Patents

Literature

333results about How to "Good water stop effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

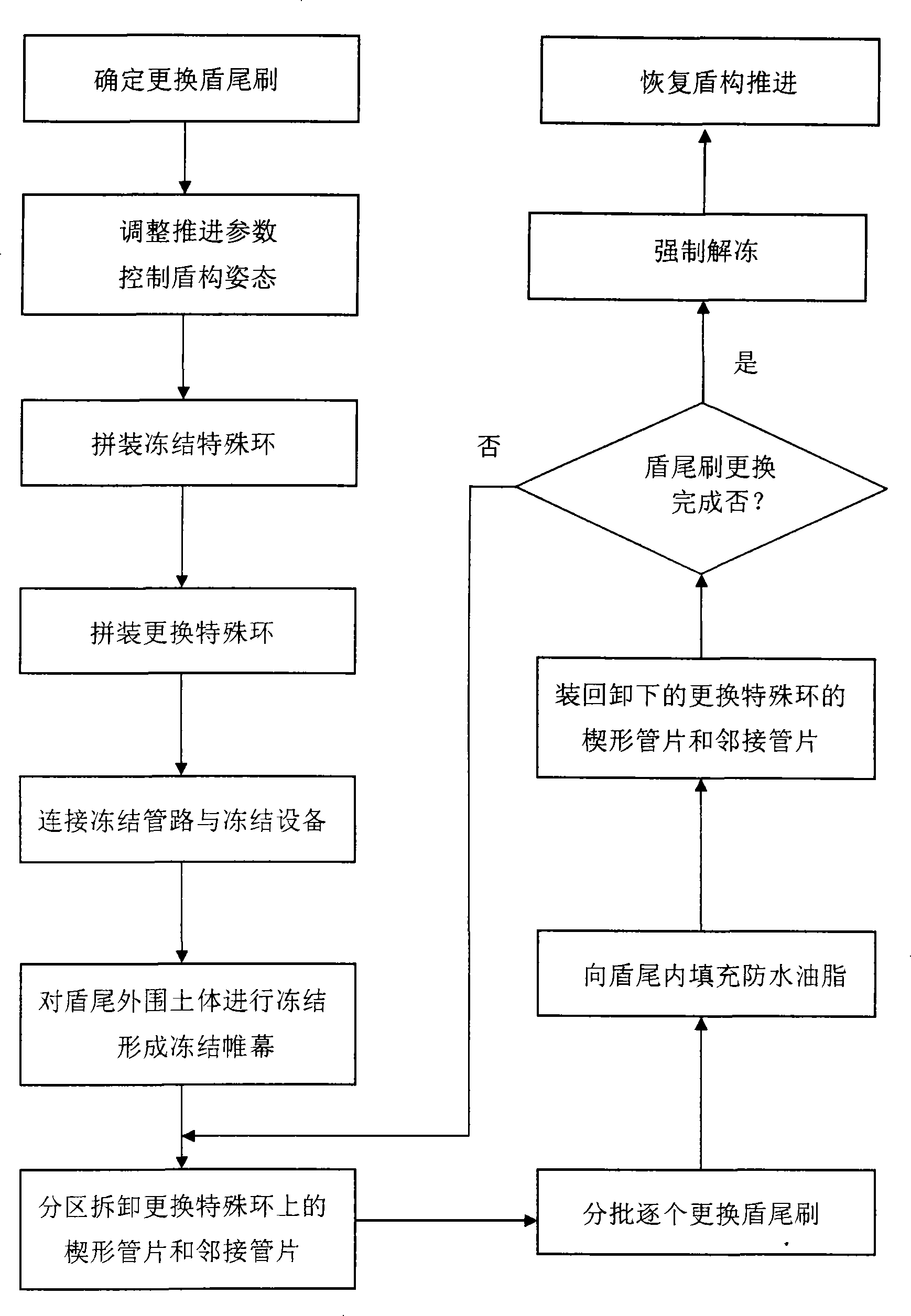

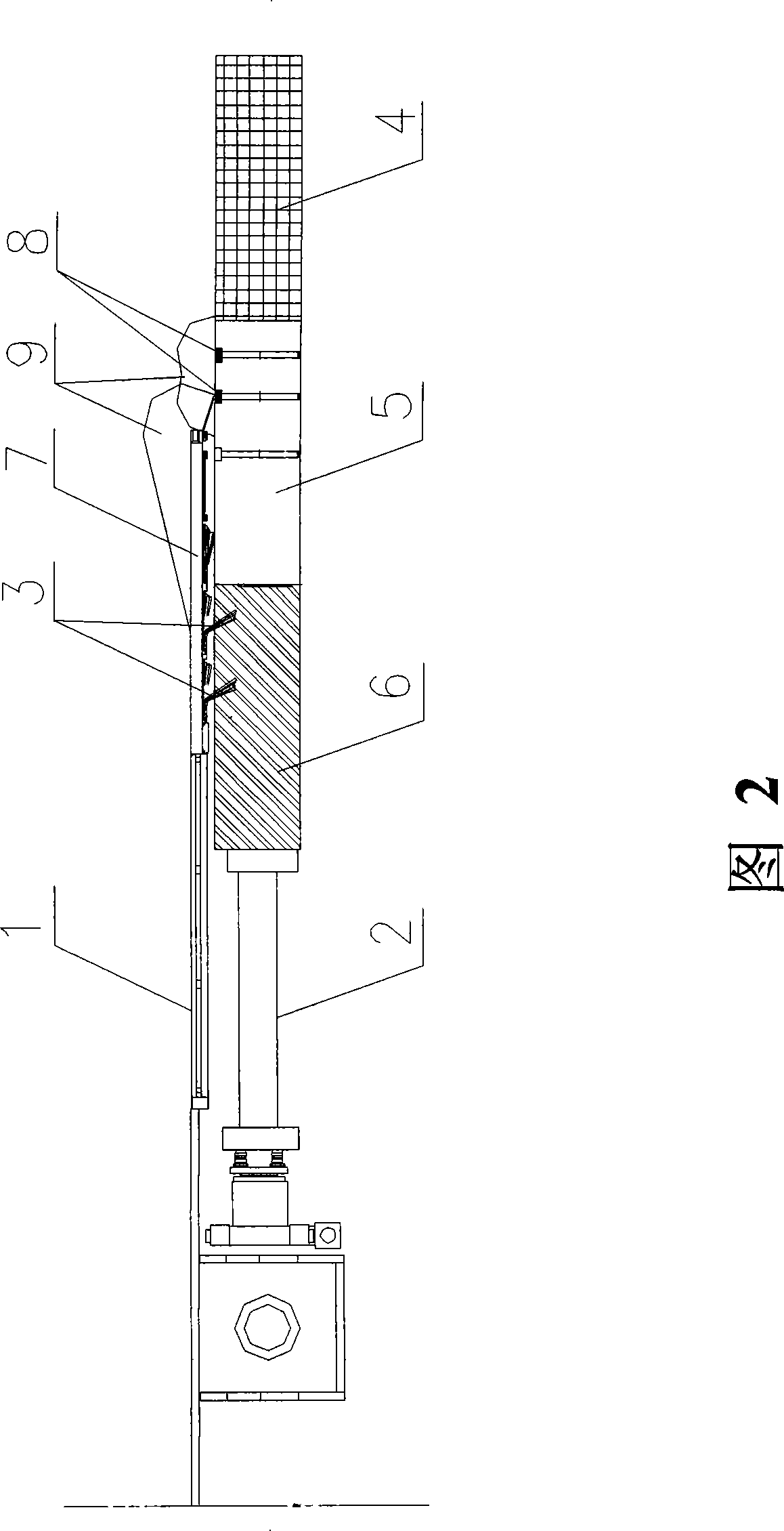

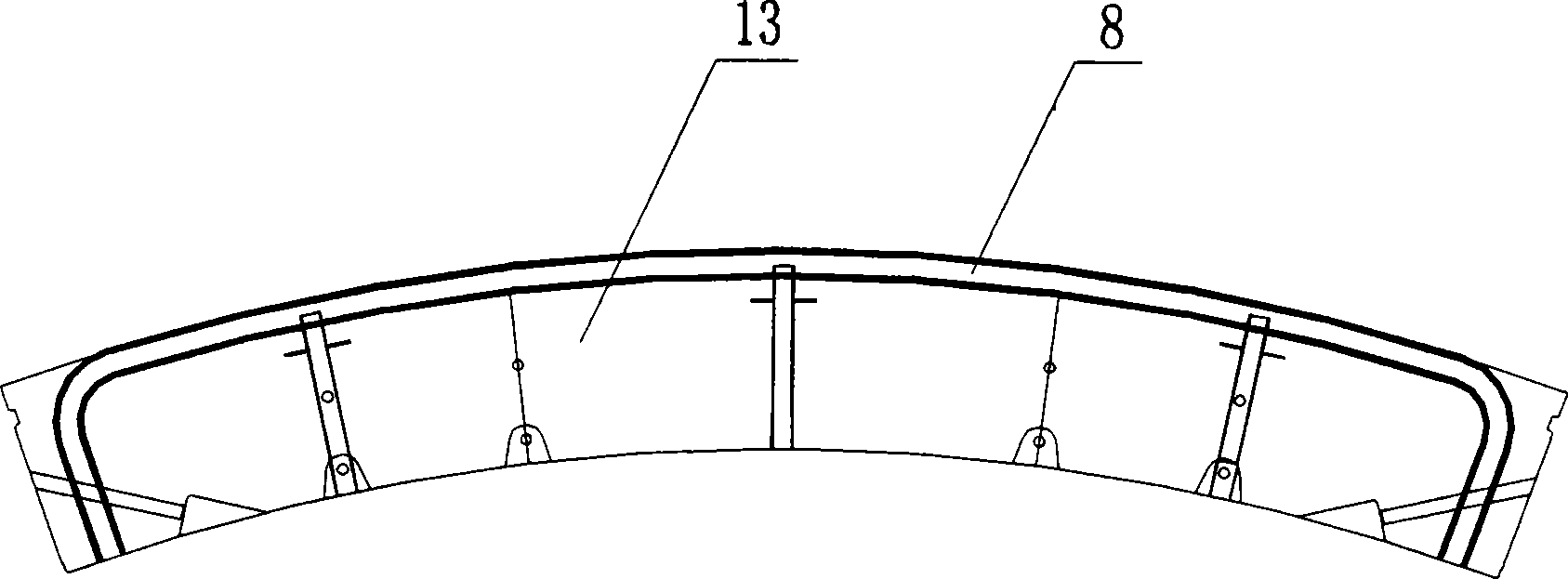

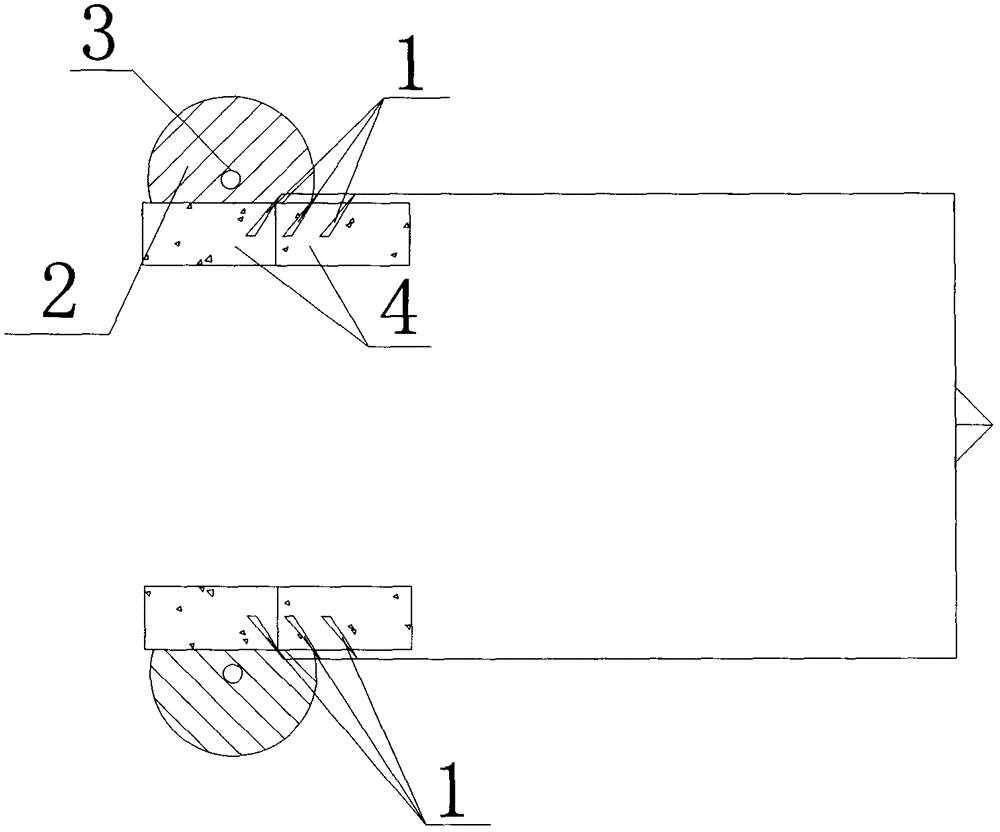

Construction method for exchanging shield ventral brush

The invention relates to a construction method for replacement of tail brushes of a shield, wherein, a tail device of a shield machine is provided with preset freezing pipes. The invention comprises the following operation steps that: replacement of the tail brushes is determined; a propulsion parameter of the shield is adjusted, and the shield posture is controlled; a special freezing ring is assembled in front of a common ring by utilization of freezing segments; the freezing pipes and temperature tubes are buried into the freezing segments in advance; a special replacement ring which is used for replacement of the tail brushes is assembled in front of the special freezing ring; the freezing pipes and freezing equipment are connected; the peripheral soil mass of a shield tail is frozen, and a freezing purdah for waterstop is formed on the rear of the tail brushes; the tail brushes are replaced one by one under the protection of the freezing purdah, and waterproof greases are infused into the tail brushes; the freezing purdah is forced to be unfrozen after replacement of the tail brushes is finished; normal propulsion of the shield is restored. The construction method for replacement of the tail brushes of the shield has the advantages of good waterstop effect, safety and reliability, simple and convenient operation and strong environmental suitability, is widely suitable for various complex special geological conditions and is particularly suitable for construction of a large-scale large-diameter bridge tunnel.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

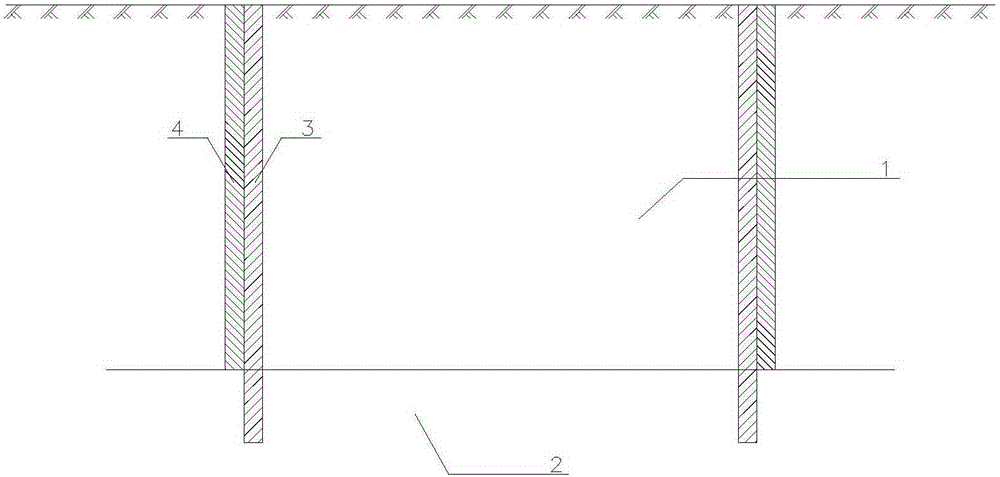

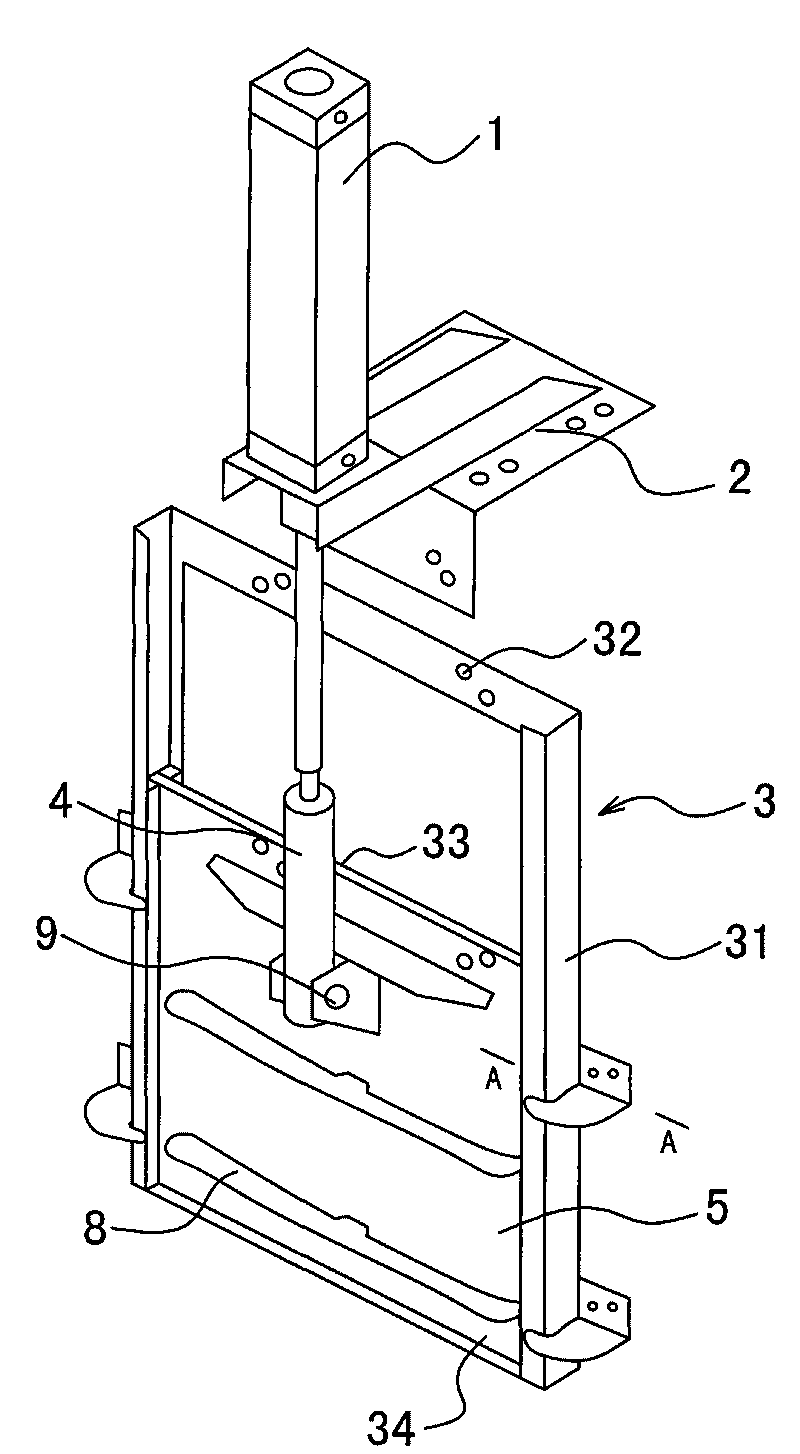

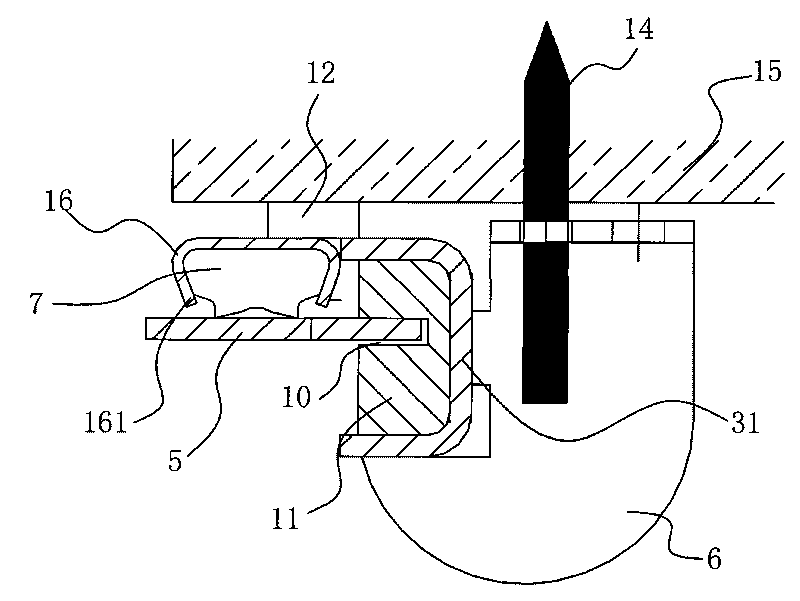

Cross steel plate water-stopping joint continuous concrete wall and joint construction method thereof

InactiveCN101608447AIncreased shear strengthImprove integrityArtificial islandsUnderwater structuresSlurry wallCement slurry

The invention provides a cross steel plate water-stopping joint of a continuous concrete wall and a joint construction method thereof. The cross steel plate joint comprises a longitudinal water-stopping steel plate and a horizontal head steel plate, wherein the longitudinal water-stopping steel plate is about 35-50 cm long, a detouring flow line of cement slurry is lengthened, the impermeability of the joint of the continuous concrete wall is enhanced, the bottom of the horizontal head steel plate extends to the tank bottom level or is inserted into the soil by 20 cm, and the detouring flow line of concrete and sand pulp along the bottom of the head steel plate is blocked; during constructing, a cross steel plate and a steel reinforcement cage are welded into a whole which is then deposited into a tank section so that the joint and a wall body have better integrity; a counterforce box is deposited at the back of the cross steel plate and is impacted to enter soil by over + / -30 cm, and then carpolite or clay are backfilled at the back for sealing; the concrete is cast in the tank section; the counterforce box is pulled out, then a flushing or shoveling tool corresponding to the cross steel plate in structure is adopted to remove the attachment at the part so as to ensure the water-stopping effect and the joint intensity of the cross steel plate.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

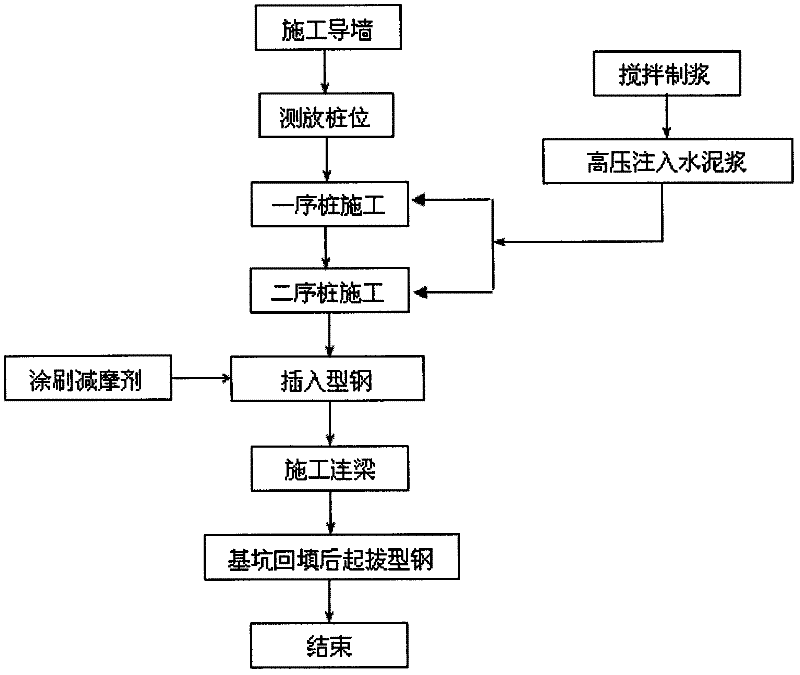

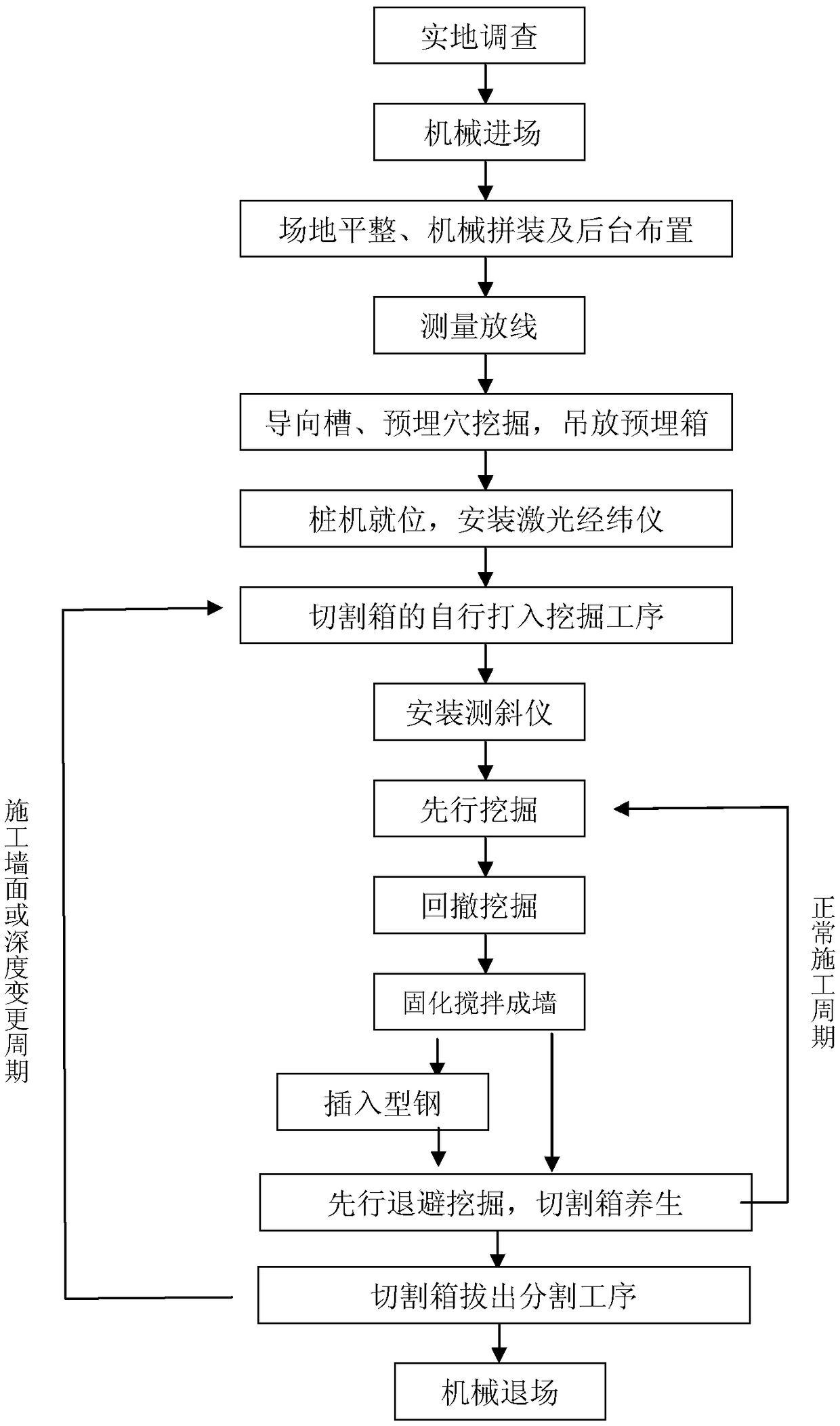

Construction method of long spiral high-pressure mixing and spraying cement-soil continuous wall

InactiveCN102296630AGood effectImprove efficacyArtificial islandsUnderwater structuresSupporting systemJet injection

The invention provides a construction method of a long spiral high-pressure spraying cement-soil continuous wall, which comprises the following steps: 1) making a guide wall or digging a guide ditch along the center line of the pile, and determining the pile position of the spraying pile; 2) injecting the long spiral high-pressure spraying The slurry stirring pile-forming device is aligned with the pile position as the drilling center, and drilled into the hole; 3) Start the grouting pump, and use the long spiral high-pressure jet grouting to stir the pile-forming device during the lifting or lowering process of high-pressure rotary spraying until it is formed. 4) insert section steel into the spigot pile; 5) repeat the steps 2), 3) and 4) until the continuous cement-soil continuous wall is formed; 6) construct the joint beam; 7) backfill the foundation pit, Pull out the section steel after finishing. Compared with the general slope protection pile support system, firstly, the section steel can be recycled, and secondly, cement soil is used instead of concrete, so it is relatively more economical and more efficient, and can achieve the two walls of the supporting wall and the curtain wall. The water stop effect is also better than the system composed of general slope protection piles + rotary grouting piles.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

