Patents

Literature

1175 results about "Calcium aluminate cements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium aluminate cements are cements consisting predominantly of hydraulic calcium aluminates. Alternative names are "aluminous cement", "high-alumina cement" and "Ciment fondu" in French. They are used in a number of small-scale, specialized applications.

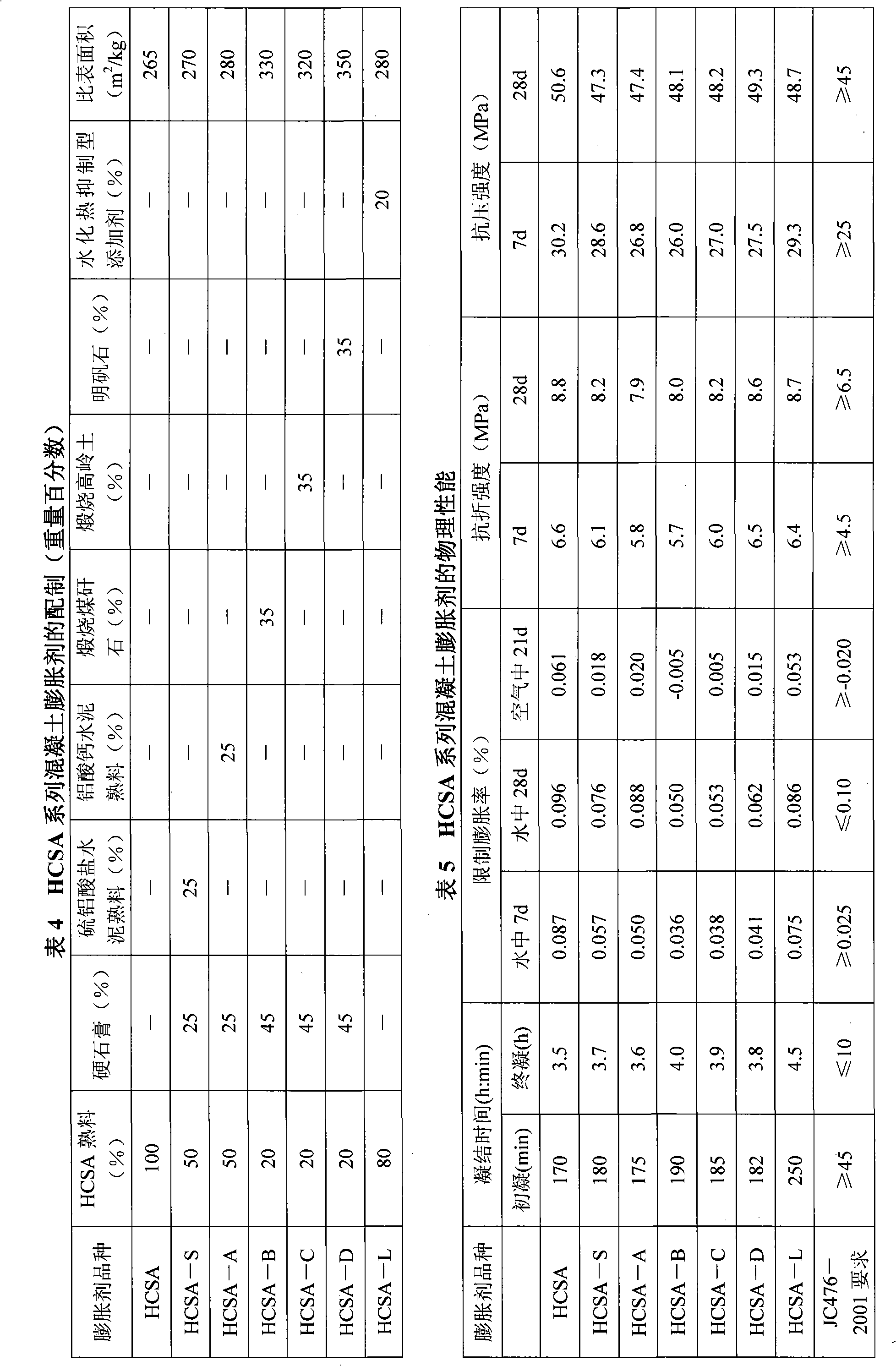

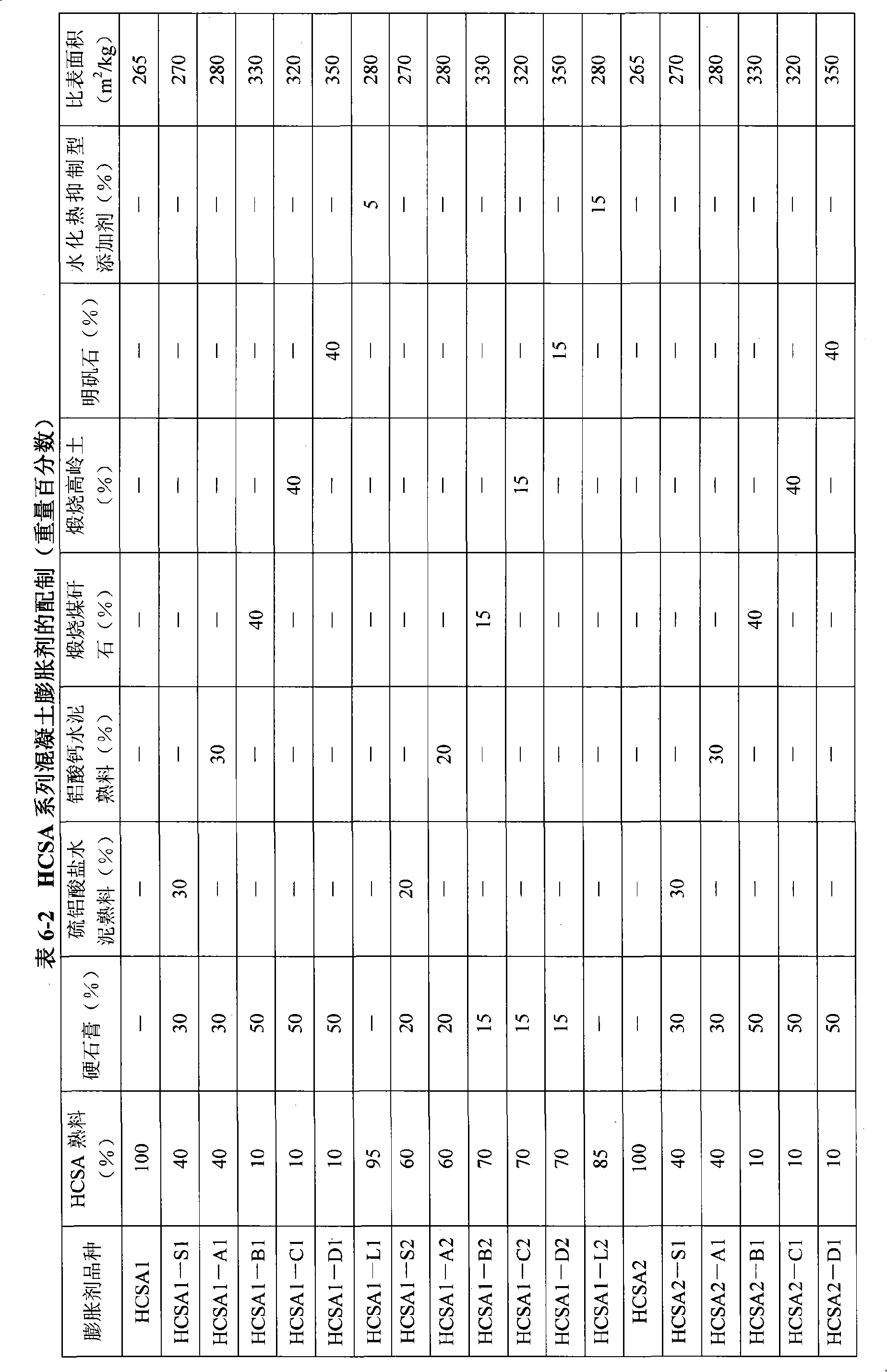

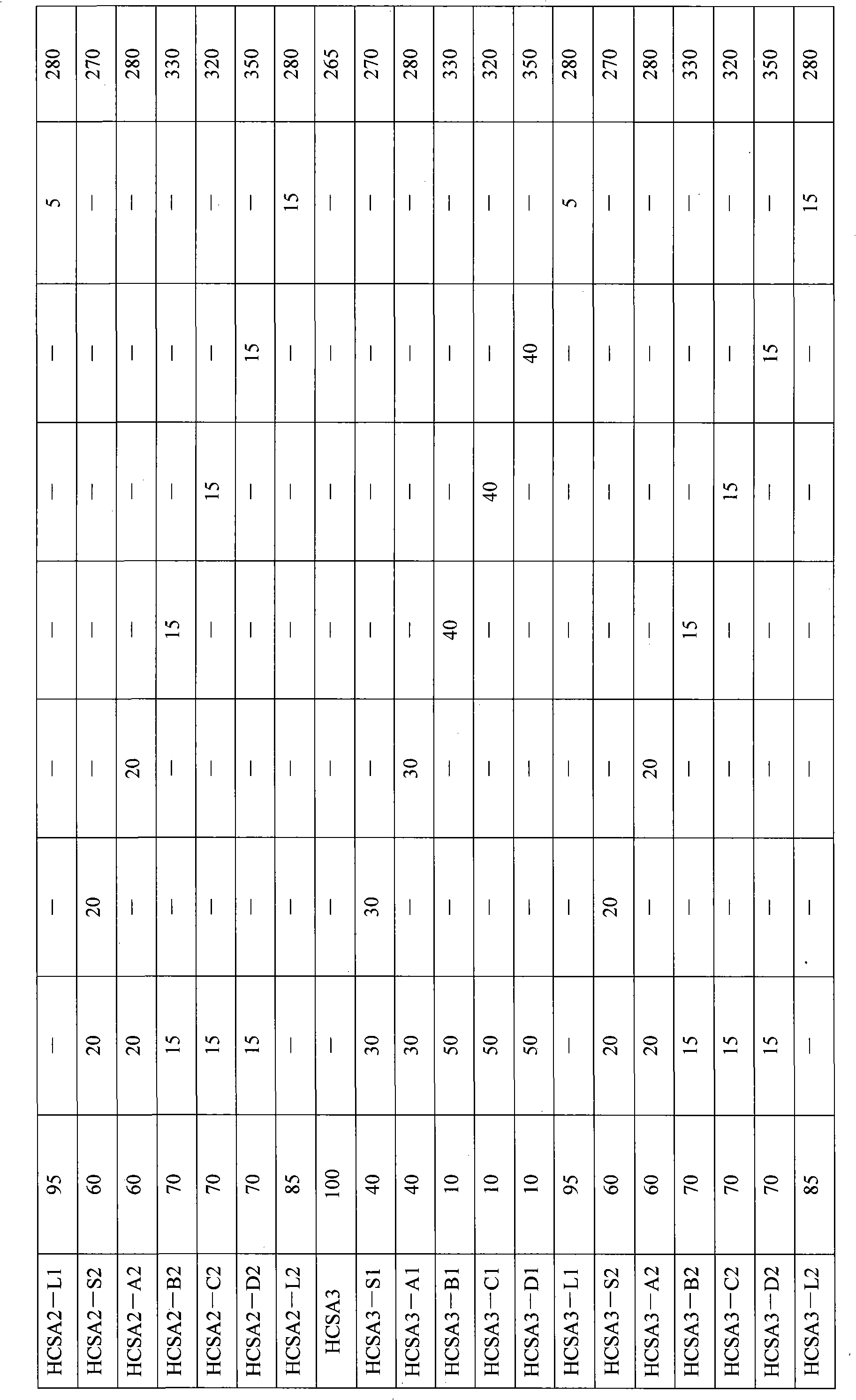

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

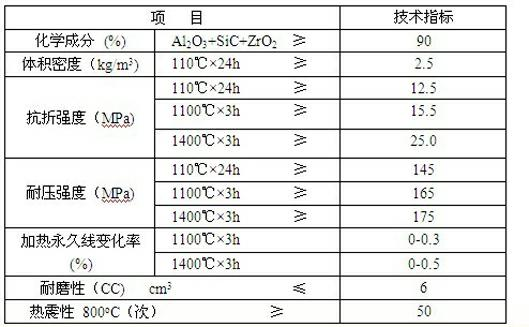

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

Special castable for kiln outlet

The invention discloses a special castable for a kiln outlet, which belongs to the field of refractory materials. According to the invention, the special castable comprises the following components in percentage by weight: 8-25% of silicon carbide, 10-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 1-5% of zirconium diboride, 1-5% of silicon nitride,5-15% of alumina micropowder, 3-6% of pure calcium aluminate cement, 0.5-1% of explosion-proof fiber and 0.06-0.2% of sodium tripolyphosphate, which is an additive. By using the special castable for the kiln outlet, disclosed by the invention, the phenomenon of poor wear resistance, block falling and the like in the kiln outlet can be effectively improved; the service life of the cement kiln outlet can be largely prolonged; and the special castable for the kiln outlet, disclosed by the invention, has the advantages of high temperature resistance, heat shock resistance, wear resistance, high strength, irreversible micro expansion and the like.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Fire-proof pouring material of iron tap channel of blast-furnace and production thereof

A fire-proof pouring material for blast-furnace iron tap channel and its production are disclosed. The pouring material consists of industrial schmigel, SiC fines, high-temperature asphalt superfine powder, alumina or calcium aluminate cement, a-Al2O3 superfine powder, SiO2 superfine micro-powder and metal silicon. The process is carried out by taking sodium tripolyphosphate or calgon or aluminum powder as additives, adding into aluminous fly ash, agitating, mixing, obtaining the pouring material, adding into 3-7% water, agitating, mixing, adding into mould, vibrating for vibrating bar or plate, naturally hardening and drying, demoulding, drying at 80-700 Deg C., heat treating and removing moisture. It costs low and has good availability.

