Patents

Literature

624results about How to "Uniform stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

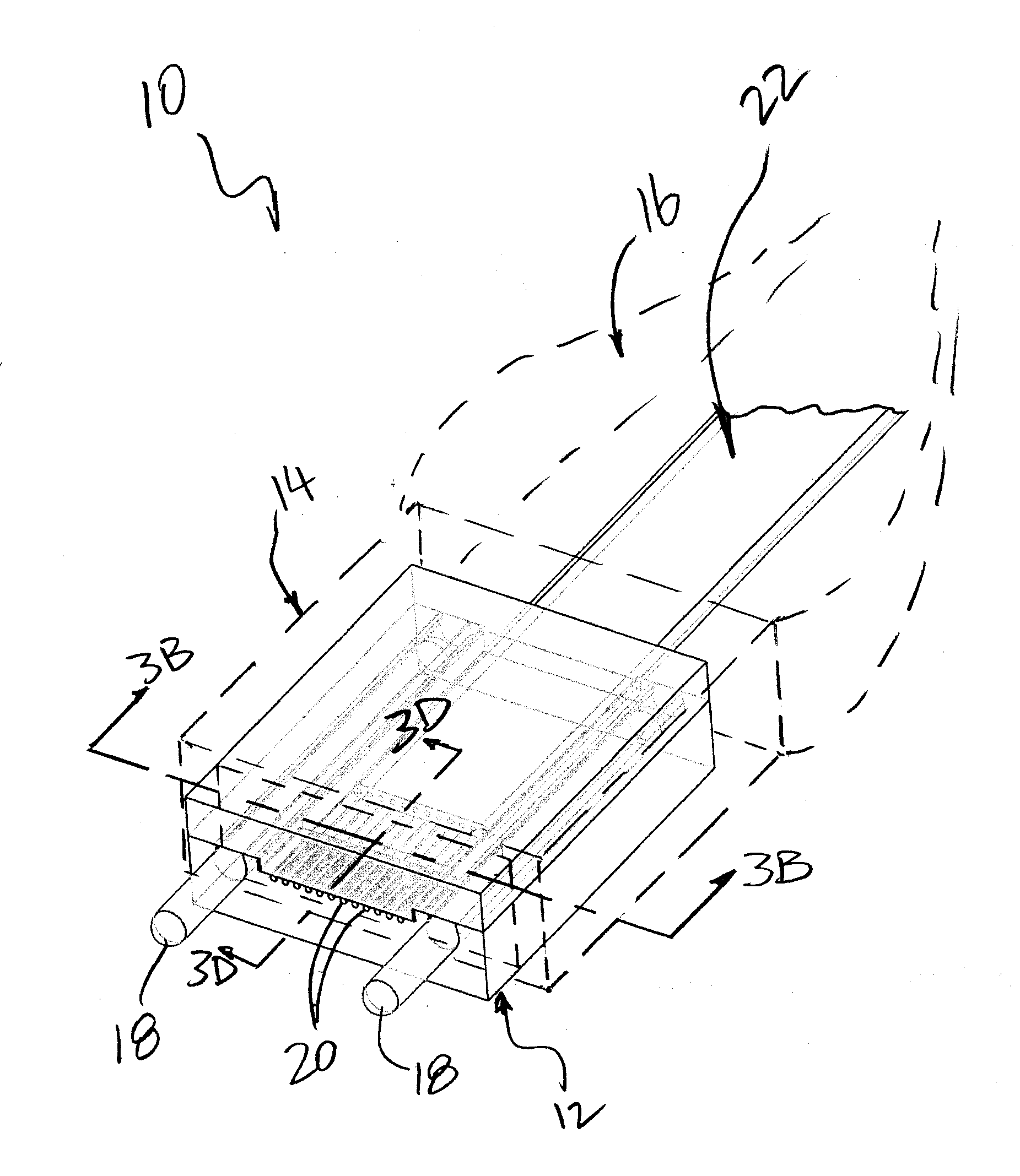

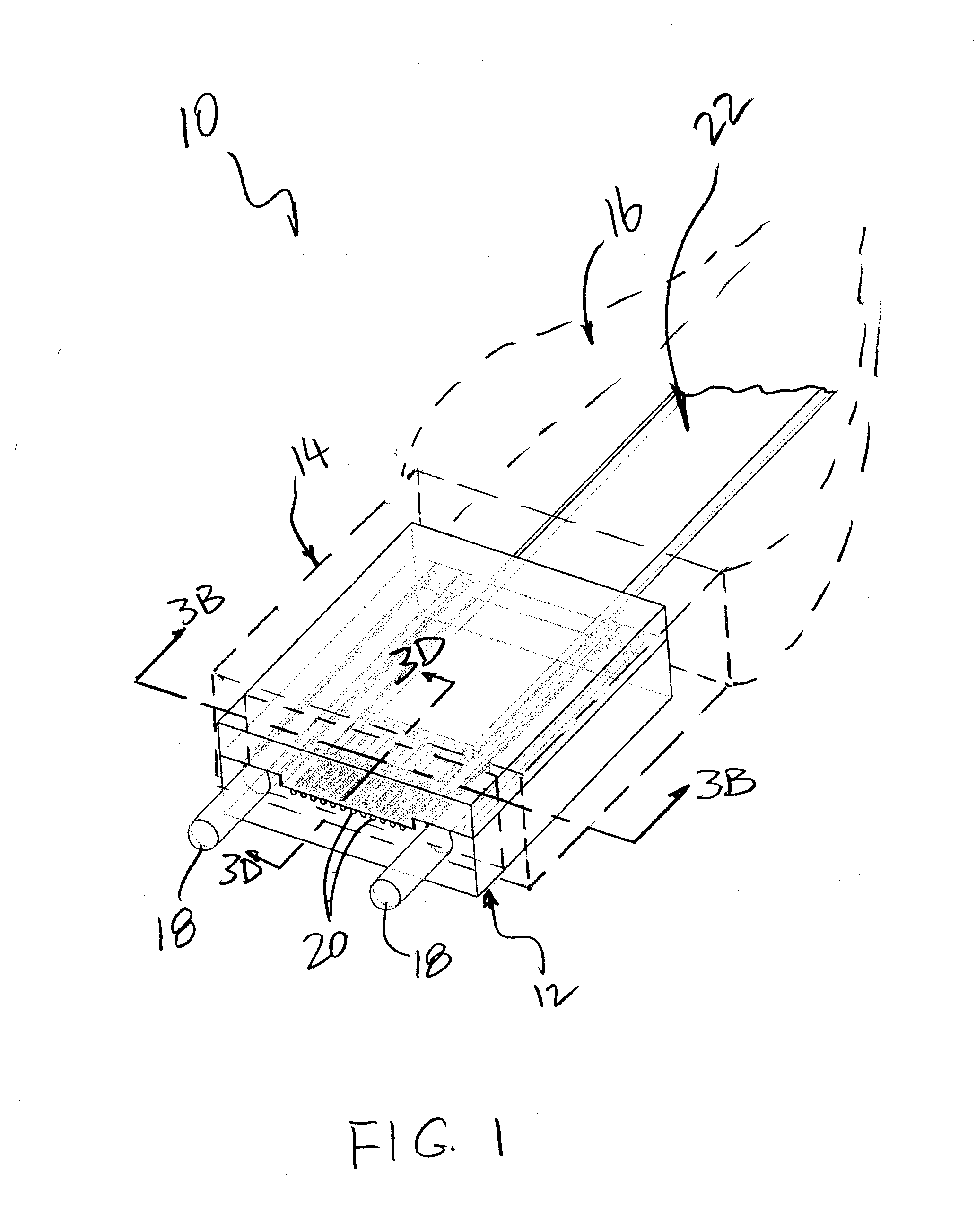

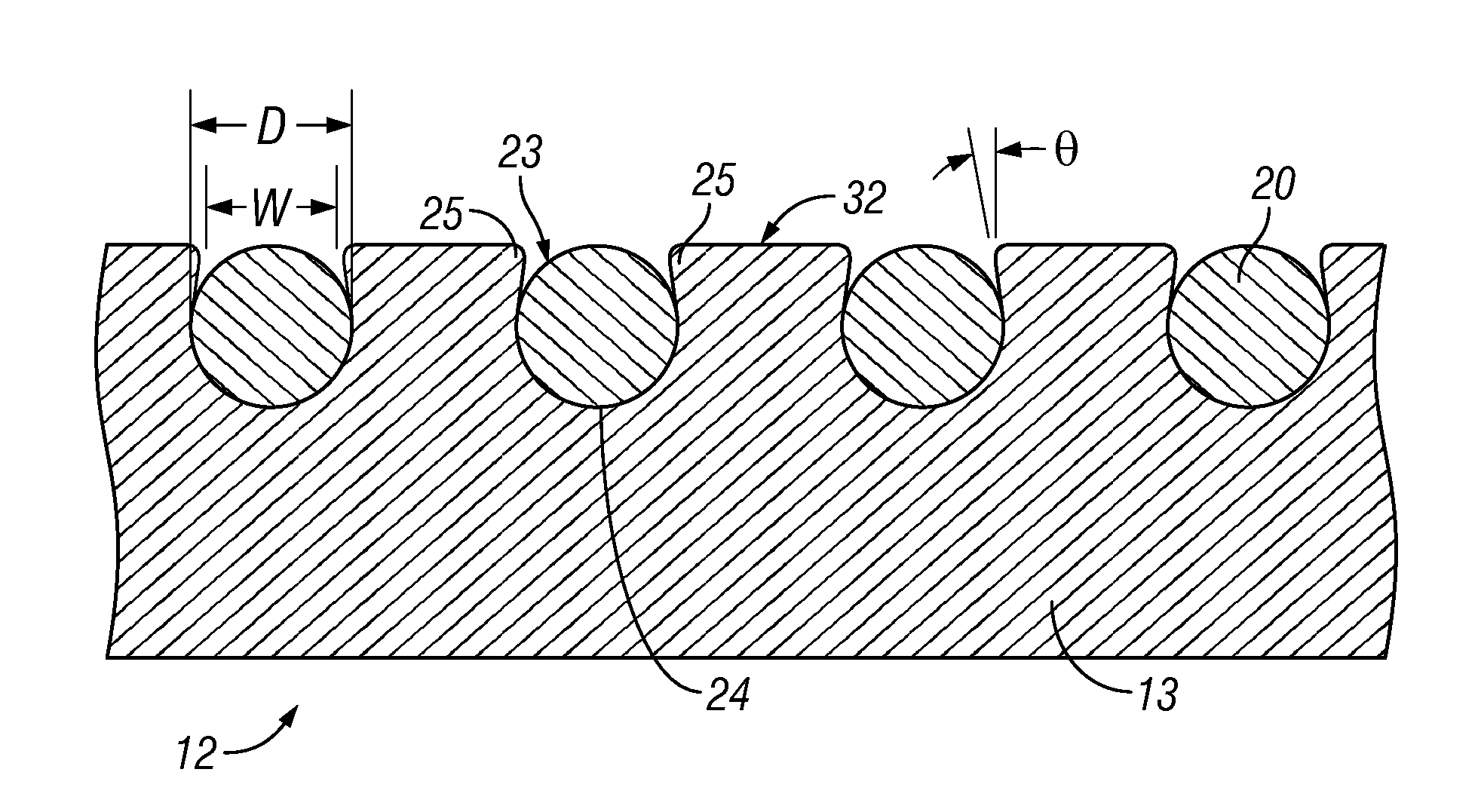

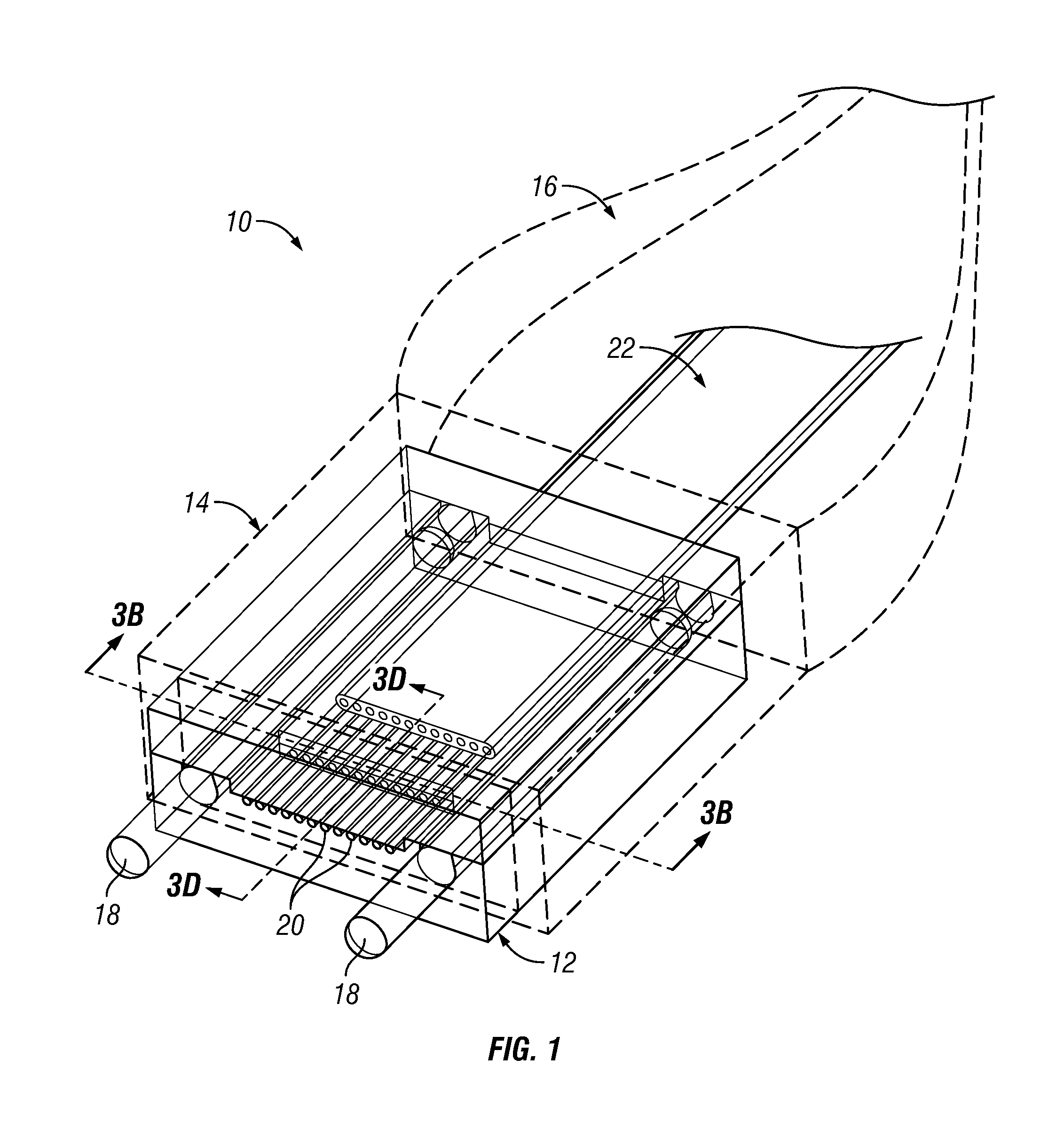

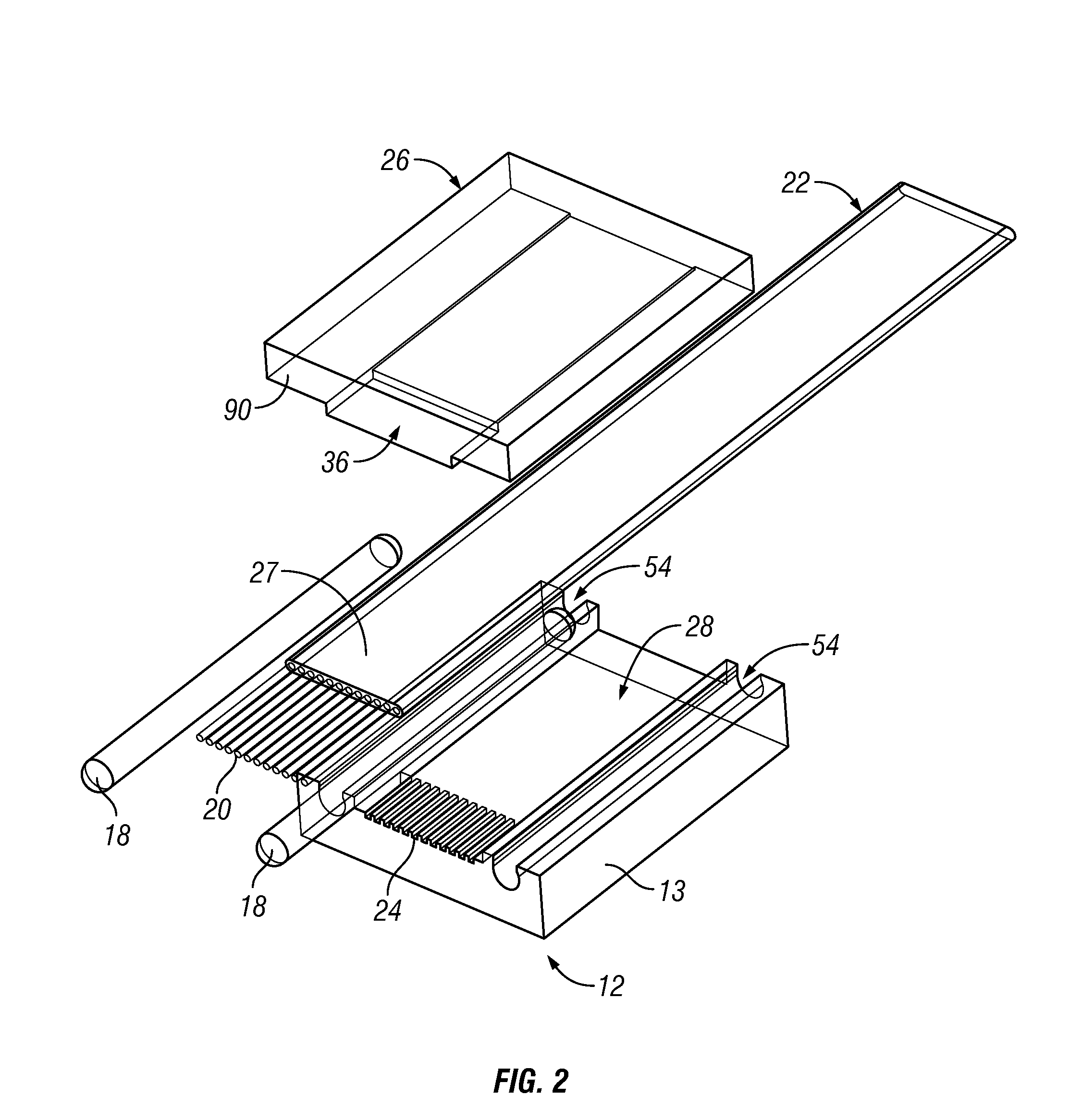

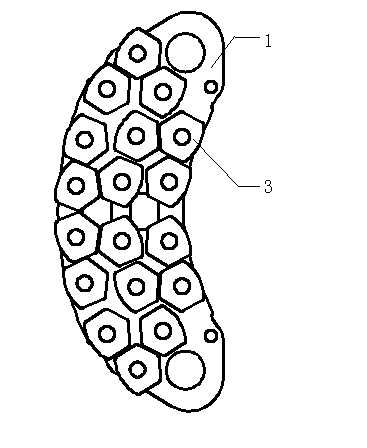

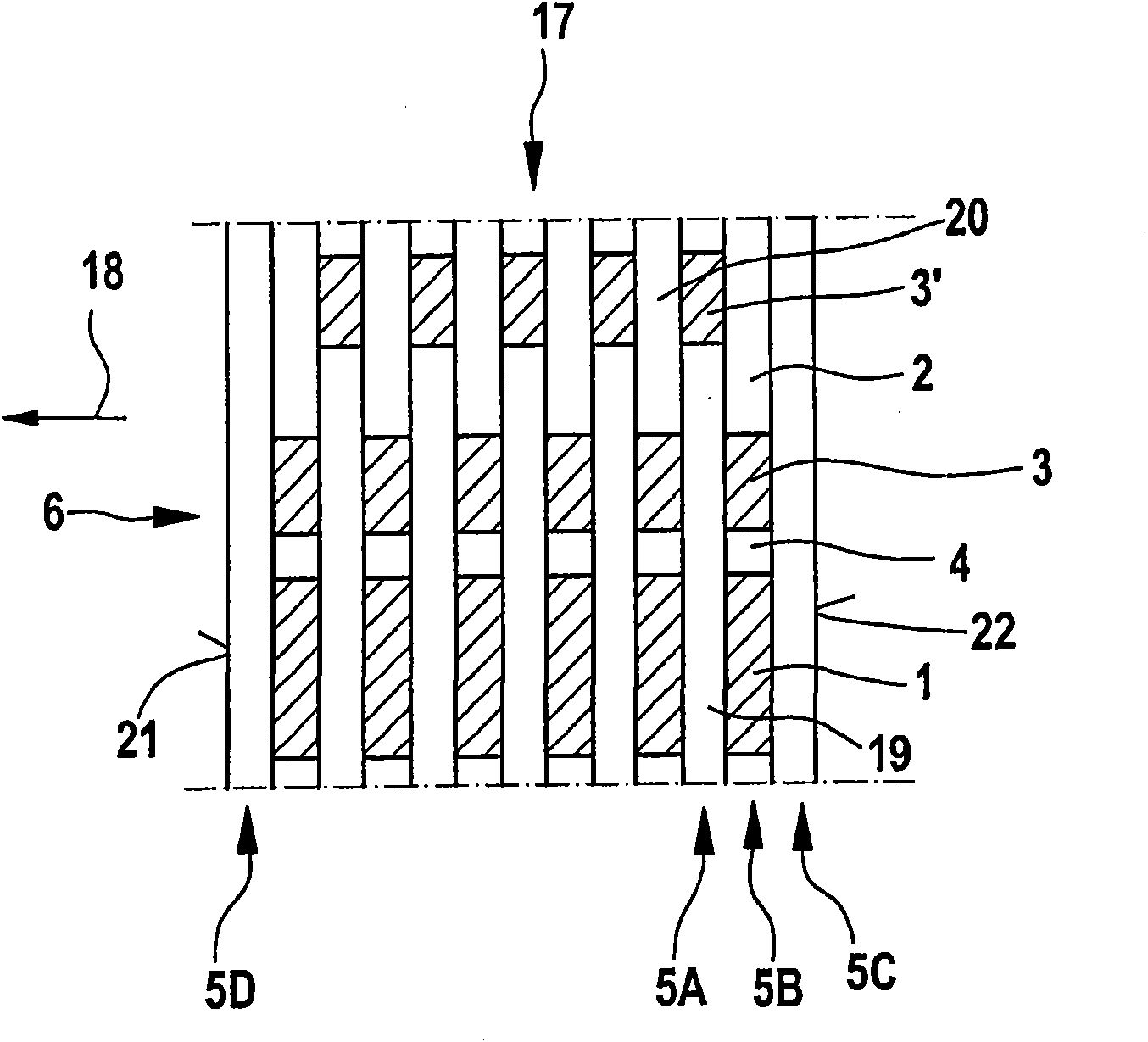

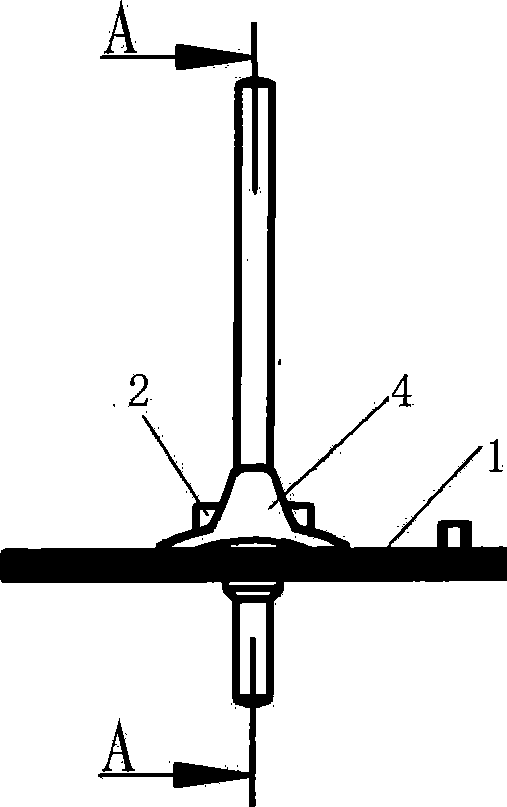

Optical fiber connector ferrule having open fiber clamping grooves

A ferrule for an optical fiber connector having open fiber clamping grooves. The ferrule has a body having a plurality of open grooves for clamping the terminating end sections of optical fibers. At least a section of the longitudinal opening of the groove is provided with opposing lips to provide a clamping effect. The width of the longitudinal opening defined between the lips along at least a section of the grooves is narrower than the diameter of the optical fibers to create a tight fit. The grooves and the width of the longitudinal groove openings are shaped and sized to retain the fibers without any clearance to allow for movement of the fiber relative to the groove. Similar grooves may be provided in the ferrule body for alignment guide pins. The grooves are precision formed by high throughput processes, such as stamping and extrusion.

