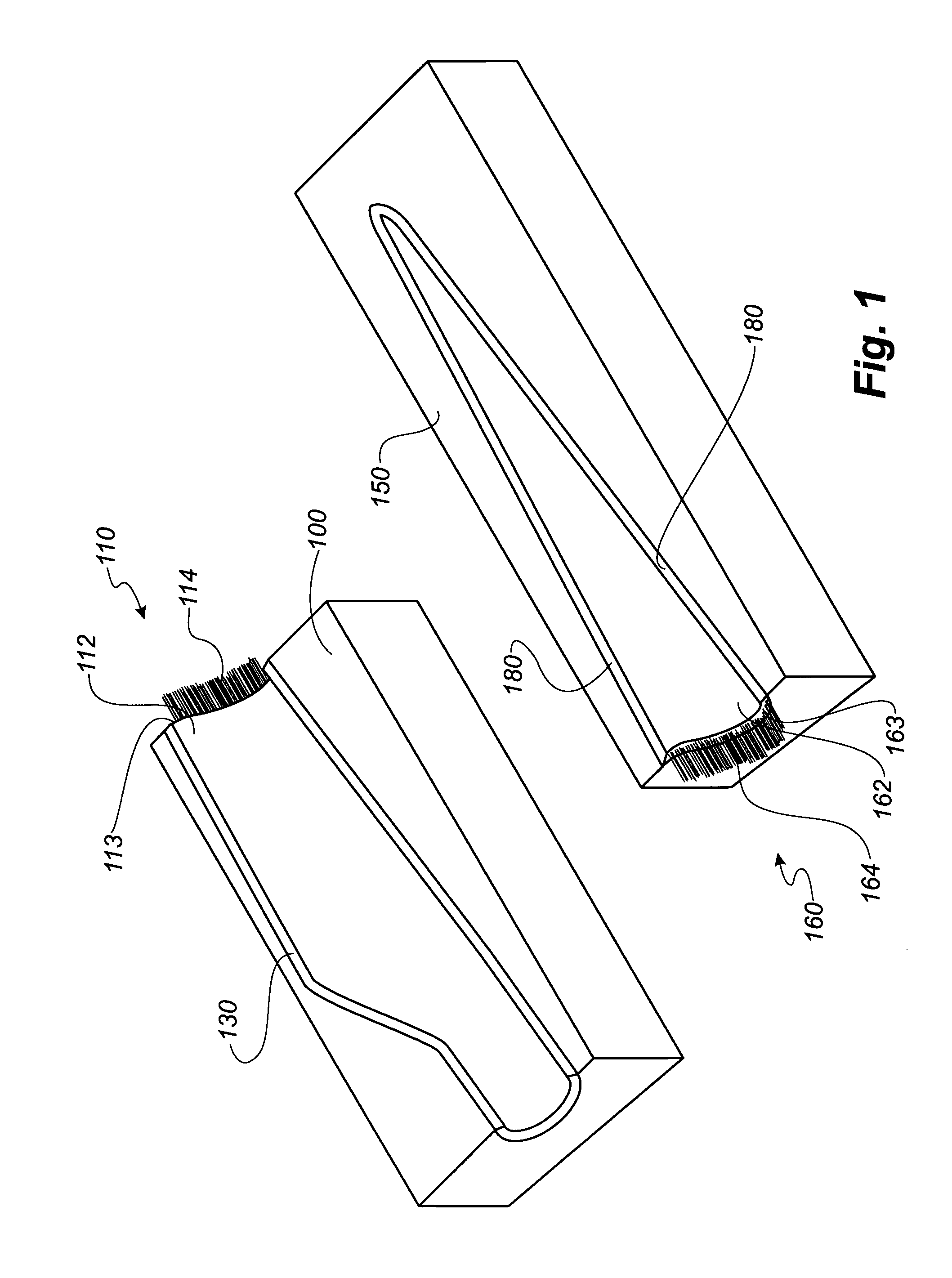

Method of producing a composite structure via intermediate products, the related apparatus and a composite structure obtainable by the method

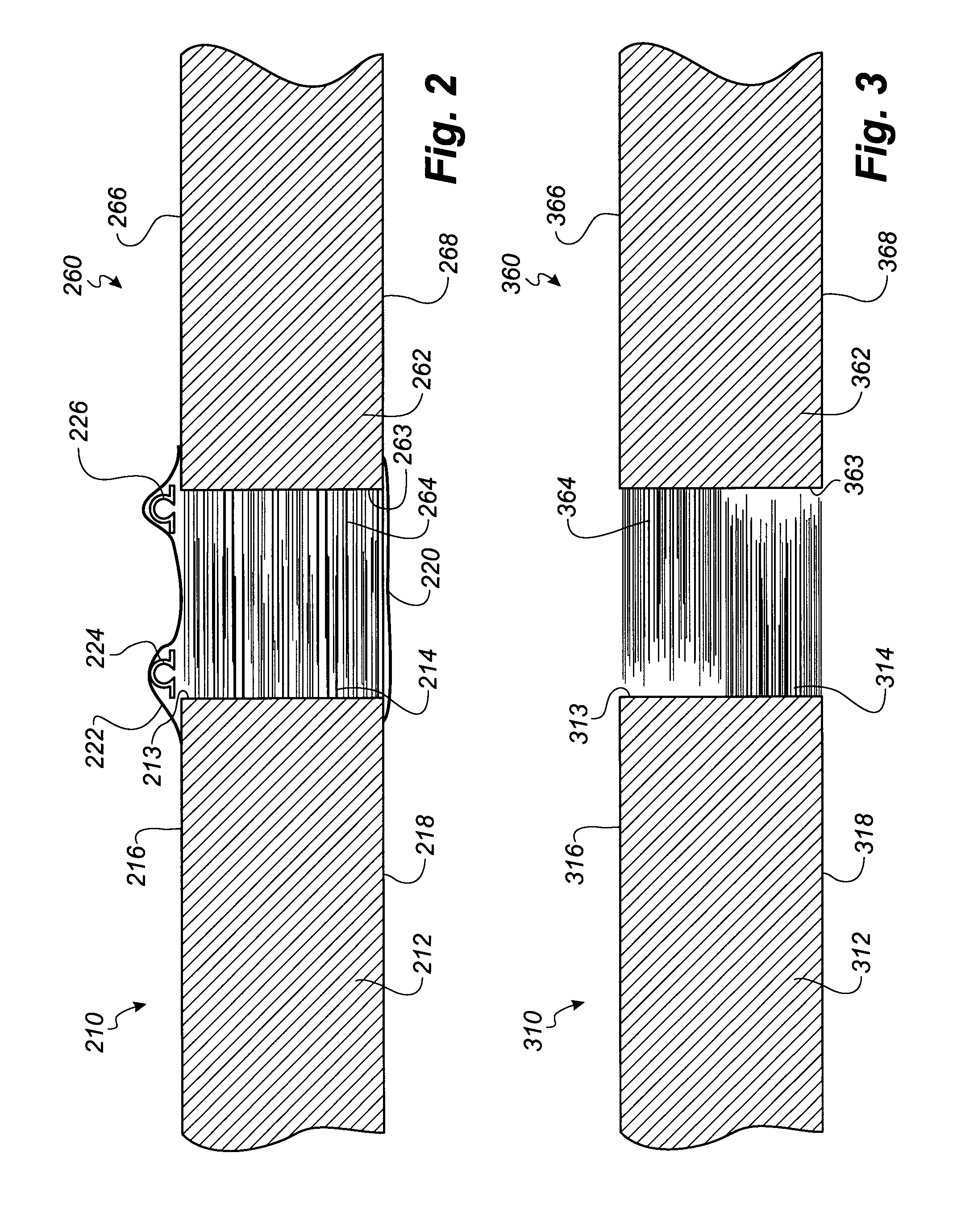

ActiveUS20100304170A1High fiber densityFirmly connectedLaminationLamination apparatusFiberLiquid resin

A method of producing a composite structure comprising fibre reinforced material and having a longitudinal direction is described. The method comprises the following steps: a) manufacturing a first structure comprising a first cured composite part having a first thickness and a longitudinal direction with a first end, and a number of first fibre layers extending from the first end, b) manufacturing a second structure comprising a second cured composite part having a second thickness and a longitudinal direction with a second end, and a number of second fibre layers extending from the second end, and c) arranging the first structure and the second structure so that the first end faces towards the second end, and arranging the first fibre layers and the second fibre layers so that at least a part of the first fibre layers overlap at least a part of the second fibre layers in the longitudinal direction, d) supplying liquid resin in order to impregnate the first fibre layers and the second fibre layers, and e) curing the liquid resin in order to form the composite structure comprising the first cured composite part, the second cured composite part, and an intermediate composite part including the first fibre layers and the second fibre layers.

