Patents

Literature

608results about How to "Extended burn time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

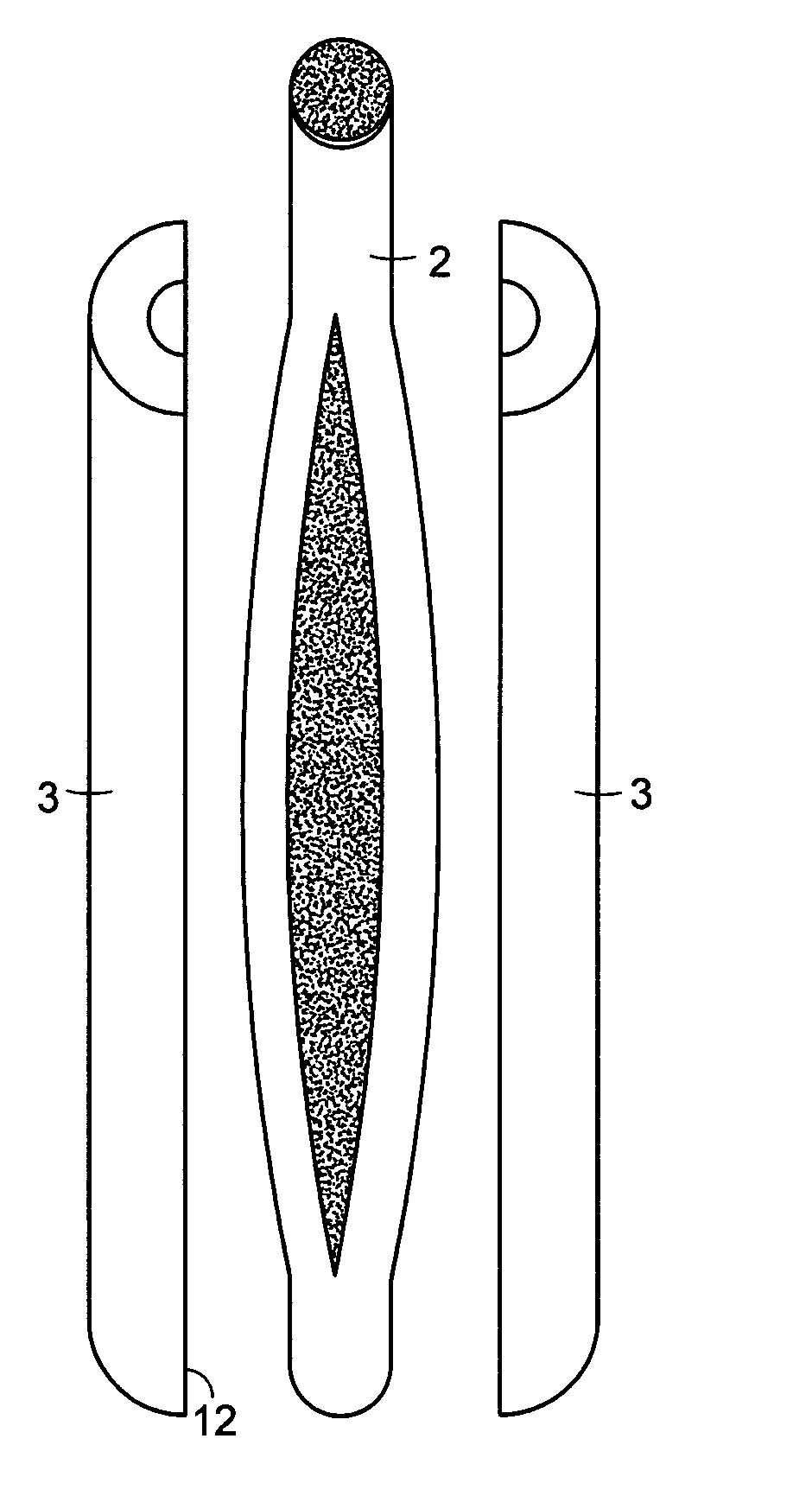

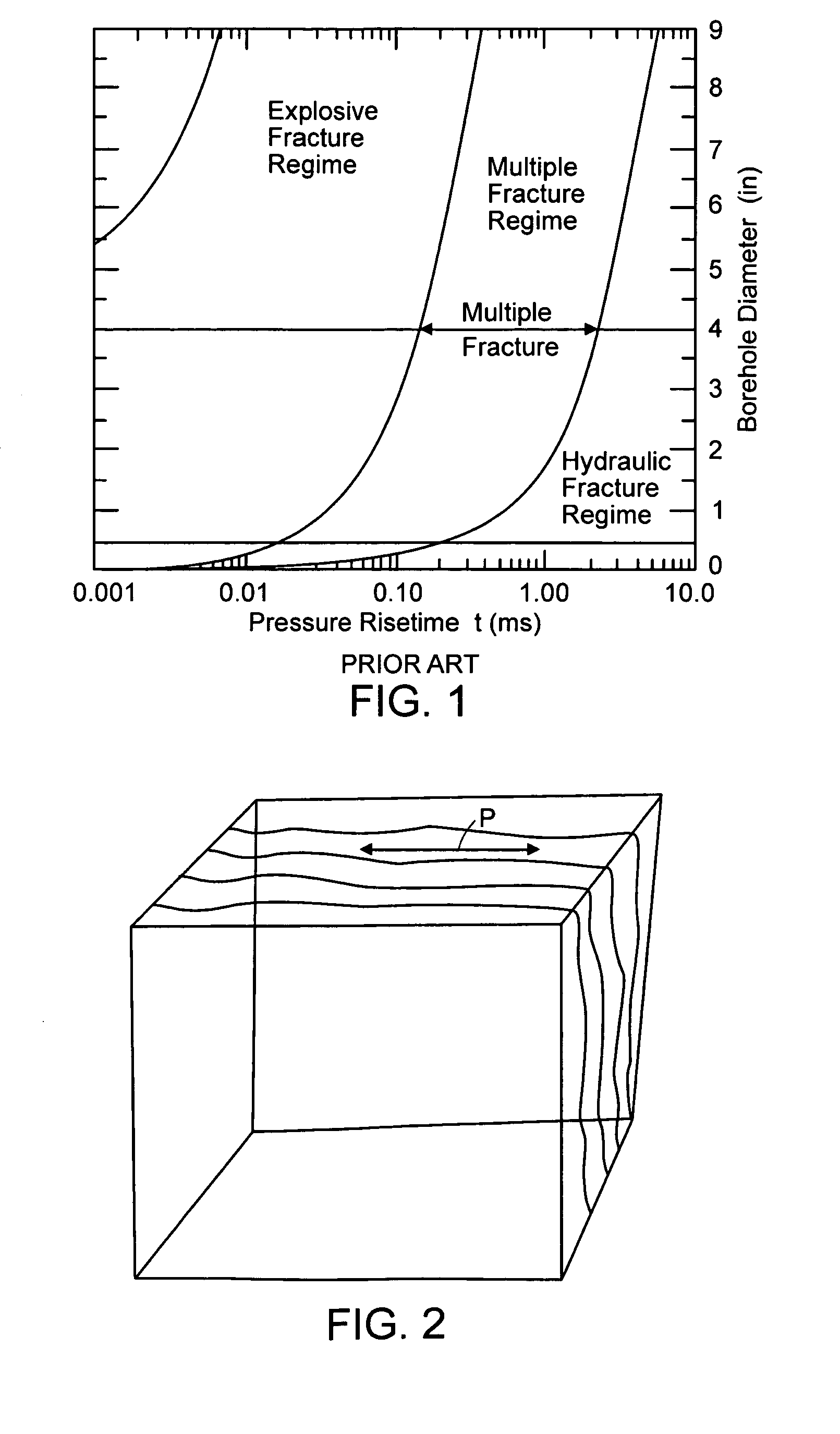

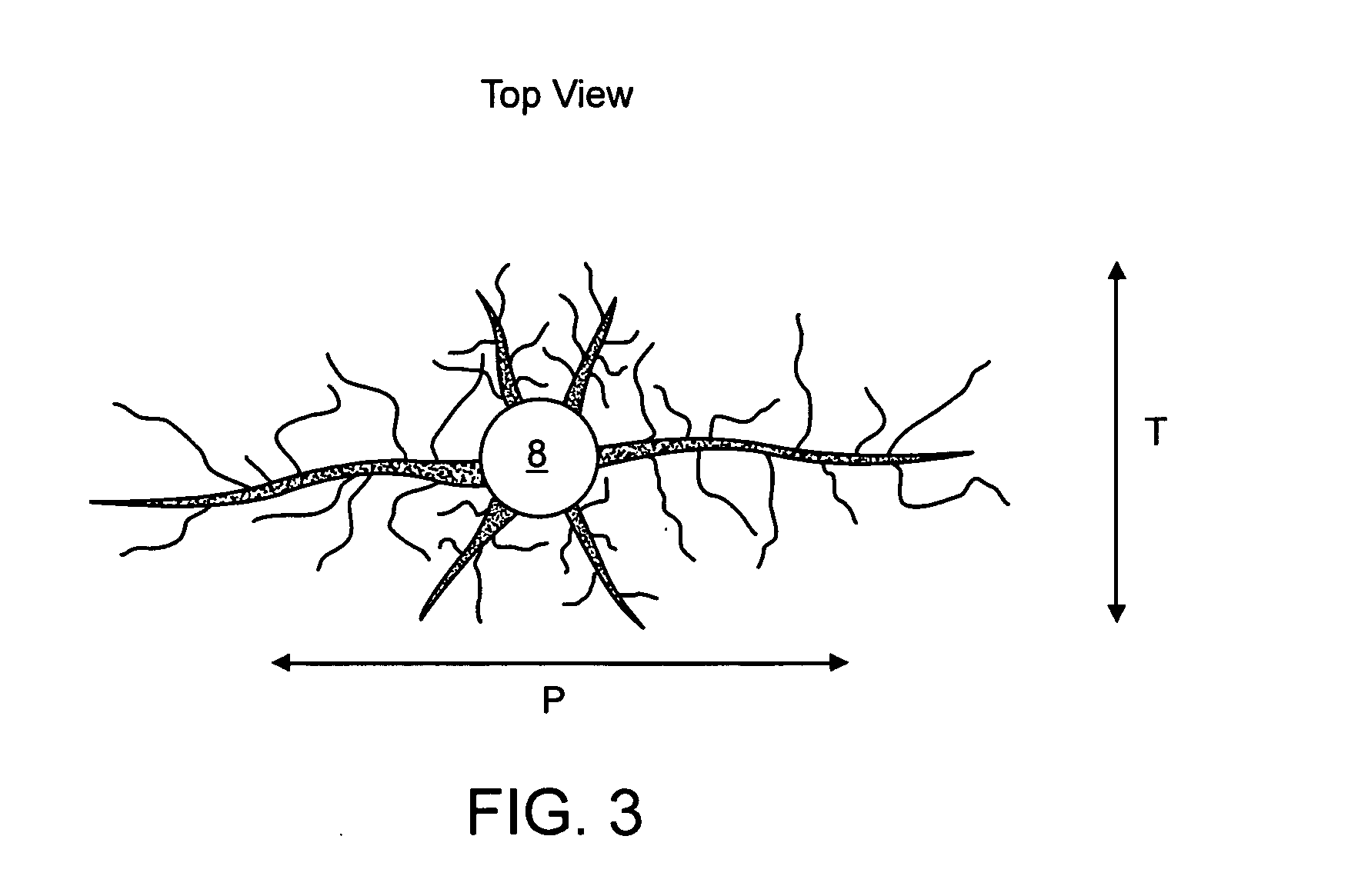

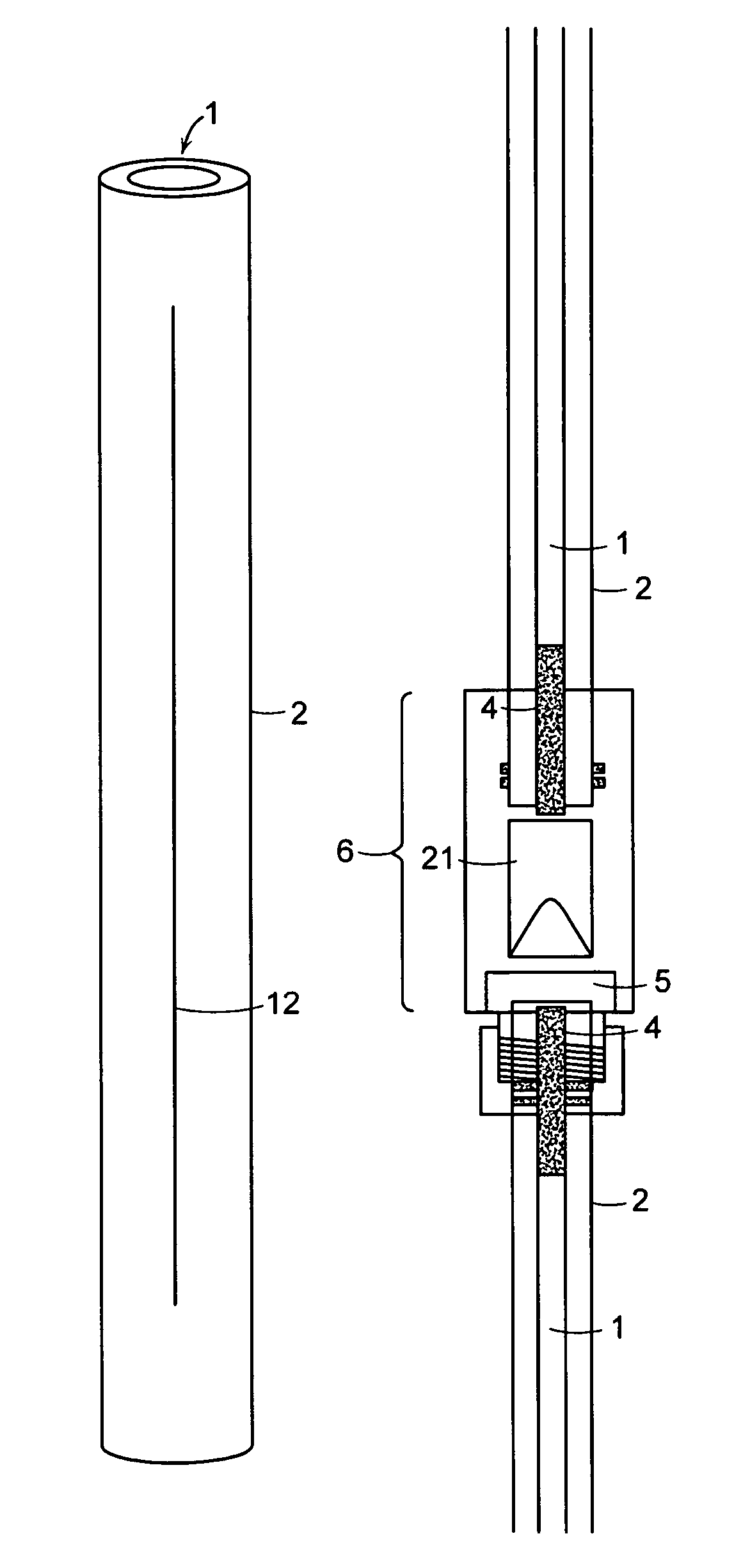

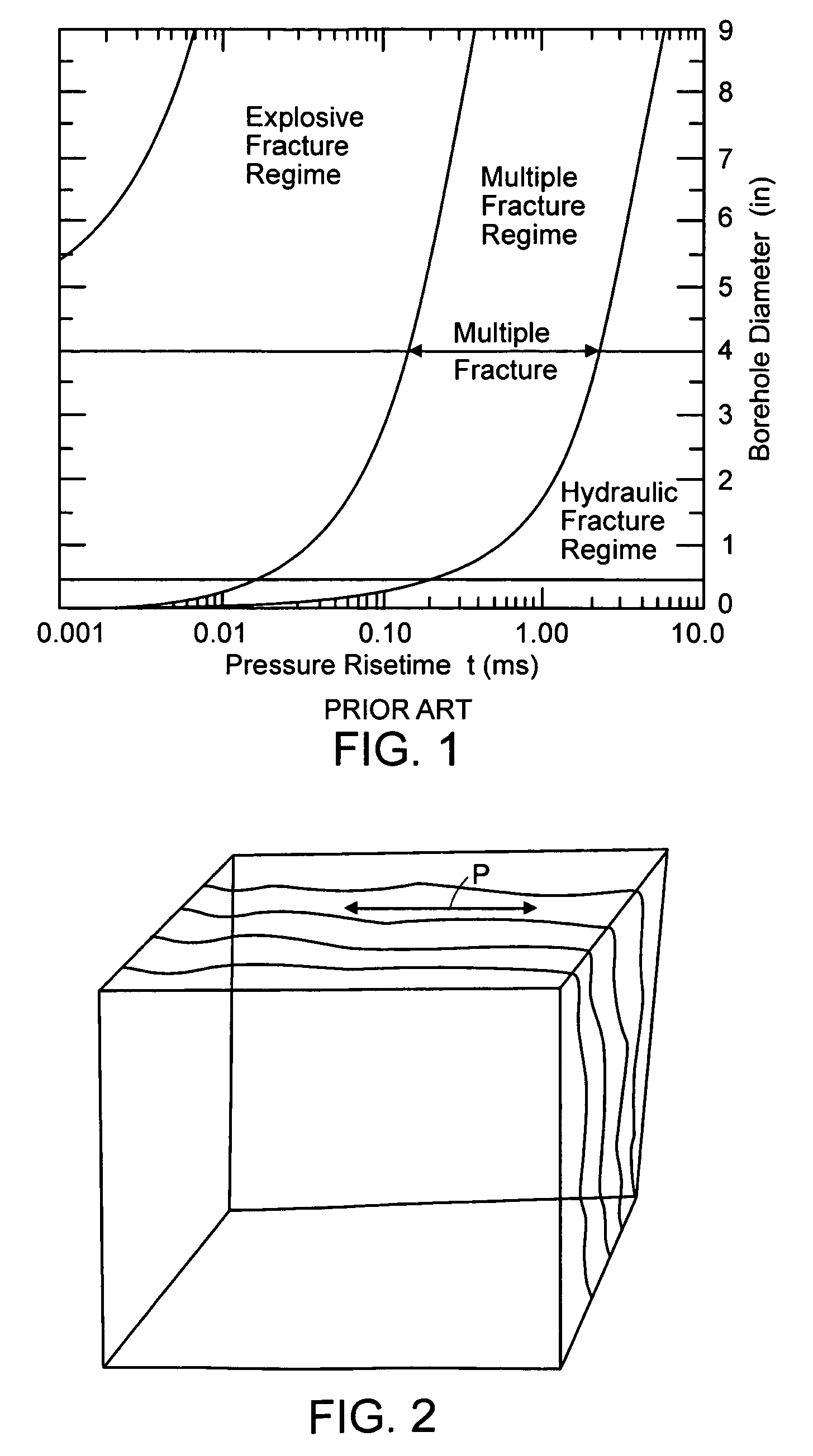

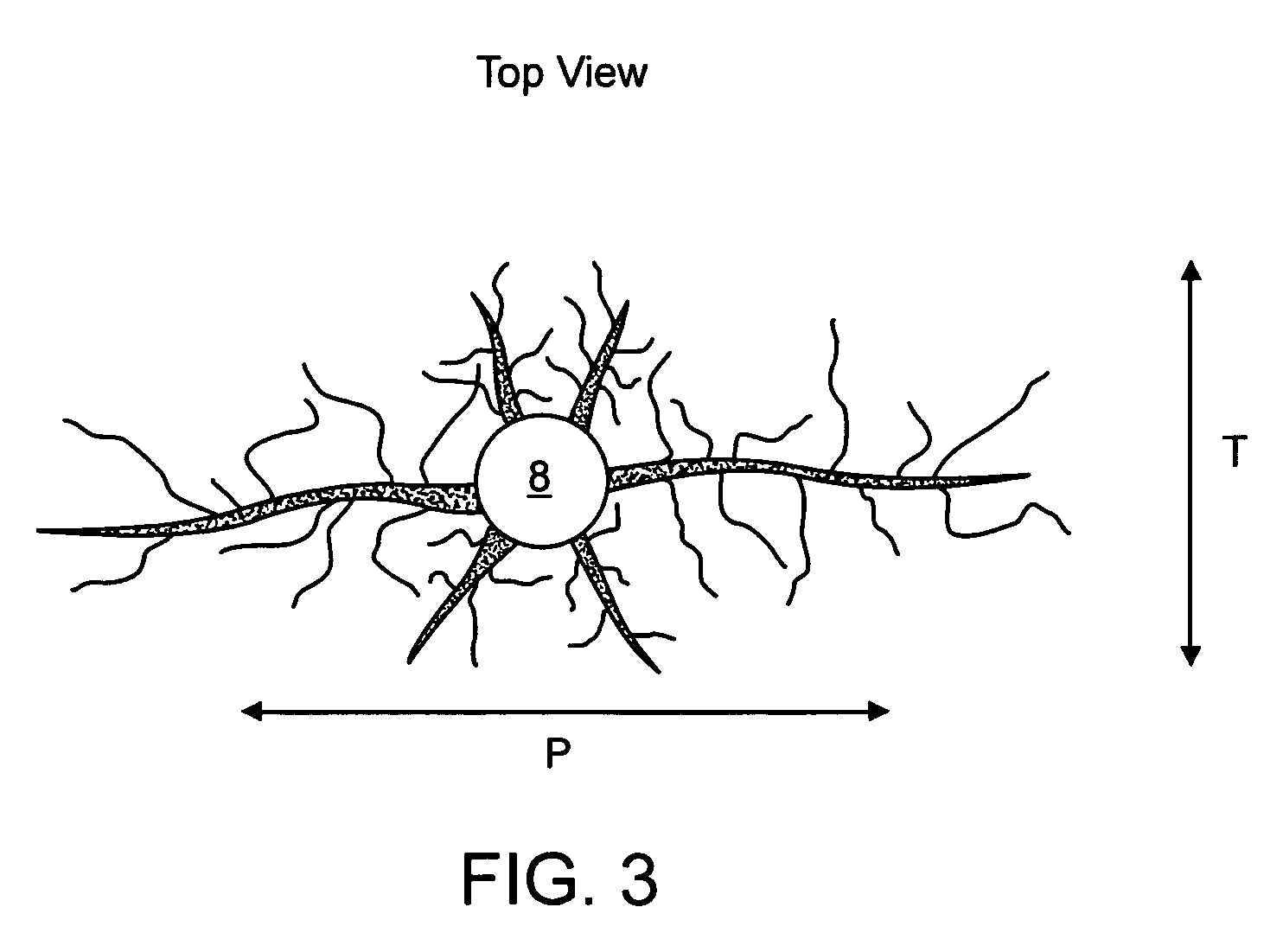

Method and apparatus for stimulating wells with propellants

ActiveUS20060185898A1Multiple fracture regimeExtend fractureBlasting cartridgesNuclear explosivesPorosityEngineering

The present invention relates to apparatus and methods to stimulate subterranean production and injection wells, such as oil and gas wells, utilizing rocket propellants. Rapid production of high-pressure gas from controlled combustion of a propellant, during initial ignition and subsequent combustion, together with proper positioning of the energy source in relation to geologic formations, can be used to establish and maintain increased formation porosity and flow conditions with respect to the pay zone.

Owner:SEEKFORD DALE B

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

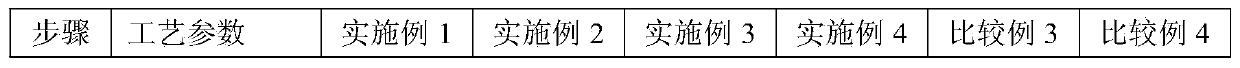

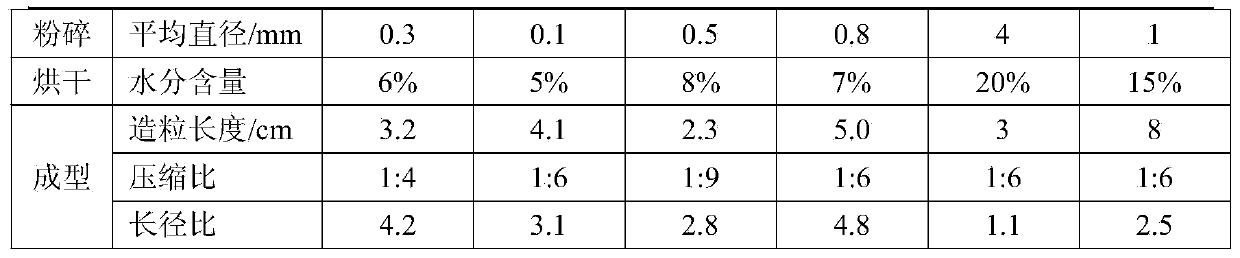

Biomass solid fuel and processing technique thereof

InactiveCN103374427AAchieve innovative resultsAchieving a circular economy modelBiofuelsSolid fuelsAlternative fuelsToxic material

The invention relates to a biomass solid fuel and a processing technology thereof. The biomass solid fuel is prepared by pressing the following raw materials in percentage by weight: 90% of a biomass raw material and 10% of water, wherein the biomass raw material adopts crop derelicts, bamboo-wood processing residues or residual branches and leaves after timber cutting. The biomass solid fuel can replace coal, oil and other primary energy sources and serves as an alternative fuel; because the biomass solid fuel is a renewable energy source, the short supply of energy sources is alleviated; the biomass