Patents

Literature

2334 results about "BENZYL ALCOHOL/WATER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

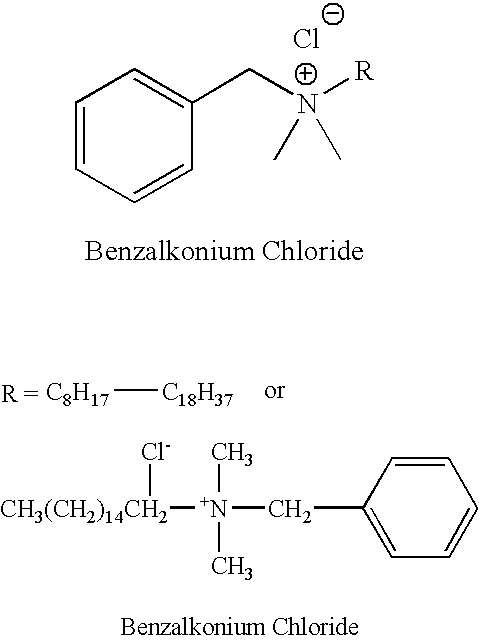

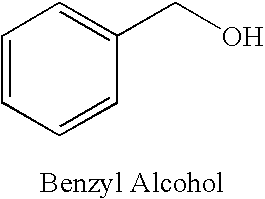

Benzyl alcohol has moderate solubility in water (4 g/100 mL) and is miscible in alcohols and diethyl ether. The anion produced by deprotonation of the alcohol group is known as benzylate or benzyloxide.

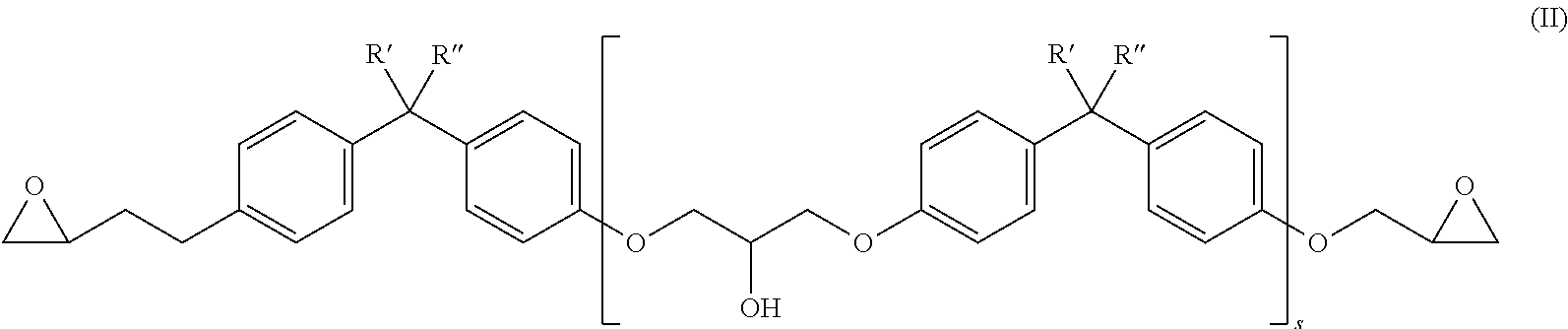

Process for applying a streamable epoxy adhesive

InactiveUS20050070634A1Low viscosityHigh strength bondAdhesive processes with adhesive heatingEpoxy resin adhesivesBENZYL ALCOHOL/WATERViscosity

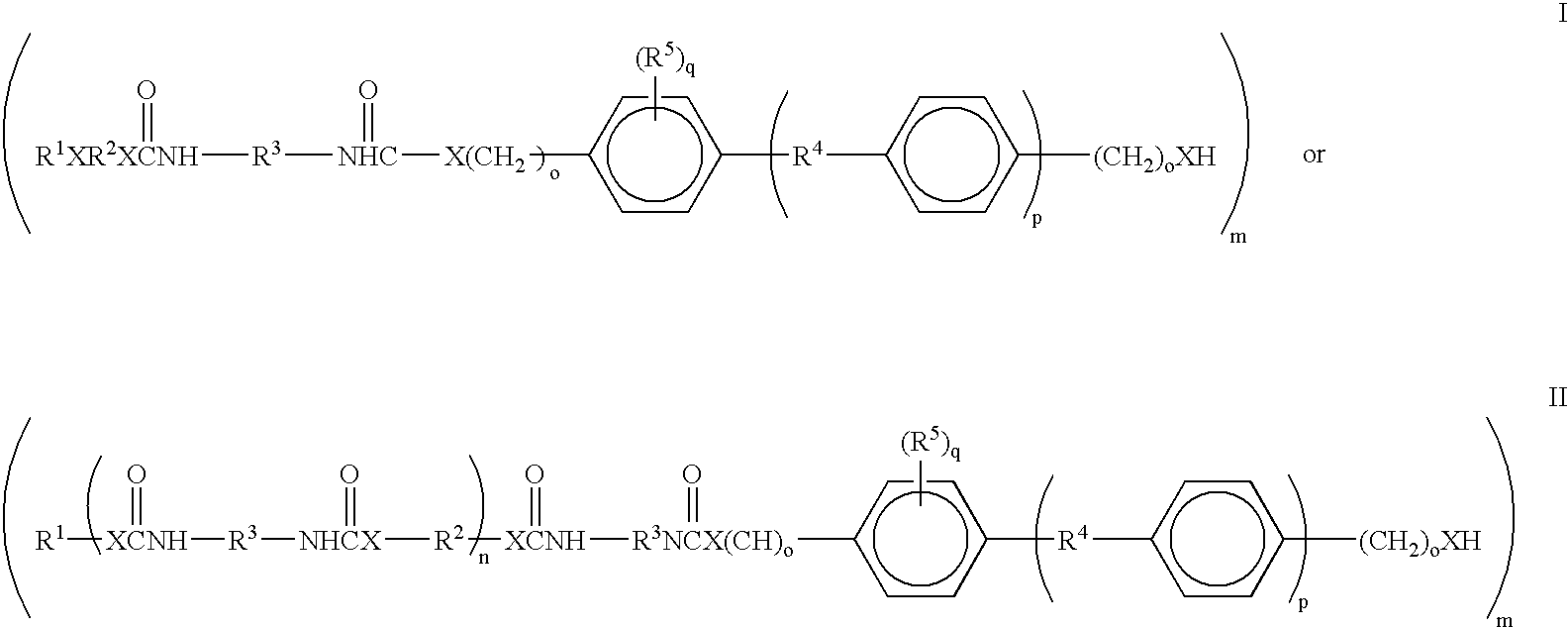

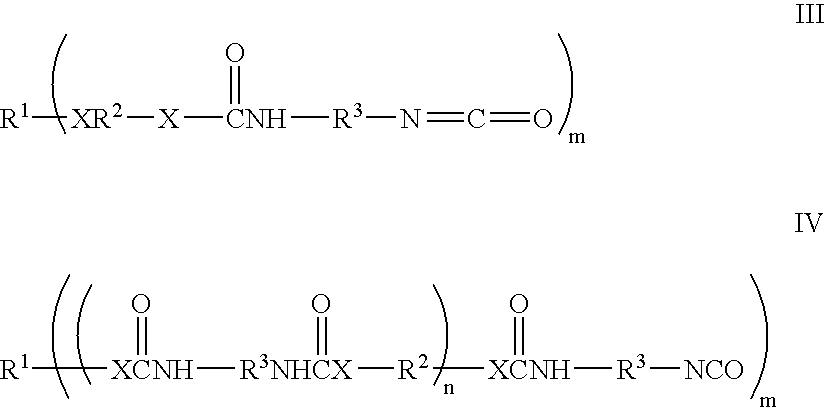

The invention is a composition comprising applying to a substrate a stream of an adhesive comprising: one or more epoxy resins; one or more rubber modified epoxy resins; one or more toughening compositions comprising the reaction product of one or more isocyanate terminated prepolymers and one or more capping compounds having one or more phenolic, benzyl alcohol, aminophenyl, or, benzylamino groups wherein the reaction product is terminated with the capping compounds; one or more curing agents for epoxy resins and one or more catalysts which initiate cure at a temperature of about 100° C. or greater; and optionally; fillers adhesion promoters, wetting agents or rheological additives useful in epoxy adhesive compositions; wherein the adhesive composition has a viscosity at 45° C. of about 20 Pa.s to about 400 Pa.s. The composition can be used as an adhesive and applied as a stream using a high speed streaming process.

Owner:DOW GLOBAL TECH LLC

Compositions and method for removing photoresist and/or resist residue at pressures ranging from ambient to supercritical

InactiveUS20040050406A1Accelerate photoresist strippingImprove reaction kineticsNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingResistAlcohol

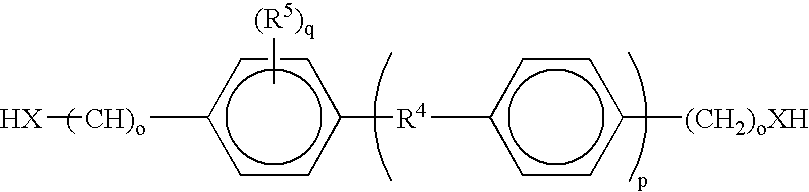

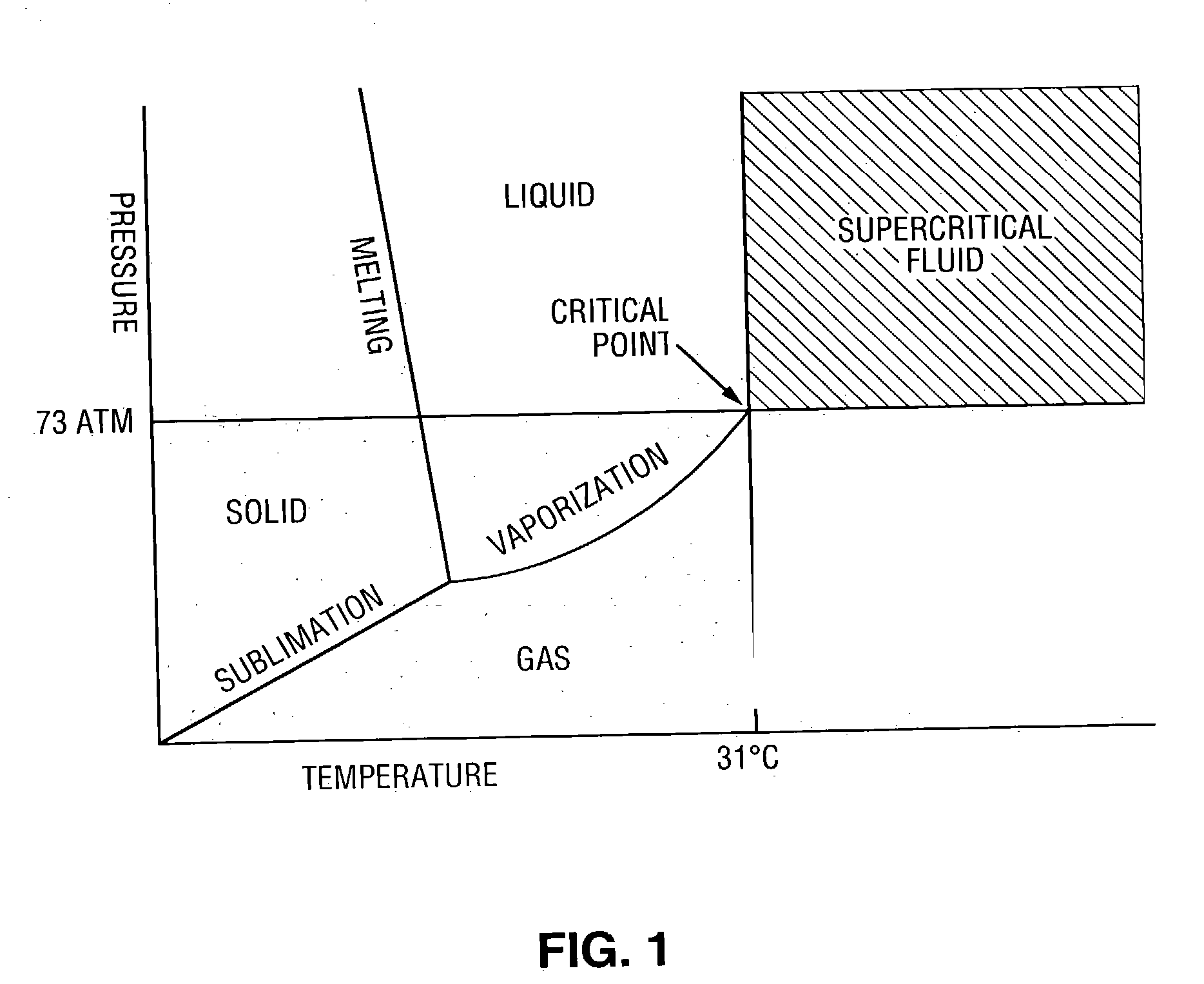

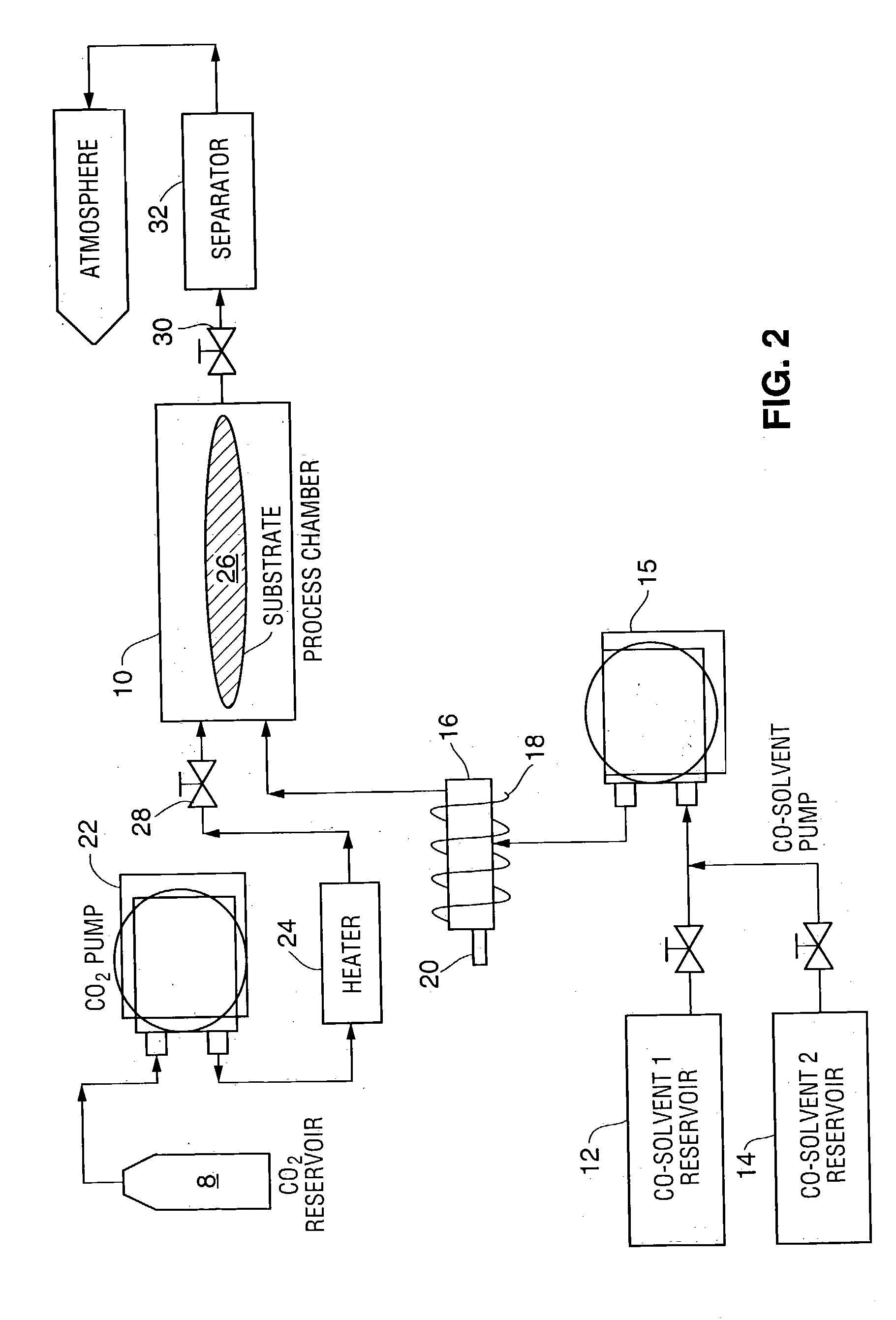

A method of enhancing removal of photoresist and / or resist residue from a substrate includes exposing the substrate to an environmentally friendly, non-hazardous co-solvent mixture comprising a carbonate, an oxidizer and an accelerator. The stripping process may be performed under ambient conditions, or in the presence of a supercritical fluid such as supercritical carbon dioxide with the supercritical cleaning step itself being a desirable "green" process. In one embodiment, the co-solvent mixture includes propylene carbonate, benzyl alcohol, hydrogen peroxide and an accelerator such as formic acid. If desired, supercritical carbon dioxide in combination with a second co-solvent mixture may be subsequently applied to the substrate to rinse and dry the substrate. In one embodiment, the second co-solvent mixture includes a lower alkyl alcohol such as isopropyl alcohol.

Owner:SCP GLOBAL TECH INC

Microbicidal composition

A microbicidal composition containing: (a) 1,2-benzisothiazolin-3-one; and (b) at least one microbicide selected from among benzalkonium chloride, benzethonium chloride, benzyl alcohol, caprylyl glycol, chlorphenesin, 2,2′-dithiobis(N-methylbenzamide), diazolidinyl urea, ethylenediamine tetraacetic acid, ethylparaben, imidazolidinyl urea, methylparaben, phenoxyethanol, linoleamidopropyl PG-dimonium chloride phosphate, cocamidopropyl PG-dimonium chloride phosphate, propylparaben, cis-1-(3-chloroallyl)-3,5,7-triaza-1-azoniaadamantane chloride, dehydroacetic acid or its salts, benzoic acid or its salts, sodium hydroxymethylglycinate and zinc pyrithione.

Owner:DDP SPECIALTY ELECTRONICS MATERIALS US 8 LLC

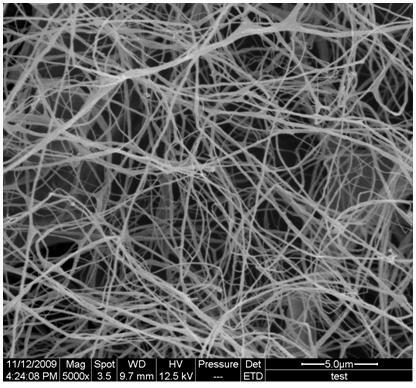

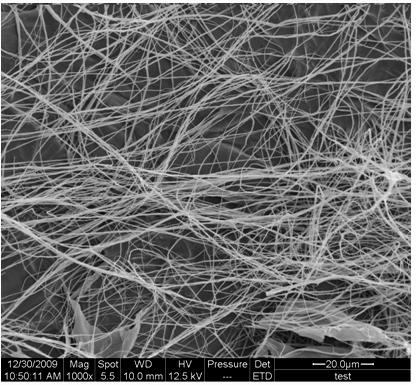

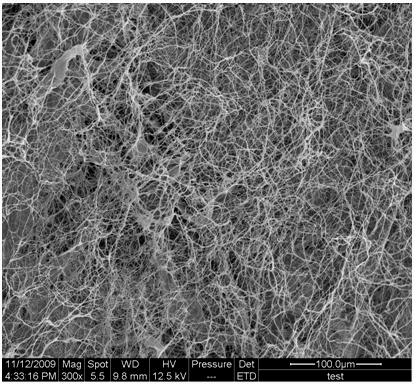

Preparation method of homogenized fine nano-cellulose fiber

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

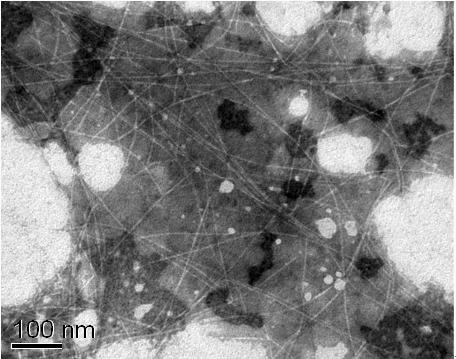

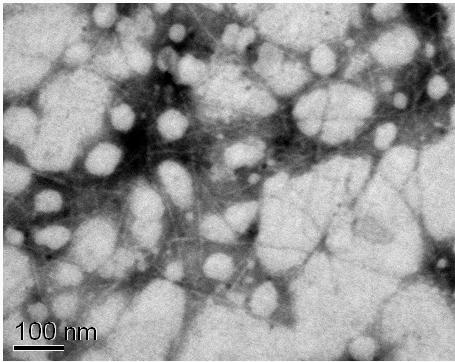

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Barrier coatings for fluids contacting medical devices

The invention relates to methods and materials that, for example, function to increase the barrier properties of containers including polymeric drug medication reservoirs and related containers such as infusion set tubing. Embodiments of the invention include aqueous container systems having containers coated with a composition selected to have one or more material properties including an ability to reduce the diffusion or permeation of compounds such as oxygen, carbon dioxide, and preservatives (e.g. phenol, benzyl alcohol and m-cresol) into or through a wall of the container.

