Patents

Literature

9102 results about "Oil supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ability to supply oil for world demand affects the ultimate price of the product. The world's supply of oil centers around the capacity of reserves. Reflected as the available supply, oil reserves are most often expressed in terms of "proven reserves.".

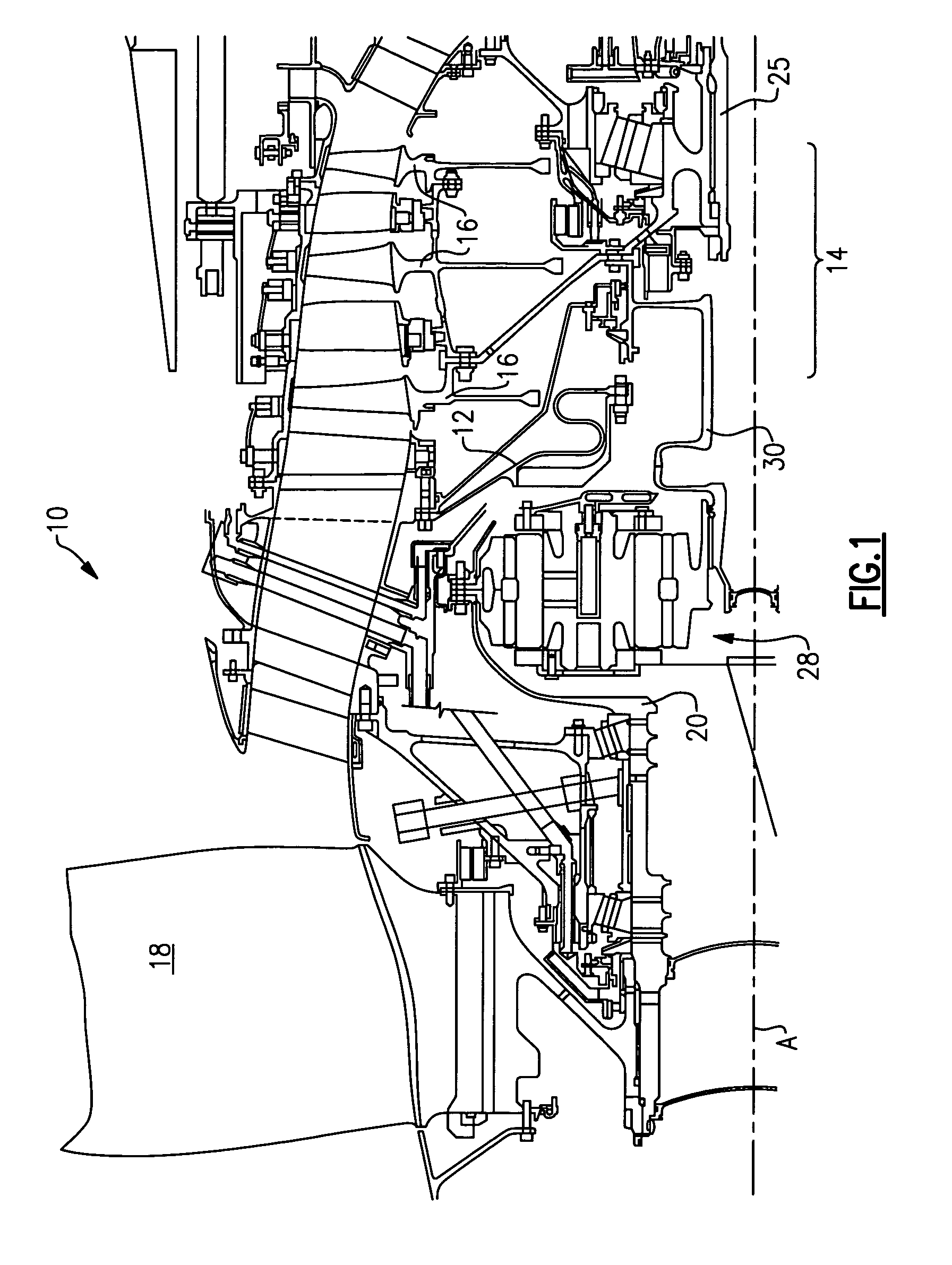

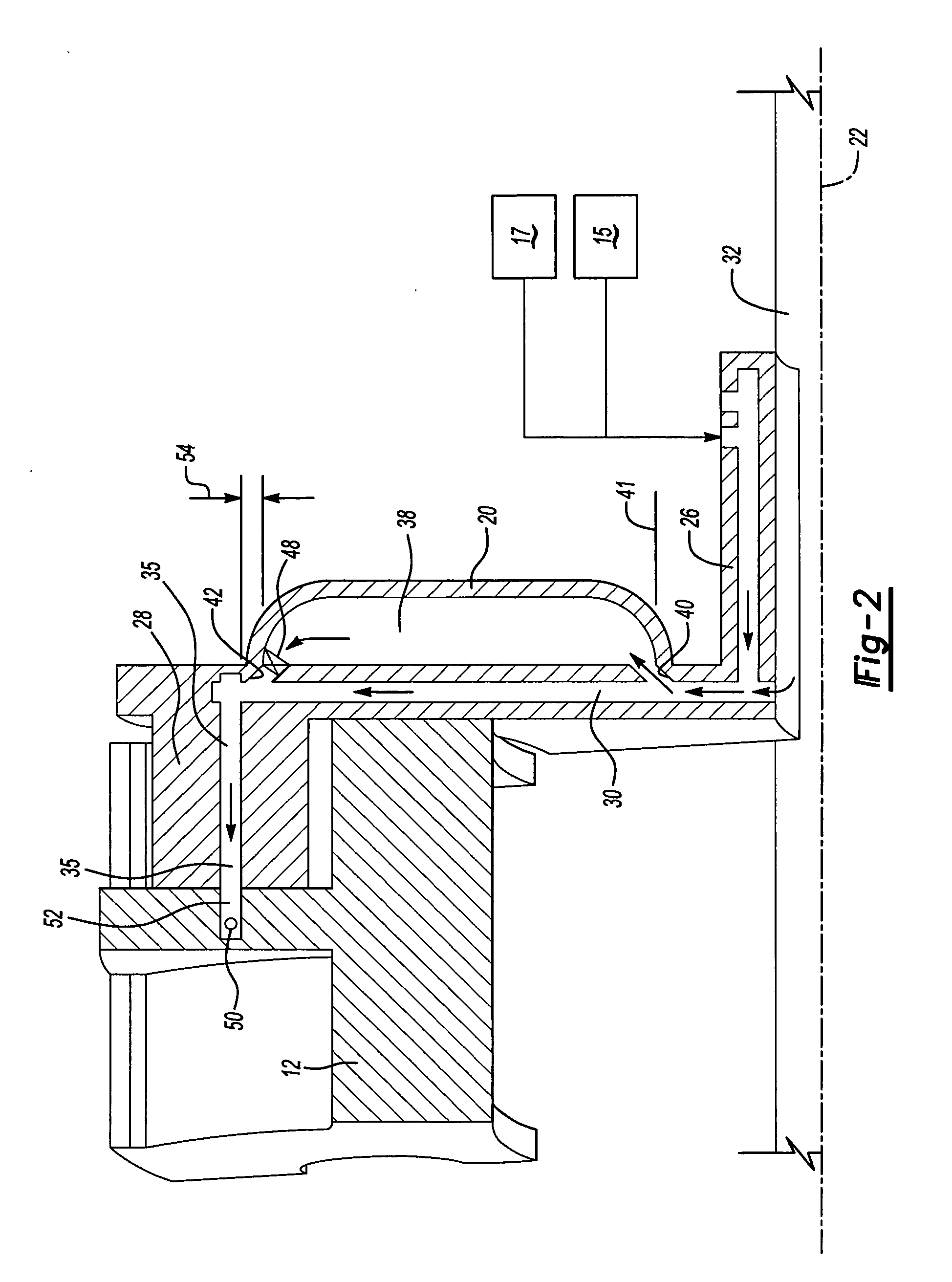

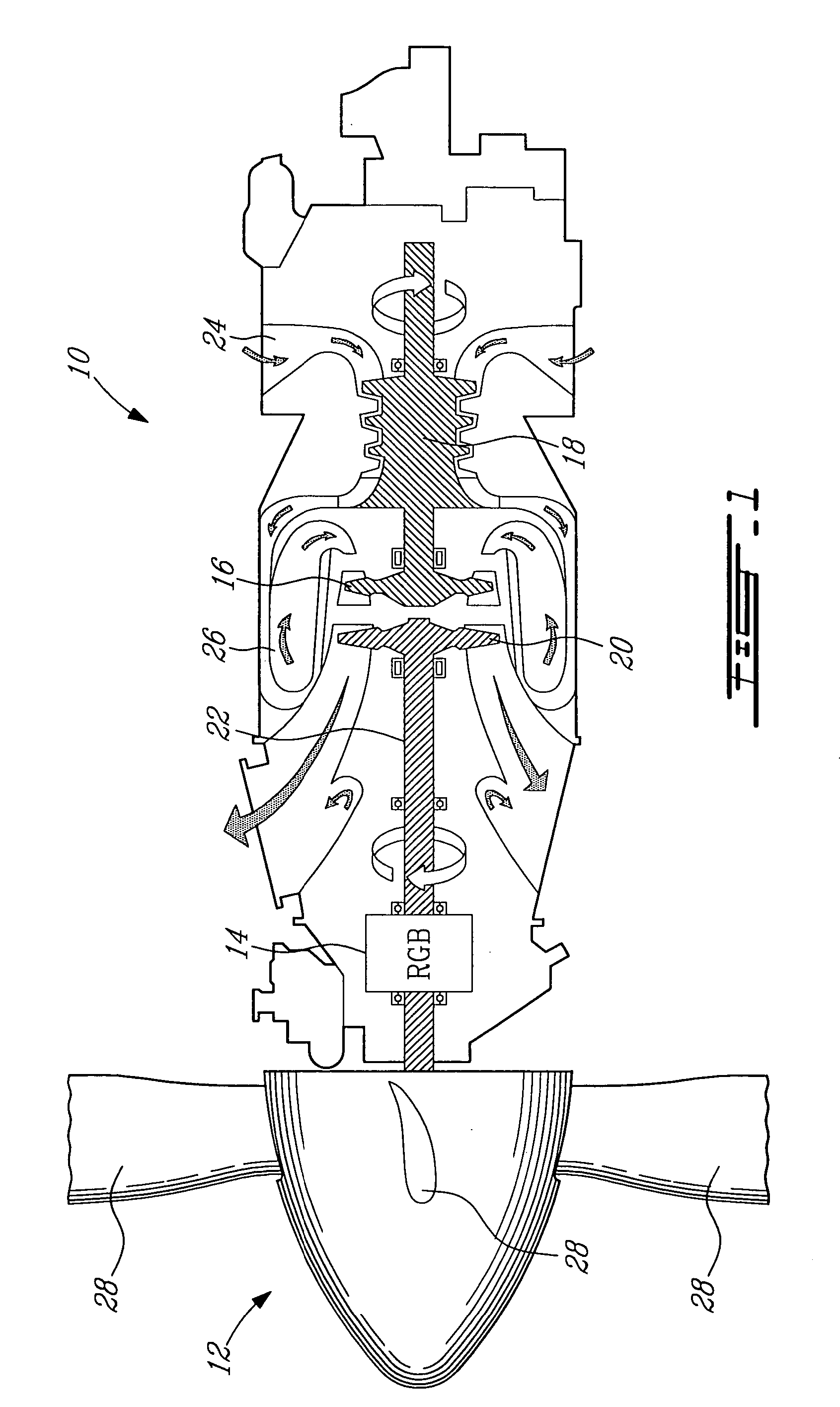

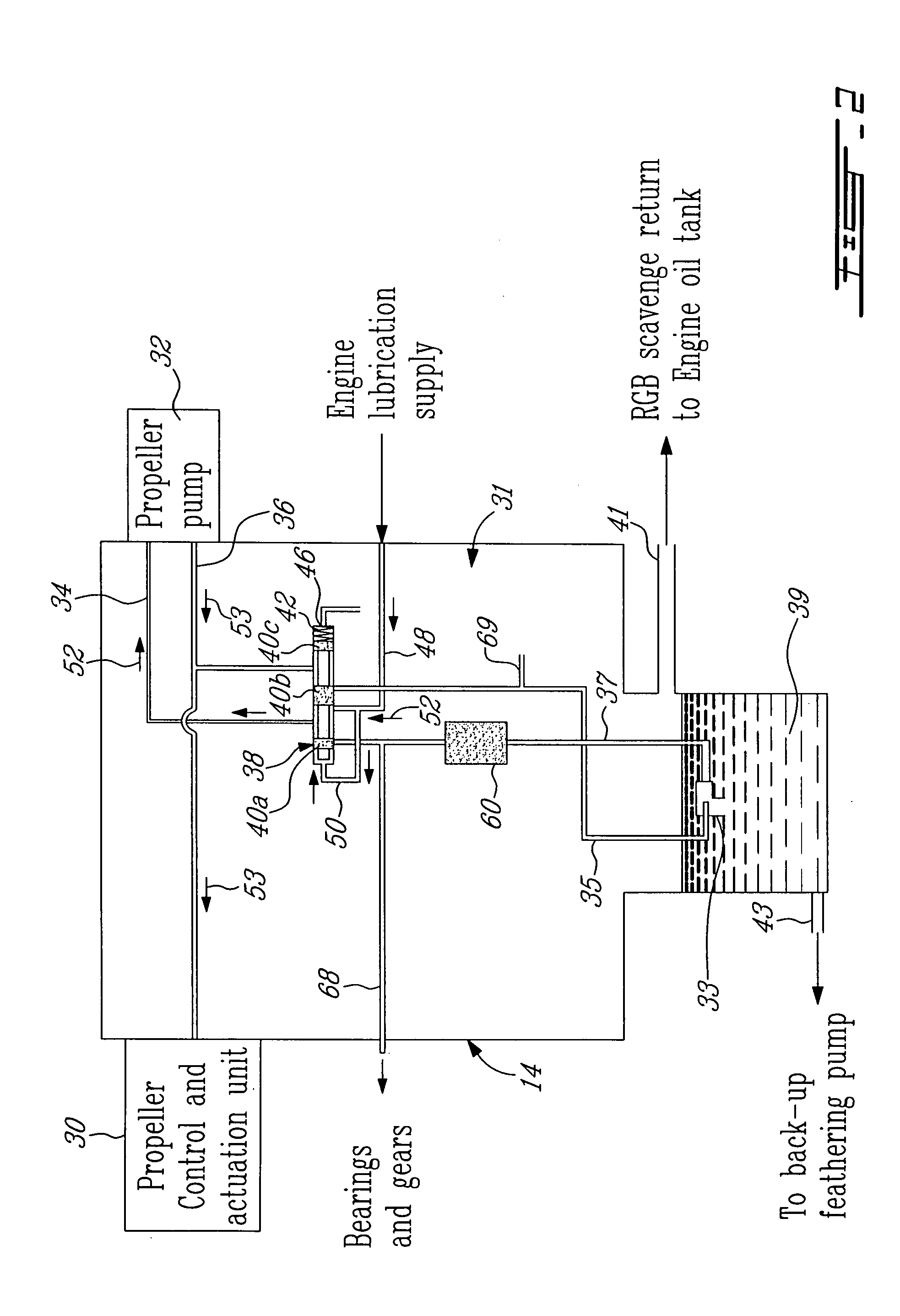

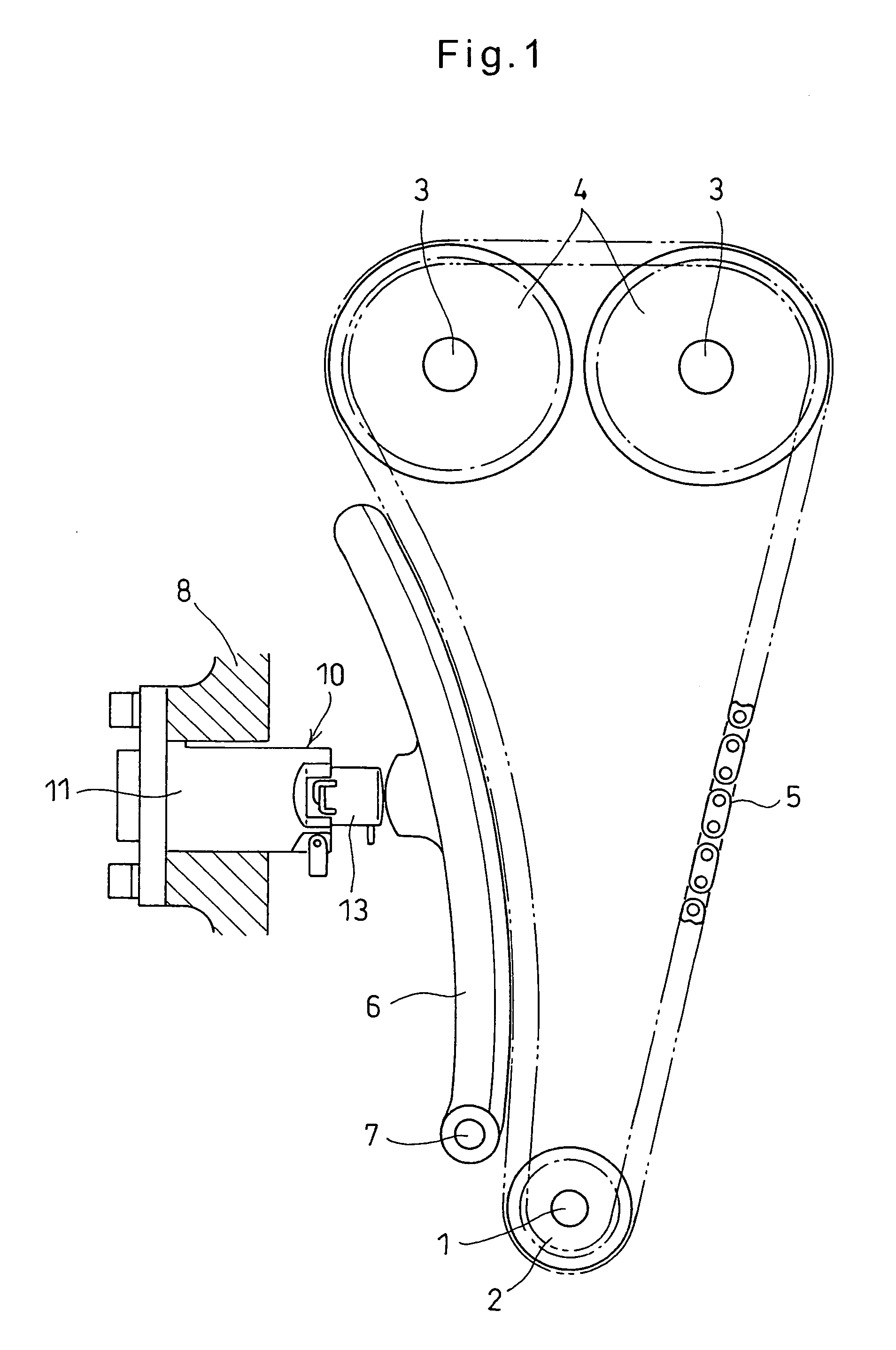

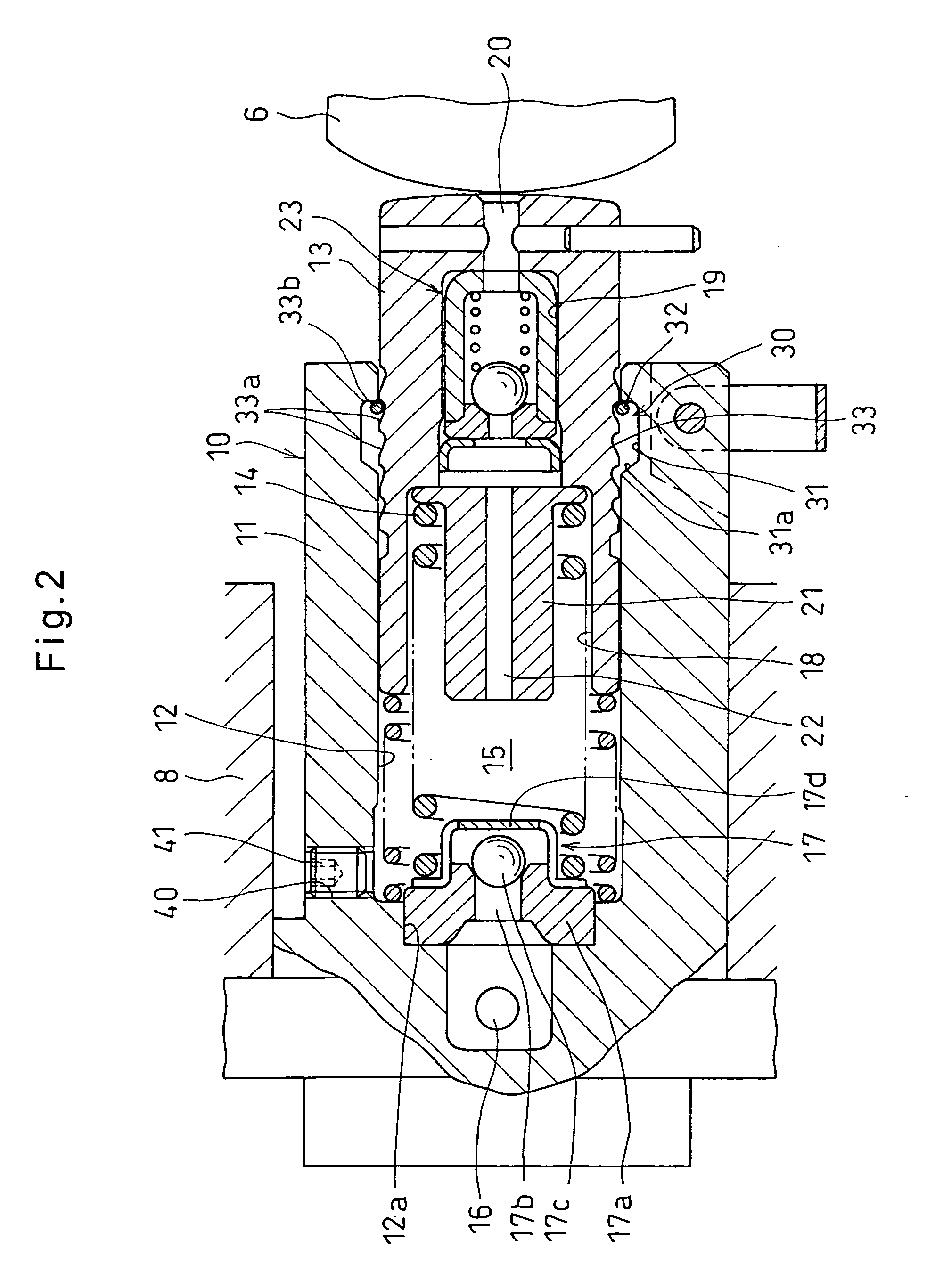

Lubrication of windmilling journal bearings

A support shaft provides lubrication to a journal bearing during windmilling operation of a gear set. A primary oil pump provides oil from an oil supply during driven operation of the fan, and a secondary oil pump provides oil from an internal sump during windmilling operation of the fan. During driven operation of the fan, oil is pumped with the primary oil pump through a primary oil flow path to an outer surface of the support shaft. During windmilling fan operation, oil is pumped from an internal sump with a secondary oil pump through the secondary oil flow path. The secondary oil flow path has a smaller flow capacity, and the secondary oil pump is a smaller capacity pump.

Owner:RTX CORP

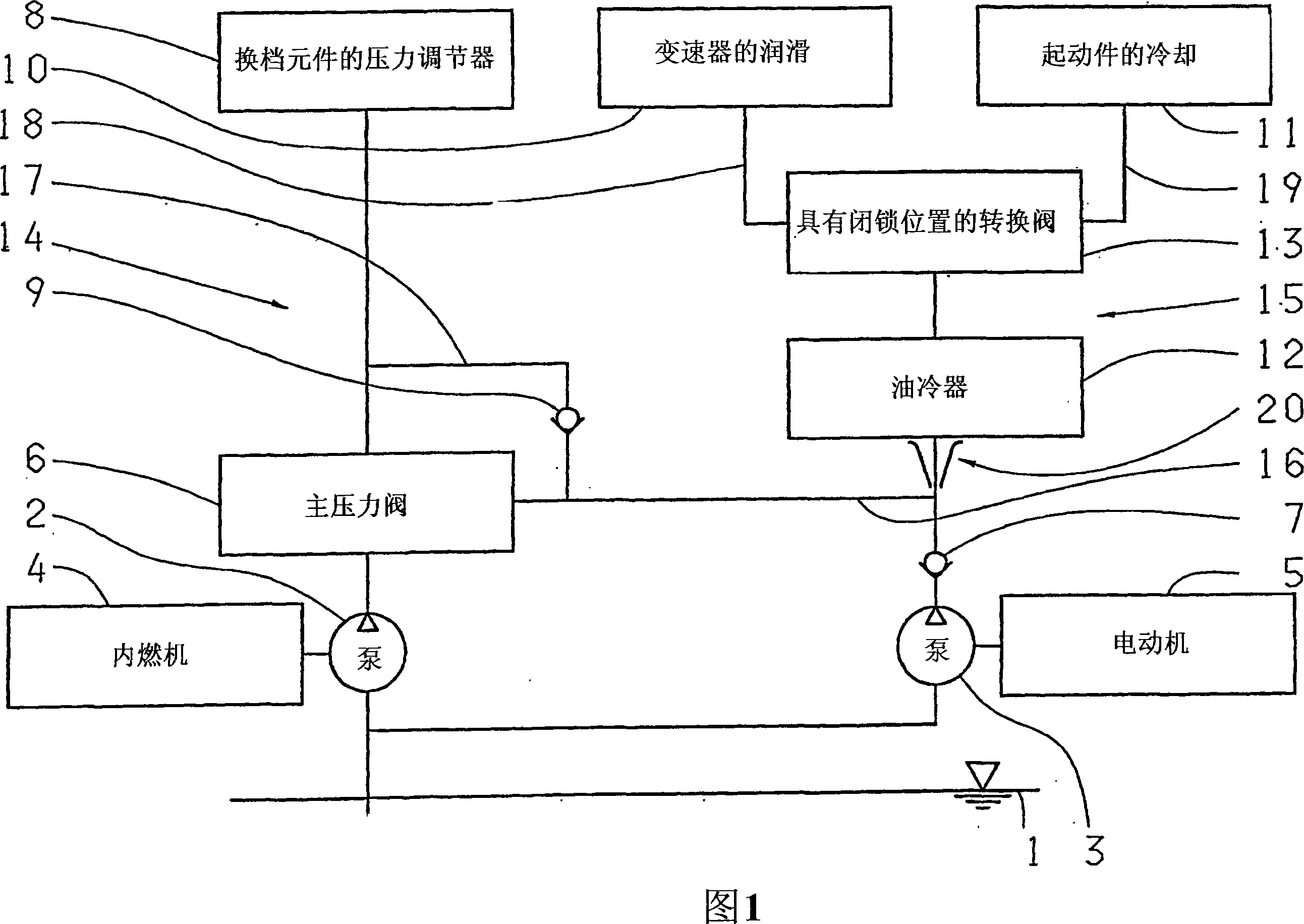

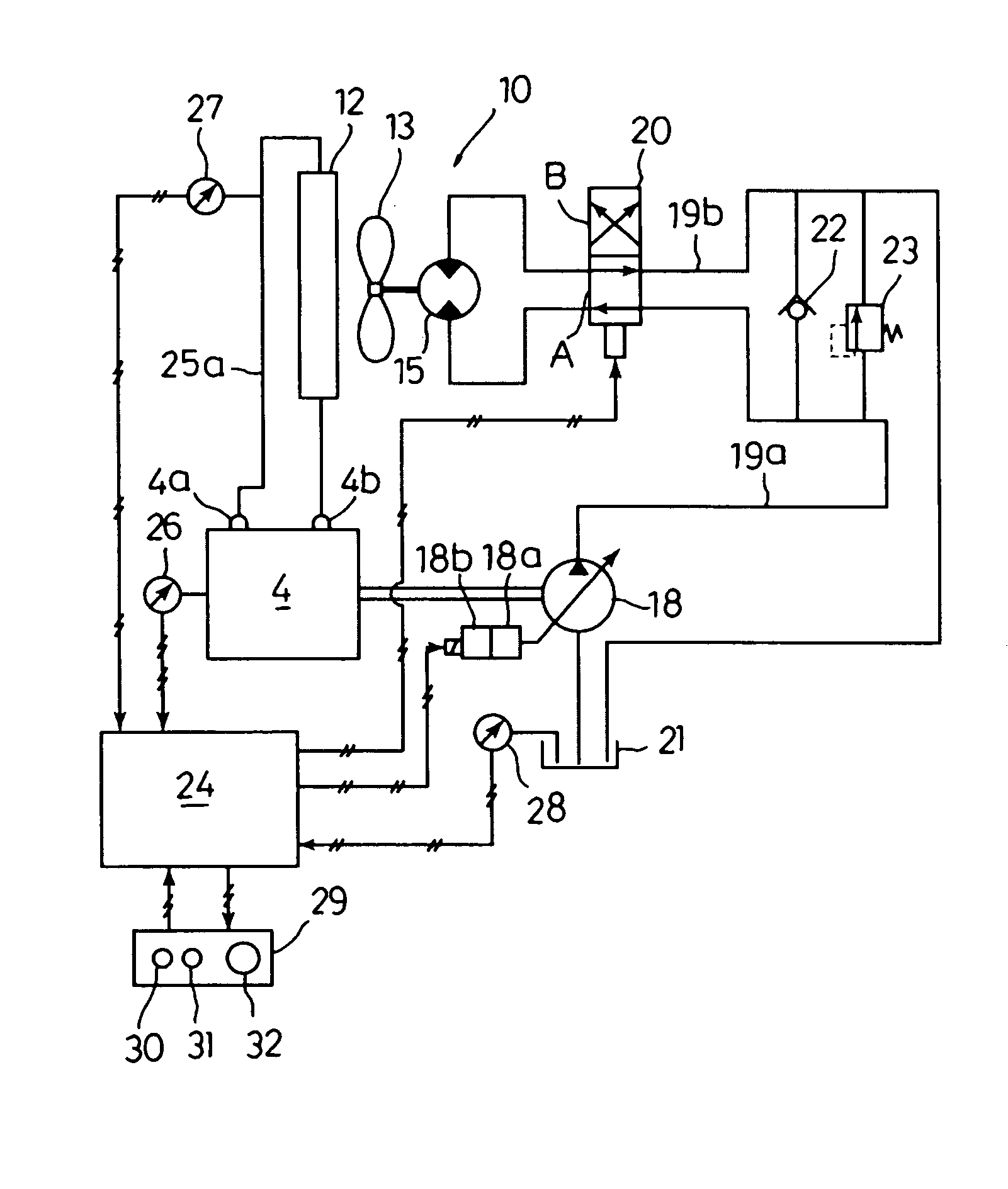

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveCN101147014AAvoid emissionsSave fuelGear lubrication/coolingGearing controlHydraulic control unitAutomatic transmission

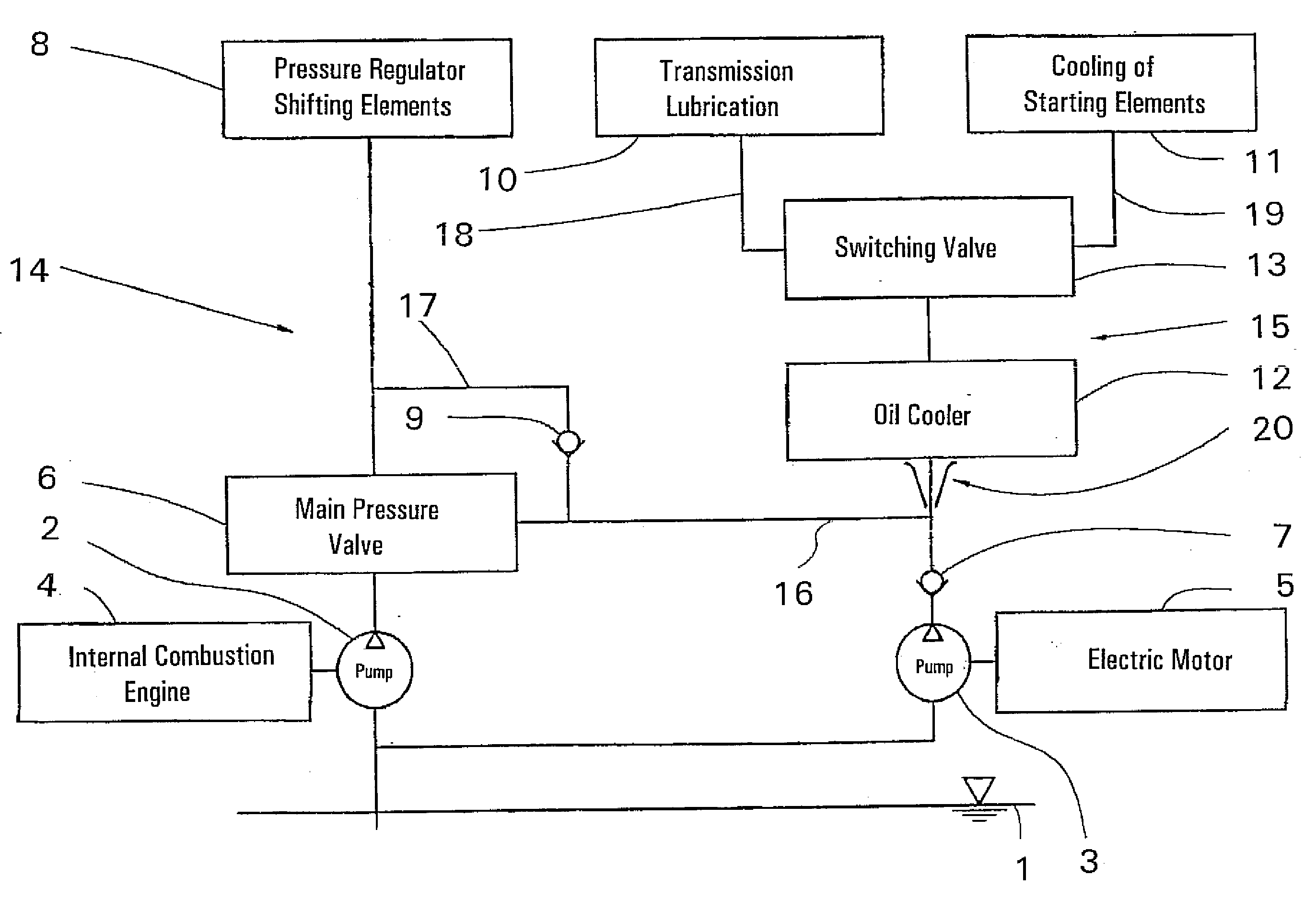

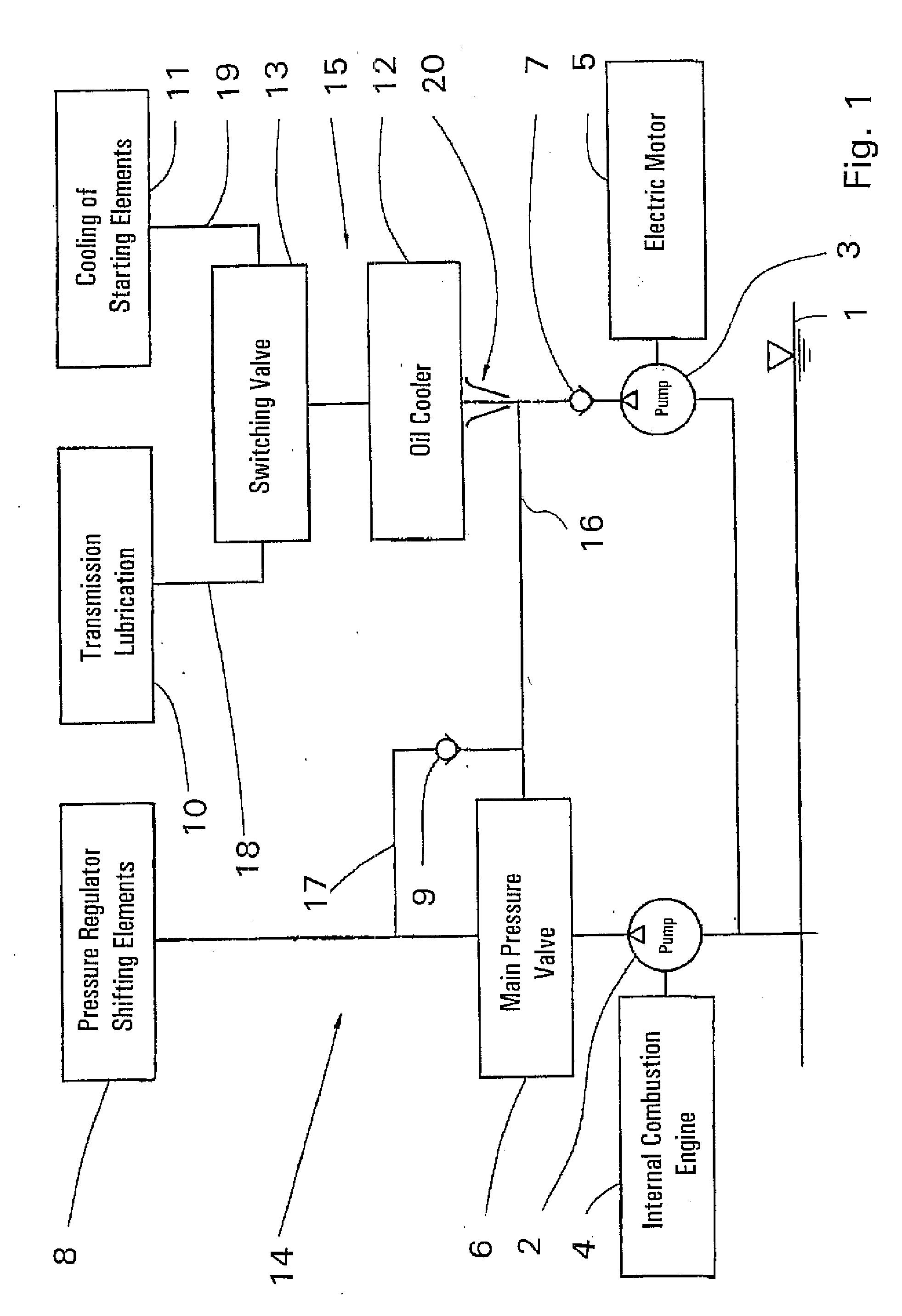

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveUS20090232673A1Avoiding substantial energy lossIncrease productionLiquid coolingGear lubrication/coolingHydraulic control unitElectricity

