Patents

Literature

31results about How to "Improve distribution structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

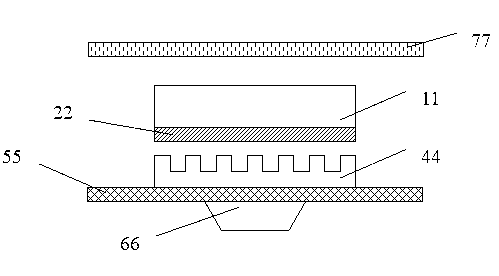

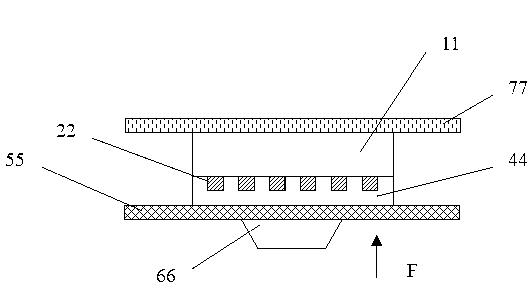

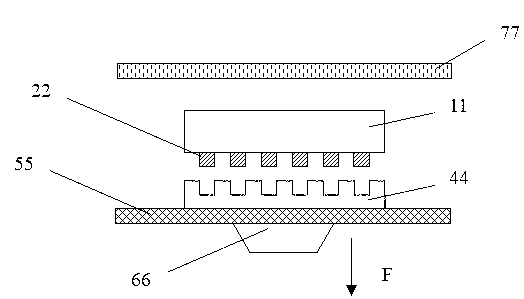

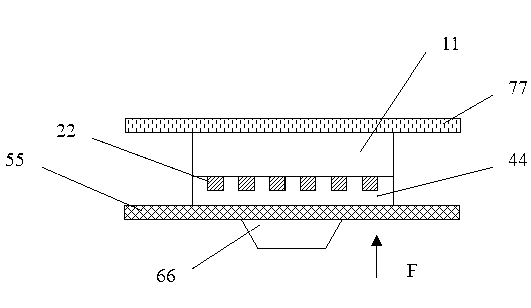

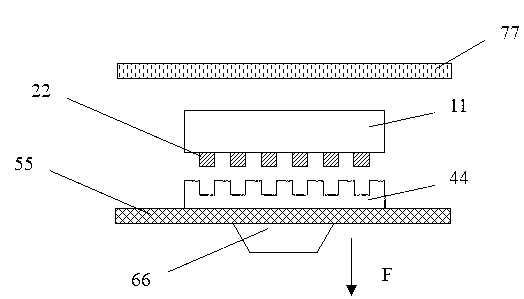

Method for manufacturing silicone micro-nano optical structure by using imprinting technology

InactiveCN102707378AGood thermal stabilityGood light transmissionDecorative surface effectsPhotomechanical apparatusWeather resistancePolymer

The invention discloses a method for manufacturing a silicone micro-nano optical structure by using an imprinting technology. Firstly, a template serving as a seal during the imprinting is designed and processed according to the requirements of the structure of a device; secondly, an appropriate substrate material is selected and used according to the requirements of the micro-nano optical structure of the device, and then covered with imprinting glue; afterwards, structural patterns on the template are transferred to the imprinting glue by adopting an imprinting process, the imprinting glue is solidified and molded, the template is released after the template and the substrate are both cooled, and then a micro-nano optical structure with embossed figures is obtained; and finally, a polymeric optical bounding layer covers above imprinted lines according to the design of the device, and then the whole micro-nano optical structure is formed. By adopting the method, optical devices whichhave good weatherability and strong thermal stability and cause low loss can be prepared; and besides, the process is simple, so that the method has a cost advantage.

Owner:SOUTH CHINA NORMAL UNIVERSITY

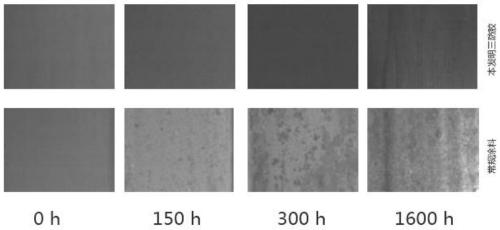

Water-borne nano ultra-thin steel structure fire retardant coating and preparation method thereof

The invention discloses a water-borne nano ultra-thin steel structure fire retardant coating, which comprises a carbon source, an acid source, an air source and auxiliaries, and consists of the following components by weight percentage: 20-40% of acrylic ester emulsion, 10-30% of ammonium polyphosphate (APP), 5-15% of pentaerythritol, 1-10% of melamine, 1-10% of nanometer material, 0.001-5% of auxiliaries, and 10-30% of water. The invention also discloses a preparation method of the fire retardant coating. The prepared fire retardant coating has the characteristics of stable performance and good fire resistant performance, the thickness of the prepared fire retardant coating is no more than 2mm, and the fire reissuance duration of the prepared fire retardant coating is up to 120 minutes.

Owner:浙江川科防保材料发展有限公司

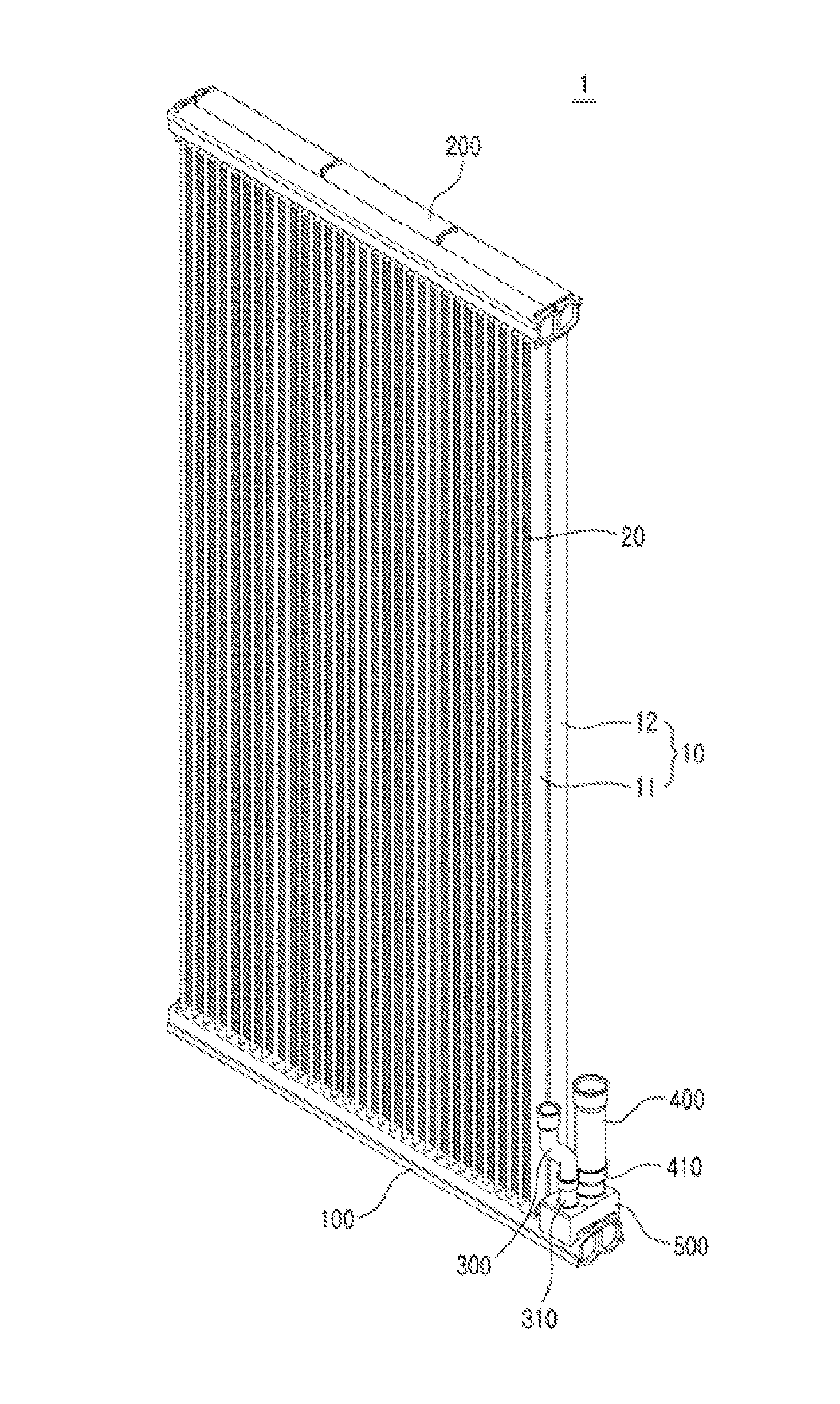

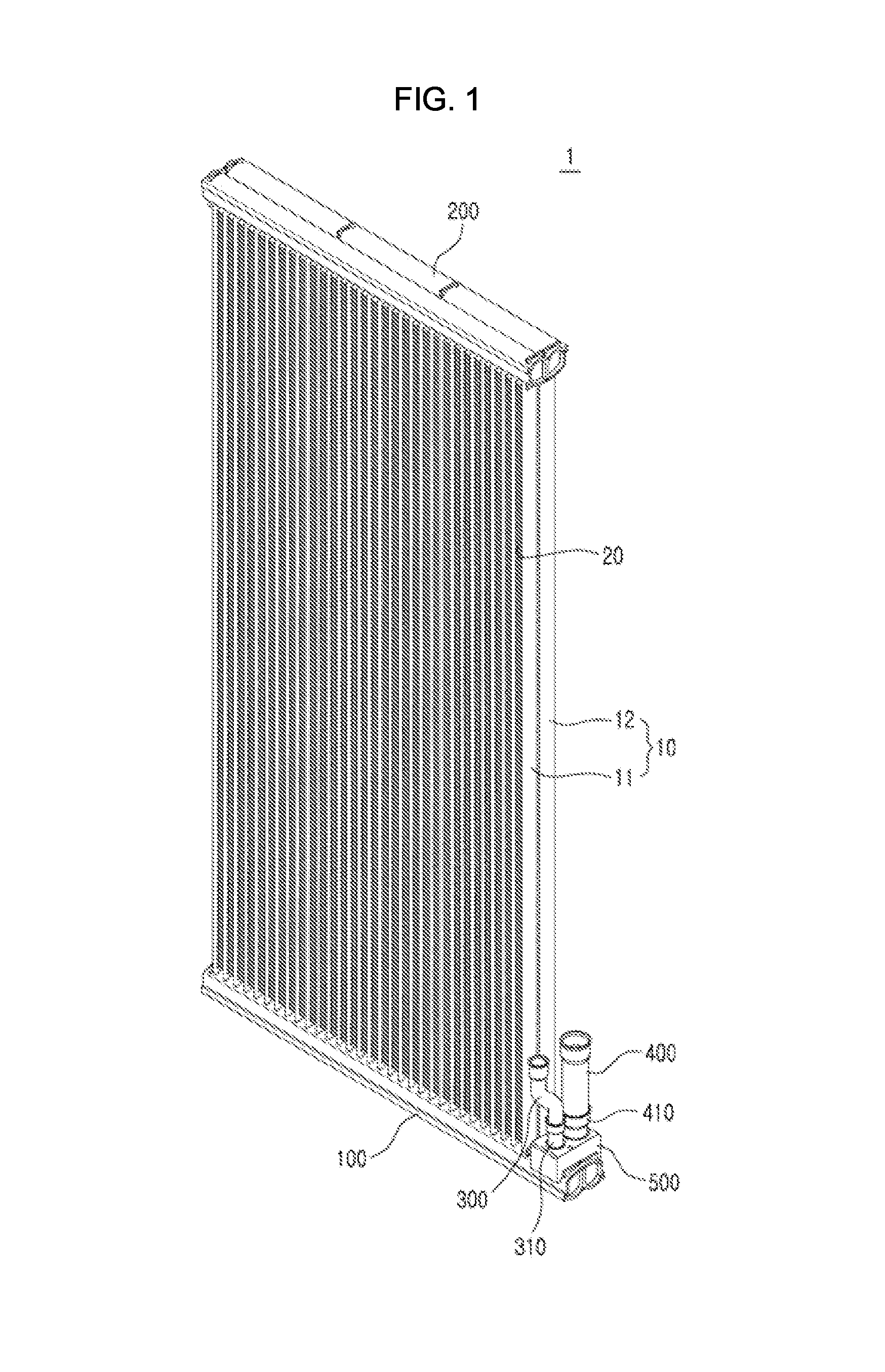

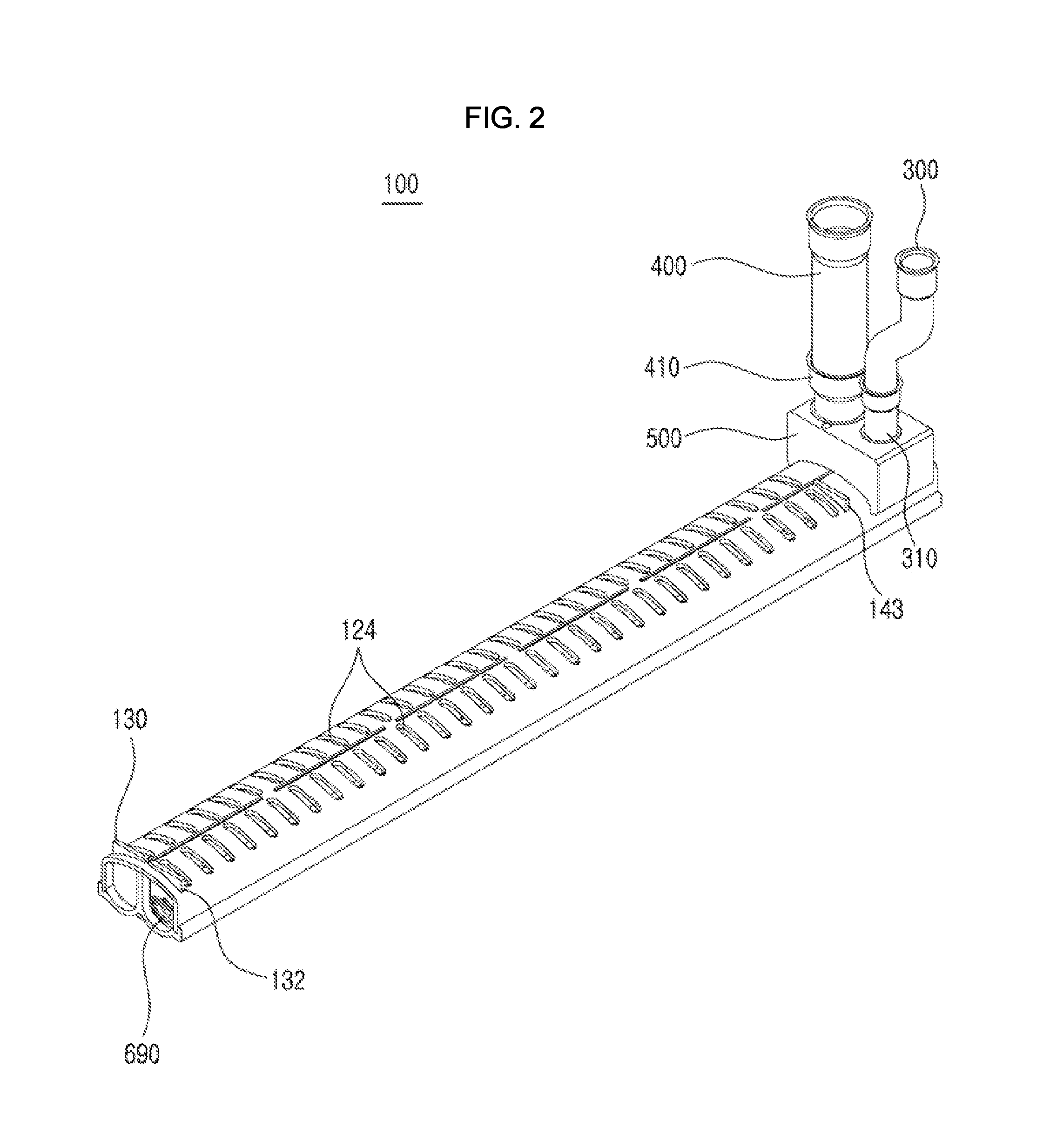

Heat exchanger

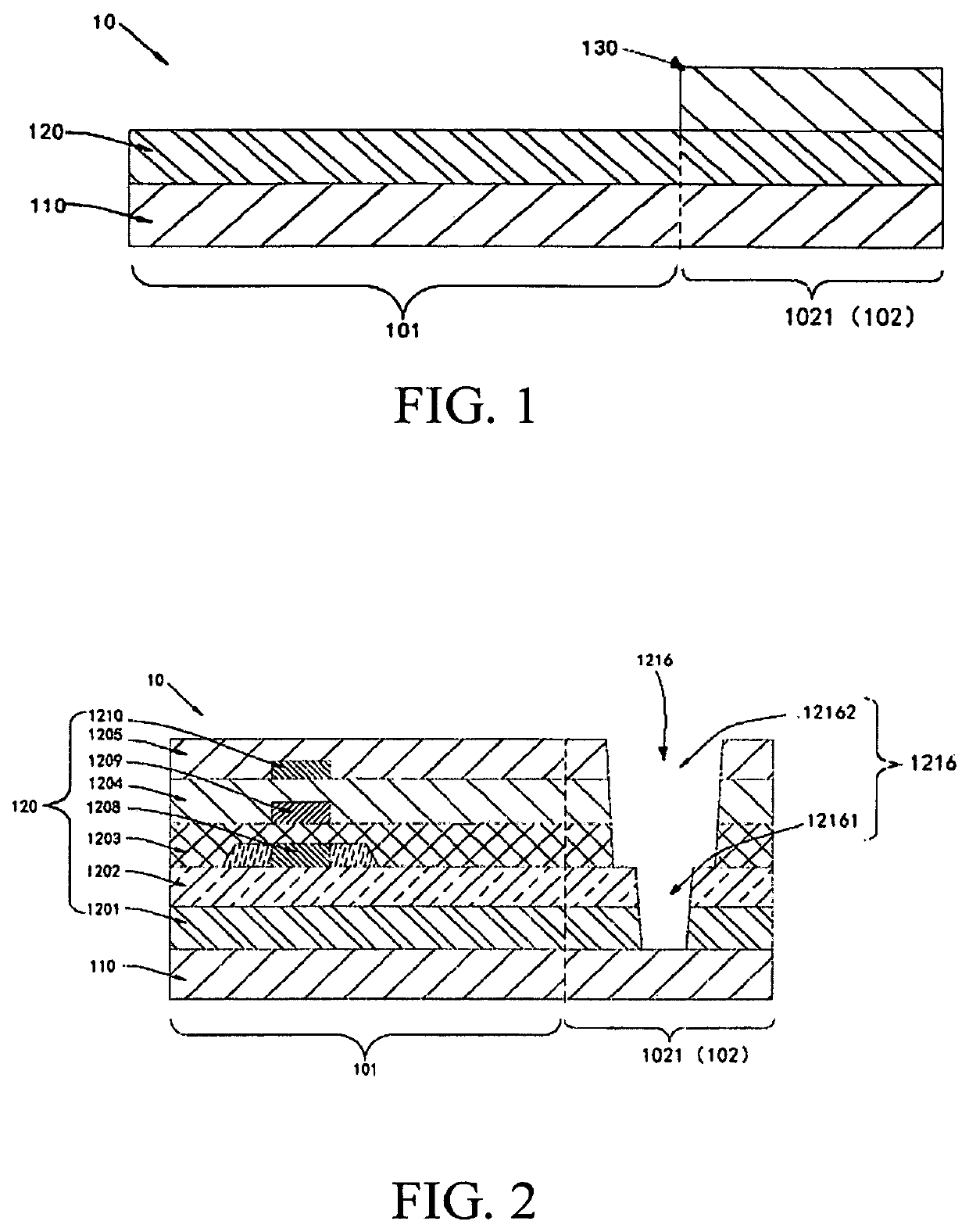

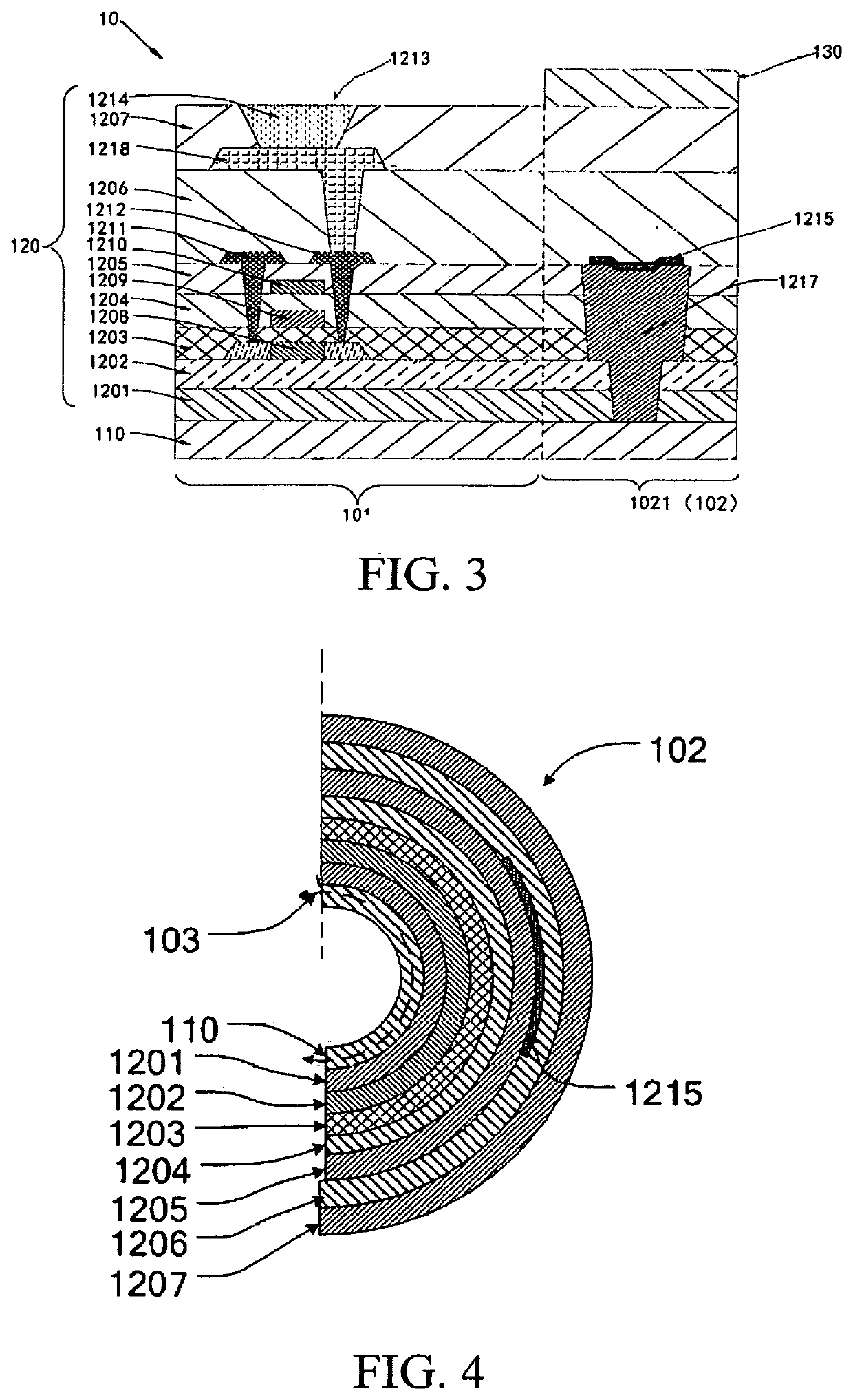

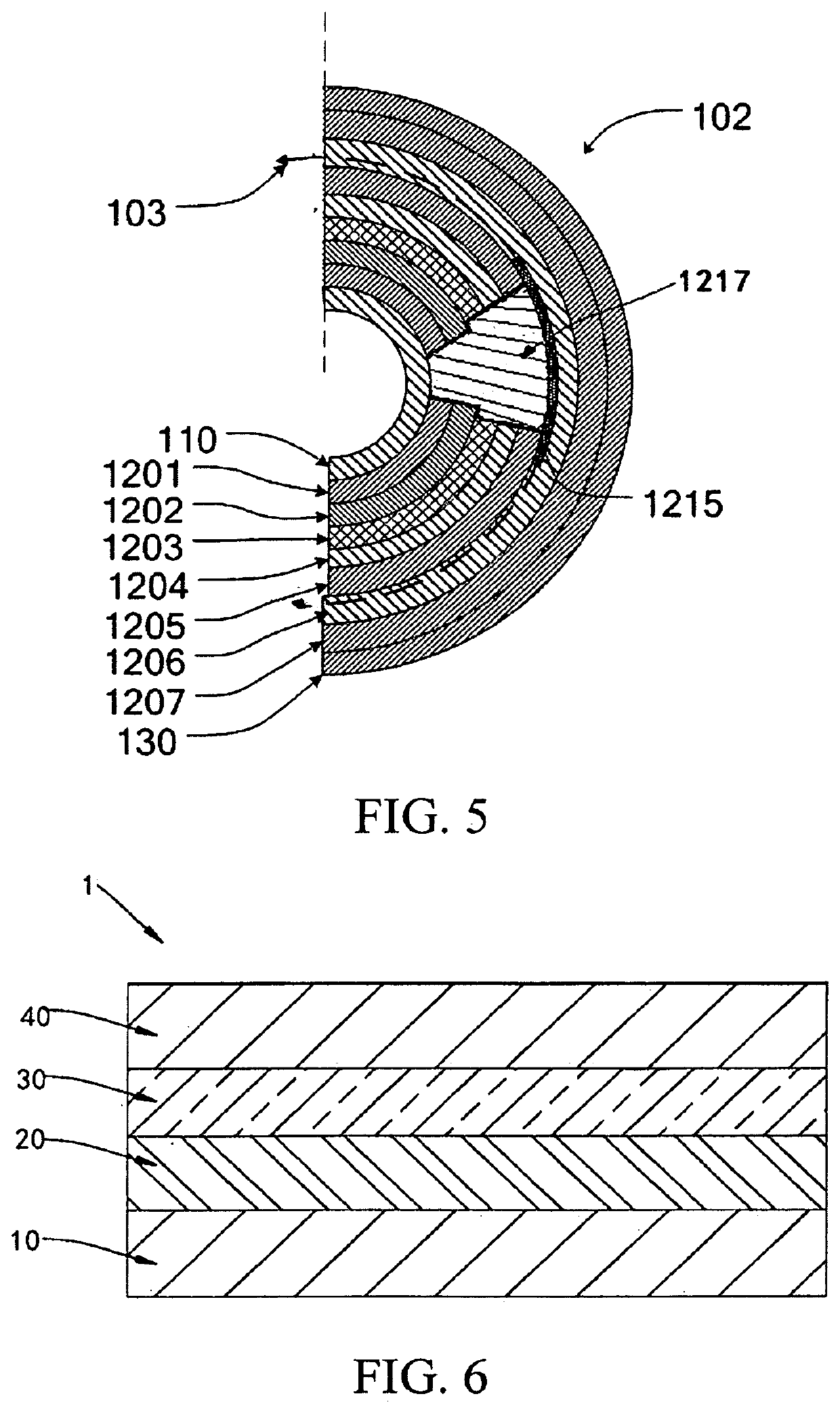

InactiveUS20140096944A1Improved refrigerant distribution structureImprove distribution structureClosure meansStationary conduit assembliesEngineeringRefrigerant

