Patents

Literature

1288 results about "Calcium aluminates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium aluminates are a range of minerals obtained by heating calcium oxide and aluminium oxide together at high temperatures. They are encountered in the manufacture of refractories and cements.

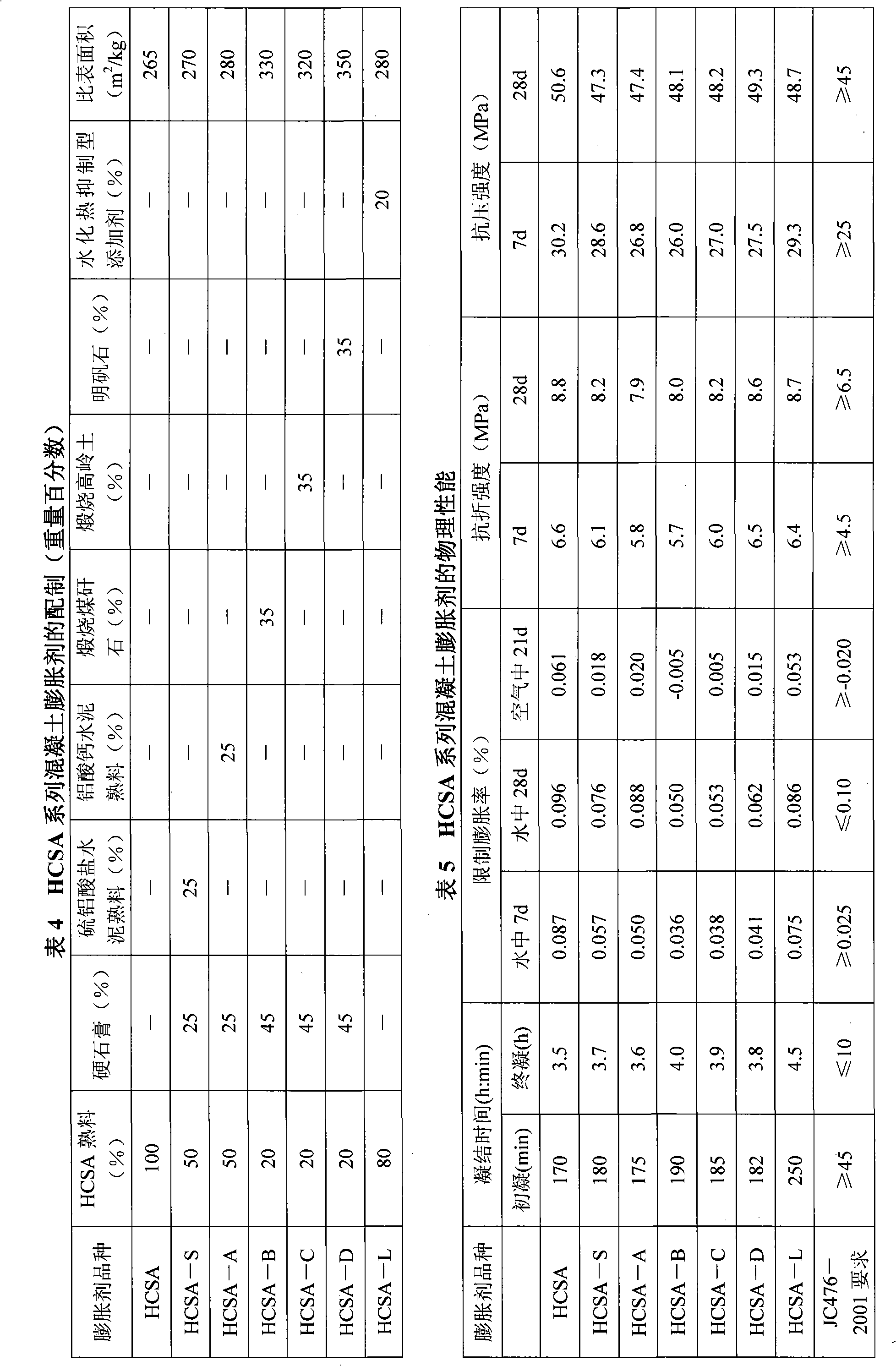

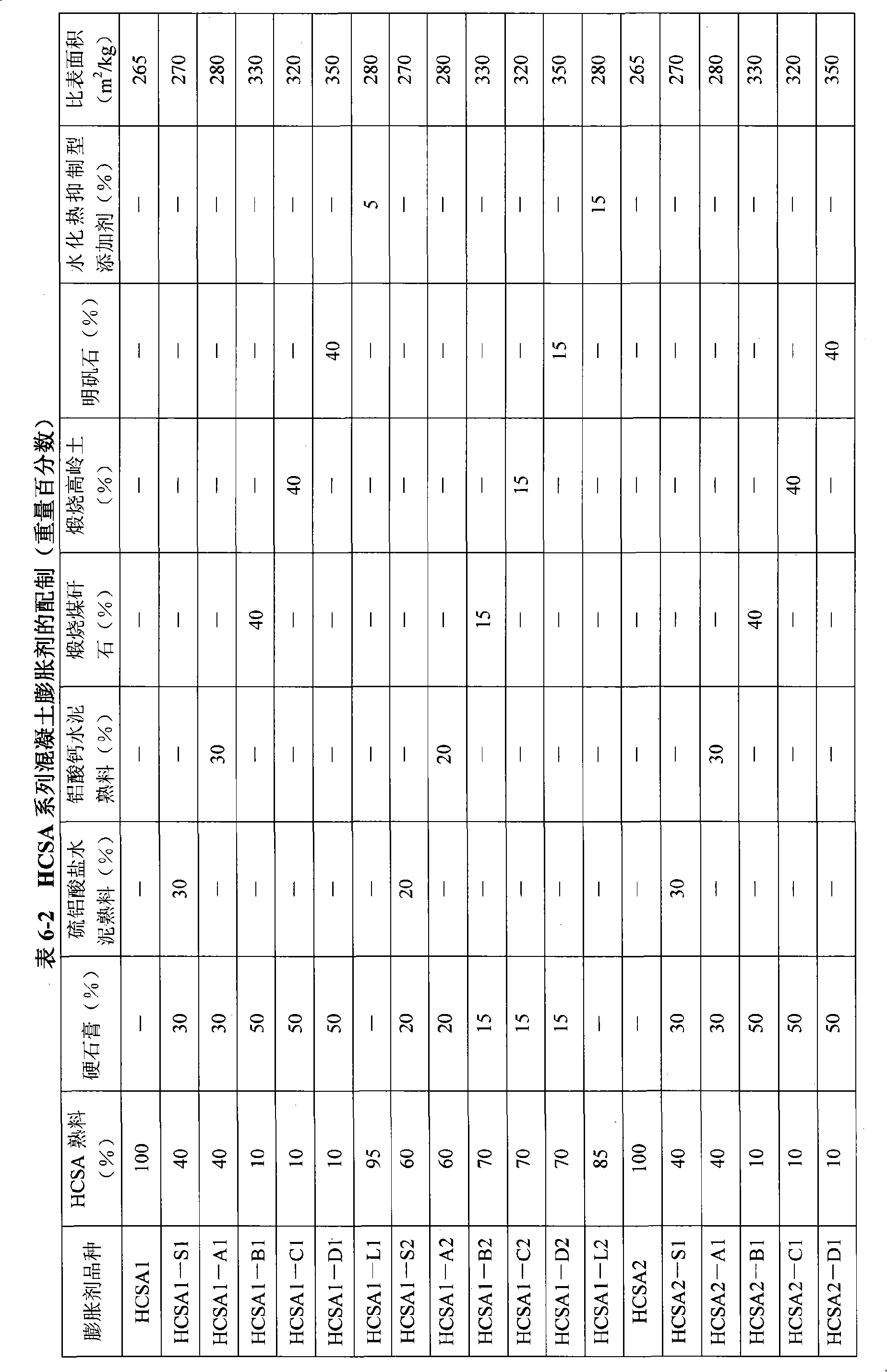

