Composite brazing material for connecting Si3N4 ceramic and 42CrMo steel and brazing method by using same

A composite solder and ceramic technology, which is applied in the direction of welding/welding/cutting articles, welding/cutting media/materials, welding media, etc., can solve the problems of high residual stress and low joint strength, achieve broad prospects, improve strength, The effect of good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

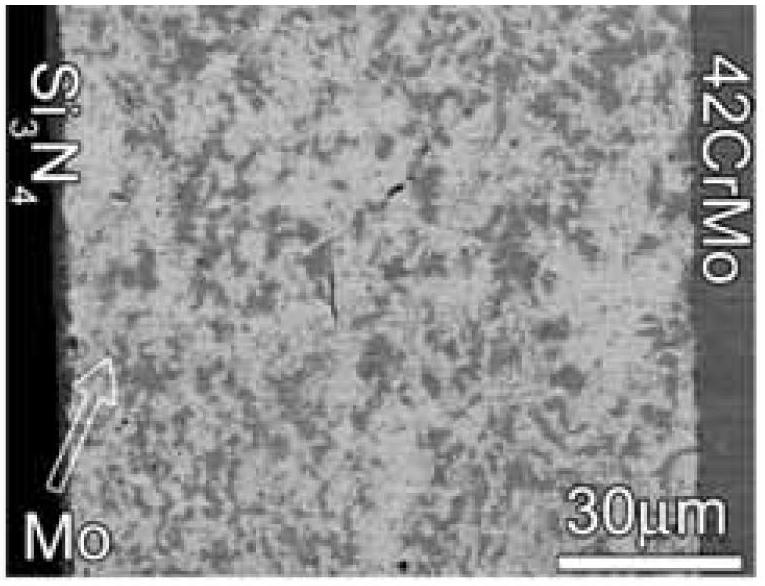

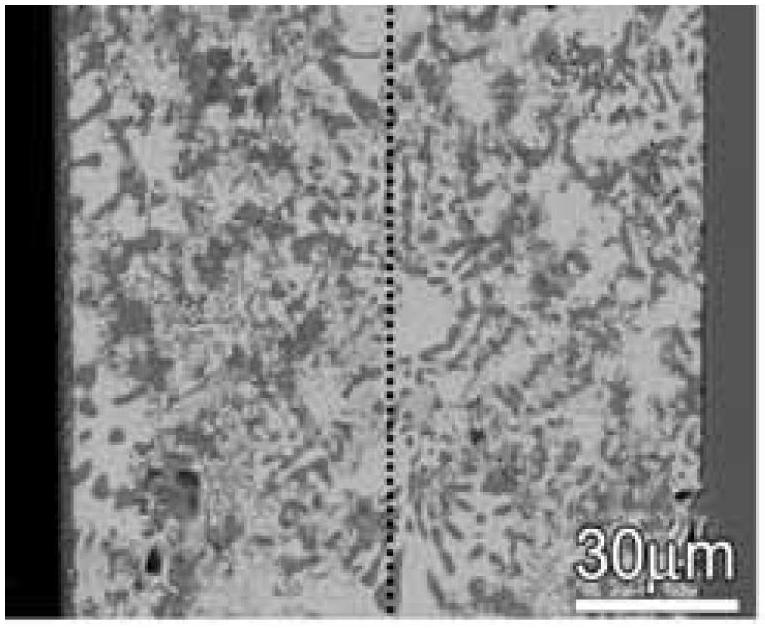

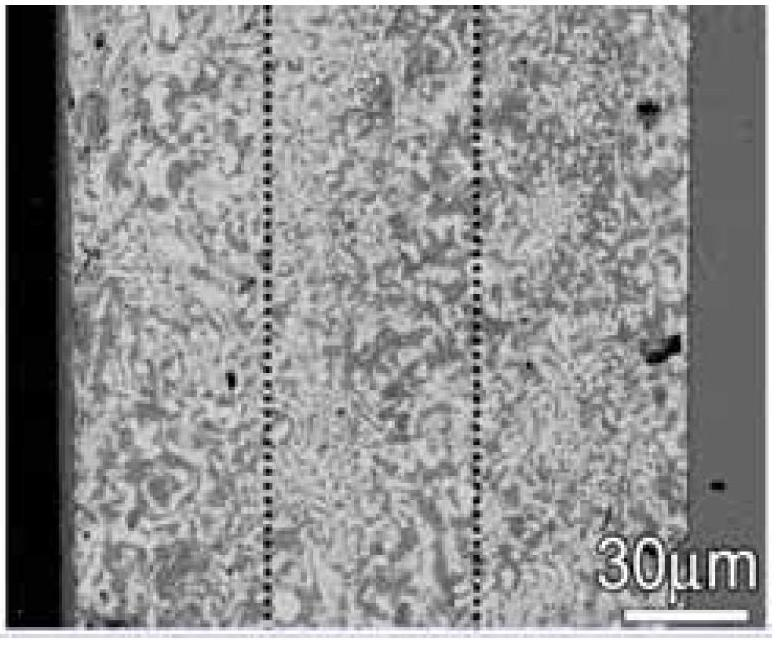

[0040] Specific implementation mode 1: This implementation mode is used to connect Si 3 N 4 The composite solder of ceramics and 42CrMo steel is composed of mixed powder and reinforcing phase; the mixed powder is composed of 60%-75% Ag powder, 20%-35% Cu powder and 3%-6% Ti powder ; The reinforcing phase is Mo powder or WC powder accounting for 5% to 40% of the volume of the mixed powder.

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment one is that it is used to connect Si 3 N 4 The composite solder of ceramics and 42CrMo steel is composed of mixed powder and reinforcing phase; the mixed powder is composed of 65%-73% Ag powder, 22%-30% Cu powder and 4%-5.5% Ti powder. ; The reinforcing phase is Mo powder or WC powder accounting for 10% to 30% of the volume of the mixed powder.

specific Embodiment approach 3

[0042] Specific embodiment three: this embodiment adopts the method for connecting Si described in specific embodiment one 3 N 4 The method that the composite solder of ceramics and 42CrMo steel carries out brazing is to realize through the following steps:

[0043] 1. Mix 60% to 75% of Ag powder, 20% to 35% of Cu powder and 3% to 6% of Ti powder according to mass percentage to obtain mixed powder;

[0044] 2. Add a reinforcing phase accounting for 5% to 40% of the volume of the mixed powder to the mixed powder to obtain powder A, and then put the powder A into a ball mill tank and perform ball milling at a speed of 200 to 300r / min for 1 to 10 hours to obtain Composite solder;

[0045] 3. Mix the composite solder and hydroxyethyl cellulose into a paste, and dry it at a temperature of 20-100°C to form a composite solder sheet with a thickness of 80-260 μm;

[0046] Four, the Si 3 N 4 The surface to be welded of ceramics and 42CrMo steel was ultrasonically cleaned with acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com