Patents

Literature

87results about How to "High fiber density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

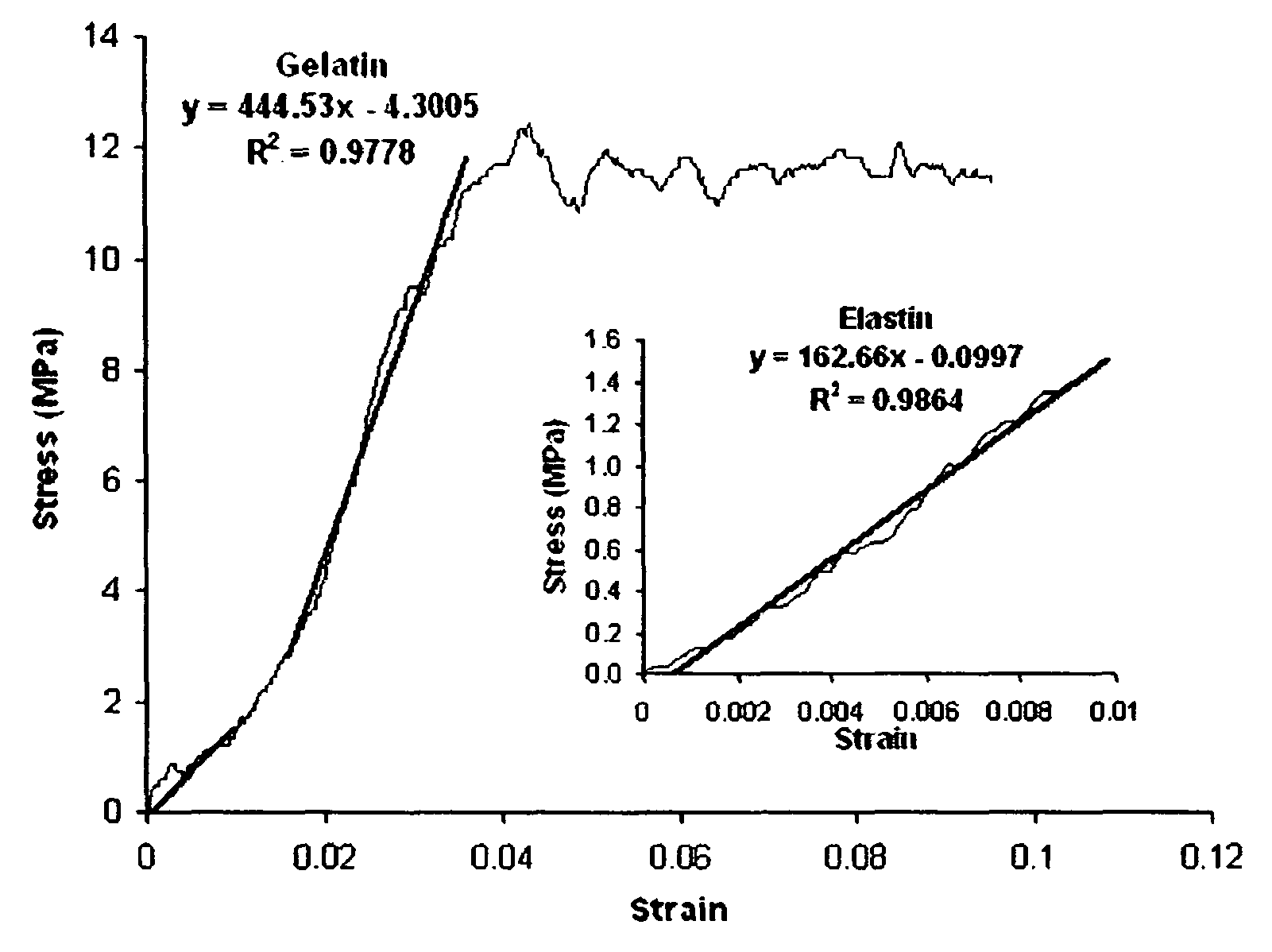

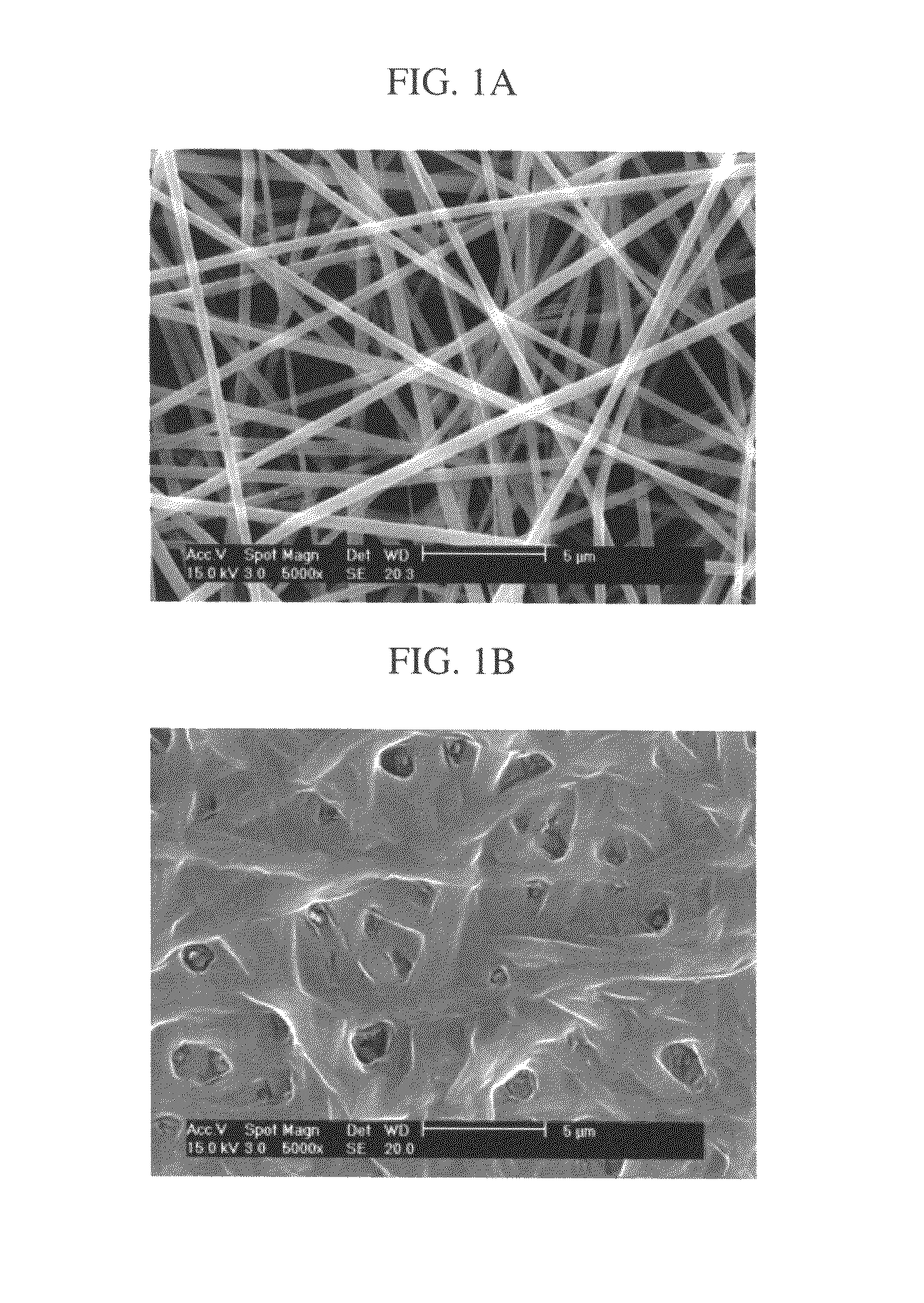

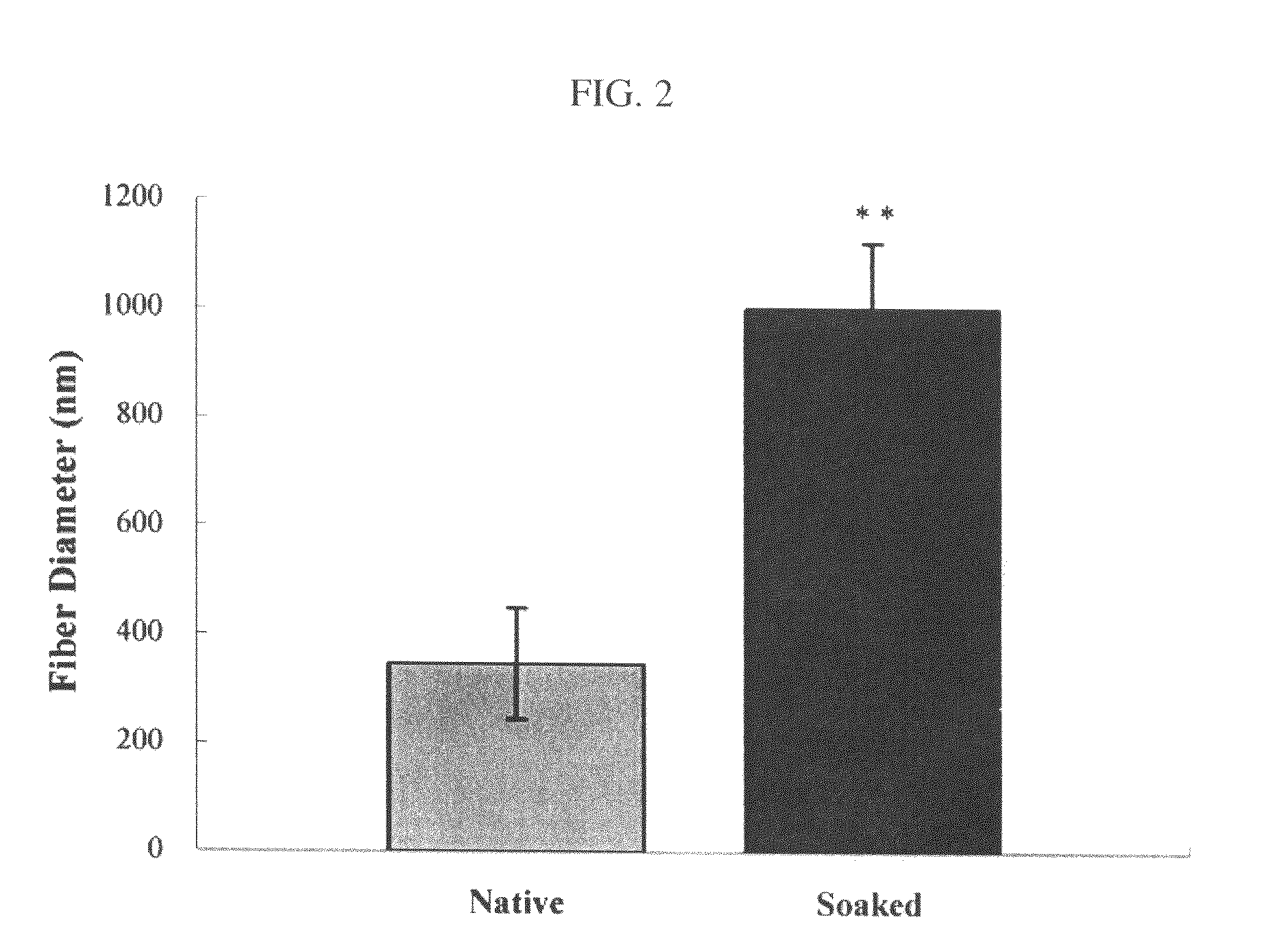

Electrospun blends of natural and synthetic polymer fibers as tissue engineering scaffolds

InactiveUS20060263417A1Facilitate cell penetrationFacilitate proliferationBiocidePeptide/protein ingredientsFiberPolymer science

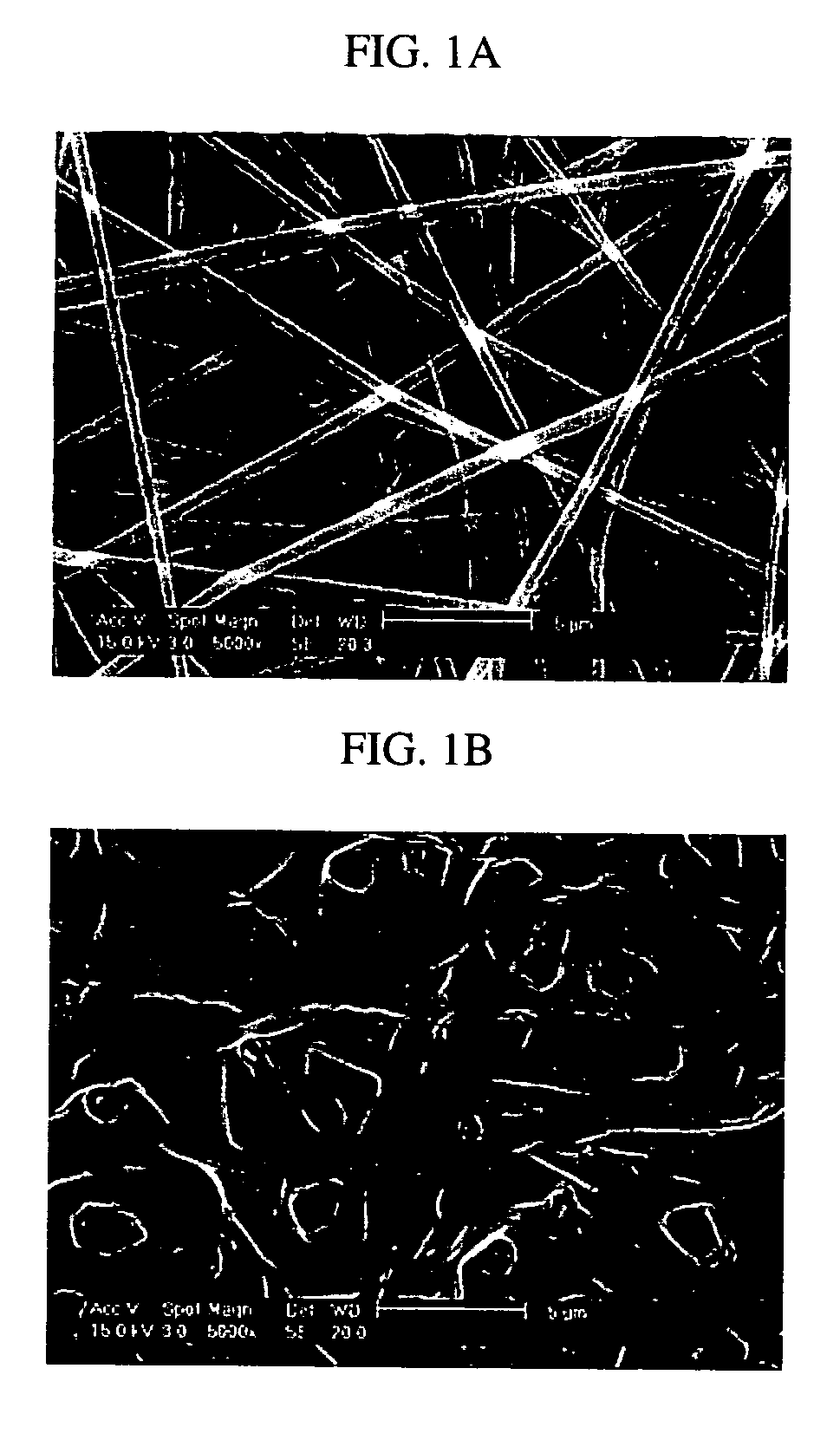

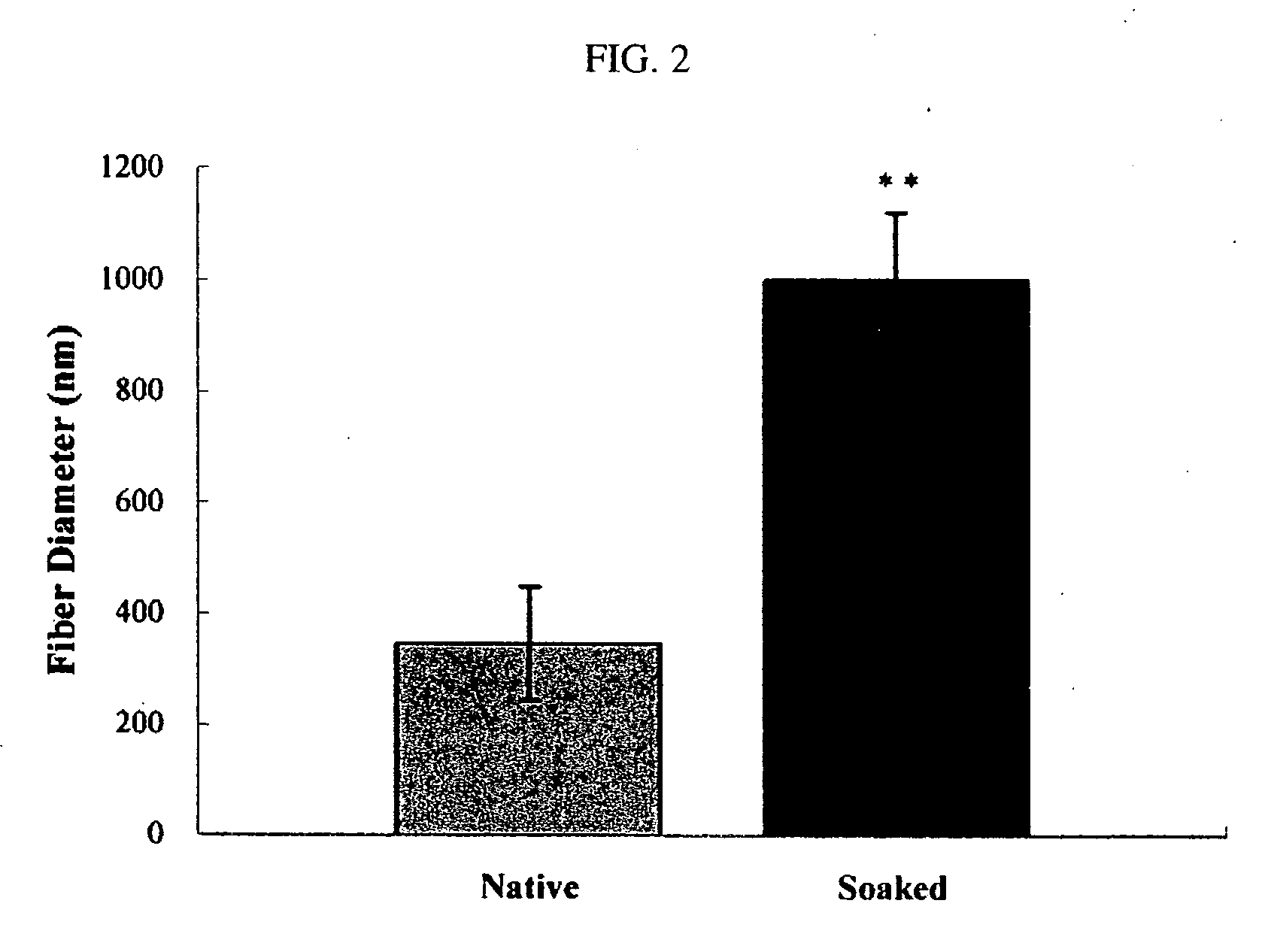

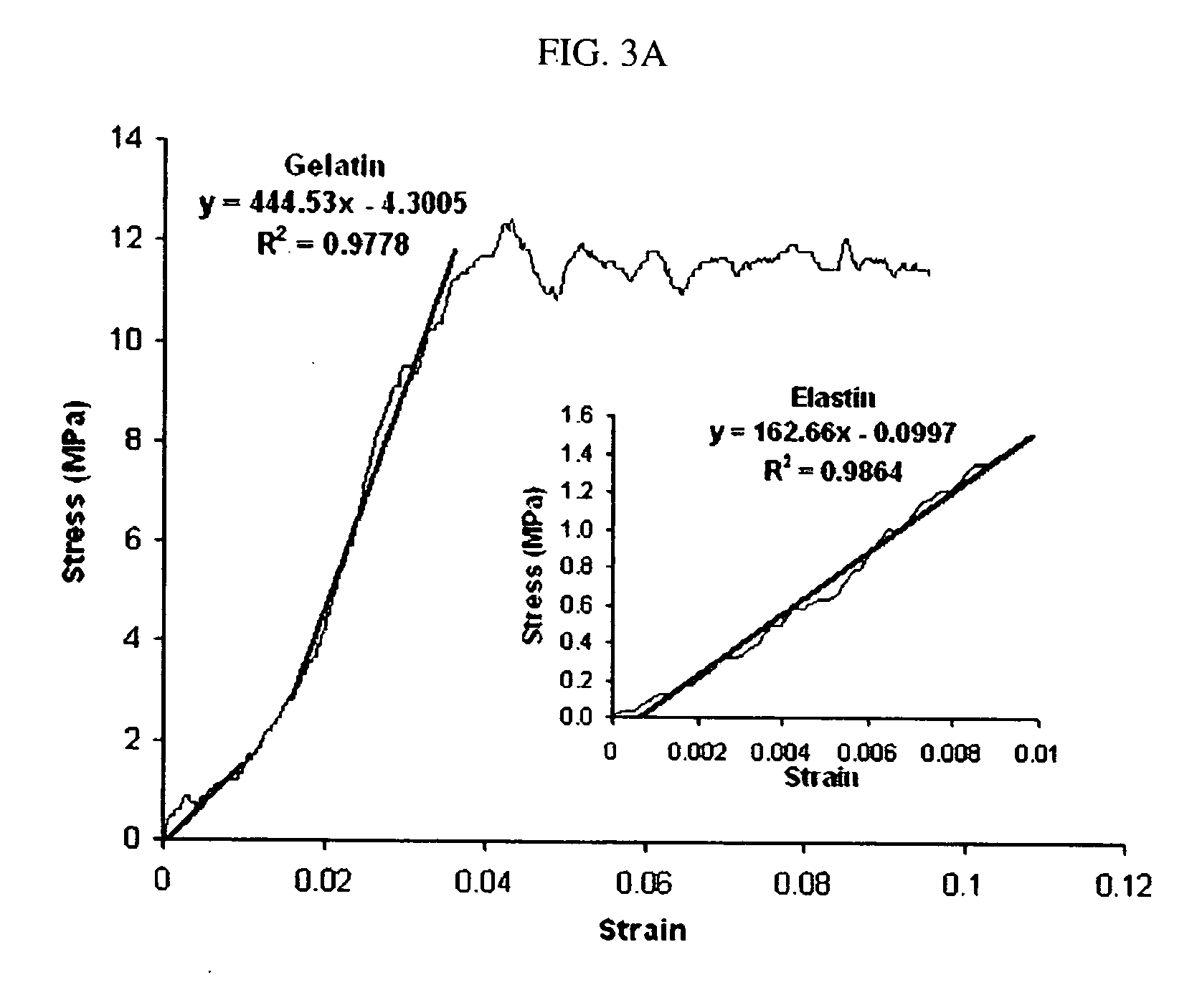

Non-woven fibrous scaffolds made by electrospinning from the synthetic biodegradable polymer such as, for example, poly(lactic-co-glycolic acid) (PLGA) and natural proteins, such as, for example, gelatin (denatured collagen) and elastin and a method of making thereof.

