Patents

Literature

83 results about "Free wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based shrinkage-free wall hole-penetrating blocking material and preparation method and construction method

ActiveCN103159440AGuaranteed tightnessPrevent infiltrationBuilding material handlingBuilding insulationsEtherFree wall

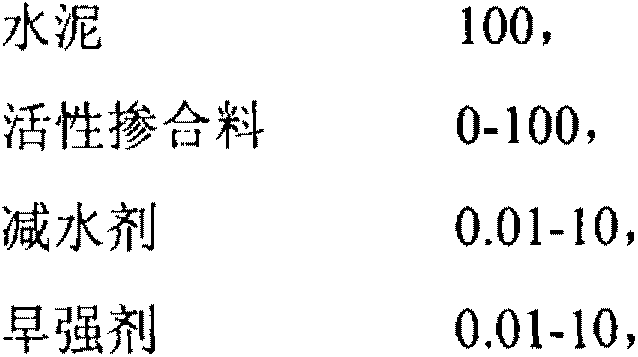

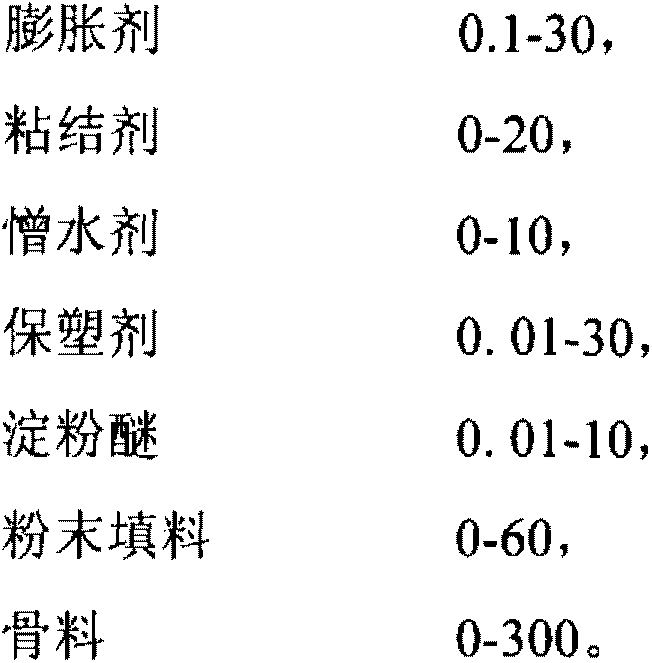

The invention relates to cement-based shrinkage-free wall hole-penetrating blocking materials and a preparation method and a construction method. The materials comprise, by weight, 100 cement, 0-100 active admixture, 0.01-10 water reducing agent, 0.01-10 early strength agent, 0.1-30 expanding agent, 0-20 adhesion agent, 0-10 water repellent, 0.01-30 plastic retaining agent, 0.01-10 starch ether, 0-60 power filler and 0-300 aggregate. Compared with the prior art, the cement-based shrinkage-free wall hole-penetrating blocking materials have the advantages of being good in construction performance, and long in operational time. New mixing slurry has good plasticity, adhesive power and anti-falling performance, a caulking gun or a caulking machine can be used for pressing, injecting or sealing holes, a flowing phenomenon cannot appear even big holes are filled, and the big holes can be filled until the big holes are full and until reaching the deep hole, and completely sealed, and the sealing materials can fully come into play.

Owner:杭州固特建筑加固技术工程有限公司

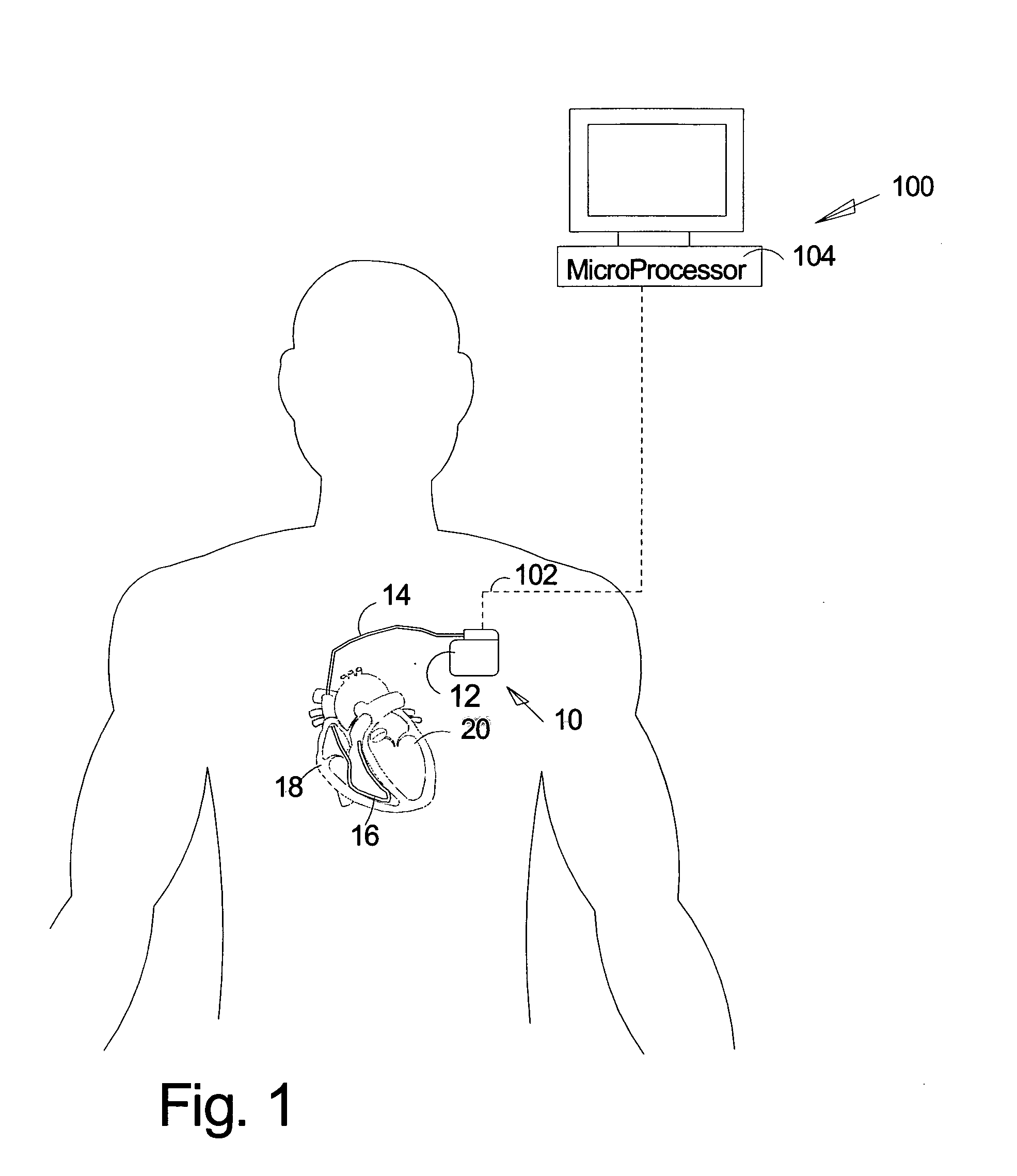

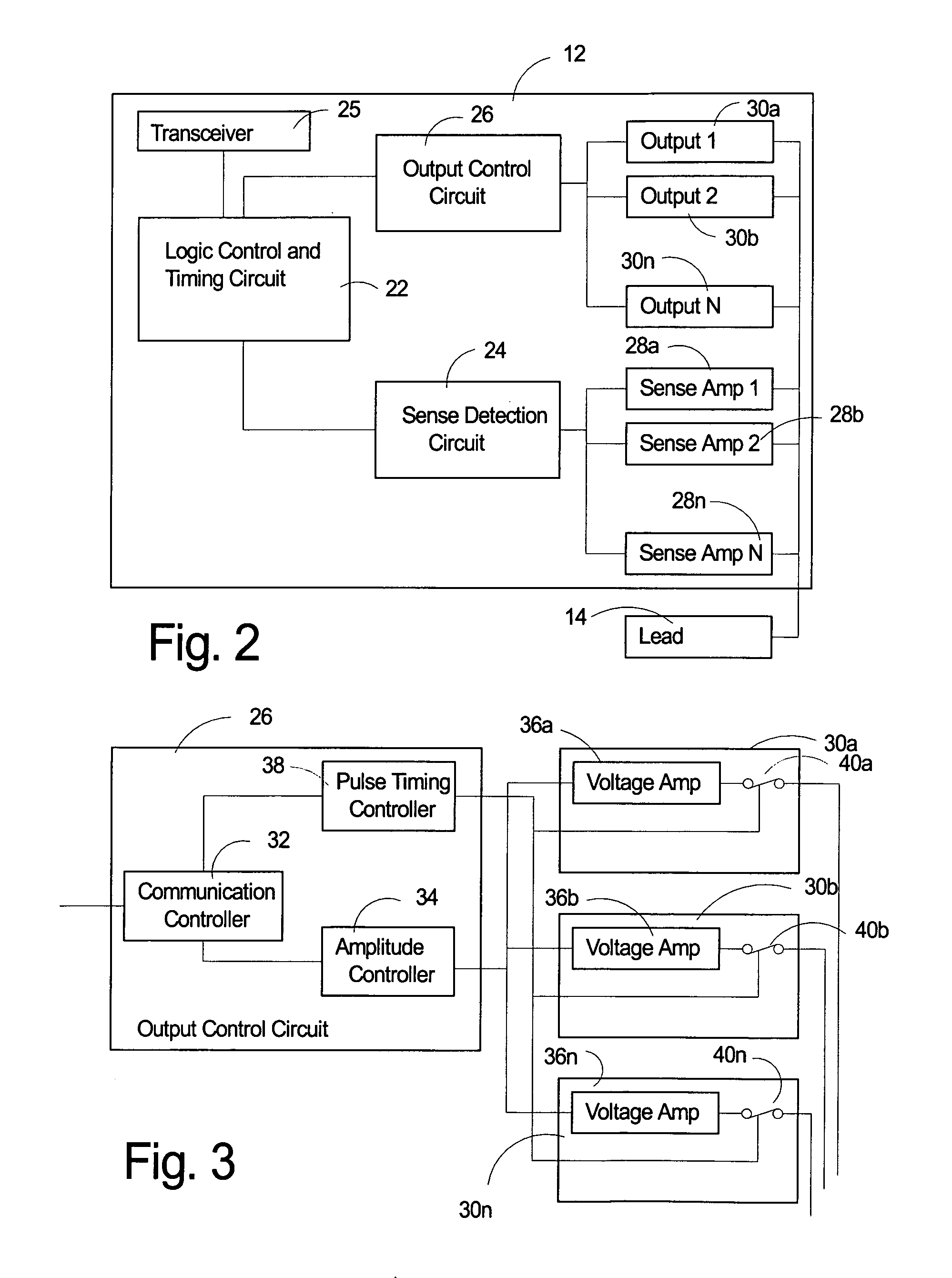

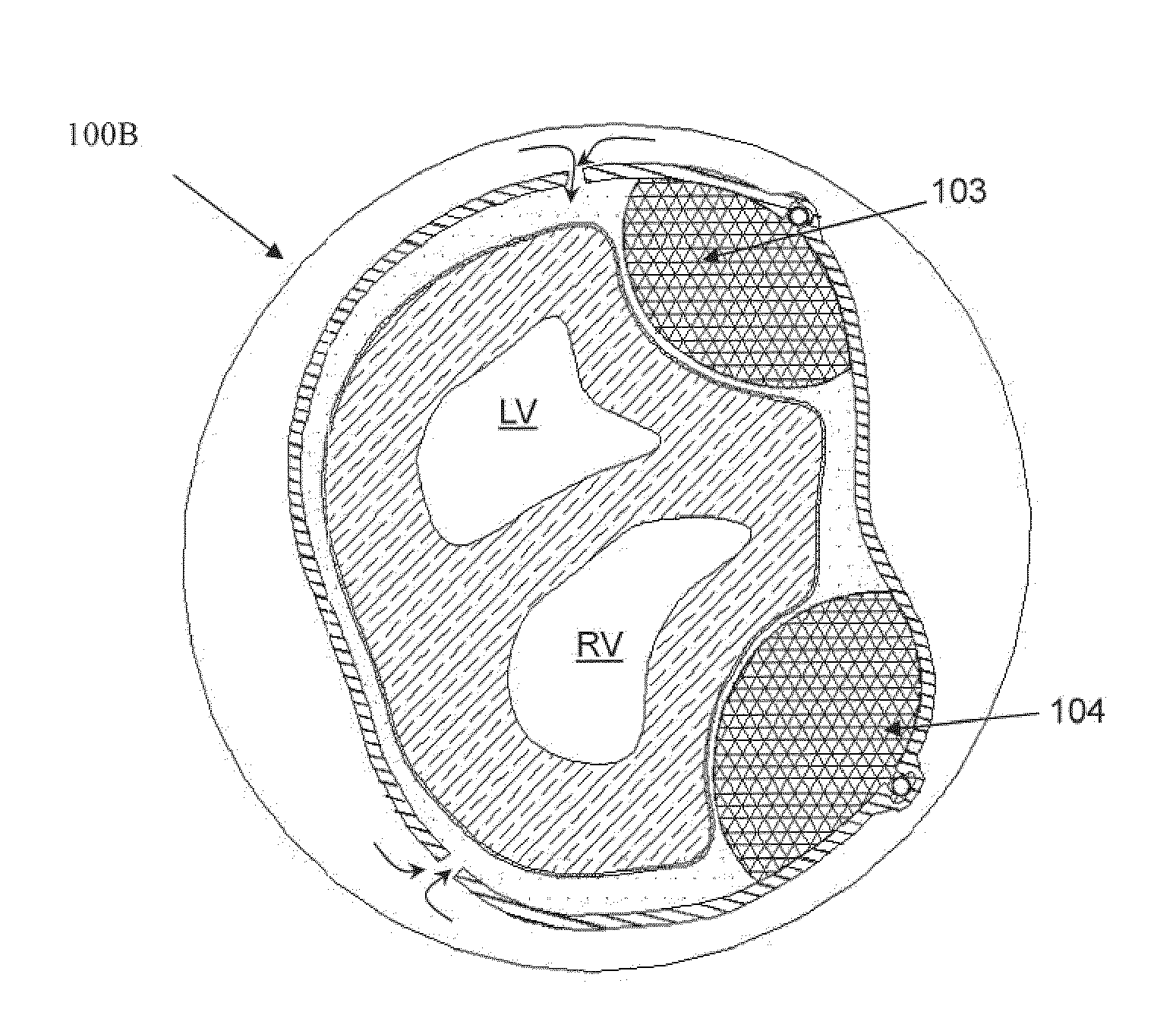

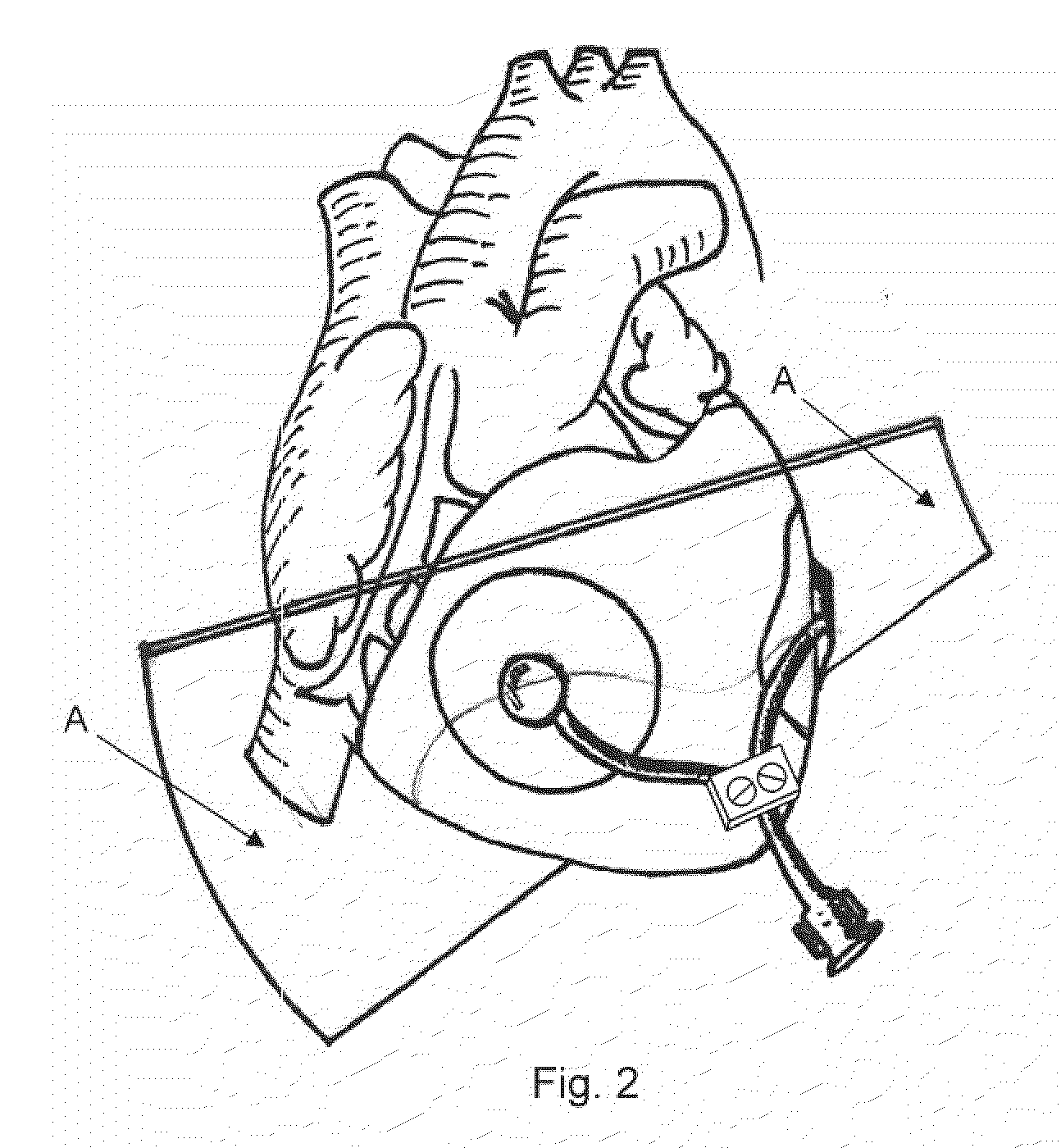

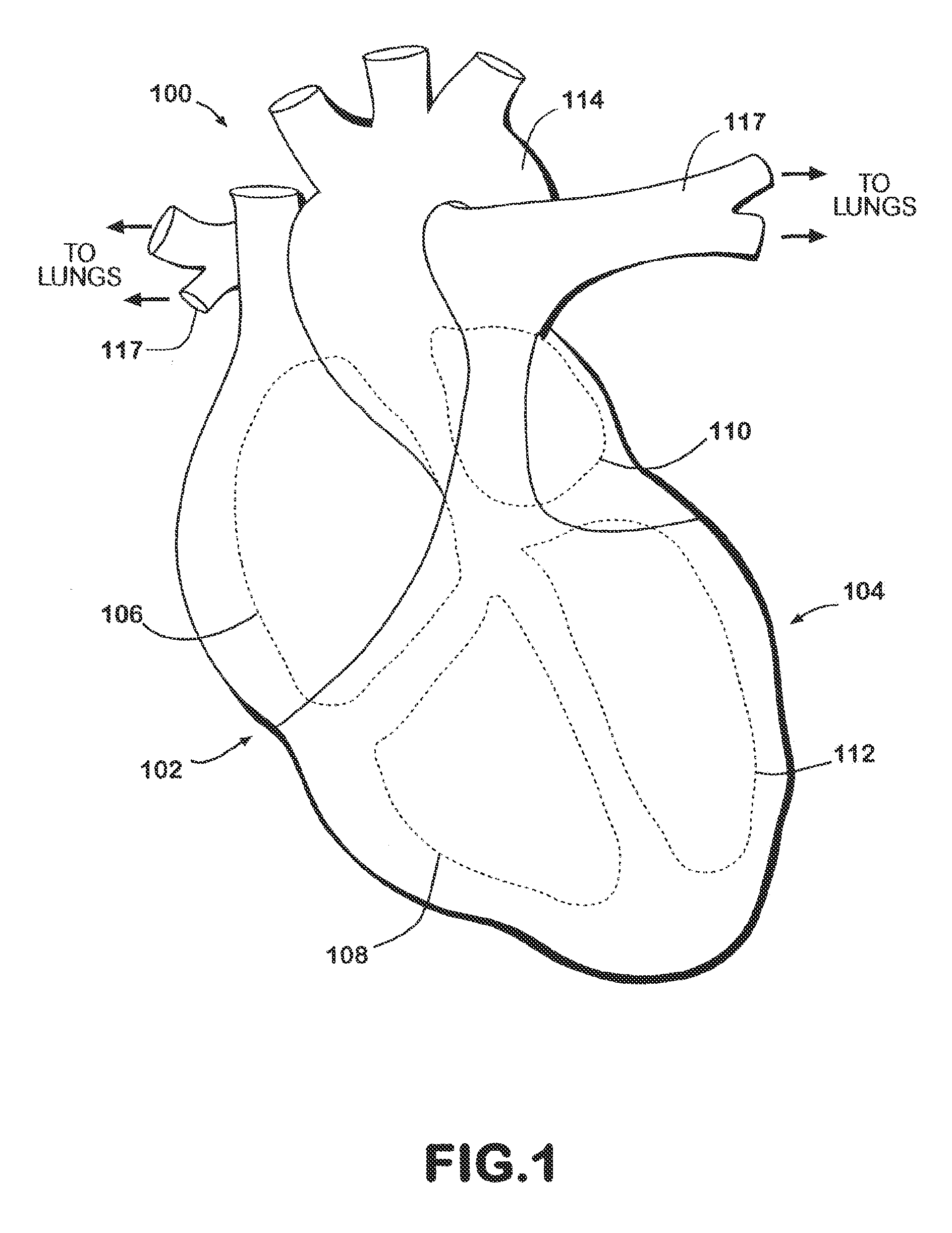

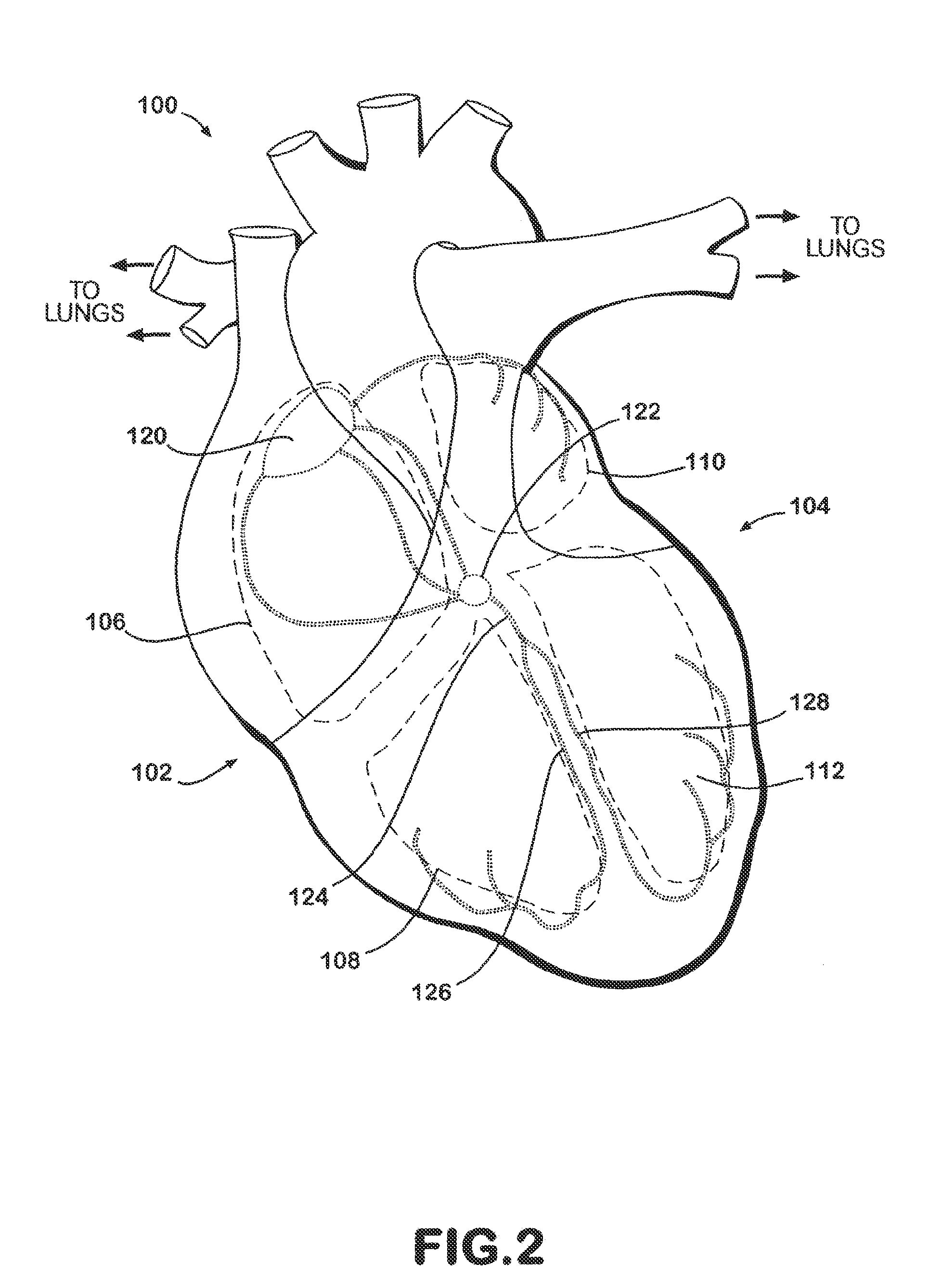

Method for multiple site, right ventricular pacing with improved left ventricular function

InactiveUS20050203580A1Prevent and slow and reverse progressionImprove heart functionHeart stimulatorsVentricular outflow tractLeft ventricular size

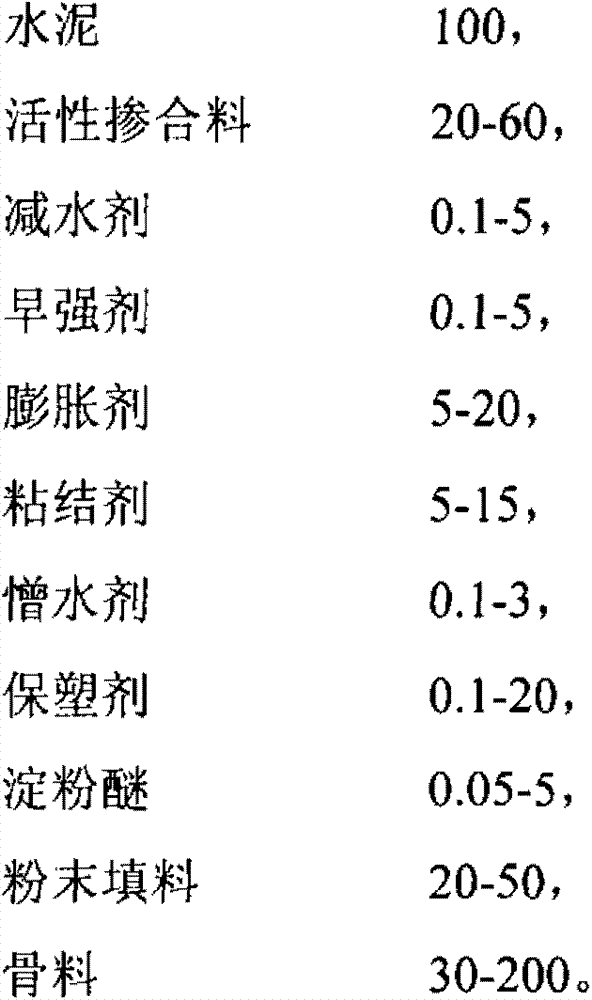

A method for treatment of congestive heart failure from the right side of the heart, by stimulating at numerous points along the right-ventricular septum to produce a fused line of stimulation upon breakthrough of wave fronts into the left ventricular septum and an LV action potential that simultaneously propagates toward the apex, base, and left free wall. Five electrodes, all in contact with the septum and spaced approximately 1.5 cm apart, produce a fused action potential in an average adult human within 10 ms of delivering simultaneous pacing pulses. Breakthrough of this fused region of stimulation will occur within 20 ms of delivering the pacing pulses. The most proximal electrode may be located in or near the right-ventricular apex. The most distal electrode may be located somewhere near the right-ventricular outflow tract, generally somewhere near the moderator band.

