An installation base for an offshore platform crane

A technology for installing bases and offshore platforms, applied in cranes and other directions, can solve the problems of large space occupied by the installation base and increased volume of the installation base, and achieve the effects of material saving, low structure design and small structure size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

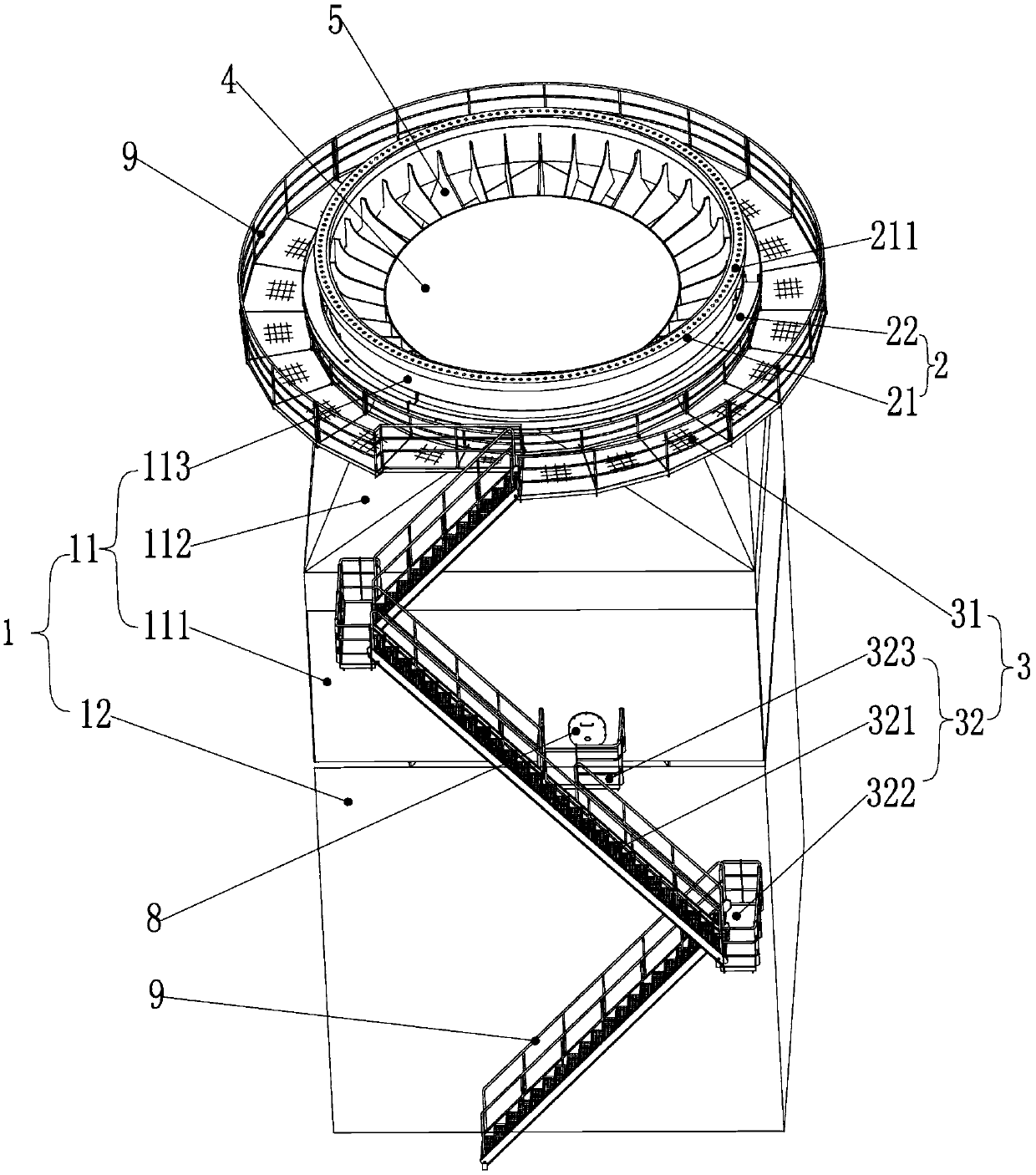

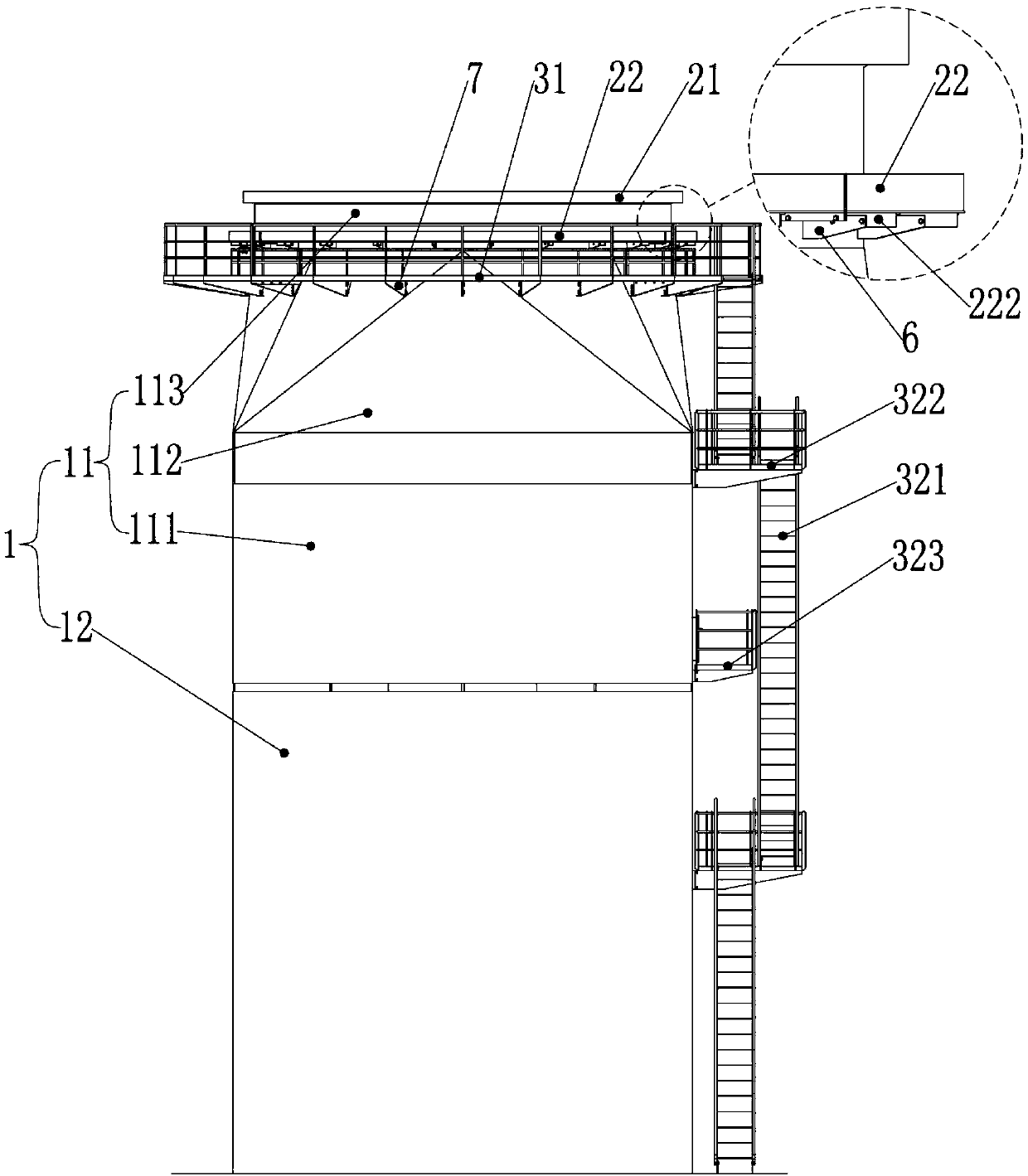

