Drill-hole waterstop device and method

A water-stopping device and water-stopping technology, which are used in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve the problems of long cement slurry setting time, large cement consumption, complicated operation process, etc. The effect of waiting time, reduction of cement consumption, and uniform distribution of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

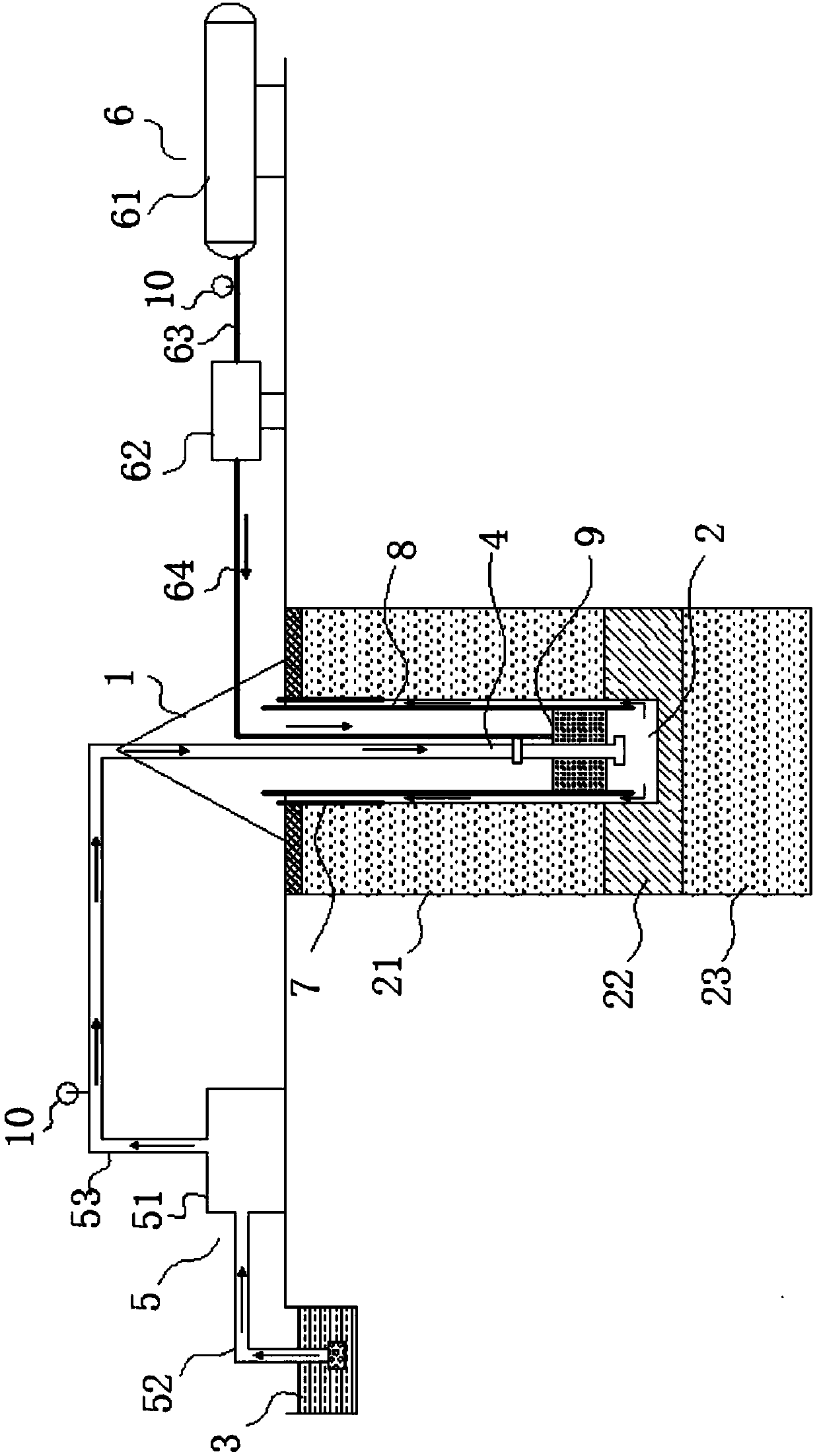

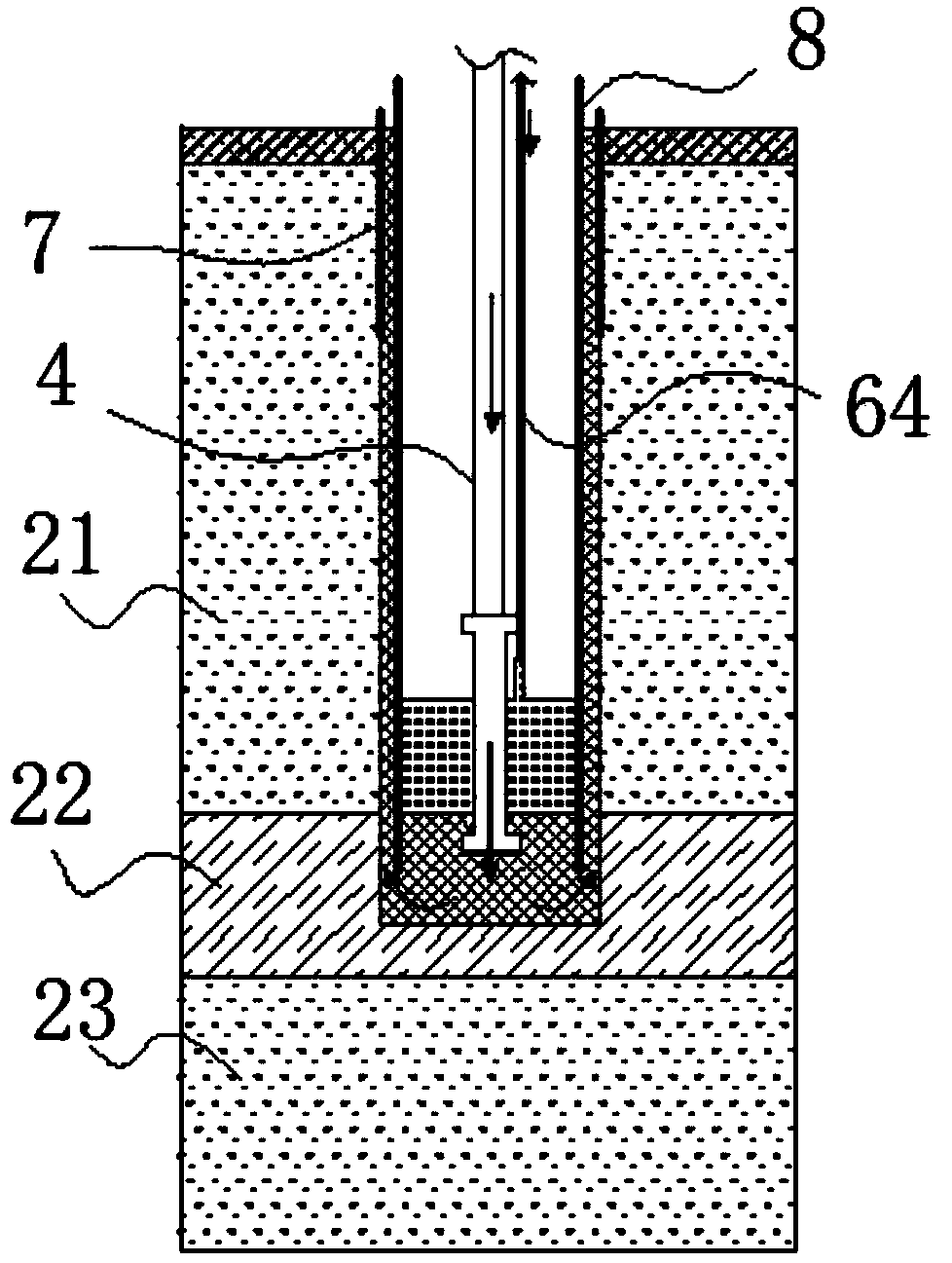

