Patents

Literature

90 results about "Aluminum hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

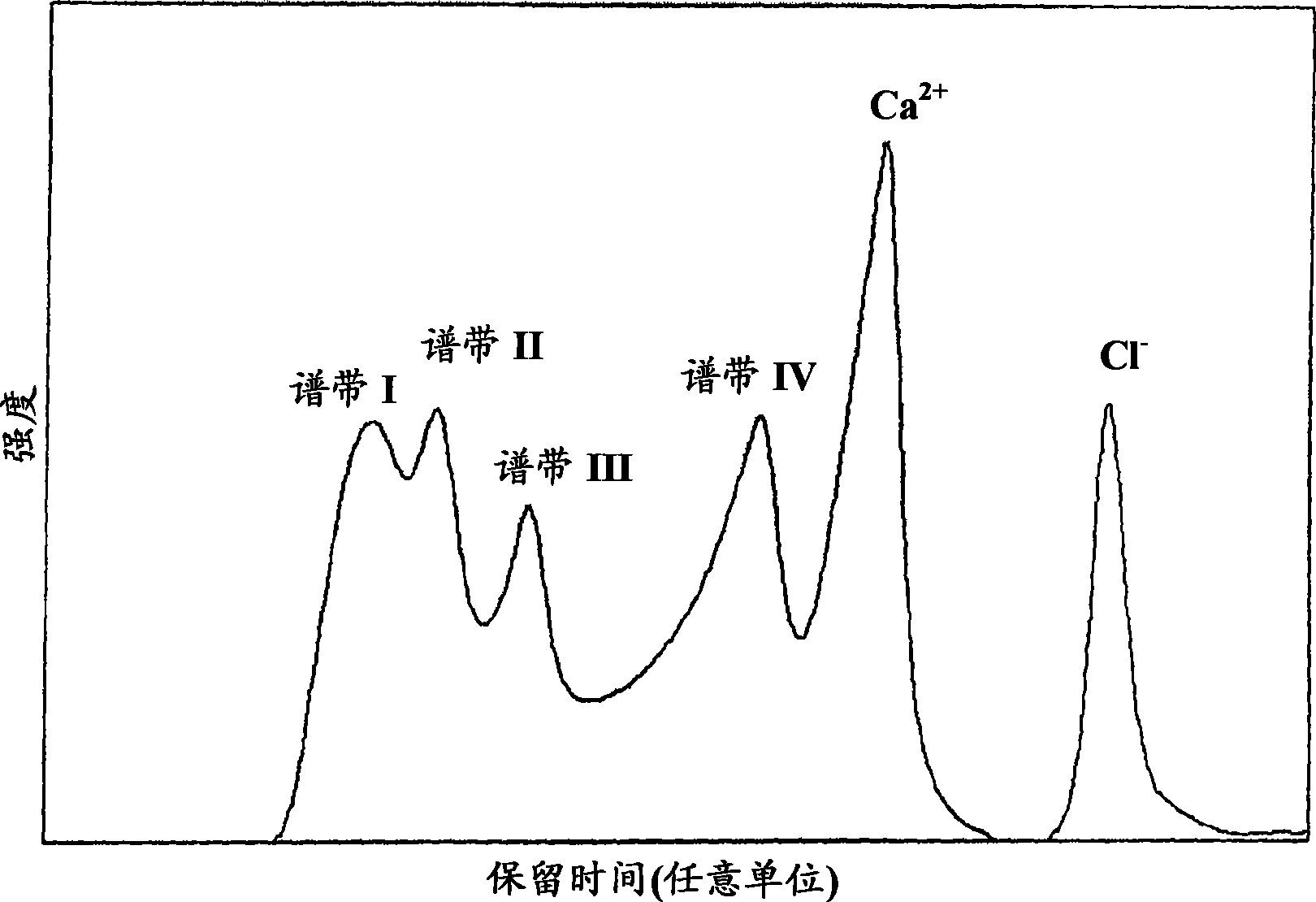

High pH antiperspirant compositions of enhanced efficacy

InactiveUS7087220B2Good curative effectIncrease valueCosmetic preparationsToilet preparationsIrritationStrontium