Owner:LM GLASSFIBER

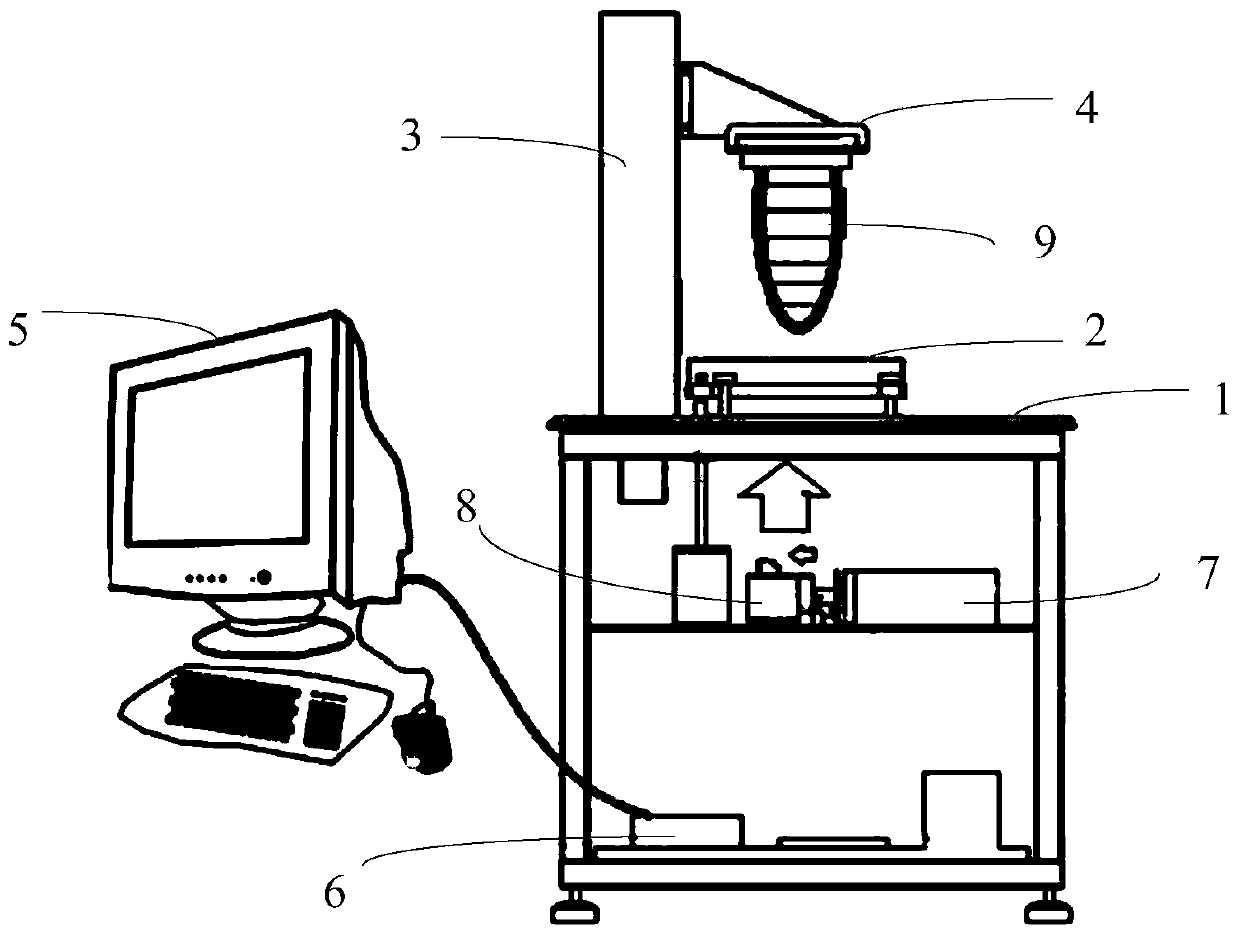

DLP principle based 3D printer

The invention discloses a DLP principle based 3D printer. The 3D printer includes: a resin tank, the bottom plate of which is light-transmitting; a vertical lifting mechanism, which is in fixed connection with a forming platform and is used for adjusting the distance between the resin tank and the forming platform; a computer, which is used for processing a three-dimensional model and segmenting the three-dimensional model into several profile graphs with certain thickness sequentially, and is connected to an electrical control device for controlling automatic lifting of the forming platform by the vertical lifting mechanism and controlling irradiation of a DLP projector on the liquid level of light-cured resin in the resin tank; and the DLP projector, which is arranged below the resin tank and is connected to the computer, and makes the graph light path of the profile graphs transmit the bottom plate of the resin tank so as to irradiate the light-cured liquid resin. According to the invention, the DLP projection technology is adopted and the light cured material forming technology is combined to form a set for system. The system has the characteristics of simple components and compact whole structure, the formed products have improved precision, the manufacturing cost is low, and the product forming speed is faster.