Owner:MEDTRONIC MIMIMED INC

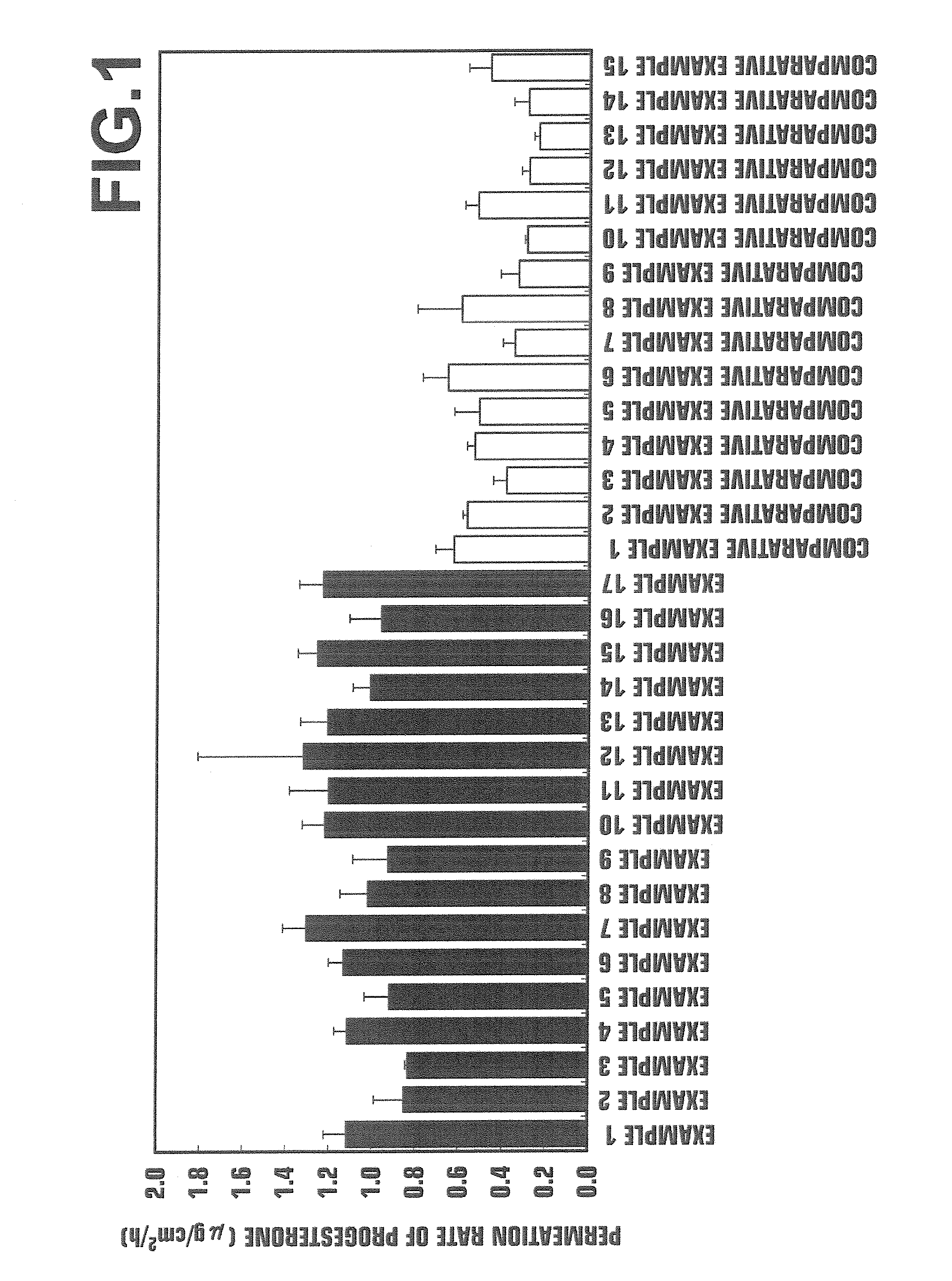

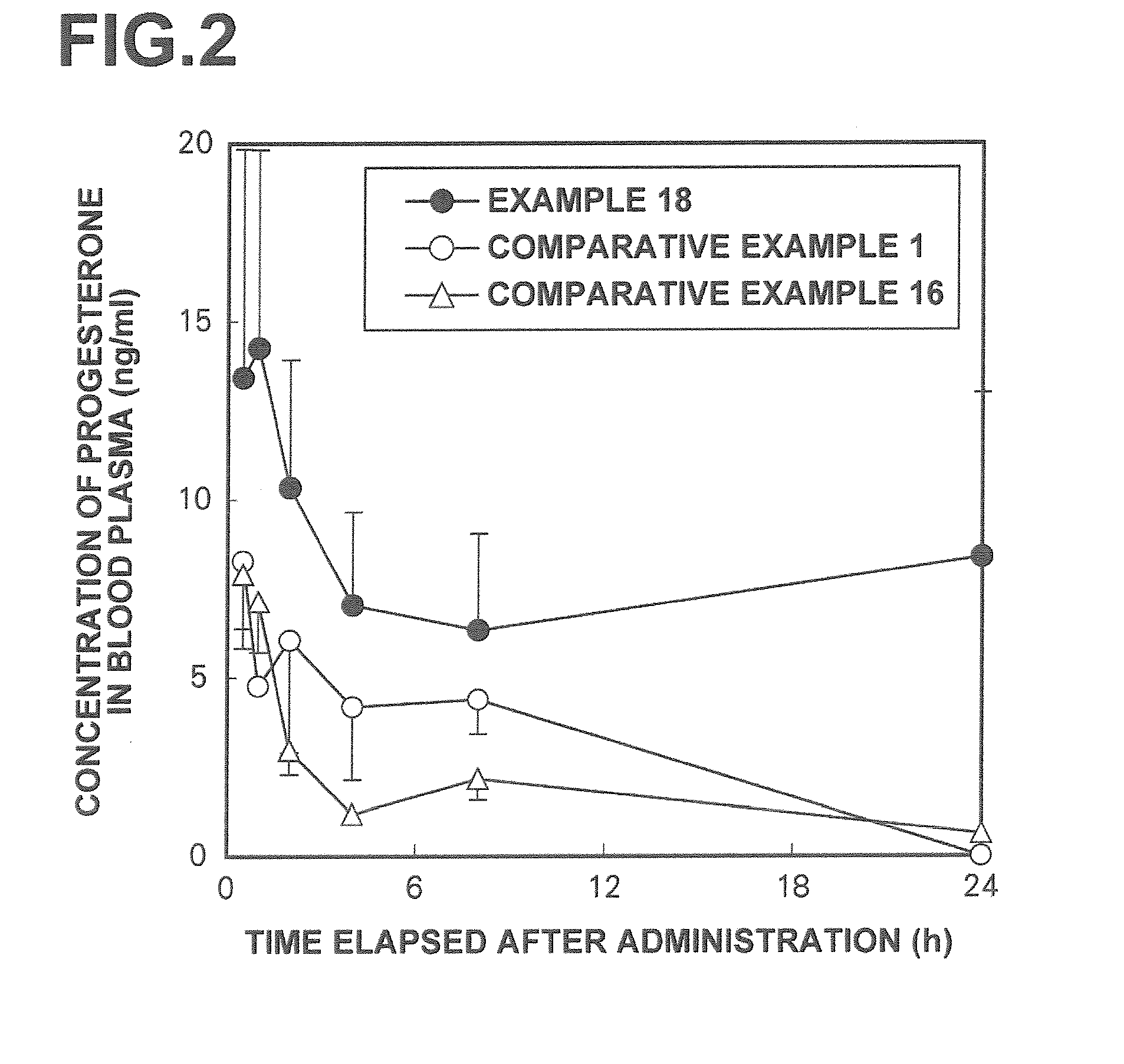

Transdermally absorbable preparation

InactiveUS8507467B2Efficient and long-acting systemic effectExcellent in usability and stabilityOrganic active ingredientsOintment deliveryEthylene oxideOLEYL ETHER

A transdermally absorbable preparation comprises a natural type sex hormone, a polyoxyethylene oleyl ether having a molar number of ethylene oxide units added of 20, at least two kinds of oily ingredients selected from the group consisting of diisopropyl adipate, cetyl alcohol, benzyl alcohol, and propylene glycol dicaprate, a polyhydric alcohol, and ethanol.

Owner:SHISEIDO CO LTD

Paint stripping compositions

InactiveUS6479445B1Improve combination effectImprove efficacyChemical paints/ink removersDetergent solventsAlcoholPropylene carbonate

This invention concerns a composition useful as a paint remover, comprising: an organic carbonate, an alcohol, an activator, hydrogen peroxide, and water. The alcohol may be benzyl alcohol. The organic carbonate may be propylene carbonate, ethylene carbonate, or combination thereof. The activator may be an alkyl-substituted cycloalkane (naphthene), a soy oil, an alkyl soyate, or combination thereof.

Owner:HUNTSMAN PETROCHEMICAL LLC

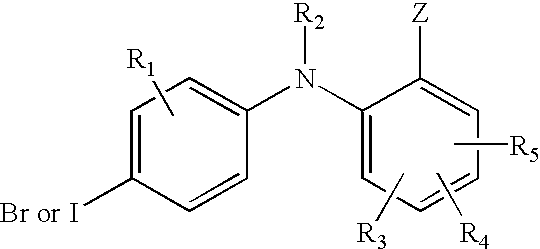

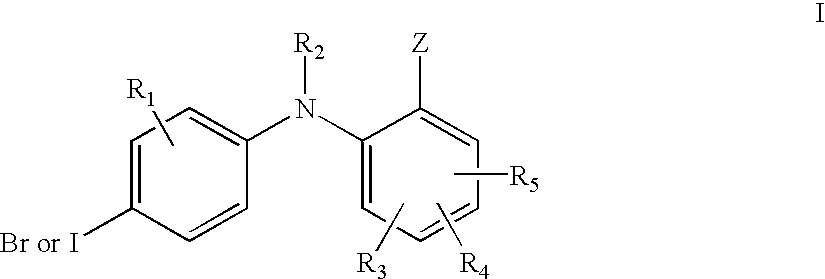

2-(4-bromo or 4-iodo phenylamino) benzoic acid derivatives

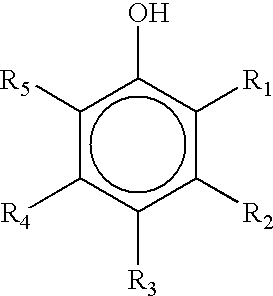

Phenylamino benzoic acid, benzamides, and benzyl alcohol derivatives of the formula where R1, R2, R3, R4, R5, and R6 are hydrogen or substituent groups such as alkyl, and where R7 is hydrogen or an organic radical, and Z is COOR7, tetrazolyl, CONR6R7, or CH2OR7, are potent inhibitors of MEK and, as such, are effective in treating cancer and other proliferative diseases such as inflammation, psoriasis and restenosis, as well as stroke, heart failure, and immunodeficiency disorders.

Owner:WARNER-LAMBERT CO

Composition to Treat Herpes, Pseudomonas, Staph, Hepatitis and Other Infectious Diseases

InactiveUS20090191288A1Safe and economical and effectiveGood and consistent resultOrganic active ingredientsBiocideBENZYL ALCOHOL/WATERInfectious illness

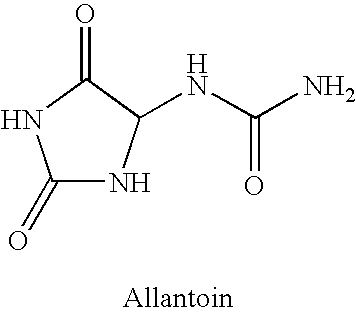

An improved method (process) and medicinal composition is provided to treat herpes, pseudomonas, hepatitis, staph (staphylococci) and other infectious diseases The inexpensive medicinal composition can be self-administered and maintained for a prescribed time. The attractive medicinal composition can comprise a quaternary ammonium salt surfactant, a skin protectant and an alcohol. The quaternary ammonium salt surfactant can comprise benzalkonium halide, preferably benzalkonium chloride. The skin protectant can comprise Allantoin. The alcohol can serve as a pain reliever and can comprise benzyl alcohol. The medicinal composition can also include other compounds, additives, herbal extracts and / or carriers.

Owner:SQUIRES MERYL J

Enhanced activity hydrogen peroxide disinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:TRIKON TECH LTD +1

Paint coatings remover comprising propylene carbonate and hydrogen peroxide

InactiveUS6040284ALow toxicityImprove efficacyChemical paints/ink removersDetergent solventsAlcoholGlycol ethers

This invention concerns a composition useful as a paint remover, comprising: alkylene carbonate such as propylene carbonate or ethylene carbonate, hydrogen peroxide, and water, and optionally an alcohol such as benzyl alcohol. In another broad respect, this invention concerns a process for removing paint, comprising: applying a composition containing alkylene carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. In another broad respect, this invention is a composition useful as a paint remover, comprising: dialkyl carbonate, hydrogen peroxide, and water, optionally containing an alcohol, optionally containing a glycol ether. In another broad respect, this invention is a process for removing paint, comprising: applying a composition containing dialkyl carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

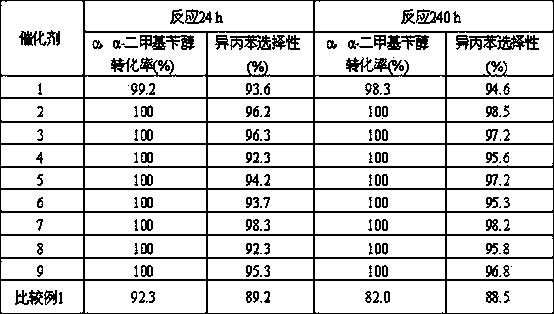

Alpha, alpha-dimethyl-benzyl carbinol direct hydrogenolysis method for preparing isopropyl benzene

The invention relates to an alpha, alpha-dimethyl-benzyl carbinol direct hydrogenolysis method for preparing isopropyl benzene, and mainly solves the problem of poor stability of catalyst in the prior art for isopropyl benzene production by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis. A technical scheme for solving the problem is as below: introducing raw materials of hydrocarbons containing alpha, alpha-dimethyl-benzyl alcohol and hydrogen into a hydrogenolysis reaction zone, and reacting the raw materials with a catalyst by contact to produce isopropyl benzene. The catalyst comprises the following components by weight: a) 0.2-2.0 parts of Pd; b) 91.0-98.0 parts of active carbon; and c) 1.0-10.0 parts of at least one selected from Ni or oxide thereof, Co or oxide thereof, Cu or oxide thereof and Sn or oxide thereof. The method can be used for industrial production of isopropyl benzene by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

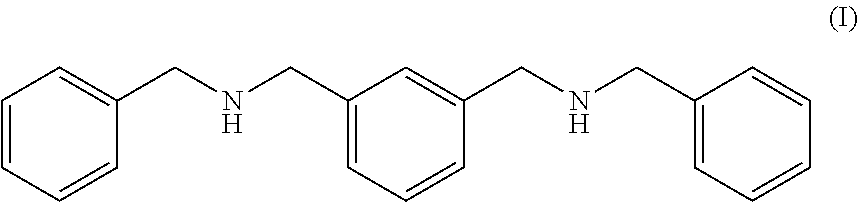

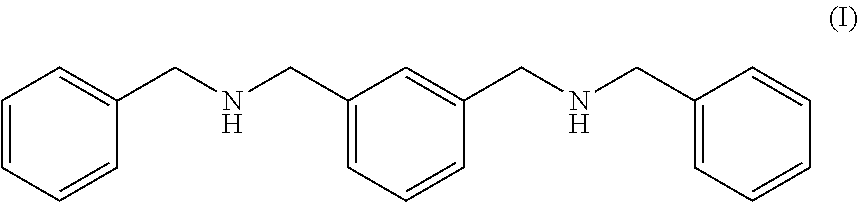

Low-emission hardener for epoxy resins

The present invention concerns a low-odor, low-viscosity hardener for epoxy resins comprising the amine of formula (I),as well as a method for thinning of hardeners for epoxy resins by adding the amine of formula (I). These hardeners harden with epoxy resins quickly and without blushing to form films of high hardness and little brittleness, even without non-incorporable thinners such as benzyl alcohol. They are especially suitable for low-emission coatings.

Owner:SIKA TECH AG

Paint stripping compositions

InactiveUS20030119686A1Improve combination effectImprove efficacySurface-active detergent compositionsChemical paints/ink removersAlcoholPropylene carbonate

This invention concerns a composition useful as a paint remover, comprising: an organic carbonate, an alcohol, an activator, hydrogen peroxide, and water. The alcohol may be benzyl alcohol. The organic carbonate may be propylene carbonate, ethylene carbonate, or combination thereof. The activator may be an alkyl-substituted cycloalkane (naphthene), a soy oil, an alkyl soyate, or combination thereof.

