Patents

Literature

564 results about "Sulfosuccinic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

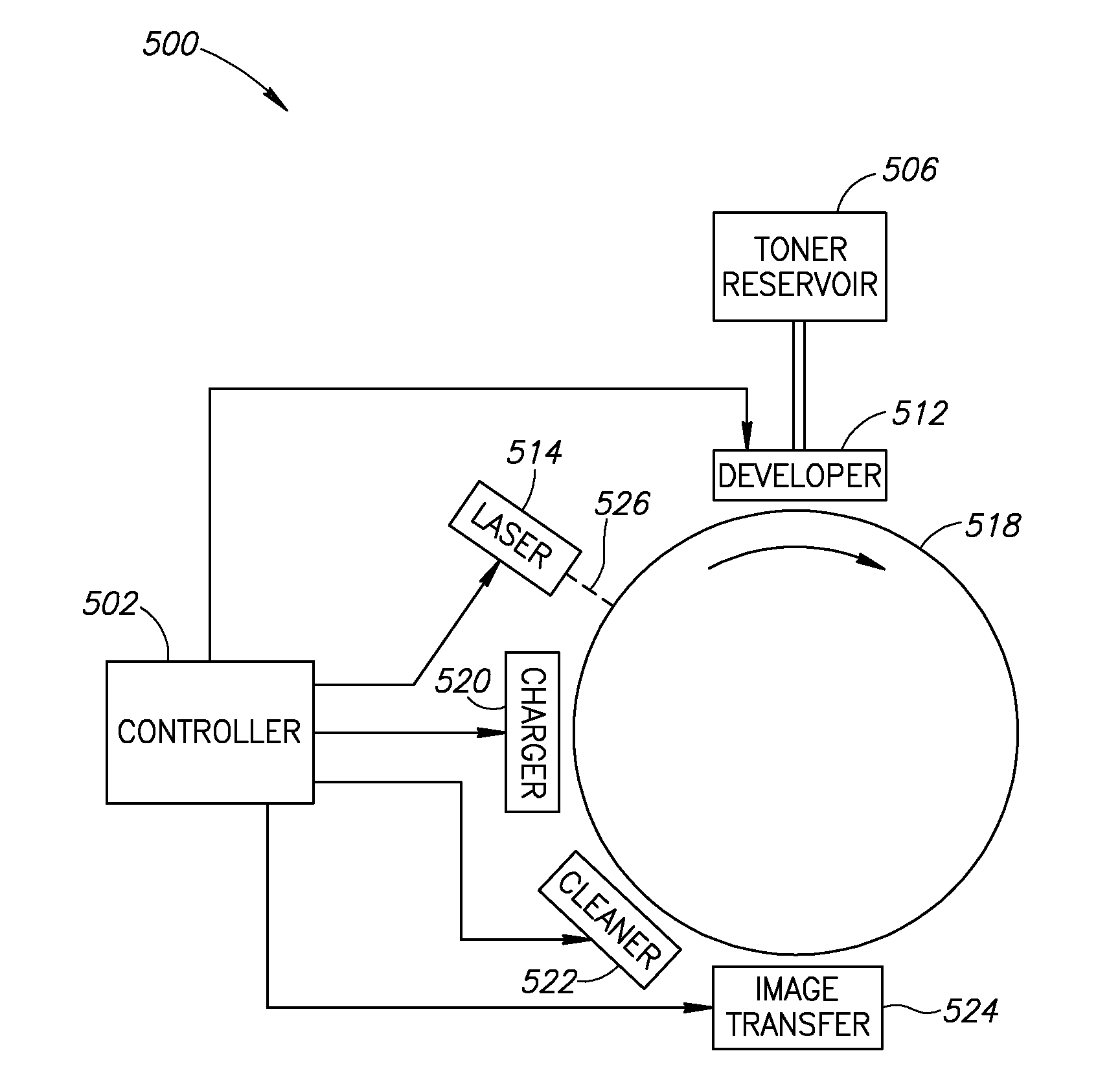

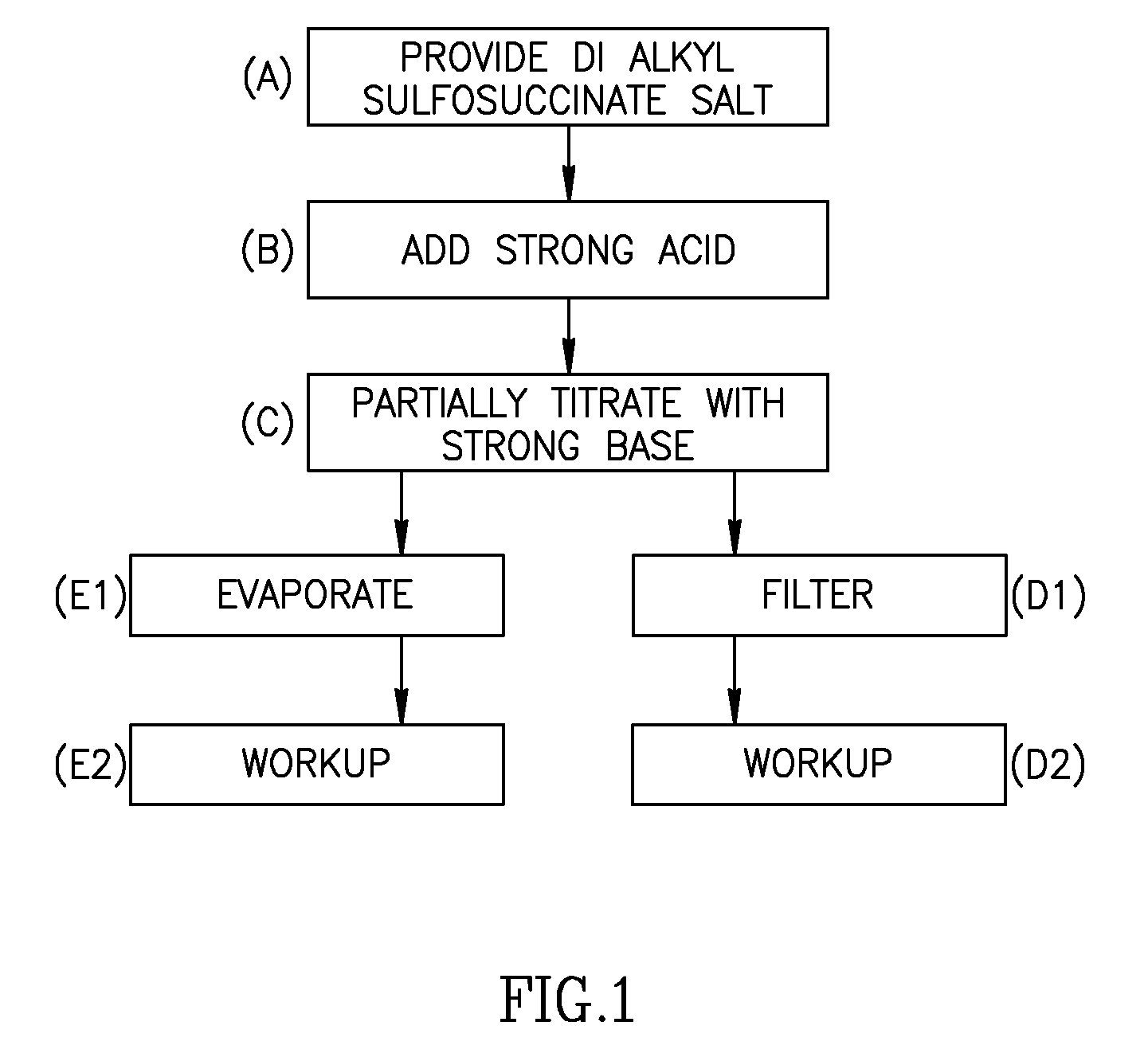

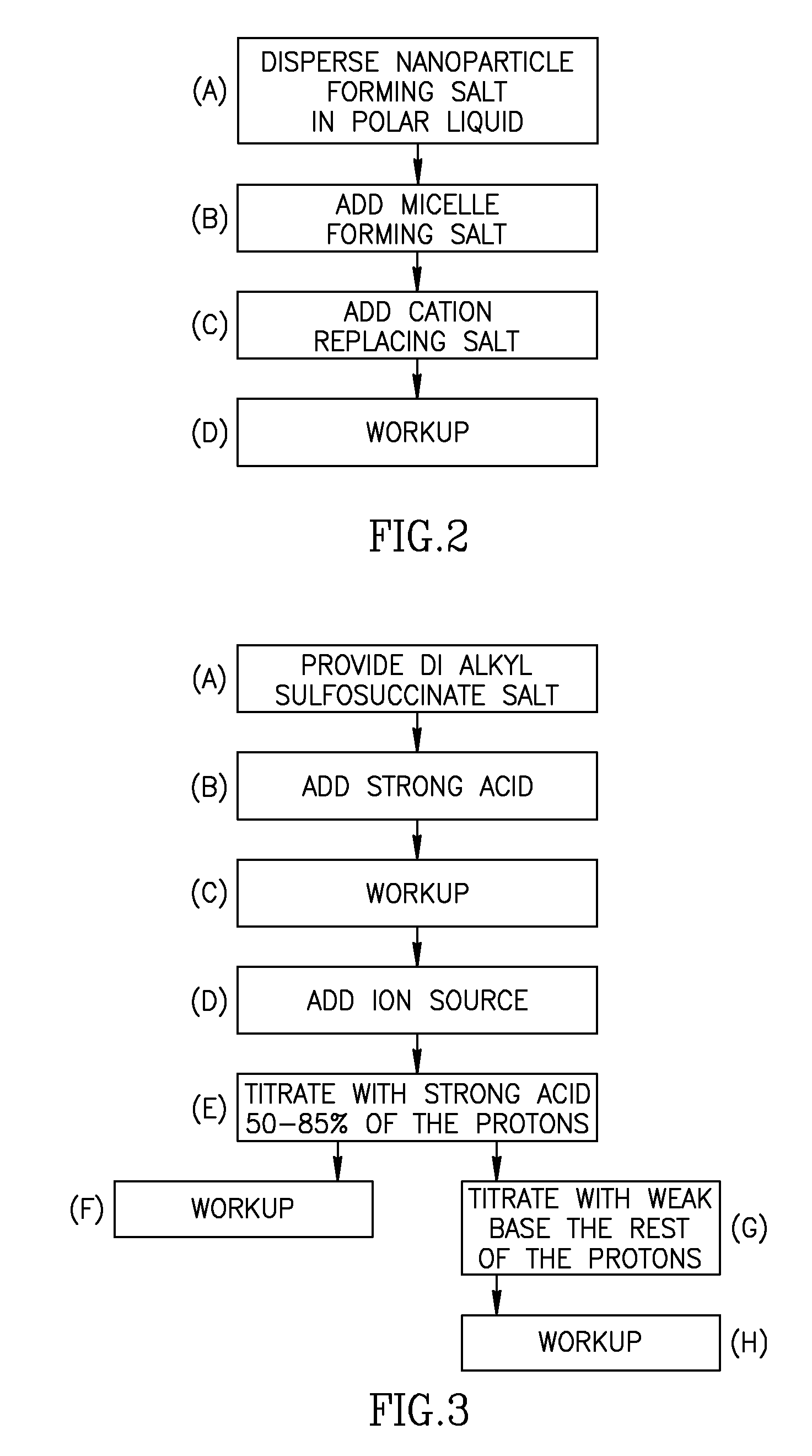

Charge Director for Liquid Toner

InactiveUS20090311614A1Less water-sensitiveEasy to controlMaterial nanotechnologyIndividual molecule manipulationHydrogenNanoparticle

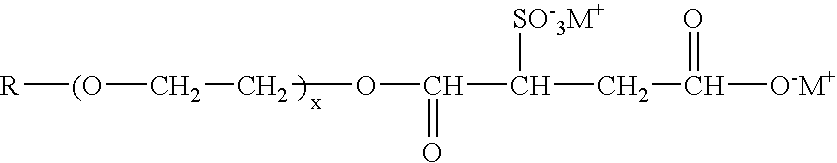

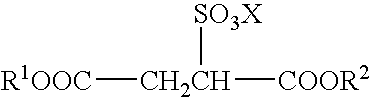

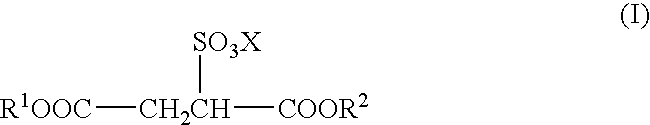

A charge director material for charging a liquid toner, the charge director material comprising (a) nanoparticles of a simple salt and (b) a sulfosuccinate salt of the general formula MAn, wherein M is a metal, n is the valence of M, and A is an ion of the general formula (I)[R1—O—C(O)CH2CH(SO3−)C(O)—O—R2], (I)wherein each of R1 and R2 is an alkyl group;said charge director material being substantially free of acids of the general formula (I),wherein one or both of R1 and R2 is hydrogen, and if only one of them is hydrogen, the other is an alkyl group,

Owner:HEWLETT PACKARD DEV CO LP

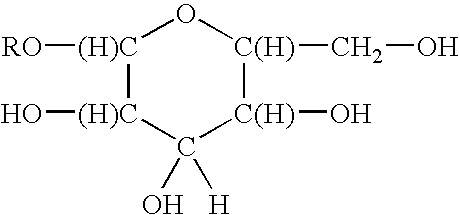

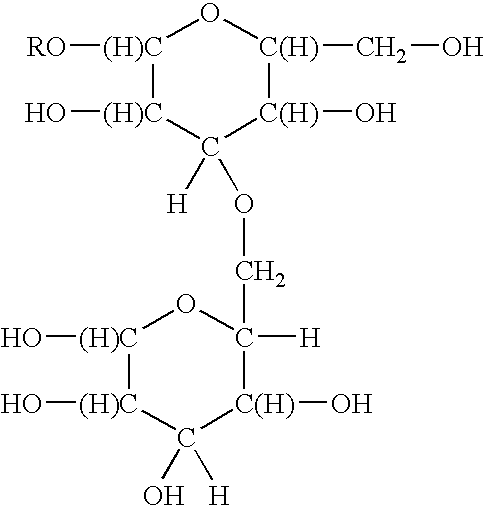

Alkyl polyglycoside derived sulfosuccinates

ActiveUS7087571B1Cosmetic preparationsOrganic detergent compounding agentsGlycoside formationAlkyl polyglycoside

The invention relates to a series of polyglycoside derivatives that contain water-soluble sulfosuccinate groups introduced into the molecule by reaction with the hydroxyl groups present in the starting polyglycoside molecule, with the chloro material. The preferred products have more than one water-soluble group per molecule and are made with mild reagents to avoid discoloration and mal odor. The most preferred products have between 2 and 3 functional groups per molecule.