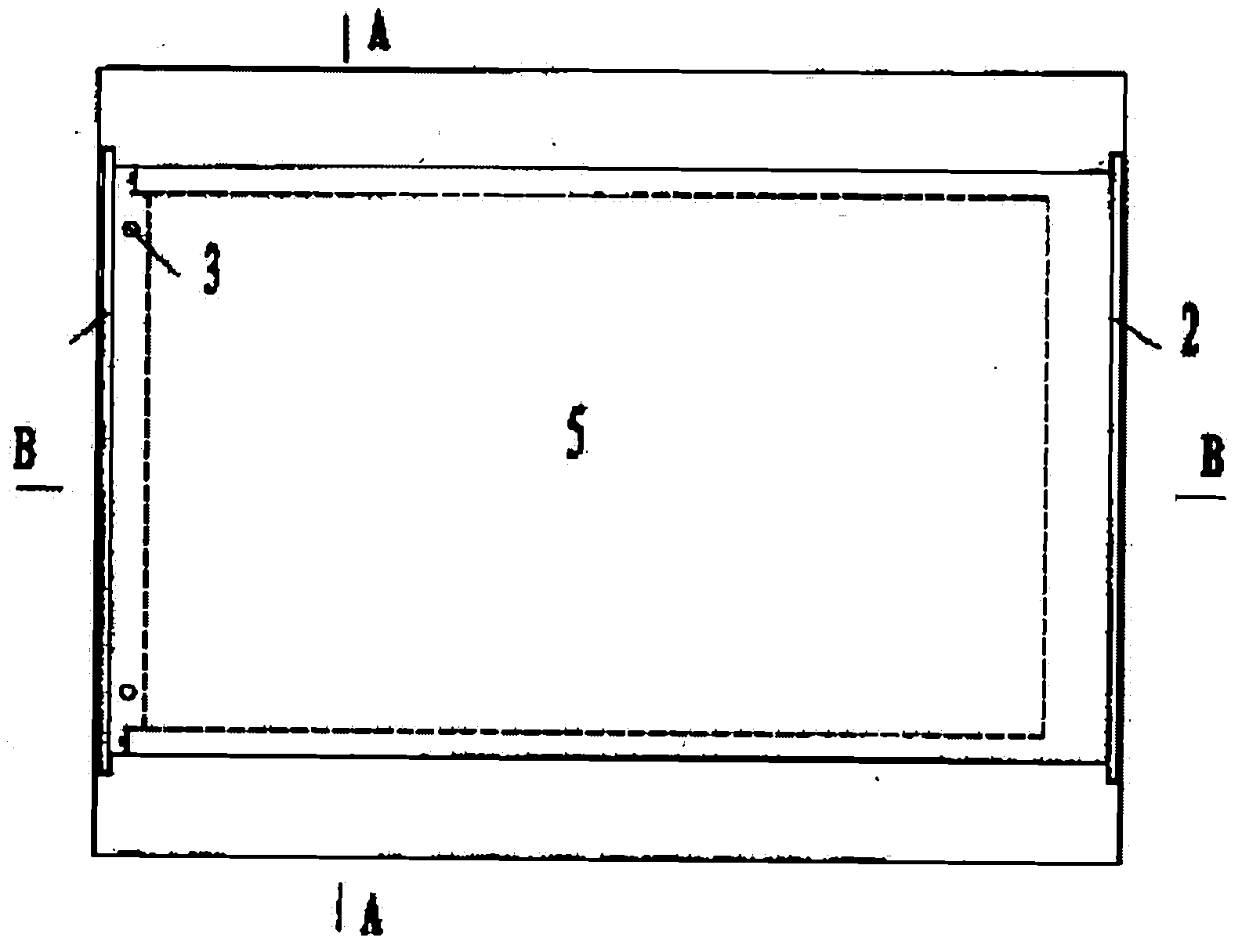

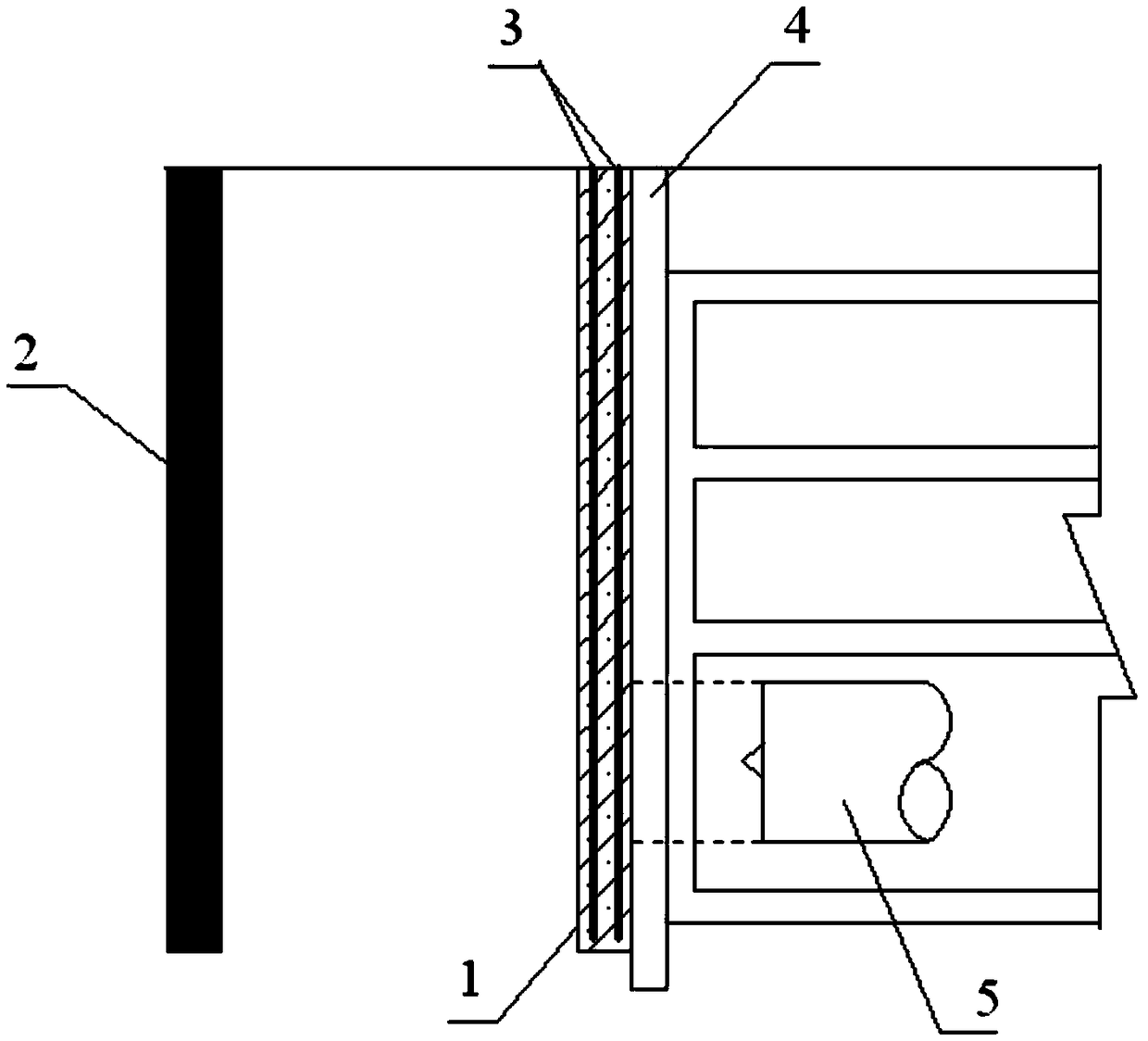

Water stop body for plane gate of inflating type water gate and installing method thereof

The invention discloses a water stop body for a plane gate of an inflating type water gate and an installing method thereof. The water stop body comprises a left gate pier, a right gate pier, a gate bottom plate, a first water stop strip, a second water stop strip, the plane gate and a water stop plate, wherein the first water stop strip and the second water stop strip have the same structure; the gate bottom plate is respectively connected into a whole with the bottom end of the left gate pier and the bottom end of the right gate pier; vertical door grooves are respectively formed in the inner side walls of the left gate pier and the right gate pier; a first air pipe and a second air pipe are respectively arranged in the door grooves formed in the left side and the right side; the plane gate is glidingly arranged in the two door grooves; rolling wheels are arranged between the plane gate and the inner walls of the door grooves; embedding grooves are respectively formed in the side walls of the two door grooves; an L-shaped protection plate is arranged in each embedding groove; the top surface of each protection plate is aligned with the top surfaces of the left and right gate piers, and the first water stop strip is arranged in a groove defined by the protection plate and the embedding groove on the left gate pier. The water stop body has the characteristics that the structure is reasonable, the water stop effect is good, the gate opening and closing force is small, durability is realized, the operation is simple and convenient, and the like. The water stop body belongs to an advanced water gate plane gate water stop body.

Owner:HEFEI UNIV OF TECH

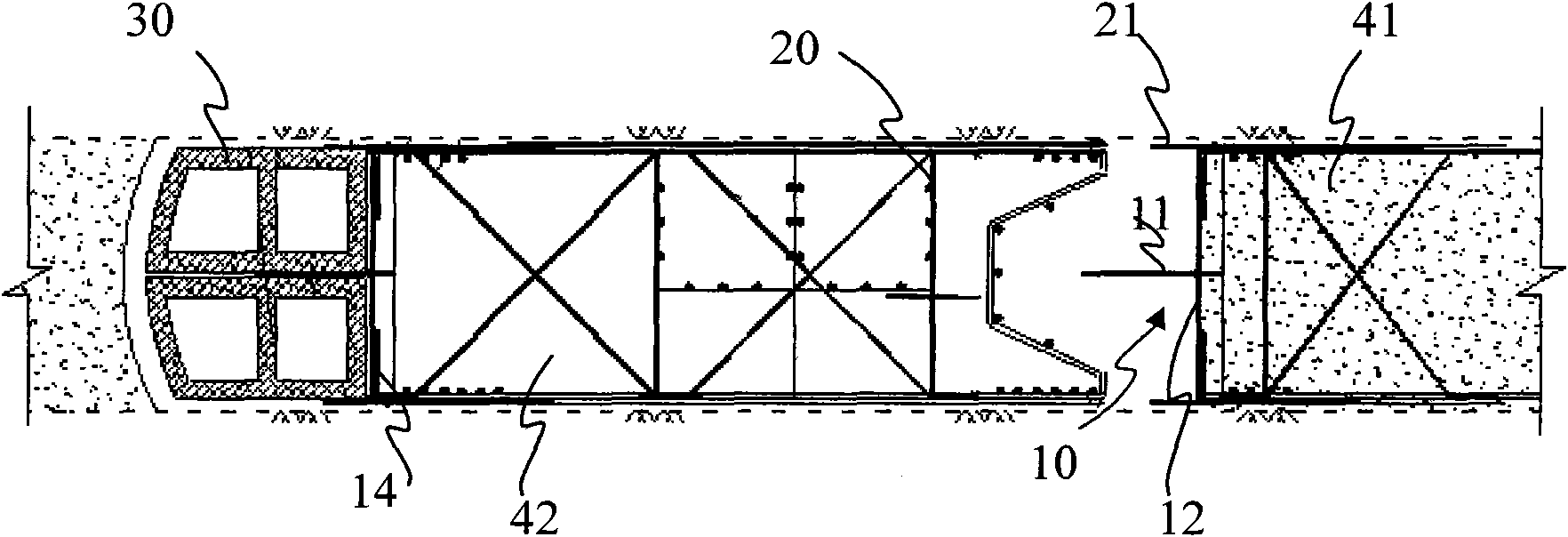

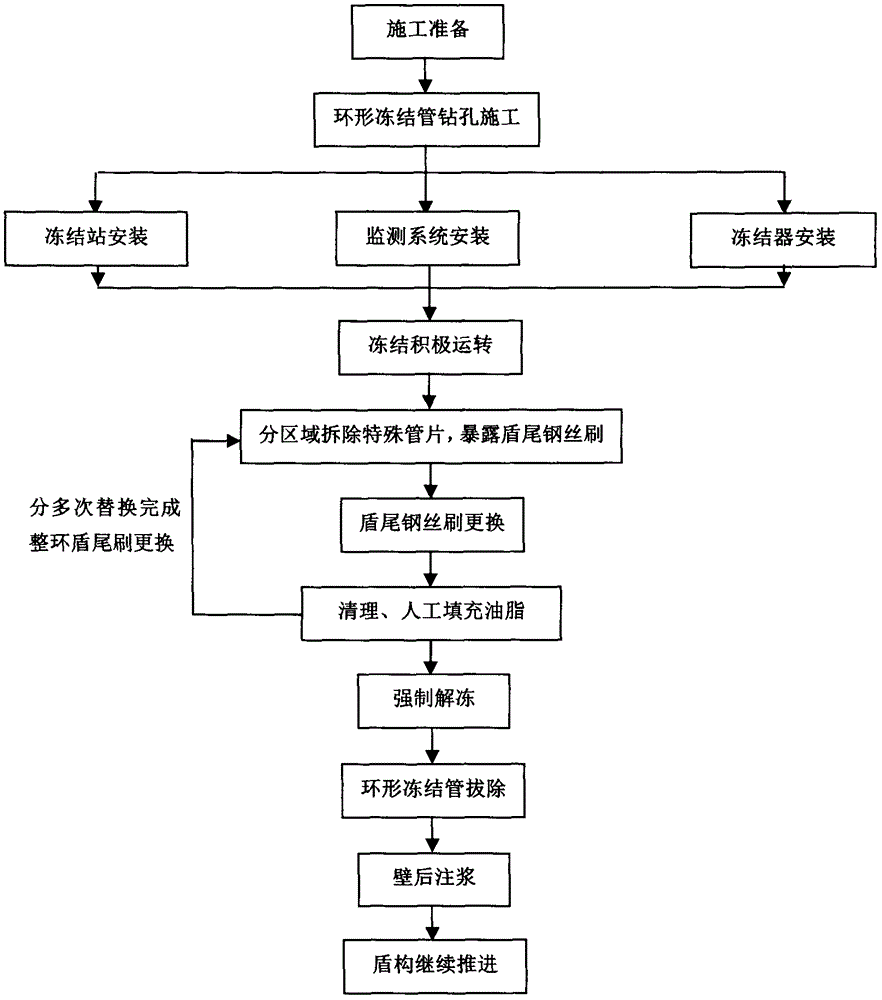

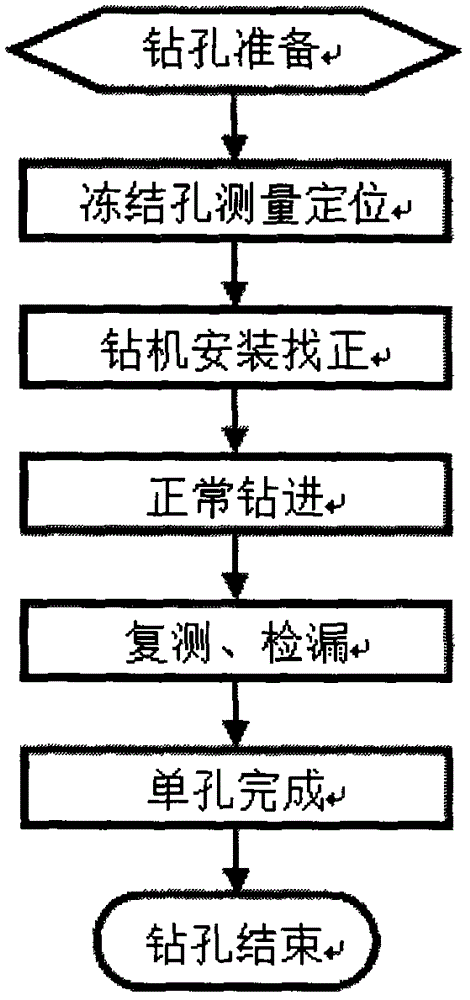

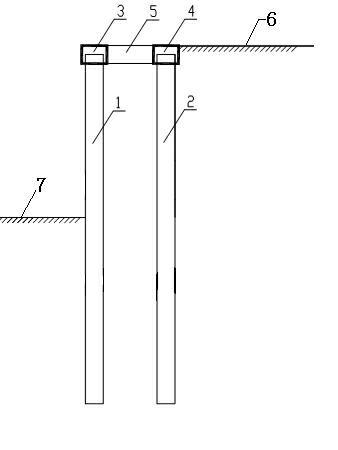

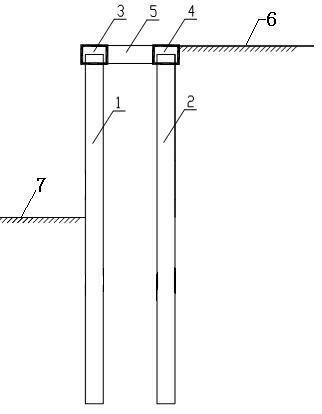

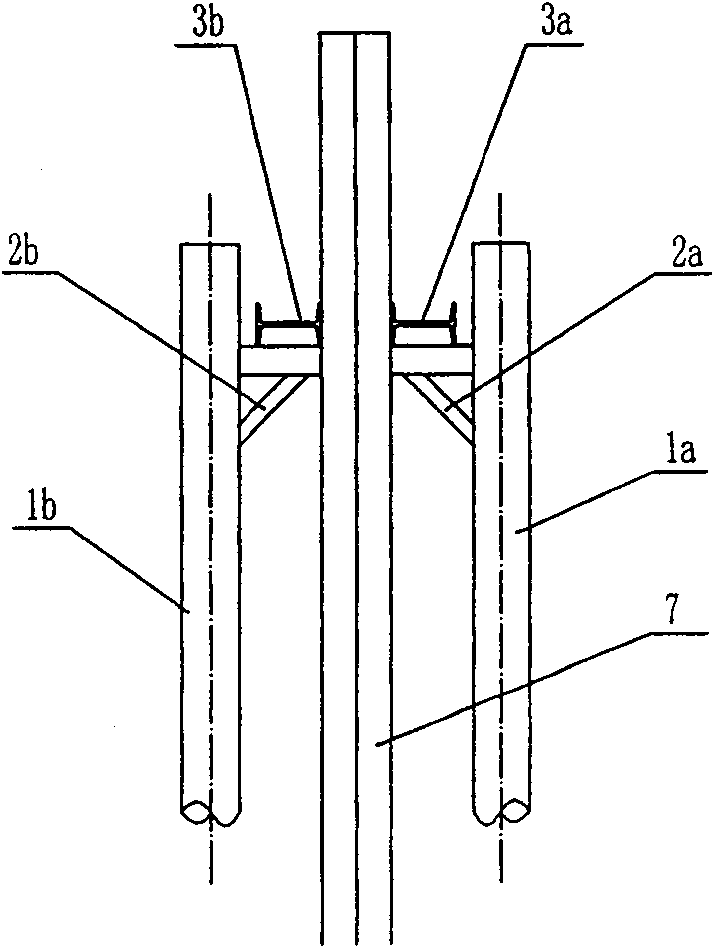

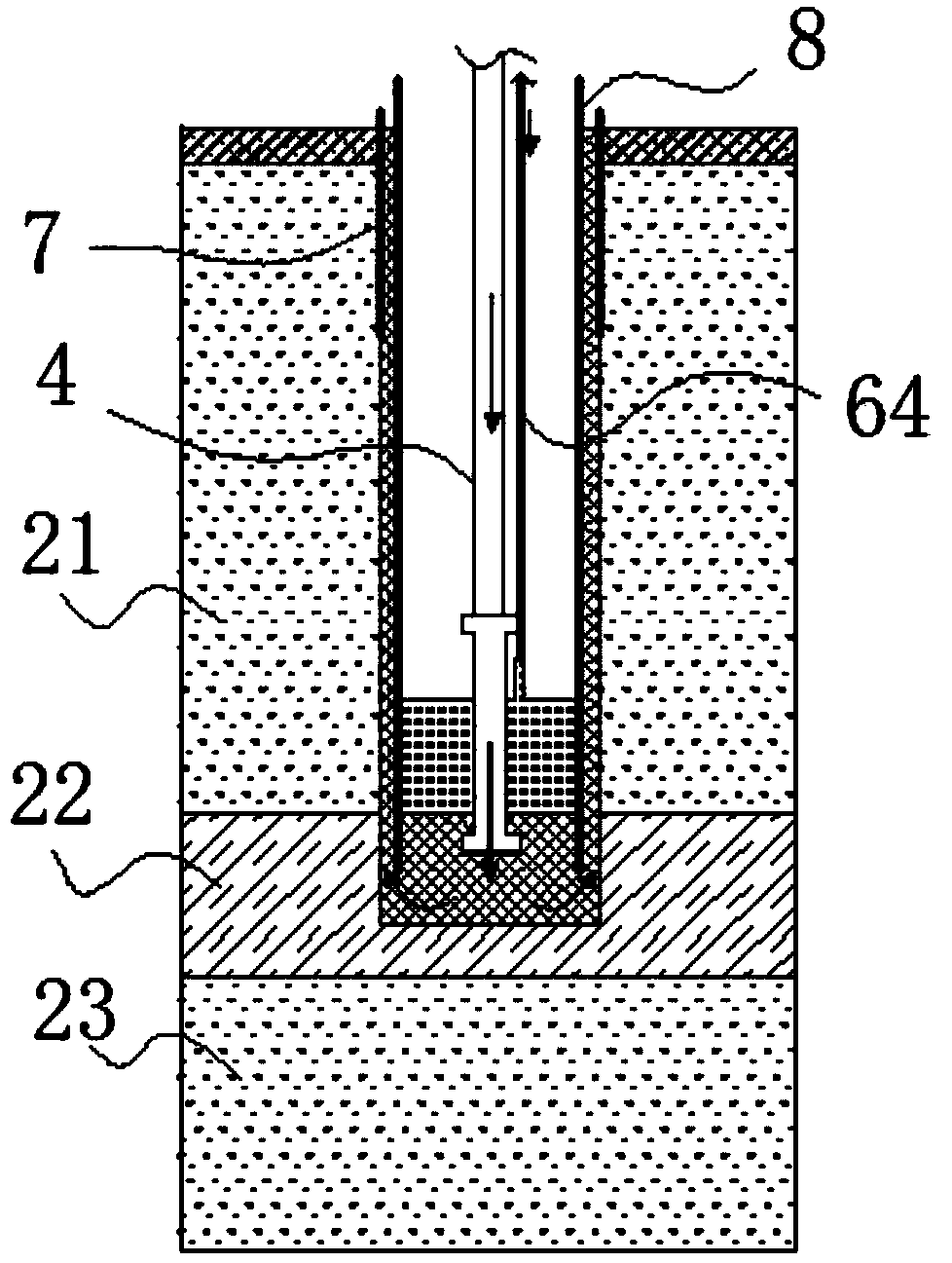

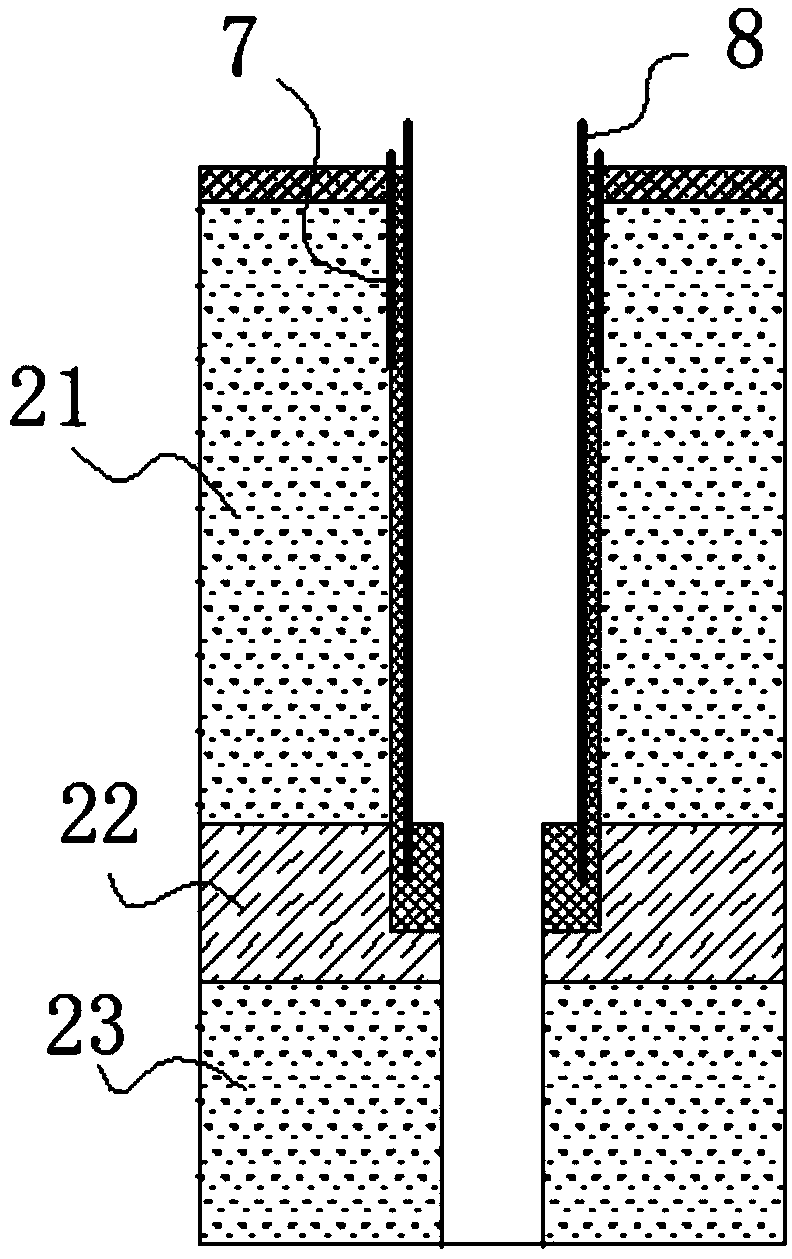

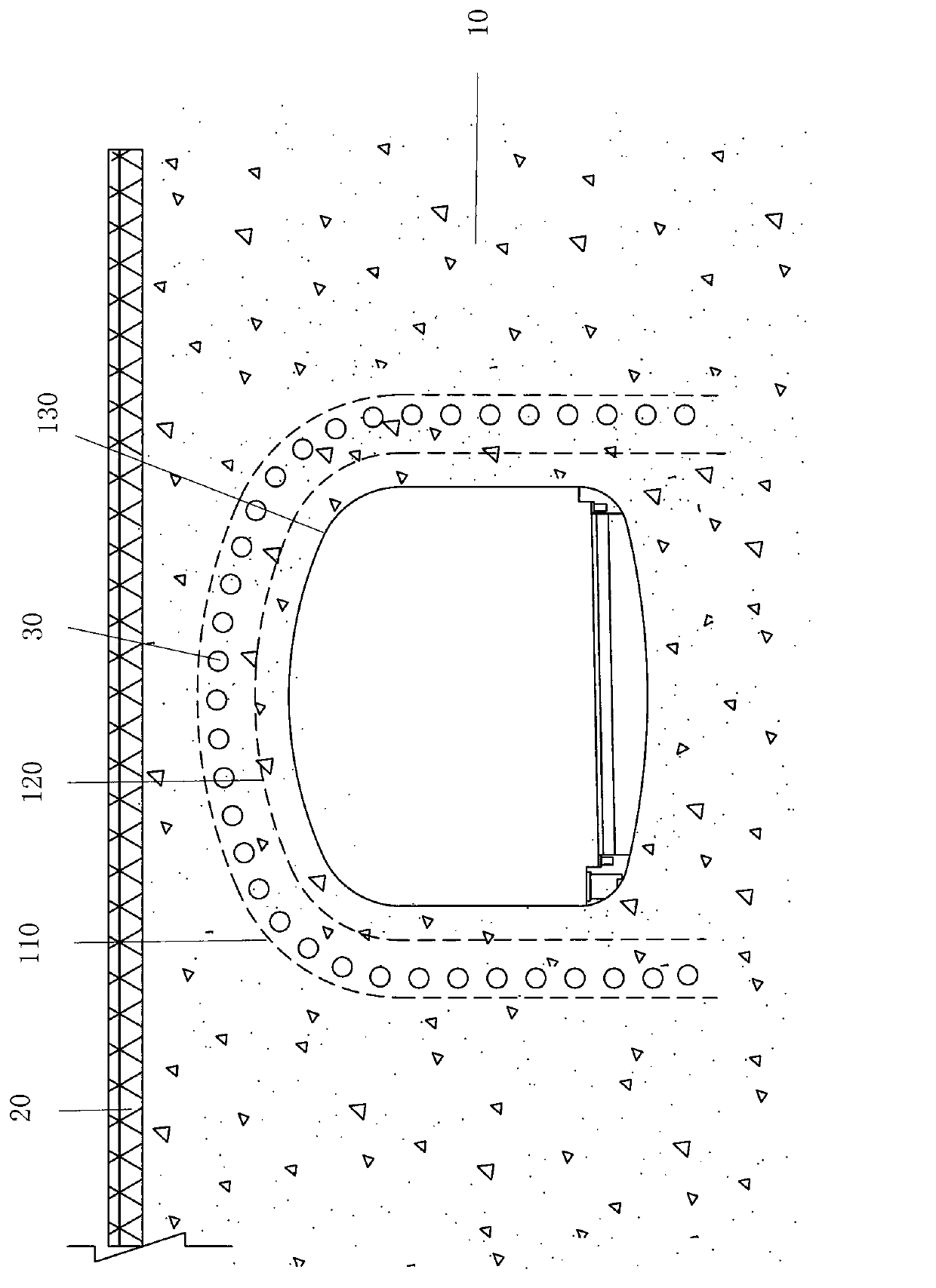

Shield tail brush replacement annular freezing reinforcing water seal structure and construction method thereof

ActiveCN105840202APerfect emergency planFlexible and diverse punching formsUnderground chambersTunnel liningTemperature measurementStructure of the Earth

The invention discloses a shield tail brush replacement annular freezing reinforcing water seal structure and a construction method thereof; the reinforcing water seal structure uses annular freezing pipe construction equipment to bury 1-2 annular freezing pipes in the soil body position needs to replace the shield tail brush, and uses an artificial freezing mode to enable the soil body around the annular freezing pipes to form a temporary annular frozen soil curtain reinforcing water seal structure; the specific technical process is listed as below: construction preparation-annular freezing pipe boring construction-freezing system and temperature measurement system installation-active freezing(temperature monitoring)-dismounting duct piece and replacing shield tail brush (freezing maintenance)-forced unfreezing-annular freezing pipe extraction (sealing hole)-back filled grouting-shield continue propulsion. The construction method is simple, easy to operate and realize, strong in construction practicality, convenient in construction quality control, good in reinforcing effect and water seal effect, outstanding in safety and reliability, and has very big application values.

