Patents

Literature

2450 results about "Furfural" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Furfural is an organic compound with the formula C₄H₃OCHO. It is a colorless liquid, although commercial samples are often brown. It consists of a aldehyde group attached to the 2-position of furan. It is a product of the dehydration of sugars, as occur in a variety of agricultural byproducts, including corncobs, oat, wheat bran, and sawdust. The name furfural comes from the Latin word furfur, meaning bran, referring to its usual source. Furfural is only derived from lignocellulosic biomass, i.e. its origin is non-food or non-coal/oil based. Aside from ethanol, acetic acid and sugar it is one of the oldest renewable chemicals. It is also found in many processed foods and beverages.

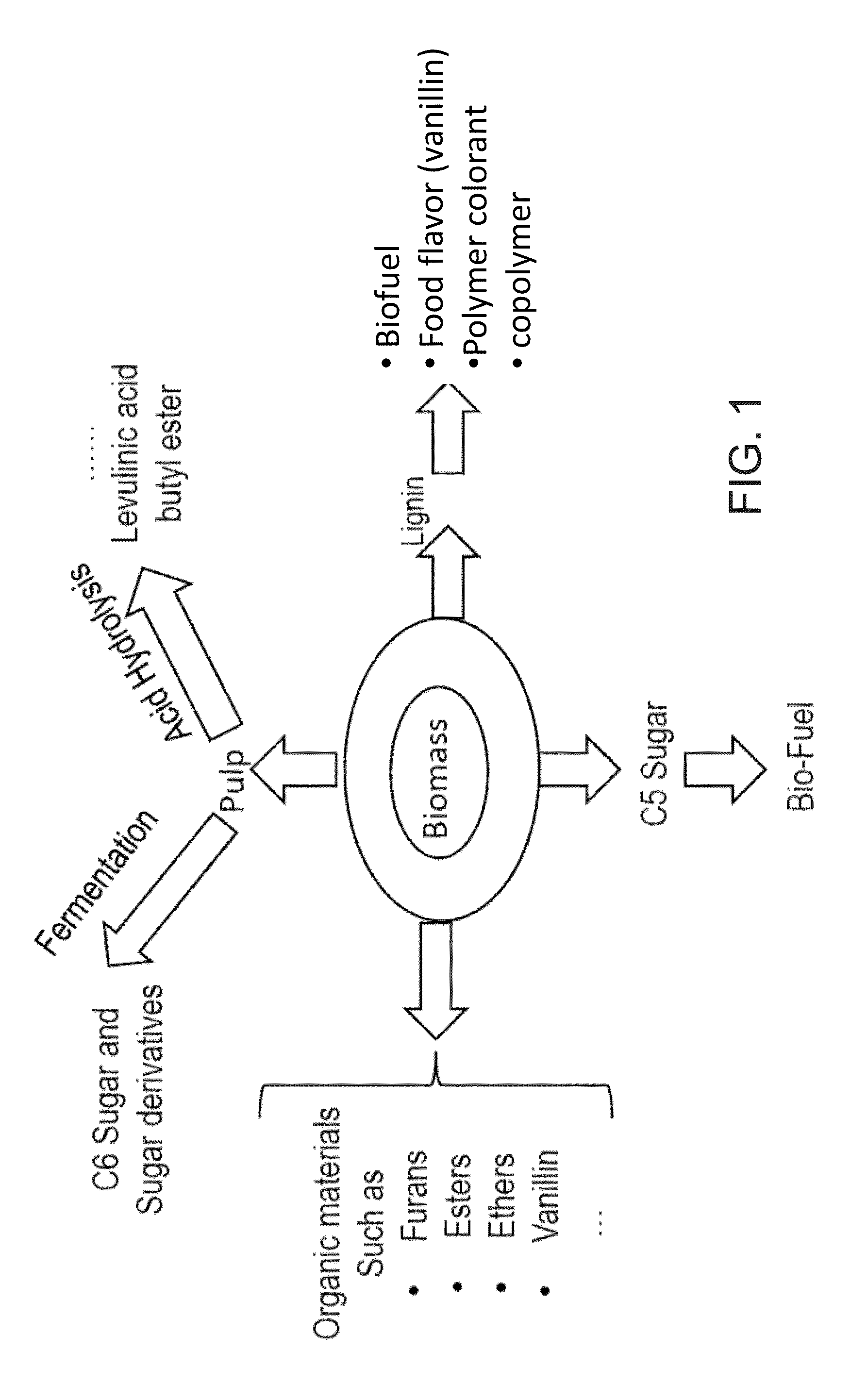

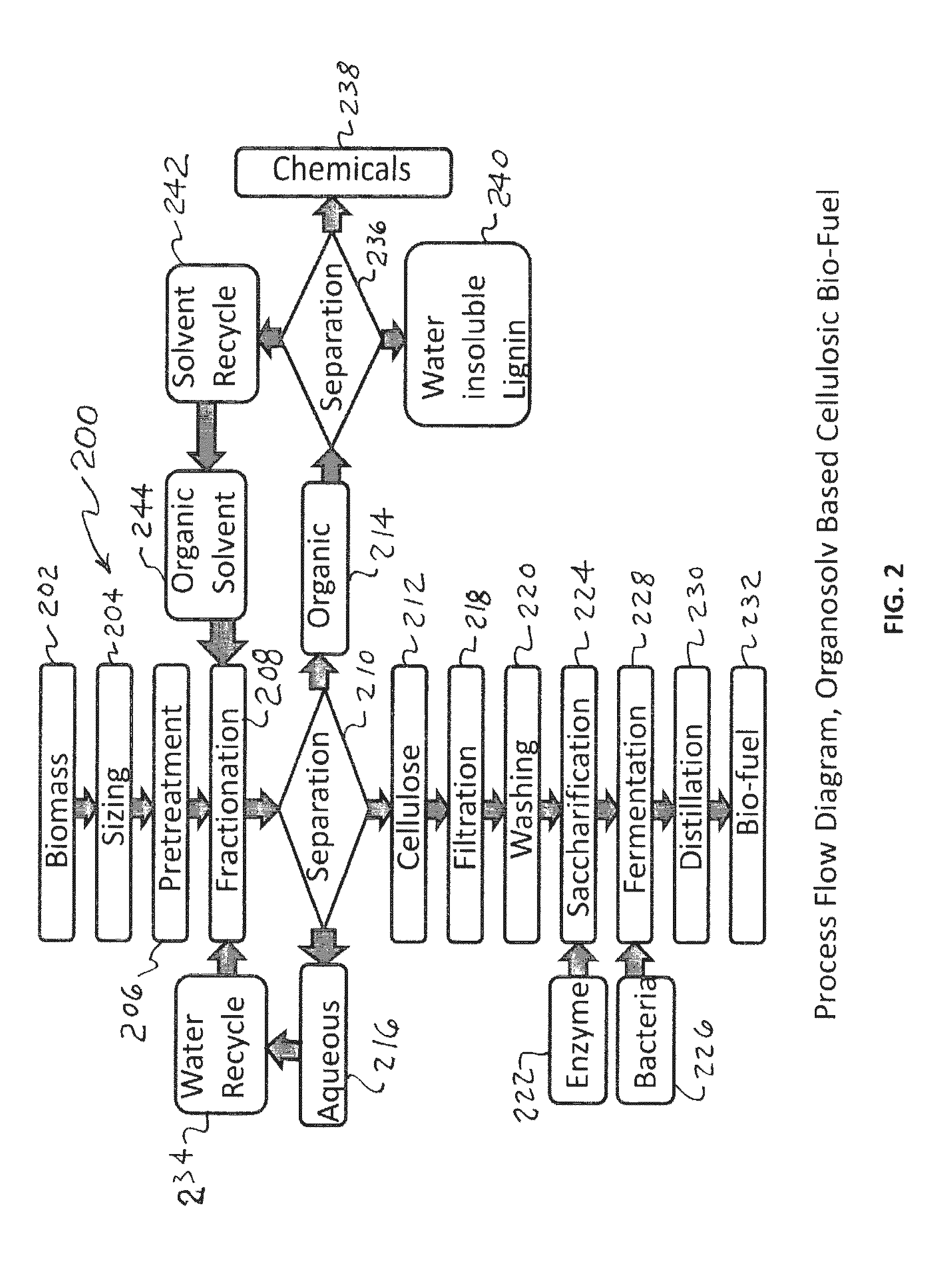

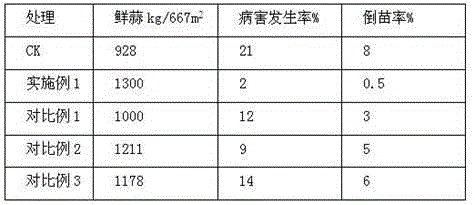

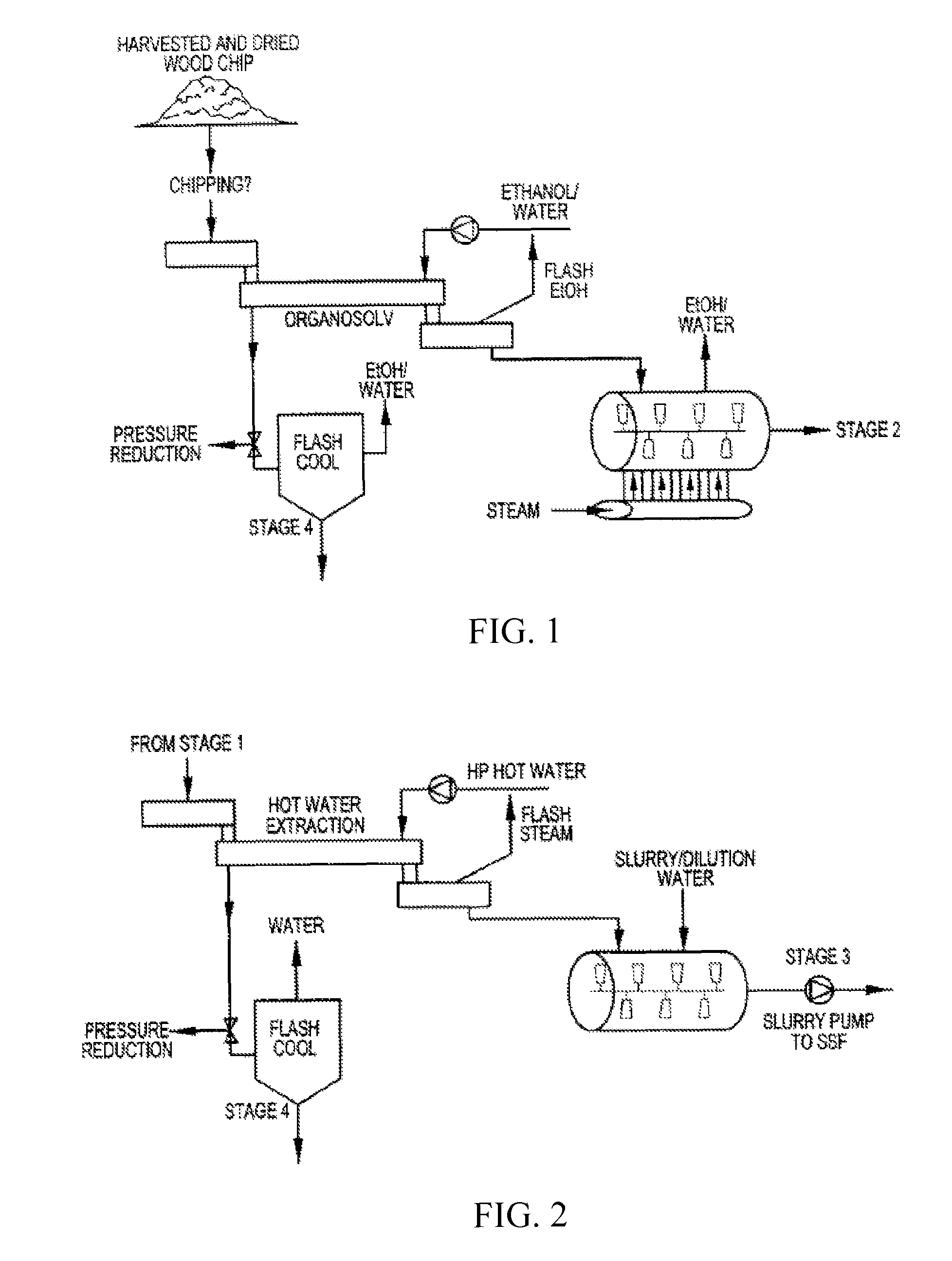

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

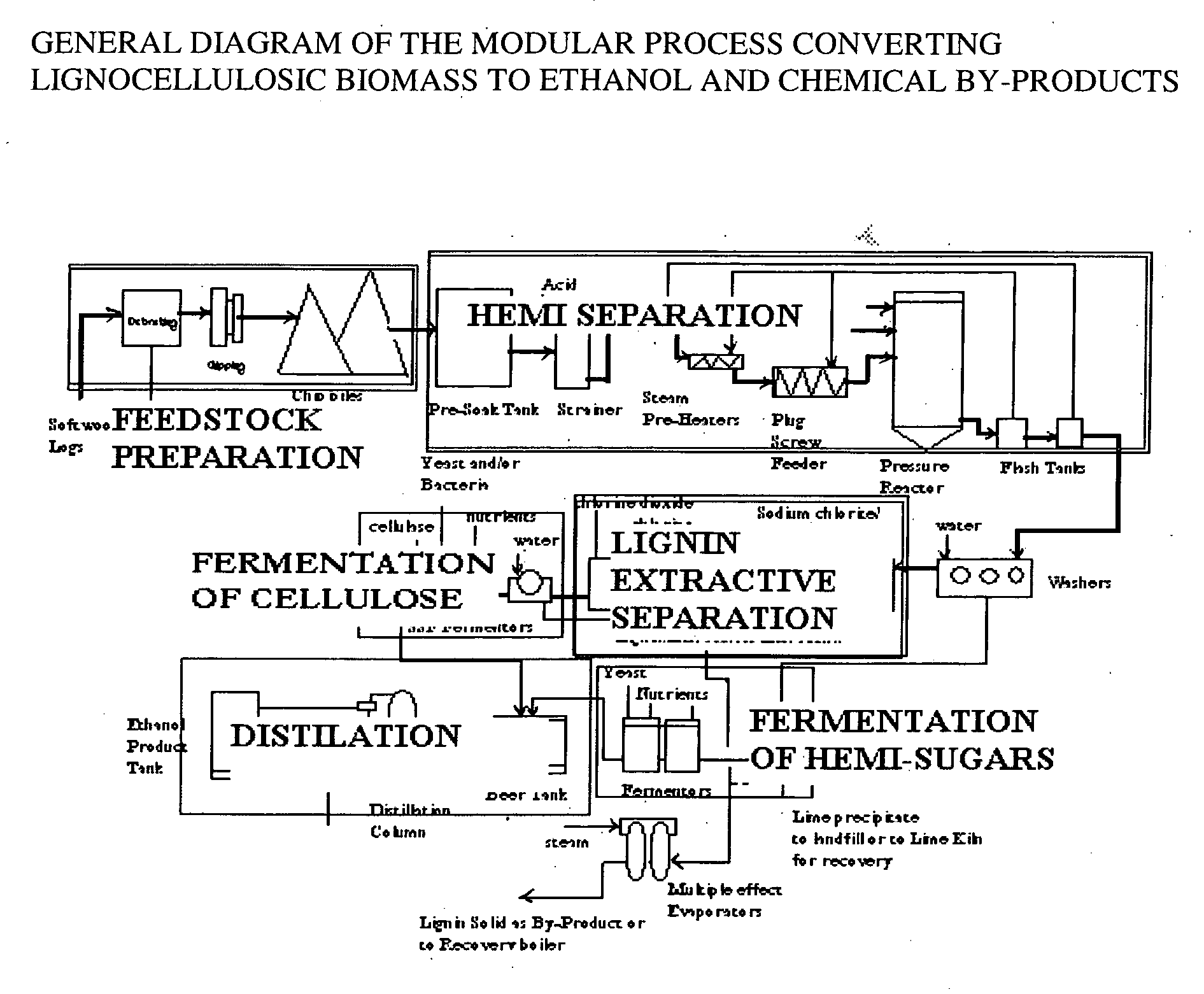

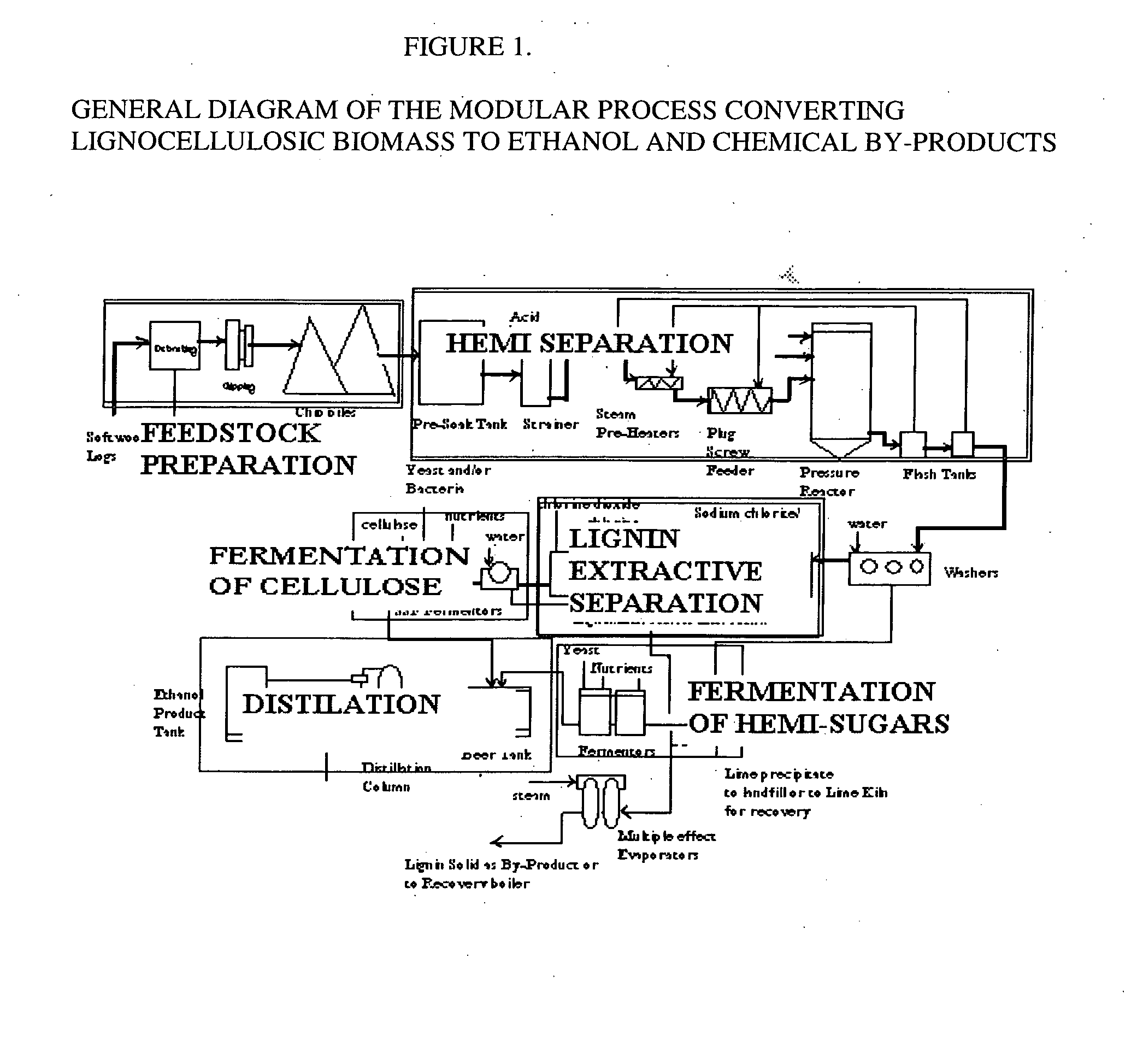

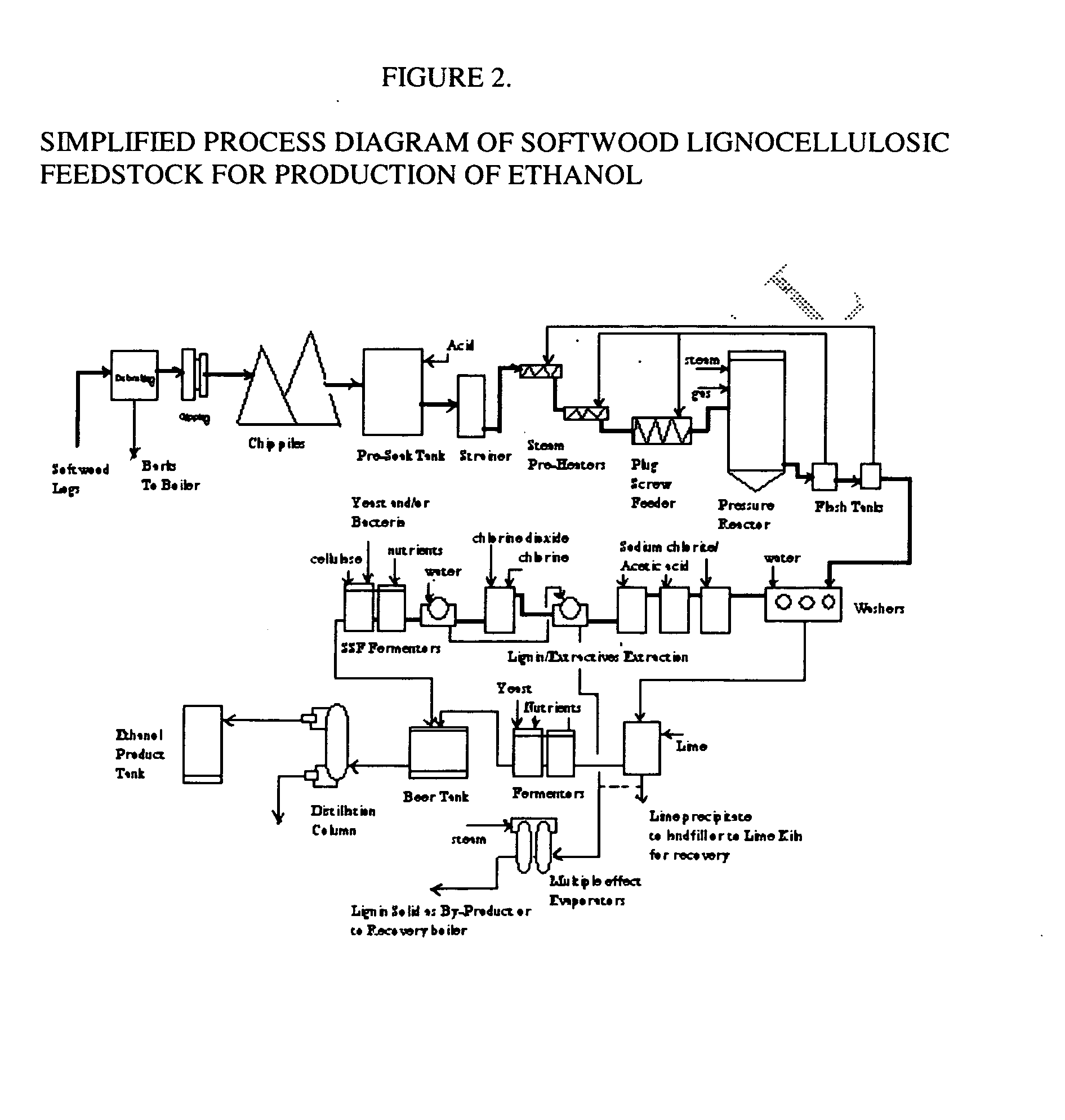

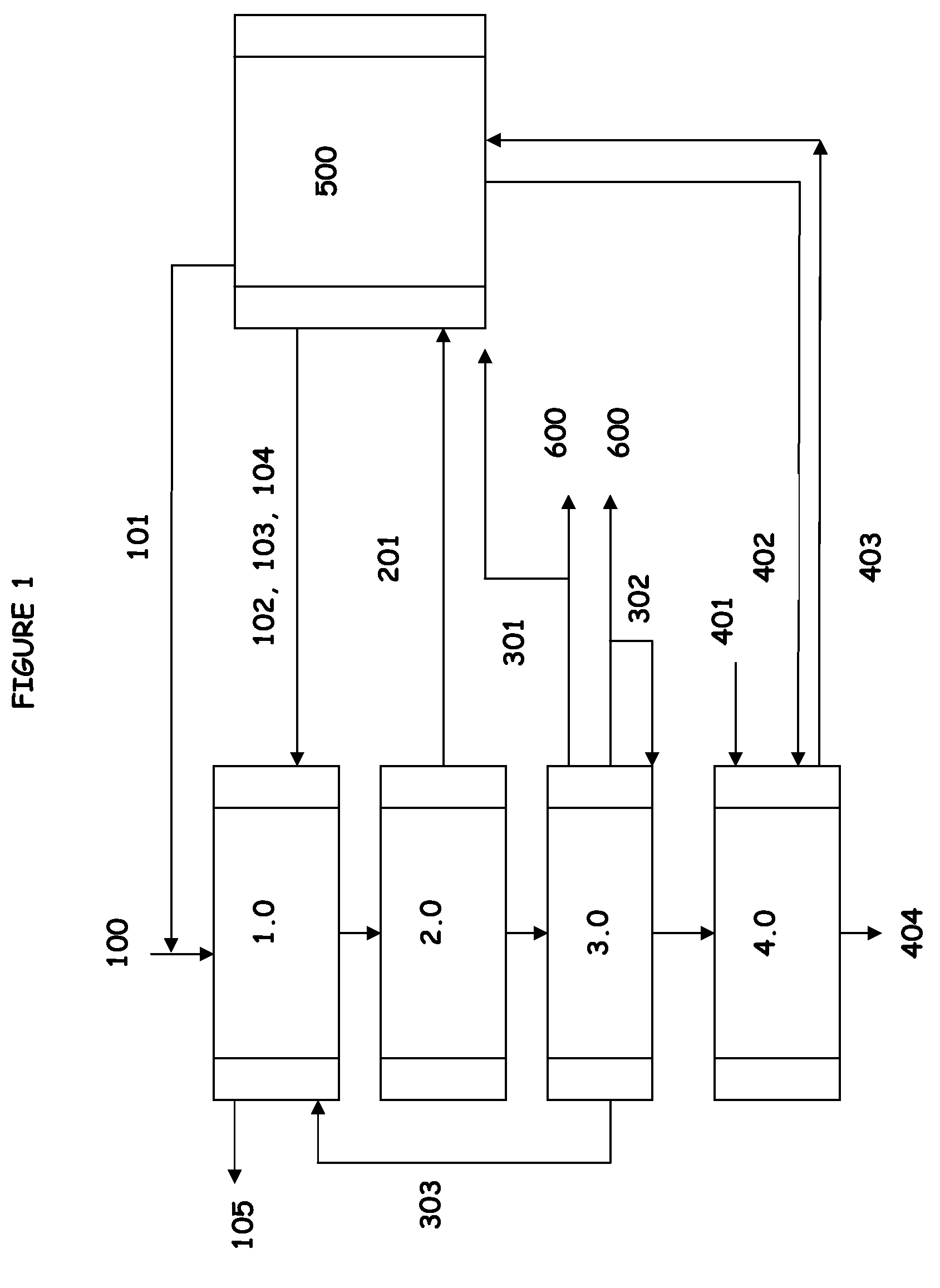

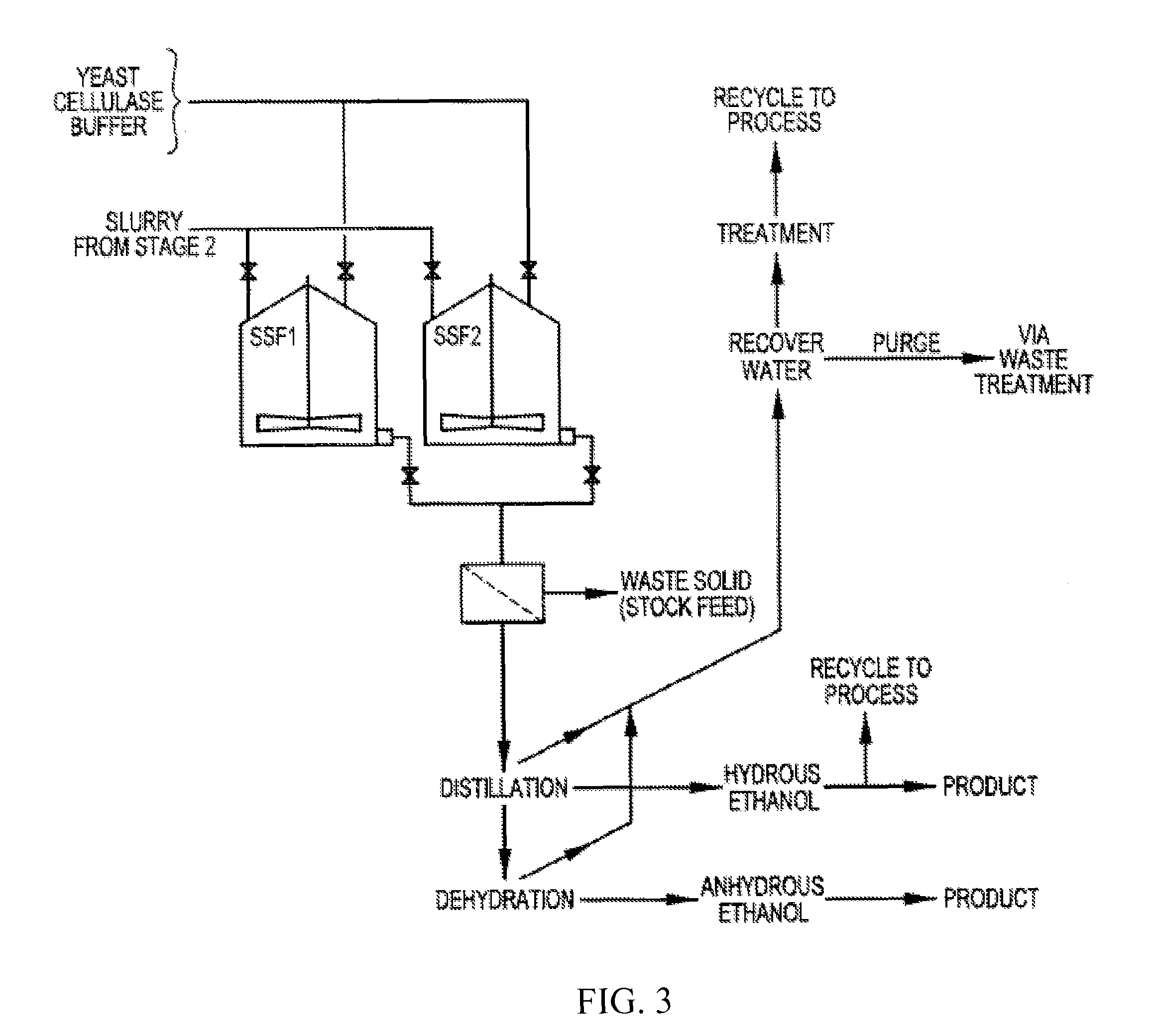

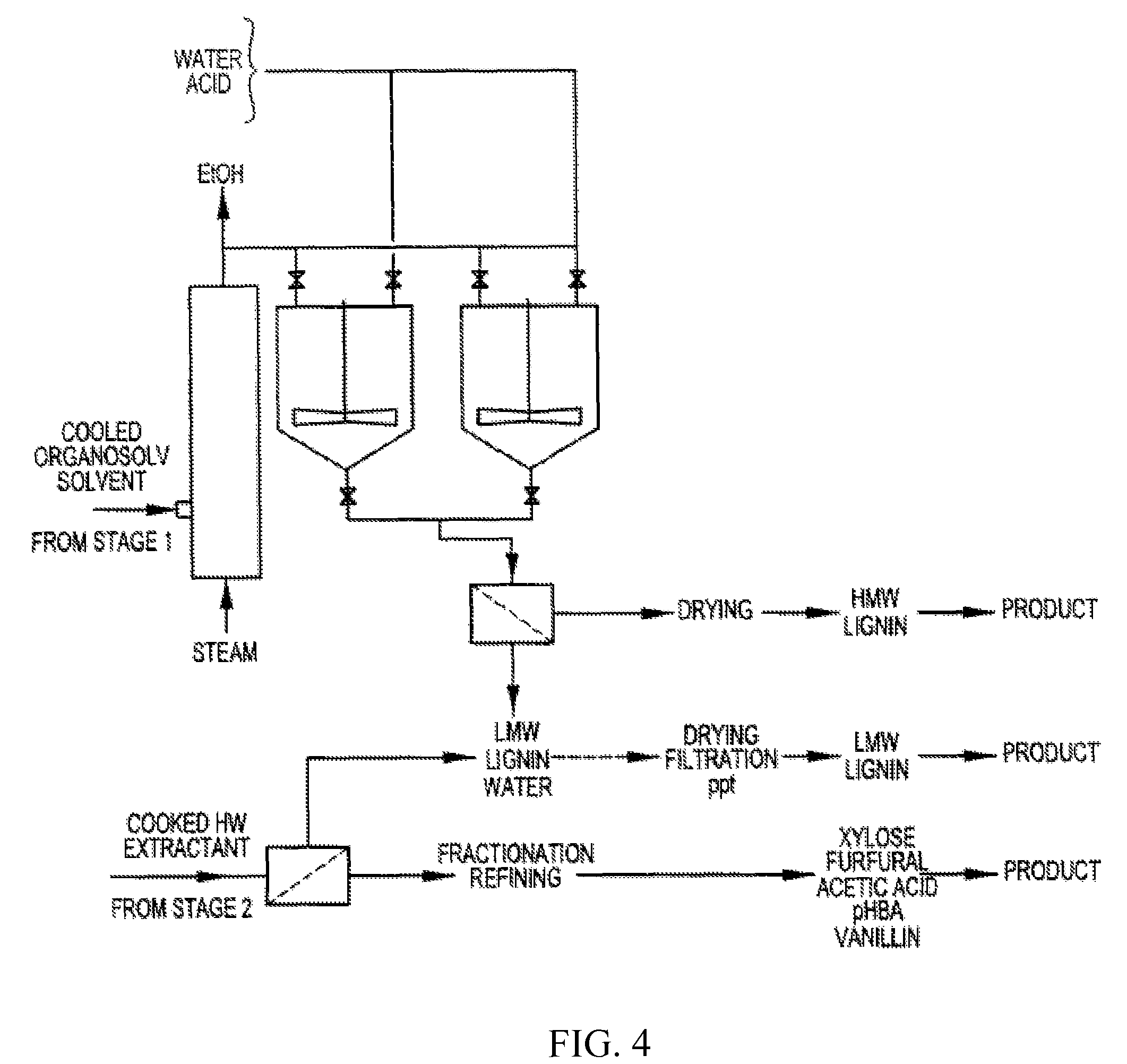

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

Production Process of Polyacrylic Acid (Salt) Water-Absorbent Resin

ActiveUS20080161512A1Improve relationshipPromote absorptionAbsorbent padsBandagesPolymer scienceALLYL SUCROSE

An embodiment of the present invention allows for production, with a high productivity, of a water-absorbent resin including an improved relationship between absorption capacity and water-soluble polymer which are conflicting properties of the water-absorbent resin, being easily controlled for polymerization reaction, being of no odor, being less colored, and being of high absorption properties. In one embodiment of the present invention, acrylic acid composition is neutralized with a basic composition including an iron content of 0.2 to 5 ppm by weight (relative to a basic compound exclusive of a solvent); and then polymerizing a resultant neutralized product, the acrylic acid composition including: (i) a methoxyphenol content of 10 to 200 ppm by weight relative to the weight of acrylic acid; and (ii) at least one compound content of which is 0 to 10 ppm by weight relative to the weight of acrylic acid, the compound being selected from the group consisting of protoanemonin and furfural.