Owner:无锡市南方耐材有限公司

Method for preparing high alumina castable without being moistened by aluminum liquid

The invention discloses a method for preparing a high alumina castable without being moistened by aluminum liquid. The high alumina castable comprises the following raw materials in percentage by weight: 63 to 70 percent of high alumina granular materials, 16 to 23 percent of high alumina fine powder, 3 to 7 percent of silicon oxide micropowder, 0 to 7 percent of aluminum oxide micropowder, 3 to 10 percent of pure calcium aluminate cement and 1 to 6 percent of aluminum liquid moisture resistant agent consisting of BaSO4 and Na3AlF6. The preparation method comprises the following steps of: grinding the aluminum liquid moisture resistant agent and the high alumina fine powder according to the weight percentage in a vibration mill for 20 to 30 minutes; and uniformly mixing the obtained homogenized powder and other components. In the preparation method, the aluminum liquid moisture resistant agent and the high alumina fine powder are subjected to homogenization treatment, and then the homogenized powder is added to the high alumina castable; the content of Al2O3 in the prepared high alumina castable is improved to 90 percent from 40 percent; and the non-wettability of the high alumina refractory castables to aluminum liquid is obviously strengthened.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Special pouring material for coal injection pipe

The invention discloses a special pouring material for a kiln opening and belongs to the field of a refractory material. The special pouring material comprises the following components by weight percent: 10-25% of silicon carbide, 15-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 5-15% of aluminum oxide micro powder, 3-8% of silicon micro powder, 2-5% of pure calcium aluminate cement, and 0.5% and 0.2% of anti-explosion fibers and sodium tripolyphosphate serving as additives. The special pouring material is capable of efficiently improving the wear resistance and avoiding the hot peeling phenomenon of the cement kiln coal injection pipe, has the characteristics of high temperature resistance, heat vibration resistance, wear resistance, high strength, irreversible micro inflation, and the like, and is capable of greatly prolonging the service life of the cement kiln coal injection pipe.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Composite fire resistant pouring material