Owner:SHANGHAI KUNRONG IND

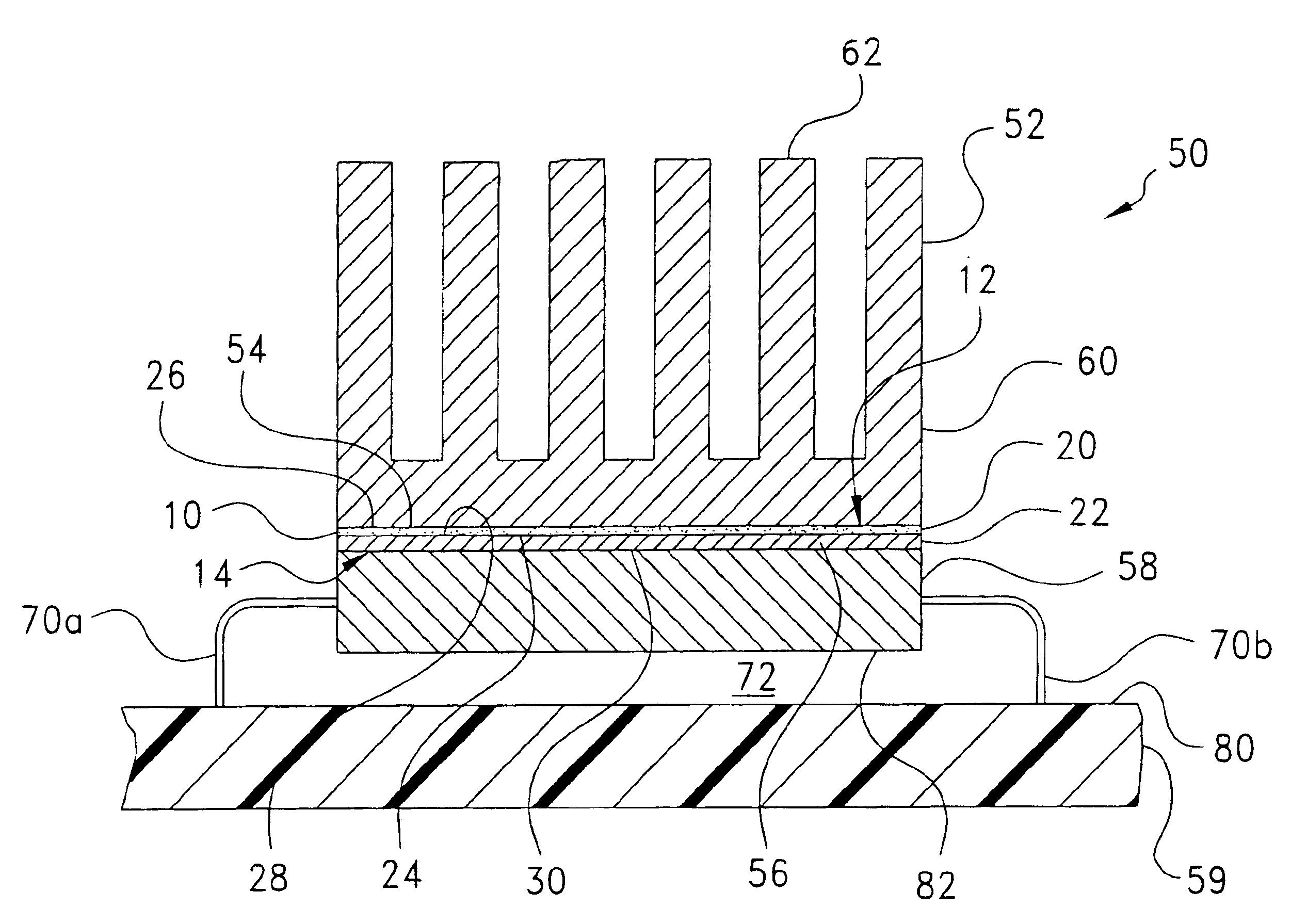

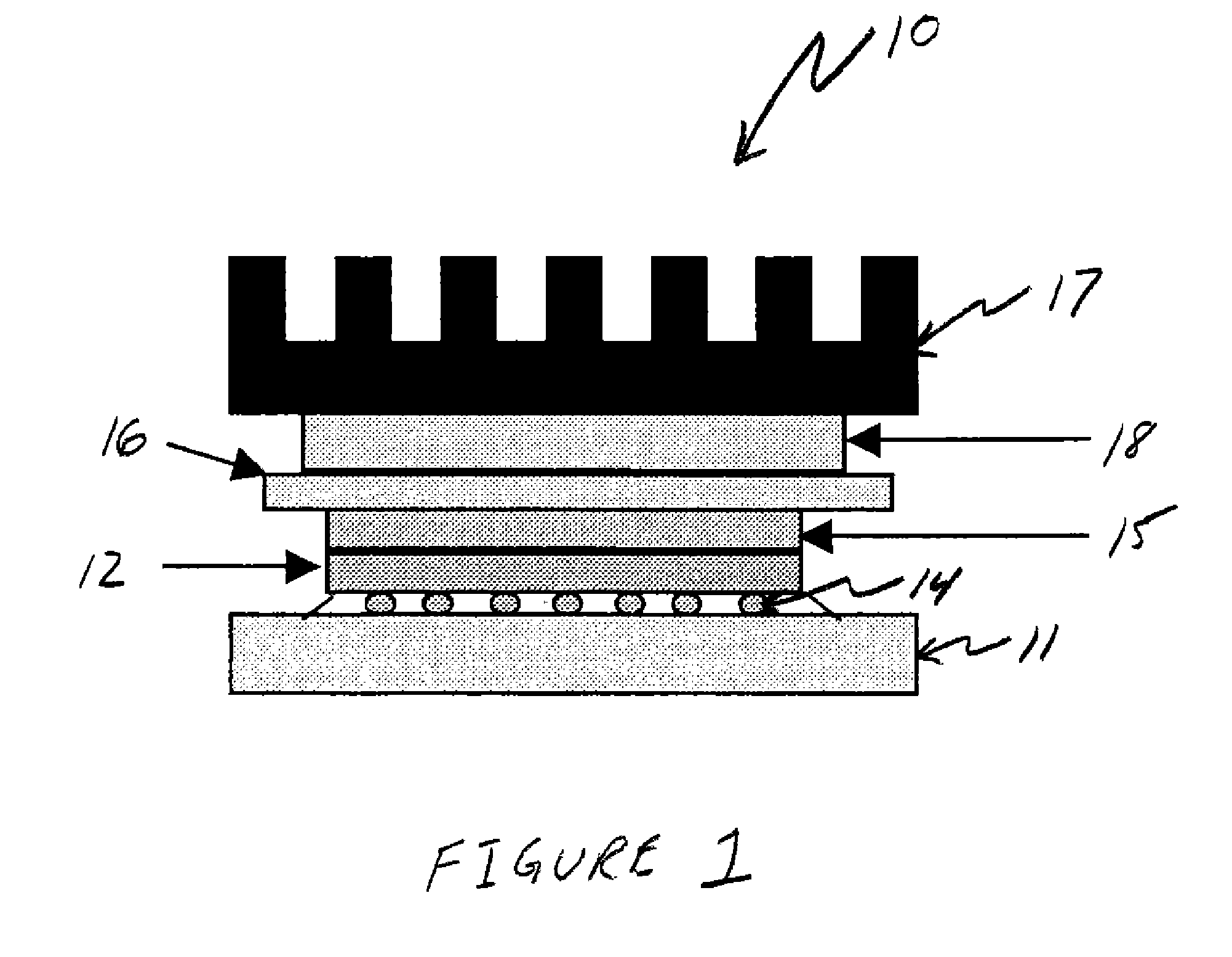

High temperature stable thermal interface material

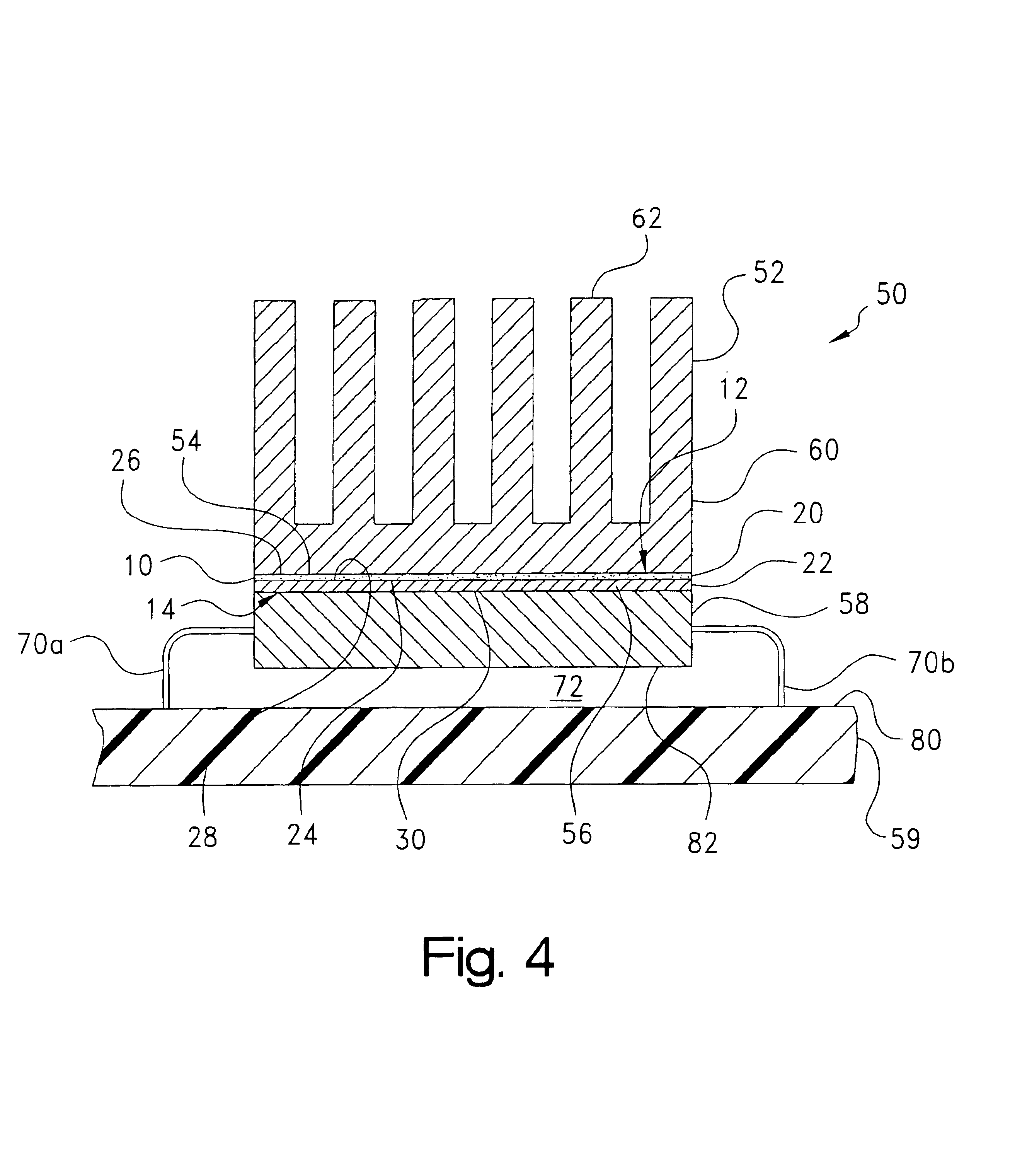

InactiveUS6956739B2Reduce thermal resistanceImprove performanceSemiconductor/solid-state device detailsSynthetic resin layered productsParticulatesLiquid resin

A thermally-conductive interface interposable intermediate a first heat transfer surface and an opposing second heat transfer surface to provide a thermal pathway therebetween. The interface includes a thermally-conductive compound formed into a layer which is conformable between the first and second heat transfer surface. The compound is an admixture of: (a) a liquid resin constituent; and (b) a particulate filler constituent. The liquid resin constituent may be an ethylene-propylene copolymer (EPM) or a terpolymer (EPDM) of ethylene and propylene and a diene which may be ethylidene norbornene (ENB) or dicyclopentadiene (DCPD).

Owner:PARKER INTANGIBLES LLC

Three-dimensional printing systems for rapidly producing objects

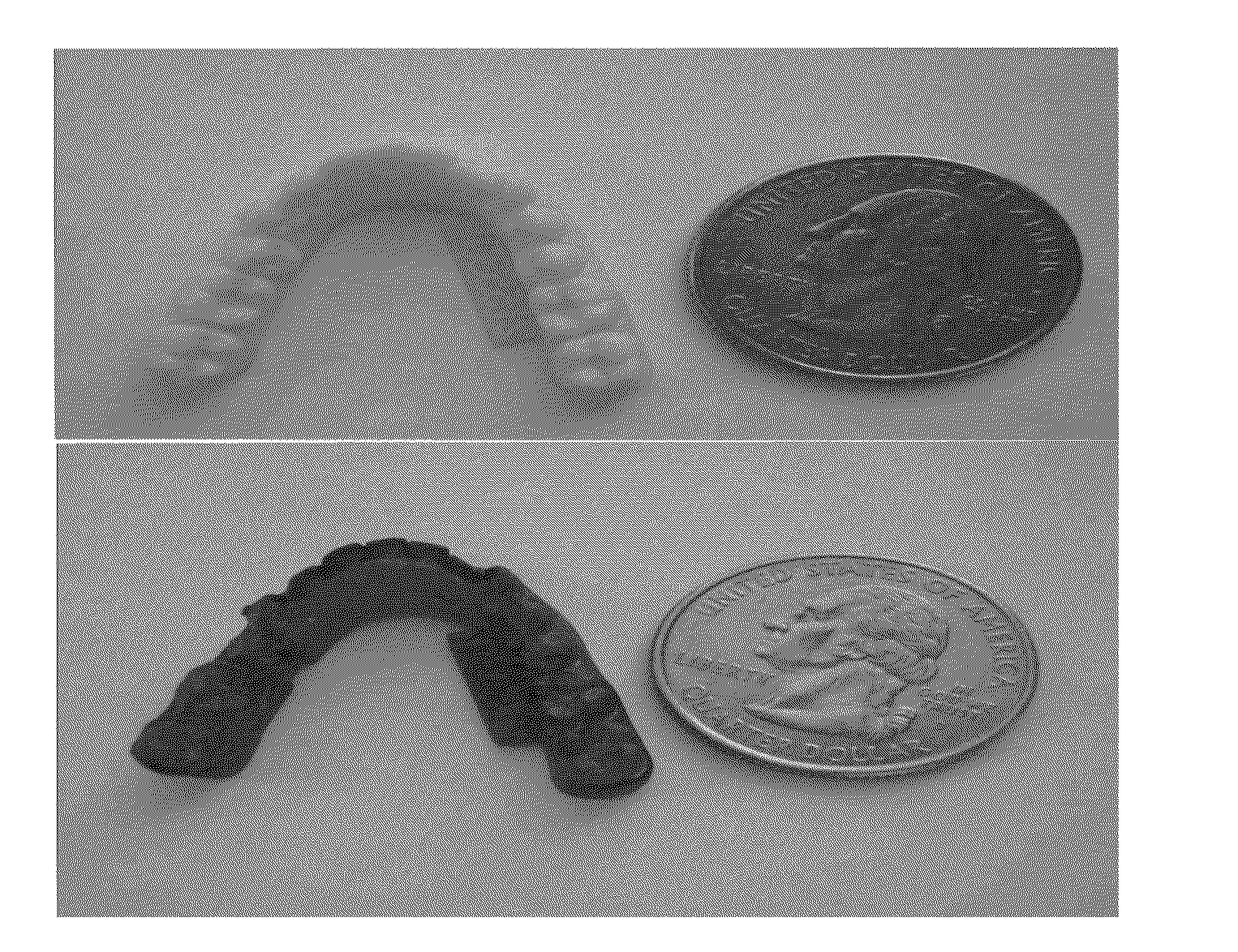

This invention relates to rapid prototyping systems, specifically, a continuous moving surface liquid resin system (CMSL) and fast printing method for making any 3D objects, such as dental devices, including but not limited to artificial teeth, dentures, orthodontic appliances, aligners, splints, veneers, inlays, onlays, copings, frame patterns, crowns and bridges and the like. 3D printers, such as DLP or stereolithography printer, are used to cure polymerizable material in a layer-by-layer manner to build-up the object rapidly and continuously.

