Patents

Literature

131results about How to "Guaranteed combustion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

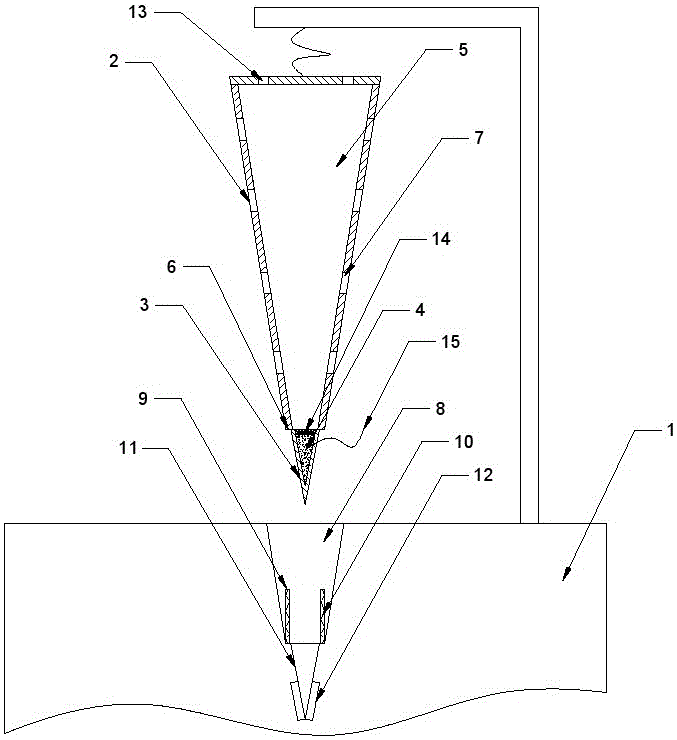

Pre-combustion type plasma igniter and ignition method

ActiveCN107842427AEasy to assembleIncrease production capacityTurbine/propulsion fuel supply systemsGas turbine plantsFuel oilHigh pressure

The invention discloses a pre-combustion type plasma igniter and an ignition method. The pre-combustion type plasma igniter comprises a shell, an oil conveying pipe, a hydrocyclone, a spark plug and agas channel base. A jetting opening is formed in the upper end of the shell. The hydrocyclone is arranged in the shell and connected with the shell. The hydrocyclone divides an inner cavity of the shell into a pre-combustion chamber and a rectification chamber. The spark plug is arranged on the inner cavity of the shell, penetrates the hydrocyclone and is connected with the hydrocyclone, and thehigh-voltage electrode of the spark plug is located in the pre-combustion chamber. An oil conveying cavity is formed in the shell wall of the portion, corresponding to the pre-combustion chamber, of the shell. The oil conveying pipe communicates with the oil conveying cavity. An atomizing hole is formed in the position, corresponding to the pre-combustion chamber, of the inner wall of the shell and communicates with the oil conveying cavity. The atomizing hole is used for atomizing fuel and then spraying the fuel to the pre-combustion chamber. The gas channel base is arranged at the lower endof the shell, connected with the shell, and used for providing combustion-supporting gas for the rectification chamber. A high-pressure lead of the spark plug penetrates the gas channel base and extends out of the shell. The igniter can ignite mainstream fuel oil in the pre-combustion chamber of an aircraft engine, and the reignition height of the aircraft engine is increased.

