Technical method for separating organic constituent of biomass

A process method and biomass technology, applied in the direction of sugar derivatives, sugar derivatives, organic chemistry, etc., can solve the problems of poor utilization of urban plant waste, waste of organic components, large pollution, etc., and achieve good adjustable Effects of controllability, improvement of response speed, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

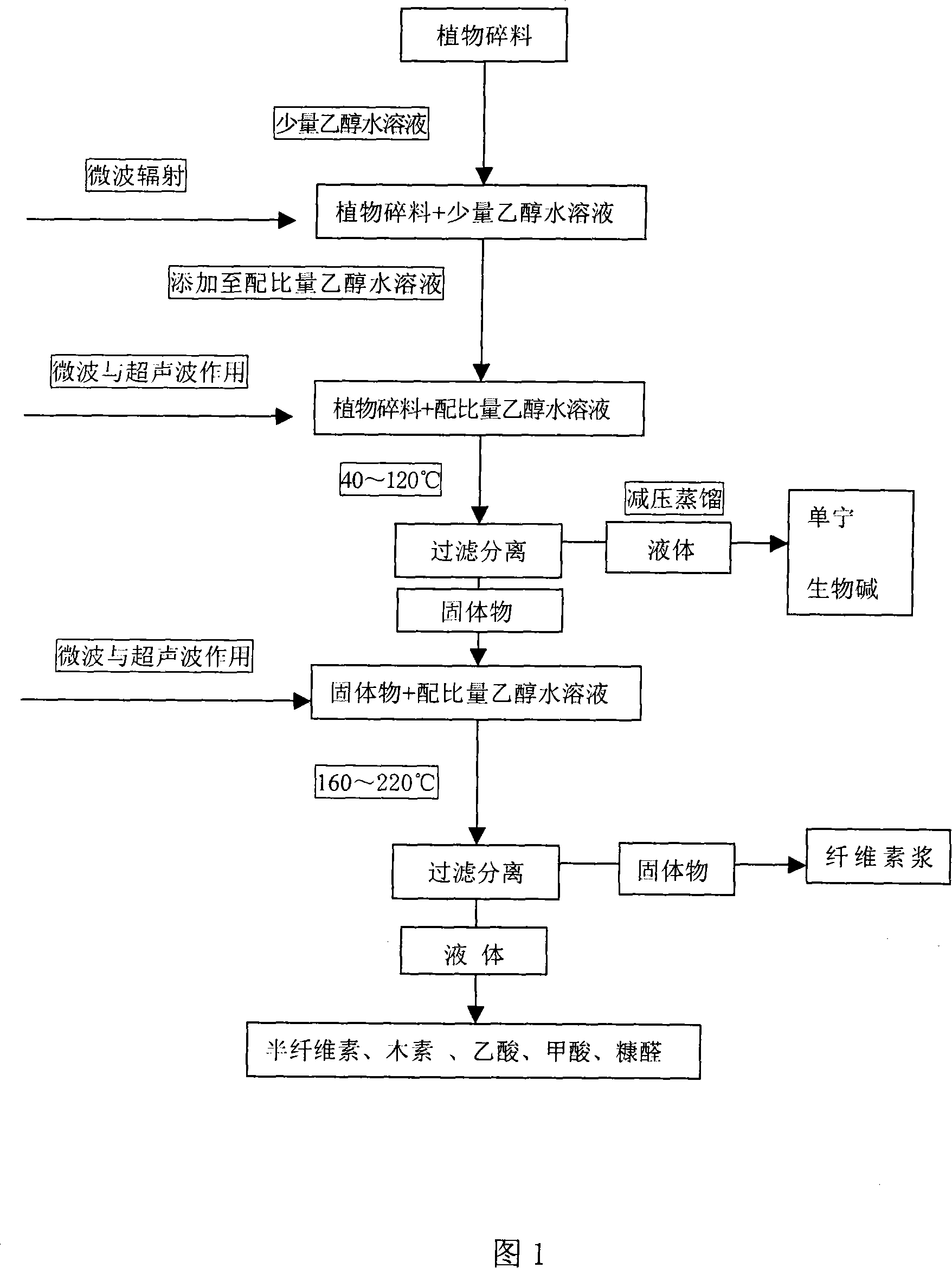

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (taking Cizhu as raw material)

[0027] Wash and chop Cizhu into bamboo pieces of about 1cm×1cm, fully dry, and evaporate the water remaining on the plants after cleaning; take 500g, put it into a high-pressure reaction kettle, and add ethanol with a concentration of 500% by volume 0.5L aqueous solution, make it wet, under normal pressure, use 2450MHz, 750W microwave, heat for 5min; then add 1L of 50vol% ethanol aqueous solution, keep at 60℃ under 0.5MPa pressure, and then use 50KHz, 300W ultrasonic wave and 2450MHz, 750W microwave for 10min at the same time. After the treatment stops, the solid-liquid separation is carried out through a filter screen. The liquid separated from the solid-liquid is an ethanol aqueous solution containing extract components. The liquid is distilled under reduced pressure at 55°C and the pressure is 7KPa. After volatilizing water and ethanol, 26g is obtained. The jelly, the main component is a mixture of tannins and alkaloids,...

Embodiment 2

[0028] Embodiment 2 (with wood as raw material)

[0029] Wash the pine wood and chop it into about 0.5cm×0.5cm×0.5cm, fully dry it, evaporate the water remaining on the plant after cleaning; take 500g, put it into the autoclave, add the concentration of 50% by volume 0.5L ethanol aqueous solution, make it infiltrated, under normal pressure, use 2450MHz, 750W microwave, heat for 10min; then add 1L ethanol aqueous solution with a concentration of 50% by volume, keep it at 80°C under 0.5MPa pressure, and then use 50KHz / 800W ultrasonic wave Work together with 2450MHz / 750W microwave, and treat at the same time for 10 minutes. After the treatment stops, the solid-liquid separation is carried out through the filter screen. The liquid separated from the solid-liquid is ethanol aqueous solution containing the extracted components. The liquid is at 55°C and the pressure is 7KPa. Distilled under reduced pressure, after volatilizing water and ethanol, 75g of jelly was obtained, the main c...

Embodiment 3

[0030] Embodiment 3 (with corn stalk as raw material)

[0031] Wash the corn stalks and chop them into about 2cm×2cm, fully dry, take 500g, put it into a high-pressure reaction kettle, add 0.5L of ethanol aqueous solution with a concentration of 50% by volume to make it infiltrate, under normal pressure, use 2450MHz microwave 750W, heat for 5min; then add 1L of ethanol aqueous solution with a concentration of 50% by volume, keep it at 60°C under 0.5MPa pressure, and then use 50KHz, 500W ultrasonic wave and 2450MHz / 750W microwave together to treat for 5min at the same time. After the treatment stops, pass The filter screen is used for solid-liquid separation, and the liquid separated from the solid-liquid is ethanol aqueous solution containing the extracted components. The liquid is distilled under reduced pressure at 55°C and the pressure is 7KPa. After volatilizing water and ethanol, 20g of jelly is obtained. The ingredients are mixtures of tannins, alkaloids, etc., which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com