Owner:QUETZAL BIOMEDICAL

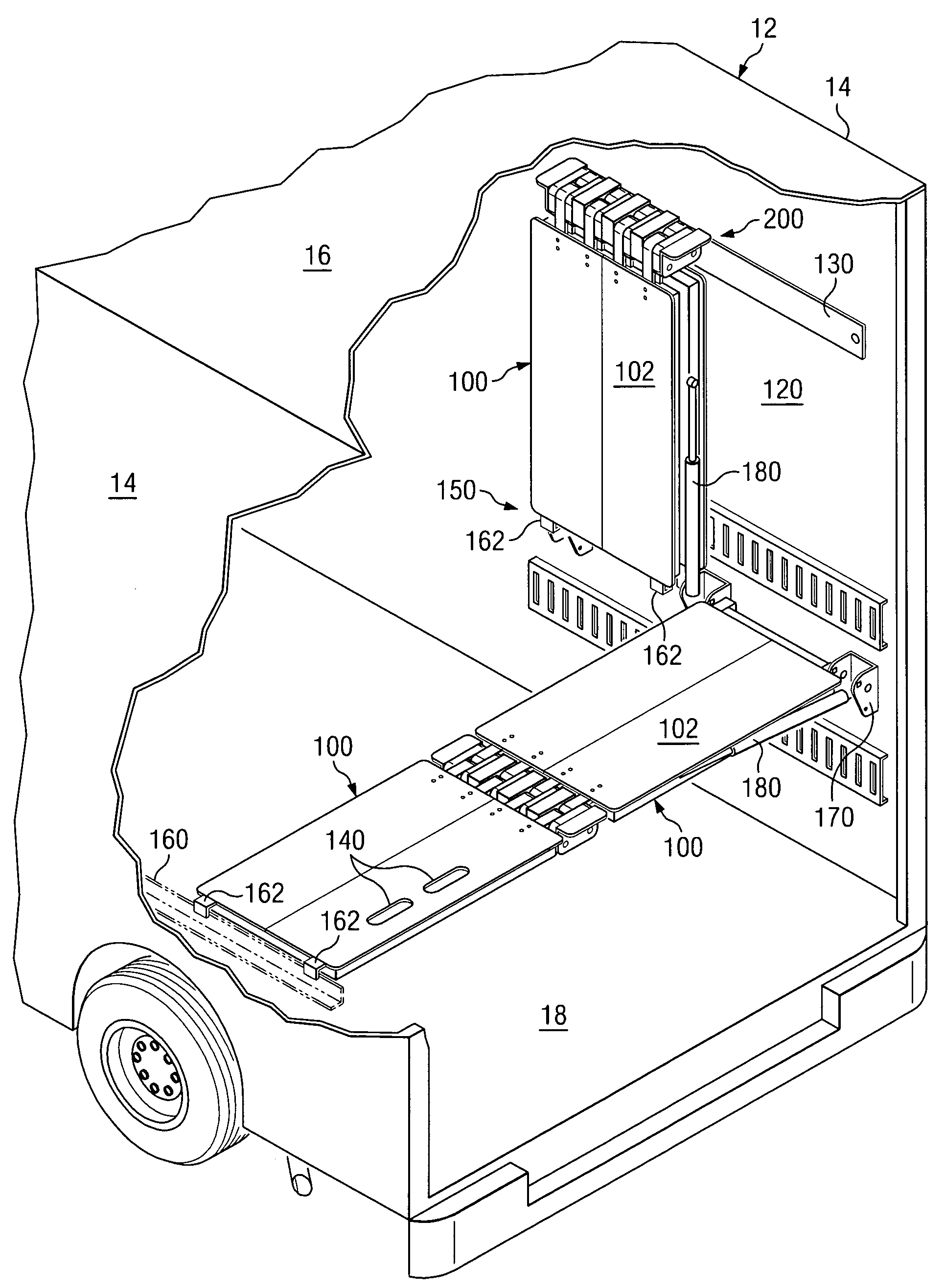

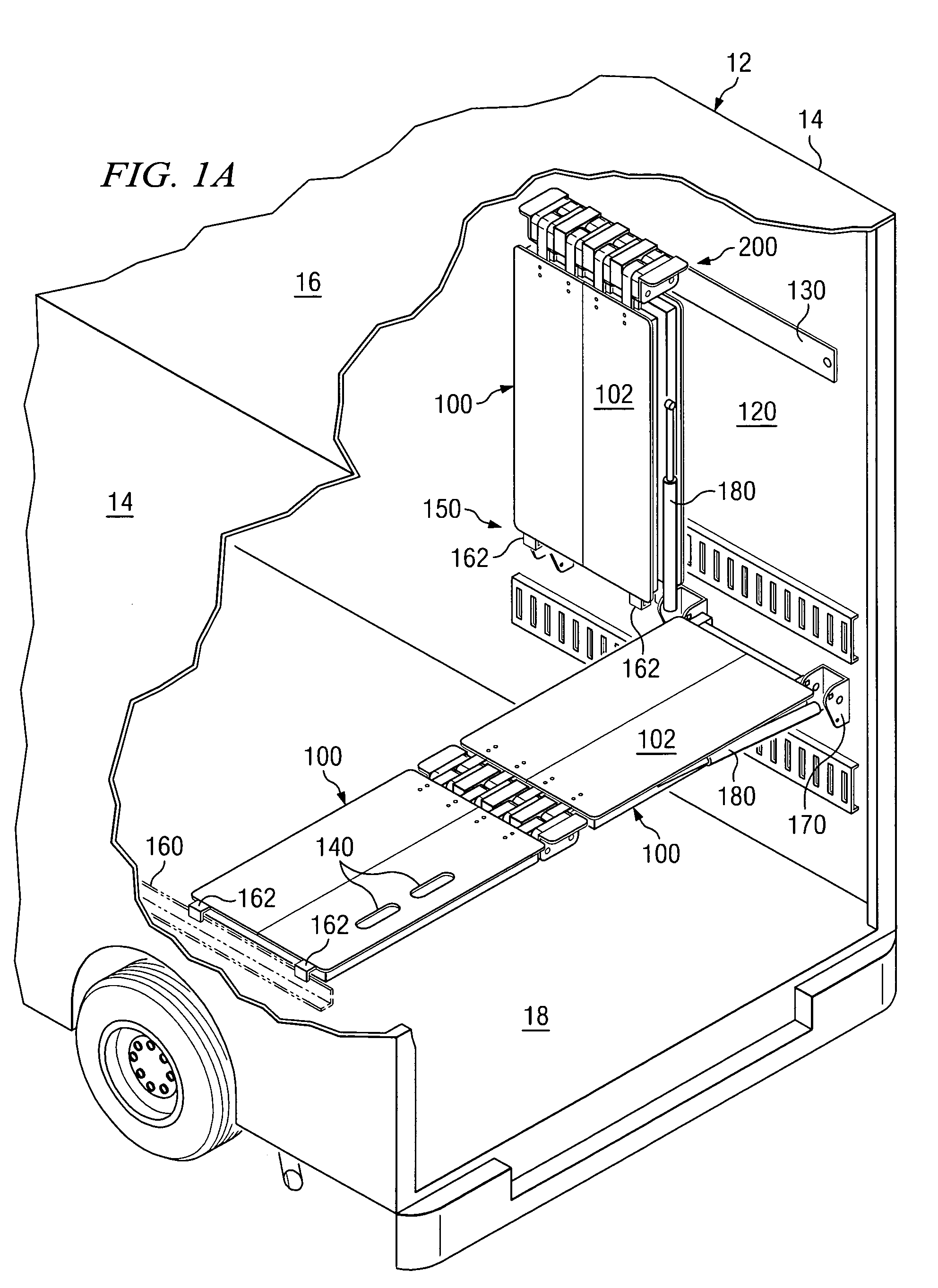

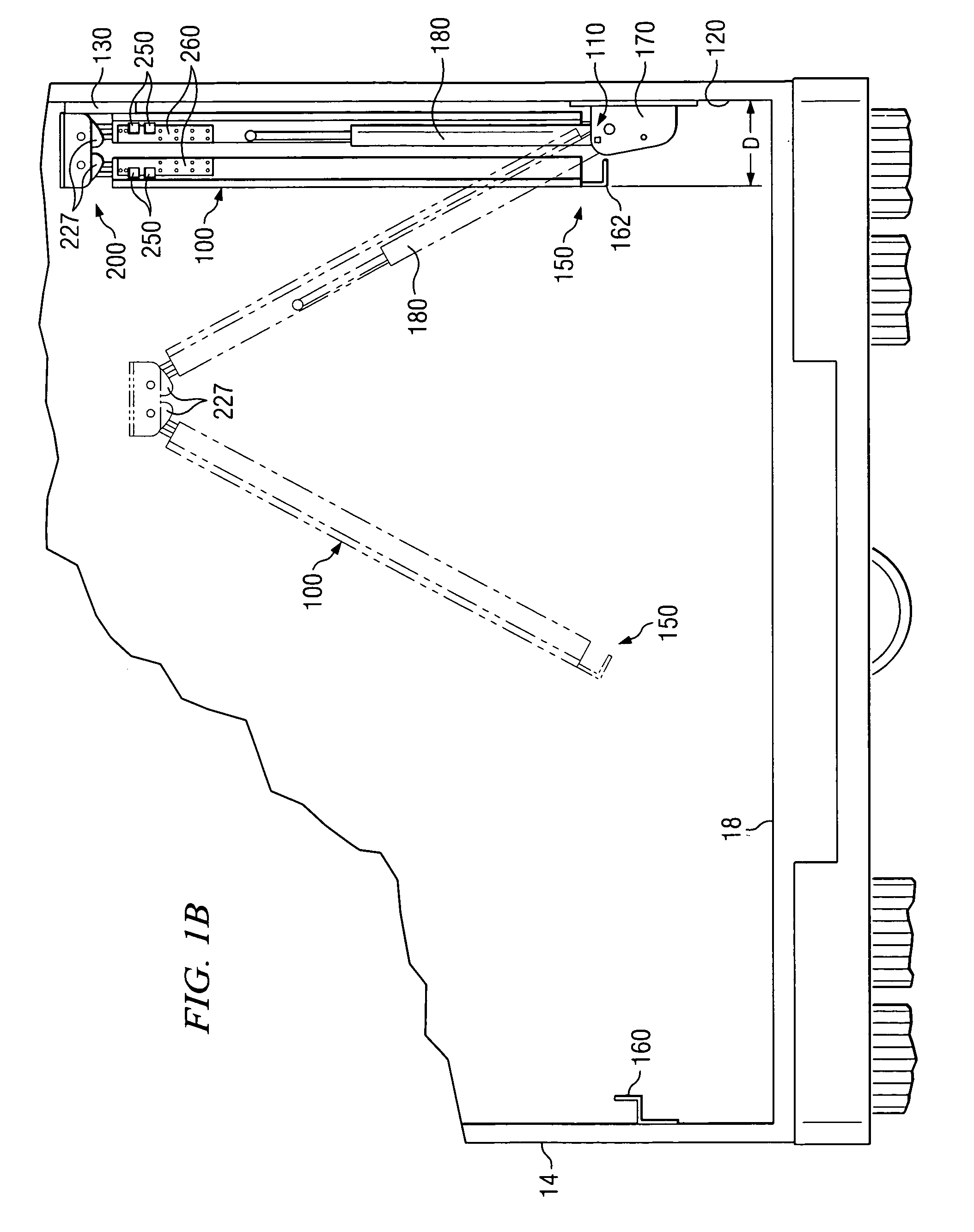

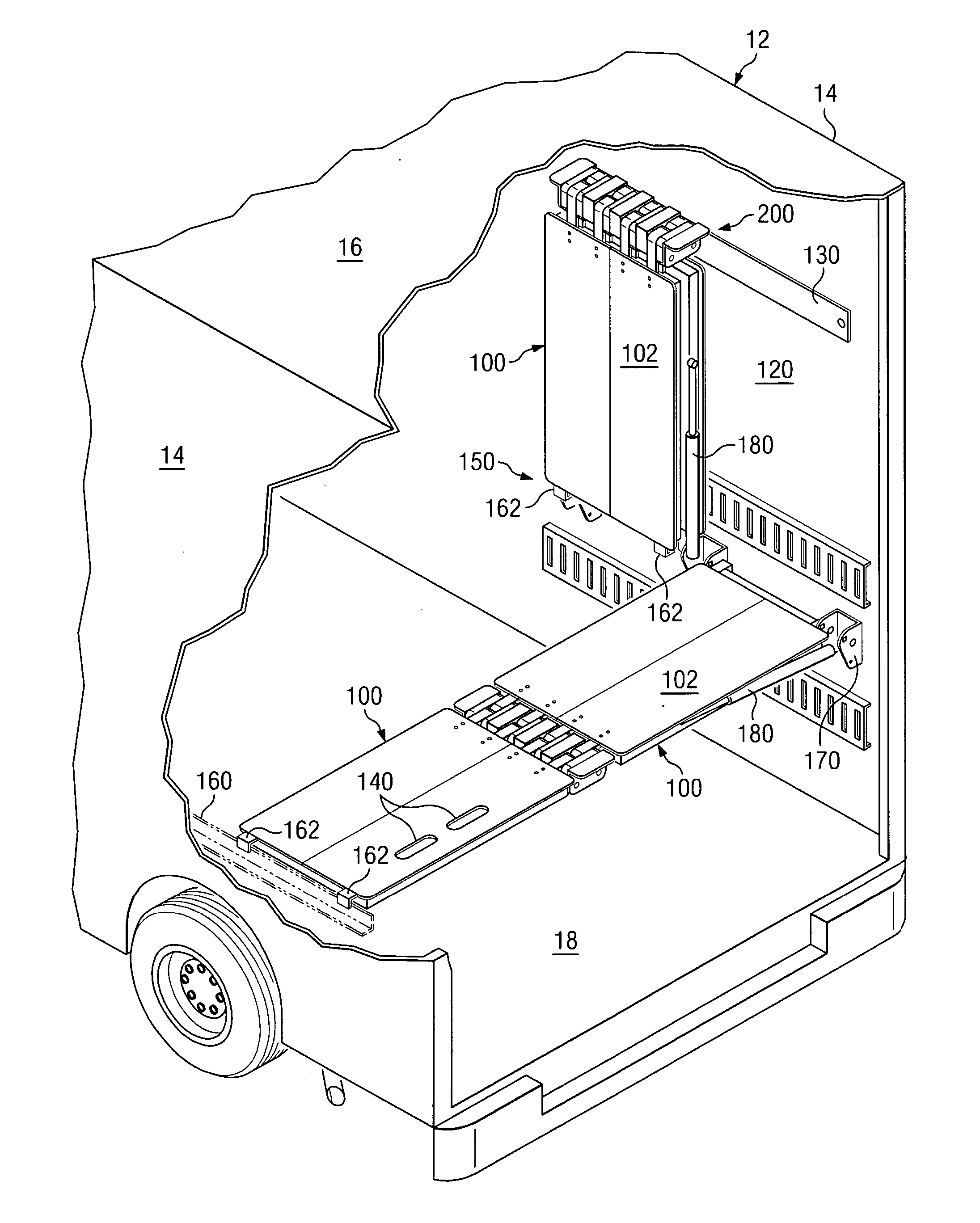

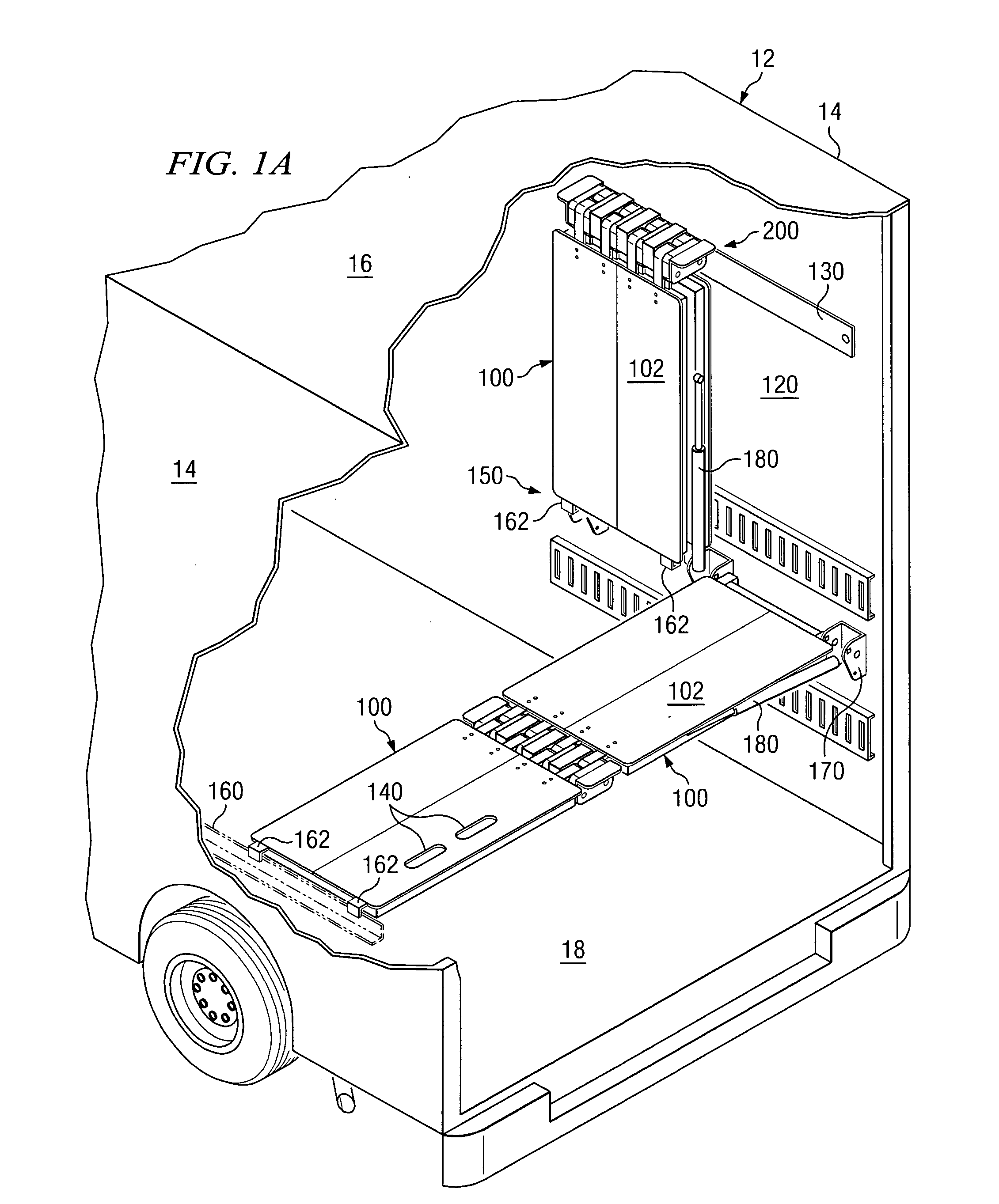

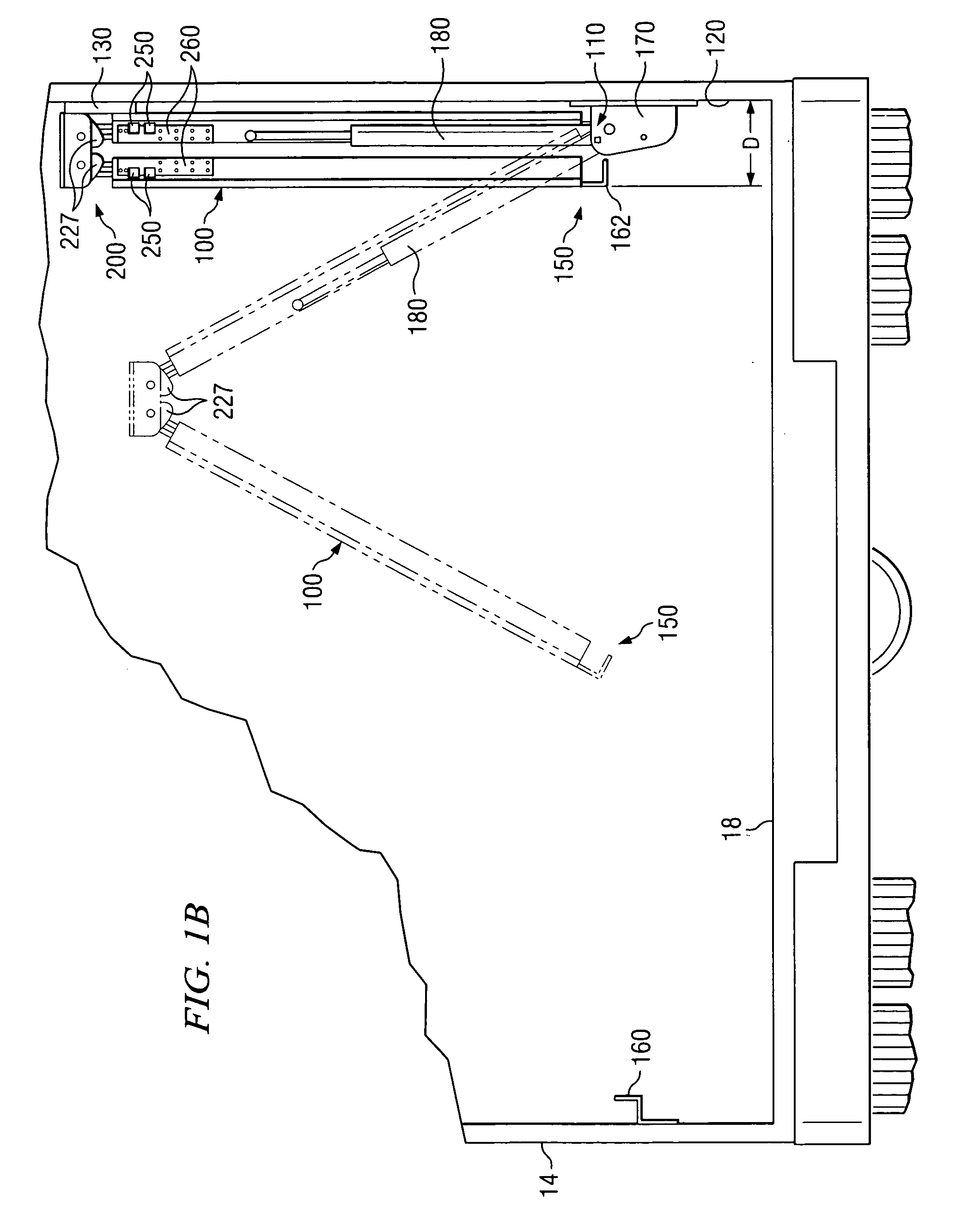

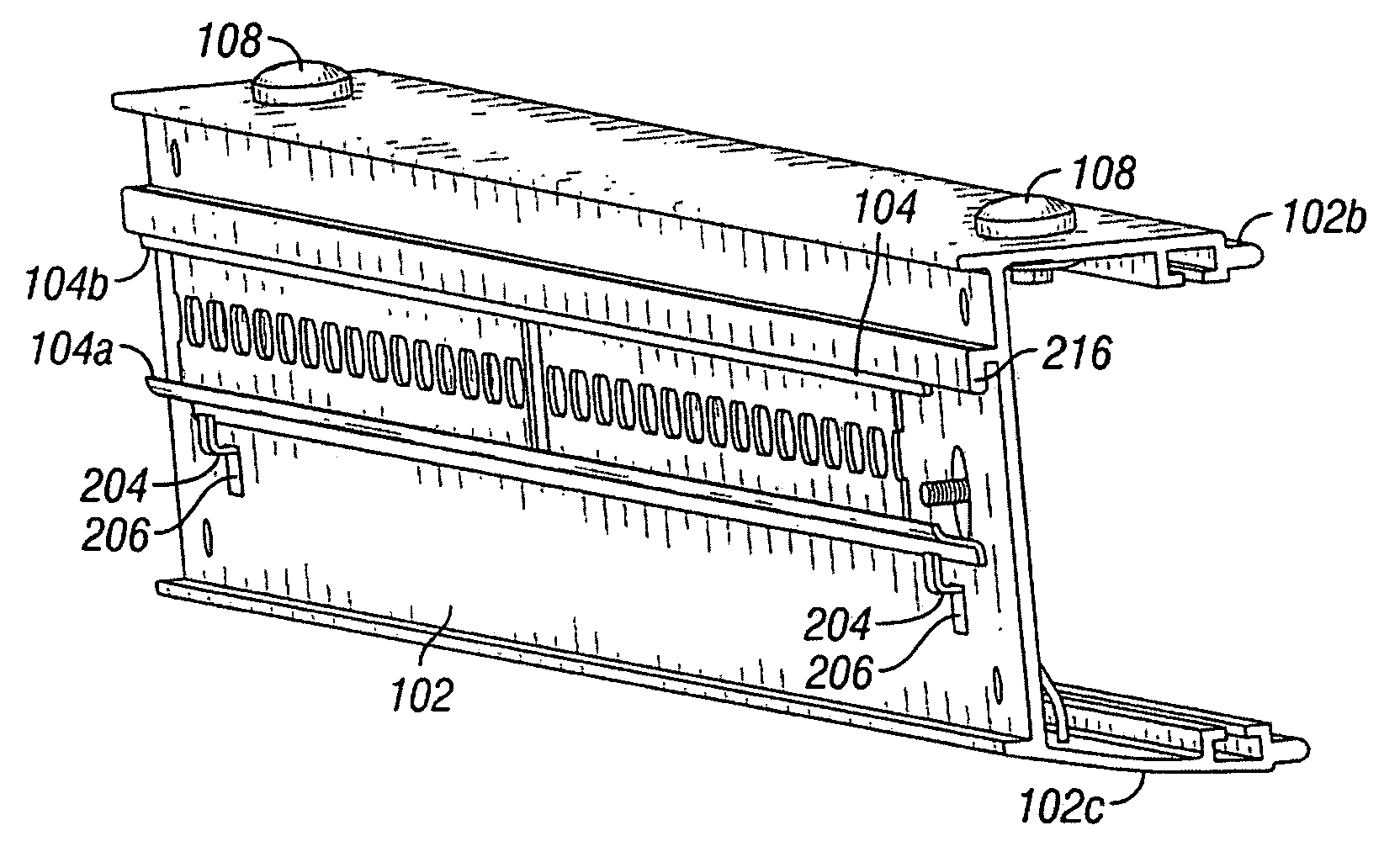

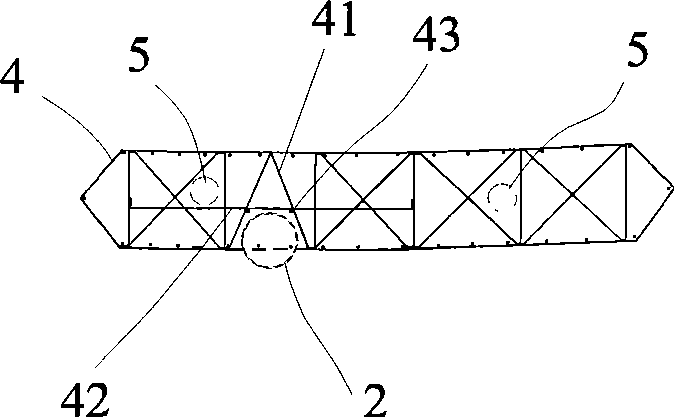

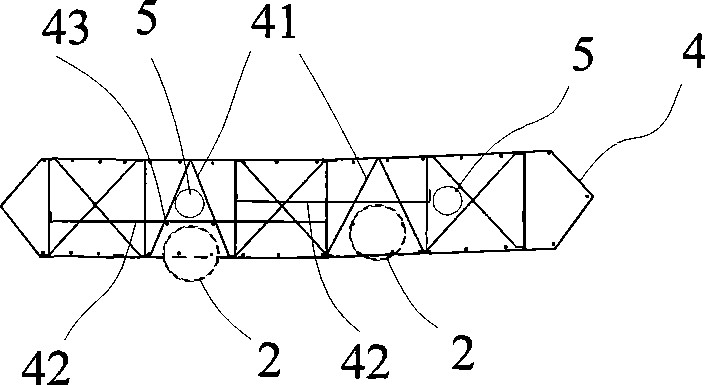

Double jointed hinge and foldable deck using same

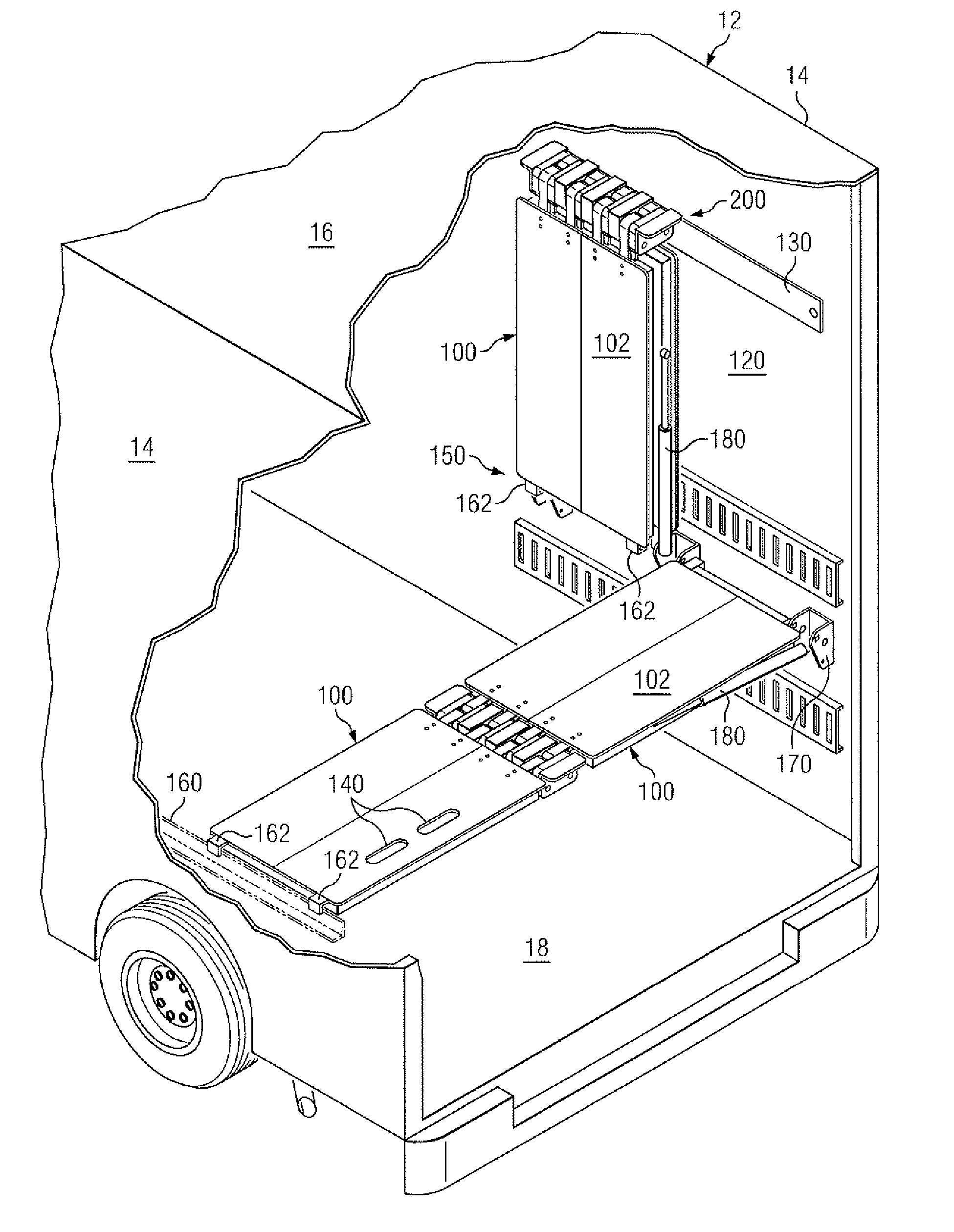

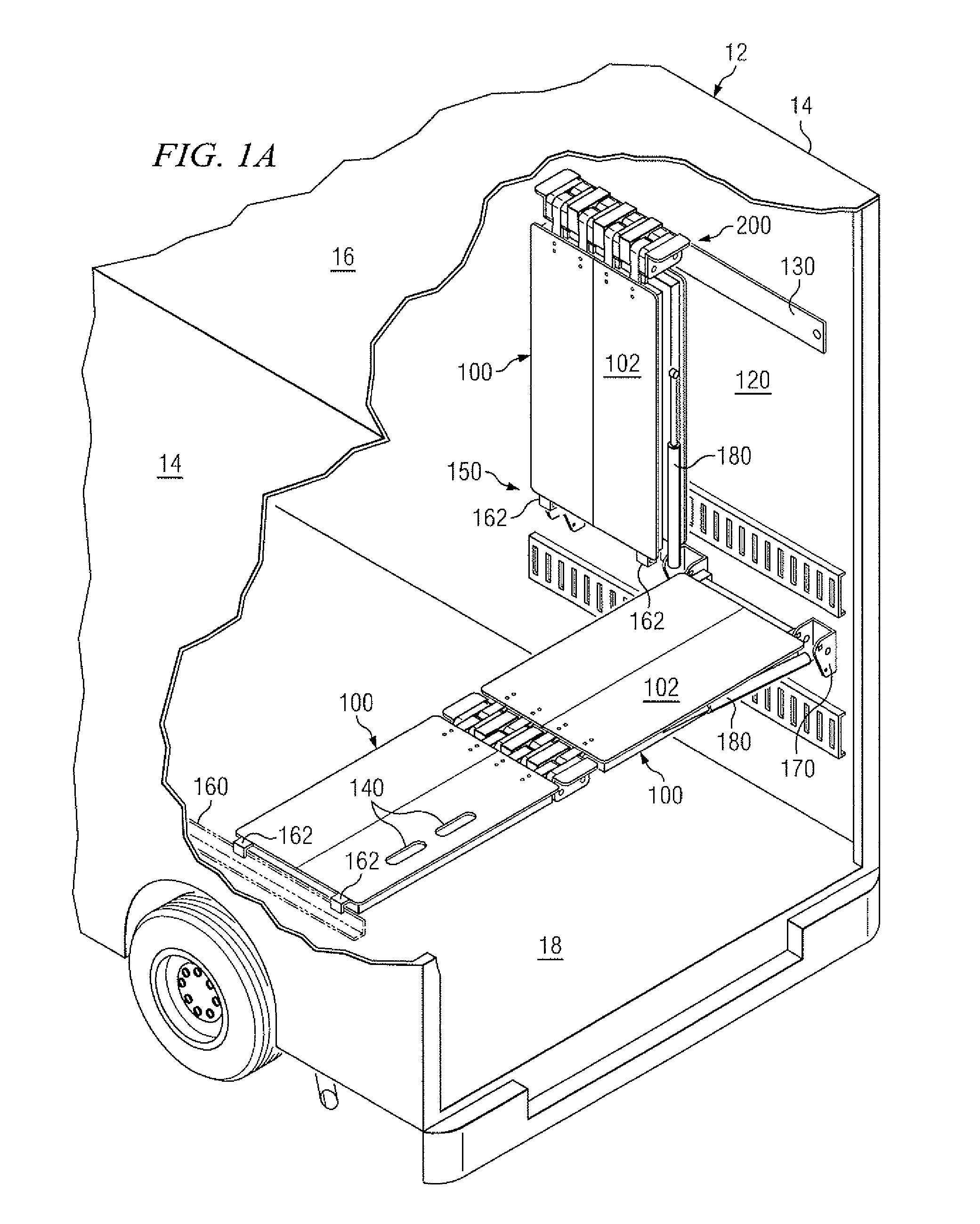

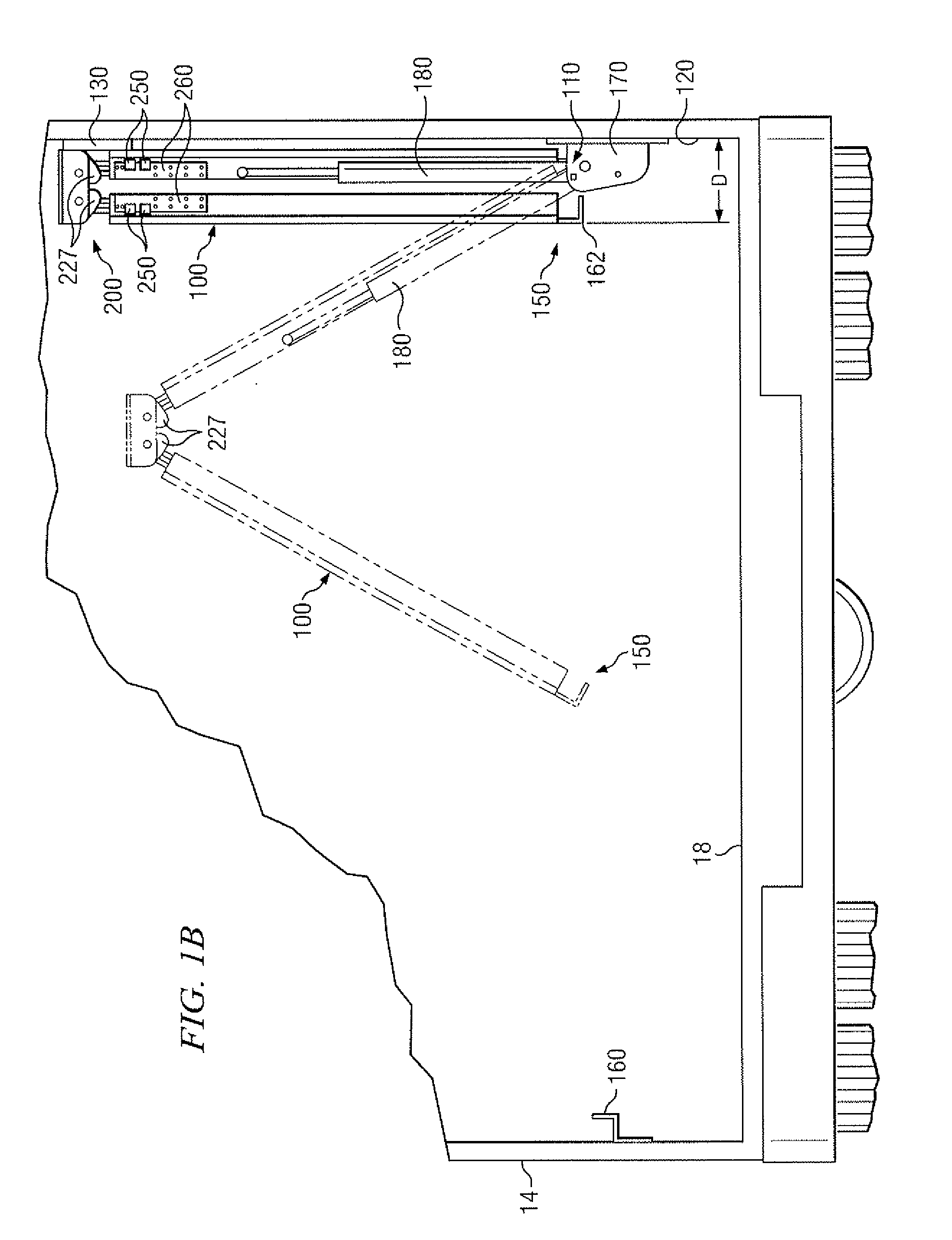

InactiveUS7293813B2Efficient designEconomicallyVehicle arrangementsLoading/unloading vehicle arrangmentFree wallAerospace engineering

A foldable deck for supporting cargo in a freight compartment is provided. The foldable deck includes a pair of deck panels connected by a double jointed hinge. The foldable deck is mounted on one of the side walls of the freight compartment and is capable of movement between a secure upright position and an extended horizontal deployed position. When the deck panels are in their deployed position they at least partially define a platform above the floor of the vehicle freight compartment. The double jointed hinge has a hinge member having a pair of pivot pins and slot pins that alternate between a deployed position and an upright position. The free end rests upon a channel or catch rail on the free wall opposite the attachment wall.

