Proton exchange membrane having self-repairing capability and preparation method thereof

A proton exchange membrane, self-healing technology, applied in the field of proton exchange membrane with self-healing ability and its preparation, can solve problems such as the failure of proton exchange membrane materials, achieve restoration of initial mechanical and other properties, prolong service life, and optimistic application Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

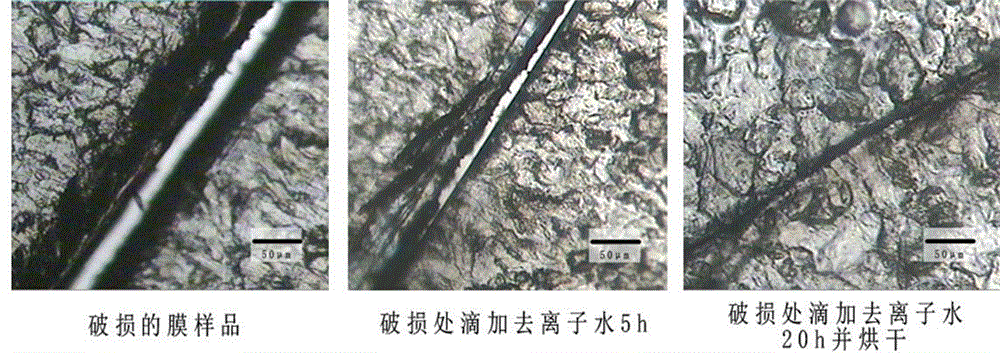

[0024] Preparation of self-repairing proton exchange membrane: 0.5g polyvinyl alcohol (PVA-124) dissolved in 20ml 70 o C deionized water, add 0.5g sulfosuccinic acid after cooling to room temperature, stir evenly, at 50 o Scrape the glass plate under C, and form a film after drying.

[0025] Self-repair conditions: Take the damaged film, drop a drop of deionized water on the damaged place, leave it at room temperature for 24 hours and then dry, the repair is complete.

Embodiment 2

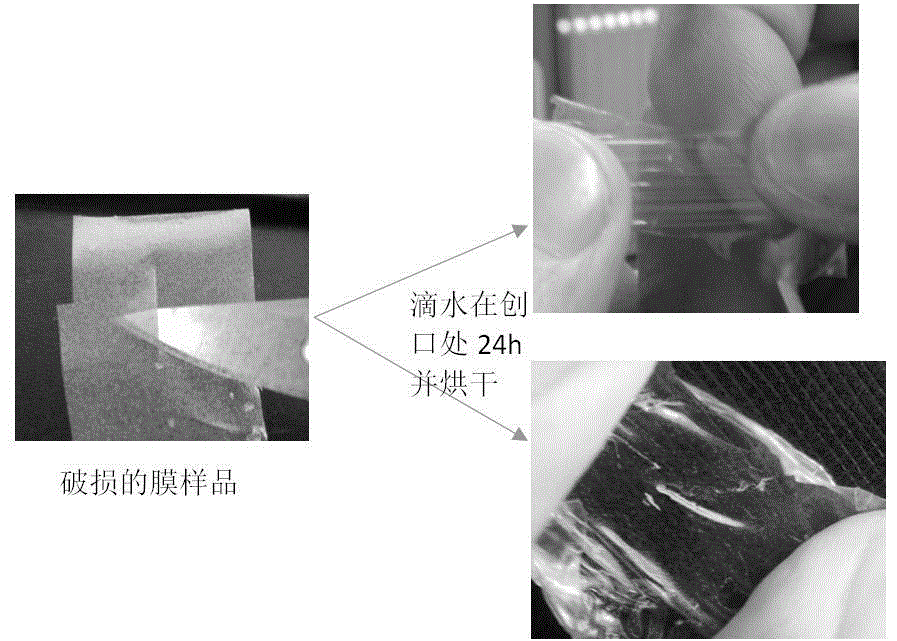

[0027] Preparation of self-repairing proton exchange membrane: 0.3g of chitosan was dissolved in 20ml of about 4% acetic acid solution, and an alcohol solution containing 0.7g of Nafion was added at room temperature. After stirring at room temperature for 1 hour, it was poured into the flat membrane frame. o Dry film under C.

[0028] Self-repair conditions: Take the damaged film, drop a drop of deionized water on the damaged place, leave it at room temperature for 24 hours and then dry, the repair is complete.

Embodiment 3

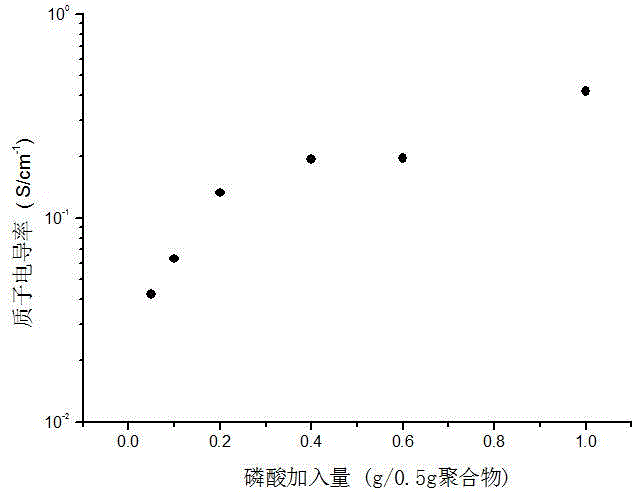

[0030] Preparation of 2,2’-bisfuranyl-5,5’-benzimidazole: Add 2.1643g of diaminobenzidine to 40ml of dry dioxane, and after dissolving in N 2 Under protection, add 40ml of dioxane solution with 2.6376g of furoyl chloride dissolved in an ice water bath. After half an hour of dripping, return to normal temperature and continue the reaction for 30 minutes. Then, 2.9266 g of boron trifluoride ether complex and another 80 ml of dioxane were added. The mixture was refluxed for 3 hours, the obtained product was poured into cold water, stirred overnight, filtered with suction and washed with ethanol and water several times to obtain the product.

[0031] Preparation of self-repairing proton exchange membrane: Dissolve the 2,2'-bisfuranyl-5,5'-benzimidazole prepared above in 30ml of DMF, and then add 0.3771g of N,N'-hexamethylene Maleimide, 0.26g anhydrous phosphoric acid, stir evenly and pour into the glass film frame at 60 o Dry film under C.

[0032] Self-repair conditions: place the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com