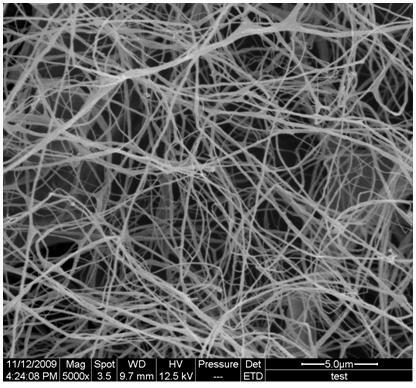

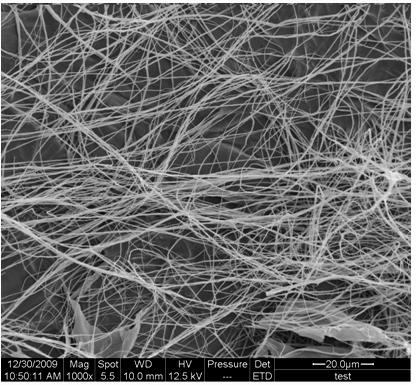

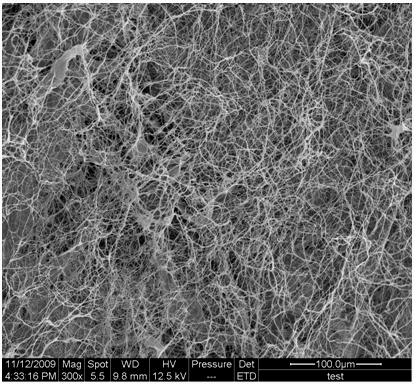

Preparation method of biomass cellulose nanofibers with high length-diameter ratio

A biomass fiber and nanofiber technology is applied in the field of preparation of nanocellulose fibers, which can solve the problems of easy mutual aggregation of nanocellulose fibers, high cost of microbial fermentation, small aspect ratio, etc., and achieves low cost and is conducive to application. , the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment 1: The preparation method of the high aspect ratio biomass cellulose nanofiber of the present invention is carried out according to the following steps: 1. Weigh the biomass fiber and benzene alcohol solution according to the mass ratio of 1:50-100, And put the biomass fiber in the benzyl alcohol solution, and extract it for 5h-7h at a temperature of 85°C-95°C; 2. Prepare a sodium chlorite solution with a concentration of 1%-2% (mass), and Adjust its pH value to 4-5, then add the biomass fiber treated in step 1 into the sodium chlorite solution for 4h-6h, and continue to add nitrite to the sodium chlorite solution every 0.9-1.1h during this period. Sodium chlorate and glacial acetic acid are 1%~2% (quality) to keep the concentration of sodium chlorite in the sodium chlorite solution, and the pH value of the sodium chlorite solution is 4~5; Three, will pass through step two The treated biomass fiber is added to the KOH solution with a concentration of...

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the biomass fibers described in step 1 are wood fibers of 50 mesh to 70 mesh, bamboo fibers of 50 mesh to 70 mesh, and cotton fibers of 50 mesh to 70 mesh , 50-70 mesh hemp fiber or 50-70 mesh crop straw fiber. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the biomass fiber described in step one is 60 mesh wood fiber, 60 mesh bamboo fiber, 60 mesh cotton fiber, 60 mesh hemp fiber or 60 mesh fiber. Purpose Crop straw fiber. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com