Patents

Literature

40results about How to "Improved stress distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integral engineering rack of interface osteochondro tissue with bionic function

InactiveCN101020083AIncrease connection areaImprove connection strengthJoint implantsSubchondral boneBiocompatibility Testing

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

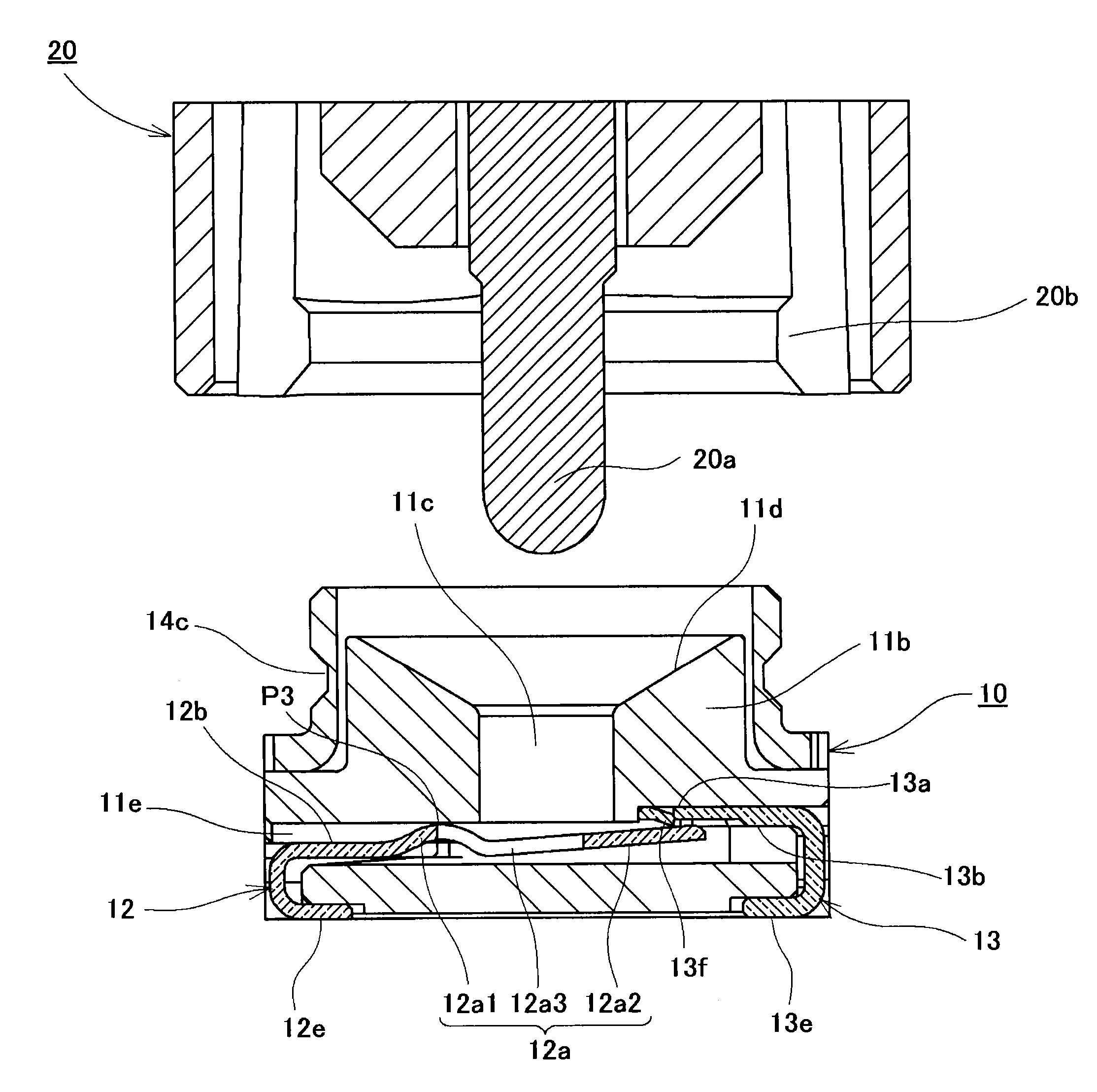

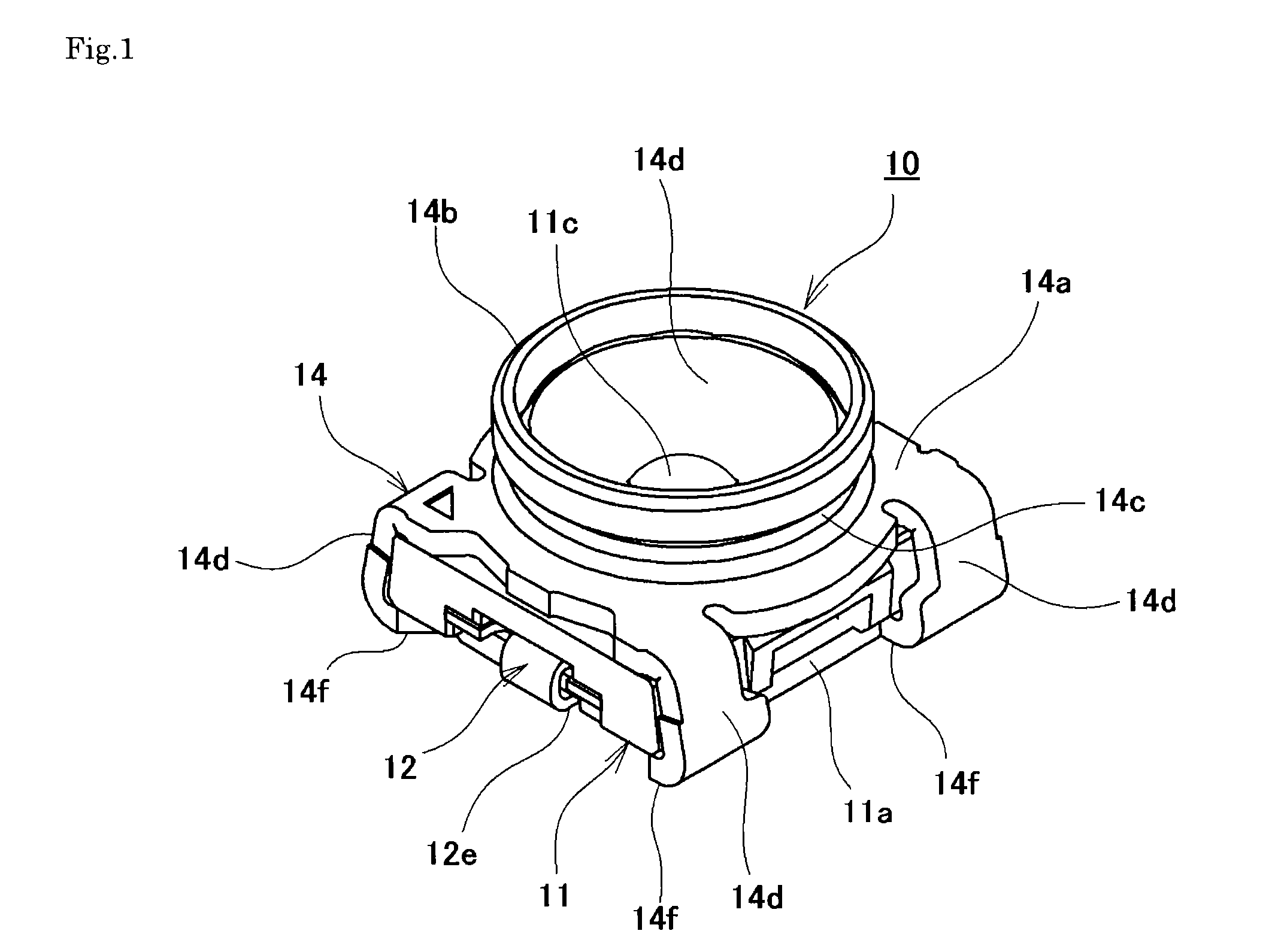

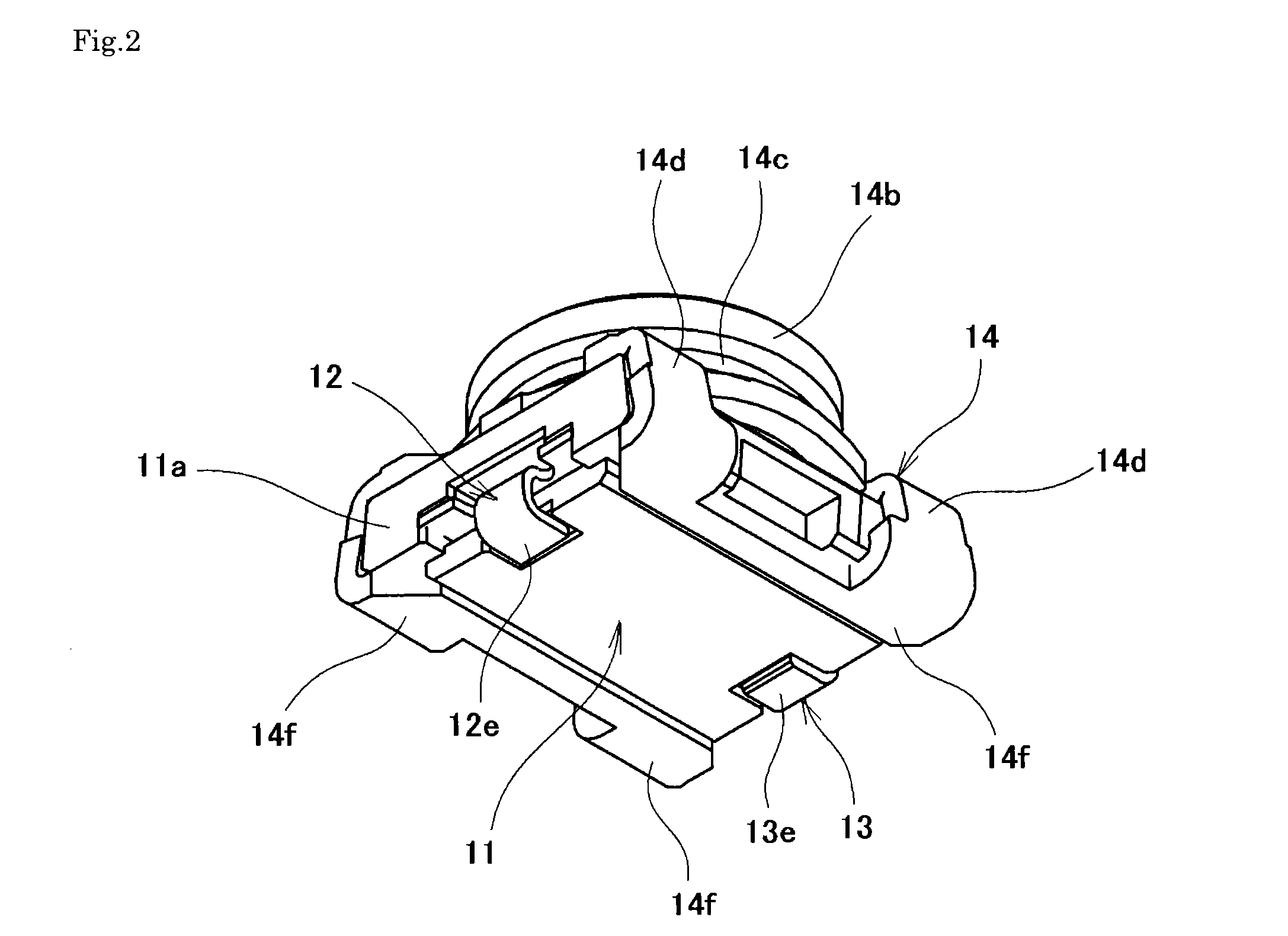

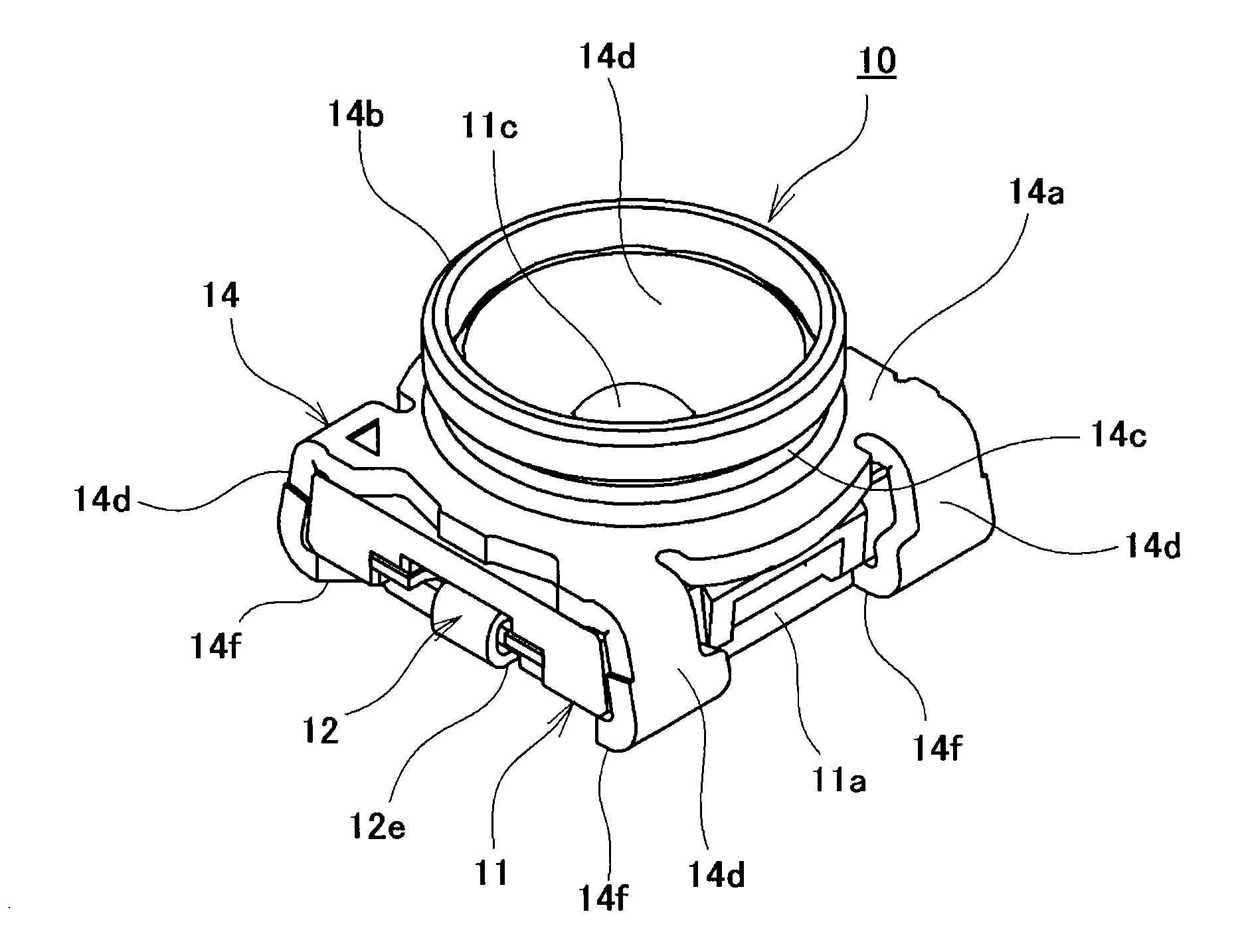

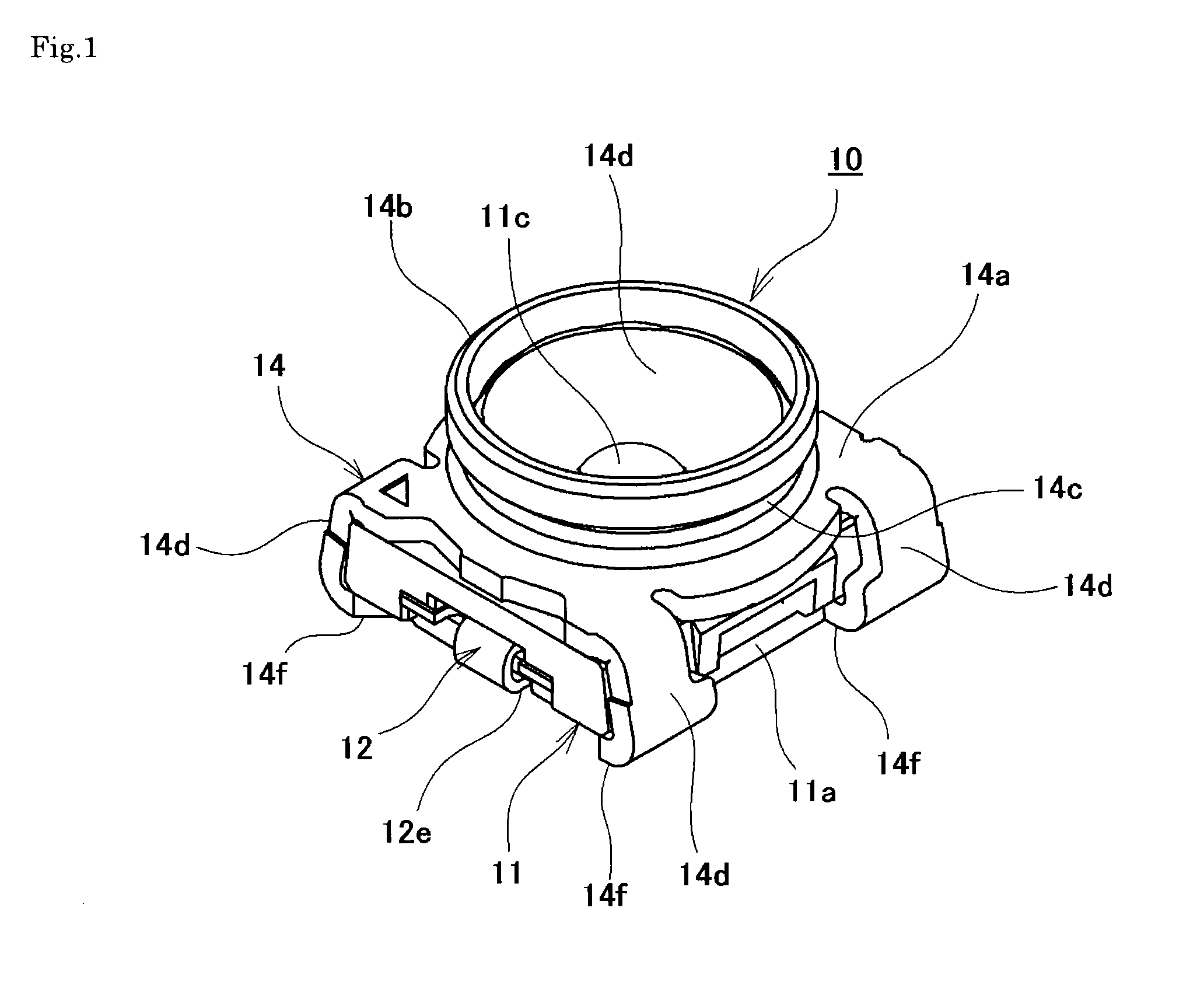

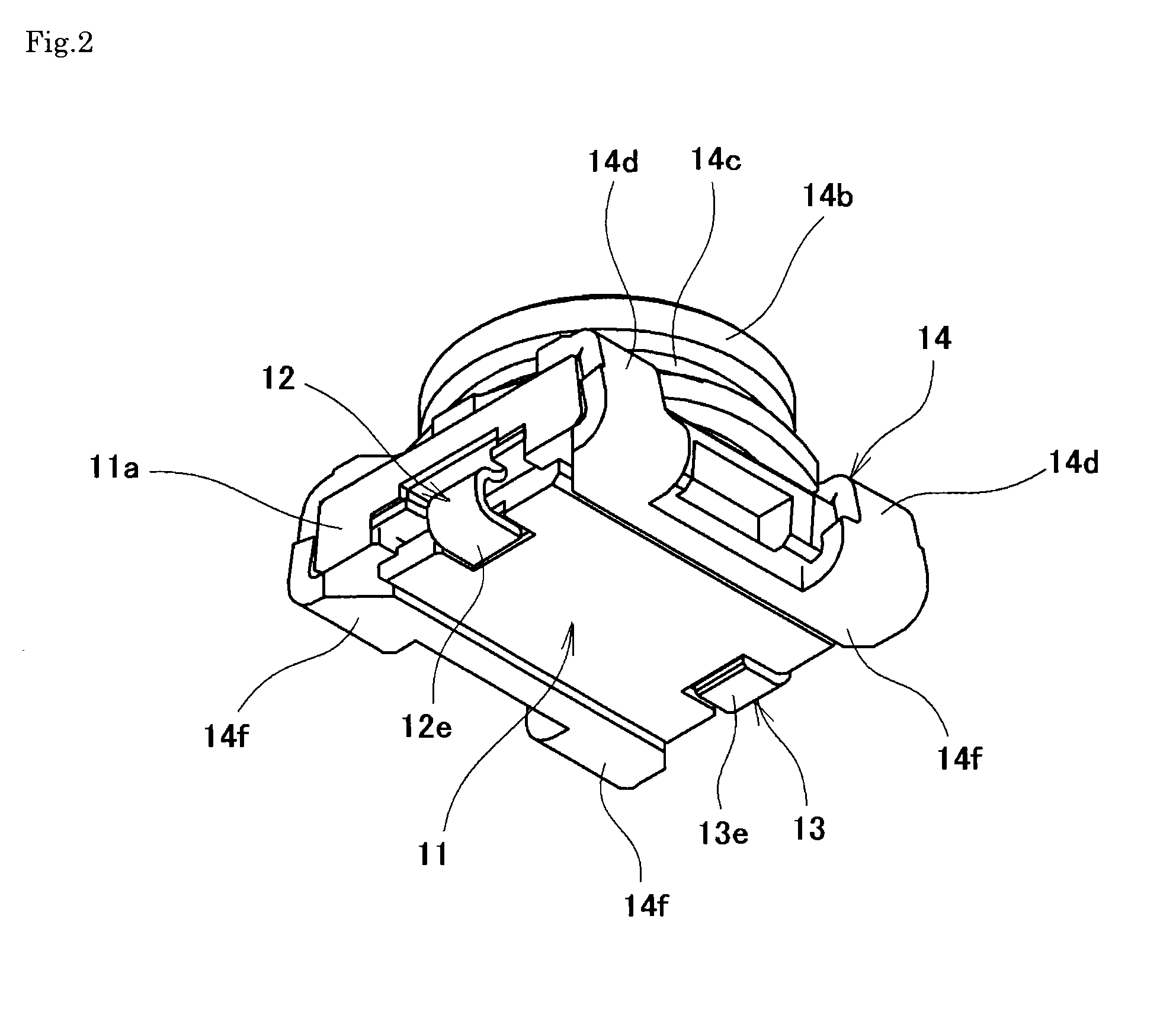

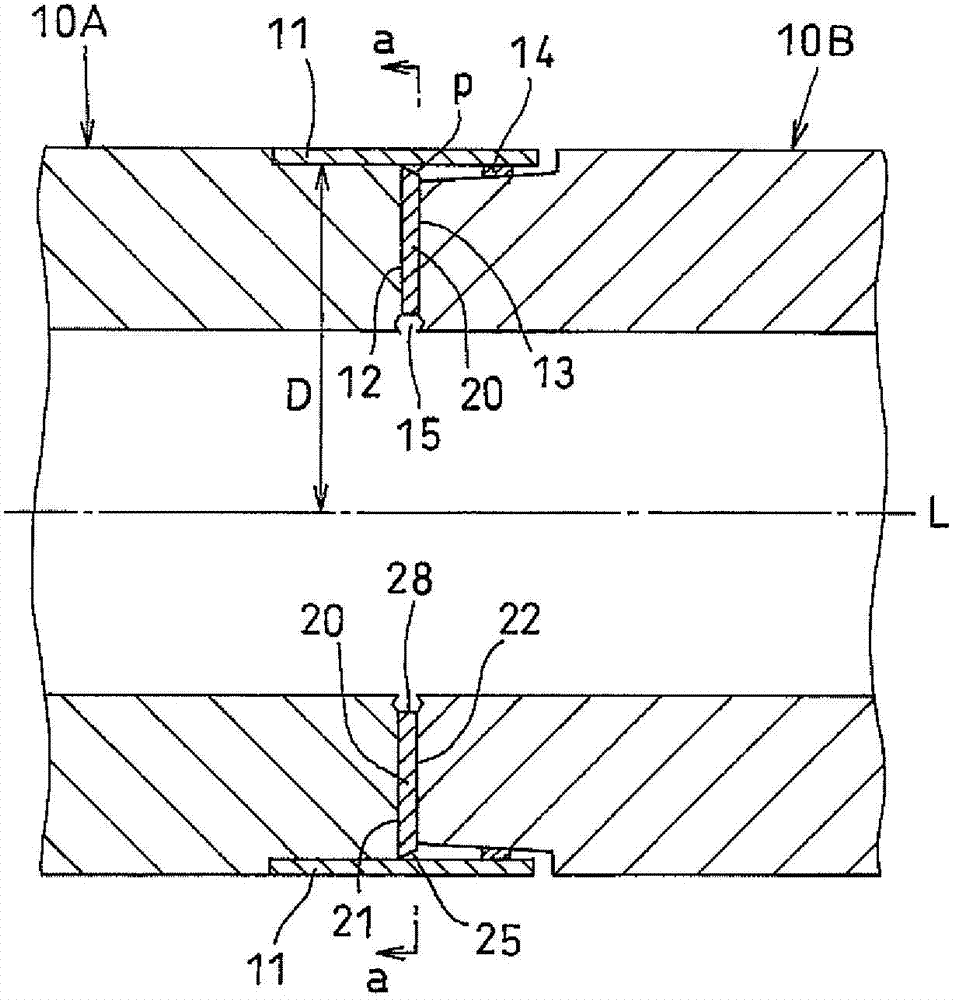

Switch-equipped coaxial connector

InactiveUS8986043B2Simple configurationAvoid plastic deformationElectrically conductive connectionsCoupling device detailsElectricityCurve shape

