Patents

Literature

206results about How to "Improve residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

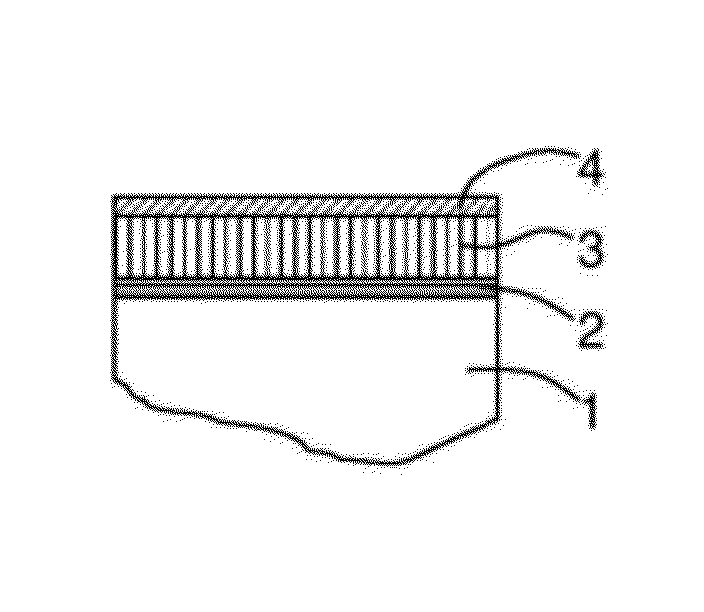

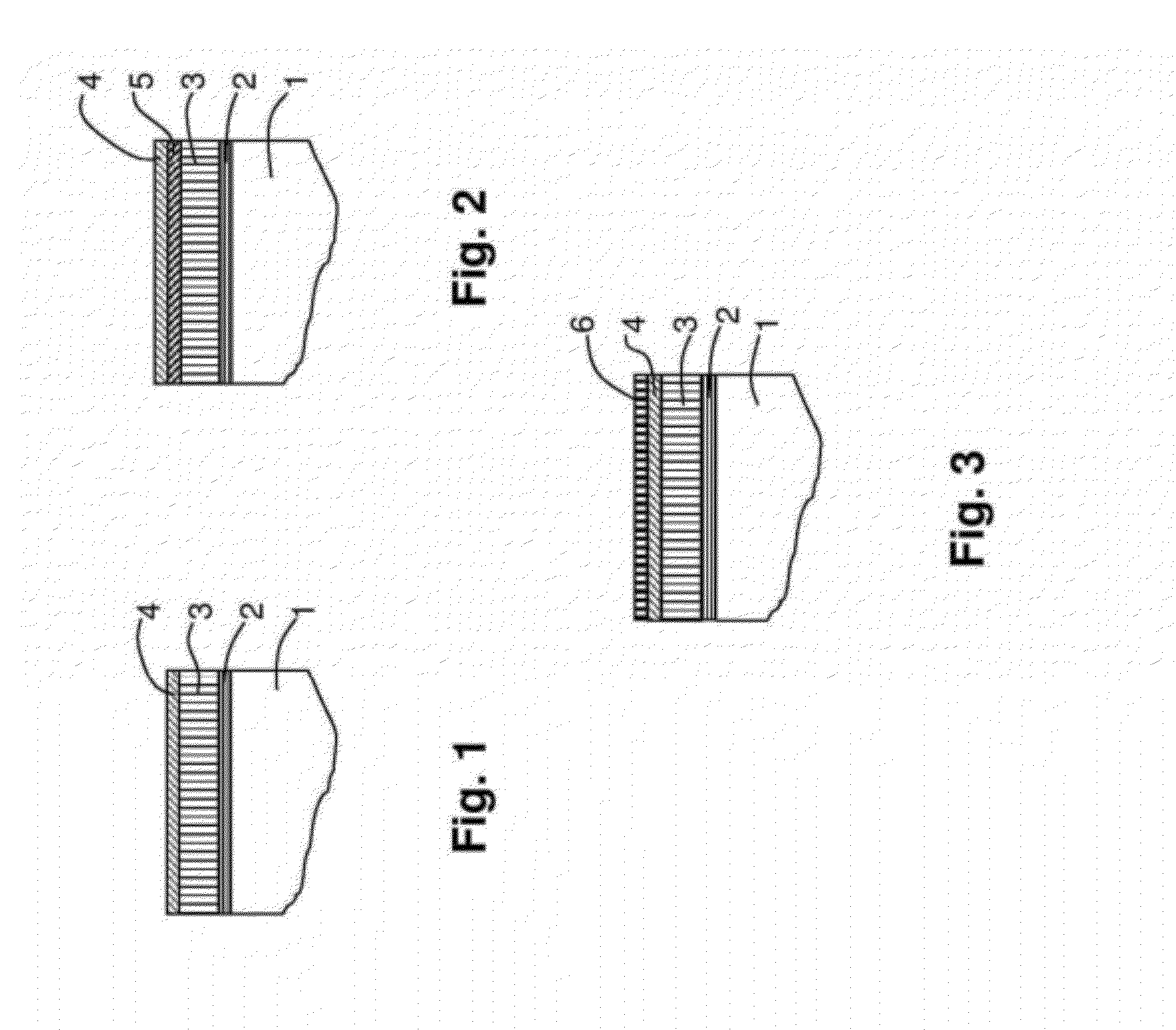

Multilayer thermal barrier coating

InactiveUS20090324989A1Improved thermal barrier coatingAttackLiquid surface applicatorsMolten spray coatingThermal barrier coatingZirconium oxide

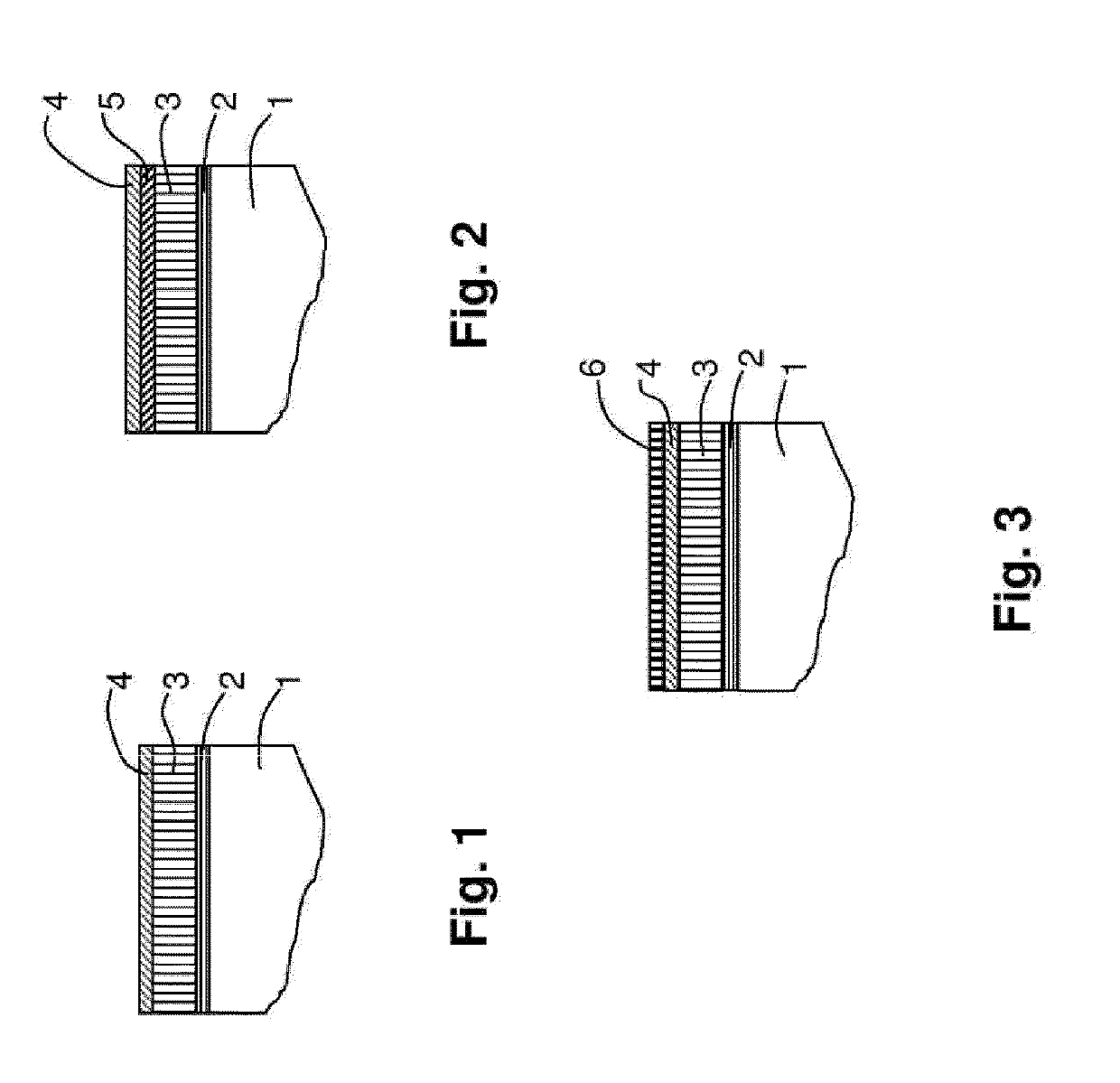

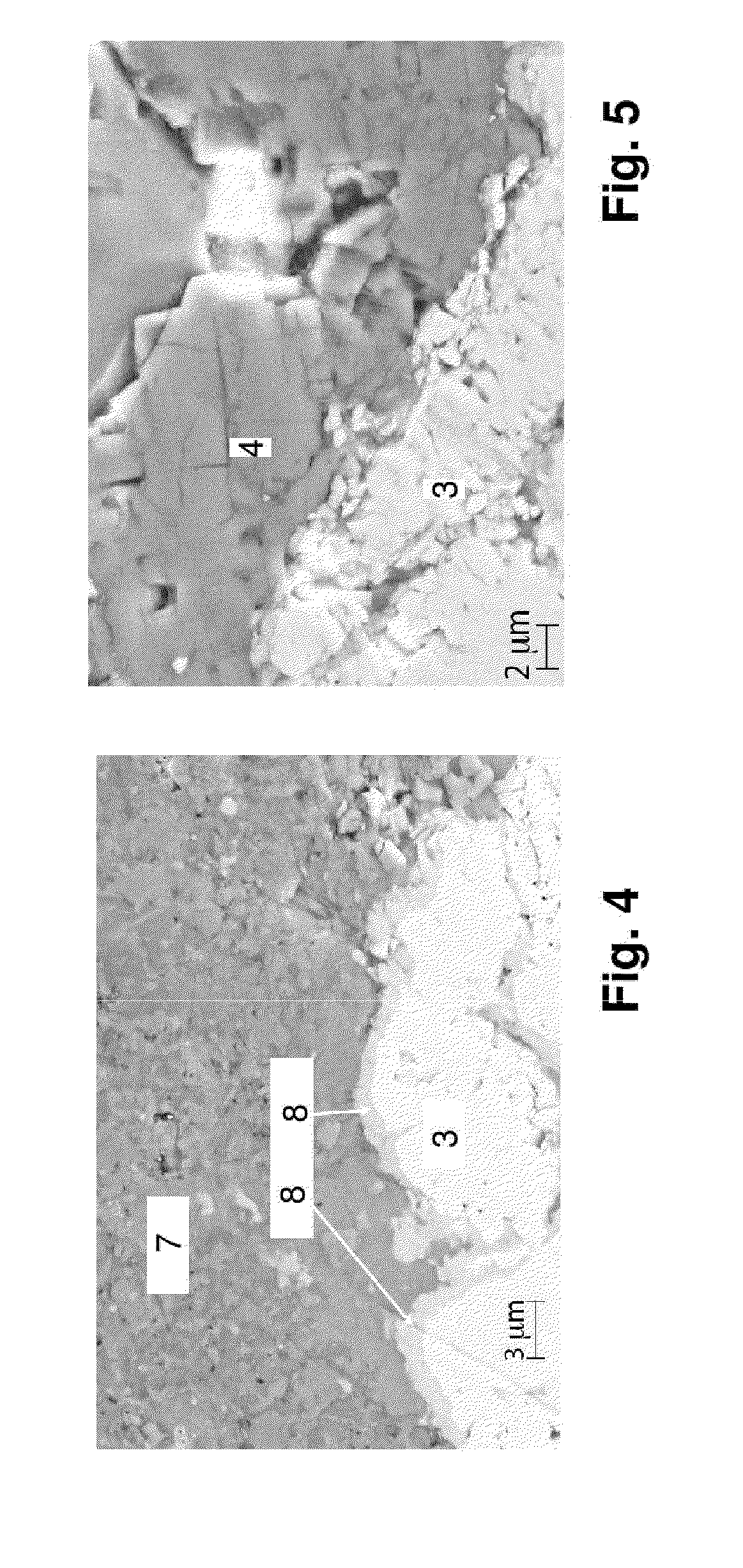

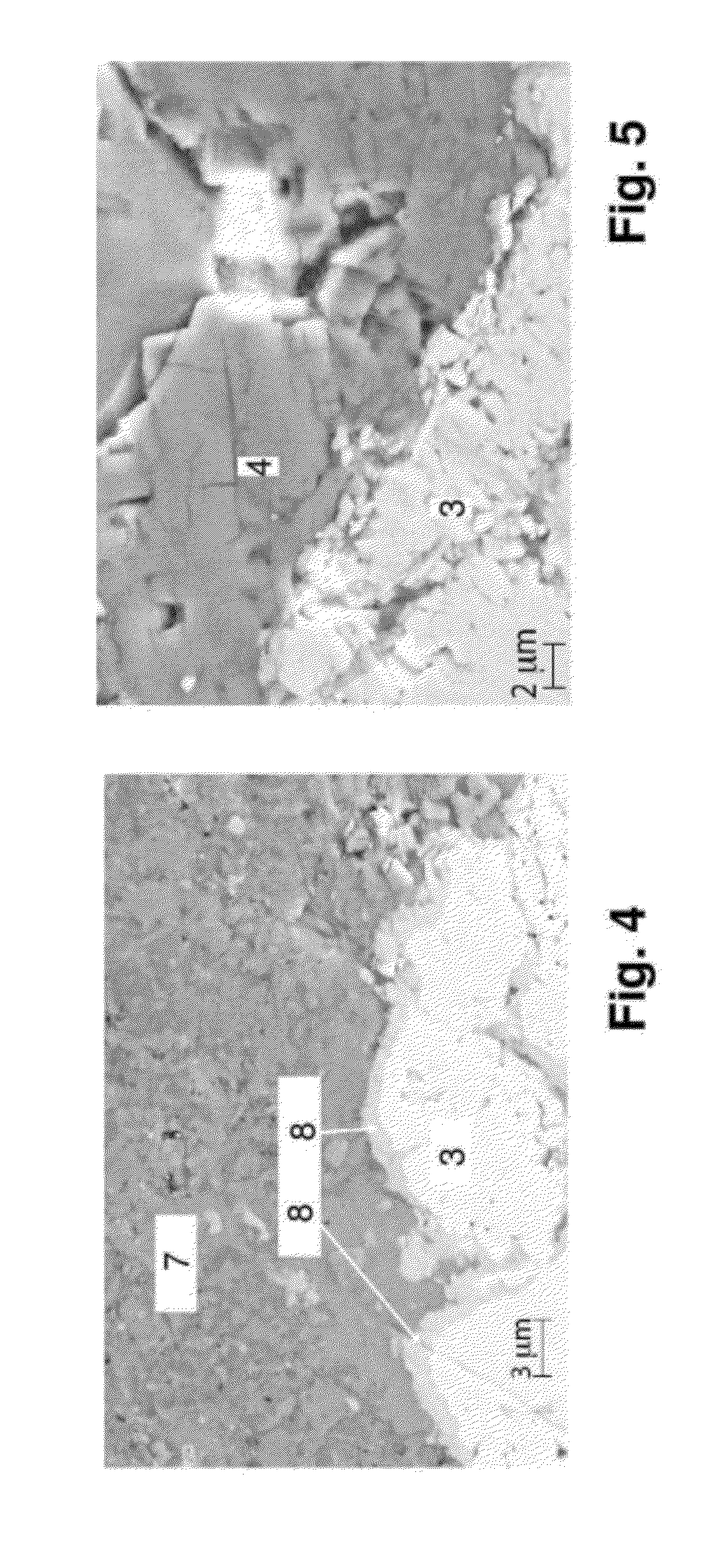

Components (1) have a thermal barrier coating (2-6) on the surface thereof, wherein the thermal barrier coating includes at least one layer (3) having chemically stabilized zirconia, and wherein at least indirectly adjacent to the layer (3) with chemically stabilized zirconia and on its surface facing side, there is provided a protective layer (4) and / or a infiltration zone (5) which does not react with environmental contaminant compositions that contain oxides of calcium and which does not react with the material of the layer (3) having chemically stabilized zirconia. Methods for making such components as well as to uses of specific systems for coating thermal barrier coatings, can prevent CMAS.

Owner:ANSALDO ENERGIA IP UK LTD +1

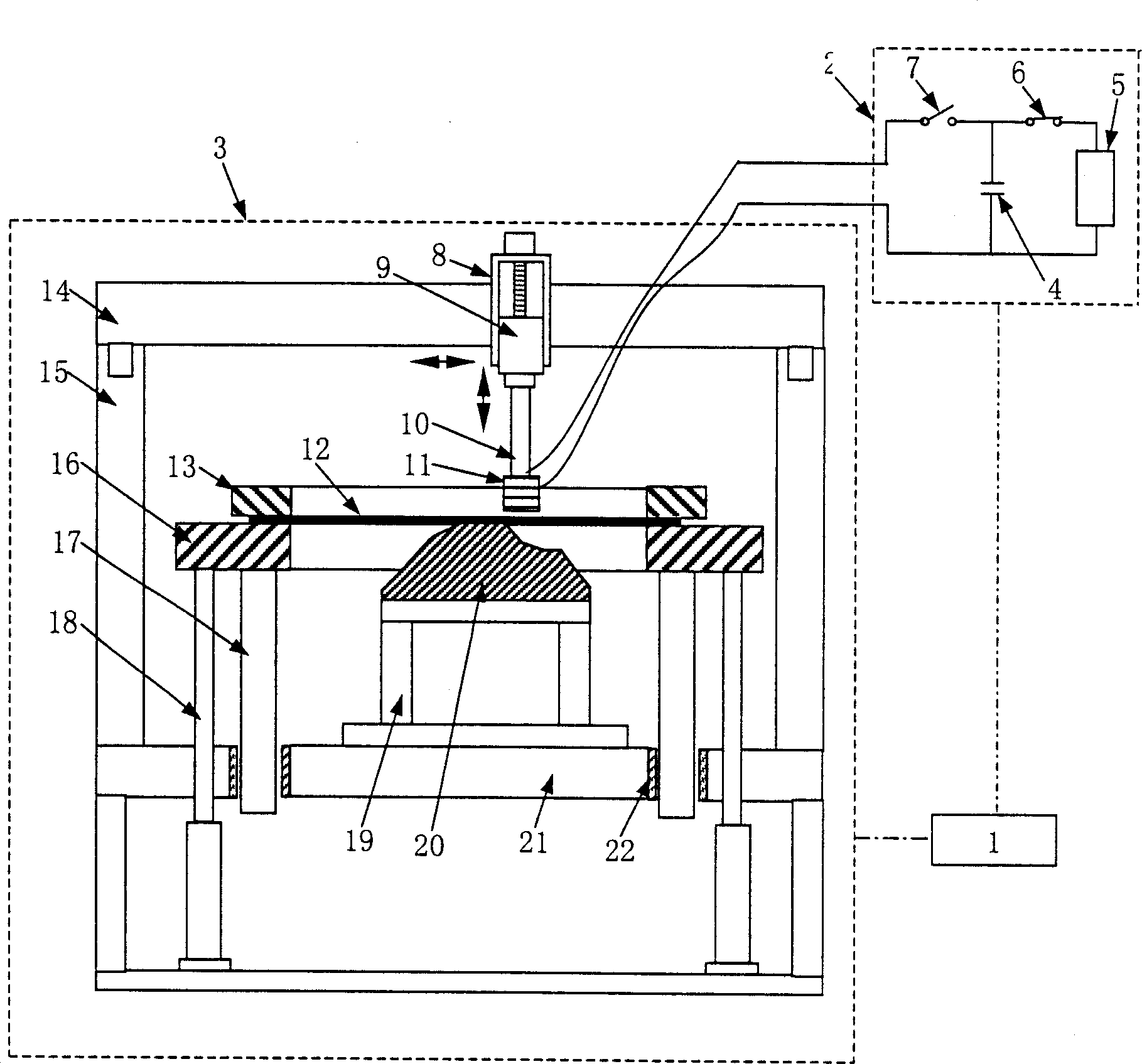

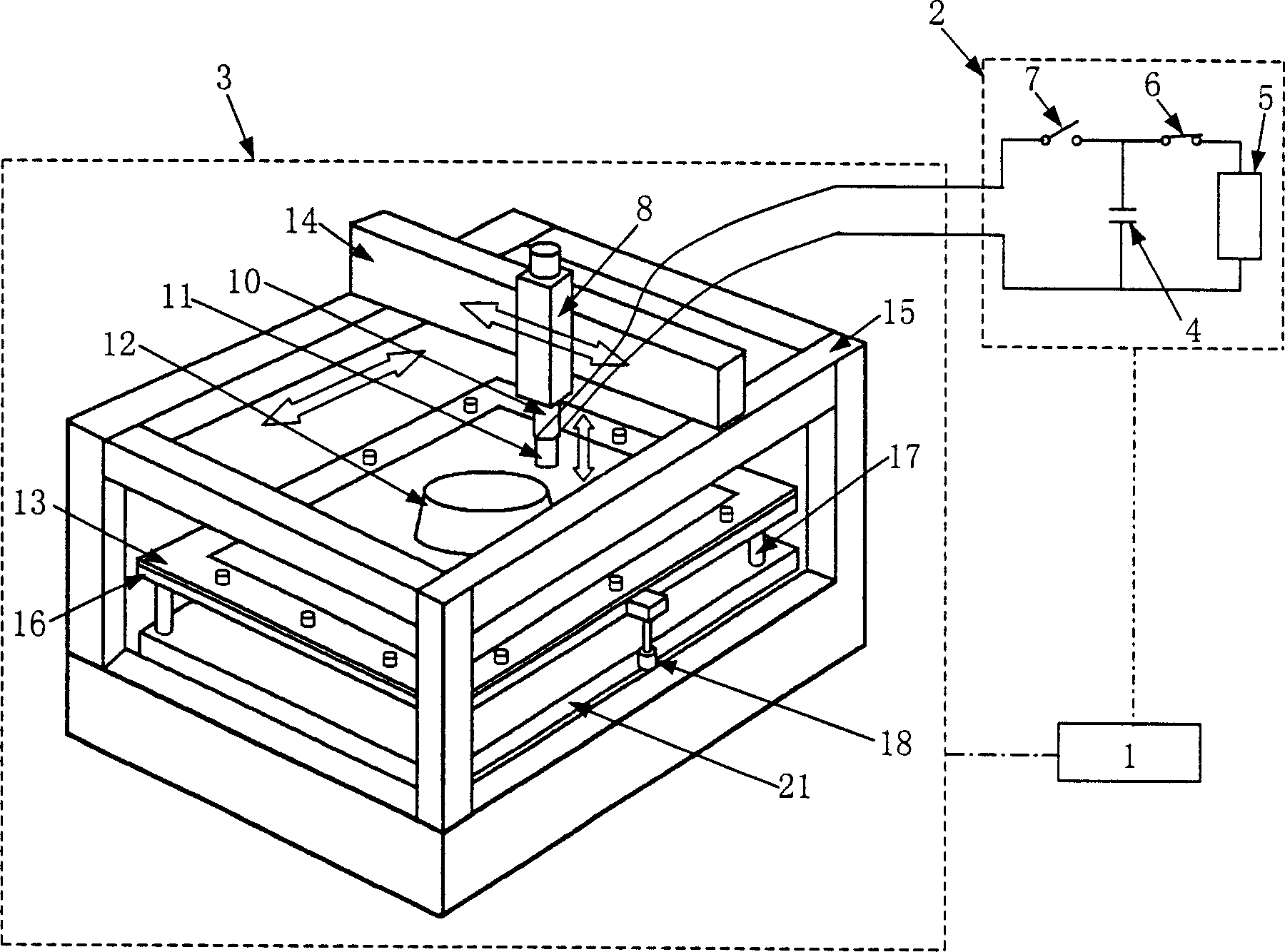

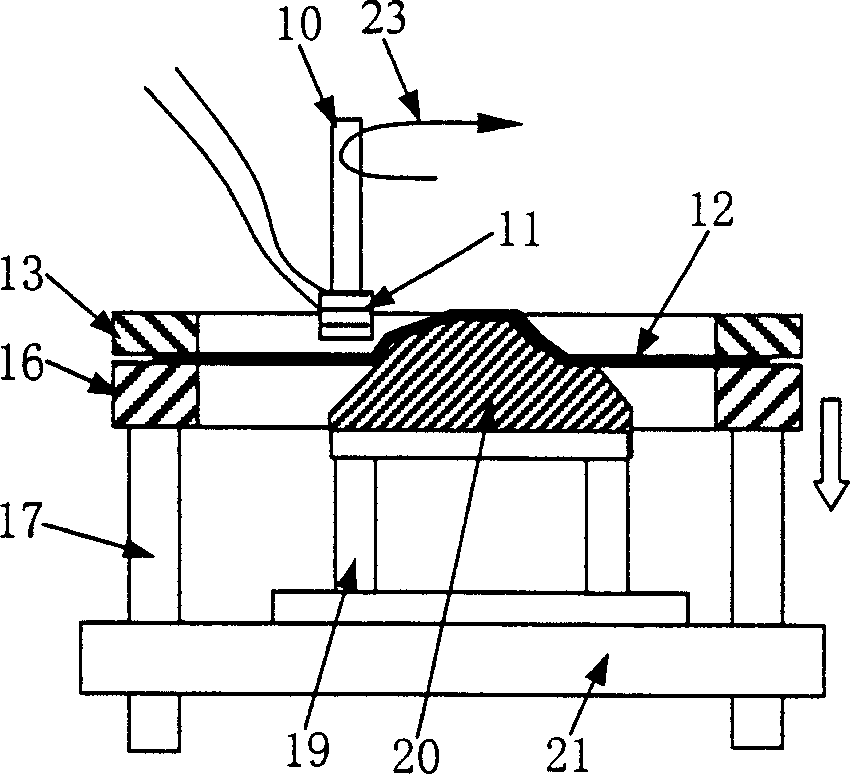

Electromagnetic inching forming method and its device for plate moving coil

InactiveCN1821910AGood repeatabilityEasy energy control and automated productionProgramme controlComputer controlEngineeringElectromagnetic pulse

This invention relates to an electromagnetic progressive shaping method for plate moving coils and a device, in which, said device includes a computer control system, an electromagnetic force generation system and a three-shaft digital control shaping system including a plate clamping elevating device, a supporting model frame and an electromagnetic shaping clamping rod, in which, the computer controls the coil to move downward along the contour of a model profile from the top according to the contour data of the model profile and the plate is formed partly relying on the magnetic force of coil till to the bottom of the model and finish the entire process.

Owner:HUAZHONG UNIV OF SCI & TECH

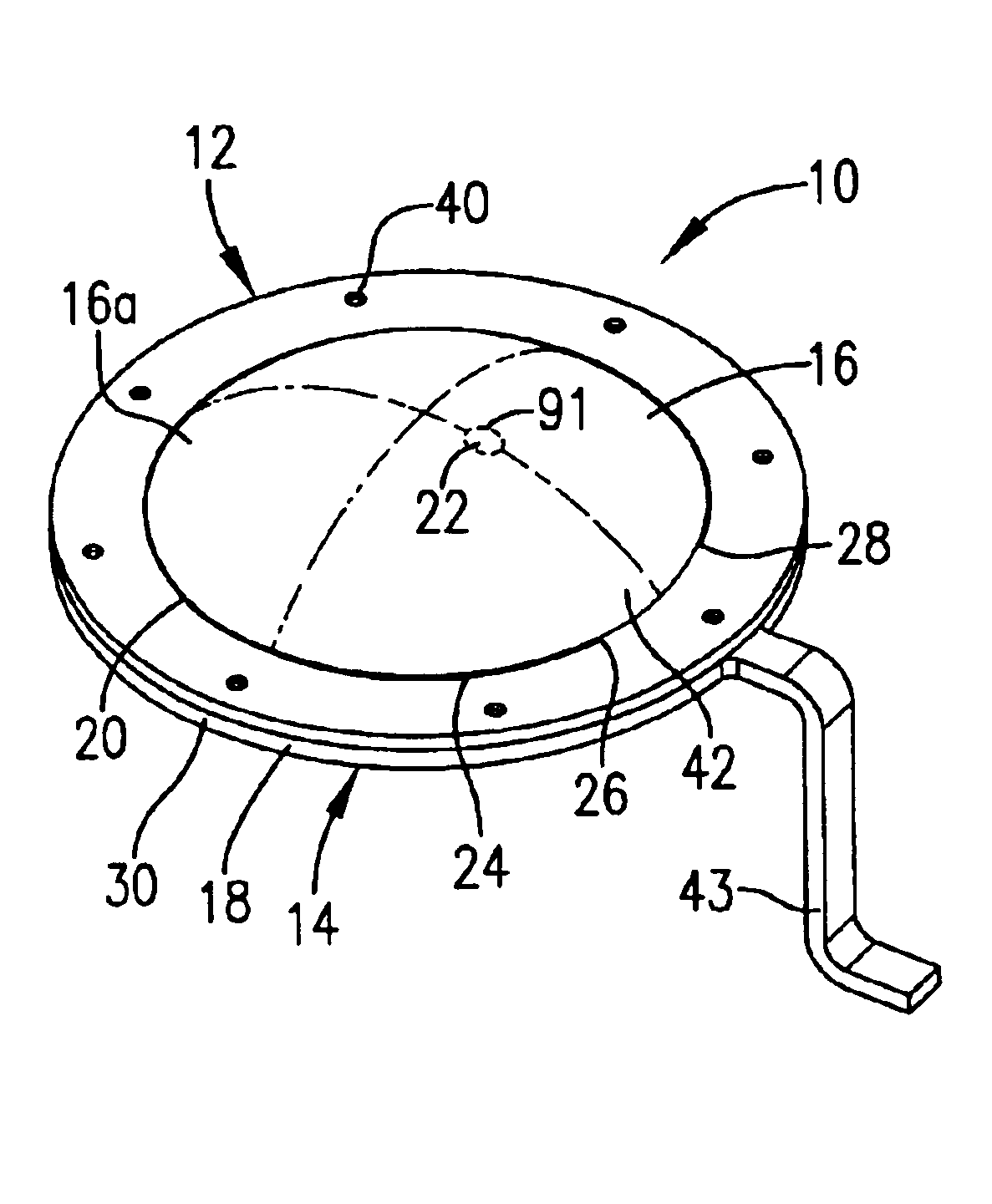

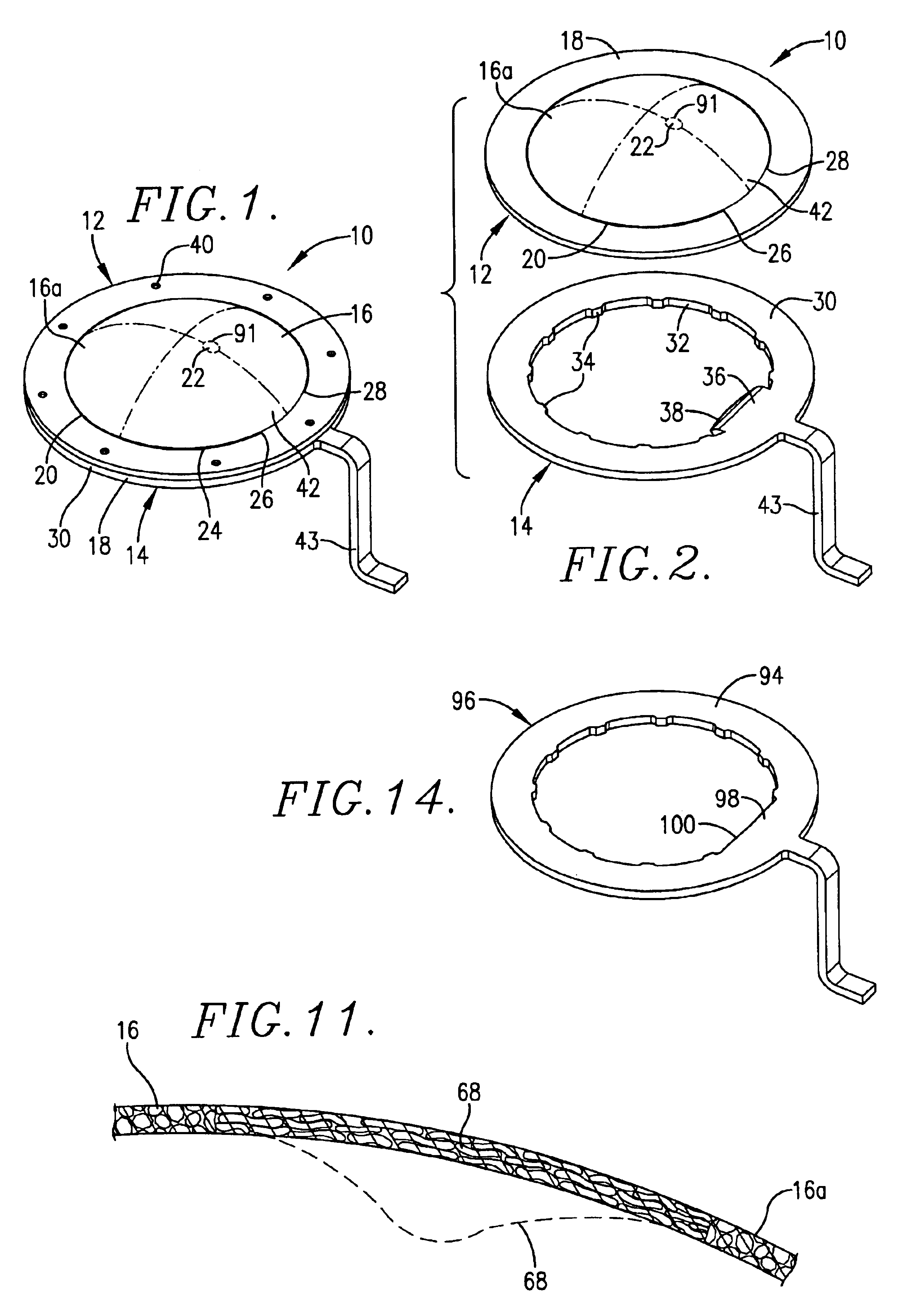

Reverse buckling sanitary rupture disc assembly

InactiveUS6945420B2Flat surfaceAltered grain structureLarge containersEqualizing valvesEngineeringRupture disc

A metal reverse buckling sanitary rupture disc is provided having a central bulged section in which the convex surface of the bulged section is relatively smooth and of substantially uninterrupted configuration. A small segment region of the central bulged section is strain hardened by plastic deformation causing the segment region to have greater residual stress than the remainder of the central bulged section. When the disc is subjected to an overpressure condition against the convex surface of the bulged section sufficient to effect reversal of the bulged section, such reversal commences at the higher residual stress segment region of the bulged section.