Owner:DENTSPLY SIRONA INC

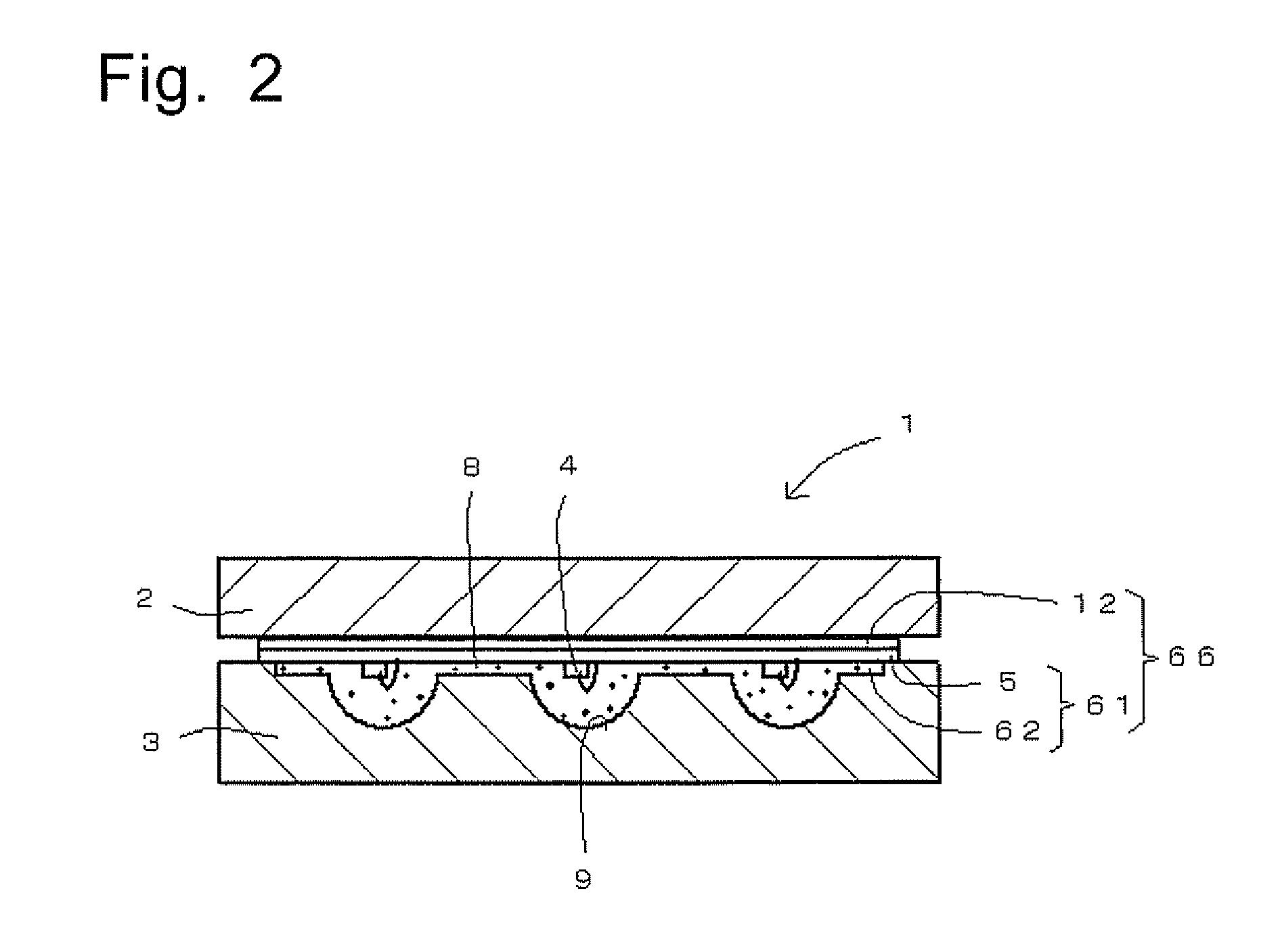

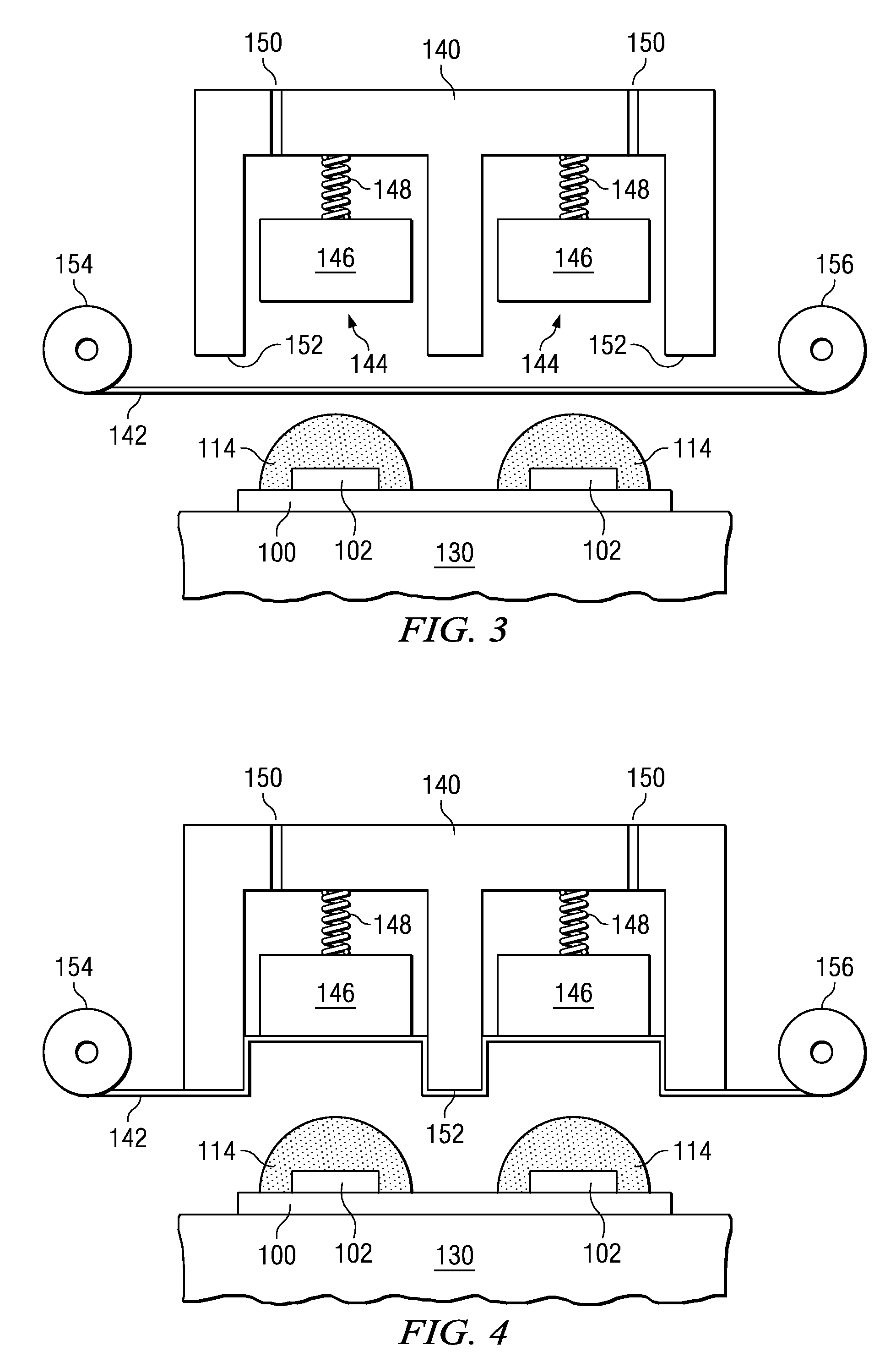

Method of compression-molding light-emitting elements

InactiveUS20100065983A1Inhibition formationImprove production efficiencySolid-state devicesOptical articlesCompression moldingShell molding

A method of compression-molding light emitting elements is provided, which can efficiently prevent the formation of a resin burr on a frame on which LED chips (light-emitting elements) are mounted. A tape for resin burr prevention is adhered to a surface of the frame, i.e. the surface on which no light-emitting element is mounted, to form a tape-applied frame. The tape-applied frame is supplied and set onto a setting section of an upper die, with the LED chips directed downwards. A required amount of transparent liquid resin material is dripped by a dispenser into a large cavity including small cavities. Then, both the upper and lower dies are clamped with a required clamping pressure, whereby the LED chips are individually immersed in the resin contained in the small cavities inside the large cavity and compression-molded to form a molded frame (light emitters).

Owner:TOWA

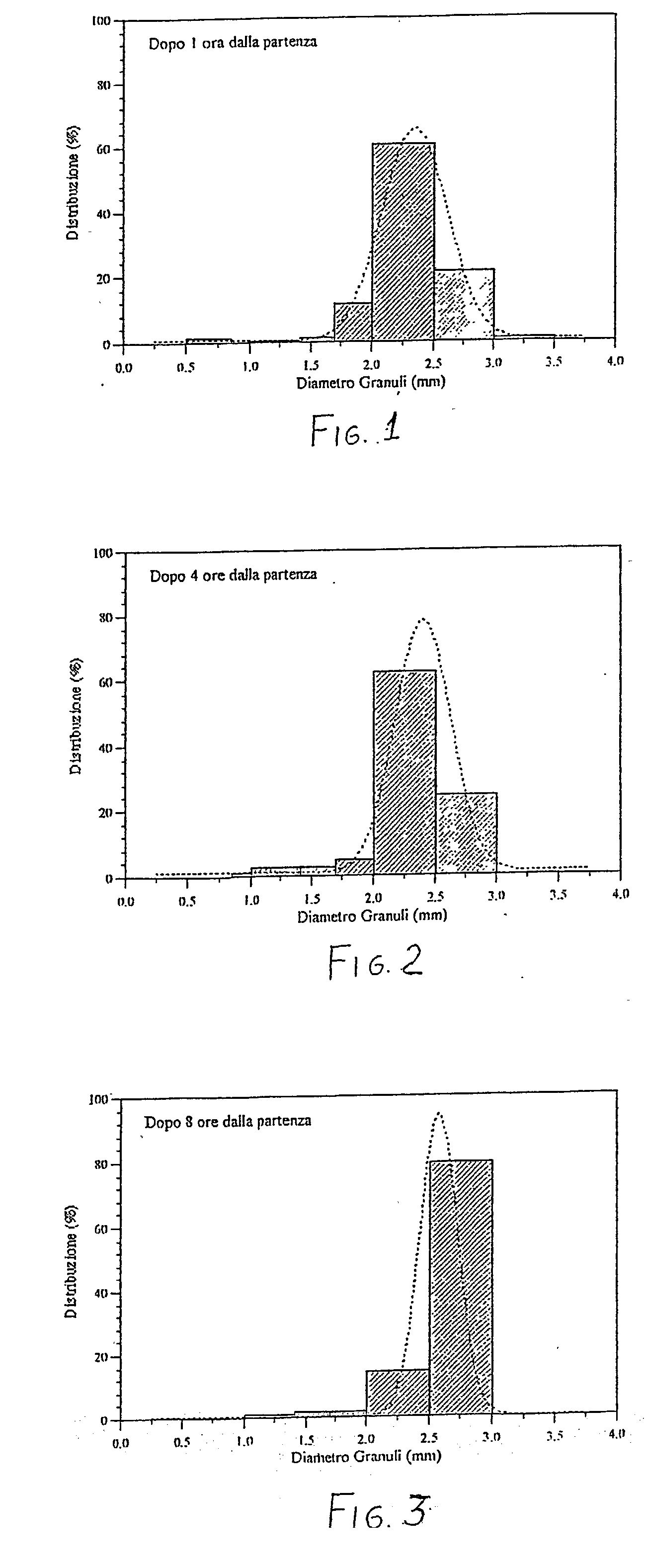

Method for making nitrogenous and complex fertilizers in highly homogenized spherical granule form starting from urea formaldehyde liquid resins and the fertilizer made thereby

InactiveUS20030154754A1Easily and accurately controlSafe and reliableSolid/semi-solid fertilisersUrea compound fertilisersSpherical granuleNitrogen

The present invention relates to a method for making nitrogenous and complex fertilizers, in granule form, suitable for slowly releasing nitrogen, comprising the steps of preparing an aqueous urea / formaldehyde dispersion with a molar ratio from 0.8:1 to 2:1, adding an aqueous catalyzer solution in a weight ratio from 0.1 to 4%, controlling the pH of the aqueous dispersion to hold it within a range from 4.0 to 7.0, and supplying the aqueous dispersion to a recirculating granulating device, as a growth seed.

Owner:COSTA GIANCARLO +1

Thermal Interface Material

InactiveUS20070179232A1Non-macromolecular adhesive additivesOther chemical processesPolymer chemistryLiquid resin

A composition for use as a thermal interface material in a heat-generating electronic device is provided. The composition comprises a blend of acrylic polymer, one or more liquid resins, conductive filler particles and optionally one or more solid resins.