Owner:DAIICHI SEIKO CO LTD

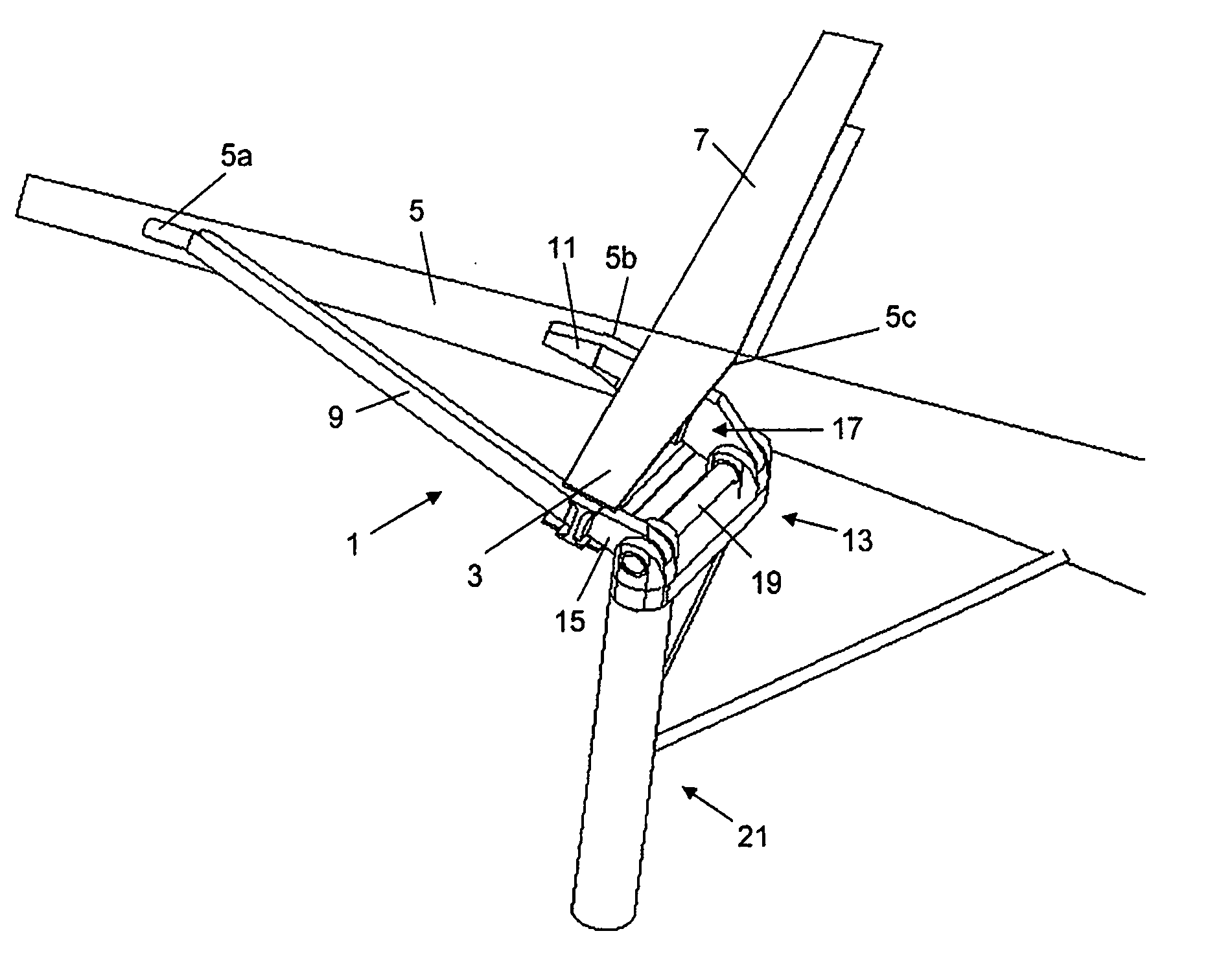

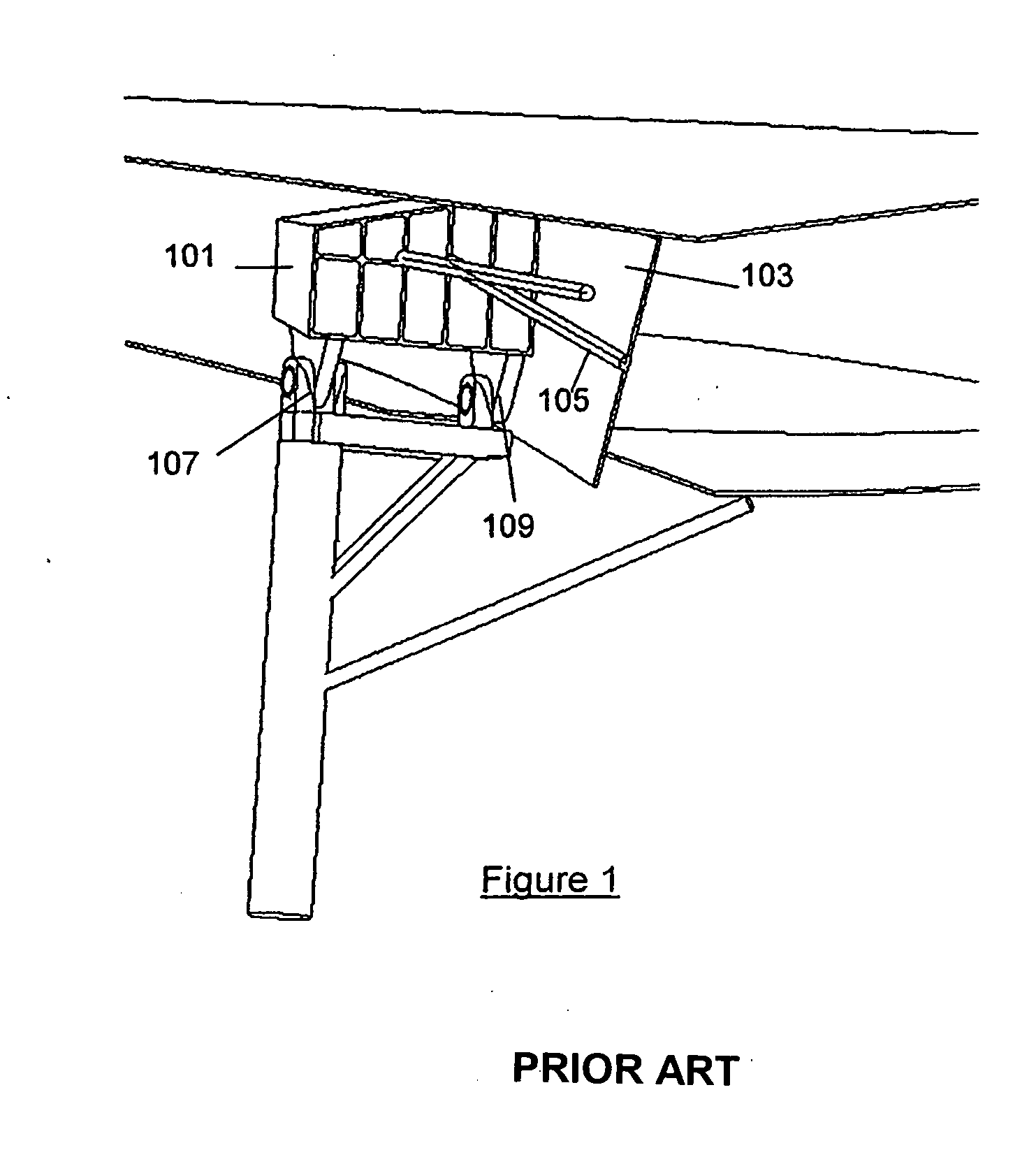

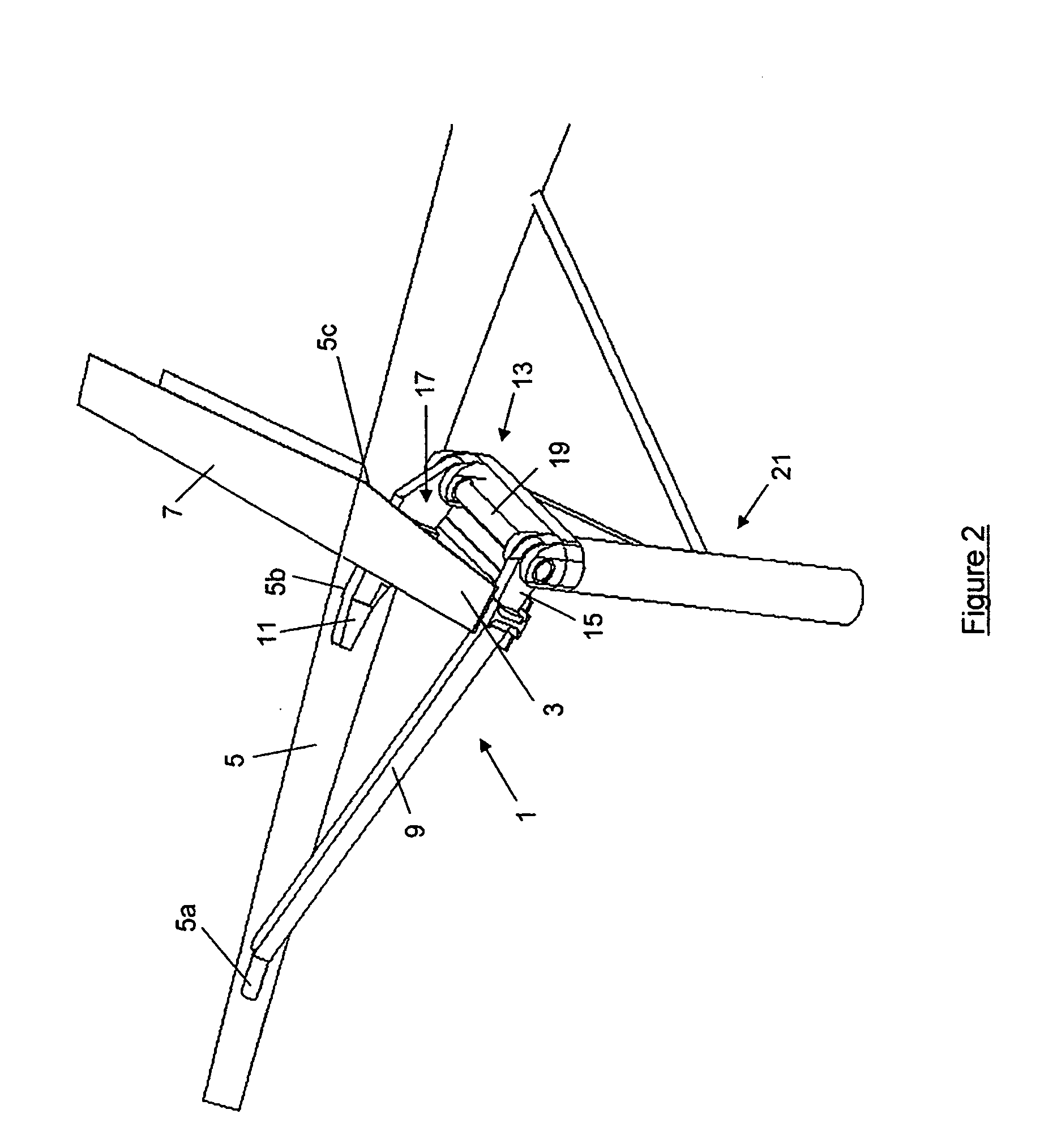

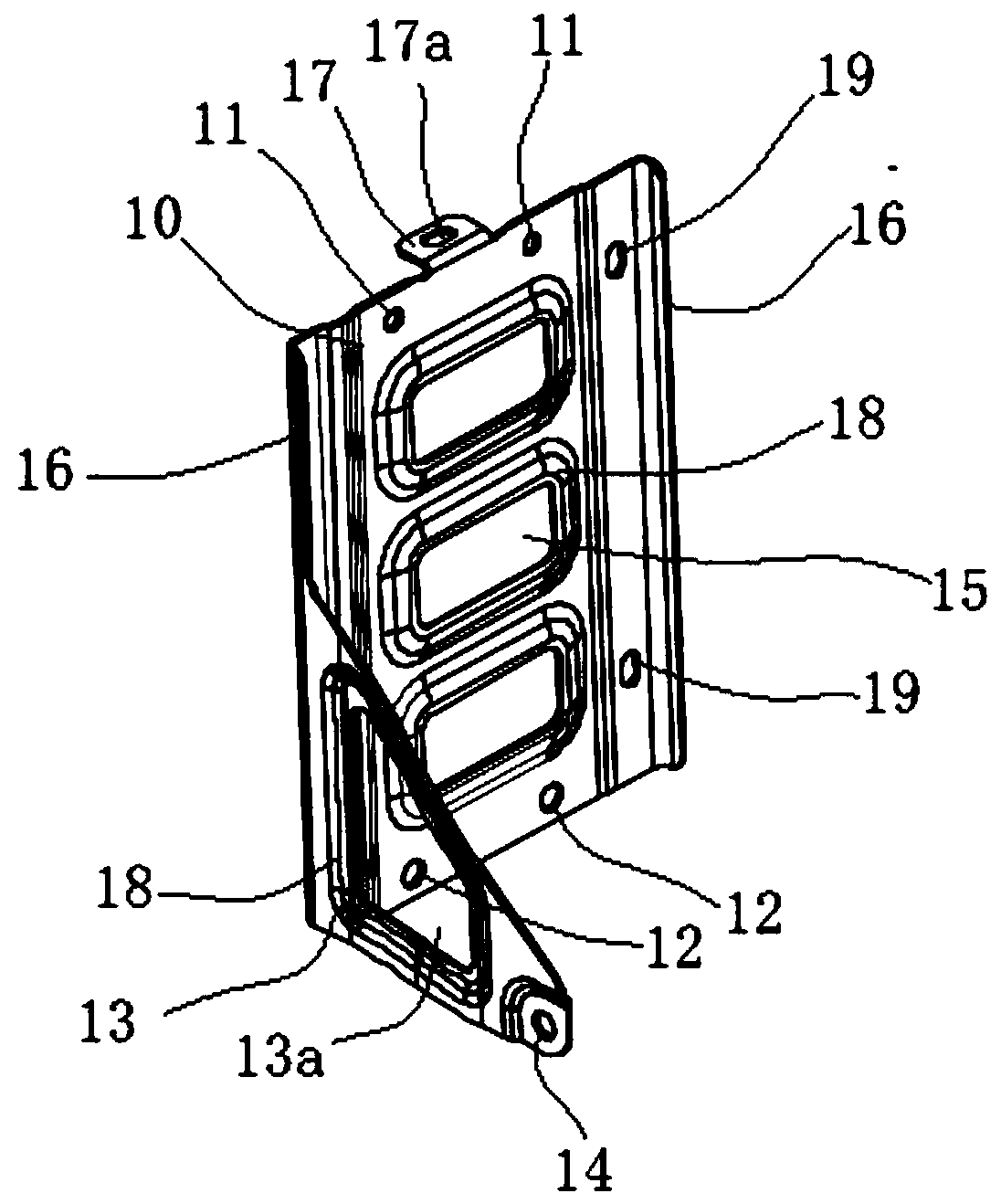

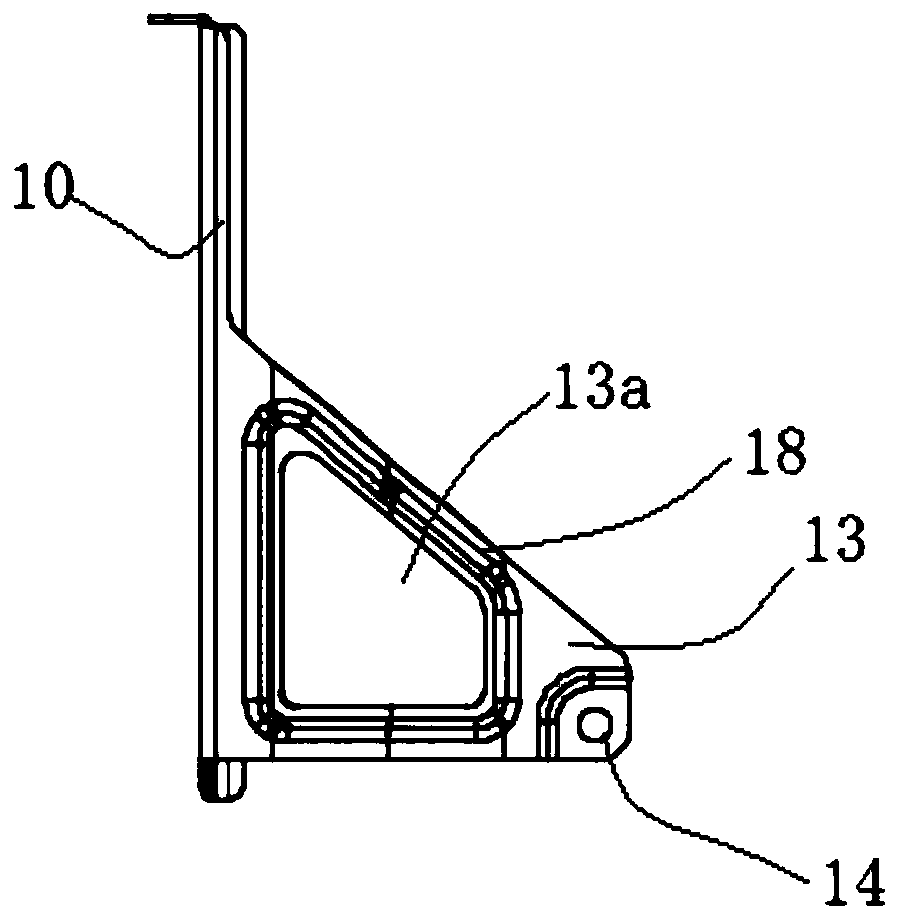

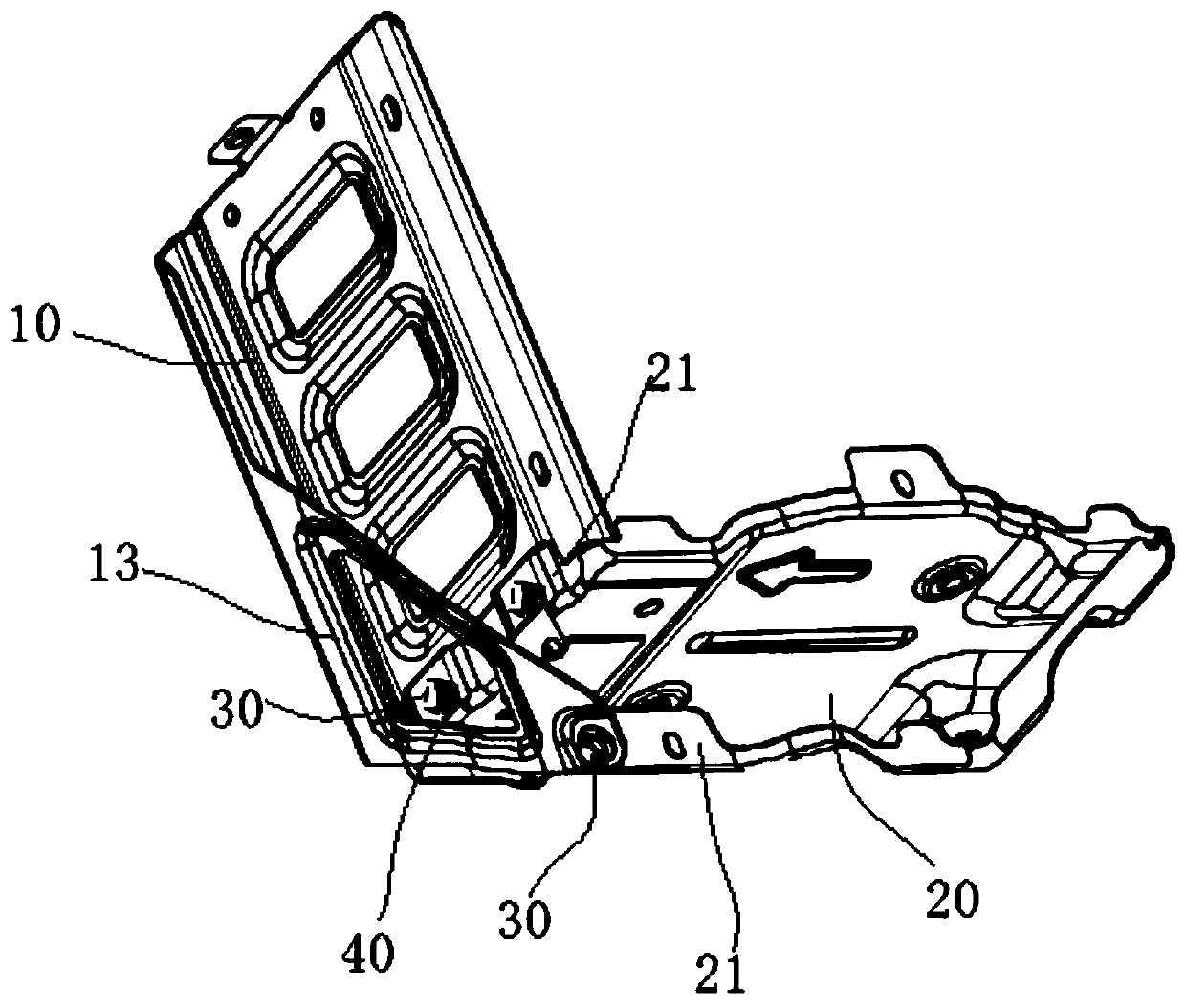

Landing gear support

InactiveUS20060060700A1Improved stress distributionImprove stress distributionFuselage framesSkis/runnersAirplaneShear force

Owner:AIRBUS OPERATIONS LTD

Damping rubber material

InactiveCN105440464AImprove mechanical propertiesImprove shock absorptionRubber materialParaffin wax

The invention discloses a damping rubber material. Raw materials of the damping rubber material comprise, by weight, 50-70 parts of butyl rubber, 30-50 parts of butadiene-acrylonitrile rubber, 50-70 parts of a composite filler, 15-25 parts of micro-encapsulation red phosphorus, 10-15 parts of melamine phosphate, 5-8 parts of tributyl phosphate, 10-15 parts of epoxidized soybean oil, 15-25 parts of tributyl citrate, 0.5-0.8 part of sulphur, 0.1-0.2 part of stearic acid, 0.1-0.15 part of zinc oxide, 0.2-0.4 part of a promoter DM, 2-4 parts of a Ca / Zn compound stabilizer, 2-4 parts of dibutyltin dilaurate, 0.1-0.3 part of an anti-aging agent RD, 0.1-0.2 part of an anti-aging agent 445, 0.2-0.4 part of an anti-fatigue agent PL and 3-5 parts of paraffin. Raw materials of the composite filler contain modified nano-white carbon black and beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic octadecanol. The damping rubber material of the invention has good damping performance.