Owner:SURFATECH

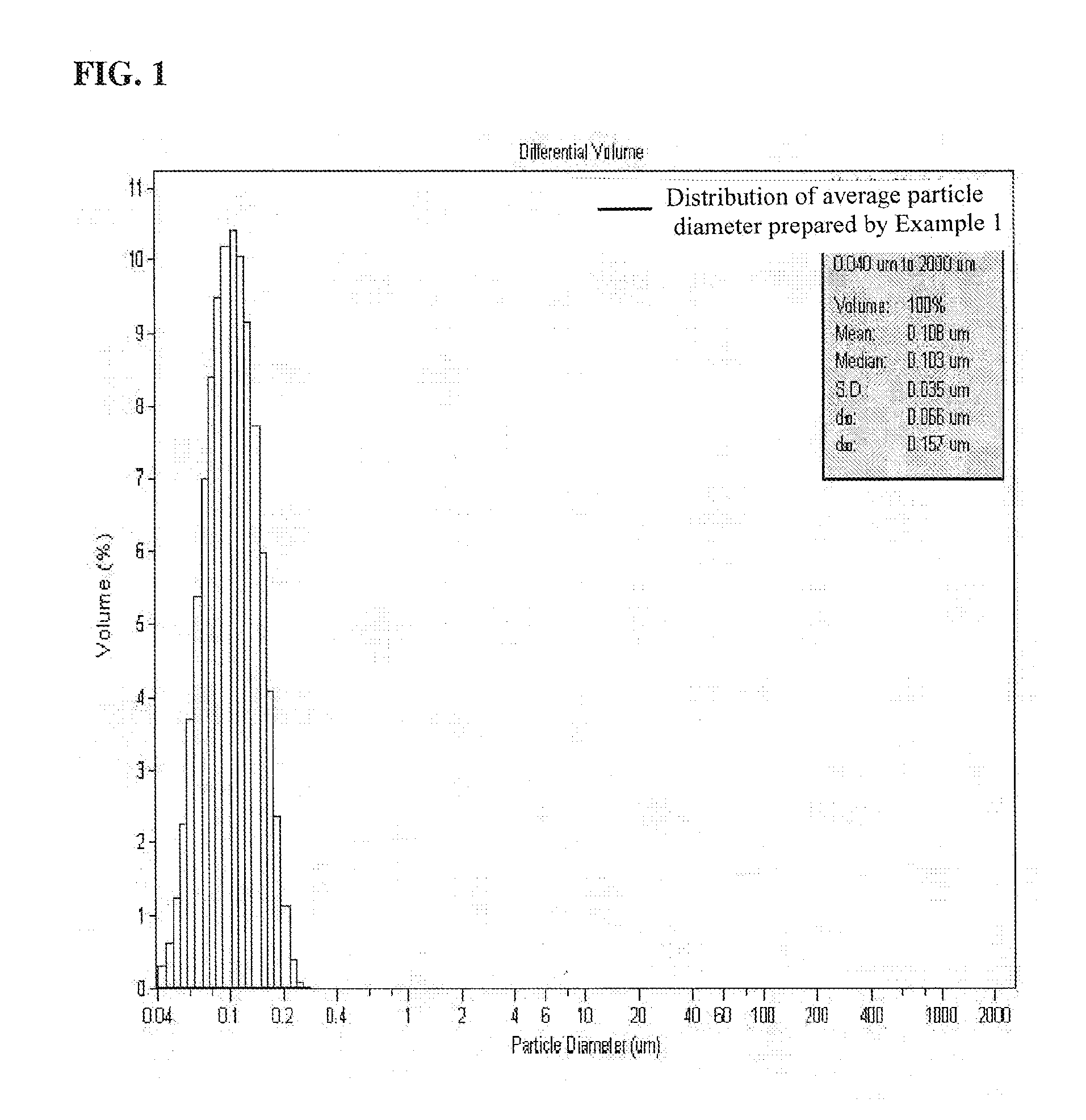

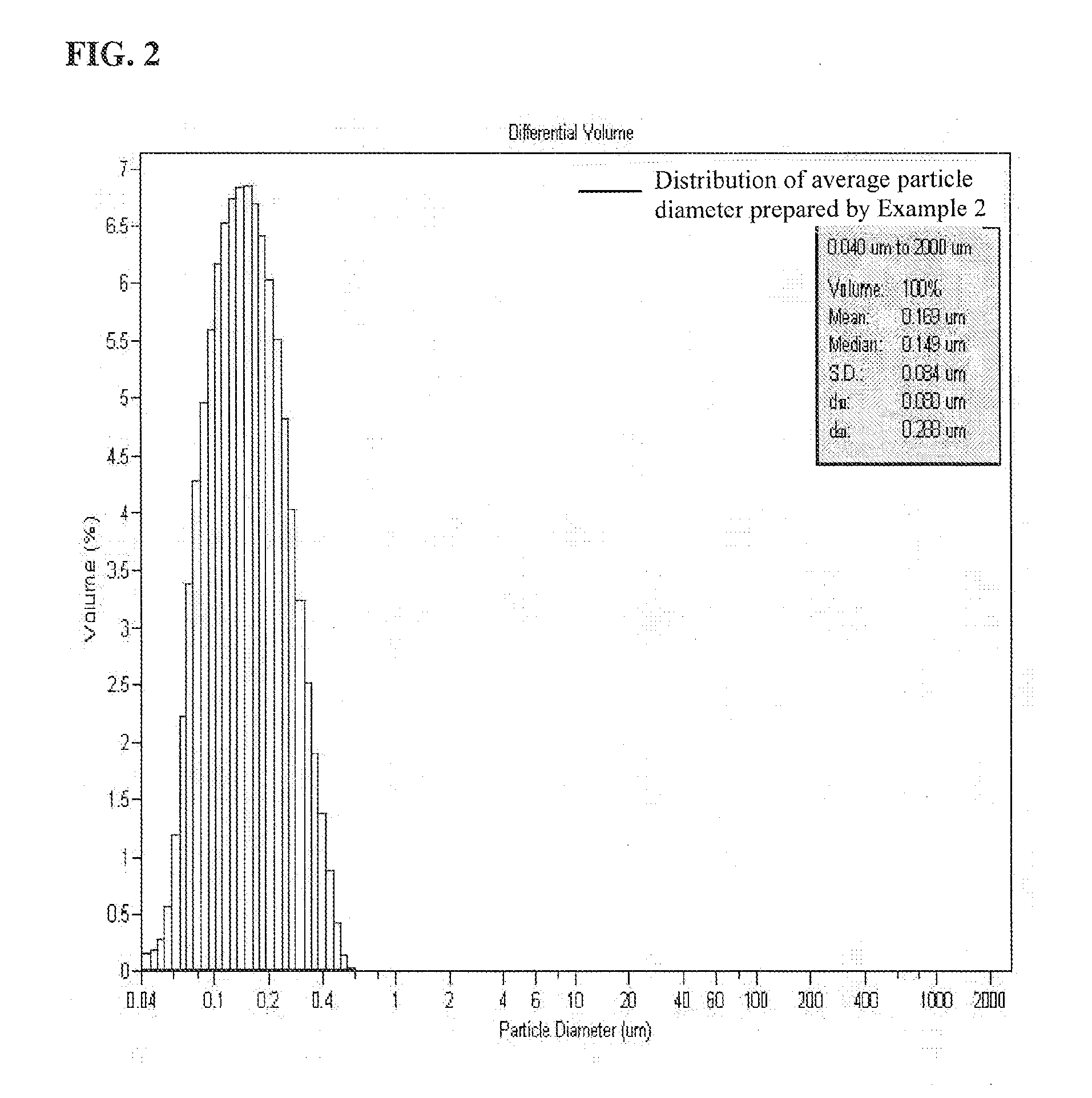

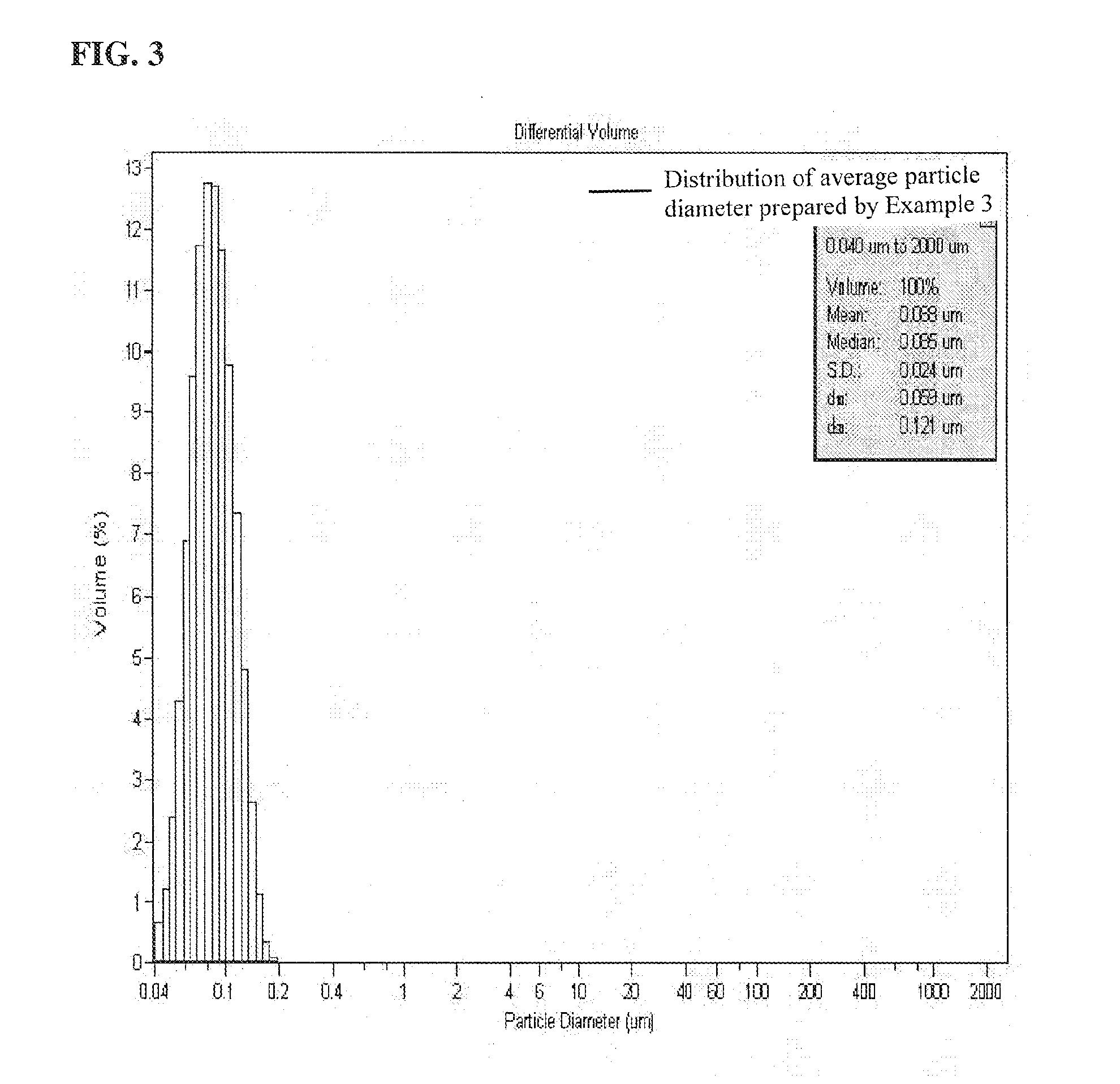

Disperse system having fine powder-typed inorganic metal oxide dispersed in water and preparing method for the same

InactiveUS20080188574A1Easy to cleanFeel lightCosmetic preparationsOther chemical processesAlkoxylationAqueous dispersion

This invention provides a disperse system having fine powder-typed inorganic metal oxide dispersed in water and preparing method for the same and more particularly, it provides a method for preparing a disperse system having fine powder-typed inorganic metal oxide dispersed in water characterized in that a) a hydrophobically treated fine powder-typed inorganic metal oxide; b) a sulfosuccinate or sulfosuccinamate or an alkoxylated alcohol dispersant; and c) water are mixed and dispersed by a high-speed bead mill and a disperse system having fine powder-typed inorganic metal oxide dispersed in water prepared by the same.The disperse system having fine powder-typed inorganic metal oxide dispersed in water of the present invention has excellent characteristics in that it has high transparency in the visible ray spectrum, it has excellent UV protection ability when applied to cosmetics, it provides better feelings than oil dispersions, and it has better water-proof property than existing water dispersions.

Owner:SUNJIN BEAUTY SCI CO LTD +1

Enhanced activity hydrogen peroxide disinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:TRIKON TECH LTD +1