Owner:DREXEL UNIV

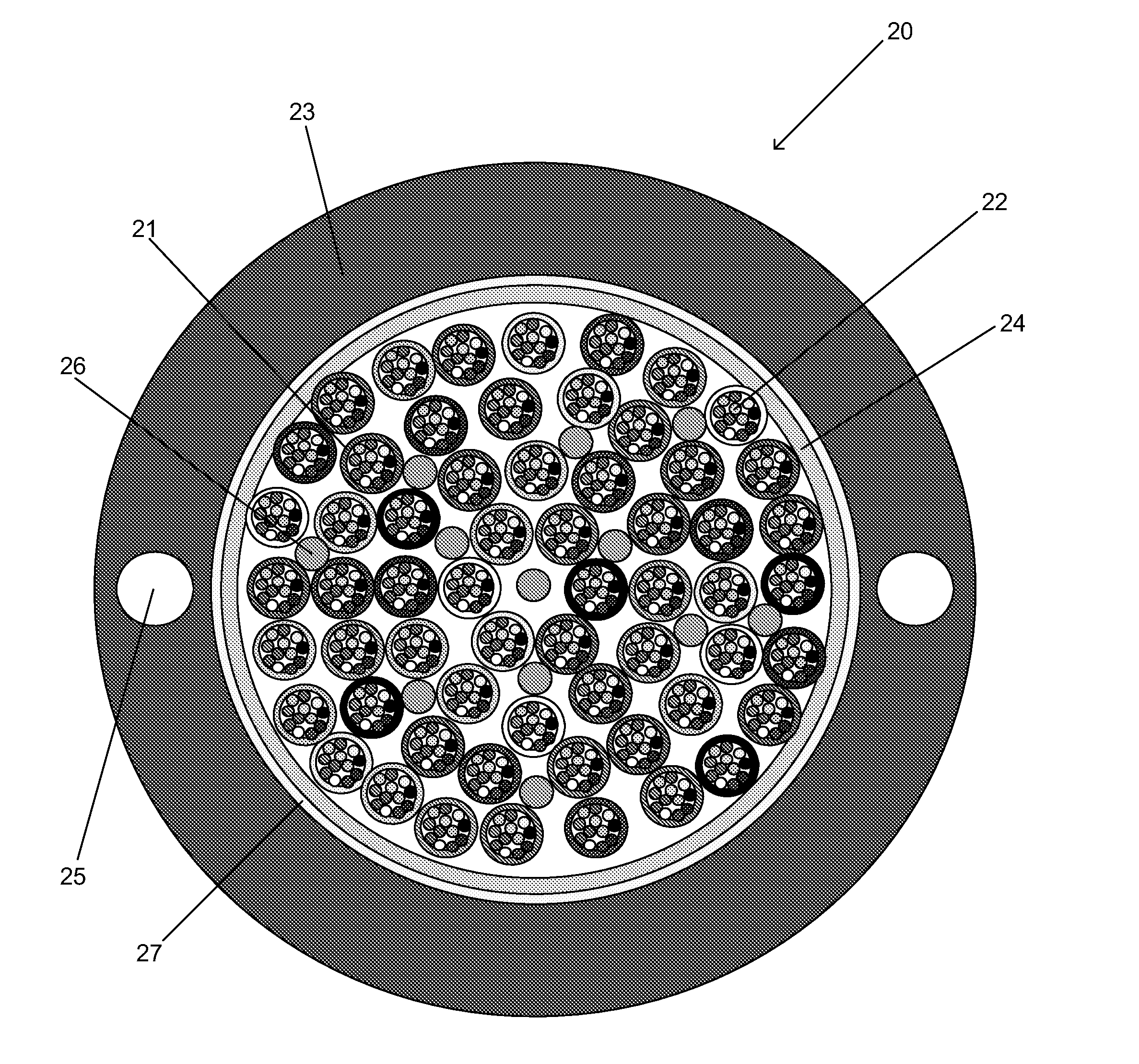

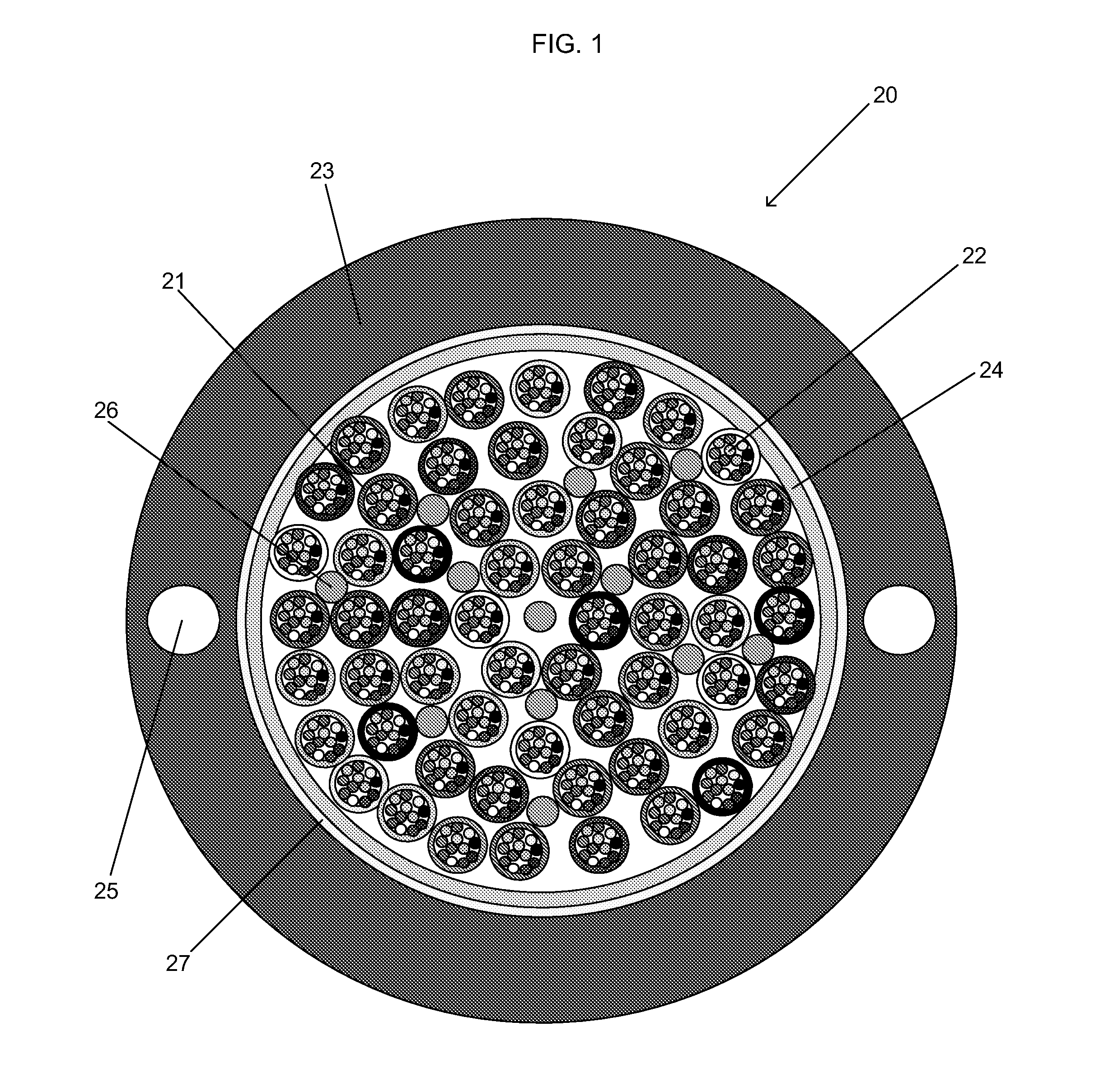

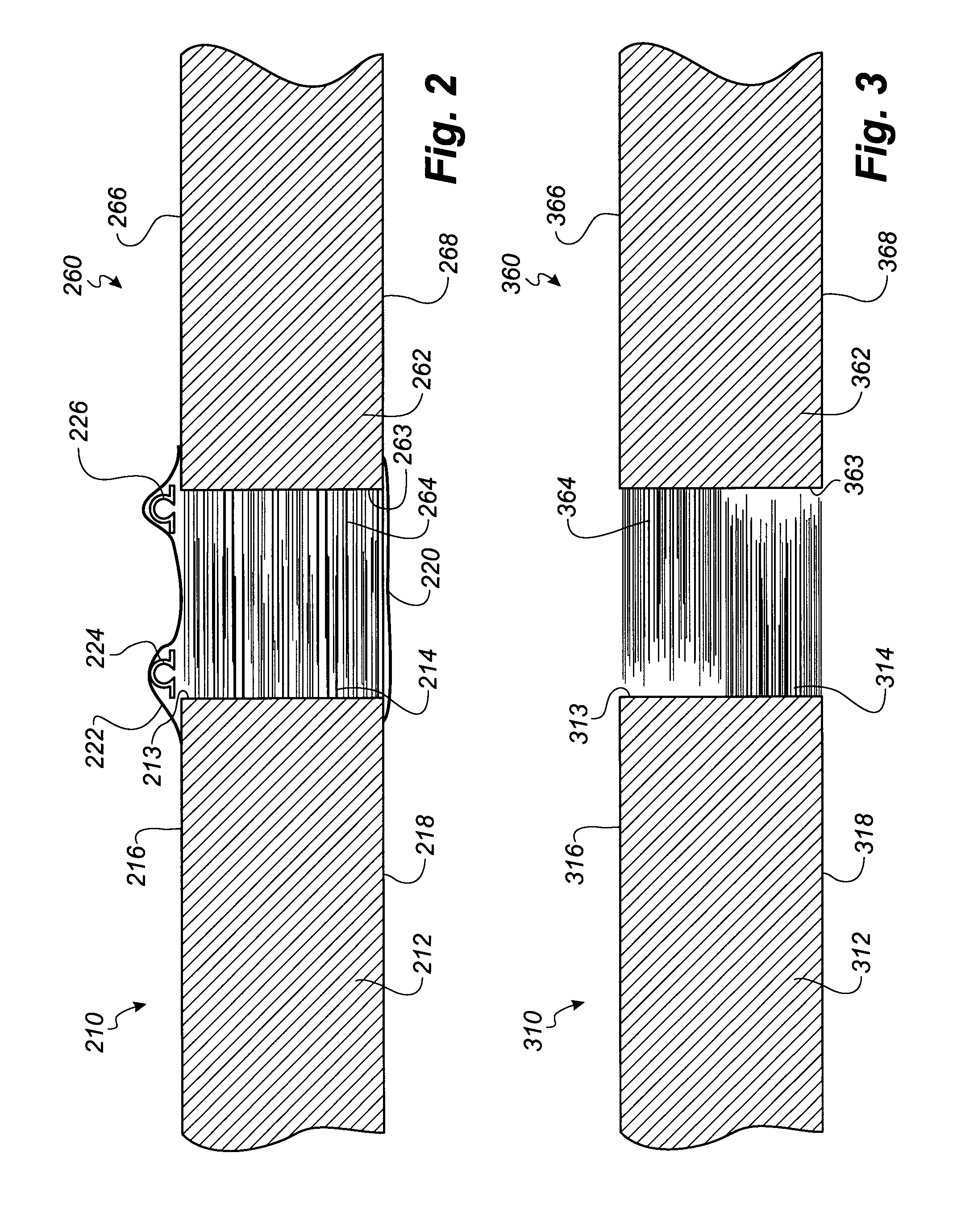

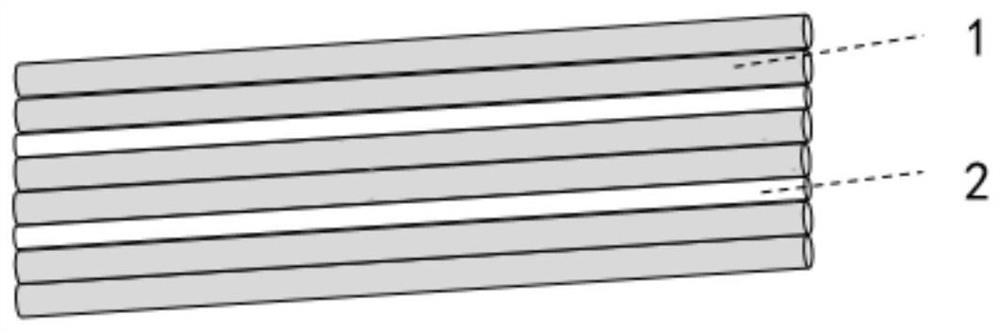

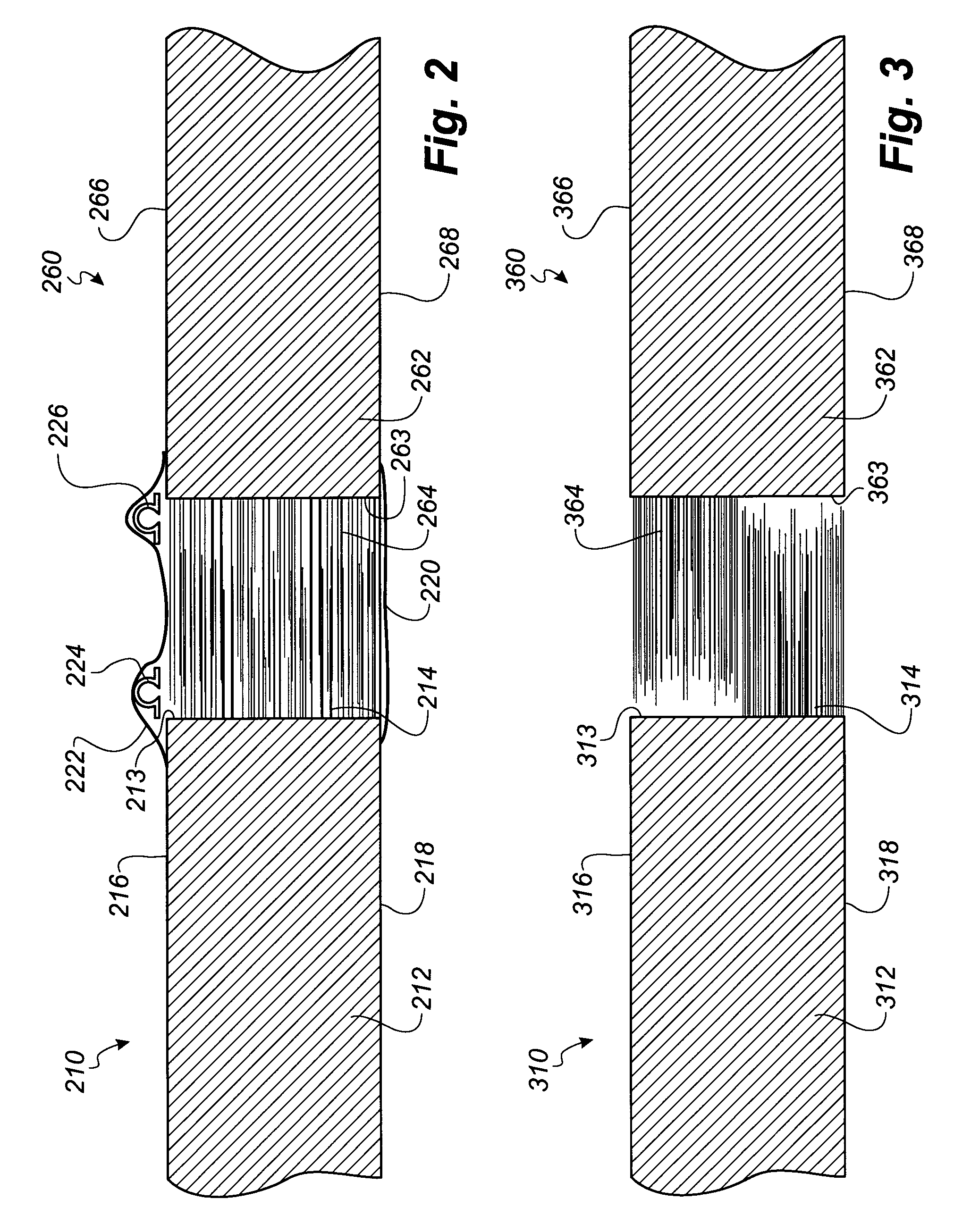

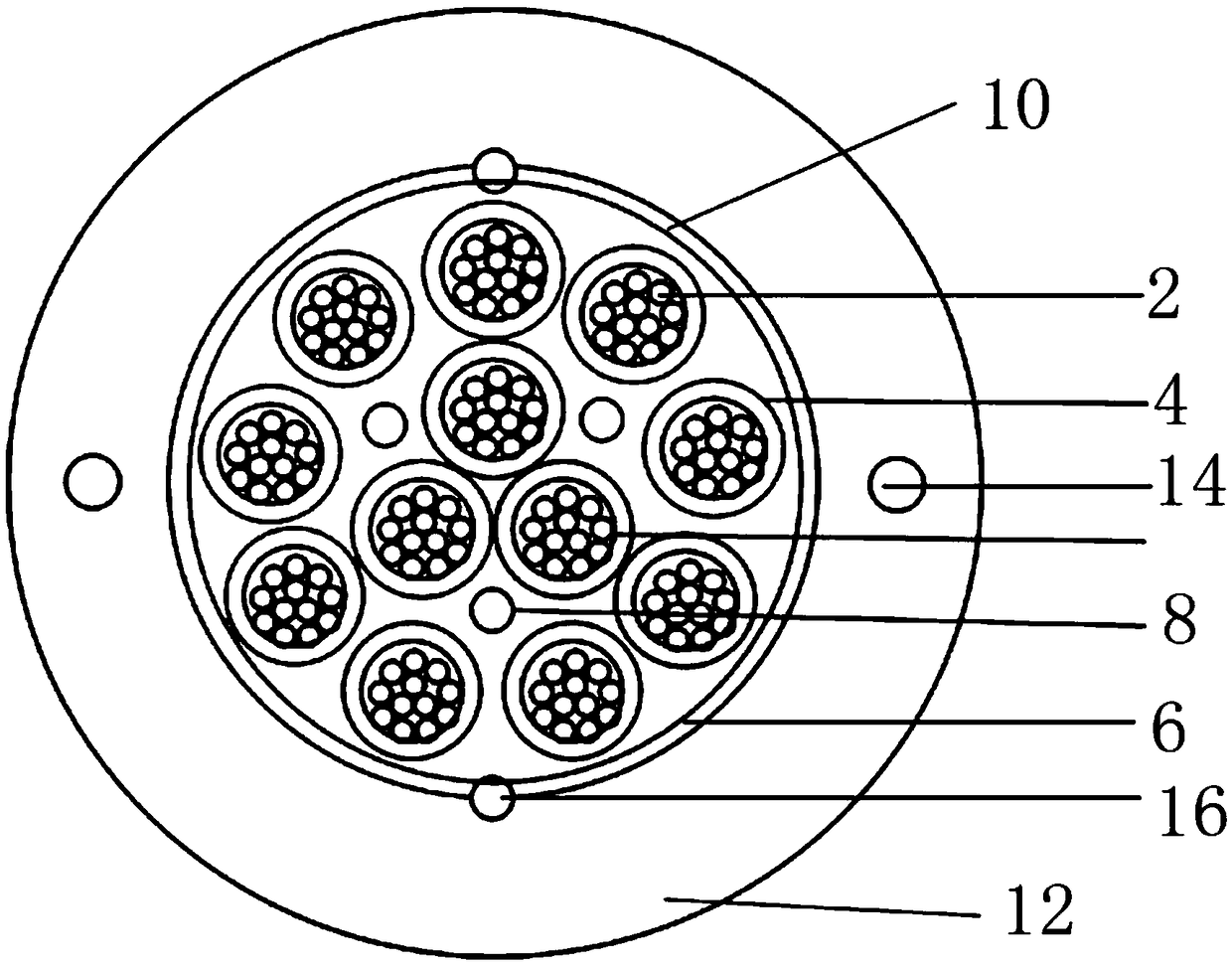

Optical-Fiber Cable Having High Fiber Count and High Fiber Density

ActiveUS20110091171A1Raise countHigh fiber densityFibre mechanical structuresEngineeringOptical fiber cable

Owner:DRAKA COMTEQ BV

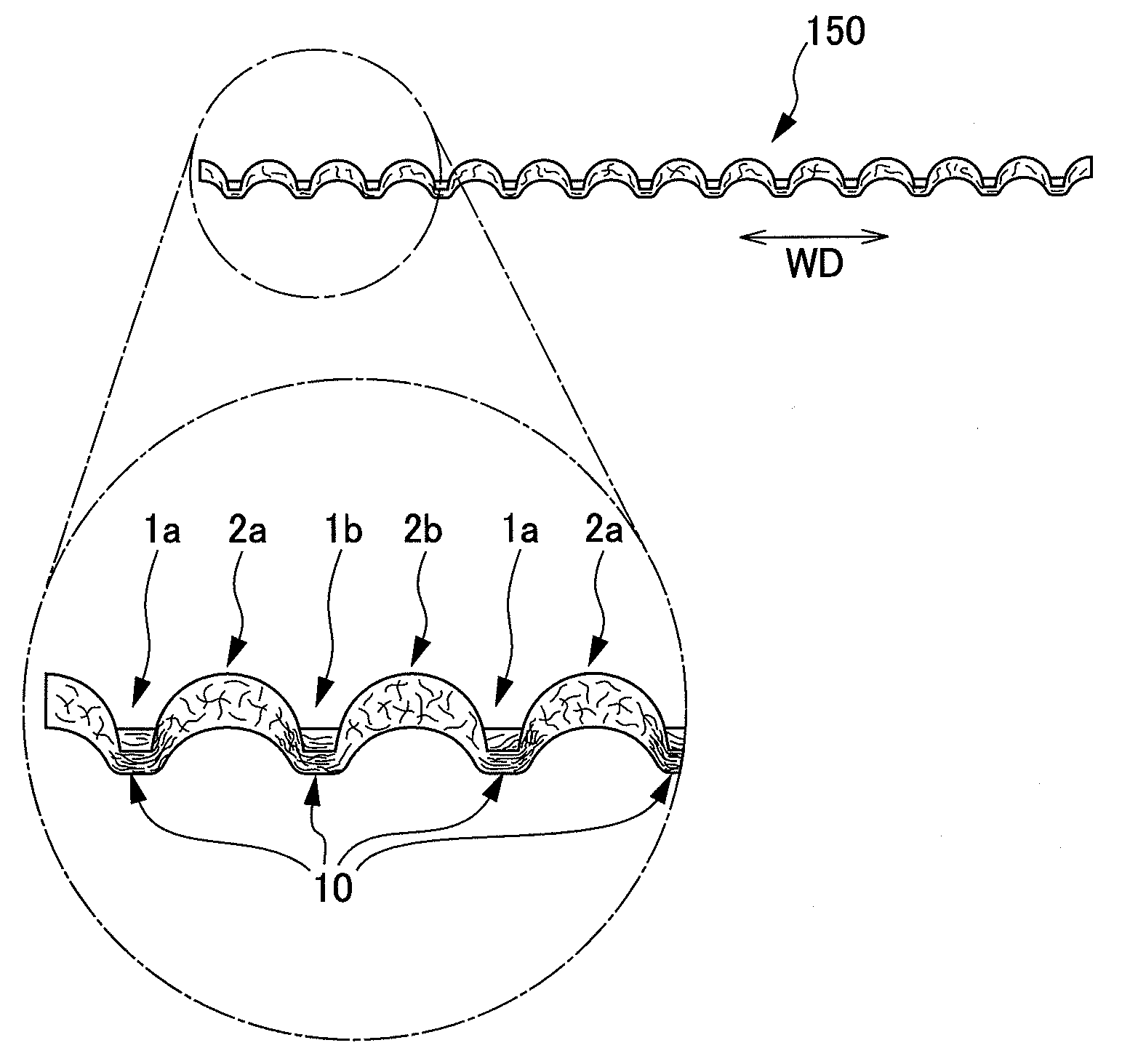

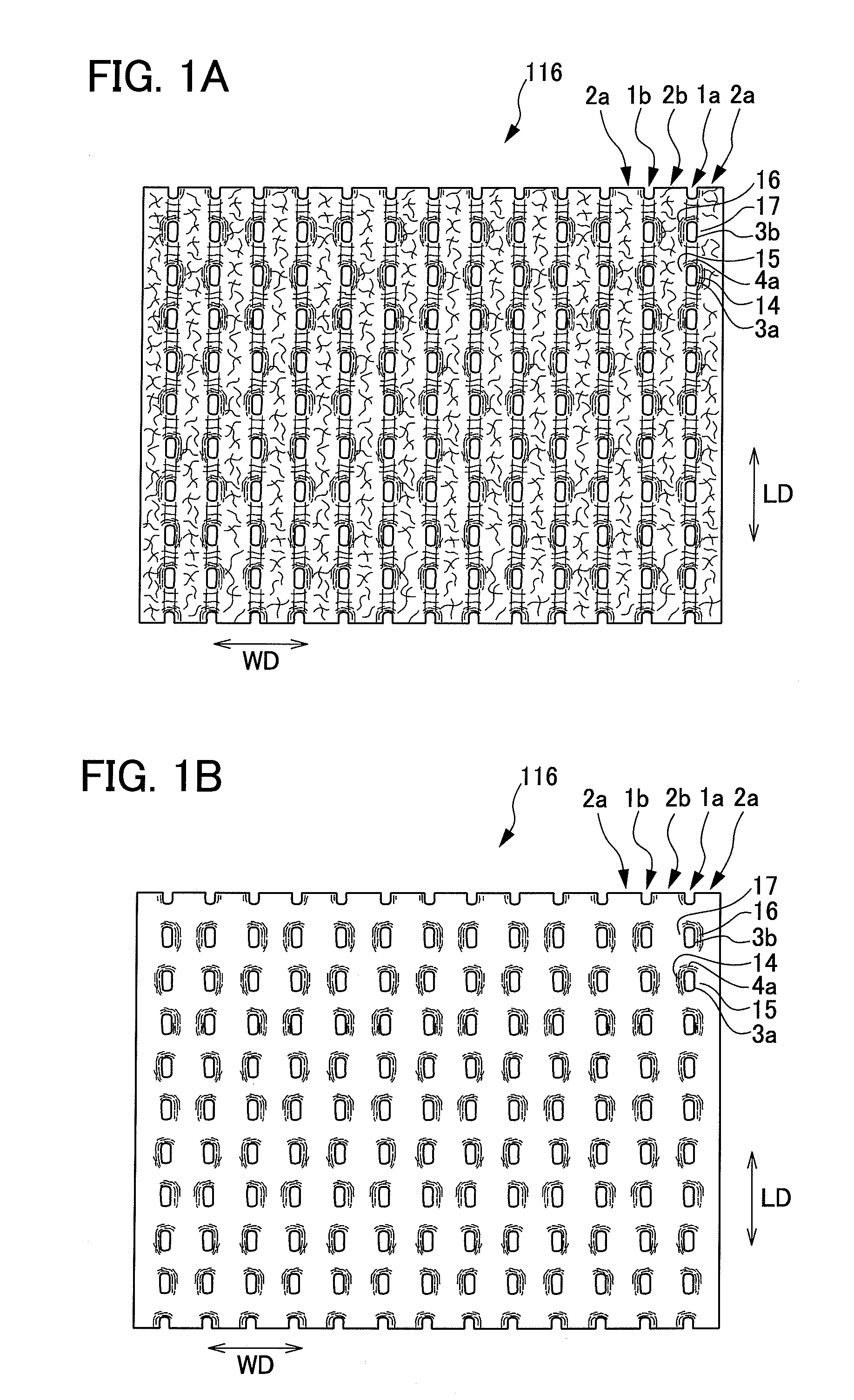

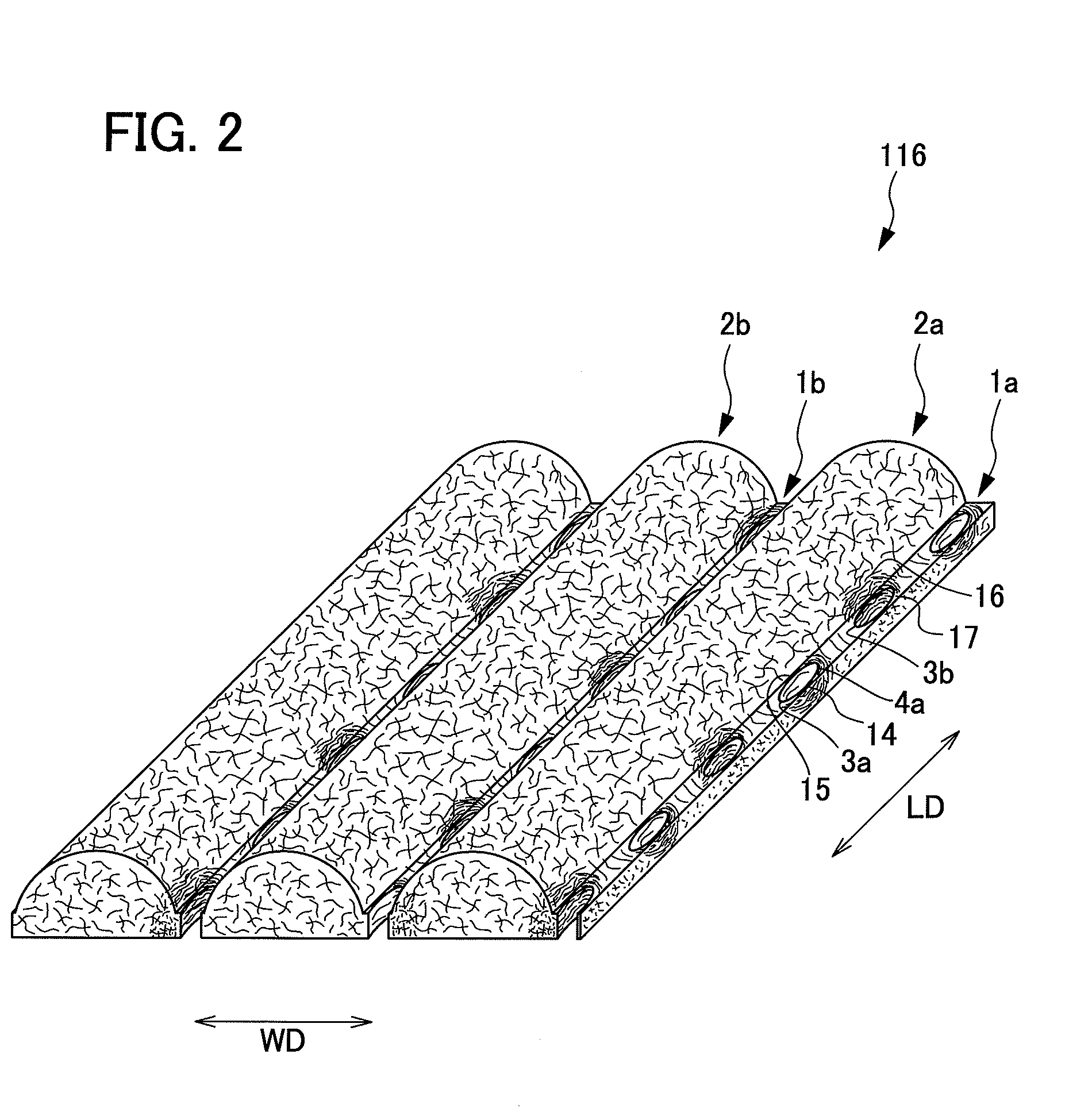

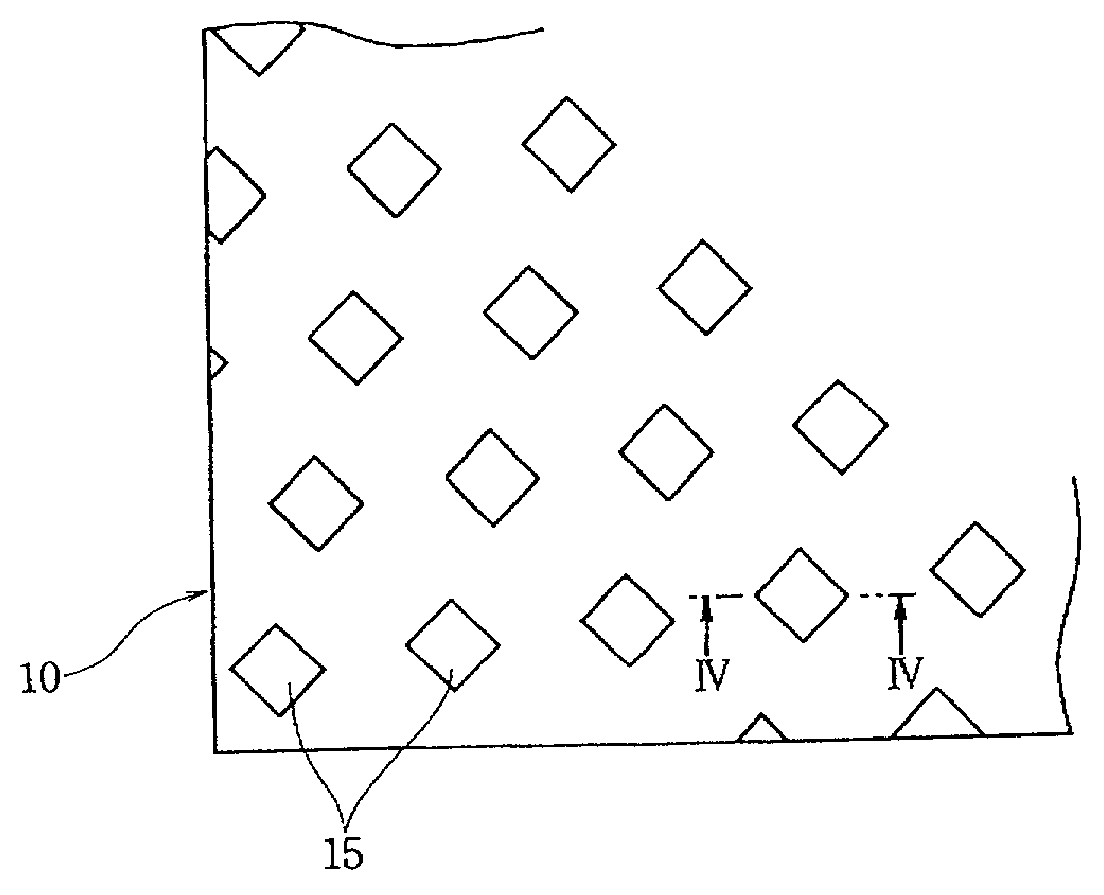

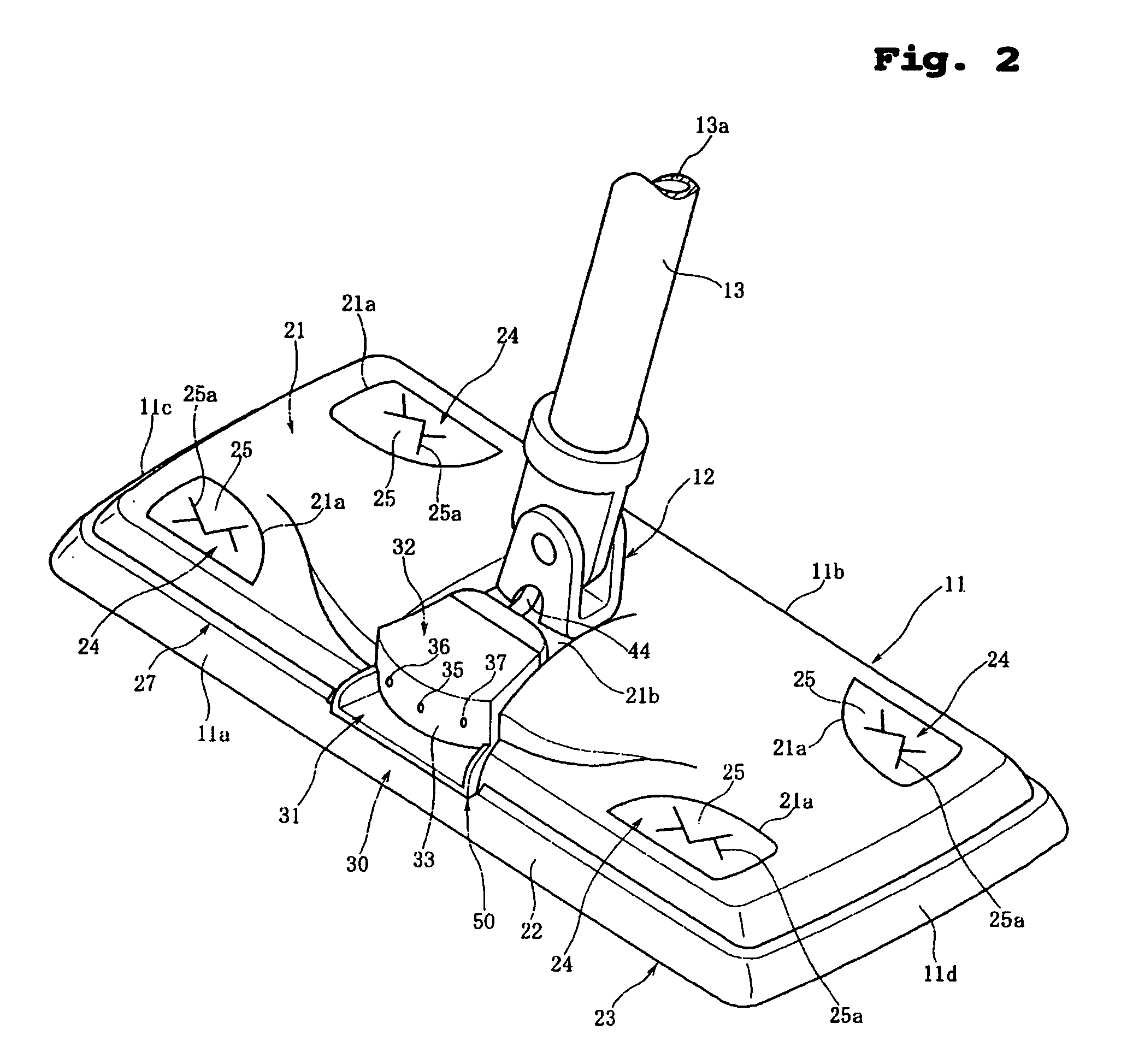

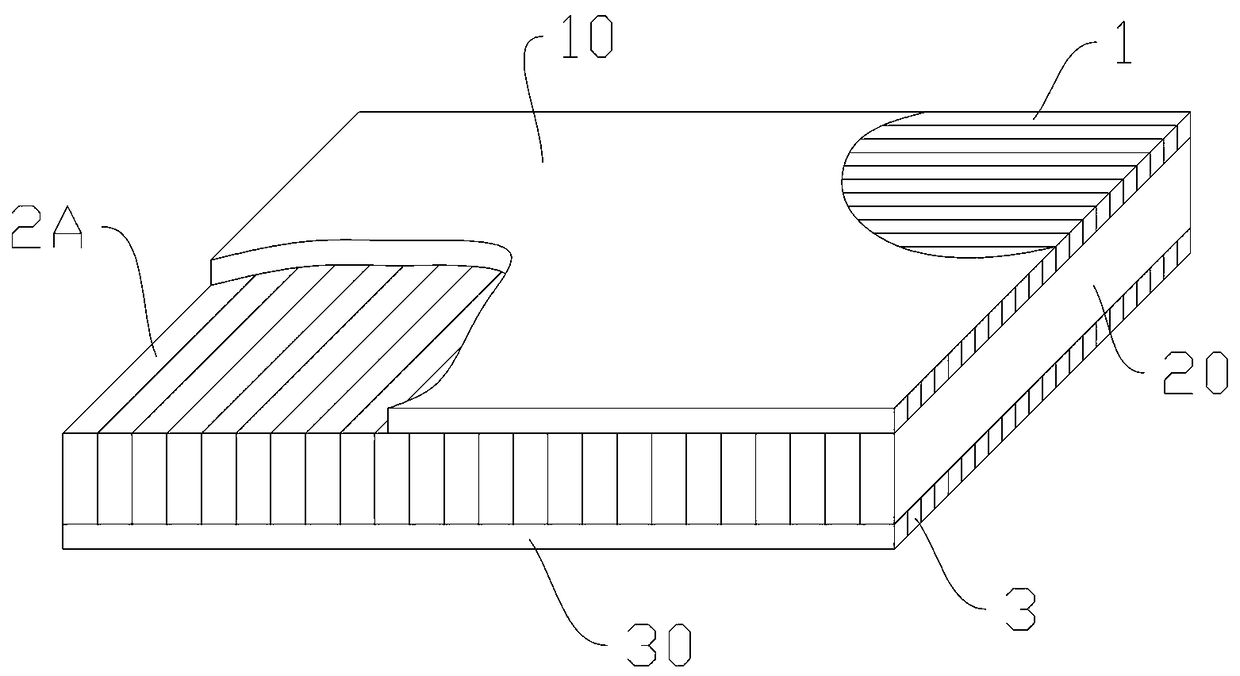

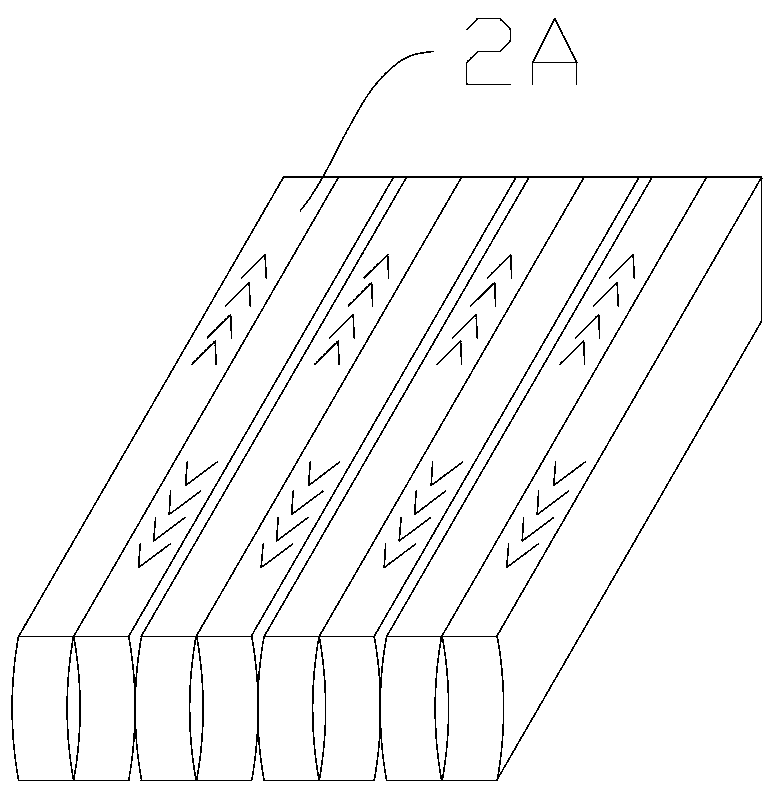

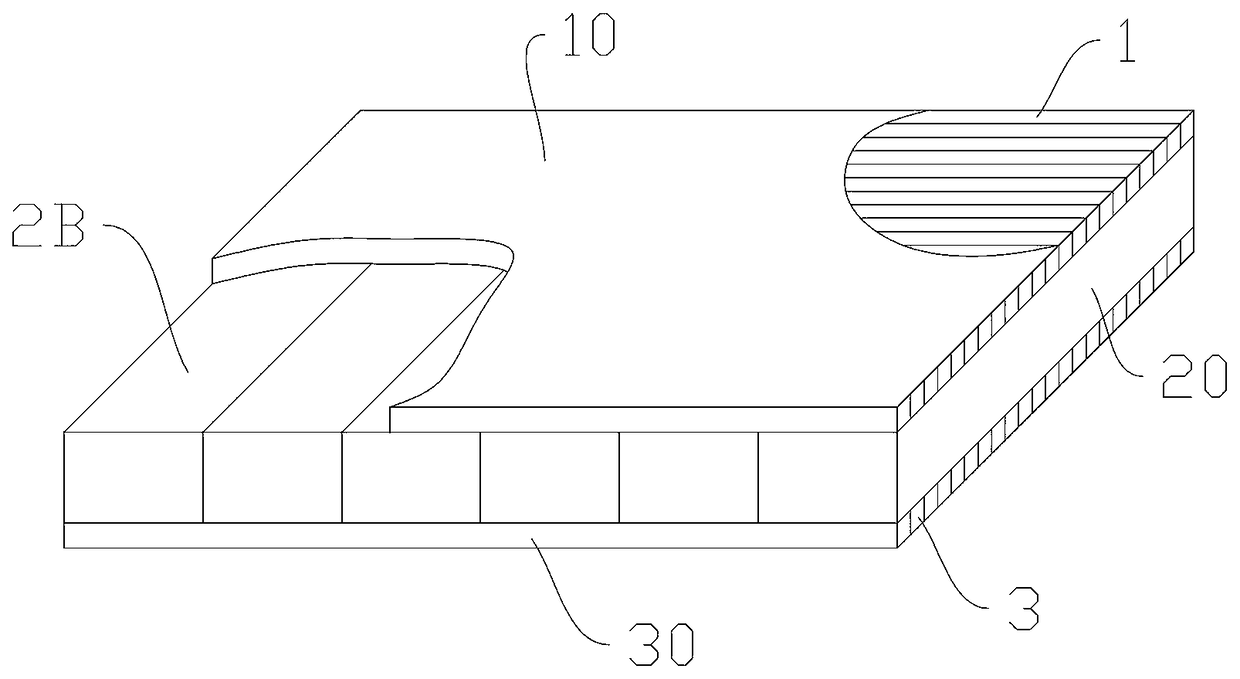

Nonwoven fabric

A nonwoven fabric provided with concave / convex portions, and openings, which can be adjusted to densify only a part of the peripheral edges of the openings, without excessively increasing the fiber density in the convex portions and the concave portions. A fiber web can be moved to an area where the down-slanting wires of woven wire extending in the direction of width (WD), thereby forming a first side edge portion in the openings. The fiber web is hardly displaced to the opposite side edges of the first side edges, namely a second side edge portions.