Owner:NIPPON SHOKUBAI CO LTD

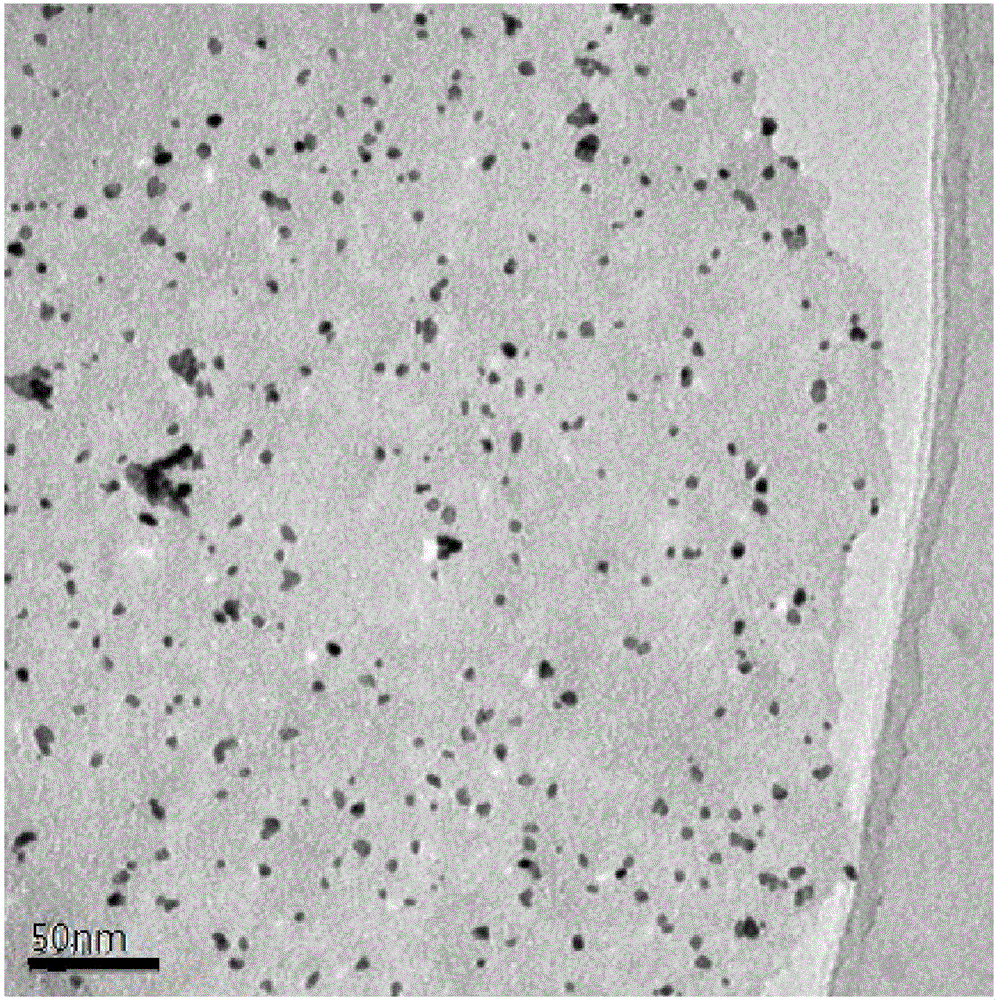

Nano-catalytic-solvo-thermal technology platform bio-refineries

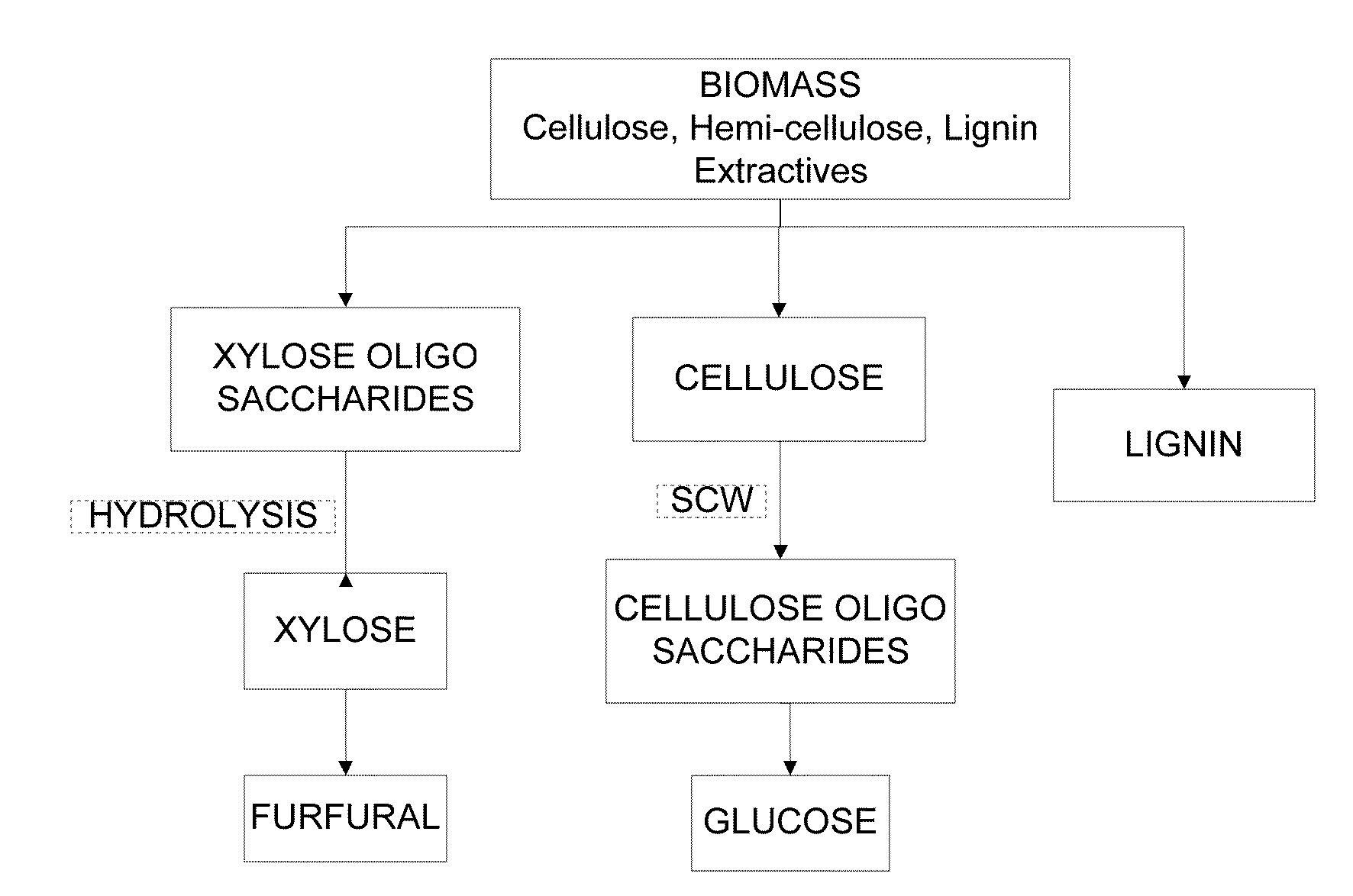

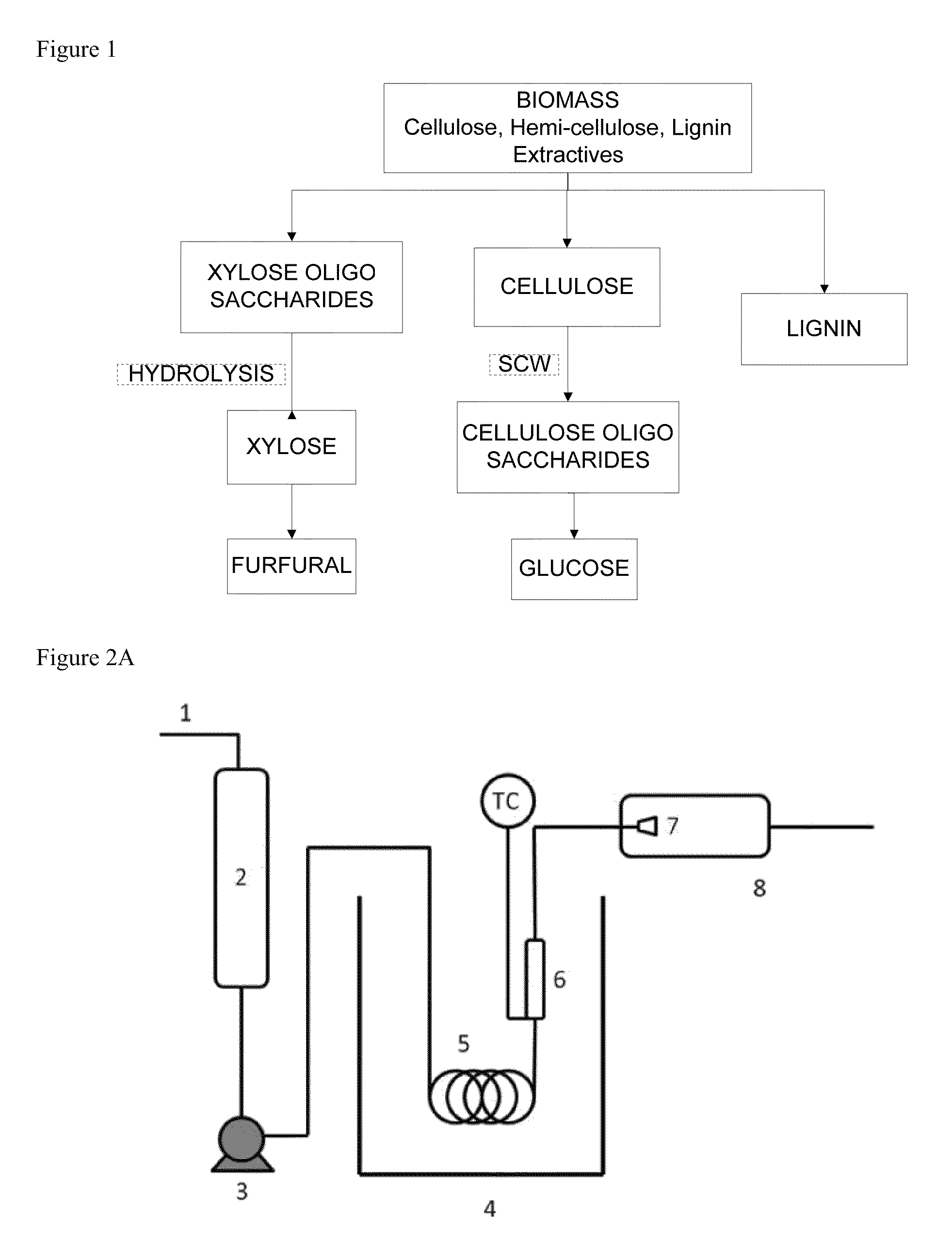

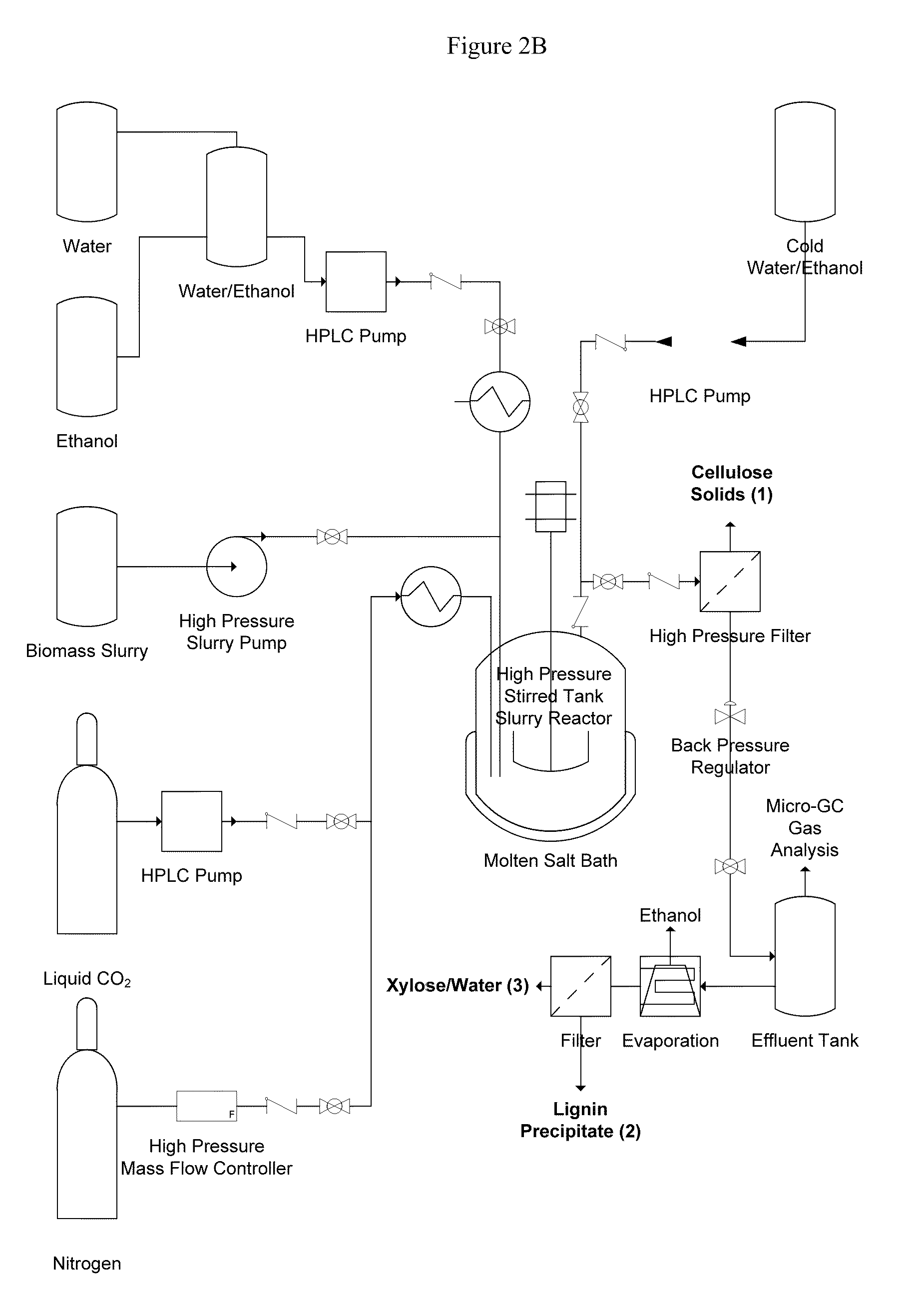

Methods of making glucose and / or furfural from biomass require one or more supercritical fluids that may be used to process biomass, cellulose from the biomass, and / or xylose from the biomass. Examples of supercritical fluids for use in processing biomass include ethanol, water, and carbon dioxide at a temperature and pressure above the critical points for ethanol and carbon dioxide but at a temperature and / or pressure below that of the critical point for water. A supercritical fluid containing carbon dioxide and water may be used to convert cellulose to glucose or convert xylose to furfural. The fluid has a temperature and pressure above the critical point of carbon dioxide, but at least one of the temperature and pressure is below the critical point for water.

Owner:RENMATIX INC

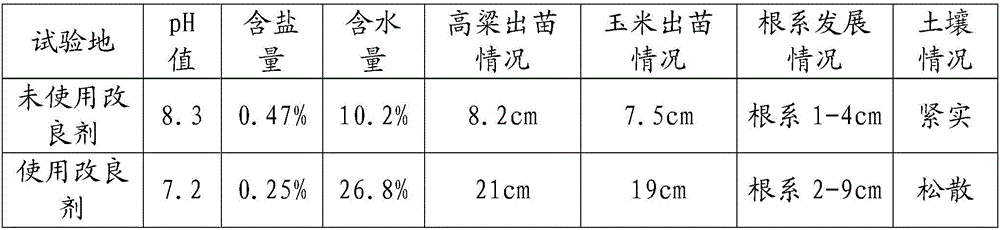

Alkali soil modification fertility intensifying amendment and preparation method thereof

The invention discloses a fertilizing and conditioning agent for improving the saline alkali soil, and the fertilizing and conditioning agent includes an organic material, an inorganic material and a regulator for the plant growth, wherein, the weight proportion between the organic material and the inorganic material is 3:2 to 1:1. The organic material is fermented and maturated by one or a plurality of such organic matters as town living sludge, excrements of livestock and poultry, and furfural slag; and the inorganic material is formed by one or a plurality of such industrial waste and materials as desulfurized gypsum, phosphogypsum, and ammonium sulphate. Moreover, appropriate growth regulator for plant which is added according to the growing requirements can not only improve the saline alkali soil and fertilize the soil, but also can improve the plant growth and promote the plant to grow well as well as providing an effective path for promoting the recycling of the waste resources and reducing the secondary pollution to the town and the country.

Owner:天津市北方绿业生态科技有限公司

Production of levulinic acid and levulinate esters from biomass

InactiveUS20100312006A1Improve production yieldHigh purityPreparation by ester-hydroxy reactionOrganic compound preparationPropanoic acidFurfural

A process for producing levulinic acid and its esters from biomass is disclosed comprising: (i) feed preparation module characterized by subjecting biomass to a high-temperature refining treatment; (ii) hydrolysis reaction module that facilitates the hydrolysis of biomass to its respective sugars and their subsequent transformation to levulinic acid, formic acid, furfural, and char as well as facilitates the separation of lignin-based char by-product; (iii) product separation and recovery module utilizing a solvent extraction technique such as using furfural by-product as extracting solvent; and (iv) optionally, conversion of levulinic acid to levulinate ester. When desired, the disclosed process may be integrated into existing pulp mills.

Owner:MEADWESTVACO CORP

Comprehensive treatment agent for soda alkaline land and use method thereof

InactiveCN101481281ALower pHSimple structureClimate change adaptationExcrement fertilisersDesorptionIon exchange