The invention relates to an organic-inorganic composite combined advanced monolithic refractory which has the formula of 40 to 56 percent of 5-1mm corundum or bauxite, 12 to 30 percent of 1-0.0088mm corundum or bauxite, 16 to 25 percent of corundum or bauxite with d90 less than 0.088mm, 0 to 5 percent of alpha alumina micropowder, 1 to 8 percent of hydratable alumina, 1 to 6 percent of siliceous dust, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid, 1 to 6 percent of external water and 0 to 3 percent of external heat-resistant steel fiber. Casting materials of the invention have excellent performances of condensation, hardening, demoulding, drying and heating and are suitable for high-temperature furnace projects with changeful field conditions.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

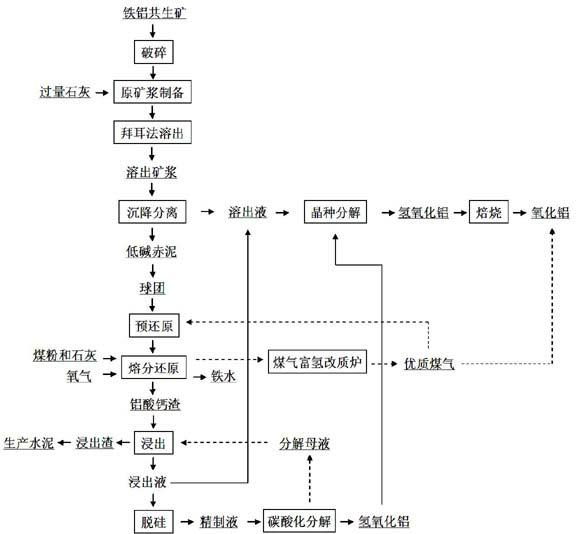

Comprehensive utilization method of high-ferrum and low-grade bauxite

ActiveCN102583477AReduce alkalinityHigh dissolution rateAluminium oxide/hydroxide preparationCarbon captureRotary furnaceCalcium aluminate cements

A comprehensive utilization method of high-ferrum and low-grade bauxite belongs to the technical of metallurgy and is carried out according to the steps as follows: a large proportion of aluminium oxide is extracted through a Bayer process technology that excess lime is added, produced low-alkali red mud is pre-reduced through a coal-based rotary furnace process technology, then high-temperature melting separation of aluminium slag / ferrum is realized by adopting a ferrum bath oxygen coal jetting technology, formed aluminium slag generates calcium aluminate cement after being quenched and tempered, calcium aluminate cement slag is leached with low sodium carbonate solution, a part of leached crude solution and digestion slurry by the Bayer process are mixed and enter a Bayer process system to extract aluminium oxide, and the other part is desilicated and then is resolved in a carbonation manner, aluminum hydrate, which is the decomposition product, is conveyed to the Bayer process system as seed crystal, and resolved mother liquid is used for leaching calcium aluminate cement slag after being mixed. The method provided by the invention can not only ensure efficient dissociation extraction of ferrum and aluminium, but also be practicable in technology and economic benefit, thereby comprehensively utilizing high-ferrum bauxite resource of China effectively.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Explosion-proof iron runner castable