Owner:CHINA RAILWAY TIMES BUILDING DESIGIN INST CO LTD

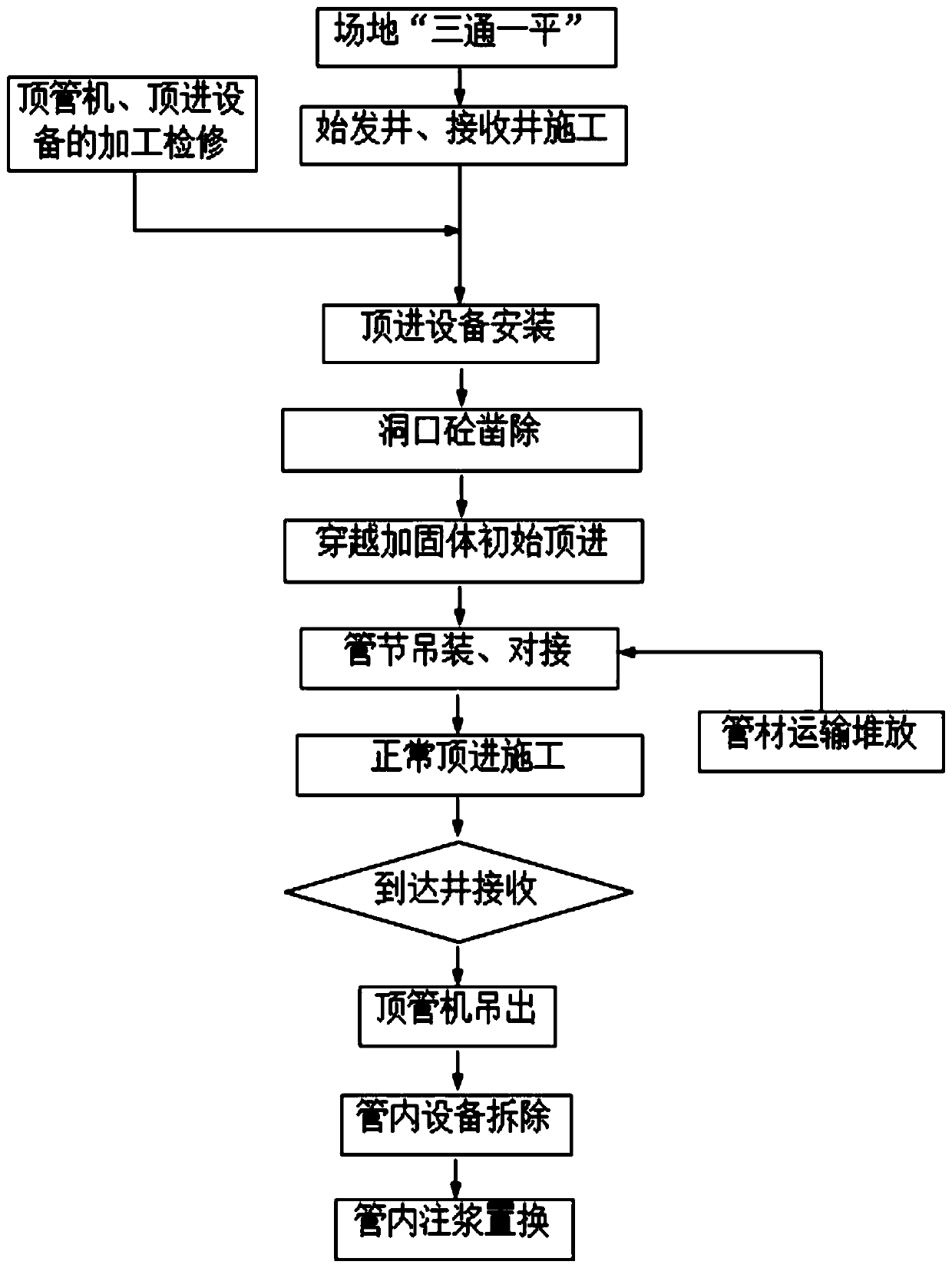

Rectangular pipe jacking construction method for outlet and inlet channel of subway station

ActiveCN111075474AReduce coefficient of frictionReduce frictional resistanceUnderground chambersTunnel liningLine tubingArchitectural engineering

The invention provides a rectangular pipe jacking construction method for an outlet and inlet channel of a subway station. The construction method specifically comprises the steps of constructing an initial well and a receiving well, calculating and determining jacking parameters, smearing wax on the outer wall of a pipe before jacking, connecting a head of a pipe jacking machine and three adjacent pipe sections into a whole during jacking, simultaneously injecting pressure injection thixotropic slurry into the back of the pipe sections in the jacking process, and arranging a stopping device to prevent the pipe jacking machine from retreating; erecting a receiving platform to receive the pipe jacking machine, after the jacking construction is finished, plugging pipe section gaps and the gaps between the pipe sections and two end openings, and finally adding cement slurry to replace the thixotropic slurry to consolidate a pipe jacking channel. It is ensured that the underground pipelinedoes not settle, crack, leak or the like, and compared with construction of a traditional open excavation method, the construction method has the advantages of small environmental impact, safe construction, simple operation, single procedure, low manufacturing cost, cost saving and good popularization significance.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP +1

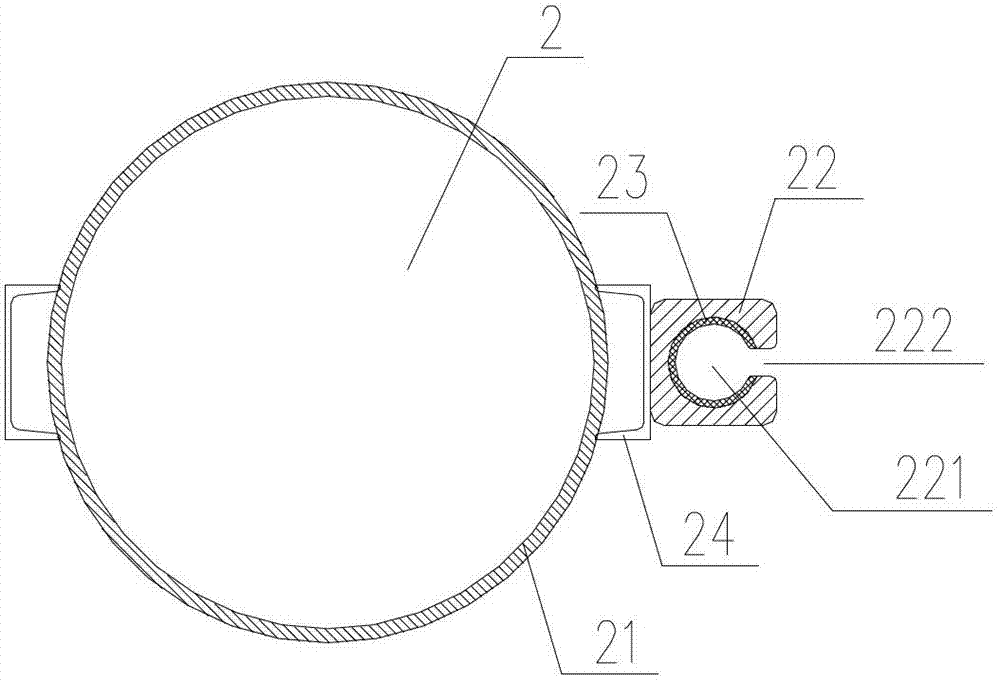

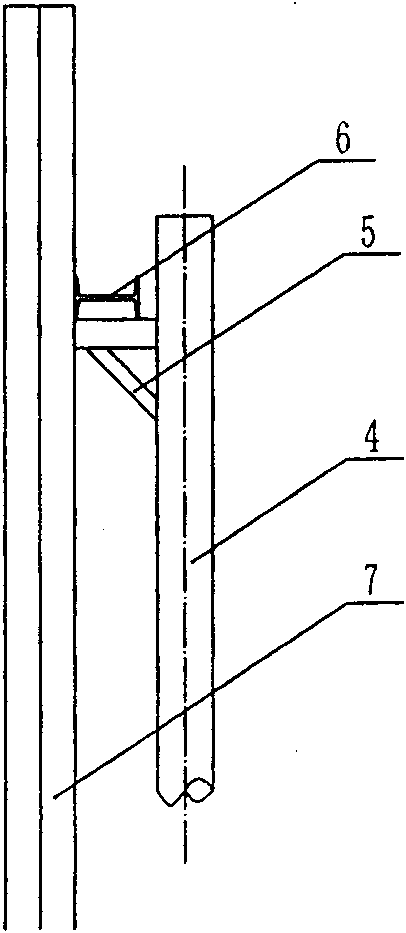

Combined steel pile cofferdam provided with water swellable waterproof rubber fore shaft

InactiveCN102900089AFast constructionGood waterproof performanceBulkheads/pilesStructural rigidityWater resistance

The invention discloses a combined steel pile cofferdam provided with a water swellable waterproof rubber fore shaft, which comprises cofferdam pegs and cofferdam long piles used for connecting two adjacent cofferdam pegs. Each cofferdam peg comprises a U-shaped steel sheet pile and a fore shaft sub-part, and the left and right ends of each U-shaped steel sheet pile are respectively and fixedly connected with one fore shaft sub-part. Each cofferdam long pile comprises a steel pipe pile, a fore shaft parent part arranged at the outer side of the steel pipe pile, and a water swellable rubber liner arranged in the fore shaft parent part; a tubular inner cylinder matched with each fore shaft sub-part and a notch connecting the interior of each tubular inner cylinder with the exterior of each tubular inner cylinder are arranged on the fore shaft parent part; each water swellable rubber liner is fixedly arranged on the inner wall of the corresponding tubular inner cylinder; each fore shaft sub-part is sleeved into the corresponding tubular inner cylinder; and bentonite compound filler is filled in a gap between each fore shaft sub-part and each water swellable rubber liner. By taking the combination of a rigid steel pile and a flexible steel pile to have complementary advantages, the combined steel pile cofferdam has good water resistance; the fore shaft is reliable in connection; the material of the combined steel pile cofferdam is easy to obtain; and the combined steel pile cofferdam is strong in integral structural rigidity and low in cost and is quick to construct.

Owner:SOUTHEAST UNIV

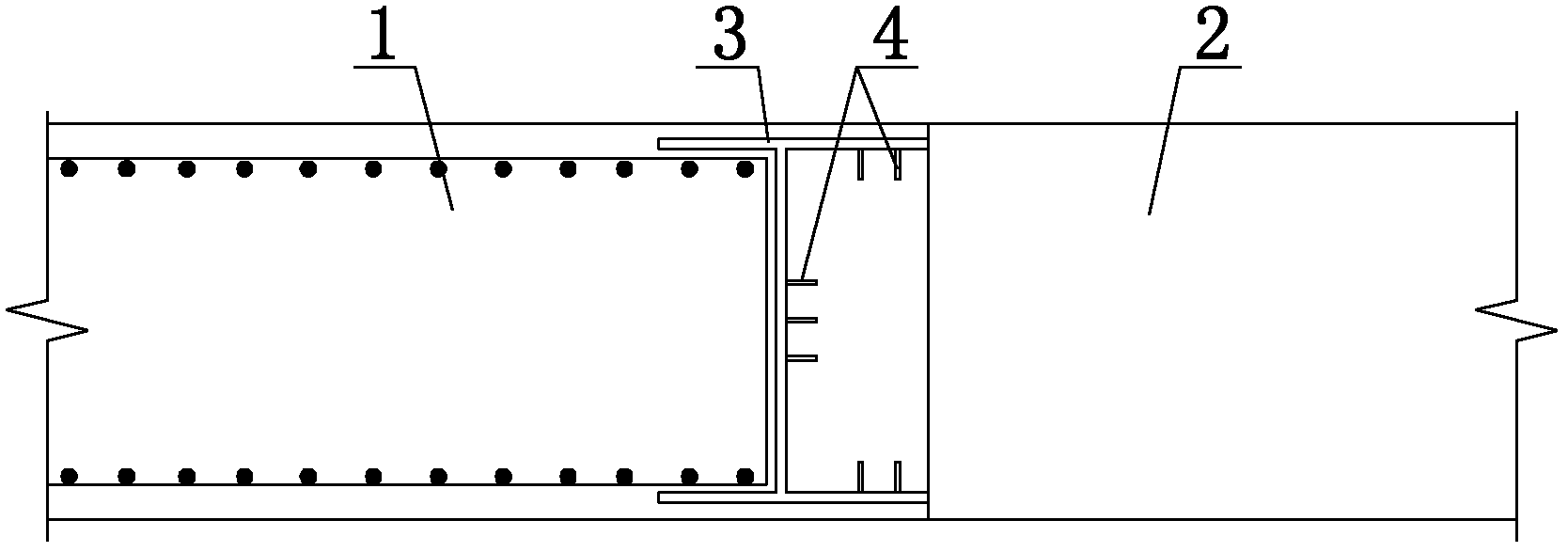

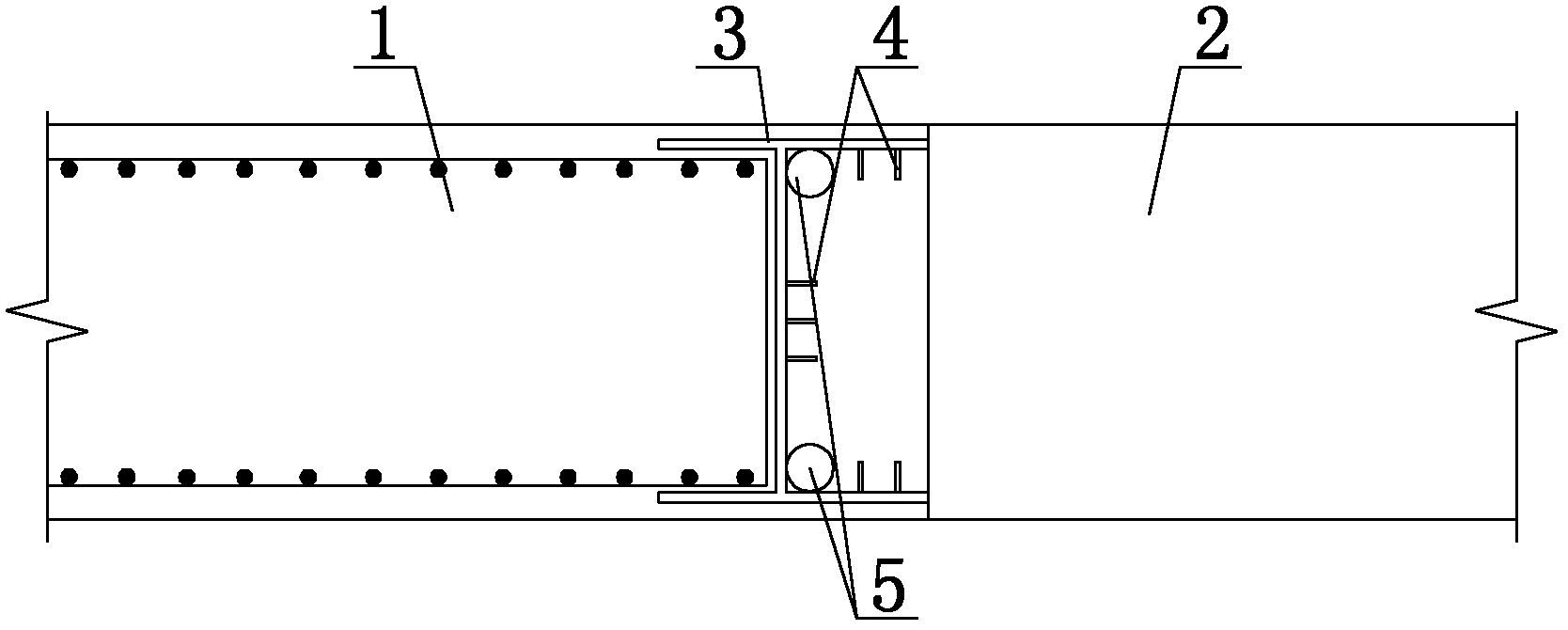

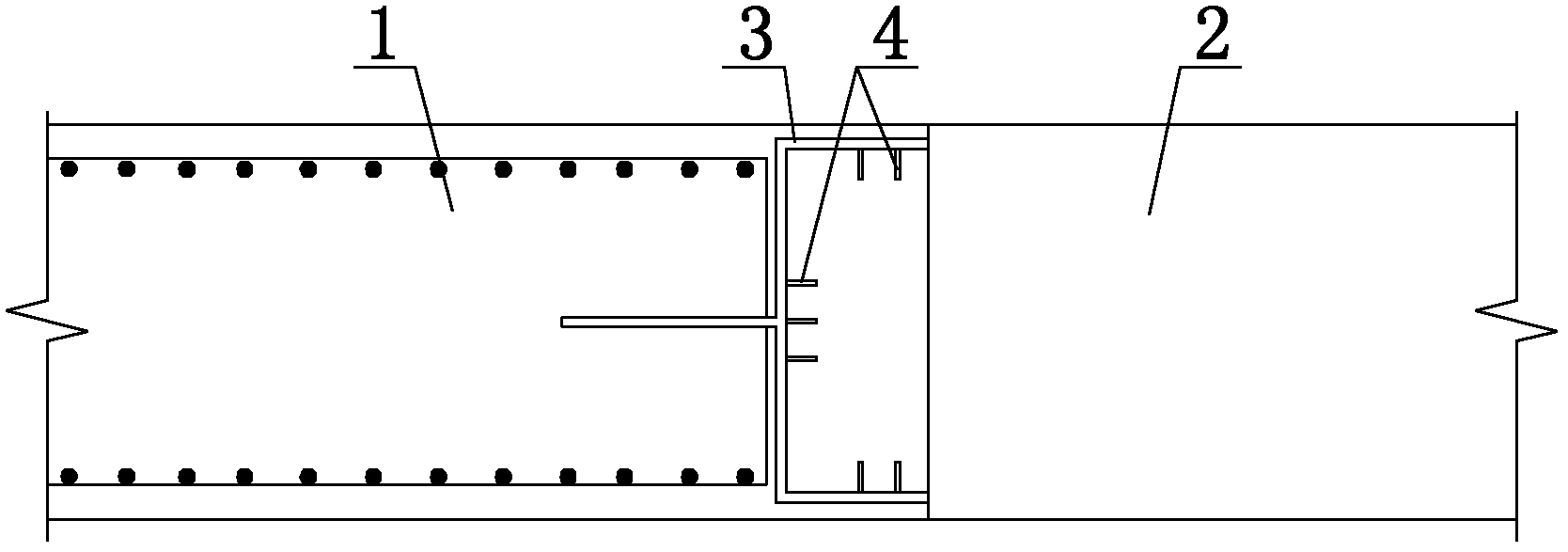

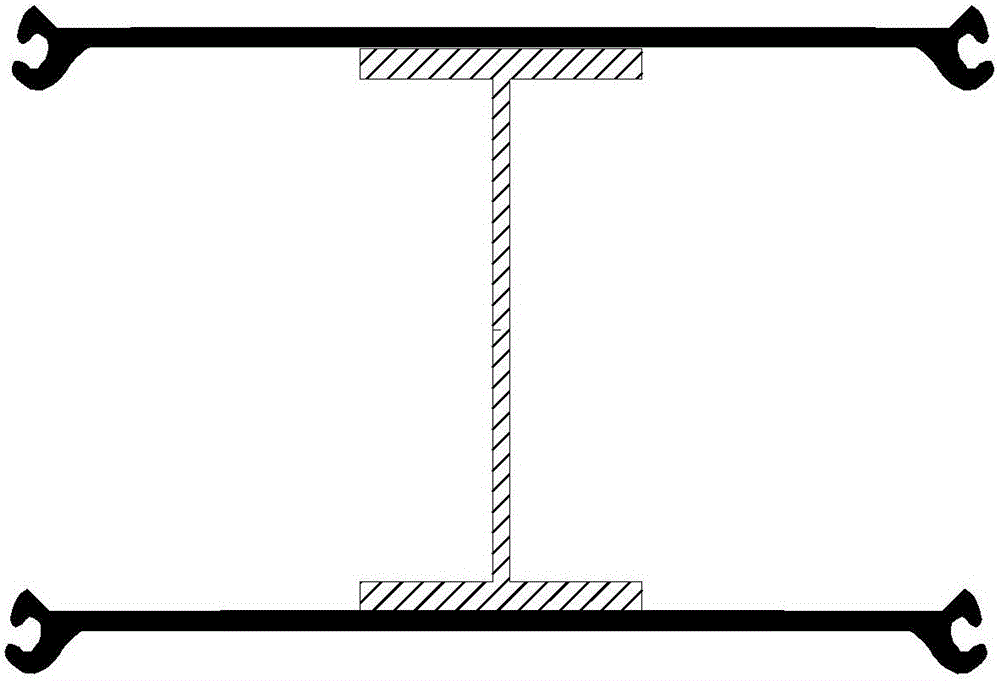

I-shaped steel joint structure for underground continuous wall and construction method for I-shaped steel joint structure

InactiveCN102535519AGood anti-seepageOvercoming the problem of seam leakageArtificial islandsUnderwater structuresSlurry wallCasting mold

The invention discloses a steel joint structure for an underground continuous wall and a construction method for the steel joint structure, belongs to the technical field of underground continuous walls and aims to provide a steel joint structure for the underground continuous wall which is simple and has a good water stopping effect. According to technical key points, the steel joint structure comprises a front terrae spacing, a rear adjacent terrae spacing and I-shaped steel which is connected between the front terrae spacing and the rear adjacent terrae spacing, wherein anchor bars are distributed among connecting parts between the I-shaped steel and the rear adjacent terrae spacing. The construction method mainly comprises the following steps of: (1) excavating a ground groove of the front terrae spacing; (2) manufacturing a reinforcement cage of the front terrae spacing, and arranging an I-shaped steel joint on the end part of the reinforcement cage of the front terrae spacing; (3) arranging the anchor bars; (4) hoisting and placing the reinforcement cage, and arranging a mud blocking joint pipe on the outer sides of the anchor bars; (5) performing cast molding on concrete; (6) excavating a ground groove of the rear adjacent terrae spacing, manufacturing a reinforcement cage, hoisting a joint pipe, hoisting and placing the reinforcement cage, and cleaning the anchor bars; (7) performing cast molding on the concrete; and (8) circulating the steps from (2) to (7) to form the continuous wall.

Owner:中煤江南建设发展集团有限公司

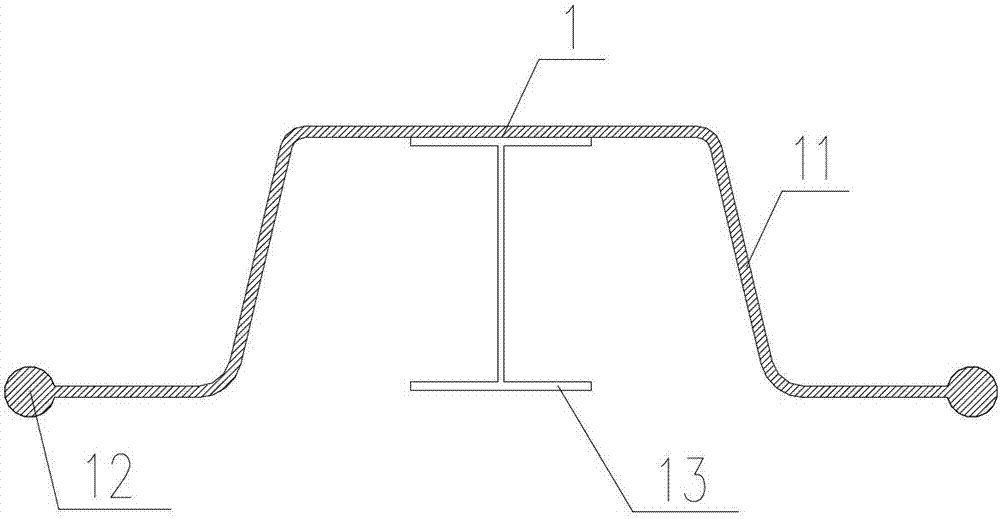

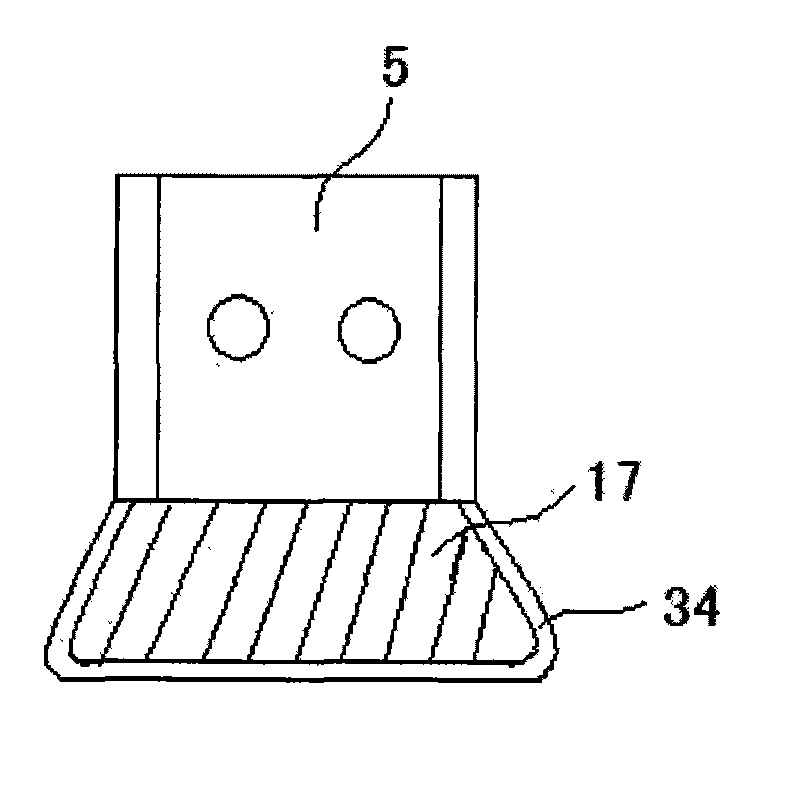

Precast U-shaped plate pile with mixed structure of steel and concrete

The invention discloses a precast U-shaped plate pile with a mixed structure of steel and concrete. The U-shaped plate pile comprises reinforced concrete and a steel structure which is combined with the reinforced concrete; the cross section main body of a plate pile is in a U shape; a stressed steel bar of a pile body is a prestressed steel bar or a common steel bar; a hooping and a waist steel bar are arranged on the pile body; the U-shaped plate pile is characterized in that a T-shaped through slot is arranged in one side of a lower flange of the plate pile; the direction of the T-shaped through slot is along the length of the pile body; the other side of the lower flange is combined with an inverted H-shaped steel bar; half of the inverted H-shaped steel bar is left outside the pile body structure, and the other half of the inverted H-shaped steel bar is embedded in the internal part of the pile body structure. When sunken construction of plate pile is conducted, the adjacent plate piles are firstly assembled integrally through the inverted H-shaped steel bar and the T-shaped through slot, and then the piles are sunken by machines. The U-shaped precast plate pile provided by the invention has the characteristics of convenient in construction, reliable in connection, good in water sealing effect and saves construction period and the like. If the plate pile is used as a temporary structure, after the construction is completed, the inverted H-shaped steel bar can be recycled and reused.