Owner:JPS CORP

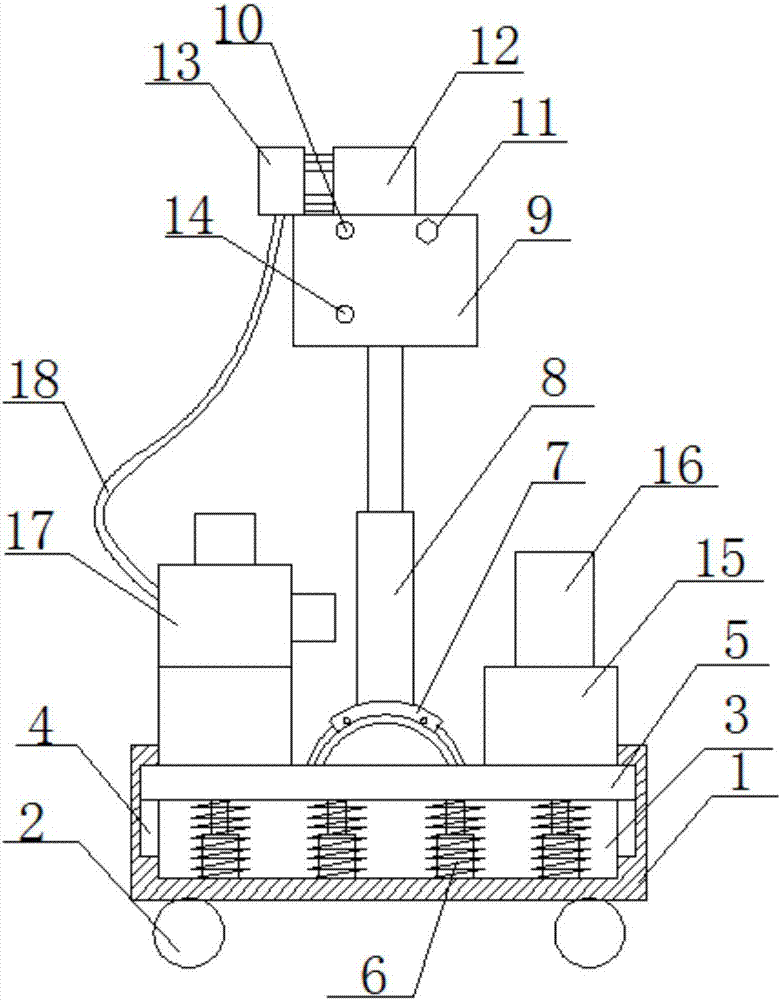

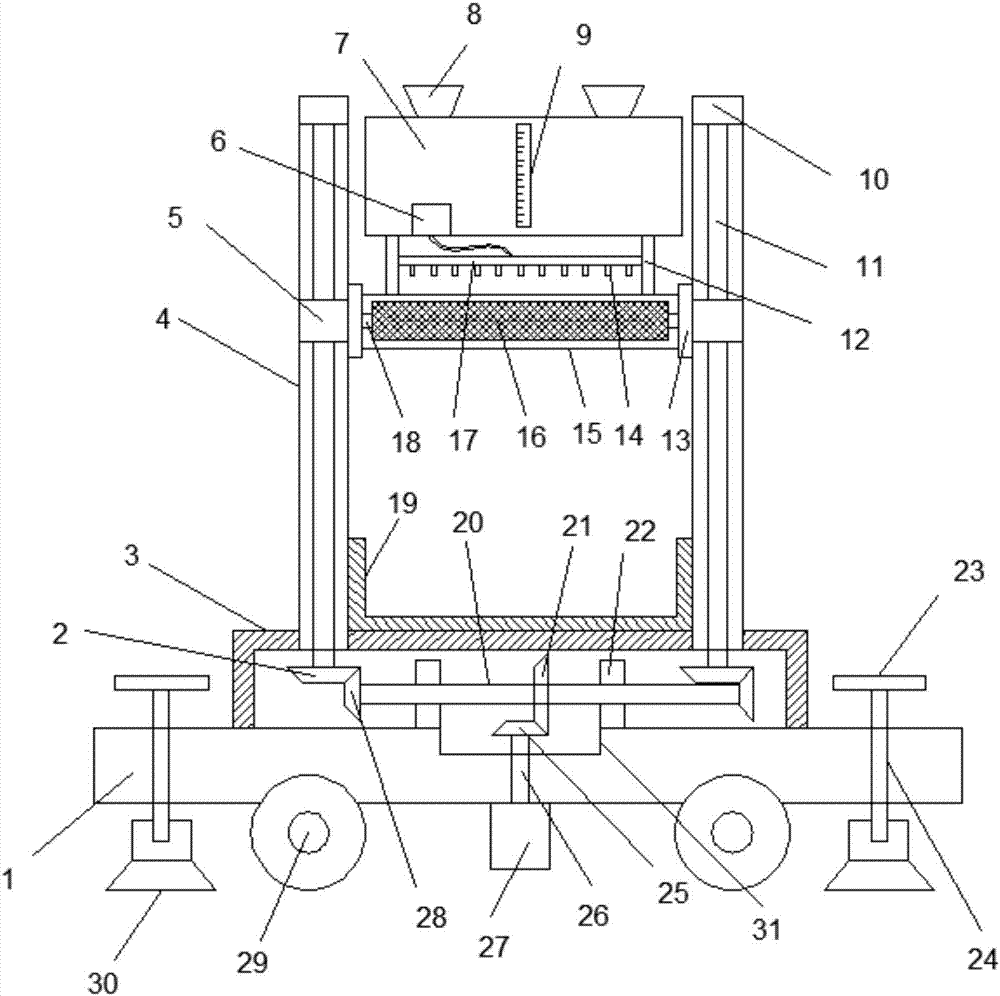

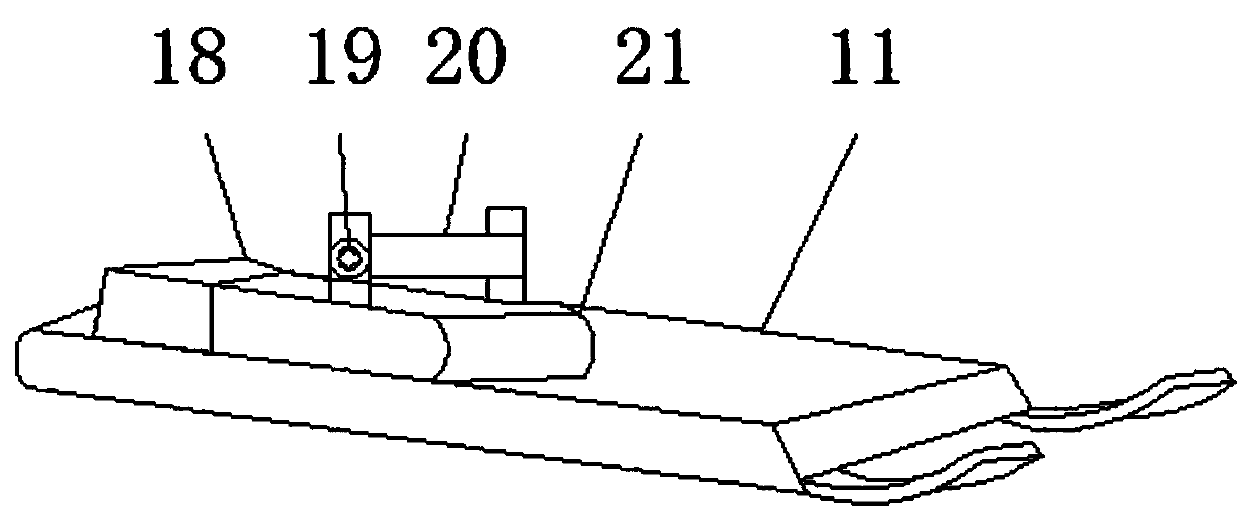

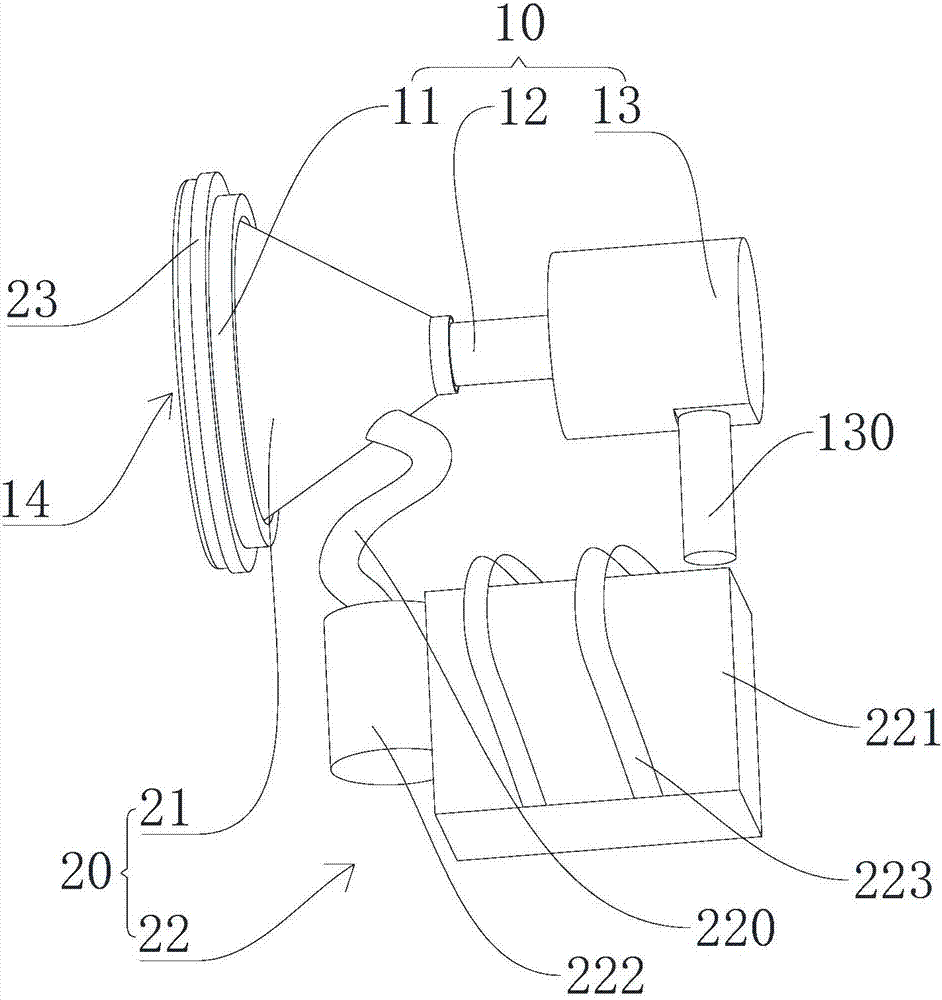

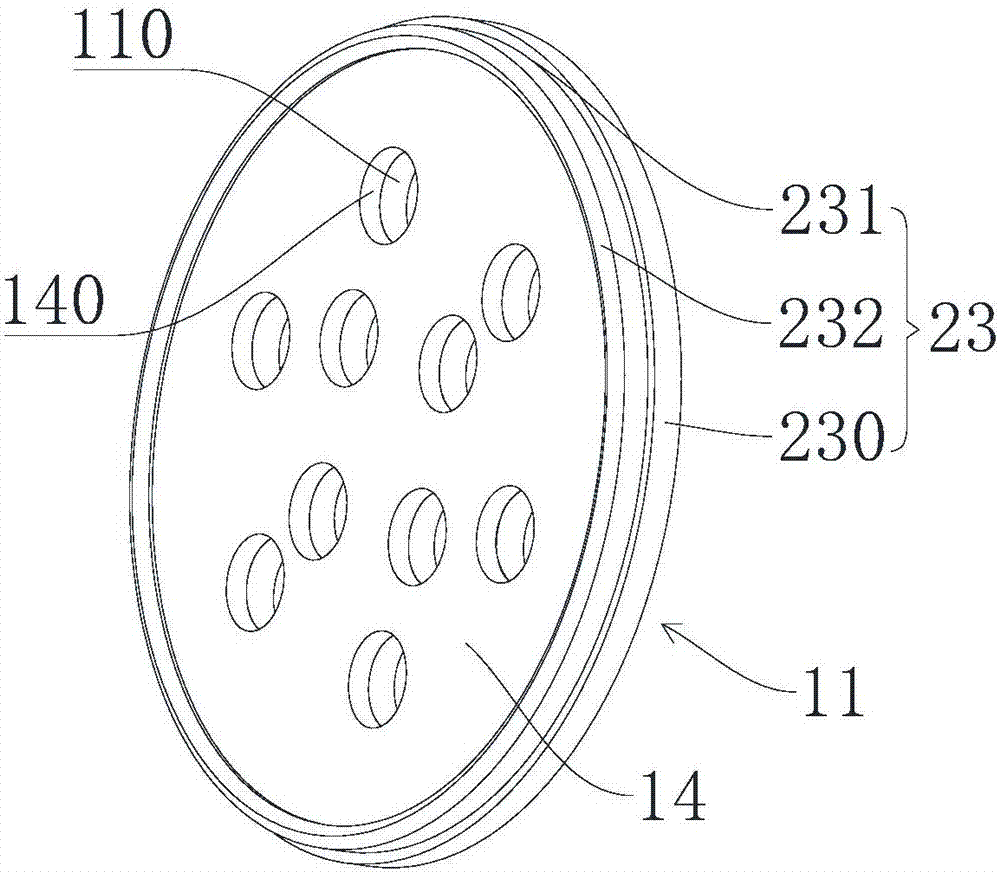

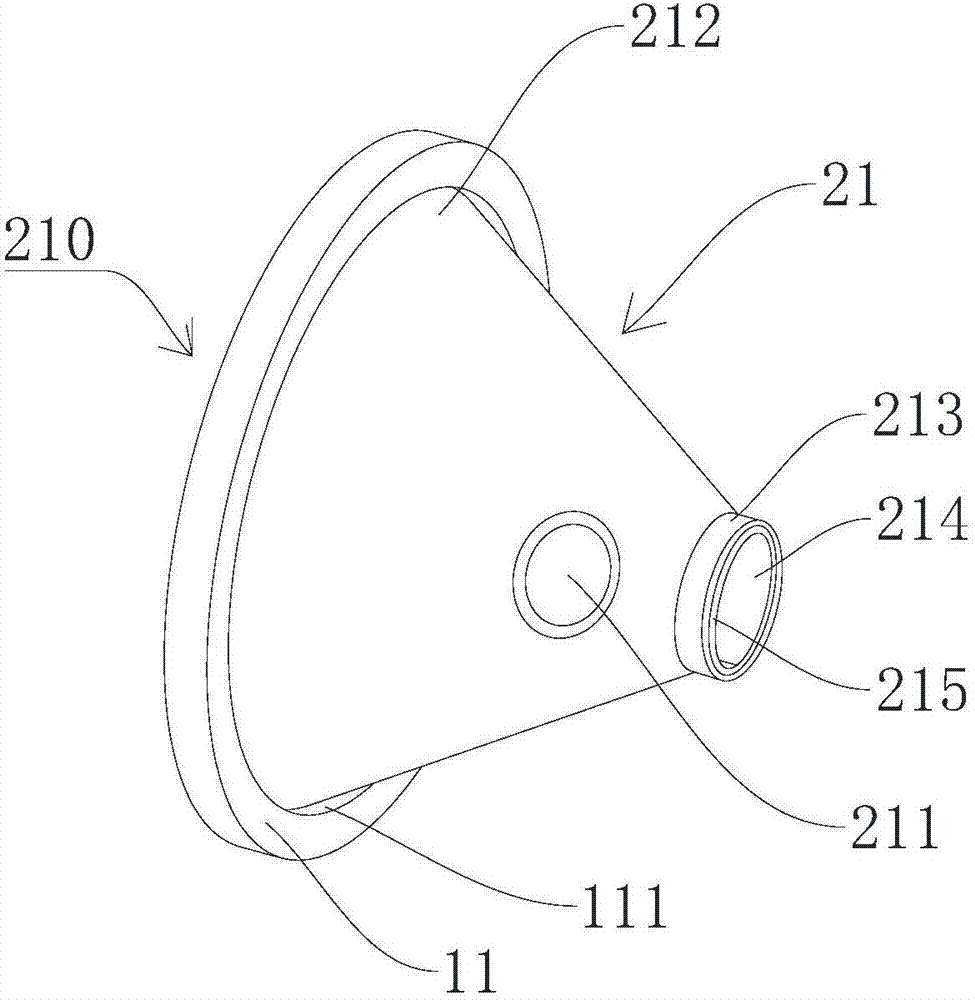

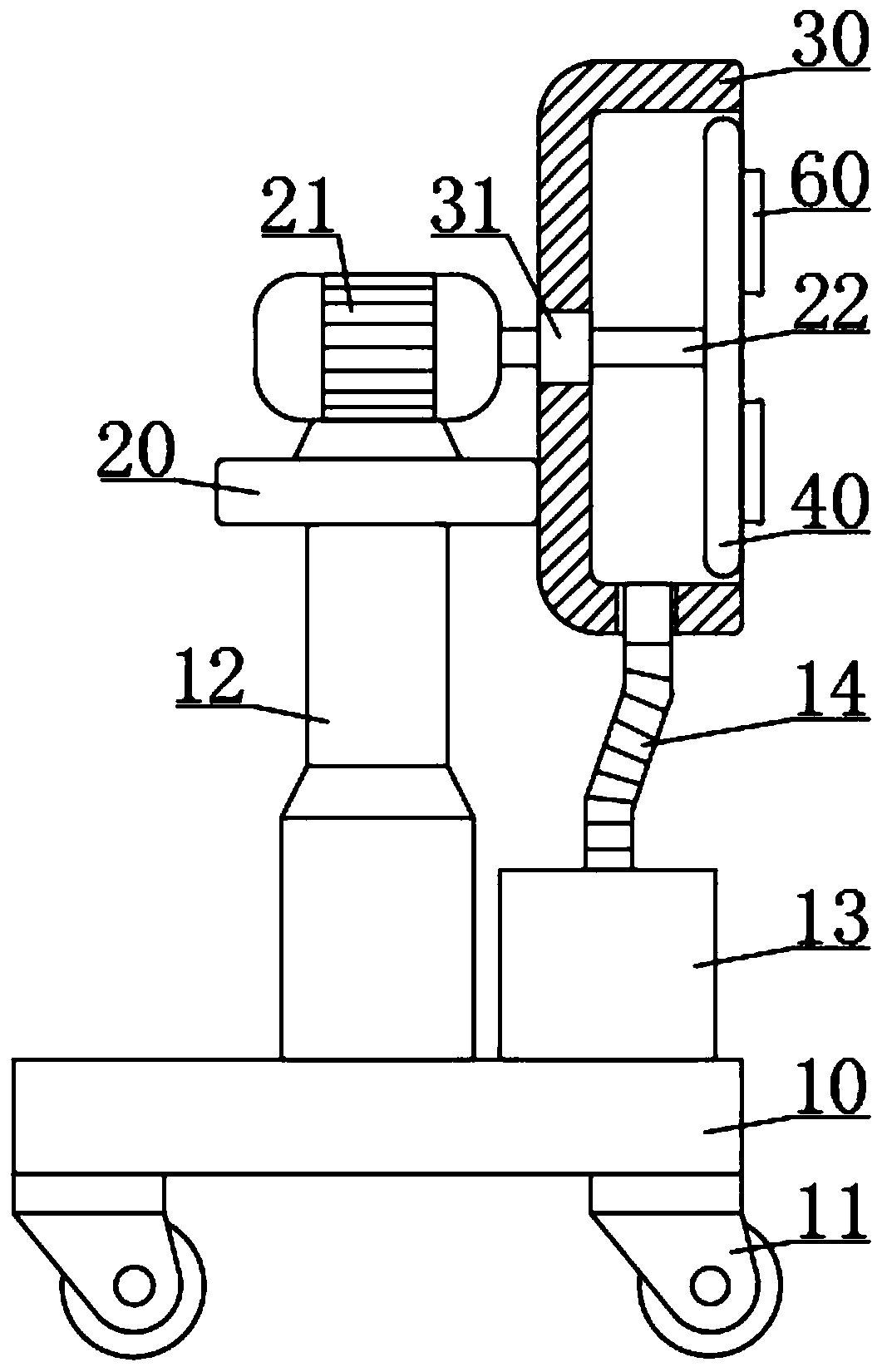

Multi-angle adjusted dust-free wall sanding machine

InactiveCN106863042AAffect qualityEasy dischargeGrinding carriagesGrinding bedsFree wallPulp and paper industry

The invention discloses a dust-free wall grinder with multi-angle adjustment, which comprises a base, and grooves are arranged on the upper side of the base, slide grooves are symmetrically arranged inside the groove, and a groove is arranged between the two slide grooves. A support plate, a number of shock absorbing devices are provided between the underside of the support plate and the bottom of the groove, an angle adjustment device is provided in the middle of the upper side of the support plate, and a telescopic device is provided on the upper side of the arc-shaped sliding frame, The upper end of the telescopic device is provided with a U-shaped bracket, the inner upper end of the U-shaped bracket is provided with a mounting plate, the upper side of the mounting plate is provided with a second motor, the output end of the second motor is provided with a grinding wheel, and the upper side of the support plate is left and right Counterweights are arranged symmetrically, and a dust collection box is provided on the upper side of the counterweight on the left side. The dust collection box communicates with the inside of the protective cover through a suction pipe, and the dust collection box includes a box body. The invention has the advantages of simple structure, convenient use, adjustable angle, wide application range, good damping effect and dustproof function.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Foldable Deck

InactiveUS20080012372A1Efficient designEconomicallyVehicle arrangementsVehicle with loading gatesFree wallAerospace engineering

A foldable deck for supporting cargo in a freight compartment is provided. The foldable deck includes a pair of deck panels connected by a hinge assembly. The foldable deck is mounted on one of the side walls of the freight compartment and is capable of movement between a secure upright position and an extended horizontal deployed position. When the deck panels are in their deployed position they at least partially define a platform above the floor of the vehicle freight compartment. The free end rests upon a channel or catch rail on the free wall opposite the attachment wall.

Owner:JPS CORP

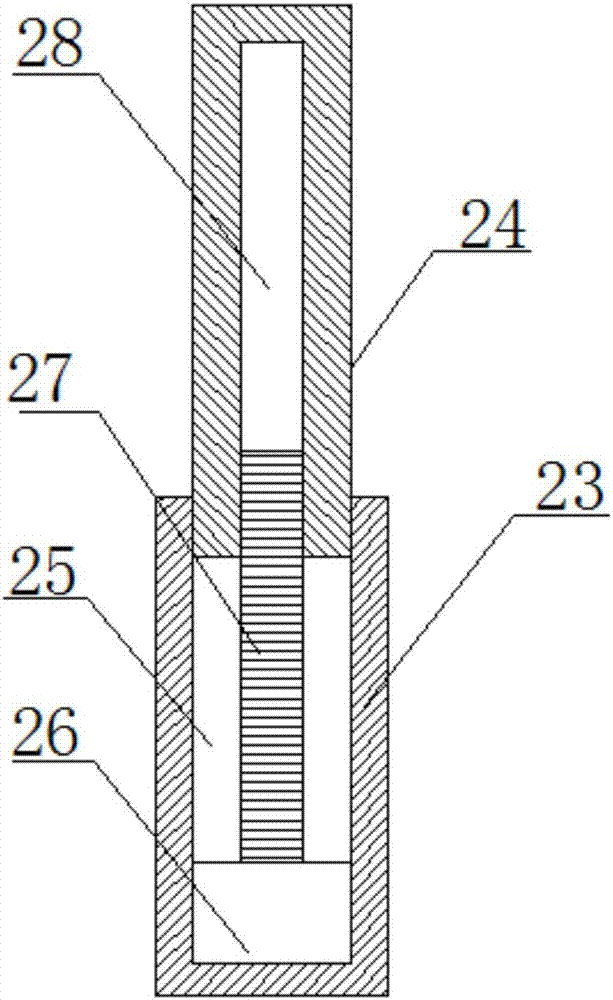

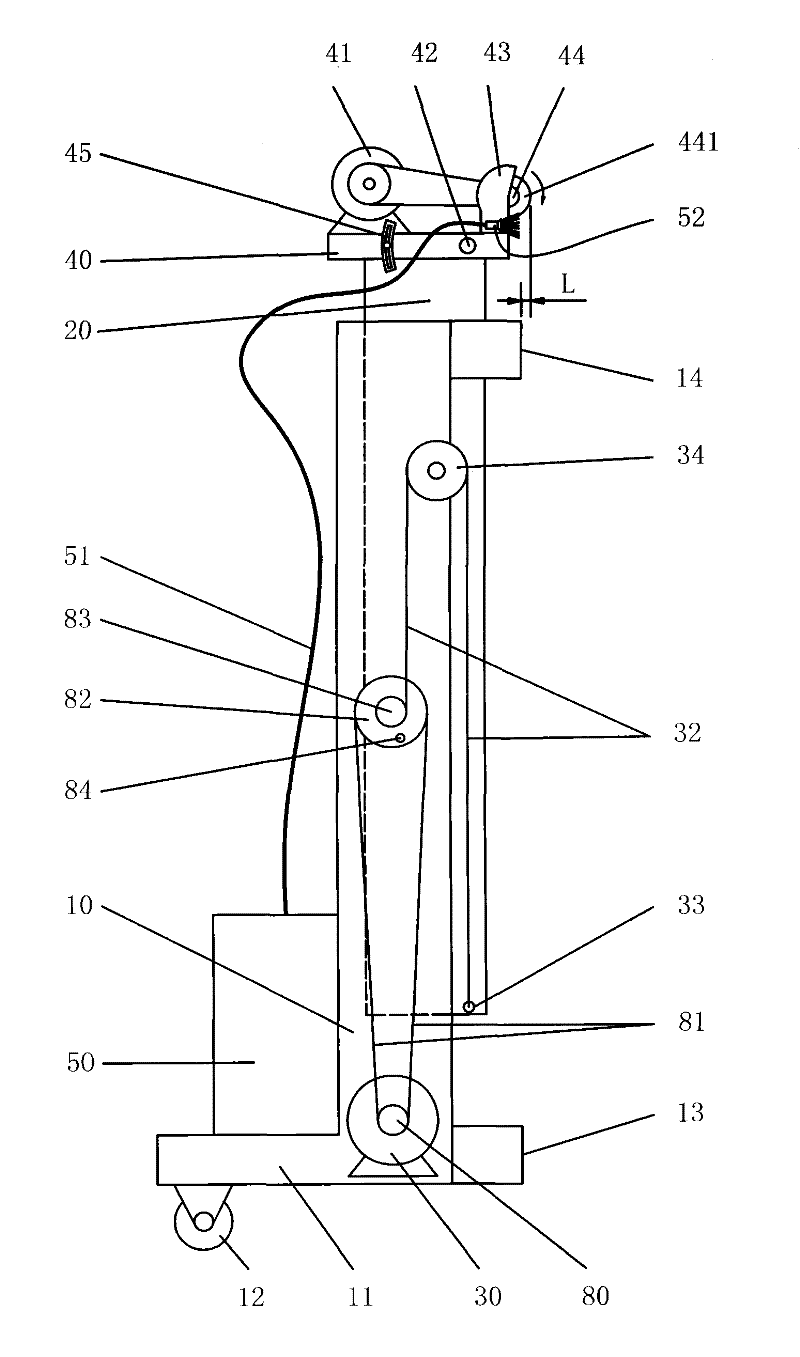

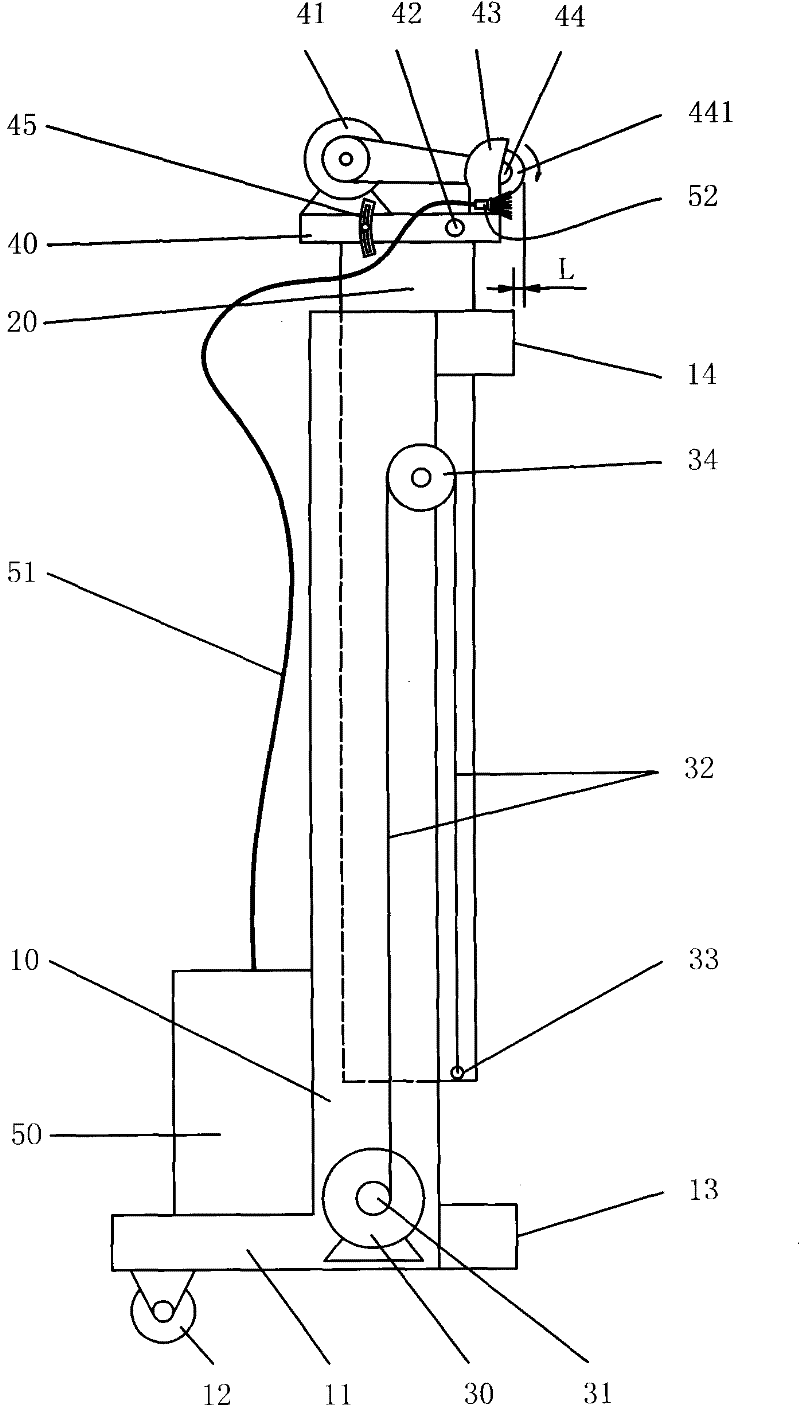

Retractable dust-free wall grooving machine

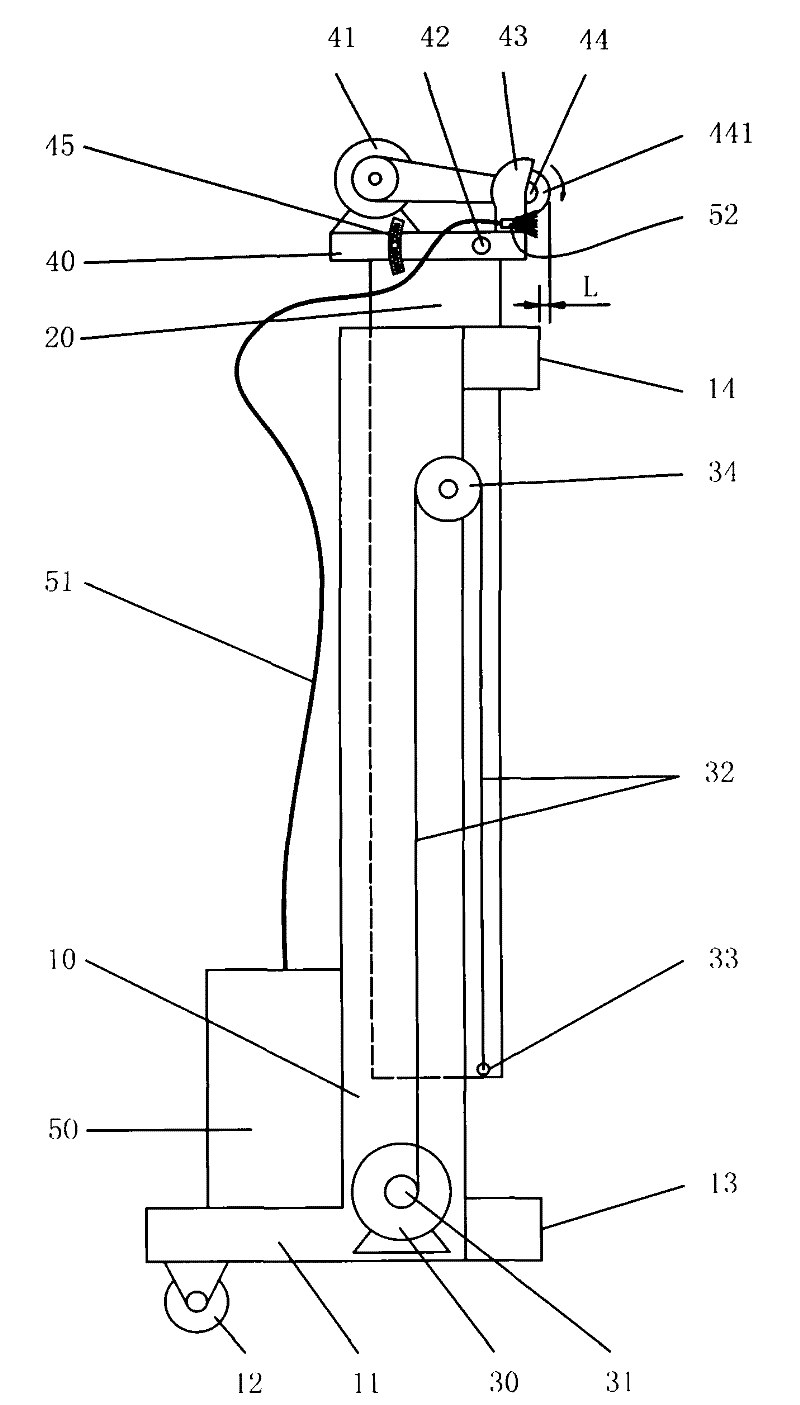

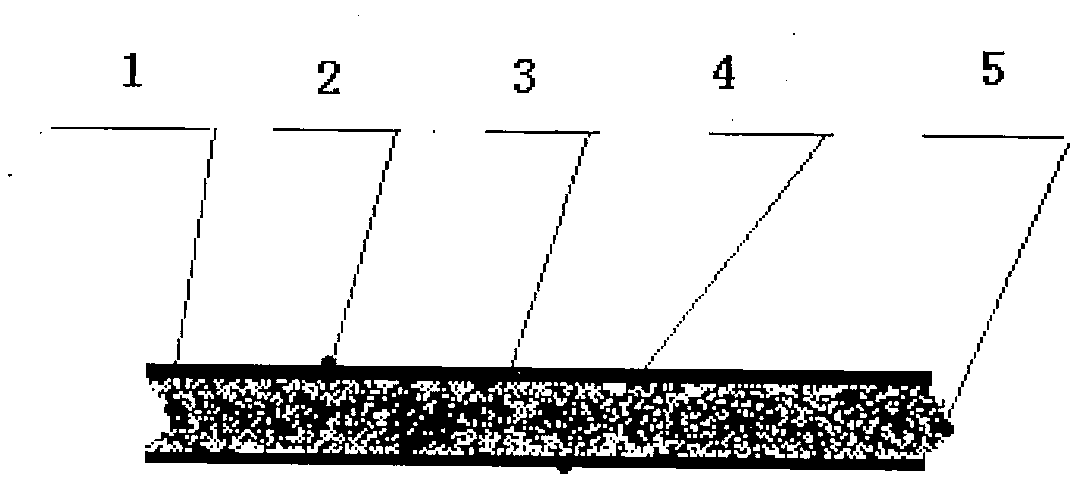

InactiveCN102174853ASimple construction processIncrease productivityBuilding constructionsSpray nozzleCircular saw