Owner:宁国市开源橡塑汽车零部件有限公司

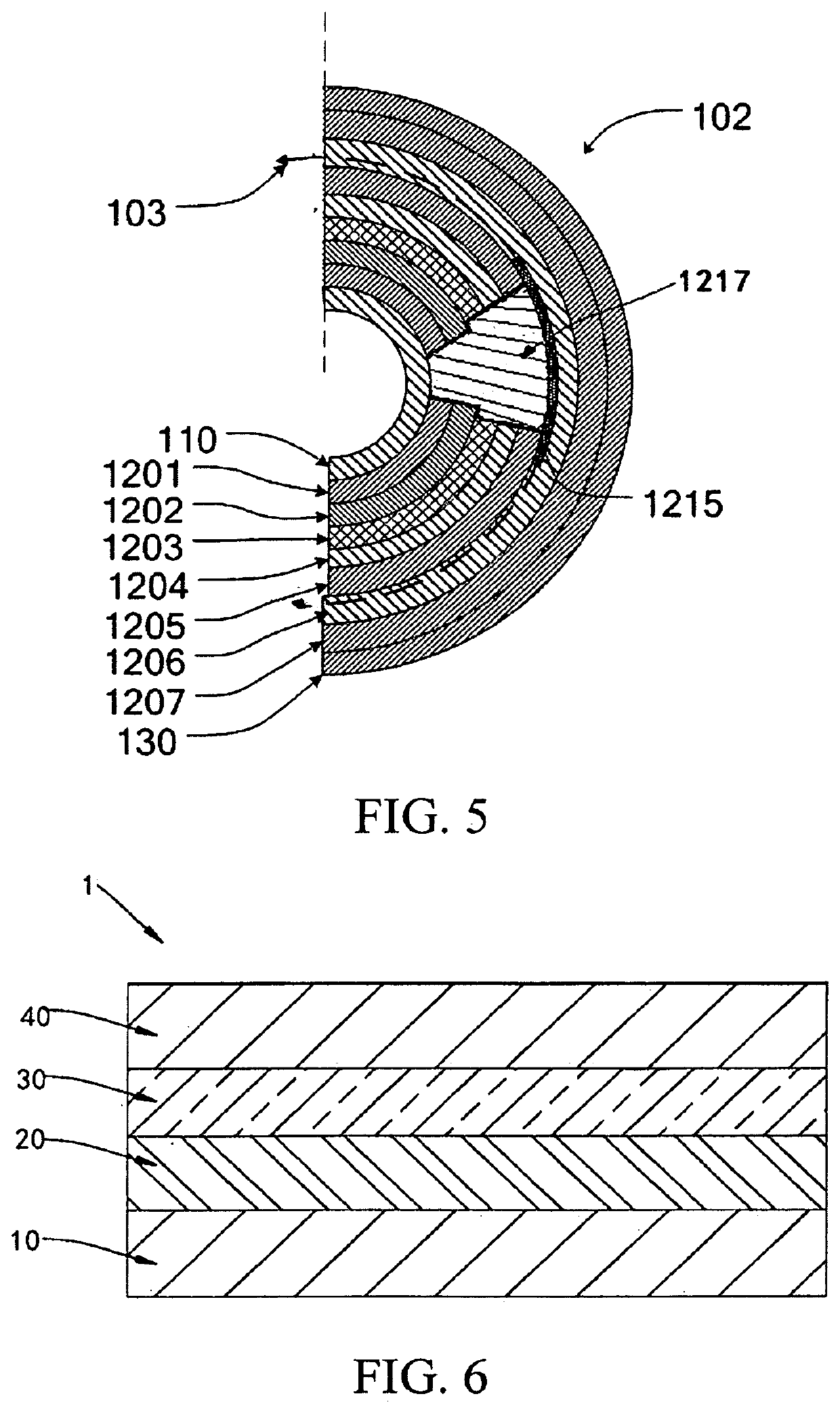

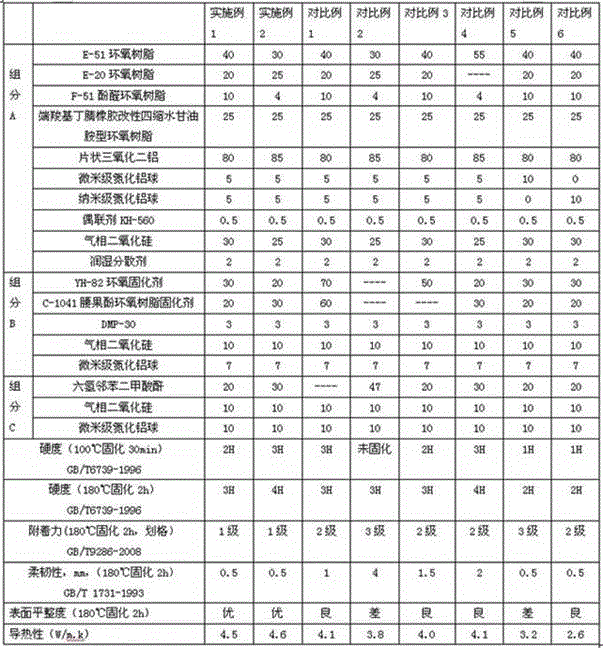

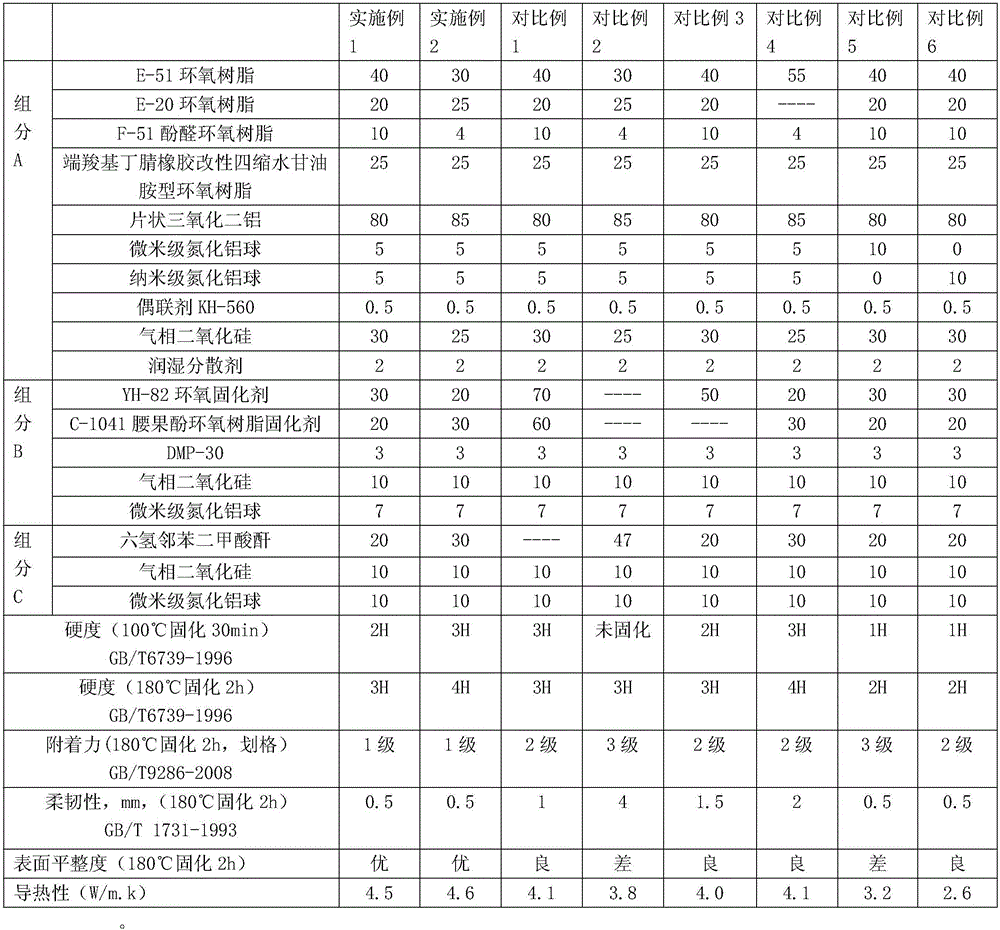

High temperature-resistant step-cured epoxy paint and application method thereof

ActiveCN103319984AImprove high temperature resistanceImprove interface adhesionEpoxy resin coatingsHexahydrophthalic anhydrideGas phase

The invention discloses a high temperature-resistant step-cured epoxy paint and an application method of the paint. The high temperature-resistant step-cured epoxy paint is obtained by mixing ingredient A, ingredient B and ingredient C in A certain proportion, wherein the ingredient A is an epoxy resin ingredient and comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic aldehyde epoxy resin, carboxylate-terminated nitrile butadiene rubber modified tetraglycidylamine type epoxy resin, aluminum oxide, aluminum nitride, fumed silica, a wetting dispersant, and a coupling agent; the ingredient B is a first curing agent ingredient and comprises an YH-82 epoxy curing agent, a C-1041 anacardol epoxy resin curing agent, DMP-30, fumed silica, and aluminum nitride; and the ingredient C is a second curing agent ingredient and comprises hexahydrophthalic anhydride, fumed silica, and aluminum nitride. The high temperature-resistant step-cured epoxy paint disclosed by the invention can be pre-cured at low temperature, does not form an unsmooth paint film, is cured at a high temperature, and remains the advantages of high strength and good adhesive force of the paint film which is cured at a high temperature.