Owner:SENKO ADVANCED COMPONENTS

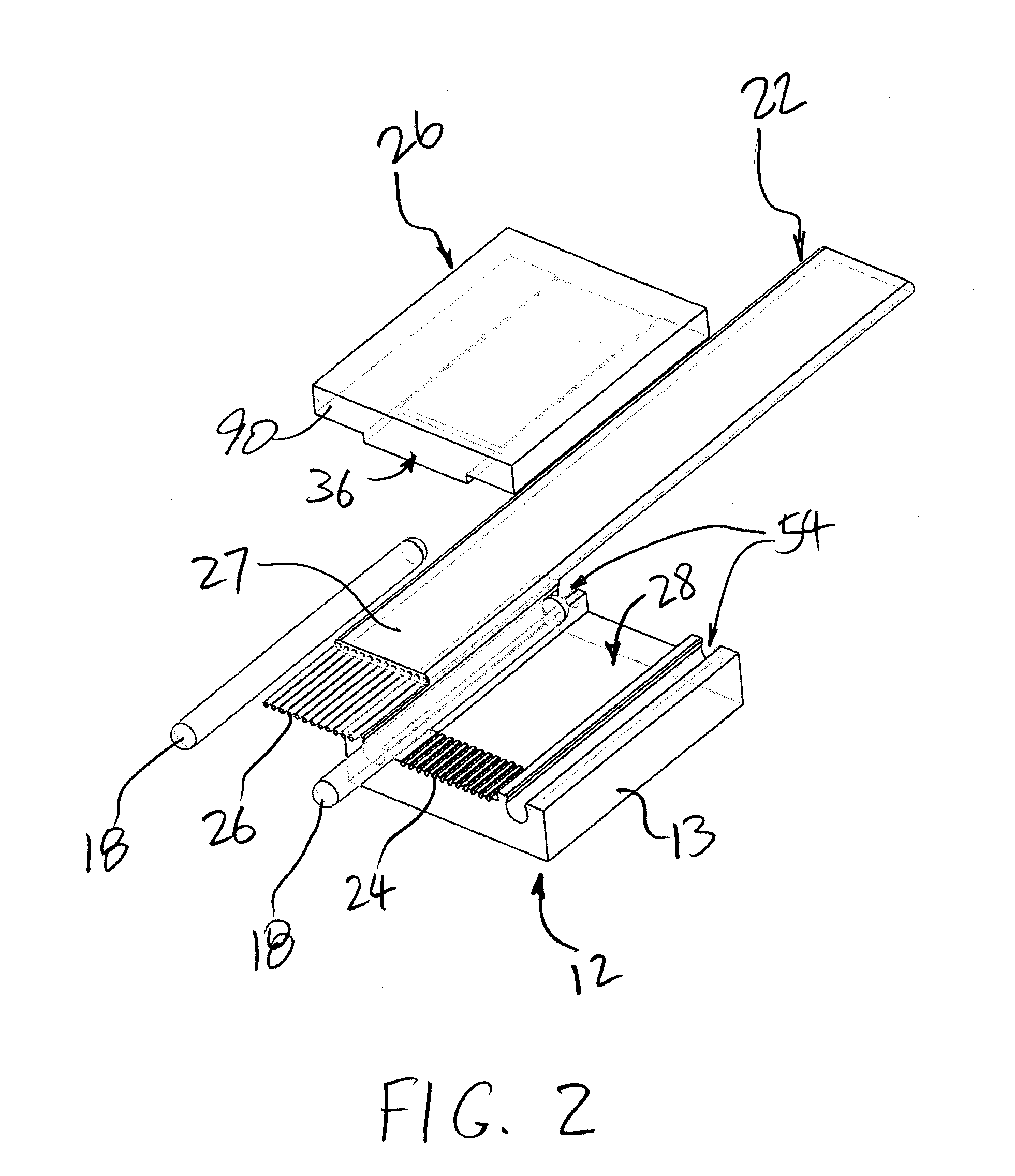

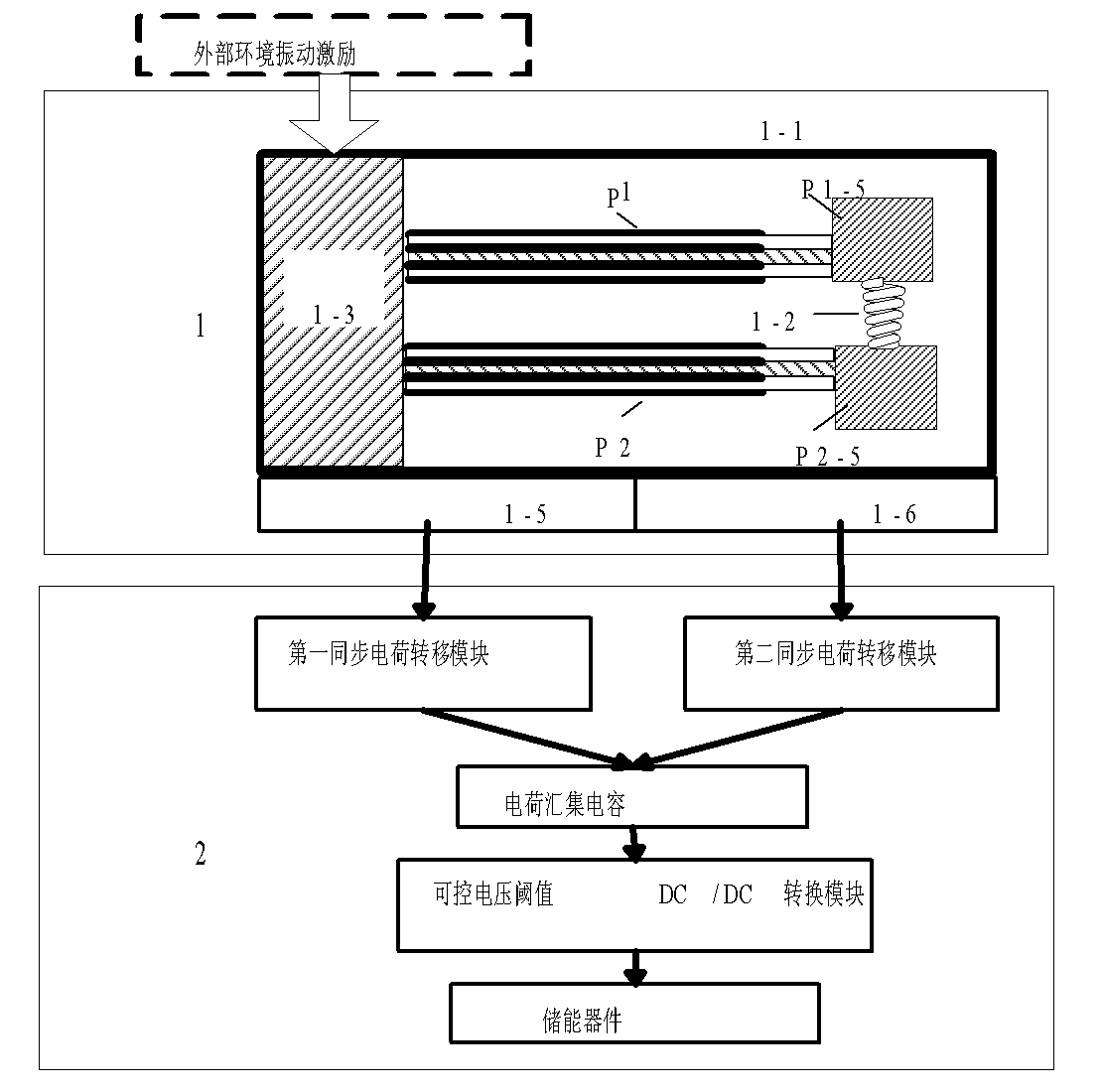

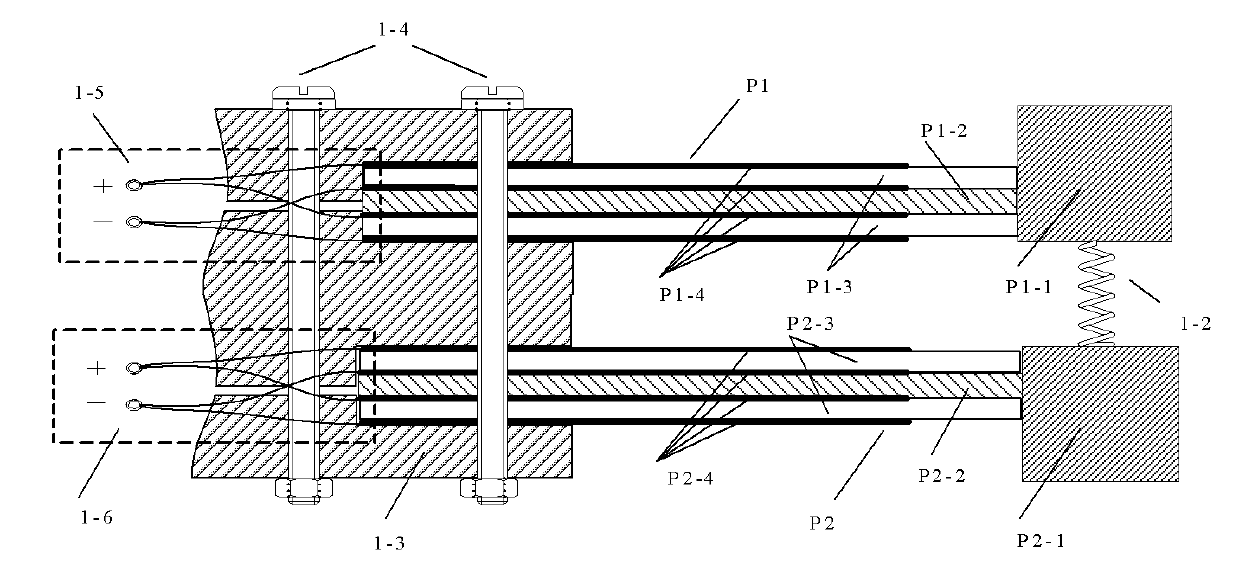

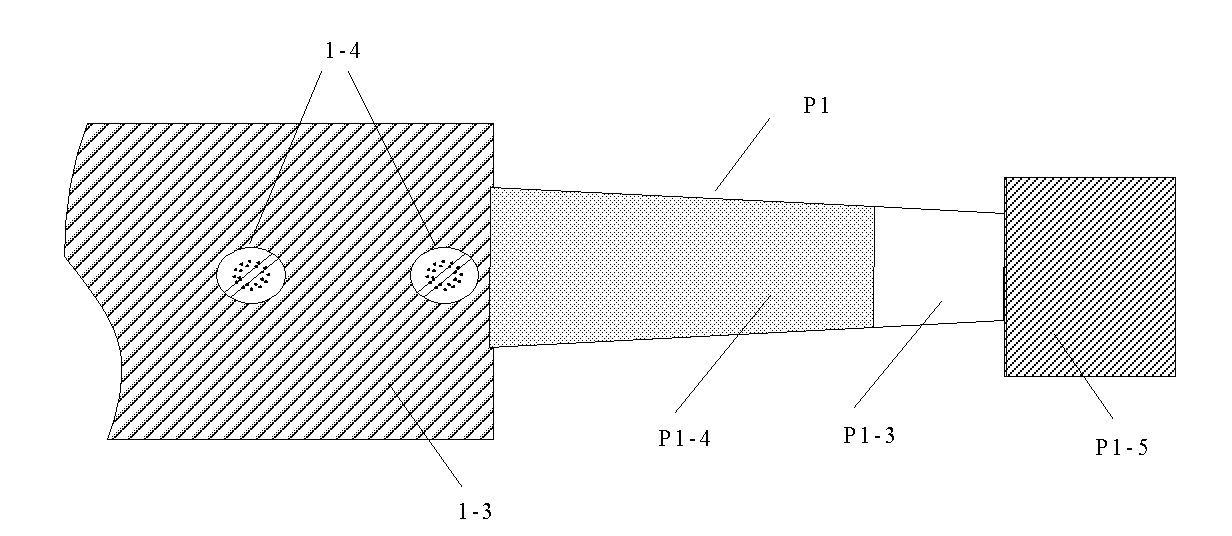

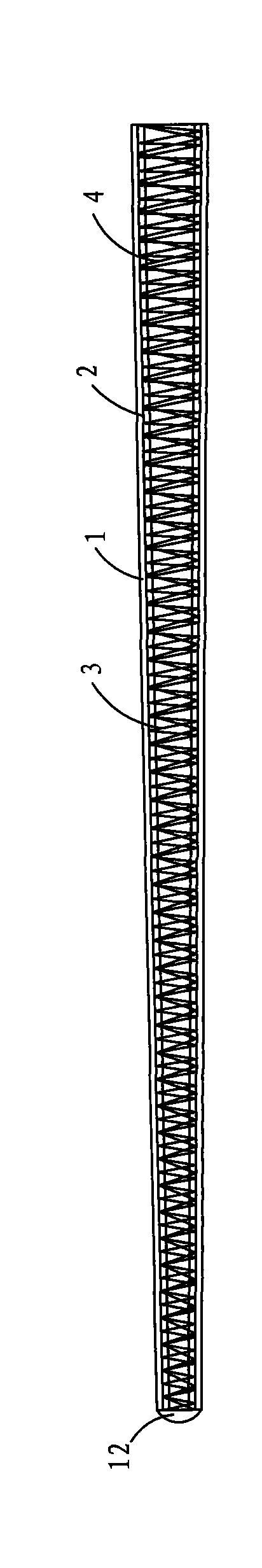

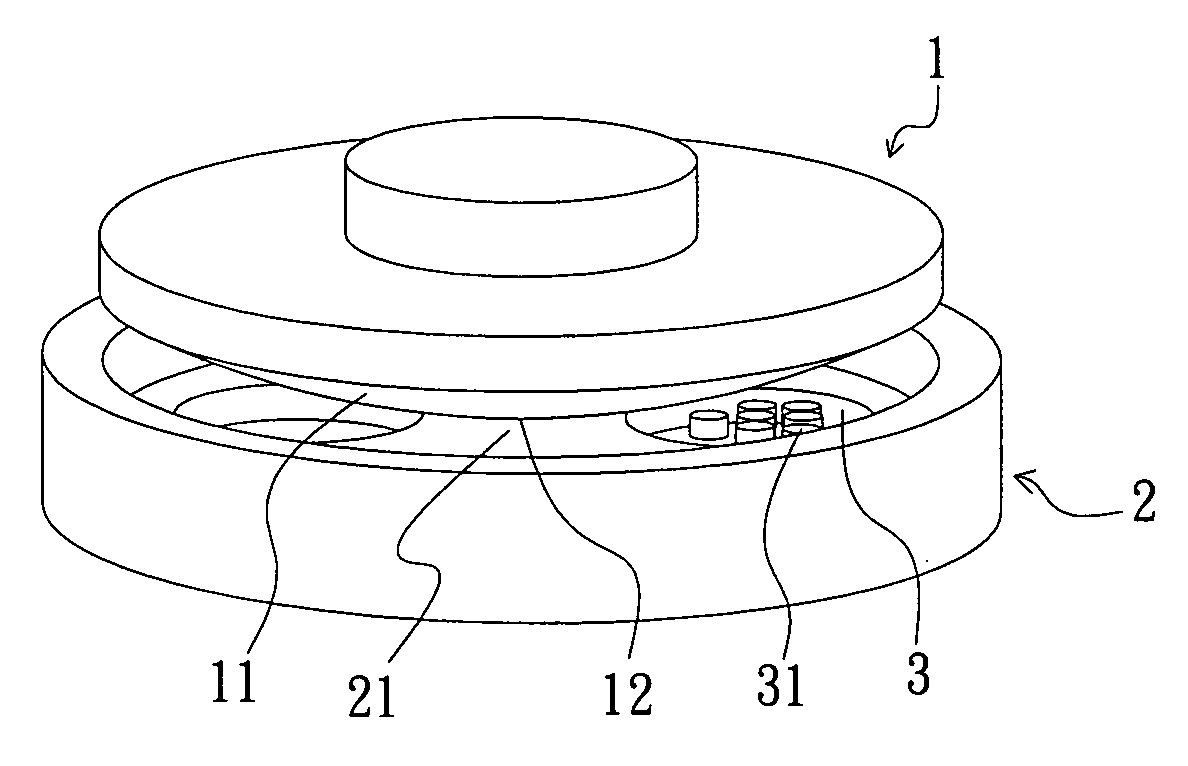

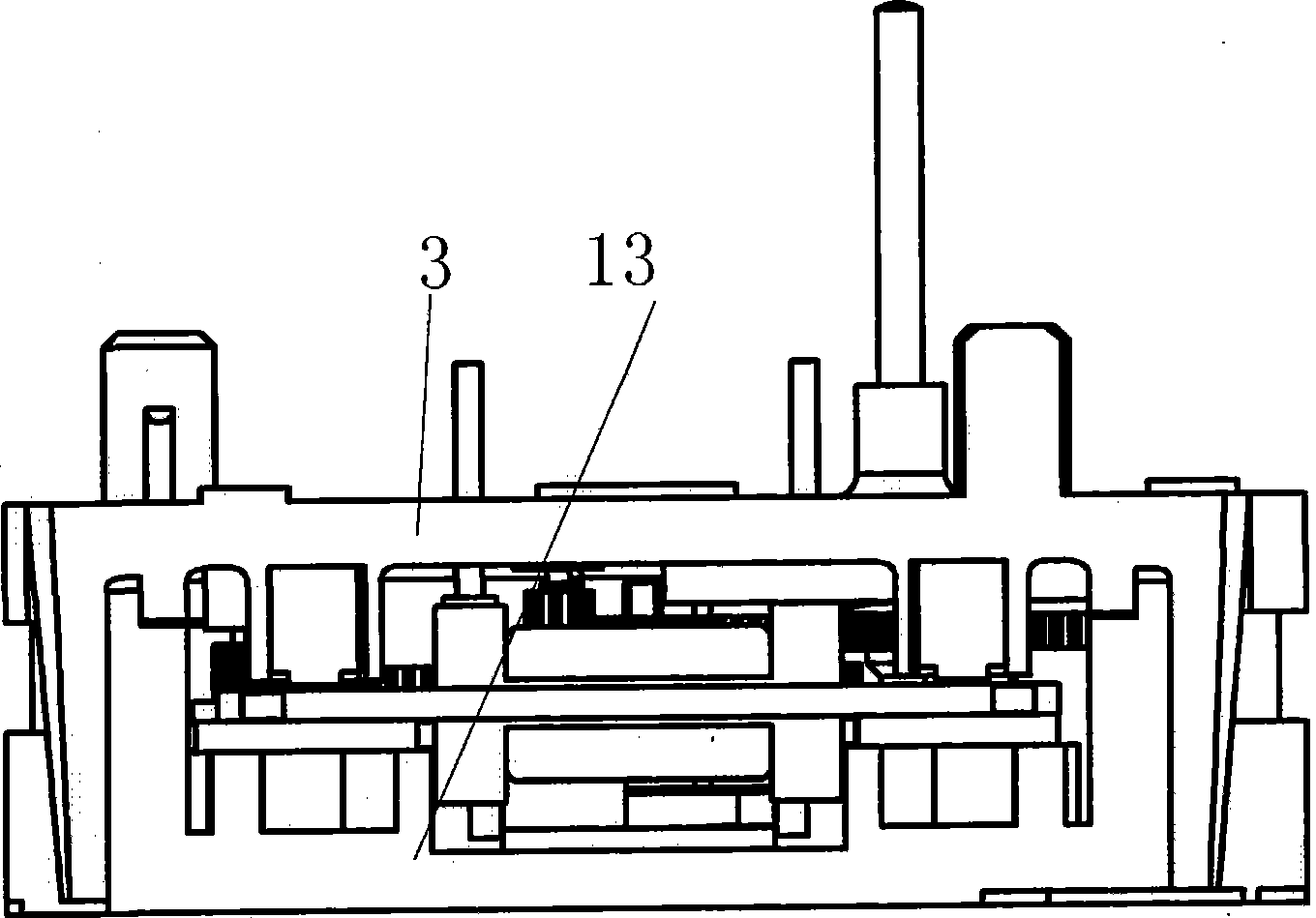

Ambient vibration energy collecting device based on two-DOF (Degree of Freedom) piezoelectric vibrator

InactiveCN102170248AExtended resonant operating bandwidthImprove energy conversion efficiencyElectrical storage systemPiezoelectric/electrostriction/magnetostriction machinesBroadbandPower regulation

The invention discloses a ambient vibration energy collecting device based on a two-DOF (Degree of Freedom) piezoelectric vibrator which comprises two parts, namely energy conversion and power regulation, wherein an vibration unit containing piezoelectric material in a vibration energy conversion device can respond ambient vibration transmitted by a base and convert mechanical energy into electric energy; a power regulation circuit accumulatively store electric energy after extraction and regulation. The vibration unit is provided with two piezoelectric vibrators with SDOF (Single Degree of Freedom) cantilever beam structure, which are fixed on the base in parallel horizontally, and a spring vertically connected with a vibrator mass block; the beam thickness of the two vibrators and the weight of the mass block are different, thus a broadband resonance two-DOF system of which adjacent first-order resonance frequency and second-order resonance frequency are adjacent is formed. The power regulation circuit is provided with a low-power-consumption synchronous charge transfer circuit module, a charge collection capacitor, a controllable voltage threshold DC / DC (direct current) conversion module and a power storage component. The device has a broader resonance response frequency band and low power consumption, can work without an external power supply so as to achieve high efficiency, and is suitable for self-powered devices or devices getting electrical energy supply from environment.

Owner:CENT SOUTH UNIV

Fluorinated polyurethane nanometer composite material and preparation method thereof

InactiveCN101585902AImprove hydrophobicityImprove hydrophobicity and oleophobicityPolyurea/polyurethane coatingsWear resistantNanoparticle

The invention relates to fluorinated polyurethane nanometer composite material and a preparation method thereof. The invention combines a polycondensation co-polymerization process and fluorine-introducing ultrasonic dispersion technology in the preparation process, nanometer aluminum oxide and nanometer silicon carbide are added and compounded in homogeneous phase in the polycondensation and the co-polymerization process, thereby obtaining nanometer particle reinforced fluorinated polyurethane nanometer composite material. A coating material with micron / nanometer dual structure surface and having hydro-oleophobic, wear resistant and erosion resistant functions, is obtained after film forming by spray coating on the base, drying and curing. The coating material prepared by the method has Hydro-oleophobic performance, and satisfies heat resisting, anticorrosion and wear resistant characteristics under hypergravity or high speed impact conditions.

Owner:HUNAN UNIV +1

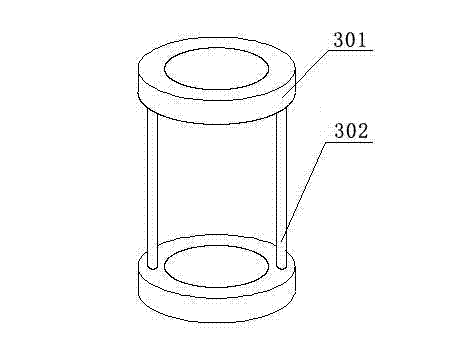

Annular prestressed concrete electric pole and production process thereof

InactiveCN101654963AHigh strengthUniform stressShaping reinforcementsTowersPre stressArchitectural engineering

The invention relates to an overhead line apparatus for power communication transmission, in particular to a concrete electric pole used for erecting a transmission line and a production process thereof. The electric pole comprises a concrete pole body and a steel reinforcement cage buried in the pole body. The concrete pole body is of a cone shape of which the conical degree of the concrete polebody is 1:75. The head of the concrete pole body is provided with an end cover. The steel reinforcement cage is formed by binding a plurality of main reinforcements, internally spiral reinforcements and externally spiral reinforcements which are equal in length. The main reinforcements are uniformly distributed in the annular side wall of the concrete pole body with the central line of the concrete pole body as an axis. The internally spiral reinforcements and externally spiral reinforcements are uniformly wound and distributed on the inner and outer sides of the main reinforcements with the central line of the concrete pole body as an axis as well. A concrete protective layer of the steel reinforcement cage in the concrete pole body is no less than 10mm.