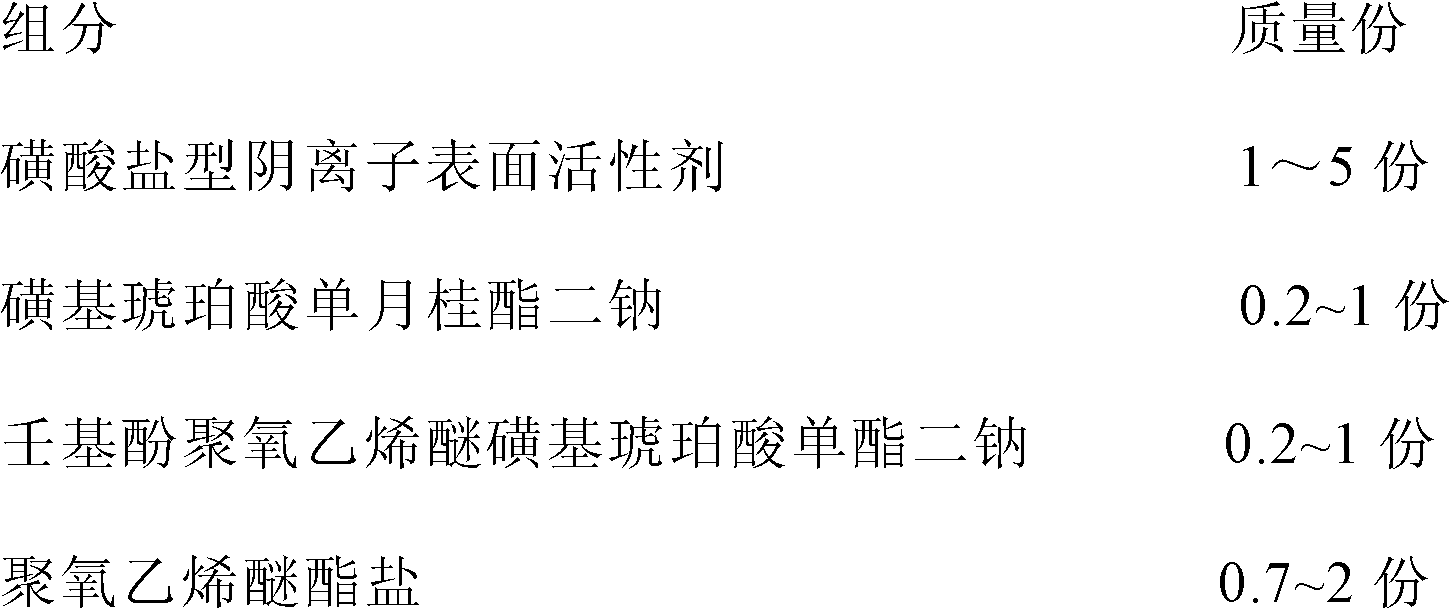

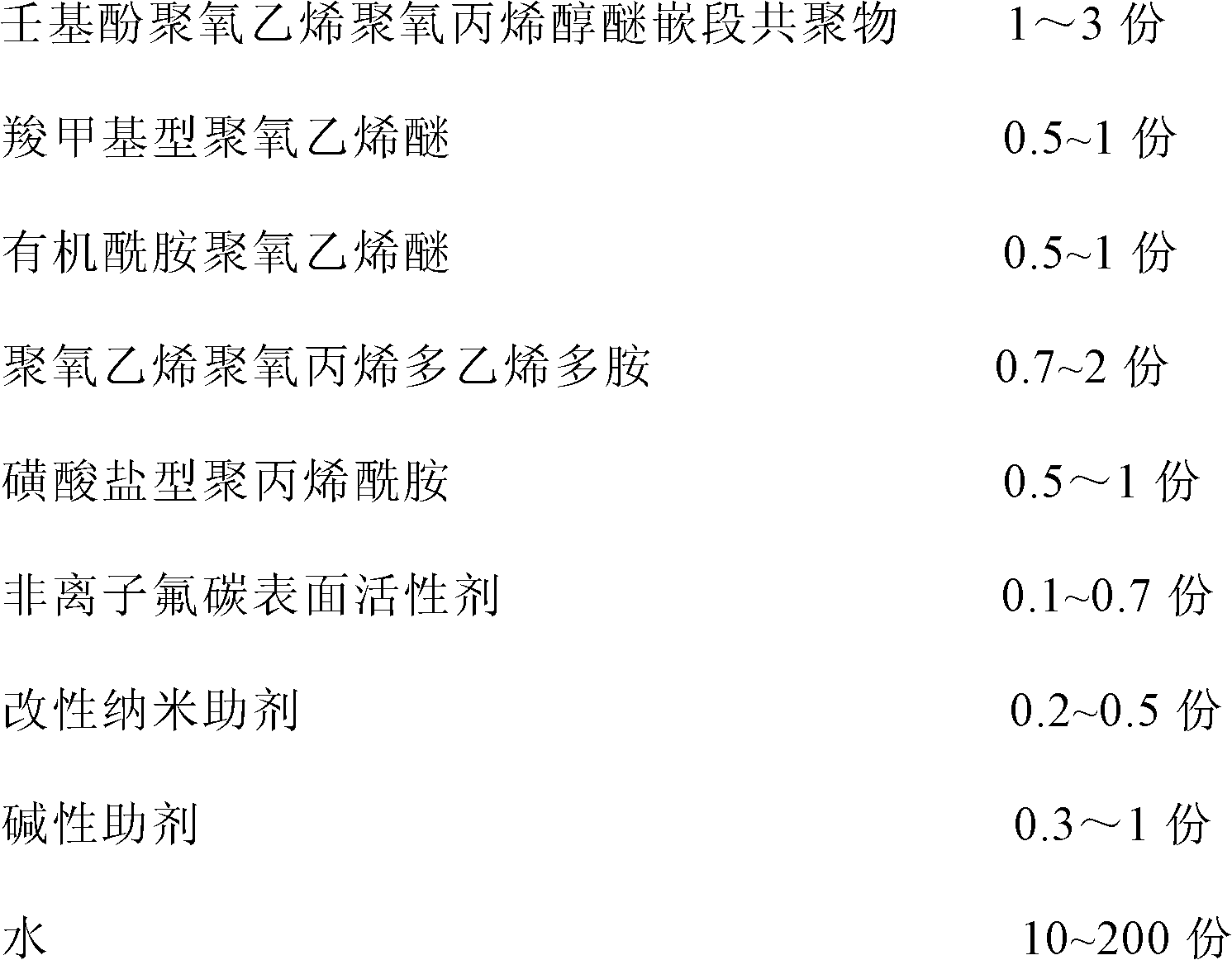

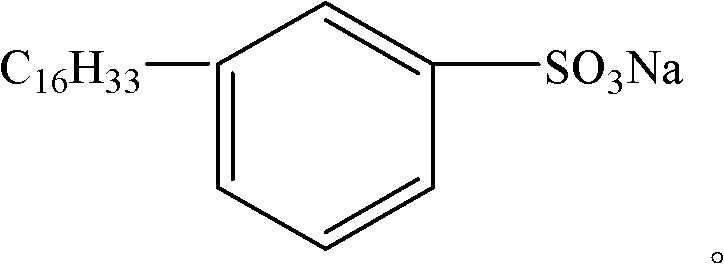

Salt- and temperature-resistant emulsification viscosity reducer for heavy oil

The invention relates to a salt- and temperature-resistant emulsification viscosity reducer for thick oil. The emulsification viscosity reducer is applied in oil fields for emulsification viscosity reduction of heavy oil and super heavy oil and is characterized by comprising the following components by mass: 1 to 5 parts of sulfonate anionic surfactant, 0.2 to 1 part of disodium monolauryl sulfosuccinate, 0.2 to 1 part of polyoxyethylene nonylphenyl ether disodium monoester sulfosuccinate, 0.7 to 2 parts of polyoxyethylene ether ester salt, 1 to 3 parts of polyoxyethylene nonylphenyl-polyoxypropylene alcohol ether block copolymer, 0.5 to 1 part of carboxymethyl polyoxyethylene ether, 0.5 to 1 part of organic amide polyoxyethylene ether, 0.7 to 2 parts of polyoxyethylene polyoxypropylene polyethylene polyamine, 0.5 to 1 part of sulfonate polyacrylamide, 0.1 to 0.7 part of nonionic fluorocarbon surfactant, 0.2 to 0.5 part of a modification nanometer auxiliary agent, 0.3 to 1 part of an alkalescence auxiliary agent and 10 to 200 parts of water. The beneficial effects of the emulsification viscosity reducer are as follows: salt resistance is up to 24*10<4> mg / L, resistance to a temperature as high as 150 DEG C is realized, and emulsification viscosity reduction of super heavy oil with a viscosity of 500 Pa.s at a temperature of 50 DEG C is realized.

Owner:PETROCHINA CO LTD

Liquid detergent composition for improved low temperature grease cleaning and starch soil cleaning

InactiveUS20060019851A1Non-ionic surface-active compoundsAmpholytes/electroneutral surface-active compoundsSulfosuccinic acidDimethyl Oxide

Owner:THE PROCTER & GAMBLE COMPANY

Fire mitigation and moderating agents

ActiveUS8080186B1Alkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPolymer adhesiveDiammonium phosphate

The fire mitigation and moderating agent includes by weight one percent (1%) to five percent (5%) potassium hydroxide, two percent (2%) to seven percent (7%) citric acid, four percent (4%) to thirty six percent (36%) diammonium phosphate, four percent (4%) to twenty percent (20%) carbamide, and point five percent (0.5%) to four percent (4%) surface tension reducing component which comprises by weight twenty percent (20%) to fifty five percent (55%) octyldimethylamine oxide, fifteen percent (15%) to thirty five percent (35%) modified polyether organosiloxane, five percent (5%) to twenty percent (20%) sugar based surfactant, three percent (3%) to twelve percent (12%) 1,4-Bis(ethylhexyl)sodium sulfosuccinate, point zero one percent (0.01%) to point one percent (0.1%) anionic phosphate fluorosurfactant, and point one percent (0.1%) to two point five percent (2.5%) polymer adhesive mixture. The polymer adhesive mixture comprises seventy percent (70%) water and thirty percent (30%) polymer adhesive.

