Airflow air laid fiber cotton preparing process and manufactured fibre cotton

An air-laid and preparation technology, which is applied in the field of fiber cotton, can solve the problems of a single range of fiber-laid material selection, and achieve the effects of a wide range of raw material selection, saving a lot of resources, and improving the fiber distribution structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

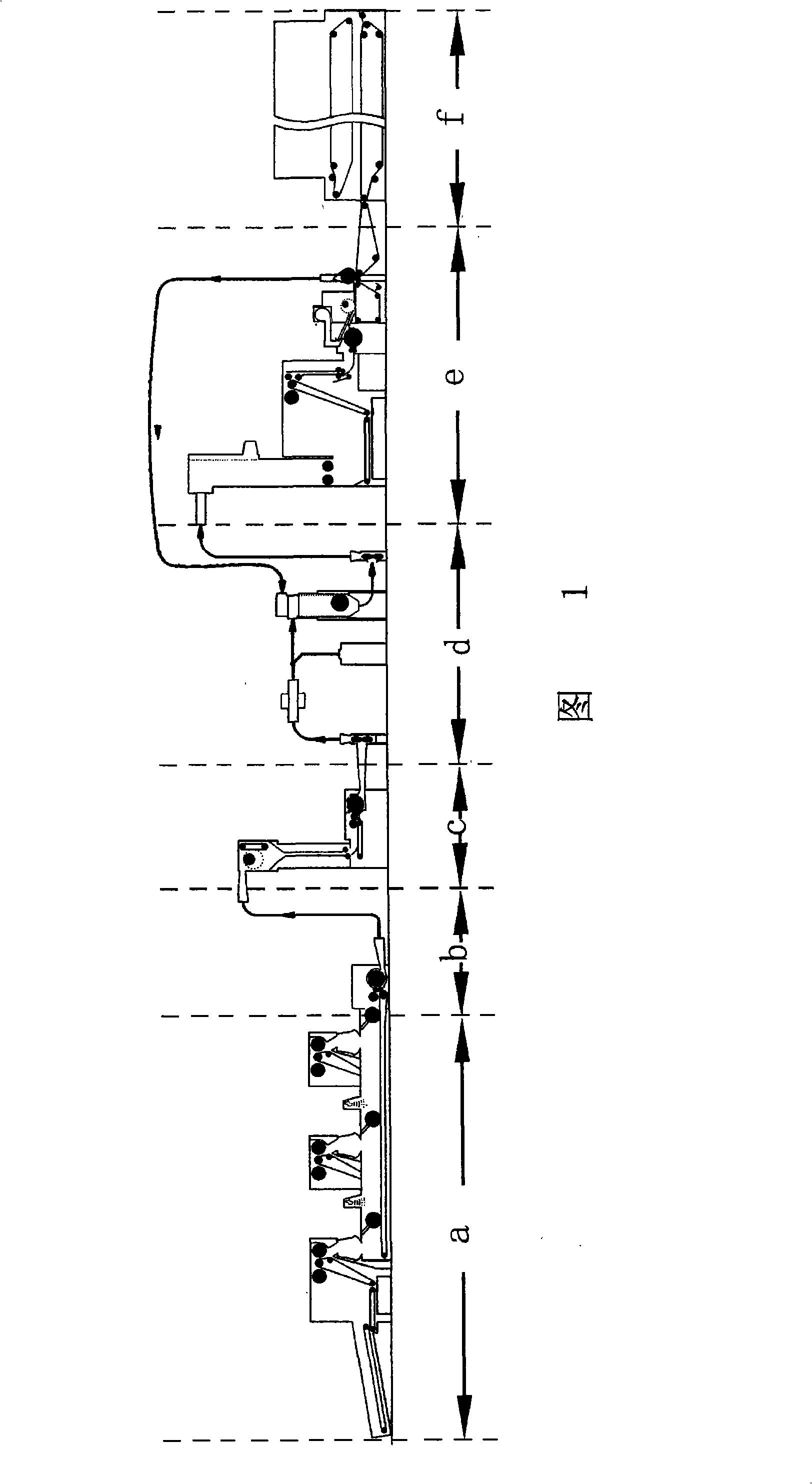

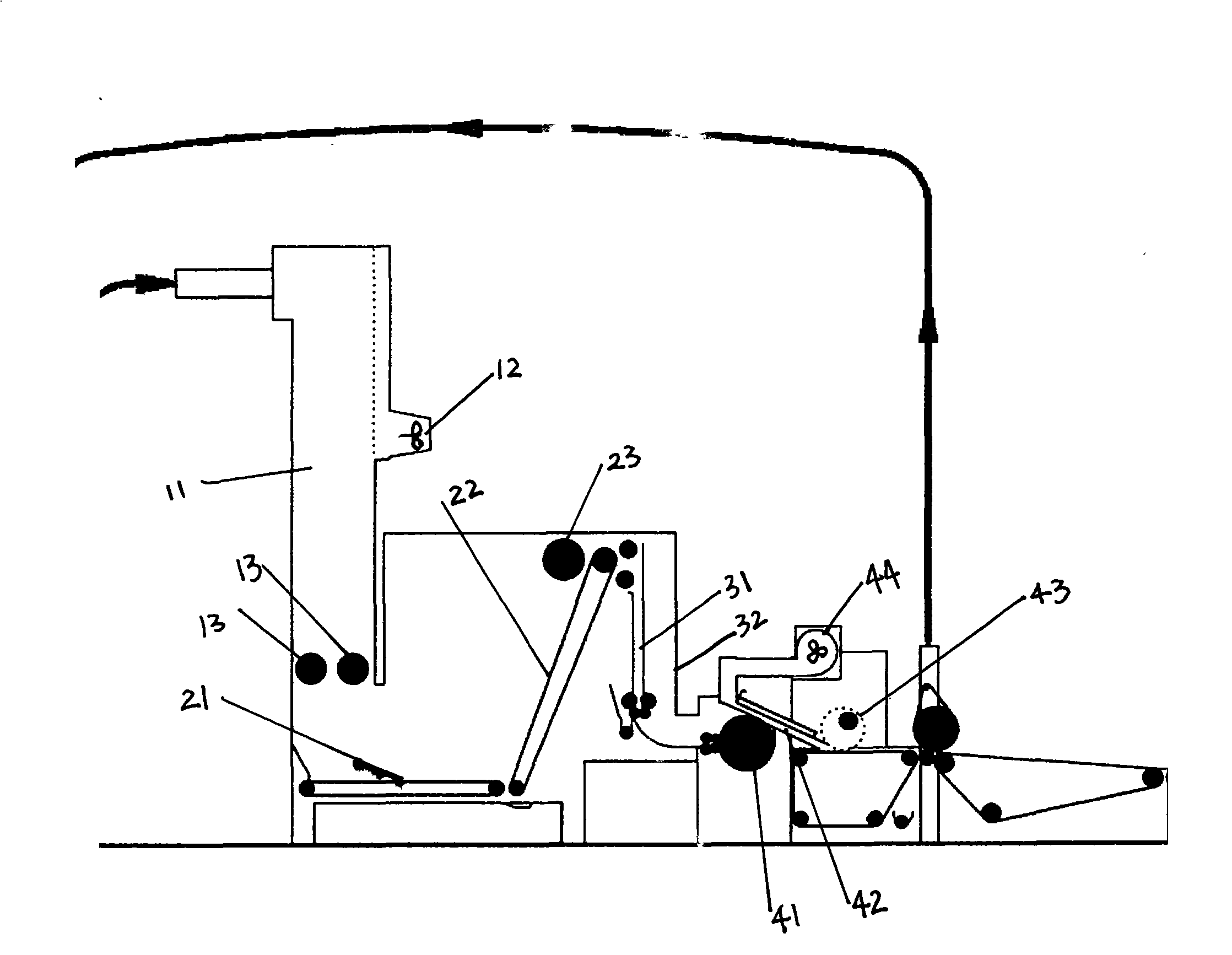

[0029] Referring to Fig. 1, it is a schematic diagram of the production process and equipment structure for the application of the air-laid fiber cotton of the present invention. The invention can be applied to a fully enclosed (only a few import and export materials) computer-controlled automatic production line.

[0030] The production process of air-laid fiber cotton preparation includes: weighing ingredients, rough opening, fine opening, air-laid, heat-bonding, shaping, slitting and packaging, etc., which are respectively introduced as follows:

[0031] a. Weighing ingredients: adopt 5% to 85% low-melt fiber and 95% to 15% of other fibers to prepare raw materials, and this embodiment adopts 20% low-melt fiber LMF (4080 low-melt fiber) and 80% broken sponge Mixing (generally completed by a feeder mixer), after repeated mixing evenly, the prepared raw materials are sent into the

[0032] b. Coarse opening: using an opening machine (the working principle is the same as that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com