Owner:陈子成

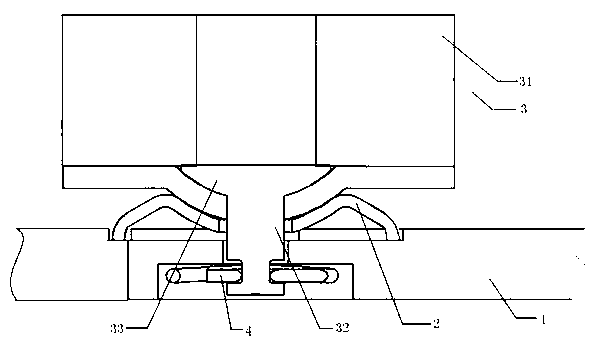

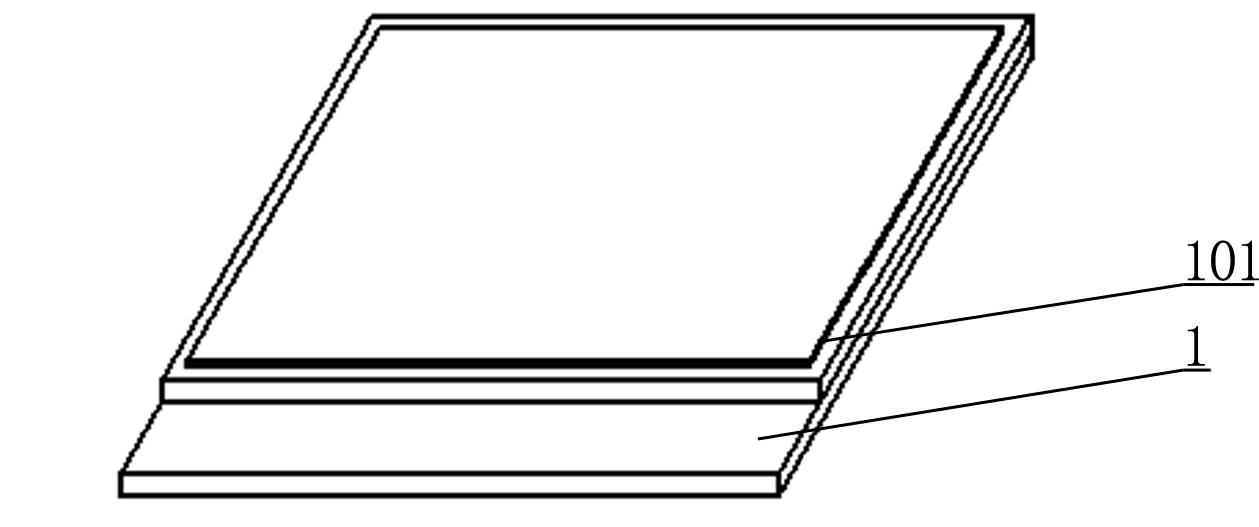

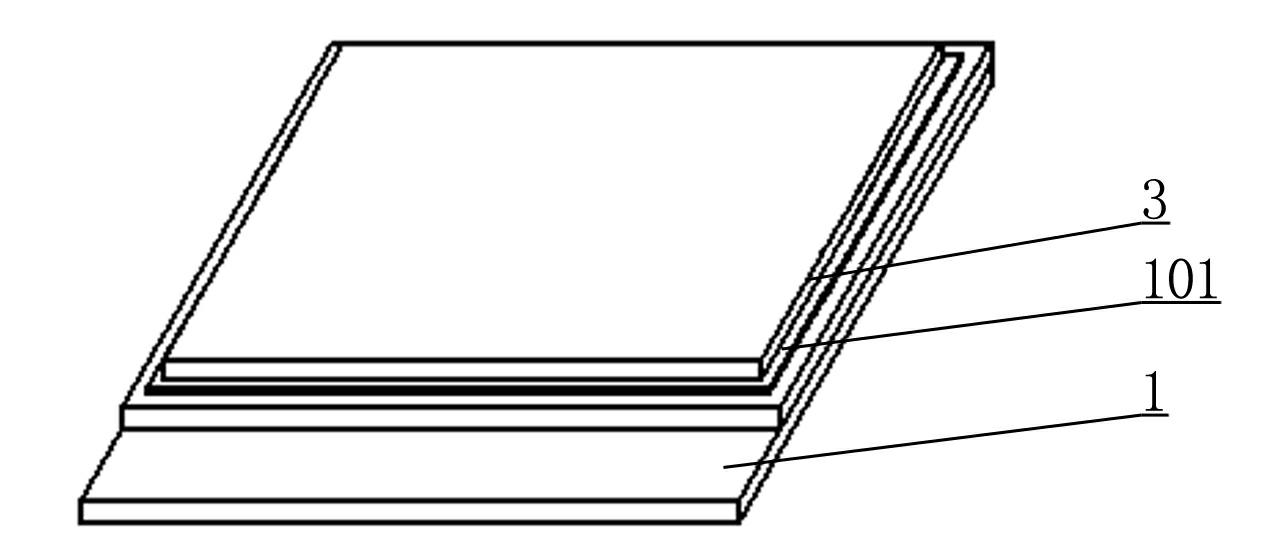

Display panel, method of manufacturing the same, protective film and display device thereof

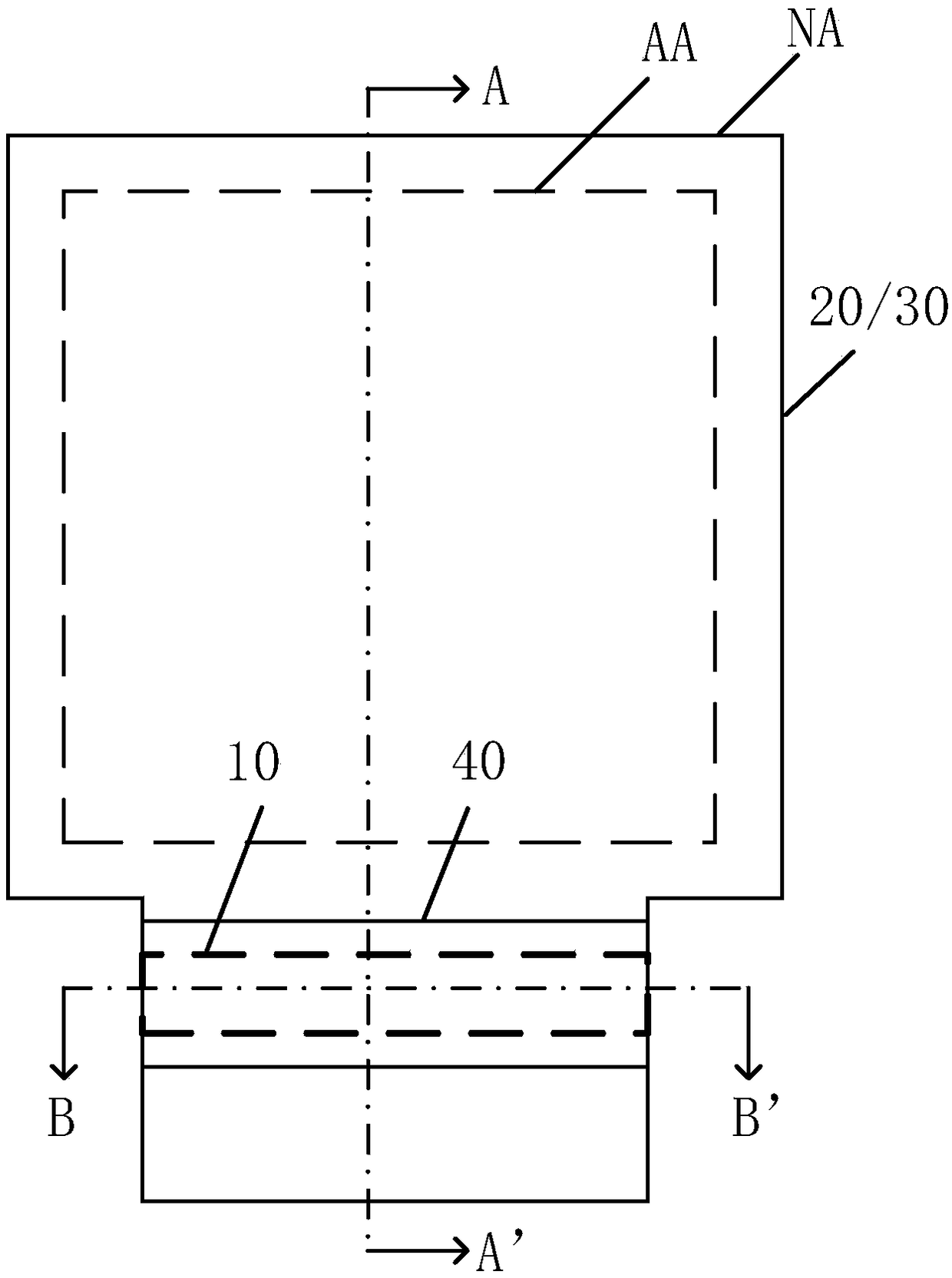

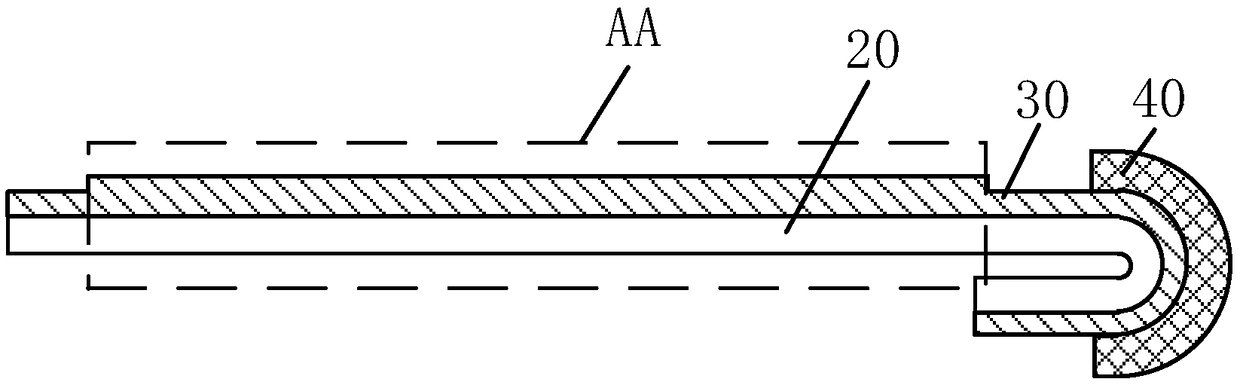

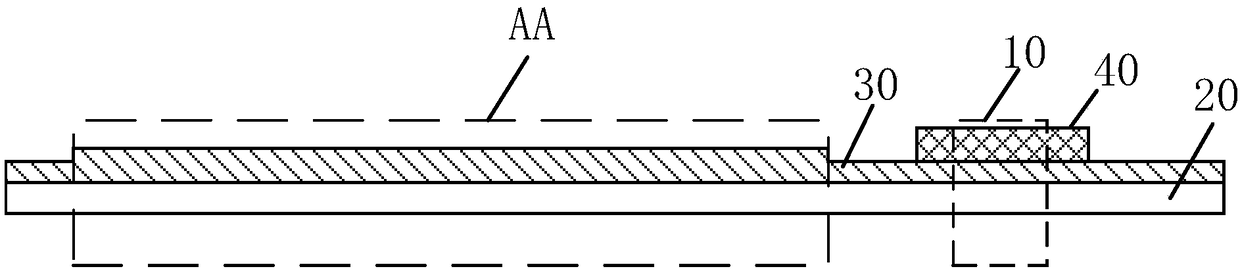

ActiveCN109166894AUniform stressSolid-state devicesIdentification meansVertical projectionComputer graphics (images)

The invention discloses a display panel and a manufacturing method thereof, a protective film and a display device, comprising a display area, a non-display area and a bent area; A flexible substrate,a display layer and a bending protective layer, wherein the bending protective layer is located in a non-display area and the bending protective layer is at least partially located in the bending area; The bent protective layer includes an upper surface, a lower surface, and a side surface connecting the upper surface and the lower surface. In at least one first section, the length of the vertical projection of the sides on the flexible substrate is L, and the lengths of the upper and lower surfaces in a direction perpendicular to the display panel are D, wherein 0 <= L <= D / 10, the first section is perpendicular to the display panel and perpendicular to the edges of the cut display panel. The invention effectively avoids the circuit traces whose stress concentrates on the edge of the bending region when bending, so that the stress on the circuit traces in the display layer in the bending region is relatively uniform.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

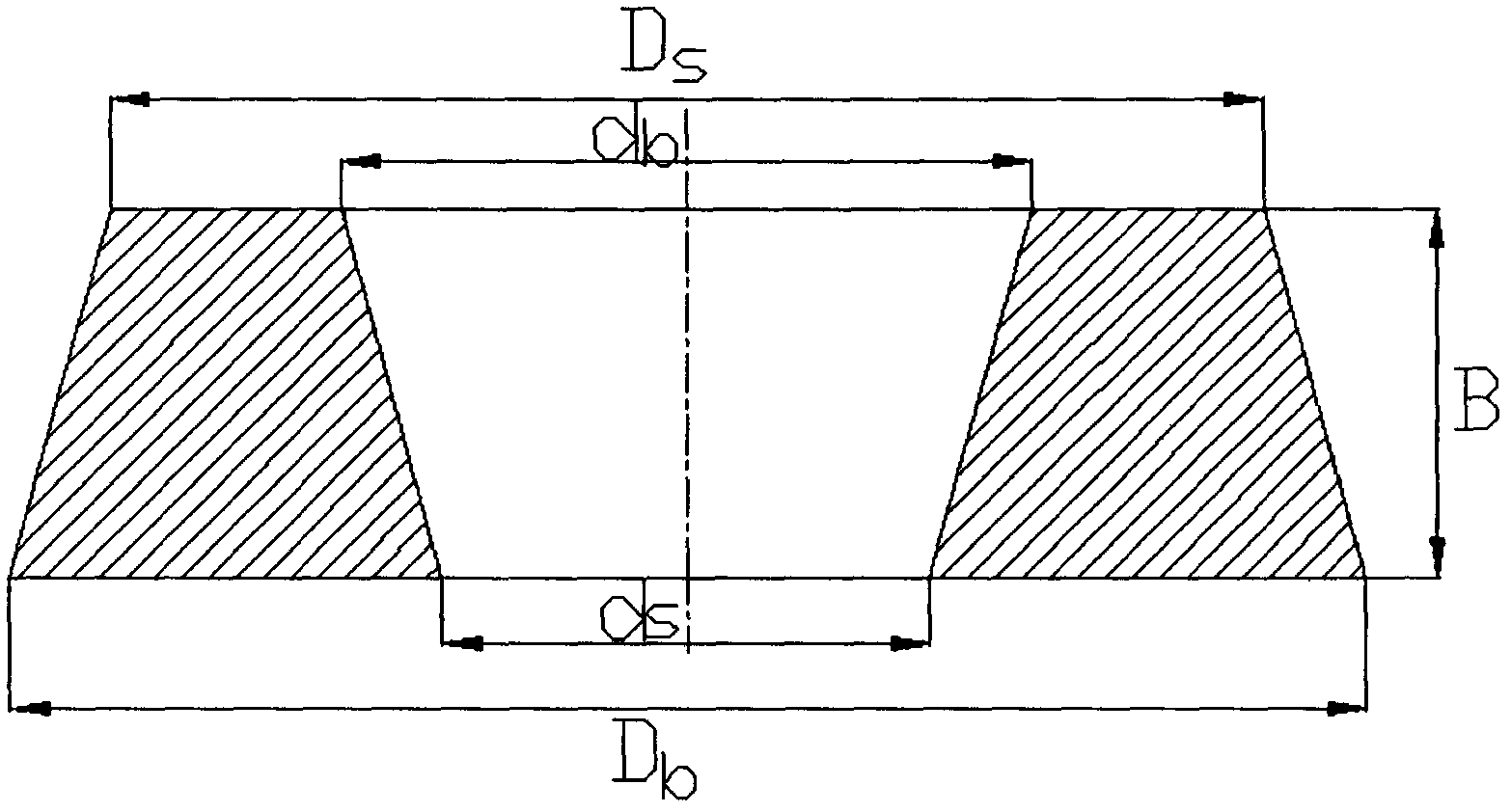

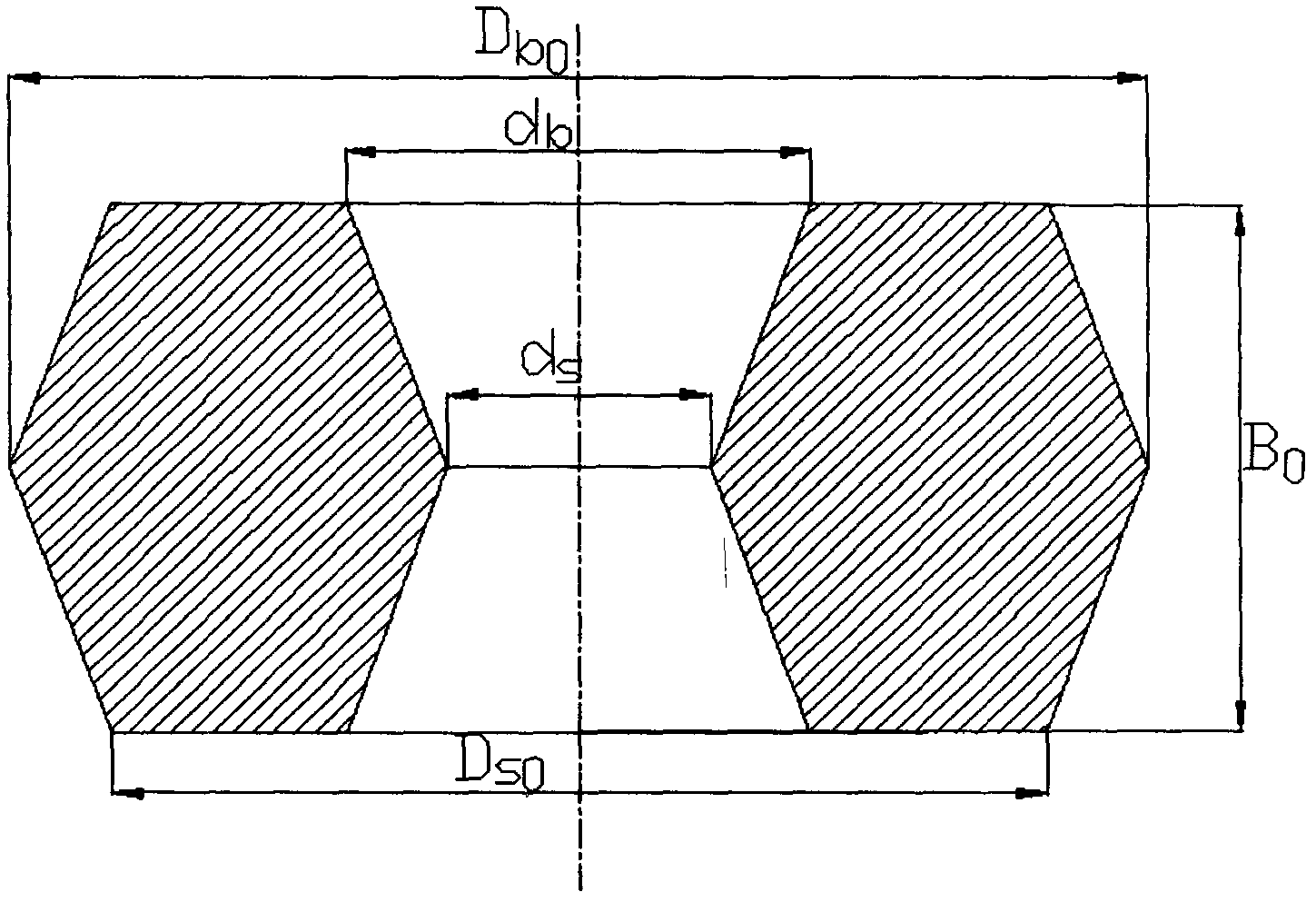

Method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces

ActiveCN102615223AReduce heating timesImprove organizationGas flame welding apparatusMetal rollingRoom temperatureEngineering

The invention relates to a method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces. The method comprises cutting a cylindrical billet into material sections; heating the material sections from room temperature to austenitizing temperature evenly and keeping warm; then heading, punching and chambering the material sections to be manufactured into ring piece blanks to be rolled and expanded; baking again and heating the obtained blanks to reach target temperature and keep warm; placing the obtained blanks into a hole mould of a ring rolling machine formed by an irregular-shaped driving roller and an irregular-shaped core roller to be rolled, expanded and formed; achieving the ring forge pieces which is narrow at two ends and wide in middle and with the axial height as twice as the height of a target trapezoid flange; cutting the ring forge pieces from the middle of the axial height, symmetrically dividing a work piece into two parts to obtain two trapezoid-cross-section flange ring forge pieces; and finally turning the forge pieces into end product flanges. The method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces is high in production efficiency, energy-saving, environmental-friendly and capable of improving utilization rate of raw materials and quality of products.

Owner:SHANDONG JIANZHU UNIV

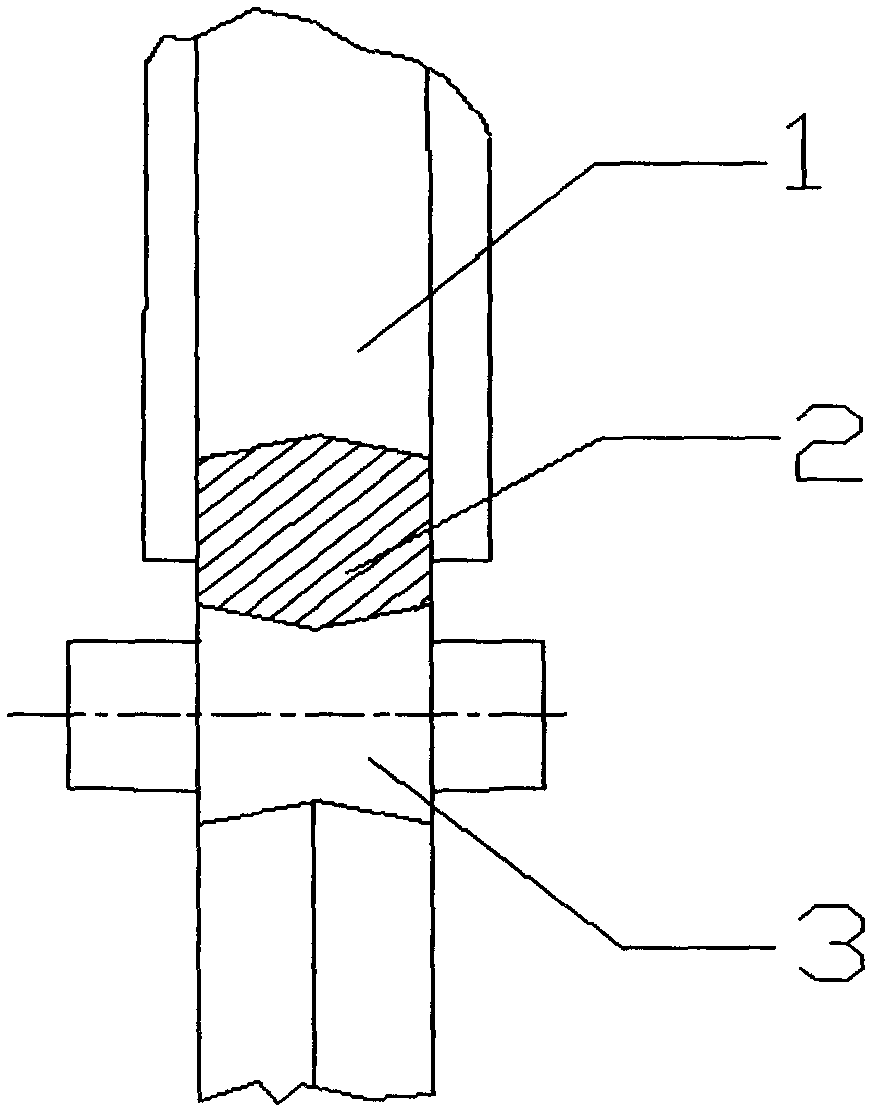

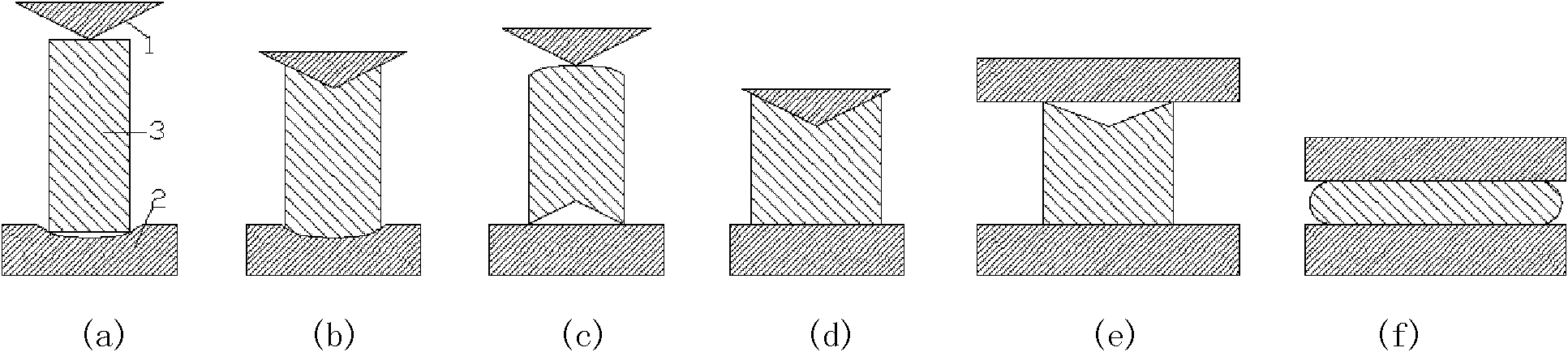

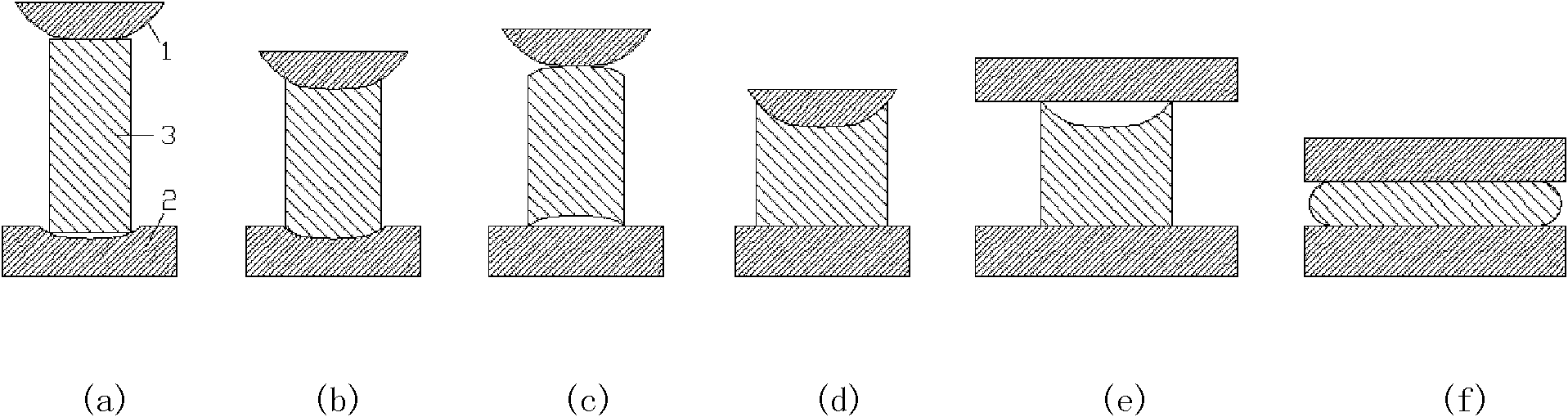

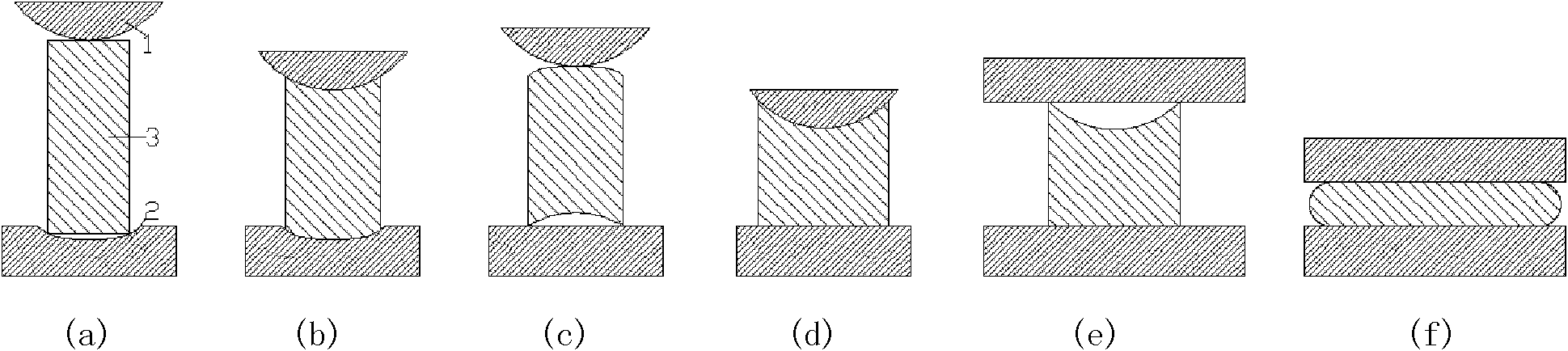

Hot upsetting process for cast ingot with large height to diameter ratio for ultra large ring forging