A heat exchanger having an improved distribution structure in which one inlet pipe is connected to a header which is partitioned into a first sub-chamber in which a refrigerant flows through the inlet pipe and a second sub-chamber in which tubes communicate with each other, and a distribution pipe is installed at the header and causes the first sub-chamber and the second sub-chamber to communicate so that the refrigerant in the first sub-chamber can be distributed to the tubes. The distribution pipe can pass through and can be combined with a partitioning baffle that is combined with the header to partition a chamber of the header into the first sub-chamber and the second sub-chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

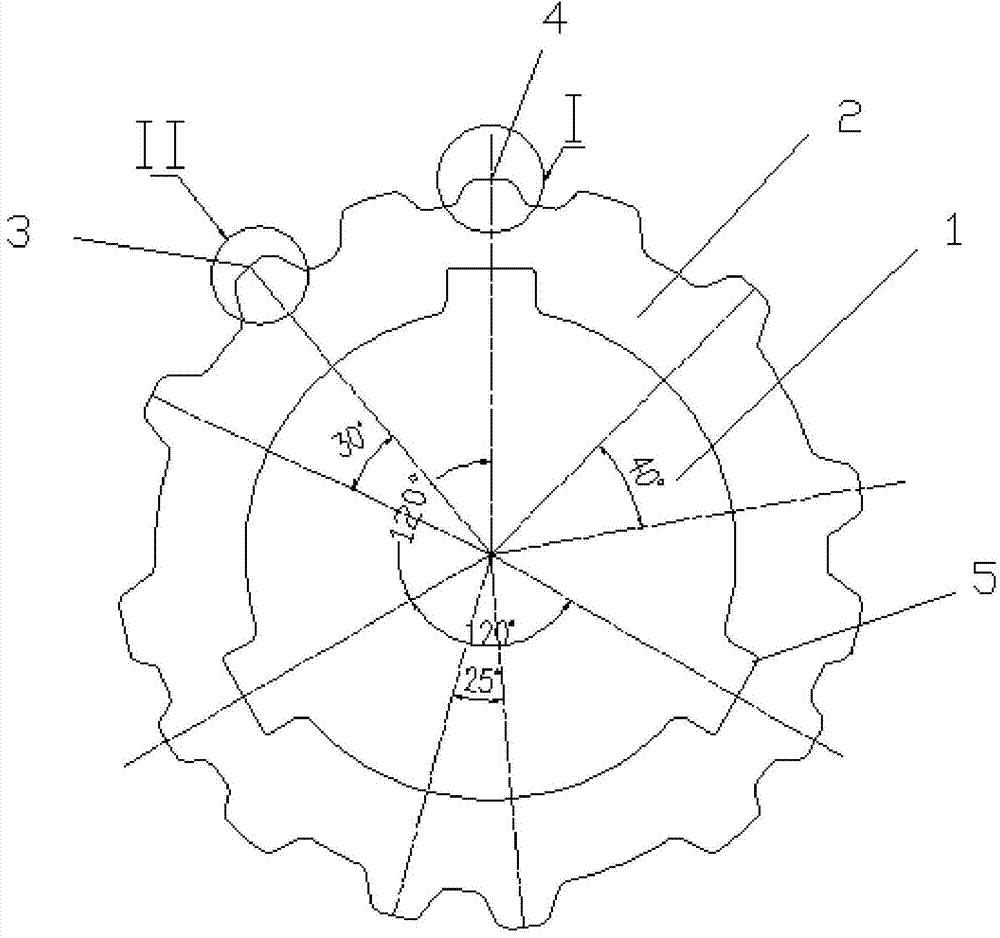

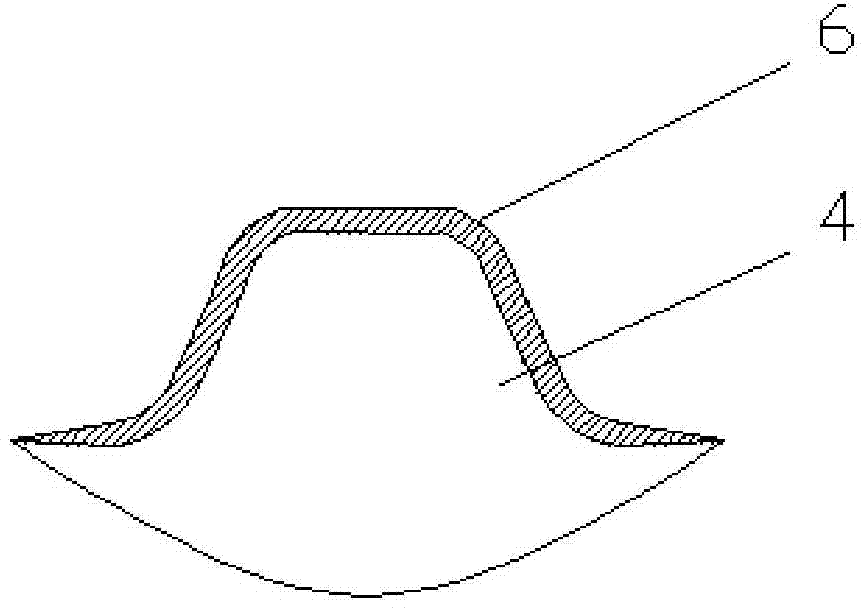

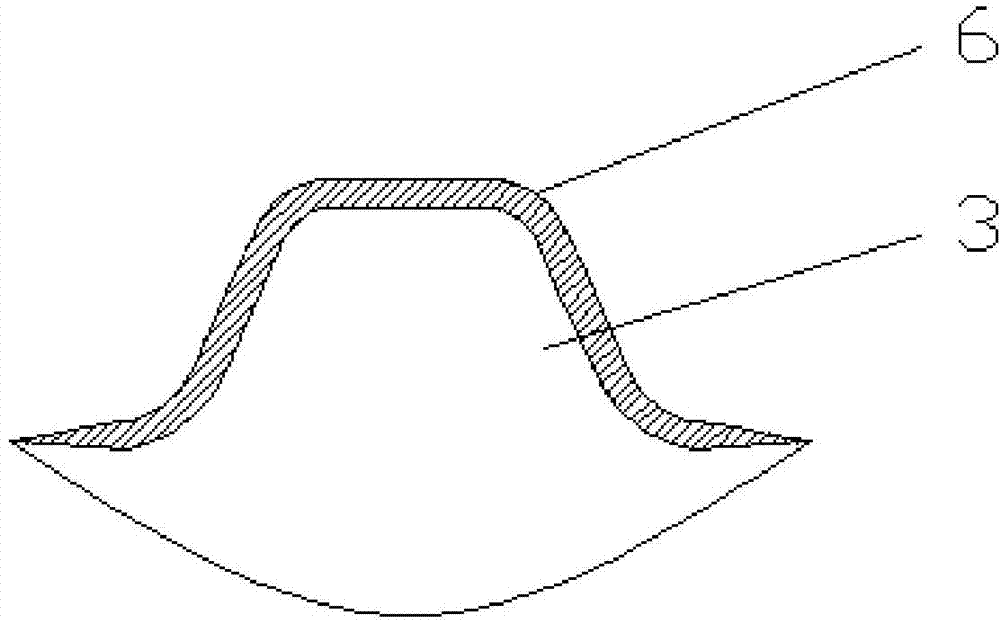

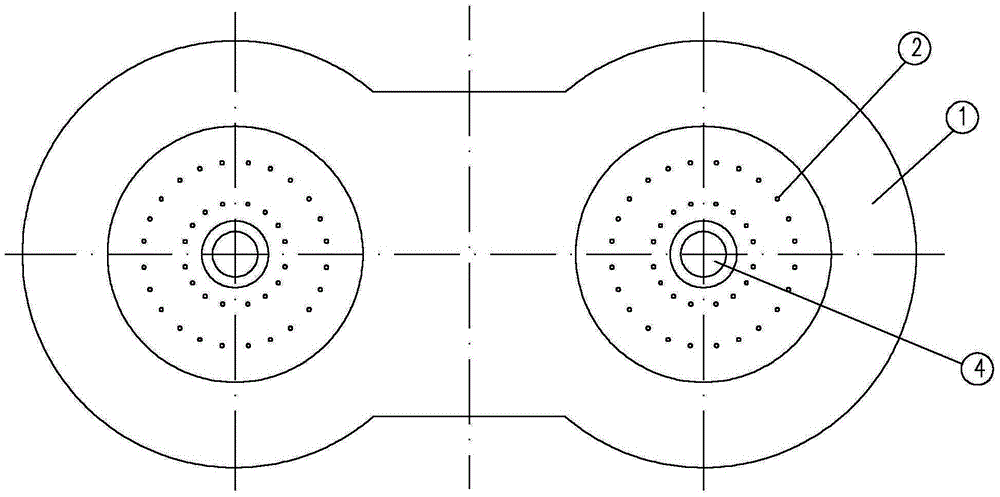

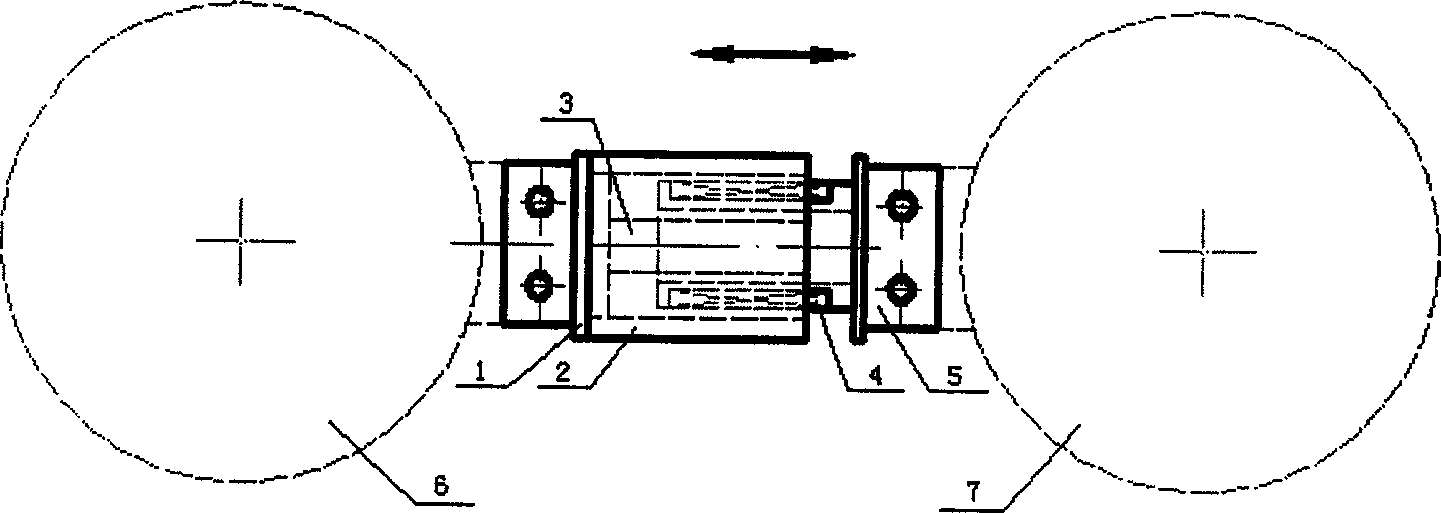

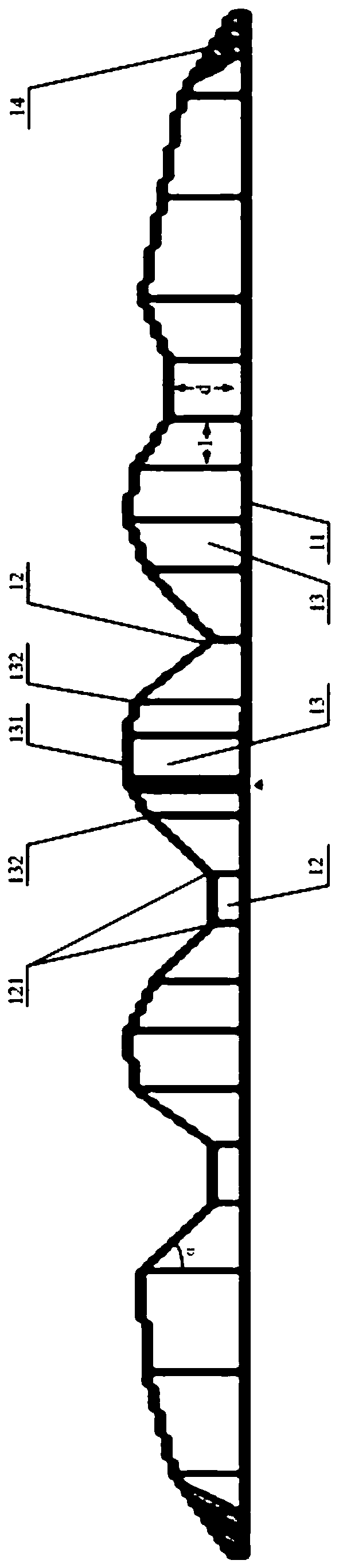

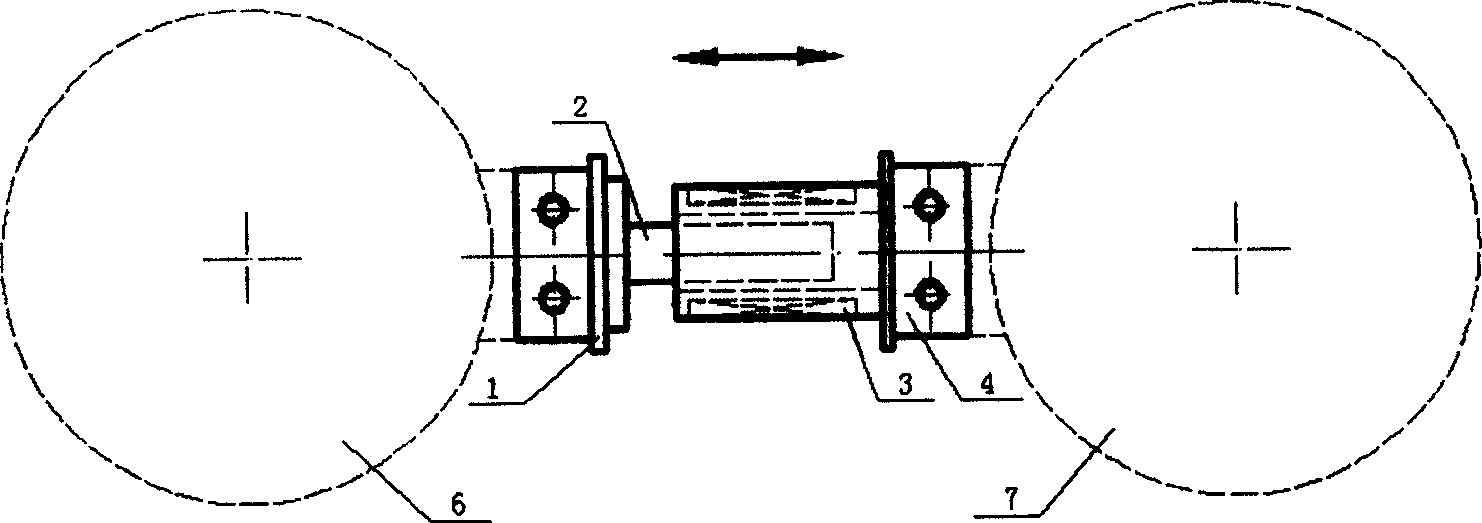

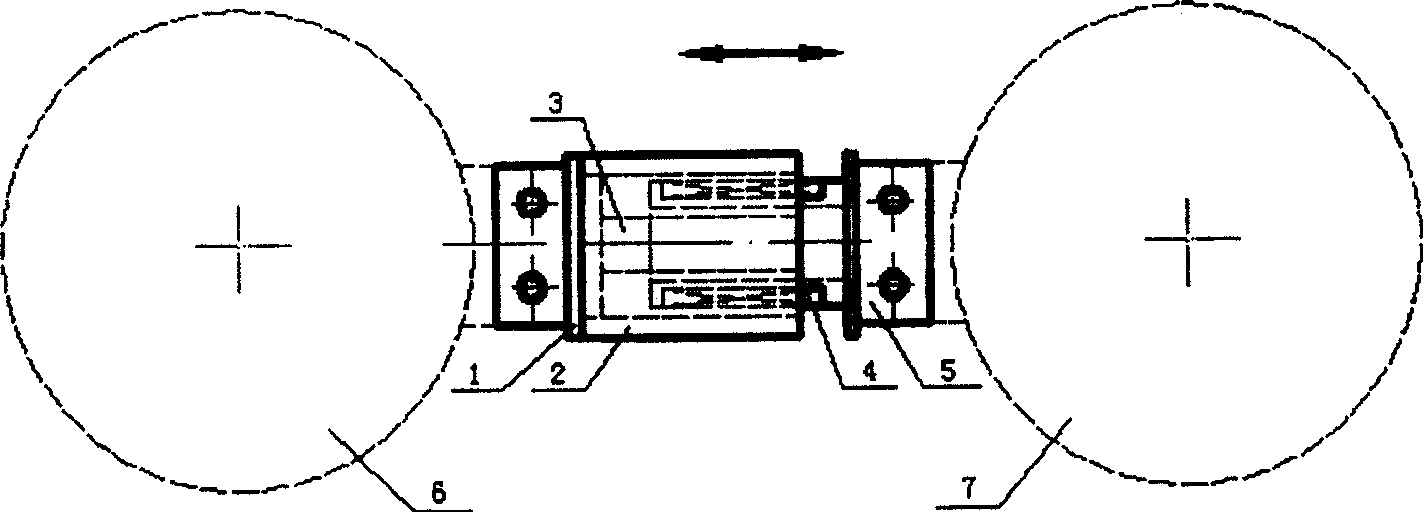

Roller of roll type crusher

InactiveCN103691517AImprove distribution structureImprove firm performanceGrain treatmentsEngineeringCrusher

The invention discloses a roller of a roll type crusher. The roller comprises a roller hole (1), a roller surface (2), large roll teeth (3), small roll teeth (4) and key grooves (5), wherein the roller hole is arranged at the center of the roller surface, and the large roll teeth and the small roll teeth are arranged on the outer edge of the roller surface; three key grooves are distributed in the roller hole, and the included angle between the adjacent key grooves is 120 degrees; three small roll teeth are arranged, the included angle between the adjacent small roll teeth is 120 degrees and the small roll teeth correspond to the key grooves in position; more large roll teeth are not uniformly distributed. The roller disclosed by the invention has the advantages that the large roll teeth are not uniformly distributed, three small roll teeth and three key grooves are correspondingly and uniformly distributed, the included angle between the adjacent small roll teeth or key grooves is 120 degrees, the arrangement of the three key grooves is beneficial to installation and angle adjustment of the equipment, and since only one key groove is used in installation and use, the roll teeth on the adjacent rollers are staggered mutually, so that the firmness for meshing the materials between the adjacent roller is improved and the crushing efficiency of clinkers is improved.