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

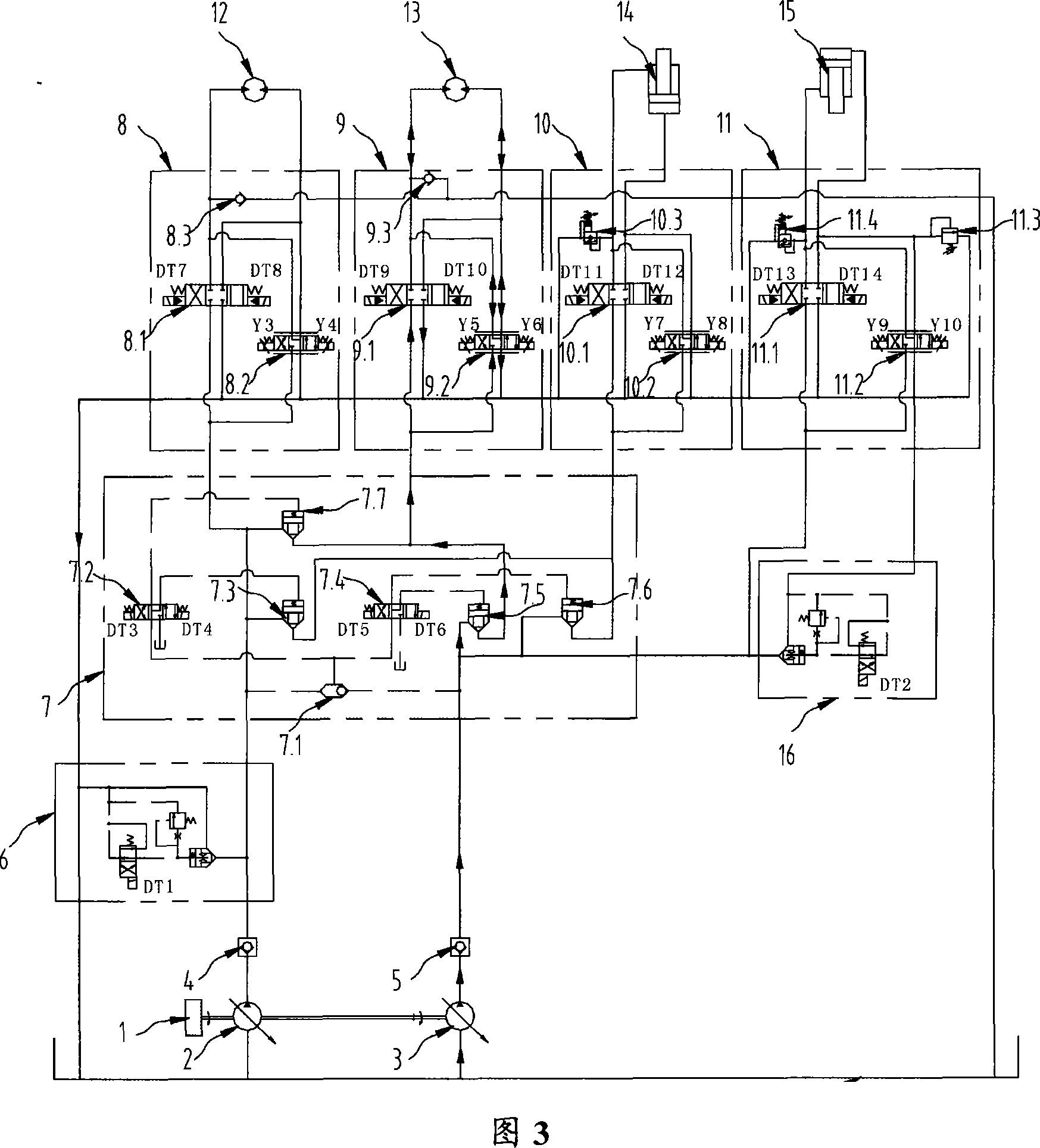

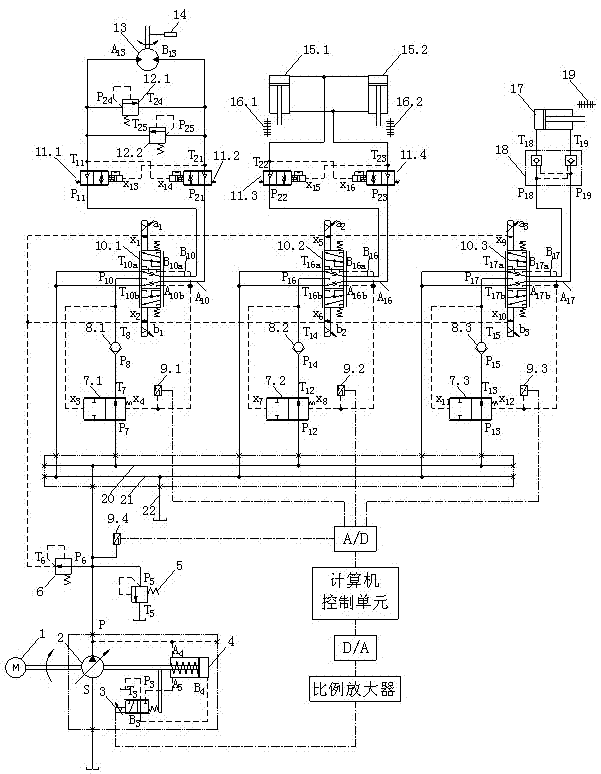

Hydraulic oil distribution controlling device for crane hydraulic system

InactiveCN101229902AHigh speedImprove work efficiencyServomotor componentsLoad-engaging elementsDistribution controlOil distribution

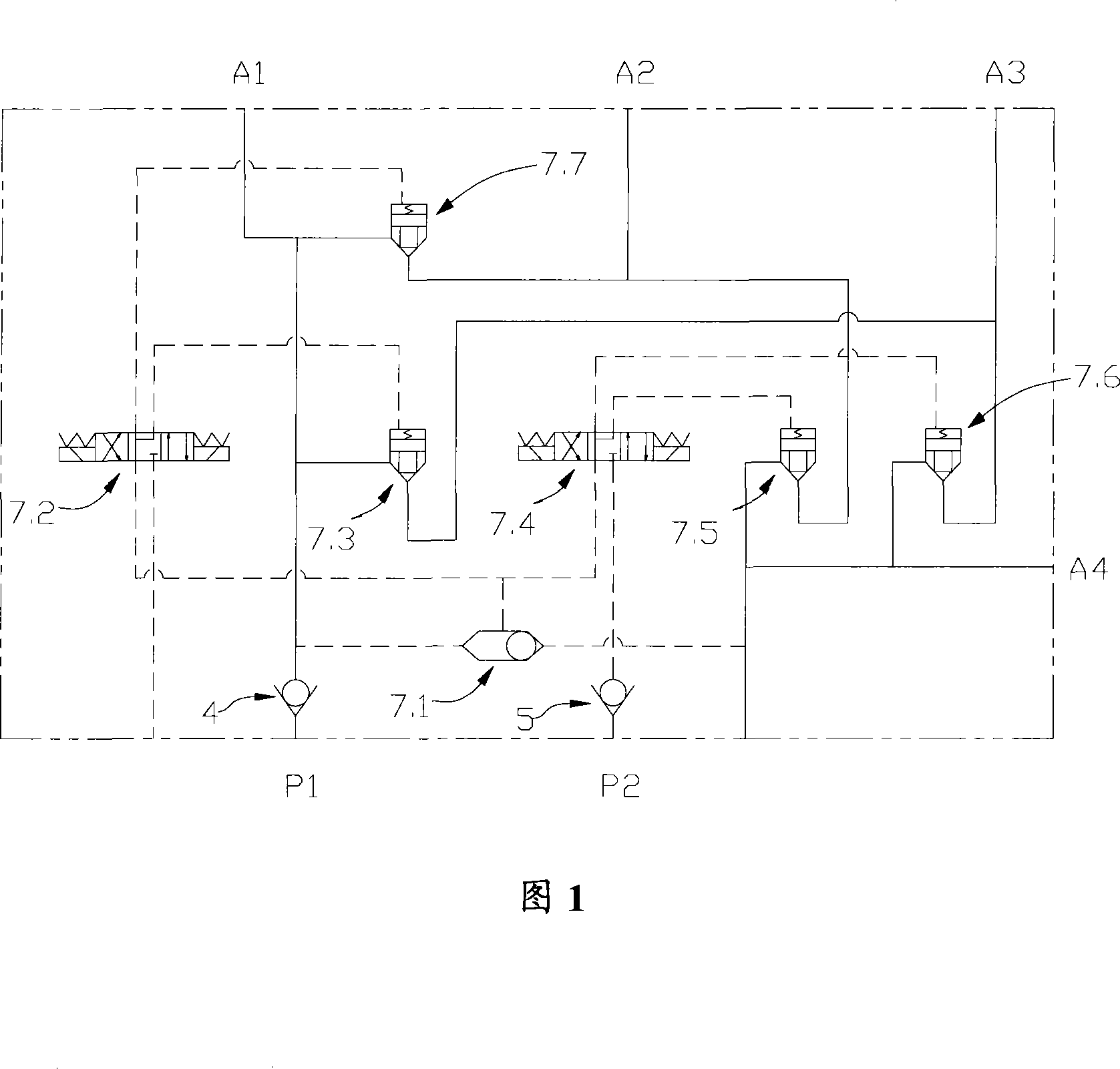

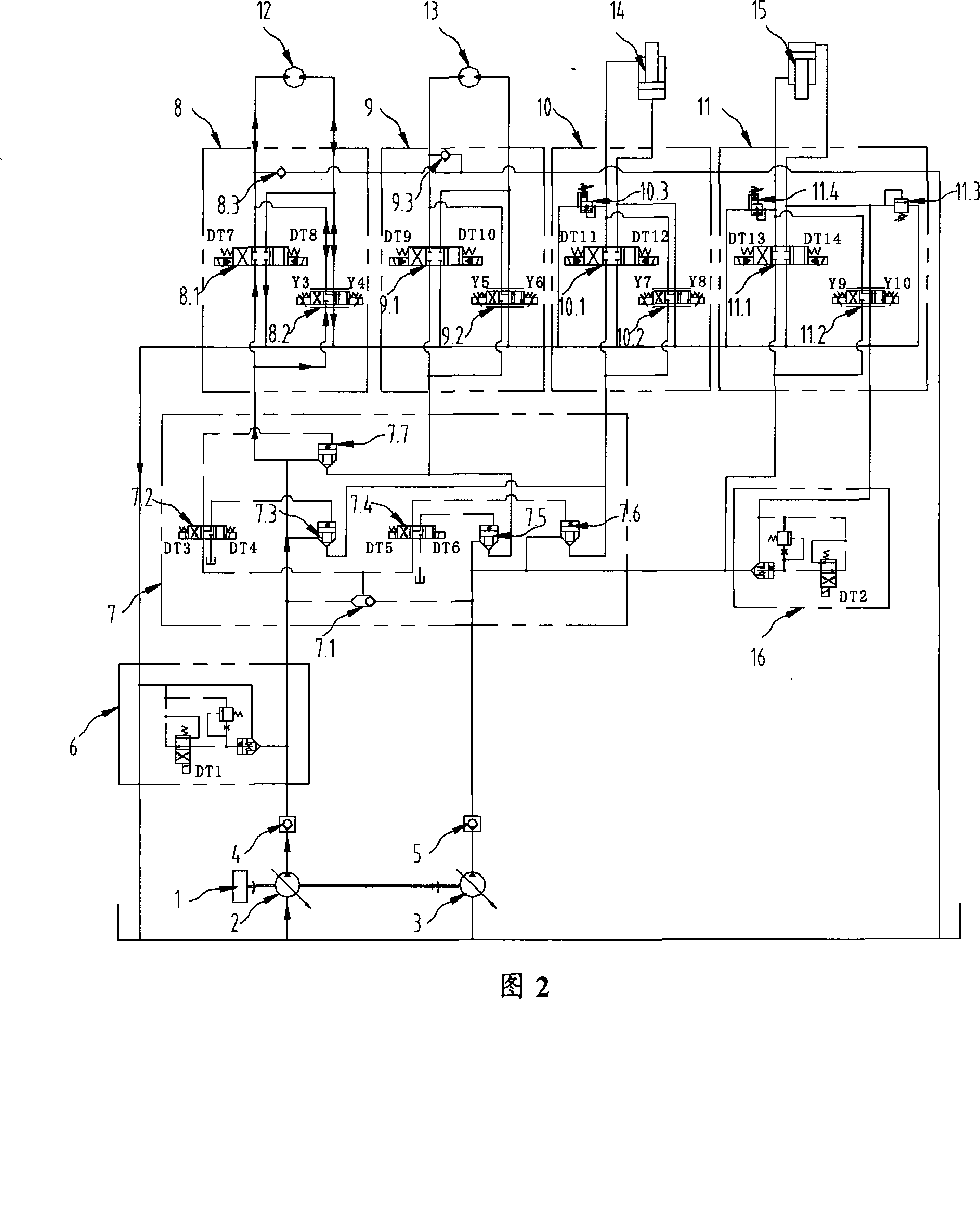

The invention relates to a hydraulic oil distributing and controlling device of a crane hydraulic system, which consists of a first oil inlet and a second oil inlet which are used for communicating with at least two duplex pumps, a first oil outlet and a second oil outlet which are used for supplying oil for a main hoisting motor and an auxiliary hoisting motor as well as a third oil outlet and a fourth oil outlet which are used for supplying oil for a derricking cylinder and a telescopic cylinder; the first oil inlet and the second oil inlet are communicated with the four oil outlets through an oil circuit; control valves are arranged at least on the communicating oil circuits of the first oil inlet and the second oil outlet as well as the third oil outlet and the fourth oil outlet; the control valves are arranged at least on the communicating oil circuits of the second oil inlet and the first oil outlet as well as the second oil outlet and the third oil outlet. The hydraulic oil distributing and controlling device can realize interfluent oil supply of the two duplex pumps so as to improve the operation speed of the corresponding operating condition and operation efficiency, and can use any duplex pump to supply oil respectively to realize a flexible and convenient flow distribution proposal combined by diversified operating conditions.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Oil supply device for engine

An oil supply device for an engine includes a first oil suction passage, a second oil suction passage, a first pump for sucking and discharging oil from the first oil suction passage, a second pump arranged in series with the first pump, the second pump for sucking and discharging oil from at least one of the first pump and the second oil suction passage, a check valve for blocking oil circulation, a first oil passage, a second oil passage, a third oil passage for establishing communication between the first oil passage and the second oil passage, and a supply volume control device for varying oil supply volume to a lubrication system portion, to a cooling system portion, or to the lubrication system portion and the cooling system portion in accordance with a change in at least one of an engine oil temperature, an engine rotation speed, and an engine load.

Owner:AISIN SEIKI KK

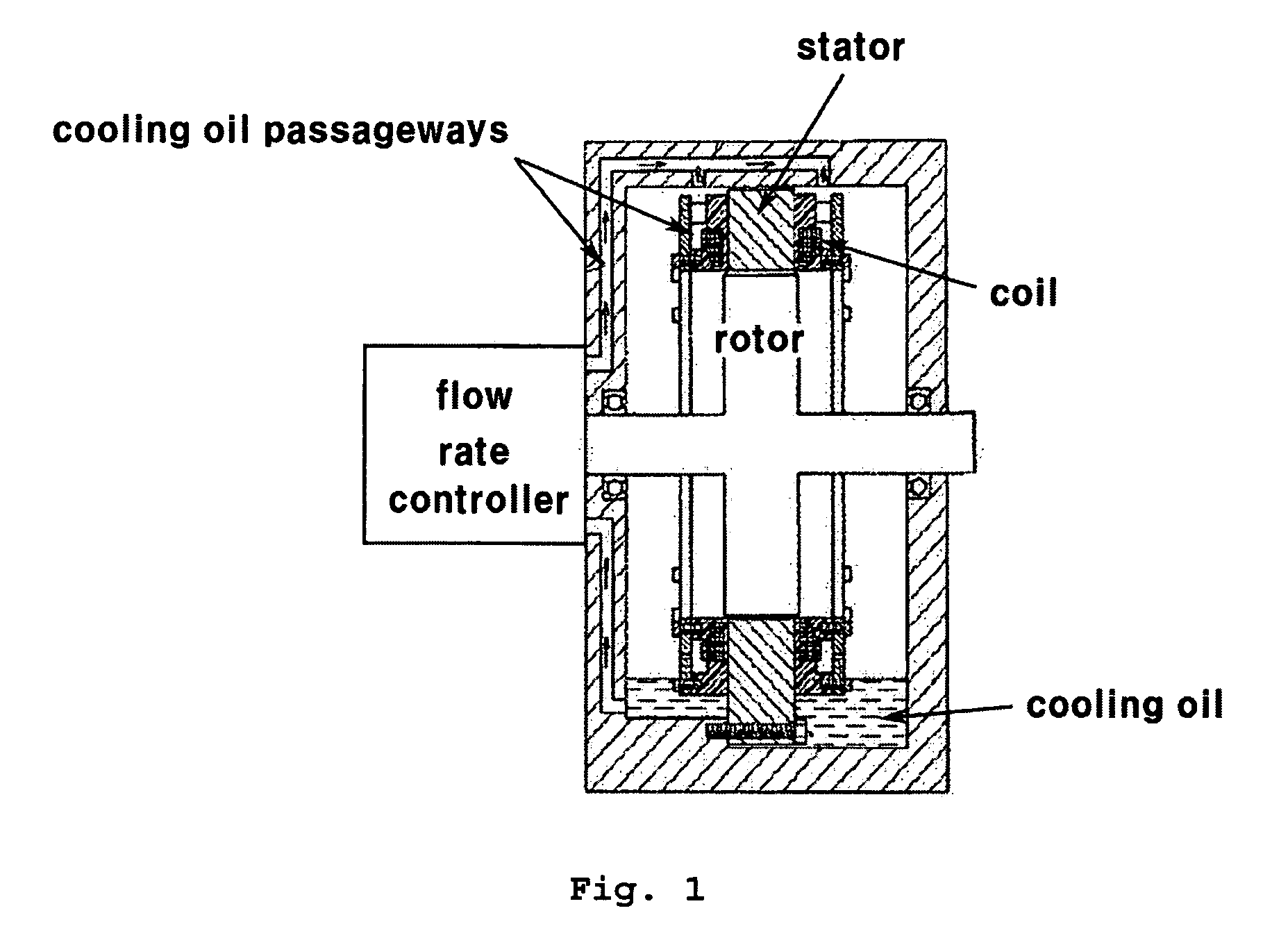

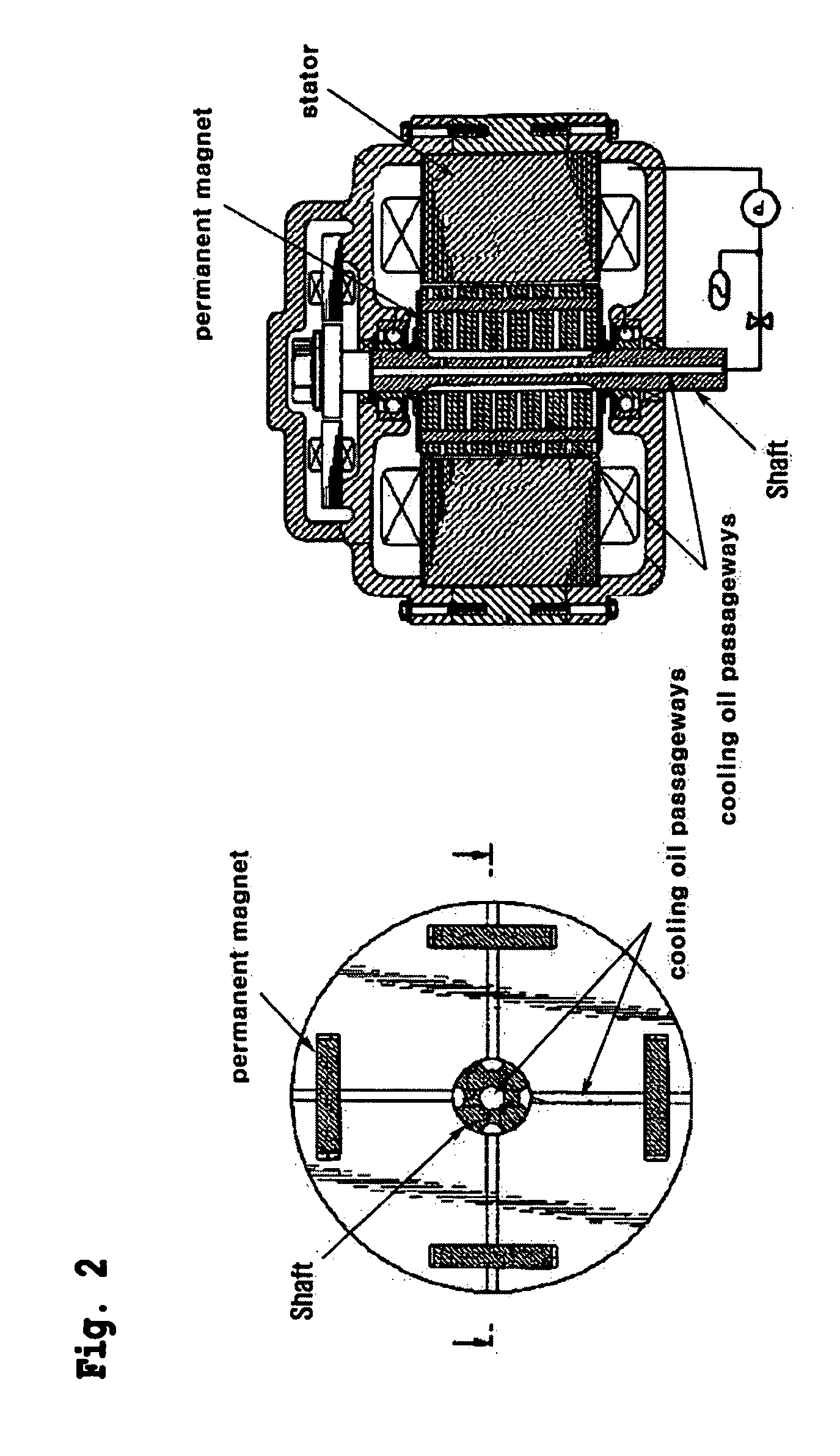

Device and method for cooling motor for hybrid electric vehicles

The present invention provides a device for cooling a motor for hybrid electric vehicles, which comprises: an oil pump mounted on an outer surface of the motor housing in such a fashion as to be disposed coaxially relative to the shaft; a cooling oil supply line mounted in such a fashion as to be extended to an inner surface of the spider from an outlet of the oil pump; and a cooling oil return line mounted in such a fashion as to interconnect a bottom portion of the motor housing in which cooling oil is filled and an inlet of the oil pump.

Owner:HYUNDAI MOTOR CO LTD

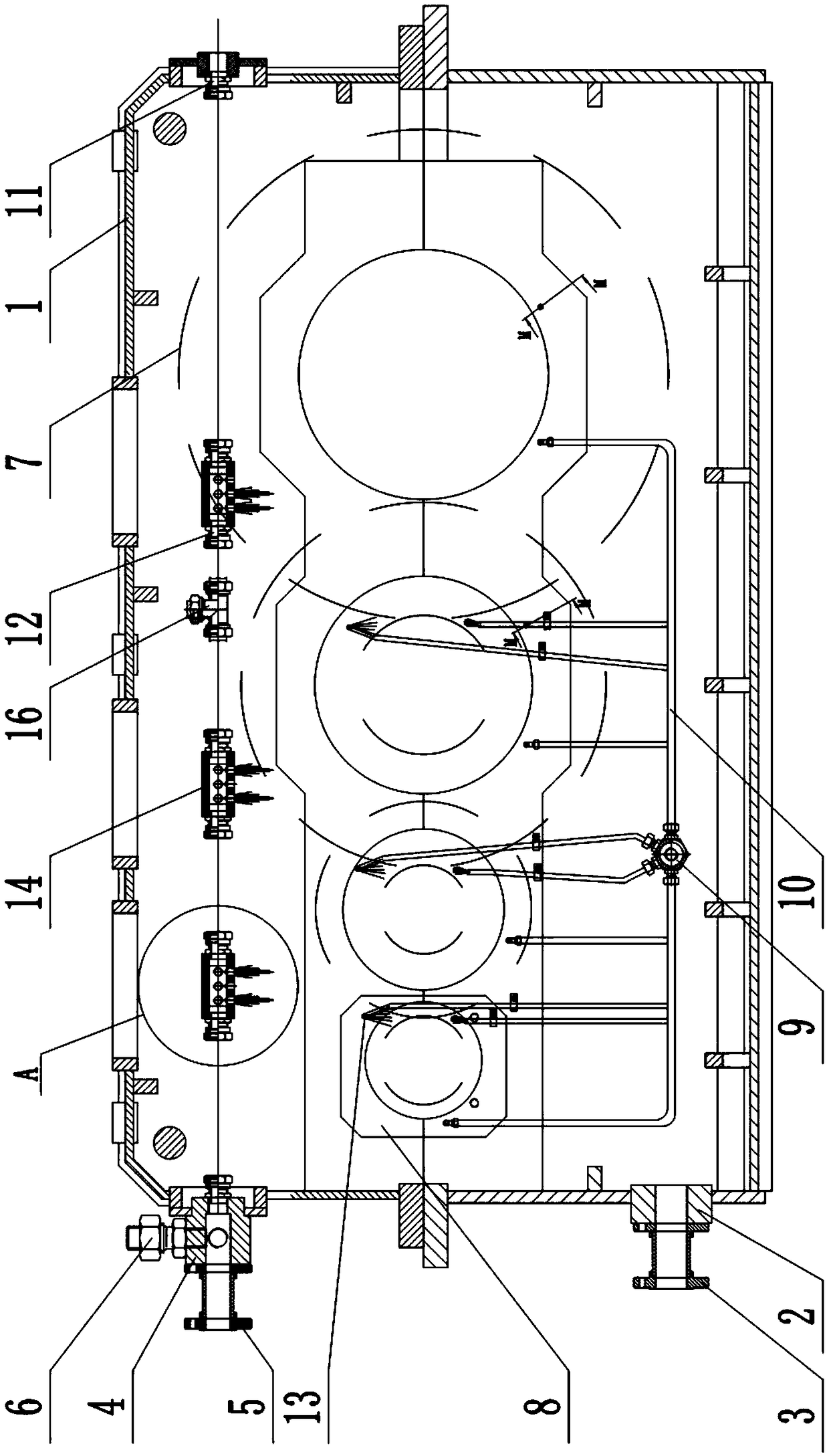

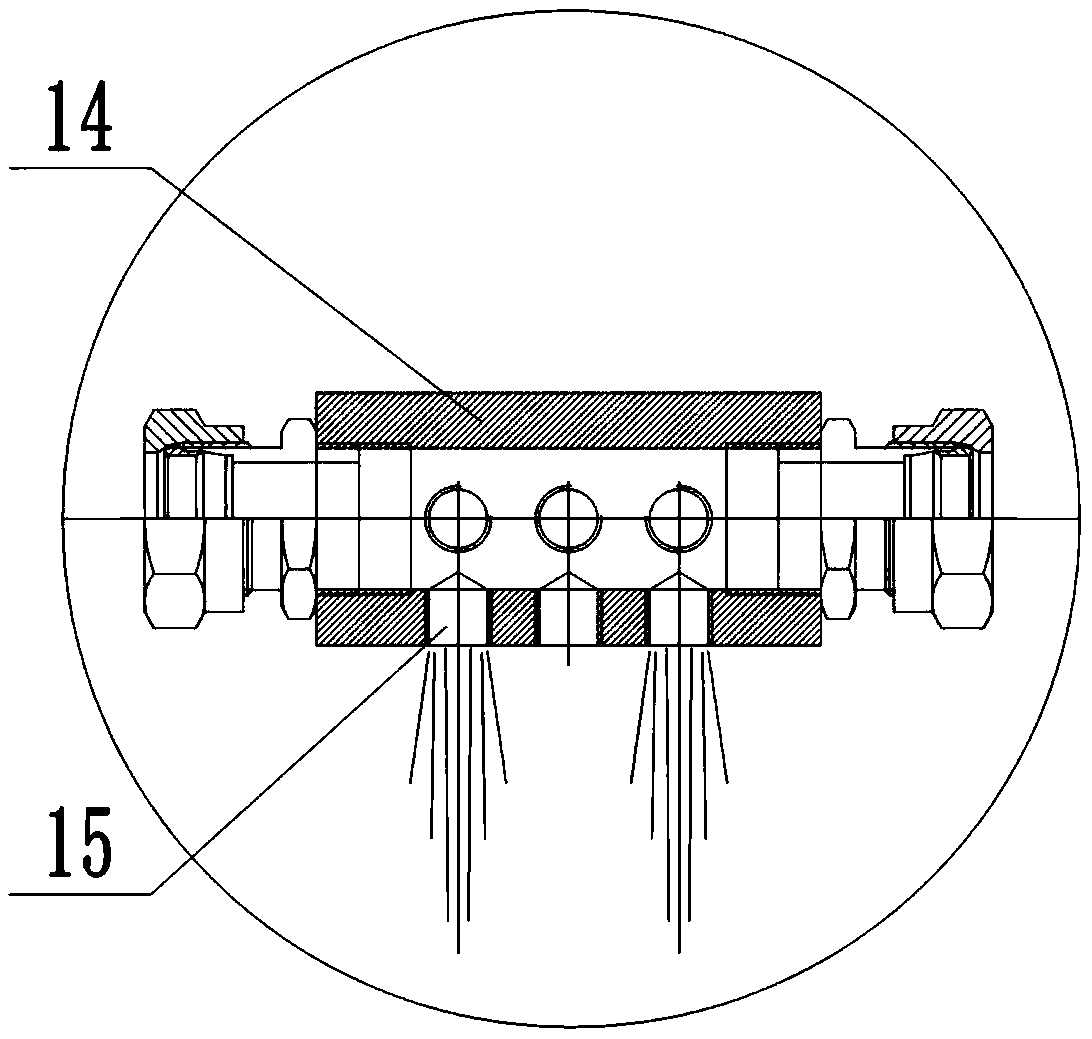

Speed reducer lubrication discharge pipe structure

ActiveCN108799473AExtended service lifeImprove the lubrication effectGear lubrication/coolingGear wheelReducer

The invention discloses a speed reducer lubrication discharge pipe structure. The speed reducer lubrication discharge pipe structure comprises a speed reducer box; an oil outlet pipe is arranged at the lower part of one side of the speed reducer box; a main distributor is arranged under multiple speed reducer gears and multiple bearing cavities in the speed reducer box; multiple oil outlets are formed in the main distributor; the oil outlets of the main distributor are connected with oil supply branch pipes; multiple secondary distributors are transversely arranged above the engaged places ofeach pair of speed reducer gears; the secondary distributors near an oil inlet pipe communicate with the oil inlet pipe through oil pipes; and the secondary distributors far from the oil inlet pipe are connected with first clamping joints. The oil supply branch pipes positioned in the bearing cavities of a speed reducer fully lubricate bearings of the speed reducer through a point-to-point arrangement form; the oil supply branch pipes in the engaged places of gears of the speed reducer lubricate the gears of the speed reducer; damping holes in the secondary distributors reduce the pressure ofredundant lubricating oil pumped by a lubricating pump; and during reducing of the pressure, the gears of the speed reducer are lubricated again, so that the lubricating effect of the bearings and thegears of the speed reducer is excellent, and the service life of a lubricating pump is long.