Owner:RENCK ALLISON +2

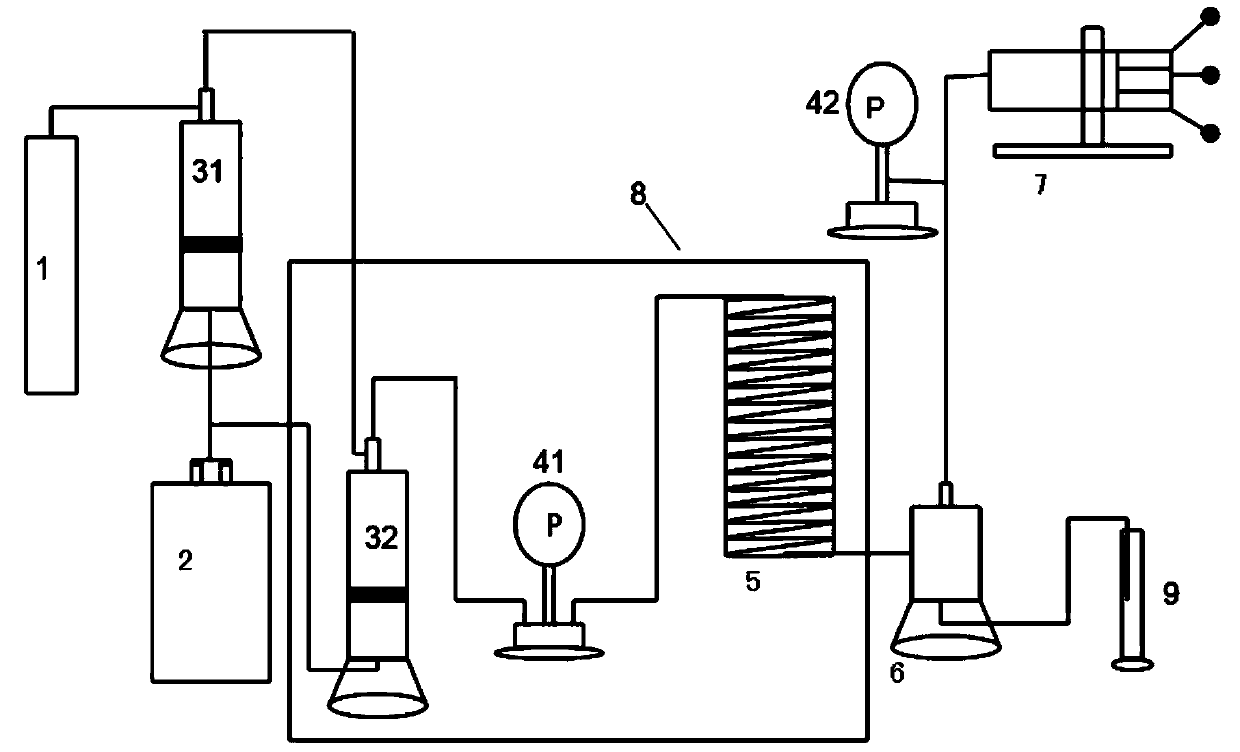

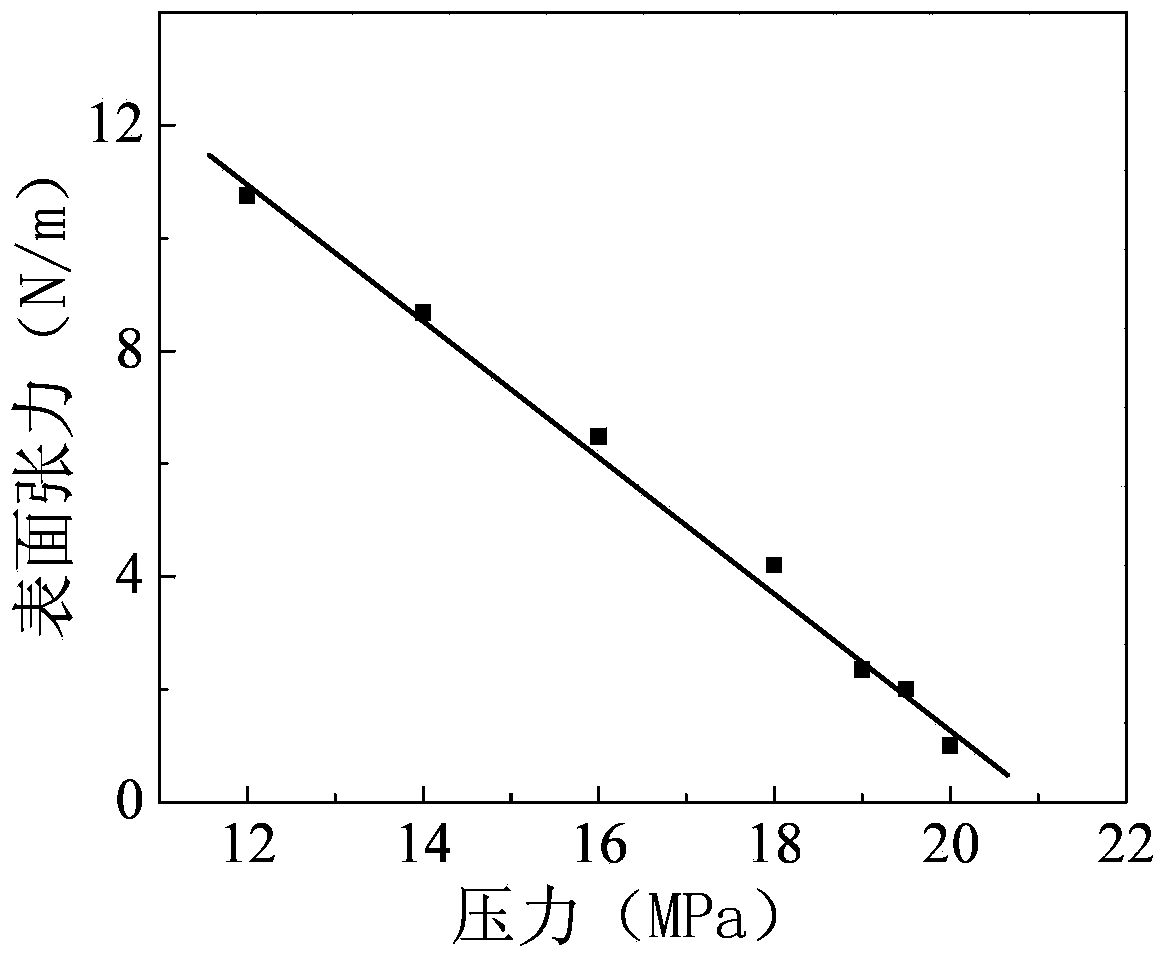

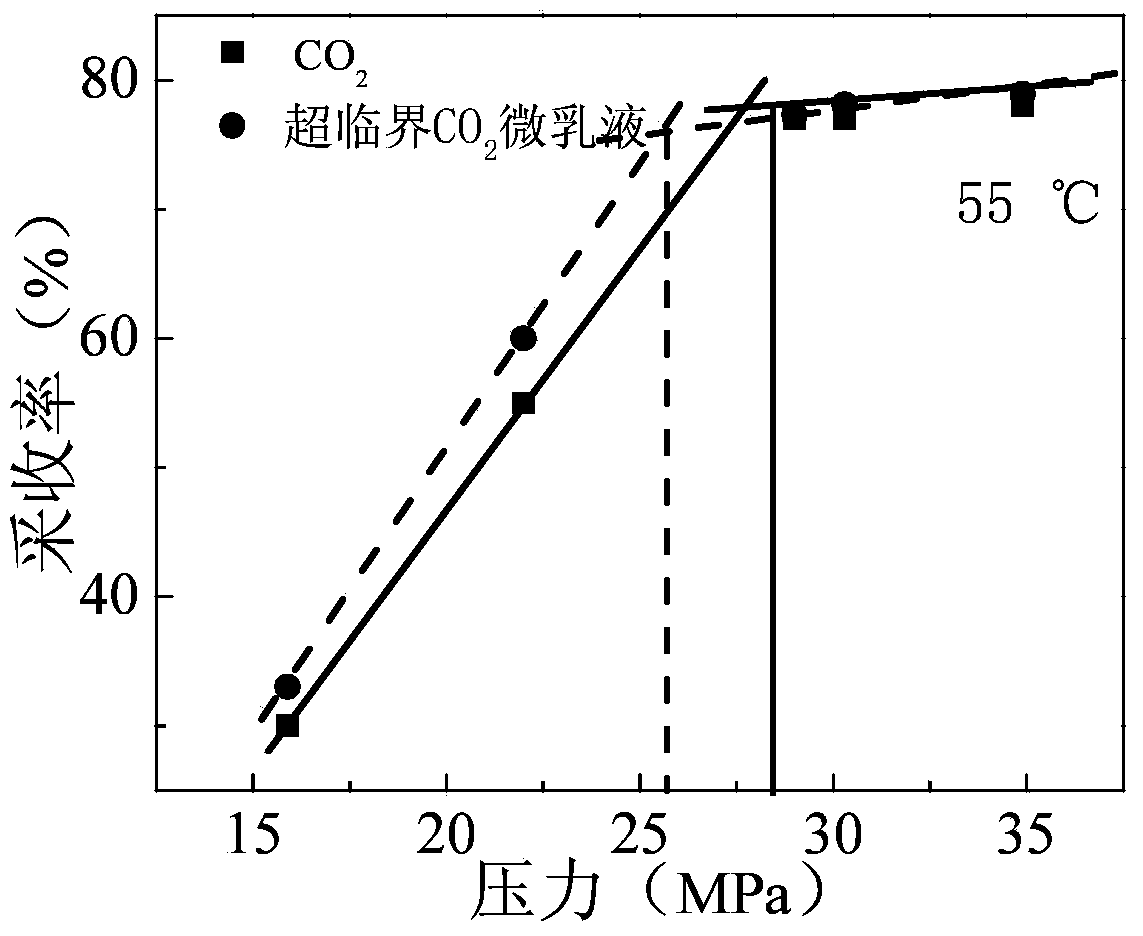

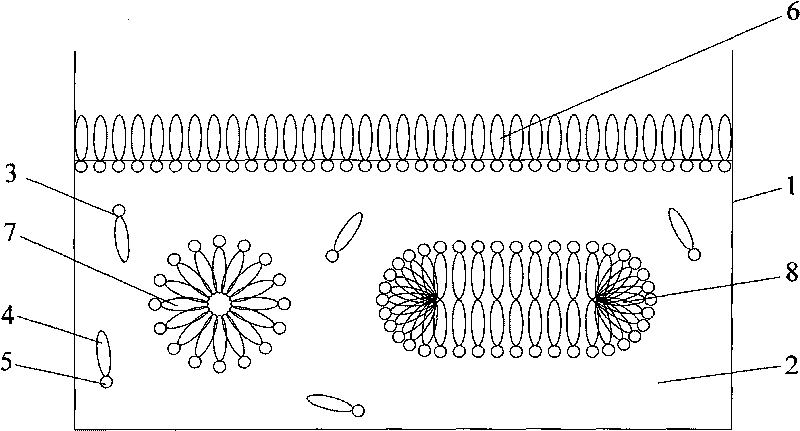

Supercritical CO2 microemulsion and method for improving oil recovery factor

InactiveCN104194762AReduce the minimum miscibility pressureEnhanced overall recoveryDrilling compositionBulk chemical productionPhosphatePolyethylene glycol

The invention provides a supercritical CO2 microemulsion and a method for improving an oil recovery factor. The supercritical CO2 microemulsion comprises the following raw materials in percentages by weight: 4.5*10<-3>wt% to 16.5*10<-3>wt% of a surfactant, 12.0wt% to 14.5wt% of a cosurfactant, 0.2wt% to 1.8wt% of water, and 83.7wt% to 87.8wt% of CO2, wherein the surfactant is one of 2-(1-ethyl-2-methyl-1-pentyl) sodium sulfosuccinate or a homolog of 2-(1-ethyl-2-methyl-1-pentyl) sodium sulfosuccinate, polyethylene glycol-2,6,8-trimethyl-4-nonyl ether, perfluorinated alkyl polyoxyethylene, polyacrylic acid 1,1-perfluorooctyl dihydrogen phosphate, polydimethylsiloxane, and polyacrylic acid 1,1-dihydrogen perfluorinated octyl methyl ester-b-polyoxyethylene; and the cosurfactant is ethanol, propyl alcohol, butanol, pentanol or hexyl alcohol. The invention also provides a method for improving an oil recovery factor. The method comprises a step of improving the oil recovery factor by adopting the supercritical CO2 microemulsion.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

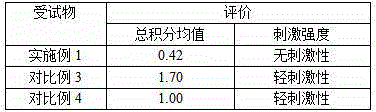

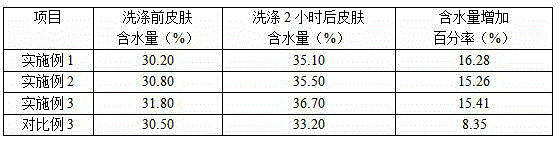

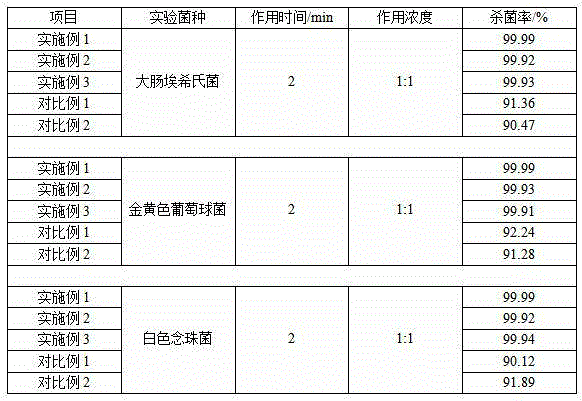

Antibacterial soap-based shower gel and preparation method thereof

ActiveCN104800123AImprove antibacterial propertiesGood moisturizing effectCosmetic preparationsToilet preparationsShower gelGlycerol

The invention discloses an antibacterial soap-based shower gel and a preparation method thereof. The shower gel comprises the following ingredients: thymol, salicylic acid, plants extracts, ethyl alcohol, propylene glycol, erythritol, lauric acid, myristic acid, palmitic acid, potassium hydroxide, glycol distearate, dihexyl sodium sulfosuccinate, cocamidopropyl betaine, sodium cocoyl glycinate, polyquaternium-7, polyglyceryl fatty acid ester composition, ethylene diamine tetraacetic acid tetrasodium, sodium chloride, citric acid, essence, a preservative and water. The antibacterial soap-based shower gel is soft and friendly to skin, can effectively resist bacteria and moisturize skin and is particularly applicable to people with thicker cuticle, high grease secretion, skin pruritus and tinea corporis.

Owner:WALCH GUANGZHOU COMMODITY

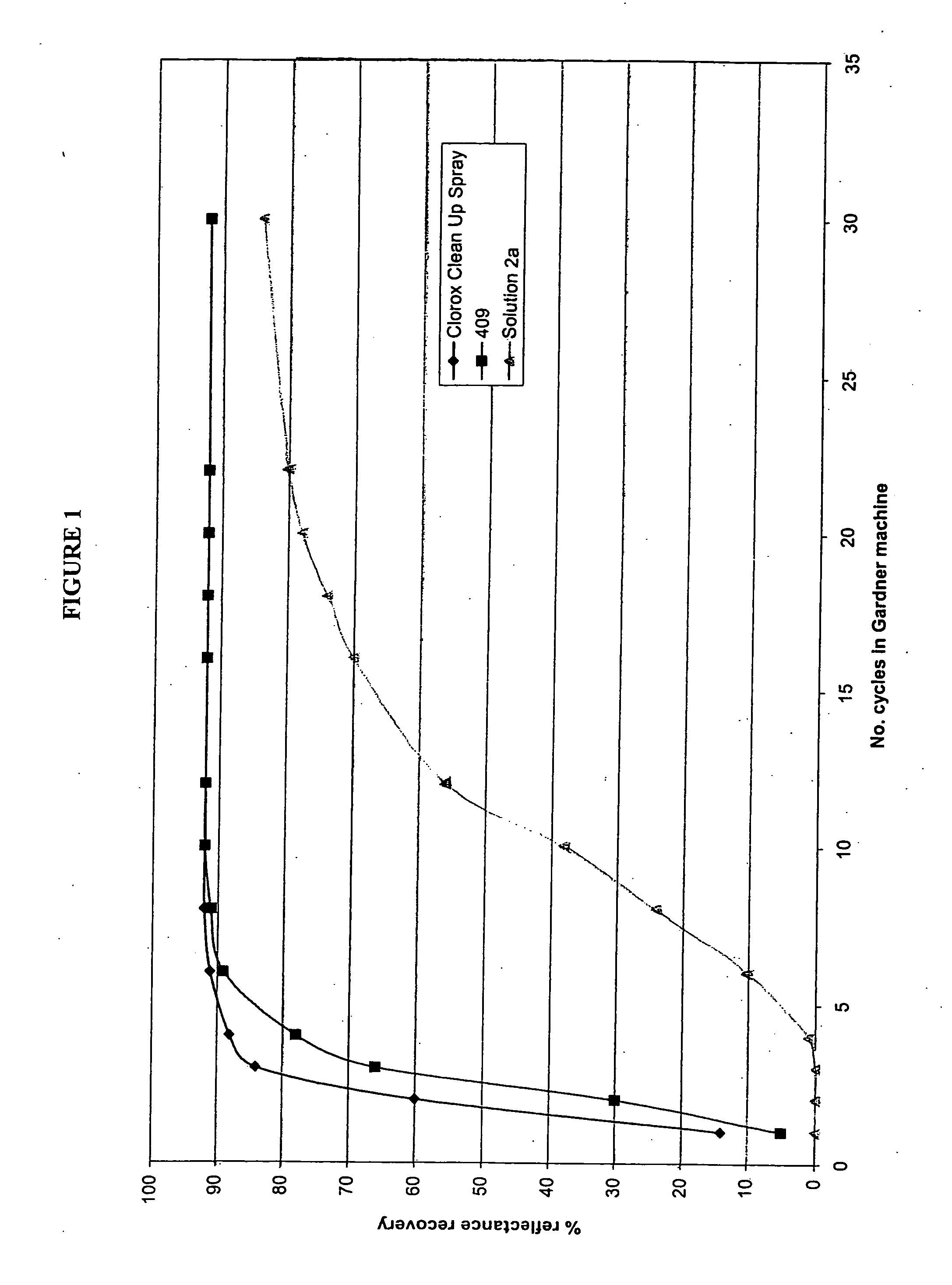

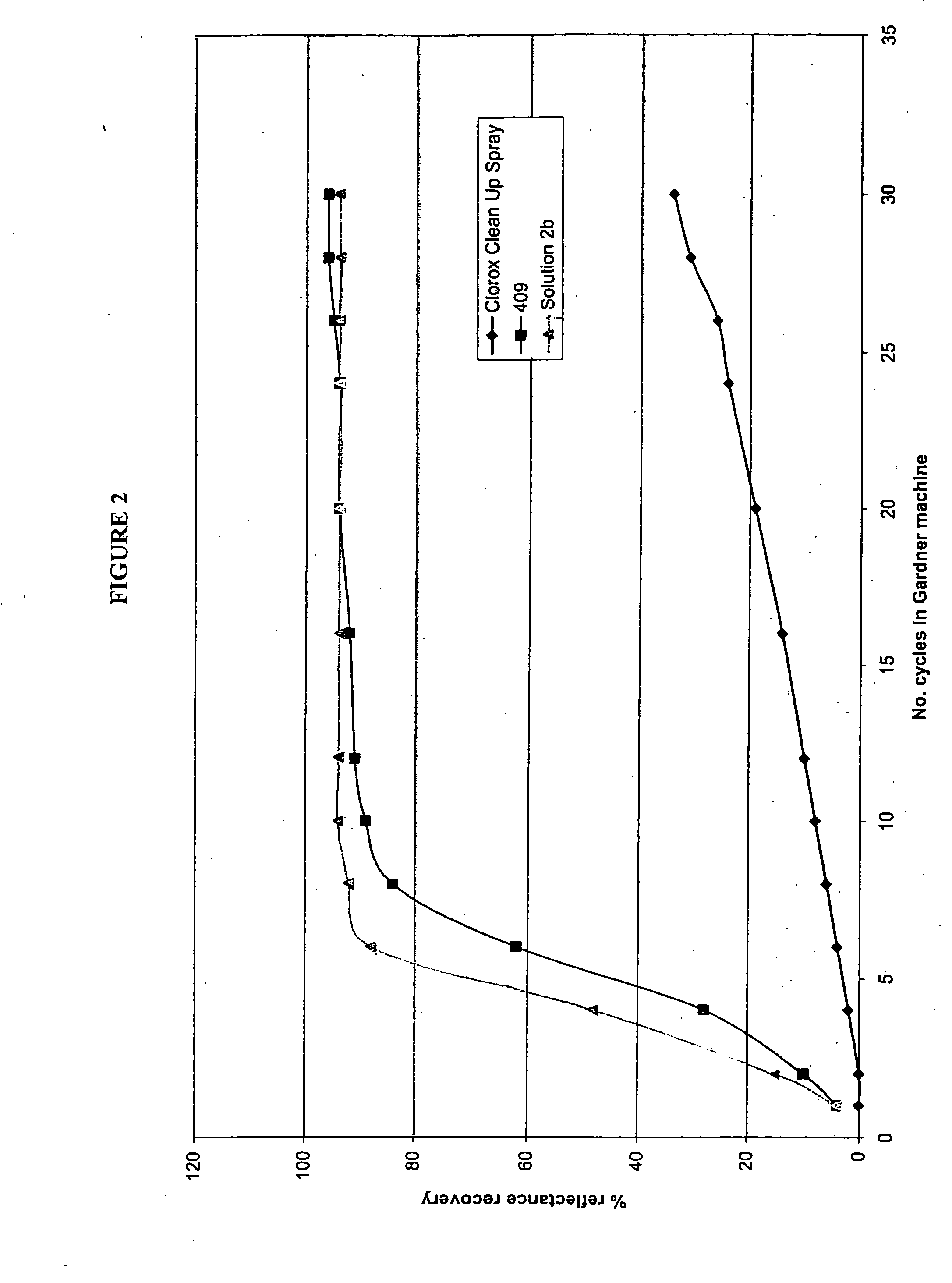

Transparent anti-fog anti-splash coating compositions

The present invention is directed to an anti-fogging / anti-splash composition that can be used for anti-fog / anti-splash applications. When applied to the surface of a transparent or reflective substrate, the composition dries relatively clear and comprises a solution of a non-toxic, fast drying solvent or alcohol and a surface active agent containing sodium lauryl ether sulfate, and either a block ethylene oxide / polyethylene oxide copolymer, an ethoxylated amine, an ethoxylated acetylenic alcohol, sodium sulfosuccinate, ethoxylated sorbitan ester, random EO / PO polymers on butyl alcohol, or mixtures thereof. When applied to the surface of a substrate, the present invention provides a coating of high transparency which cures rapidly, is sufficiently surface active to be an anti-fog agent when "dry", will persist when "wet" under water spray conditions (such as on a dental mirror) for a period substantial enough to be practicable, and will provide anti-splash benefits throughout the use cycle.

