Patents

Literature

838 results about "Sodium chlorite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Chlorite (NaClO₂) is a chemical compound used in the manufacturing of paper and as a disinfectant.

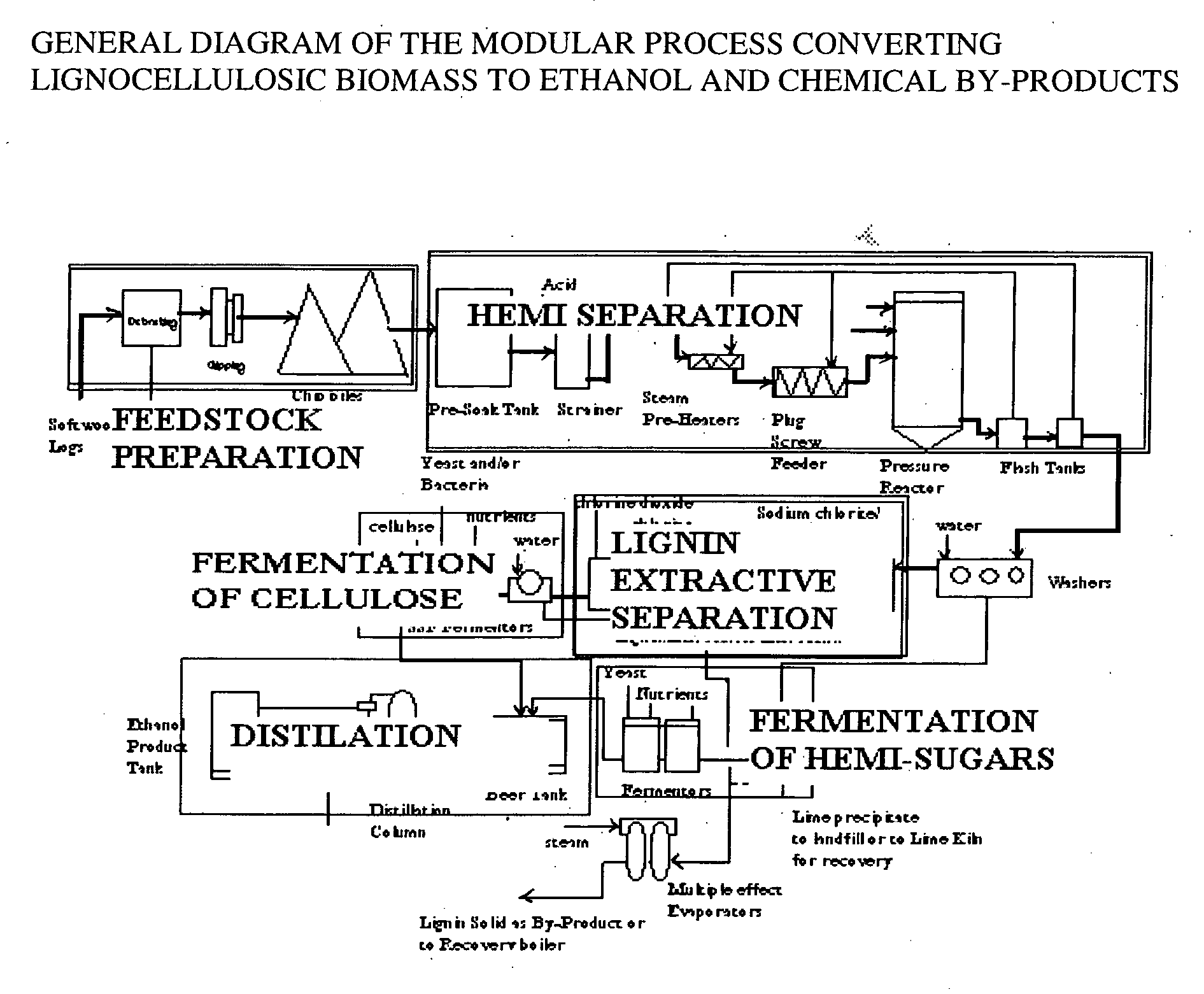

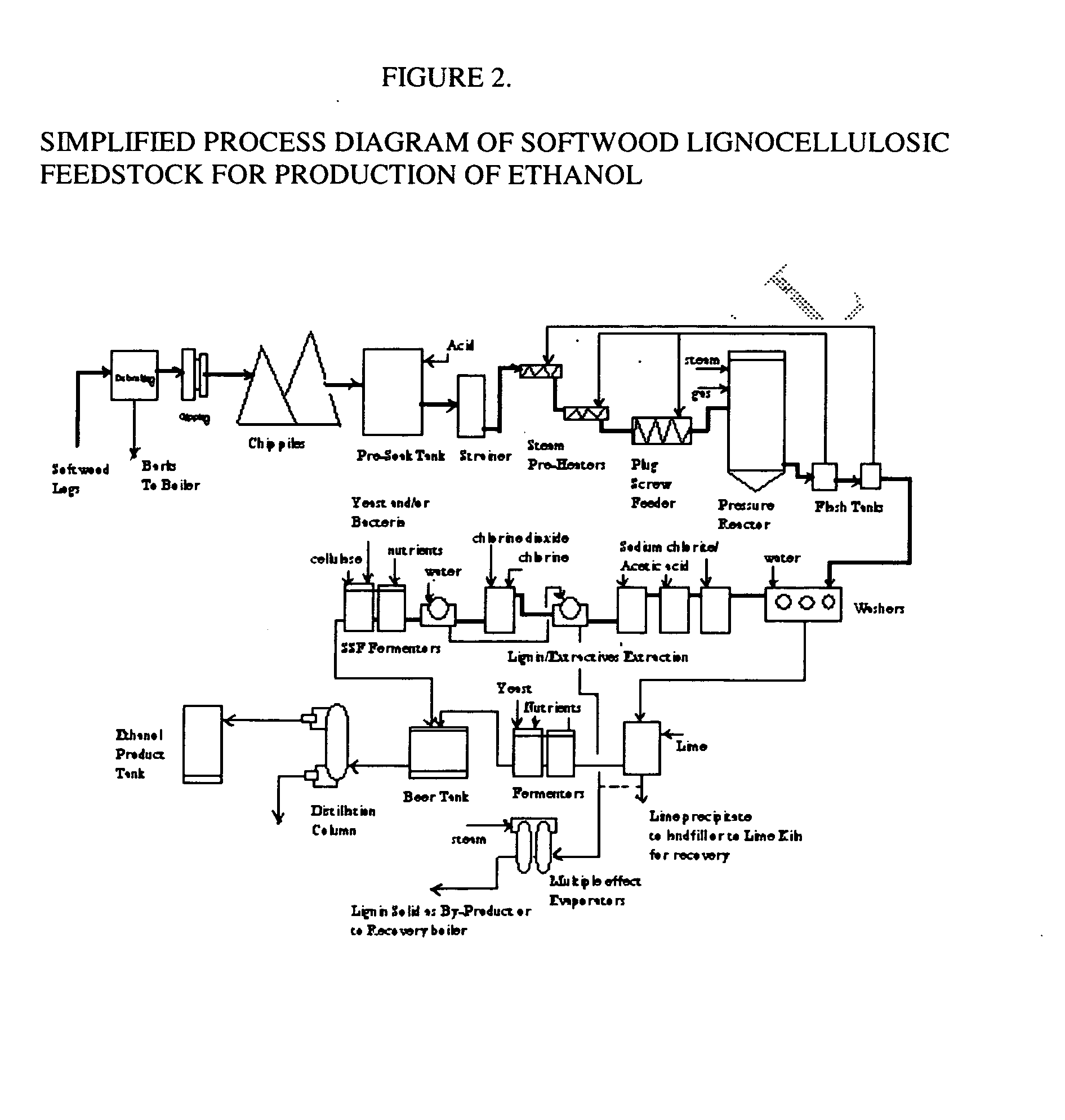

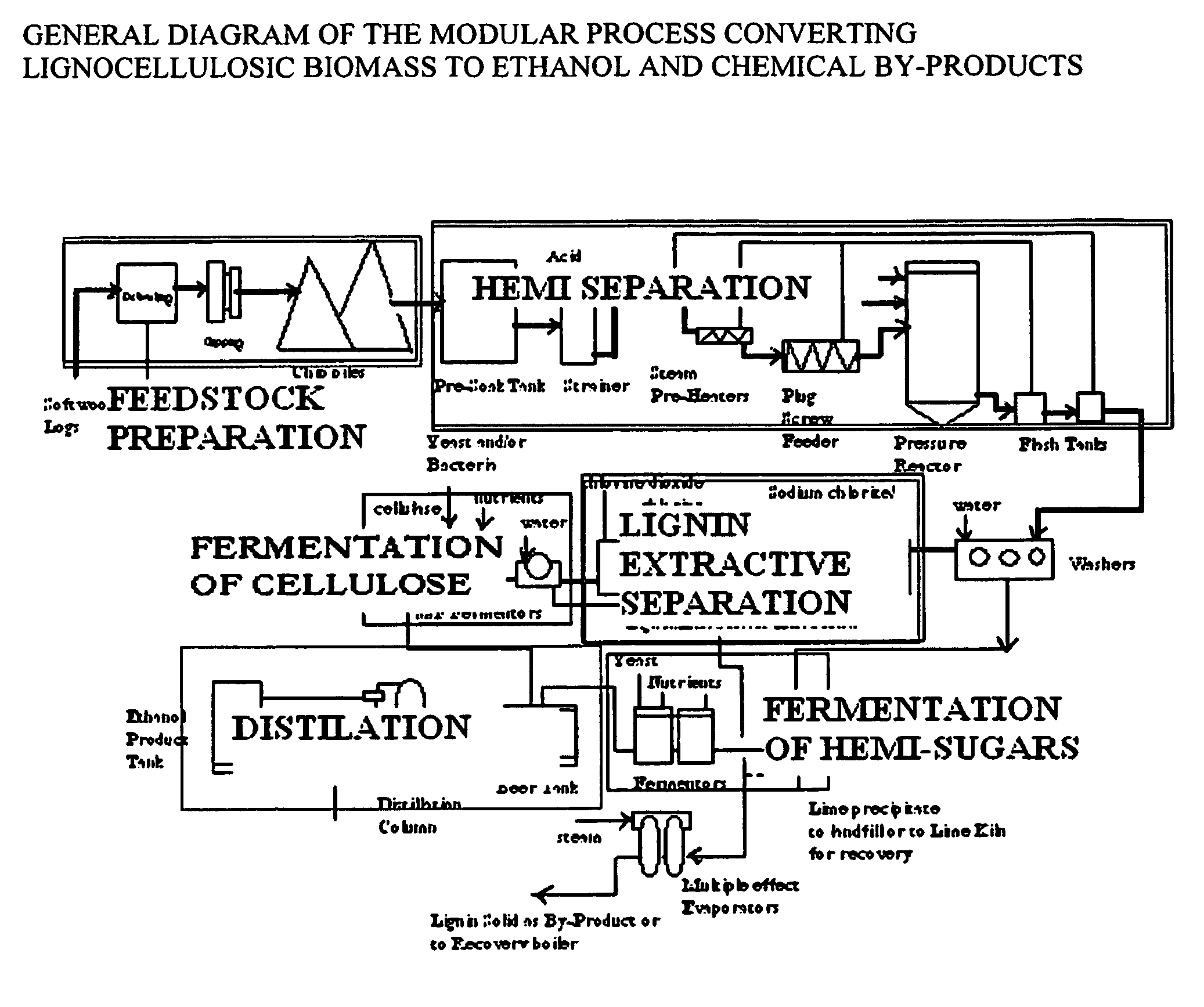

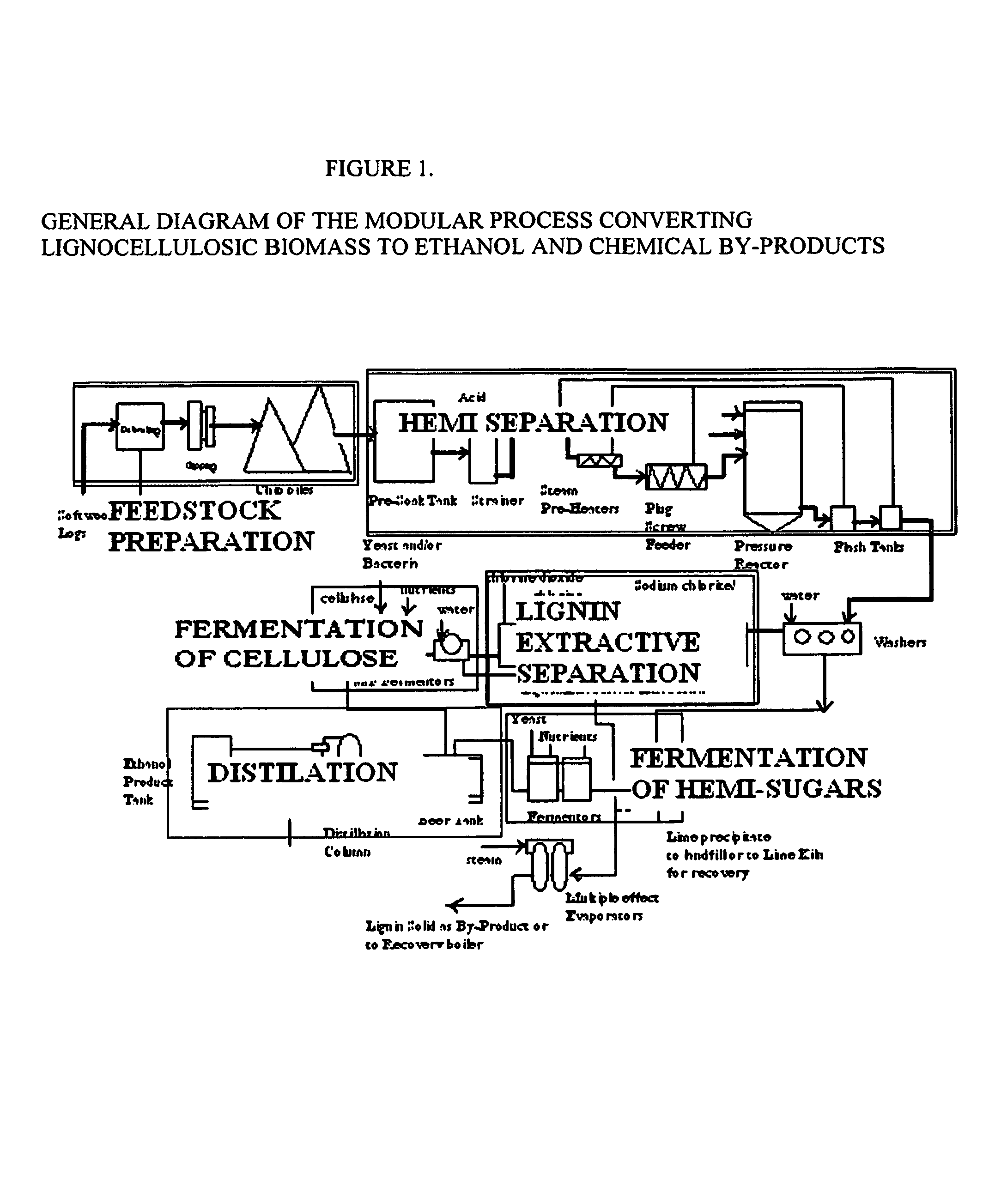

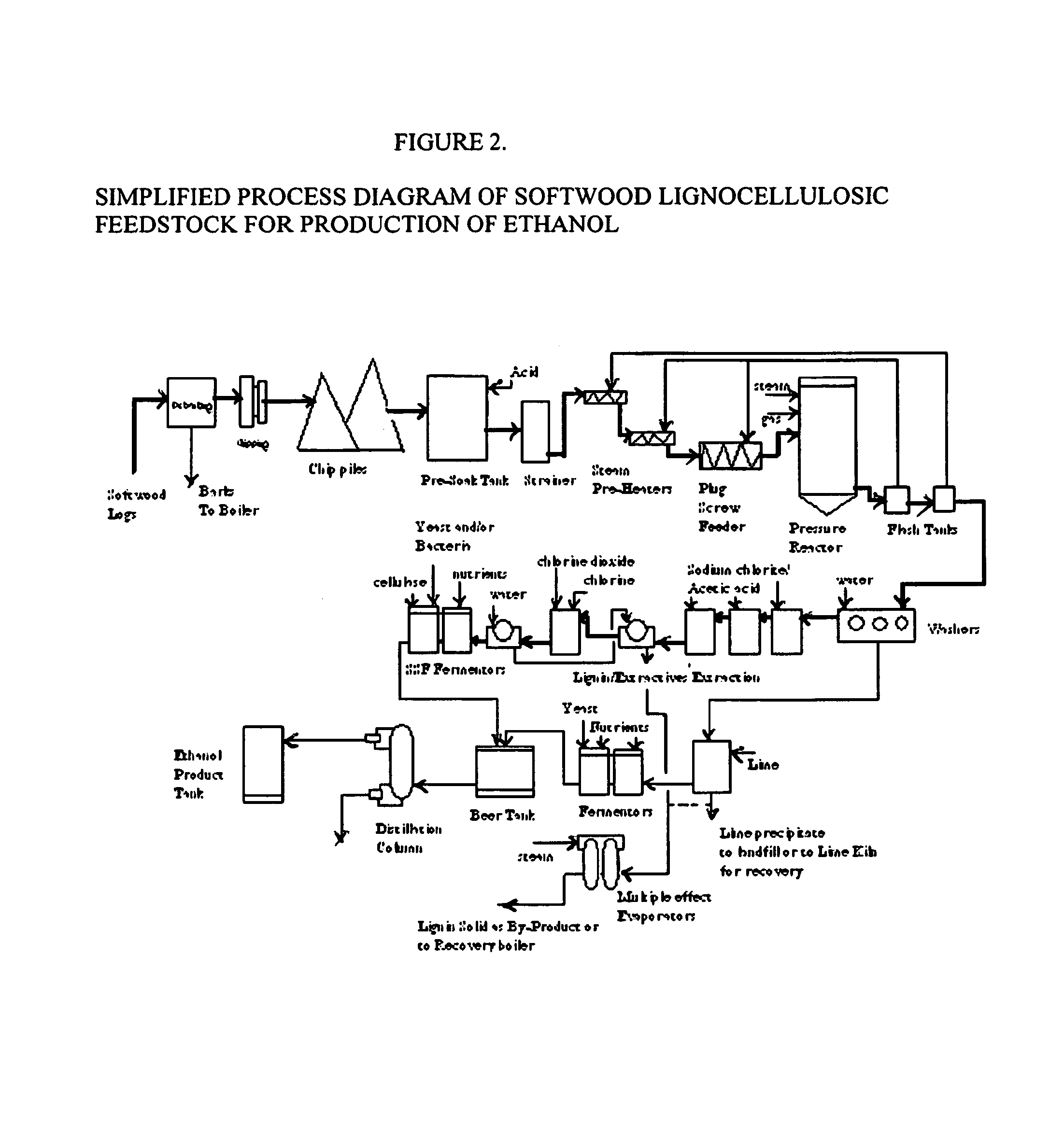

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

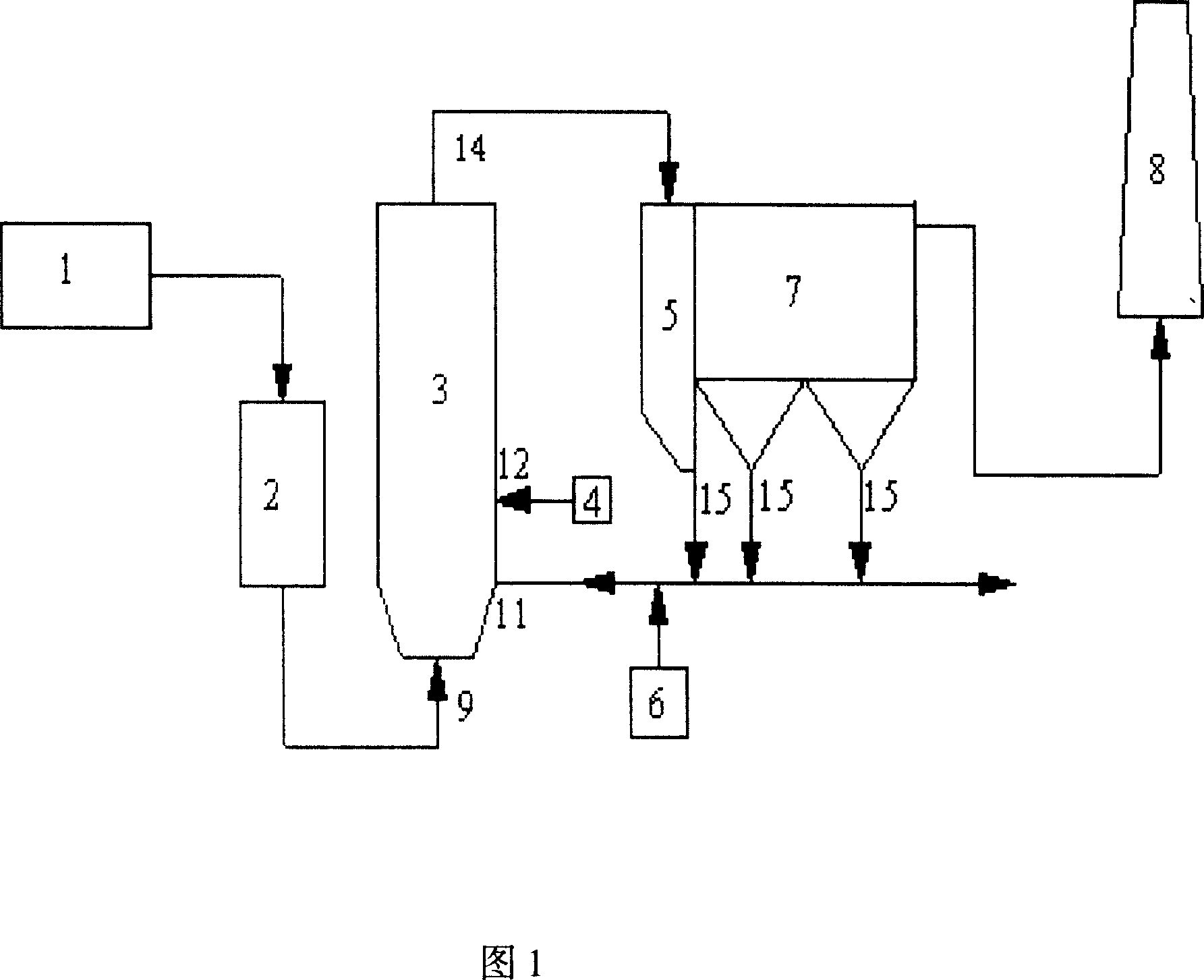

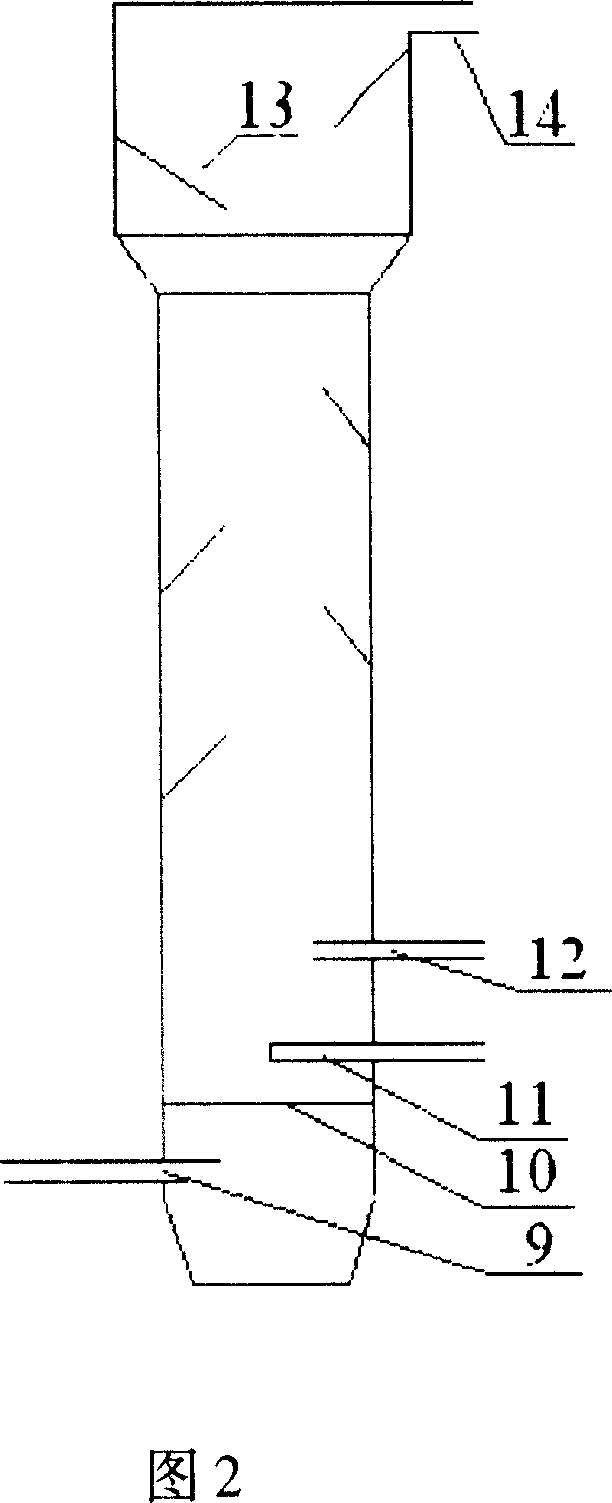

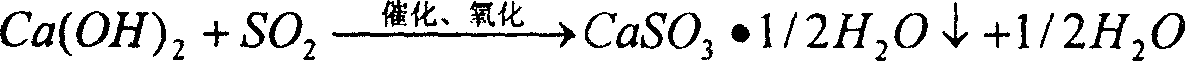

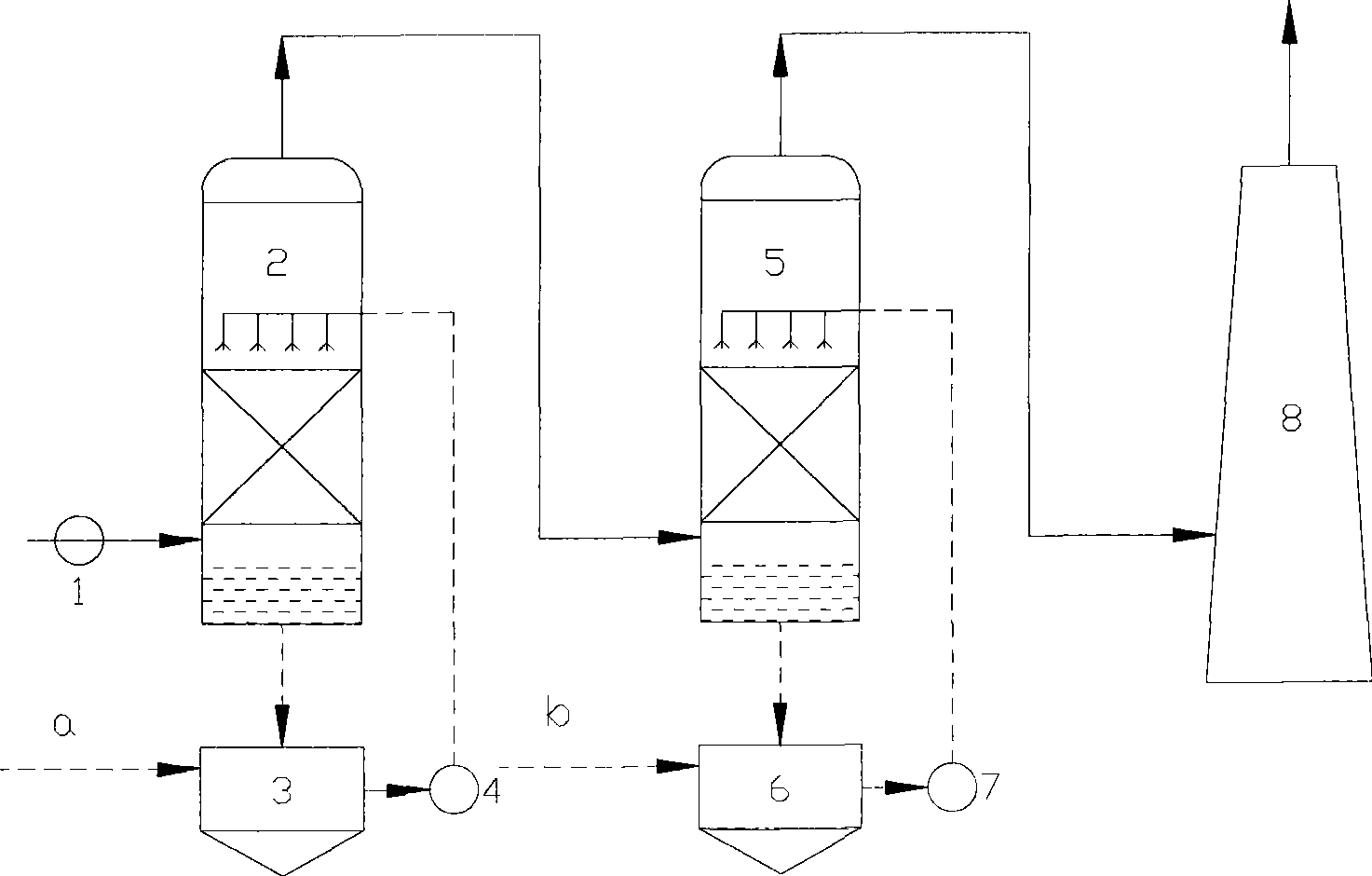

Method and apparatus for removing sulfur, nitrate and mercury simultaneously from boiler flue gas

InactiveCN1962034AExtended stayIncrease profitDispersed particle separationOxygenCalcium hypochlorite

The invention relates to a method for realizing desulfuration, denitration and demercuration of boiler smoke synchronously, wherein it comprises feeding smoke into cycle fluidize bed reactor, and injecting oxygen-enriched active absorber; said absorber is formed by coal ash at 20-70, lime hydrate at 27-80, additive at 0.5- 3 as kalii permangana KMnO4, sodium chlorite NaClO2, natrii chloridum NaCl, calcium hypochlorite Ca(ClO)2 or acetic hyctro peroxide CH3COOH. The invention's desulfuration efficiency can reach 90%, the denitration efficiency can reach 60%, and the demercuration can reach 50%, with low cost and non pollution.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

