Patents

Literature

3257 results about "Proportional valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As the name already indicates, a proportional valve is a valve which can be used to change the output result proportionally to the value at the input. For example: the higher the flow, the larger the flow rate. We distinguish between two different proportional valves.

Proportional valve with shape memory alloy actuator

InactiveUS6840257B2Limited sizeReduce weightTemperature control without auxillary powerOperating means/releasing devices for valvesClosed loopAlloy

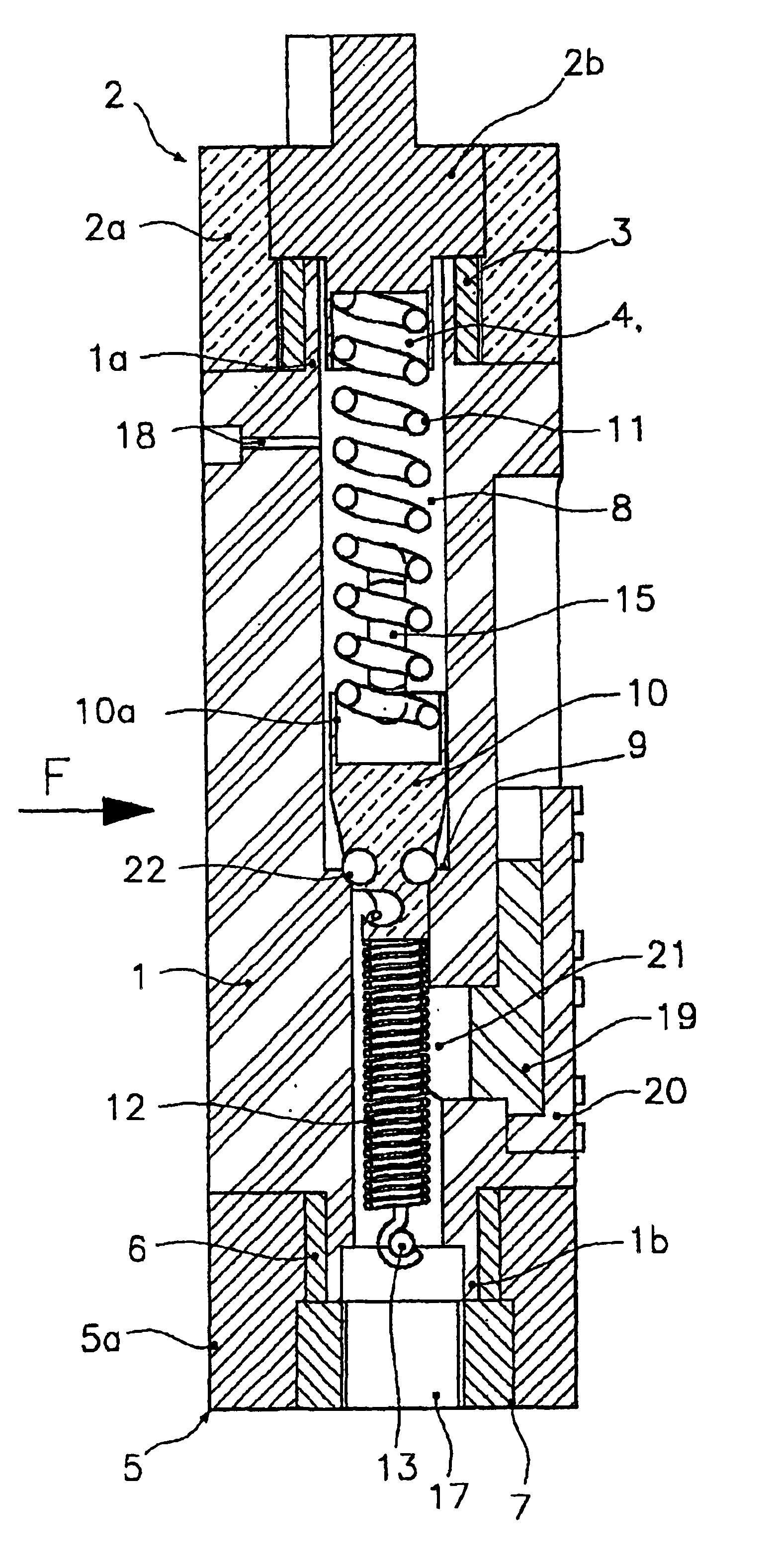

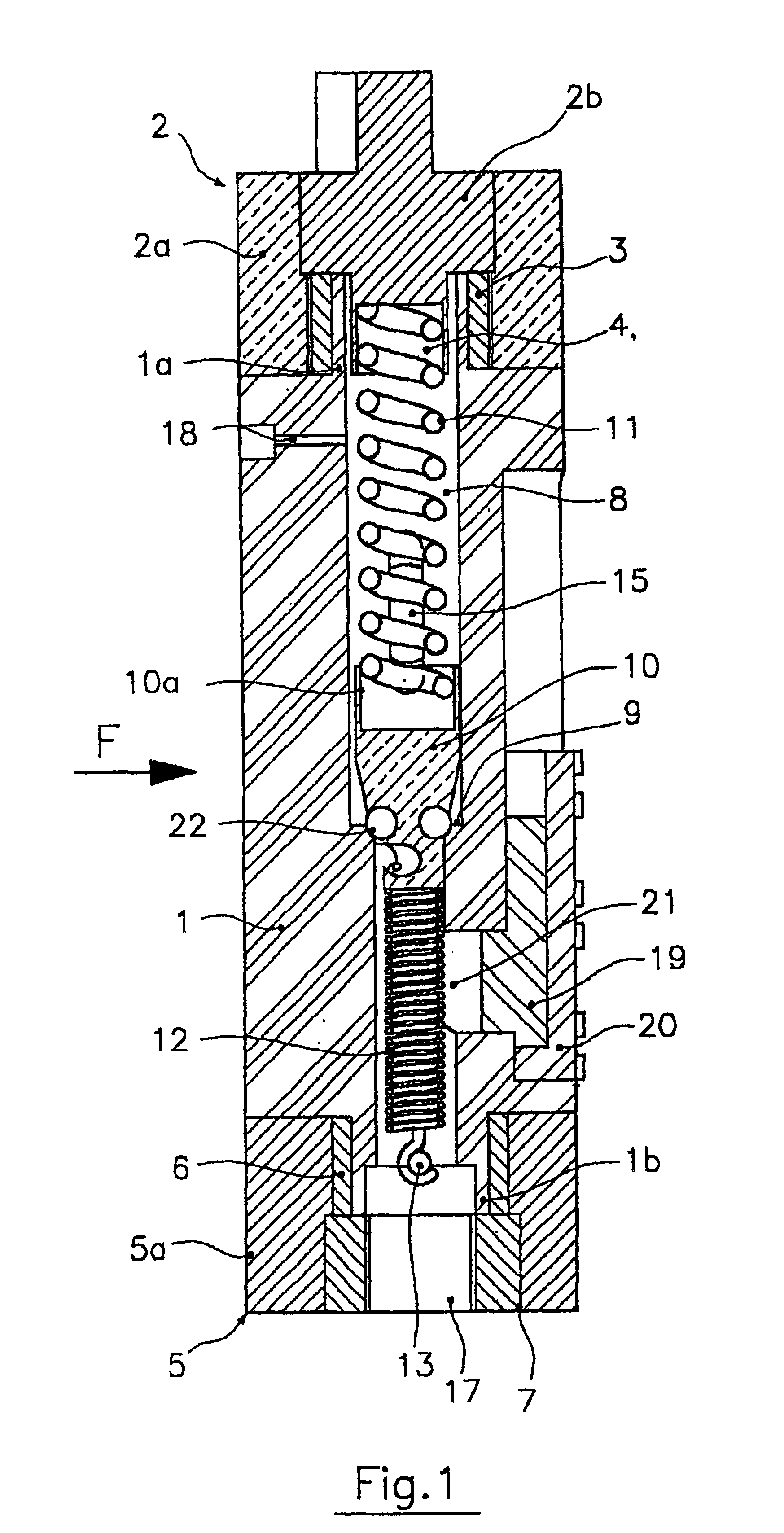

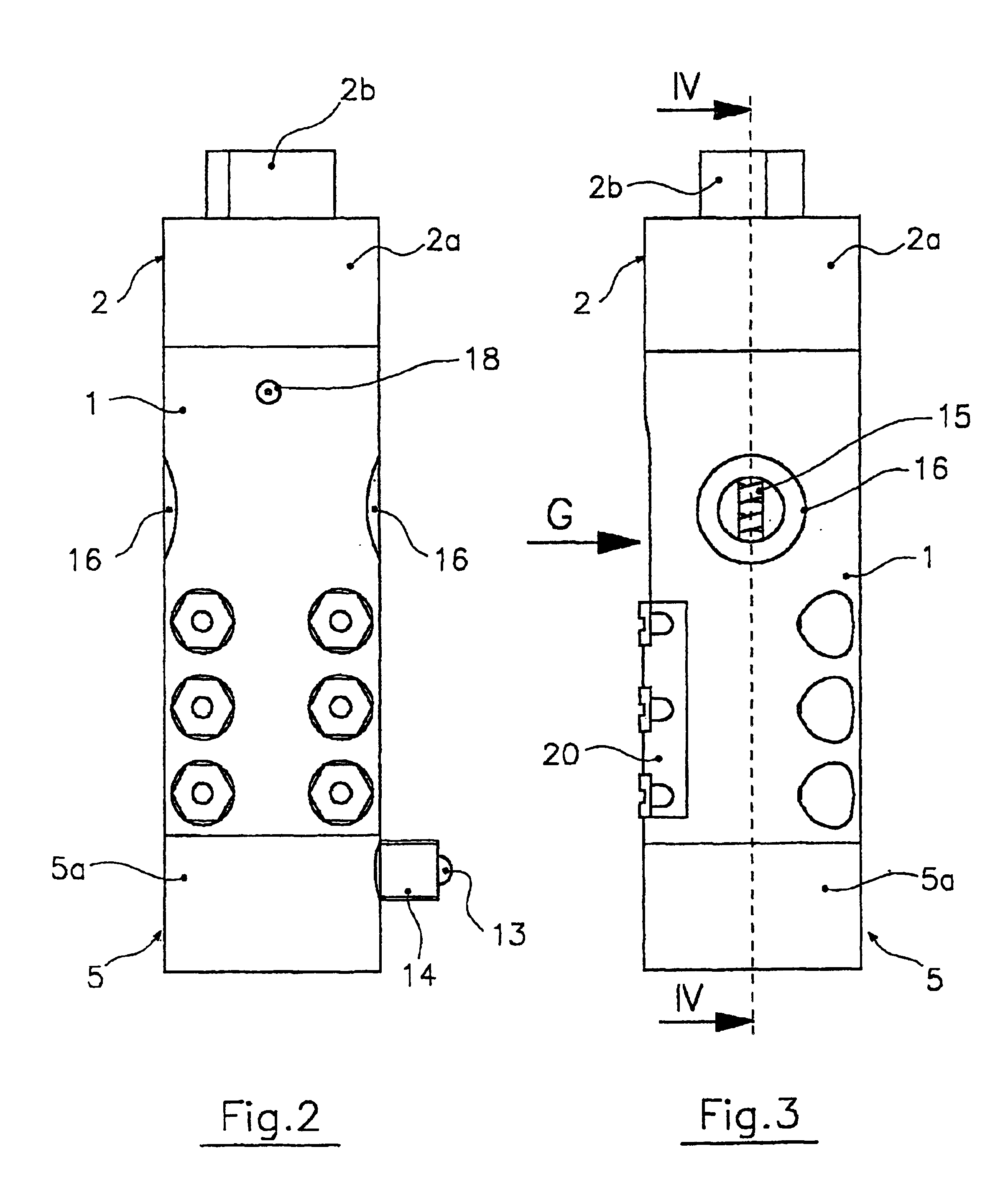

A proportional valve is disclosed for controlling the outlet pressure of a fluid flowing therethrough. The valve comprises a valve body having an inlet port and an outlet port for the fluid. The valve also has an inner chamber, within which there is formed a valve seat that may be opened and closed variably by a shutter axially movable from and towards the valve seat. Movement of the shutter is controlled by a shape memory alloy (SMA) actuating member operating antagonistically to an elastic member, the temperature of the fluid being lower than the transition temperature of the shape memory alloy. The actuating member and the elastic member are connected to the body valve at opposite sides relative to the valve seat. A power control circuit is also provided for circulating an electric current through the actuating member so as to heat the same by Joule effect from a temperature lower than the transition temperature to one that is higher. At least one vent hole is formed in the valve body for putting a portion of the chamber upstream of the valve seat into fluid communication with the outside or a collection network. The actuating member is housed in that portion of chamber corresponding to the inlet port of the fluid, whereby a continuous flow of fluid around the actuating member is ensured for accelerating the cooling process. A closed-loop control circuit for the power control circuit controls the circulating current as a function of a pressure signal generated by fluid pressure sensing means and in such a way as to offset the retarding effect produced by the fluid during heating of the actuating member.

Owner:ARENA ALBERTO +2

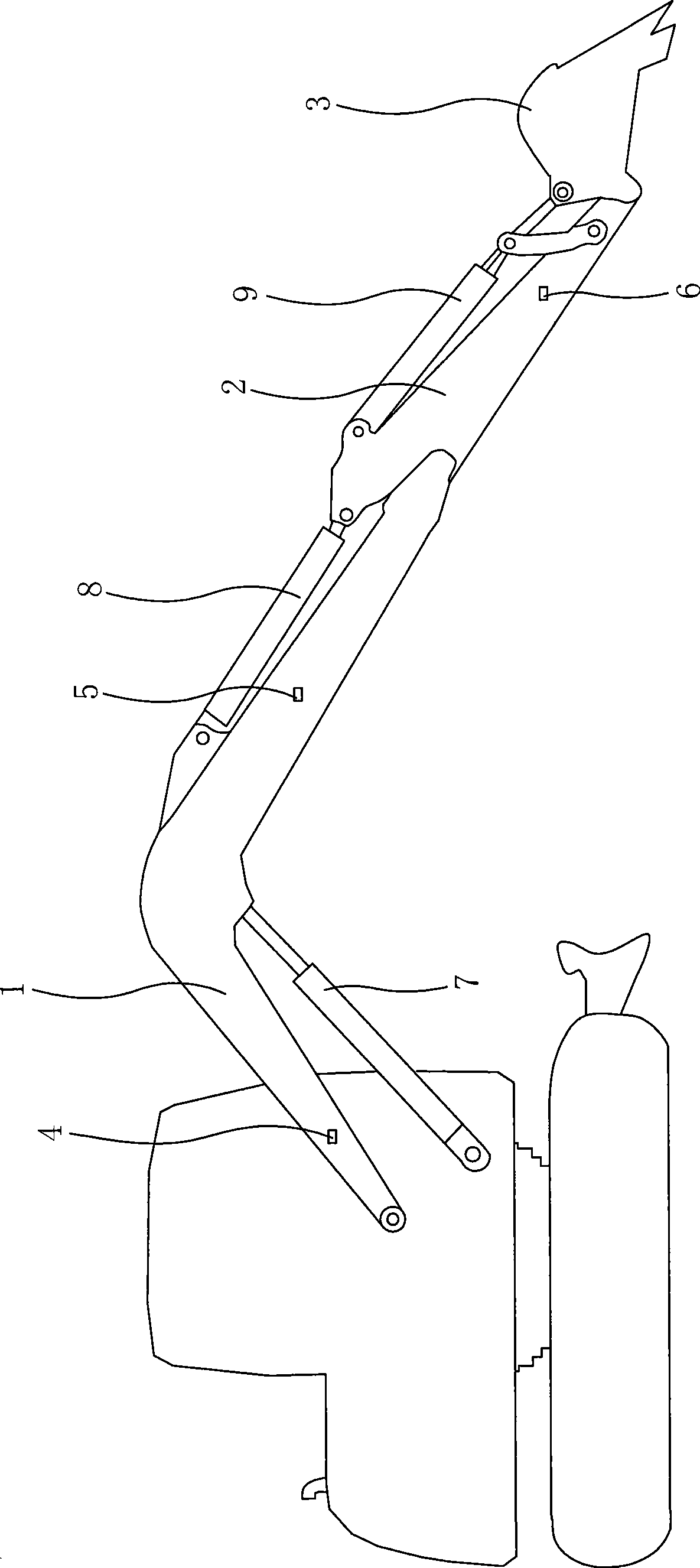

Intelligence control system for aerial platform, aerial platform and control method thereof

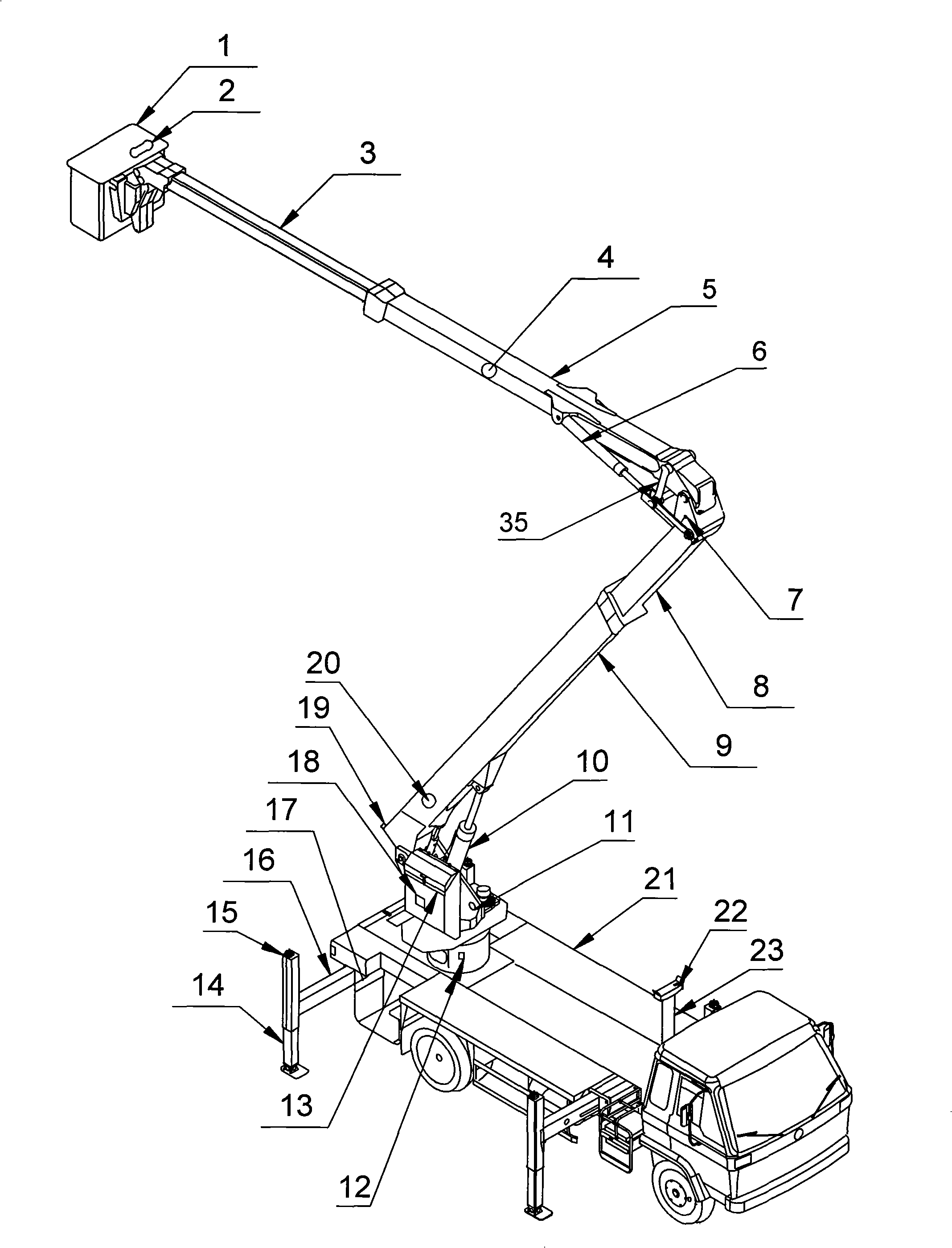

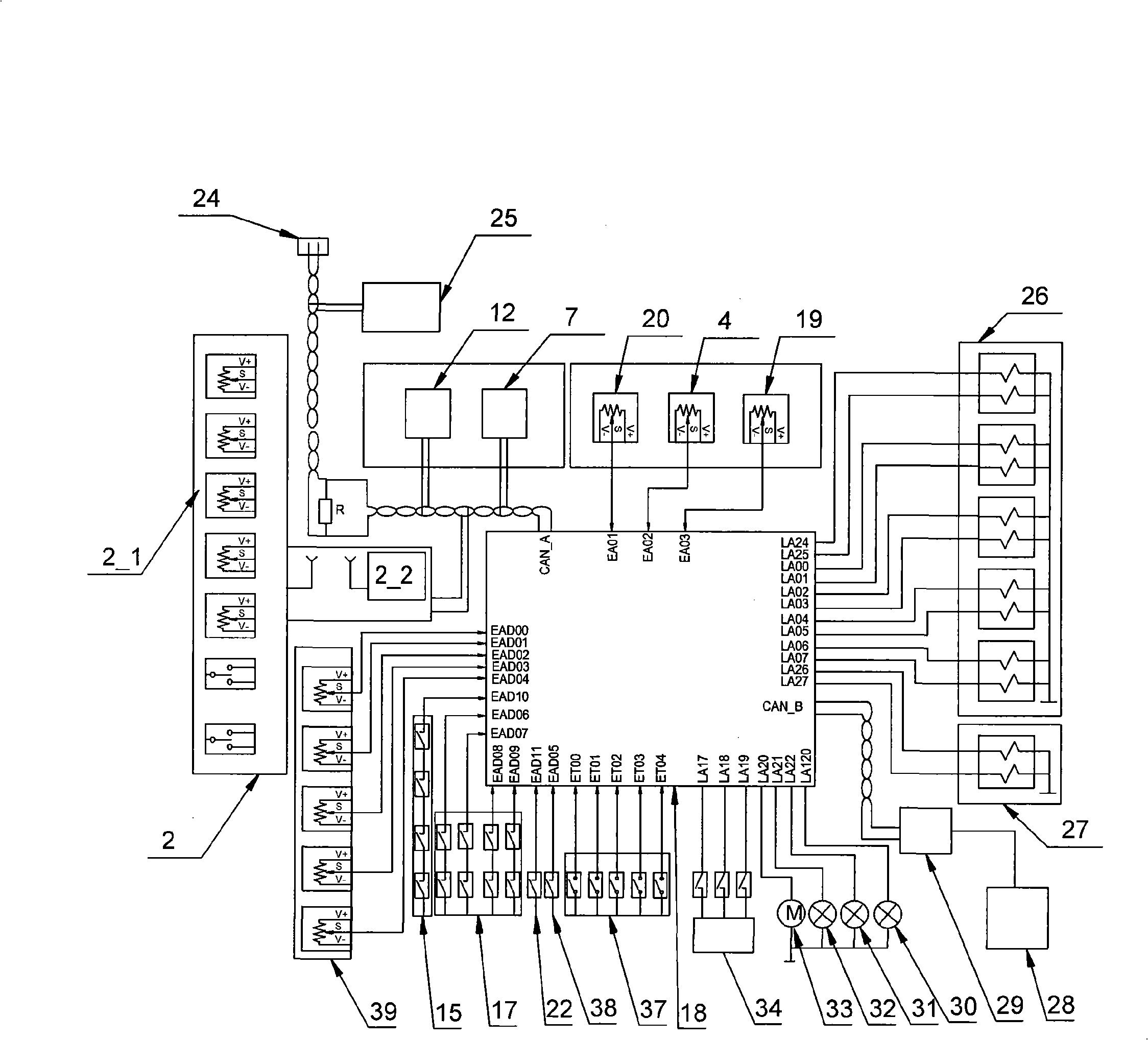

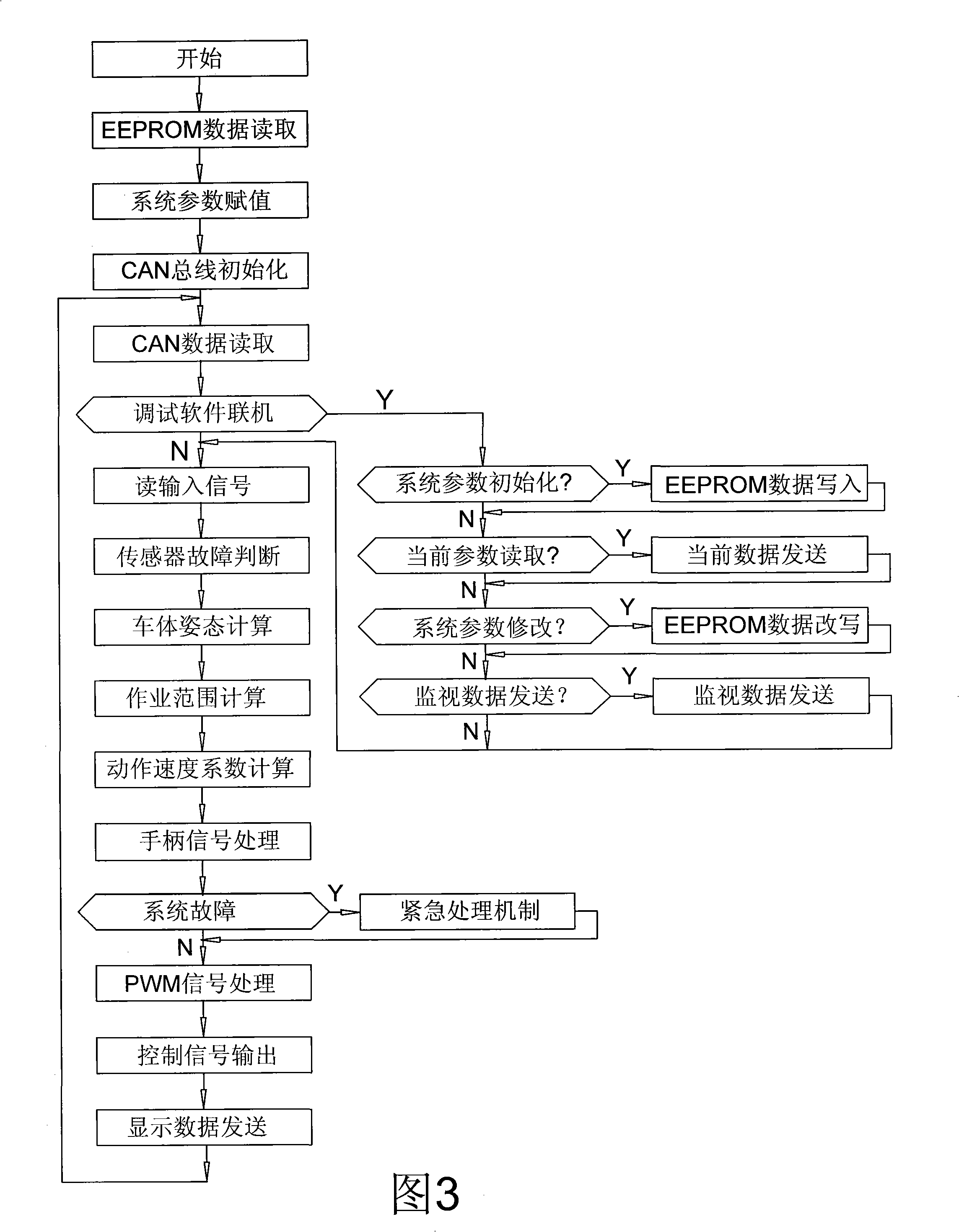

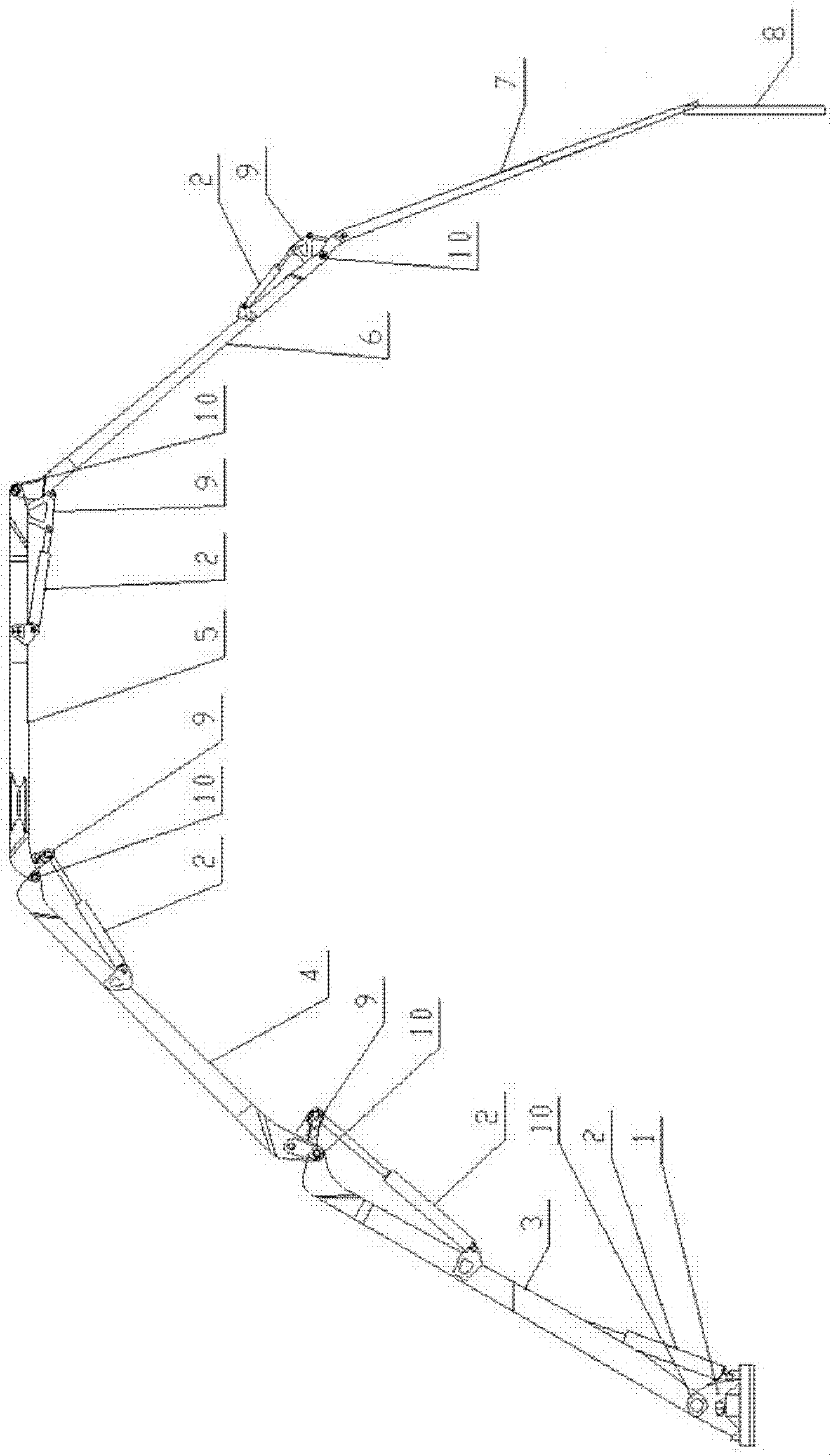

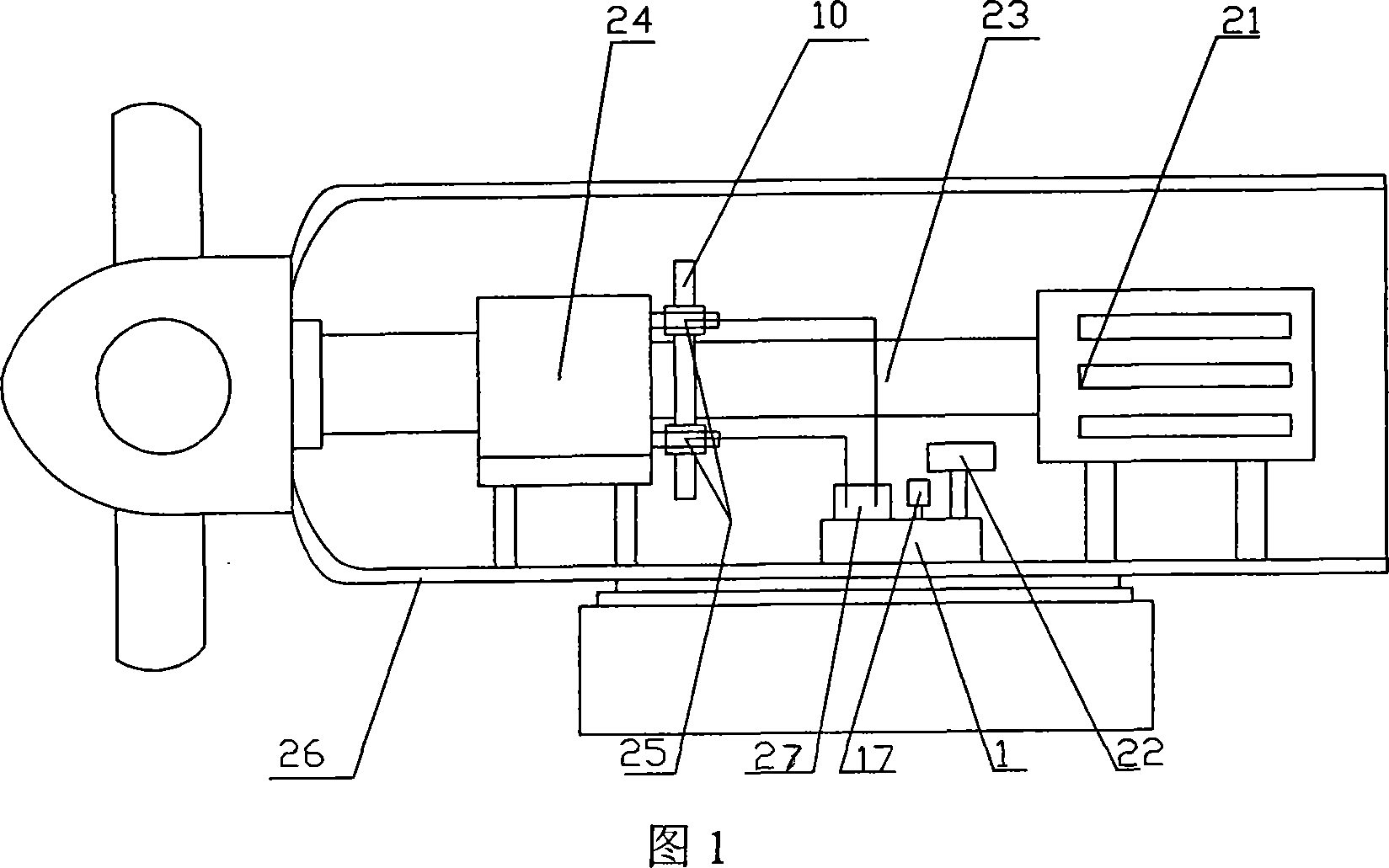

The invention relates to an intelligent control system of an insulative aerial platform vehicle, an aerial platform vehicle with the intelligent control system and a control method thereof. The intelligent control system of the aerial platform vehicle comprises a wireless remote control device, an upper arm length sensor, an upper and lower arm angle encoder, a turntable rotating angle encoder, a leg grounding detection travel switch, a horizontal extending detection travel switch, a controller, a lower arm angle sensor, a lower arm length sensor, an arm bracket travel switch, a program download port, a liquid crystal screen, a quintuple proportional valve group, an oil circuit switching valve, a turntable operating switch, a leg action switch and a turntable potentiometer handle. A TTC200 controller is adopted as the controller of the aerial work platform, a wireless remote control handle is arranged at the insulative bucket part, the turntable is provided with the potentiometer handle to control the mechanism movement; the setting and the adjustment of various important parameters in the controller are completed through displaying the work condition of the vehicle body on the LCD display and debugging the software. The method has wide operational range, safety, reliability and high automatization through controlling the work condition of the entire vehicle by the controller.

