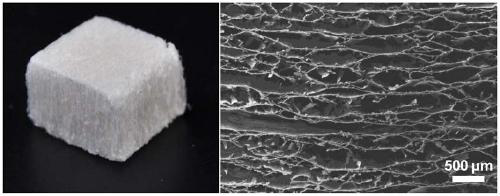

Anisotropic wood-based nanofiber aerogel and preparation method thereof

A nanofiber, anisotropic technology, applied in the field of anisotropic wood-based nanofiber aerogel and its preparation, can solve the problems of high specific surface area, high porosity, and high preparation cost, and achieve broad application prospects and good compression. The effect of performance and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare a sodium chlorite solution with a concentration of 2%, and adjust the pH to 4.5 with acetic acid, and make a balsa wood block with a size of 20mm×20mm×20mm (density about 90mg / cm 3 ) immersed in an acidic sodium chlorite solution and treated at 80°C for 8 hours;

[0030] Immerse the above treated wood in 25% hydrogen peroxide solution, heat treatment at 50°C for 10 hours;

[0031] The above-mentioned treated wood was further put into 8% sodium hydroxide solution, and treated at 70°C for 8 hours to obtain a wood-based nanofiber hydrogel material; the hydrogel material was repeatedly washed with distilled water to remove residual chemicals;

[0032] Soaking the above-mentioned nanofibrous hydrogel in a gradient solution of tert-butanol for 20 hours at room temperature to replace the water in the hydrogel to form a nanofibrillar sol;

[0033] The above-mentioned nanofiber alcohol sol was frozen in a refrigerator for 8 hours, and then moved to a vacuum freeze dryer...

Embodiment 2

[0035] Embodiment 2: A kind of preparation method of anisotropic wood-based nanofiber aerogel, the steps are as follows: (1) select density as 80~150mg / cm 3 The balsa wood is the initial raw material, washed with distilled water, and air-dried for subsequent use;

[0036] (2) Wood is immersed in acidic sodium chlorite solution to carry out delignification treatment, and the treatment time is 5 hours;

[0037] (3) Dip the above-mentioned treated wood in the hydrogen peroxide solution, and heat treatment;

[0038] (4) Immerse the above-mentioned treated wood in a sodium hydroxide solution, heat treatment at 80° C. for 6 hours to obtain a wood-based nanofiber hydrogel, and wash the hydrogel material with distilled water;

[0039] (5) Soak the above-mentioned nanofiber hydrogel in tert-butanol solutions with three concentration gradients sequentially at room temperature, and soak in each solution for 20 hours to obtain nanofiber alcohol sol;

[0040] (6) Vacuum freeze-drying the a...

Embodiment 3

[0041] Embodiment 3: A kind of preparation method of anisotropic wood-based nanofiber aerogel, the steps are as follows: (1) select density as 80~150mg / cm 3 The balsa wood is the initial raw material, washed with distilled water, and air-dried for subsequent use;

[0042] (2) Submerging the wood in an acidic sodium chlorite solution for delignification treatment, the treatment time is 3 to 9 hours;

[0043] (3) Dip the above-mentioned treated wood in the hydrogen peroxide solution, and heat treatment;

[0044] (4) Immerse the above-mentioned treated wood in a sodium hydroxide solution, heat treatment at 90° C. for 10 hours to obtain a wood-based nanofiber hydrogel, and wash the hydrogel material with distilled water;

[0045] (5) Soak the above-mentioned nanofiber hydrogel in tert-butanol solutions with three concentration gradients sequentially at room temperature, and soak in each solution for 22 hours to obtain nanofiber alcohol sol;

[0046] (6) vacuum freeze-drying the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com