Owner:XI AN JIAOTONG UNIV

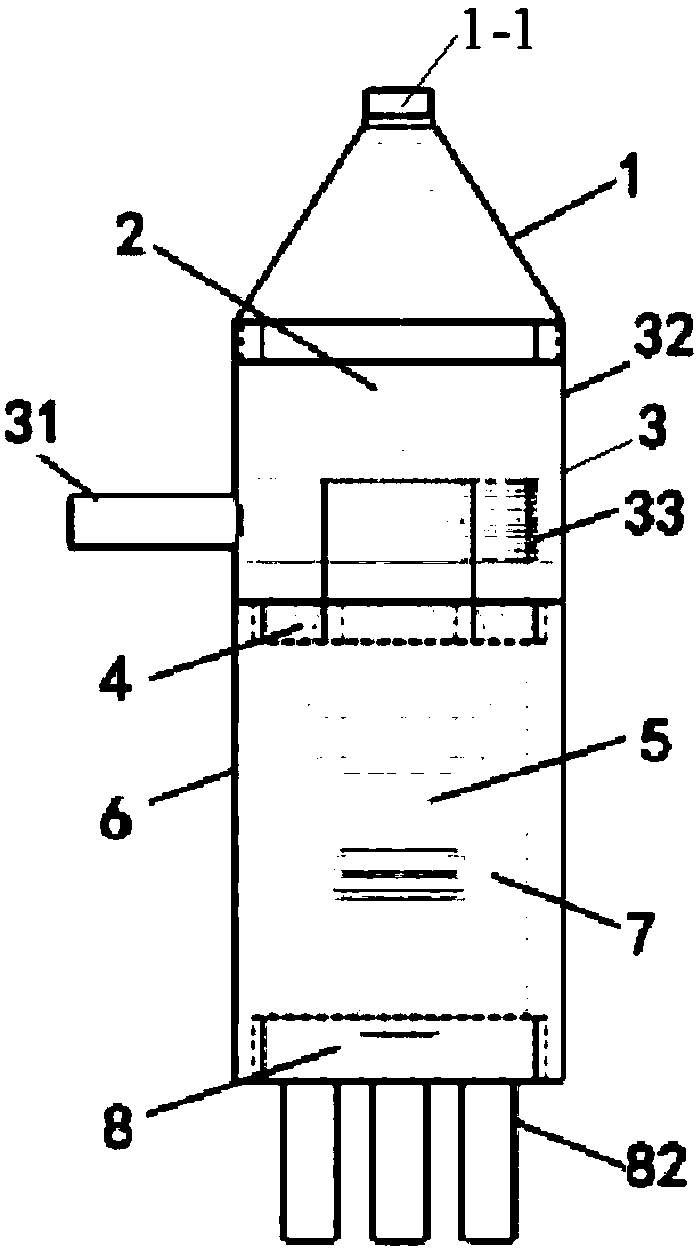

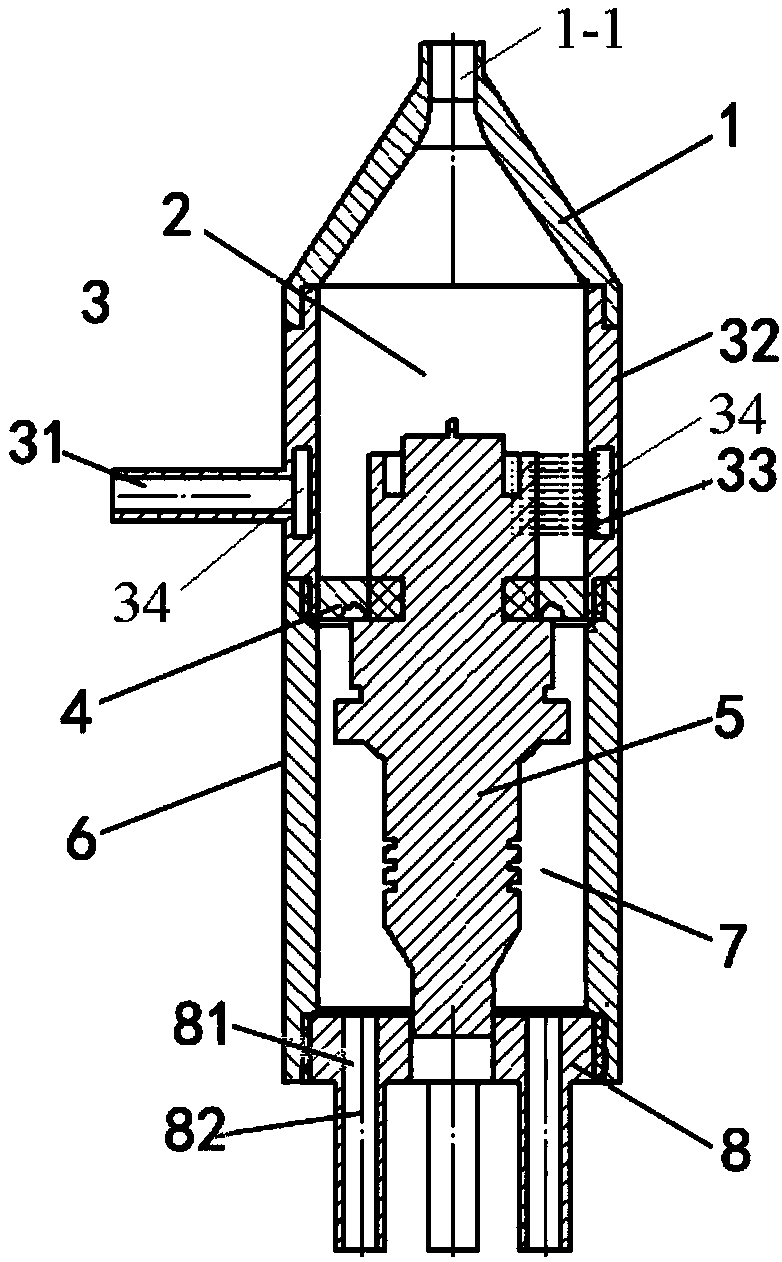

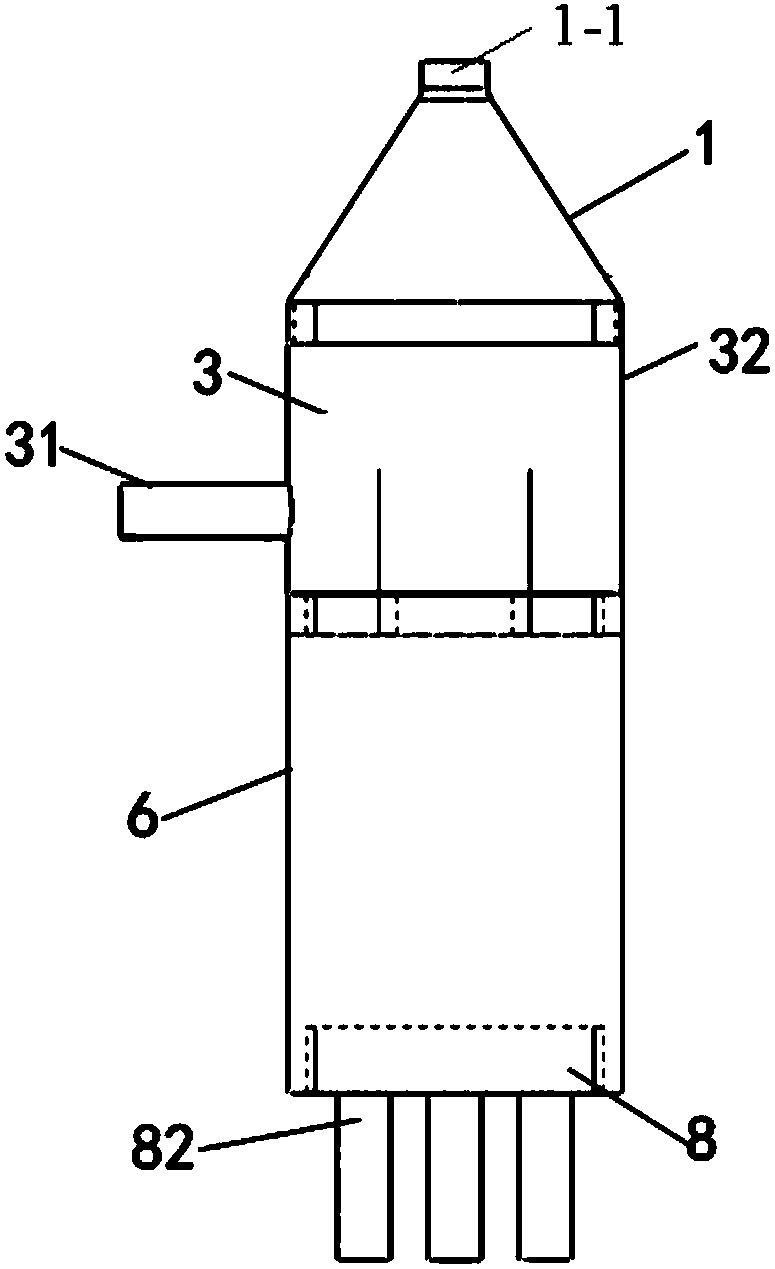

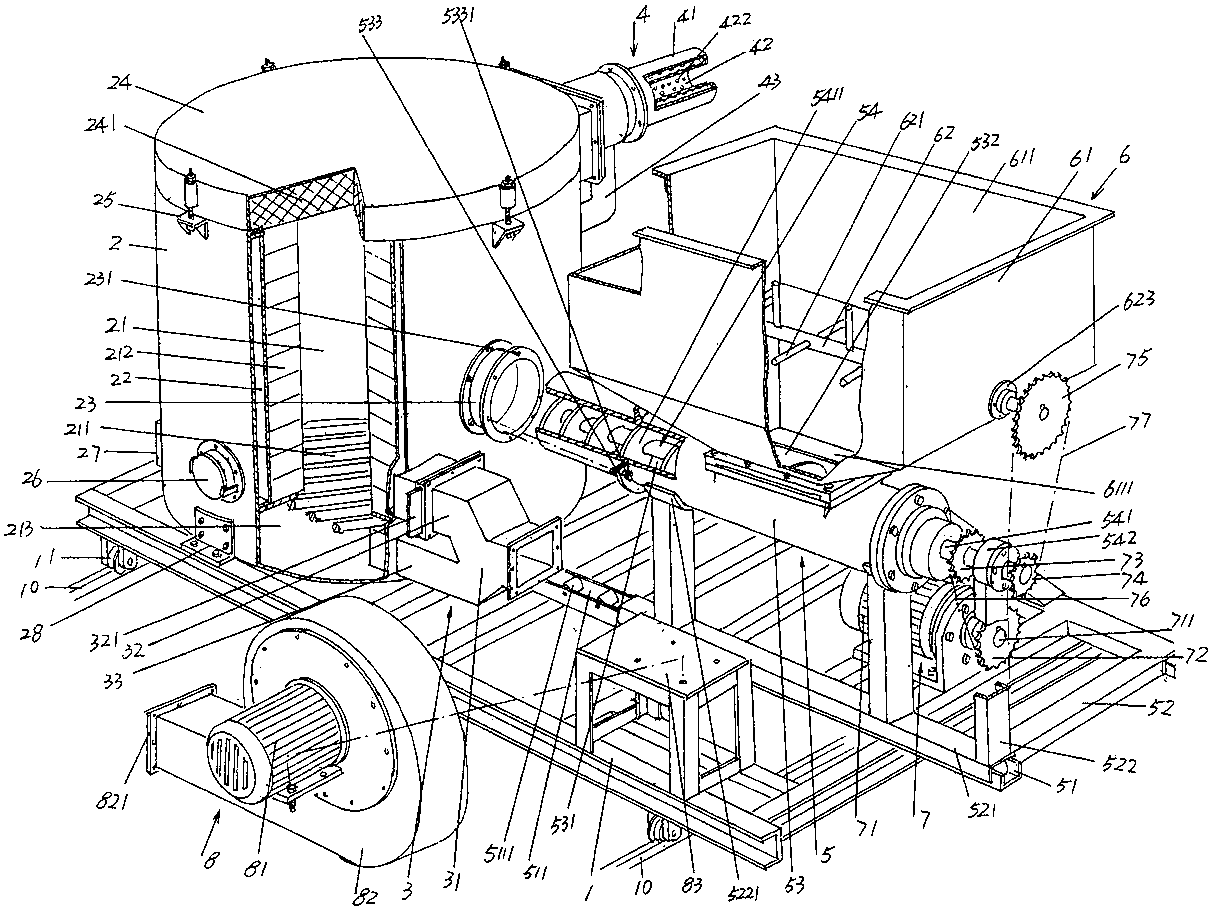

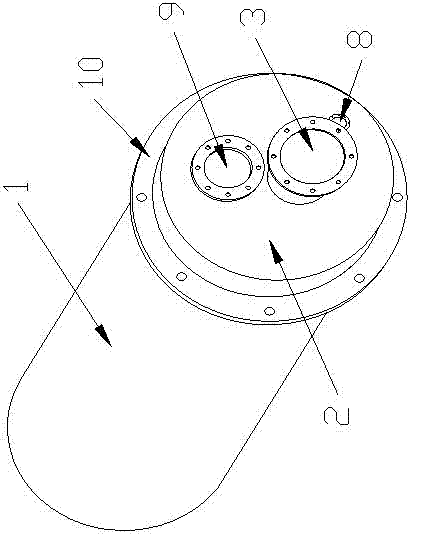

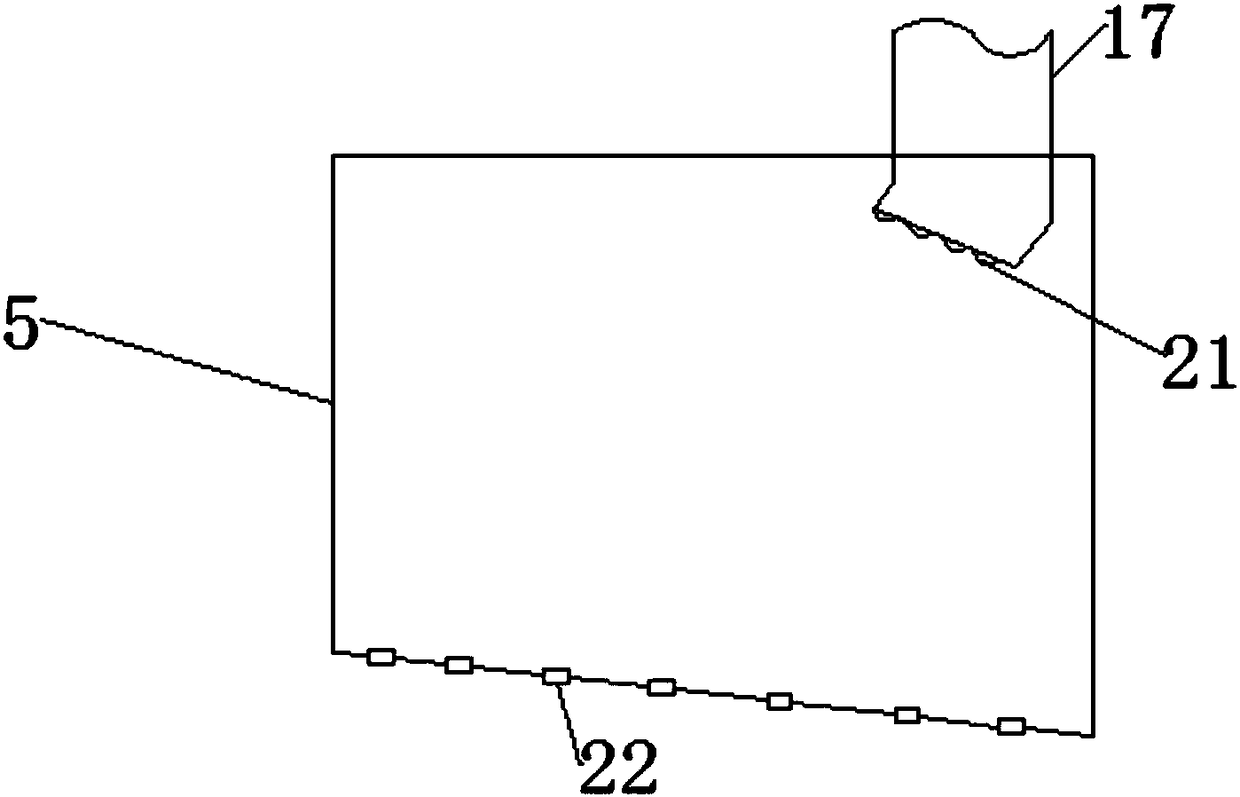

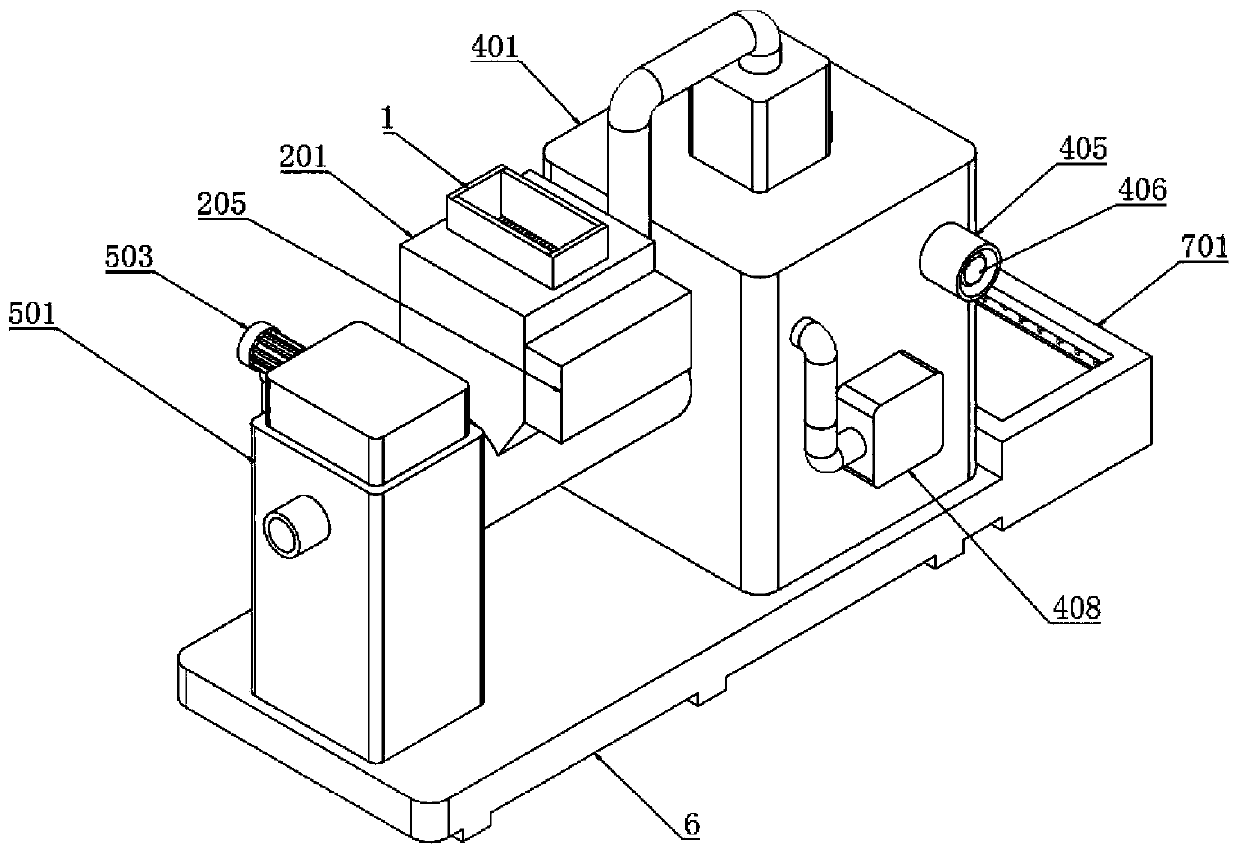

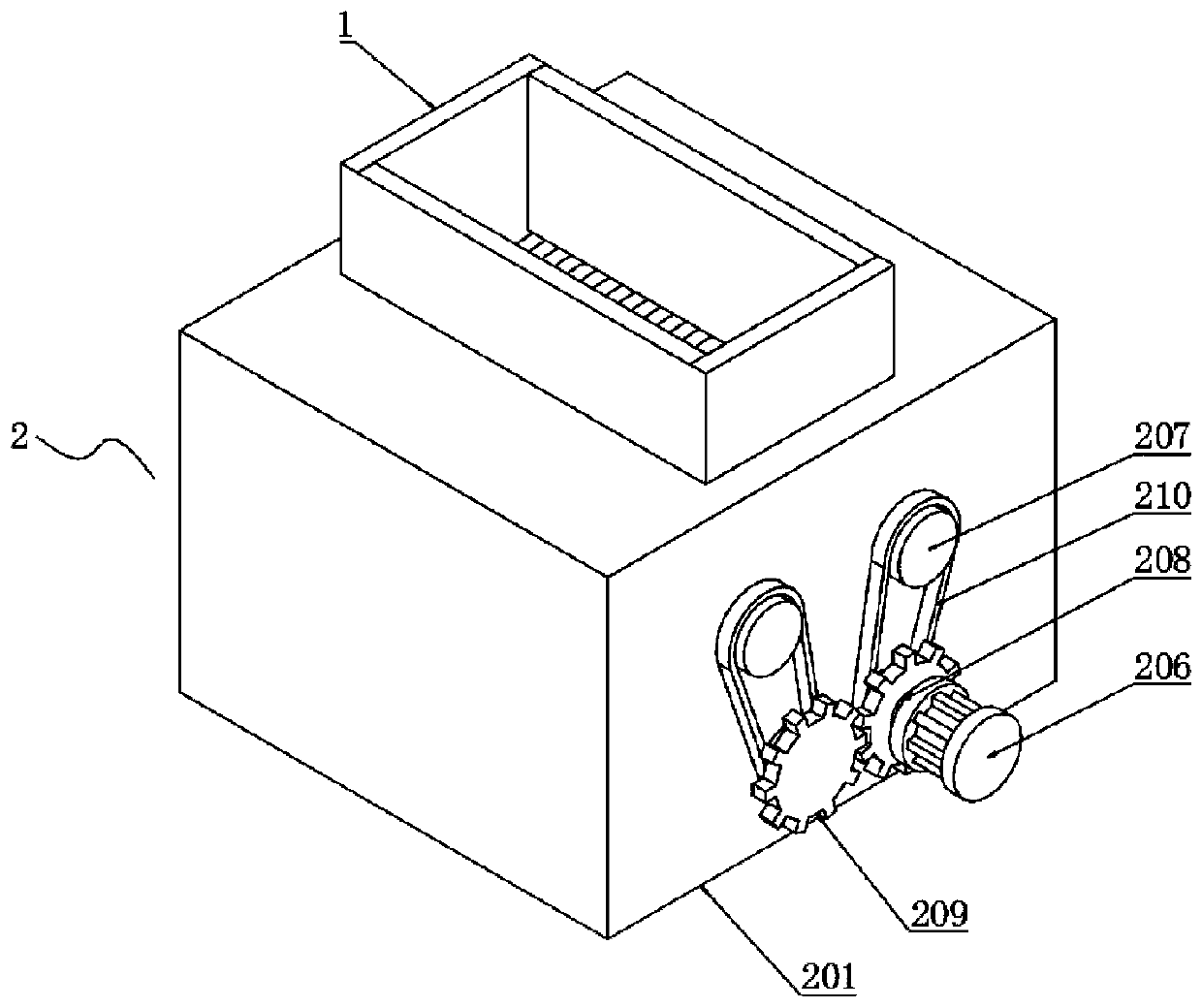

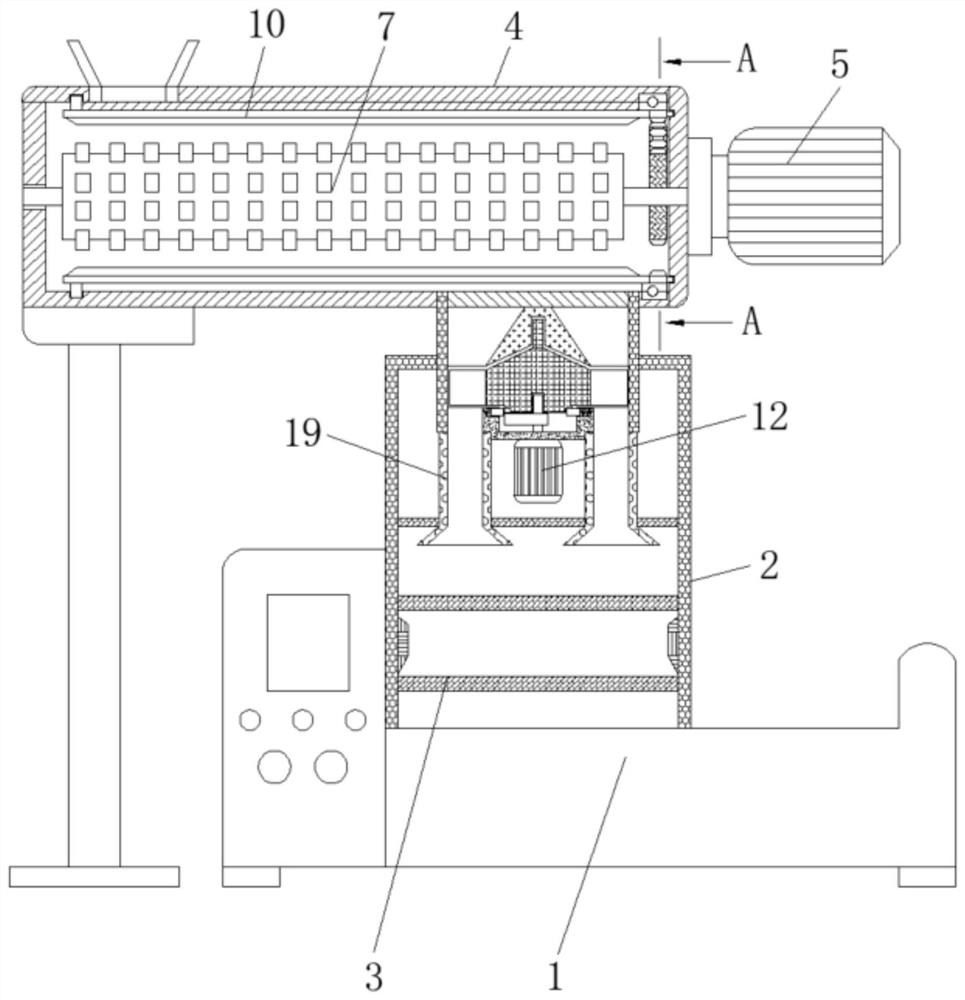

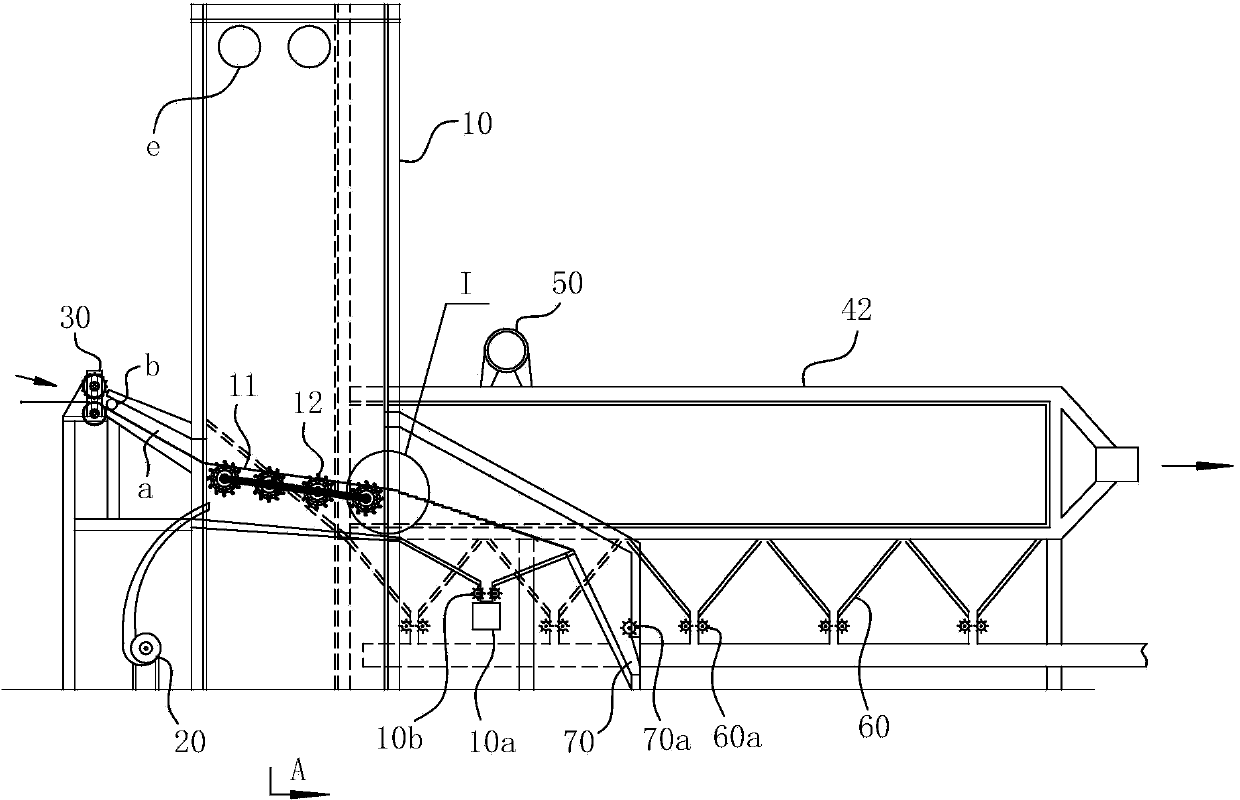

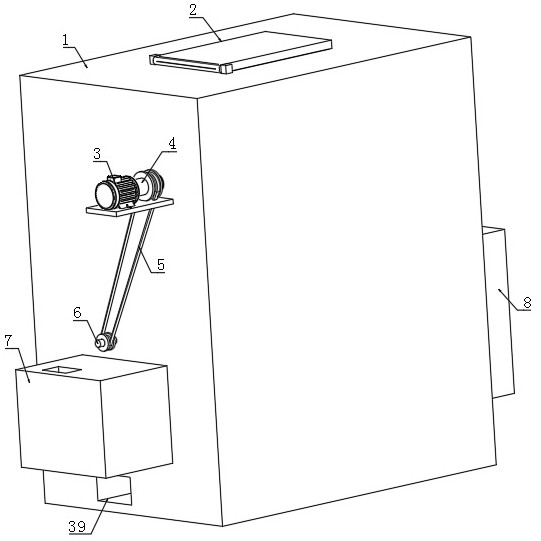

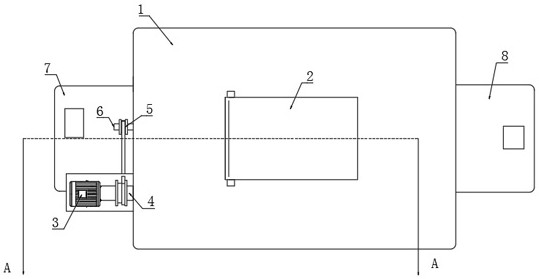

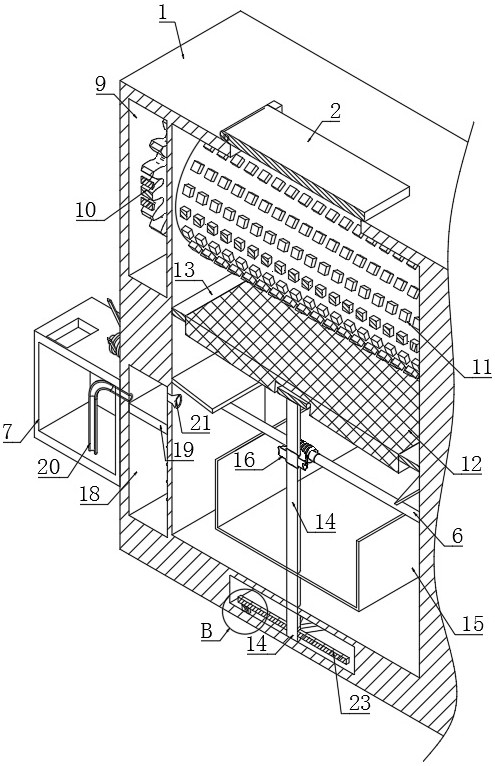

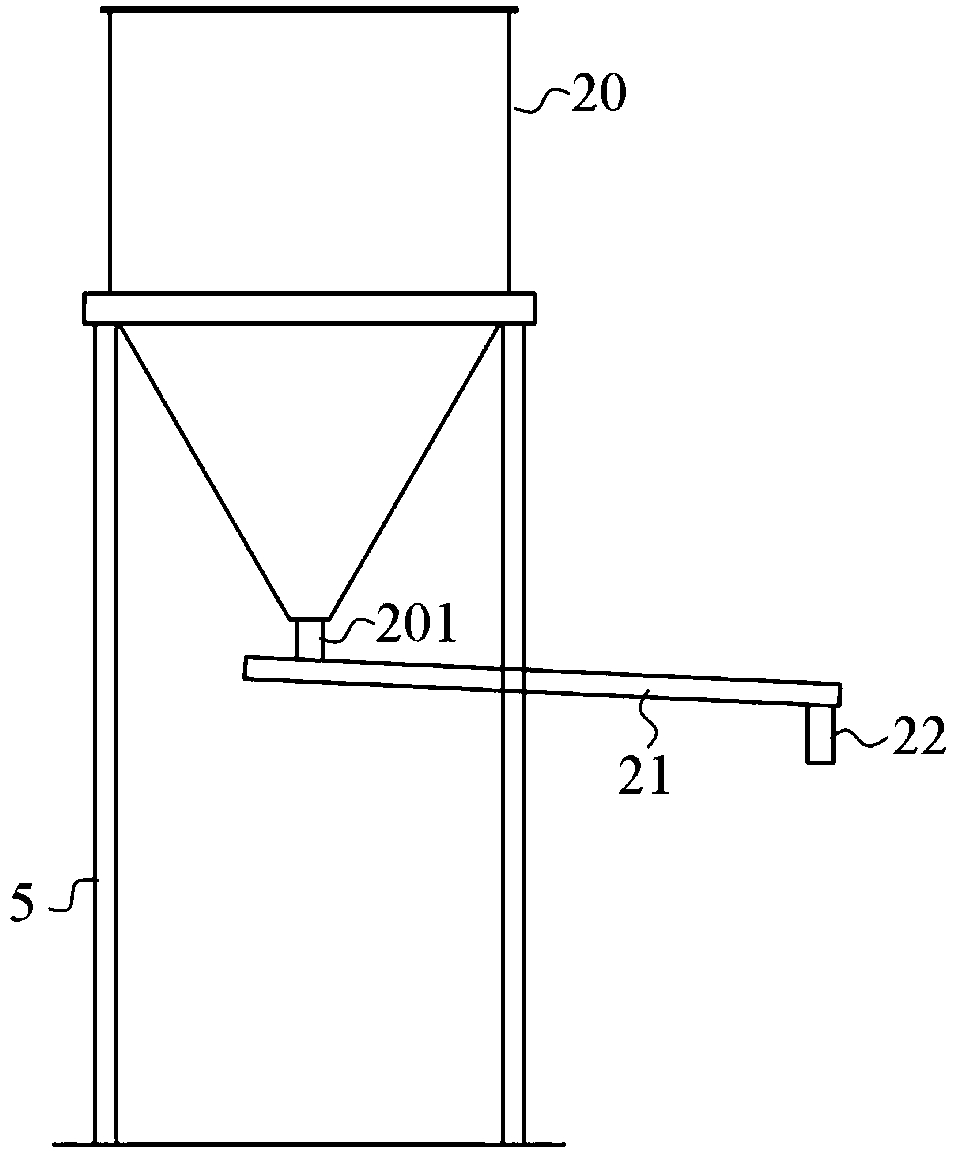

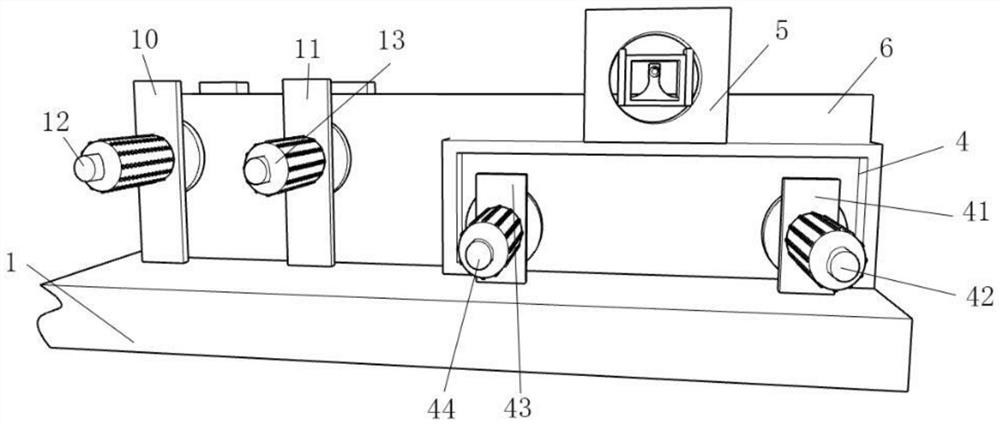

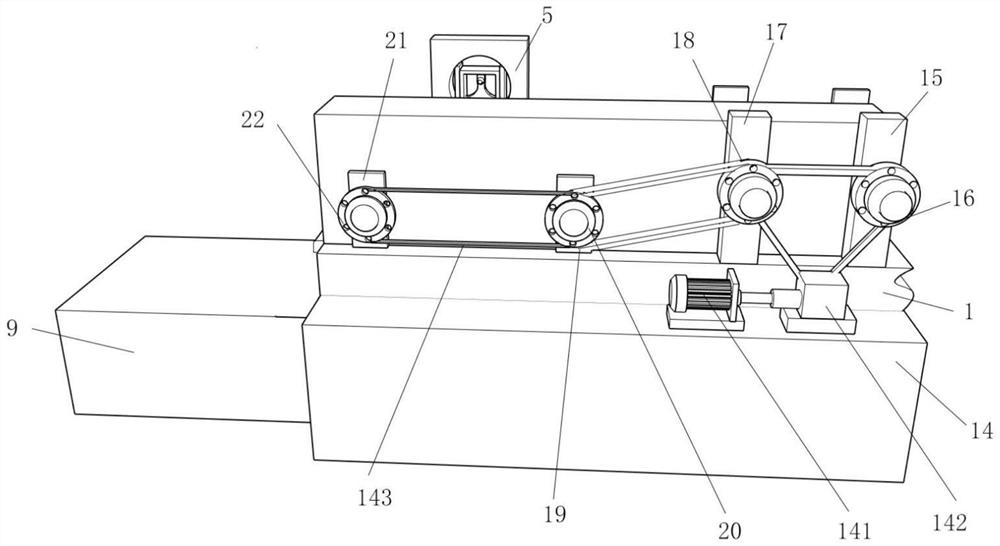

Biomass sawdust fuel burning furnace

InactiveCN103017143AImprove protectionWide variety of sourcesSolid fuel combustionNon-combustible gases/liquids supplyCombustionProcess engineering

The invention relates to a biomass sawdust fuel burning furnace, comprising a chassis frame, an incinerator, a spitfire mechanism, a fuel supply mechanism, a fuel supply box, a power transmission mechanism and an oxygen supply mechanism, wherein the chassis frame is arranged on floor; the incinerator is fixed at one end of the chassis frame, the outer wall of the incinerator constitutes a jacket and is provided with a feeding hole and a combustion-supporting air introduction mechanism, and a cover is arranged on the top of the incinerator in a matching manner; the spitfire mechanism is connected with the upper side part of the incinerator in a matching manner; the fuel supply mechanism is arranged on the other end of the chassis frame, and comprises a pair of guide rails, a moving frame, a screw rod cylinder and an extrusion screw rod; the fuel supply box is arranged on the fuel supply mechanism; the power transmission mechanism is arranged on the other end of the chassis frame; and the oxygen supply mechanism is arranged on the other end of a stand. The biomass sawdust fuel burning furnace disclosed by the invention has the advantages of high combustion efficiency, large heating quantity, low ignition point and high heating property, is friendly to the environment, good for protecting non-renewable natural resources such as petroleum and coal to embody the circular sustainable development of economy, concise in structure and convenient and safe to use; and a combustion effect can be guaranteed by introducing dense biomass sawdust into a hearth.