InactiveCN101972830AUniform stressUniform strain distributionMetal-working apparatusDiameter ratioIngot

The invention relates to a hot upsetting process, in particular to a hot upsetting process for a cast ingot with a large height to diameter ratio for an ultra large ring forging. The process is characterized by comprising the following steps of: 1) hanging a heated high-temperature cast ingot with a large height to diameter ratio on a lower female die; 2) adjusting the position of an upper male die so as to ensure that the central line of the upper male die is coincided with the central lines of the cast ingot and the lower female die; 3) driving the upper male die to move downward by using a power mechanism; 4) further moving the upper male die downward so as to continuously decrease the height to diameter ratio of the cast ingot; 5) reversing the cast ingot which is in a contact molding state by hot upsetting, replacing the lower female die by using a flat plate die and further lowering the upper male die; and 6) replacing the upper male die by using a flat plate die and further lowering the upper male die until the cast ingot is upset to a cast ingot with a required blank height and size so as to obtain an upset blank. On the premise of ensuring that the hot upsetting process of the cast ingot with the large height to diameter ratio is performed successfully, the process also ensures the stress, uniform strain distribution, small bulge and uniform internal structure of the unset blank after upsetting is finished and provides an unset blank with high performance for the manufacturing of a subsequent forging.

Owner:WUHAN UNIV OF TECH

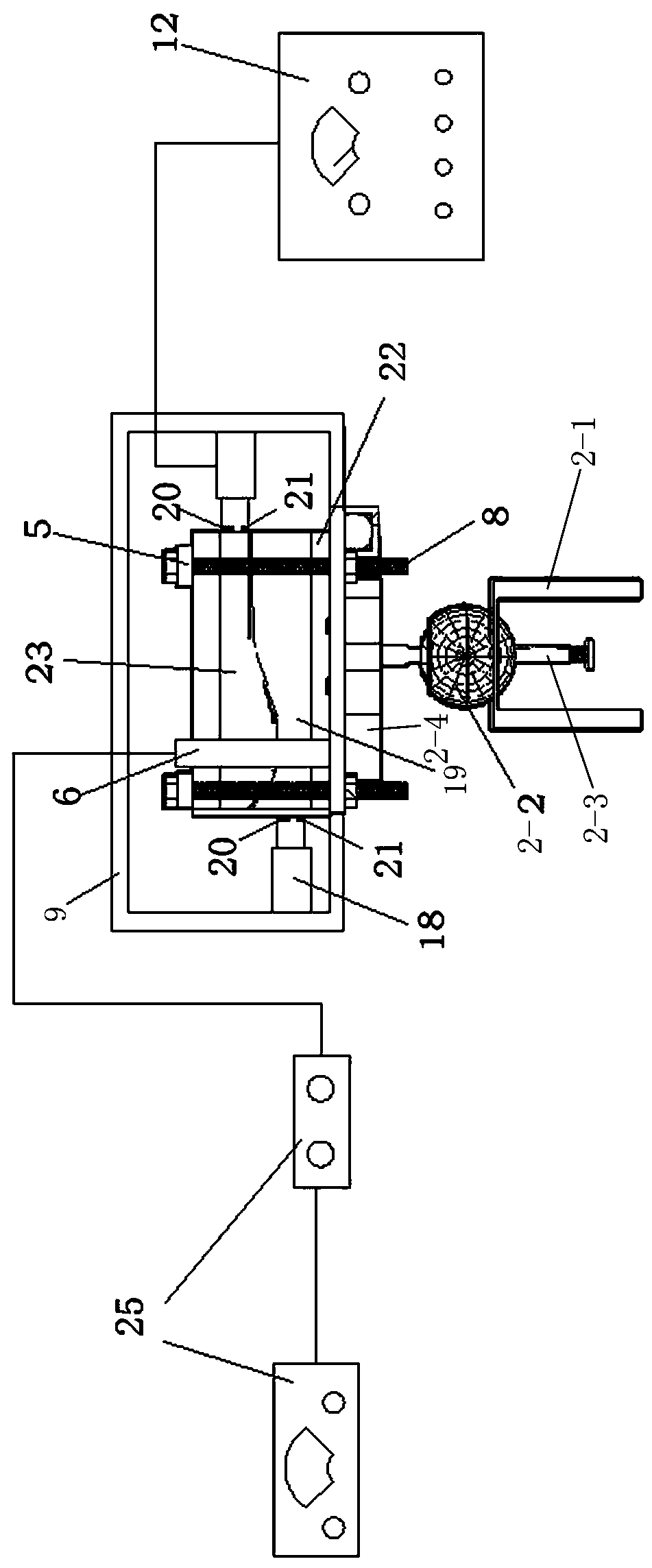

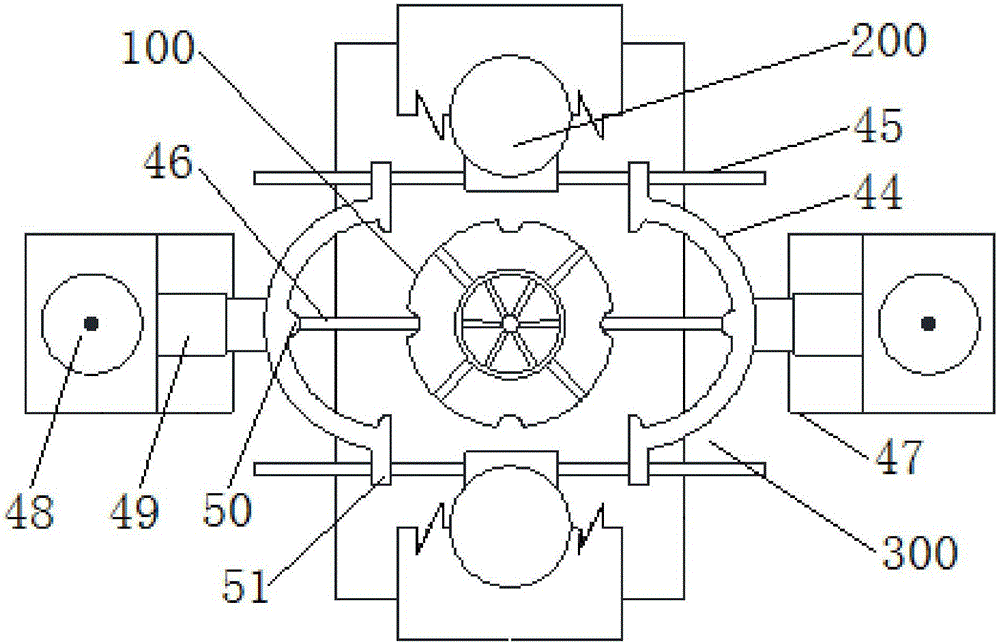

Device and method for simulating visual gap seepage by magnetic fluid

ActiveCN110296928AUniform stressStable pressurePermeability/surface area analysisEngineeringStress sensor

A device for simulating visual gap seepage by magnetic fluid comprises a main body framework, wherein a camera is arranged in the main body framework and is hinged with a mobile auxiliary framework bya top universal ball on the main body framework, a visual rock sample is placed on an upper surface of a shearing counter-force rack by an expansion pressurization pad and comprises upper cover platetransparent resin and a conventional rock sample, a gap is formed between the upper cover plate transparent resin and the conventional rock sample, two side surfaces of the visual rock sample are connected with an inner side wall of the shearing counter-force rack by a hydraulic rod loading device, a stress sensor and a displacement sensor are arranged at the hydraulic rod loading device, and a paste / water injection pipe of a paste / water injection device is matched with the gap between the upper cover plate transparent resin and the conventional rock sample. With the device and method for simulating visual gap seepage by magnetic fluid, provided by the invention, the seepage rules under various conditions are researched by the magnetic fluid to simulate gap seepage conditions under conditions of multi-angle different confining pressure and yawing forces.

Owner:CHINA THREE GORGES UNIV

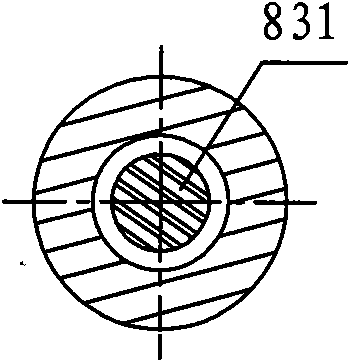

Optical fiber connector ferrule having open fiber clamping grooves

A ferrule for an optical fiber connector having open fiber clamping grooves. The ferrule has a body having a plurality of open grooves for clamping the terminating end sections of optical fibers. At least a section of the longitudinal opening of the groove is provided with opposing lips to provide a clamping effect. The width of the longitudinal opening defined between the lips along at least a section of the grooves is narrower than the diameter of the optical fibers to create a tight fit. The grooves and the width of the longitudinal groove openings are shaped and sized to retain the fibers without any clearance to allow for movement of the fiber relative to the groove. Similar grooves may be provided in the ferrule body for alignment guide pins. The grooves are precision formed by high throughput processes, such as stamping and extrusion.

Owner:SENKO ADVANCED COMPONENTS

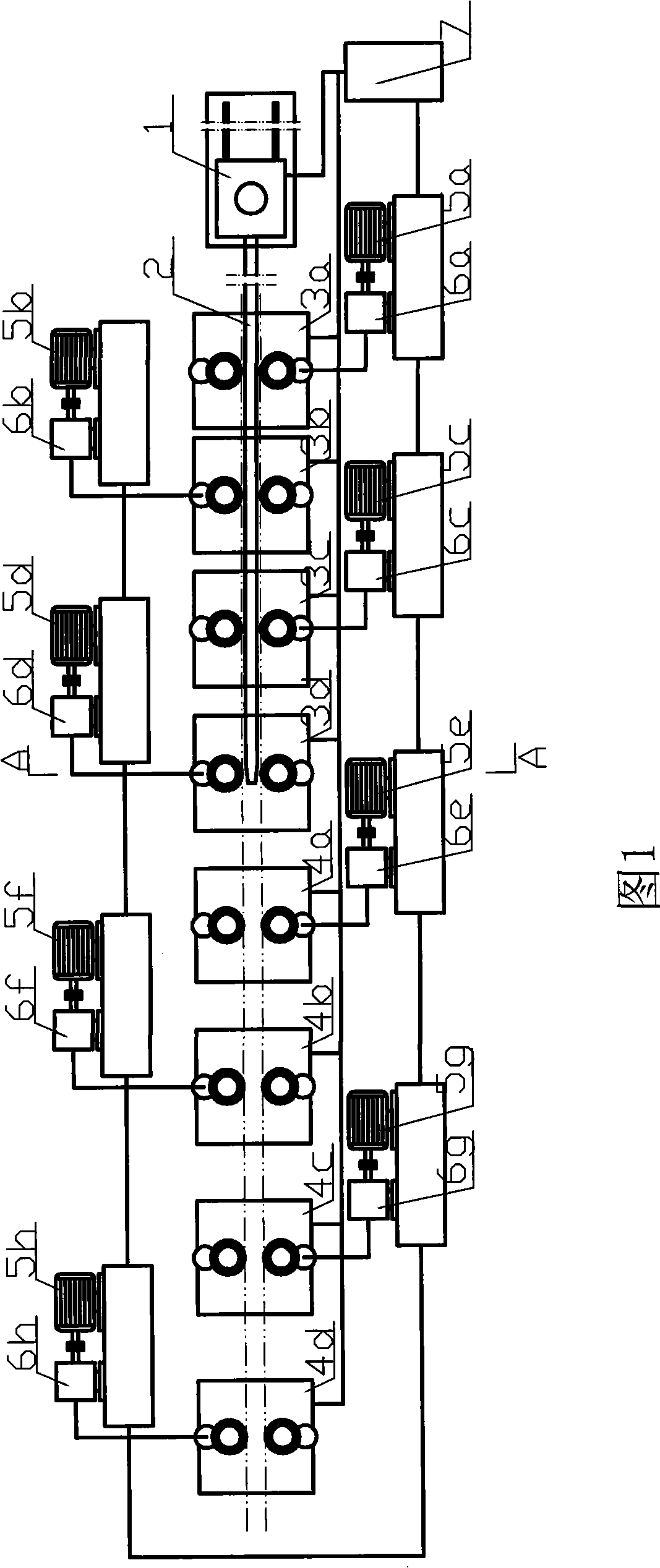

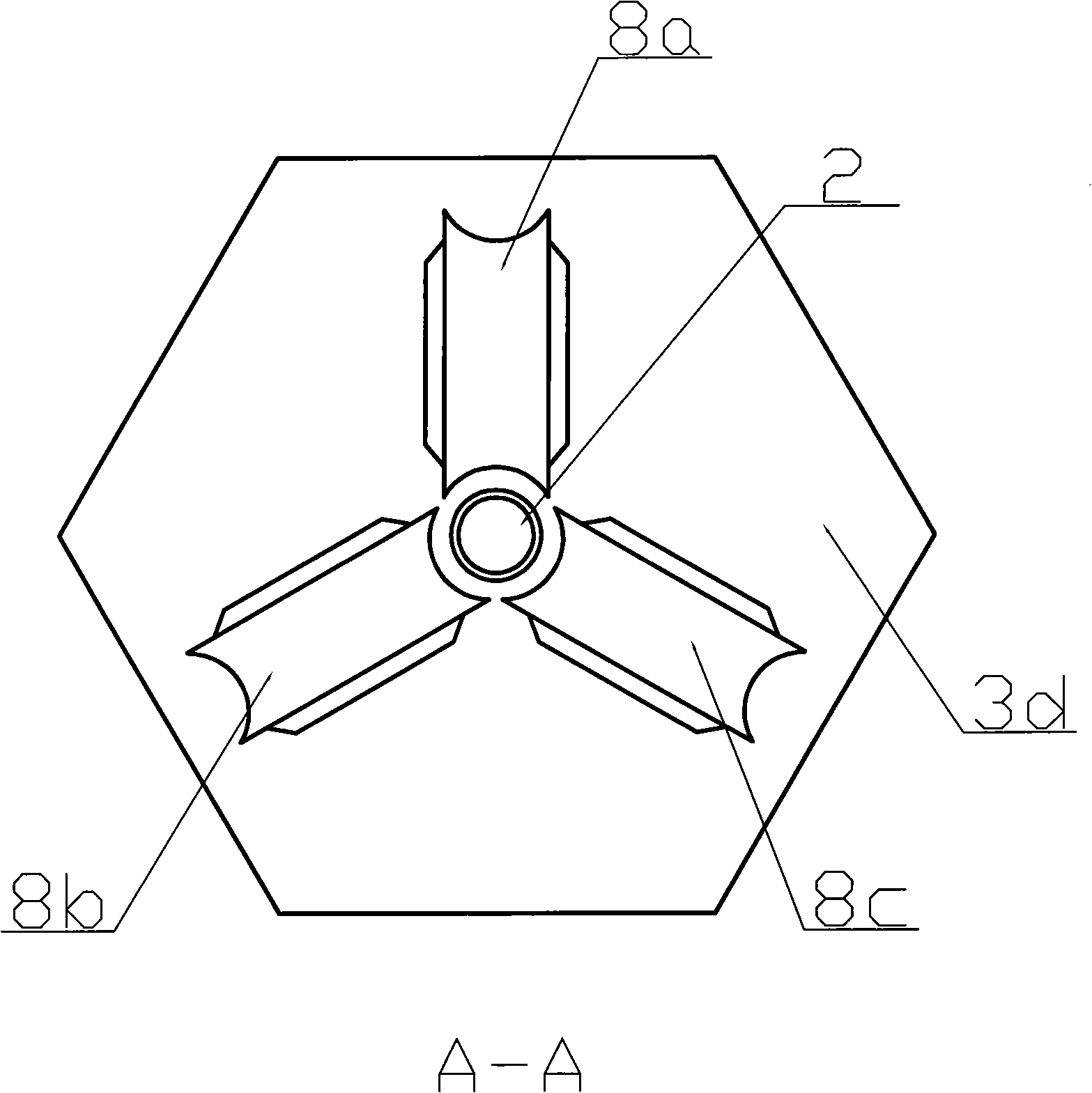

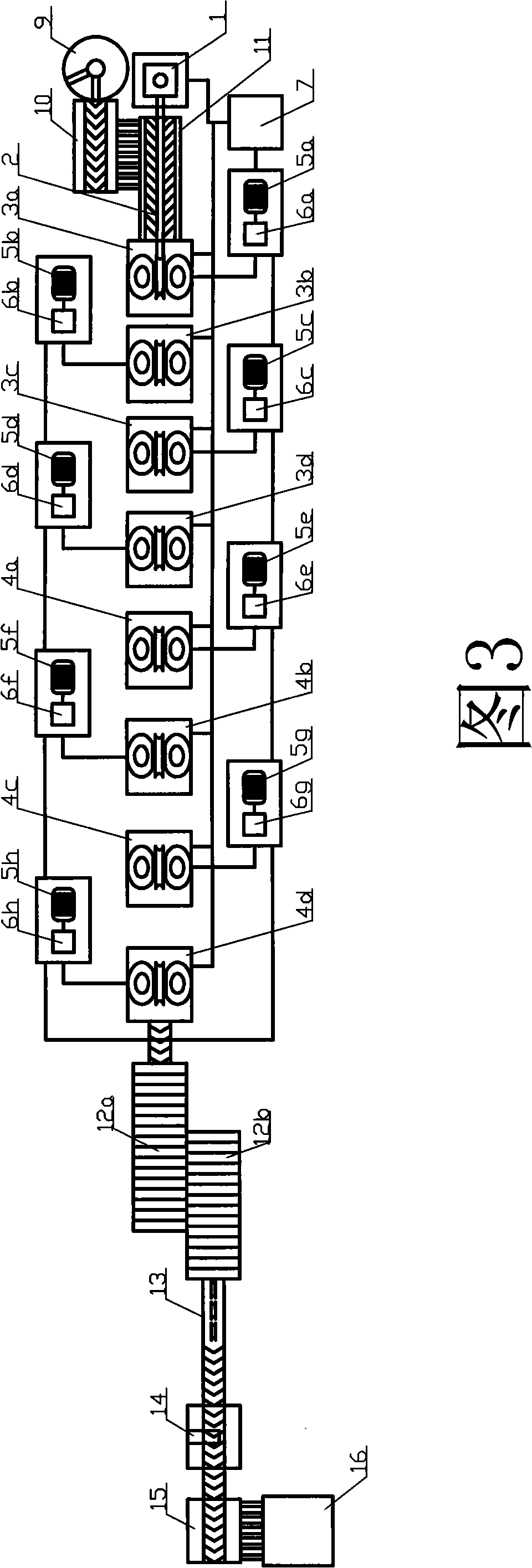

Fewer stands longitudinal hot rolling minor diameter thin wall seamless steel tube rolling technique and equipment thereof

InactiveCN101259588AEnsure implementationIncrease speedTemperature control deviceMandrelsHeating furnace% diameter reduction

The invention discloses the rolling technology of a fewer stander longitudinal hot rolling small diameter thin wall seamless steel tube which uses a heating furnace to heat a pierced billet to 950 DEG C to 1150 DEG C, a mandrel trolley pushes a mandrel into the heating pierced billet and is pushed to move forward, and the pierced billet is pushed into a wall reduction rolling unit that is formed by a plurality of wall reduction rolling mills to lead the pierced billet to be carried out longitudinal wall reduction rolling; the pierced billet that breaks away from the mandrel continues to be pushed into a stretch reducing rolling unit that is formed by a plurality of stretch reducing rolling mills to lead the pierced billet to be carried out longitudinal stretch reducing rolling until the rolling is finished; the pierced billet is put into a cold bed to cool; a straightening machine is used for straightening; a finished product is used for delivering and cutting; a flat head machine is used and a detecting machine is used for inspecting; a hydrostatic testing machine is used for detecting; the finished product is bundled and is put in storage. The invention uses the combination of the three-roll longitudinal rolling technology and a retained mandrel to adjust the straight roller longitudinal rolling with umbrella-shaped gears hydraulically and preciously to carries out diameter reduction and wall reduction rolling, and a rolled tube pipeline main control cabinet is used for operating stepless speed regulation of various stands so as to guarantee implementation of the technology, thus rolling the small diameter thin wall seamless steel tube with the diameter of Phi 12mm to Phi 76mm and wall thickness of 1mm to 6mm.