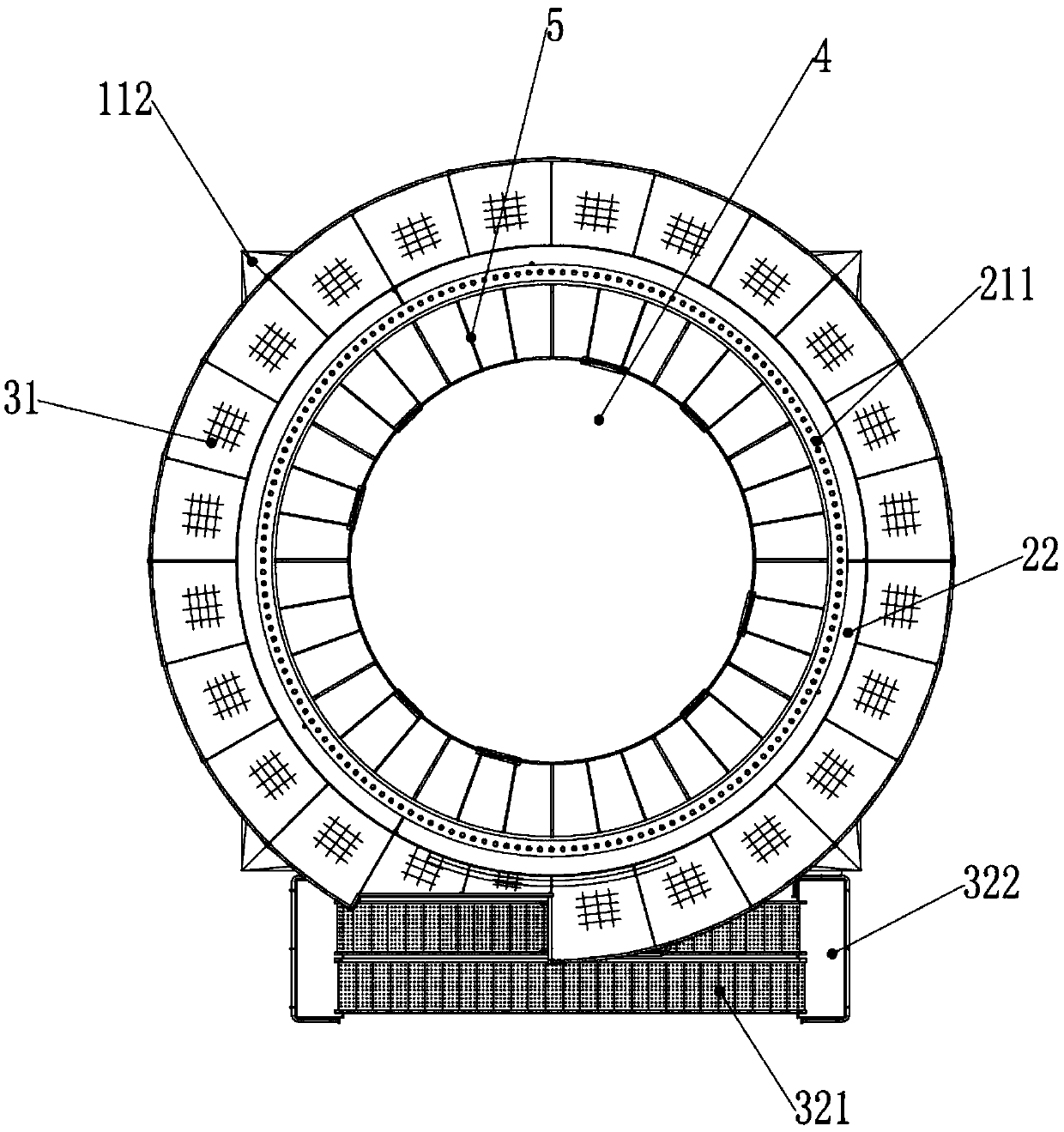

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0026] like figure 1 and image 3 As shown, an installation base of an offshore platform crane includes a base 1 and a bearing device 2; the base 1 includes an upper base 11 and a lower base 12; the lower half of the upper base 11 is a square column structure 111 , the upper half is a trapezoidal platform structure 112 transition, and its top is a cylindrical structure 113 transition; the lower base 12 is a square column structure; the upper base 11 and the lower base 12 are welded and fixed to each other; the base 1 A circular column hole 4 for installing pile legs is provided through the interior, and the top of the circular column hole 4 and the cylindrical structure 113 are concentric ring structures;

[0027] A plurality of first rib plates 5 are arranged between the circular column hole 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com