Owner:WORLD TRANSMISSION TECH TIANJIN SHARE LTD

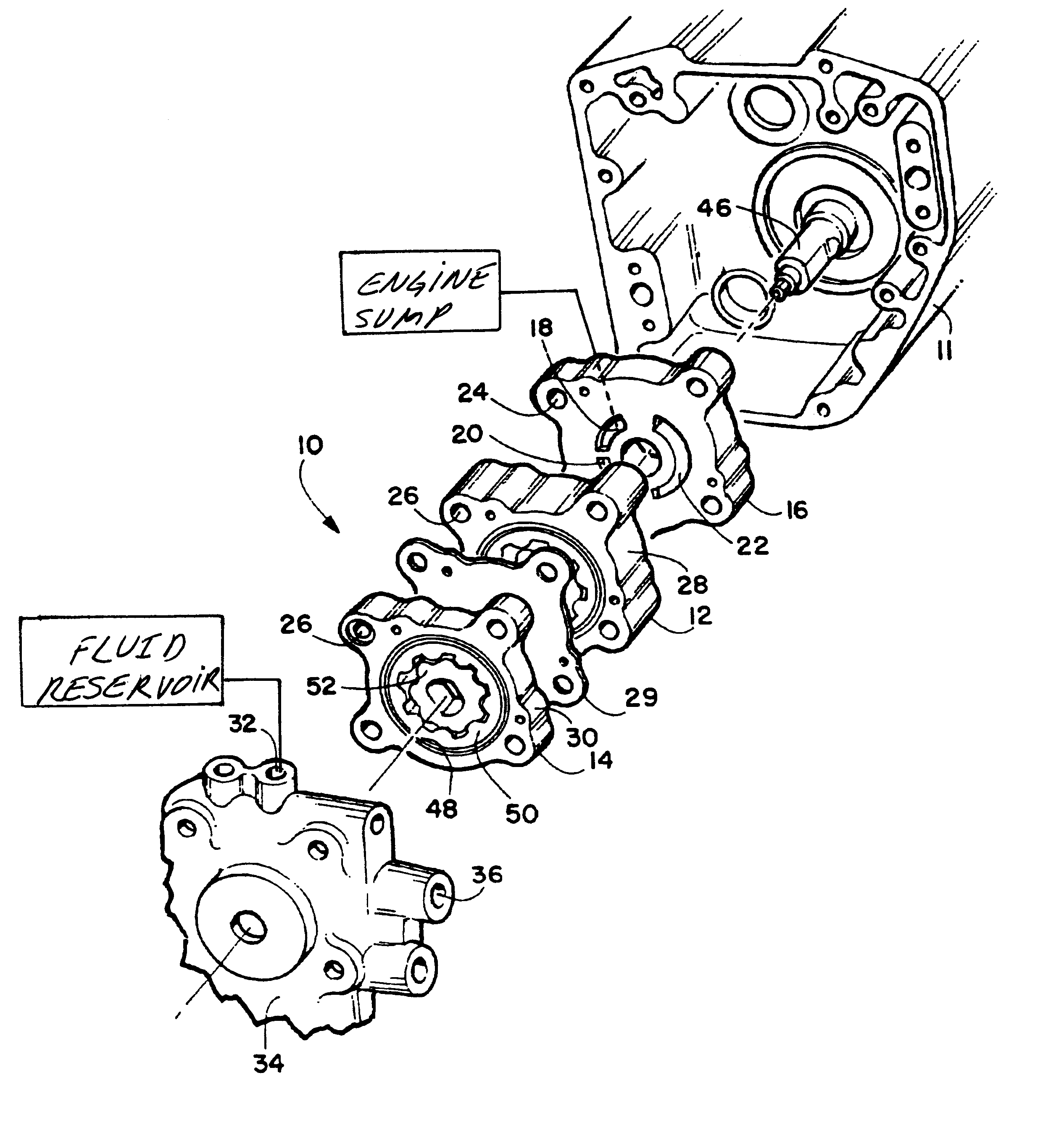

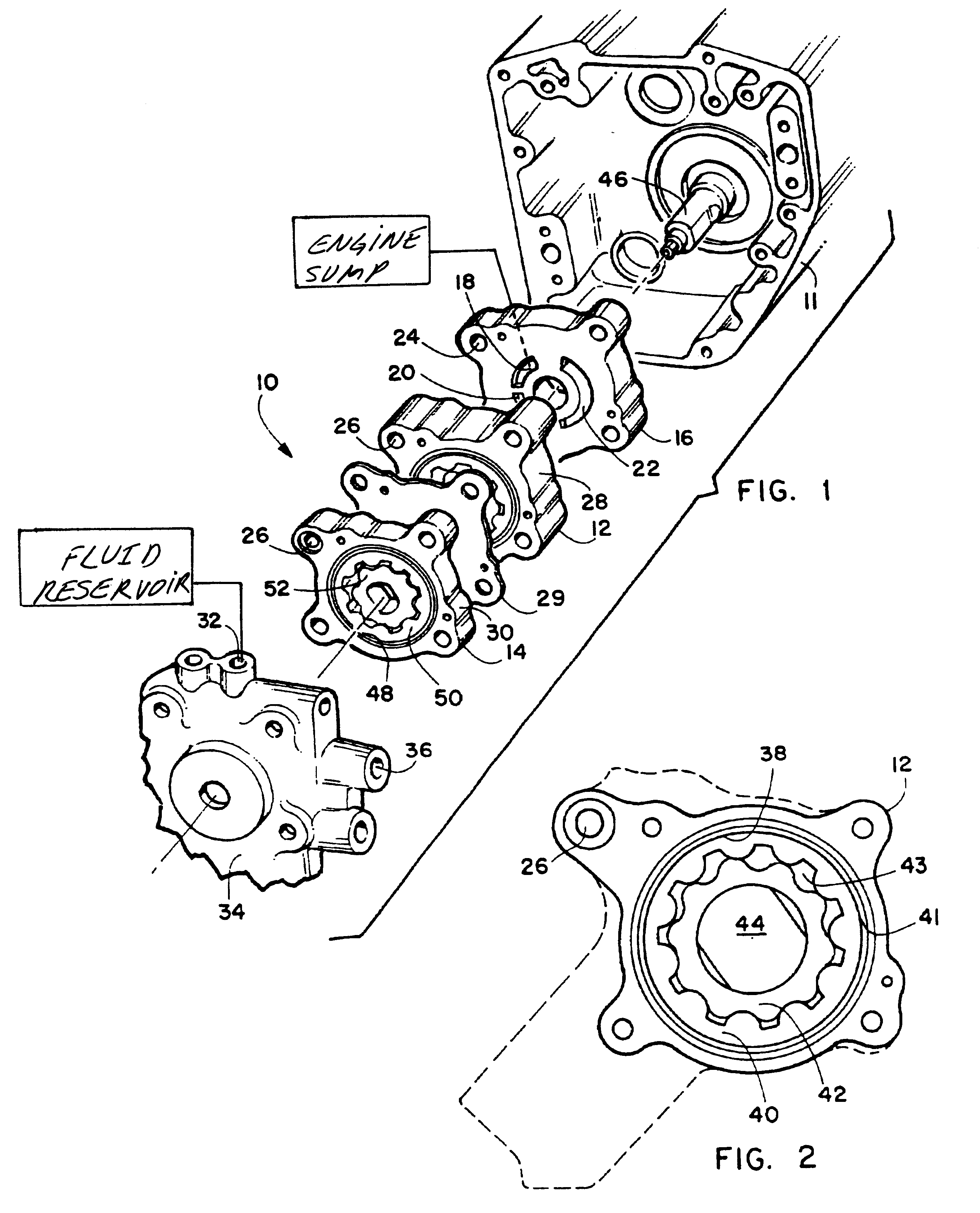

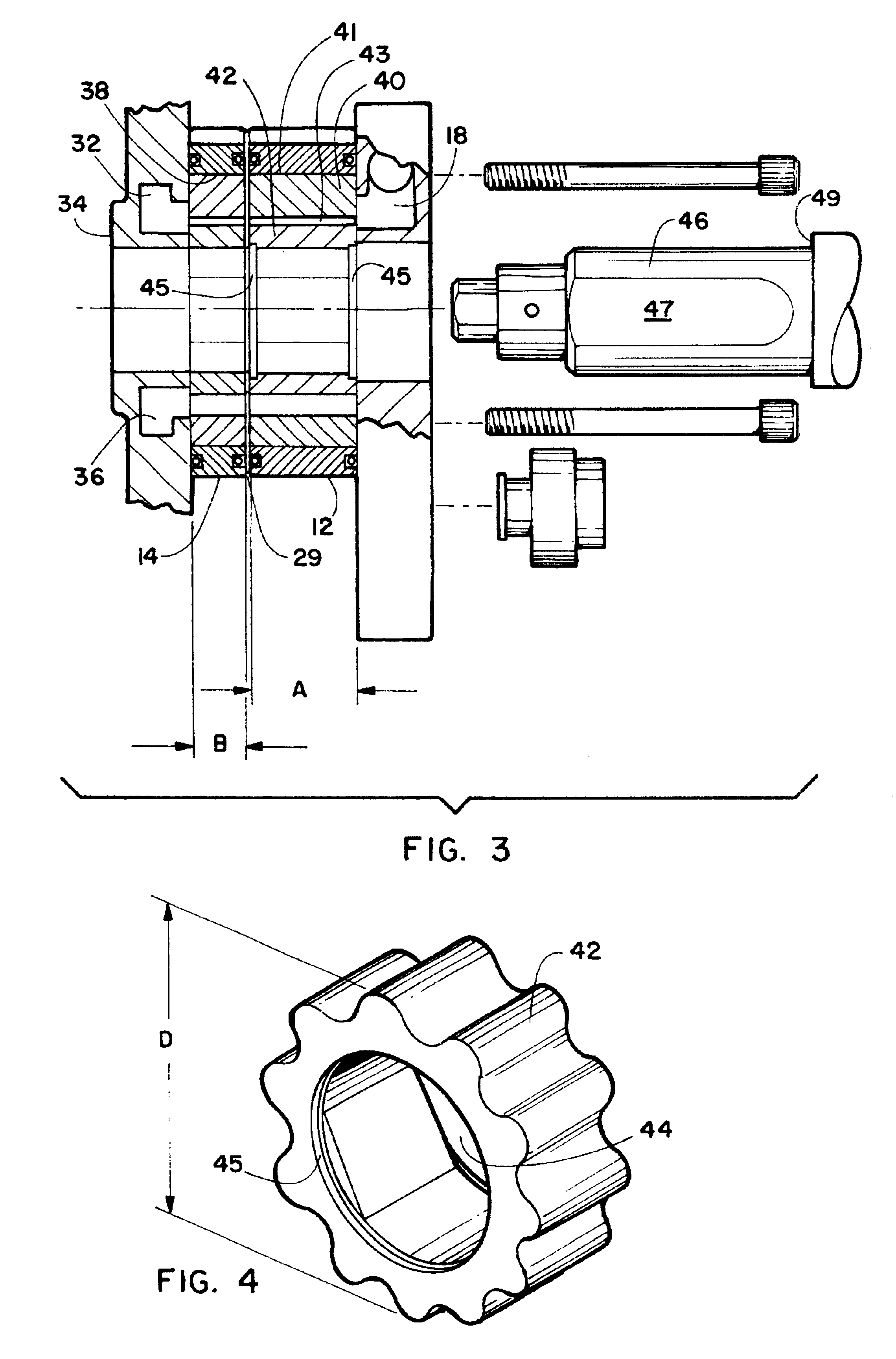

Oil pump

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

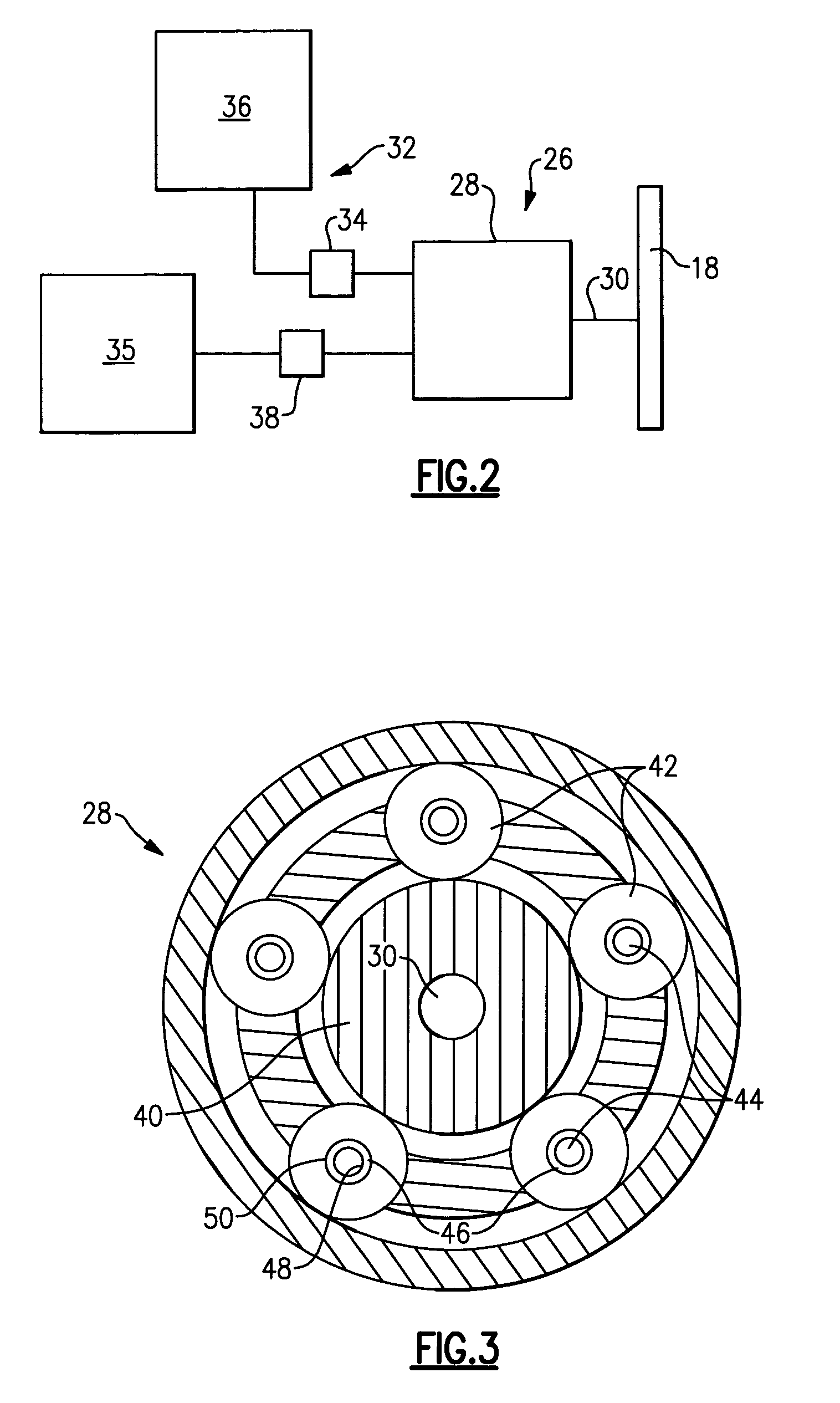

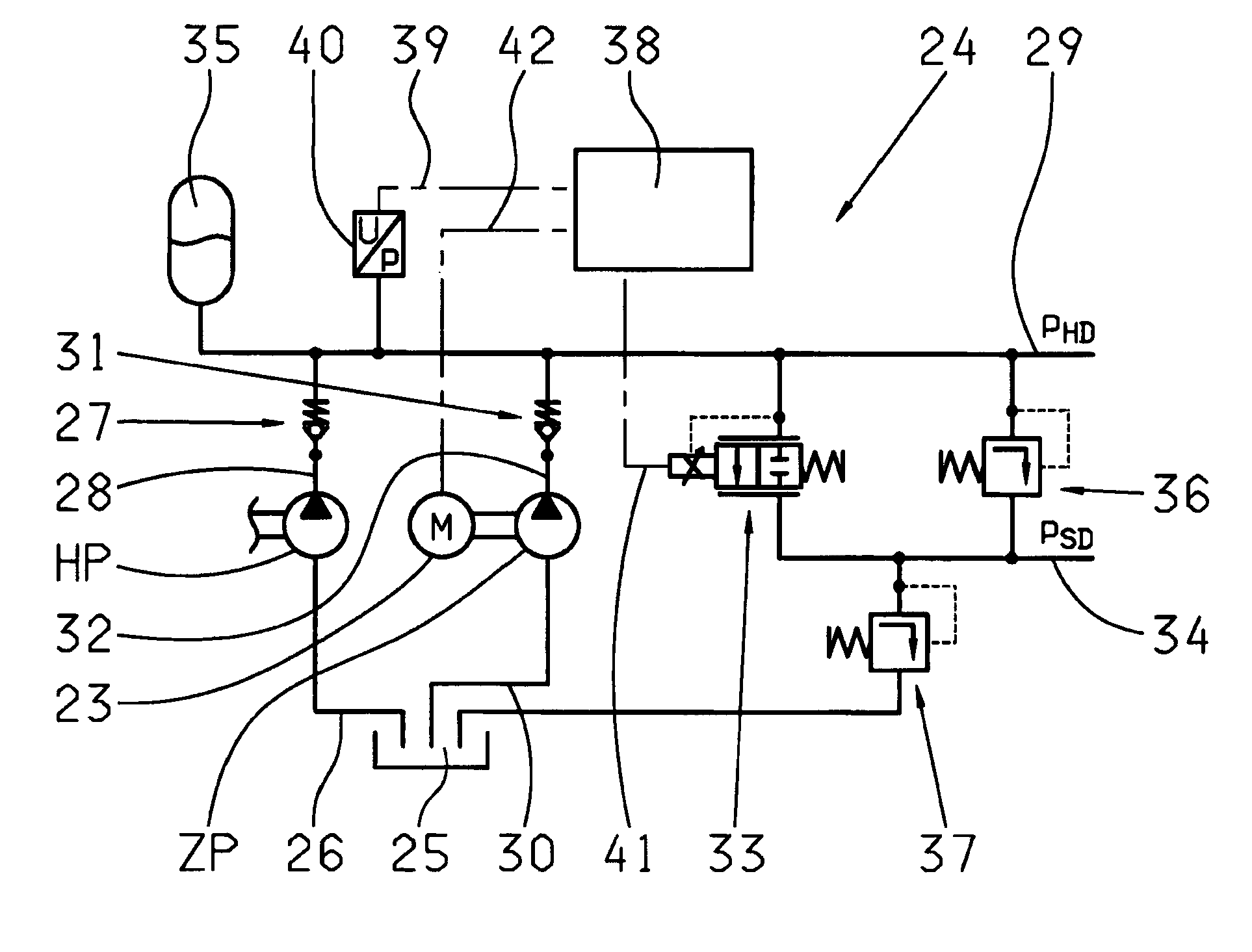

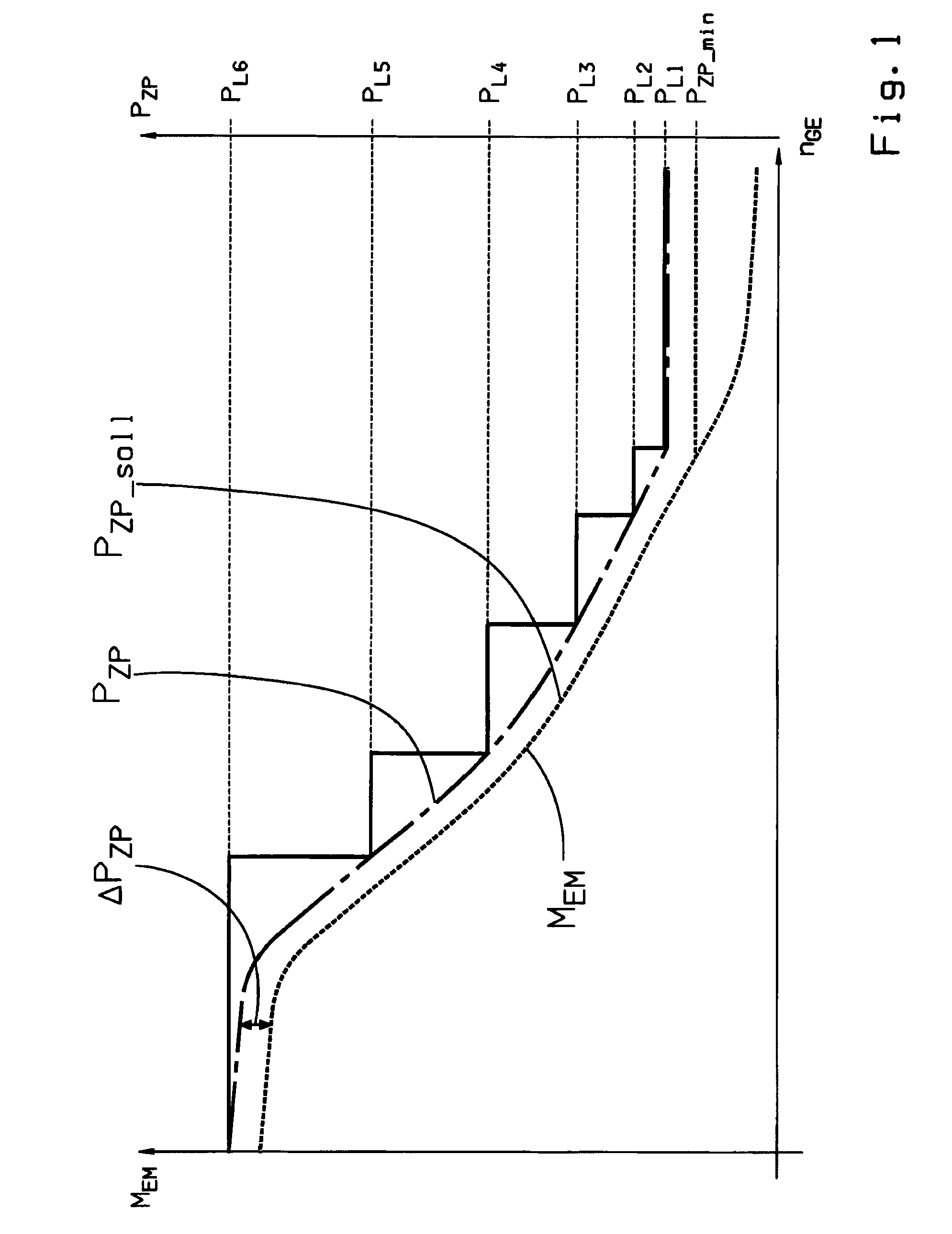

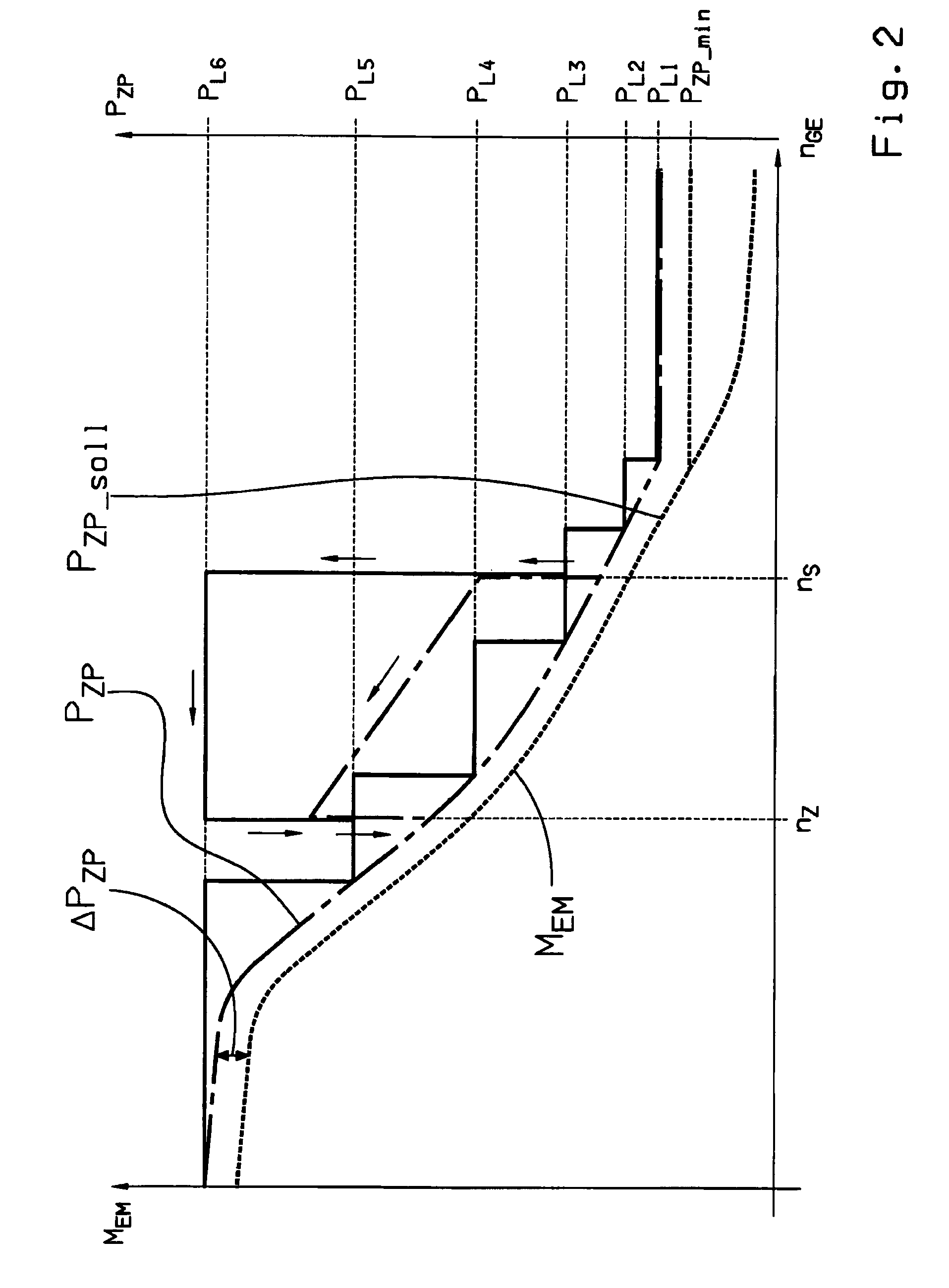

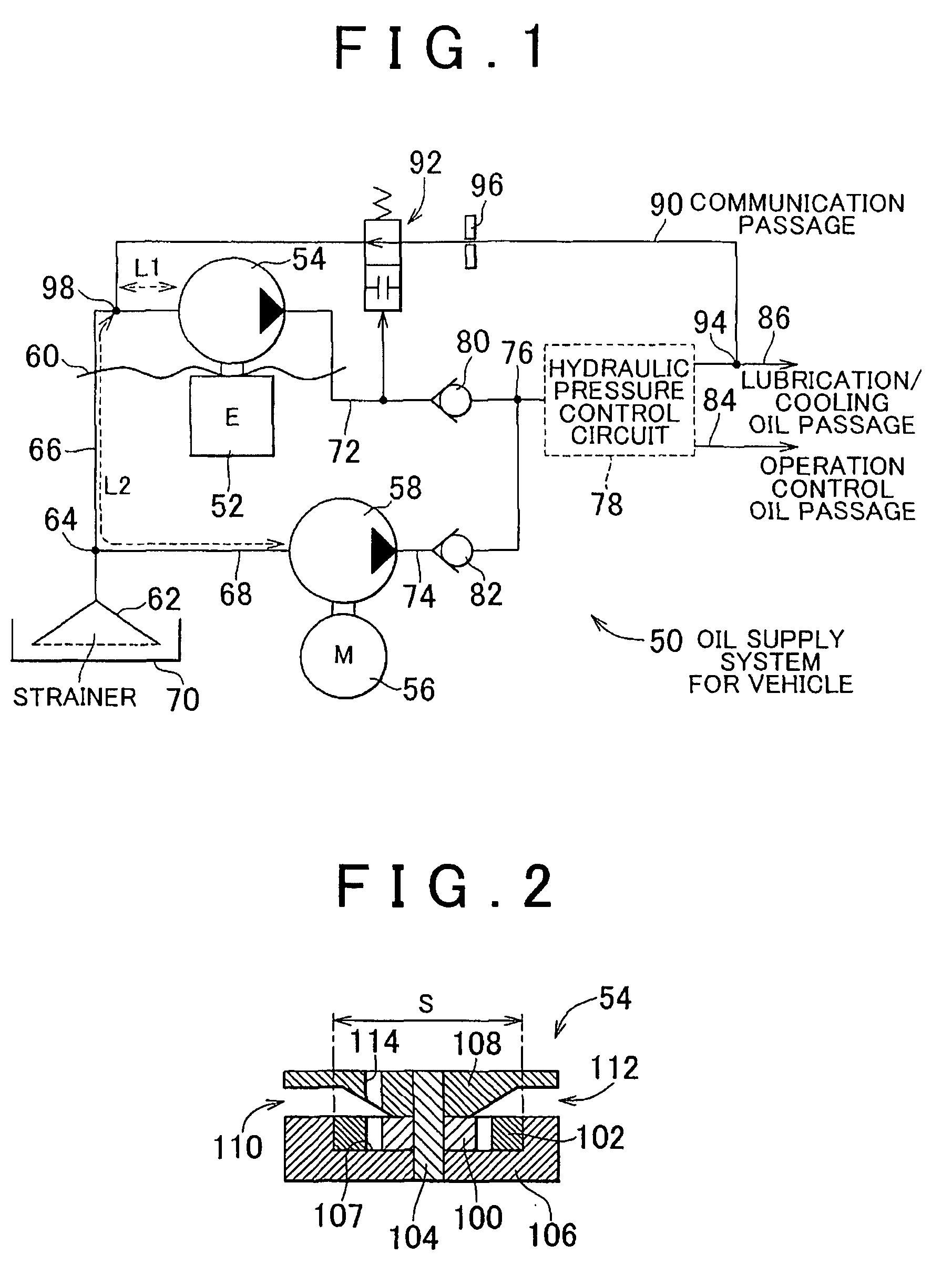

Method for controlling the oil supply of an automatic planetary transmission

InactiveUS20100018808A1Improve accessibilityIncrease installation spaceElectric propulsion mountingGear lubrication/coolingEngineeringInternal combustion engine

The invention relates to a method for controlling the oil supply device of an automatic planetary transmission, comprising a main oil pump (HP), which is mechanically drivably connected to the drive shaft of an internal combustion engine (VM), and an auxiliary oil pump (ZP) that may be driven via a controllable electric motor, the automatic transmission (ATG) being part of a parallel hybrid powertrain of a motor vehicle having an input shaft (5), which may be connected via a separating clutch (K) to the drive shaft (2) of the internal combustion engine (VM) and is permanently drivably connected to the rotor (4) of an electric machine (EM).In order to achieve an oil supply to the automatic transmission (ATG) as and when needed, it is provided that the current oil requirement (PHD<sub2>—< / sub2>soll) of the automatic transmission is determined as a function of at least one currently captured operating parameter, and that the delivery rate (PZP) of the auxiliary oil pump (ZP) is set, by a correspondingly actuation of the associated electric motor, in the combustion and combined driving mode below a minimum input speed of the main oil pump (HP) and in the electric driving mode to at least the total oil requirement, and at least in the combined driving mode above the minimum input speed of the main oil pump (HP) is set to at least the residual oil requirement exceeding the delivery rate (PHP) of the main oil pump.