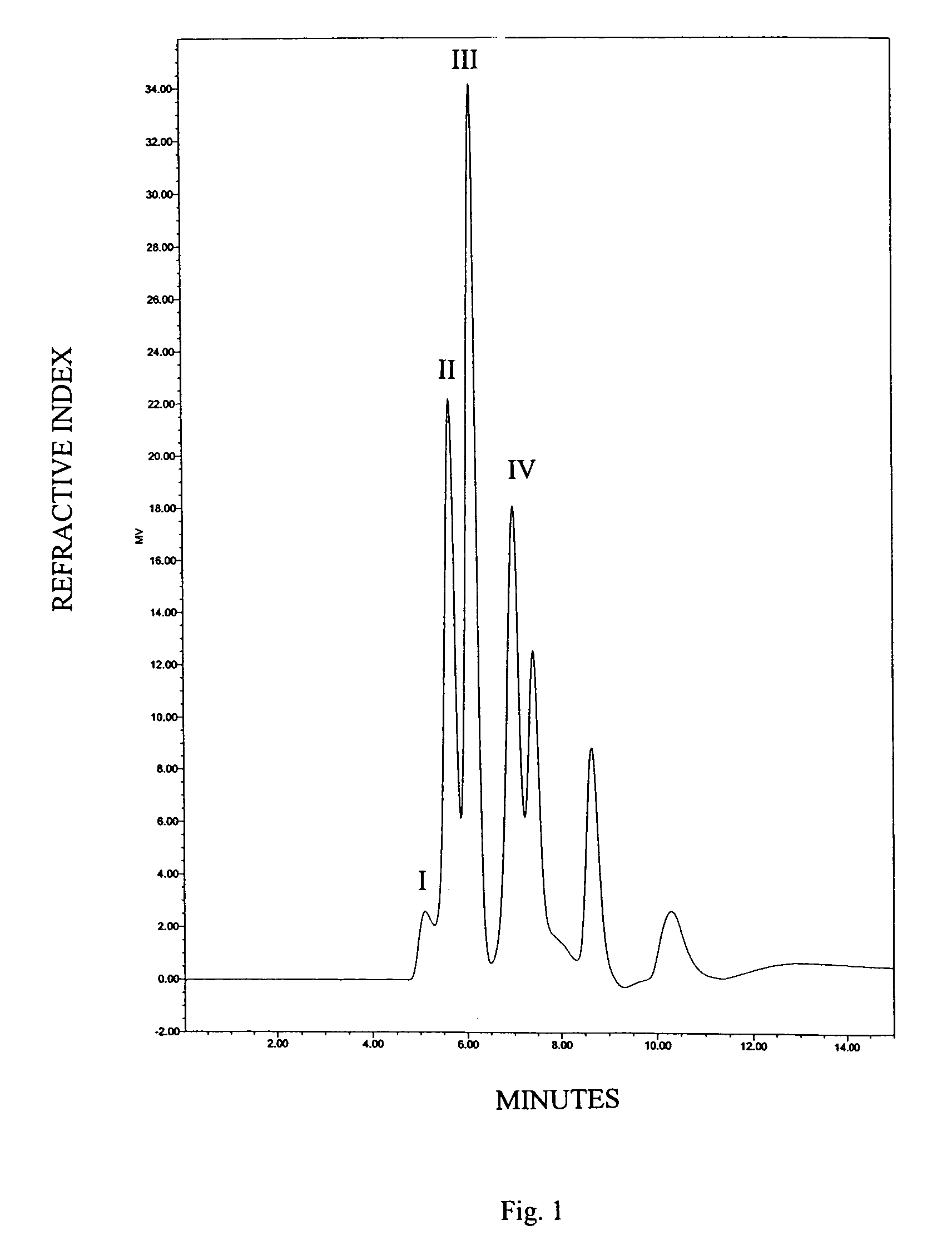

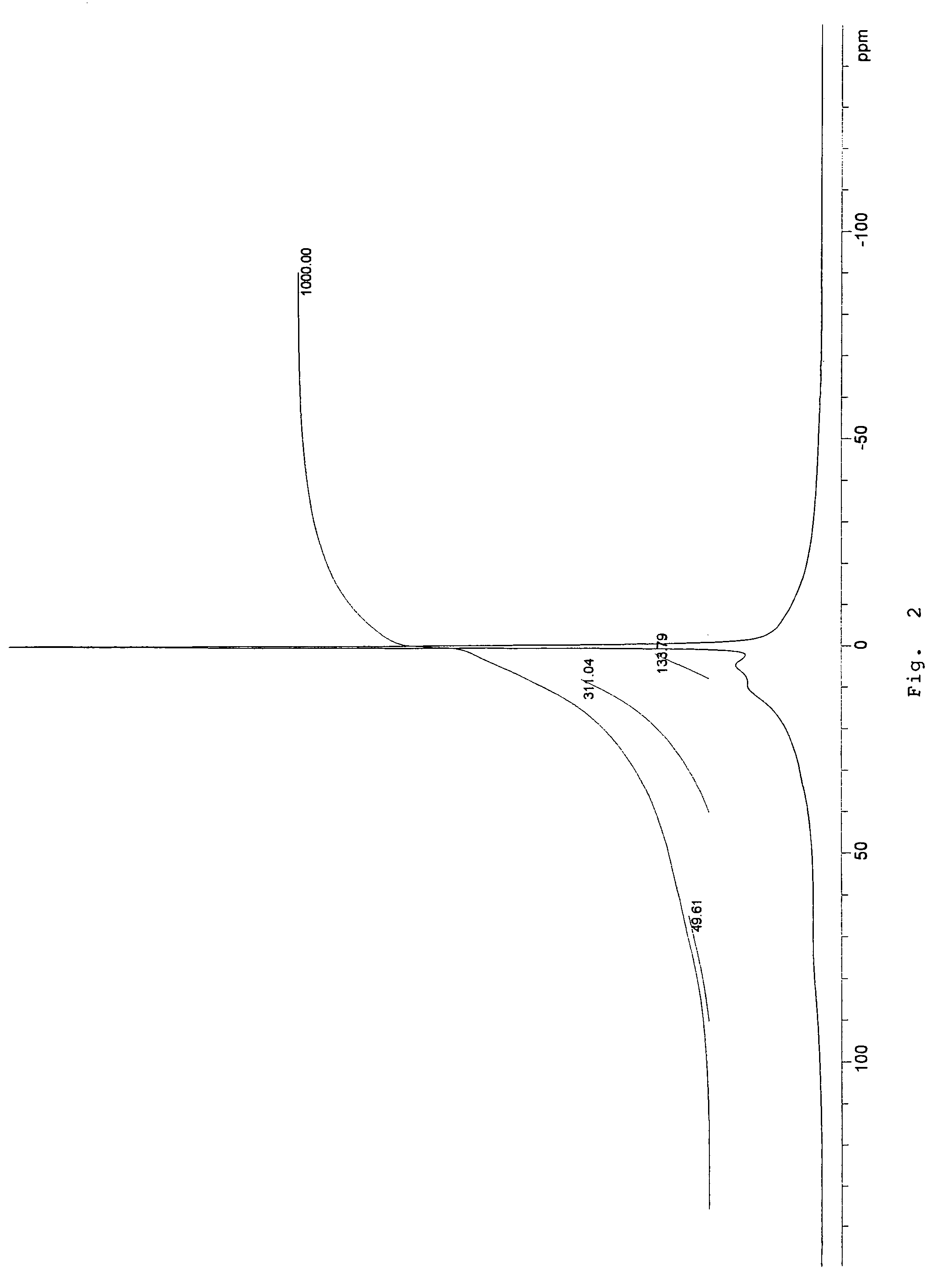

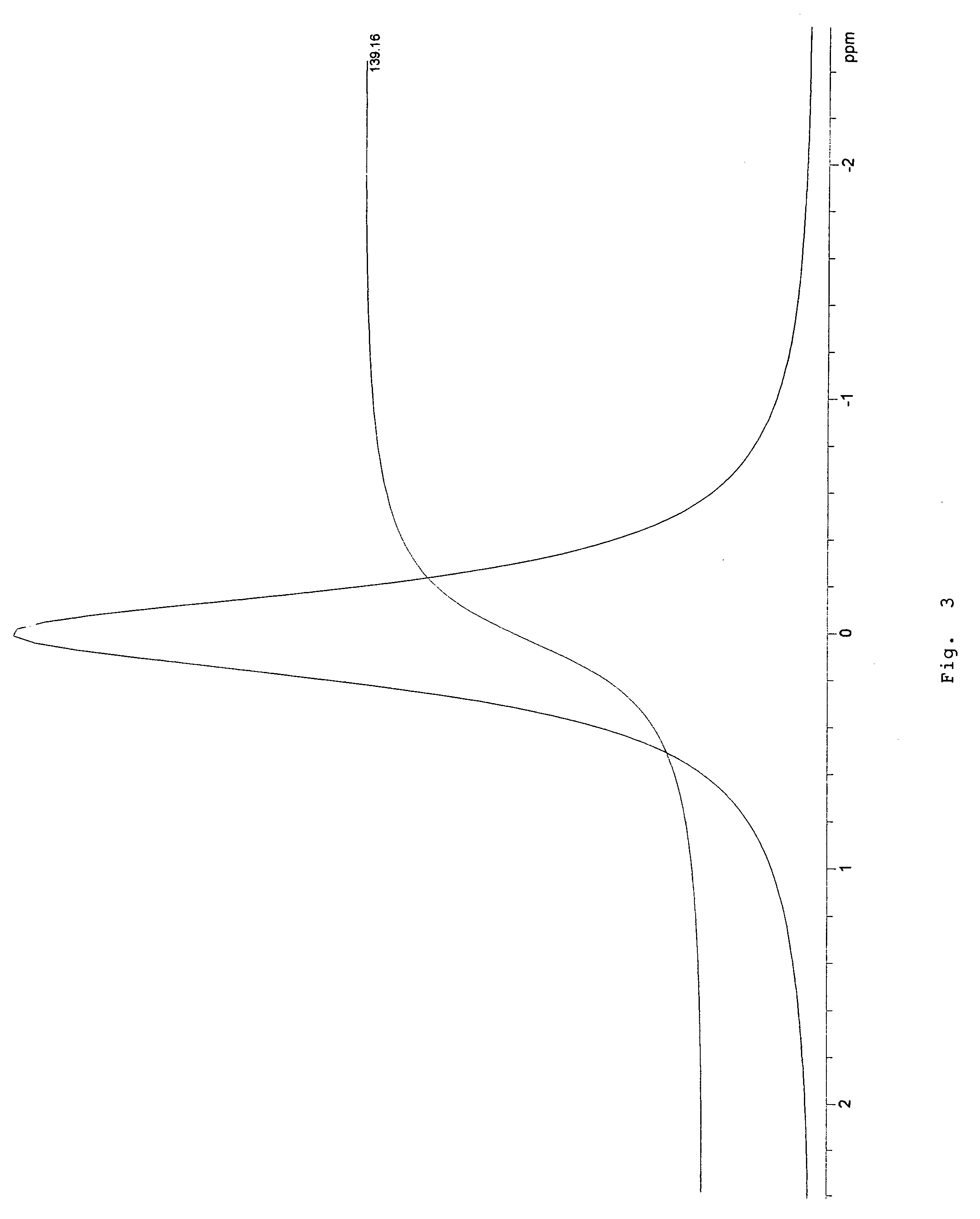

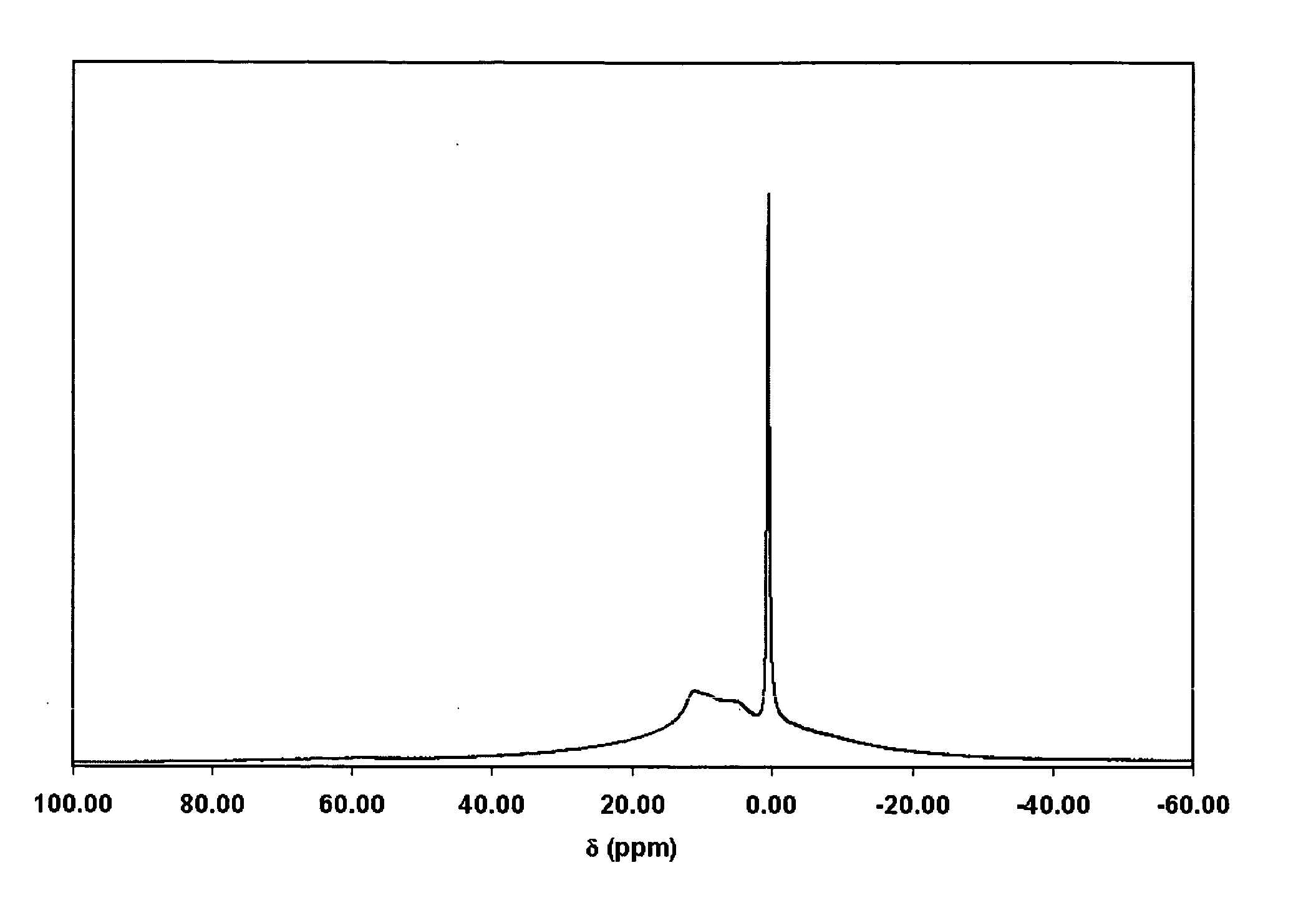

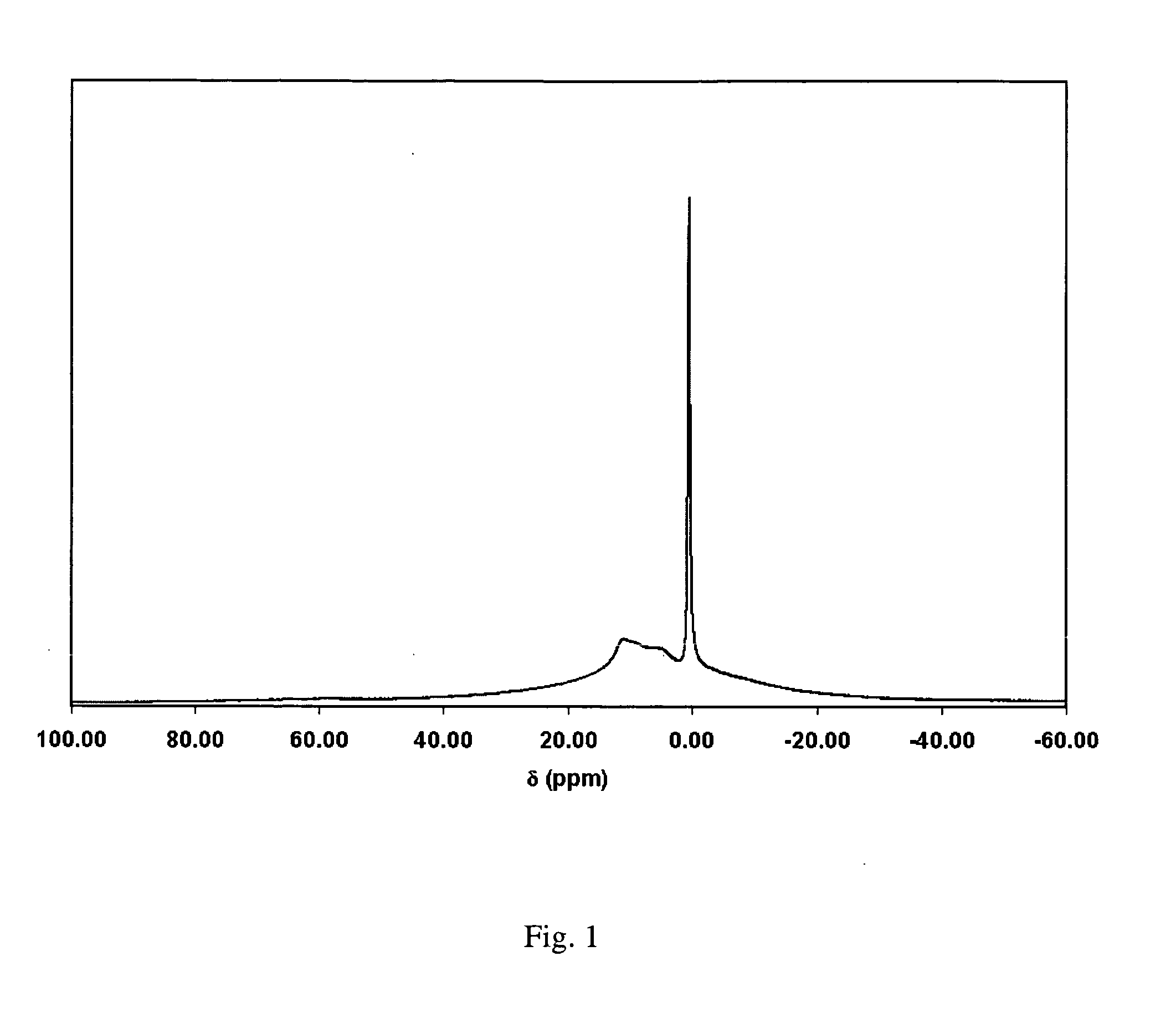

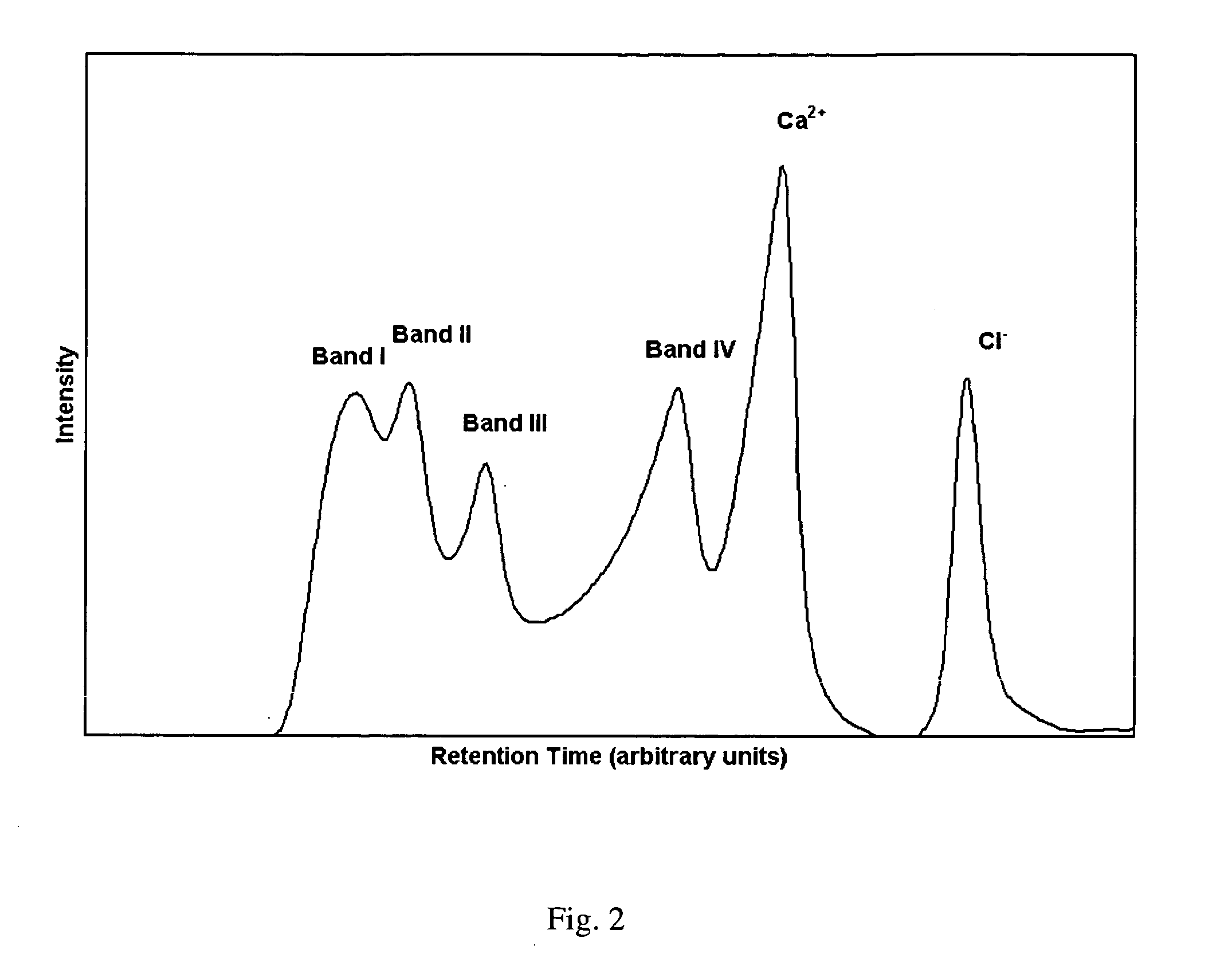

Aluminum and aluminum-zirconium antiperspirant compositions of enhanced efficacy and a pH value of at least 3.5 are provided that are made by reaction with insoluble, strongly alkaline strontium or calcium salts. The aluminum and aluminum-zirconium strontium or calcium compositions show high pH values with characteristic HPLC Band III to Band II ratios of at least 0.5. The basic aluminum halohydrate (or nitrate) solutions typically have aluminum to anion ratio of less that 1.9. The solution compositions are stable with respect to both HPLC Band III to Band II ratio and viscosity at concentrations of about 20% to about 40% by weight of anhydrous solid. The solid state compositions form hard sticks with low irritation, at low metal to chloride ratios of about 0.9 to about 1.2.

Owner:SUMMIT RES LAB

Polyaluminum calcium hydroxychlorides and methods of making the same

InactiveUS20080131354A1Improve efficiencyReduce sludge generationCosmetic preparationsChloride preparationAluminum hydrateHigh pressure

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60° C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM LLC