solid fuel is an environment-friendly fuel, and the combustion emission data reaches the national environmental protection standard, so that the pollution to the air is reduced, and the living environment is improved; and meanwhile, the biomass solid fuel is simple in processing technique, and the production process does not generate toxic substances and can not cause damages to the environment, so that the biomass fuel has an important significance for promoting the construction of a new socialist countryside.

Owner:佛山市三水环能再生能源有限公司

Method and apparatus for stimulating wells with propellants

ActiveUS7565930B2Multiple fracture regimeExtend fractureBlasting cartridgesNuclear explosivesPorosityEngineering

The present invention relates to apparatus and methods to stimulate subterranean production and injection wells, such as oil and gas wells, utilizing rocket propellants. Rapid production of high-pressure gas from controlled combustion of a propellant, during initial ignition and subsequent combustion, together with proper positioning of the energy source in relation to geologic formations, can be used to establish and maintain increased formation porosity and flow conditions with respect to the pay zone.

Owner:SEEKFORD DALE B

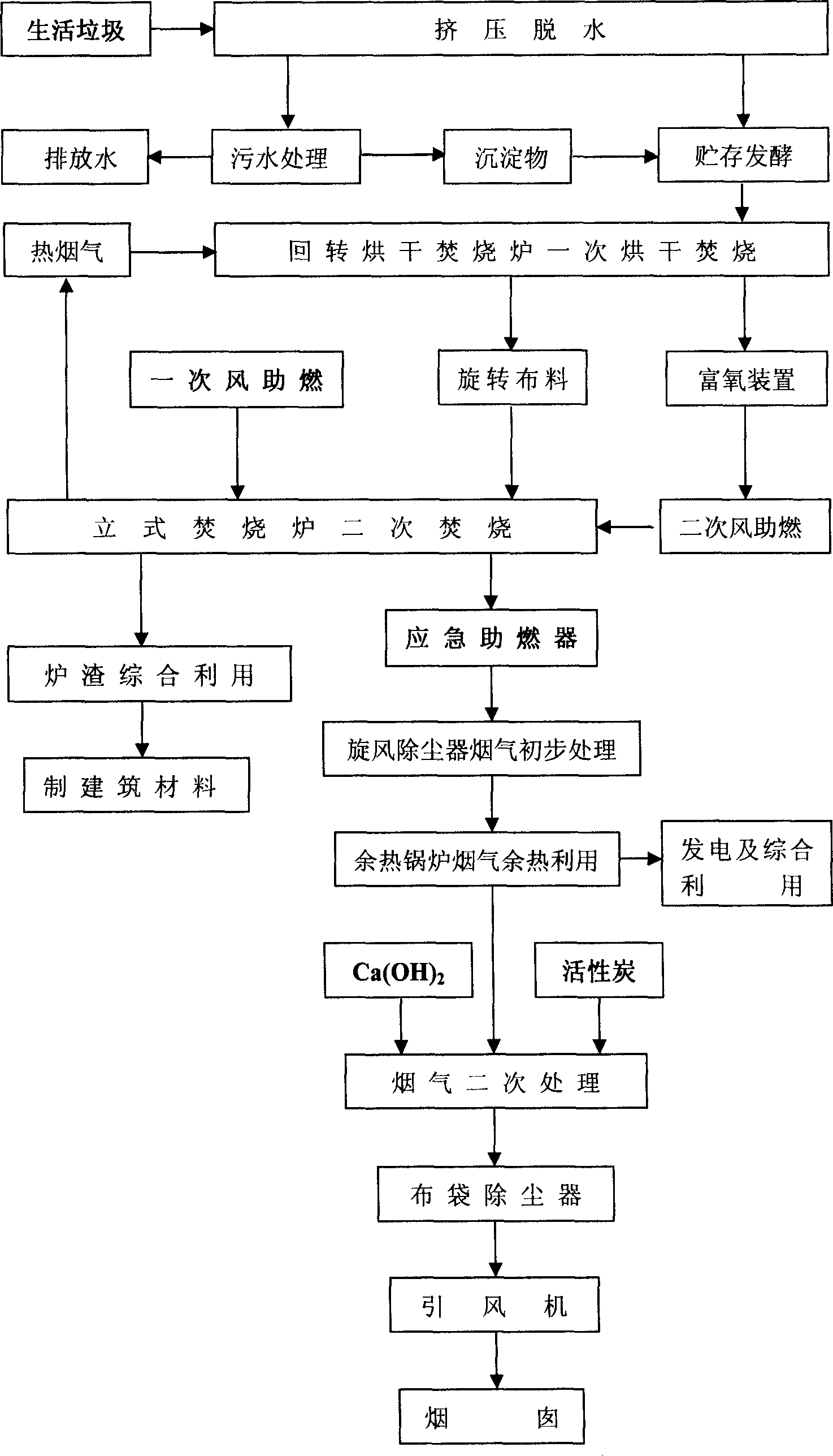

Life-garbage comprehensive treatment technology

InactiveCN1850370AIncrease temperatureExtended burn timeSolid waste disposalIncreasing energy efficiencySlagEnvironmental engineering

The present invention relates to a comprehensive treatment process of house refuse. Said treatment process includes the following steps: (1), squeezing and dehydrating; (2), storing and making fermentation, (3), using rotary baking incinerator to make firest incineration; (4), using vertical incinerator to make secondary incineration; (5), smoke primary treatment; (6), smoke waste heat utilization for power goneration and heating water; (7), secondary treatment of smoke; and (8), utilization of incinerator slag to make building material.