Owner:杭州爱知工程车辆有限公司

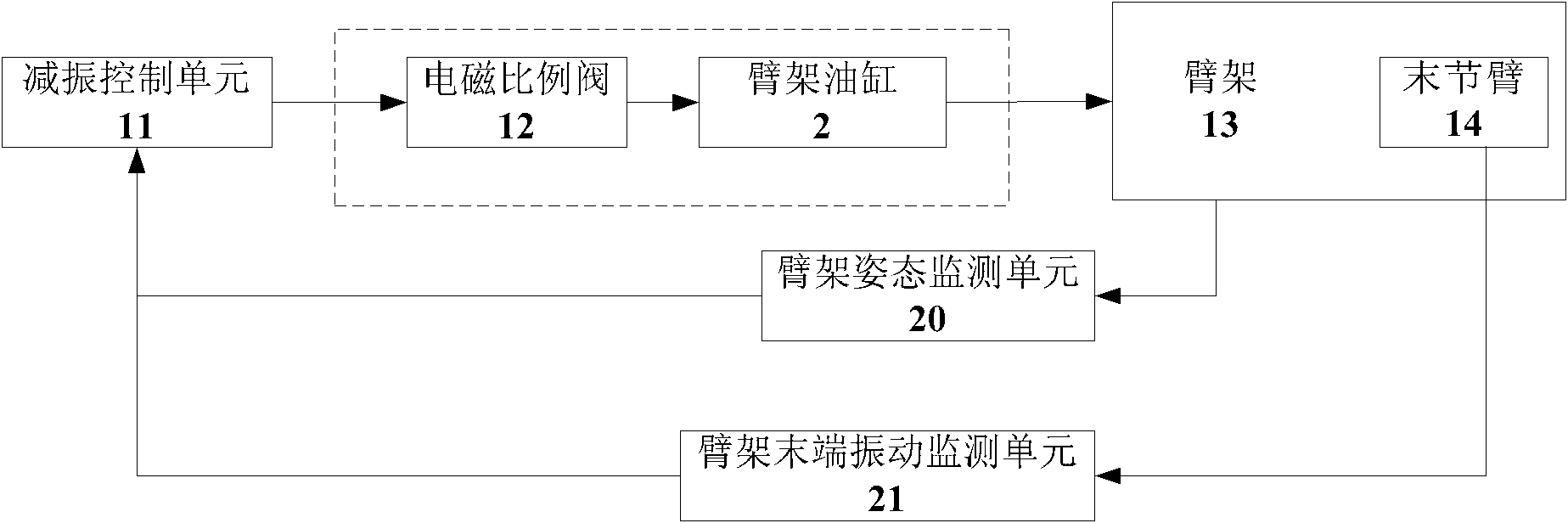

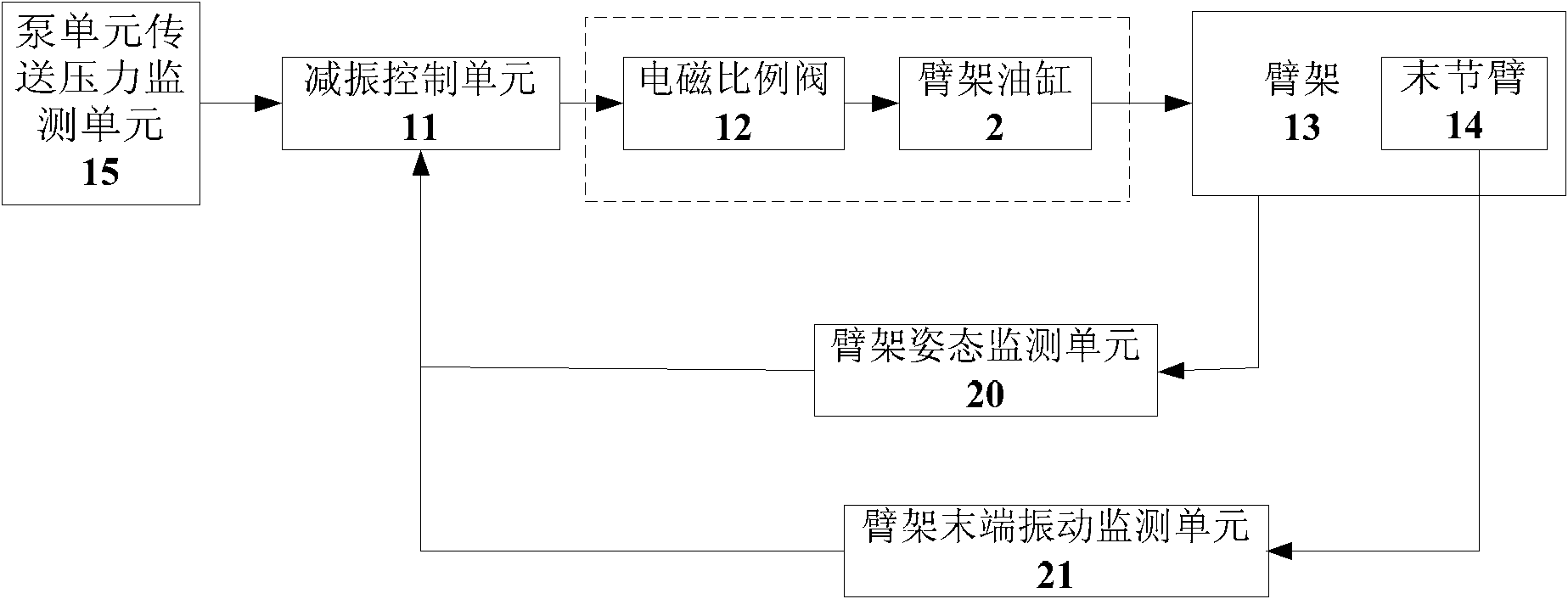

Concrete pump truck, damping device and method for concrete pump truck arm support

ActiveCN102071809ASimple structureGood vibration reduction effectPump controlPumpsVibration amplitudeControl signal

The invention provides a concrete pump truck, a damping device and a damping method for a concrete pump trunk arm support. The damping device of the concrete pump trunk arm support comprises a damping control unit, an arm support tail end vibration monitoring unit and an arm support posture monitoring unit, wherein the damping control unit is connected with an electromagnetic proportional value connected with an arm support cylinder; the arm support tail end vibration monitoring unit monitors amplitude parameters of a tail arm of the arm support and transmits amplitude parameter signals to the damping control unit; and the arm support posture monitoring unit monitors angle parameters of the arm support and transmits angle parameter signals to the damping control unit. The concrete pump truck also comprises the damping device of the concrete pump truck arm support. The damping method for the concrete pump truck arm support comprises the following steps of: monitoring operation parameters of a concrete pump and the arm support; generating control signals according to monitoring parameters; and outputting an electromagnetic proportional valve control current according to the control signals to control a piston position of the arm support cylinder, wherein the monitoring parameters of the arm support comprise the vibration amplitude parameters of the tail arm of the arm support and the angle parameters of the arm support.

Owner:ZOOMLION HEAVY IND CO LTD

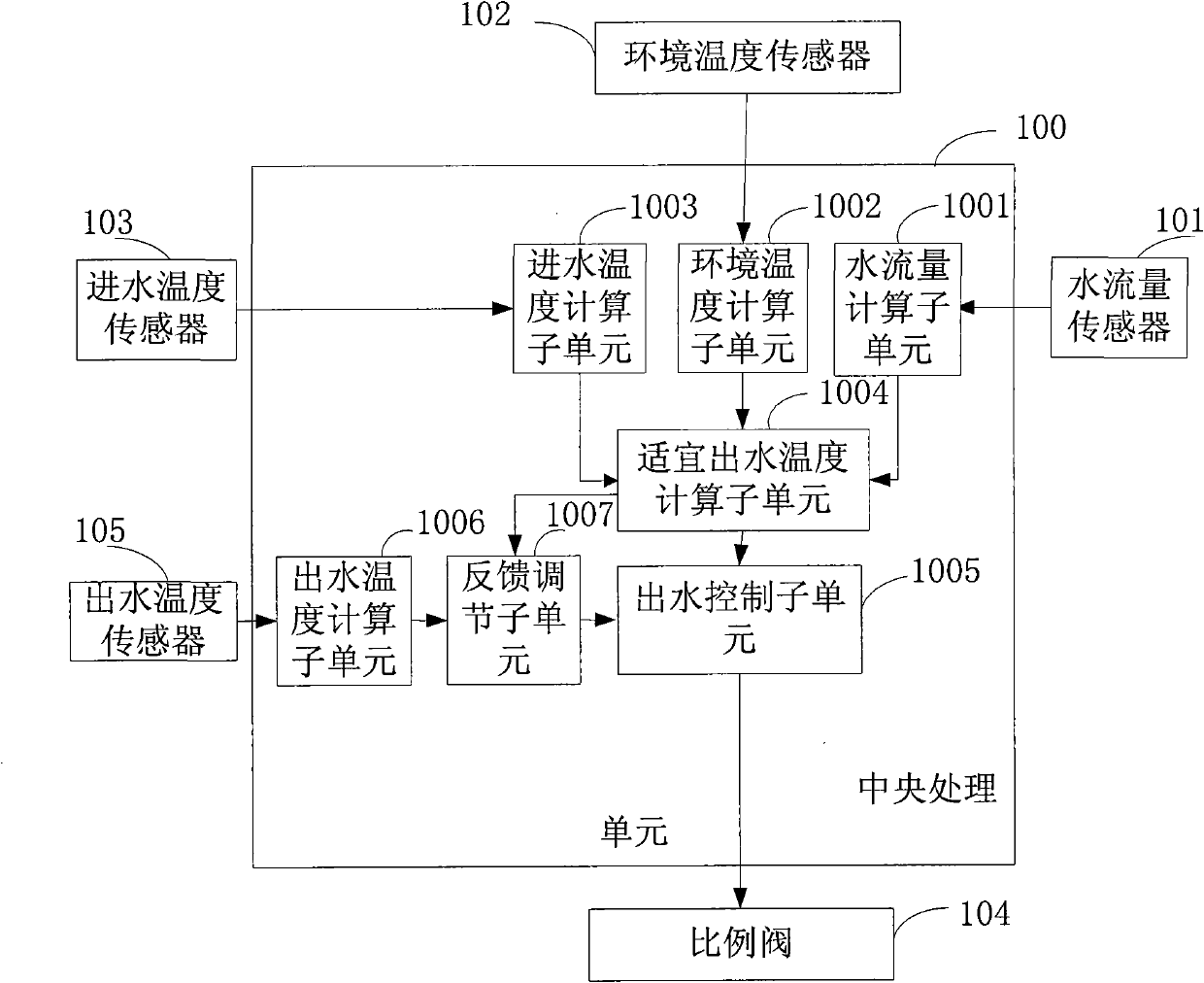

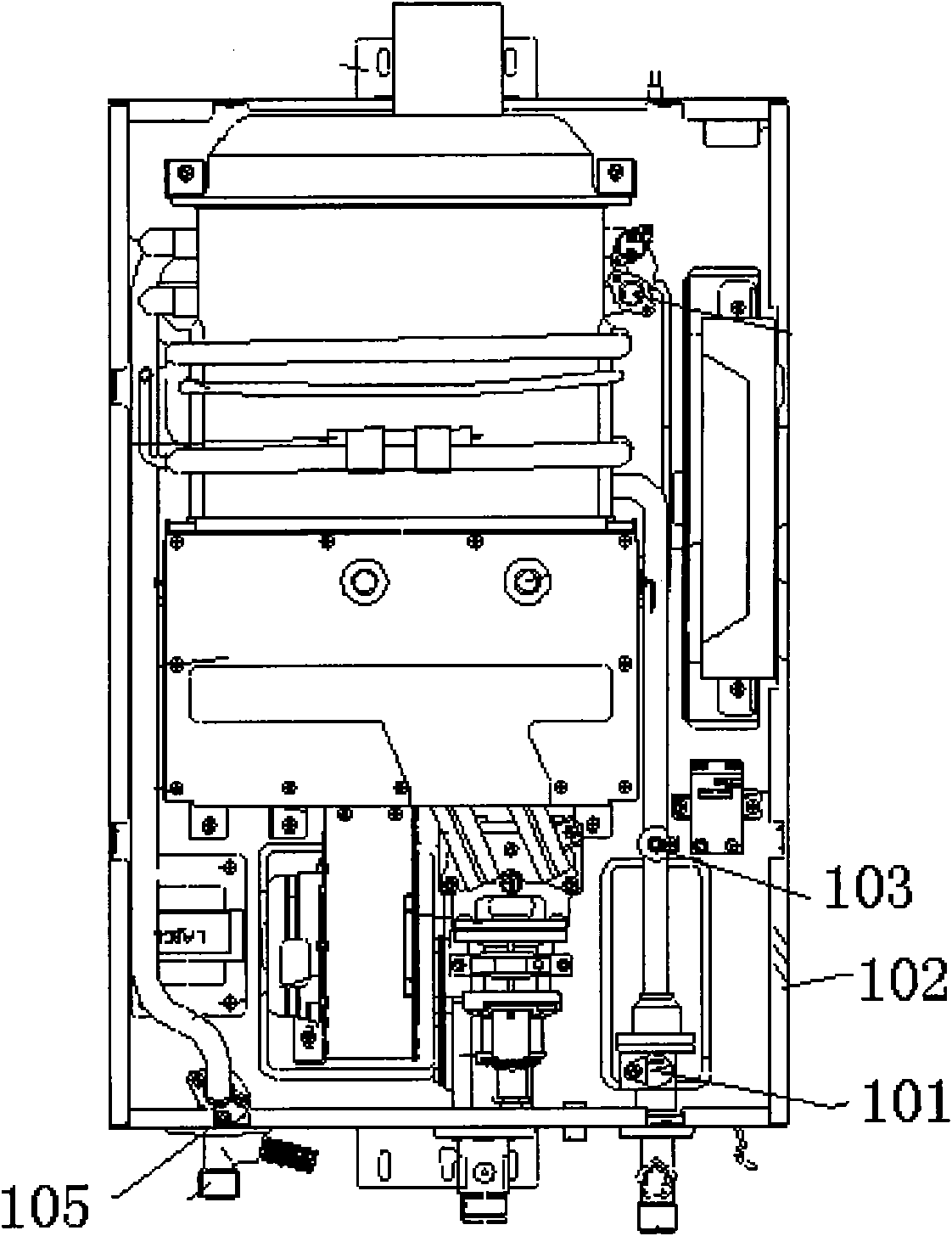

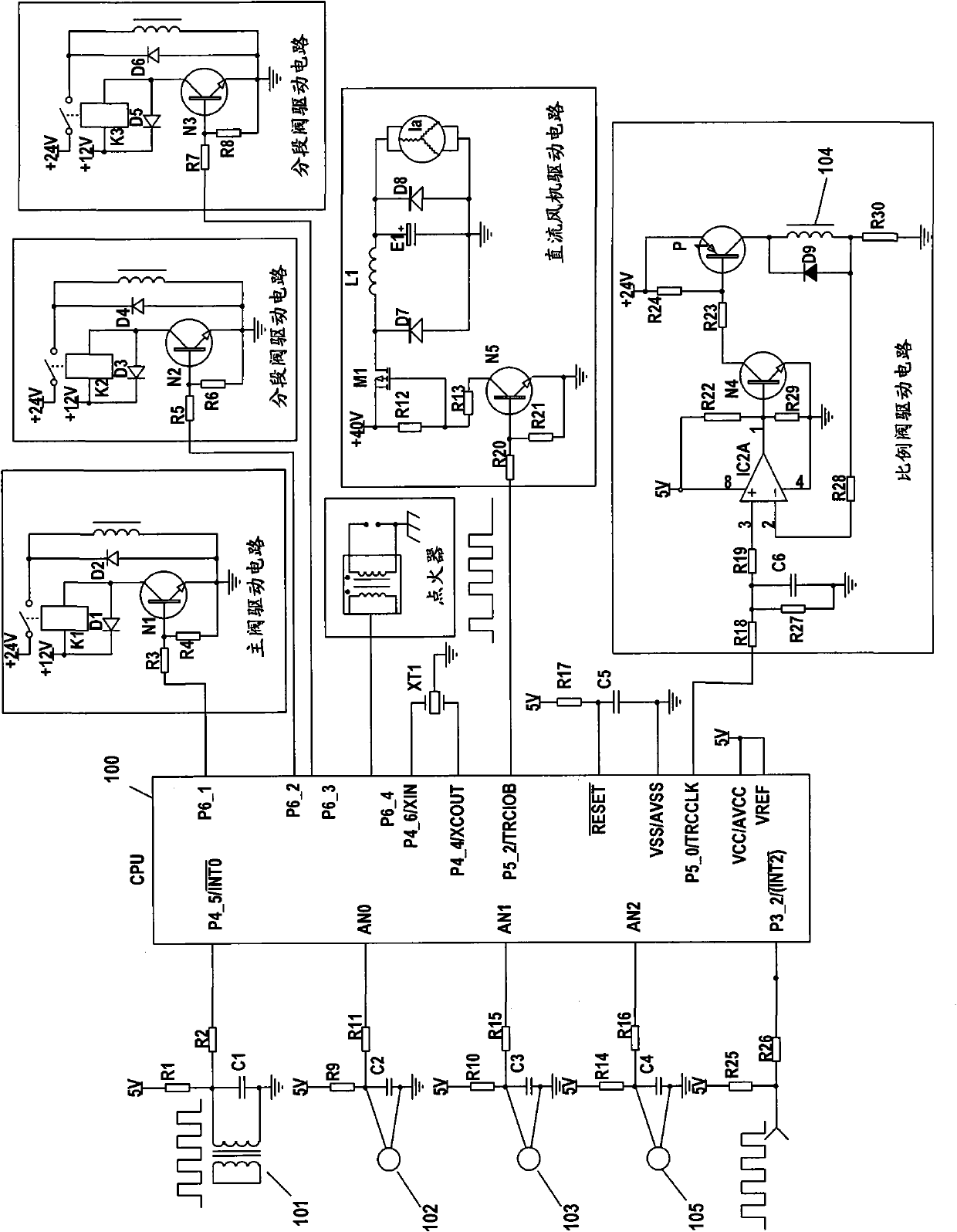

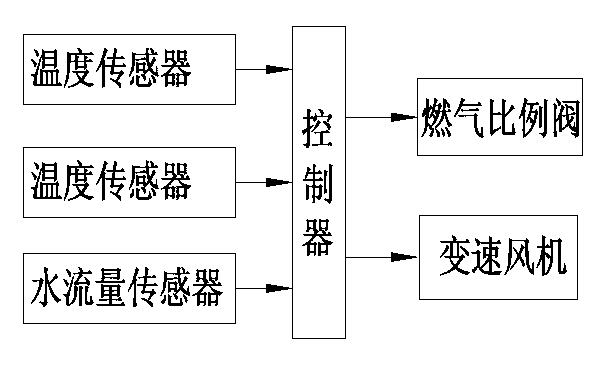

Water temperature control device and water temperature control method for gas water heater

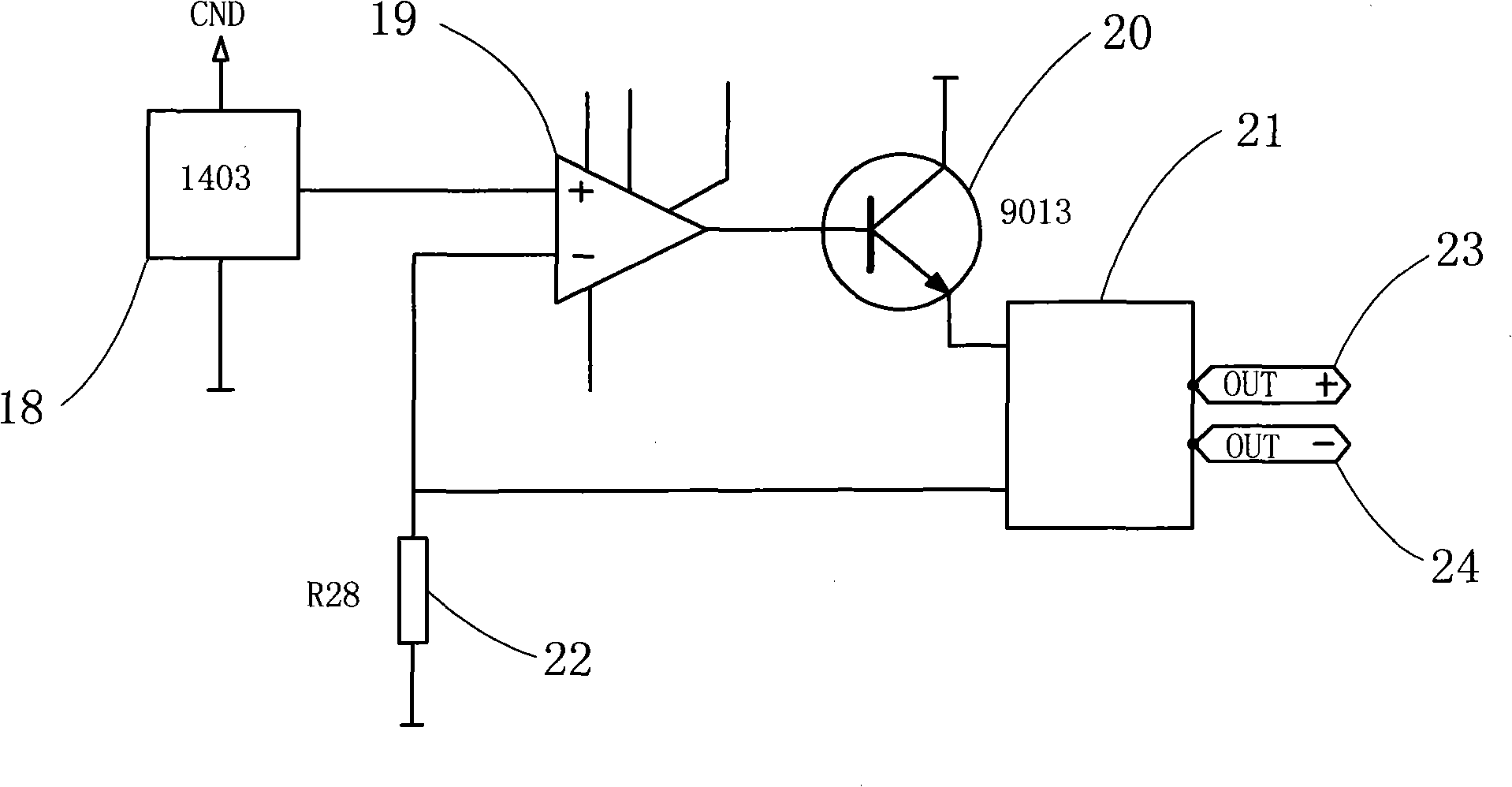

ActiveCN102022832AFluid heatersTemperature control using electric meansAuto regulationVoltage regulation

The invention provides a water temperature control method for a gas water heater. The method comprises the following steps of: A, detecting an environment temperature and a water inflow temperature; B, detecting water outlet flow; C, setting a proper water outlet temperature based on a preset algorithm according to the detected water outlet flow, the detected environment temperature and the detected water inflow temperature; D, calculating an opening control voltage of a proportional valve according to the proper water outlet temperature; and E, regulating the output gas amount according to the opening control voltage of the proportional valve so as to regulate fire power. The invention also provides a water temperature control device for the gas water heater. By the device and the method, the proper water outlet temperature can be automatically regulated according to the external condition without manual regulation.