Owner:FIKE CORP

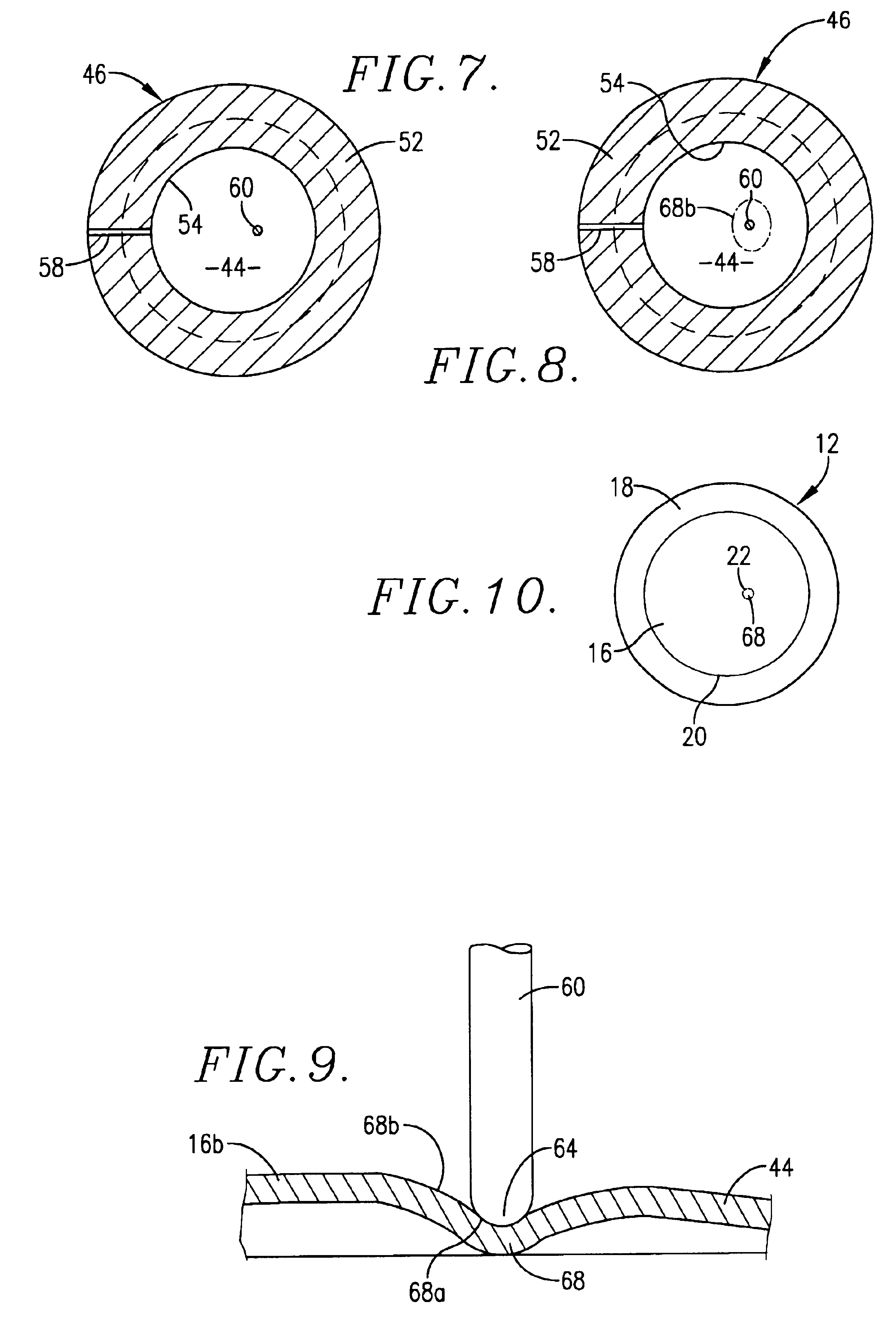

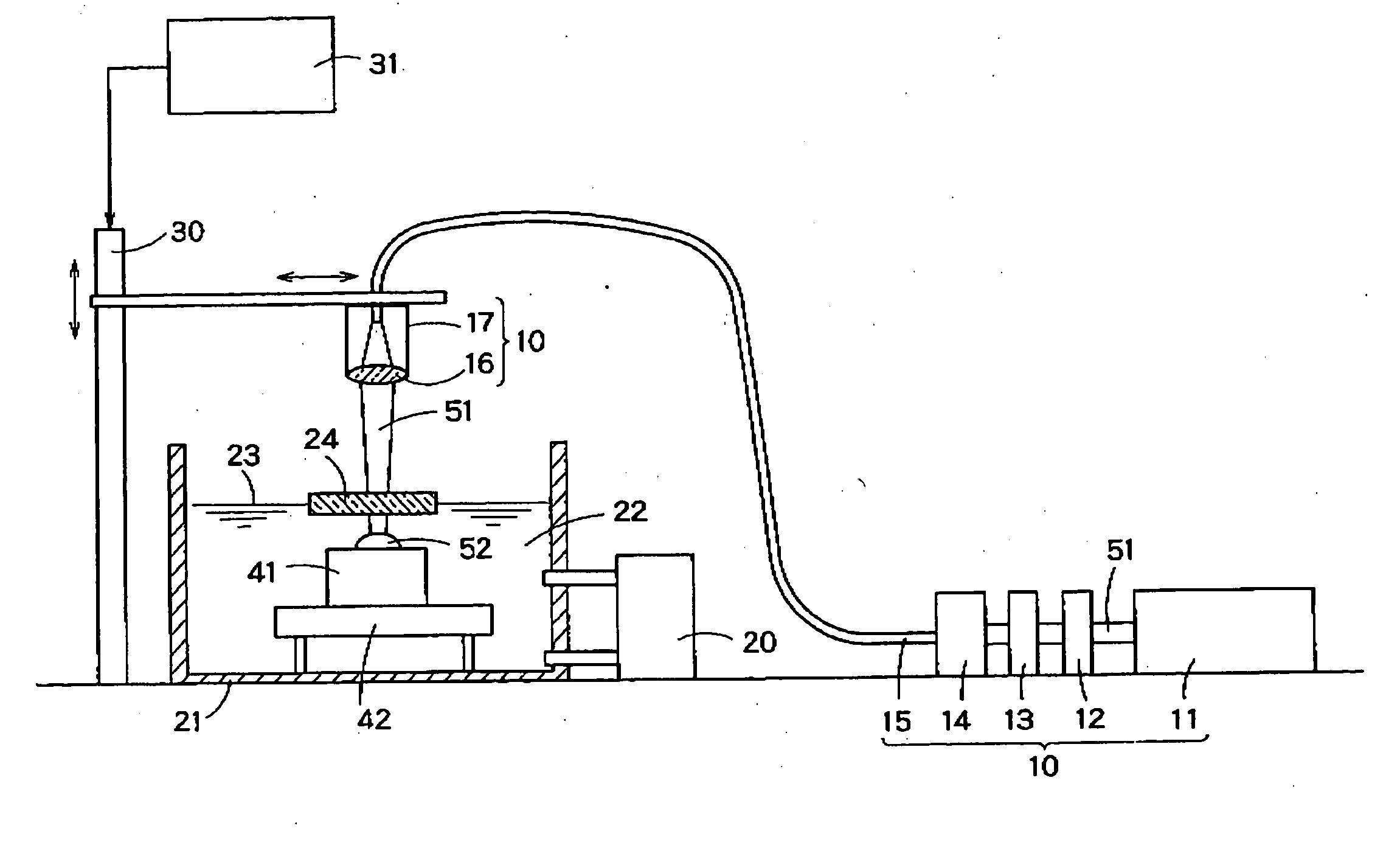

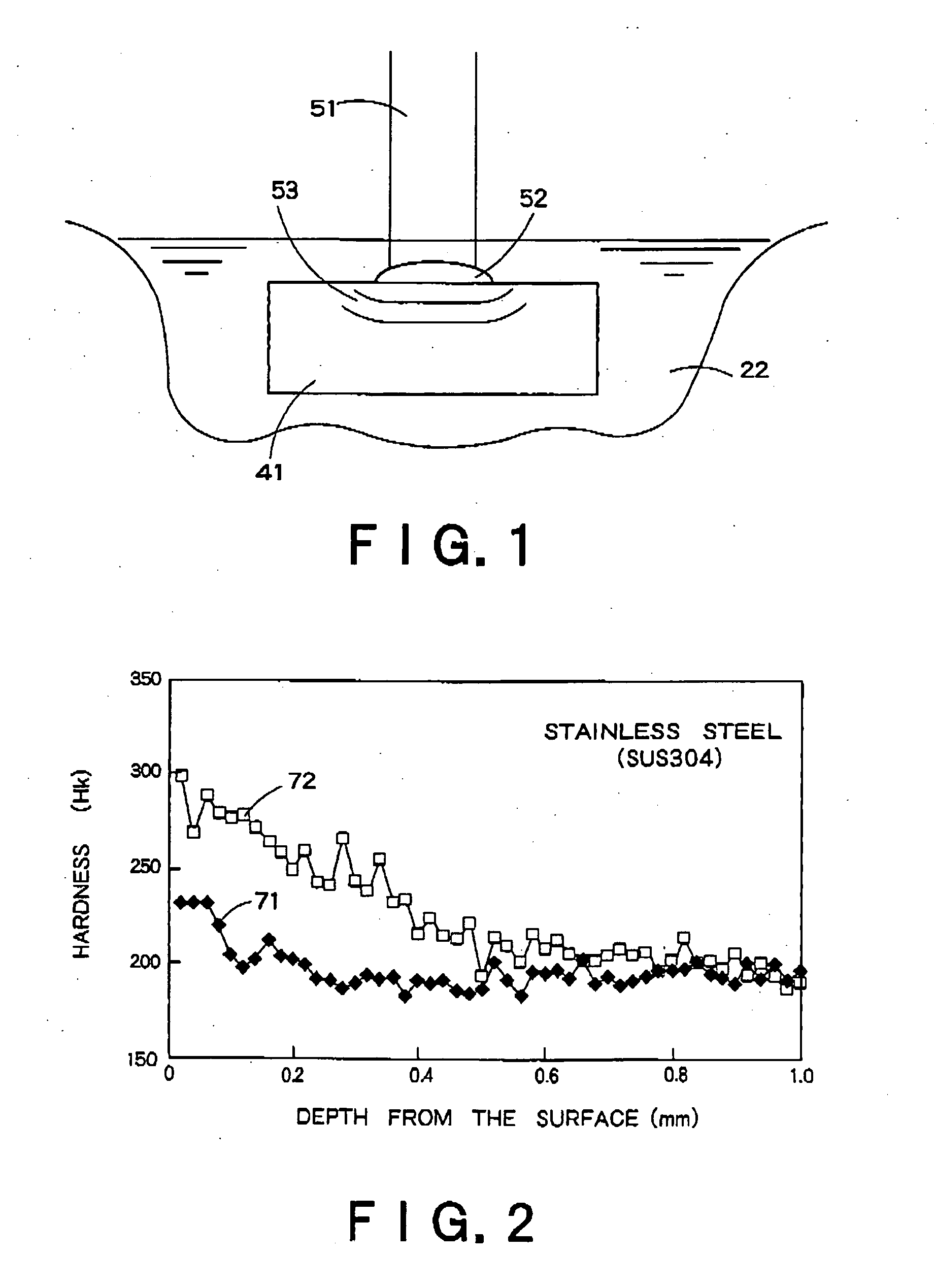

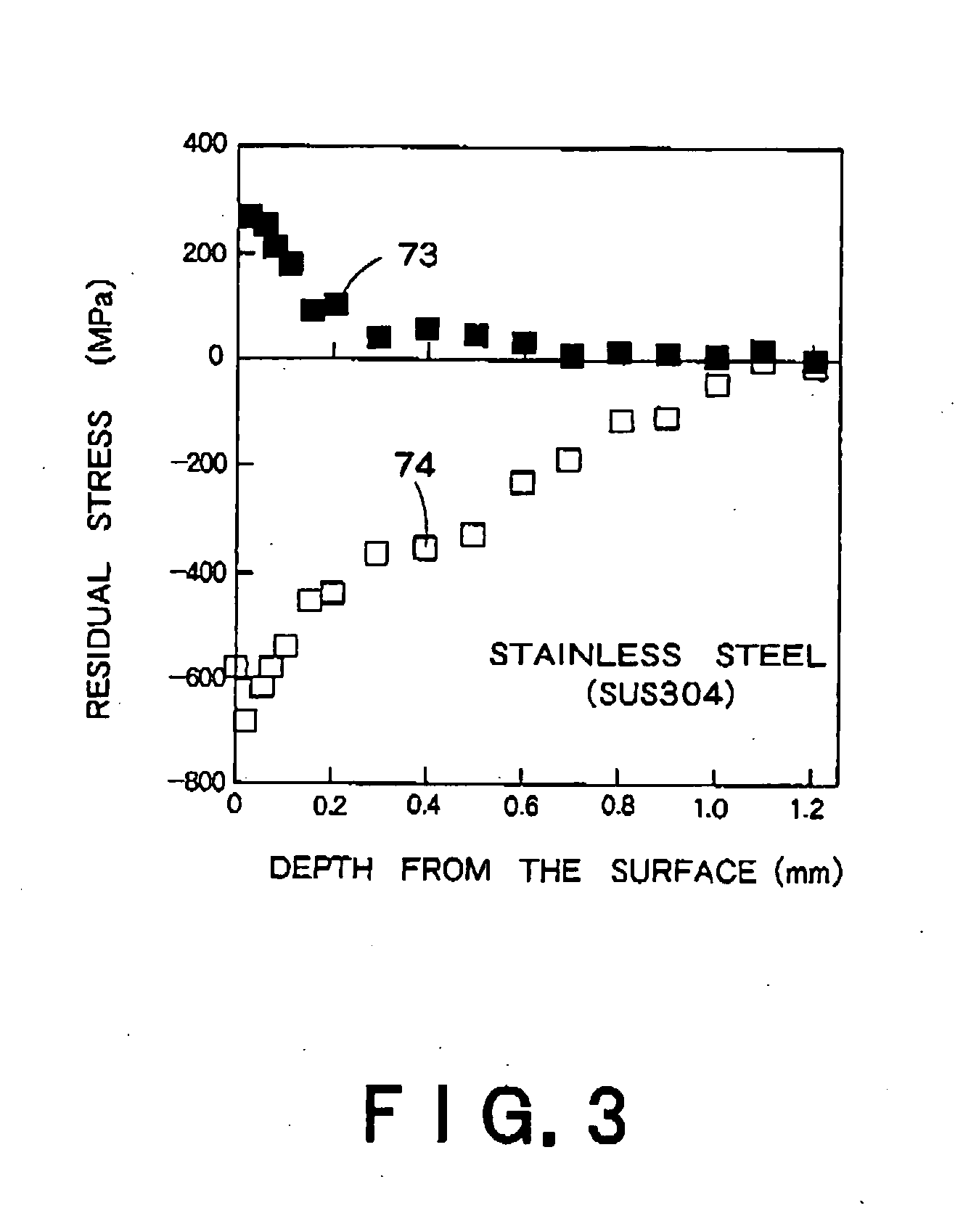

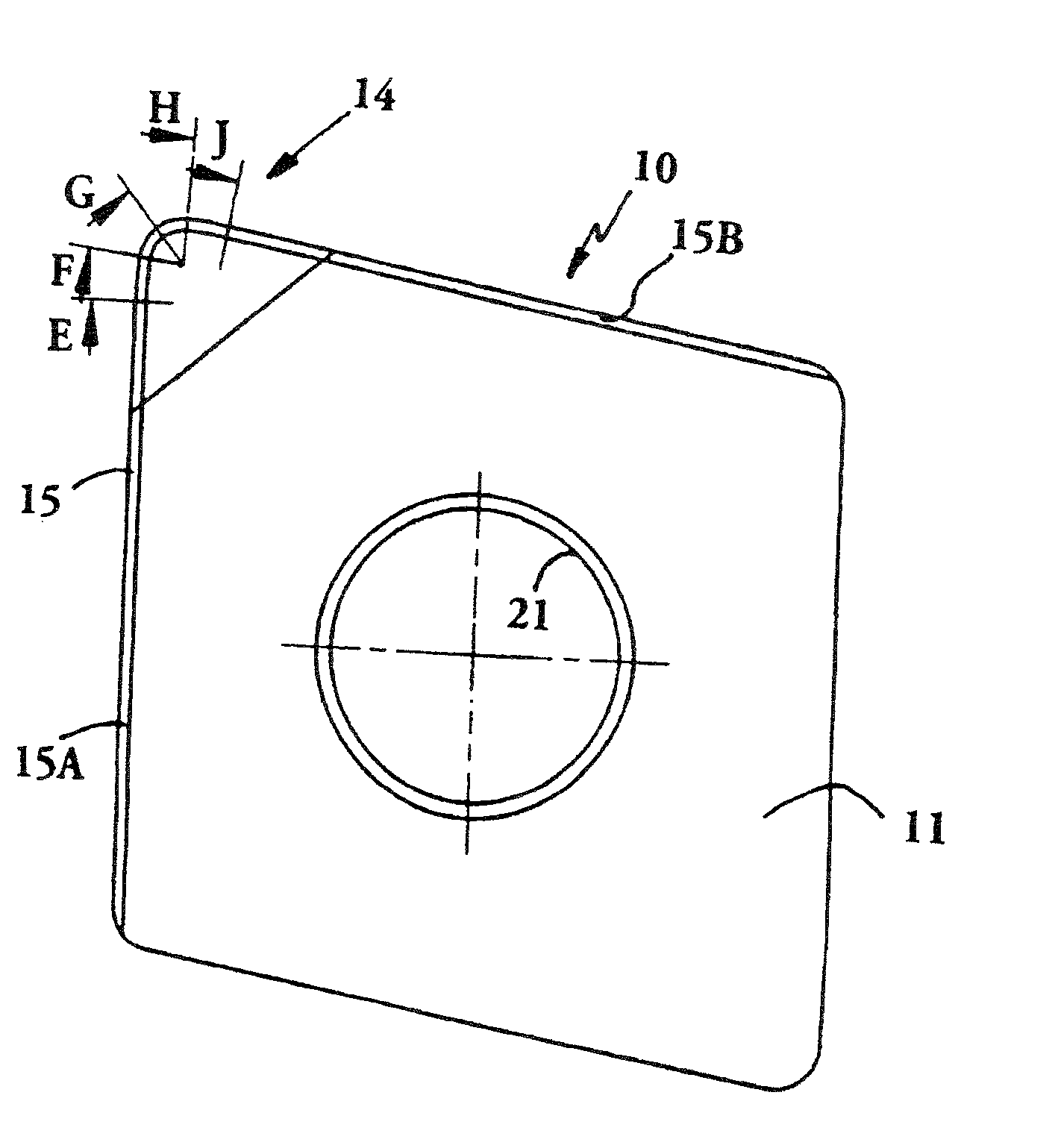

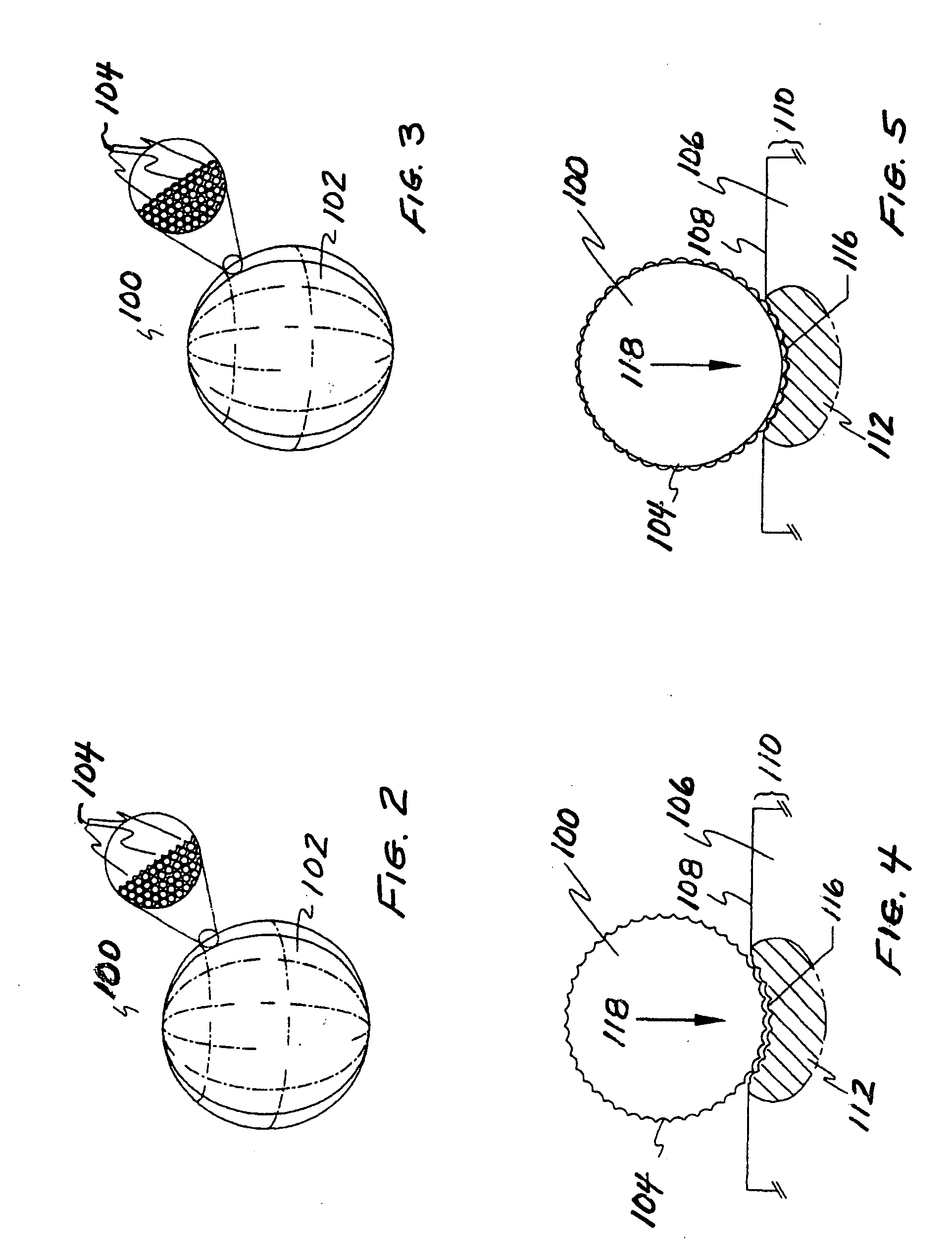

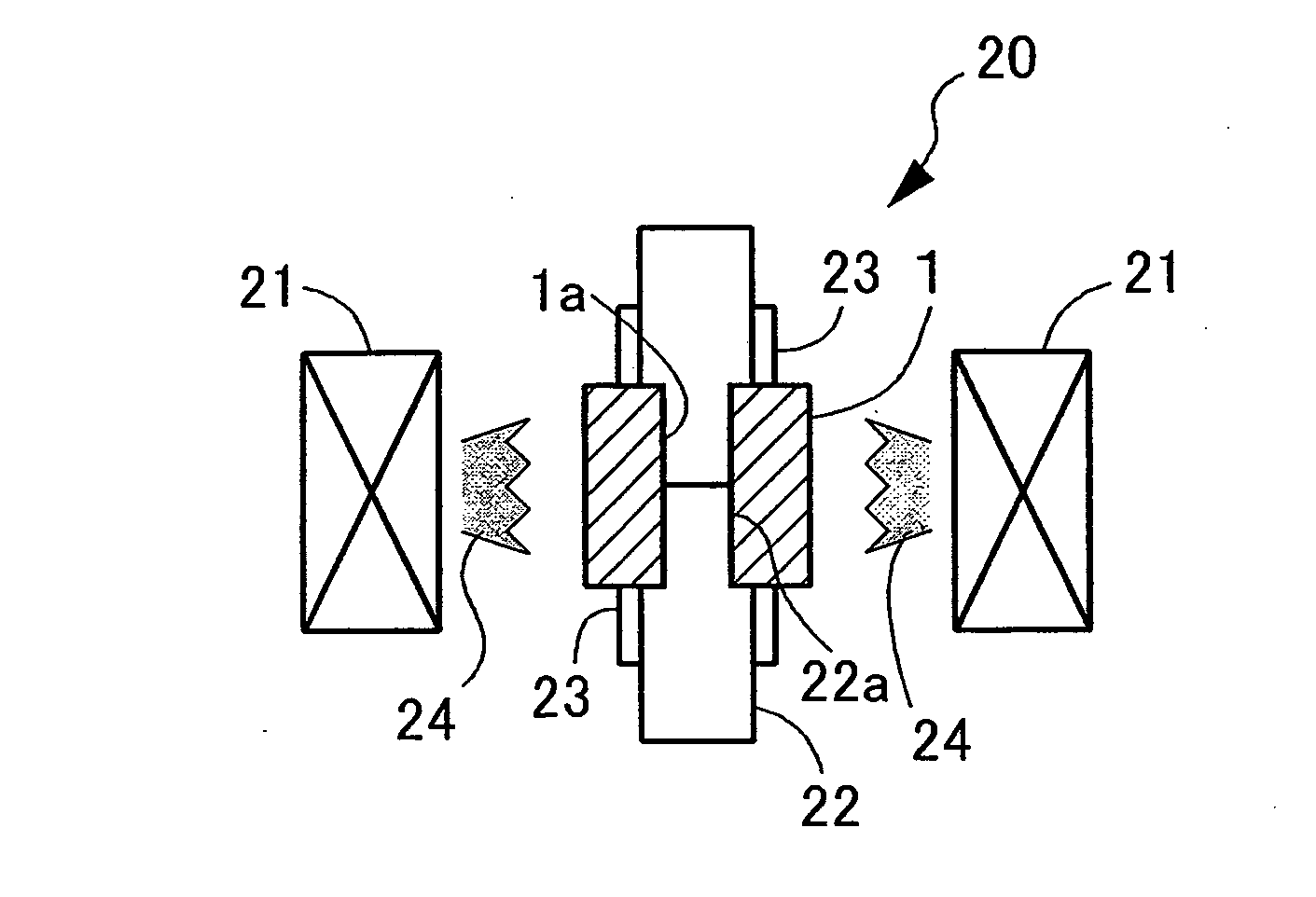

Laser shock hardening method and apparatus

ActiveUS20070262063A1Increase processing speedReduce burdenWelding/soldering/cutting articlesLaser beam welding apparatusOptical pathShock hardening

There is provided an improved laser shock hardening method and apparatus which can eliminate spattering of a liquid and waving of the liquid surface upon laser irradiation, and can stably irradiate a workpiece with a laser beam. Thus, the present invention provides in a laser shock hardening method for carrying out surface processing of a workpiece in contact with a liquid by irradiating through the liquid the surface of the workpiece with a pulsed laser beam intermittently emitted from a laser irradiation device, the improvement comprising: providing a solid transparent to the wavelength of the laser, serving as an entrance window to the surface of the liquid; allowing the liquid to be present in the light path of the laser beam between the solid and the surface of the workpiece; and allowing the laser beam to enter through the solid and irradiating through the liquid the surface of the workpiece with the laser beam, thereby shock-hardening the surface of the workpiece.