Owner:SHANGHAI ZHONGJI PILE IND +1

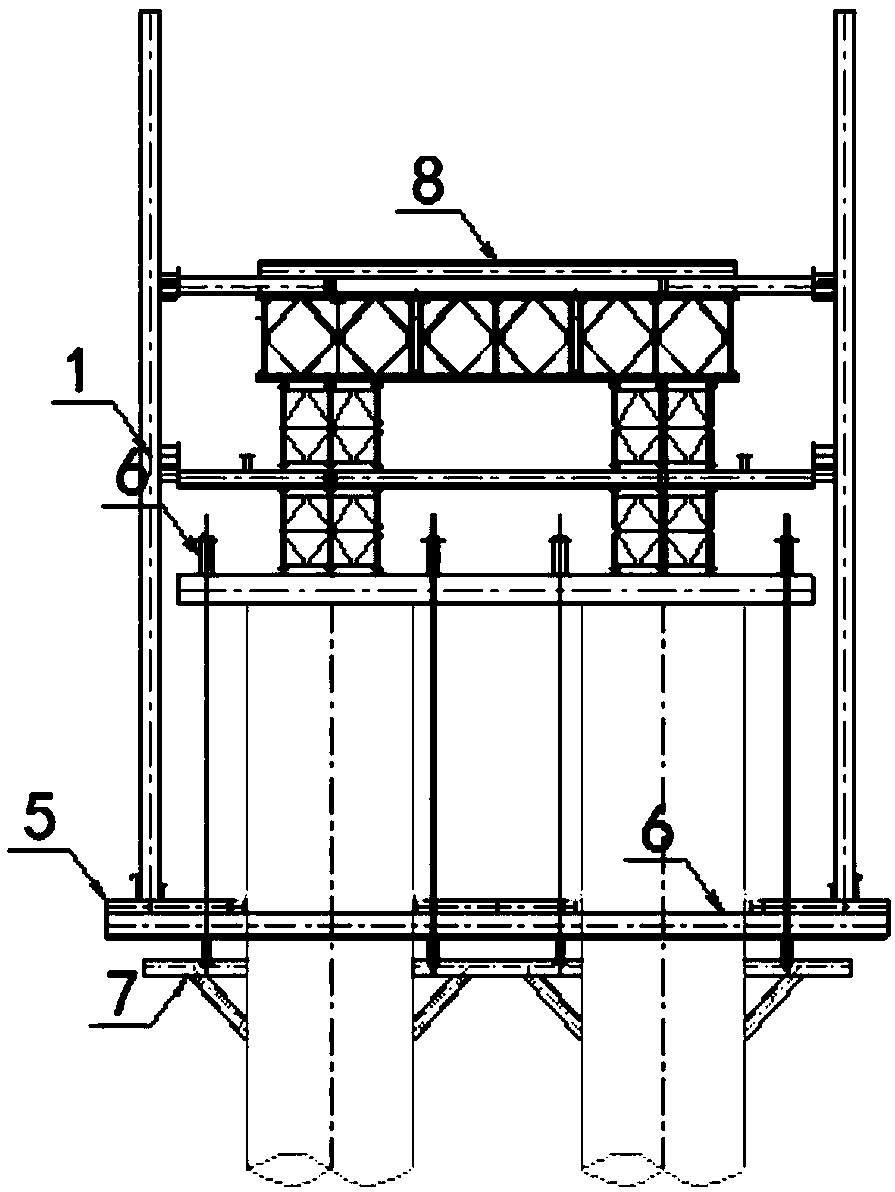

Construction method of deep water high pile bearing platform steel hanging box cofferdam

The invention discloses a construction method of a deep water high pile bearing platform steel hanging box cofferdam. The construction method comprises the following steps: 1) design of a steel hanging box cofferdam: Larson steel plate piles are adopted as wall plates of the steel hanging box cofferdam; 2) assembly and placement of the steel hanging box cofferdam: the steel hanging box cofferdam adopts high assembly and overall placement technologies; 3) bottom cover concrete construction: a bottom cover construction process is performed twice; after primary bottom covering, water in the steelhanging box cofferdam is extracted to a bottom cover surface; and then, the secondary bottom cover concrete casting is performed; and 4) disassembly of the steel hanging box cofferdam: after a bearing platform and part of underwater piers are constructed, the water is injected in the steel hanging box cofferdam to reach balanced inner and outer water levels; and the steel hanging box cofferdam isdisassembled. In the construction method, through the Larson steel plate piles as the wall plates of the steel hanging box cofferdam and twice bottom cover construction process, the construction progress can be accelerated, the economical cost is saved, and the engineering quality is guaranteed.

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

Water stop method for upper-soft and lower-hard water-rich stratum foundation pit engineering retaining structure

The invention discloses a water stop method for an upper-soft and lower-hard water-rich stratum foundation pit engineering retaining structure. The method includes the steps that firstly, a cast-in-situ bored pile is constructed; secondly, on the outer side of the cast-in-situ bored pile, a high-pressure jet grouting pile or a three-shaft stirring pile is constructed; thirdly, a hole is drilled in the center of the high-pressure jet grouting pile or the three-shaft stirring pile, and high-pressure jet grouting or sleeve valve pipe grouting is performed; fourthly, deep hole curtain grouting is performed; fifthly, a first-layer small guiding pit is excavated; sixthly, preliminary-stage supporting is performed on an upright excavation face of the first-layer small guiding pit; seventhly, core soil is reserved during excavation of a first-layer foundation pit; eighthly, a first-layer transverse steel purlin is arranged, and a steel cross brace is erected; and ninthly, when the pre-designed strength of the retaining structure is achieved and the monitored and measured result is accurate, next circulation is performed, and the fourth step, the fifth step, the sixth step, the seventh step and the eighth step are repeated till construction ends. The method is good in main water stop effect and good in flexibility. The technology is simple, the construction risk is small, influences on the environment are small, and adaptability to a complicated stratum is high.

Owner:FUJIAN UNIV OF TECH

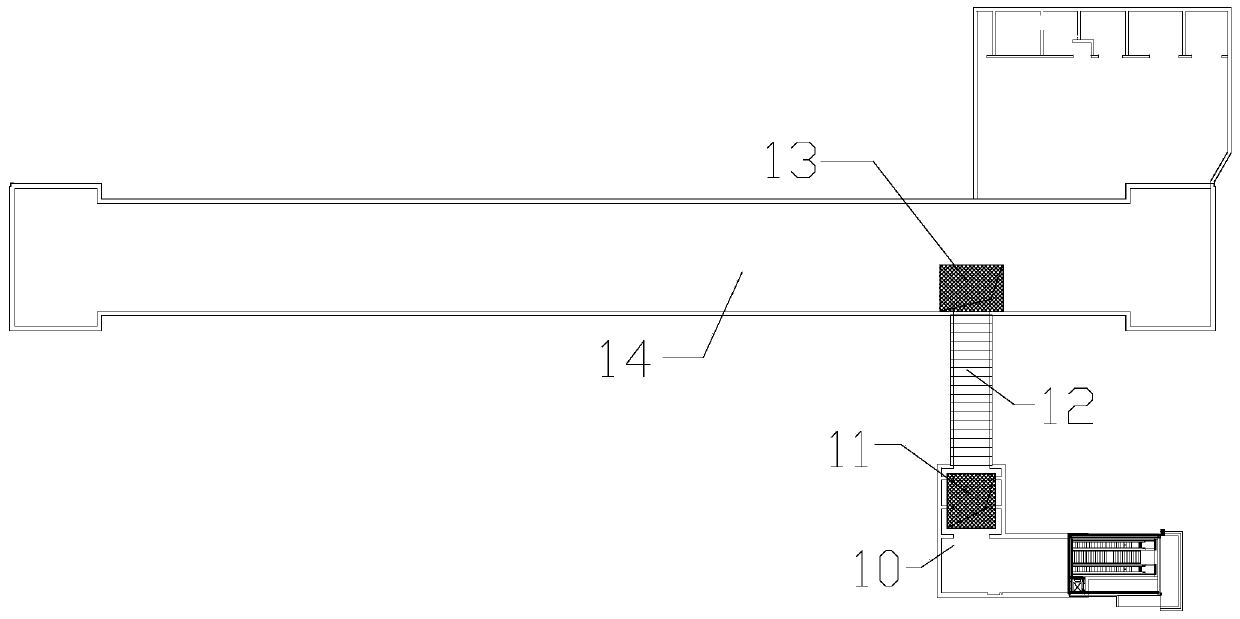

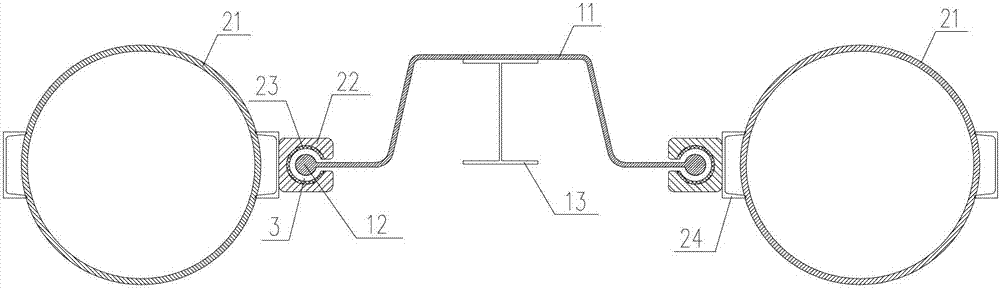

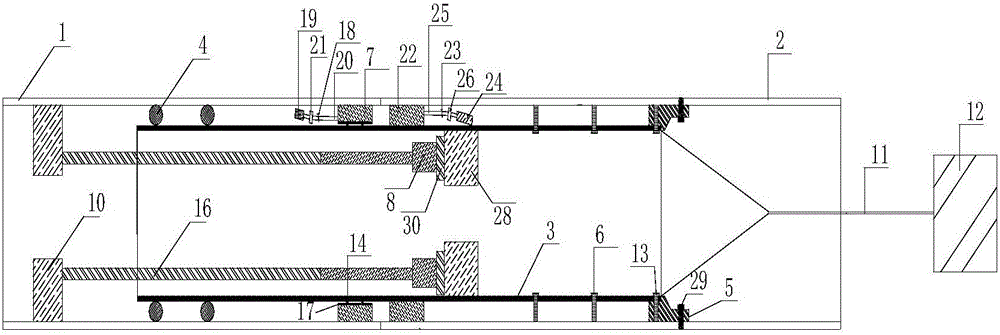

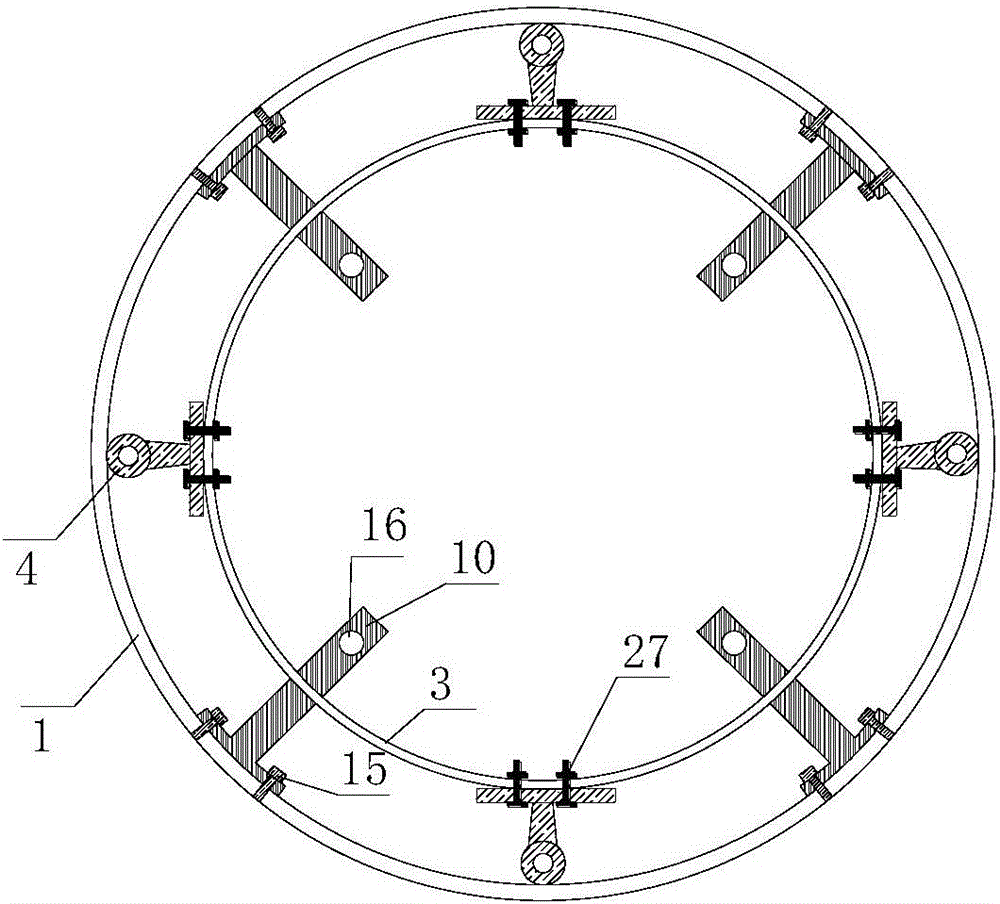

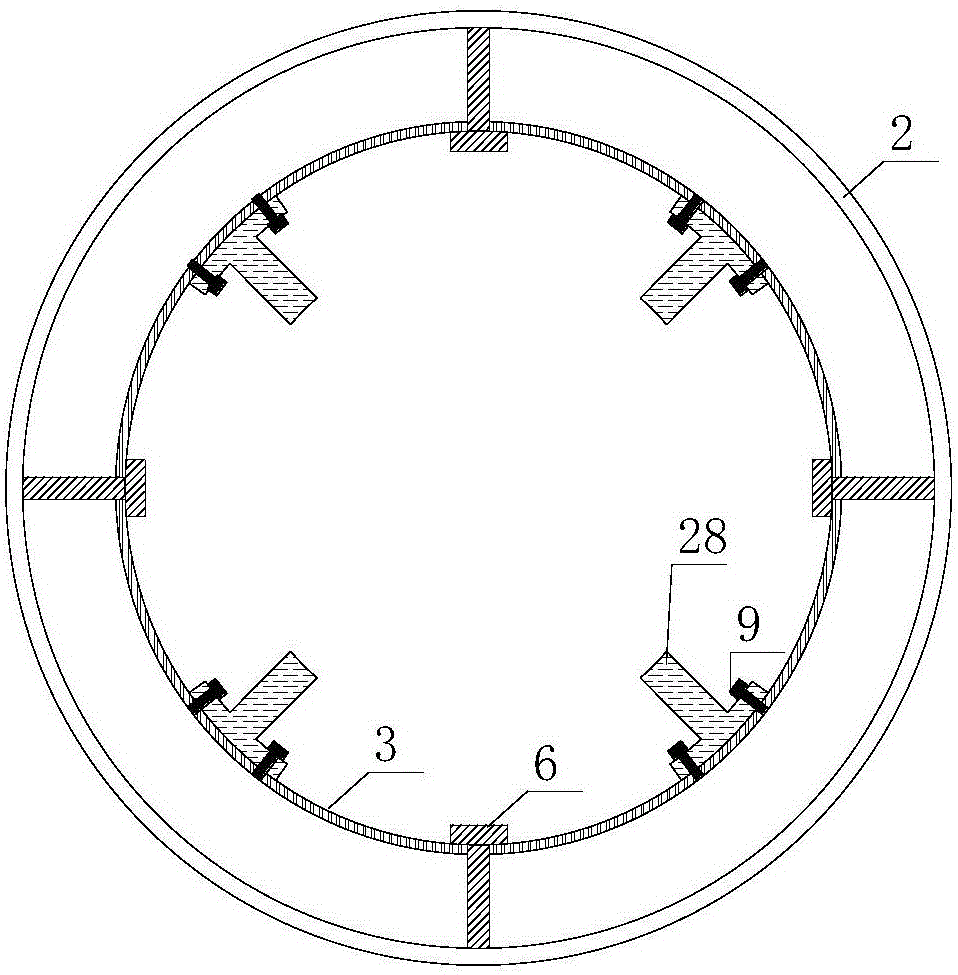

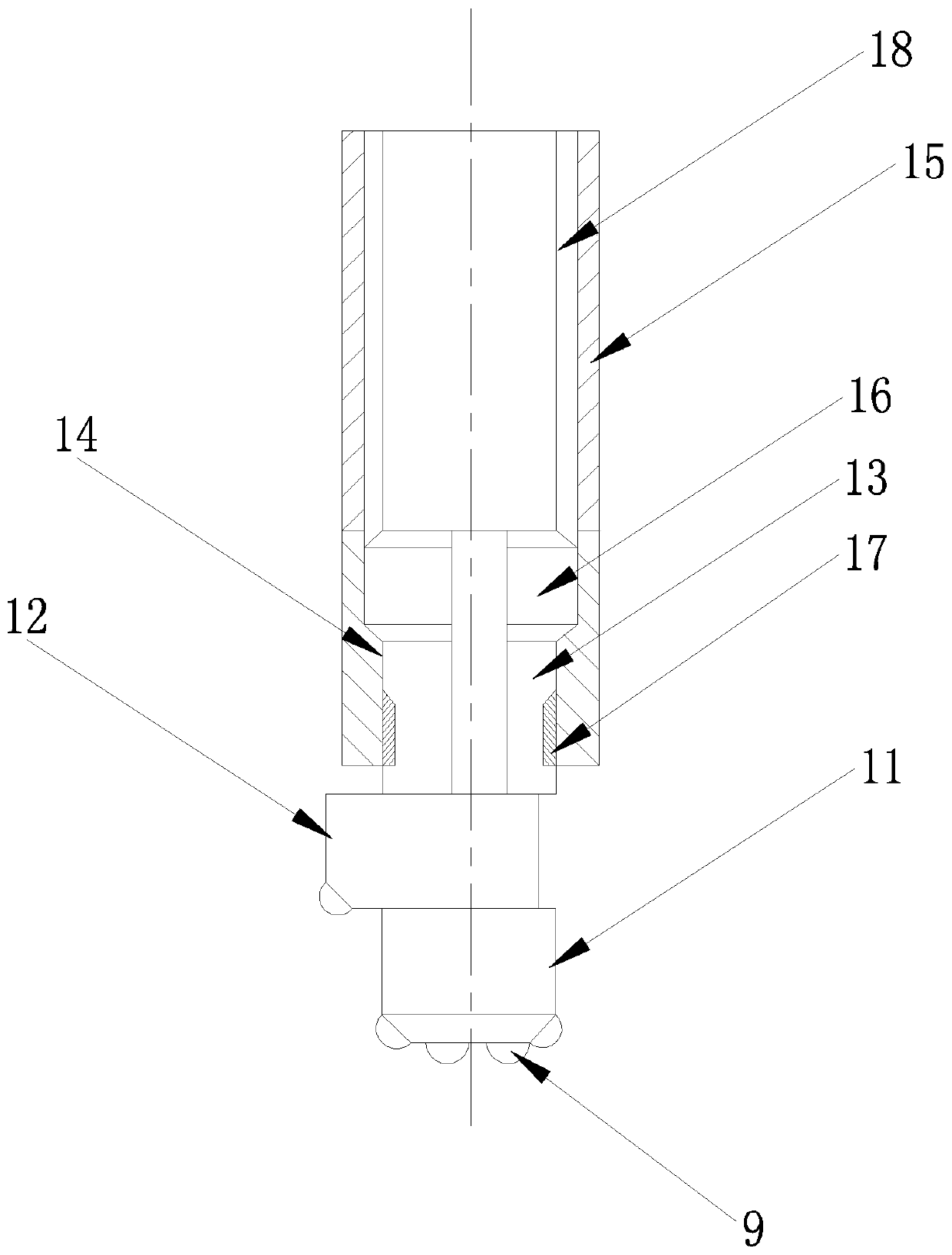

Combined type steel tube intermediate jacking station equipment for jacking pipe construction and construction method

ActiveCN105889625AEasy constructionReduce construction costsPipe laying and repairArchitectural engineeringSteel tube

The invention discloses combined type steel pipe intermediate jacking station equipment for jacking pipe construction and a construction method. The rear end surface of each front jacking pipe is connected with the front end surface of a corresponding rear jacking pipe, each intermediate jacking station round steel pipe is positioned in the corresponding front jacking pipe and the corresponding rear jacking pipe; a steel ring and annular sealing rings sleeve the outer wall of each intermediate jacking station round steel pipe; a first sealed inflatable bag sleeves the outer wall of each steel ring; a second sealed inflatable bag sleeves the outer wall of each intermediate jacking station round steel pipe and is positioned at the rear of the corresponding first sealed inflatable bag; heavy universal castors are mounted at assigned positions of the outer wall of each intermediate jacking station round steel pipe; fixed pedestals are mounted at assigned positions of the inner wall of each rear jacking pipe; after penetrating through each intermediate jacking station round steel pipe, a corresponding fixing screw is tightened and is propped against the inner wall of the corresponding rear jacking pipe; a jack is mounted on the periphery of the inner wall of the front end of each intermediate jacking station round steel pipe; and jack receiving seats are welded on the inner wall of each front jacking pipe at intervals. The construction method comprises the following steps: (1) mounting the intermediate jacking station equipment; (2) jacking; (3) detaching relevant fixing components of the intermediate jacking station round steel pipes; and (4) pulling out the intermediate jacking station round steel pipes. The combined type steel pipe intermediate jacking station equipment is reasonable in structure, convenient to construct, good in water stopping effect, convenient to assemble and disassemble and low in cost, and is used in jacking construction of long-distance jacking pipes.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

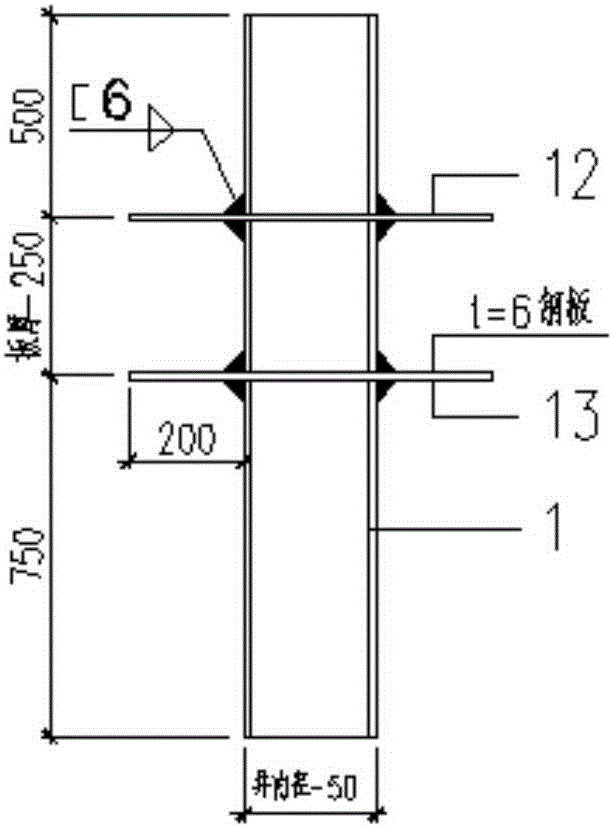

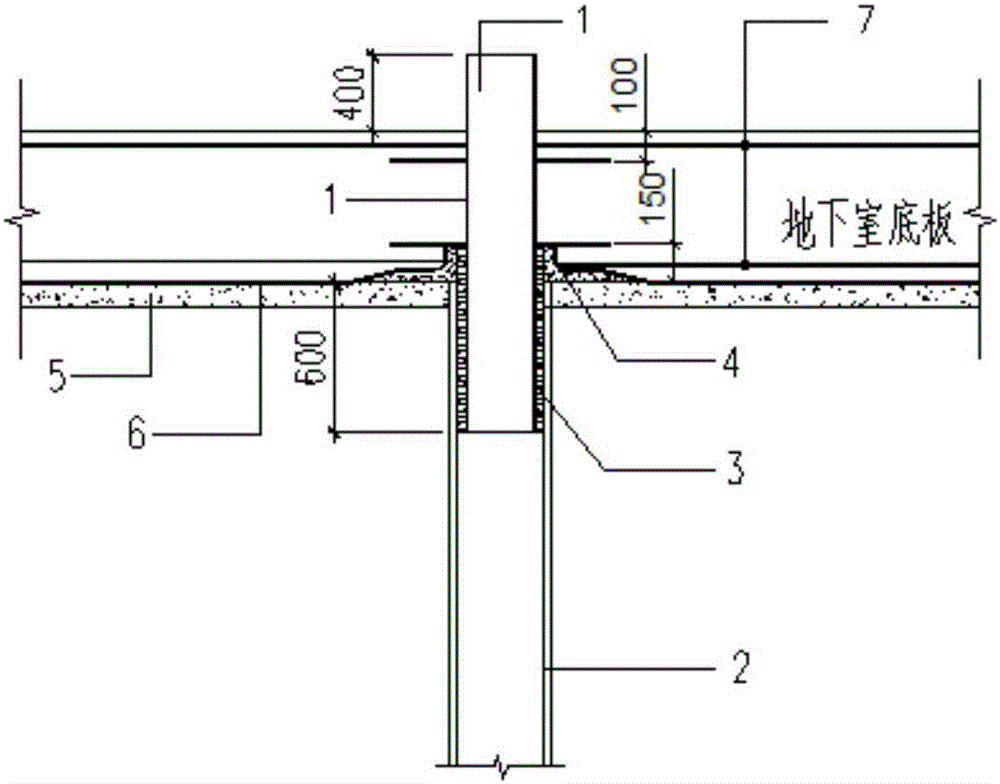

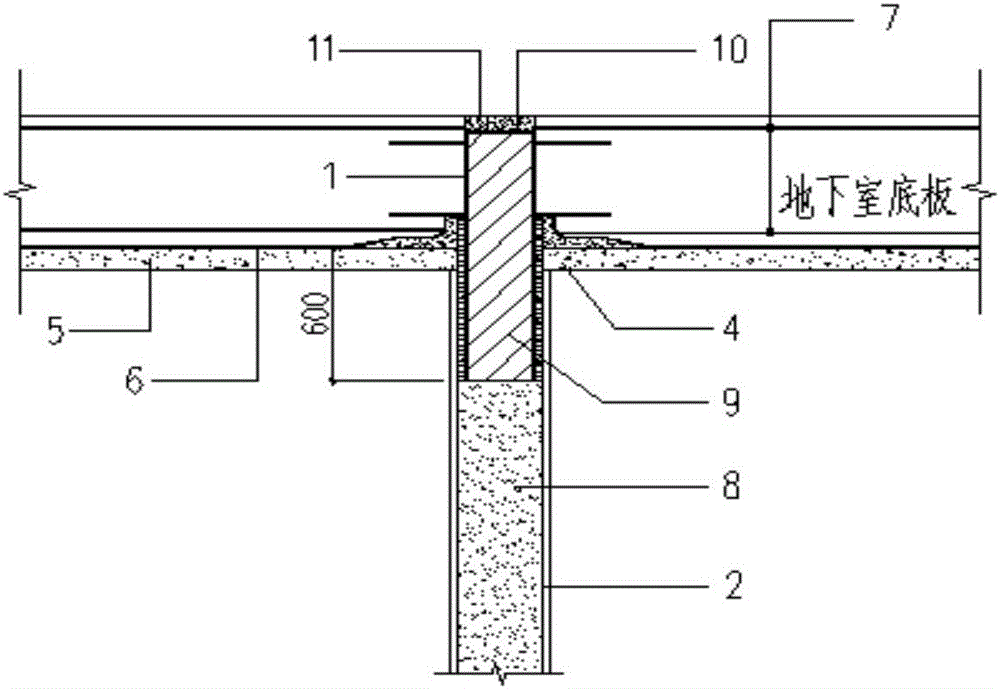

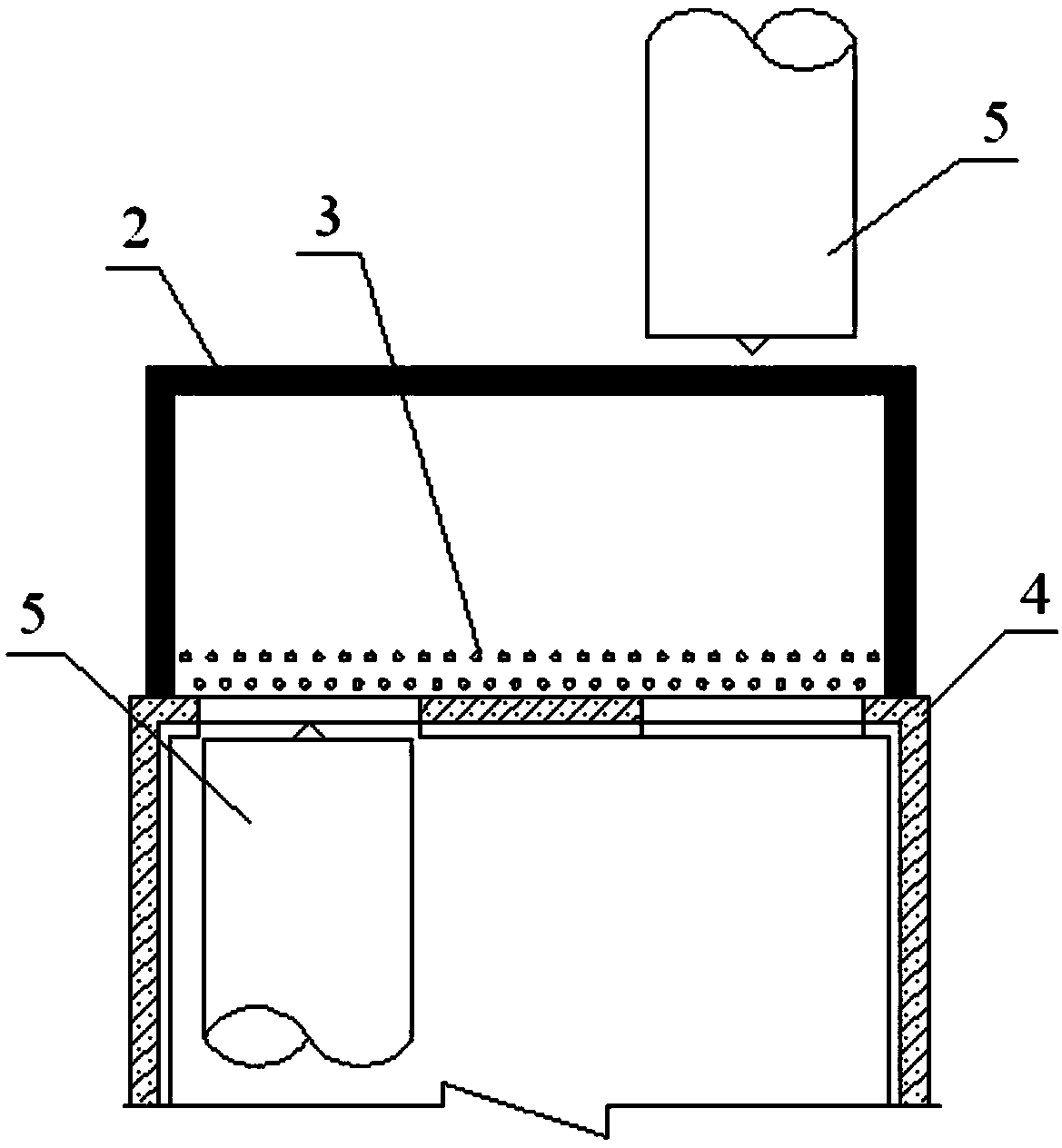

Treatment method of plugging water stop construction for foundation pit dewatering well to penetrate through concrete base plate of basement