Owner:中农网联(北京)科技发展有限公司

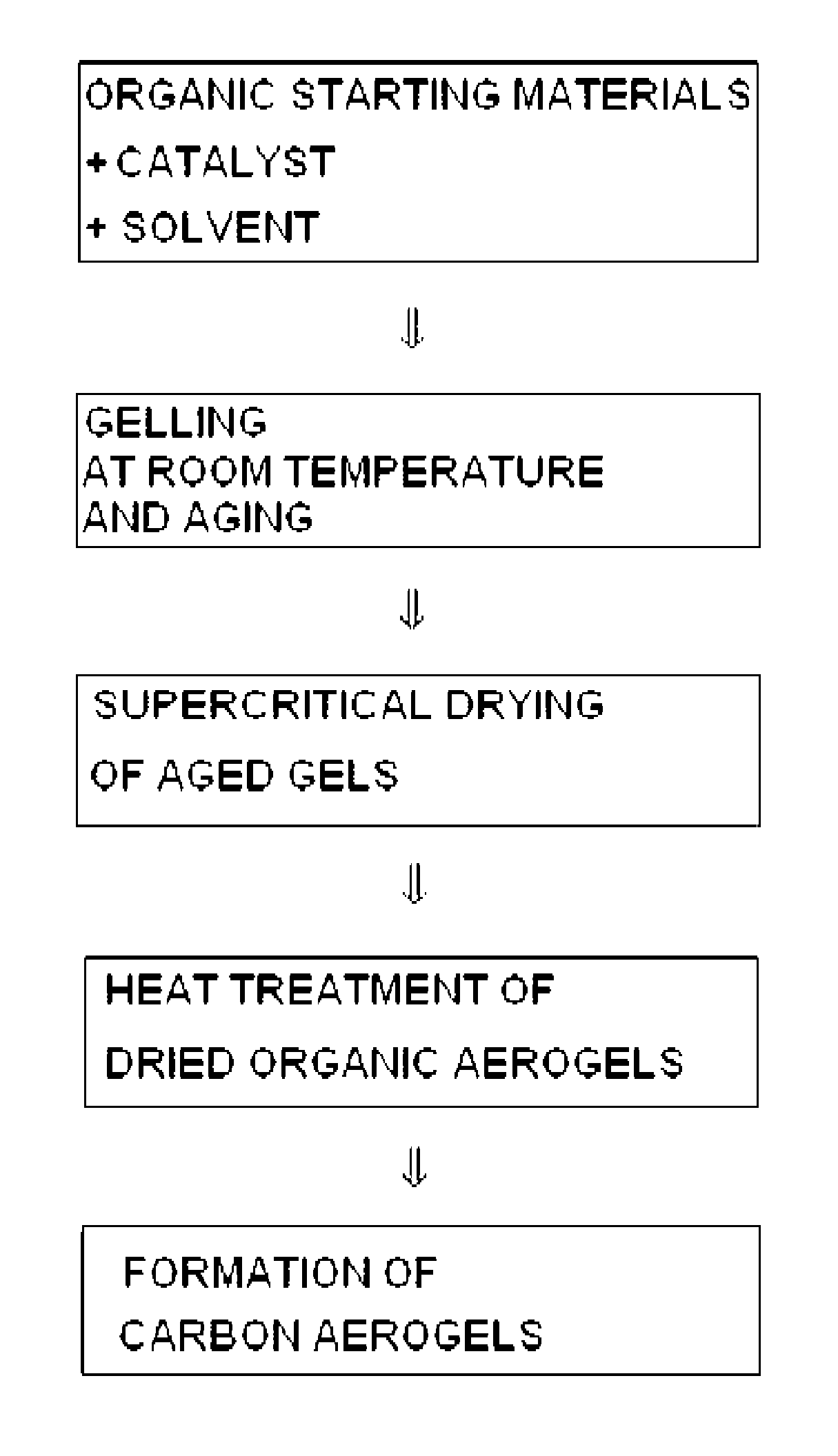

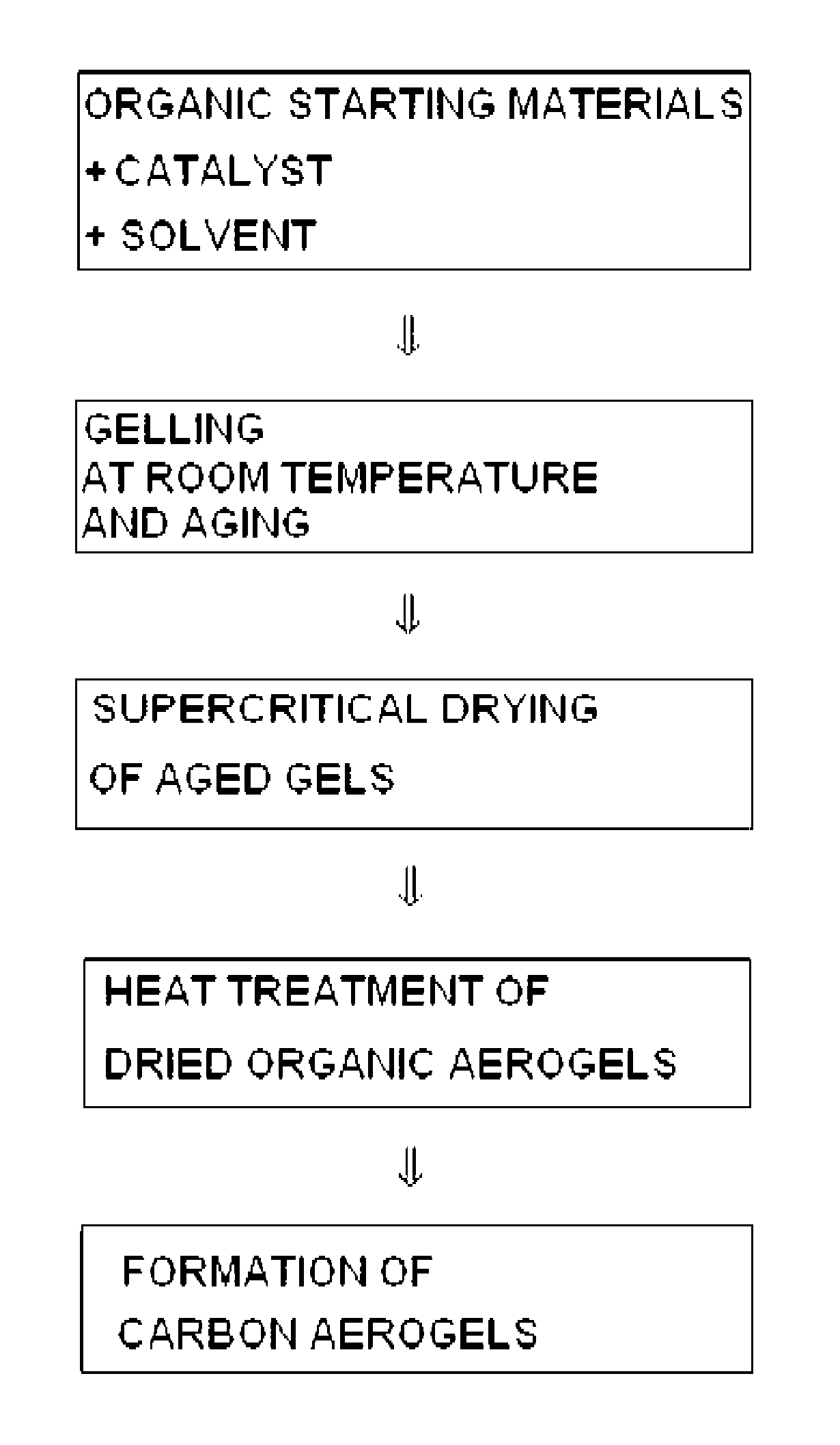

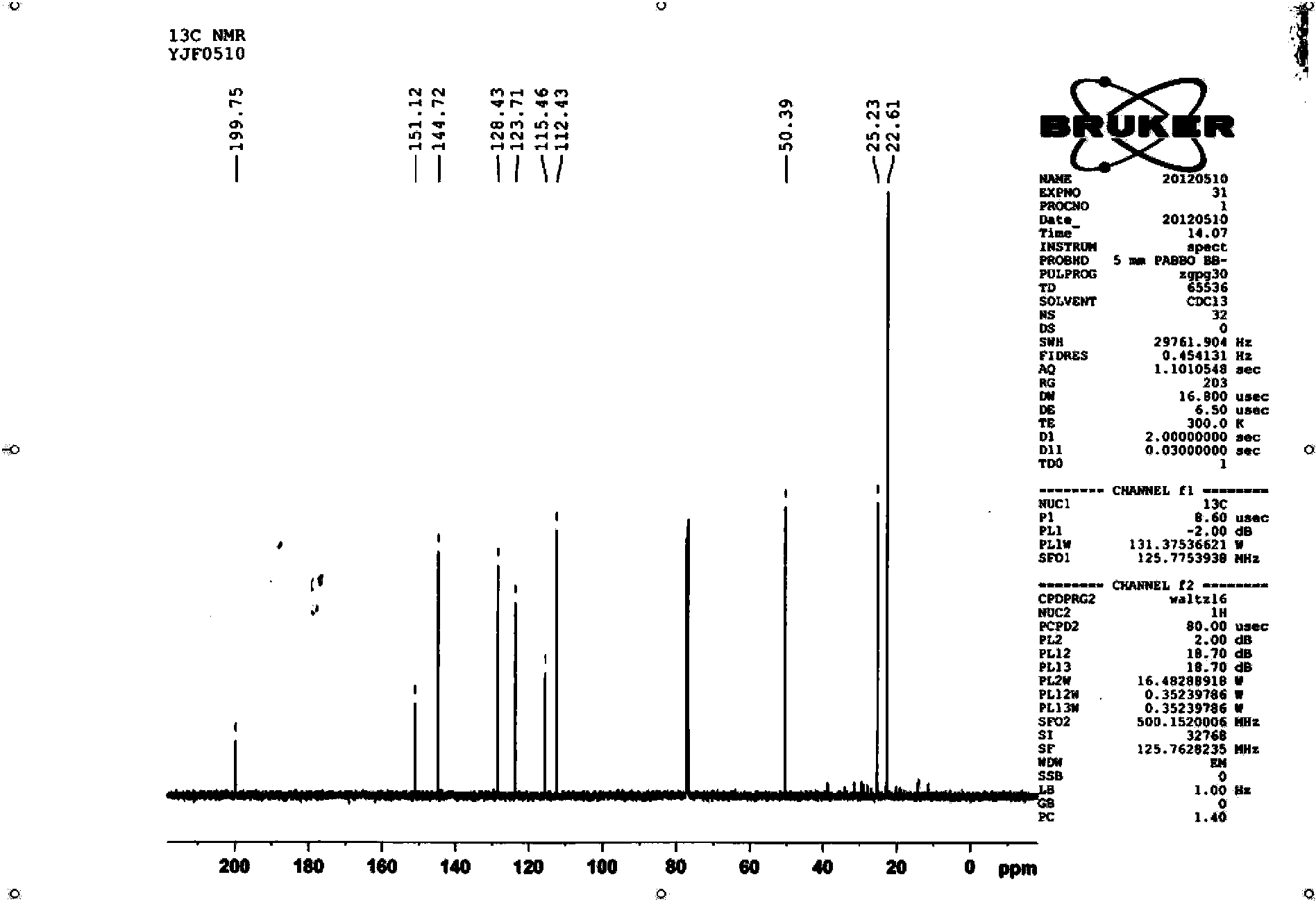

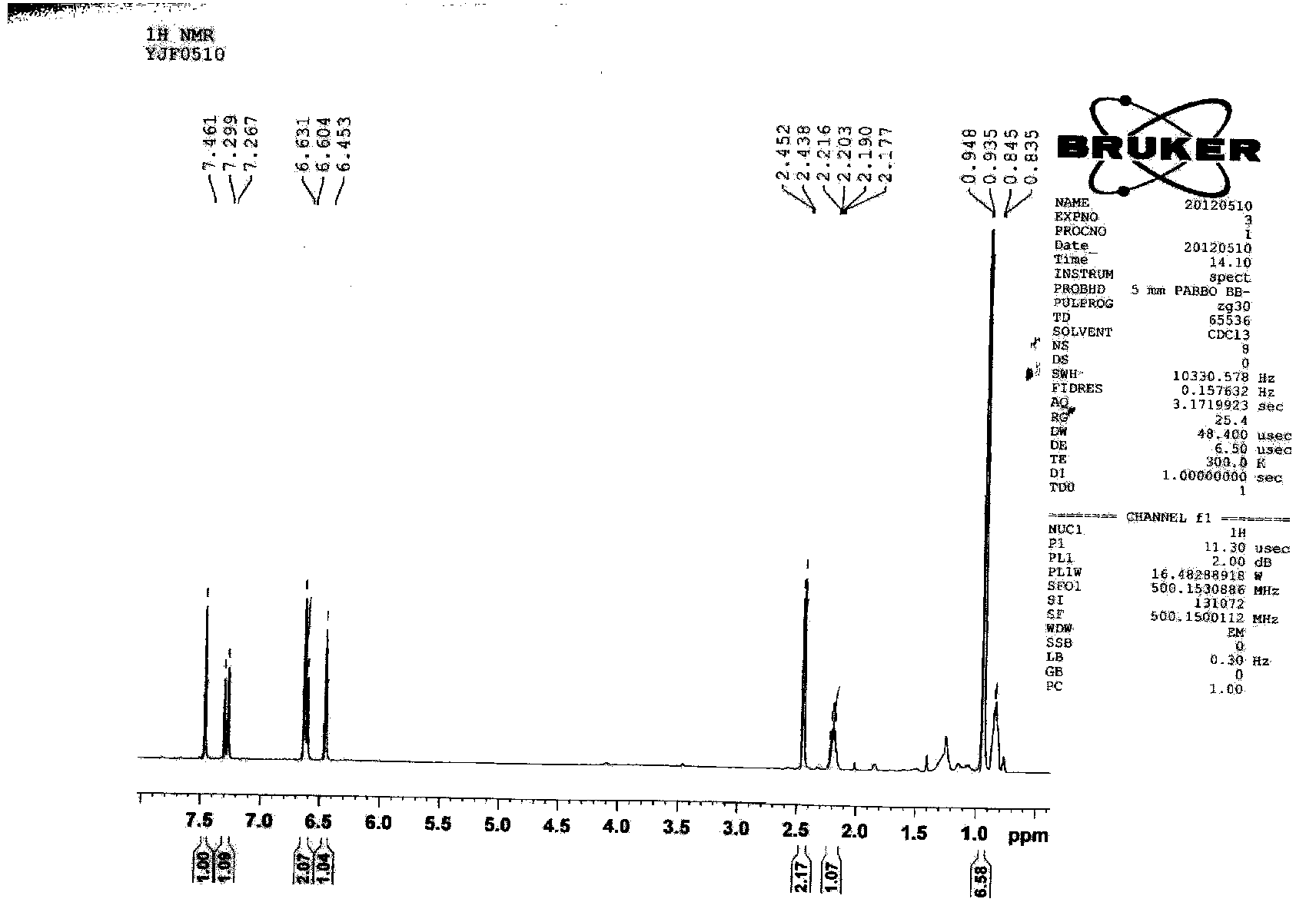

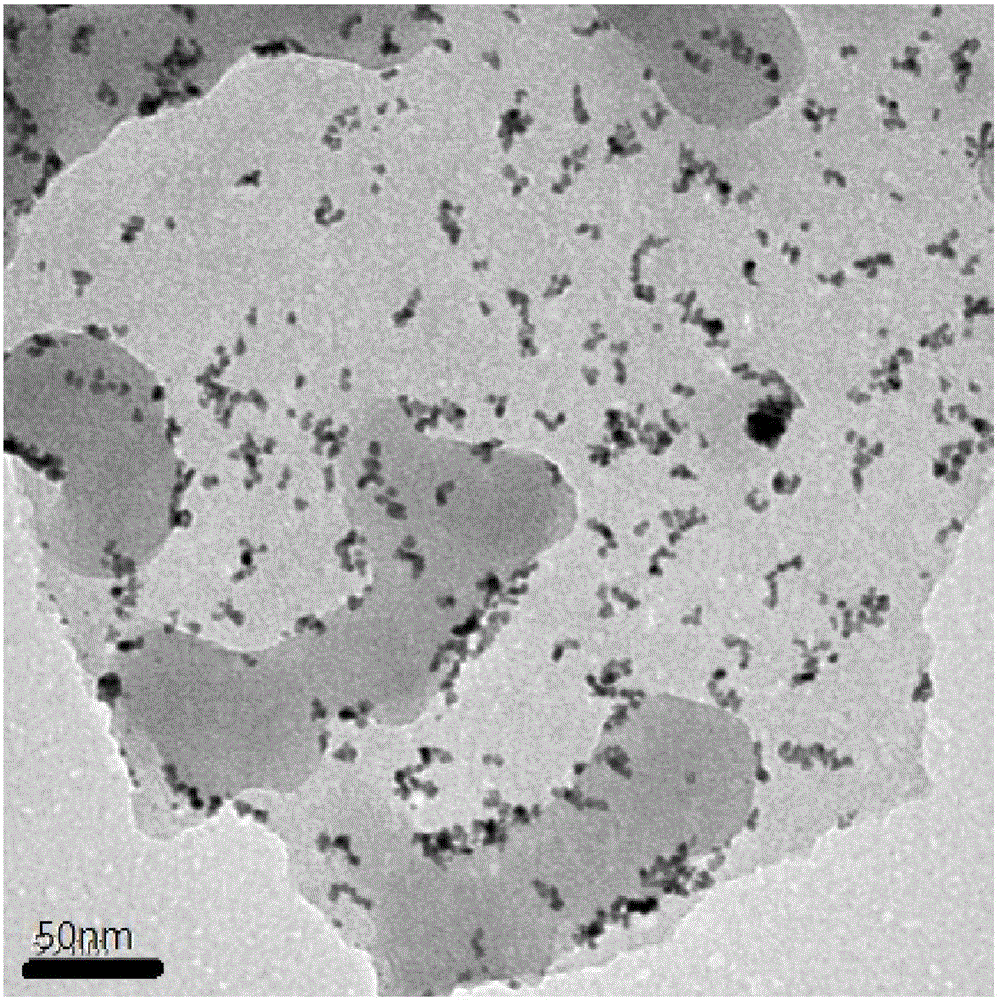

Carbon aerogels for supercapacitors and method of manufacturing the same

InactiveUS8480930B2Large specific surface areaShort processConductive materialNon-conductive material with dispersed conductive materialSupercritical dryingFurfural

A method for preparing carbon aerogels and carbon aerogels obtained therefrom are disclosed. The method for preparing carbon aerogels comprises: mixing organic starting materials including phloroglucinol and furfural with a solvent capable of dissolving the organic materials in a predetermined ratio to form a sol solution; adjusting pH of the sol solution adequately by using an acidic or basic catalyst, gelling the sol solution at room temperature under atmospheric pressure, and aging the resultant gels; substituting the solvent in thus obtained gels with liquid carbon dioxide, followed by drying in a supercritical state, to form organic aerogels; and pyrolyzing the organic aerogels in an electric furnace under inert atmosphere to obtain carbon aerogels. Particularly, the gels are formed at room temperature in a short period of time by adequately adjusting pH of the sol solution. Therefore, the method provides improved time efficiency and energy efficiency as compared to existing methods for preparing gels. Additionally, the method allows supercritical drying while avoiding a need for an additional solvent substitution, thereby simplifying the overall process. Further, the method enables preparation of carbon aerogels for supercapacitors having a high specific surface area and high capacitance even in the absence of additional activation step.

Owner:KOREA INST OF SCI & TECH

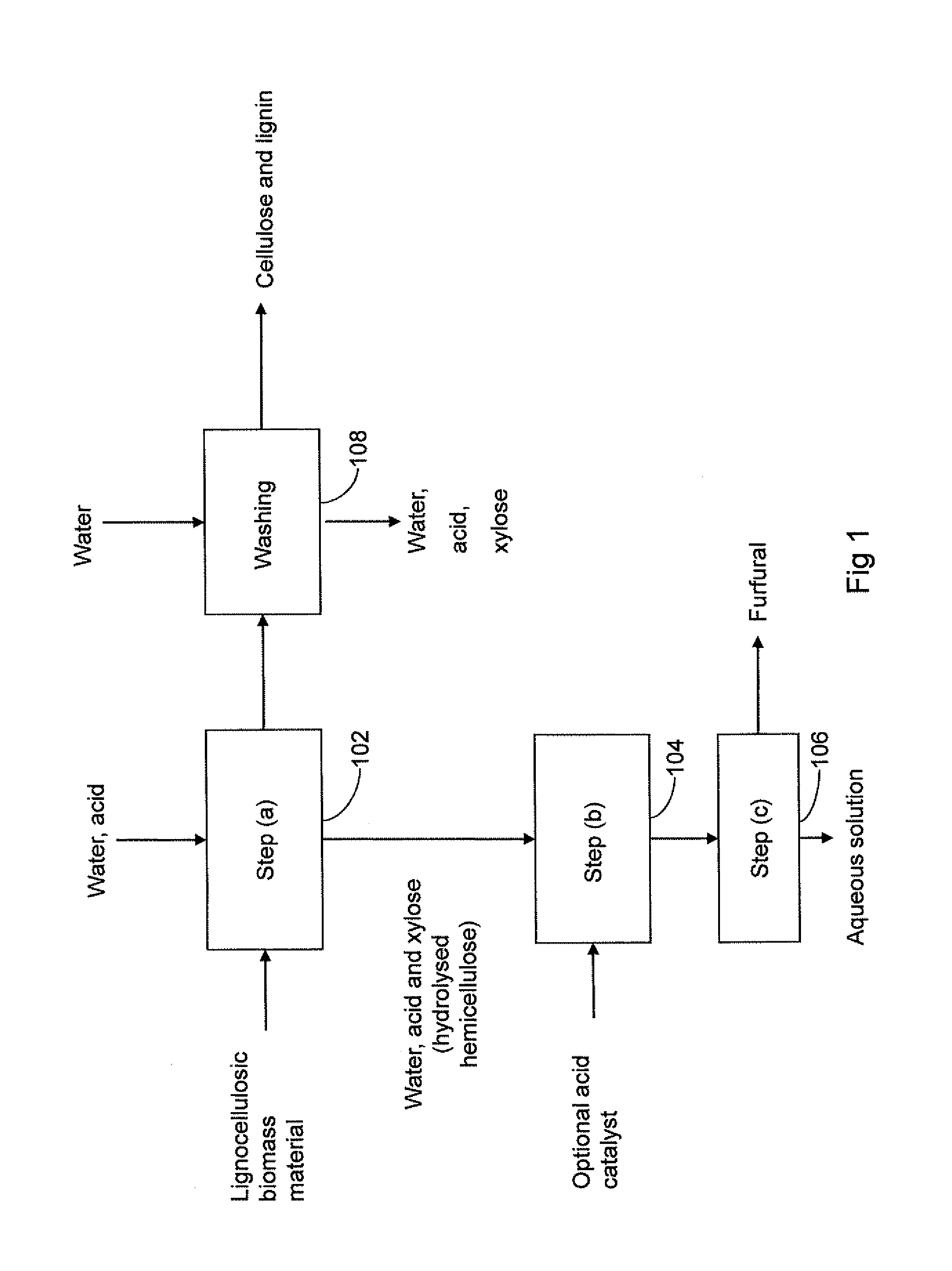

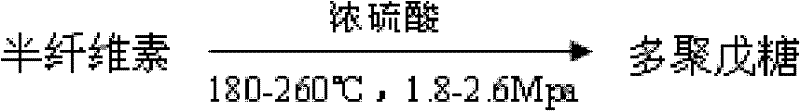

Method for producing furfural from lignocellulosic biomass material