The invention belongs to the technical field of wall grooving machines, and relates to a retractable dust-free wall grooving machine. A base is provided with a slide rail and an atomization dedusting mechanism; a sliding rod which moves along the slide rail and a sliding rod lifting mechanism are arranged on the slide rail; both the upper part and the lower part of the front side face of the slide rail are provided with a limited block; a grooving operation part is hinged on the upper part of the sliding rod; in the grooving operation part, a motor is arranged on a mounting frame, more than two circular saw blades are arranged on a rotating shaft driven by the motor, a safety hood is arranged on the rear part of the circular saw blade, and a spray nozzle which is connected with the atomization dedusting mechanism by a guide pipe is arranged on the lower side of the safety hood; and in the sliding rod lifting mechanism, a steel cable unreeling and reeling barrel is arranged on a motor shaft which is arranged on the base, one end of a steel cable is fixed on the steel cable unreeling and reeling barrel, and the other end of the steel cable passes through a pulley arranged on the upper part of the slide rail and is fixed at the lower end of the sliding rod. The machine has a simple structure, a good dedusting effect, low labor intensity, high efficiency, low production cost and adjustable grooving depth and is suitable for grooving a wall.

Owner:李茂铁

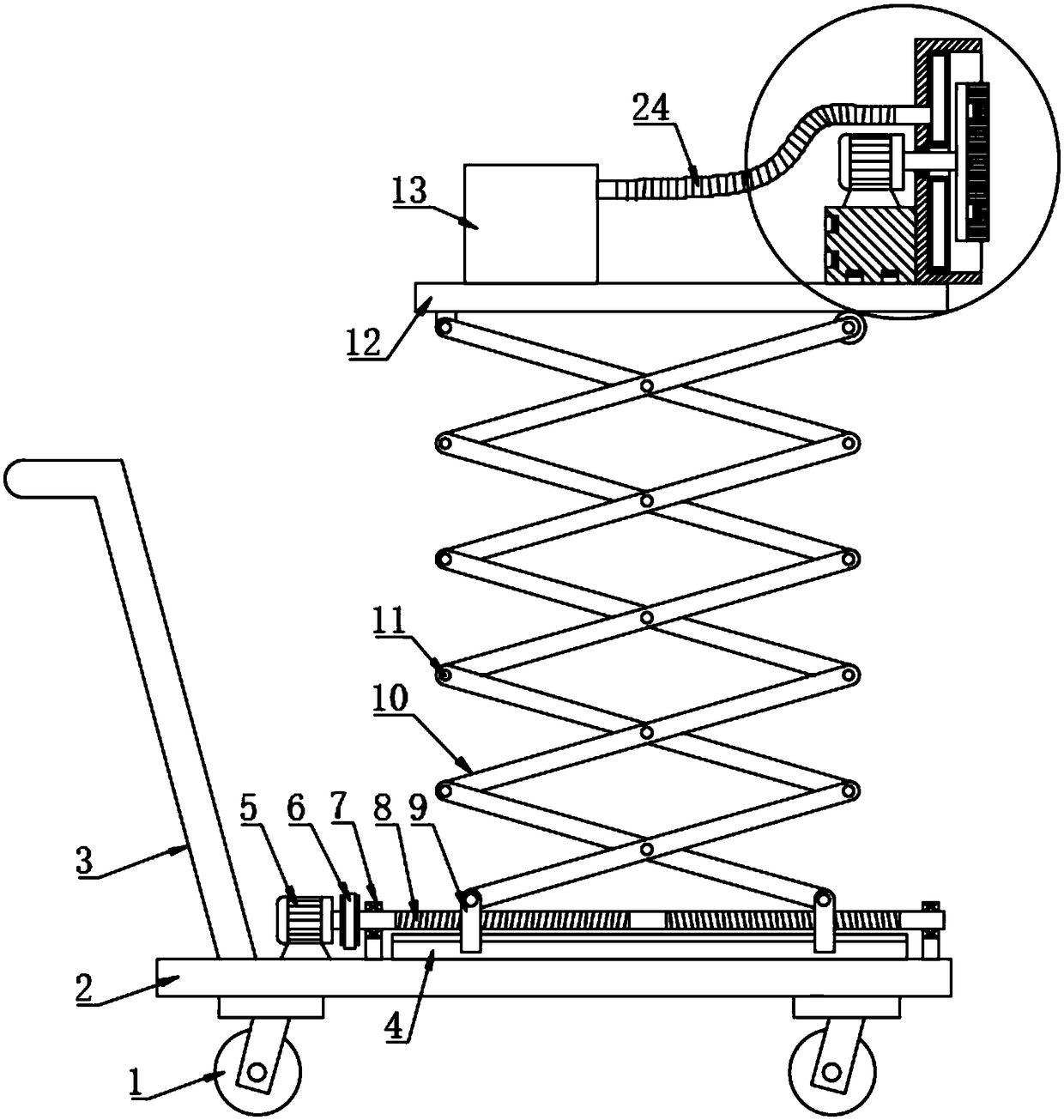

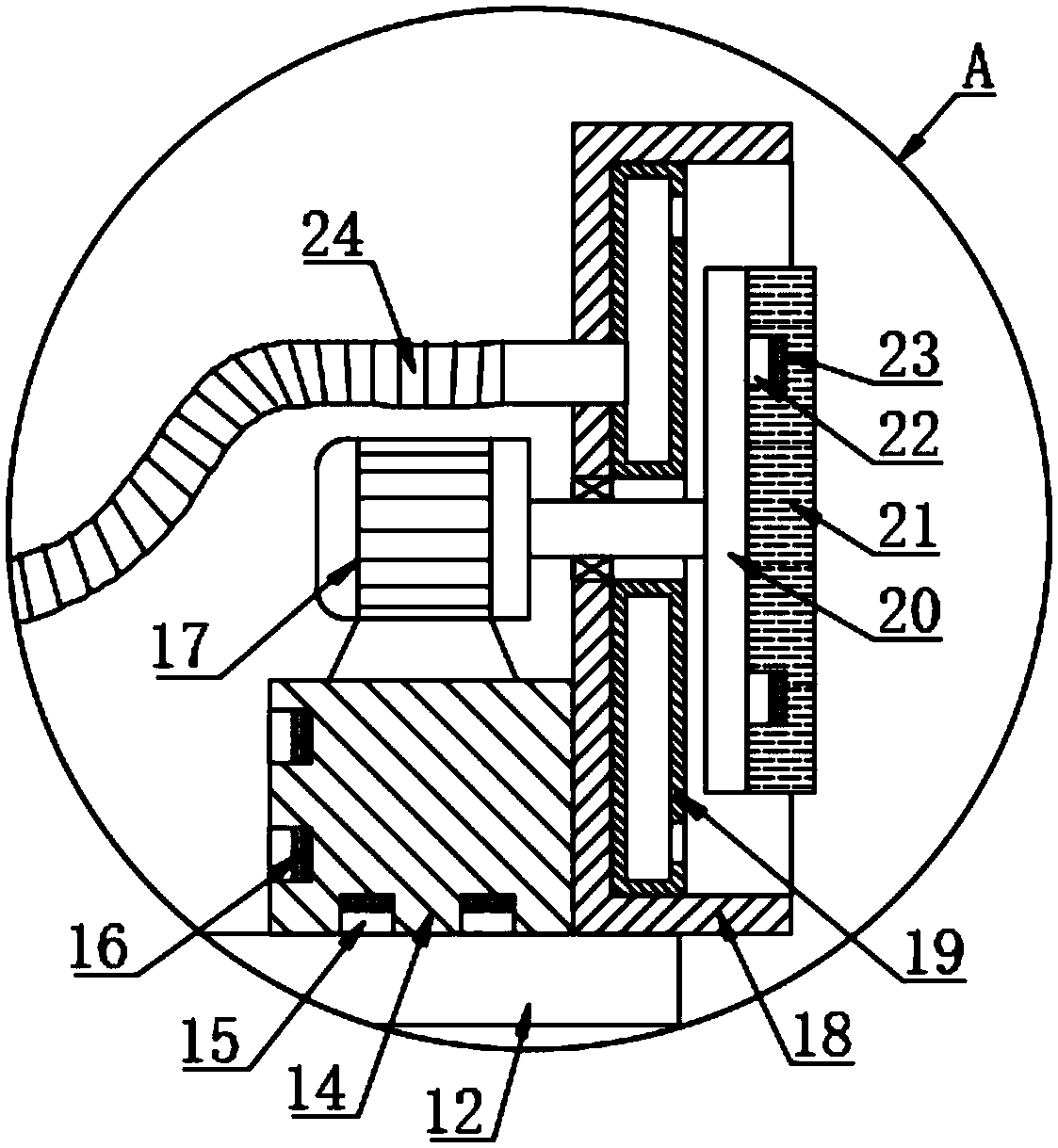

Lifting type dust-free wall grinding machine for decoration engineering

InactiveCN108890428AEasy to replaceEasy to disassembleGrinding drivesPlane surface grinding machinesFree wallArchitectural engineering

The invention discloses a lifting type dust-free wall grinding machine for decoration engineering. The lifting type dust-free wall grinding machine comprises a base, universal wheels are arranged at the bottom of the base, a push bar is fixedly connected to the left side of the top of the base, two front and back slide rails are arranged at the top of the base, the above of each slide rail is slidably connected with two left and right moving seats, and a shears-fork type lift mechanism is hinged above the left and right moving seats; a top plate is arranged above the shears-fork type lift mechanism; an adjusting seat is arranged at the top of the top plate, a dust-free cover is fixedly connected to the right wall of the adjusting seat, a motor is fixedly arranged at the top of the adjusting seat, a motor shaft at the right end of the motor penetrates the dust-free cover to be fixedly connected with a rotary disk, and a grinding disk is connected with the right end face of the rotary disk. By the arrangement, the top plate can be easily adjusted in height, and walls or wall tops of different heights can be ground and polished conveniently; the grinding disk is arranged upwards through adjustment, ceilings can be ground and polished, and the lifting type dust-free wall grinding machine is wide in application.