Owner:LUOYANG BANGQIANG MACHINERY

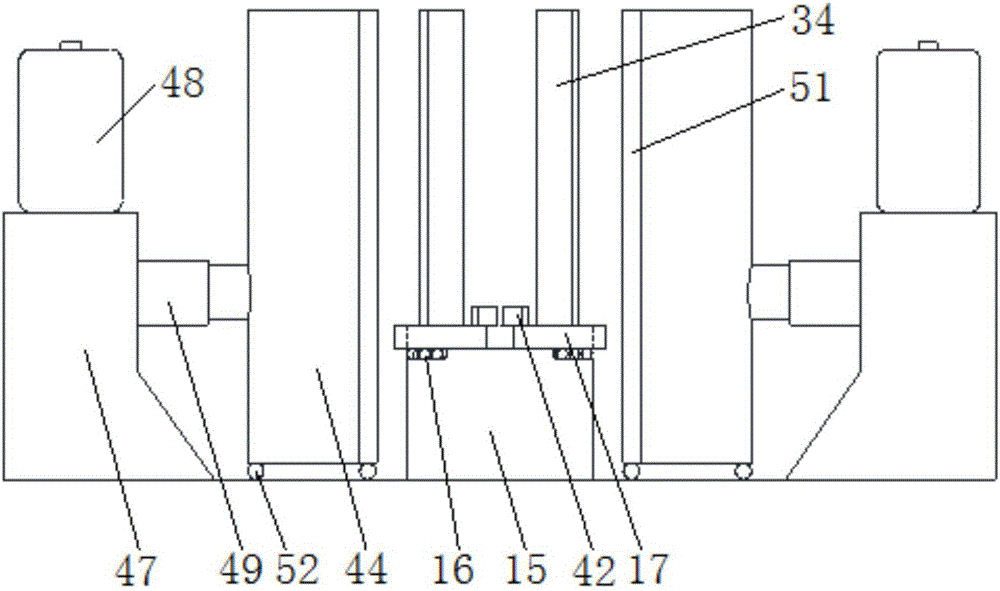

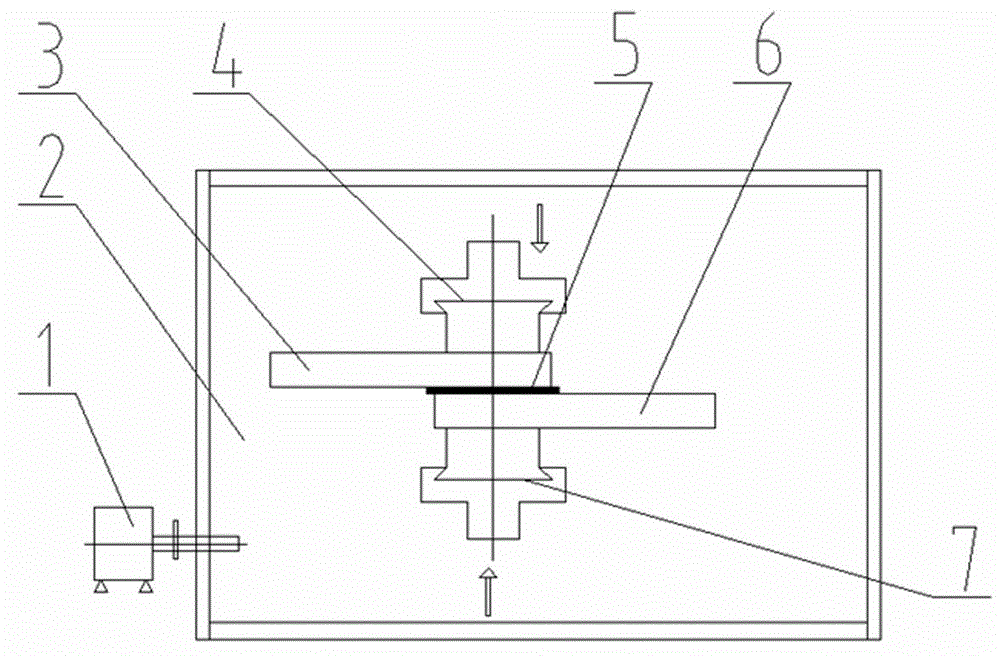

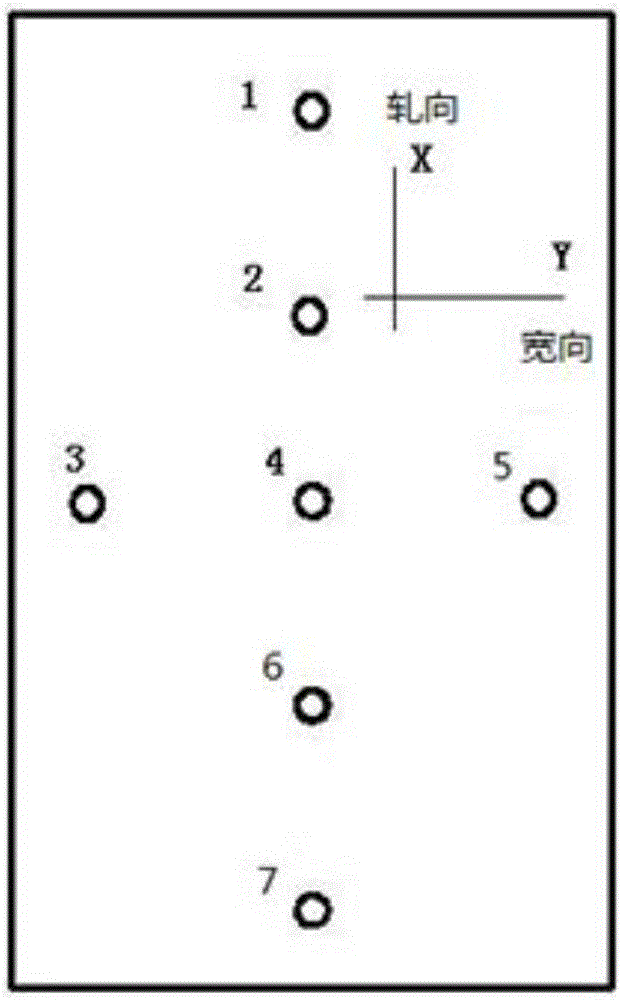

Device suitable for ring shear test and soil sample preparation of vertical shearing surface

ActiveCN106840810AAvoid breaking unevennessUniform stressPreparing sample for investigationMaterial strength using steady shearing forcesLift systemEngineering

The invention relates to a device suitable for ring shear test and soil sample preparation of a vertical shearing surface. The device comprises a shearing box, a lifting system, a power rotating system, a monitoring control system, a soil sample preparation system and a frame, wherein shearing plates are uniformly fixed on an annular base plate along the radial direction of the annular base plate; an outer cover of the shearing box is covered on the annular base plate and the shearing plates and is assembled and fixed with the annular base plate through a guide strip and a guide slot; the outer cover of the shearing box is connected with a rotating force arm of the power rotating system and is used for transmitting torque; a coupling pressing plate is aligned and embedded into a central hole of a top plate of the outer cover of the shearing box and is driven by the lifting system to load normal force; the annular base plate is aligned and embedded into a cylindrical support platform; and under the effect of driving torque, an inner cylindrical side wall generated by the circling motion of the annular base plate under the driving of the shearing plates is the vertical shearing surface. According to the invention, the shearing displacement and the uniform distribution of the shearing stress on the shearing surface can be guaranteed, the thickness of the vertical shearing surface is not limited and the device has the functions of sample preparation and vertical shearing test.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

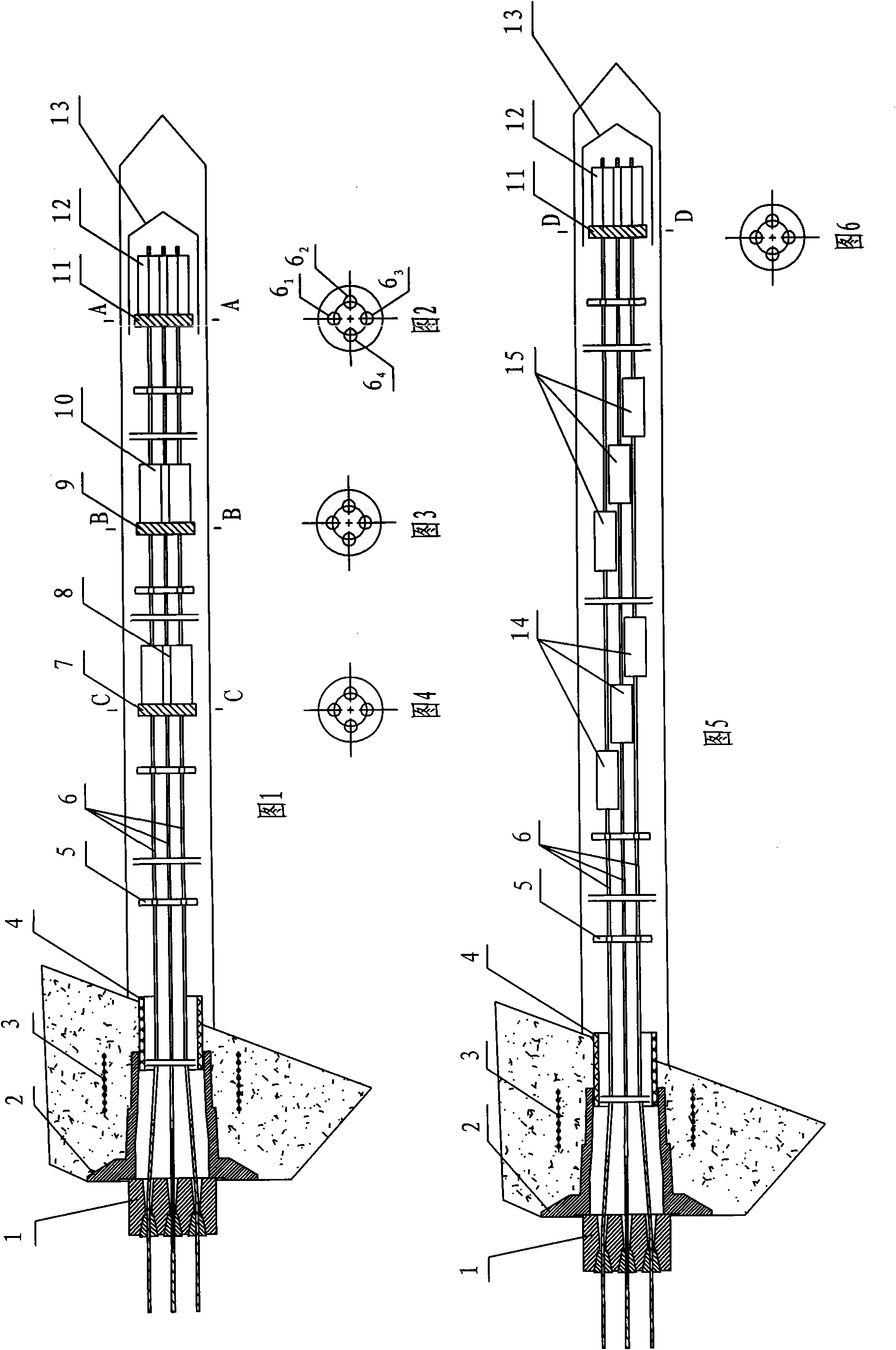

Uniform pressure distribution type anchor cable

ActiveCN101638893AImprove carrying capacityReduce stress concentrationBulkheads/pilesStress concentrationPre stress

The invention relates to a uniform pressure distribution type anchor cable, which comprises an outer anchor head, an anchor cable body and a multilevel cable body bearing structure. The first-level bearing structure of the cable body is a permanent bearing structure consisting of an extruding anchorage device and a bearing plate, the rest bearing structures at all levels are pressure-yielding bearing structures only consisting of pressure-yielding anchorage devices or consisting of pressure-yielding anchorage devices and bearing plates, the lengths of all prestressing tendons for forming the anchor cable body are equal, and the number of the bearing structures on each prestressing tendon is the same. The pressure-yielding anchorage device comprises an extruding sleeve and an anchoring medium, wherein the extruding sleeve and the anchoring medium are extruded and anchored on the prestressing tendons to form a pressure-yielding anchorage device; the anchoring medium is a spring wire witha circular cross section; and the prestressing tendons are non-bonded tendons made of stranded wires or wire cables or stranded wires and wire cables. The anchor cable has the advantages of having even integral stressed state, greatly reducing stress concentration of the anchored section in the anchor cable, and having excellent anchoring performance, simple construction process and safe operation.

Owner:LIUZHOU OVM MASCH CO LTD

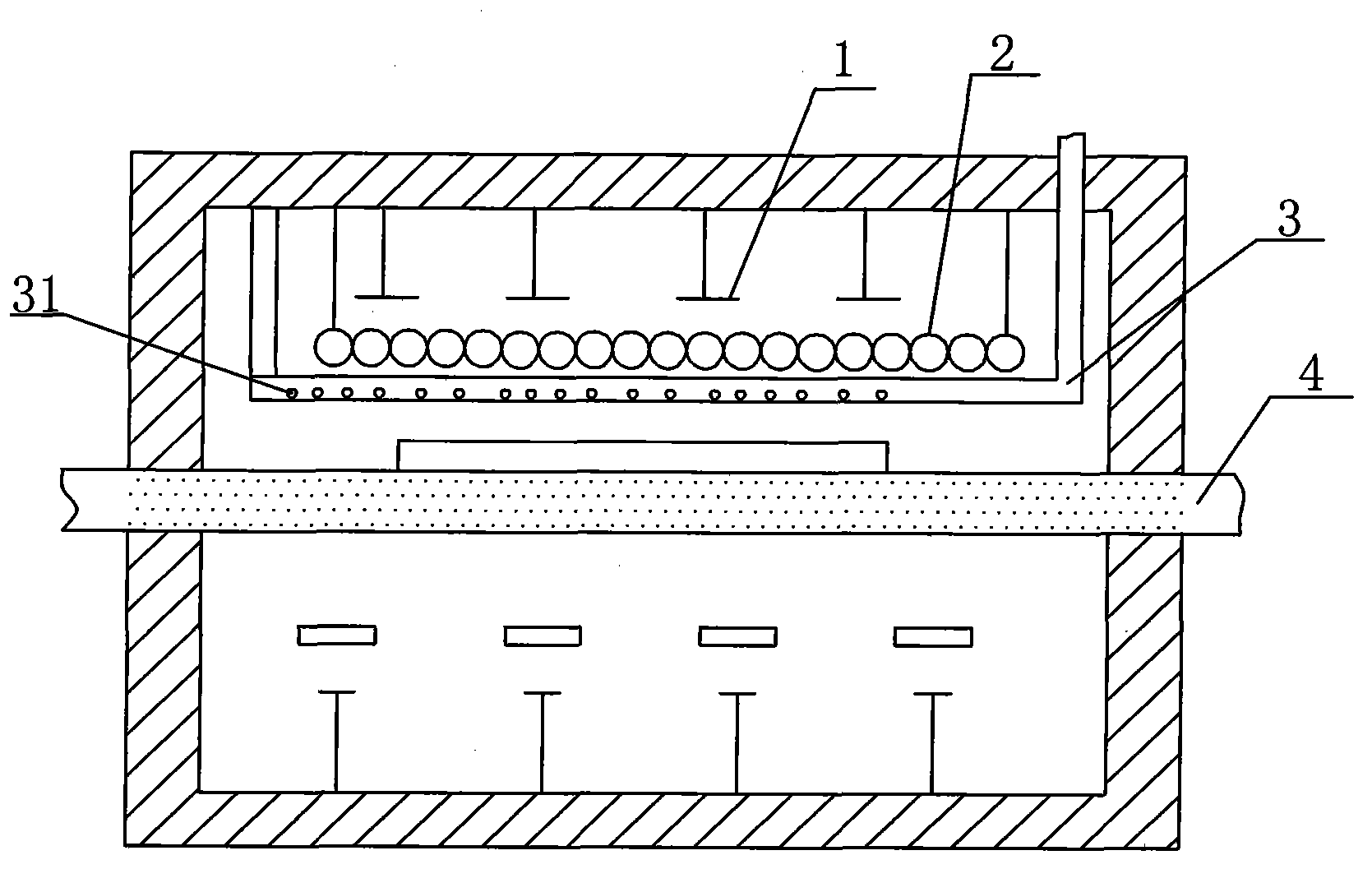

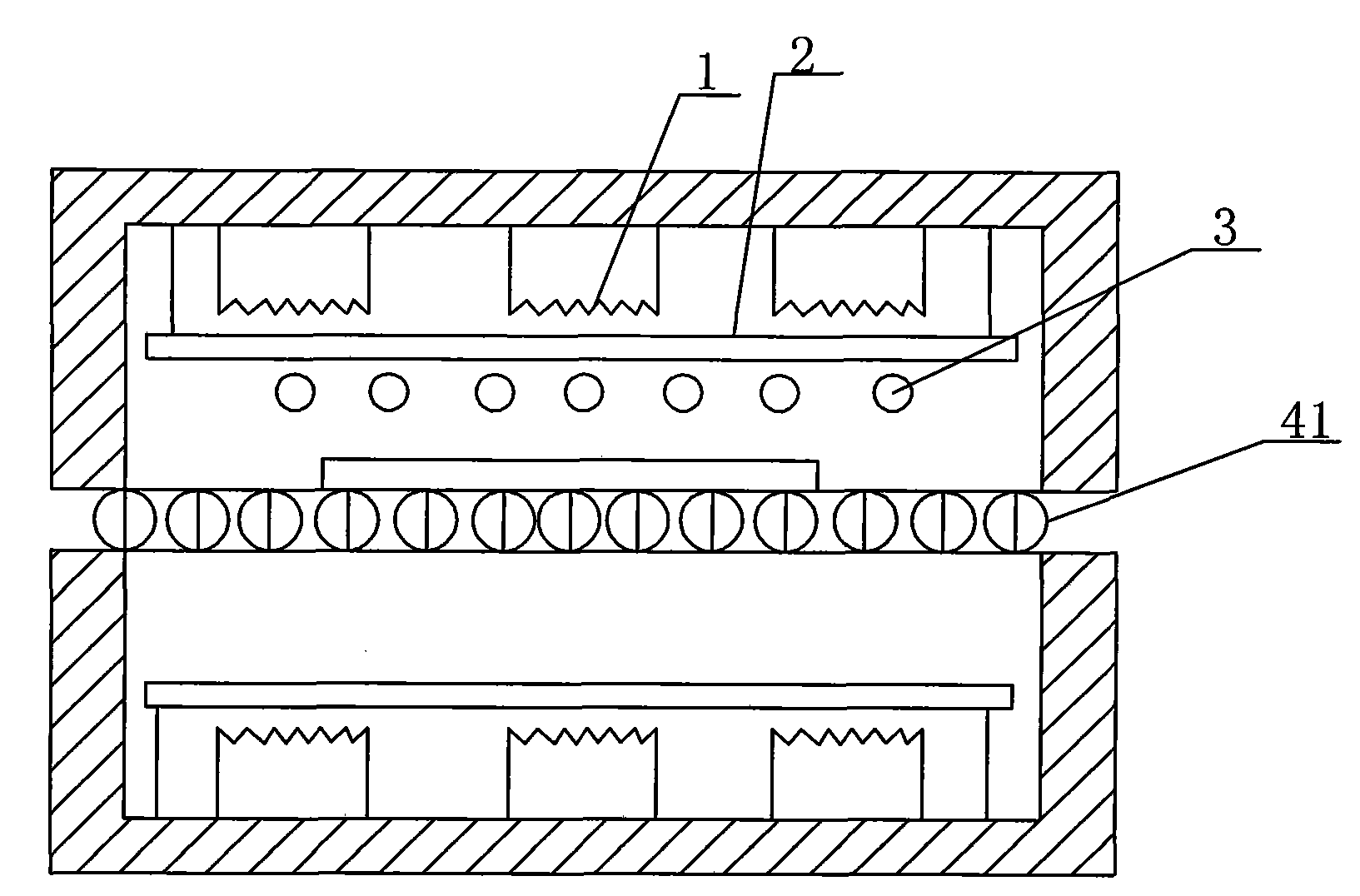

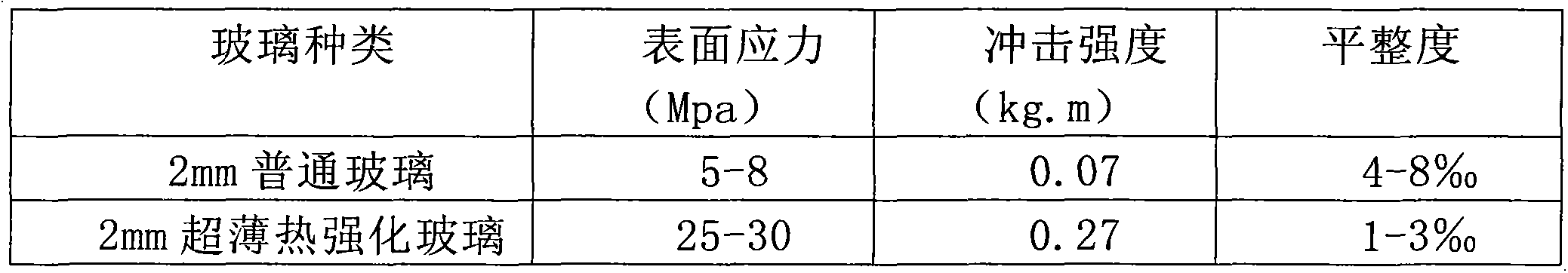

Manufacturing method of ultrathin heat-reinforced glass

InactiveCN103319082AHeating fastRadiation area is largeGlass tempering apparatusGlass manufactureToughness

The invention discloses a manufacturing method of ultrathin heat-reinforced glass. The manufacturing method comprises the following steps of: flatly placing ultrathin glass with the thickness of 1.8-2.2mm on a rolling way, adjusting the pressure of convection air in a toughening furnace to be 2000-4000pa / cm<2> with the convection time of 30-50s, simultaneously using the rolling way to drive the glass to do reciprocating movement for 40-50S in the toughening furnace at a speed of 20-30mm / s, and then adjusting the operating speed of the rolling way to be 160-175mm / s till the glass is heated to be 623-630 degrees. The glass manufactured by utilizing the method has the advantages that the generation of 'white mist' is avoided, and the glass is good in flatness, high in strength and good in toughness.

Owner:CHANGZHI SHENGLONG IND

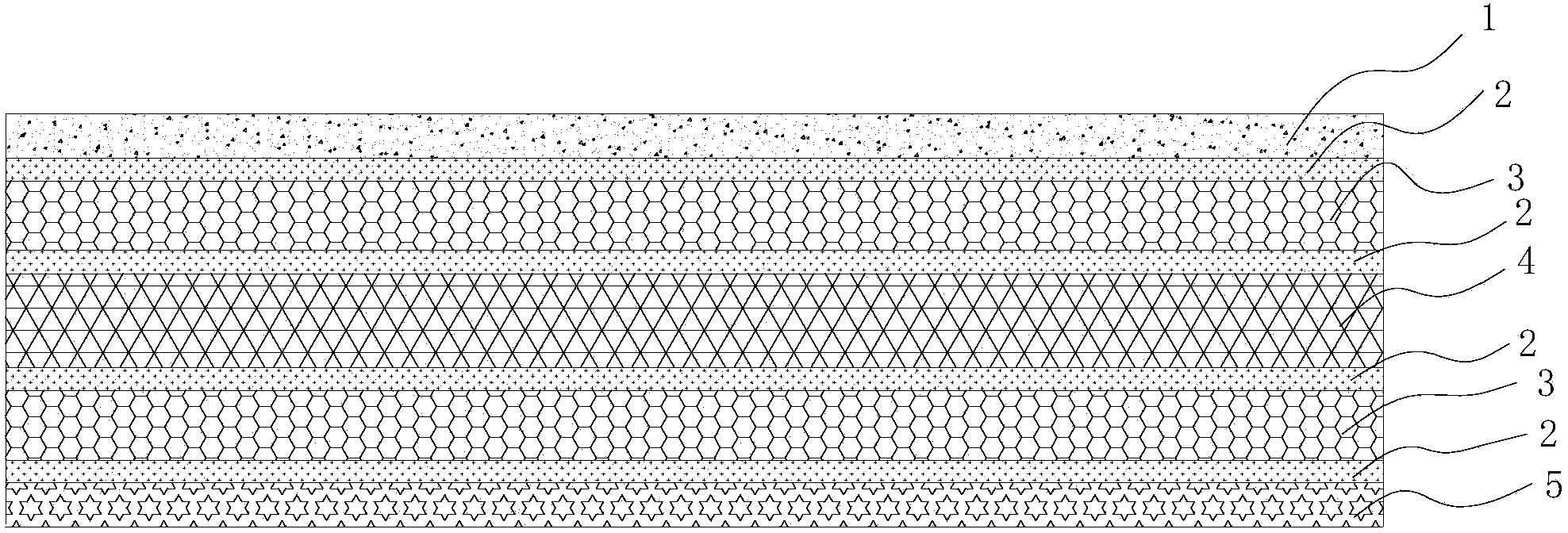

Composite pressure-resistant casing and molding method thereof

The invention discloses a composite pressure-resistant casing and a molding method thereof. The molding method includes manufacturing the pressure-resistant casing, which can work normally without visible deformation under deep water, by metal and polymer . The pressure-resistant casing is light in weight when the criteria of strength and rigidity are met. The pressure-resistant casing molded by the molding method comprises a metallic framework, a first glass fiber reinforced plastic layer, a titanium wire wound layer, a second glass fiber reinforced plastic layer, a carbon fiber layer and a protective layer, wherein the first glass fiber reinforced plastic layer, the titanium wire wound layer, the second glass fiber reinforced plastic layer, the carbon fiber and the protective layer are arranged outside the metallic framework at one step. The metallic framework can be adopted as the framework of the pressure-resistant casing and for reducing weight of the integral structure. By the integral member made of materials different in performances and features, internal stress can be ensured to uniformly distribute, and external impact can be borne to some extent.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

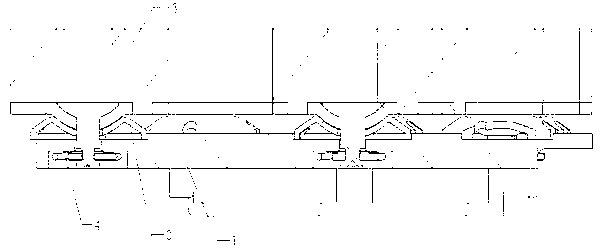

Floating brake pad

The invention discloses a floating brake pad which comprises a pad back plate, a friction block, a clamp spring, an elastic support sheet arranged between the friction block and the pad back plate. The elastic support sheet comprises a spherical support surface and a support pawl on the outer side of the spherical support surface, wherein the spherical support surface is bonded with a spherical support part of the friction block, and a guiding hole suitable for a positioning part of the friction block to penetrate through is formed at the bottom center of the spherical support surface. The support pawl extend to the bottom of the spherical support surface from the periphery of the spherical support surface in the direction away from the guiding hole, the connection edge of the support pawl is connected with the periphery of the spherical support surface through a smooth transition section, and the support pawl and the support edge extend out of the bottom of the spherical support surface. The floating brake pad solves the problem that a pawl of the elastic support part of the existing brake pad is bent inwards instead of extending outwards, so that when stressed, the elastic support can extend outwards along the direction of the support pawl, and support of the corresponding part cannot fail.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