Owner:KK TOSHIBA

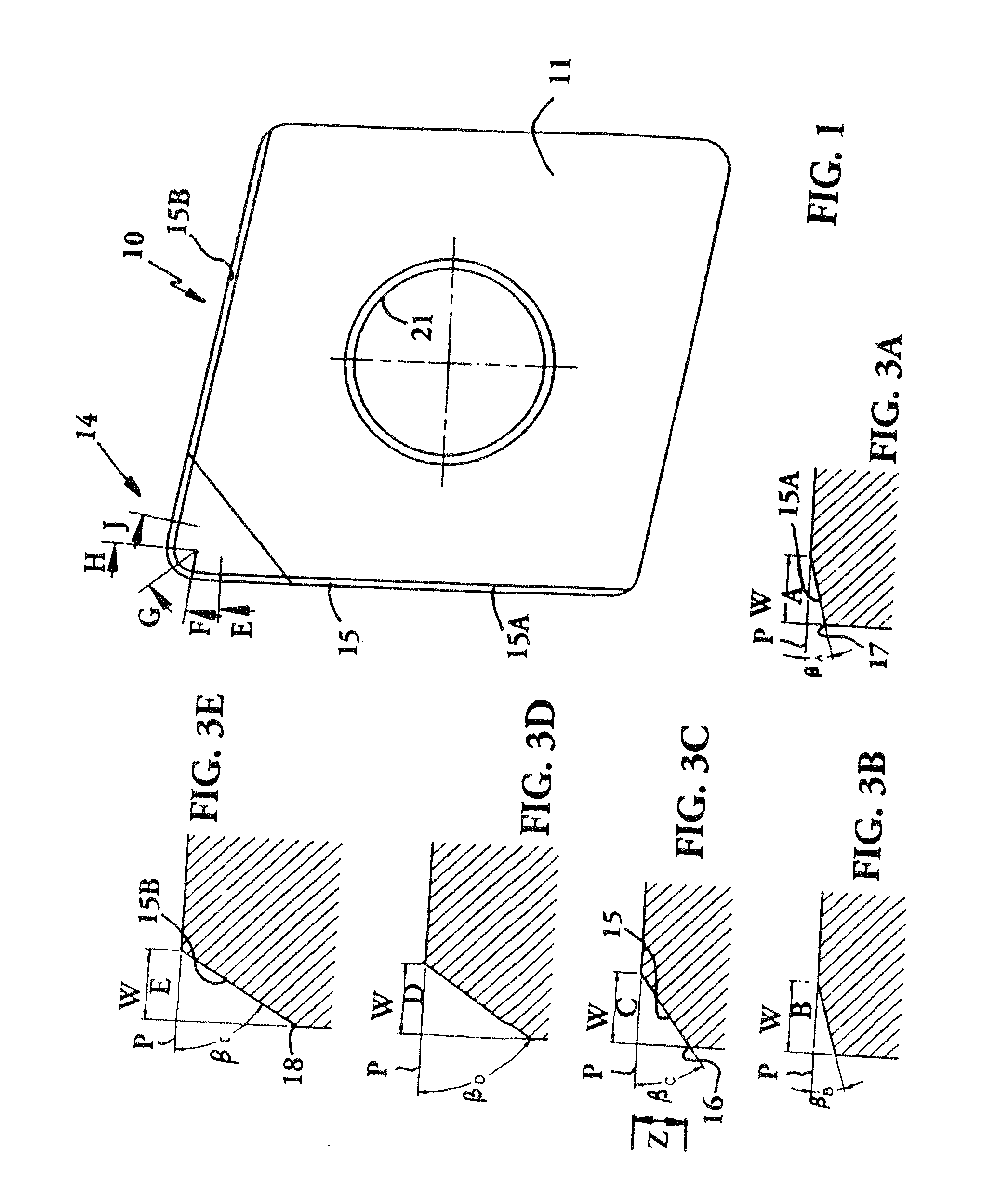

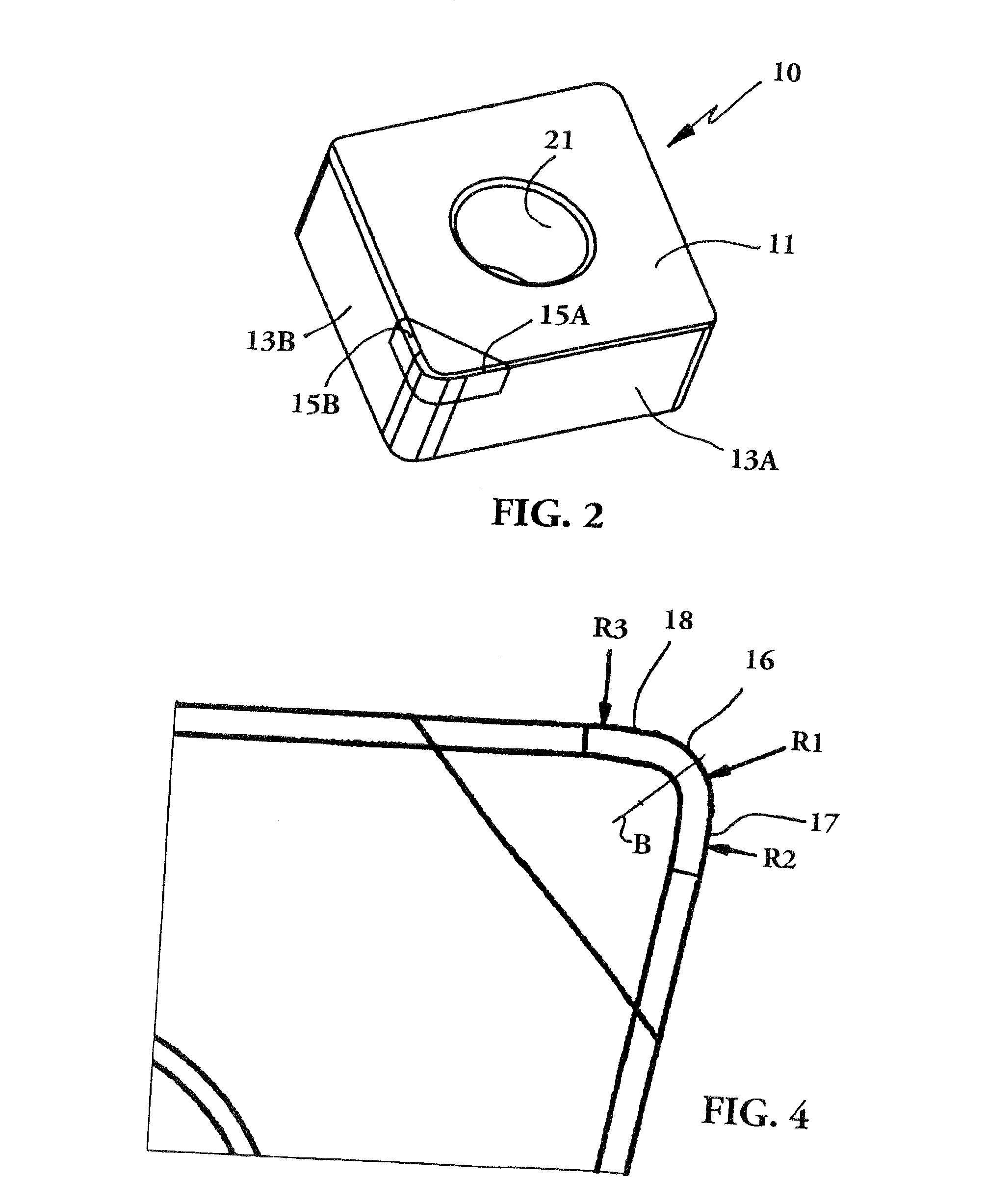

Tool

The present invention relates to a metal cutting insert that is primarily intended for turning operations. The cutting insert comprises an upper surface, a lower surface substantially parallel with the upper surface, and at least three side surfaces extending between the upper and lower surfaces. A transition between two adjacent side surfaces forms a rounded nose radius surface at a cutting insert corner. The cutting insert comprises a peripheral land bridging the upper and side surfaces at least at the corner portion at a chamfer angle. An intersection of the land and the nose radius surface forms a nose cutting edge. The nose cutting edge is defined by at least one radius. The cutting corner comprises at least one curved wiper edge. The chamfer angle in a cross-section at the nose cutting edge is smaller than the chamfer angle in a cross-section a distance away from the nose cutting edge. The chamfer angle has a minimum at a bisector of the corner portion.

Owner:SECO TOOLS AB

Method for manufacturing non-smooth surface of organism and device

The invention discloses a 'method for manufacturing a non-smooth surface of an organism and a device', relates to the field of laser processing, and particularly relates to an auxiliary manufacturing method for laser shock plastic forming under the condition of dynamic strain aging temperature and a device. The scheme includes that a manufactured mold with a specific shape is placed on a space between the surface of a metal workpiece and an absorption layer required by laser shock, and is heated in a vacuum heating box until the dynamic strain aging temperature is reached; a laser beam irradiates on the absorption layer, powerful shock force is generated, the surface of a part of the metal workpiece plastically deforms under the joint effect of the shock force and heating of a substrate, and patterns opposite to those of the mold are formed as a result of plastic deformation jointly generated by the laser shock and the heating of the substrate of the metal workpiece.

Owner:JIANGSU UNIV

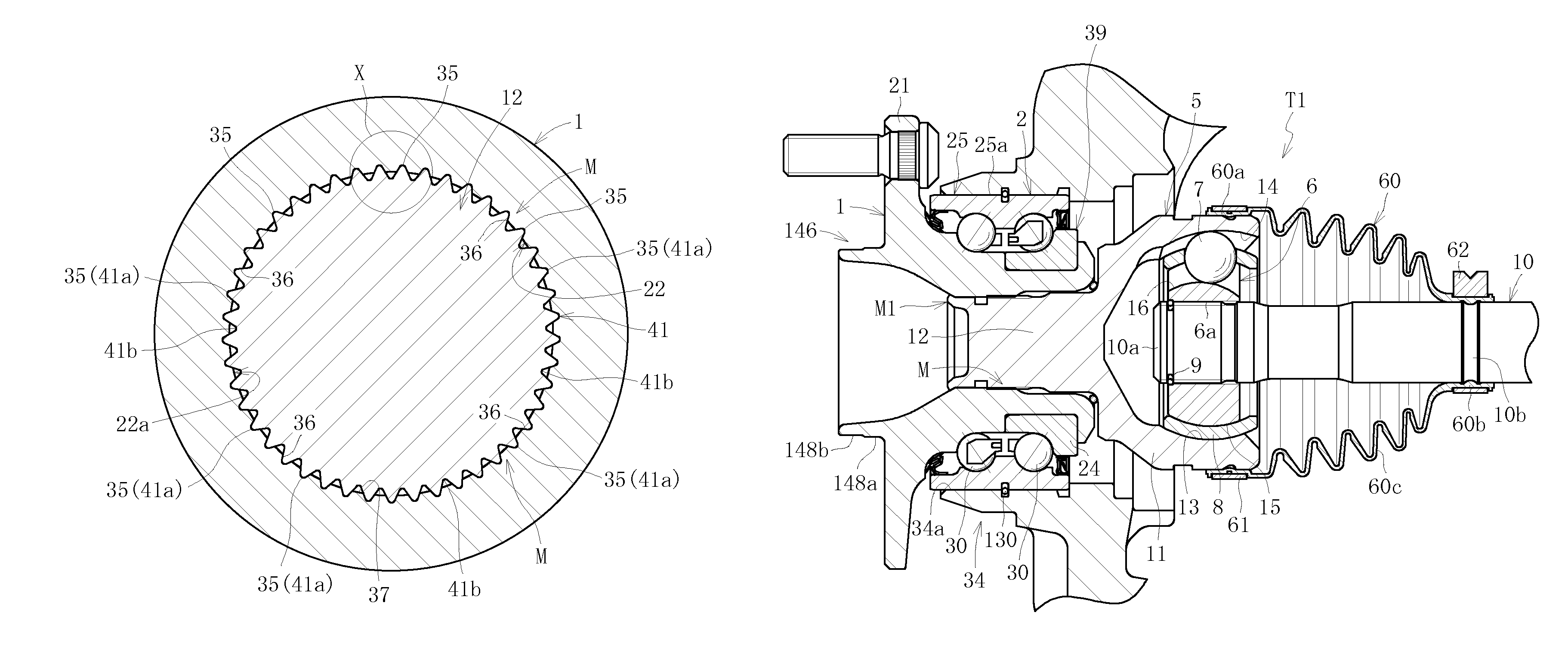

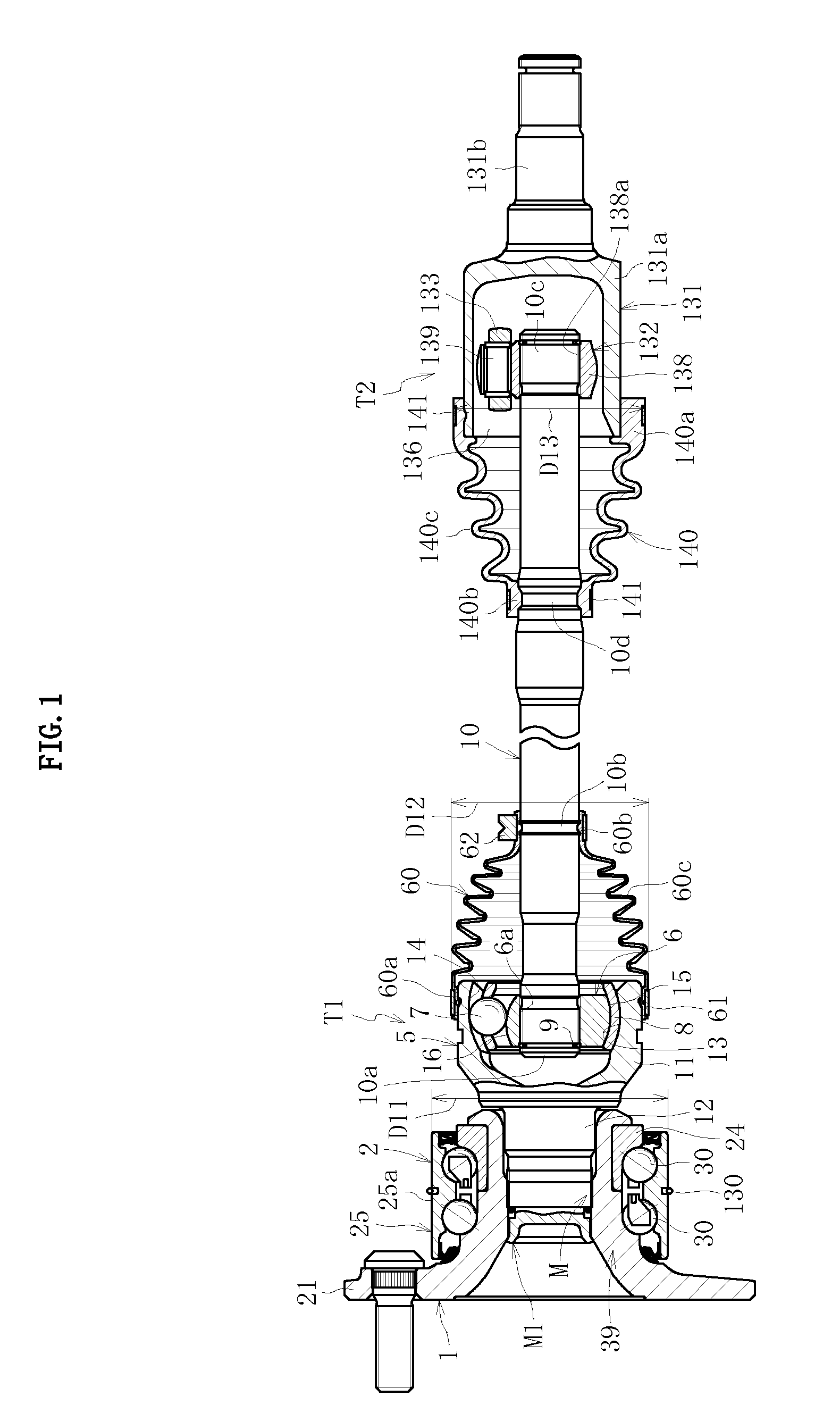

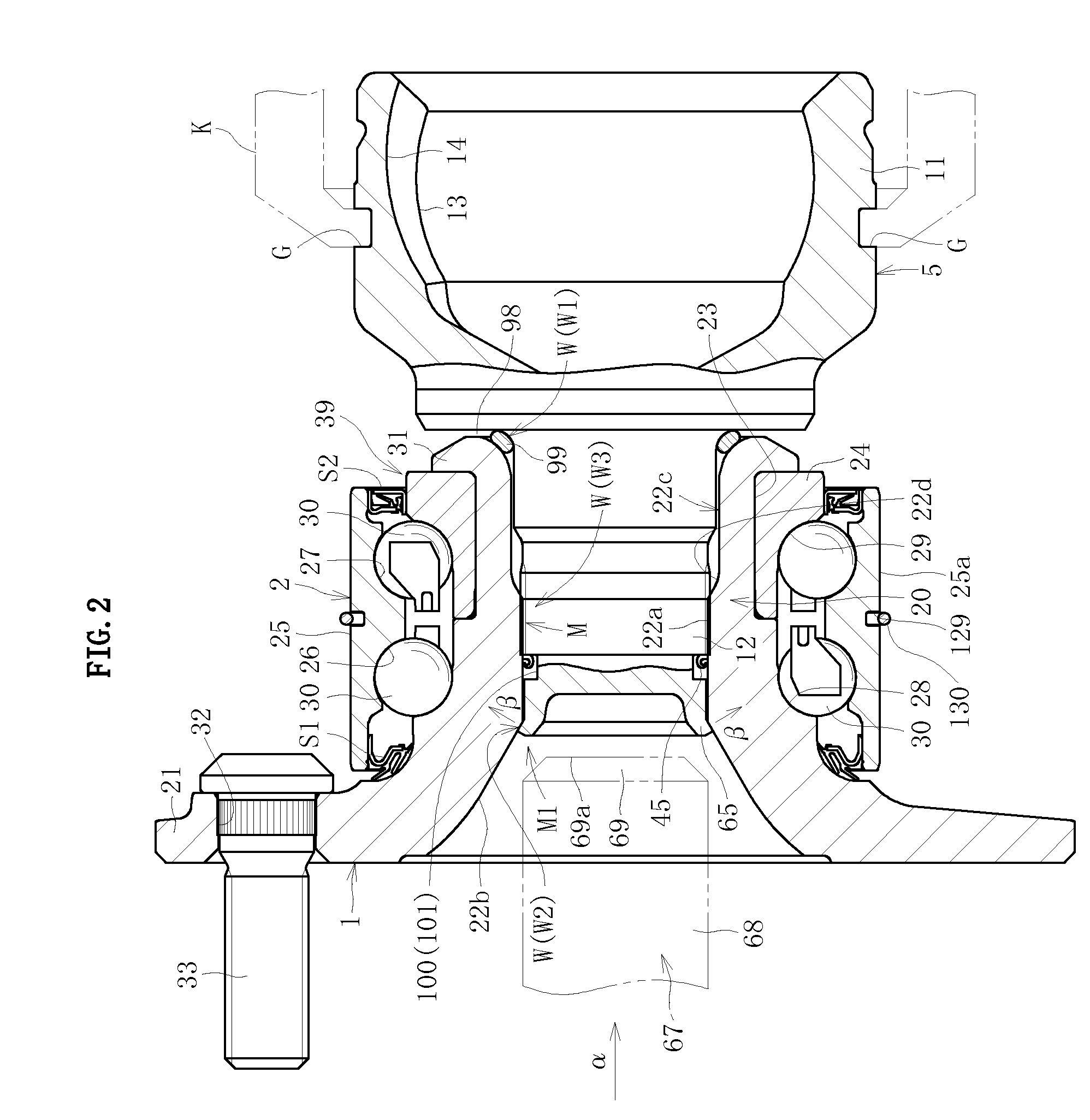

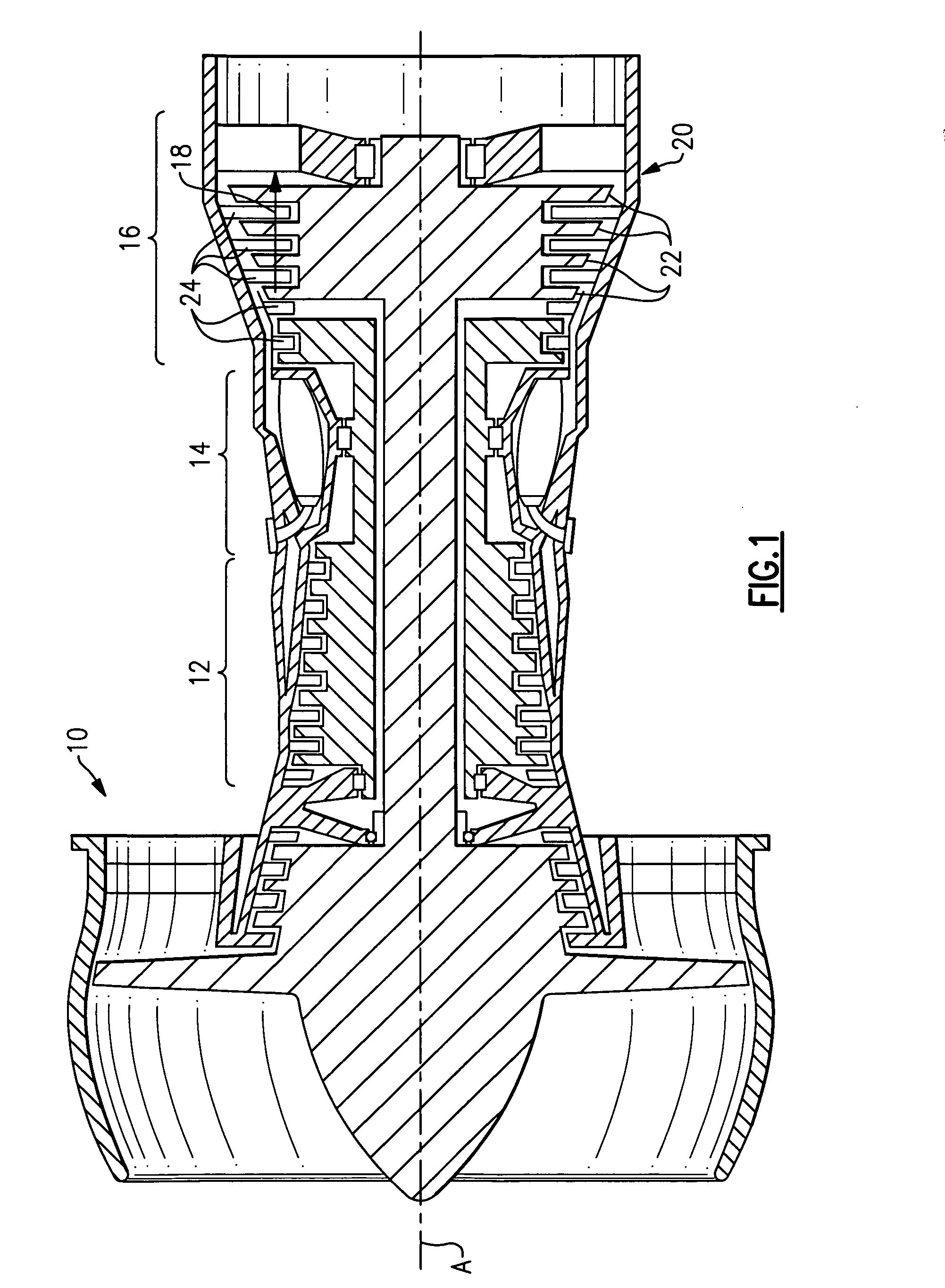

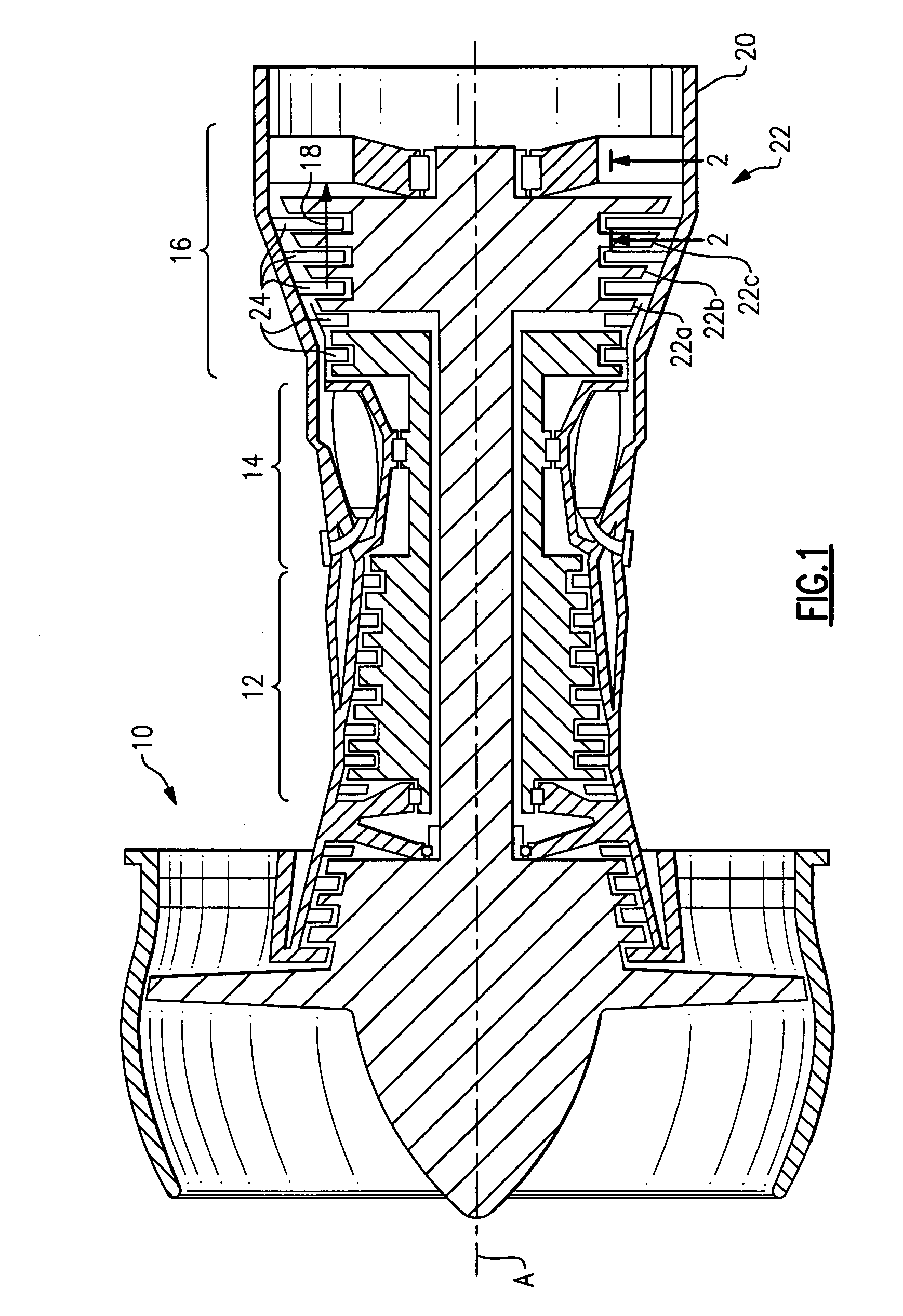

Wheel bearing apparatus and axle module

ActiveUS8556737B2Reduce oxidationReduce distortion problemsYielding couplingRolling contact bearingsEngineeringMechanical engineering

A recess-projection fitting structure includes projections extending in an axial direction on an outer diameter surface of a shaft section of an outer joint member or an inner diameter surface of a hole of a hub wheel, press-fitting the projections in another of the outer diameter surface and the inner diameter surface along the axial direction, and forming recesses brought into contact and fitted with the projections by press fitting in the other of the outer diameter surface and the inner diameter surface, the projections and the recesses being held in contact with each other through intermediation. An outer member is fitted in a hole of a knuckle of a vehicle. Annular grooves are formed respectively in an outer peripheral surface of the outer member and an inner peripheral surface of the hole of the knuckle, and a snap ring is engaged with both the annular grooves.

Owner:NTN CORP

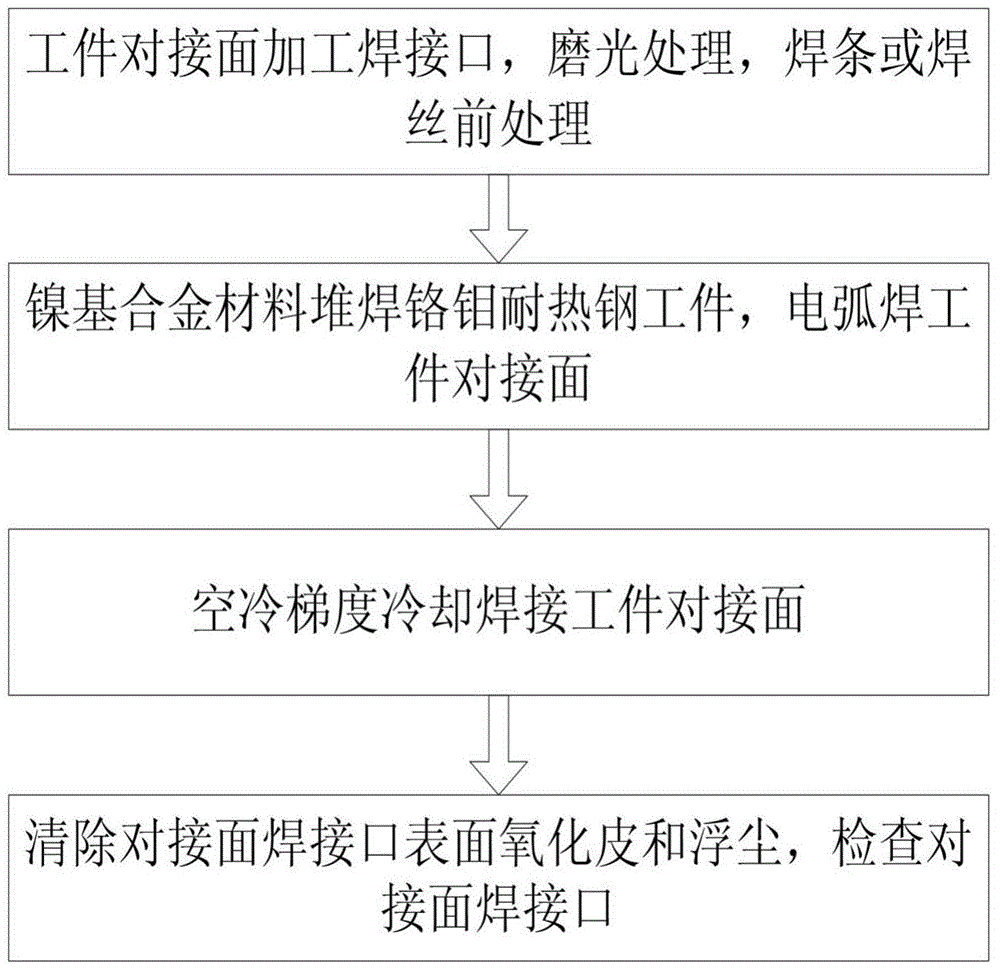

Welding technology of austenitic stainless steel and chrome molybdenum heat resistant steel

ActiveCN104801839AImprove the excellent characteristics of no cracksImprove residual stressArc welding apparatusAlloyAustenite

The invention provides a welding technology of austenitic stainless steel and chrome molybdenum heat resistant steel. The welding technology comprises the following steps: processing before welding: processing welding ports on the butt joint surfaces of workpieces, polishing the beveled edges and truncated edges of the butt joint surfaces of workpieces, removing oil contamination on the butt joint surfaces, and removing oil contamination and oxidation film on the surfaces of a welding strip or a welding silk via organic solvent; adopting nickel-based alloy welding silk for executing overlaying treatment on chrome molybdenum heat resistant steel workpiece, adopting manual metal-arc welding or argon tungsten-arc welding for welding; after welding, adopting the air cooling gradient cooling method for cooling the welding ends; removing surface scale and floating dust on the welding ports of the butt joint surfaces, and checking whether the welding ports of the butt joint surfaces have welding problem or not. The leakage problem of connection welding line of the austenitic stainless steel and chrome molybdenum heat resistant steel is solved, ideal different steel welding joint can be obtained and the use performance of the different steel welding welded junction is greatly improved.

