Cigarette manufacturing method

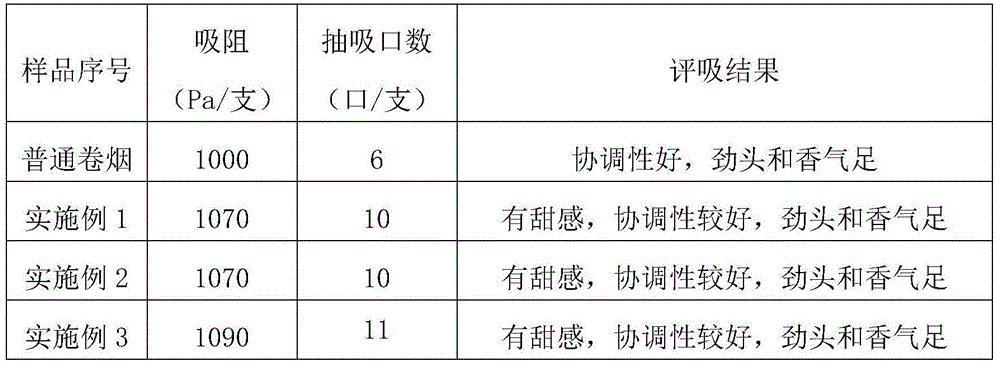

A technology for cigarettes and cigarette sticks, which is applied in the directions of tobacco, tobacco processing, and paper cigarette manufacturing, etc., can solve the problems of difficulty in ensuring the distribution of cut tobacco, unable to guarantee the formula of cut tobacco, and short smoking time of cigarettes, so as to achieve uniform formula of cigarettes and solve uneven mixing. , good coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing cigarettes, comprising the steps of:

[0024] 1) The cigarette leaves are ground into a 60-mesh fine powder (meaning that the fine powder can all pass through a 60-mesh sieve), the sucrose is dissolved in water and boiled to make a syrup with a weight concentration of 70%, and the syrup is mixed with the fine powder (the syrup The weight ratio of fine powder to fine powder is 1:5.5), made into a soft material that is agglomerated by hand, lightly pressed and then dispersed, and then granulated through a 12-mesh sieve, and the prepared granules are processed in a fluidized bed at a temperature below 70°C. dry;

[0025] 2) Add 0.5% magnesium stearate as a lubricant to the dried granules, mix and pack into a mold and press into a cigarette stick with a density of 2.2g / ml;

[0026] 3) Wrap the cigarette stick with cigarette paper, connect it with a filter, and make a cigarette according to a conventional method.

Embodiment 2

[0028] A method for preparing cigarettes, comprising the steps of:

[0029] 1) Powder the cigarette leaves into 80-mesh fine powder (meaning that the fine powder can all pass through the 80-mesh sieve), dissolve sucrose in water and boil it into a syrup with a weight concentration of 60%, and mix the syrup and fine powder to make Soft materials are granulated through a 15-mesh sieve, and the prepared granules are dried in a fluidized bed;

[0030] 2) Add 0.8% magnesium stearate to the dried granules, mix them evenly, put them into a mold and press them into a cigarette stick with a density of 2g / ml;

[0031] 3) Wrap the cigarette stick with cigarette paper, connect it with a filter, and make a cigarette according to a conventional method.

Embodiment 3

[0033] A method for preparing cigarettes, comprising the steps of:

[0034] 1) Cigarette tobacco leaves are ground into 70-mesh fine powder, sucrose is dissolved in water and boiled into a syrup with a weight concentration of 80%, the syrup and fine powder are mixed to make a soft material and granulated through a 8-mesh sieve. The obtained granules are dried in a fluidized bed;

[0035] 2) Add 0.3% magnesium stearate to the dried granules, mix them evenly, put them into a mold and press them into a cigarette stick with a density of 2.5g / ml;

[0036] 3) Wrap the cigarette stick with cigarette paper, connect it with a filter, and make a cigarette according to a conventional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com