Owner:MACHSON ROGER

Enhanced activity hydrogen peroxide disinfectant

InactiveUS20070059380A1Commercially acceptable stability and cleaning abilityWithout usingAntibacterial agentsBiocideMagnesium saltDisinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:JOHNSONDIVERSEY INC

Foaming agent type shampoo

ActiveCN102697670AReduce contact timeReduce chance of baldnessCosmetic preparationsHair cosmeticsSodium lactateCopolymer

The invention relates to foaming agent type shampoo which comprises (30 percent) 20 percent to 40 percent of lauryl alcohol polyoxyethylene ether sulpho succinate monoester disodium salt, (30 percent) 20 percent to 40 percent of lauroyl sodium sarcosinate, 0.1 to 0.5 percent of disodium EDTA, 1 to 5 percent of sodium lactate, (40 percent) 1 to 5 percent of polyquat-7, (30 percent) 2 to 5 percent of acrylate copolymer, 1 to 6 percent of PEG-12 dimethyl silicone, 0.1 to 1 percent of aromatic oil or essence, 0.01 to 0.3 percent of citric acid, and 0.04 to 1 percent of preservative agents, and the rest is deionized water. the foaming agent type shampoo is characterized in that foam is squeezed out through a mousse pump head, and the shampoo is not centralized at the top of the head but applied and diffused to other parts, so that the contact of chemical substances and the scalp can be reduced, the probability of furfur, calvities and balding can be reduced, and the effects of economy, environmental friendliness and no side effect can be achieved.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

Mild, moisturizing sulfosuccinate cleansing compositions

InactiveUS20060019858A1Mild to hair and skinFine foamCosmetic preparationsHair removalSulfosuccinic acidSURFACTANT BLEND

Compositions used for cleansing hair and skin based on the combination of an ethoxy sulfosuccinate surfactant and an amphoteric surfactant are described that are very mild but do not compromise in-use properties and economy. It has been found desirable to utilize a mixture of a Mid-Chain alkyl ethoxy sulfosuccinate and a Long-Chain alkyl ethoxy sulfosuccinate wherein the Long-Chain component is present in the composition at a level from about 0.1% to about 6% based on the total weight of the Mid-Chain component.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Dedusting agent composition and using method thereof

ActiveCN101717617AReduce water consumptionReduce surface tensionOther chemical processesDust removalChlorideCarbon chain

The invention discloses a dedusting agent composition and a using method thereof. The dedusting agent composition is prepared by fully mixing the following components in percentage by weight: 0.04 to 0.06 percent of sodium diisooctylester sulfosuccinate, 0.04 to 0.06 percent of empgen BB, 99.547 percent to 99.91 percent of water and 0.111 to 0.333 percent of calcium chloride, wherein the mixture of the components is pressed into a spraying dust-settling system on a coal mine working surface for spraying. In the method, the sodium diisooctylester sulfosuccinate, the empgen BB, the water and the calcium chloride are fully mixed together; and the sodium diisooctylester sulfosuccinate and the empgen BB are substances with surface activity, the molecules of the sodium diisooctylester sulfosuccinate and the empgen BB consist of hydrophilic groups and hydrophobic groups, the hydrophobic groups generally consist of long organic carbon chains, and the molecules are similar to the characteristics of surface molecule of coal dust and can generate absorption easier than water molecules, so the dust catching efficiency of the water is improved, the dedusting efficiency of the dedusting agent is over 90 percent, and the water consumption for dedusting is saved.

Owner:SHANDONG UNIV OF SCI & TECH

Enhanced activity hydrogen peroxide disinfectant

InactiveUS7632523B2Commercially acceptable stability and cleaning abilityWithout usingAntibacterial agentsBiocideDisinfectantMagnesium salt