InactiveUS20110144359A1The process is simple and effectiveEasy to useOrganic chemistryOrganic acidLignocellulosic biomass

A method for producing furfural from lignocellulosic biomass material is provided, comprising (a) contacting the lignocellulosic biomass material with a mixture comprising water and an organic acid at a temperature of at least 100° C. and a pressure of at most 10 bar (absolute) to obtain a first liquid stream comprising hydrolysed hemicellulose and a second stream comprising lignin and cellulose; (b) maintaining the first liquid stream comprising hydrolysed hemicellulose at a temperature of at least 130° C. to obtain a second liquid stream comprising furfural; and (c) separating the furfural obtained in step b) from the second liquid stream.

Owner:SHELL OIL CO

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

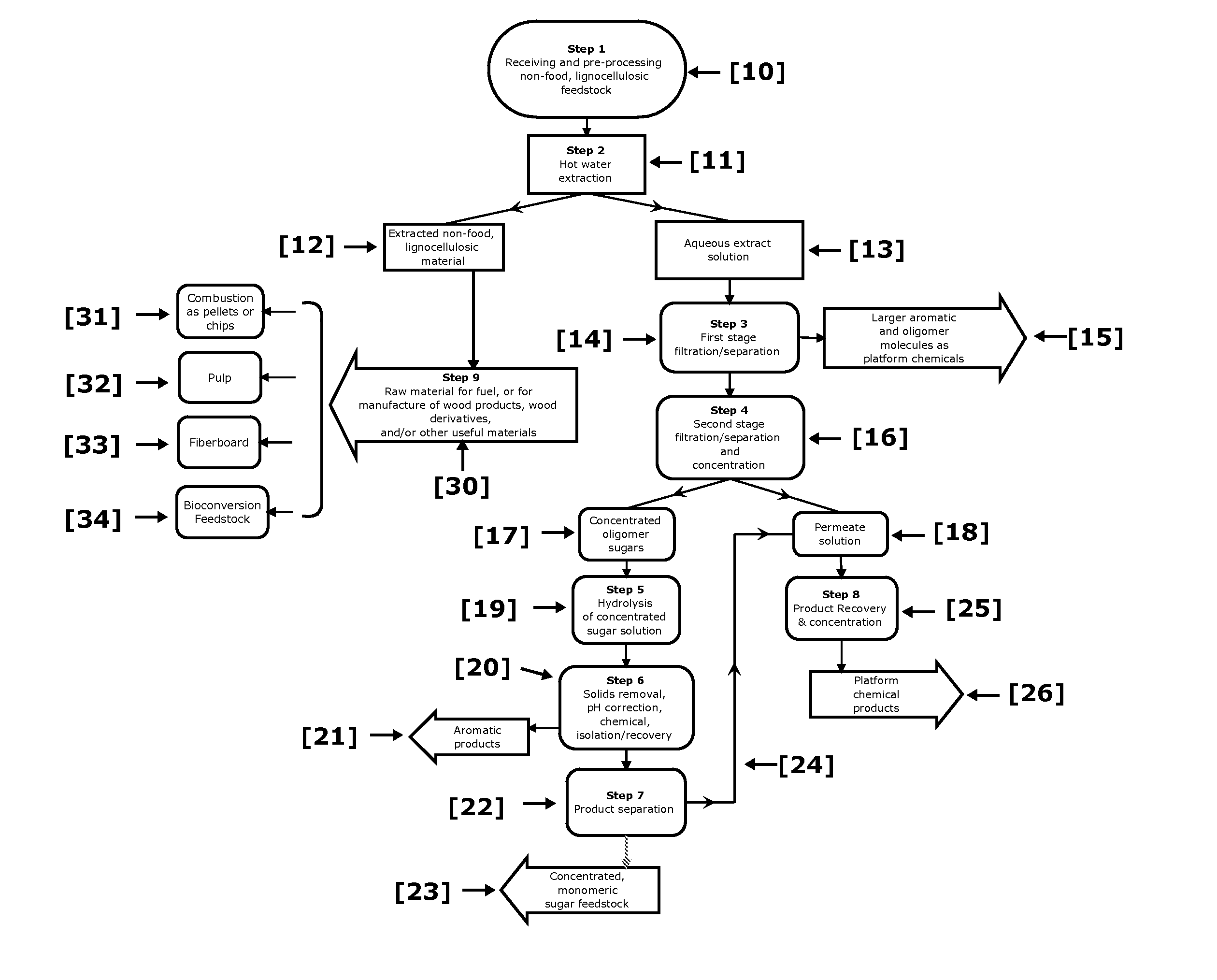

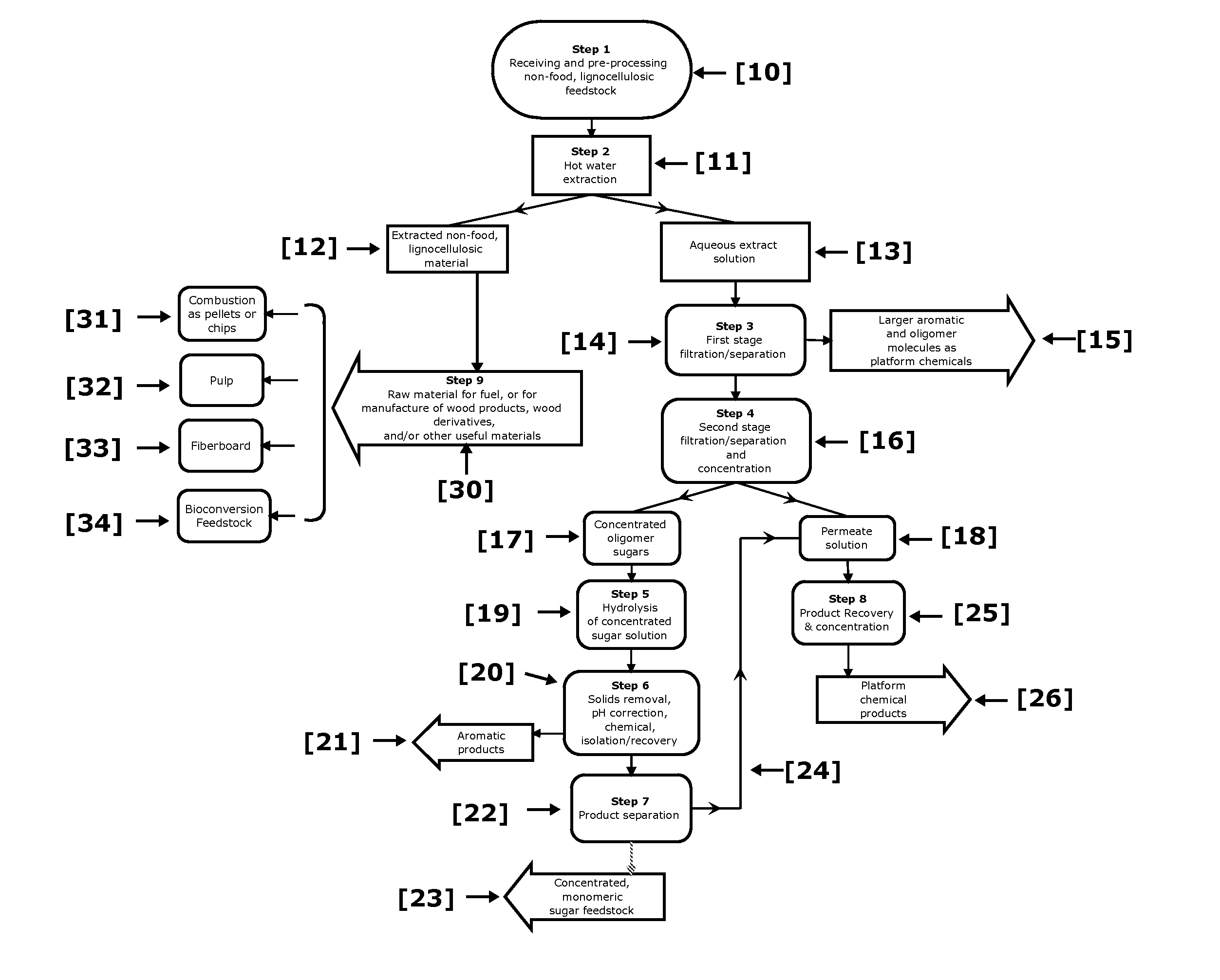

Biorefinery Process for Extraction, Separation, and Recovery of Fermentable Saccharides, other Useful Compounds, and Yield of Improved Lignocellulosic Material from Plant Biomass

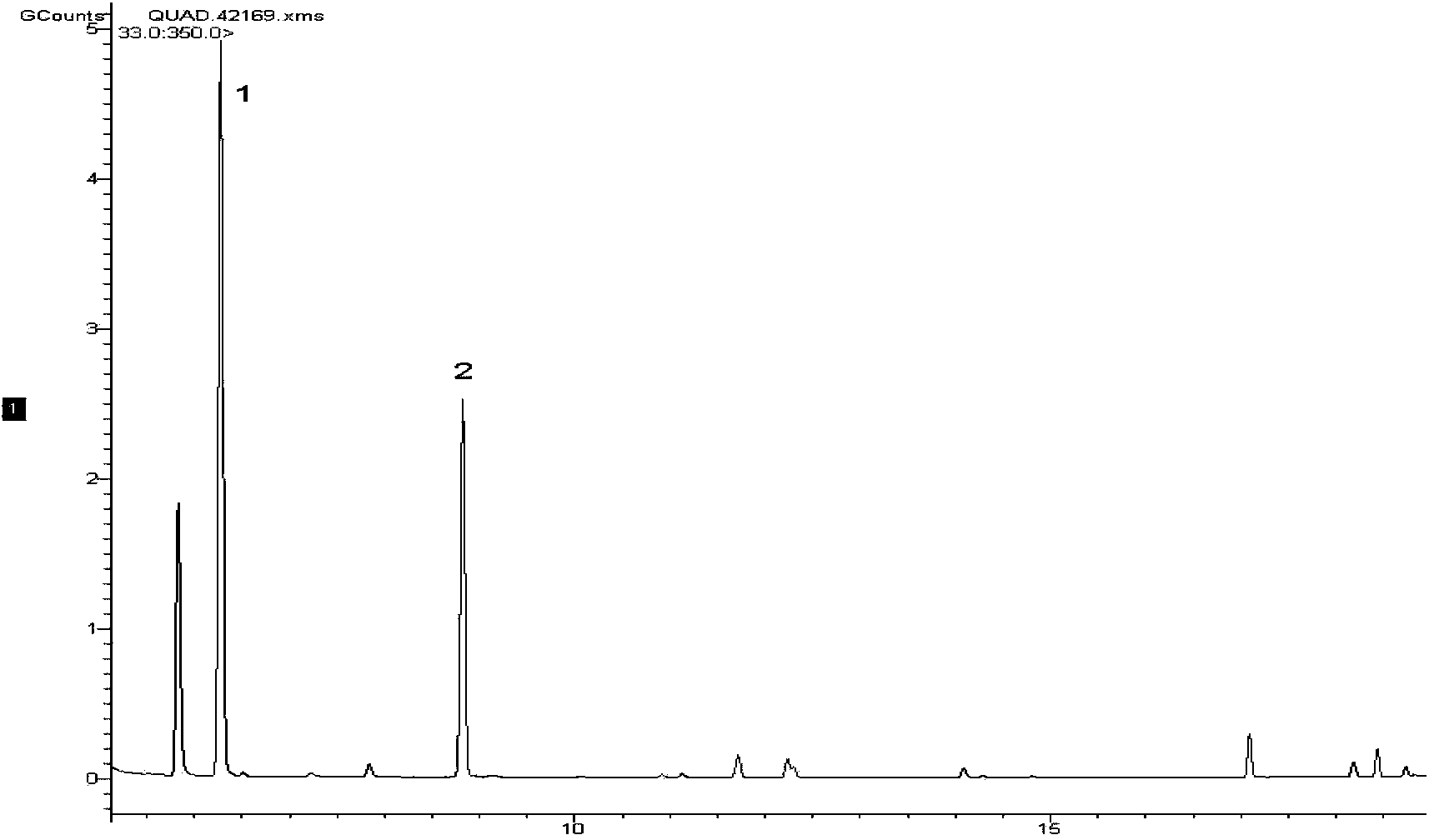

ActiveUS20110129886A1Increase diversityIncrease probabilityCellulosic pulp after-treatmentBiofuelsFurfuralAqueous extract

Non-food plant biomass is subjected to hot-water extraction in a pressurized vessel at an elevated temperature up to about 250° C. and at a pH below about 7.0, to yield an aqueous extract containing hemicellulosic components, other wood-derived compounds, and a lignocellulosic residue. The separated aqueous extract or liquor is purified and concentrated through a multi-step process producing fermentable sugars. At each stage, inhibitory chemicals such as acetic acid, lignin, and furfural are separated and eventually recovered as commercial chemicals. The lignocellulosic residue may be further processed, as a material with enhanced resistance to sorption of water, for manufacture of improved pulp and paper, construction materials, pellet fuel, and / or other useful products.