Owner:ZF FRIEDRICHSHAFEN AG

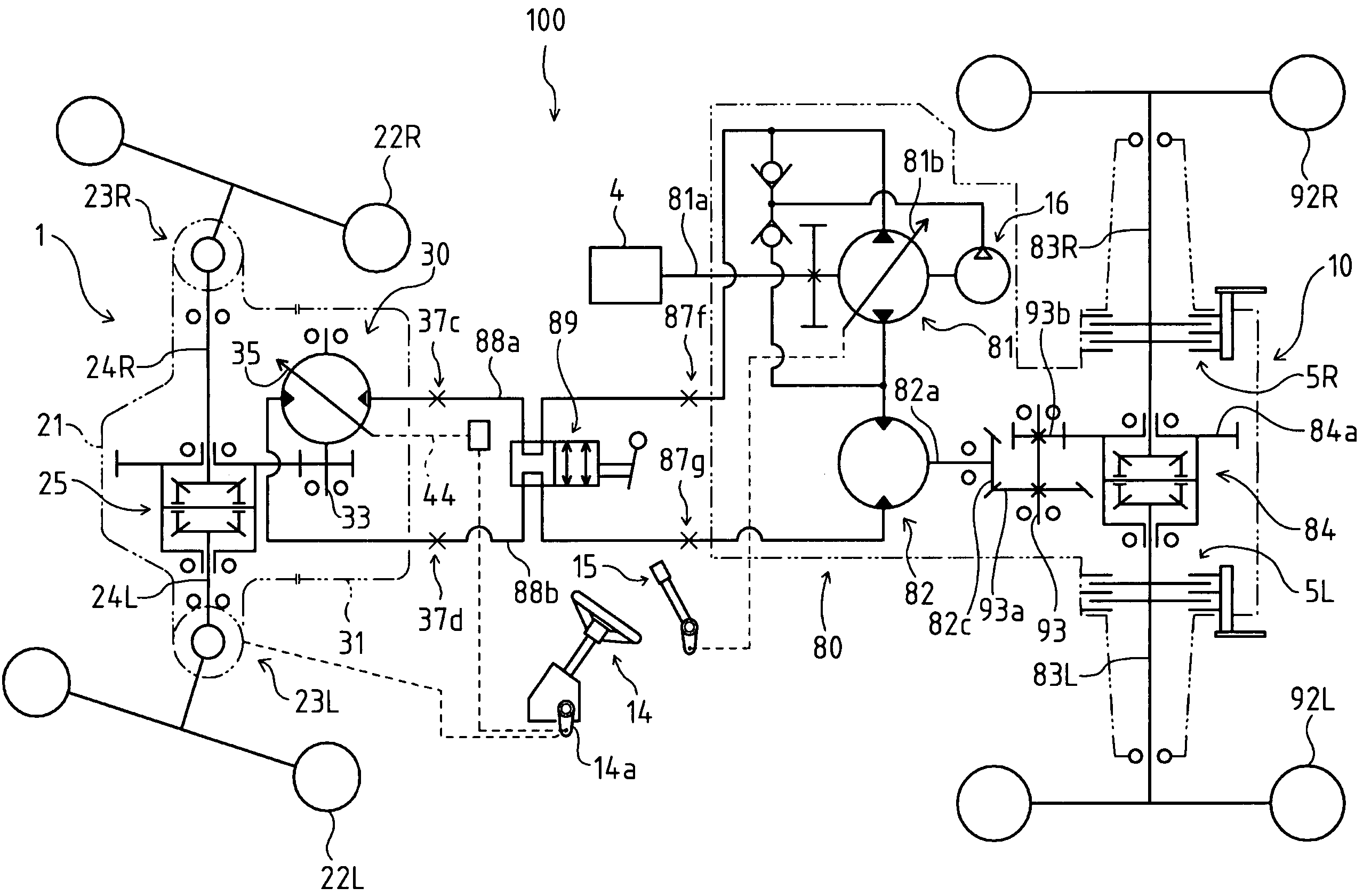

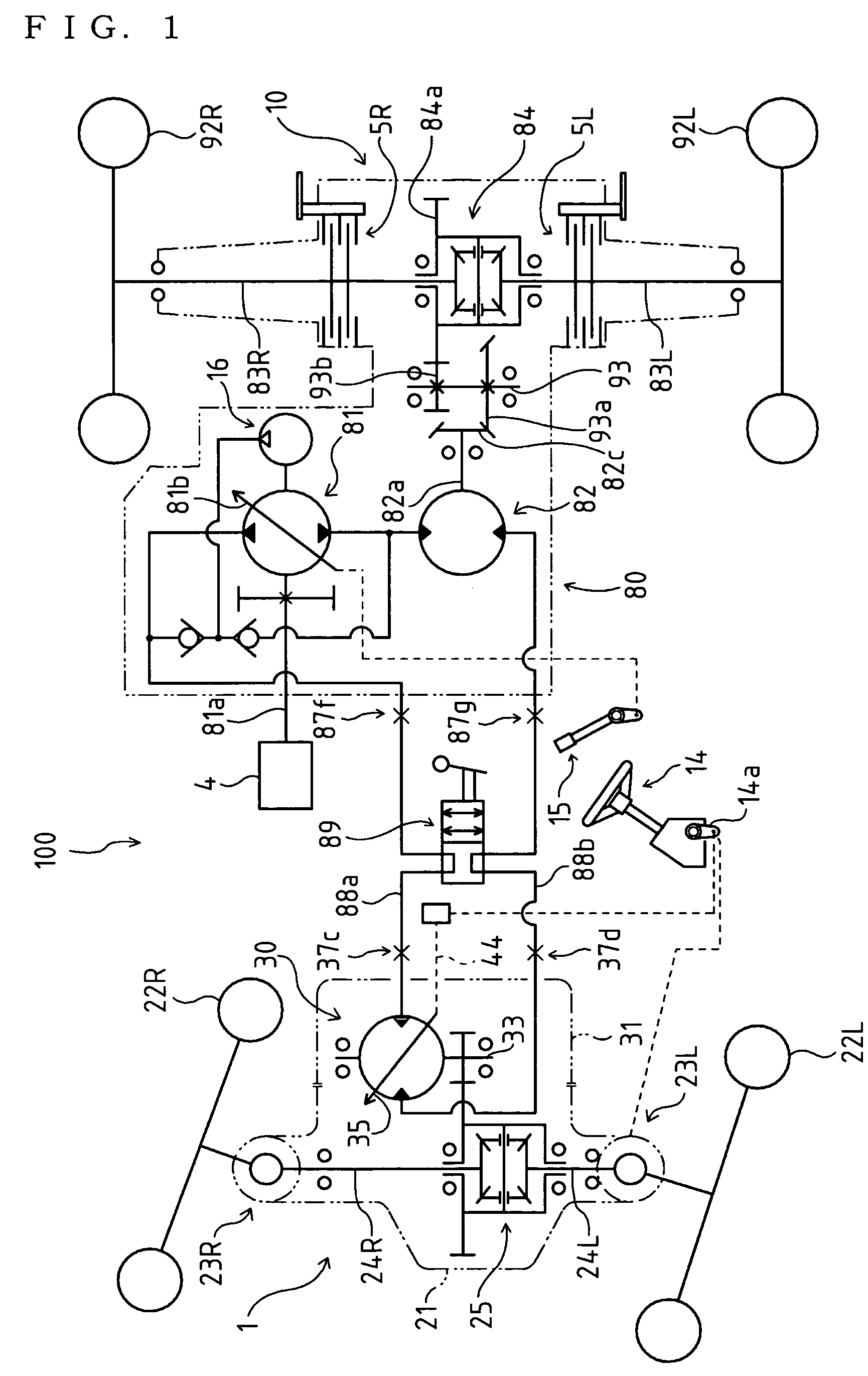

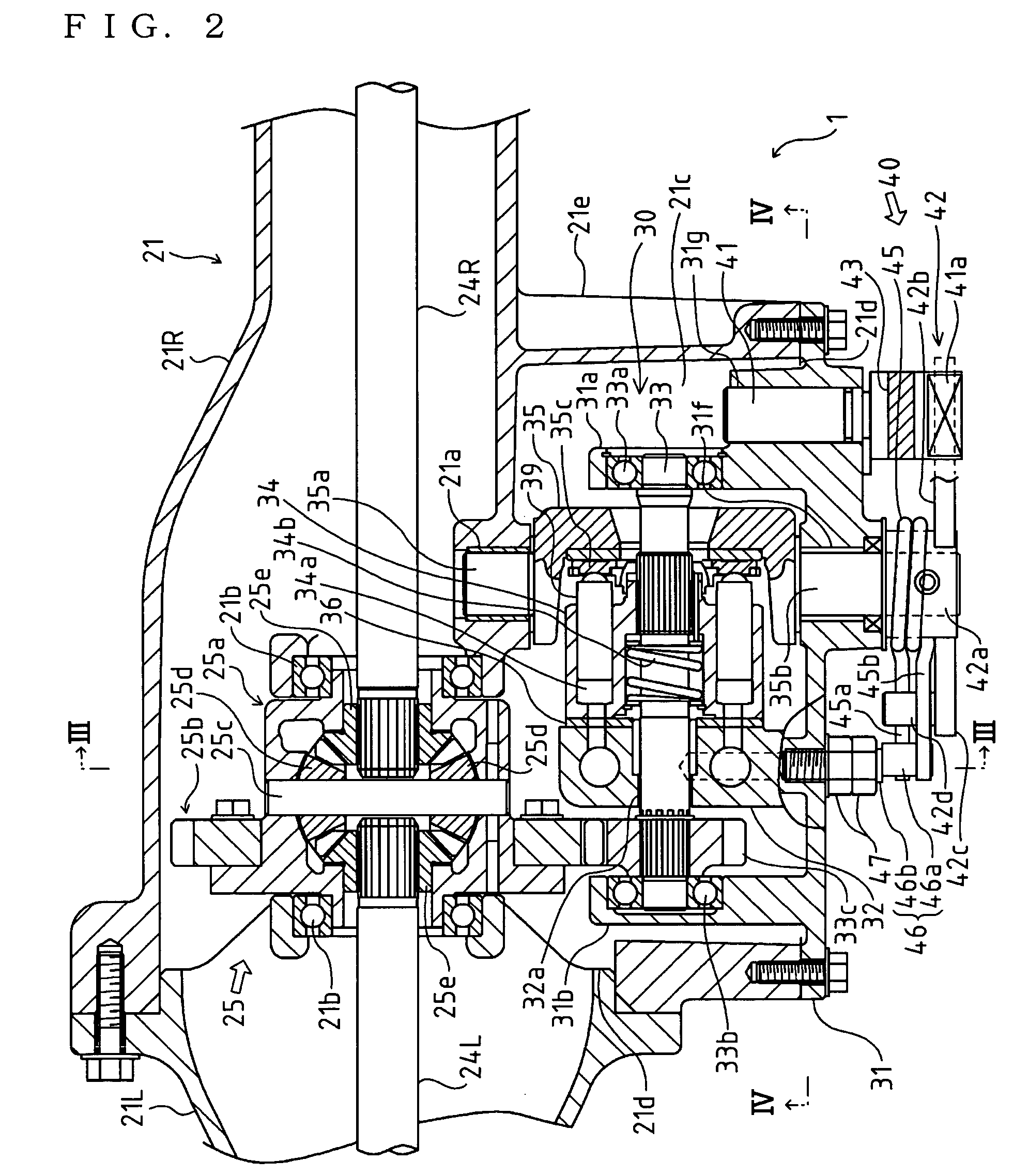

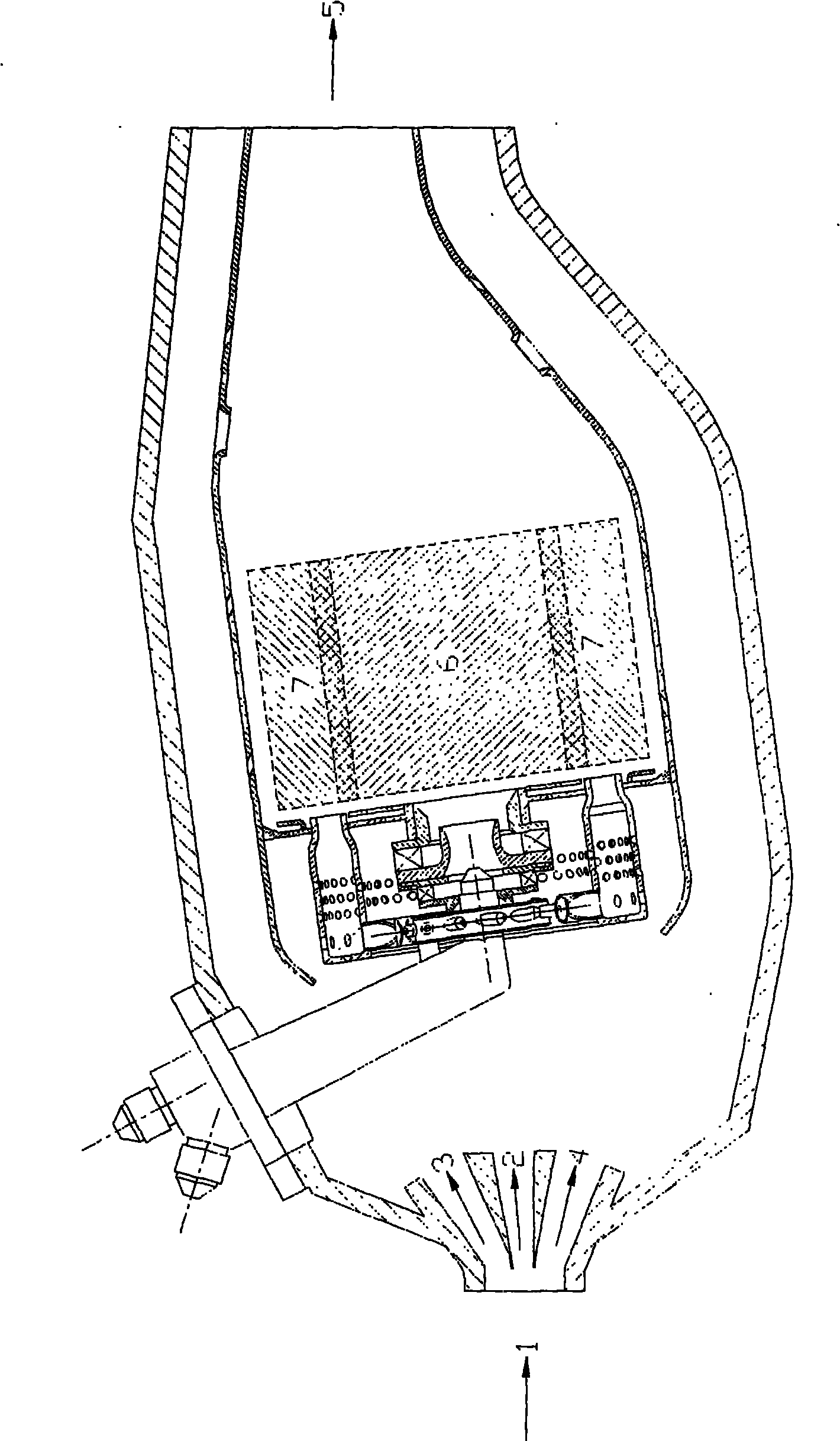

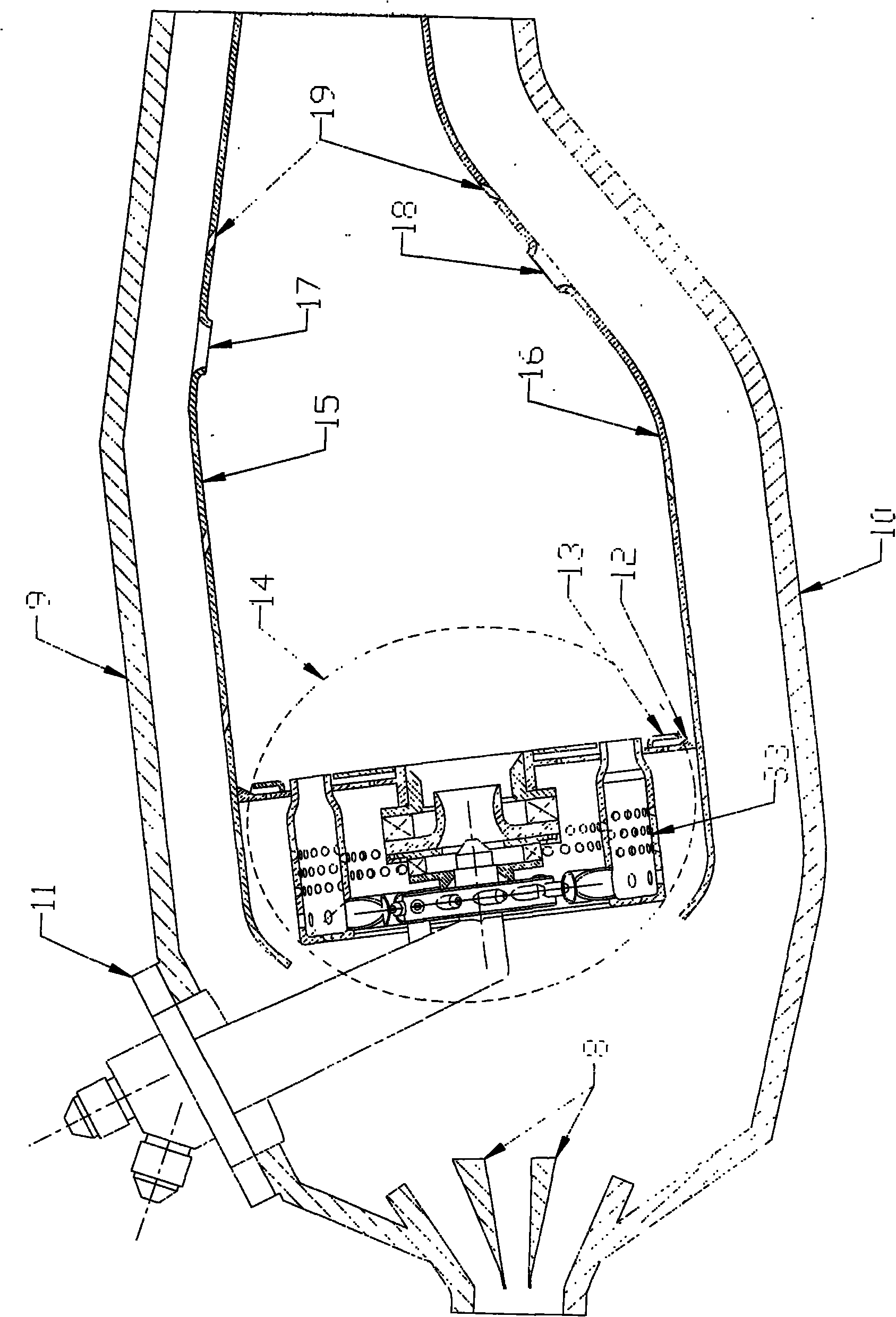

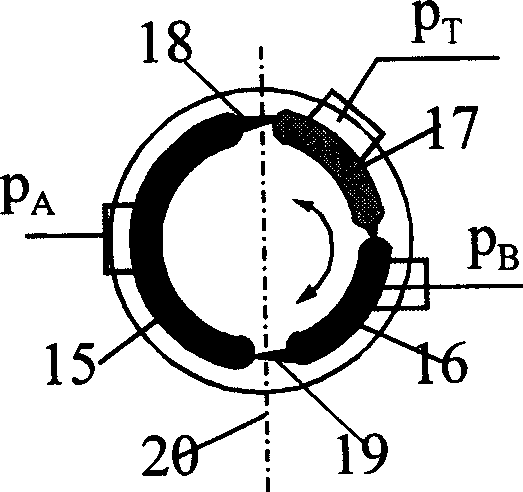

Hydraulic steering transaxle and hydraulic driving vehicle

A steering transaxle comprises: left and right drive shafts drivingly connected to respective steerable wheels; a differential gear unit differentially connecting the drive shafts to each other; a transaxle casing having an opening, the transaxle casing incorporating the differential gear unit and the drive shafts; a cover for covering the opening of the transaxle casing; a variable hydraulic motor having a movable swash plate, the hydraulic motor being provided on the inside of the cover; a motor control mechanism for controlling the movable swash plate, the motor control mechanism being provided on the outside of the cover; and a hydraulic oil port for oil supply and delivery to and from the hydraulic motor, the hydraulic oil port being provided on the outside of the cover. The cover, the hydraulic motor with the movable swash plate, the motor control mechanism and the hydraulic oil port constitute an assembly unit, which is detachably attached to the transaxle casing so that, by covering the opening with the cover, the hydraulic motor is disposed in the transaxle casing so as to be drivingly connected to the differential gear unit.

Owner:KANZAKI KOKYUKOKI MFG

Main combustible stage tangential oil supply premix and pre-evaporation combustion chamber

The invention relates to a main combustion stage tangential oil supply premix and pre-evaporation combustion chamber. The combustion chamber is in a single-ring chamber structure and is designed by adopting the conceptual design of staging combustion, and all the used amount of gas for combustion is supplied by the precombustion stage and the main combustion stage. The combustion chamber mainly comprises a flow-dividing type diffuser, a combustion chamber outer case, a combustion chamber inner case, a fuel nozzle, the precombustion stage, the main combustion stage, a flame tube outer wall and a flame tube inner wall. The precombustion stage utilizes a low-speed flow returning zone generated by swirl air entering the combustion chamber by a precombustion stage swirler component; the fuel needed by the main combustion stage is ejected by the tangential main combustion stage nozzle, is atomized under the air flow effect generated by entering of atomized air of the main combustion stage nozzle into a pipe, then flows into a premix and pre-evaporation ring pipe for evaporation, and is further blended with air; and even oil-gas mixed gas formed at the outlet of the premix and pre-evaporation ring pipe enters a flame tube and combusts under the pilot combustion of the precombustion stage flame. The combustion chamber has simple structure, and can effectively reduce the discharge of pollution simultaneously while guaranteeing that an aeroengine is in normal working state.

Owner:BEIHANG UNIV

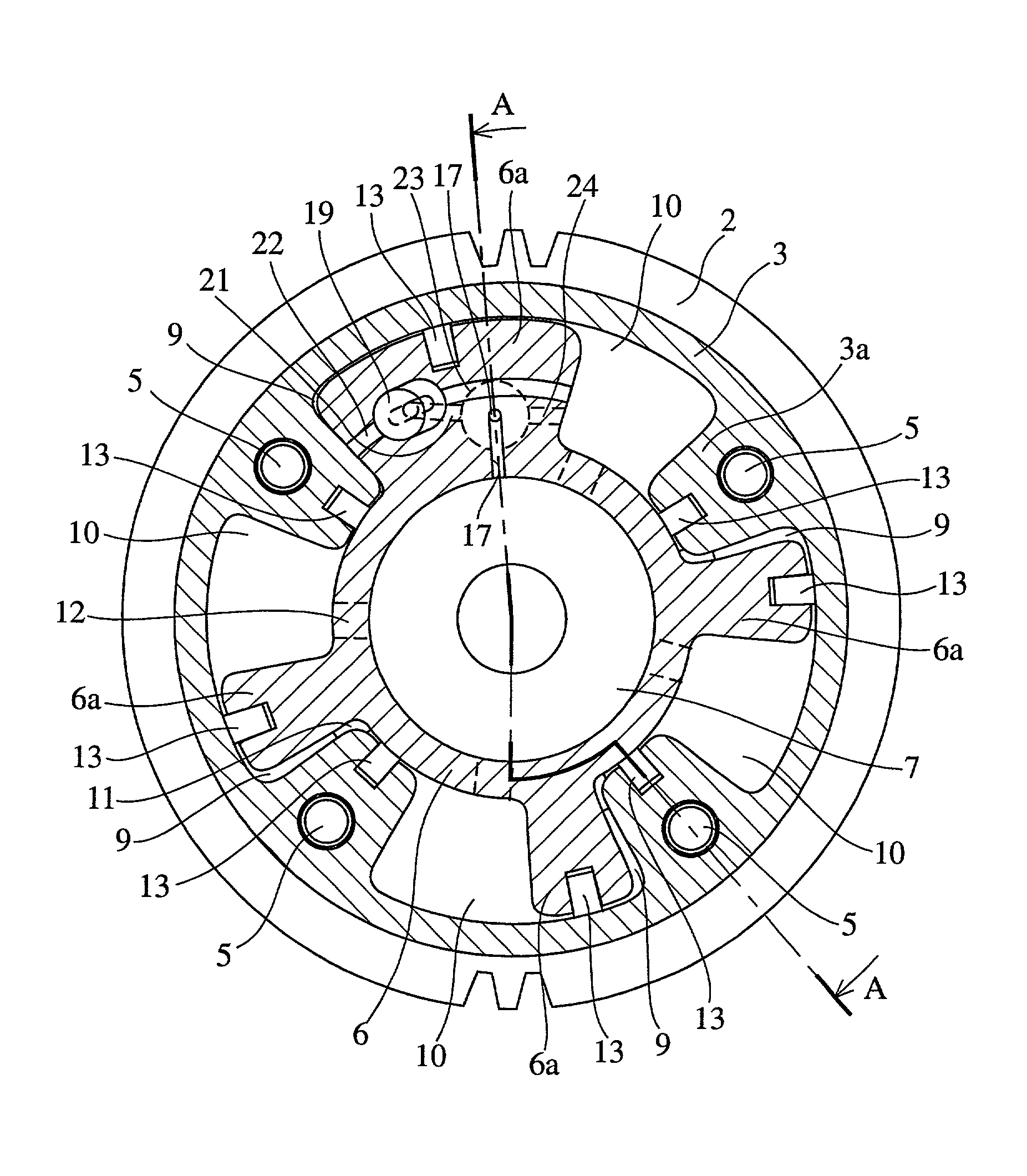

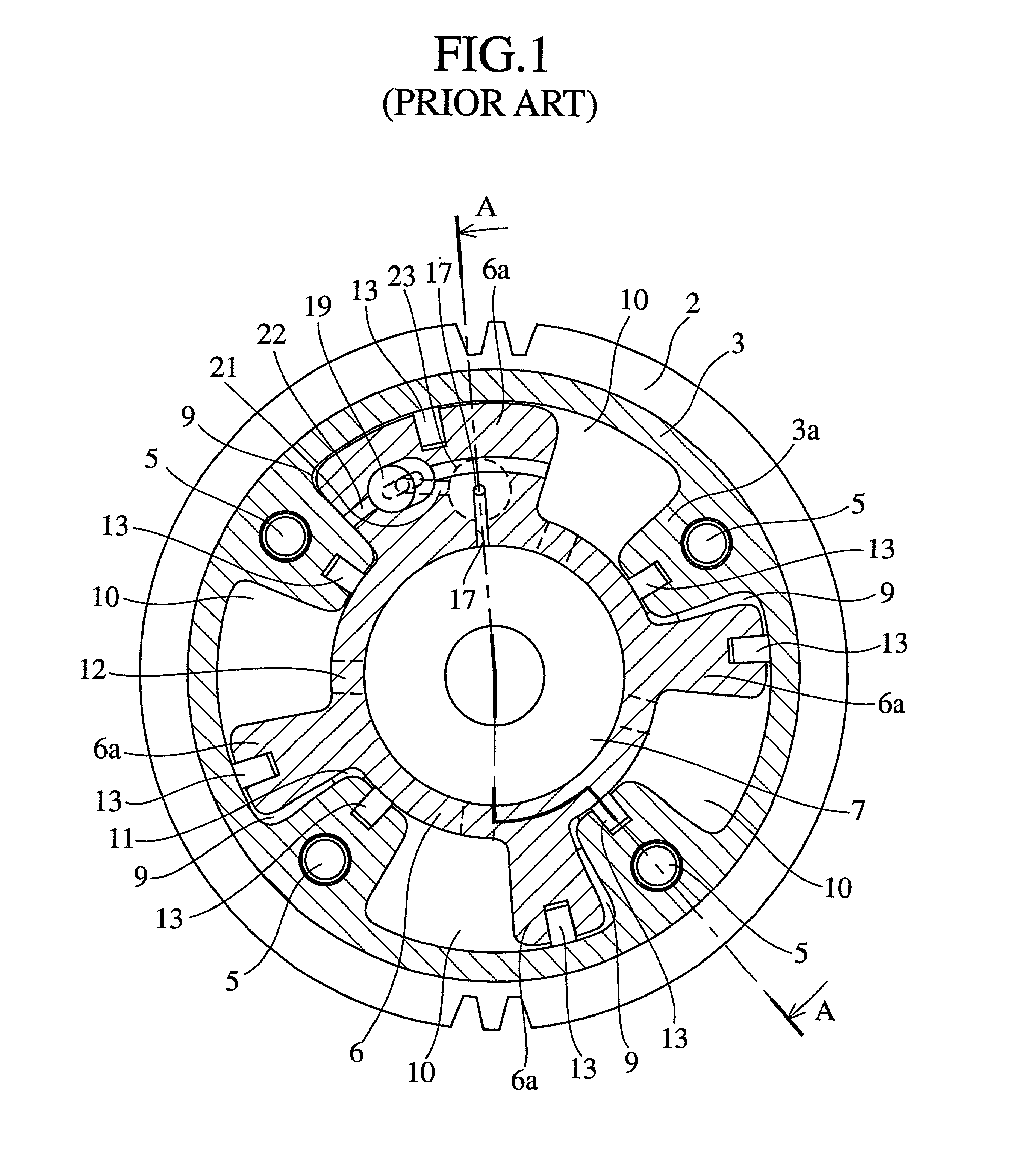

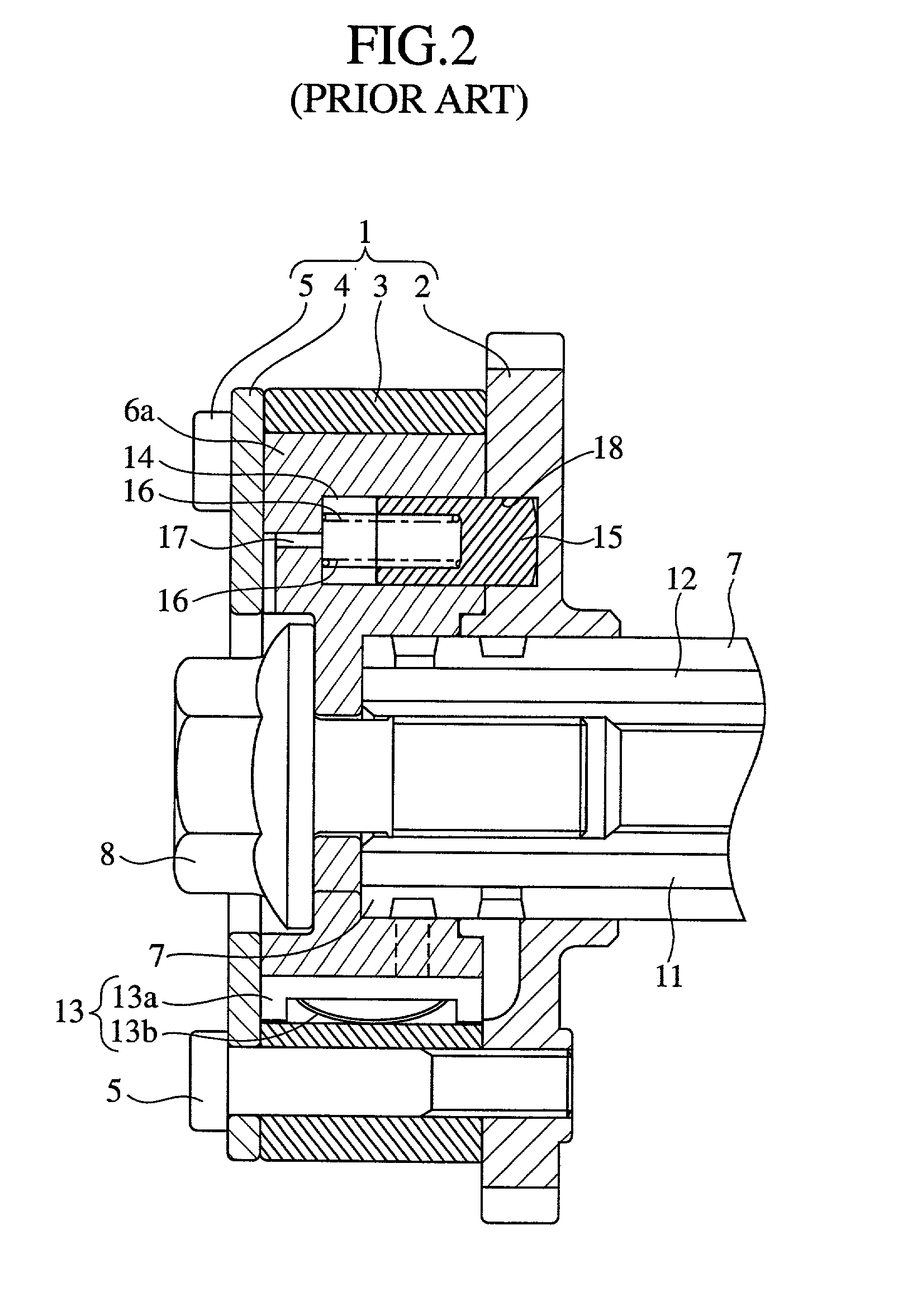

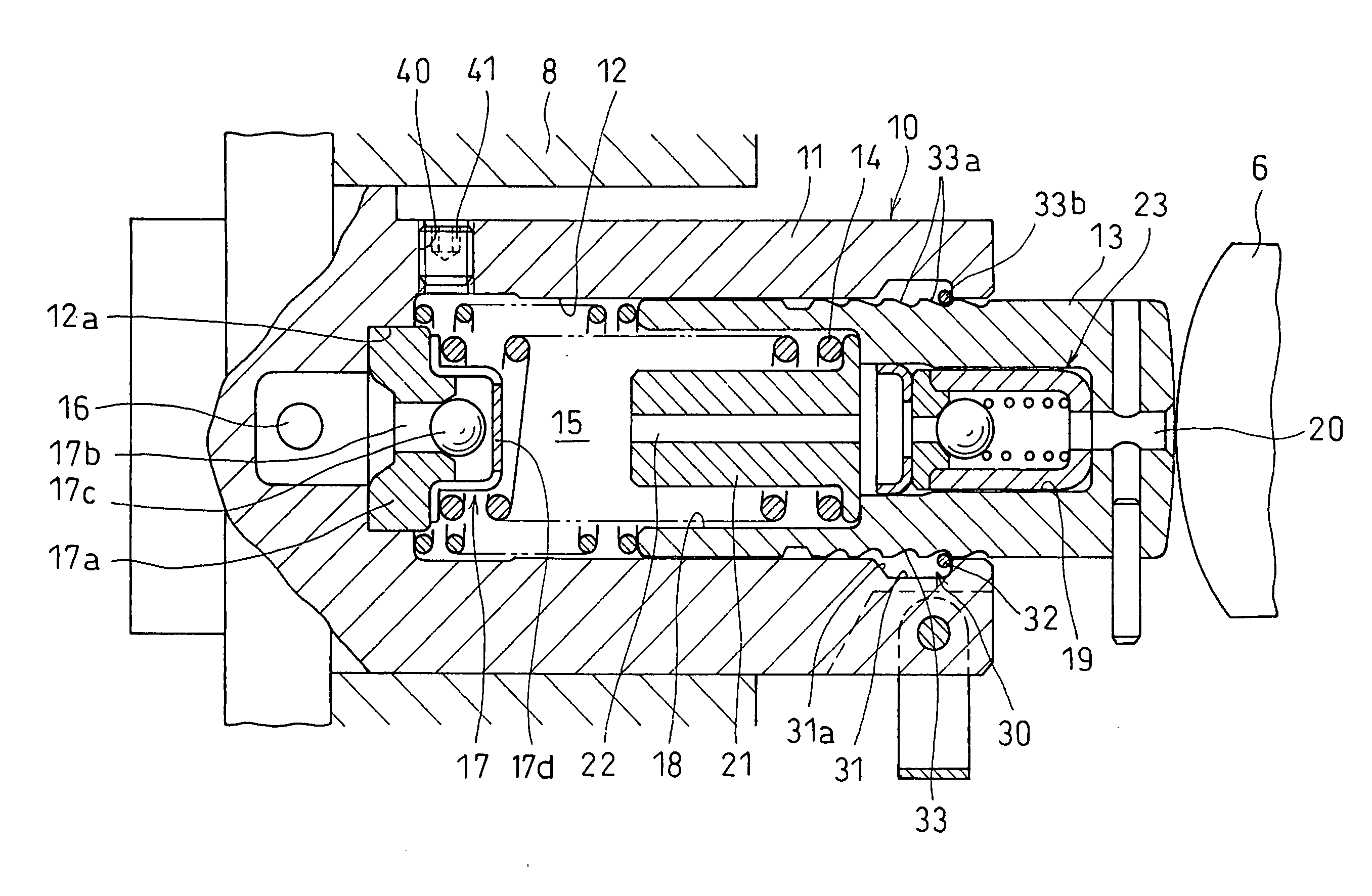

Valve timing control device

InactiveUS20020078913A1Avoid it happening againEasy to operateValve arrangementsMachines/enginesEngineeringResidual pressure

A valve timing control device includes a purge path communicating between a hydraulic chamber allowing the entry of hydraulic pressure on starting an engine and a backward pressurized section in an accommodation hole. When the hydraulic chamber allowing the entry of hydraulic pressure on starting the engine is the retardation side hydraulic chamber, a hydraulic pressure derived from an oil pump is supplied to the retardation side hydraulic chamber on starting the engine. On the way, air-mixed oil is discharged to outside of the device by way of a purge path, a backward pressurized section in the accommodation hole and the discharge hole. When the air is discharged, a residual pressure is produced in the backward pressurized section due to oil supplied thereto. The residual pressure results in the increase of an unlocking hydraulic pressure to prevent a locking member from being unlocked. When the application of a retardation side hydraulic pressure is switched to that of an advance side hydraulic pressure, the pressure presses a front end of a locking member against only a biasing force of a biasing means to unlock a locking relation. The valve timing control device allows the use of any kinds of locking pins, and prevents the occurrence of beat noise (abnormal noise) when air-mixed oil unlocks a locking relation on starting the engine.