Owner:北京艺轩吉装饰工程有限公司

Double jointed hinge and foldable deck using same

InactiveUS20060255609A1EconomicallyEfficient designVehicle arrangementsLoading/unloading vehicle arrangmentFree wallAerospace engineering

A foldable deck for supporting cargo in a freight compartment is provided. The foldable deck includes a pair of deck panels connected by a double jointed hinge. The foldable deck is mounted on one of the side walls of the freight compartment and is capable of movement between a secure upright position and an extended horizontal deployed position. When the deck panels are in their deployed position they at least partially define a platform above the floor of the vehicle freight compartment. The double jointed hinge has a hinge member having a pair of pivot pins and slot pins that alternate between a deployed position and an upright position. The free end rests upon a channel or catch rail on the free wall opposite the attachment wall.

Owner:JPS CORP

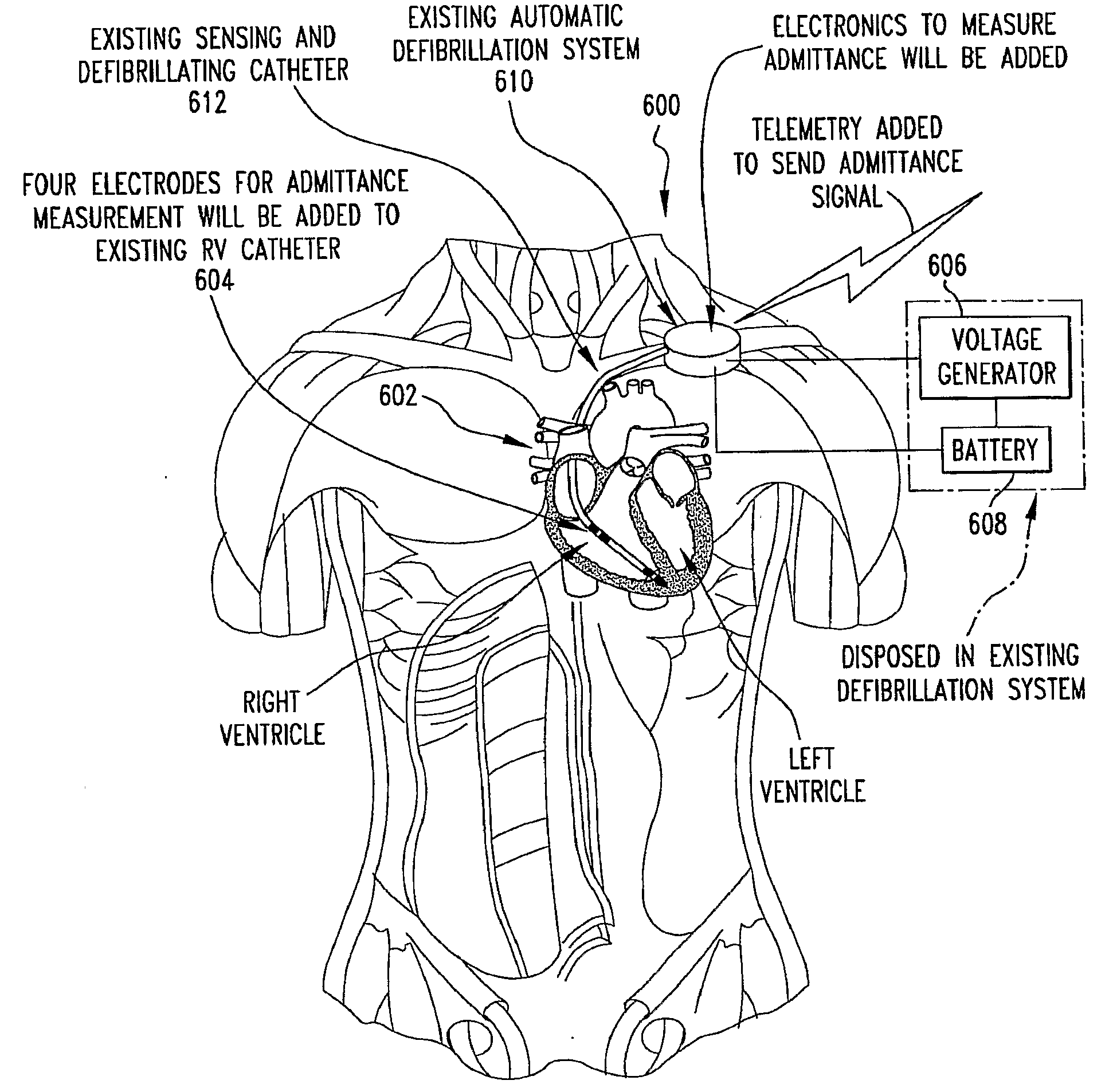

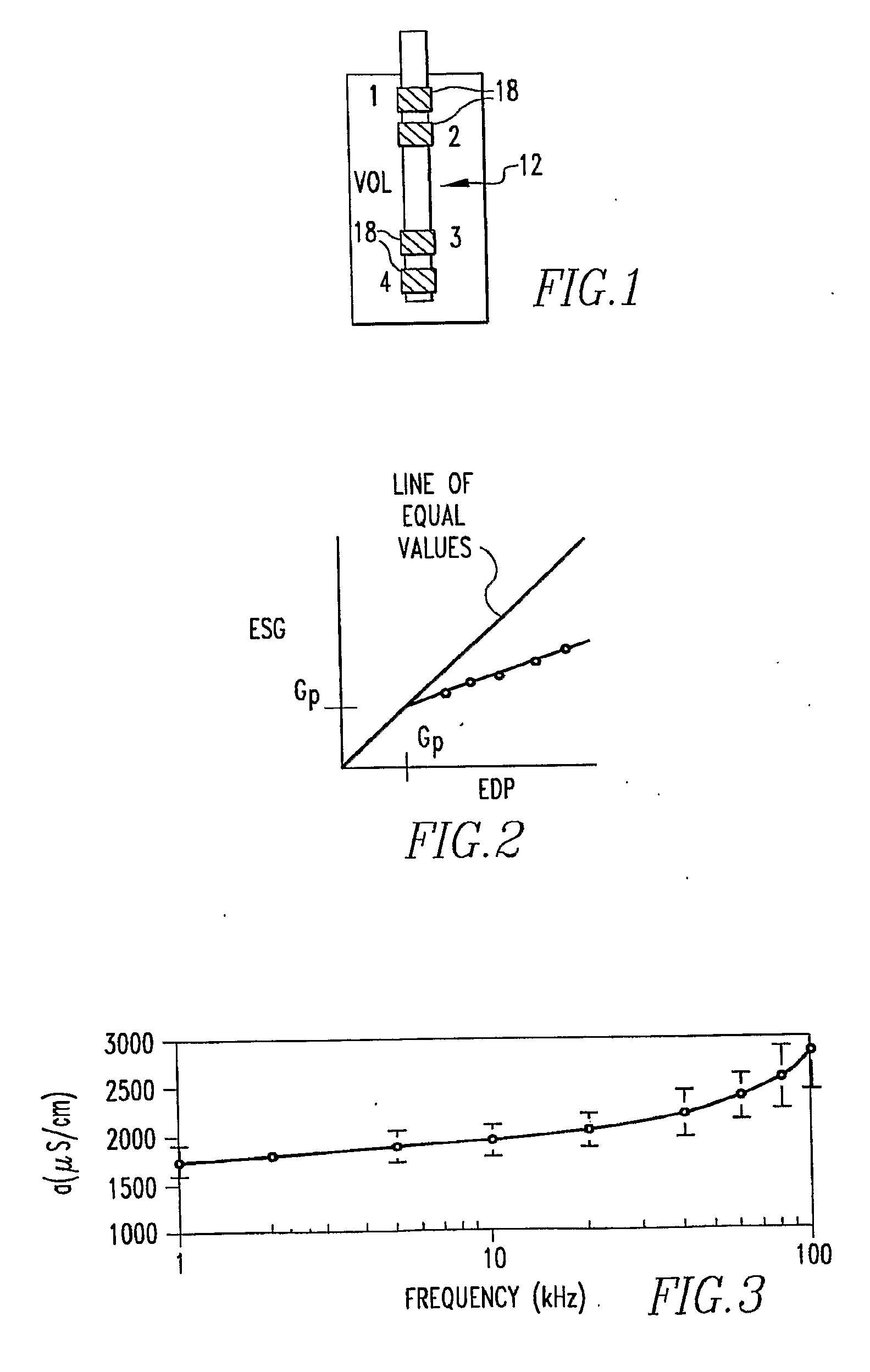

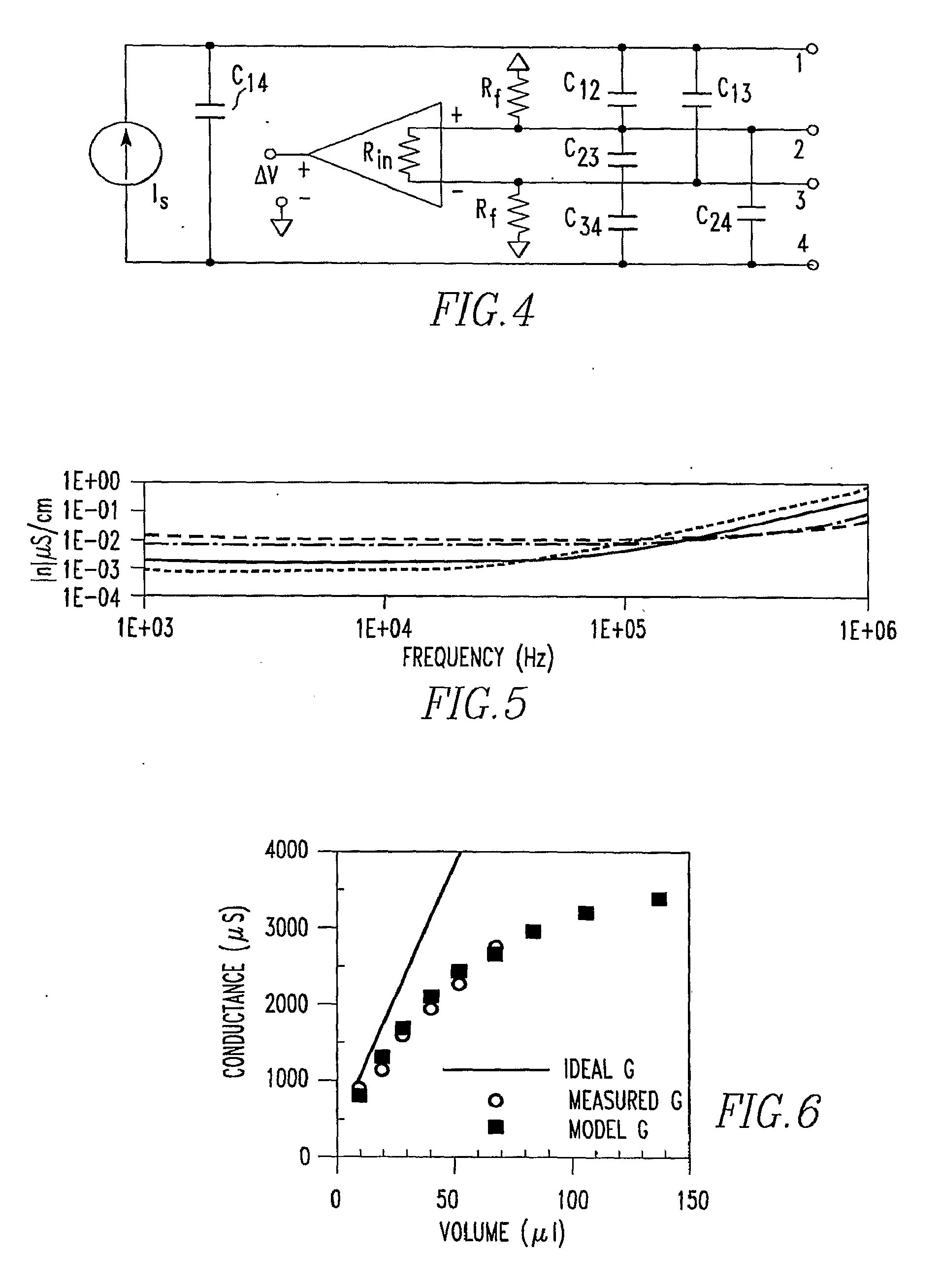

Method and Apparatus for Determining Cardiac Performance in a Patient

PendingUS20090210020A1Determining performanceDetermining volumeHeart defibrillatorsCatheterVoltage generatorCardiac pacemaker electrode

An apparatus for determining heart transplant rejection of a heart in a patient includes at least two electrodes adapted to be sewn into the heart that span the left ventricle. The apparatus includes a voltage generator adapted to be inserted in the patient which generates a voltage to the two electrodes and senses the resulting voltage from the two electrodes. A method for determining heart transplant rejection of a heart in a patient. A pacemaker for a patient (including bi-ventricular pacing and AICDs). The pacemaker includes an RV lead having four electrodes adapted to be inserted into the RV apex. The pacemaker includes a voltage generator which generates a voltage signal to the electrodes and senses the instantaneous voltage along the length of the RV and determines the real and imaginary components to remove the myocardial components of the septum and RV free wall to determine absolute RV blood volume. The pacemaker includes a battery connected to the voltage generator. The pacemaker includes a defibrillator connected to the battery. The pacemaker can also be a bi-ventricular pacemaker to restore RV and LV synchrony during contraction. A method for assisting a heart of a patient.

Owner:FELDMAN MARC D +2

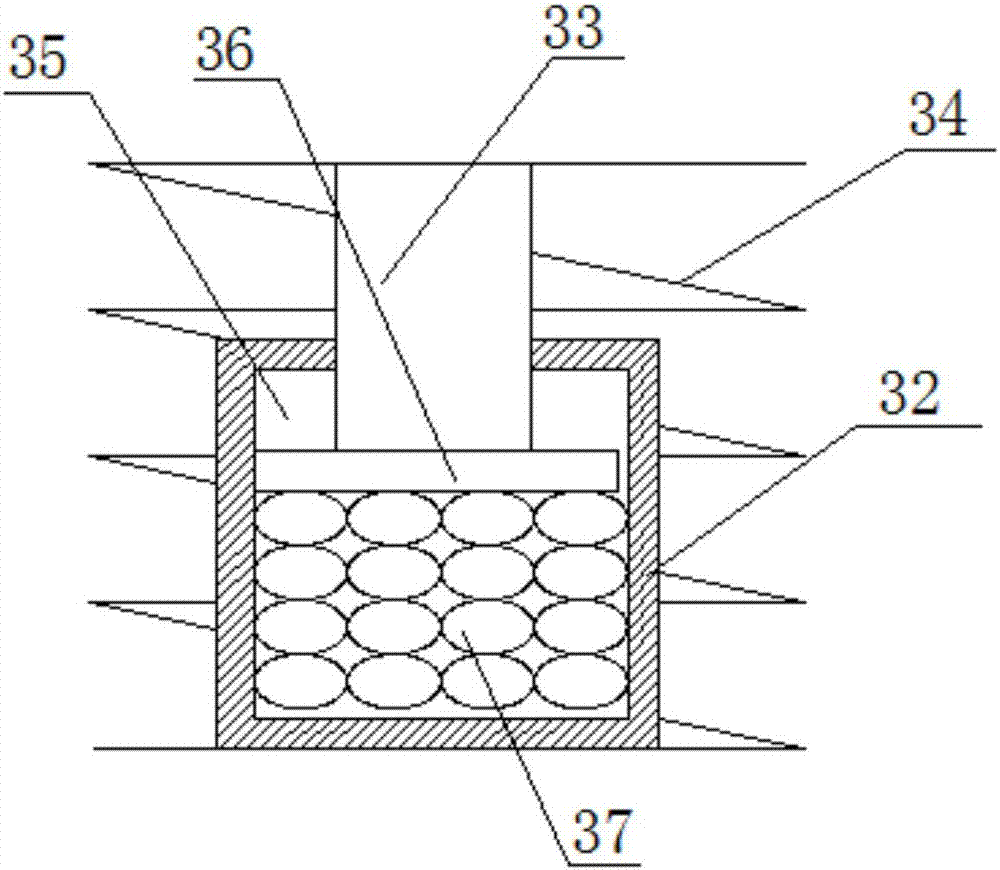

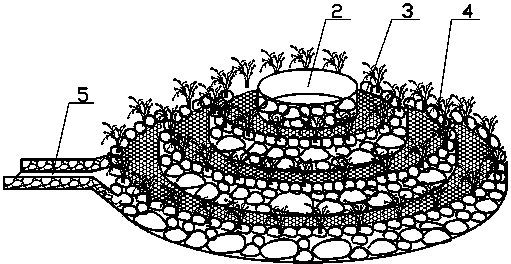

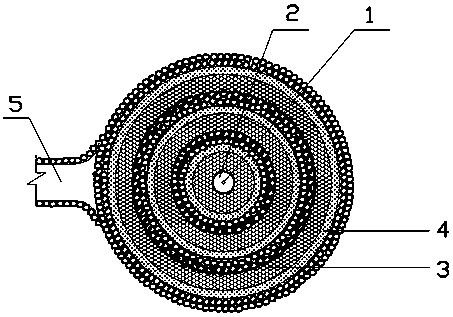

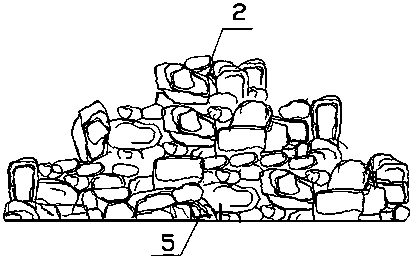

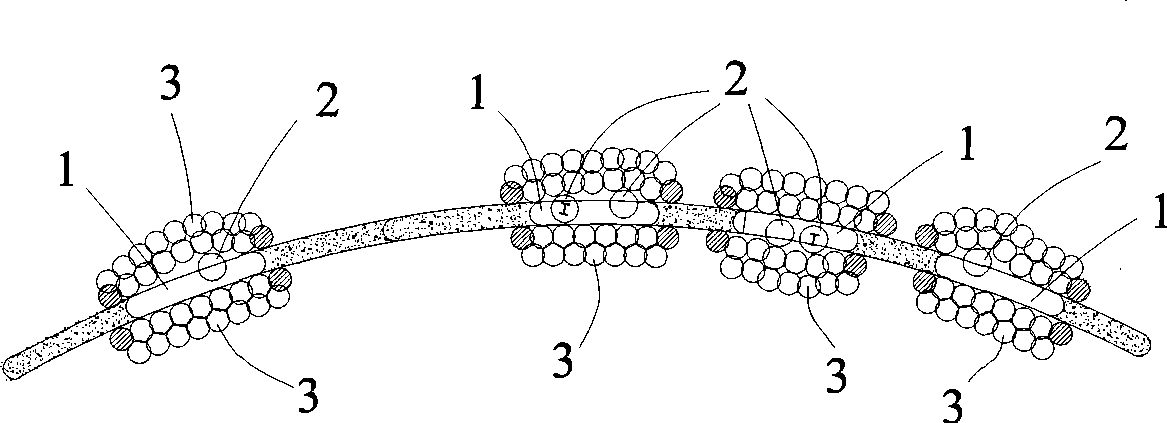

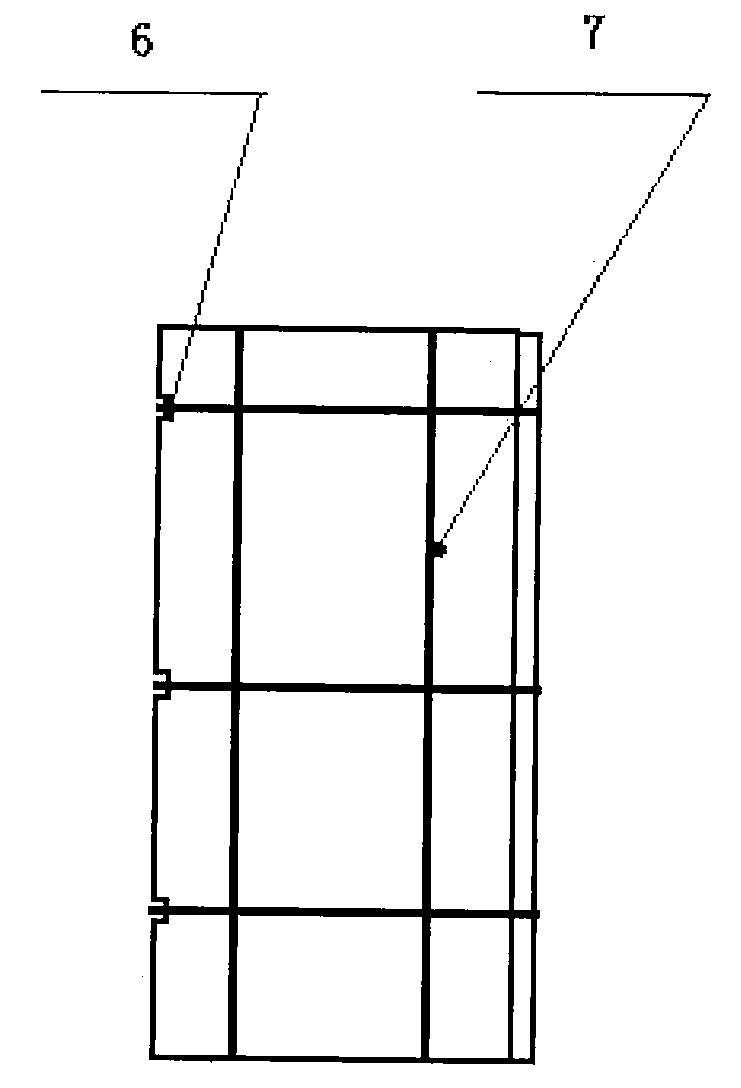

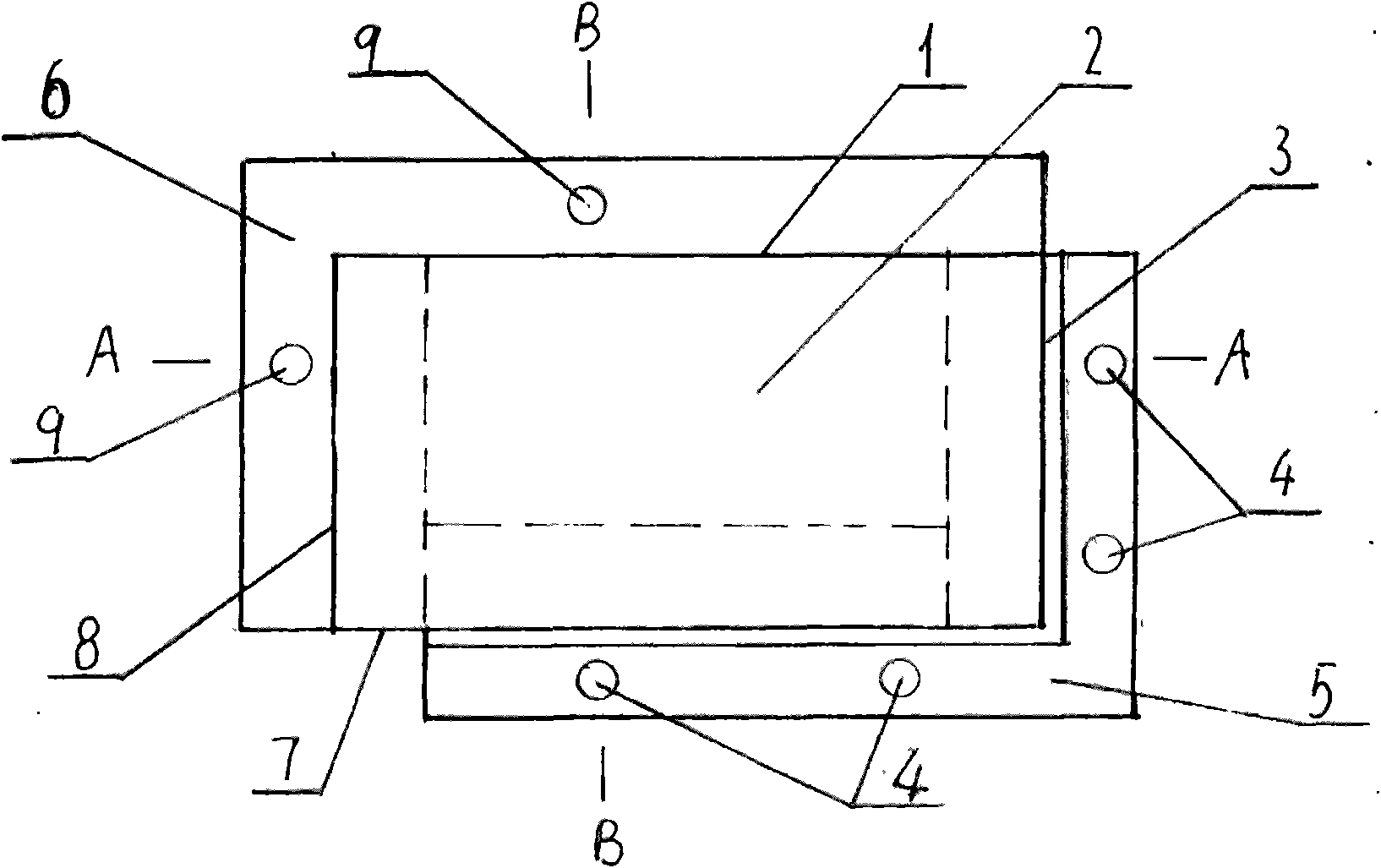

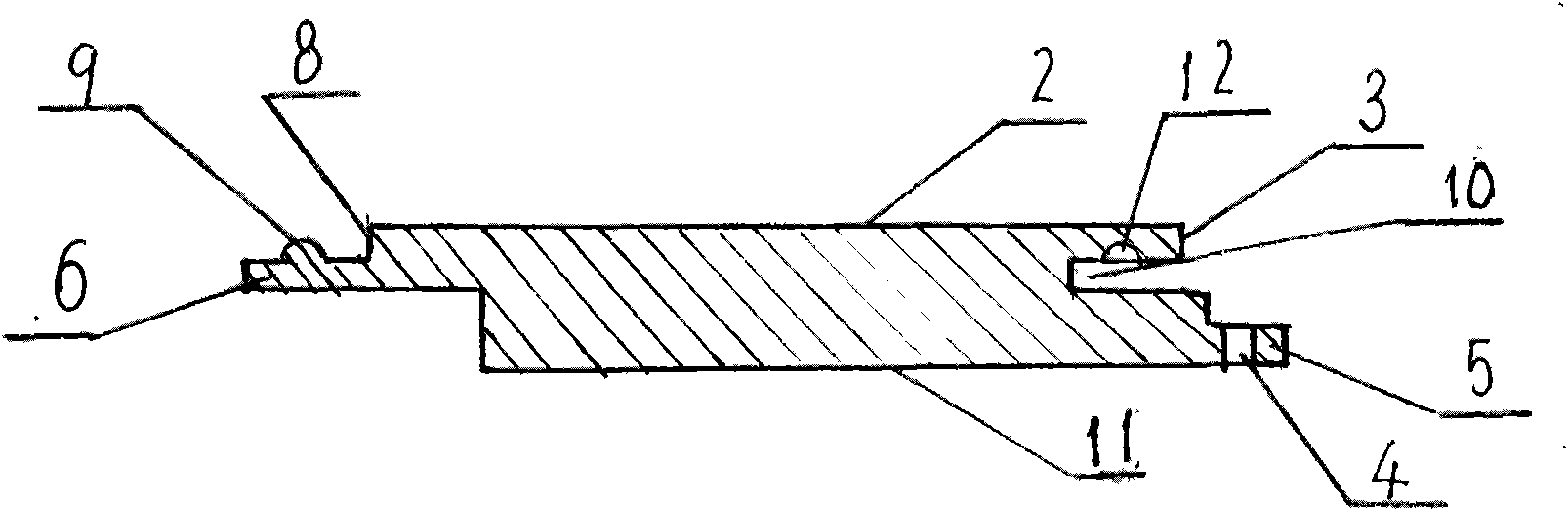

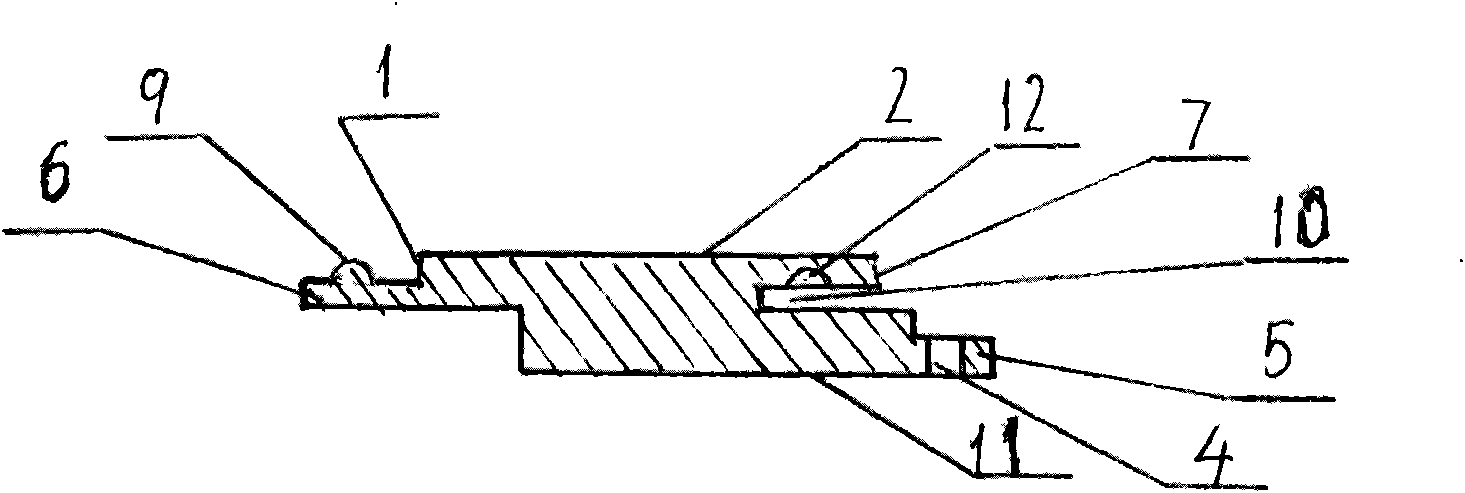

View tower type device for water aeration and biological purification, and purification method