ActiveCN105951859ASimple structureGood water stop effectFoundation engineeringSealing/packingHemp fiberRebar

The invention discloses a treatment method of plugging water stop construction for a foundation pit dewatering well to penetrate through a concrete base plate of a basement. The treatment method comprises the following steps of producing a water stop steel sleeve pipe; casting bedding concrete of a basement base plate; cutting a dewatering well strainer on a cushion surface; winding the lower end of the water stop steel sleeve pipe with bituminous hemp fibers, then inserting into the dewatering well trainer, filling seams with cement mortar and sealing; constructing a waterproof layer on the cushion surface of the basement base plate; banding reinforcing steel bars on the concrete base plate, and continuously dewatering; casting basement base plate concrete, and continuously dewatering; ending dewatering for the dewatering well one by one; and plugging the dewatering well. According to the treatment method disclosed by the invention, the double-wing-ring water stop steel sleeve pipe is adopted and is inserted into a dewatering well mouth; a plugging structure of the well mouth has the advantages of simplicity, scientificity, reasonability, safety, reliability and good water stop effect, and can well adopt to dewatering requirements of the basement base plate construction under different working conditions; and the dewatering demand of the basement reinforced concrete base plate in the construction process is met, and the problem of water stop plugging of the dewatering well penetrating through the basement reinforced concrete base plate when the dewatering is ended is well solved.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method for special underground continuous wall

The invention provides a method for constructing a special underground continuous wall. The underground continuous wall comprises a wall body with indelible embedded barriers, wherein the wall body with the indelible embedded barriers is positioned between barrier-free wall bodies. The construction method comprises the following steps: (a) the normal barrier-free wall bodies on the left and the right sides of the wall body with the embedded barriers are constructed; (b) the operation of groove wall reinforcement is carried out on the grooving area of the wall body with the embedded barriers, and a reinforced structure and the barrier-free wall bodies on both sides form a relatively enclosed area; and (c) special grooving technological construction is carried out in the relatively enclosed wall body area. By adopting the method, the indelible barriers in the wall body of the underground wall can work together with the underground wall, thereby guaranteeing the integrality and the constructional feasibility of the underground continuous wall used as a permanent structure or a space enclosing structure, shortening man-hour, and saving the production cost.

Owner:LONGYUAN CONSTR GROUP

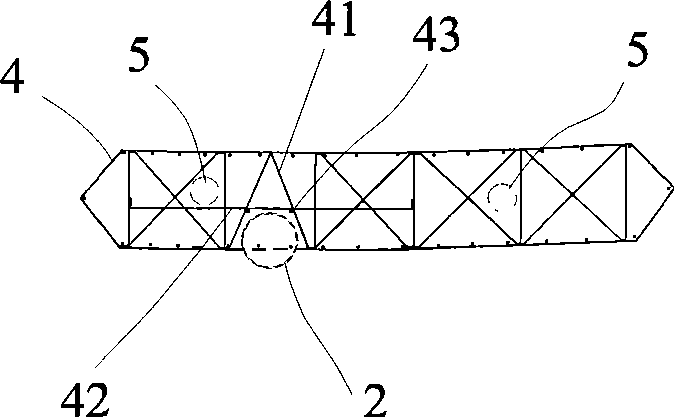

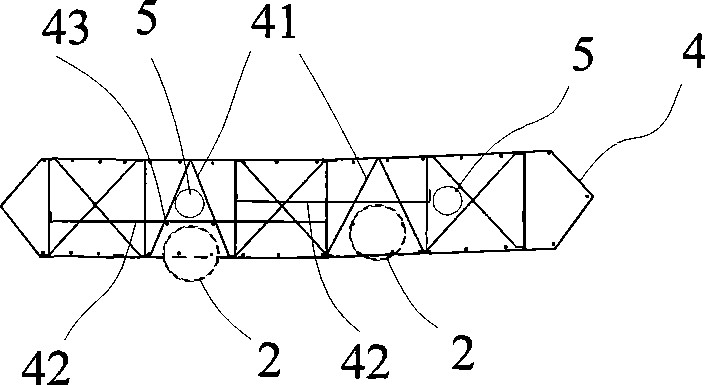

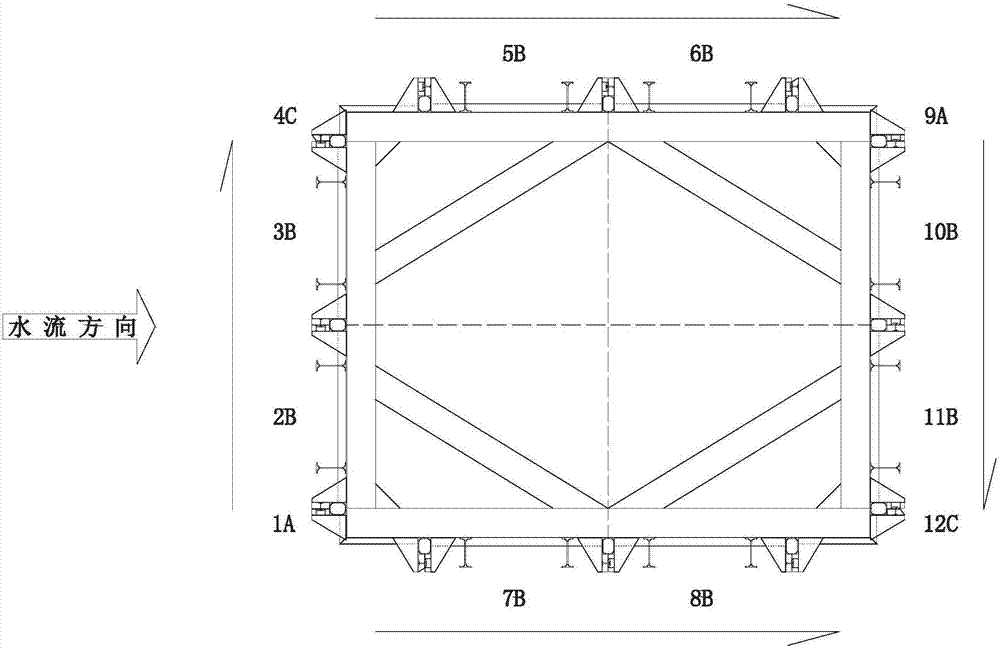

Steel caisson enclosure structure at island-tunnel combination part

The invention discloses a steel caisson enclosure structure at an island-tunnel combination part. The enclosure structure adopts a steel box body structure; water stop gates are arranged at the two ends of the box body; and the cavity part in the middle of the box body is a dock chamber of a tunnel to be built. The bottom plate and two side walls of the box body are in a hollow structure formed by welding a steel truss and a steel plate; and multiple grids are arranged and internally filled with underwater concrete. A steel box beam is arranged at the upper part of each water stop gate. The top of the box body also serves as a bidirectional back shore of a construction platform. The bottom plate of the box body is provided with a vertical foundation cast-in-place pile reserved sleeve penetrating through the bottom plate; and the reserved sleeve extends upwards and is connected with the bidirectional back shore at the top of the box body. The enclosure structure disclosed by the invention has a good water stop effect, reduces the construction difficulty, improves the construction efficiency, shortens the construction period, creates conditions for mounting the tunnel immersed tube as early as possible, and does not cause interference to the construction at the butt joint of an overwater tunnel immersed tube.

Owner:NO 5 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

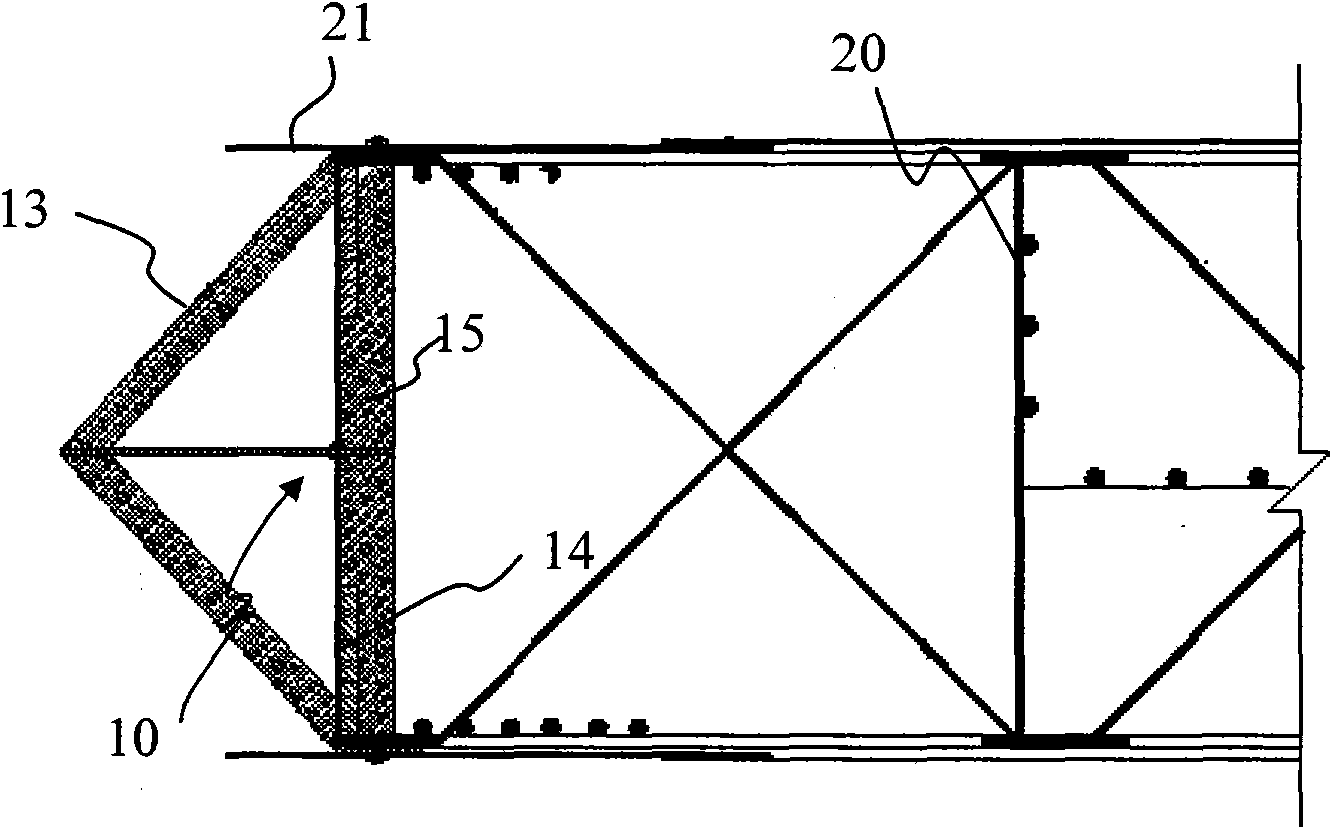

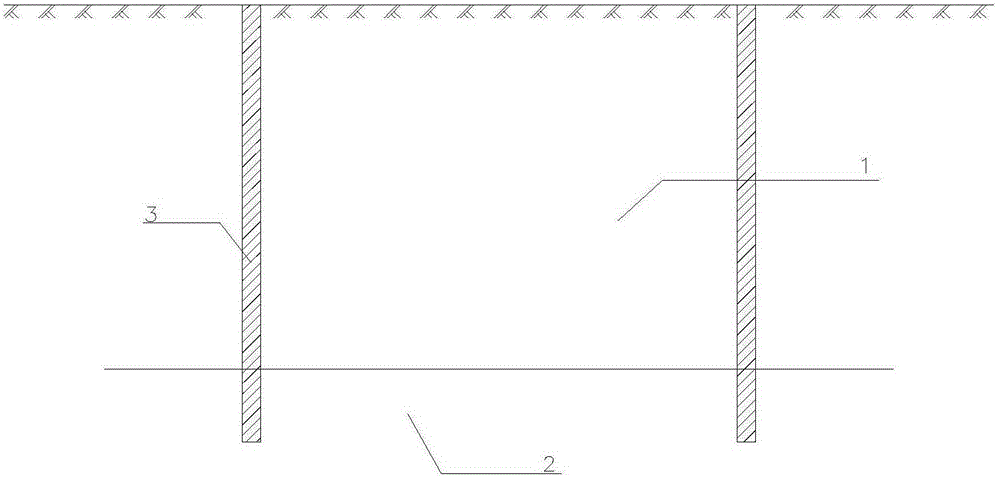

Combined bracing structure for foundation pit and construction method thereof

InactiveCN102116030AGood water stop effectSimple and fast constructionExcavationsSheet pileBuilding construction

The invention provides a combined bracing structure for a foundation pit and a construction method thereof, relating to the combined bracing structure for the foundation pit and belonging to the technical field of geotechnical engineering. The combined bracing structure for the foundation pit comprises a cast-in-situ bored pile used as the bracing structure and a steel sheet pile used as a waterproof curtain, wherein a space truss structure is formed by the cast-in-situ bored pile and the steel sheet pile through an inner pile block ring beam, an outer pile block ring beam as well as inner and outer pile block connecting beams. The invention achieves the purposes of simple and fast construction, easy quality control, cycle use and high integral rigidity.

Owner:SOUTHEAST UNIV

Method of replacing shield tail brush of shield tunneling machine

InactiveCN107387101AImprove continuityImprove uniformityUnderground chambersTunnel liningEngineeringShield tunneling

The invention discloses a method of replacing a shield tail brush of a shield tunneling machine; the method comprises the steps of I, setting circular bamboo reinforcement grouting holes, and performing grouting construction; II, replacing the shield tail brush; III, mounting a segment; IV, taking protective measures after the replacement of the shield tail brush. The method of the invention has the advantages that directional localized grouting can be performed according to field actual conditions; the method has low manufacture cost, high construction practicability, zero tunnel space taken by reinforcing equipment, short construction period and the like; little influence is caused to structural durability of the segment, and no adverse influence is caused to the structural stability of a shield tunnel; the method is highly worthy of popularization and application.

Owner:WUYI UNIV

Foundation pit construction method

InactiveCN101793023ALight weightEasy constructionExcavationsBulkheads/pilesArchitectural engineeringSmall footprint

The invention mainly discloses a foundation pit construction method. In the method, steel sheet piles are used as the supporting structures along the inner diameter of the foundation pit, the earth is excavated downwards and then the inner supports in the steel sheet piles are kept not deformed by support until the bottom of the foundation pit is sealed. The foundation pit construction method has the following advantages: the steel sheet piles have lighter weight, are simple and convenient to construct and dispense with huge construction equipment; the foundation pit has small floor area and can reduce the construction land to the greatest extent during shortage of construction sites or construction in cities; pollution to the surrounding environment can not be produced and the method has environment-friendly characteristic; construction is fast, the construction efficiency is high and the construction period can be greatly shortened; the steel sheet piles have good interchangeability and watertightness; the method can ensure the whole maintenance structure to be more economic and reasonable while meeting the requirements of different geology, depth and supporting structures by changing the section shapes and the length of the steel sheet piles.

Owner:JIANGSU SHUNDA ENG TECH

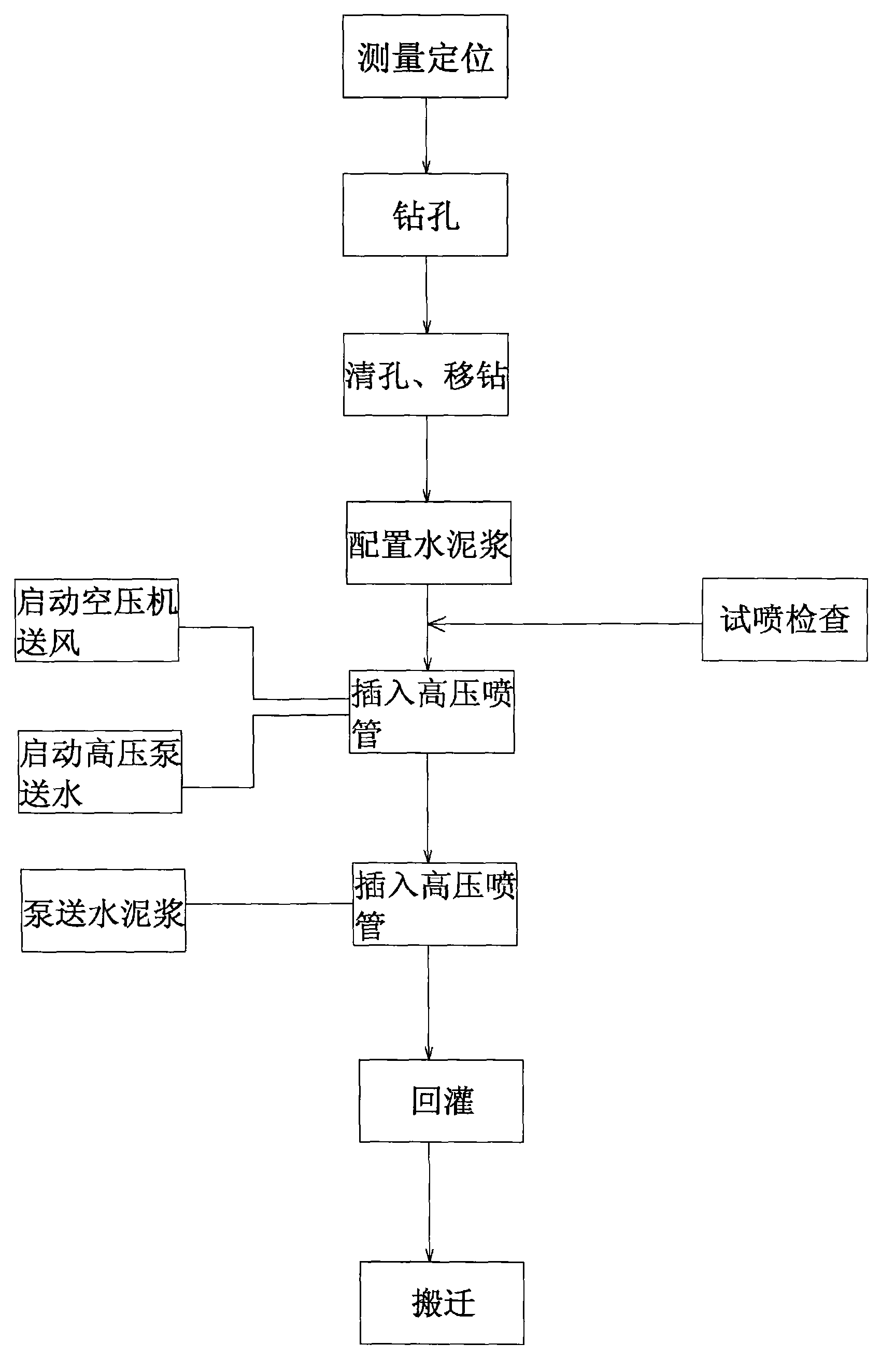

Novel construction technology of waterproof curtain

InactiveCN103806457AFast constructionFast construction processFoundation engineeringEngineeringHigh pressure water

The invention relates to a novel construction technology of a waterproof curtain. The novel construction technology includes the following processing steps: (1) carrying out measurement positioning, (2) enabling a hole leading drilling machine to be in place according to the marked position to carry out hole drilling, (3) cleaning a hole after hole drilling is completed, moving the hole leading drilling machine to a next hole position, and repeating the step (2) and the step (3), (4) preparing cement paste, (5) inserting a high-pressure spraying pipe into the hole, meanwhile, starting an air compressor to supply air, and starting a high-pressure water pump to supply water, (6) carrying out high-pressure jet grouting operation: forming the waterproof curtain by pumping the cement paste, and enabling the high-pressure spraying pipe to be lifted in a rotary mode, (7) carrying out recharging to enable the hole to be filled with the paste, and (8) carrying out movement: moving the high-pressure spraying pipe to the next hole position, repeating the step (5), the step (6) and the step (7), and finally completing construction of the whole waterproof curtain. The novel construction technology of the waterproof curtain has the advantages of being rapid in construction, good in waterproof effect, capable of keeping a soil layer structure stable and the like.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG

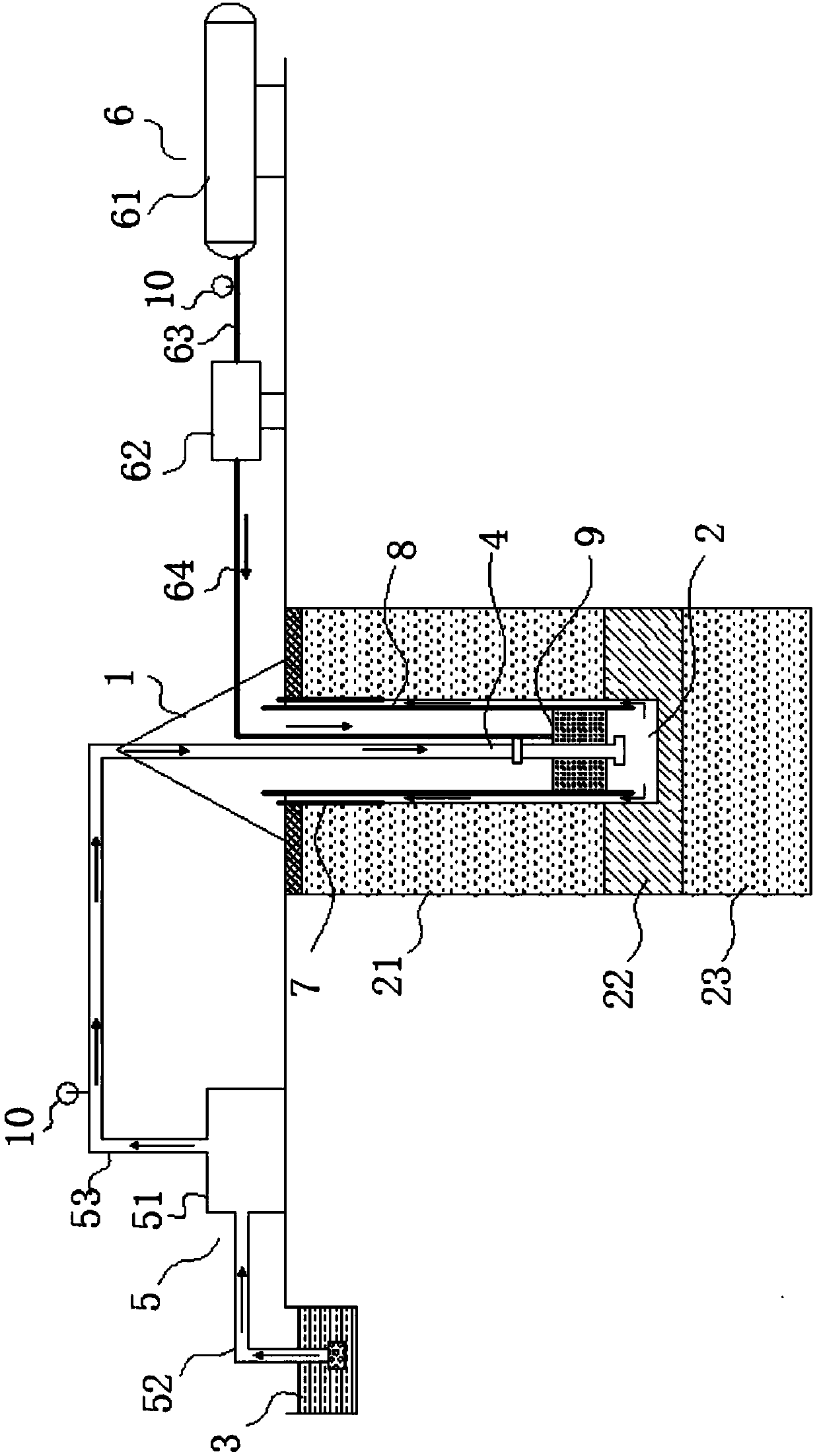

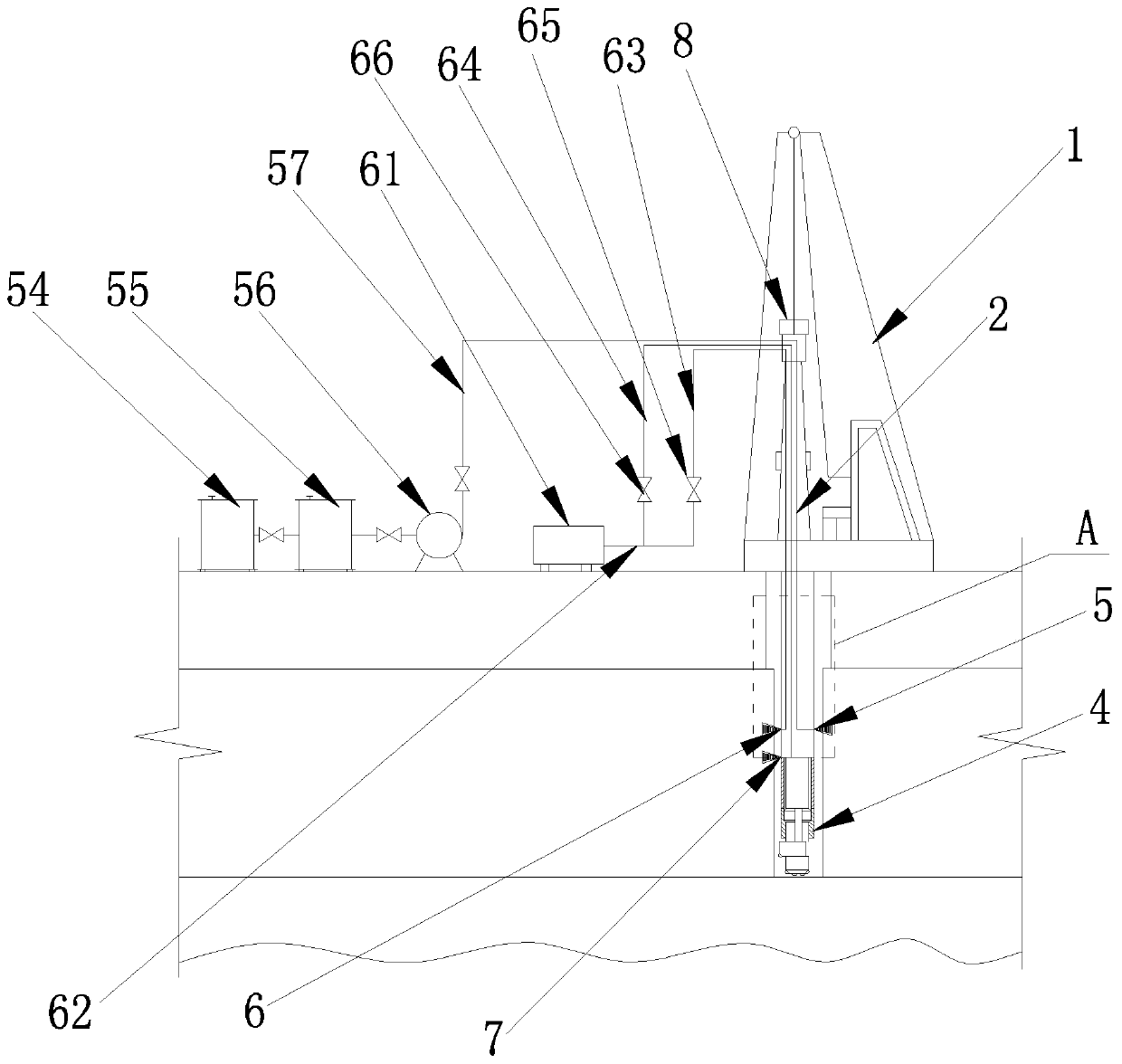

Drill-hole waterstop device and method

The invention relates to a drill-hole waterstop device. The drill-hole waterstop device comprises a drilling machine, a drill pipe, a packer and a casing pipe, wherein the drill pipe is connected withthe drilling machine, one end of the drill pipe is connected with a slurry supply device, the other end of the drill pipe is used for extending into a drill well, the packer is arranged on the drillpipe in a sleeving mode and located in the drill well, the packer communicates with an air supply unit, the casing pipe is arranged on the periphery of the packer in a sleeving mode, and a certain gapis left between the casing pipe and the inner wall of the drill well. The slurry supply device is used for injecting slurry into the drill well through the drill pipe, and the packer is configured tobe that when the air supply unit supplies air to the packer, the packer expands and the size of the packer is increased, so that a channel between the drill pipe and the casing pipe is closed. The invention further relates to a waterstop method utilizing the drill-hole waterstop device. The waterstop method comprises the steps that the casing pipe is down into the drill well, then the packer is down into the casing pipe, the channel between the casing pipe and the drill pipe is blocked off, the slurry is supplied into the drill well through the drill pipe, and therefore a gap between the casing pipe and the well wall is filled with the slurry. According to the waterstop method, the waterstop time can be shortened, the slurry using amount is decreased, and the good waterstop effect is achieved.