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:JOHNSONDIVERSEY INC

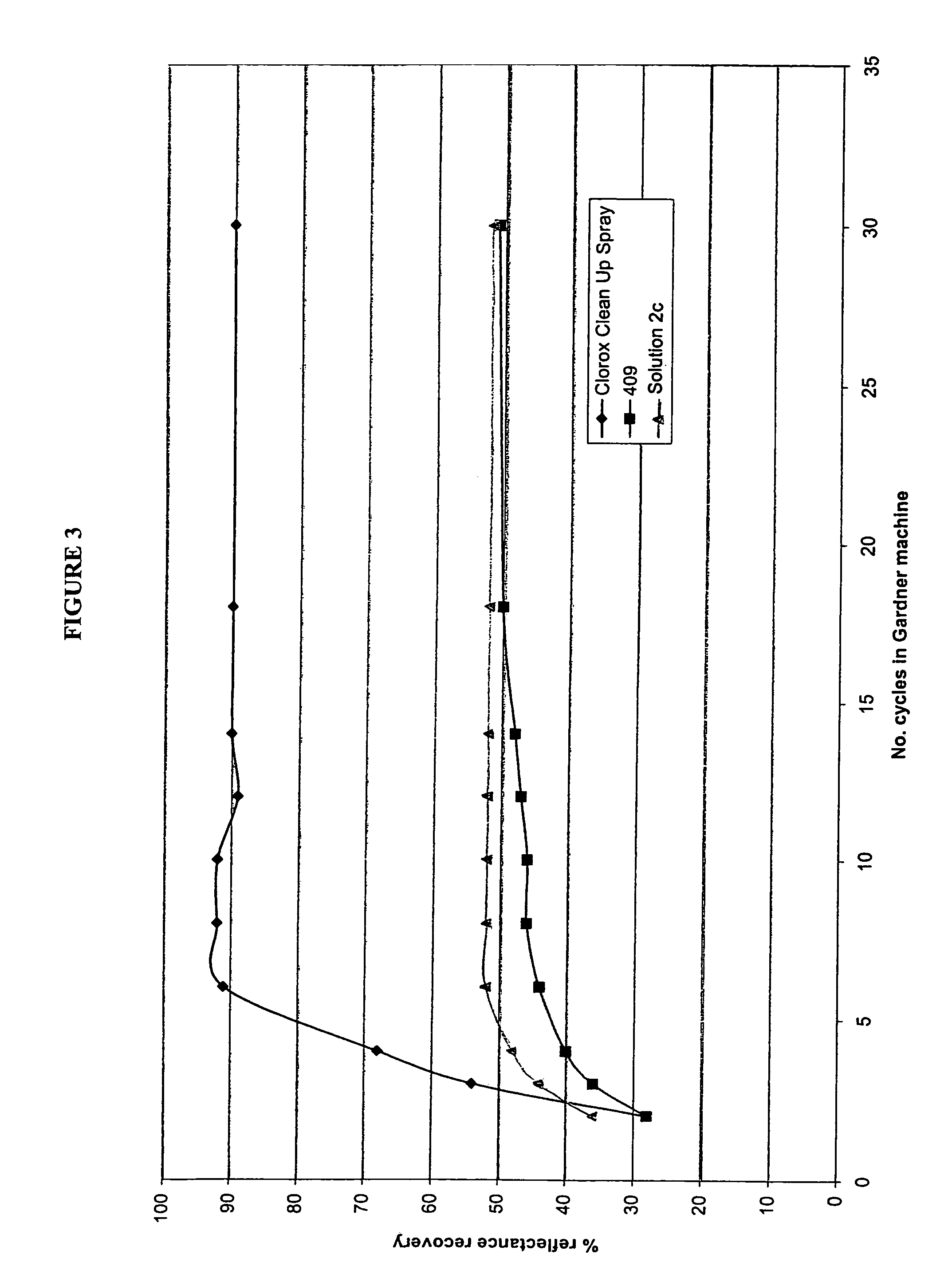

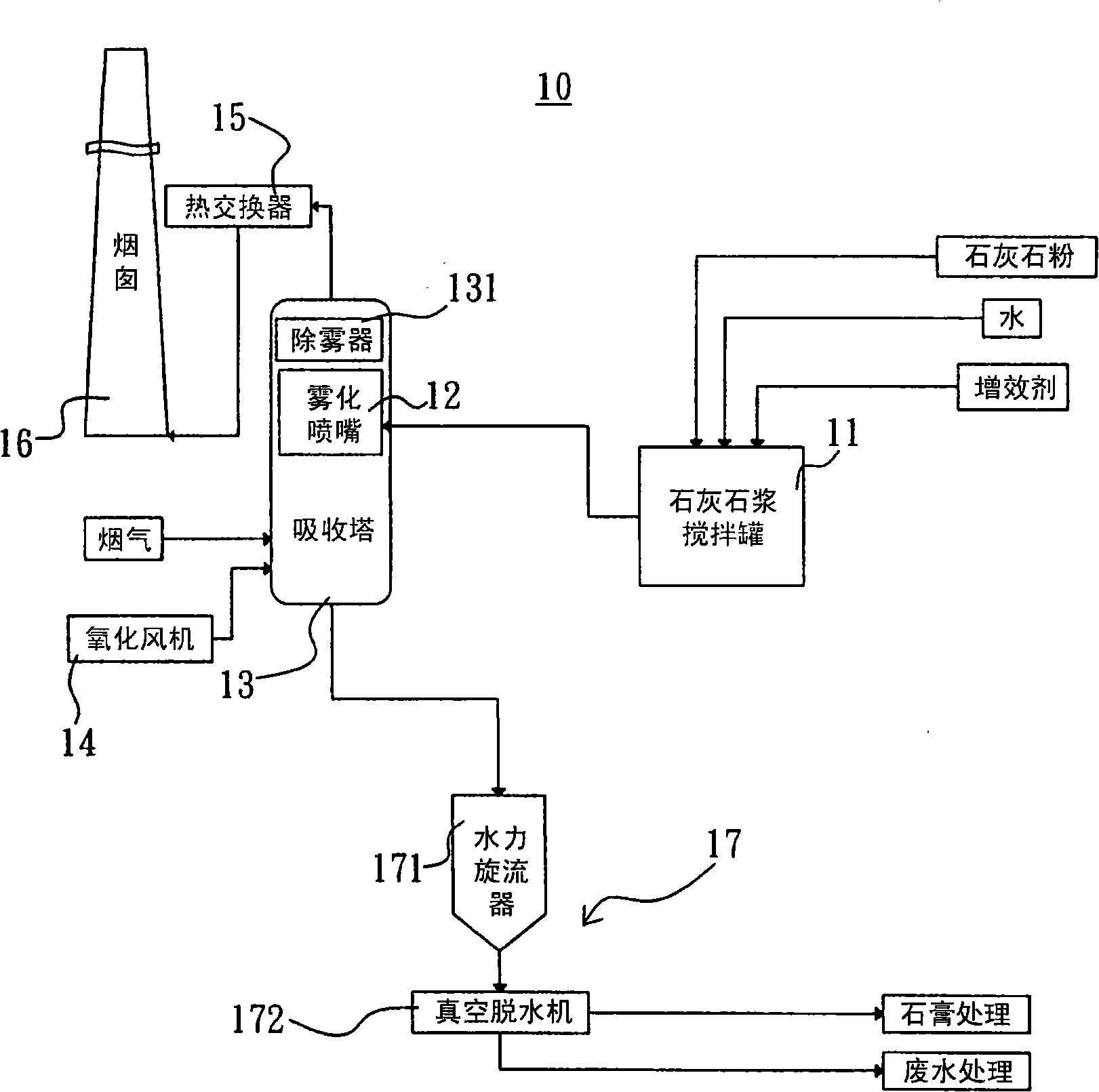

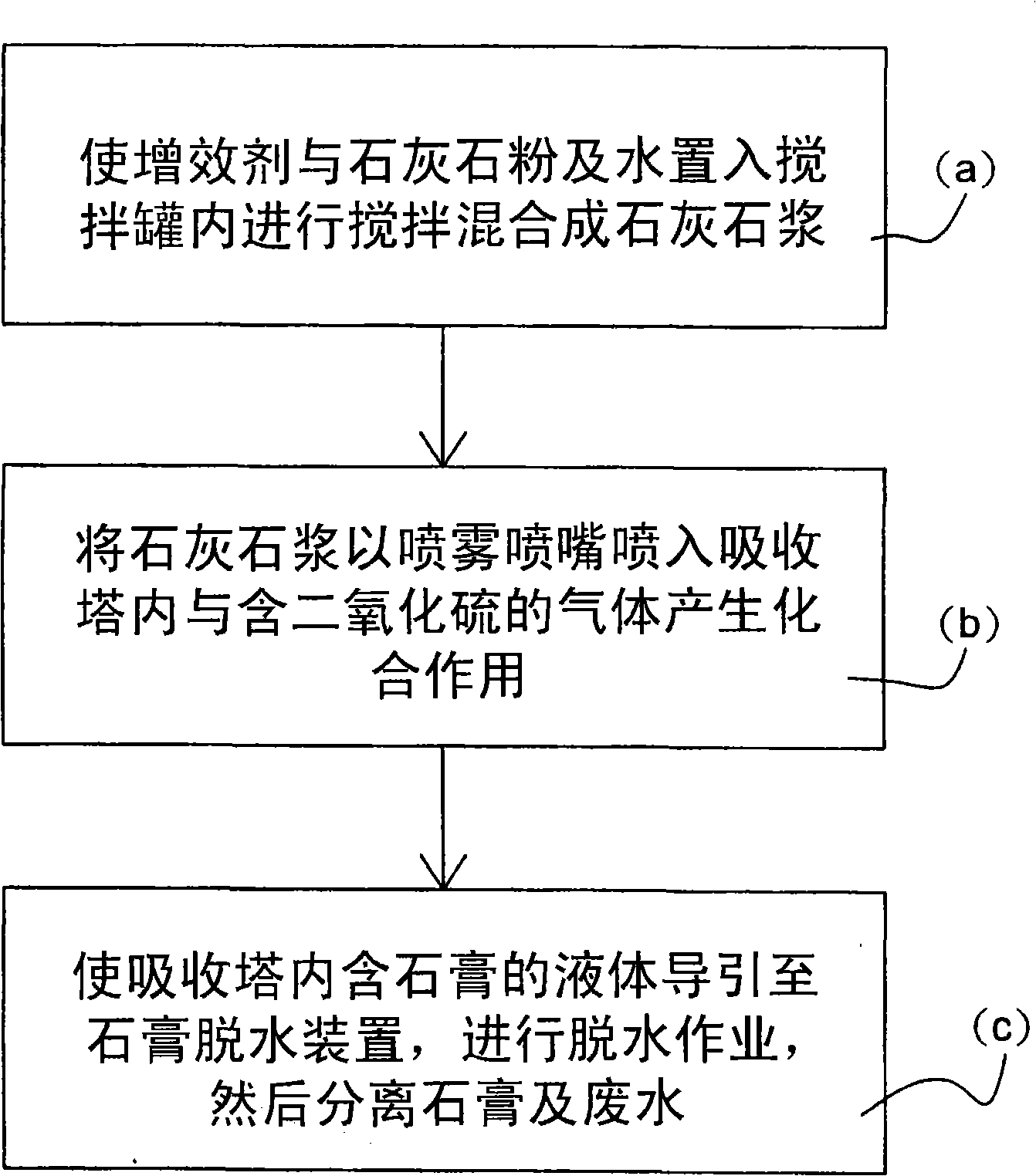

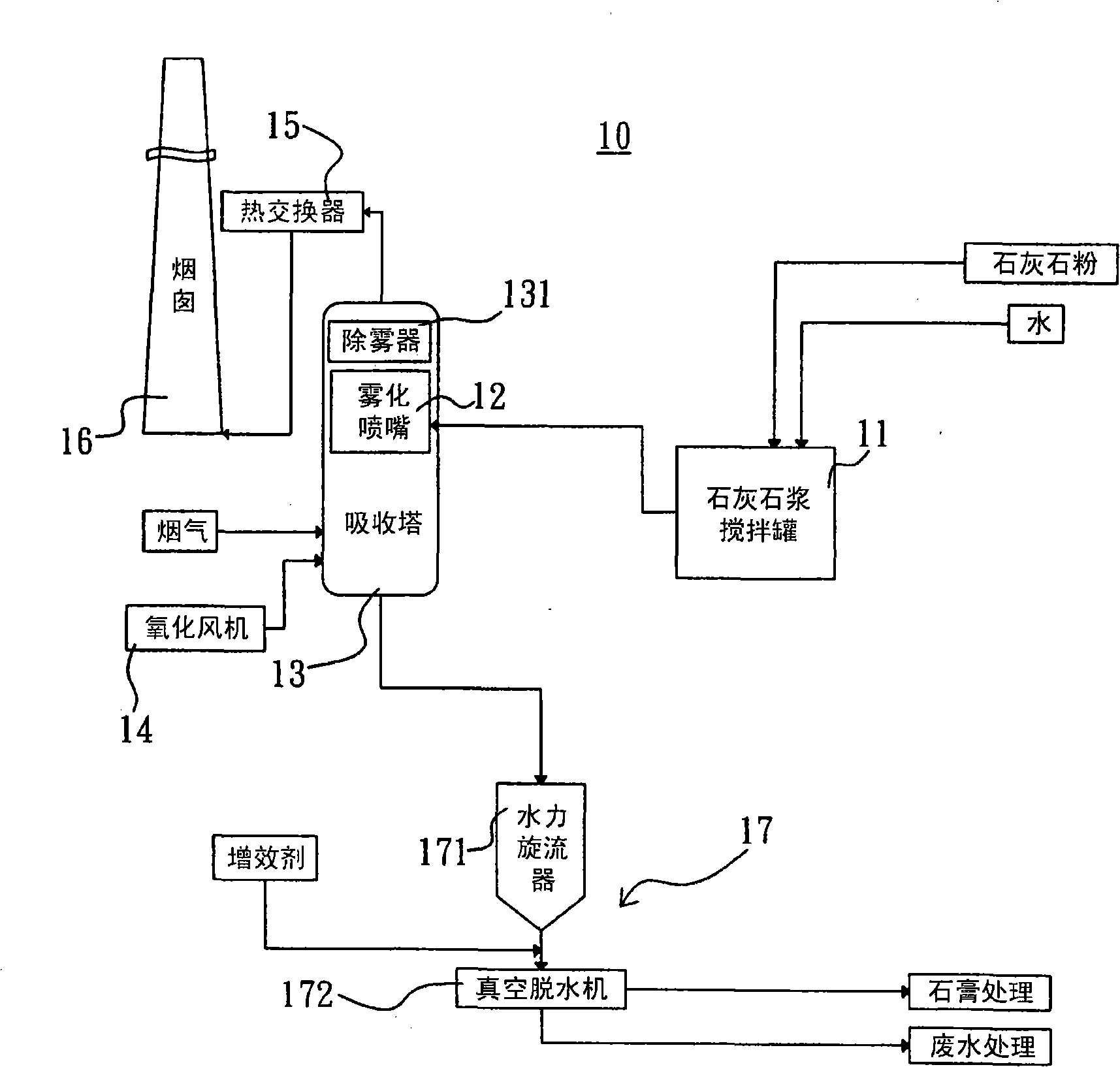

Desulfurizing method and synergistic agent thereof

ActiveCN101574615AIncrease moistureImprove permeabilityDispersed particle separationSulfosuccinic acidTower

The invention relates to a desulfurizing method and a synergistic agent thereof. The synergistic agent is formed by combing alkyl sulfo sulfonic ester and other humectants. The synergistic agent is mixed into limestone mortar and enters an absorption tower of a wet flue gas desulfurization system in a spraying mode. The desulfurizing method can increase the desulfurization efficiency of the limestone mortar and the dehydration efficiency of gypsum, reduce the use quantity of limestone and the output of byproduct gypsum, relieve the problems of gypsum accumulation and environmental protection treatment and save massive amount of operation electric energy. The synergistic agent does not contain any heavy metal and chlorine, is nontoxic to the environment and is convenient to use.

Owner:江丰明 +1

Foaming agent type shampoo

ActiveCN102697670BReduce contact timeReduce chance of baldnessCosmetic preparationsHair cosmeticsSodium lactateCopolymer

The invention relates to foaming agent type shampoo which comprises (30 percent) 20 percent to 40 percent of lauryl alcohol polyoxyethylene ether sulpho succinate monoester disodium salt, (30 percent) 20 percent to 40 percent of lauroyl sodium sarcosinate, 0.1 to 0.5 percent of disodium EDTA, 1 to 5 percent of sodium lactate, (40 percent) 1 to 5 percent of polyquat-7, (30 percent) 2 to 5 percent of acrylate copolymer, 1 to 6 percent of PEG-12 dimethyl silicone, 0.1 to 1 percent of aromatic oil or essence, 0.01 to 0.3 percent of citric acid, and 0.04 to 1 percent of preservative agents, and the rest is deionized water. the foaming agent type shampoo is characterized in that foam is squeezed out through a mousse pump head, and the shampoo is not centralized at the top of the head but applied and diffused to other parts, so that the contact of chemical substances and the scalp can be reduced, the probability of furfur, calvities and balding can be reduced, and the effects of economy, environmental friendliness and no side effect can be achieved.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

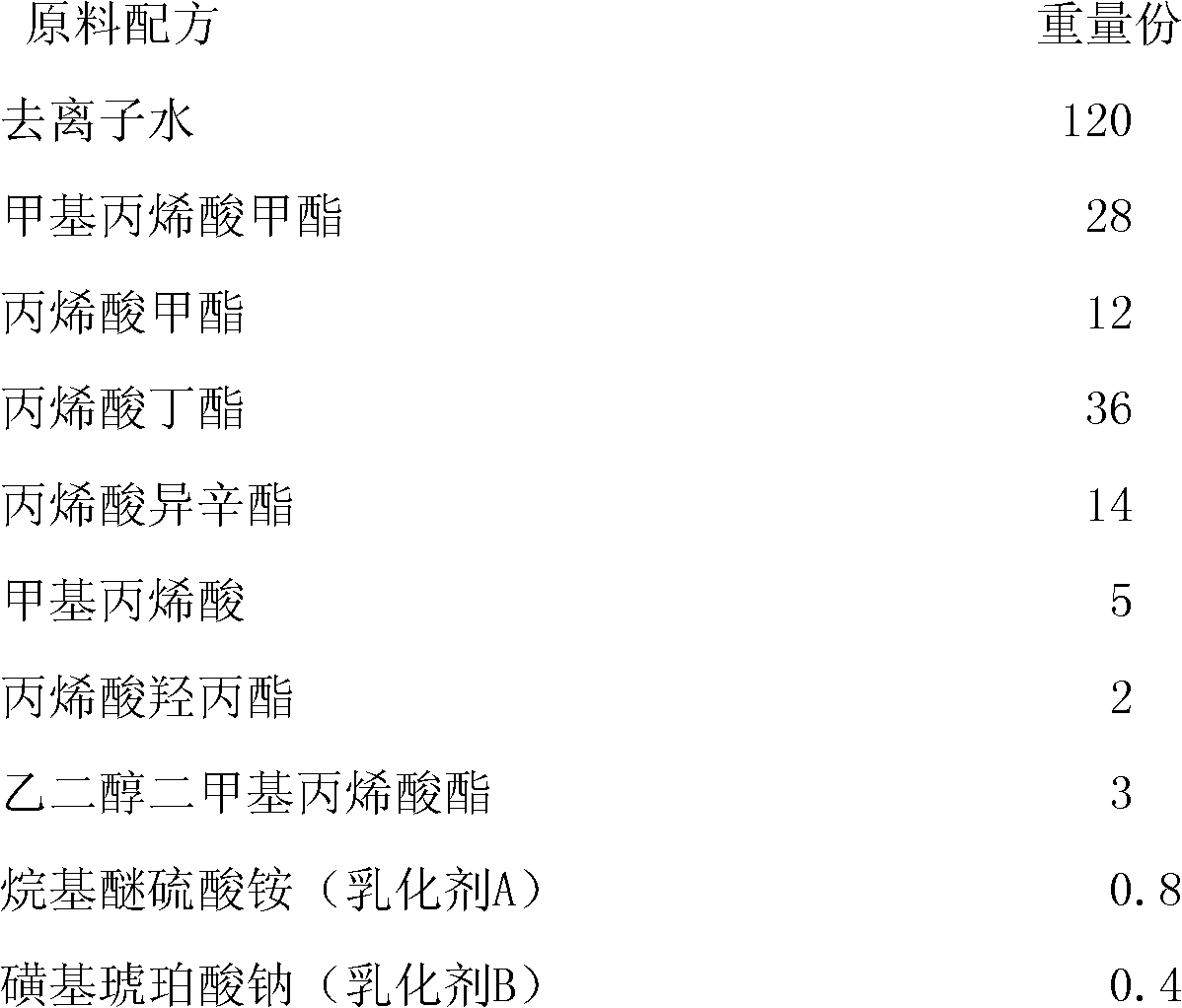

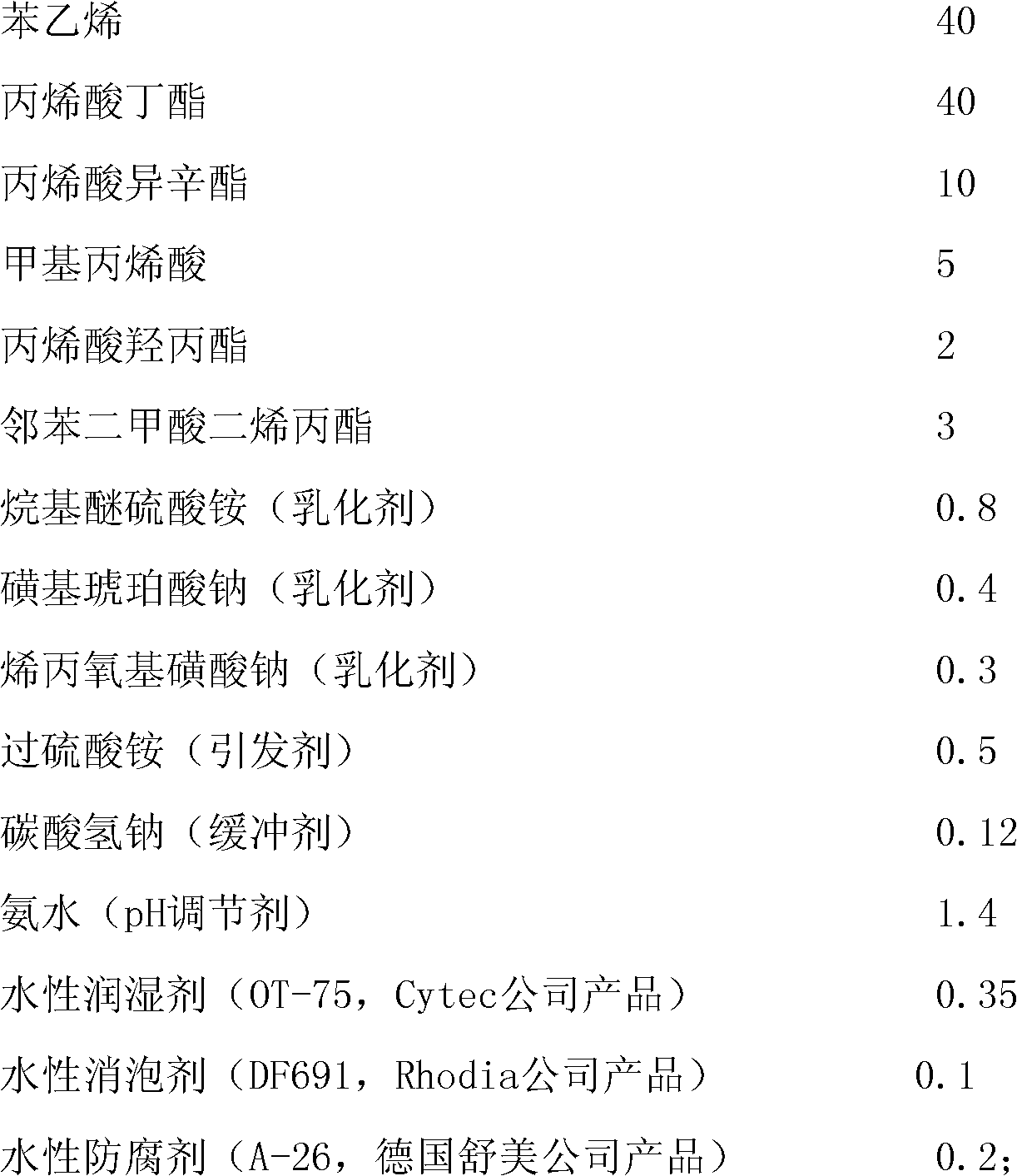

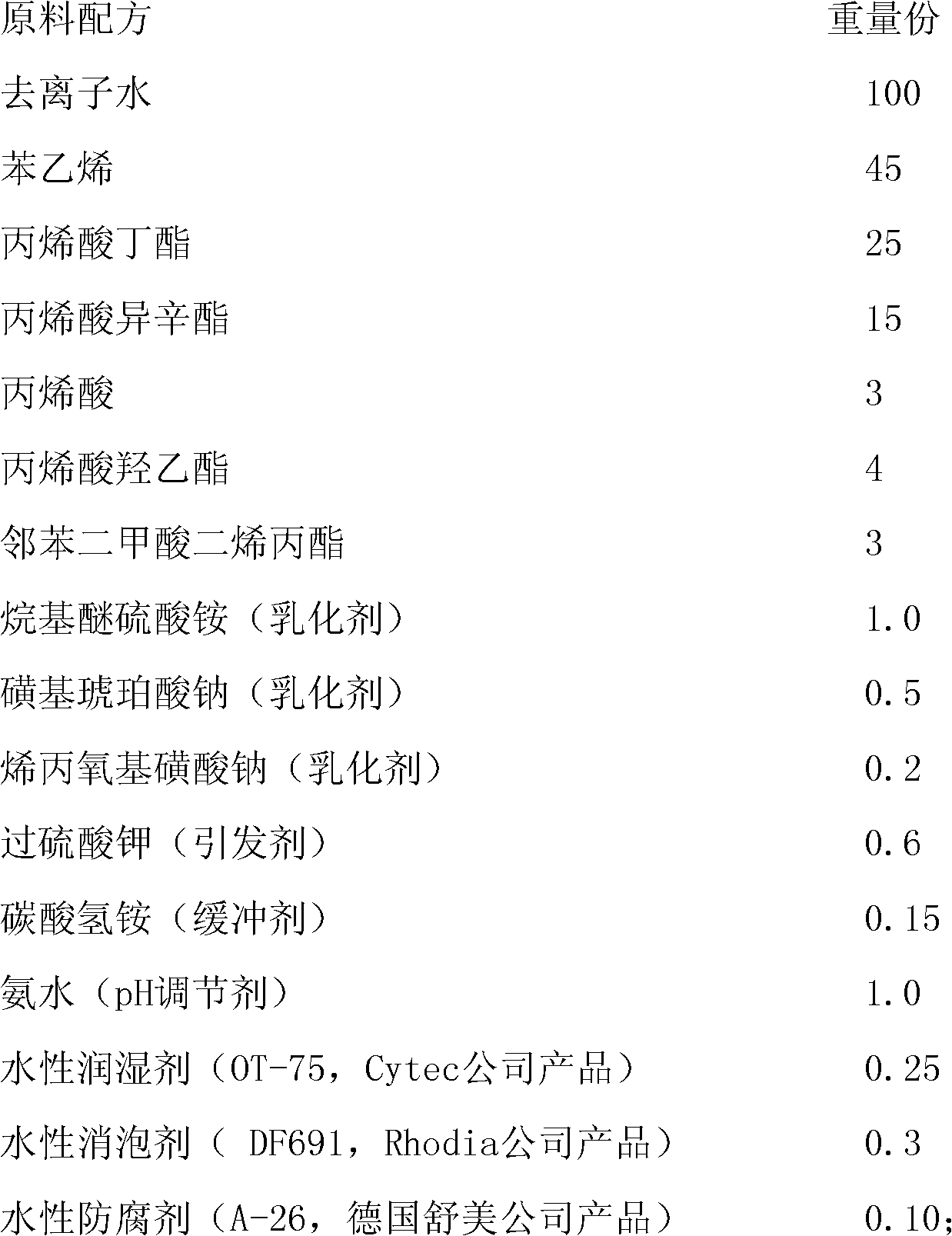

Water-based polyacrylic emulsion laminating adhesive and preparation method thereof

InactiveCN102140320AReduce the amount addedImprove initial tack performanceEster polymer adhesivesWater basedFunctional monomer

The invention discloses a water-based polyacrylic emulsion laminating adhesive and a preparation method thereof, which belong to the field of adhesives. The laminating adhesive with solid content of between 40 percent and 50 percent is prepared from raw materials of monomers, an emulsifier, an initiator, a buffering agent, a pH regulator, a waterborne aid and deionized water by adopting steps of pre-emulsification, seed reaction, polymerization and compounding, wherein the monomers include a hard monomer, a soft monomer and a functional monomer containing -COOH and -OH groups; the emulsifier consists of alkyl ether ammonium sulfate, sulpho sodium succinate and allyloxyl alkyl sodium sulfonate in the ratio of 2:1:(0.4-0.8); and the waterborne aid comprises a waterborne wetting agent, a waterborne defoaming agent and a waterborne preservative. The allyloxyl alkyl sodium sulfonate serving as a reactive emulsifier is introduced into the laminating adhesive, so that the influence of the migration of emulsifier micromolecules onto a paper / plastic interface is reduced, and initial adhesion and bonding strength are enhanced; and the functional monomer containing the -COOH and -OH groups is introduced, so that the bonding strength is enhanced, and the low-temperature adhesive property and ink affinity are improved.

