Comprehensive utilization method of high-ferrum and low-grade bauxite

A technology of low-grade bauxite and high-iron bauxite, which is applied in the field of metallurgy, can solve the problems of effective separation of difficult iron and aluminum minerals, difficulty in industrial realization, and high production cost, so as to reduce production cost, concentration, and The effect of alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

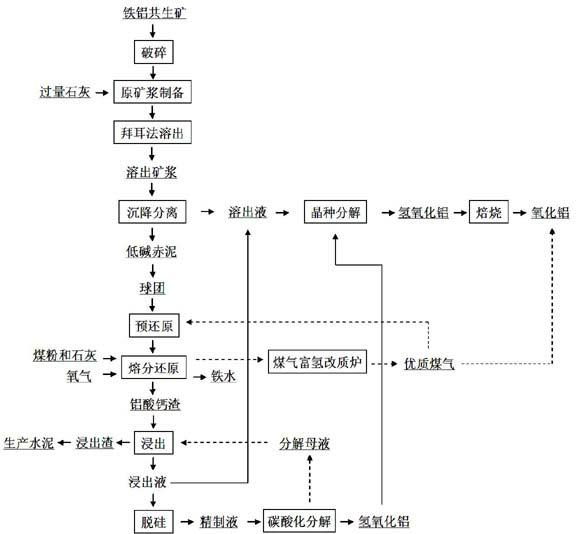

Image

Examples

Embodiment 1

[0025] First the mass percentage is: Al 2 o 3 60%, Fe 2 o 3 15%, SiO 2 20%, the rest is impurity high-iron bauxite crushed to 2~5mm, and then the ore powder is ground to a particle size of -0.074mm, accounting for more than 85%. Add lime and lye to prepare raw ore pulp, wherein the amount of lime added is 35% of the mass of bauxite, and the lye is circulating sodium aluminate solution with a concentration of Na 2 O 180 g / L, α k =2.7, the solid content of raw ore pulp is 400g / L.

[0026] The raw ore slurry is subjected to Bayer method dissolution, the dissolution temperature is 300°C, and the dissolution time is 30 minutes; the dissolved slurry is subjected to solid-liquid separation, and the obtained solid is red mud. ) 3 , and finally calcined to obtain alumina.

[0027] Wash the red mud obtained after dissolution and add water to the rotating disc pelletizer to make cue balls, add water and feed continuously, make the cue balls grow up and dry to form pellets; put...

Embodiment 2

[0033] First the mass percentage is: Al 2 o 3 40%, Fe 2 o 3 40%, SiO 2 10% of the high-iron bauxite is crushed to 2-5mm, and the rest is impurity, and then the ore powder is ground to a particle size of -0.074mm, accounting for more than 85%. Add lime and lye to prepare raw ore slurry, wherein the amount of lime added is 15% of the mass of bauxite, and the lye is circulating sodium aluminate solution with a concentration of Na 2 O 260 g / L, α k =3.5, the solid content of raw ore pulp is 200g / L.

[0034] The raw ore slurry was stripped by the Bayer method, the stripping temperature was 240°C, and the stripping time was 120 minutes; the stripped slurry was subjected to solid-liquid separation, and the obtained solid was red mud, and the obtained stripping liquid was decomposed by adding aluminum hydroxide seeds to obtain Al(OH ) 3 , and finally calcined to obtain alumina.

[0035] Wash the red mud obtained after dissolution and add water to the rotating disc pelletizer...

Embodiment 3

[0041] First mass percentage is: Al 2 o 3 50%, Fe 2 o 3 27%, SiO 2 15%, the rest is impurity high-iron bauxite crushed to 2-5mm, and then the ore powder is ground to a particle size of -0.074mm, accounting for more than 85%. Add lime and lye to prepare raw ore pulp, wherein the amount of lime added is 25% of the mass of bauxite, and the lye is circulating sodium aluminate solution with a concentration of Na 2 O 220 g / L, α k =3.1, the solid content of raw ore pulp is 300g / L.

[0042] The raw ore slurry is subjected to Bayer method dissolution, the dissolution temperature is 270 ° C, and the dissolution time is 60 minutes; the dissolved slurry is subjected to solid-liquid separation, and the obtained solid is red mud. ) 3 , and finally calcined to obtain alumina.

[0043] Wash the red mud obtained after dissolution and add water to the rotating disc pelletizer to make cue balls, add water and feed continuously, make the cue balls grow up and dry to form pellets; put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com