Owner:HAIER GRP CORP +1

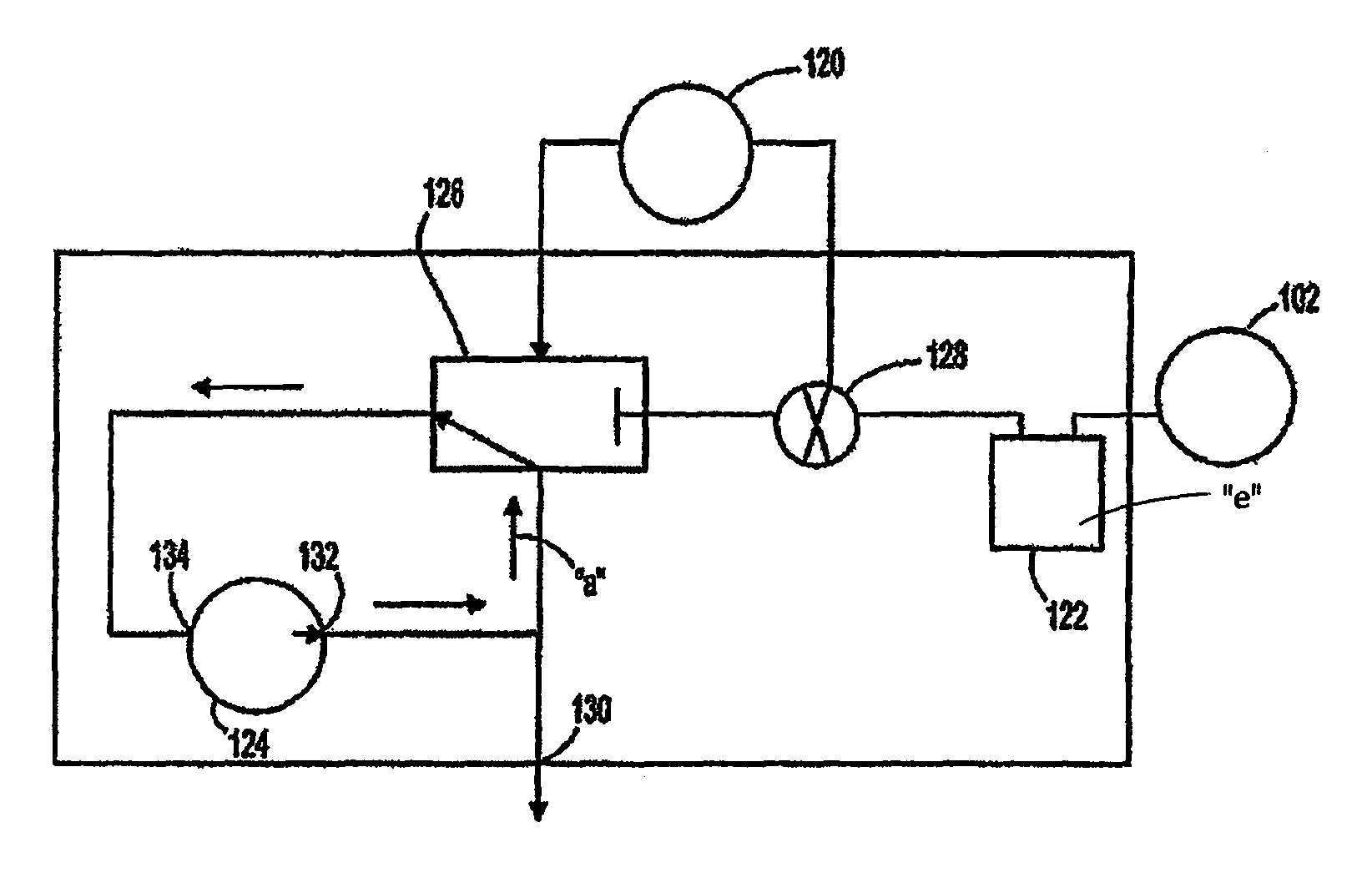

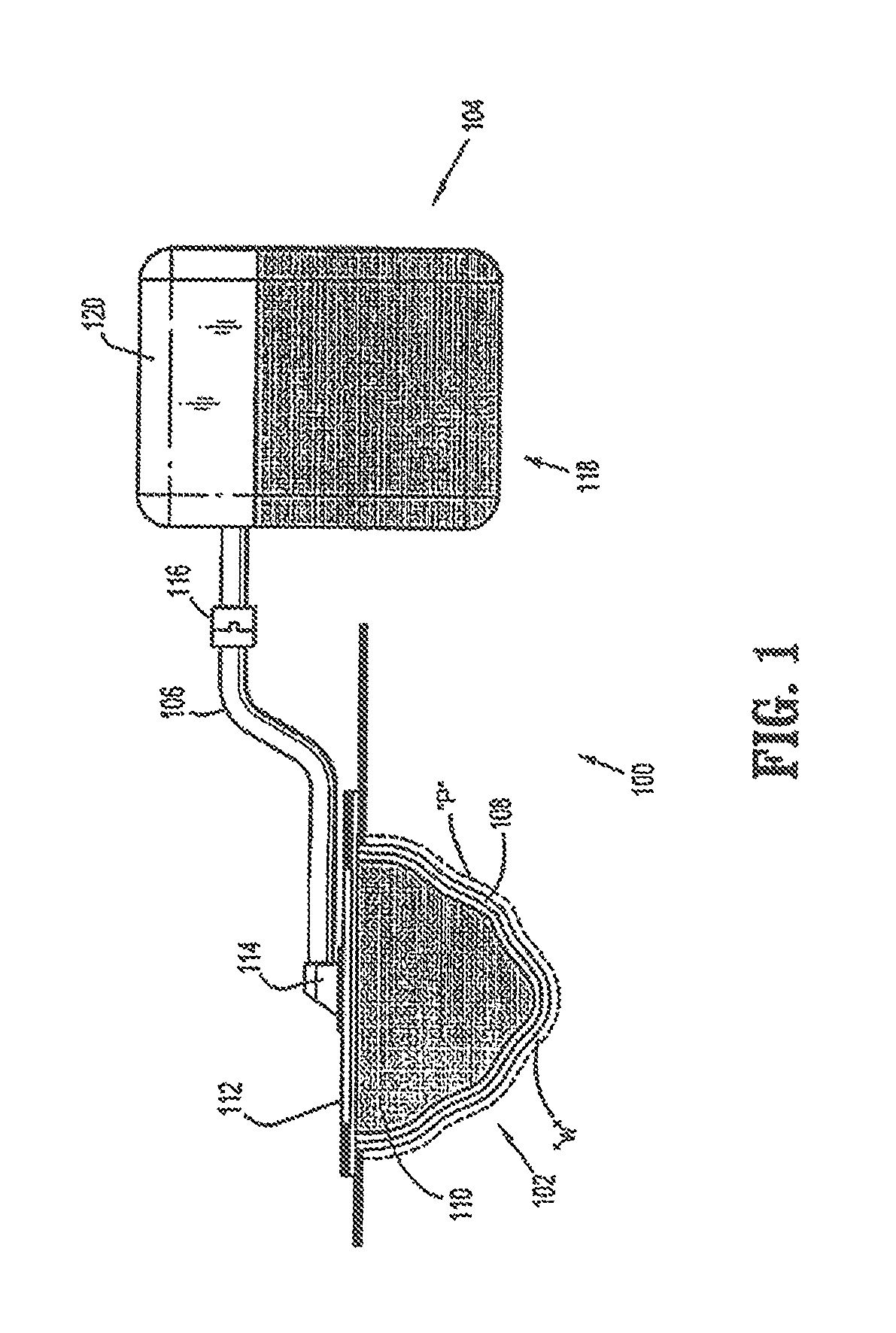

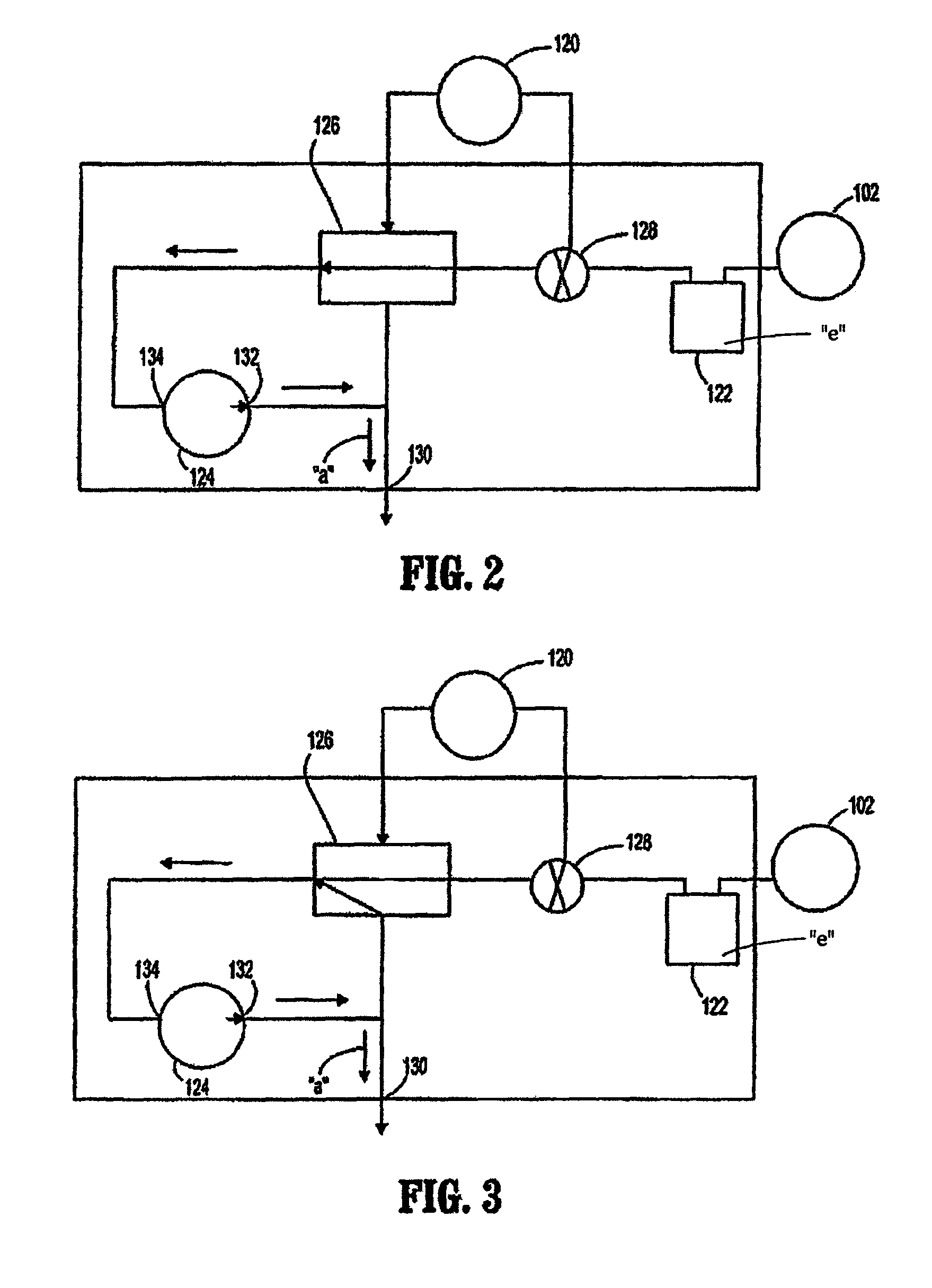

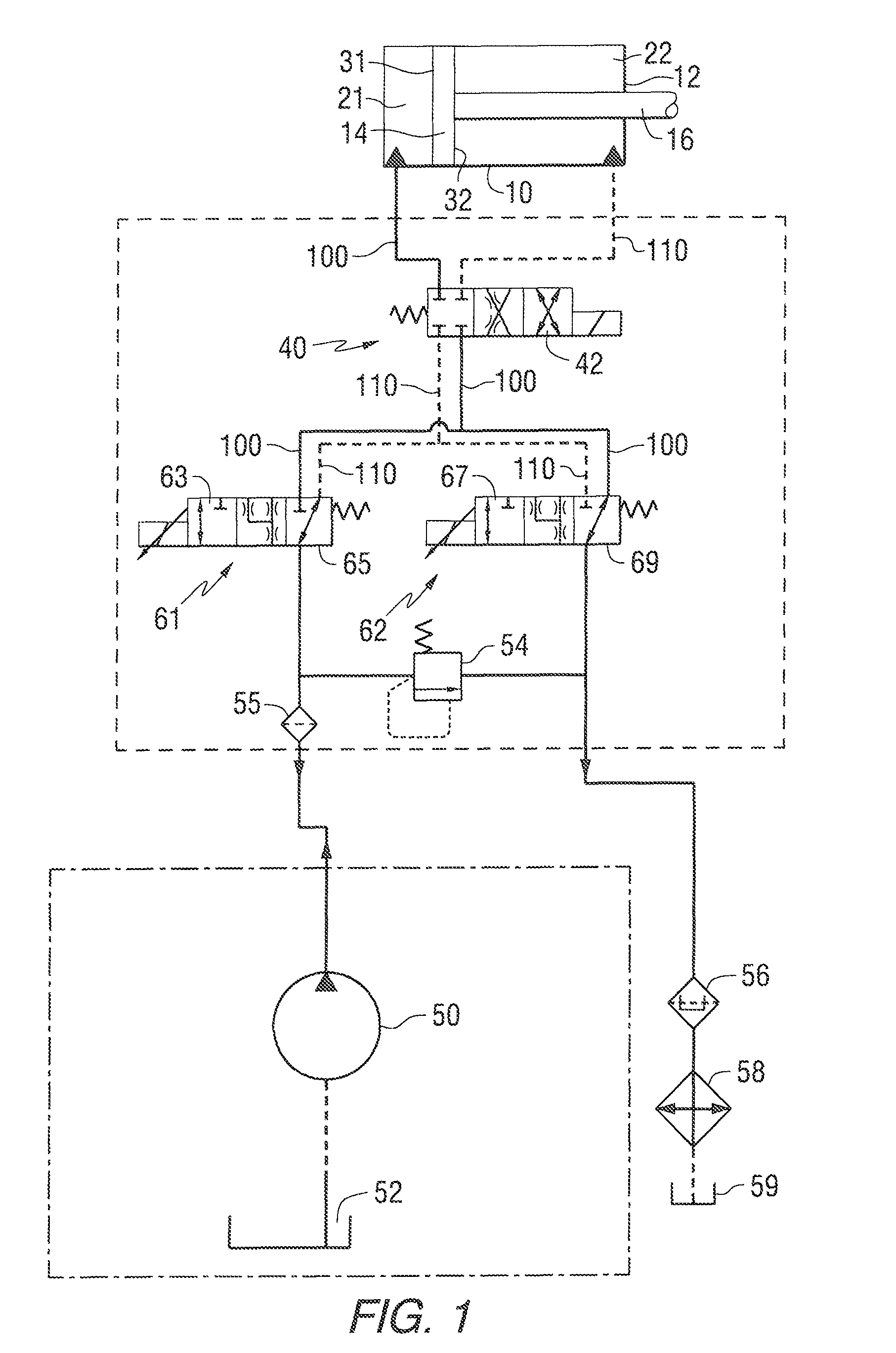

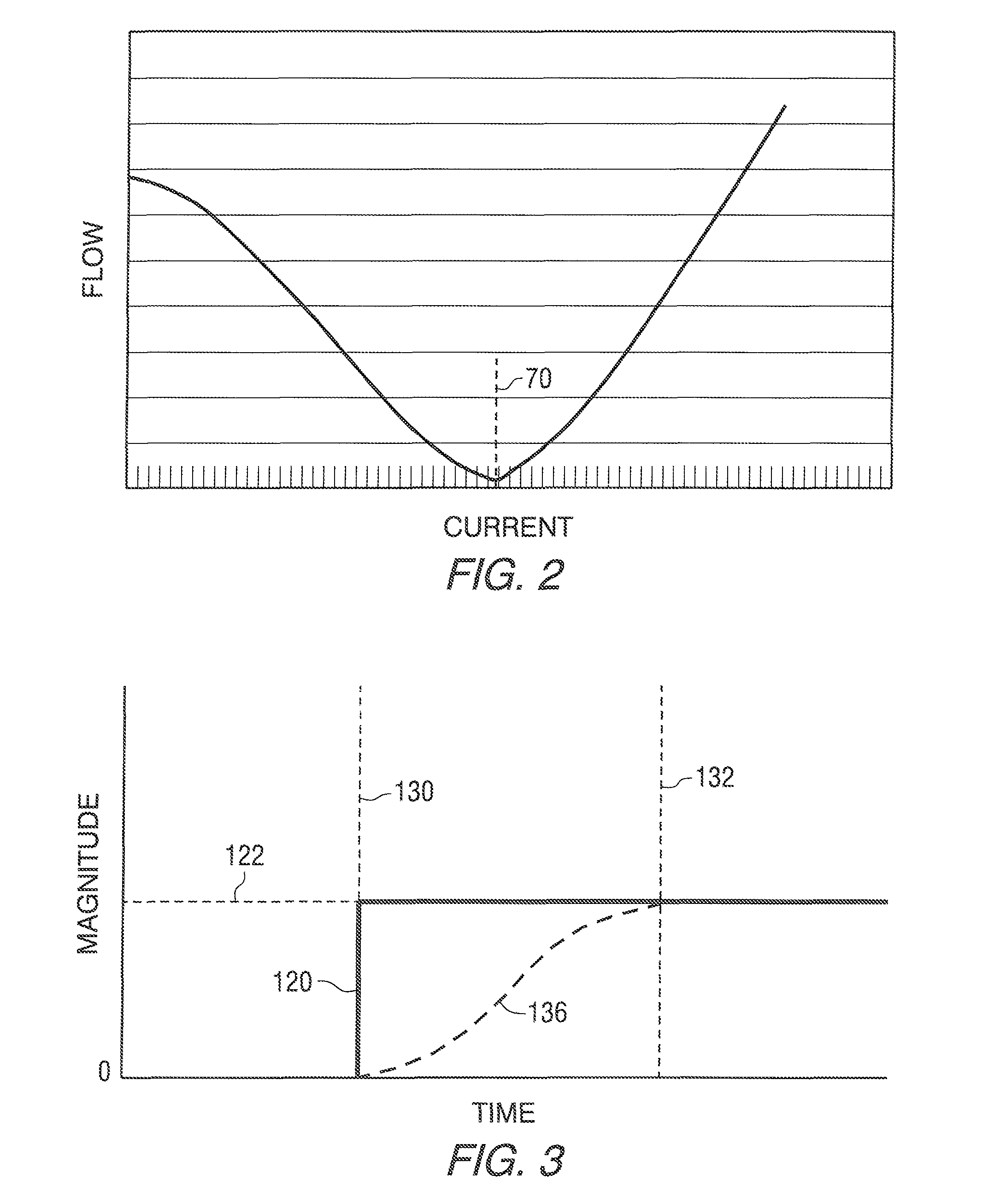

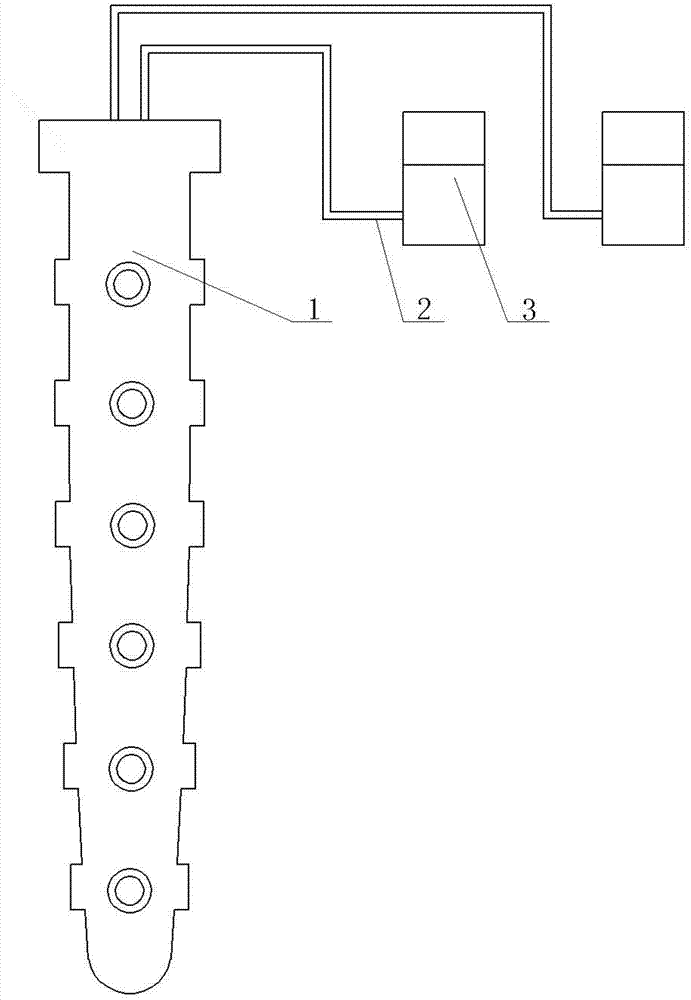

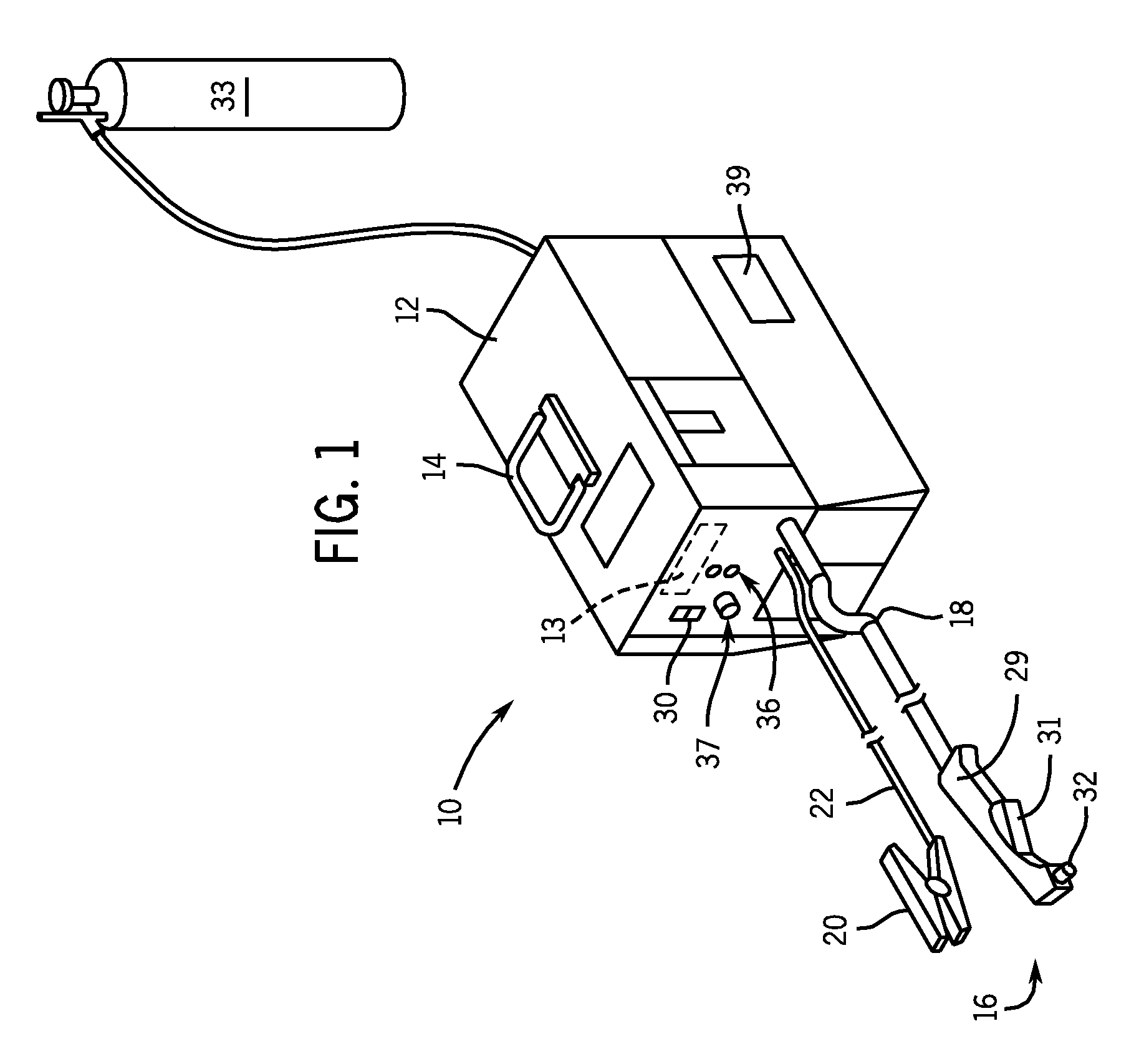

Wound therapy system with proportional valve mechanism

A system for subatmospheric pressure therapy in connection with healing a wound includes a wound dressing adapted for positioning relative to a wound bed of a subject to apply a subatmospheric pressure to the wound and a subatmospheric pressure mechanism. The subatmospheric pressure mechanism may be portable and adapted to be carried or worn by the subject.

Owner:SMITH & NEPHEW INC

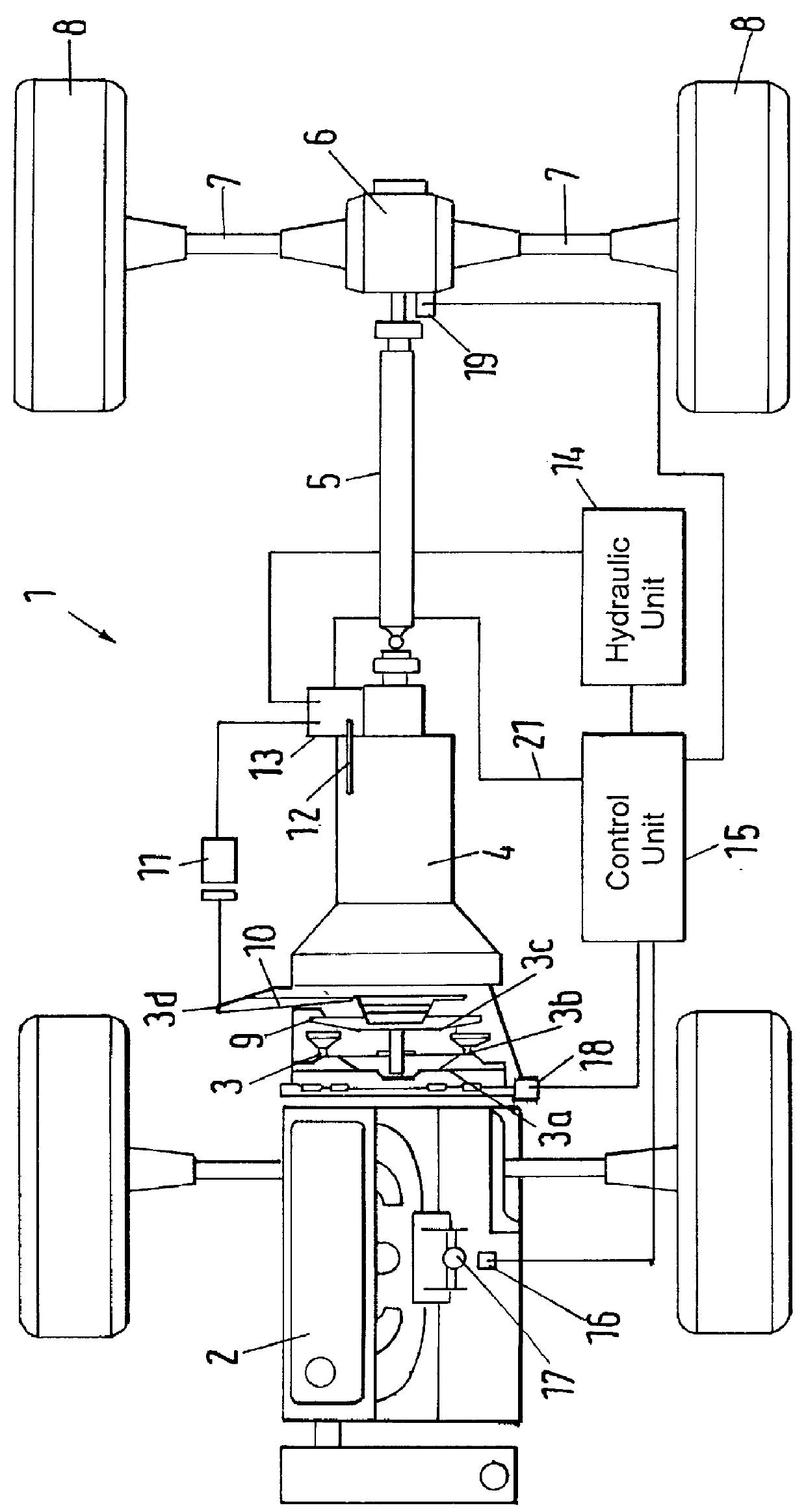

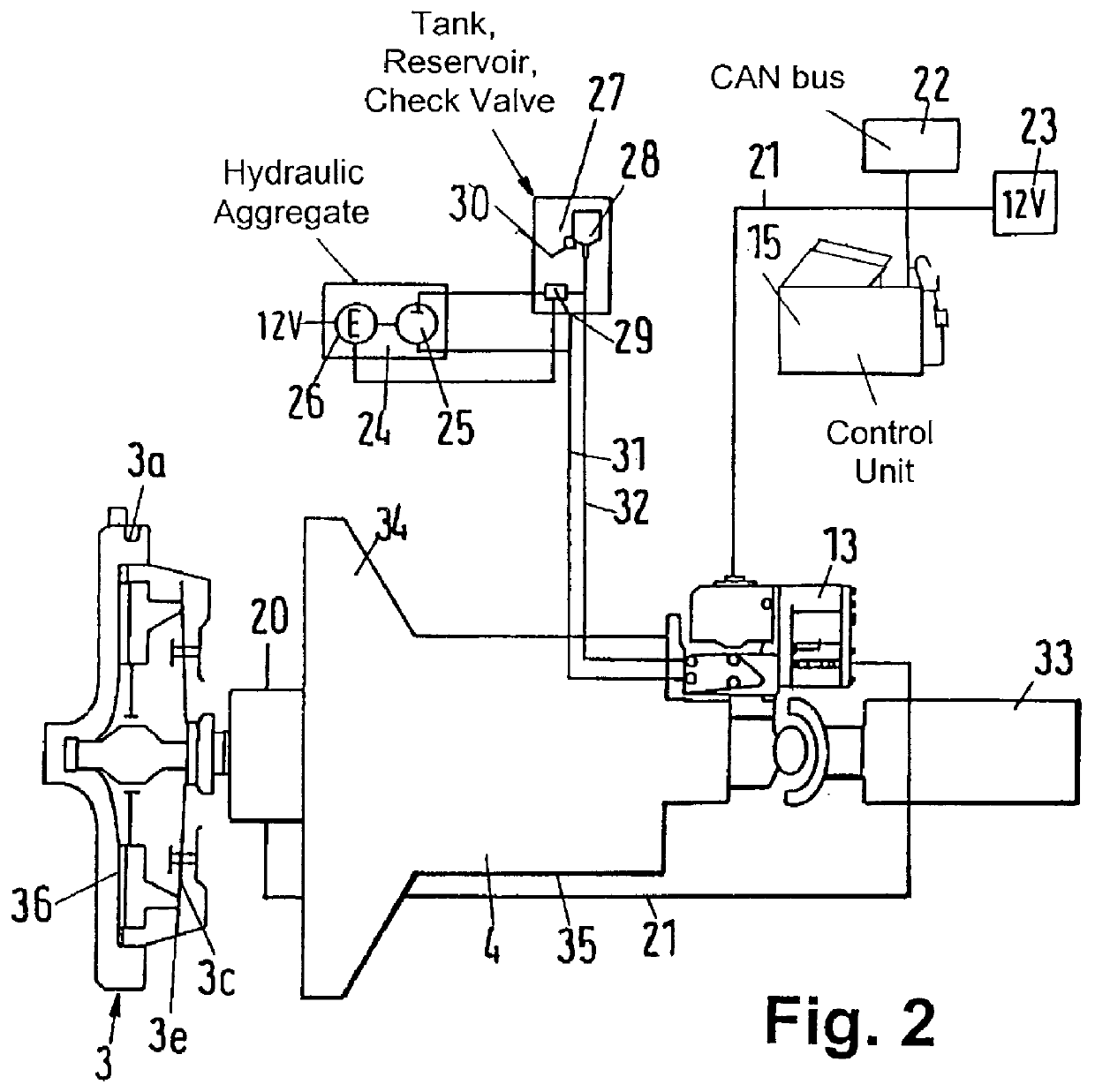

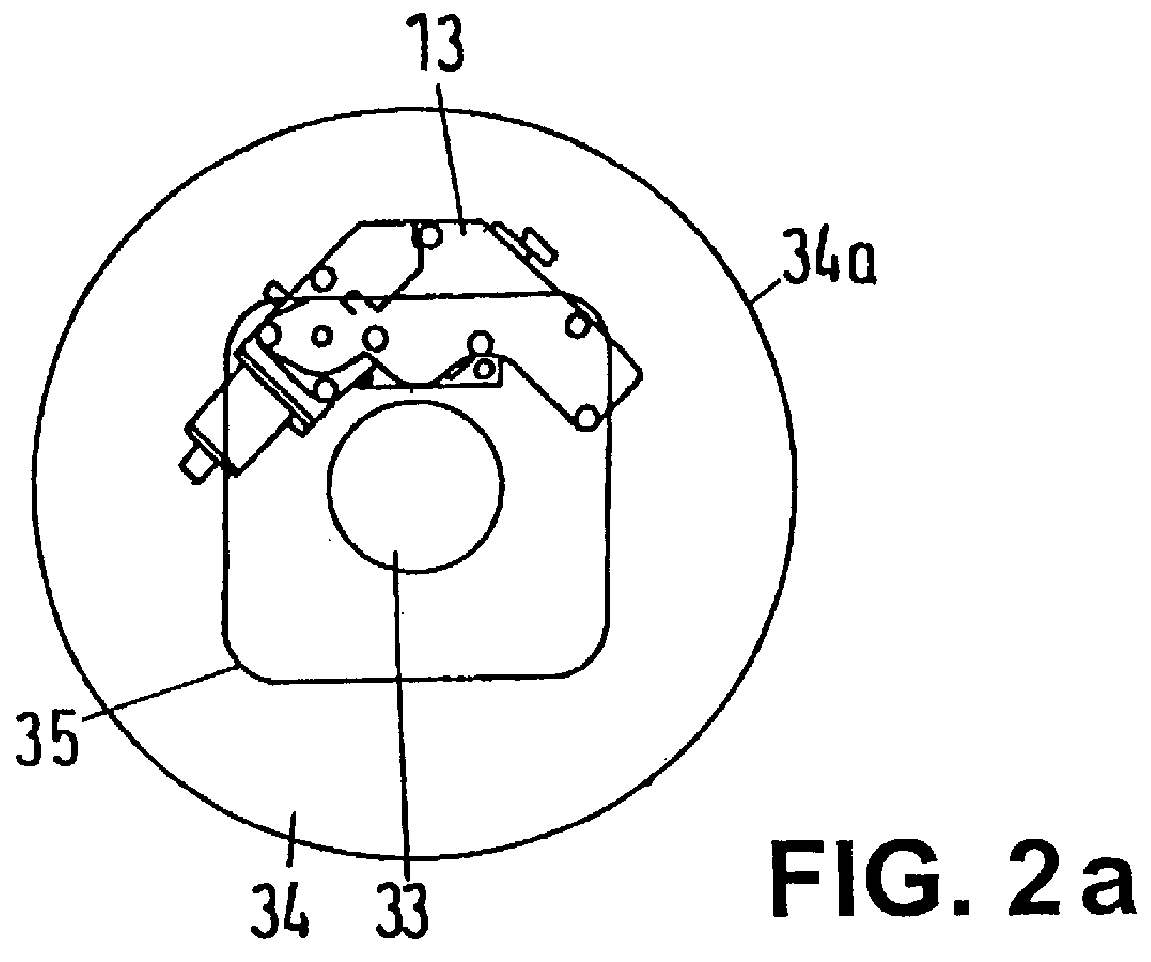

Method of and apparatus for actuating the torque transmitting system and the transmission in the power train of a motor vehicle

PCT No. PCT / DE96 / 01755 Sec. 371 Date Oct. 23, 1997 Sec. 102(e) Date Oct. 23, 1997 PCT Filed Sep. 12, 1996 PCT Pub. No. WO97 / 10456 PCT Pub. Date Mar. 20, 1997The friction clutch between the engine and an automated transmission in the power train of a motor vehicle are operated and controlled by an actuator which effects changes in the extent of engagement of the clutch as well as the selection of and shifting into particular gears. The actuator forms part of a unit which receives a pressurized hydraulic fluid from a source including an accumulator and a proportional valve which latter selects the fluid pressure necessary to shift the transmission into a selected gear.

Owner:LUK GETRIEBE SYST +3

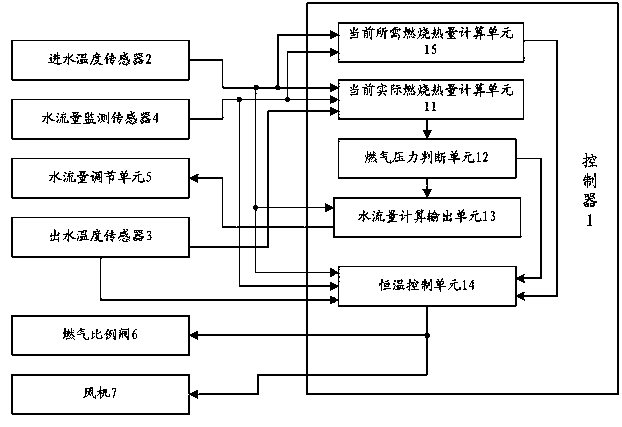

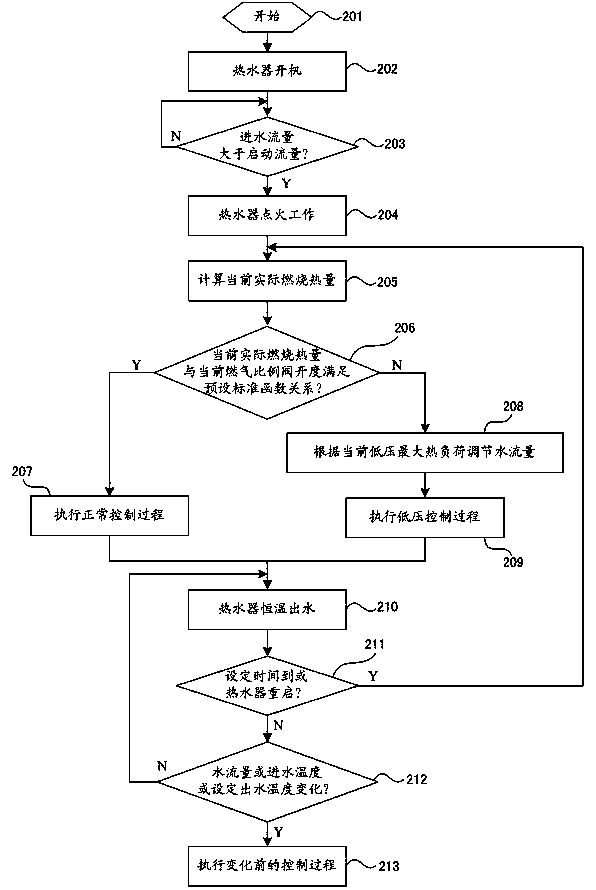

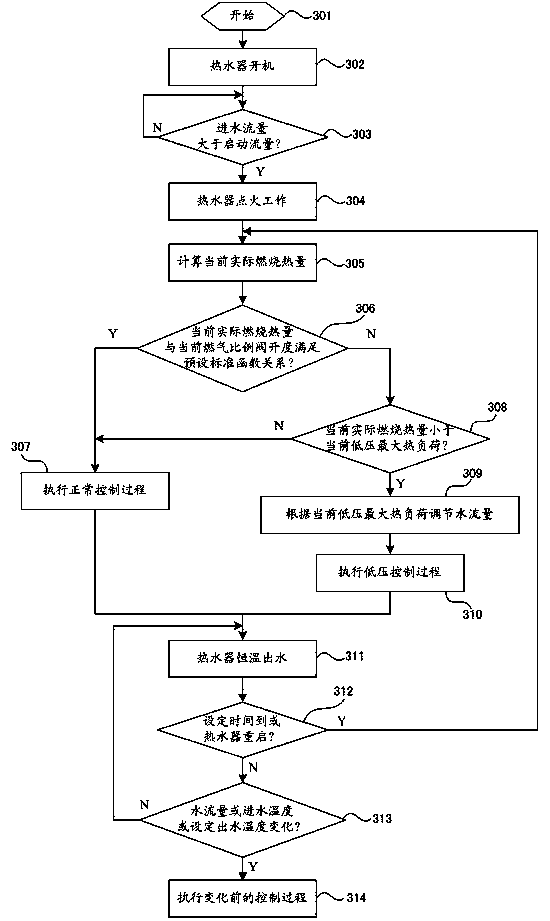

Control method and system of gas water heater and gas water heater

The invention discloses a control method and system of a gas water heater and the gas water heater. The control method comprises the following steps that in the working process of the gas water heater, the current opening degree of a gas proportional valve of the water heater is monitored, and current practical combustion heat quantity is worked out; whether the current opening degree of the gas proportional valve and the current practical combustion heat quantity accord with a preset standard function relation is judged; when the current opening degree of the gas proportional valve and the current practical combustion heat quantity do not accord with the preset standard function relation, it is determined that gas pressure is insufficient, and a low pressure control process is executed according to the current low pressure maximum thermal load; when the current opening degree of the gas proportional valve and the current practical combustion heat quantity accord with the preset standard function relation, a normal control process is executed. By applying the method and system to the gas water heater, the problems that because the gas pressure is insufficient, flameout and fire spreading are caused and the temperature of discharged water cannot reach a set temperature can be solved.

Owner:HAIER GRP CORP +1

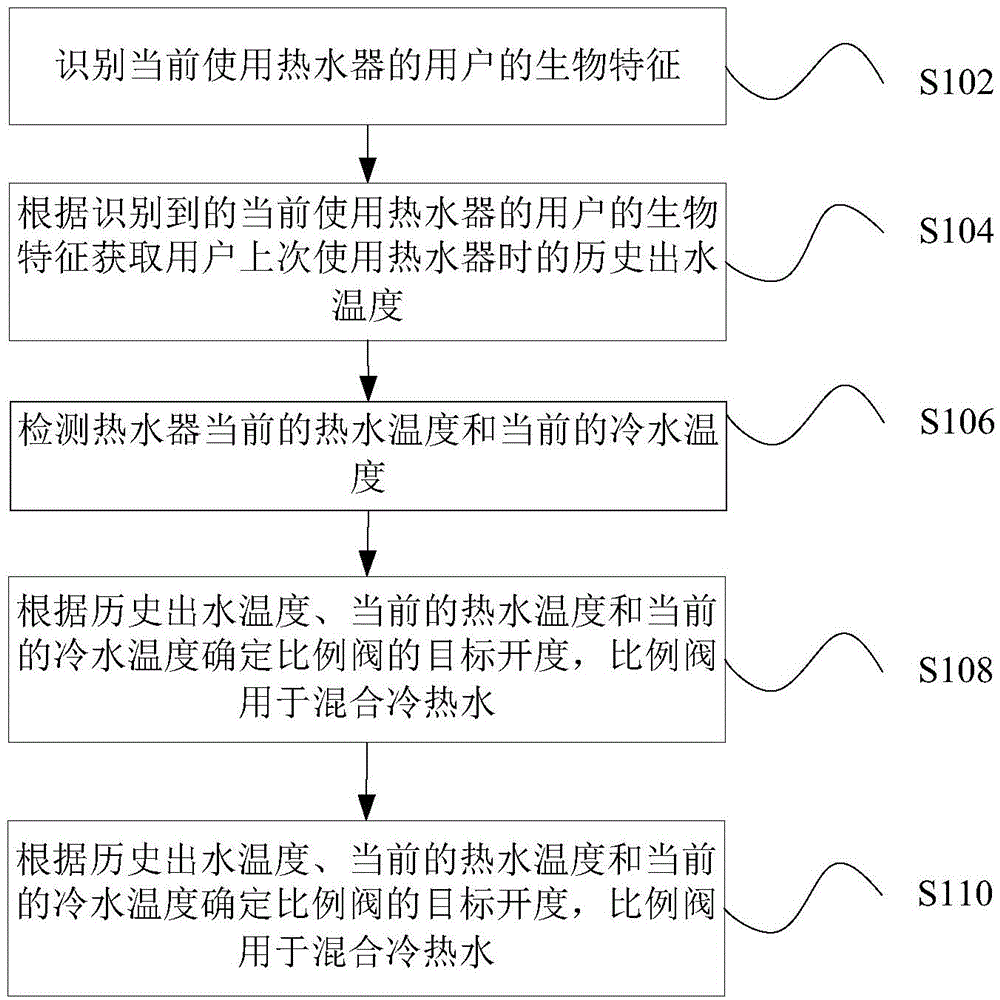

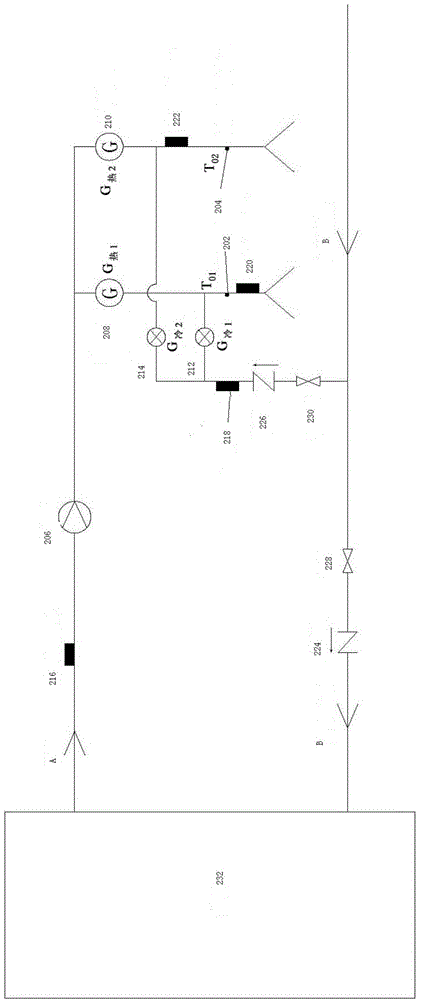

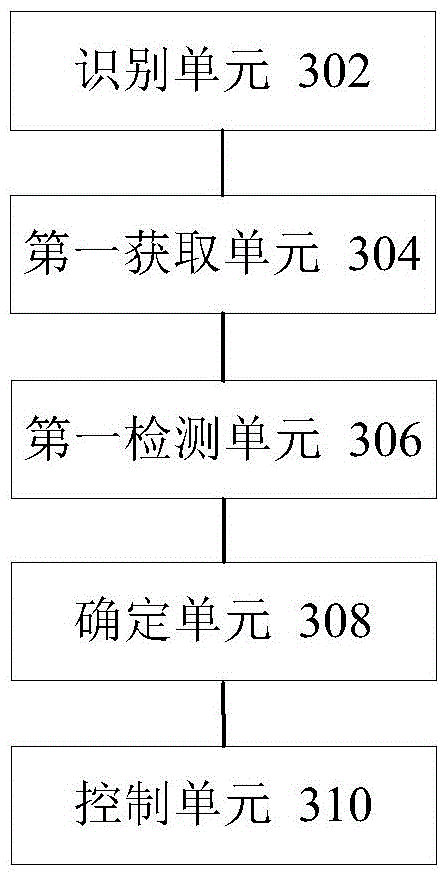

Control method and device of water heater

ActiveCN104482655ASolve the problem of water outlet with high water temperature accuracyFluid heatersSolar heat devicesEngineeringWater state

The invention discloses a control method and a control device of a water heater, wherein the control method of the water heater comprises the following steps: distinguishing biological characteristics of an current water heater user; obtaining the historical outlet water temperature when the user uses the water heater according to the distinguished biological characteristics of the current water heater user; detecting the current hot water temperature and the current cold water temperature of the water heater; determining the target openness of the proportional valve according to the historical outlet water temperature, the current hot water temperature and the current cold water temperature, wherein the proportional valve is used for mixing cold and hot water; and controlling the current outlet water state when the user uses the water heater according to the target openness of the proportional valve, wherein the current water outlet state comprises the current water outlet flow rate and / or the current outlet water temperature. The control method and the control device can be used for solving the problem that the outlet water with high water temperature precision cannot be provided based on different users when the water heater is used in the associated technology is solved.