Owner:QINGDAO PROSPECTING INST OF GEOLOGICAL ENG +1

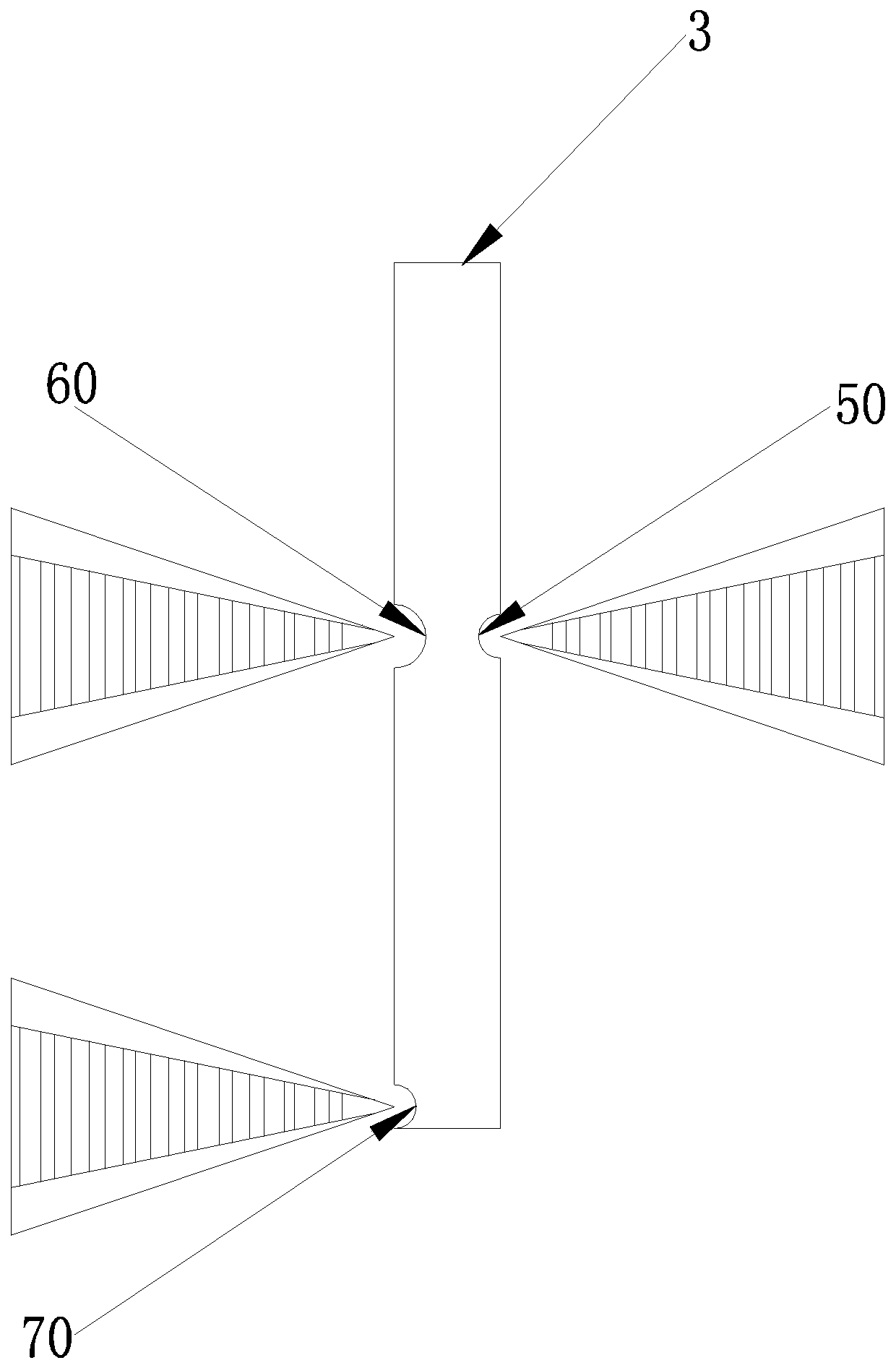

High-pressure jet grouting pile hole leading construction integrated device and construction method thereof

PendingCN111577136ASimple structureHigh pile strengthDirectional drillingBorehole drivesPipeUltimate tensile strength

The invention relates to a high-pressure jet grouting pile hole leading construction integrated device and a construction method thereof. The high-pressure jet grouting pile hole leading constructionintegrated device comprises a jet grouting drilling machine, a high-pressure jet grouting drill rod and a triple pipe, wherein the triple pipe is fixedly arranged at the bottom of the high-pressure jet grouting drill rod, and a down-the-hole hammer is fixedly arranged at the bottom of the triple pipe; and the triple pipe comprises a grout outlet ejector, an inner air outlet ejector and an outer air outlet ejector which are sequentially arranged from inside to outside. The high-pressure jet grouting pile hole leading construction integrated device is simple in structure, convenient to use and practical, the construction technology of combining the triple pipe and the down-the-hole hammer is adopted for the environment of a complex geological layer, and by optimizing construction technical parameters, an obtained pile body is high in strength and good in construction quality. Compared with a traditional high-pressure jet grouting pile construction method, the input mechanical materials are few, the cost is low, construction is safe, and construction is rapid.

Owner:浙江岩科建设有限公司

Water level and water quality layering control weir of drainage ditch of rice field

InactiveCN101892655AEasy accessReduce typesBarrages/weirsSoil drainageLeaking waterHigh concentration

The invention relates to a water level and water quality layering control weir of a drainage ditch of a rice field. Three types of five weir plates in different heights are designed according to the characteristics of each growth period of rice; the heights of the five weir plates are determined according to the buried depth of underground water required by the rice in different growth periods; by combining the five weir plates, outlet control weirs in different heights of the drainage ditches can be formed, and the drainage control requirements of rice reviving, early stage of tillering, late stage of tillering, booting stage, tasseling stage, milky ripeness stage, yellow ripening stage and late stage of fertilizing; two hand grabs are arranged on the lateral surface of each weir plate; an arc rubber waterstop band is arranged at the bottom of each weir plate which ensures overall seamless joint water stop among the weir plates; doorframe grooves are arranged on two sides of the drainage ditch; rubber waterstop bands are arranged on two sides in the doorframe grooves; the weir plates can be slidingly taken out or placed into the frame grooves and cannot leak water; two pull rod handles for taking and placing the weir plates are additionally arranged; and rhombus rings of the pull rod handles can be sleeved with hand grabs on the weir plates to place or take out the weir plates from the doorframe grooves on two sides of the drainage ditch. The invention has the advantages that the combined height of the weir plates cannot cause the flooding damage on the rice, can be used for retaining nitrogen, phosphor and other nutrients in the rice field and reducing the pollution of high-concentration nitrogen and phosphor in the drain to a water body. The invention saves the water consumption for irrigation, improves the utilization rate of underground water resources, has favorable waterstop effect among the weir plates and is convenient to manually operate.