Owner:HUNTSMAN PETROCHEMICAL LLC

Antimicrobial composition

InactiveUS20140322147A1Inhibiting growth)Cosmetic preparationsBiocideAdditive ingredientDisinfectant

Disclosed herein are antimicrobial compositions and methods of producing an antimicrobial effect in which a citrus extract such as Biosecur® is used in combination with benzyl alcohol and one or more additional agent selected from the group consisting of lauroyl arginate / glyceryl laurate and essential oils or constituents thereof such as galangal oil, thyme oil, thymol, cinnamon leaf oil, cinnamon bark oil, lemongrass oil, orange oil, pine oil, cedarwood oil, curry leaf oil, and rosemary oil. These compositions may be used as natural preservatives for personal care products, foods, beverages, and as topical or surface disinfectants.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

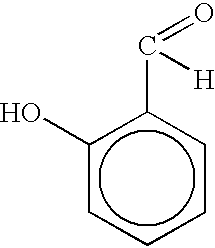

Salicylaldehyde-containing composition having antimicrobial and fragrancing properties and process for using same

InactiveUS6495512B1Alter aromaEffective amountBiocideCosmetic preparationsEscherichia coliSalicylaldehyde

Described are synergistic antimicrobial-fragrance compositions including broad spectrum antimicrobial compositions containing salicylaldehyde and at least one organoleptically-compatible antimicrobial synergism cofactor substance. The weight ratio range of salicylaldehyde:synergism cofactors substance is from 1:10 up to 10:1. The cofactor substance is such that the degree of synergism of the resultant mixture is defined according to the IFF Antimicrobial Synergism Test wherein the difference between the actual and expected antimicrobial values of the mixture is greater than or equal to a multiple of (i) 0.05 and (ii) the expected antimicrobial value of the mixture. Cofactor substances include phenolics such as cresol, caravacrol and thymol; ethyl vanillin; benzyl alcohol; indol; beta-orcinol; and terpinenol-4. Microorganisms against which the synergistic compositions are effective include:Escherichia coli;Enterococcus hirae;Pseudomonas aeruginosa;Staphylococcus aureus; andSaccharomyces cerevisae.The compositions have application in all-purpose cleaning compositions, gel-type toilet rim articles, liquid-type toilet rim articles, personal shower cleaning compositions, and body and hair care products including shower gel compositions, shampoo compositions and foam bath compositions.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES +2

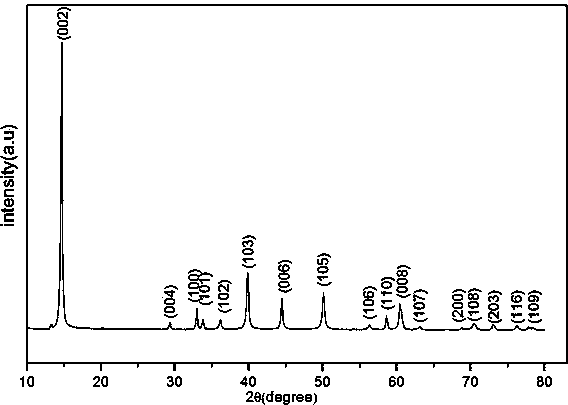

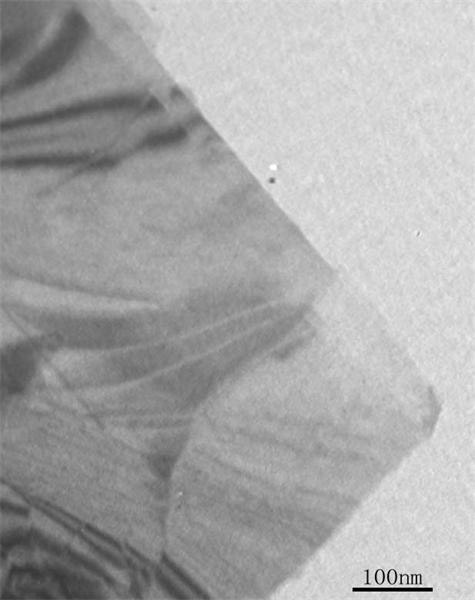

Method for preparing molybdenum disulfide (MoS2) nanosheet

The invention discloses a method for preparing a molybdenum disulfide (MoS2) nanosheet by two steps, namely a hydrothermal method and a liquid phase ultrasonic stripping method. The method disclosed by the invention is realized by the following technological steps: evenly mixing the bought MoS2 powder with lithium carbonate according to the molar ratio of 1: 42, putting the mixture into a high pressure kettle filled with 40ml of benzyl alcohol, and sealing; maintaining for 48 hours at the temperature of 200 DEG C; carrying out natural cooling and vacuum drying to obtain an intermediate product; putting 0.2-0.6g of intermediate product into mixed liquid of 20ml of dimethyl formamide and 10ml of water, and carrying out ultrasonic dispersion for 12 hours; centrifuging the obtained dispersed liquid for 30-45 minutes at the speed of 500-600rpm (revolutions per minute), and then centrifuging the supernatant liquid for 6 minutes at the speed of 6000-8000rpm; cleaning the product by 3% HCl for twice, and then cleaning the product by deionized water until the product is neutral; and finally, carrying out vacuum drying on the product to obtain the nano MoS2 sheet. The MoS2 nanosheet is stripped by the method disclosed by the invention. The method has the characteristics of being simple, easy to realize and popularize and suitable for large-scale industrial production.