Owner:广东顺召涂料有限公司

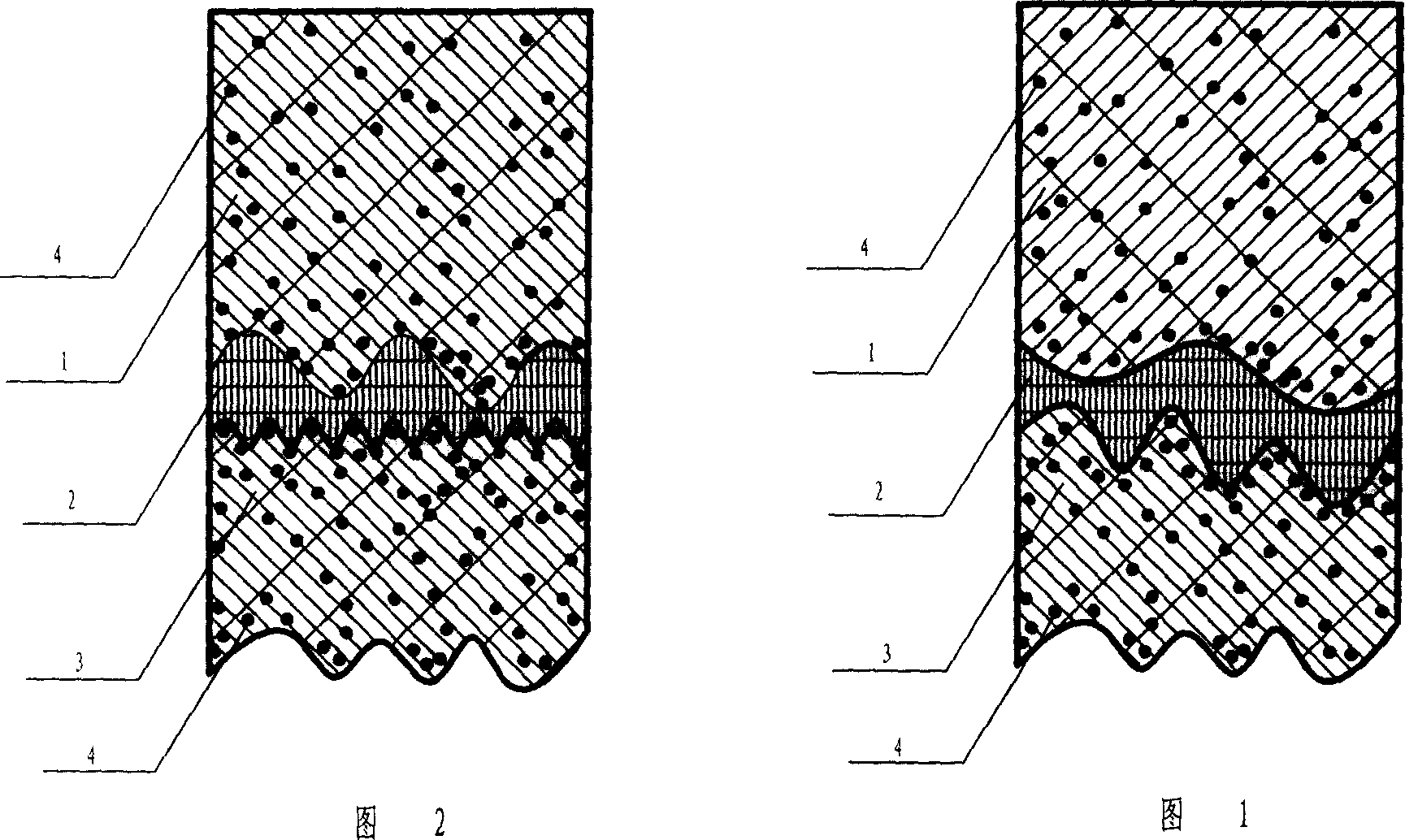

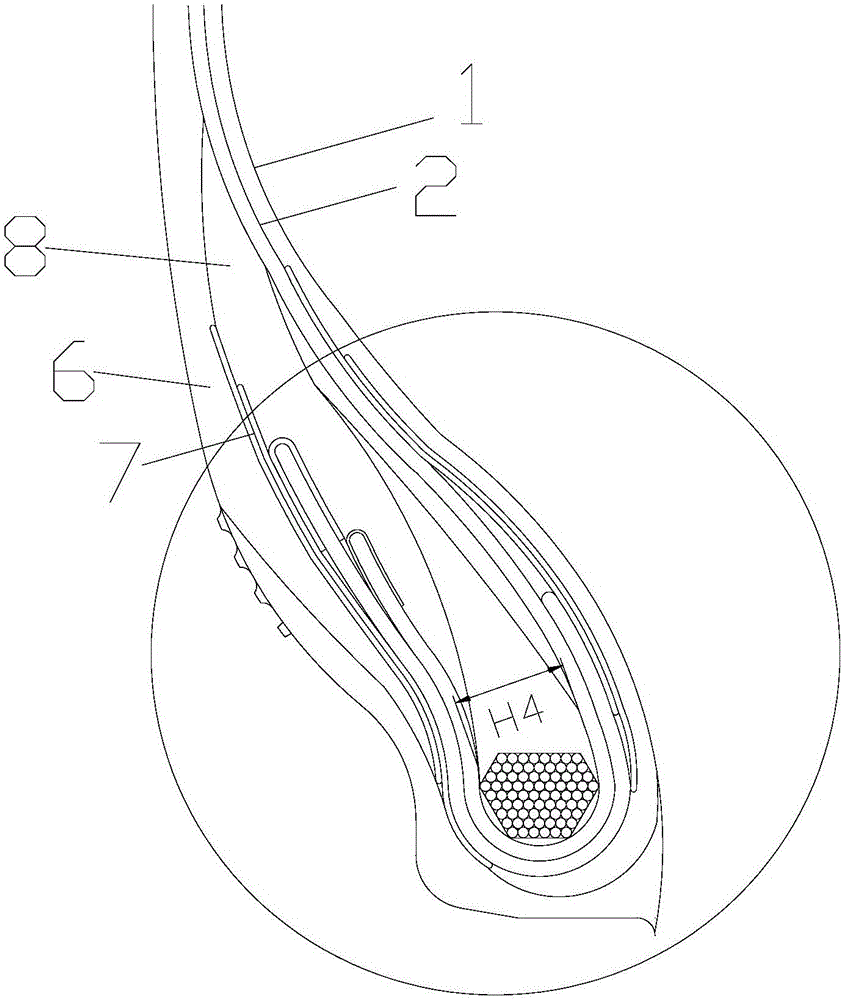

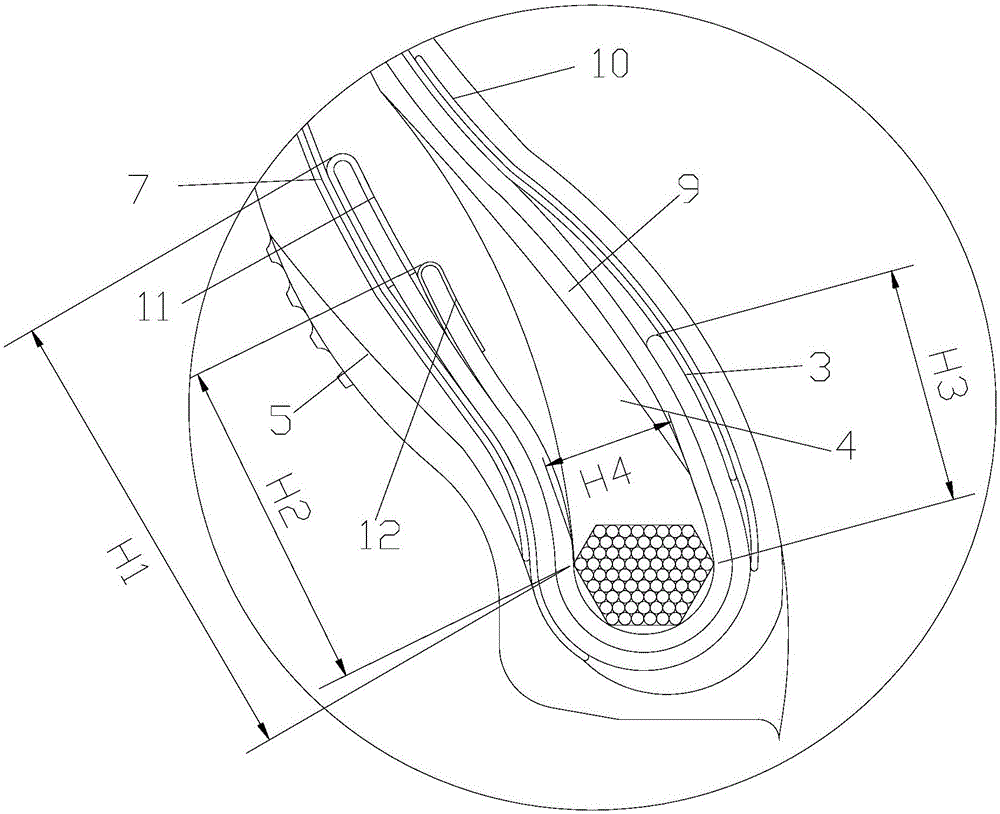

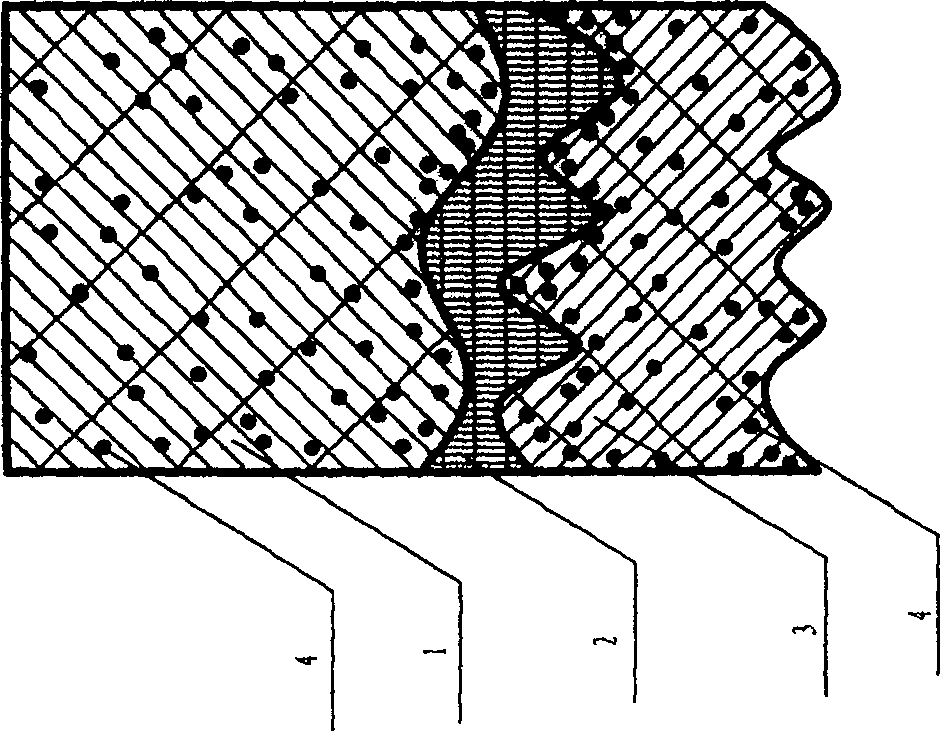

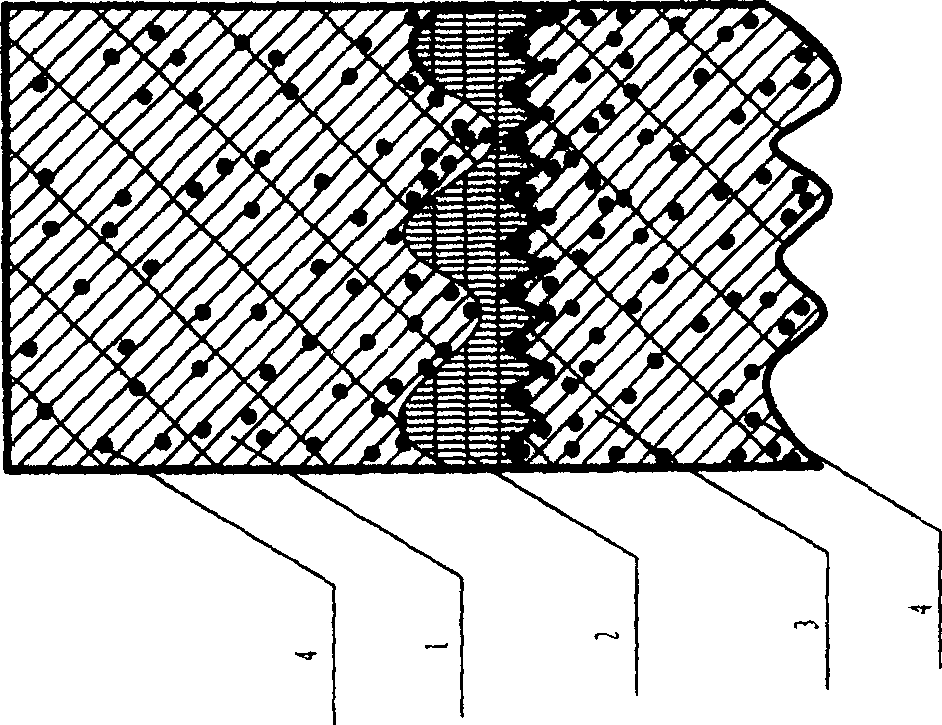

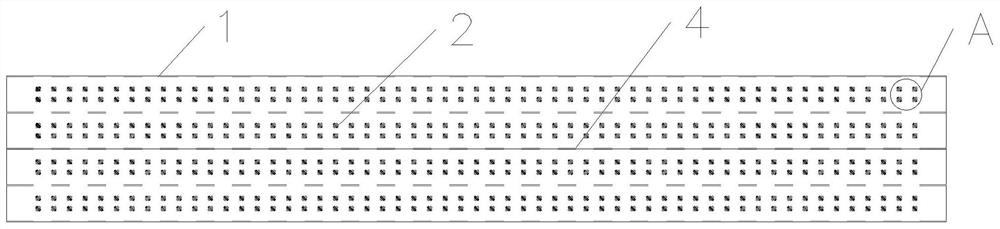

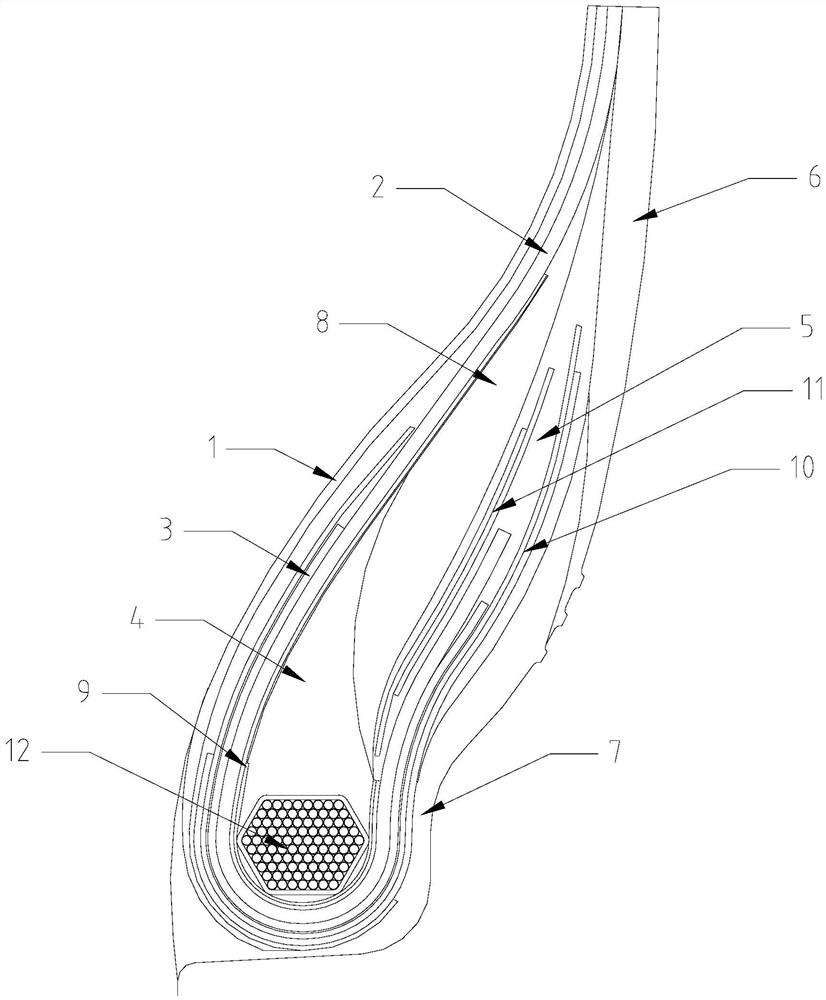

Radial tire bead

InactiveCN106114075AImprove support performanceImproved flexural rigidityTyre beadsEngineeringTextile

The invention discloses a radial tire bead. The radial tire bead comprises a lining layer (1), a carcass fabric (2), a bead strengthening wirecord fabric (3), bead rubber (5) and sidewall rubber (6), wherein the lining layer (1), the carcass fabric (2) and the bead strengthening wirecord fabric (3) wrap the inner side of the bead, and the bead rubber (5) and the sidewall rubber (6) wrap the outer side of the bead. The radial tire bead is characterized by further comprising three composite rubber cores, wherein the three composite rubber cores include a filling rubber core (9), a hard triangular rubber core (4) and a soft triangular rubber core (8), the hard triangular rubber core (4) is positioned inside, the soft triangular rubber core (8) is positioned outside, the filling rubber core (9) is positioned on one side, which is close to the inner side of the bead, of the hard triangular rubber core (4), and the filling rubber core (9), the hard triangular rubber core (4) and the soft triangular rubber core (8) are wrapped by the carcass fabric (2) and the bead strengthening wirecord fabric (3) in sequence from inside to outside. According to the radial tire bead, the support performance of the tire bead can be effectively improved, and the deflection rigidity of the bead in the condition of high load is effectively improved.

Owner:SHANDONG LINGLONG TIRE

Switch-equipped coaxial connector

InactiveUS20130224992A1Function increaseIncrease spanElectrically conductive connectionsCoupling device detailsCurve shapeElectrical connection

With a simple configuration, plastic deformation of contacts can be prevented while avoiding increase in size, and occurrence of failure in electrical connection due to dust can be well prevented. In an elastic beam-like member of a first-side contact extending like a cantilever in an insulating housing, a bent extending part which substantially increases the span length of the elastic beam-like member is formed to be bent to have a curved shape at a root part serving as a part coupled to a fixing base part. A through hole is formed in a region including at least part of the bent extending part to ensure flexibility while enhancing elasticity of the contact, thereby preventing permanent deformation of the contact. Meanwhile, dust which has entered the equipment is caused to fall through the through hole, thereby ensuring electrical conductivity well.

Owner:DAIICHI SEIKO CO LTD

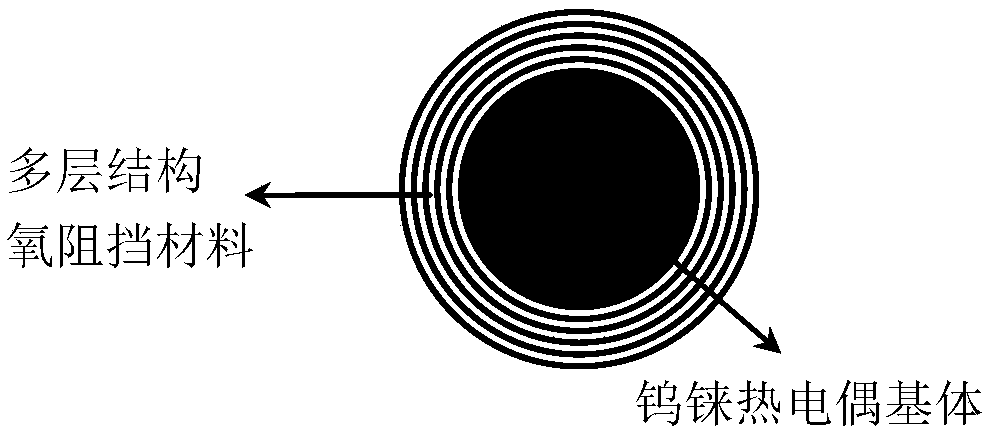

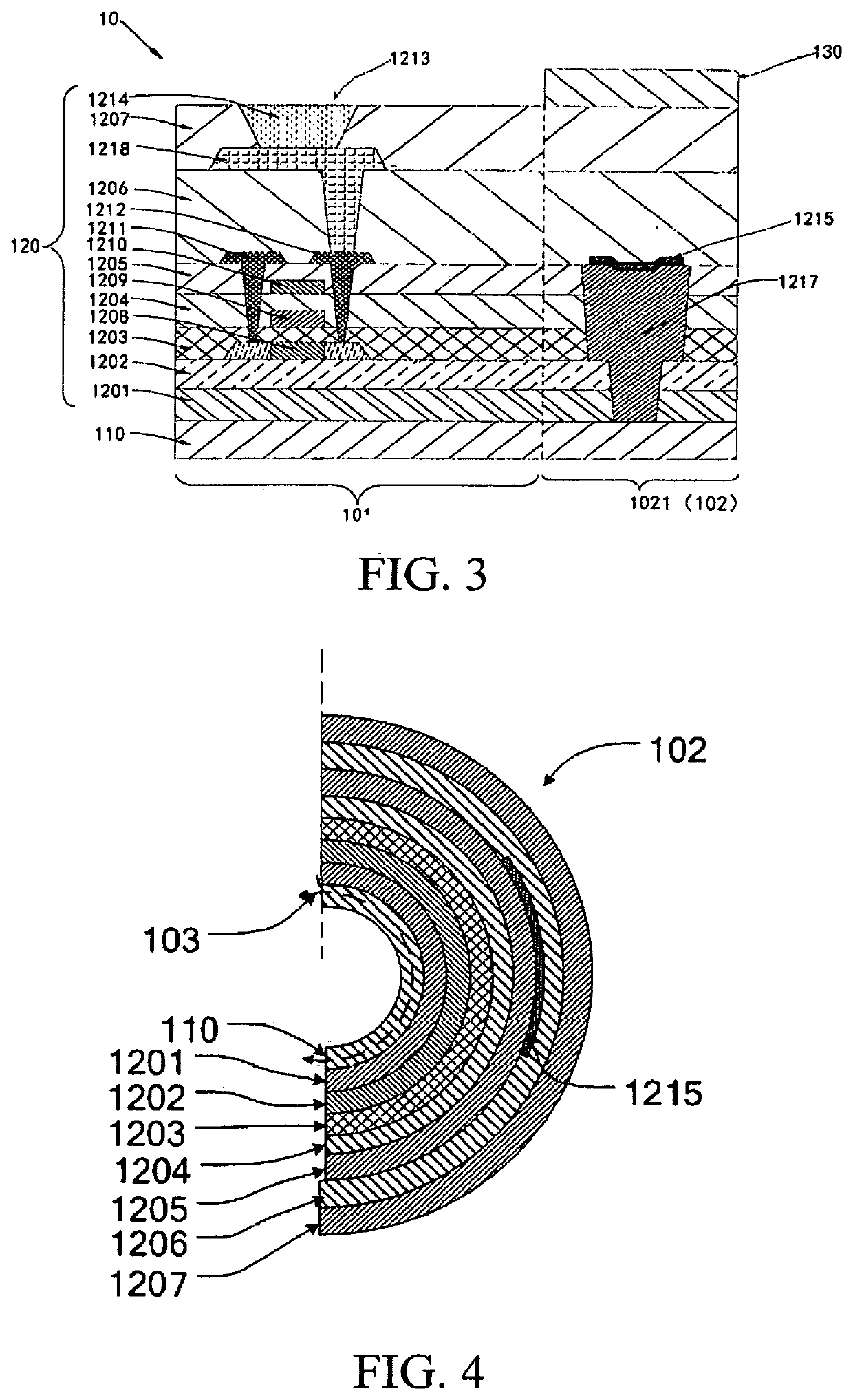

Oxygen barrier material in tungsten-rhenium thermocouple anti-oxidation coating structure, and application thereof