Owner:UNI CHARM CORP

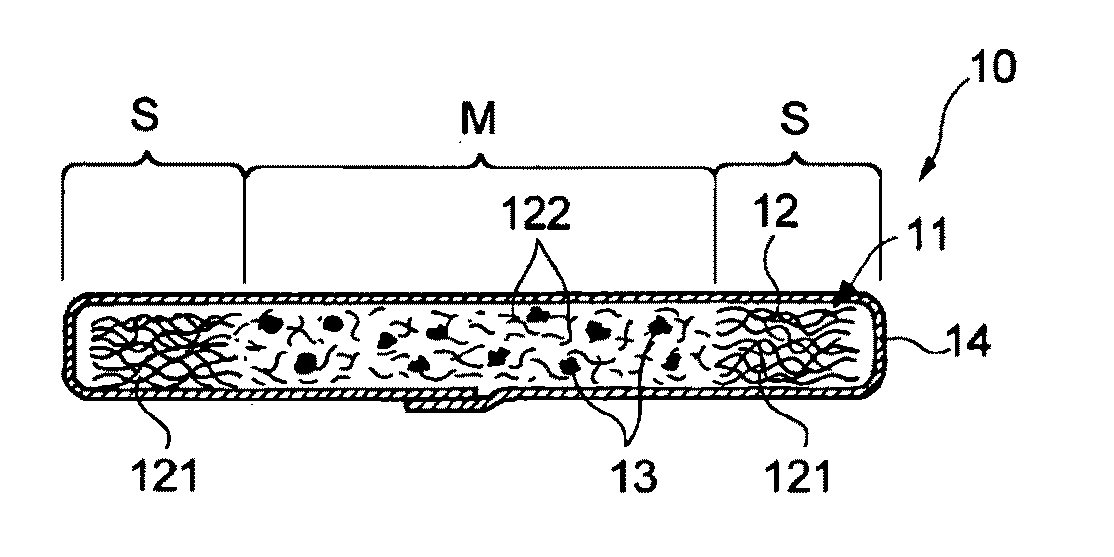

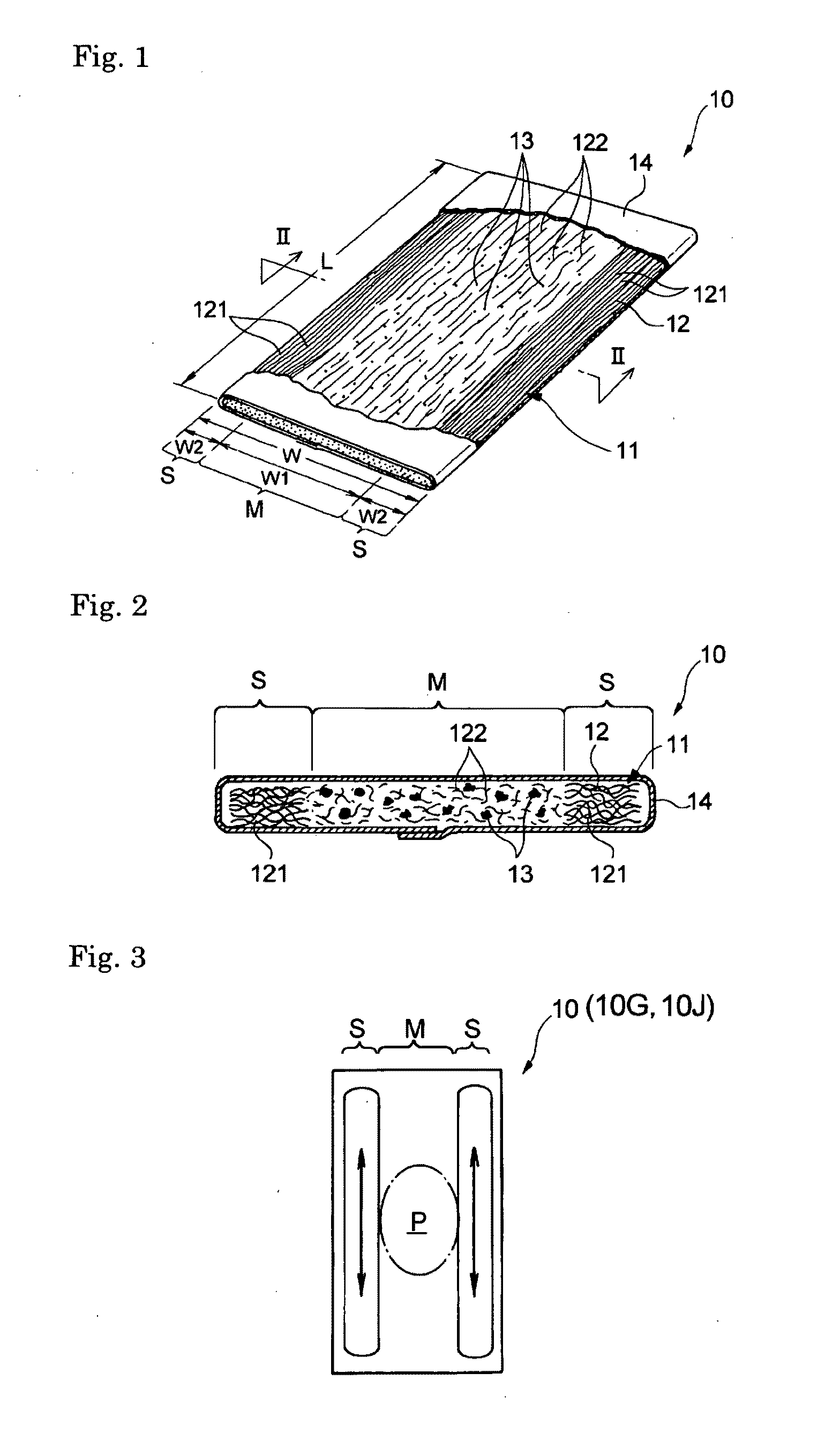

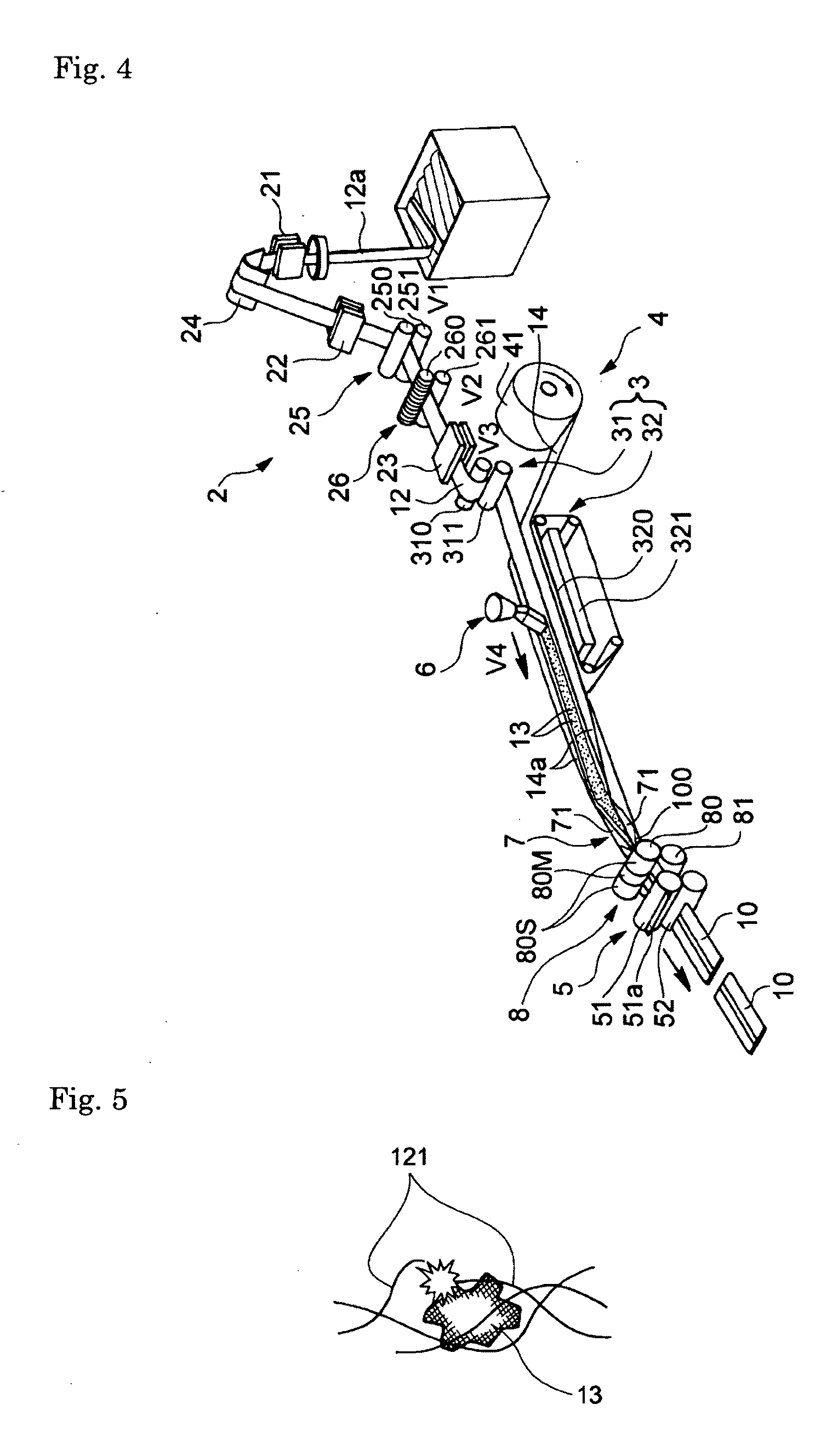

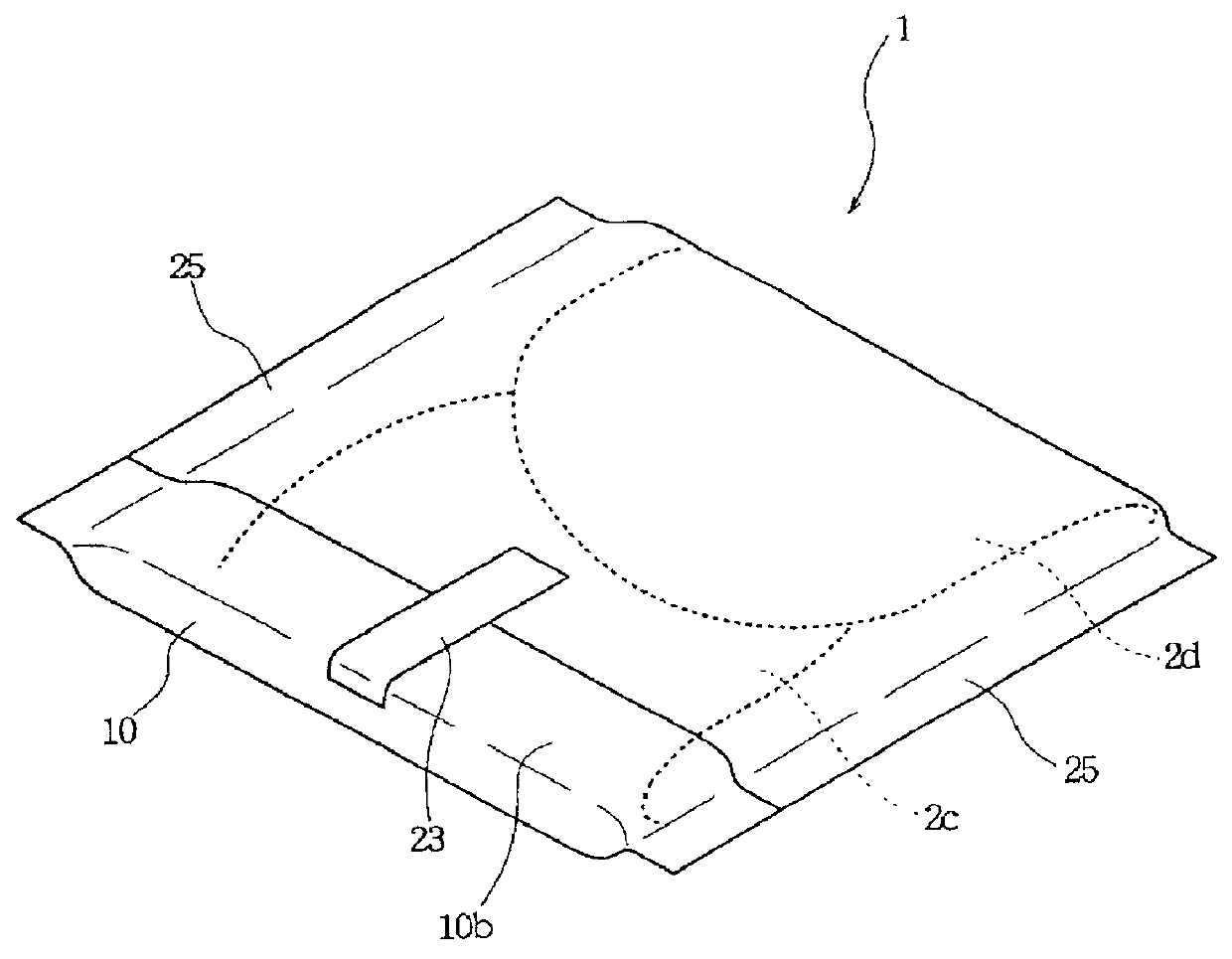

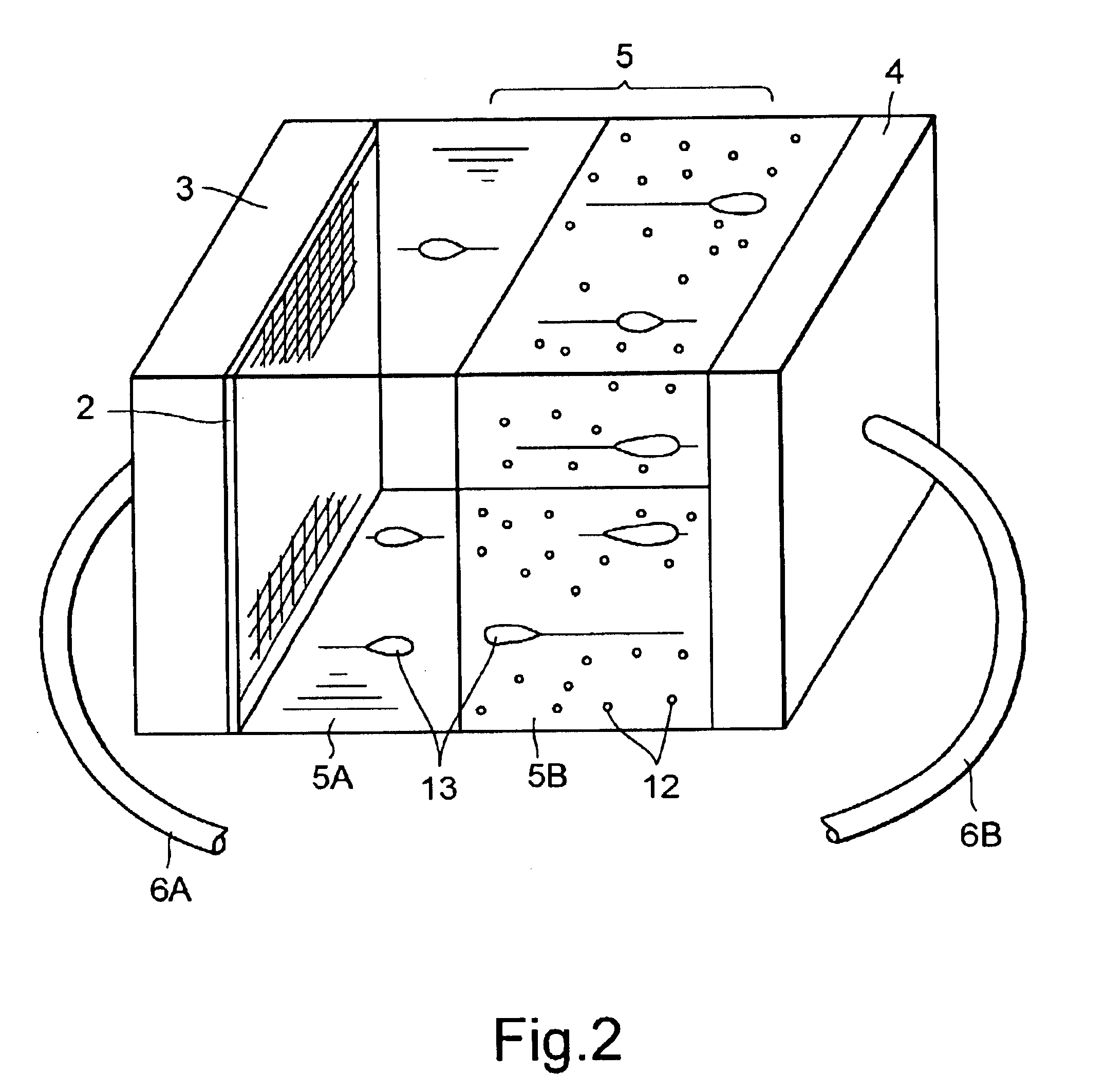

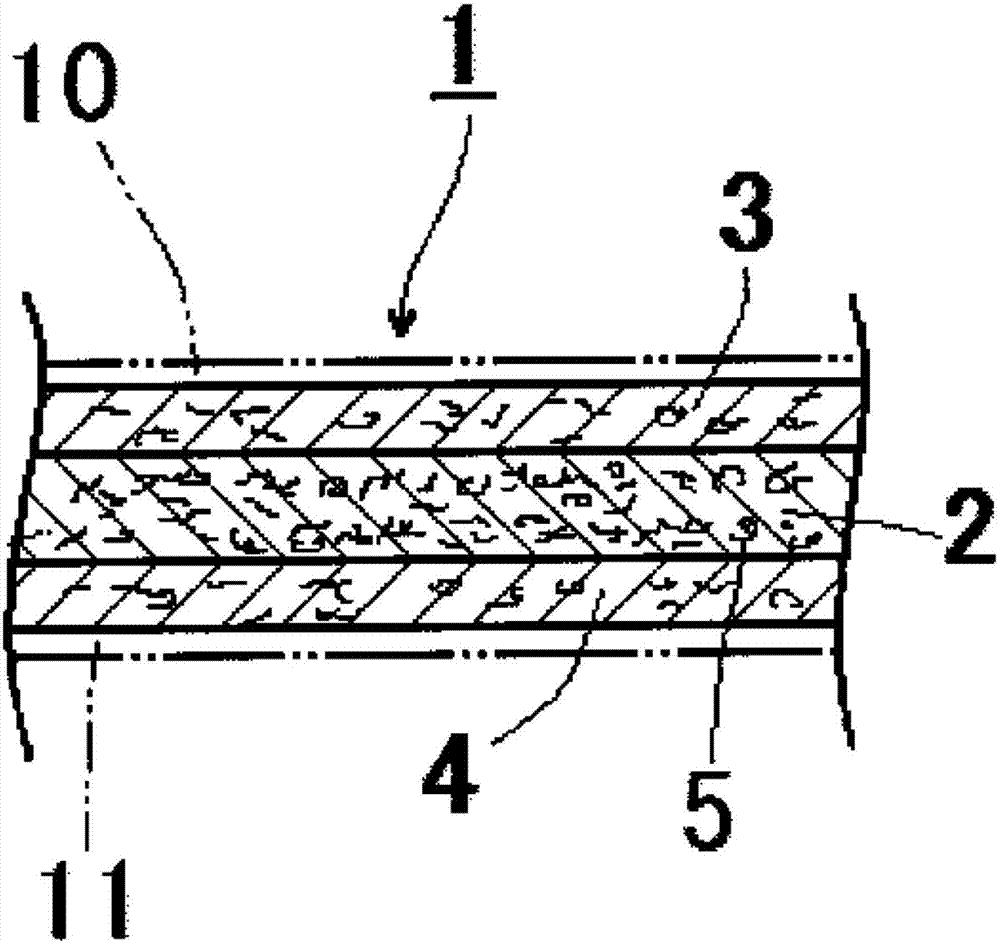

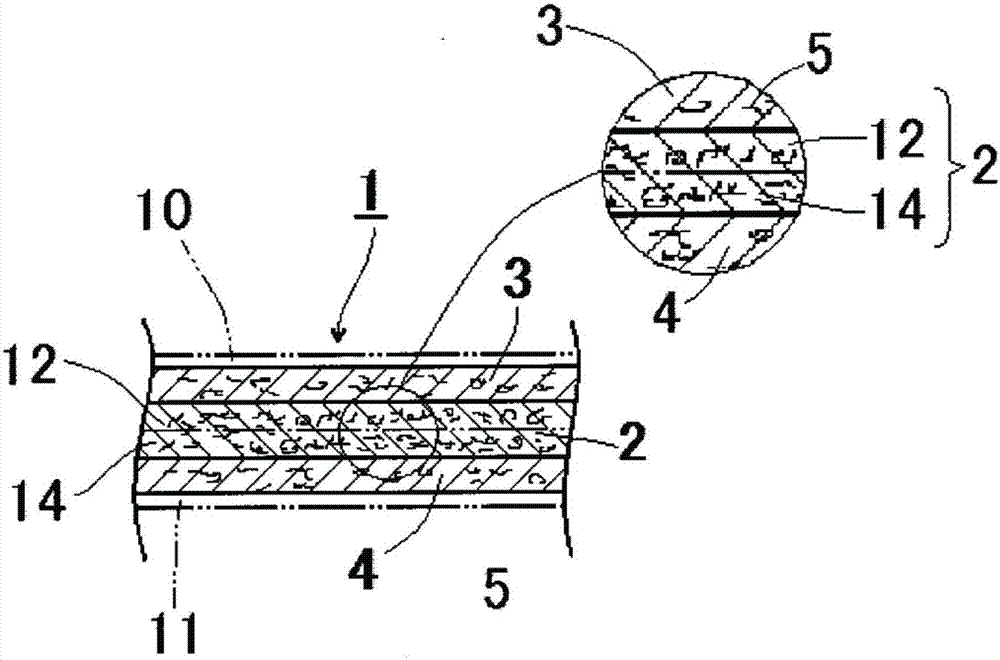

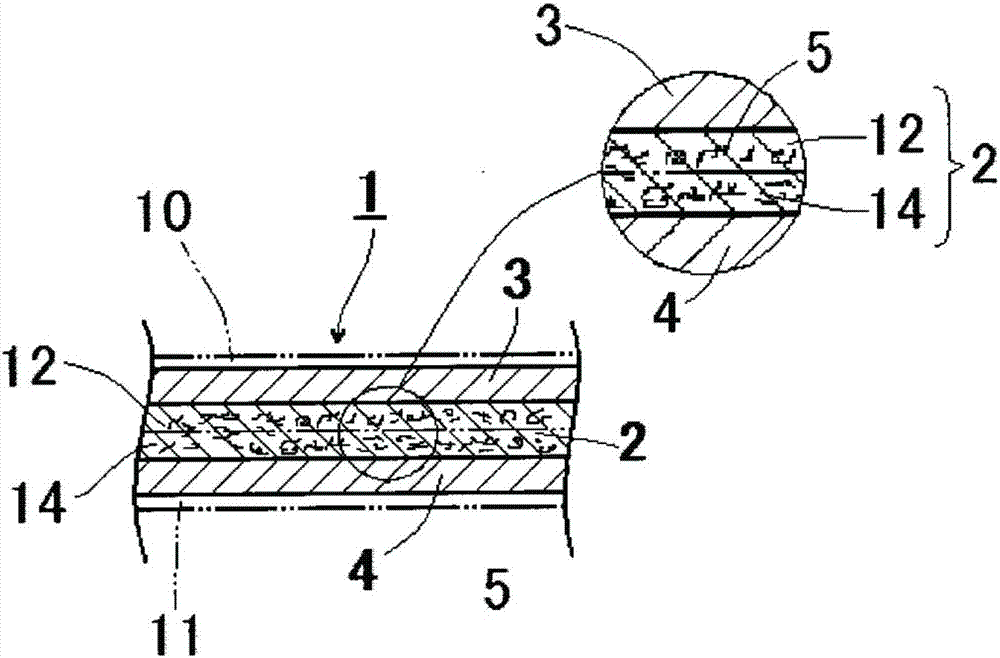

Absorbent Member and Method of Producing the Same

An absorbent member (10) of the invention has a hydrophilic continuous fiber web (12) and lumpy particles of an absorbent polymer (13) held in the web (12). The absorbent polymer (13) is localized in part in a planar or thickness direction of the absorbent member (10). The continuous fibers in a region (M) in a planar direction of the web (12) where the absorbent polymer is distributed are in a state cut into a large number of staple fibers (122). A method of producing an absorbent member includes the step of spreading lumpy particles of an absorbent polymer (13) on a continuous fiber web (12) and pressing the continuous fibers in part of the web (12) onto the absorbent polymer (13) to cut the continuous fibers.

Owner:KAO CORP

Package for absorbent article

InactiveUS20010056270A1Causes less zipping or rustling soundImprove breathabilityDiagnosticsSurgical needlesEngineeringNonwoven fabric