Owner:XINJIANG UNIVERSITY

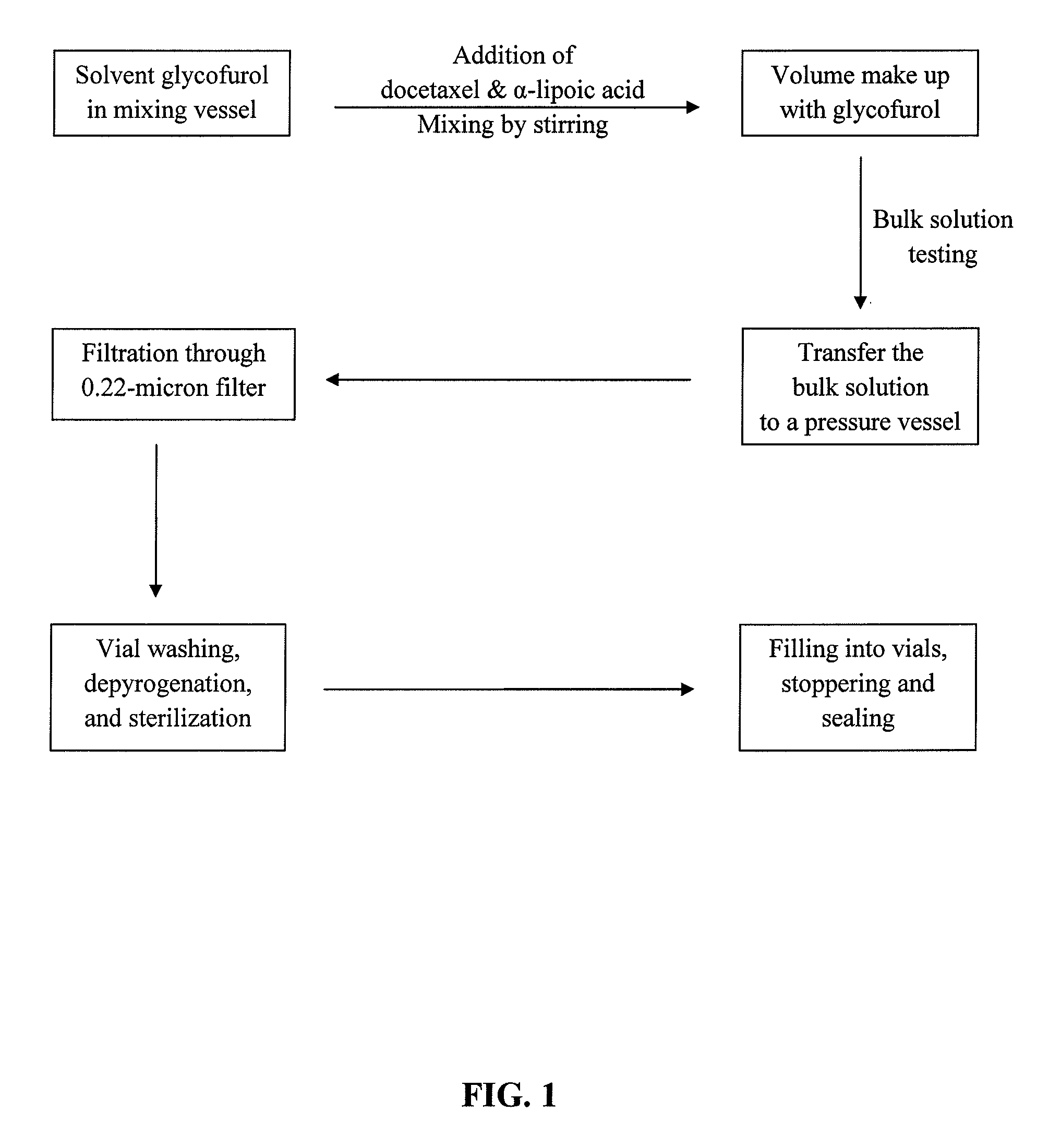

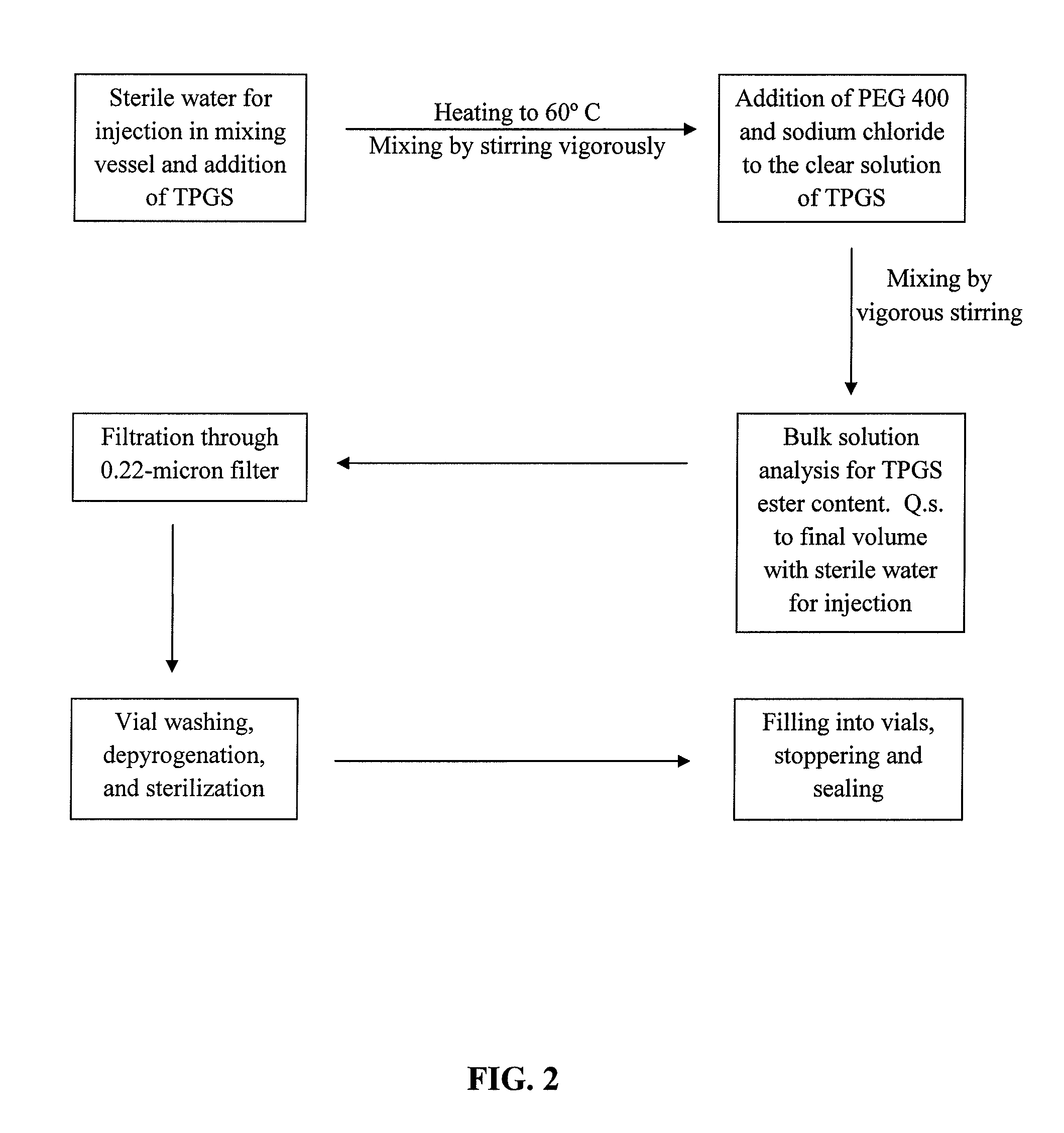

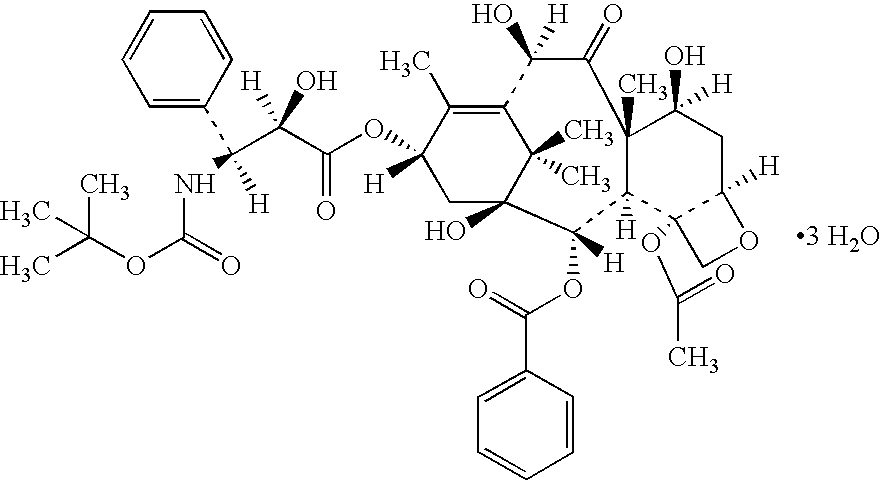

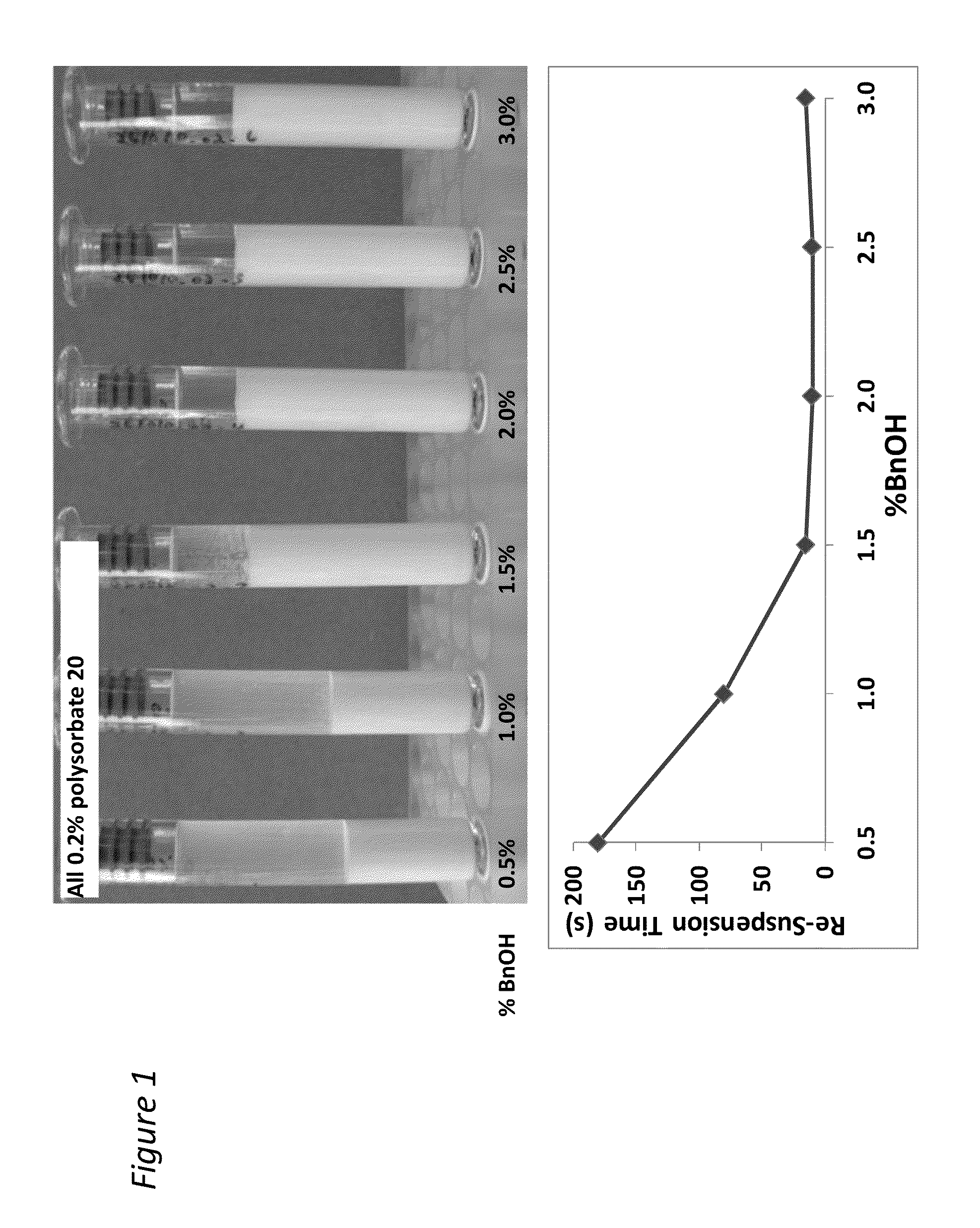

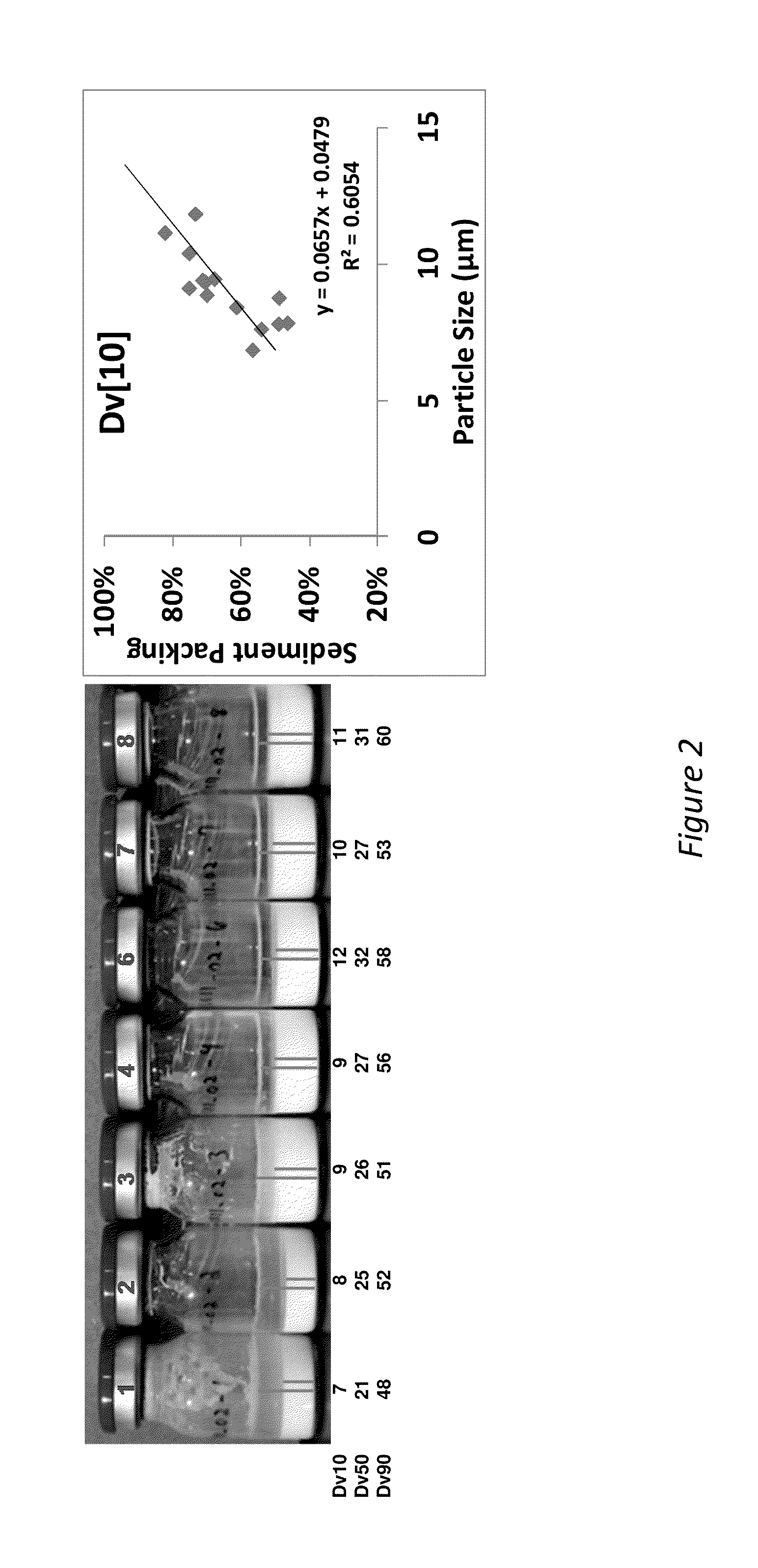

Docetaxel formulations with lipoic acid

Pharmaceutical formulations comprising docetaxel, solubilizer, and α-lipoic acid, wherein the formulation is substantially free of polysorbates and polyethoxylated castor oil. The solubilizer may comprise glycofurol, acetic acid, benzyl alcohol, or ethanol. The α-lipoic acid, at certain concentrations, may impart stability and prevent degradation of docetaxel while the formulations are in storage. The formulations may be combined with a diluent, which comprises one or more hydrotropes such as tocopherol polyethylene glycol succinate and polyethylene glycol. The formulations combined with the diluent also exhibit stability after storage. Methods of administering docetaxel comprise preparing the formulation comprising docetaxel, solubilizer, and α-lipoic acid; mixing the formulation with a diluent; diluting the resulting formulation in saline, water for injection, or the like; and then injecting the formulations into patients in need thereof.

Owner:SCIDOSE

Huangguanyin black tea processing technology

InactiveCN103392849AGolden colorSimple processing technologyPre-extraction tea treatmentGeraniolPhenethyl alcohol

The invention discloses a Huangguanyin black tea processing technology. The Huangguanyin black tea processing technology utilizes Huangguanyin which is a Tieguanyin-Huangjingui hybrid as a raw material. The Huangguanyin black tea has effects of generating body fluid and clearing heat, inducing dieresis, diminishing inflammation and killing bacteria, removing toxins, and nourishing stomach. The Huangguanyin black tea processing technology improves the existing processing technology, reduces volatilization of aromatic alcohol, geraniol, benzyl alcohol, alpha-phenethyl alcohol, cis-3-vinyl ester and methyl salicylate, and reduces harmful substances such as trans-2-hexenal. Through the Huangguanyin black tea processing technology, the Huangguanyin black tea has a good fragrance, a mellow taste and a golden color.

Owner:贵州省湄潭县黔茗茶业有限责任公司

Thickened paint and coating remover

InactiveUS6239090B1Low toxicityImprove efficacyInorganic/elemental detergent compounding agentsChemical paints/ink removersAlcoholTrimethylene carbonate

A thickened composition and process useful for removing paint, comprising: a carbonate such as propylene carbonate or ethylene carbonate, a thickener such as polyvinyl pyrrolidone (PVP), hydrogen peroxide and water. The composition may include additional cosolvents such as glycol ethers and alcohols such as benzyl alcohol, and / or dibasic ester (DBE).

Owner:HUNTSMAN PETROCHEMICAL LLC

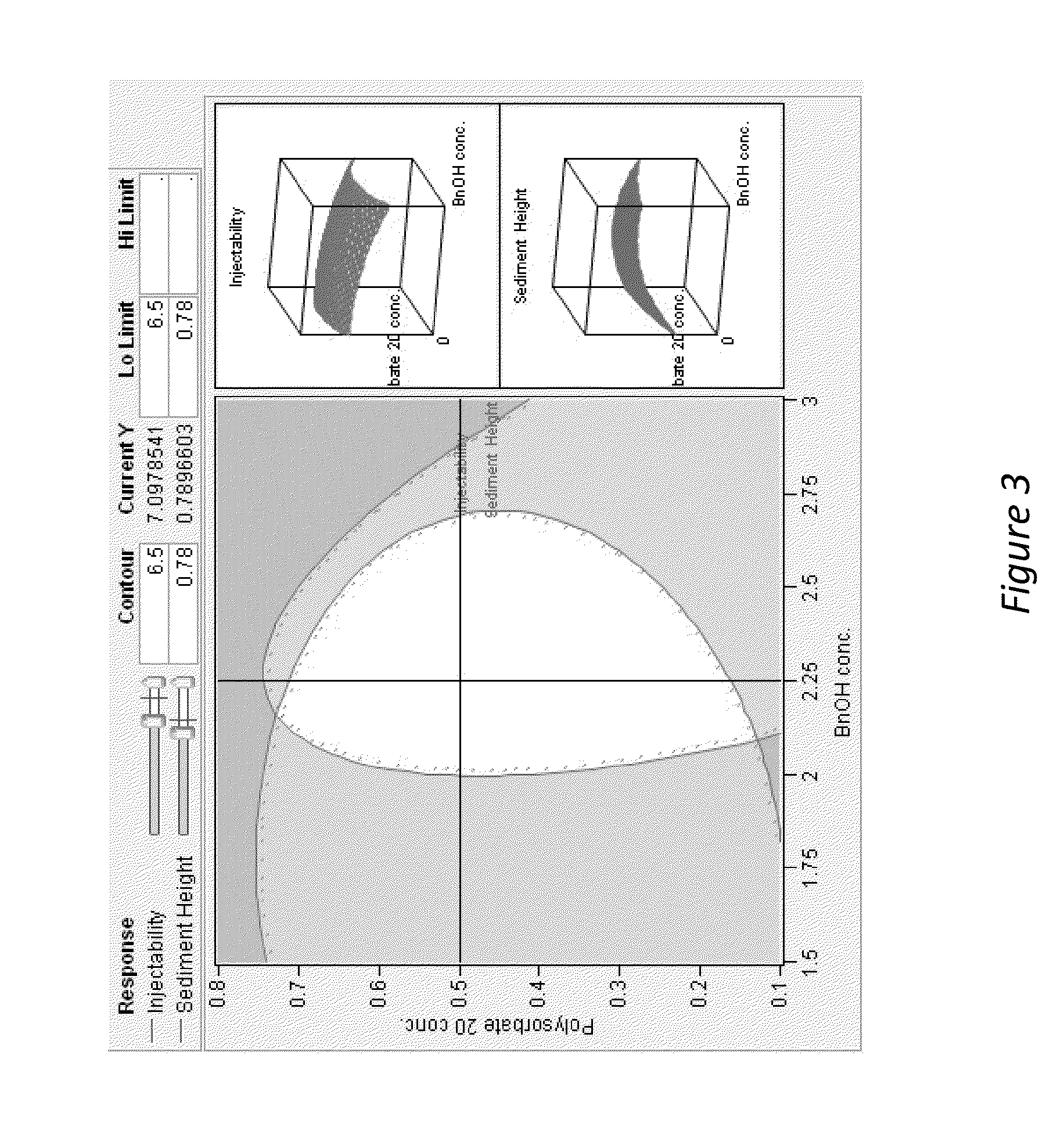

Pharmaceutical compositions comprising benzyl alcohol

ActiveUS20130267505A1Patient compliance is goodOptimizing pharmacological profileBiocideNervous disorderCarboxylic acidBENZYL ALCOHOL/WATER

The present invention relates to a pharmaceutical composition comprising benzyl alcohol and polyoxyethylene derivatives of sorbitan esters of carboxylic acids that are useful for the delivery of anti-psychotic drugs.