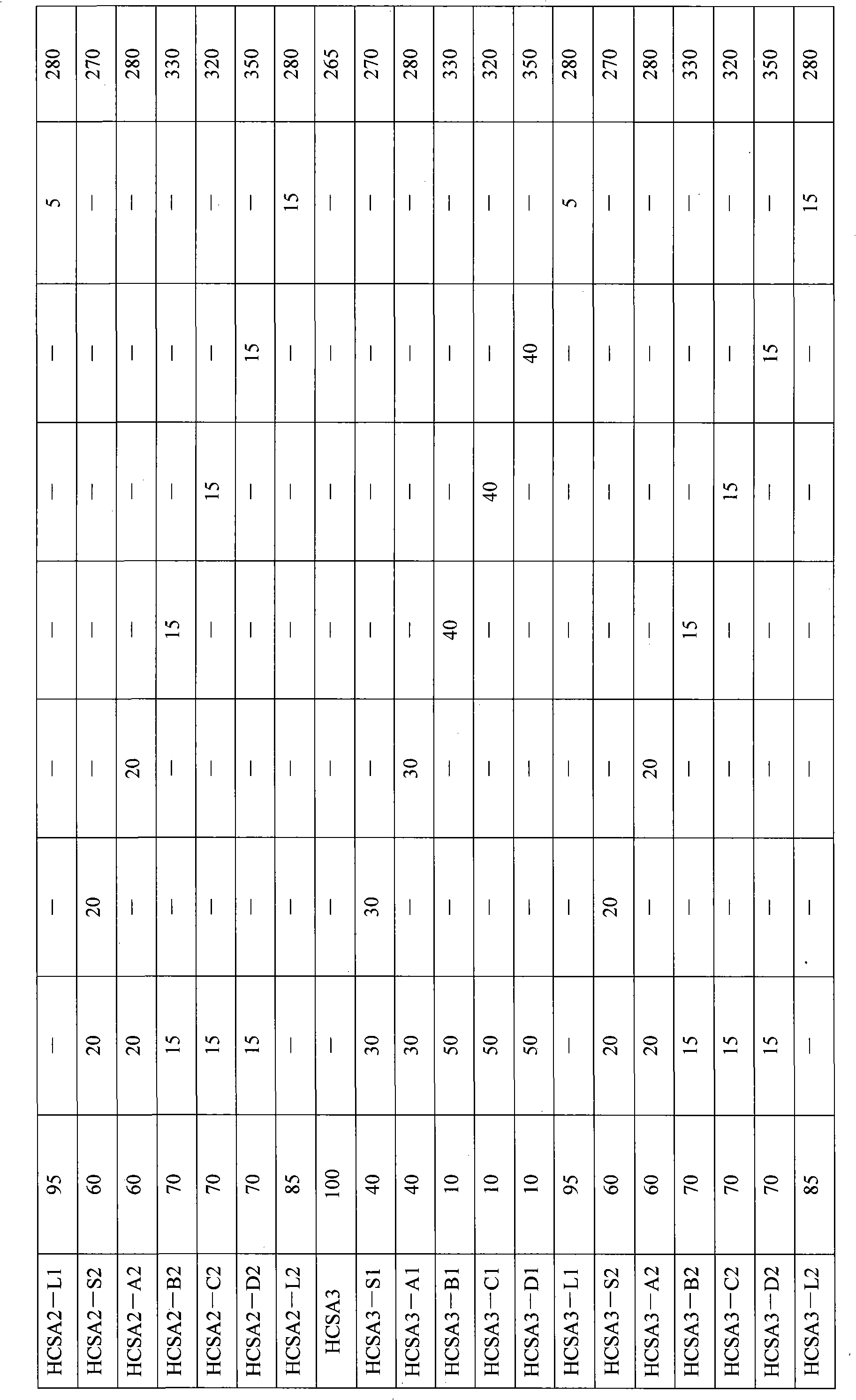

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

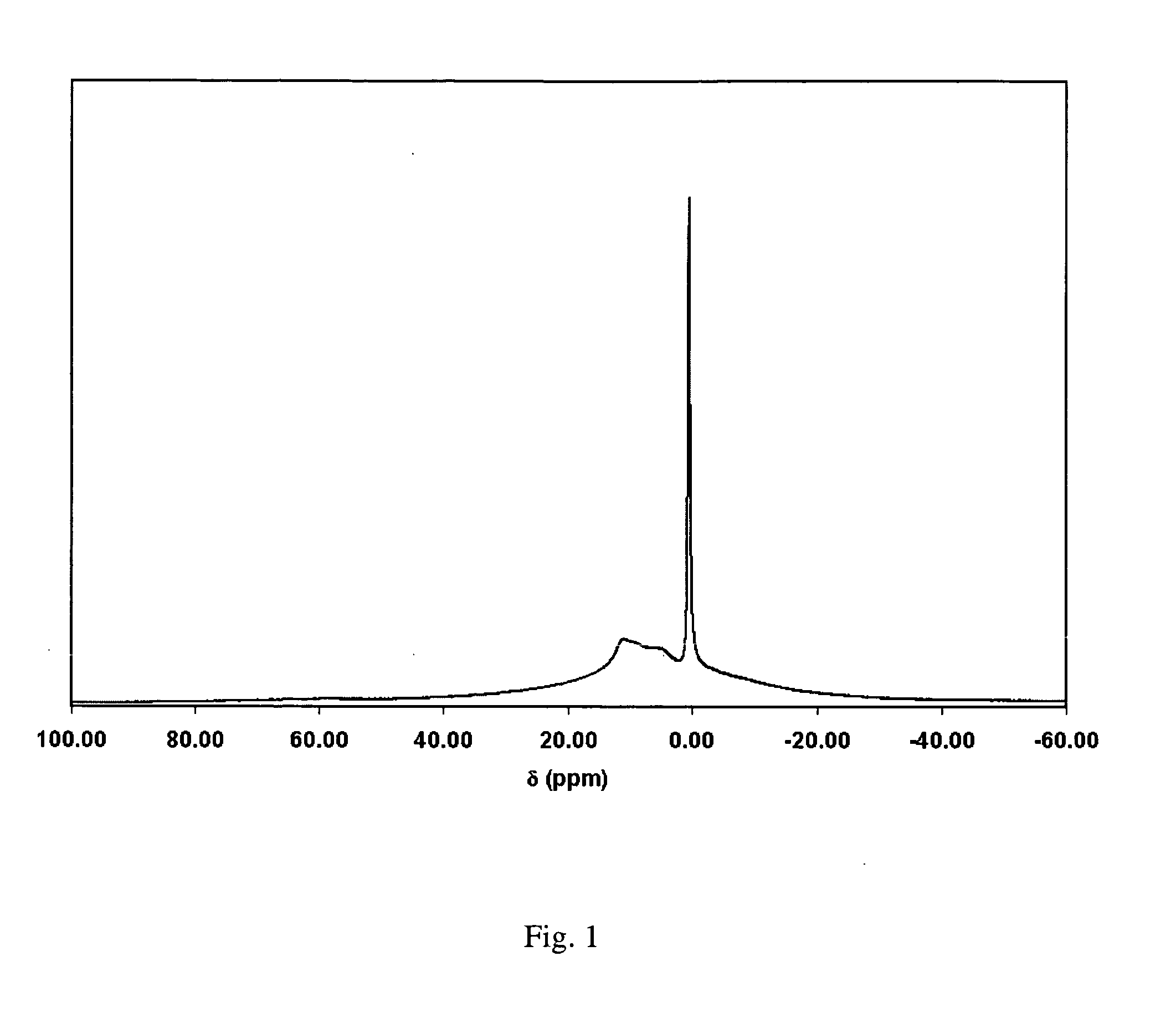

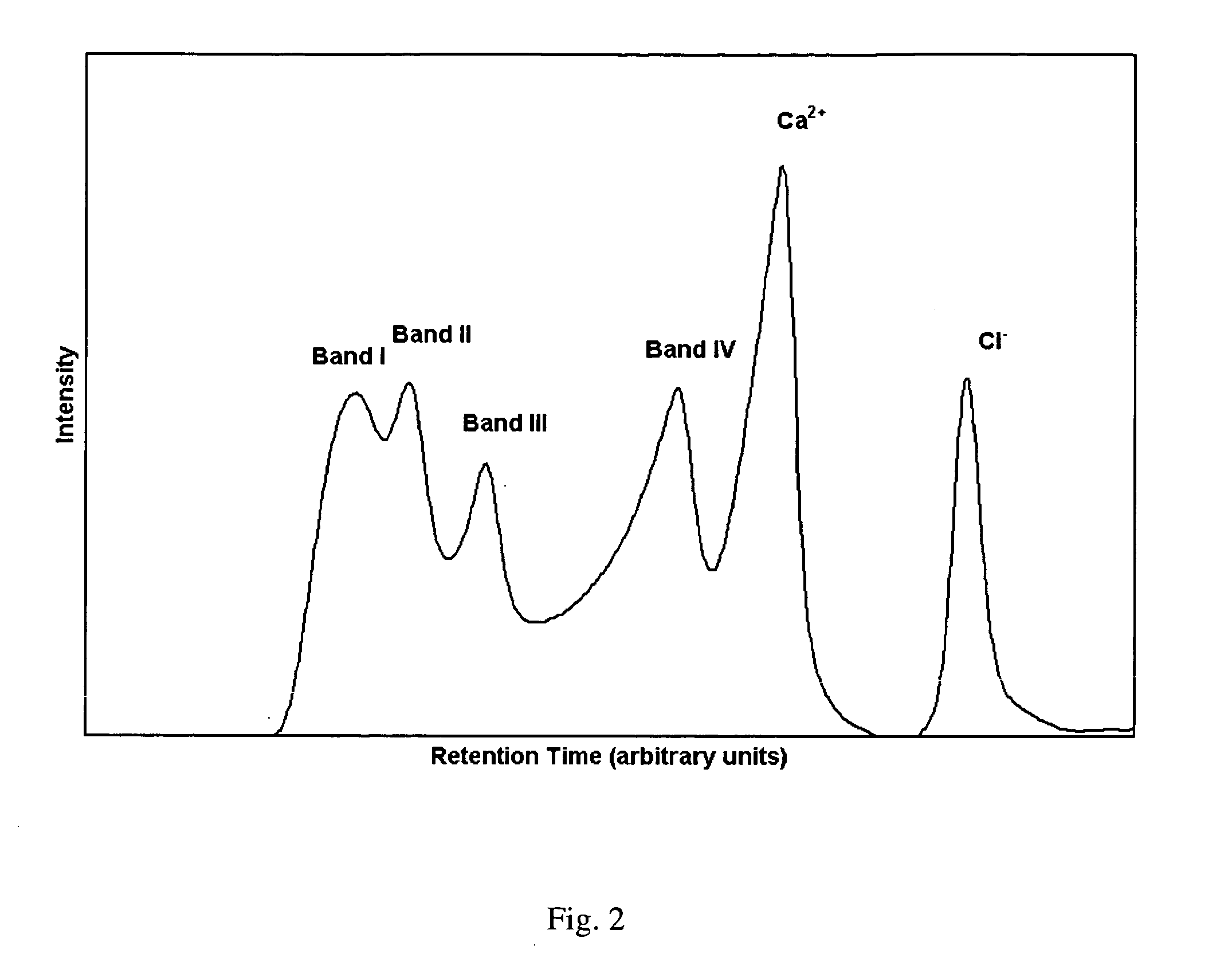

Polyaluminum calcium hydroxychlorides and methods of making the same

InactiveUS20080131354A1Improve efficiencyReduce sludge generationCosmetic preparationsChloride preparationAluminum hydrateHigh pressure