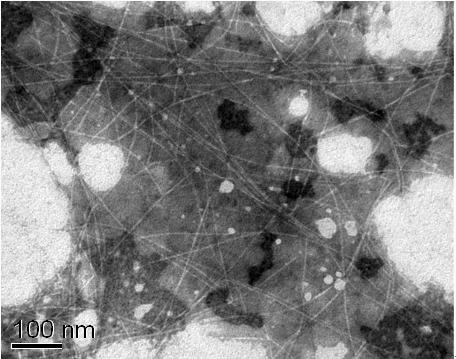

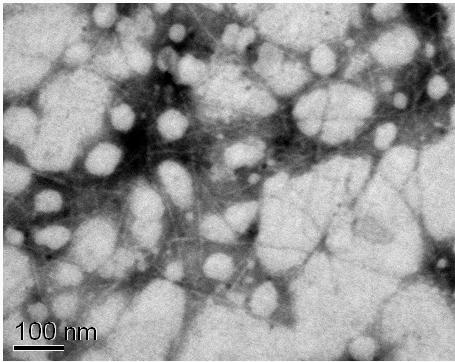

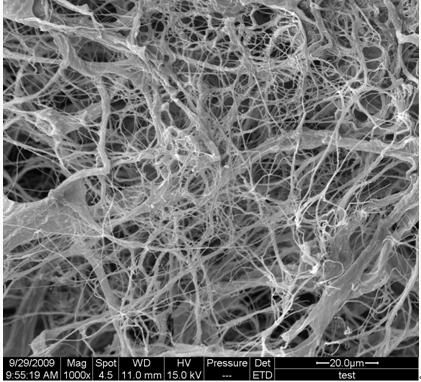

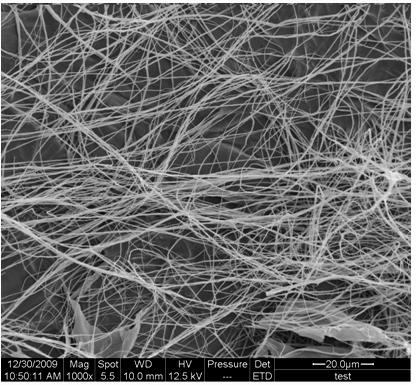

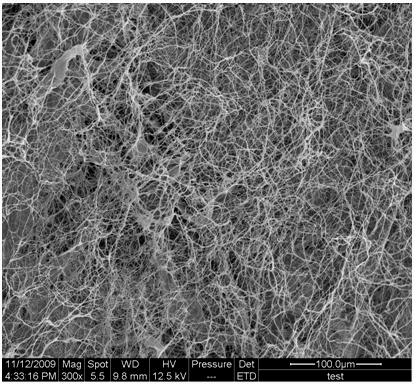

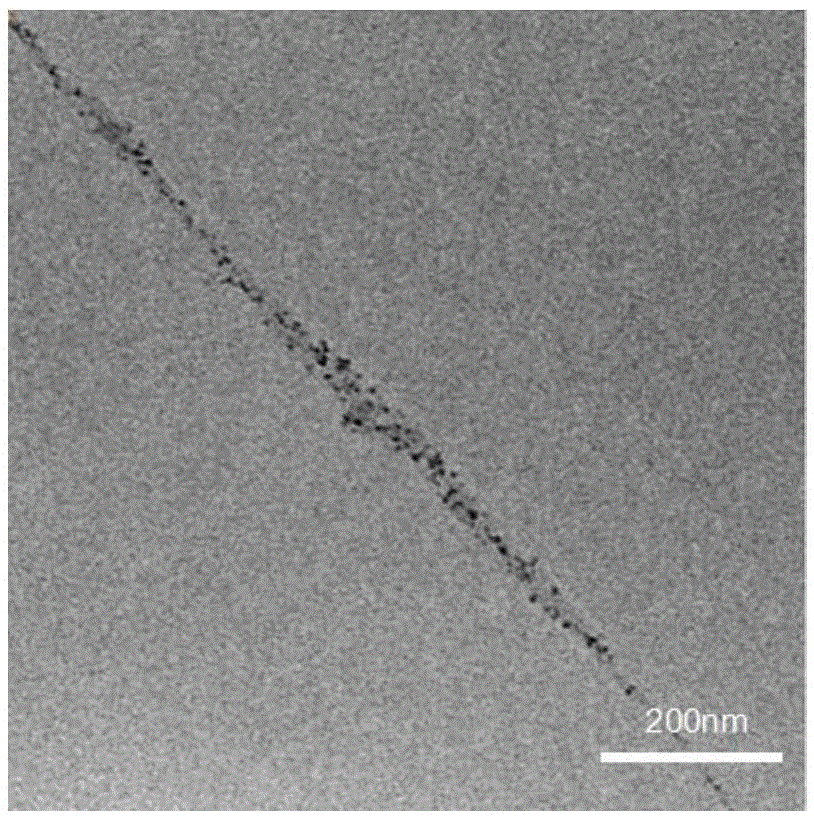

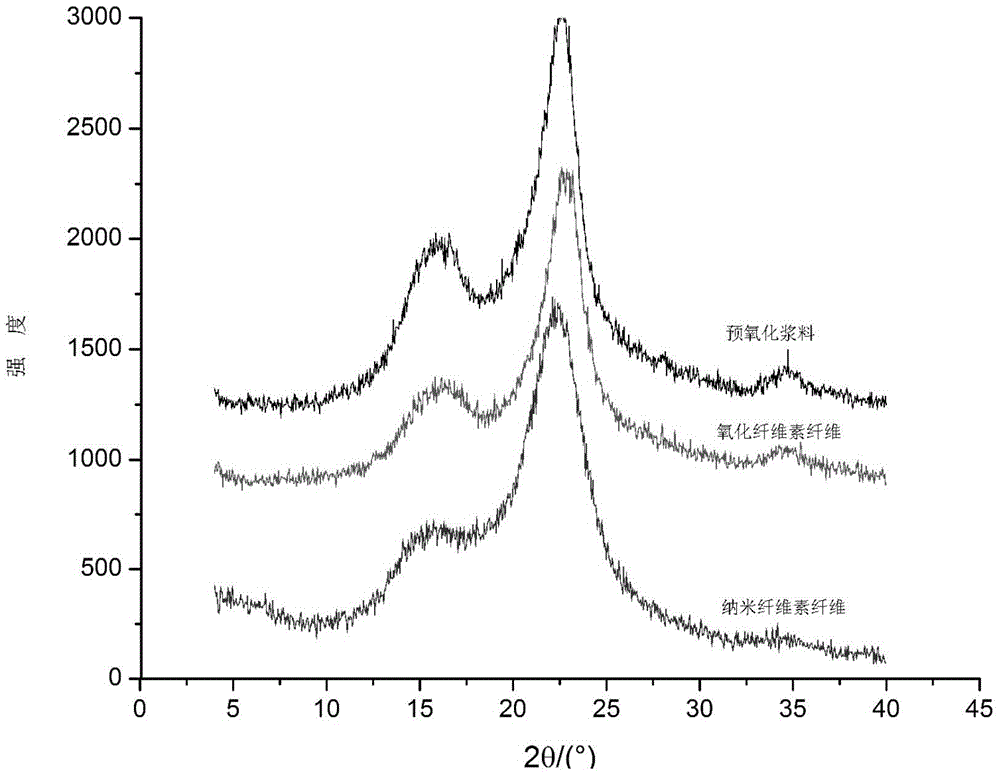

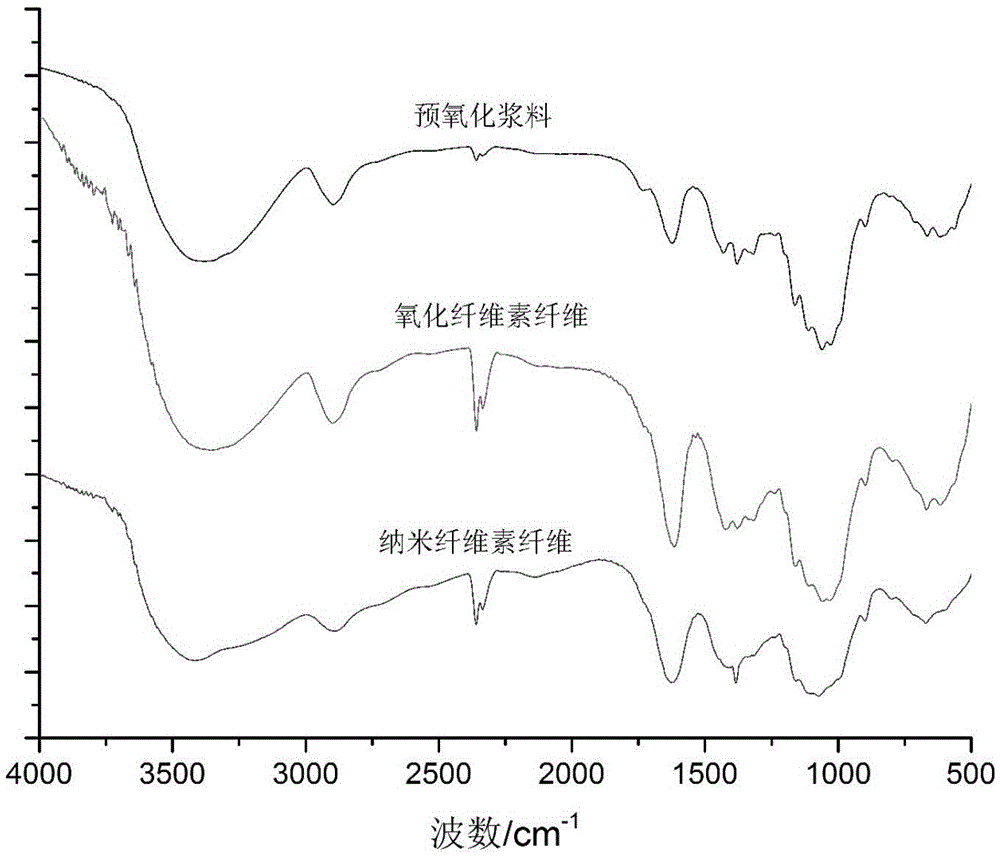

Preparation method of homogenized fine nano-cellulose fiber

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

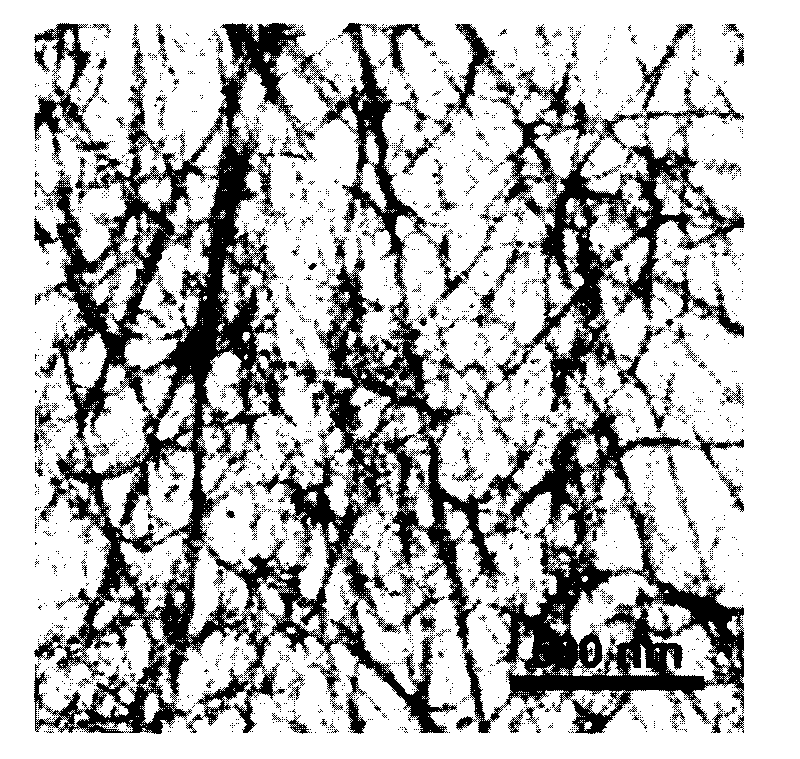

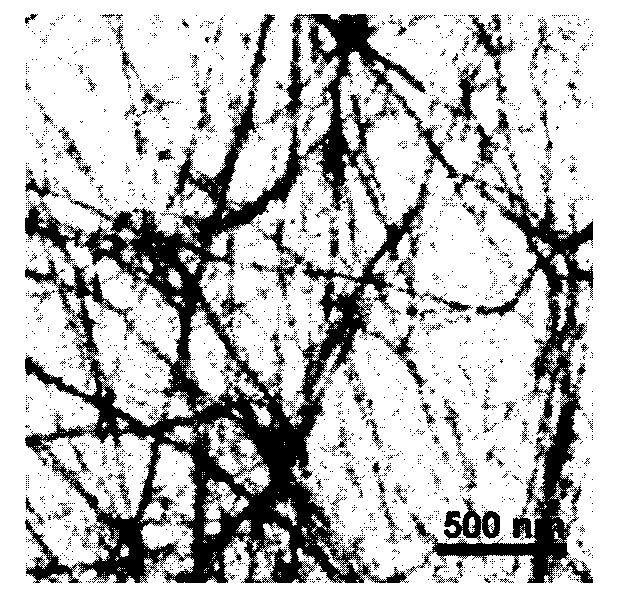

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Liquid-phase oxidation-absorption two-stage wet method flue-gas denitration technique

ActiveCN101385942ALow investment costLow running costDispersed particle separationPartial oxidationGas phase

The invention discloses a wet method smoke gas denitration technology of two segments of liquid phase oxidation and absorption, which adopts solution or mixtures of one or more of potassium permanganate, sodium chlorite, sodium hypochlorite, calcium hypochlorite, oxyful and chlorine dioxide as oxidizing agents to ensure nitrogen oxide in smoke gas contact and react with the oxidizing agents. After the nitrogen oxide is partially oxidized into nitrogen dioxide, oxidized nitrogen oxide in the smoke gas is absorbed by alkali liquid to generate corresponding nitrite. The technology adopts liquid phase oxidation to replace gas phase oxidation so as to reduce the investment and the running cost, simplify the technical process and the system structure, and enhance the operability. Compared with a method that oxidation and absorption are simultaneously carried out in the liquid phase, the two-segment technology not only can increase the removal efficiency, avoid secondary pollution caused by incomplete absorption of NO2, but also can achieve the purposes of selectively generating and recovering the nitrite in the absorption stage by controlling the oxidation degree of the oxidation stage.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Massive bodies containing free halogen source for producing highly converted solutions of chlorine dioxide

InactiveUS7182883B2Increase conversion rateImprove permeabilityBiocideOrganic chemistryHalogenLiquid water

A massive body, e.g., a tablet, for producing a solution of chlorine dioxide when the massive body is added to liquid water. The massive body comprises a metal chlorite such as sodium chlorite, an acid source such as sodium bisulfate and a source of free halogen such as the sodium salt of dichloroisocyanuric acid or a hydrate thereof. The concentration of free halogen in the solution will be:(a) less than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.25:1 by weight; or(b) equal to or greater than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.50:1 by weight.

Owner:ENGELHARD CORP

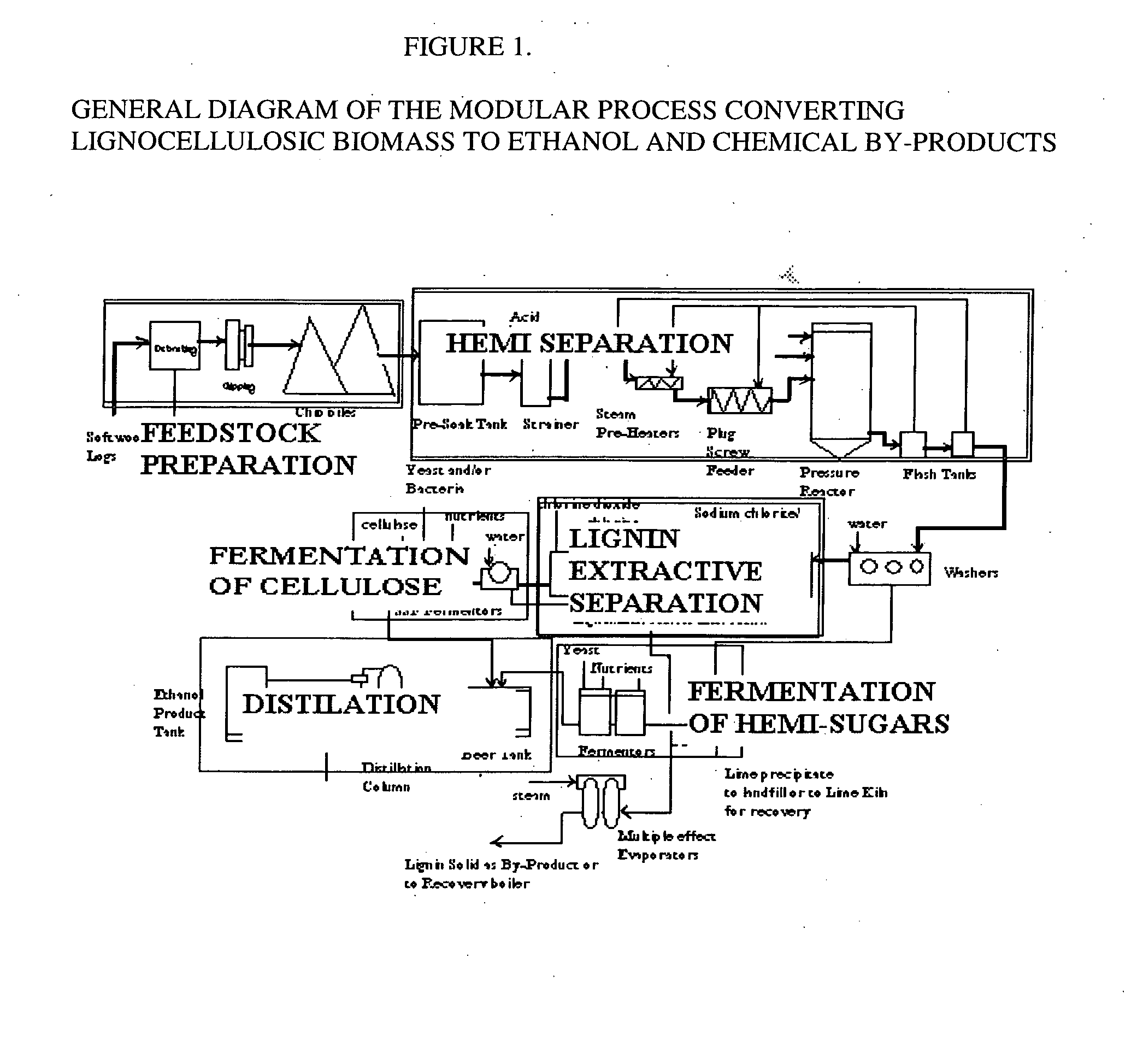

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS7666637B2Robust and cost-effectiveImproving biological reactivity of celluloseChemical industryBiofuelsChemical treatmentHydrolysate

The invented process separates main components in lignocellulosic biomass, specifically hardwoods, softwoods into lignin and fractions of high purity sugars which are used for ethanol production. The invented process comprises of treatment stages at high temperature and high pressure with hydrochloric acid or sulfuric acid. Residual lignin and extractives in the cellulosic solid fraction are selectively removed by chemical treatments of sodium chlorite, anhydrous acetic acid, chlorine and chlorine dioxide to enhance the purity and biological conversion of cellulose to ethanol. The pre-hydrolysate generated from the acid treatment stage, containing xylose, arabinose, galactose, glucose and the purified cellulosic fraction are enzymatically hydrolyzed and fermented to produce ethanol. Significant amount of lignin from the process is recovered as a by-product.