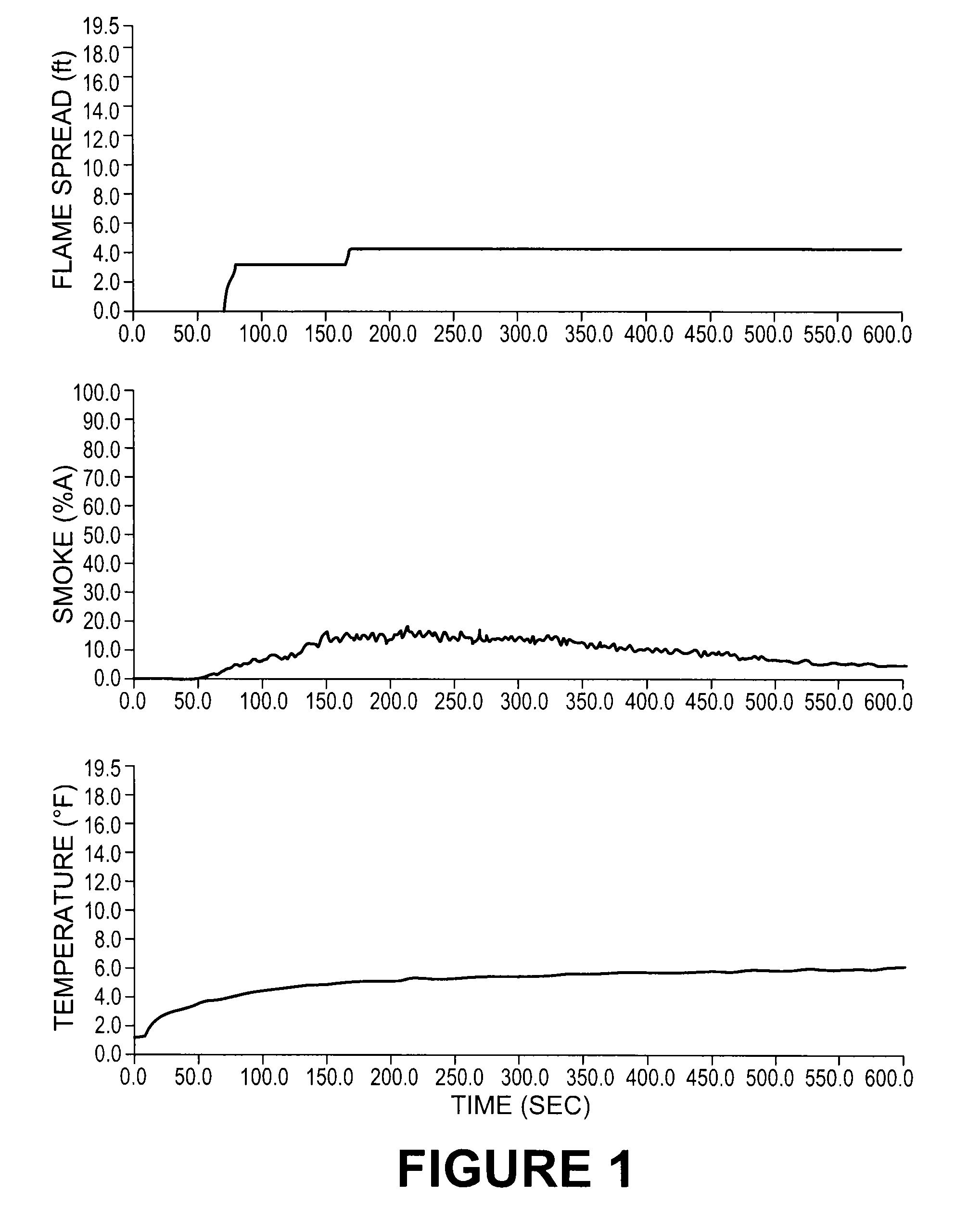

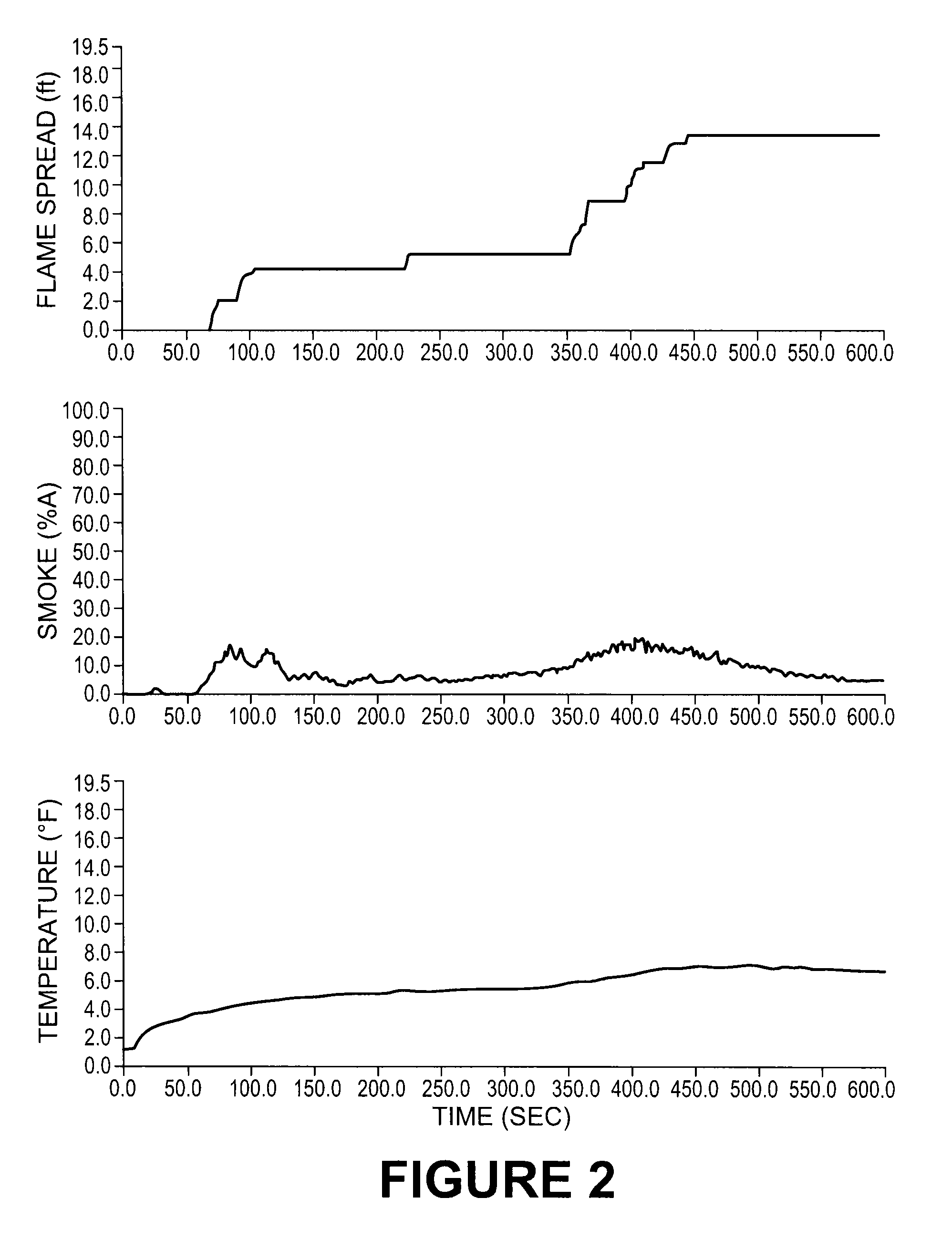

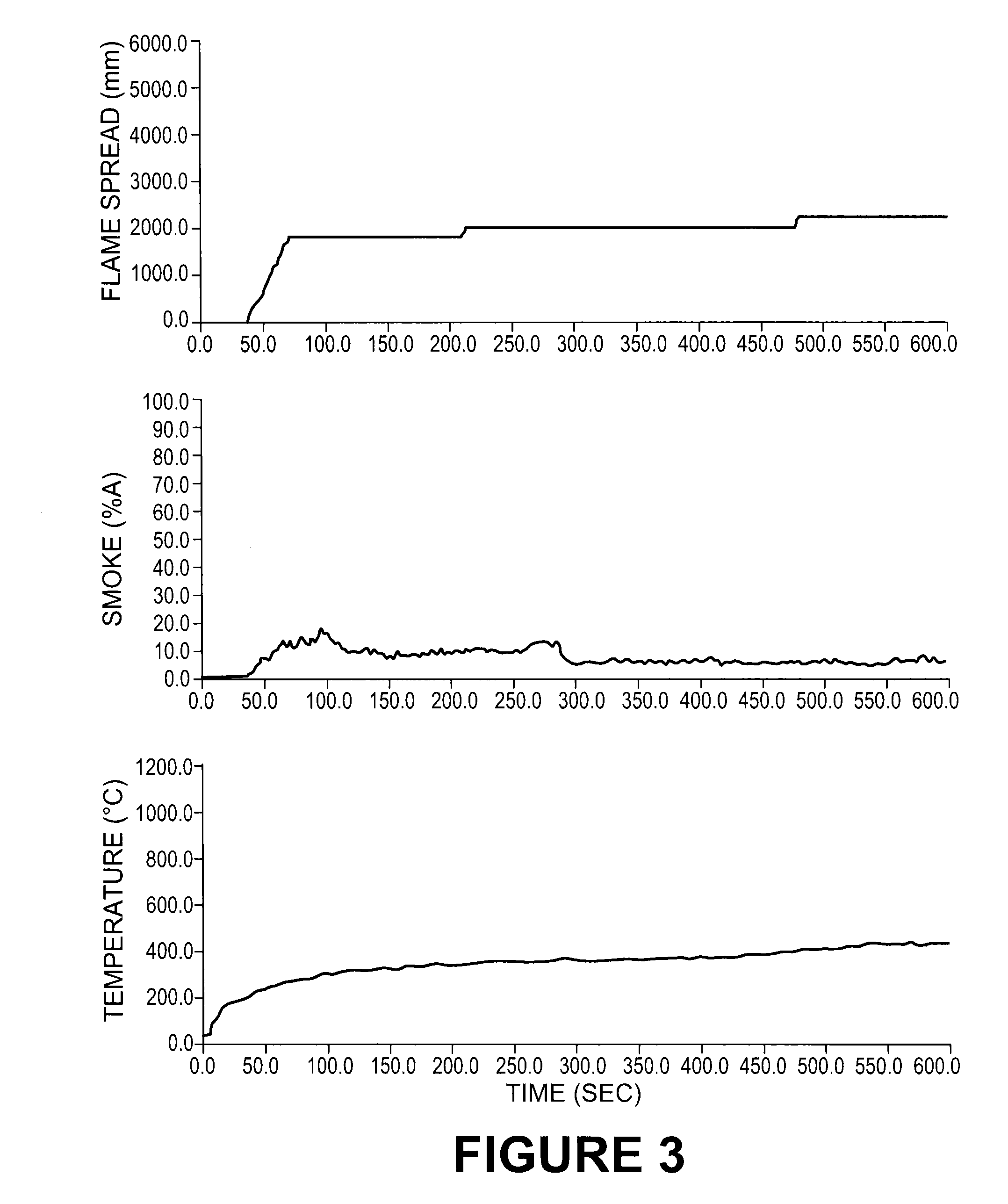

Fire resistant timber coating compositions and methods of manufacture

This application relates to compositions and methods for coating timber and the like to increase the fire resistant properties of the timber. Specifically, the compositions include water, acrylic resin, aluminum trihydrate and ammonium polyphosphate that can be used to effectively coat lumber products and impart fire-resistant properties to the lumber products. In addition, the compositions can include an anti-microbial agent to increase the anti-microbial properties of the coated timber products. The compositions can also include a coloring agent in order that coated lumber products have a recognizable tint indicating to users that the lumber products have been treated with the compositions to increase the fire-resistance and anti-microbial properties of the lumber.

Owner:CANO COATINGS

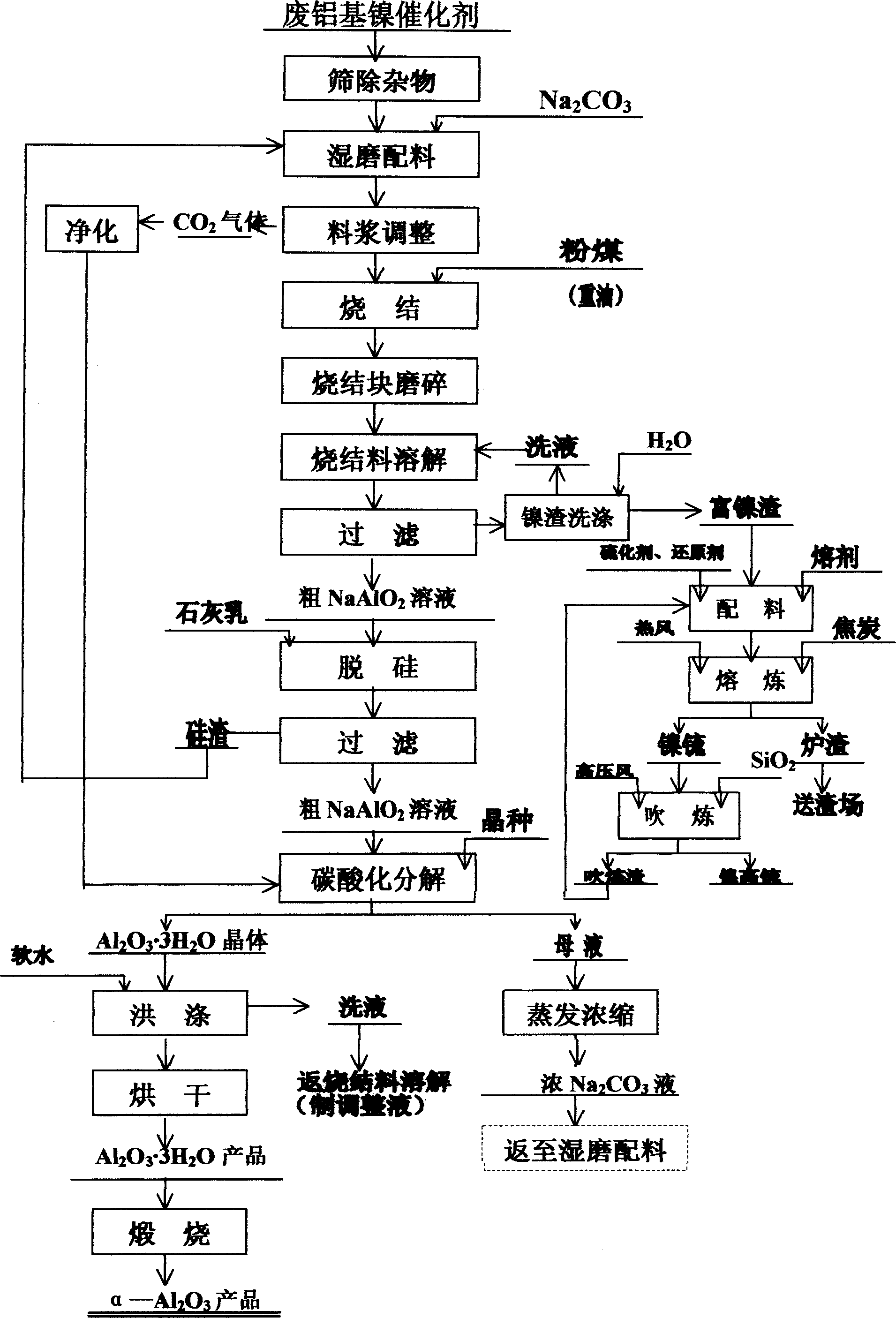

Method for recovering nickel and aluminum from waste aluminum based nickel-containing catalyst

InactiveCN1544666AEfficient separationEfficient recyclingProcess efficiency improvementDecompositionSodium aluminate

The invention is a method of recovering nickelic and aluminum from waste aluminum-based nickel catalyst, it has the characters of novel technique, reasonable flow, simple and convenient method and easy operation, and convenient scaled production, and benefits environmental protection. It includes the steps: sodium carbonate sintering and state-changing--boiling water dissolving sodium aluminate and separating aluminum--- making reducing-matte-making melting on nickel residues to obtain nickel matte Ni3S2-FeS-Ni-Fe alloy or copper-nickel matte Cu2S-Ni3S2-FeS alloy---blowing to obtain high-grade nickel matte Ni3S2 or high-grade copper-nickel matte Cu2S-Ni3S2-Cu-Ni alloy---desiliconizing crude NaAlO2 solution---making carbonated decomposition to obtain aluminum hydrate Al2O3íñ3H2O---calcining to obtain anhydrous aluminum oxide alpha-Al2O3. It is suitable to recover nickel and aluminum from the waste residue generated by extracting molybdenum and vanadium from waste aluminum-based nickelic catalysts and disabled catalysts containing nickel, aluminum, molybdenum and vanadium.

Owner:SHENYANG JIAHE METALLURGICAL FURNACE CHARGE

Water super-thin steel structure fire-proof paint and preparation method thereof

An aqueous fire proofing coating with ultra-thin steel structure and its production are disclosed. The fire proofing coating consists of acrylic acid emulsion, amine poly-phosphate, tetramethylolmethane, melamine, expanding graphite, aluminum hydrate, antifoaming agent, leveling agent, dispersant, plasticizer, coupling agent, thickening agent. The process is carried out by adding amine poly-phosphate, tetramethylolmethane, melamine, aluminum hydrate and partial accessories into ball grinder, agitating, grinding, adding expanding graphite and residual accessories into ball grinder, agitating and filtering to obtain final product. It's cheap, simple and convenient, has better flame retardant performance, short drying time and no environmental pollution.

Owner:HUNAN UNIV

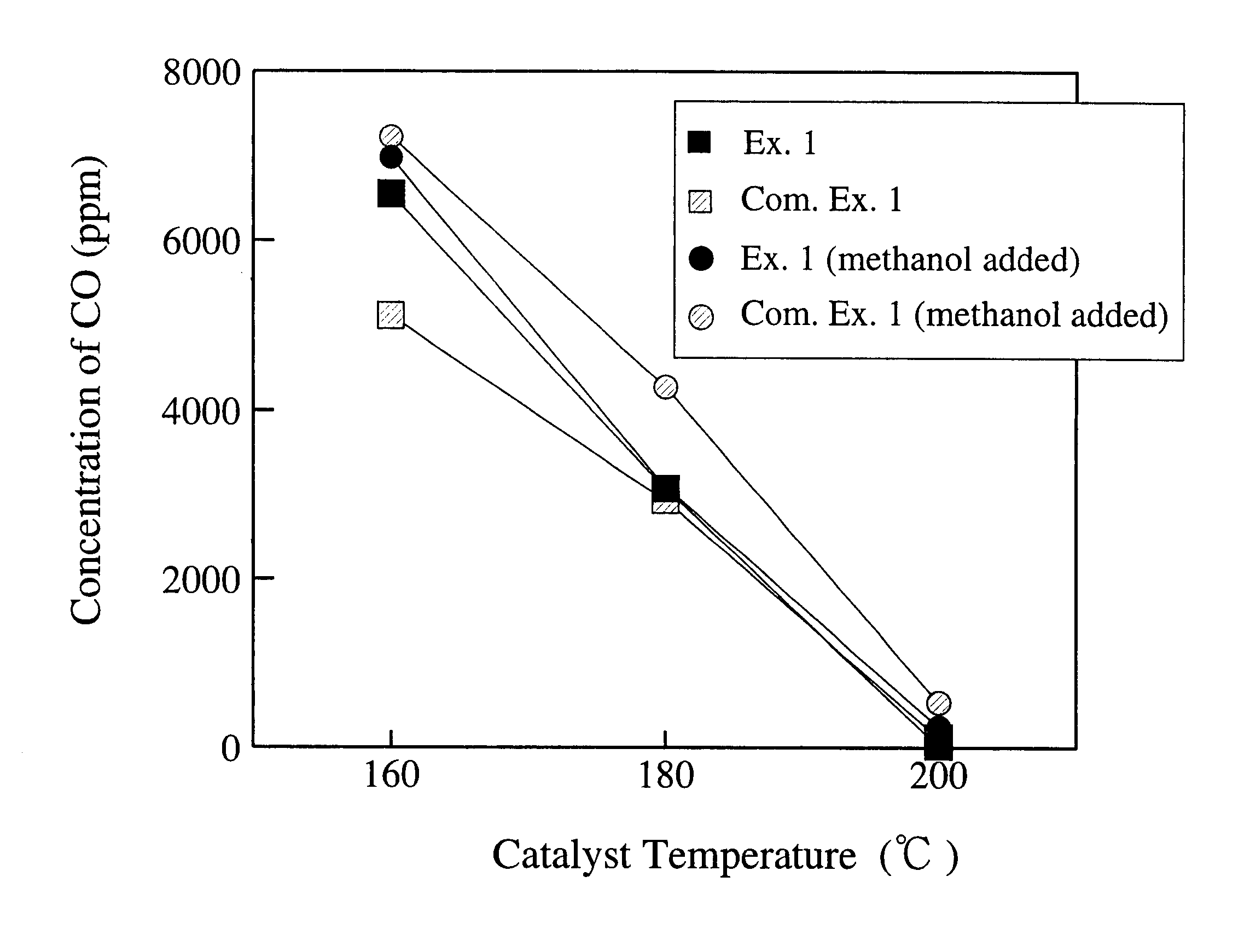

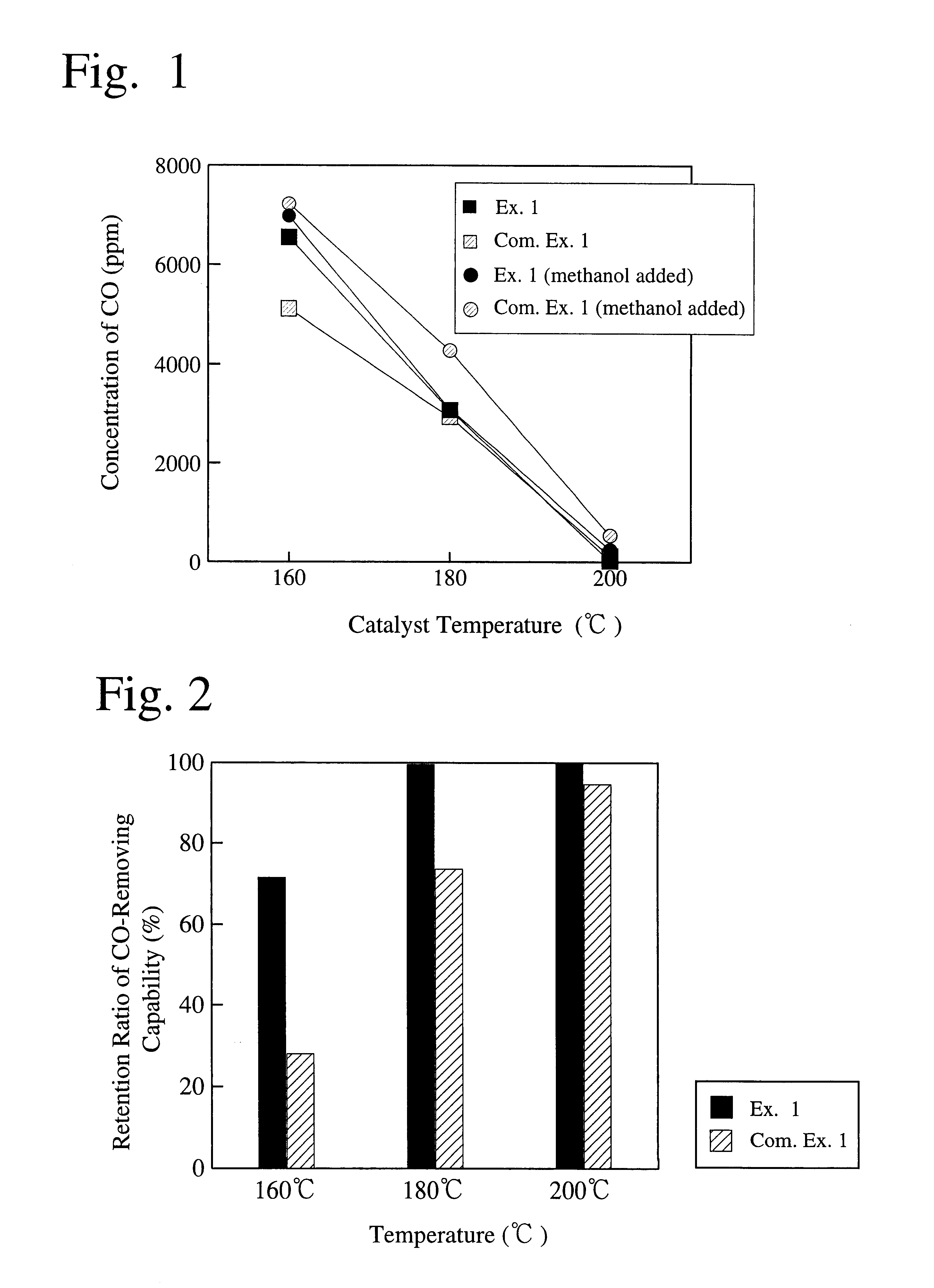

Catalyst and method for selectively oxidizing carbon monoxide in hydrogen-containing gas and solid polymer electrolyte-type fuel cell system using such catalyst