Owner:MITSUBISHI ELECTRIC CORP

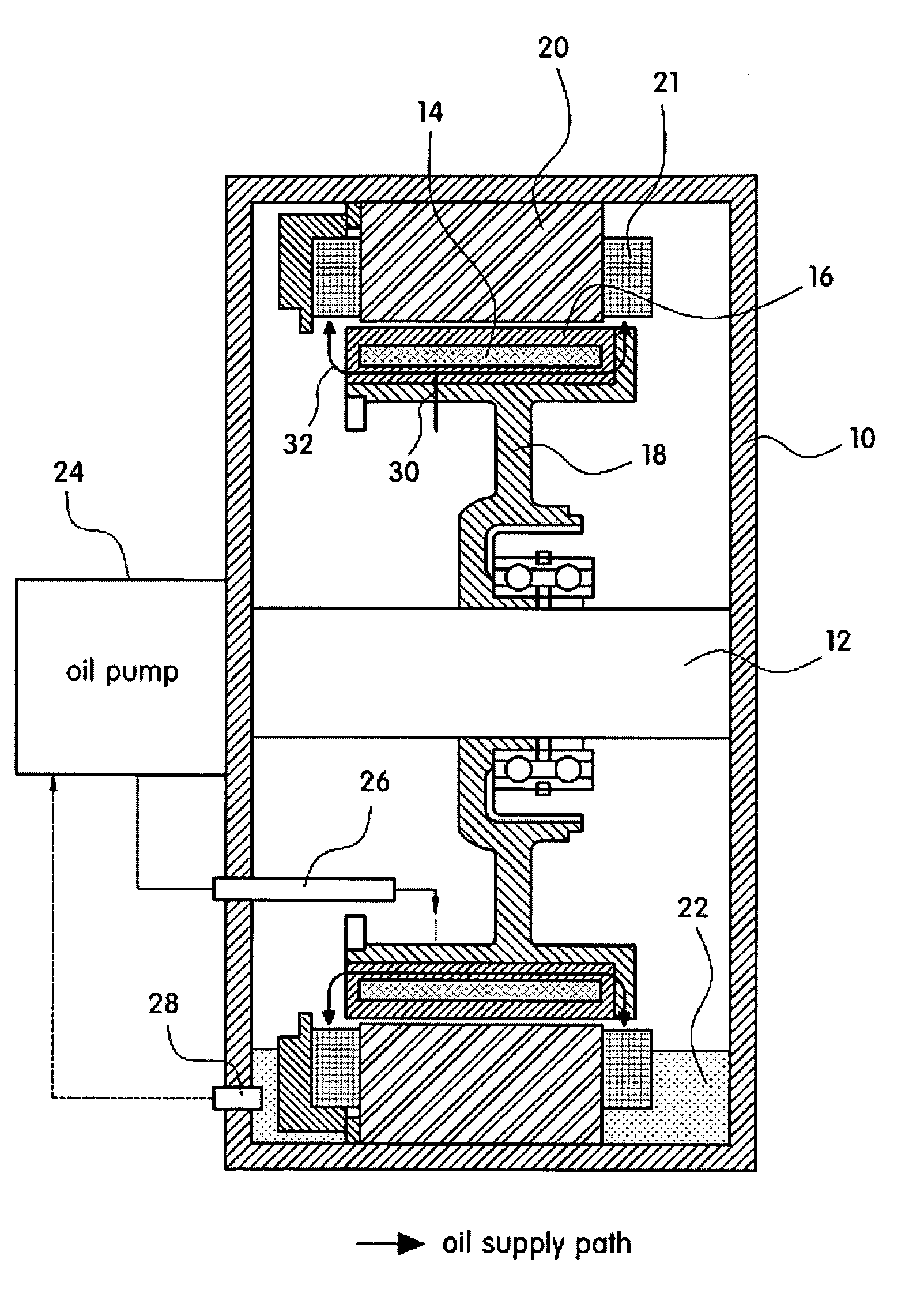

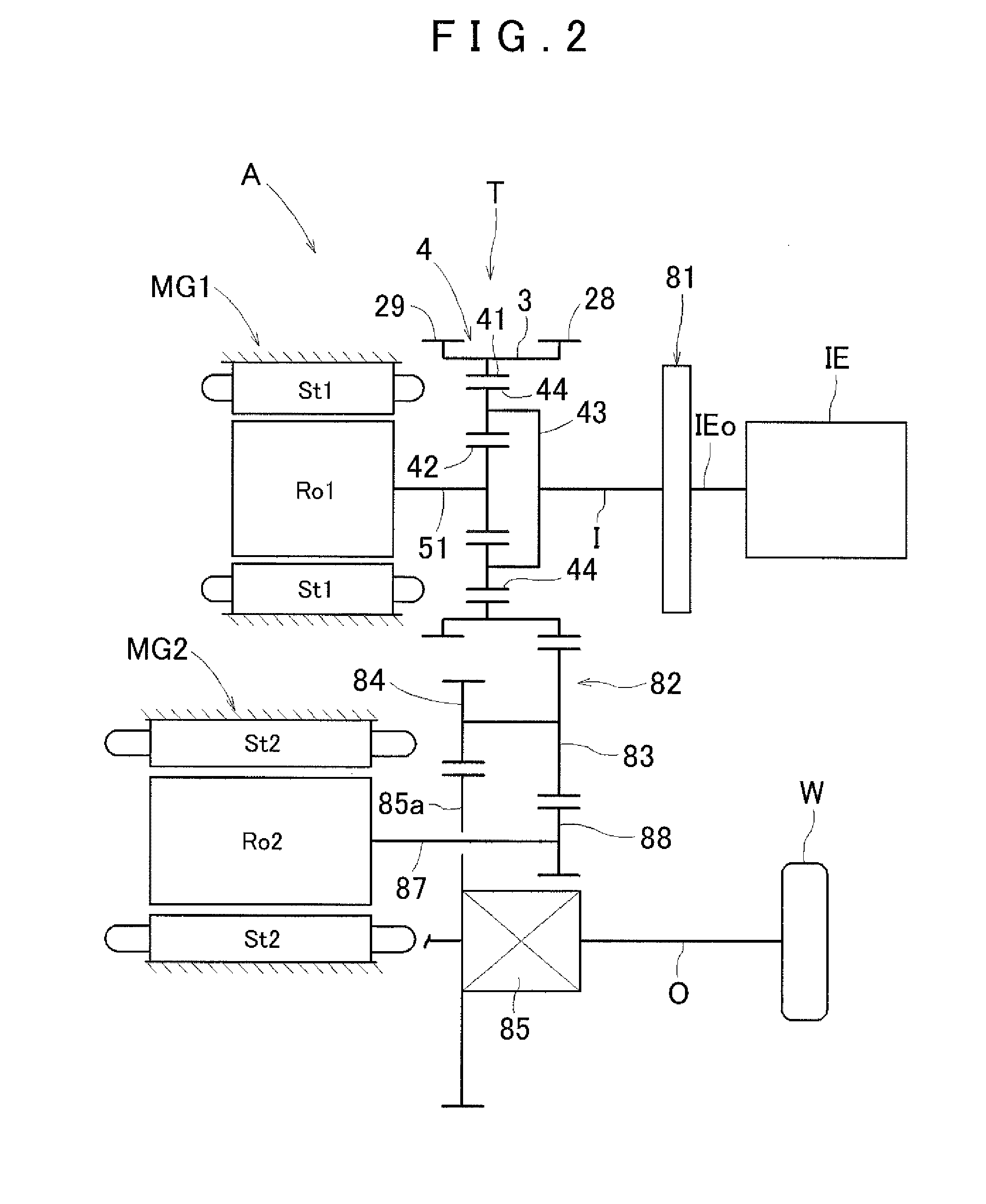

Hydraulic pressurizer system

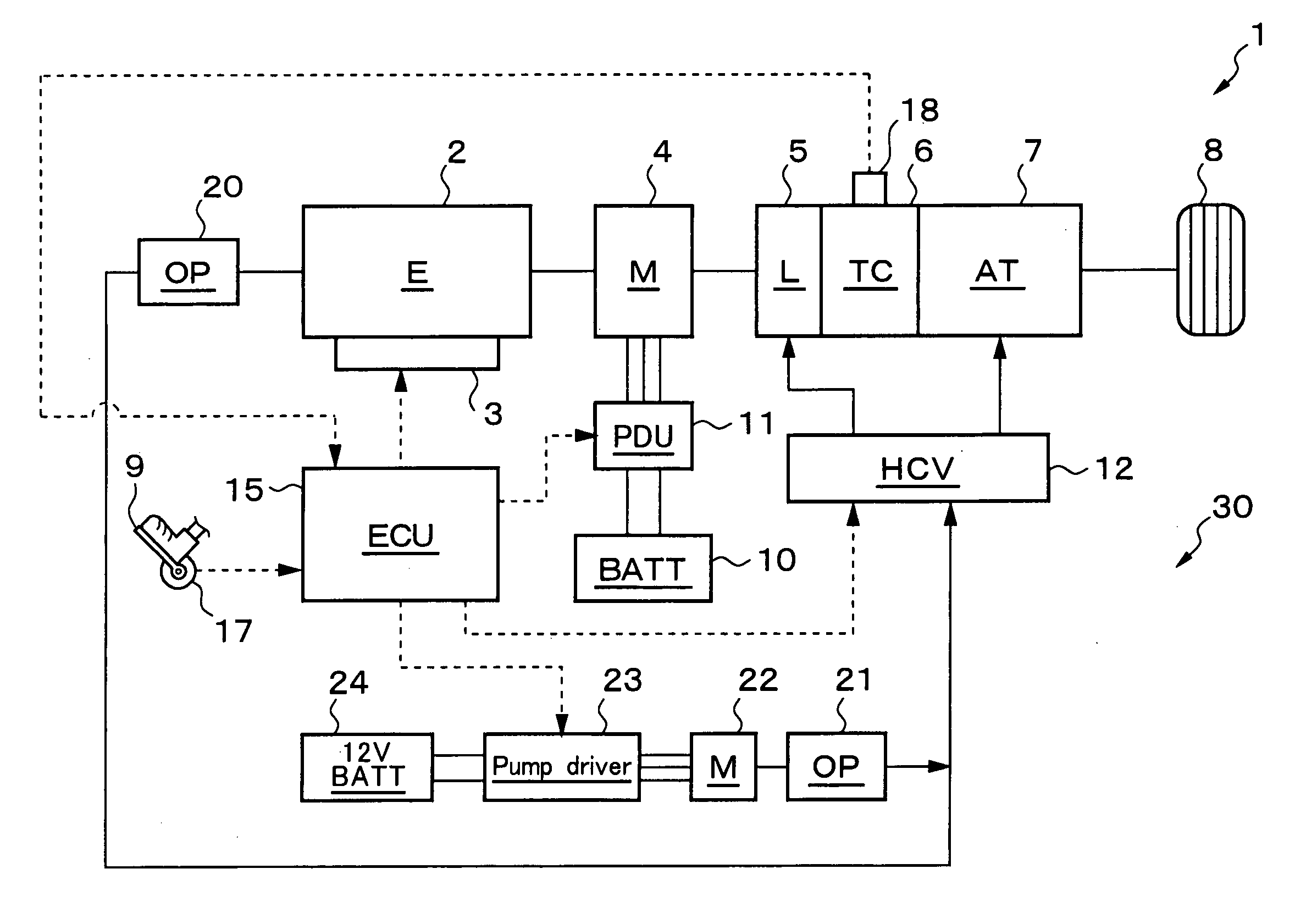

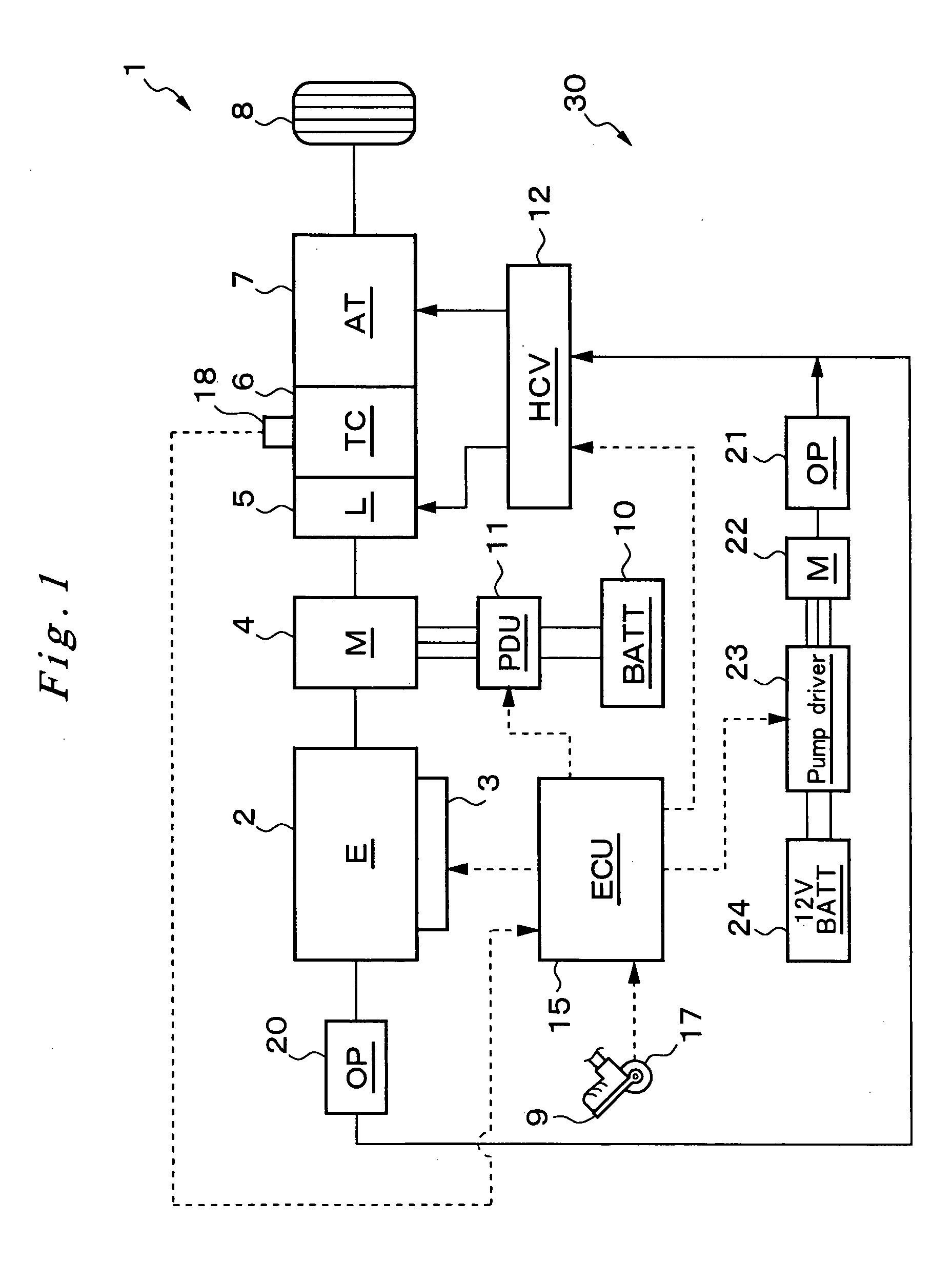

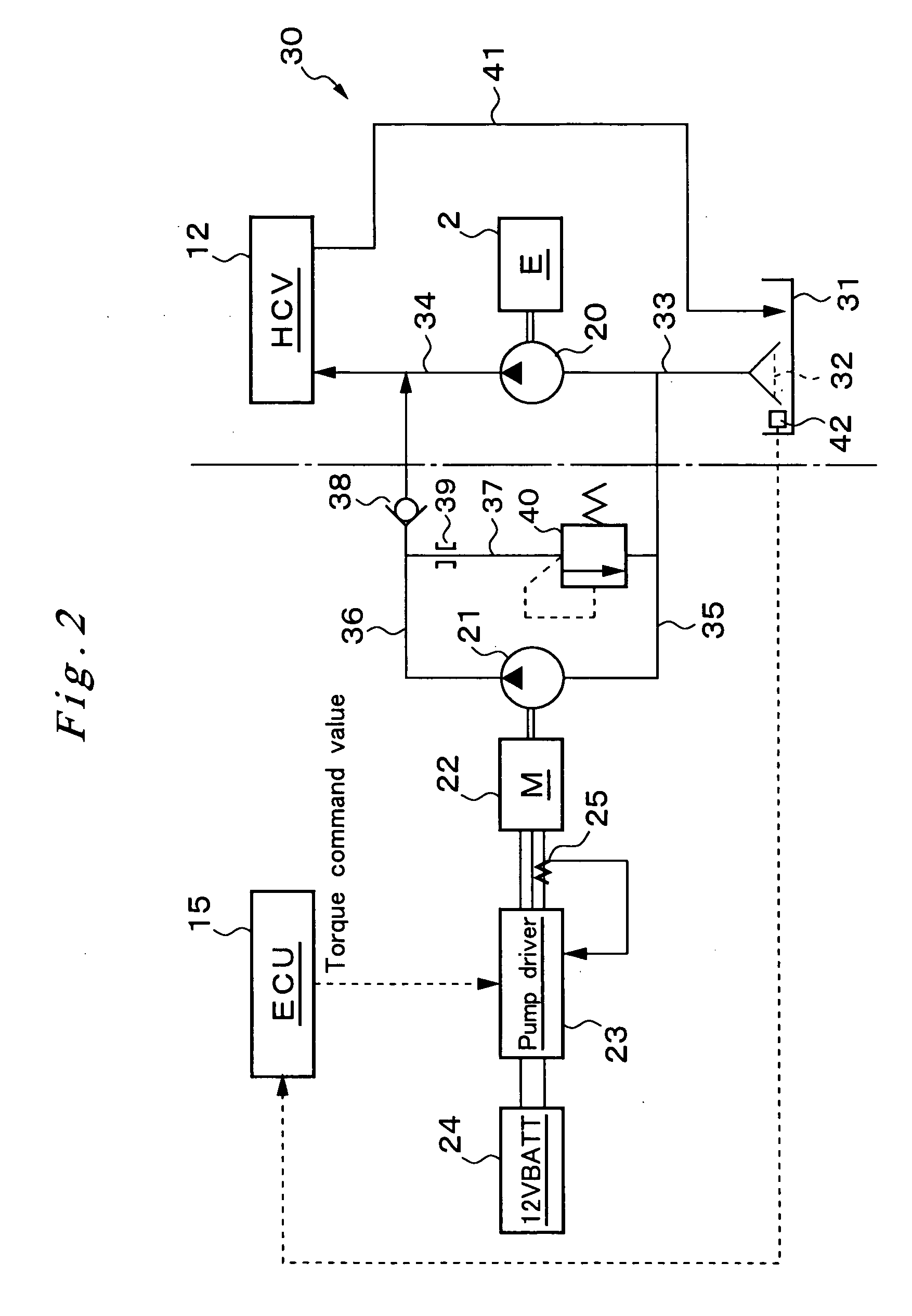

InactiveUS20060120876A1Maintain pressureCost-effective manufacturingRotary clutchesGearing controlHybrid vehicleMotor–generator

A hydraulic pressurizer system 30 comprises a drive source (an engine 2 and a motor generator 4), which drives a hybrid vehicle 1, a mechanical oil pump 20, which is driven by the drive source, an electrical motor 22, which is activated by a 12V battery 24, an electrical oil pump 21, which is driven by the electrical motor 22, and a control unit 15, which activates the electrical motor 22. The pressurizer further comprises a ratio-change mechanism 7, which is activated by hydraulic oil supplied by the mechanical oil pump 20 and by the electrical oil pump 21 to establish a speed change ratio, at which the rotational driving force of the drive source is transmitted to wheels 8 with a rotational speed change. The control unit 15 memorizes a characteristic value CV, which is specified from the temperature of the hydraulic oil and from the rotational speed of the electrical motor 22, and a threshold value NTH2 for the rotational speed Np of the electrical motor 22, which threshold value corresponds to the characteristic value CV. While the control unit 15 is executing a so-called idling-stop control, it cancels the idling-stop control if the rotational speed Np of the electrical motor 22 reaches the threshold value NTH2.

Owner:HONDA MOTOR CO LTD +1

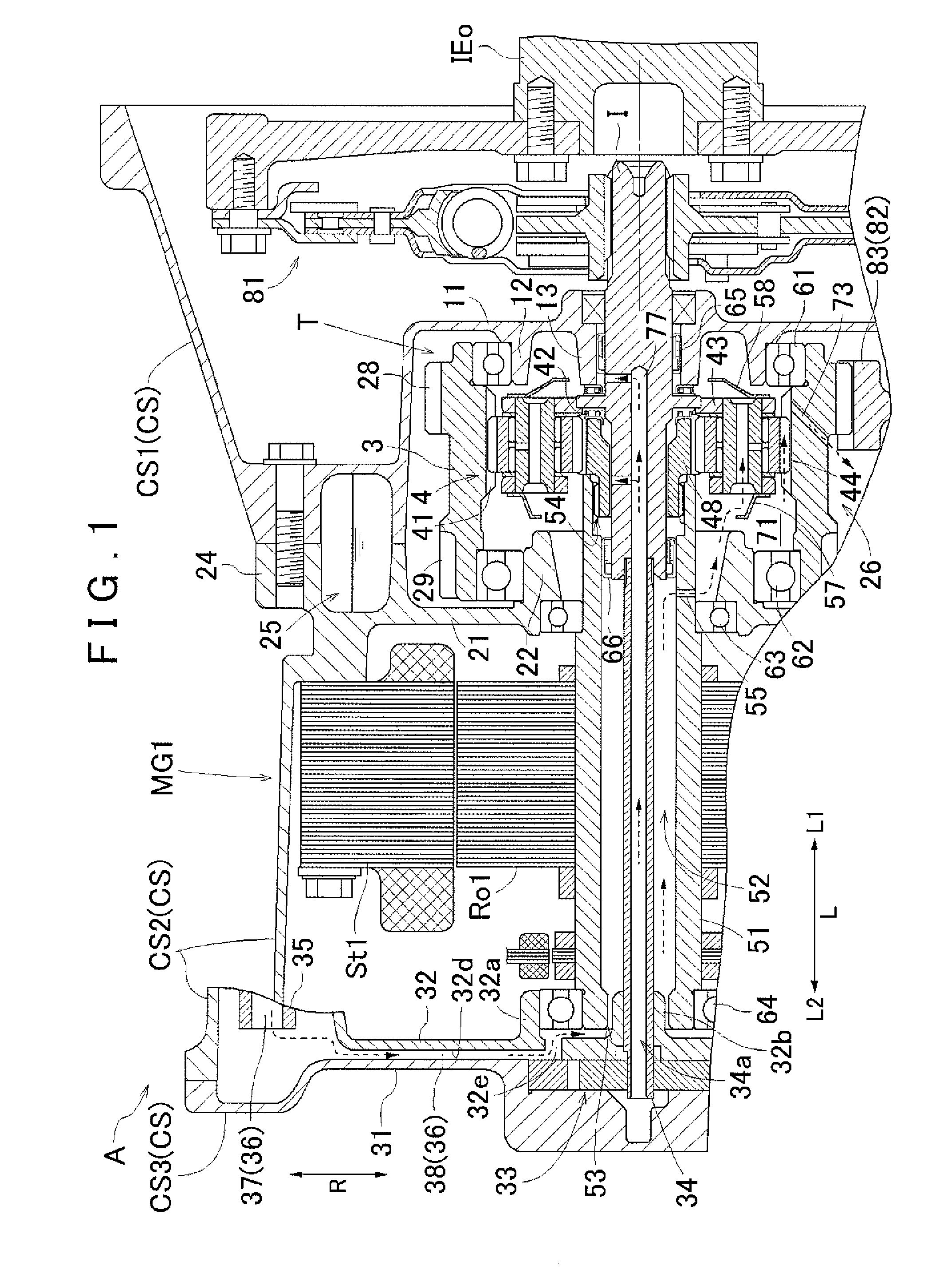

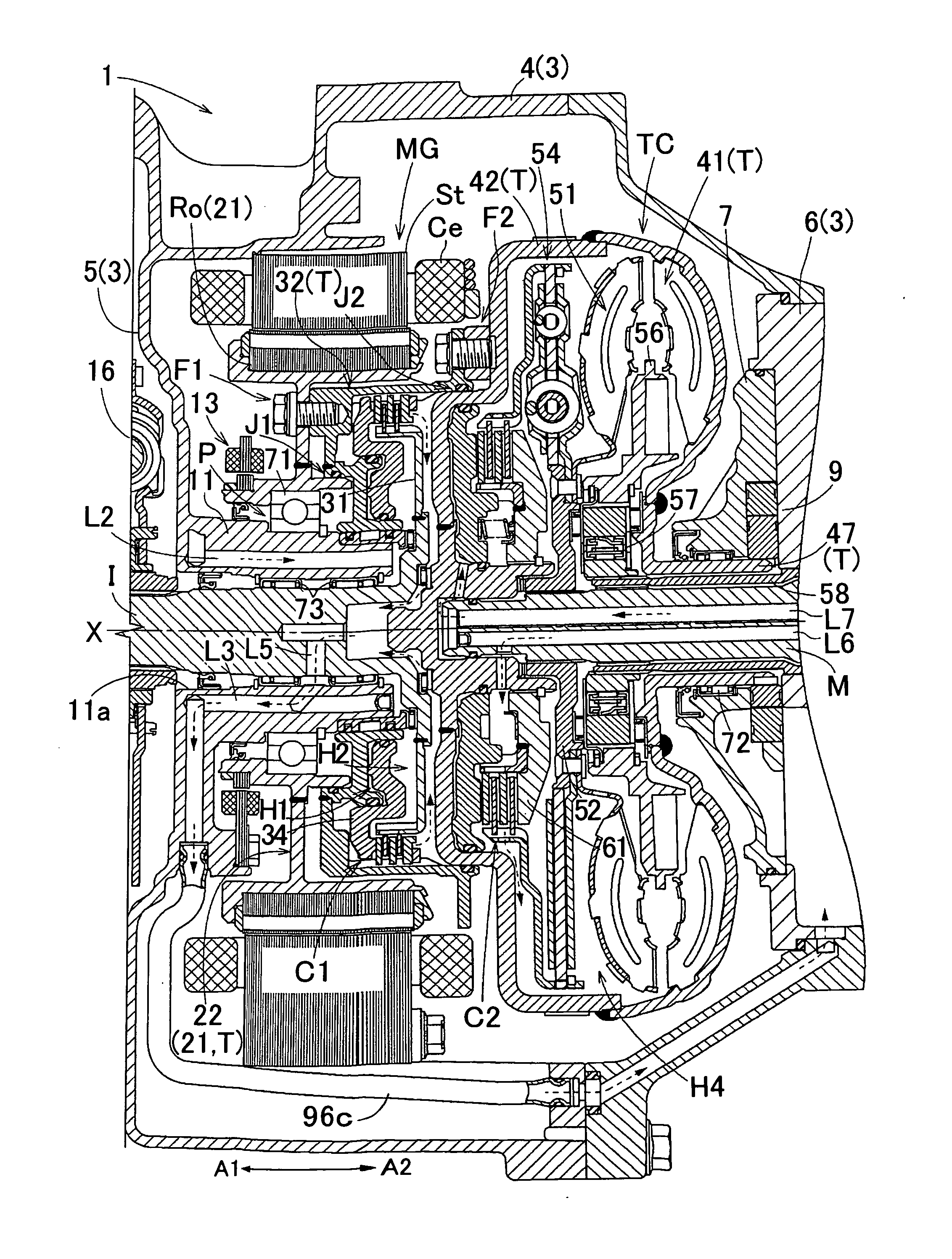

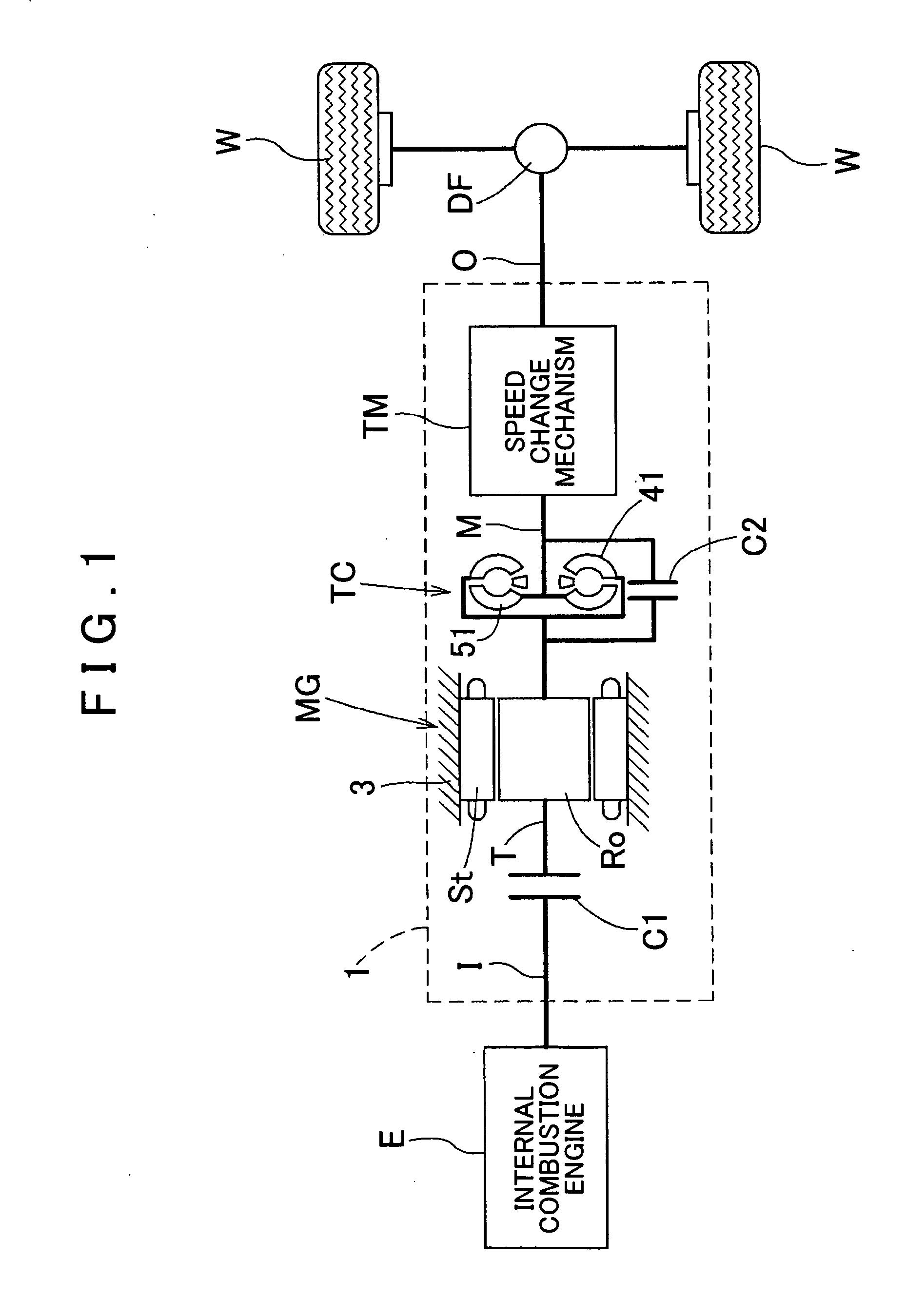

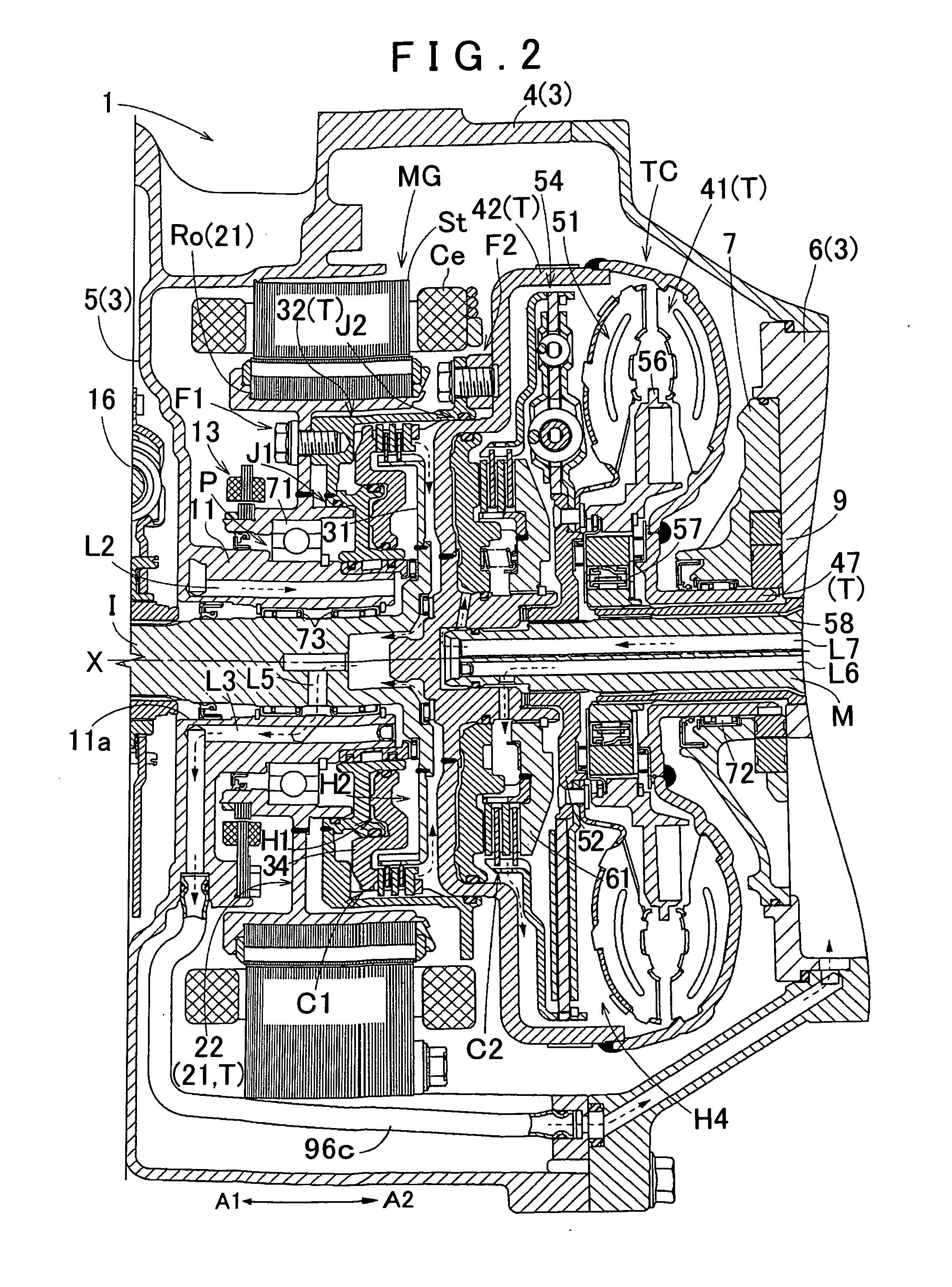

Vehicle drive device

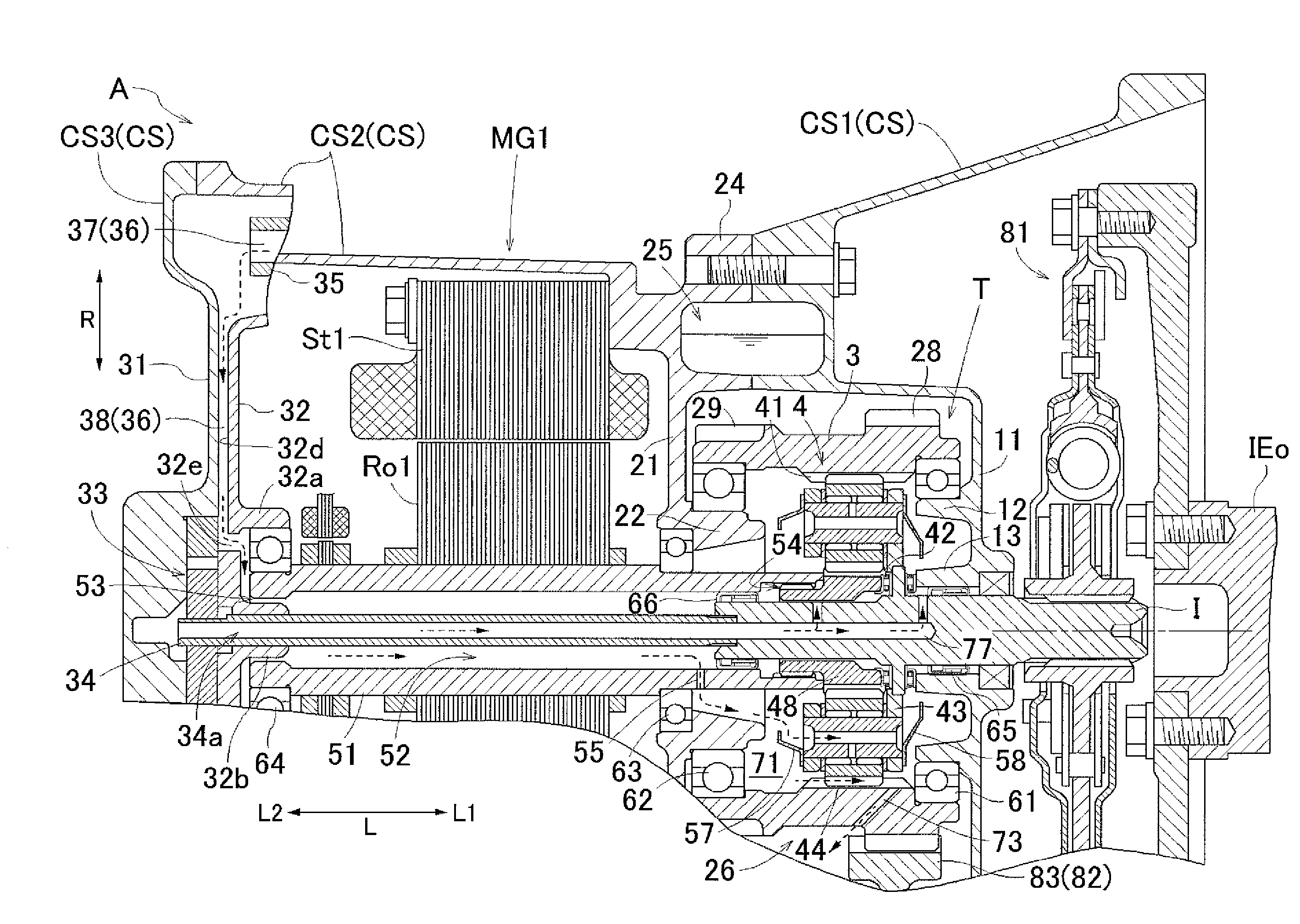

InactiveUS20130283972A1Smooth supplyPrecision lubricationHybrid vehiclesPropulsion using engine-driven generatorsElectric machineEngineering

A vehicle drive device configured with reduced axial dimensions, while still having appropriate lubrication. The vehicle drive device is configured with an input shaft coupled to an engine, a rotary electric machine, and an output shaft coupled to wheels. A power transfer mechanism couples input shaft, the rotary electric machine, and the output shaft. A case houses at least the rotary electric machine and the power transfer mechanism. An oil reserving portion capable of reserving oil supplied by rotation of the power transfer mechanism is provided above the rotor shaft inside the case. A communication oil passage is oriented between the oil reserving portion and an inner circumferential space formed inside the rotor shaft. The rotor shaft is disposed to be inserted into the inside housing space, and has a supply communication hole that communicates between the inner circumferential space and the inside housing space.