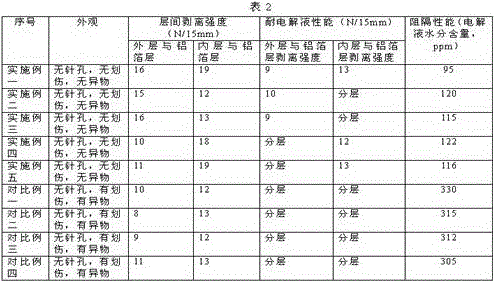

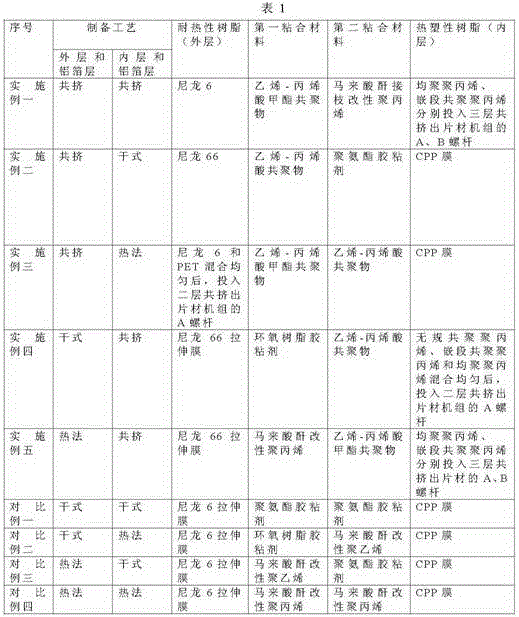

Preparing method for aluminum plastic film for lithium battery packaging

InactiveCN106808662AImprove bindingHigh bonding strengthSynthetic resin layered productsFlat articlesMolten stateMetallurgy

The invention discloses a preparing method for an aluminum plastic film for lithium battery packaging. The method comprises the following steps that firstly, an outer layer material and a first bonding material are added in a screw A and a screw B of a two-layer co-extrusion sheet unit and are melted and co-extruded in a screw extruder to be in tape casting to one side of aluminum foil to become a film; secondly, an inner layer material and a second bonding material are added in the screw A and the screw B of the two-layer co-extrusion sheet unit and are melted and co-extruded in the screw extruder to be in tape casting to the other side of the aluminum foil to become a film; and then the aluminum plastic film for lithium battery packaging can be obtained. The outer layer material or the inner layer material is melted and co-extruded to be in tape casting to the surface of the aluminum foil to become the film in the screw extruder melting, co-extrusion and tape casting manner; the outer layer material (or the inner layer material) in the molten state and the bonding material can seep into each other among the layers, and when the outer layer material (or the inner layer material) and the bonding material are in tape casting to the surface of the aluminum foil to be laminated, interlayer bonding is firmer, and the interlayer bonding strength is further improved.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

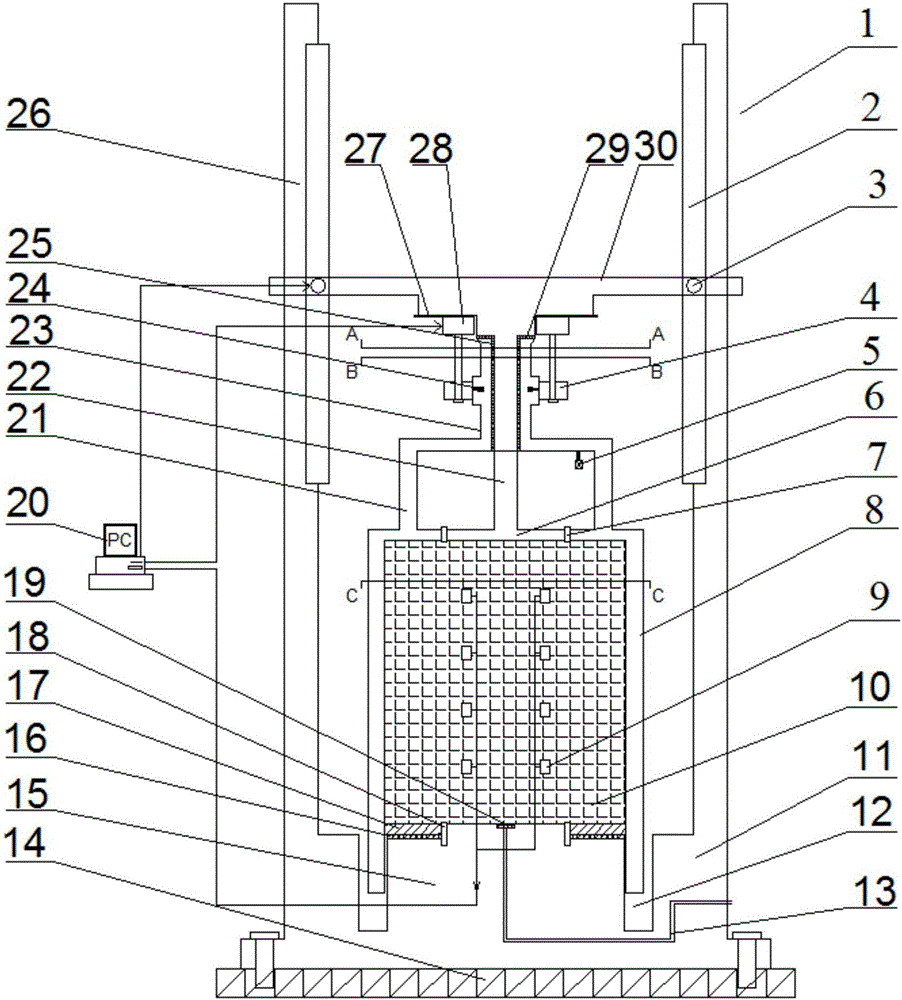

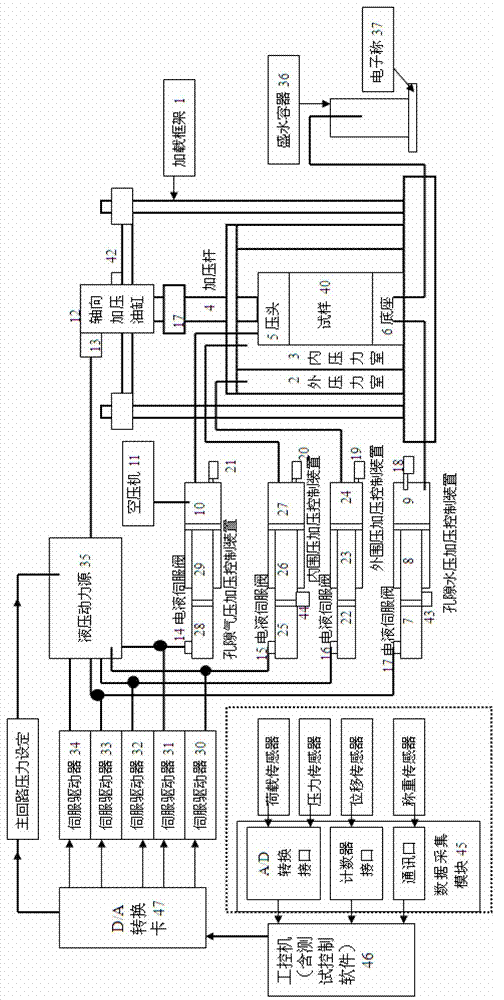

Stress path full-automatic hydraulic servo control type rigid-flexible multifunctional triaxial apparatus

InactiveCN102818726ARealize fully automatic controlAccurate measurementStrength propertiesInternal pressureStress path

The invention discloses a stress path full-automatic hydraulic servo control type rigid-flexible multifunctional triaxial apparatus which comprises a loading frame, a double chamber pressure chamber, a base, a pressure head, a loading system, a data measurement and collection device and a control device, wherein the double chamber pressure chamber is arranged at the periphery of a sample, the pressure head and the base are respectively arranged at the upper end and the lower end of the sample, the loading frame is arranged at the outer side of the double chamber pressure chamber, the double chamber pressure chamber comprises an inner pressure chamber and an outer pressure chamber arranged at the periphery of the inner pressure chamber, the loading system is used for carrying out a loading test on the sample, the data measurement and collection device is used for collecting and measuring loading test data, and the control device is respectively connected with the loading system and the data measurement and collection device and used for controlling the loading system and acquiring the loading test data obtained by the data measurement and collection device. With the adoption of the stress path full-automatic hydraulic servo control type rigid-flexible multifunctional triaxial apparatus, accurate measurement of unsaturated soil volume deformation can be carried out.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

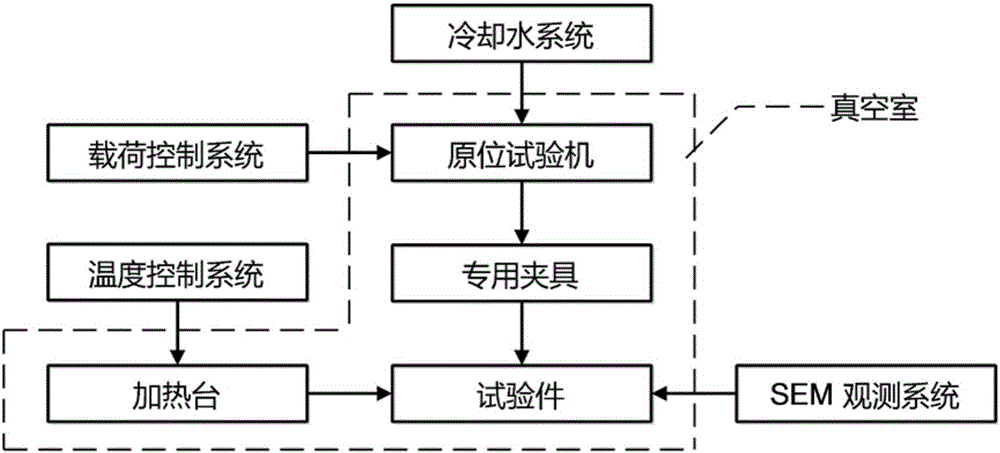

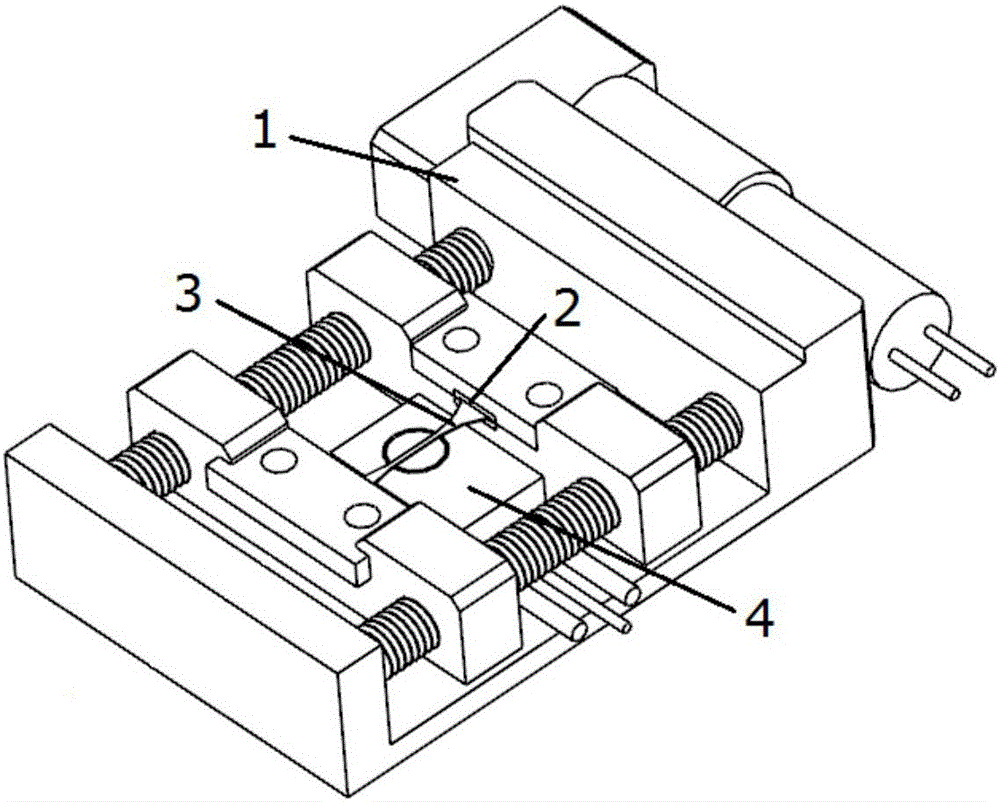

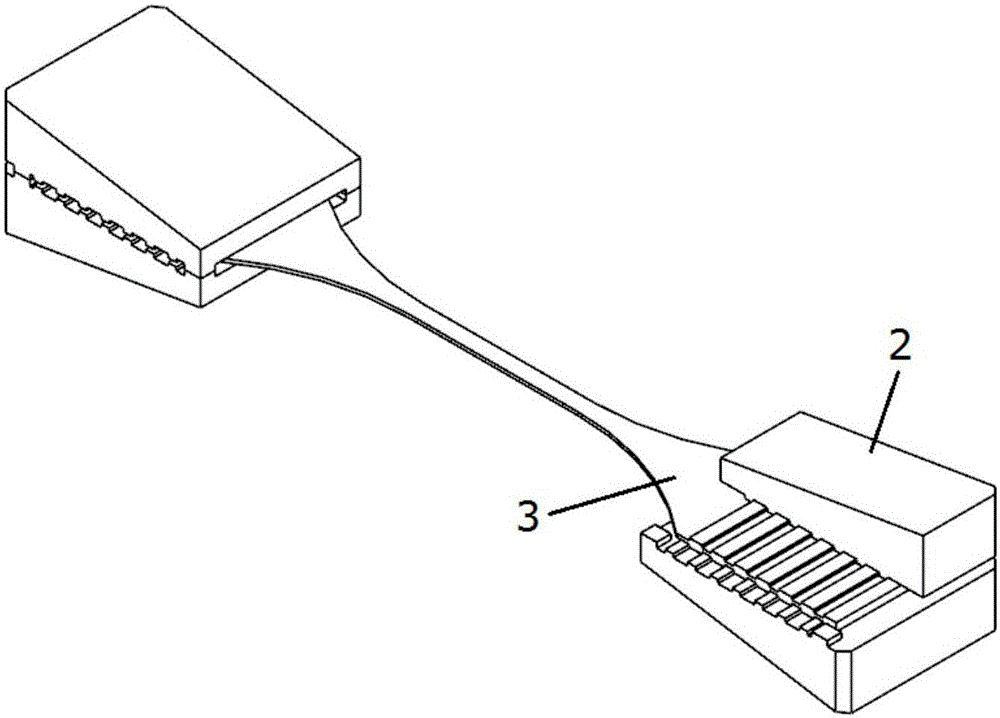

High-temperature mechanical property in-situ tension test system and method for small-sized monocrystalline silicon test piece

ActiveCN105092387ASimple structureEasy to implementMaterial strength using tensile/compressive forcesAutomotive engineeringMonocrystalline silicon

The invention discloses a high-temperature mechanical property in-situ tension test system and method for a small-sized monocrystalline silicon test piece. The system comprises a load control system, an in-situ testing machine, a special jig, the purpose-made test piece, a temperature control system, a heating table, a cooling water system and an SEM observing system. By the adoption of the system and method, the high-temperature mechanical property of the small-sized monocrystalline silicon test piece is tested through a uniaxial drawing method.

Owner:BEIHANG UNIV

Flexible package aluminum-plastic film material for lithium battery

InactiveCN104241556AImprove ductilityGood mechanical propertiesSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPolyesterElectrolytic agent

The invention relates to a flexible package aluminum-plastic film material for a lithium battery. The flexible package aluminum-plastic film material for the lithium battery comprises a layer structure, wherein the layer structure comprises an aluminum-based layer (AL) in the middle and layers on the inner side and the outer side of the aluminum-based layer, wherein a novel functional adhesive resin layer (AD), a polyester layer (PET), a novel functional adhesive resin layer (AD) and a copolymer propylene layer (CPP) are sequentially distributed on the inner side from inside to outside; a polyester layer (PET), a novel functional adhesive resin layer (AD) and a homopolymer propylene layer (PP) are sequentially distributed on the outer side from inside to outside. The polyester layer (PET) is used as a functional barrier layer and has the stable chemical performance and high electrolyte resistance; the copolymer propylene layer (CPP) is used as a functional material layer and has the high electrolyte resistance, heat-sealing performance and high heat-sealing strength; the novel functional adhesive resin layer (AD) is made of a PP material and has the strong adhesive fastness with the aluminum-based layer (AL), the polyester layer (PET), the homopolymer propylene layer (PP) and the copolymer propylene layer (CPP). The layering can not occur by adopting a casting process technology.

Owner:广东赛洋科技有限公司

Binding method for capacitive touch screen

InactiveCN102501560AUniform thicknessUniform stressLaminationLamination apparatusUltravioletUltraviolet irradiation

The invention relates to a binding method for a capacitive touch screen, which comprises the following steps: evenly coating ultraviolet curable resin on the binding face of a first board body to serve as a bonding layer; then, performing binding in a vacuum environment; and finally, removing the vacuum environment, and fully curing the bonding layer by adopting ultraviolet irradiation so as to firmly bind the first board body with a second board body together. The first board body and the second board body are bound in the vacuum environment, and therefore, a bubble problem cannot exist between the first board body and the second board body, and the binding of large-sized board bodies can be realized. As the ultraviolet curable resin is coated evenly, and in the coating process, the use level of the ultraviolet curable resin and area are in direct ratio, the use level of the ultraviolet curable resin can be accurately controlled, so that large-area flowing cannot occur after the binding is finished, thereby, the thickness and the stress of all areas are quite uniform. The first board body and the second board body can be bound in a board-jointed state. The binding method for the capacitive touch screen is suitable for manufacturing board-jointed capacitive touch screens, and has higher production efficiency.

Owner:SHANTOU GOWORLD DISPLAY (PLANT II) CO LTD

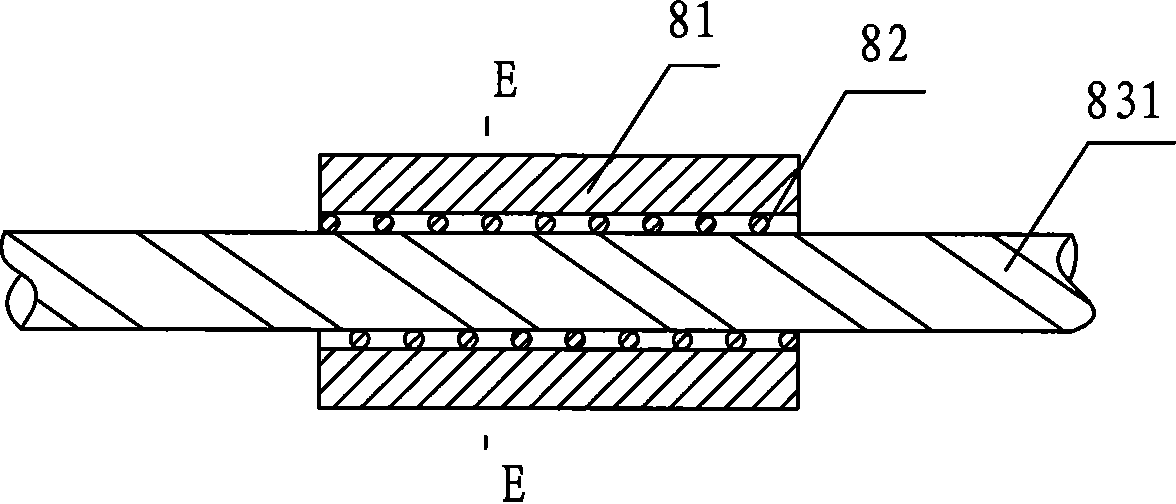

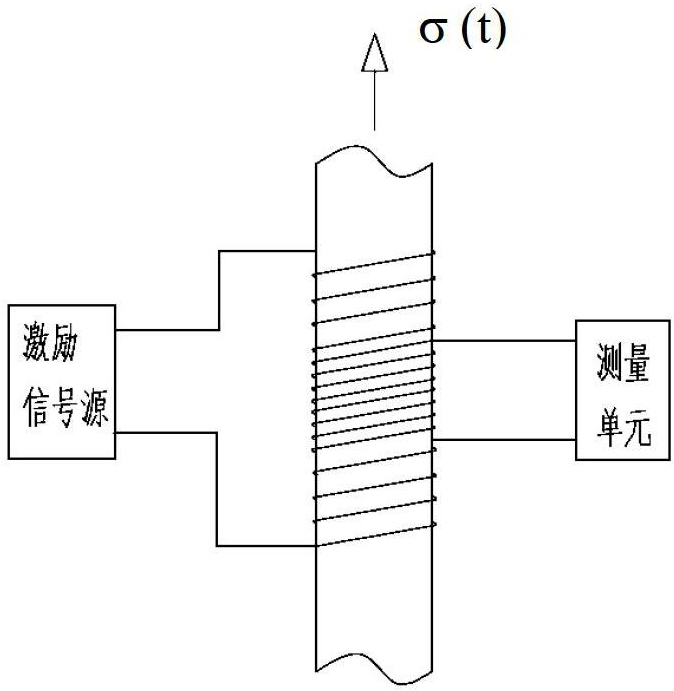

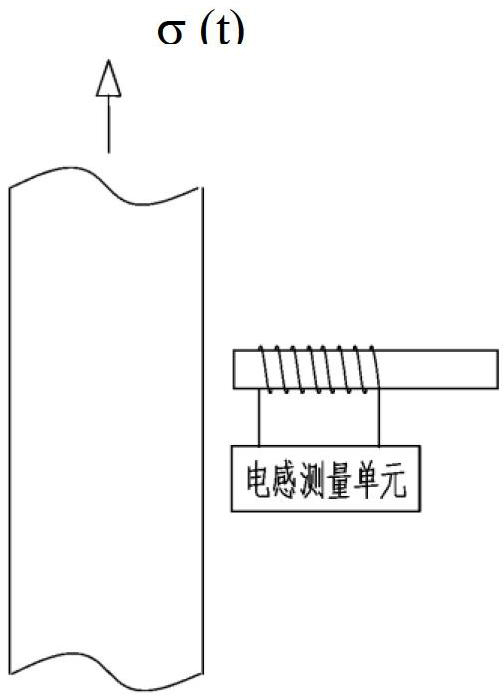

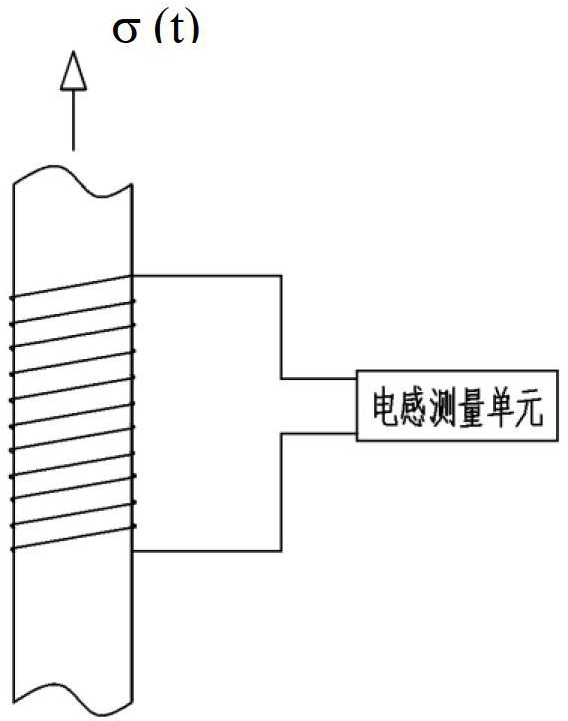

Coupled external mounted steel stay rope force detection device and method

InactiveCN102680156AThe induced voltage signal is largeSolving Tension Measurement ProblemsResistance/reactance/impedenceTension measurementPull forceMagnetic poles

The invention discloses a coupled external mounted steel stay rope force detection device and a method. The device comprises an excitation assembly and a winding displacement coupling sensor, wherein the excitation assembly comprises a magnetic core, an excitation coil with a capacitive discharge circuit is sheathed on the magnetic core, a first magnetic pole and a second magnetic pole are arranged at two ends of the magnetic core and are respectively provided with a first press plate and a second press plate, the first magnetic pole and the first press plate are detachably connected, the second magnetic pole and the second press plate are detachably connected, a first clamp hole is arranged at a connecting part of the first magnetic pole and the first press plate, a second clamp hole is arranged at a connecting part of the second magnetic pole and the second press plate, and round lining pads are arranged on the inner walls of the first clamping hole and the second clamping hole. The method comprises the following steps that the device is used for detection, and in addition, magnetic feature curves of a steel stay rope to be detected are obtained; the device is used for detection, in addition, a group of standard magnetic feature curves are obtained; and the magnetic feature curves of the steel stay rope to be detected are compared with the group of standard magnetic feature curves to obtain the tension in the steel stay rope to be detected.