Owner:APPLIED BIOREFINERY SCI

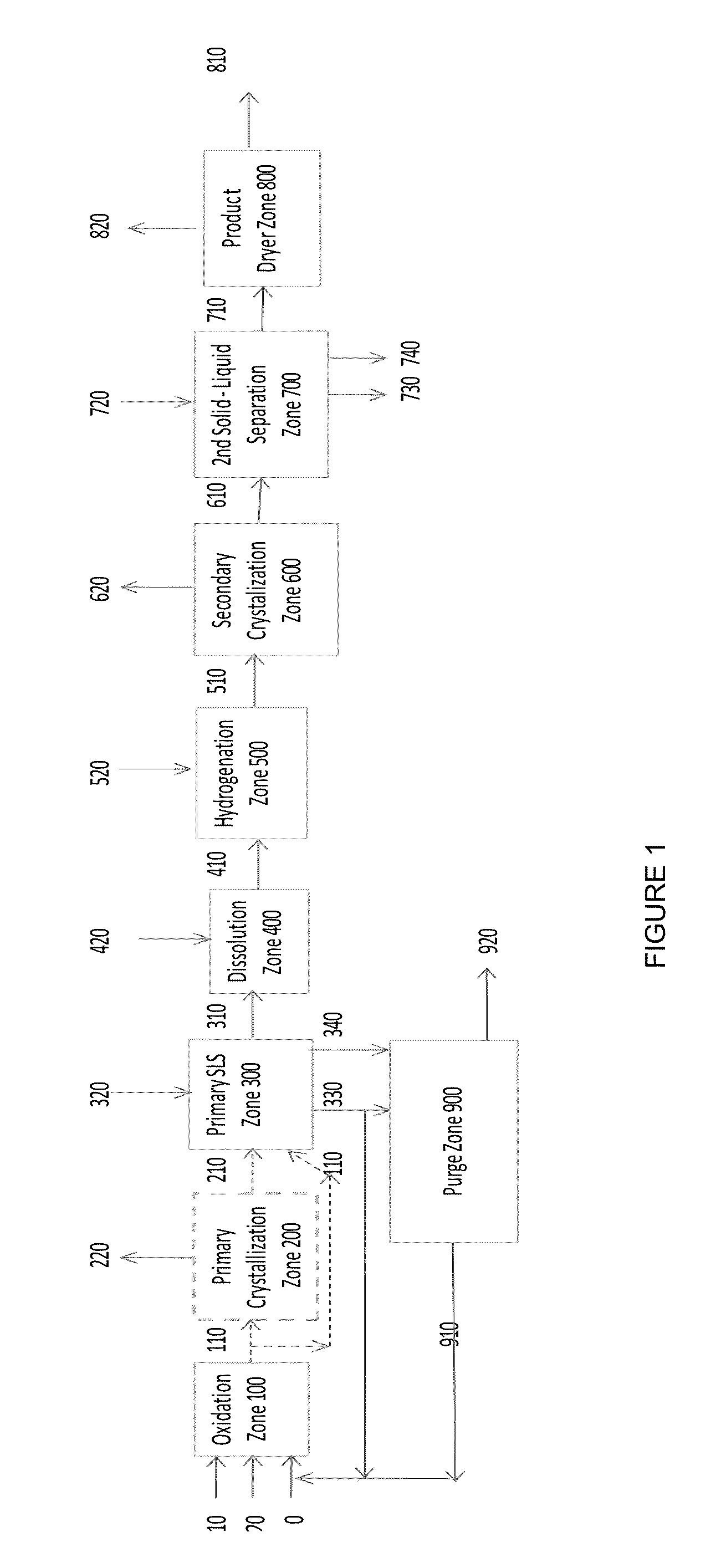

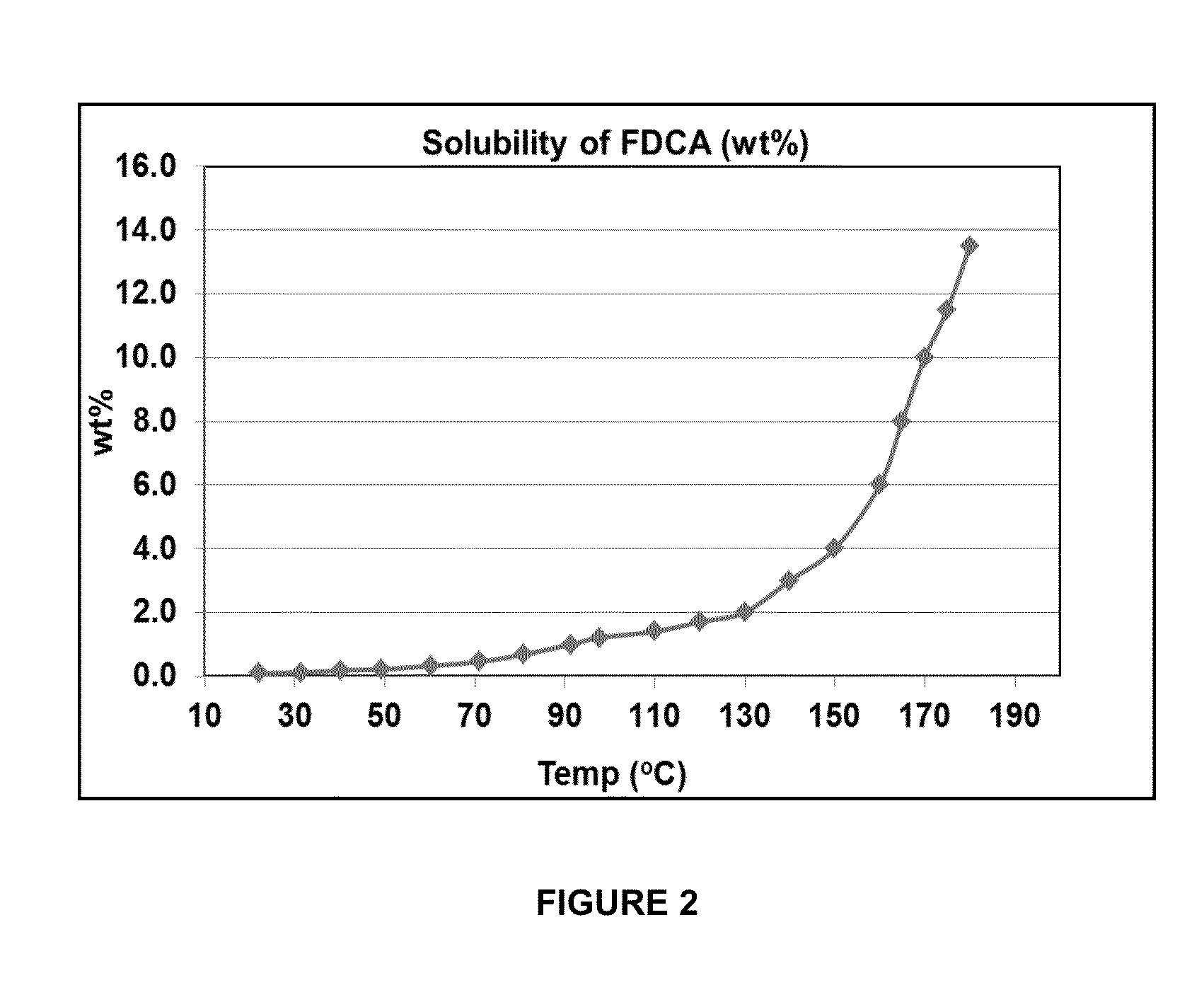

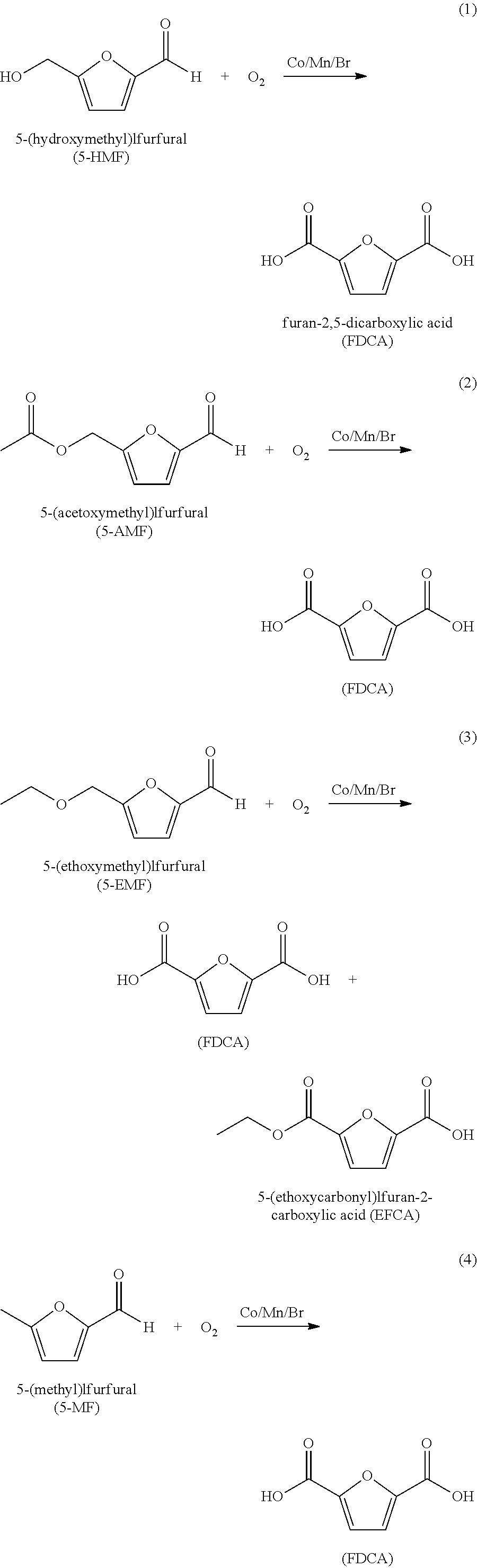

Process for purifying crude furan 2,5-dicarboxylic acid using hydrogenation

A process to produce a dry purified furan-2,5-dicarboxylic acid (FDCA) is described. After oxidation of 5-(hydroxymethyl)furfural (5-HMF), a crude FDCA stream is produced that is fed to a crystallization zone followed by a solid-liquid displacement zone to form a low impurity slurry stream. The solids in the low impurity slurry stream are dissolved in a dissolution zone to produce a hydrogenation feed that is hydrogenated in a hydrogenation reactor to generate a hydrogenated FDCA composition. The hydrogenated FDCA composition is routed to a crystallization zone to form a crystallized produce stream that is separated from liquid in a solid-liquid separation zone to generate a purified wet cake stream containing FDCA that can be dried in a drying zone to generate a dry purified FDCA product stream.

Owner:EASTMAN CHEM CO

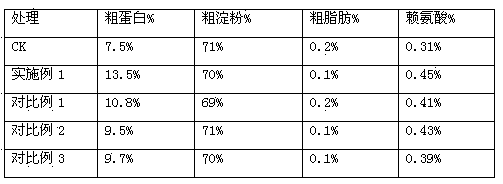

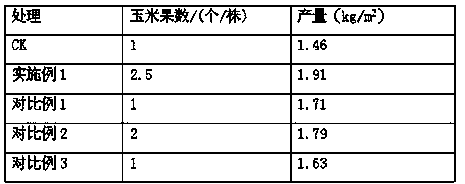

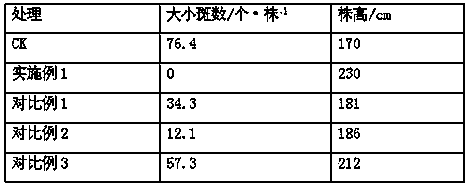

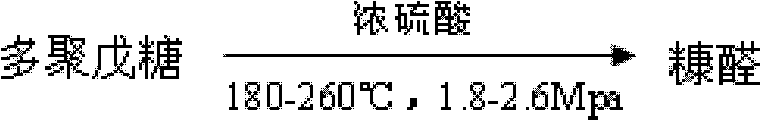

Disease-resistant compound biofertilizer special for corn and preparation method thereof

ActiveCN104003817AImprove the micro-ecological environmentPromote growthFertilizer mixturesDiseasePhosphate

The invention belongs to the technical field of fertilizer, particularly relates to disease-resistant compound biofertilizer special for corn and further relates to a preparation method of the disease-resistant compound biofertilizer special for the corn. The disease-resistant compound biofertilizer special for the corn comprises carbamide, compound microbial agents, bran, chitosan, furfural residues, ammonium sulfate, potassium sulfate, monoammonium phosphate, rape seed cakes, manure, humic acid, sesame seed cakes, microelements, calcium superphosphate and plant ash. The nutrient elements of the disease-resistant compound biofertilizer special for the corn are balanced, microelement compositions are abundant, soil productivity and soil fertility can be improved effectively, addition of compound microbial agents can remarkably restrain main corn diseases occurring universally, the disease-resistant compound biofertilizer special for the corn is long in fertilizer efficiency, corn yield can be improved by 25 to 30 percent effectively, the corn diseases can be prevented and cured effectively, soil can be improved effectively through long-term utilization of the disease-resistant compound biofertilizer, and the disease-resistant compound biofertilizer special for the corn can play a role in the whole growth period of the corn.