Owner:杭州华政新能源科技有限公司

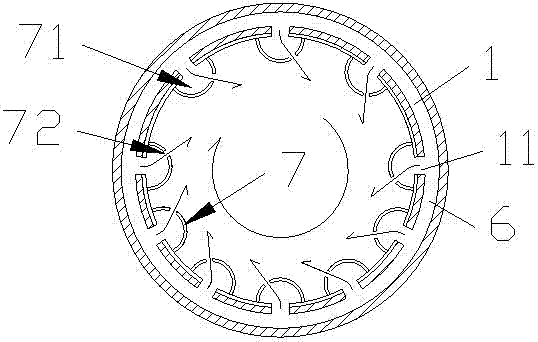

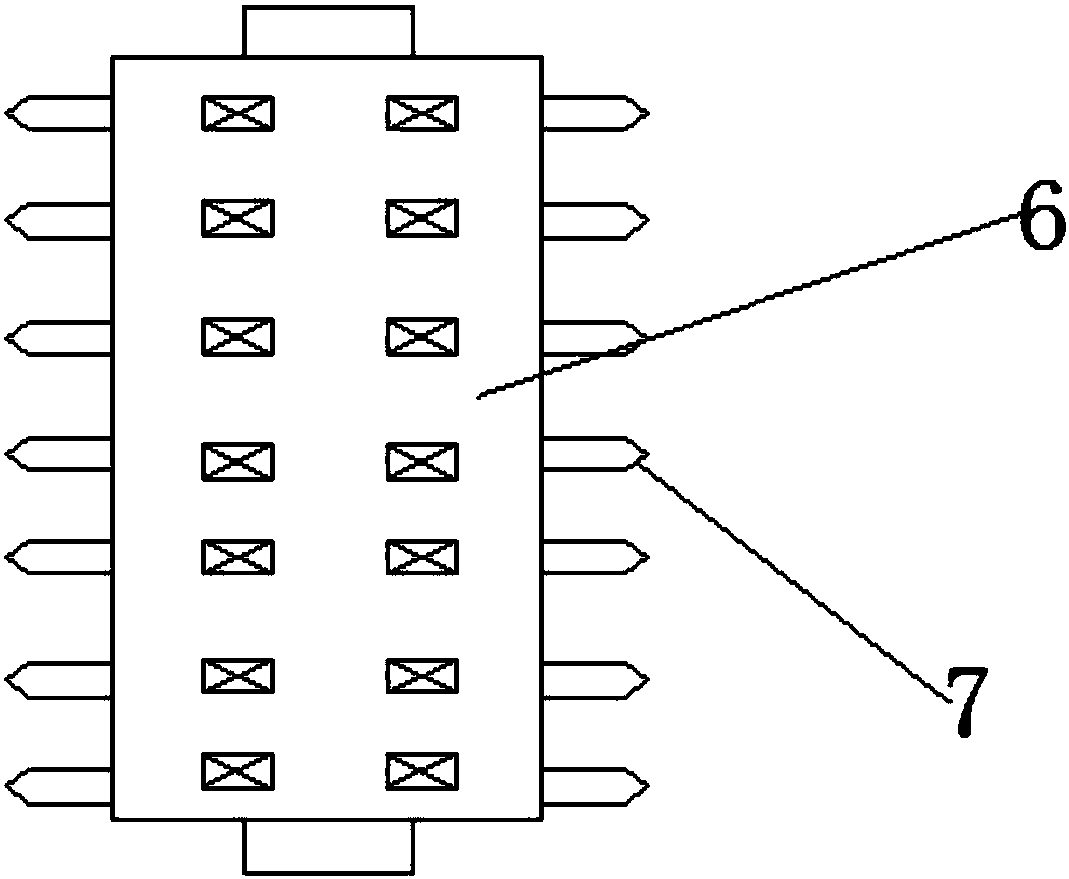

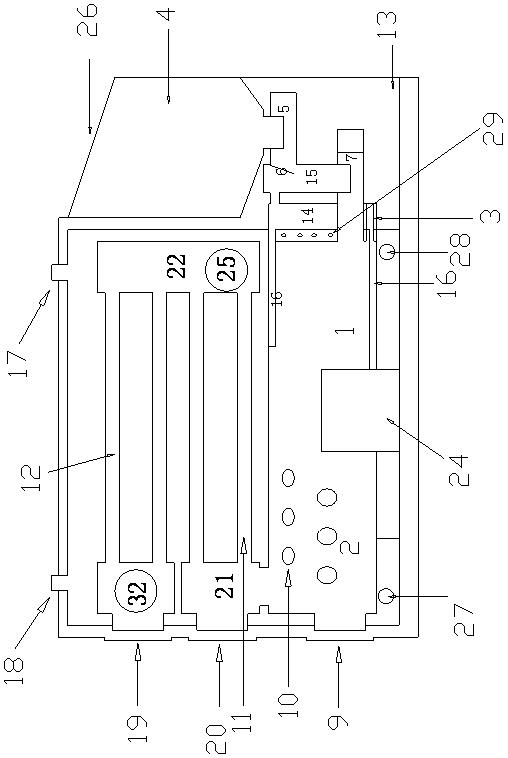

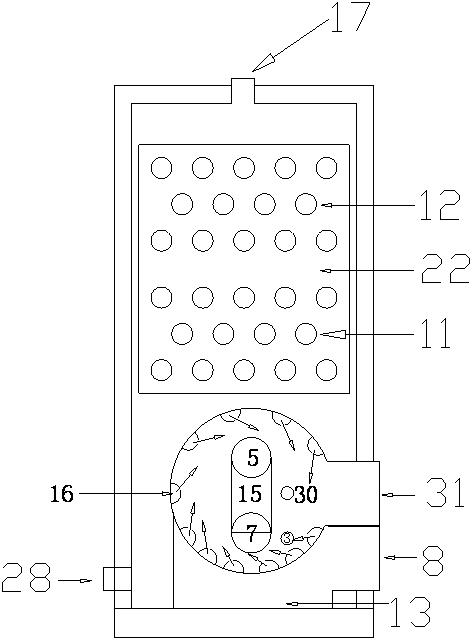

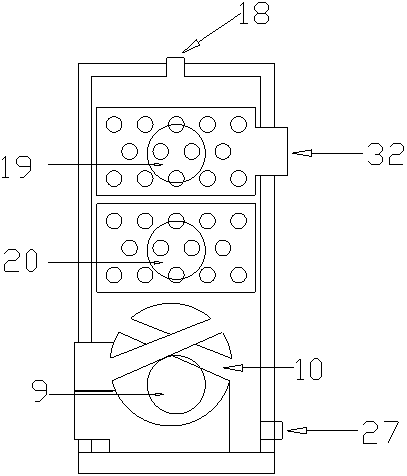

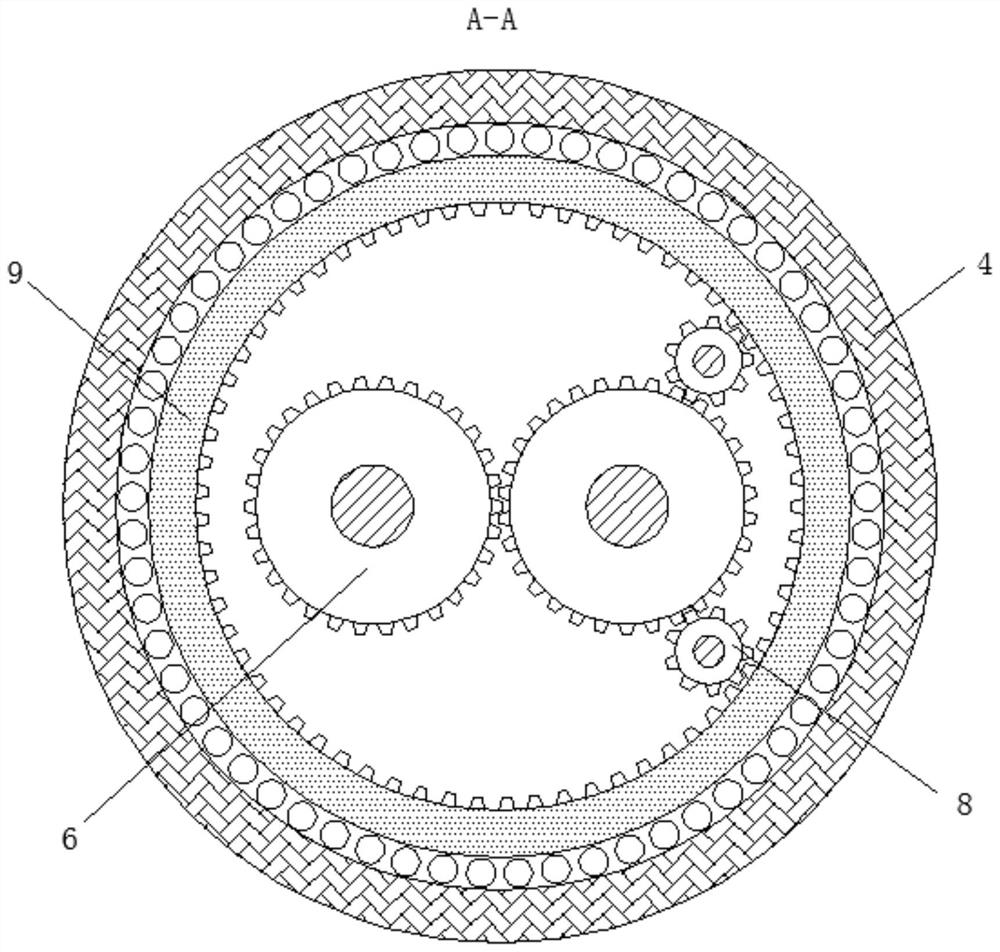

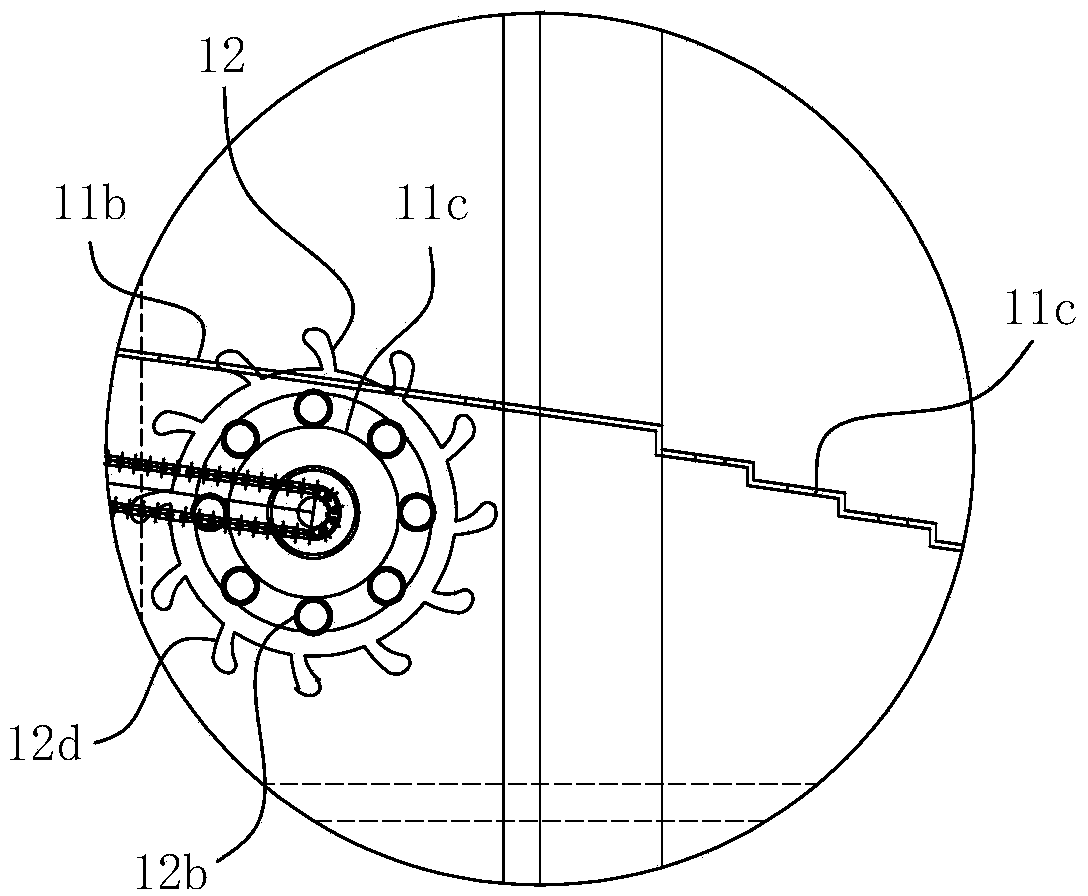

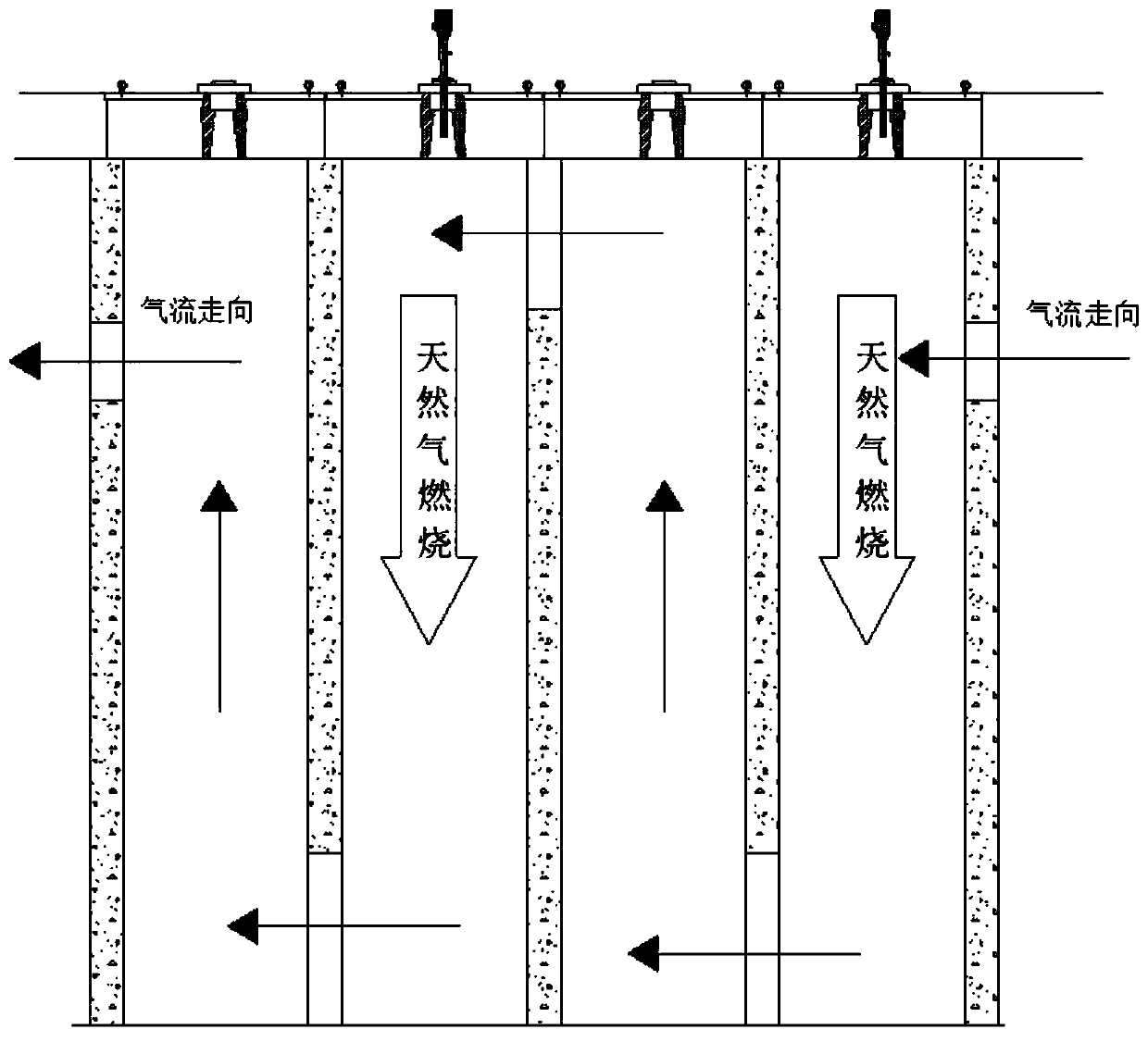

Horizontal type cyclone combustion biomass burning machine

ActiveCN103090364AGuaranteed combustion effectPrevent backfireSolid fuel combustionBlast-producing apparatusAutomotive engineeringAcute angle

The invention provides a horizontal type cyclone combustion biomass burning machine, wherein the horizontal type cyclone combustion biomass burning machine enables fuel to burn sufficiently, prevents the fuel from coking and accumulating and has a long service life. The horizontal type cyclone combustion biomass burning machine comprises a horizontal type cylindrical combustion chamber, wherein one end of the combustion chamber is closed, and the closed end is provided with an outlet of a fuel feeding passageway. A feeding auger is arranged inside the fuel feeding passageway, and a blower nozzle which is used for blowing air to the outlet of the fuel feeding passageway is arranged on the fuel feeding passageway. A wind inlet passageway is formed in the wall of the combustion chamber, a cyclone pipe is arranged on the inner wall of the combustion chamber, and an inner cavity of the cyclone pipe is communicated with the wind inlet passageway. Wind outlets are formed in the cyclone pipe, an acute angle is formed between the axial direction of each wind outlet and the radial direction of the cylindrical combustion chamber, and therefore gas which enters the inner cavity of the cyclone pipe from the wind inlet passageway and comes out from the wind outlets is enabled to form vortexes rotating in the same direction in the cylindrical combustion chamber.

Owner:胡光

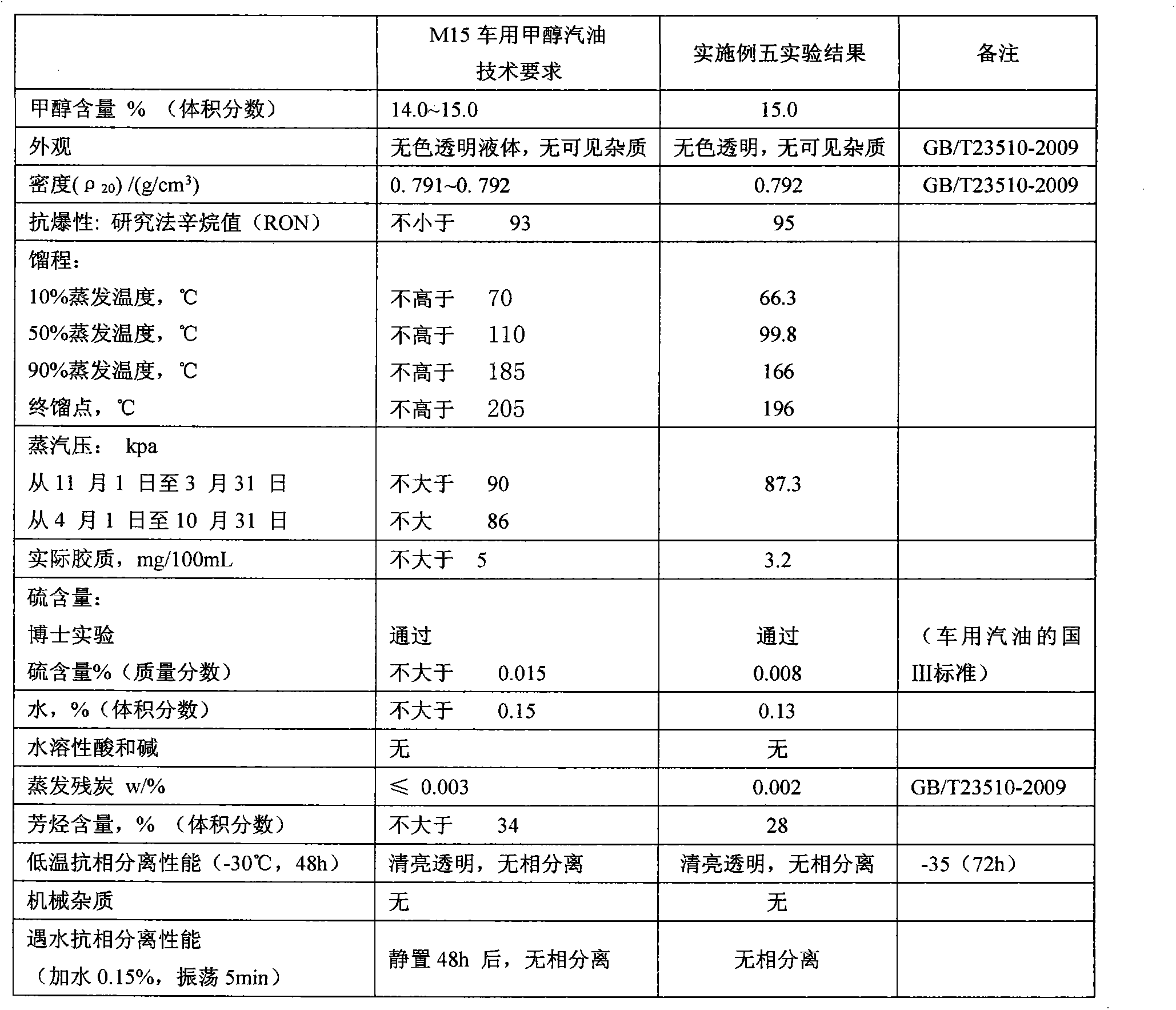

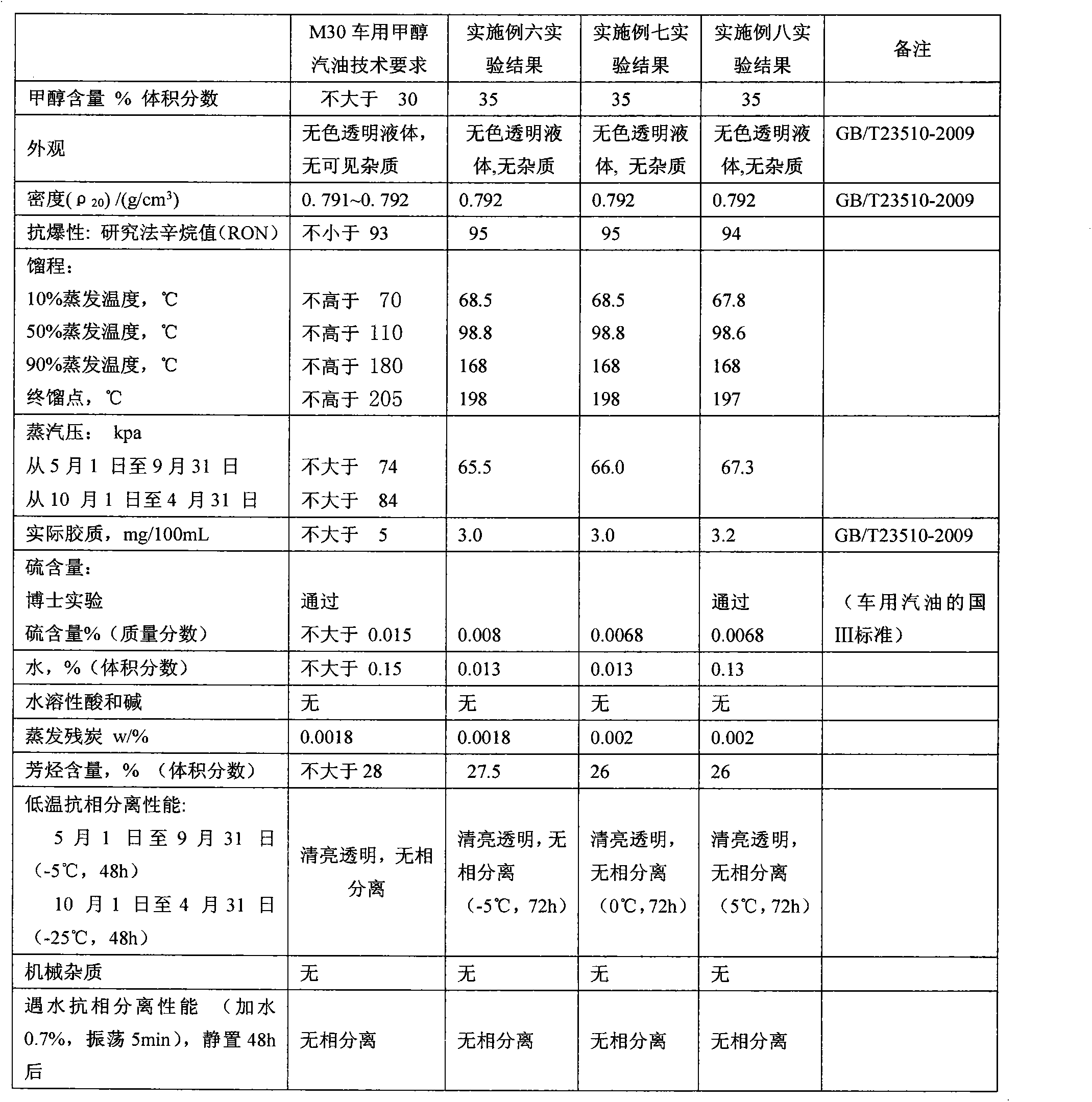

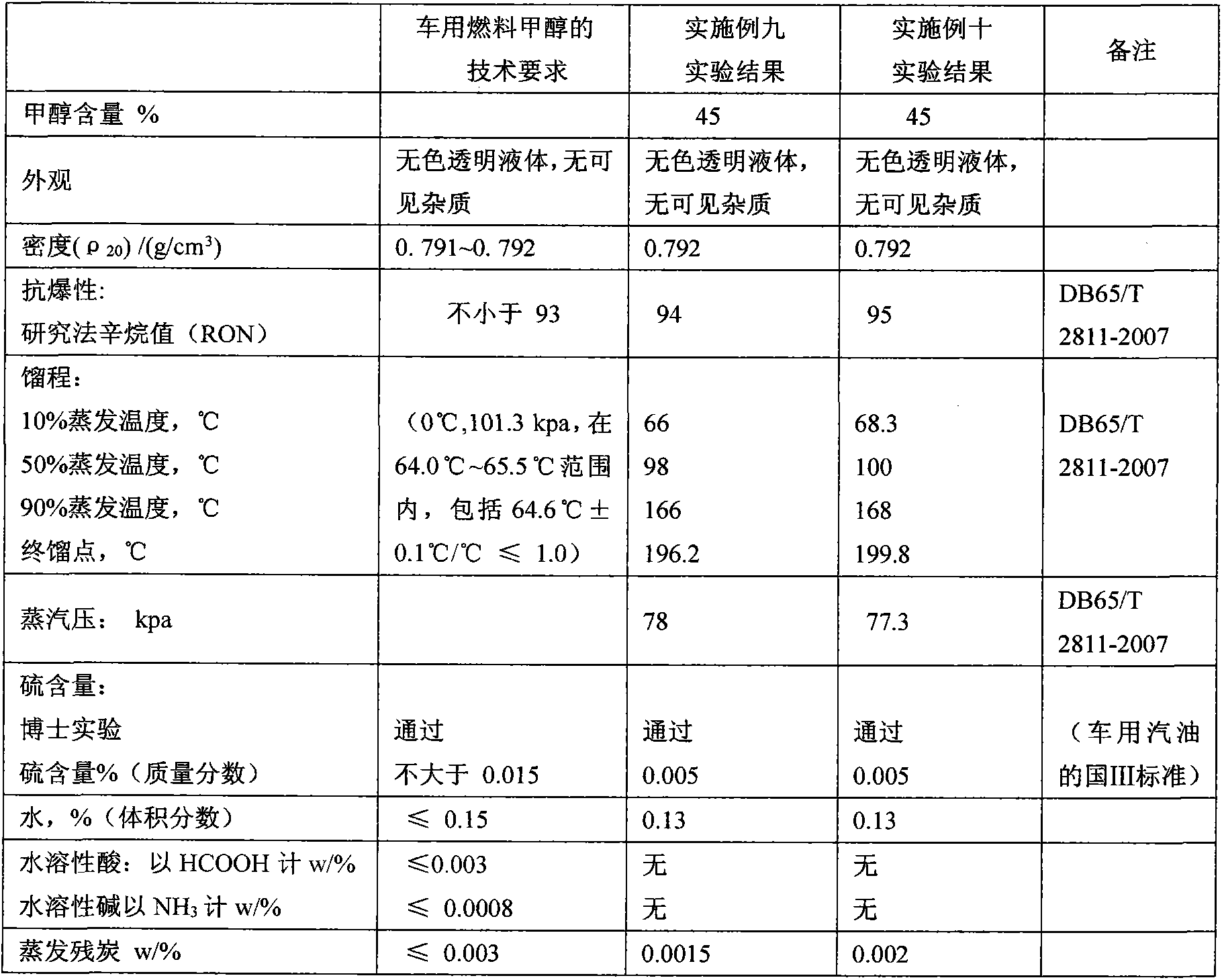

Methanol gasoline additive and methanol gasoline containing same

InactiveCN103710058AGood compatibilityLight colorOther chemical processesAluminium silicatesIsobutanolSolvent

The invention relates to a methanol gasoline additive and a methanol gasoline containing the same. The methanol gasoline additive comprises the following components in parts by mass: 4-32% of toluene, 4-42% of dimethylbenzene, 0.5-10% of C5H12 and C7H16, 3-43% of isobutanol, 4-33% of isopropanol, 0.8-15% of isoamyl alcohol, 1-8% of ethanol, 1-6% of antifreezing agent, 0.2-3% of antioxygen antigum inhibitor, 0.05-0.6% of metal passivator, 0.008-0.06% of detergent dispersant, 1-6% of preservative and 2-8% of emulsifier. The methanol gasoline is prepared by the following steps: uniformly mixing gasoline, naphtha, petroleum ether, 120# solvent oil, light hydrocarbon, methanol fuel and the methanol gasoline additive, and filtering through a modified attapulgite adsorption stabilizer. The methanol gasoline produced from the methanol gasoline additive is especially suitable for high altitude anoxia regions. The methanol gasoline has the advantages of quick cycling start, stable idle speed, low harmful substance emission during combustion, favorable dynamic performance in high altitude anoxia regions, high corrosion resistance, and no stratification at low temperature, and does not generate air resistance.