InactiveUS6562499B1High removal rateLarge volume of catalystHydrogen separation using solid contactFinal product manufactureAlumina hydrateAluminum hydrate

A catalyst for selectively oxidizing carbon monoxide in a hydrogen-containing gas comprises an alumina hydrate carrier and at least platinum supported thereon. With an aluminum hydrate as a carrier, the catalyst is resistant to deactivation which would be caused by an oxygen-containing hydrocarbon in a hydrogen-rich gas. The method for selectively removing carbon monoxide comprises the steps of adding oxygen to a hydrogen-rich gas containing carbon monoxide, in an amount necessary to oxidize at least part of carbon monoxide, and bringing the resulting mixture into contact with the catalyst for selectively oxidizing carbon monoxide. The solid polymer electrolyte-type fuel cell system utilizes the above method for selectively removing carbon monoxide.

Owner:HONDA MOTOR CO LTD

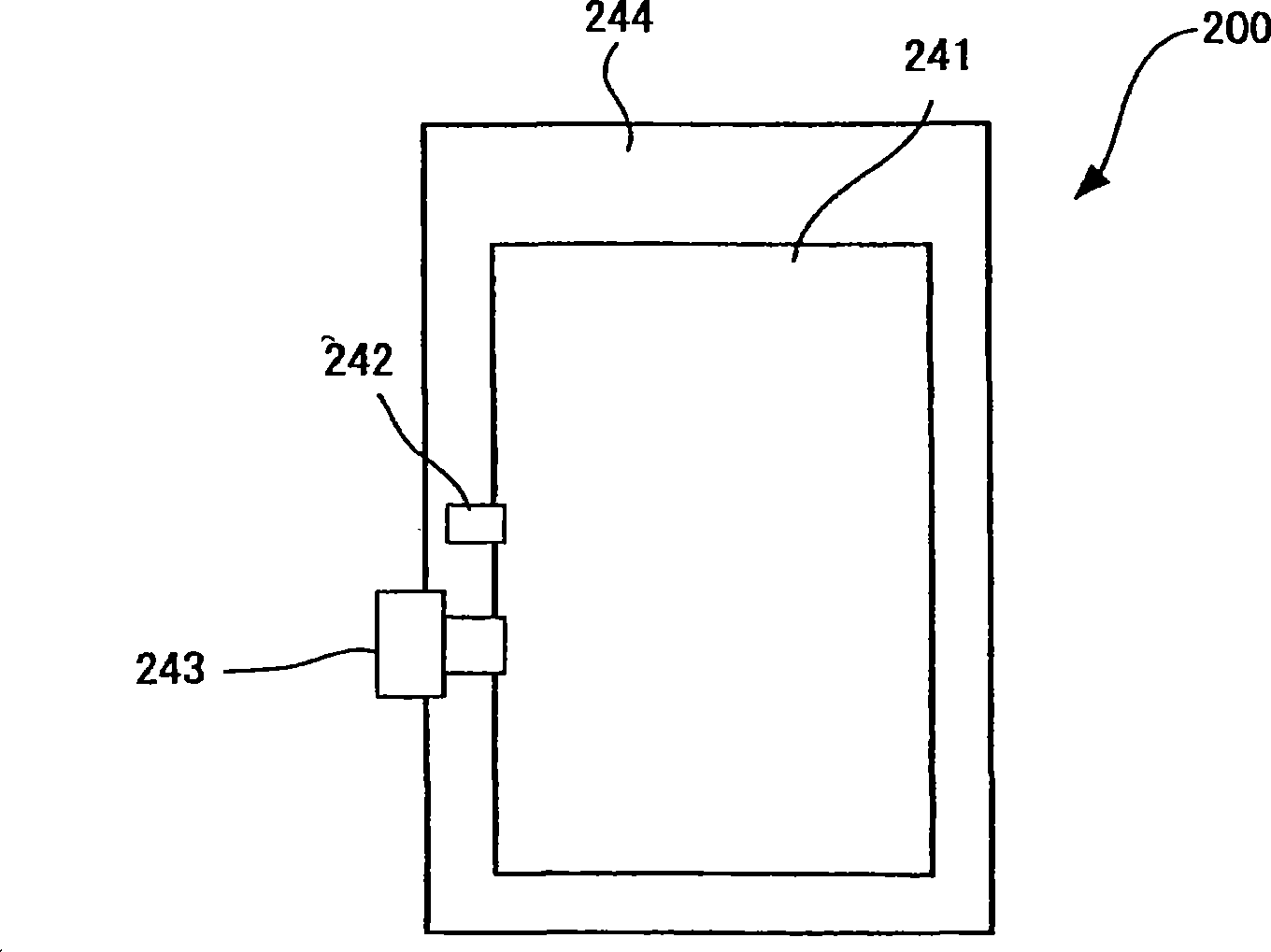

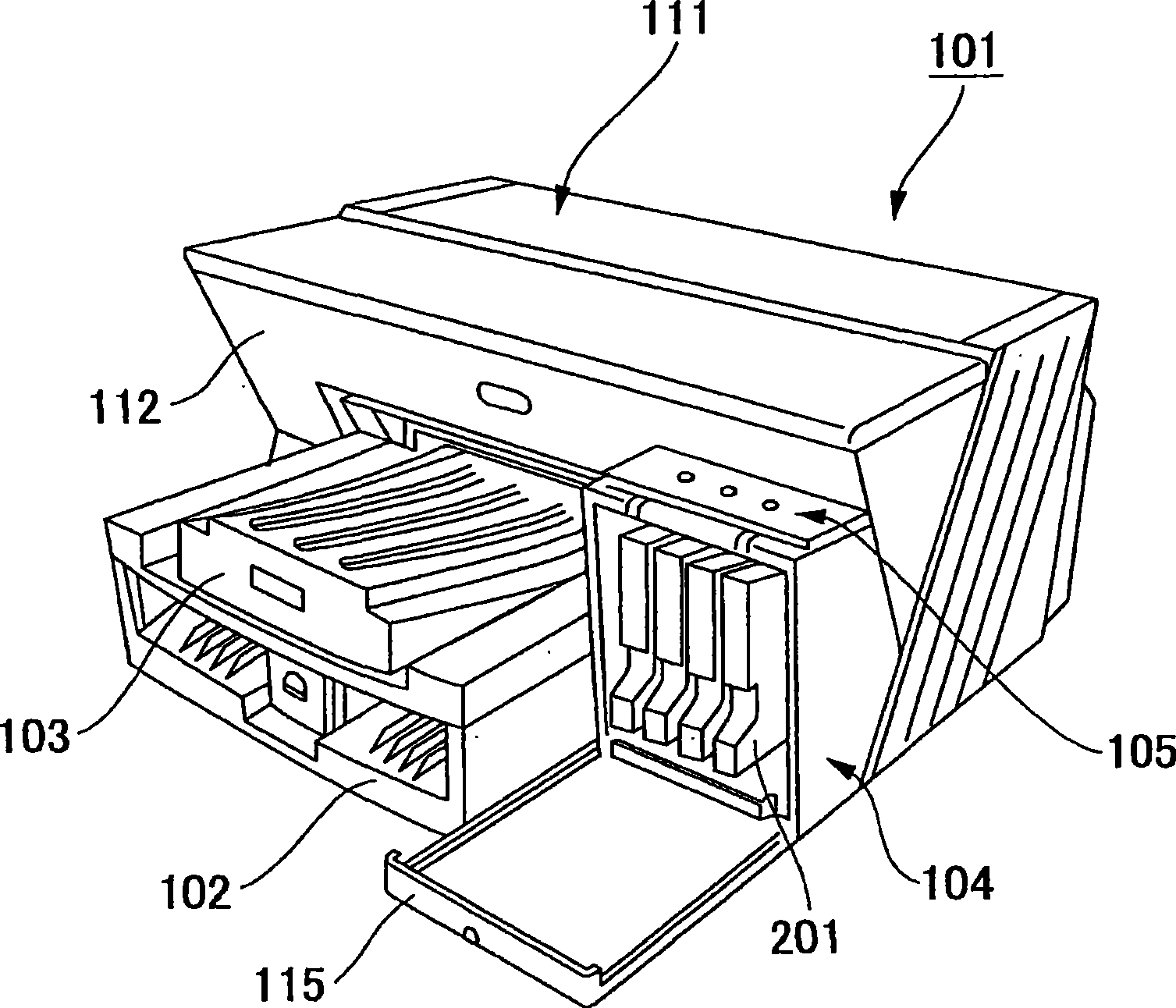

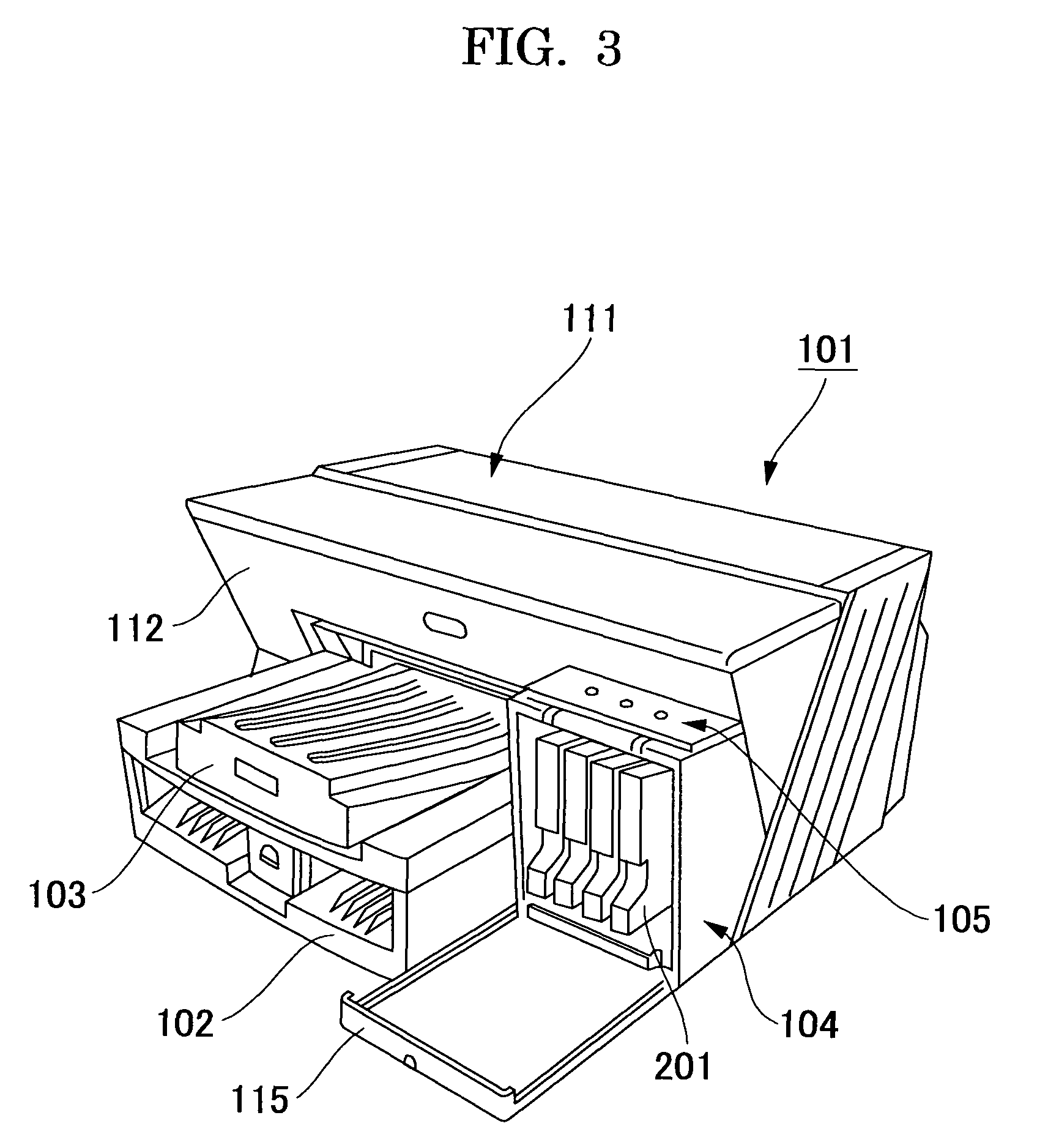

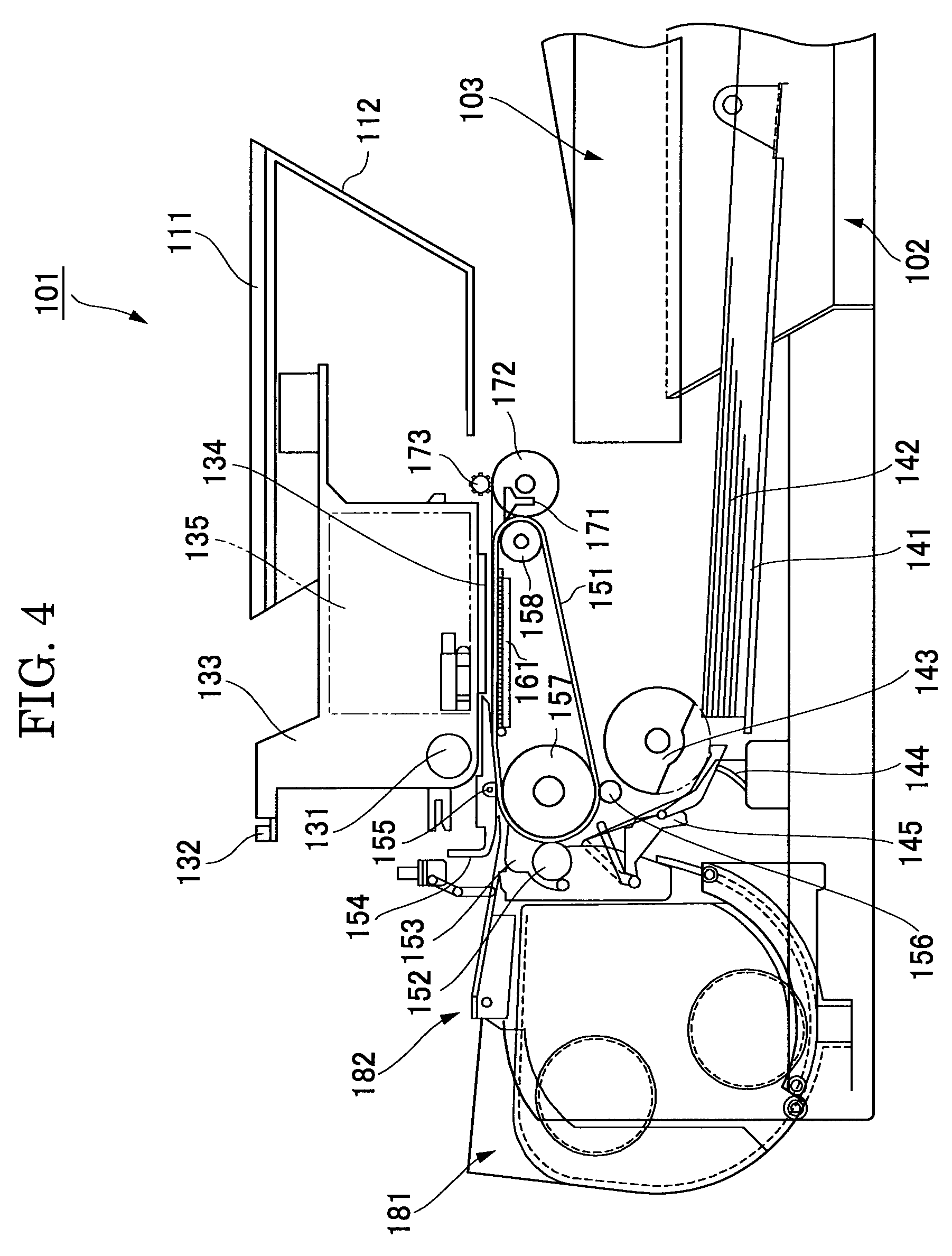

Ink for inkjet recording, ink set for inkjet recording, ink media set for inkjet recording, ink cartridge, inkjet recording method, and inkjet recording apparatus

InactiveCN101365761AImprove printing qualityHigh glossDuplicating/marking methodsInksWater dispersibleOrganic solvent

To provide an ink for inkjet recording containing water, water-soluble organic solvent, water-dispersible resin, fluorochemical surfactant or derivative thereof, and coloring agent containing pigment, wherein the ink has a surface tension of 20-35 mN / n and viscosity of 5 mPas or more at 25 DEG C, total amount of the water-dispersible resin and the coloring agent in the ink is 5-40% by mass, and mass ratio A / B of the water-dispersible resin A to the coloring agent B is 0.5-4, wherein the ink is applied for a recording medium for inkjet recording containing a support containing cellulose pulp, and one or more barrier layers disposed on at least one face of the support, and wherein the barrier layer contains 30% by mass or more of inorganic pigment having refractive index of 1.5 or more, excluding aluminum hydrate, and 10% by mass or more of inorganic pigment having a refractive index of less than 1.5.