Owner:JINAN HANGCHEN BIOTECHNOLOGY CO LTD

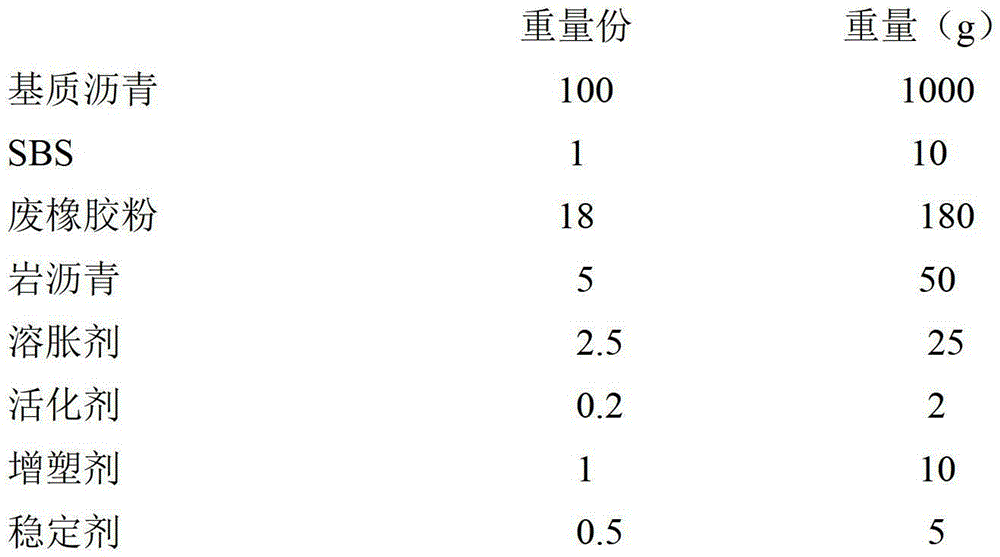

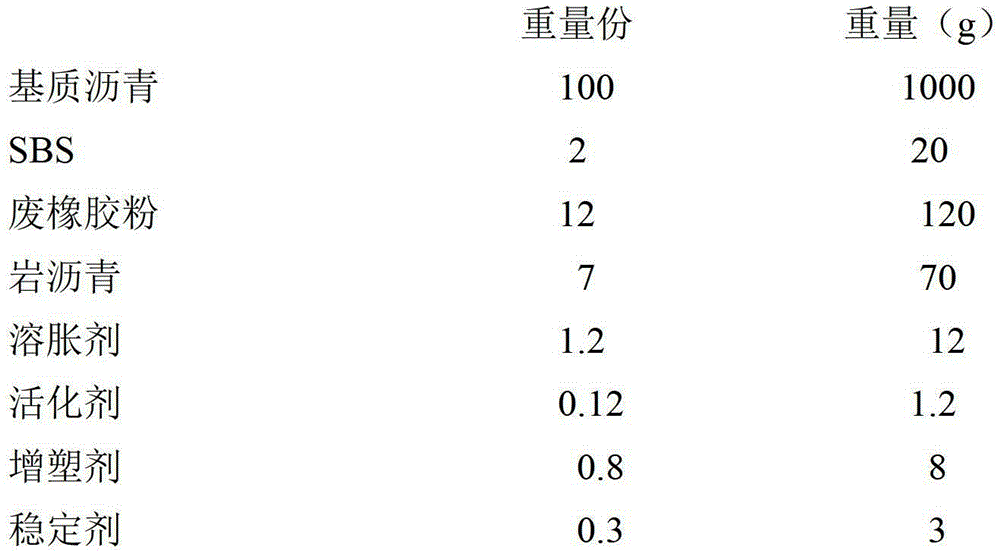

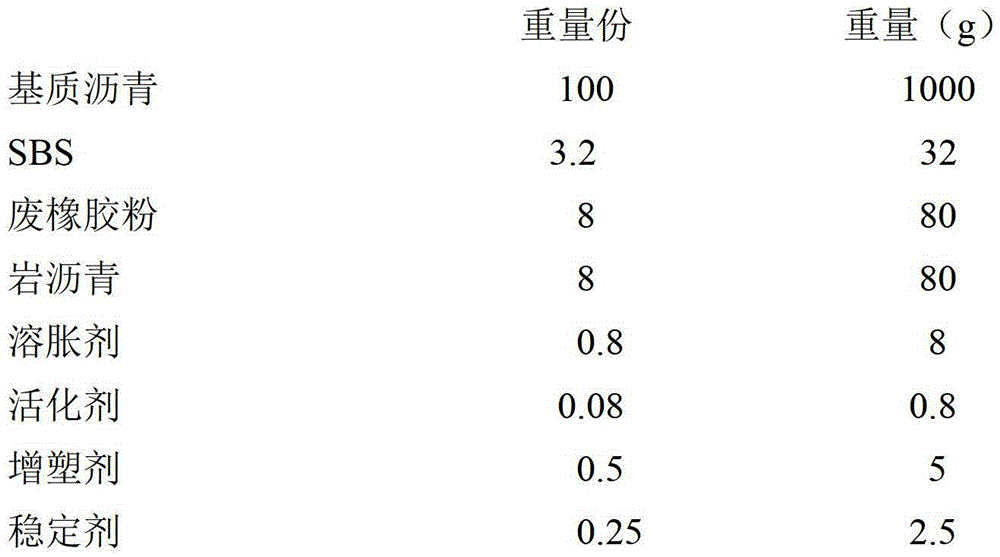

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

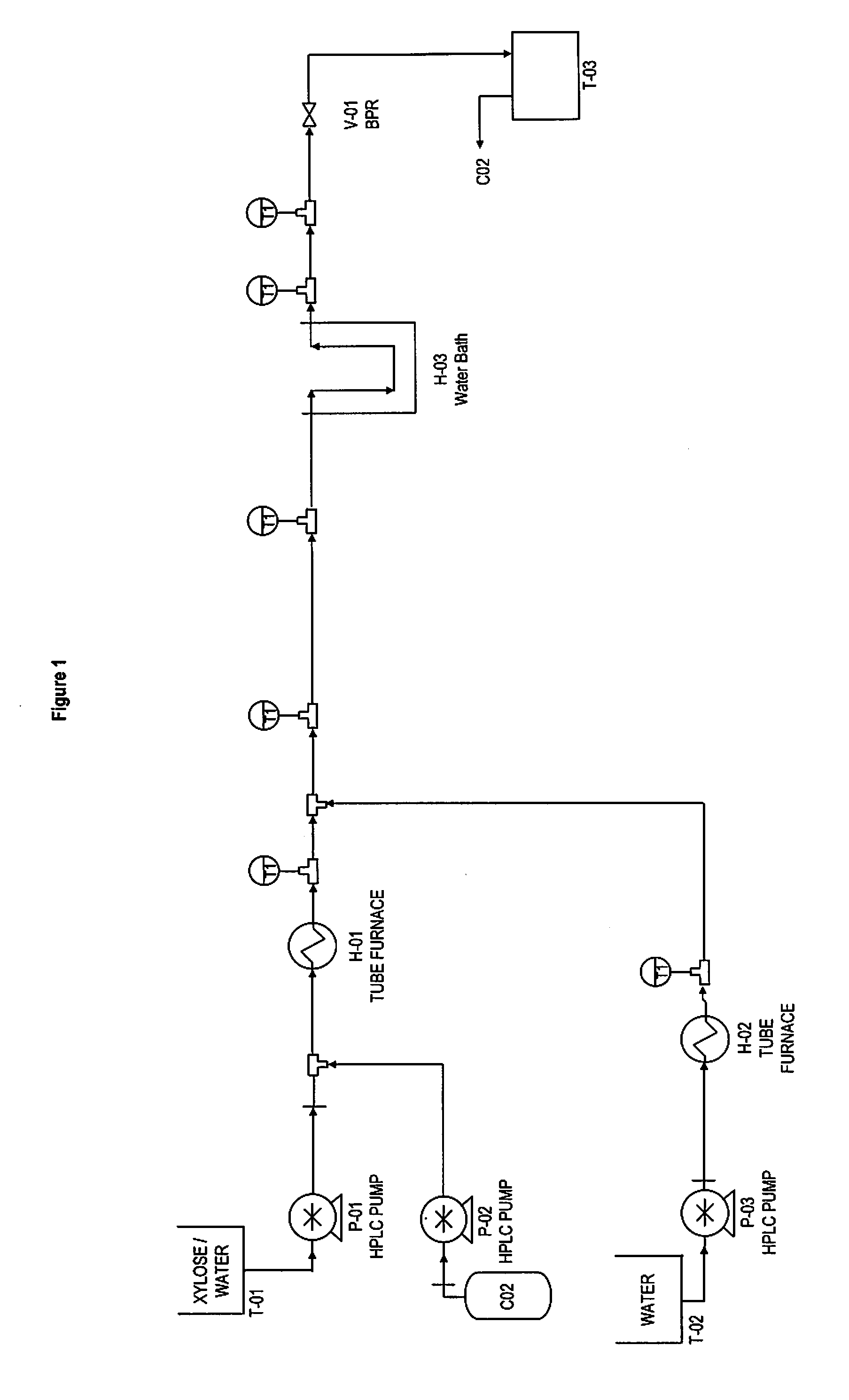

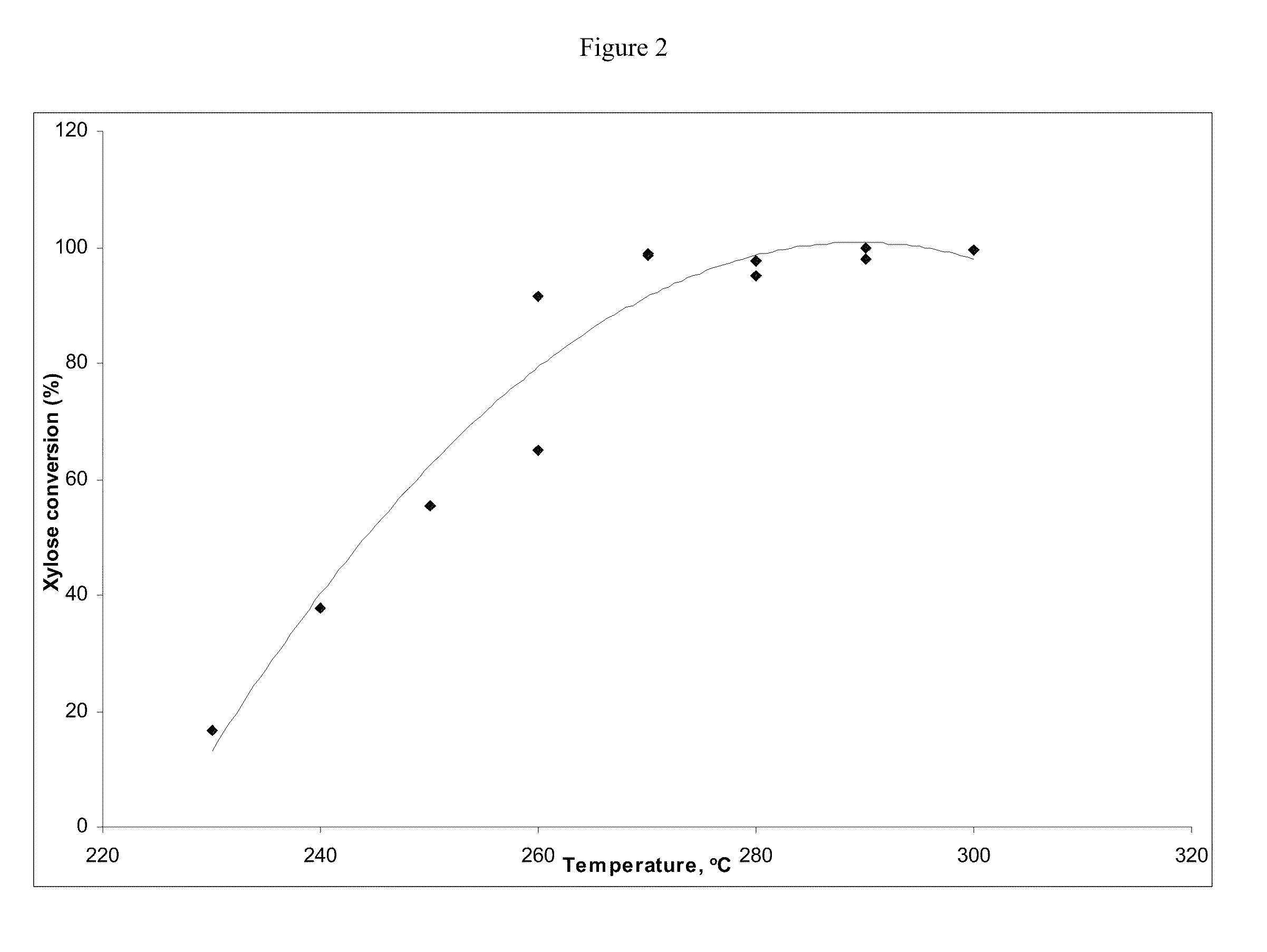

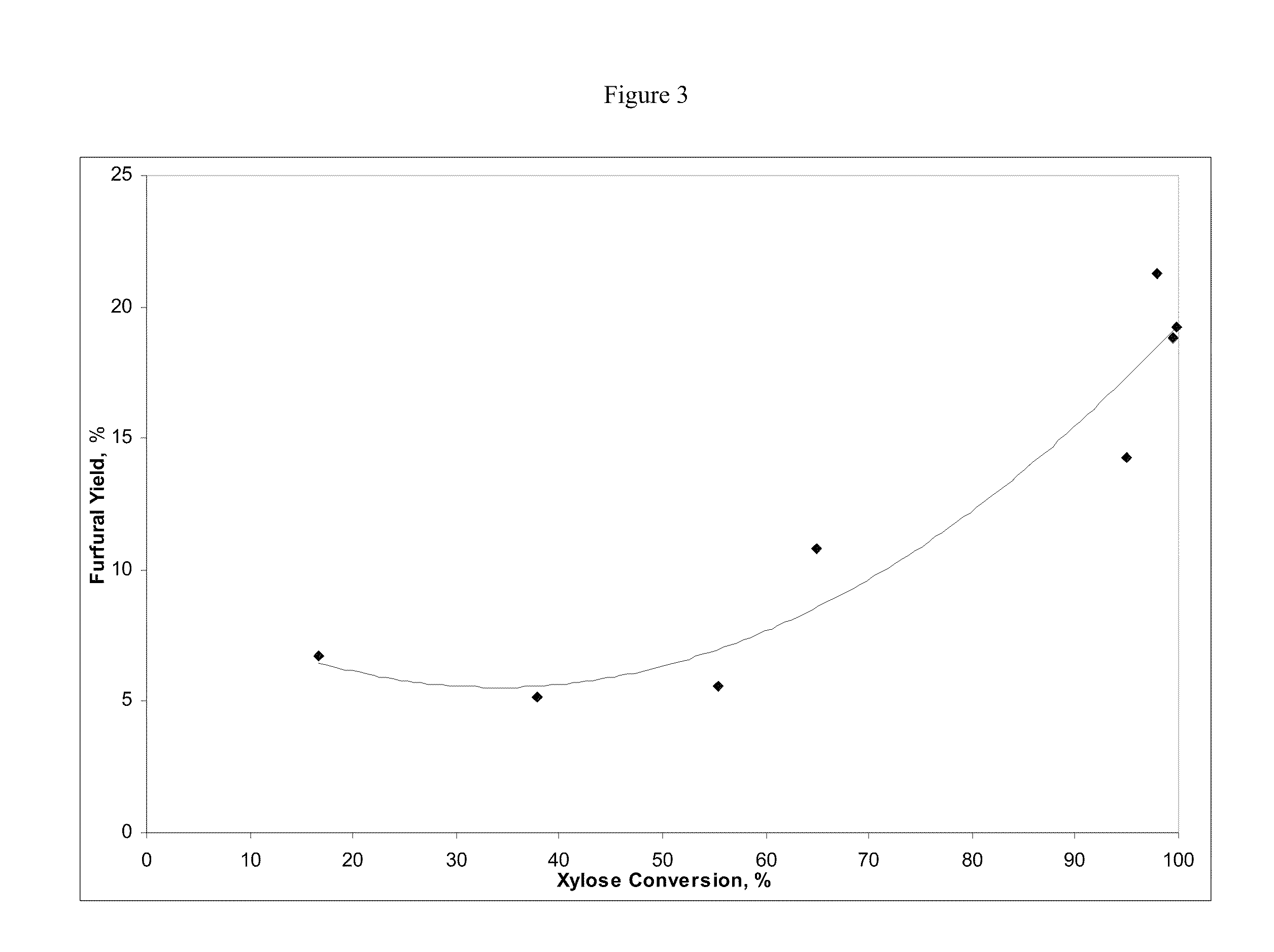

Solvo-thermal hydrolysis of xylose

ActiveUS20100048924A1Rapid coolingOrganic chemistryChemical/physical/physico-chemical processesSolventFurfural

The invention relates to a process for producing furfural from xylose comprising: (a) mixing an aqueous xylose solution containing xylose oligosaccharides with sub-critical or near-critical water to form a mixture at a first temperature and a first pressure; (b) maintaining the mixture at the first temperature and the first pressure for a first time period; and (c) rapidly cooling the mixture to a second temperature and a second pressure, wherein furfural is produced by the process (d) process can also be carried out with or without mixing of carbon dioxide with aqueous xylose solution before it is mixed with sub-critical or near-critical water to form a mixture at a first temperature and pressure.

Owner:RENMATIX INC

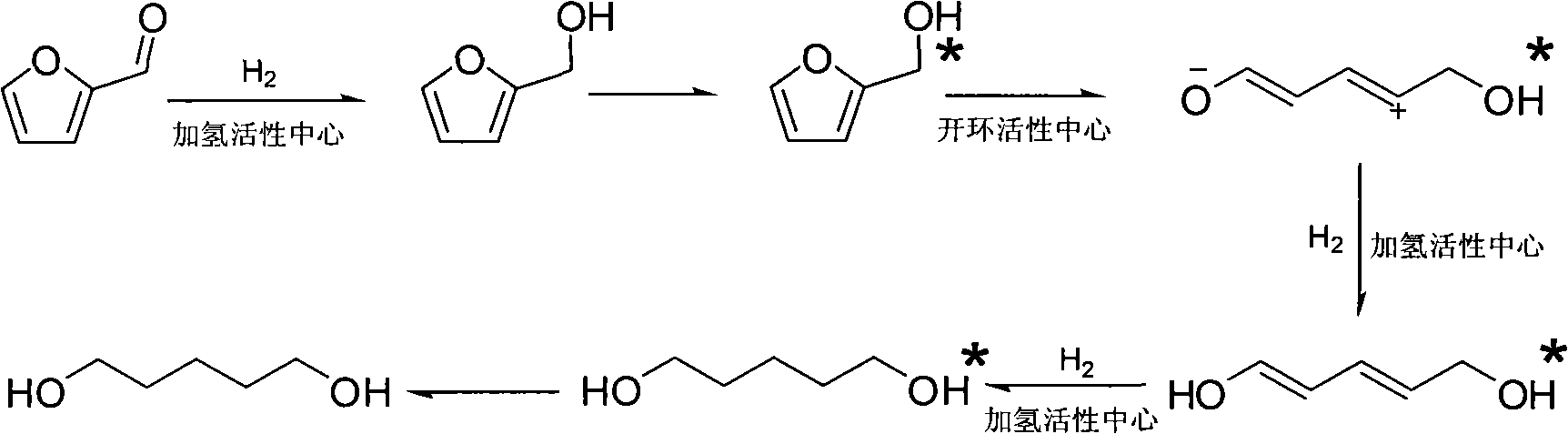

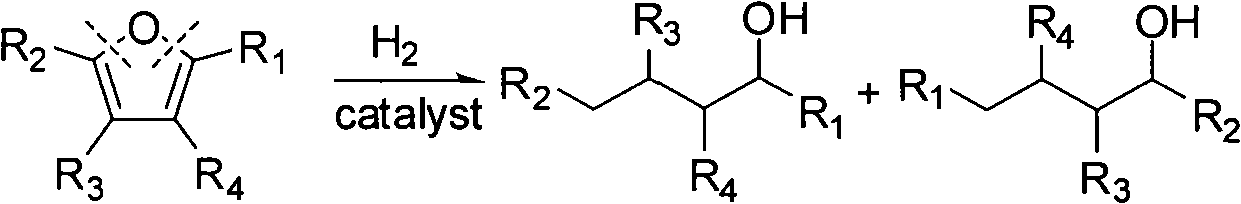

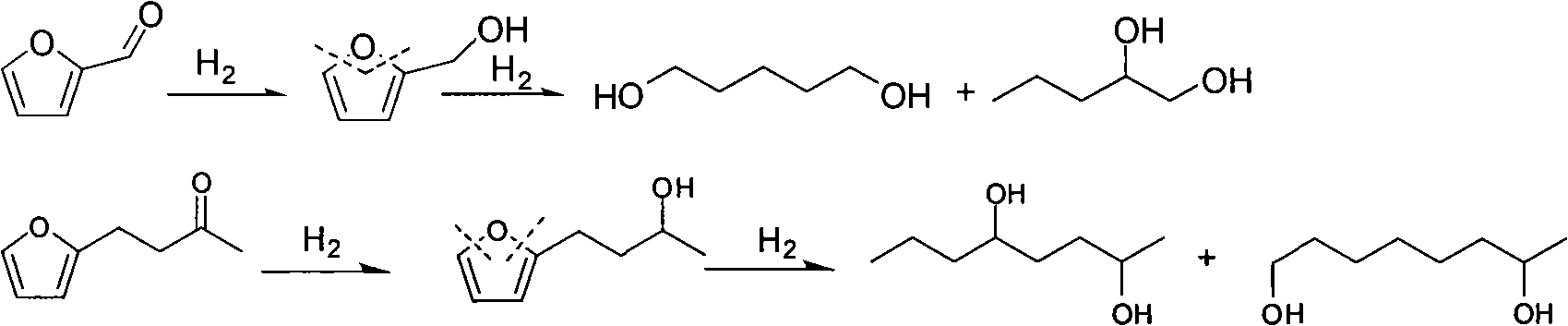

Catalyst used in ring-opening hydrogenation reaction of furan derivative

InactiveCN102068986AHigh activityGood choicePreparation by hydrogenationHydroxy group formation/introductionFuranHydrogenation reaction

The invention relates to a catalyst used in a ring-opening hydrogenation reaction of a furan derivative. The catalyst is applied to direct preparation of one-step ring-opening hydrogenation of 1,5-pentanediol and 1,2-pentanediol by taking furfural or furfuryl alcohol serving as a raw material under a mild condition. The catalyst can provide two active ingredients, namely the ring-opening active center of a transition metal oxide and the hydrogenation active center of Pt, Pd, Rh, Ru, Co or Ni, wherein the active center of the transition metal oxide is mainly used for adsorbing furfural or furfuryl alcohol and directly hydrogenating a furan ring for opening the furan ring; and the hydrogenation active center of a noble metal or Co, Ni and the like is mainly used for quickly hydrogenating an intermediate material and hydrogenating subsequent enol so as to obtain 1,5-pentanediol and 1,2-pentanediol. An environmentally-friendly, reproducible, low-cost, mild and effective method is provided for producing 1,5-pentanediol and 1,2-pentanediol. The high-performance ring-opening hydrogenation catalyst is also suitable for the ring-opening hydrogenation reaction of other furan derivatives.

Owner:EAST CHINA UNIV OF SCI & TECH

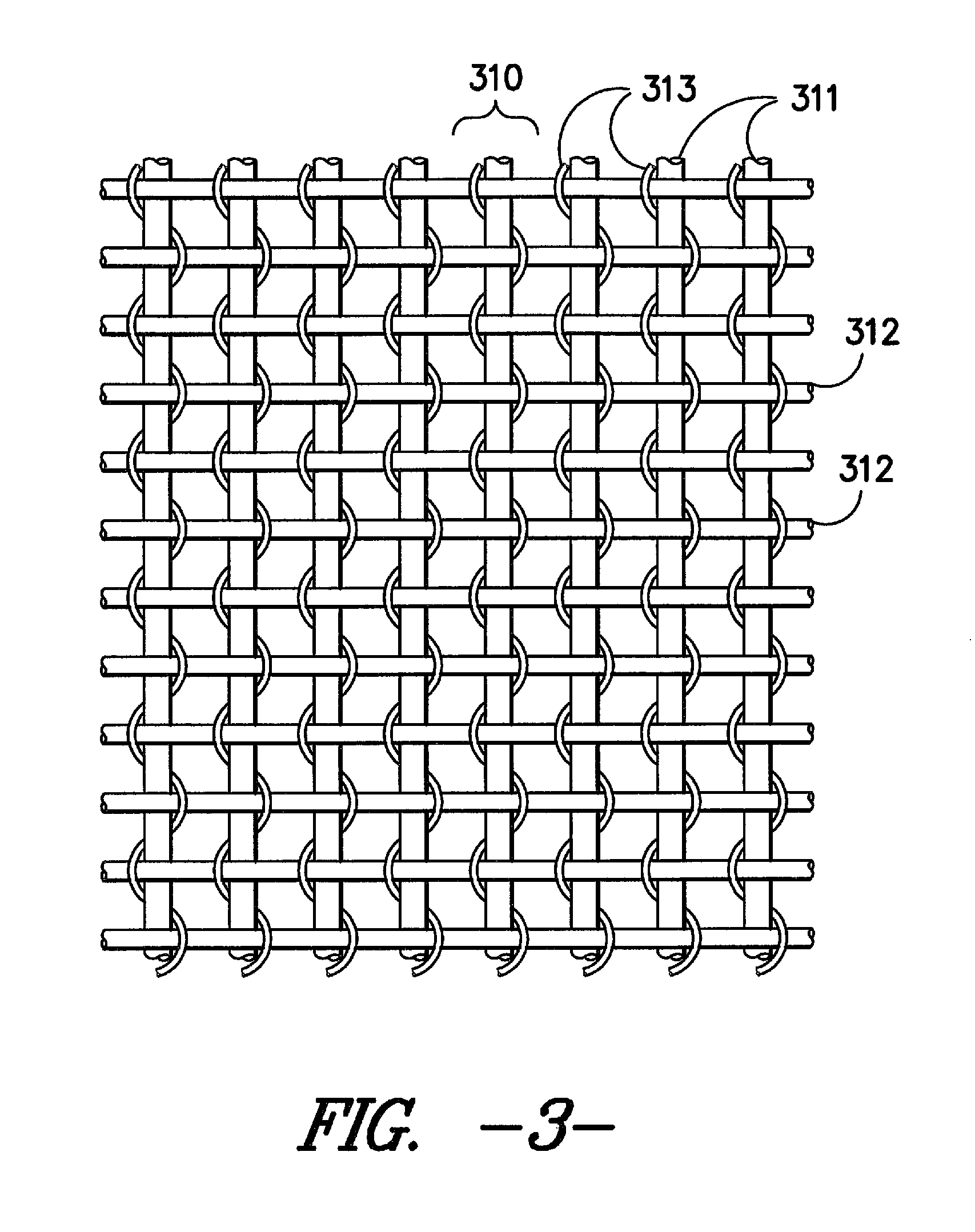

Adhesion composition and textile materials and articles treated therewith

InactiveUS8247490B1Hydrogenated nitrile rubber adhesivesPaints for electrolytic applicationsRubber materialPolymer science