Owner:中石化工建设有限公司

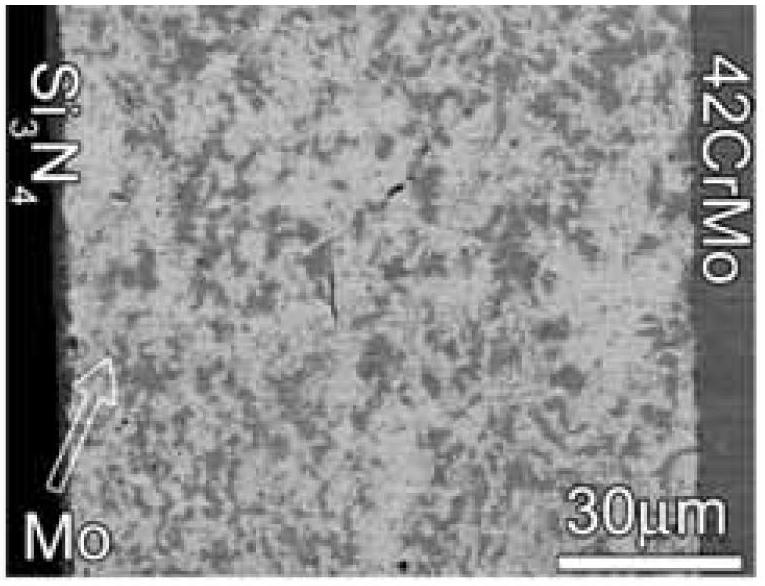

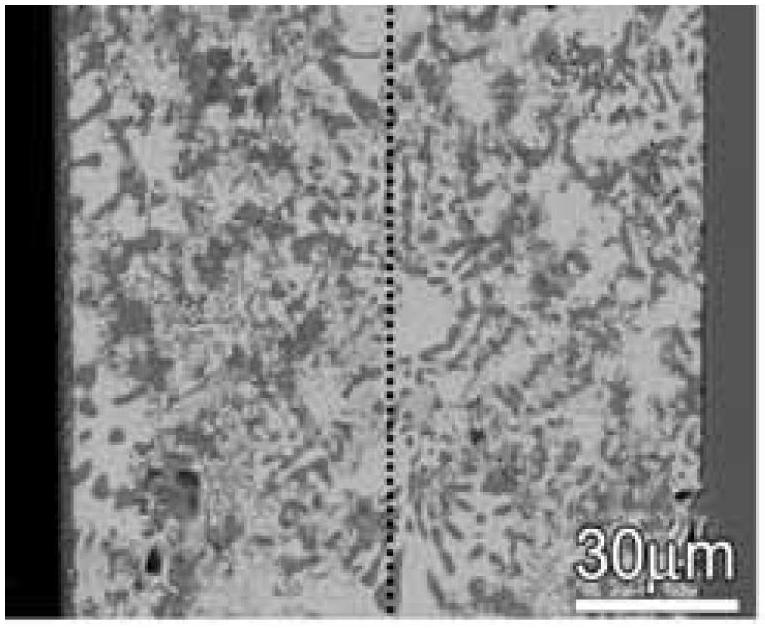

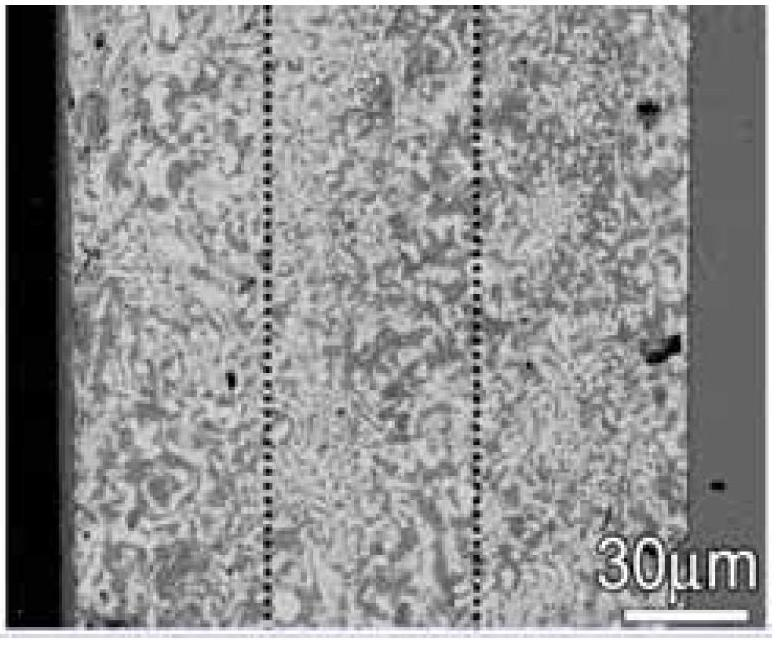

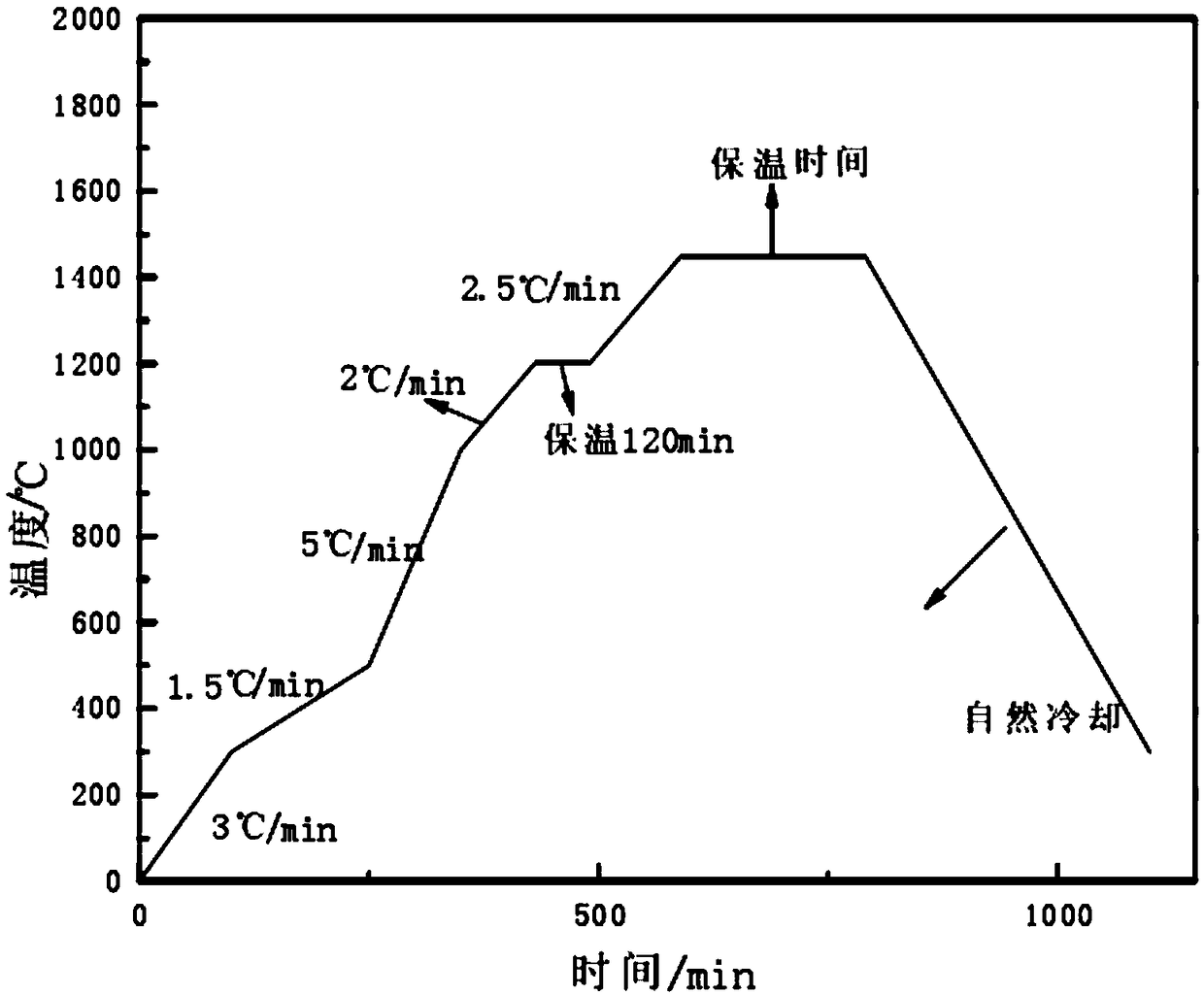

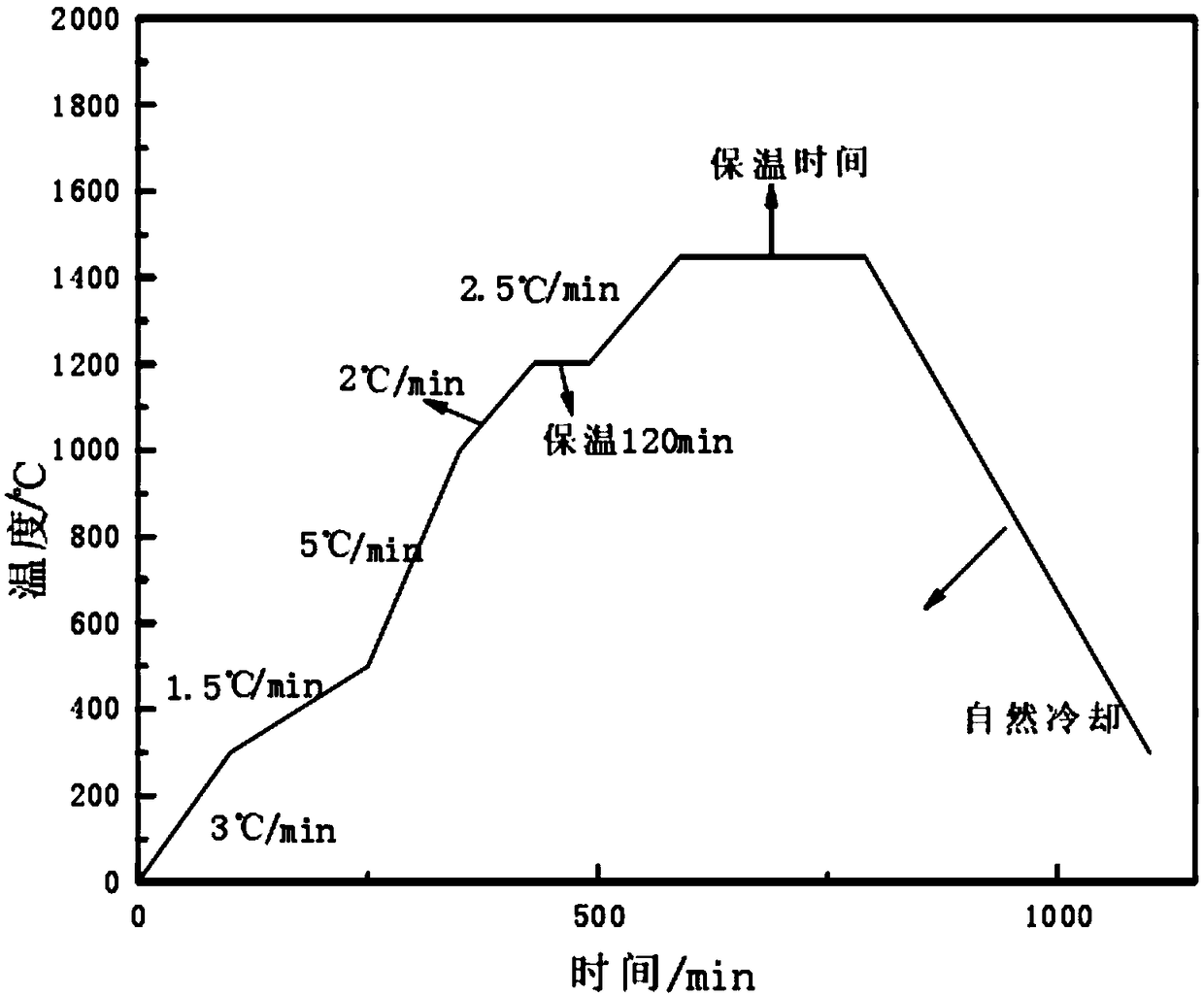

Composite brazing material for connecting Si3N4 ceramic and 42CrMo steel and brazing method by using same

InactiveCN102689108AImprove plasticityImprove residual stressWelding/cutting media/materialsWelding/soldering/cutting articlesCeramicResidual stress

The invention relates to a brazing material for connecting ceramic and steel and a brazing method, particularly a composite brazing material for connecting Si3N4 ceramic and 42CrMo steel and a brazing method by using the same... The invention aims to solve the problems of high residual stress and low strength of the brazing joint formed by connecting the Si3N4 ceramic and 42CrMo steel by the existing brazing material. The brazing material is prepared from Ag powder, Cu powder, Ti powder and a reinforcing phase. The method comprises the following steps: mixing Ag powder, Cu powder, Ti powder and an reinforcing phase, carrying out ball milling, mixing with hydroxyethyl cellulose, and drying to obtain a composite brazing material sheet; putting the composite brazing material sheet between the to-be-brazed surface of the Si3N4 ceramic and the to-be-brazed surface of the 42CrMo steel to obtain a to-be-brazed piece; and putting the to-be-brazed piece in a vacuum brazing furnace to carry out vacuum brazing, thereby completing the brazing of the composite brazing material for connecting the Si3N4 ceramic and the 42CrMo steel. The invention has the advantages of low residual stress and high strength of the brazing joint, and is applicable to brazing connection of ceramic and steel.

Owner:HARBIN INST OF TECH

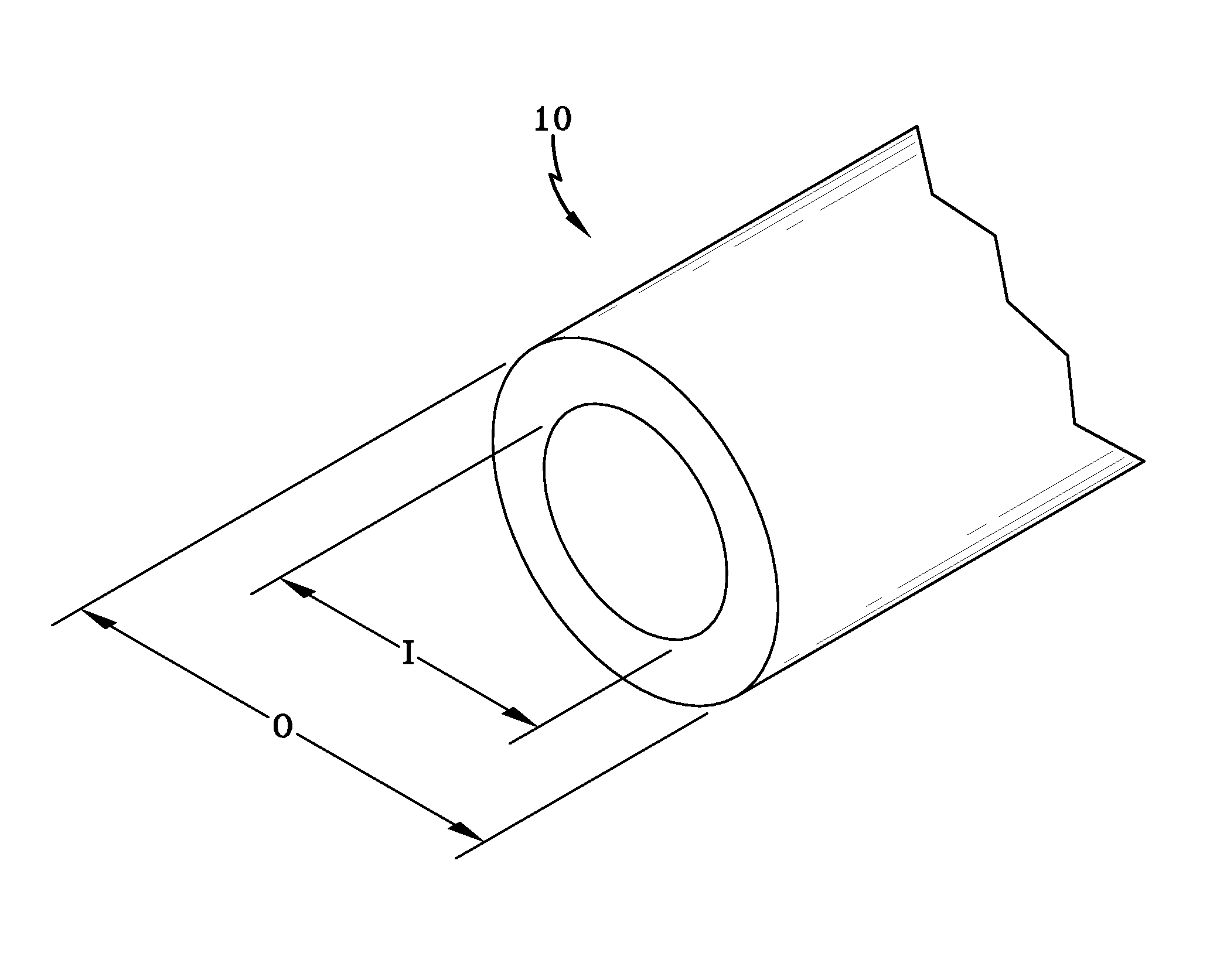

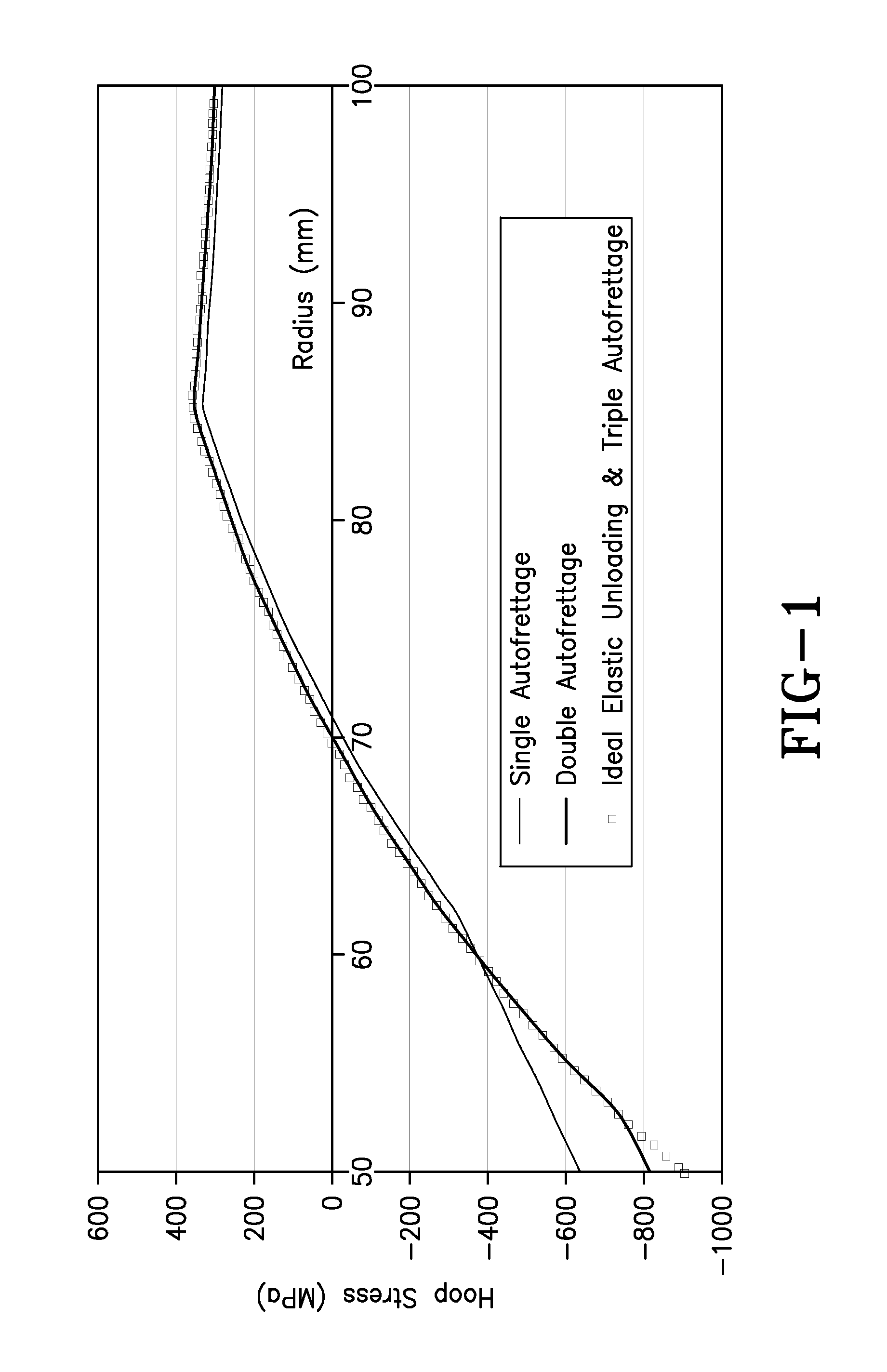

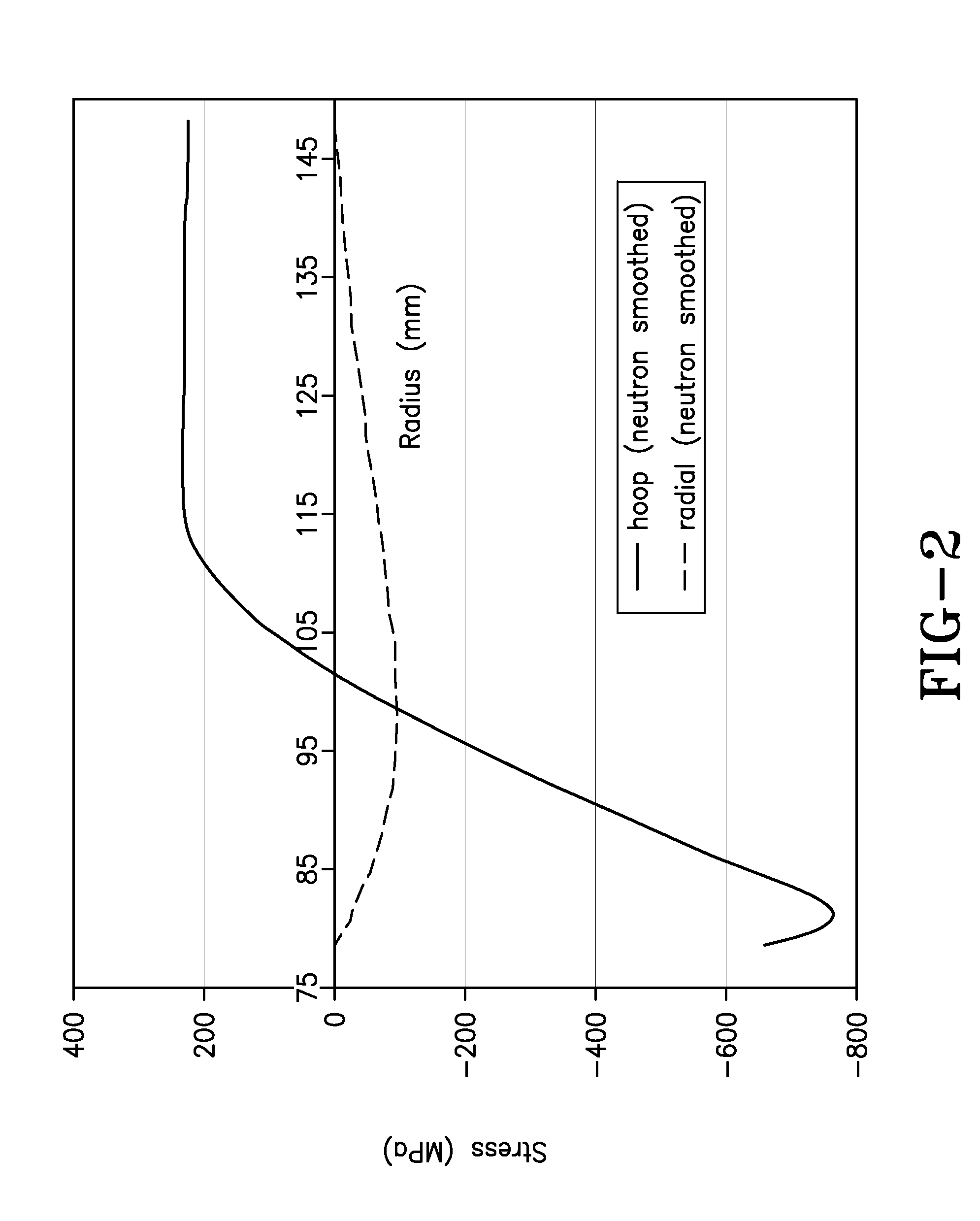

Multiple autofrettage

InactiveUS7818986B1Improve residual stressIncrease resistanceMetal working apparatusProcess engineeringGun barrel

A manufacturing method includes a first step of performing swage autofrettage on an object; a second step of heat soaking the object; and a third step of performing hydraulic autofrettage on the object. The second and third steps may be repeated one or more times. A final step may be heat soaking the object. The object may be, for example, a pressure vessel or gun barrel.

Owner:ARMY U S GOVERNMENT AS REPRESENTED BY SEC OF

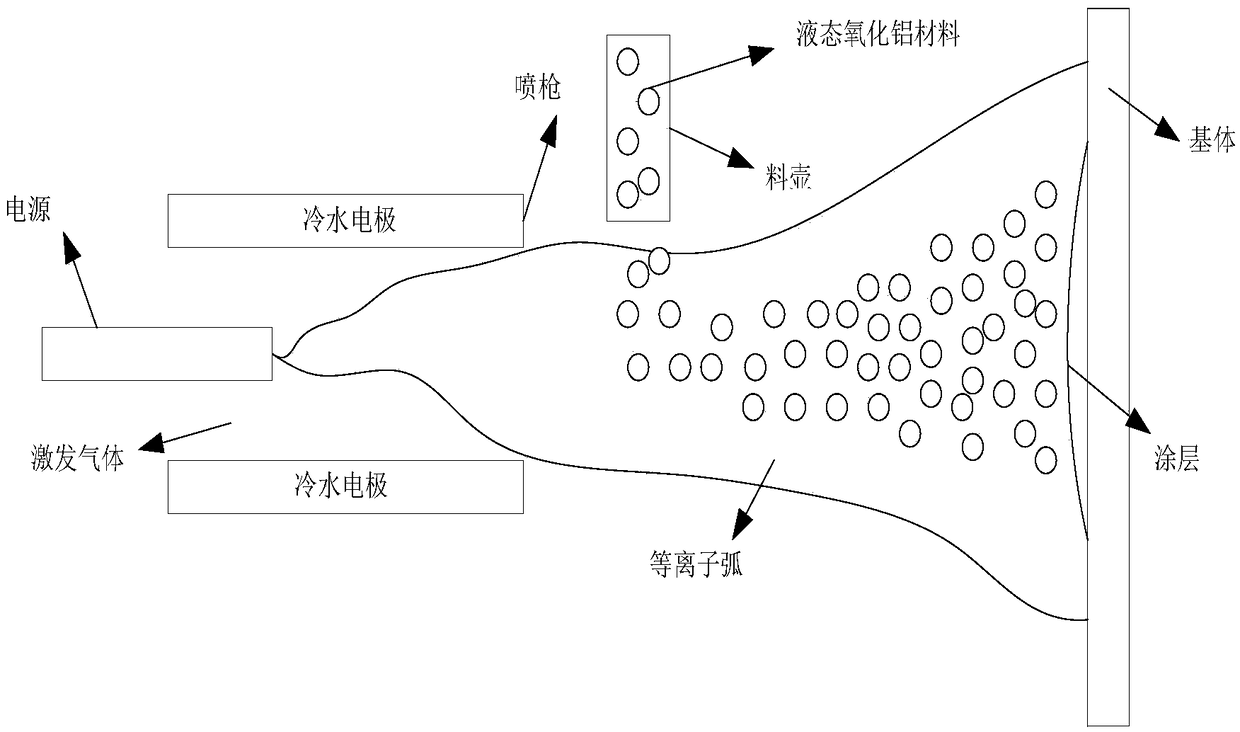

Aluminum oxide ceramic coating and preparation method thereof

PendingCN109440051AImprove bindingThe binding effect is not enough to meet the strength goodMolten spray coatingMolten stateCeramic coating

The invention belongs to the technical field of plasma arc spraying, and particularly relates to a high-hardness, high-wear-resistance and high-toughness aluminum oxide ceramic coating and a preparation method thereof. The method comprises the following steps that (1.1) a matrix is selected; (1.2) sand blasting or sanding pretreatment is carried out on the matrix; (1.3) aluminum oxide raw materialpowder is prepared; (1.4) the aluminum oxide nano-sintered powder is heated to a molten state; and (1.5) an aluminum oxide nano-liquid material is sprayed. The core step of the method is the molten step which before the aluminum oxide nano-liquid material is sprayed, a traditional aluminum oxide spraying technology is characterized in that aluminum oxide nano particles are directly placed into aspray gun for heating and spraying, and the combination effect cannot sufficiently meet a strength requirement and an adhesion degree requirement; and the sintered powder is melted into the molten state before feeding by the spray gun through the method, so that the defect is avoided, and the comprehensive parameters of the strength, hardness, toughness and the like of the ceramic coating are obviously better than the effect of a common spraying technology.

Owner:陈涛

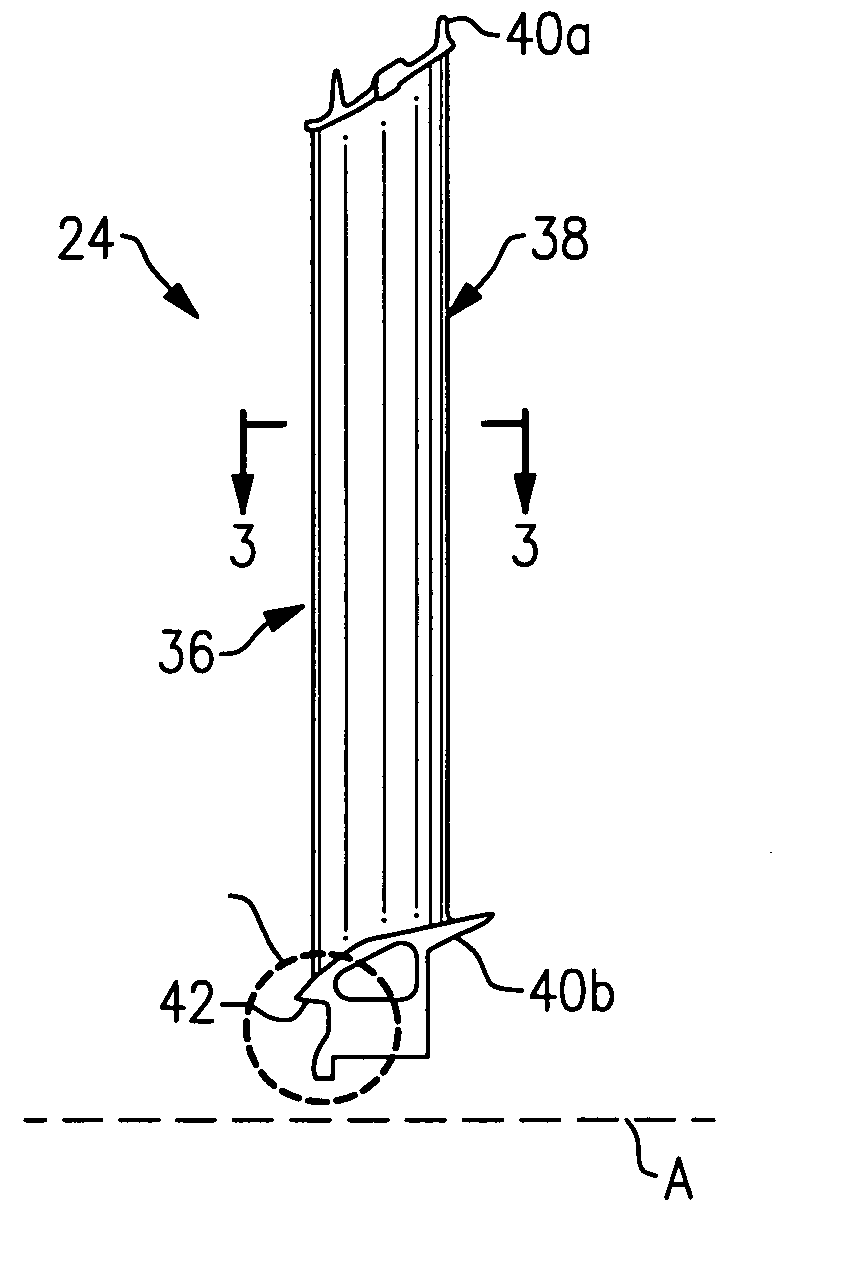

Turbine component trailing edge and platform restoration by laser cladding

ActiveUS20070160476A1Extended useful lifeExtended service lifeTurbinesBlade accessoriesFilling materialsTrailing edge

A method of restoring a gas turbine engine component includes depositing a filler material onto a sulphidation section of an underside of a turbine engine platform and laser consolidating the filler material to produce a restored surface on the underside. The sulphidation section includes sulphidation pit portions that are filled during the laser consolidating to produce the restored surface. An eroded trailing edge of a turbine airfoil is laser cladded to produce a restored trailing edge thickness.