Owner:ALKERMES PHARMA IRELAND LTD

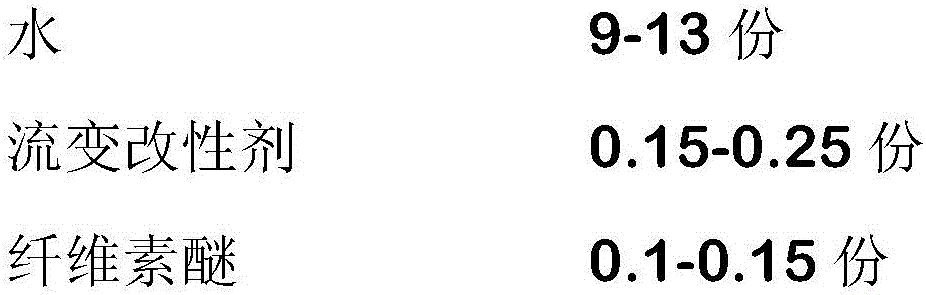

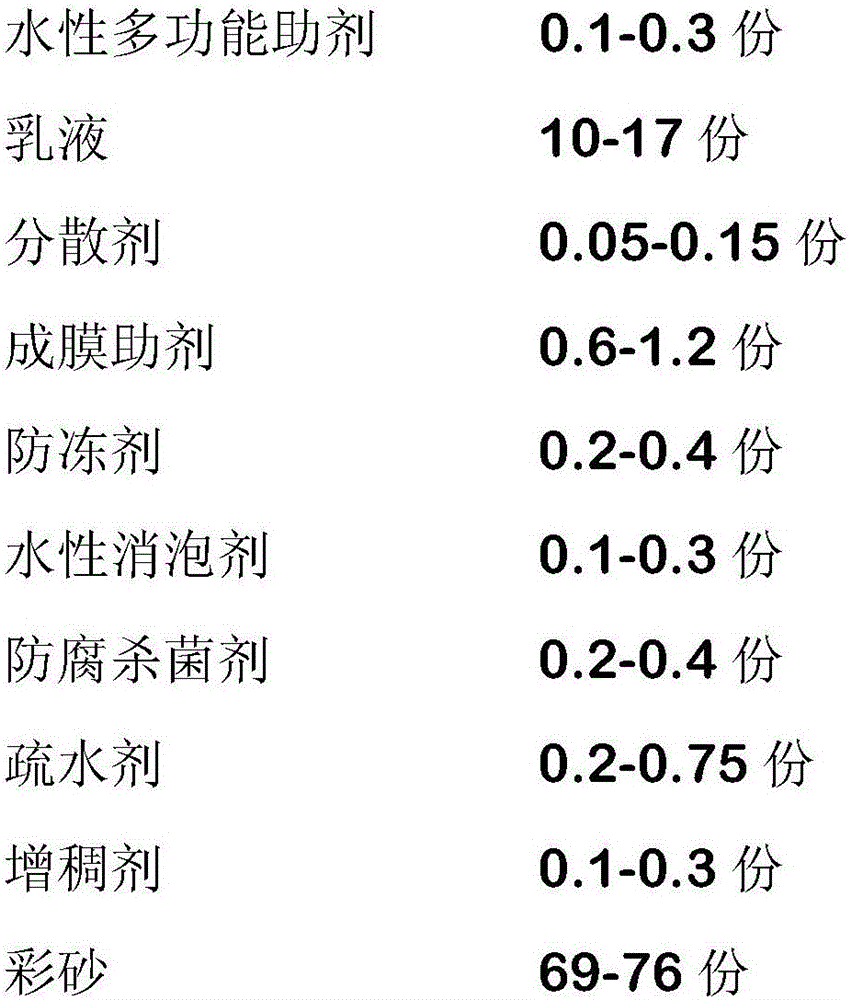

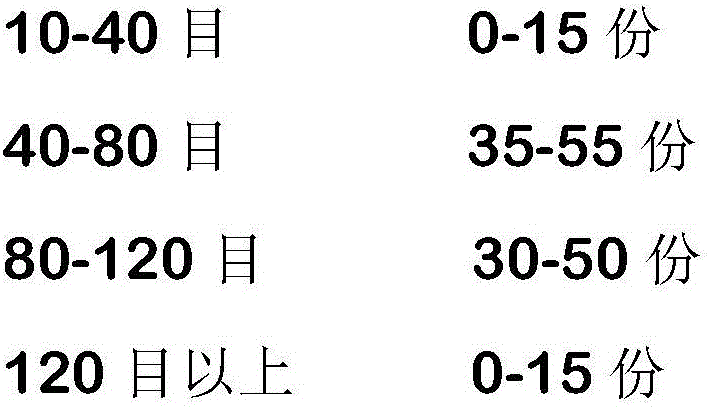

Real-stone paint and preparation method thereof

ActiveCN106590268AFast film formationImprove water resistanceAntifouling/underwater paintsPaints with biocidesCellulosePolymer science

The invention relates to real-stone paint and a preparation method thereof and belongs to the technical field of building decorative materials. Firstly, an inorganic mineral rheological agent and a nonionic water-soluble cellulose ether are combined, so that the two components have the synergistic effect of guaranteeing viscosity of the real-stone paint and excellent constructability, and on the basis hereinabove, the usage amount of cellulose ether, which has water retention effect, in the real-stone paint is reduced, so that a paint film is reduced in the water retention effect and moisture volatilization is improved; secondly, alcohol ester-12 is combined with any one of four film forming additives, comprising ethylene glycol monobutyl ether, propylene glycol butyl ether, diethylene glycol butyl ether and benzyl alcohol, which have high volatile speed, thus accelerating film forming. For solving of a problem of poor antifouling performance of the real-stone paint, through reasonable combination of particle size of color sands and usage of a hydrophobic agent, the real-stone paint can form a compact film and a nano hydrophobic coating layer, which is completely composed of nano hydrophobic particles, is formed on the surface of the paint film, so that the paint film is reduced in surface energy and water absorbency, and is improved in antifouling performance.

Owner:BEIJING SATELLITE MFG FACTORY

Water-solubility printing ink washing agent

InactiveCN101638532ASimple recipeEasy to manufactureChemical paints/ink removersSolubilityAlkylphenol

A water-solubility printing ink washing agent comprises A component, B component and solvent according to weight ratio of 1: (1.5-2.5): (0.04-0.08), wherein raw materials of the A component are as follows according to weight parts: 12-15 parts of fatty alcohol-polyoxyethylene ether, 0.5-1 part of alkylphenol polyoxyethylene, 8-10 parts of aviation kerosene, 2-4 parts of dibutyl phthalate, 1-3 parts of butyl cellosolve, 1-2 parts of benzyl alcohol and 1-3 parts of butyl acetate; raw materials of the B component are as follows according to weight parts: 5-8 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ethanolamine, 1-3 parts of diethanolamide, 0.5-1 part of urea, 0.5-1 part of sodium carbonate, 0.3-0.5 part of sodium silicate, and 45-55 parts of water. The preparation of the invention is simple, has simple and convenient manufacture, stable performance, safe usage, does not easily burn, does not corrode device and does not pollute the environment. The washing agent has good washing effect, is safe and non-toxic, has easily obtained and stored raw materials, has high stability, can be repeatedly used, and has wide market prospect.

Owner:MAOMING COLLEGE

Catalyst for synthesizing benzaldehyde and benzyl alcohol from toluol, the preparation process and application thereof

InactiveCN1485131AEasy to separateEase of usePreparation by oxidation reactionsCarbonyl compound preparation by oxidationAlkaline earth metalBenzaldehyde

A catalyst of synthesizing benzaldehyde and benzyl alcohol by methylbenzene, its manufacturing method and application. The active component is zirconium, or transit metals, alkaline metal, alkaline-earth metals, metals of IIIAíóIVA and VA Group in the Periodic Table. The method comprises solving a zirconium compound or a zirconium compound and a compound of an element as the active component, adding a precipitator; drying, burning, pulverizing to particles. In reactions, a gas containing oxygen is the oxygen source, such as oxygen and air, an organic solution wouldn't be used. The catalyzing reaction is 180-195 degree C, the pressure is 0.8-1.2Mpa. when the conversion rate of methylbenzene is 13.0úÑ, the total selectivity of benzaldehyde and benzyl alcohol is 86.6úÑ. In the method, the catalyst is easy to be separated and could be recyclable, the reaction condition is mild.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