Owner:滕清华 +1

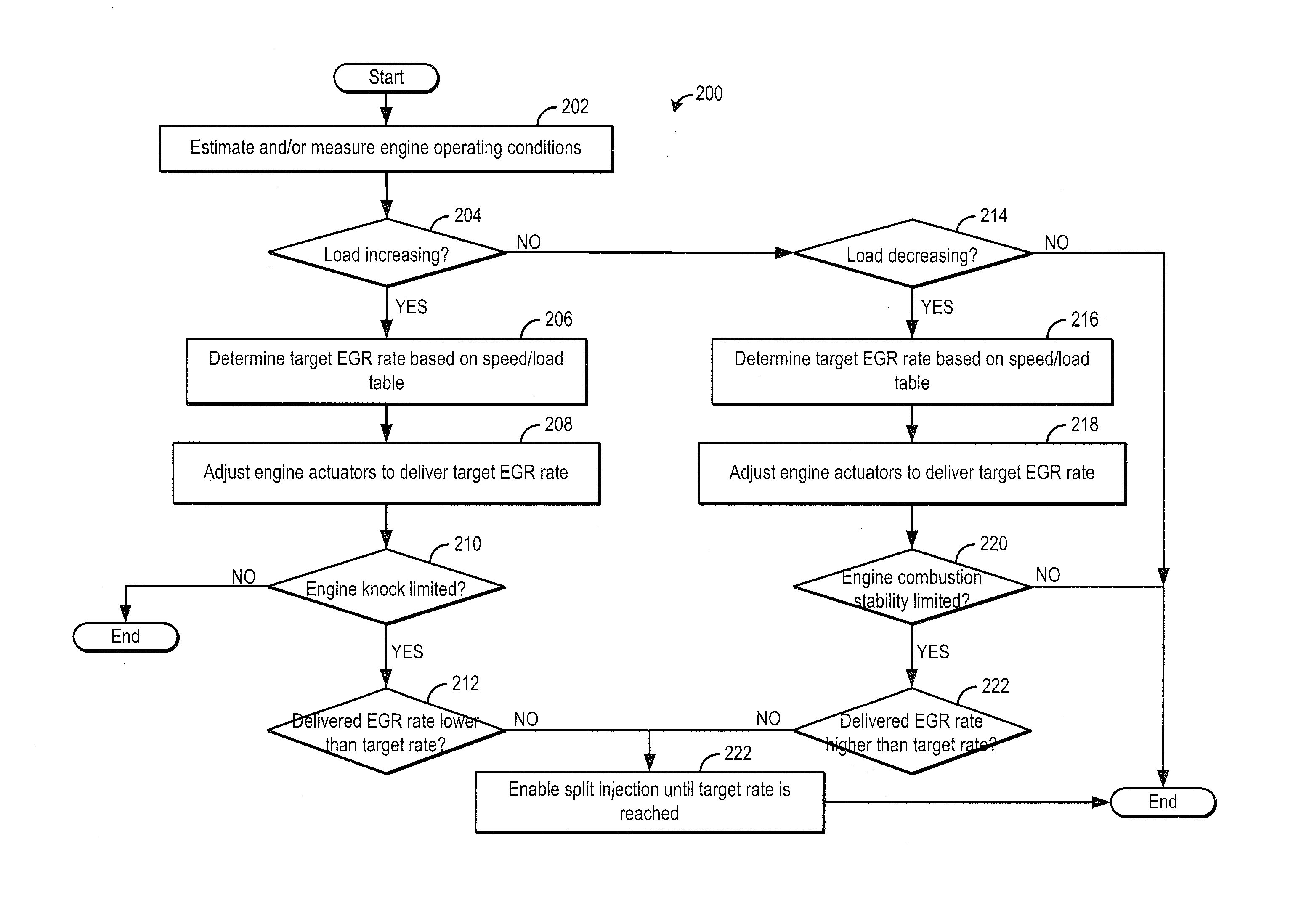

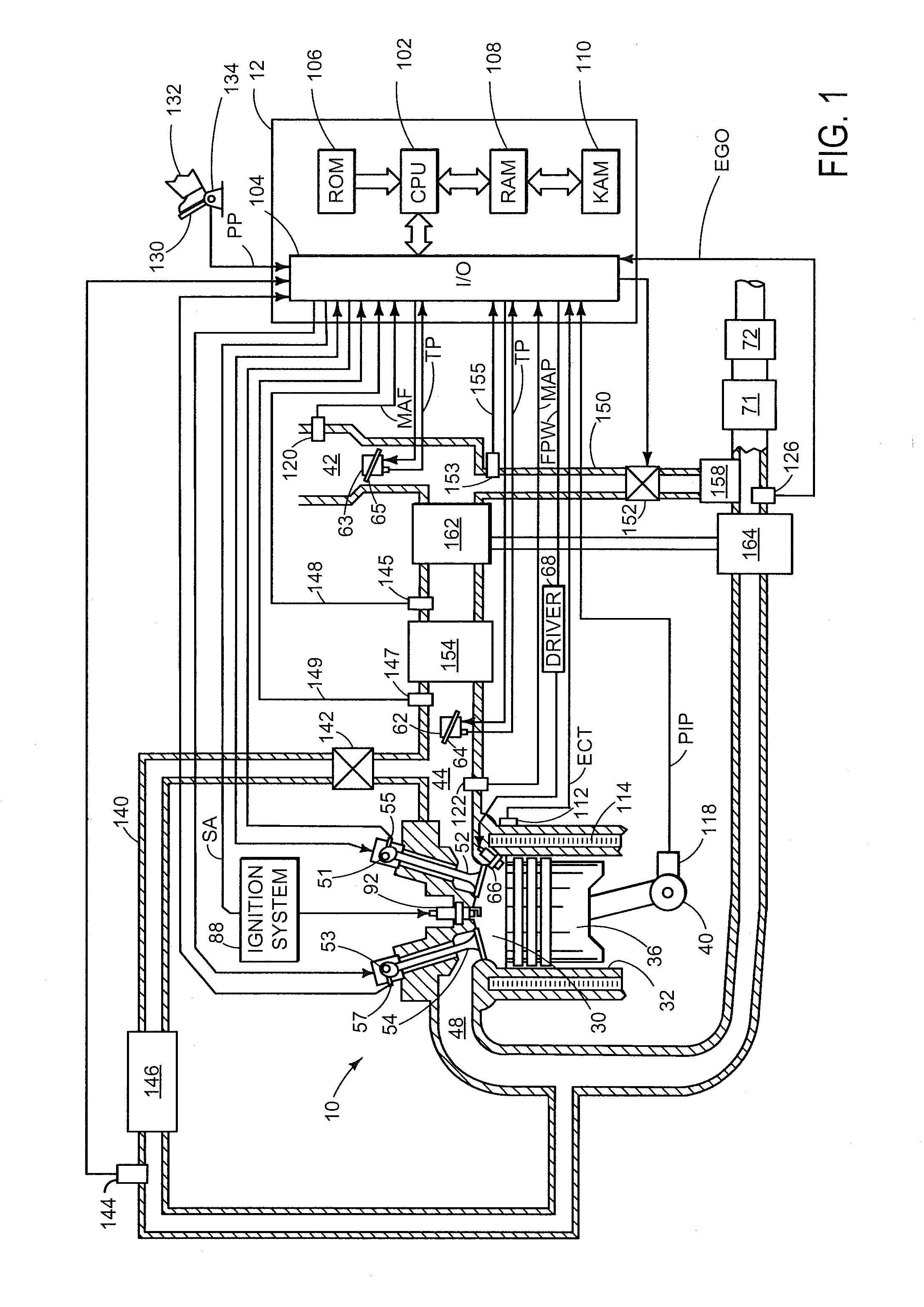

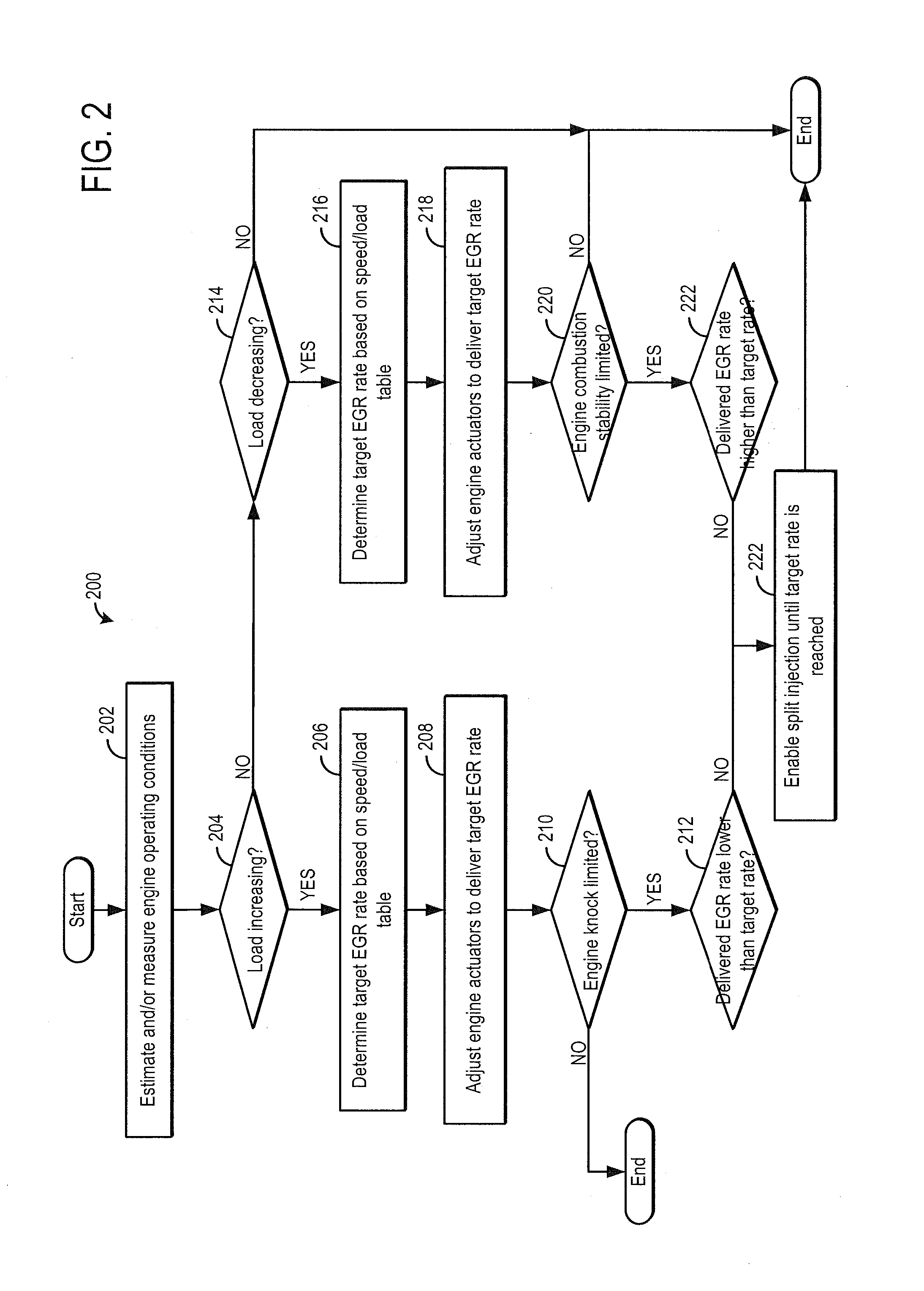

Method and system for improved dilution tolerance

ActiveUS20150057911A1Improve fuel economyImprove vehicle emissionElectrical controlInternal combustion piston enginesCombustionLow load

Methods and systems are provided for improving combustion stability, in particular during transient operations such as tip-out to lower load conditions, when EGR is being purged. Until a desired LP-EGR rate is achieved, fuel may be delivered as a split injection with at least an intake stroke injection and a compression stroke injection. Subsequently, single fuel injection may be resumed.