Owner:RICOH KK

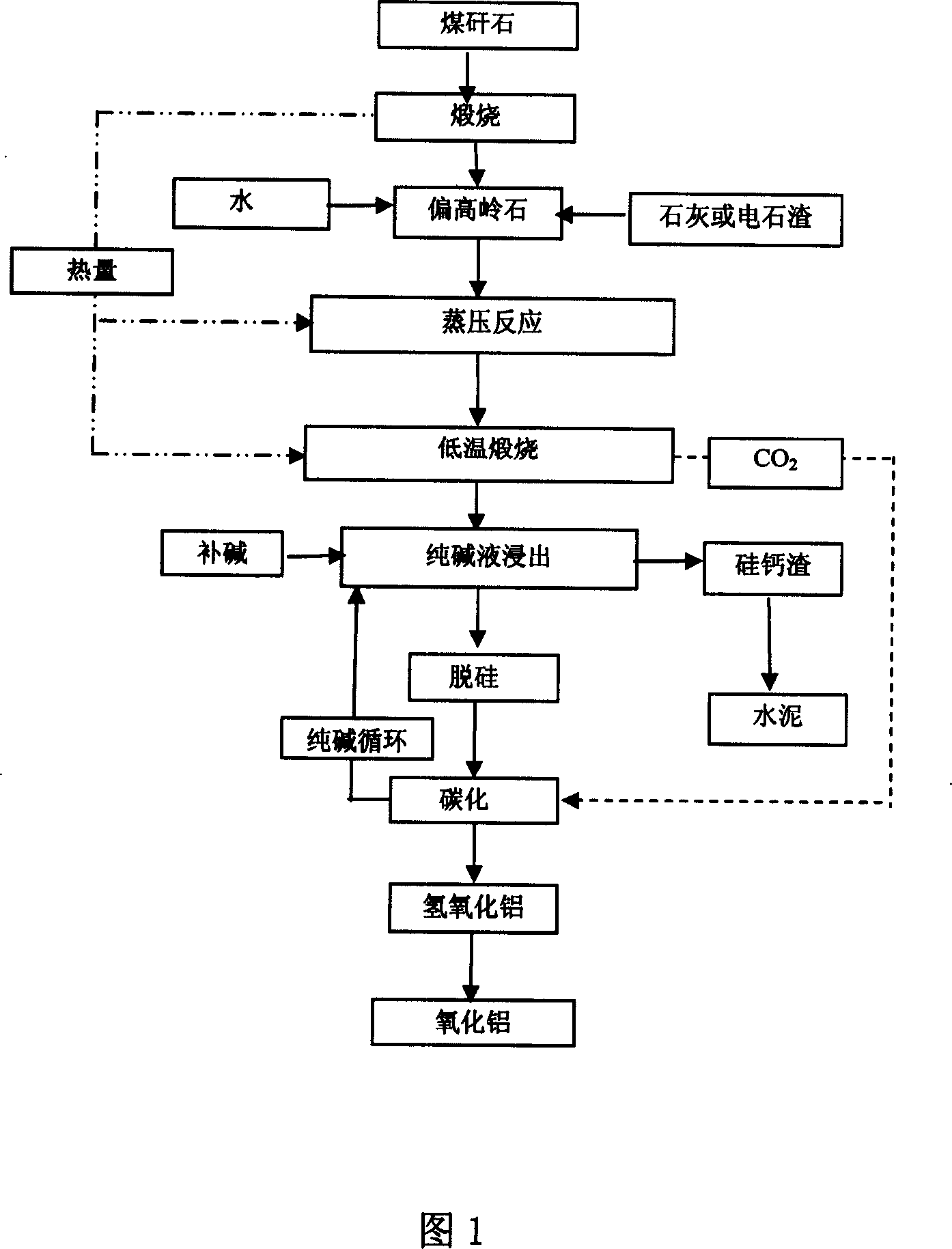

Method for extracting aluminum hydrate or alumina from coal gangue and method for producing cement from fag end

InactiveCN101028935AReduce manufacturing costRealize comprehensive utilizationAluminium oxide/hydroxide preparationCement productionSteam pressureAluminium hydroxide

A process for extracting aluminum hydroxide (or oxide) from coal gangue and using the residual dregs to prepare cement includes such steps as calcining coal gangue, mixing with lime or calcium carbide dregs and water, steam pressure reaction to generate the resultant containing hydrated calcium silicoaluminate and calcium hydroxide, calcining to obtain the dodecylcalcium hepatoaluminate and dicalcium silicate, extracting in sodium carbonate solution, adding lime for desiliconizing, carbonizing to obtain aluminum oxide, calcining to obtain aluminum oxide, and using the SiCa dregs to prepare cement.

Owner:CHANGAN UNIV

Fire-proof paint modifier of tunnel based on polymer/clay intercalation modifying technology and production thereof

A fire-proof paint modifier of tunnel based on polymer / clay inserting layer modification technology and its production are disclosed. The modifier consists of polymer, modified clay and additive, polymer is bromo-bisphenol A epoxy resin or amino resin solution, modified clay is insert modified roseite, concavo-convex rod clay or montmorillonite, and additive is expendable graphitic, magnesium hydroxide, aluminum hydrate and nanometer TiO2. The process is carried out by destroying clay structure, stripping it into basic unit, dispersing in polymer matrix, and obtaining modifier. Its advantages include better hydrophobicity and thermal stability, higher strength and toughness, to prevent smoke from eroding and improve corrosion and water resistances.

Owner:XIAMEN UNIV

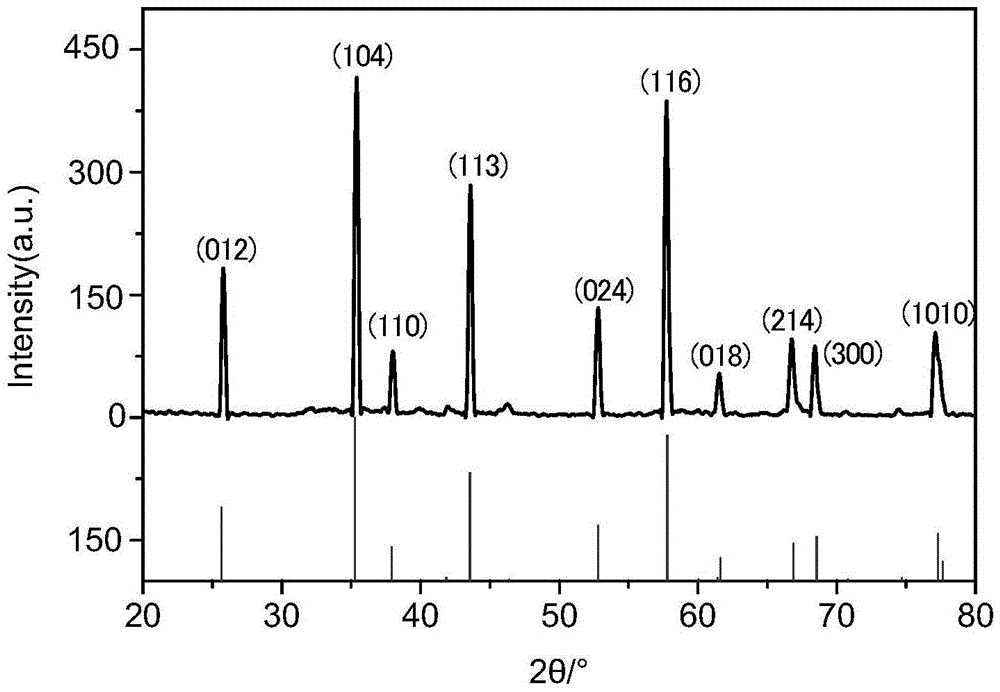

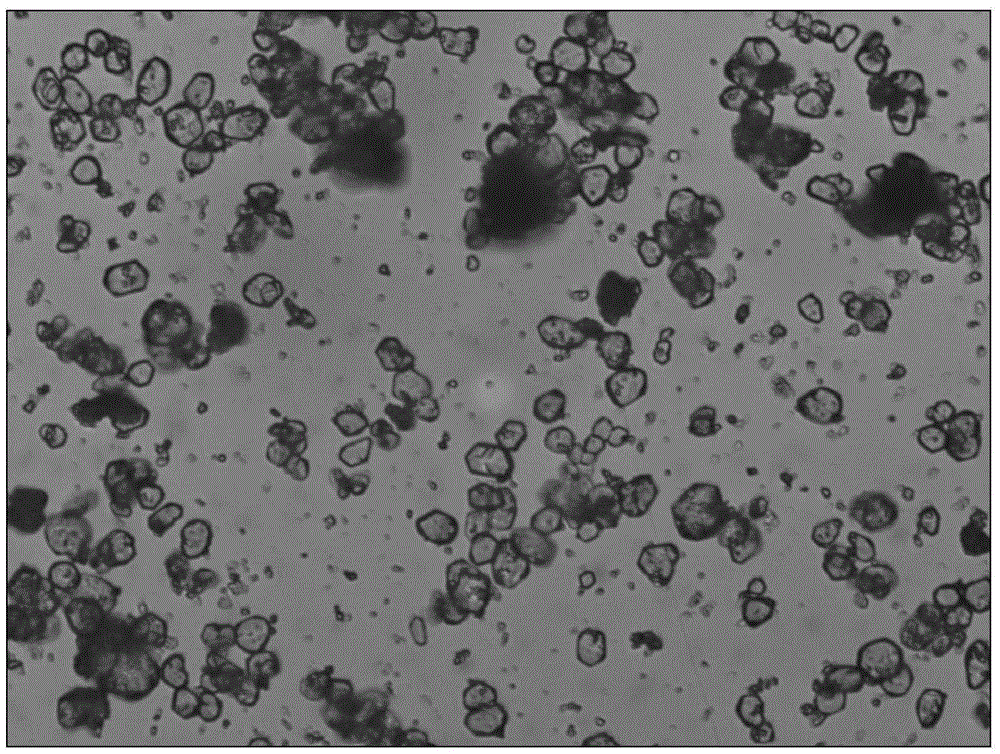

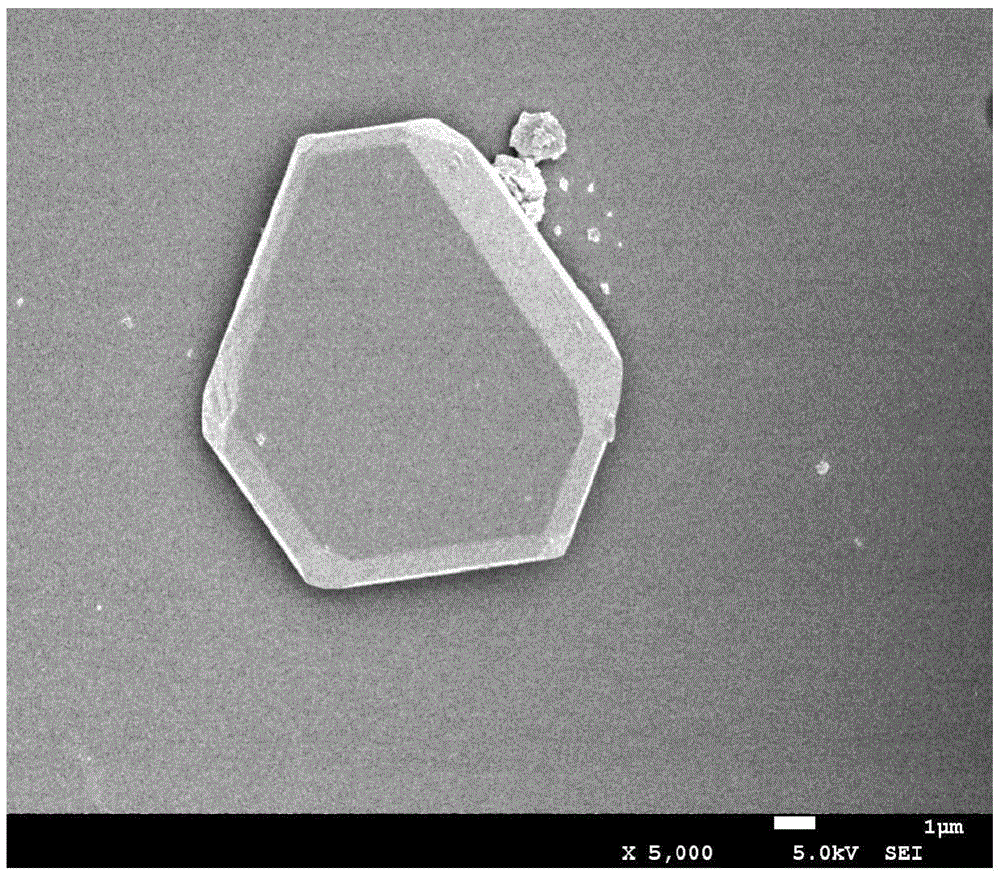

Platy-monocrystal alpha-aluminum oxide, and preparation method and application thereof

InactiveCN105645445AReduce pollutionSimple processCoatingsAluminium oxides/hydroxidesDispersityHeat conducting

The invention relates to a platy-monocrystal alpha-aluminum oxide, and a preparation method and application thereof, belonging to the field of inorganic non-metal materials. The method comprises the following steps: a. by using aluminum hydrate or transitional-phase aluminum oxide as a raw material, adding a fused salt, mixing, and grinding; b. adding a fluoride into the ground material in the step a, grinding, and uniformly mixing to obtain a mixture; c. calcining the mixture at 700-1200 DEG C at the heating rate of 1-20 DEG C / minute for 0.5-4 hours, and cooling to room temperature; d. dissolving the cooled material in the step c in 60-100-DEG C hot water, washing and filtering; and e. repeating the step d until the fused salt is completely removed, and drying to obtain the platy-monocrystal alpha-aluminum oxide. The preparation method has the advantages of simple technique and no environment pollution. The prepared alpha-Al2O3 has the advantages of controllable shape, uniform size and favorable dispersity, and can be used in a high-polymer material as a heat-conducting filler for enhancing the heat conductivity coefficient.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

