Construction method for special underground continuous wall

A construction method and a special technology, applied in excavation, foundation structure engineering, construction, etc., can solve the problems of groove formation and wall formation without precedent, so as to ensure smooth construction, good water sealing effect and integrity, and increase overall rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

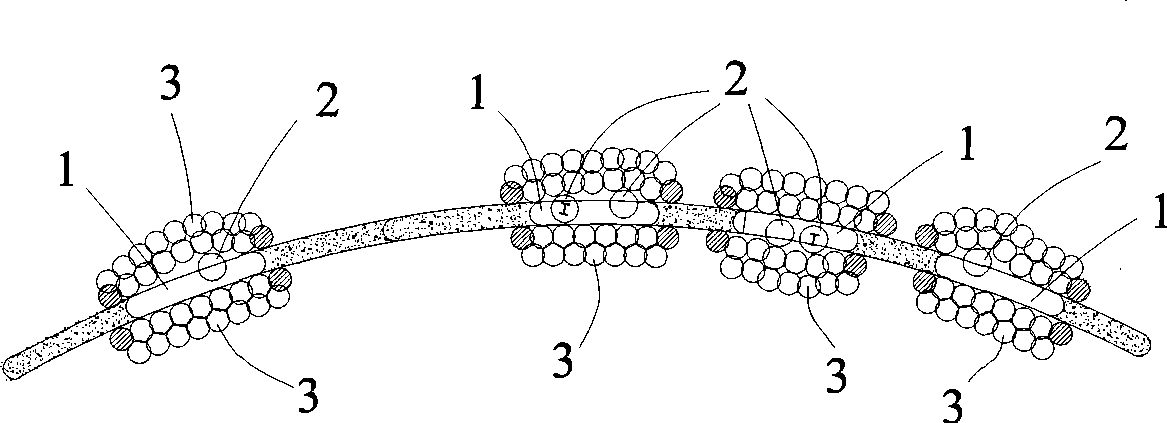

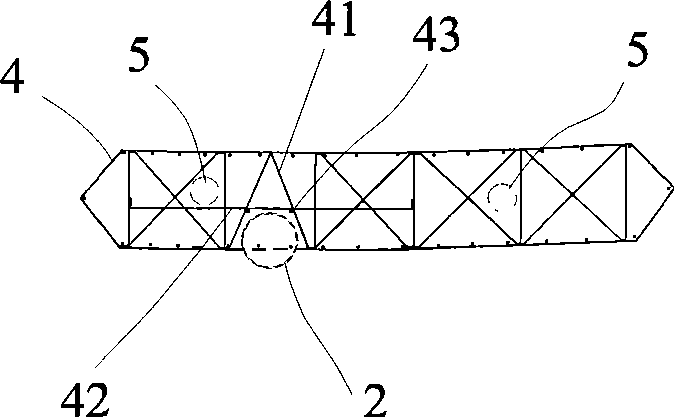

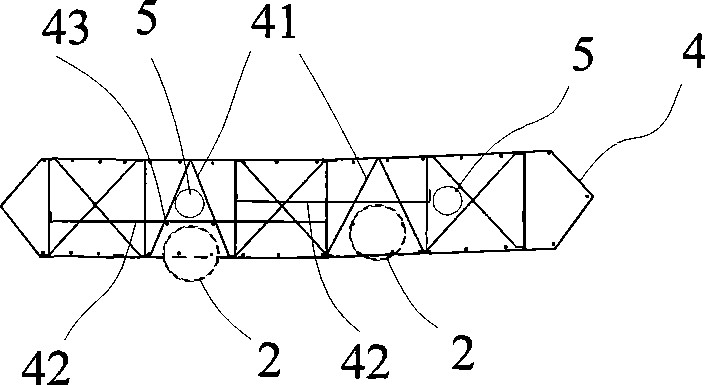

[0019] The invention relates to a construction method of a special underground continuous wall. The underground continuous wall is formed by connecting multiple walls. In a preferred embodiment, the underground continuous wall is a circular arch structure. At least one wall structure in the underground continuous wall retains obstacles, such as steel pipe piles or steel piles. In this embodiment, there are six steel pipe piles 2 retained in the four walls 1, such as figure 1 shown.

[0020] Before construction, the actual position of the existing steel pipe piles in the deep layer is measured first, and according to the actual position of the existing steel pipe piles in the deep layer, the groove section of the ground wall is divided, and the reinforcement range of the groove wall is determined. When dividing the ground wall groove section, make the two sides of the collision pile groove section be normal underground wall groove sections. That is, the bumper pile groove sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com