Device and method for simulating visual gap seepage by magnetic fluid

A magnetic fluid and fissure technology, applied in the field of rock fissure test, can solve the problems of lack of test equipment and methods, and achieve clear and reliable pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

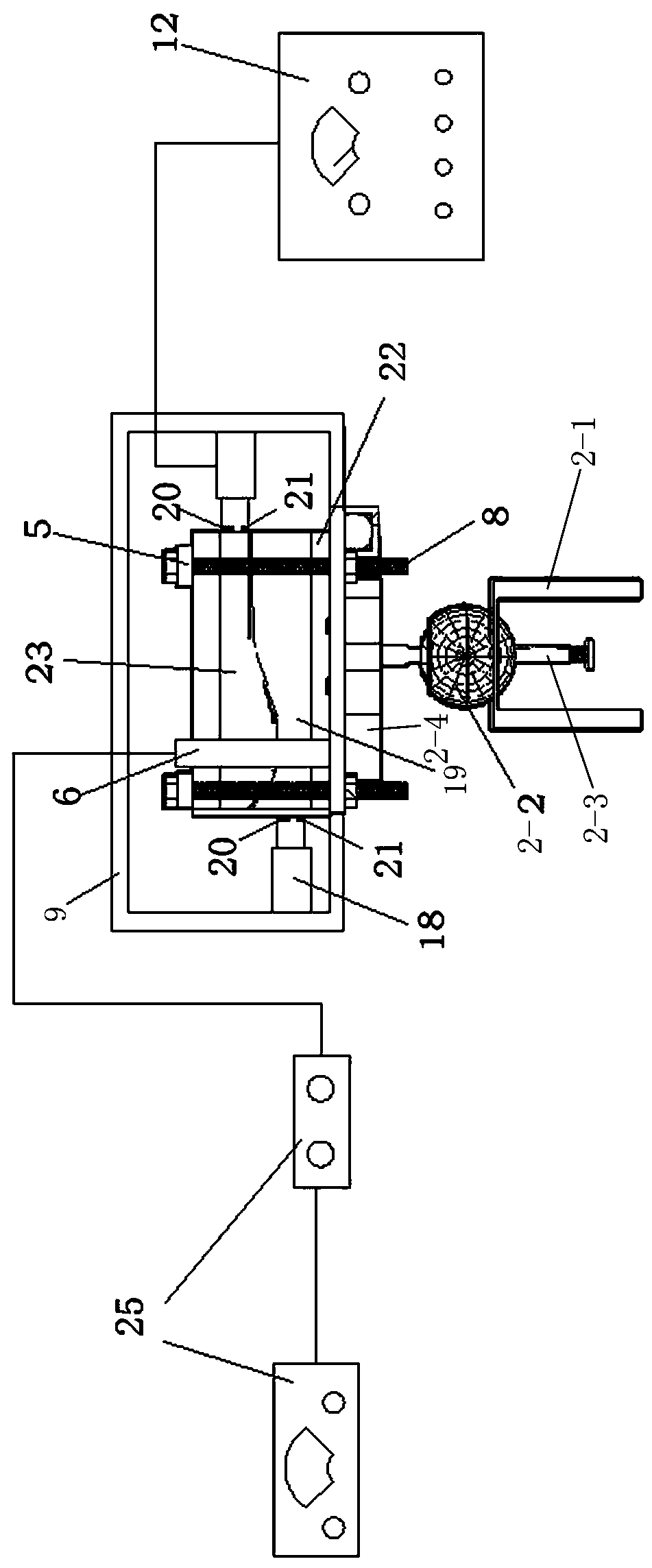

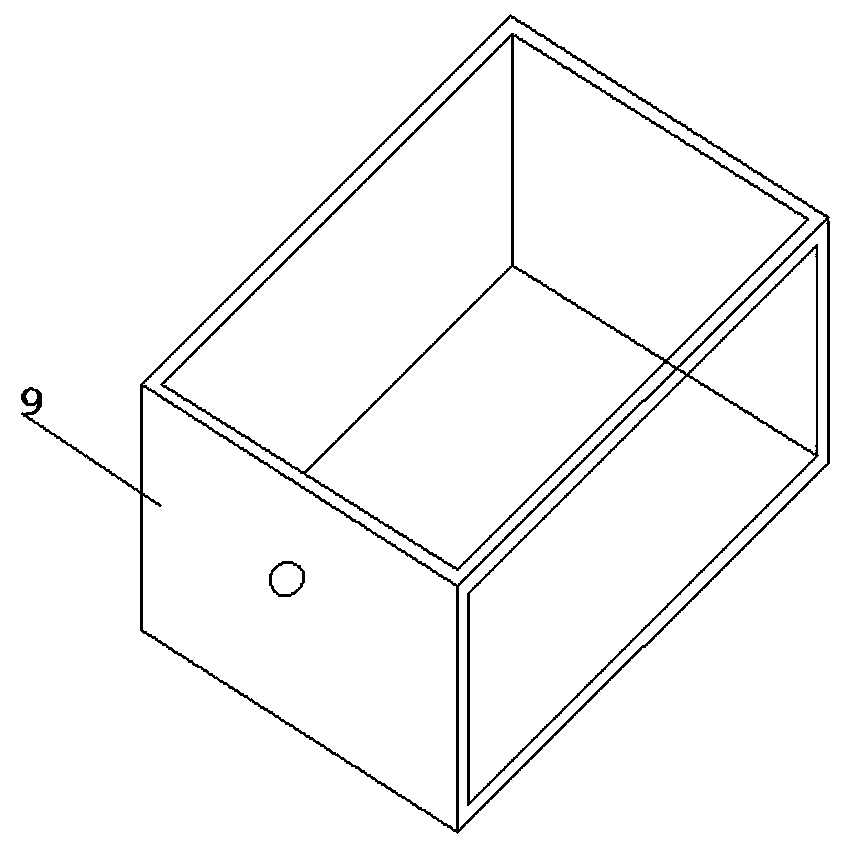

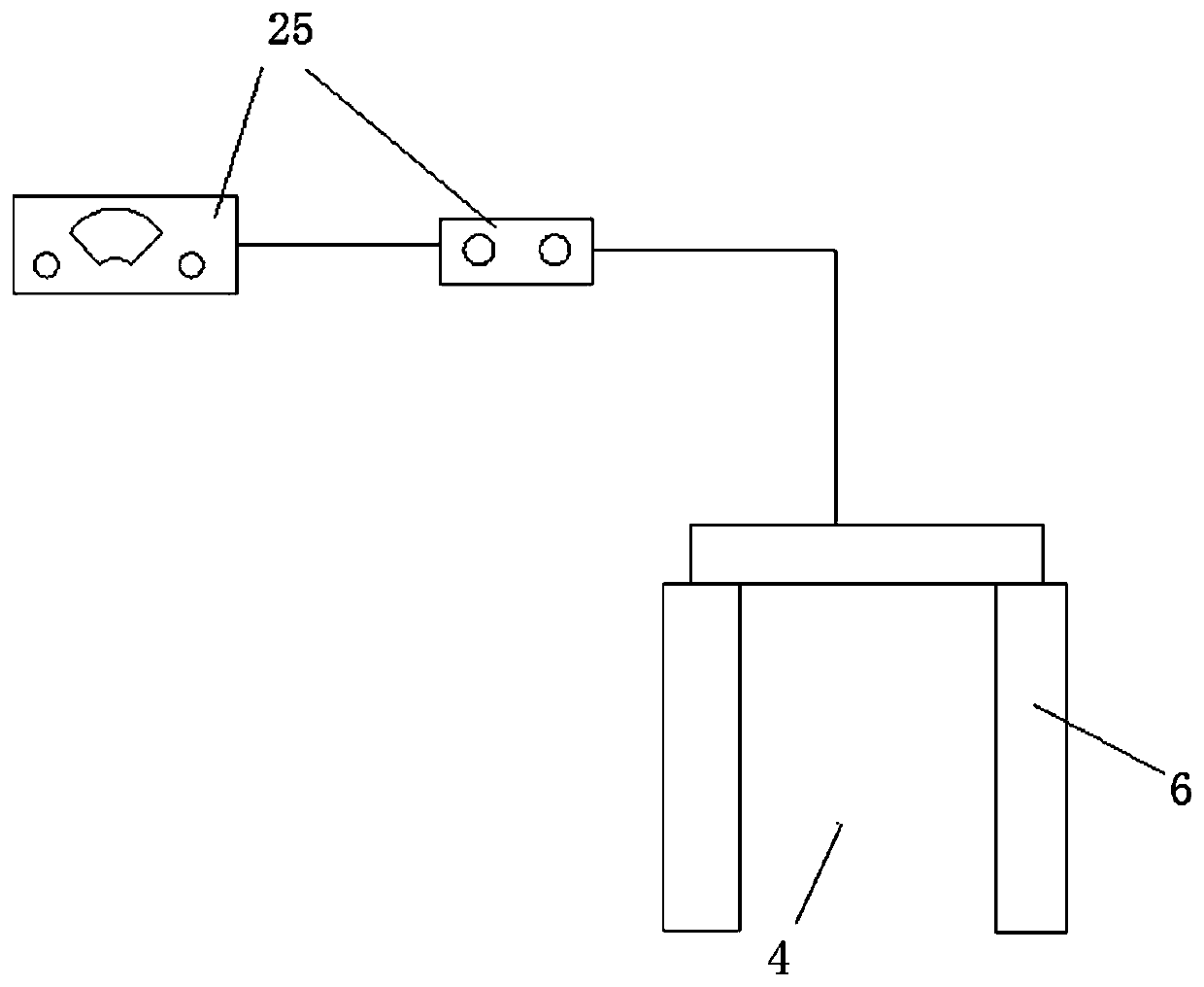

[0030] Such as Figure 1-Figure 4 As shown, a device for simulating and visualizing fissure seepage by using magnetic fluid includes a main frame 1, on which a telescopic support rod is arranged, and a movable sub-frame 10 is slidably connected to the top surface of the main frame 1, and is installed on the main frame 1 The camera 7 inside is connected to the movable sub-frame 10 through the top universal ball joint 11 on the main frame 1, and the shearing reaction frame 9 is installed on the bottom plate 1-1 of the main frame 1 through the universal ball joint reaction device 2 On the surface, the visualized rock sample 26 is placed on the upper surface of the shear reaction force frame 9 through the expansion pressurized