Owner:XUZHOU CHINA UNITED CEMENT CO LTD

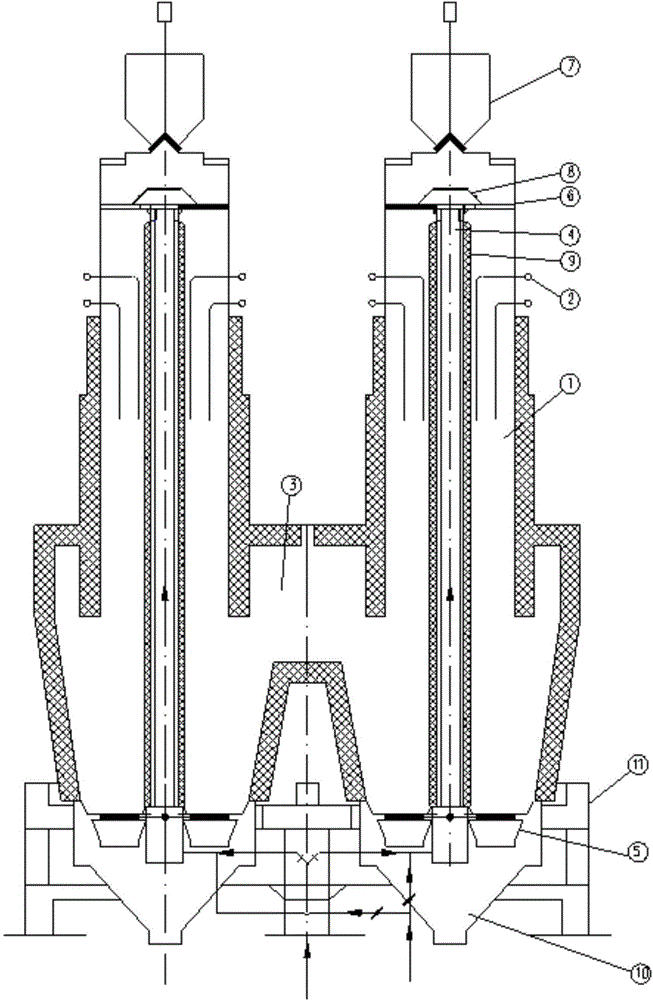

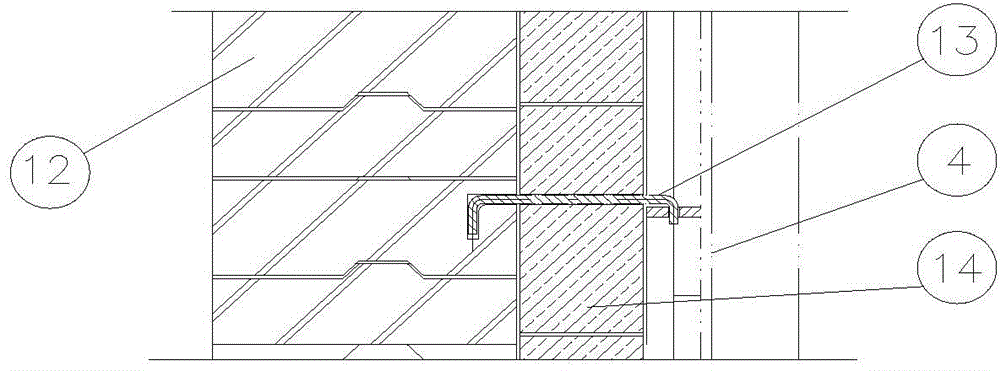

Sleeve type double-hearth shaft kiln

The invention relates to the field of roasting kilns and in particular relates to a sleeve type double-hearth shaft kiln. The sleeve type double-hearth shaft kiln is characterized in that inner sleeves are respectively arranged at the centers of two kiln hearths; the upper ends of the inner sleeves are hinged to the upper sides of the kiln hearths; the end sockets of axial positioning clamps are hinged to kiln hearth shells; the inner sleeves are of steel structure bodies from bottom to top; protection covers made of fireproof materials are built outside the inner sleeves; air channels are formed in the inner sleeves; the specification and the size of the shaft kiln are only related to a regional area of an annular section; basically, heights of a preheating region, a roasting region and the like of the kiln body are not changed along with the change of the specification of the kiln. Compared with the prior art, the sleeve type double-hearth shaft kiln disclosed by the invention has the beneficial effects that the resistance loss of the kiln body is low, the phenomenon that heat cannot be distributed uniformly in a roasting process is improved, the quality of a product is high, electric energy can be saved, and the problem in large sizes of lime and dolomite double-hearth shaft kilns is solved; the sleeve type double-hearth shaft kiln is suitable for new construction, reconstruction and extension and the technical design of the conventional kiln with the daily yield being more than 600 tons and even the daily yield being more than thousands of tons.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

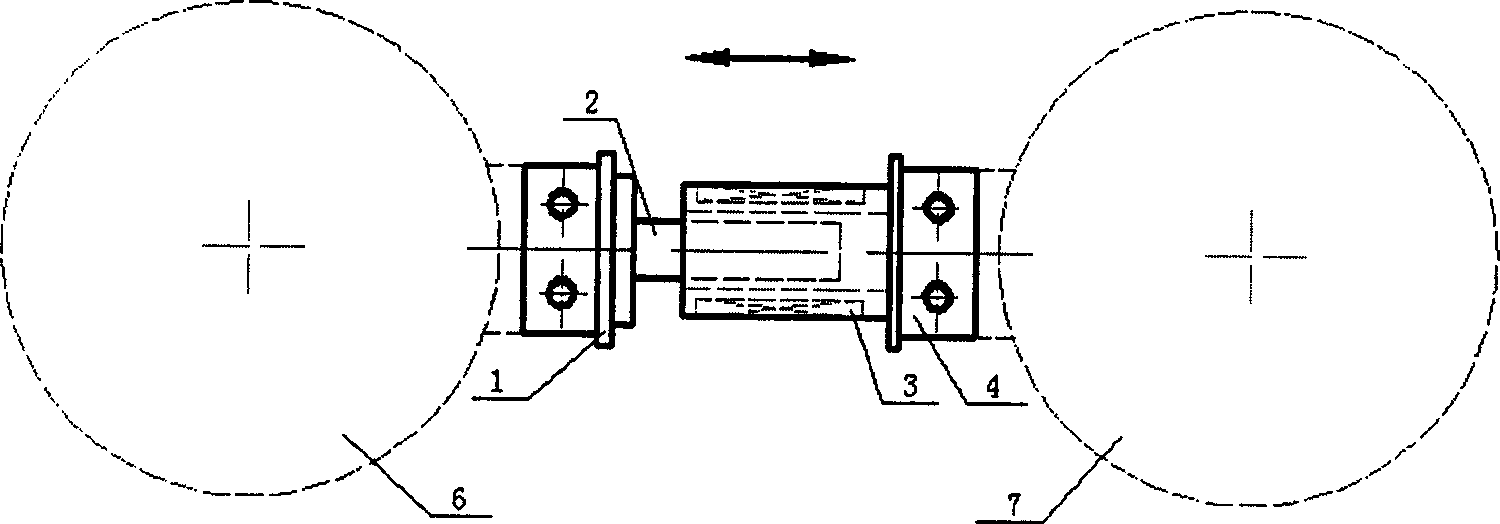

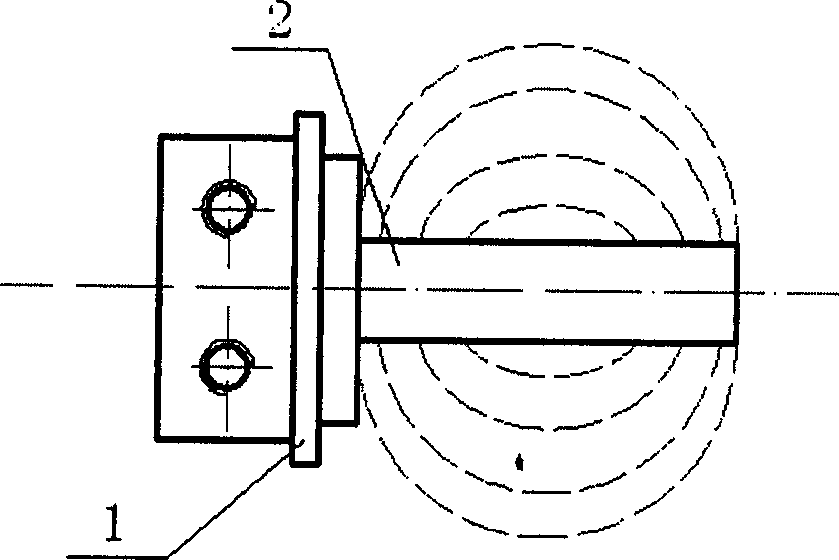

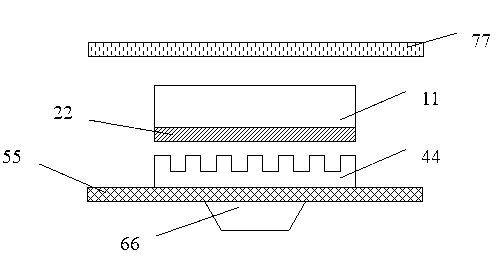

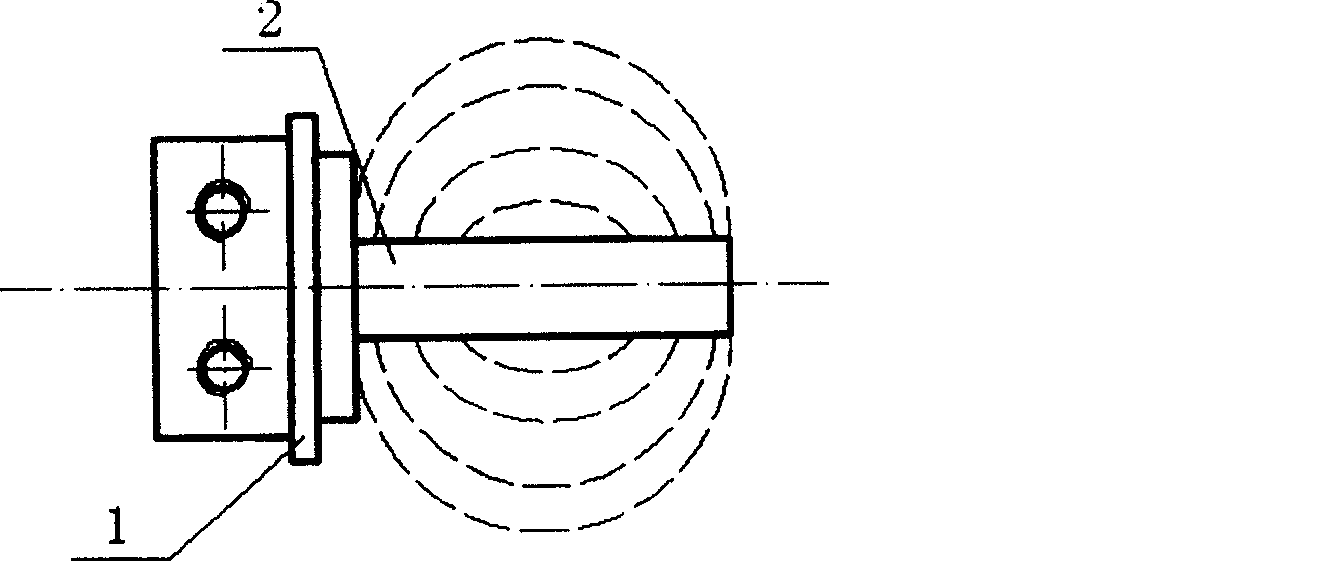

Detecting unit of coriolis quality flow meter

ActiveCN1793800AImprove distribution structureReduce nonlinear effectsTesting/calibration apparatusDirect mass flowmetersMagnetic linePhysics

A detection unit of Carioles mass flowmeter is prepared as fixing central magnetic conductor and ring magnetic steel on base to form circular gap between the two and to form uniform parallel magnetic field, moving detection coil and coil frame in formed circular gap to cut magnetic line for outputting signal in proportion to moving speed.

Owner:BEIHANG UNIV

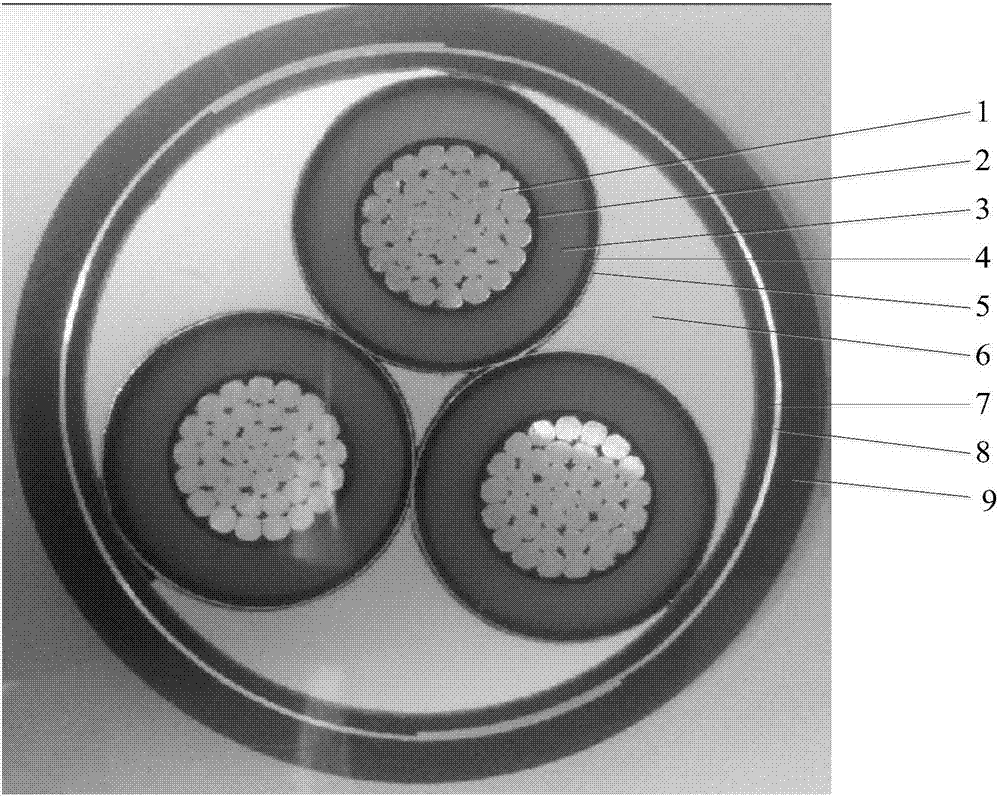

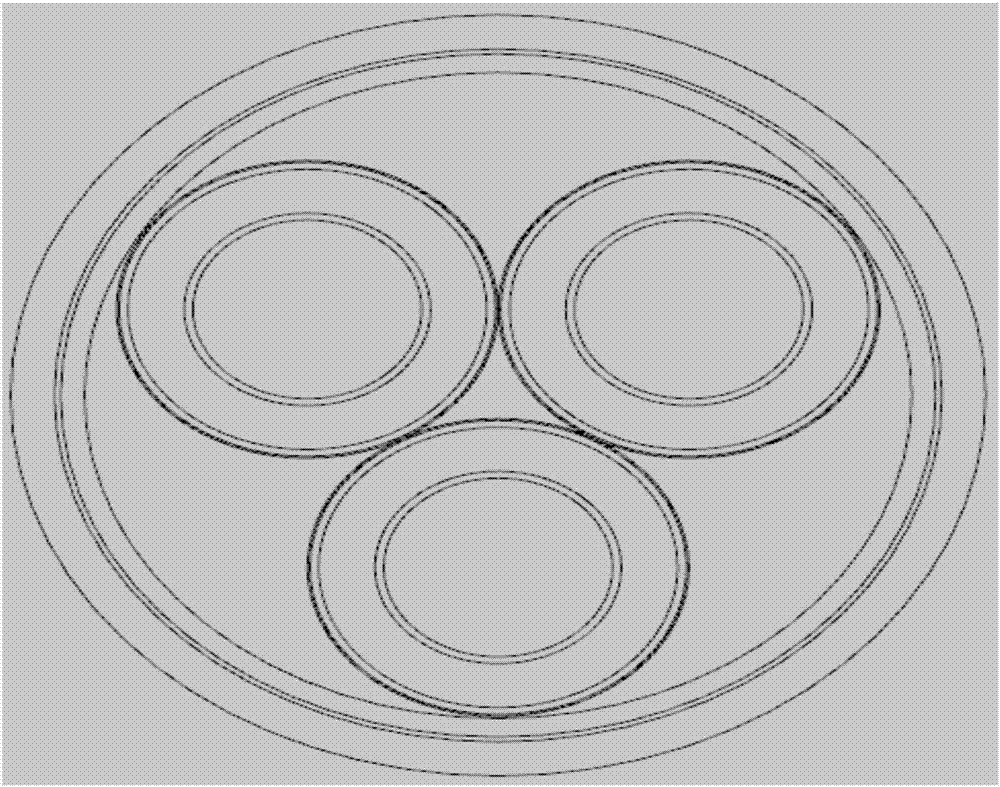

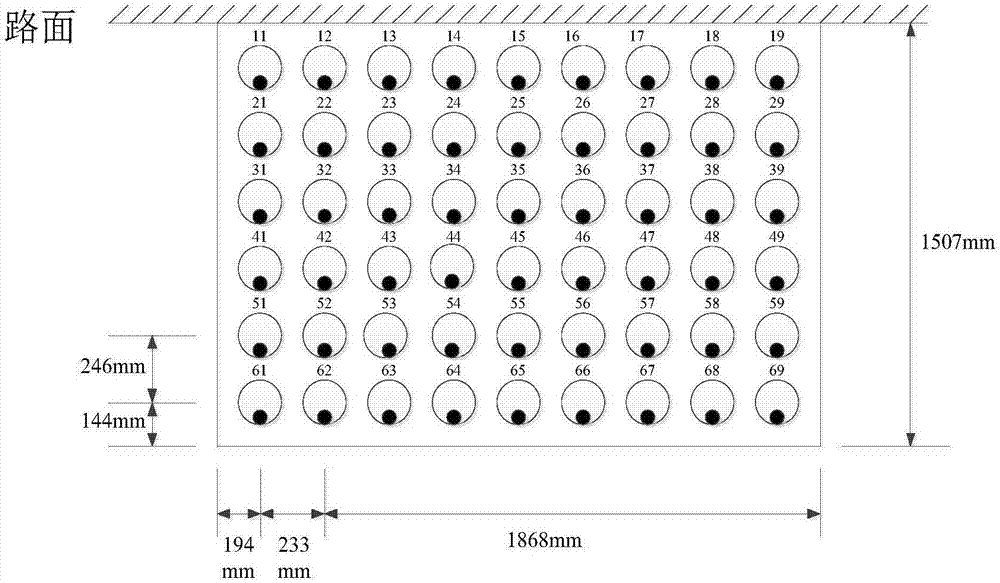

Finite element calculation method for temperature fields of multiple cross-linked polyethylene insulated cables during trench sharing

InactiveCN107315860AImprove distribution structureCalculation speedDesign optimisation/simulationSpecial data processing applicationsEngineeringField analysis

The invention discloses a finite element calculation method for temperature fields of multiple cross-linked polyethylene insulated cables during trench sharing. The method comprises the steps of 1, calculating related parameters of the cross-linked polyethylene insulated cables; 2, building a cable model; 3, building a trench sharing model and a cable trench temperature field calculation model of the cross-linked polyethylene insulated cables; and 4, according to the related parameters, obtaining heating loss of a unit-length unit-area lead wire core, heating loss of an insulation medium and heating loss of an armor layer, loading the heating losses to the polyethylene insulated cables in the cable trench temperature field calculation model to serve as heat sources of the polyethylene insulated cables to perform temperature field analysis, and calculating the temperature fields of the polyethylene insulated cables. Compared with a conventional method for calculating the temperature fields by utilizing IEC-60287 standards, the finite element calculation method has the advantages of high calculation speed and high calculation precision, and can calculate a distribution condition of the temperature fields under the condition more accurately.

Owner:STATE GRID HUBEI ELECTRIC POWER CO LTD WUHAN POWER SUPPLY CO +1

Display panel and display device having same

ActiveUS20210126073A1Improved stress distributionFail or degrade in performanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

A display panel and a display device having the display panel are provided. The display panel includes a display region for displaying images; a non-display region disposed outside the display region, and the non-display region includes a bending region; a metal trace extending from the display region to the bending region; and a stress adjustment layer disposed on the metal trace and corresponding to the bending region. The display panel and the display device having the display panel can effectively solve problems such as performance degradation and failure caused by cracking and peeling on the metal trace when the display panel is bent through adding the stress adjustment layer which has a material with the same flexibility as the flexible substrate on an array substrate or different flexibility from the flexible substrate on the array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

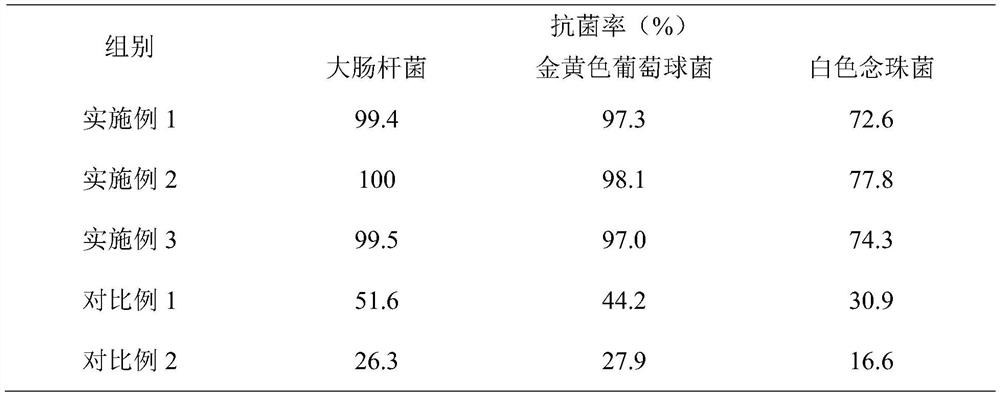

Fabric antibacterial treatment liquid and preparation method thereof

PendingCN112144277APowerful and unique antibacterial propertiesPowerful and unique antioxidant propertiesBiochemical fibre treatmentAntioxidant capacityActive agent

The invention discloses a fabric antibacterial treatment liquid and a preparation method thereof. The preparation method comprises the steps that chitosan is hydrolyzed and dissolved in water, an active agent is added, after uniform stirring is conducted, sodium alginate and auxiliaries are added, stirring is conducted till the sodium alginate is completely dissolved, and the fabric antibacterialtreatment liquid is obtained, wherein the active agent is prepared by mixing unique manuka factor and honeycomb powder according to the mass ratio of 1:(50-200). According to the fabric antibacterialtreatment liquid and the preparation method thereof, the active agent composed of the unique manuka factor and the honeycomb powder is adopted, the active agent is a natural component and is harmlessto human body and environment, the unique manuka factor has strong and unique antibacterial and antioxidant capabilities, can be not influenced by external factors such as illumination and high temperature, and keeps stable for a long time, and the honeycomb powder also has efficient antibacterial, bactericidal and antiviral effects; more importantly, after the honeycomb powder is activated, the honeycomb powder can provide excellent adsorbability and dispersity and can improve the distribution structure of the unique manuka factor when being used together with the unique manuka factor, so that the binding force between the unique manuka factor and the fabric is enhanced, and the antibacterial finishing effect of a product is remarkably improved.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