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60° C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM LLC

Composite fire resistant pouring material

The invention relates to an organic-inorganic composite combined advanced monolithic refractory which has the formula of 40 to 56 percent of 5-1mm corundum or bauxite, 12 to 30 percent of 1-0.0088mm corundum or bauxite, 16 to 25 percent of corundum or bauxite with d90 less than 0.088mm, 0 to 5 percent of alpha alumina micropowder, 1 to 8 percent of hydratable alumina, 1 to 6 percent of siliceous dust, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid, 1 to 6 percent of external water and 0 to 3 percent of external heat-resistant steel fiber. Casting materials of the invention have excellent performances of condensation, hardening, demoulding, drying and heating and are suitable for high-temperature furnace projects with changeful field conditions.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

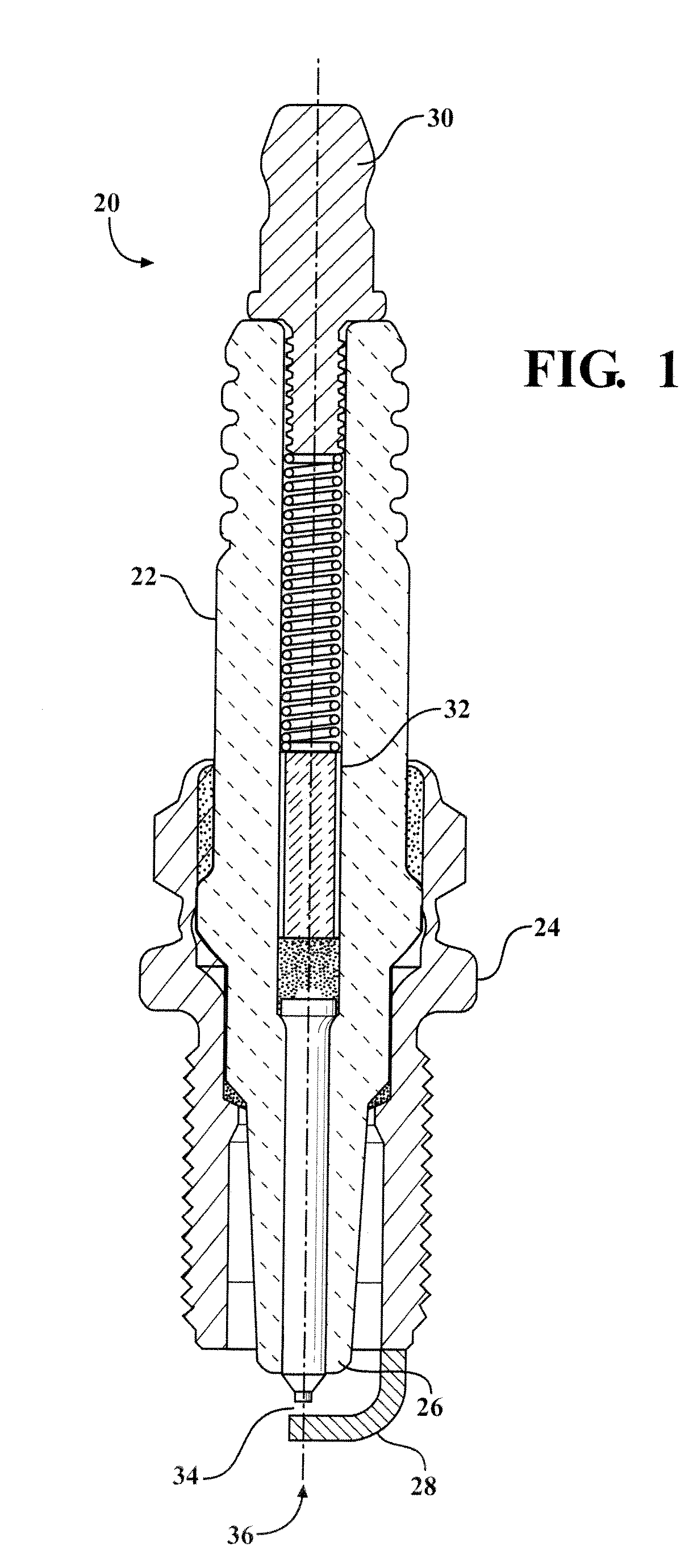

Alumina ceramic for spark plug insulator

ActiveUS20110077141A1Improve conductivityHigh strengthElectric discharge tubesDischarge tube main electrodesAluminateMullite

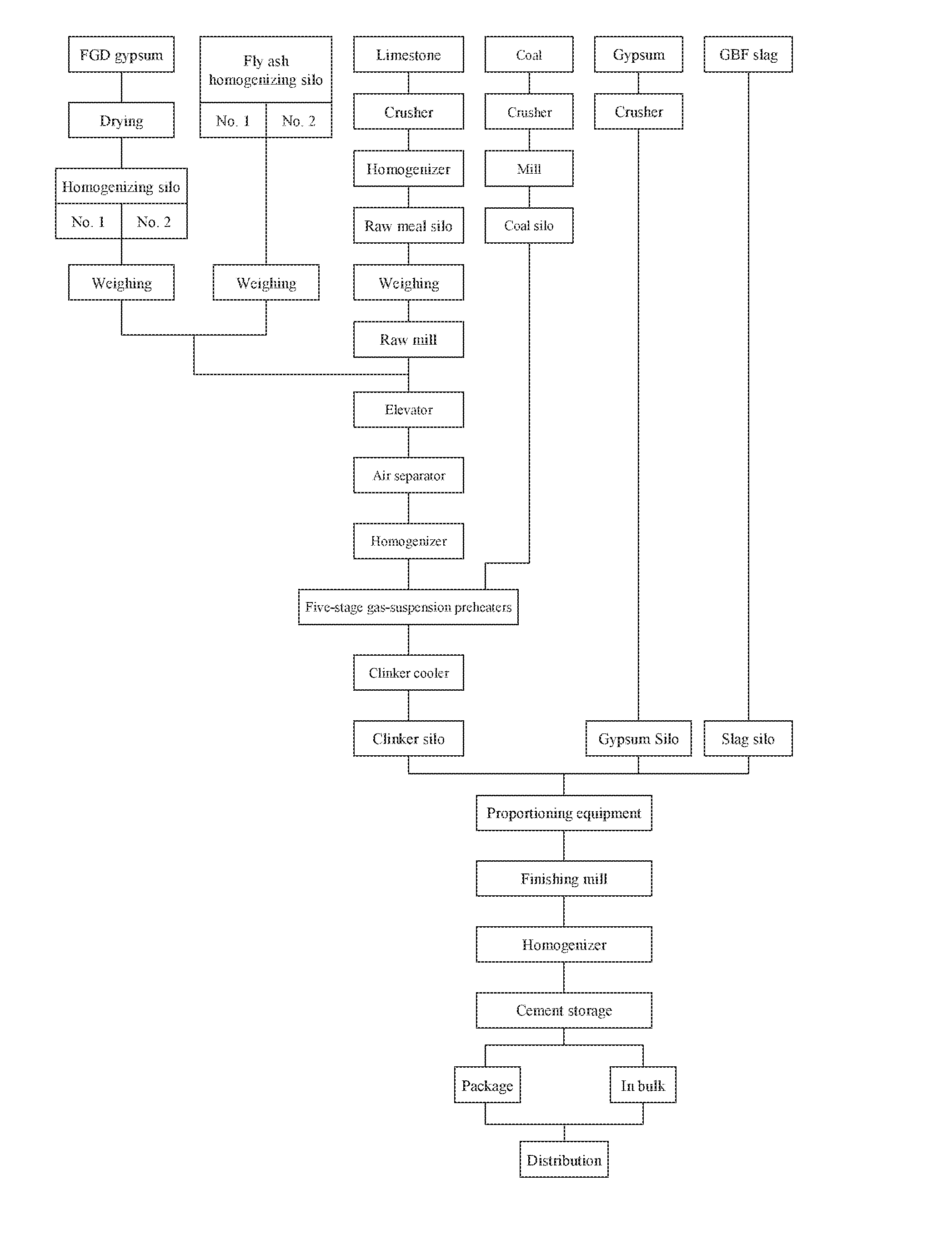

A spark plug includes an insulator formed of a ceramic material. The ceramic material comprises Al2O3 in an amount of 98.00 wt % to 99.50 wt %; Group 2 oxides in an amount of 0.16 wt % to 0.70 wt %; SiO2 in an amount of 0.25 wt % to 0.75 wt %, Group 4 oxides in an amount of 0.01 wt % to 0.16 wt %, Group 1 oxides in an amount less than 0.0060 wt %, and P2O5 in an amount of less than 0.0040 wt %. The Al2O3 is formed of particles having a D50 median particle size by volume of 1.2 μm to 1.8 μm. The ceramic material is pressed, sintered, and formed to a predetermined shape. The sintered ceramic material includes a glass phase comprising the Al2O3, Group 2 oxides, and SiO2. The sintered ceramic material also includes secondary crystals of calcium hexa-aluminate (CaAl12O19) spinel (MgAl2O4), anorthite (CaAl2Si2O8), and mullite (Al6Si2O13).