Owner:SOUTHEAST UNIV

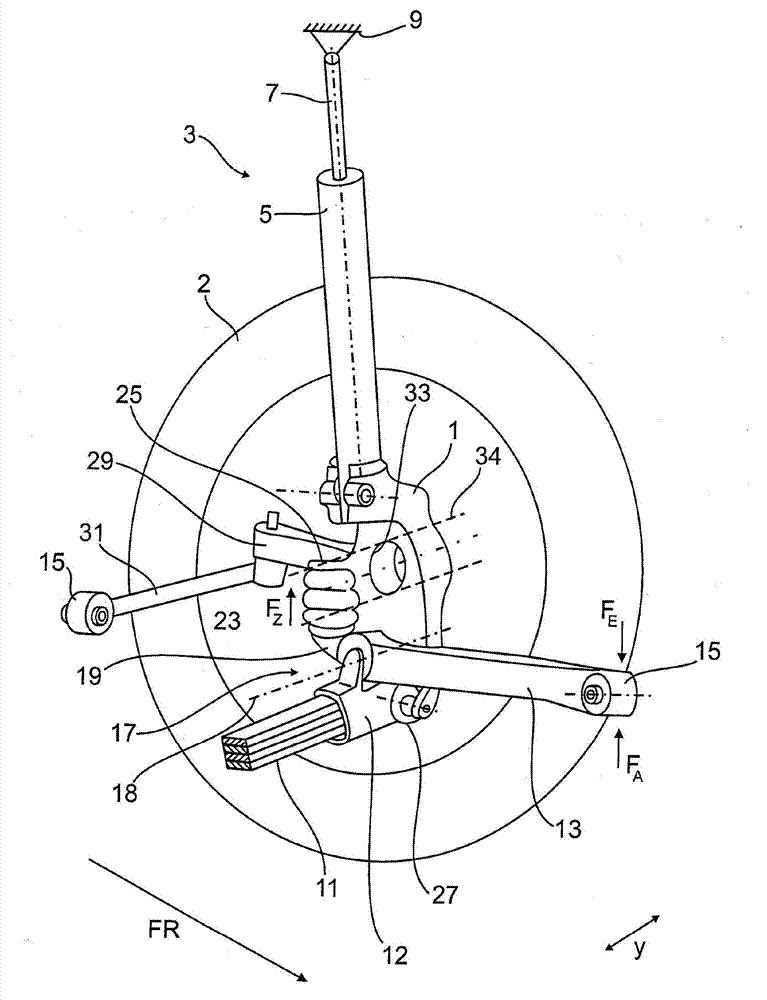

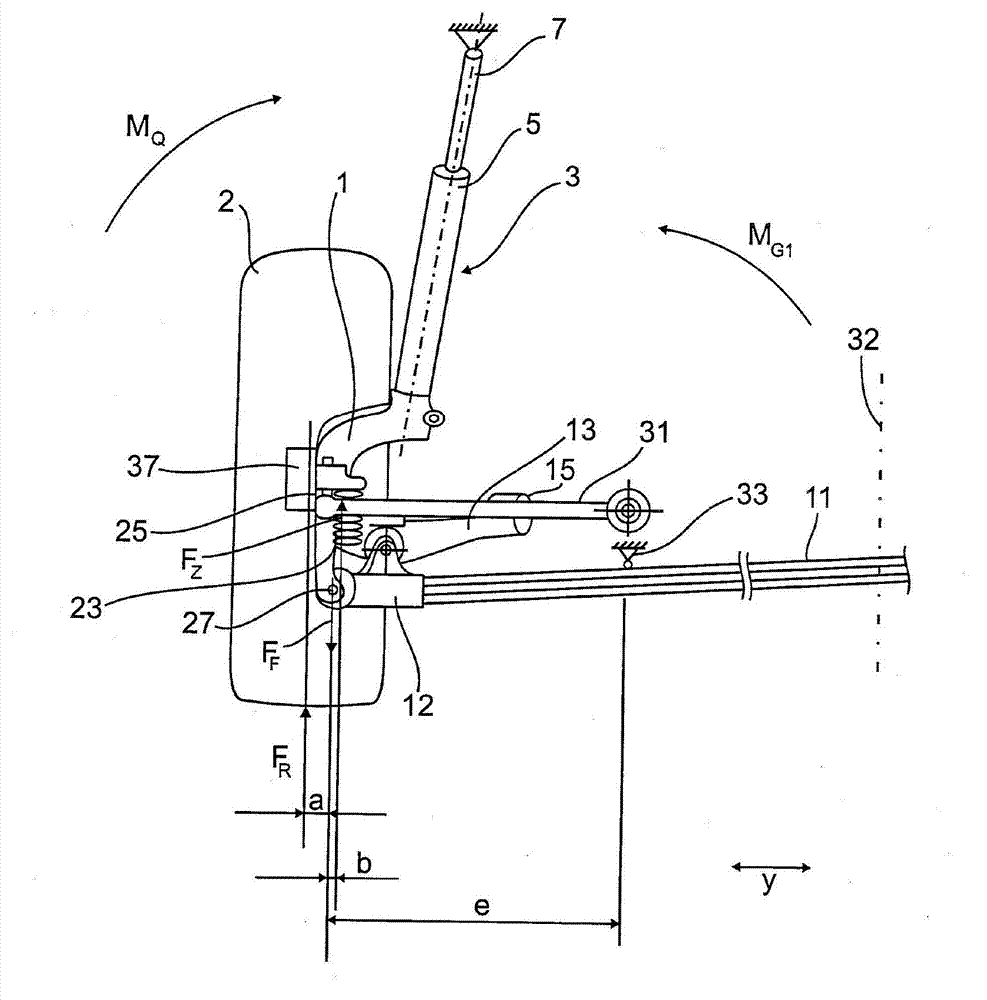

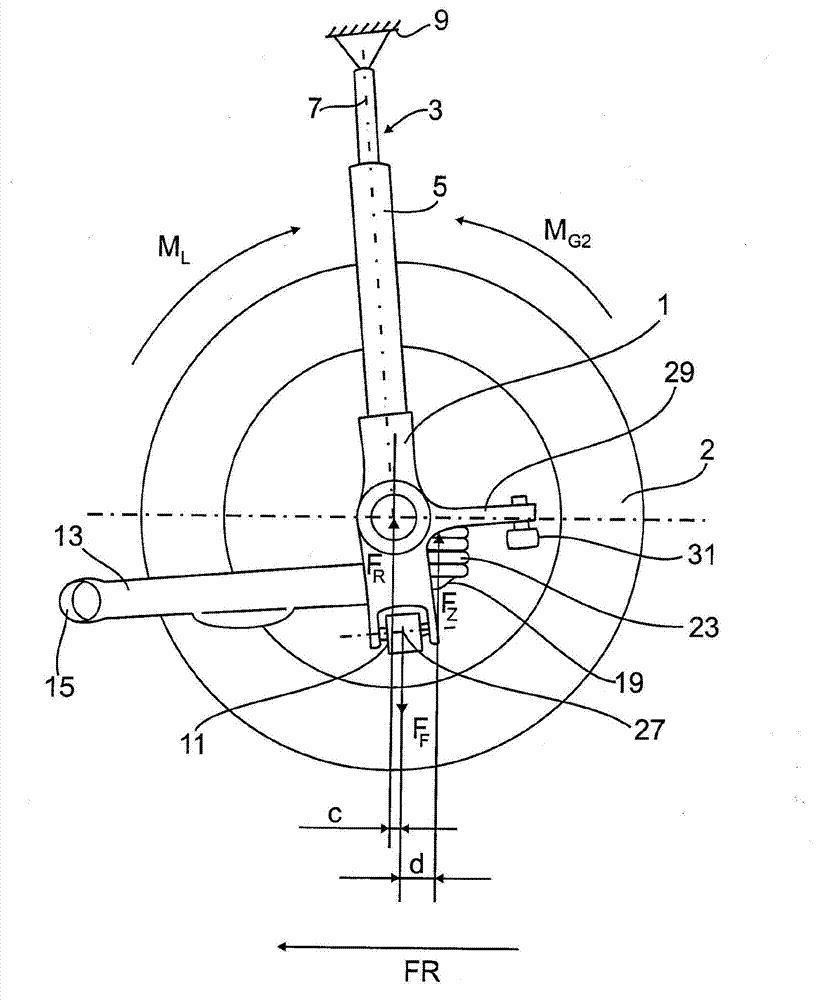

Wheel suspension for a vehicle

ActiveCN102848873ACompact structureSave spaceResilient suspensionsPivoted suspension armsLeaf springSuspension spring

The wheel suspension has a suspension spring (11) and a damper (3) connected to a wheel carrier (1) of a vehicle. The wheel carrier is hinged to a vehicle body (9) over a wheel guiding element. The suspension spring is formed as a leaf spring, and the leaf spring is articulated as a wheel guide element on the wheel carrier. The leaf spring directly or indirectly bears an additional spring (23).

Owner:AUDI AG

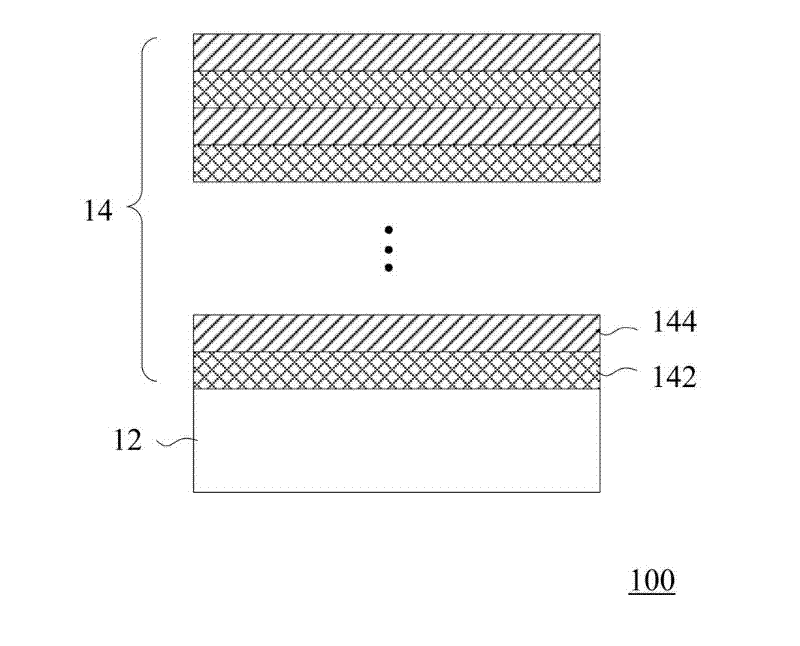

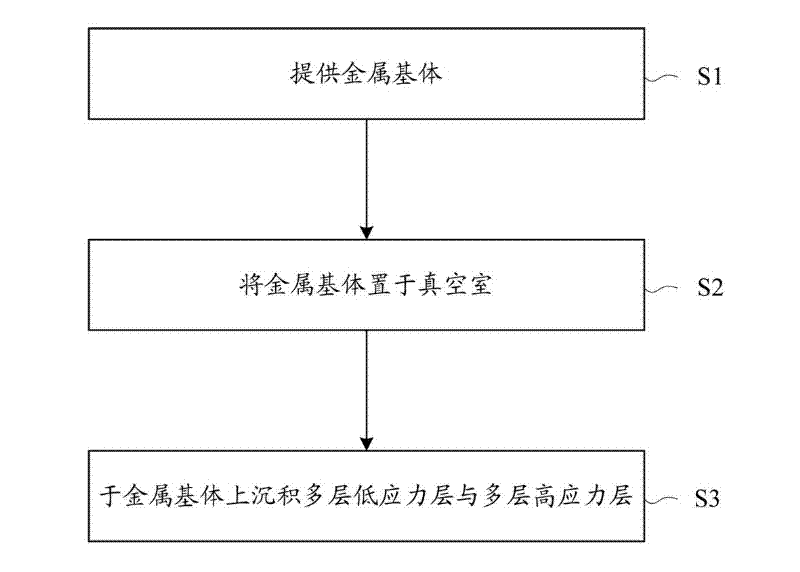

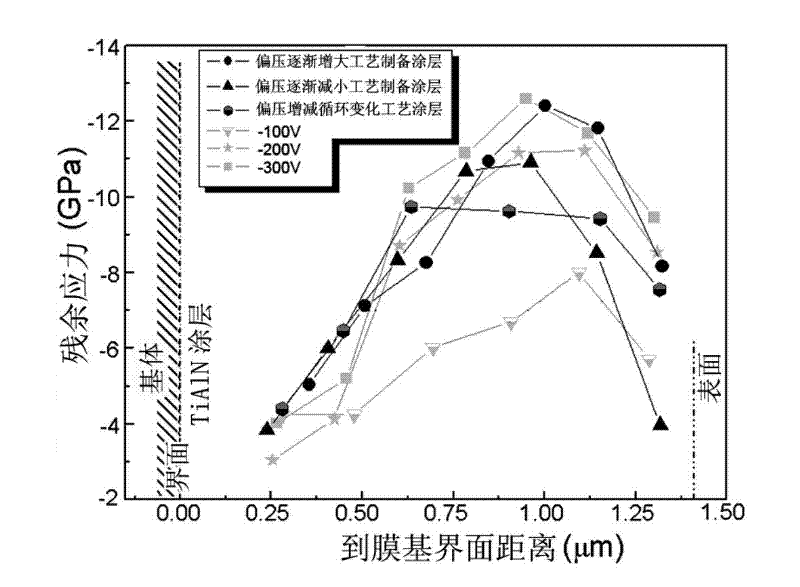

Hard coating and preparation method thereof

ActiveCN102634753AUniform stressImprove residual stressVacuum evaporation coatingSputtering coatingBonding strengthHardness

The invention relates to a hard coating and a preparation method thereof. The hard coating comprises multiple low stress layers and multiple high stress layers; the low stress layers and the high stress layers are alternatively formed on a metal matrix. The invention also provides a preparation method of the hard coating. The hard coating and the preparation method thereof of the invention can improve the residual stress distribution in the hard coating, and can increase the film-matrix bonding strength with the proviso that the high hardness and high wear resistance of the hard coating are maintained.

Owner:广东华升纳米科技股份有限公司

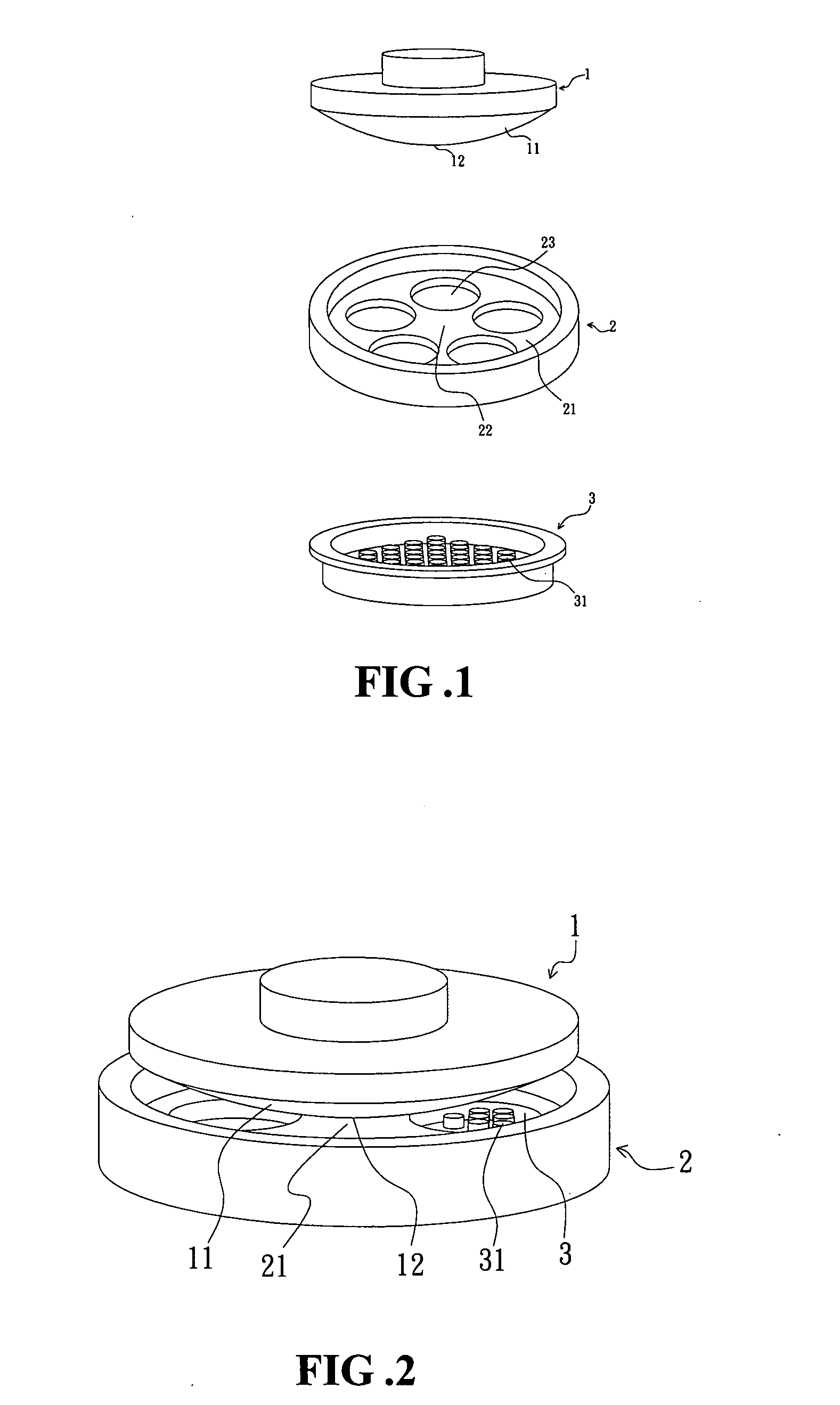

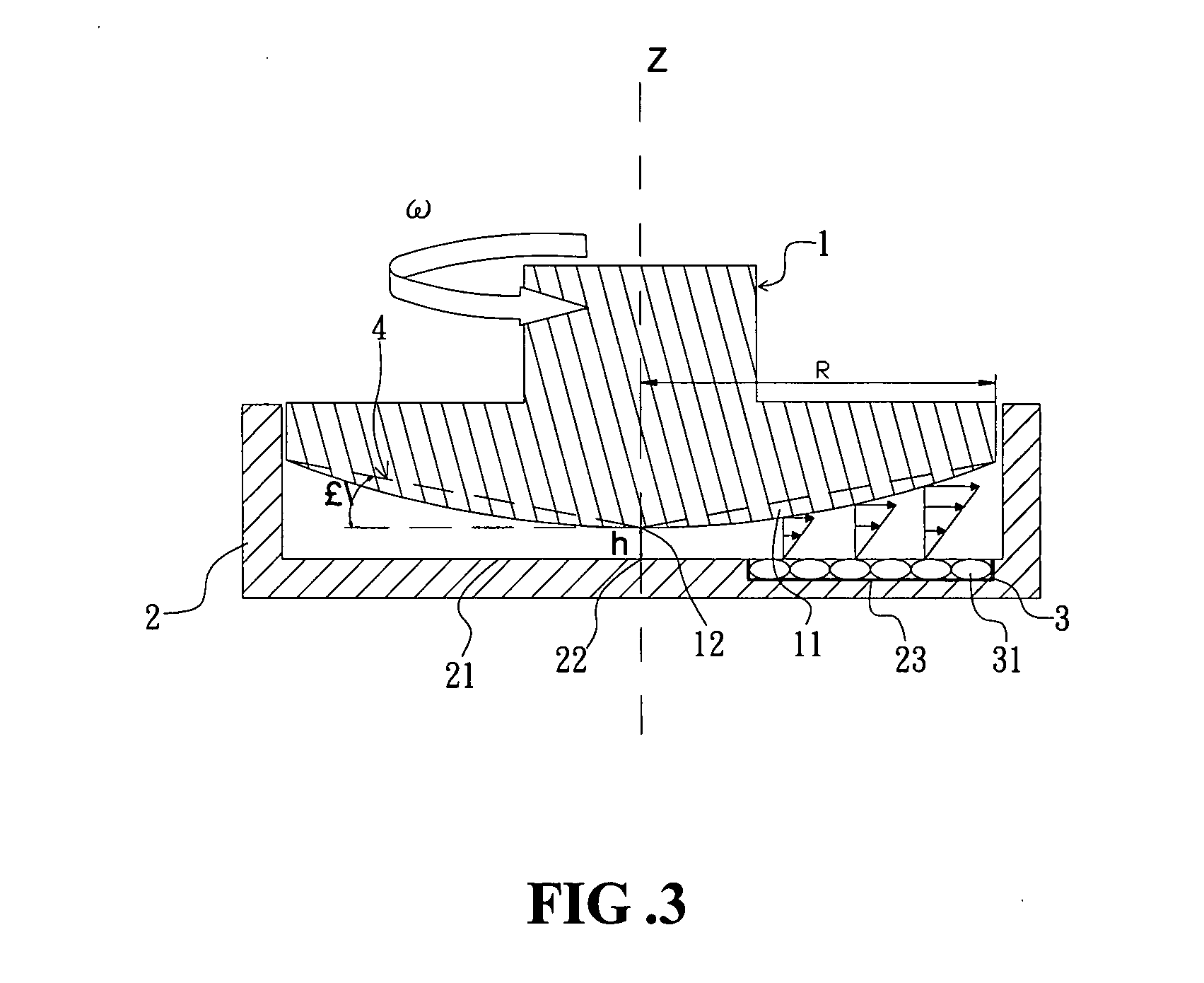

Novel bioreactor for generating uniform shear stress distribution

InactiveUS20080038816A1Enlarge areaUniform stressBioreactor/fermenter combinationsBiological substance pretreatmentsCatenaryCulture mediums

The present invention relates to a bioreactor for generating uniform distribution of shear stress, comprising: a cone, having a cone surface with an outline of modified catenary; a container, having a fixed plate at the bottom inside the accommodating space of said container, and said fixed plate comprises a plurality of reservoirs; wherein the cone tip located above the center of said fixed plate is capable of loading culture media into the accommodating space of said container, that is, into the space between the cone surface and the fixed plate. More uniform shear stress can be generated in the culture media to act on the sample in the reservoirs of the fixed plate when the cone rotates and makes the culture media run. The bioreactor of the present invention can be applied to generate uniform shear stress acting on the fixed plate despite the distance between the cone tip and the fixed plate.

Owner:CHUNG CHENG INST TECH

Vacuum resistive brazing method for lap piece

InactiveCN104668688ARemove air conditionQuality improvementSoldering apparatusFiller metalMaterials science

The invention relates to a vacuum resistive brazing method for a lap piece. The vacuum resistive brazing method comprises the following steps: 1, cleaning a to-be-lapped piece; 2, fixing brazing filler metal on the contact surface of the to-be-lapped piece by using upper and lower electrodes; 3, vacuumizing a brazing furnace, and putting the to-be-lapped piece fixed with the brazing filler metal into the vacuum brazing furnace, wherein the internal vacuum degree of the vacuum brazing furnace is 1.0*10<-1>-1.0*10<-4>Pa by vacuumizing; 4, heating the brazing filler metal until the temperature is higher than the welding point of the brazing filler metal by 30-80 DEG C; 5, cooling a resistive brazing piece, and discharging the resistive brazing piece from the furnace. The to-be-lapped piece to be resistively brazed is assembled and then is arranged in a vacuum environment, the influence on the to-be-lapped piece caused by air in the environment in the resistive brazing process is eliminated, and air conditions caused by air holes in the resistive brazing process are eliminated; meanwhile, the brazing surface is pollution-free in the welding process, and the welded brazing surface is pollution-free.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

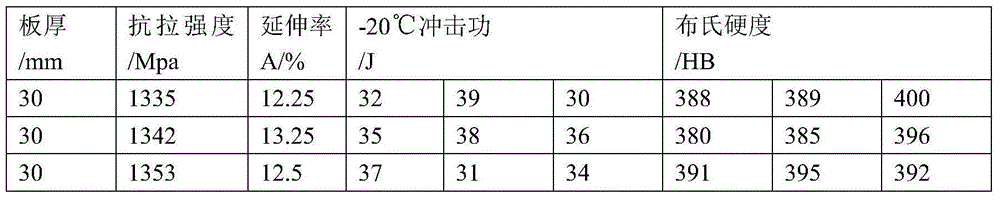

Wear-resistant steel with 400-level Brinell hardness and manufacturing method thereof

The invention discloses wear-resistant steel with 400-level Brinell hardness and a manufacturing method thereof. The steel comprises, by mass, 0.14-0.21% of C, 0.20-0.40% of Si, 0.9-1.4% of Mn, 0.015% of P or less, 0.008% of S or less, 0.5-0.8% of Cr, 0.05-0.08% of Ni, 0.2-0.4% of Mo, 0.02-0.05% of Als, 0.02-0.03% of Ti, 0.02% of V or less, 0.005% of B or less, and the balance iron and inevitable impurities. The manufacturing method includes the following steps that the chemical components are proportionally subjected to vacuum melting and cast into blanks, and then plate blank heating, rolling, cooling, quenching and low-temperature tempering are performed to obtain finished steel plates. The wear-resistant steel is good in residual stress uniformity, free of cracking or deformation in the use process, resistant to wear and long in service life.