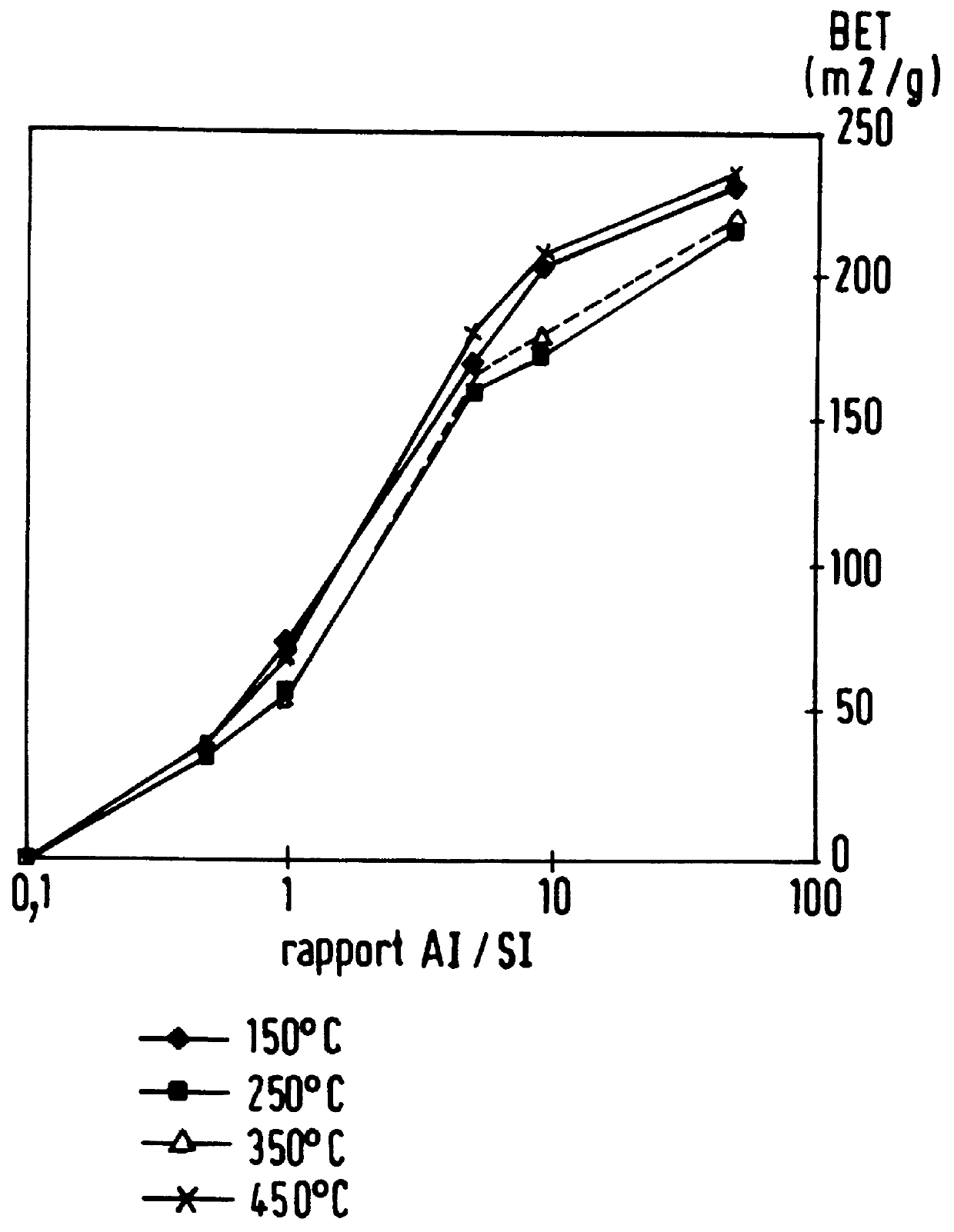

Alumina-based abrasive grains and method for preparing same

InactiveUS6015442AImprove the immunityImprove mechanical propertiesPigmenting treatmentOther chemical processesAluminum hydrateSodium silicate

PCT No. PCT / FR96 / 01609 Sec. 371 Date Sep. 22, 1998 Sec. 102(e) Date Sep. 22, 1998 PCT Filed Oct. 15, 1996 PCT Pub. No. WO97 / 14759 PCT Pub. Date Apr. 24, 1997Alumina-based abrasive grains having a skin constituted by a mixture of finely dispersed aluminum hydrate and sodium silicate, and a process for the production of such grains consisting of (a) preparing a gel by mixing a solution of sodium silicate and a colloidal solution of aluminum hydrate in acid medium, (b) coating the abrasive grains with the gel in an amount of 0.1 to 5 percent weight, and (c) subjecting the coated grains to a drying treatment at a temperature of between 100 and 500 DEG C. The grains according to the invention are used for the manufacture of cloths and abrasive paper and also grinding wheels.

Owner:PEM ABRASIFS REFRACTAIRES

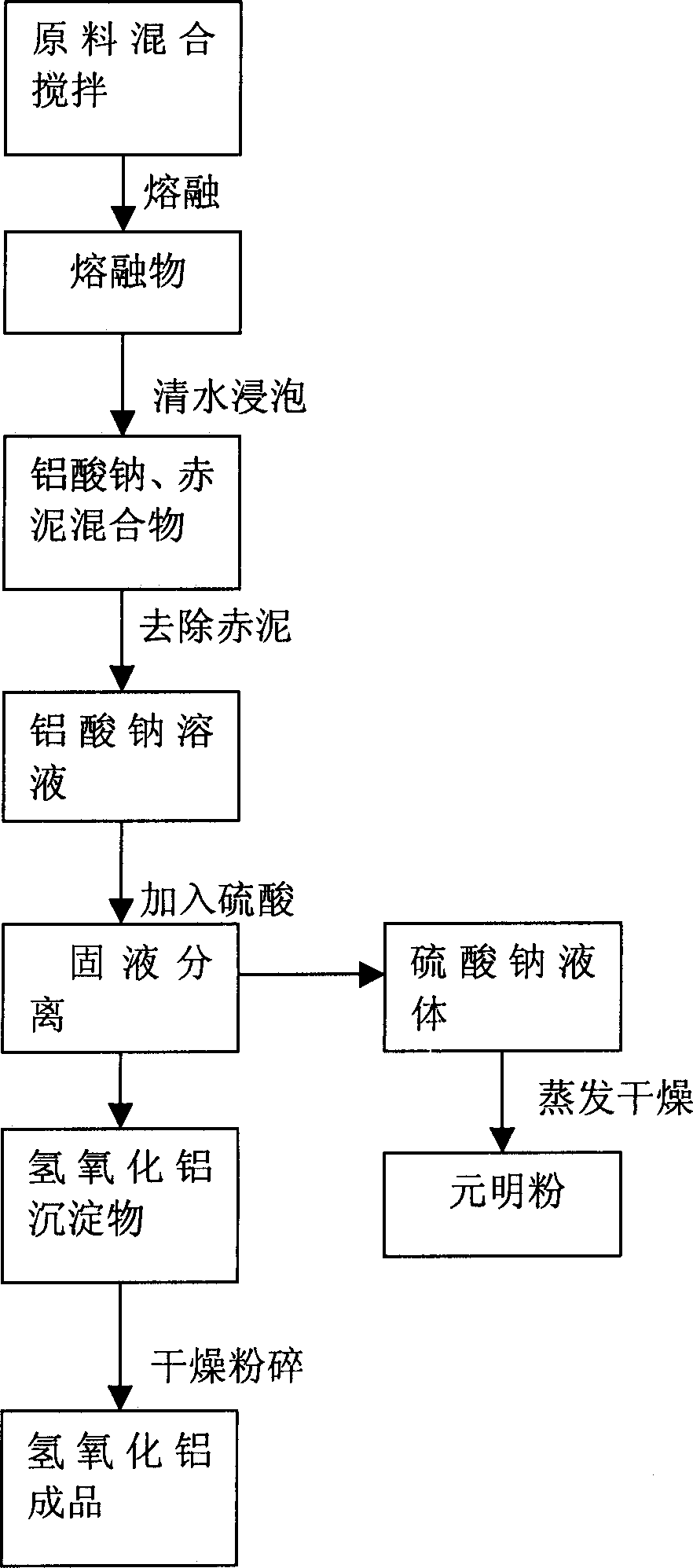

Production of aluminium hydrate from aluminium ash

InactiveCN1817795ATake advantage ofNo secondary pollutionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfatesAluminium hydroxideSodium aluminate

Production of aluminum hydrate from aluminum ash is carried out by mixed agitating in proportion=100:80-120 of aluminum ash and solid sodium carbonate, melting solid mixture at 900-1500 degrees C for 1-5hrs, immersing melts in water above 10hrs, removing deposits to obtain sodium aluminate solution, adding sulfuric acid into sodium aluminate solution in proportion=2:0.9-1.1mol, solid-liquid separating by filter to obtain aluminum hydrate deposits and sodium sulfate solution, drying aluminum hydrate deposits at 20-80 degrees C and crushing to obtain final product. It is cheap and simple, has no environmental pollution and uses of regenerative resources fully.

Owner:杜梅生 +1

Antibacterial Titanium Dioxide Compositions

InactiveUS20080187457A1Improve the bactericidal effectImprove sterilityRadiation applicationsPhotomechanical apparatusTitanium dioxidePolymer composition

An acrylic or other polymer composition, optionally containing aluminum trihydrate, and having undoped or doped titanium dioxide dispersed throughout is disclosed. Said composition provides a “renewable” surface and further provides a highly-sterile surface upon photoactivation of the surface by at least either low-level ultraviolet irradiation or ambient / natural light (as when using doped titanium dioxide).

Owner:OPTIMUS SERVICES

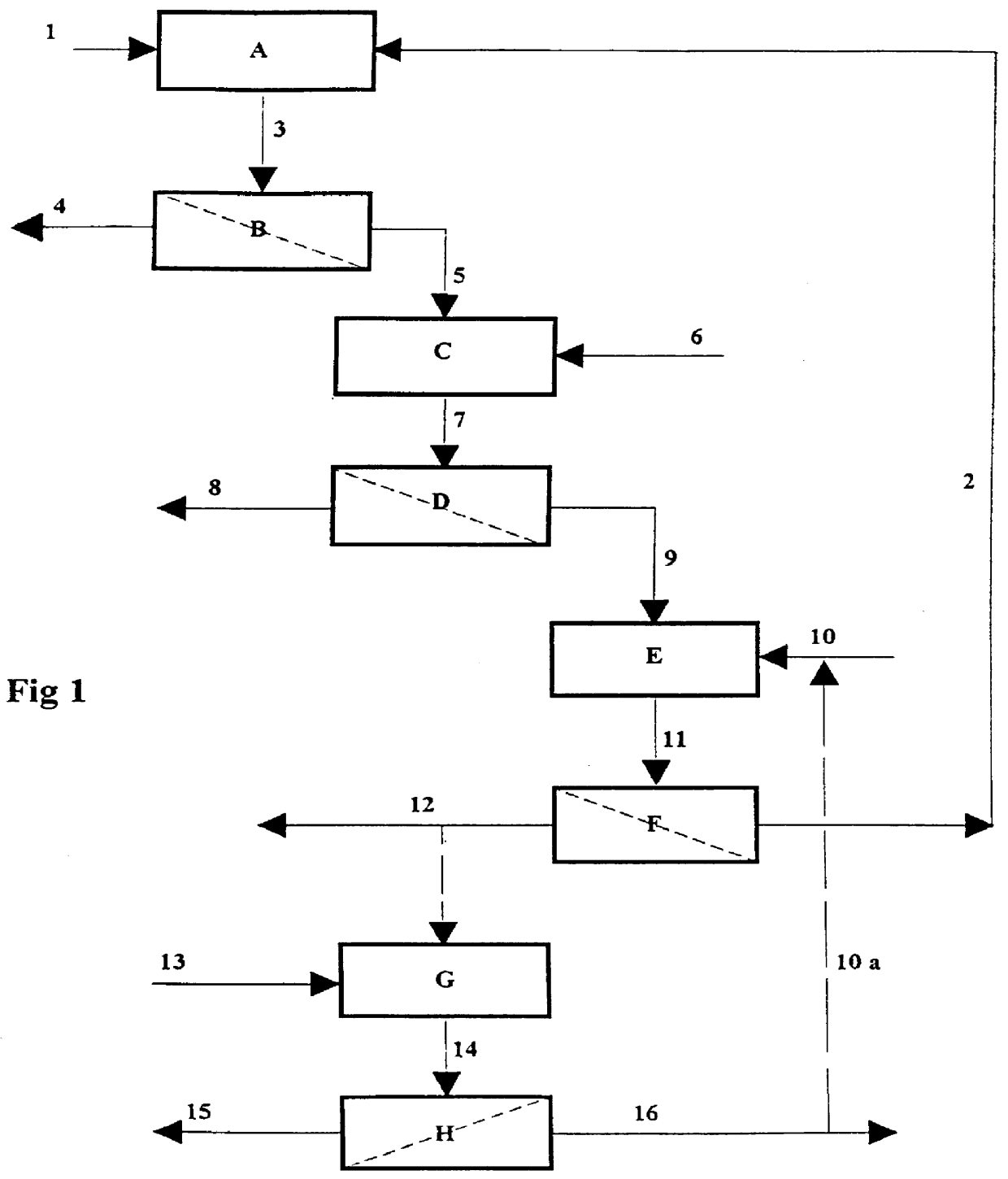

Process for recovering the sodium contained in industrial alkaline waste

InactiveUS6110377AEasy to eliminateLow costSolvent extractionIon-exchanger regenerationRed mudElution

The invention concerns a process that uses an ion exchanger resin to recover the sodium contained in industrial alkaline waste and, in particular, in the "red mud" and sodium effluents coming from the manufacture of aluminum hydrate according to the Bayer process. It includes putting the alkaline resins (1), usually "red mud" in the form of an aqueous suspension in contact with an RH+ type cationic resin, preferably, a carboxylic resin to attach the sodium selectively and quantitatively to the resin (5) and then to extract it quantitatively in the form of NaOH (8) by displacement using a lime suspension (6), preferably, lime milk. The resin (9), after attaching the calcium, is then regenerated for reuse at the beginning of the process (2) by elution of the calcium as CaCl2 (12) with a diluted hydrochloric acid solution (10).

Owner:ALUMINUM PECHINEY

Heavy, residual oil hydrogenating catalyst and its preparation

InactiveCN1552813AIncrease the areaLarge hole volumeRefining to eliminate hetero atomsHydrodesulfurizationActive component

The invention relates to a catalyst of hydrodesulfurization of heavy oil and residual oil and its preparing method. The catalyst takes gama-Al2O3 as its carrier, with VIB family and VIII family metals as active components, and with Ti etc. as active assistants. The catalyst assistants Ti of the invention is drawn into by ultrasonic wave in aluminum hydrate gelatinization. The catalyst is prepared by complete mixed kneading method, i.e., adding alkaline solution containing Mo and / or W into aluminum hydrate dry gel powder of Ti drawn by ultrasonic wave to intensively mix until aluminum hydrate powder is wetted by alkaline solution completely, re-adding acid solution containing Co and / or Ni to be mixed until materials become plastic body, extrusion molding, drying, and roasting to get catalyst. Distribution of the catalyst assistants Ti prepared by the method is of more uniform, having pore capacity and specific area improved apparently with excellent performance in use.