Owner:HOHAI UNIV

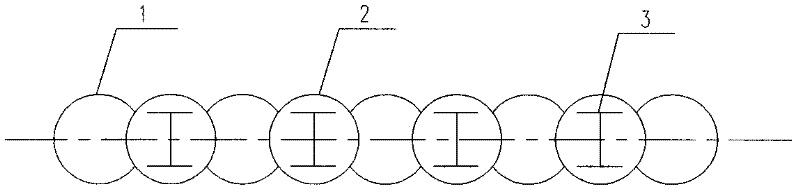

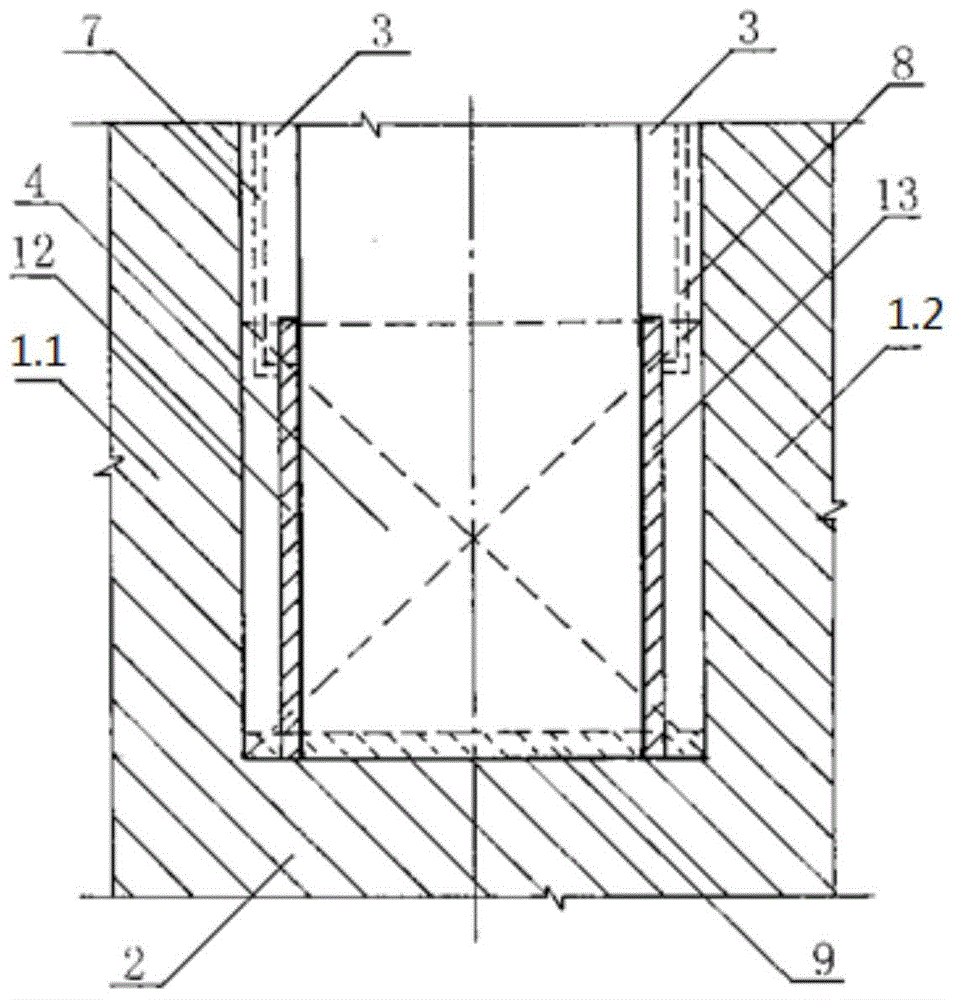

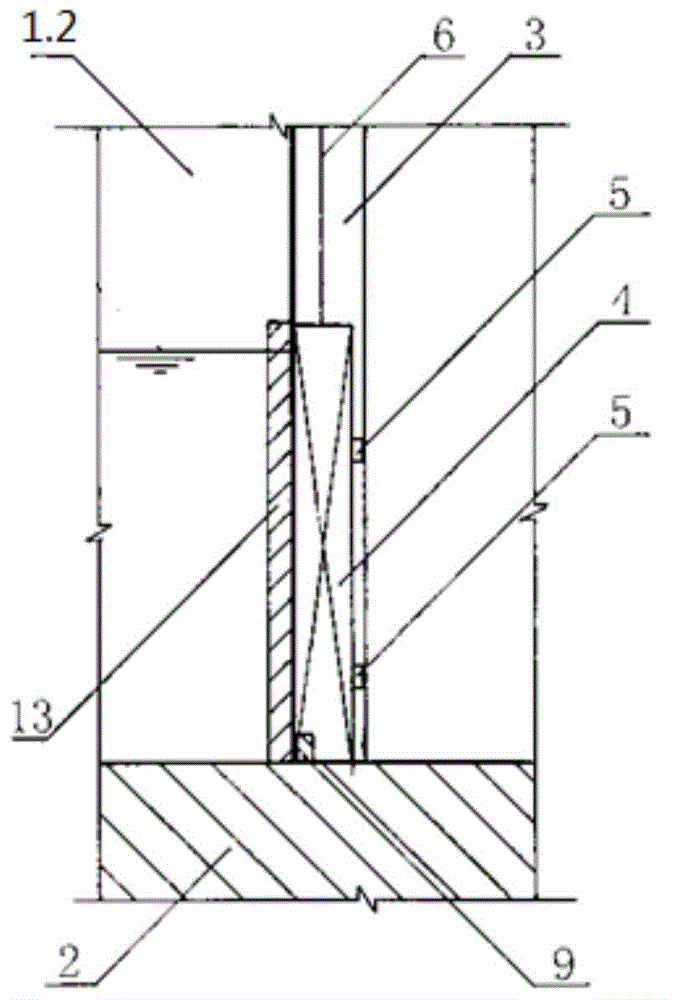

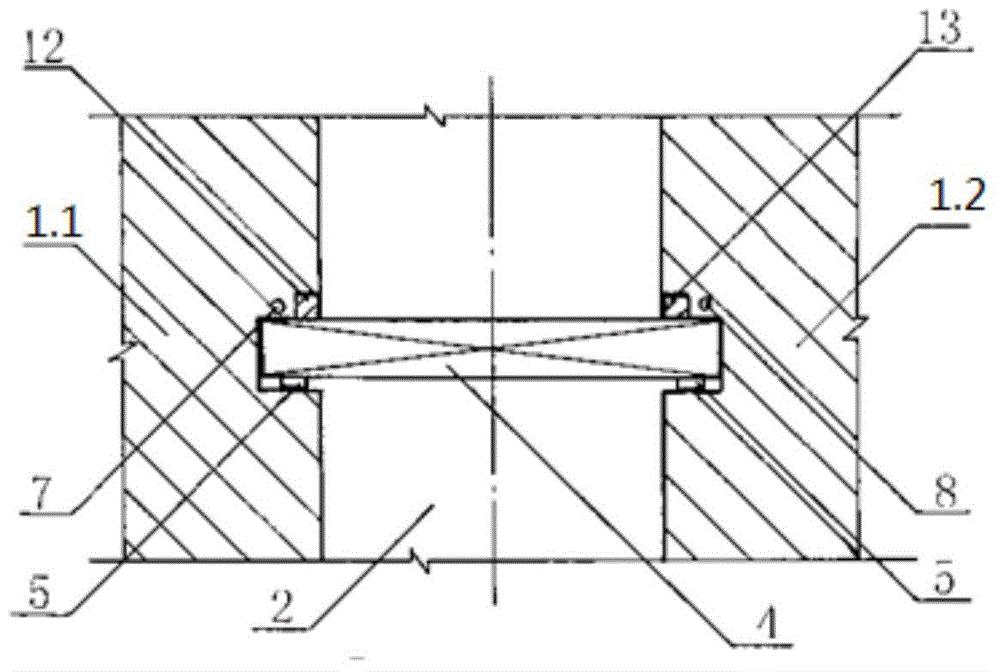

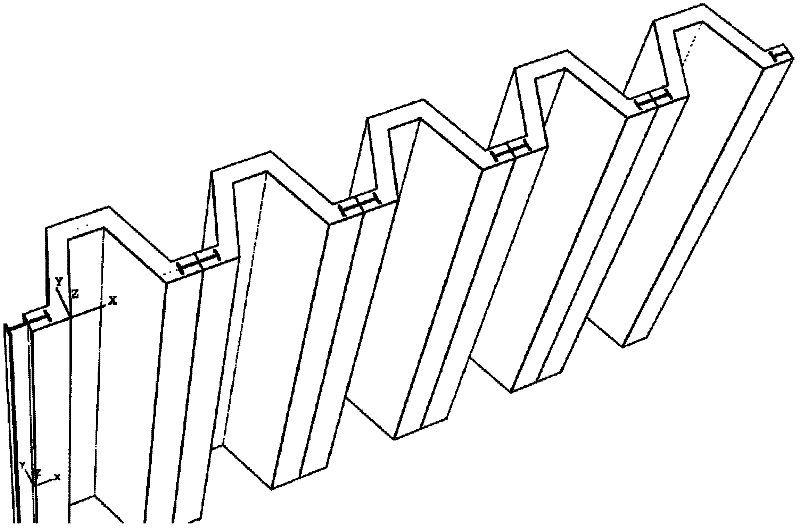

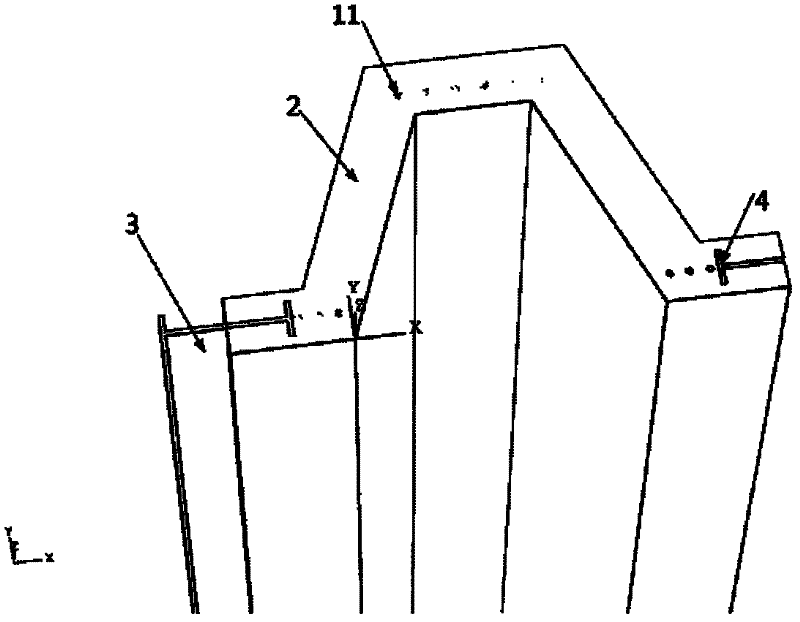

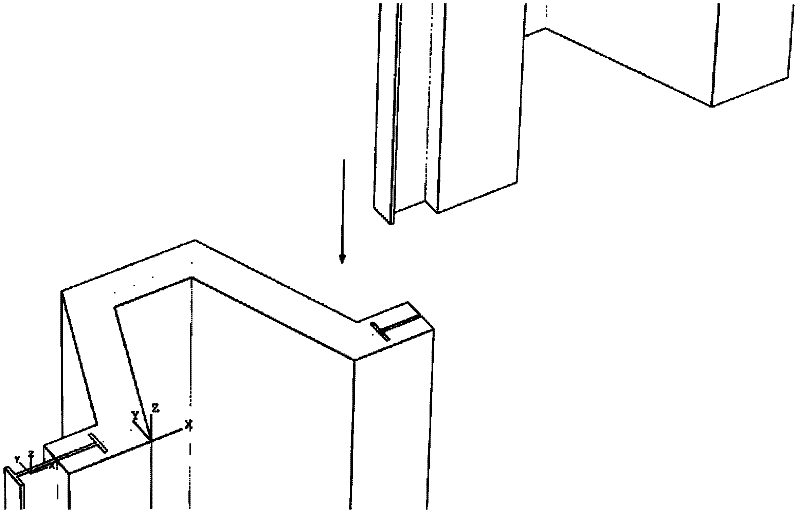

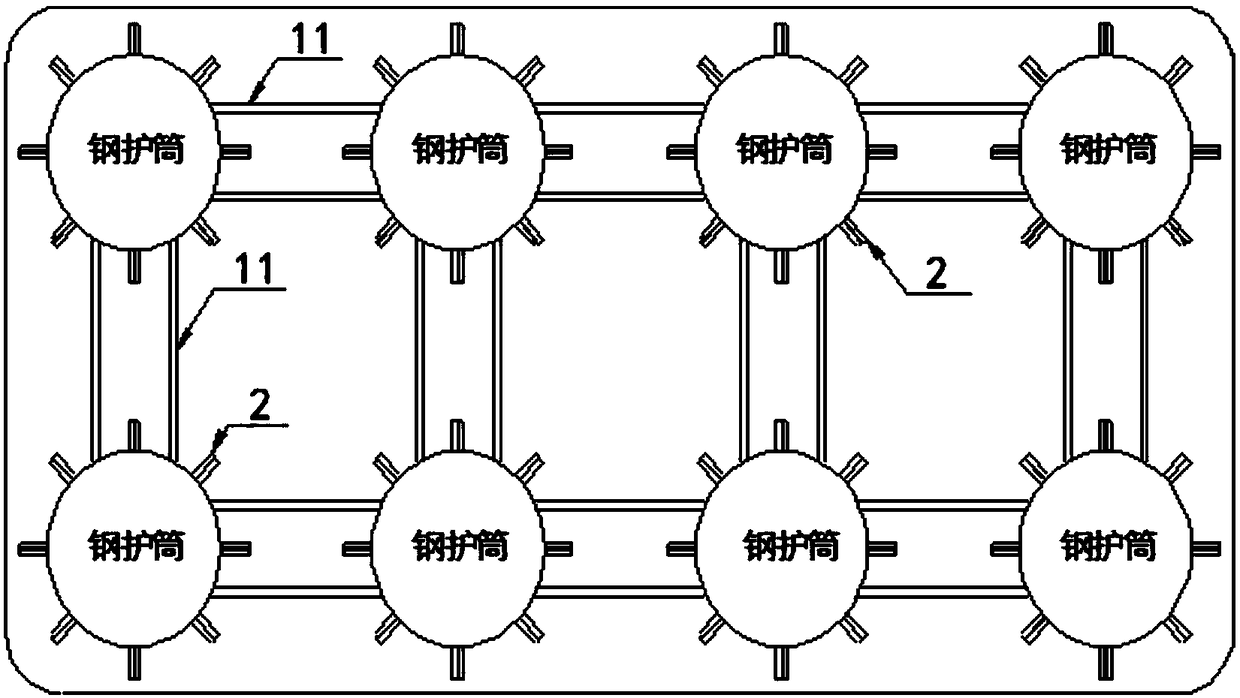

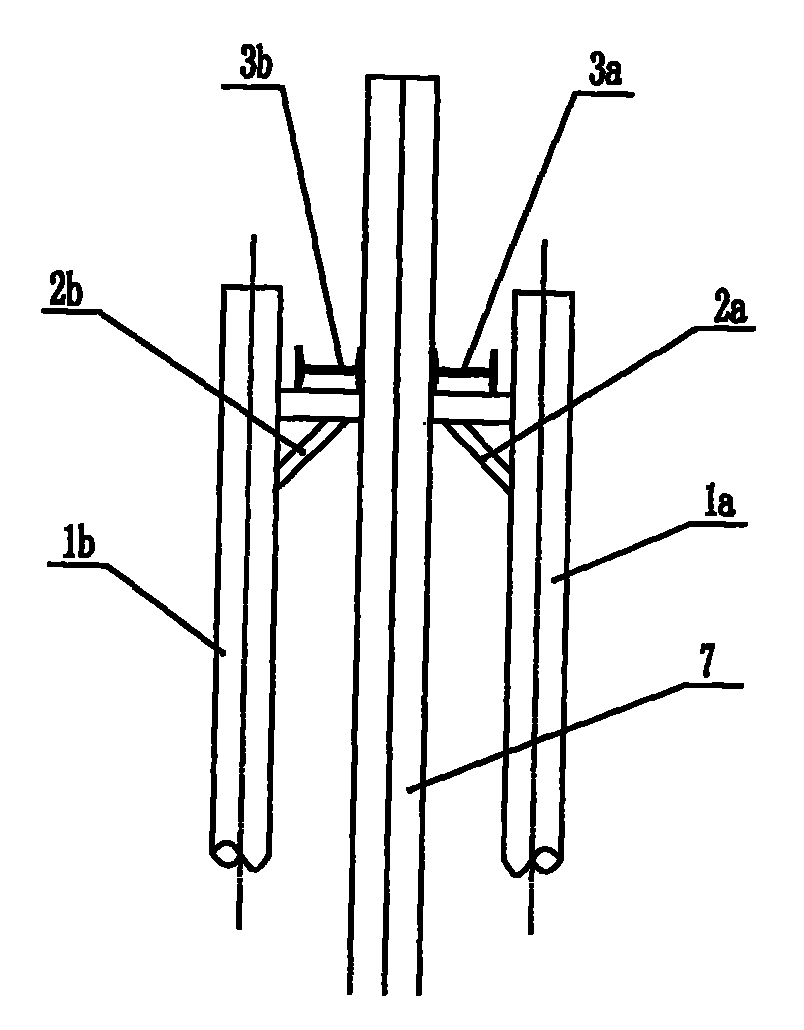

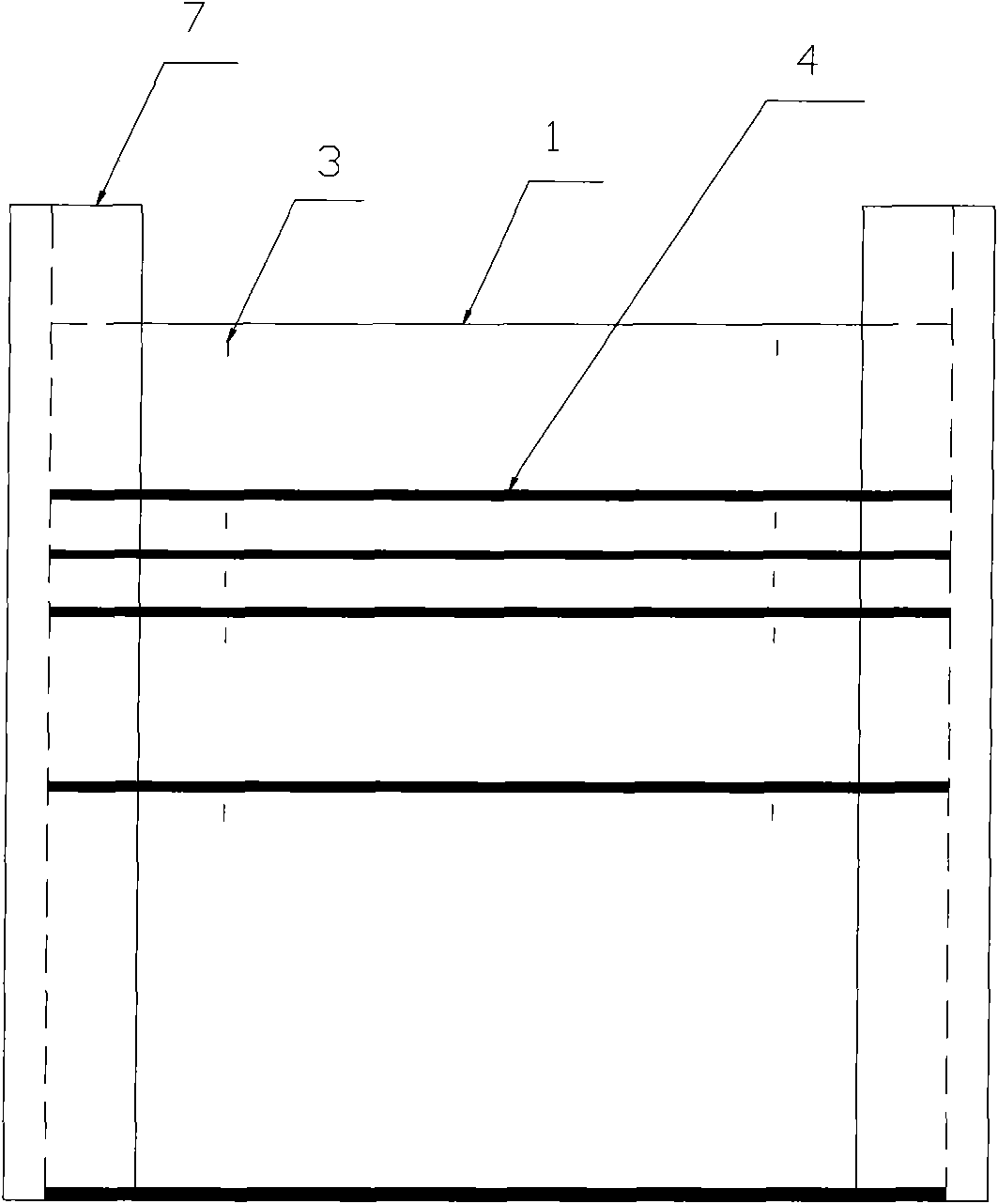

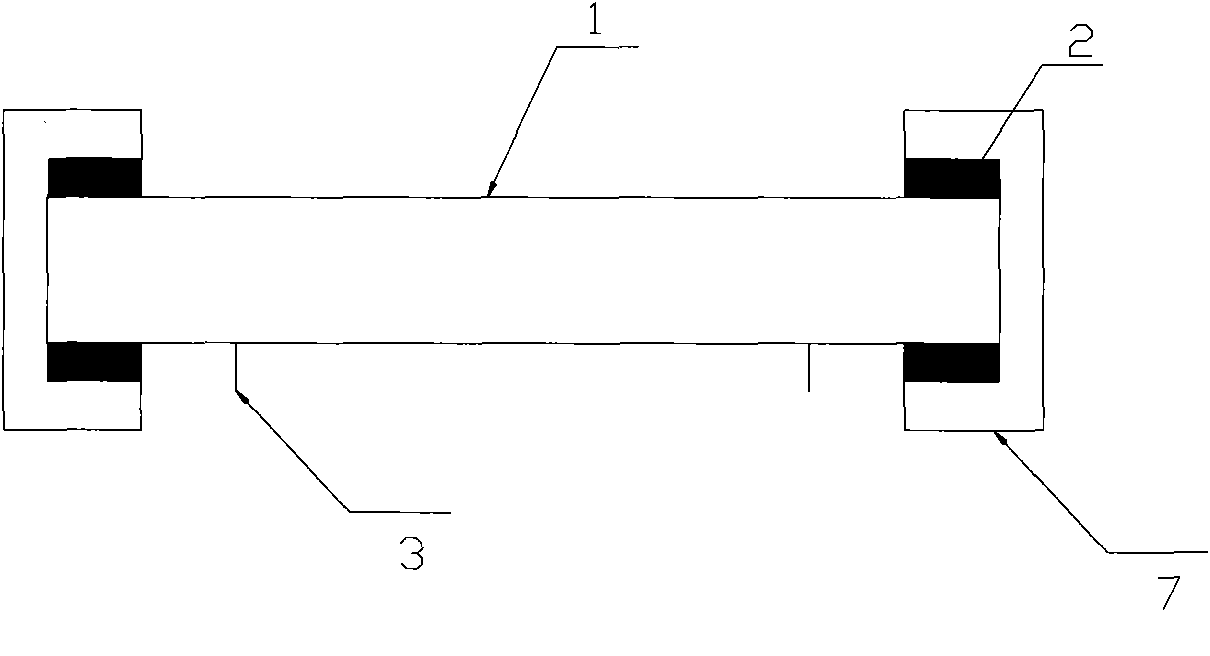

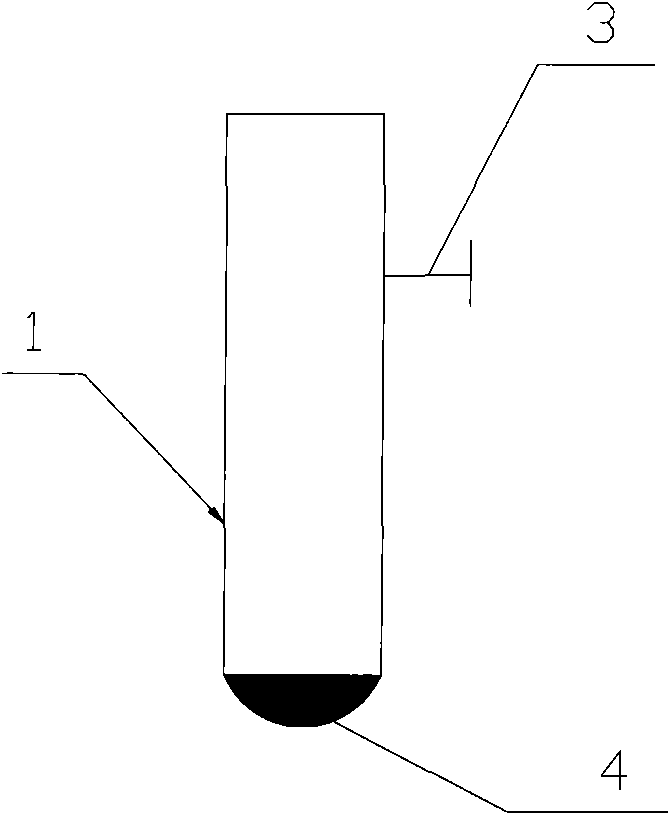

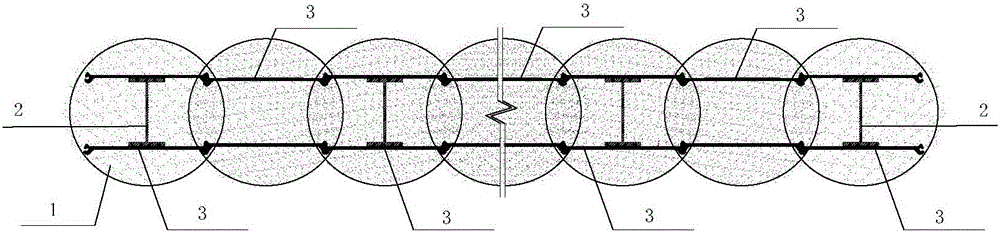

Lattice type combined steel sheet pile cemented soil composite pile and construction method thereof

InactiveCN106088102AGood water stop effectSolve the problem of large horizontal deformationExcavationsBulkheads/pilesEngineeringWater table

The invention discloses a lattice type combined steel sheet pile cemented soil composite pile and a construction method thereof. The lattice type combined steel sheet pile cemented soil composite pile comprises linear steel sheet piles (3), narrow wing I-shaped steel (2), cemented soil deep mixed piles (1), pile top crown beams and supports in a foundation pit. The combined steel sheet piles are inserted into the cemented soil deep mixed piles, so that cemented soil is sealed in lattices of the combined steel sheet piles, the stressed state of the cemented soil is changed, and the unidirectional stretch bending stress state of the cemented soil, arranged on the outer side of profile steel in a traditional construction method, of the lattice type combined steel sheet pile cemented soil composite pile is changed into a three-way pressured state. According to the lattice type combined steel sheet pile cemented soil composite pile and the construction method thereof, the lateral rigidity of a traditional SMW construction method pile is substantially improved, and the defect that the lateral rigidity of the traditional SMW construction method pile is relatively small is overcome; meanwhile, the characteristics of being good in waterstop performance, high in construction speed, recyclable in steel, good in economy and the like of an original technology are inherited; and the lattice type combined steel sheet pile cemented soil composite pile and the construction method thereof are suitable for soft soil, floury soil and silt stratum foundation pit engineering supporting structure which is large in excavation depth and high in underground water level.

Owner:NANJING UNIV OF TECH

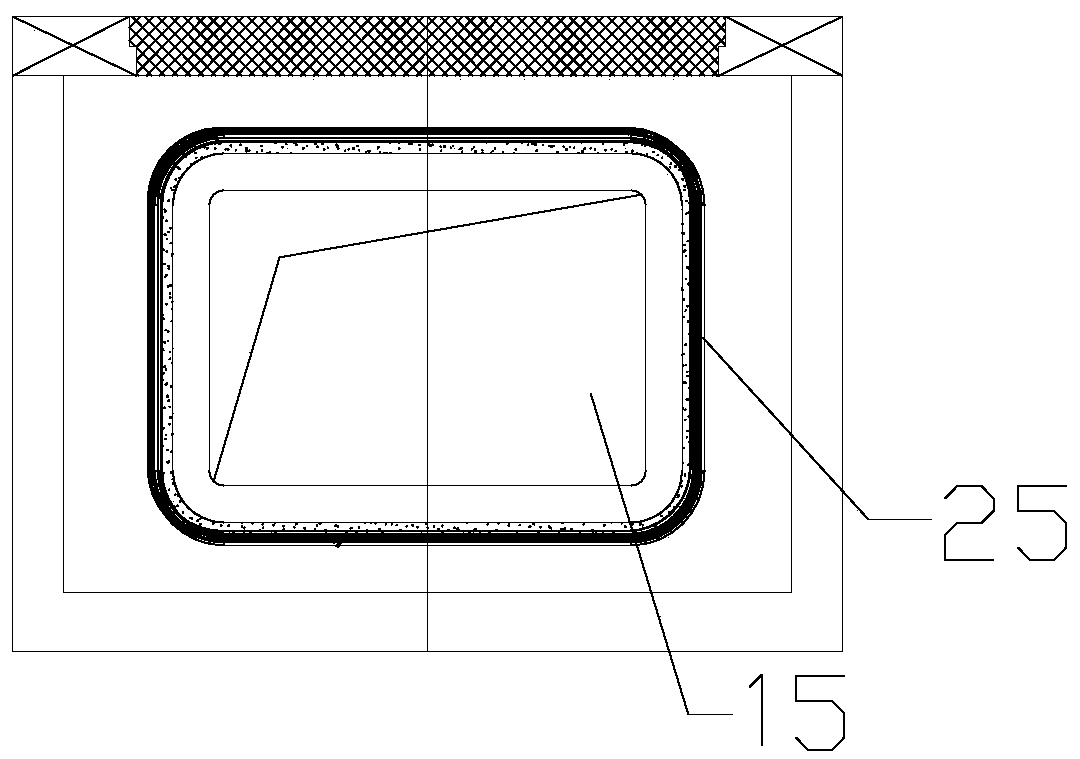

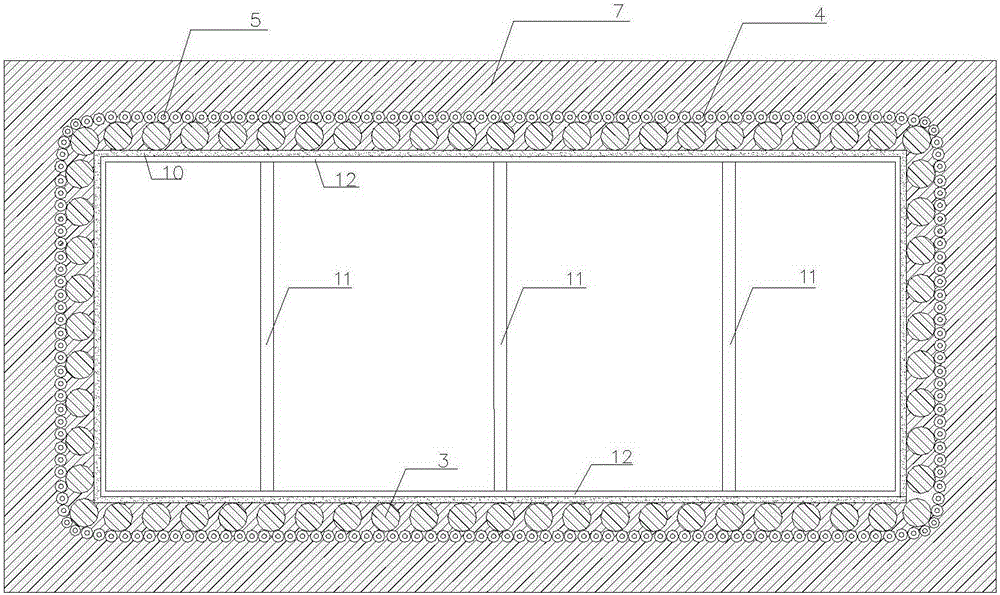

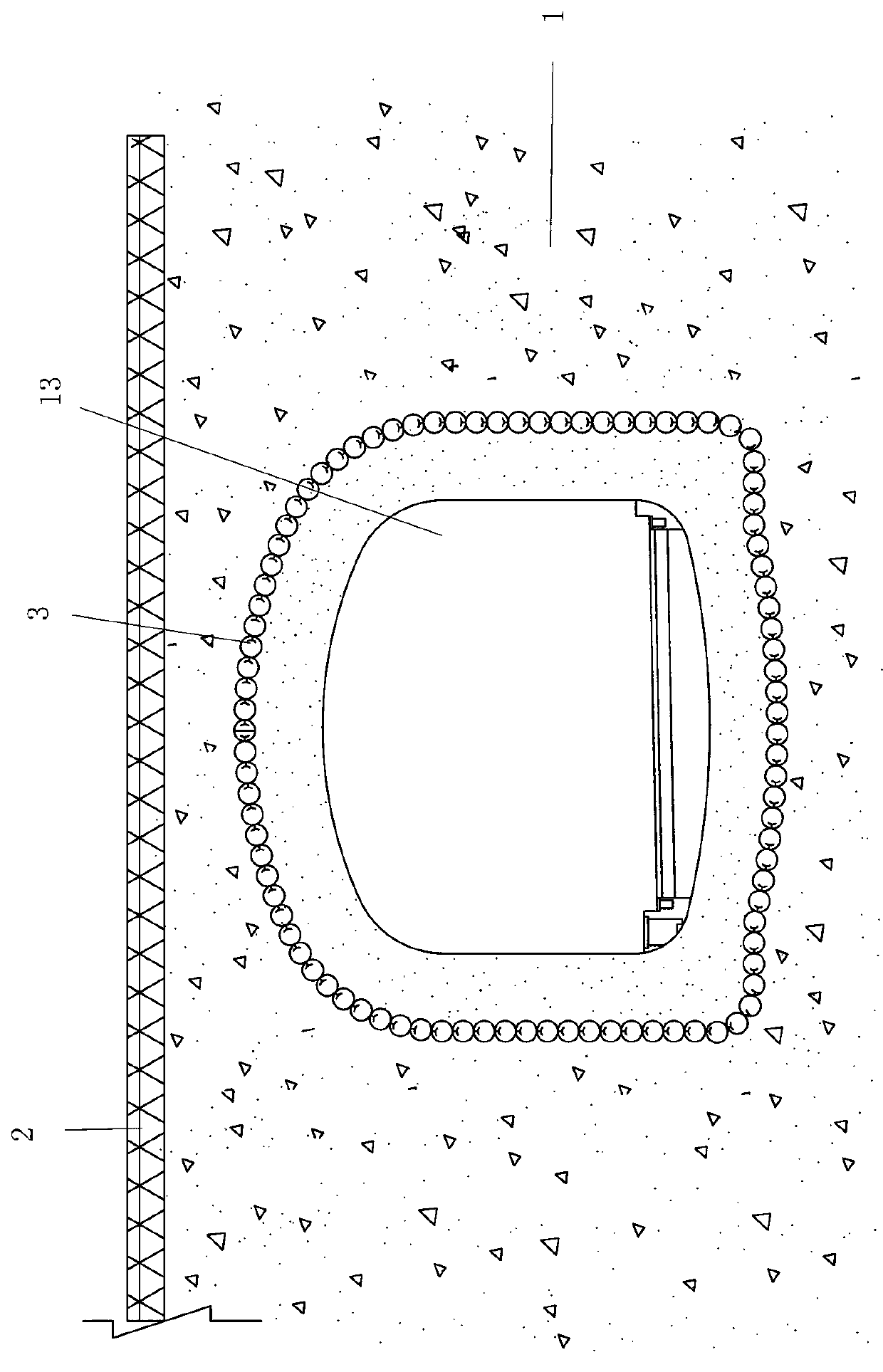

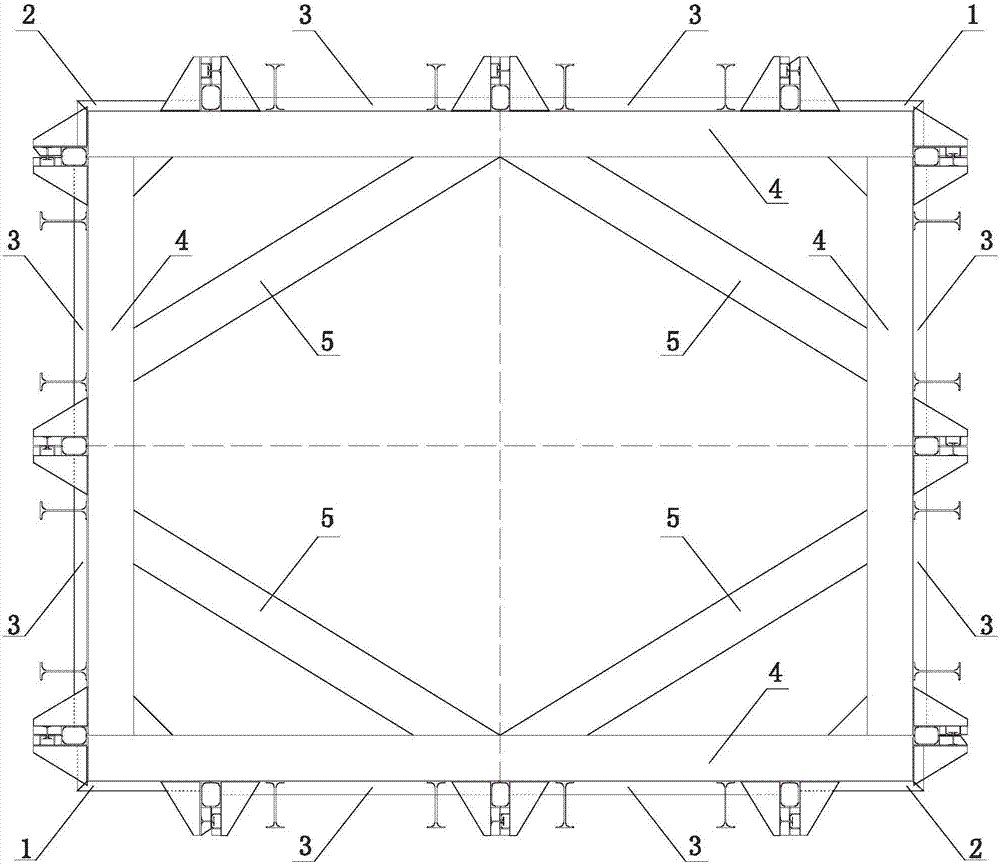

Joint reinforcement structure for shield tunnel end and a construction method

PendingCN109209396AGuaranteed accuracyImprove digging effectUnderground chambersTunnel liningSoil mixingEngineering

The invention discloses a joint reinforcement structure for a shield tunnel end and a construction method. The joint reinforcement structure is a rectangular box structure as a whole, and the rectangular box structure is formed by reinforcement structures surrounded on four sides. The reinforcement structure near a foundation pit is a frozen soil wall, and the reinforcement structures on the remaining three sides are cement soil continuous walls. The method includes a first step of construction of cement soil continuous walls by using a TRD method to construct continuous walls of cement soil with a three-cycle method; a second step of construction of vertical frozen soil wall by firstly, drilling of freezing holes, installing a freezing station at the same time; after confirming that the freezing meets the door chiseling condition, starting to break a hole wall, forcibly unfreezing before a shield main machine enters into the hole, pulling out a vertical freezing tube after the shieldmain machine completes entering and exiting the hole, and grouting. The joint reinforcement structure has the beneficial effects that strong construction practicability, convenient construction quality control and outstanding reinforcement effect. Compared with a traditional cement-soil mixing piles reinforcing method, the method saves cost and greater promotion and application value is ensured.

Owner:HAINAN UNIVERSITY

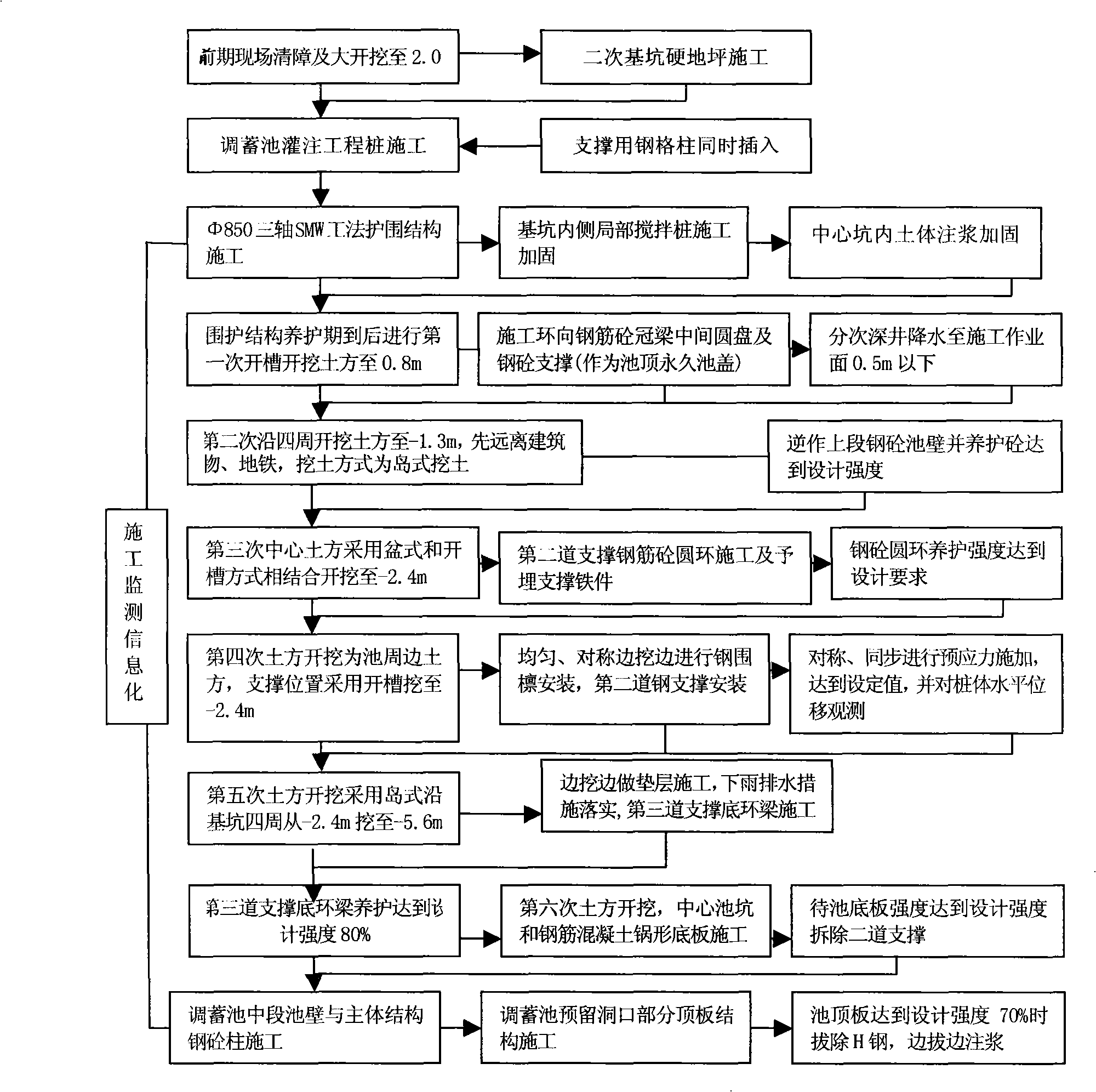

Semi-inverse construction method of super large diameter, ultra-burial depth storage pond

ActiveCN101353896AAchieve securityLow costArtificial islandsExcavationsMotherboardBuilding construction

The invention relates to a semi-reverse construction method for a regulation pool with huge diameter and embedded depth, which relates to the technical field of building engineering construction, in particular to a construction method technique of a regulation pool with the diameter more than 30m and the embedded depth exceeding 7m. An SMW method pile is adopted in the retaining and protecting structure of the invention, and the manufacturing procedures are a pool top cover, an upper pool wall, a pool motherboard and a lower pool wall. The method combines the excellent performances of the bottom-up method and the reverse method, can not only realize the construction safety of the regulation pool, but also save the expenses of supporting and protecting the structure because deformation displacement in complicated surrounding environment is controlled. In addition, a construction process has little water penetration and is characterized by saving labor force and construction cost.

Owner:JIANGSU JIANGDU CONSTR GRP

Paddle valve

InactiveCN101713469ARealize the water stop effectPlay the role of water stopSlide valveEngineeringUltimate tensile strength

The invention discloses a GLP03 type paddle valve comprising a floodgate frame and a flashboard; a seal valve buckle is fixed on the floodgate frame; the seal valve buckle is in a U-shaped structure which is arranged between the flashboard and an installation wall surface; the opening of the U-shaped structure is towards the flashboard; a double lip-shaped rubber sealing strip is installed in the sealing floodgate frame; and the lip-shaped part of the double lip-shaped rubber sealing strip is contacted with the flashboard, which plays a seal function. Interference close fit is formed between the lip-shaped part of the double lip-shaped rubber sealing strip and the flashboard, thus preventing fluid medium at the internal direction and the external direction of the paddle valve from passing through, and realizing bidirectional water stopping effect. Foamed rubber sealing strips are arranged between the floodgate frame and the installation wall surface and between the sealing valve frame and the installation surface, which play the function of water stop. The paddle valve of the invention has simple and lightweight design structure, high strength, convenient installation and maintenance and good bidirectional water stopping effect; compression resisting safety factor is larger than 6; and the highest adaptive water pressure can reach 10 water heads.