Owner:FEDERAL MOGUL IGNITION

Desulfurization and novel sorbents for same

InactiveCN1384770AOctane dropReduce hydrocarbon contentRefining with metalsOther chemical processesAluminateCalcium silicate

Particulate sorbent compositions which are suitable for the removal of sulfur from streams of cracked-gasoline or diesel fuel are provided which have increased porosity, improved resistance to deactivation through the addition of a calcium compound selected from the group consisting of calcium sulfate, calcium silicate, calcium phosphate or calcium aluminate to the support system comprised of zinc oxide, silica and alumina having thereon a promotor wherein the promotor is metal, metal oxide or metal oxide precursor with the metal being selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium or mixtures thereof and wherein the valence of such promotor has been substantially reduced to 2 or less. Process for the preparation such sorbent systems as well as the use of same for the desulfurization of cracked-gasolines and diesel fuels are also provided.

Owner:CHINA PETROLEUM & CHEM CORP

Corundum and spinel castable and preparation method thereof

The invention relates to corundum and spinel castable and a preparation method thereof. According to the scheme, the method comprises the following steps of: blending 1 to 10 weight percent of magnesia-alumina spinel fine powder, 5 to 10 weight percent of white fused corundum fine powder, 5 to 10 weight percent of alpha-Al2O3 micro powder, 2 to 8 weight percent of pure calcium aluminate cement, 0.06 to 0.2 weight percent of poly carboxylic acid water reducing agent, and 0.01 to 0.1 weight percent of organic fiber, and precasting mixed powder; performing dry-blending on 6 to 18 weight percent of partially stable zirconia particles or calcium zirconate particles, 45 to 70 weight percent of tabular corundum particles and 1 to 10 weight percent of magnesia-alumina spinel particles which are used as aggregate for 4 to 6 minutes, adding the mixed powder, and milling for 15 to 30 minutes; and adding water in an amount which is 3 to 6 percent based on the weight of the mixed powder and aggregate, milling for 3 to 5 minutes, vibrating and performing casting moulding, curing for 20 to 26 hours, demoulding, drying at the temperature of between 100 and 120 DEG C for 20 to 26 hours, raising temperature to 1,450 to 1,750 DEG C, and preserving heat for 2 to 4 hours. The prepared corundum and spinel castable is high in thermal shock resistance, high-temperature strength, and strength retention rate after thermal shock, and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Rapid-setting and hardening, high-belite sulfoaluminate cement clinker as well as application and production process thereof

ActiveUS20170050882A1Increase heightHigh-strength rapid-hardeningSolid waste managementCement productionChemical compositionSlag

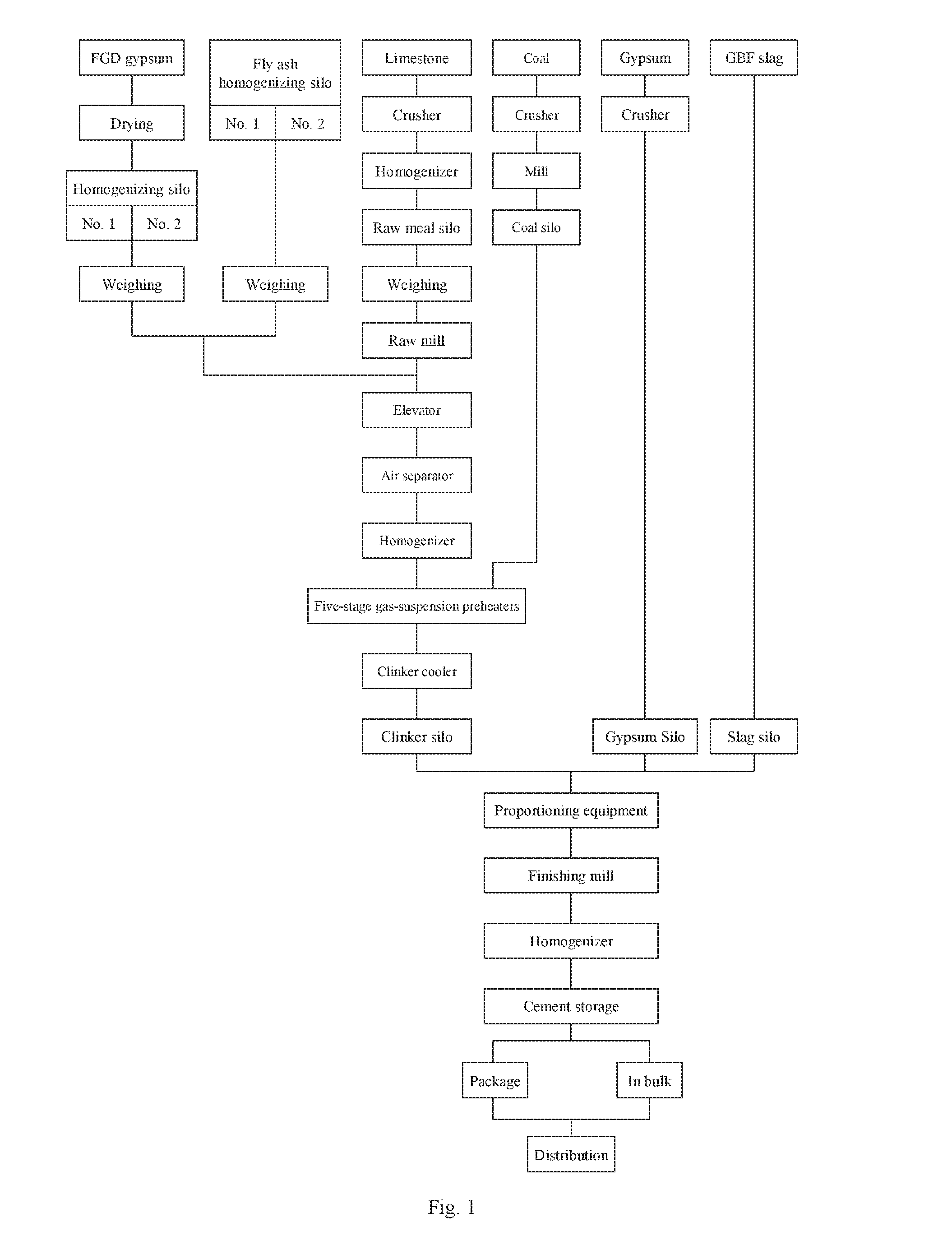

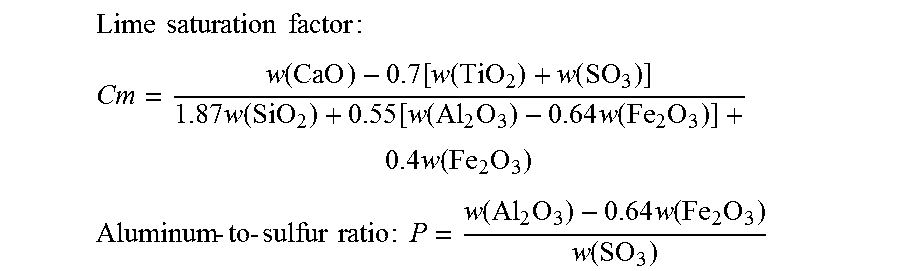

The invention discloses a rapid-hardening high-belite calcium sulfoaluminate cement clinker and relates generally to a rapid-hardening high-belite calcium sulfoaluminate cement clinker and methods to use and to manufacture the clinker. The clinker of the present invention comprises 20% to 35% by weight of C4A3S 3% to 9% by weight of C4AF, 37% to 47% by weight of C2S, 0.5% to 4.6% by weight of f-Ca° and 14% to 26.3% by weight of CaSO4. The chemical compositions of the clinker are 12.9% to 16.1% by weight of SiO2, 12% to 19% by weight of Al2O3, 1% to 3% by weight of Fe2O3, 49% to 54% by weight of CaO and 12% to 18.43% by weight of SO3. It is manufactured by calcining, at a temperature of 1300° C.±50° C. in a rotary kiln, the raw meal, comprising 33% to 62% by weight of limestone, 10.5% to 28% by weight of fly ash, and 19% to 45% by weight of FGD gypsum. A group of rapid-hardening high-strength cements of various strength classes can be manufactured by mixing and grinding 26% to 97% by weight of clinker, 3% to 19% by weight of anhydrite and 0% to 55% by weight of granulated blast furnace slag.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Method for comprehensive utilization of red mud, phosphogypsum and coal gangue

A method for comprehensive utilization of red mud, phosphogypsum and coal gangue comprises the following steps: red mud, phosphogypsum and coal gangue are used as main original burning materials, a correction material is taken as a secondary original burning material, a homogeneous moisture material is prepared through two-stage batching process and is shaped or dried and crushed, and then a clinker product including main ingredients of dicalcium silicate, calcium sulphoaluminate and calcium sulphoferrite is prepared through calcination. The clinker produced by the method can be not only directly sold as a product but also further processed into a cementing material or product for sale by utilizing the prior art. The method provided by the invention is simple in process and low in investment, the production scale can be either big or small, a rapid hardening early strength clinker produced by the method is wide in use and relatively higher in value, not only are lots of clay resources and non-renewable burning coal saved, but also environmental pollution caused by waste pollutants are effectively reduced, secondary disasters is prevented, and high industrial competitiveness and favorable investment economical efficiency are realized.