Owner:FORD GLOBAL TECH LLC

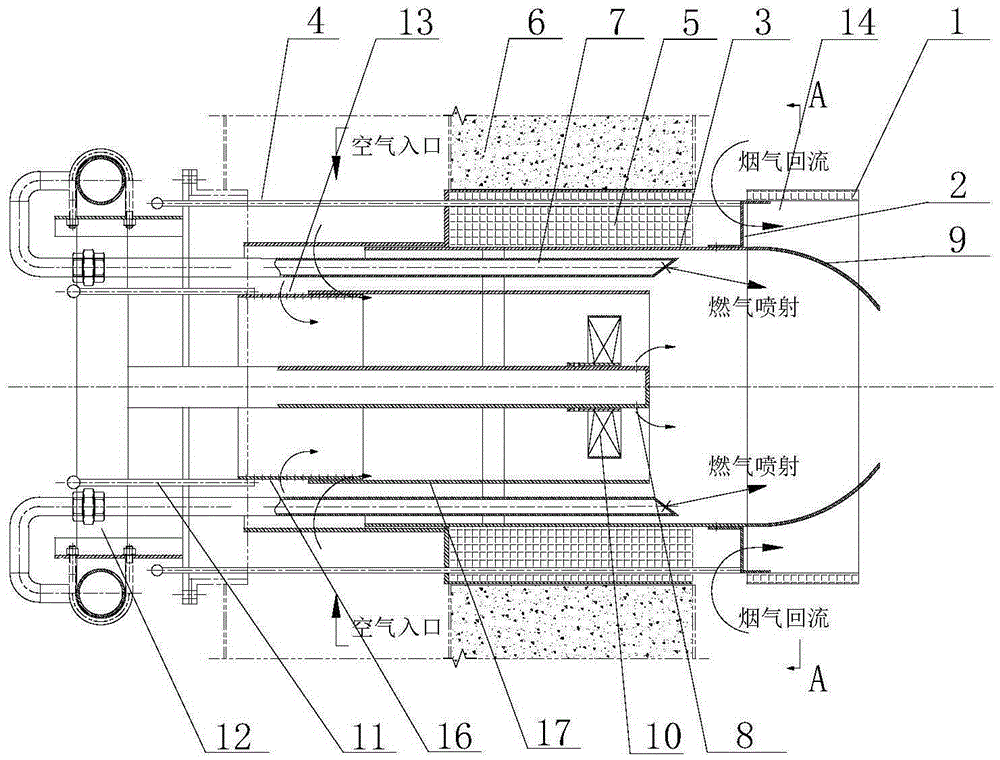

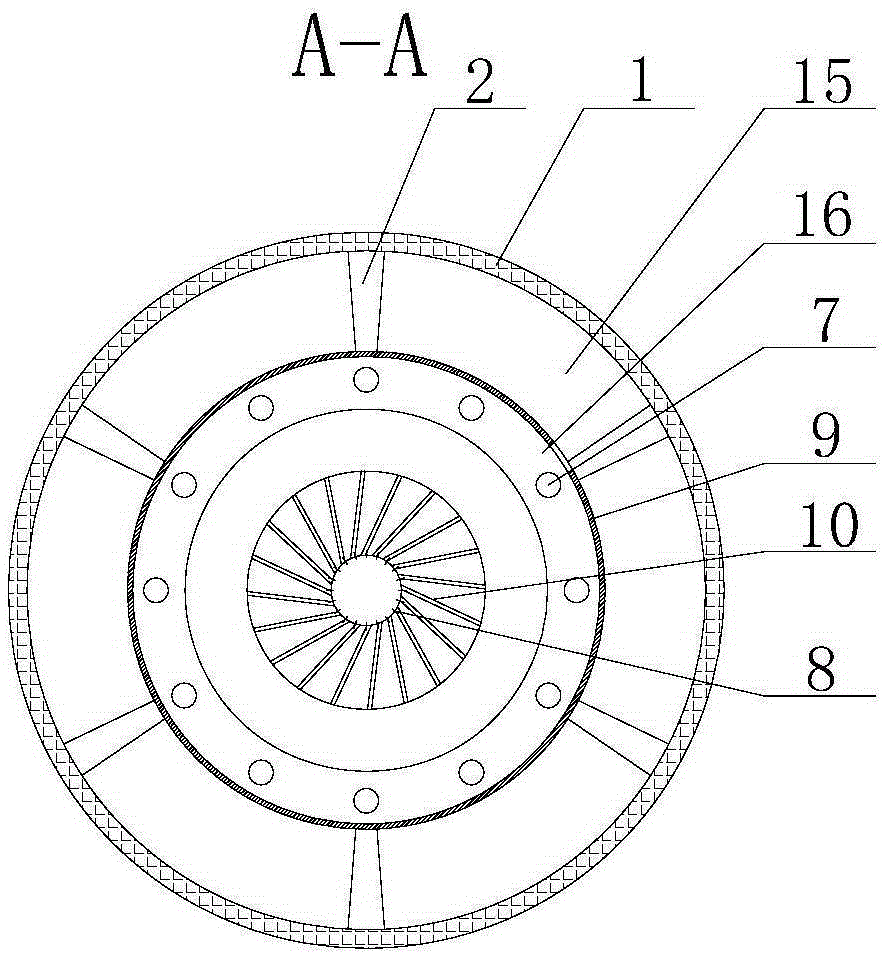

Smoke internal circulation low-nitrogen combustor

InactiveCN105299651ADilute oxygen concentrationExtended burn timeGaseous fuel burnerCombustorLow nitrogen

The invention discloses a smoke internal circulation low-nitrogen combustor which comprises an outer barrel. An inner barrel is arranged in the outer barrel. Main gas spray guns are arranged in a clearance between the outer barrel and the inner barrel. A center gas spray gun is arranged in the inner barrel. A mixed gas outlet flow guide shrinkage cover is fixedly connected with the end of the outer barrel and sleeved with a smoke backflow cover. The smoke backflow cover can slide front and back along the axis of the outer barrel. A smoke backflow channel is arranged between the mixed gas outlet flow guide shrinkage cover and the smoke backflow cover. According to the scheme, smoke in a hearth can flow into a flame area of a combustor outlet through the smoke backflow channel, and therefore the oxygen concentration in mixed gas is diluted, the combustion time of fuel is prolonged, the combustion strength is lowered, high-temperature areas are avoided, and finally the aim of reducing NOx emission is achieved. By means of the structure, no circulating smoke pipeline or circulating fan needs to be additionally arranged, and therefore the investment cost is low.

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD +1

Biomass particle fuel

InactiveCN101955830AAvoid or reduce flowHigh calorific valueBiofuelsSolid fuelsEngineeringAnthracite

The invention discloses a biomass particle fuel. The biomass particle fuel comprises the following components in percentage by weight: 50 to 60 percent of plant straw, 2 to 5 percent of anthracite, 15 to 20 percent of coal slime, 2 to 5 percent of yellow mud, 2 to 5 percent of waste grease, 8 to 12 percent of food wastes, 8 to 12 percent of water and 10 to 15 percent of large animal manure. The fuel has the characteristics that: firstly, heat value is increased remarkably and unit heat value is up to 5,000 kilocalories; secondly, burning point is lowered greatly; thirdly, due to the addition of supporting materials such as the yellow mud and the like, air permeability is improved and heat utilization ratio is increased; fourthly, combustion time can be prolonged from 1.5 hours of a pure biomass fuel on average to over 3 hours; fifthly, a large number of food wastes are consumed, so that drainage oil and garbage pigs are reduced and prevented from being sold on the market; and sixthly, the pollution of the large animal manure on the environment is reduced.

Owner:王德明

Biomass pellet fuel and preparation method thereof

ActiveCN105542893AReduce moisture contentHigh lignin contentBiofuelsSolid fuelsPropanoic acidSodium Bentonite

The invention provides a biomass pellet fuel and a preparation method thereof. The biomass pellet fuel comprises the following components, by weight: herbivorous animal manure, agricultural waste, illegal cooking oil, calcium oxide, calcium sulfate, propionic acid, kaolin, diatomaceous earth, bentonite, calcium peroxide, aluminum hydroxide, propylene glycol, polyvinyl alcohol, an oxygenate, an antiknock agent, a combustion improver, and a bulking agent. The biomass pellet fuel has low water content and high lignin content. According to the invention, a large amount of agricultural waste and animal manure are utilized. Air pollution caused by the activities of burning agricultural waste is greatly reduced, and animal manure can be effectively treated, such that recycling application value is improved, and the fuel is more environment-friendly. Compared to conventional biomass pellet fuels, the biomass pellet fuel provided by the invention has the advantages of high combustion value, long combustion time, no harmful gas emission after combustion, and no corrosion to combustion equipment.

Owner:太仓东浔生物科技有限公司

Biomass fuel and preparation method therefor

The present invention provides biomass fuel and a preparation method therefor. The biomass fuel comprises the following ingredients in parts by weight: lignin, agricultural wastes, sea mud, sepiolite flocking, aluminum oxide, silane coupling agents, ammonium chloride, dimethyl silicone oil, yeast extract powder, capsaicin, di-tert-butyl hydroquinone, oxygenates, a shock-resistant and antiknock agent, a combustion improver, and a bulking agent. The biomass fuel has low moisture content and high lignin content. With the use of a large amount of agricultural wastes, air pollution caused by burning agricultural wastes and other activities is greatly reduced, and recycling utilization value is improved, so that the biomass fuel is more environmentally friendly. Compared with conventional biomass fuel particles, the biomass fuel provided by the present invention has a high fuel value, a long burning time, no discharge of harmful gas after combustion, and no corrosion on a combustion device.

Owner:太仓东浔生物科技有限公司

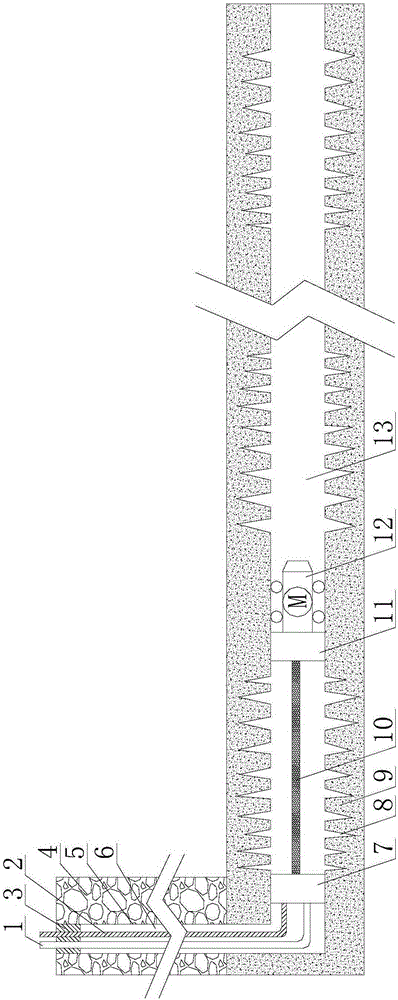

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

Novel biomass granular fuel

InactiveCN102876418AWide variety of sourcesIncrease the content of seed charcoalBiofuelsSolid fuelsPrillMaterials science

The invention discloses a novel biomass granular fuel, and belongs to the field of biomass granular fuels. The novel biomass granular fuel comprises the following three raw materials by mass percent: 20-60 percent of wood chips, 20-45 percent of rice hull and 10-40 percent of coal gangue powder. According to the proportion, the wood chips and the rice hull are pulverized, the coal gangue powder is added and then the mixture is uniformly mixed; and the mixture is subjected to drying, compressing, screening, cooling and packaging procedures to prepare the biomass granular fuel. According to the invention, the novel biomass granular fuel can solve the problems of single raw material source, short fuel burning time, incomplete burning and the like of the conventional biomass granular fuel and has the advantages that the raw material sources are wider, the energy saving and environmental protection purposes are achieved, the fuel burning time is prolonged, and the heating value of the biomass granular fuel is increased.

Owner:郭丰亮

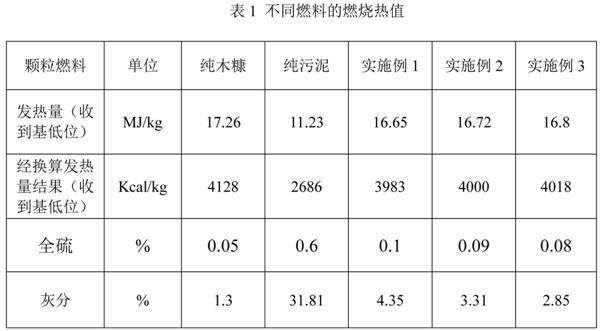

Environment-friendly biomass granular fuel and preparation method thereof

The invention discloses an environment-friendly biomass granular fuel, which comprises the following components in part by weight: 80-85 parts of sawdust, 5-10 parts of sludge and 0.1-1 part of illegally recycled waste cooking oil. A preparation method of the environment-friendly biomass granular fuel comprises the following steps: drying the sawdust and the sludge, adding the illegally recycled waste cooking oil to the sawdust and the sludge, agitating the mixture uniformly, and processing the mixture into cylindrical grains under conditions of a high temperature and a high pressure. By using the biomass granular fuel provided by the invention, the production cost is decreased; the energy consumption is decreased; the combustion heat value is high; the combustion time is long; the wear of a machine is reduced; the environment is protected effectively; the fuel problem is solved; simultaneously, the health is also protected; the biomass granular fuel is environment-friendly; the cost is decreased; after the biomass granular fuel is combusted, waste residues can be returned to the nature to be used as a fertilizer, and also can be used as a raw material of an environment-friendly brick; and the resource utilization and the harmless treatment of waste materials such as the sludge, the illegally recycled waste cooking oil and the like are achieved.

Owner:曹其宽

Combustion-supporting, desulfurization and coal-saving additive used for boiler fire coal

InactiveCN101230301AHigh thermal efficiencyPrevent coking accidentsSolid fuelsFuel additivesCombustionPotassium dichromate

The invention provides a combustion-supporting desulfurating coal-saving additive which is used in the burning coal in boiler, the preparation of which is composed of 24-35 percent combustion improvers of methanol, aether, tween-80; 32-38 percent oxidants of potassium permanganate, potassium chlorate and potassium dichromate; 4-28 percent desulfurizer in which quicklime, potassium permanganate, potassium chlorate and potassium dichromate take part in; 18-22 percent anti-coking agent which contains potassium dichromate and quicklime; the rest is water, which complement the total volume of the additive to be 100 percent. The additive is prepared by adding water in the quicklime to produce lime cream; heating the water for acting as solution, after potassium permanganate, potassium chlorate and potassium dichromate are added into the solution and are stirred evenly; adding and mixing the methanol and tween-80 into the solution evenly, and then adding and mixing the lime cream into the solution evenly; finally adding and mixing the aether into the solution evenly; and preserving the heat for 1 hour. The invention can improve the desulfurization rate by 40 percent, improve the coal saving rate by 25 percent, and improve the thermal efficiency of the boiler by up to 5-10 percent; and can prevent the occurrence of boiler coking accident.

Owner:周兴泽

Preparation method of biomass sludge regenerated fuel charcoal

The invention relates to a preparation method of biomass sludge regenerated fuel charcoal. The method comprises the following steps: taking sludge, deodorizing, sterilizing, grinding biomass fuels, mixing the two materials, performing high temperature sterilization, and screening to obtain a product. The method can be adopted to dispose and comprehensively utilize sludge and waste biomass fuels; and the prepared fuel charcoal is environmentally-friendly and low in ignition point. The combustion products of the fuel charcoal are fewer and have low sulfur content. The method can be used for fully utilizing sludge and various wastes (biomass fuels), thus the purposes of energy conservation, emission reduction and development of circular economy can be realized.