Owner:GREE ELECTRIC APPLIANCES INC

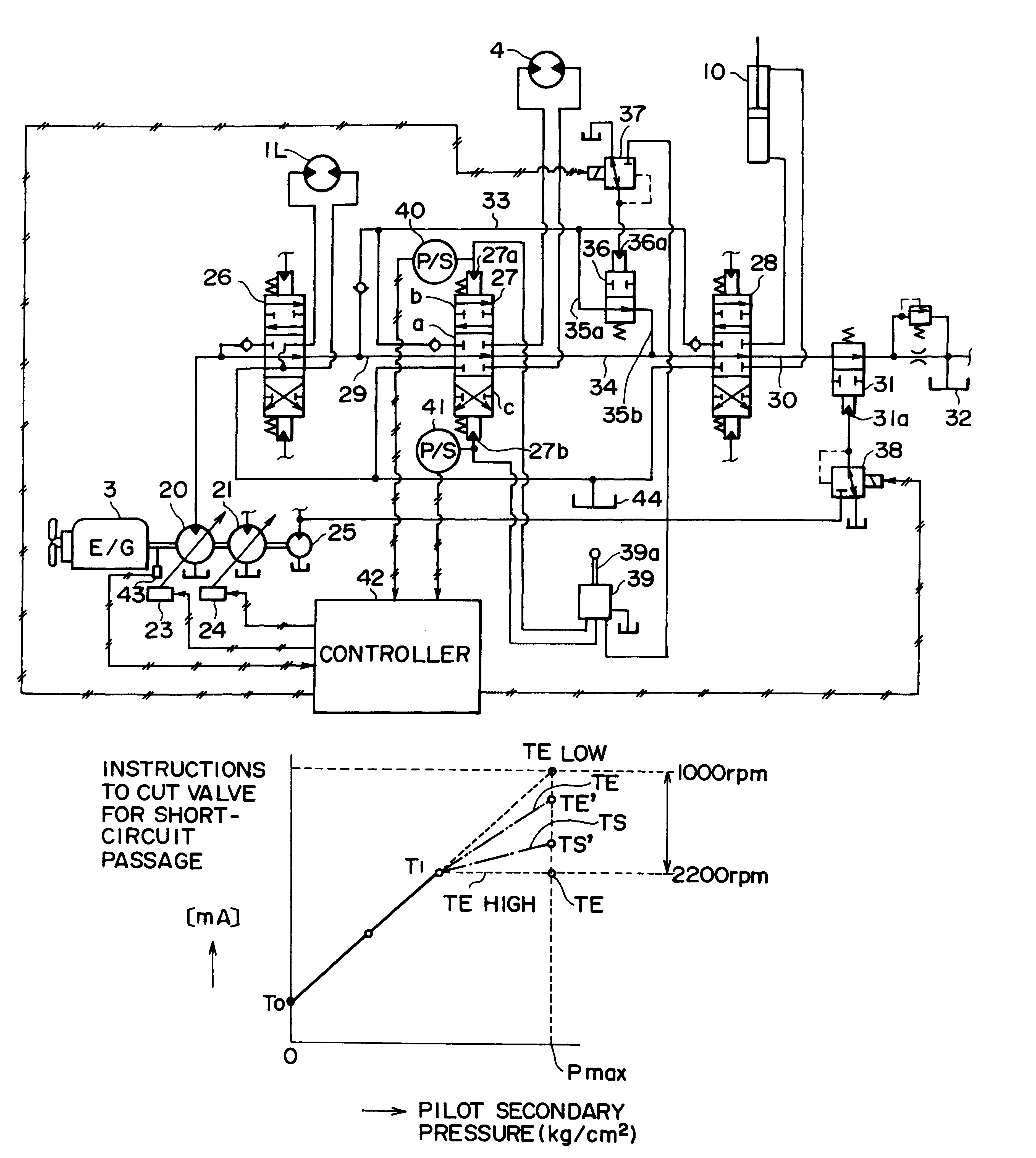

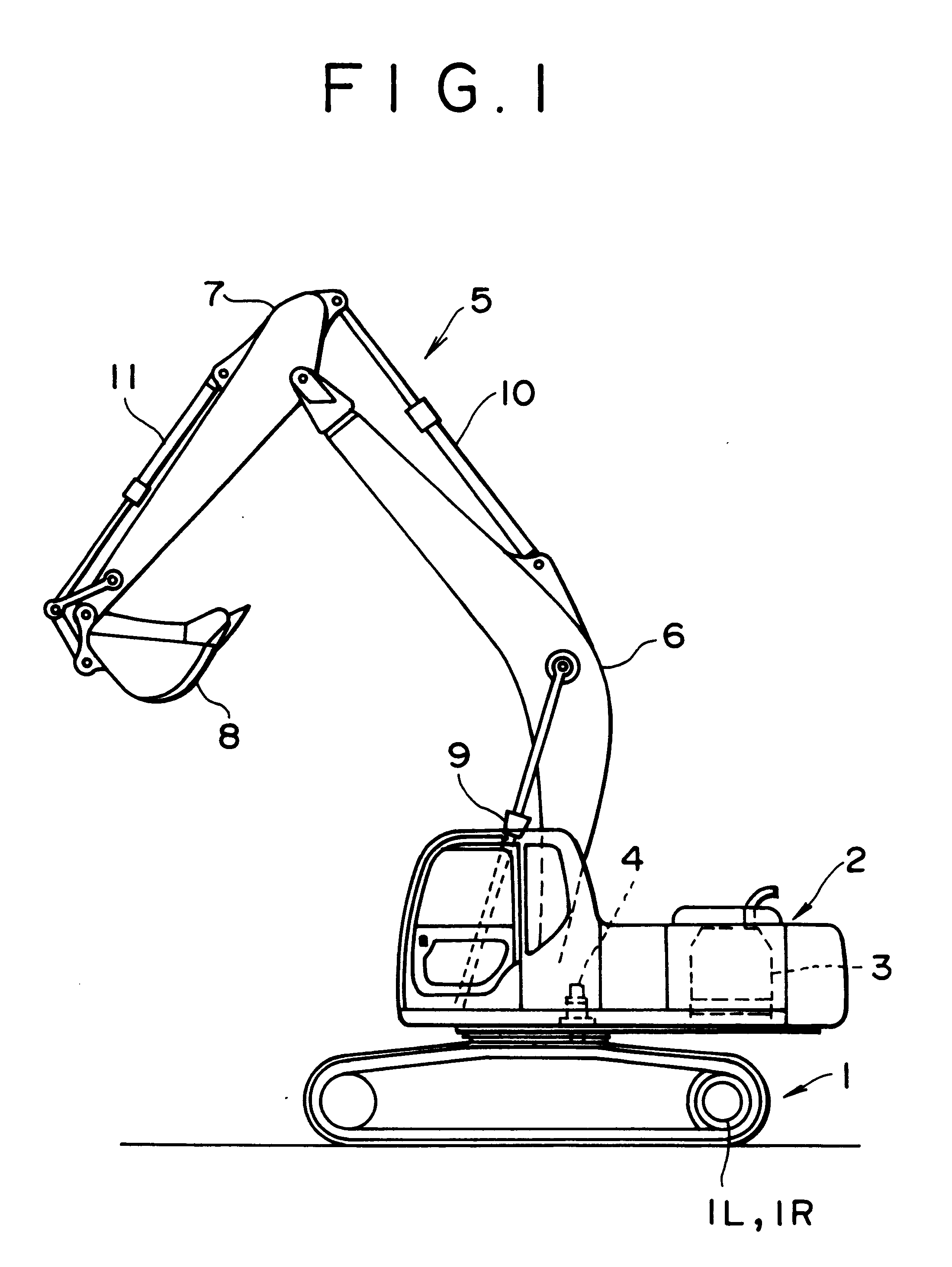

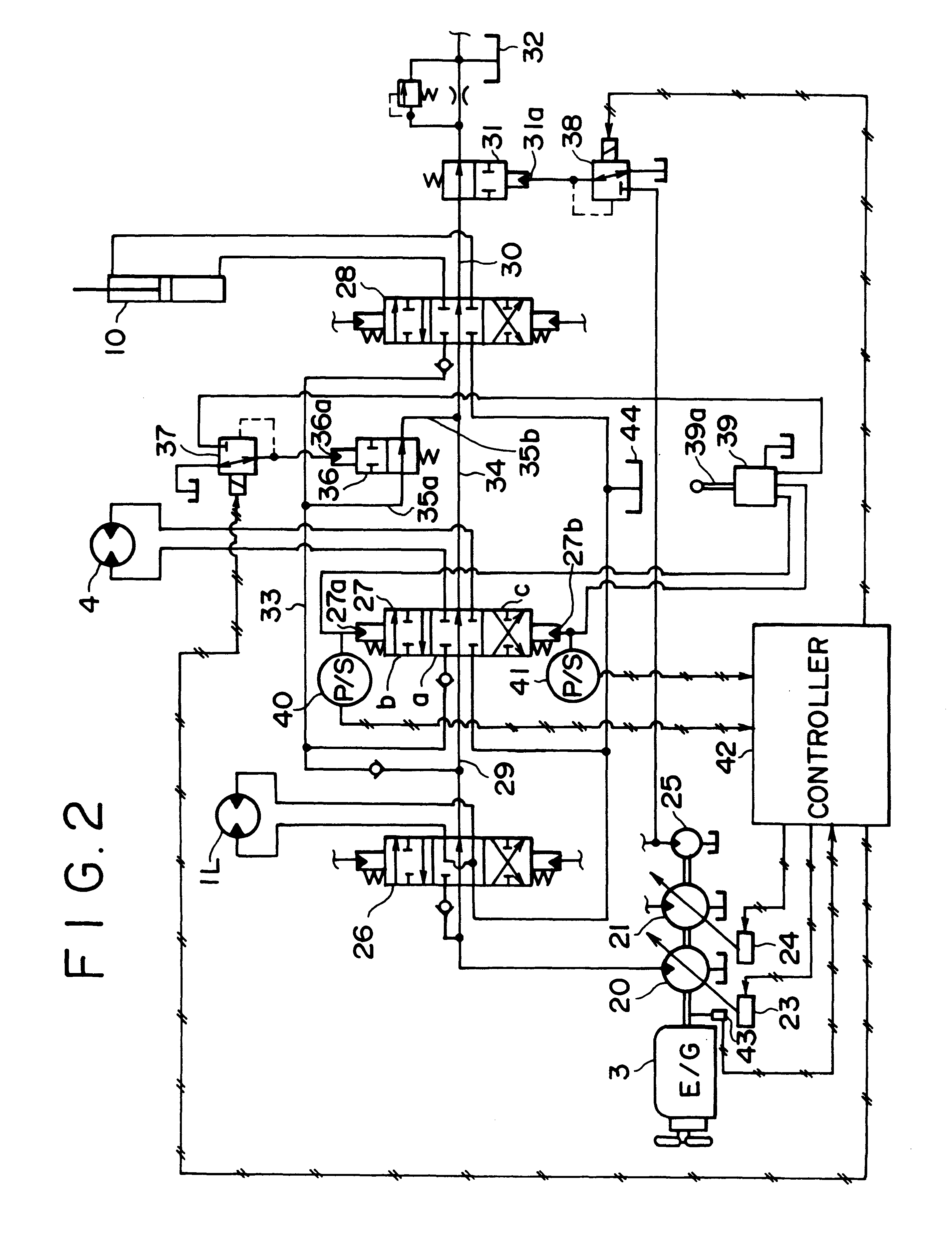

Hydraulic control device of a working machine

A hydraulic control apparatus for a working machine in which a flow rate and a direction of pressure oil discharged from a hydraulic pump are controlled by a control valve to supply it to a swing motor, comprising: a bleed-off oil path for bleeding off a part of the pressure oil supplied to the swing motor, a cut valve provided on the bleed-off oil path to adjust a bleed-off amount, a controller for controlling the cut valve through a solenoid proportional valve, and pressure sensors for detecting an operating amount of a remote control valve for swing, characterized in that the controller sets the bleed-off amount according to the operating amount detected by the pressure sensors, controls an opening area of the cut valve on the basis of the bleed-off amount set, and suppresses the shock when sudden swinging operation takes place.

Owner:KOBE STEEL LTD

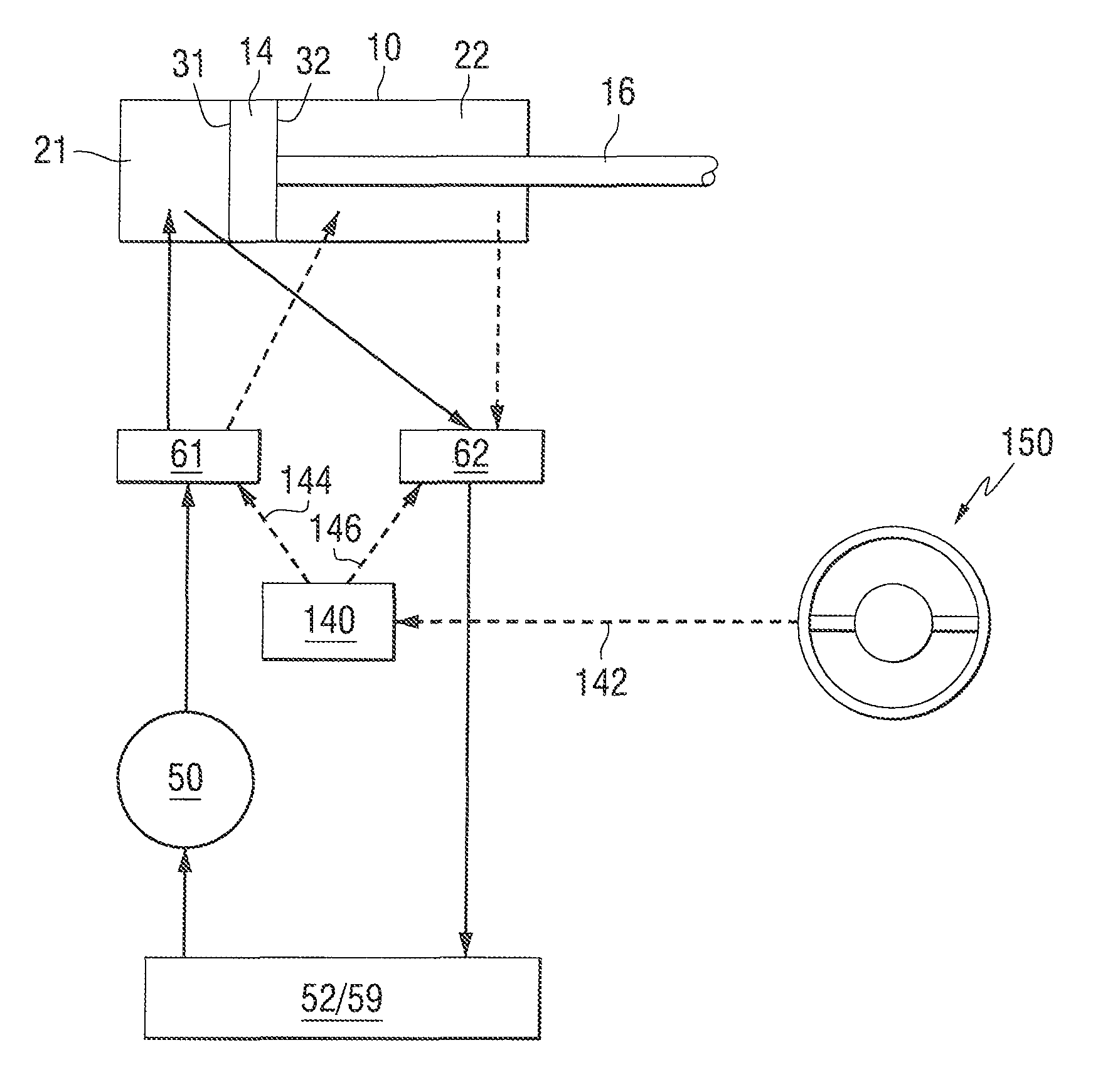

Control system for a marine vessel hydraulic steering cylinder

ActiveUS8046122B1Increase the areaDigital data processing detailsServomotorsHydraulic cylinderSteering wheel

A control system for a hydraulic steering cylinder utilizes a supply valve and a drain valve. The supply valve is configured to supply pressurized hydraulic fluid from a pump to either of two cavities defined by the position of a piston within the hydraulic cylinder. A drain valve is configured to control the flow of hydraulic fluid away from the cavities within the hydraulic cylinder. The supply valve and the drain valve are both proportional valves in a preferred embodiment of the present invention in order to allow accurate and controlled movement of a steering device in response to movement of a steering wheel of a marine vessel.

Owner:BRUNSWICK CORPORATION

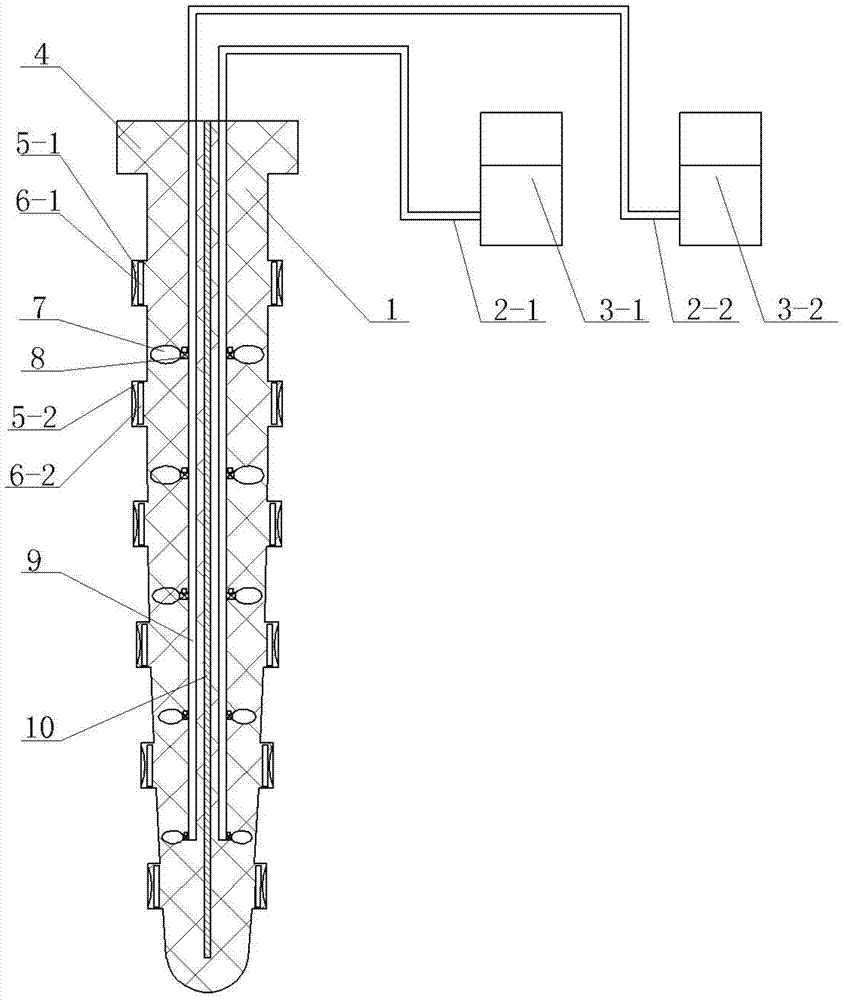

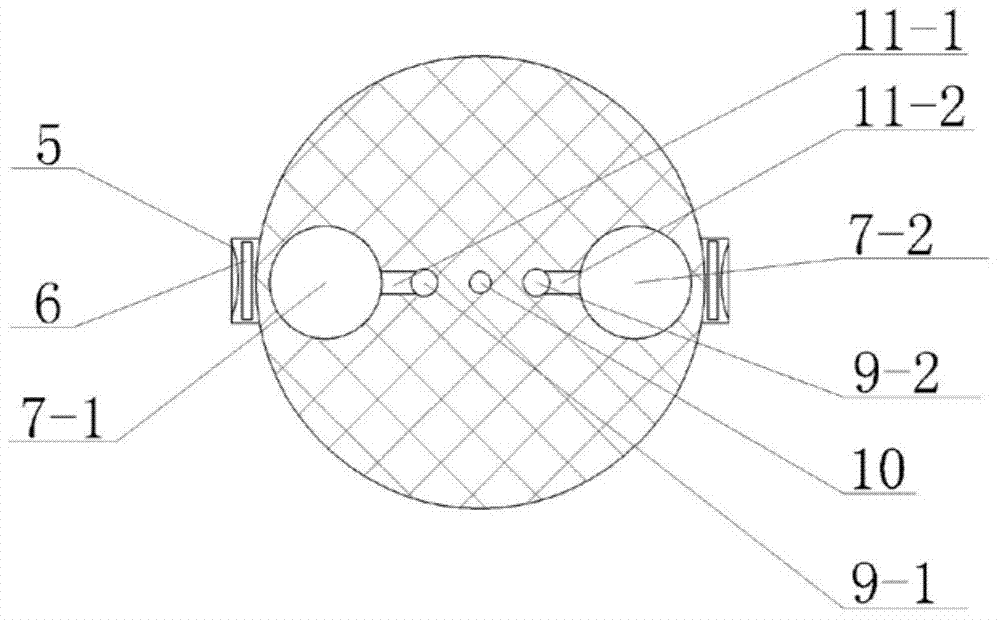

Octopus tentacle imitating adaptive capture soft manipulator and capture method thereof

ActiveCN103753524AEffective windingEfficient coatingProgramme-controlled manipulatorGripping headsShape changeMagnetic valve

The invention discloses an octopus tentacle imitating adaptive capture soft manipulator and a capture method thereof. The octopus tentacle imitating adaptive capture soft manipulator mainly comprises a tentacle, an air pipe, an electrical proportional valve, strain gages and a magnetic valve, wherein the tentacle imitates the shape of an octopus tentacle and is in an irregular strip cone shape, a tentacle protrusion with a large diameter is arranged at the end of the tentacle, groups of ellipsoidal pressure regulating cavities are evenly distributed in the tentacle, main air channels are distributed along the axle direction of the tentacle in the tentacle, each row of ellipsoidal pressure regulating cavities distributed along the axial direction corresponds to a main air channel, the main air channels do not directly pass through the ellipsoidal pressure regulating cavities and are connected with the ellipsoidal pressure regulating cavities through branch air channels, magnetic valves are arranged at the positions of the branch air channels for connecting the ellipsoidal pressure regulating cavities and the main air channels, the strain gages are placed between each two groups of the ellipsoidal pressure regulating cavities, the ellipsoidal pressure regulating cavities produce different shape changes so as to control tentacle to bend through feedback of signals of the strain gages and match between the magnetic valve and the electrical proportional valve, and the tentacle winds objects by controlling a plurality of groups of the pressure regulating cavities.

Owner:BEIJING UNIV OF CHEM TECH

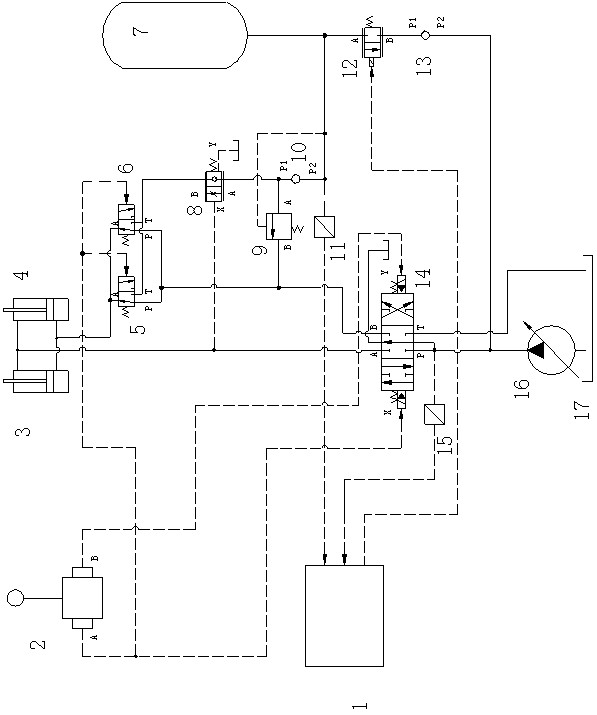

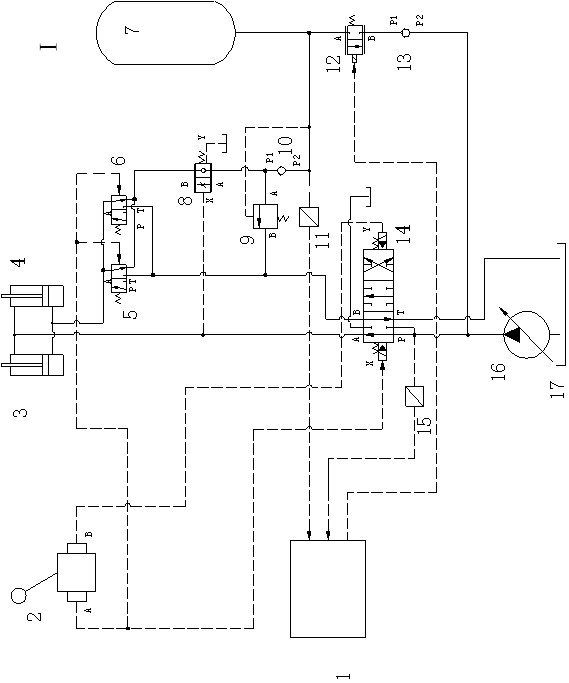

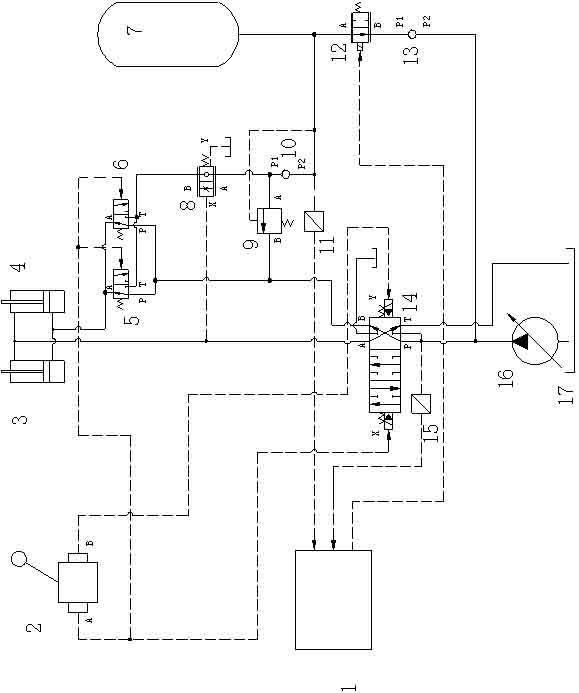

Hydraulic excavator flow rate control method and control loop

InactiveCN102011416AAvoid damageImprove work efficiencyServomotorsSoil-shifting machines/dredgersNegative feedbackElectric control

The invention discloses a hydraulic excavator flow rate control loop which comprises a hydraulic and electric control loop. The hydraulic excavator flow rate control loop is characterized by comprising two electromagnetic proportional valves and two or-gate type three-way shuttle valve, wherein the electric control ends of the proportional valves are respectively connected with the controller, the input end is connected with a pilot pressure pump of an excavator, the output end is connected with a input opening P1of one three-way shuttle valve, input openings P2 of the two three-way shuttle valves are respectively connected with a front negative feedback valve core and a back negative feedback valve of the excavator, and output openings A of the three-way shuttle valves are respectively connected with a front negative feedback regulator and a back negative feedback regulator. A method comprises the following steps of: receiving sensor signals by a controller; sending electromagnetic proportional valve electric control signals; opening proportional valve and shuttle valve paths; controlling the corresponding negative feedback regulators through the pressure of the proportional valves; and finally controlling the delivery capacity of the pump. The method realizes the limitation on the system delivery capacity through controlling the delivery capacity of the pump by using the electromagnetic proportional valves, so the flow rate maintains the normal state when a rotating or walking device works singly, and the damage to a motor caused by high flow rate is avoided.

Owner:SANY HEAVY MACHINERY

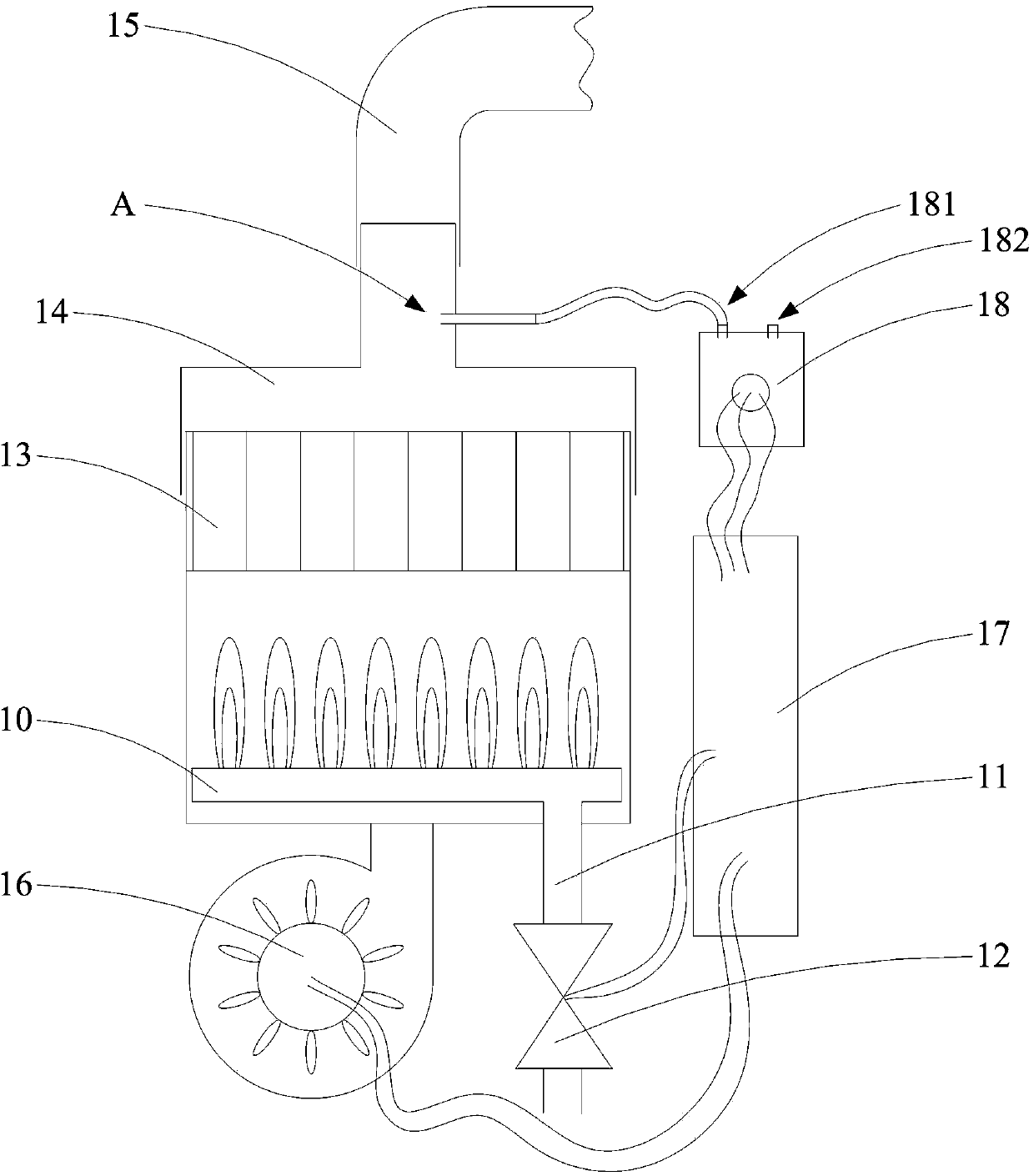

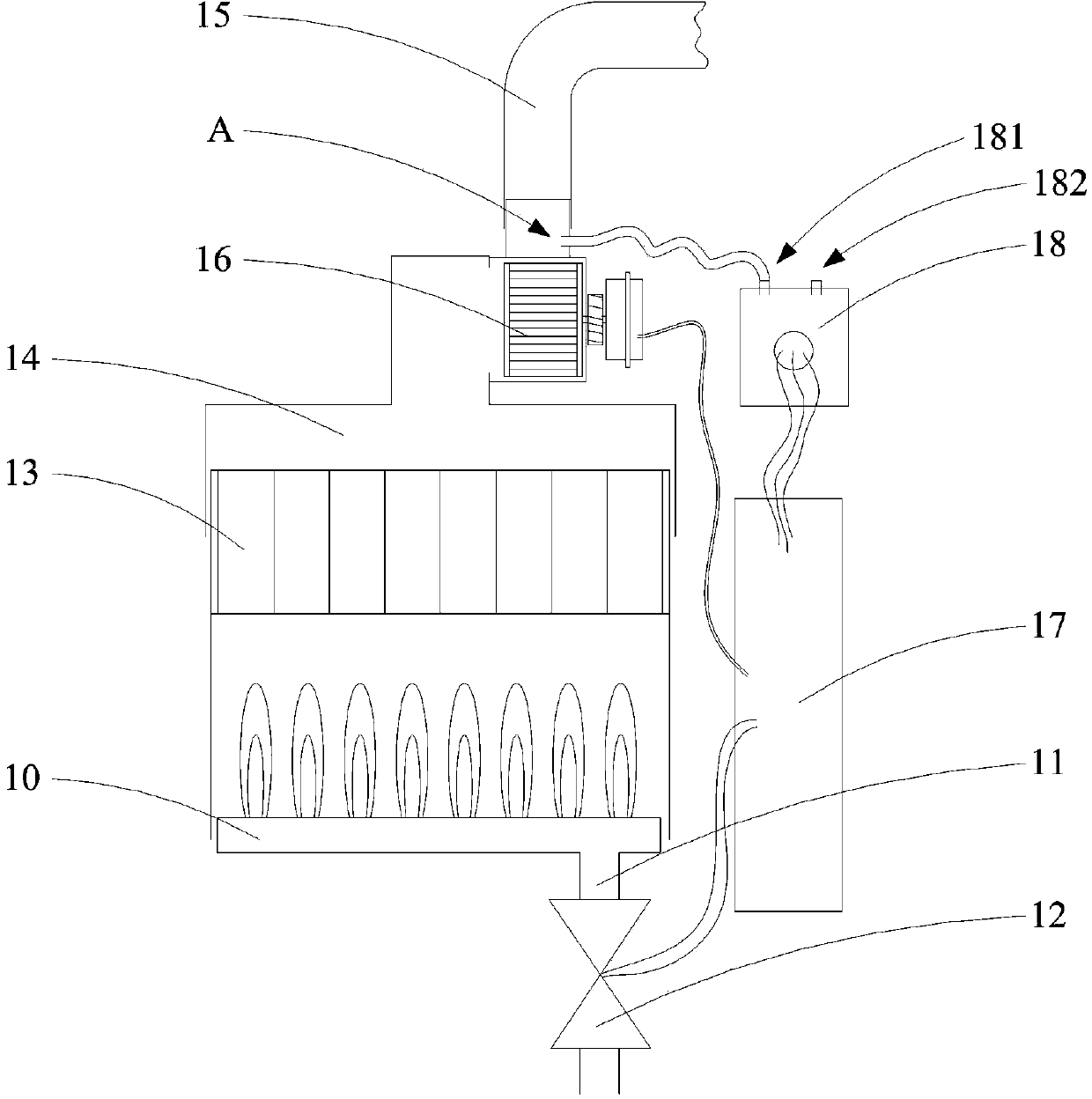

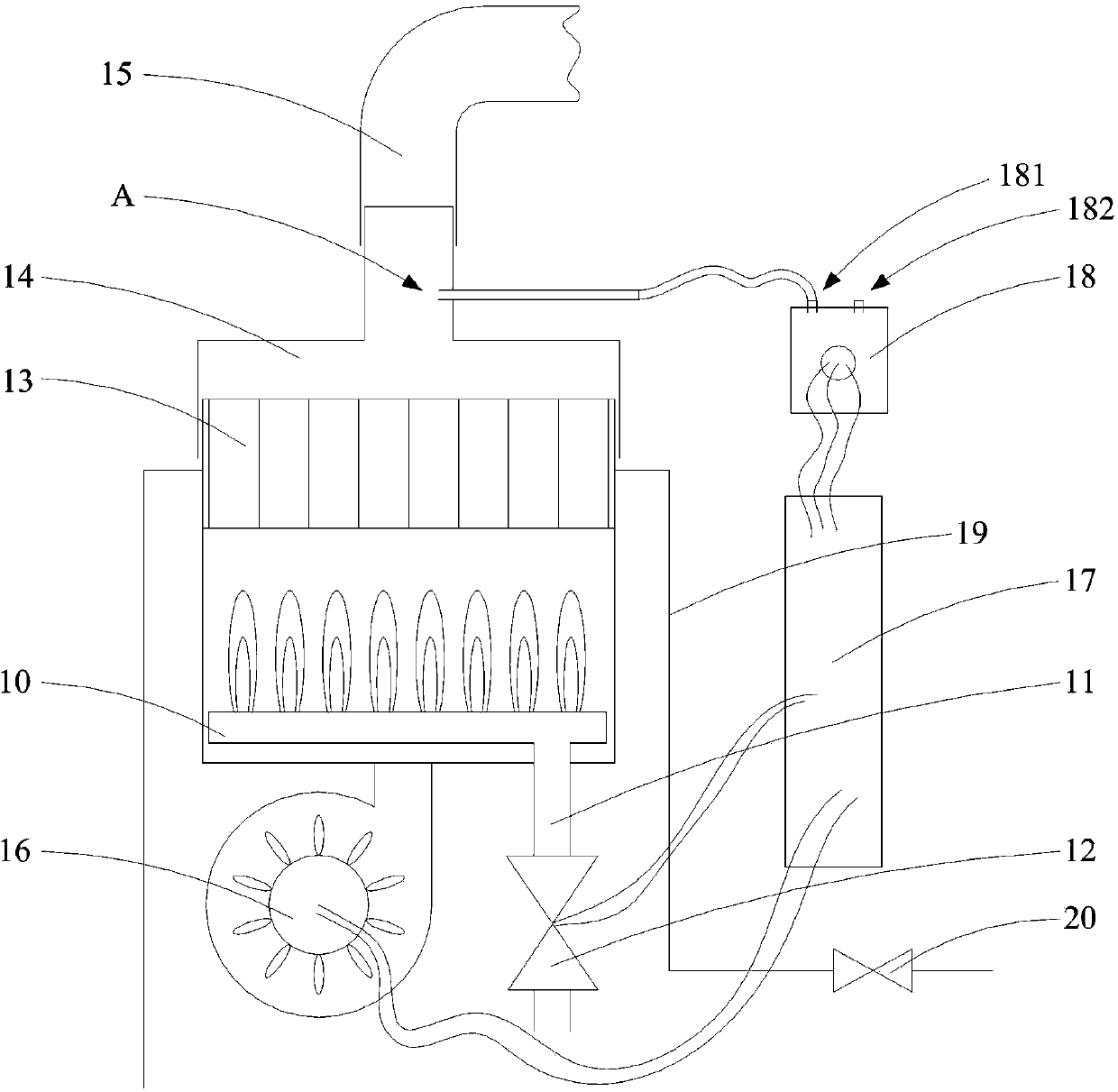

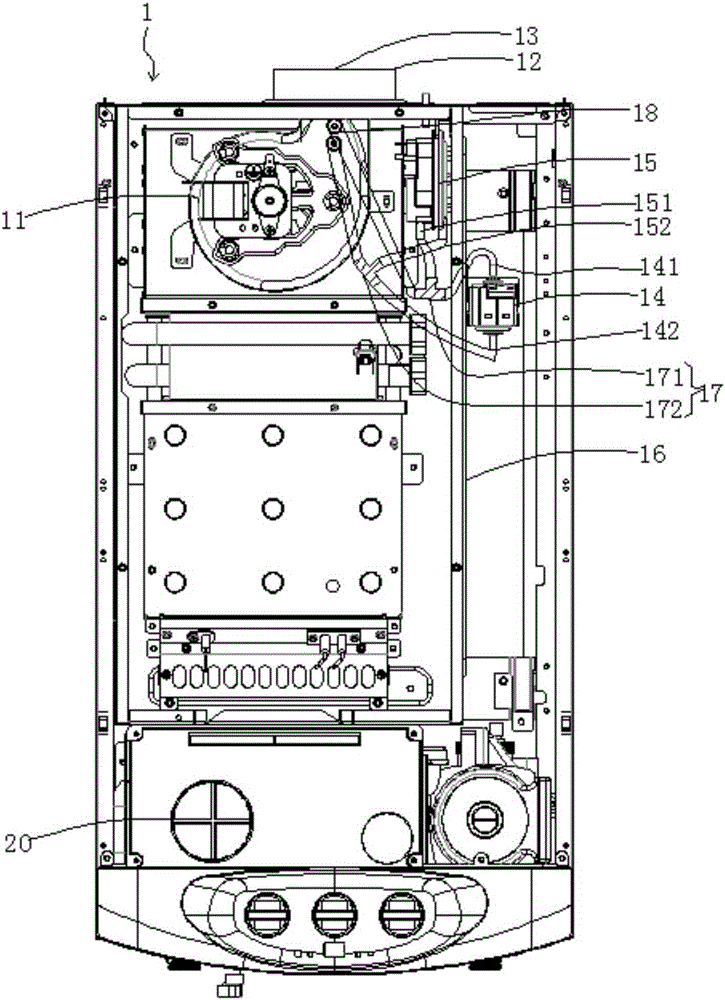

Gas water heater

The invention discloses a gas water heater. The gas water heater comprises a combustor, a gas pipe, a flue gas discharging pipe, a fan assembly and an air pressure protection control circuit, wherein the air pressure protection control circuit comprises a control mainboard, an air pressure detection unit and a gas proportional valve arranged on the gas pipe, the control mainboard is electrically connected with the air pressure detection unit, the gas proportional valve and the fan assembly, and the air pressure detection unit is used for detecting the pressure of air in the flue gas discharging pipe. Due to the facts that measured air pressure values are converted into voltage signals which are continuously output, and the voltage signals are transmitted to the control mainboard, control over the gas proportional valve, a water proportional valve and the fan assembly can be achieved, the working state of the gas water heater is adjusted according to the current air pressure value, the gas water heater can adapt to changes of the environment, combustion performance of the gas water heater is ensured, the using performance of the gas water heater is improved, and the requirements for safety, environmental friendliness and practicability are met. The invention further discloses a gas water heater. The gas water heater adapts to changes of the environment through control over the flue gas discharging power of the fan assembly.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