Owner:HENKEL KGAA

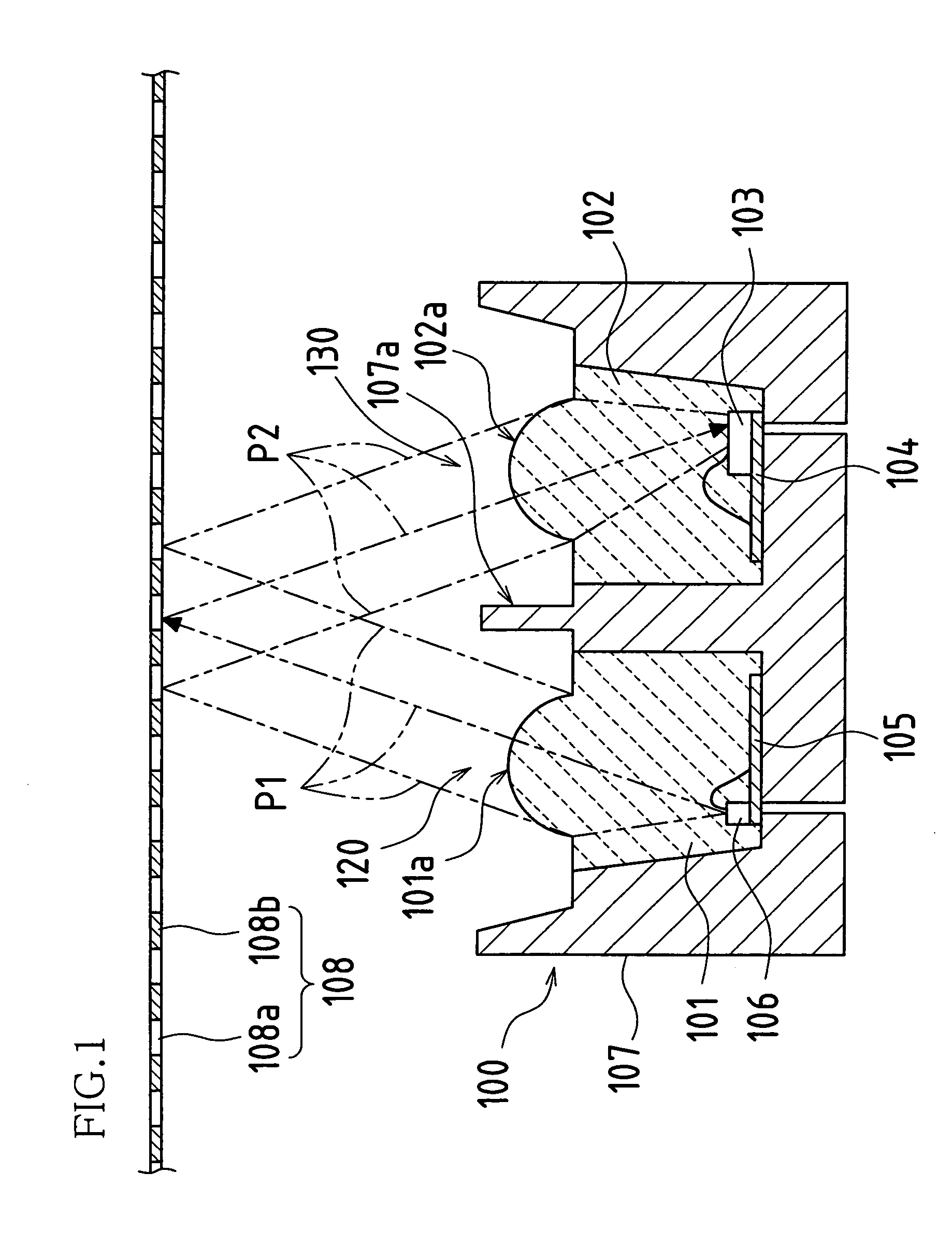

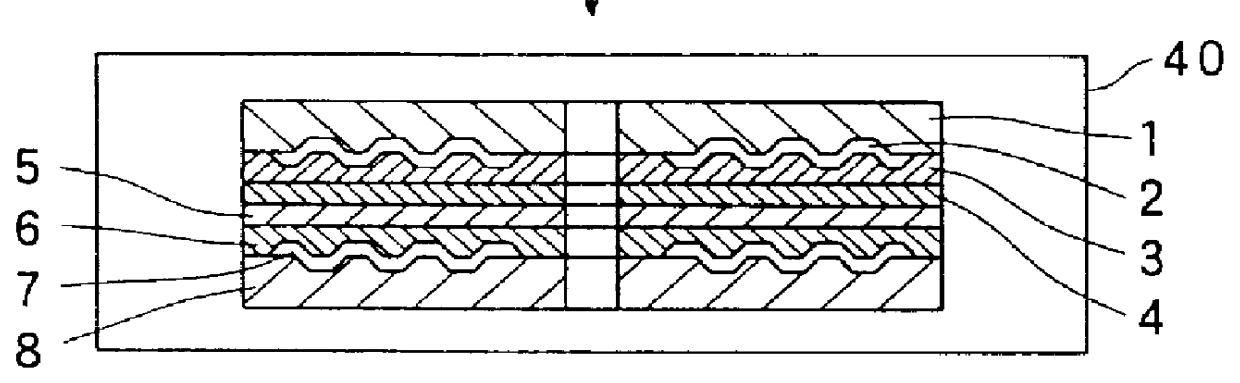

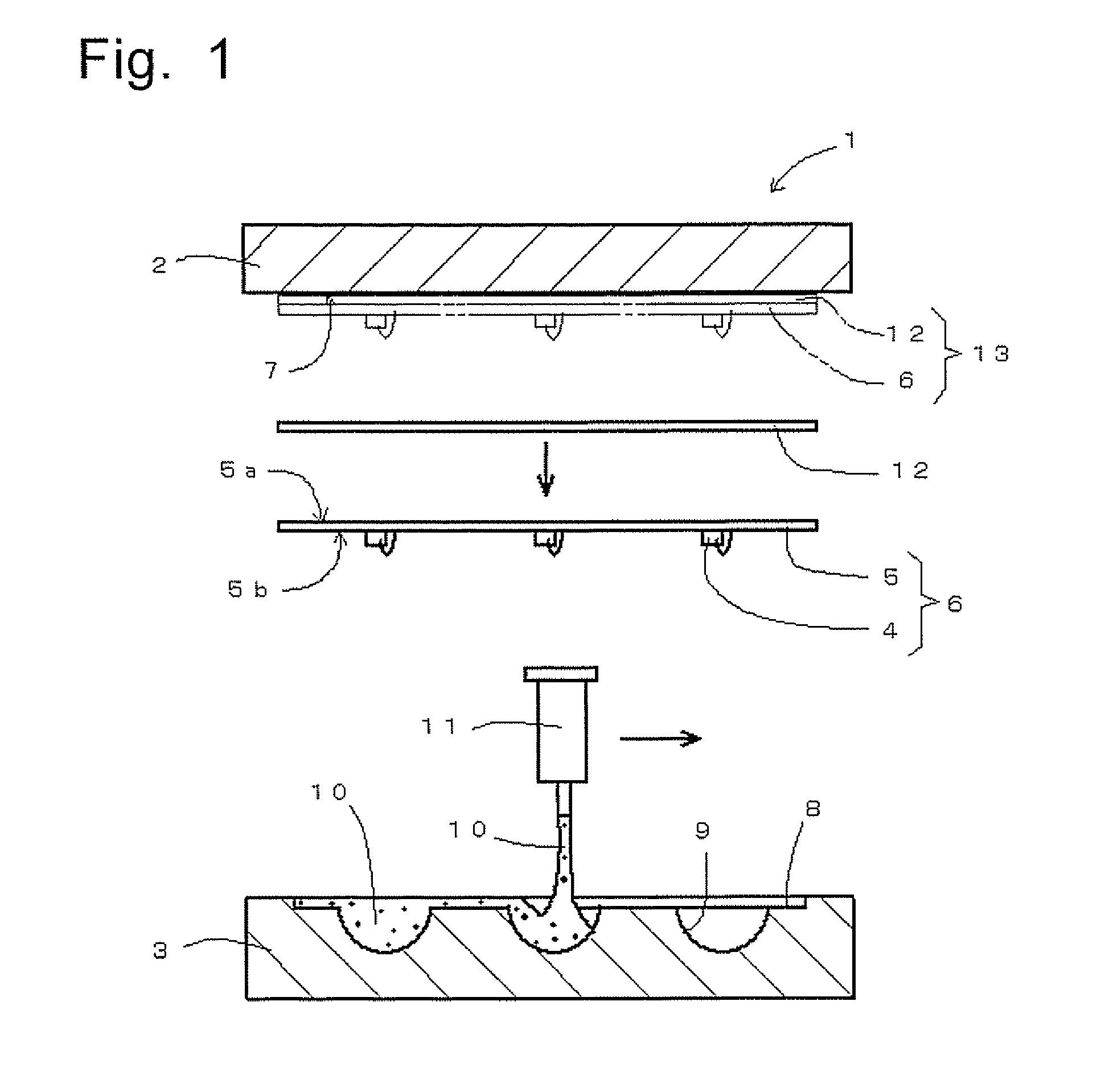

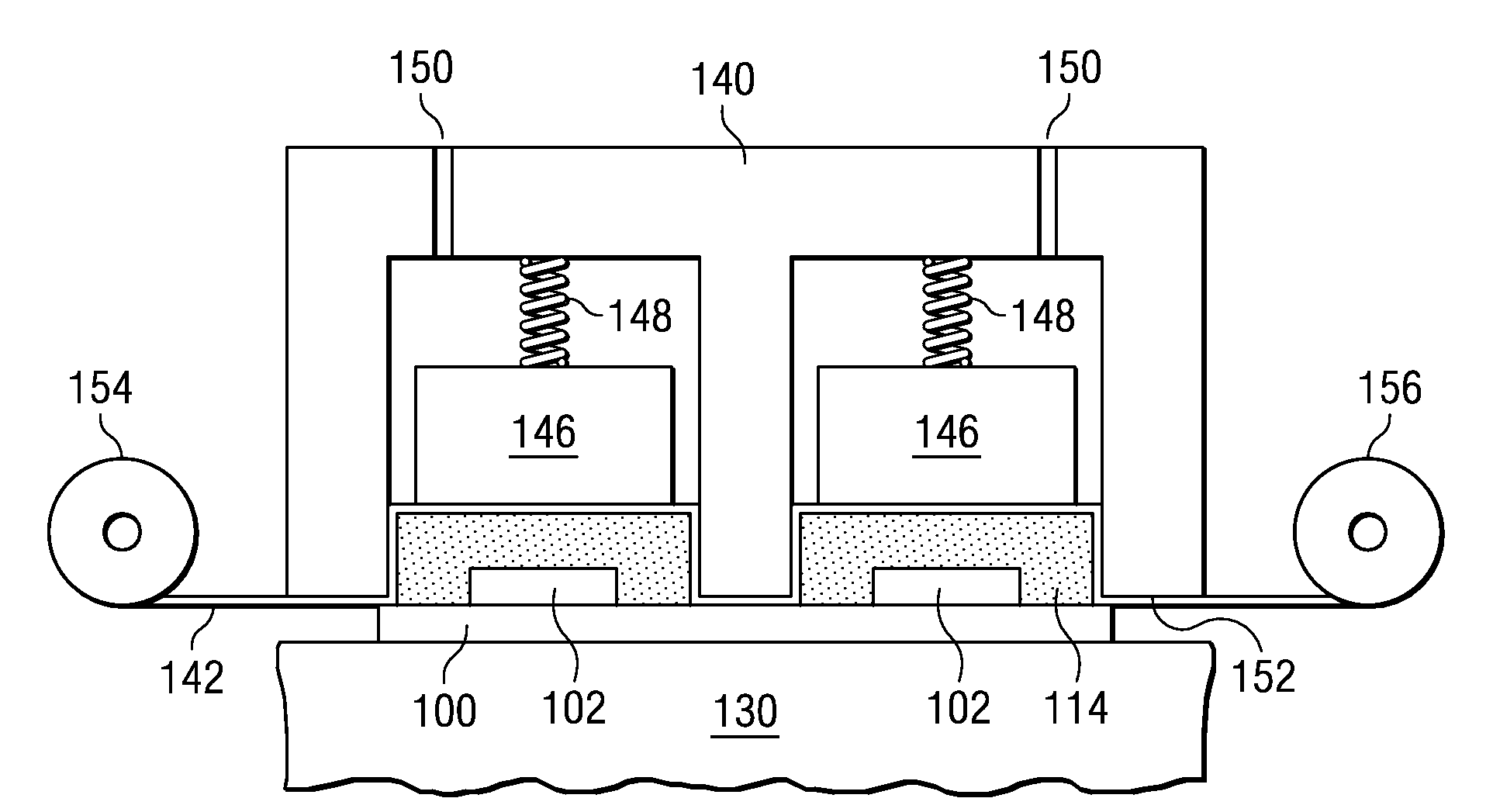

Method of manufacturing a semiconductor device

ActiveUS7520052B2Printed circuit assemblingSemiconductor/solid-state device detailsSemiconductor chipEngineering

The objective of the invention is to provide a method of manufacturing a semiconductor device that allows individual molding of plural semiconductor chips carried on a surface of the substrate. It includes the following process steps: a process step in which plural semiconductor elements 102 are arranged on the surface of substrate 100; a process step in which the inner side of substrate 102 is fixed on lower die 130; a process step in which liquid resin 114 is supplied from nozzle 112 onto each of the semiconductor elements in order to cover at least a portion of each of semiconductor chips 102; a process step in which the upper die having plural cavities 144 formed in one surface is pressed onto the lower die, and liquid resin 114 is molded at a prescribed temperature by means of plural cavities 144; and a process step in which cavities 144 of upper die 140 are detached from the substrate, and plural molding resin portions are formed individually.