Owner:兰州市新城炼化厂

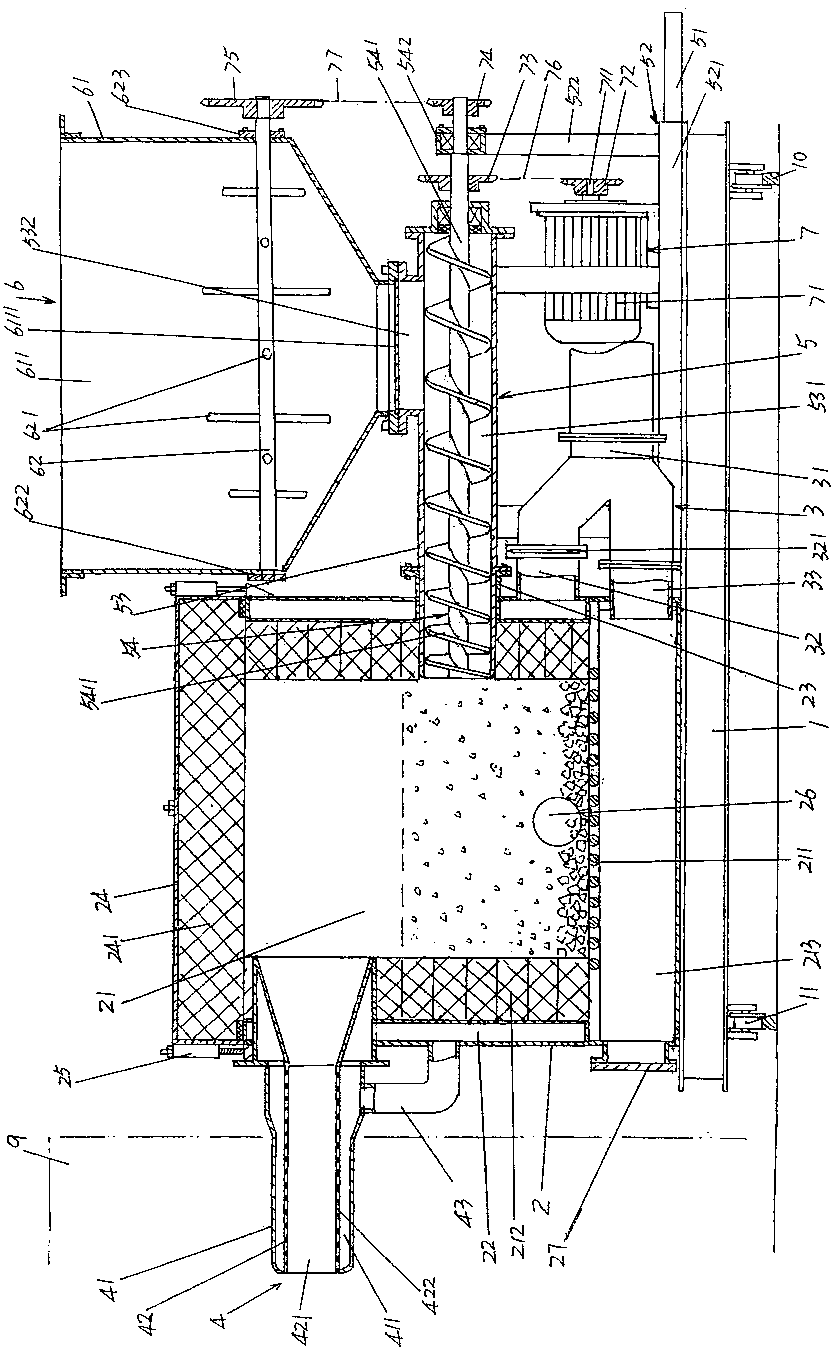

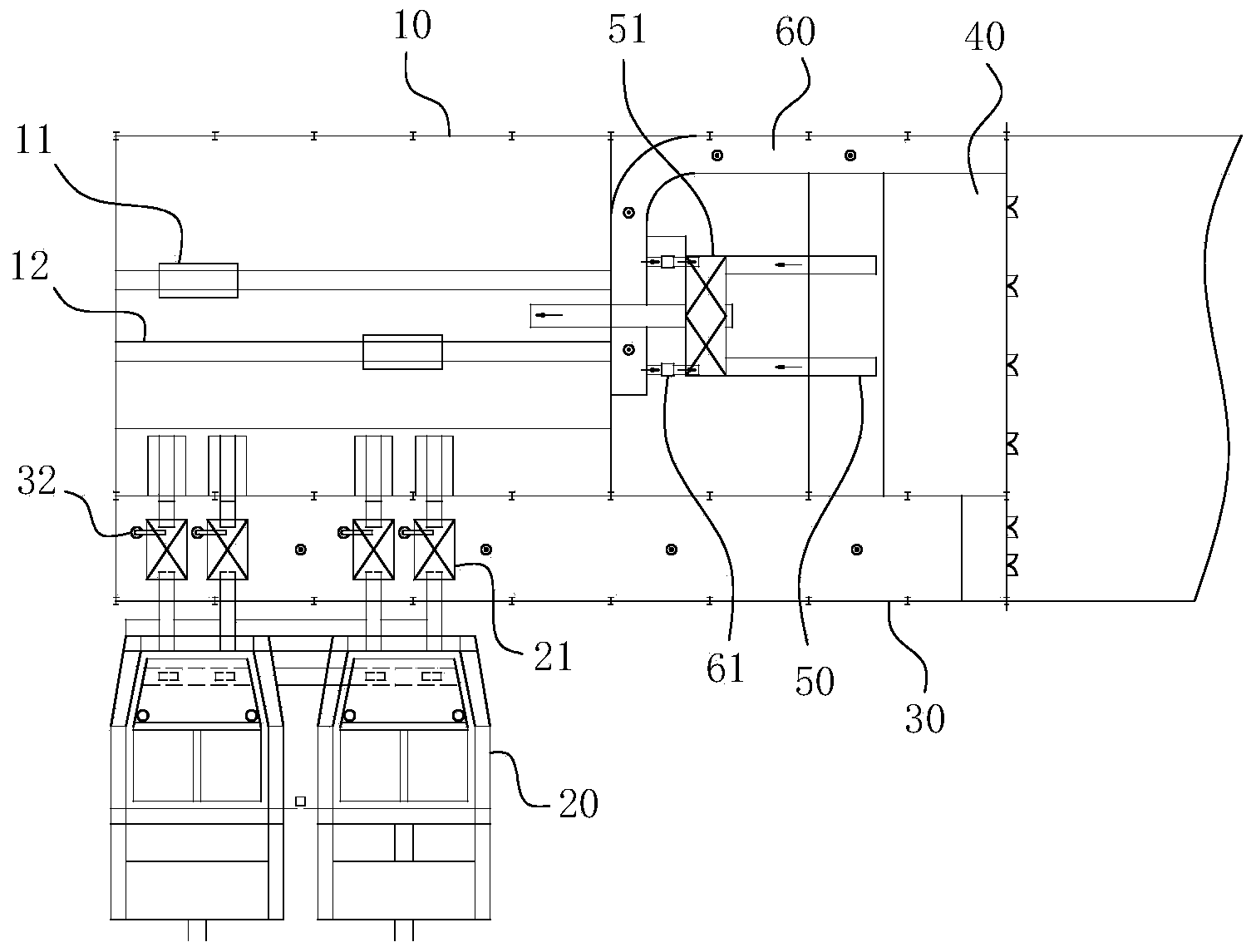

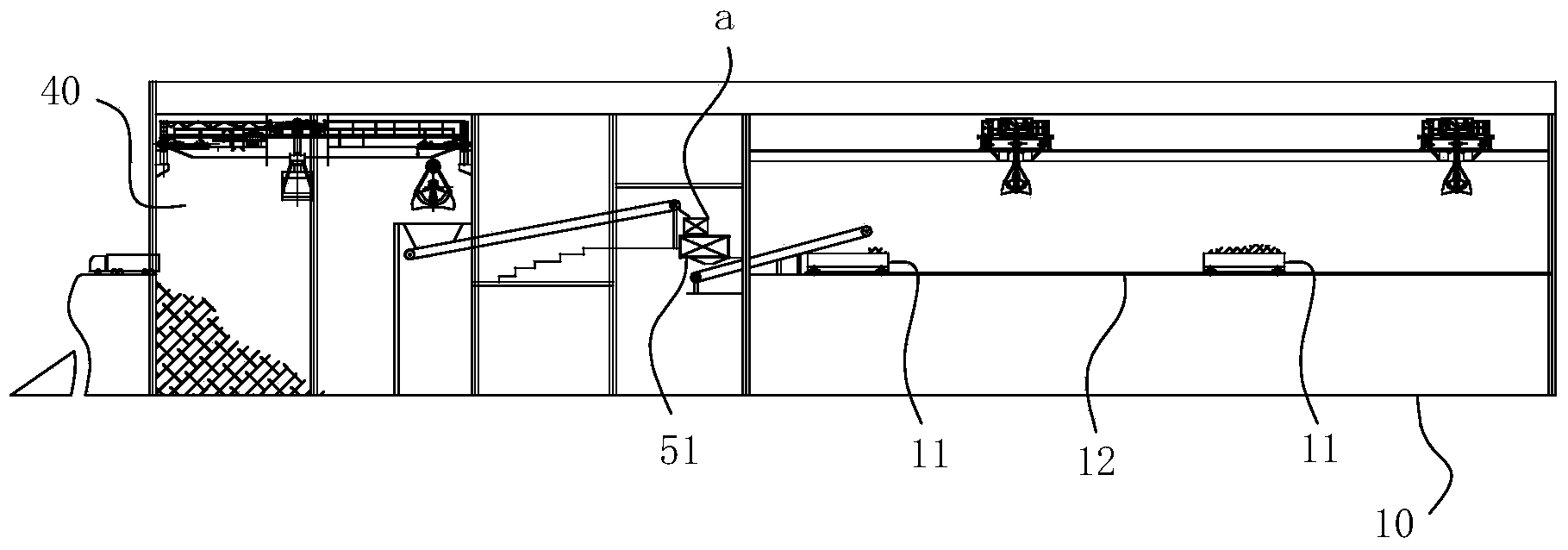

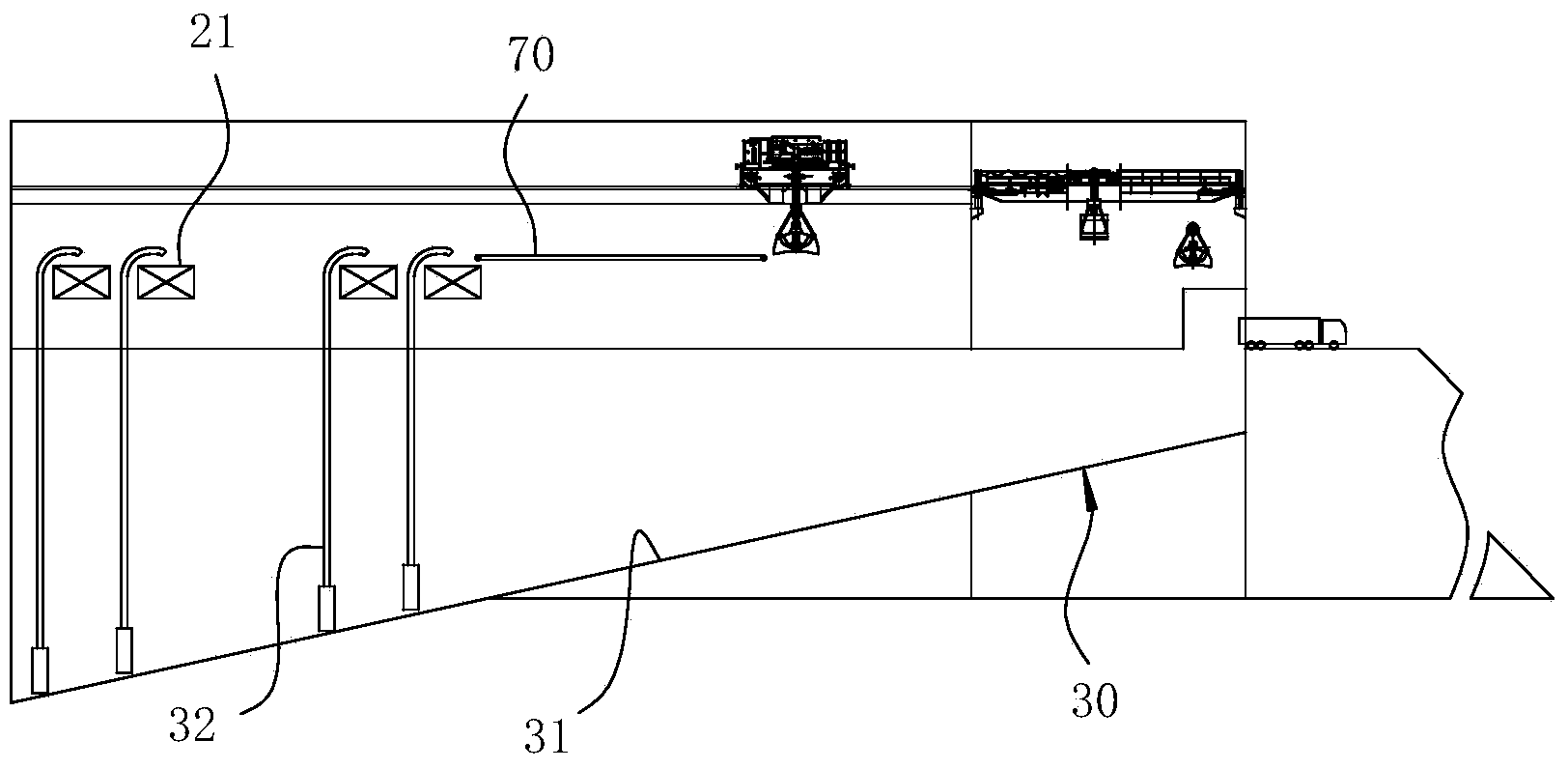

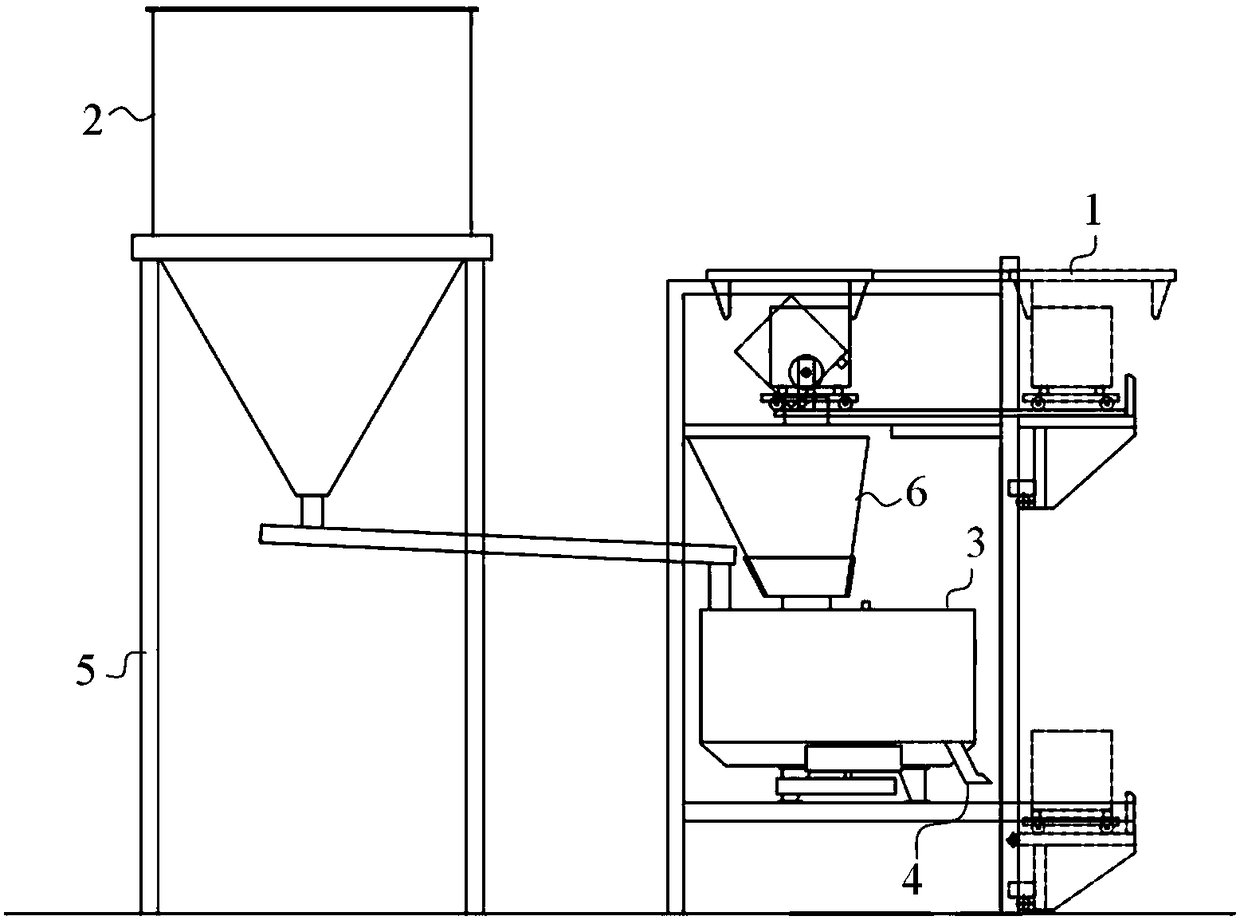

Mixed waste disposal system

InactiveCN103759273AReduce moisture contentHigh calorific valueSolid waste disposalIncinerator apparatusMixed wasteMunicipal solid waste

The invention belongs to the field of municipal solid waste disposal and particularly relates to mixed waste disposal system. The mixed waste disposal system at least comprises a waste pile-up unit used for waste pile-up fermentation and a waste incineration unit used for waste incineration. The mixed waste disposal system further comprises a sludge storage disposal pool, a material sliding ramp used for conveying materials is arranged in the sludge storage disposal pool, and the material sliding ramp is in the shape of an inclined face or a step-shaped structure becoming lower gradually. A sludge feeding end is arranged at the higher end of the material sliding ramp, and the lower end of the material sliding ramp forms a sludge discharging end. The time for sludge to flow from the sludge feeding end to the sludge discharging end along the material sliding ramp is longer than or equal to the number of days for the sludge to undergo set pile-up and warm-up fermentation and aerobic reaction. Both the waste pile-up unit and the discharging end of the sludge storage disposal pool are communicated with the feeding end of the waste incineration unit. Due to the simple and practical structure, mixed incineration disposal effect on municipal sludge and household waste can be achieved efficiently.