Owner:王东

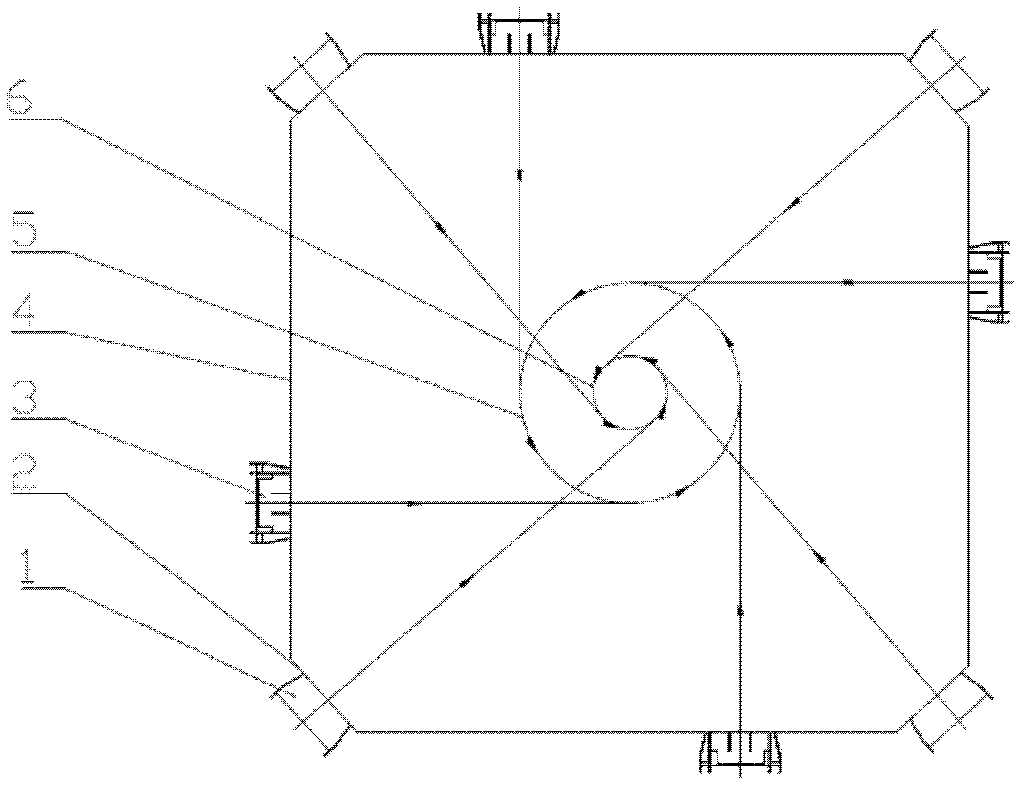

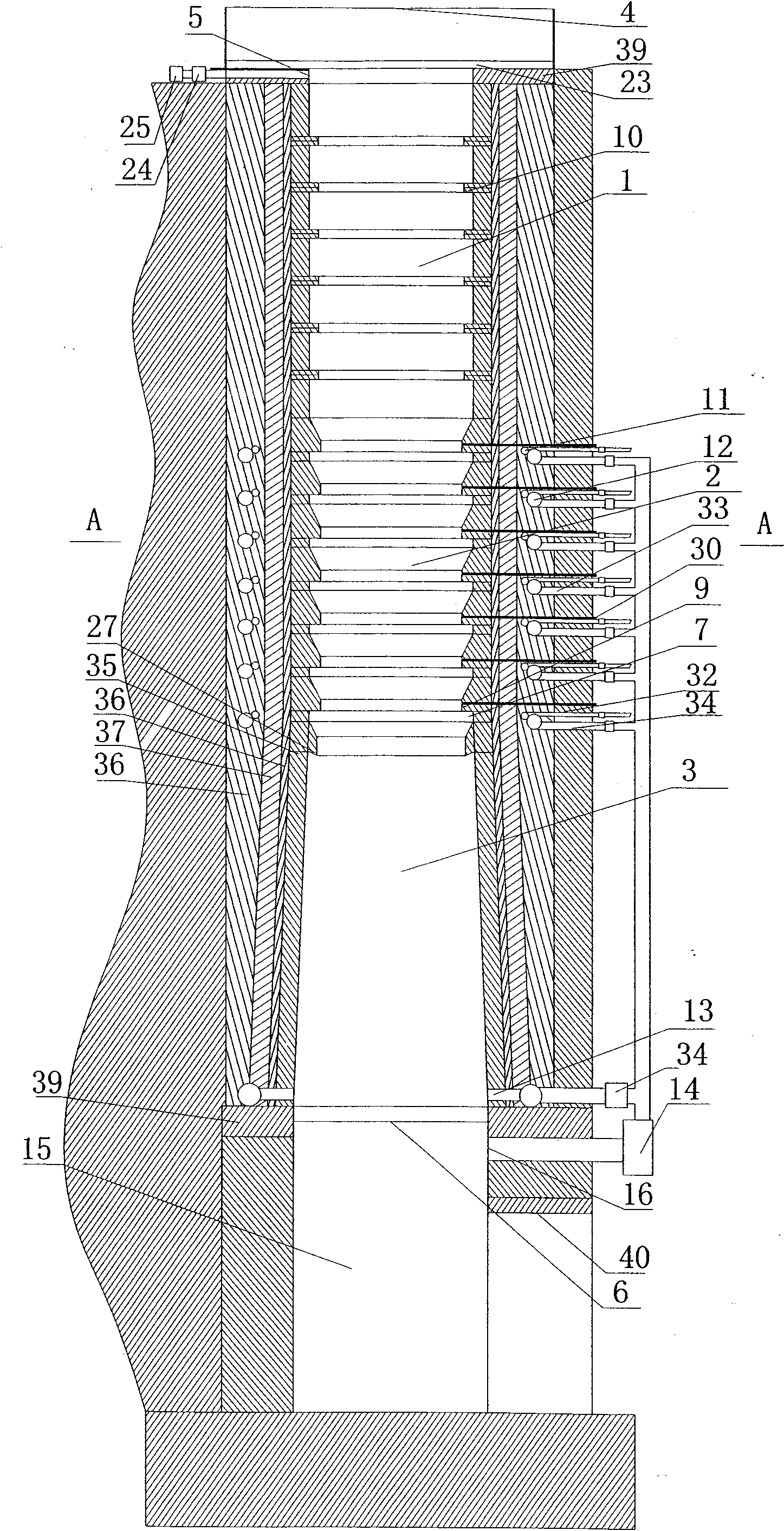

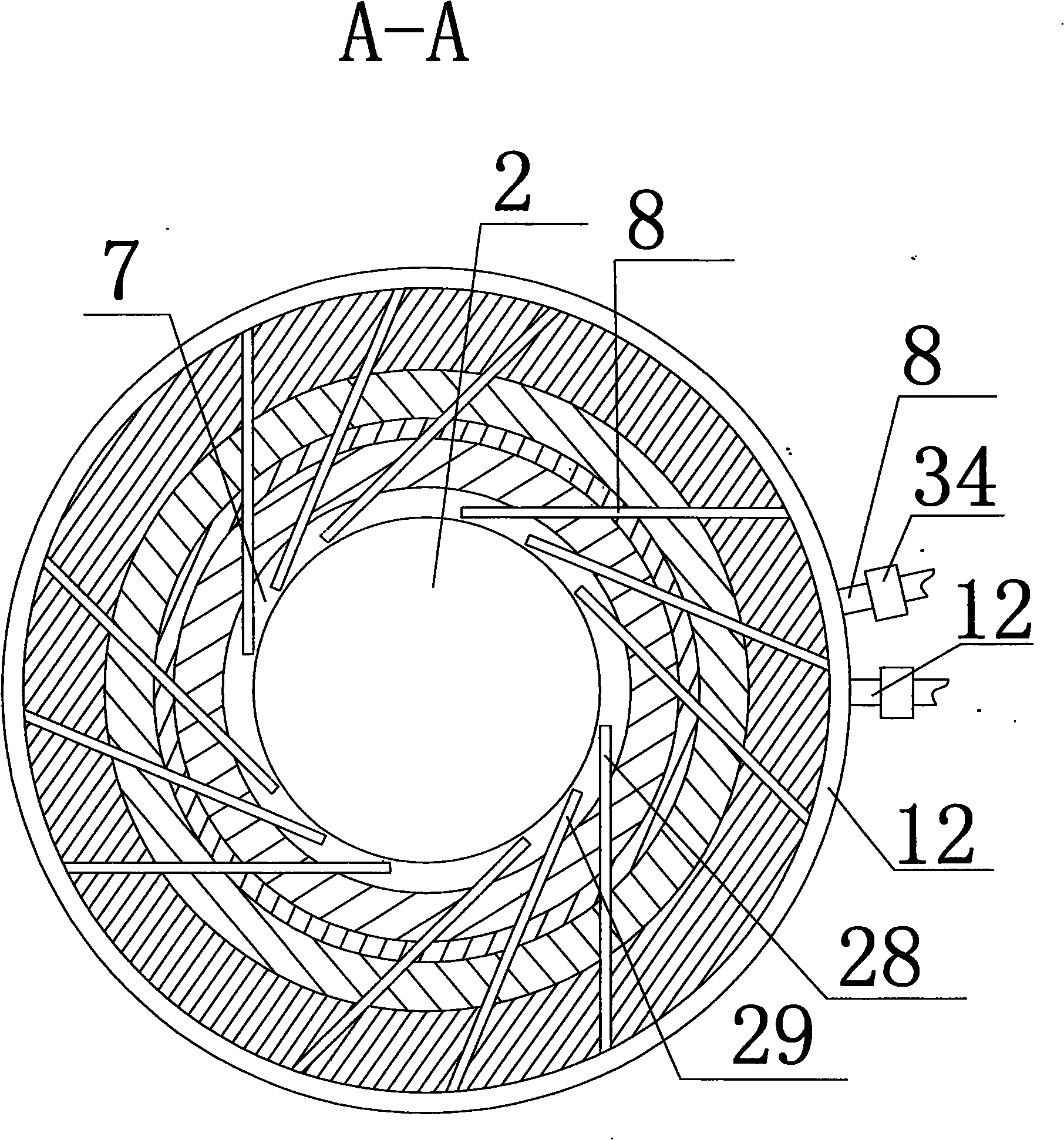

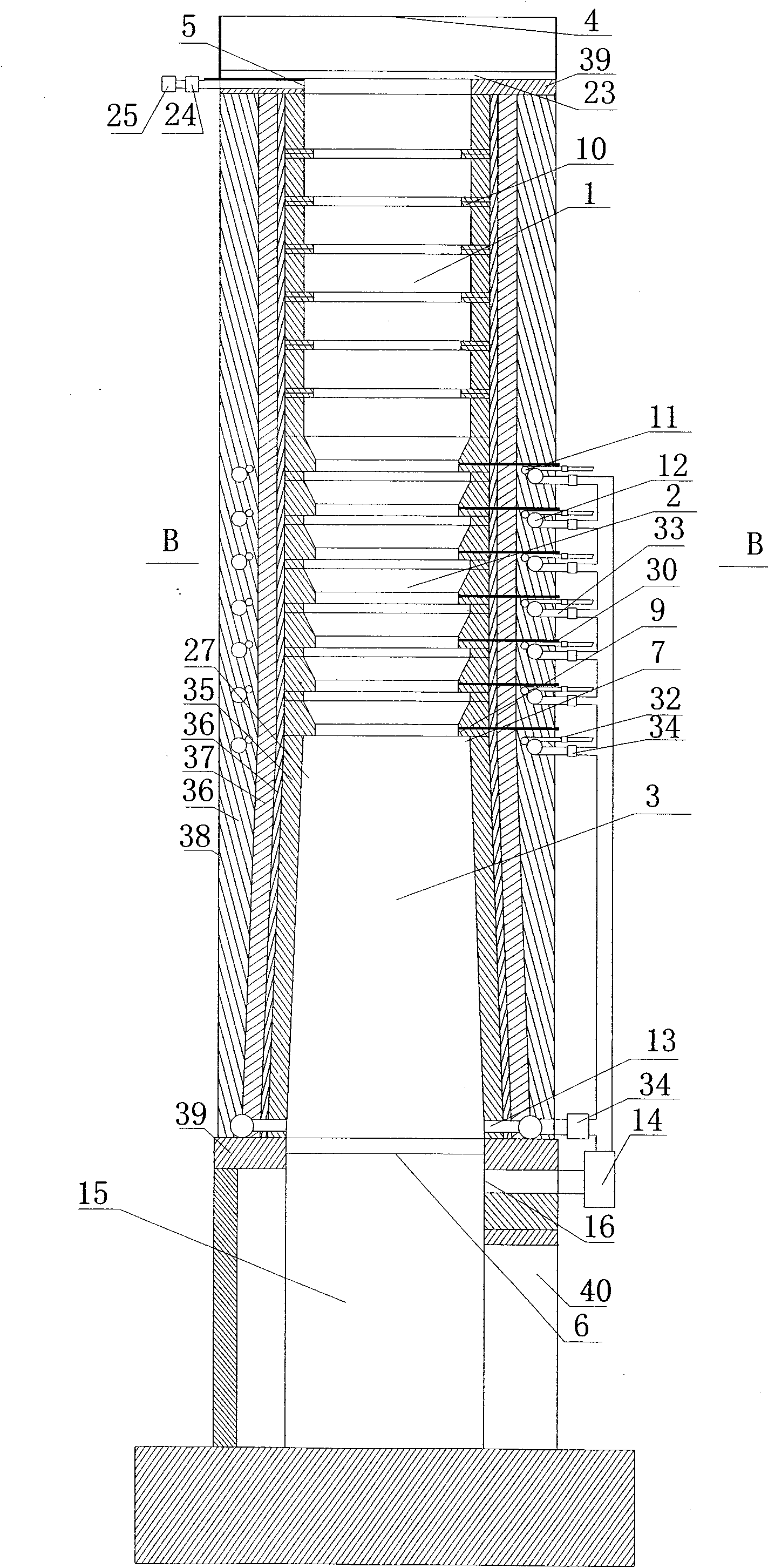

Multi-corner tangential multi-scale pulverized coal decoupling combustion device and decoupling combustion method thereof

InactiveCN103134049AOvercoming the Persistent Problem of Combustion-Coupled EmissionsDecoupled combustion reducesCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCENBOLCombustion

The invention relates to a multi-corner tangential multi-scale pulverized coal decoupling combustion device and a decoupling combustion method thereof; based on pulverized coal combustion characteristics and substance transformation rules, in a microcosmic scale, each column of primary air nozzles (3) on a multi-corner tangential combustion furnace hearth is arranged in a manner that at least 2 or more than 2 nozzles are centralized and adjacent to each other up and down, and the nozzles (3) are relatively centralized at an area in the hearth close to the flame center and with a very high temperature, so multi-area horizontal front-and-back fractional combustion is realized; in a medium scale, second-stage secondary air nozzles (1) are arranged in a local centralization mannerto form a strong reducibility area and a weak reducibility area or a weak oxidability area respectively before and after mixing with the primary air nozzles (3), so multi-area horizontal left-and-right fractional combustion is realized; in a macroscopic scale, peripheral over-fire air nozzles (8) and center over-fire air nozzles (9) are disposed to respectively form a reducibility area and an oxidability area at the lower and upper parts of the hearth, so vertical up-and-down air fractional combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Environmental-friendly solid fuel manufactured by municipal solid waste without manual classification and manufacturing method thereof

ActiveCN101831339AQuality improvementEfficient desulfurizationBiofuelsSolid fuelsBiotechnologySolid fuel

The invention discloses solid fuel manufactured by municipal solid wastes without manual classification. The solid fuel is manufactured by the following components in percentage by weight: 75%-85% of treated municipal solid wastes, 2%-7% of coal dust containing fixed carbon and 10%-20% of mixed additives. The invention aims at overcoming the defects in the prior art and increasing a novel treatment technology taking a biotechnology as a main technology to carry out advanced treatment on the municipal solid wastes, thereby providing the solid fuel which turns wastes into useful things by taking the municipal solid wastes as raw materials, has low production cost and little pollution, is beneficial to the environmental protection and has high combustion efficiency; and in addition, the invention has an other purpose of additionally providing a method which has simple process and environmental protection and is used for producing the solid fuel for changing a biochemical treatment methodof percolate generated in the wastes treatment process, wherein the biochemical treatment method has high production cost.