Owner:NGUYEN XUAN NGHINH

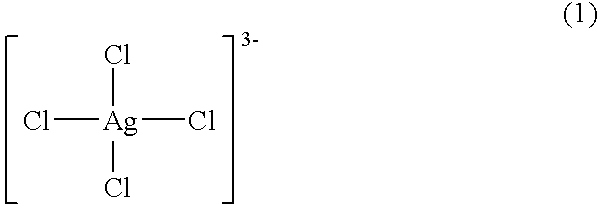

Antimicrobial agents

InactiveUS6726936B1Wide disinfecting spectrumAvoid problemsInorganic/elemental detergent compounding agentsBiocideMicrobial agentSolvent

An antimicrobial agent includes silver-chloro complex salts and chloride, and further oxidizing agents such as sodium hypochlorite or sodium chlorite. As a result, it is possible to provide the antimicrobial agent having immediate and residual disinfecting and antimicrobial effects on bacteria and molds of a wide variety of species and capable of demonstrating instantaneous deodorizing effect. The antimicrobial agent includes the silver-chloro complex salts and chloride, and further a compound, for example, such as alcohols or surfactants, which has compatibility with a solvent such as water which dissolves the chloride. As a result, it is possible to provide the antimicrobial agent which can be used conveniently at the stored concentration, and which has immediate effect and cleansing ability without causing rust or deposition of salts in use. Further, the antimicrobial agent includes the silver-chloro complex salts, and chloride, for example, such as polyaluminium chloride or benzalkonium chloride, which has at least (I) a property capable of existing as a supersaturated aqueous solution in the presence of a crystal nucleus at least at room temperature for 24 hours or longer and (II) a property capable of being decomposed when dissolved in water.

Owner:YOKOSAWA METAL

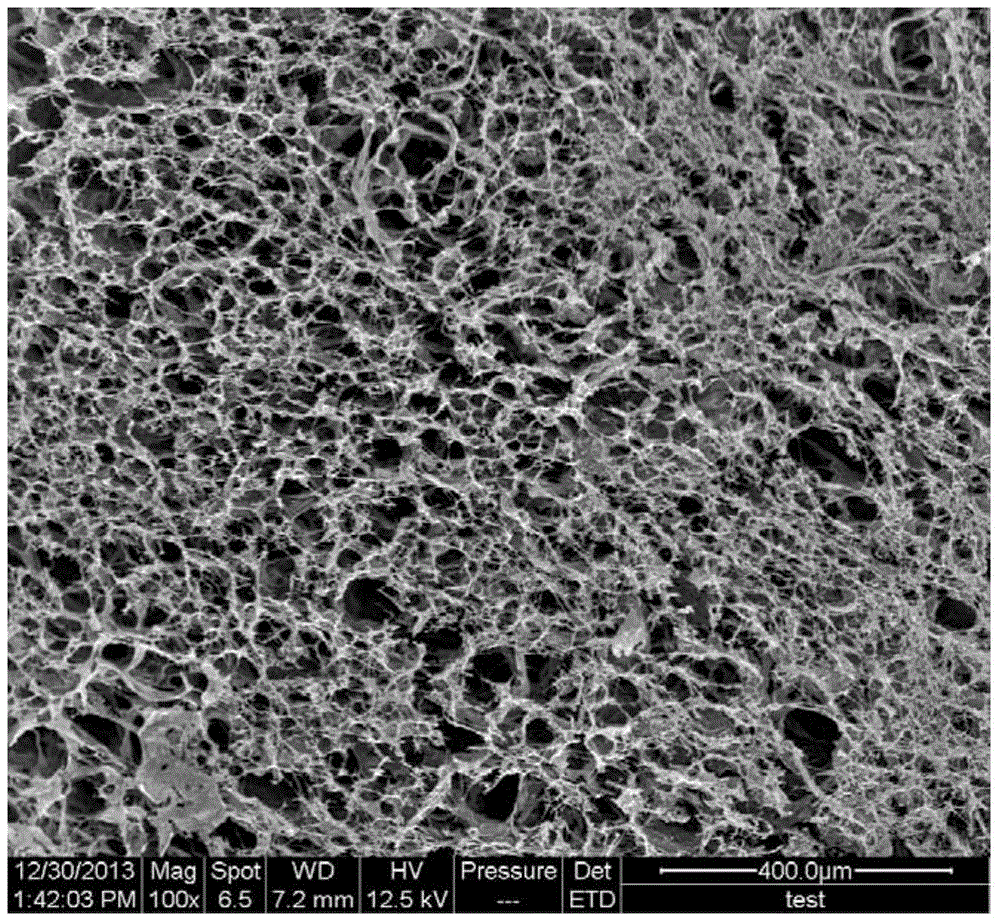

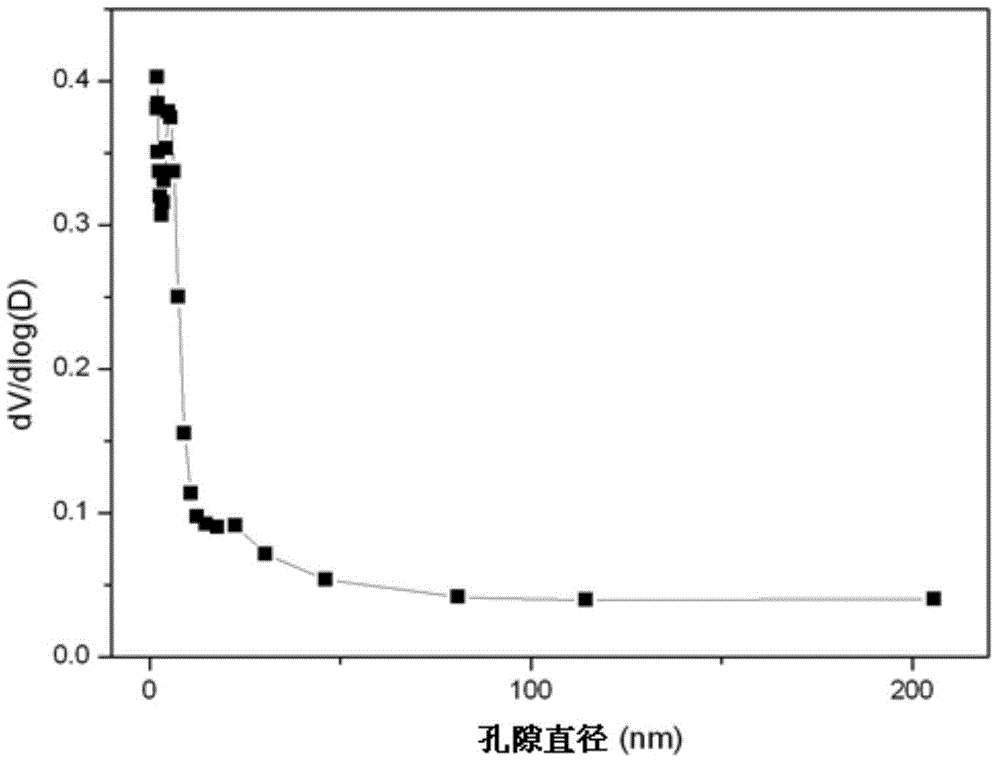

Preparation method of biomass nano cellulose carbon aerogel

The invention relates to a preparation method of a carbon aerogel, particularly a preparation method of a biomass nano cellulose carbon aerogel, and aims to solve the problems of complex preparation process and lack of raw materials in the traditional carbon aerogel. The method comprises the following steps: 1. treatment of biomass material: treating the biomass material with acidified sodium chlorite, and treating with a 1-10 wt% potassium hydroxide solution to obtain purified cellulose; 2. preparing purified cellulose water solutions with different concentrations; 3. mechanical treatment: carrying out ultrasonic treatment on the purified cellulose water solution, carrying out high-pressure homogenization treatment to obtain a nano cellulose water suspension, and standing the nano cellulose water suspension to obtain the nano cellulose aquagel by self-assembly; 4. drying the nano cellulose aquagel to prepare the nano cellulose aerogel; and 5. carrying out carbonizing treatment on the nano cellulose aerogel in a pipe furnace in an inert gas protective atmosphere to prepare the nano cellulose carbon aerogel. The method is applicable to the field of aerogel materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

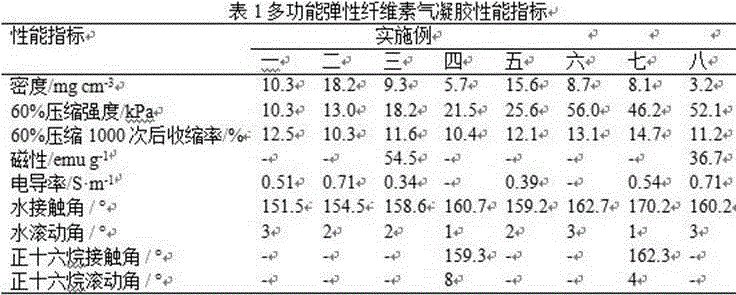

Preparation method of multifunctional cellulose elastic aerogel

The invention discloses a preparation method of a multifunctional cellulose elastic aerogel, belonging to the field of aerogel materials. The preparation method comprises the following steps: dispersing cellulose in water, carrying out pretreatment by adding sodium chlorite or / and in a solvothermal way, and cleaning with deionized water to obtain a purified cellulose dispersion solution; adding a modifier to perform chemical modification, thereby obtaining a modified cellulose suspension; dispersing the modified cellulose suspension in an organic solvent, forming, drying to form a modified cellulose gel, and finally, carrying out heat treatment on the modified cellulose gel to obtain the multifunctional cellulose elastic aerogel. The cellulose is subjected to pretreatment and chemical modification, thereby lowering the density of the aerogel, greatly enhancing the elasticity and mechanical strength of the aerogel, endowing the aerogel with excellent magnetism, electric conductivity, superhydrophobicity, superoleophobicity and many other functions, and widening the application range of the traditional cellulose aerogel.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

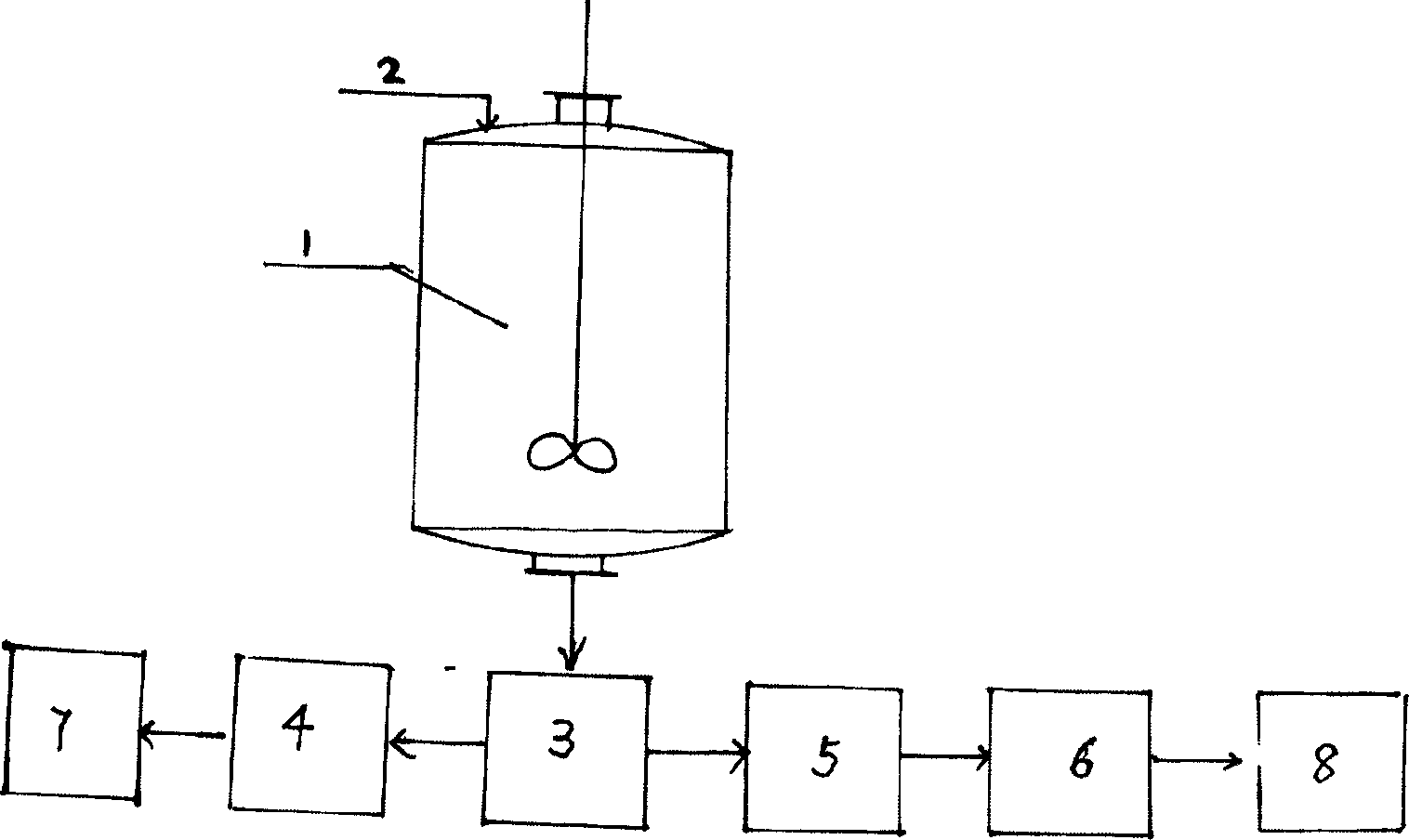

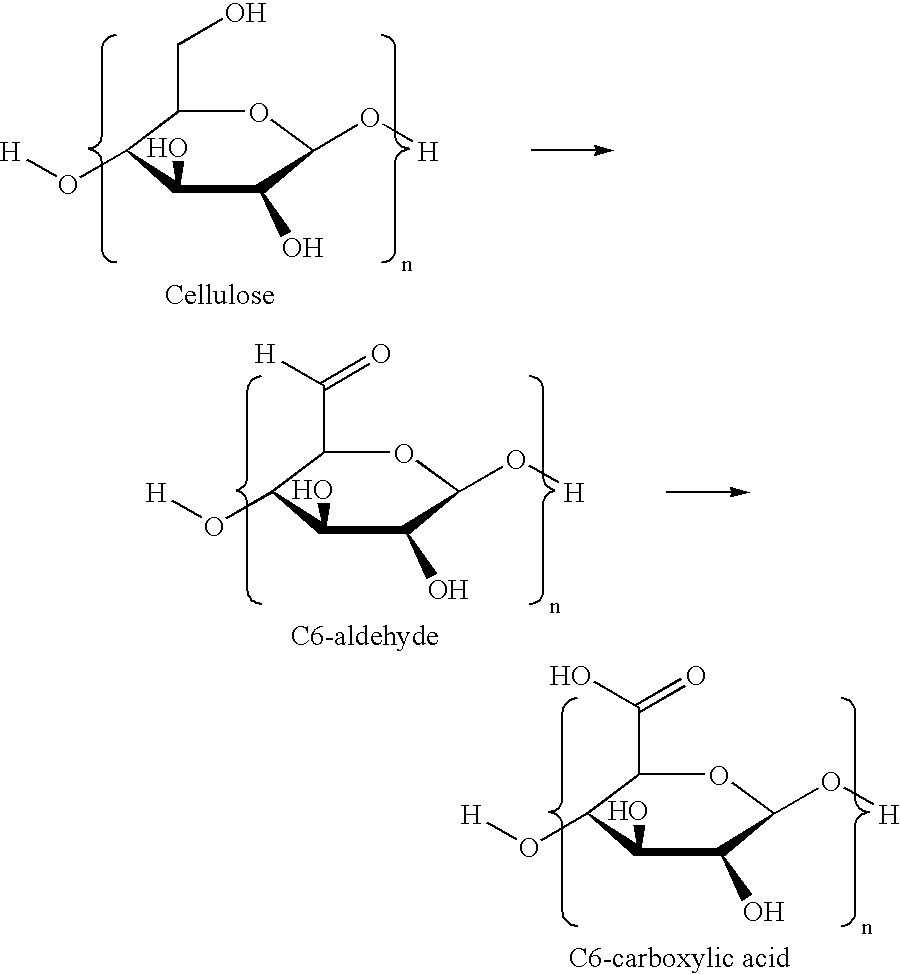

Solid stable chlorinedioxide antiseptics and preparation thereof

A stable solid ClO2 disinfectant is prepared from sodium chlorite, solid acid, composite coating agent and composite trigger through compounding and passivating. Its advantages are high stability and safety, and long storage period.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