Owner:长沙紫宸科技开发有限公司

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

Light-weight Al2O3-SiC-C refractory casting material and preparation method thereof

The invention relates to a light-weight Al2O3-SiC-C refractory casting material and a preparation method thereof. The light-weight Al2O3-SiC-C refractory casting material comprises the following raw materials: 40-55 wt% of porous corundum particle, 8-12 wt% of corundum particle, 6-12 wt% of SiC particle, 6-10 wt% of SiC fine powder, 5-8 wt% of corundum fine powder, 8-12 wt% of active aluminum oxide micropowder, 3-5 wt% of calcium aluminate cement, 2-4 wt% of silicon oxide micropowder, 2-4 wt% of ball asphalt, 1.5-2.0 wt% of silicon powder, 0.1-0.3 wt% of aluminum powder and 0.1-0.3 wt% of boron carbide powder. The preparation method comprises the following steps: mixing the raw materials with 8-15 wt% of water, 0.2-0.6 wt% of water reducing agent and 0.02-0.04 wt% of organic explosion-proof fiber, stirring, casting, molding, and naturally drying at 110 DEG C for 12-48 hours to obtain the light-weight Al2O3-SiC-C refractory casting material. According to the invention, the process is simple; and the prepared product has the characteristics of high strength, excellent thermal shock stability, low heat conductivity and high medium erosion resistance, and also has the advantage that the apparent porosity and pore size can be controlled.

Owner:WUHAN UNIV OF SCI & TECH

Calcium titanium-aluminate prefabricated part for vanadium smelting reverberatory furnace lining and preparation method thereof

The invention relates to a calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace lining and a preparation method thereof. According to the technical scheme, 60-75 wt% of calcium titanium-aluminate particles, 10-20 wt% of calcium titanium-aluminate fine powder, 2-7 wt% of titanium dioxide micro powder, 5-10 wt% of alpha-Al2O3 micro powder and 1-6 wt% of rho-Al2O3 micro powder are used as raw materials; 0.05-0.30 wt% of water reducing agent and 3.5-6.0 wt% of water of the raw materials are added; stirring is conducted for 5-8 minutes, vibration forming is achieved, maintenance is carried out for 18-24 hours under the natural condition, demolding is performed, heat preservation is conducted for 18-24 hours at the temperature of 90-110 DEG C, and accordingly the calcium titanium-aluminate prefabricated part for the vanadium smelting reverberatory furnace lining is obtained. The calcium titanium-aluminate prefabricated part has the advantages of being low in production cost, and capable of saving resources and protecting the environment. The obtained calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace is high in high-temperature strength, good in acidity vanadium slag corrosion resistance and good in permeability.

Owner:WUHAN UNIV OF SCI & TECH

Production of polymerized ferric-aluminum chloride composite coagulating agent

InactiveCN101074128AReduce manufacturing costLow costWater/sewage treatment by flocculation/precipitationPhosphateChlorate salt

Production of inorganic polymer coagulating agent is carried out by controlling Fe2+ concentration between 75-90g / L in hydrochloric acid pickling effluent, taking it as ferric source, taking calcium aluminate powder as aluminum source with Al2O3 content 47-56 wt%, putting two kinds of raw material into reactor in proportion of calcium aluminate powder: hydrochloric acid pickling effluent=0.05-0.10, reacting while agitating at 50-80 degree for 1-3 hrs, adding into minor chlorate oxidant and phosphate stabilizer, heating, reacting while agitating, and cooling to room temperature to obtain final product. It's simple and can be used for domestic sewage and industrial effluent treatment.

Owner:SHANGHAI UNIV

Aluminum-magnesium series lightweight pouring material and manufacturing method thereof

The invention discloses a making method of aluminium-magnesium systemic light-quality casting material, which comprises the following steps: adopting 40-70% aluminium-magnesium porous ceramic particle and 0-20% aluminium-magnesium particle as aggregate; selecting 15-55% fine aluminium-magnesium powder, 2-15% pure calcium aluminate and 2-8% active alpha-aluminium micropowder as substrate; blending the mass; adding 8-25% water, 0.1-0.8% silica powder and 0-3% dehydragent to stir evenly; casting; vibrating; moulding; drying for 8-48h under 110 deg.c.

Owner:WUHAN UNIV OF SCI & TECH

Lightweight reformed main iron runner pouring material

The invention discloses a lightweight reformed main iron runner pouring material. The pouring material comprises alumina, brown aluminum oxide, SiC, SiO2 micropowder, alpha-Al2O3 micropowder, spherical asphalt, aluminum oxide hollow sphere, explosion-proof fiber, metal silicon powder, andalusite fine ore powder, calcium aluminate cement and sodium tripolyphosphate. In the invention, lightweight reformation is carried out on the traditional heavy refractory material iron runner material by introducing the aluminum oxide hollow sphere into a main iron runner material; and due to the popularization and application of the lightweight reformed main iron runner pouring material, the consumption of the refractory material can be reduced for a user, the heat preservation and energy saving of high-temperature equipment are favorably promoted. By adding the aluminum oxide hollow sphere, the volume density of the product is reduced, the heat conduction coefficient is reduced, and the heat preserving effect on the main iron runner pouring material is achieved.

Owner:佘成其

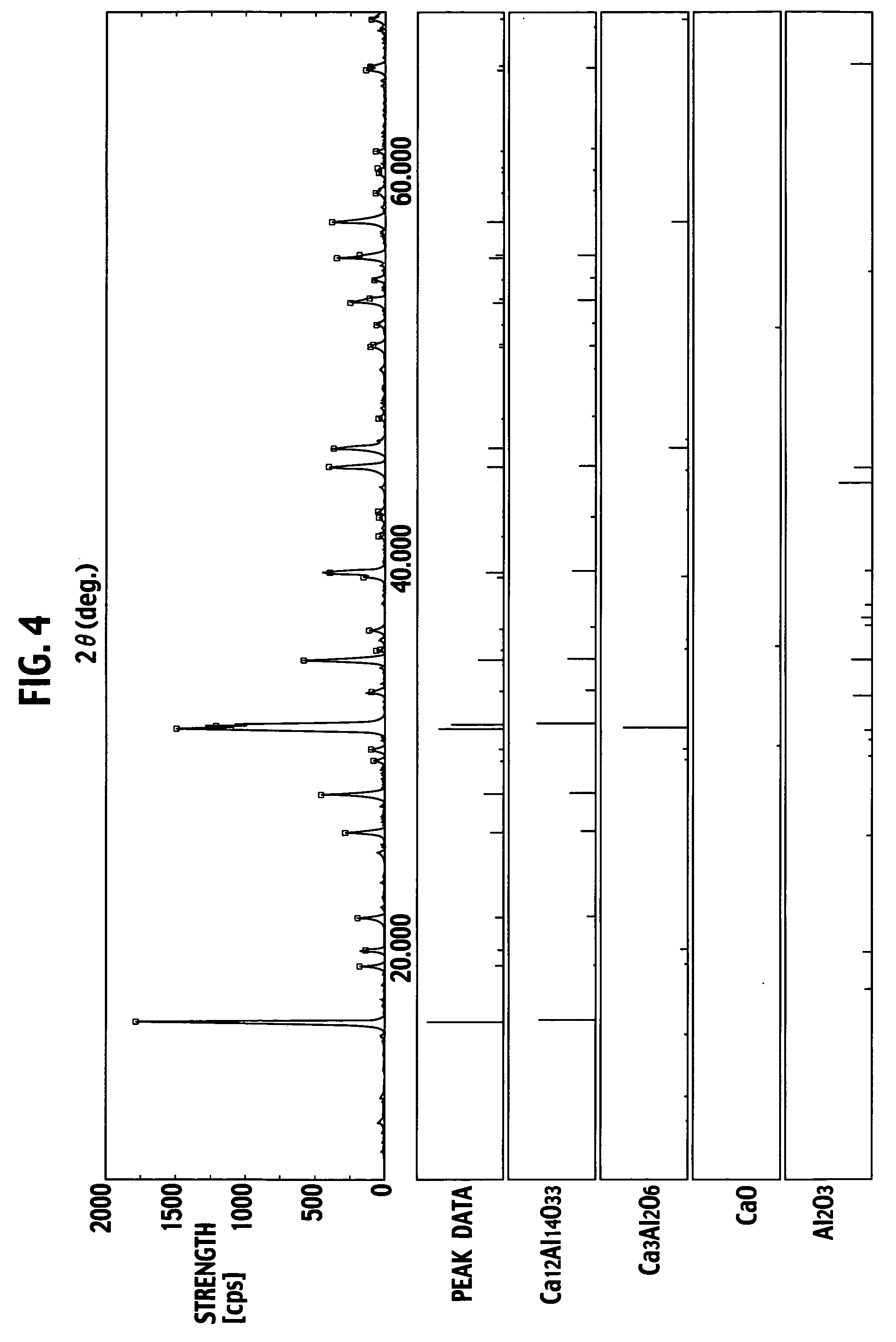

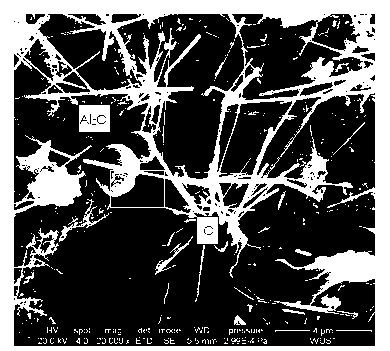

Processing method for recycling aluminum dross

ActiveCN101913634ANo pollutionReduce pollutionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSocial benefitsPtru catalyst

The invention discloses a processing method for recycling aluminum dross, which comprises the following steps: adding crushed limestone and catalyst to aluminum dross, thoroughly homogenizing and mixing the three materials, carrying out catalyzed calcination on the thoroughly homogenized and mixed materials in a calcination reaction furnace, and directly grinding the calcined products or grinding the calcined products after cooling, thus obtaining the calcium aluminate powder product. The processing method has a simple operational process, and can not cause new environmental pollution, thereby according with the policy for industry development. The invention recycles the aluminum dross, simultaneously reduces environmental pollution caused by the aluminum dross, improves the environmental management on surrounding areas, and also provides a reasonable and effective way to recycle waste aluminum dross. Thus, the invention has obvious economic benefits and social benefits.