Owner:RAYTHEON TECH CORP

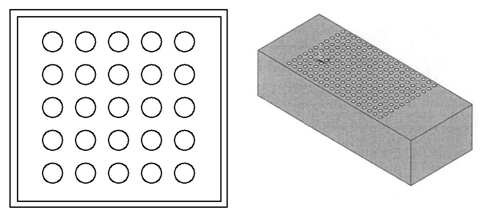

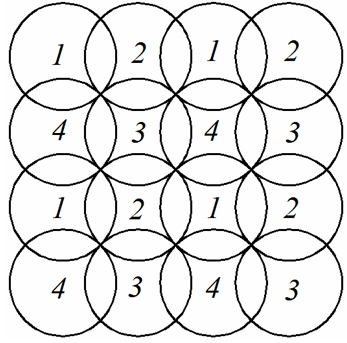

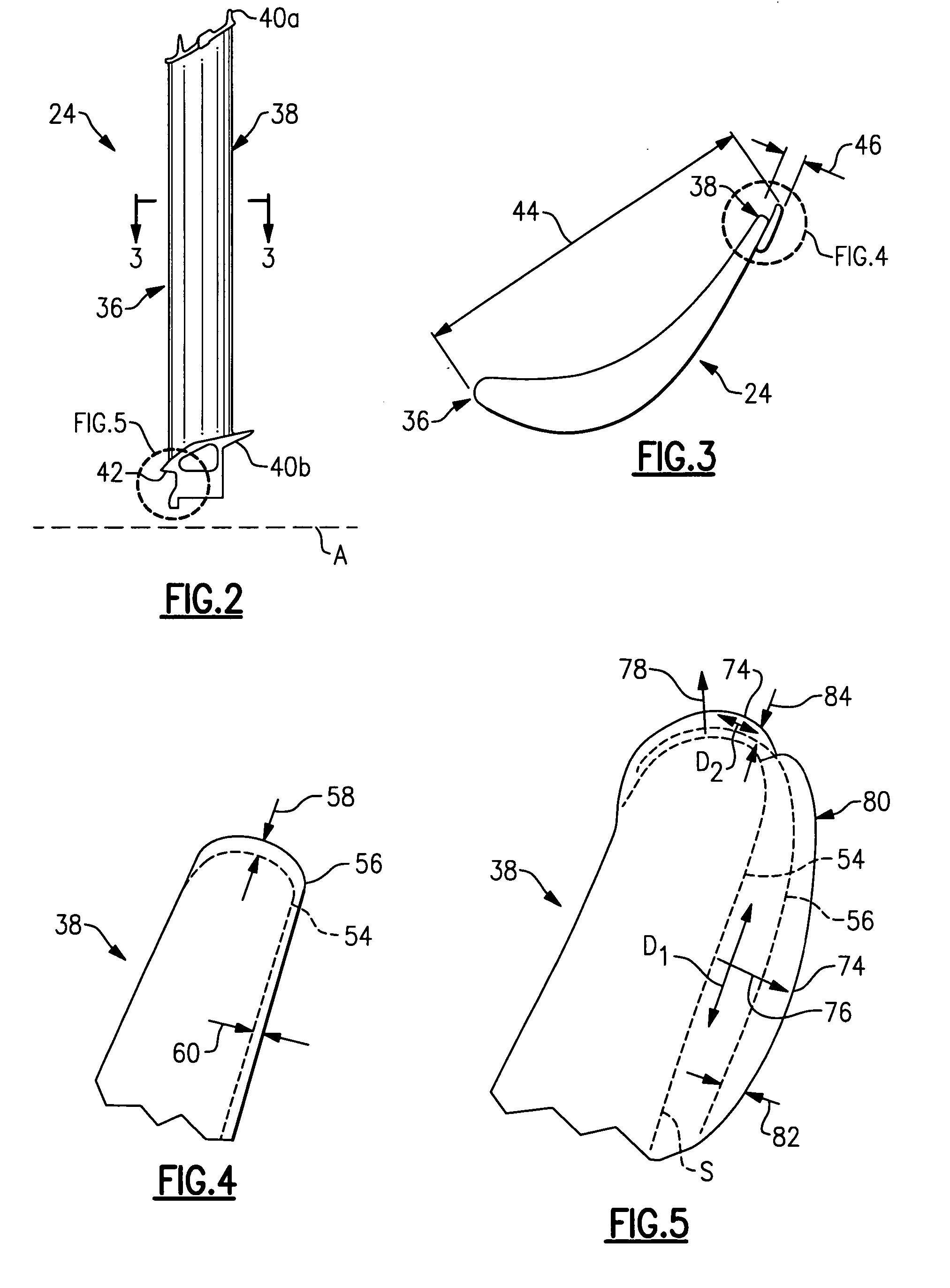

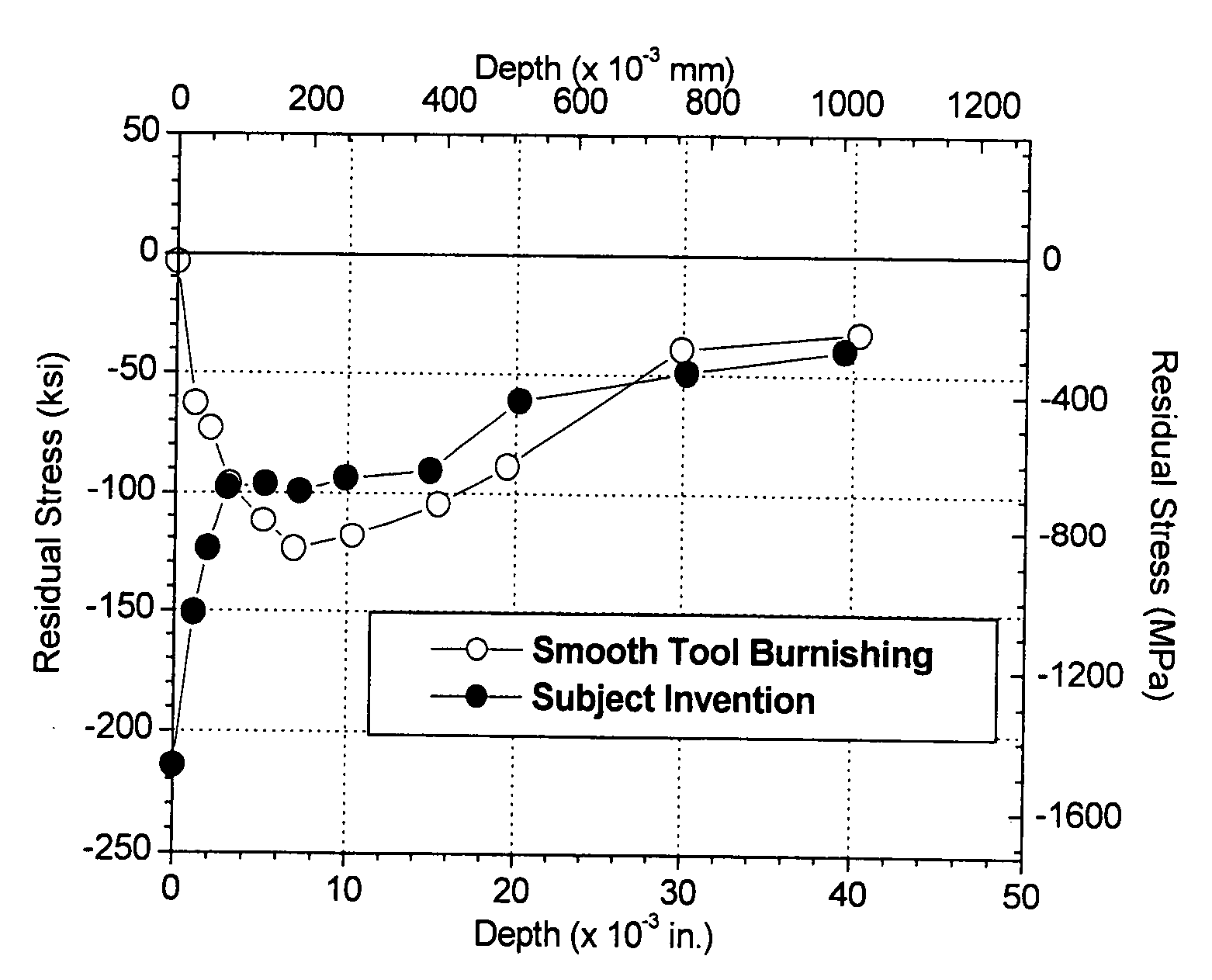

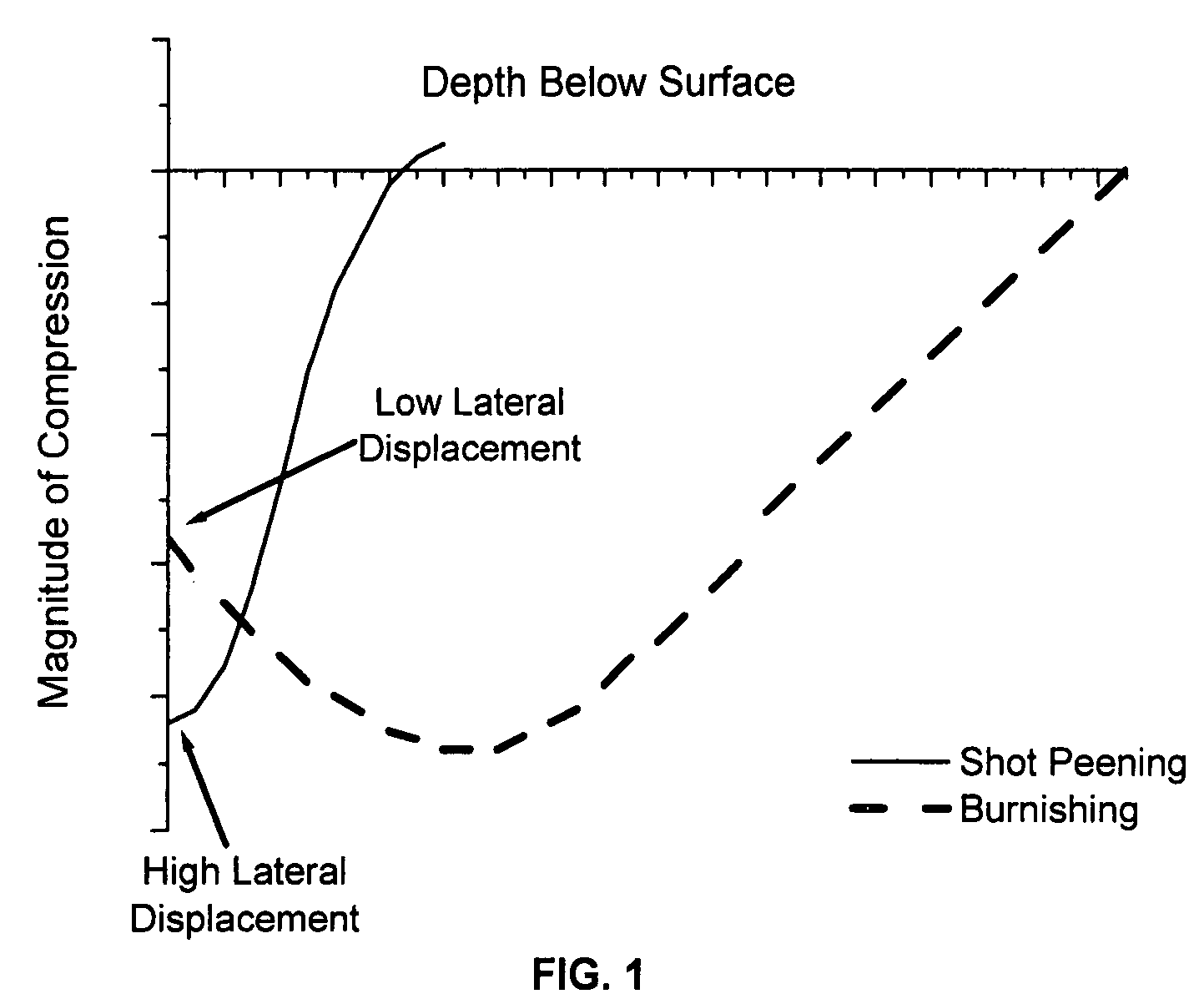

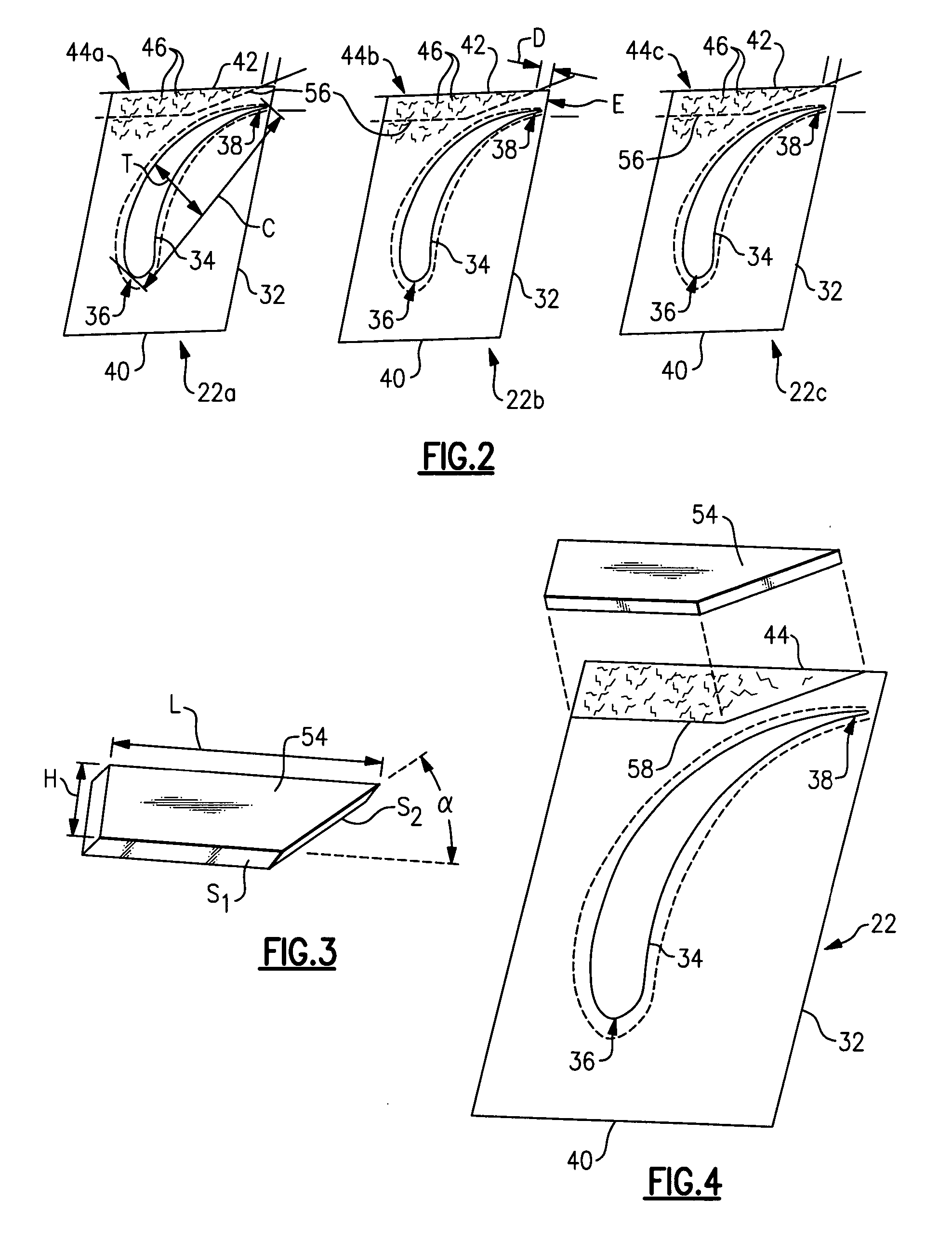

Method and apparatus for improving the distribution of compressive stress

InactiveUS20080081208A1Prevent removalHigh of contaminationLayered productsThin material handlingCompressive strengthLateral displacement

A surface treatment element having a textured surface with a plurality of deforming features is pressed against the surface of an article to induce deep and shallow layers of compressive residual stress to form a continuous layer of compressive residual stress extending from the surface to a depth beneath the surface. A method whereby a surface treatment apparatus is pressed into the surface of the apparatus to cause Hertzian loading thereby inducing a deep, high magnitude compressive residual stress below the surface. The deforming features of the surface treatment element cause the lateral displacement of material on the surface of the article thereby cold working the surface and providing a more shallow layer of compressive residual stress at the surface.

Owner:PREVEY PAUL S +1

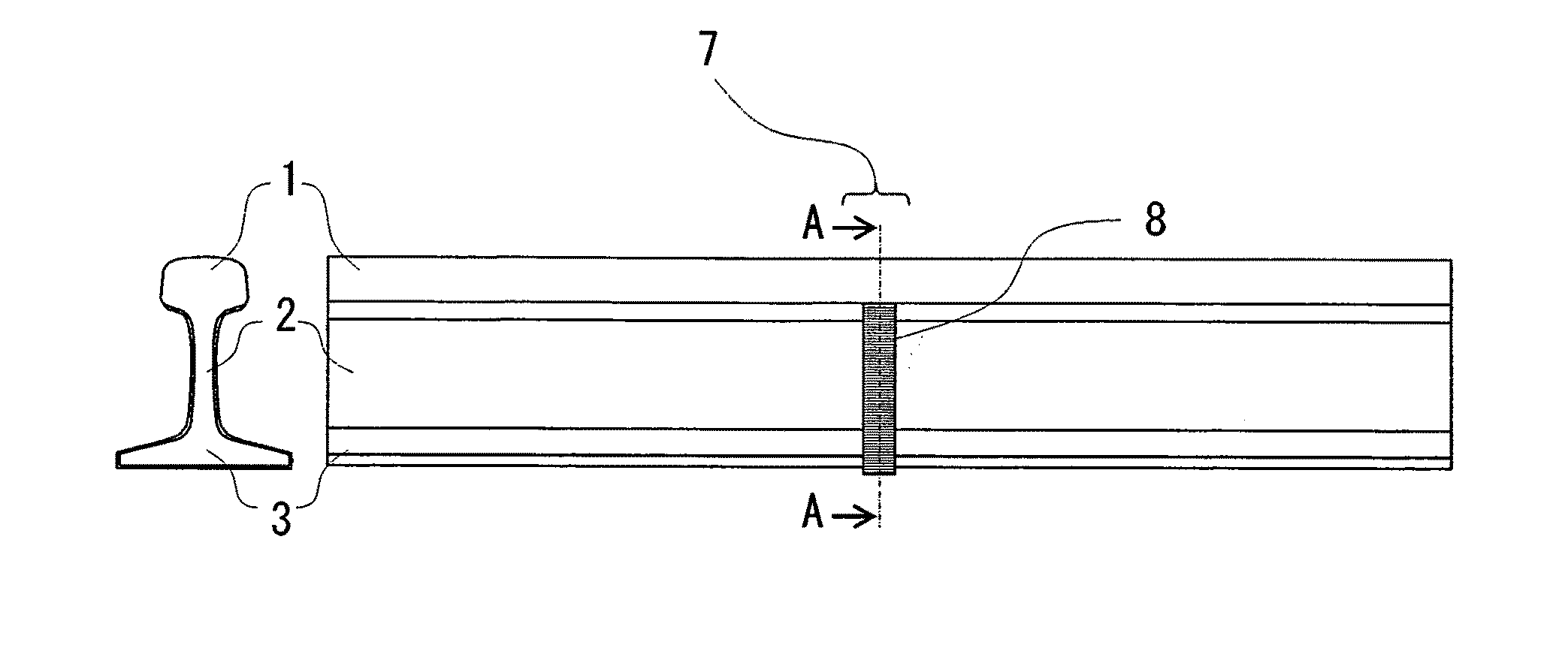

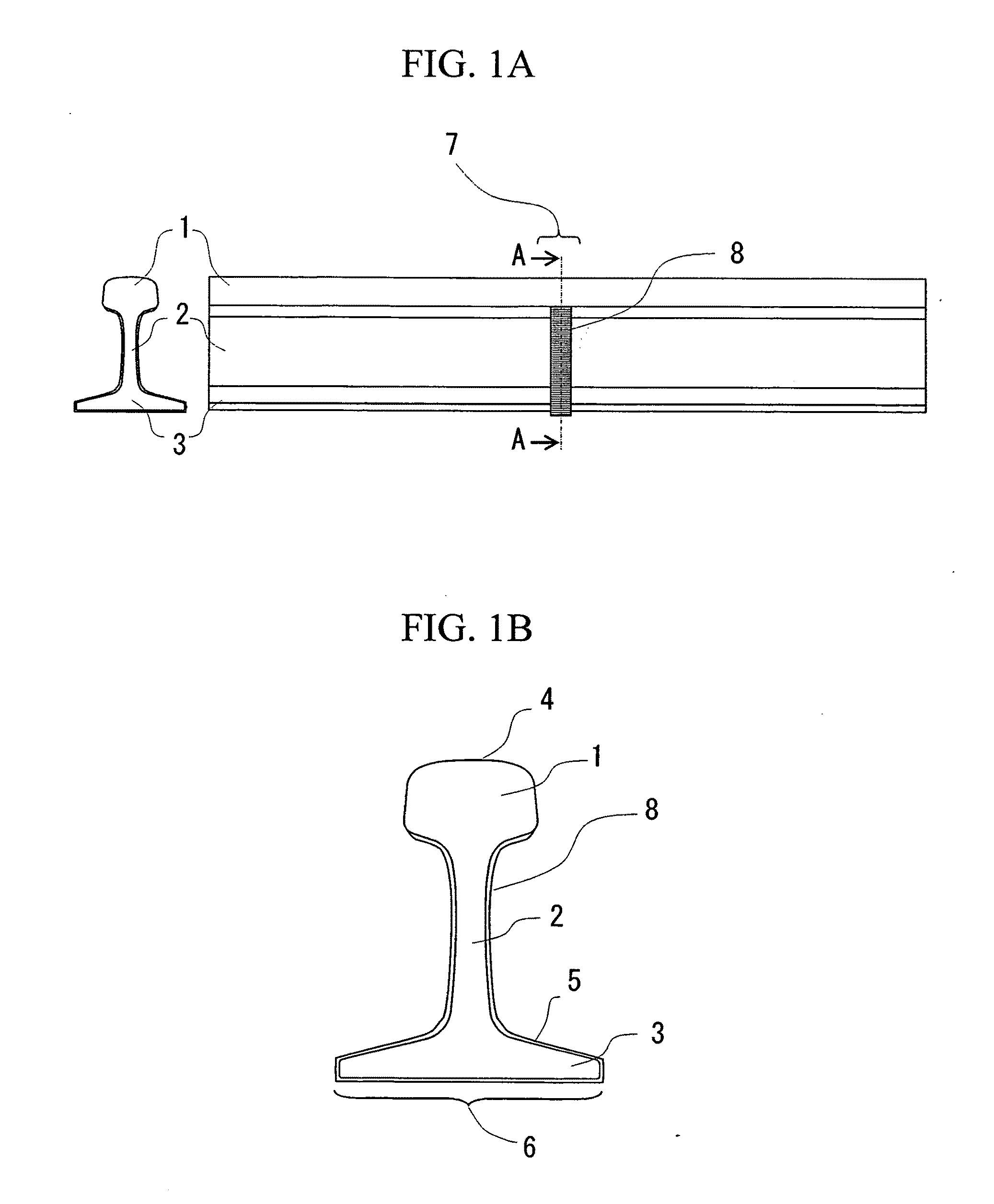

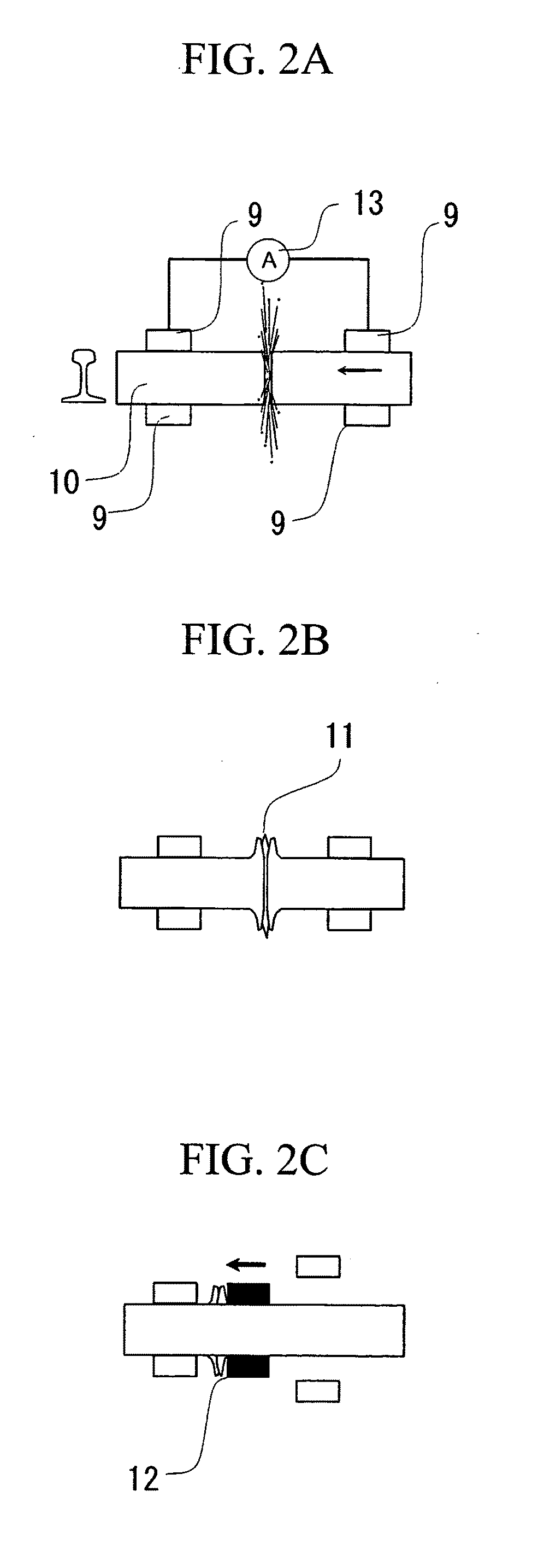

Method of cooling rail weld zone, device for cooling rail weld zone, and rail weld joint

InactiveUS20120015212A1Improve residual stressAvoid fatigue crackingRailsFurnace typesEngineeringMechanical engineering

The invention provides a method of cooling a rail weld zone. The method includes a first rail web portion cooling process of cooling a rail web portion cooling region of the rail weld zone in a part of a temperature range until the completion of transformation from austenite to pearlite, a second rail web portion cooling process of cooling the rail web portion cooling region after the entire rail web portion of the rail weld zone is transformed to pearlite, a foot portion cooling process of cooling a foot portion of the rail weld zone, and a head portion cooling process of cooling a head portion of the rail weld zone. When cooling time of the first and second rail web portion cooling processes is t minute, a k value satisfies an expression represented as −0.1t+0.63≦k≦−0.1t+2.33.

Owner:NIPPON STEEL CORP

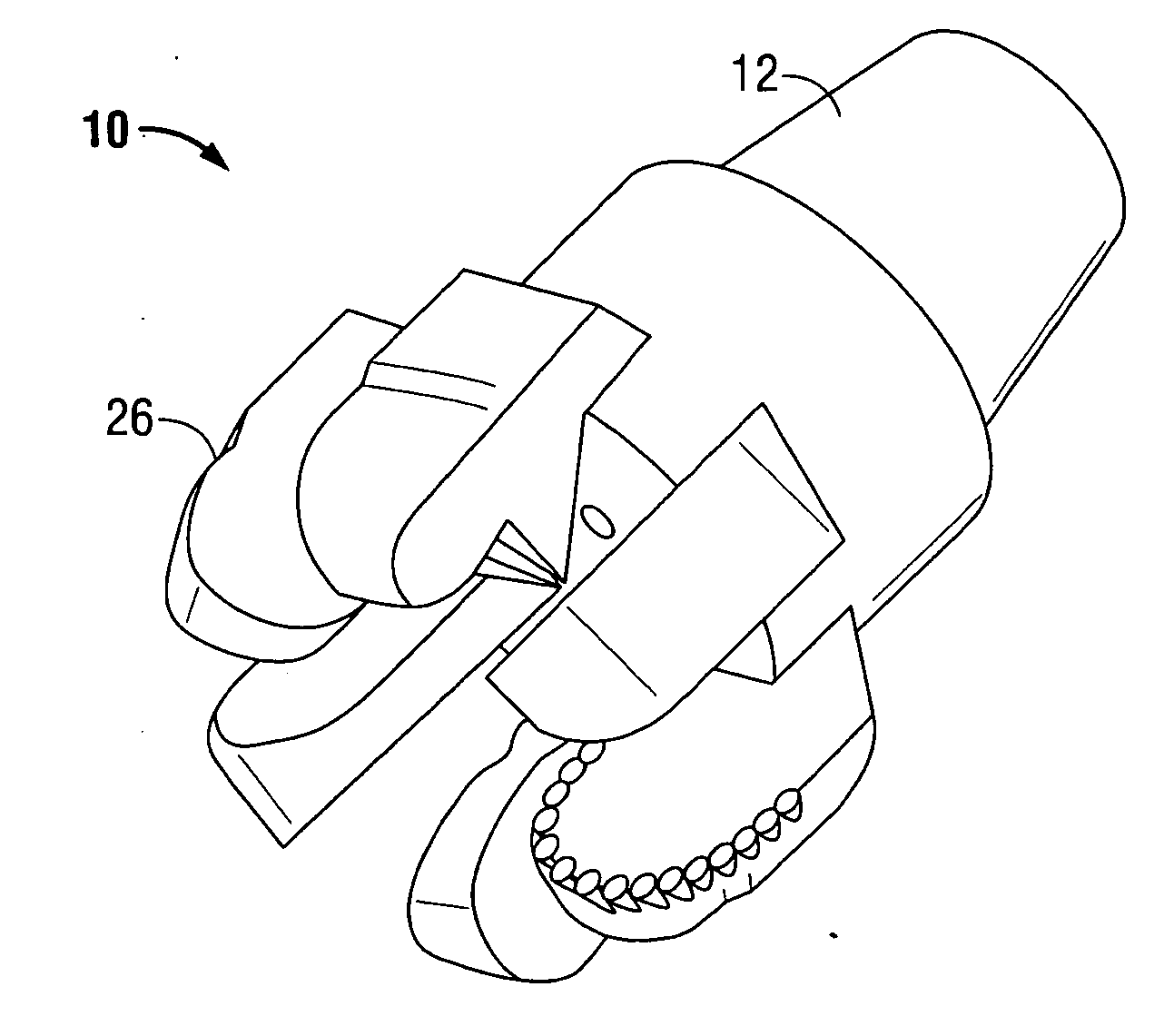

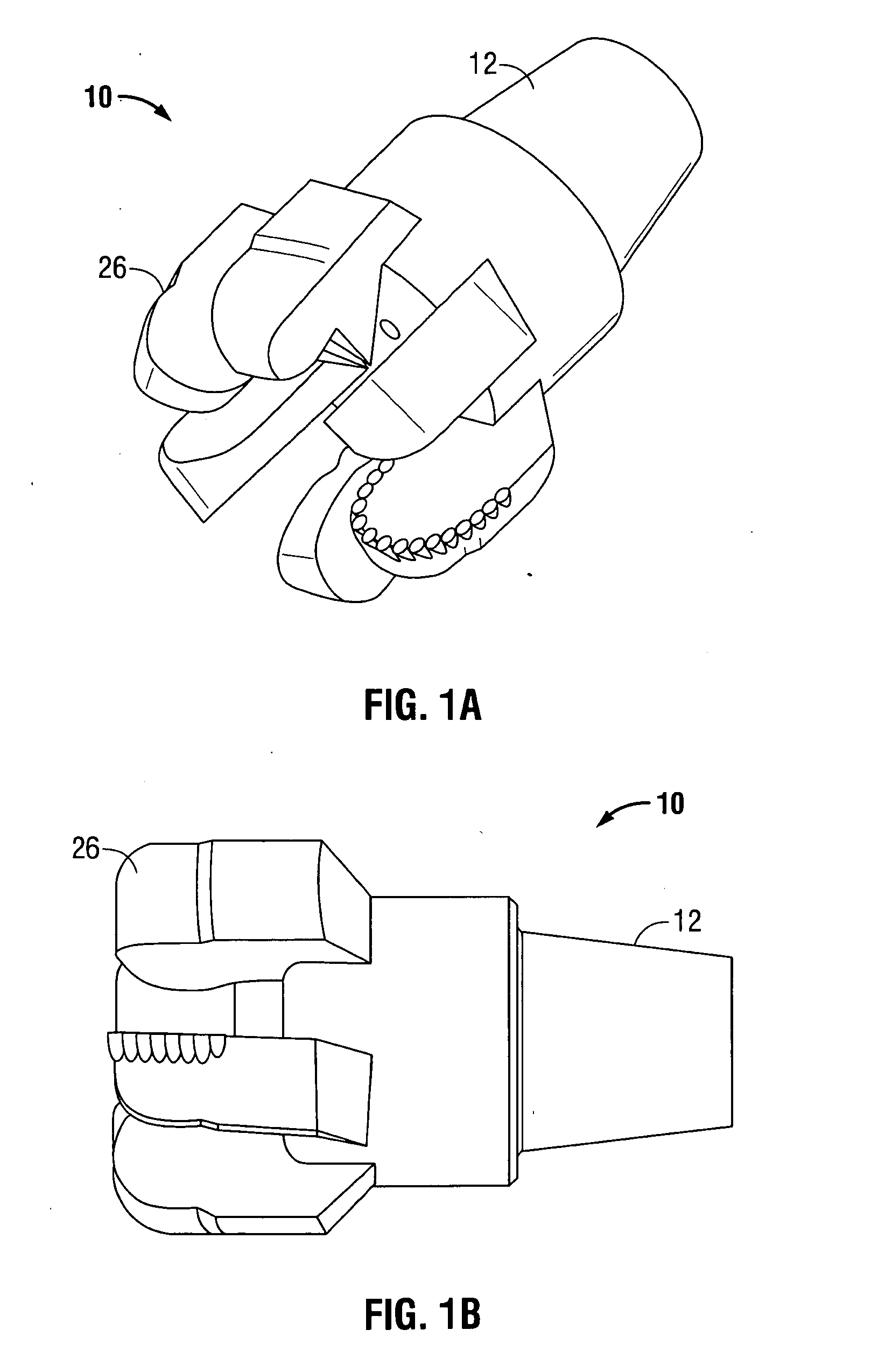

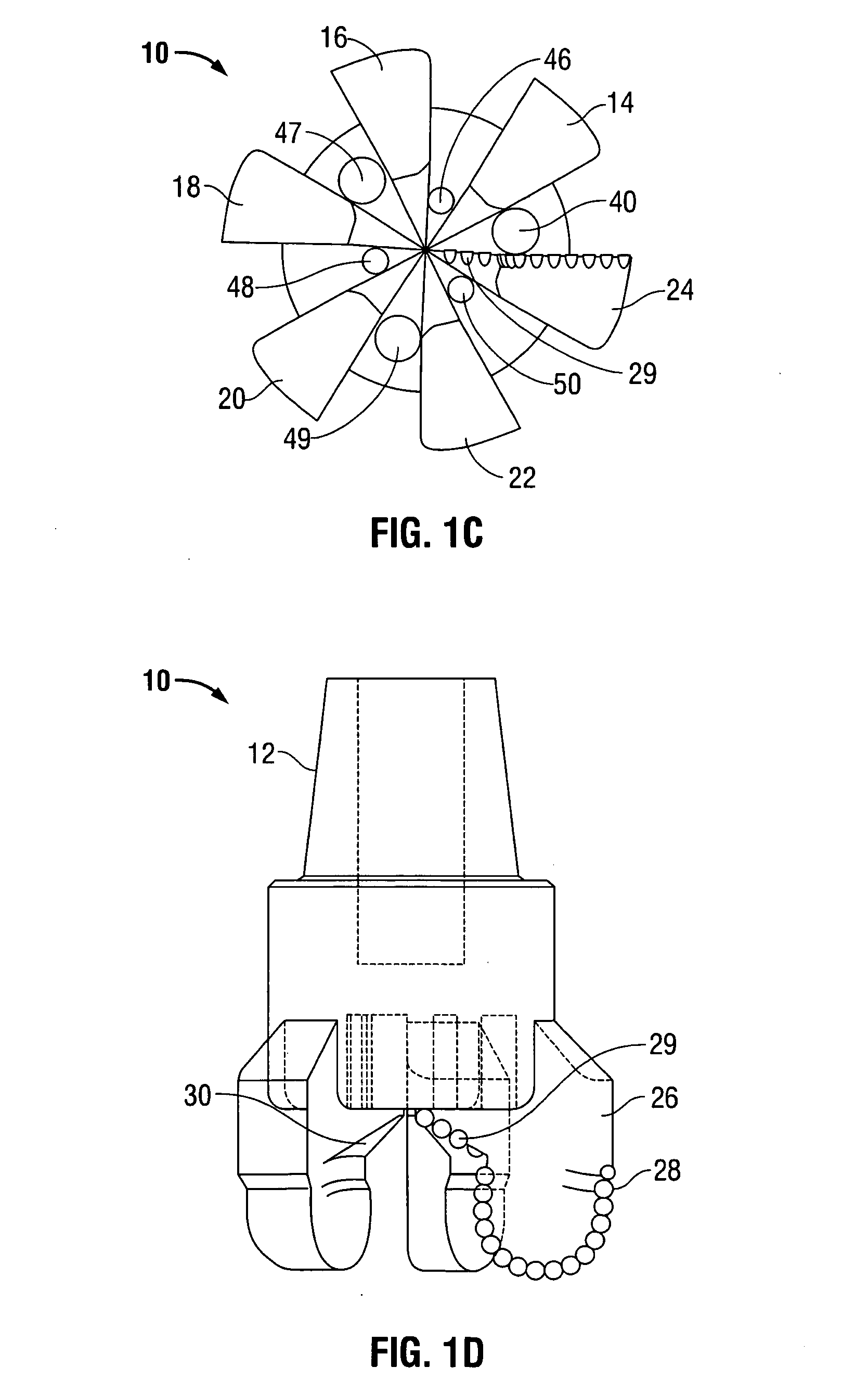

Combination coring bit and drill bit using fixed cutter PDC cutters

InactiveUS20100101870A1Improve drilling performanceLower the volumeArtificial islandsDrill bitsPolycrystalline diamondEngineering

A drill bit having fixed Polycrystalline Diamond Compact cutters is used to drill a borehole having a core stump therein. A plurality of additional fixed Polycrystalline Diamond Compact cutters are disposed in the dome of the bit and are usable to concentrate stresses in the top end of the core stump to facilitate the cutting down of the core stump.