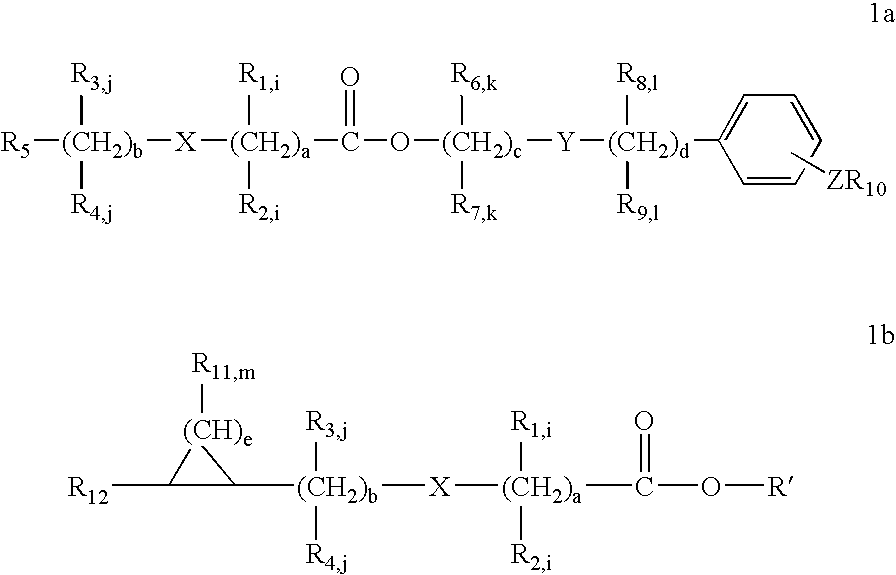

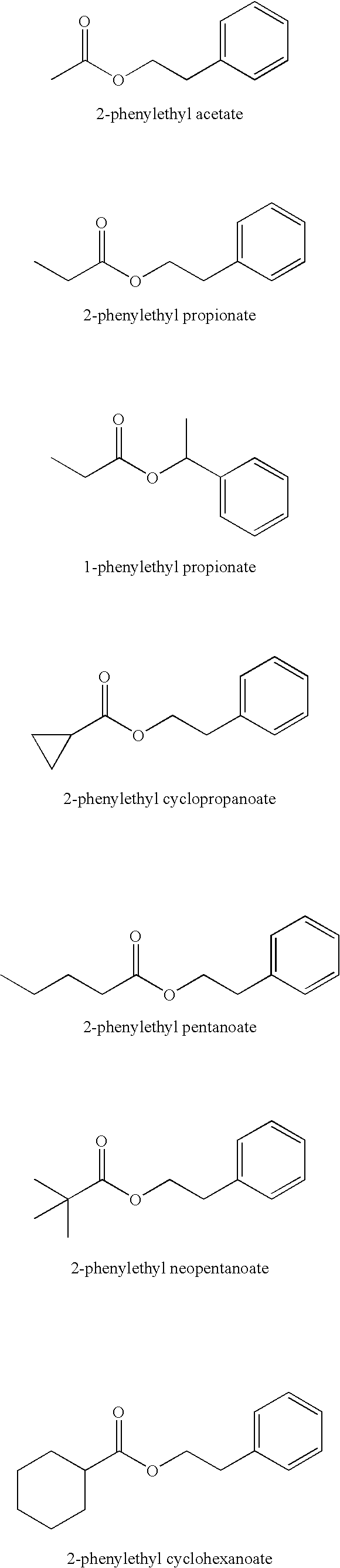

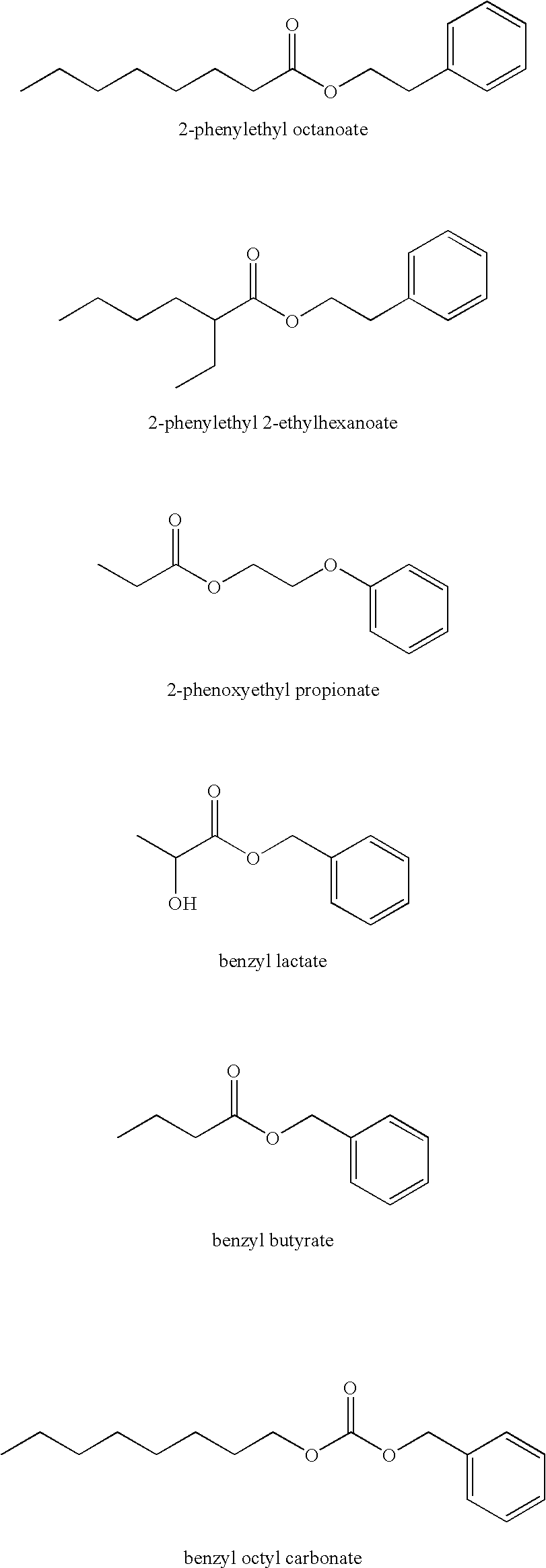

Solubilizing agents for active or functional organic compounds

An active or functional organic compound is solubilized by an ester of an aryl alcohol, e.g., phenethyl, benzyl or substituted benzyl alcohol, and an alkyl or cycloalkyl carboxylic acid, or by a carbonate of said aryl alcohol and an alkyl or cycloalkyl carbonic acid.

Owner:ISP INVESTMENTS LLC

Pharmaceutical composition applicable to body tissue

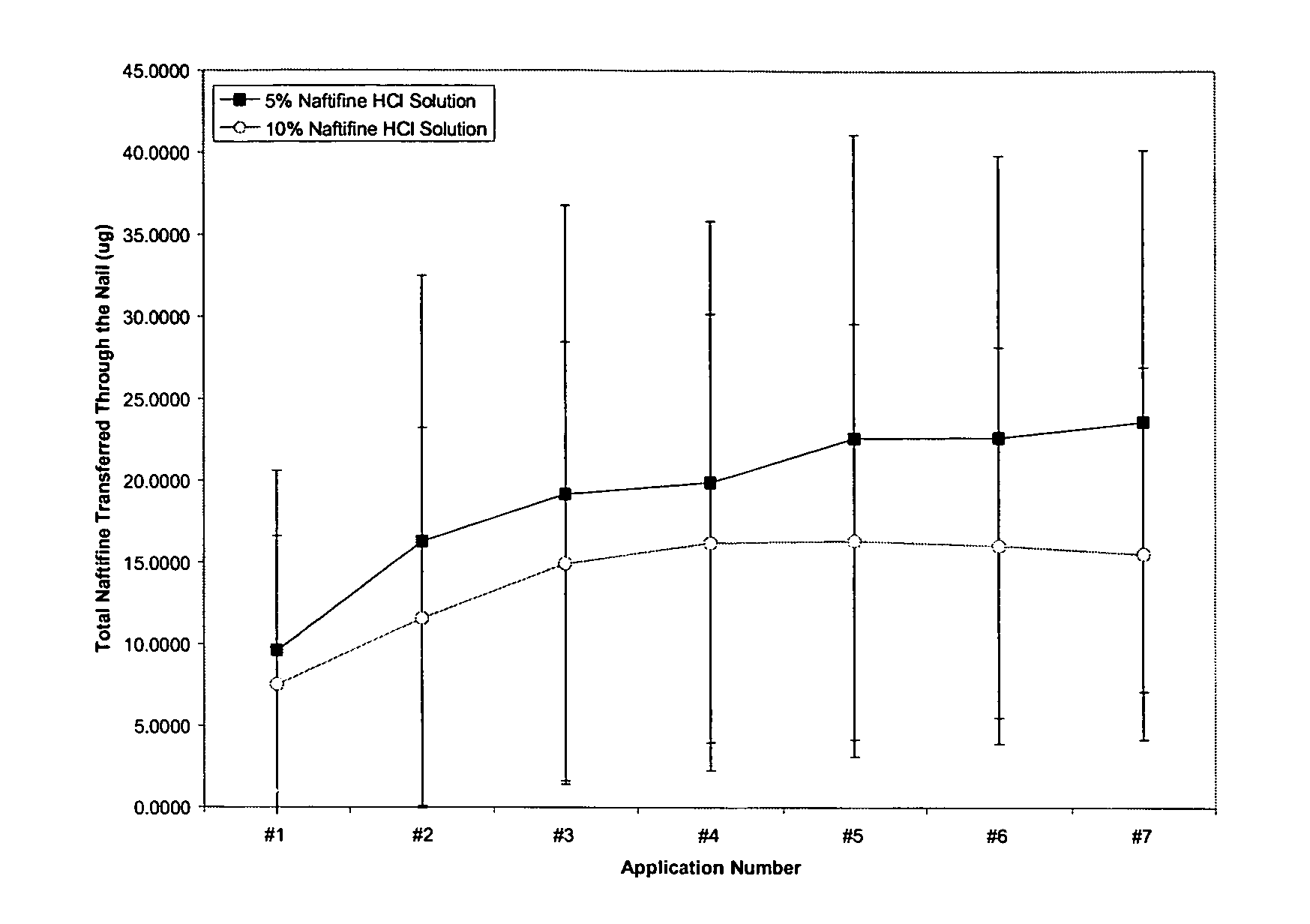

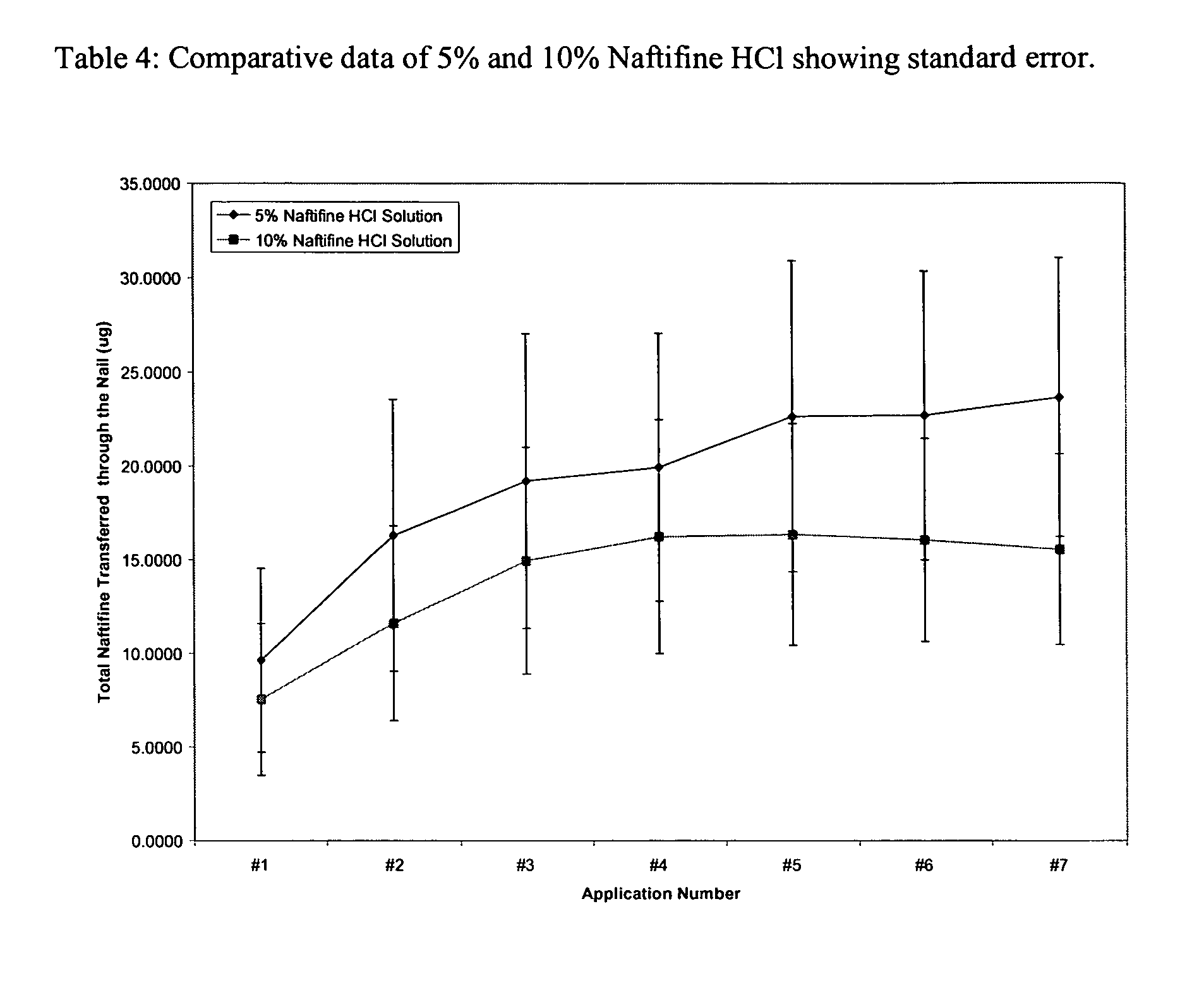

The present invention provides a non-water soluble, film-forming composition which adheres to body tissue and forms a pharmaceutical carrier to provide localized delivery of an antifungal agent to a treatment site. The composition will typically include: (a) an alkyl cellulose; (b) a hydroxyalkyl cellulose; (c) a pharmaceutically acceptable polar protic solvent; (d) an antifungal agent selected from the group of naftifine, ciclopirox, terbinafine, pharmaceutically acceptable salts thereof, and combinations thereof; (e) an glycol ether; (f) an antipruritic agent selected from the group of camphor, menthol, butamben picrate, metacresol, benzyl alcohol, camphorated metacresol, juniper tar, phenol, phenolate sodium, resorcinol, camphorated metacresol, carbolic acid, and combinations,; and (g) a solubility enhancing agent, a surfactant, a wetting agent, or a combination thereof. The present invention also provides for the use of the composition composition of the present invention, in treating a fungal infection (e.g., nail fungus) in a mammal afflicted with such an infection.

Owner:QLT USA INC

Preparation method of biomass cellulose nanofibers with high length-diameter ratio

InactiveCN101864606AHigh crystallinityBroad nanoscaleMonocomponent cellulose artificial filamentStrong acidsDiameter ratio

The invention relates to a preparation method of biomass cellulose nanofibers with a high length-diameter ratio, in particular to a preparation method of nano cellulose fibers, solving the problems that nano cellulose fibers prepared by using a traditional method for hydrolyzing biomass cellulose with strong acid have short length and small length-diameter ratio, nano cellulose fibers prepared by using a mechanical shearing method are easy to mutually aggregate, and a microbial fermentation method has high cost. The method comprises the following steps of: (1) purifying biomass cellulose with a benzyl alcohol solution; (2); treating with acidified sodium chlorite; (3) treating lye; (4) treating with the acidified sodium chlorite again; (5) treating with KOH; (6) treating with hydrochloric acid; and (7) ultrasonically treating and drying to obtain biomass cellulose nanofibers with high length-diameter ratio not less than 1500, fiber diameter from 50 nm to 300 nm, length not less than 150 um and length-diameter ratio not less than 1500. The biomass cellulose nanofibers are mutually interwoven into a tightly wound mesh structure. The invention has low cost and is suitable for preparing nano cellulose fibers from wood, bamboo, cotton, linen and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Two-component epoxy decorating sealant and preparation method thereof

ActiveCN105802451ANo saggingWon't flowAntifouling/underwater paintsPaints with biocidesGlycidyl ethersColloid

The invention provides a two-component epoxy decorating sealant, comprising component A and component B. The component A comprises, by weight: 70-90 parts of first epoxy resin, 0-7 parts of glycidyl ether type diluent, 1-5 parts of a coupling agent, 3-7 parts of a first thixotropic agent, 0.1-0.3 part of a yellowing aid, and 0.1-0.3 part of a defoaming agent; the component B comprises 20-25 parts of an alicyclic curing agent, 20-30 parts of second epoxy resin, 25-30 parts of benzyl alcohol diluent, 3-6 parts of an accelerant, 3-7 parts of a second thixotropic agent, and 5-10 parts of a pigment. After being constructed and cured, the two-component epoxy decorating sealant attaches tightly to ceramic tiles, and water and dust never enter a gap to cause mold or leakage. In addition, colloid of the decorating sealant of the invention never flows or sags during construction, construction is facilitated, and construction efficiency is improved. The invention also provides a preparation method of the two-component epoxy decorating sealant.