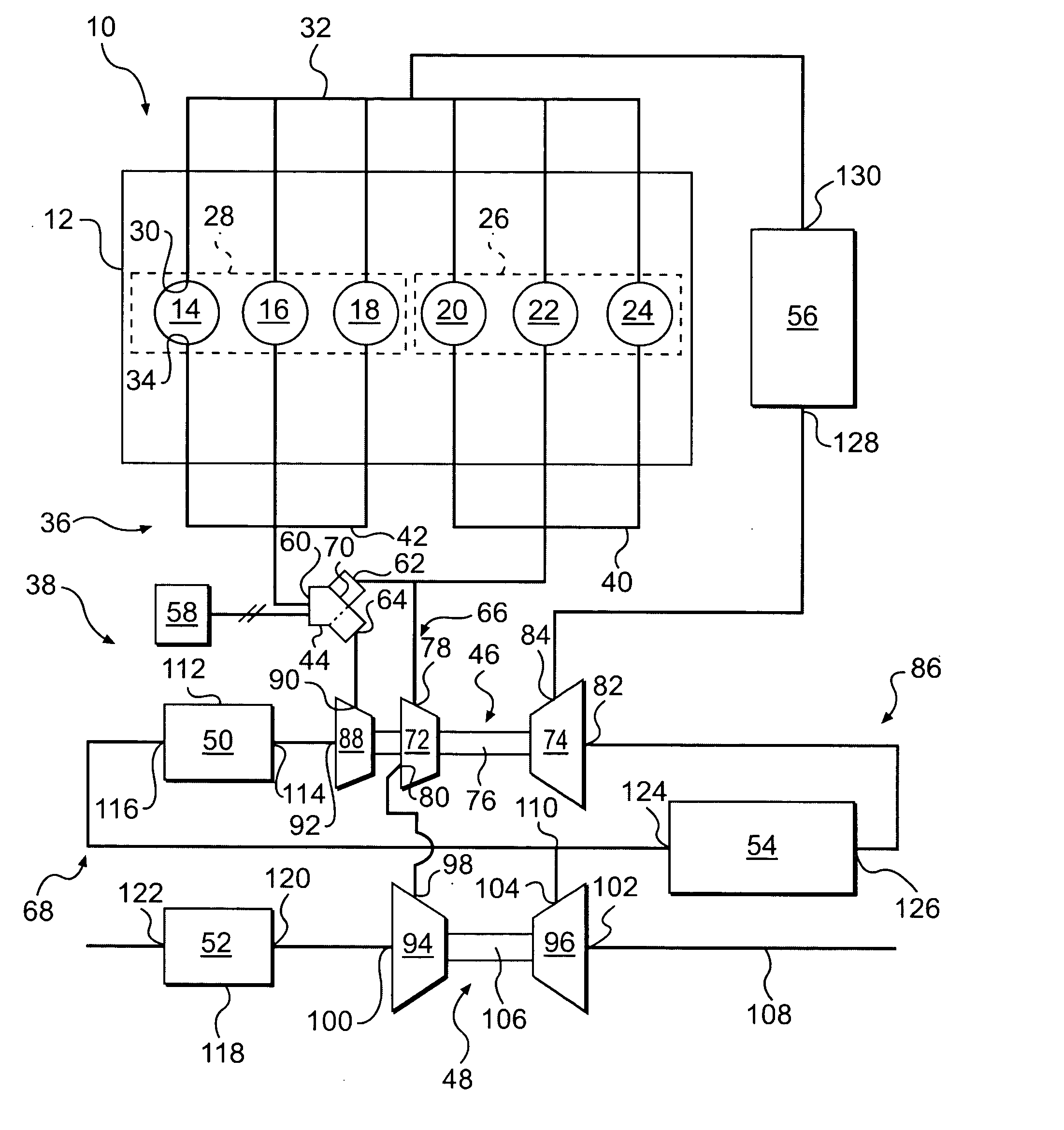

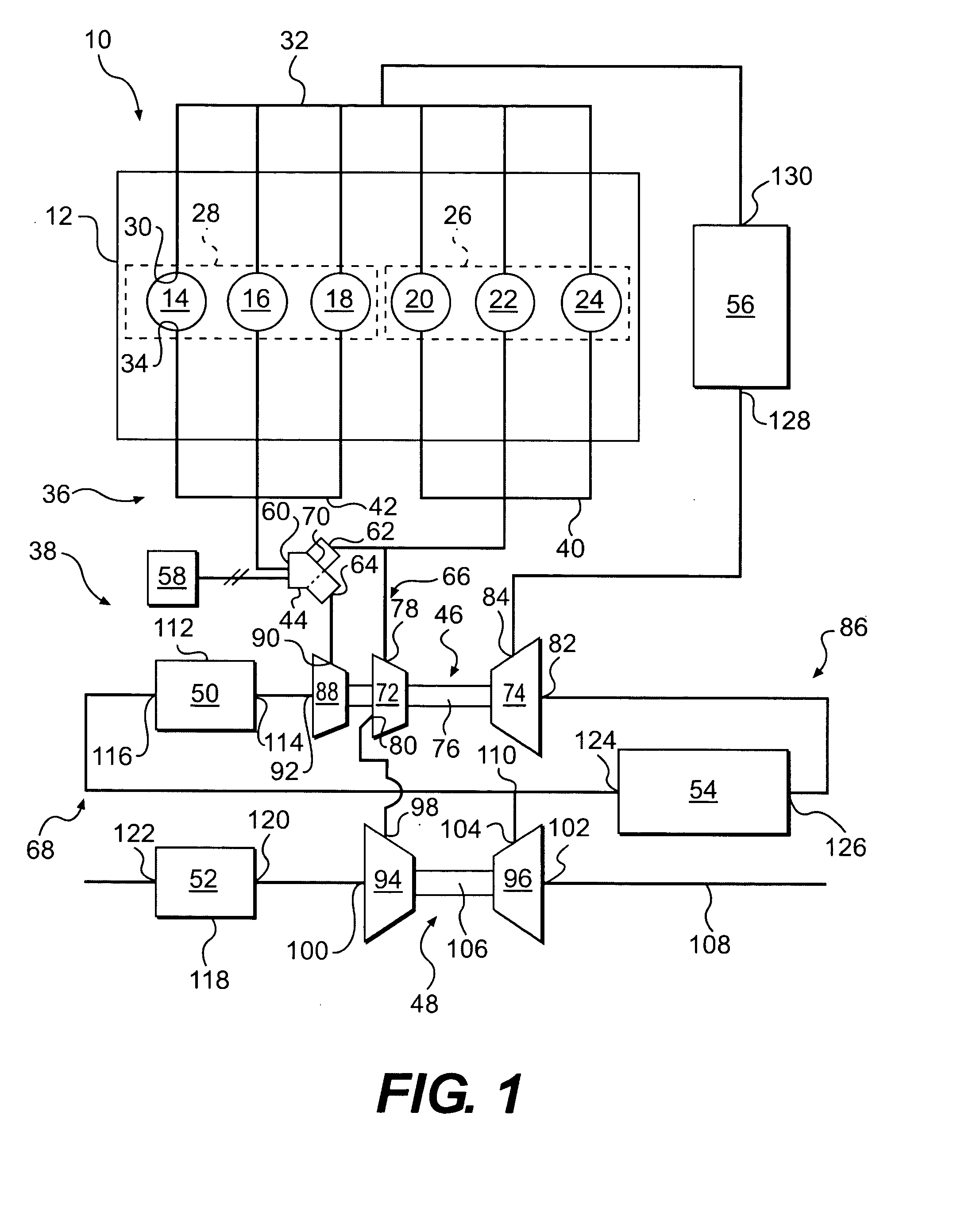

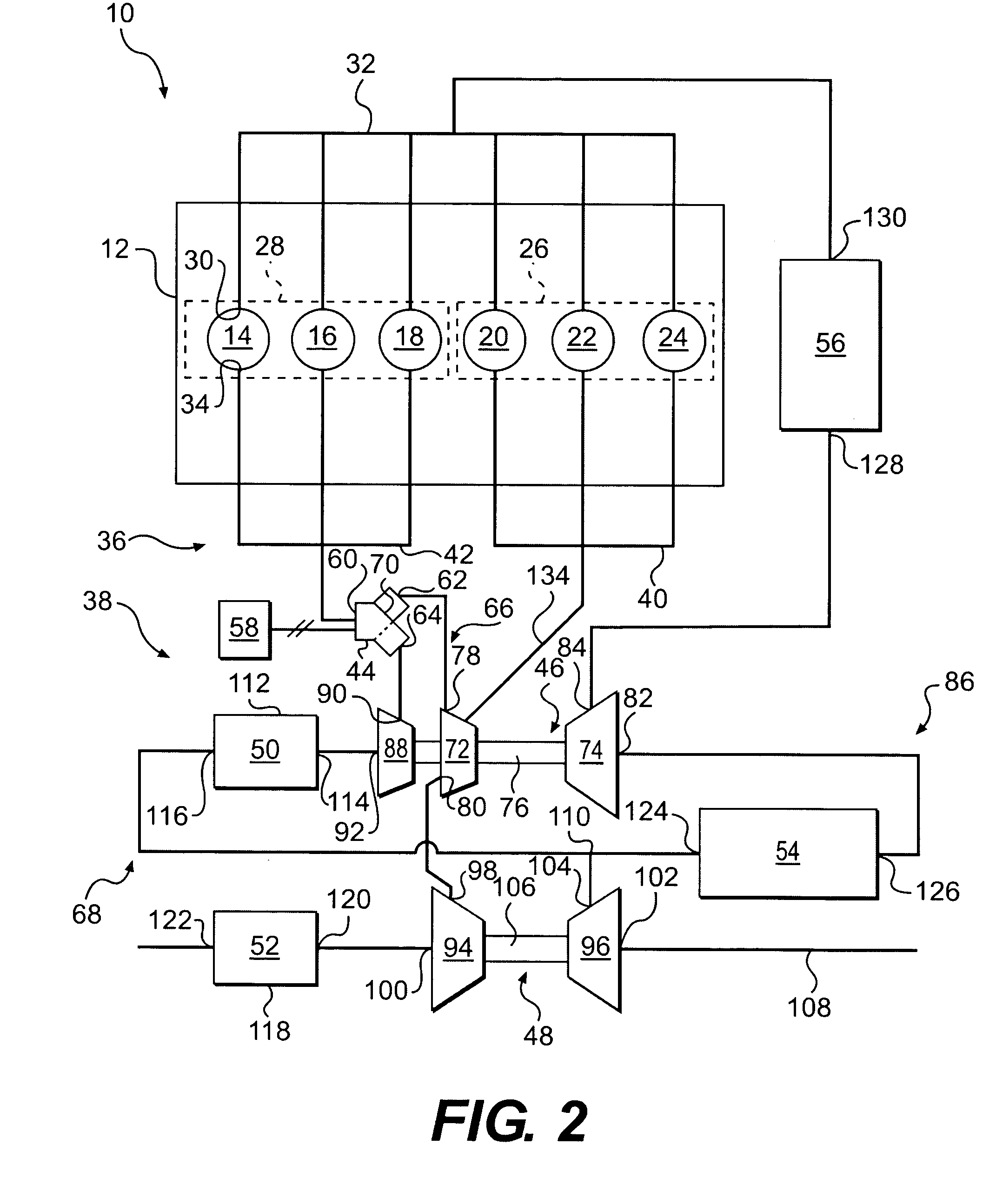

System and method for exhaust recirculation

InactiveUS20080000228A1Electrical controlInternal combustion piston enginesTurbochargerExhaust gas recirculation

An engine assembly may include an engine having a plurality of combustion cylinders, and an exhaust manifold configured to receive exhaust from the plurality of combustion cylinders. The exhaust manifold may be divided into first and second sections. The first section may be fluidly coupled to a first group of combustion cylinders, and the second section may be fluidly coupled to a second group of combustion cylinders. The engine assembly may also include a turbocharger having an exhaust turbine configured to receive exhaust from the first section. The engine assembly may further include a proportional valve assembly configured to selectively fluidly couple the second section to at least one of the turbocharger and an exhaust recirculation loop.

Owner:CATERPILLAR INC

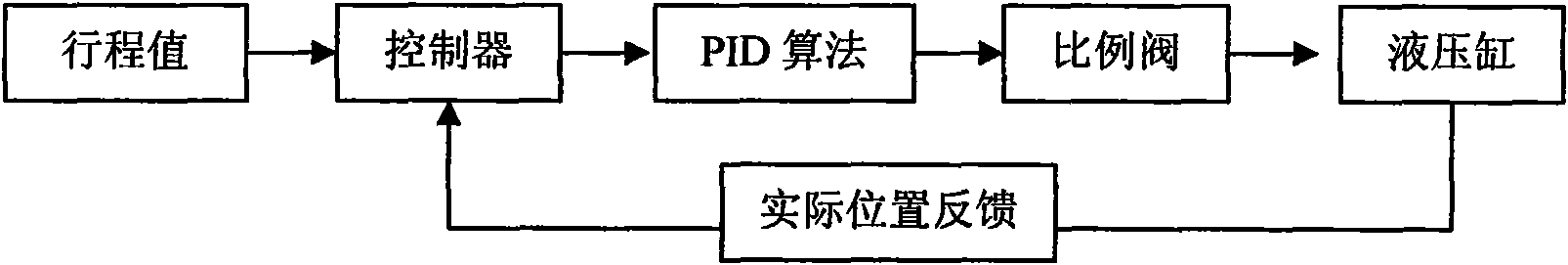

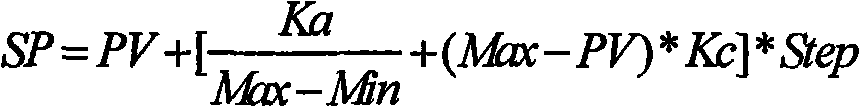

Multi-hydraulic cylinder synchronization control method

ActiveCN101672311AMove fastServomotorsFluid-pressure actuator componentsHydraulic cylinderEngineering

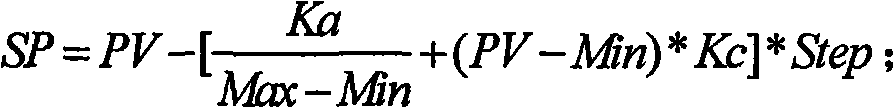

The invention discloses a multi-hydraulic cylinder synchronization control method, and the control method comprises the following steps: A, using a controller to judge whether the displacement actualvalue PV of cylinders at a certain time achieves the stroke value or not, if so, leading the set value SP of a PID to be equal to the stroke value; if not, figuring out the set value SP of the PID according to the actual position value PV of the hydraulic cylinders; using the PID algorithm to obtain the set value of the opening degree of a proportional valve according to the SP and the PV, leadingthe proportional valve to carry out movement of a valve core according to the set value of the opening degree and initiating the motion of the hydraulic cylinders; and B, feeding back the actual position value PV of the hydraulic cylinders to the controller and returning to the step A. The synchronization control method does not limit the number of the moving cylinders and does not divide the work of the master moving cylinder and the slave moving cylinders, the motion speed and the precision of the cylinders can be regulated through parameters, the motion speed of the cylinders is not fixed,the target value can be achieved by the fast speed, and the closer the displacement value between the forefront cylinder and the last cylinder is, the faster the overall motion speed is.

Owner:CISDI ENG CO LTD

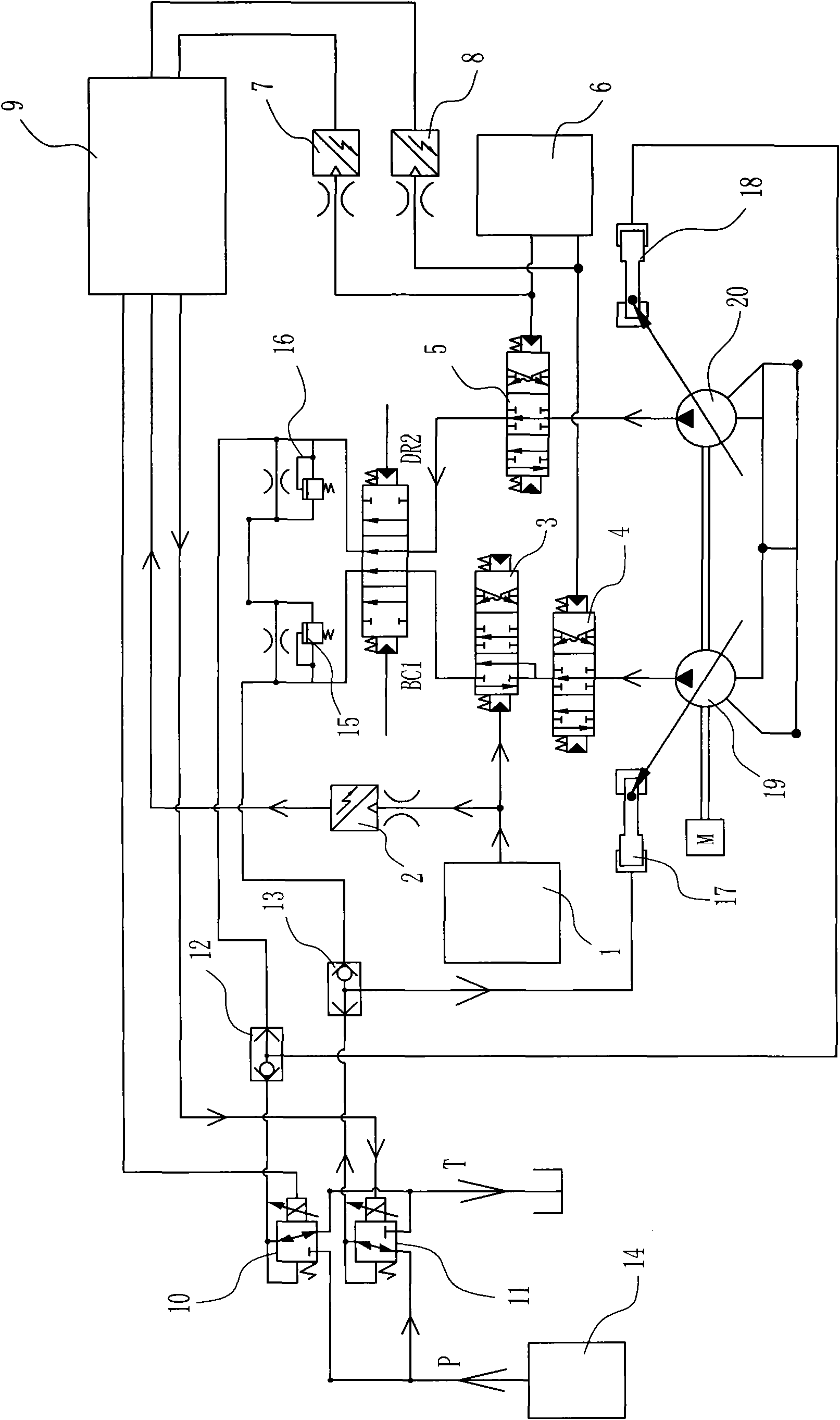

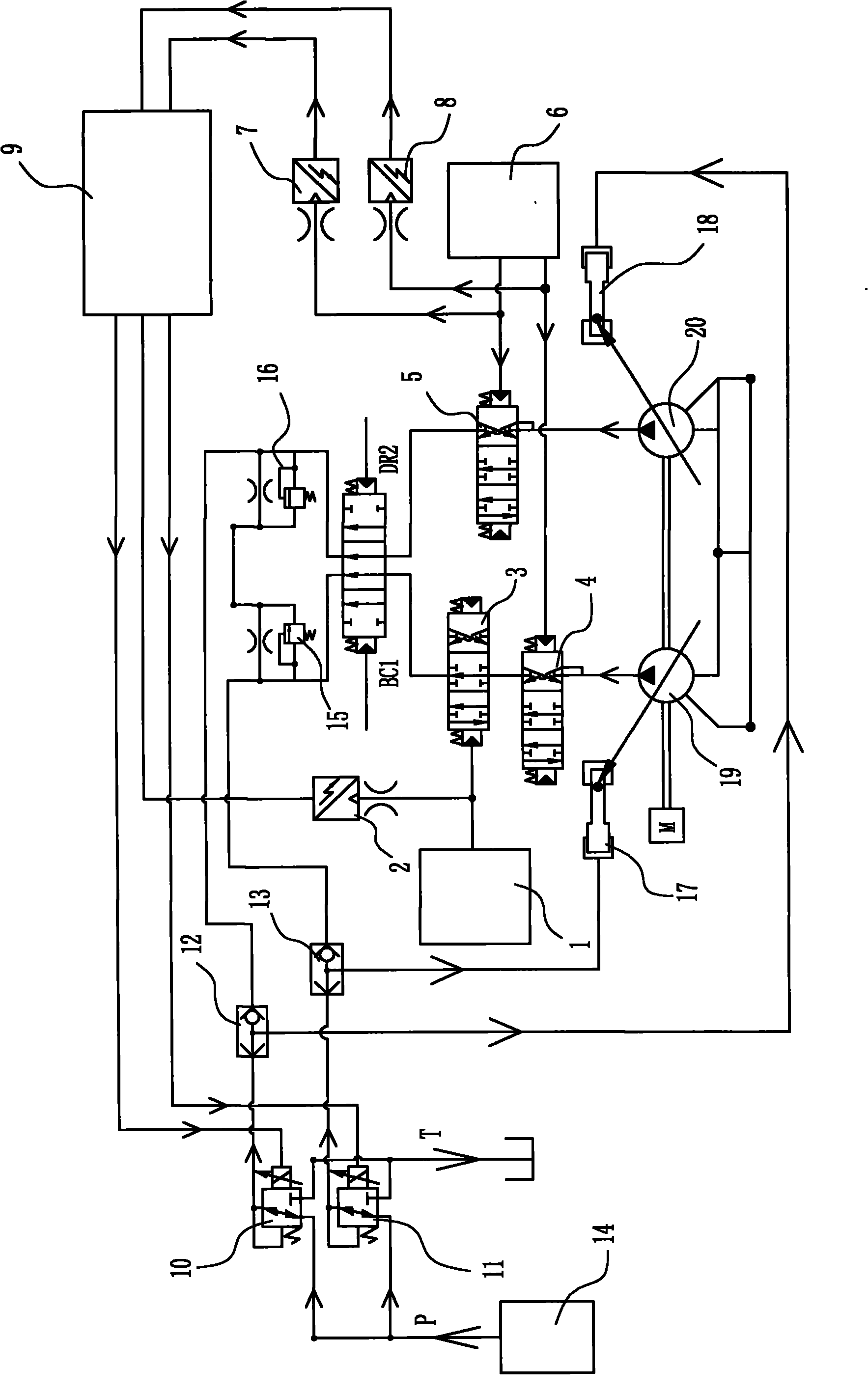

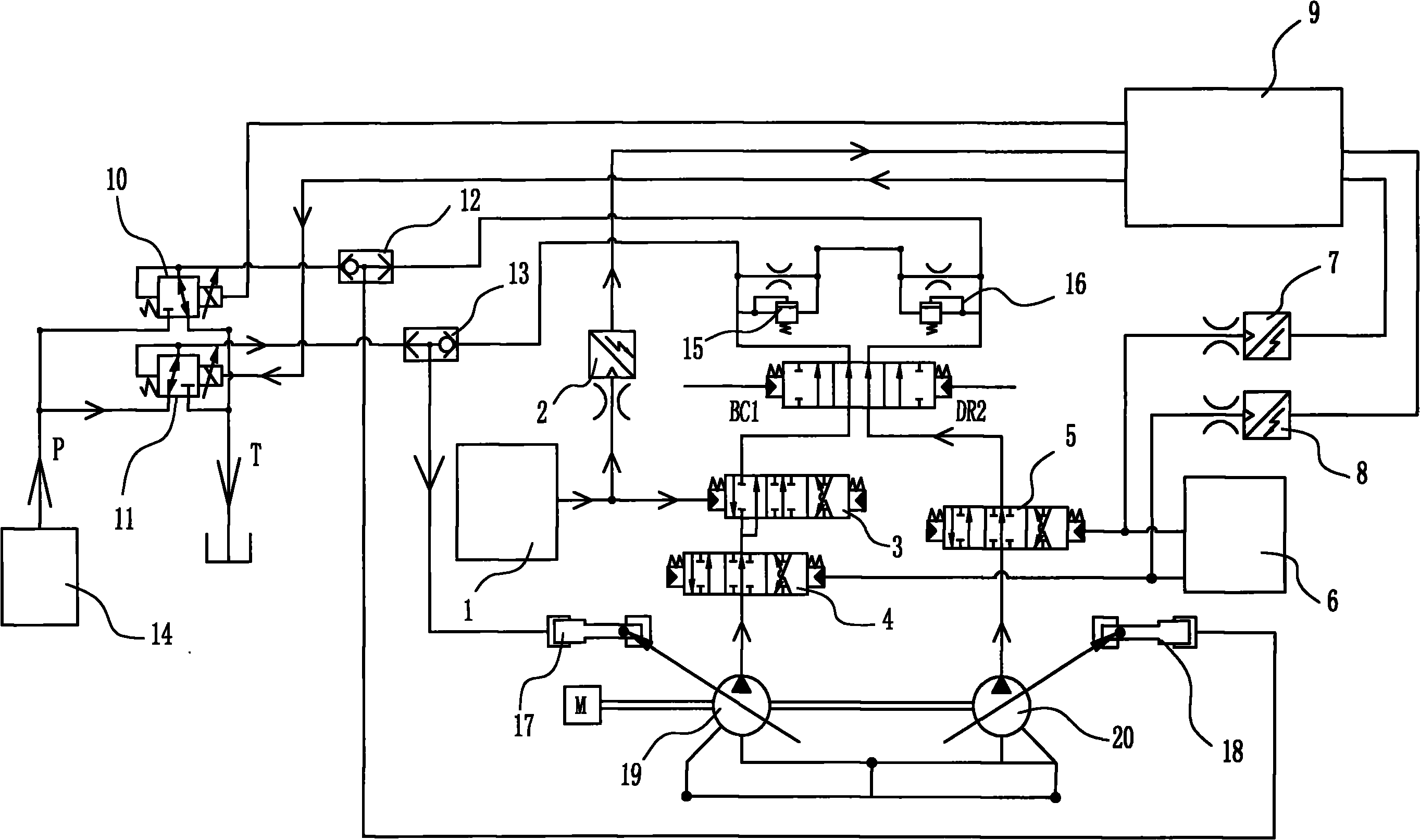

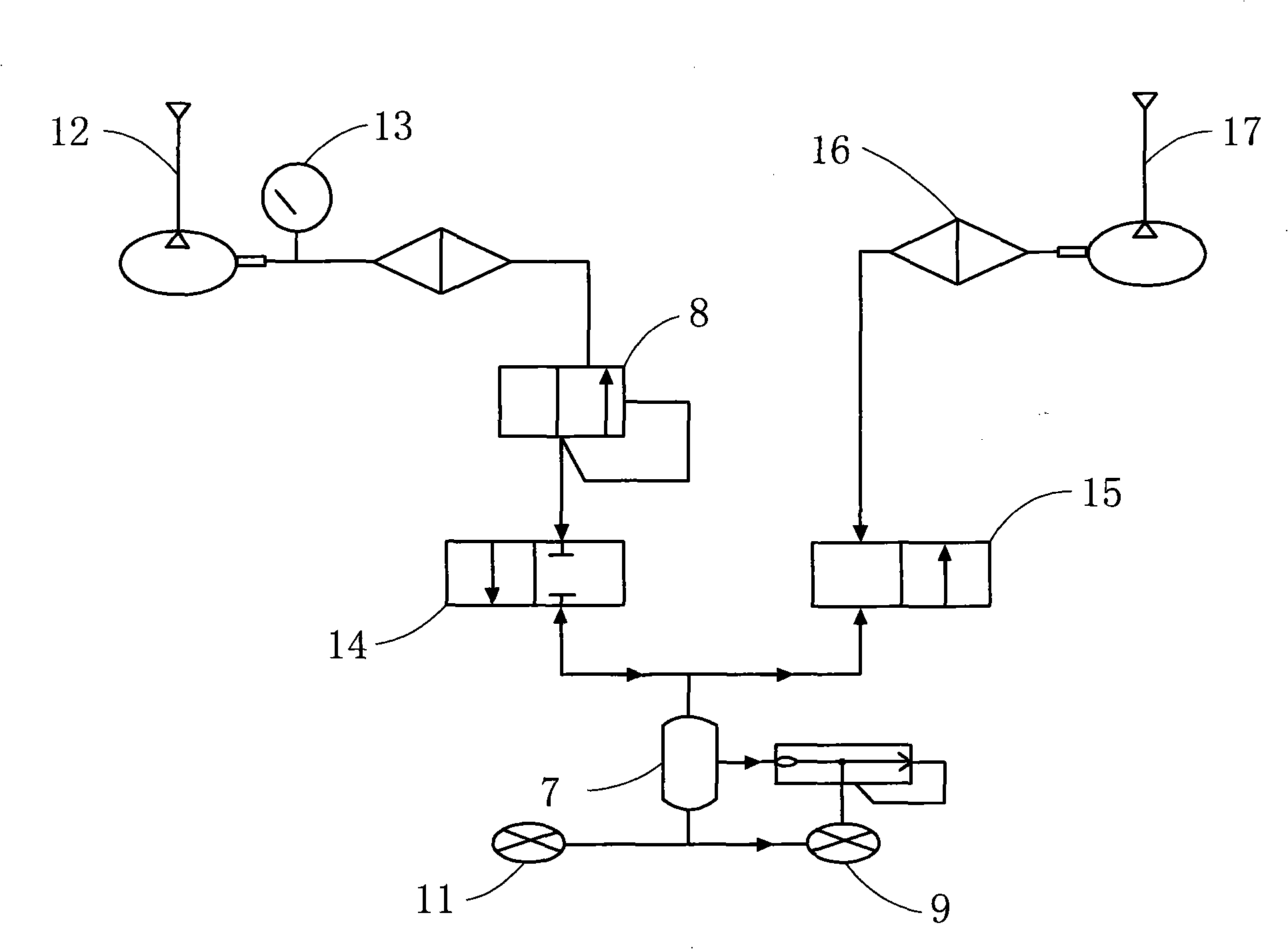

Large and middle wind turbine digital intelligent hydraulic brake system

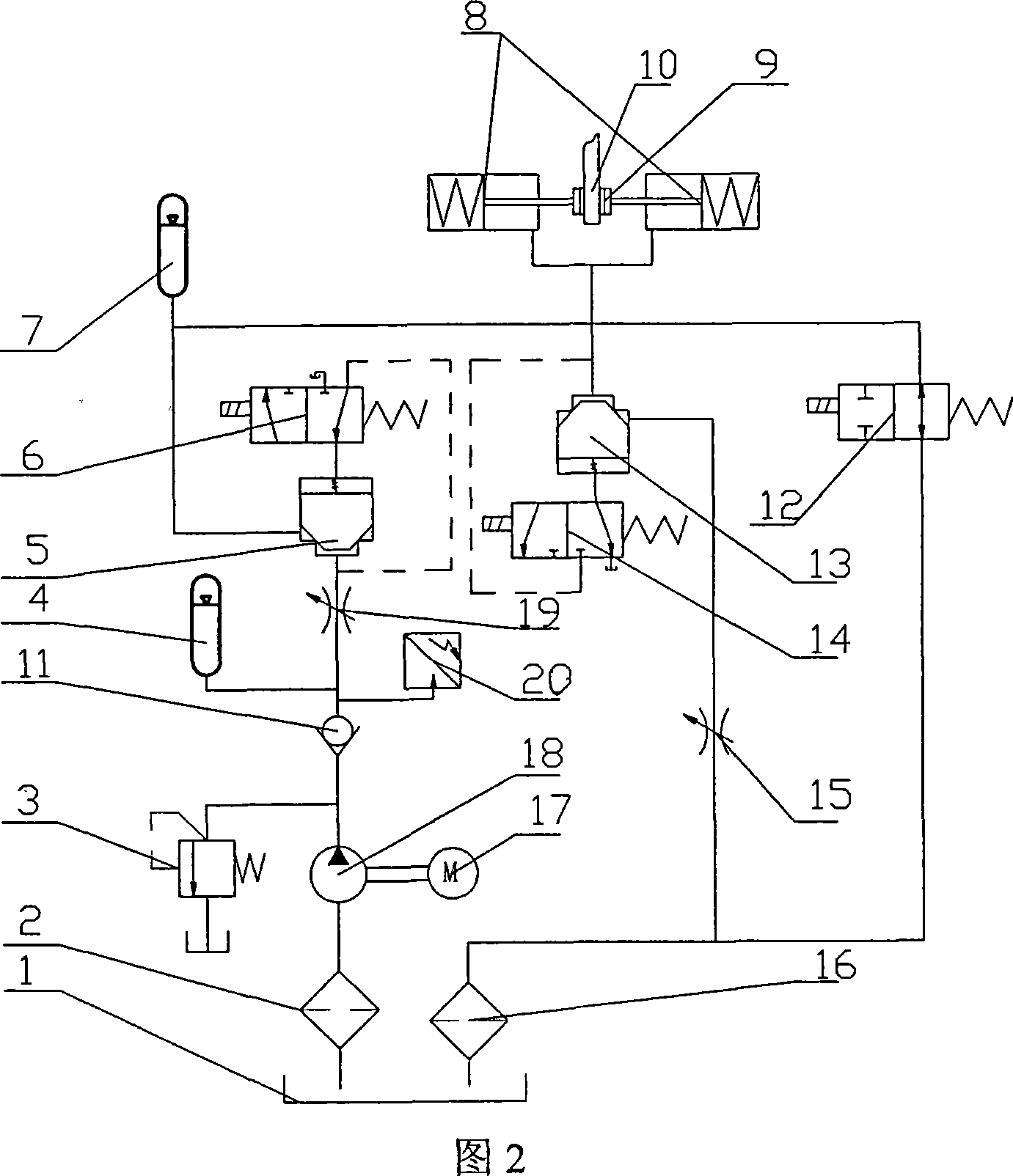

InactiveCN101033733AWork reliablySimple structureWind motor controlAxially engaging brakesTime ratioFuel tank

The invention discloses a digital, intelligent and hydraulic brake system of large and medium wind machine. The output end of the oil supply system links uniflow valve. Its output end joints to the first accumulator, pressure relay and input end of first plug-in valve through the first throttle valve. The output end of first plug-in valve links the second accumulator. Equip hydraulic cylinders with brake blocks on sucker-rod cavity end, two of which are taken as one group and are located relatively. The sucker-rod cavities of the hydraulic cylinders connect with the output ends of the first and second plug-in valve and the third linking switch valve through the bus. The output end of the second plug-in valve meets oil tank through second throttle valve. Two high-speed switch valves are taken as pilot stage together with two plug-in valves to form digital electro-hydraulic proportional valve. Brake blocks are equipped on both sides of brake chuck of the wind machine to change the open-close time ratio of high-speed switch valves and adjusts hydraulic braking force of the brake chuck. When meeting the working condition of unit braking, adjust the duty ratio of high-speed switch valves in unit time depending on wind speed and main shaft speed to realize intelligent control on braking force.