Owner:AISIN AW CO LTD +1

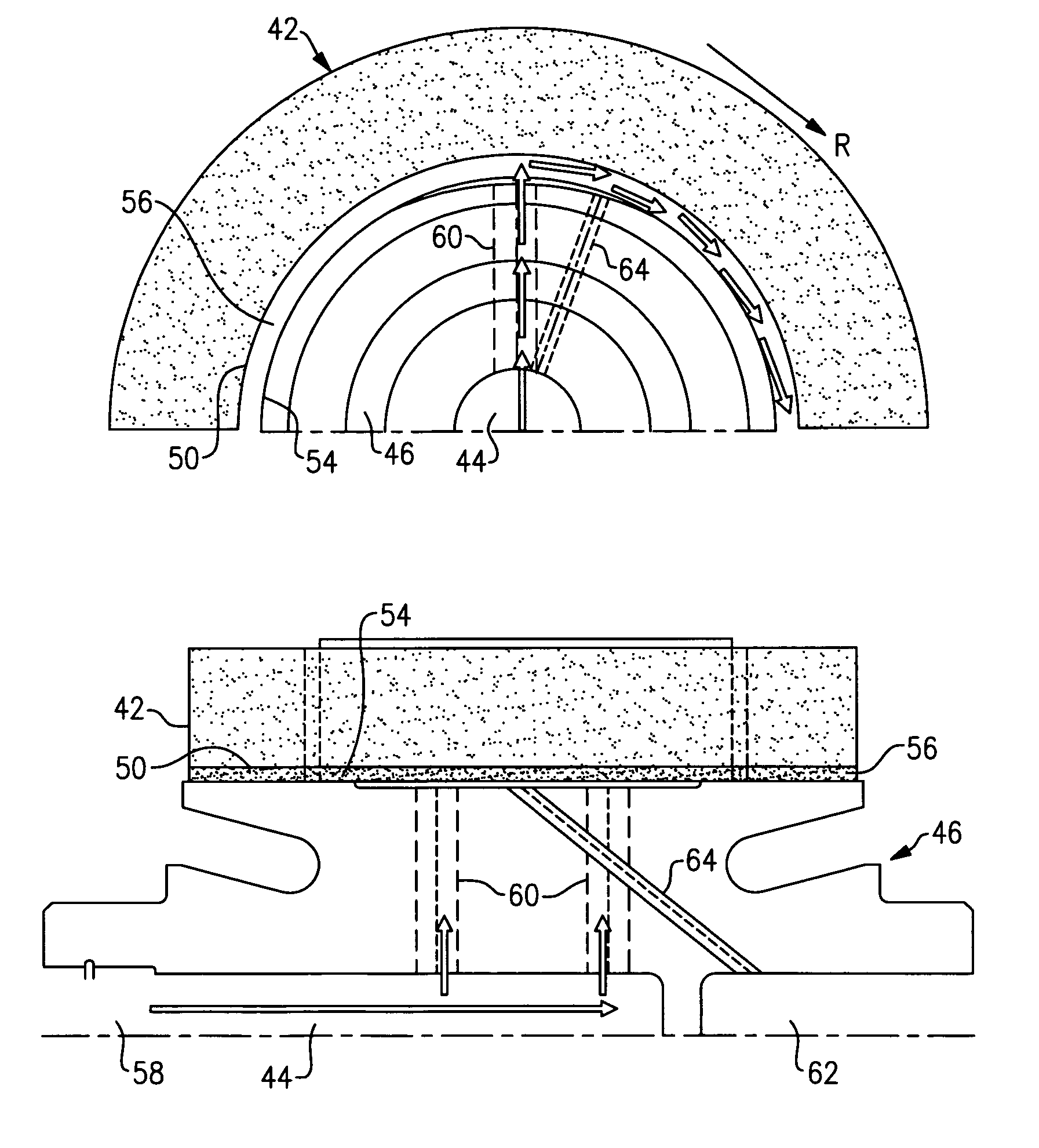

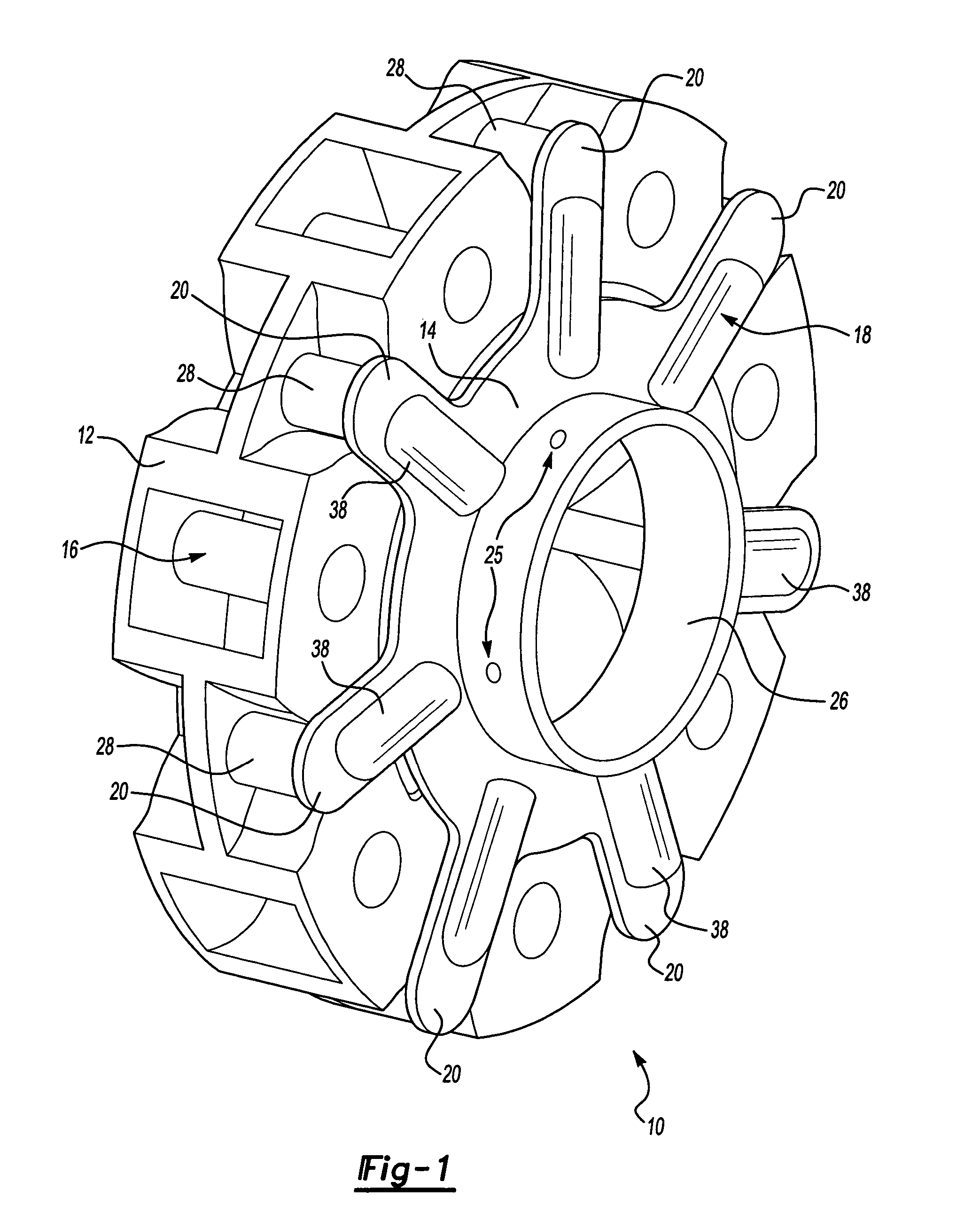

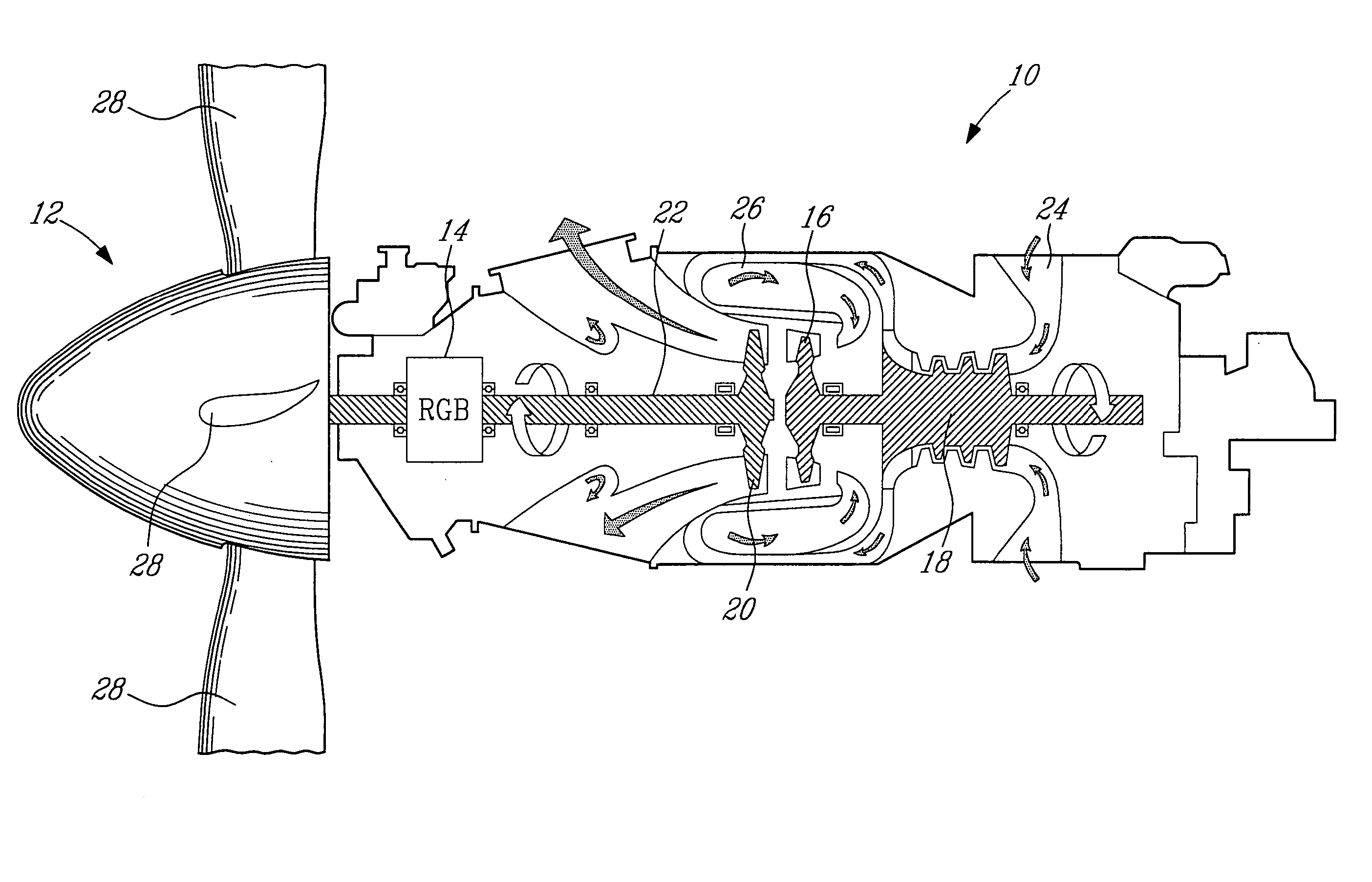

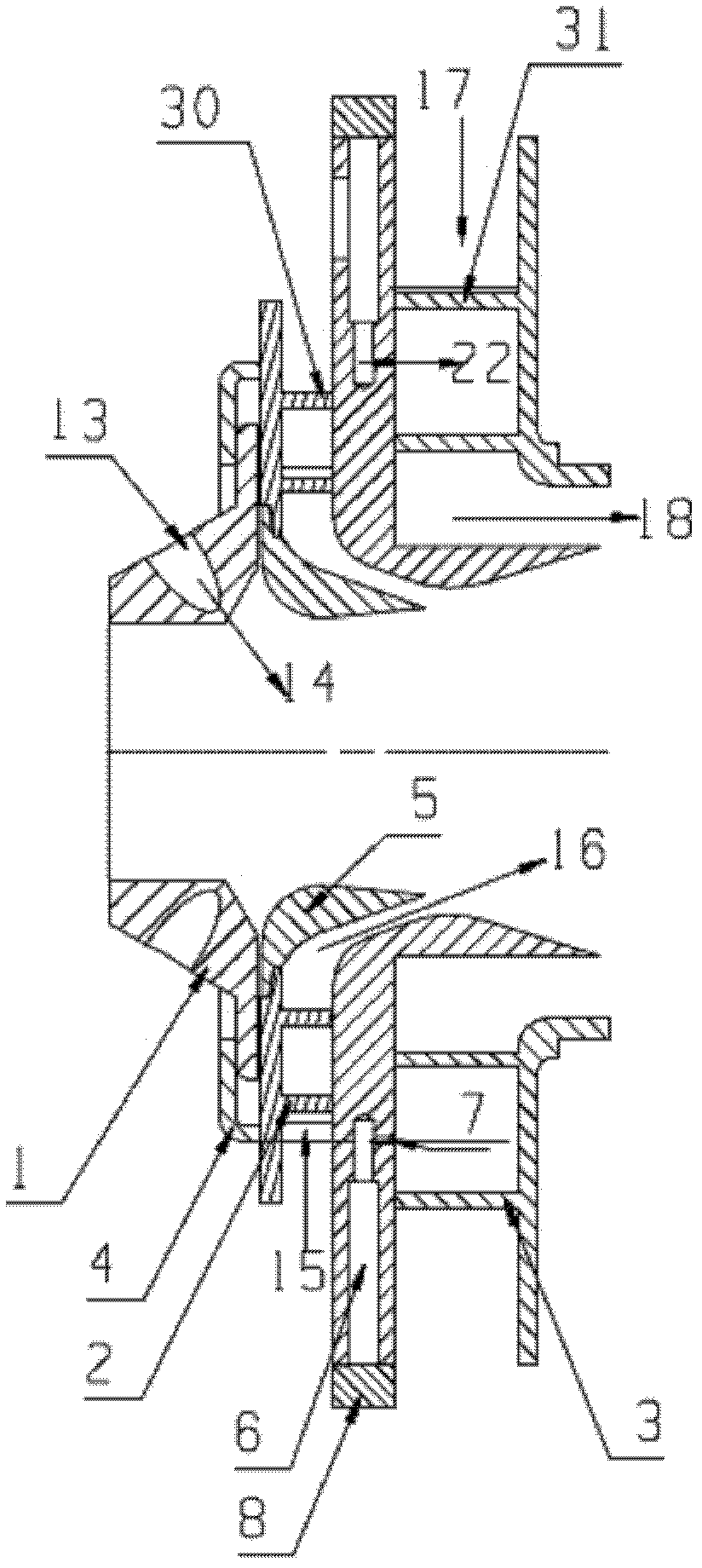

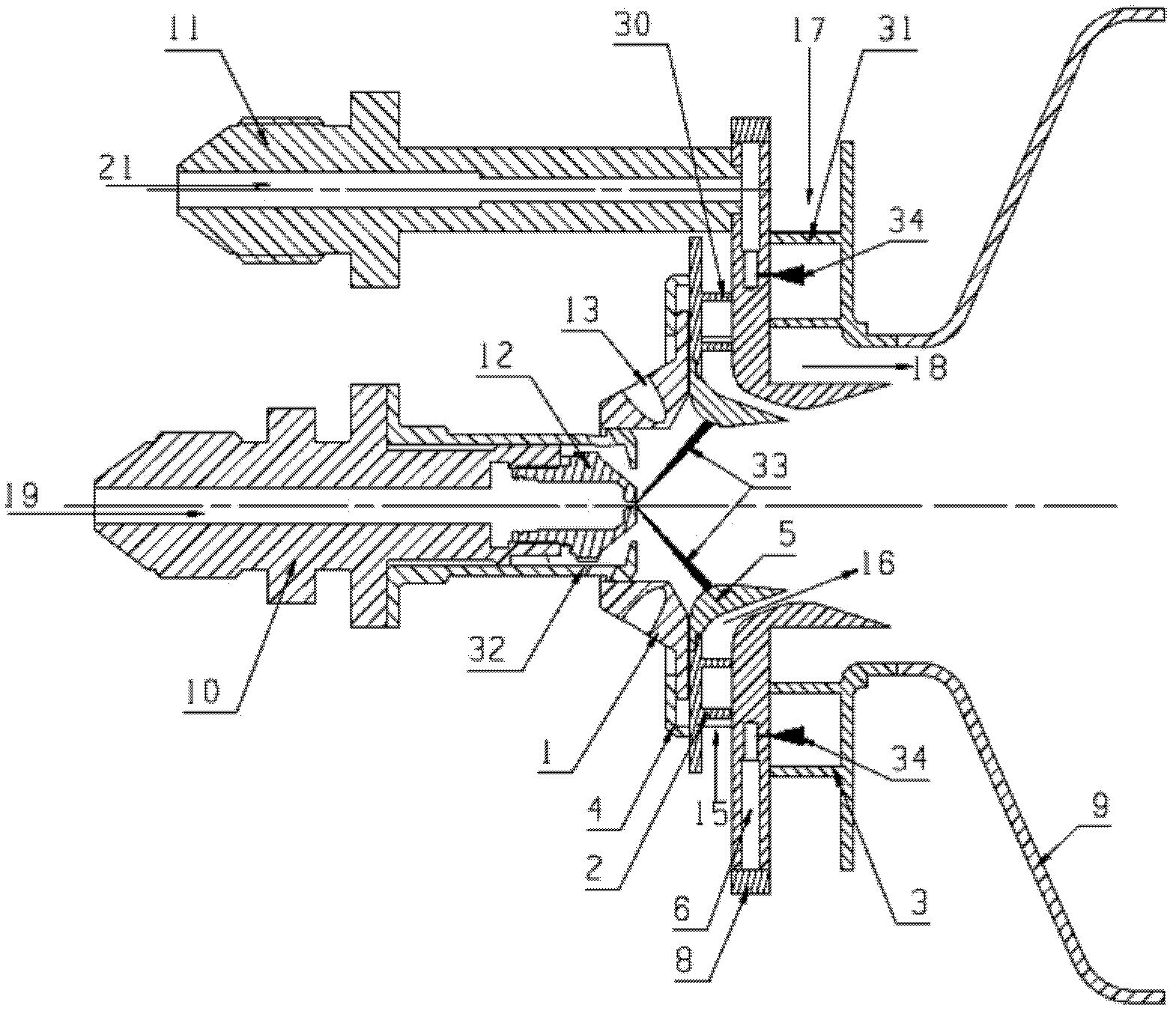

Uninterruptible oil supply in planetary system

A planetary carrier includes a journal bearing for supporting a planetary gear. The journal bearing receives lubricant to produce a lubricant film to support gear loads. A torque frame is attached to the carrier housing to transmit torque and to prevent twisting of the carrier housing. The torque frame includes several lubricant communication passages to provide lubricant to each of the separate journal bearings. Each of the lubricant communication passages includes an accumulator for storing lubricant during normal operation. The accumulator stores a desired amount of lubricant to provide lubricant to the adjacent journal bearing for the interim period between primary system stoppage and reestablishment of lubricant flow by a secondary system.

Owner:RAYTHEON TECH CORP

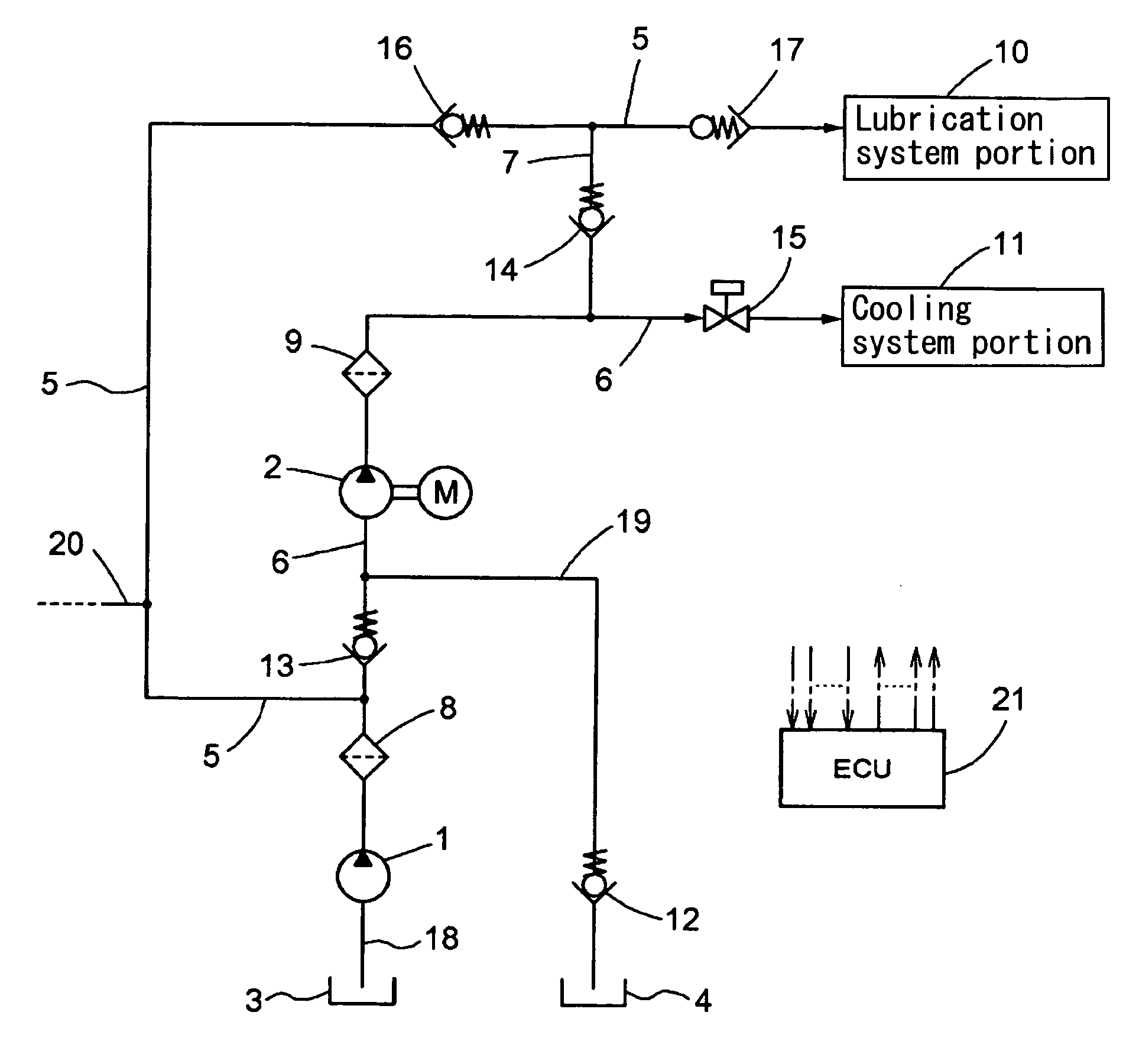

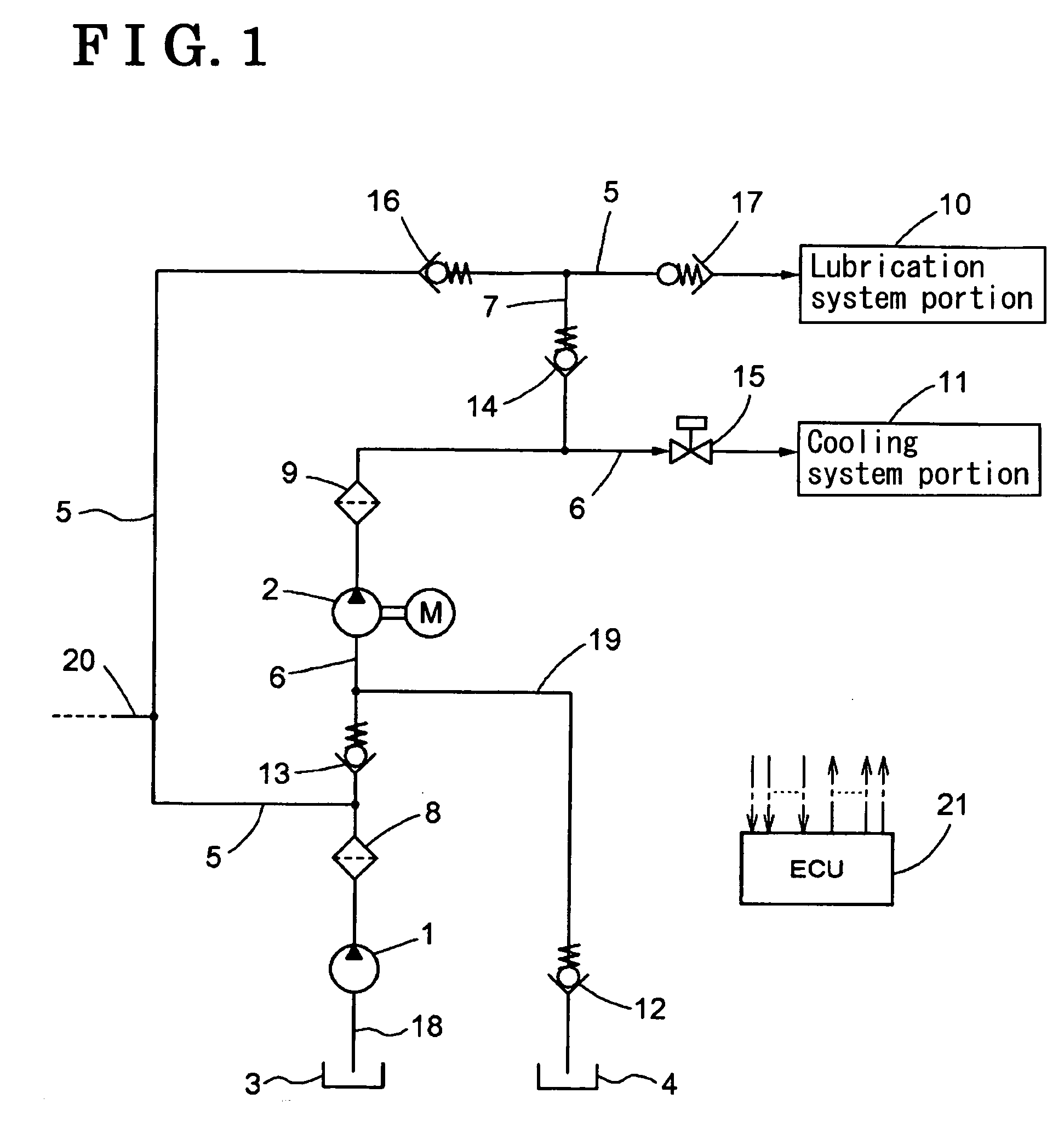

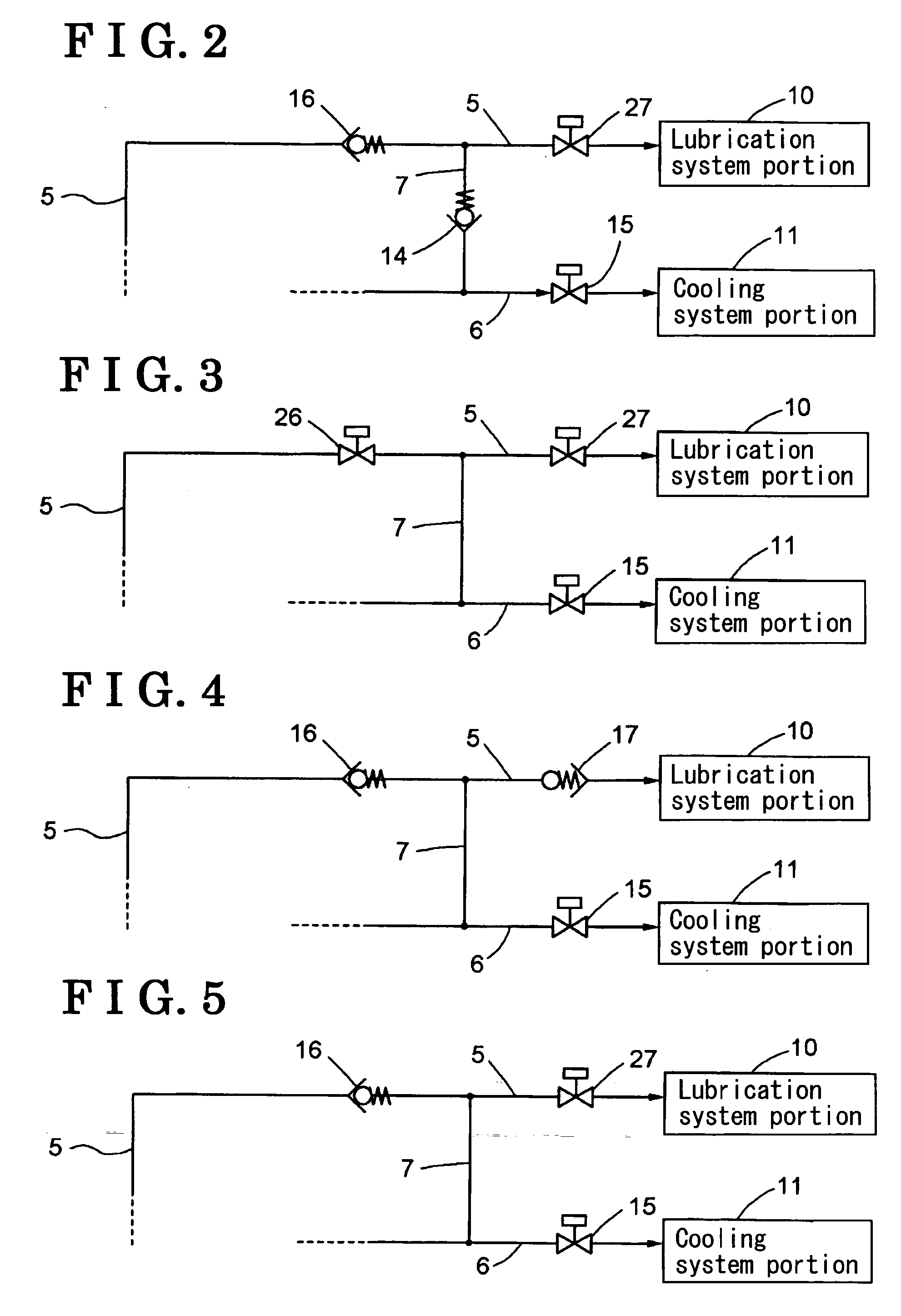

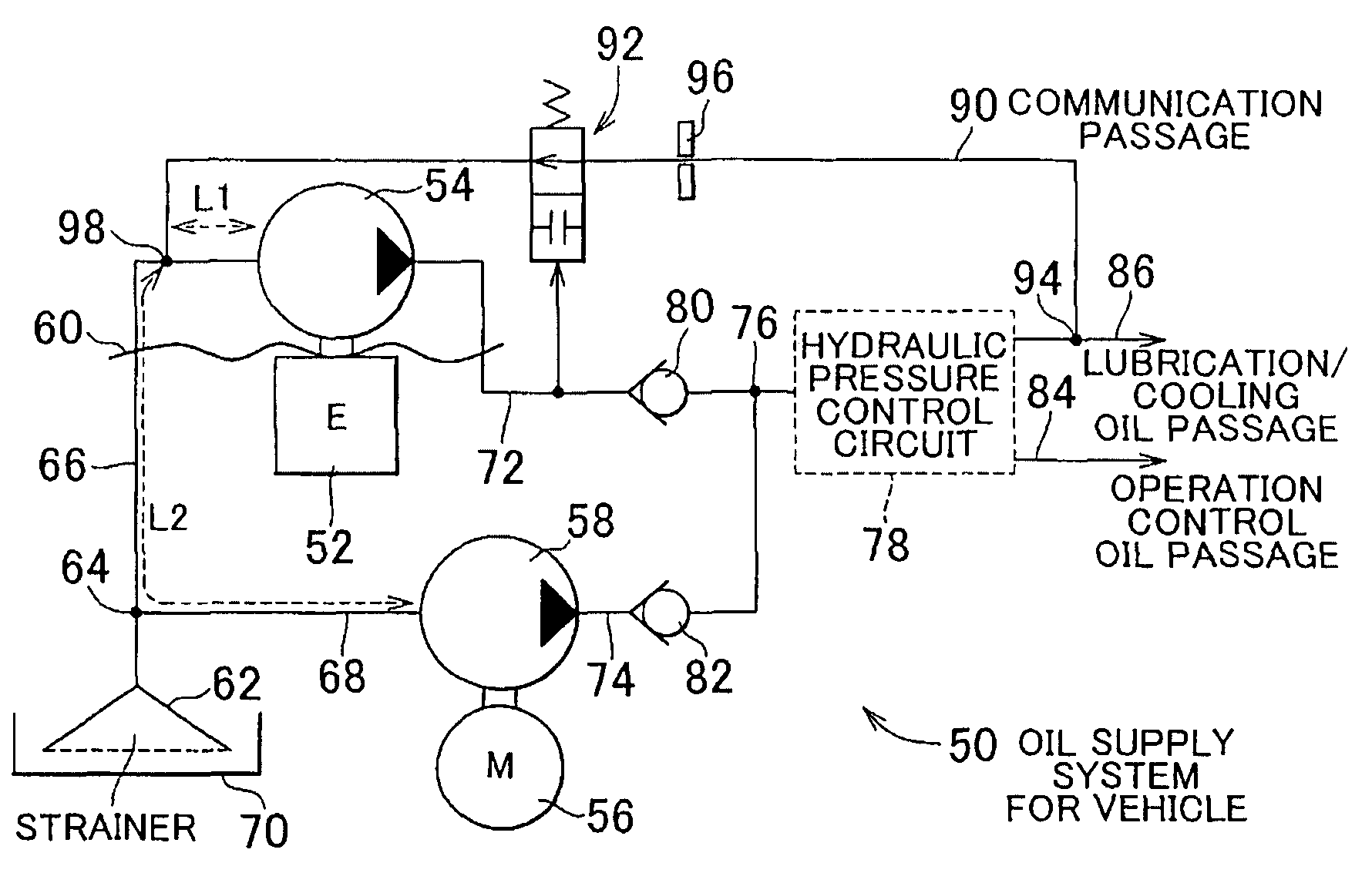

Oil supply system for vehicle

InactiveUS20080308355A1Deterioration of characteristicAvoid airGearboxesGear lubrication/coolingControl circuitLubrication

An oil supply system for a vehicle includes: a mechanical oil pump driven by an engine; an electric oil pump driven by an electric motor; a hydraulic pressure control circuit supplied with oil from the mechanical oil pump and the electric oil pump through an oil discharge passage for the mechanical oil pump and an oil discharge passage for the electric oil pump, which are connected to each other; a lubrication / cooling oil passage that is supplied with the oil from the hydraulic pressure control circuit; and a communication passage that provides communication between the lubrication / cooling oil passage and the mechanical oil pump. With this oil supply system, it is possible to prevent the electric oil pump from causing air-sucking noise, for example, in the motor-power cruise mode, and to improve the rising characteristics of the hydraulic pressure produced by the mechanical oil pump during startup of the engine.

Owner:TOYOTA JIDOSHA KK +1

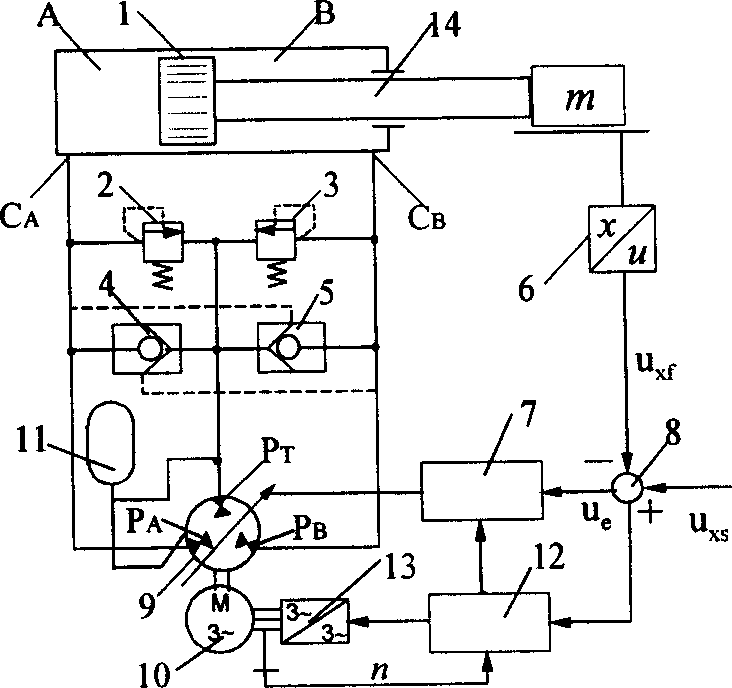

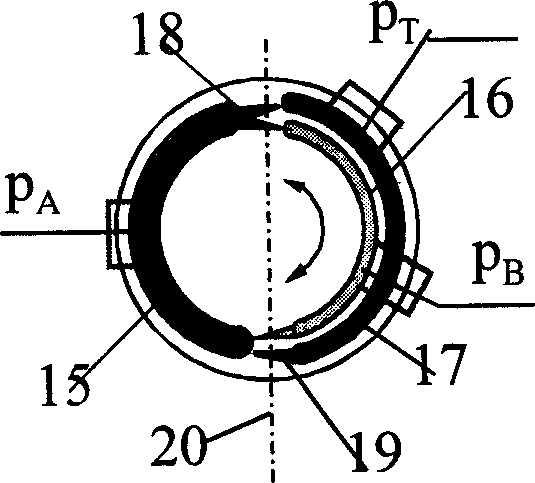

Closed electrohydraulic controlling system

InactiveCN1818382AControl movementPromote sportsFluid-pressure actuatorsPump controlHydraulic cylinderControl system

A closed electro-hydraulic control system comprised a differential hydraulic cylinder, two safety valves, a small path fluid one-way valve, a displacement transducer, a subtractor, two controllers, a hydraulic pump, a prime motor, a low-pressure oil-supply system and a rotational speed governor. The hydraulic pump has three oil ports connected with a rod-free cavity, a rod cavity of the differential hydraulic cylinder and the low-pressure oil-supply system separately.

Owner:TAIYUAN UNIV OF TECH

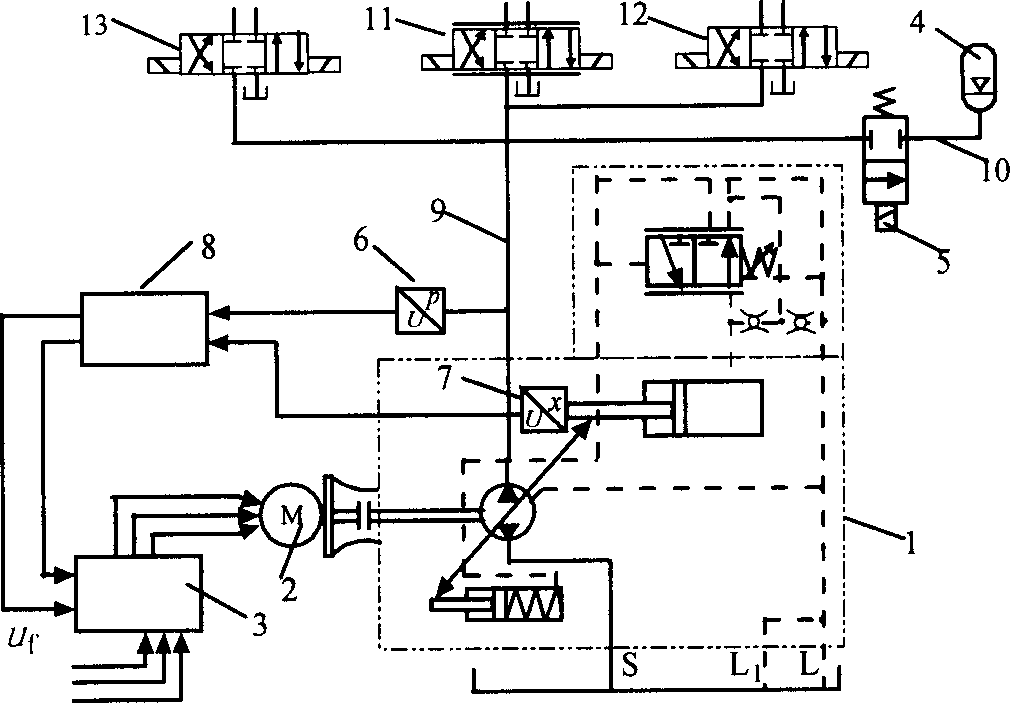

Low idling energy consumption hydraulic power source

InactiveCN1821574AIncrease speedReduce volumePump controlPositive-displacement liquid enginesConstant powerSolenoid valve

The hydraulic power source with low idling energy consumption belongs to the field of fluid transmission and control technology, and is one oil supply device designed to lower the energy consumption in the non-work period and partial load work condition of hydraulic system. The present invention consists of hydraulic pump, motor, motor rotation speed controller, energy accumulator, solenoid valve, pressure sensor, displacement sensor, controller, pipeline, executor controlling proportion valve, direction valves and other parts. The present invention features that the hydraulic pump is one constant pressure variable capacity pump with displacement sensor for detecting the displacement of the pump, altering the rotation speed of the pump can reach the composite functions of making the power source possess constant pressure, constant flow and constant power, and lowering the rotation speed in the non-work period and partial load work condition of hydraulic pump can lower the power consumption of the system.

Owner:TAIYUAN UNIV OF TECH

System and method for determining oil grade

The grade of oil used in a machine or apparatus can be determined by determining a temperature and pressure within an oil supply and determining the oil grade in response to determining the temperature and pressure.

Owner:CATERPILLAR INC

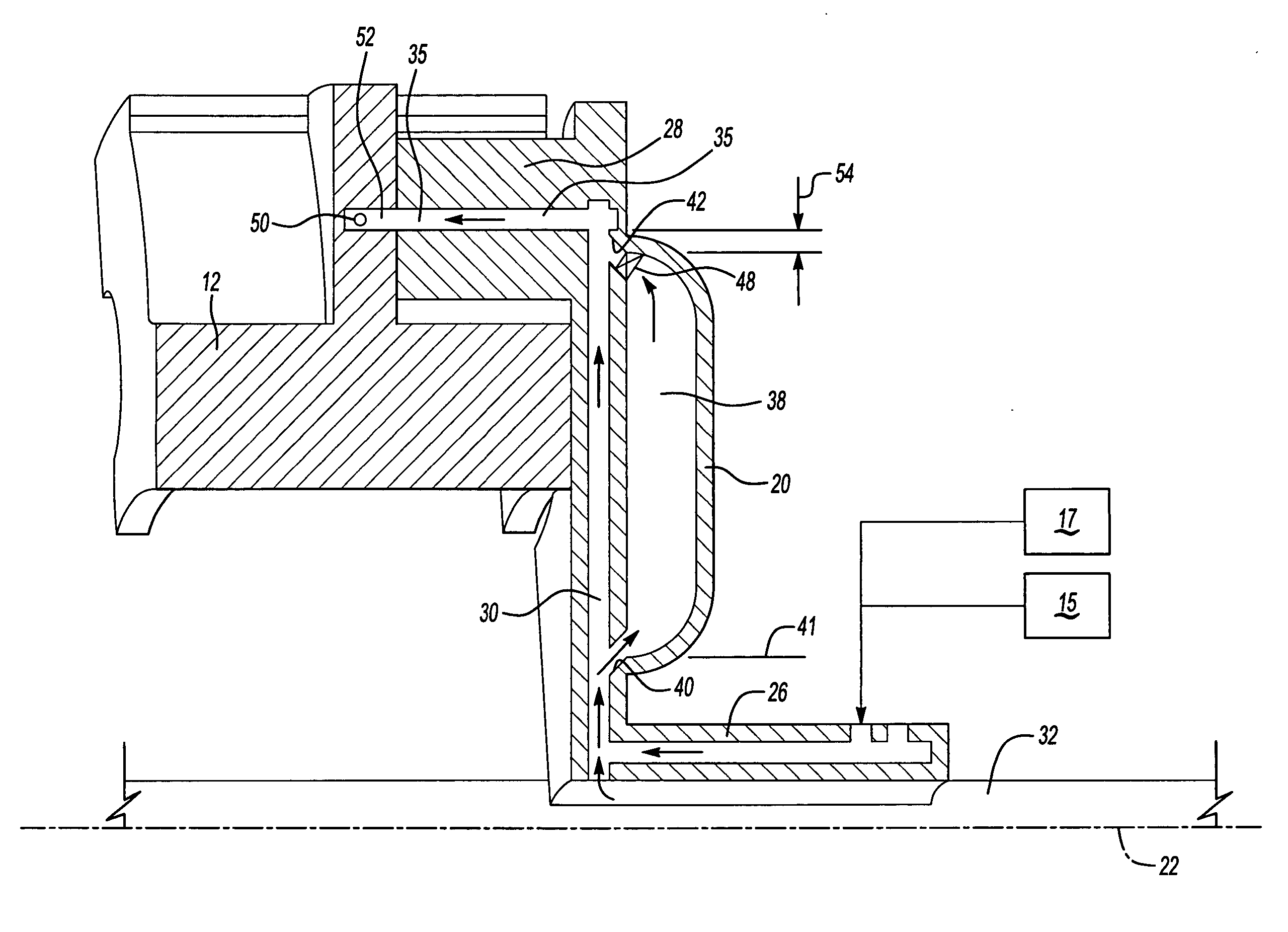

Vehicle drive device

ActiveUS20110240430A1Improve cooling effectImprove manufacturabilityRotary clutchesGear lubrication/coolingFluid couplingElectric machine

A drive device for a vehicle configured between an internal combustion engine and a wheel. The drive device includes a rotary electric machine, and an engagement device connecting the drive device to the engine by a fluid coupling using hydraulic pressure. A case houses at least a portion of the drive device and includes a support wall extending radially, and a cylindrical projecting portion projecting from the support wall toward a side in an axial second direction that is in a direction opposite to the axial first direction. The engagement device includes an operating oil pressure chamber supplied with the hydraulic pressure. A rotor member of the rotary electric machine is radially supported by the cylindrical projecting portion in a rotatable state via a support bearing. The cylindrical projecting portion is formed with an operating oil supply passage supplying oil to the operating oil pressure chamber.