Owner:DIAMANT DRILLING SERVICES

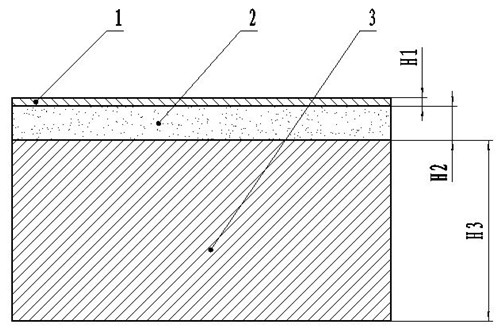

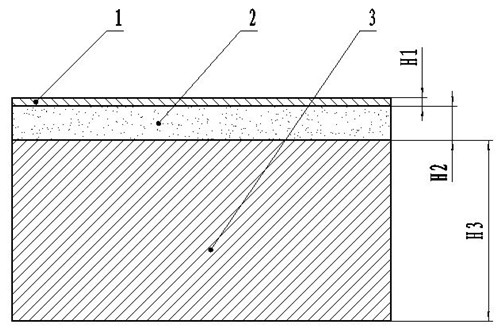

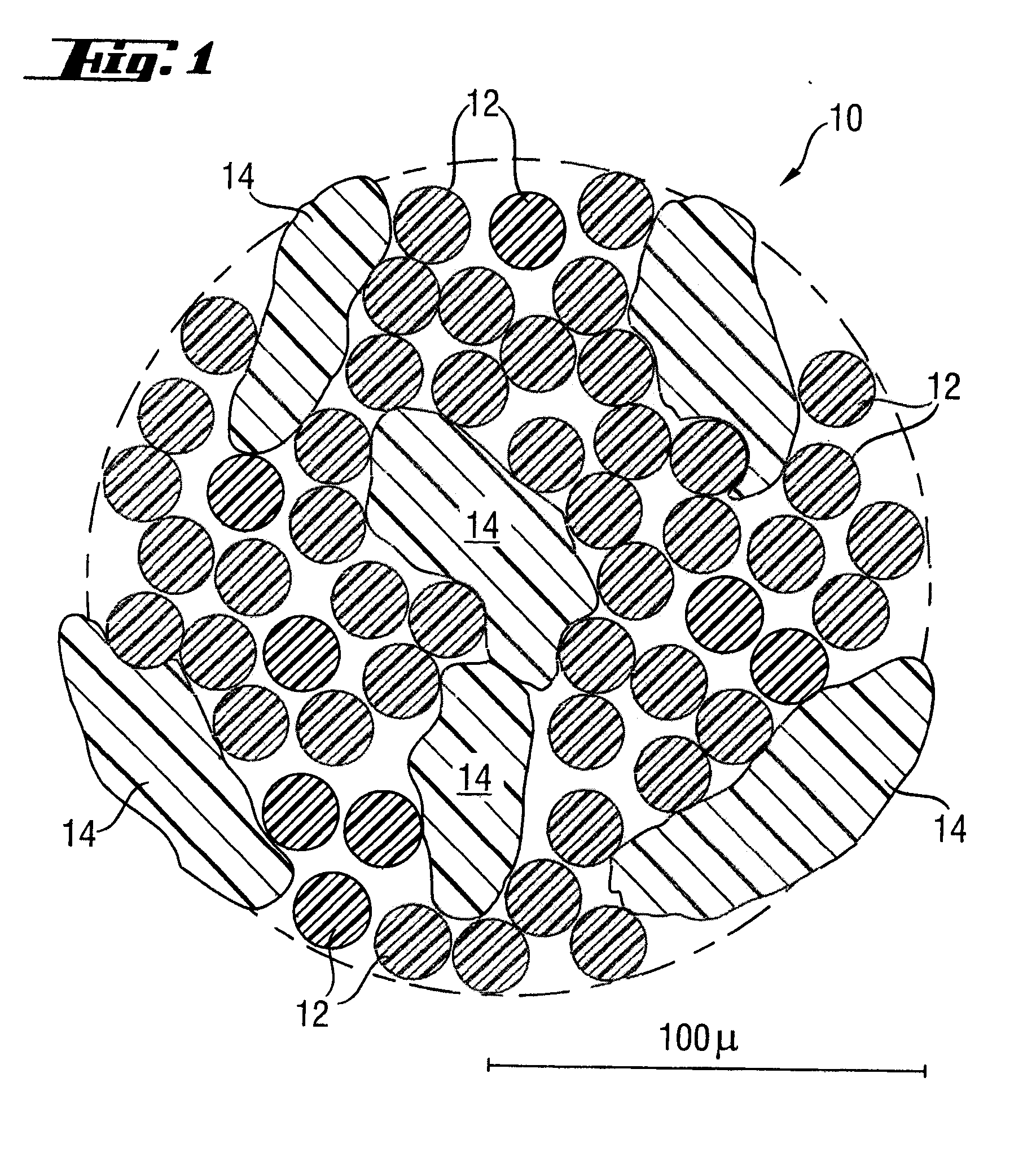

Preparation method of diamond compact

InactiveCN102019426AThe sintered structure is dense and uniformGood synthesis reproducibilityAlloy substrateMetal alloy

The invention discloses a preparation method of a diamond compact. The method comprises the following steps: arranging a diamond powder layer (2) between a metal alloy plate (1) and a hard alloy substrate (3) to prepare a sintered blank; then putting the sintered blank into the synthesis cavity of a graphite pipe, carrying out warming-pressurizing sintering for 3-30 minutes at 1200-1500 DEG C under the pressure of 5.0-6.0GPa; and cooling and depressurizing the sintered product, thus obtaining the diamond compact. By utilizing the method provided by the invention, the problems that the product prepared in the prior art has poor sintered histology compact uniformity and large residual stress are solved.

Owner:柳州市大荣非金属材料有限公司

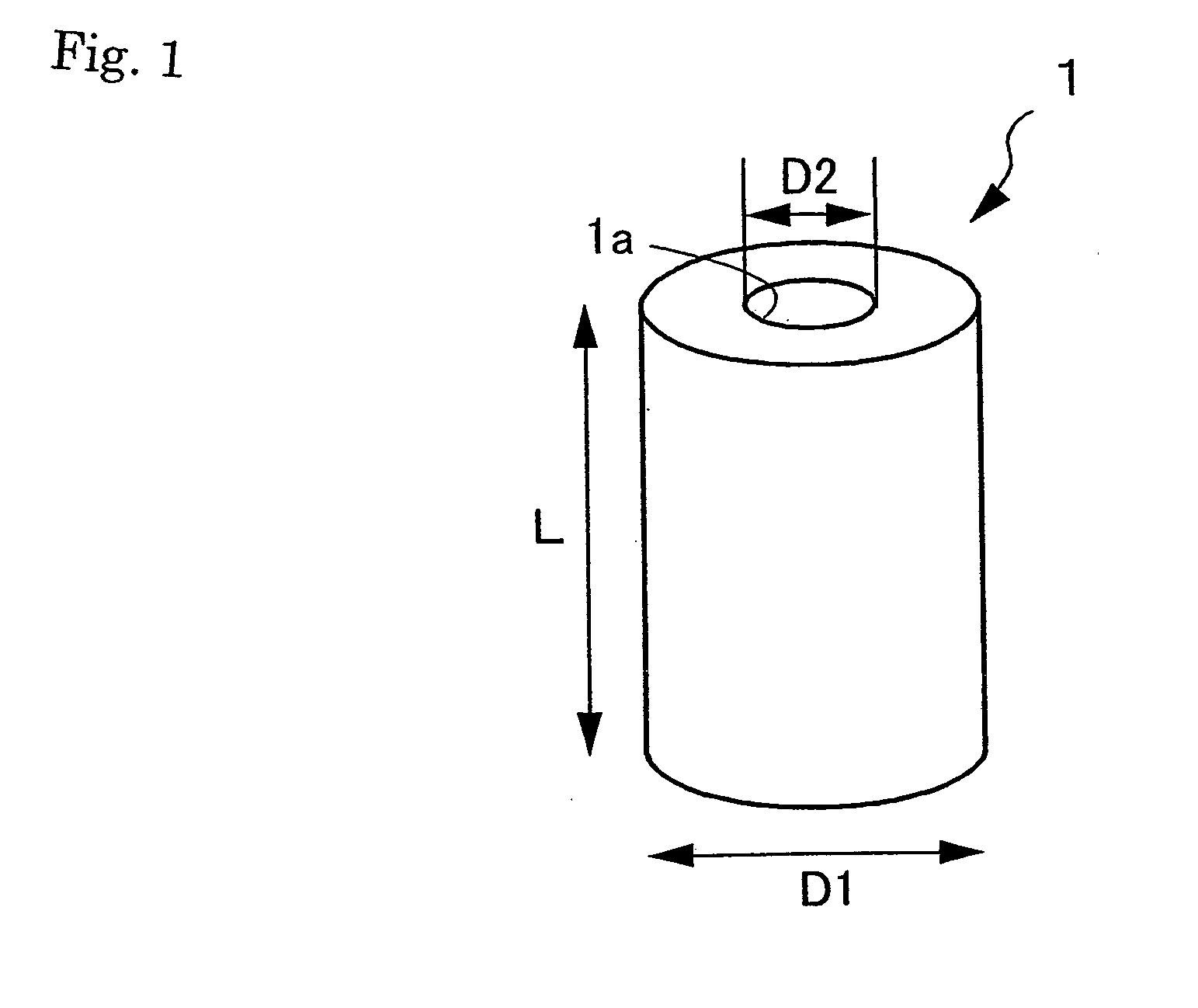

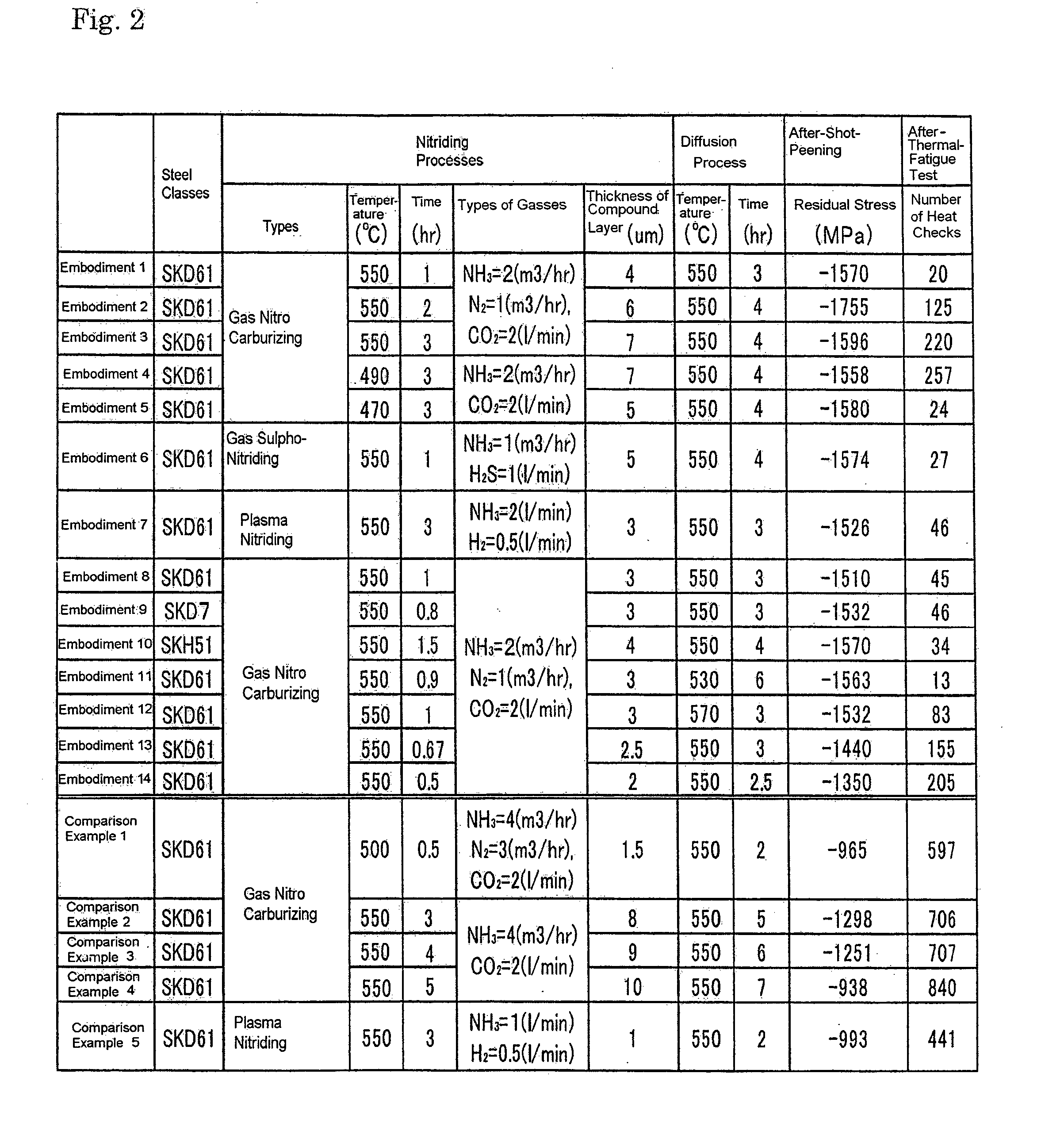

Mold for casting and method of surface treatment thereof

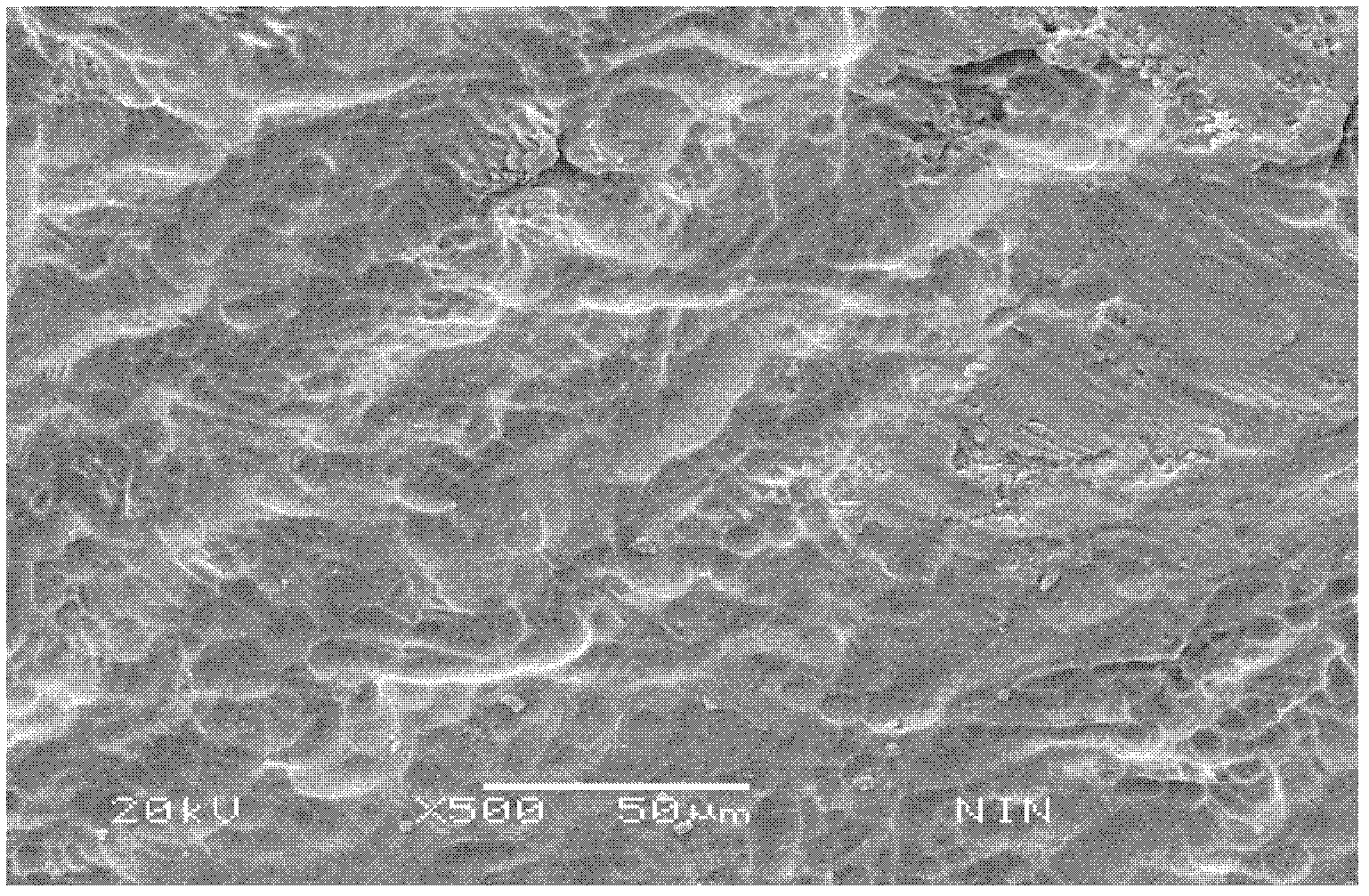

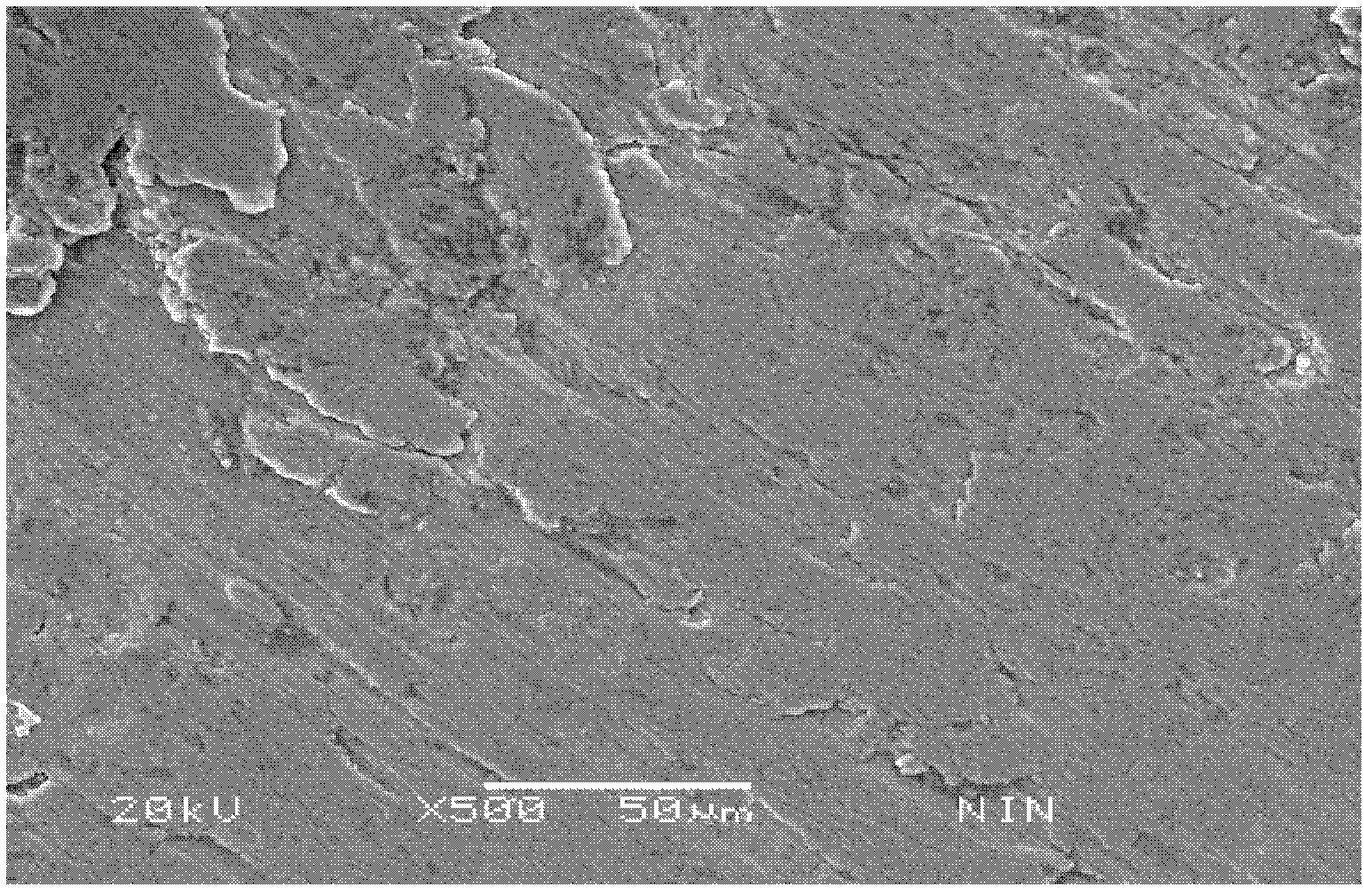

InactiveUS20060201650A1High hardnessExcellent durabilityFoundry mouldsSolid state diffusion coatingHardnessShot peening

A method of the surface treatment of a mold for casting, which comprises subjecting a cavity surface of a fixed mold made by the use of a SCM420 material to first shot peening, a sulfurizing-nitriding treatment and second shot peening. The resulting cavity surface of the fixed mold exhibits a high hardness of 700 or higher in terms of Vickers hardness due to the presence of a sulfurized and nitrided layer, and further has a compression residual stress of more than 1200 Mpa and a largest height, which is a surface roughness value defined by JIS standard, of 8 μm or less.

Owner:HONDA MOTOR CO LTD

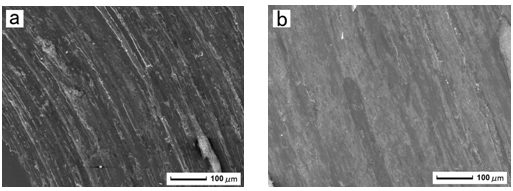

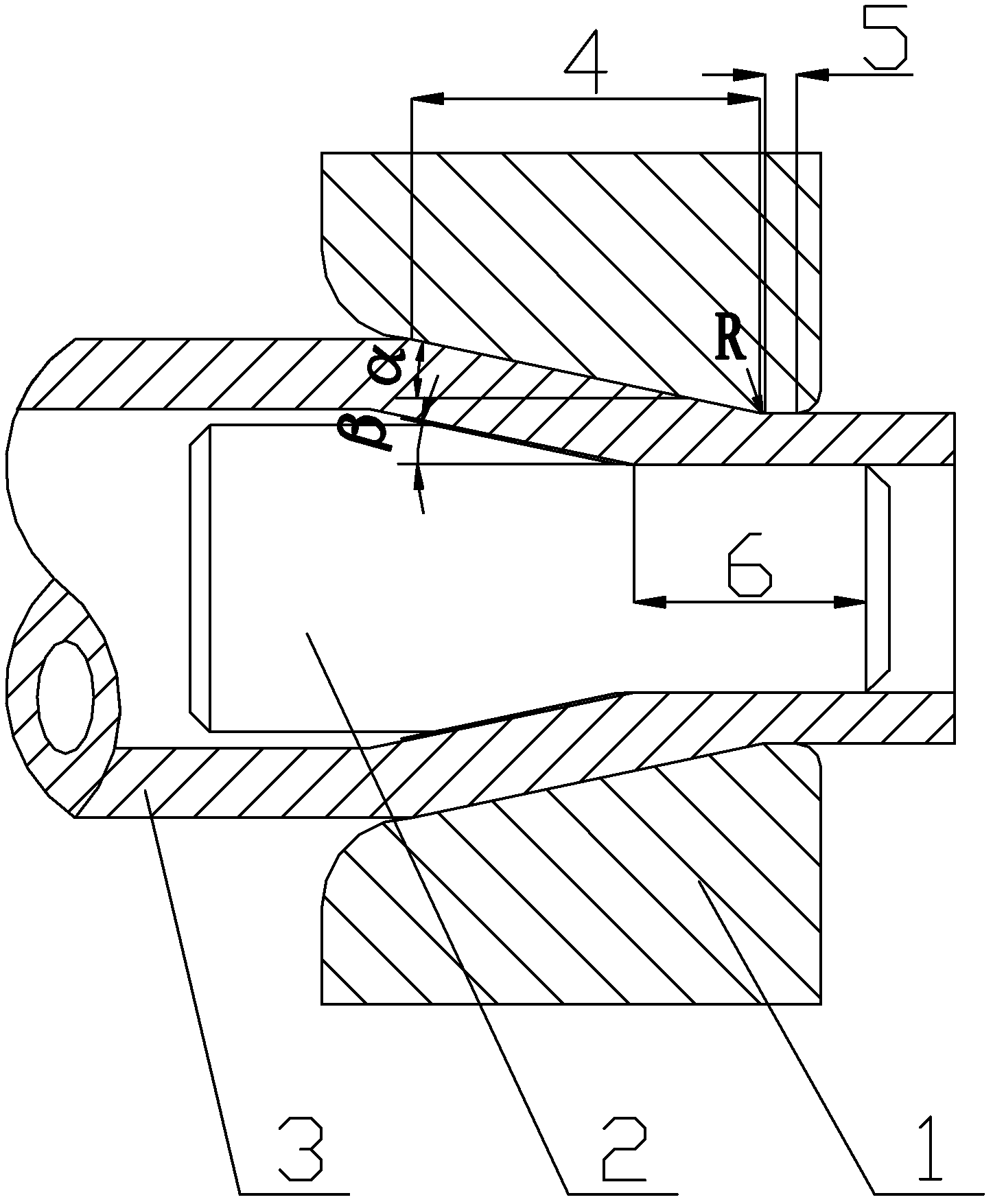

Method for improving surface quality of titanium and titanium alloy pipes and drawing die

The invention discloses a drawing die comprising an outer die for determining the outer diameter of a pipe and a movable core print for determining the inner diameter of the pipe, wherein the outer die half-cone angle alpha of the outer die is 10-20 degrees; the fixed-diameter section 1 of the outer die is 0.5mm-3mm long; the radius R of a transitional circular arc between the conical section and the fixed-diameter section 1 of the outer die is 5mm-8mm; the core print half-cone angle beta of the core print is 5-18 degrees; and the fixed-diameter section 2 of the movable core print is 0.5mm-5mm long. The invention also discloses a method for improving the surface quality of titanium and titanium alloy pipes by using the drawing die. With the drawing die provided in the invention, surface rolling friction in the traditional cold rolling deformation of the titanium and titanium alloy pipes can be changed into sliding friction; therefore, the shortcomings of pipe surface pits, wrinkles, microcracks and the like easily caused by repeated rolling compaction of the die during rolling are reduced, and the purpose of improving the quality of both the inner surface and the outer surface of the pipes is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

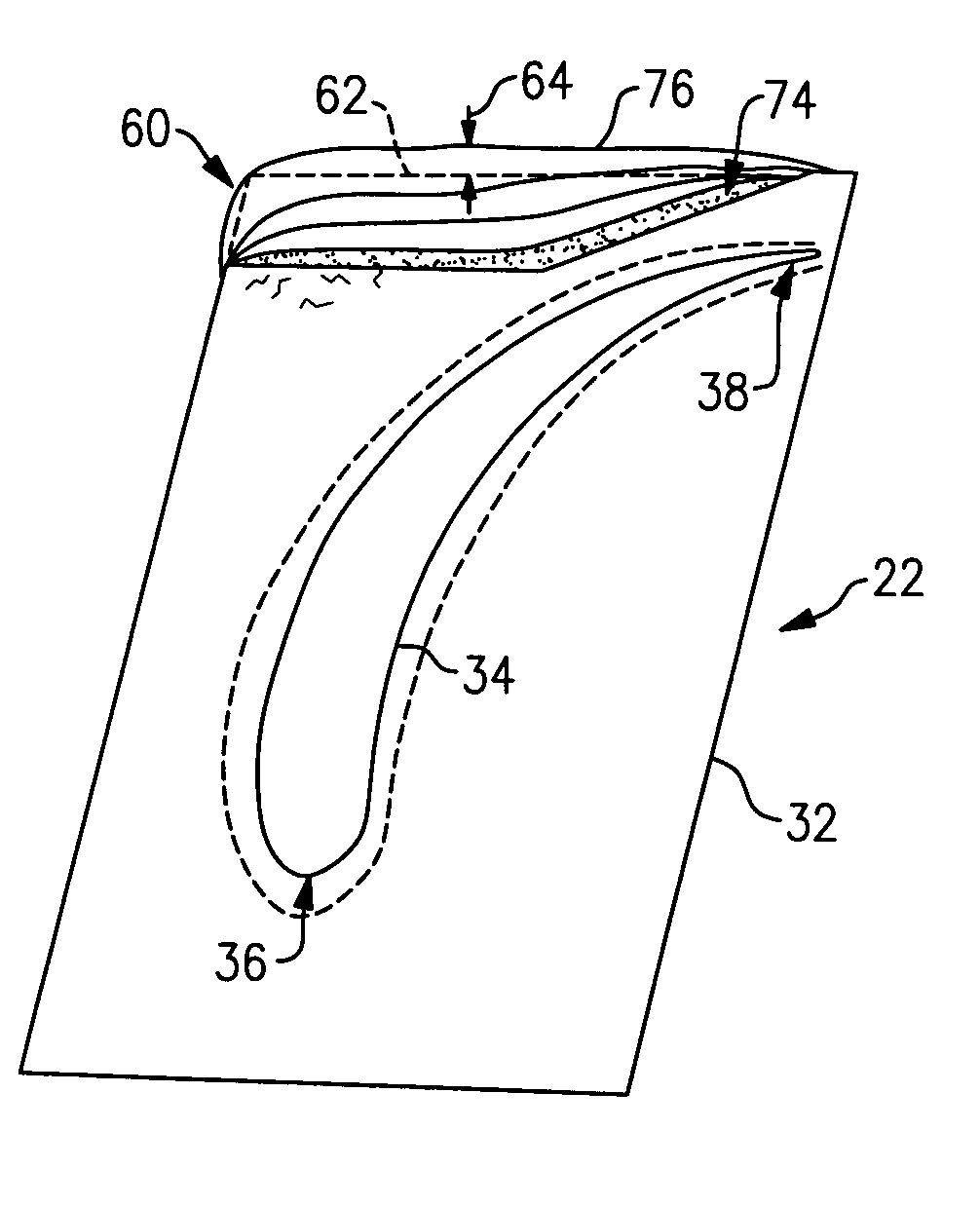

Turbine platform repair using laser clad

InactiveUS20070163115A1Prolong lifeImprove residual stressTurbinesBlade accessoriesTurbineGas turbines

A method of restoring a gas turbine engine component includes removing a defect section of a turbine engine component according to a template. The template has a standardized shape and is used in a standardized location on the turbine engine component. The template is produced based upon common defect sections from other turbine engine components. A laser cladding is used to build a replacement section in place of the defect section. Thus, the turbine engine component is restored to near its original shape.