Owner:郭华为

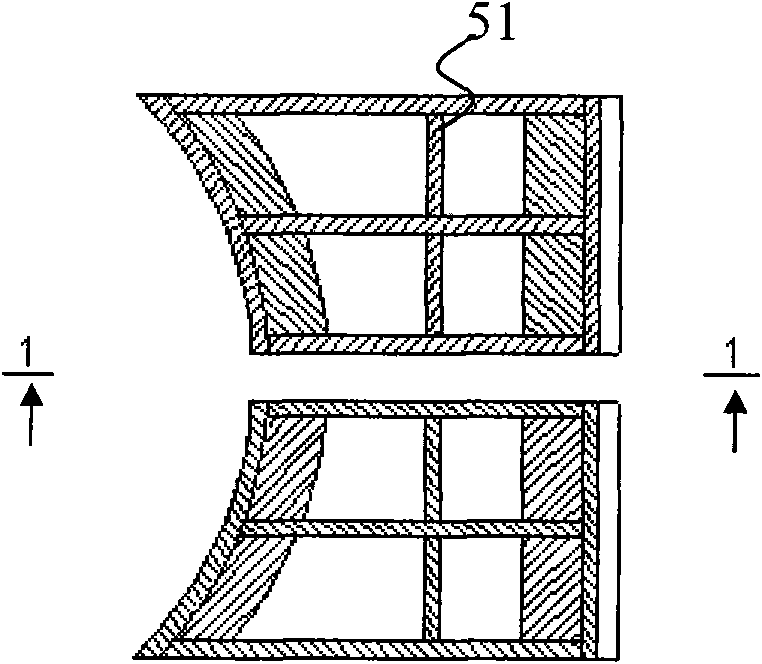

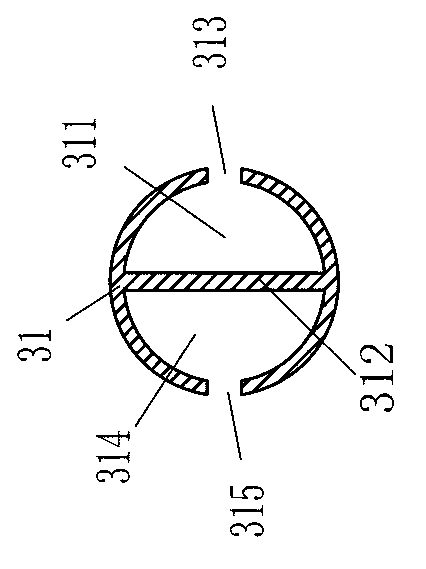

Horizontal steel tube occluding water blocking tube curtain and construction method thereof

ActiveCN103276741AGood water stop effectReduce processing costsFoundation engineeringWater blockCement mortar

The invention discloses a horizontal steel tube occluding water blocking tube curtain and construction method of the horizontal steel tube occluding water blocking tube curtain, and relates to a waterproof structure of an underground passage and a construction method of the waterproof structure. Horizontal steel tubes of the horizontal steel tube occluding water blocking tube curtain comprises a reference occluding steel tube, a bidirectional occluding steel tube and a plurality of unidirectional occluding steel tubes, and the reference occluding steel tube, the bidirectional occluding steel tube and the unidirectional occluding steel tubes are connected in sequence to form an annular surrounding curtain which surrounds a road underneath passing passage. A stand plate is arranged in the reference occluding steel tube and divides the inner hole of the occluding steel tube into a left space and a right space. Inserting grooves are formed in the left side and the right side of the reference occluding steel tube respectively. T-shaped wing plates are arranged on the left side and the right side of the bidirectional occluding steel tube respectively, a T-shaped wing plate is arranged on the left side of each unidirectional occluding steel tube, and an inserting groove is formed in the right side of each unidirectional occluding steel tube. The wing plate of a first unidirectional occluding steel tube is inserted into the right space on the right side of the reference occluding steel tube, and the wing plate of each of the rest unidirectional occluding steel tubes is inserted into the inner hole of the unidirectional occluding steel tube ahead. The wing plates on the two sides of the bidirectional occluding steel tube are inserted into the inner hole of a last unidirectional occluding steel tube and the left space in the left side of the reference occluding steel tube respectively. The reference occluding steel tube and the inner holes of all the unidirectional occluding steel tubes are all filled with cement mortar.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

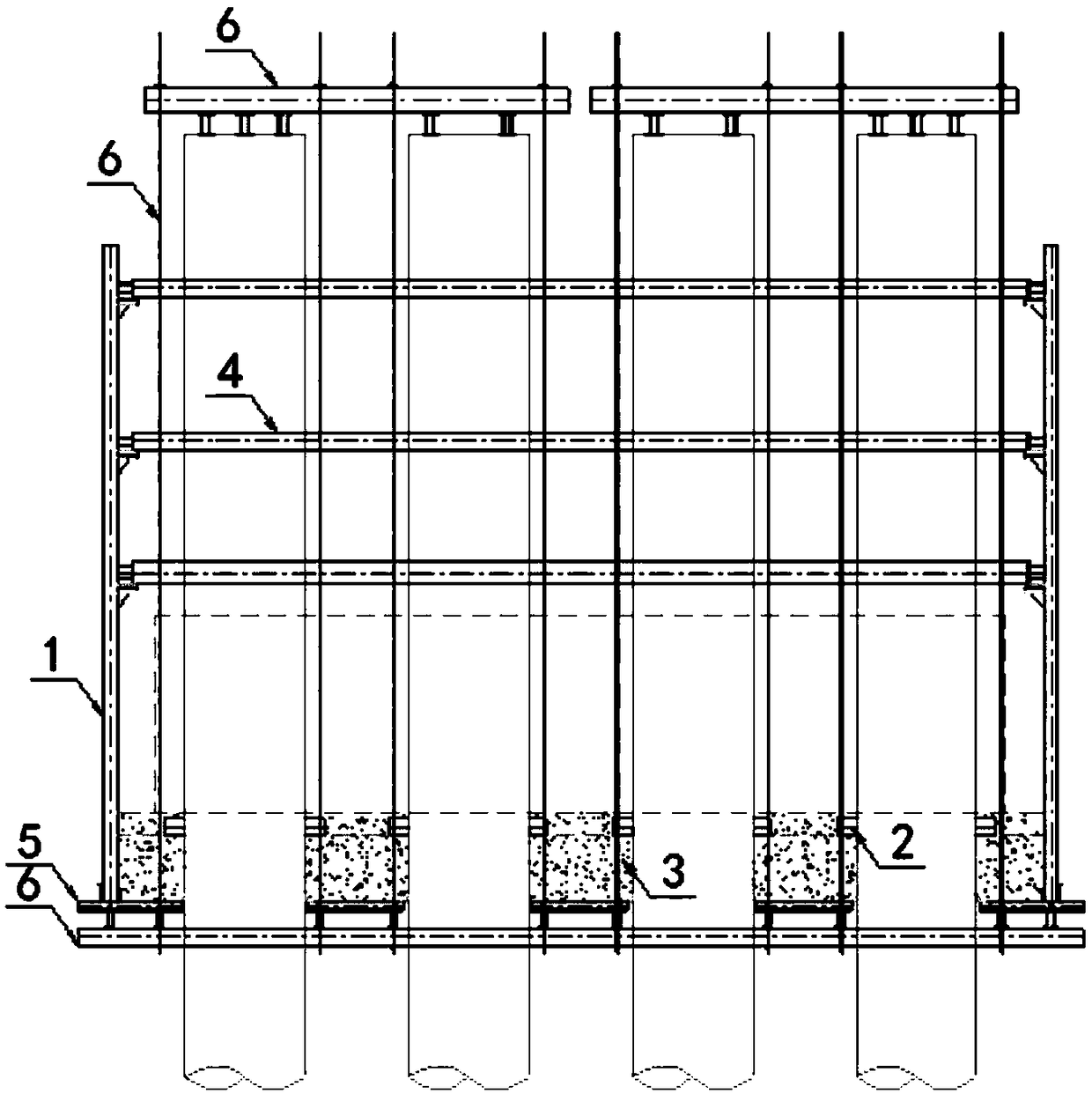

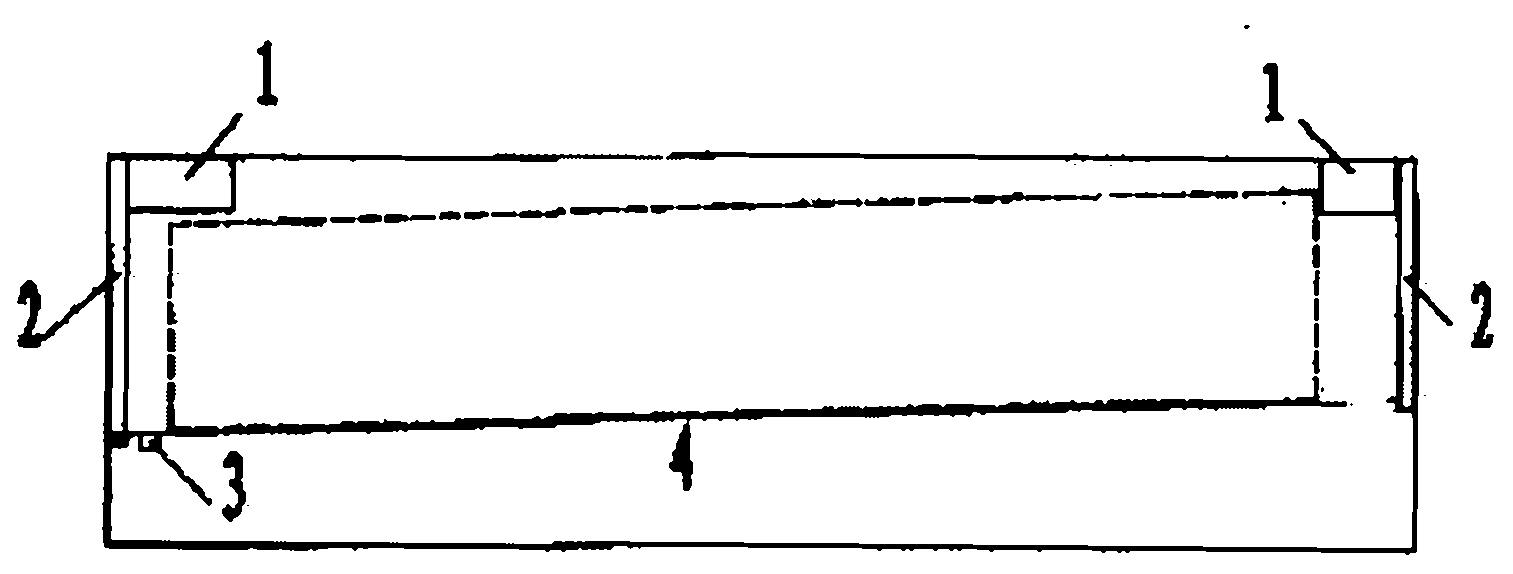

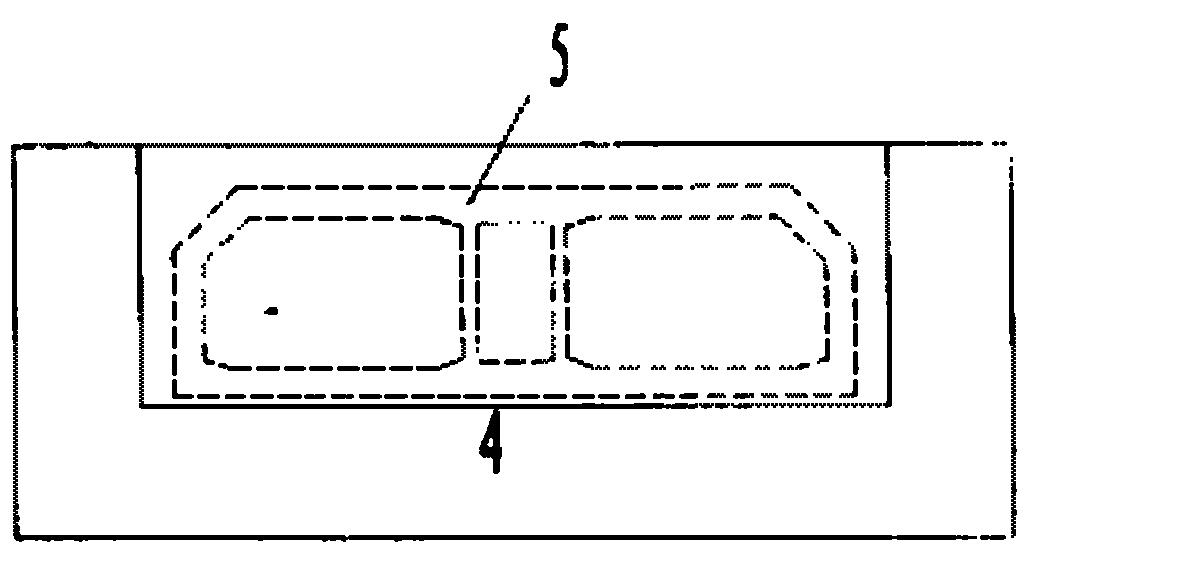

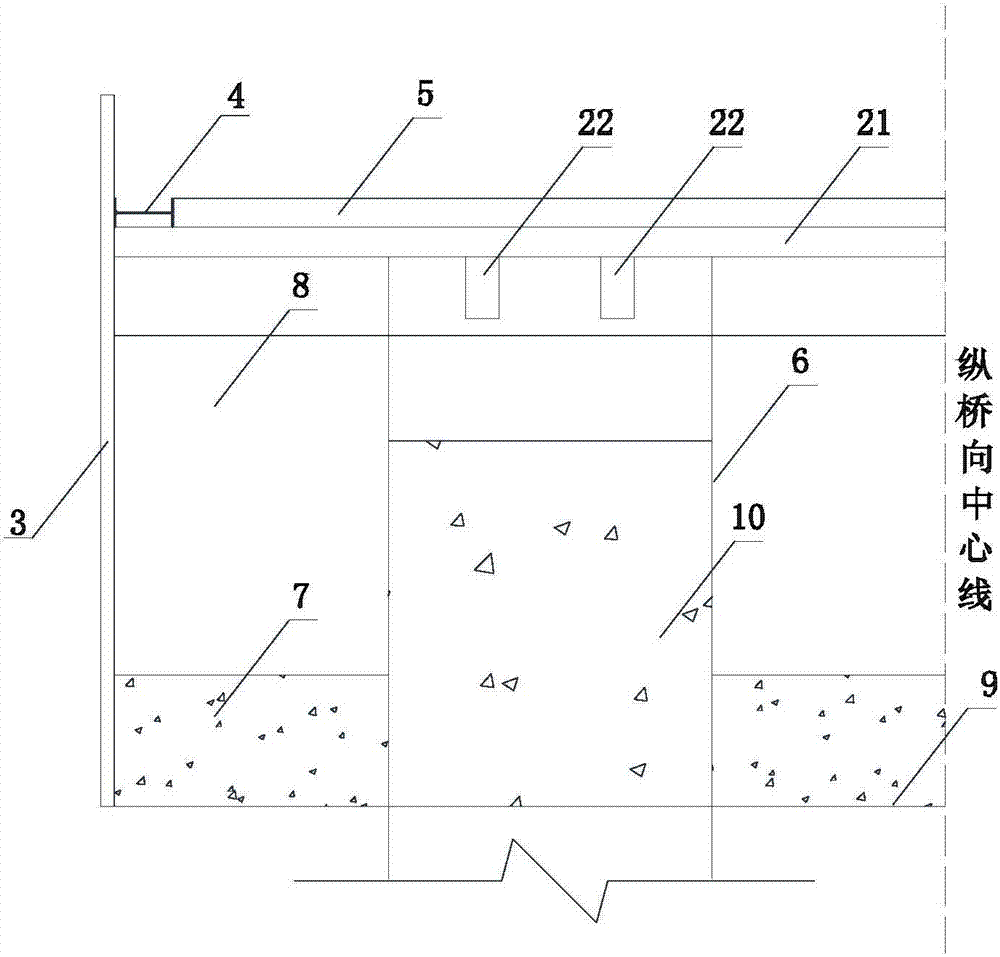

Block assembling type bottomless single-wall steel bushing box cofferdam and construction method thereof

PendingCN107044129AShen Fang is simpleReduce weightArtificial islandsUnderwater structuresCofferdamEngineering

The invention provides a block assembling type bottomless single-wall steel bushing box cofferdam and a construction method thereof. The steel bushing box cofferdam comprises steel bushing box side plates, side plate connecting devices, inner guide beams and inner supports. The steel bushing box side plates are of ribbed slab structures and comprise steel panels, horizontal stiffening ribs and vertical stiffening ribs, and the steel panels, the horizontal stiffening ribs and the vertical stiffening ribs are integrally welded. The steel bushing box side plates comprise the A-shaped side plates, the B-shaped side plates and the C-shaped side plates. The A-shaped side plates and the C-shaped side plates are used at the corners of the steel bushing box cofferdam. The B-shaped side plates are used on the periphery of the steel bushing box cofferdam. The side plate connecting devices are of female and male connector inserted-connected structures. After female connectors and male connectors are connected in an inserted mode, two groove steel parts opposite to each female connector and the corresponding male connector form a rectangular shaft, fine aggregate concrete is poured in each rectangular shaft, and water stopping structures connected between the adjacent steel bushing box side plates are formed. The block assembling type bottomless single-wall steel bushing box cofferdam is simple in structure, low in manufacturing cost, convenient to assemble and fold and accurate in positioning control, and the steel bushing box side plate joint water stopping devices are convenient and effective.

Owner:中国葛洲坝集团建设工程有限公司

Slow expansion type building water-stop glue and preparation method thereof

ActiveCN103740317AExtend the lifespanEasy to useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiphenylmethanePolymer science

The invention belongs to the technical field of waterproof materials and specifically discloses a slow expansion type building water-stop glue and a preparation method thereof. The main technical scheme is as follows: drawing hydrophilic polyether diol, hydrophilic polyether glycol, polyoxypropylene glycol, polyoxypropylene triol and a prepolymer plasticizer into a reaction kettle, stirring, heating, performing reaction and dehydration under vacuum conditions, and then adding toluene diisocyanate and diphenylmethane-4, 4'-diisocyanate for reaction to obtain a hydrophilic polyurethane prepolymer; and then sequentially adding the hydrophilic polyurethane prepolymer, ethyl acetoacetate or acetylacetone, a coupling agent, kaolin, nano-modified calcium carbonate, a water-stop glue catalyst and glass microbeads into a stirring tank for stirring reaction to obtain the slow expansion type building water-stop glue. The water-stop glue has the characteristics of high expansion rate in using process, no loss of expansion factor and high retention rate of the expansion rate after repeated expansion.

Owner:衡水大众橡塑有限公司

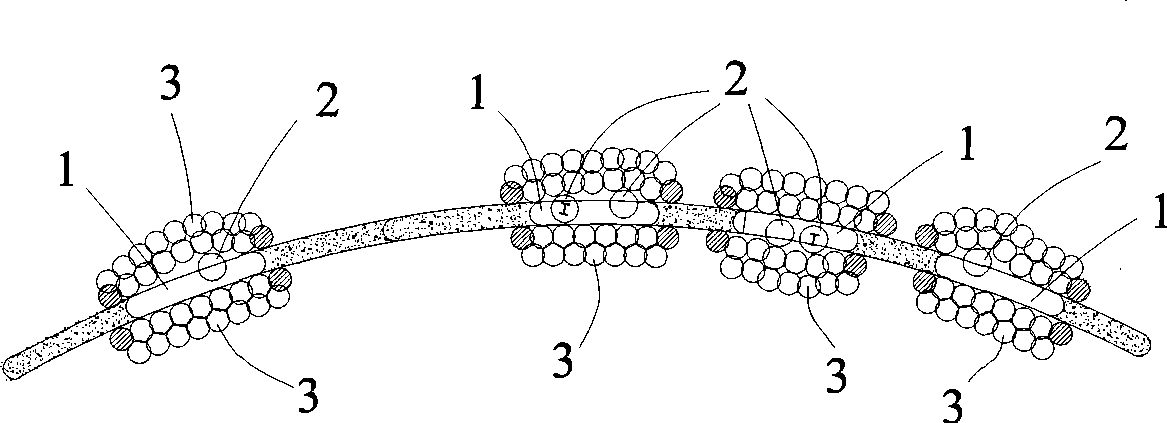

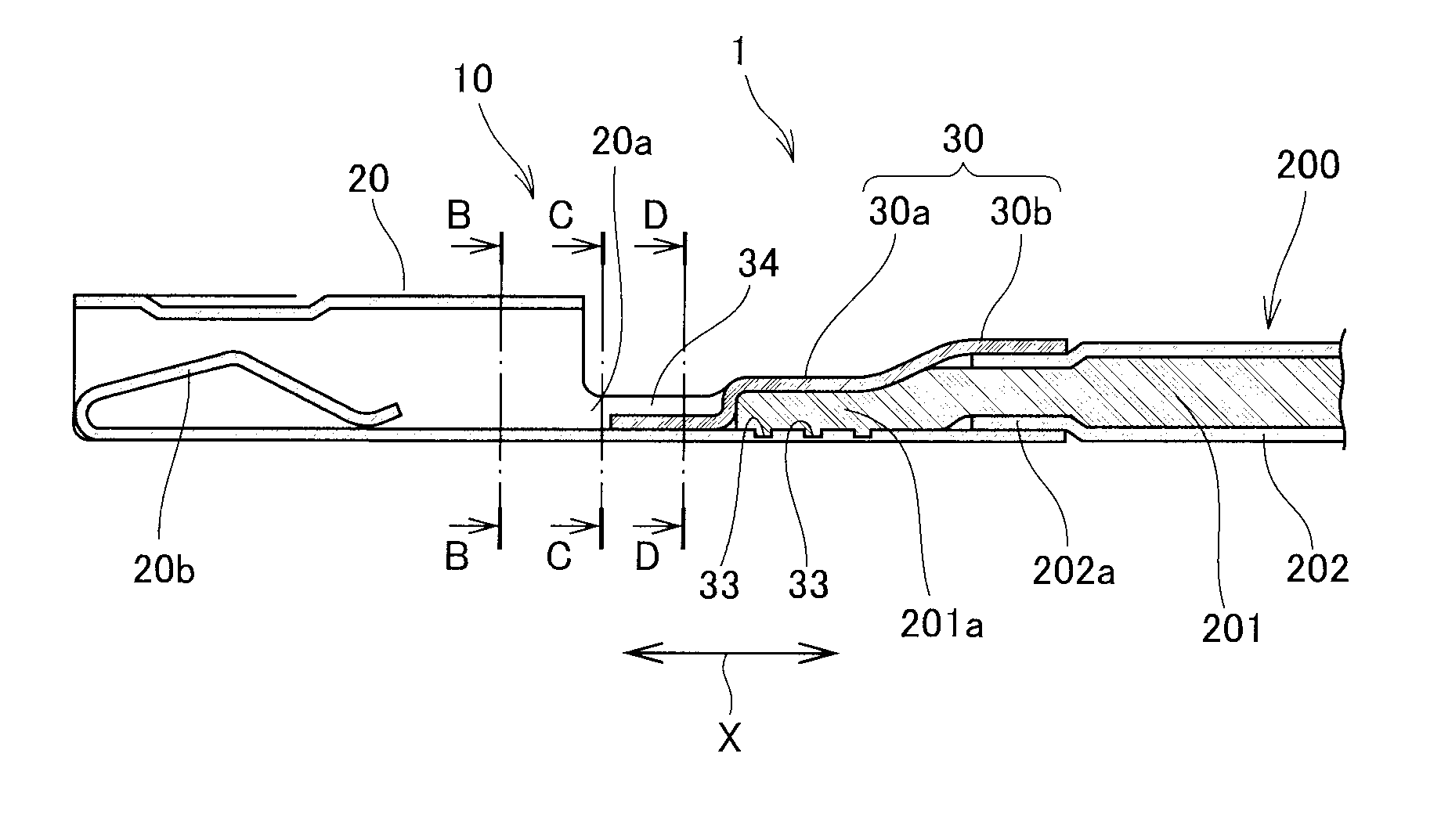

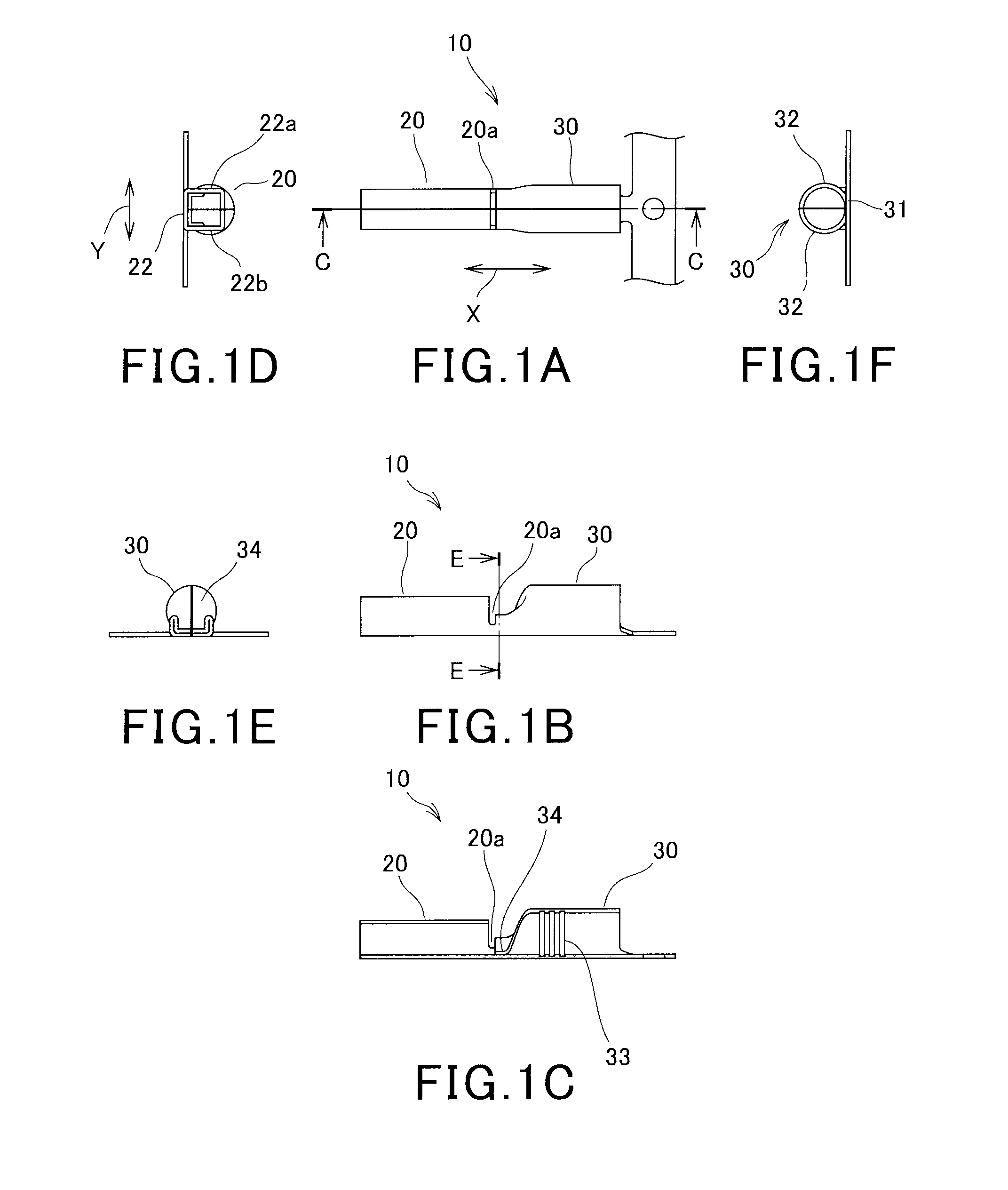

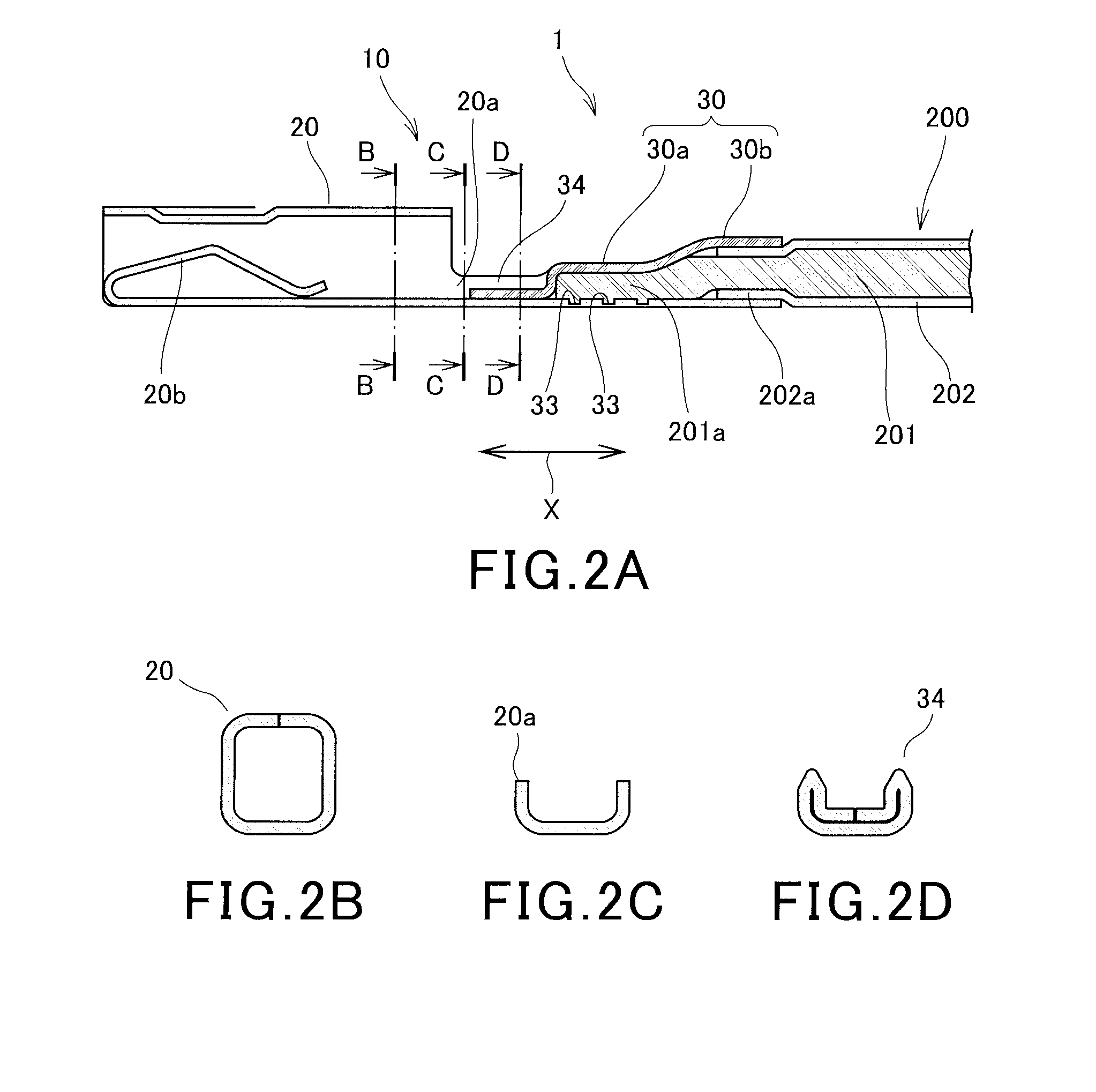

Crimp terminal, method of manufacturing crimp terminal, electrical wire connection structure, and method of manufacturing electrical wire connection structure

ActiveUS20150340772A1Good water stop effectJoint strengthConnections effected by permanent deformationConnection formation by deformationUltimate tensile strengthElectric wire

A crimp terminal that can maintain excellent water-stop performance over a long term and is enhanced in joint strength between a fitting portion and a covered electrical wire connection portion. The crimp terminal has a fitting portion at a tip thereof and an electrical wire connection portion at a rear end thereof, the electrical wire connection portion is configured in a tubular shape, a tip of the tube is crushed to be superimposed and closed, and a portion between the fitting portion and the electrical wire connection portion is formed by superimposing and bending two or more sheets of a plate material.

Owner:FURUKAWA ELECTRIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com