InactiveCN108091758AReduce thermal stressImprove adhesionMolten spray coatingLiquid/solution decomposition chemical coatingRheniumOxidation resistant

The invention belongs to the technical field of temperature measurement, and relates to an oxygen barrier material in a tungsten-rhenium thermocouple anti-oxidation coating structure, and applicationof the oxygen barrier material. The oxygen barrier material is of a multilayer structure with a total thickness of 50-200 mu m. The oxygen barrier material in the multilayer structure has compositional gradients and concentration gradients, ie, thermal expansion coefficients of materials in layers of the oxygen barrier material are gradually increased in a direction away from a tungsten-rhenium thermocouple base body, and oxygen erosion resistance of the materials in layers of the oxygen barrier material is gradually increased in a direction away from the tungsten-rhenium thermocouple base body through adjusting types or proportions of the materials in each layer, thereby increasing the adhesive force of a high-temperature anti-oxidation coating of a tungsten-rhenium thermocouple, and reducing stress of the high-temperature anti-oxidation coating of the tungsten-rhenium thermocouple.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing reinforced carbon aerogel with silica sol

InactiveCN108298519AReinforced Fiber Pore StructureHigh strengthCarbon preparation/purificationAerogel preparationSucroseFilter cake

Owner:胡果青

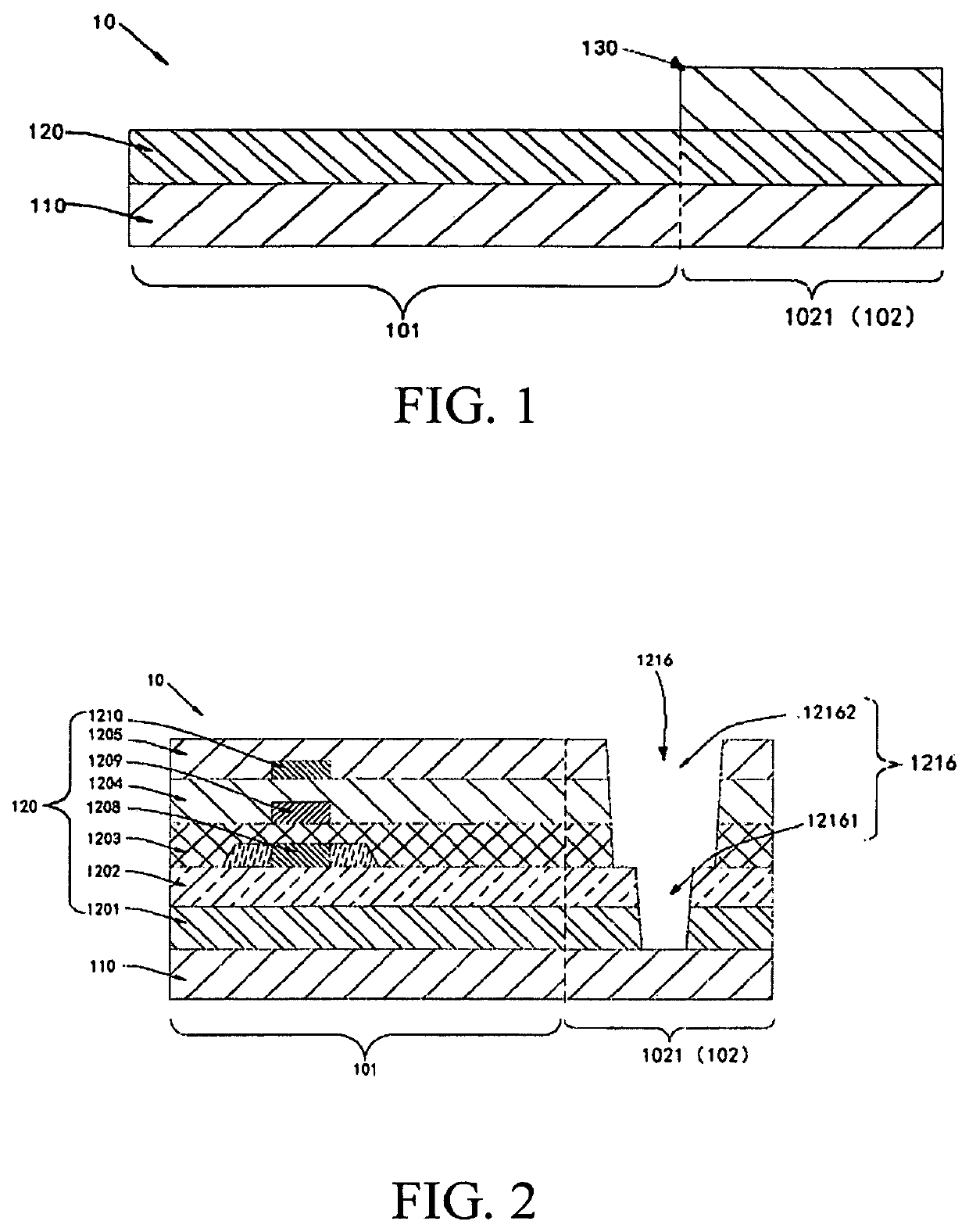

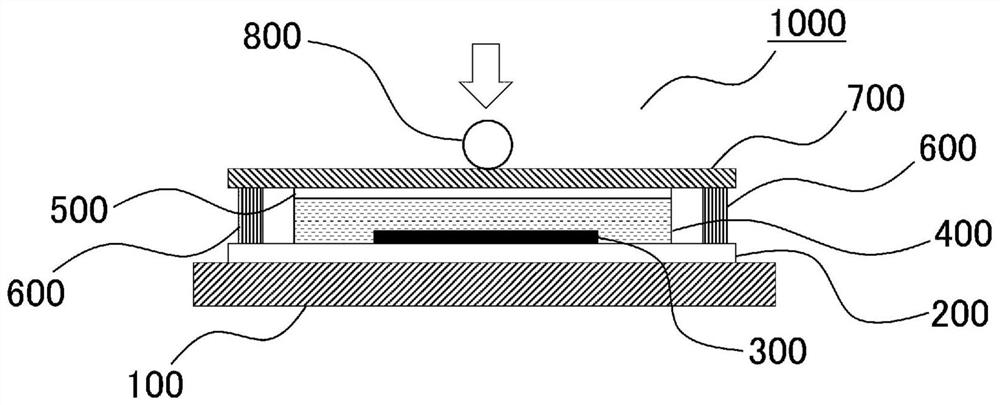

Display panel and display device having same

ActiveUS20210126073A1Improved stress distributionFail or degrade in performanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

A display panel and a display device having the display panel are provided. The display panel includes a display region for displaying images; a non-display region disposed outside the display region, and the non-display region includes a bending region; a metal trace extending from the display region to the bending region; and a stress adjustment layer disposed on the metal trace and corresponding to the bending region. The display panel and the display device having the display panel can effectively solve problems such as performance degradation and failure caused by cracking and peeling on the metal trace when the display panel is bent through adding the stress adjustment layer which has a material with the same flexibility as the flexible substrate on an array substrate or different flexibility from the flexible substrate on the array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

High-temperature resistant sectional curing epoxy paint and use method thereof

ActiveCN106010127ANo crackDoes not reduce adhesionFireproof paintsEpoxy resin coatingsNitrile rubberHexahydrophthalic anhydride

The invention relates to high-temperature resistant sectional curing epoxy paint and a use method thereof. The high-temperature resistant sectional curing epoxy paint comprises a component A, a component B and a component C which are mixed in a certain ratio, wherein the component A is an epoxy resin component which comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic epoxy resin, carboxyl terminated nitrile rubber modified tetra-glycidyl amide type epoxy resin, aluminium oxide, micron-grade and nanometer-grade aluminum nitride balls, fumed silica, a wetting dispersant and a coupling agent; the component B is a first curing agent component which comprises a YH-82 epoxy curing agent, a C-1041 cardanol epoxy resin curing agent, DMP(Dimethylphthalate)-30, fumed silica and micron-grade aluminum nitride balls; the component C is a second curing agent component which comprises hexahydrophthalic anhydride, fumed silica and micron-grade aluminum nitride balls. The high-temperature resistant sectional curing epoxy paint prepared by the invention has the effects of low temperature pre-curing for avoiding uniform paint films, and high temperature curing, thereby keeping high strength and good adhesion of the paint films formed by low temperature curing.

Owner:中国森田企业集团有限公司

Heatproof damping rubber material

The invention discloses a heatproof damping rubber material. Raw materials of the heatproof damping rubber material contain, by weight, 50-70 parts of silicone rubber, 20-30 parts of butyl rubber, 57-83 parts of a composite filler, 0.6-0.8 part of gamma-methacryloxypropyltrimethoxysilane, 15-25 parts of zinc borate, 10-15 parts of nano-sized magnesium hydroxide, 15-25 parts of epoxy acetyl methyl linoleate, 15-25 parts of epoxidized soybean oil, 1-1.5 parts of dicumyl peroxide, 0.2-0.4 part of triethylenediamine, 0.1-0.2 part of a promoter D, 0.1-0.3 part of a promoter BZ, 1-3 parts of a Ca / Zn compound stabilizer, 1-3 parts of methyl tin mercaptide, 0.1-0.3 part of an antioxidant 1076, 0.1-0.2 part of an antioxidant 168, 0.1-0.3 part of an anti-ageing agent and 1-3 parts of montanin wax. The heatproof damping rubber material of the invention has good heat resistance and good damping performance.

Owner:宁国市开源橡塑汽车零部件有限公司

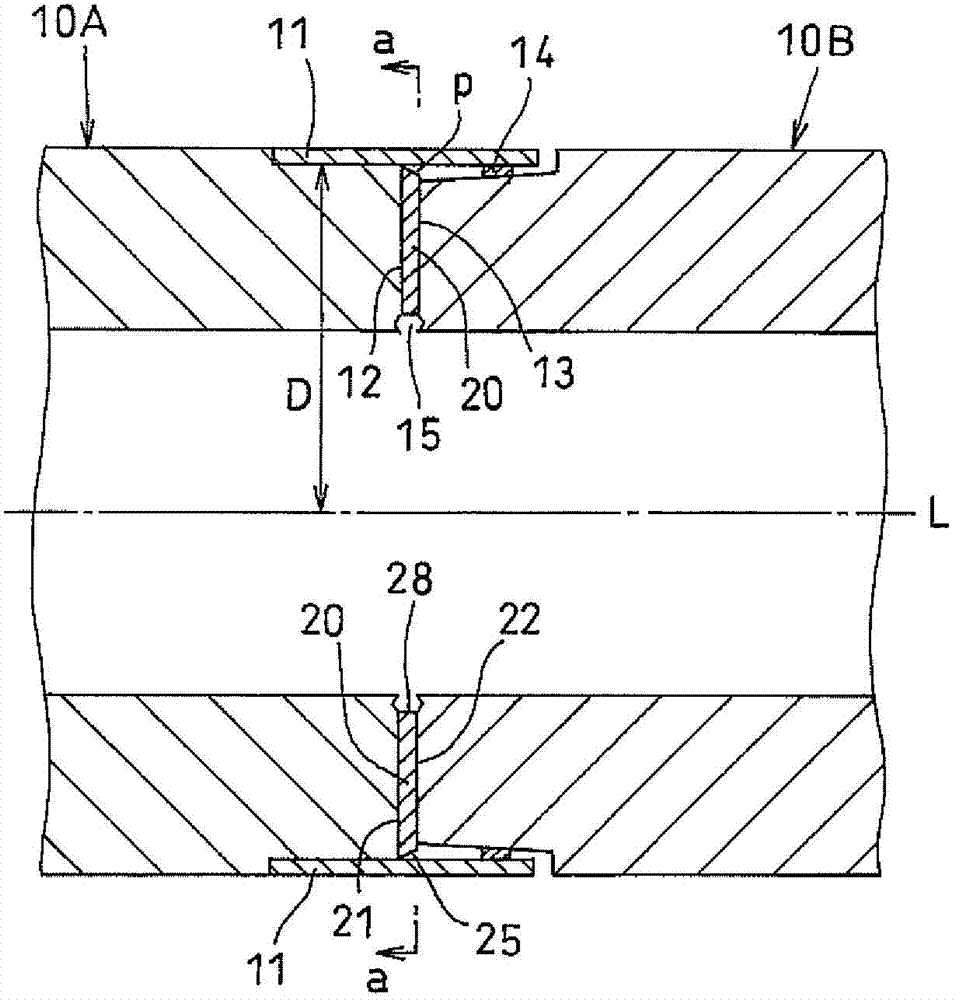

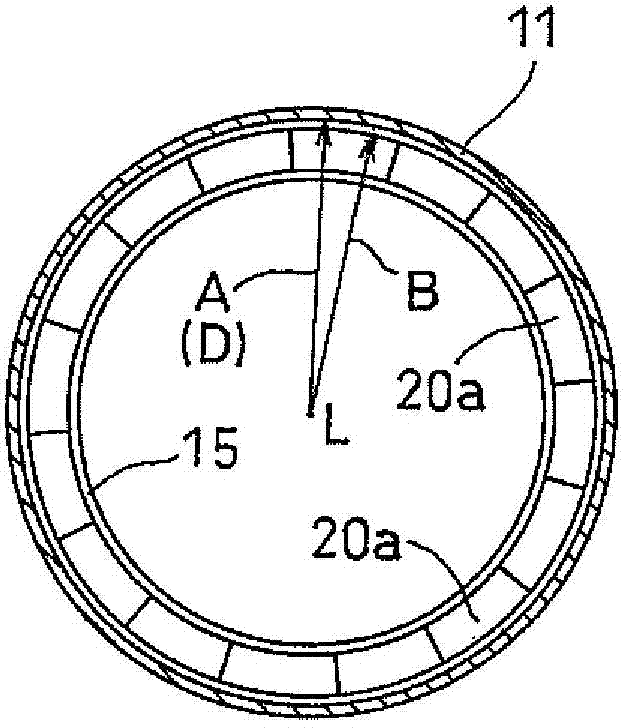

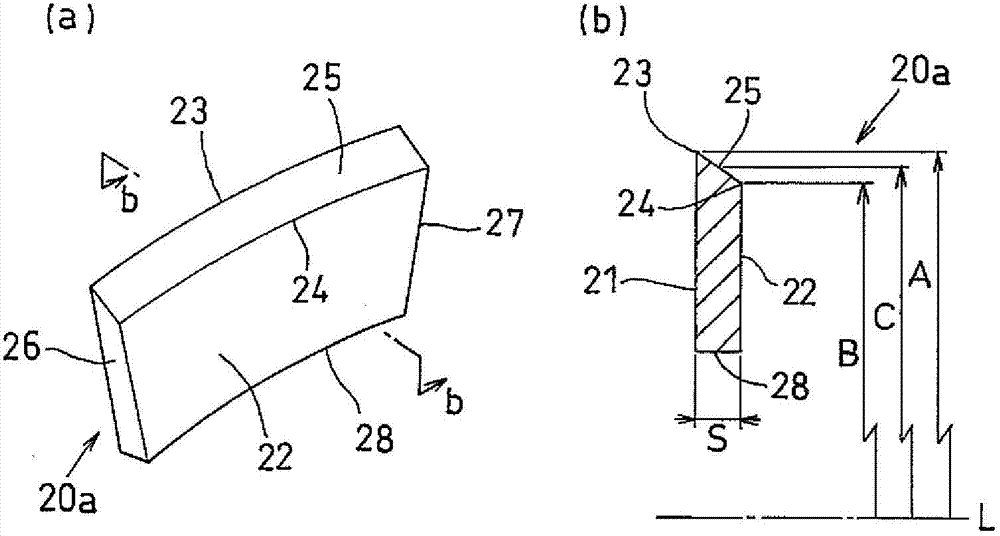

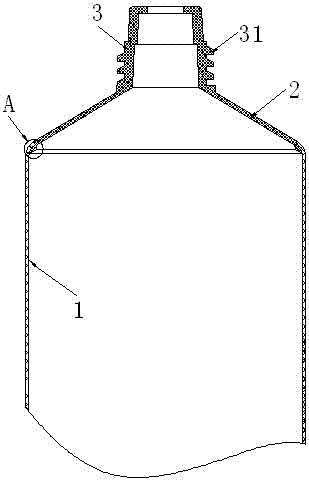

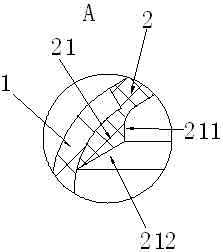

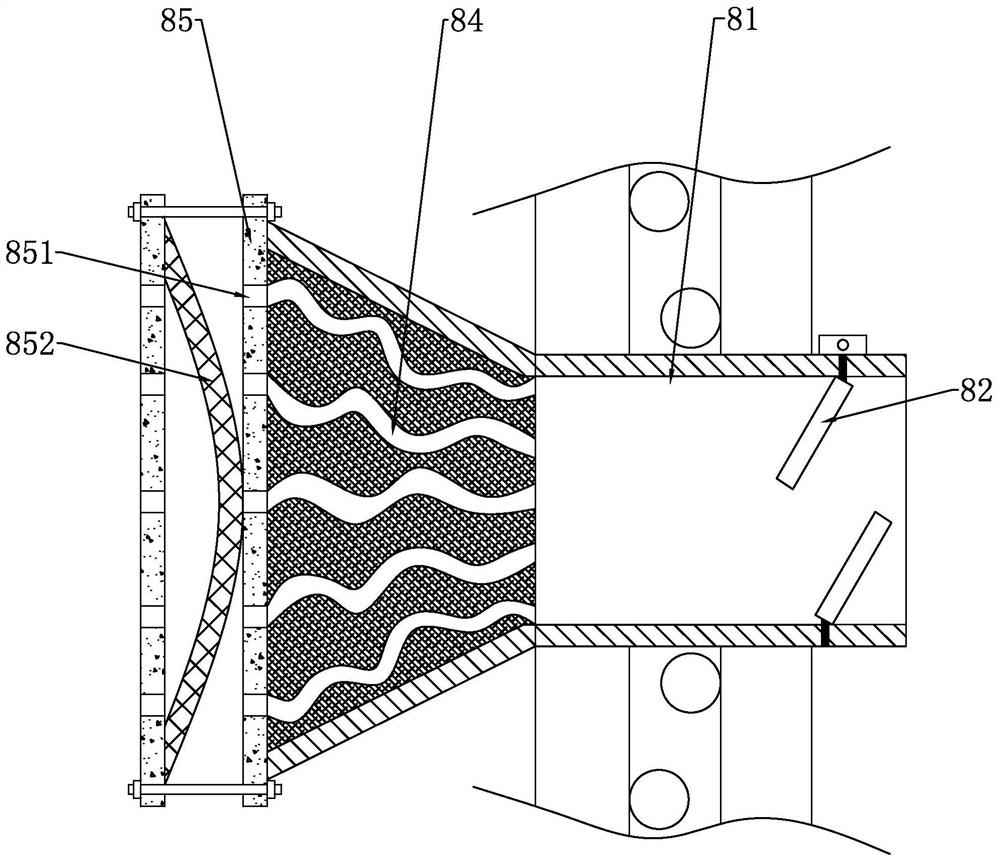

Jacking pipe cushioning material, and jacking pipe

ActiveCN102770622AAvoid deformationAvoid breakingSleeve/socket jointsPipe laying and repairCushioningEngineering

