Sludge coal ash high-strength ceramsite and preparation method thereof

A high-strength ceramsite and fly ash technology, applied in the production of clay products, other household appliances, ceramic materials, etc., can solve the problems of low absorption rate, low compressive strength of sludge fly ash ceramsite cylinder, etc., and achieve high absorption rate, shortening of setting time, and the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

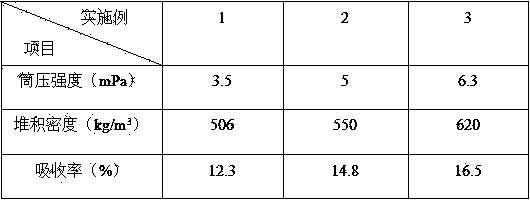

Examples

Embodiment 1

[0037] 1) Put sludge, fly ash, calcium sulfoaluminate, phthalate, water glass and deodorant into the stirring mixing tank according to the following proportions by weight and mix for 3 minutes to prepare the mixture 1 ;

[0038] The weight ratio of described sludge, fly ash, calcium sulfoaluminate, phthalate, water glass and deodorant is 67 parts, 30 parts, 0.5 part, 0.5 part, 1 part, 1 part; Wherein , the water content of the sludge is 40wt%, the solid content of the water glass is 80wt%, and the deodorant is "Leida" brand microbial deodorant;

[0039] 2) Add water to the mixture 1 obtained in step 1) until the water content is 13wt%, and then stir evenly to obtain the mixture 2;

[0040] 3) Transfer the mixture 2 obtained in step 2) into an extrusion granulator to obtain raw meal balls with a particle size of 5mm, wherein the impact force of the extrusion granulator is not less than 20kN;

[0041] 4) Transfer the raw pellets obtained in step 3) into a rotary kiln through a...

Embodiment 2

[0047] 1) Put sludge, fly ash, calcium sulfoaluminate, phthalate, water glass and deodorant into the stirring mixing tank according to the following proportions by weight and mix for 4 minutes to prepare the mixture 1 ;

[0048] The proportioning by weight of the sludge, fly ash, calcium sulfoaluminate, phthalate, water glass and deodorant is 50 parts, 45 parts, 1 part, 1 part, 2 parts, 1 part Wherein, the water content of the sludge is 50wt%, the solid content of the water glass is 85wt%, and the deodorant is "Leida" brand microbial deodorant;

[0049] 2) Add water to the mixture 1 obtained in step 1) until the water content is 14wt%, and then stir evenly to obtain the mixture 2;

[0050] 3) Transfer the mixture 2 obtained in step 2) into an extrusion granulator to obtain raw meal balls with a particle size of 15mm, wherein the impact force of the extrusion granulator is not less than 20kN;

[0051] 4) Transfer the raw pellets obtained in step 3) into a rotary kiln through ...

Embodiment 3

[0057] 1) Put the sludge, fly ash, calcium sulfoaluminate, phthalate, water glass and deodorant into the stirring mixing tank according to the following proportions by weight and mix for 5 minutes to prepare the mixture 1 ;

[0058] The proportioning by weight of the sludge, fly ash, calcium sulfoaluminate, phthalate, water glass and deodorant is 45 parts, 49 parts, 1.5 parts, 1 part, 3 parts, 0.5 parts Wherein, the water content of the sludge is 35wt%, the solid content of the water glass is 90wt%, and the deodorant is "Leida" brand microbial deodorant;

[0059] 2) Add water to the mixture 1 obtained in step 1) until the water content is 15wt%, and then stir evenly to obtain the mixture 2;

[0060] 3) Transfer the mixed material 2 with a moisture content of 15wt% obtained in step 2) into an extrusion granulator to obtain raw meal pellets with a particle size of 20mm, wherein the impact force of the extrusion granulator is not less than 20kN;

[0061] 4) Transfer the raw pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com