Owner:UNI CHARM CORP

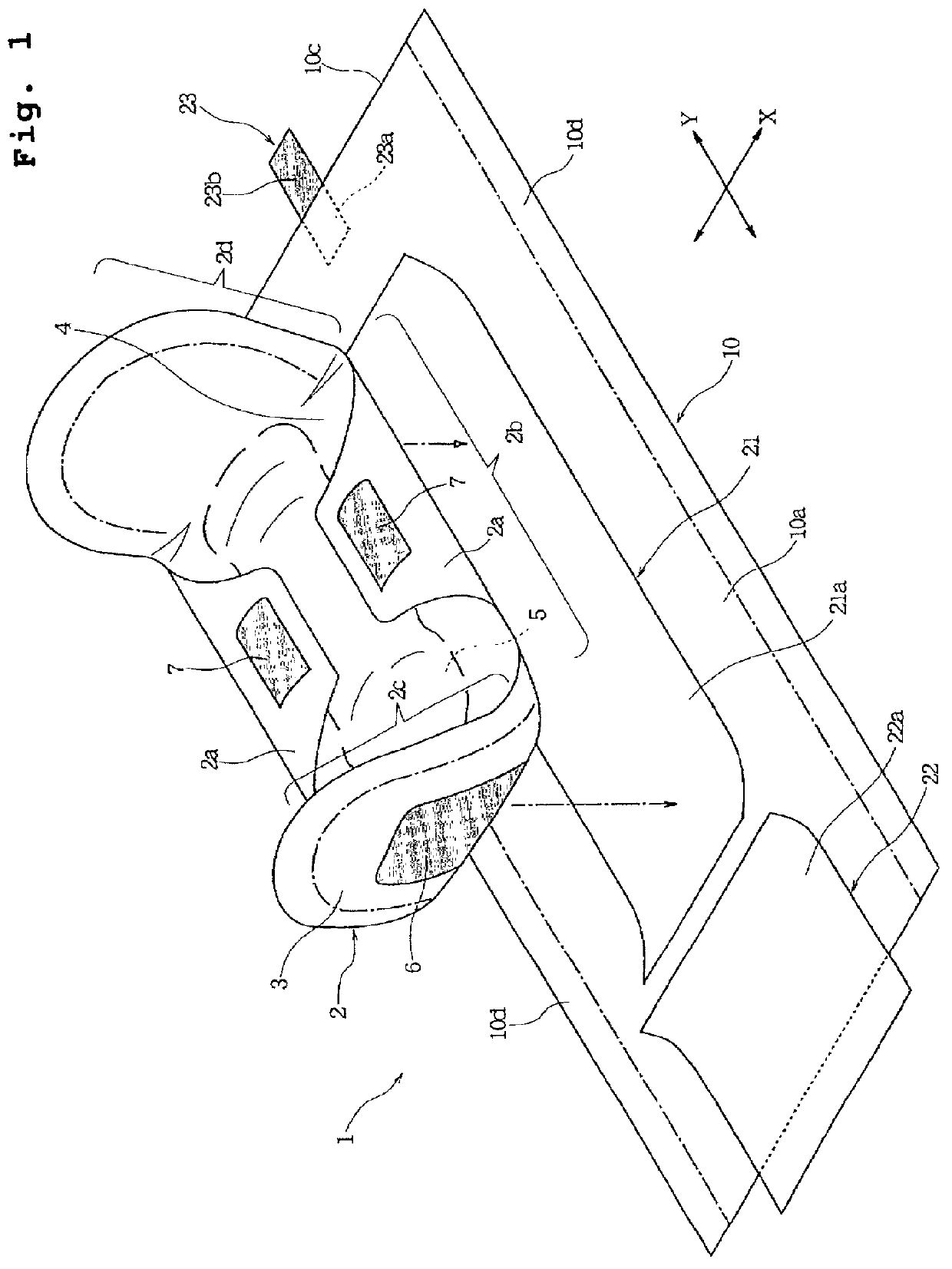

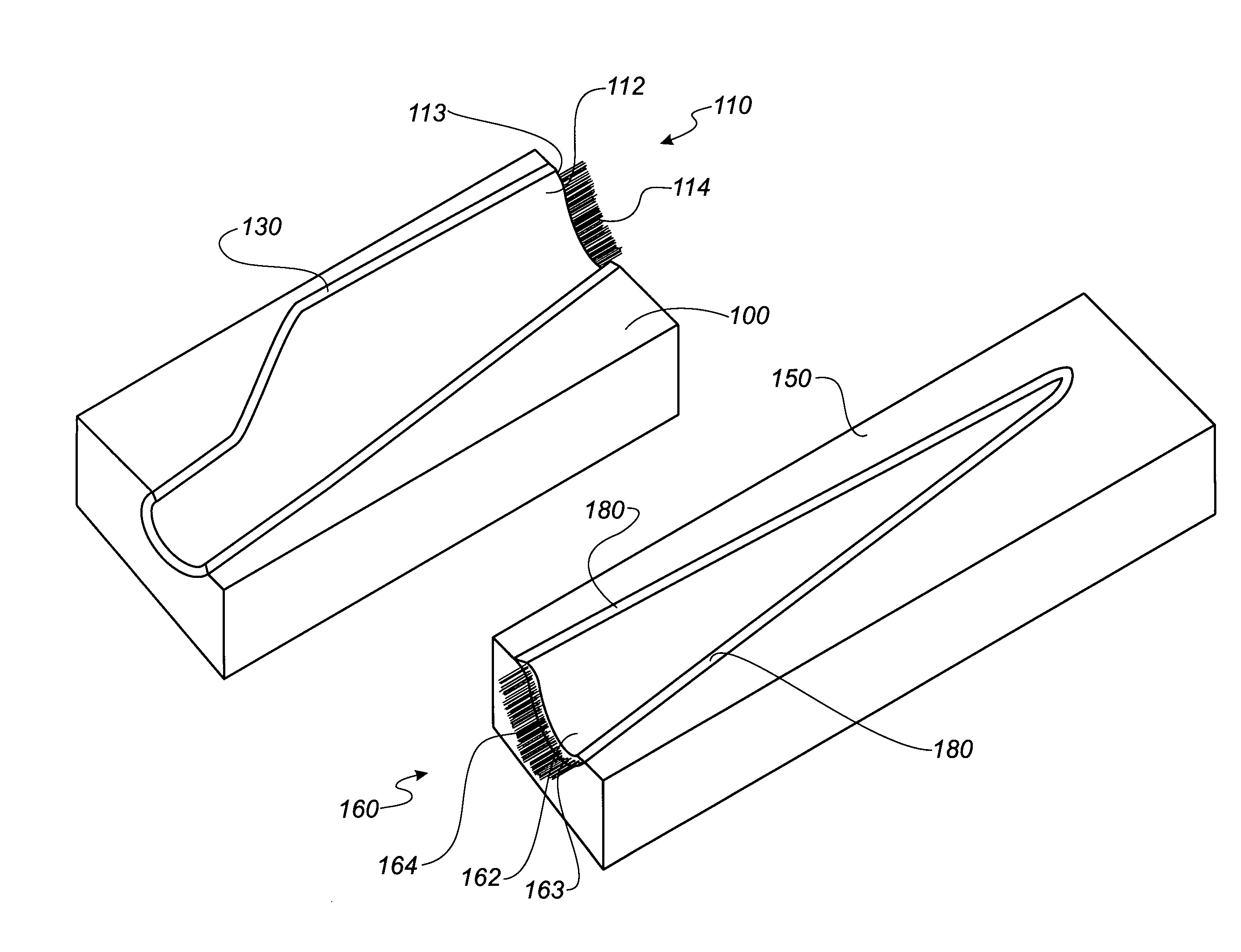

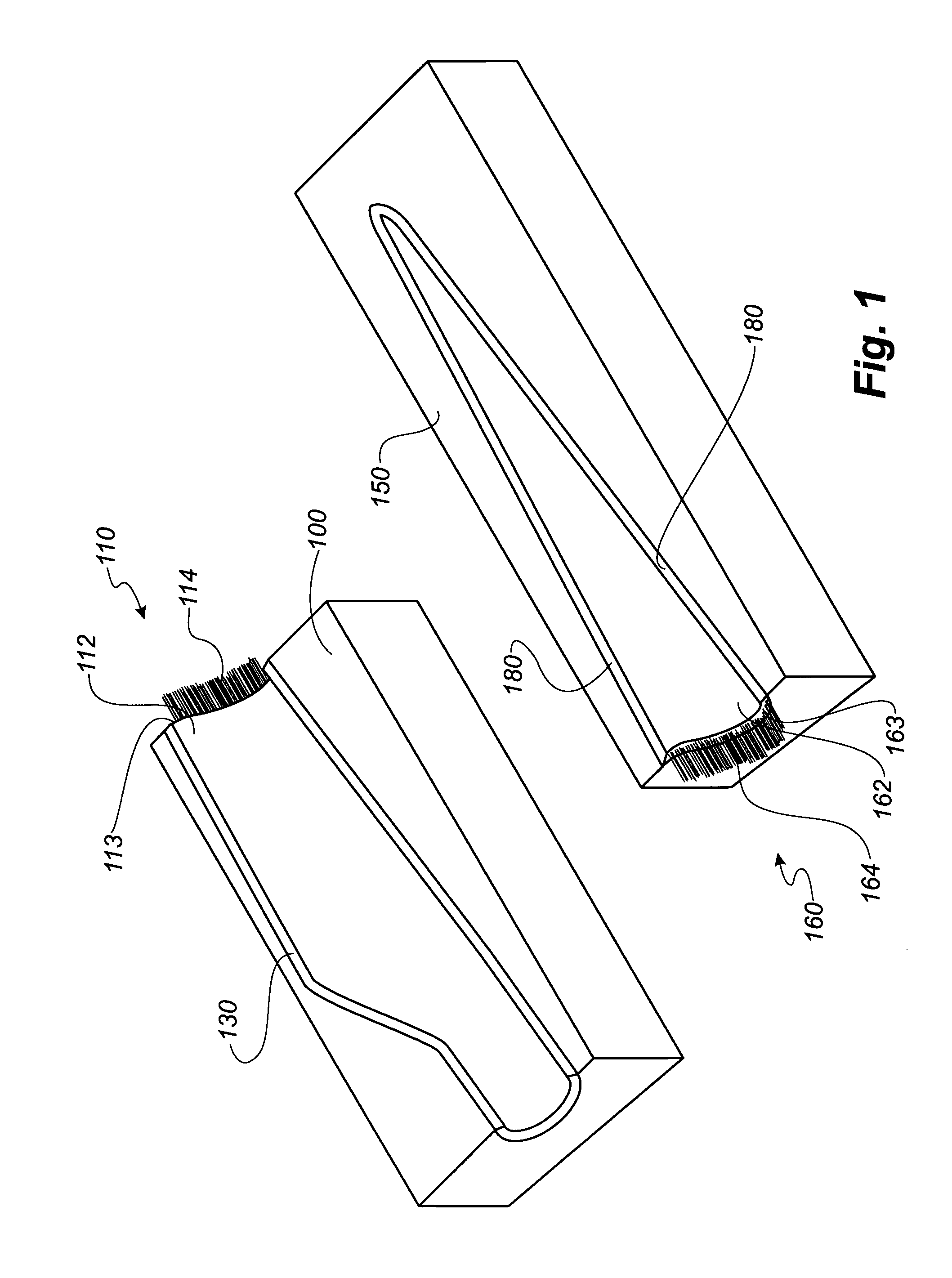

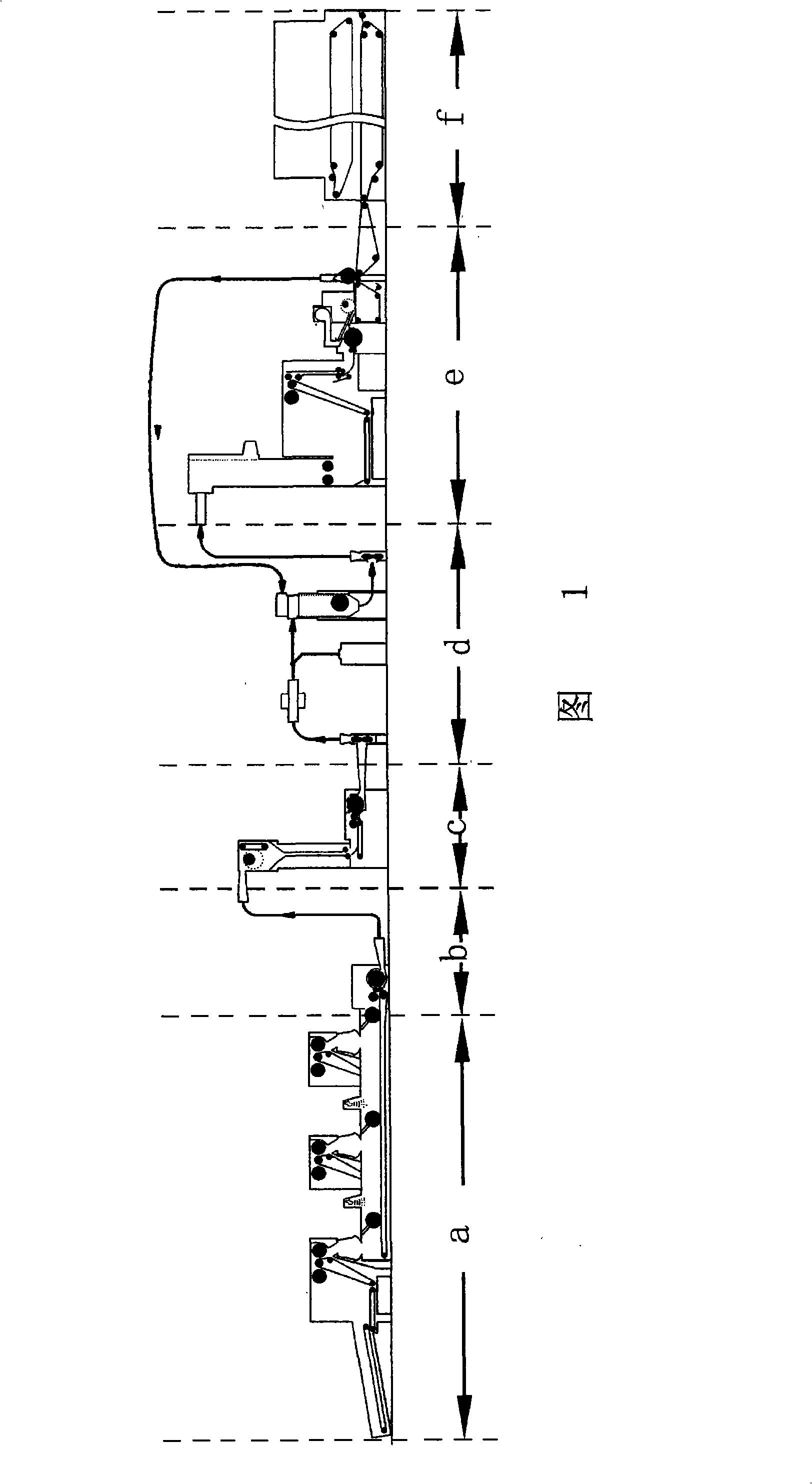

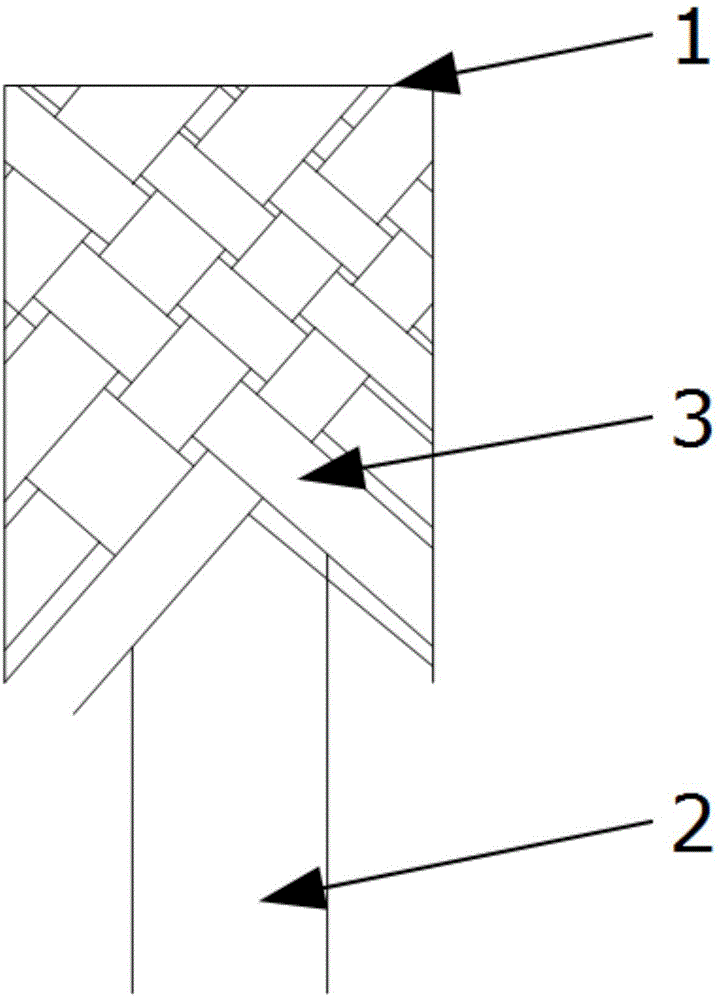

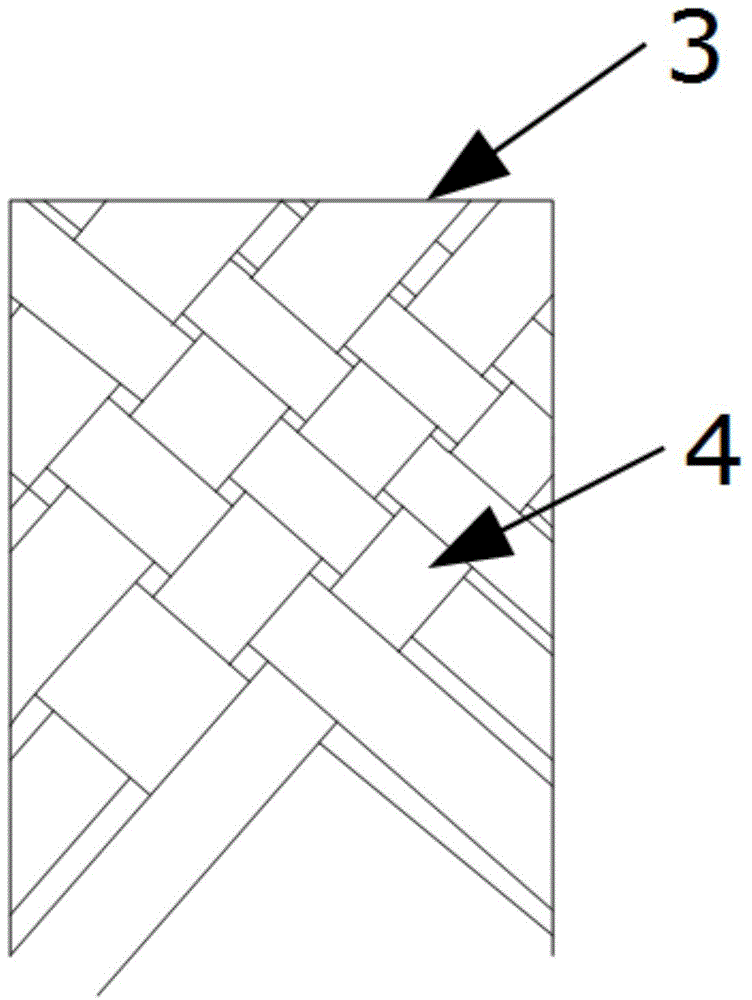

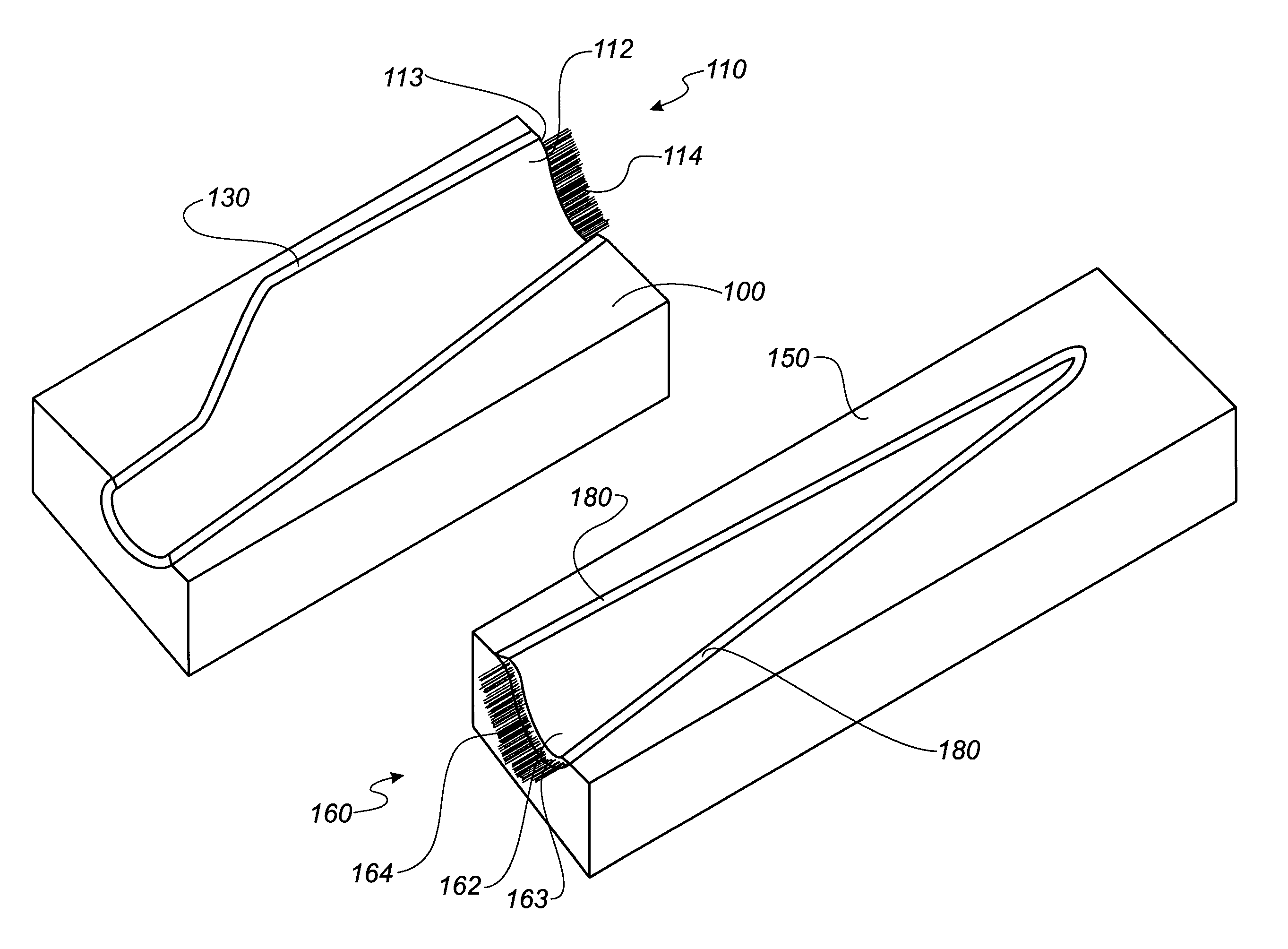

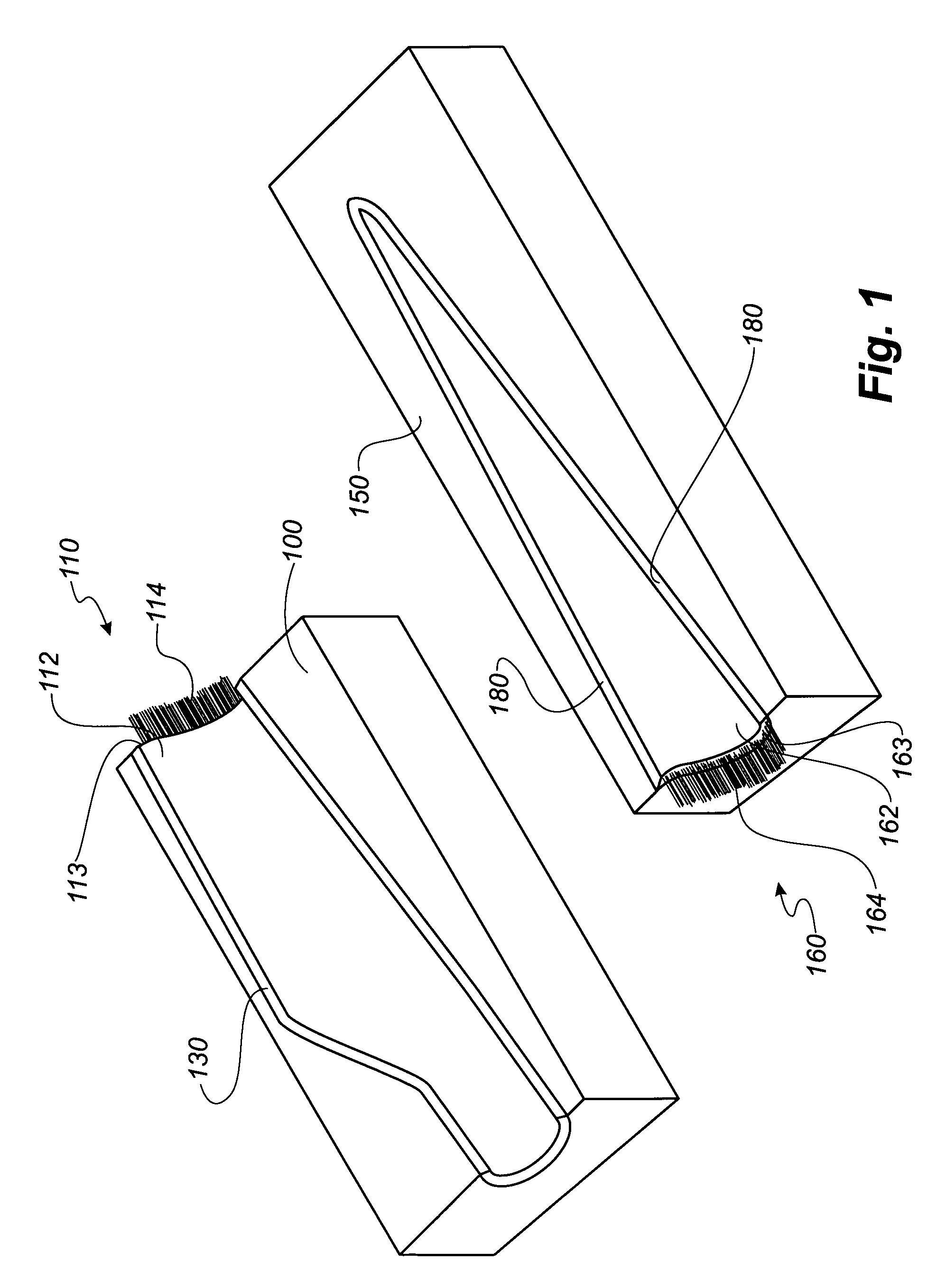

Method of producing a composite structure via intermediate products, the related apparatus and a composite structure obtainable by the method

ActiveUS20100304170A1High fiber densityFirmly connectedLaminationLamination apparatusFiberLiquid resin

A method of producing a composite structure comprising fibre reinforced material and having a longitudinal direction is described. The method comprises the following steps: a) manufacturing a first structure comprising a first cured composite part having a first thickness and a longitudinal direction with a first end, and a number of first fibre layers extending from the first end, b) manufacturing a second structure comprising a second cured composite part having a second thickness and a longitudinal direction with a second end, and a number of second fibre layers extending from the second end, and c) arranging the first structure and the second structure so that the first end faces towards the second end, and arranging the first fibre layers and the second fibre layers so that at least a part of the first fibre layers overlap at least a part of the second fibre layers in the longitudinal direction, d) supplying liquid resin in order to impregnate the first fibre layers and the second fibre layers, and e) curing the liquid resin in order to form the composite structure comprising the first cured composite part, the second cured composite part, and an intermediate composite part including the first fibre layers and the second fibre layers.