Owner:NANTONG GAOMENG NEW MATERIAL

Pipeline cleaning agent

InactiveCN103740489AEfficient removalKeep clean for a long timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBetaineActive agent

The invention relates to a pipeline cleaning agent which comprises the following components by weight: 15-28 parts of organic acid, 20-35 parts of an asurface active agent, 18-30 parts of a penetrating agent and 0.5-3 parts of an acorrosion inhibitor, wherein the surface active agent comprises one or more ofpolyether, butyl cellosolve, coconut oil fatty acid diethanol amide and fatty alcohol-polyoxyethylene ether sulfate sodium; the penetrating agent comprises one or more of alcohol, sodium dodecyl sulfate, sodium dioctyl sulfosuccinate,dodecyl dimethyl betaine, sodium oleoyl methylamine ethanesulfonate and calcium chloride; the corrosion inhibitor comprises one or more of imidazolinequaternary ammonium salts or imidazoline amides. The pipeline cleaning agent can effectively remove grease and dirt in a pipeline to keep the pipeline unblocked, is safe and non-toxic, cannot corrode equipment, is harmless tohuman skin and conforms to emission standards.

Owner:BEIJING DAISI SCI & TECH

Antiseptic solutions containing silver chelated with polypectate and edta

ActiveUS20060240122A1Improve long-term stabilityExtended antimicrobial effectiveness of solutionInorganic/elemental detergent compounding agentsBiocideBetaineAdditive ingredient

A liquid antiseptic and cleanser having improved long-term stability includes at least the following principal ingredients: deionized water; silver ion, polypectate, and ethylenediaminetetraaceticacid (EDTA). Presently preferred embodiments of the technology also include glycerine; 1,2-propanediol (a.k.a. propylene glycol); at least one surfactant from any of the families of alkylsulfates, sulfonates, alkanolamides, betaines, amine oxides, sarcosinates and sulfosuccinates; and a buffering compound sufficient to achieve a pH value within a range of 7.2 to 7.8.

Owner:MINER E ODELL

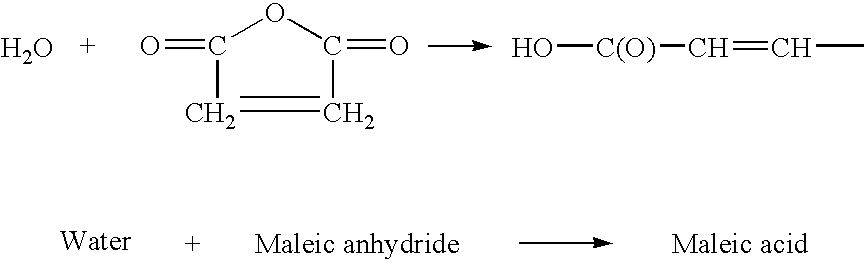

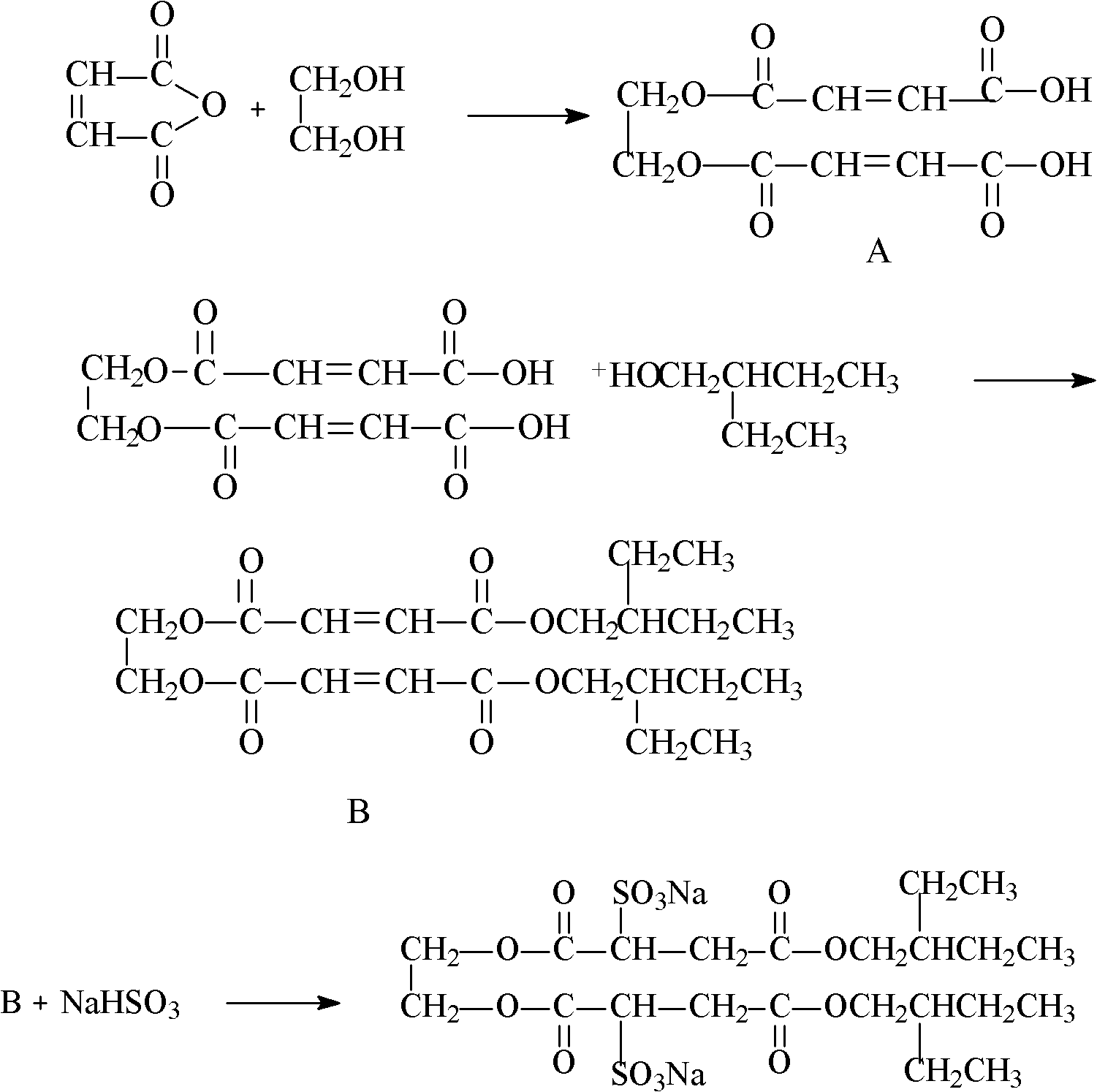

Method for preparing disodium ethylene glycol bis(2-ethyl-1-butyl)sulfosuccinate

InactiveCN102351745AEasy to manufactureLow priceSulfonic acids salts preparationPolymer scienceEthylene glycol bis

The invention discloses a method for preparing disodium ethylene glycol bis(2-ethyl-1-butyl)sulfosuccinate. The method comprises the following steps of: combining maleic anhydride and two hydroxyl radicals on ethylene glycol to perform mono-esterification to obtain ethylene glycol bis(monomaleate); performing di-esterification on the ethylene glycol bis(monomaleate) and 2-ethyl-1-butanol to obtain ethylene glycol bis(2-ethyl-1-butyl) dimaleate; and performing conjugate addition on the ethylene glycol bis(2-ethyl-1-butyl) dimaleate and sodium hydrogensulfite to obtain the product, wherein whenthe maleic anhydride is reacted with the ethylene glycol, a carbon-based solid acid catalyst is adopted. The method is simple, and easy to implement; the consumption of raw materials is reduced; the cost is saved, and impurities of the product are reduced.

Owner:临沂小豆娃食品有限公司

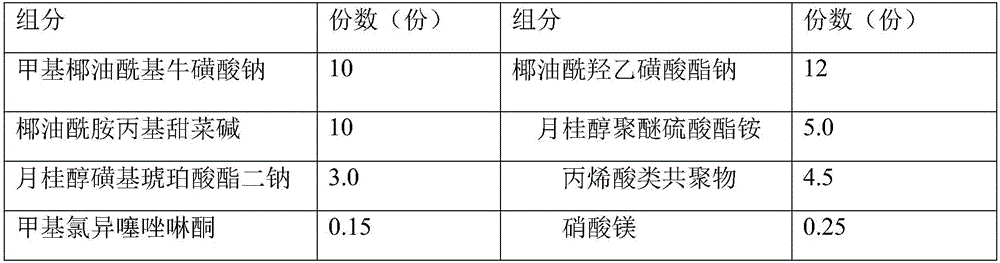

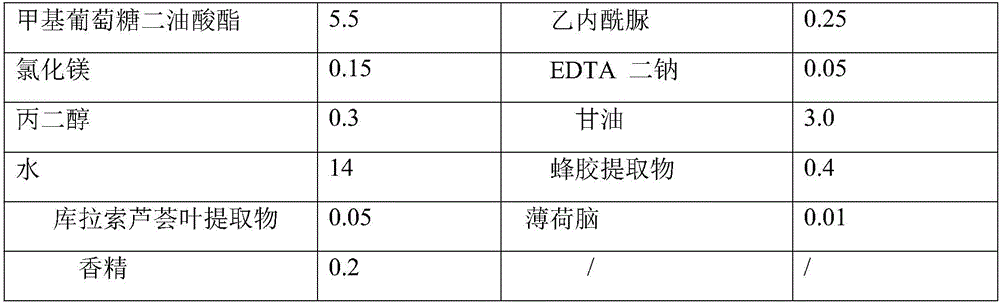

Facial cleanser and preparation method thereof

ActiveCN106038330APromote absorptionCosmetic preparationsToilet preparationsSODIUM METHYL COCOYL TAURATECocamidopropyl betaine

The invention discloses a facial cleanser and a preparation method thereof. The problem of skin tension caused by using the present facial cleanser for cleaning skin is solved. According to the technical scheme, the facial cleanser comprises the following components in parts by weight: 8-22 parts of sodium methyl cocoyl taurate, 3-12 parts of sodium cocoyl isethionate, 2-5 parts of lauryl sulfo succinate disodium, 2-10 parts of cocamidopropyl betaine, 1-5 parts of lauryl alcohol polyether ammonium sulfate, 3-10 parts of a thickening agent, 0.1-0.5 part of a preservative, 0.05-0.2 part of EDTA disodium, 0.2-0.6 part of propylene glycol, 2-12 parts of glycerinum, 0.1-0.5 part of essence and 10-18 parts of water. The prepared facial cleanser belongs to an amino acid facial cleanser, has the characteristics of safety, no stimulation, skin-relieving effect and deep skin-cleaning effect, and can be used by a user for a long term.