Owner:CHINA PETROLEUM & CHEM CORP +1

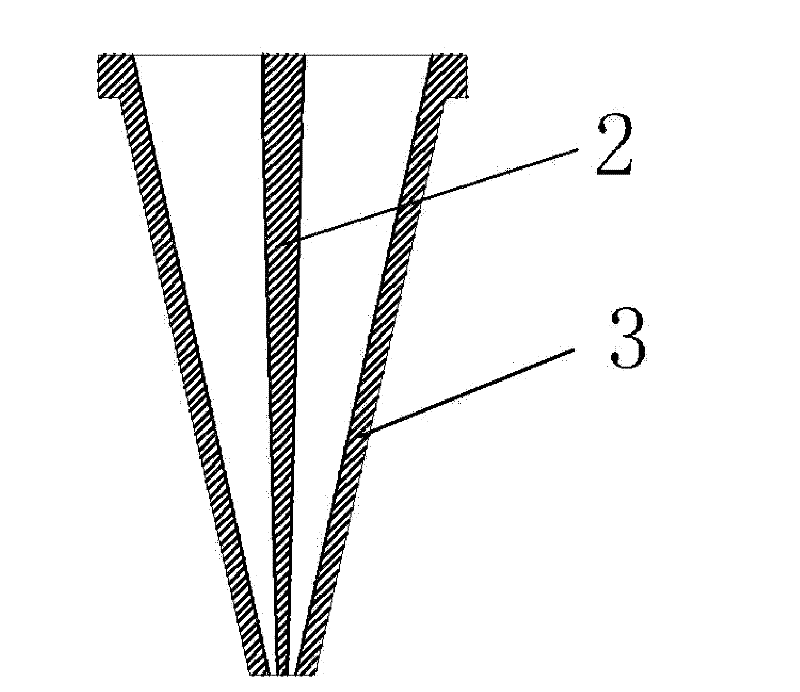

Hollow fiber ceramic membrane and preparation method thereof

The invention belongs to the technical field of material preparation, and provides a hollow fiber ceramic membrane with high filtering flux and a preparation method thereof. The hollow fiber ceramic membrane comprises the following components in parts by weight: 40-80 parts of powdery aluminum hydrate, 10-20 parts of powdery soft refractory ball clay, 1-10 parts of powdery albite, 1-10 parts of powdery dolomite, 6-10 parts of powdery borosilicate glass powder, 1-7 parts of carboxymethyl cellulose and 1-3 parts of glycerin, and is prepared through burdening, ball milling, mud squeezing and dehydration, vacuum pressing, extrusion molding and sintering. Preferably, the outer diameter of the hollow fiber ceramic membrane with high filtering flux is 3-6 millimeters, the inner diameter is 1-2 millimeters, and the length is 100-1,000 millimeters; and the porosity factor is 50-56 percent, the pure water flux is 10,000-12,500 L / m<2>.h.Mpa, and the bending strength is 35-85 MPa, which are 3-5 times that of an ordinary hollow fiber ceramic membrane.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

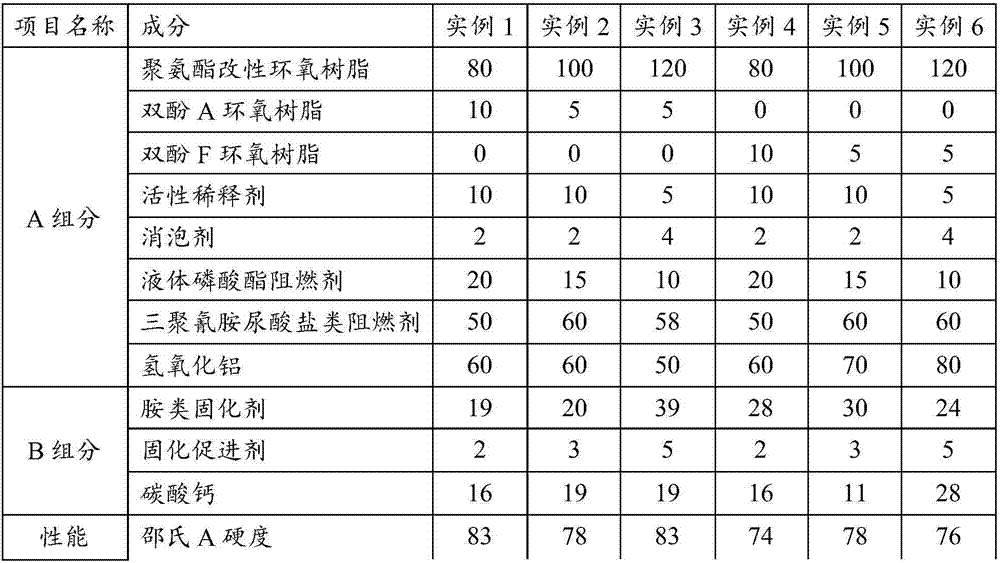

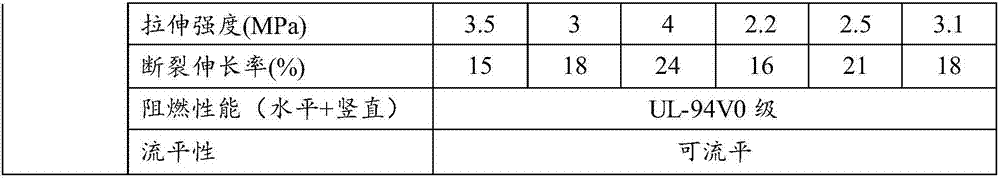

Elastic epoxy fire-proof potting compound and preparation method thereof

ActiveCN107418498AElasticEasy to peelNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPhosphate

The invention provides an elastic epoxy fire-proof potting compound. The potting compound comprises a component A and a component B, wherein the component A is prepared from polyurethane modified epoxy resin, epoxy resin, an active diluting agent, a defoaming agent, melamine powder flame retardant, liquid phosphate flame retardant and aluminum hydrate filler; and the component B is prepared from a curing agent, a curing accelerant and calcium carbonate filler. The elastic epoxy fire-proof potting compound is prepared from a system of low-viscosity flexible epoxy resin, flexibilizer and a curing agent combined with tributyl phosphate, epoxy resin environment-friendly flame retardant, aluminum hydrate and the like, so that the epoxy components A and B have the advantages of low viscosity and levelling performance, the condensate is elastic and can be easily peeled, and epoxy resin condensate UL94 reaches V-1 level in a flame-retardant test.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

Method for producing aluminum oxide with alumyte

InactiveCN102249274AEmission reductionLow dissolution rateAluminium compoundsAluminium hydroxideRed mud

The invention discloses a method for producing aluminum oxide with alumyte. The method comprises the following steps of: (1) smashing alumyte, adding a reduction aid, calcined soda and lime stone and blending to obtain a mixed green stock; (2) performing milling grinding on the mixed green stock and adding the mixed green stock into a furnace for performing hard fire; (3) dissolving and separating hard fire clinker out to obtain a sodium aluminate solution, and separating red mud from the hard fire clinker by adopting a direct sedimentation method; and (4) purifying the sodium aluminate solution, decomposing and separating aluminum hydrate out, and discharging the red mud. Due to the adoption of the method, the reduced ratio of the clinker is remarkably lowered, the productivity of a clinker kiln is increased, the production cost is greatly lowered, and the discharging amount of red mud is reduced by over 50 percent. The method has the advantages of lower firing temperature and low dissolution rate of silicon, and is particularly suitable for treating ferric alumyte or treating complex polymetallic bauxite; and the siliceous modulus of raw liquor is increased remarkably.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Ink for inkjet recording, ink set for inkjet recording, ink media set for inkjet recording, ink cartridge, inkjet recording method, and inkjet recording apparatus

InactiveUS8252207B2Improve printing qualityHigh densityMeasurement apparatus componentsLayered productsWater dispersibleRefractive index

To provide an ink for inkjet recording containing water, water-soluble organic solvent, water-dispersible resin, fluorochemical surfactant or derivative thereof, and coloring agent containing pigment, wherein the ink has a surface tension of 20-35 mN / m and viscosity of 5 mPa·s or more at 25° C., total amount of the water-dispersible resin and the coloring agent in the ink is 5-40% by mass, and mass ratio A / B of the water-dispersible resin A to the coloring agent B is 0.5-4, wherein the ink is applied for a recording medium for inkjet recording containing a support containing cellulose pulp, and one or more barrier layers disposed on at least one face of the support, and wherein the barrier layer contains 30% by mass or more of inorganic pigment having refractive index of 1.5 or more, excluding aluminum hydrate, and 10% by mass or less of an inorganic pigment having a refractive index of less than 1.5.

Owner:RICOH KK

Solar Reflective Coating

InactiveUS20140121297A1Improved performance characteristicsImprove solar reflectivityGreenhouse cultivationCultivating equipmentsSilica particleSilicon dioxide

Presented are solar reflective coating compositions comprising a mixture of polymeric binder system of acrylic and alkyd dispersion. Also presented are various fillers and pigments of high infra-red (IR) reflecting property of large crystalline size containing aluminum dioxide, titanium dioxide, aluminum trihydrate and silicon dioxide particles.

Owner:IMRAE

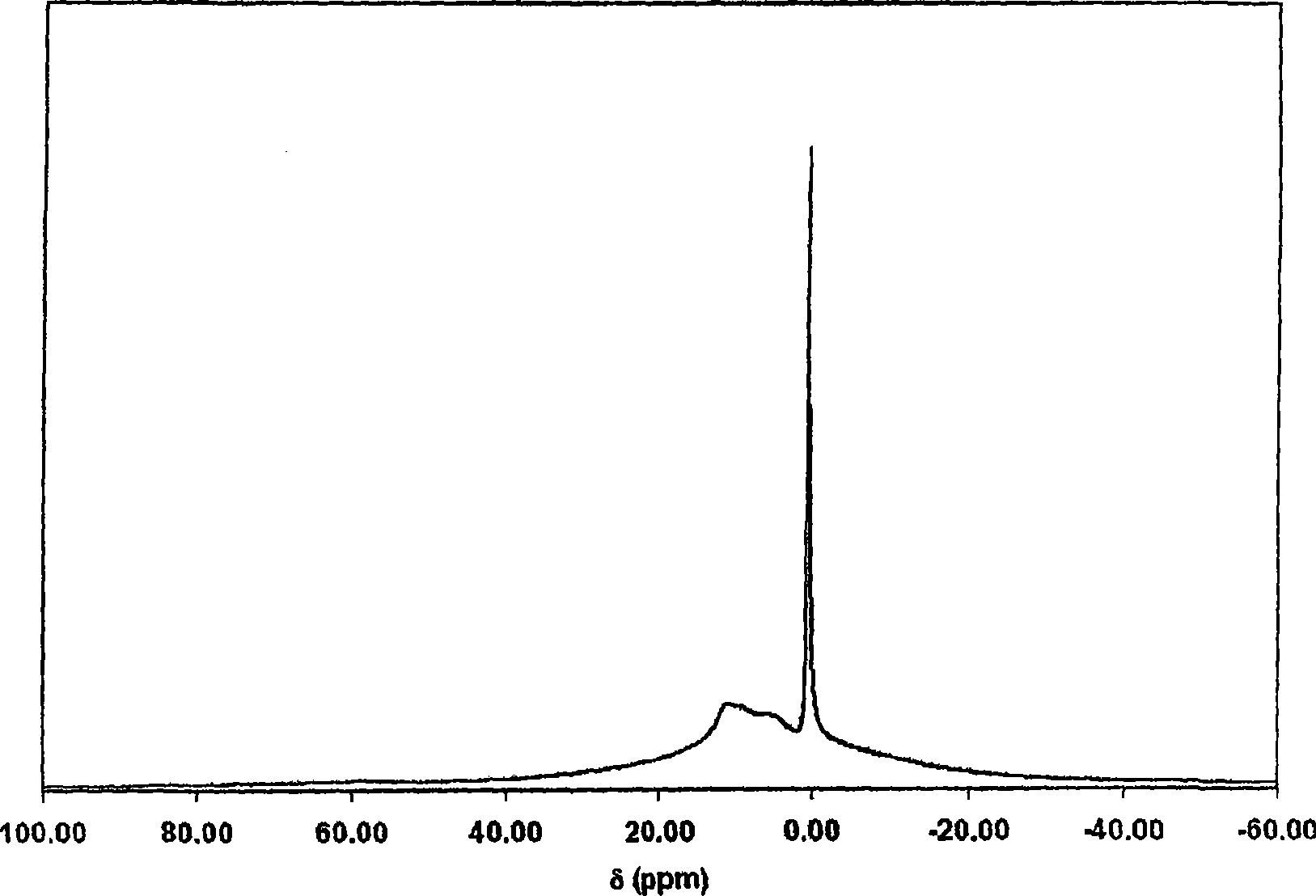

Polyaluminum calcium hydroxychlorides and methods of making the same

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60 DEG C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM CORP

High-chlorine-capacity high-intensity alumina de-chlorinating agent

InactiveCN102357354AHigh pore volumeLarge specific surface areaIon-exchange process apparatusOther chemical processesAluminum hydrateHigh intensity

The invention discloses a high-chlorine-capacity high-strength alumina de-chlorinating agent, which is characterized by consisting of 30-60 percent by weight of aluminum hydrate and 30-50 percent by weight of sodium hydrate, preferably by consisting of 55 percent by weight of alumina and 45 percent by weight of sodium hydrate. The de-chlorinating agent is prepared by the following steps of: precipitating and mixing to form a colloid; and recrystallizing the colloid, washing, drying and baking. The de-chlorinating agent has the advantages of high pore capacity, long service life, high mechanical strength, wear resistance, small amount of dust, no blockage of an equipment pipeline, low treatment cost, long service cycle, good comprehensive using effect and the like, and is widely applied to de-chlorinating industrial towers.

Owner:胡自斌

Sulfur tolerant alumina catalyst support

InactiveUS20120122670A1Improve anti-sulfur poisoning performanceExtreme simplicityDispersed particle separationCatalyst activation/preparationCounterionSulfur

The present invention is directed to a method for making a sulfur tolerant alumina, that includes the steps of: forming aluminum hydrate from one or more water soluble aluminum salts, said salts each comprising an aluminum cation or aluminum anion and an oppositely charged counterion, in an aqueous medium, contacting the aluminum hydrate with a silica precursor in the aqueous medium and in the presence of counterions of the one or more aluminum salts, isolating silica precursor-contacted aluminum hydrate particles from the aqueous medium, and calcining the silica precursor-contacted aluminum hydrate particles to form particles of the sulfur tolerant alumina.

Owner:RHODIA OPERATIONS SAS

Paper coating compositions

A composition for coating paper includes at least one pigment selected from the group consisting of polymeric pigments, aluminosilicates, calcium carbonate, titanium dioxide, talc, barium sulfate, zinc oxide, aluminum trihydrate, amorphous silica and silicates; wherein the pigment is dispersed in an aqueous dispersion of a polymeric binder that is a copolymer of vinyl acetate, ethylene, at least one ethylenically unsaturated sulfonic acid or salt thereof and optionally one or more other monomers, wherein vinyl acetate units constitute in a range of 70-90 wt % of the polymeric binder and ethylene units constitute in a range of 10-30 wt % of the polymeric binder; and wherein the polymeric binder has a mean particle size in a range from 0.1 μm to 0.3 μm and the optional one or more other monomers do not include any N—(C1-4) alkylol (meth)acrylamide; and wherein the aqueous dispersion of the polymeric binder is free of alkylphenol ethoxylate surfactants and includes a nonionic surfactant component consisting of a polyethylene oxide / polypropylene oxide block copolymer and optionally one or more other nonionic surfactants, and optionally includes an anionic surfactant component consisting of one or more anionic surfactants.

Owner:WACKER CHEM GMBH

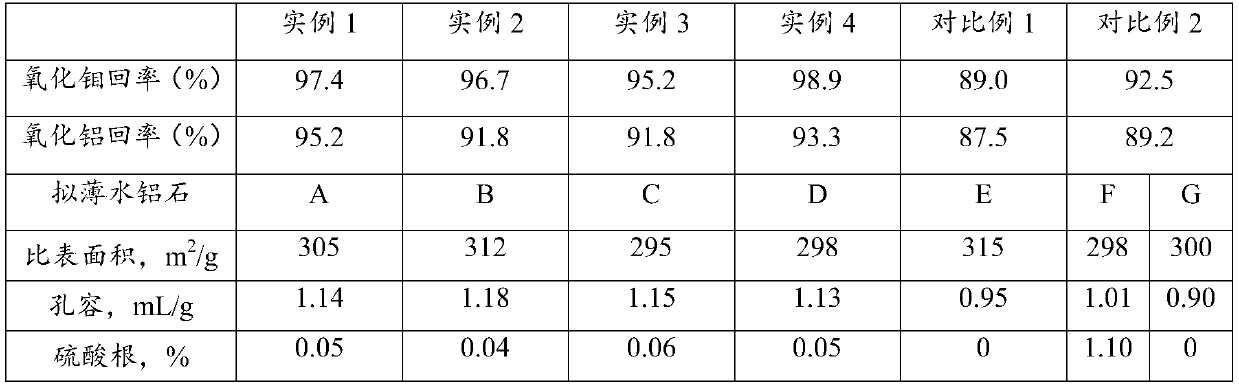

Waste catalyst recycling method

InactiveCN111573733AEfficient manufacturingReduce anion excessMolybdeum compoundsChemical recyclingHydration reactionAluminum Ion

The invention discloses a waste catalyst recycling method, and particularly discloses a method for preparing a hydrogenation catalyst from a molybdenum-nickel waste catalyst. The method comprises thefollowing steps of: carrying out mixed roasting and leaching on pretreated molybdenum-nickel waste catalyst powder and alkali to obtain a molybdate solution and aluminum oxide filter residues, and adjusting the pH value of the molybdate solution to remove aluminum ions to obtain molybdic acid; mixing the aluminum oxide filter residues with alkali, and carrying out secondary roasting and leaching to obtain a sodium aluminate solution and a nickel oxide solid; cooling and crystallizing the sodium aluminate solution, performing filtering and separation to obtain a hydrated sodium aluminate solidand a diluted sodium aluminate solution; drying the hydrated sodium aluminate solid to obtain sodium aluminate; introducing carbon dioxide into the dilute sodium aluminate solution, and obtaining a first-stage product after a reaction is finished; carrying out second-stage parallel flow reaction on the first-stage product and acid liquor; and finally, performing aging, filtering and drying to obtain pseudo-boehmite. According to the method of the invention, the pore volume of the pseudo-boehmite is effectively increased, and the problem of repeated utilization of a waste catalyst carrier is solved.

Owner:大连众智创新催化剂有限公司

Paint metaphenylene sheet moulding plastic bumper for automobile external-decoration

The invention relates to a car external-decorating paint iso-phthalic sheet mould plastic safety bar, using iso-phthalic unsaturated polyester as main material, calcium carbonate or / and aluminum hydrate as filling, peroxides as initiator, alkaline earth oxide or / and hydrate as thickening agent, polystyrenes or polyvinyl acetates as low-contraction additive, and stearic acid or stearates as internal mold release, mixing uniformly to make into resin paste, coating the resin paste on the loading film of sheet-making set, adding in glass fiber as reinforcing material to dip and compound to make into sheets, then pressing the sheets into pressed products of the safety bar, and then spraying paint to make into the finished products. It has good mechanical performance, chemical corrosion resistance, good tenacity and water resisting property, etc.