Owner:AISIN AW CO LTD +1

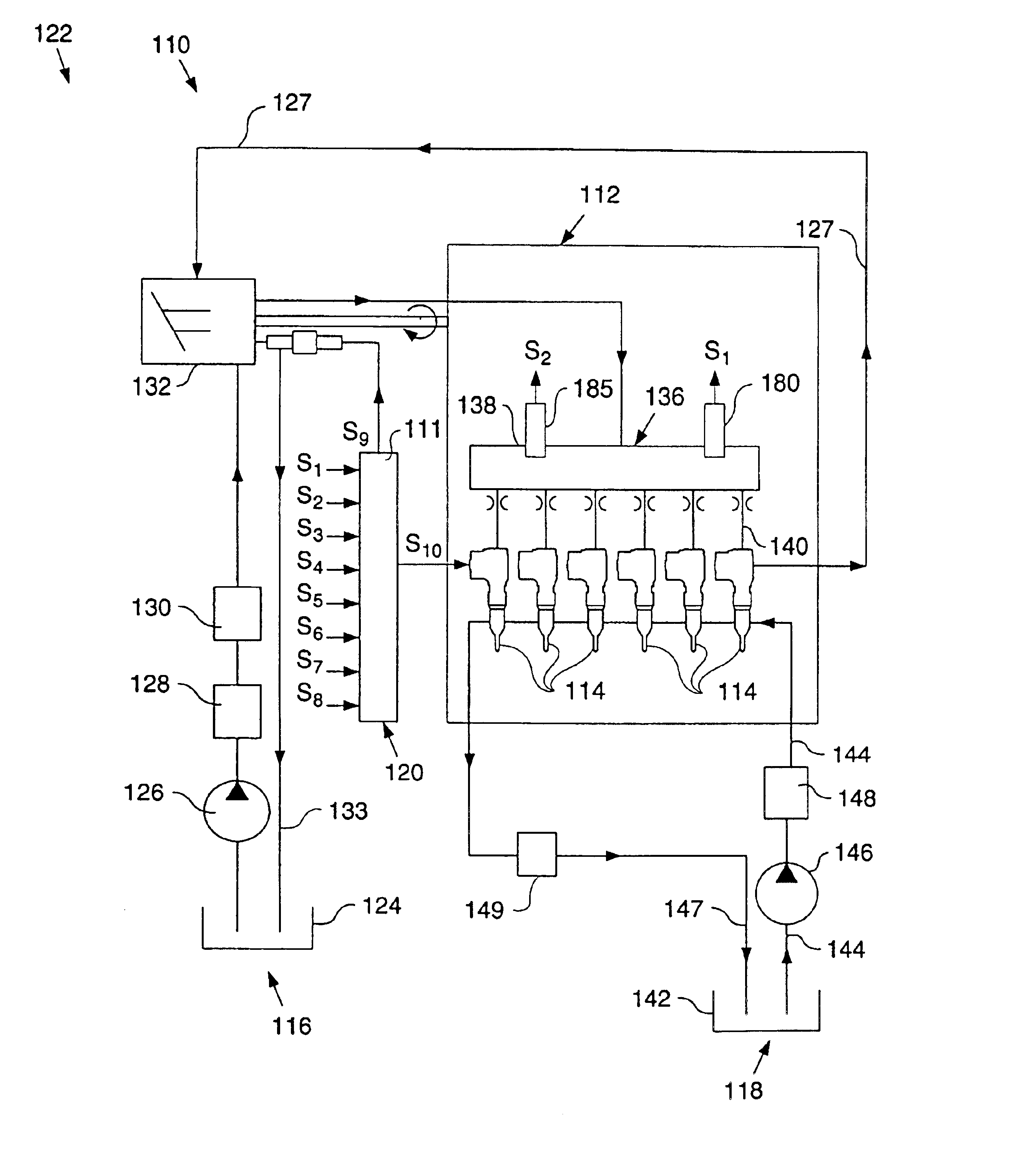

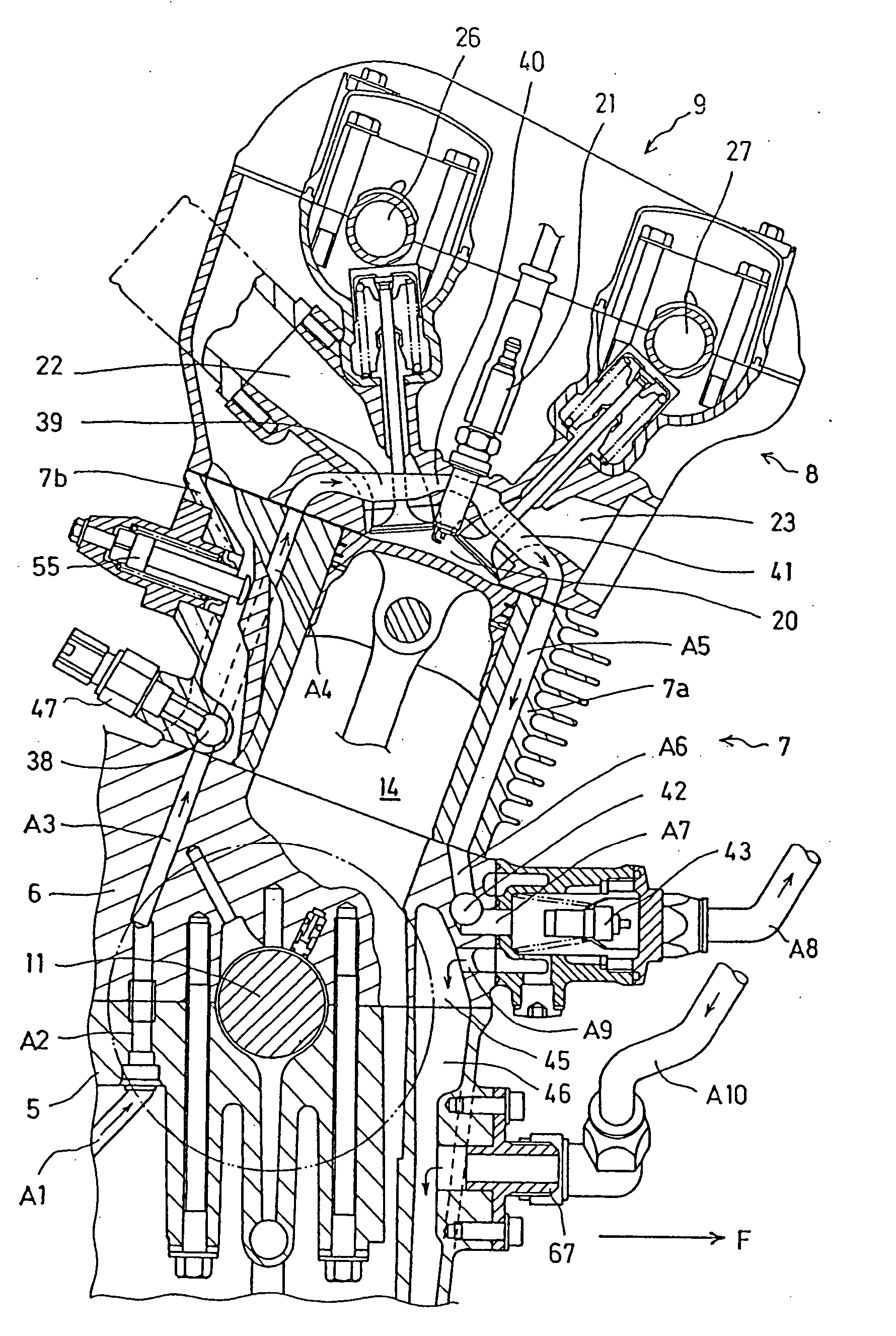

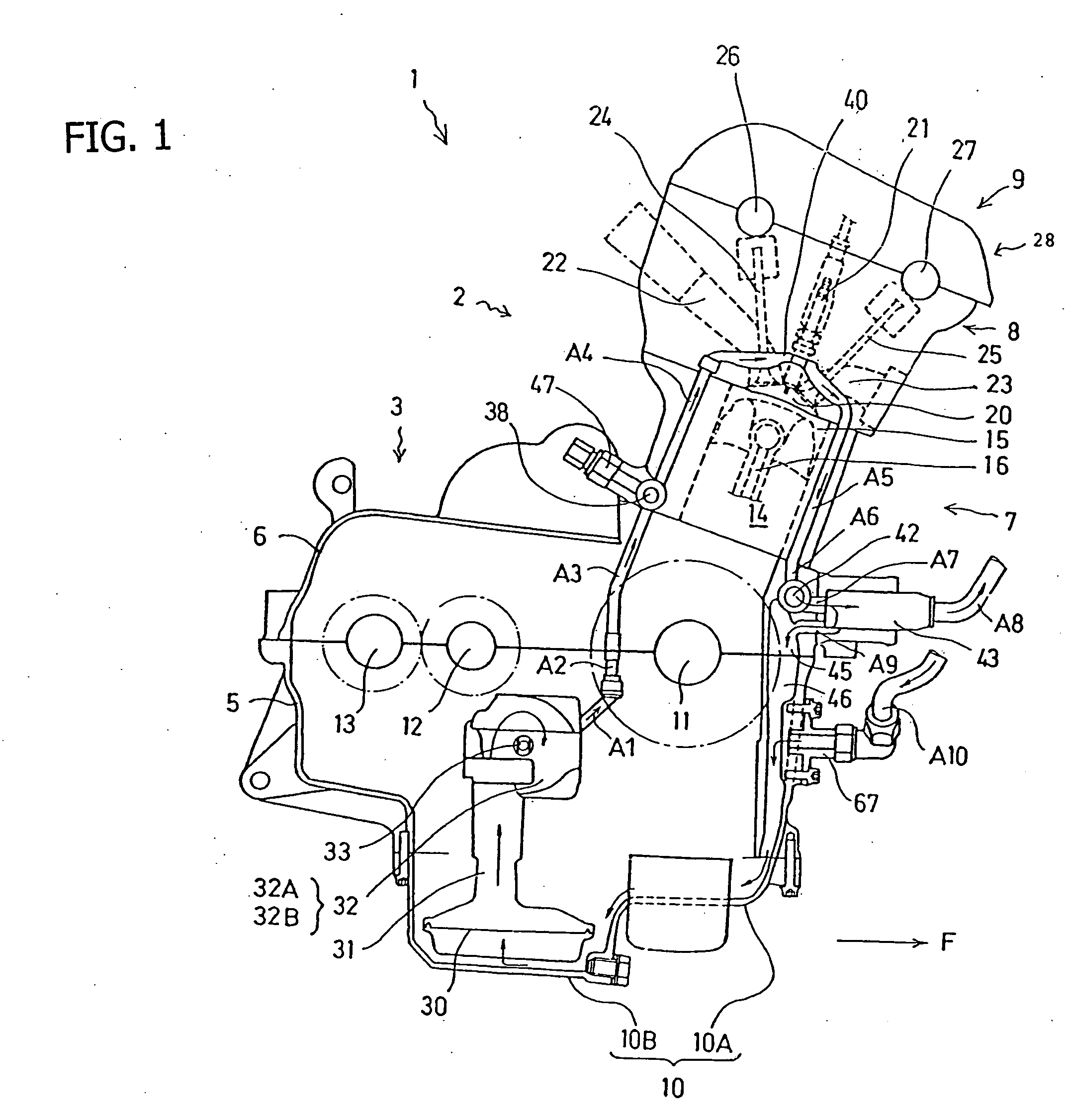

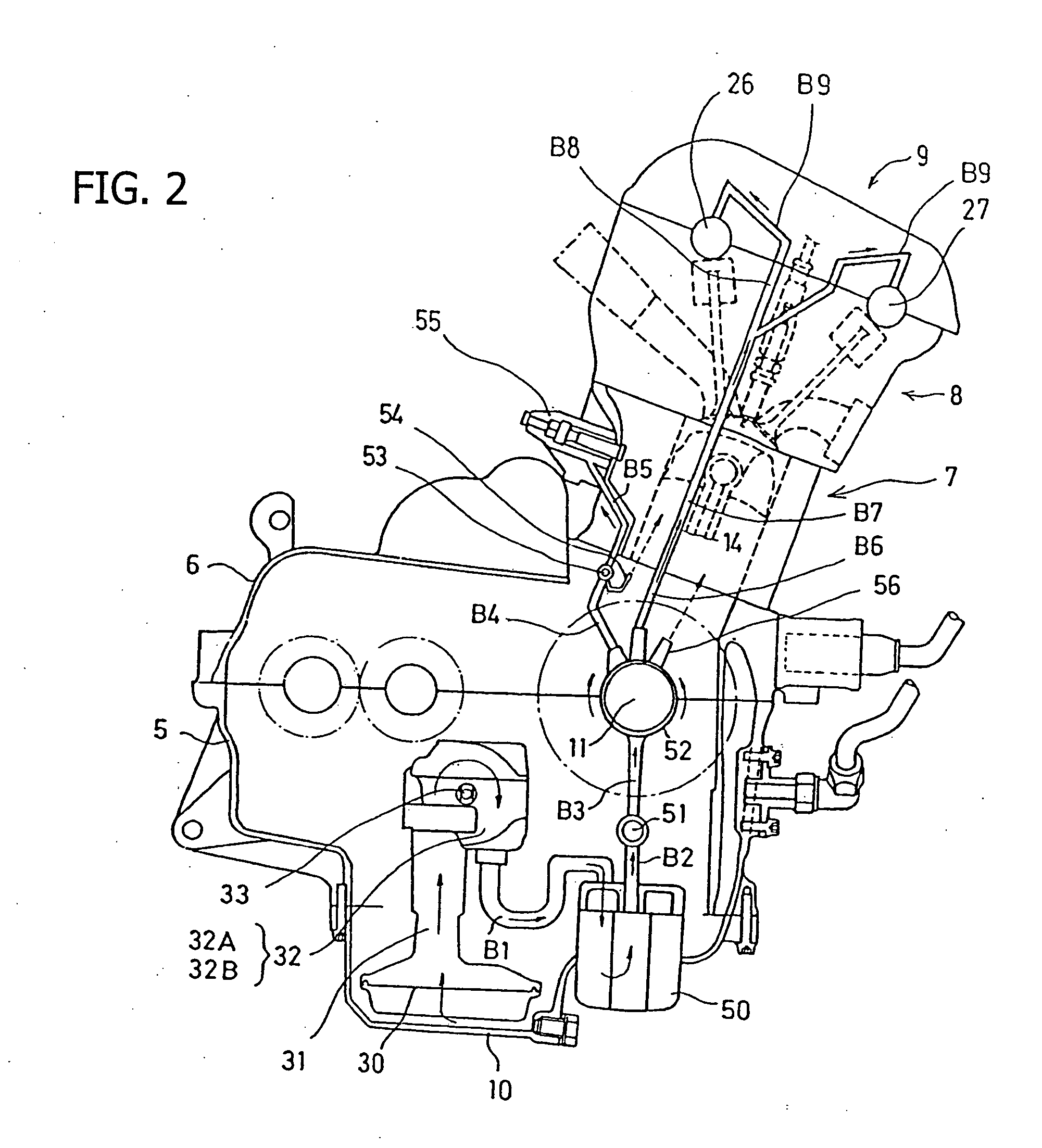

Cylinder head cooling structure for an internal combustion engine, including an oil temperature sensor and an oil temperature control system

ActiveUS20060065218A1Efficient use ofAvoid contactLiquid coolingCoolant flow controlTemperature controlCylinder head

A cylinder head cooling structure and an oil temperature control system are provided for an internal combustion engine having a plurality of cylinders, each having a plurality of intake ports and a plurality of exhaust ports. The engine includes cooling oil jackets surrounding the spark plugs in the cylinder head, a thermostat attached to the front surface of the crankcase independently of an oil filter, and an oil temperature sensor disposed on a rear face of the cylinder block above the crankcase in an oil supply path formed on the cylinder rear face for supplying oil to the oil jackets. Oil passages conducting oil into the oil jacket are provided between two separate parts of a bifucated intake port and between two separate parts of a bifurcated exhaust port, and only cooling system oil reaching high temperatures is allowed to flow through the thermostat, thereby improving temperature control response.

Owner:HONDA MOTOR CO LTD

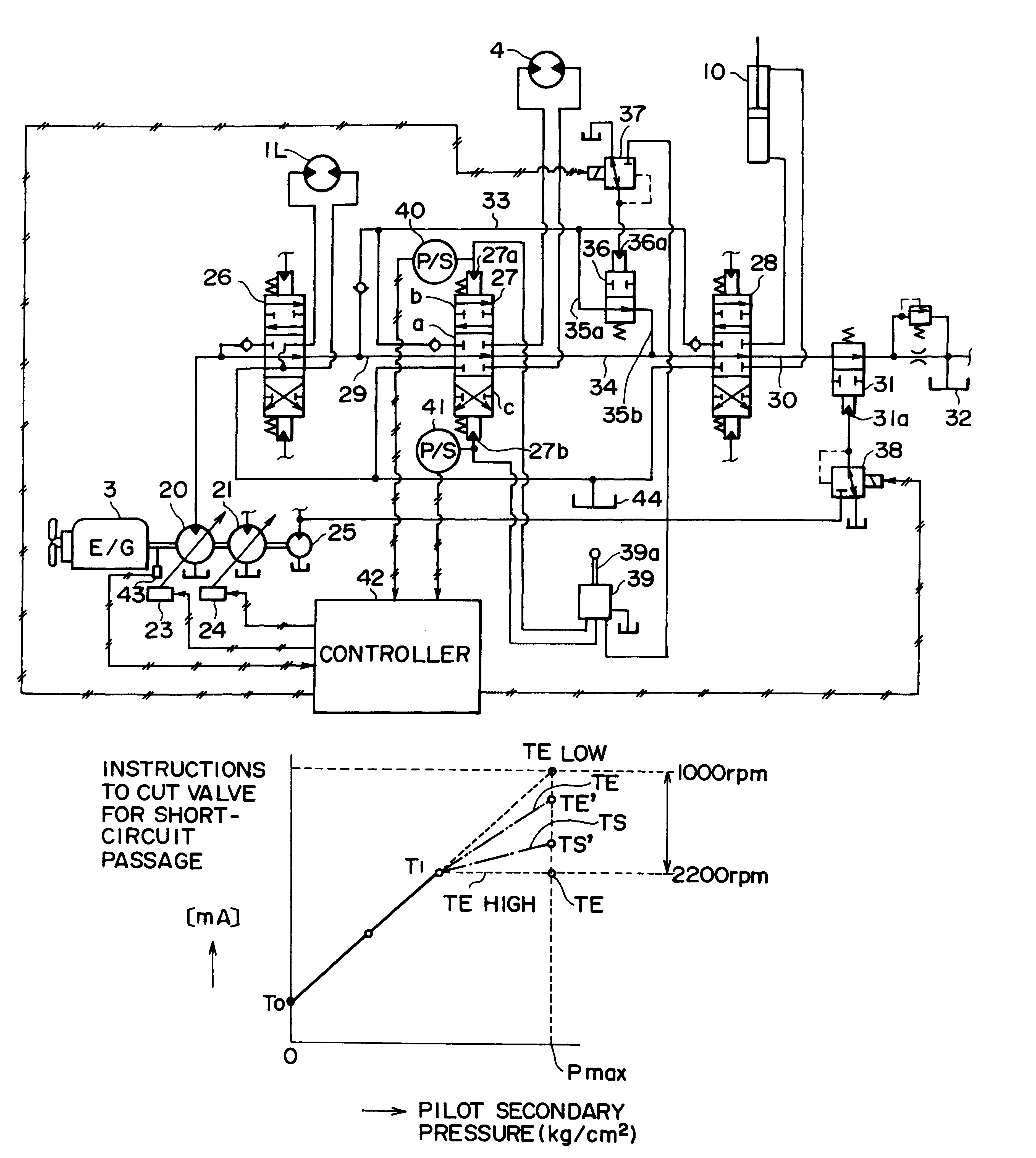

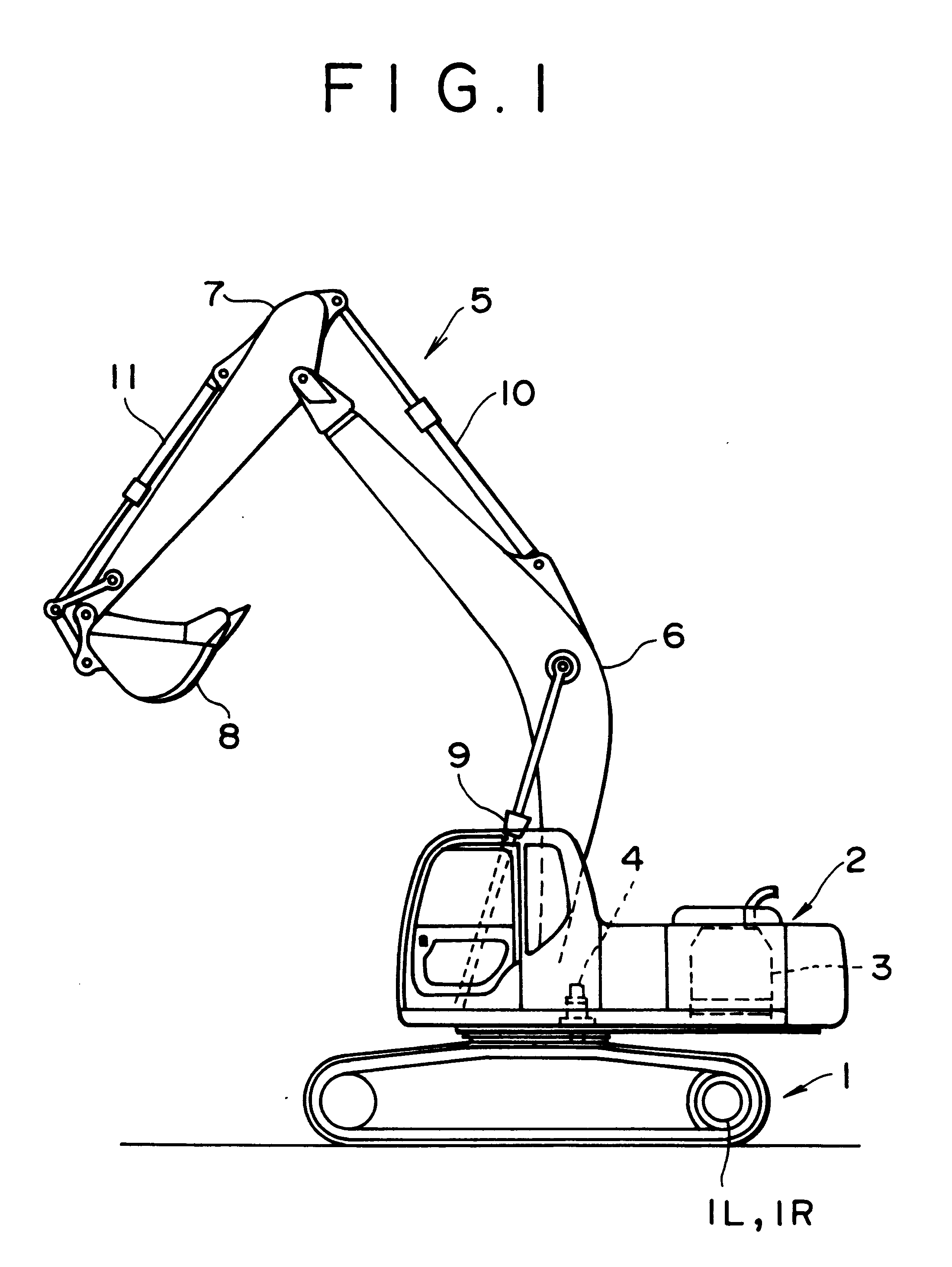

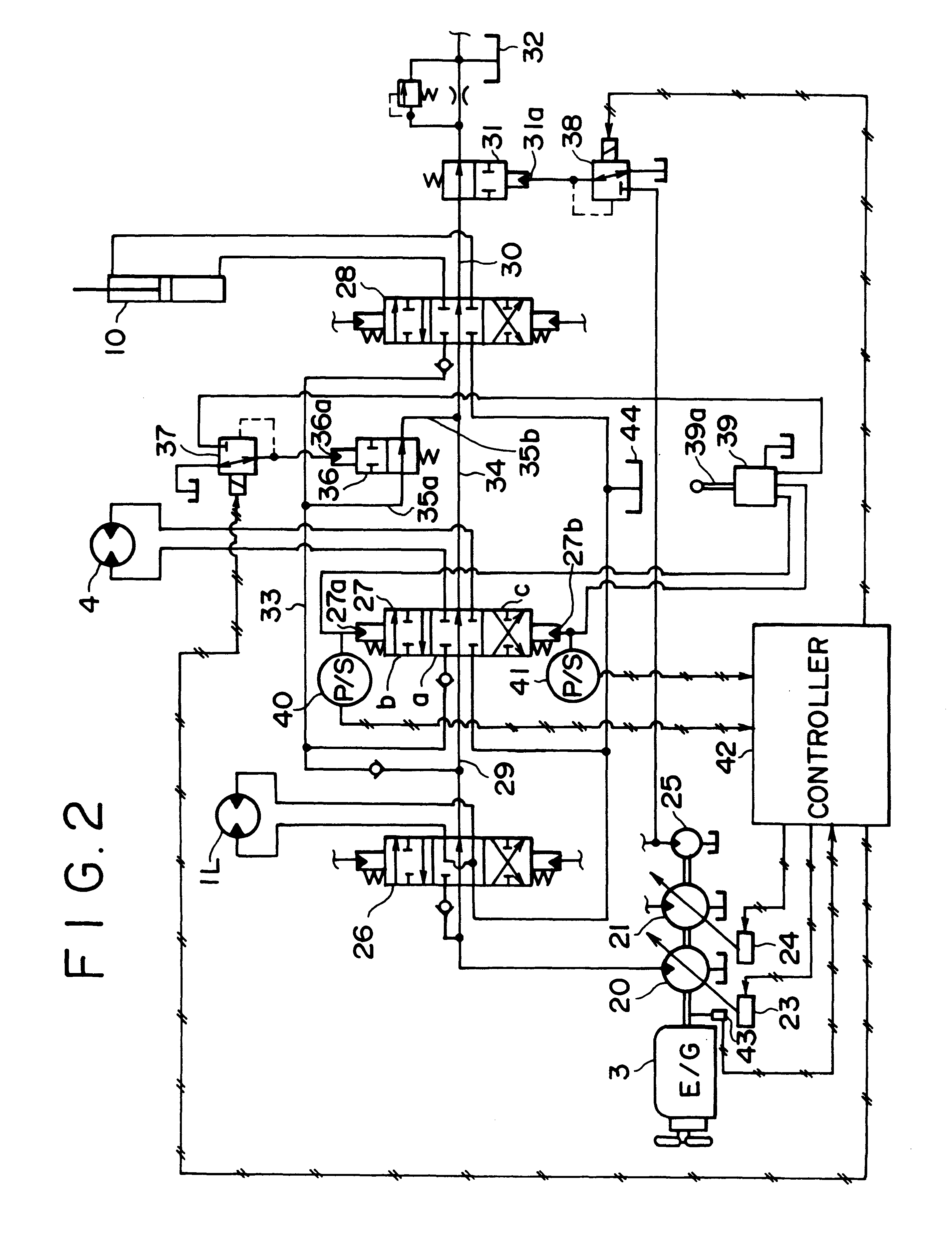

Hydraulic control device of a working machine

A hydraulic control apparatus for a working machine in which a flow rate and a direction of pressure oil discharged from a hydraulic pump are controlled by a control valve to supply it to a swing motor, comprising: a bleed-off oil path for bleeding off a part of the pressure oil supplied to the swing motor, a cut valve provided on the bleed-off oil path to adjust a bleed-off amount, a controller for controlling the cut valve through a solenoid proportional valve, and pressure sensors for detecting an operating amount of a remote control valve for swing, characterized in that the controller sets the bleed-off amount according to the operating amount detected by the pressure sensors, controls an opening area of the cut valve on the basis of the bleed-off amount set, and suppresses the shock when sudden swinging operation takes place.