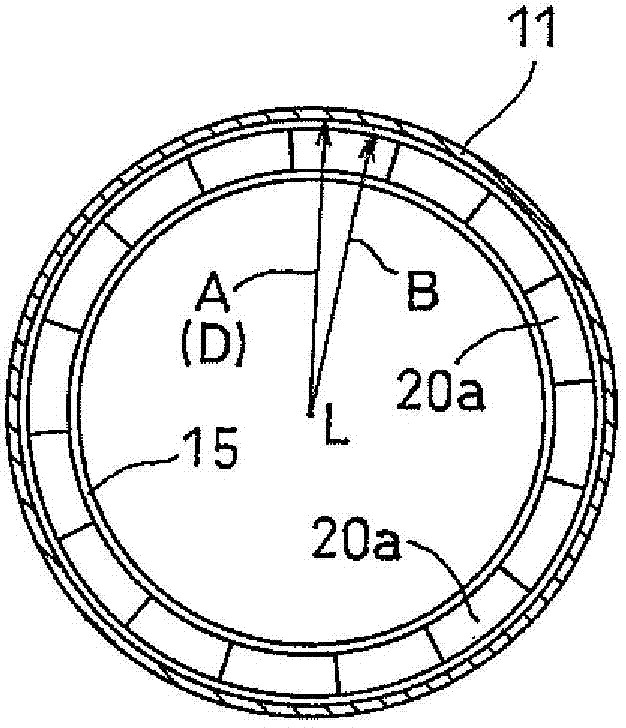

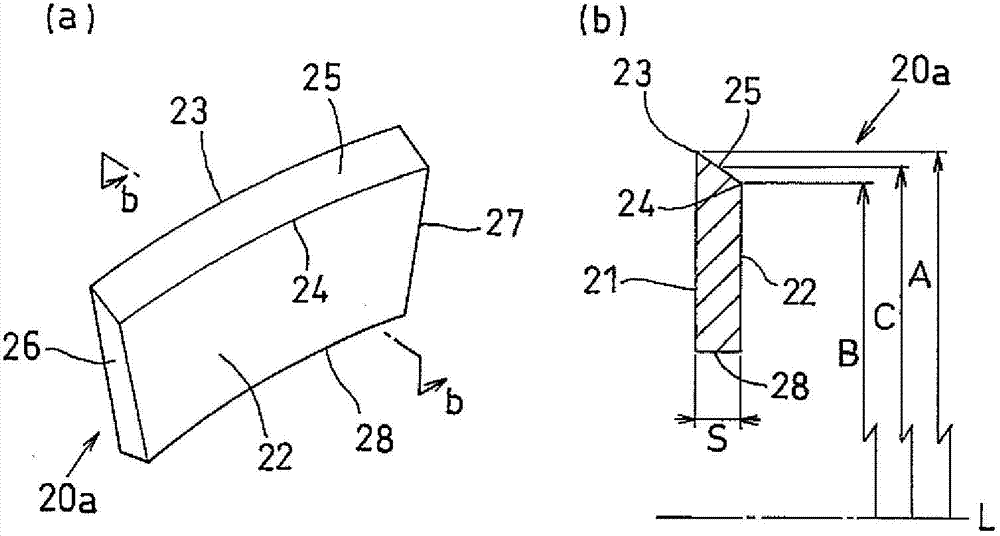

Provided is a jacking pipe cushioning material that exhibits a superior stress-dispersion effect and is easy to position. The jacking pipe cushioning material (20) (cushioning material pieces (20a)) is a ring-shaped plate member comprising a first side surface (21) and a second side surface (22), which are disposed so as to be substantially parallel at a prescribed distance (s) from one another, as well as an outer peripheral surface (25) positioned at the outer peripheral edges of both side surfaces. If the diameter (radius of curvature) from the center (L) of the ring to the outer circumferential edge (23) of the first side surface (21) is represented by A, the diameter (radius of curvature) to the outer circumferential edge (24) of the second side surface (22) is represented by B, and the diameter (radius of curvature) to an arbitrary position along the axial direction of the outer circumferential surface (25) is represented by C, then A >= B and A > C.

Owner:SEKISUI PLASTICS CO LTD

Integral engineering rack of interface osteochondro tissue with bionic function

InactiveCN100522265CIncrease connection areaImprove connection strengthJoint implantsBiocompatibility TestingOrganic layer

The invention discloses an osteochondral composite tissue integrated engineering support with bionic function interface, which is composed of cartilage layer, calcification layer and subchondral bone layer from top to bottom, between the cartilage layer and calcification layer, calcification layer and subchondral bone The organic connection between the layers; the cartilage layer is composed of type II collagen and chitosan, and type II collagen / chitosan is connected in the form of covalent bonds; the composition of the calcified layer is type II collagen and hydroxyapatite, II Type I collagen / hydroxyapatite are connected by covalent bonds; the subchondral bone layer is composed of type I collagen and hydroxyapatite, and type I collagen / hydroxyapatite are connected by covalent bonds; the cartilage layer and More than one pore is provided in the subchondral bone layer, and the pore diameter of the pore is 100 μm to 500 μm. The stent of the present invention has good biocompatibility, controllable degradability and sufficient mechanical strength, and has a bionic functional interface; after being transplanted into the patient's body, it can withstand the stress of the normal state and meet the mechanical requirements of the implanted site; The rate of degradation and absorption matches the growth rate of new tissue in the host.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

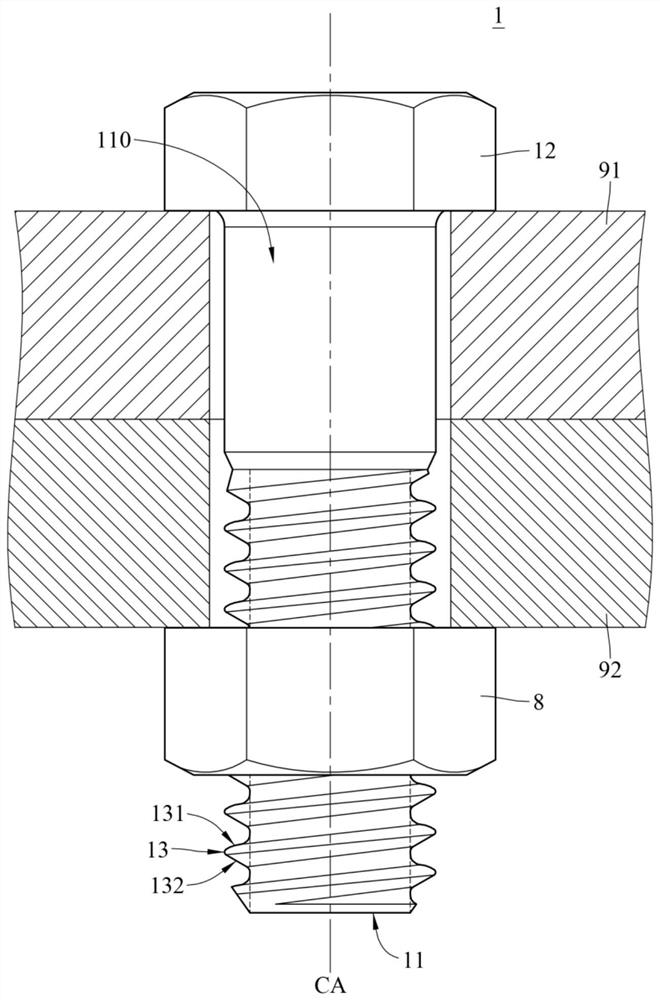

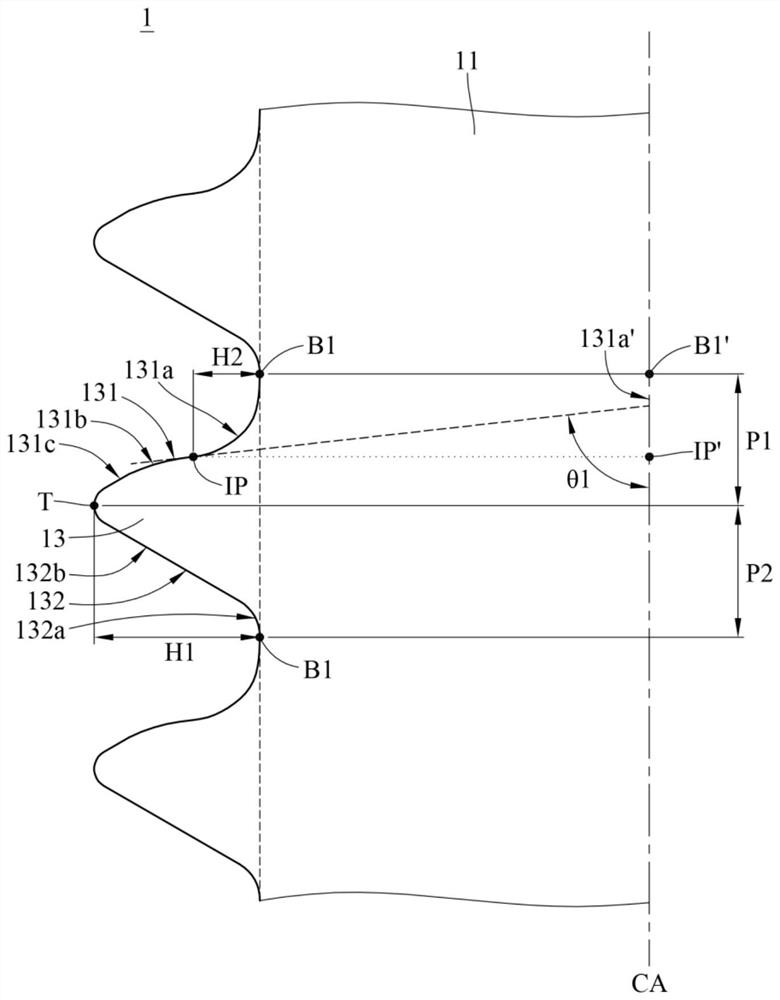

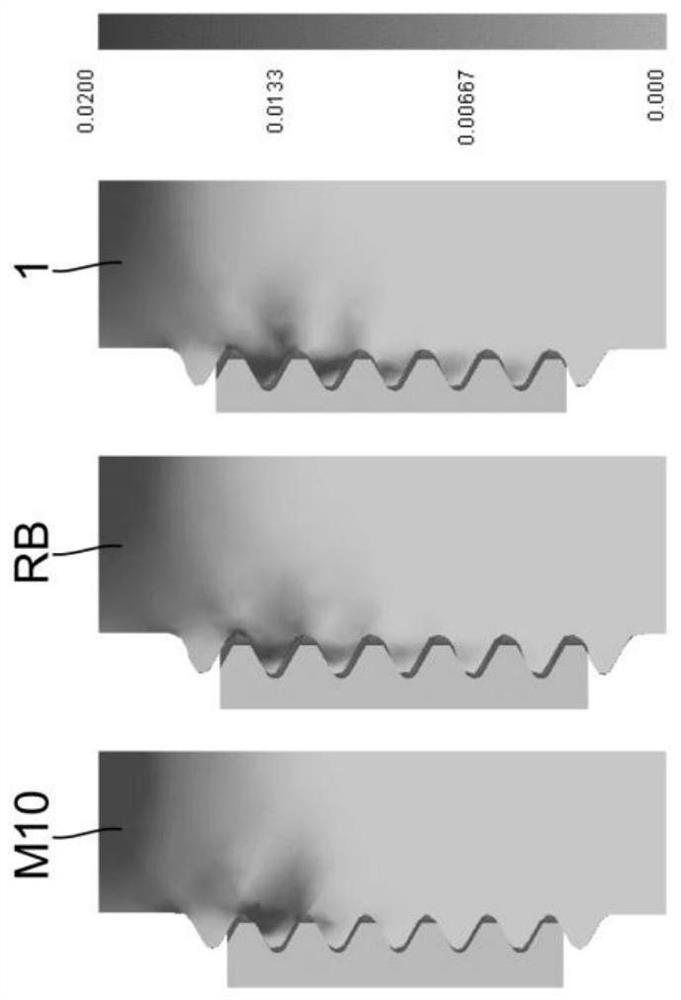

bolt

The invention discloses a bolt, which comprises a body, a head and a threaded part. The body has a central axis. The head is arranged at one end of the body. The threaded portion spirally surrounds and connects to the body along the central axis. The threaded part has a bearing surface facing the head. The load-bearing surface is a surface with a continuous slope or an inflection point. The load-bearing surface includes a concave curved surface, a convex curved surface and a load-bearing tooth ventral surface. The concave curved surface touches the body, and the convex curved surface is farther away from the body than the concave curved surface. One side of the convex curved surface is connected to the concave curved surface and the other side of the convex curved surface is connected to the load-bearing tooth ventral surface .

Owner:CHUN YU WORKS

A kind of high temperature resistant segmental curing epoxy paint and its application method

ActiveCN106010127BNo crackDoes not reduce adhesionFireproof paintsEpoxy resin coatingsNitrile rubberHexahydrophthalic anhydride

The invention relates to high-temperature resistant sectional curing epoxy paint and a use method thereof. The high-temperature resistant sectional curing epoxy paint comprises a component A, a component B and a component C which are mixed in a certain ratio, wherein the component A is an epoxy resin component which comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic epoxy resin, carboxyl terminated nitrile rubber modified tetra-glycidyl amide type epoxy resin, aluminium oxide, micron-grade and nanometer-grade aluminum nitride balls, fumed silica, a wetting dispersant and a coupling agent; the component B is a first curing agent component which comprises a YH-82 epoxy curing agent, a C-1041 cardanol epoxy resin curing agent, DMP(Dimethylphthalate)-30, fumed silica and micron-grade aluminum nitride balls; the component C is a second curing agent component which comprises hexahydrophthalic anhydride, fumed silica and micron-grade aluminum nitride balls. The high-temperature resistant sectional curing epoxy paint prepared by the invention has the effects of low temperature pre-curing for avoiding uniform paint films, and high temperature curing, thereby keeping high strength and good adhesion of the paint films formed by low temperature curing.

Owner:中国森田企业集团有限公司

High-strength silicate/polyurethane urea-based composite reinforcing material and preparation method thereof

A component A is mainly composed of sodium silicate water glass, lithium silicate water glass, glycerol and water; a component B is composed of polyphenyl polymethylene polyisocyanate, a polyurethane prepolymer and trioctyl citrate; and a component C is composed of a DMAEE catalyst, a BDMA catalyst, an N, N-dimethylcyclohexylamine catalyst, an EFKA-2550 defoaming agent, an UN-025 anti-hydrolysis agent, an XY-KM003 anti-mildew agent and an HY11190 ultraviolet light absorber. The high-strength silicate / polyurethane urea-based composite reinforcing material can be obtained by uniformly stirring and mixing the component A and the component C, defoaming, and mixing and reacting with the defoamed component B through a mixing head of a grouting machine. Or the high-strength silicate / polyurethane urea-based composite reinforcing material can be formed by mixing the materials through a mixing head of a grouting machine and directly grouting the materials into roadbed cracks, open joints or tunnel and coal seam cracks. The composite reinforcing material is high in comprehensive mechanical property and excellent in reinforcing effect on defects such as roadbed cracks and open joints or tunnel cracks, cracks and loose coal seams.

Owner:山西凝固力新型材料股份有限公司

VCU mounting bracket

Owner:LAUNCH DESIGN INC LTD

Milan tile and production method thereof

InactiveCN107383885AIncreased durabilityEvenly distributedRoof covering using tiles/slatesLaminationEconomic benefitsAlloy

The invention relates to a tile and a production method thereof, in particular to a Milan tile and a production method thereof, belongs to the technical field of building metal tiles and aims to solve the problems of poor stability, low durability and short service life of composite structures on metal tile surfaces in the prior art. An Al-Zn alloy coated steel sheet is stamped into a base plate with a stamping mold; the base plate is placed in a mold, silicone rubber and color sand are mixed and injected into the mold, and a mixed layer is formed on the upper surface of the base plate; the base plate in the step 2 is demolded and cured; protection layers are sprayed on two sides of a cured tile. The process is simple, color sand particles and silicone rubber have good contact uniformity, color sand is uniformly distributed, and the tile has uniform thickness, high stress dispersing performance and good economic benefits.

Owner:江苏特福特建材有限公司

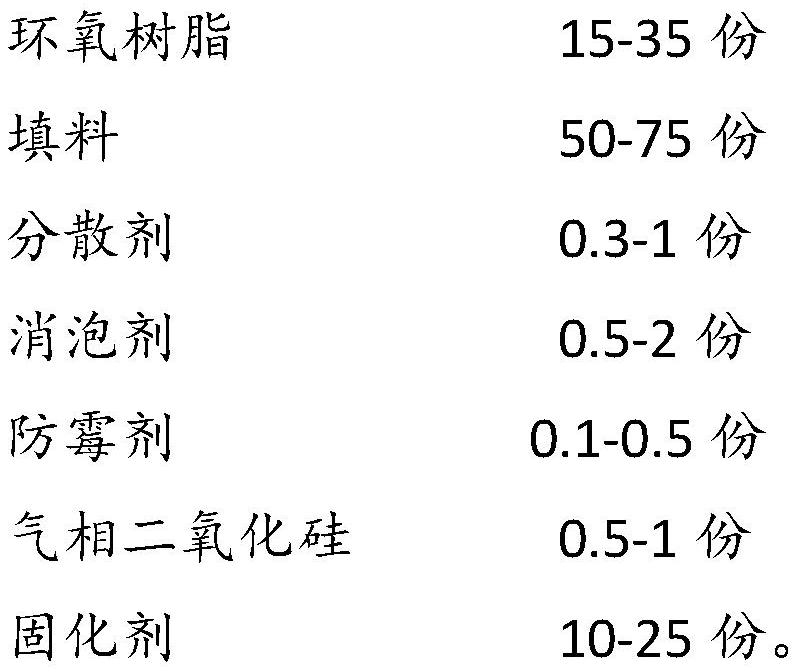

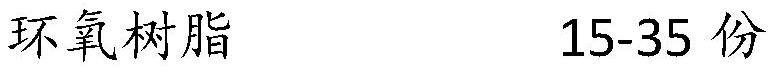

Epoxy orange-peel wall paint and preparation method thereof

InactiveCN113480910AEasy constructionShort construction periodAntifouling/underwater paintsPaints with biocidesPolymer scienceFirming agent

The invention discloses an epoxy orange-peel wall paint and a preparation method thereof. The epoxy orange-peel wall paint comprises the following raw materials by weight: 15-35 parts of an epoxy resin, 50-75 parts of a filler, 0.3-1 part of a dispersant, 0.5-2 parts of an antifoaming agent, 0.1-0.5 part of a mildew inhibitor, 0.5-1 part of fumed silica, and 10-25 parts of a curing agent. The epoxy orange-peel wall paint is simple and convenient to prepare, short in construction period, uniform in stress dispersion, not prone to cracking, compact in paint film, high in glossiness, excellent in moisture-proof and mildew-proof effect, high in chemical resistance, environmentally friendly and good in stability, can present the orange-peel three-dimensional aesthetic artistic effect, and meets the requirements of the market and consumers.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

A kind of women's shoes with anti-cracking vamp and its preparation method

The application relates to the field of shoes, and discloses a women's shoe with an anti-crack vamp and a preparation method thereof. A women's shoe with an anti-cracking vamp, including a vamp and a sole, a flax fiber layer is bonded to the lower surface of the vamp, and a coating agent is coated on the upper surface of the vamp, and the coating agent includes the following parts by weight Raw materials: 40-50 parts of polybutylene terephthalate; 5-8 parts of phenylenediamide phthalamide; 3-4 parts of dicyclopentadiene; 1-2 parts of cross-linking agent; the preparation method is: S1. Preparation of coating agent; S2. Surface coating of shoe upper; S3. Women's shoe molding; The advantages of this application are: phenylenediamide and dicyclopentadiene are cross-linked to form a cross-linked network, and then combined with thread Blending of polybutylene terephthalate, so that polybutylene terephthalate randomly penetrates into the cross-linked network, can form a dense and loose two-phase network structure, and destroy the uniformity of the cured network , which is conducive to stress dispersion, which can play a toughening role and improve the anti-cracking performance of the upper.