Owner:南京溧水石湫机场科技工业园开发有限公司

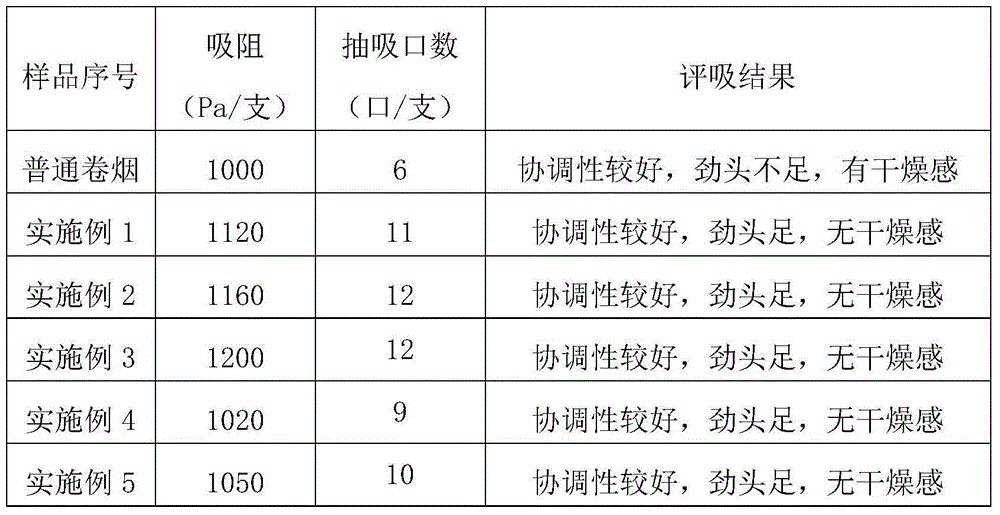

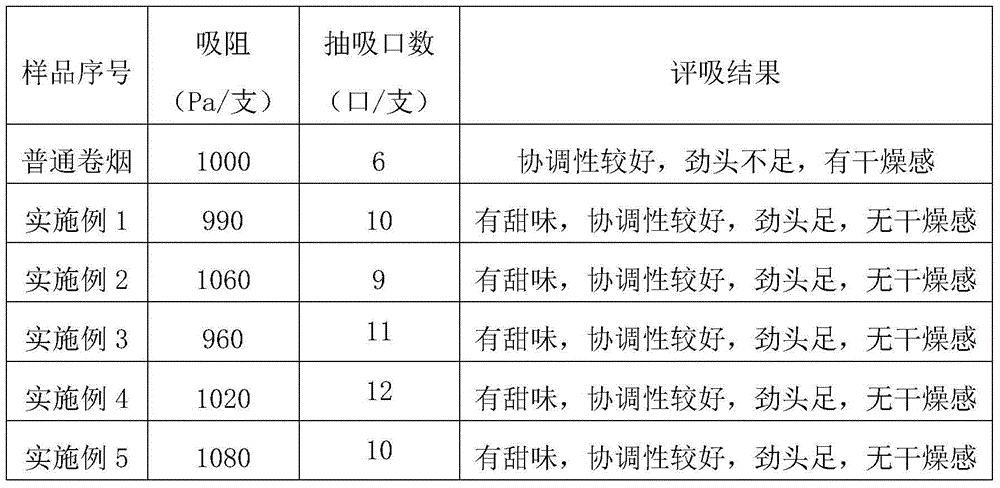

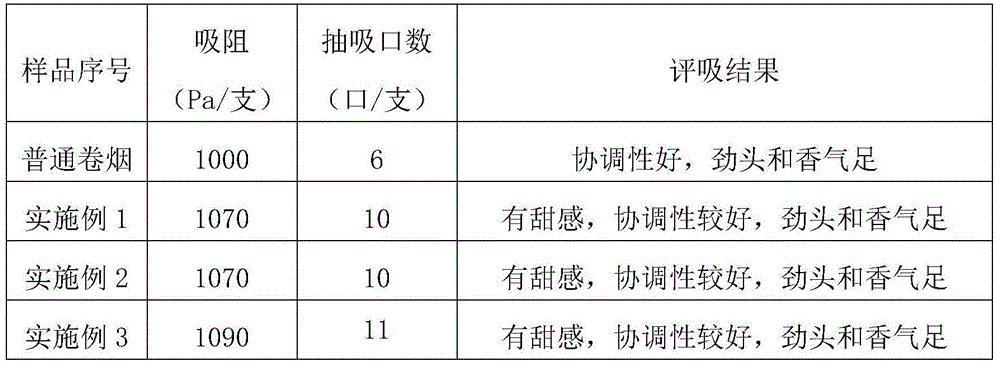

Method for preparing cigarette from tobacco beads

The invention discloses a method for preparing a cigarette from tobacco beads. The method for preparing the cigarette from the tobacco beads comprises the steps that firstly, cigarette tobacco is smashed into fine powder; secondly, adhesives are added, so that a soft material is prepared, and the cigarette beads are prepared through an extruding-rounding method; thirdly, the cigarette beads are rolled into a cigarette bar; finally, the cigarette bar is wrapped by cigarette paper, a filter tip is connected to the cigarette bar, and the cigarette is prepared according to a conventional method. The prepared cigarette is novel in form and capable of bringing brand-new experience to customers; the formula of the cigarette is even, and the stability of cigarette smoking quality is guaranteed; meanwhile, the combustion time of the cigarette is prolonged, and number of puffs is increased; the sense of satisfaction of the customer is stronger.

Owner:HUBEI CHINA TOBACCO IND +1

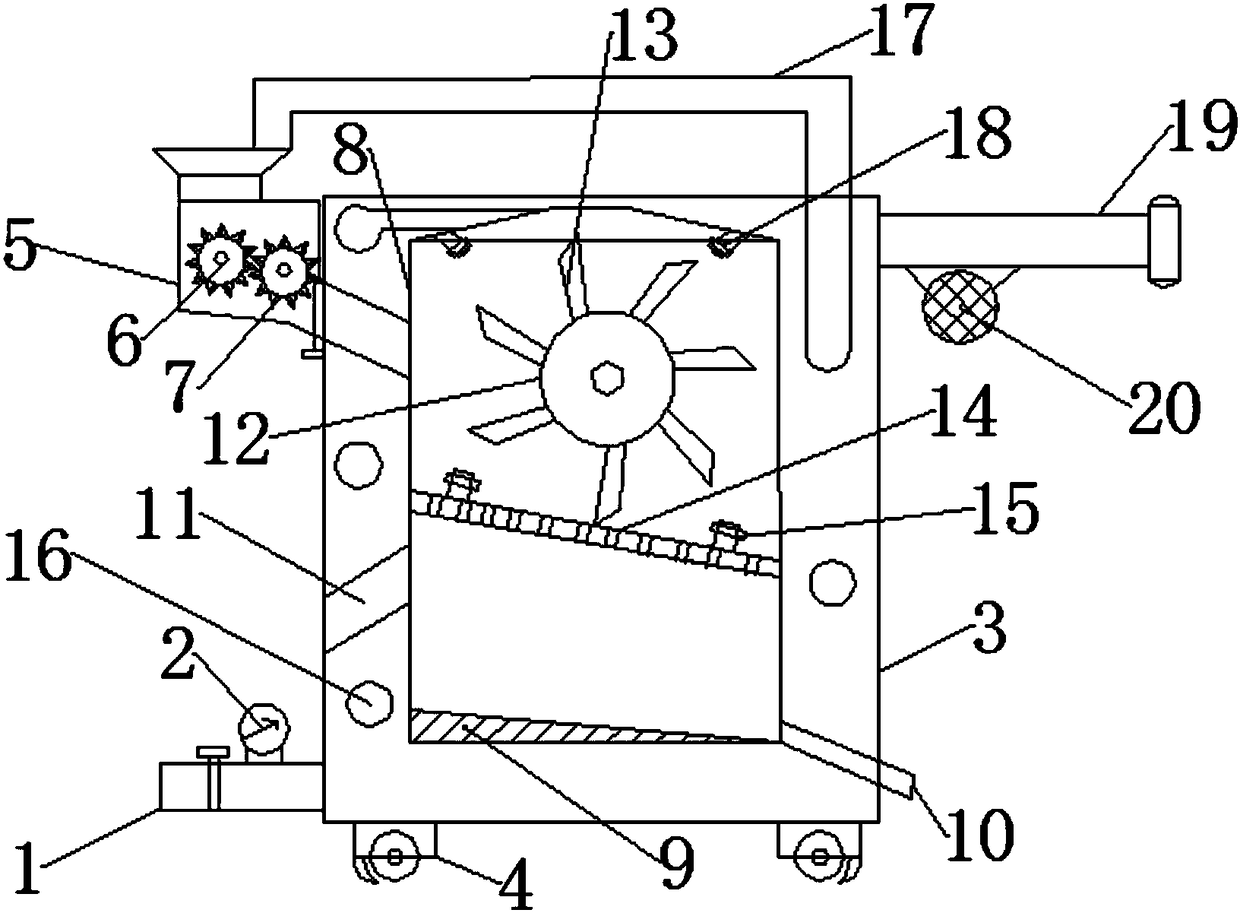

Efficient and energy-saving garbage fuel stirring water heater

InactiveCN108332209AEfficient use ofAvoid wastingWater heatersIncinerator apparatusCombustionHeat losses

The invention discloses an efficient and energy-saving garbage fuel stirring water heater. The efficient and energy-saving garbage fuel stirring water heater comprises a water inlet pipe, a shell, a pulverizer, a rotary barrel, smashing cutters, a combustion furnace, an air inlet pipe, a stirring roll, stirring blades, a combustion plate, a heat exchange pipe, an air outlet pipe and a water outletpipe. The combustion furnace is arranged in the shell, and the combustion plate is obliquely arranged in the combustion furnace. A plurality of electronic igniters are arranged on the upper surface of the combustion plate, and the air inlet pipe is arranged between the side wall of the shell and the combustion furnace. The stirring roll is arranged in the combustion furnace, and the stirring blades are evenly arranged on the stirring roll, and the rotary barrel is arranged in the pulverizer. The smashing cutters are evenly arranged on the outer wall of the rotary barrel, and a secondary igniter is arranged at the top end of the combustion furnace. The top end of the combustion furnace is connected with one end of the heat exchange pipe, the other end of the heat exchange pipe communicateswith the air outlet pipe, and the outlet end of the air outlet pipe is provided with an air spraying head. According to the efficient and energy-saving garbage fuel stirring water heater, the heatingeffect is improved, energy waste is avoided, and energy is greatly saved; heat losses are reduced, and the utilization rate of energy is increased; and the structure is simple, use is convenient, energy is saved, and the efficient and energy-saving garbage fuel stirring water heater is beneficial to popularization.

Owner:田迎华

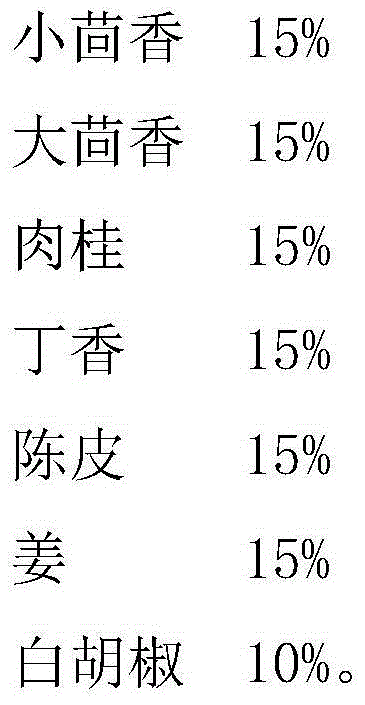

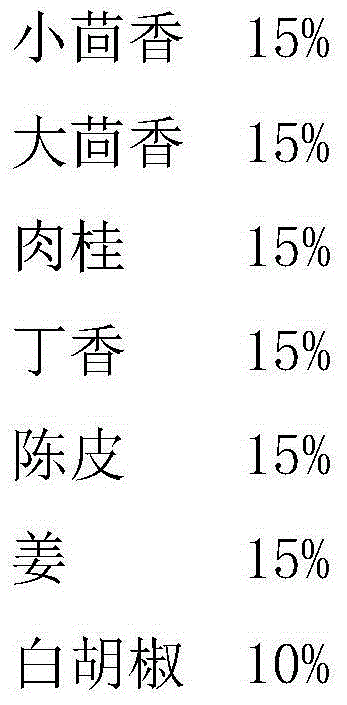

Method for preparing spicy cigarette from cigarette beads

ActiveCN104921292ANoveltyUniform cigarette formulaCigarette manufactureEssential-oils/perfumesFlavorSmoke paper

The invention discloses a method for preparing a spicy cigarette from cigarette beads. The method comprises the following steps: firstly, crushing cigarette tobacco leaves and spicy plant perfume materials into fine powder; secondly, adding an adhesive to prepare a soft material, and processing to form the cigarette beads by using an extrusion-rolling method; thirdly, pressing the cigarette beads into a cigarette stick; finally, coating the cigarette stick with cigarette paper, and connecting a filter tip to the cigarette stick to prepare the cigarette according to a conventional method. The prepared cigarette is in a novel form and can bring a brand new experience to a consumer, a cigarette prescription is uniform, and the stability of the smoking quality of the cigarette is guaranteed; meanwhile, the combustion time of the cigarette is also prolonged, the number of smoking times is increased, and the consumer feels more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

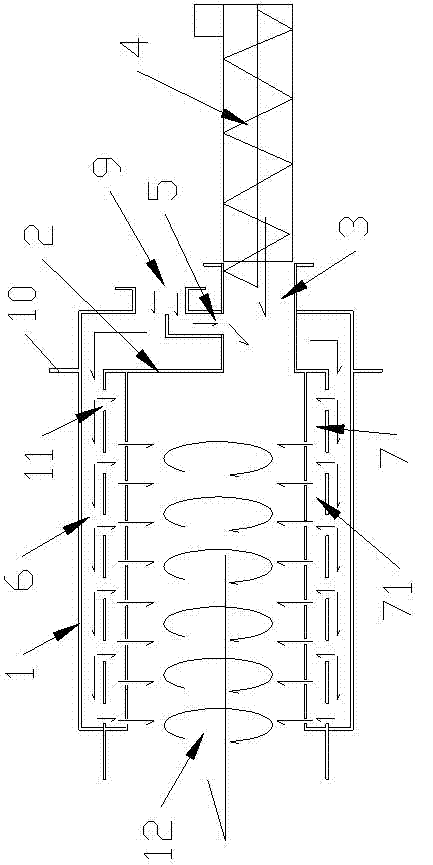

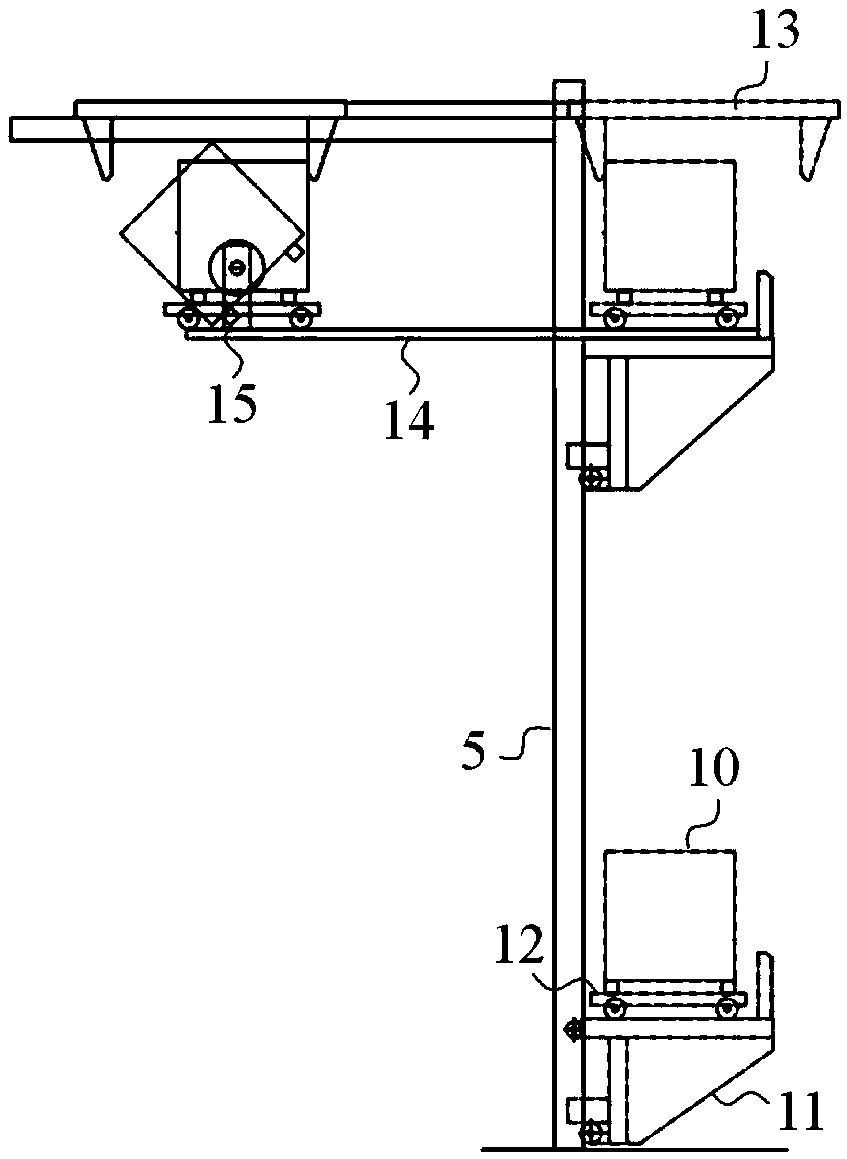

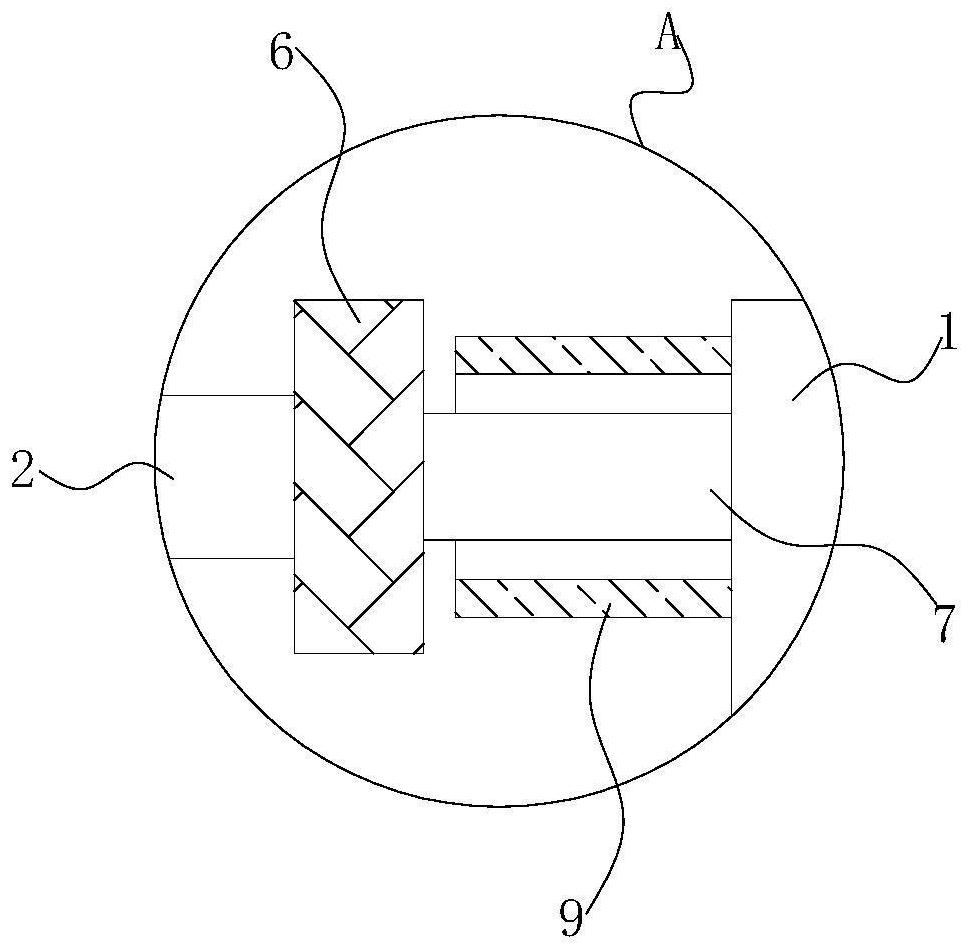

Biomass horizontal type cyclone burning boiler

ActiveCN103307593AGuaranteed combustion effectBest burning stateSolid fuel combustionCombustion technology mitigationCycloneCombustion chamber

The technology provides a biomass horizontal type cyclone burning boiler, which can allow fuels to burn sufficiently, prevent the fuels from coking and stack, and is convenient and comfortable to use and maintain. The boiler comprises horizontal type cyclone air pipes and a horizontal type combustor, wherein a plurality of the semi-cylindrical cyclone air pipes are evenly arranged on the inner wall at the back end of the combustor; front ends, positioned inside the combustor, of the cyclone air pipes are sealed, and the back ends of the cyclone air pipes are communicated with an airing and air distributing chamber; the front end of the combustor is communicated with a heat transfer smoke pipe, and the back end of the combustor is separated by a combustor back plate and the airing and air distributing chamber; a slag box is arranged at the lower part of connecting parts of the front ends of the cyclone air pipes and the combustor; a heat transferring medium chamber is arranged on the periphery of the combustor and the heat exchange smoke pipe; a first feeding packing auger is arranged in a first fuel feeding channel; a blower nozzle is arranged on the first fuel feeding channel; air outlets are formed in pipe walls of the cyclone air pipes, axial directions of the air outlets and the radial direction of the combustor form acute angles to allow airs entering into the combustor from the air outlets to form an eddy rotating in a same direction; and the airing and air distributing chamber is communicated with an outlet of the combustor.