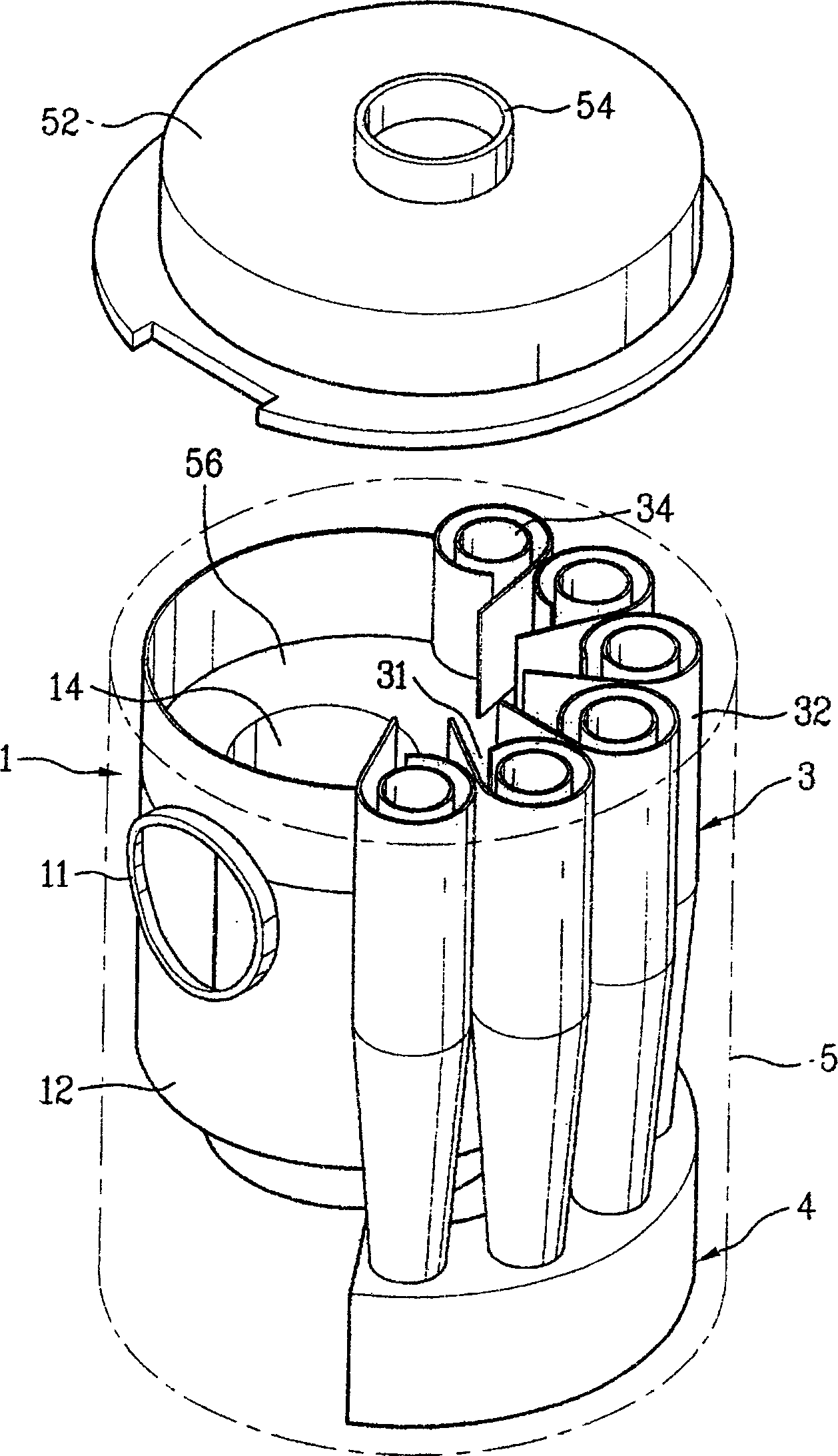

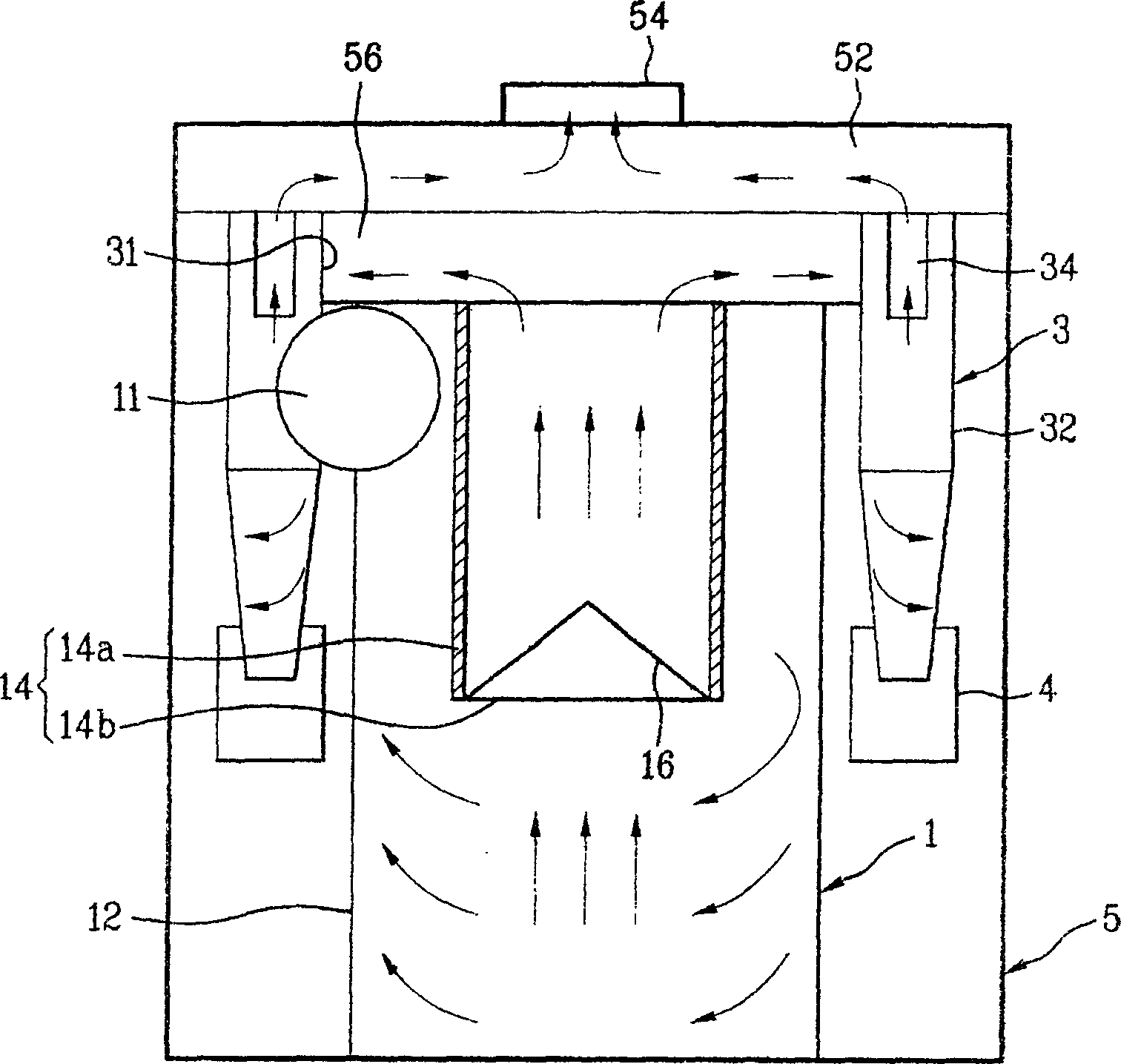

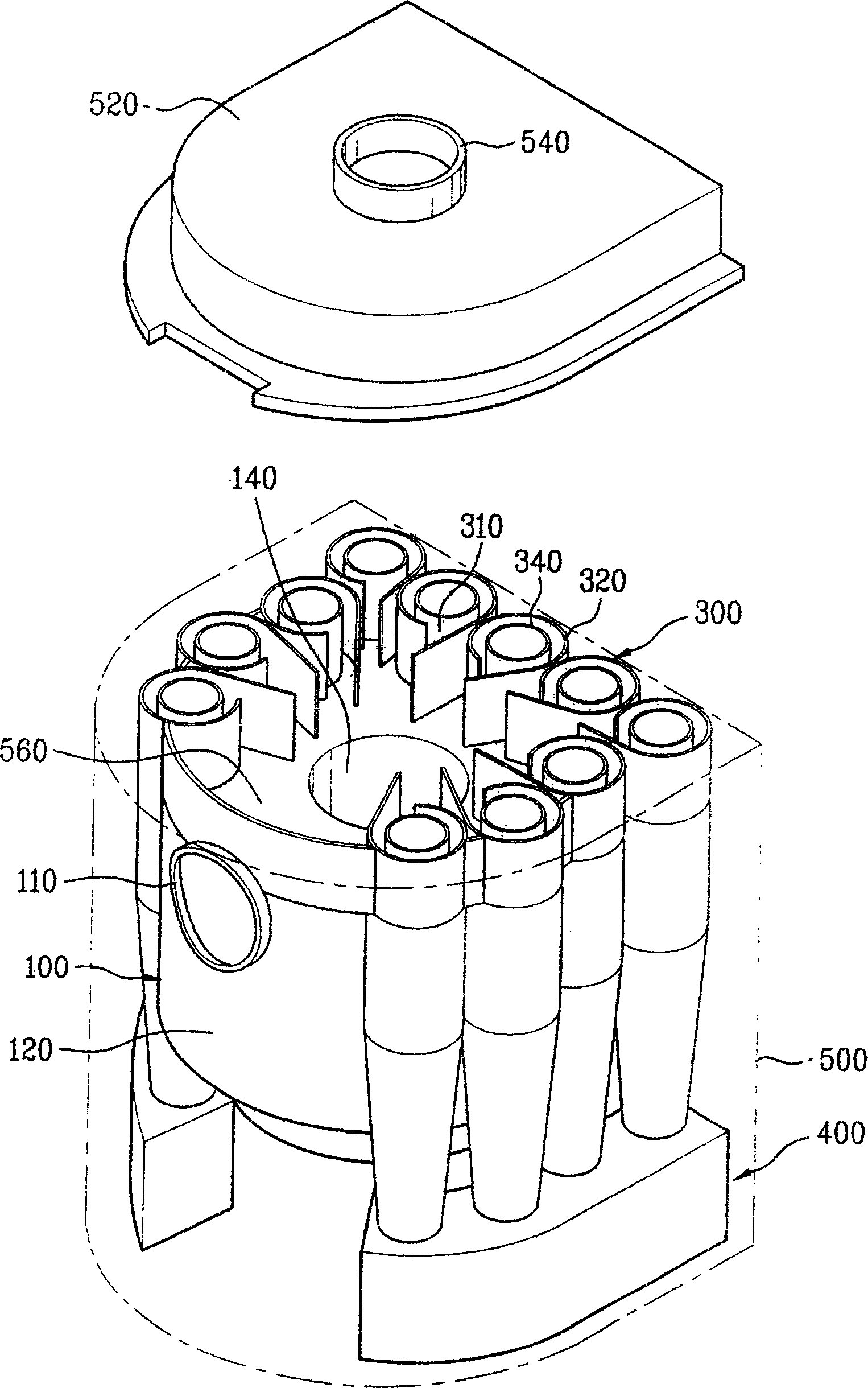

Multiple cyclonic dust collector

InactiveCN1887187AImprove distribution structureIncrease the number ofSuction filtersSingle direction vortexCycloneDust collector

The multiple -cyclonic dust collector includes one first cyclone unit, several second cyclone units, one dust collecting tub and one casing. The first cyclone unit sucks air from outside and collects dust for the first time; the second cyclone units around the first cyclone unit and connected to the first cyclone unit collects fine dust from the air the first cyclone unit separates out; the dust collecting tub connected to the bottoms of the second cyclone units collects the fine dust the second cyclone units separates out; and the casing holds the first cyclone unit, the second cyclone units and the dust collecting tub for separating them from outside and has at least one angled part.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

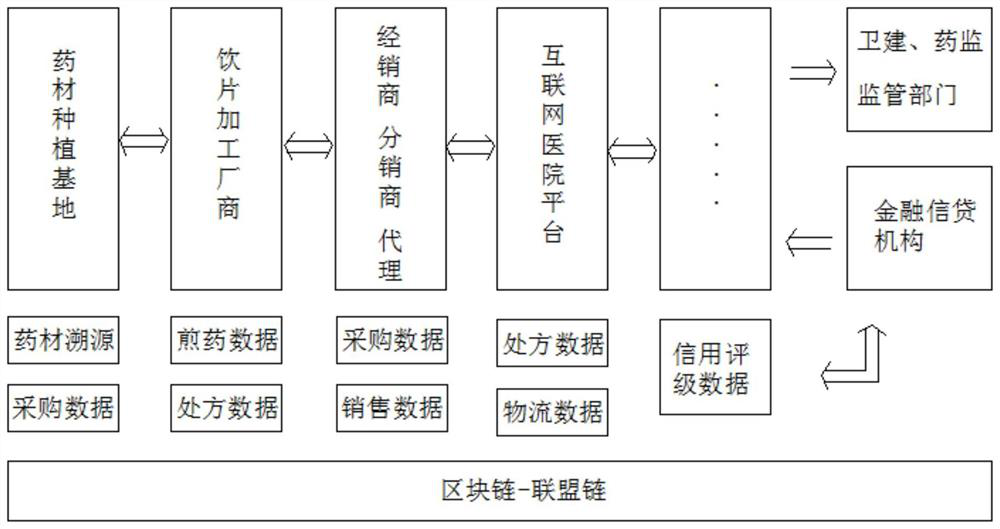

Block chain-based traditional Chinese medicine supply chain industry financial system establishment method

PendingCN113538128AFull circulationReduce bad debt rateFinanceDatabase distribution/replicationBusiness enterpriseBusiness data

The invention provides a block chain-based traditional Chinese medicine supply chain industry financial system establishment method. Upstream and downstream main enterprises in a traditional Chinese medicine supply chain industry are combined, a financial credit institution and an industry supervision department are introduced, an authority framework is established, business generation nodes and processes in traditional Chinese medicine supply chain production are combed, and an alliance chain intelligent contract is complied; related intersection business data systems are combed in upper, middle and lower subject enterprises, the researched and developed block chain smart contract is embedded into a corresponding business system, a credit value is generated according to business data, the business data generated by the upper, middle and lower subjects are verified, authenticated and queried by a financial credit subject and a supervision subject, the TOKEN voucher of the related main enterprise is queried as credit data in the traditional Chinese medicine supply chain industry, the invention provides the method for establishing the traditional Chinese medicine supply chain industry financial system based on the block chain, which can improve the full circulation of funds in the traditional Chinese medicine supply chain industry and reduce the bad debt rate.

Owner:杭州甘之草科技有限公司

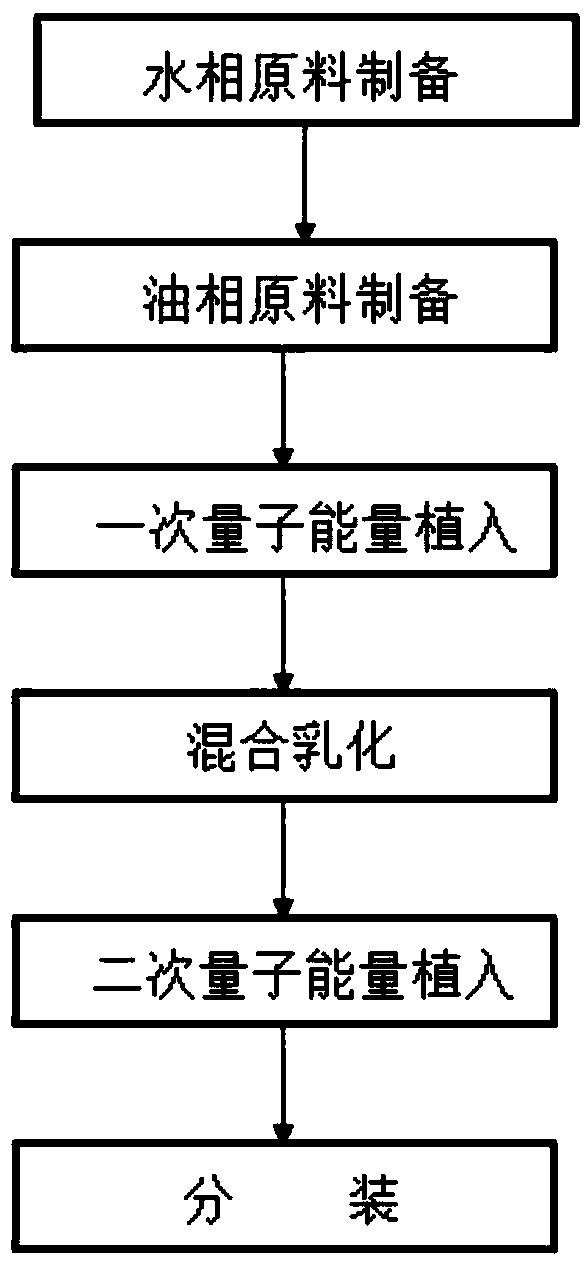

Preparation process of quantum energy implantation modified type cream

InactiveCN109248131AImprove work efficiencyIncrease productivityCosmetic preparationsToilet preparationsOil phaseQuantum

The invention relates to a preparation process of quantum energy implantation modified type cream. The preparation process of the quantum energy implantation modified type cream comprises six steps ofwater phase raw material preparation, oil phase raw material preparation, primary quantum energy implantation, mixed emulsification, secondary quantum energy implantation, split charging. Compared with the prior art, the preparation process of the quantum energy implantation modified type cream effectively improves the working efficiency of raw material mixing, emulsification and homogenization operation and effectively reduces the production cost while the production efficiency is improved; the activity of molecules and ions among various components in the cream is effectively improved, andthe distribution structure of the molecules and ions among various components in the cream is greatly improved, so that the efficacy of the cream components is improved, and meanwhile, the absorptionutilization rate of a human body is effectively improved; and meanwhile, the production process of a cream product is simplified, and the production efficiency and quality of the product are improved,so that the overall benefit of the cream product is greatly improved.

Owner:广州市欧蔓护肤品有限公司

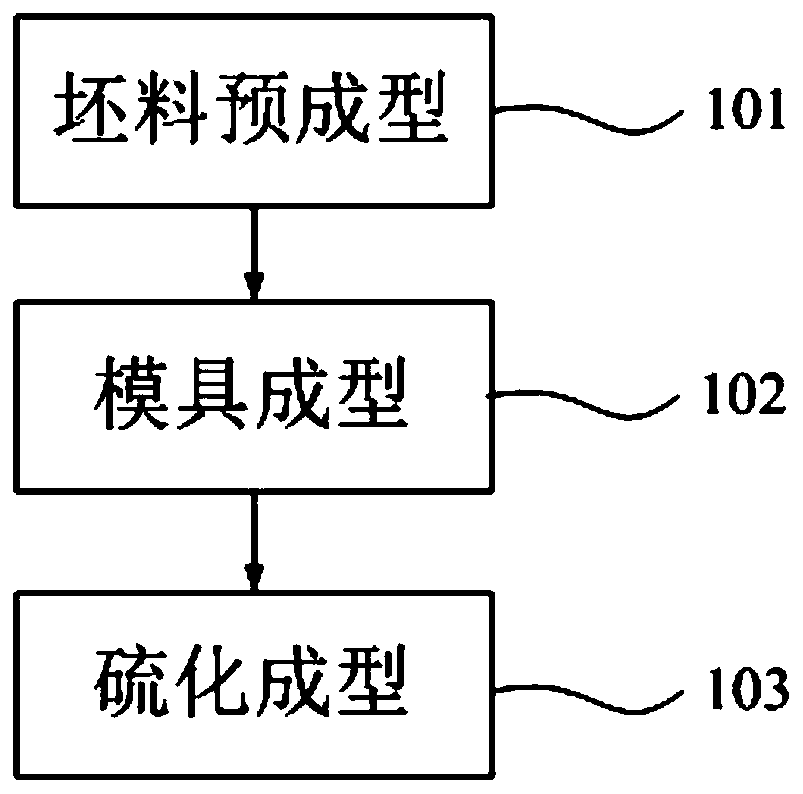

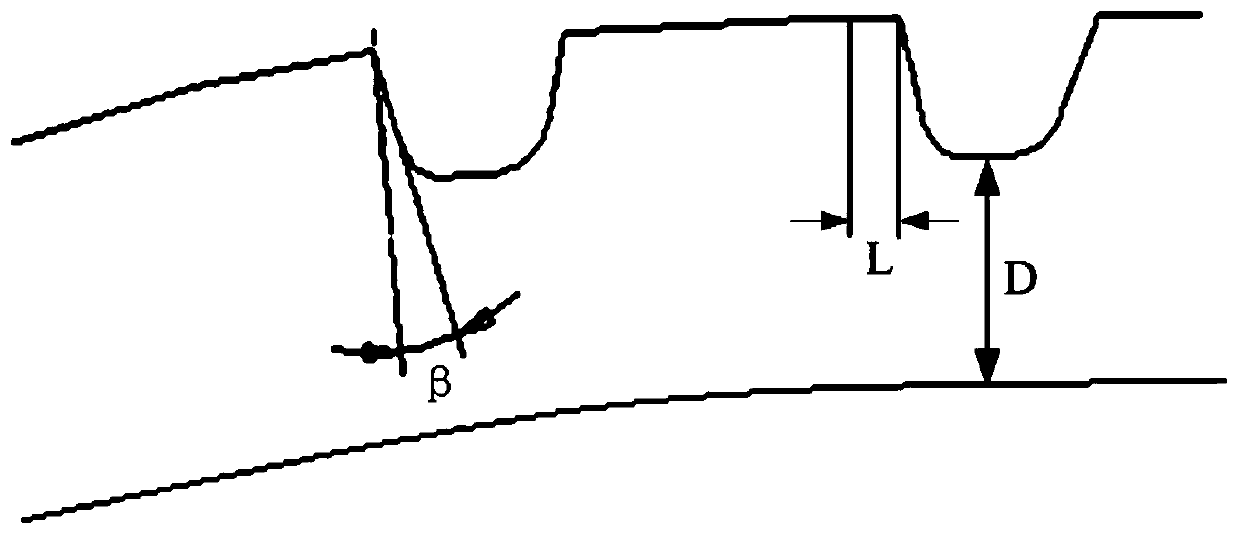

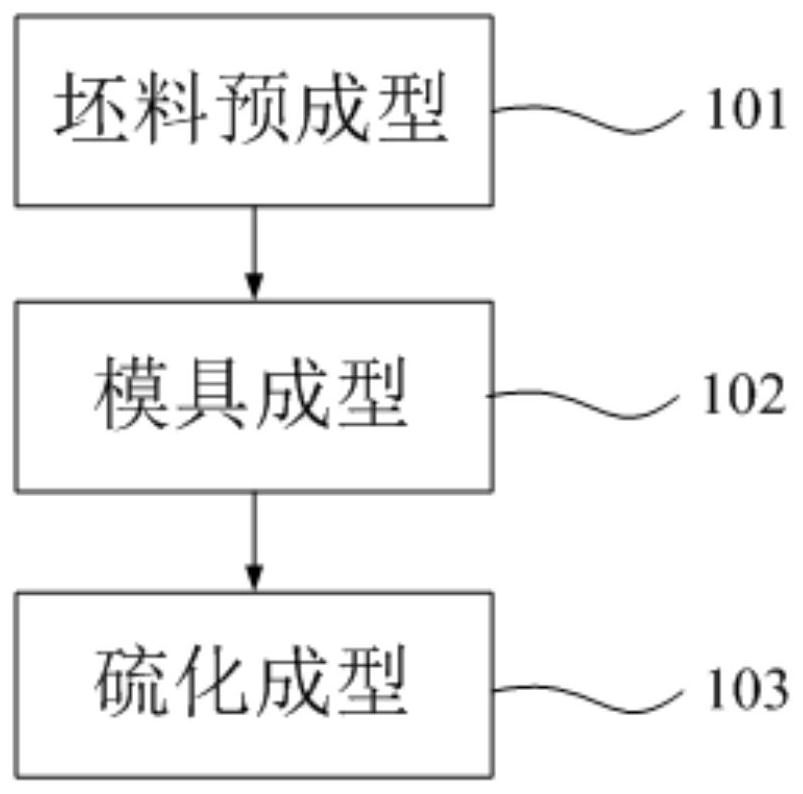

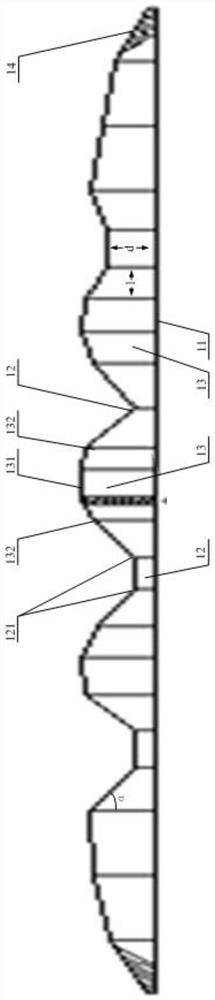

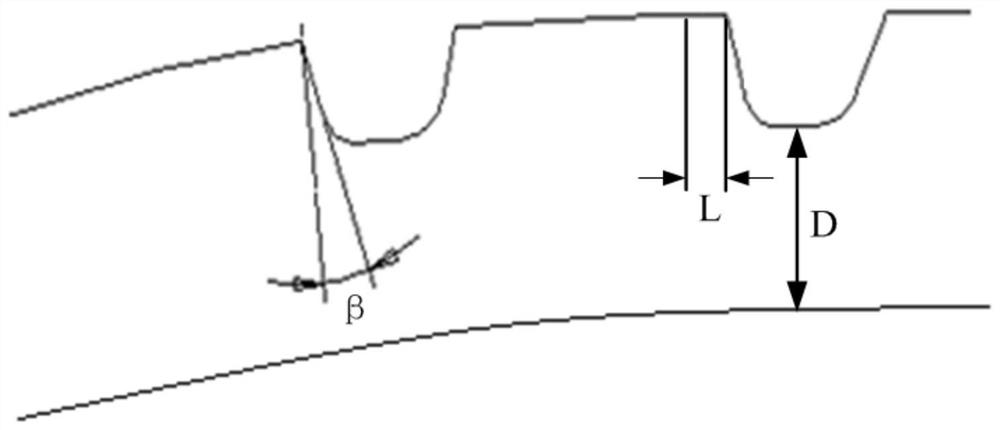

Tire machining forming method

The invention discloses a tire machining forming method. The tire machining forming method comprises the steps of blank preforming, mold forming, vulcanization forming and the like in sequence. A plurality of preforming gutters and preforming protrusions are pre-machined in a rubber blank which is not subjected to mold machining so that the rubber blank can be matched with structures in a mold cavity and corresponding tread pattern grooves and tread pattern strips can be machined, especially, through the blank preforming procedure, rubber can be orderly guided and uniformly distributed, accordingly, the phenomena that due to follow-up mold machining and related forming technology implementation, possibly, the rubber flows and is accumulated on edge parts of the tread pattern strips are effectively avoided, and thus, the phenomenon that the rubber of the tread pattern strips partially protrudes is further avoided; and accordingly, the rubber distribution structure at the tread pattern strips of a tire subjected to machining forming is effectively optimized, the performance of the tire is improved remarkably, the service life of the tire is prolonged remarkably, and the whole vehicleperformance is optimized correspondingly.