Owner:温州美联美鞋业有限公司

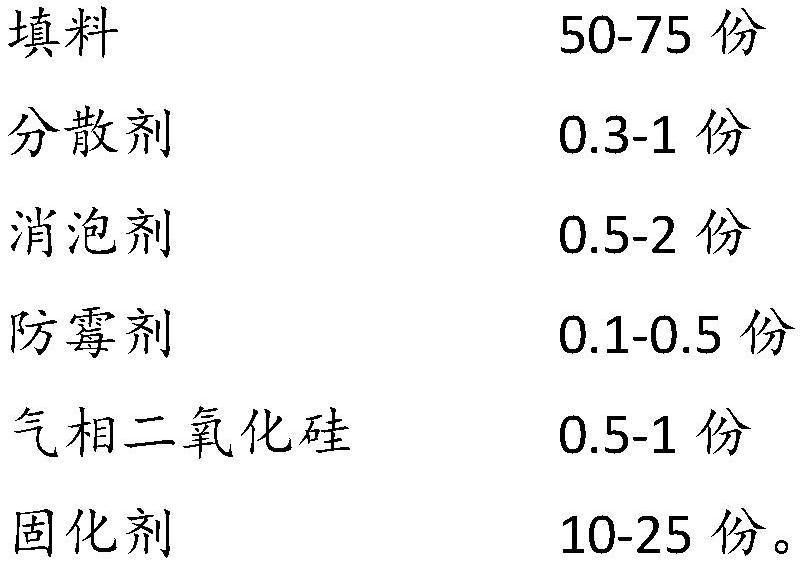

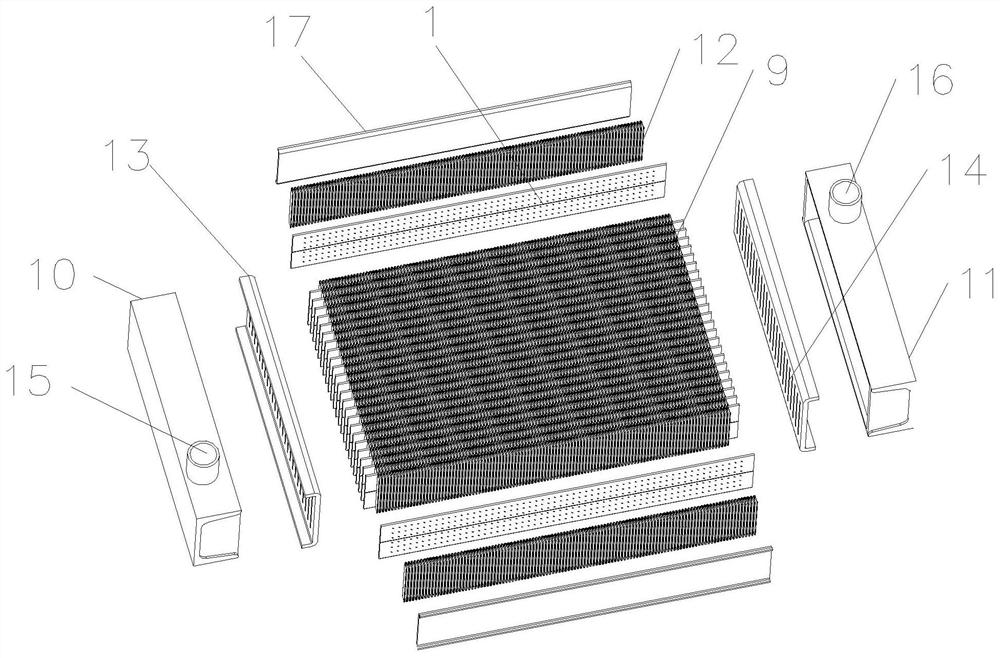

Oil cooler formed by staggered dotting oil cooler pipes

ActiveCN112682500AGuaranteed to workImprove spoiler effectInternal combustion piston enginesGear lubrication/coolingWorking pressureThermal efficiency

The invention discloses an oil cooler formed by staggered dotting oil cooler pipes. The oil cooler comprises a body, and the body comprises a core, an oil inlet chamber and an oil outlet chamber. The core comprises heat dissipation belts and the oil cooler pipes, the heat dissipation belts and the oil cooler pipes are arranged alternately, main pieces are welded to the two ends of the core, and oil passing holes are formed in the positions, corresponding to the oil cooler pipes, of the main pieces. The oil inlet chamber and the oil outlet chamber are welded to the main pieces of the core correspondingly, a groove is formed in a pipe body of each oil cooler pipe, and protection plates are welded to the two heat dissipation belts on the outer layer correspondingly. The oil cooler is small in weight, high in strength, capable of bearing large working pressure, high in assembling speed, convenient and fast to install, high in sealing performance and small in flow resistance and wind resistance. The oil cooler pipe is high in overall strength and good in stress dispersion, deformation, leakage and the like are not likely to occur in the using process, and the heat exchange efficiency, the sealing quality and the stability of the oil cooler are guaranteed. The oil cooler and the accessories used by the oil cooler have wide popularization and application value, and the market competitiveness of enterprises is improved.

Owner:NANNING ANHE MECHANICAL EQUIP CO LTD

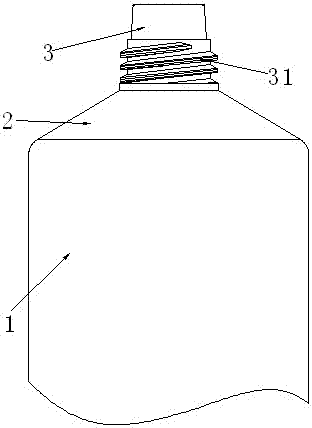

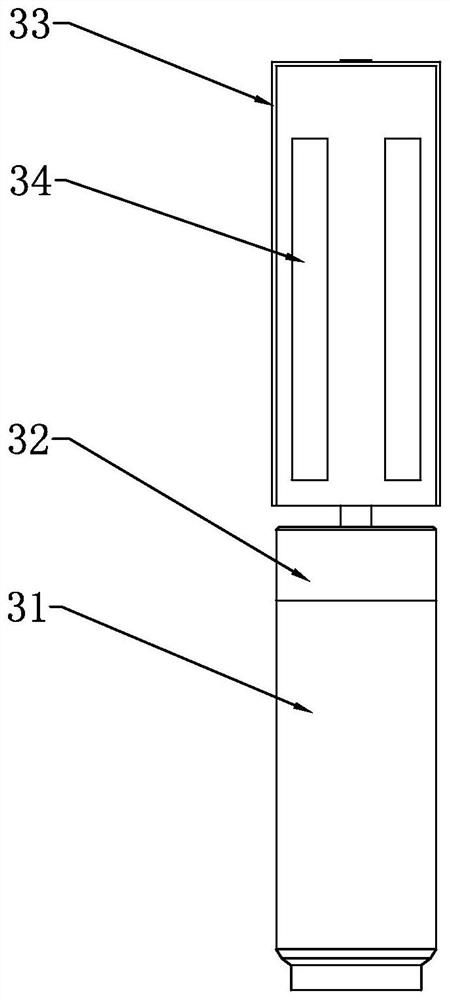

Soft-bag type cosmetic container

PendingCN107960722AEnsure the firmness of the connectionAdapt to structural requirementsPackaging toiletriesPackaging cosmeticsLinear low-density polyethylenePolymer science

The invention discloses a soft-bag type cosmetic container. The cosmetic container solves the problem that there are a lot of cosmetics remaining in existing cosmetic containers after the cosmetics are used. According to an adopted technical measure, the soft-bag cosmetic container includes a pipe body, a pipe shoulder and a cylindrical hollow liquid outlet head, the liquid outlet head is connected to the pipe shoulder, and the pipe shoulder is connected to the pipe body. The cosmetic container is characterized in that the liquid outlet head and the pipe shoulder are made of a homogenous material and formed in an injection molding mode, wherein the homogenous material is linear polyethylene with low density, and the pipe body is of a multi-layer structure; the wall thickness of the pipe shoulder is within a range from 0.4 mm to 0.8 mm, the wall thickness of the pipe body is within a range from 0.35 mm to 0.5 mm, and the wall thickness of the liquid outlet head is at least twice largerthan that of the pipe shoulder.

Owner:郑春根

A kind of high temperature resistant segmented curing epoxy paint and using method thereof

ActiveCN103319984BNo crackDoes not reduce adhesionEpoxy resin coatingsGas phaseHexahydrophthalic anhydride

The invention discloses a high temperature-resistant step-cured epoxy paint and an application method of the paint. The high temperature-resistant step-cured epoxy paint is obtained by mixing ingredient A, ingredient B and ingredient C in A certain proportion, wherein the ingredient A is an epoxy resin ingredient and comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic aldehyde epoxy resin, carboxylate-terminated nitrile butadiene rubber modified tetraglycidylamine type epoxy resin, aluminum oxide, aluminum nitride, fumed silica, a wetting dispersant, and a coupling agent; the ingredient B is a first curing agent ingredient and comprises an YH-82 epoxy curing agent, a C-1041 anacardol epoxy resin curing agent, DMP-30, fumed silica, and aluminum nitride; and the ingredient C is a second curing agent ingredient and comprises hexahydrophthalic anhydride, fumed silica, and aluminum nitride. The high temperature-resistant step-cured epoxy paint disclosed by the invention can be pre-cured at low temperature, does not form an unsmooth paint film, is cured at a high temperature, and remains the advantages of high strength and good adhesive force of the paint film which is cured at a high temperature.

Owner:广东顺召涂料有限公司

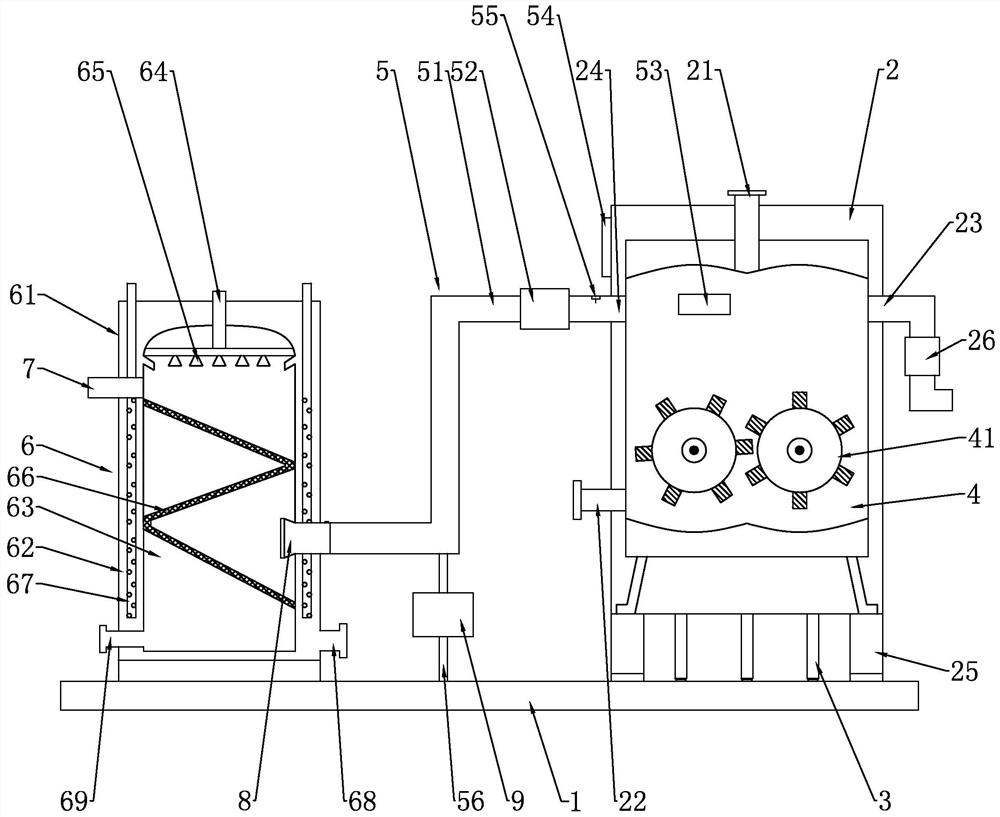

Internal mixer for V belt production and V belt capable of reducing dynamic heat generation

PendingCN114654614AEvenly distributedImprove filtering effectCombination devicesBeltsThermodynamicsFilter system

The invention relates to an internal mixer for V-belt production. The internal mixer comprises a bottom plate; the internal mixer body is provided with a feeding port, a discharging port, a first air inlet and a first air outlet, and the bottom of the internal mixer body is provided with supporting legs and a plurality of damping parts; a booster pump; a rotor is arranged in the internal mixing cavity; the exhaust system is used for exhausting waste gas in the internal mixing cavity; a filtration system; wherein the internal mixer body and the filtering system are both arranged on the bottom plate, the internal mixing cavity is formed in the internal mixer body, the feeding port and the discharging port are both communicated with the internal mixing cavity, the first air inlet and the second air outlet are both communicated with the internal mixing cavity, the booster pump is connected with the first air inlet in series, and the first air outlet is communicated with the exhaust system. Compared with the prior art, the internal mixer has the advantages that waste gas generated in the working process of the internal mixer can be effectively treated, and noise generated in the working process of the internal mixer is low.

Owner:浙江保尔力橡塑股份有限公司

Buffer material for pipe jacking and pipe jacking

ActiveCN102770622BPrecise positioningImproved stress distributionSleeve/socket jointsPipe laying and repairCushioningEngineering