Owner:LM GLASSFIBER

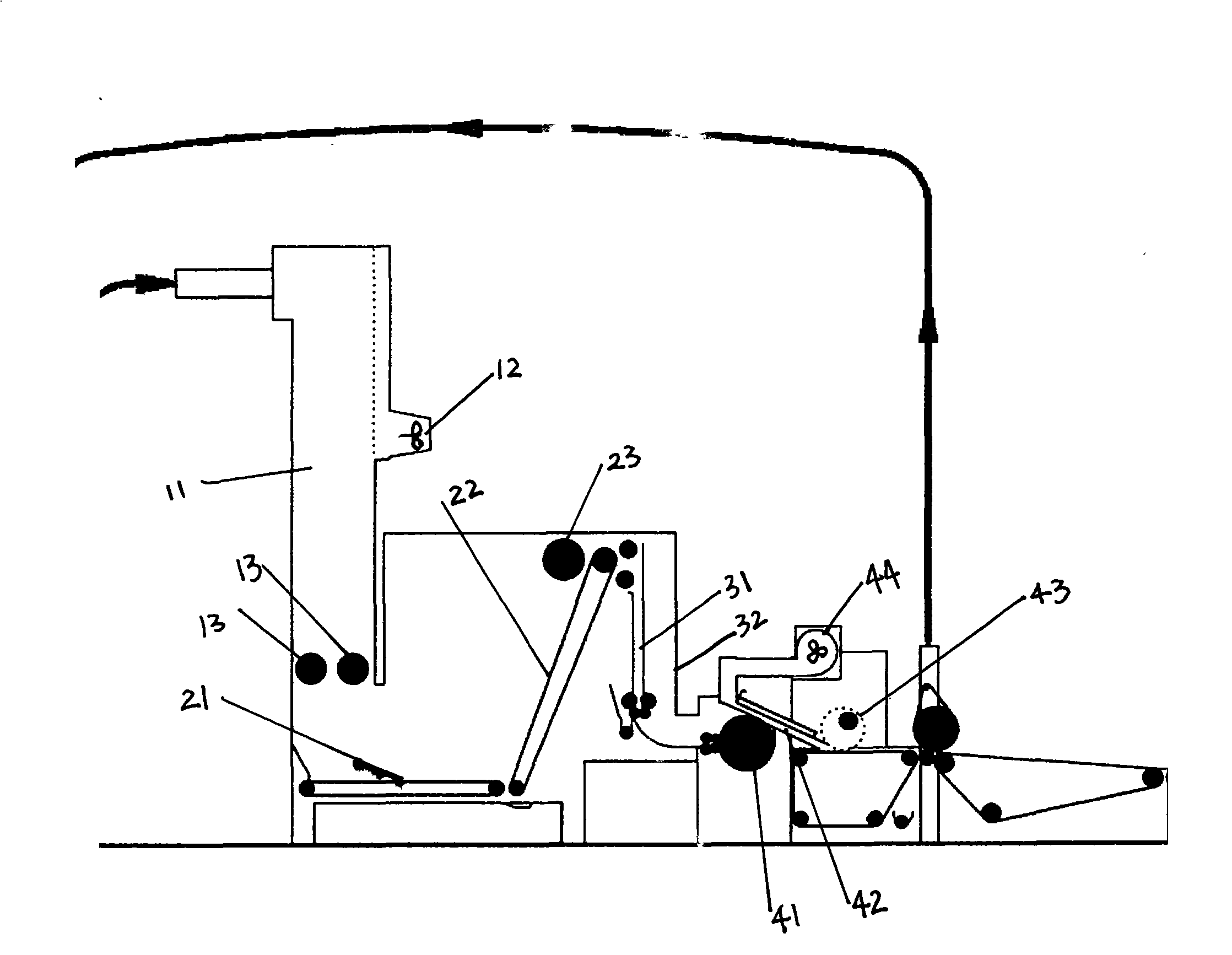

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

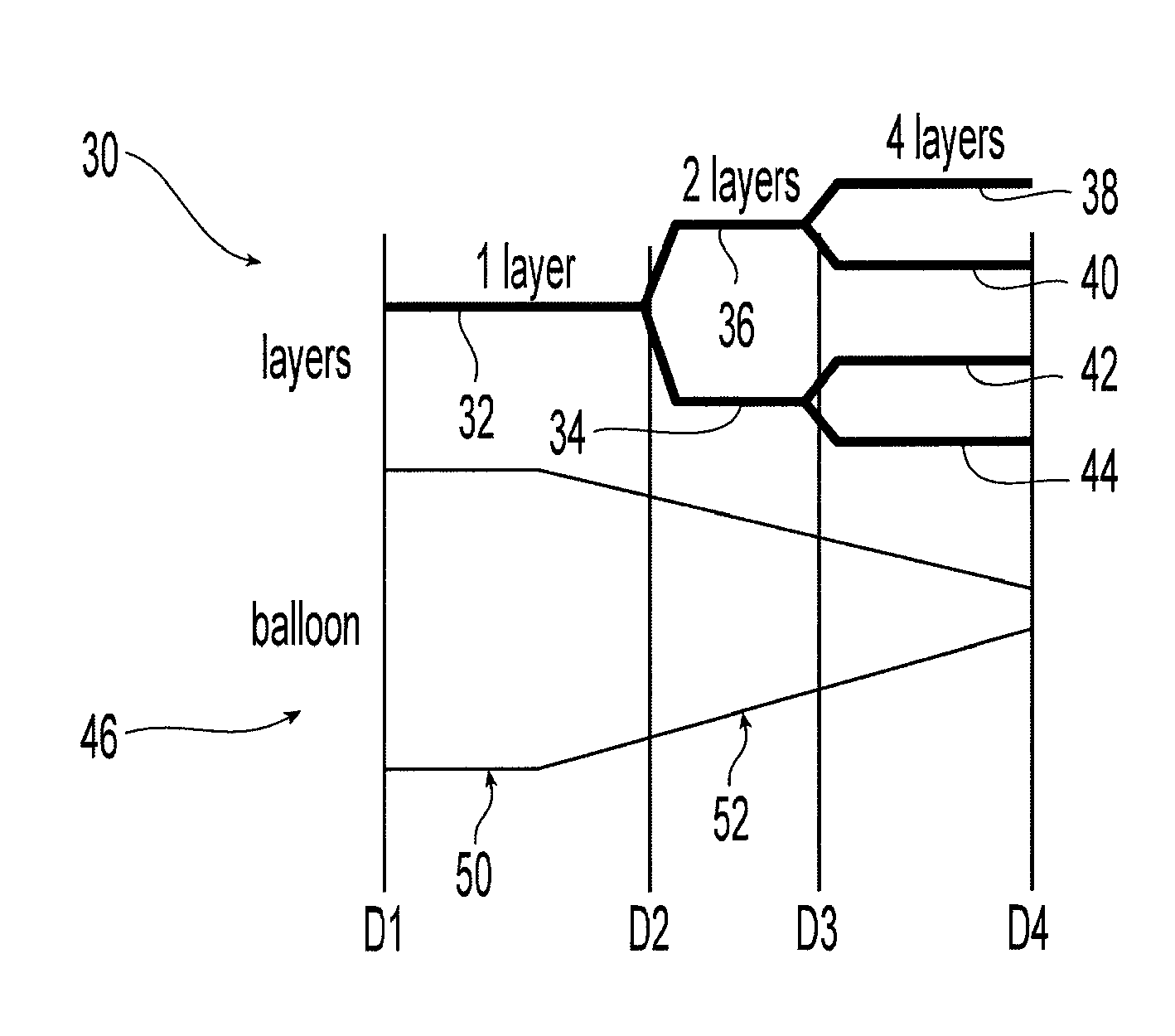

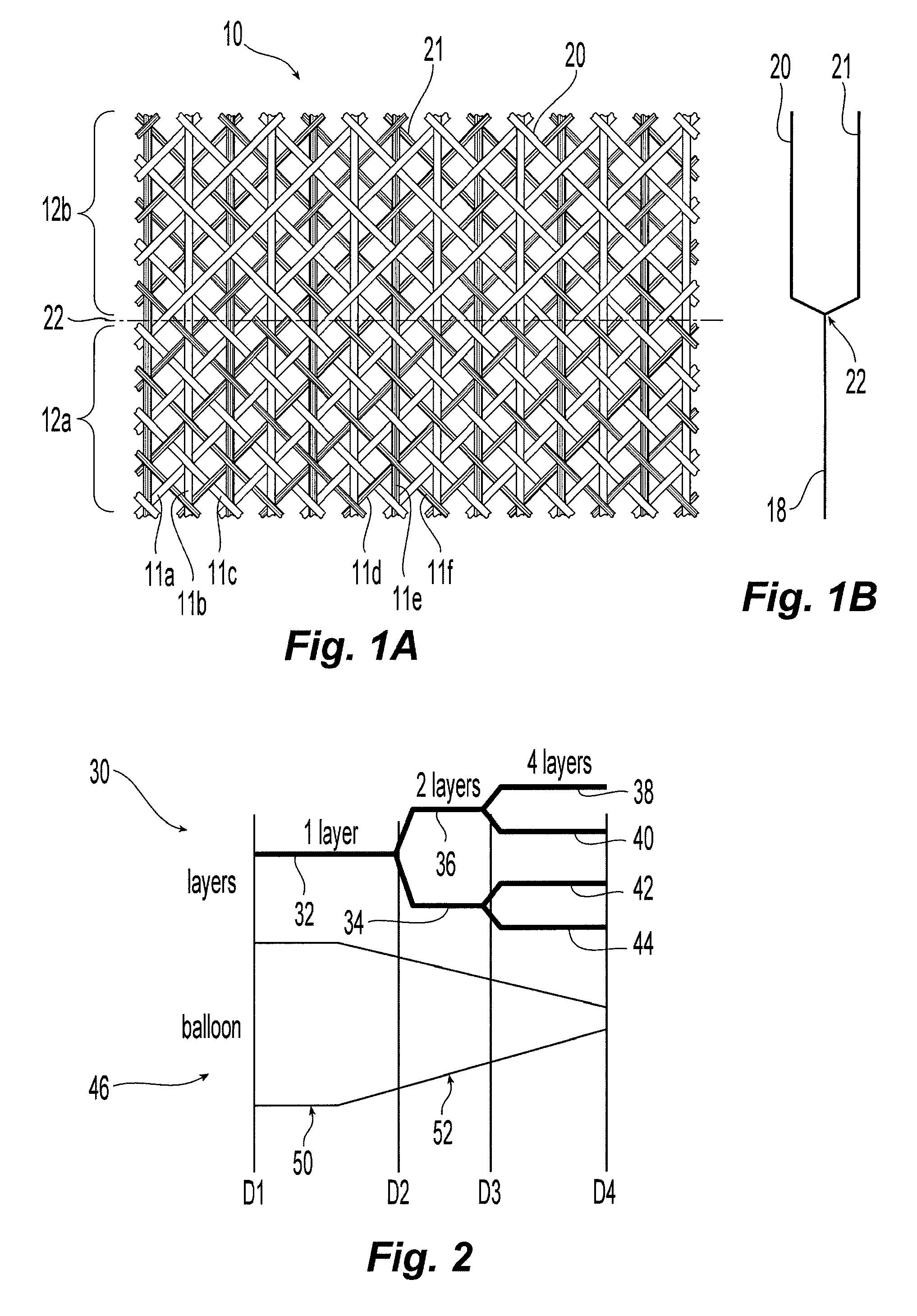

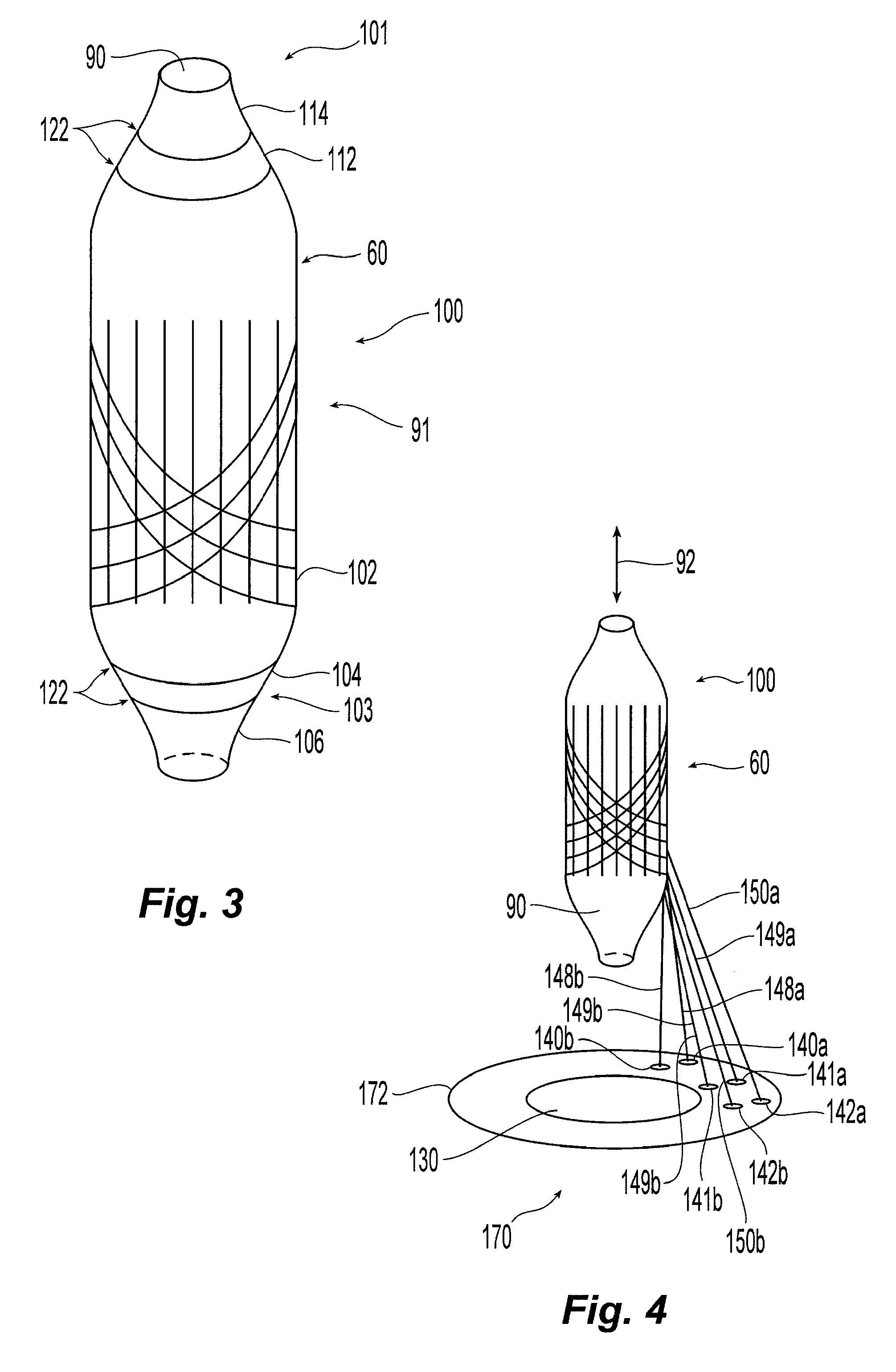

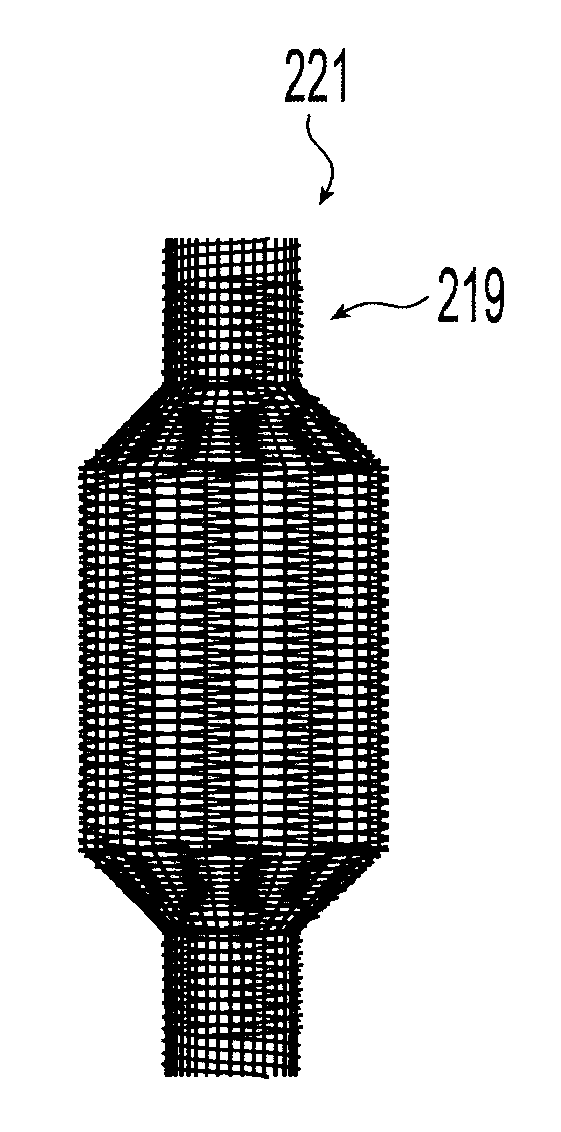

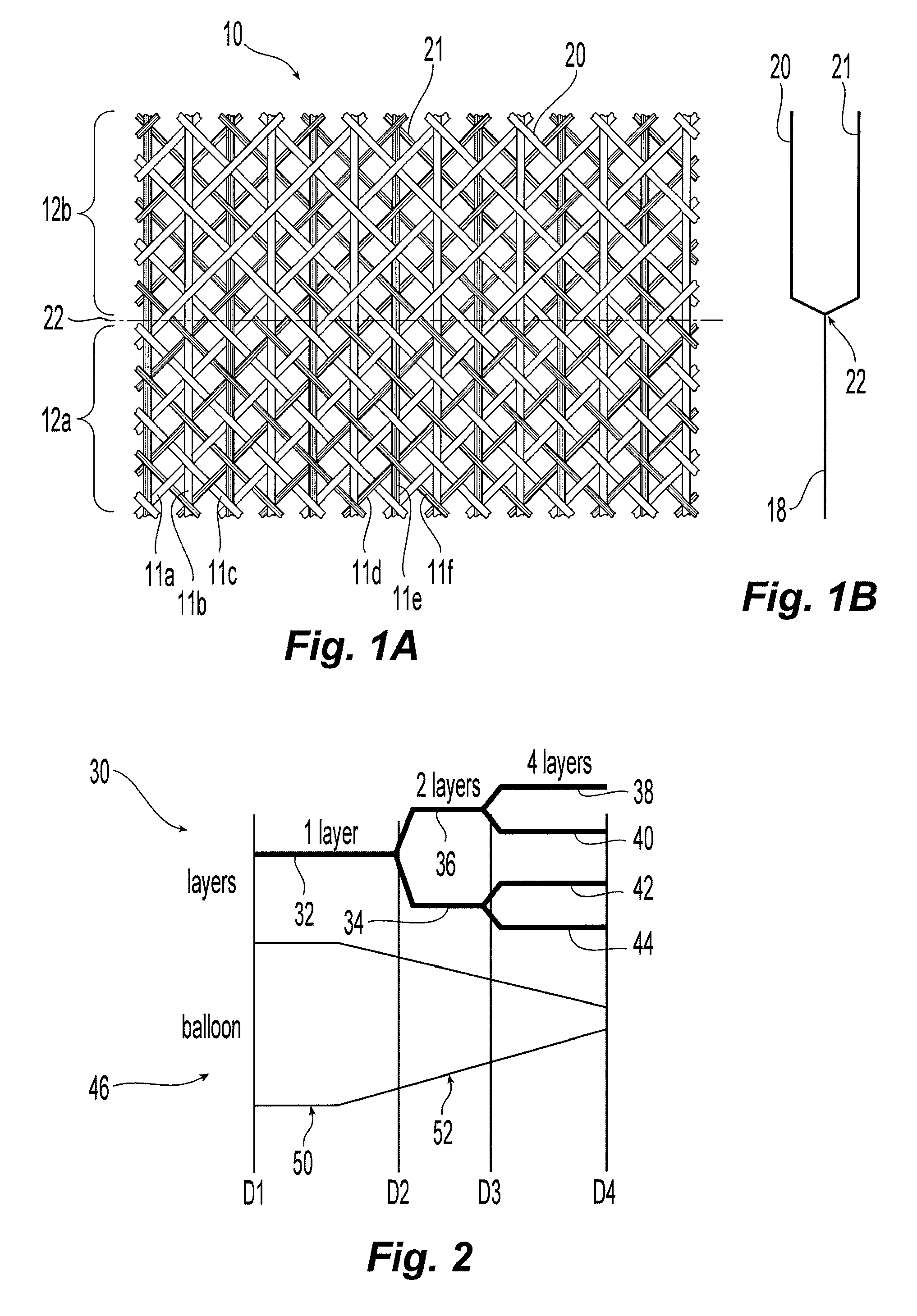

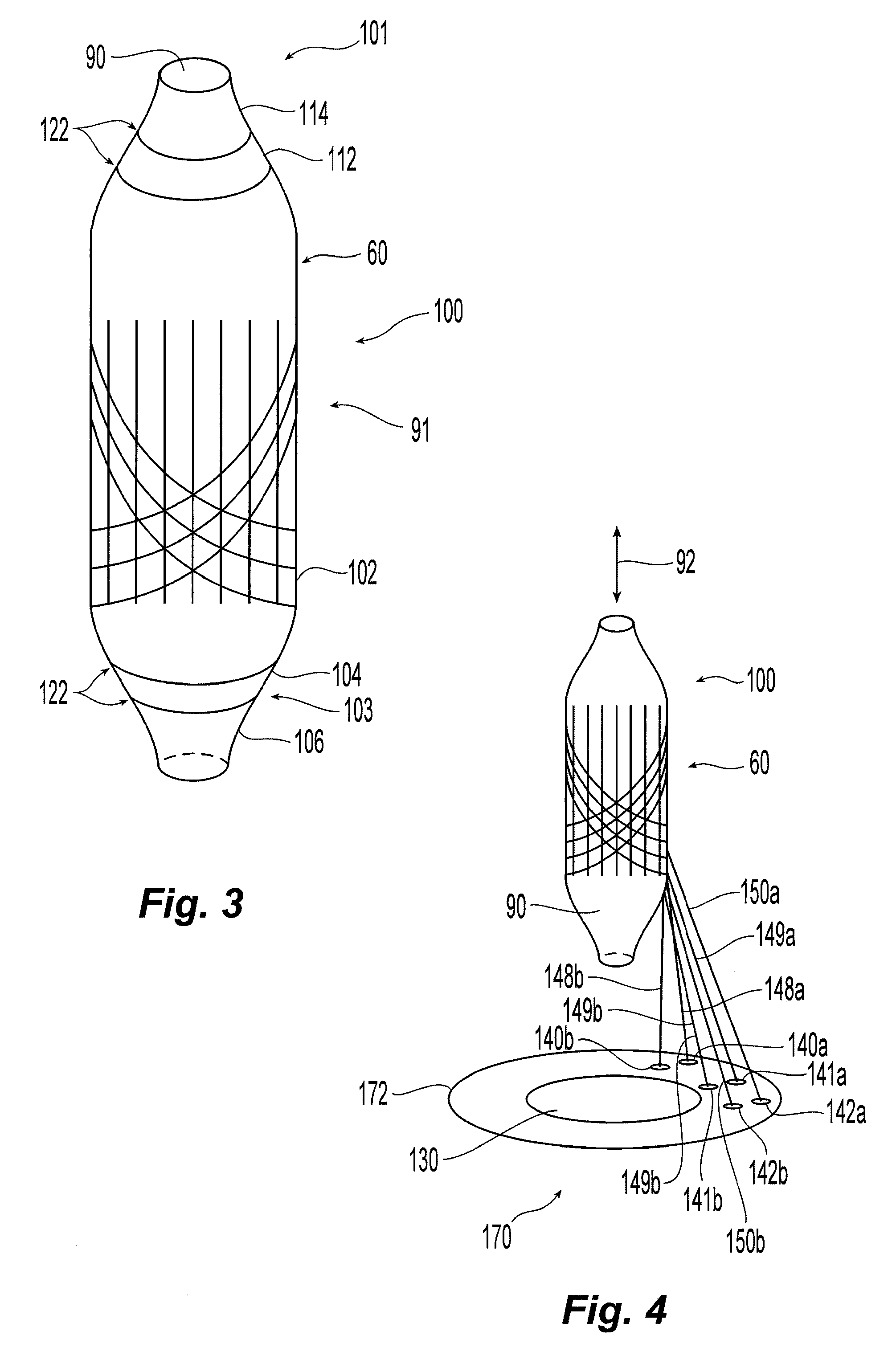

Balloon with dividing fabric layers and method for braiding over three-dimensional forms

ActiveUS8122809B2Minimize jammingMinimize jamming and bunchingStentsBalloon catheterEngineeringMultiple layer

A medical balloon with a variable diameter that is reinforced with continuous fibers woven to form a fabric with a varying number of layers and fiber densities. Portions of the balloon having a relatively smaller diameter are reinforced with a fabric having a reduced fiber density and an increased number of layers to facilitate the placement of the layers. The fabric also includes a braiding pattern that facilitates the transition from a single layer fabric to a multiple layer fabric. Also described is a manufacturing method for the braiding and layering.

Owner:CR BARD INC

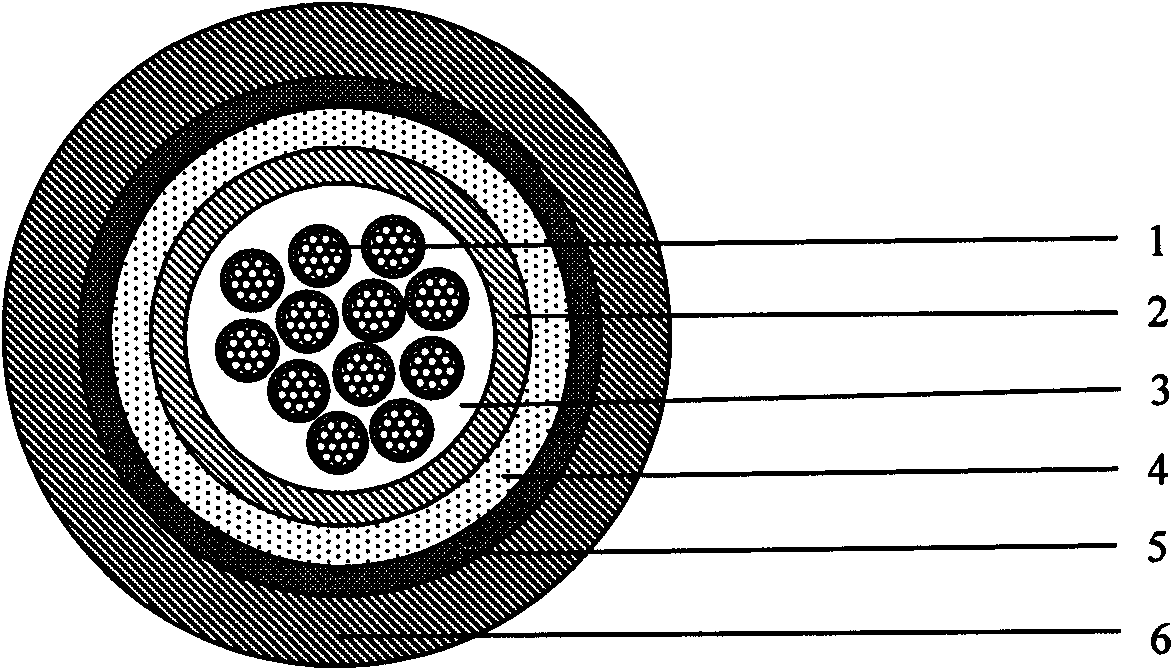

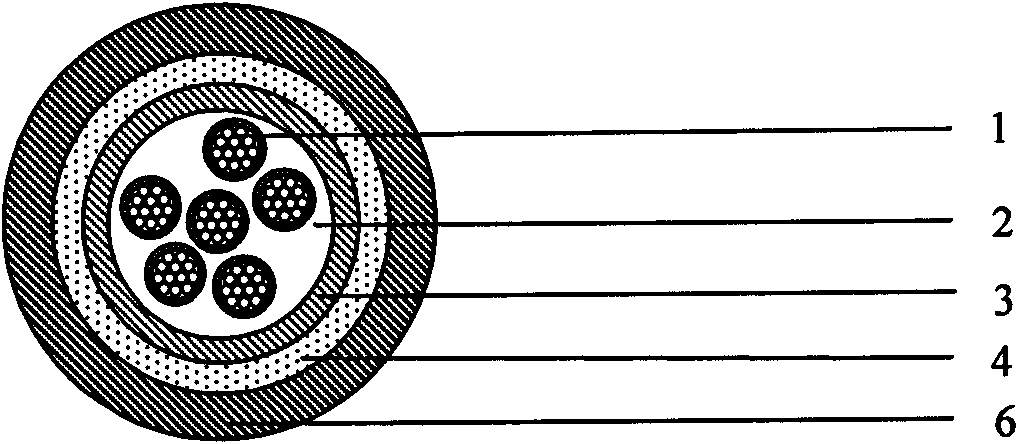

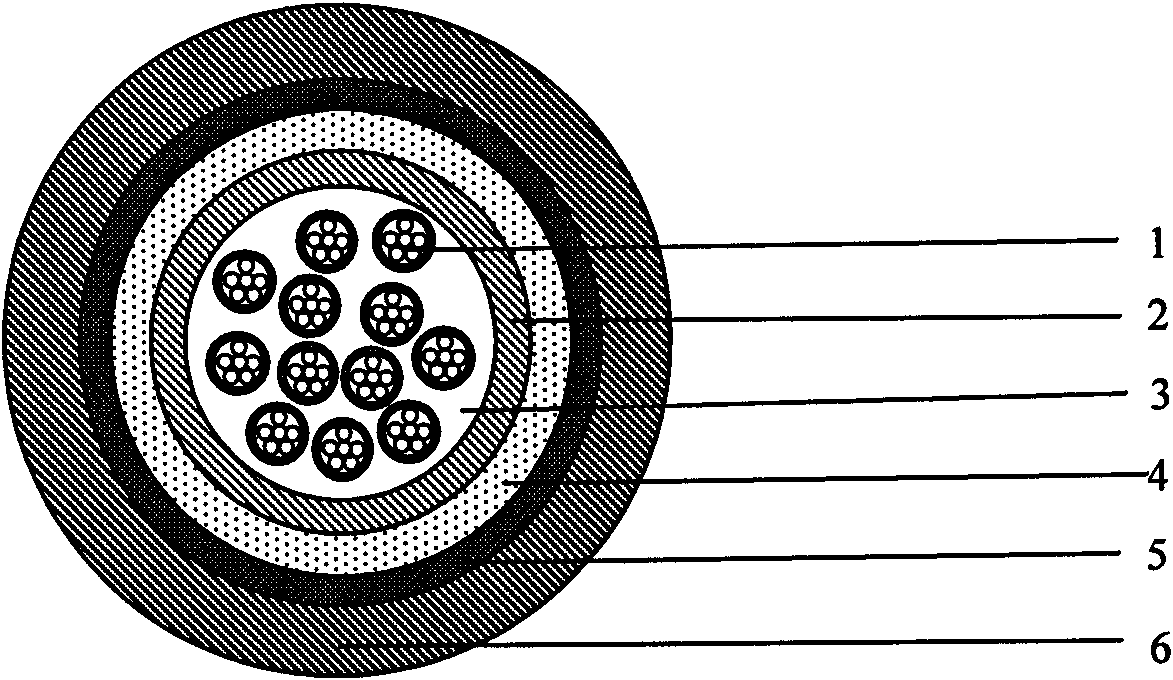

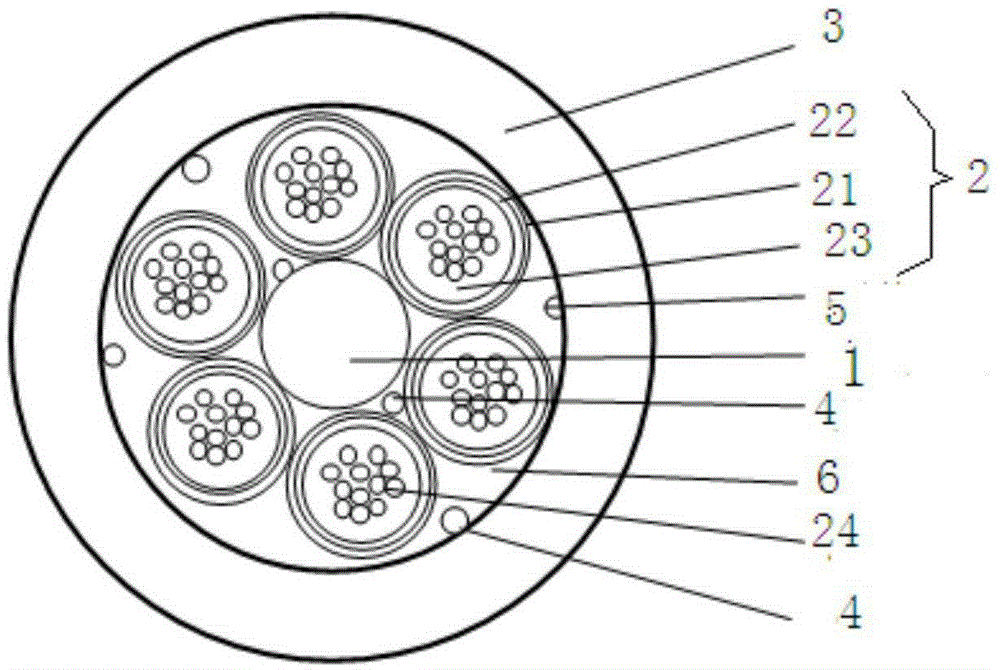

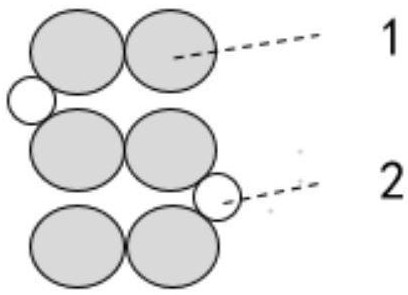

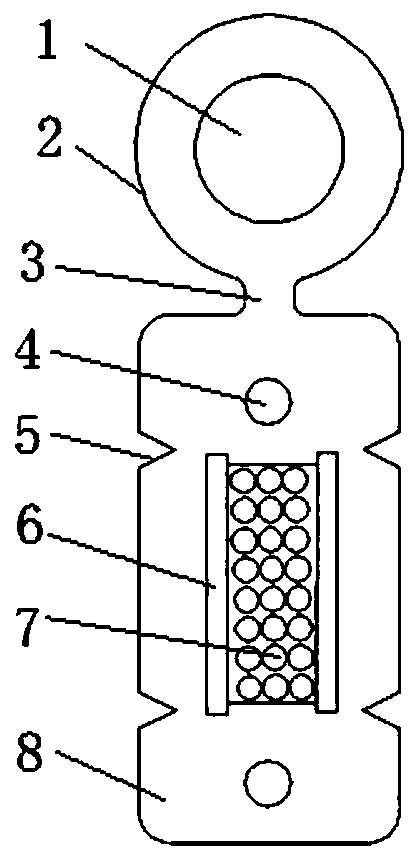

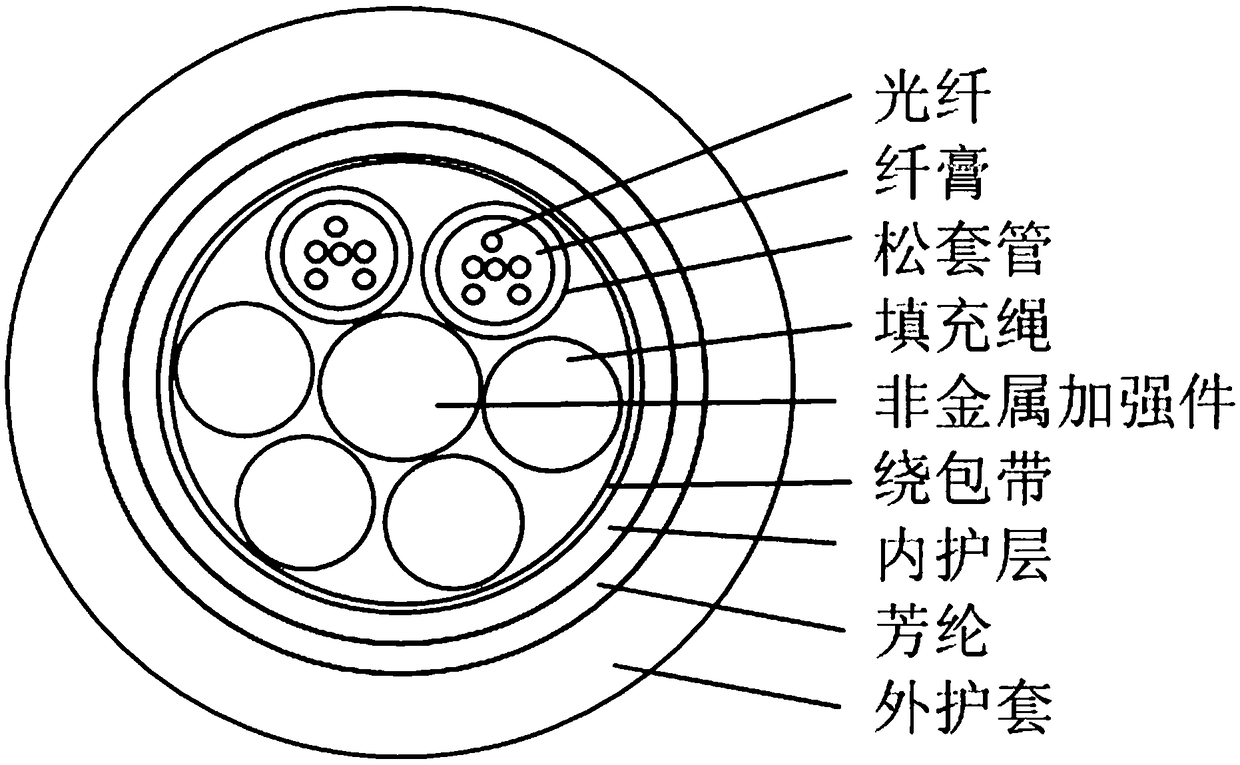

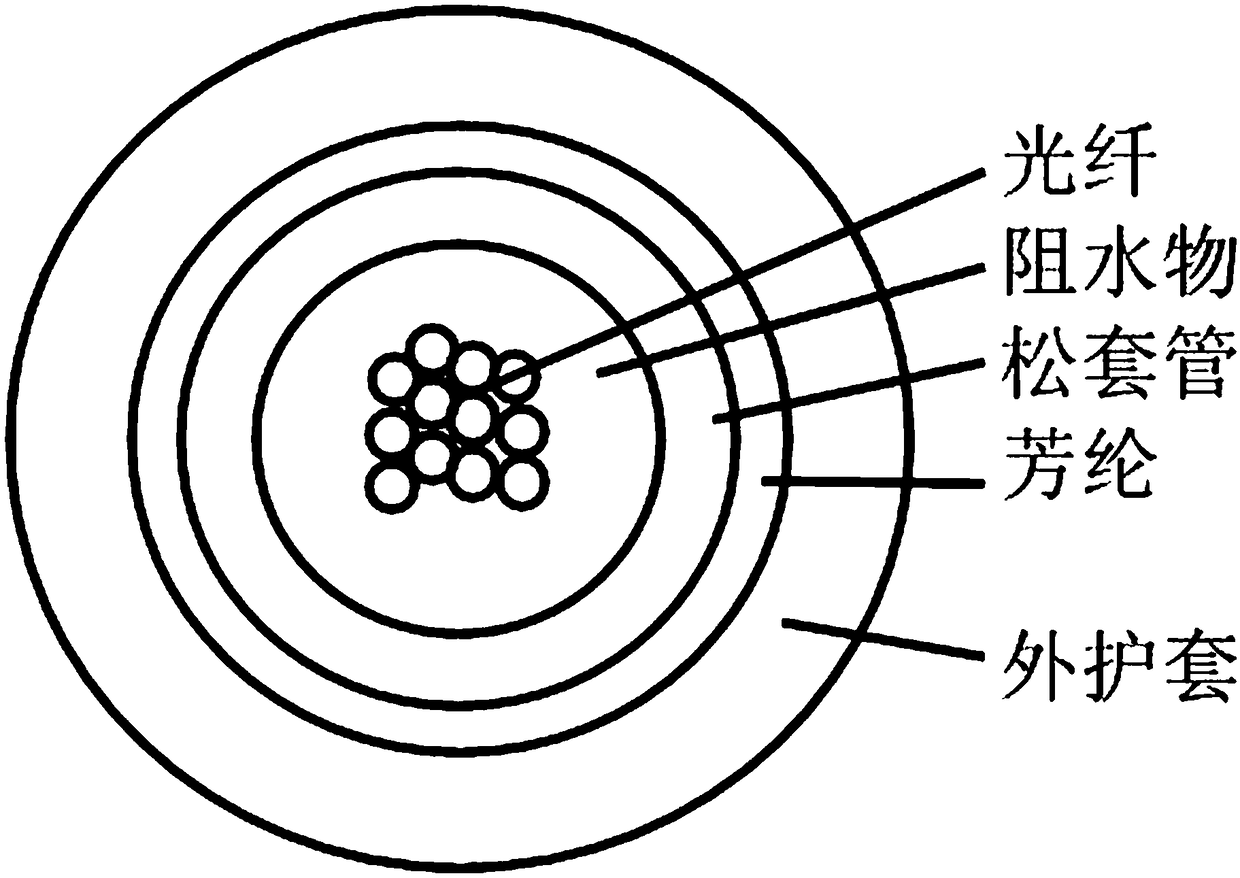

Novel fiber bundle central tube type optical cable

InactiveCN101840044AHigh fiber densityReduce volumeFibre mechanical structuresUltrasound attenuationHigh rate

The invention relates to an optical cable for a communication network, in particular to a novel fiber bundle central tube type optical cable. The while cross section of the optical cable is round, and the optical cable comprises an outer sheath (6), a reinforcing piece (4) and a loose sleeve (2) in turn from outside to inside, wherein a plurality of fiber bundles (1) are arranged in the loose sleeve (2); a water-blocking ointment (3) is filled among the fiber bundles (1); the fiber bundles (1) are made of a plurality of optical fibers (12) by adopting an ultraviolet light curing process; a layer of ultraviolet light cured resin is formed outside the fiber bundles; and an optical fiber water-blocking ointment (11) is filed among the optical fibers. For the novel fiber bundle central tube type optical cable, a plurality of the fiber bundles which are produced by the ultraviolet light curing process and are filled with the water-blocking ointment are placed in the loose sleeve, and compared with the traditional central tube type optical fiber ribbon optical cable, the novel fiber bundle central tube type optical cable has a series of advantages of high fiber density, small volume, light weight, high rate of finished products and the like. The novel fiber bundle central tube type optical cable solves the problems that optical fiber ribbons are scattered easily and are distorted extensively in production or can make the optical fibers on the extreme edge generate large attenuations.

Owner:FENGHUO COMM SCI & TECH CO LTD

Electrospun blends of natural and synthetic polymer fibers as tissue engineering scaffolds

InactiveUS8048446B2Improve permeabilityFacilitate proliferationBiocidePeptide/protein ingredientsFiberPolymer science

Non-woven fibrous scaffolds made by electrospinning from the synthetic biodegradable polymer such as, for example, poly(lactic-co-glycolic acid) (PLGA) and natural proteins, such as, for example, gelatin (denatured collagen) and elastin and a method of making thereof.