Owner:CHENG SHIN RUBBER CHINA

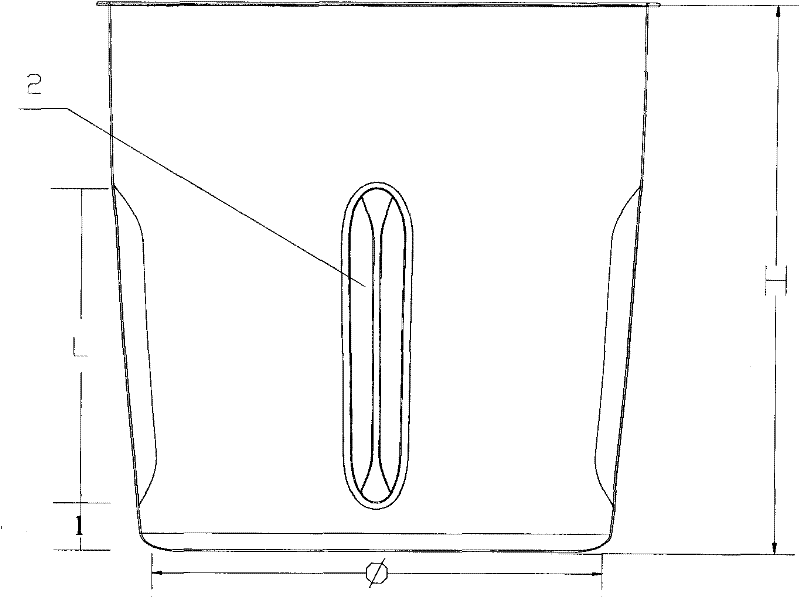

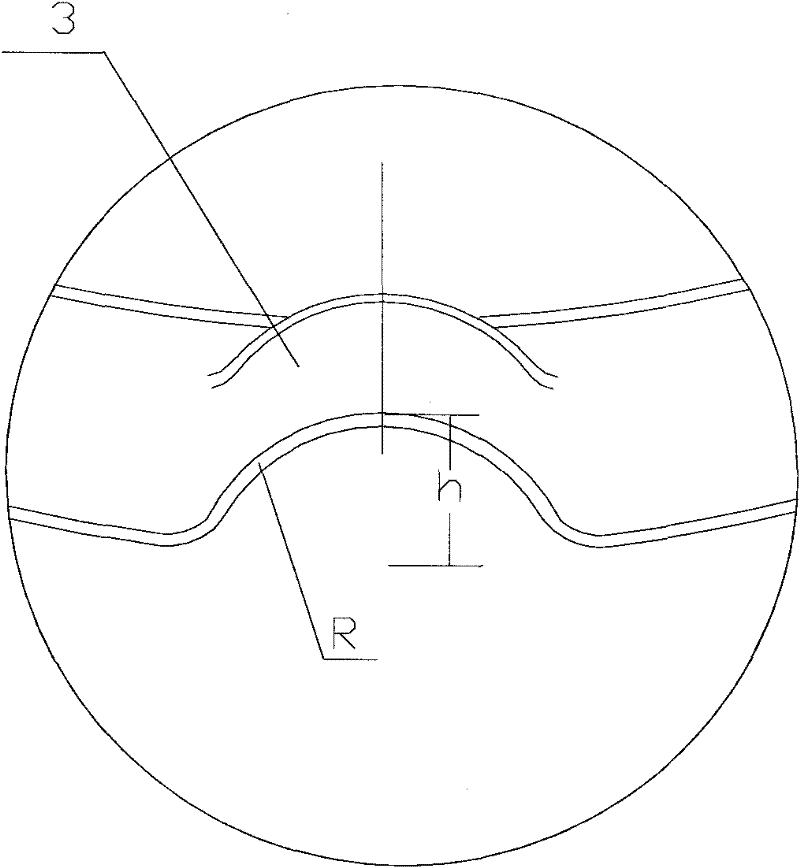

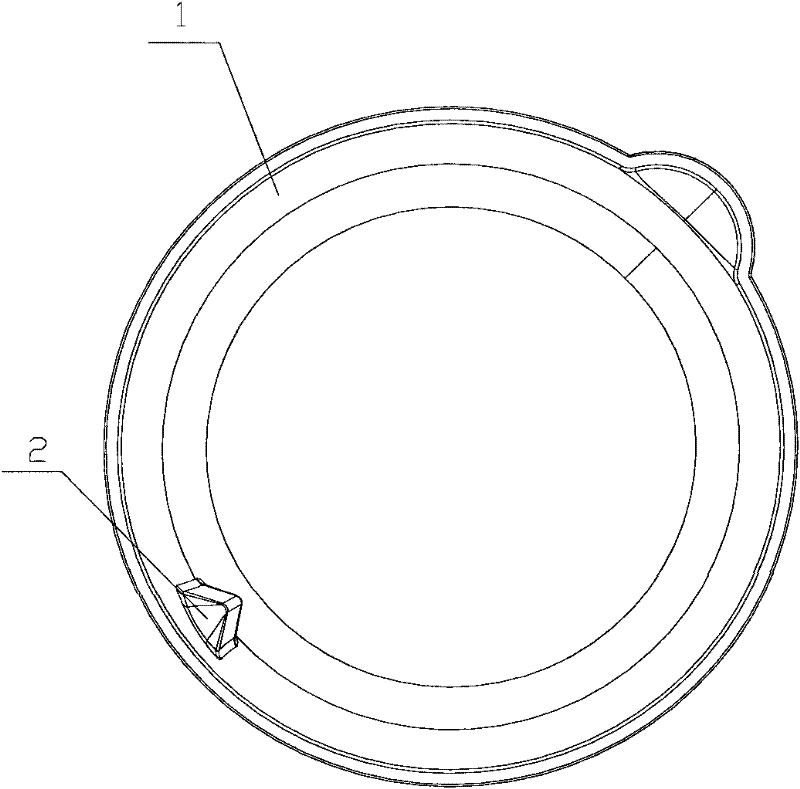

Cup body of soybean milk maker without filter screen

InactiveCN102172255AHigh efficiency spoiler effectEasy to cleanBeverage vesselsMilk substitutesEngineeringMetal

The invention belongs to the technical field of a soybean milk maker without a filter screen, and particularly discloses a cup body of a soybean milk maker without a filter screen, wherein the cup body is used for solving the defect that the turbulent flow effect of the existing soybean milk maker without the filter screen is not good. The specific scheme is as follows: the cup body is made of a metal material; the inner side face (1) of the cup body is provided with a plurality of steel bars (2); the included angle of the stream resisting face (3) of each steel bar and the inner side face (1) is 120-145 degrees; the number of the steel bars (2) is 1-5; and when the number of the steel bars is more than 2, the steel bars (2) are evenly distributed on the inner side face (1). The cup body provided by the invention can achieve an efficient turbulent flow effect, and can effectively satisfy the fine grinding effect needed in pulping.

Owner:MIDEA GRP CO LTD

Water-borne nano ultra-thin steel structure fire retardant coating and preparation method thereof

Owner:浙江川科防保材料发展有限公司

Method for manufacturing silicone micro-nano optical structure by using imprinting technology

InactiveCN102707378BImprove thermal stabilityGood light transmissionDecorative surface effectsPhotomechanical apparatusWeather resistancePolymer

Owner:SOUTH CHINA NORMAL UNIVERSITY

Graphene high-thermal-conductivity material

PendingCN112980369AHigh resin contentImprove cohesionNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer sciencePtru catalyst

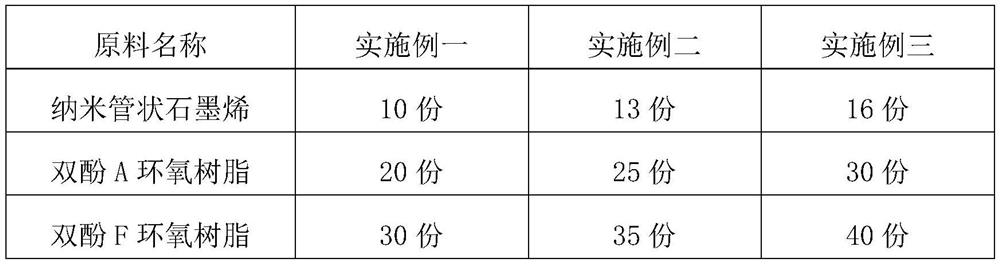

The invention relates to the technical field of graphene, and discloses a graphene high-thermal-conductivity material which comprises the following raw material components: 10-16 parts of nano tubular graphene, 20-30 parts of bisphenol A epoxy resin, 30-40 parts of bisphenol F epoxy resin, 20-30 parts of a modified thiol curing agent, 3-6 parts of hydrophobic fumed silica and 1-3 parts of a catalyst. Compared with the existing graphene heat conduction material, the graphene high-thermal-conductivity material disclosed by the invention is high in heat conduction coefficient and high in bonding strength.

Owner:重庆索梦得新材料科技有限公司

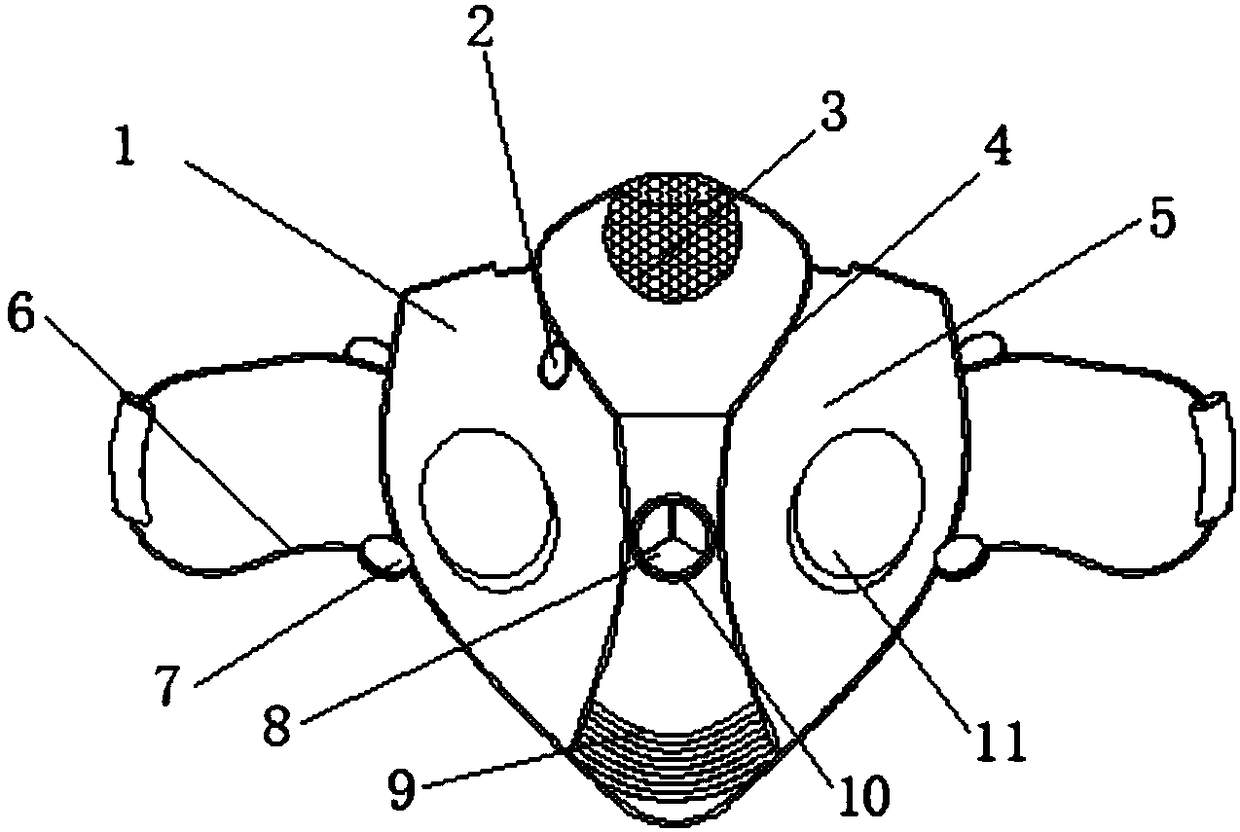

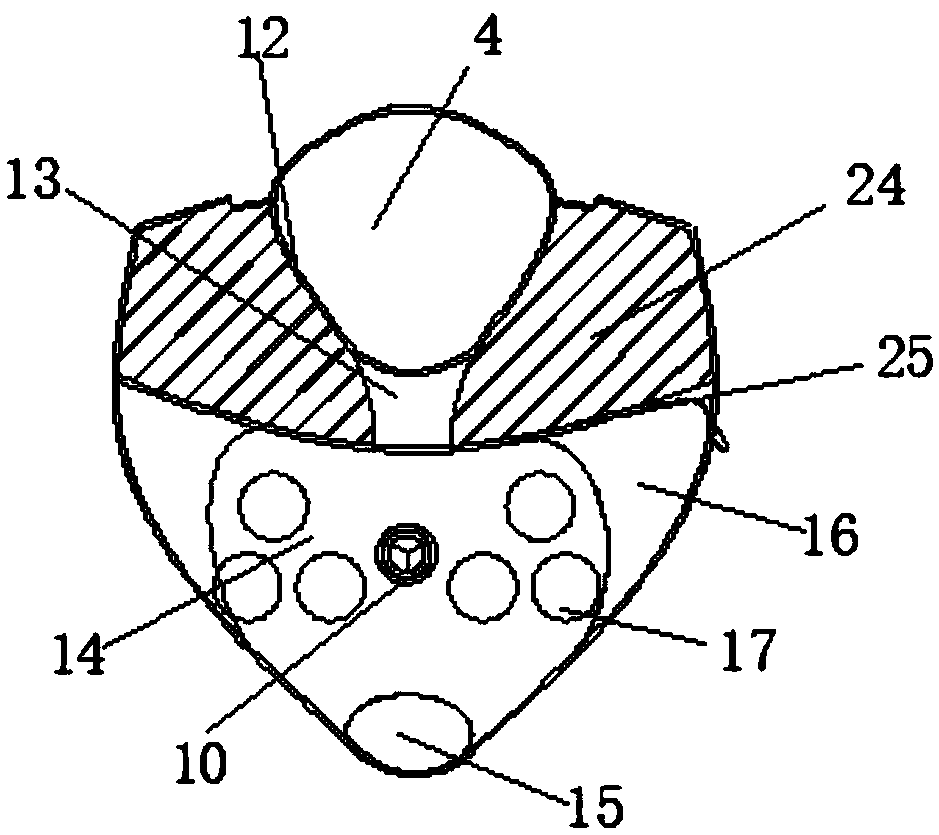

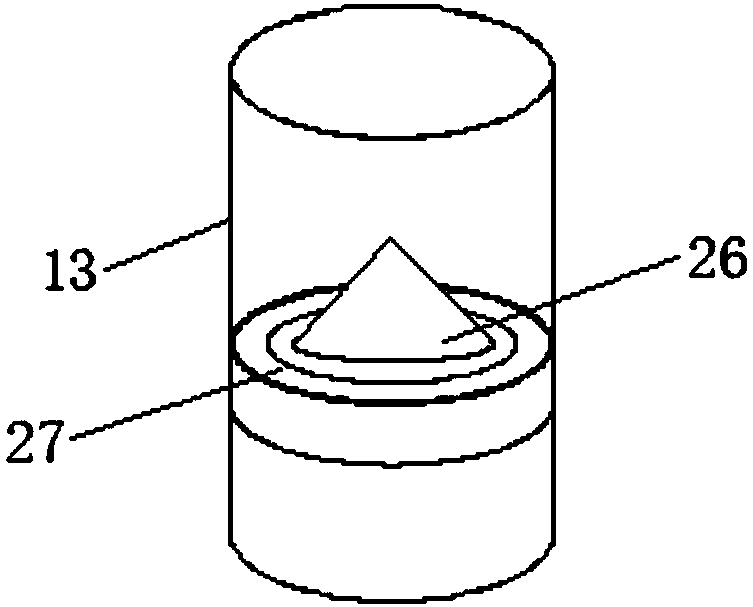

A smoking mask that effectively solves the problem of second-hand smoke

The invention discloses a smoking mask capable of solving a passive smoking problem effectively. The smoking mask comprises a mask body and a filter, the mask body comprises an outer layer, an inner layer and elastic ear hooks, the elastic ear hooks are fixedly connected to two sides of the mask body, a nose accommodating cavity is fixedly mounted on an upper portion of the outer layer, a smoking hole is embedded in the middle of the outer layer, the inner layer comprises a breathing cavity and an exhaust cavity, a nose accommodating cavity is communicated with the exhaust cavity through a through groove, a non-return piece is fixedly mounted in an inner cavity of the through groove, an air hole is formed in an outer edge of the non-return piece, and the filter is mounted in the exhaust cavity and comprises a smoke inlet valve, a filtering gasket and a fan. The smoke mask capable of solving the passive smoking problem effectively is reasonable in design and convenient to use, a user can breathe healthy air normally by wearing the mask which have a smoking function, cigarette smoke can be purified and exhausted as a gas harmless to the environment, and environment-friendliness and broad popularization prospect are realized.

Owner:仙桃市中意安全防护用品有限公司

Detecting unit of Coriolis quality flow meter

ActiveCN100480646CImprove distribution structureReduce nonlinear effectsTesting/calibration apparatusDirect mass flowmetersMagnetic linePhysics

A detection unit of Carioles mass flowmeter is prepared as fixing central magnetic conductor and ring magnetic steel on base to form circular gap between the two and to form uniform parallel magnetic field, moving detection coil and coil frame in formed circular gap to cut magnetic line for outputting signal in proportion to moving speed.