Owner:TEXAS INSTR INC

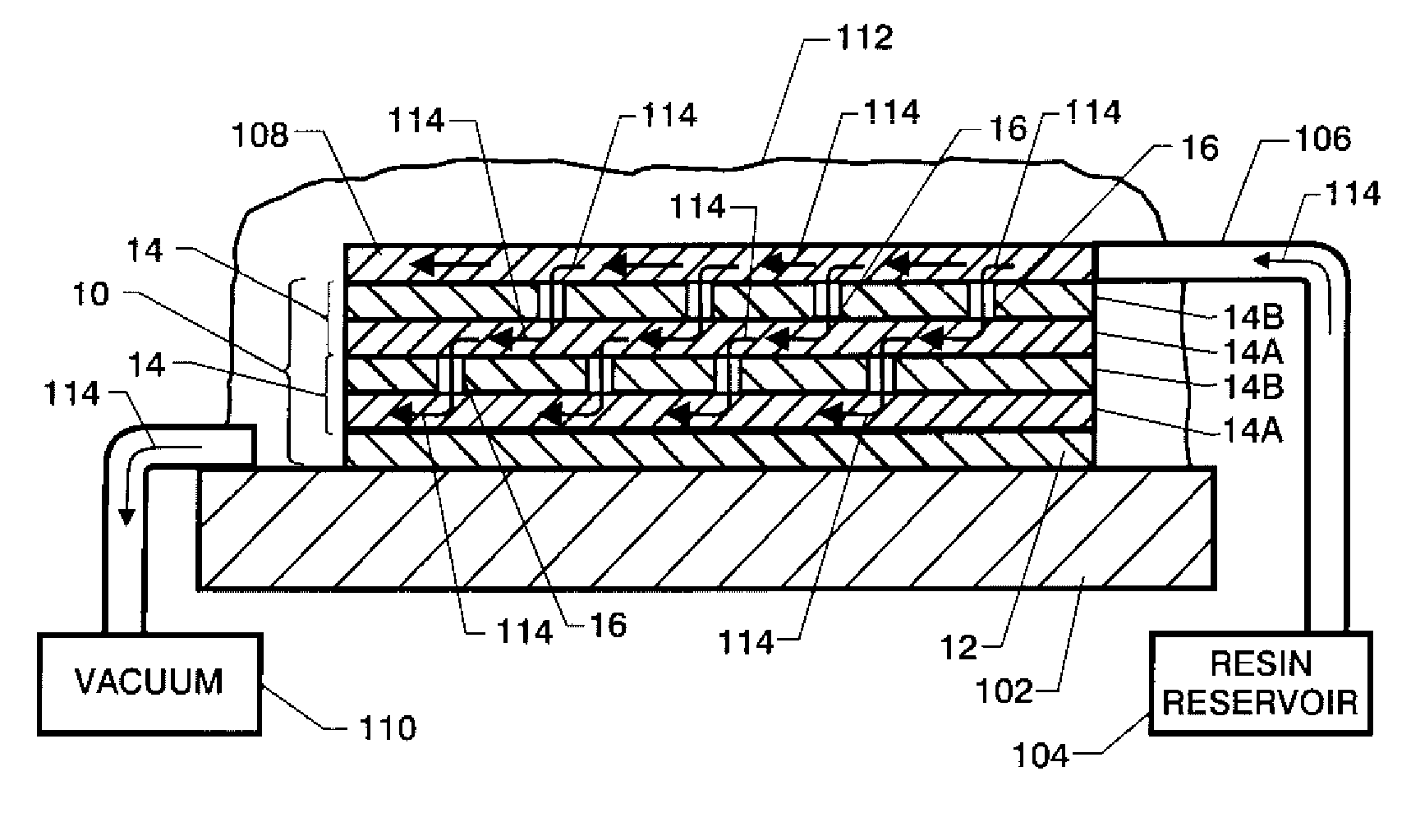

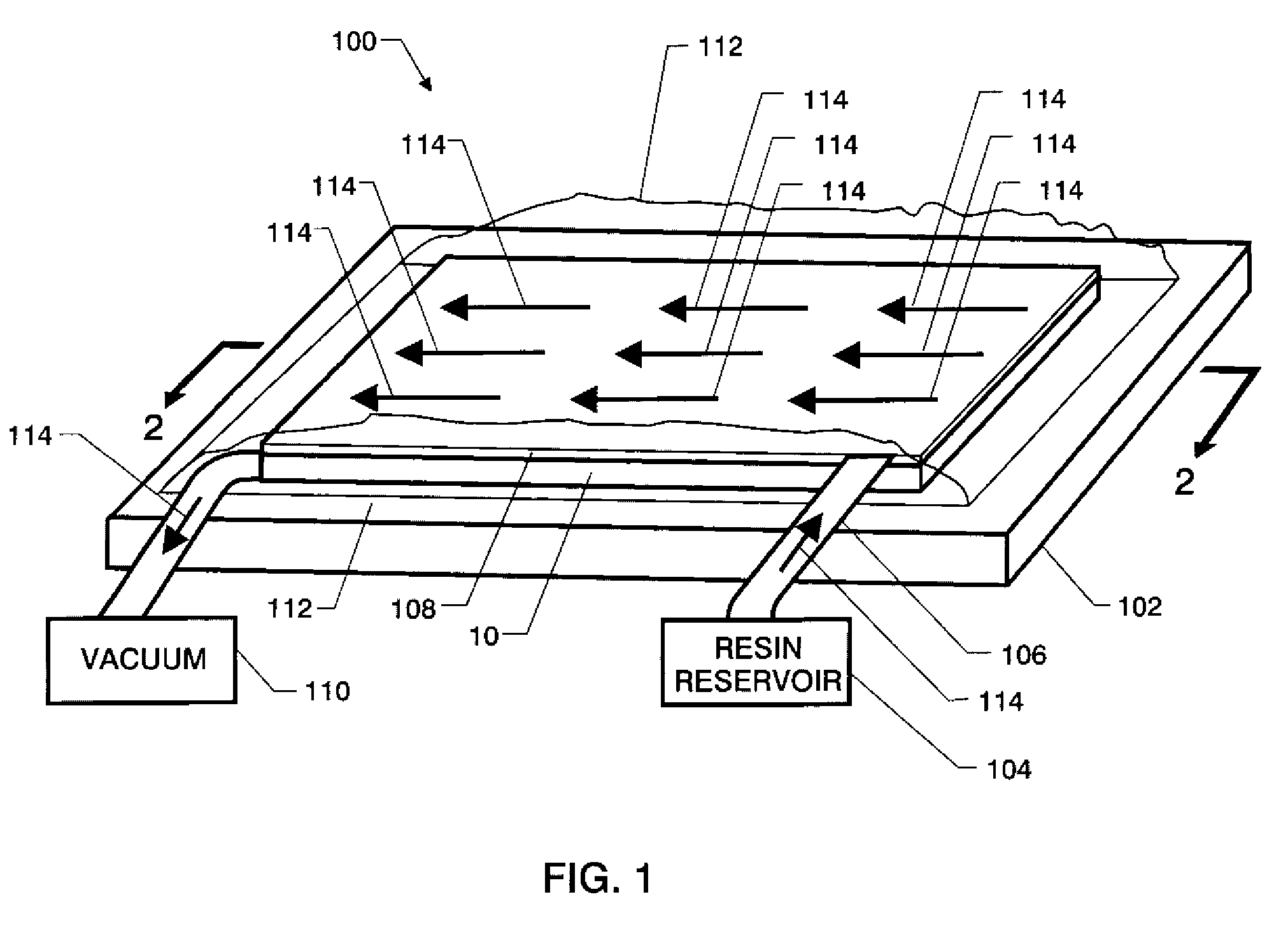

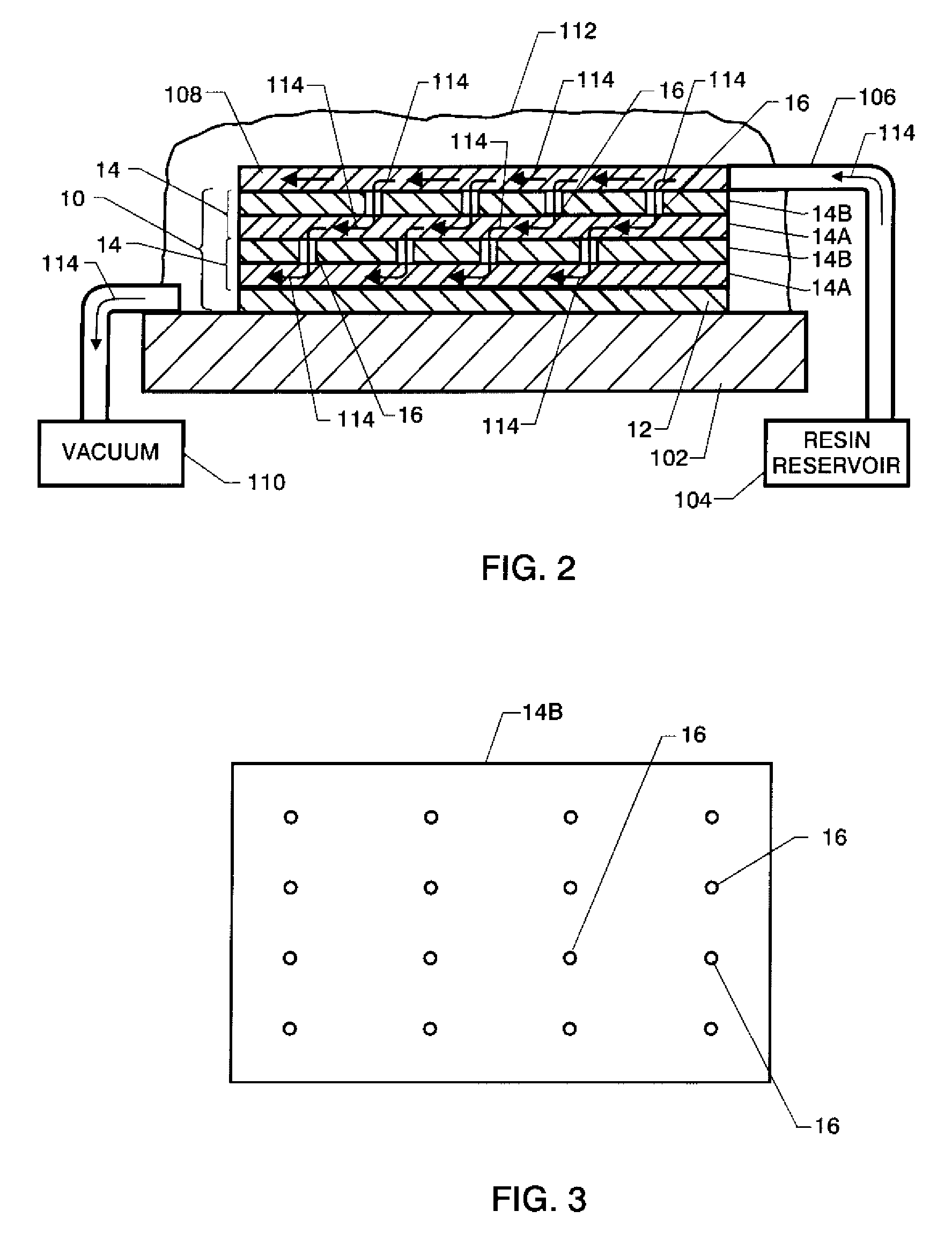

Resin infusion of layered metal/composite hybrid and resulting metal/composite hybrid laminate