Owner:DREXEL UNIV

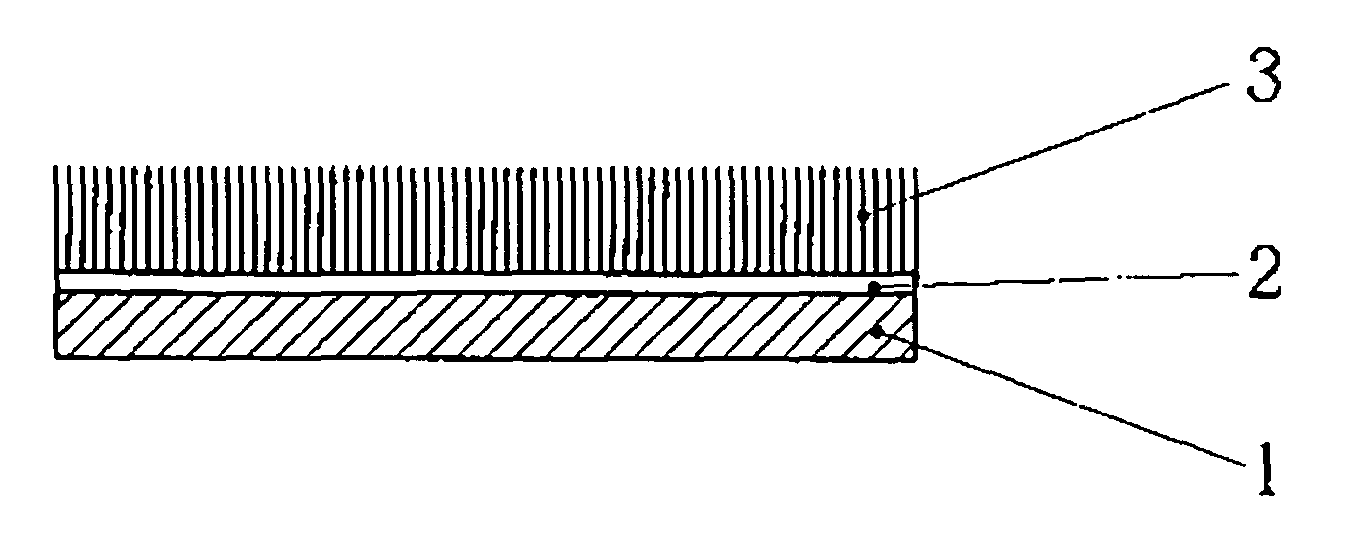

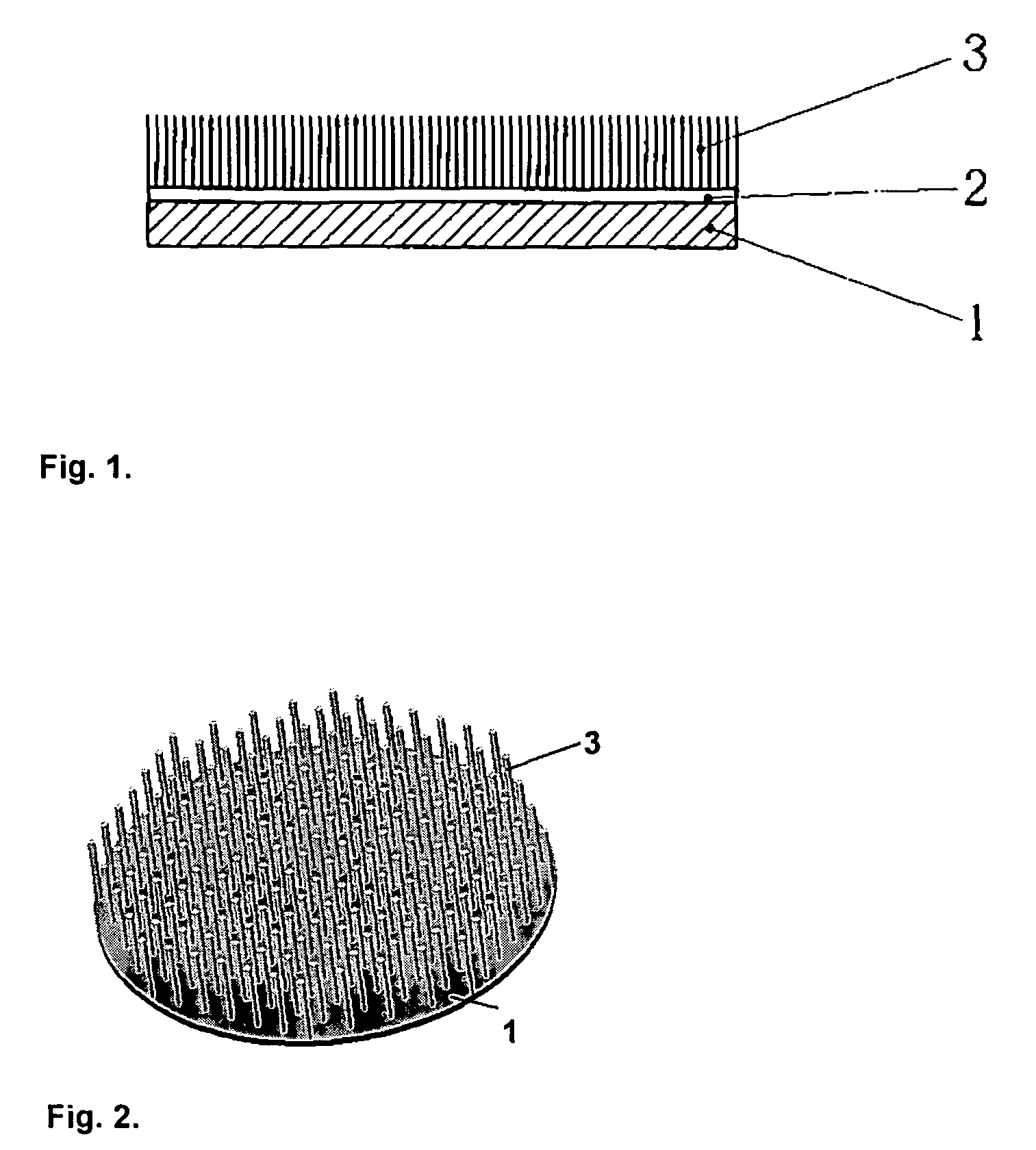

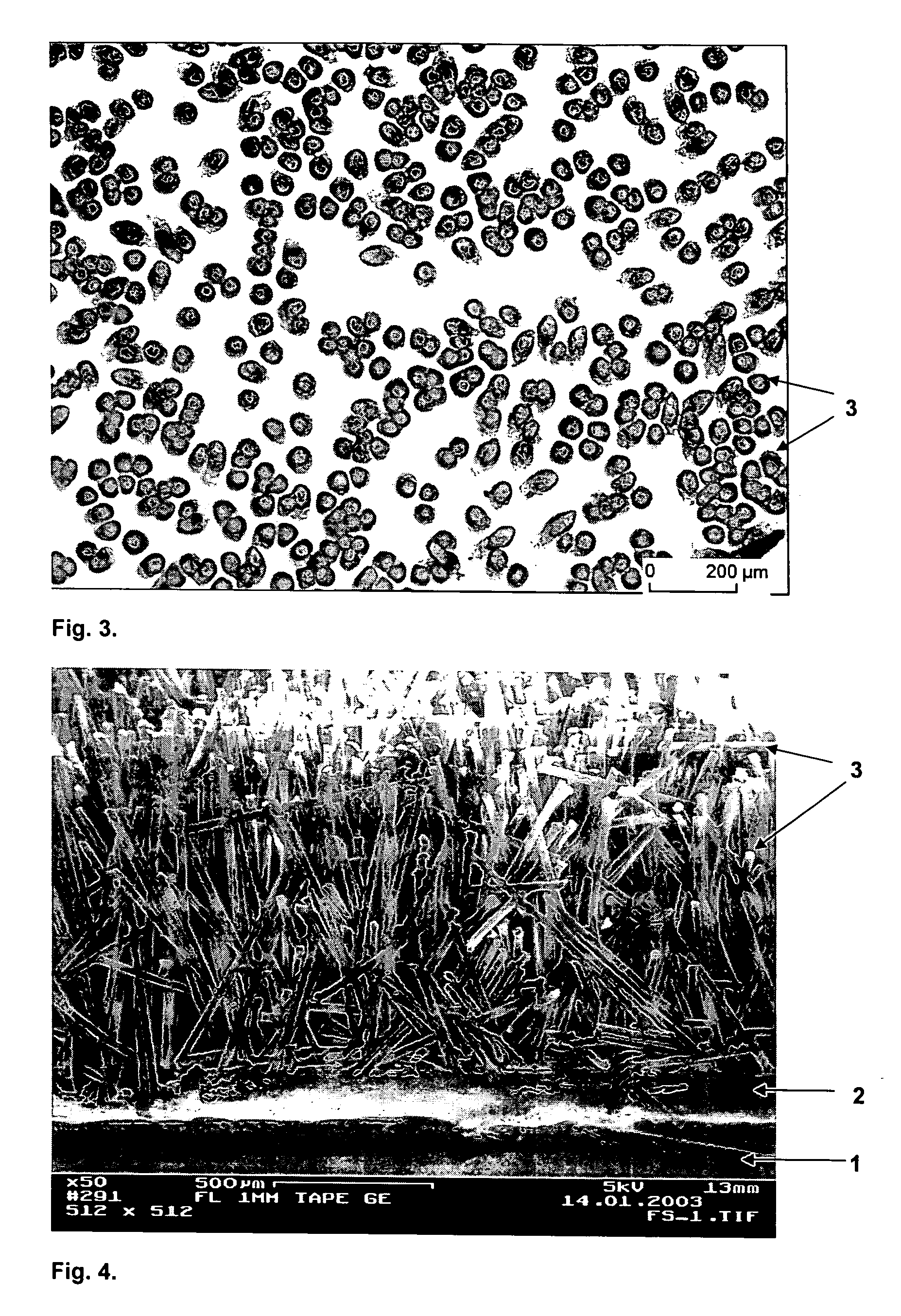

Support material for tissue engineering, for producing implants or implant materials, and an implant produced with the support material

InactiveUS7763272B2High fiber densityStable against compressionAdditive manufacturing apparatusSkin implantsIn vivoColonization

A scaffold for tissue culture and cell culture and for producing implant materials, in particular bone, cartilage or skin replacements or extra-corporal organ replacements or for other applications in medicine or biotechnology is made of biocompatible materials. It has at least one base material which is electrostatically flocked with fibers on at least one side. Through the electrostatic flocking the fibers are arranged almost perpendicularly on the surface of the base material and exhibits a high fiber pull-out resistance. The scaffold provides an elastic growth lattice, which is stable against compression, for cell colonization in vitro or the ingrowth of cells in vivo. Implants or implant materials can be produced with the scaffold.

Owner:DRESDEN UNIVERSITY OF TECHNOLOGY

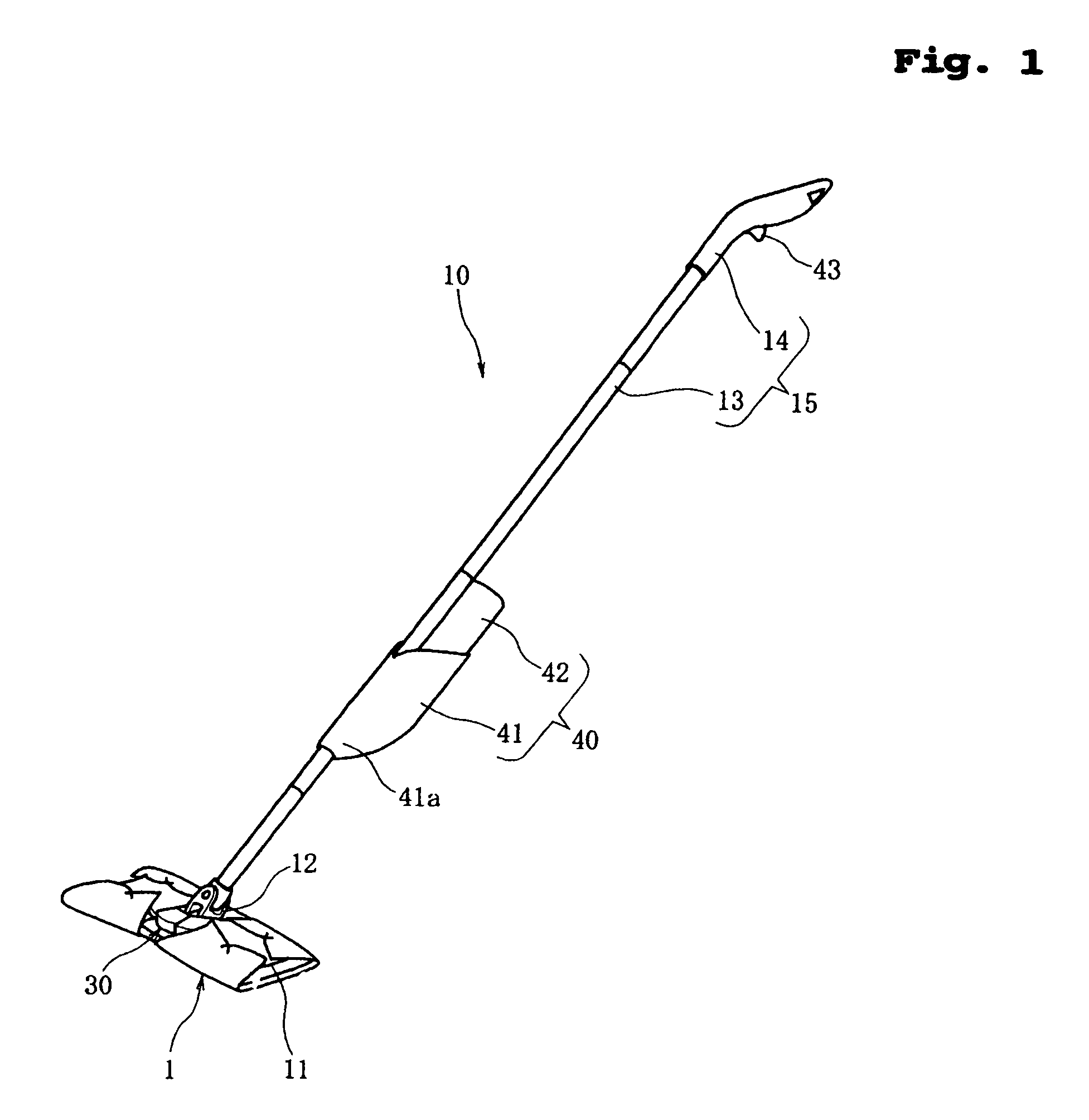

Cleaning sheet

ActiveUS7451516B2High fiber densitySuitable for cleaningKitchenware cleanersLayered productsEngineeringNonwoven fabric

Disclosed is a cleaning sheet having a cleaning surface side to be applied to an object to be cleaned. The cleaning surface has second regions along its longer sides and a first region between the second regions. In the first region, an exterior nonwoven fabric is exposed externally; in the second regions, a liquid permeable sheet having a lower density than the exterior nonwoven fabric is exposed externally. Liquid on a floor surface is allowed to pass through the liquid permeable sheet in the second regions and be absorbed by a liquid absorbent sheet. This prevents excess liquid between the exterior nonwoven fabric and the floor surface.

Owner:UNI CHARM CORP

Balloon With Dividing Fabric Layers And Method For Braiding Over Three-Dimensional Forms

ActiveUS20100010438A1Minimize jammingMinimize jamming and bunchingStentsBalloon catheterEngineeringMultiple layer

A medical balloon with a variable diameter that is reinforced with continuous fibers woven to form a fabric with a varying number of layers and fiber densities. Portions of the balloon having a relatively smaller diameter are reinforced with a fabric having a reduced fiber density and an increased number of layers to facilitate the placement of the layers. The fabric also includes a braiding pattern that facilitates the transition from a single layer fabric to a multiple layer fabric. Also described is a manufacturing method for the braiding and layering.

Owner:CR BARD INC

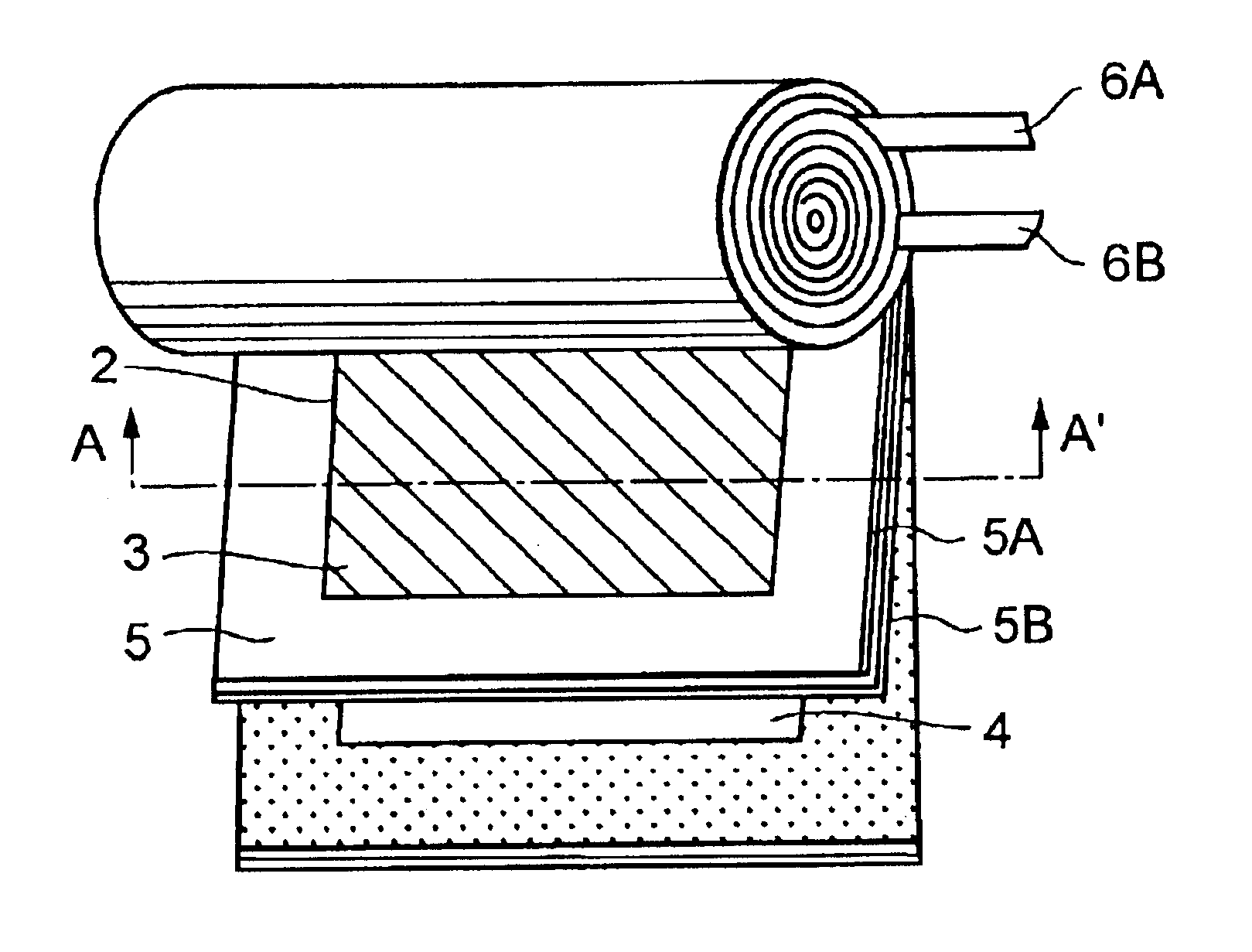

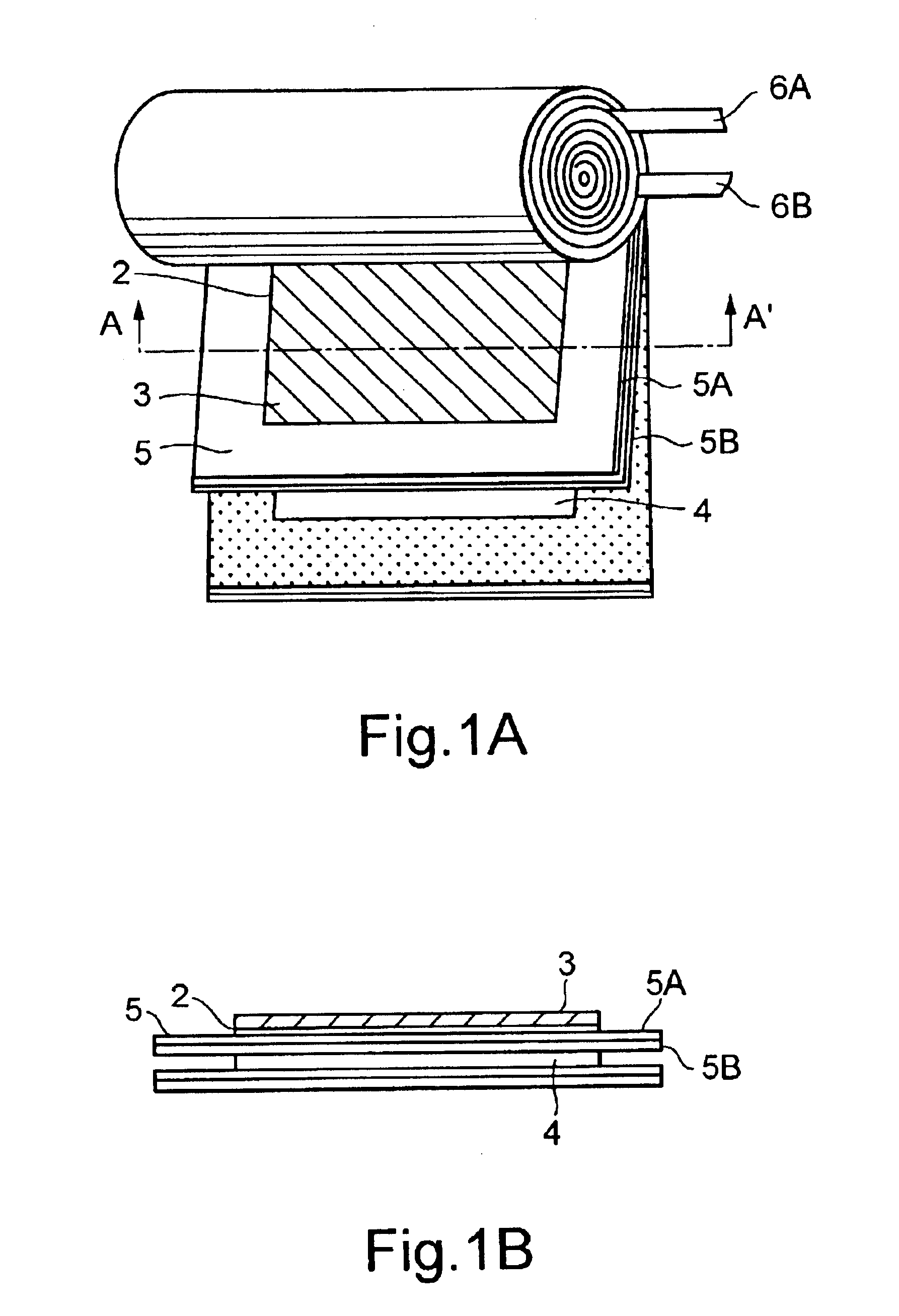

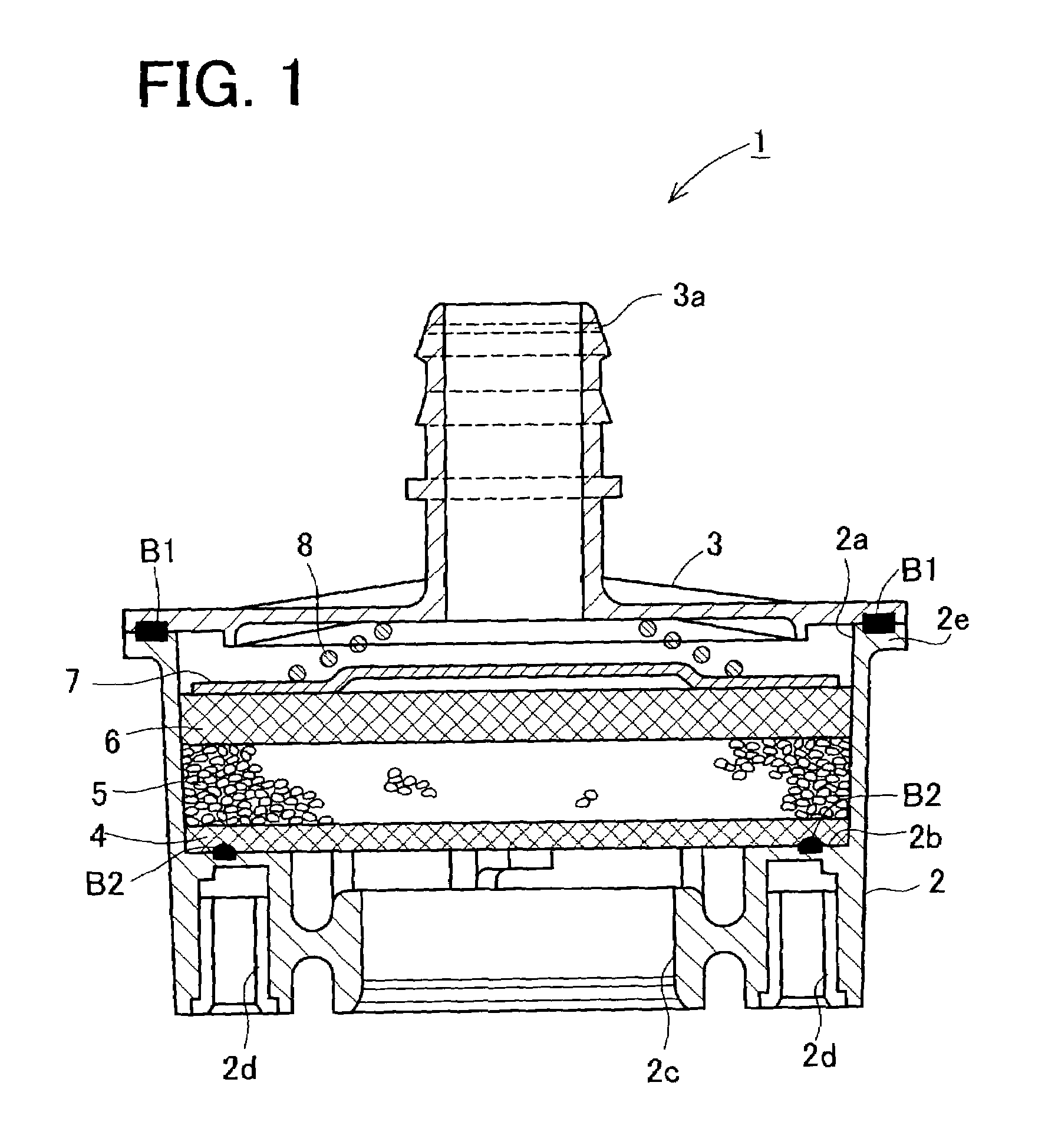

Electrolytic capacitor and a fuel cell drive car using the capacitor

InactiveUS6853537B2High fiber densityLiquid electrolytic capacitorsCapacitor electrodesElectrolysisFuel cells

Electrolytic capacitor for of a high voltage and a high capacity is provided, which is suited for an auxiliary power supply of a fuel cell vehicle. A cathode and an anode foil are arranged to face each other. A dielectric film may be provided on the surface of the anode foil. The anode foil and the cathode foil 4 are wound into a roll, with a compound separator including the first and second separators and arranged there between. In the compound separator, electrolyte is impregnated and conductive fine particles are dispersed in the second separator.

Owner:JELMAX

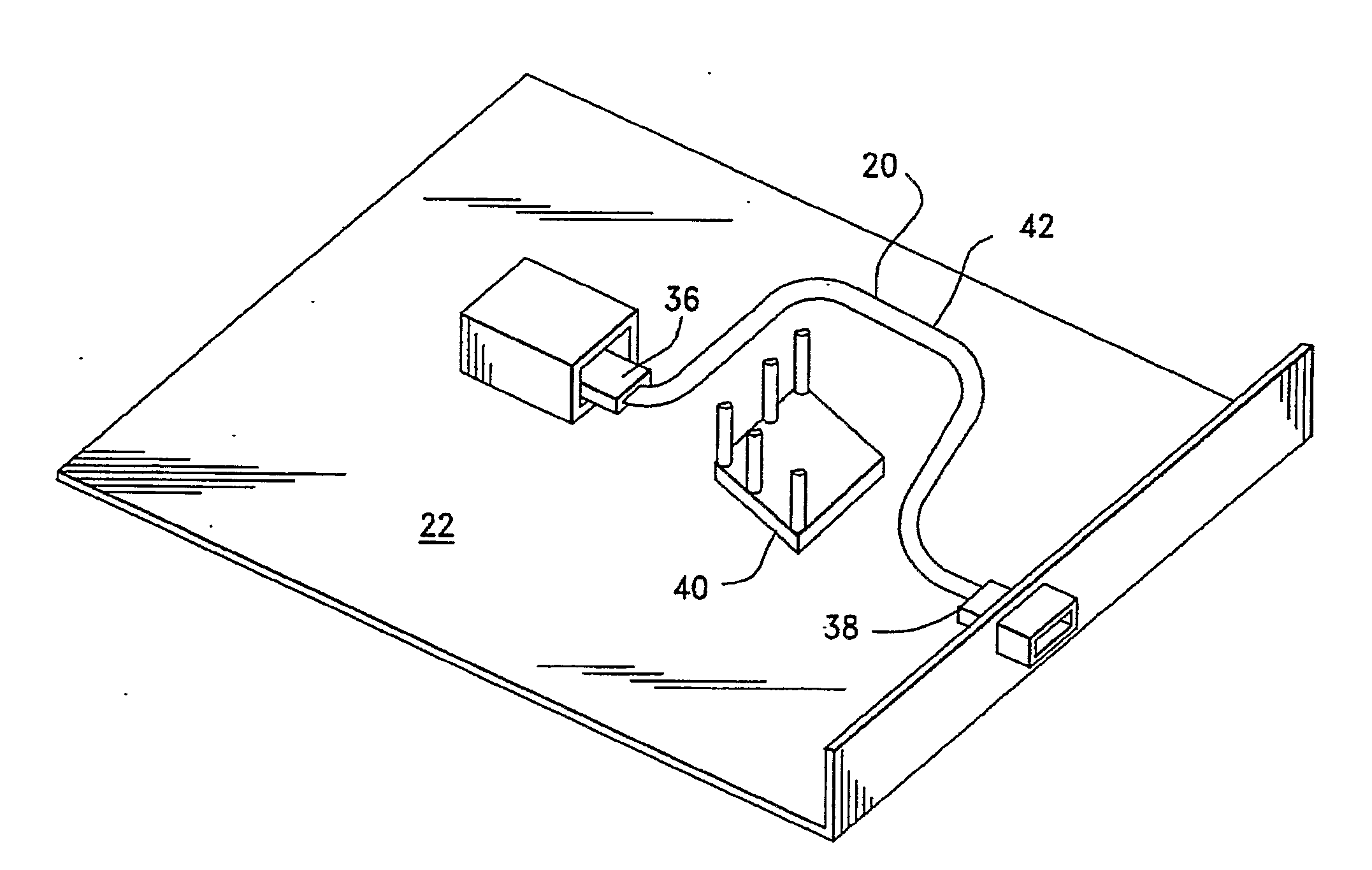

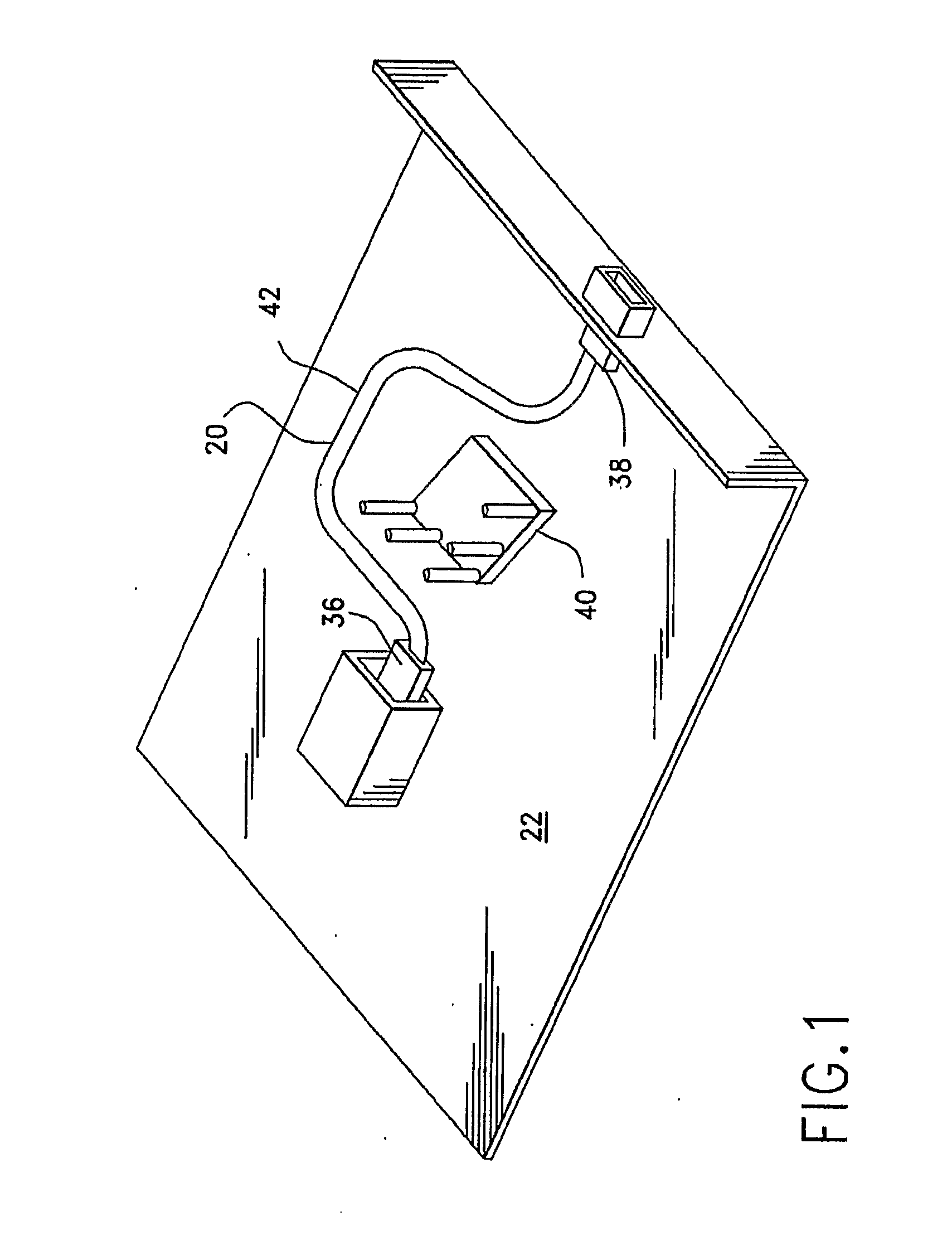

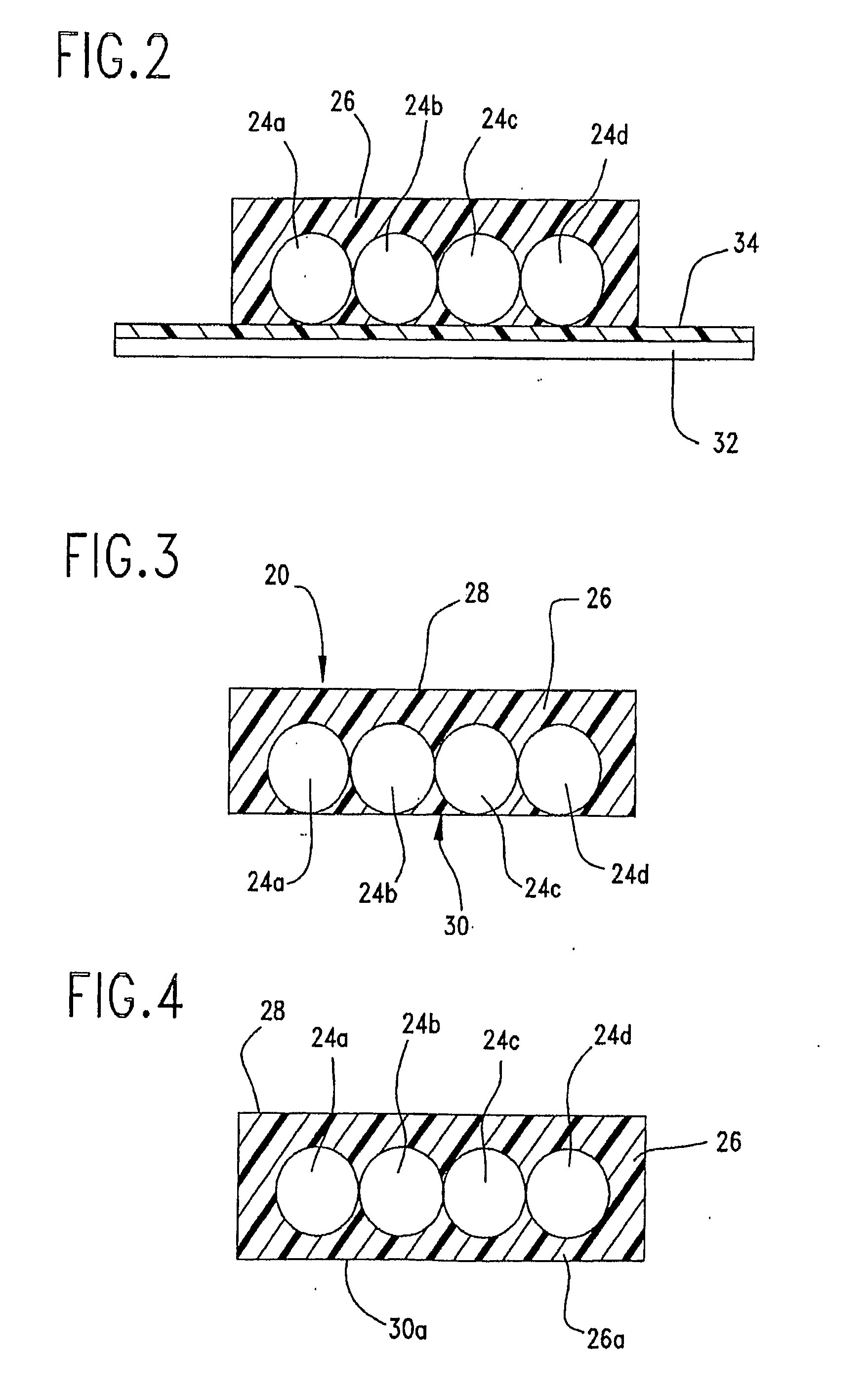

Optical ribbon and method of forming same

ActiveUS20120045166A1Improve life expectancyEnsure clearanceMetal rolling stand detailsCoupling light guidesConformal coatingEngineering

An optical ribbon (20) includes at least one optical fiber and a conformal coating at least substantially encapsulating said at least one optical fiber. The optical ribbon is flat and has a generally curved section (42) which can be routed around components (40) on a printed wiring board (22) or can be used as a built-in ferrule retermination loop.