Owner:BEIHANG UNIV

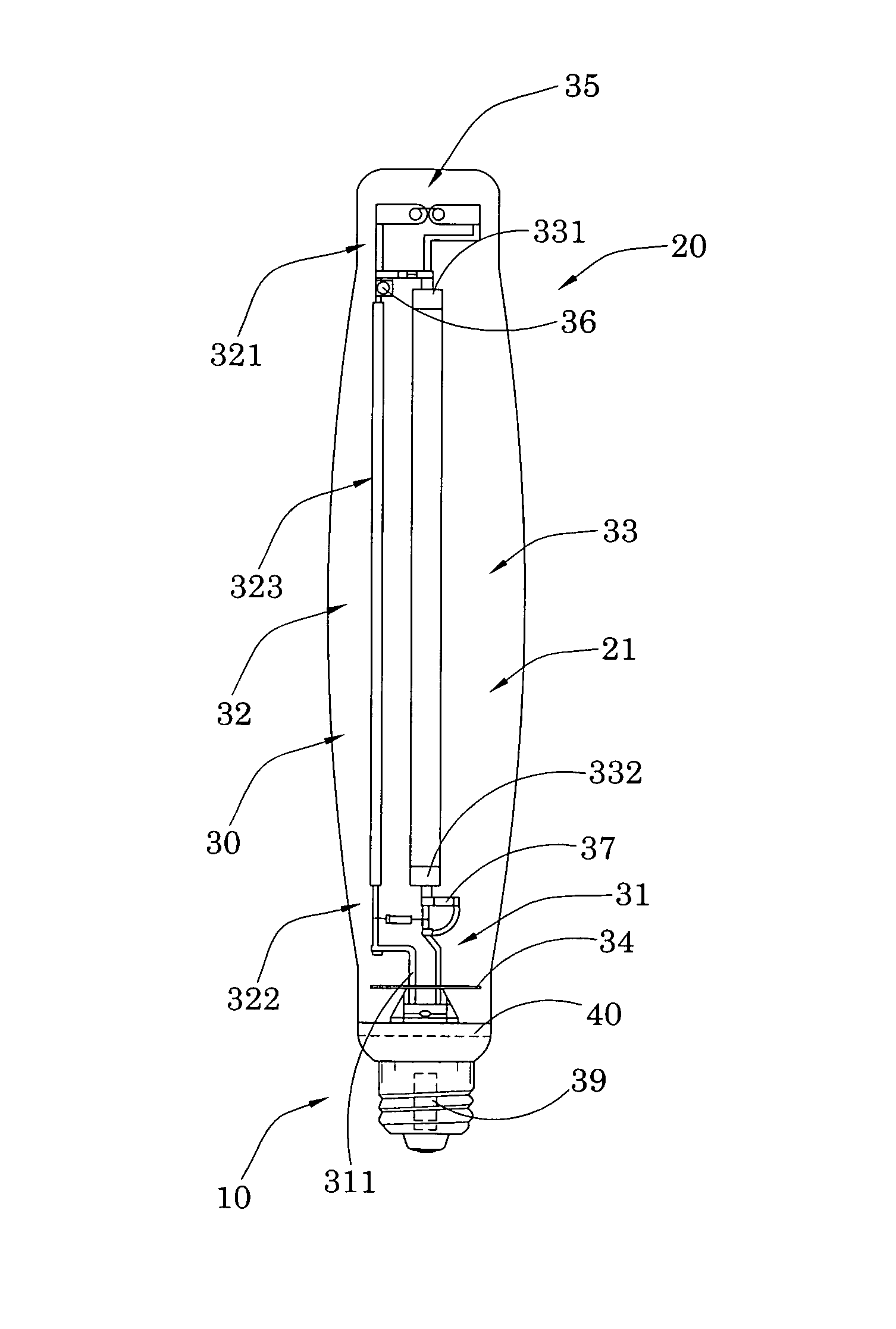

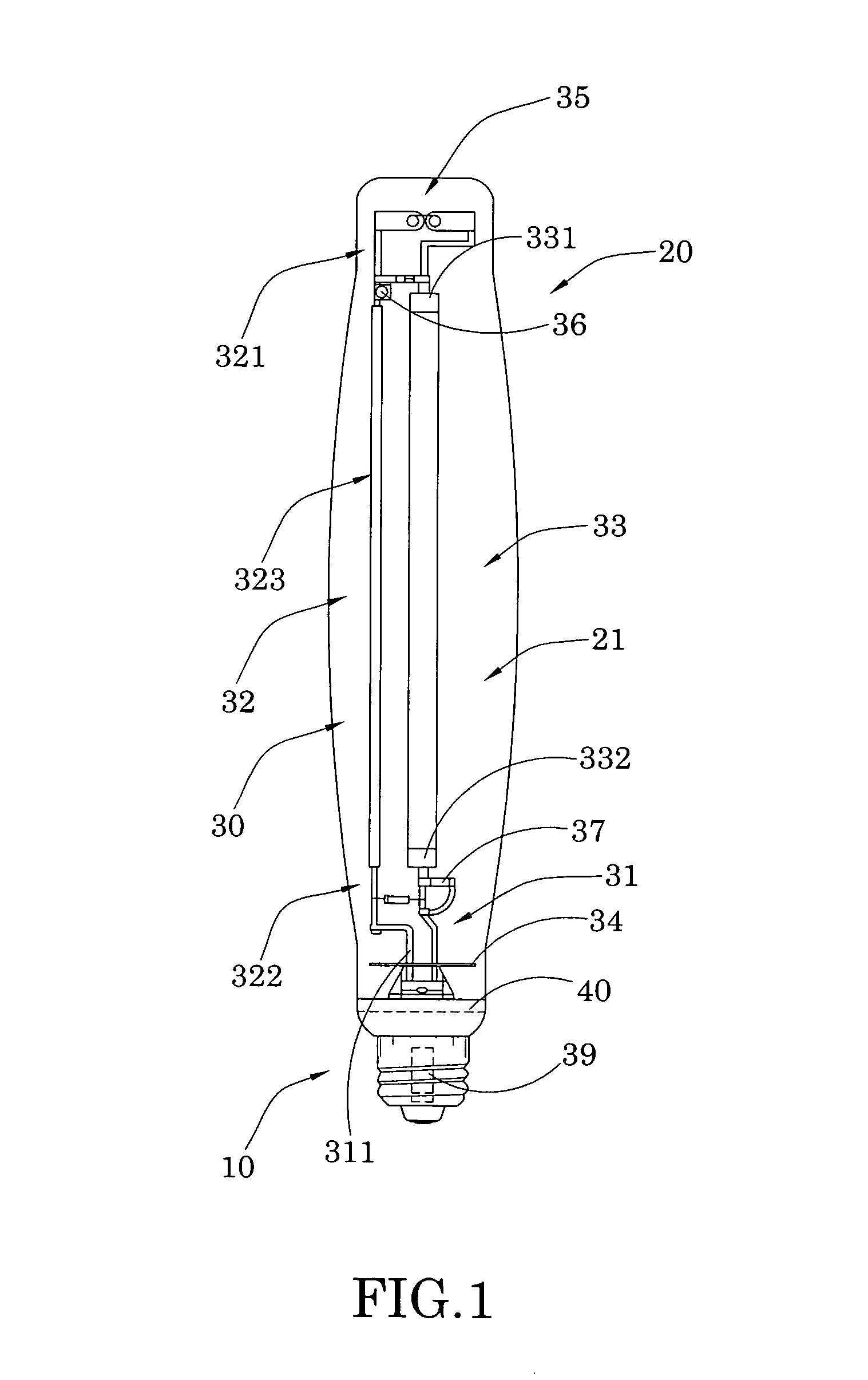

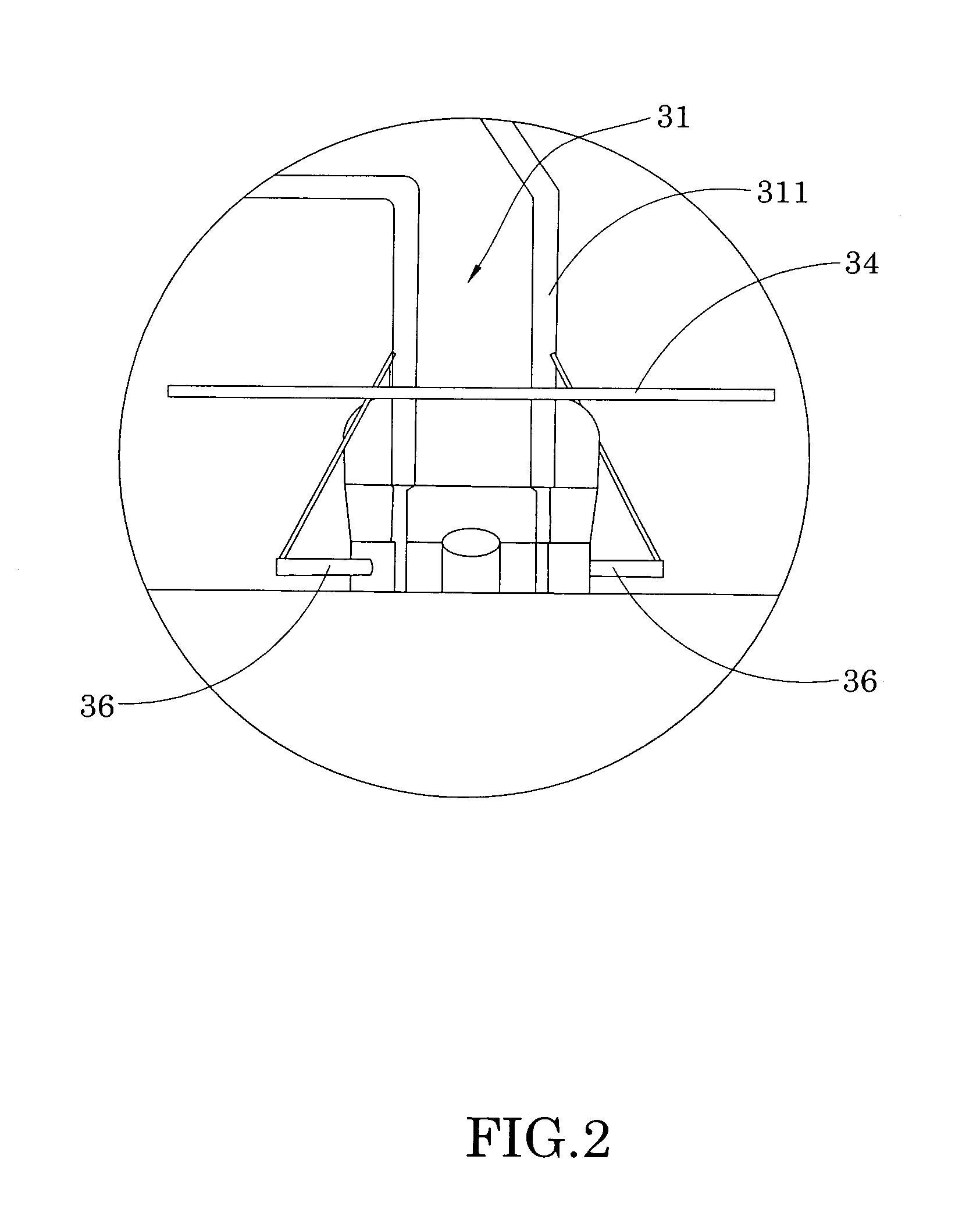

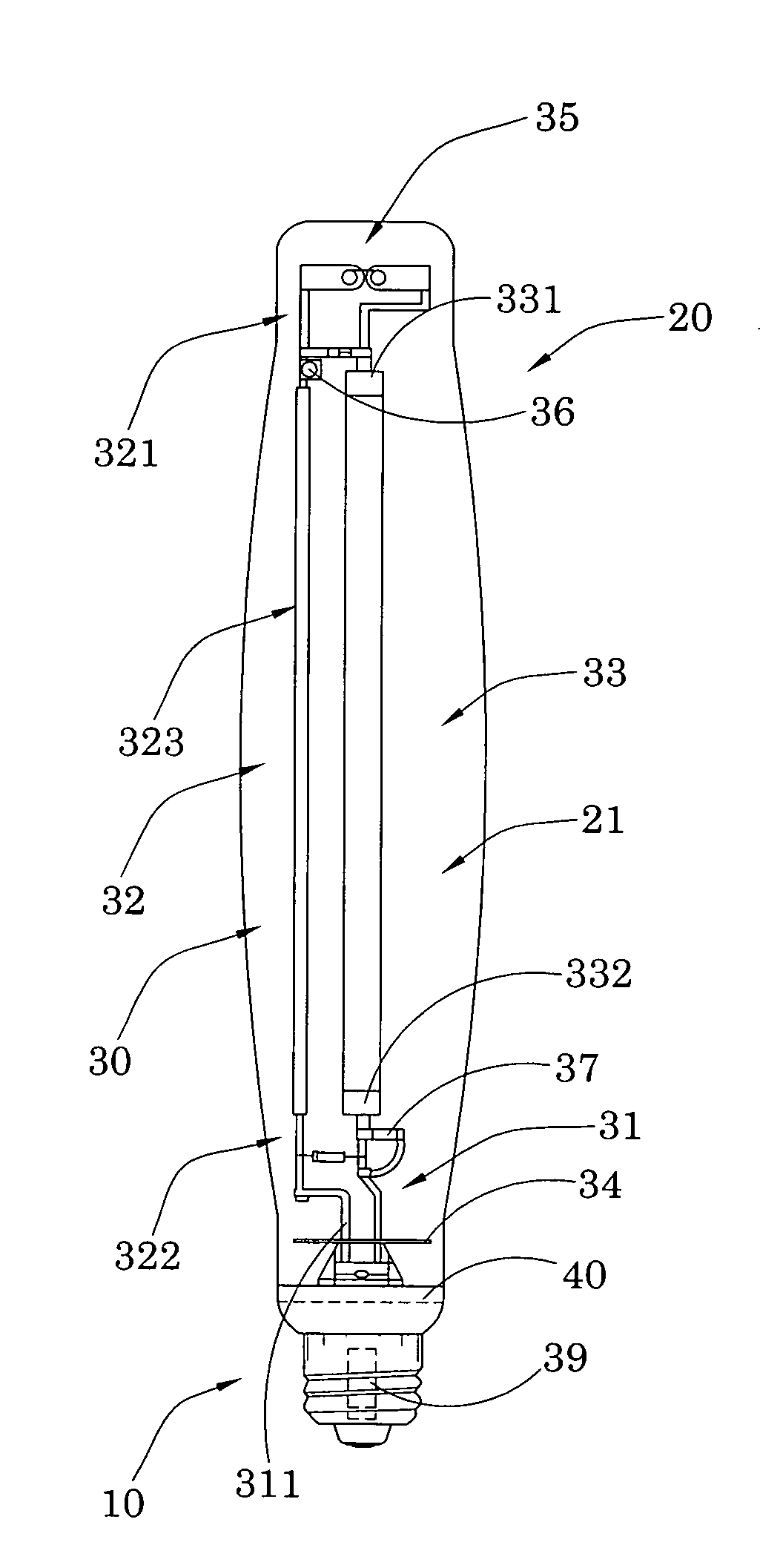

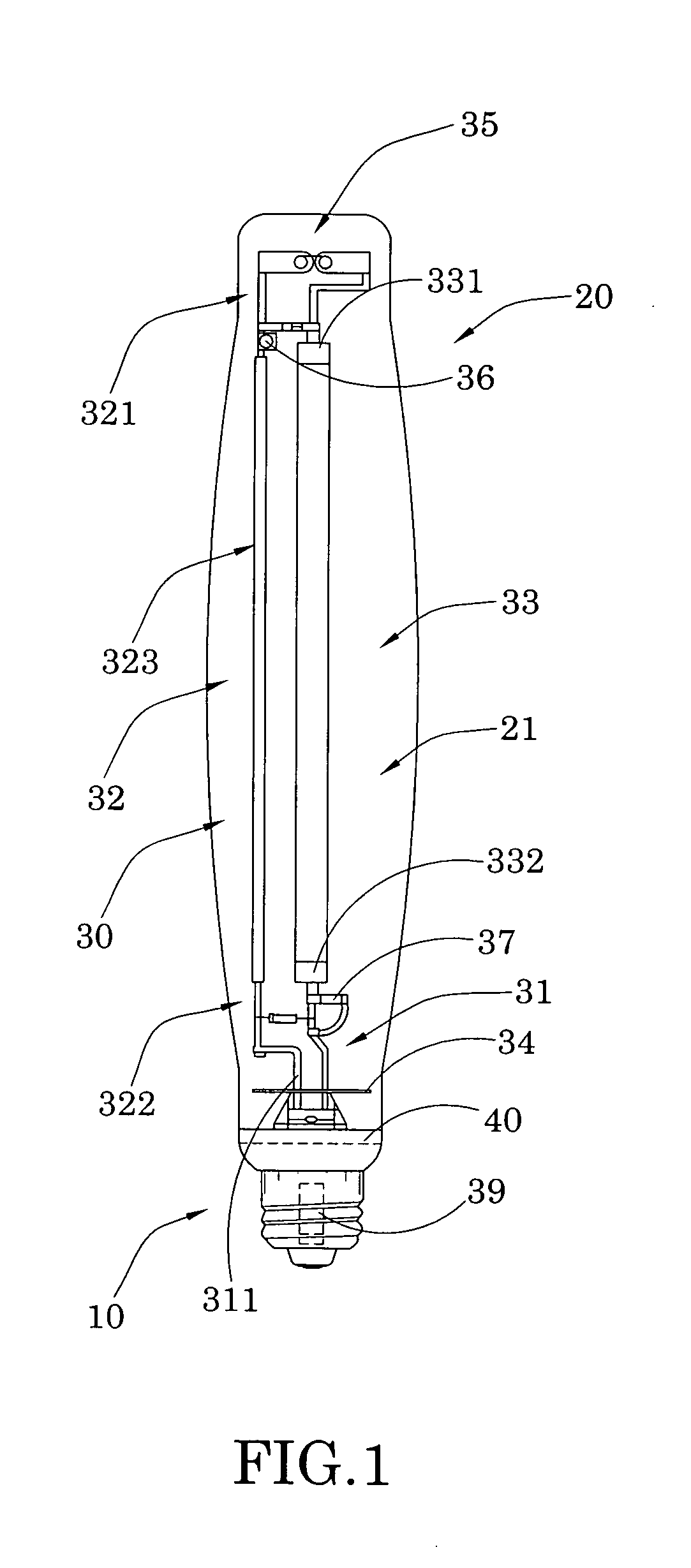

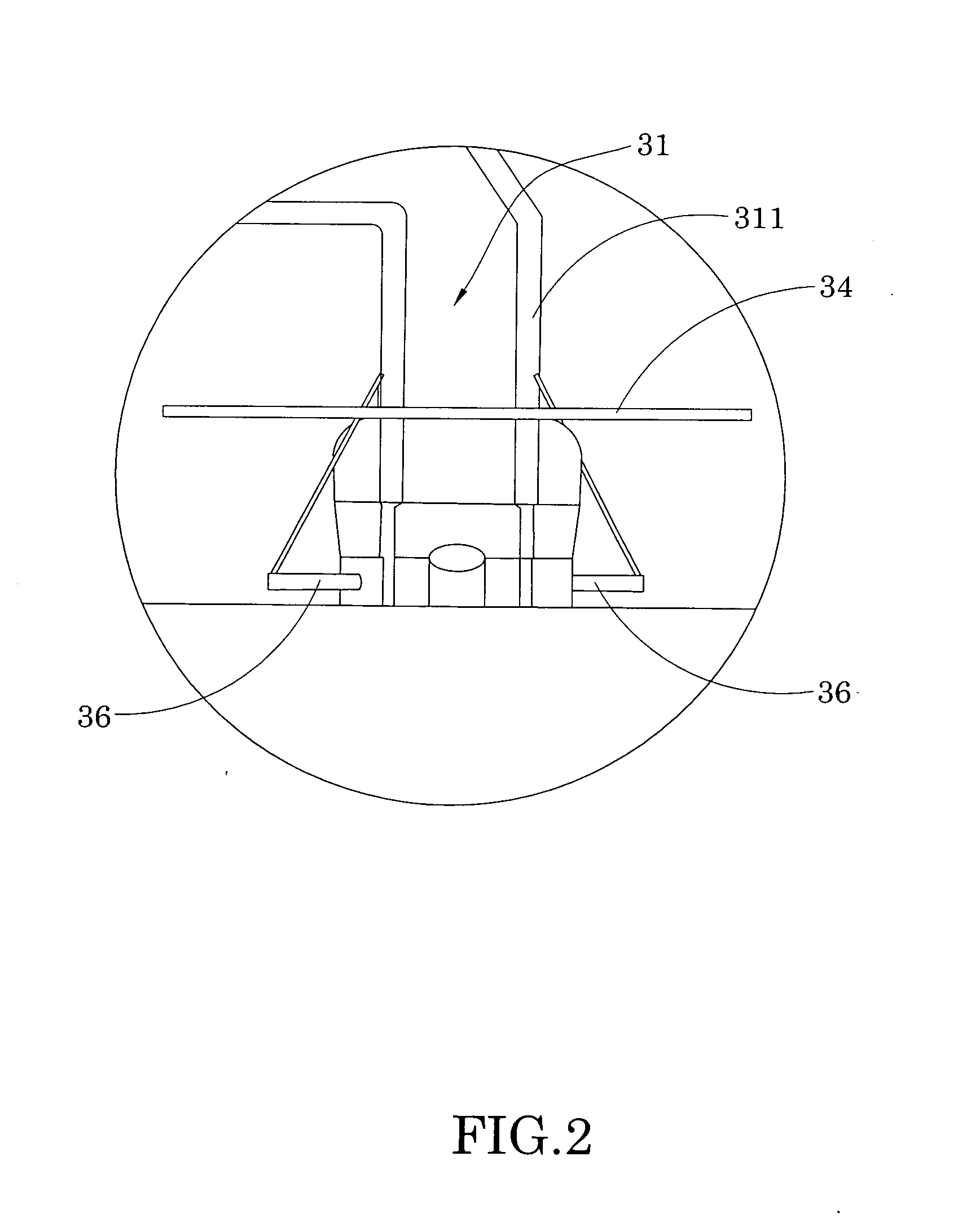

High pressure sodium lamp

ActiveUS8450932B2Sufficient toleranceNot to damageDischarge tube main electrodesSolid cathode detailsElectricityEngineering

A high pressure sodium lamp includes a lamp base, a light admissible housing and a sodium vapor illumination arrangement, which includes a light core extended from the lamp base into the light admissible housing; a supporting frame, and an arc tube. The supporting frame longitudinally extends in the light admissible housing, and has an upper end portion supported by an upper portion of the light admissible housing, and a lower end portion supported by the light core. The arc tube has a first and a second electrode formed at two ends thereof and electrically connected with the upper end portion of the supporting frame and the light core respectively, wherein sodium vapor in the arc tube is electrically excited to discharge light having an intensity equivalent to that generated by more than 1000 W power.