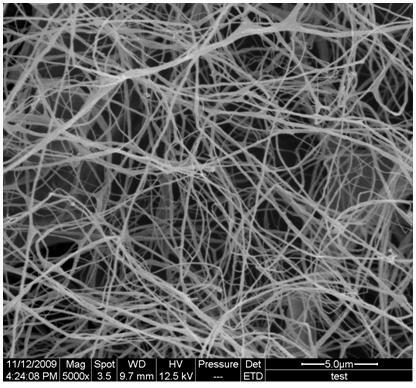

Method for preparing lignocellulosic nanofibrils

ActiveCN101691698AHigh yieldReduce forcePulping with acid salts/anhydridesPulping with inorganic basesAcetic acidFibril

The invention discloses a method for preparing lignocellulosic nanofibrils, which relates to a method for preparing nanofibrils. The method solves the problems that the traditional cellulose fiber manufactured by taking timber as a raw material has poor strengthening and toughening effects and cellulose fibrils obtained through the preparation have low yield. The method comprises the steps of: 1, extracting wood meal; 2, mixing raw materials and performing heating treatment on the mixture; 3, then adding glacial acetic acid and sodium chlorite into the mixture, and performing heating treatment after the mixing; 4, removing lignin; 5, removing hemicellulose; 6, re-removing the lignin; 7 re-removing the hemicellulose; and 8, performing ultrasonic crushing treatment to obtain the lignocellulosic nanofibrils. The yield of the manufacturing method is between 80 and 90 percent and is high; and the lignocellulosic nanofibrils prepared by the method have good strengthening and toughening effects.

Owner:NORTHEAST FORESTRY UNIVERSITY

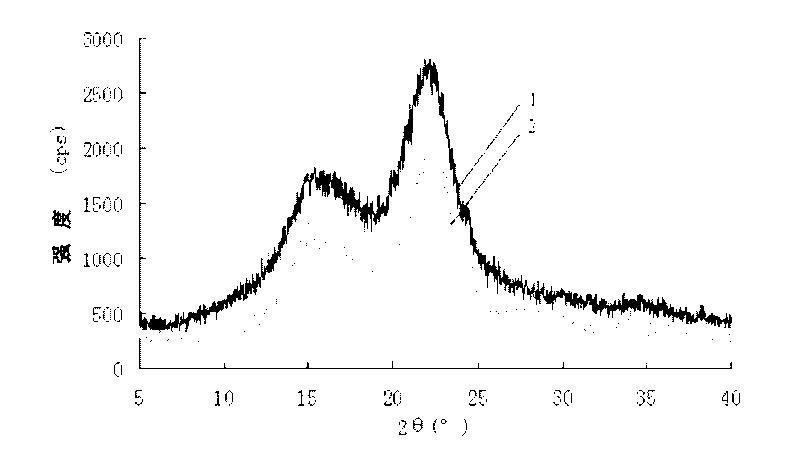

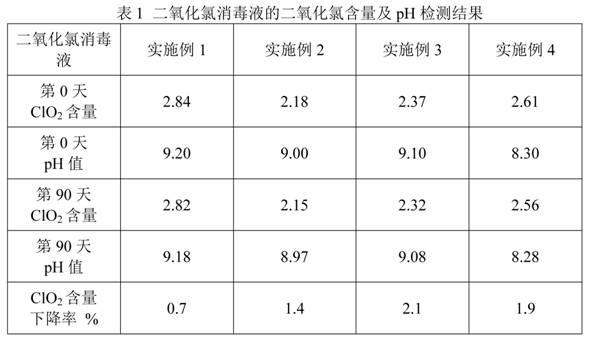

Stabilized chlorine dioxide disinfection solution and its preparation method

The invention discloses a stabilized chlorine dioxide disinfection solution and its preparation method. The disinfection solution is composed of component A and component B, wherein component A is stabilized sodium chlorite solution consisting of chlorite, a stabilizing agent, a complexing agent, a pH stabilizing agent, and the balance a pH conditioning agent and water; component B is an activating agent, which can be at least one of citric acid and hydrochloric acid. The product of the invention has the advantages of stability, long shelf-life, and a validity period up to 2 years, and can be used as a disinfectant. The disinfection solution of the invention has simple process and convenient usage. In the invention, the original mode of pH value adjusting by acid is changed, and zinc chloride and zinc acetate are employed to remove sodium hydroxide in raw materials and reach the purpose of pH value adjusting. Simultaneously, zinc acetate and sodium hydroxide generate no amphoteric substance, and the actual operation is easier.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

Sterilizing bath lotion for furry pets

InactiveCN101810542AEasy to rinse offMild in natureCosmetic preparationsHair cosmeticsLotionSodium chlorite

The invention provides sterilizing bath lotion for furry pets, which comprises surfactant, humectant, hair care agent, chelating agent, bactericide, thickening agent and essence, wherein the bactericide is one of stable liquid chlorine dioxide, stable solid chlorine dioxide or sodium chlorite. The sterilizing bath lotion of the invention overcomes the defects of the existing product or the prior art, and really realizes synchronous completion of three effects of removing dirt, caring hair and quickly sterilizing. The sterilizing bath lotion has the advantages of mild property, no any stimulation to the fur of animals and the skin of people, good dirt removing and sterilizing effects, low foam, easy cleaning, no residue, safety and environment friendliness, and meanwhile plays a role in caring the fur of the animals so that the fur of the washed pet does not knot; and the sterilizing bath lotion is glossy, flexible and easy to card, and is quite suitable for the daily care of the furry pets.

Owner:BEIJING OKEANOS TECH

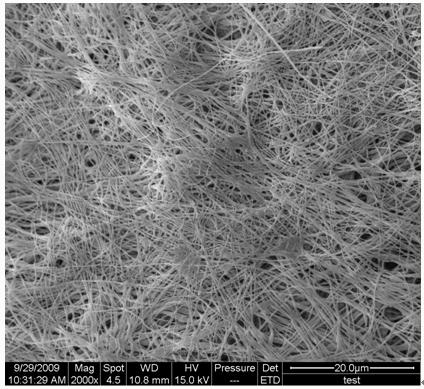

Method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment

InactiveCN101851801AUniform fibrillationRegular shapeArtificial filaments from cellulose solutionsBenzeneAlcohol

The invention provides a method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment, which relates to a preparation method of nanometer cellulose fiber. The invention solves the problems of short length, nonuniform fiber diameter distribution and easy interweaving between fiber into cluster nanometer fiber of the nanometer cellulose fiber prepared by the existing method only using mechanical high-pressure homogenization treatment. The method of the invention comprises the following steps that: 1. biomass fiber is extracted by an alcohol benzene solution; 2. the treatment by acidified sodium chlorite is carried out; 3. alkali liquor gradient treatment is carried out; 4. an ultrasonic cell crushing machine is used for treatment; and 5. high-pressure homogenization treatment is carried out, and nanometer cellulose fiber is obtained after being dried. The fiber diameter distribution is uniform, the length is longer than or equal to 150 mum, the slenderness ratio is larger than or equal to 600, and the fiber is mutually interwoven into a reticular winding structure. The method of the invention is applicable to the preparation of nanometer cellulose fiber from wood pulp, papermaking pulp materials, wood materials, bamboo materials and crop straws.

Owner:NORTHEAST FORESTRY UNIVERSITY

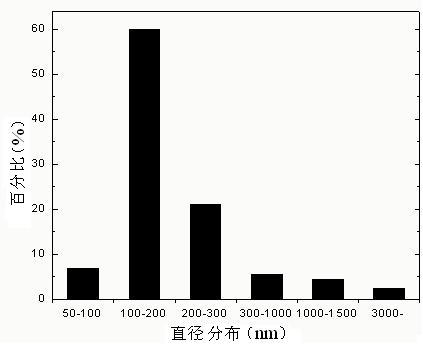

Preparation method of biomass cellulose nanofibers with high length-diameter ratio

InactiveCN101864606AHigh crystallinityBroad nanoscaleMonocomponent cellulose artificial filamentStrong acidsDiameter ratio

The invention relates to a preparation method of biomass cellulose nanofibers with a high length-diameter ratio, in particular to a preparation method of nano cellulose fibers, solving the problems that nano cellulose fibers prepared by using a traditional method for hydrolyzing biomass cellulose with strong acid have short length and small length-diameter ratio, nano cellulose fibers prepared by using a mechanical shearing method are easy to mutually aggregate, and a microbial fermentation method has high cost. The method comprises the following steps of: (1) purifying biomass cellulose with a benzyl alcohol solution; (2); treating with acidified sodium chlorite; (3) treating lye; (4) treating with the acidified sodium chlorite again; (5) treating with KOH; (6) treating with hydrochloric acid; and (7) ultrasonically treating and drying to obtain biomass cellulose nanofibers with high length-diameter ratio not less than 1500, fiber diameter from 50 nm to 300 nm, length not less than 150 um and length-diameter ratio not less than 1500. The biomass cellulose nanofibers are mutually interwoven into a tightly wound mesh structure. The invention has low cost and is suitable for preparing nano cellulose fibers from wood, bamboo, cotton, linen and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for the synthesis of chlorine dioxide

Owner:DEGUSSA CORP

Solid chlorine dioxide sustained-release material and preparation method thereof

InactiveCN108751385AAchieve securityAchieve long-term effectBiocideFungicidesChemical reactionSilicon dioxide

The invention discloses a solid chlorine dioxide sustained-release material and a preparation method thereof, raw materials comprise sodium chlorite, a solid acid, a carrier material, a coating agentand auxiliary agents; the carrier material is silicon dioxide aerogel micro powder; and the auxiliary agents include an accelerator, a stabilizer, and a binder. The solid chlorine dioxide sustained-release material can realize a controllable release rate of chlorine dioxide by silicon dioxide aerogel micro powder loading, polymer coating and accelerator adjustment, and has more excellent air purification effect; the safety, long-term stability and stability of the chlorine dioxide released by the solid chlorine dioxide sustained-release material can be realized by controlling of the mass transfer of a chemical reaction process for producing the chlorine dioxide; the solid chlorine dioxide sustained-release material product prepared by the method is convenient to use, can effectively removeair pollutants (such as formaldehyde), deodorizes (H2S), and sterilizes, air is purified, and the solid chlorine dioxide sustained-release material product is safe and environmentally-friendly, is stable and reliable in production process, high in efficiency and low in cost, and has a good market prospect.

Owner:SUZHOU SASENS CO LTD

Sustained-release chlorine dioxide disinfectant and method for preparing same

InactiveCN108651453AThe finished product is safe and reliableNo harmBiocideDispersed particle separationDisinfectantHazardous substance

The invention discloses a sustained-release chlorine dioxide disinfectant and a method for preparing the same. The method includes steps of S1, mixing sodium chlorite powder, silica gel powder and diatomaceous earth with one another according to certain proportions to obtain coating agents; S2, mixing the coating agents and carrier granules with one another, feeding the coating agents and the carrier granules into granulators, spraying adhesive into the granulators and carrying out coating, granulating and drying to obtain the sustained-release chlorine dioxide disinfectant; S3, packing the sustained-release chlorine dioxide disinfectant in air permeable bags. The sustained-release chlorine dioxide disinfectant and the method have the advantages that finished products of the sustained-release chlorine dioxide disinfectant prepared by the aid of the method are safe and reliable and are free of harm on human bodies; bacteria and viruses in air can be effectively killed by the sustained-release chlorine dioxide disinfectant, and harmful substances such as formaldehyde can be degraded by the sustained-release chlorine dioxide disinfectant; the finished products are long in shelf life,and the shelf lives of the finished products can be greatly prolonged under wet-insulation storage conditions.

Owner:张志 +1

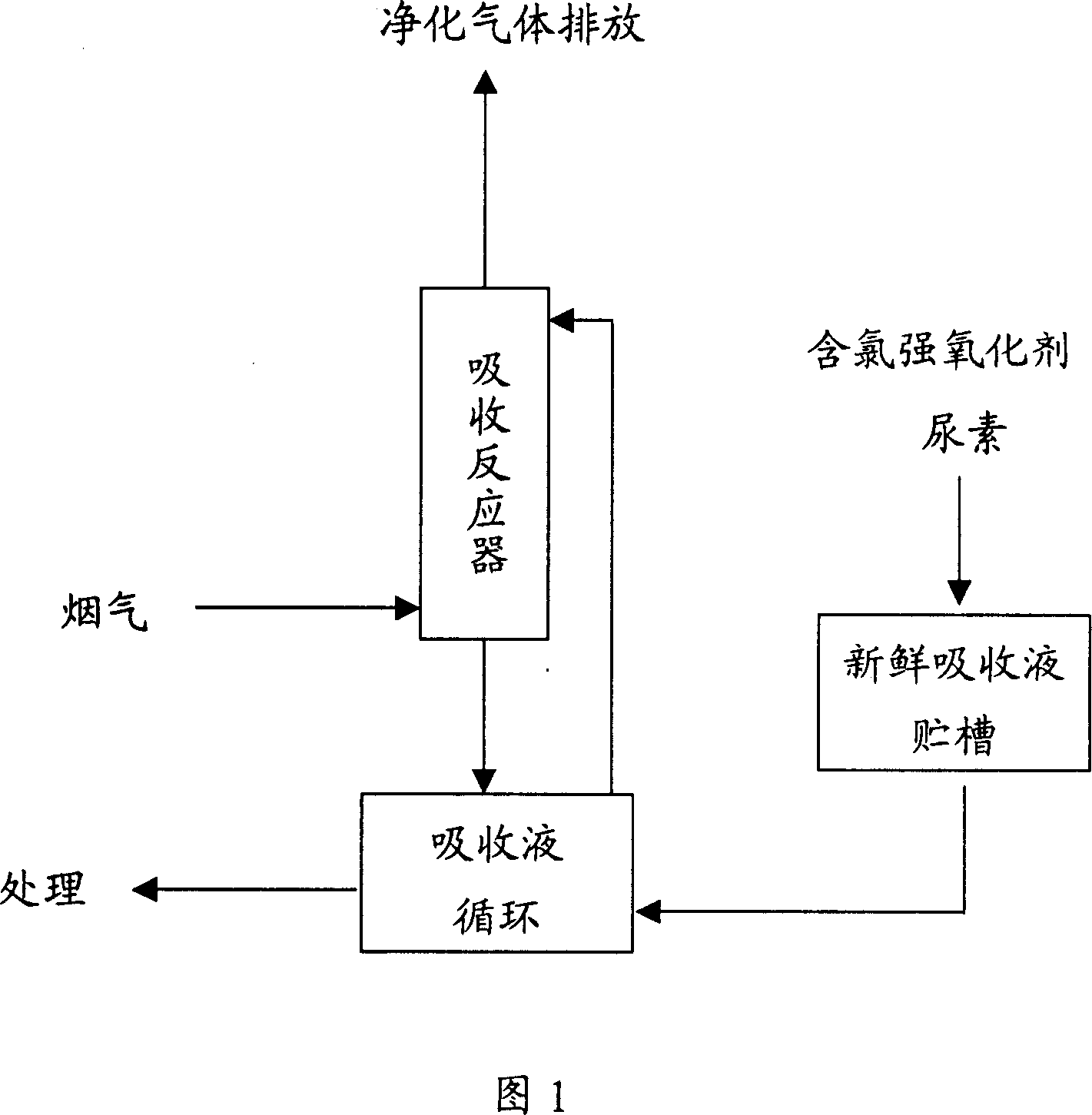

Chloric strong oxidant enhanced wet combined urea desulfurizing and denitrifying process