Owner:MOLEX INC

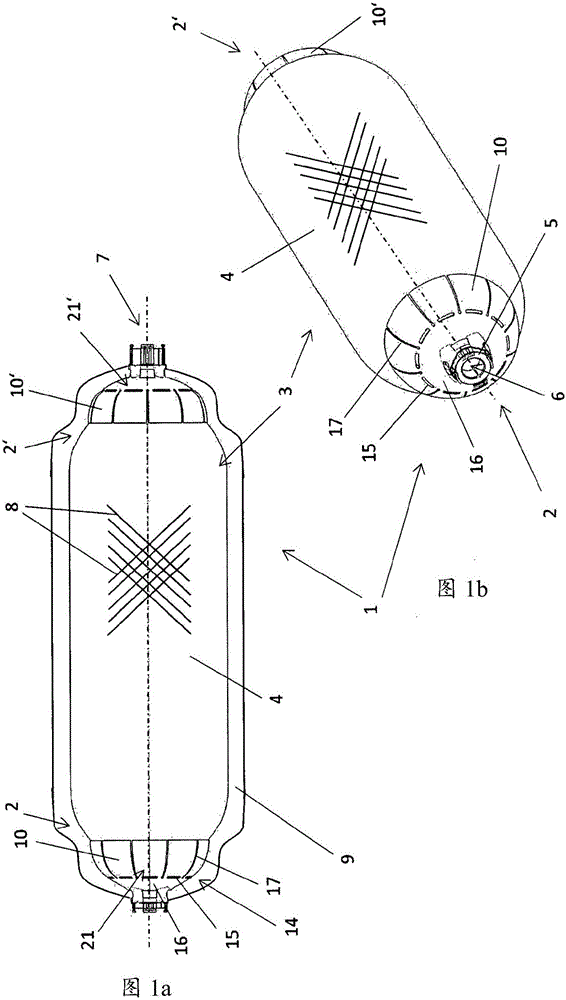

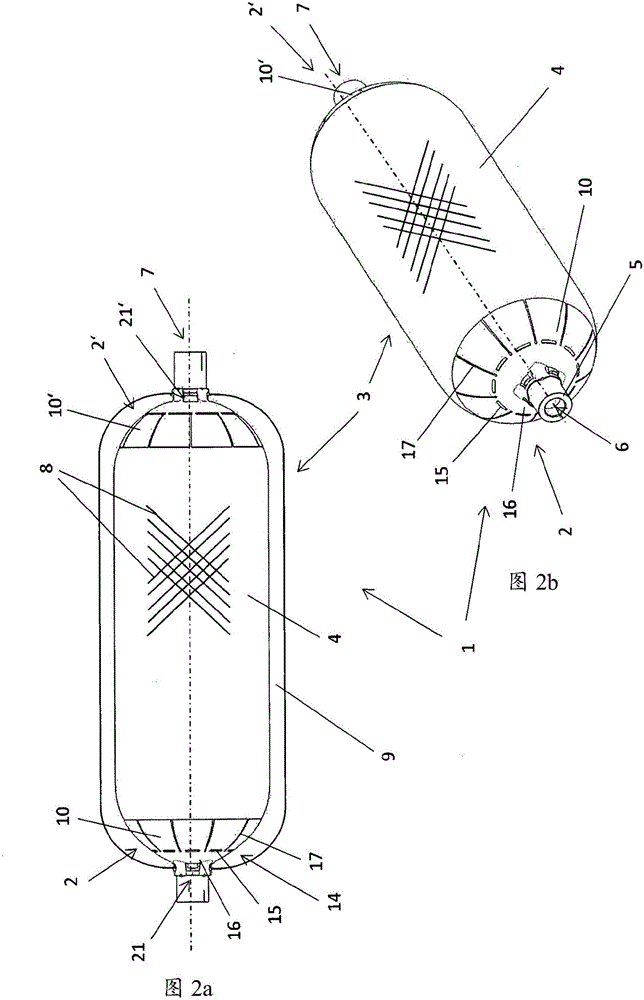

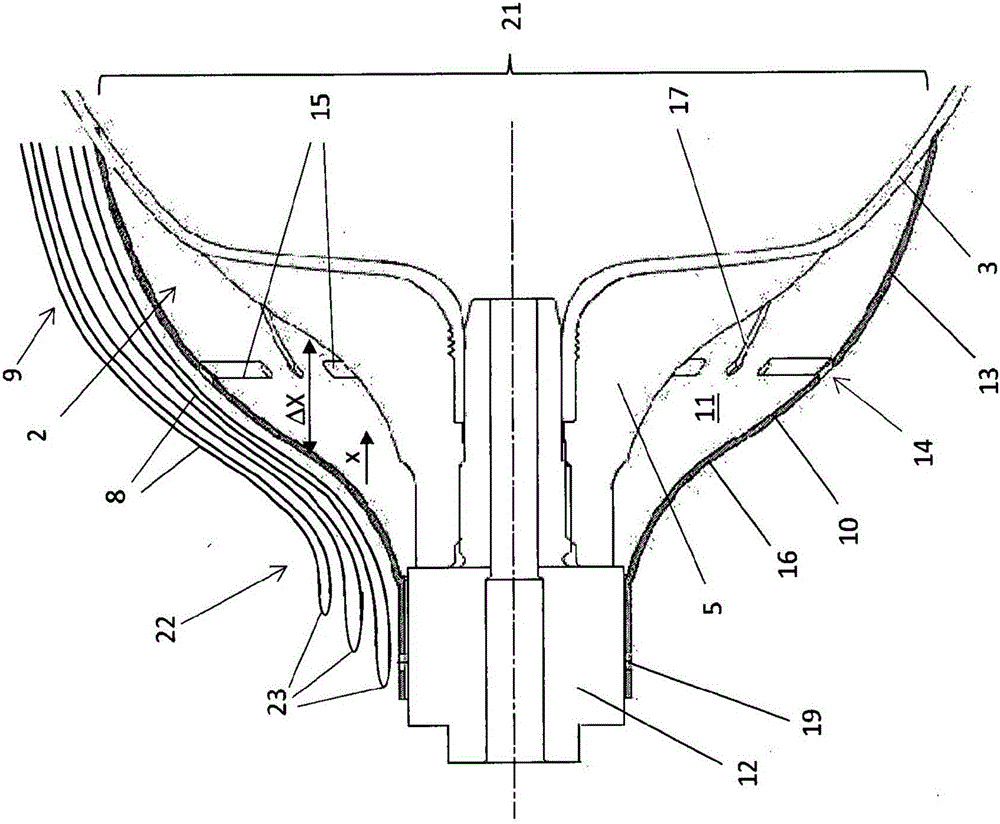

Method for producing a pressure accumulator, and pressure accumulator

InactiveCN105793019AReduce feedingIncrease volumeVessel mounting detailsVessel manufacturingFiberPressure vessel

The invention relates to a method for producing a pressure accumulator (1), in particular for storing hydrogen in motor vehicles. First, a pressure accumulator (1) liner (3) which has at least one pole cap (2, 2') is produced preferably by means of a plastic blow molding method, and the outside of the liner (3) is then provided, preferably braided, with a multi-ply reinforcing layer (9), which has reinforcing fibers (8). According to the invention, a fiber supply cap (10, 10') is applied on the pole cap (2, 2') prior to applying the reinforcing fibers (8), the outer surface of the fiber supply cap being spaced from the pole region (21, 21') of the pole cap (2, 2'). The reinforcing fibers (8) are applied onto the body of the liner (3) and in the pole region (21, 21') so as to correspond to the outer surface of the fiber supply cap (10, 10') while the reinforcing layer (9) is being applied such that the inner reinforcing layer (9) plies which are formed by the reinforcing fibers (8) are provided with a fiber supply (22) in the pole region (21, 21') on the basis of the distance between the outer surface of the fiber supply cap (10, 10') and the pole region (21, 21') of the pole cap (2, 2'). The invention also relates to a pressure accumulator (1) produced in a corresponding manner.

Owner:REHAU AG CO

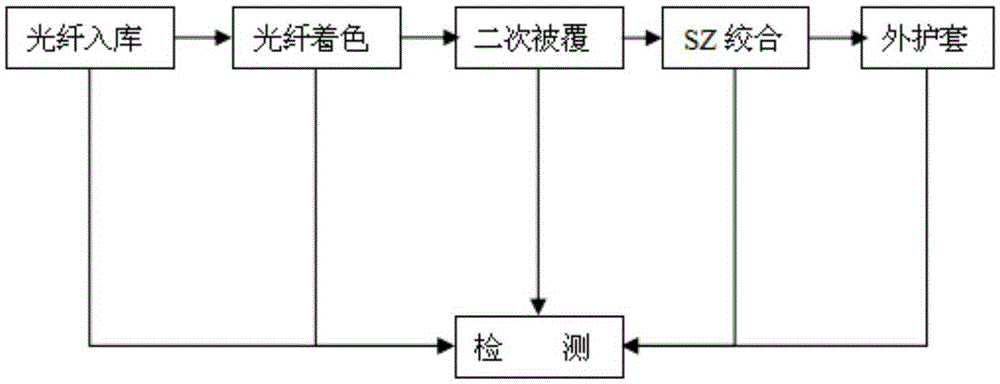

Double layer co-extrusion method for extremely micro air-blowing optical cable, and the extremely micro air-blowing optical cable

InactiveCN105278066AHigh fiber densitySmall cable diameterFibre mechanical structuresCo extrusionEngineering

The invention relates to a double layer co-extrusion method for an extremely micro air-blowing optical cable. The method comprises optical fiber storage, optical fiber coloring, secondary coating, SZ intertwist, an oversheath process and a secondary coating process, wherein PC materials and PBT materials are respectively dried and extruded through different extruding machine units; through different distribution cones and channels in the unit heads, the PC materials are extruded from the inner layer of each loose tube; and the PBT materials are extruded from the outer layer of each loose tube. The double layer co-extrusion method utilizes the PC material and PBT material double layer co-extrusion technology to prepare an extremely micro air-blowing optical cable, and can enable the loose tubes of the optical cable to have the advantages of the two types of materials. By means of accurate control of the technical parameters, the double layer co-extrusion method can realize limit control of the geometric dimension of the optical cable and reduce the external diameter of the optical cable to the minimum theoretically, and has the advantages of being high in intensity of the optical cable, being small in the cable diameter and being light in mass, and is the best choice for air-blowing laying.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Conductive sheet and electrode

ActiveUS20110318642A1Improve discharge performanceLower resistanceHybrid capacitor electrodesLayered productsFiberPolymer science

The present invention provides a conductive sheet having a surface resistance of 10 Ω / sq or lower on both surfaces, the conductive sheet comprising a sheet (A) and a sheet (B) laminated to the sheet (A), the sheet (A) having an apparent specific gravity of 0.05 g / cm3 to 0.50 g / cm3 and being formed from fibers having a diameter within the range between 3 and 20 μm, and the sheet (B) being formed from fibers having a diameter of 3 μm or smaller. The sheet (A) may be a fibrous material comprises an organic polymer fiber as its main component.

Owner:KURARAY CO LTD

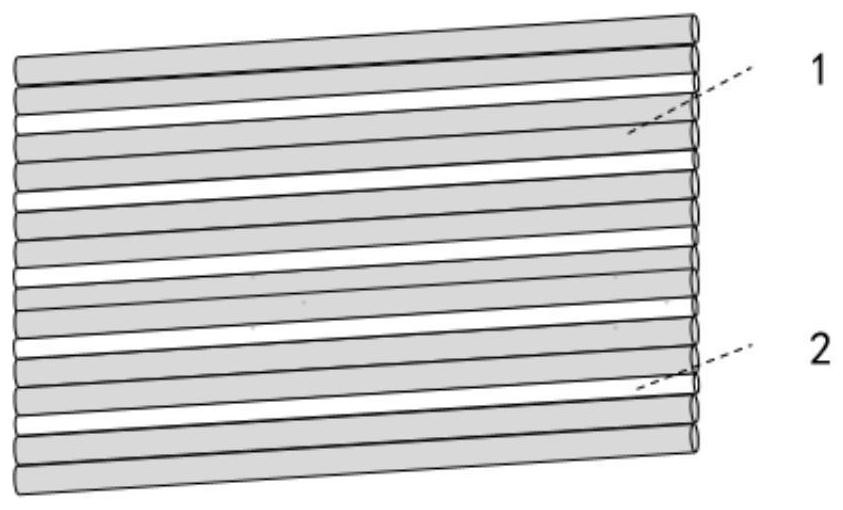

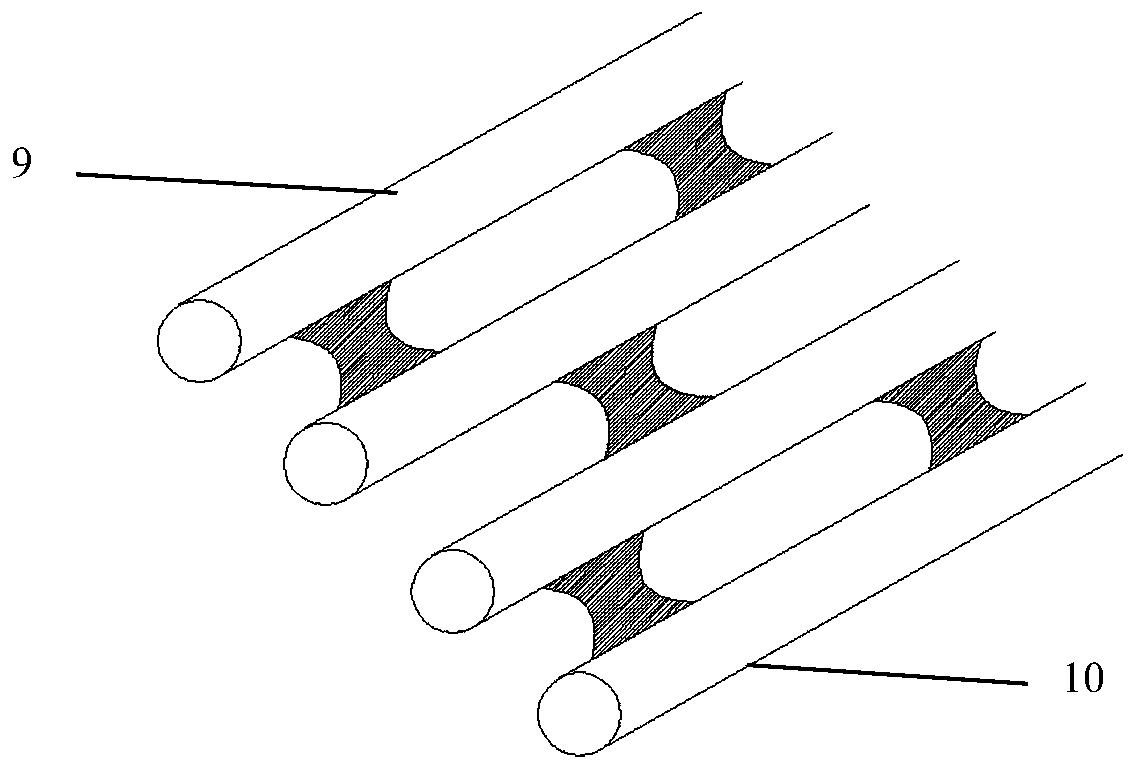

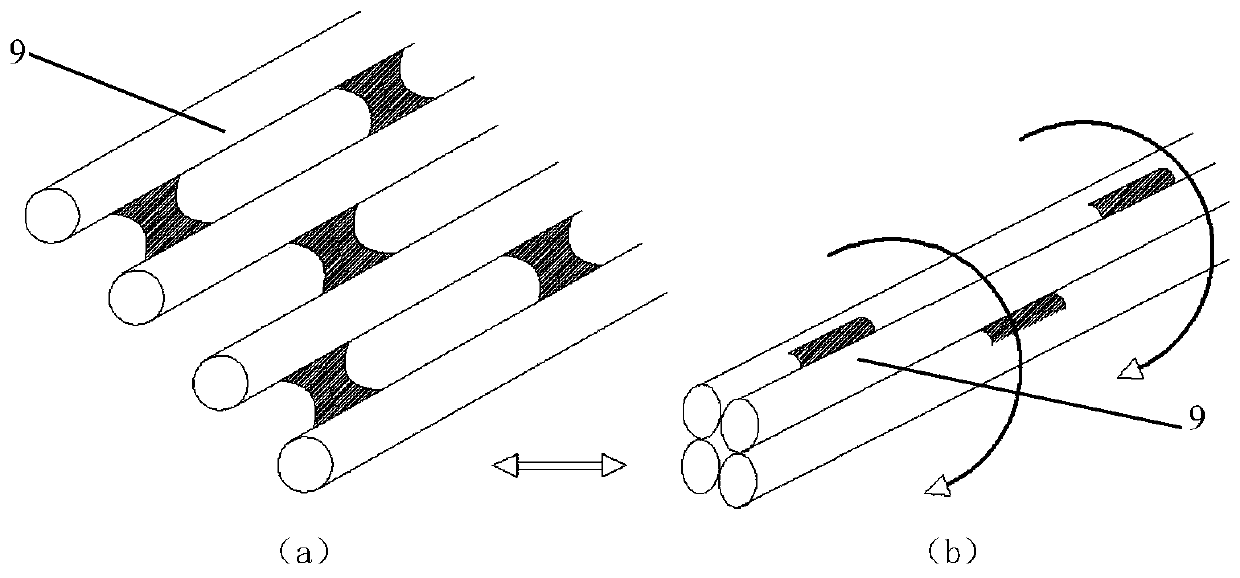

Layer-stranded optical fiber ribbon cable and production process thereof

ActiveCN113325532AHigh fiber densityReduce overall outer diameterFibre mechanical structuresFiberUV curing

The invention discloses a layer-stranded optical fiber ribbon optical cable and a production process thereof, wherein the layer-stranded optical fiber ribbon optical cable comprises loose tubes and optical fiber units arranged in the loose tubes, and a central reinforcing member is arranged in the plurality of stranded loose tubes; a water-blocking tape, a metal tape and a sheath layer are arranged outside the loose tubes; the optical fiber units comprise a plurality of layers of bendable optical fiber ribbons; and the bendable optical fiber ribbons are formed by continuously and alternately arranging optical fiber bundles and bonding layers, each optical fiber bundle is formed by combining at least two optical fibers after UV curing of light-cured resin, and the bonding layers are hot melt adhesive resin layers continuously coated between the optical fiber bundles, so that the optical fiber bundles can be axially bent along the bonding layers. According to the prepared layer-stranded optical fiber ribbon cable, the optical fiber bundles have bending performance and mobility in the optical fiber ribbons, so that the duty ratio of the optical fibers in the loose tubes and the fiber loading density of the optical fibers in the optical cable are improved, meanwhile, the outer diameter size of the optical cable can be reduced, the self weight of the optical cable is reduced, the installation and welding time of the optical fiber ribbon cable is saved favourably, and the installation and laying efficiency of the optical cable is improved.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP +1

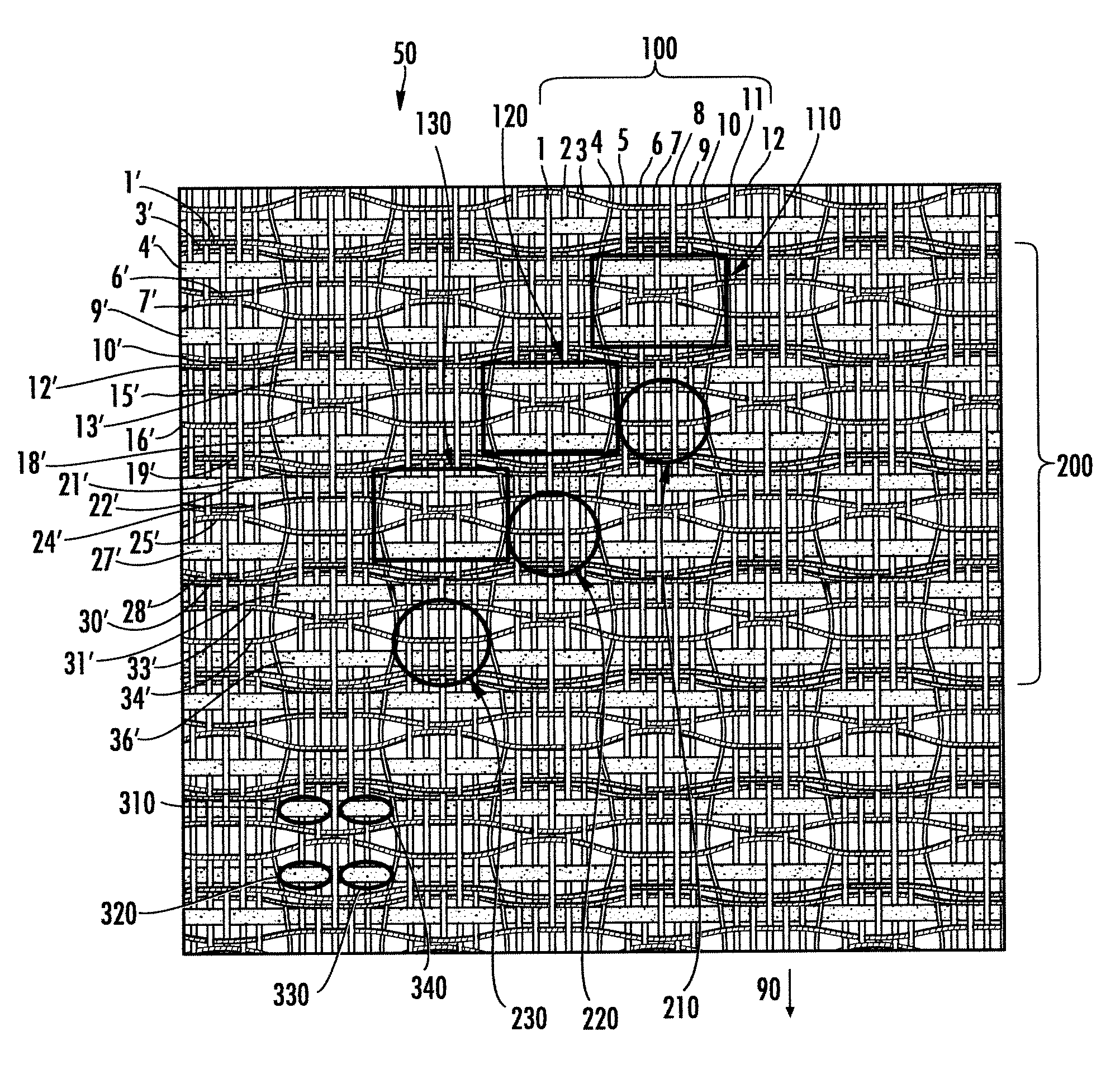

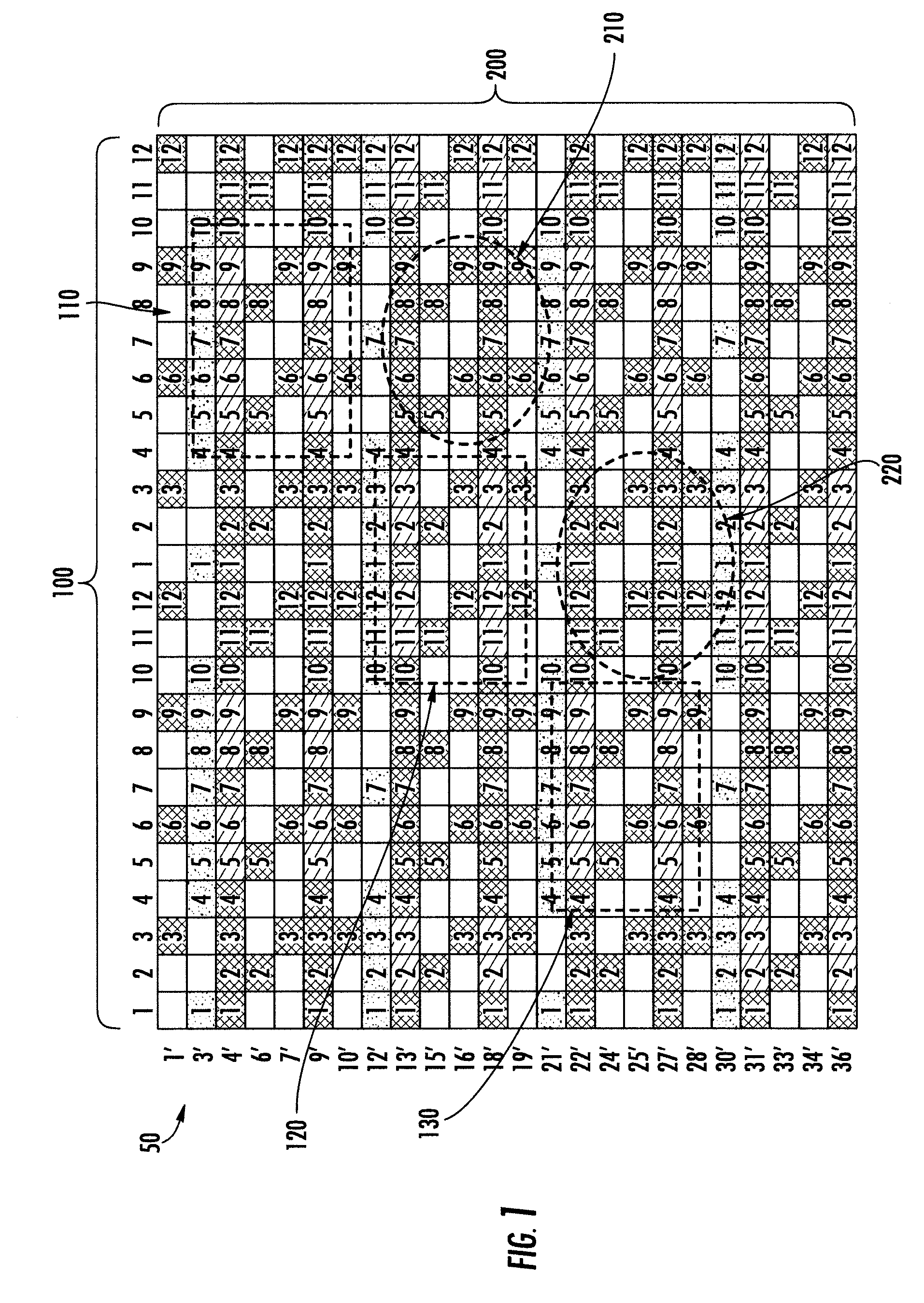

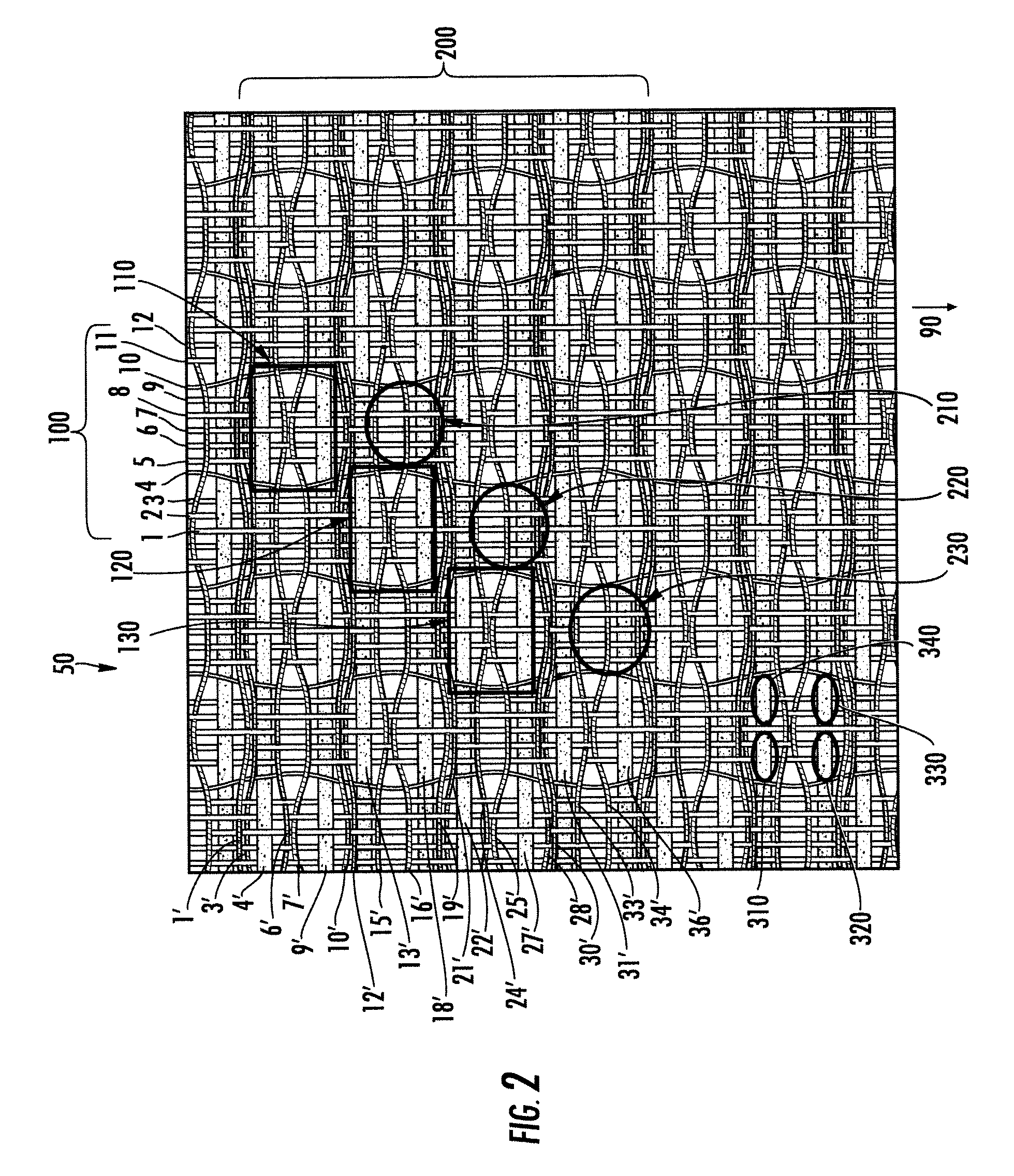

Papermaker's fabric to develop caliper and topography in paper products

ActiveUS20090078388A1Improve uniformityHigh fiber densityMachine wet endPress sectionPapermakingTopography

A papermaker's fabric including at least one system of warp yarns interwoven with at least first and second systems of weft yarns, with the weft yarns of the first system of weft yarns having a vertical dimension that is greater than a vertical dimension of the weft yarns of the second system. The fabric has a papermaking surface and a machine side surface, and in the papermaking surface, the yarns of the first system of weft yarns are interwoven with the warp yarns to provide groups of four weft yarn floats which form four corners of a box shape, the yarns of the second system of weft yarns are interwoven with the warp yarns so as to pass through the bottom of the box shape, and further provide support areas in pockets located adjacent to the box shapes, and at least one yarn from the second system of weft yarns interweaves with the warp yarns to occupy space in a center plane of the fabric so as to restrict or retard drainage and thereby increase a CPR of the fabric.