Owner:ZHEJIANG UNIV

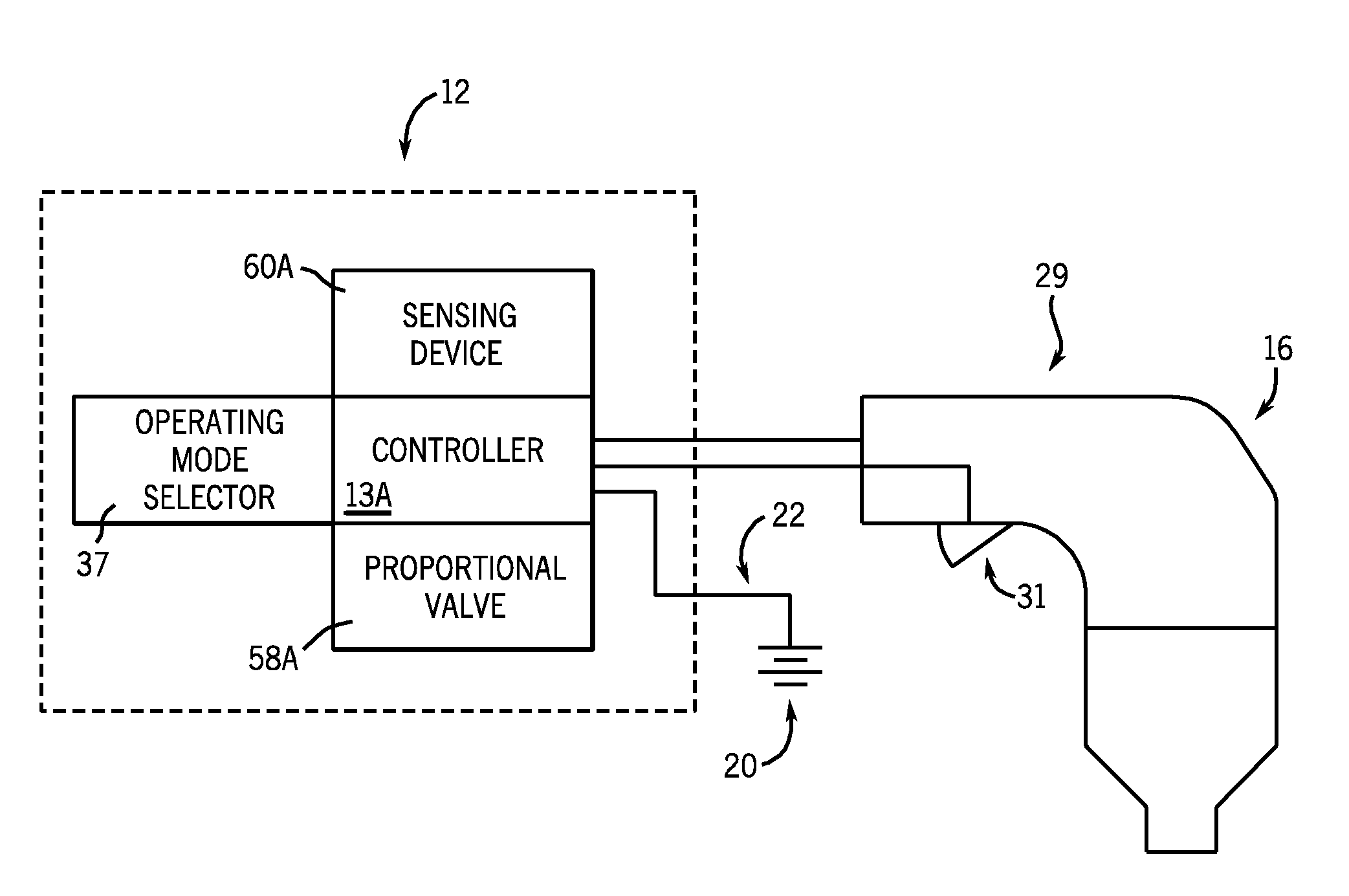

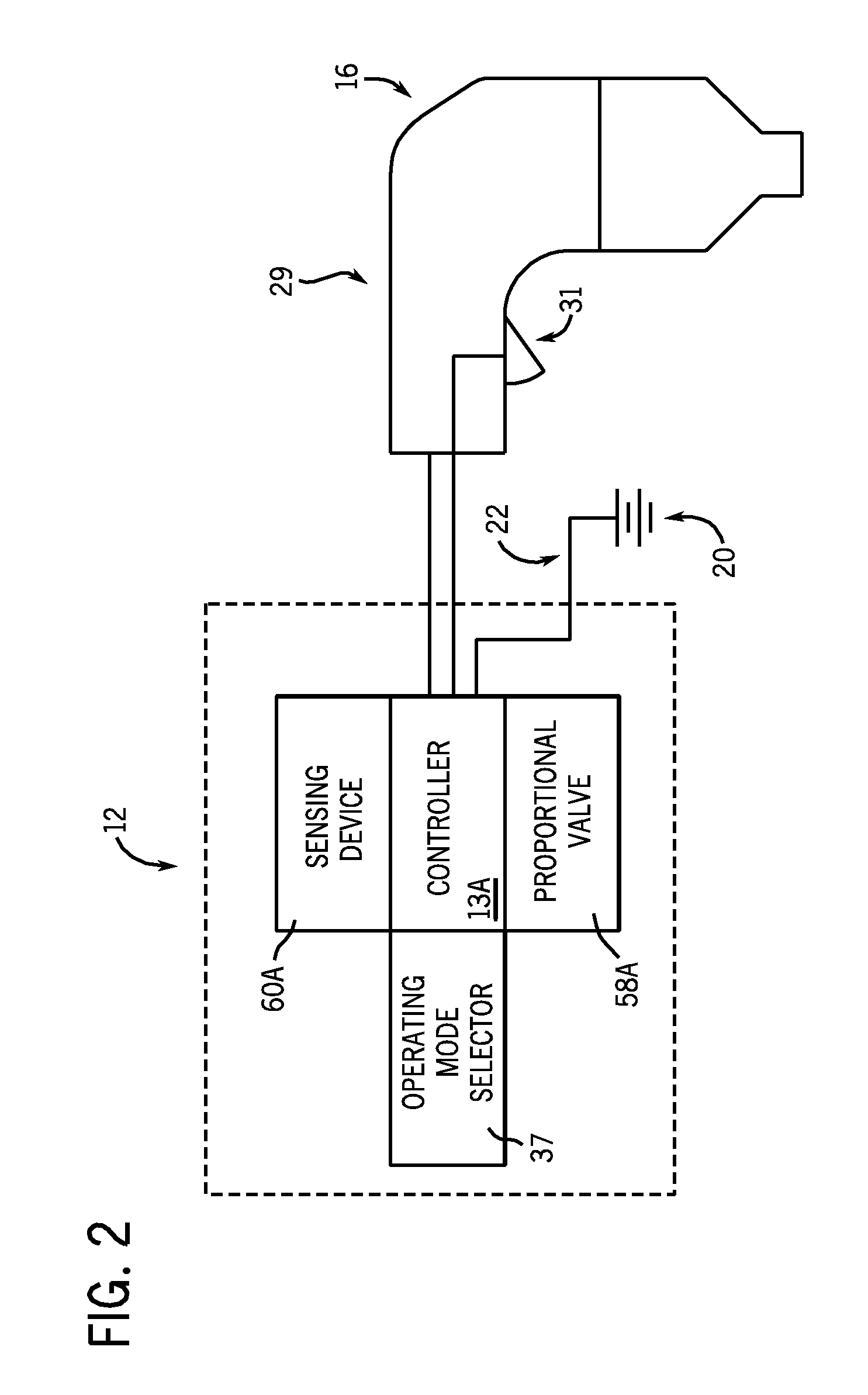

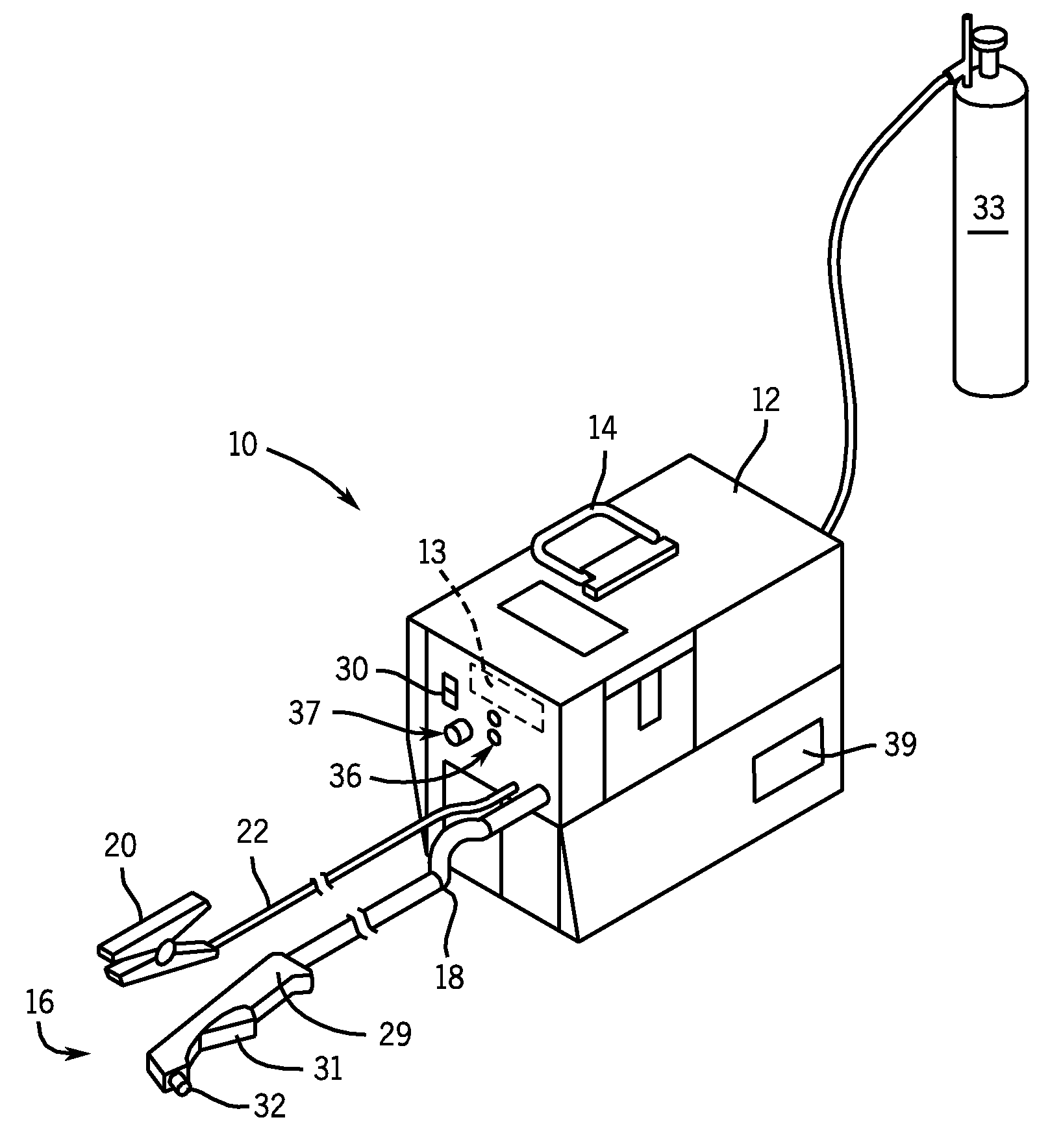

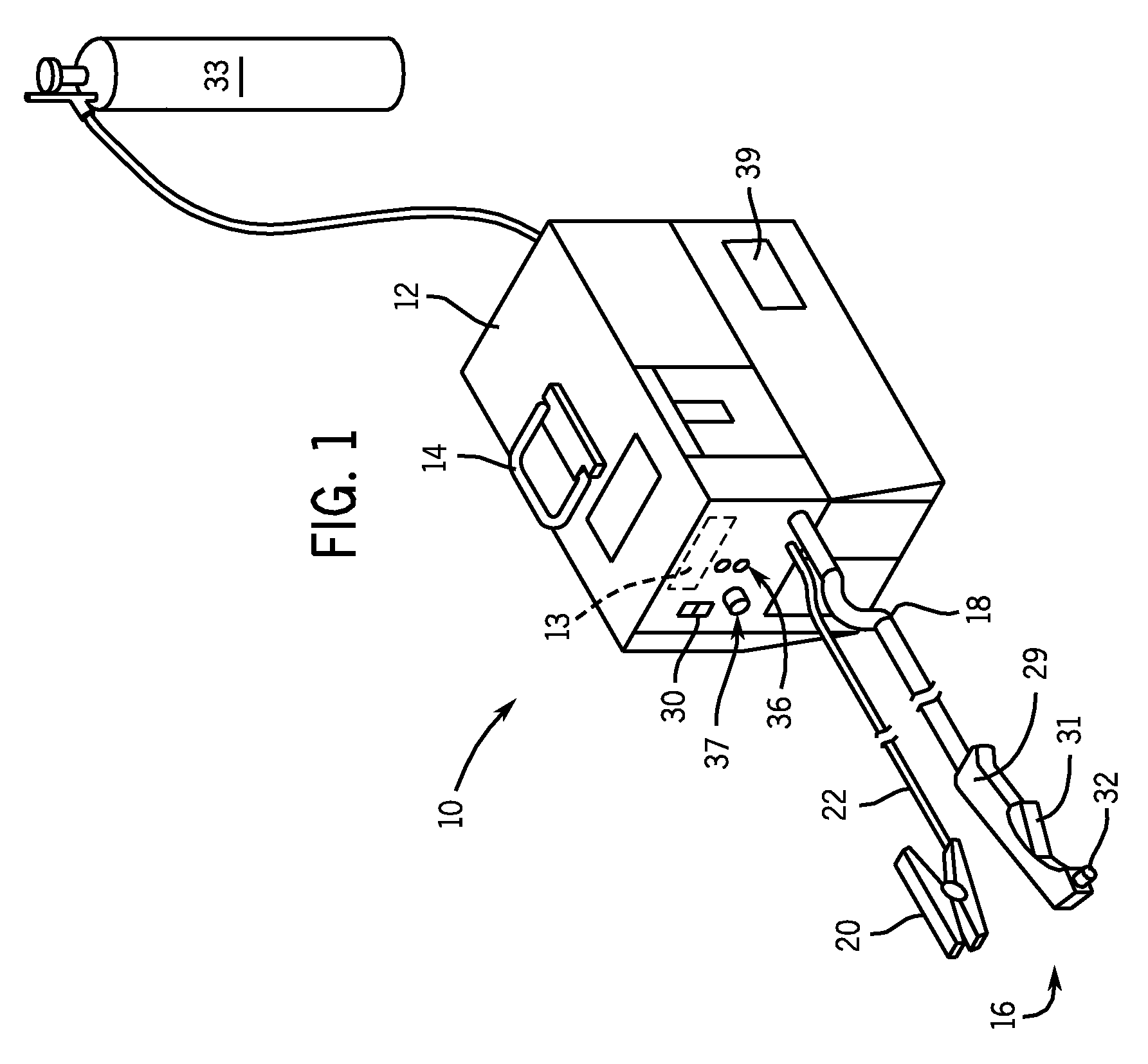

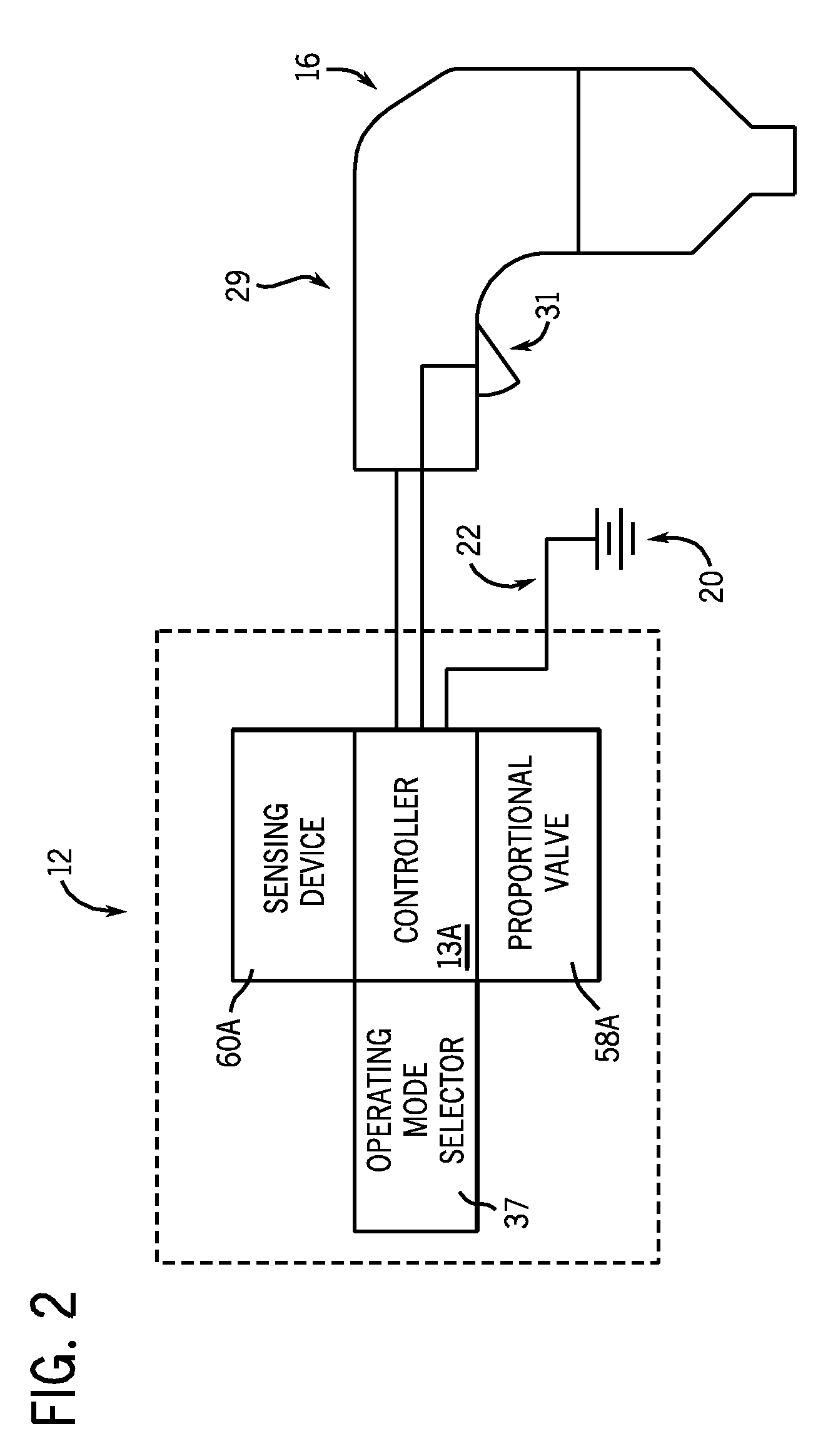

Method and apparatus for automatically controlling gas pressure for a plasma cutter

A system for providing a dynamically controlled plasma cutting system. The plasma cutting system includes a proportional valve and a sensing device arrangement and a controller connected to this arrangement. The system is configured to dynamically control gas flow in a plasma torch. The system measures gas pressure at a proportional valve and makes necessary gas pressure adjustments in the system by way of controlling a drive signal sent to the proportional valve to control gas flow.

Owner:ILLINOIS TOOL WORKS INC

System for differential recovery of potential energy of boom of oil liquid hybrid power excavating machine

InactiveCN102094434AReduce conversionReduce churnMechanical machines/dredgersFuel oilElectric potential energy

The invention discloses a system for differential recovery of potential energy of a boom of an oil liquid hybrid power excavating machine. The system comprises a variable capacity pump, a multi-channel valve, a boom cylinder, an operating handle, a controller, a hydraulic control reversing valve, a hydraulic control reversing and throttling valve, a hydraulic control unloading valve, an energy accumulator, an electro-hydraulic proportional valve and a one-way valve. The controller is used for controlling the electro-hydraulic proportional valve and the variable capacity pump according to pressure at an outlet of the variable capacity pump and a pressure signal of the energy accumulator, thereby solving the flow distribution problem of the energy accumulator and the variable capacity pump. The energy accumulator is an energy storage element which can transform descending kinetic energy and potential energy of the boom to hydraulic energy and reasonably distribute the energy for a main power source and an auxiliary power source, and a working device is driven by the pump-energy accumulator. The system can avoid the waste of a large amount of the descending kinetic energy of the boom, reduce the energy transformation link, enable an engine to stably work in a high-efficient fuel oil region, improve the fuel coil economy of the excavating machine and reduce the emission of the system.

Owner:ZHEJIANG UNIV

Control method and control device for hydraulic shovel scraper bucket

InactiveCN101481918ALow technical requirementsLow input costMechanical machines/dredgersProgrammable logic controllerTransducer

The invention discloses a method for controlling the movement of a scraper bucket of a hydraulic excavator, comprising the steps: (1) the included angle value of each part of a working device or the length value of a piston rod is measured by a transducer; (2) the value is input into a programmable controller, and each displacement distance value of the working device, which is required to keep the horizontal displacement of the scraper bucket is obtained through calculation; (3) the oil supply amount of each oil cylinder is obtained through conversion and then is transmitted to each working device; and (4) the step (1) is repeated until the operation is accomplished. Devices for the method comprise angular transducers, a programmable controller with a software program and proportional valves controlling the oil volume of oil cylinders of each working device, wherein the signal output end of each transducer is connected with the programmable controller with the software program, and the output end of the controller is connected with each proportional valve controlling the oil volume. The method has the technical scheme that angular or length signals are obtained through measurement by each transducer, and oil is quantificationally supplied to the oil cylinders by the calculation of the controller, thereby realizing the horizontal movement of the scraper bucket, simplifying the operation and improving the accuracy of the leveling operation.

Owner:SANY HEAVY MACHINERY

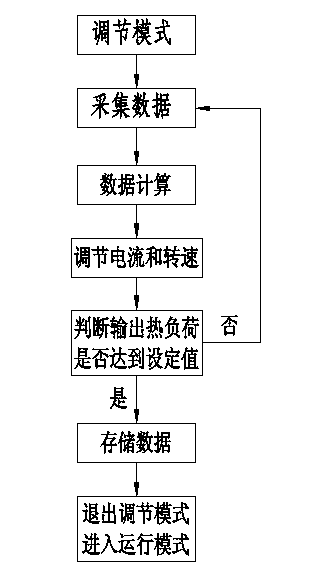

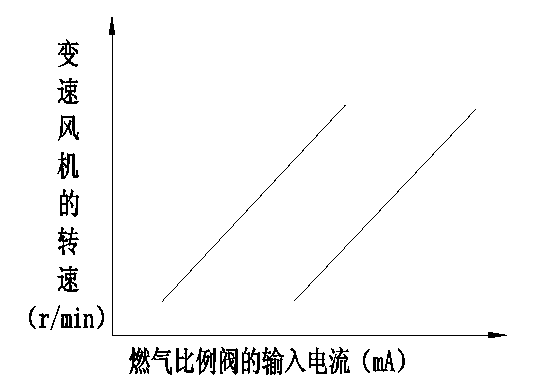

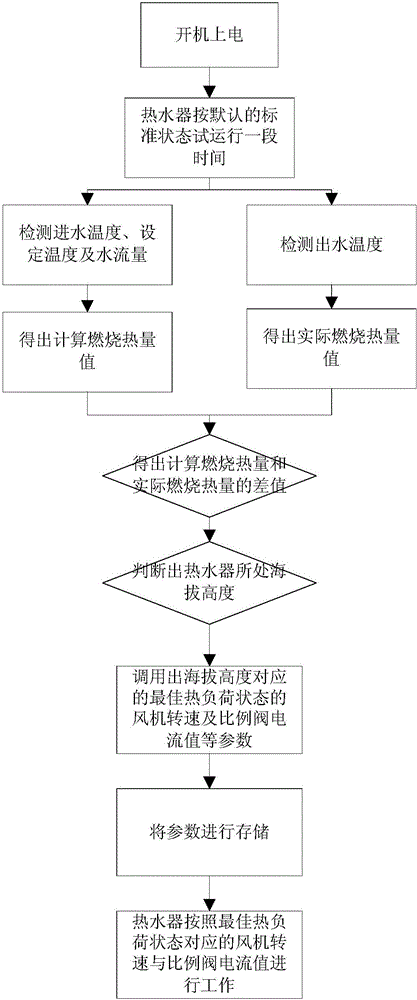

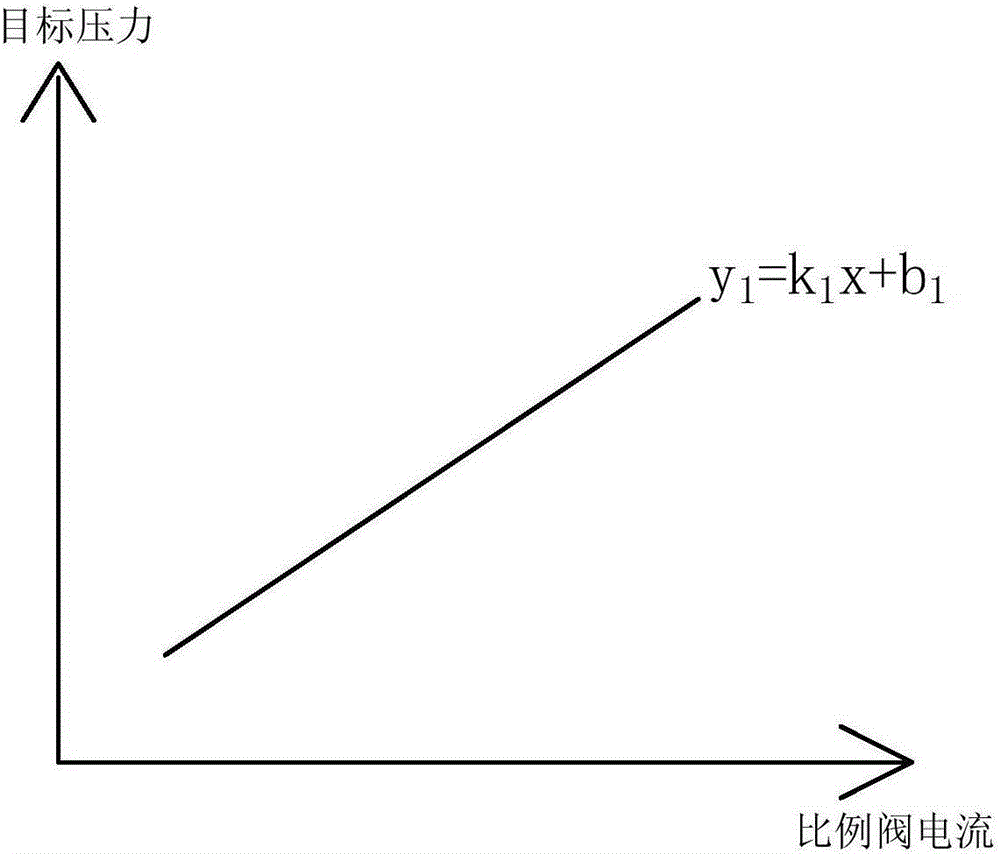

Control method for gas water heater for automatically adapting to multiple gas sources

The invention belongs to the technical field of the control of a gas water heater and discloses a control method for the gas water heater for automatically adapting to multiple gas sources. The control method comprises the following steps: 1) collecting the data of inlet water temperature, outlet water temperature and water flow by a controller; 2) calculating the data by the controller according to a preset formula; 3) automatically adjusting an input current of a gas proportional valve and a rotating speed of a speed-changing fan according to the calculated data, till an output heat load reaches a preset value; and 4) storing the data of the input current of the gas proportional valve, the input voltage of the speed-changing fan and the input current of the speed-changing fan at the moment. By improving the control method according to the invention, the gas water heater can adapt to multiple gas sources, without exchanging or improving the gas water heater, so that the cost of a user is greatly saved.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

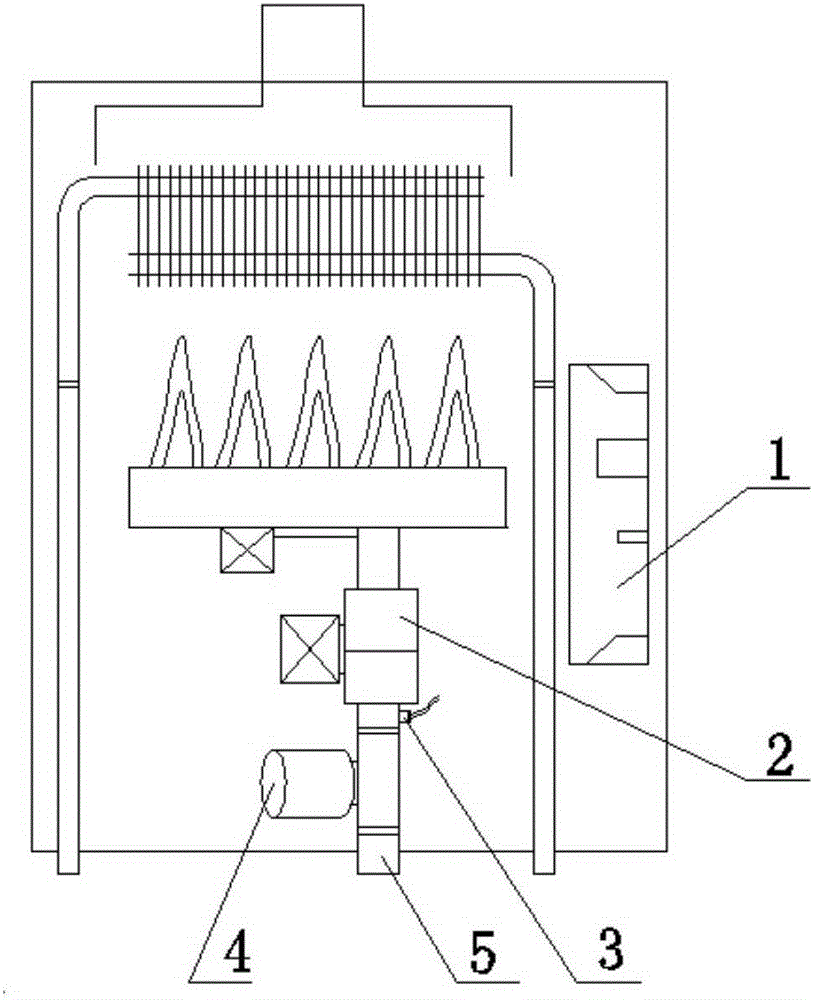

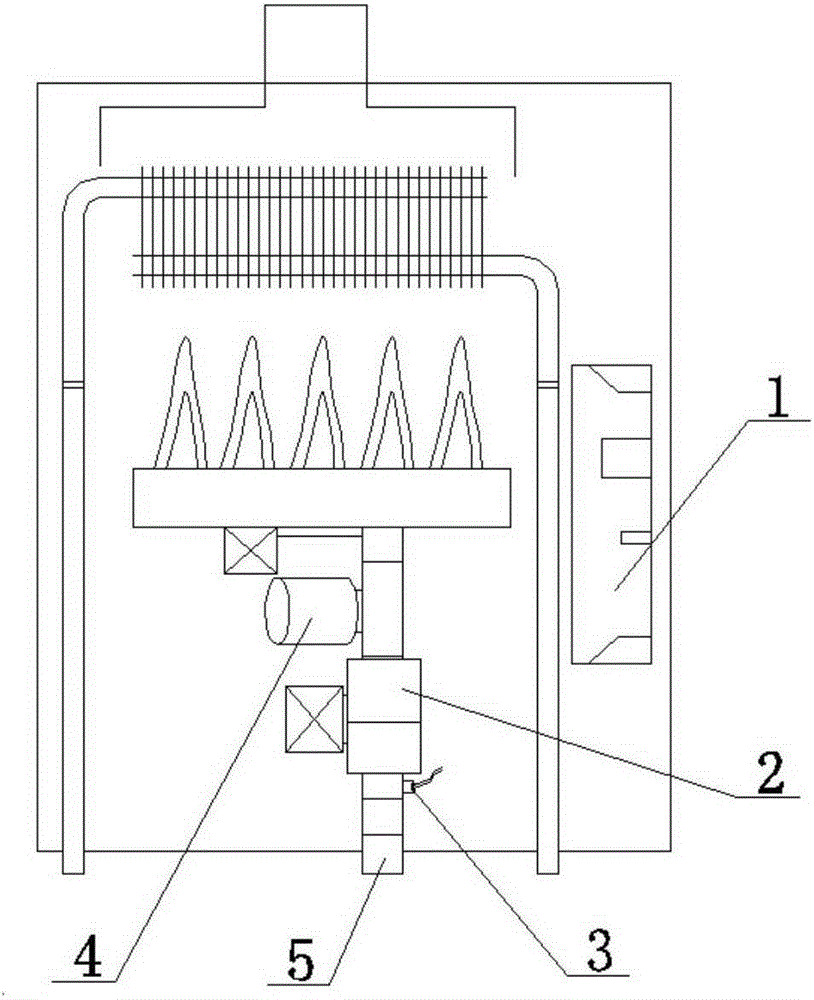

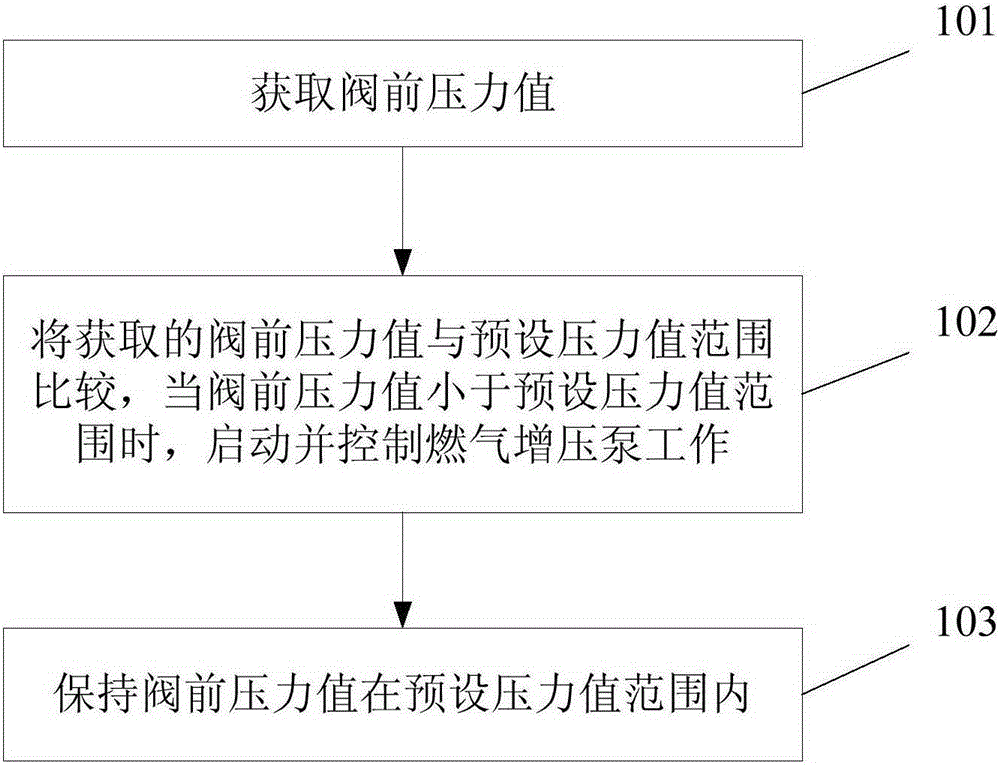

Automatic fuel gas supercharging device and method of gas water heater

The invention discloses an automatic fuel gas supercharging device of a gas water heater. The automatic fuel gas supercharging device comprises a controller and a proportional valve controlled by the controller; a gas inlet / gas outlet of the proportional valve or a fuel gas channel in the front portion of the gas inlet / gas outlet of the proportional valve is internally provided with a pressure sensor and a fuel gas supercharging pump, and the controller receives fuel gas pressure detected by the pressure sensor, enables the pressure to be compared with a preset value, and accordingly controls starting and stopping or running of the fuel gas supercharging pump. The invention further discloses an automatic fuel gas supercharging method of the gas water heater. The method includes the steps of obtaining a before-valve pressure value of the proportional valve; comparing the obtained before-valve pressure value with a preset pressure value scope, and starting and controlling the fuel gas supercharging pump to work when the before-valve pressure value is smaller than the preset pressure value scope; and keeping the before-valve pressure value to be within the preset pressure value scope. According to the automatic fuel gas supercharging device and method, the water heater cannot achieve constant-temperature burning when the before-valve pressure value is too small, the controller controls opening and closing of the fuel gas supercharging pump and adjusts the output pressure of the fuel gas supercharging pump, and automatic control over the fuel gas supercharging pump is achieved.