Owner:MILLIKEN & CO

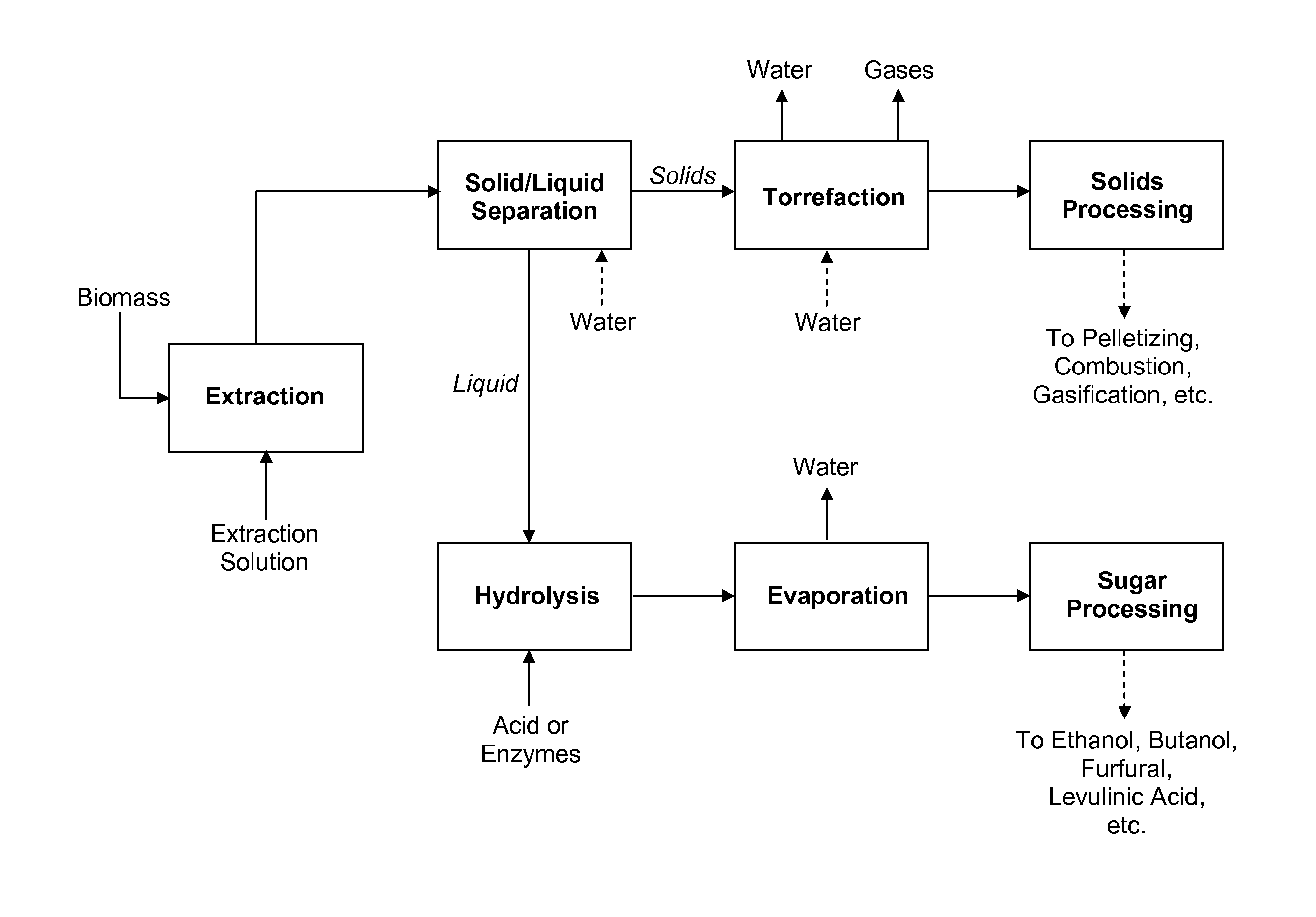

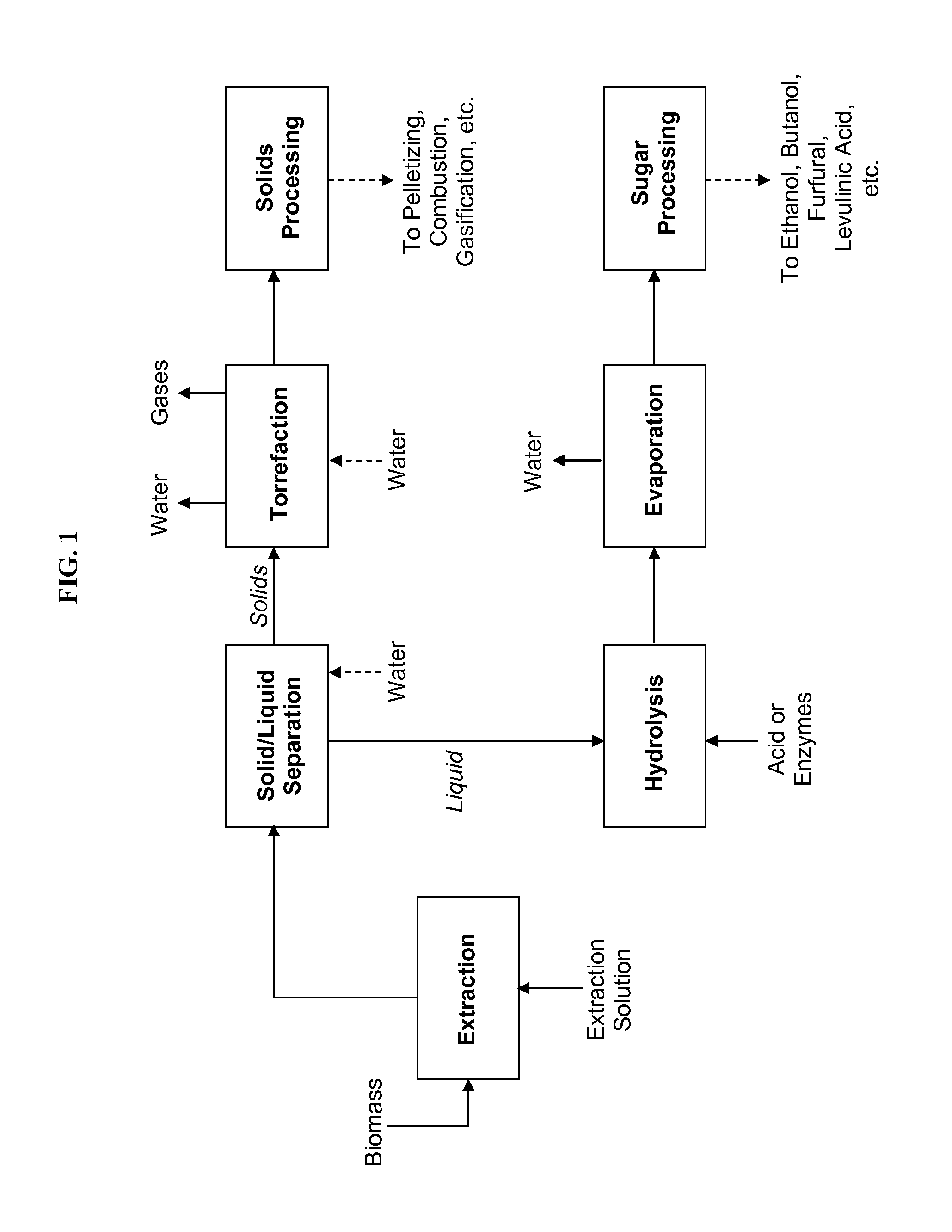

Processes for producing energy-dense biomass and sugars or sugar derivatives, by integrated hydrolysis and torrefaction

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

N-doped porous carbon supported metal catalyst, and preparation method and application thereof

ActiveCN106622327ARich pore structureLarge specific surface areaPhysical/chemical process catalystsPreparation from heterocyclic compoundsHydrogenAlcohol

The invention relates to a catalyst which using N-doped porous carbon as a carrier to support metal. The catalyst is composed of 0.1wt%-30wt% of metal particles and 70wt%-99.9wt% of bio-N-doped porous carbon carrier, and can be used for catalyzing aqueous phase hydrogenation of bio-furfural to highly selectively prepare furfural alcohol or cyclopentanone. The catalyst uses the raw materials which are renewable resources, wide in distribution, green and environmental, simple and easy to obtain, rich in resource, low in cost, free from inactivation when recycled for more than 50 times, and stable to air, water and heat. For example, in reaction of catalyzing the hydrogenation of the furfural to prepare the furfural alcohol, conversion rate of the supported metal catalyst can reach 100% and selectivity of the furfural alcohol is larger than 99% in an aqueous phase system.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Intensive processing method for stalk articles or agricultural castoff

InactiveCN101492700AEasily hydrolyzedCompletely hydrolyzedBiofuelsMicroorganism based processesFiltrationMonopotassium phosphate

The invention provides a method for intensive processing of straw-type materials or wastes of agriculture and forestry. The method has the following steps: the straw-type materials or the wastes of agriculture and forestry are first ground and then soaked in hot water; hydrolyzation is carried out by diluted acid or monopotassium phosphate solution, the hydrolyzate is used for producing furfural or xylose, solid content after the hydrolyzation is washed and added with alkali substances for neutralization, then cellulase and feruloyl esterase are added to synergetically hydrolyze cellulose in solid content, the cellulose is broken down into 6-carbon monosaccharide and exists in sugar liquor; adsorption filtration is carried out on the sugar liquor by activated carbon, then high-temperature sterilization and cooling are carried out on the sugar liquor before inoculation of fermentation strain to produce acetone, butanol and ethanol by fermentation; the method of the invention maximizes the application of the straw-type materials or the wastes of agriculture and forestry, thus turning existing wastes into the valuables while finding new raw material sources and a new method for producing acetone, butanol and ethanol and bringing more economic and social benefits to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

Catalyzer for preparing furfuryl alcohol through hydrogenation in liquid phase furfural

InactiveCN1562477AEasy to makeEasy to useOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFurfuralHigh activity

A catalyst for preparing furfuryl alcohol by hydrogenating liquid-phase furaldehyde contains CuO, Cr2O3 and Pd. Its advantages are high activity, conversion rate and selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

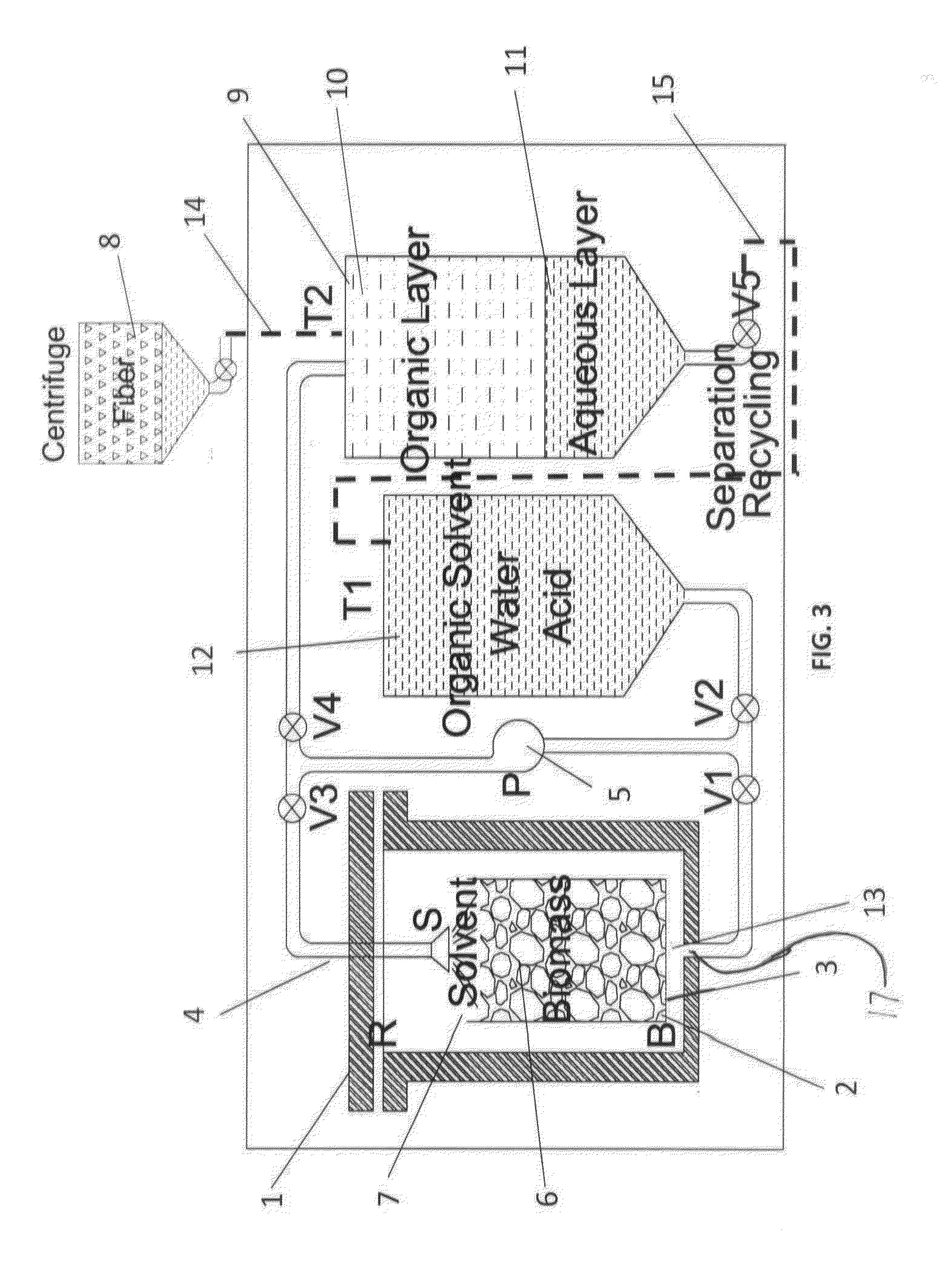

System and method for extraction of chemicals from lignocellulosic materials

ActiveUS20140227161A1Oxygen-containing compound preparationOrganic compound preparationFuranCellulose

An organosolv process for producing bio-products by decomposing lignocellulosic materials comprises providing an initial lignin solvent with water, an acid, and a lignin dissolving chemical comprising at least one of an organic ester, butyl acetate, an organic furan, and furfural. The process also includes placing the lignin solvent in contact with a biomass to form a circulation solvent, and recycling at least a portion of the circulation solvent by circulating the circulation solvent back into contact with the biomass. The circulating of the circulation solvent occurs for a period of time, after which, the process then includes separating material such as chemicals and lignin from the circulation solvent. The chemicals can be recycled as new solvent or sold while lignin can be used as natural and renewable colorant for polymers such as poly lactic acid.

Owner:AMERICAN SCI & TECH

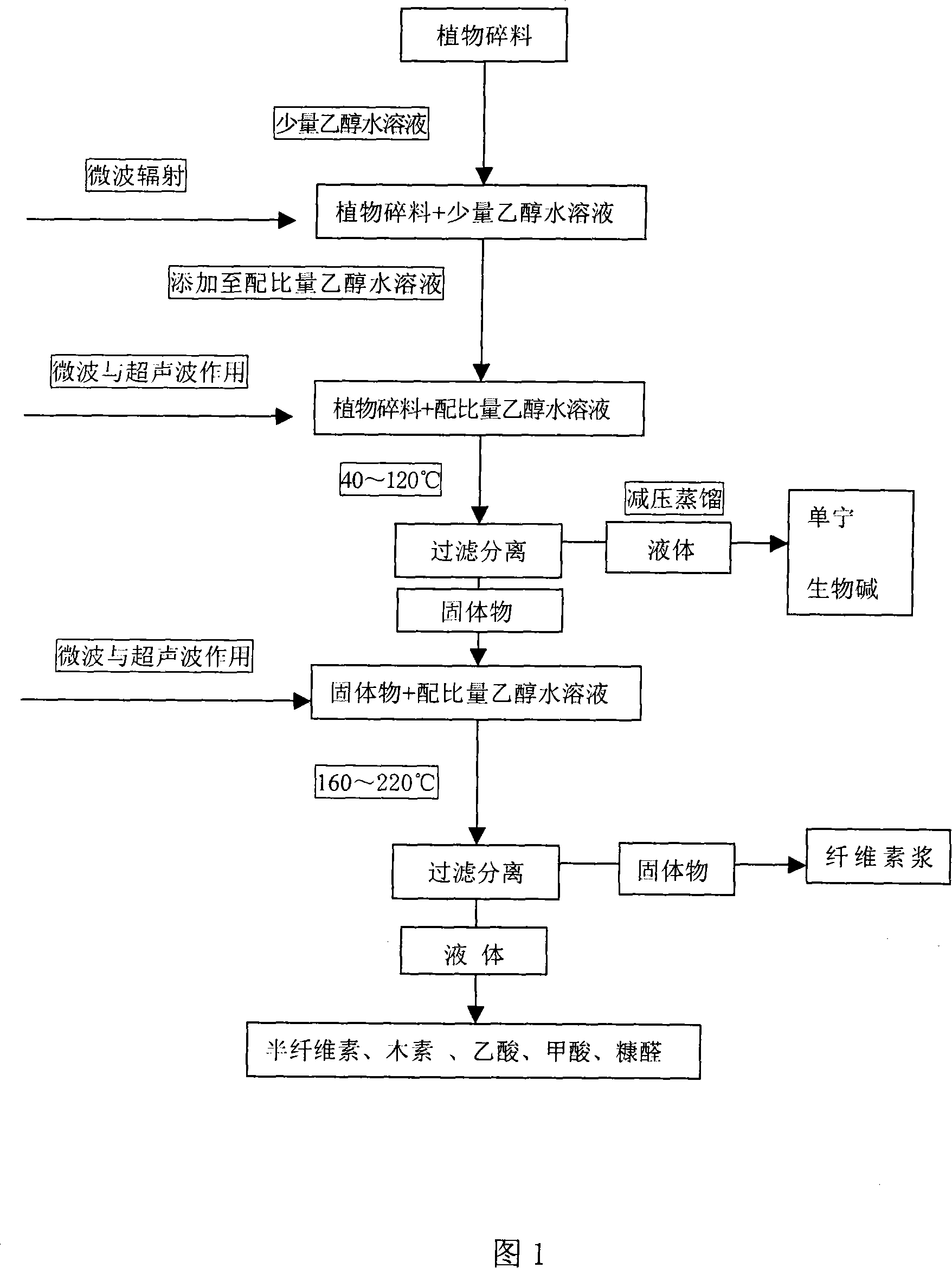

Technical method for separating organic constituent of biomass

ActiveCN101092435ATake advantage ofEasy to separateSugar derivativesLignin derivativesReaction temperatureHigh pressure

This invention discloses a method for separating biomass organic components. The method comprises: washing classified raw materials, decomposing in a high-pressure reactor under the actions of microwave and ultrasonic wave, and extracting organic components from biomass with 20-70 vol. % aqueous solution of an organic solvent. The separation process comprises: (1) extracting low-temperature-soluble organic component from biomass at 40-120 deg.C under 0.4-0.6 MPa; (2) separating cellulose pulp at 160-220 deg.C; (3) separating acetic acid, lignin and furfural from the liquid (separated by solid-liquid separation) by centrifuge and precipitation. According to different plants, the powers and frequencies of microwave and ultrasonic wave, as well as the reaction temperature and time can be adjusted. The method has such advantages as low organic molecule loss, little change, no harm of the products, high cellulose purity (higher than 95%), low lignin residue (not higher than 2%), and no environmental pollution.

Owner:贾海涛

Method for preparing porous calcium titanate heavy metal adsorbent

InactiveCN102430382AStrong acid and alkali resistanceStrong heat resistanceOther chemical processesSolid waste disposalSorbentFurfural

The invention discloses a method for preparing a porous calcium titanate heavy metal adsorbent. In the method, the porous flaky calcium titanate heavy metal adsorbent is prepared by taking solid wastes in furfural industry, namely furfural residues as a template agent by a sol-gel method. The method comprises the following steps of: crushing the dried furfural residues, adding calcium titanate sol, stirring uniformly, and drying to obtain a furfural residue-calcium titanate gel composite; and calcining at high temperature, and oxidizing and decomposing organic matters in the furfural residues and the calcium titanate gel to obtain the porous calcium titanate adsorbent. The porous calcium titanate heavy metal adsorbent is used for adsorbing and removing multiple kinds of heavy metals such as lead, cadmium, nickel, copper, zinc, silver and the like simultaneously. The furfural residues are used as the template agent, so the solid wastes are utilized, and the high adsorbability and high stability of the calcium titanate are utilized simultaneously; and the adsorbent synthesized by the method has the advantages of low cost, simple process, large adsorption capacity, wide application range, high hydrothermal stability, high acid and alkali resistance, and the like, and is convenient to regenerate and recover.