air cushion 22, and the expanded pressurized air cushion 22 communicates with the inflatable device 24. Composition, a crack is formed between the transparent resin 23 of the upper cover plate and the common rock sample 19, and the two sides of the visualize...

Embodiment 2

[0037] A method for simulating and visualizing fracture seepage using the above-mentioned device, the method includes the following steps:

[0038] Step 1: Adjust the angle of the top universal ball joint 11 so that the camera 7 is perpendicular to the top surface of the visualized rock sample 26;

[0039] Step 2: Adjust the height of the telescopic support rod, and place the camera 7 in a suitable position (it can clearly capture the visual seepage situation without reflections, ghosting, etc. that affect the later experimental data processing);

[0040]Step 3: Inject gas into the expansion pressurized air cushion 22 through the inflation device 24 (use the pressure gauge on the high-pressure nitrogen cylinder to adjust the pressure), and adjust the normal stress on the visualized rock sample 26;

[0041] Step 4: Turn on the shearing loading device 18, and control the magnitude of the shearing force by adjusting the thrust of the hydraulic rod. The magnitude of the shearing f...

Embodiment 3

[0045] In the first embodiment above, the preparation method of the visualized rock sample 26 is as follows:

[0046] Step a: Prepare the rock split surface: collect rocks with natural joints and fissures (including opposite surfaces) or split a block of rock to obtain a split surface, the size of which depends on the test requirements;

[0047] Step b: prepare test silica gel according to the mass ratio of hardener and liquid silica gel at 1:50, pour liquid silica gel evenly on the cracked surface of the rock sample to be simulated, wait for it to solidify and harden after 3 hours, and take it out Down;

[0048] Step c: Preparation of transparent resin: take a certain amount of liquid resin in a suitable container, first add accelerator with mass content of 0.6%-0.8% and stir for 2 minutes, then add accelerator with mass content of 0.6%-0.8% Hardener, stir for 2 minutes, finally add defoamer with a mass content of 0.6%-1.2%, stir slowly for 2 minutes, the whole process shoul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com