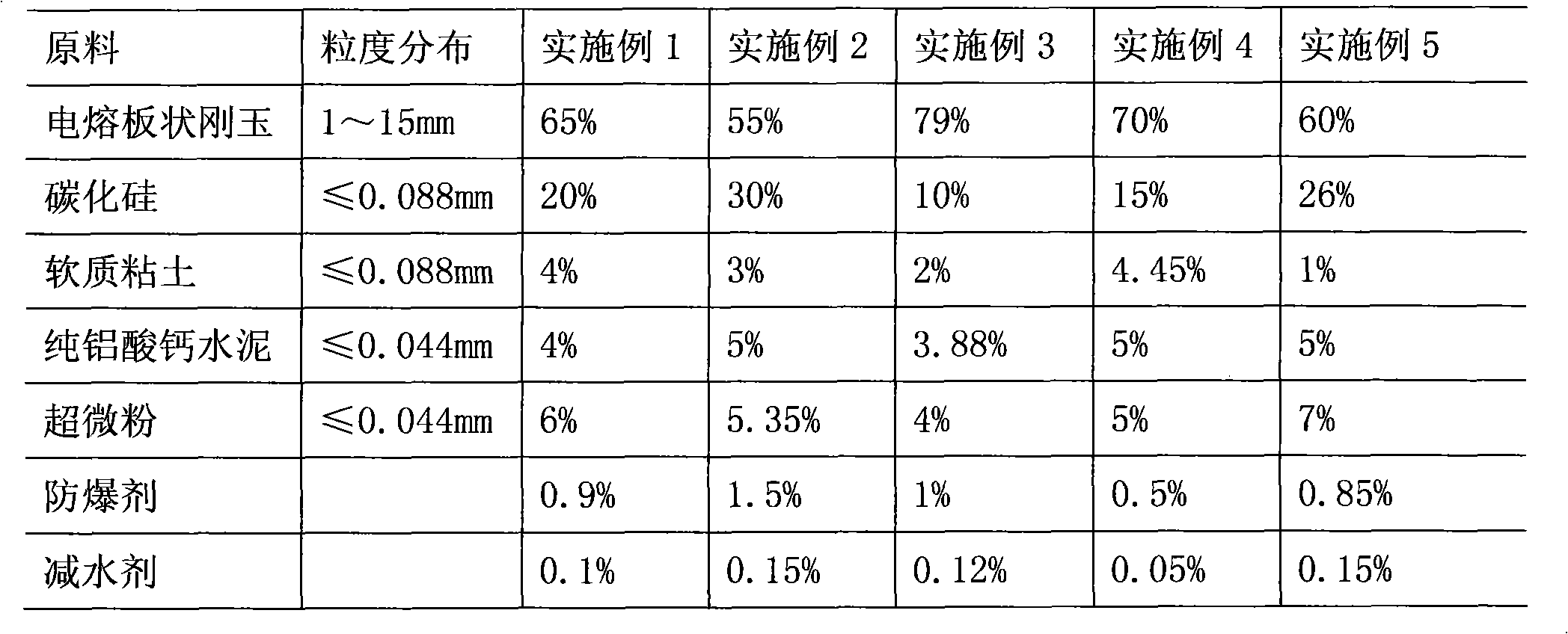

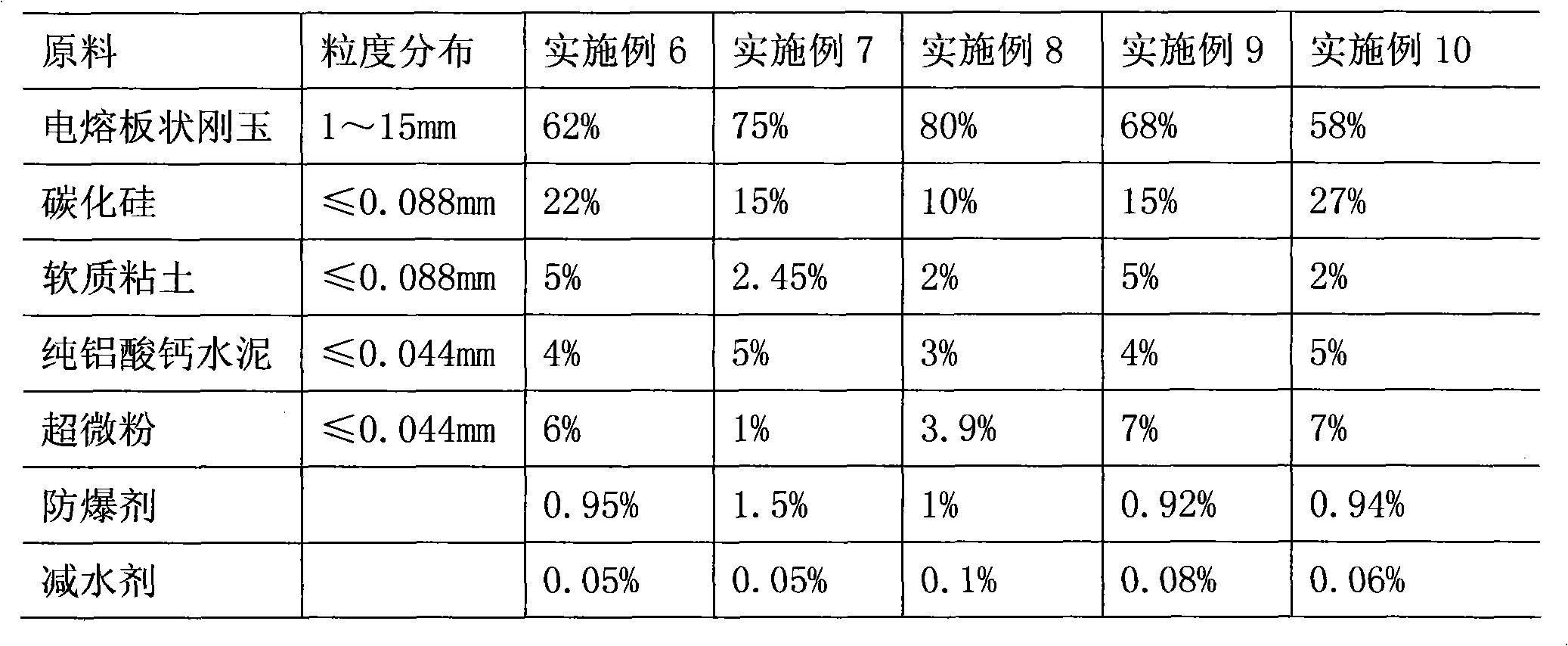

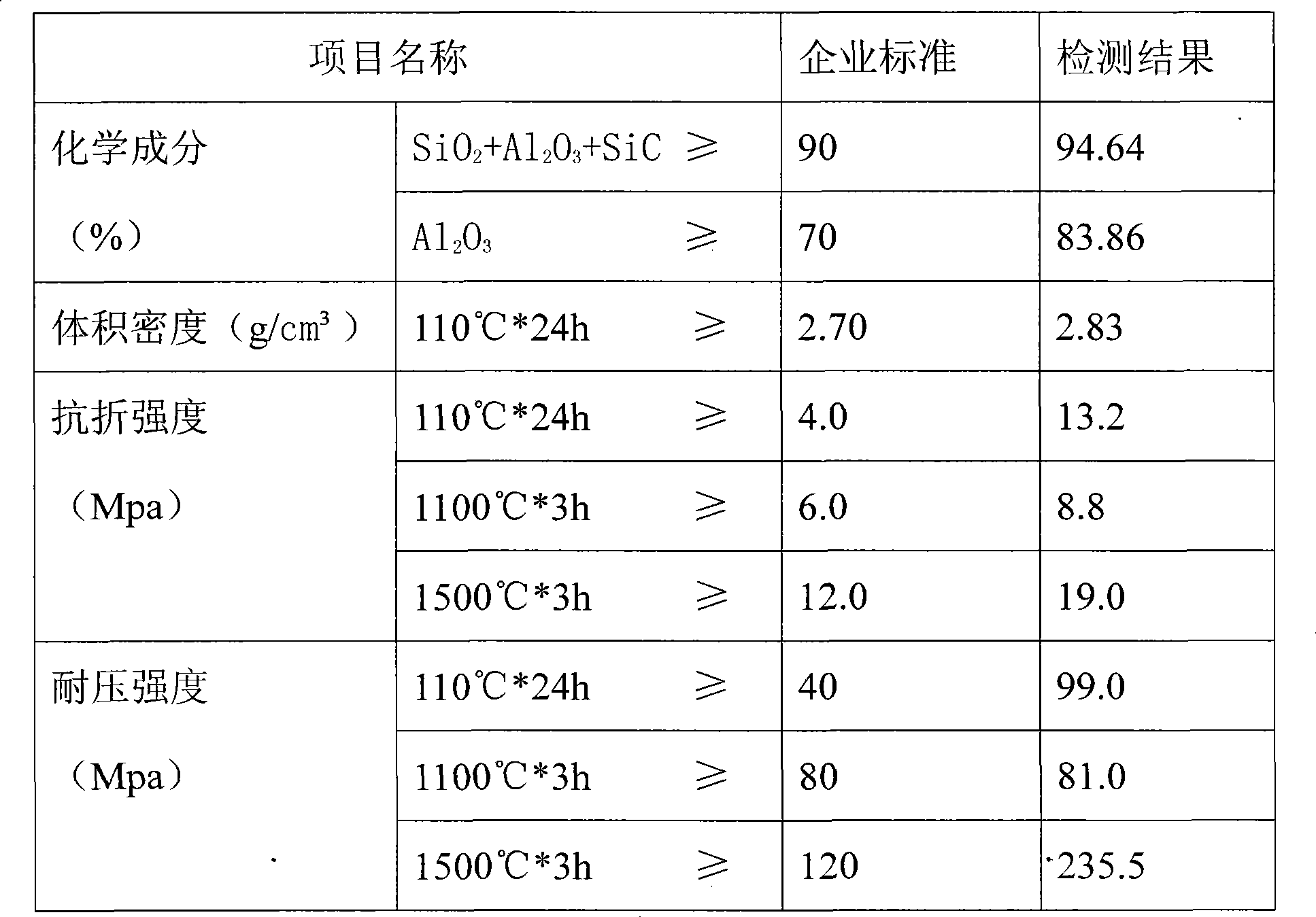

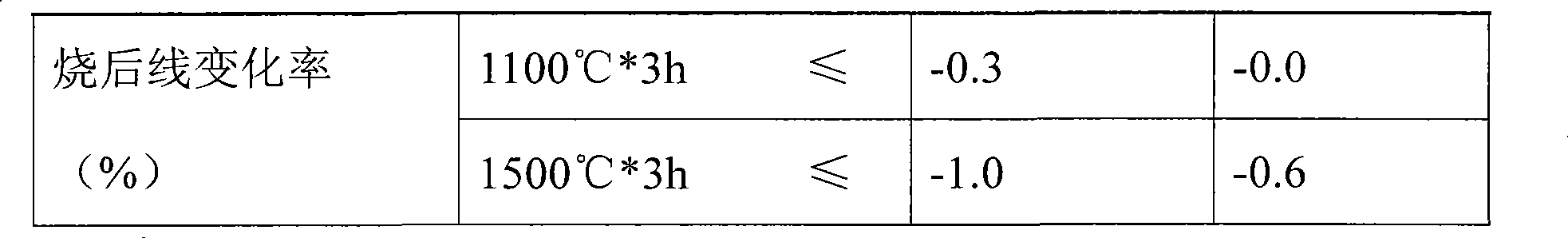

The invention relates to an explosion-proof iron runner castable which comprises the following raw materials in percentage by weight: 55-80 percent of fusion tabular corundum, 10-30 percent of silicon carbide, 1-5 percent of soft clay, 2-5 percent of pure calcium aluminate cement, 1-7 percent of submicron powder, 0.5-1.5 percent of explosion-proof agent and 0.05-0.15 percent of water reducing agent, wherein the explosion-proof agent is a mixture of aluminum powder, aluminum lactate, explosion-proof fiber and boron carbide powder with the weight ratio of 1-2:2.5-4:1-2.5:2-4. The castable of the invention has no cracks after demoulding and drying and no spalling during baking, has the safe explosion-proof temperature of 800 DEG C increased from 500 DEG C, can be subjected to construction under heat state and rapid temperature rise without spalling and can meet the operating requirements of rapid construction of middle and small size blast furnace iron runner. The castable has long service life, can improve the environment of a casting house, greatly reduces the labor intensity of the workers, improves the quality of molten iron and enhances the application safety factor of the iron runner.