Owner:HENAN KETAI WATER PURIFYING MATERIALS

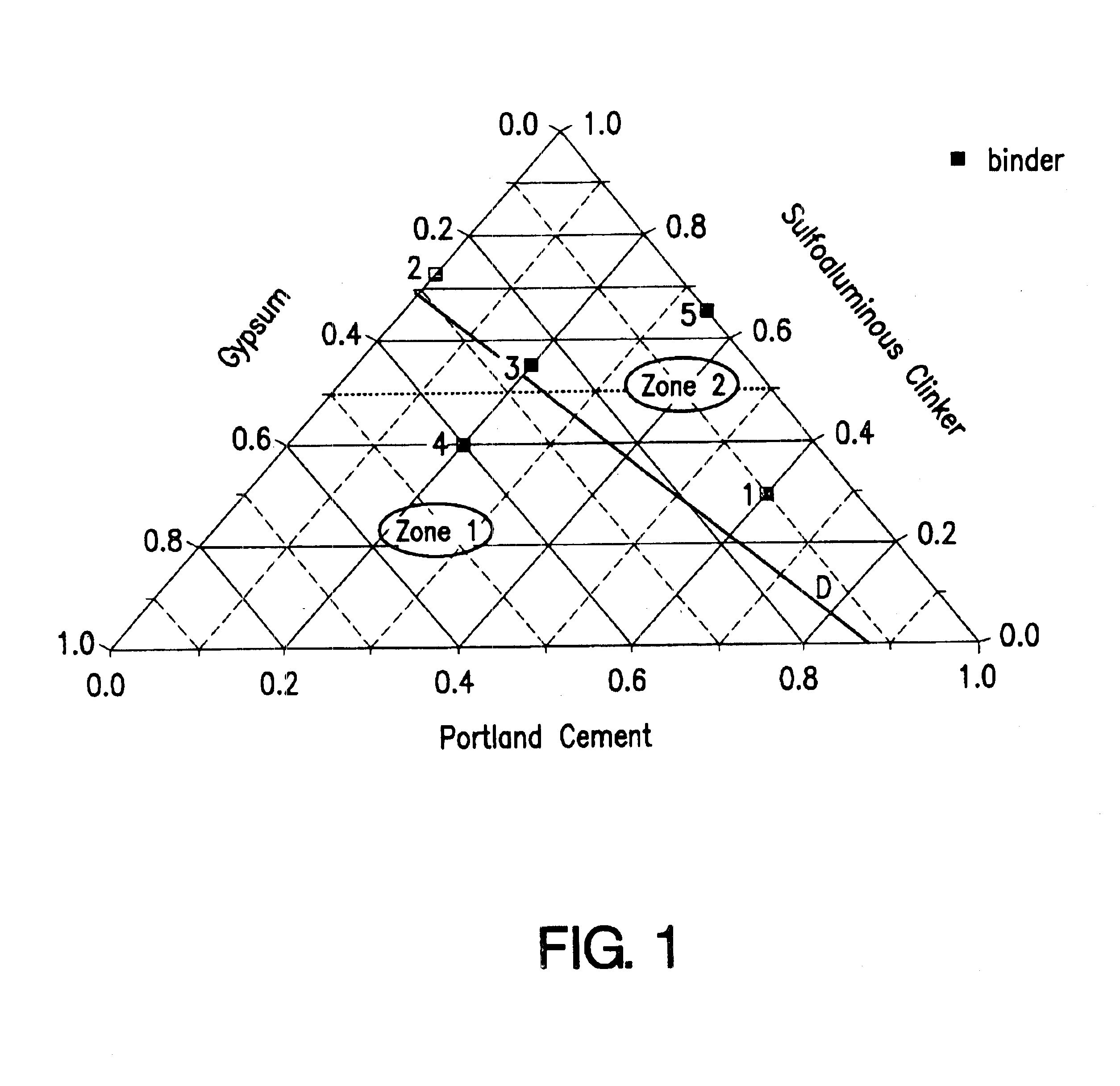

Sulfoaluminous clinker without iron and without free lime, its process of preparation and its use in white binders

The lightly colored sulfoaluminous clinker contains: more than 55% by weight of calcium sulfoaluminate phase (C4A3S), more than 10% by weight of belite phase (C2S), less than 10% by weight of anhydrite (C{overscore (S), and contains practically no ferrite phase, nor a gehlenite phase (C2AS), nor free lime. It is prepared by a process of roasting carried out at temperatures comprised between about 1250° C. and 1350° C. It can be used for a wide range of applications by combining it with a source of calcium sulfate and / or Portland cement, to obtain binders having specific properties (color, setup time, mechanical strength, expansion or contraction . . . ).

Owner:SOC DES CIMENTS FR

Ultra-pure steel corrosion-free type covering agent and production method thereof

The invention discloses an ultra-pure steel corrosion-free type covering agent and a production method thereof. The covering agent comprises the following components in percentage by weight: not more than 6 percent of SiO2, 40 to 45 percent of CaO, 7 to 11 percent of MgO, not more than 1.5 percent of Fe2O3, 29 to 35 percent of Al2O3, not more than 1 percent of Na2O, not more than 1 percent of F and not more than 1 percent of fixed carbon. The invention has the advantages that: premelting type refining slag, premelting type aluminum-calcium slag, calcium aluminate cement and light-roasted dolomite carbon-free low-silicon high-alkalinity materials are used as raw materials, the materials are reasonably matched with one another, and a covering slag atomization granulation production process is used for production, so that the covering agent has the advantages of high spreadability, no incrustation and no silicon addition, is easy and convenient to operate and use, improves the quality ofpurified molten steel during use, is granular, does not have dust pollution, and the like.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Corundum spinel castable with micro-nano pore structure and preparation method of corundum spinel castable

The invention relates to a corundum spinel castable with a micro-nano pore structure and a preparation method of the corundum spinel castable. The technical scheme of the invention is as follows: the preparation method comprises the following steps of: dry-blending 45-82 percent by weight of tabular corundum particles and 1-15 percent by weight of magnesium aluminate spinel particles to obtain mixed aggregate, and dry-blending 1-10 percent by weight of magnesium aluminate spinel fine powder, 4-12 percent by weight of corundum fine powder, 5-15 percent by weight of Alpha-Al2O3 micropowder, 2-8 percent by weight of pure calcium aluminate cement and 0.1-0.5 percent by weight of SiO2 micropowder to obtain mixed powder; then adding a water reducing agent, water and foams which respectively account for 0.2-1.0 percent by weight, 3.5-4.5 percent by weight and 5-15 percent by weight of the aggregate and the powder to the mixed powder, and stirring to prepare mixed slurry; and pouring the mixed aggregate into the mixed slurry, stirring, moulding by casting, curing, demoulding, baking, heating to 1450-1760 DEG C and maintaining the temperature for 2-4 hours. The preparation method disclosed by the invention has the characteristics of simple process and easiness for construction and industrial production; and the prepared corundum spinel castable is high in comprehensive property, good in thermal shock resistance and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