A method of fabricating a metal / composite hybrid laminate is provided. One or more layered arrangements are stacked on a solid base to form a layered structure. Each layered arrangement is defined by a fibrous material and a perforated metal sheet. A resin in its liquid state is introduced along a portion of the layered structure while a differential pressure is applied across the laminate structure until the resin permeates the fibrous material of each layered arrangement and fills perforations in each perforated metal sheet. The resin is cured thereby yielding a metal / composite hybrid laminate.

Owner:NASA

Method of Making Ceramic Discharge Vessels Using Stereolithography

InactiveUS20070072762A1Shorten the timeReduce expensesAdditive manufacturing apparatusGas discharge lampsOptoelectronicsViscosity

A method of manufacturing a ceramic discharge vessel for a lamp application is described. The method uses a low viscosity suspension of ceramic powder in a liquid resin. The discharge vessel is formed layer by layer using a stereolithography system. Preferably, the layers are formed by locally exposing the ceramic-resin mixture to a UV light source that solidifies and cures the resin only in the areas which correspond to the particular cross-sectional profile of the discharge vessel for a respective layer.

Owner:OSRAM SYLVANIA INC

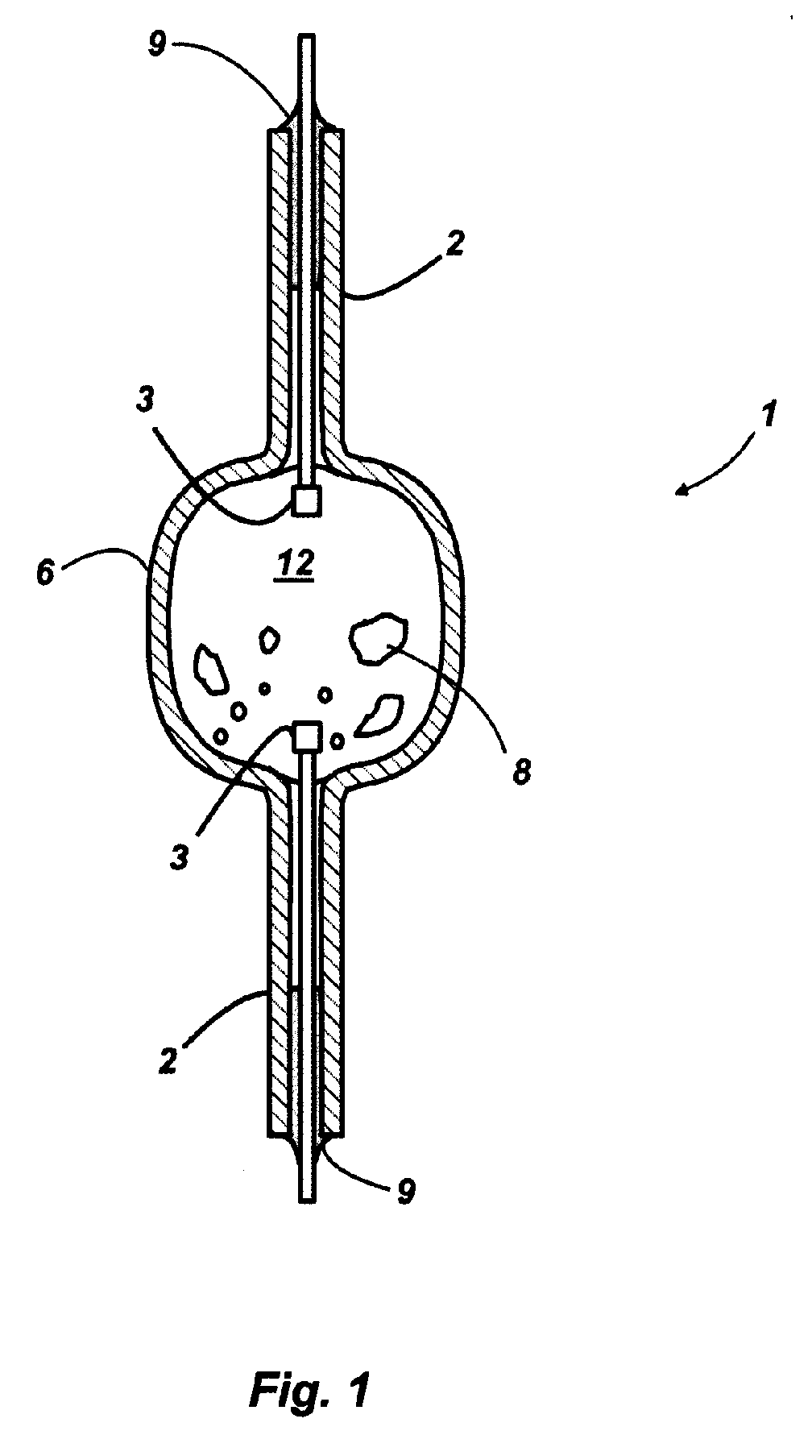