Owner:茹兆祥 +2

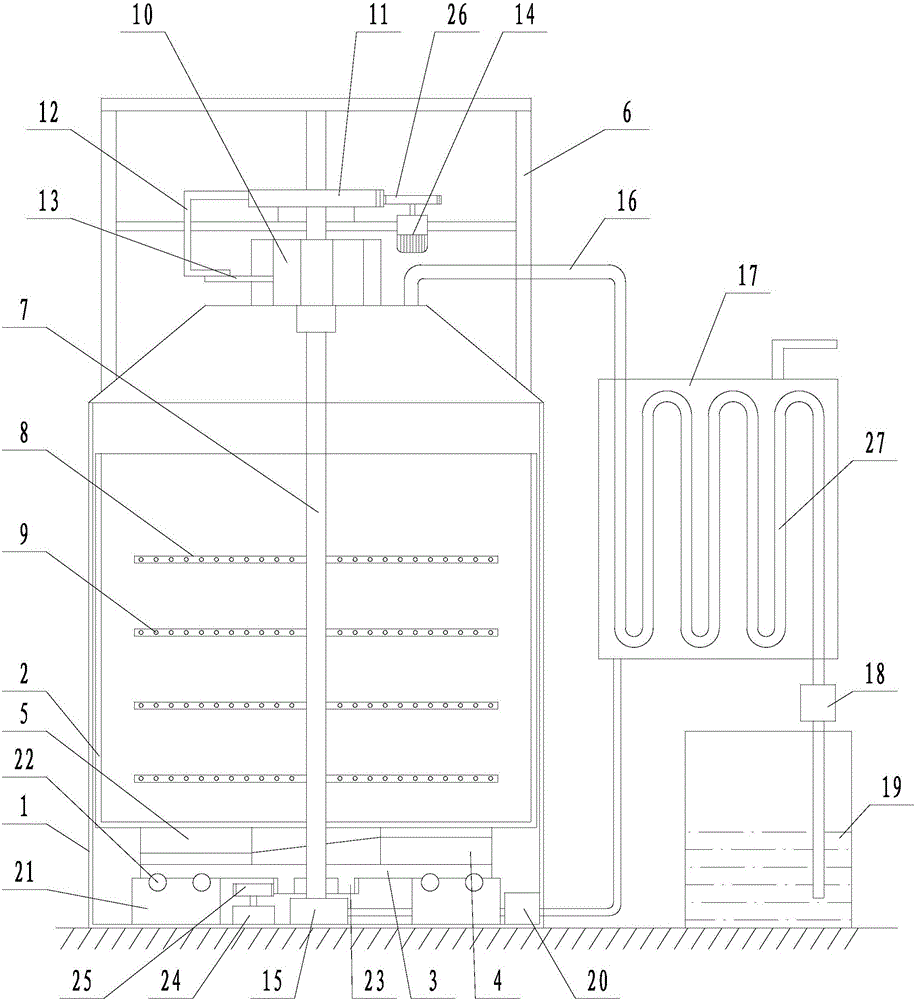

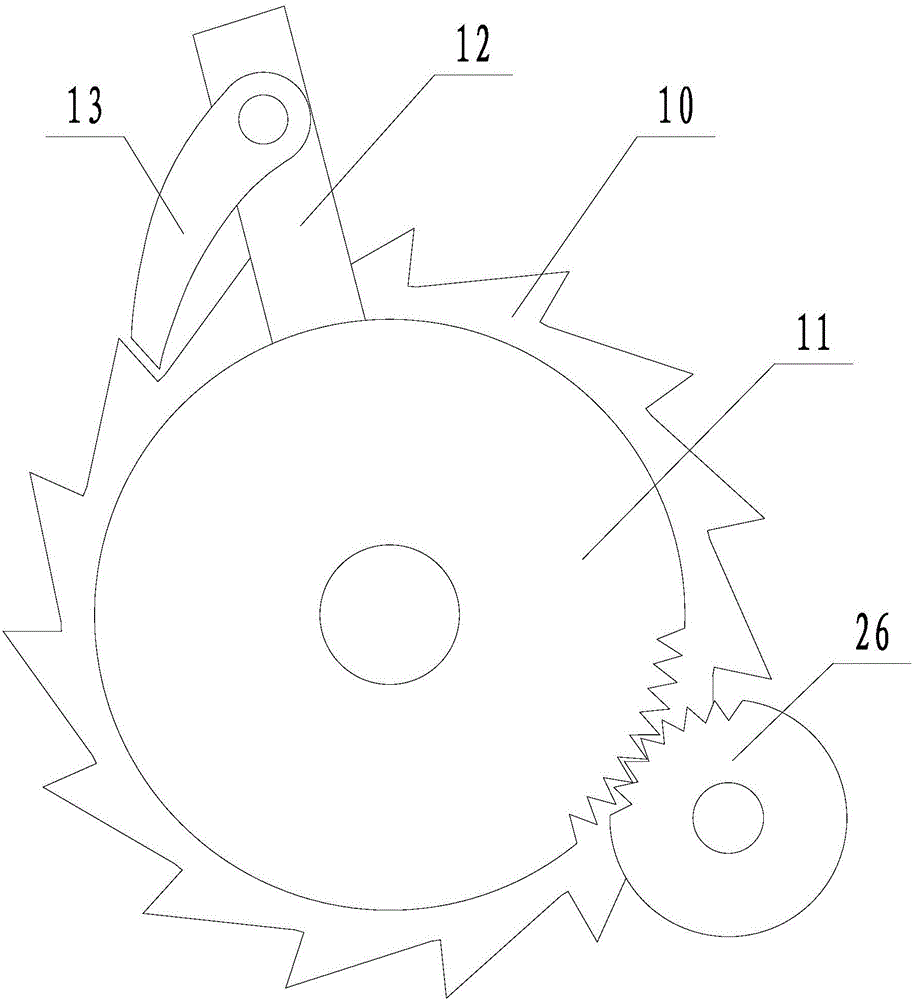

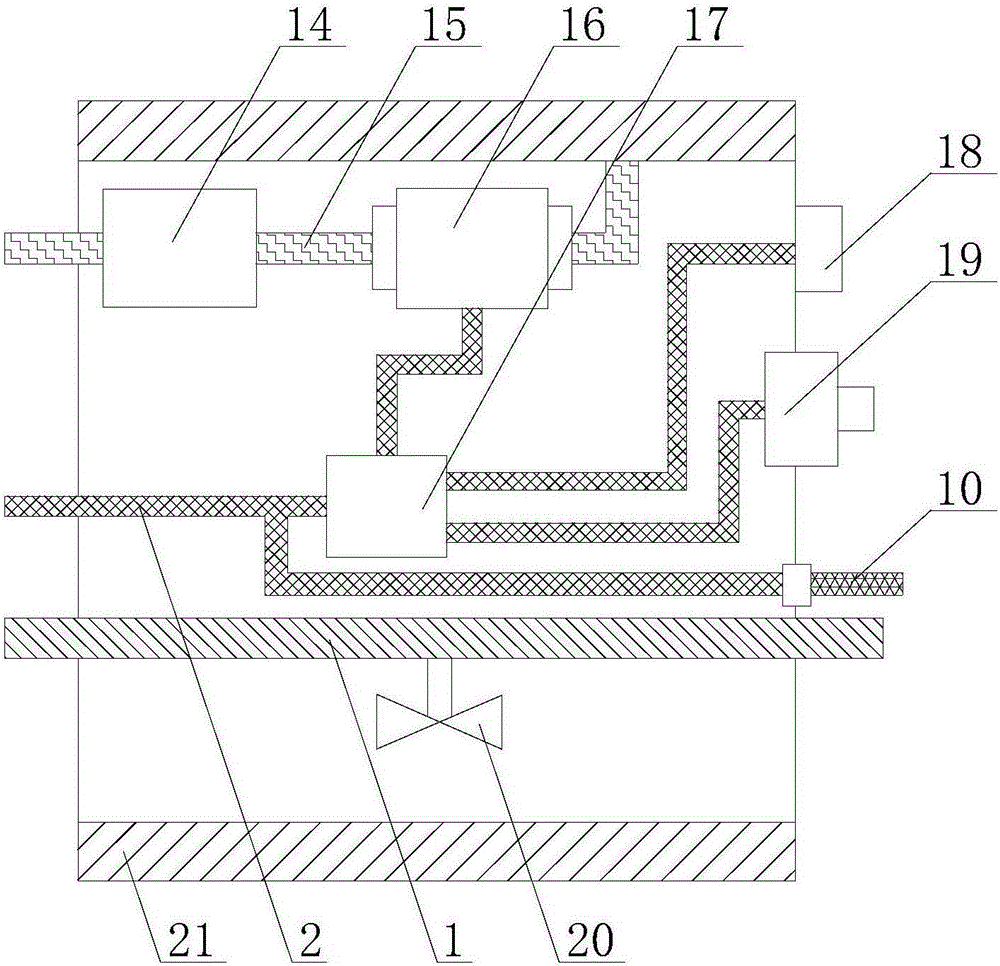

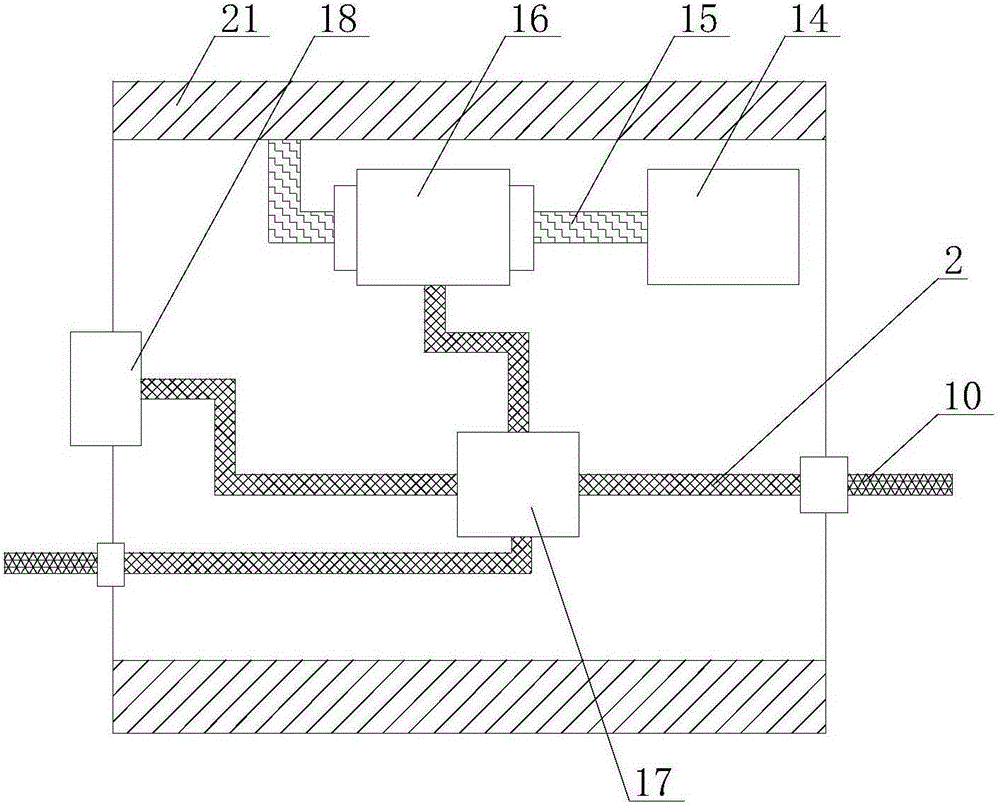

Garbage incineration device and method

InactiveCN105864789AImprove combustion effectBurn completelyIncinerator apparatusSmokeHeat exchanger

The invention discloses a garbage incineration device and method and aims to solve the problems that an existing garbage incineration furnace is incomplete in garbage incineration, low in incineration speed and poor in incineration effect. The garbage incineration device comprises an incineration tank, an incineration furnace is connected in the incineration tank in a sleeved mode, and a rotating disc capable of pushing the incineration furnace to shake up and down is installed on the inner bottom surface of the incineration tank; a hollow stirring shaft is arranged in the incineration furnace, hollow stirring rods are connected to the stirring shaft and communicate with the stirring shaft, air outlet holes are formed in the stirring rods, ratchet wheel is connected to the upper end of the stirring shaft, and a driving disc is movably connected to the position, over the ratchet wheel, of the stirring shaft in a sleeving mode and connected with a pawl; a supporting base is connected to the inner bottom surface of the incineration tank, the lower end of the stirring shaft is rotationally connected to the supporting base in a sealed mode, the upper end of the incineration tank is connected with a smoke outlet pipe, and the smoke outlet pipe is connected with a smoke inlet of a heat exchanger; a smoke outlet of the heat exchanger is connected with an exhaust fan, an air outlet of the heat exchanger is connected with an air blower, and an air outlet of the air blower is connected to the supporting base through a pipeline and communicates with the stirring shaft.