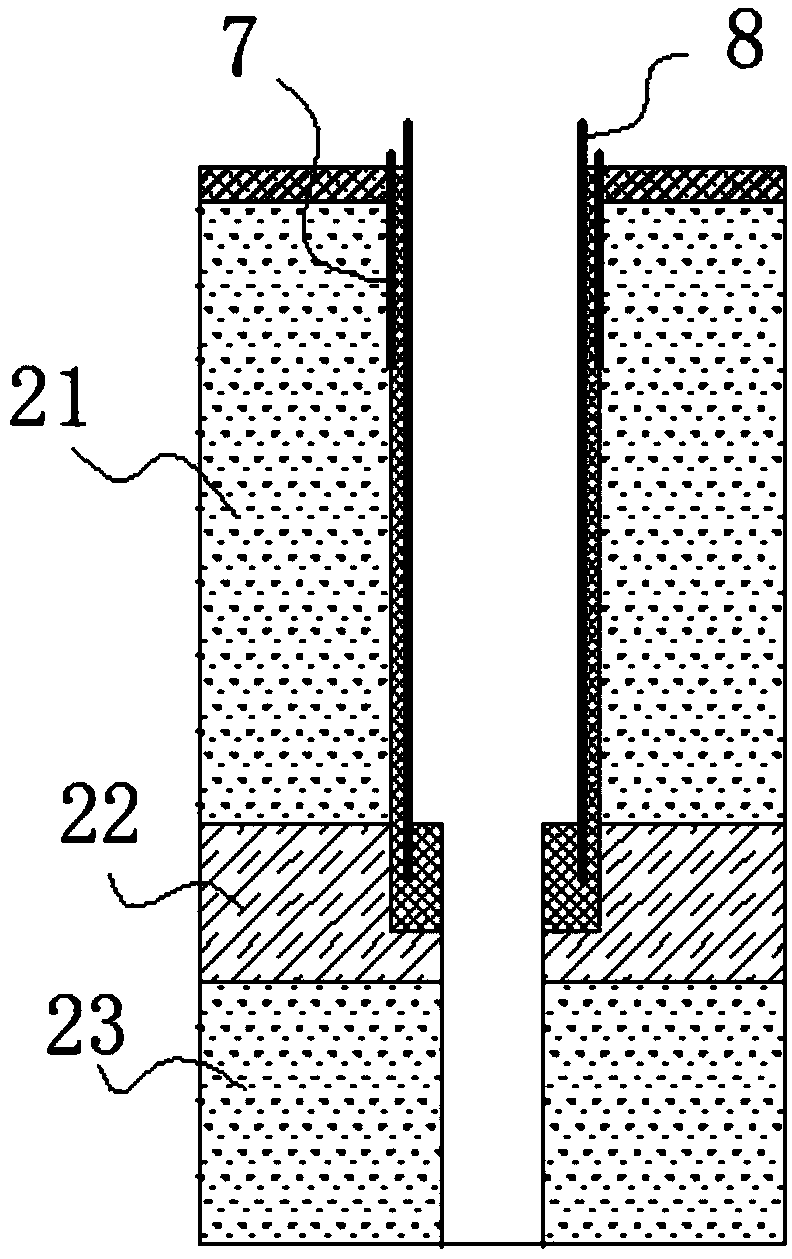

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as Figure 1 to Figure 3 As shown, the arrows in the figure represent the flow direction of slurry and airflow.

[0030] A drilling water stop device, comprising a drilling rig 1, erected on a drilling 2, and a drilling rod 4 connected to the drilling rig 1, the drilling rod 4 is at least supported by the drilling rig 1, and one end of the drilling rod 4 is connected to the slurry supply device 5, the other end is used to extend into the drilling 2, and the packer 9 that is sleeved on the drill pipe 4 and located in the drilling 2, the packer 9 communicates with the gas supply unit 6, and the packer 9 The volume can be expanded, and the casing 8 is set on the periphery of the packer 9 . The bottom of the well 2 is an aquifer 22 , above the aquifer 22 is a phreatic aquifer 21 , and below the aquifer 22 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com