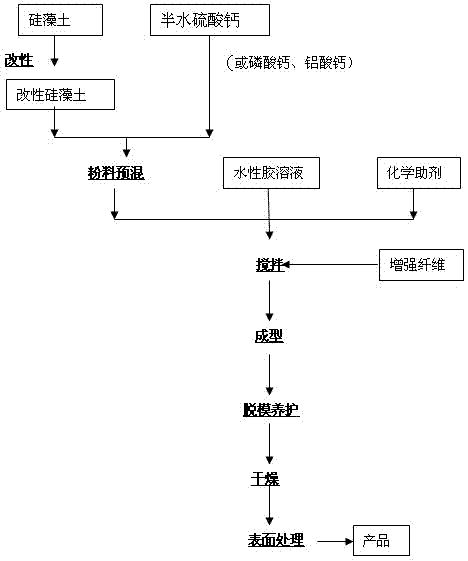

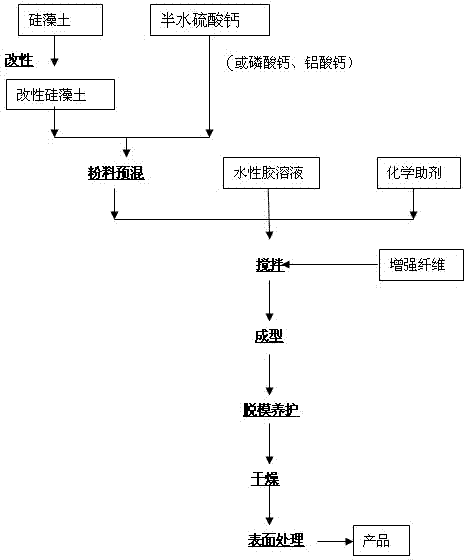

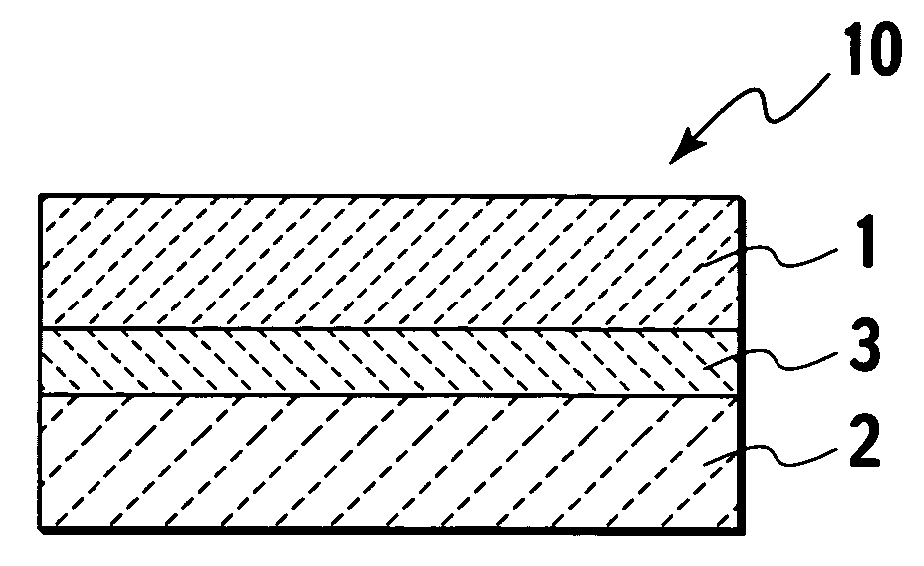

Algae calcium compound material, decorative panel and production method

ActiveCN102515678ASimple processAdsorption functionality is limitedCeramic shaping apparatusFiberWater based

The invention belongs to a building material and particularly relates to an algae calcium compound material, a decorative panel and a production method. Kieselguhr and a calcium-containing inorganic building material substrate are hydrated, gelled and compounded, thereby forming the algae calcium compound material, wherein the calcium-containing inorganic building material substrate is selected from one or more of hemihydrate calcium sulfate, calcium phosphate and calcium aluminate; preferably, the components are mixed at a weight ratio of the calcium-containing inorganic building material substrate to kieselguhr to enhanced fiber chopped strand to water-based gel solution to chemical auxiliaries being 100:(10-50): (1.2-2.0): (50-65): (5-10); and the raw materials are subjected to raw material pretreatment, mixing and stirring, filling and molding, maintaining and drying, and surface treatment, thereby forming a decorative material product. The excellent plasticity and environmental friendliness of the novel compound material are fully excited while the microporosity of the kieselguhr is utilized to endow the material with excellent functions of humidifying and absorbing harmful gas, such as, formaldehyde, and the like, and the environmental protecting functions, such as sterilization, and the like.

Owner:湖北格林森绿色环保材料股份有限公司

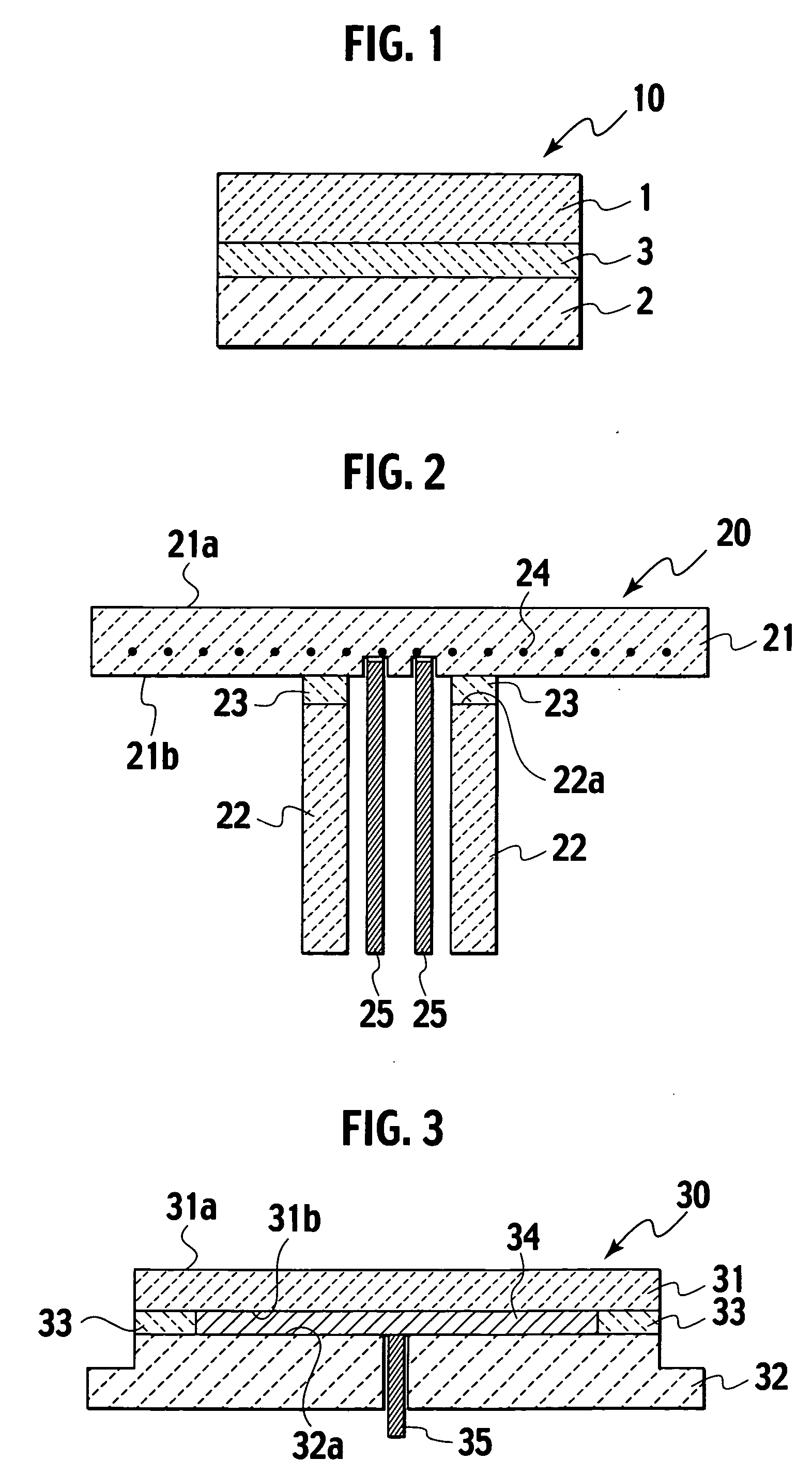

Bonding agent, aluminum nitride composite body, and manufacturing method of the same

InactiveUS20060110624A1Improve abilitiesLower bonding temperatureCeramic layered productsInorganic adhesivesRare-earth elementCalcium aluminates

Owner:NGK INSULATORS LTD

Aluminum-silicon light heat insulation brick and preparation method thereof

ActiveCN102167622ARaw materials are cheap and easy to getSimple production processCeramicwareInsulation layerBrick

The invention relates to an aluminum-silicon light heat insulation brick and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 40-55 percent by weight of light alumina aggregate, 25-40 percent by weight of bauxite chamotte, 5-12 percent by weight of calcium aluminate cement, 8-13 percent by weight of organic polymer, 2-5 percent by weight of silicon powder, 0.05-0.15 percent by weight of water reducing agent and 15-25 percent by weight of water, calendering and molding by casting; curing under the condition of room temperature for 24-48 hours, demolding and drying at the temperature of 100-120 DEG C for 20-36 hours; and preserving heat at the temperature of 1,400-1,550 DEG C for 3-5 hours to obtain the aluminum-silicon light heat insulation brick. The preparation method has the advantages of wide raw materials, simple process and low production cost; the prepared aluminum-silicon light heat insulation brick has the advantages of high compressive strength, low volume density, low heat conductivity, high using temperature, low re-burning linear change rate, high thermal shock stability and the like; the product is applied to various industrial furnace heat insulation layers, has a wide application range and remarkably-reduced energy consumption and temperature outside a furnace, and can be safely and effectively produced.

Owner:WUHAN UNIV OF SCI & TECH

Lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate and preparation method thereof

The invention discloses a lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate for lightweight refractory castables and a preparation method thereof. The lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate is obtained by taking 3 to 7 weight percent of lime, 12 to 18 weight percent of magnesite and 75 to 85 weight percent of industrial aluminum hydroxide as initiative materials, adding a binding agent in an amount which is 3 to 6 percent of the total weight of the initial materials, performing wet co-grinding and machine molding, drying a green body and then calcining the green body, and crushing a product obtained after calcination. The lightweight microporous aggregate has the advantages of high stability in reducing atmosphere and alkaline environment, excellent thermal shock resistance and thermal insulation property and the like, so that the service life of the material is prolonged andthe loss of energy consumption is reduced.