InactiveCN1986033AIncrease the degree of oxidationImprove denitrification efficiencyDispersed particle separationAir quality improvementNitrogen oxideSodium chlorite

The wet combined fume desulfurizing and denitrifying process with chloric strong oxidant enhanced urea has the fume to be treated contacted sufficiently with the mixed absorbent liquid containing urea and chloric strong oxidant inside the absorbing reactor so as to eliminate NOx and SO2 through absorption before being exhausted. The chloric strong oxidant is sodium chlorite, sodium hypochlorite, bleaching powder or their mixture. The process has high denitrifying efficiency, high fume purifying effect, simple structure, easy operation and small occupied land. The said process can reach NOx eliminating rate of 75-98 % and desulfurizing efficiency over 95 %.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Method for preparing cellulose nano-fibril film by utilizing wood powder

InactiveCN102899949AReduce hydrogen bondingHelp removeFibrous raw materialsFibrilPotassium hydroxide

The invention relates to a method for preparing a cellulose nano-fibril film by utilizing wood powder, which comprises the following steps: 1) chemically pre-processing; 2) mechanically separating; and 3) preparing a film. The method has the advantages: the acid-base pre-processing is combined with wood powder grinding and is adopted for preparing; the lignin in the wood powder is removed by mainly utilizing sodium chlorite under an acidic condition; the half-fibril is removed by using the diluted potassium hydroxide and the remained substrate is cellulose; and the diluted hydrochloric acid is used for splitting the cellulose. The acting force of hydrogen bonds in the fibril is reduced by adopting the splitting treatment, so that the biomass cellulose nano-fibril at high length-diameter ratio is obtained; the mineral substance in the fiber is removed by utilizing HCl treatment, the alkali insoluble half-cellulose in the purified cellulose is influenced and the effect of purifying the cellulose fiber is achieved; the chemical constituents are detected through Fourier transform infrared; the grinding treatment is simple and easy to operate and the mass production is performed; the modulus of elasticity is 3105.27MPa; and the tensile strength is 64.24MPa.

Owner:襄垣县鑫瑞达连氏塑木制造有限公司 +1

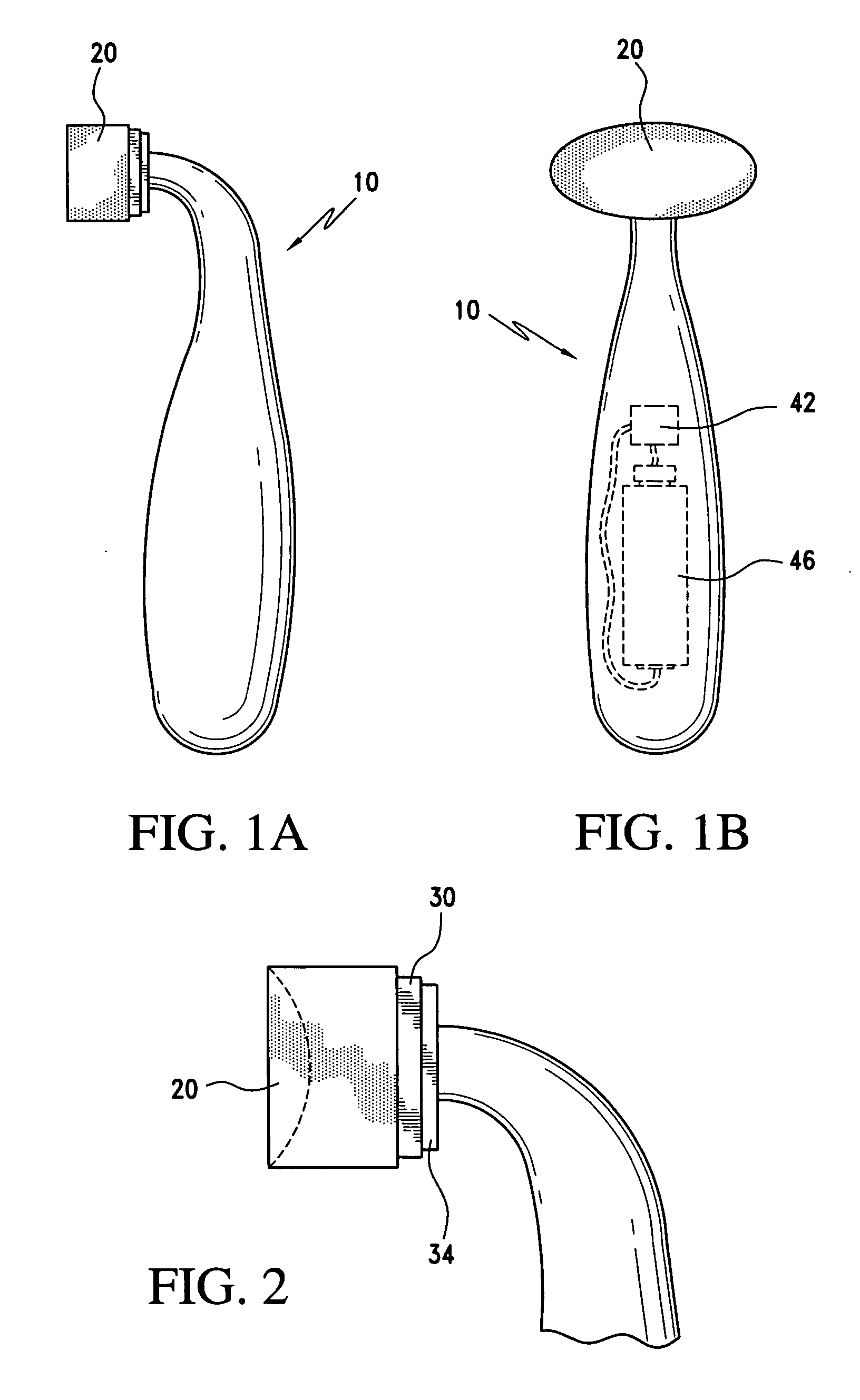

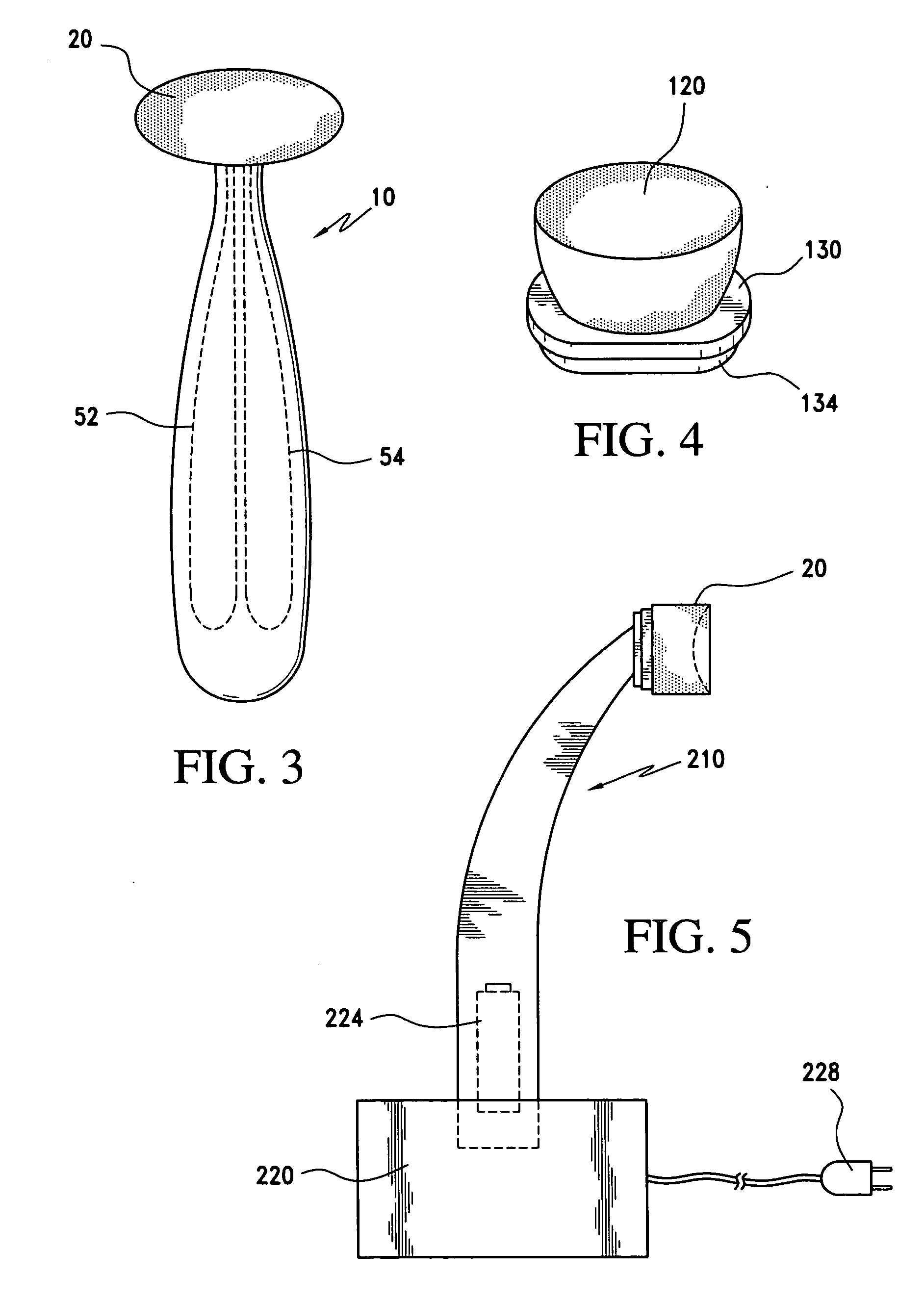

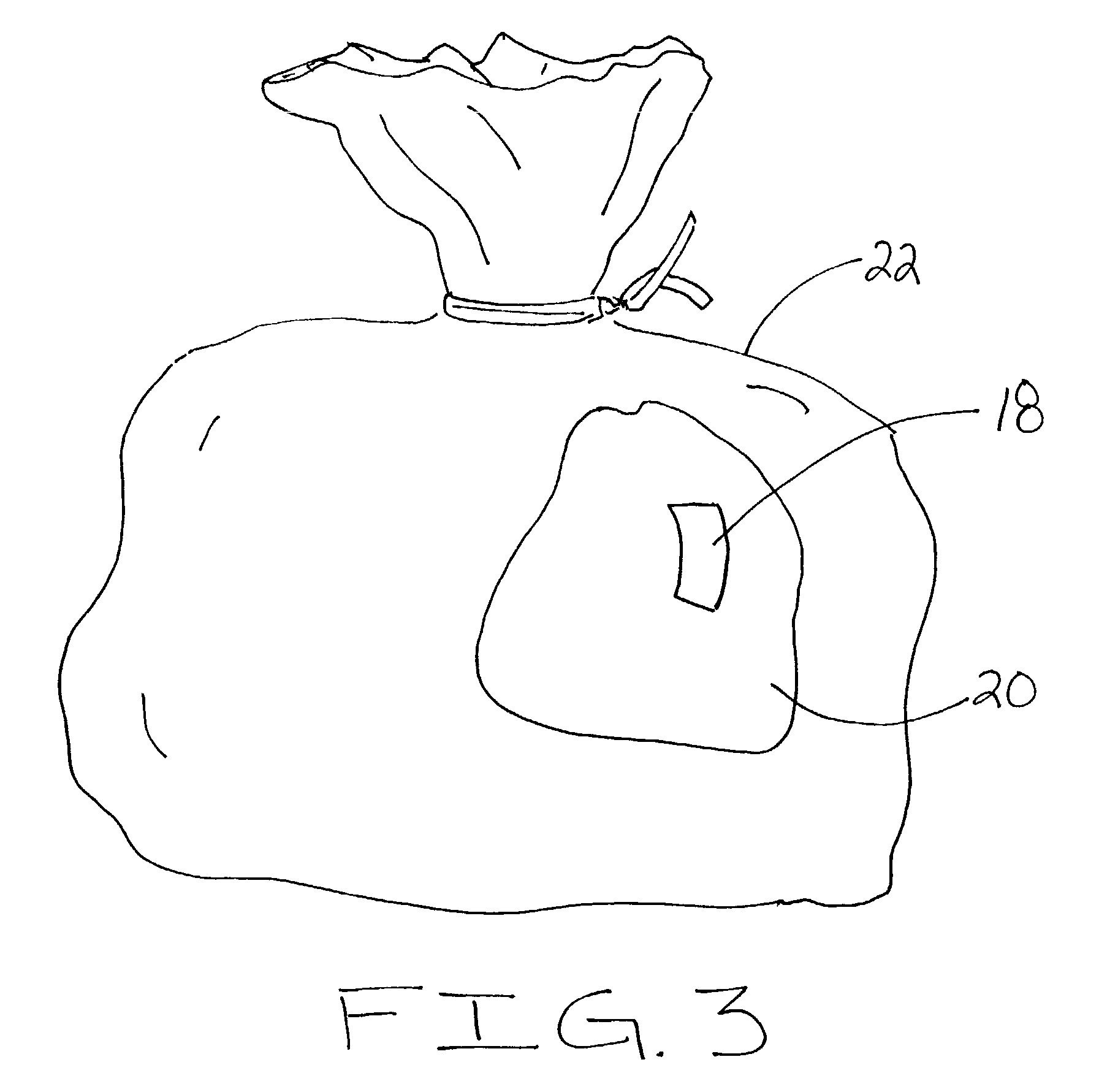

Method and device for whitening teeth

InactiveUS20070009857A1Rapid and efficient whiteningSpeed up the processCosmetic preparationsTeeth fillingCarbamide peroxideAcoustic wave

Method rapidly whitens teeth by using whitening compound containing an oxidizing agent, such as carbamide peroxide, hydrogen peroxide, sodium chlorite, and / or chlorine dioxide. Sonic device emits sonic waves directly to the tooth, transfers the sonic waves through a medium which may be a mist, an encapsulated liquid, a solid, a sponge, or any combination. Device may have a heat source which has controlled temperature of 1°-3° F. to increase the temperature of the tooth whitening compound. Sonic device sonic energy emission to whitening compound applied to teeth, and temperature increase, increases the kinetics, and speeds up the tooth whitening process. A pH adjusting agent included in the whitening compound or directly applied to the teeth may be a pre-treatment rinse, or be via a coating in an encapsulated bag, or within a moistened sponge-like material for releasing onto teeth when the sponge material is pressed against teeth.