Owner:HENAN HUAXI FURNACE REFRACTORY

Corundum and spinel castable and preparation method thereof

The invention relates to corundum and spinel castable and a preparation method thereof. According to the scheme, the method comprises the following steps of: blending 1 to 10 weight percent of magnesia-alumina spinel fine powder, 5 to 10 weight percent of white fused corundum fine powder, 5 to 10 weight percent of alpha-Al2O3 micro powder, 2 to 8 weight percent of pure calcium aluminate cement, 0.06 to 0.2 weight percent of poly carboxylic acid water reducing agent, and 0.01 to 0.1 weight percent of organic fiber, and precasting mixed powder; performing dry-blending on 6 to 18 weight percent of partially stable zirconia particles or calcium zirconate particles, 45 to 70 weight percent of tabular corundum particles and 1 to 10 weight percent of magnesia-alumina spinel particles which are used as aggregate for 4 to 6 minutes, adding the mixed powder, and milling for 15 to 30 minutes; and adding water in an amount which is 3 to 6 percent based on the weight of the mixed powder and aggregate, milling for 3 to 5 minutes, vibrating and performing casting moulding, curing for 20 to 26 hours, demoulding, drying at the temperature of between 100 and 120 DEG C for 20 to 26 hours, raising temperature to 1,450 to 1,750 DEG C, and preserving heat for 2 to 4 hours. The prepared corundum and spinel castable is high in thermal shock resistance, high-temperature strength, and strength retention rate after thermal shock, and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Corundum-mullite self-flow refractory castable

The invention discloses a corundum mullite artesian fireproof casting material, which comprises 30-35% of plate-shaped corundum, 5-8% of carborundum powder material, 4-5% of pure calcium aluminate cement, 35-45% of mullite, 10-15% of alpha-Al2O3 micropowder and 3-5% of bonite by mass percentage. The casting material is characterized by good fluidity, good resistance to thermal shock, low porosity rate of entity after casting, good chemical resistance, high intensity and long service life.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