Owner:UNITED TECH CORP

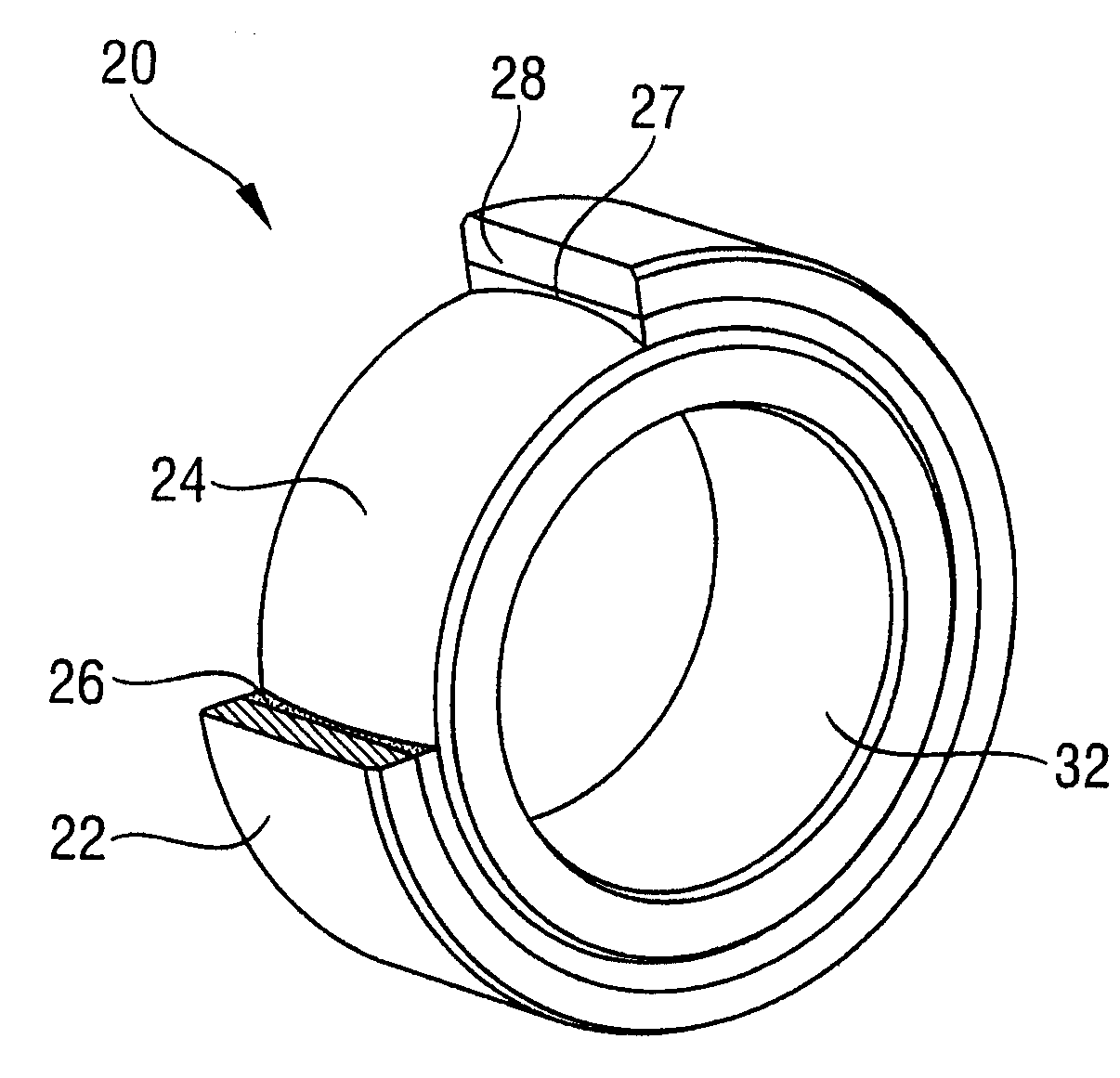

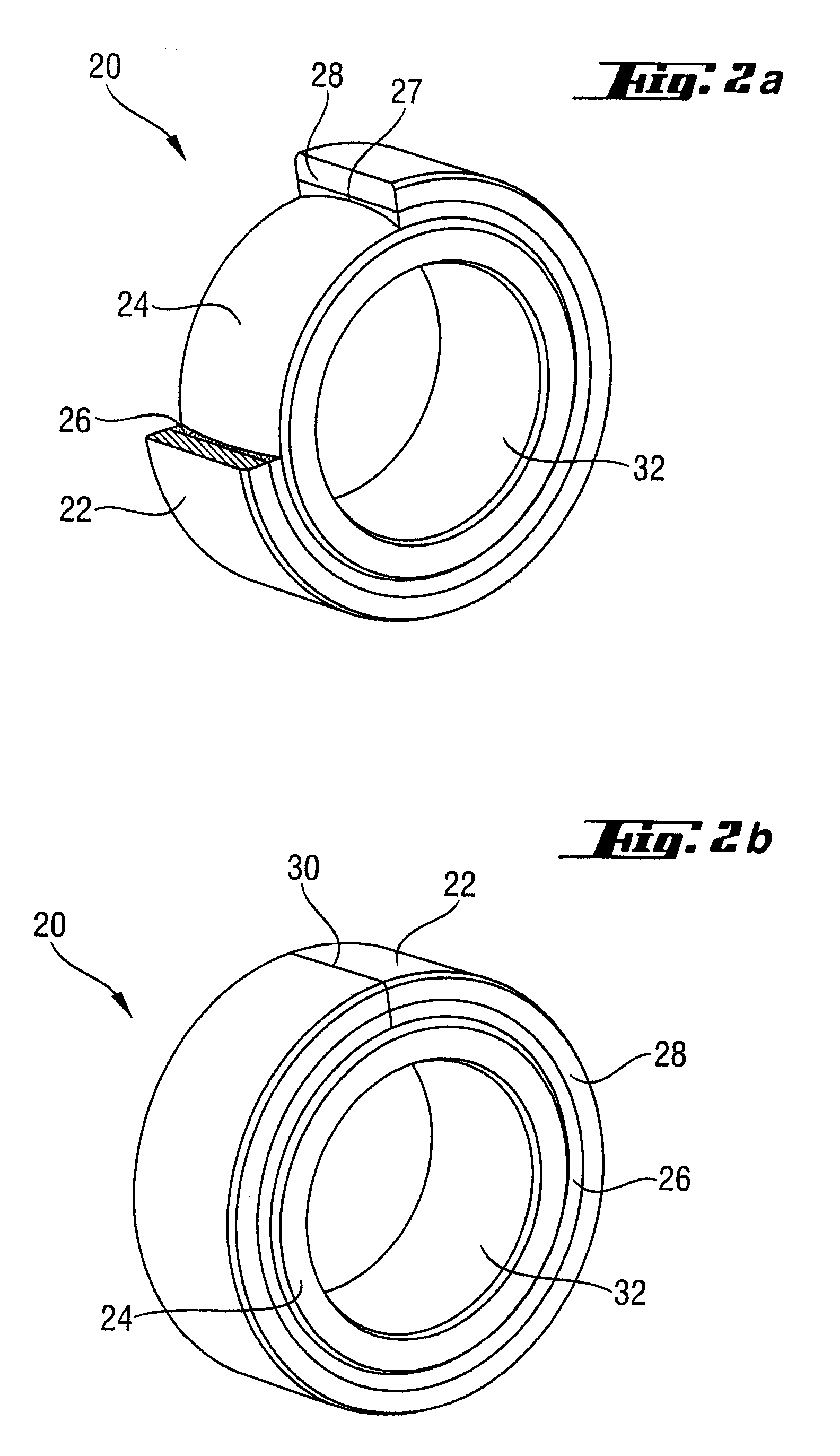

Universal joint bearing with plastic outer ring and procedure for its porduction

ActiveUS20080161117A1Excellent Adhesive PropertiesImprove mechanical propertiesYielding couplingRolling contact bearingsFiberUniversal joint

An outer race for a rocker bearing includes an internal sliding layer and an external support layer, wherein the sliding layer and the bearing layer are formed from a wound composite fiber material. The outer race is identified by exactly one parting line. A rocker bearing with such an outer race and a method for its production is also provided, in which a sliding layer and a support layer of synthetic resin impregnated fibers are wound in succession onto a winding mandrel, and outer races are formed after setting on the winding body thus produced. The sliding layer and the support layer are wound onto a cylindrical winding mandrel, and the outer race is provided with exactly one parting line opening it, and sliding layer material on its inside is removed to such an extent that a partially spherical contour is obtained for receiving a complementary inner race.

Owner:FEDERAL MOGUL DEVA

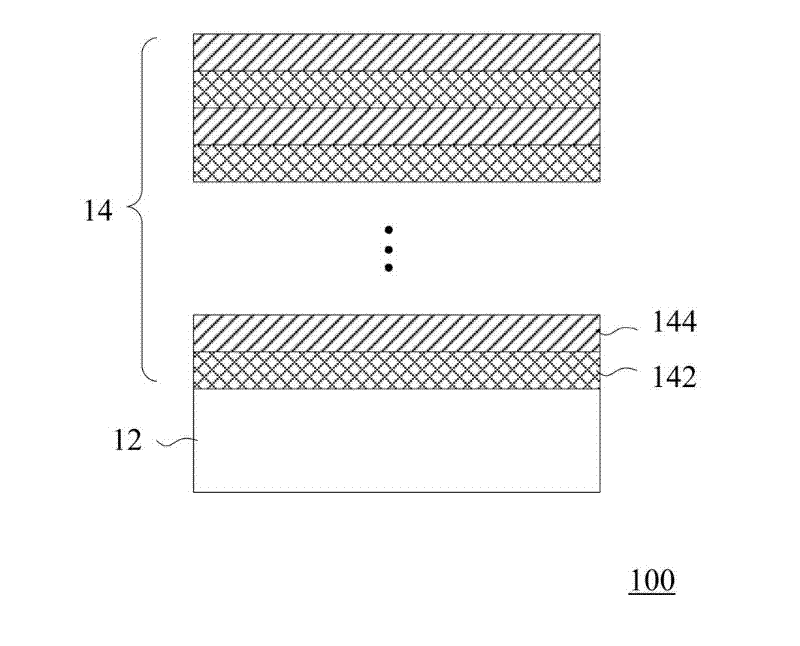

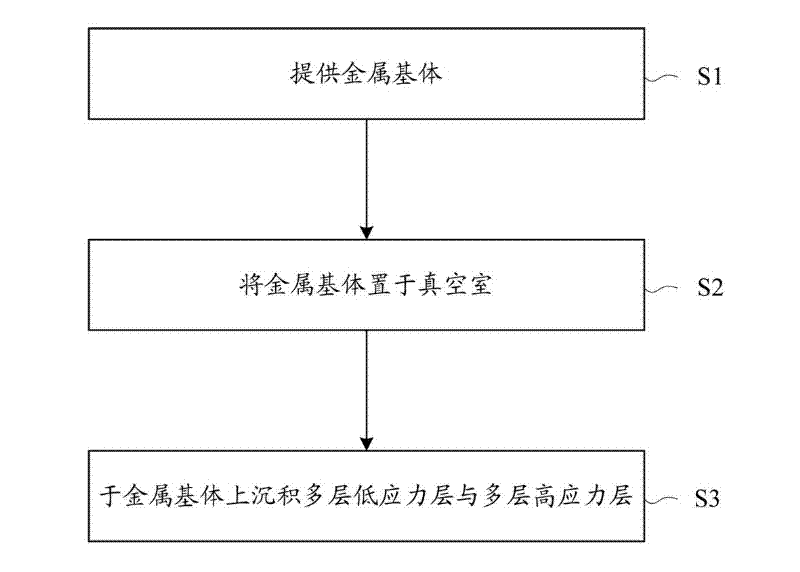

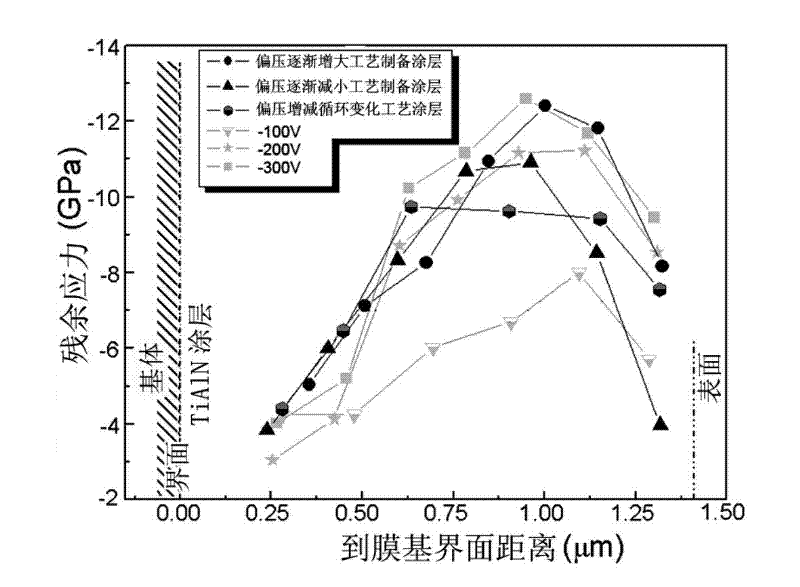

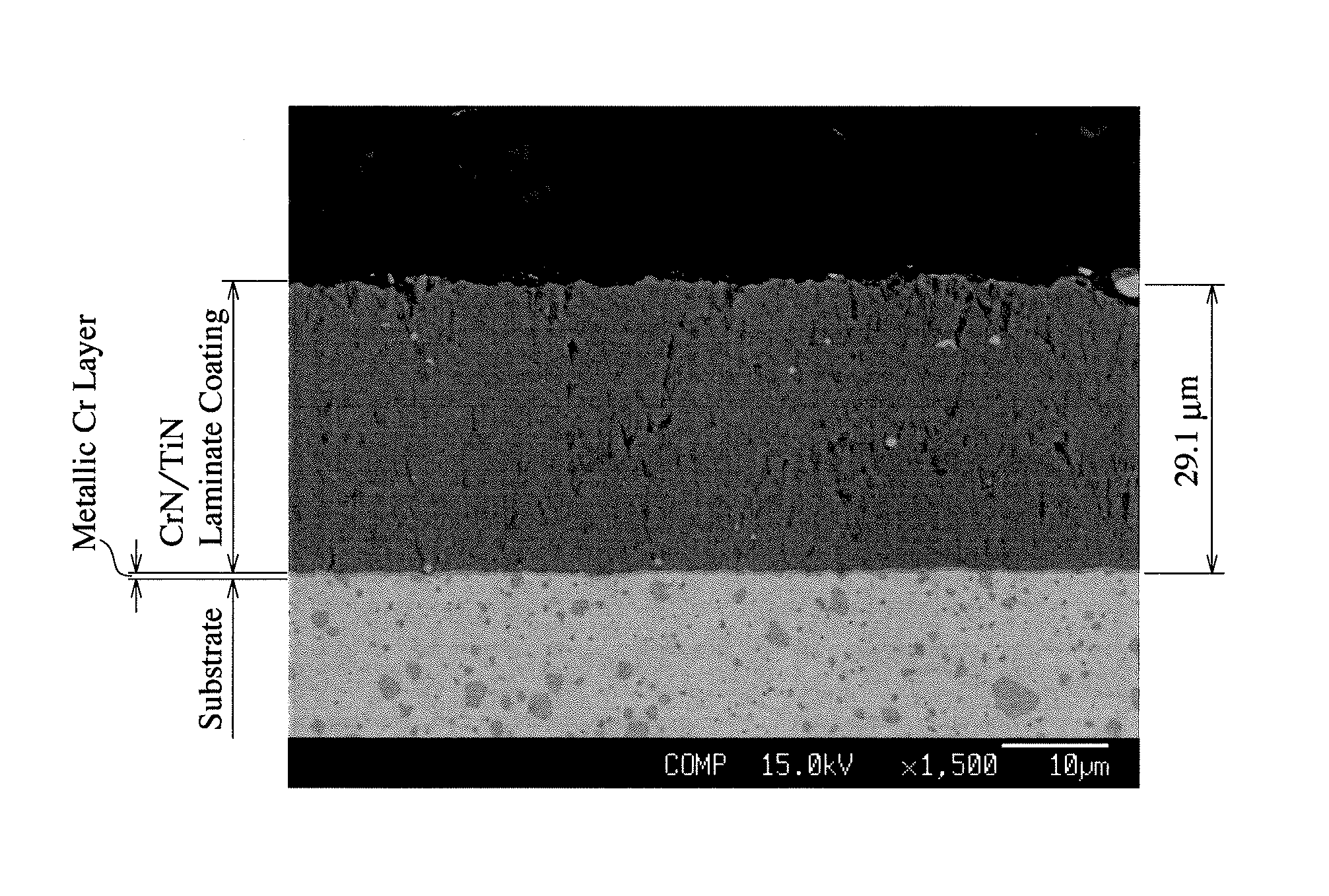

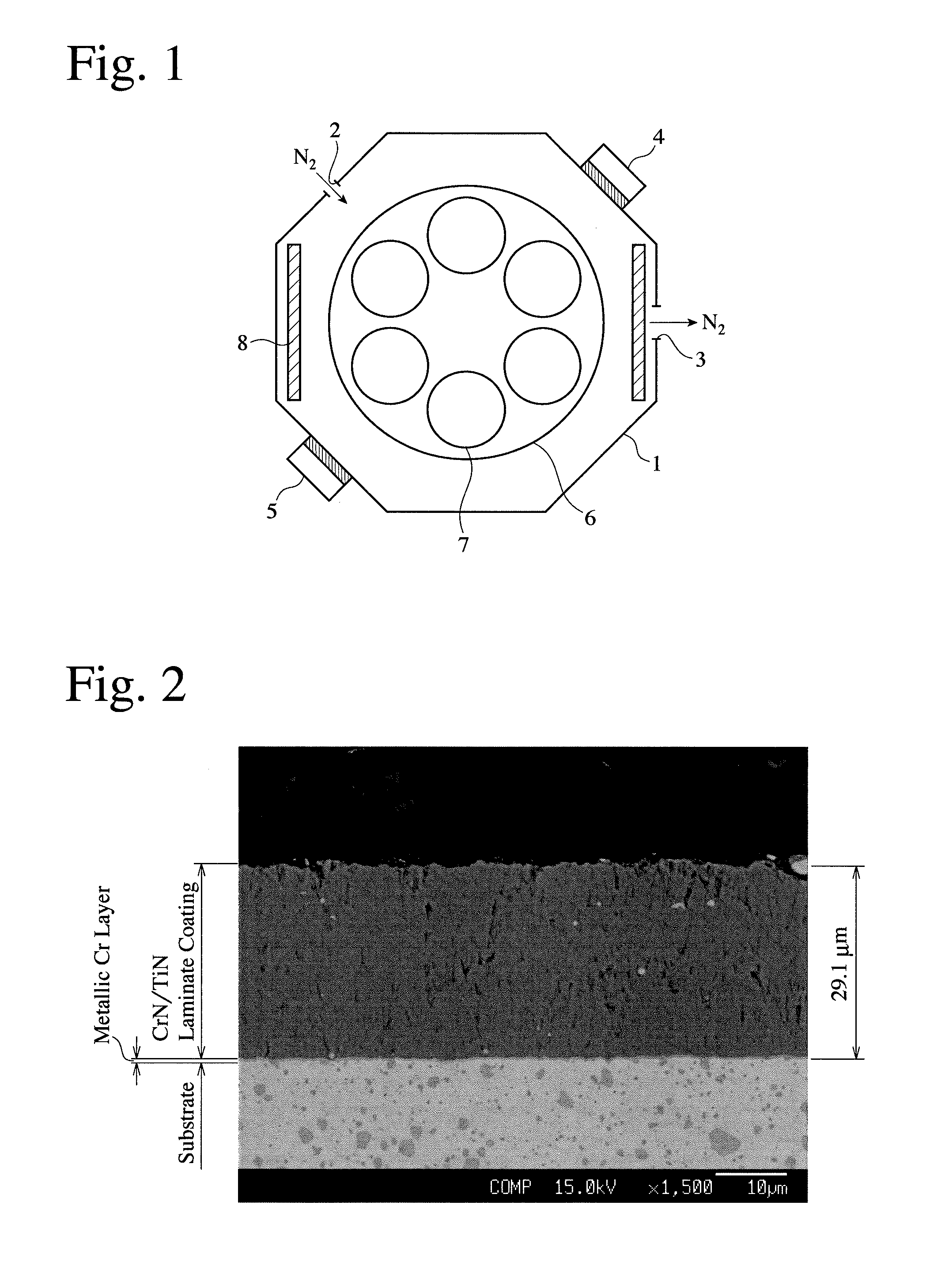

Hard coating and preparation method thereof

ActiveCN102634753AUniform stressImprove residual stressVacuum evaporation coatingSputtering coatingBonding strengthHardness

The invention relates to a hard coating and a preparation method thereof. The hard coating comprises multiple low stress layers and multiple high stress layers; the low stress layers and the high stress layers are alternatively formed on a metal matrix. The invention also provides a preparation method of the hard coating. The hard coating and the preparation method thereof of the invention can improve the residual stress distribution in the hard coating, and can increase the film-matrix bonding strength with the proviso that the high hardness and high wear resistance of the hard coating are maintained.

Owner:广东华升纳米科技股份有限公司

Superthin float glass

ActiveCN1712375AQuality improvementStable quality and increased yield of thin glassHardnessChemical stability

Super-thin float glass consists of SiO2 71.5-72.5wt%, Al2O3 1.3-2.5wt%, Fe2O3 0.04-0.9wt%, CaO 6.0-8.20wt%, MgO 4.3-5.0wt%, K2O 0.5-1.5wt%, and Na2O 11.0-13.4wt%. Its advantages include higher transmittance and elastic modulus, better hardness and quality, and no production defect.

Owner:CLFG LONGHAI ELECTRONICS GLASS

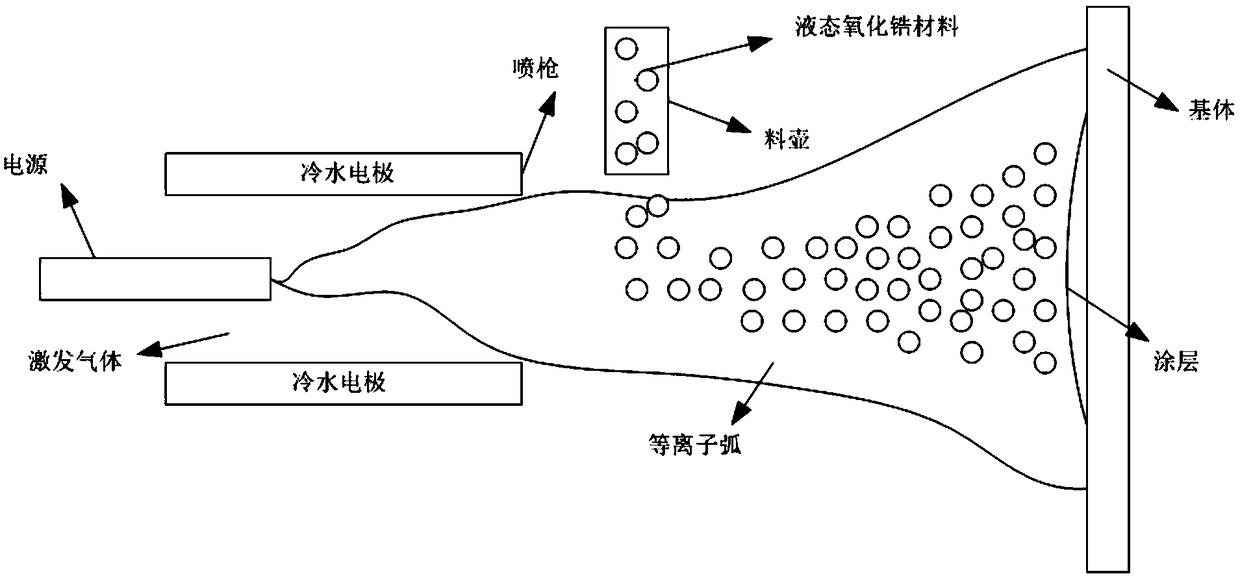

Zirconia ceramic coating and preparation method thereof

PendingCN109437892AImprove bindingThe binding effect is not enough to meet the strength goodMolten stateExtensibility

The invention belongs to the technical field of plasma arc spraying and particularly relates to a zirconia ceramic coating with high hardness, wear resistance, toughness and extensibility and a preparation method of the zirconia ceramic coating. The method comprises the following steps: (1.1) selecting a substrate; (1.2) performing sand blast or frosted pretreatment on the substrate; (1.3) preparing zirconia raw material powder; (1.4) heating the sintered zirconia nano-powder to a molten state; (1.5) spraying a liquid zirconia nanomaterial to form the liquid zirconia ceramic coating. The corestep lies in melting before spraying of the liquid zirconia nanomaterial, in the traditional alumina spraying technology, alumina nanoparticles are directly placed into a spray gun for heating spraying, however, a combination effect cannot meet demands for sufficient strength and adhesion. In the method, the sintered powder is molten into the molten state before spray gun charging, the defect is overcome, and comprehensive parameters such as strength, hardness and toughness of the ceramic coating are obviously better than those in the common spraying technology.

Owner:陈涛

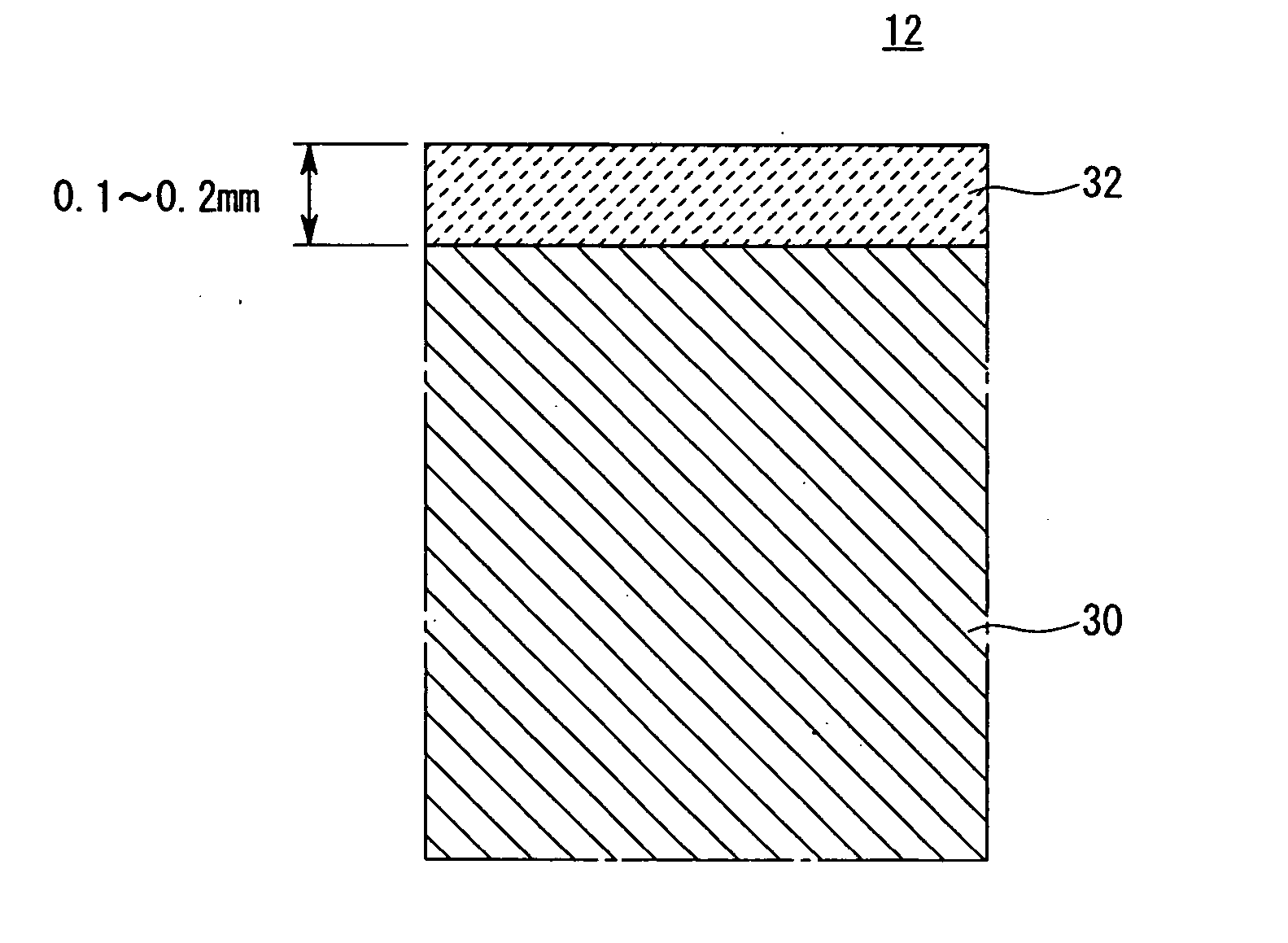

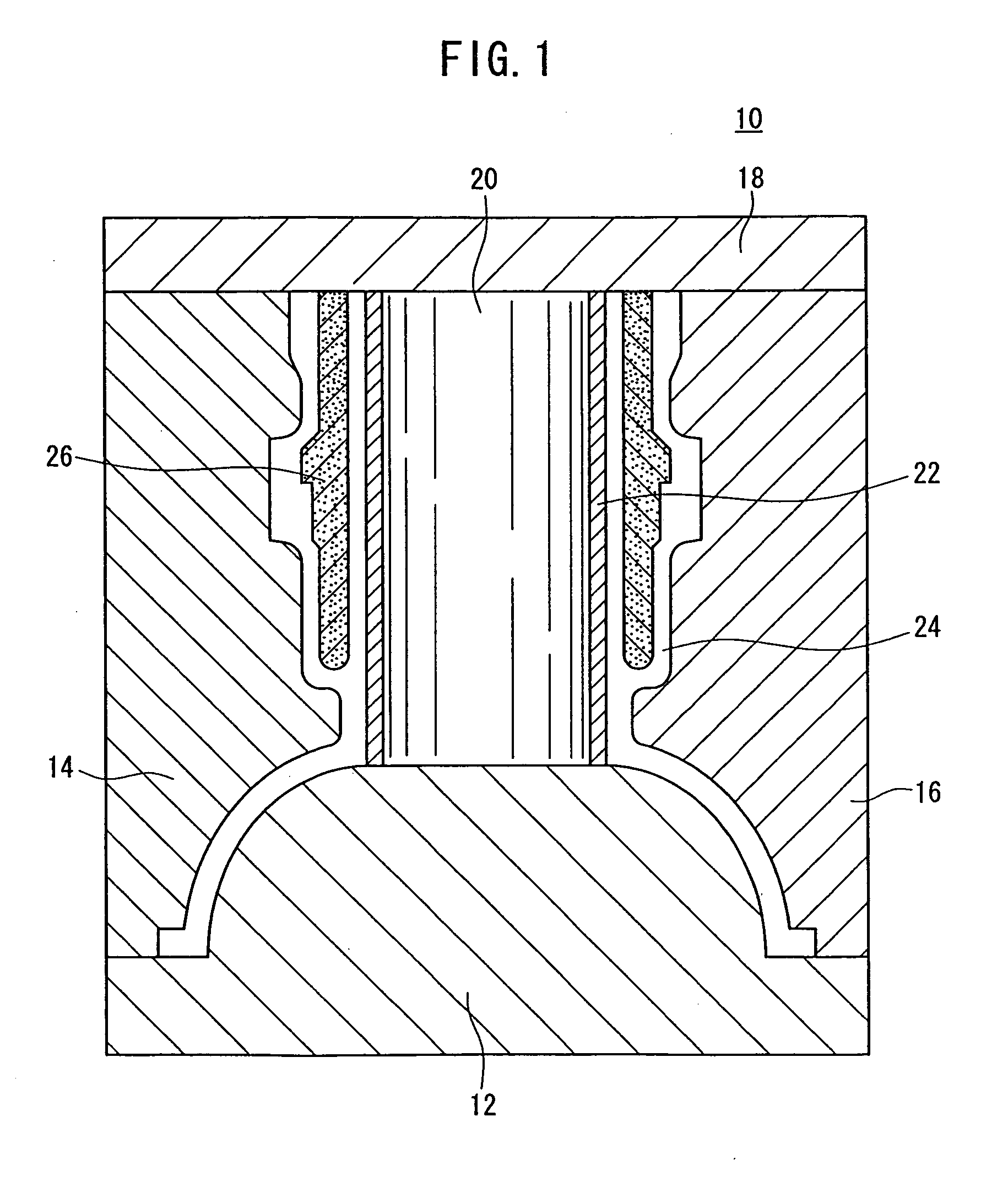

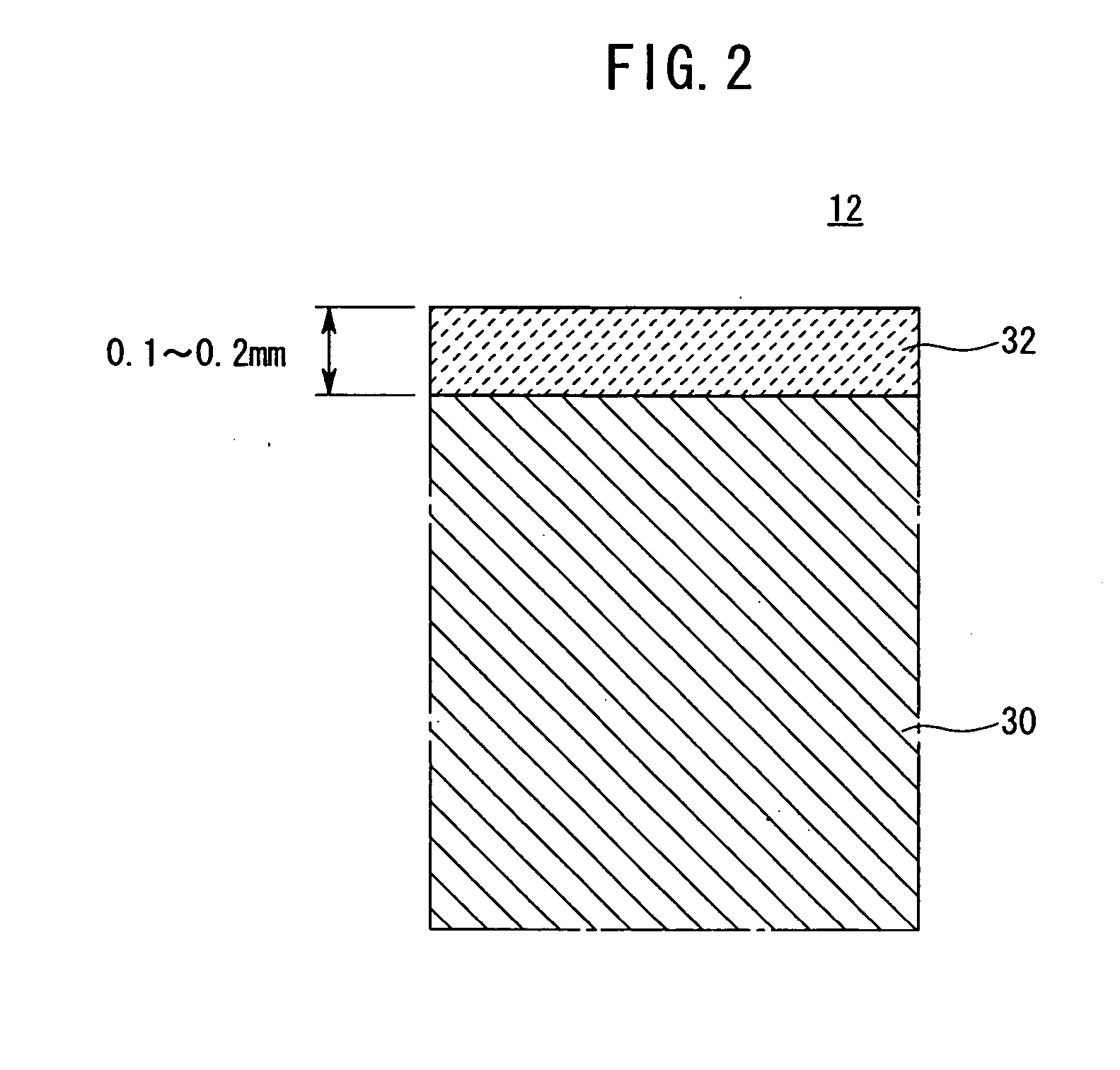

Multilayer thermal barrier coating

InactiveUS8216689B2Improve residual stressLiquid surface applicatorsMolten spray coatingThermal barrier coatingZirconium oxide

Components (1) have a thermal barrier coating (2-6) on the surface thereof, wherein the thermal barrier coating includes at least one layer (3) having chemically stabilized zirconia, and wherein at least indirectly adjacent to the layer (3) with chemically stabilized zirconia and on its surface facing side, there is provided a protective layer (4) and / or a infiltration zone (5) which does not react with environmental contaminant compositions that contain oxides of calcium and which does not react with the material of the layer (3) having chemically stabilized zirconia. Methods for making such components as well as to uses of specific systems for coating thermal barrier coatings, can prevent CMAS.