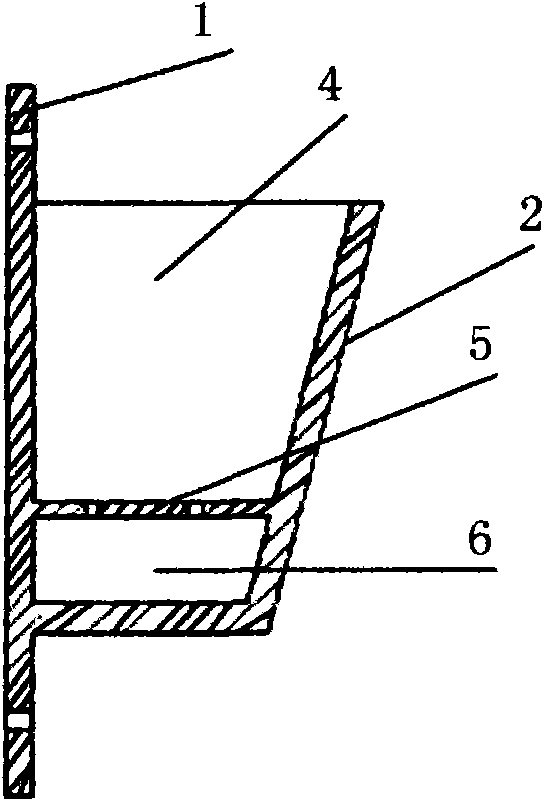

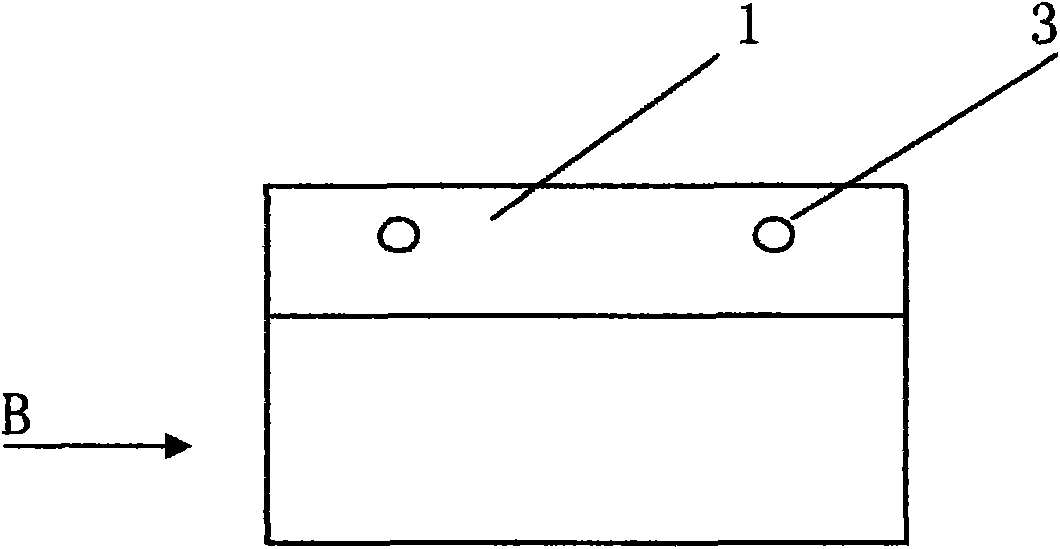

InactiveCN103833138AIncrease dissolved oxygen concentrationImprove processing efficiencyBiological water/sewage treatmentConstructed wetlandPurification methods

The invention relates to a view tower type device for water aeration and biological purification. The structure of the view tower type device is a tower type structure, and the device comprises a water outlet 1, a spill pit 2 and an outlet channel 5, wherein the water outlet 1 is formed at the center of the spill pit 2, and the outlet channel 5 is communicated with the water outlet 1; a plurality of functional layers are arranged to surround the spill pit 2, each functional layer comprises a biological ball purification region 3 and a landscape aquatic plant region 4, and the landscape aquatic plant region 4 is arranged to surround the biological ball purification region, one end of the spill pit 2 is connected with a water duct 7, and a water pump 6 is mounted at the other end of the water duct 7. The view tower type device has the advantages that the dissolved oxygen concentration in sewage is improved by virtue of free wall fall, and a biological enhanced treatment function is added so that the treatment efficiency of constructed wetlands can be improved obviously and the water quality of the sewage plant effluent can be improved. Compared with existing techniques, the landscape functions of the constructed wetlands are not damaged, and the landscape effect of the constructed wetlands and the sewage plants also are added. In addition, the view tower type device for water aeration and biological purification is simple in structure, low in construction cost and convenient to repair.

Owner:HOHAI UNIV

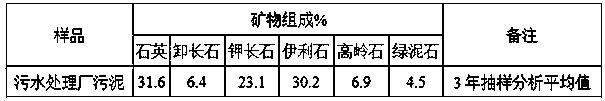

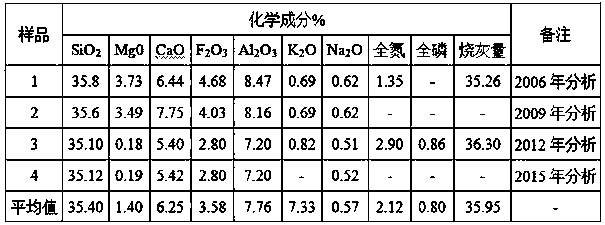

Method for pressing steaming-free and baking-free wall body block from dehydrated sludge in sewage treatment plant

The invention discloses a method for pressing a steaming-free and baking-free wall body block from dehydrated sludge in a sewage treatment plant. The method specifically comprises the following steps:dehydrating sludge of the sewage treatment plant, modifying the dehydrated sludge by virtue of seashell dust, ferrous sulfate and calcium hydroxide, so as to obtain modified sludge; mixing the modified sludge, the seashell dust, calcium sulfate, silica fume, slag charge, an F14 liquid activating agent and water, so as to obtain a mixture; digesting the mixture, so as to obtain a digested material; mixing the digested material, a solidifying agent and a YW-type surfactant, so as to obtain a blank preparing material; preparing a product workblank from the blank preparing material by virtue of apunching system; and carrying out pre-maintenance on the product workblank, and carrying out thermal air circulating reaction maintenance on the product workblank, so as to obtain the wall body block. The method has the beneficial effects that the problems in the effective treatment and resource utilization of the dehydrated sludge and industrial waste residue or engineering muck in the sewage treatment plant are solved, the cost is low, an obtained baking-free brick has excellent compressive strength, has no radioactivity, can be used for producing multiple specifications of wall body blocksand can be manufactured into building components for various uses.

Owner:宁波纯恒固废科技有限公司

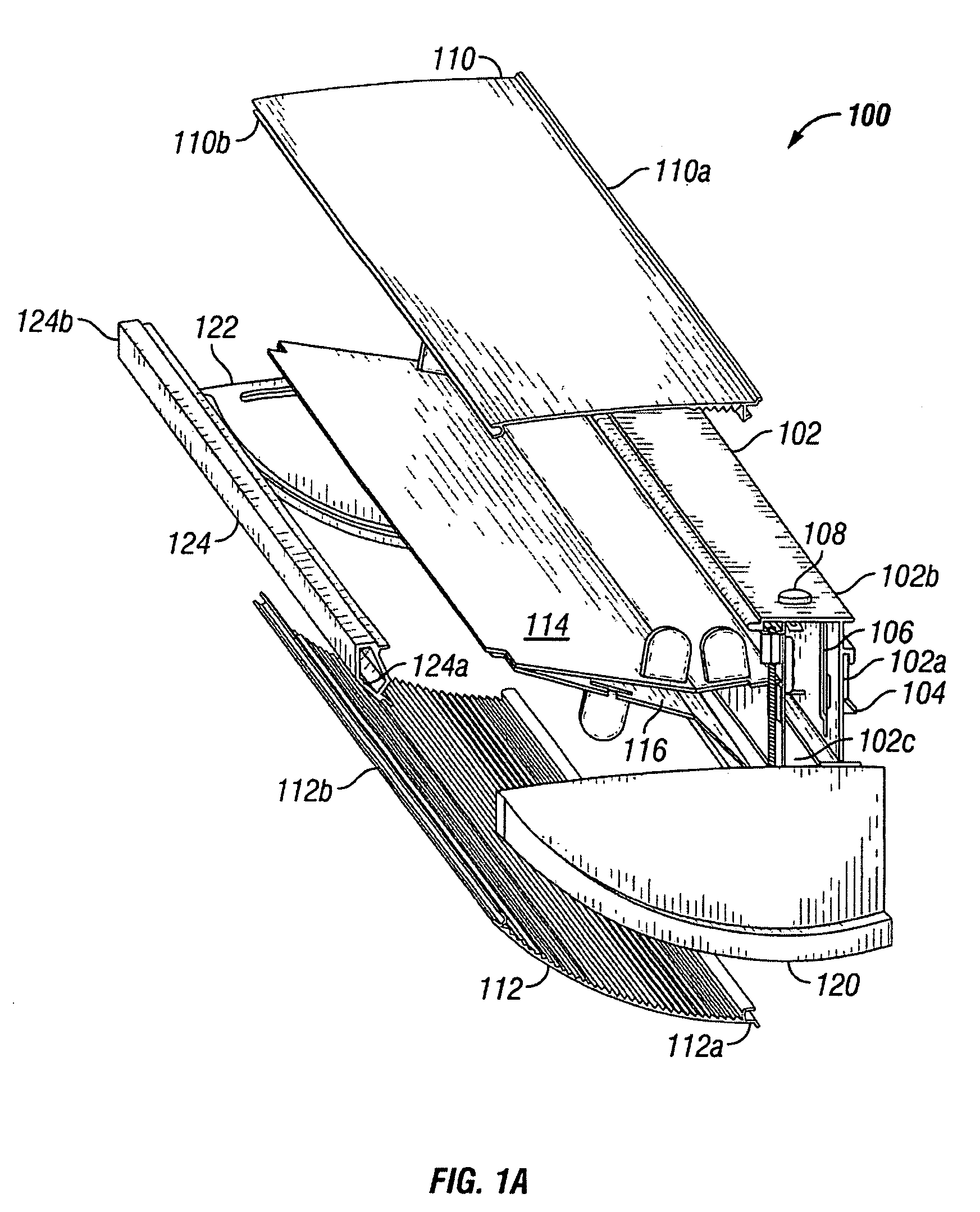

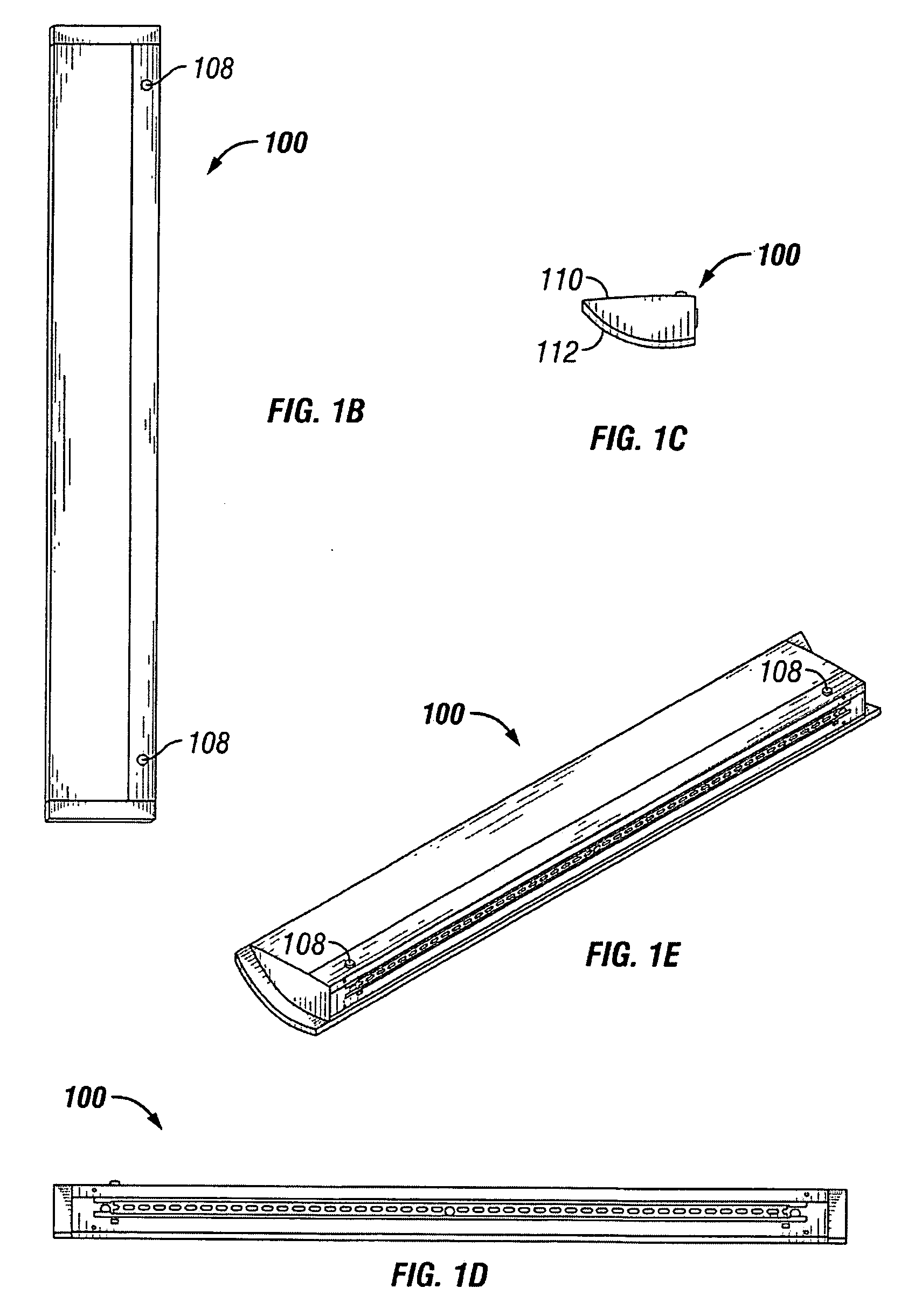

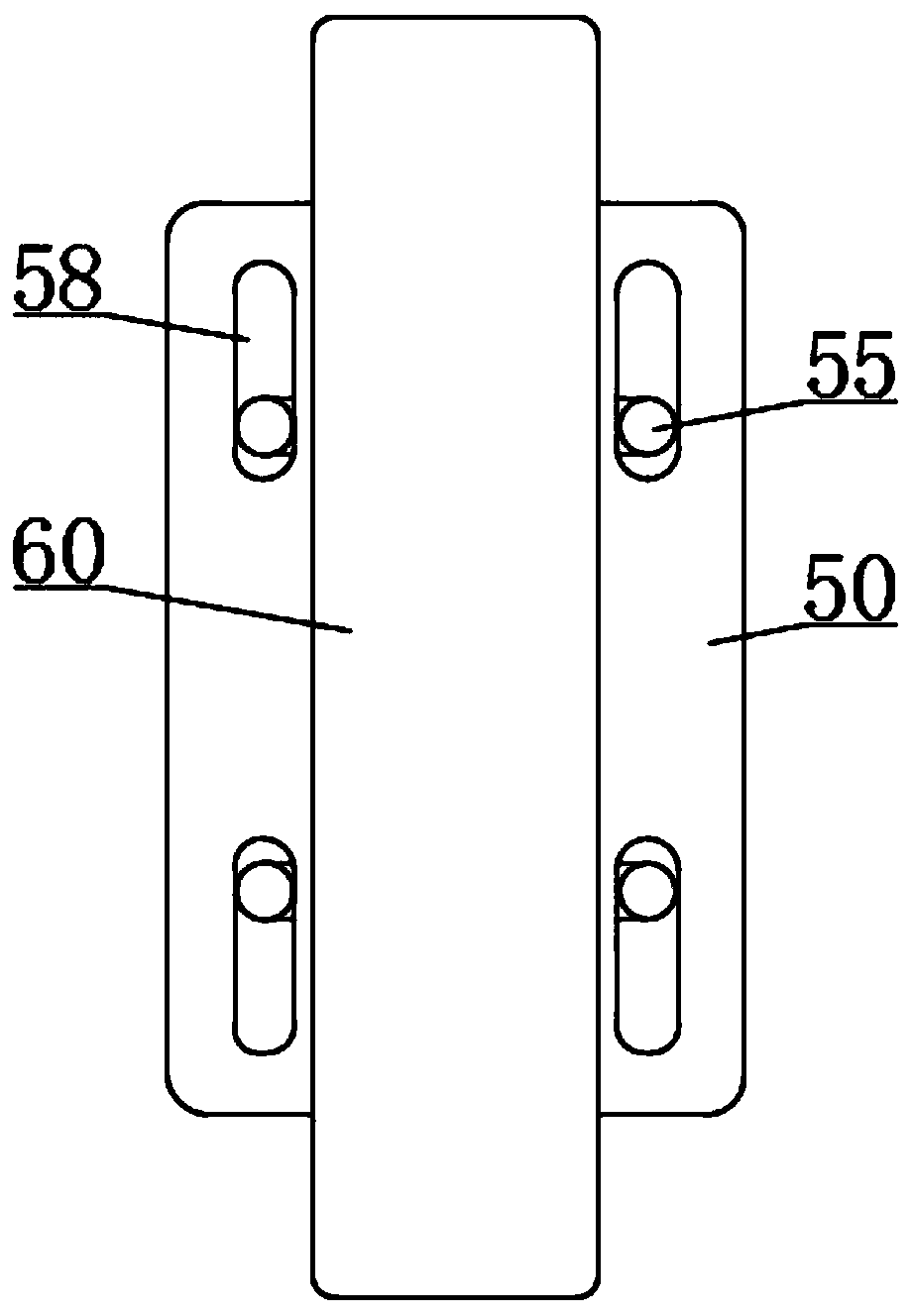

Apparatus and Method for Tool Free Wall Mount Installation of a Luminaire

The wall mountable lighting fixture does not require tools to attach and remove the fixture from a wall surface. The wall mountable lighting fixture includes an attachment mechanism that can be manipulated from a first position to a second position by the push of a button. The button is pressed and the dimension of the attachment mechanism is increased and placed about the edges of a DIN rail attached to the wall. When the button is released, a biasing member returns the attachment mechanism to the first position, thereby reducing the dimension of the attachment mechanism. Once reduced, the dimension is smaller than the critical dimension of the DIN rail and either grips or rests within the DIN rail, thereby holding the fixture to the wall surface. Reversing the steps allows for the removal of the fixture from the wall for repair or replacement.

Owner:COOPER TECH CO

Construction method for special underground continuous wall

The invention provides a method for constructing a special underground continuous wall. The underground continuous wall comprises a wall body with indelible embedded barriers, wherein the wall body with the indelible embedded barriers is positioned between barrier-free wall bodies. The construction method comprises the following steps: (a) the normal barrier-free wall bodies on the left and the right sides of the wall body with the embedded barriers are constructed; (b) the operation of groove wall reinforcement is carried out on the grooving area of the wall body with the embedded barriers, and a reinforced structure and the barrier-free wall bodies on both sides form a relatively enclosed area; and (c) special grooving technological construction is carried out in the relatively enclosed wall body area. By adopting the method, the indelible barriers in the wall body of the underground wall can work together with the underground wall, thereby guaranteeing the integrality and the constructional feasibility of the underground continuous wall used as a permanent structure or a space enclosing structure, shortening man-hour, and saving the production cost.

Owner:LONGYUAN CONSTR GROUP

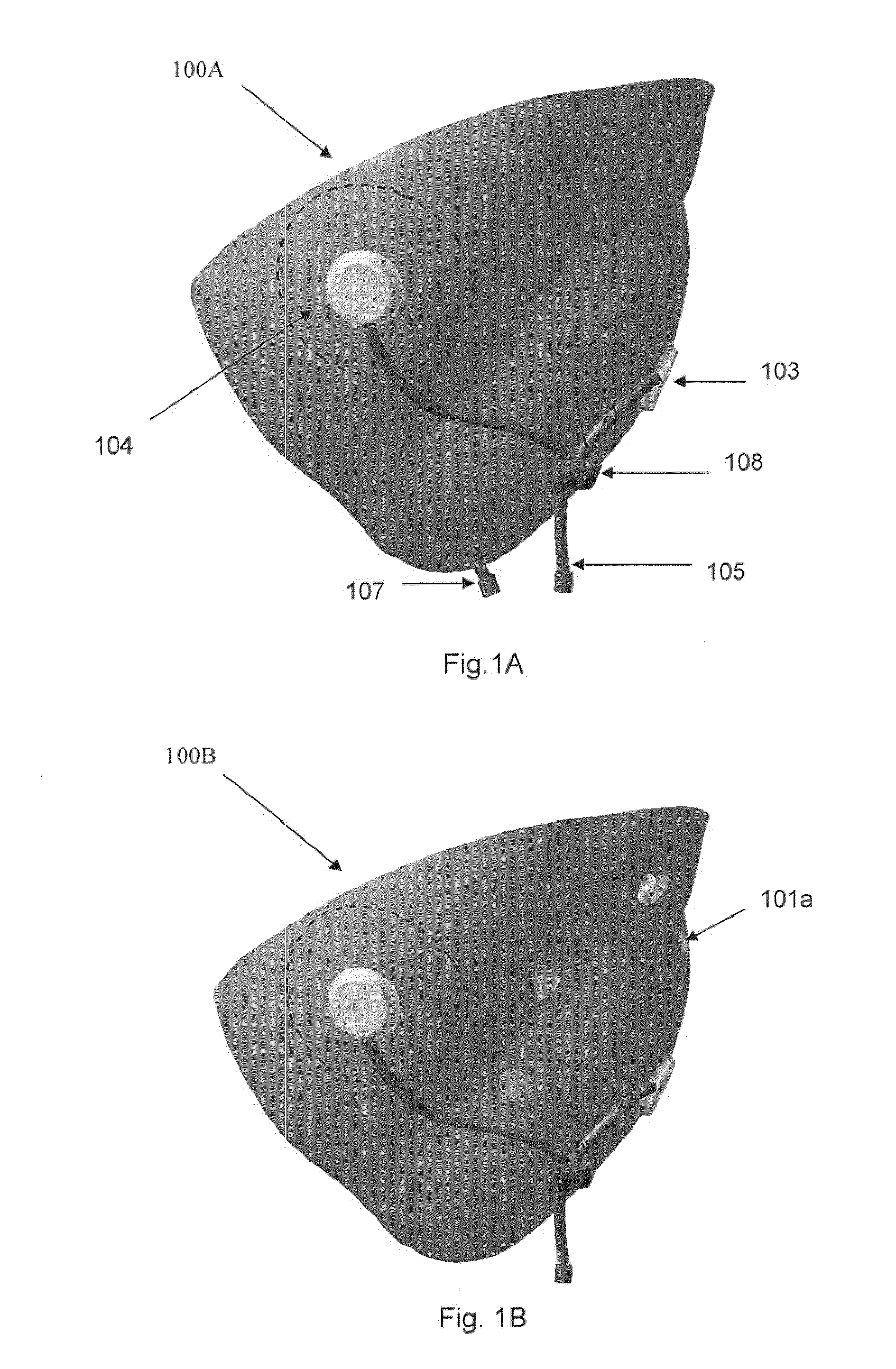

Cardiac Compression System

InactiveUS20100256441A1Improve efficiencyReducing vascular afterloadElectrocardiographyControl devicesFree wallCardiac muscle

The present direct cardiac compression (DCC) design, termed Cardiac Resynchronization Compression Sac System (CRCSS), combines together the mechanical and electrical characteristics associated with DCC and cardiac resynchronization therapy (CRT), respectively. The CRCSS comprises a shell, at least one opening on the shell, and at least one inflatable balloon, and a pumping system. The shell is custom manufactured to substantially conform to the contour of a portion of a heart, the contour of the heart being obtained by an imaging system. The opening on the shell is designed for passing pericardial fluid so as not to impede the myocardial contraction. The inflatable balloon attaches to at least one predetermined location of the inner surface of the shell. Furthermore, the shell naturally positions in the pericardium space without resorting to any artificial force to prevent it from dislodging from the heart, and when the inflatable balloon inflates at least one ventricular free wall of the heart is compressed.