Owner:ZHEJIANG OCEAN UNIV

Efficient and environment-friendly coal additive and preparation method thereof

The invention discloses an efficient and environment-friendly coal additive, comprising the following components in parts by weight: 2-15 parts of tea seed cake or rapeseed dregs, 5-33 parts of slag, 0.5-2 parts of sodium percarbonate, 0.8-4 parts of potassium chlorate, 1-8 parts of potassium perchlorate, 2-8 parts of sodium chloride, 4-12 parts of barium hydroxide, 1-5 parts of light magnesium oxide, 0.1-1.7 parts of manganese dioxide, 0.5-2.5 parts of nano-titania and 1-21 parts of humic acid. A preparation method comprises the following steps of: mixing the raw materials in weight ratio, crushing to 40-60 meshes, and placing into a stirrer to be stirred for 5-10 minutes. The coal additive provided by the invention is efficient and environment-friendly. The preparation method is simple and convenient and low in cost.

Owner:HUNAN XINWANG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

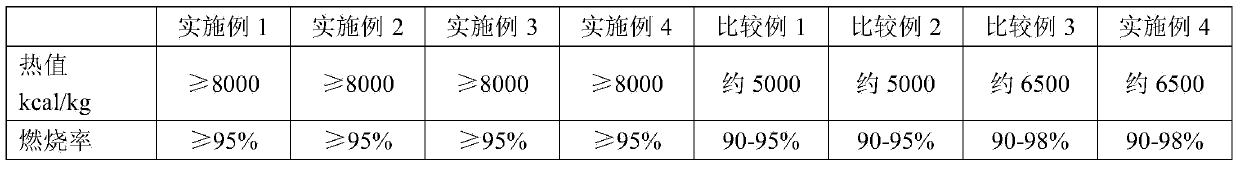

Environmental protection type under-well formation fracturing device

The invention relates to an environmental protection type under-well formation fracturing device, belonging to the technical field of permeability improvement fracturing for horizontal wells, inclined shafts and vertical wells. The device comprises a wellhead plugging device, an under-well tugger, in-well packers, a high-pressure hose, an in-well armored cable, a high-strength cable, an operating control mechanism and a sensor assembly. The under-well tugger is operated through the operating control mechanism to drag the two in-well packers to a set position and form a set under-well fracturing formation space, then the high-pressure hose is controlled to respectively pour spacer fluid, a liquid explosive and a primary explosive into an under-well space to be fractured according to the proportion of formula, and the in-well cable is controlled for electronic ignition to carry out the high-energy high-pressure gas fracturing formation operation; through such manipulation, repetitive or non-repetitive formation fracturing operation in different formation spaces and under different formation conditions is realized. The efficient, economic and environmental-protection formation fracturing device is provided for coal bed gas / shale gas mining, the operation fracturing effect is good, fracture extension can form a wide range of fracture system, the permeability and the desorption rate of a reservoir can be increased, and the purpose of increasing production is achieved. The device is worthy of adoption and promotion.

Owner:ZHONGBEI UNIV

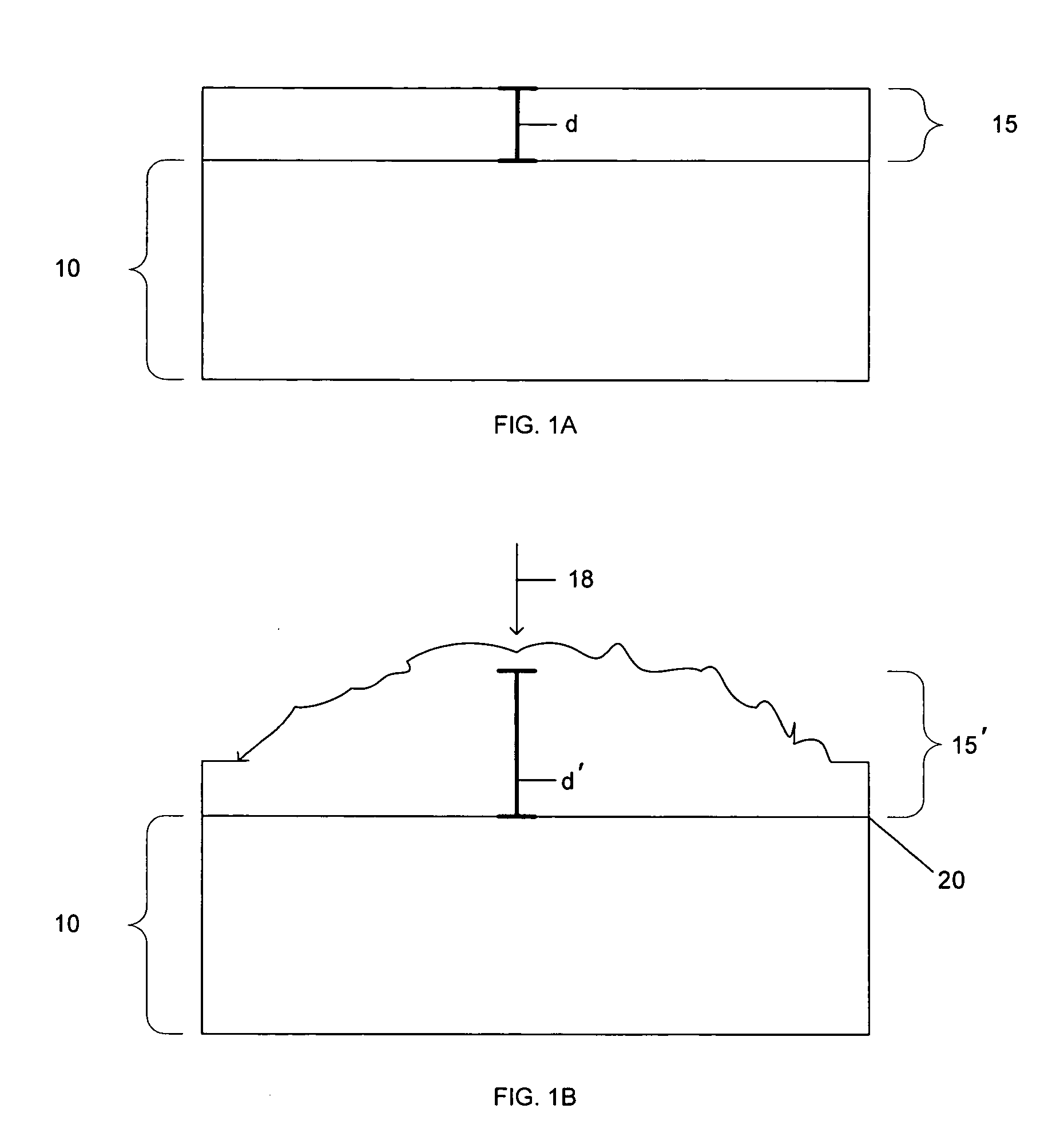

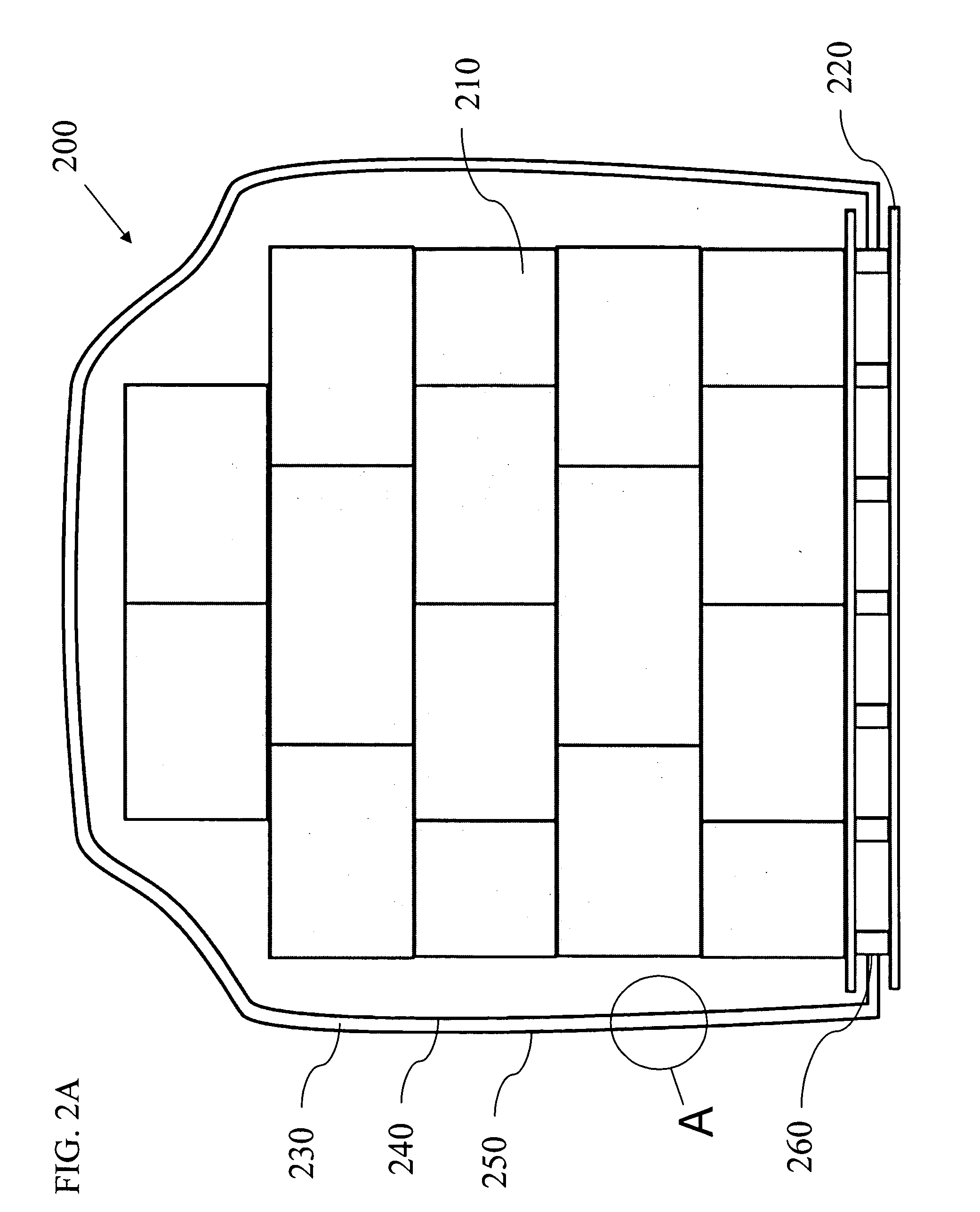

Fire barrier fabric and related fire protective systems

InactiveUS20080302544A1Limit flame spreadExtended burn timeElectrical apparatusFire rescueFire resistanceStandard test

A fire barrier fabric for improving the fire-resistance abilities of a fire protective system includes a fabric having an exterior surface and an interior surface, and an intumescent coating disposed on a portion of at least one of the exterior surface or the interior surface. The intumescent coating as disposed on the fabric achieves class A requirements of ASTM E84 standard test and exceeds a three hour burn-through test. The fire protective system can be used to protect cargo on air, ground, or water vehicles, to protect cables, and / or to protect structures or equipment from fire and water damage.