Owner:DENTOVATIONS

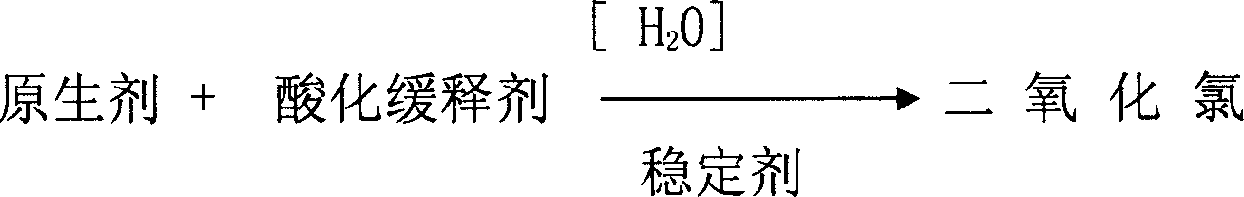

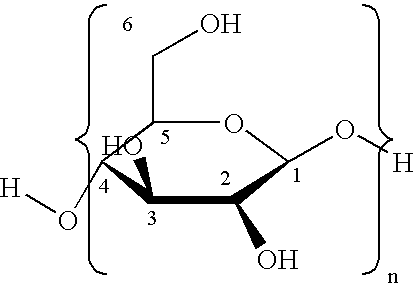

Nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof

InactiveCN105463606AIncrease the total carboxyl contentGuaranteed crystallinityOther chemical processesArtificial filaments from cellulose derivativesPolymer scienceFreeze-drying

The invention belongs to the technical field of biomass nanometer materials and discloses a nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof. A preparation method comprises the steps of preheating fiber slurry for 0.5-1.5h with sodium periodate at the temperature of 50-60 DEG C; adding a sodium chlorite solution and acetum into the slurry to be reacted for 1-3h at the temperature of 30-50 DEG C, adding TEMPO, NaClO2 and NaClO, and performing microwave heating to the temperature of 55-65 DEG C to enable the mixture to be reacted for 1-3h; performing ultrasonic dispersion and freeze drying to obtain the nano-crystalline cellulose fiber high in carboxyl group content. According to the nano-crystalline cellulose fiber, hydroxyl at the positions of C2 and C3 of cellulose is oxidized into a formyl group which is oxidized into carboxyl by sodium chlorite, hydroxyl at the position of C6 is selectively oxidized into carboxyl through a TEMPO neutral oxidation system, and accordingly the total carboxyl group content of the fiber is greatly increased, and obtained products can be used for advanced treatment of waste water at the middle section of paper making.

Owner:SOUTH CHINA UNIV OF TECH

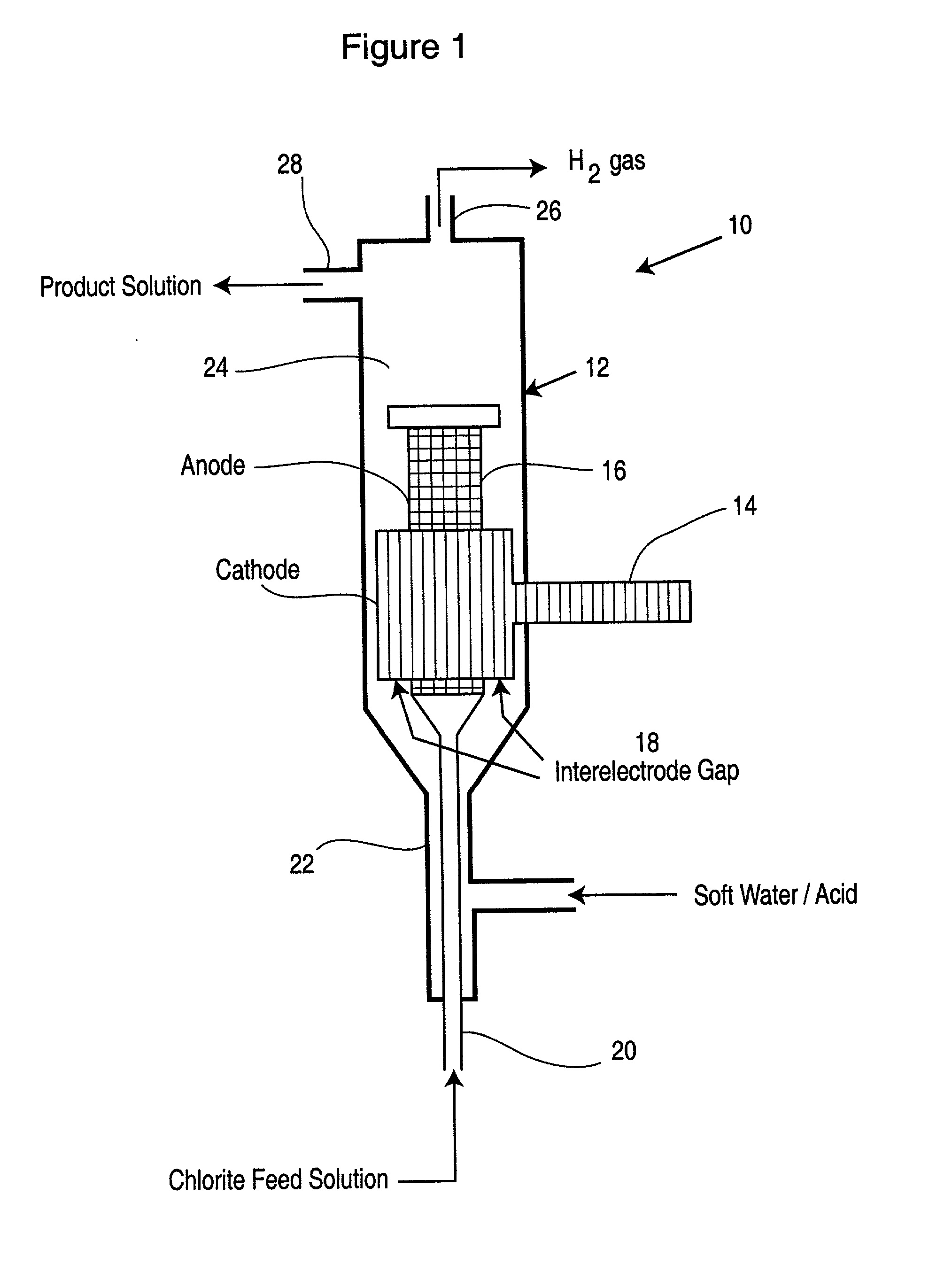

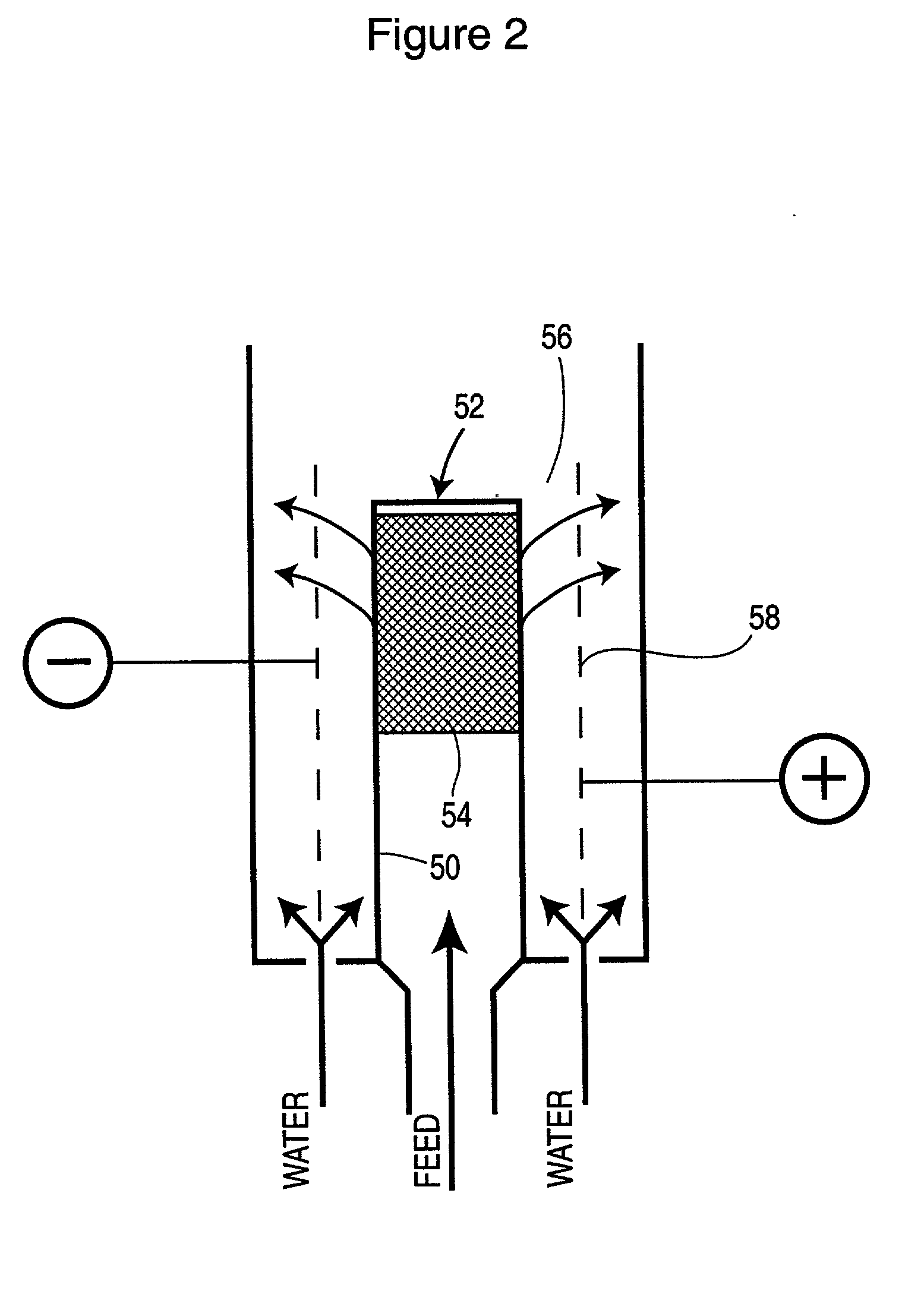

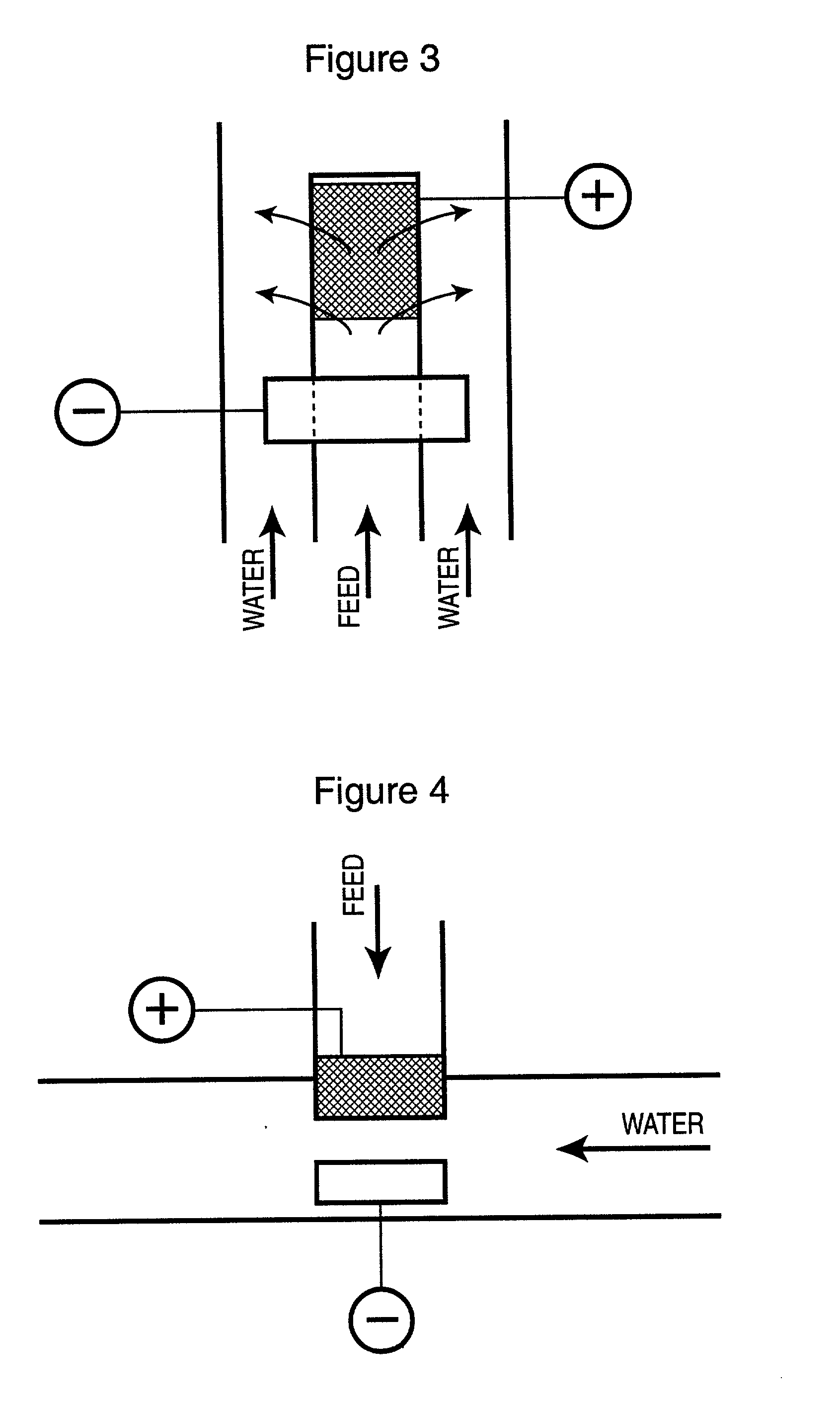

Electrolytic process for the production of chlorine dioxide

InactiveUS20030000848A1Speed up the conversion processIncrease contributionCellsPhotography auxillary processesSodium chloriteAqueous solution

Chlorine dioxide is produced at high conversion rates from aqueous sodium chlorite solution by electrochemical oxidation in an undivided electrochemical cell. The cell utilizes an anode of high surface area through which the aqueous sodium chlorite solution flows into an interelectrode gap between the anode and a cathode. Water or acidified water is fed into the interelectrode gap to function as catholyte and also to dilute the electrolyzed sodium chlorite solution to provide an aqueous solution of chlorine dioxide exiting from the electrochemical cell.

Owner:STERLING PULP CHEM +2

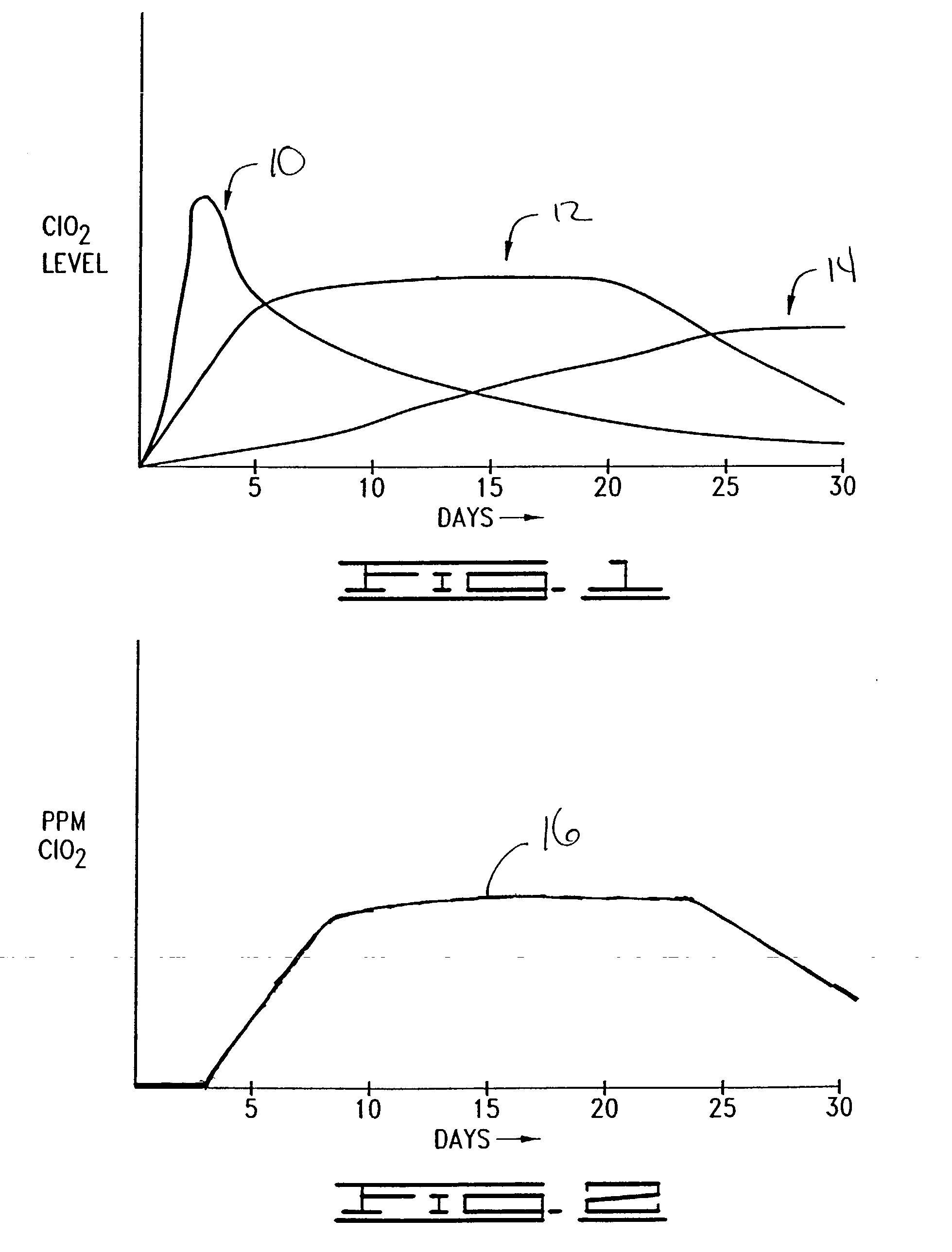

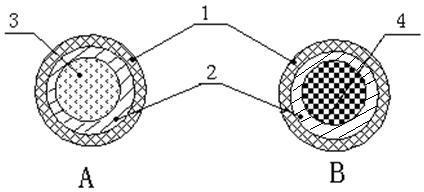

Microbial and odor control using amorphous calcium silicate impregnated with sodium chlorite

InactiveUS20030021819A1Long time-rangeIncrease time scaleHeavy metal active ingredientsBiocideCalcium silicateDisinfectant

The present invention is directed to the a composition and method for microbial and odor control. In one embodiment, the method includes mixing amorphous calcium silicate impregnated with a chlorite salt to form a reactant, combining the reactant with an activator to form the composition, and applying the composition to the treatment area. The present invention also includes the preparation of a product usable as a disinfectant and deodorizer, wherein the product includes a mixture of an amorphous and a chlorite salt and wherein the product is packaged as a tablet, permeable sachet, or a permeable patch attachable to a plastic bag. The present invention may also be applied using several methods to reduce the spoilage of produce. The present invention further includes a method for producing chlorine dioxide in accordance with a step-function release profile.