Owner:3R LIFE SCI TAIWAN

Plastering-free wall brushing machine for building wall face

InactiveCN107201823ARealize the powder wall effectPowder wall effect avoidBuilding constructionsDrive wheelDrive shaft

The invention discloses a plaster-free plastering machine for building walls, which comprises a base, two ends of the base are connected with a rotating screw, the upper end of the rotating screw is connected with a driving handle, the lower end of the rotating screw is connected with a supporting seat, and the middle part of the upper end of the base is connected with a driving handle. The drive box is equipped with a driven shaft, the middle part of the driven shaft is connected with the driven wheel, the lower end of the driven wheel is connected with the driving wheel, the two ends of the driven shaft are connected with the rotating wheel, the upper end of the rotating wheel is connected with the driving wheel, and the upper end of the driving wheel is connected with Screw rod, the middle part of the screw rod is connected with a lifting block, the outer side of the lifting block is provided with a support column, the inner side of the lifting block is connected with a fixed plate, the rear ends of the fixed plates are connected with a lifting plate, the front ends of the fixed plates are connected with a powder wall shaft, and a powder wall shaft The middle part is connected with a plaster wall tube, the two sides of the upper end of the lifting plate are connected with reinforcing rods, and the upper end of the reinforcing rods is connected with a mortar bucket. The invention realizes the plastering effect on the building wall surface, avoids the use of a hydraulic system, and simultaneously realizes the automatic plastering of the plastering shaft.

Owner:展亚男

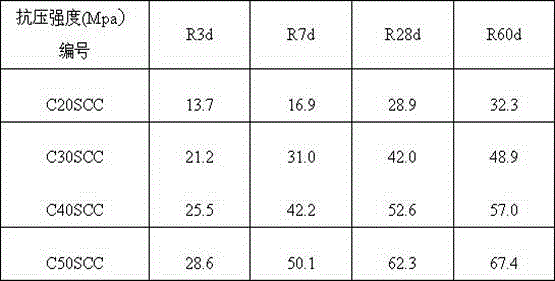

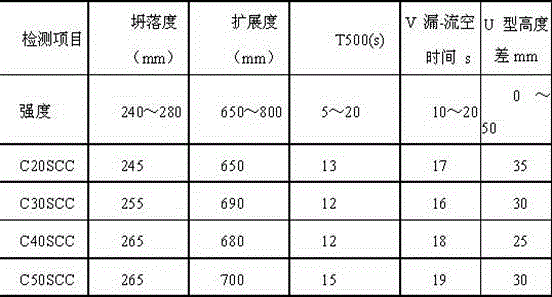

Iron ore waste rock self-compaction concrete

The invention discloses an iron ore waste rock self-compaction concrete which is prepared by mixing and stirring iron ore waste rock, cement, sand, an admixture, water and an additive. The iron ore waste rock is continuous-graded macadam with the particle size of 5-20mm prepared by carrying out mechanical crushing and screening on ore-free wall rock and horse stone after iron ore exploitation. The additive is a compound additive compounded from a polycarboxylic acid high efficiency water reducing agent, an air entraining agent and a tackifier. The admixture is a compound material from any one or more of fly ash, granulated blast-furnace cinder powder, silica fume and rock powder. The sand is Region-II natural medium sand or mixed medium sand. By developing and utilizing the iron ore waste rock, the exploitation quantity and exploitation energy consumption of the natural iron ores are lowered, and the damage of the iron ore waste rock to the environment is reduced, so that the iron ore waste rock self-compaction concrete has obvious social benefits. Besides, the development and utilization of the iron ore waste rock can greatly lower the concrete production cost, thereby generating great economic benefits.

Owner:CHINA MCC17 GRP

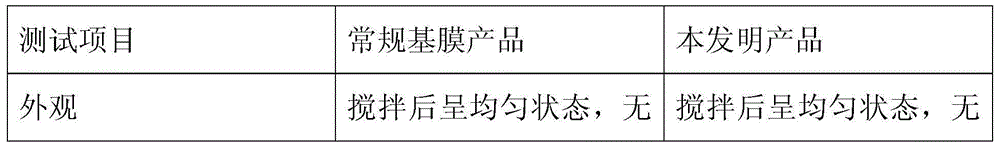

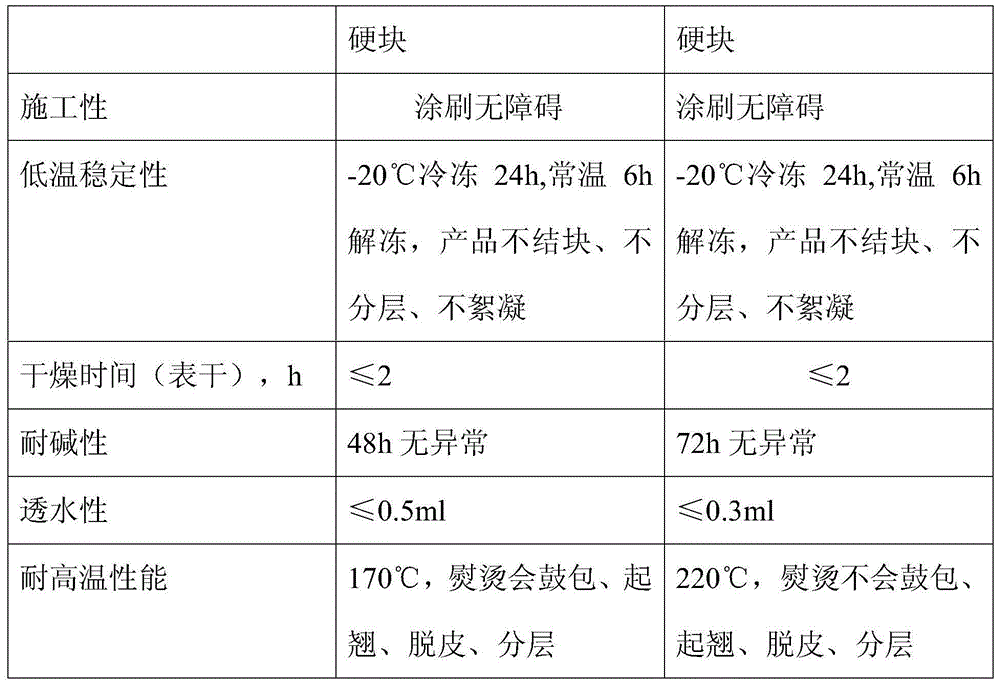

High-temperature-resistant wallpaper basic film and preparation method thereof

ActiveCN104558368AMeet the performance requirements of high temperature resistanceMeet the process requirementsAcid polymer adhesivesCoatingsPotassium persulfateSodium acetate

The invention belongs to the field of wallpaper auxiliary materials, and in particular relates to a high-temperature-resistant wallpaper basic film and a preparation method thereof. The high-temperature-resistant wallpaper basic film is prepared by stirring and mixing the following raw materials in parts by weight: 160-165 parts of acrylic acid, 9-10 parts of butyl acrylate, 15-16 parts of ethyl acrylate, 8-9 parts of methyl acrylate, 35-37 parts of methyl methacrylate, 70-75 parts of acrylonitrile, 3-3.5 parts of sodium lauryl sulfate, 9-10 parts of an emulsifying agent, 2-2.4 parts of sodium acetate, 1.2-1.4 parts of potassium persulfate, 0.8-0.9 part of ammonium persulfate, 1.5-1.6 parts of divinylbenzene, 5-7 parts of sodium hydroxide, 1.8-1.9 parts of a bactericide and an appropriate amount of water. The product provided by the invention is mainly applied to a construction base surface of glue-free wall cloth to solve the problem that a common basic film cannot meet requirements for the construction base surface of the glue-free wall cloth.

Owner:GAREFU TECH CO LTD

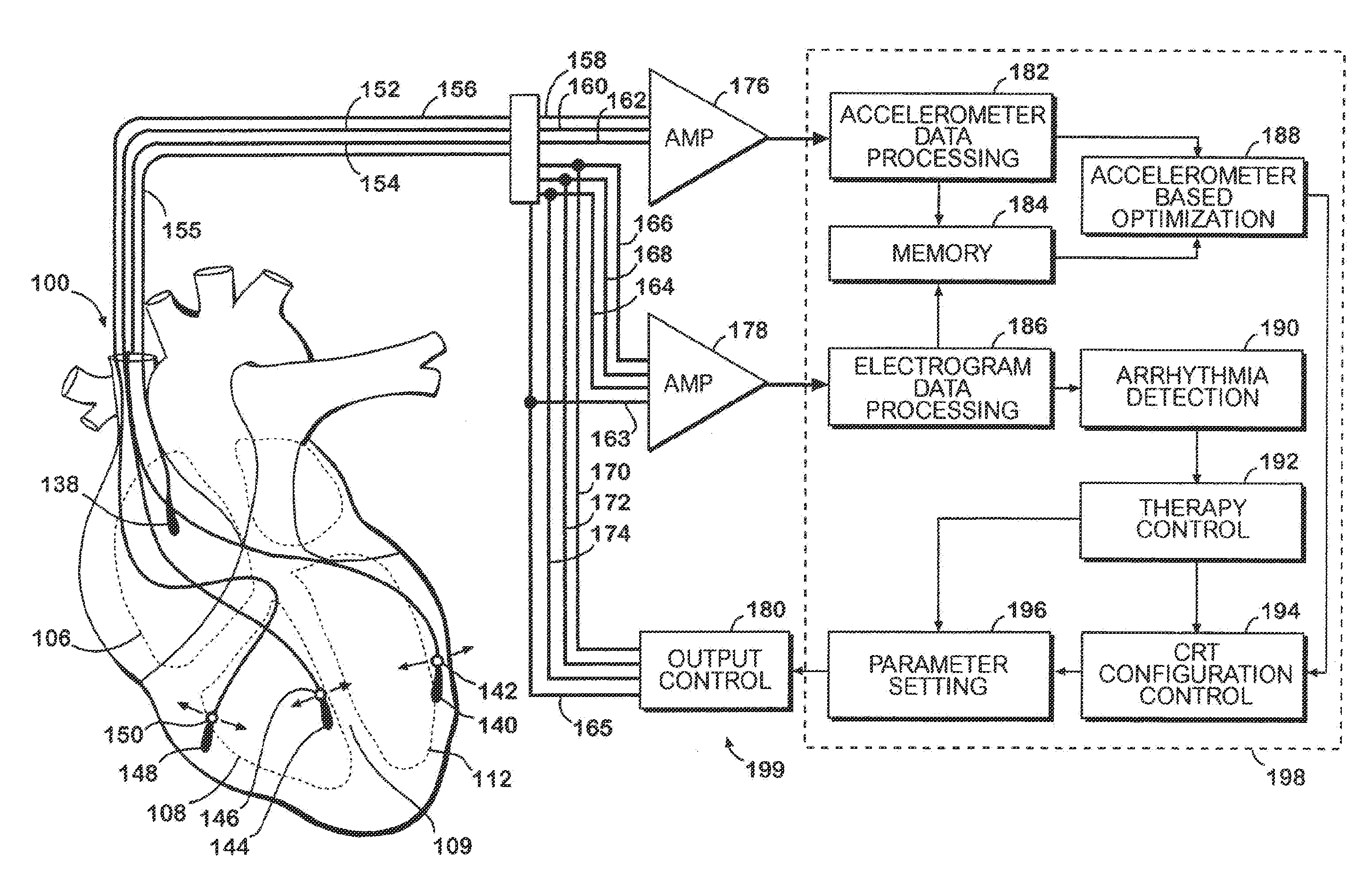

Cardiac resynchronization system employing mechanical measurement of cardiac walls

Methods and devices are disclosed for employing mechanical measurements to synchronize contractions of ventricular wall locations. Accelerometers that may be placed within electrode leads are positioned at ventricular wall locations, such as the left ventricle free wall, right ventricle free wall, and the anterior wall / septum wall. The accelerometers produce signals in response to the motion of the ventricular wall locations. A processor may then compare the signals to determine a difference in the synchronization of the ventricular wall location contractions. The difference in synchronization can be determined in various ways such as computing a phase difference and / or amplitude difference between the accelerometer signals. One or more stimulation pulses may be provided per cardiac cycle to resynchronize the contractions as measured by the accelerometers to thereby constantly and automatically optimize the cardiac resynchronization therapy.

Owner:CARDIAC PACEMAKERS INC

Method for sealing closed gas drainage hole in soft coal bed areas

ActiveCN103244073ASolve the problem of air leakageReasonable designSealing/packingFree wallCement paste

The invention relates to the technical field of mine ventilation and safety-type coal bed gas drainage, particularly to a method for sealing soft coal bed gas drainage hole areas, and solves the problem of severe air leakage of soft coal bed gas drainage hole areas. The method comprises the steps of (1), sealing gas drainage holes on a roadway lane; (2), evenly distributing 2-4 closed short holes which are 6-8m in depth within a range with the circle center of each gas drainage hole serving as the center and the radius of 1-1.5m; (3), filling each closed short hole with low-consistence high-expansion cement which permeates into coal bed fracture areas until cement paste seeps from a coal wall; (4), standing for 20-24h for solidification of cement paste to form a fracture-free wall composed of coal bodies and cement. According to the method, the design is reasonable, the hole sealing technology is improved, the defects of existing hole sealing technologies are overcome, and the problem of air leakage of coal walls is solved thoroughly.

Owner:JINCHENG MINGSHI COAL LAYER USING

Waste coal, mine slag thermostable baking-free wall, floor and tile

InactiveCN101139856AHigh strengthExtended service lifeConstruction materialSolid waste managementFiberSlag

The invention relates to a high-temperature non-burned wall, floor or panel brick made of waste coal and slag. The brick mainly comprises the following raw materials: Waste cinder powder: 25 to 35 shares; waste firebrick powder: 15 to 25 shares; calcium aluminate cement: 8 to 12 shares; ceramic fiber: 1.5 to 2.5 shares; water glass: 2.5 to 3.5 shares; and alumine, mullite or emery: 30 to 40 shares. The preparation method comprises the following technique steps: Step one, crush waste cinder and waste firebricks into powder before screening for use; step two, put the waste cinder powder, the waste firebrick powder, the calcium aluminate high-temperature cement, the ceramic fiber and the alumina, mullite or emery into a mixing container, before adding high-temperature adhesive agent water glass and suitable volume of water and mixing them uniformly; step three, put the mixture from step two into moulds to form molded firebrick blanks; step four, let the firebrick blanks in a ventilated place to dry naturally before end products of high-temperature non-burned bricks for walls, floors and panels made of waste coal and slag. The invention has advantages of saving energy, environmental protection, and no oxidation reaction with magnet steel, long service life and being possible to be reused for more than 150 turnaround times.

Owner:冯金清

Combined adhesive-free wall body surface decorative brick

A combined adhesive-free wall body surface decorative brick belongs to a building wall body decorative product. A base brick is provided with a mounting and connecting fixed hole and a countersunk head screw hole; a mounting and connecting fixed column matched with the mounting and connecting fixed hole is arranged on the inner side surface of a surface brick and is inserted and configured in the mounting and connecting fixed hole; and the surface brick is fixedly arranged on the outer surface of the base brick to form a whole. The brick adopts a surface brick and base brick combined structure, is free from using any adhesive during pavement on the wall surface and has the characteristics of novel and reasonable design, easy pavement, favorable pavement quality, easy operation, low labor intensity, high operation efficiency and long service life.

Owner:姚福才

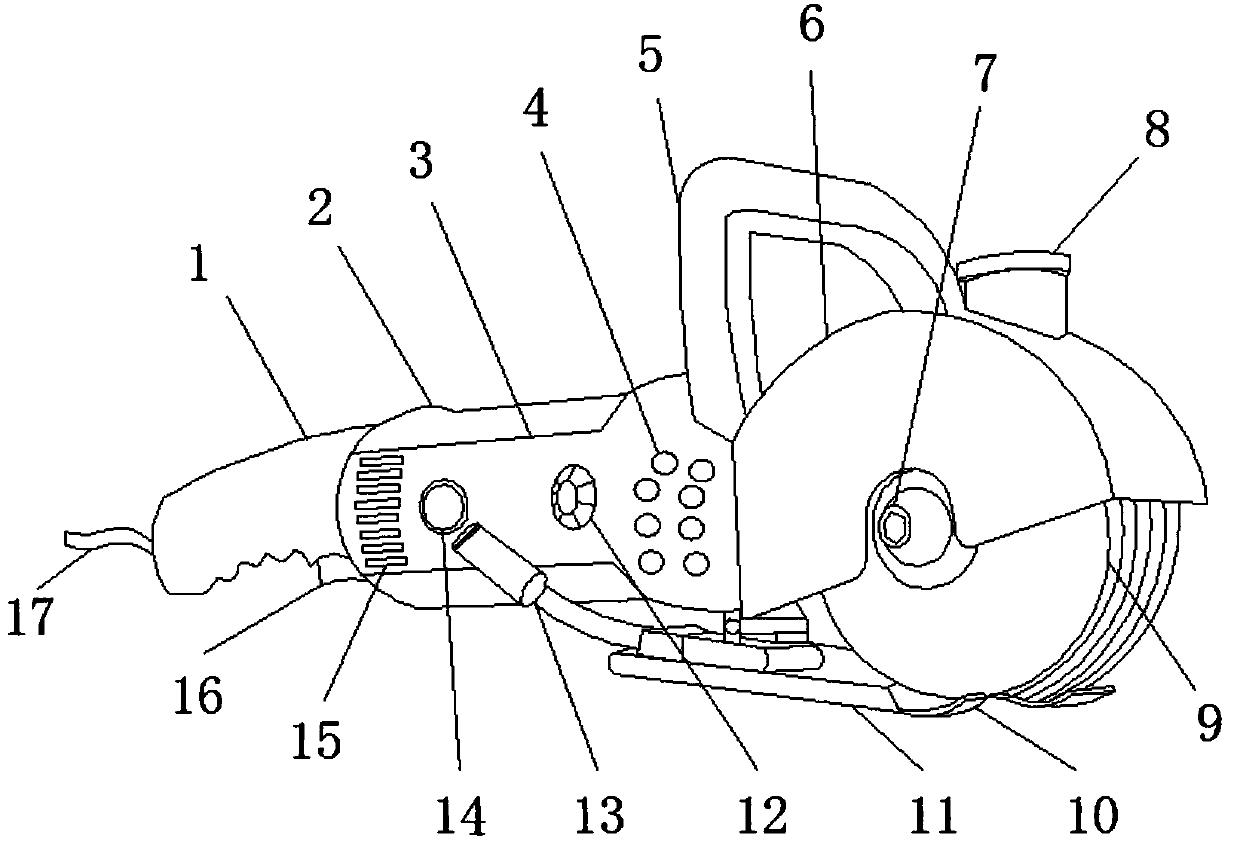

Dust-free wall grooving machine

InactiveCN109866345AHold firmlyNo slippingWorking accessoriesStone-like material working toolsFree wallWorking environment

The invention discloses a dust-free wall grooving machine. The machine comprises a main machine box, a control panel, a protective shell and a fixing plate, wherein a control handle is arranged on theleft side of the main machine box, a starting button is arranged on the lower side of the control handle, a power line is installed on the left side of the main machine box, a control panel is installed on the front surface of the main machine box, an oil tank opening is formed in the surface of the control panel, a lifting handle is arranged on the upper side of the main machine box, a protective shell is arranged on the right side of the main machine box, the lower side of the protective shell is provided with a fastening screw ring, the lower side of the main machine box is provided with the fixing plate, the right side of the fixing plate is provided with a baffle plate, the upper side of the fixing plate is provided with a supporting rod, the surface of the supporting rod is providedwith a screw, the upper side of the fixing plate is provided with a hydraulic device, and the hydraulic device is connected with the oil tank opening through an oil supply pipe. According to the machine, a dust removal pipe arranged on the upper side of the protective shell can be connected with an air draft device to clean dust generated in the grooving process, and cleanliness of a working environment of the machine is improved.

Owner:闫宇

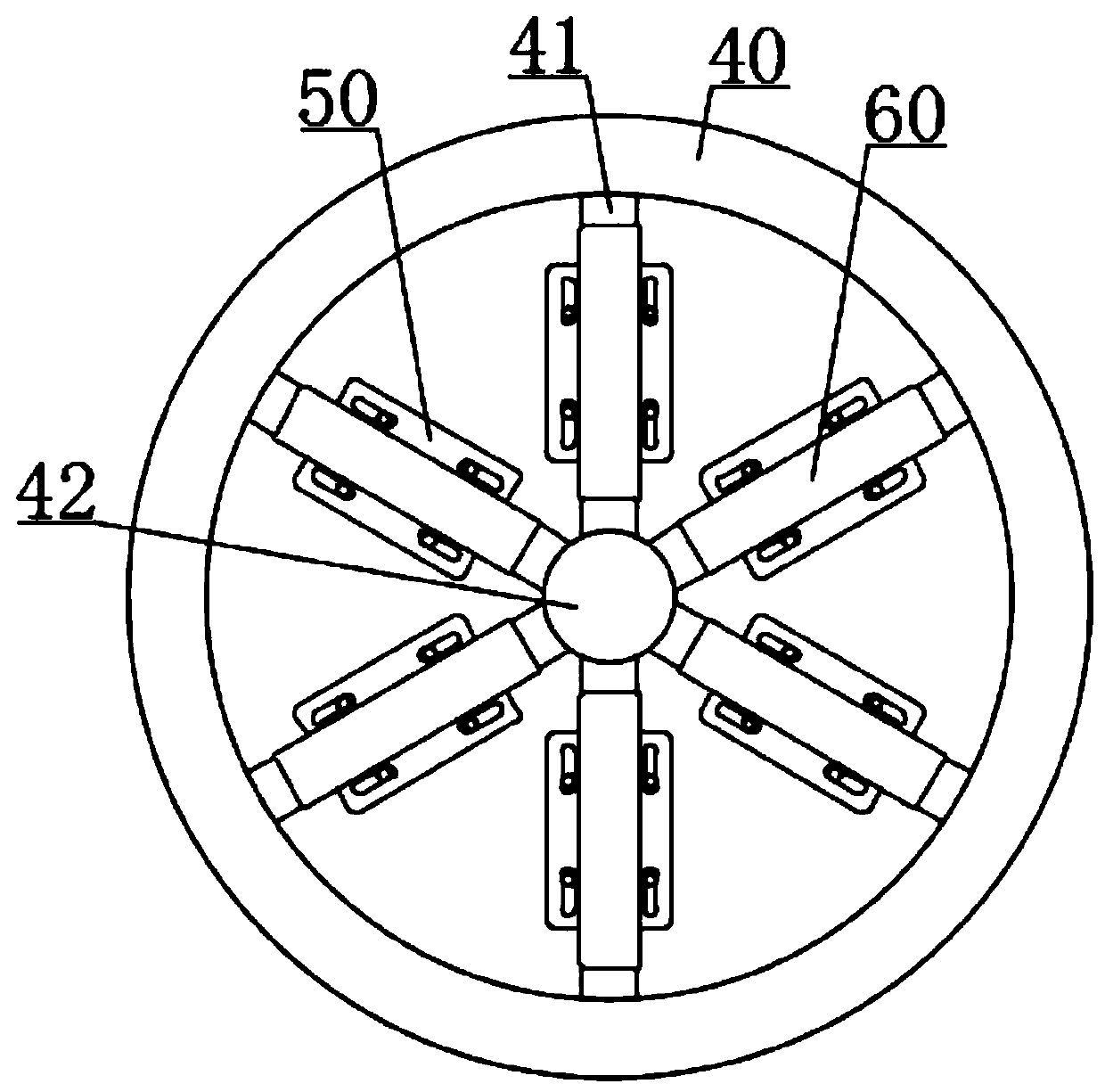

Dust-free wall surface grinding machine for building decoration

InactiveCN107150291AImprove grinding efficiencyEasy to operatePlane surface grinding machinesGrinding/polishing safety devicesFree wallArchitectural engineering

The invention provides a dust-free wall surface grinding machine for building decoration and relates to the field of building decoration tools. The dust-free wall surface grinding machine for building decoration comprises a grinding mechanism and a dust removal mechanism. The grinding mechanism comprises a millstone. Abrasive paper is arranged on one side of the millstone, the millstone is provided with a first through hole, and the abrasive paper is provided with a second through hole. The dust removal mechanism comprises a first sealing part and a dust suction part. The first sealing part is of a bowl-shaped structure with an opening formed in one end. The end, with the opening, of the first sealing part is movably buckled on the side, away from the abrasive paper, of the millstone. The first sealing part is provided with a third through hole. The dust suction part communicates with the first sealing part through the third through hole. During grinding, a second sealing part is attached to a wall surface and seals the side, used for grinding, of the millstone, and powder cannot leak. The first sealing part is buckled on the other side of the millstone and seals the other side of the millstone, and the dust is sucked by the dust suction part immediately reaching the first sealing part. The dust suction part is provided with straps, and a worker can carry the dust suction part around. The device is high in grinding efficiency and good in dust removal effect.