Owner:JIANGYIN XIETONG AUTOMOBILE ACCESSORY

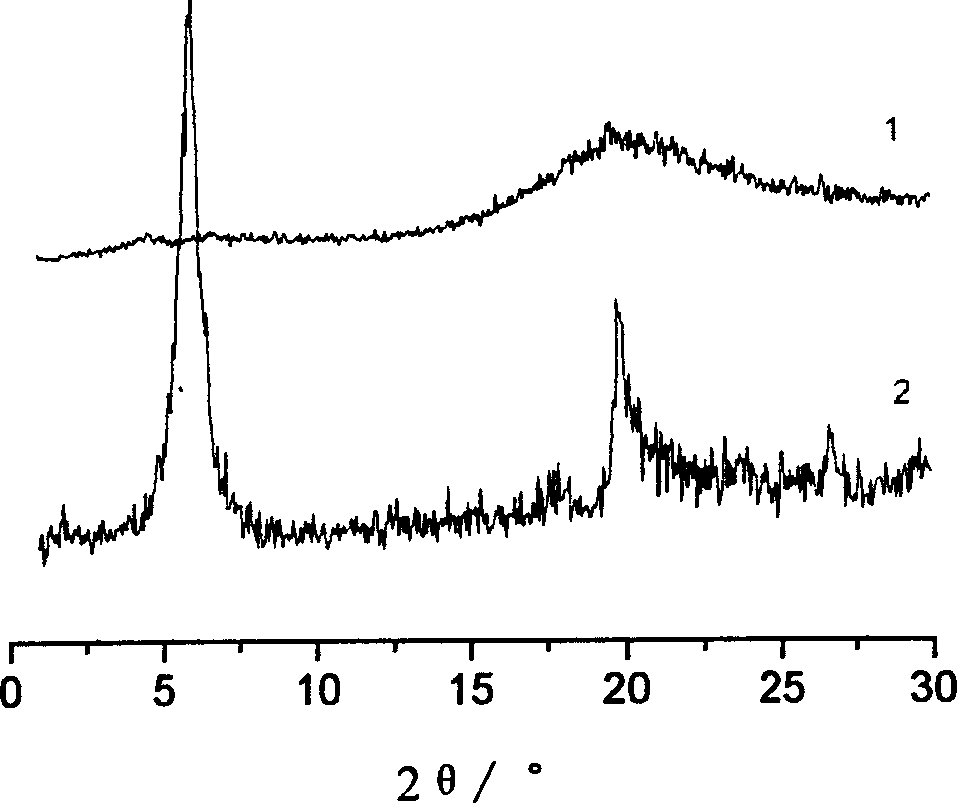

Silicon-phosphorus contained aluminum hydrate and its preparation

InactiveCN1552526AExcellent deep hydrofining activityReduce competitionCatalyst carriersCatalyst activation/preparationAluminium hydroxideAluminum hydrate

An aluminium hydroxide particle containing Si and P dispersed on its surface is disclosed, which can be used for hydrorefining the fractional oil or preparing the hydrocatalyst. It is prepared by introducing the cheap Si-contained compound and P-contained compound in the process for preparing the alpha-AlO(OH) type aluminium hydroxide by Co2 method step by step. Its advantages are excellent physical and chemical properties, large pore volume and specific surface area, proper, surface acidity and better peptization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Marble-like decorating material

This invention relates to an imitation marble decorative material and manufacturing method thereof. This imitation marble comprises the semiopaque outer layer and substrate, between which is the printed natural marble pattern resembling with that of natural one. The out layer contains resin, aluminum hydrate powder, cobalt iso-octoate, methylethyl ketone peroxide, sands and dye paste. While, the substrate contains resin, cobalt iso-octoate, methylethyl ketone peroxide, sand and dye paste.

Owner:胡宁

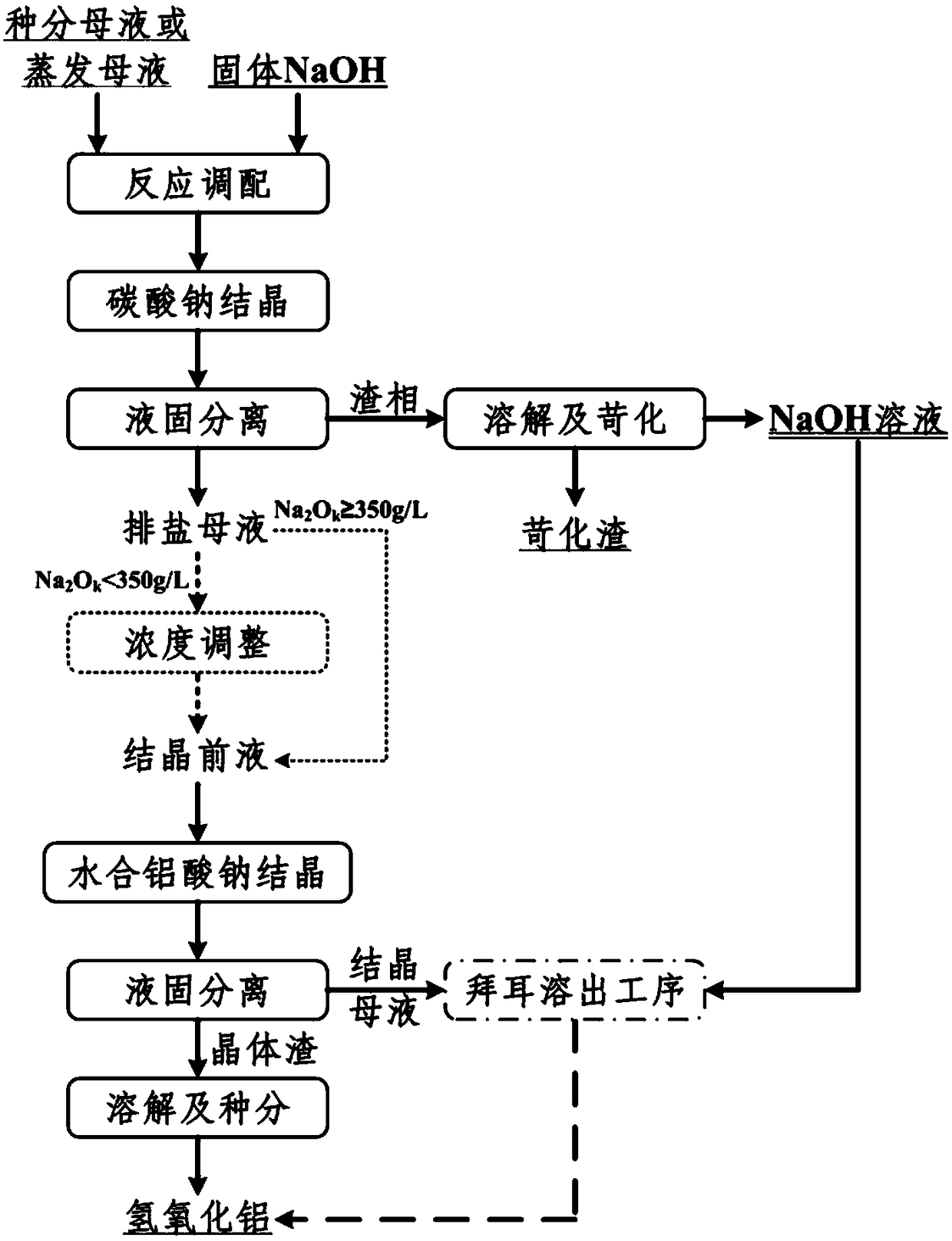

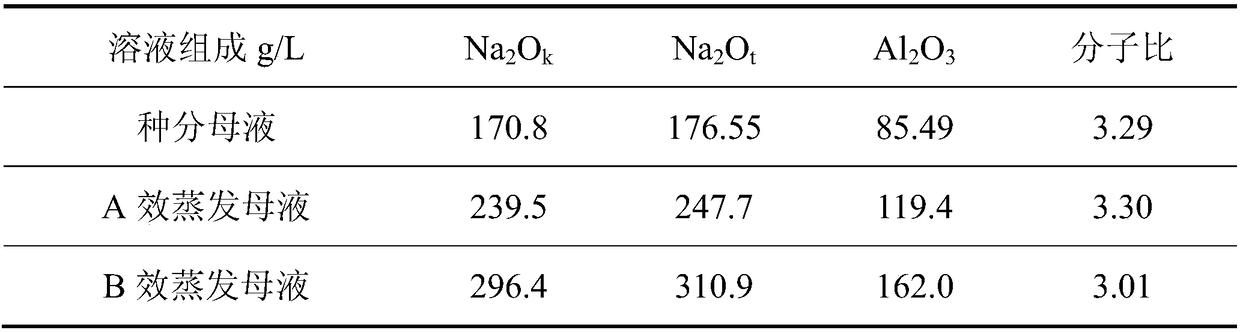

Method for improving production efficiency of aluminium oxide produced with Bayer process

InactiveCN108658111ASave big investmentImprove medium circulation efficiencyAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationChemistryMother liquor

The invention relates to a method for improving production efficiency of aluminium oxide produced with the Bayer process. According to the method, caustic soda flakes required to be supplemented for an aluminium oxide plant are subjected to a reaction with Bayer-process seeded precipitation spent liquor or evaporation mother liquor, a sodium aluminate solution with high alkali and high molecular ratio is formed, and carbon alkali removal and causticizing of Bayer mother liquor can be realized without forced effect evaporation and other processes; by means of efficient crystallization of sodiumaluminate hydrate as an intermediate product, circulating efficiency of dissolution media and production capacity of the conventional equipment can be improved. Synchronous salt elimination and causticizing and improvement of medium circulating efficiency can be realized on the premise that other substances or energy are or is not input; the newly added sodium aluminate hydrate crystallization process is mild in condition, equipment investment is low, industrial controllability is high, and economic benefit is obvious. The aluminium oxide product prepared with the method is identical to thatof the aluminium oxide product produced with the Bayer process, no new waste gas, waste liquor or solid waste is produced, and energy conservation and environmental protection are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

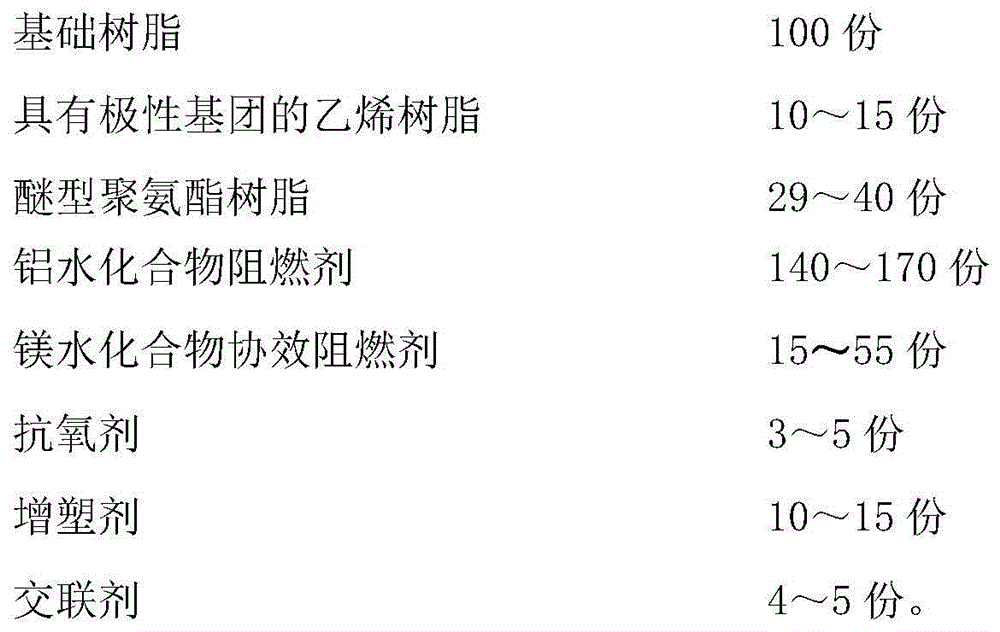

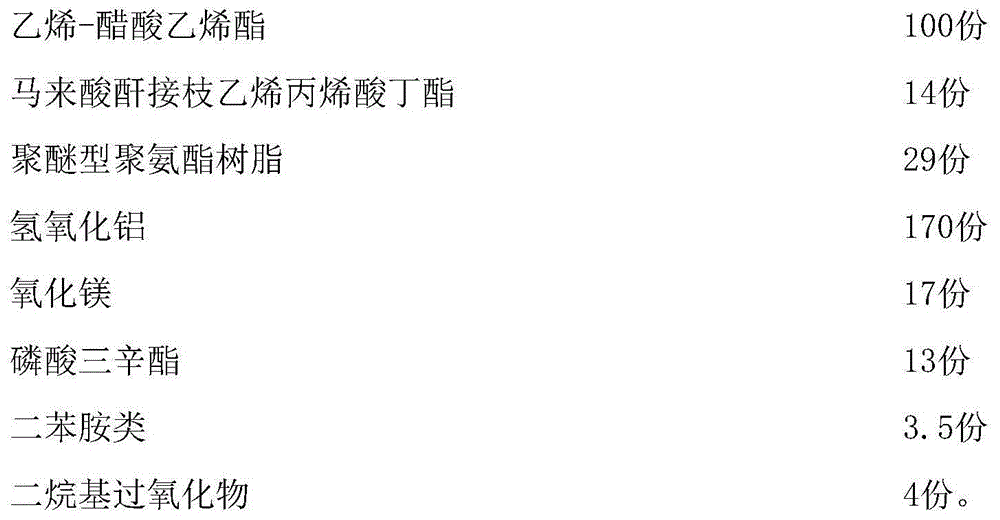

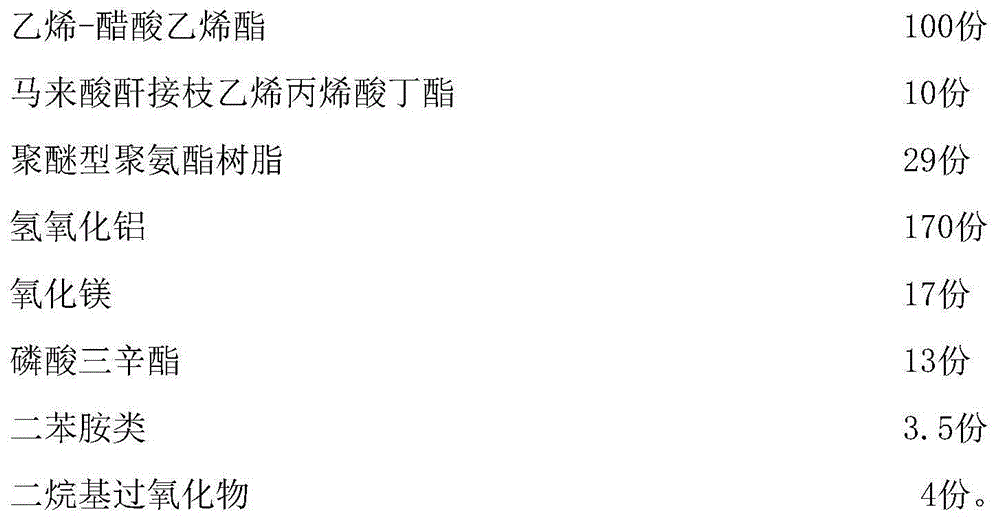

Low temperature resistant oil-proof type halogen-free flame retardant cable material

InactiveCN104672731AStay flexibleComply with flame retardant requirementsPlastic/resin/waxes insulatorsInsulated cablesAntioxidantAluminum hydrate

The invention relates to a low temperature resistant oil-proof type halogen-free flame retardant cable material, comprising the following raw materials in parts by weight: 100 parts of ethylene-vinyl acetate, 10-15 parts of vinyl resin with polar groups, 29-40 parts of polyether polyurethane resin, 140-170 parts of aluminum hydrate, 15-55 parts of magnesium hydrate, 3-5 parts of antioxidant, 10-15 parts of plasticizer and 4-5 parts of crosslinking agent. The cable material related in the invention is halogen-free, and cannot release toxic gas harmful to human body if burning on ships. The cable material also meets the requirement on flame retarding property of cables on general purpose vessels, and the polymer resin material under the low temperature condition of -40 DEG C still can keep elasticity. Meanwhile, the cable material meets the requirement of the standard IEC (International Electrotechnical Commission) 60092-359 on oil-proof property of cables on ships, and also meets the requirement of the standard NEK(Norsk Electrotecnisk Komite)606 on oil-proof property of marine structures.

Owner:JIANGSUSNGSHANG CABLE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com