Owner:SHENYANG LIGONG UNIV

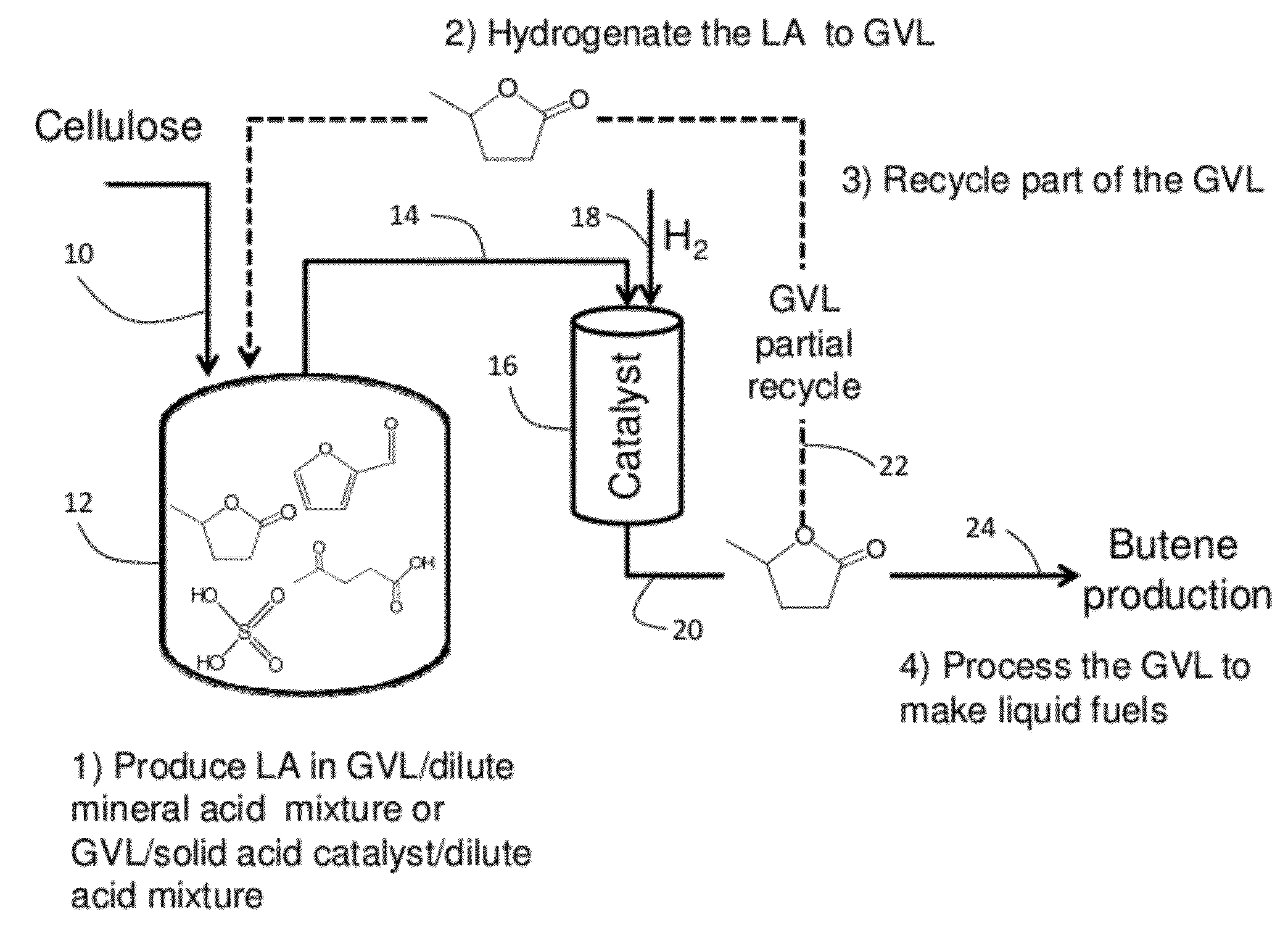

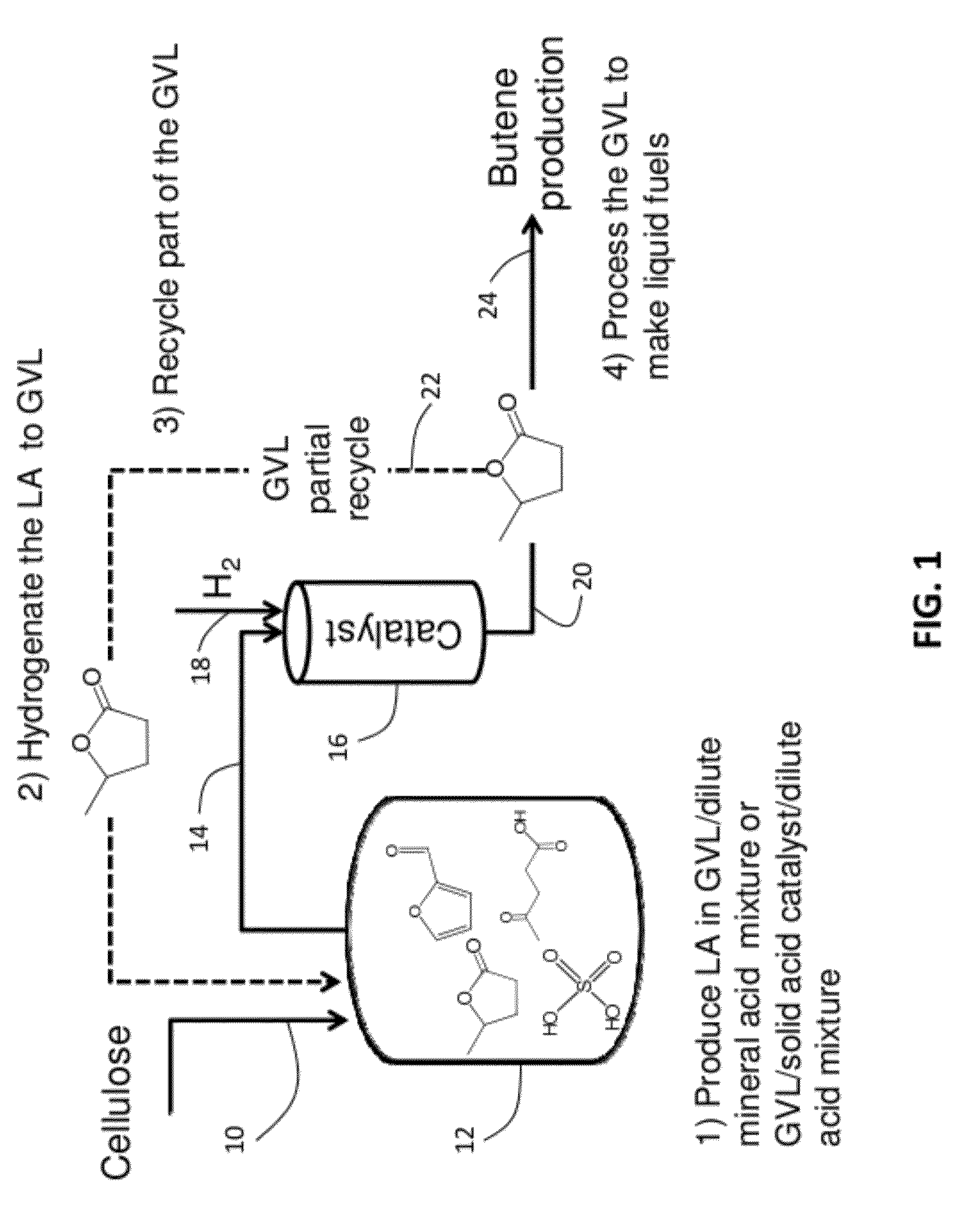

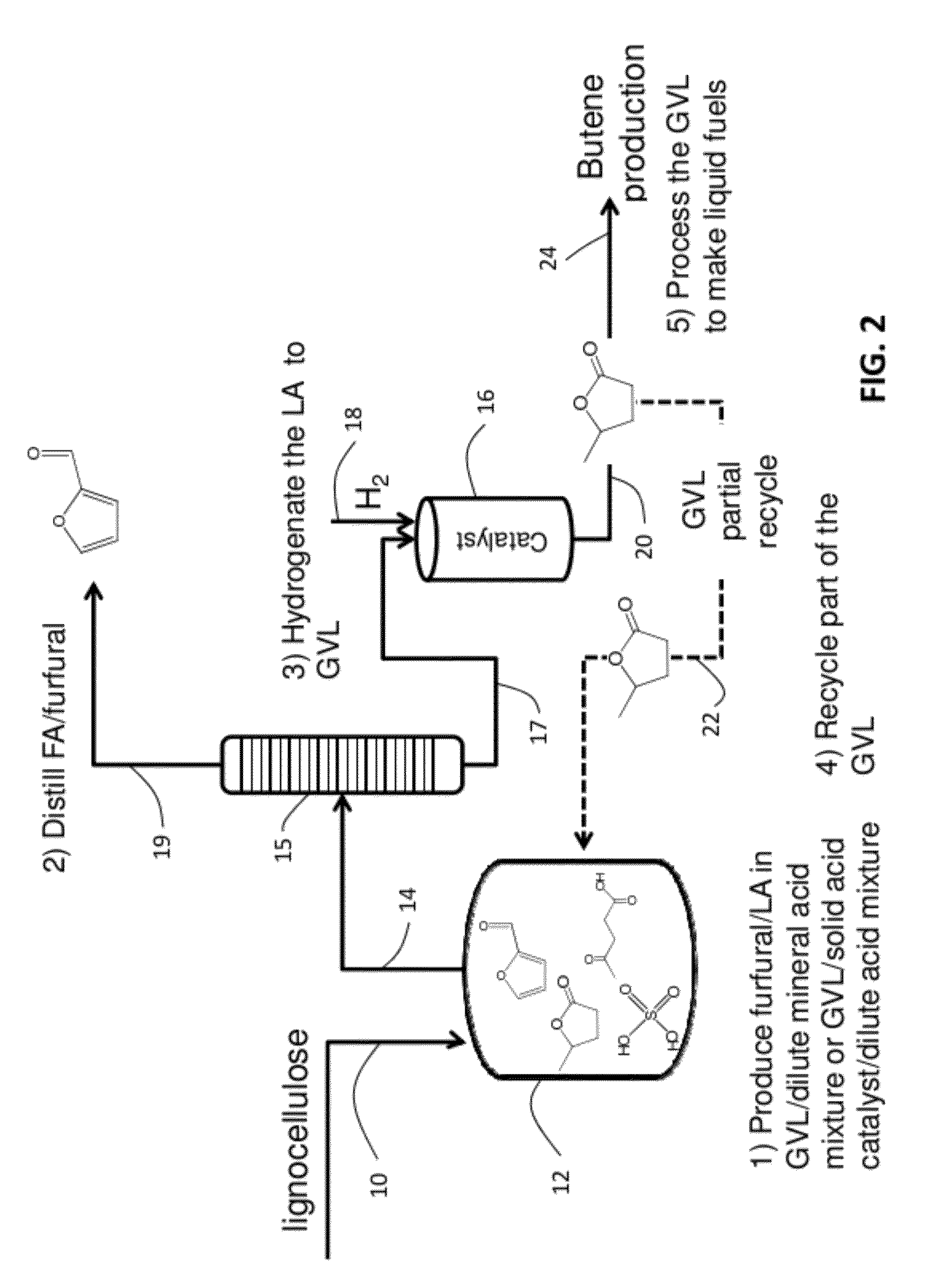

PRODUCTION OF LEVULINIC ACID, FURFURAL, AND GAMMA VALEROLACTONE FROM C5 and C6 CARBOHYDRATES IN MONO- AND BIPHASIC SYSTEMS USING GAMMA- VALEROLACTONE AS A SOLVENT

ActiveUS20120302767A1Organic compound preparationCarbonyl compound preparationCellulosePropanoic acid

A method to make levulinic acid (LA), furfural, or gamma-valerolactone (GVL). React cellulose (and / or other C6 carbohydrates) or xylose (and / or other C5 carbohydrates) or combinations thereof in a monophasic reaction medium comprising GVL and an acid; or (ii) a biphasic reaction system comprising an organic layer comprising GVL, and a substantially immiscible aqueous layer. At least a portion of the cellulose (and / or other C6 carbohydrates), if present, is converted to LA and at least a portion of the xylose (and / or other C5 carbohydrates), if present, is converted into furfural.

Owner:WISCONSIN ALUMNI RES FOUND

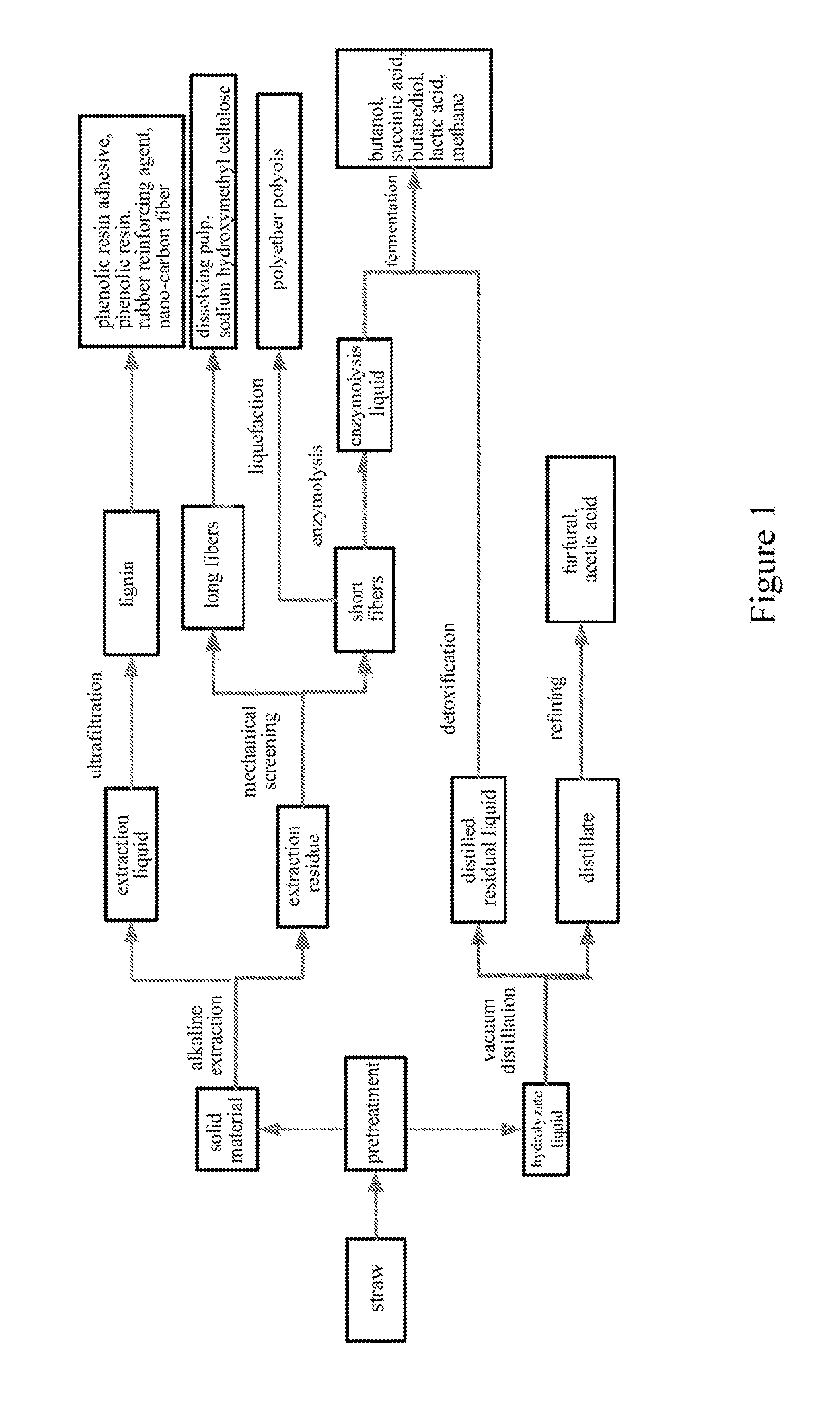

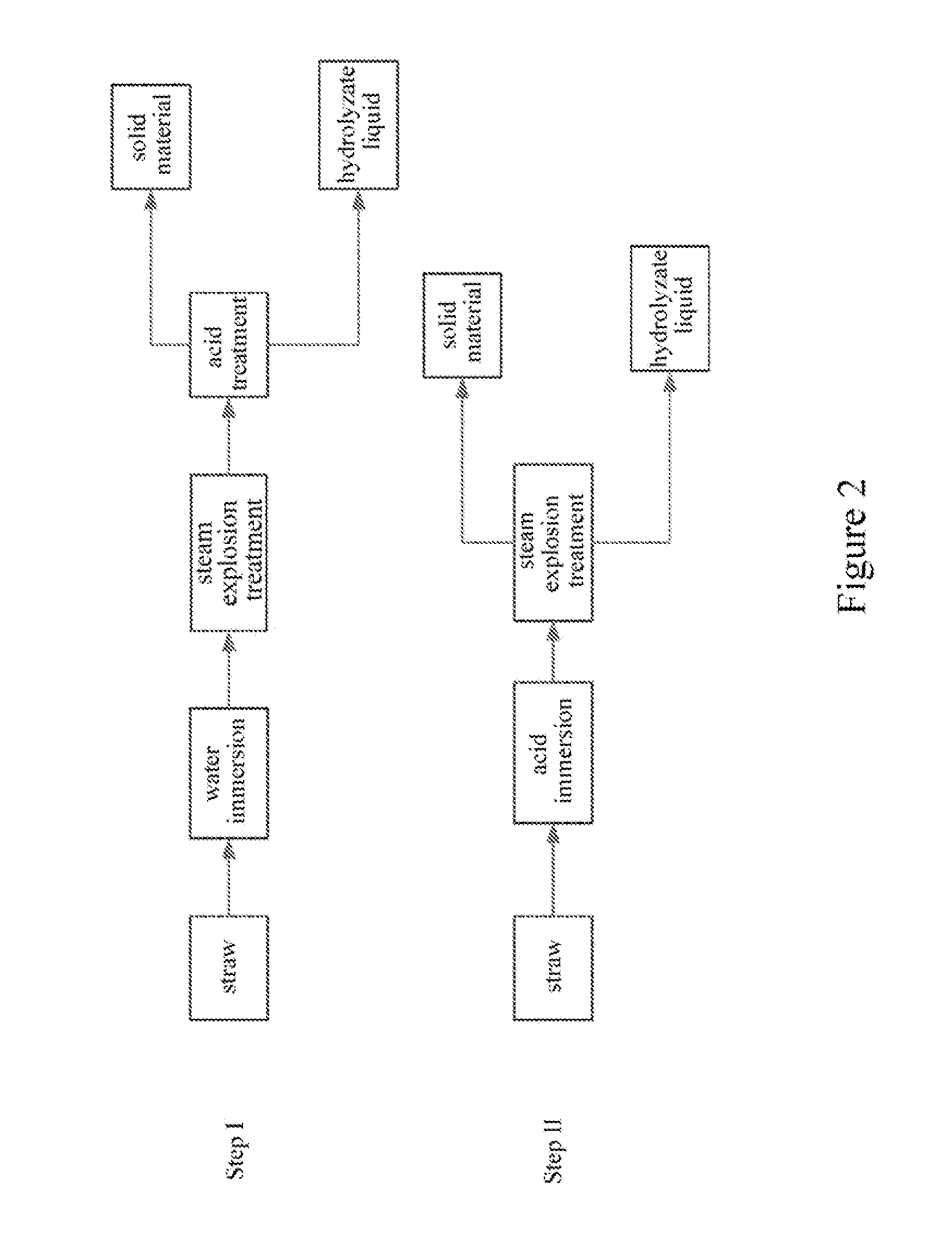

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

Saline-alkali soil improving agent, and preparation method thereof

InactiveCN106242892AImprove aggregate structureGood water permeabilityExcrement fertilisersBioloigcal waste fertilisersFiberAlkali soil

The invention discloses a saline-alkali soil improving agent, and a preparation method thereof. The preparation method comprises following steps: fermented plant fiber and fermented animal excreta are uniformly mixed and grinded so as to obtain a mixture of 80 to 100 meshes; wood vinegar and water are added, uniform mixing is carried out, and an obtained mixed material is subjected to pelletizing and drying until water content ranges from 3 to 8%, wherein the adding amount of water accounts for 5 to 30% of the total weight amount of the mixture; an obtained product is sieved so as to obtain a granular mixture with a particle size ranging from 3 to 5mm; the granular mixture is subjected to drying and cooling, and a microorganism agent is sprayed onto the surface of the granular mixture; and an obtained semifinished product is uniformly mixed with a mixture A and a mixture B so as to obtain a finished product, wherein the mixture A is obtained via uniform mixing and grinding of ground phosphate rock, vermiculite, medical stone, sodium alginate, and polyacrylamide to 120 to 200 meshes, and the mixture B is obtained via uniform mixing and grinding of humic acid and furfural residue to 80 to 100 meshes. The saline-alkali soil improving agent is capable of reducing soil alkalinity, activating soil, reducing salinity and alkalinity effectively, improving saline-alkali soil structure, improving soil fertilizer conservation and water-holding capacity, improving saline-alkali soil physical and chemical properties, and realizing positive cycling of saline-alkali soil.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

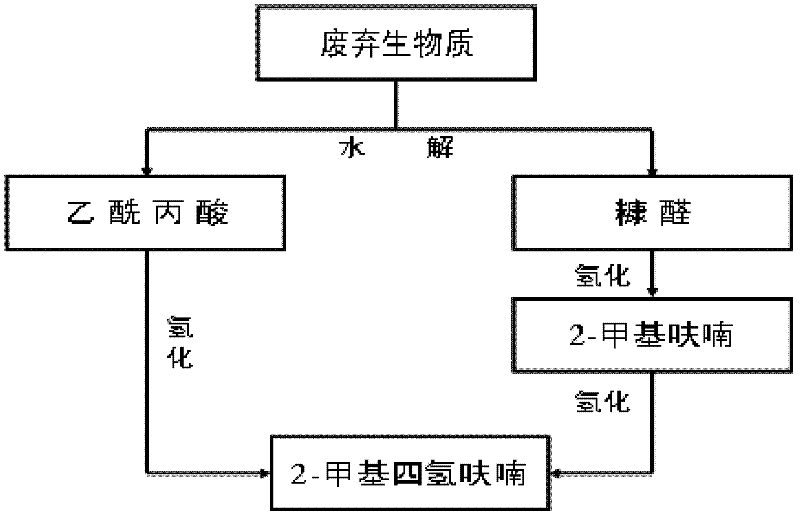

Method for preparing 2-methyltetrahydrofuran from waste biomass

ActiveCN102558106AReduce pollutionReduce manufacturing costOrganic chemistryLevulinic acidPropanoic acid

The invention discloses a method for preparing 2-methyltetrahydrofuran from waste biomass, which comprises the following steps: carrying out acid hydrolysis reaction on the waste biomass to obtain furfural and levulinic acid; sequentially carrying out first hydrogenation reaction and second hydrogenation reaction on the furfural to obtain the 2-methyltetrahydrofuran; and carrying out hydrogenation reaction on the levulinic acid to obtain the 2-methyltetrahydrofuran. The method provided by the invention more sufficiently utilizes the waste biomass, and adopts non-noble metal catalysts, thereby lowering the production cost.

Owner:北京雷恩新材料科技有限公司

Special organic microbial bacterial manure for garlic and preparation method thereof

ActiveCN104016807ABalanced nutritionMeet the nutritional requirements for growthFertilizer mixturesEcological environmentMicrobial agent

The invention belongs to the technical field of manure, and in particular relates to special organic microbial bacterial manure for garlic and a production method for the special organic microbial bacterial manure for garlic. The special organic microbial bacterial manure for garlic comprises the following components: furfural residue, mushroom bran, composite microbial agent, ammonium hydrogen carbonate, calcium superphosphate, potassium chloride, zinc sulfate, plant ash, potassium sulfate, animal manure, potassium humate, rice hull powder and rape seed cakes. The special organic microbial bacterial manure for garlic, prepared by adopting the method disclosed by the invention, contains a large amount of nutrients required for the growth of garlic and various trace elements and amino acids, and has the effects of efficiently, synergistically and enduringly improving soil, improving the fertility, resisting diseases and the like; in addition, soil probiotic floras are added into organic matters, so that the nutrients can be better absorbed and utilized, and the micro-ecological environment of the soil can be continually repaired. Through testing, the special organic microbial bacterial manure for garlic, disclosed by the invention, can be used for effectively improving the yield of garlic by 20-30%.

Owner:QILU UNIV OF TECH

Methods for isolating and harvesting lignin and isolated lignin preparations produced using the methods

InactiveUS8053566B2Great potentialTotal calories lowLignin derivativesPulp by-products recoveryElastomerFiber

Owner:VERTICHEM CORP

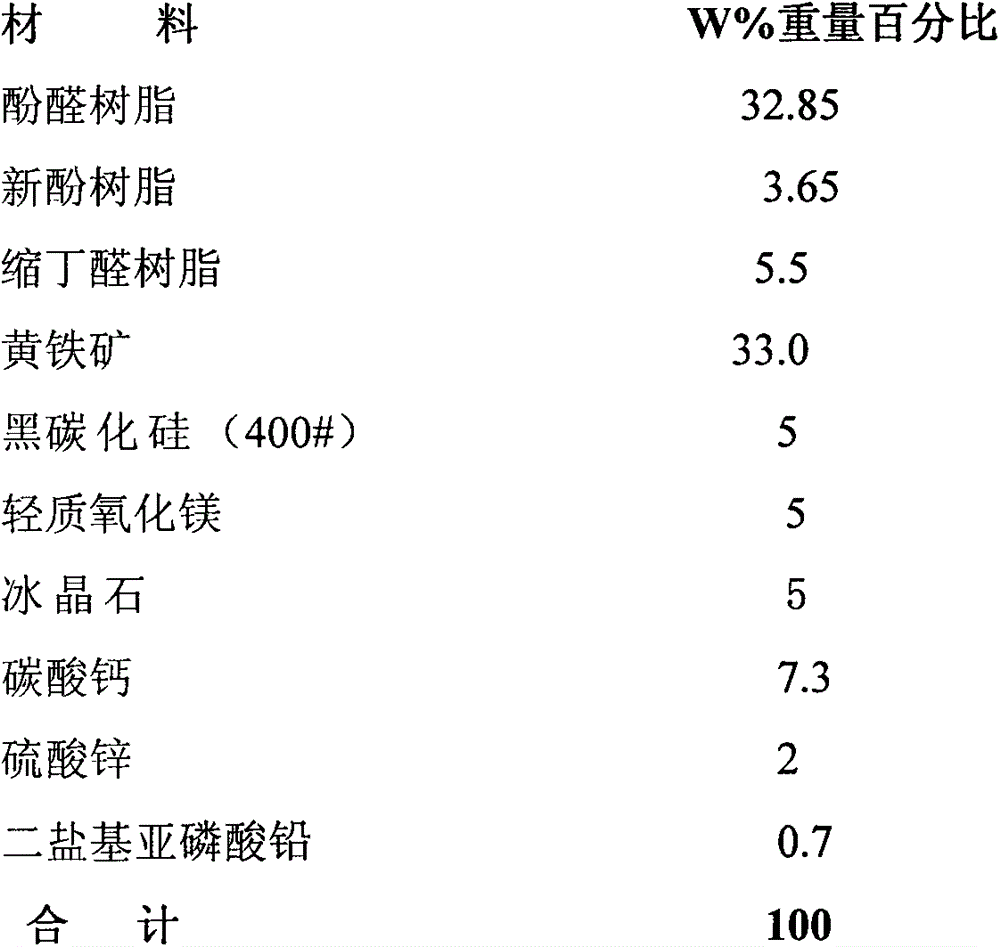

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com