Owner:SEKISUI PLASTICS CO LTD

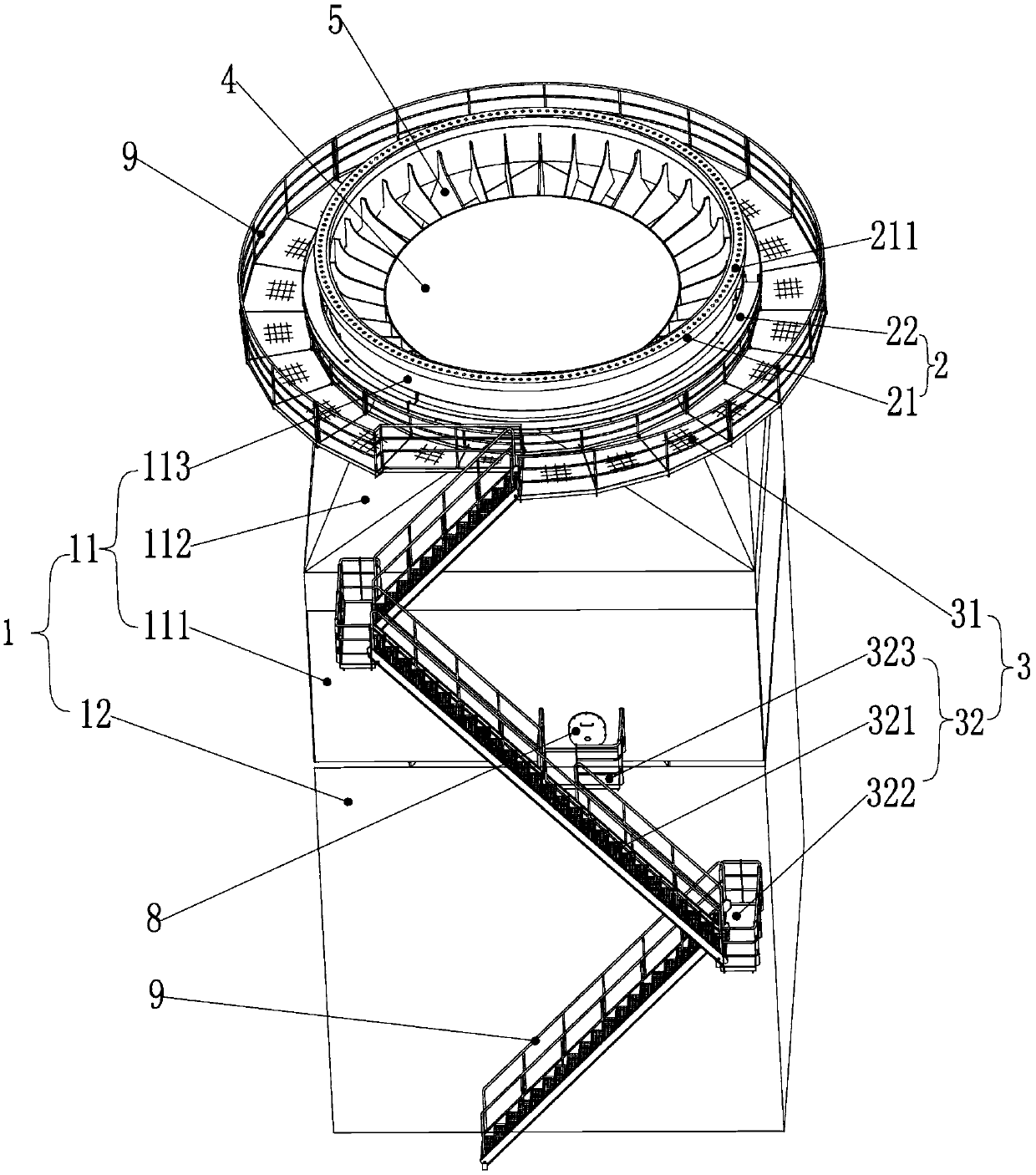

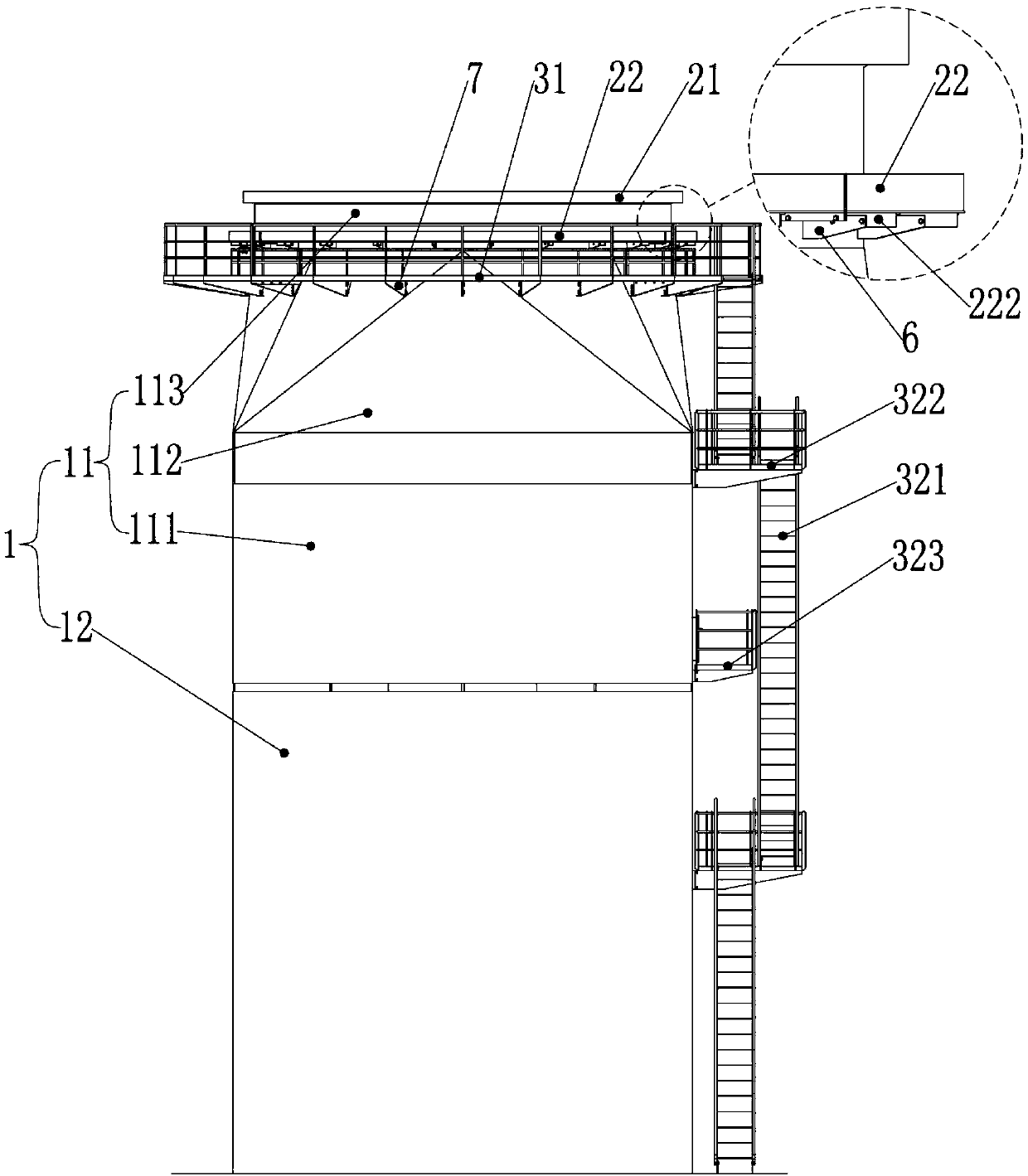

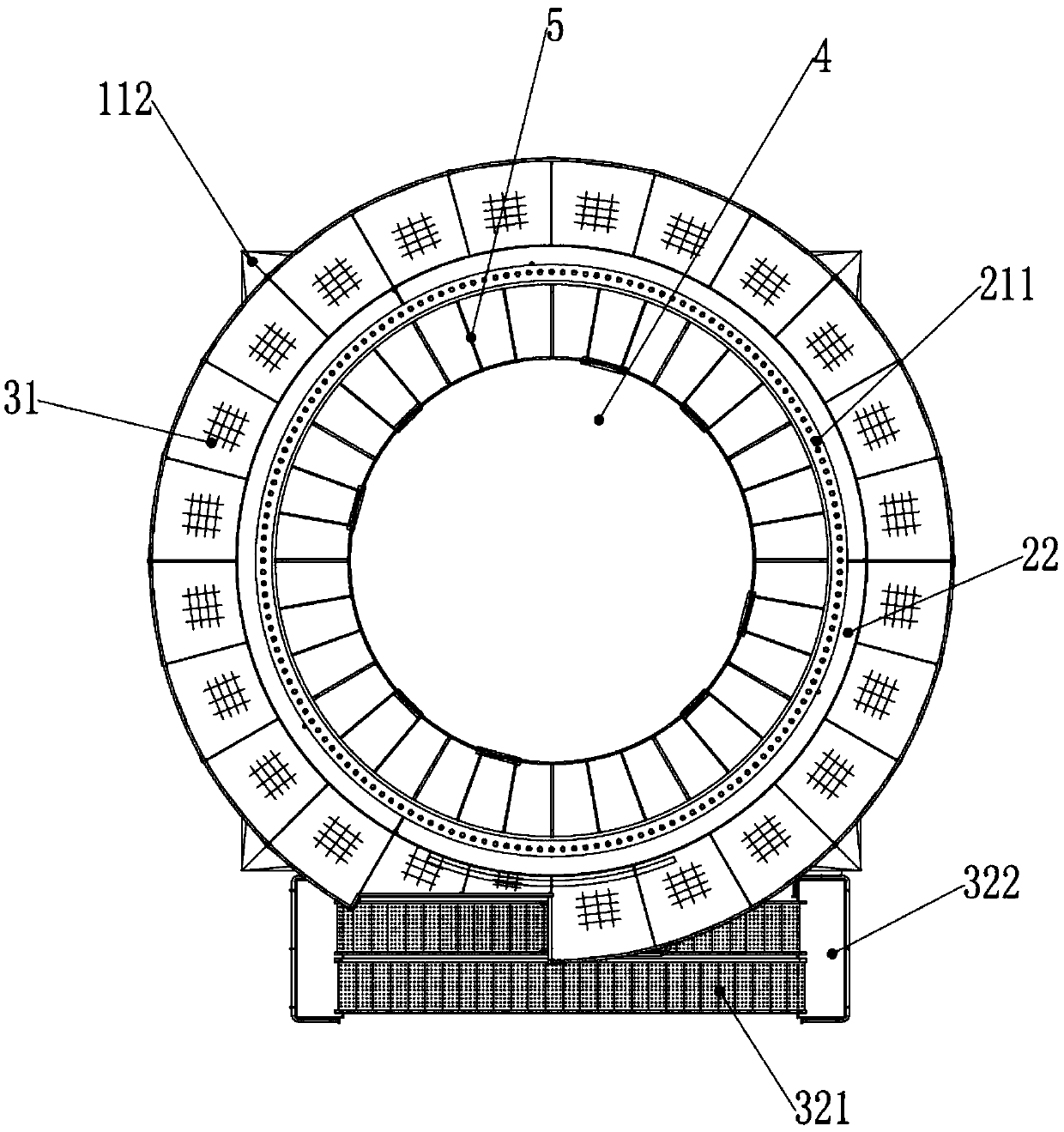

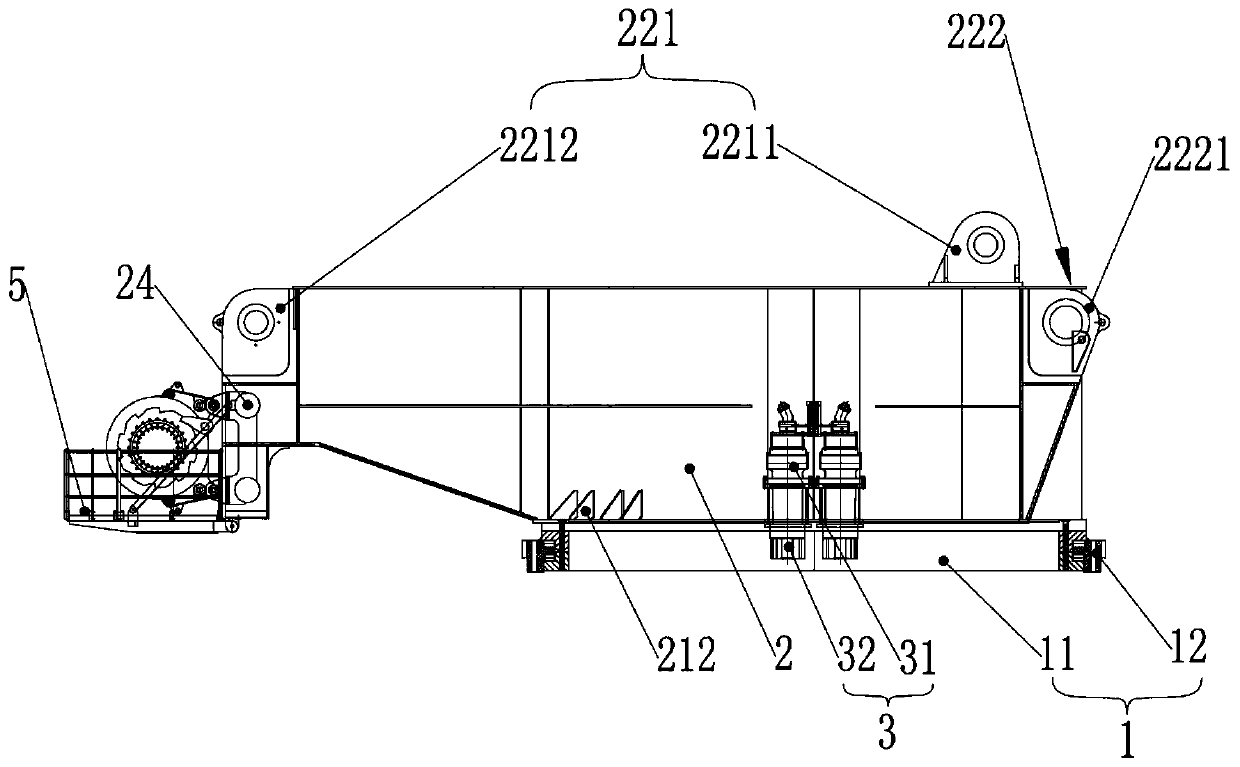

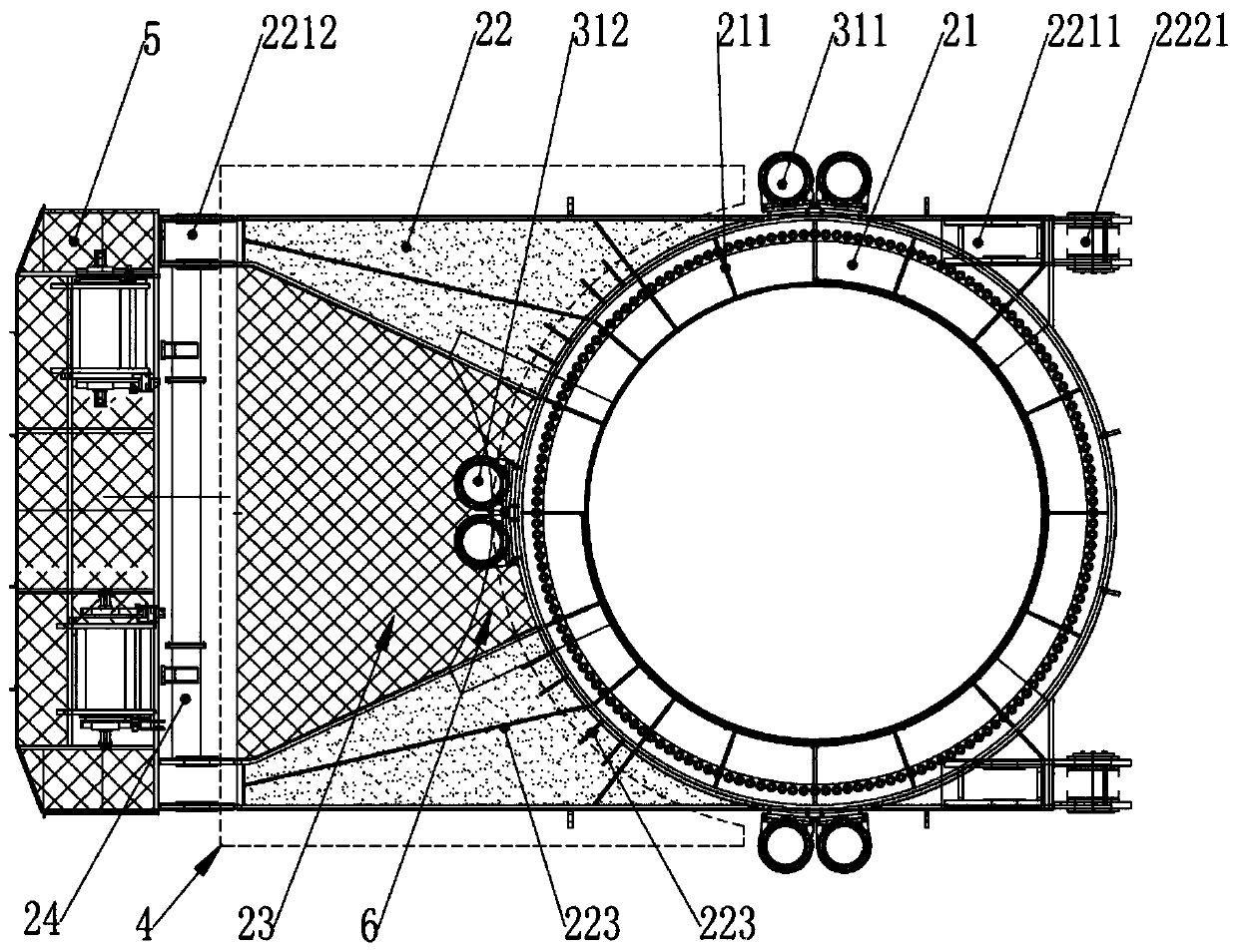

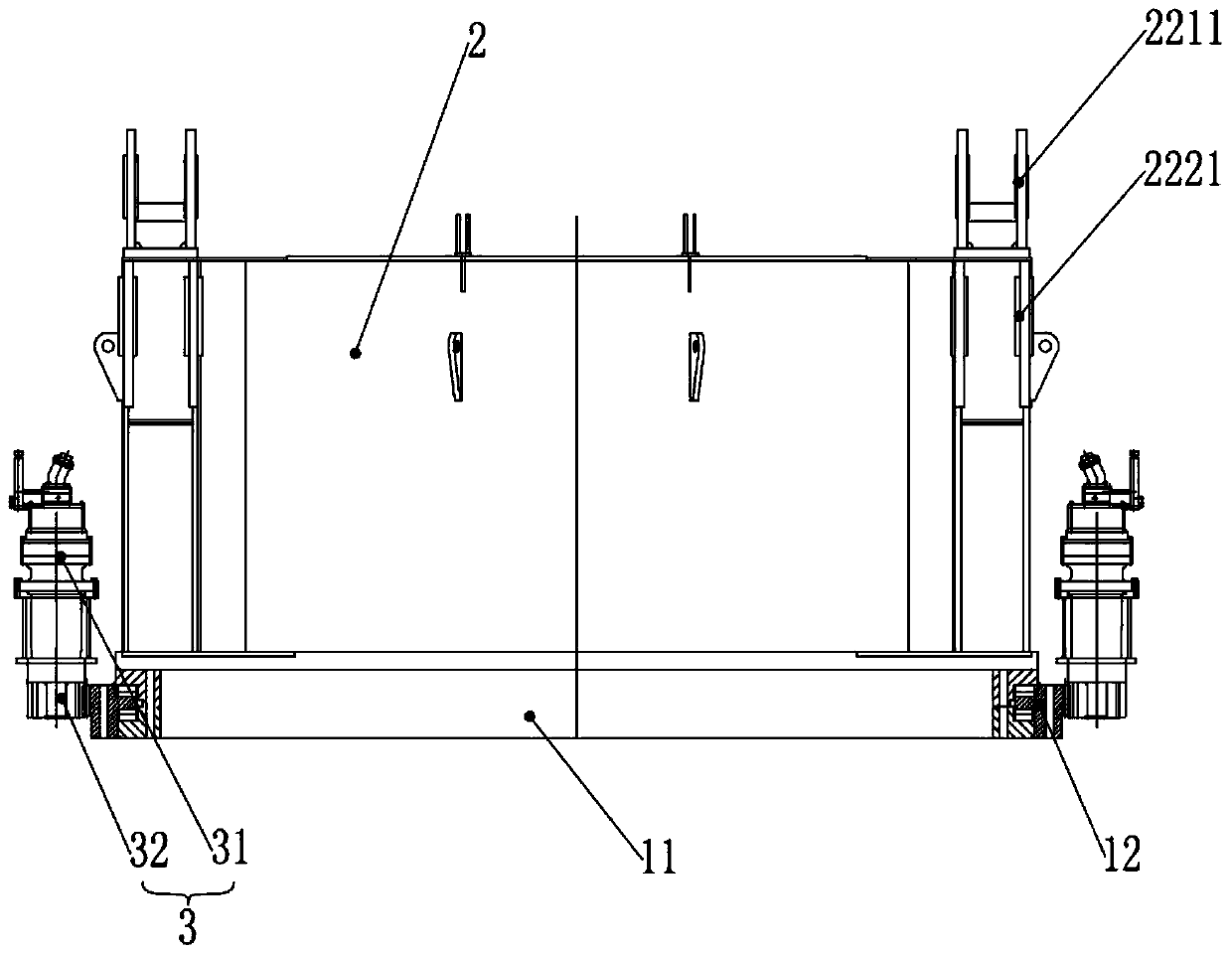

An installation base for an offshore platform crane

A mounting base of an ocean platform crane comprises a pedestal and a bearing device. The pedestal comprises an upper pedestal body and a lower pedestal body, the lower half part of the upper pedestal body is of a square cylinder structure, the upper half part of the upper pedestal body is of a trapezoidal-table structure for transition, and the top of the upper pedestal body is of a cylindrical structure for transition. The lower pedestal body is of a square cylinder structure. A cylindrical hole is formed in the pedestal in a penetrating mode, the top of the cylindrical hole and the cylindrical structure are of a concentric-ring structure, and first reinforcing rib plates are arranged between the cylindrical hole and the inner wall of the upper pedestal body and are symmetrically distributed with the cylindrical hole as the axis center. Edges of the two sides of each first reinforcing rib plate are matched with the cross section between the cylindrical hole and the inner wall of the upper pedestal body in shape, the edge of the top of each first reinforcing rib plate upwards tilts from the cylindrical hole to the inner wall of the cylindrical structure, and the tail end of each first reinforcing rib plate is in arc transition. The bearing device comprises a rotating device supporting ring and is mounted at the top of the cylindrical structure. The mounting base of the ocean platform crane is stable in bearing, more uniform in stress and more compact, stable and reasonable in structure, and the manufacturing cost is lowered.

Owner:江苏海龙风电科技股份有限公司

A slewing device for an offshore platform crane

A slewer of an ocean platform crane comprises a bearing device, a rotating body and a driving device. The bearing device comprises a supporting ring body and fixing pieces which are installed on the outer side of the supporting ring body. The rotating body comprises an annular sleeve and two supporting arms; the annular sleeve is vertically installed at the top of the supporting ring body; first reinforcing rib plates are arranged between the inner sleeve wall and the outer sleeve wall of the annular sleeve and vertically distributed with an inner sleeve as the axis in a central symmetry mode; the two supporting arms are connected to the two sides of the annular sleeve correspondingly and are parallel to each other; the rear end of each supporting arm is of a triangular column structure; the outer side faces of the two triangular column structures are parallel to each other; and the supporting arms and the annular sleeve are of an integrated structure. The driving device is installed on the outer side of the bottom of the rotating body and used for driving the rotating body to move rotationally with the supporting ring body as a rotating shaft. The slewer of the ocean platform crane can effectively disperse the stress effect and is higher in overall strength and bearing capacity and more balanced and stable in stress.

Owner:KEEN OFFSHORE ENG CO LTD

Toe structure of all-steel radial tire with inner tube

PendingCN112440630AImprove deformation resistanceEliminate destructionTyre beadsComposite materialAutomotive engineering

The invention relates to a toe structure of an all-steel radial tire with an inner tube. The toe structure is characterized in that a hard apex rubber core and a soft apex rubber core are sequentiallywrapped by a tire framework and a toe reinforcing layer in a U shape from inside to outside, the end head of the outer side of the tire framework is lower than the end head of the upper end of the soft apex rubber core, the two ends of the toe reinforcing layer are located below the two end heads of the tire framework respectively, an outer nylon protective layer is located on the outer side of the soft apex rubber core, the end head of the lower end of the outer nylon protective layer is located between the tire framework and the end head of the outer side of the toe reinforcing layer, the end head of the upper end of the outer nylon protective layer is lower than the end head of the upper end of the soft apex rubber core, an inner nylon protective layer is located on the outer side of the soft apex rubber core, and the end head of the lower end of the inner nylon protective layer is located on the inner side of the tire framework turn-up. According to the invention, by applying thetoe wrapping cloth structure and the tire bead lower wrapping cloth structure, the deformation resistance of the tire bead position of the tire is improved, and the damage to the tire toe caused by the stress concentration of the carcass turn-up endpoint and the bead ring endpoint is eliminated.

Owner:通力轮胎有限公司

Resin foam body and foam member

ActiveCN113677746AImproved stress distributionImprove heat resistanceFilm/foil adhesivesChemical industryPolymer sciencePolymer chemistry

Provided is a resin foam body that has high stress distributing capabilities and excellent heat resistance. A resin foam body according to the present invention has a cellular structure, an apparent density of 0.05 g / cm<3> to 0.50 g / cm<3>, a 50% compression load of 2.0 N / cm<2> to 30 N / cm<2>, and satisfies the relationship in formula (1) between the apparent density D (g / cm<3>) and the residue R (%) at 650 DEG C. (1): 1 <= {(100-R) / D} / 100 <= 10.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com