Owner:QIAN FUQING +1

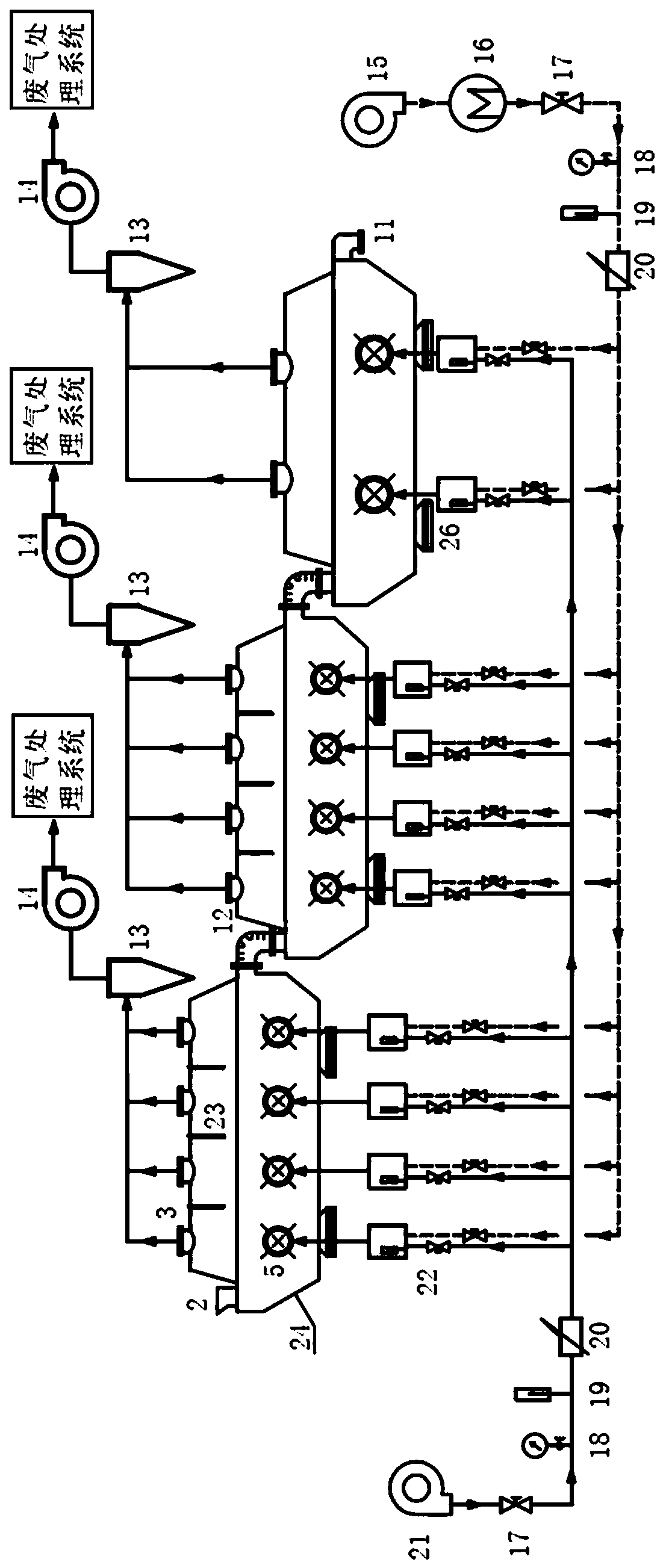

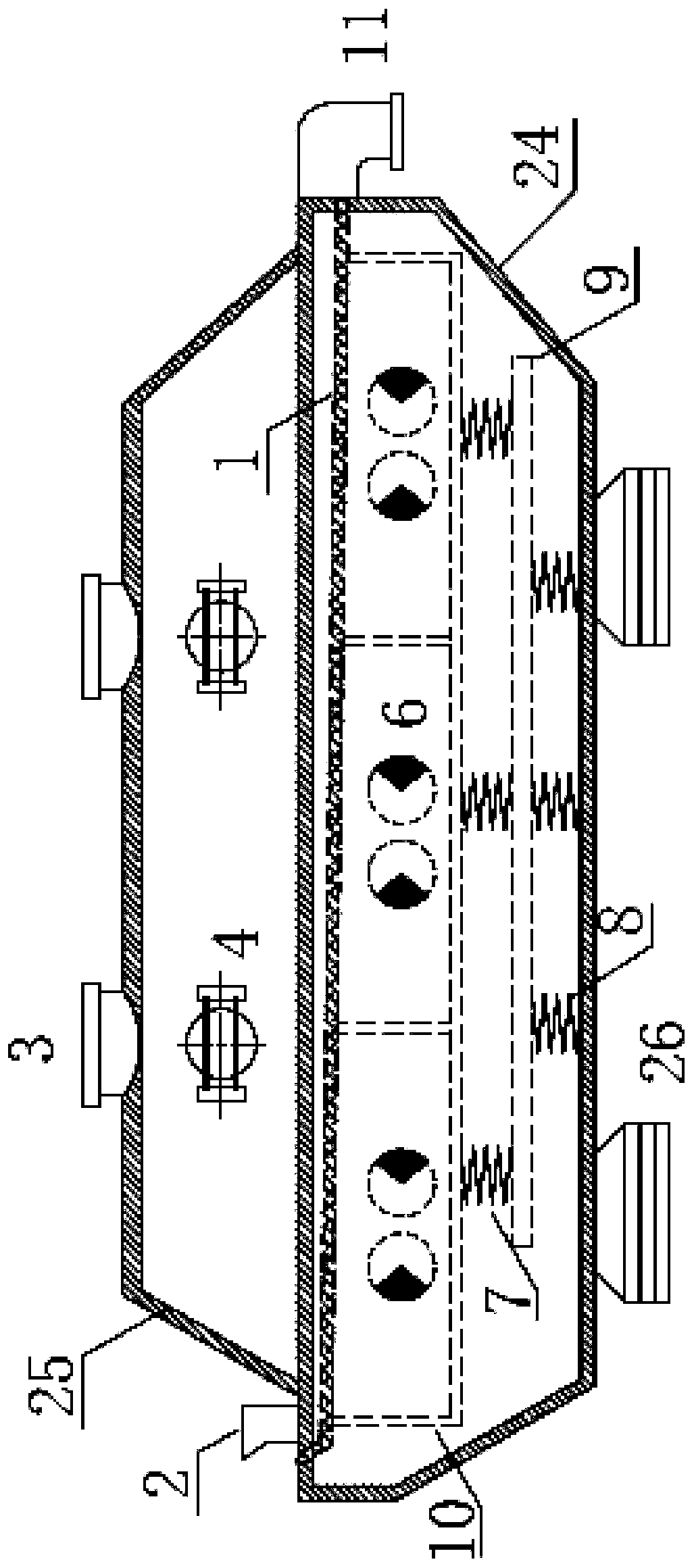

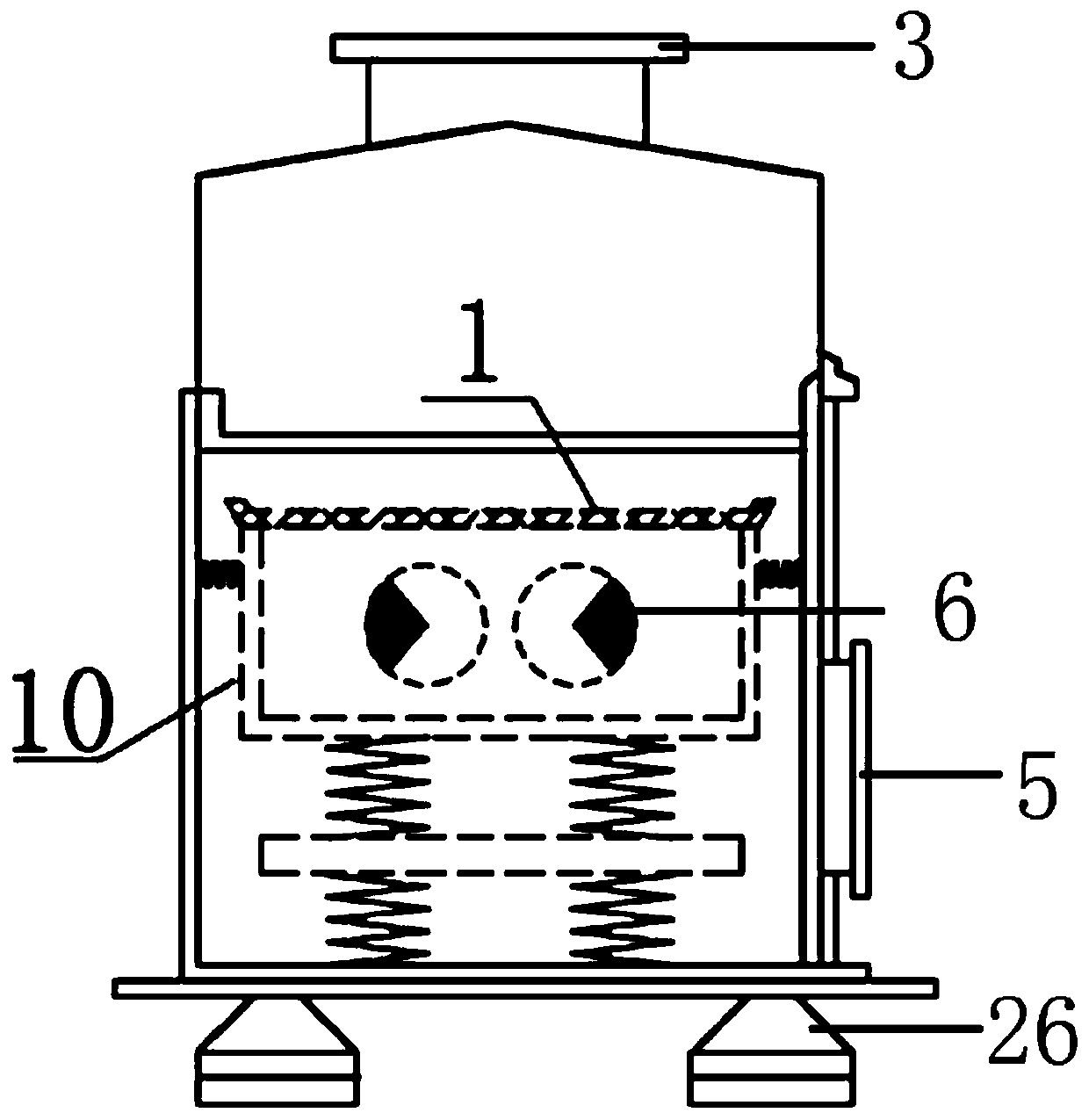

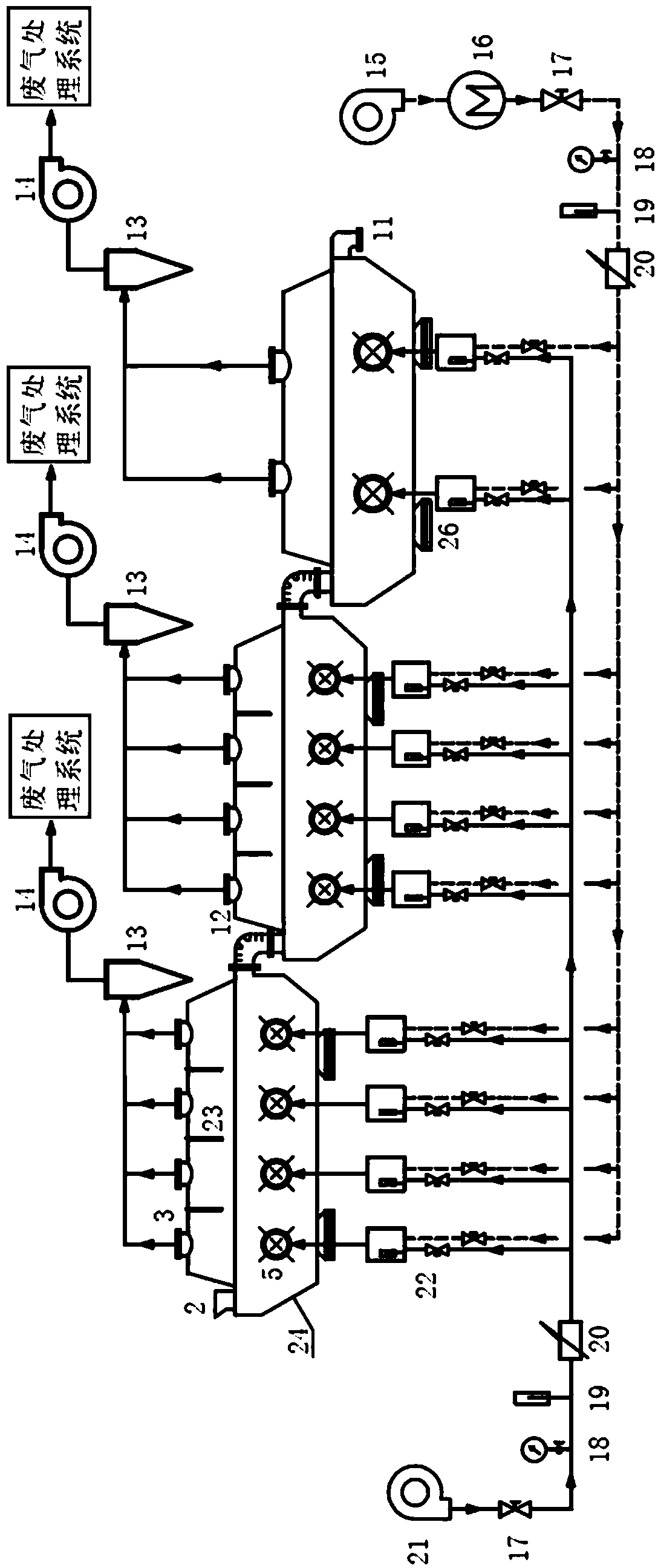

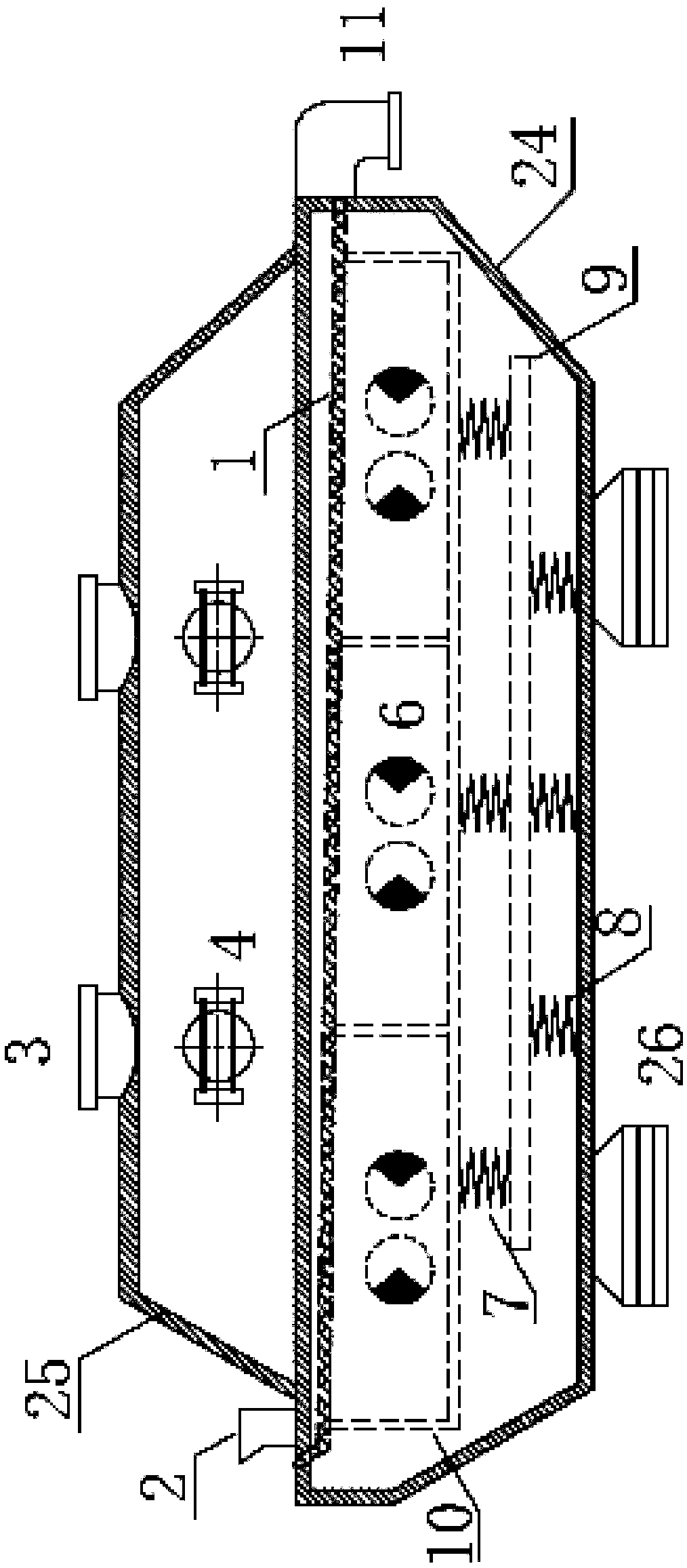

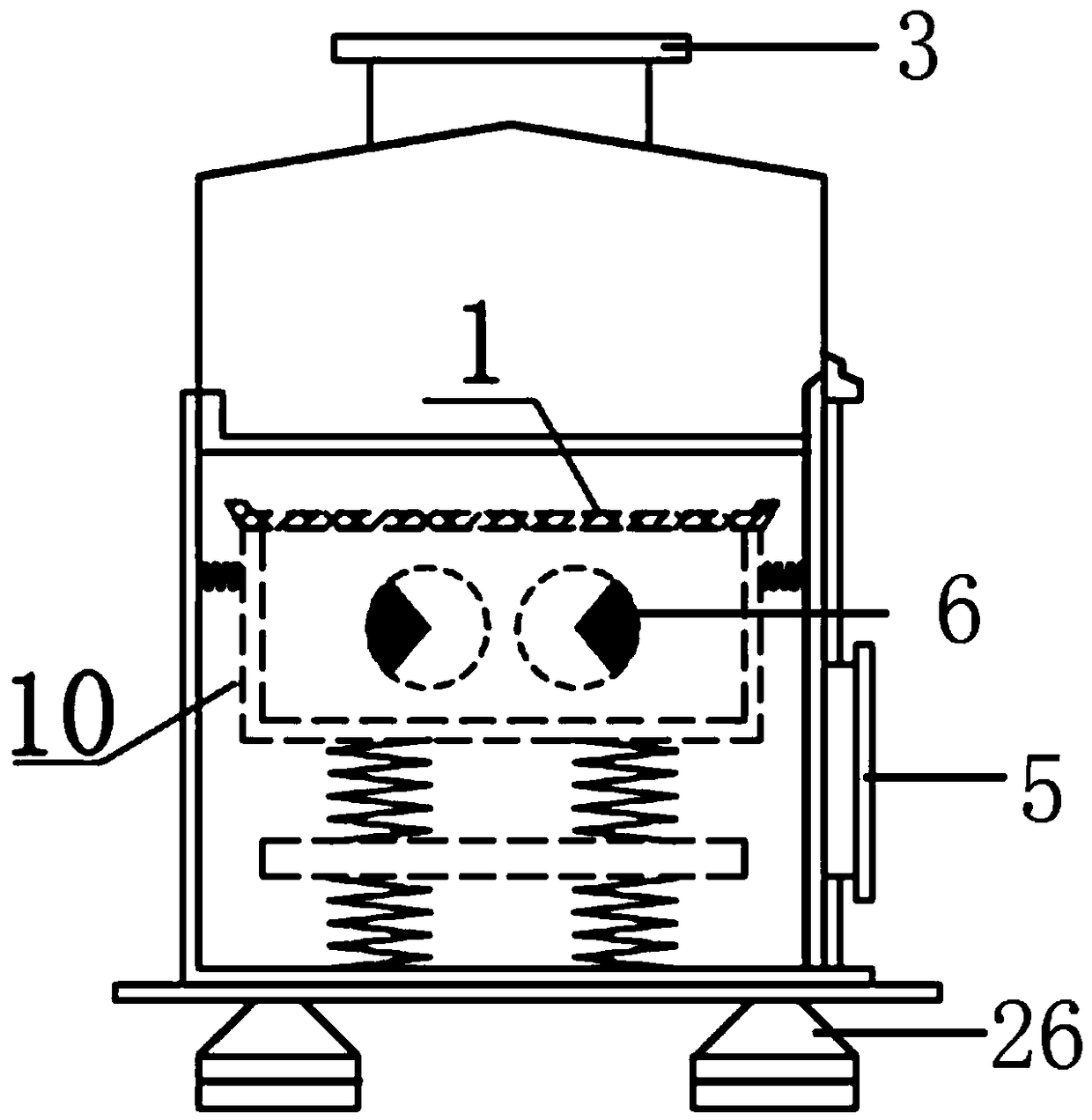

Multi-stage temperature difference frequency vibratory fluidization system and method for oxidizing and non-melting coal tar pitch pellets

ActiveCN108940135BContinuous operationImprove production efficiencyDispersed particle separationChemical/physical processesTemperature controlTemperature difference

Owner:SOUTHEAST UNIV

Multistage-heating difference frequency vibration fluidization system and method for oxidative infusibility of coal tar pitch spheres

ActiveCN108940135AContinuous operationImprove production efficiencyDispersed particle separationChemical/physical processesTemperature controlProcess engineering

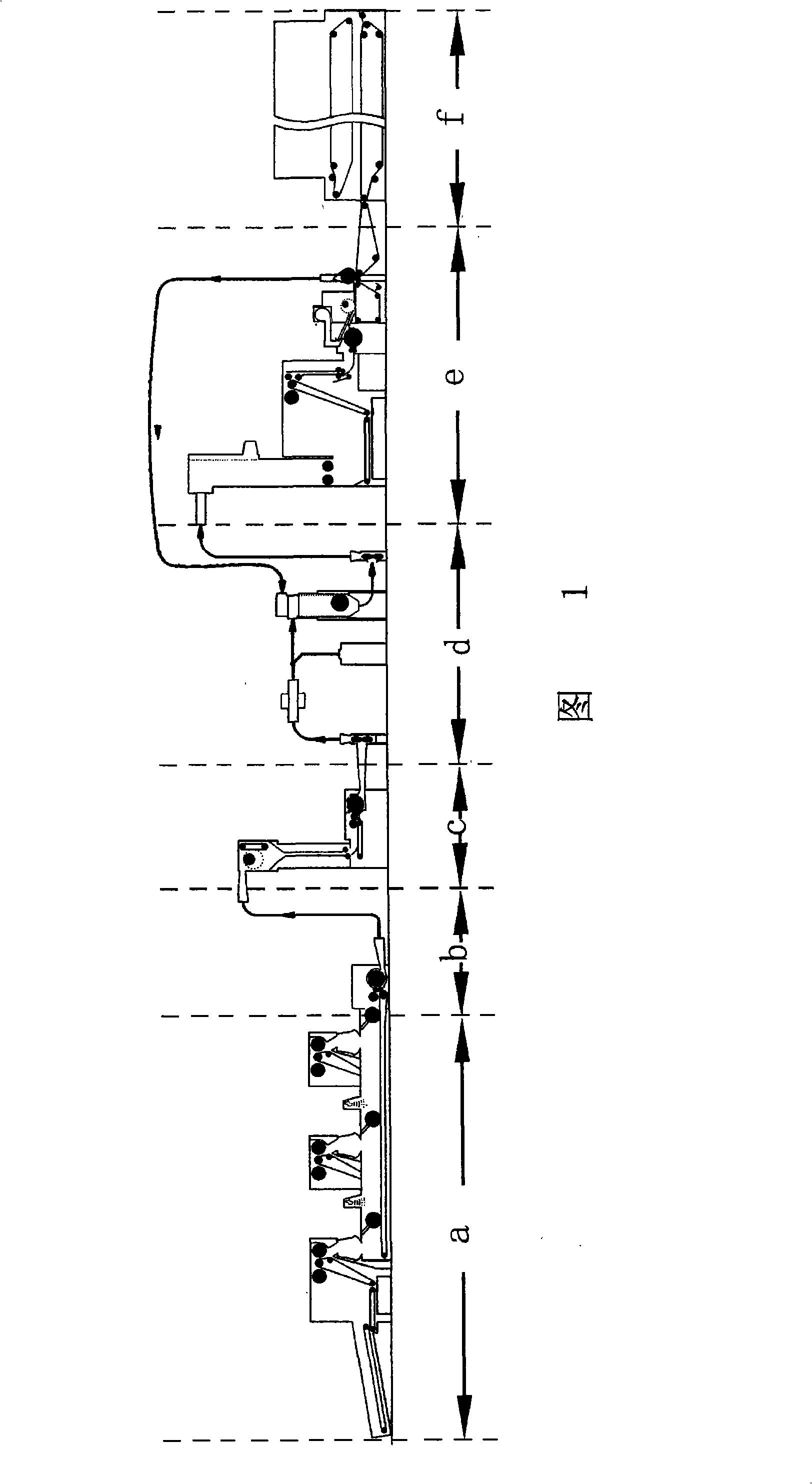

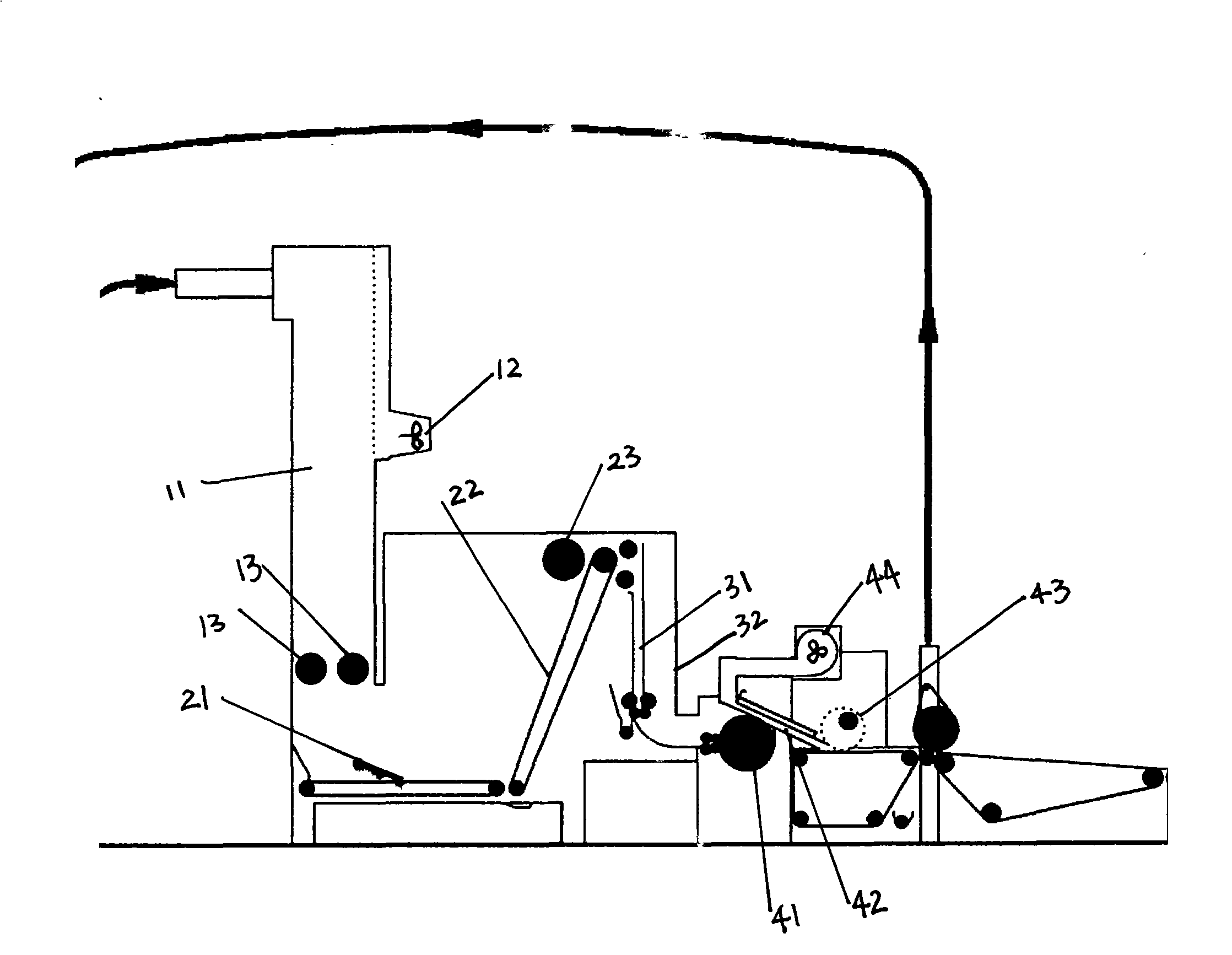

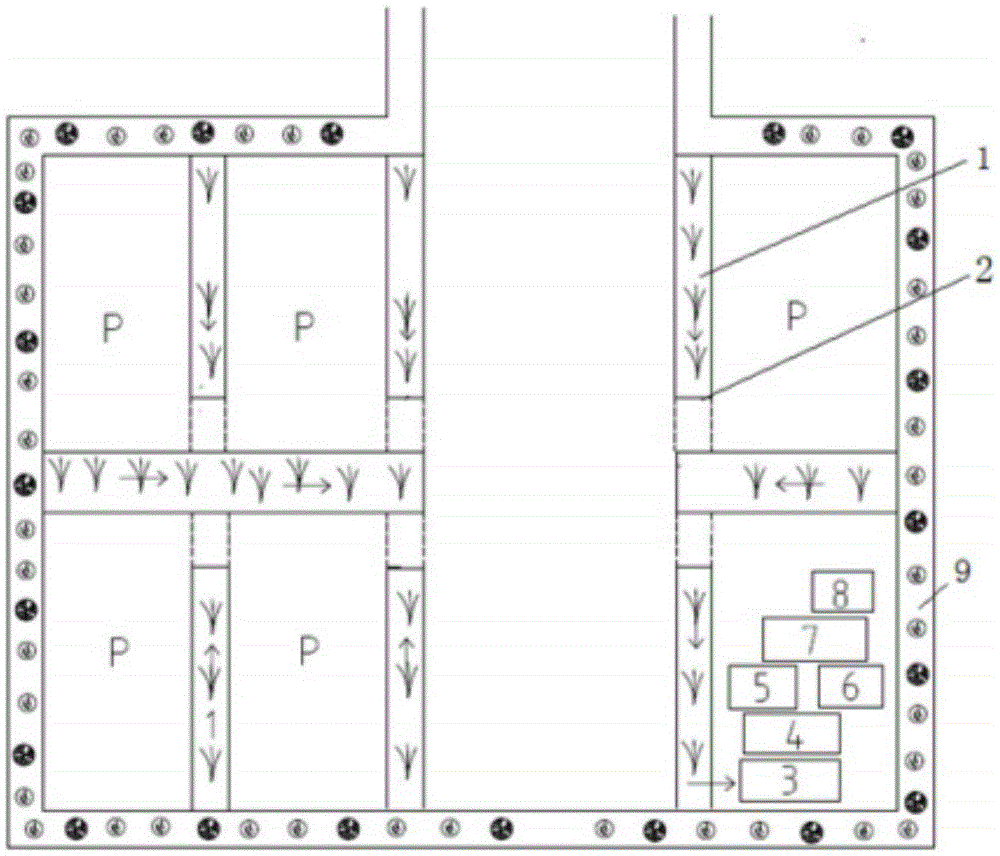

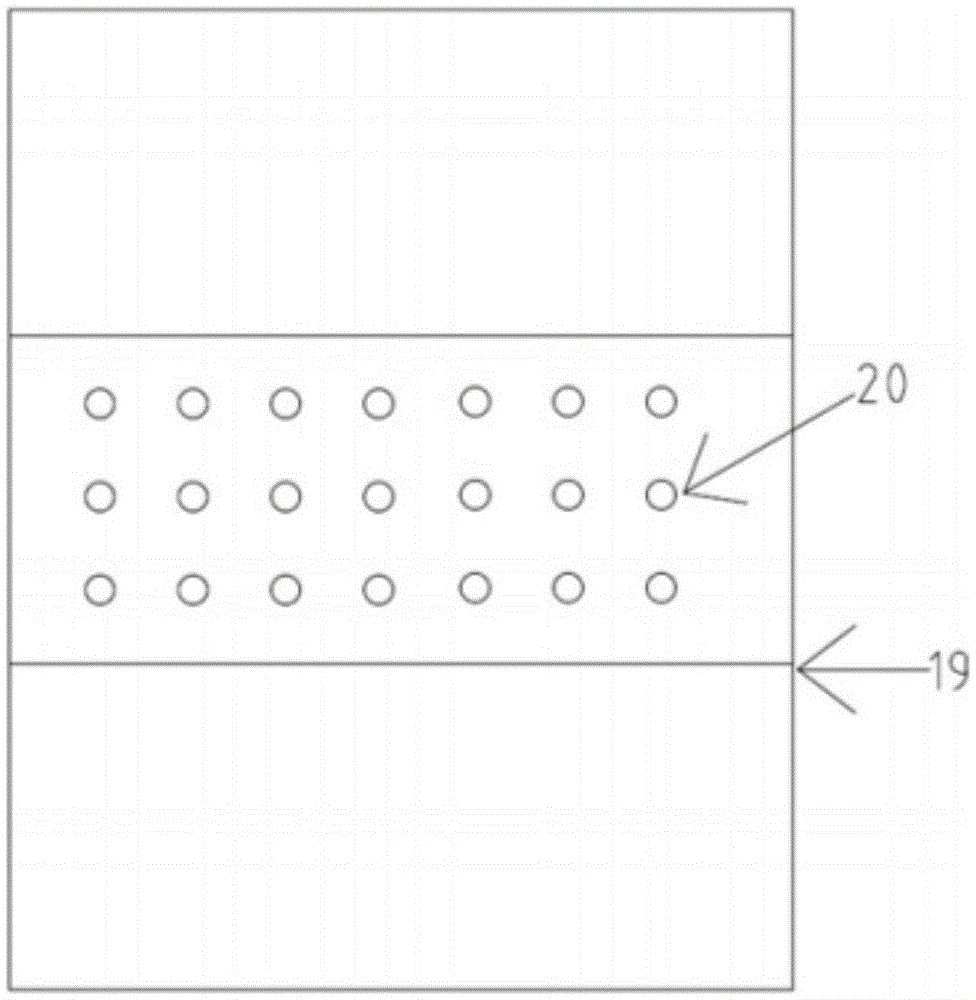

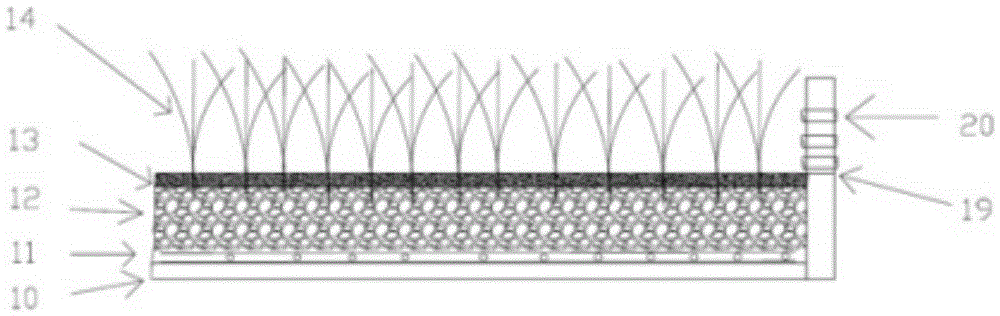

The invention discloses a multistage-heating difference frequency vibration fluidization system for oxidative infusibility of coal tar pitch spheres, which includes multiple stages of fluidized bed reactors and a temperature-controlling gas feeding apparatus, wherein the fluidized bed reactors are successively connected to each other in a stepwise distribution manner. Each fluidized bed reactor includes a shell, a porous distribution board, and a vibration exciter, wherein the shell is provided with a feeding inlet, a discharge outlet, an air inlet and an air outlet; the feeding inlet and thedischarge outlet are respectively disposed on two ends of the porous distribution board that is inclined from the feeding side to the discharge side; the discharge outlet of one fluidized bed reactoris connected to the feeding inlet of the next one fluidized bed reactor. The system significantly increases the oxidizing efficiency of the coal tar pitch spheres and reduces breaking ratio of coal tar pitch sphere granules.