Owner:CHONGQING HAIER WATER HEATER

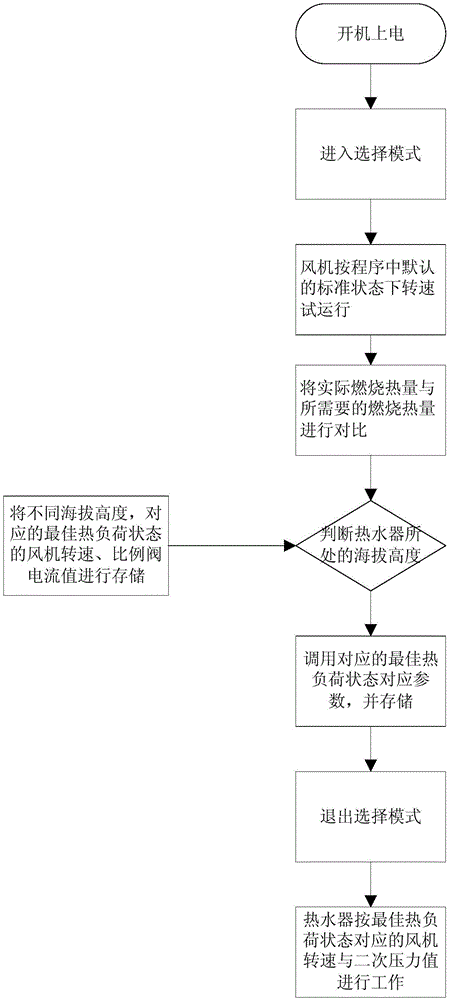

Method for controlling gas water heater adaptable to different altitudes

The invention relates to a method for controlling a gas water heater adaptable to different altitudes. The method is characterized in that the water heater tries to run according to set fan rotating speed, actual combustion heat is compared with calculated combustion heat, altitude at which the water heater is positioned is judged, fan rotating speed corresponding to optimal thermal load state at corresponding altitude is matched with proportional valve current value, parameters are stored, and the water heater is enabled to work according to corresponding fan rotating speed and proportional valve current value. By the above method, the water heater can automatically recognize and judge the altitude at which the water heater is positioned to be matched with corresponding fan rotating speed and proportional valve current value, so that gas utilization rate of the water heater is increased so as to achieve the objectives of saving energy resources and improving gas efficiency. The gas water heater control method is remarkable in effect and suitable for popularization and application.

Owner:HAIER GRP CORP +1

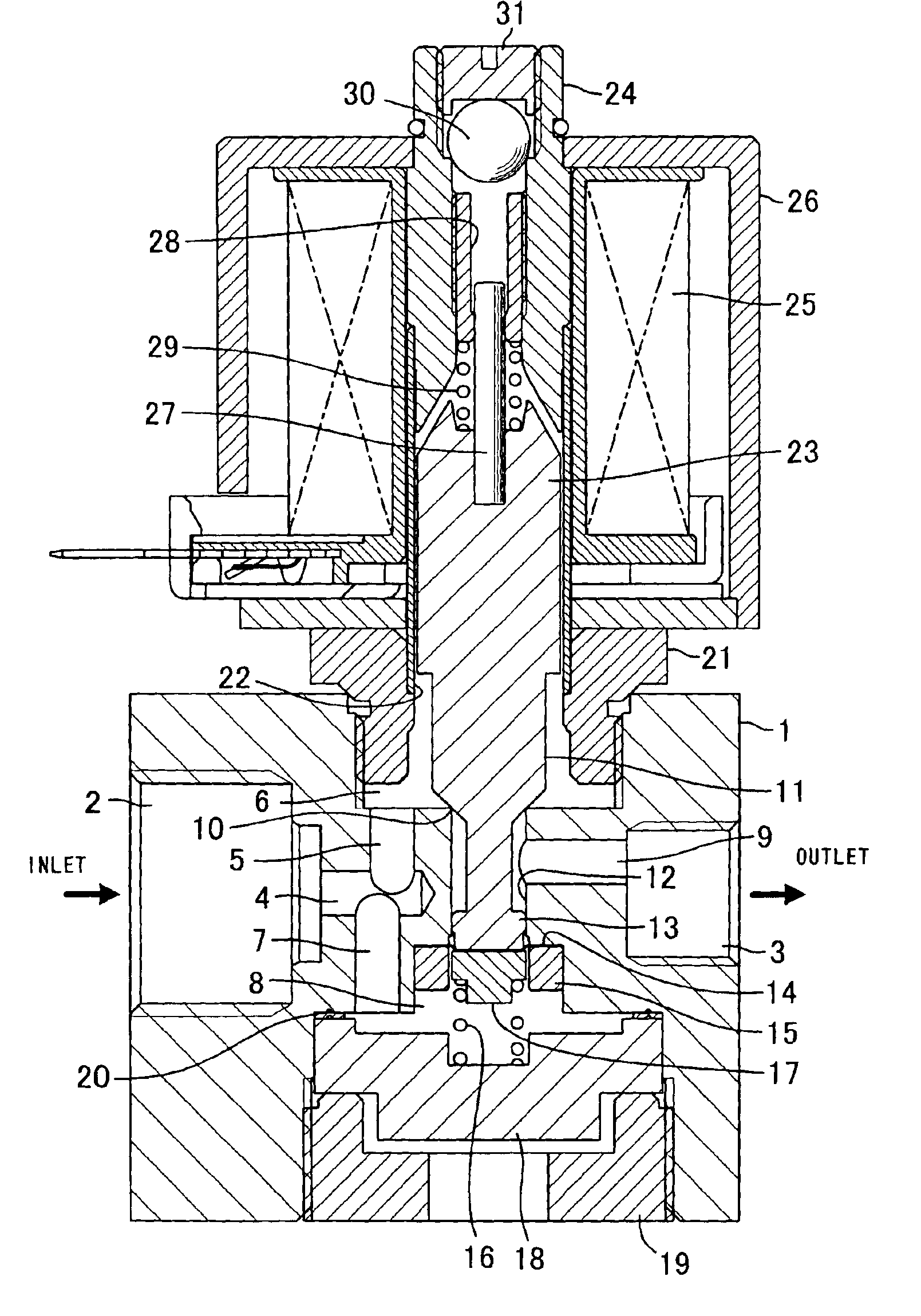

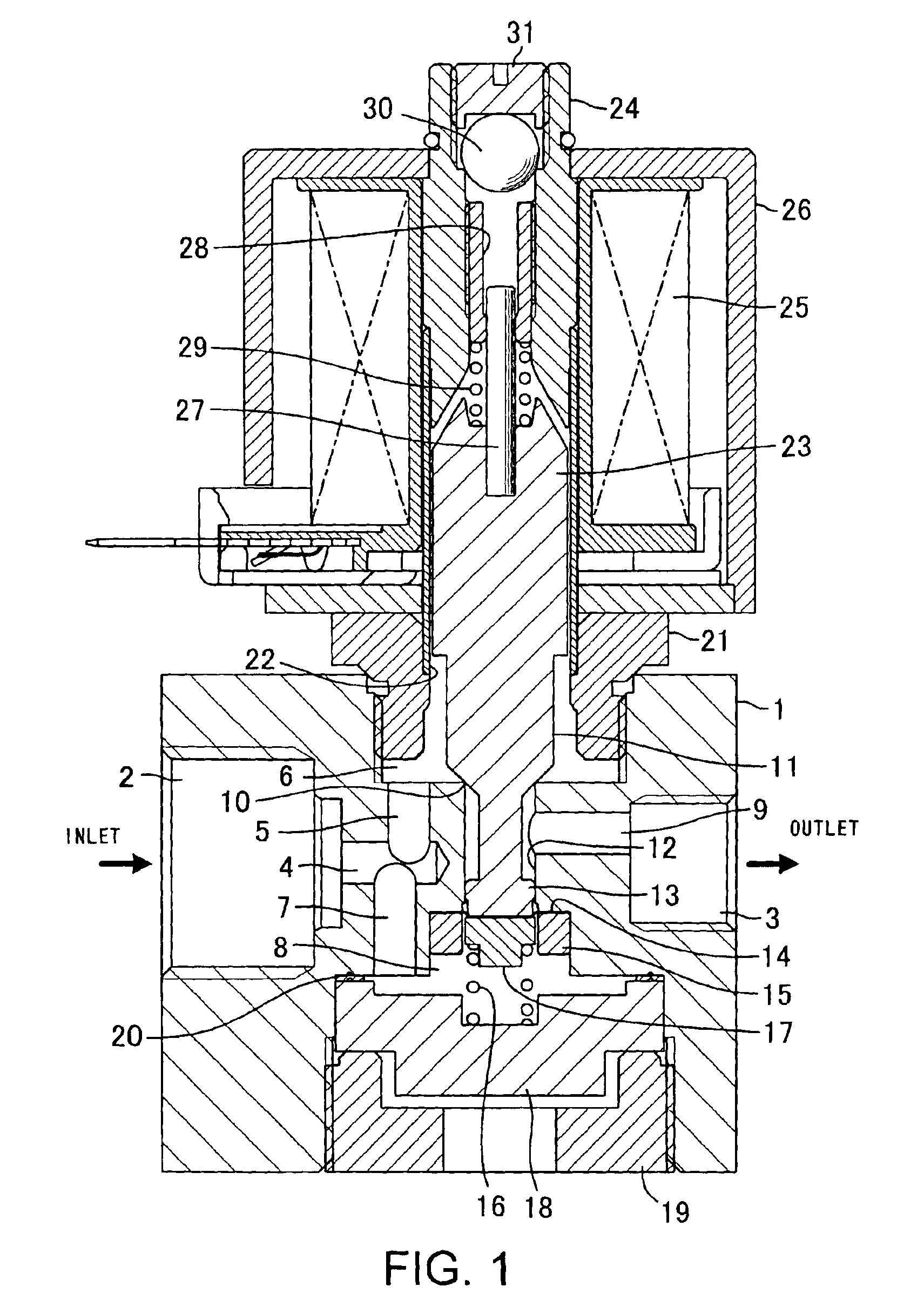

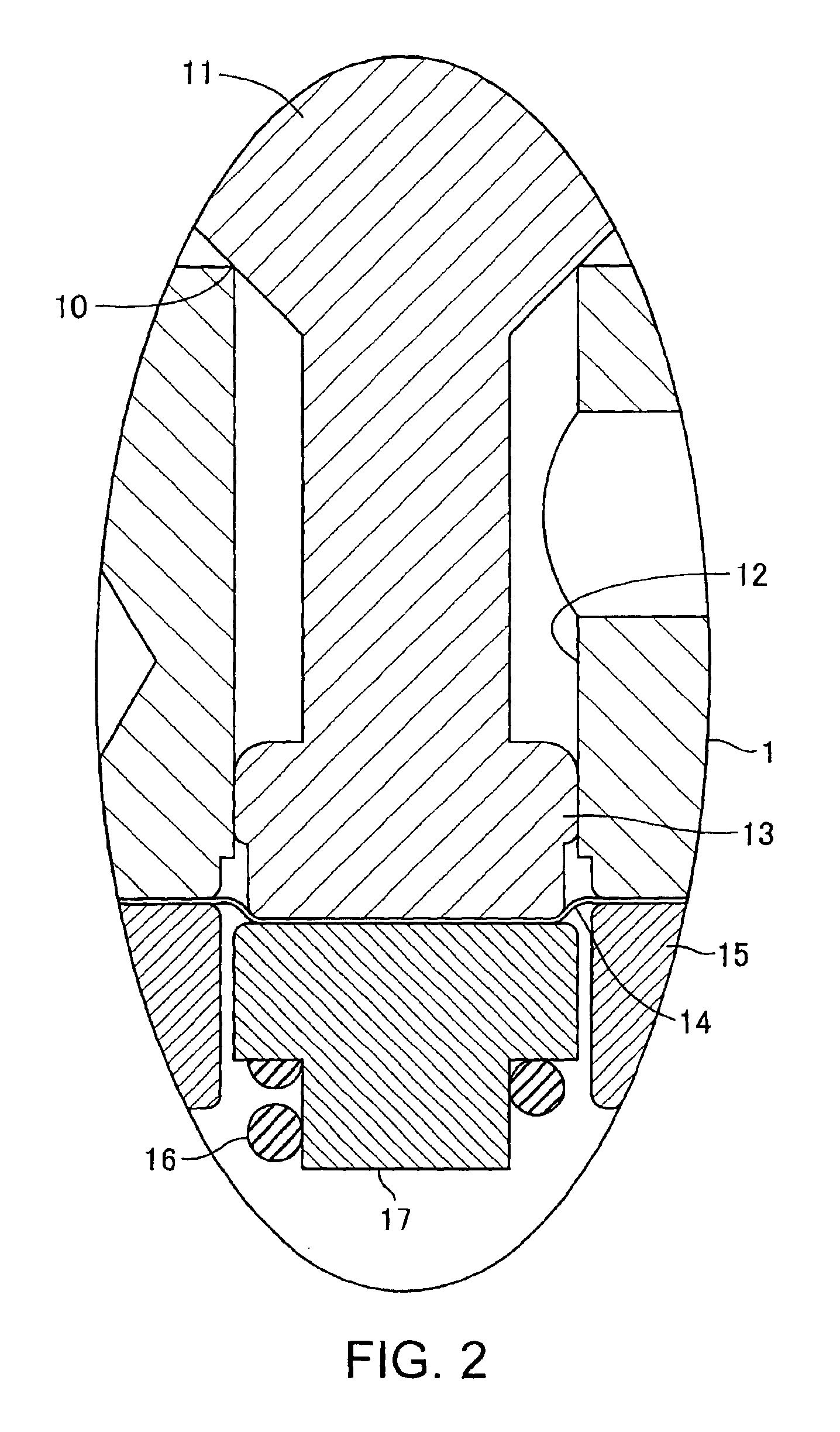

Proportional valve

InactiveUS6866242B2Air-treating devicesOperating means/releasing devices for valvesProportional valveVALVE PORT

The object of the present invention is to provide a proportional valve which does not open or close by itself and is free of internal leakage. A valve element is formed integrally with a piston having a cross-sectional area equal to that of a valve hole constituting a valve seat, and a diaphragm having an outer peripheral portion secured to a body by a holder is disposed in contact with a pressure-receiving end face of the piston. The diaphragm is mounted in a displaced state such that when the valve element is seated on the valve seat, the pressure receiving area of the diaphragm is at a maximum and is equal to that of the valve element. Change in the pressure receiving area of the valve element corresponding to the lift amount thereof is canceled out by change in the pressure receiving area of the diaphragm corresponding to the amount of displacement thereof, thus preventing the valve from opening or closing by itself due to the difference between the pressure receiving areas. Also, a sliding portion of the piston is shut off by the diaphragm, whereby internal leakage can be completely prevented.

Owner:TGK

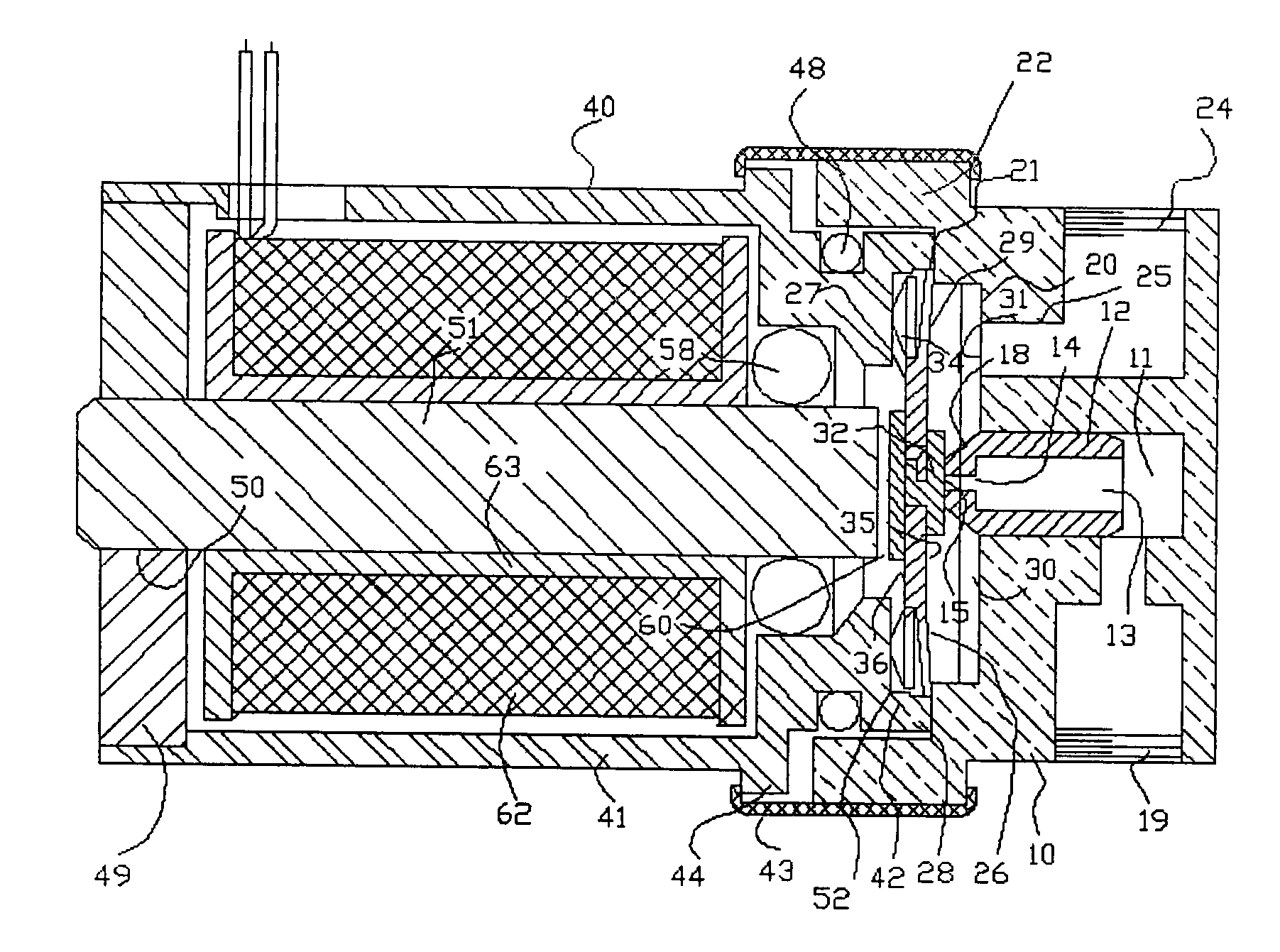

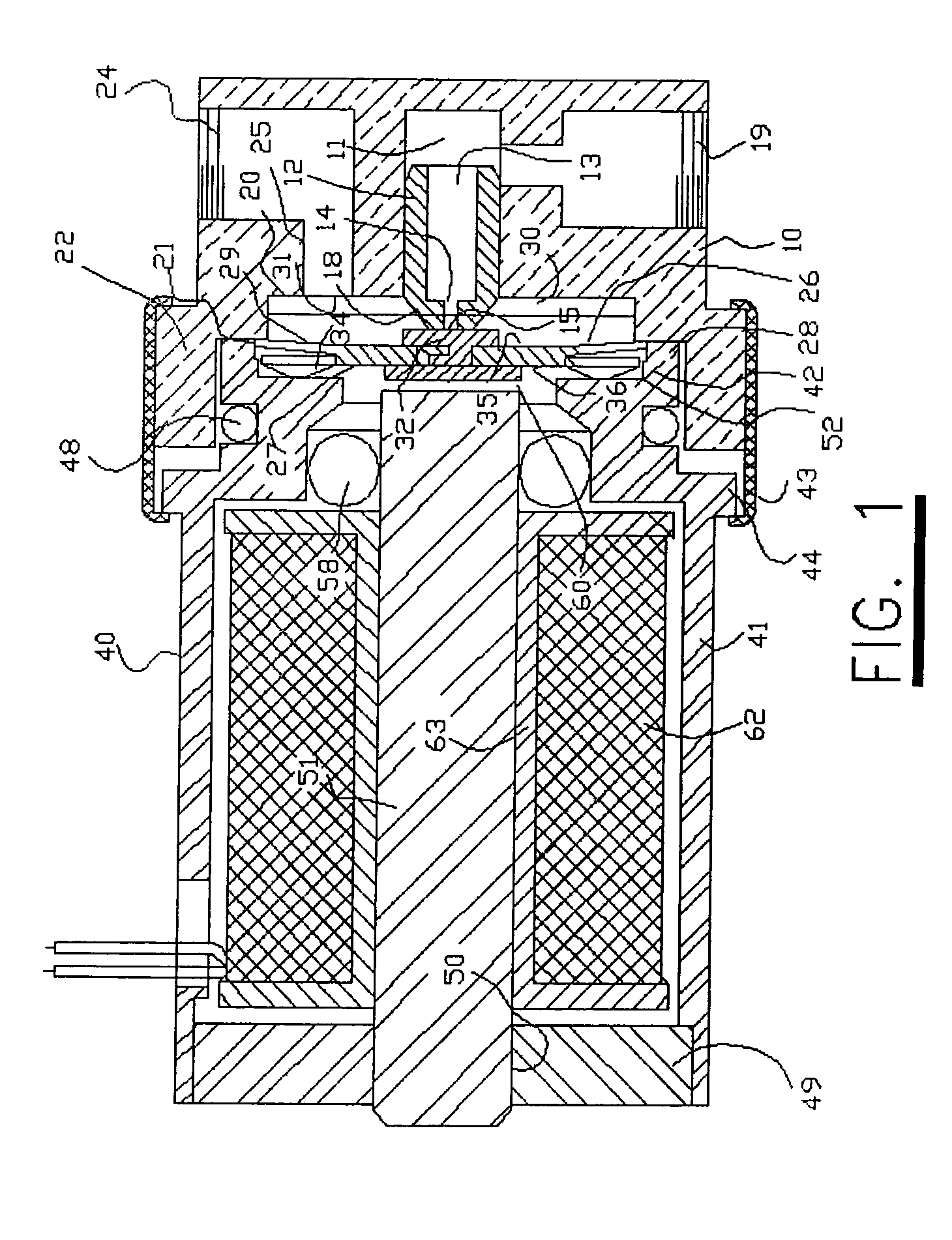

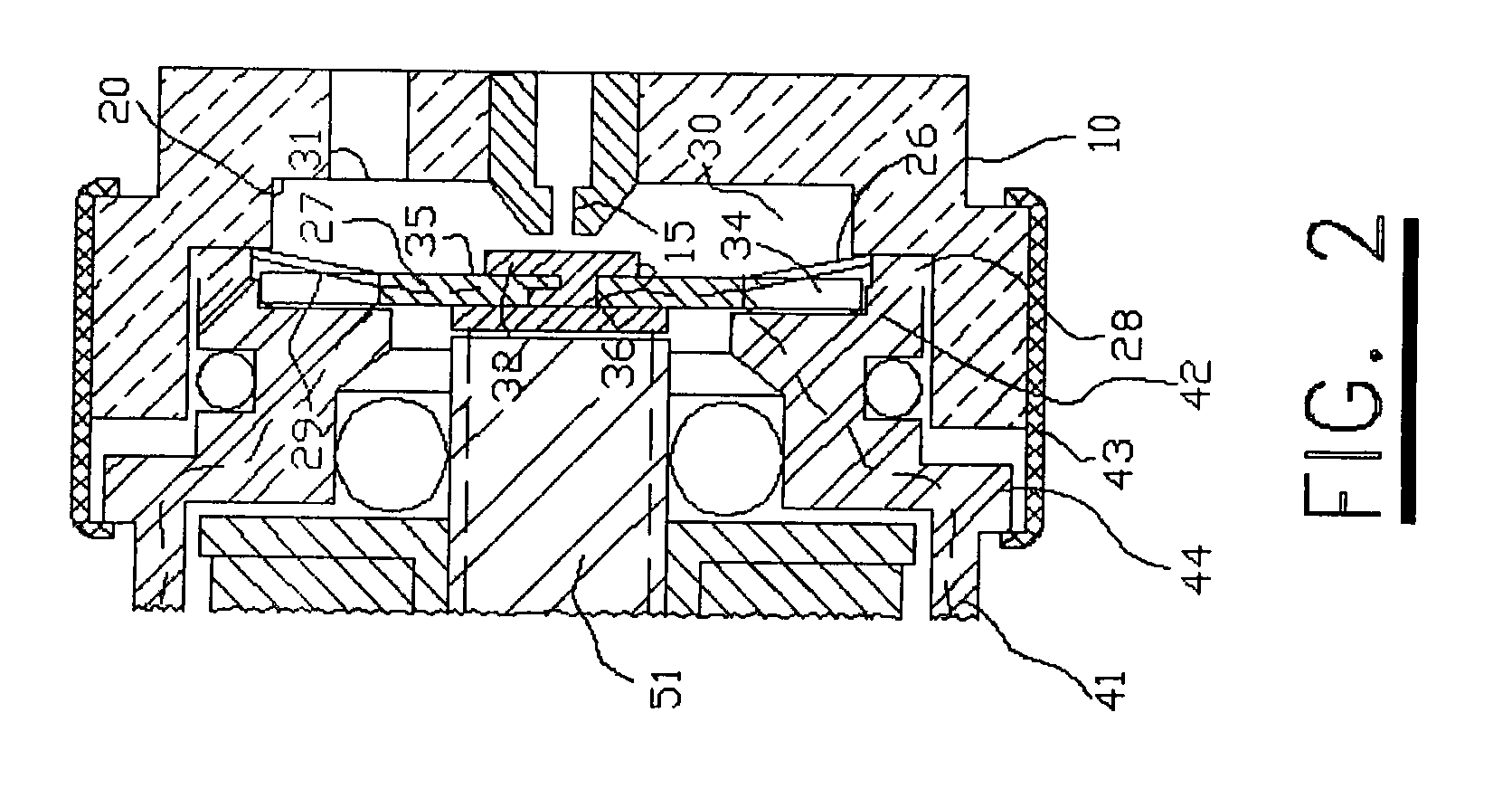

Electrically controlled proportional valve

ActiveUS7748683B1Large range of performanceHigh resolutionOperating means/releasing devices for valvesMachines/enginesElectric controlProportional valve

An electrically controlled proportional valve provides for precise control of armature movement using an armature which is positioned at the center of the valve by centering leaf springs. The armature is supported and biased axially by angled leaf springs that support the armature in an orbital fashion. These angled orbital leaf springs support the armature for elastic movement in the axial direction, and hold it biased against a first port, so that the armature functions as a valve element, which normally closes that port. A magnet coil is positioned so that when an electrical current passes through the coil, it exerts a force on the armature which overcomes the bias of the orbital leaf springs and draws the armature away from the first port and toward the magnet coil.

Owner:KELLY EDMUND F

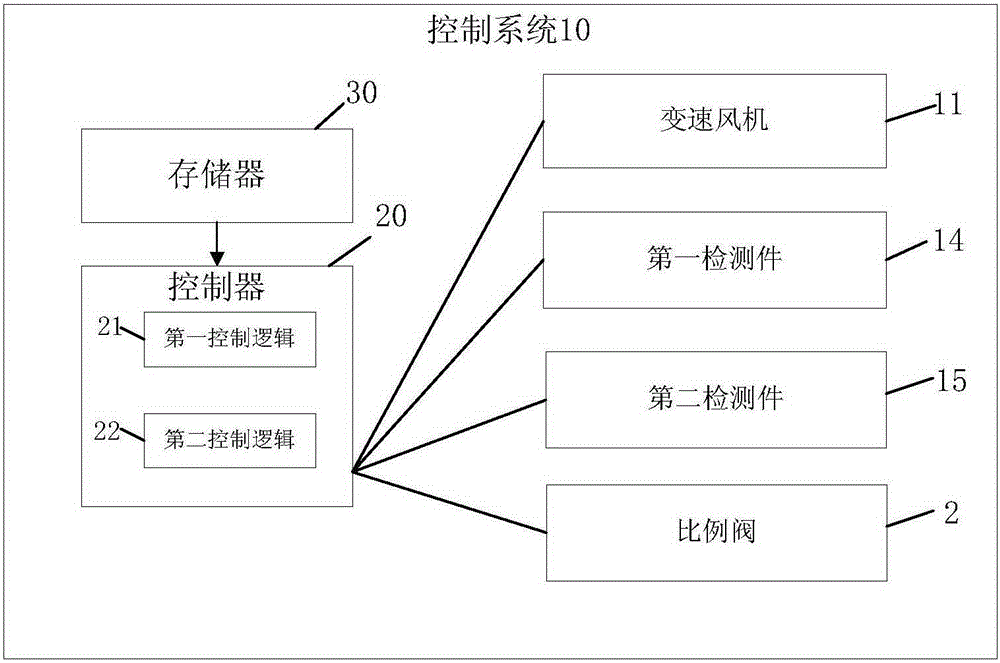

Control system of gas-fired water heating device

The invention discloses a control system of a gas-fired water heating device. The gas-fired water heating device is provided with a speed-variable fan and a proportional valve. An air flow channel is formed from the air inlet to the smoke outlet of the gas-fired water heating device. The control system comprises a first detector, a second detector and a controller at least having first control logic and second control logic. The first control logic controls the speed-variable fan and / or the proportional valve according to the detection information of the first detector, and the second control logic controls the speed-variable fan and / or the proportional valve according to the detection information of the second detector. When the first control logic is in service and the information detected by the first detector goes beyond the preset range, the first control logic will be switched to the second control logic for service. The control system of the gas-fired water heating device can lower the failure rate of the gas-fired water heating device, improve the reliability of the gas-fired water heating device and improve the user experience.