Owner:胡光

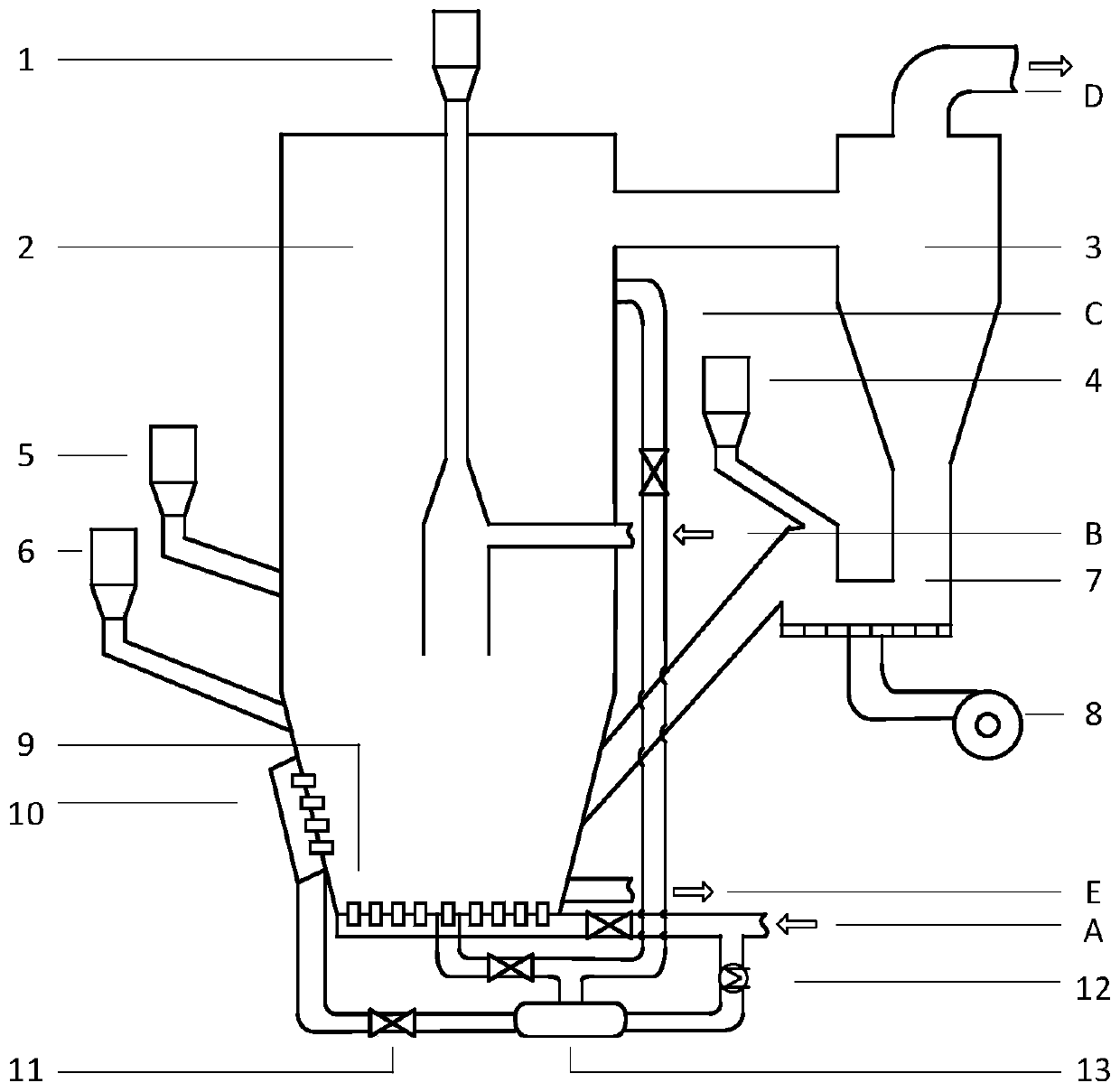

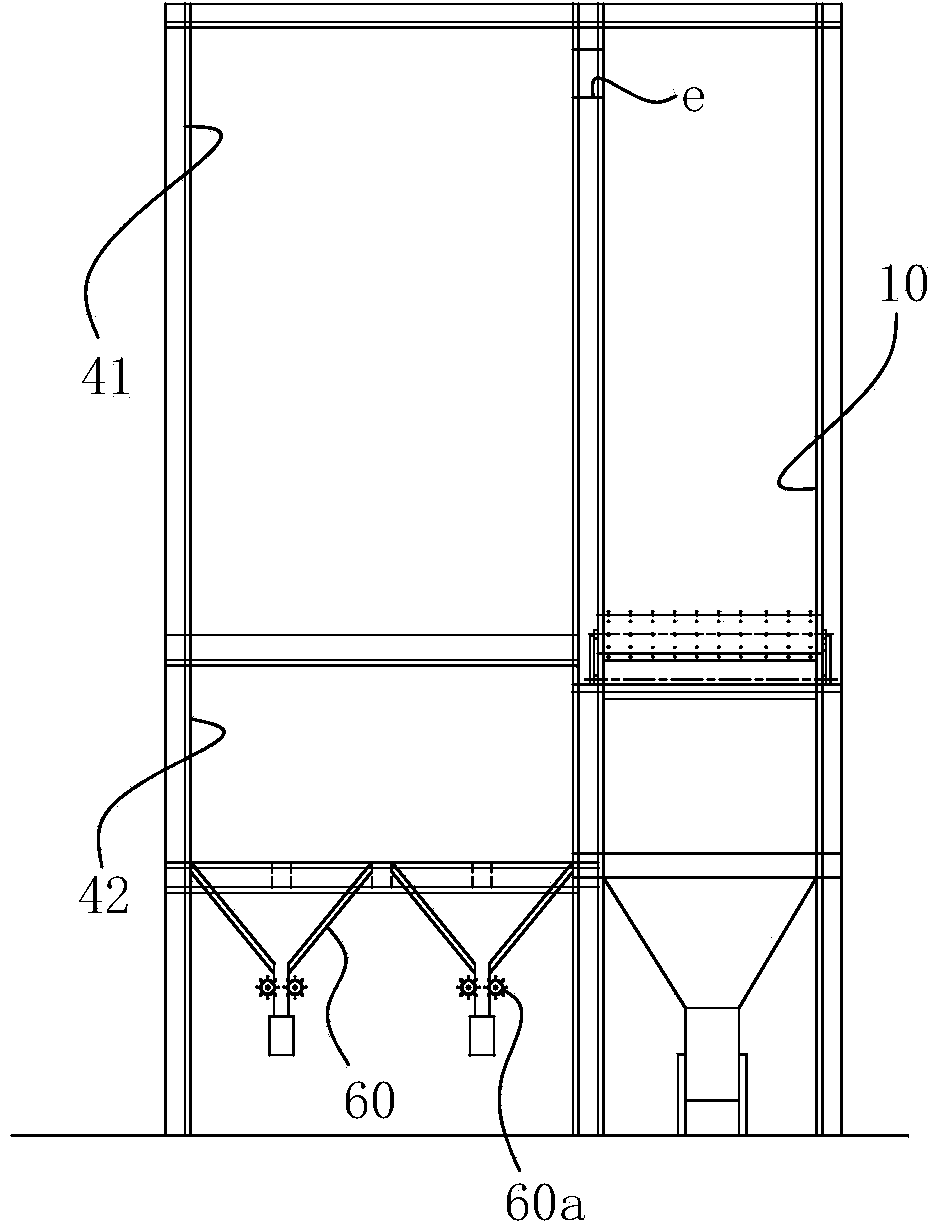

Combustion recycling system for gasified fly ash of fluidized bed

ActiveCN110260302AIncrease disturbanceExtended stayFluidized bed combustionIndirect carbon-dioxide mitigationCombustionFluidized bed

The invention discloses a combustion recycling system for gasified fly ash of a fluidized bed. The combustion recycling system for the gasified fly ash of the fluidized bed comprises a first fuel bin, a cyclone separator, a limestone bin and an air film separator, wherein the first fuel bin is arranged on the upper portion of a furnace hearth, and conveys fuel through a gradual enlargement pipeline to a boundary position of a furnace hearth dense phase zone and a furnace hearth lean phase zone, an inlet of the cyclone separator is connected with an outlet of the furnace hearth, an outlet of the cyclone separator is connected with an inlet of an ash bucket, an outlet of a gasified fly ash bin is connected with the ash bucket, an air blower is connected with the ash bucket, an outlet of the ash bucket is connected with the downside dense phase of the furnace hearth, the limestone bin is connected with the middle of the furnace hearth, a second fuel bin is connected with the downside dense phase zone of the furnace hearth, a downside wind distribution plate is arranged on an inclined plane on the bottom side of the furnace hearth, a bottom wind distribution plate is arranged at the bottom of the furnace hearth, the air film separator is arranged on the lower side of the exterior of the furnace hearth, an inlet of the air film separator is connected with an outlet of an air compressor, and an outlet of the air film separator is respectively connected with an over fire air pipeline, the bottom wind distribution plate and the downside wind distribution plate. The combustion recycling system for the gasified fly ash of the fluidized bed can achieve efficient consumption of the gasified fly ash in a circulating fluidized bed boiler, and reduces fuel consumption and NOx discharge amount of the circulating fluidized bed boiler on the premise of effectively using the gasified fly ash.

Owner:XI AN JIAOTONG UNIV

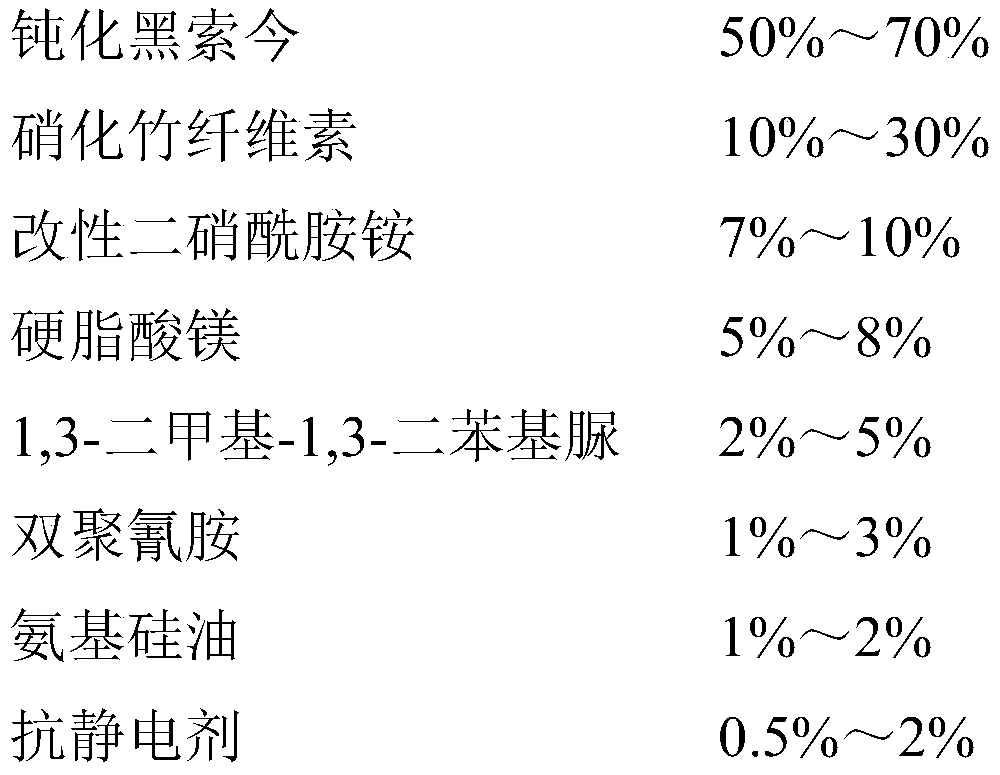

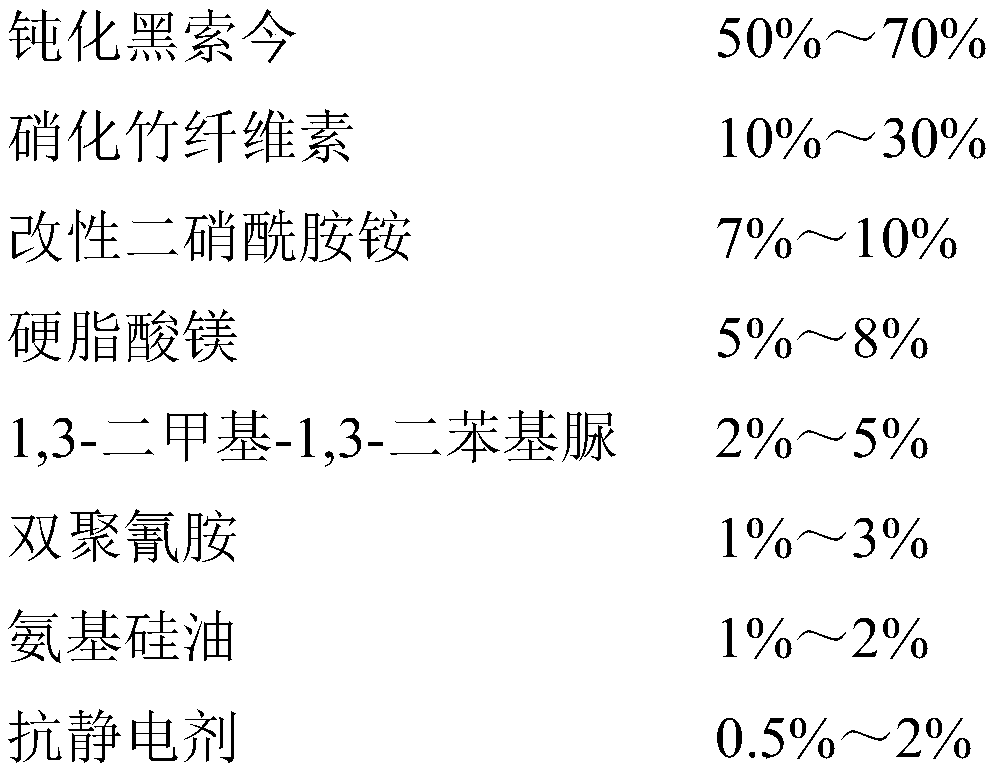

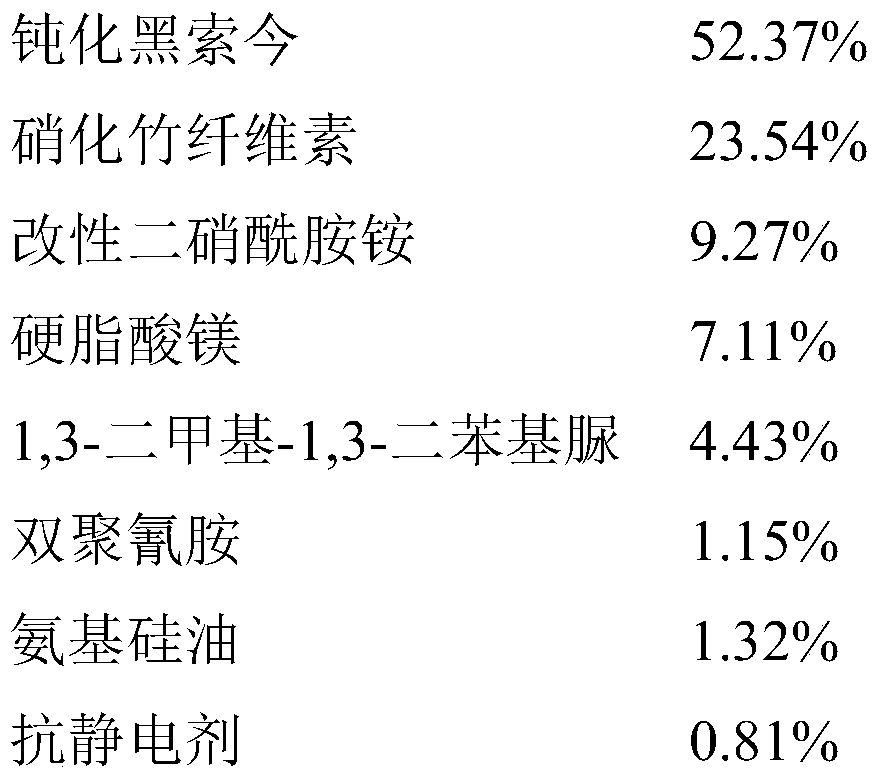

Antistatic smokeless sulfur-free firecracker nitrate agent and preparation method thereof

PendingCN110981657ASufficient oxygenGuaranteed combustion effectExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsCelluloseNitration

The invention relates to an antistatic smokeless sulfur-free firecracker nitrate agent and a preparation method thereof, belonging to the field of environment-friendly pyrotechnic compositions. The firecracker nitrate agent comprises, desensitized hexogen, nitrified bamboo cellulose, modified ammonium dinitramide, magnesium stearate, 1,3-dimethyl-1,3-diphenyl urea, dicyandiamide, amino silicon oiland an antistatic agent. According to the invention, desensitized hexogen is used as a main component, and modified ammonium dinitramide is used as an oxidant, so an oxygen content is sufficient, andcombustion effect is ensured; the nitrified bamboo cellulose, 1,3-dimethyl-1,3-diphenyl urea, magnesium stearate and dicyandiamide are adopted, and the antistatic agent and amino silicone oil are added, so the mechanical properties, stability and antistatic capacity of the firecracker nitrate agent can be remarkably improved, and the safety and reliability of the firecracker nitrate agent in theprocesses of production, storage and use are guaranteed; meanwhile, the firecracker nitrate agent does not contain a sulfur element or any metal powder, so the preparation of the smokeless sulfur-freefirecracker nitrate agent can be truly realized.

Owner:江西吉润花炮新材料科技有限公司

Method for detecting quality characteristics of fired coal raw material

InactiveCN108801841AIncrease costEasy to operateWeighing by removing componentMaterial heat developmentEngineeringOxygen

The invention relates to a method for detecting quality characteristics of fired coal raw material. The method comprises the following steps of 1, using a coal stack as a sampling unit, and obtaininga coal sample with granularity smaller than 13mm; 2, putting the coal sample with granularity smaller than 13mm into an air drying box with temperature not higher than 40 DEG C to dry, and measuring the external moisture; crushing the coal sample until the granularity is smaller than 3mm, putting into the air drying box with temperature of 105 to 110 DEG C to dry, and measuring the internal moisture, so as to obtain the total moisture of the fired coal; 3, crushing the coal sample until the granularity is smaller than 0.15mm, drying for 0.5h in an oven with temperature of 50 DEG C, putting into the drying box with temperature of 105 to 110 DEG C to dry, and measuring the air dry base moisture; 4, putting the coal sample with granularity smaller than 13mm into an oxygen bomb with pressure of 2.8 to 3 MPa, measuring by a constant-temperature type oxygen bomb calorimeter, and measuring the air dry base low-grade heat value; 5, according to the total moisture of the fired coal, the air drybase moisture and the air dry base low-grade heat, judging whether the quality requirement standard of the coal is met or not. The method has the advantage that the actual moisture content and minimum heat value of the fired coal can be precisely measured, so as to more comprehensively and accurately judge the quality of the fired coal.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +1

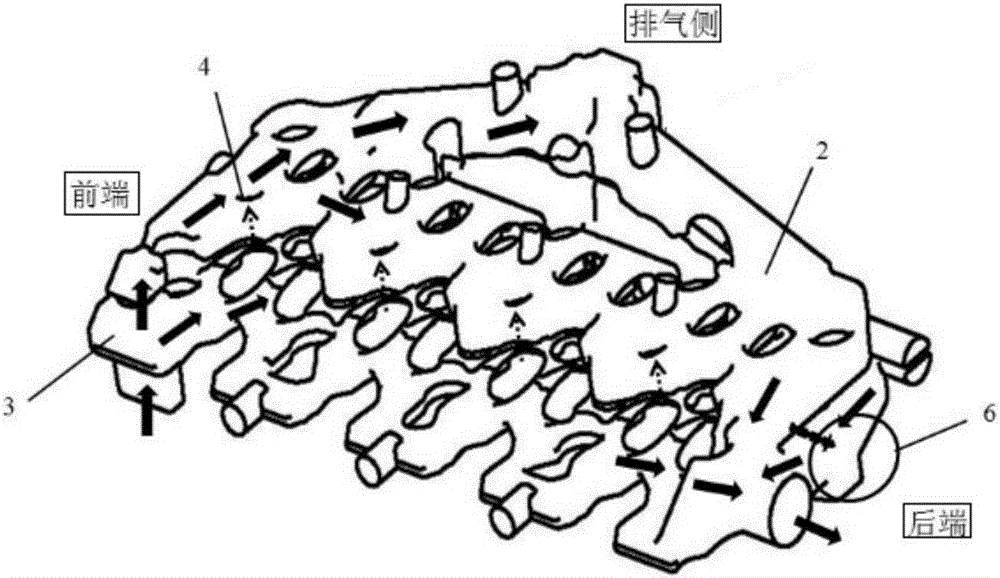

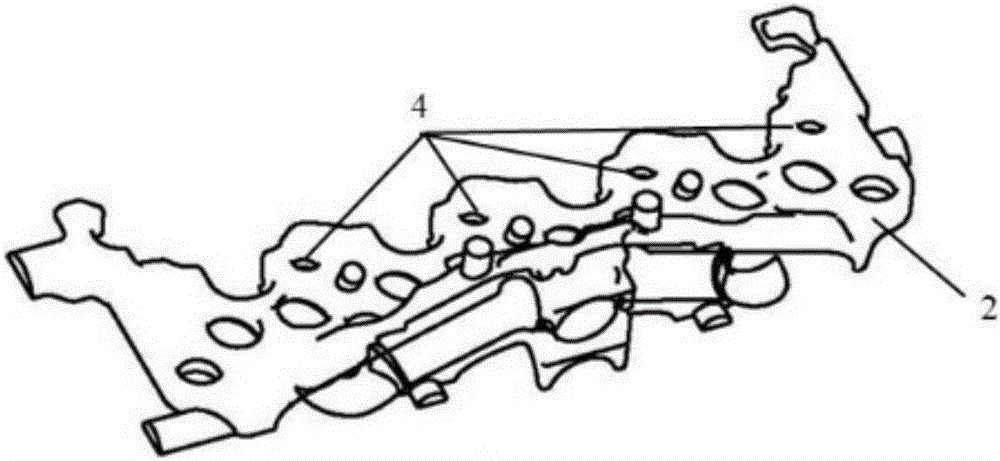

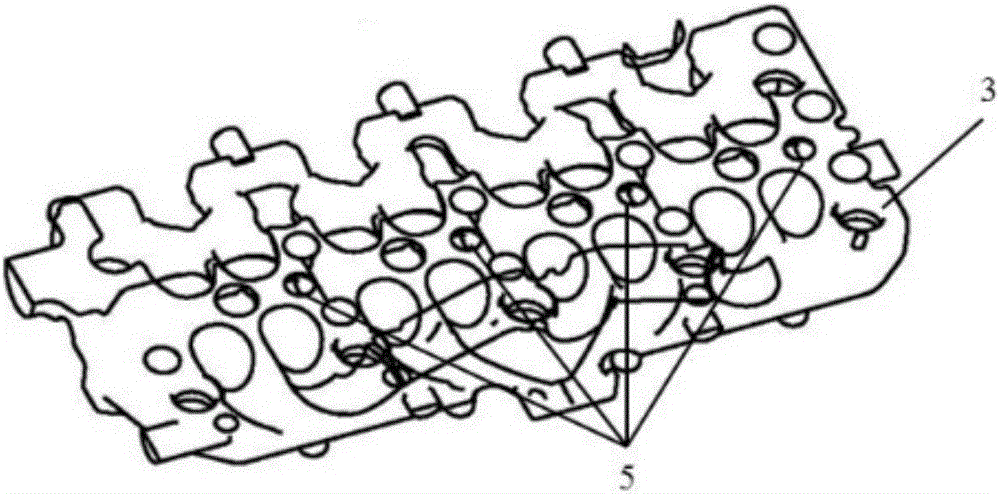

Water jacket structure of cylinder cover covering exhaust manifold

InactiveCN105971757AImprove cooling efficiencyImprove pass rateCylinder headsCylindersStructural engineeringWater jacket

The invention relates to a water jacket structure of a cylinder cover covering an exhaust manifold. The structure comprises a cylinder cover body, wherein an upper water jacket and a lower water jacket are arranged in the cylinder cover body. The structure is characterized in that four water filling holes sleeve the upper water jacket, four water inlets are formed on the lower water jacket, and the four water filling holes are in one-to-one correspondence to the four water inlets, respectively; the upper water jacket covers an exhaust duct of a first cylinder and a fourth cylinder as well as an exhaust collecting port of the first cylinder and the fourth cylinder; and the lower water jacket covers an exhaust duct of a second cylinder and a third cylinder as well as an exhaust collecting port of the second cylinder and the second cylinder. The structure provided by the invention can satisfy the cooling requirement of the cylinder cover and can inhibit gas and air retention during casting, the product yield is improved, and the structure has good manufacturability.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Efficient incineration equipment for waste incineration processing

InactiveCN111594849AScientific and reasonable structureEasy to useIncinerator apparatusElectric machineGear wheel

The invention discloses efficient incineration equipment for waste incineration processing. The bottom end of a feeding channel is fixedly connected with a pulverization mechanism; the pulverization mechanism comprises a pulverization box, a pulverization chamber, thick grinding rollers, thin grinding rollers, a transmission box, a rotary motor, upper rotary shafts, lower rotary shafts, gears andbelts, wherein the bottom end of the feeding channel is fixedly connected with the pulverization box; the pulverization chamber is arranged in the pulverization box; and the top position of the innerwall of the pulverization chamber is symmetrically rotatably connected with the thick grinding rollers. The efficient incineration equipment has a scientific and reasonable structure, and is safe andconvenient to use. Since the efficient incineration equipment is provided with the pulverization mechanism, waste can be pulverized into tiny scraps through the pulverization mechanism, so that the waste can be fully burnt, an incineration effect is improved, meanwhile, the rotary motor drives the lower rotary shafts, through the cooperation of the gears and the belts, the rotary motor can simultaneously drive the thick grinding rollers and the thin grinding rollers to rotate together, transmission efficiency is improved, and waste pulverization efficiency is improved.