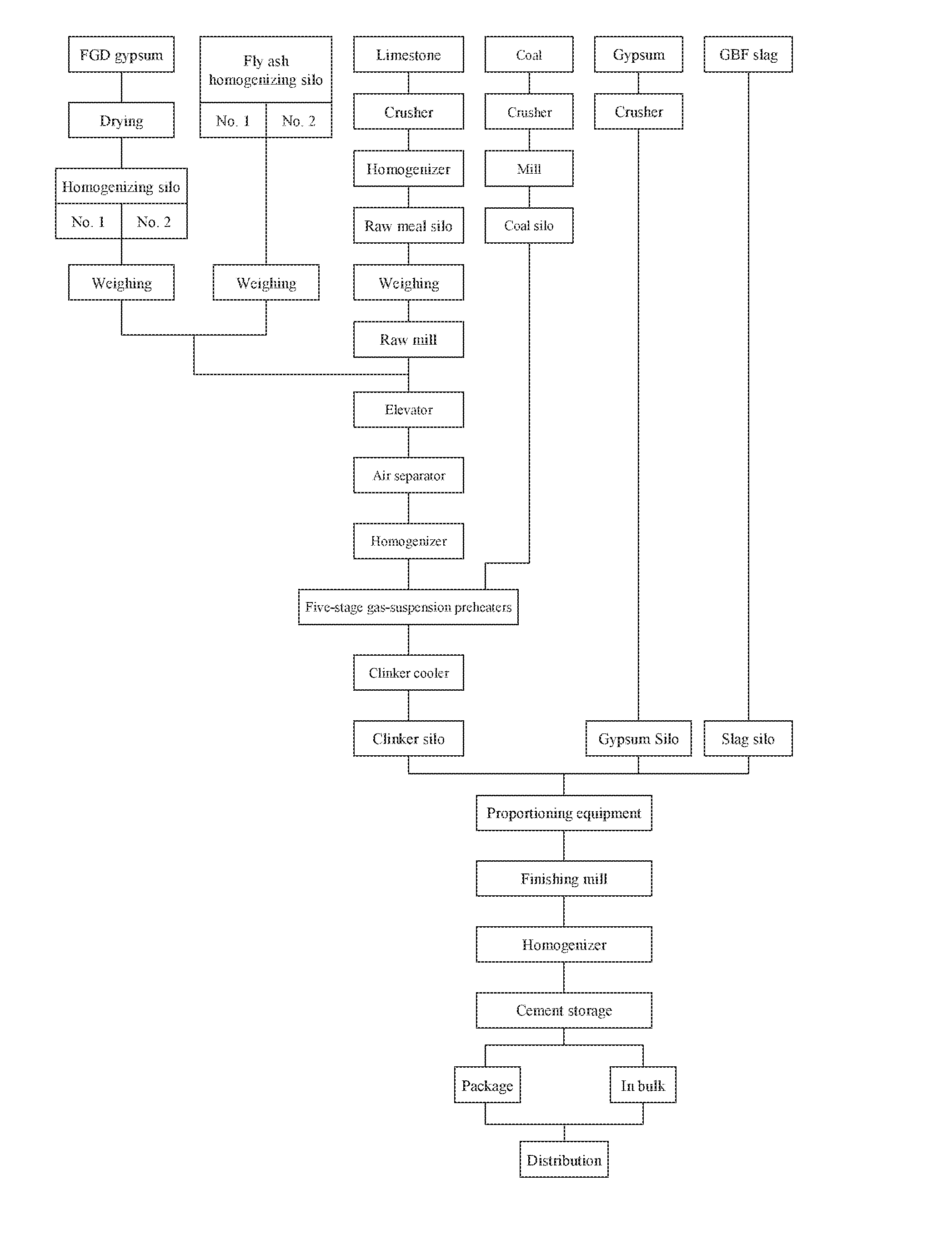

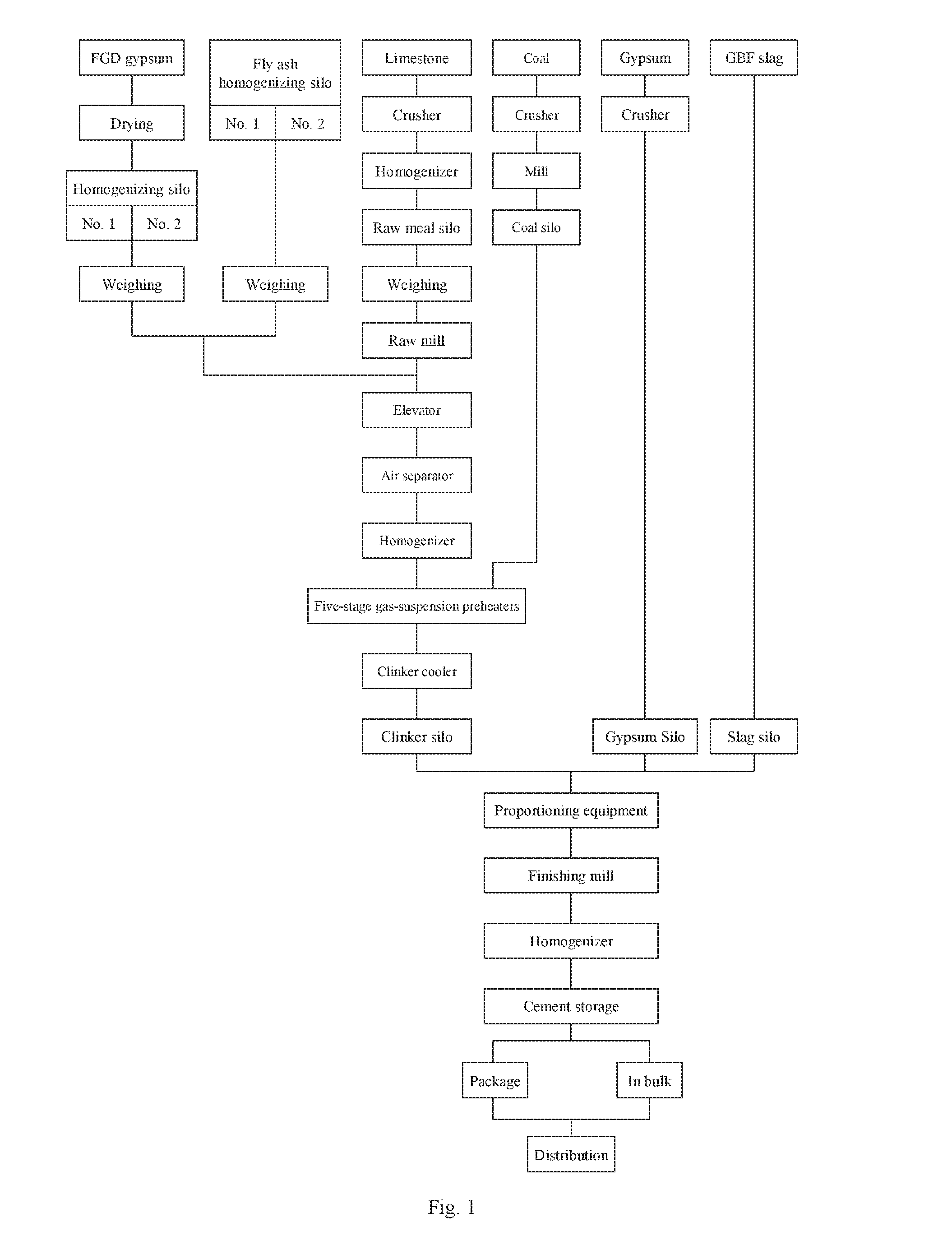

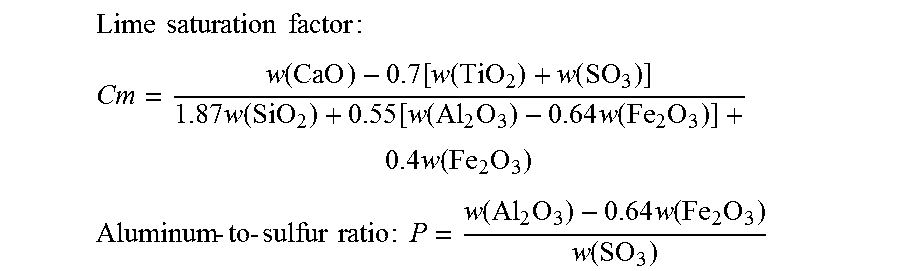

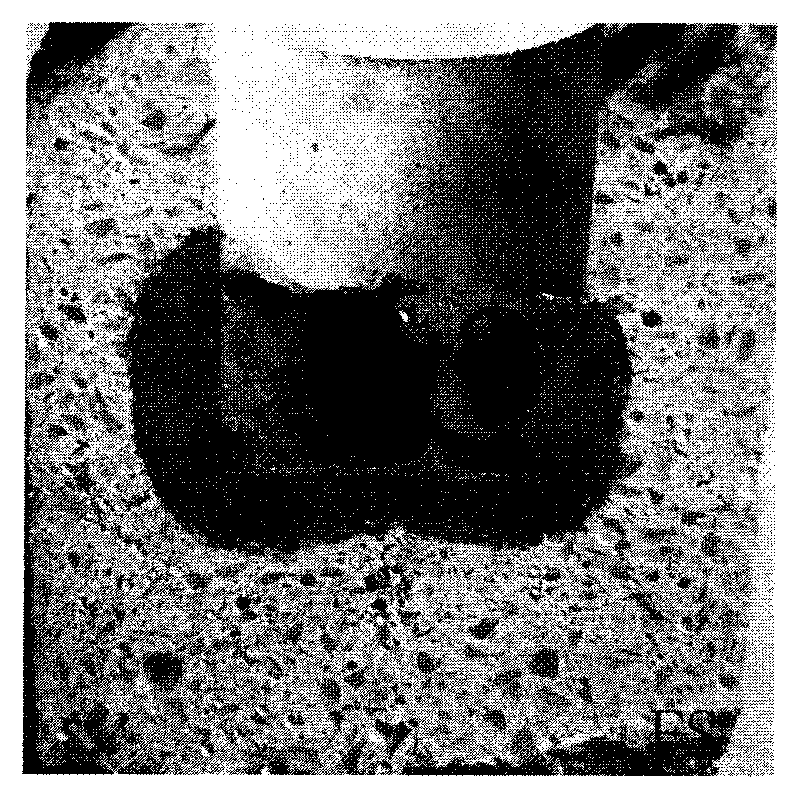

Rapid-setting and hardening, high-belite sulfoaluminate cement clinker as well as application and production process thereof

ActiveUS20170050882A1Increase heightHigh-strength rapid-hardeningSolid waste managementCement productionChemical compositionSlag

The invention discloses a rapid-hardening high-belite calcium sulfoaluminate cement clinker and relates generally to a rapid-hardening high-belite calcium sulfoaluminate cement clinker and methods to use and to manufacture the clinker. The clinker of the present invention comprises 20% to 35% by weight of C4A3S 3% to 9% by weight of C4AF, 37% to 47% by weight of C2S, 0.5% to 4.6% by weight of f-Ca° and 14% to 26.3% by weight of CaSO4. The chemical compositions of the clinker are 12.9% to 16.1% by weight of SiO2, 12% to 19% by weight of Al2O3, 1% to 3% by weight of Fe2O3, 49% to 54% by weight of CaO and 12% to 18.43% by weight of SO3. It is manufactured by calcining, at a temperature of 1300° C.±50° C. in a rotary kiln, the raw meal, comprising 33% to 62% by weight of limestone, 10.5% to 28% by weight of fly ash, and 19% to 45% by weight of FGD gypsum. A group of rapid-hardening high-strength cements of various strength classes can be manufactured by mixing and grinding 26% to 97% by weight of clinker, 3% to 19% by weight of anhydrite and 0% to 55% by weight of granulated blast furnace slag.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Refractory pouring material used for melten iron desulfur agitator

The present invention discloses a refractory pouring material for molten iron desulfurization stirrer. It is formed from pouring material base material and proper quantity of additive. The composition of the base material of pouring material includes (by wt%) 55-65% of general electrofused mullite 3-10% of jiaobaoshi, 3-7% of silicon micropowder, 5-10% of alpha-Al2O3 micropowder, 3-10% of pure calcium aluminate cement and 1.5-2.5% of compact corundum fine powder, and the described additive is formed from heat-resistant steel fibre, aluminium lactate and / or metal aluminium powder and sodium triphosphate and / or trimeric cyanamide.