Owner:HENAN UNIV OF SCI & TECH

Lightweight insulated calcium hexaluminate castable

The invention relates to a lightweight insulated calcium hexaluminate castable prepared from the following raw materials by weight percent: 25-35% of super lightweight calcium hexaluminate of which the grain size is 3-6mm, 10-15% of super lightweight calcium hexaluminate of which the grain size is 1-3mm, 15-20% of super lightweight calcium hexaluminate of which the grain size is 0.088-1mm, 0-25% of super lightweight calcium hexaluminate of which the grain size is smaller than 88mu m, 0-25% of corundum fine powder of which the grain size is smaller than 88 mu m, 0-10% of alpha-Al2O3 micro-powder and 5-20% of pure calcium aluminate cement, and in addition, a water reducer which is 0.12-0.18% of total weight of the raw materials. The lightweight insulated calcium hexaluminate castable disclosed by the invention has the advantages of small volume density, good thermal insulating properties, high strength, low impurity content, high refractoriness and strong anti-erosion capability.

Owner:河南竹林庆州耐火材料有限公司

Al2O3-SiC-C iron runner casting material and preparation method thereof

InactiveCN103011868AImprove high temperature performanceGood toughening effectPtru catalystAnti oxidant

The invention particularly relates to an Al2O3-SiC-C iron runner casting material and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: carrying out uniform dry mixing on raw materials 50-60 wt% of electrofused brown corundum granules, 8-12 wt% of electrofused brown corundum fine powder, 3-10 wt% of silicon carbide granules, 6-11 wt% of silicon carbide fine powder, 3-7 wt% of alpha-Al2O3 micropowder, 2-4 wt% of pelleted pitch, 2-4 wt% of silicon dioxide micropowder, 2-4 wt% of calcium aluminate cement, 2-4 wt% of metal antioxidant and 0.1-0.3 wt% of dispersant together with catalyst accounting for 0.1-3 wt% of the raw materials to obtain the Al2O3-SiC-C iron runner casting material. The invention has the advantage of low preparation cost; and the prepared Al2O3-SiC-C iron runner casting material has the advantages of low water addition amount, high flow value, favorable high-temperature service performance and high thermal shock stability, and so that the blast furnace iron runner has high iron flux and low refractory material consumption.

Owner:WUHAN UNIV OF SCI & TECH

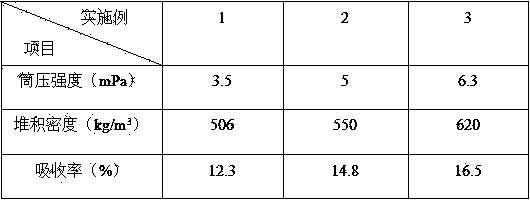

Sludge coal ash high-strength ceramsite and preparation method thereof

ActiveCN104261802AIn line with the principles of sustainable developmentRaise the ratioCeramic materials productionClaywaresSludgeExpanded clay aggregate

The invention discloses sludge coal ash high-strength ceramsite and a preparation method thereof. By using sludge and coal ash as main raw materials, the ceramsite is prepared by mixing, prilling and calcining by synergic match with an additive. The ceramsite is prepared from the following raw materials in parts by weight: 40-70 parts of sludge, 30-55 parts of coal ash, 0.5-1.5 parts of calcium sulphoaluminate, 0.5-1 part of phthalate, 1-3 parts of water glass and 0.5-1 part of a deodorant, wherein the water content of sludge is controlled within 35-50wt%. The sludge coal ash high-strength ceramsite is prepared by the following steps: mixing the materials; prilling; drying; calcining; and cooling. The ceramsite disclosed by the invention is economical, environment-friendly, efficient and energy-saving and scientific and reasonable in match of components of raw materials, and the prepared sludge coal ash high-strength ceramsite has the advantages of high cylinder compressive strength and high absorption.

Owner:CHONGQING HAOPAN ENERGY SAVING TECH

Micropore high-strength corundum-calcium hexaluminate composite refractory raw material and preparation method thereof

The invention relates to a micropore high-strength corundum-calcium hexaluminate composite refractory raw material and a preparation method of the material. The technical scheme adopted by the invention is as follows: 94-98wt% of aluminum oxide fine powder or aluminium hydroxide fine powder is taken as an aluminium source; 1-6wt% of calcium carbonate fine powder or calcium hydroxide fine powder is taken as a calcium source; water is added into the raw materials, and the quantity of the water is 30-60wt% of the total quantity of the raw materials; the raw materials are mixed in the water; wet grinding is carried out on the mixture by virtue of a ball grinding mill for 0.5-2 hours; after being solidified, the slurry processed by wet grinding is subjected to heat preservation for 12-48 hours at the temperature of 110-200 DEG C; then, heat preservation is carried out at 1750-1900 DEG C for 3-5 hours; and finally, after the product is burnt and crushed, the micropore high-strength corundum-calcium hexaluminate composite refractory raw material can be obtained. The micropore high-strength corundum-calcium hexaluminate composite refractory raw material prepared by the method has the characteristics of being high in slag resistance, excellent in thermal shock resistance and heat-insulating property and the like, and can be used at the parts such as a steel ladle and the like contacted with molten steel and used for replacing corundum in other refractory material taking the corundum as a raw material, so that the service life of the material is prolonged, and the energy consumption is reduced.

Owner:JIANGSU JINGXIN NEW MATERIAL

Formula and process for producing polymeric aluminum chloride

InactiveCN101531388AReduce moisture contentAchieve reuseAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium chlorohydrate

The invention relates to a formula and a process for producing polymeric aluminum chloride. 5 tons of running water are added into a reaction tank and 14.2 tons of 31 percent hydrochloric acid are added into the reaction tank at the same time, and stirring is started for uniformly mixing; steam heating is started, 4.25 tons of bauxite are put at the same time, the timing is started when the temperature reaches 95 DEG C, and the reaction time is 40 to 60 minutes; after the reaction completes, the temperature is kept above 75 DEG C, 5 tons of calcium aluminum powder are put when 8 tons of running water are added, and the temperature is kept above 95 DEG C after the addition of the running water and the calcium aluminum powder completes for reaction for 2 hours; after the reaction completes, 5 tons of running water are added, and after the aluminum oxide content is adjusted to 10.0 percent, the mixture in the reaction tank is transferred to a sedimentation tank to allow large sludge particles to settle; after the content of the polymeric aluminum chloride water insoluble matters in the sedimentation tank reach 2.0 percent, the sludge is furthered removed to form a qualified product through the treatment of sludge-removing equipment; and water content in the sludge is reduced and the COD removal rate is improved.

Owner:DONGYING HUATAI FINE CHEM

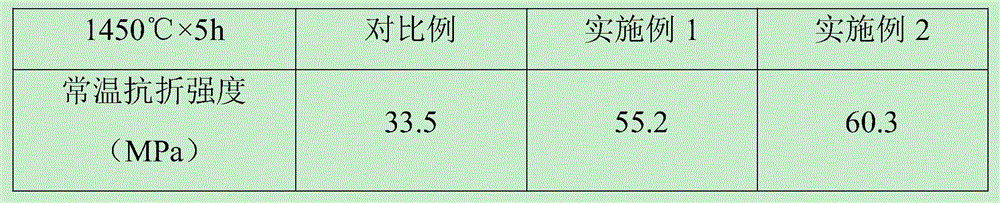

Calcium aluminate cement-combined corundum castable and preparation method thereof

The invention discloses calcium aluminate cement-combined corundum castable and a preparation method thereof. With calcium aluminate cement as a binding agent, tabular corundum and activated aluminum oxide as main components, and titanium dioxide / calcium carbonate / magnesium oxide micro-powder as a compound additive, the high-strength calcium aluminate cement-combined corundum castable is prepared. By combining with the characteristics of accelerating sintering by virtue of titanium dioxide and forming spinel and calcium carbonate to convert into high-activity calcium oxide at a high temperature by reaction of magnesium oxide and corundum, the strength of the corundum castable is greatly improved. The prepared high-strength calcium aluminate cement-combined corundum castable has excellent performance, and can be applicable to the industries such as building materials, metallurgy and petrifaction; and the service life of equipment such as a cement kiln opening, a coal-injection duct, an induction furnace lining and a high-temperature wear-resisting lining is effectively prolonged.

Owner:湖北安耐捷炉衬材料有限公司

Method for producing calcium aluminate with waste aluminum gray

InactiveCN101172635ASimple processWide applicabilityAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationElectric arc furnaceCalcium aluminates

The invention relates to a method of utilizing wasted aluminum ash to produce calcium aluminate. The method comprises the steps as follows: wasted aluminum ash and calcium oxide are adopted as the raw materials; coke as the reducing agent and scrap iron as the settling agent are added, and smelted under high temperature in an electric arc furnace; the calcium aluminate produced after the melting is poured and cooled, and mulled and sieved, and utilized as the desulfurizer in making steel. The invention of simple technique does not require to process the wasted aluminum ash, which can instead bauxite to produce high-purity calcium aluminate, so that the invention reduces the production cost of the calcium aluminate, recycles the wasted aluminum ash which causes environmental pollution easily, and brings about remarkable comprehensive benefits socially and economically.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com