Owner:ASTENJOHNSON

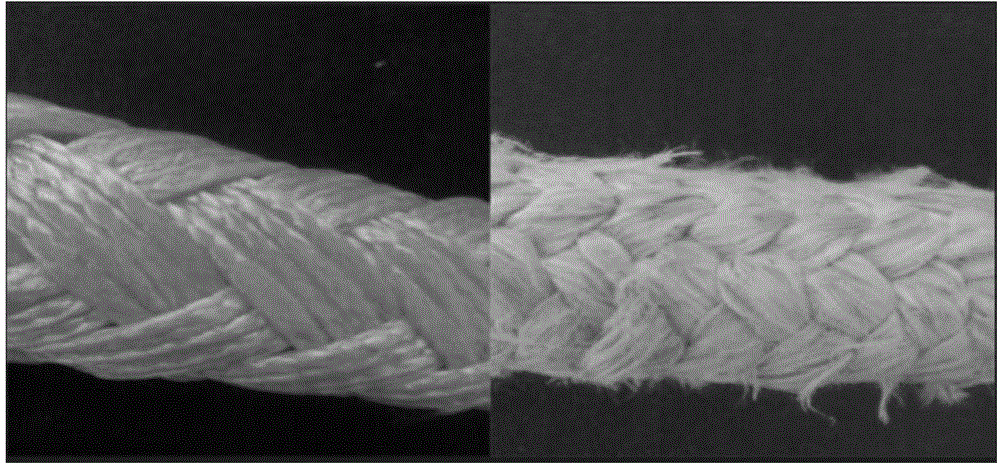

Double-layer knitted mooring rope

InactiveCN105316967AHigh fiber densityReduce resistanceTextile cablesMarine engineeringFiber drawing

The invention discloses a double-layer knitted mooring rope. The double-layer knitted mooring rope comprises a rope core and an outer wrapping layer wrapping the outer layer of the rope core. The double-layer knitted mooring rope is characterized in that the outer wrapping layer is formed by knitting multiple thin ropes in a crossed mode, and each thin rope is formed by knitting multiple fibers in a crossed mode. According to the design, the knitted outer wrapping layer is higher in fiber compactness, the surface of the outer wrapping layer is smoother, the fiber drawing phenomenon is not prone to happening when friction is generated, and resistance during movement is reduced; meanwhile, the strength of the mooring rope is increased, the service life of the mooring rope is prolonged, and cost is reduced to a certain extent.

Owner:GUANGDONG HIGH ALTITUDE WIND POWER TECH

Method for UV (Ultra-Violet Ray) lustering of offset press through hollowing lining papers

The invention relates to a method for UV (Ultra-Violet Ray) lustering of an offset press through hollowing lining papers, which has advantages of low production cost, high efficiency and improvement of service life of rubber blankets. The method specifically comprises the following steps of: choosing 3-6 pieces of lining papers, wherein the width of the lining papers is 750-800mm, the length is 1000-1100mm and the thickness of each piece of lining paper is 0.1-0.3mm; cutting the areas of the lining papers where corresponded to non-image parts of a print to form hollows, and reserving printing areas; according to the specification and the thickness of the papers of the print, calibrating the pressures among the ink rollers of all printing units, and then installing color sequence printing plate; flatly paving and correspondingly arranging the cut lining papers on the printing area of the rubber blanket, then installing the lining papers and the rubber blanket on a rubber roller, and then fixing and locking; choosing an anilox roller, starting a gloss oil after calibrating printing pressure, and then pumping UV gloss oil to a gloss oil chamber; adding ink to a printing color unit, then calibrating the pressures of the ink rollers and the printing pressure among the three rollers, and then starting the offset press.

Owner:SICHUAN JINSHI PRINTING

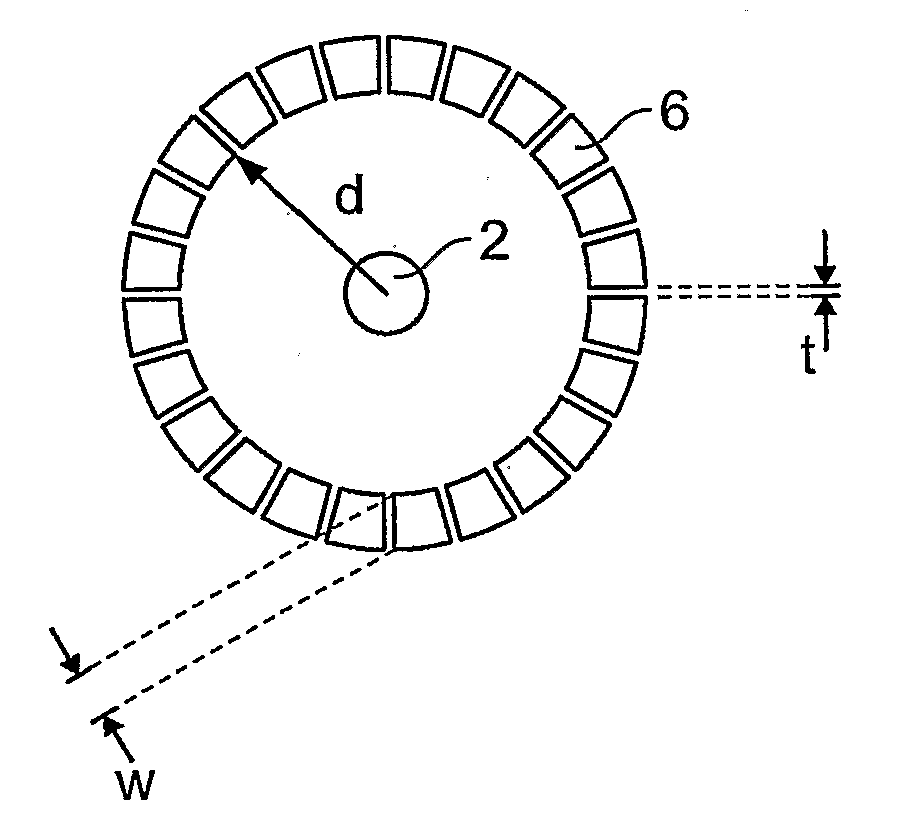

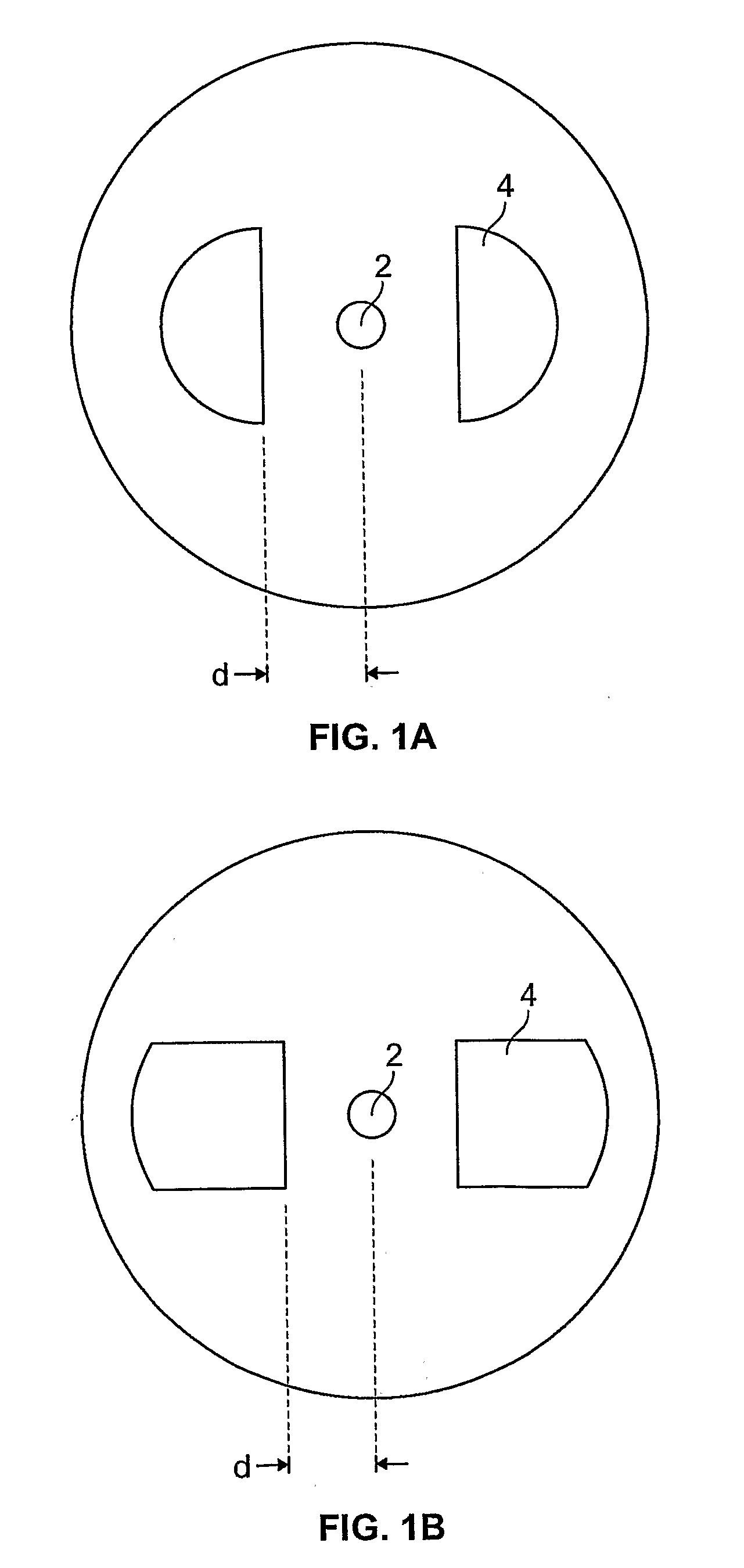

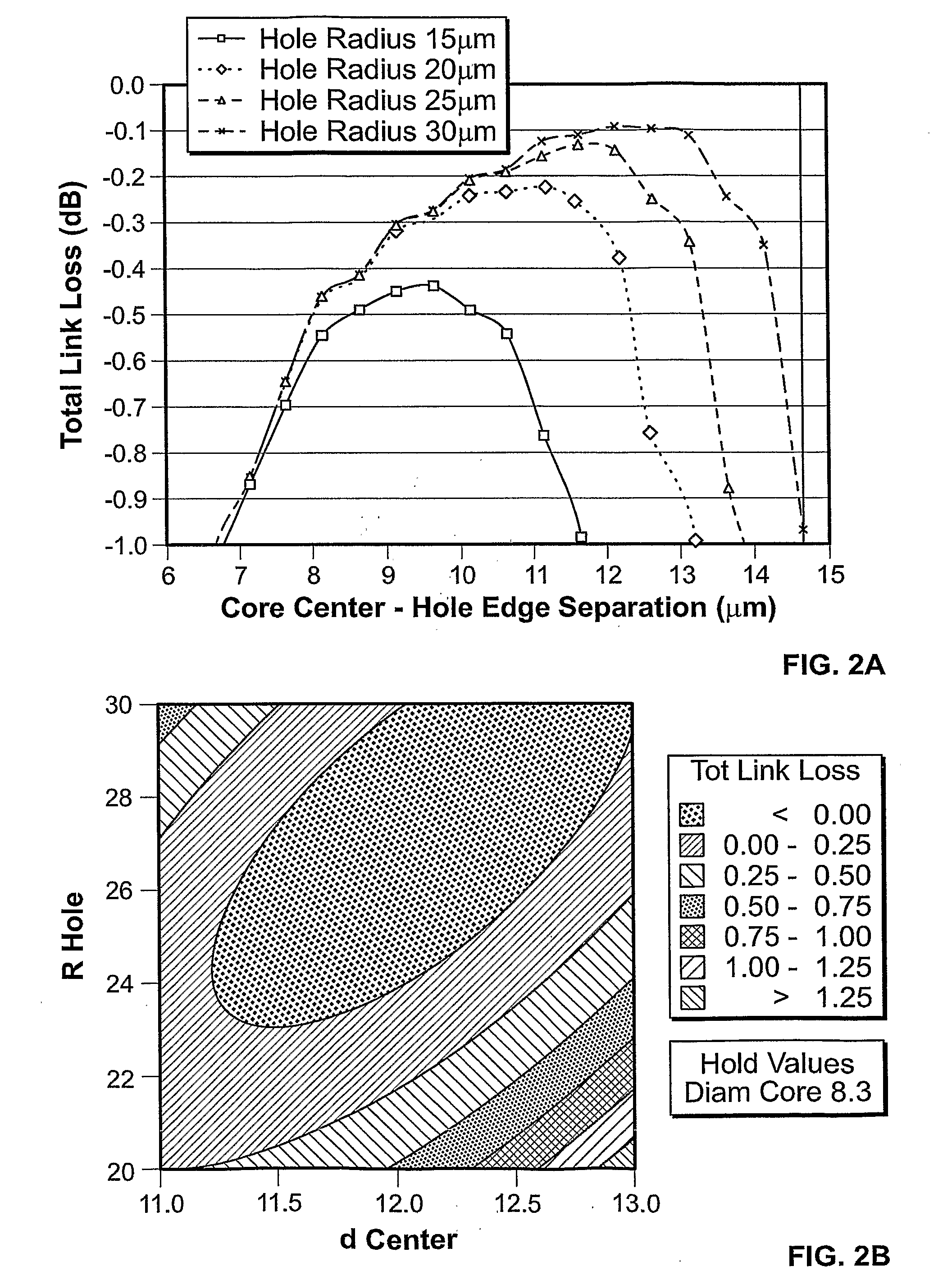

Hole arranged photonic crystal fiber for low loss, tight fiber bending applications

InactiveUS20100135616A1High fiber densityReduce laborOptical fibre with polarisationOptical fibre with multilayer core/claddingPhotonic crystalEngineering

A microstructured fiber or photonic crystal fiber is described having a doped solid core region and a cladding region, holes being provided in the cladding region, the fiber having a low hybrid splice loss to conventional fiber as well as being able to be tightly bent due to the microstructured cladding. The cladding region can contain a plurality of holes surrounding and distanced from the core. These holes are preferably located symmetrically around the core and extend longitudinally along the length of fiber. The holes may be two or more D-shaped holes or truncated D-shaped holes arranged symmetrically around the care. In other embodiments, the holes comprise hole structures arranged symmetrically around the core in a ring. The holes may be arranged having the inner side facing the core formed from arcs of a circle, e.g. equal arcs of a circle. Between the arcs circular holes may be provided called capillaries, i.e. smaller holes. According to the present invention, any number of holes may surround the core, preferably three or more. The fiber has low loss at small bending radii.

Owner:TYCO ELECTRONICS RAYCHEM BVBA

Baseless double-sided adhesive sheet or tape, and method for manufacturing the same

ActiveCN107418458AHigh fiber densityAnti-strippingLayered product treatmentPolyureas/polyurethane adhesivesAdhesiveEngineering

The invention provides a baseless double-sided adhesive sheet or tape configured to prevent seepage of an adhesive during a storage period or during cutting into a predetermined dimension, represent an expected performance of anti-peeling cohesion, and avoids sacrifice of an initial bonding intensity, and a method for manufacturing the same. In the baseless double-sided adhesive sheet or tape, an adhesive layer formed from an adhesive serves as a center layer, and adhesive layers and formed from an adhesive are layered onto a front face and a rear face of the adhesive layer serving as the center layer. Fibers are least dispersed in the adhesive layer serving as the center layer, and the adhesive layer serving as the center layer between the adjacent adhesive layers has a relatively high fiber density and relatively low flowability.

Owner:KYODO GIKEN CHEM

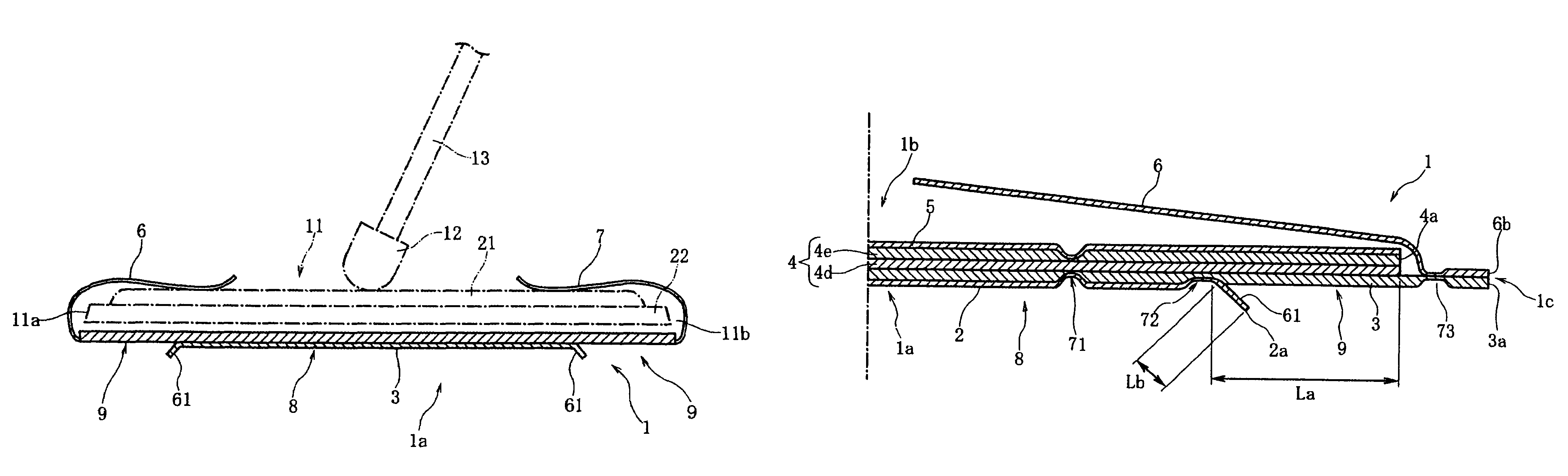

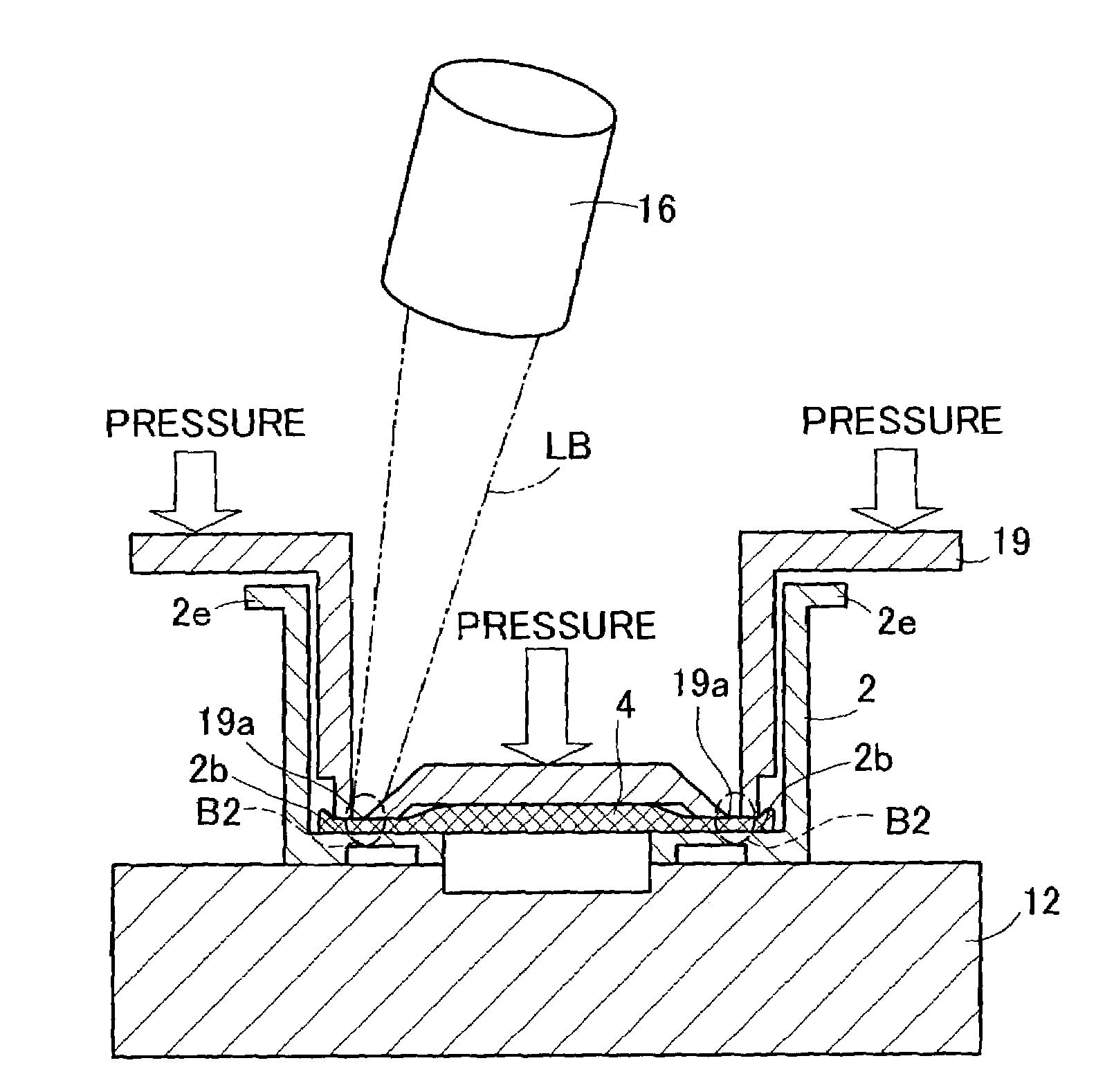

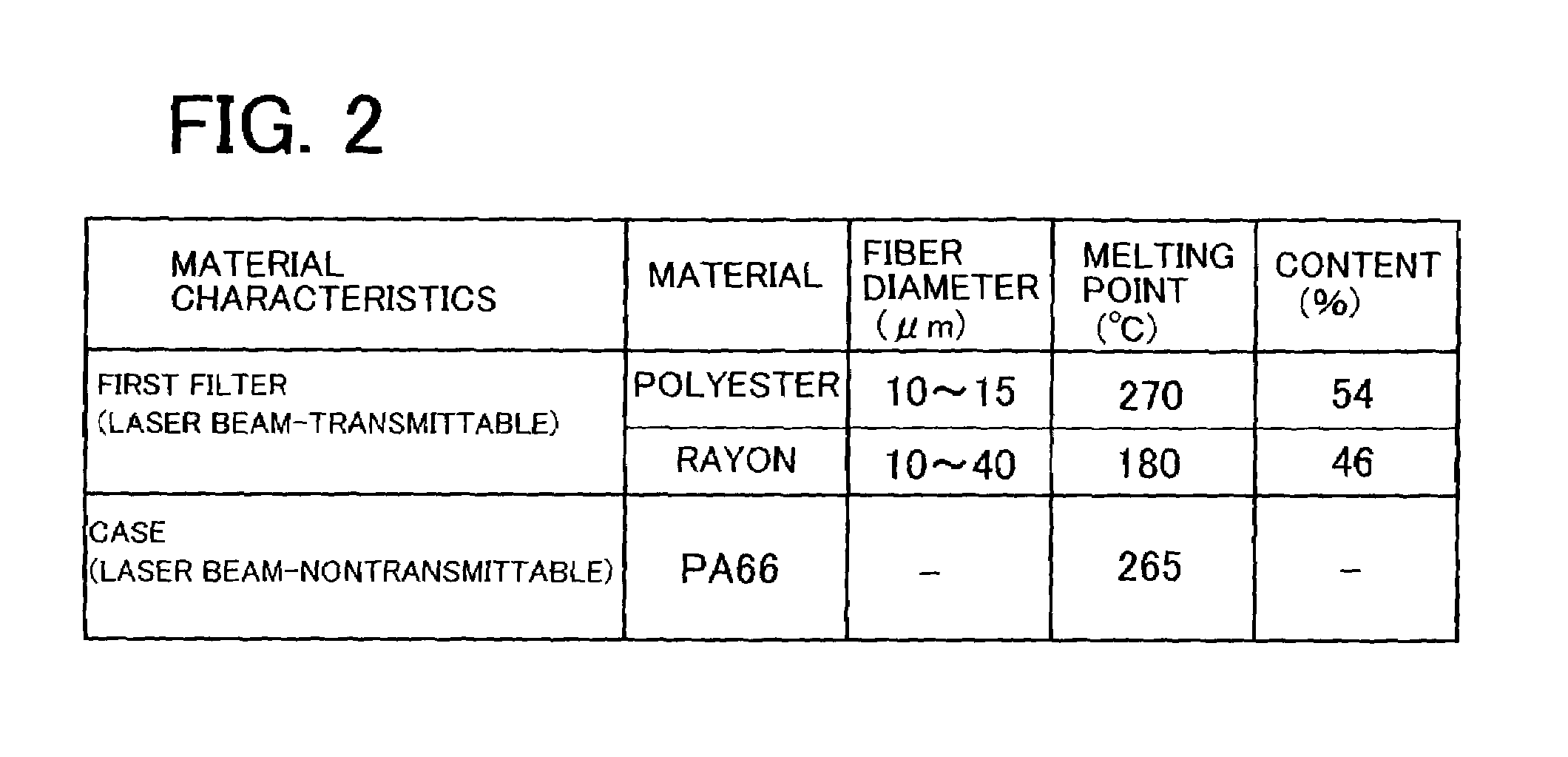

Laser welding method

ActiveUS6989070B2Improve welding strengthAvoid defectsLamination ancillary operationsNon-fuel substance addition to fuelVolumetric Mass DensityEngineering

To weld a filter made of a laser beam-transmittable fiber material to a case made of a laser beam-nontransmittable resin material by a laser beam the filter is first placed on the case; subsequently, the filter is pressurized by a jig to increase the fiber density of a welding portion; and then the welding portion is irradiated by the laser beam. In the step of increasing the fiber density, a periphery of the welding portion is pressurized by the jig to increase the fiber density of the filter in a larger area than the welding portion. Accordingly, the laser beam transmitting through the filter melts a part of the case, and the melted resin material permeates through gaps between the fibers constituting the filter, thereby welding the welding portion to the case.

Owner:AISAN IND CO LTD +1

Melt-Blown Non-Woven Filter Material

InactiveUS20190388816A1Improve filtration efficiencyEnsure efficiency of gas circulationLayered productsElectro-spinningNonwoven fabricSolvent

The invention provides a melt-blown non-woven filter material, which is prepared by the following method: provide a polylactic acid raw material; dissolve the polylactic acid raw material into a DMF solvent; the polylactic acid electrospinning layer is prepared by electrospinning method using polylactic acid spinning solution as raw material; provide polylactic acid raw material again and provide polyphenylene sulfide raw material; and perform surface treatment. Polylactic acid raw material, polyphenylene sulfide raw material, nano-titania powder are mixed well with the processing assistant to obtain a mixture: the mixture is extruded into modified polylactic acid particles; then a modified polylactic acid melt-blown fiber layer is formed on the polylactic acid electrospinning layer by using the melt-blown method. The invention innovatively implements loading, nano-titania particles into the synthetic fiber, which makes the fiber material presented in this invention not only have filtering effects, but also have photocatalytic ability.

Owner:HUANG QIAN

Method of producing a composite structure via intermediate products, the related apparatus and a composite structure obtainable by the method

ActiveUS9221219B2High fiber densityFirmly connectedFinal product manufactureLaminationLiquid resinMaterials science

A method of producing a composite structure comprising fiber reinforced material and having a longitudinal direction is described. The method comprises the following steps: a) manufacturing a first structure comprising a first cured composite part having a first thickness and a longitudinal direction with a first end, and a number of first fiber layers extending from the first end, b) manufacturing a second structure comprising a second cured composite part having a second thickness and a longitudinal direction with a second end, and a number of second fiber layers extending from the second end, and c) arranging the first structure and the second structure so that the first end faces towards the second end, and arranging the first fiber layers and the second fiber layers so that at least a part of the first fiber layers overlap at least a part of the second fiber layers in the longitudinal direction, d) supplying liquid resin in order to impregnate the first fiber layers and the second fiber layers, and e) curing the liquid resin in order to form the composite structure comprising the first cured composite part, the second cured composite part, and an intermediate composite part including the first fiber layers and the second fiber layers.

Owner:LM GLASSFIBER

Self-supporting cicada-preventing butterfly cable and production equipment for processing same

PendingCN111399151AOptimize the space areaIncrease fiber densityFibre mechanical structuresCore (optical fiber)Electrical and Electronics engineering

The invention discloses a self-supporting cicada-preventing butterfly cable which comprises an optical cable body. The optical cable body comprises an outer sheath, a communication unit and a reinforcer, and the outer sheath wraps the communication unit and the reinforcer; the communication unit comprises a winding optical fiber ribbon and two symmetrically arranged protection sheets, and the winding optical fiber ribbon is arranged between the two protection sheets; the two sides of the outer sheath are respectively provided with two tearing grooves, and the distance between the two tearing grooves at one side is greater than the width of the protection sheet, thereby solving the problem that the optical fiber attenuation exceeds the standard or the structure of the optical cable is damaged because cicadas are attached to the optical cable. The invention also discloses production equipment for processing the self-supporting cicada-preventing butterfly cable, the protection sheet pay-off rack is additionally arranged, and the extrusion molding die core and the extrusion molding die sleeve of the plastic extruding machine are improved so that the production process of integrated extrusion molding can be completed, the integrated molding of the novel optical cable is realized, and the production efficiency is relatively high.

Owner:FURUKAWA ELECTRIC XIAN OPTICAL COMM

Recombined bamboo timber composite board and processing method thereof

InactiveCN108638226APromote absorptionReduce wasteCane mechanical workingLaminationEngineeringComposite plate

The invention discloses a recombined bamboo timber composite board. The recombined bamboo timber composite board comprises a face board, a middle core board and a base board. The face board comprisesbamboo filaments arranged in parallel. The base board comprises second bamboo battens spliced in parallel. The middle core board comprises first bamboo battens spliced in parallel. Each bamboo filament is made of a material of a middle bamboo section. Each bamboo batten is made of a bamboo green part of the middle bamboo section. Each first bamboo batten comprises a bamboo tip bar made of a bambootip section and a bamboo root bar made of a bamboo root material. The invention further discloses a processing method of the recombined bamboo timber composite board. According to the processing method, intermediate layers and bamboo green layers of the middle bamboo sections are manufactured into the face board and the base board, the bamboo tip sections or bamboo root sections are manufacturedinto the middle core board, and then the face board, the base board and the middle core board are recombined into the complete composite board. According to the recombined bamboo timber composite board and the processing method thereof, the abandoned bamboo root sections and the abandoned bamboo tip sections and the bamboo green of the middle bamboo sections are used for manufacturing the recombined bamboo composite board. The utilization rate of bamboo is fully increased, and the material cost is saved. Layout and manufacturing are reasonable and ingenious. The structural strength and stability of recombined bamboo are improved.

Owner:李阳

Full-medium self-supporting micro-beam tube ADSS optical cable

PendingCN108646368AReduce weightShorten connection timeFibre mechanical structuresPolyesterElastomer

The invention discloses a full-medium self-supporting micro-beam tube ADSS optical cable. The optical cable comprises an optical fiber bundle micro-beam tube body,a water stop tape layer and an outersheath which are sequentially arranged from inside to outside. The optical fiber is characterized in that the optical fiber bundle micro-beam tube body comprises optical fiber bundles and a micro-beamtube main body wrapping the optical fiber bundles,and the micro-beam tube main body is made of a thermoplastic polyester elastomer material; a full-dry water stop material is filled between the optical fiber bundles in the micro-beam tube main body. The full-medium self-supporting micro-beam tube ADSS optical cable can still guarantee a small outer diameter and a low optical fiber weight under the condition that the optical fiber density is high and the capacity is large,the optical cable connection time can be shortened by 50% or above,and the optical fiber has the advantages of being smallin size,easy to strip,easy to separate,low in weight,full in section and free of water seepage.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com