Owner:武钢集团有限公司

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

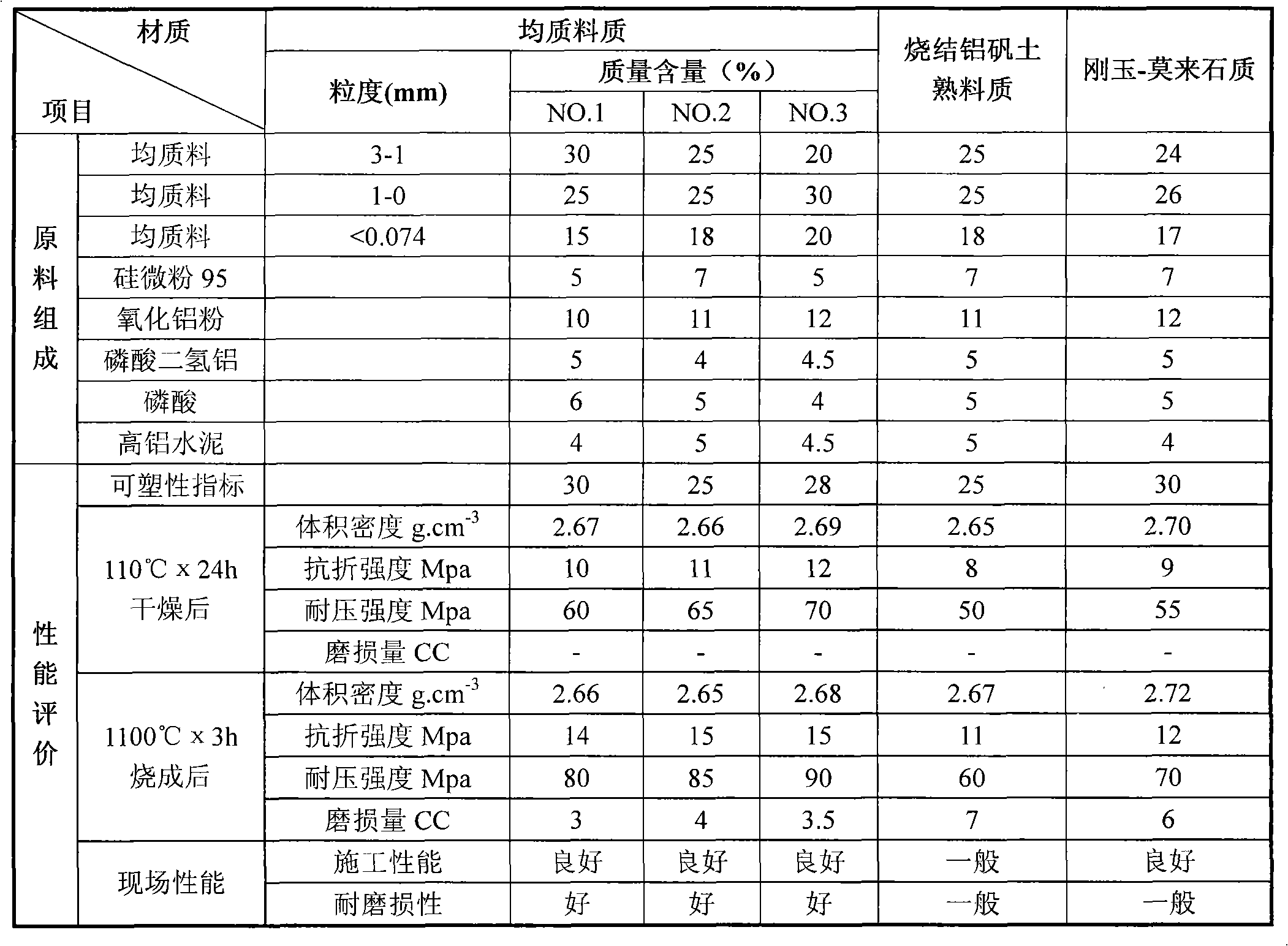

Homogeneous material-containing corundum-mullite high-strength abrasion-resisting plastic

The invention discloses a homogeneous material-containing corundum-mullite high-strength abrasion-resisting plastic, belonging to the field of high-temperature abrasion-resisting fireproofing material, comprising high-aluminum homogeneous material, alumina fine powder, silica fine powder, clay, phosphoric acid, aluminum dihydrogen phosphate solution, pure calcium aluminate cement and the like as raw materials, wherein the homogeneous material is as follows: the content of Al2O3 is 70-90% and the volume density is 2.9-3.5g.cm<-3>. Synthetic homogeneous material with low water-absorption, low porosity and high homogeneity is used for substituting the traditional natural raw material of sintered alumina clinker with high-absorption, high porosity and low homogeneity or composite raw material system of corundum and mullite to produce homogeneous corundum-mullite high-strength abrasion-resisting plastic. Distinguished from the castable, the plastic can be directly utilized in the construction method of smearing and ramming without supporting a module. The material of the invention is good in workability, high in strength, good in abrasive resistance and optimal in on-site usage effect, which is in favour of prolonging service life of furnace lining and improving utilization efficiency of the high-temperature furnace.

Owner:TONGDA REFRACTORY TECH CO LTD

Light-weight Al2O3-SiC-C refractory casting material and preparation method thereof

The invention relates to a light-weight Al2O3-SiC-C refractory casting material and a preparation method thereof. The light-weight Al2O3-SiC-C refractory casting material comprises the following raw materials: 40-55 wt% of porous corundum particle, 8-12 wt% of corundum particle, 6-12 wt% of SiC particle, 6-10 wt% of SiC fine powder, 5-8 wt% of corundum fine powder, 8-12 wt% of active aluminum oxide micropowder, 3-5 wt% of calcium aluminate cement, 2-4 wt% of silicon oxide micropowder, 2-4 wt% of ball asphalt, 1.5-2.0 wt% of silicon powder, 0.1-0.3 wt% of aluminum powder and 0.1-0.3 wt% of boron carbide powder. The preparation method comprises the following steps: mixing the raw materials with 8-15 wt% of water, 0.2-0.6 wt% of water reducing agent and 0.02-0.04 wt% of organic explosion-proof fiber, stirring, casting, molding, and naturally drying at 110 DEG C for 12-48 hours to obtain the light-weight Al2O3-SiC-C refractory casting material. According to the invention, the process is simple; and the prepared product has the characteristics of high strength, excellent thermal shock stability, low heat conductivity and high medium erosion resistance, and also has the advantage that the apparent porosity and pore size can be controlled.

Owner:WUHAN UNIV OF SCI & TECH

Aluminiferous casting material for blast furnace tapping and preparation method thereof

The invention relates to an aluminiferous casting material for blast furnace tapping and a preparation method thereof, belonging to the technical field of fire-proof material. The main raw materials of the casting material contain industrial corundum powder, Si powder, high-temperature pitch grain powder, alumina concrete or calcium aluminum concrete, Aplha-Al2O3 superfine powder, SiO2 superfine powder and metallic silicon powder. Sodium tripolyphosphate or sodium hexametaphosphate is used as dispersing agent. Explosion-proof organic fiber and aluminum ash are added to acquire the casting material for blast furnace tapping. The casting material can be used, after adding 4% to 6% of water and mixing in the casting material, molding the mixture by pouring into a mould for blast furnace tapping, naturally hardening, drying, de-molding, drying at a temperature of 85 DEG C to 700 DEG C and removing water by performing thermal treatment. The casting material has high blast furnace slag resistant property and usability. By adopting the components Al2O3, Al, SiO2, etc., in the aluminum ash instead of the aluminum material and siliceous material in the casting material for blast furnace tapping, the invention can efficiently lower the cost of the casting material and find a new way to comprehensively use aluminum ash.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Pouring material for steel ladle

InactiveCN101891485AExtended service lifeImprove anti-stick performanceMelt-holding vesselsSlagSilicon dioxide

The invention discloses a pouring material for a steel ladle. The pouring material consists of the following components in part by weight: 40 to 75 parts of alumina-magnesia spinel (between 25 and 0.074 mm), 10 to 20 parts of alumina fine powder, 3 to 7 parts of magnesia powder of which the magnesia content is over 95 percent, 1 to 5 parts of pure calcium aluminate cement, 0.5 to 1.5 parts of silicon dioxide fine powder, 0.05 to 0.5 part of water reducing agent, 1 to 35 parts of corundum (between 25 and 0.074 mm) and 0.5 to 5 parts of hydrated alumina powder. The pouring material for the steel ladle has the advantages of extremely high molten steel corrosion resistance, slag corrosion resistance, slag penetration resistance, no pollution to molten steel when taken as a refractory material for the liner of a molten steel accommodating container for smelting pure steel, slag bonding resistance and very long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

Refractory castable for molten iron pretreatment spray gun

The invention discloses refractory castable for a molten iron pretreatment spray gun, which is mixed by castable base stock and a proper amount of additive. The castable base stock is composed of 30-40% of sintering zirconium mullite, 10-20% of flint clay, 20-30% of andalusite, 5-10% of compact corundum fine powder, 2-5% of alpha-Al2O3 micro powder, 5-8% of rho-Al2O3 micro powder, 3-7% of silicon micro powder, 1-4% of carborundum powder and 1.5-3% of pure calcium aluminate cement by weight percent. The additive takes the total weight M of the castable base stock as a metering reference and is composed of 1-5% of heat resistant steel fiber, 0-0.1% of polypropylene fibre, 0-0.5% of aluminium lactate, 0-0.5% of metallic aluminium powder, 0-0.15% of sodium tripolyphosphate and 0-0.5% of melamine in weight percent. The castable has favorable thermal shock stability performance, high-temperature mechanical strength and corrosion resistance. The spray gun bushing manufactured by the refractory castable can effectively prolong the service life of the spray gun.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

High strength high temperature resistance semi-lightweight high alumina castable and its preparation method

InactiveCN102351547AHigh strengthImprove high temperature resistancePolymer scienceChemical composition

The invention discloses a high strength high temperature resistance semi-lightweight high alumina castable and its preparation method. The castable is prepared by mixing 60 wt% of a grading high alumina hollow ceramsite main material, 40 wt% of an auxiliary material and 0.55 wt% of an additive, wherein the main material is made from the matrix of high alumina hollow ceramsite with the particle size being 5-10mm and high alumina hollow ceramsite with the particle size being 1-5mm; the auxiliary material is composed of an expanding agent, a filler, a hard clay powder, binding clay, a volume density modifying agent and a calcium aluminate cement; and the additive is composed of a water-reducing dispersant and an anti-knock agent. The castable prepared in the invention has advantages of high strength, high temperature resistance and semi-lightweight. Detected after sintering for 3 hours at the temperature of 1350 DEG C, the average value of volume density is 1.77g / cm<3>, the average value of flexural strength is 11.4MPa, and the average value of compressive strength is 85.3MPa. Chemical components contain 35.60% of SiO2 and 48.50% of Al2O3.