Owner:那玉金

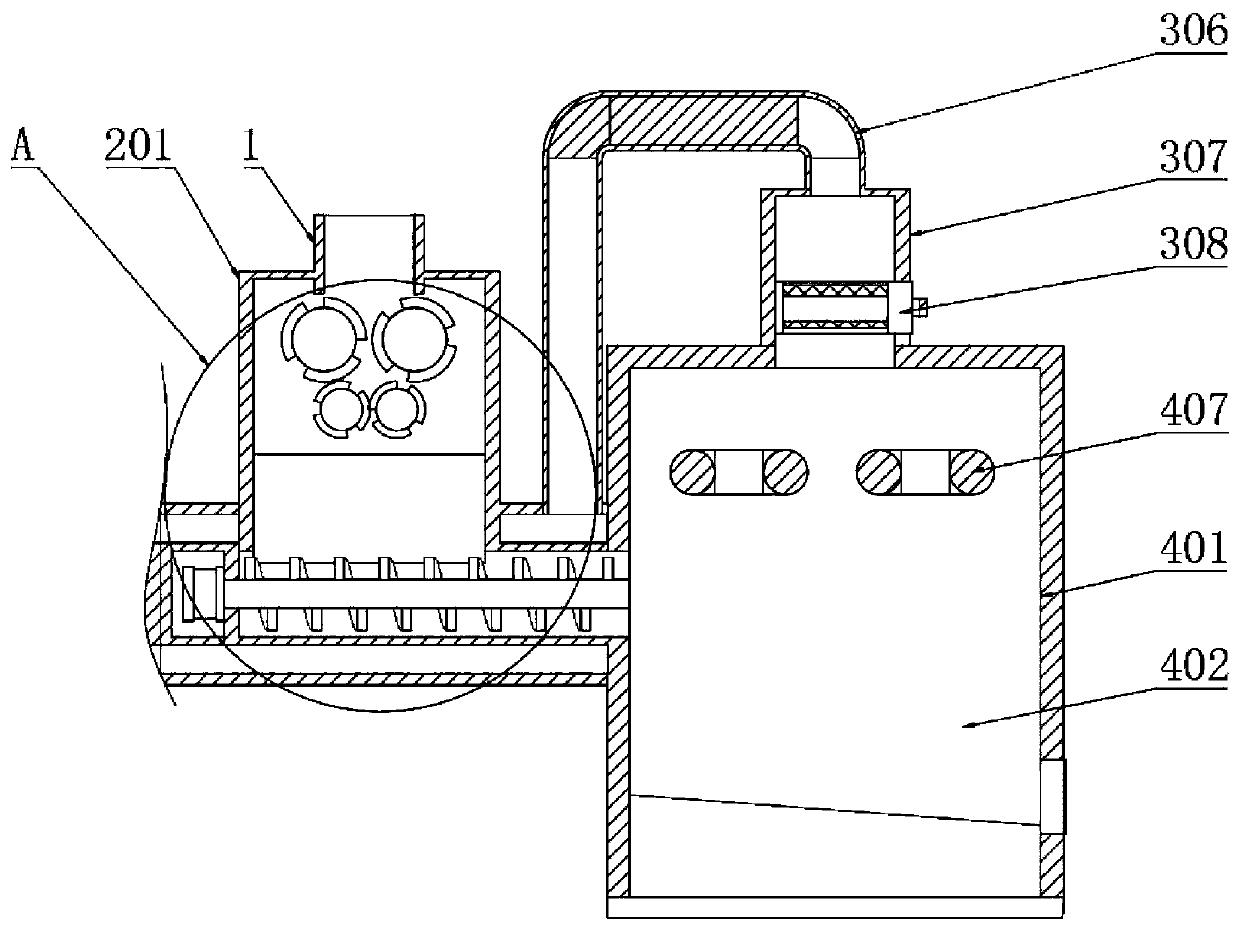

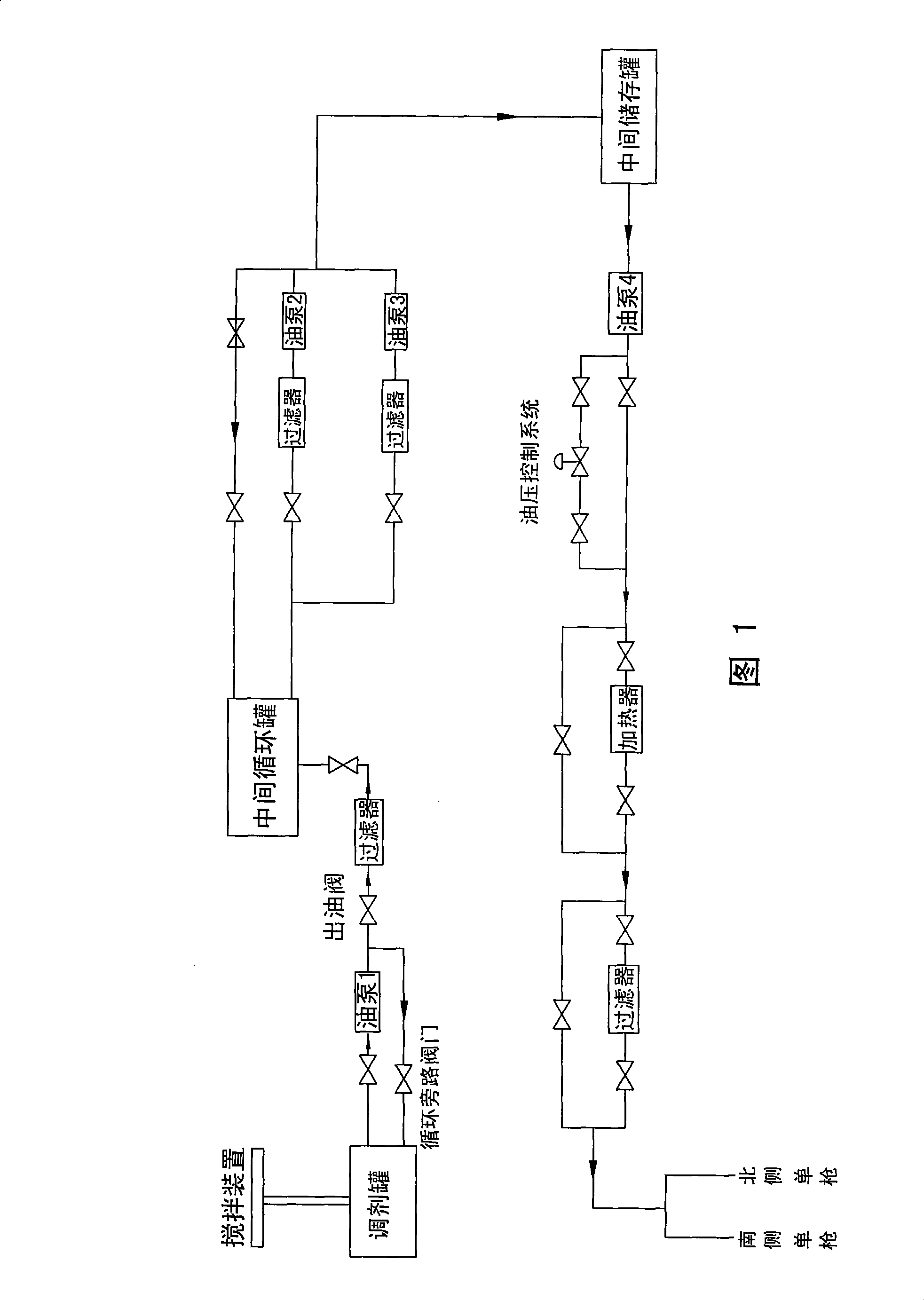

Oil coke slurry for float glass tank furnace and technology thereof

InactiveCN101362972AGuaranteed combustion effectLow costTank furnacesLiquid carbonaceous fuelsMaterials preparationCombustion

Oil coke slurry for a float glass tank furnace and a process thereof belong to the improved field of fuels for the float glass tank furnace, and the weight percentage of petroleum coke powder in the oil coke slurry is 25 to 35 percent. The process comprises the material preparation, the first compression, the first-stage filtration, the middle circulation, the second-stage filtration, the second compression, the middle storage, the third compression, the oil pressure control, the heating, the third-stage filtration and the control of a spray gun. The petroleum coke powder with 400 to 600 meshes is added in an oil coke slurry mixing tank which contains heavy oil according to the weight percentage of 29 to 31 percent, the mixture is fully stirred by a mechanical stirring device, the stirring temperature is 88 to 92 DEG C, the combustion efficiency of the oil coke slurry is close to the heavy oil under the premise of not adding any additives, a heavy oil control system and a pipeline are utilized to achieve the precise measurement and the control of the whole control process, thereby ensuring the stability of the whole control process.

Owner:JINJING GRP

A method of preparing hollow cigarettes by using tobacco leaf beads

A method of preparing hollow cigarettes by using tobacco leaf beads is disclosed. The method includes smashing tobacco leaves into fine powder, adding an adhesive to prepare into a soft material, preparing tobacco leaf beads by using an extrusion-spheronization process, pressing the tobacco leaf beads into hollow cigarette sticks, wrapping the hollow cigarette sticks with cigarette paper, connecting filter tips, and preparing the cigarettes by a conventional method. The prepared cigarettes are novel in form, can bring new experience to customers and are uniform in formula. Stability of cigarette smoking quality is ensured, the combustion time of the cigarettes is prolonged, and the puff number is increased, so that customers are more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

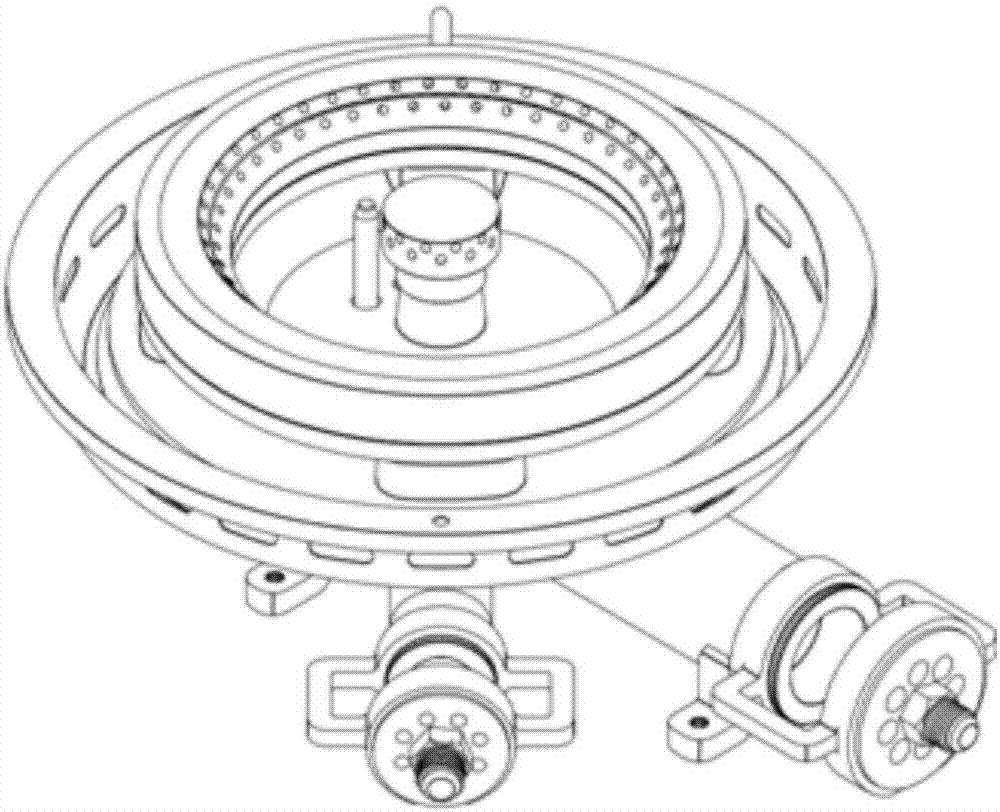

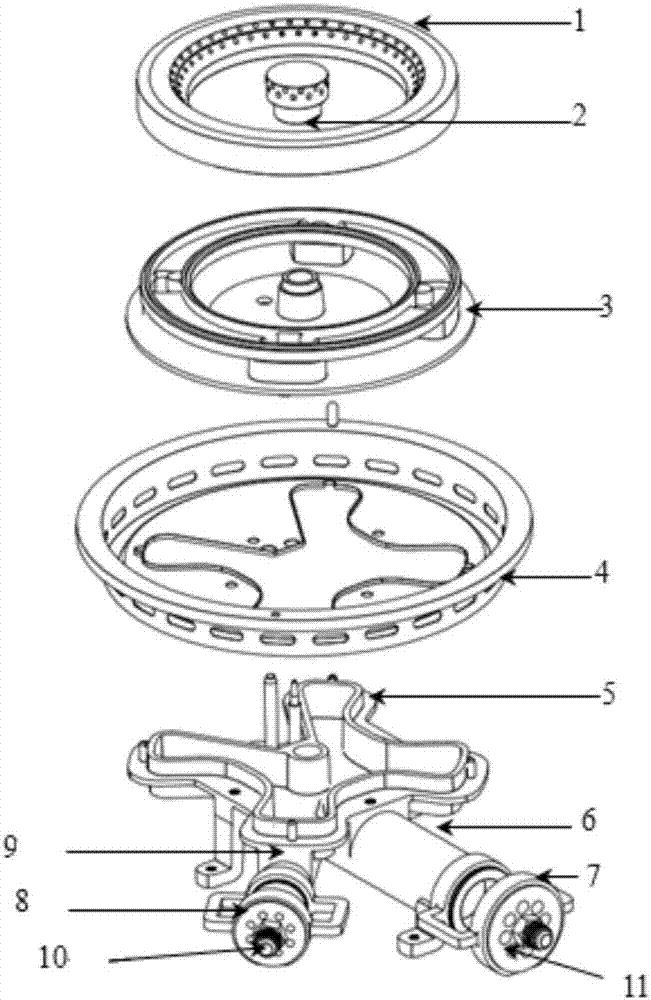

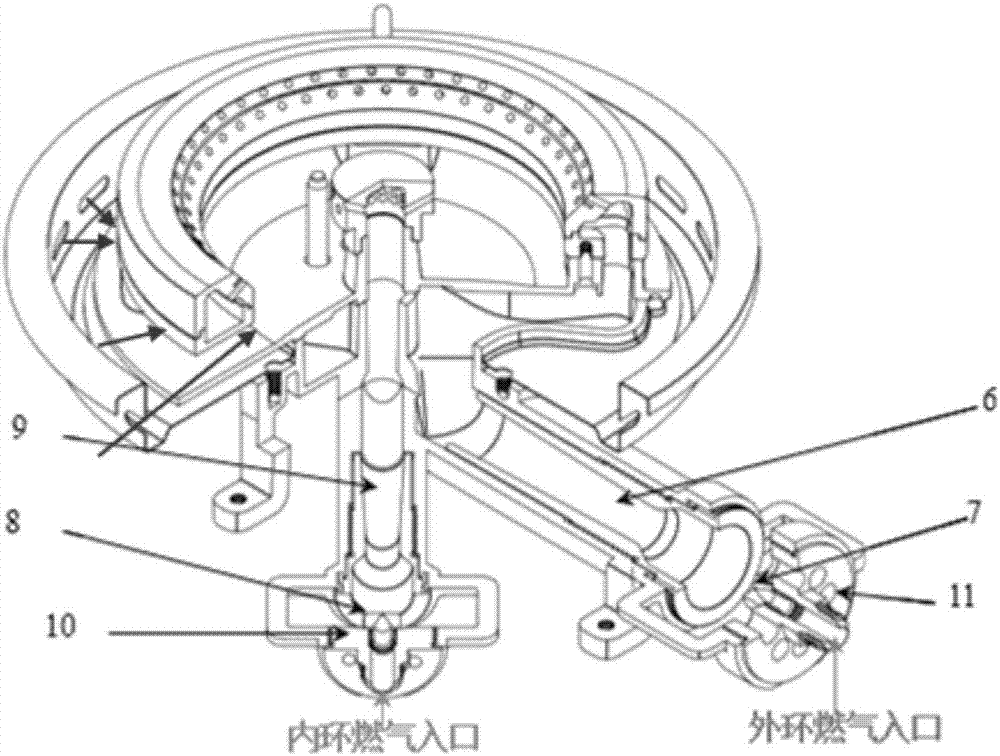

Novel inner flame sunken burner and gas stove with oxygen supplementing function

ActiveCN108006637AStable combustion conditionsSimple structureDomestic stoves or rangesGaseous fuel burnerEngineeringOxygen

The invention provides a novel inner flame sunken burner and a gas stove with an oxygen supplementing function. The novel inner flame sunken burner comprises a outer ring burner cap, an inner ring burner cap, a gas separating seat and a stove head seat, and the end faces of the gas separating seat and the stove head seat are matched; the inner ring burner cap is matched with a center gas outlet ofthe gas separating seat, and the outer ring burner cap is matched with the peripheral area of the gas separating seat; the inner ring burner cap is provided with a main flame gas outlet used for ejecting a part of gas mixtures, and a steady flame slot used for ejecting the other part of the gas mixtures; and the inner ring burner cap located above the main flame gas outlet is provided with a supplementing slot for supplementing inside secondary air for inner ring main flame. The novel inner flame sunken burner provided by the invention has the advantages of inner ring flame with the oxygen supplementing function, high heat efficiency and roaring fire.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Cigarette manufacturing method

ActiveCN104939302ANew experienceNovelty form of cigaretteTobacco treatmentCigarette manufactureEngineeringSoft materials

The invention discloses a cigarette manufacturing method. The cigarette manufacturing method includes the steps that cigarette tobacco leaves are pulverized into fine powder, syrup is added into the fine powder to obtain a soft material, particles are manufactured from the soft material and pressed into cigarette bars, and the cigarette bars are wrapped by cigarette paper, connected with filter tips and manufactured into cigarettes in a conventional method. The manufactured cigarettes are novel in style, and bran-new experience can be brought to a consumer; the cigarette formula is uniform, the stability of smoking quality of the cigarettes is ensured, the burning time of the cigarettes is prolonged, the puff number is increased, and the consumer can obtain higher satisfaction.

Owner:HUBEI CHINA TOBACCO IND

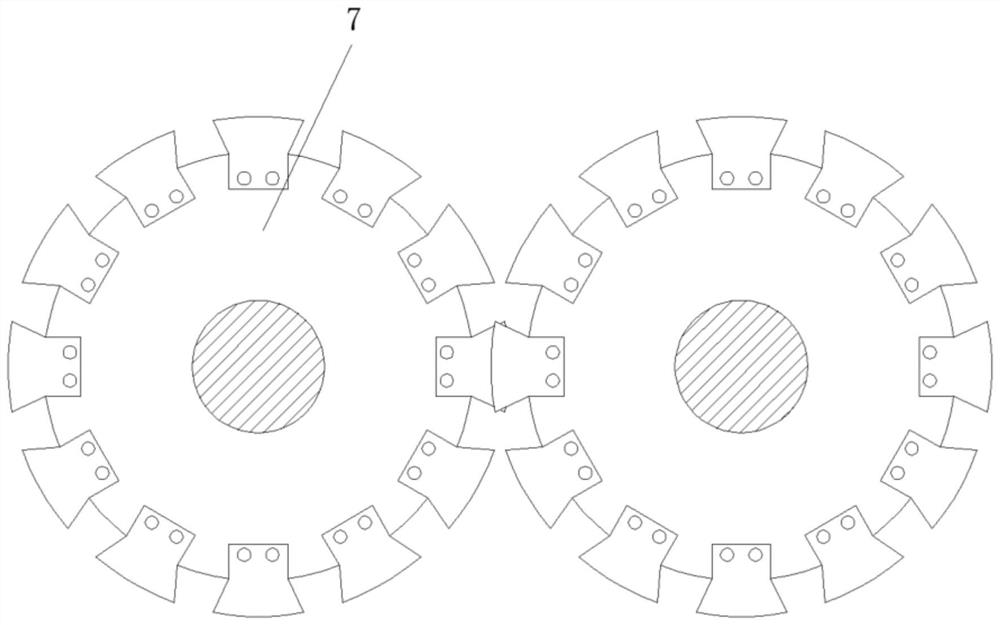

Biomass combustor capable of achieving self-smashing and intermittent equivalent feeding

InactiveCN111706852ACrushed fullyAvoid accumulationSolid fuel combustionGrain treatmentsThermodynamicsCombustion chamber

The invention relates to the technical field of combustion equipment, and discloses a biomass combustor capable of achieving self-smashing and intermittent equivalent feeding. The biomass combustor comprises a base, wherein the top of the base is fixedly connected to a combustion chamber; an inner screen board is fixedly connected inside the combustion chamber; the top of the combustion chamber isfixedly connected to a smashing chamber; the outer part of the smashing chamber is fixedly connected to a smashing motor; and the outer part of the smashing motor is fixedly connected to a main gear.According to the biomass combustor disclosed by the invention, the main gear, the smashing wheel, a connecting gear, an outer gear ring and an outer bottom frame are matched for use, so that stalks are sufficiently smashed; and meanwhile, the outer bottom frame drives the stalks inside the smashing chamber to turn over inside the smashing chamber, so that the stalks are prevented from being accumulated on the bottom of the smashing chamber, and the stalks are smashed for a second time conveniently, and therefore, the stalk smashing effect is sufficiently guaranteed, smashing speed and smashing efficiency are effectively guaranteed, the stalks are combusted sufficiently conveniently, the combustion effect is guaranteed, and sufficient combustion is effectively guaranteed.

Owner:王志强

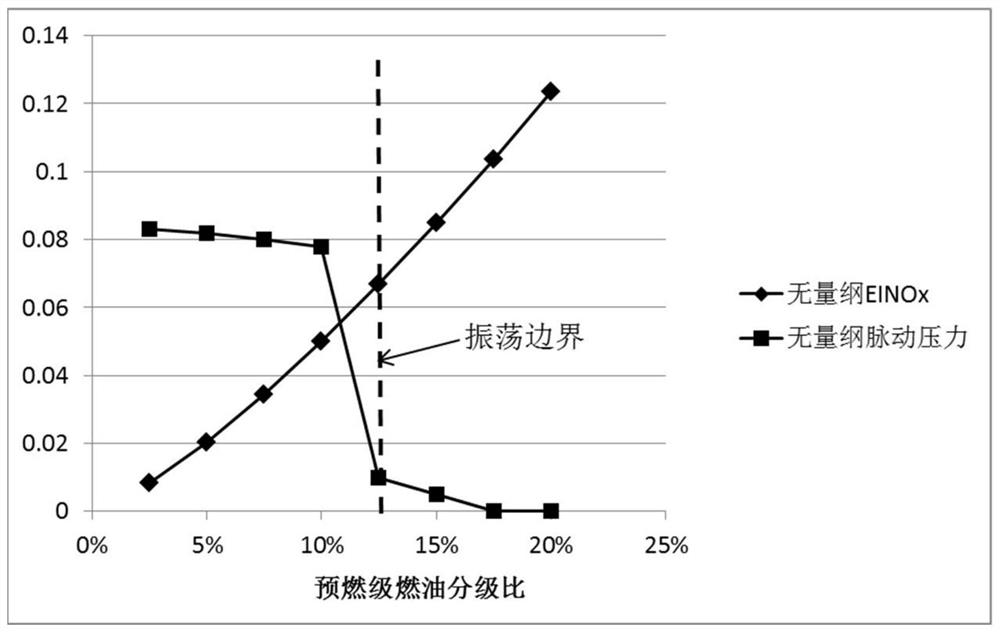

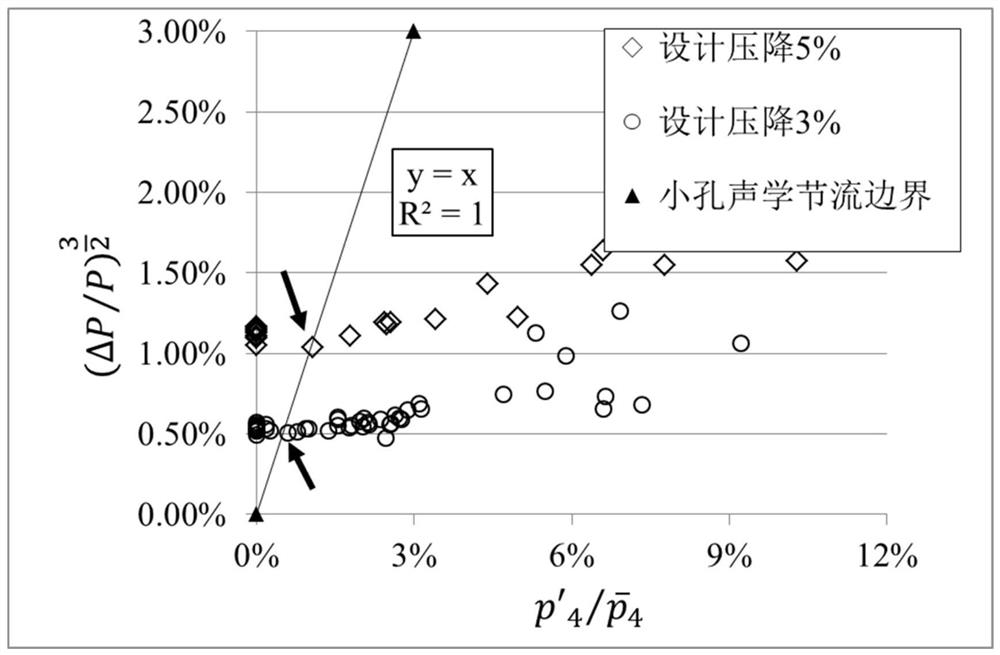

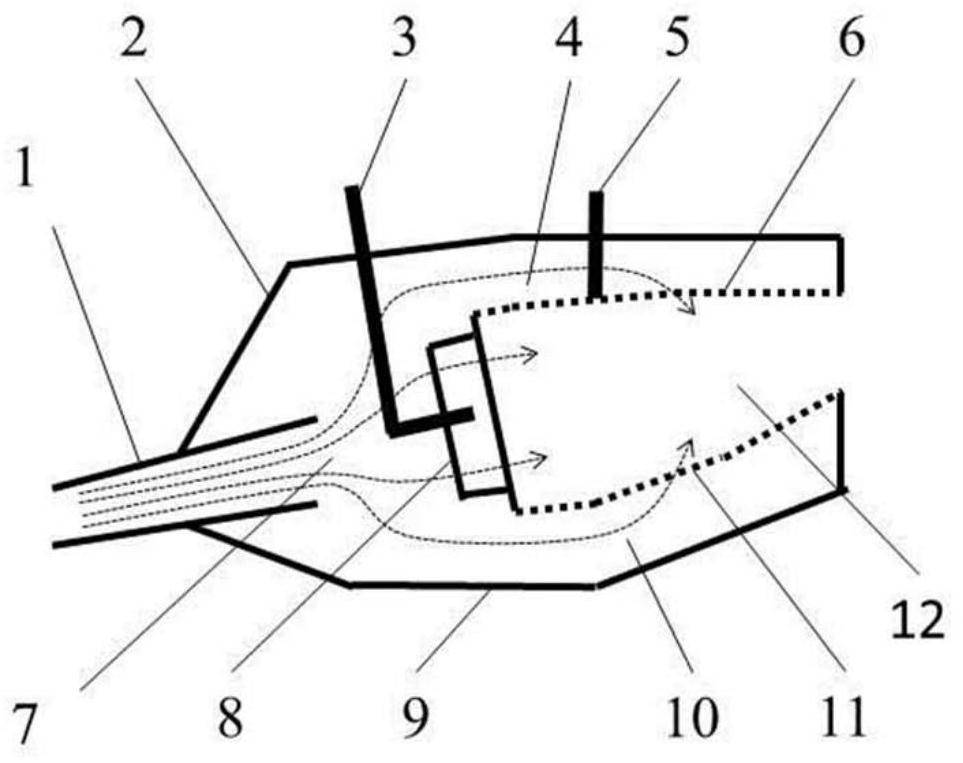

Combustion chamber, gas turbine and method for suppressing oscillatory combustion