Owner:KOBE STEEL LTD

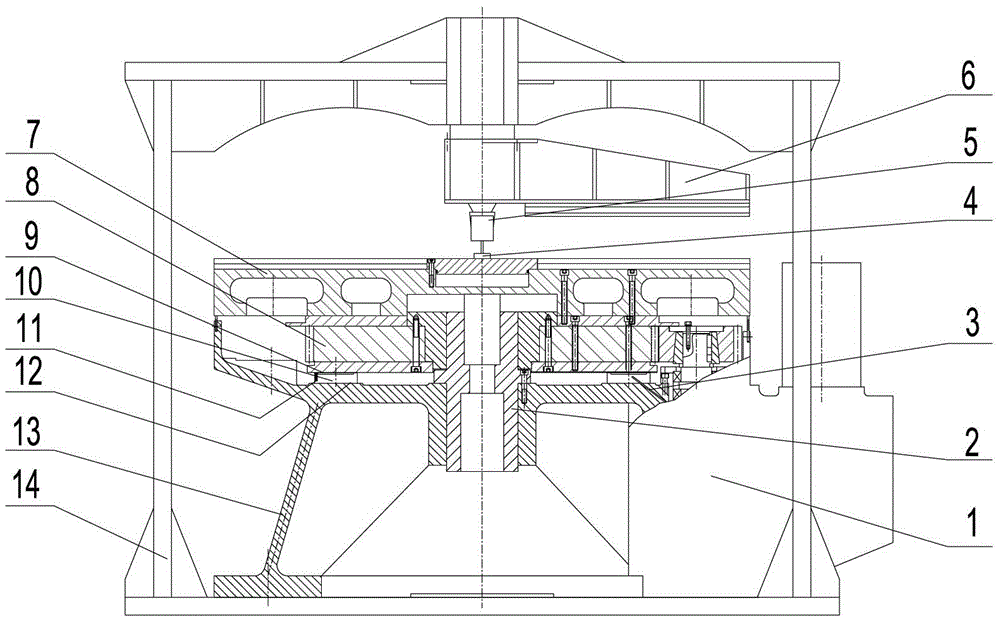

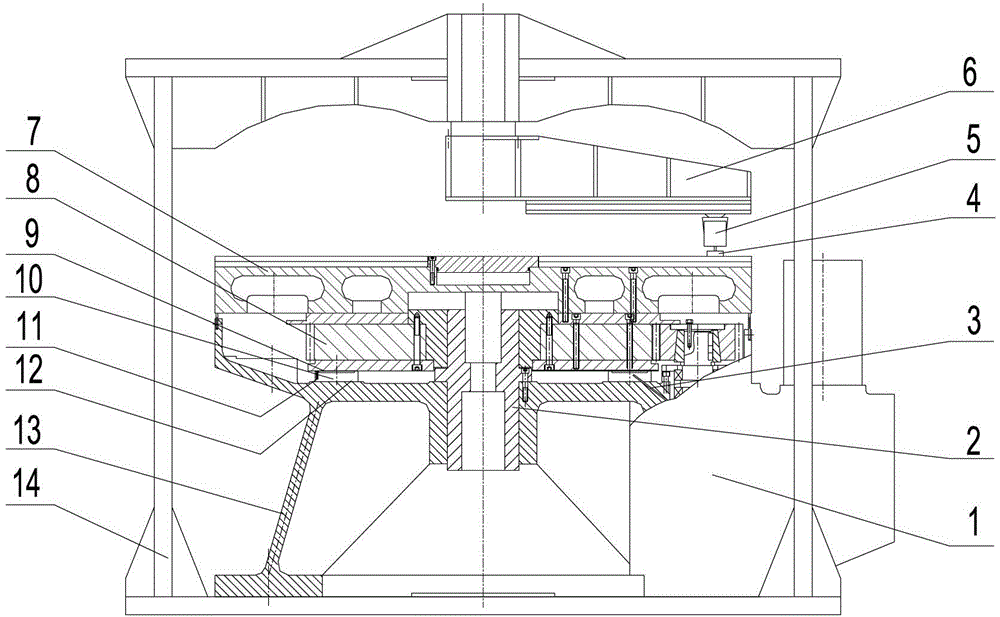

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

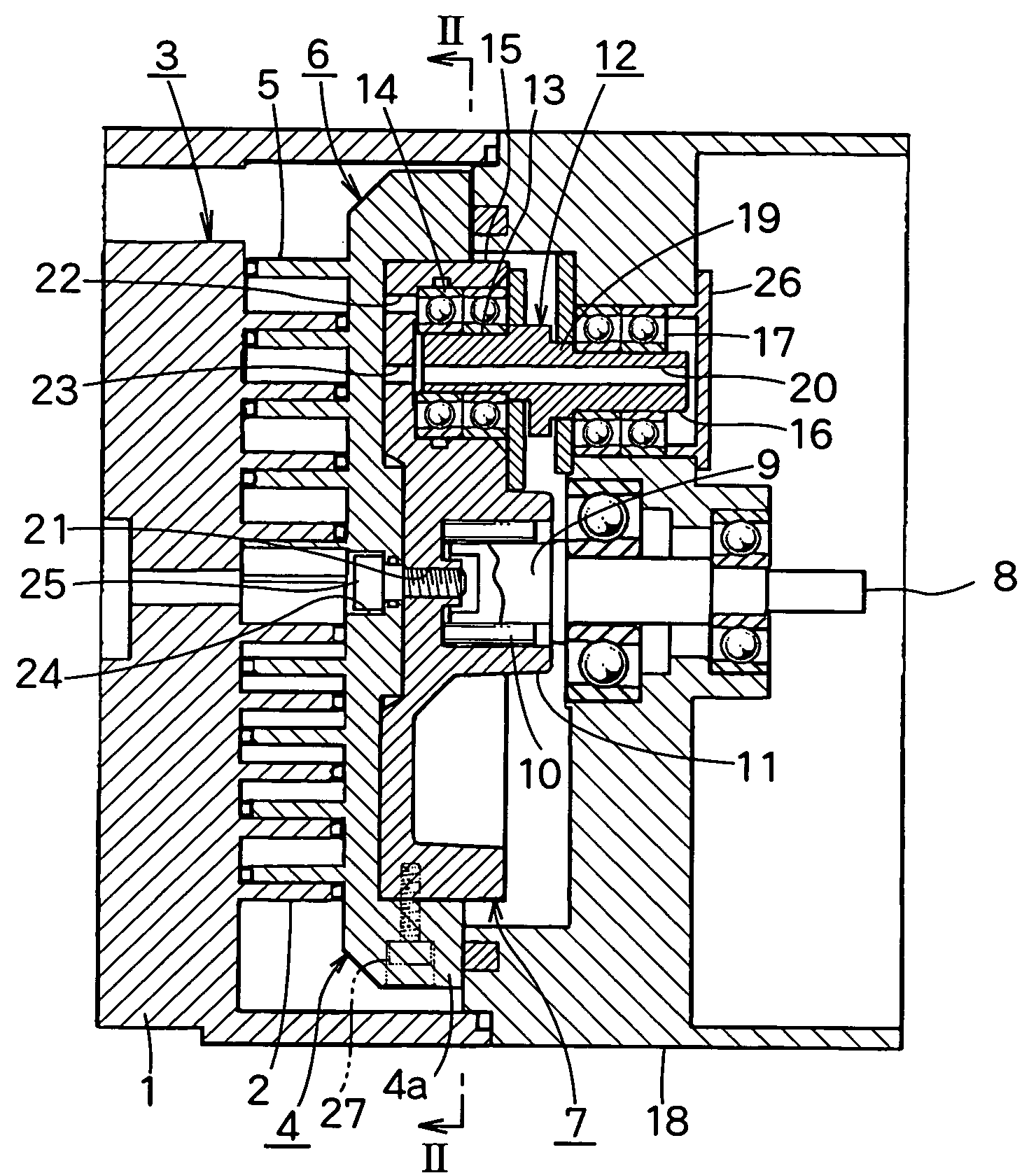

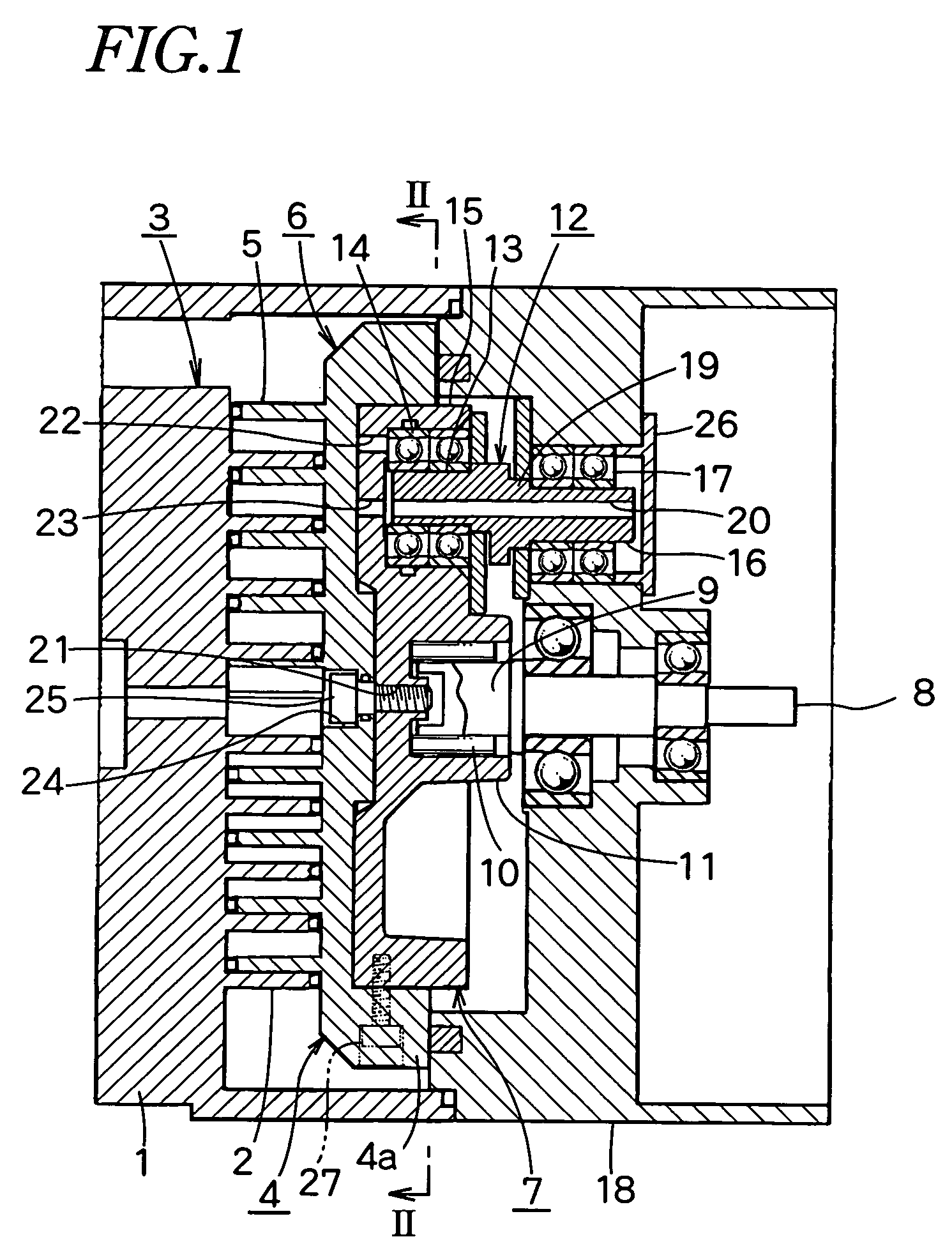

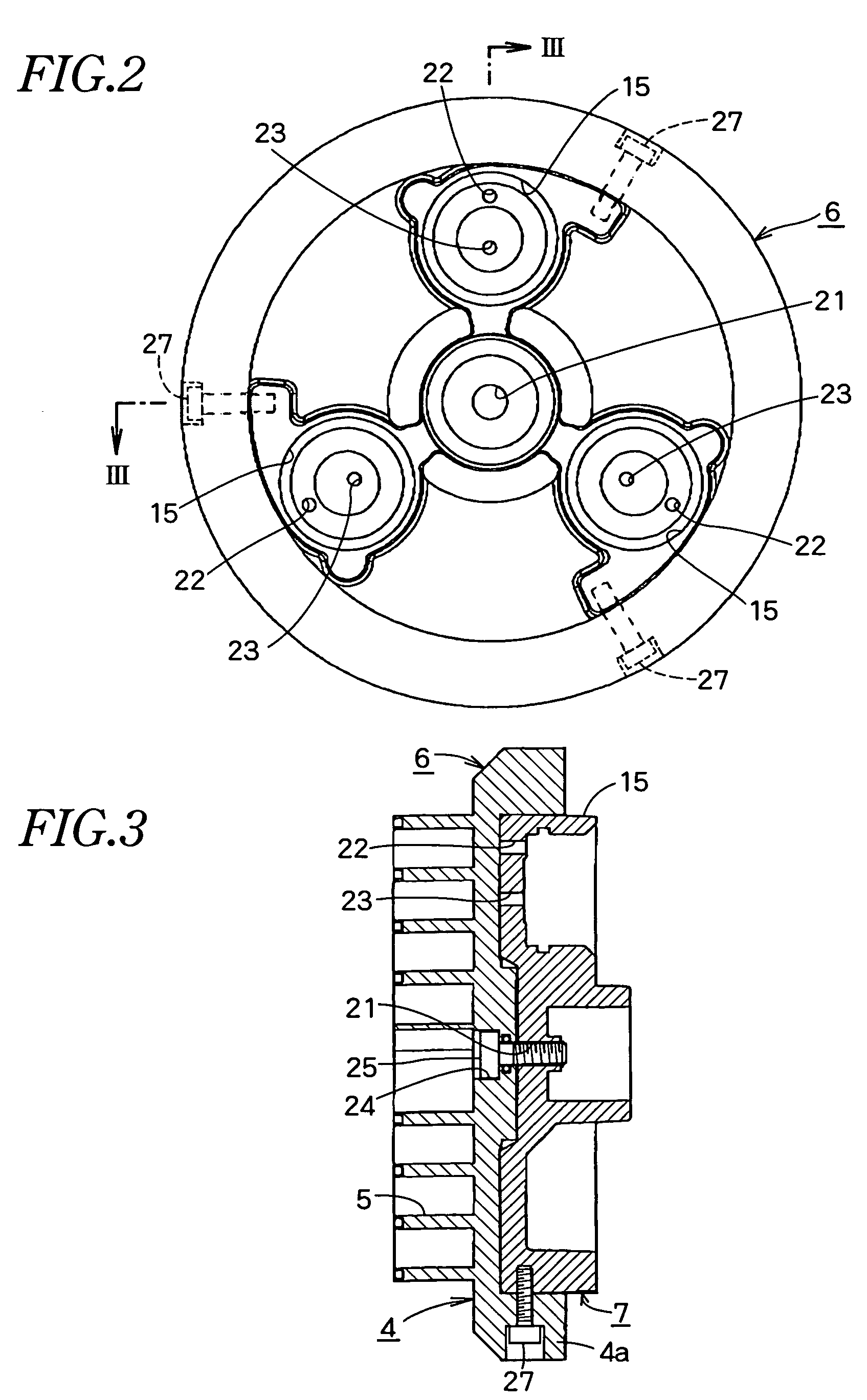

Scroll fluid machine having oil-supply holes being formed through a reinforcement bearing plate on a rear surface of the orbiting scroll

InactiveUS7404706B2Increase supplyEngine of arcuate-engagement typeOscillating piston enginesEngineeringOil supply

A scroll fluid machine comprises a fixed scroll, an orbiting scroll and a plurality of self-rotation preventing device for preventing the orbiting scroll from rotating on its own axis. On the rear surface of the orbiting scroll, a reinforcement bearing plate is fixed with a central bolt and an outer circumferential bolt. A follower of the self-rotation preventing device is provided in the reinforcement bearing plate. An oil-supply hole is formed through the reinforcement bearing plate to supply oil to the follower.

Owner:ANEST IWATA CORP

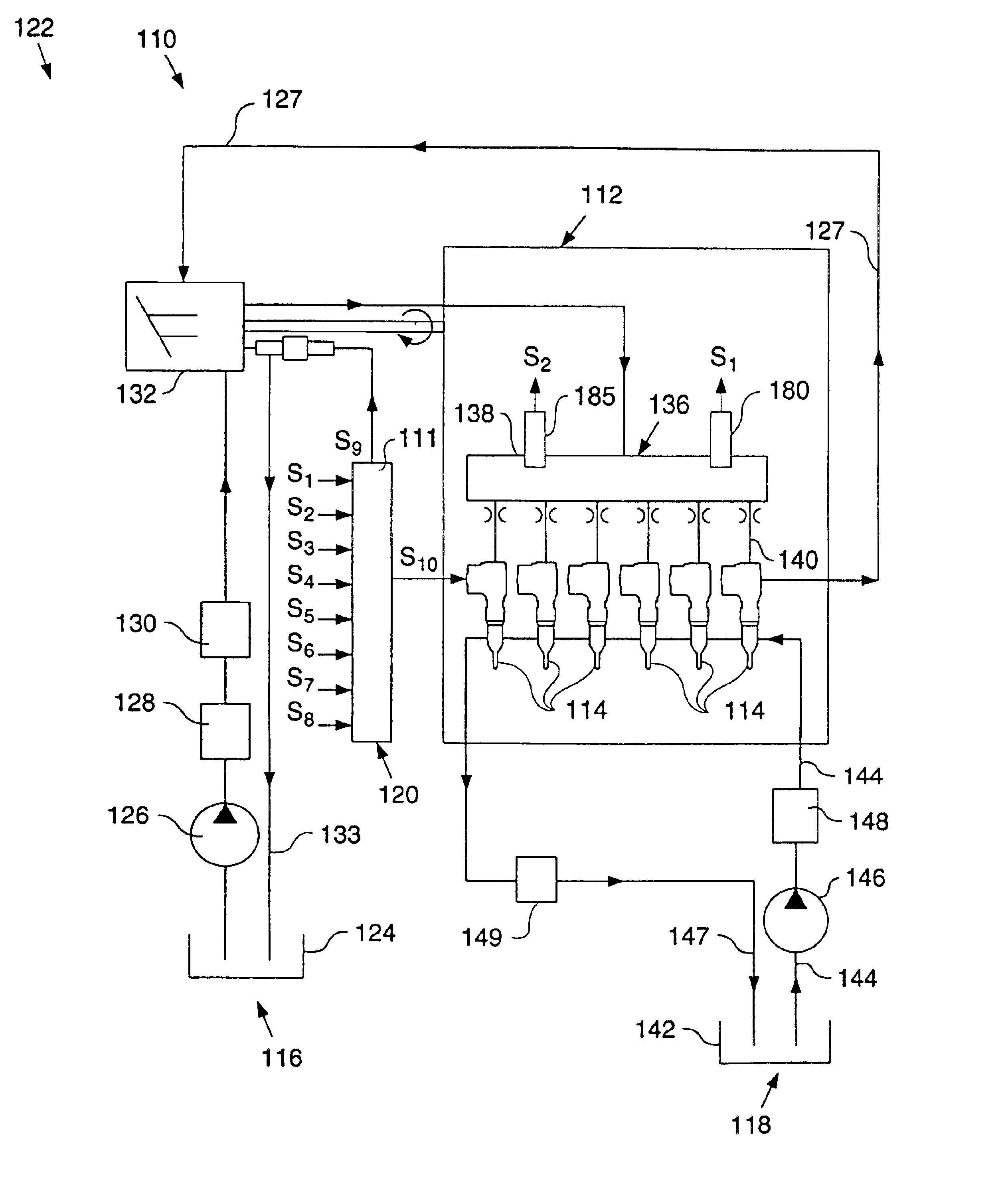

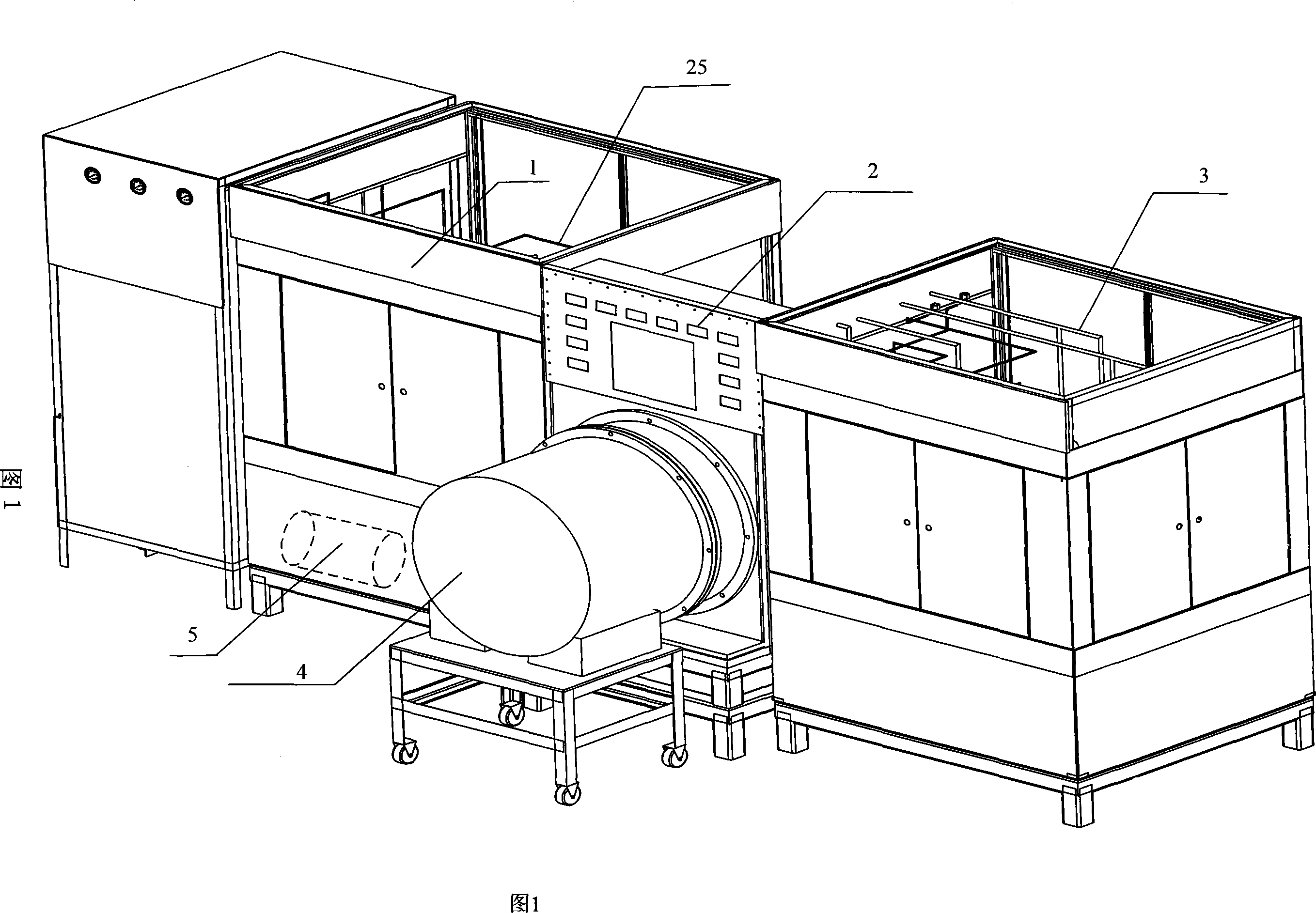

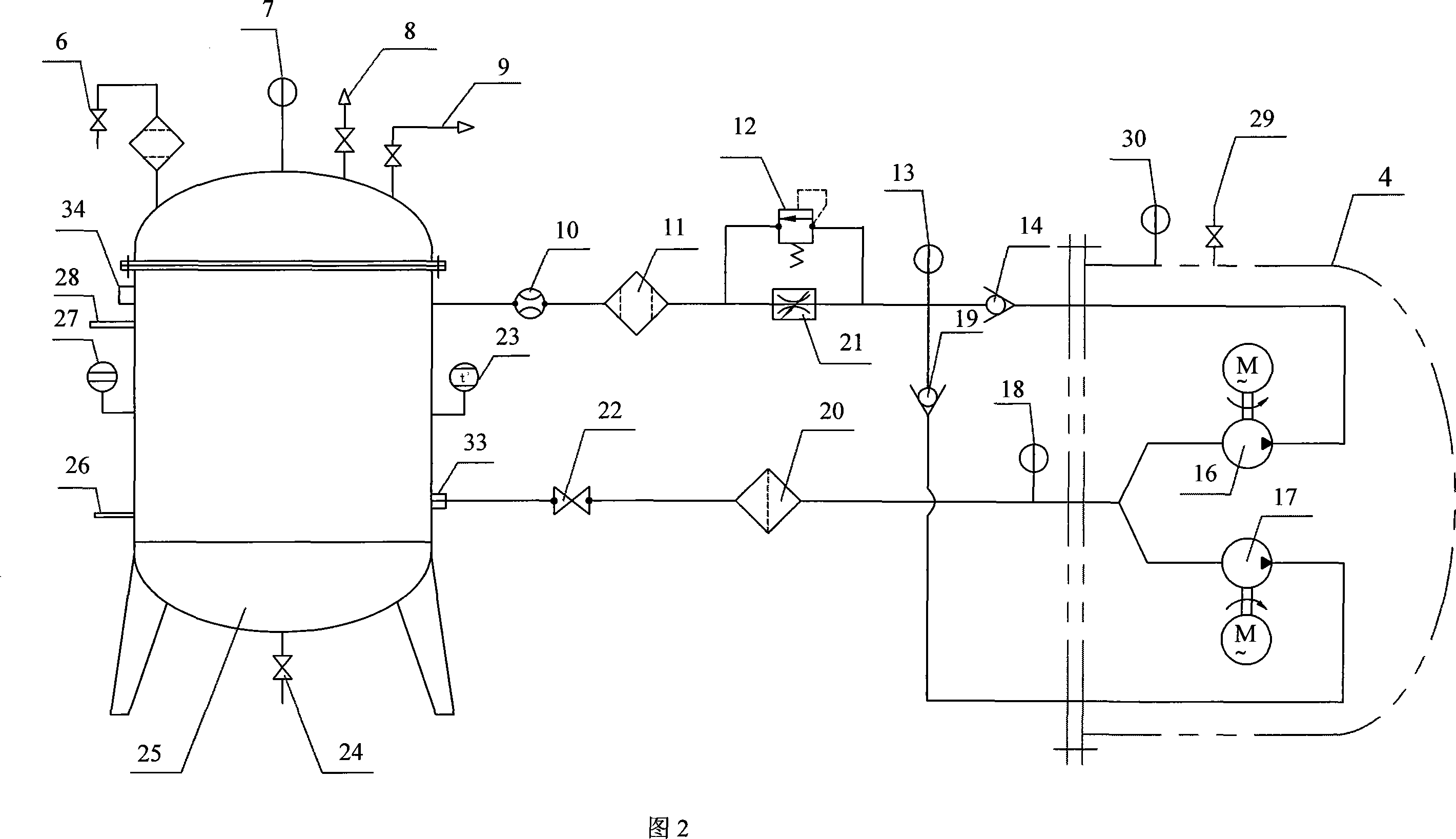

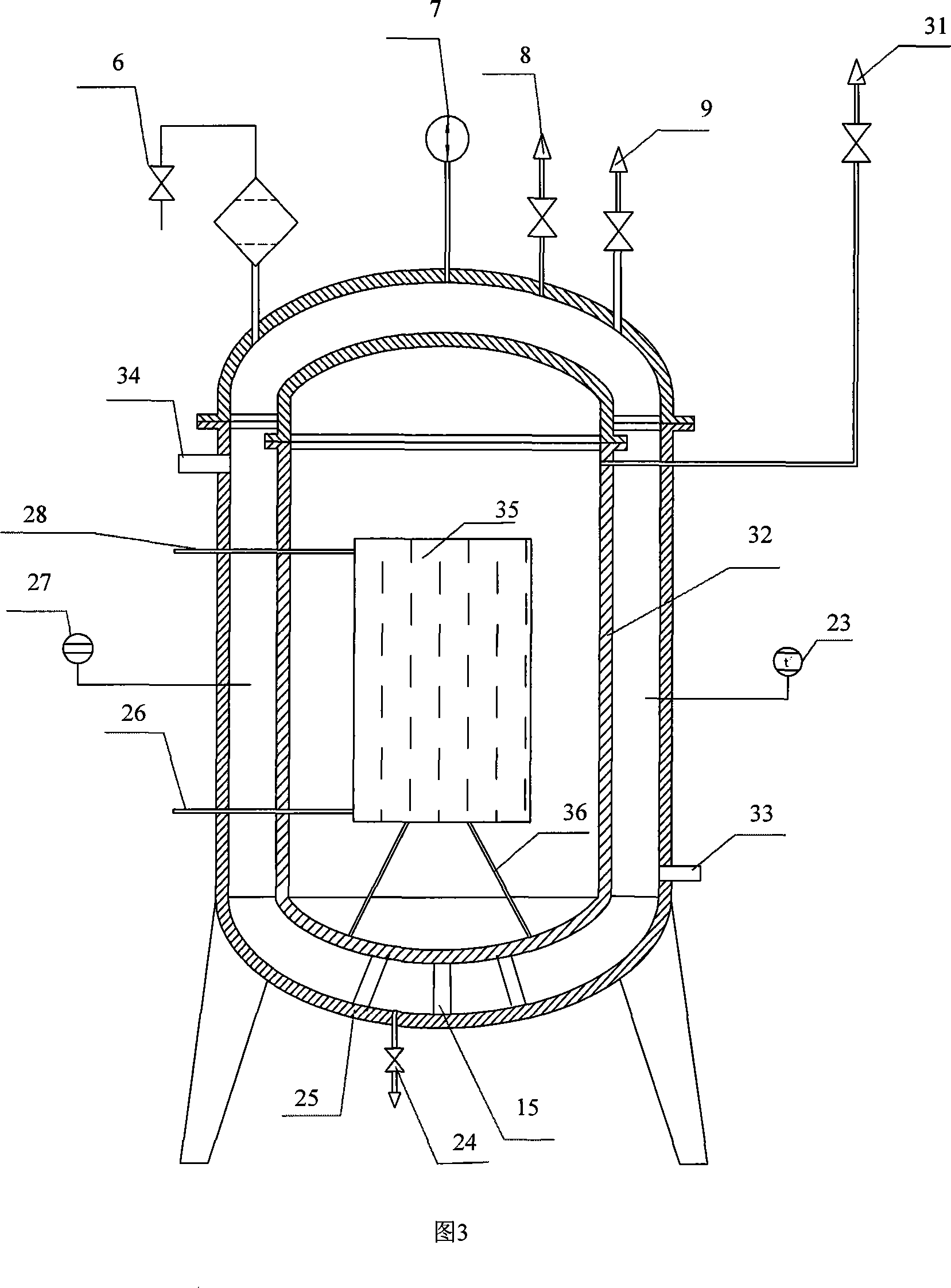

Device and method for testing upper air performance of aircraft engine fuel oil system

InactiveCN101231215AImplement performance testingAccurate control of fuel temperatureInternal-combustion engine testingAviationFuel tank

The invention discloses an aeroengine fuel system altitude performance testing unit and a test method thereof. The testing unit comprises an equipment cabinet, a control computer, a display instrument, a high altitude box, a fuel tank, an oil pipeline, a vacuum pump package and various valves, wherein, the inner part of the high altitude box is provided with a testing oil fuel pump which is connected with the fuel tank through the oil pipeline inside the equipment cabinet, the fuel tank has a structure with low temperature resistance and atmospheric depression resistance, can simulate the high altitude working environment of the fuel system of the aeroengine. The test method utilizes the fuel tank capable of simulating the atmospheric depression and the low temperature of the high altitude and a high altitude box capable of simulating the atmospheric depression, adopts the pipeline and the valves to adjust the oil inlet pressure and the oil return pressure, and uses a flowmeter, a thermometer and a pressure gauge to read the parameter values. The test of altitude simulations of an oil supply system of an electronic oil fuel pump of an aircraft piston engine can be performed by the method.

Owner:BEIHANG UNIV

Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

ActiveCN103256633AEvenly distributedInhibition formationContinuous combustion chamberCycloneCombustion chamber

The invention discloses a low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet. The low-pollution combustion chamber comprises an on-duty oil supply nozzle, a primary-combustion oil supply nozzle, three-stage cyclones and a flame tube. Fuel is respectively provided for the on-duty oil supply nozzle and the primary-combustion oil supply nozzle in two ways, and the three-stage coaxial cyclones supply air to the head of a combustion chamber. The two stages of cyclones on the inner side of the combustion chamber refer to an oblique-cutting hole cyclone and a radial cyclone, cyclone of the two-stage cyclones are in opposite directions. A centrifugal atomizing nozzle is arranged at the center of the oblique-cutting hole cyclone, and the second-stage cyclone on the inner side are combined and matched with a center on-duty nozzle. The cyclone on the outside of the combustion chamber is a radial cyclone with cyclone direction opposite to that of a second-stage cyclone. Primary combustion fuel enters a cyclone blade channel from small holes of a front wall surface of a third-stage cyclones by way of multipoint direct injection and is accelerated to be crushed and atomized in a cyclone channel to be mixed with the air, and forms premixed or partly premixed fuel-air mixture at an exit of the tertiary swirling influx to enter a primary combustion zone to be combusted. The low-pollution combustion chamber is applicable to aircraft engine combustion chambers or industry fuel turbine combustion chambers.

Owner:中科航空动力(株洲)装备制造研究院有限公司

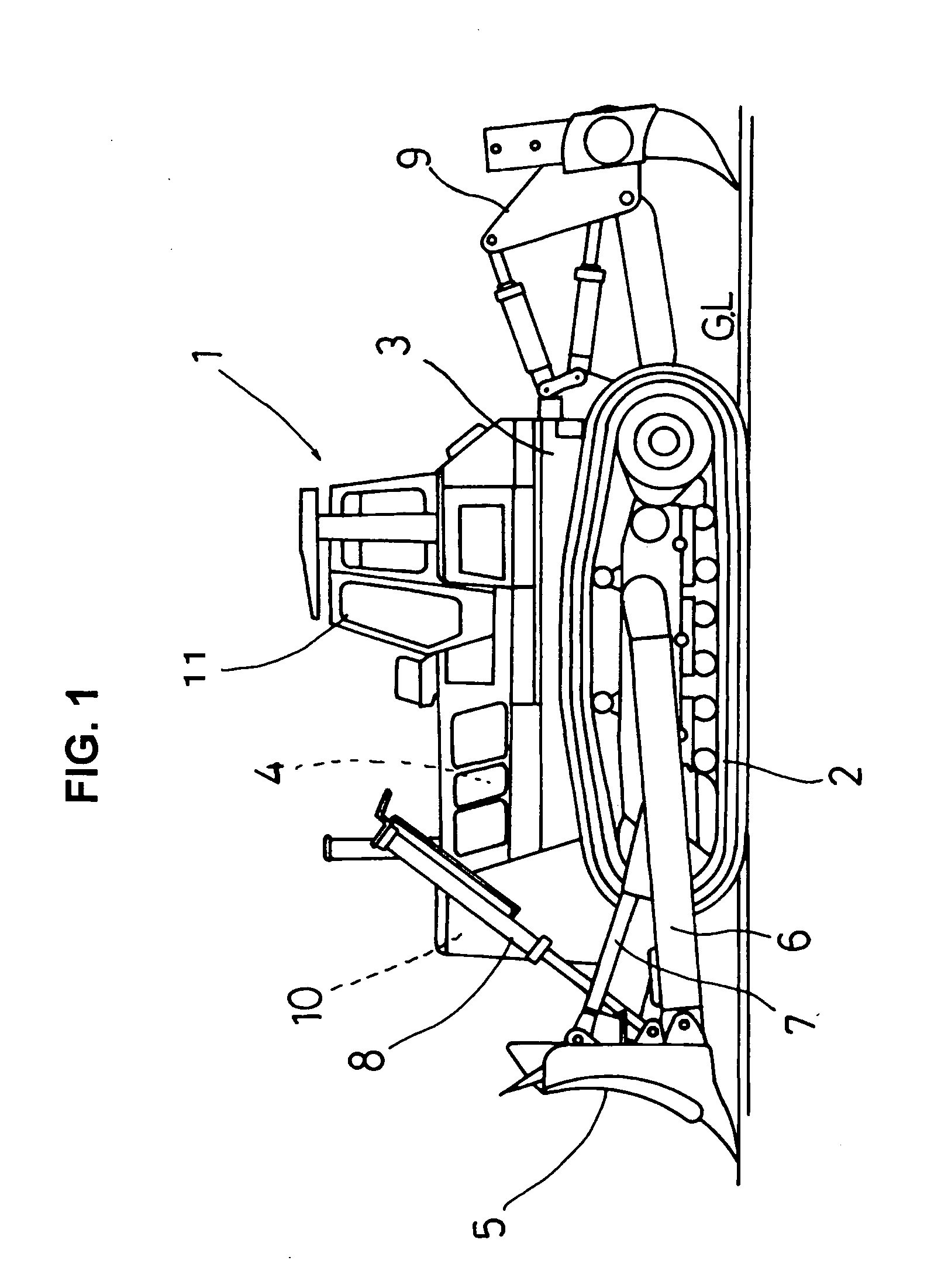

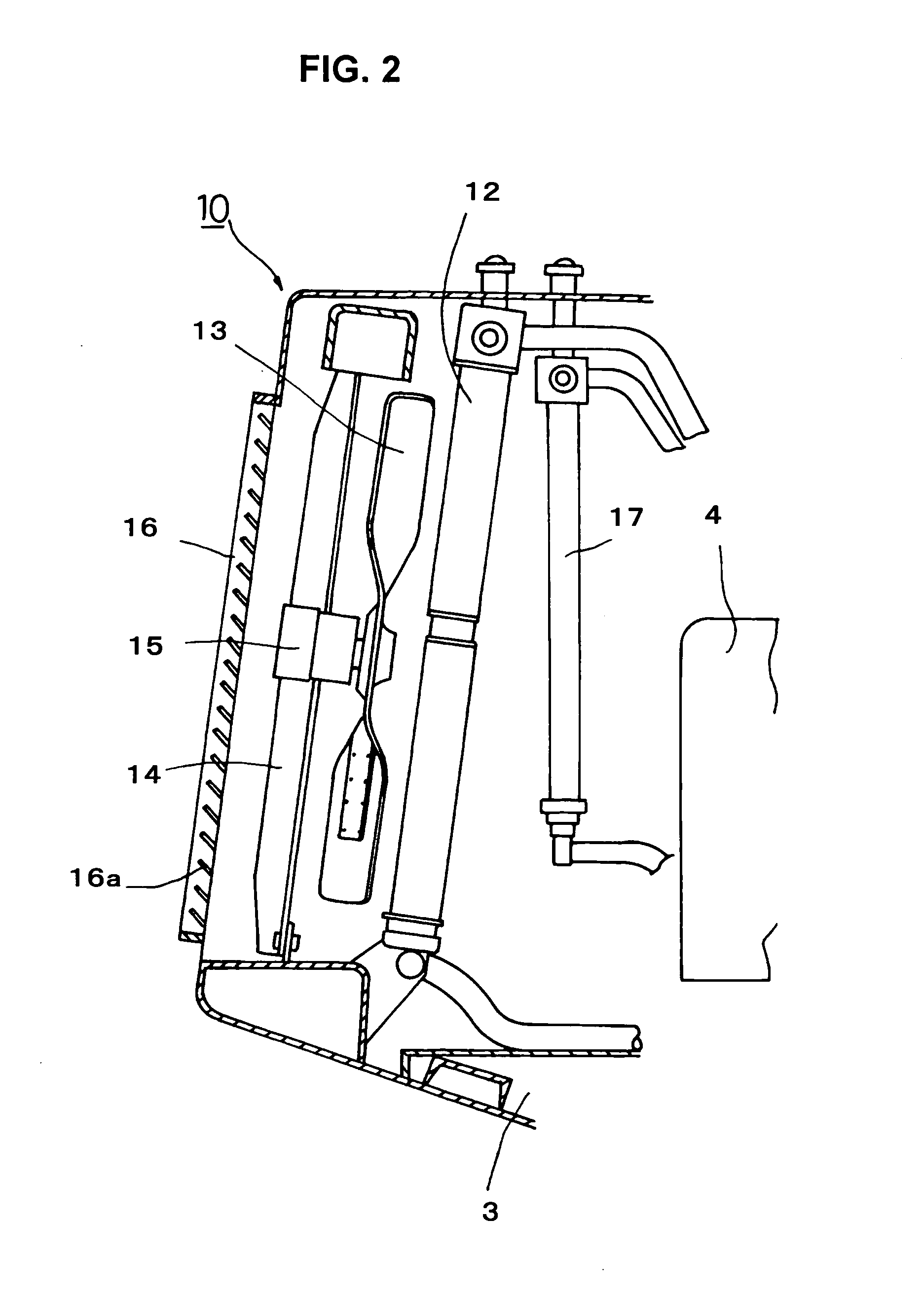

Cooling system for work machine

ActiveUS20050183417A1Minimize discharge oil rateAvoid load increaseFluid couplingsCoolant flow controlHydraulic motorHydraulic pump

A cooling system for use in a work machine is provided, in which an increase in the load imposed on a fan driving circuit and occurrence of abnormal noise can be prevented without fail by means of an inexpensive arrangement at the time of switching the rotating direction of a cooling fan. To this end, the cooling system comprises: (1) a variable displacement hydraulic pump driven by the engine; (2) a forwardly and reversely rotatable hydraulic motor operated by hydraulic oil supplied from the hydraulic pump; (3) a cooling fan driven by the hydraulic motor; (4) an electromagnetic selector valve for switching the rotating direction of the hydraulic motor between a forward direction and a reverse direction; (5) controlling means for controlling switching of the electromagnetic selector valve and controlling the hydraulic pump so as to minimize the discharge oil rate of the hydraulic pump during switching of the electromagnetic selector valve.

Owner:KOMATSU LTD

Energy-saving shield segment assembling and positioning electro-hydraulic control system adopting load-sensitive technology

InactiveCN103032396APrecise control of assembly positioningImprove construction qualityUnderground chambersServomotorsControl signalSystem pressure

The invention discloses an energy-saving shield segment assembling and positioning electro-hydraulic control system adopting a load-sensitive technology. The system comprises a motor, a variable pump, a two-position three-way proportional reversing valve, a variable cylinder, an overflow valve, a pressure reducing valve, a pressure compensating valve, a one-way valve, a multi-way valve, a balancing valve, a hydraulic lock, a hydraulic motor, a hydraulic cylinder, a moment rotation speed sensor, a displacement sensor and a pressure sensor. The multi-way valve with the pressure compensating valve in a segment assembling system is used for controlling the rotation speed of the hydraulic motor for driving the segment assembling machine to rotate and the moving speed of each hydraulic cylinder. The pressure sensor is used for detecting the pressure of a main oil passage of the system and the working pressure of each executer in real time; and a computer control unit is used for determining a variable pump control signal according to a system pressure signal, so that the displacement of the variable pump is changed with the load change so as to achieve load sensitive control. According to the invention, energy waste caused by continuous oil supply at the highest working pressure of the traditional system is avoided, the throttling loss and overflow loss are greatly reduced, and an obvious energy saving effect is obtained.

Owner:ZHEJIANG UNIV

Chain tensioner

InactiveUS20080280712A1Reliable guidingSmoothly guided into air passageGearingCheck valveScrew thread

A chain tensioner includes a housing defining a cylinder chamber. A plunger is mounted in the cylinder chamber so as to be slidable along an inner surface of the cylinder chamber. A return spring is mounted in the cylinder chamber to bias the plunger outwardly. The housing is formed with an oil supply passage communicating with a pressure chamber defined in the housing behind the plunger. A check valve is disposed at an oil exit of the oil supply passage and configured to close the oil supply passage when the pressure in the pressure chamber is higher than the pressure in the oil supply passage. The housing is formed with a threaded hole extending from an upper portion of an outer periphery of the housing to the pressure chamber. A screw has its external thread in threaded engagement with the internal thread of the threaded hole, whereby a gap, as an air bleed passage, is defined between the internal and external threads. The internal thread of the threaded hole has an internal diameter larger than an internal diameter of an internal thread under JIS.

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com