Owner:武汉钢铁有限公司

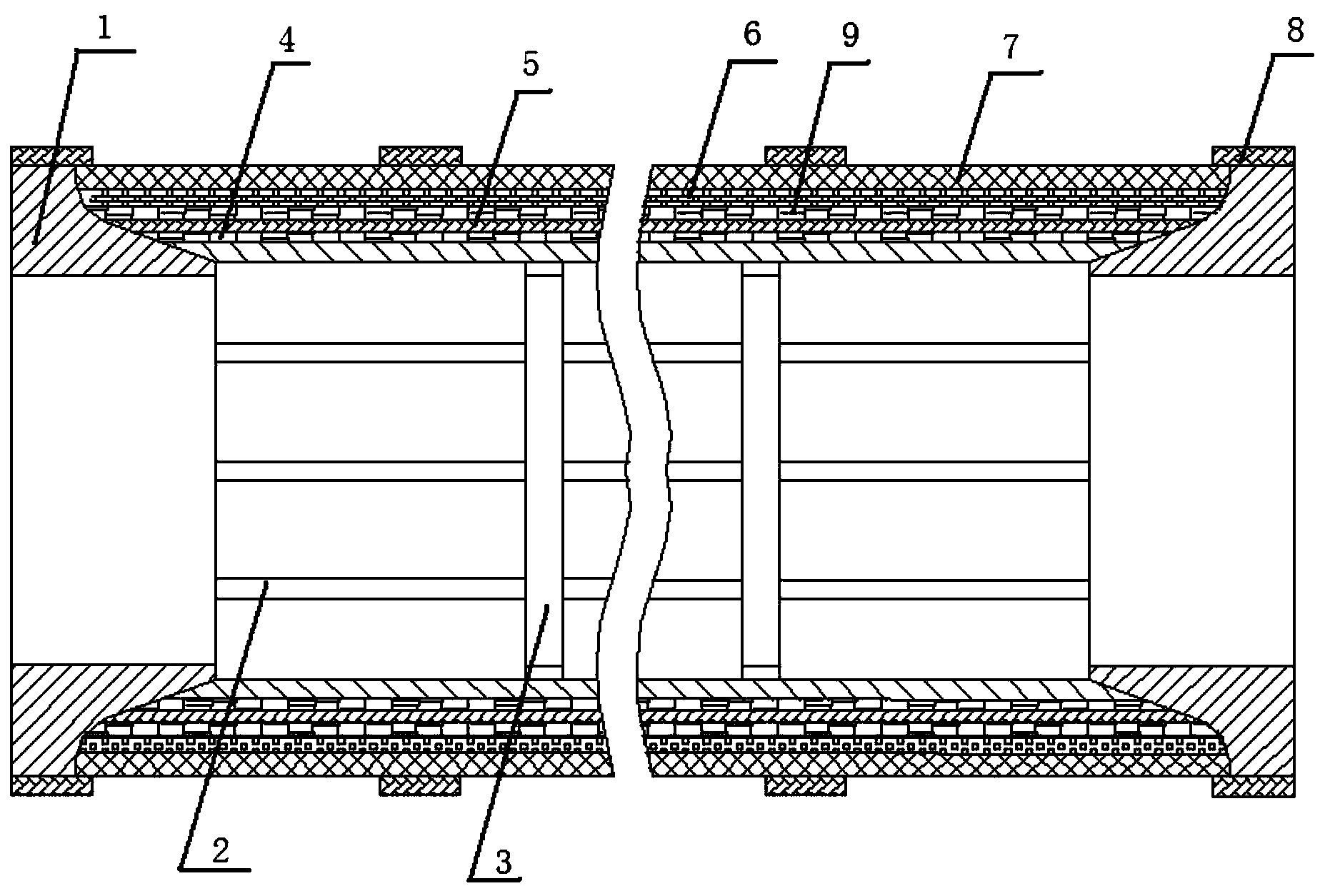

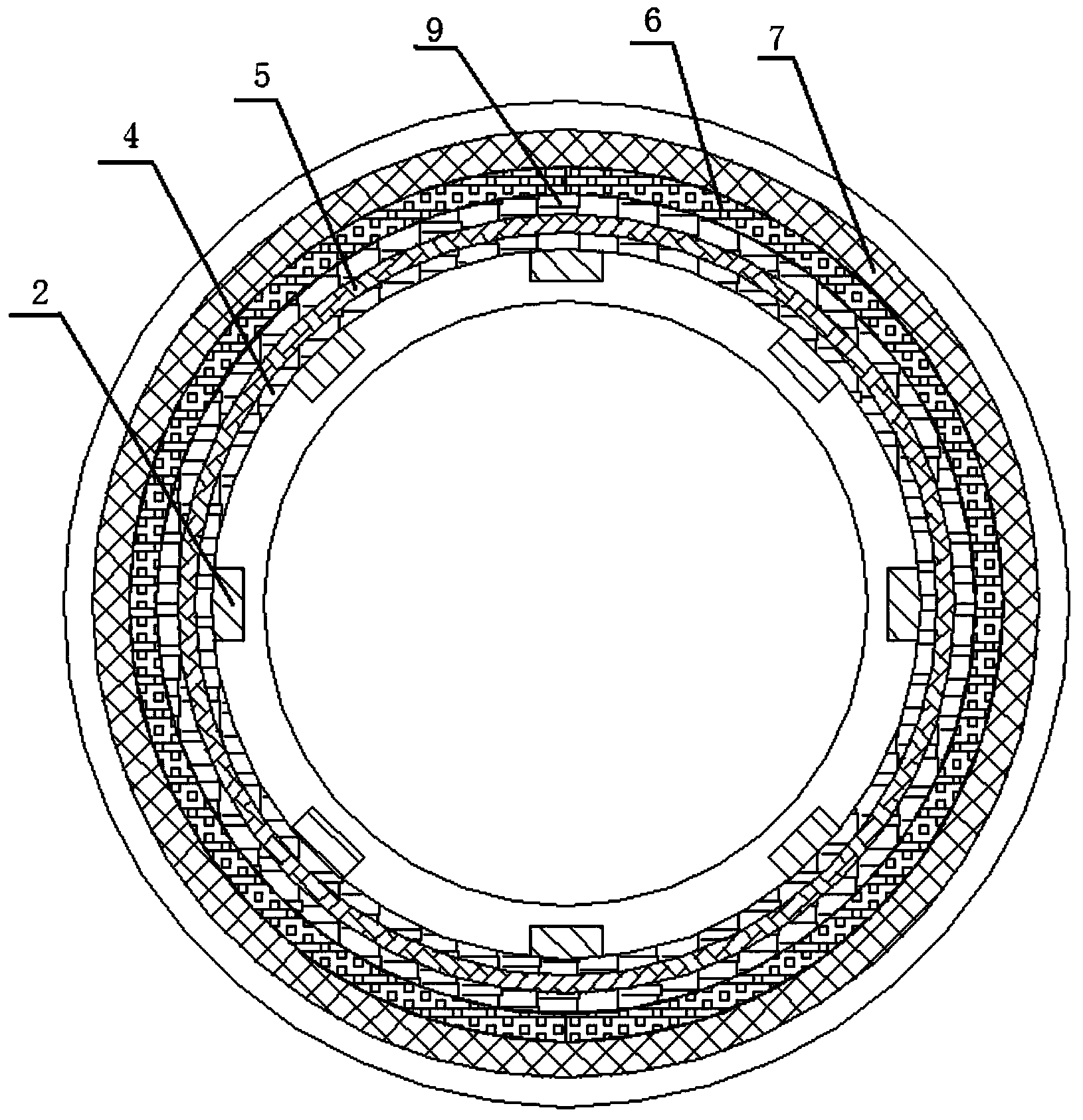

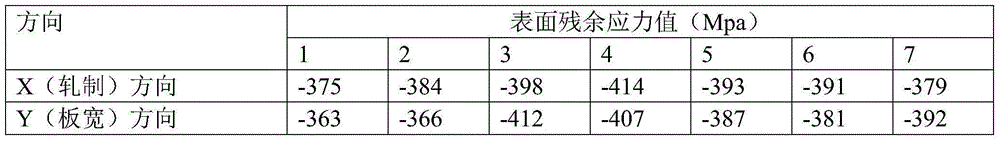

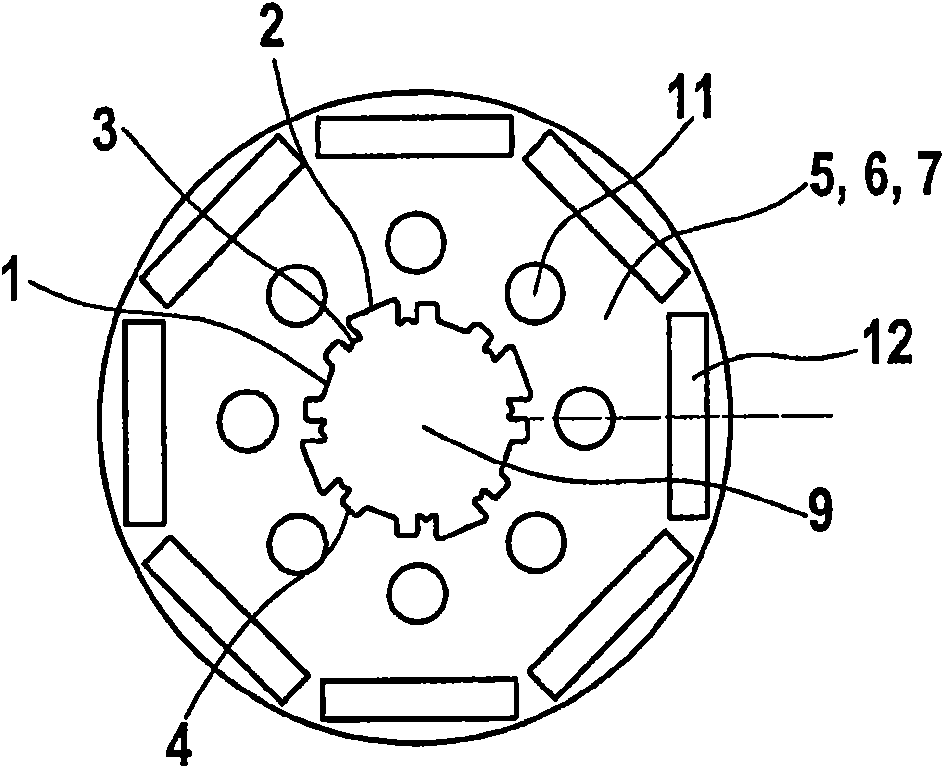

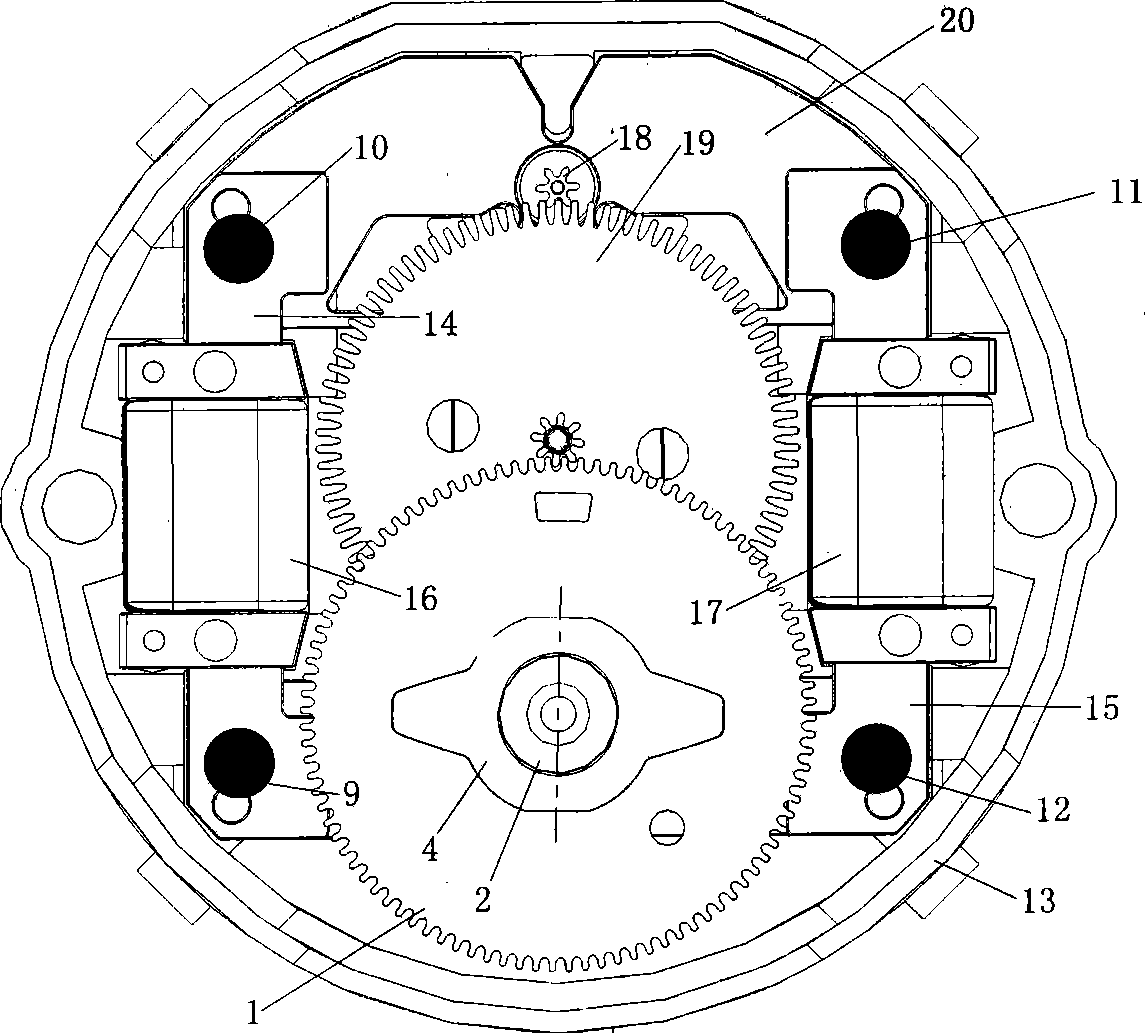

Electrical machine

InactiveCN101627521AUniform stressAvoid bend radiusMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineElectric motor

The invention relates to an electrical machine (8), in particular an electric motor, suitable for the adjustment by external force of elements of a motor vehicle, essentially for driving a steering booster. The inventive electrical machine comprises a rotor (7) and a shaft (10), the rotor having a plurality of plates (5), wherein the plates (5) are premounted on the shaft either indivdually or as a plate assembly (6) or by means of a plurality of plate assemblies (6), the rotor (7) being connected to the shaft (10). The plates (5) have resilient lugs (3) for fixing the plates (5) and / or plate assemblies (6) to the shaft (10). Furthermore, the plates (5) of the plate assemblies (6) comprise centering lugs (1) which serve to radially center the plate assembly (6) relative to the shaft (10). An attachment of the stator (15) in a housing part (16) is possible, wherein centering lugs (1) at the plates (5) of the plate assembly (6) of the stator (15) serve to center the plate assembly (6) of the stator (15) relative to the shaft (10).

Owner:ROBERT BOSCH GMBH

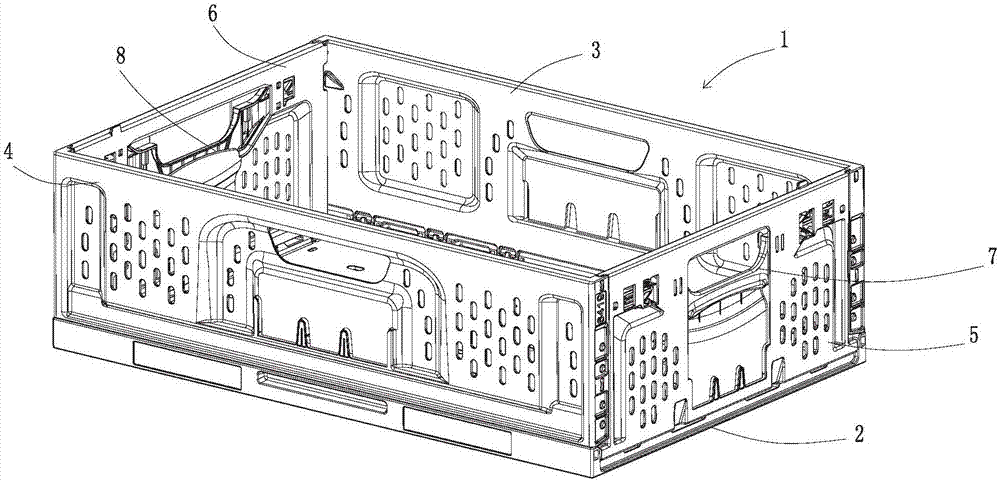

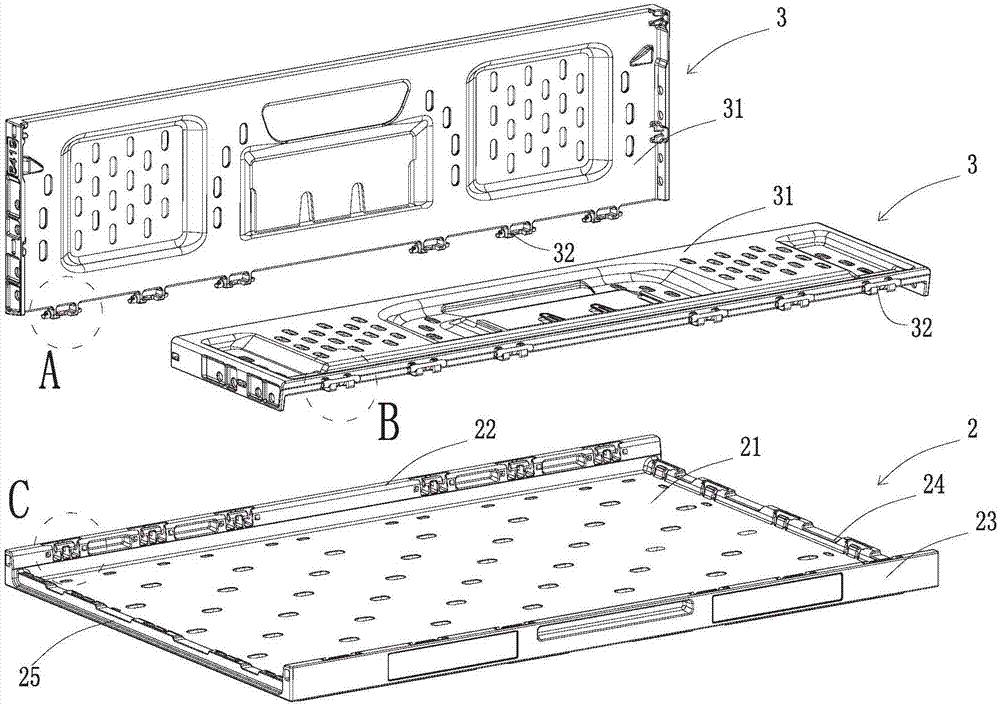

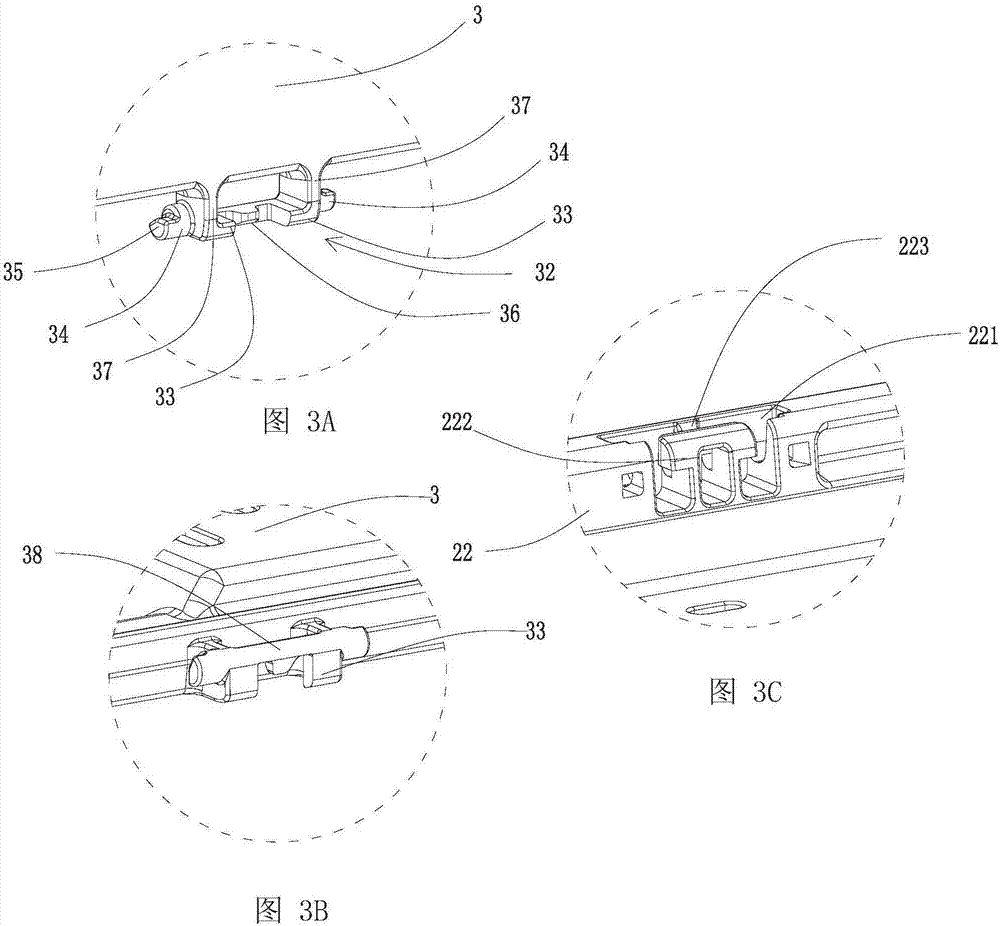

Folding box

InactiveCN106956845AImprove safety and reliabilityExtended service lifeRigid containersArchitectural engineeringClosed cavity

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

Vibration preventing automobile instrument motor

InactiveCN101505075AUniform stressReduce magnetic circuit reluctanceMechanical energy handlingSupports/enclosures/casingsStatorElectrical and Electronics engineering

The invention discloses an anti-vibration motormeter motor. An upper surface of an output shaft gear is provided with a boss integrated with the gear; a stainless steel spring piece is arranged between the gear and the inner surface of an upper cover, a central hole of the stainless steel spring piece is matched with the boss, and the convex surface of the stainless steel spring piece is contacted with the surface of the gear; the inner surface of the upper cover is provided with four protrusions which are provided with a hole respectively, and four silicon rubber bars are arranged in the four holes respectively; and when the upper cover is matched with a lower cover, two silicon rubber bards are pressed on the two ends of left coil core and the other two silicon rubber bars are pressed on the two ends of right coil core. During the operation of the anti-vibration motormeter motor, uniform pressure provided with the stainless steel spring piece enables the output shaft gear to operate smoothly during operation; and a silicon rubber spring allows the coil cores and a stator piece to be attached together tightly during operation without fastening by a bolt, and the magnetic resistance on magnetic paths of coils is reduced. The anti-vibration motormeter motor can operate stably on various vehicles in an environment at 40 DEG C below zero to 150 DEG C.

Owner:WUXI MCROT MOTOR

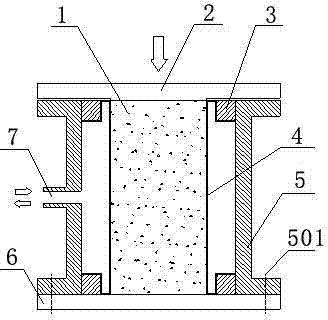

Confining pressure loading device for laboratory rock strength

InactiveCN103760028AAvoid destructionImprove reliabilityMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention relates to a confining pressure loading device for laboratory rock strength. The confining pressure loading device comprises a cylindrical drum, the lower end of the drum is fixedly arranged on a bearing seat, a loading cover for closing the drum is arranged on the upper end of the drum, the drum is internally sheathed with a sealing element, the sealing element consists of an upper lantern ring and a lower lantern ring which are connected by upright threads and are symmetrical, the peripheries of the two lantern rings are connected with the inner wall of the drum by threads, waterproof adhesive tapes are arranged on external threads of the two lantern rings, the sealing part is internally provided with a rubber sleeve for wrapping a rock test piece, an interlayer cavity is formed between the rubber sleeve and the inner wall of the drum, and the drum has a through hole which is communicated with the interlayer cavity. The circumferentially evenly distributed confining pressure applied by the confining pressure loading device can ensure uniform distribution of stress to the greatest extent before the rock test piece is damaged, thus the test effectiveness and the reliability of the test results can be improved; on the basis of meeting the laboratory demand, the device is simple in structure, easy for connection components to assemble and disassemble, and good in sealing property.

Owner:LUOYANG INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com