Elastic epoxy fire-proof potting compound and preparation method thereof

A technology of potting glue and epoxy, which is applied in the field of potting glue, can solve the problems of high viscosity, difficult leveling, easy cracking, high elastic modulus of cured epoxy resin, etc., and achieve low viscosity, elastic peeling, and easy peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing the above-mentioned elastic epoxy flame-retardant potting glue, comprising the following steps:

[0062] Preparation of component A:

[0063] Mix polyurethane modified epoxy resin, epoxy resin, diluent, liquid phosphate flame retardant and defoamer at 5-10 rpm for 5-10 minutes;

[0064] Then add melamine salt powder flame retardant and aluminum hydroxide filler, mix and stir for 20-30 minutes under the condition of 20-30rpm, and then vacuum defoam for 5 minutes to obtain component A;

[0065] Preparation of component B:

[0066] Mix and stir the curing agent and the curing accelerator at 5-10 rpm for 5-10 minutes, then add calcium carbonate filler, mix and stir at 20-30 rpm for 20-30 minutes, and vacuum defoam for 5 minutes to obtain B components;

[0067] There is no sequence restriction on the preparation of the A component and the B component.

[0068] The present invention adopts a system of low-viscosit...

Embodiment 1~6

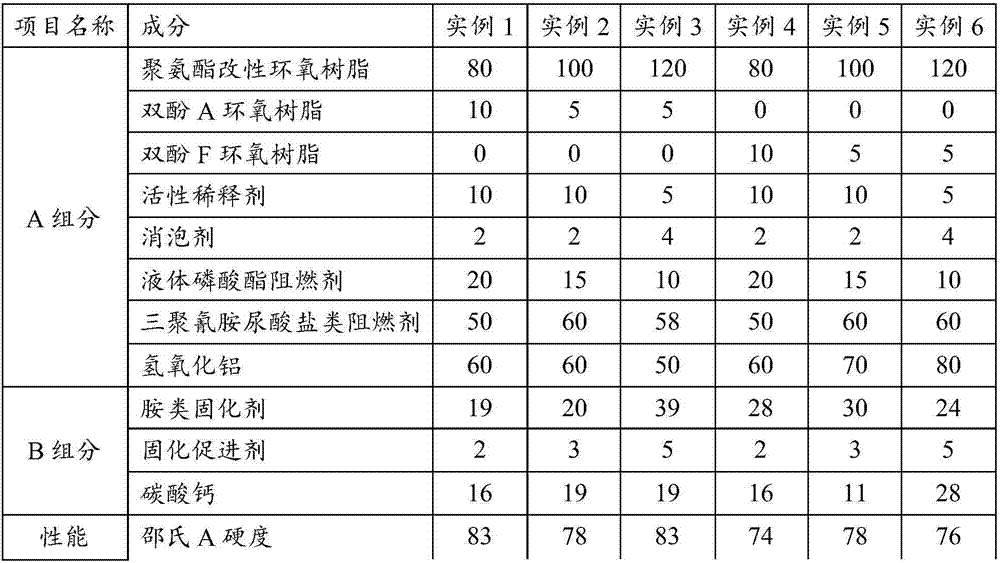

[0071] 1. Raw material ratio: Weigh the raw materials according to the types and amounts of raw materials shown in Table 1;

[0072] 2. Preparation method:

[0073] Preparation of component A:

[0074] Mix polyurethane modified epoxy resin, epoxy resin, diluent, liquid phosphate flame retardant and defoamer at 5-10 rpm for 5-10 minutes;

[0075] Then add melamine salt powder flame retardant and aluminum hydroxide filler, mix and stir for 20-30 minutes under the condition of 20-30rpm, and vacuum degassing for 5 minutes to obtain component A;

[0076] Preparation of component B:

[0077] Mix and stir the curing agent and the curing accelerator at 5-10 rpm for 5-10 minutes, then add calcium carbonate filler, mix and stir at 20-30 rpm for 20-30 minutes, and vacuum defoam for 5 minutes to obtain B components;

[0078] There is no sequence restriction on the preparation of the A component and the B component.

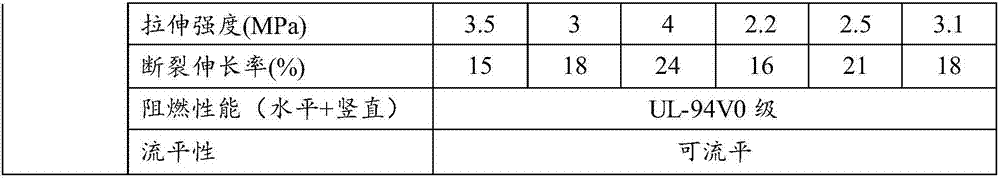

[0079] 3. Test method:

[0080] The performance test of the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com