Owner:A O SMITH CHINA WATER HEATER CO LTD

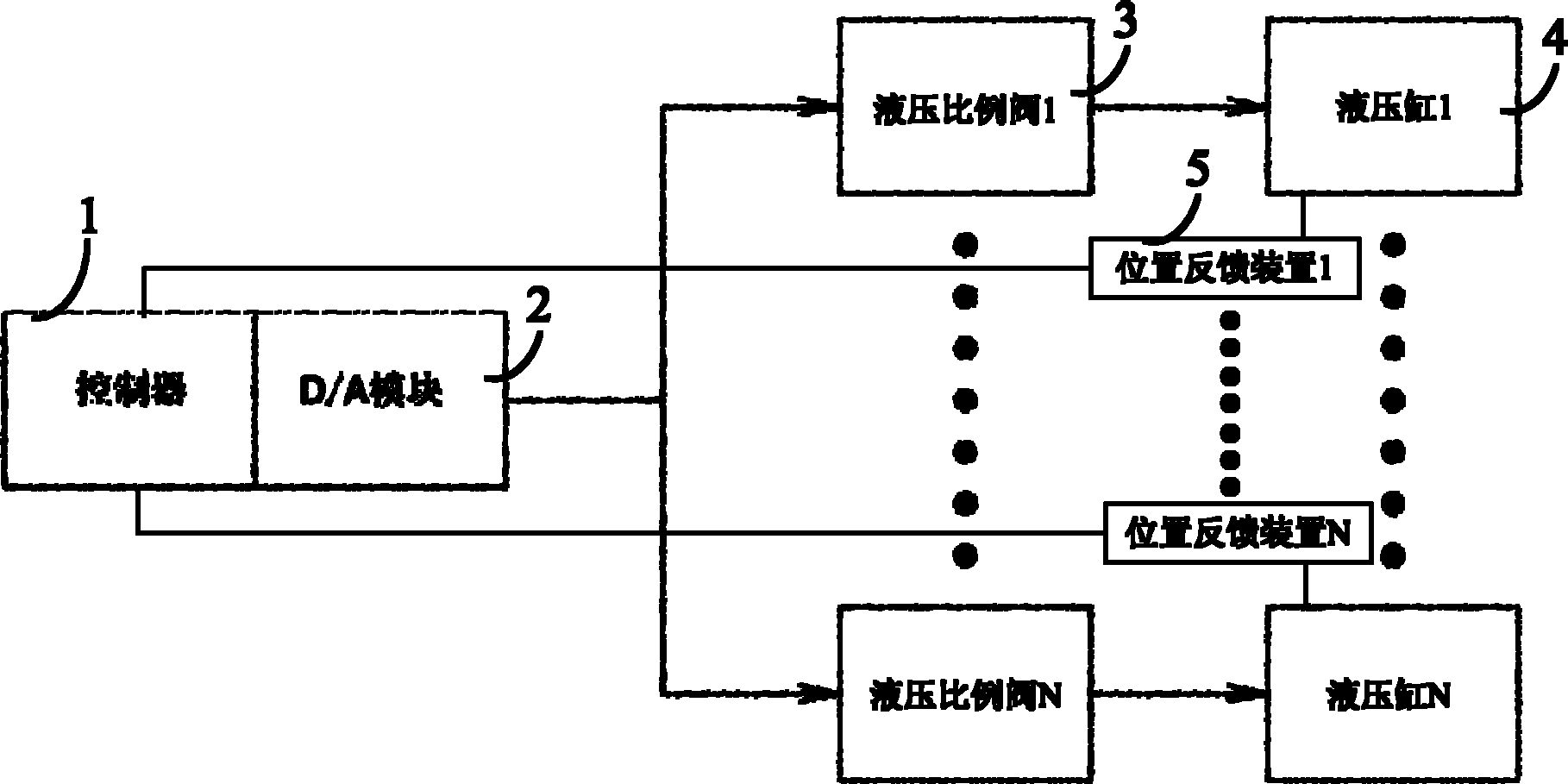

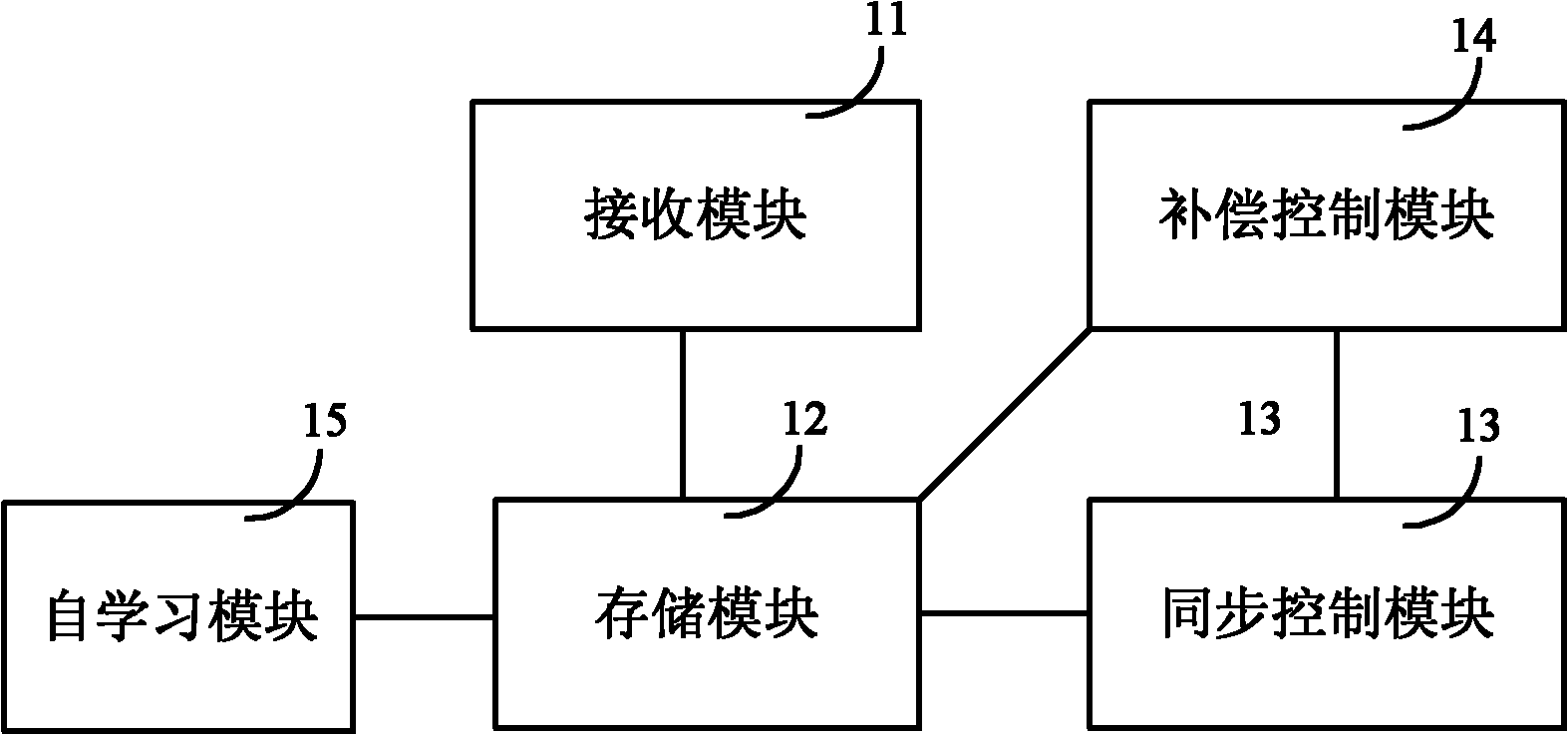

Multi-axis hydraulic synchronization control system, method and device

ActiveCN102086893ASimple structureHigh precision of synchronous controlServomotorsFluid-pressure actuator componentsHydraulic cylinderSynchronous control

The invention discloses a multi-axis hydraulic synchronization control system, method and device, and belongs to the technical field of synchronization control. The system comprises a controller, a digital-to-analogue conversion module, at least two hydraulic proportional valves and position feedback devices the number of which is equal to the number of the hydraulic proportional valves; the controller is connected with each hydraulic proportional valve through the digital-to-analogue conversion module, and each hydraulic proportional valve can drive a hydraulic cylinder which is connected with each hydraulic proportional valve; each position feedback device is respectively connected with the controller, each position feedback device can detect the position of each hydraulic cylinder, andtransmits the detected position data to the controller; and the controller can control each hydraulic proportional valve according to the position data of each hydraulic cylinder transmitted by each position feedback device and by consulting the stored synchronization data of the controller. The multi-axis hydraulic synchronization control system has the advantages of simple structure, high synchronization precision and low cost, and can be used for solving the problems of low synchronization and high cost of the existing multi-axis hydraulic synchronization.

Owner:FANTAWILD DIGITAL FILM

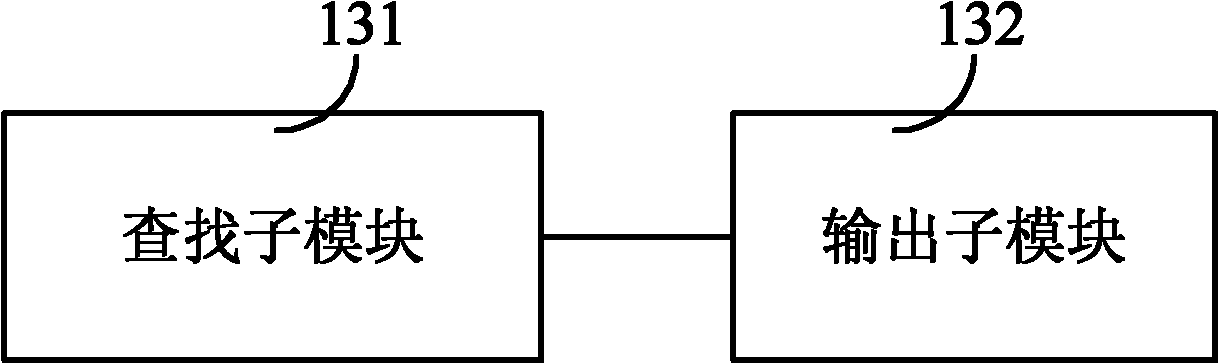

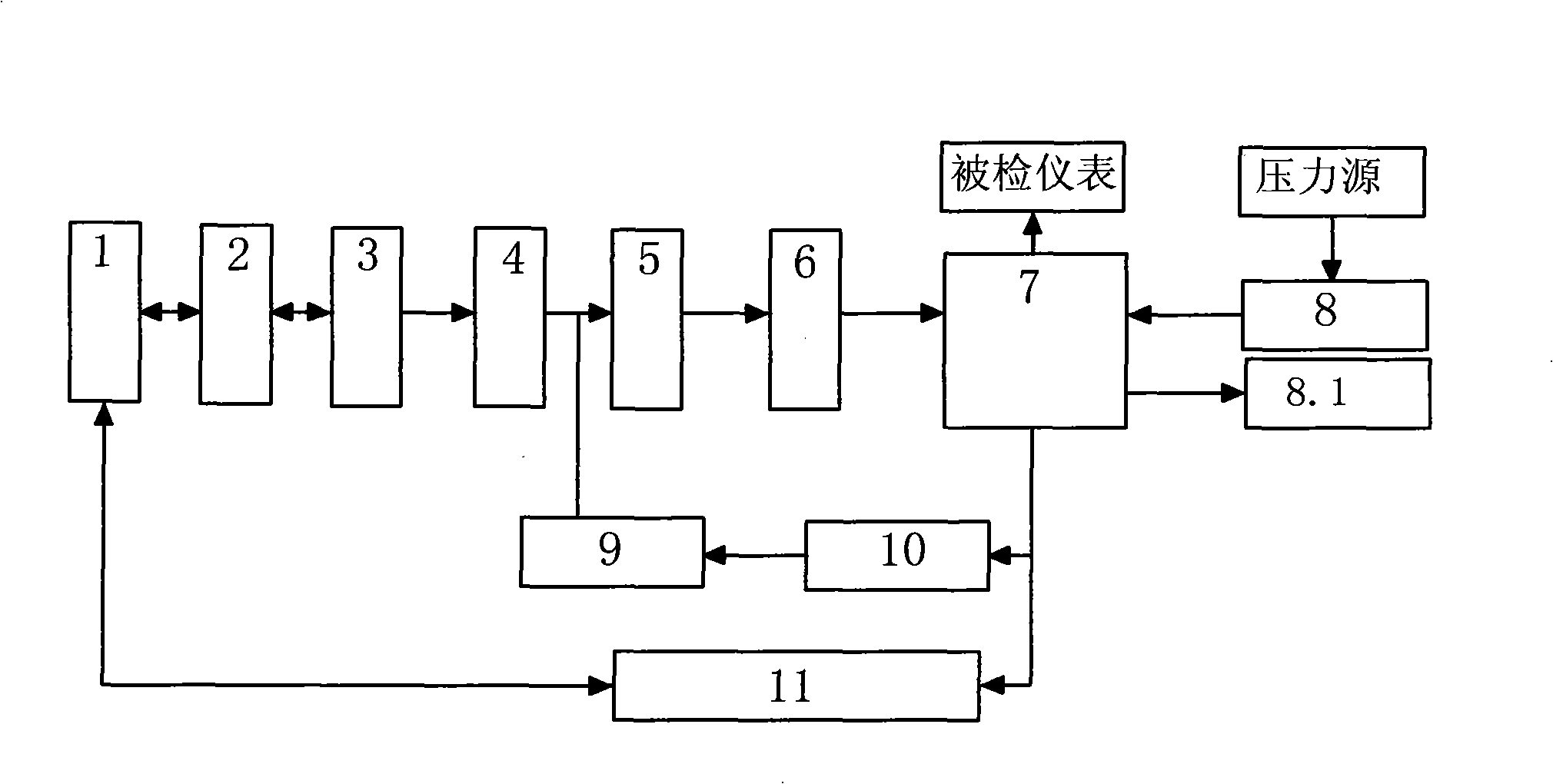

Proportional valve pair accurate atmosphere controller

InactiveCN101256417ASuitability for detectionAppropriate controlFluid pressure control using electric meansControllers with particular characteristicsAviationDual sensor

The invention provides a device for generating and controlling standard pressure signals, which is applied to the fields of aviation, aerospace and pressure metering calibration, to be specific, the invention provides a precise pressure control device based on a pair of proportional valves. The device is composed of double sensors, a pair of proportional valves, a constant flow source, a sensor conditioning circuit, a practical differential circuit, a PID control circuit, a high resolution DA converter, a proportional valve driving circuit and serial interfaces. By the device, a pressure can be controlled to a scope ranging from 0 to 1500KPa, the indefinite degree is 0.01% F.S, the control stability is better than 0.002%F.S, and the pressure control process is fast and stable. The device is suitable for pressure control and detection under various environmental conditions.

Owner:周德海 +2

Method and apparatus for automatically controlling gas pressure for a plasma cutter

InactiveUS20080023449A1Arc welding apparatusPlasma welding apparatusAutomatic controlSystem configuration

A system for providing a dynamically controlled plasma cutting system includes a plasma cutting system having a proportional valve and a sensing device arrangement and a controller connected to this arrangement. The system is configured to dynamically control gas flow in a plasma torch. The system measures gas pressure at a proportional valve and makes necessary gas pressure adjustments in the system by way of controlling a drive signal sent to the proportional valve to control gas flow.

Owner:ILLINOIS TOOL WORKS INC

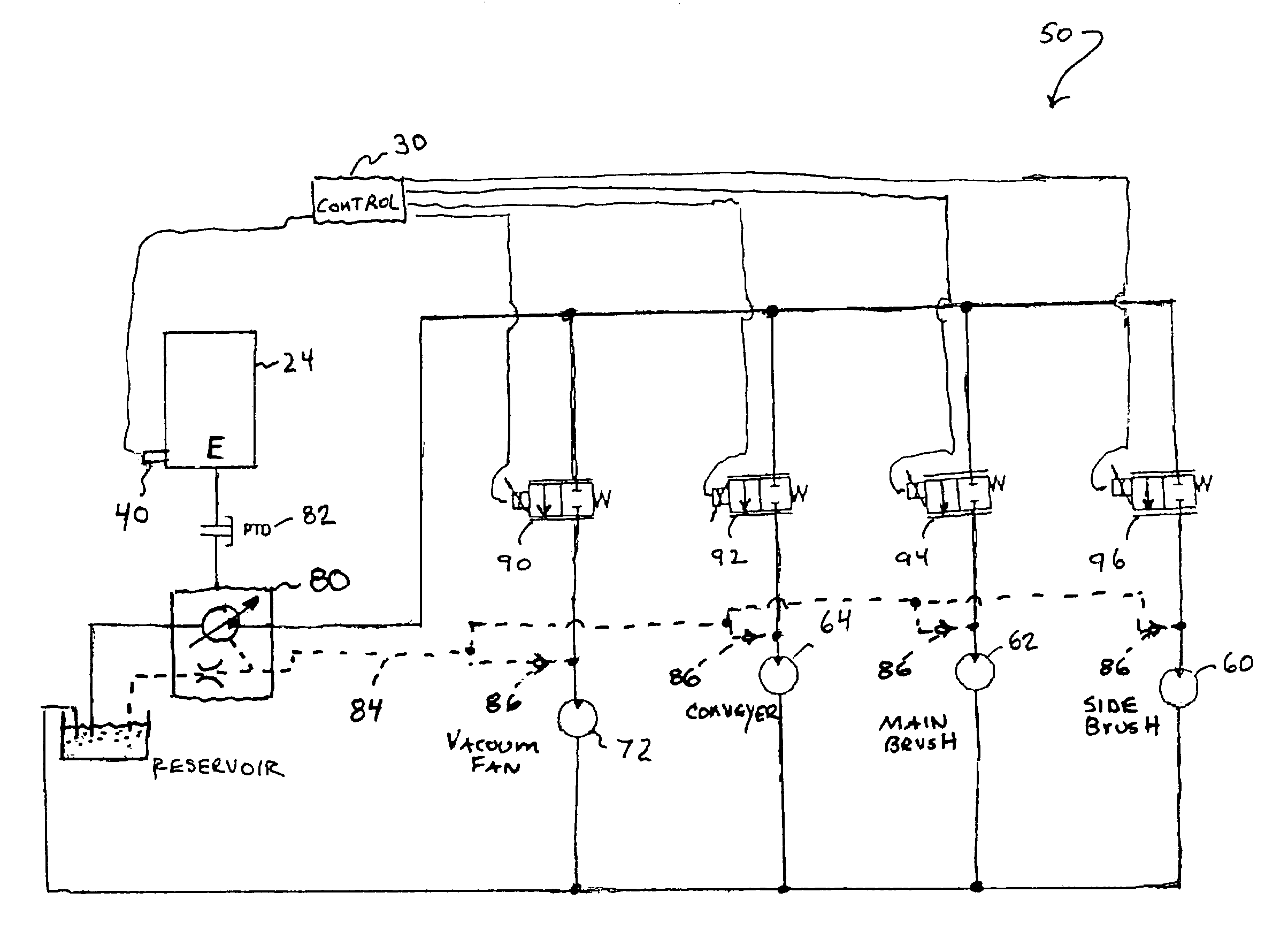

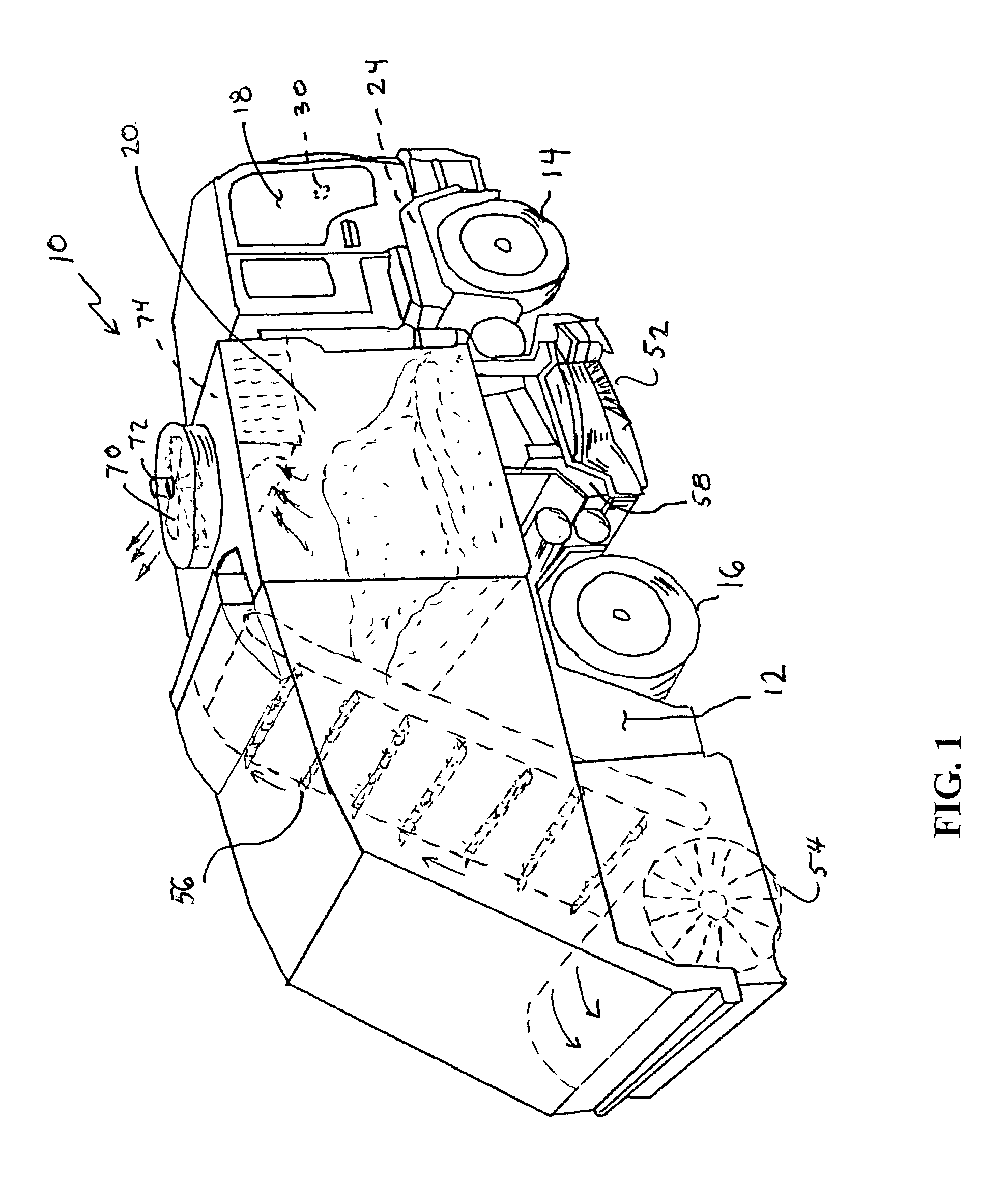

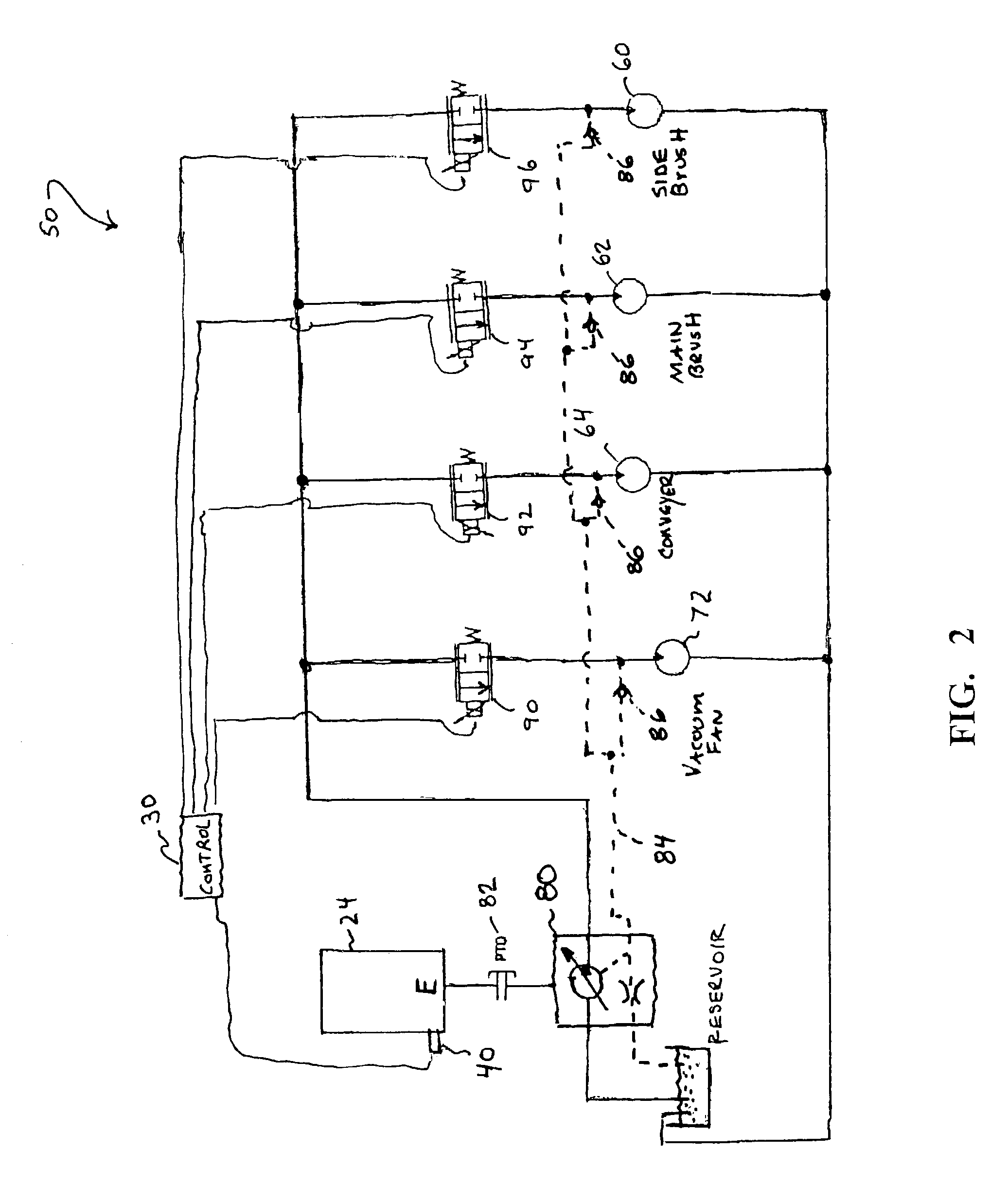

Power management system for street sweeper

InactiveUS6959466B2Cleaner sweeping operationPreferred effective speedCleaning filter meansSuction filtersRoad sweeperHydraulic pump

A power management system for a surface maintenance machine, such as a street sweeper is disclosed. The system includes a variable speed engine for transporting the surface maintenance machine, a hydraulic pump powered by the engine, a vacuum fan motor powered by the hydraulic pump, an engine speed sensor coupled to the engine, an electric proportional valve coupled between the hydraulic pump and the vacuum fan motor, said valve for selectively restricting a flow rate to the vacuum fan motor, and a control unit operatively coupled to the engine speed sensor and the proportional valve, said control unit receiving engine speed information from the engine speed sensor and communicating a predetermined signal to the proportional valve to control the flow rate to the vacuum fan motor as a function of engine speed. A method of managing engine power from a single-engine street sweeper is also disclosed.

Owner:WAYNE SWEEPERS LLC

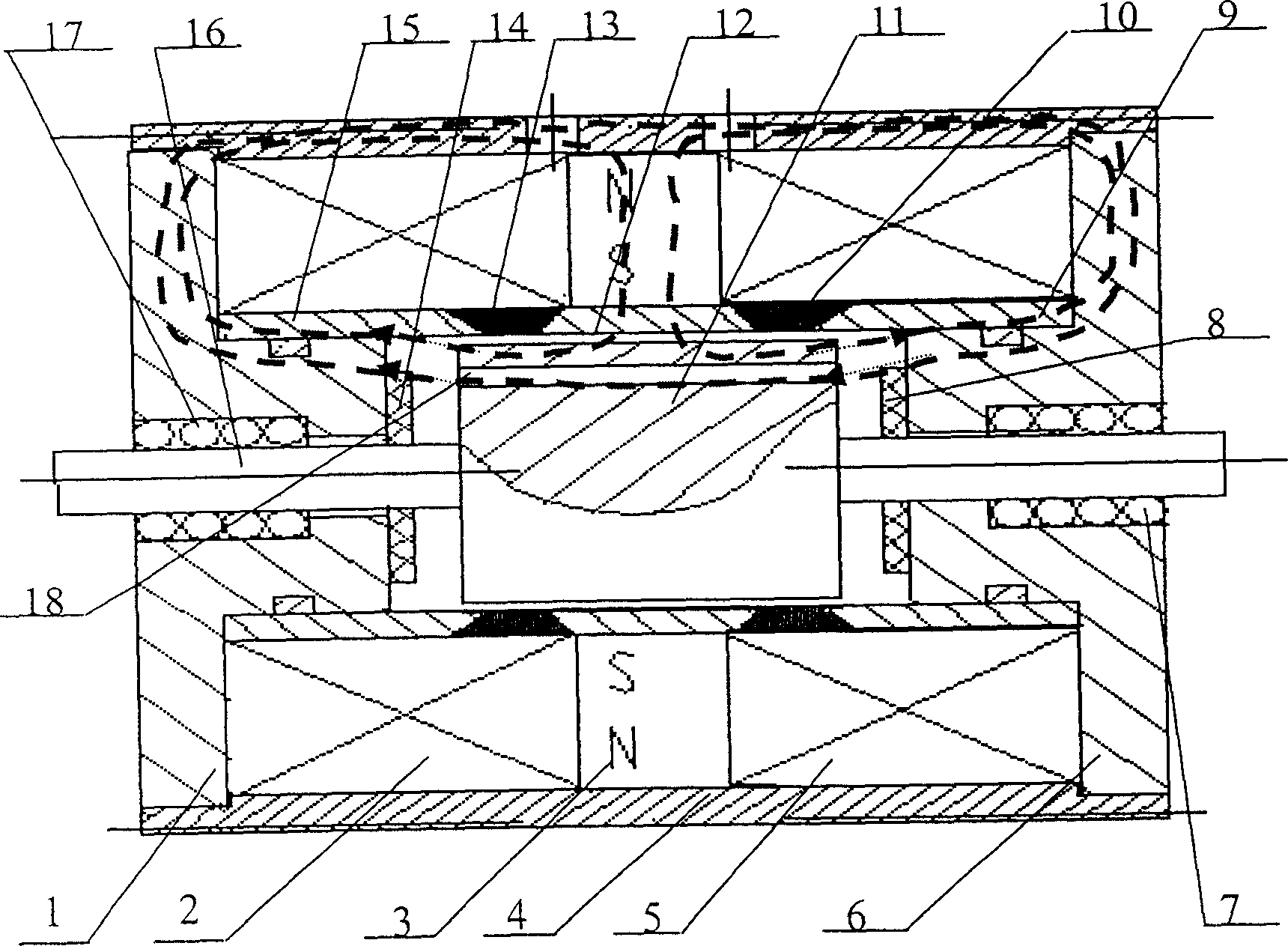

Anti high voltage permanent magnet polarized two-way ratio electromagnet

InactiveCN1588585AReduce energy consumptionLow calorific valueOperating means/releasing devices for valvesElectromagnets with armaturesProportional controlSpecial design

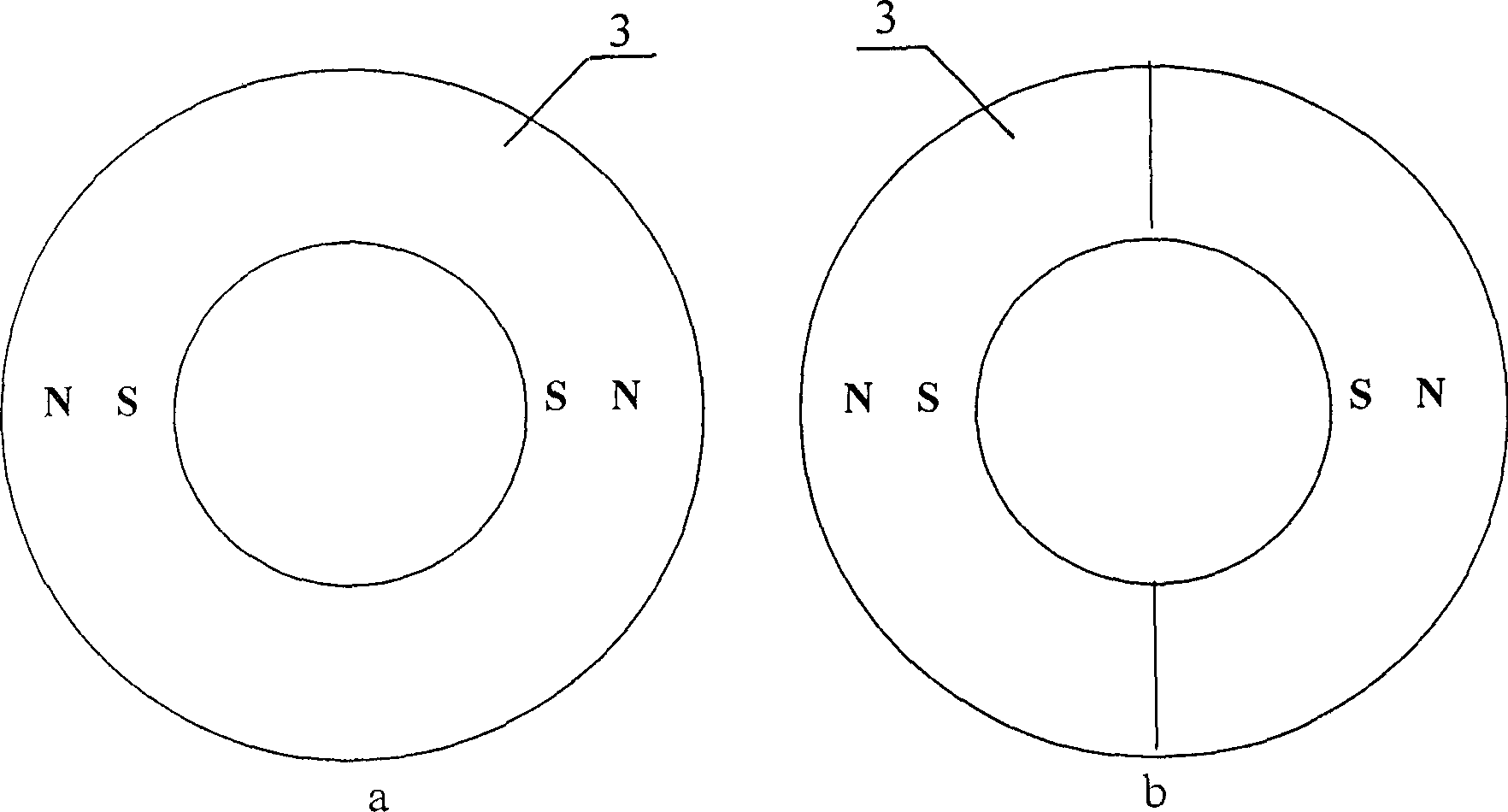

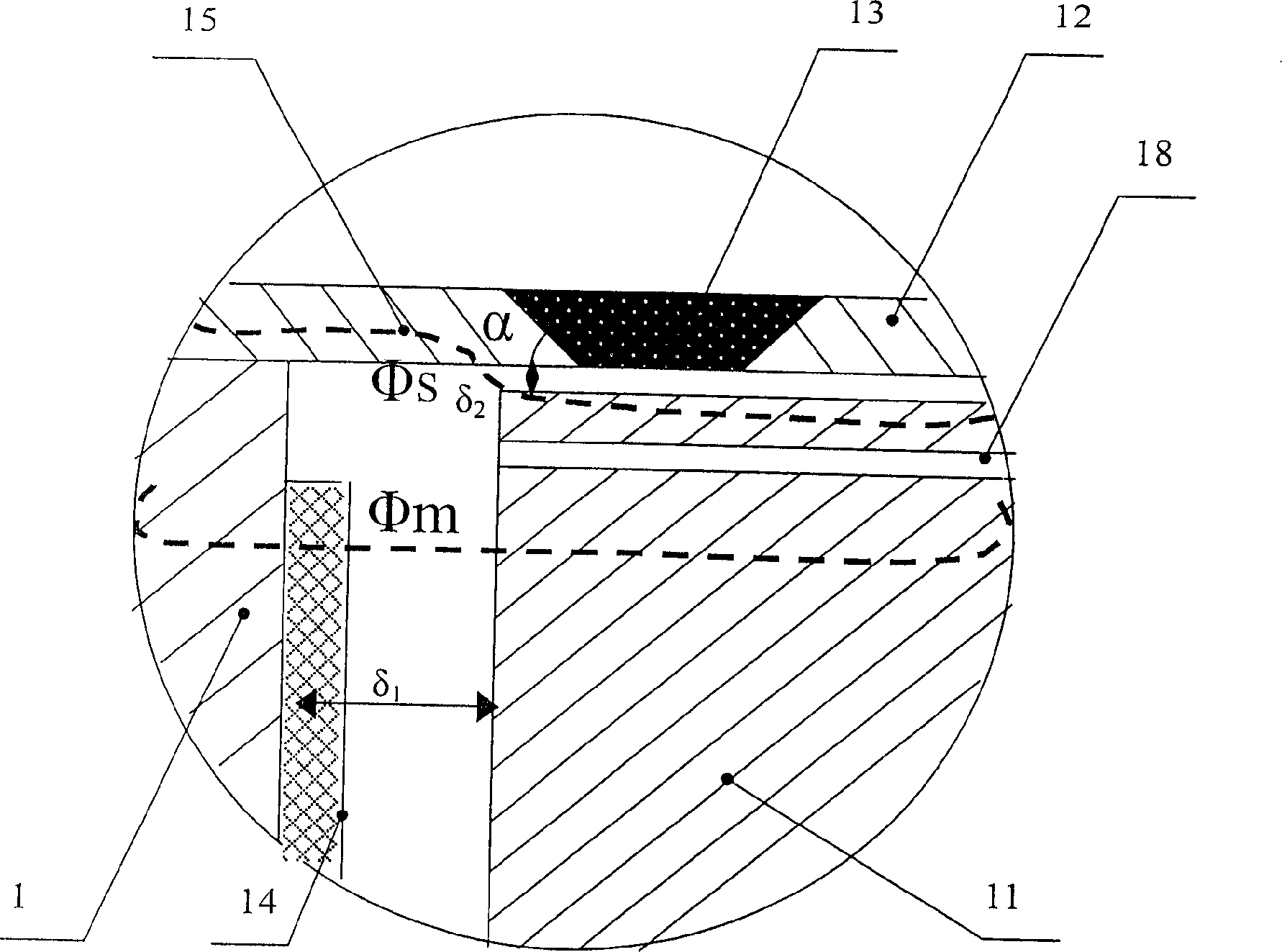

The invention discloses a high voltage resistant permanent magnet polarized two-way proportional electromagnet, belonging to an electromechanical switching mechanism, adopting a special design: using yoke iron and guide sleeve to compose a two-way basin-like pole piece structure, there is permanent magnet mounted in the guide sleeve, there are control coils installed on two sides of the permanent magnet, a polarized magnetic field generated by the permanent magnet is superposed with control magnetic fields generated by the control coils so as to obtain an output force on an armature proportional to input signal, two-way and continuous, thus achieving a good proportional control characteristic; it has low energy consumption, eliminates 'zero'dead zone, has good static and dynamic properties. Therefore, it can be widely applied to proportional valve and servo valve.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com