Owner:CHENGDU FUYANG TECH DEV

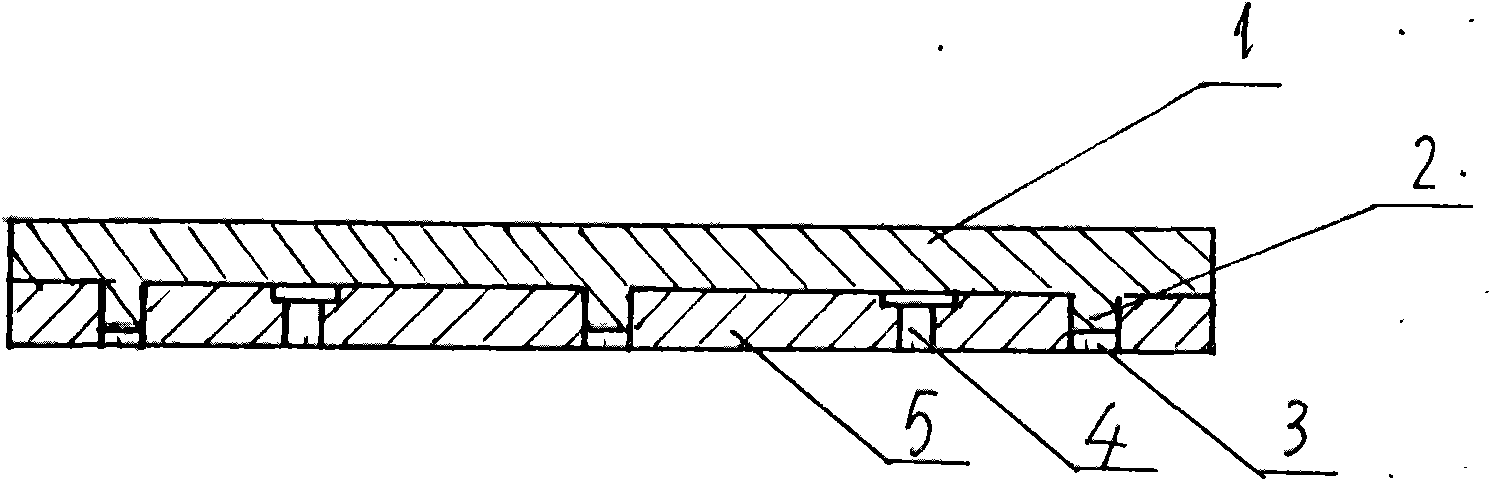

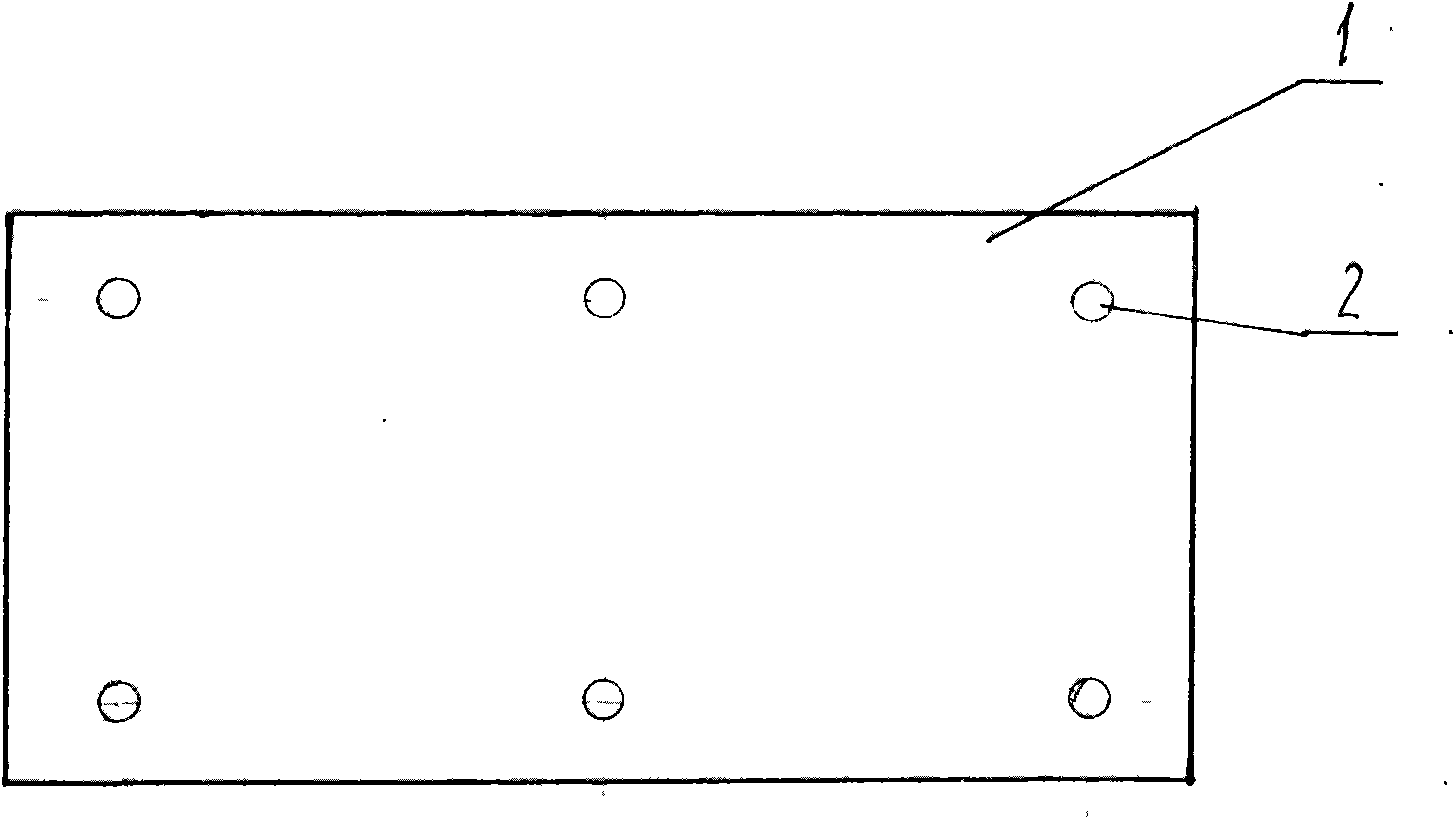

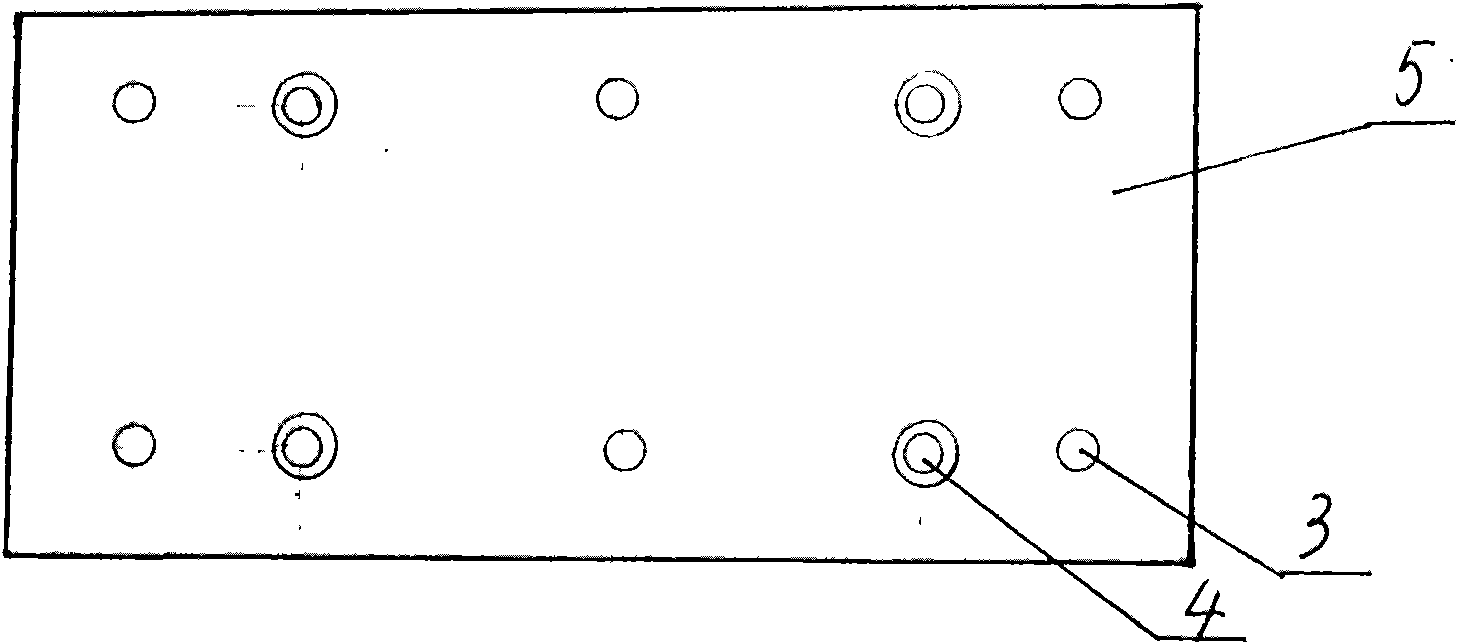

Interlayer phenomenon-free thermal insulating and soundproof cement wall board with synchronously poured and solidified three layers

Belonging to the field of building components, the invention relates to an interlayer phenomenon-free thermal insulating and soundproof cement wall board with synchronously poured and solidified three layers. Composed of concrete, foamed cement and concrete, the three-layer synchronously solidified thermal insulating and soundproof cement wall board is characterized in that the outer concrete layers and the intermediate foamed cement are almost poured and solidified synchronously and no interlayer can be generated. A special pouring device is employed to achieve synchronous pouring and solidification of the three layers so as to obtain the three-layer integrated interlayer-free wall, thus achieving the characteristics of low cost, less operation, good thermal insulating and soundproof effects, no interlayer phenomena, and large load bearing.

Owner:董禹全

Dust-free wall polishing machine used for decoration engineering

InactiveCN110605622ATo achieve the effect of grinding and dust-freeAvoid scatterPlane surface grinding machinesGrinding/polishing safety devicesFree wallArchitectural engineering

The invention discloses a dust-free wall polishing machine used for decoration engineering. The dust-free wall polishing machine used for decoration engineering comprises a base. The base comprises anelectric hydraulic push rod, a dust collector and a flexible hose. Connecting rods are uniformly and fixedly mounted between a rotary ring and a fixed disc through bolts. A supporting plate is fixedly mounted at the top of the electric hydraulic push rod through bolts. A dust cover is fixedly mounted on one side of the supporting plate through bolts. The rotary ring is located in the dust cover.The end, away from a motor, of a rotary shaft penetrates through the dust cover to be fixedly connected with the fixed disc. Mounting plates are fixedly mounted at the centers of the front sides of the connecting rods through bolts. Polishing plates are clamped to the centers of the front sides of the mounting plates. The end, away from the dust collector, of the flexible hose is connected with the dust cover in a threaded mode. According to the dust-free wall polishing machine used for decoration engineering, the dust collector collects dust in the dust cover in a centralized mode through theflexible hose so that the dust generated during polishing can be well collected and can be prevented being scattered to the outside, and accordingly, a dust-free wall polishing effect is realized.

Owner:安徽苓苓科技有限公司

Adhesive-free wall surface decorating bricks

InactiveCN101832005AReasonable and novel structure designLow technical requirements for laying operationCovering/liningsBrickAdhesive

The invention discloses adhesive-free wall surface decorating bricks, which belongs to building wall decorating products. An inserted locking groove and an installing flange are arranged on two adjacent side end faces between the outer surface of a brick body and the inner surface of a wall; a positioning locking pit is reserved on the upper or lower wall face of the inserted locking groove; an installing tack hole is reserved on the installing flange; an inserted locking flange matched with the inserted locking groove is arranged on each of another two adjacent side end faces between the outer surface of the brick body and the inner surface of the brick body respectively; and a positioning locking lug boss is arranged on the upper or lower side face of each inserted locking groove and is matched with the positioning locking pit. No adhesive is needed when the bricks are installed on the surface of a building wall; and the bricks are laid on the surface of the wall in a mechanical fixing way with mounting screws. The adhesive-free wall surface decorating bricks of the invention have the characteristics of reasonable structural design, low requirements on laying operation technology, low labor intensity, high operation efficiency, good laying quality and long service life.

Owner:姚福才

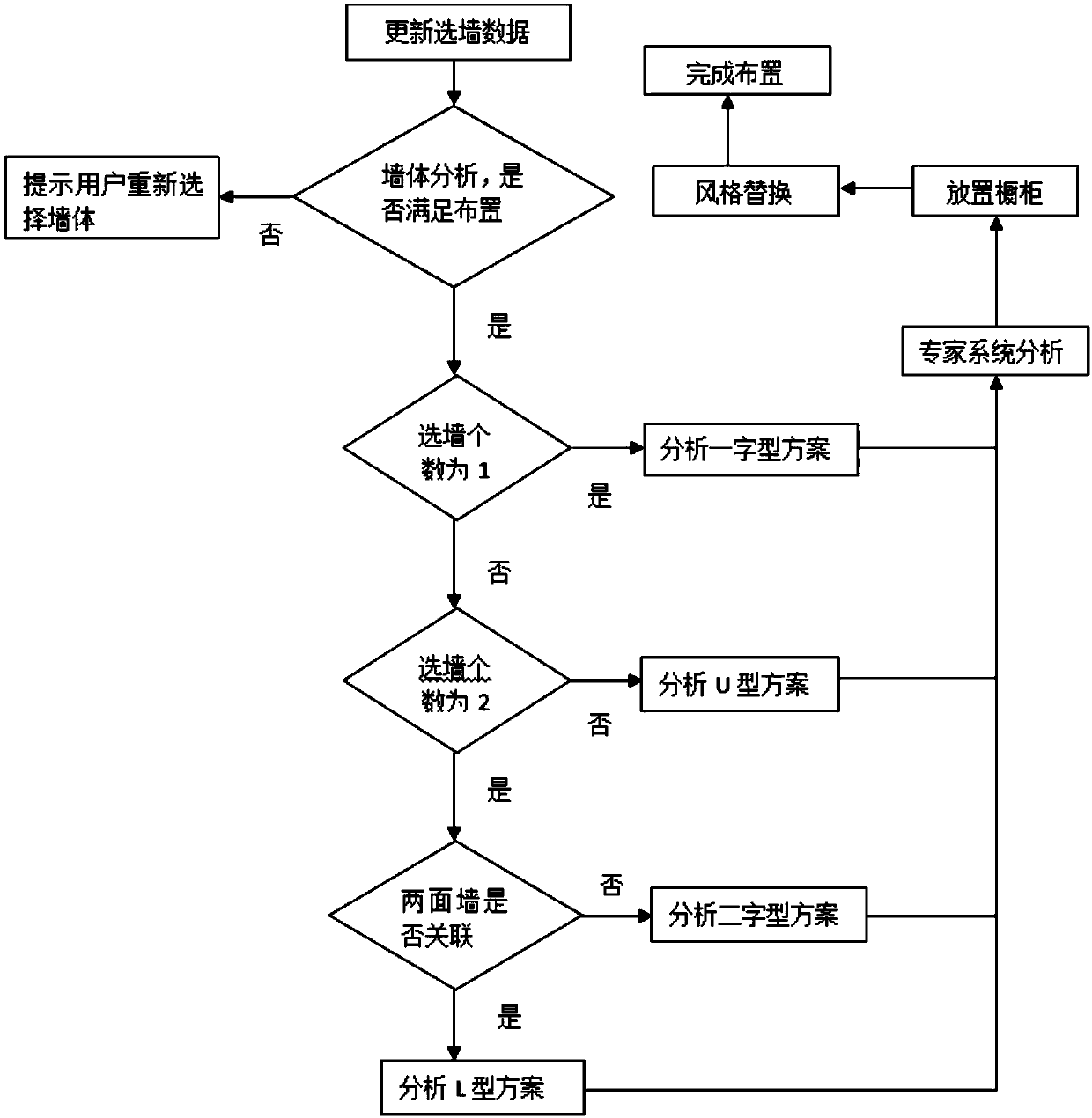

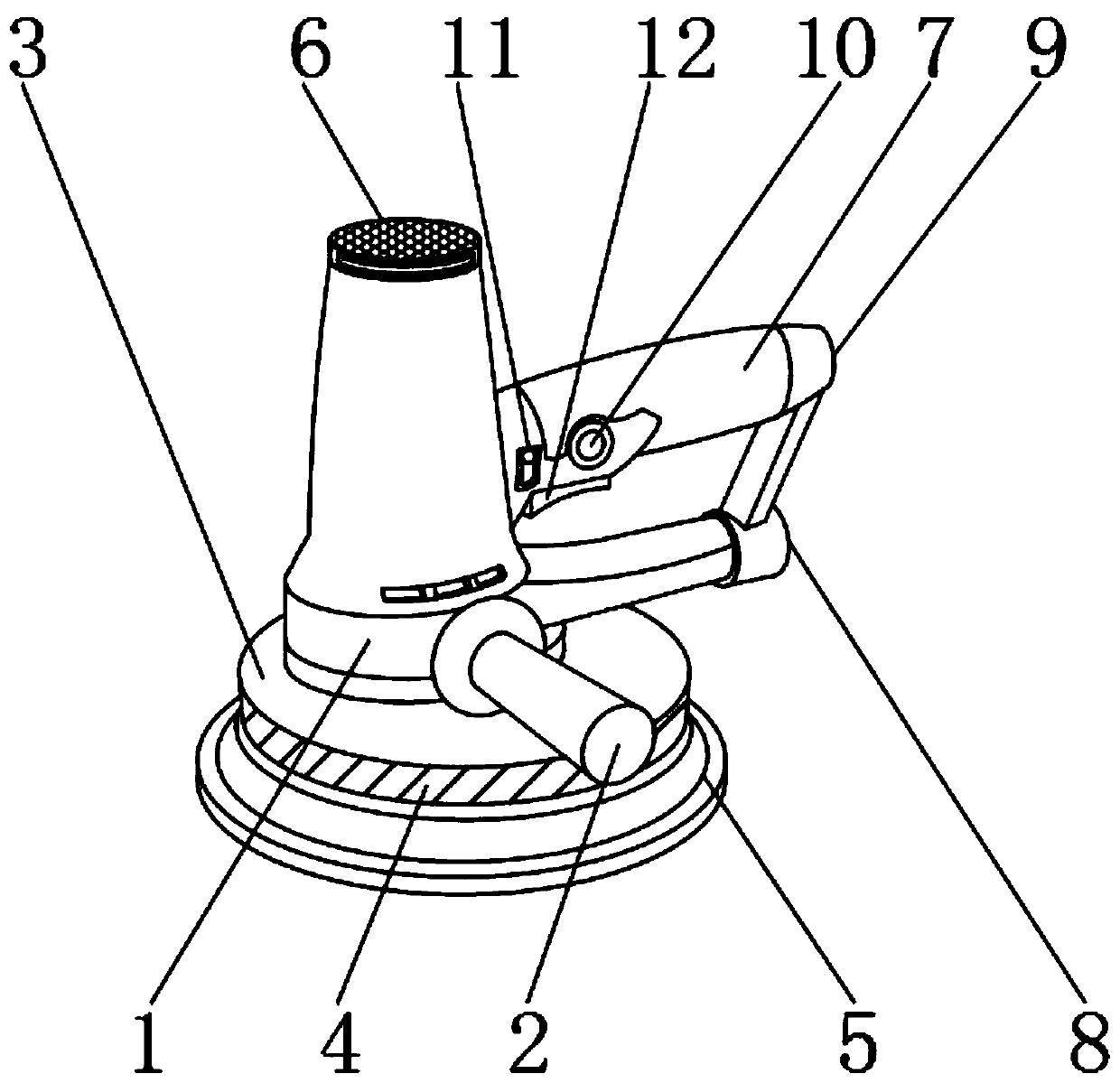

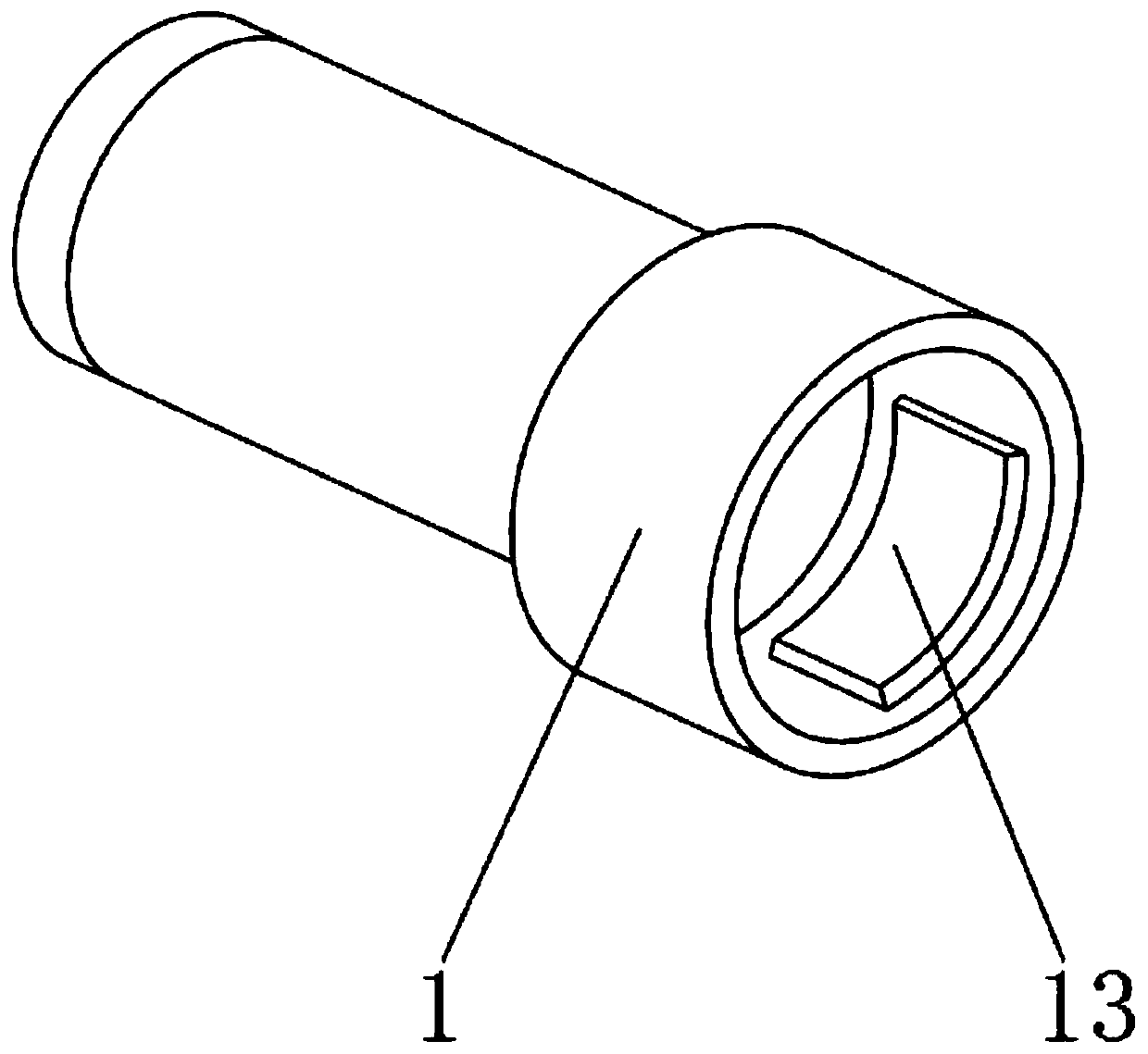

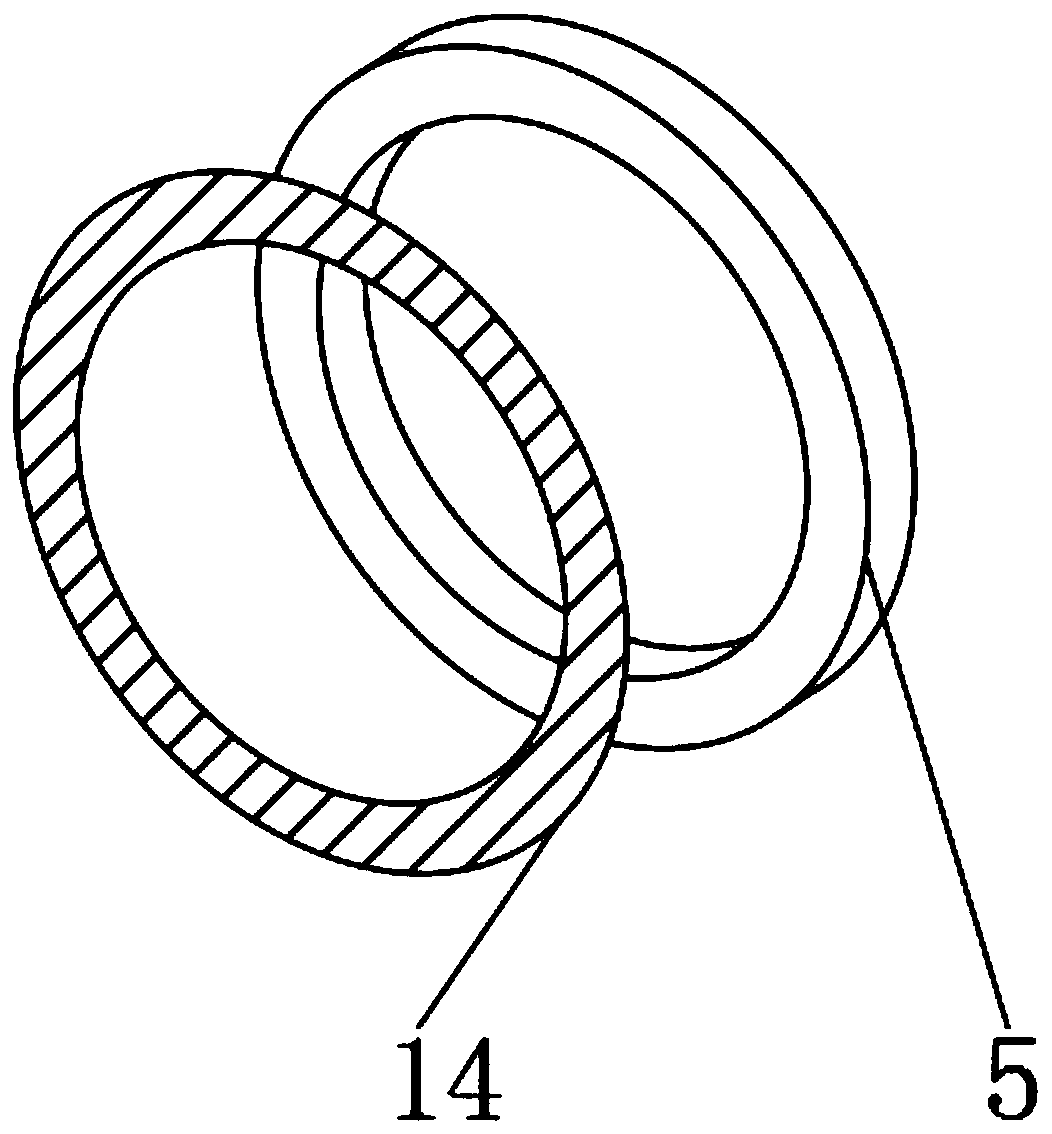

A method for intelligently generating a cabinet based on free wall selection of a user

PendingCN109598017AShorten the timePrecise layoutGeometric CADSpecial data processing applicationsFree wallMatch rule

The invention discloses a method for intelligently generating a cabinet based on free wall selection of a user. The method for intelligently generating the cabinet based on user free wall selection comprises the following specific steps: selecting a wall freely; S1: establishing a scene, entry to cabinet intelligent arrangement mode, S2, analyzing the number of walls selected by a user; allowing auser to select a wall, entering next-step arrangement operation period, S3: analyzing the kitchen pattern, determining the layout of a kitchen according to the number of walls selected by the user, S4, analyzing a cabinet body which can be placed on a wall according to wall data by adopting an expert system matching rule, S5, converting coordinates, establishing a local coordinate system, and converting wall information into the local coordinate system, S6, accurately placing the cabinet body, and S7, selecting the style and replacing the style by a user according to the established local coordinate device. The method is simple and convenient, saves user time, conforms to the technology and is accurate in cabinet arrangement.

Owner:GUANGDONG SANWEIJIA INFORMATION TECH CO LTD

Dust-free wall surface grinding machine for building decoration

InactiveCN109986426AEasy dischargeAvoid high temperature burnoutGrinding machine componentsPlane surface grinding machinesNoise pollutionFree wall

The invention discloses a dust-free wall surface grinding machine for building decoration. The dust-free wall surface grinding machine comprises a grinding machine main body, wherein a handheld handleis fixedly connected to the outer surface of one side of the grinding machine main body, an operation handle and an air receiving hole are fixedly connected to the outer surface of the rear end of the grinding machine main body, the air receiving hole is located below the operation handle, a heat dissipation end cover is fixedly connected to the outer surface of the upper end of the grinding machine main body, a grinding disc is fixedly connected to the outer surface of the lower end of the grinding machine main body, and a LED surrounding lamp belt is fixedly connected to the outer surfacesof the periphery of the grinding disc. The dust-free wall surface grinding machine for building decoration is provided with a UGT coating, a dust filtering plate and silencing cotton, so that the wearresistance of a chassis can be improved, the damage rate of the chassis is reduced, dust impurities can be prevented from entering the grinding machine, noise pollution generated by the grinding machine can be reduced, and a better application prospect is brought.

Owner:江苏金环球建设有限公司

Methods for the non-invasive determination of heart and pulmonary pressures

ActiveUS20140275961A1Image analysisBlood flow measurement devicesVibration measurementLeft ventricular size

The disclosure of the present application provides methods for the noninvasive determination of cardiac and pulmonary pressures based off of patient-specific medical images and one or more computations. In one exemplary embodiment, the method comprises noninvasively generating a patient-specific medical image of at least a portion of a heart, determining a free vibration measurement from the left ventricular free wall based on the patient-specific image, and performing at least one computation using the free vibration measurement to noninvasively determine a cardiac or pulmonary pressure.

Owner:KASSAB GHASSAN S +1

Watering-free wall-mounted flowerpot

InactiveCN101878722APromote growthLow costSelf-acting watering devicesReceptacle cultivationWater storageLife quality

The invention relates to a watering-free wall-mounted flowerpot. The flowerpot comprises a bottom plate, a front plate, planting bins and a water storage bin, wherein each hollow unit planting bin with an upward opening consists of the bottom plate and the front plate; planting soil is arranged in the planting bins; plants are planted into the planting soil; the bottom plate is provided with a mounting hole or a trough; the flowerpot is fixed on a building through screws or the trough; each planting bin is a trough body of which the sides are in a U shape or a V shape; the middle lower part of each planting bin is provided with middle plates in parallel; the water storage bin is arranged on the lower side of the middle plate; the middle plate is provided with an upper through hole and a lower through hole; the front plate at the parallel point of the middle plates or both sides of each middle plate are provided with draining holes; a plurality of planting bins can be connected and horizontally or vertically arranged; and the outer side of each planting bin is provided with a flat iron bearing frame with a corresponding shape so as to ensure safety. The watering-free wall-mounted flowerpot is widely used for greening and beatifying enclosures, building walls, elevated roads and the like, can effectively reduce noise, absorb tail gas and dust, beautify environment and improve the life quality of people and city image.

Owner:张朝峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com