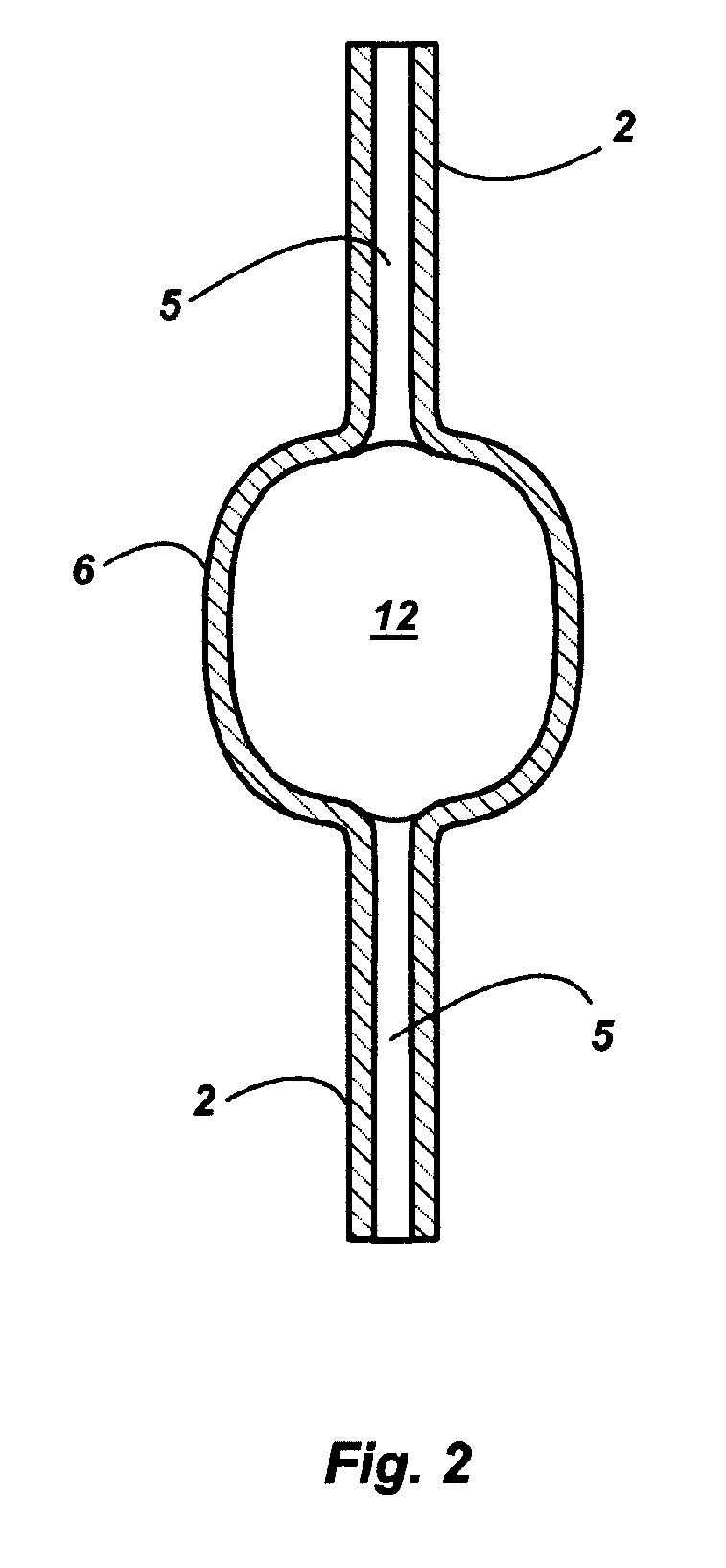

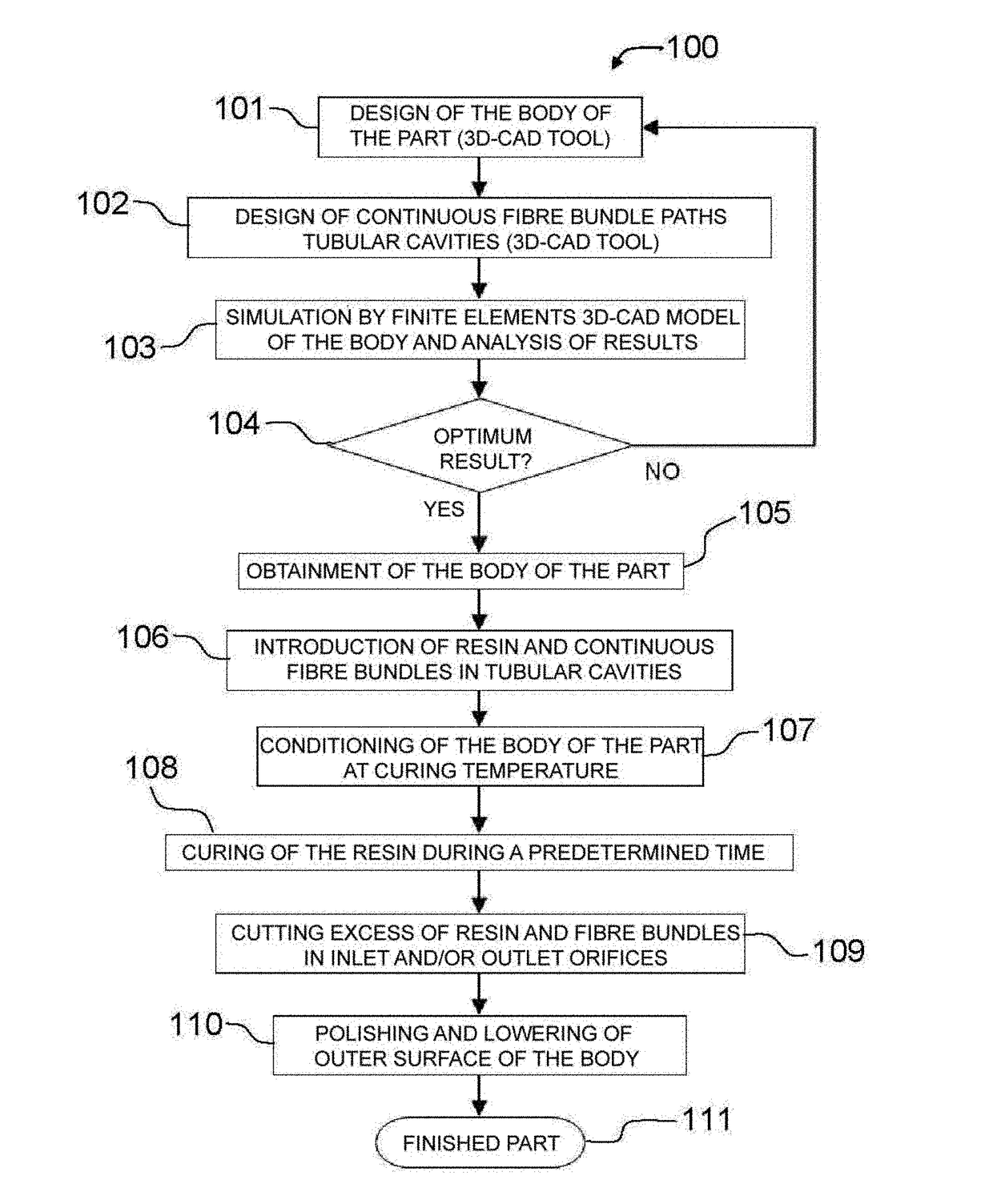

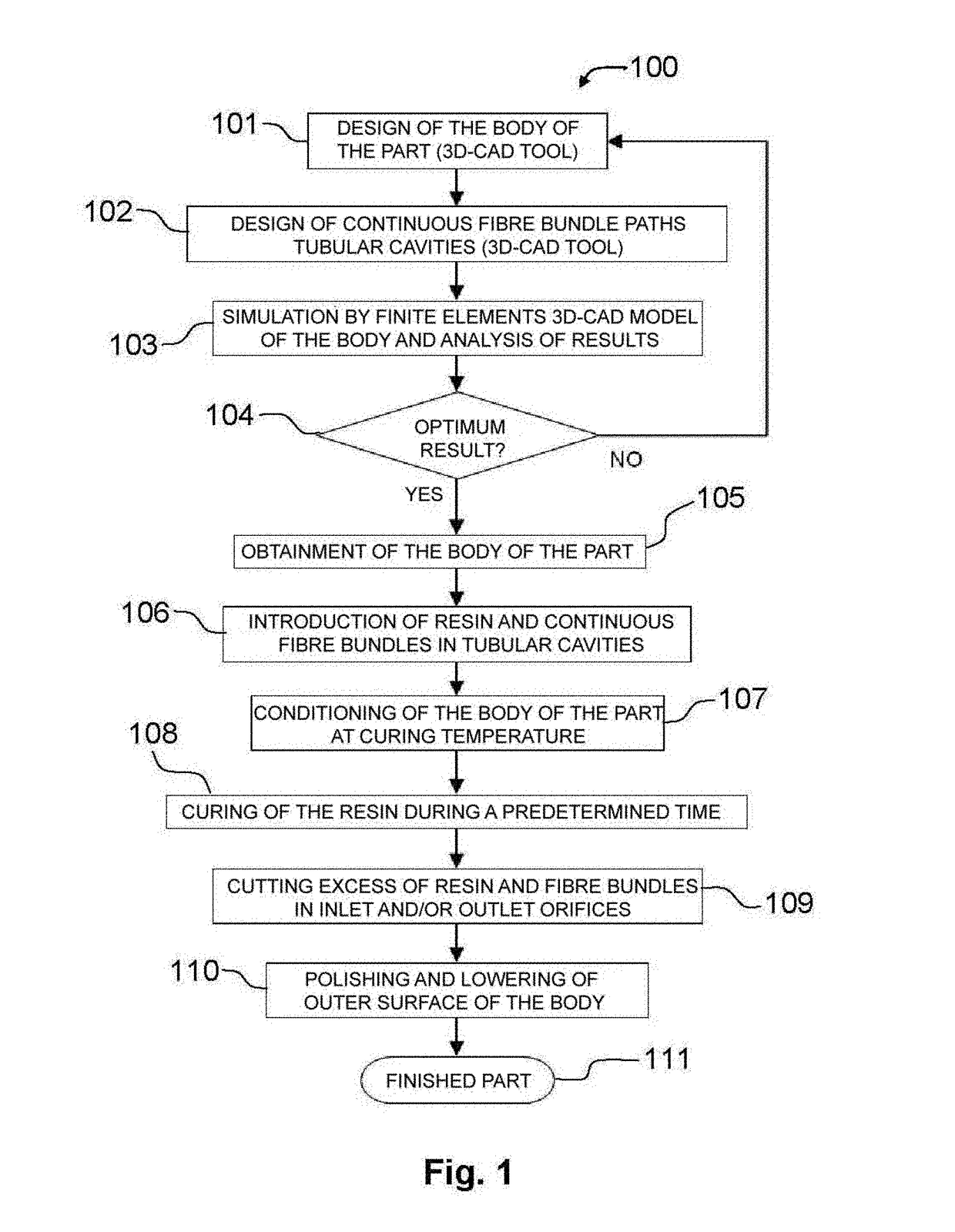

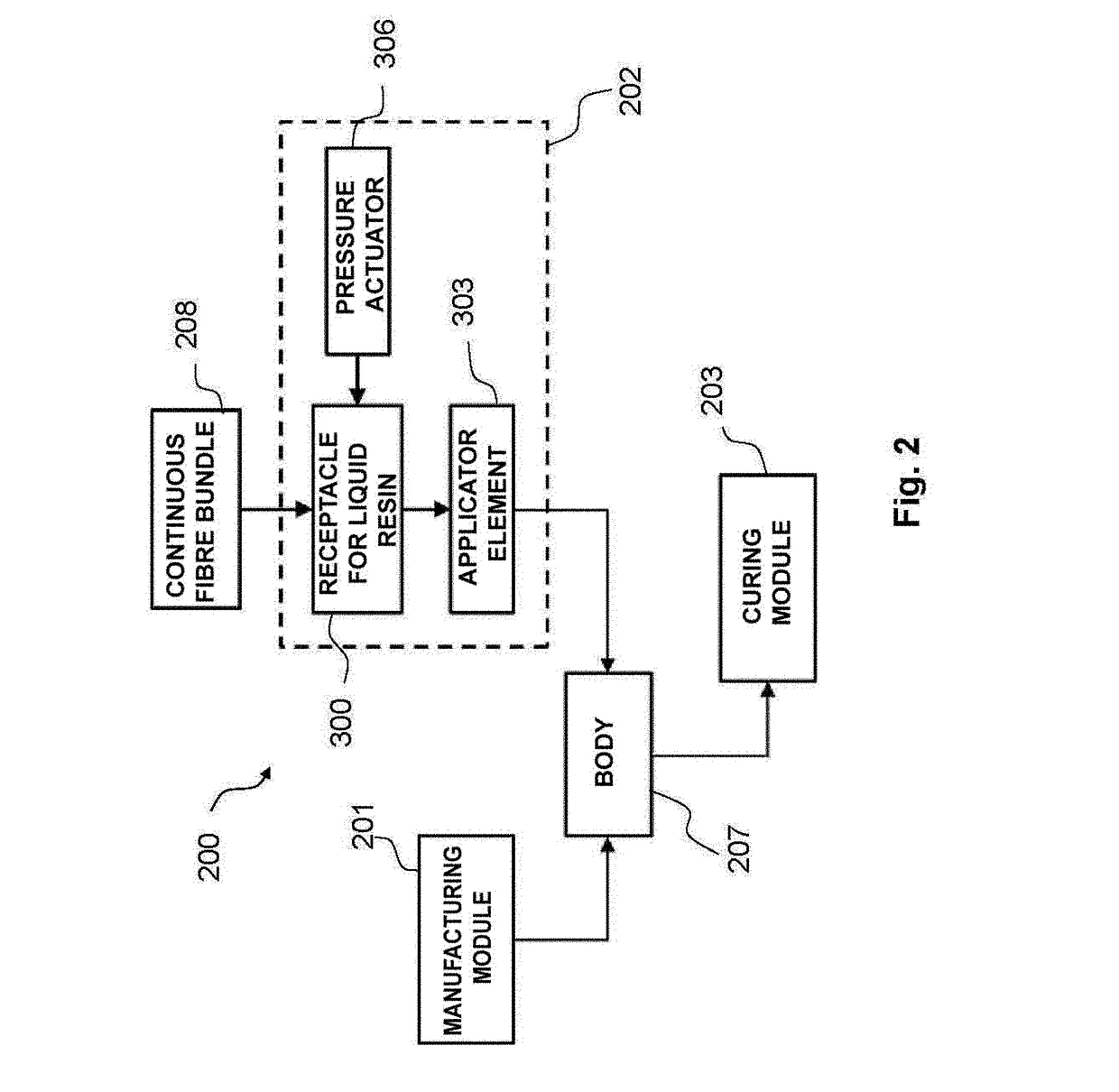

Procedure and system for manufacturing a part made from composite material and part made from composite material obtained by means of said method

ActiveUS20170361497A1Complex geometryEasy to produceAdditive manufacturing apparatus3D object support structuresFiber bundleLiquid state

The invention relates to a method for manufacturing a part made from composite material, having a body and one or more continuous fibre bundles in its interior, characterised in that it comprises the stages of: a) obtaining a body that includes one or more tubular cavities in its interior that extend between a first end, disposed on the outer surface of the body and which comprises an inlet orifice, and a second end, opposite to the first end; b) introducing resin in the liquid state and a continuous fibre bundle in the interior of at least one tubular cavity through its inlet orifice; and c) curing the resin until it solidifies, adhering to the body and fixing the continuous fibre bundle. The invention also relates to a system for manufacturing a part made from composite material and to the part made from composite material obtained.

Owner:FUNDACIO EURECAT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com