Owner:SOUTHEAST UNIV

A tire processing method

The invention discloses a tire processing and molding method, which comprises the steps of blank preforming, mold molding, vulcanization molding, etc., which are sequentially carried out, and a number of preformed grooves and preformed protrusions are preprocessed from the rubber blank which has not been molded, so as to Correspondingly adapted to each structure in the mold cavity, in order to process the corresponding tread grooves and tread ribs, especially through the above-mentioned blank preforming process, the rubber can be guided and evenly distributed, thus effectively Avoid the rubber material flow that may be caused by subsequent mold processing and related molding processes and the formation of rubber material accumulation on the edge of the tread rib, and further avoid the local rubber material protrusion of the tread rib caused by this phenomenon , so as to effectively optimize the distribution structure of the rubber material at the tire tread rib after processing and forming, thereby significantly improving the performance and service life of the tire, and optimizing the performance of the whole vehicle accordingly.

Owner:CHENG SHIN RUBBER CHINA

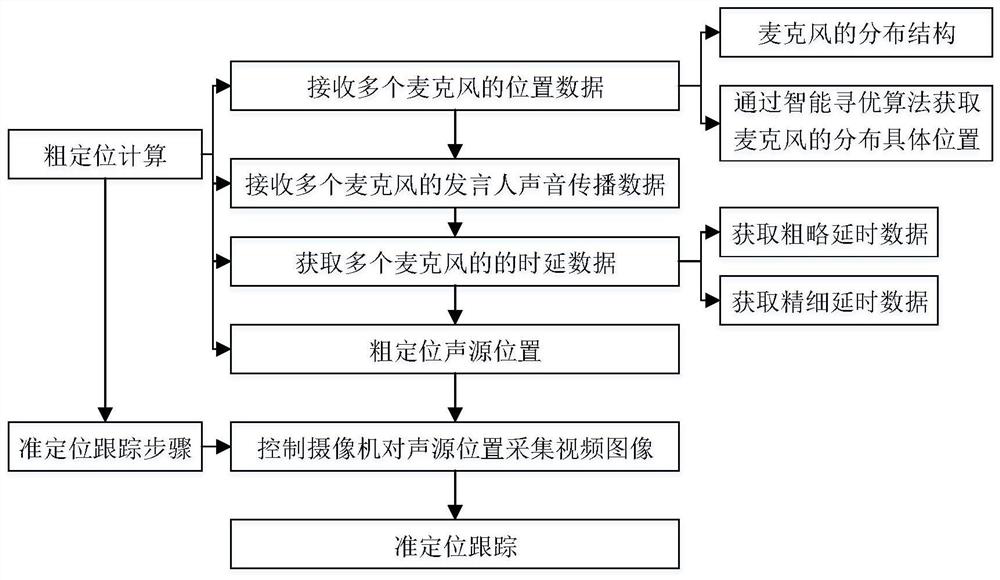

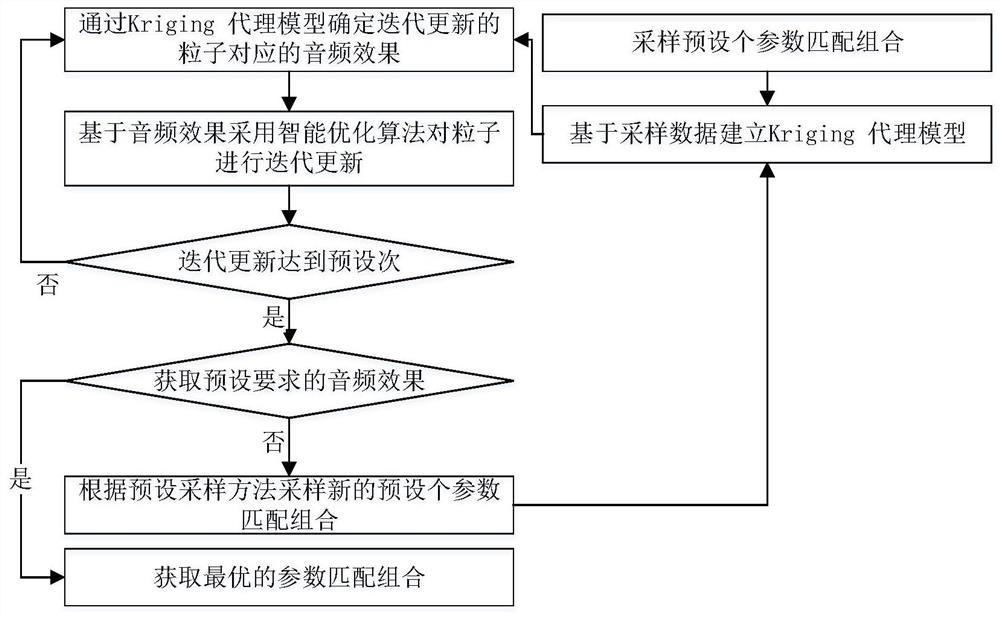

Spokesman positioning and tracking method and device based on audio and video features

InactiveCN113740803AImprove robustnessMake up for the lack of target trackingPosition fixationCharacter and pattern recognitionSound source locationCamera image

The invention discloses a spokesman positioning and tracking method and device based on audio and video features, and the method comprises the steps: a coarse positioning calculation step: receiving the position data of a plurality of microphones, receiving the sound transmission data of the same spokesman collected by the plurality of microphones and the collected time data, and determining position data of the sound source based on different positions of the plurality of microphones and receiving different time delay data of the same sound source; and a quasi-positioning tracking step: controlling the camera to collect images of the speaker objects at the sound source position, and fixing the center coordinate of the camera image with the position of each object in the speaker objects in the video stream, so that the center of the camera image is synchronized with the positions of the speaker objects. According to the invention, the distribution structure of the plurality of microphones is optimized, a better sound source data pickup effect is realized, the accuracy of obtaining the initial positioning of the spokesman based on the audio information is further improved, and the accurate positioning of the spokesman is obtained by using the complementarity between the audio information and the video information.

Owner:安徽创变信息科技有限公司

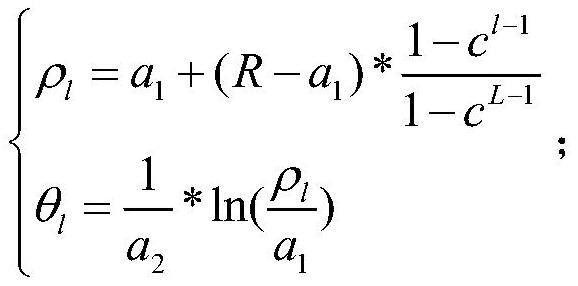

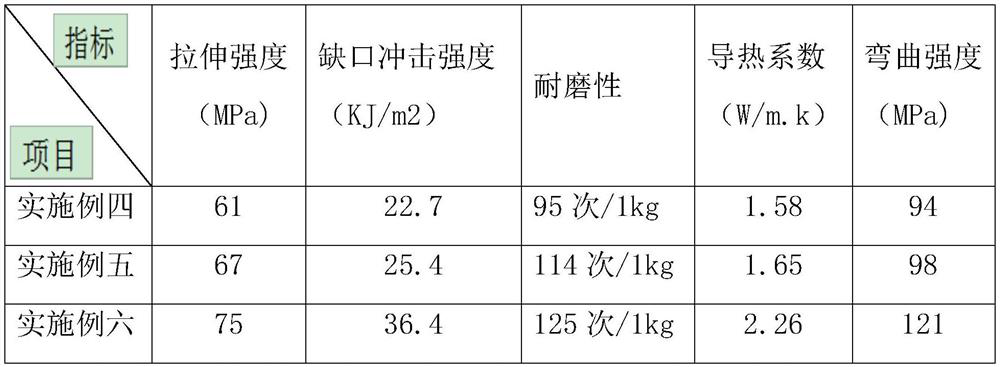

High-thermal-conductivity modified polyphenyl ether material and preparation method thereof

The invention provides a high-thermal-conductivity modified polyphenyl ether material and a preparation method thereof, and relates to the technical field of polyphenyl ether preparation. The high-thermal-conductivity modified polyphenyl ether material comprises the following raw materials in parts by weight: 15-80 parts of a high-temperature thermal-conductivity resin material, 15-80 parts of modified polyphenyl ether, 5-50 parts of a curing agent, 1-3 parts of a mixture of tri-n-butylamine and triphenylphosphine, 5-45 parts of polytetrafluoroethylene powder and 5-25 parts of a flame retardant. According to the high-thermal-conductivity modified polyphenyl ether material and the preparation method thereof, the heat-resistant temperature of the modified polyphenyl ether is increased through the reaction of the polyphenyl ether, the heptamethylcyclotetrasiloxane compound of carborane and the aluminum hydroxide, so that the heat conductivity coefficient is prevented from being reduced when the heat-conducting filler is mixed with other raw materials; the tubular graphene material is added into the rubber body, so that the overall distribution structure of the rubber layer is improved, the bonding strength is improved, the compatibility of polyphenyl ether and thermosetting resin is improved, and the preparation cost is reduced.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

High pressure sodium lamp

ActiveUS20120286660A1Sufficient toleranceNot to damageDischarge tube main electrodesIncadescent cooling arrangementsElectricityEngineering

A high pressure sodium lamp includes a lamp base, a light admissible housing and a sodium vapor illumination arrangement, which includes a light core extended from the lamp base into the light admissible housing; a supporting frame, and an arc tube. The supporting frame longitudinally extends in the light admissible housing, and has an upper end portion supported by an upper portion of the light admissible housing, and a lower end portion supported by the light core. The arc tube has a first and a second electrode formed at two ends thereof and electrically connected with the upper end portion of the supporting frame and the light core respectively, wherein sodium vapor in the arc tube is electrically excited to discharge light having an intensity equivalent to that generated by more than 1000 W power.

Owner:QIAN FUQING +1

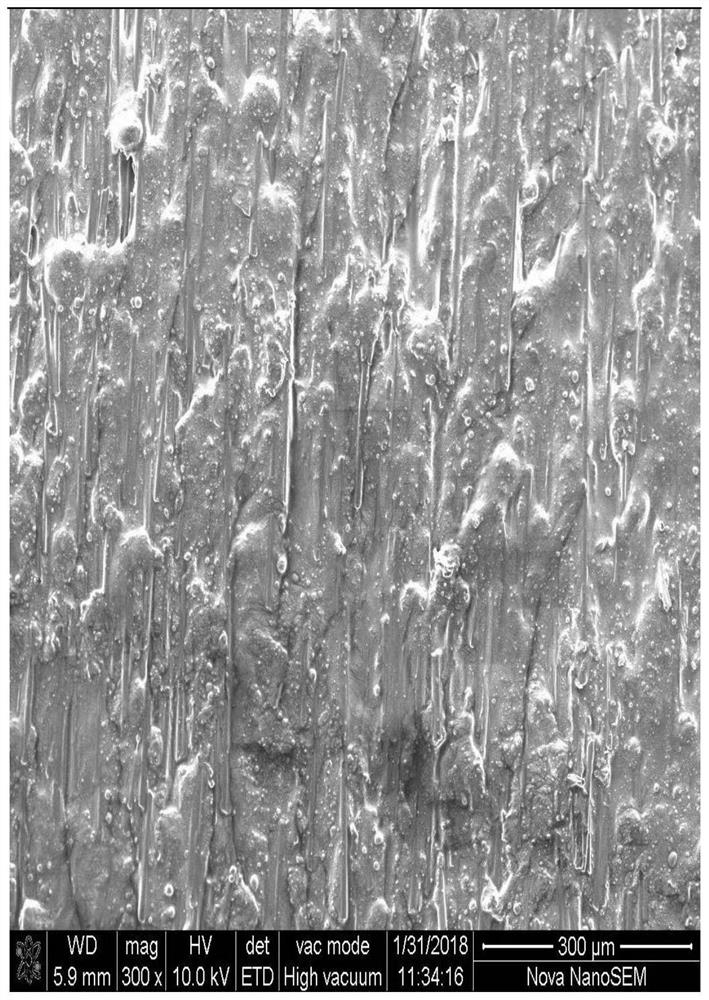

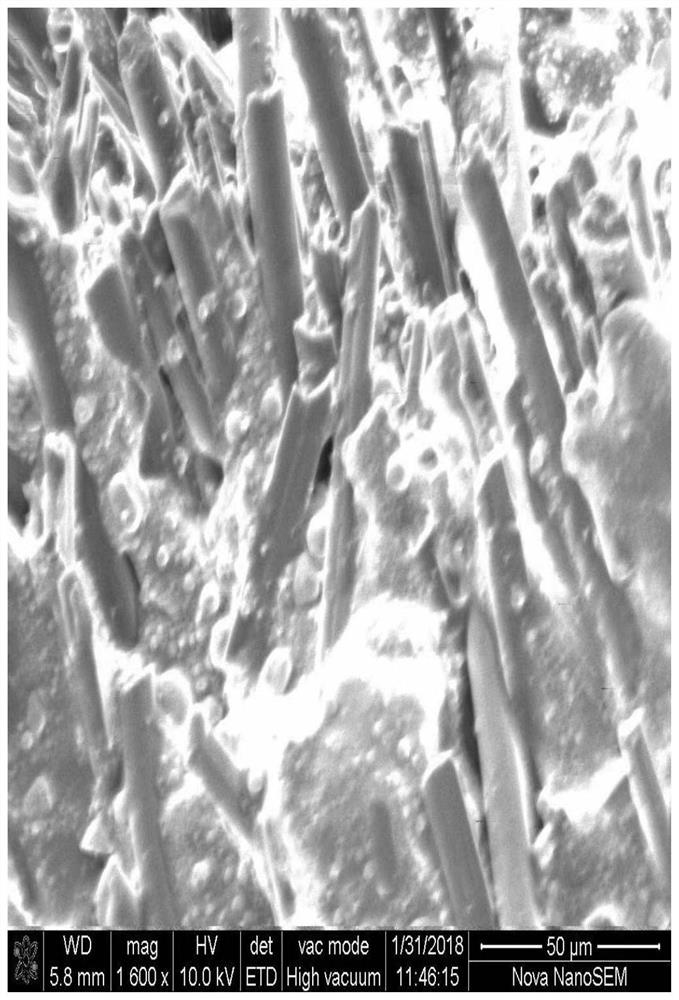

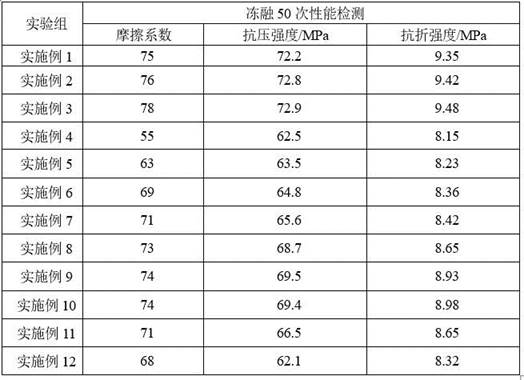

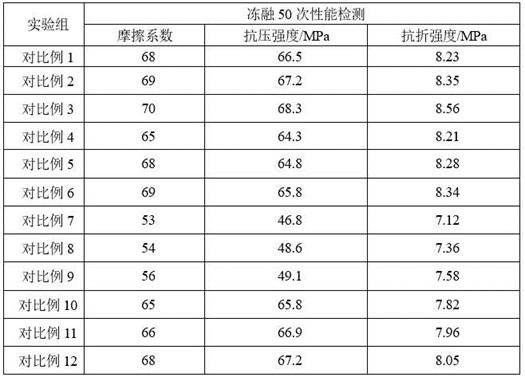

Anti-skid high-strength exposed concrete and preparation method thereof

ActiveCN112500063BImprove skid resistanceHigh mechanical strengthStructural engineeringUltimate tensile strength

Owner:靖江市恒生混凝土制造有限公司

A storage wetland system for treating parking lot rainwater and adjusting microclimate

ActiveCN104264773BRealize resource utilizationImprove distribution structureFatty/oily/floating substances removal devicesSewerage structuresTerrainEngineering

The invention provides a flow storage wetland system for treating parking lot rainwater and adjusting microclimate. Parking spaces of a parking lot are separated by intersection of driveways and interval zones, grass ditch wetlands and underground channels are separated by slow flow partition plates on the interval zones, the terrain from the grass ditch wetlands to the underground channels is elevated, the underground channels are close to the driveways and communicated with channels at the lower ends of the driveways, the terrain of the channels at the lower ends of the driveways is elevated, and low ends of the channels at the lower ends of the driveways are communicated with a front ecological pond. Polluted water is preliminarily treated by the aid of the grass ditch wetlands, the preliminarily treated water is delivered to the front ecological pond for storage by the elevated terrain of the system and then filtered by an ecological filter bed and finally enters a clean water tank for storage by an automatic clean water collection device, and the problems of pollution, rainwater resource waste, dry climate and the like caused by rainwater runoff of the parking lot.

Owner:苏州德华生态环境科技股份有限公司

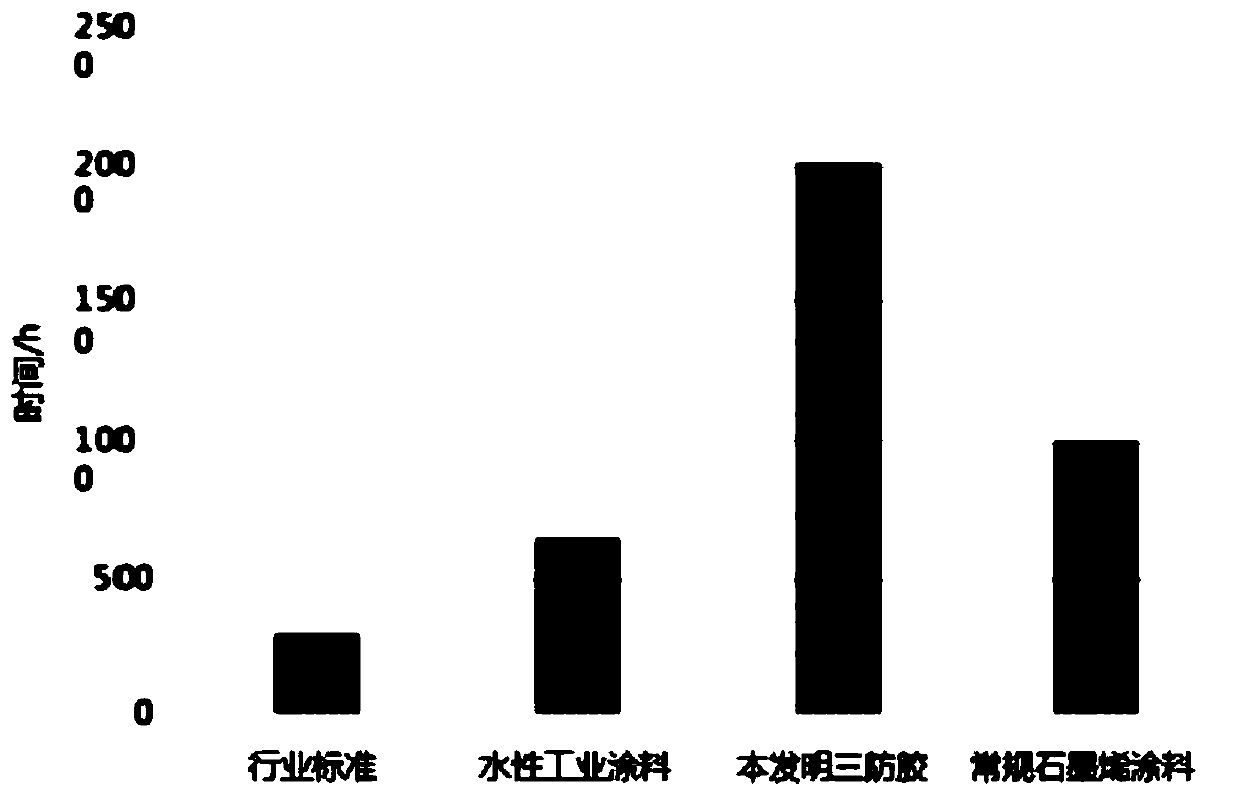

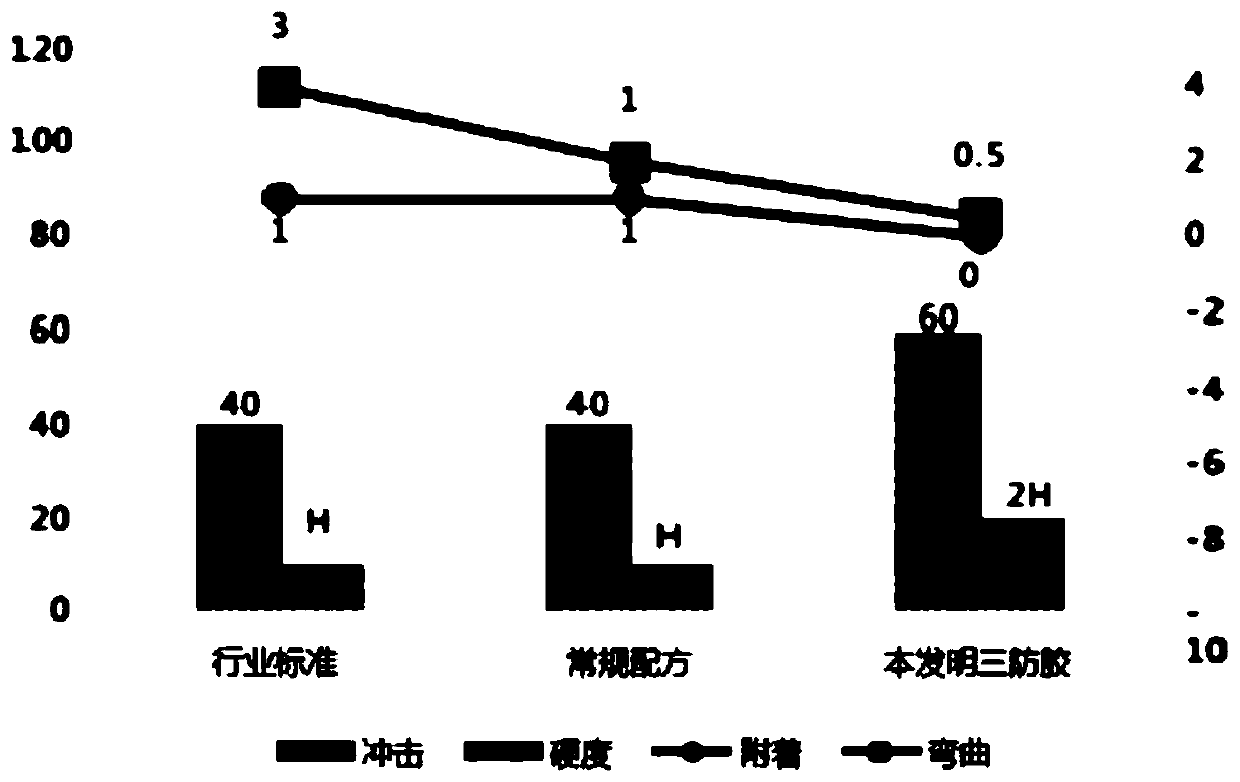

Graphene nano three-proofing adhesive and preparation method thereof

InactiveCN111394039AImprove distribution structureAdhesive optimizationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDefoaming AgentsFirming agent

The invention discloses a graphene nano three-proofing adhesive, which is prepared from the following components in percentage by mass: 20 to 30 percent of modified polyurethane resin; 20 to 30 percent of functional two-dimensional nano flake graphene; 20 to 30% of a polyurethane curing agent MDI; 1-5% of a defoaming agent; 1-5% of hydrophobic fumed silica; and 15-25% of a graphene dispersant. Thepreparation method of the graphene nano three-proofing adhesive comprises the following steps: preparing materials according to the mass percent; adding the prepared modified polyurethane resin intoa reaction kettle; adding the graphene dispersing agent and the functional two-dimensional nanosheet graphene under the condition that the temperature is raised to 50-55 DEG C, fully and uniformly stirring, cooling to 20-25 DEG C, then respectively adding the hydrophobic fumed silica, the defoaming agent and the polyurethane curing agent MDI, completely and uniformly stirring and mixing to obtaina finished product, testing and sub-packaging. The adhesive is high in bonding strength and good in salt spray resistance and physical protection performance, can be applied to appearance surface coatings of electronic products, daily household appliances, steel structures, ships, warships and the like, and fills up the domestic blank.

Owner:重庆索梦得新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com