Owner:MAANSHAN TAILAI METALLURGICAL FURNACE CHARGE

Lightweight reformed main iron runner pouring material

The invention discloses a lightweight reformed main iron runner pouring material. The pouring material comprises alumina, brown aluminum oxide, SiC, SiO2 micropowder, alpha-Al2O3 micropowder, spherical asphalt, aluminum oxide hollow sphere, explosion-proof fiber, metal silicon powder, andalusite fine ore powder, calcium aluminate cement and sodium tripolyphosphate. In the invention, lightweight reformation is carried out on the traditional heavy refractory material iron runner material by introducing the aluminum oxide hollow sphere into a main iron runner material; and due to the popularization and application of the lightweight reformed main iron runner pouring material, the consumption of the refractory material can be reduced for a user, the heat preservation and energy saving of high-temperature equipment are favorably promoted. By adding the aluminum oxide hollow sphere, the volume density of the product is reduced, the heat conduction coefficient is reduced, and the heat preserving effect on the main iron runner pouring material is achieved.

Owner:佘成其

Aluminum oxide electric furnace cover pouring material and preparation method thereof

InactiveCN101113098AImprove thermal shock resistanceImprove slag erosion resistanceFiberShock resistance

The invention relates to a casting material of alumina eafroof and the preparation material thereof. The technic proposal is as following: 1. white corundum of 50-80wt percent, high alumina- bauxite clinker of 3-30wt percent, zirconium corundum of 5-25wt percent, kyanite fine powder of 3-15wt percent, alumina micro-powder of 3-12wt percent, pure aluminate calcium cement of 0-10wt percent and silicon-aluminum gel of 1-5wt percent are mixed together; 2. water reducing agent of 0.10-0.25wt percent, organic fiber of 0.03-0.08wt percent, and water of 5.0-6.5wt percent are then added to the obtained mixture and are stirred for 5-10 minutes, and the mixture is cast for molding; 3. the mold is naturally cured for 12-24 hours and then demolded; 4. the mold is dried for 24 hours under 110 DEG C. According to the size of furnace cover and application requiremenst, the casting molding is designed for whole casting molding or block pouring molding. The block molds are assembled thereafter. The invention is characterized by no environmental pollution, dense structure, good thermal and shock resistance and erosive resistance, and long service life.

Owner:WUHAN UNIV OF SCI & TECH

Super intensified abrasion-proof pouring material

The invention discloses a hyper-high strong abrasion-proof casting material, which comprises the following parts: corundum, carborundum, pulverized corundum, bauxite powder, silicon oxide powder, pure calcium aluminate cement and additive, wherein the adding quantity of each component is forced to homogenize, which couples metal and non-metal material in the constructing course.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Corundum-spinel casting material for dip pipe of RH refining furnace

The invention discloses a corundum-spinel casting material for a dip pipe of an RH refining furnace, which is composed of a main material and an admixture, wherein the main material comprises the following components in percentage by weight: 35-60% of fused white corundum, 10-25% of fused compact corundum, 1-10% of fused magnesite powder, 1-10% of ultrafine spinel micropowder, 3-10% of active aluminum oxide powder, 3-10% of calcium aluminate cement group and 1-5% of zirconium oxide sol; and the admixture comprises an FDN water-reducing agent and explosion-proof organic fibers. Practice proves that the casting material is high in slag corrosion resistance and fine in thermal shock resistance and can effectively prolong the service life of an inserted pipe.

Owner:武汉钢铁有限公司

Corundum mullite rock wear-resistant refractory castable

InactiveCN101570442AMeet the use requirementsExcellent medium temperature strengthAluminium hydroxideWear resistant

The invention discloses a corundum mullite rock wear-resistant refractory castable which belongs to refractory materials, aiming at providing an unshaped refractory material with high medium temperature strength and good thermal shock resistance and erosion and wear resistance. According to weight percentages, the invention is formed by evenly mixing 89-96% of wet pug, 2-6% of calcium aluminate cement and 2-5% of bonding agent; the bonding agent is prepared by 20-30% of industrial aluminum hydroxide fine powder, 67-79% of phosphoric acid with concentration being 45% and 1-3% of chromium oxide green fine powder; the wet pug is prepared by taking corundum with certain particle grading or mixture of corundum and mullite as aggregate and adding the bonding agent and additive, the additive is prepared by 60-76% of white alundum powder, 15-25% of activated alumina fine powder, 5-15% of silicon fine powder, 3-8% of sodiumtripolypolyphosphate and 1-8% of sodium borate. The invention is mainly used as an ideal refractory castable for circulating fluid bed boiler lining and cement kiln lining.

Owner:贵阳明通炉料有限公司

Aluminum-magnesium series lightweight pouring material and manufacturing method thereof

The invention discloses a making method of aluminium-magnesium systemic light-quality casting material, which comprises the following steps: adopting 40-70% aluminium-magnesium porous ceramic particle and 0-20% aluminium-magnesium particle as aggregate; selecting 15-55% fine aluminium-magnesium powder, 2-15% pure calcium aluminate and 2-8% active alpha-aluminium micropowder as substrate; blending the mass; adding 8-25% water, 0.1-0.8% silica powder and 0-3% dehydragent to stir evenly; casting; vibrating; moulding; drying for 8-48h under 110 deg.c.

Owner:WUHAN UNIV OF SCI & TECH

Pouring material for manufacturing pellet ore rotary kiln and manufacturing method thereof

The invention relates to a casting material used for producing pellet rotary kiln and a preparation method thereof, the casting material is a combination, and contained components and weight percentage occupied in the combination contain: 70 to 92 percent of casting material basal body, 3 to 8 percent of micro powder of monox or micro powder of alumina, 0.001 to 5 percent of zirconium mullite or zirconite, 1 to 12 percent of carborundum, 0.005 to 5 percent calcium aluminate cement and 0.01 to 1 percent of dispersant; the casting material basal body is the combination of one or several of corundum, bauxite and porzite. The preparation method of the casting material has the following steps: first uniformly mixing the casting material basal body, then adding other components to be uniformly mixed, and finishing goods. The casting material contains the carborundum, the carborundum has the characteristic of difficult infiltration with furnace burden containing iron, and ring formation materials are difficult to be felted on a furnace brick lining; in addition, the carborundum can increase acidic furnace burden anti-corrosion performance of the casting material, and thus the life of the rotary kiln is enhanced. The preparation method of the casting material is simple and has low cost.

Owner:武钢集团有限公司

Corundum spinel castable with micro-nano pore structure and preparation method of corundum spinel castable

The invention relates to a corundum spinel castable with a micro-nano pore structure and a preparation method of the corundum spinel castable. The technical scheme of the invention is as follows: the preparation method comprises the following steps of: dry-blending 45-82 percent by weight of tabular corundum particles and 1-15 percent by weight of magnesium aluminate spinel particles to obtain mixed aggregate, and dry-blending 1-10 percent by weight of magnesium aluminate spinel fine powder, 4-12 percent by weight of corundum fine powder, 5-15 percent by weight of Alpha-Al2O3 micropowder, 2-8 percent by weight of pure calcium aluminate cement and 0.1-0.5 percent by weight of SiO2 micropowder to obtain mixed powder; then adding a water reducing agent, water and foams which respectively account for 0.2-1.0 percent by weight, 3.5-4.5 percent by weight and 5-15 percent by weight of the aggregate and the powder to the mixed powder, and stirring to prepare mixed slurry; and pouring the mixed aggregate into the mixed slurry, stirring, moulding by casting, curing, demoulding, baking, heating to 1450-1760 DEG C and maintaining the temperature for 2-4 hours. The preparation method disclosed by the invention has the characteristics of simple process and easiness for construction and industrial production; and the prepared corundum spinel castable is high in comprehensive property, good in thermal shock resistance and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com