Owner:BIO CIDE INT

Controlled release formulation of solid chlorine dioxide

InactiveCN1759679AEasy to useConvenient storage and transportationBiocideDisinfectantsSodium bicarbonateAluminium sulfate

A slowlly-releasing solid ClO2 for deodoring, sterilizing, disinfecting and antistaling purposes is prepared from sodium chlorite, quaternary ammonium salt, quaternary ammonium base, calcium chloride, iron chloride, aluminium sulfate, talc powder, calcium carbonate, and sodium dicarbonate through proportional mixing.

Owner:山东营养源食品科技有限公司

Novel mildew resistant tablet and preparation method thereof

The invention belongs to the technical field of antibacterial mould proofing piece, relates to an improved solid slow release chlorine dioxide mold proofing piece for leather and the preparation method. The invention is characterized in that the new mould proofing piece comprises the sodium chlorite, the solid acid, the stabilizing agent, the adhesive and the desiccant. The invention can be produced according to the following steps: evenly mixing the sodium chlorite and the drying agent in proportion; adding solid acid and the stabilizing agent for even agitation; adding adhesive tabletting. Air permeable packing paper is used for packaging. The mould proofing piece can be used in the sea transportation of shoes and other leather products, the packaging period, the transportation period, the shelf period and long-term preservation.

Owner:宋小芳

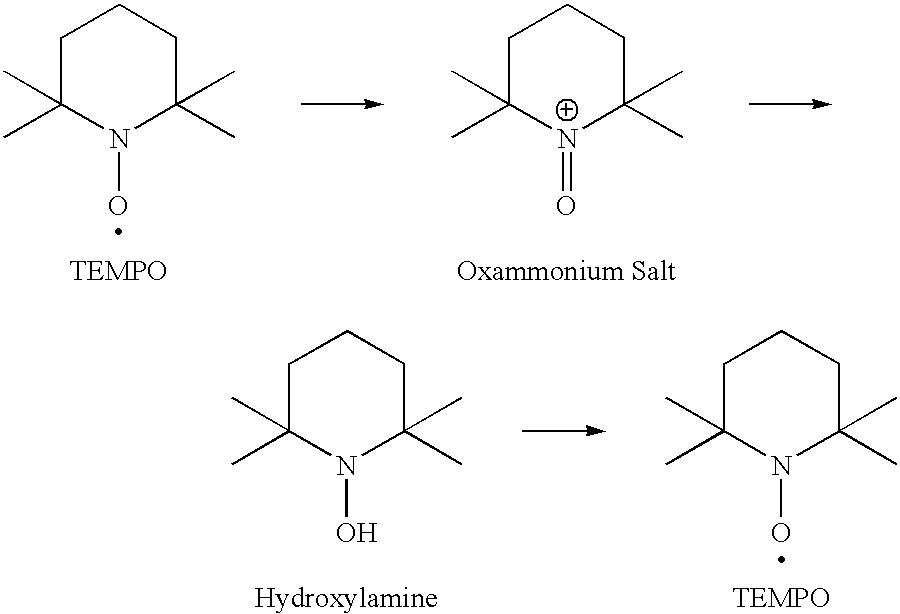

Hypochlorite free method for preparation of stable carboxylated carbohydrate products

InactiveUS6919447B2Low costEnvironmental lossPulp properties modificationSugar derivativesHydroxylamineHypochlorite

Owner:INT PAPER CANADA PULP HLDG ULC

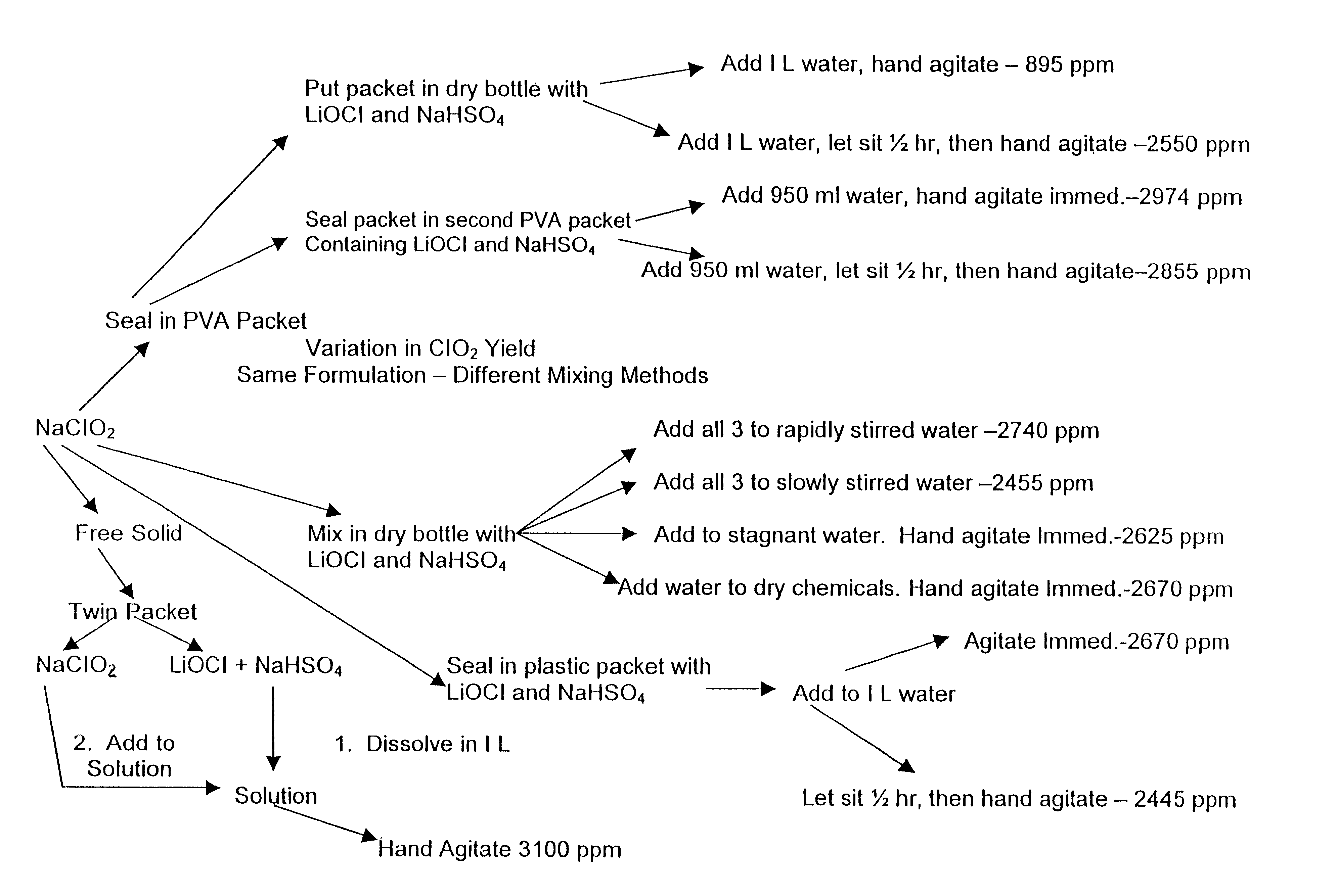

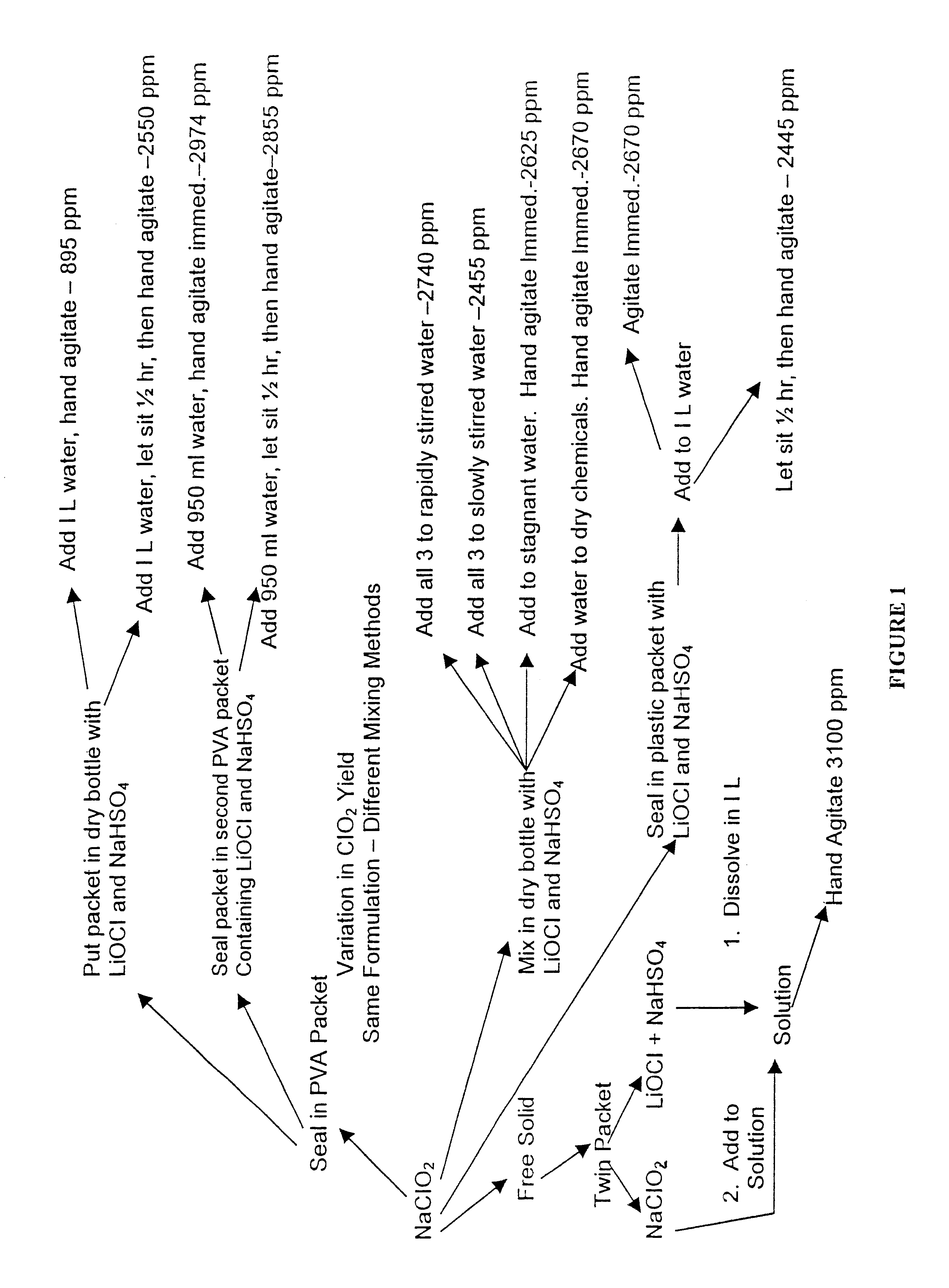

Composition for generating chlorine dioxide

InactiveUS6602442B1Transportation safetyMade preciselyBiocidePeroxide active ingredientsLithium hypochloriteSodium bisulfate

A dry disinfectant composition for the production of aqueous solutions of chlorine dioxide of predetermined concentration is formulated of a mixture of lithium hypochlorite, sodium bisulfate and sodium chlorite. Special liquid and dry formulations are also contemplated for convenience of use, for quality assurance and for safety.

Owner:OCCIDENTAL CHEM CORP

Slow-release chlorine dioxide solid disinfectant

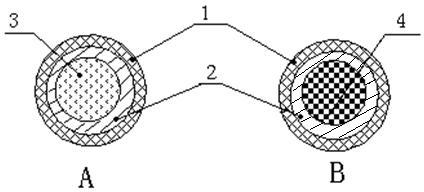

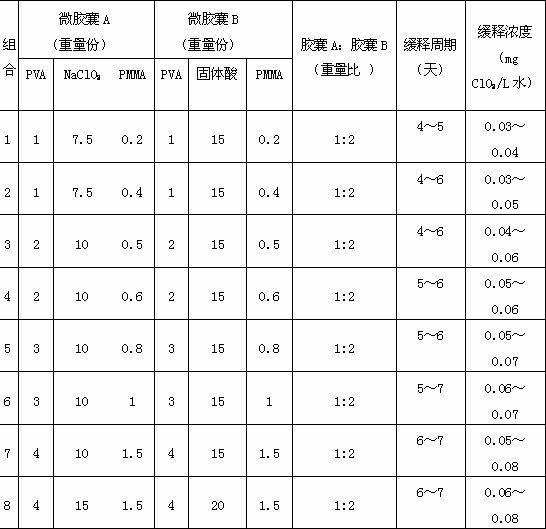

The invention relates to a slow-release chlorine dioxide solid disinfectant, which is formed by mixing sodium chlorite microcapsules and solid acid microcapsules according to a weigh ratio being 1:(1-2), core materials of the sodium chlorite microcapsules are sodium chlorite, a water-soluble organic matter layer and a water-insoluble high polymer material layer are sequentially covered outside the core materials, core materials of the solid acid microcapsules are solid acid or salts capable of releasing hydrogen ions, a water-soluble organic matter layer and a water-insoluble high polymer material layer are sequentially covered outside the core materials, the water-soluble organic matter is selected from polyvinyl alcohol, polyethylene glycol or polyacrylamide, and the water-insoluble high polymer materials are selected from polymethyl methacrylate, ethylene-vinyl acetate or polylactic acid. The disinfectant cannot be easily deliquesced, and the stability is high. After the slow-release chlorine dioxide solid disinfectant is placed into water, sodium chlorite and solid acid are respectively and slowly released onto the surfaces of the microcapsules, chlorine dioxide is generated through the reaction, the contact between the sodium chlorite and the solid acid is retarded, and good slow release performance is realized.

Owner:吕永生 +5

Method for removing iron deposits in a water system

InactiveUS7563377B1Waste water treatment from quariesSpecific water treatment objectivesSodium chloriteSediment

A method and composition and system which for the oxidation, clean up, removal and control of iron and iron deposits in water and the removal of iron deposits and bacterial bio-films from surfaces in water systems. The composition contains sodium chlorite, sodium hypochlorite and citric acid.

Owner:CHEMCAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com