ActiveCN112066412AReduce the ratioImproved temperature distribution qualityContinuous combustion chamberCombustion chamberEngineering

The invention relates to a combustion chamber of a gas turbine. The combustion chamber comprises a flame tube head, wherein the head comprises main combustion stages and a pre-combustion stage, a plurality of main combustion stages are distributed around the pre-combustion stage in the circumferential direction with the pre-combustion stage as the center, the pre-combustion stage is provided witha pre-combustion stage fuel nozzle and a pre-combustion stage outer wall located circumferentially outward of the pre-combustion stage, the main combustion stages are provided with main combustion stage inner walls, and a radial space in the pre-combustion stage outer wall provides a pre-combustion stage channel for mixing air entering the pre-combustion stage through a pre-combustion stage air inlet part with fuel injected by the pre-combustion stage fuel nozzle; the pre-combustion stage air inlet part comprises a pre-combustion stage first air inlet part and a pre-combustion stage second airinlet part; and the pre-combustion stage first air inlet part comprises a second hole channel which penetrates through the radial thickness of the pre-combustion stage outer wall and has an acousticthrottling effect.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

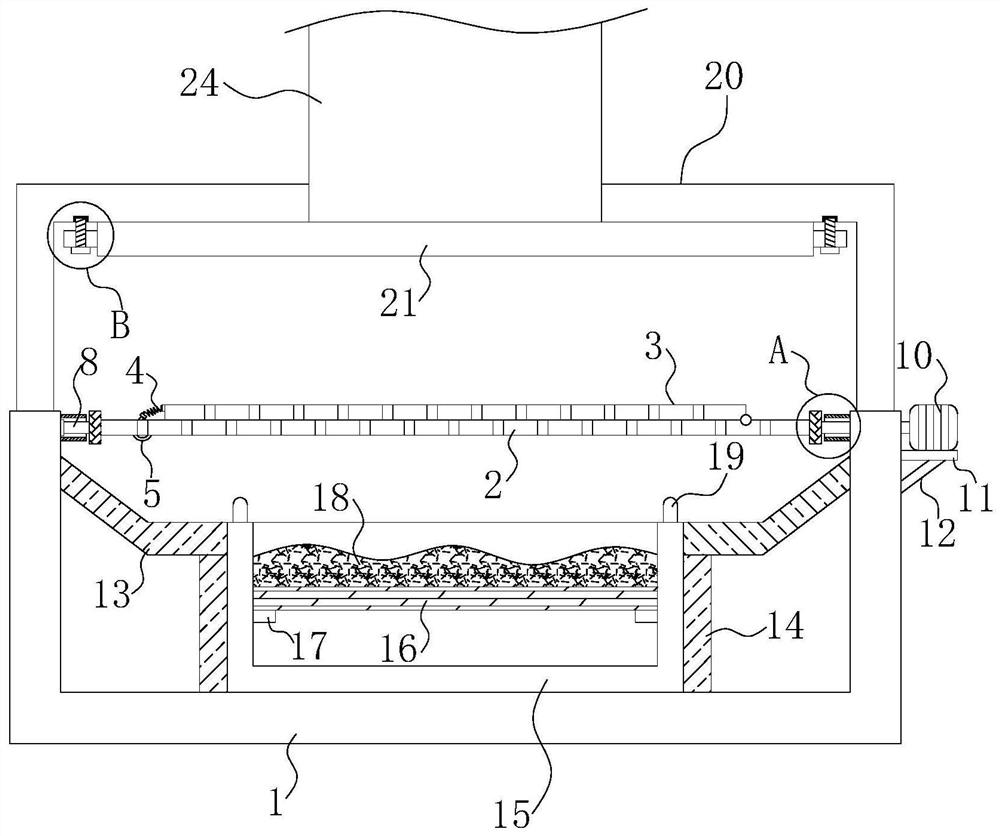

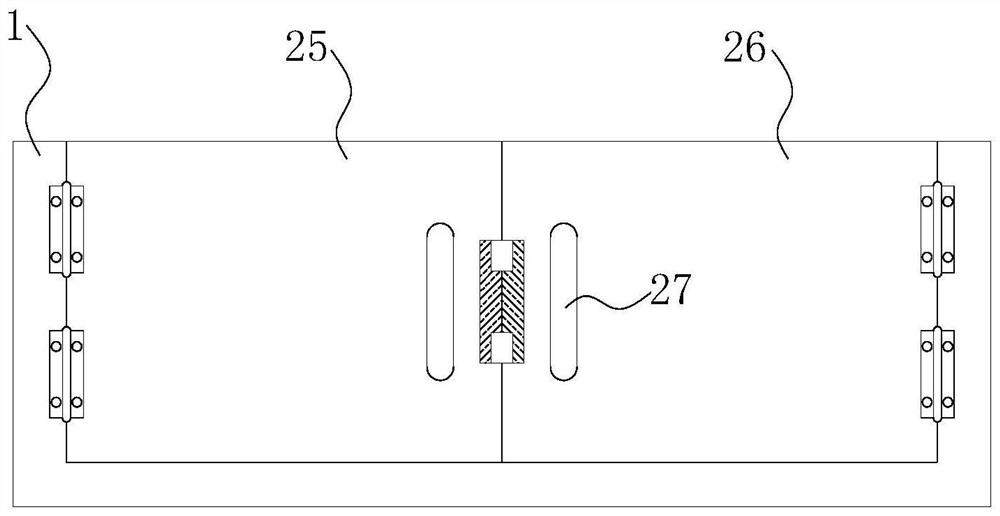

Incinerator with fixed fire grate

InactiveCN103994441AEnsure high constant temperature incineration demandEnsure high constant temperature incinerationIncinerator apparatusCombustion chamberMoisture

The invention belongs to the field of waste incineration devices and particularly relates to an incinerator with a fixed fire grate. The incinerator with the fixed fire grate is used for incinerating biomass materials such as straws and at least comprises a main combustion chamber, an air supply assembly and a smoke flue for guiding heat energy in the main combustion chamber out. The main combustion chamber is communicated with the smoke flue through a ventilation pipe, and a conveying and incinerating platform is arranged in the main combustion chamber and at least comprises a bearing plate and a stirring portion. The incinerator with the fixed fire grate further comprises a pushing portion, wherein an air return moisture removal cavity channel is arranged between the pushing portion and the main combustion chamber in a transition mode and forms a material conveying path for connecting the cavity of the main combustion chamber with the pushing portion, an air outlet is formed in the end of the air return moisture removal cavity channel and communicated with an external air draught fan, and the end of the air return moisture removal cavity channel and the pushing portion are positioned at the same end. The incinerator with the fixed fire grate is high in operation reliability and incineration efficiency, low in cost and capable of ensuring incineration at high and constant temperature and extracting and utilizing efficient heat energy of biomass fuel.

Owner:合肥康帕因设备技术有限公司

Special waste treatment equipment for veterinarian

ActiveCN114576631ABurn quicklyGuaranteed treatment effectClimate change adaptationIncinerator apparatusElectric machineryEngineering

The special waste treatment equipment comprises a box body, a treatment chamber is arranged in the box body, a discharging opening is formed in the top in the treatment chamber, a cover plate is rotationally connected to the upper end of the box body, a driving motor is installed on the left side of the box body, and a worm is rotationally connected to the left side of the box body; and the worm is in transmission connection with an output shaft of the driving motor through a transmission assembly, the right end of the worm extends into the treatment chamber, and the inner bottom of the treatment chamber is rotationally connected with a second rotating rod. When the equipment is used, a combustion improver can be sprayed multiple times according to the waste crushing time, it is ensured that the amount of the combustion improver is sufficient, subsequent waste combustion is facilitated, and due to the fact that the combustion box is in the rotating state, the combustion improver can be evenly sprayed on waste on each layer, and the waste is prevented from being burnt. And meanwhile, the crushed waste can be screened and then subjected to automatic secondary crushing, it is ensured that the waste is completely crushed to be in a combustible state, and the combustion effect on the waste is improved.

Owner:烟台市莱山区动物疫病预防与控制中心

Waste emulsion sludge treatment method

ActiveCN109385321ALow costThe treatment method is economical and practicalBiofuelsSolid fuelsEmulsionPrill

The invention discloses a waste emulsion sludge treatment method, and belongs to the field of industrial waste treatment methods. The waste emulsion sludge treatment method comprises the following steps: 1, proportioning materials: quantitatively proportioning waste emulsion sludge and fly ash for next-step operation; 2, mixing: mixing materials proportioned in the proportioning step, namely repeatedly performing rolling, stirring and mixing operation thereon to obtain powdery particles; 3, discharging: outputting a finished product obtained in the mixing step, wherein the water content of thefly ash proportioned in the proportioning step is lower than or equal to 1%, the water content of the waste emulsion sludge is lower than or equal to 50%, and the content of particles with the particle size being smaller than or equal to 1mm in the proportioned fly ash is higher than or equal to 90%. According to the waste emulsion sludge treatment method, no chemical reaction occurs and no new pollutant is produced during treatment, two industrial wastes, namely the waste emulsion sludge and the fly ash, are treated, the obtained product can be fully burned as a fuel, the treatment cost is low, the treatment method is simple, the problem that the existing waste emulsion sludge is difficult to treat is solved, and industrialized application is easy.

Owner:马钢集团设计研究院有限责任公司

Bean curd cutting method

ActiveCN106689415AShorten the processing flowExtended eating timeCheese manufactureMetal working apparatusEngineeringCotton cloth

The invention discloses a bean curd cutting method. The method comprises the following steps that preparing, wherein a bean curd cutting device is needed; cleaning, wherein the bean curd is put in clear water and rest; drying, wherein a cotton cloth is used for wiping the surface of the bean curd; oiling, wherein an upper cutting tool and a lower cutting tool are rubbed with salad oil; smoked materials, wherein the smoked materials are put in a cavity of the lower cutting tool and burns; cutting, wherein the cutting tools are driven to move in the direction of the bean curd, the cutting tools move into a groove under a guiding role of the groove, cutting work of the bean curd is completed, and the cutting tool stands in the groove for 2 min. The bean curd cutting method mainly solves the problem that the processing flow is relative long after the bean curd is shaped.

Owner:重庆乐嚼食品有限公司

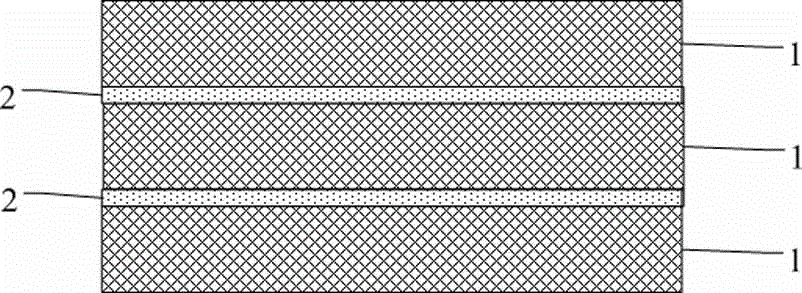

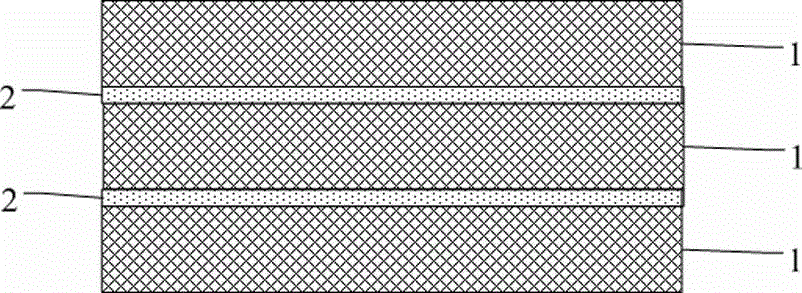

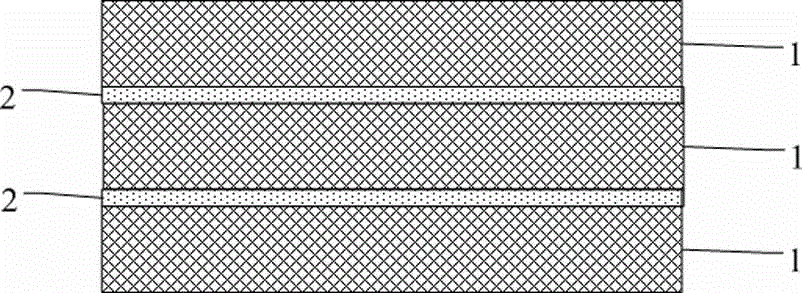

Preparation method of aeration combustion-supporting biomass briquette

The invention discloses a preparation method of an aeration combustion-supporting biomass briquette. The method includes the steps of preparation of biomass fuel substrates, preparation of aeration combustion-supporting adhesives, surface treatment of the biomass fuel substrates and lamination forming. The prepared biomass briquette comprises the multiple biomass fuel substrates formed in a lamination mode. An aeration combustion-supporting adhesion layer is arranged between every two adjacent biomass fuel substitutes. Each aeration combustion-supporting adhesion layer is a fiber adhesive and sodium bicarbonate mixture, wherein sodium bicarbonate accounts for 3-10% of the mass of the fiber adhesive and sodium bicarbonate mixture. The preparation method of the aeration combustion supporting type biomass briquette has the advantages that processing is convenient, and the product is high in combustion performance, good in universality, low in cost and convenient to produce on a large scale.

Owner:曾娘荣

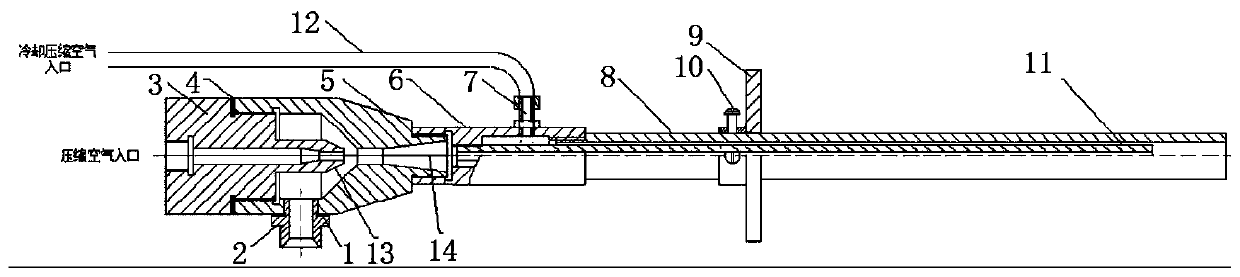

Ejector type combustor of carbon roasting furnace for aluminum

InactiveCN111486455AExtend the life cycleBroad application prospectsFurnace componentsAir supply regulationEngineeringMechanical engineering

The invention discloses an ejector combustor of a carbon roasting furnace for aluminum. The ejector type combustor includes a nozzle. The side wall of the nozzle is hermetically connected with a mixing body through a second sealing gasket. The side wall of the lower end of the mixing body is hermetically connected with a connector through a first sealing gasket. The side wall, located in the mixing body, of the nozzle is provided with an ejector nozzle. The side wall of the mixing body is provided with a diffusion pipe. The diffusion pipe is connected with the side wall of the mixing body. Theportion, away from the nozzle, of the side wall of the mixing body is hermetically connected with an ejector body matched with the diffusion pipe. The side wall of the upper end of the ejector body is hermetically connected with an air tap, and the end, far away from the ejector body, of the air tap is hermetically connected with a cooling pipe. According to the ejector combustor of the carbon roasting furnace for aluminum, natural gas can be fully mixed with air, the optimal combustion ratio is achieved, the combustion efficiency is achieved, energy is saved, gas pressure is increased, a product is uniformly heated, a burner can be rapidly cooled, coking substances and oxides left on a protective sleeve pipe and the head of the burner are blown off, and the unobstructed burner and straight flames are ensured.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +2

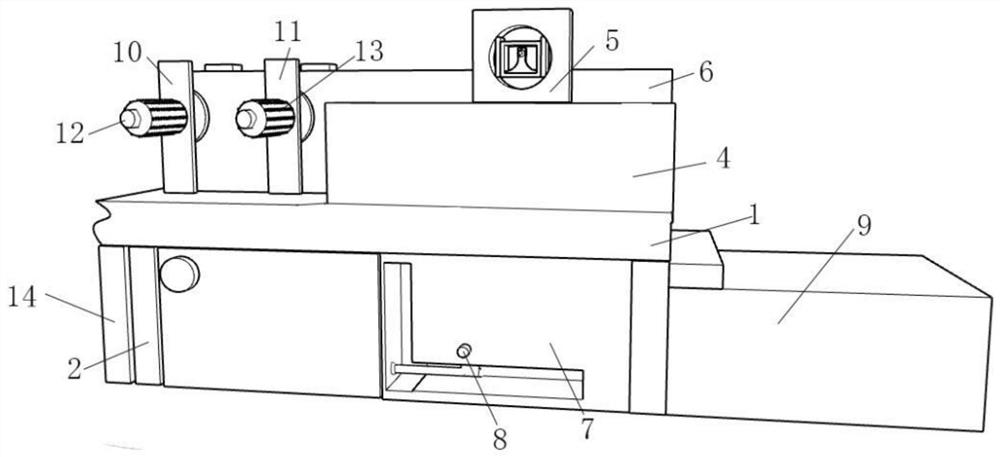

Fabric outer surface singeing device for pure cotton textile production and processing and use method thereof

InactiveCN113265819AGuaranteed combustion effectGuaranteed capacitySingeingSpinningTextile production

The invention discloses a fabric outer surface singeing device for pure cotton textile production and processing and a use method thereof, and particularly relates to the field of spinning. The fabric outer surface singeing device comprises a mounting table; the bottom of the mounting table is fixedly connected with a supporting column; the bottom of the mounting table is provided with an air storage box; the top of the mounting table is fixedly provided with a hair removal protection box; a smoke exhaust air duct is fixed to the top of the hair removal protection box; a supporting frame is mounted on one side of the mounting table; an air supply box is fixedly mounted at the bottom of the mounting table; an air flow adjusting button is rotatably mounted on the surface of the air supply box; a collecting box is fixed to one side of a supporting column; and a first mounting plate and a second mounting plate are mounted at the top of the mounting table. According to the scheme, multiple annular rubber protrusions are arranged on the surface of a friction roller; and when a fabric passes through the annular rubber protrusions, the annular rubber protrusions rub the fabric making contact with the annular rubber protrusions, the fabric and the annular rubber protrusions move and rub to generate static electricity, and the static electricity drives fluff on the surface of the fabric to be erected, so that the burning effect of the fluff on the surface of the fabric is ensured when the fabric is burnt.

Owner:桐乡市隆源纺织有限公司

Full-automatic fillet grilling machine

InactiveCN111972447ALabor savingImprove practicalityOven air-treatment devicesBaking sheets/boardsElectric machineryStructural engineering

The invention relates to the technical field of fillet grilling machines, and discloses a full-automatic fillet grilling machine. The machine comprises a fish grilling box, wherein a first net rack isarranged at the top of the fish grilling box, the first net rack is horizontally arranged, a second net rack is arranged over the top of the first net rack, connecting plates are arranged at two endsof the first net rack, the two connecting plates are vertically arranged, the two connecting plates are fixedly connected with two ends of the first net rack correspondingly, a second connecting rodand a first connecting rod are arranged at left and right ends of the first net rack correspondingly, and the second connecting rod is rotationally connected with the fish grilling box through a rotating shaft. Through the arrangement of the first net rack and the second net rack, fillet can be tightly clamped; further through the arrangement of a motor, the motor can drive the first net rack andthe second net rack to rotate; and through the arrangement of carbon blocks, the clamped fillet can be baked, so that fillet baking can be automatically completed, a large amount of labor force can besaved, and thus the full-automatic fillet grilling machine is convenient and rapid to bake fillet and relatively high in practicability.

Owner:日照民群食品科技有限公司

Aeration type biomass briquette

The invention discloses an aeration type biomass briquette. The aeration type biomass briquette comprises a plurality of biomass fuel substitutes formed in a lamination mode. An aeration adhesion layer is arranged between every two adjacent biomass fuel substitutes. Each aeration adhesion layer is a fiber adhesive and sodium bicarbonate mixture, wherein sodium bicarbonate accounts for 3-10% of the mass of the fiber adhesive and sodium bicarbonate mixture. The aeration type biomass briquette has the advantages of being high in combustion performance, good in universality, low in cost and convenient to produce on a large scale.

Owner:曾娘荣

Ignition type biomass forming fuel

The invention discloses an ignition type biomass forming fuel which comprises a plurality of laminated molding biomass fuel substrates, wherein an ignition binding layer is arranged between every two adjacent biomass fuel substrates, each ignition binding layer is a mixture of a fiber binding agent, polyester polyol and diisocyanate, the mass ratio of the polyester polyol to the diisocyanate is 1 to 5 percent of the mixture of the fiber binding agent, the polyester polyol and the diisocyanate, and the molar ratio of the polyester polyol to the diisocyanate is 1: (4 to 6). The ignition type biomass forming fuel provided by the invention has the characteristics of high combustion performance, strong versatility, low cost and convenience in scale production.

Owner:曾娘荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com