Owner:ANSALDO ENERGIA IP UK LTD +1

Cemented carbide extrusion molding adhesive and preparation thereof

InactiveCN101372556ADegreasing good shape retentionImprove the shortcomings of difficult degreasing and long degreasing timeParaffin waxAdhesive

The invention relates to a binder, in particular to a binder for extrusion molding of a hard alloy and a preparation method thereof. The binder is made from the following components by weight percentage: 65-80% of paraffin wax, 10-20% of styrene butadiene rubber, 3-5% of dibutyl phthalate, 3-5% of rapeseed oil, 3-5% of stearic acid, and the rest of organic solvents. The preparation method is as follows: the styrene butadiene rubber is dissolved into the organic solvents at normal temperature to prepare a rubber solution for spare use; the paraffin wax is added to a blender and heated to the temperature of 65-75 DEG C for melting, and then added with the dibutyl phthalate, the rapeseed oil, the stearic acid and the rubber solution and stirred for 2-5min to obtain the binder. The binder has the advantages of available and cheap raw materials, simple preparation process, good degreasing and shape retention properties, short degreasing time, improving the production efficiency and saving the production cost.

Owner:JINAN INSTITUTE OF METALLURGICAL SCIENCE CO LTD

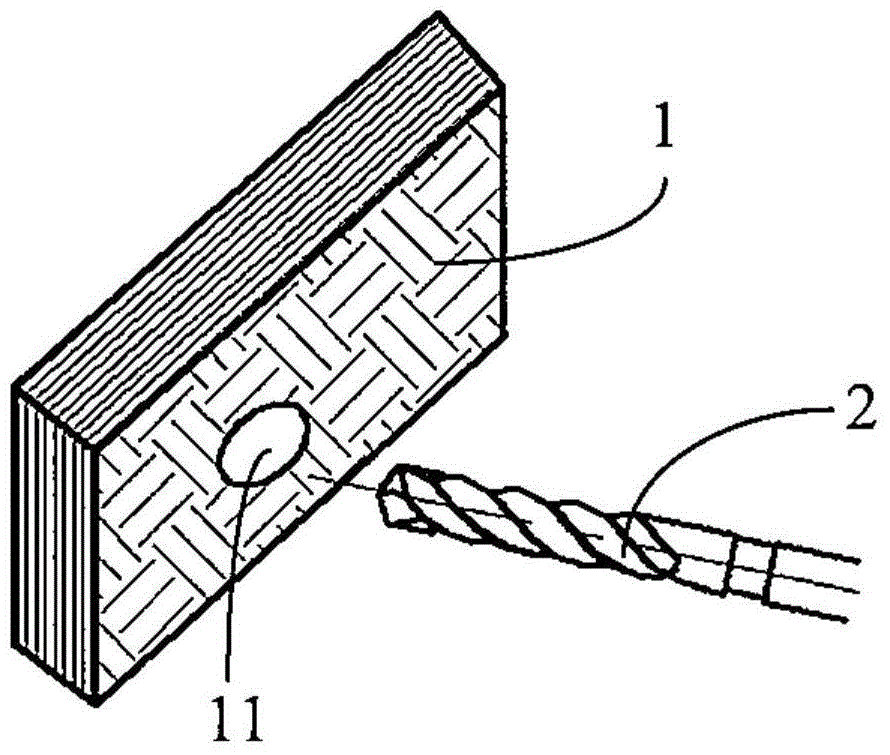

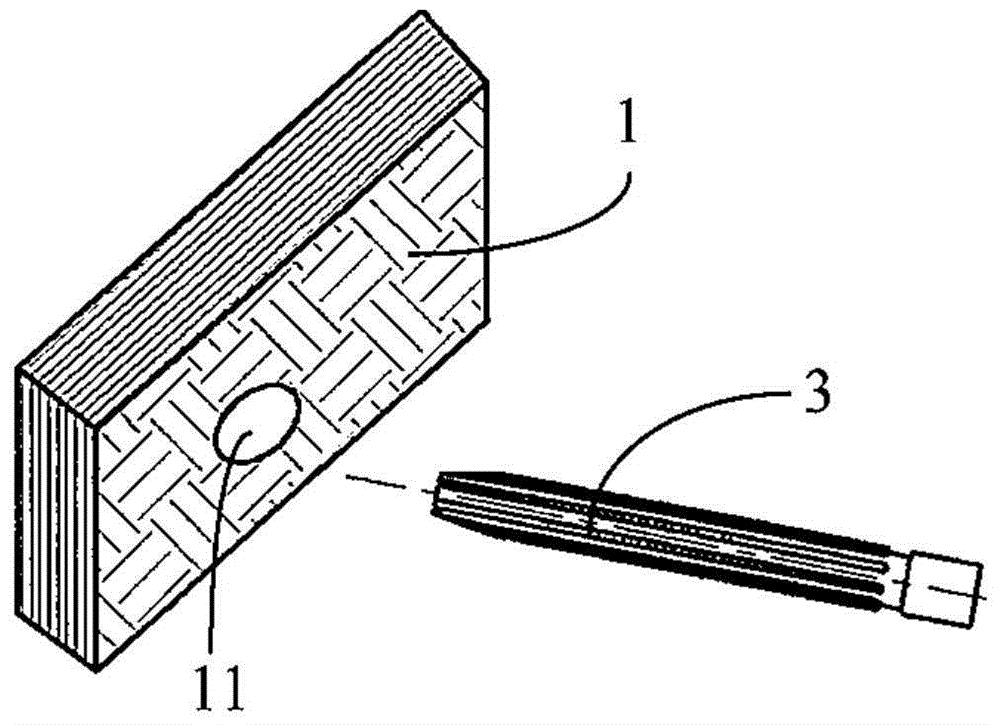

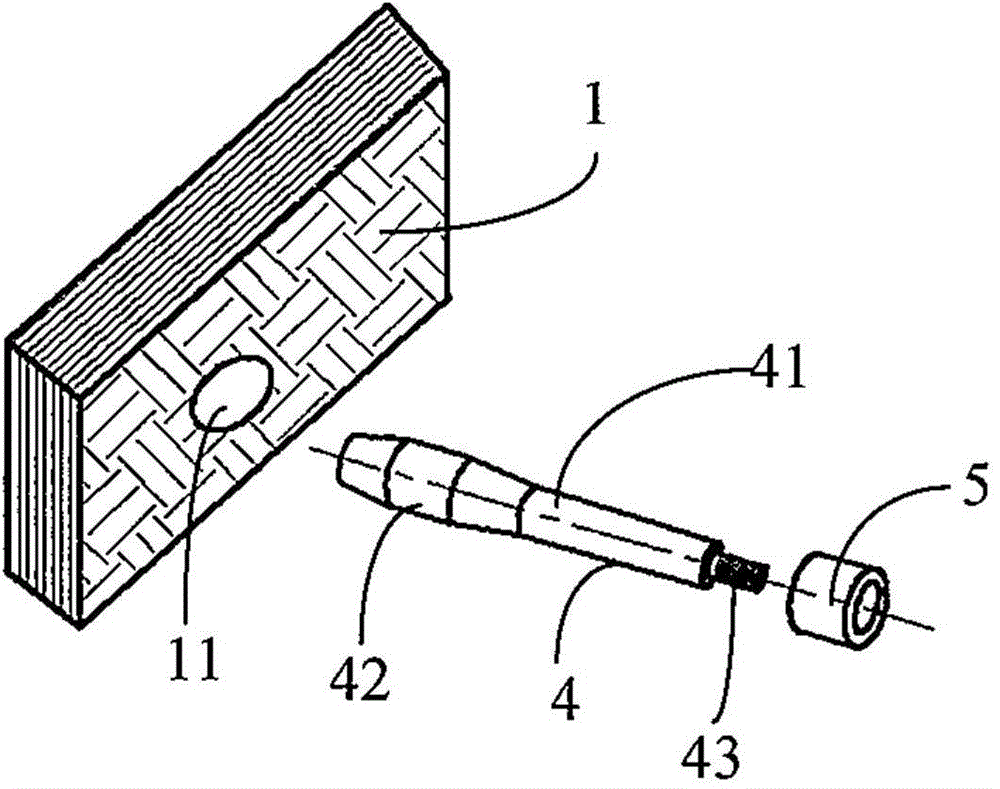

Cold extrusion strengthening method for assembling hole of CFRP composite material laminate

InactiveCN104626726AImprove fatigue lifeEasy maintenanceLamination ancillary operationsLaminationEngineeringAxial force

The invention provides a cold extrusion strengthening method for an assembling hole of a CFRP composite material laminate. The method comprises the following steps: (a) providing a bush, wherein the bush can be assembled in the assembling hole; (b) providing a metal core rod with the taper, and inserting the core rod into the bush; (c) arranging the bush in the assembling hole; (d) applying axial force to the core rod by virtue of extrusion equipment, so that the bush is extruded by the part, with the largest diameter, of the core rod; and (e) removing the core rod, so that the bush is fixedly arranged in the assembling hole. Aiming at the assembling hole of the CFRP composite material laminate, the bush is adopted and is matched with a cold extrusion strengthening process, so that the fatigue life of parts can be effectively prolonged, and the service time of an aircraft is prolonged. Because the bush is fastened in the assembling hole, the wear resistance of the connecting structure is improved, and the detachment of assembling fasteners and the maintenance of the parts can be promoted.

Owner:COMAC +1

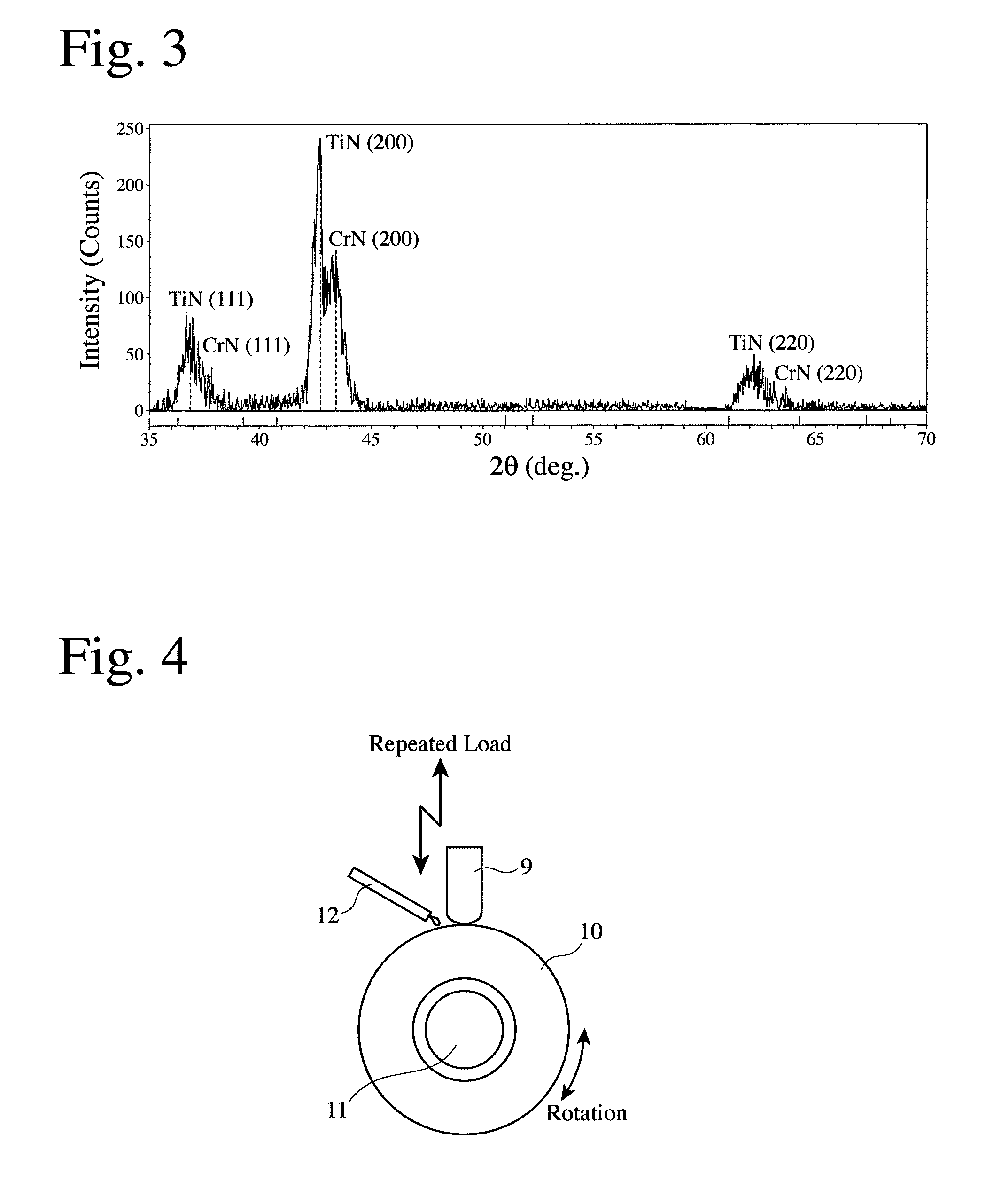

Piston ring

ActiveUS20150308573A1Easy to peelImprove wear resistancePiston ringsBraking action transmissionCADA compoundPiston ring

To provide a piston ring having a hard laminate coating for excellent scuffing resistance, wear resistance and peeling resistance, which can be used in an environment of high mechanical and thermal load in engines, the piston ring is provided with a hard laminate coating as thick as 10-60 μm on its outer peripheral surface, the laminate coating being formed by alternately laminating two types or more of layers made of different compounds, each of the compound layers being made of nitride of at least one metal selected from the group consisting of Ti, Cr, Zr, V, Hf and Al.

Owner:RIKEN CO LTD

Method for surface treatment of a die-casting die

InactiveUS20130042992A1Improve wear resistanceHigh hardnessFoundry mouldsCeramic shaping apparatusHeat resistanceDie casting

The present invention is to provide a method for surface treatment that substantially provides no nitride compound layer that causes heat checks and abrasion to a die, while nitride is introduced in large quantities into the die internally, and as a result a die-casting die with excellent heat check resistance and excellent abrasion resistance can be produced. The method comprises a step of a nitriding process for forming on an aesthetic surface of the die-casting die a nitrided layer that includes at least a compound layer composed of a nitrogen compound by introducing gas containing at least ammonia gas to a heating furnace, a step of decomposing the compound by exhausting the ammonia gas from the heating furnace and for introducing ambient gas to the heating furnace, to carry out a thermal process to decompose the nitrogen compound, and a step of processing a shot peening process on the aesthetic surface of the die. The thickness of the compound layer contained in the nitrogen layer that is formed in the step of nitriding process is within the range of from 2∫m to 7∫m.

Owner:SINTOKOGIO LTD

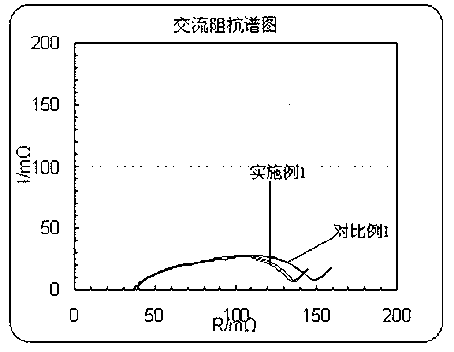

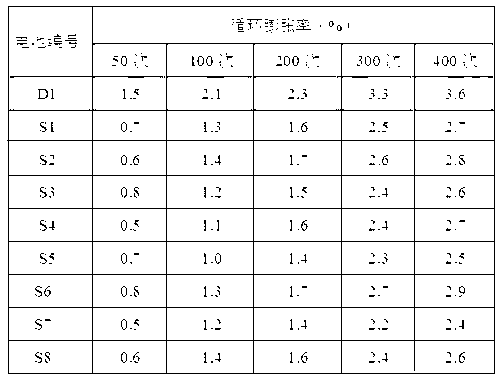

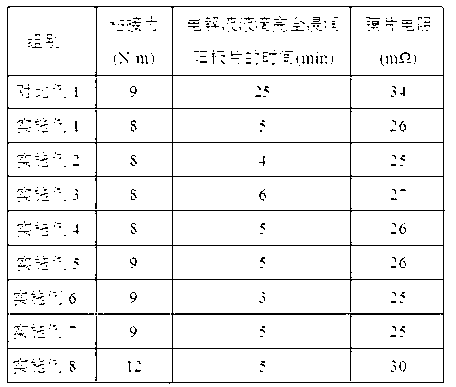

Making method of lithium ion battery anode sheet

ActiveCN103178241AGood flexibilityReduce the number of defective productsElectrode manufacturing processesHigh absorptionAdhesive

The invention belongs to the technical field of lithium ion batteries, and especially relates to a making method of a lithium ion battery anode sheet. The method comprises the following steps: 1, anode slurry preparation: adding an anode active substance, an aqueous thickening agent, an aqueous adhesive and a conductive agent to water, and uniformly stirring to prepare an anode slurry; 2, anode sheet preparation: uniformly coating the anode slurry on an anode current collector, and drying in a 60-120DEG C drying box to prepare an anode sheet; and 3, anode sheet post-treatment: carrying out secondary baking softening treatment of the anode sheet obtained in step 2 in a 250-450DEG C environment. Compared with anode sheets made through the prior art, the anode sheet made through adopting the method has the characteristics of good flexibility, high absorption performance, low impedance and the like; and a lithium ion battery containing the anode sheet made through adopting method has the characteristics of good low temperature discharge performance, long cycle life, and low cycle thickness expansion rate.

Owner:DONGGUAN AMPEREX TECH

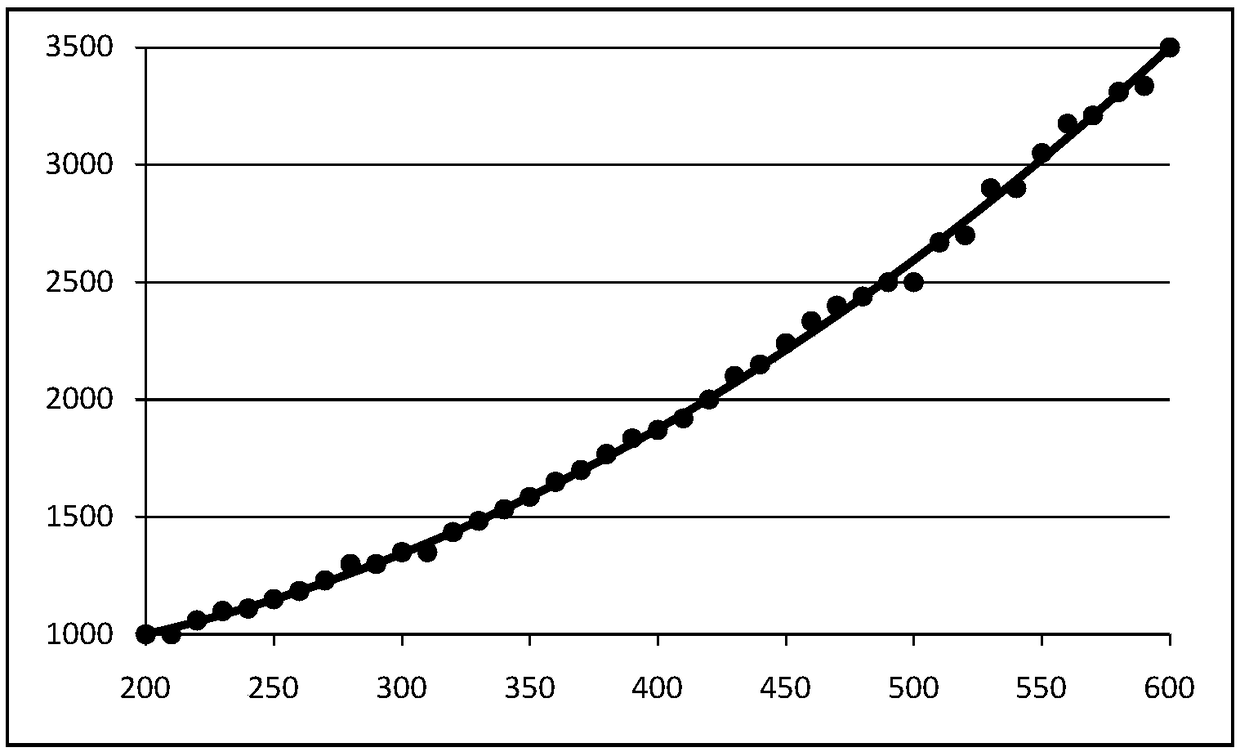

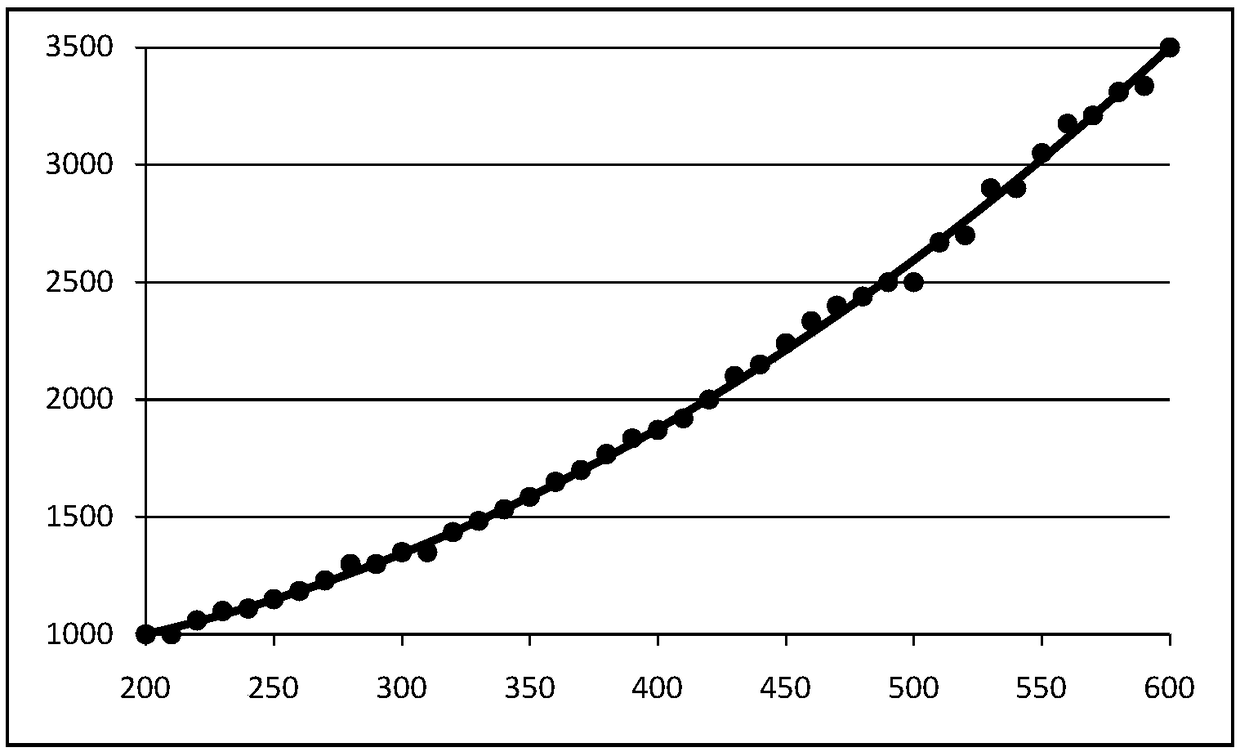

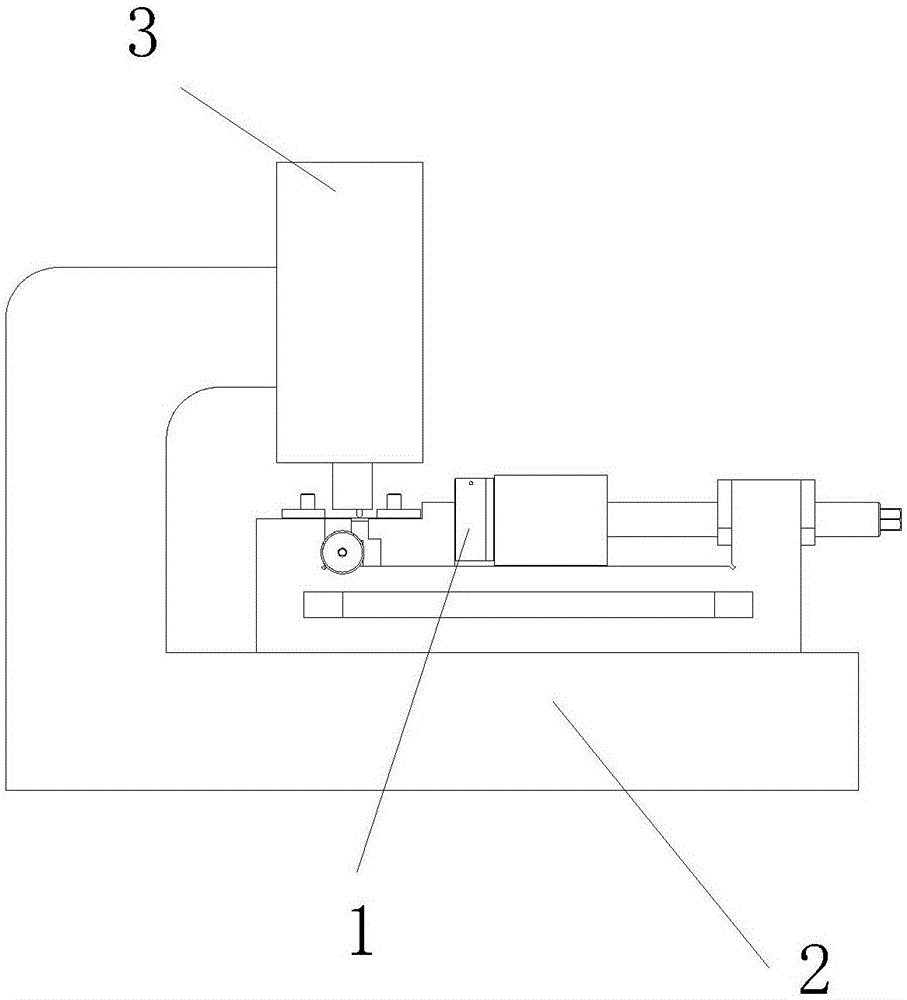

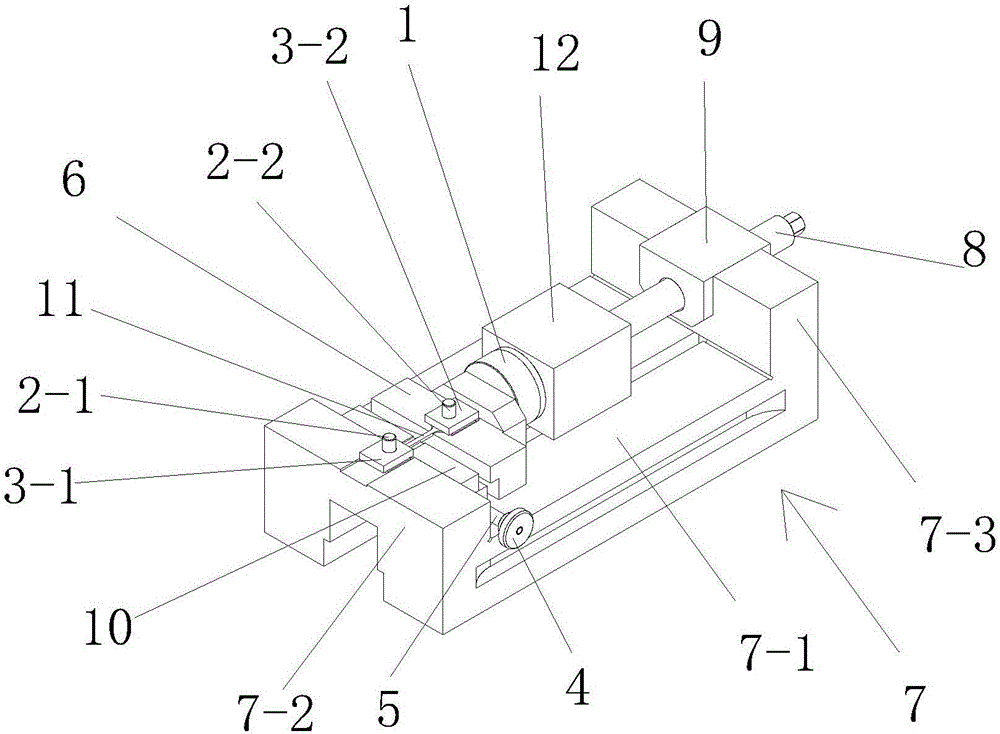

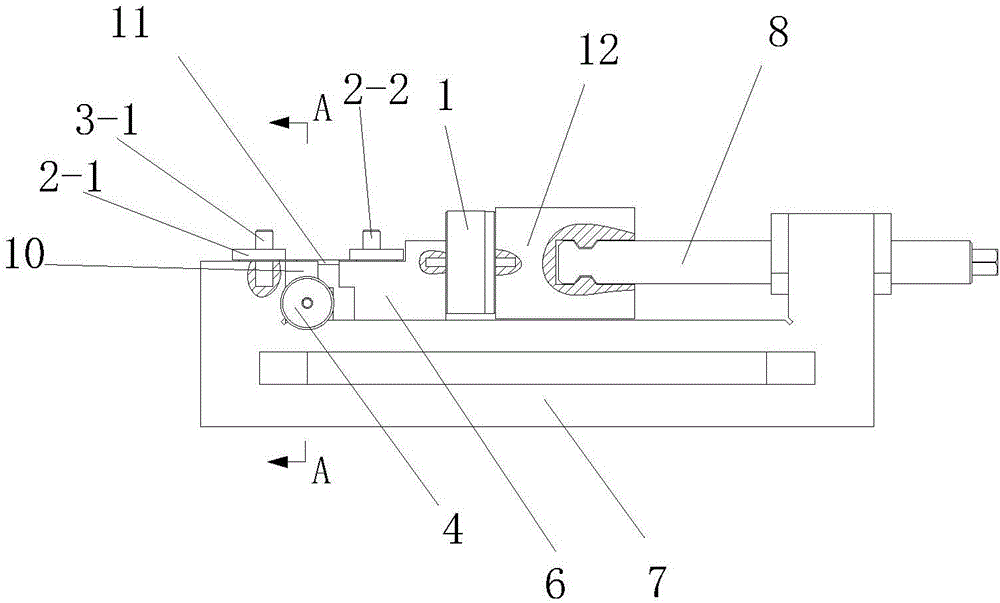

Device and method for testing relation between residual stress and surface hardness of metal component

ActiveCN106769574ASimple structureReasonable designApparatus for force/torque/work measurementProcess efficiency improvementHardnessSimulation testing

The invention discloses a device and method for testing the relation between residual stress and surface hardness of a metal component. The device comprises a testing mechanism, a residual stress simulation testing device, a hardness detection module and a monitoring device. The method comprises a method for testing the relation between residual pressure stress and the surface hardness of the metal component and a method for testing the relation between residual tensile stress and the surface hardness of the metal component. The method for testing the relation between the residual pressure stress and the surface hardness of the metal component comprises the following steps: (1) mounting and positioning a tested component; (2) carrying out simulation loading on the residual pressure stress, and acquiring simulation loading capacity of the residual pressure stress and the surface hardness; and (3) acquiring a relation curve between the residual pressure stress and the surface hardness. According to the device and the method, the relation between the residual stress and the surface hardness of the metal component is established so as to provide basis for researching the residual stress of the metal component according to the surface hardness of the metal component.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com