Owner:HUNAN KOSEN NEW MATERIAL

Paint and coating remover

InactiveUS6169061B1Improve efficiencyLow toxicityChemical paints/ink removersDetergent solventsAlcoholGlycol ethers

This invention concerns a composition useful as a paint remover, comprising: alkylene carbonate such as propylene carbonate or ethylene carbonate, hydrogen peroxide, and water, and optionally an alcohol such as benzyl alcohol. In another broad respect, his invention concerns a process for removing paint, comprising: applying a composition containing alkylene carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. In another broad respect, this invention is a composition useful as a paint remover, comprising: dialkyl carbonate, hydrogen peroxide, and water, optionally containing an alcohol, optionally containing a glycol ether. In another broad respect, this invention is a process for removing paint, comprising: applying a composition containing dialkyl carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. Advantageously, the composition of this invention may include a dibasic ester (DBE).

Owner:HUNTSMAN PETROCHEMICAL LLC +1

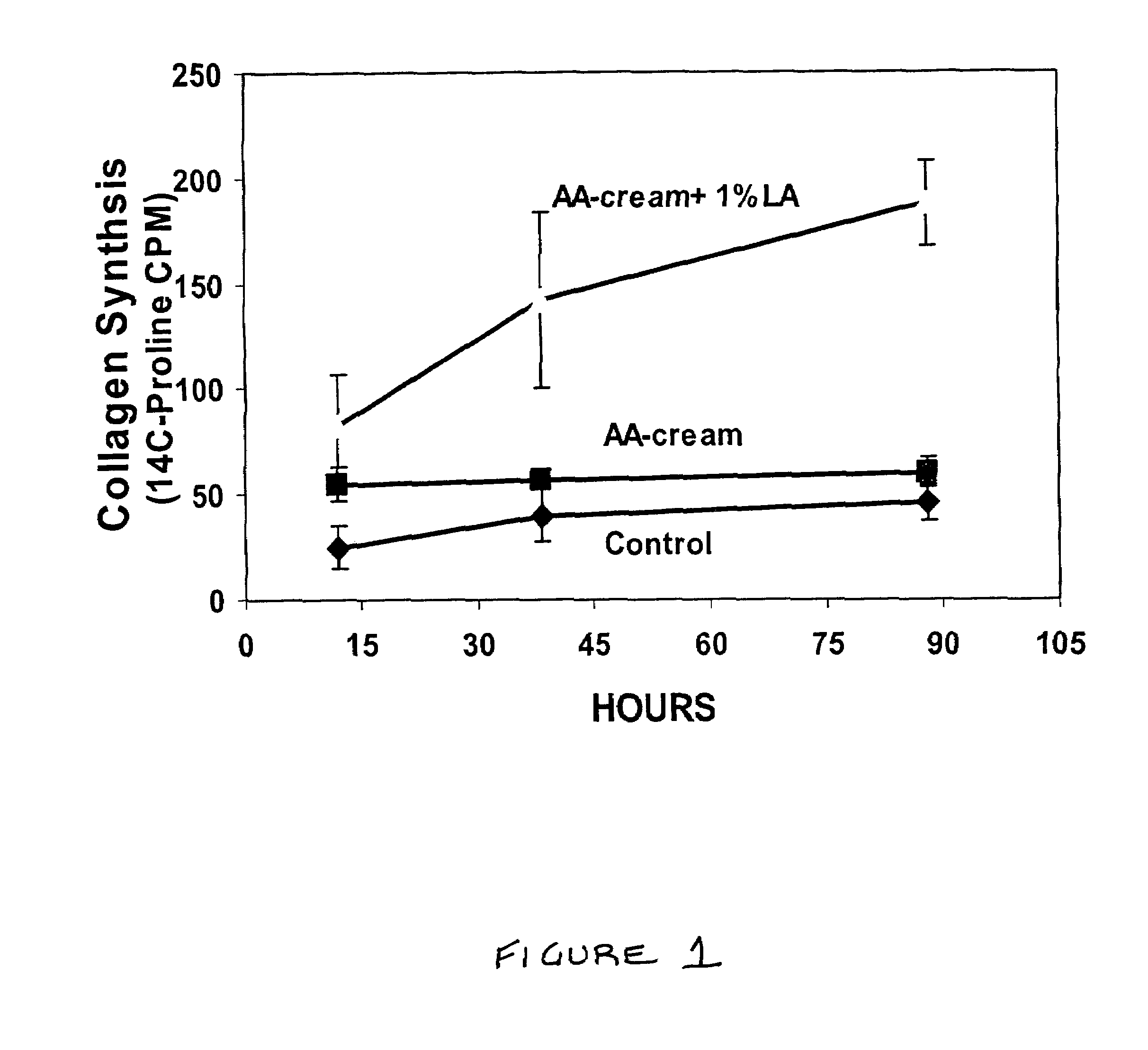

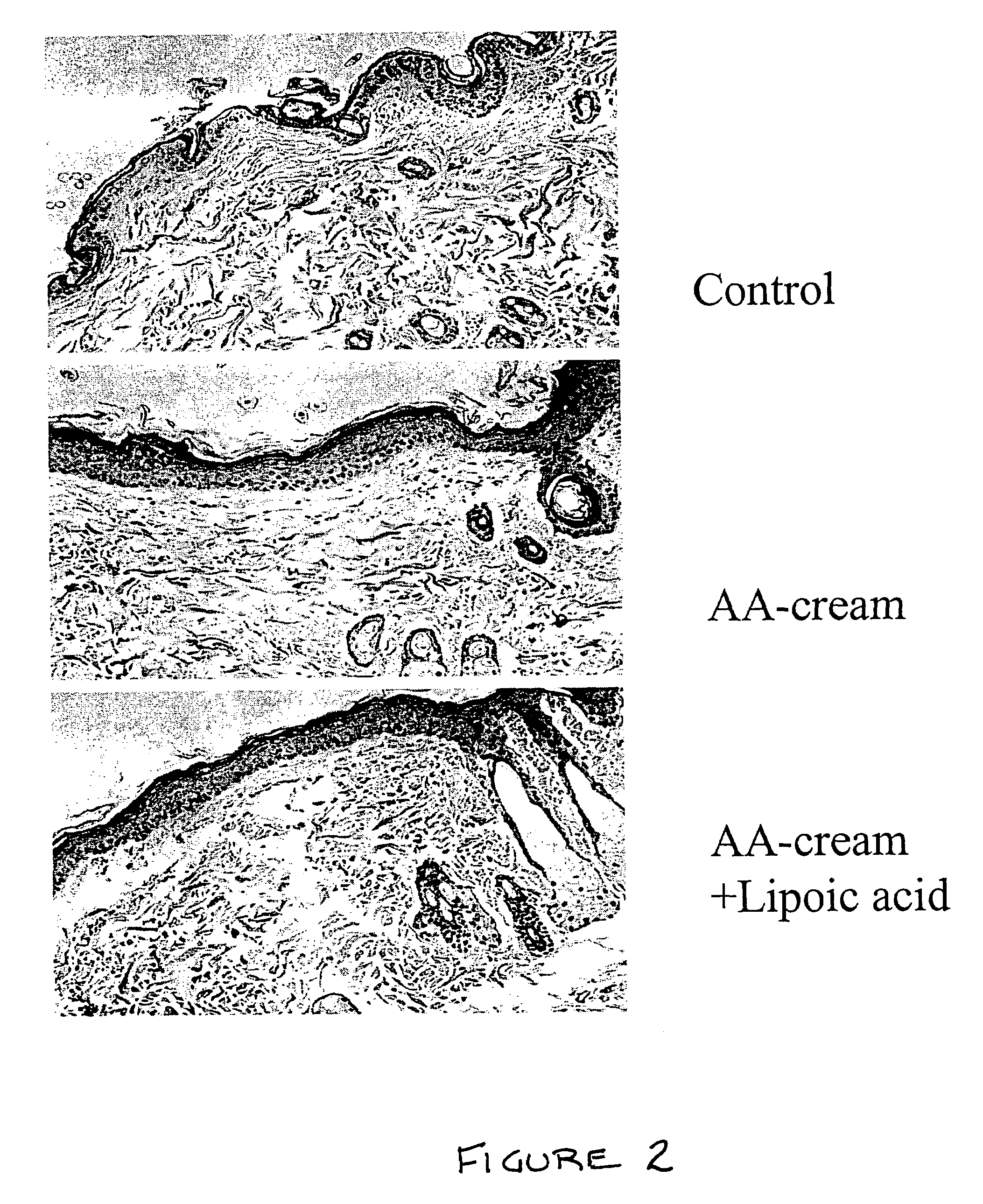

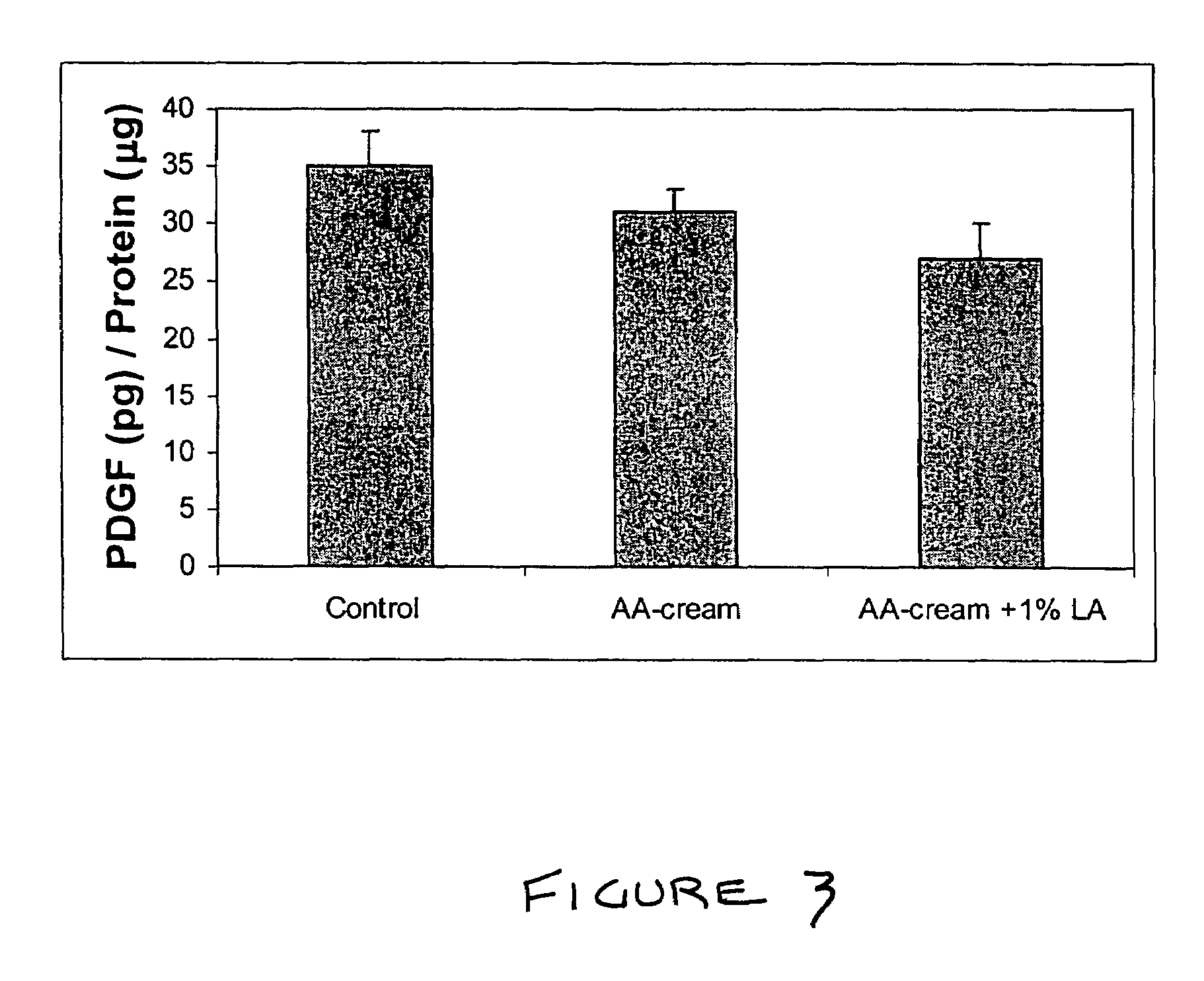

Methods and compositions for enhancing collagen and proteoglycan synthesis in the skin

ActiveUS7598291B2Increase synthesisSustainable hydrationBiocideCosmetic preparationsAdditive ingredientIsoflavones

A composition for application to the skin can stimulate the in vivo synthesis of collagen and proteoglycans and improve the appearance of the skin, increasing its elasticity and fullness. In general, a composition according to the present invention comprises: (1) an antioxidant compound in a quantity sufficient to enhance collagen synthesis in the skin; (2) an organic penetrant in which the antioxidant compound is soluble in a sufficient quantity that a concentration of the antioxidant compound sufficient to enhance collagen synthesis can be applied topically and penetrate the skin; (3) a mixture of essential amino acids; (4) a supplemental source of sulfur; and (5) a topical pharmaceutically acceptable carrier. The antioxidant compound can be lipoic acid, a lipoic acid analogue or derivative, a bioflavonoid, a constituent of ginkgo, or an isoflavone. The organic penetrant is preferably benzyl alcohol. Other ingredients, such as esters of tocopherol and ascorbic acid, can be included.

Owner:NIMNI MARCEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com