Owner:浙江高妍科技有限公司

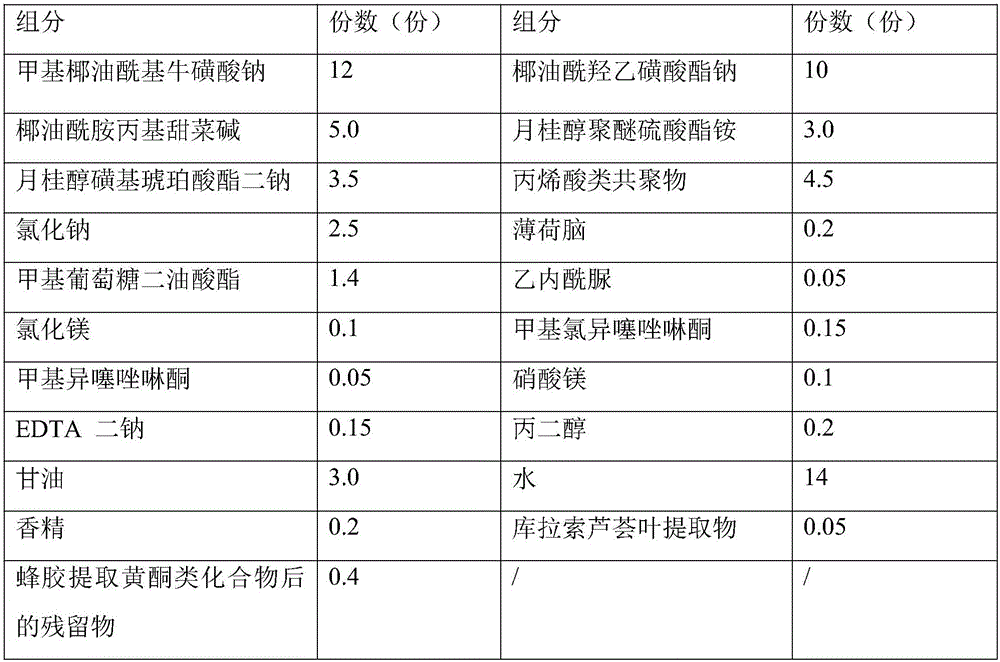

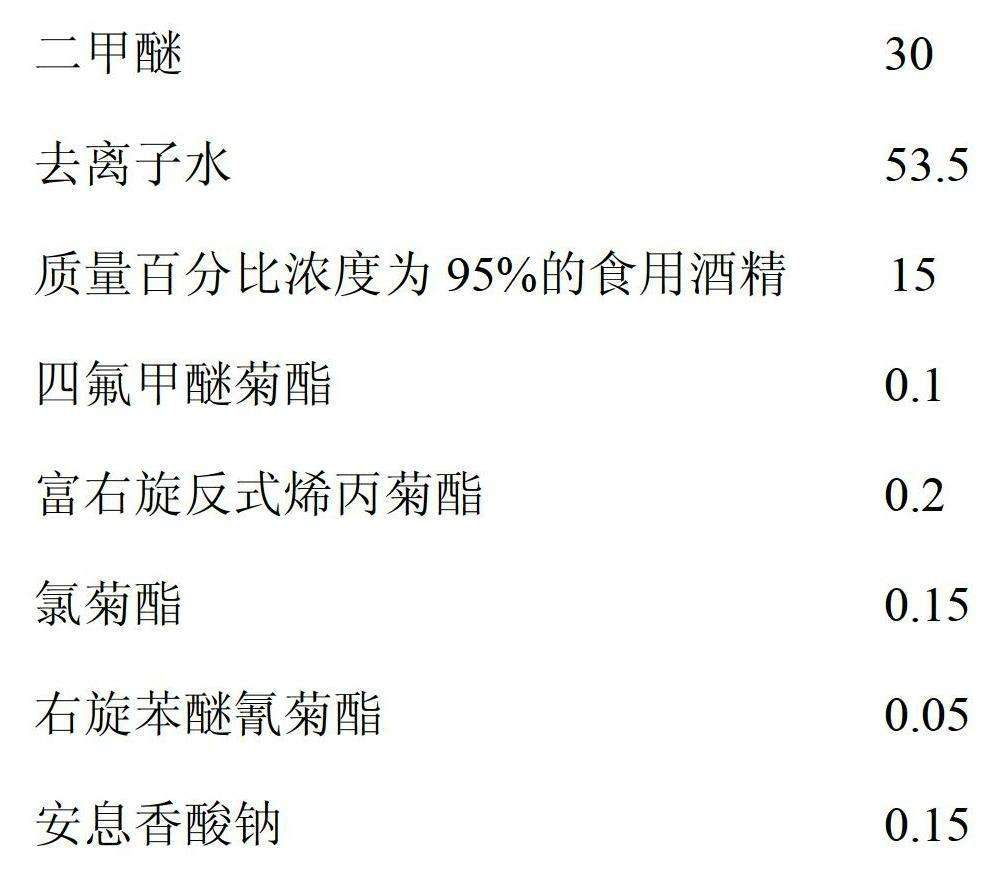

Homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content

The invention provides homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content. The homogeneous and high-efficient water-based pesticide aerosol comprises the following components in parts by weight: 25-40 parts of dimethyl ether, 40-60 parts of de-ionized water, 10-20 parts of edible alcohol with mass-percentage concentration of 95 percent, 0.05-2 parts of dimefluthrin, 0.1-0.4 part of rich-d-transallethrin, 0.1-0.3 part of permethrin, 0.05-0.2 part of d-trans-cyphenothrin, 0.05-0.2 part of sodium benzoate, 0.05-0.2 part of sodium nitrite, 0.05-0.2 part of sodium dodecyl sulfate succinate, 0.05-0.2 part of triethanolamine, 0.1-1.0 part of synergist and 0.1-0.5 part of essence. According to the homogeneous and high-efficient water-based pesticide aerosol with low VOC content, disclosed by the invention, the advantages of good atomizing effect and insert-killing effect can be achieved without vibration and shaking before use.

Owner:山东美多包装有限公司

Soil stabilizing and curing agent

InactiveCN101525541AReduce maintenance costsImprove the quality of road constructionOrganic fertilisersSoil conditioning compositionsPolyvinyl alcoholFirming agent

The invention relates to a soil stabilizing and curing agent for paving road beds and coating road surfaces by using soil adjusting materials. The soil stabilizing and curing agent adopts a technical proposal that two compositions of a soil stabilizing agent and a soil curing agent which are matched are developed, wherein the composition of the soil stabilizing agent comprises the following components in percentage by weight: 32 to 42 percent of dodecylbenzene sulfonic acid, 6 to 12 percent of dodecyl polyoxyethylene ether sodium sulfate; 0.5 to 3 percent of dilute sulphuric acid, 2 to 4 percent of disodium sulfosuccinate monoester, 1 to 3 percent of neutral water glass (modulus is between 3.1 and 3.4) and 38.5 to 54 percent of water; and the composition of the soil curing agent comprises the following components in percentage by weight: 17 to 25 percent of polyvinyl alcohol, 4 to 8 percent of polyvinyl-pyrrolidone, 3 to 6 percent of droxyethylcellulose, 5 to 10 percent of polyethylene glycol, 2 to 4 percent of hydroxypropyl methylcellulose and 47 to 69 percent of water. The use of the soil stabilizing and curing agent for processing the road beds in the road laying engineering changes the conventional road laying method, and not only improves the road laying quality, but also greatly improves the environmental protection condition in the process of construction. At the same time, the road laying cost and the maintenance and servicing expense of the roads are also reduced.

Owner:钟维安

Method of determining substrate contained in hemoglobin-containing sample

InactiveUS20070154976A1Accurate measurementReduce distractionsMicrobiological testing/measurementBiological testingActive agentSuccinic acid

The present invention provides a convenient, efficient method for determining a substrate contained in a hemoglobin-containing sample and a reagent therefor, which can be employed for a variety of automatic analyzers while reducing interference of hemoglobin contained in the sample. A method for determining a substrate contained in a hemoglobin-containing sample through reaction of an oxidase with the substrate and optical measurement of the produced hydrogen peroxide by use of a peroxidase and an oxidizable color producing reagent, characterized in that the hemoglobin-containing sample is treated with an anionic surfactant selected from among a polyoxyethylene alkyl ether sulfate salt, a polyoxyethylene alkylphenyl ether sulfate salt, a polyoxyethylene alkyl ether phosphate, a polyoxyethylene alkyl sulfosuccinate, a polyoxyethylene alkyl ether carboxylate salt, a polyoxyethylene alkyl ether sulfonate salt, triethanolamine lauryl sulfate, an alkyl sulfosuccinate, and an alkylphenyl ether sulfonate salt.

Owner:SEKISUI MEDICAL CO LTD

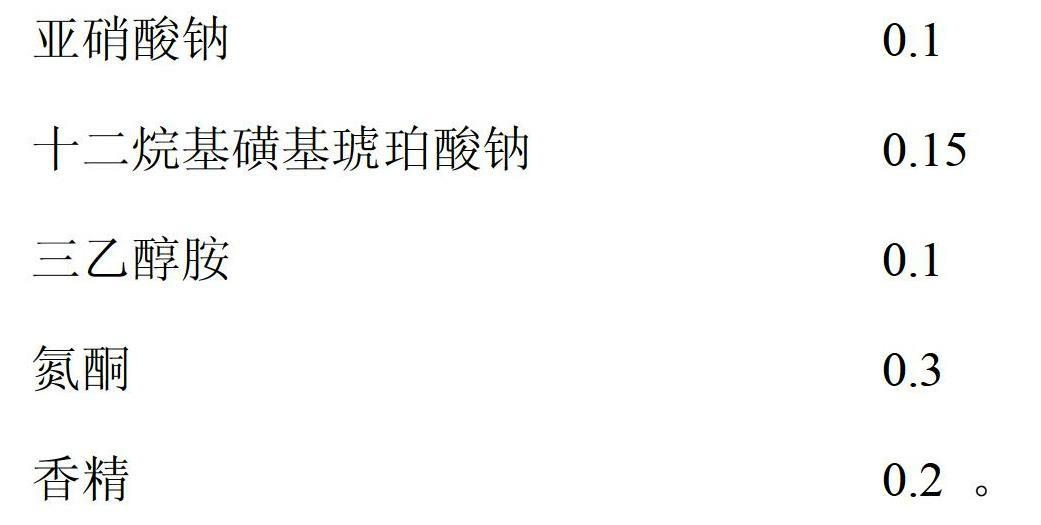

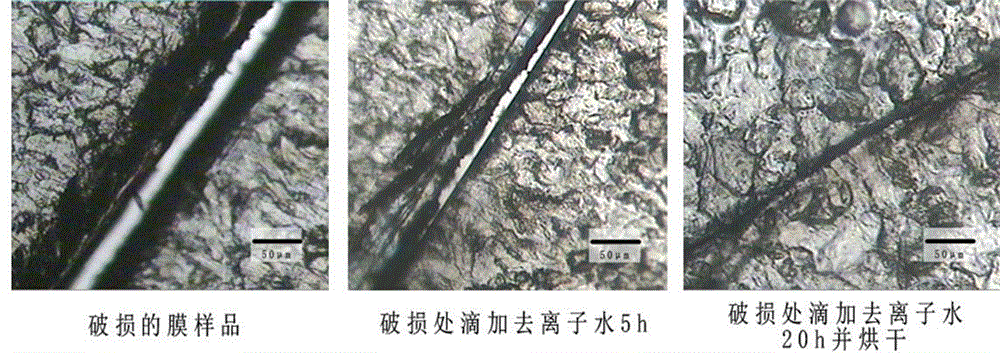

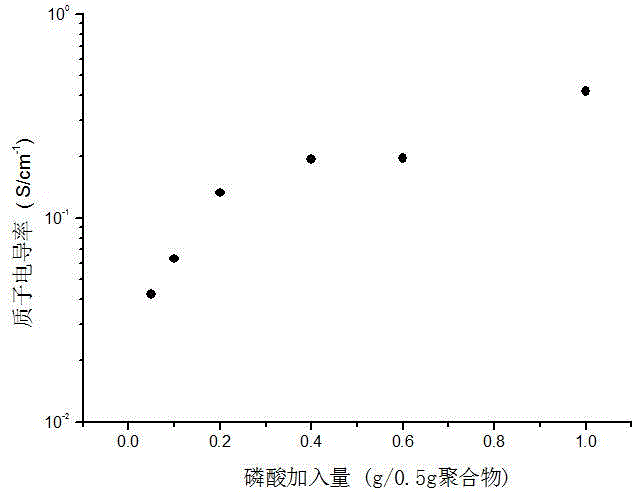

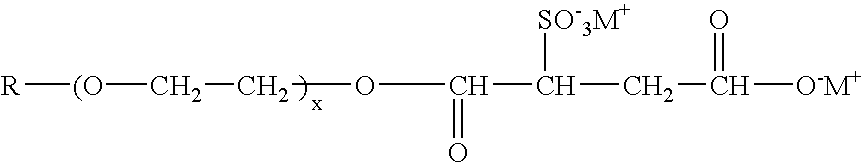

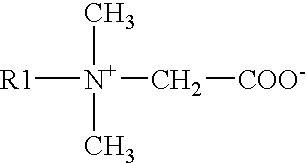

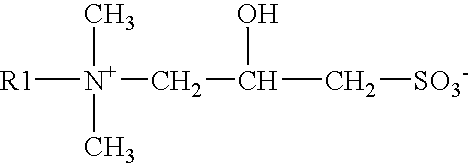

Proton exchange membrane having self-repairing capability and preparation method thereof

InactiveCN105098214AExtended service lifeAchieve self-healingSolid electrolyte fuel cellsCross-linkPolyvinyl alcohol

The invention belongs to the technical field of polymer composite materials and functional materials, and in particular relates to a proton exchange membrane having the self-repairing capability and a preparation method thereof. The proton exchange membrane disclosed by the invention is mainly composed of two components including a self-repairing material and a proton conducting material, wherein the self-repairing material comprises, but not limited to, polyvinyl alcohol, chitosan, a poly(vinyl furfural) / bismaleimide cross-linked polymer and the like; and the proton conducting material comprises, but not limited to, phosphoric acid, sulphuric acid, sulfosuccinic acid, sulfomalic acid, perfluorinated sulfonic acid resin, sulfonated polybenzimidazole, sulfonated polyether-ether-ketone, sulfonated polyimide and the like. The two components form the membrane by using the existing process after being composited through the methods, such as a blending method, a copolymerizing method and an interpenetrating polymer network method; the membrane has good proton conducting capability and self-repairing capability; after the membrane is damaged, self-repairing can be realized under the excitations of water infiltration, temperature increasing / decreasing circulation and the like; therefore, the service life of the proton exchange membrane is prolonged; the use range of the proton exchange membrane is enlarged; and the proton exchange membrane disclosed by the invention can be used in the fields of fuel cells, ion exchange, catalysts and the like.

Owner:TONGJI UNIV

Mild, moisturizing cleansing compositions

ActiveUS20060019846A1Mild to hair and skinFine foamCosmetic preparationsHair cosmeticsIntrinsic instabilitySulfosuccinic acid

Compositions used for cleansing hair and skin based on the combination of a sulfosuccinate surfactant and an amphoteric surfactant are described that are very mild but do not compromise in-use properties and economy. A route to solve the intrinsic instability of such aqueous compositions in storage has been developed based on the use of sulfosuccinic acid or a salt of sulfosuccinic acid present in an amount of at least about 4% based on the weight of the sulfosuccinate surfactant.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Sulfosuccinates

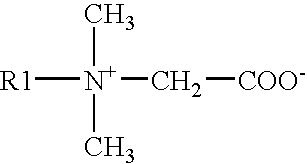

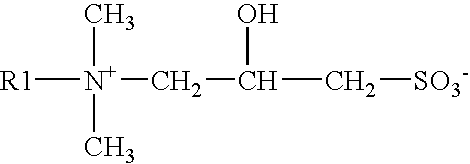

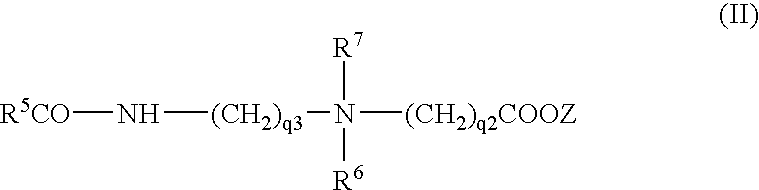

The invention provides novel sulfosuccinates of the formula wherein R1 represents a group R3CONR4(CH2)n(OCH2CH2)m—, R2 represents hydrogen, alkali metal, ammonium, alkyl ammonium or R1, R3CO represents a linear saturated acyl group having 12 to 18 carbon atoms, R4 represents hydrogen or methyl, n is a number of 2 to 4, m is a number of 2 to 10 and X is an alkali metal, ammonium or alkyl ammonium.

Owner:COGNIS IP MANAGEMENT GMBH

Essential oils based cleaning and disinfecting compositions

ActiveUS7465697B1High disinfecting efficacyImprove efficiencyBiocideCosmetic preparationsOriganumSodium Dioctyl Sulfosuccinate

The present invention provides cleaning and disinfecting compositions for cleaning, disinfecting and sanitizing inanimate and animate surfaces. The cleaning and disinfecting compositions contain thyme oil or thyme oil and origanum oil, a salt of a transition metal, sodium dioctyl sulfosuccinate and water. The cleaning and disinfecting compositions of the present invention are surprisingly stable and as such, they may be provided to consumers in the undiluted state. The cleaning and disinfecting compositions of the present invention are botanical, environmentally sustainable, non-toxic and mildly scented.

Owner:CLEANWELL

Water-based dry-type complex film adhesive and preparation method thereof

ActiveCN102134463AReduce the amount addedReduce contentHydrocarbon polymer adhesivesIsooctyl acrylateWater based

The invention discloses a water-based dry-type complex film adhesive and a preparation method thereof, belonging to the field of preparation of adhesive. The preparation method of the complex film adhesive comprises the following steps: by using monomers, an emulsifier, an initiator, a buffering agent, deionized water, a pH regulator and water-based assistants as raw materials, emulsifying, carrying out seed reaction and polymerization reaction, and compounding to obtain the complex film adhesive of which the solid content is 45-55%, wherein the monomers comprise a hard monomer, soft monomers and functional monomers; the hard monomer is styrene; the soft monomers comprise butyl acrylate and 2-ethylhexyl acrylate; the functional monomers comprise acrylic acid or methacrylic acid, 2-hydroxyethyl acrylate or 2-hydroxypropyl acrylate, and diallyl phthalate; and the emulsifier comprises ammonium alkyl ether sulfate, sodium sulfosuccinate and sodium allyloxysulfonate in a weight ratio of 2:1:(0.4-0.8). The complex film adhesive has the advantages of high bonding strength, favorable affinity and covering performance for ink, and environment protection since the content of VOCs (volatile organic compounds) is lowered.

Owner:NANTONG GAOMENG NEW MATERIAL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com