Owner:BRADFORD INDS

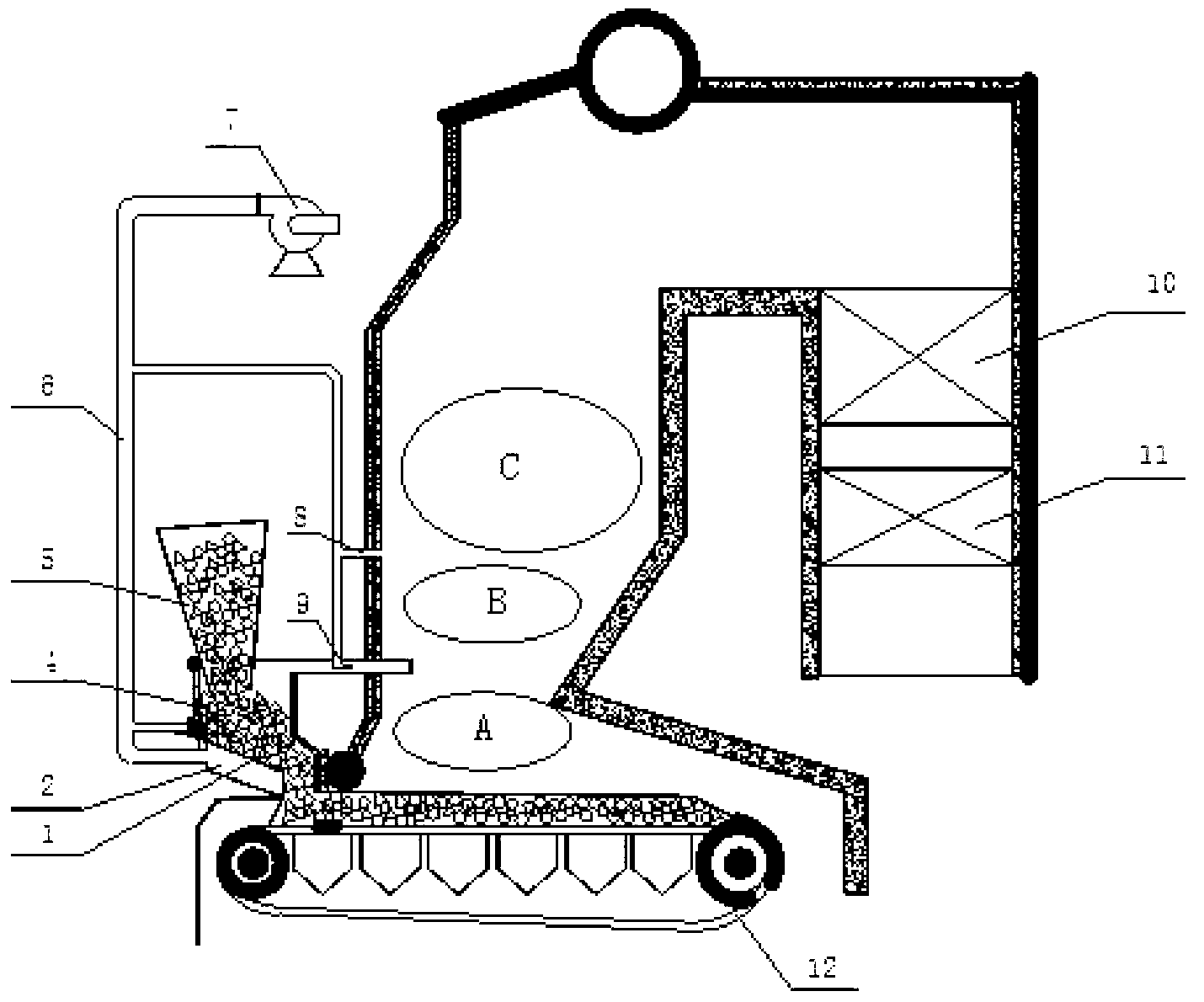

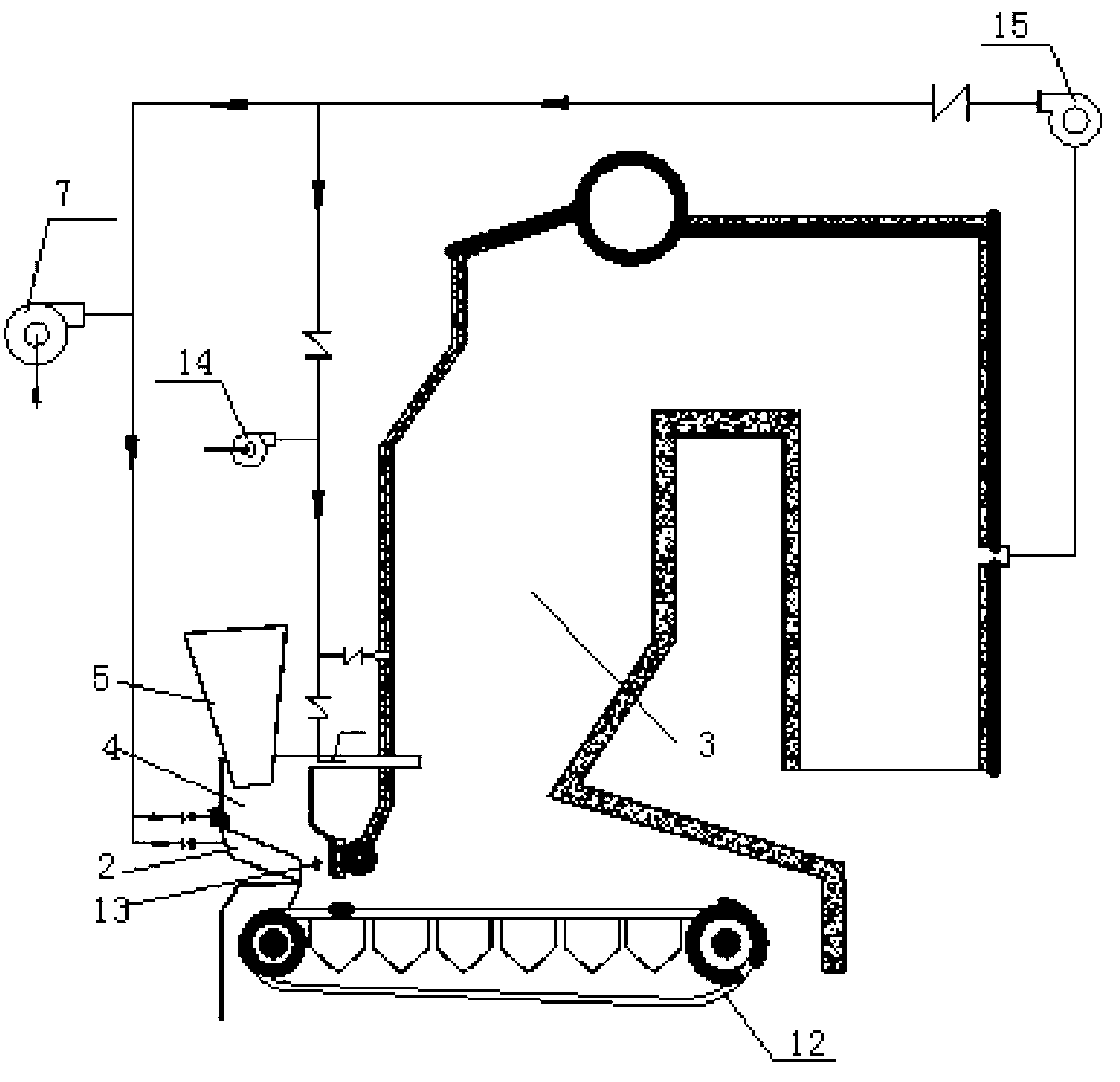

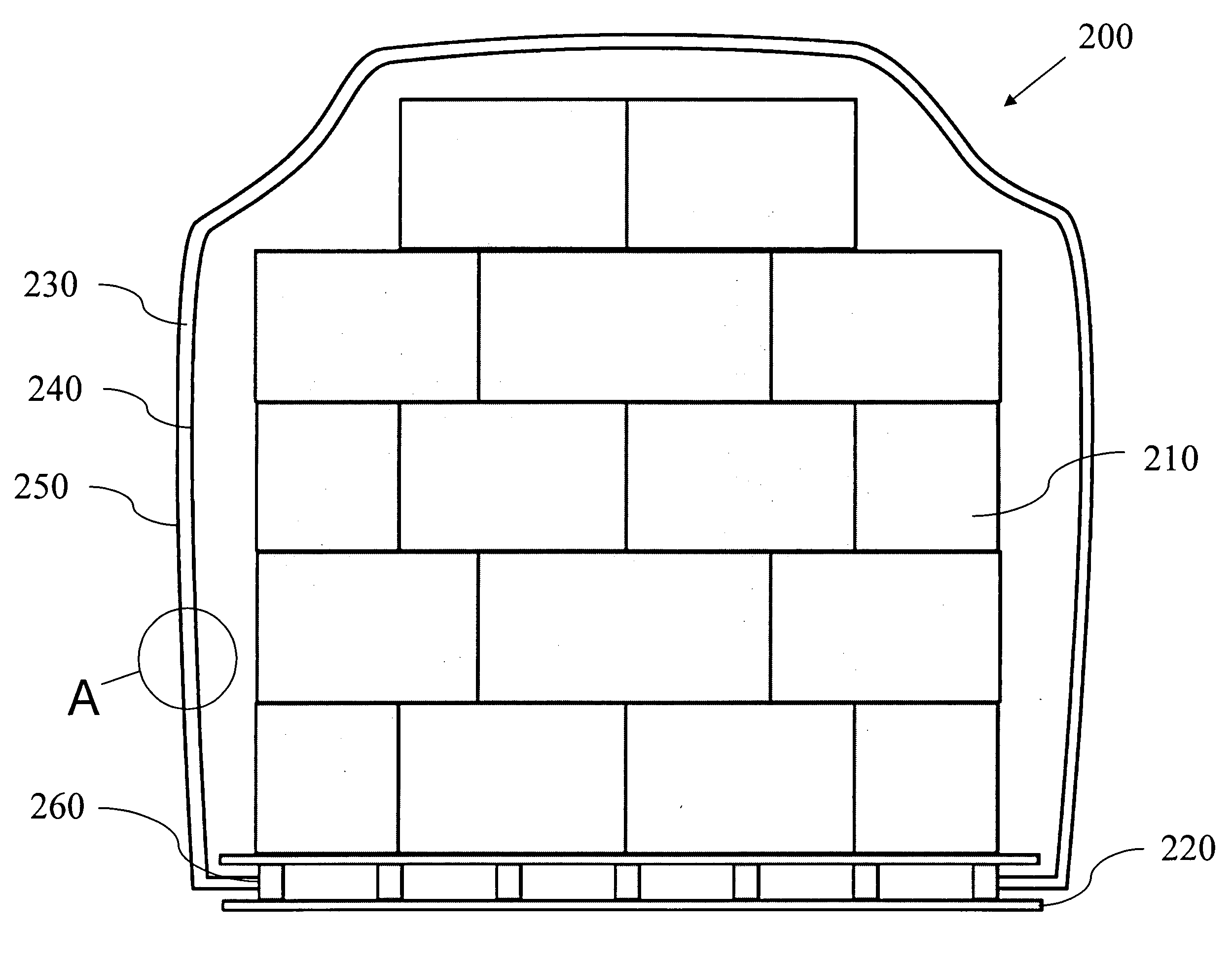

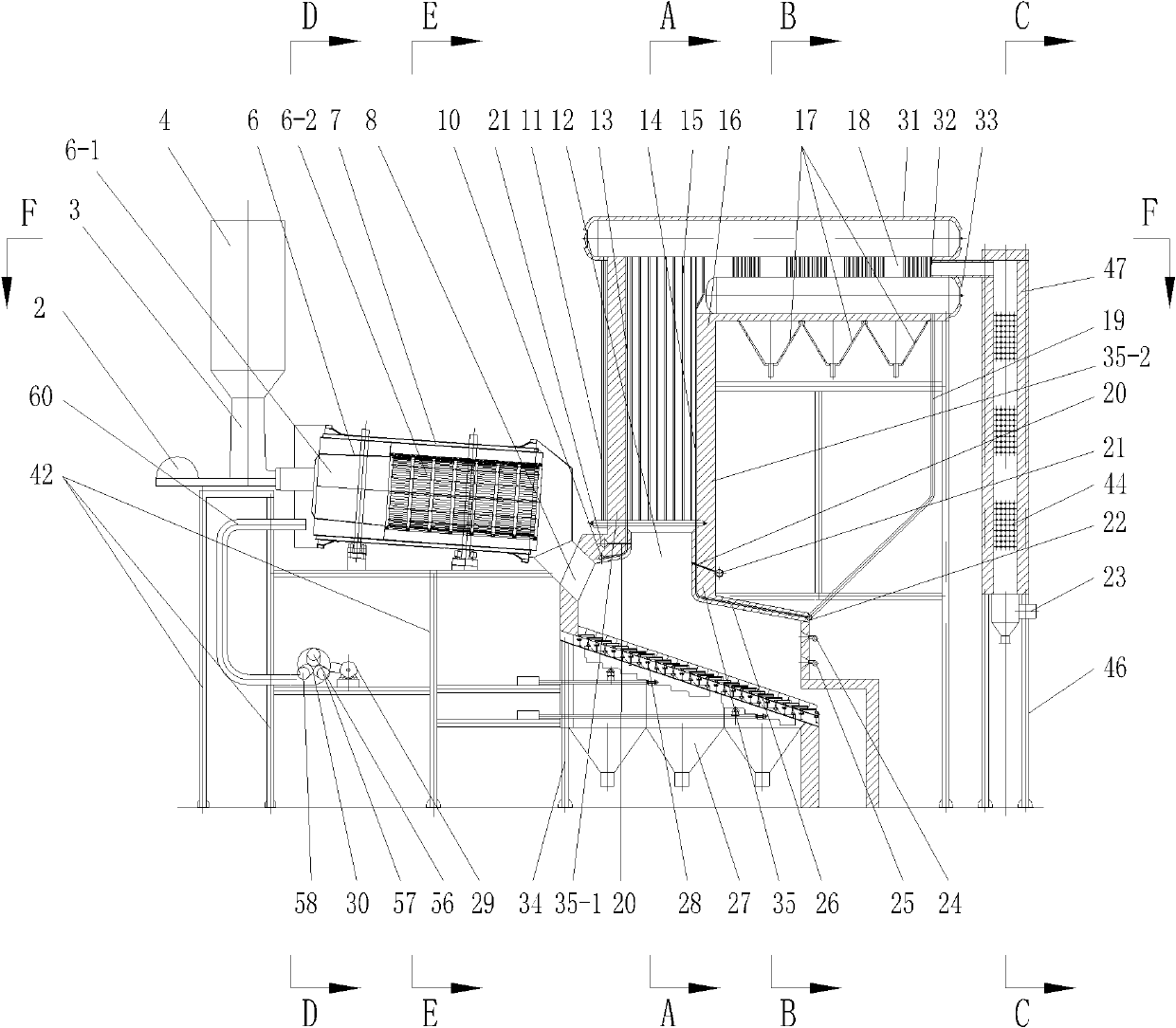

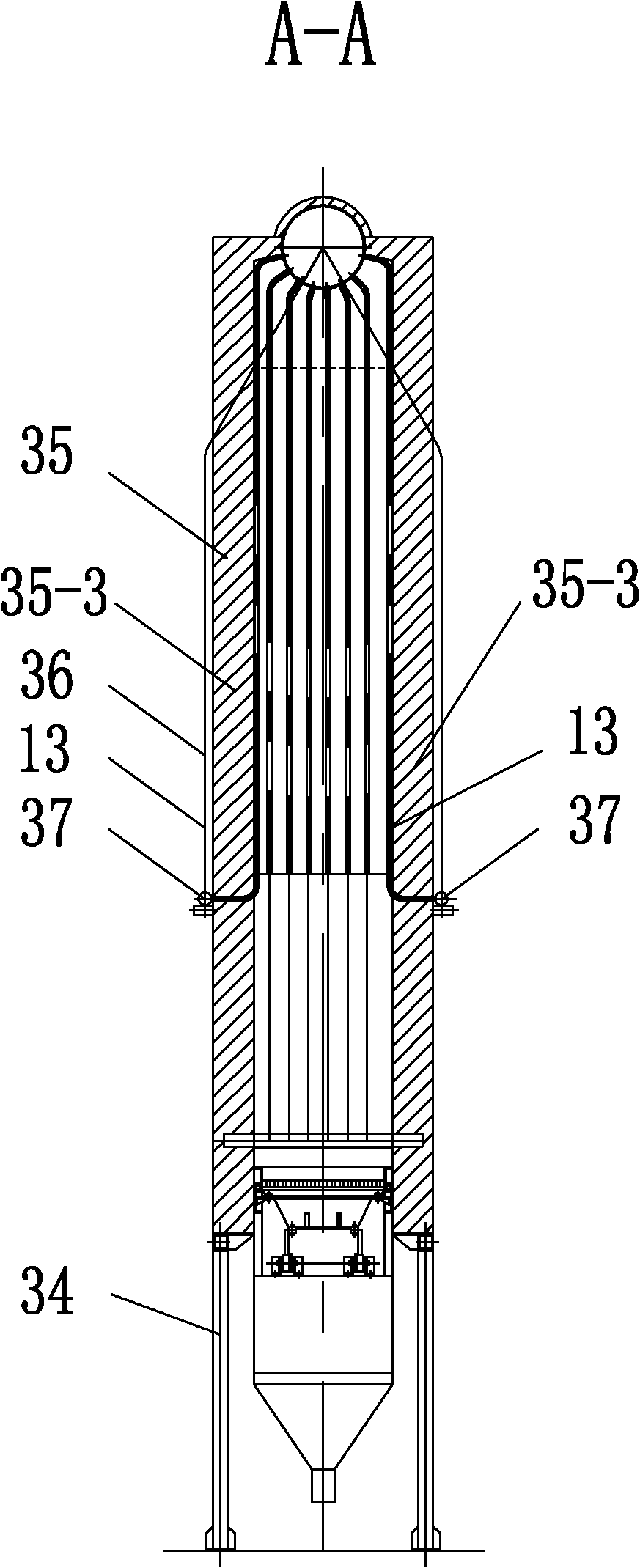

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

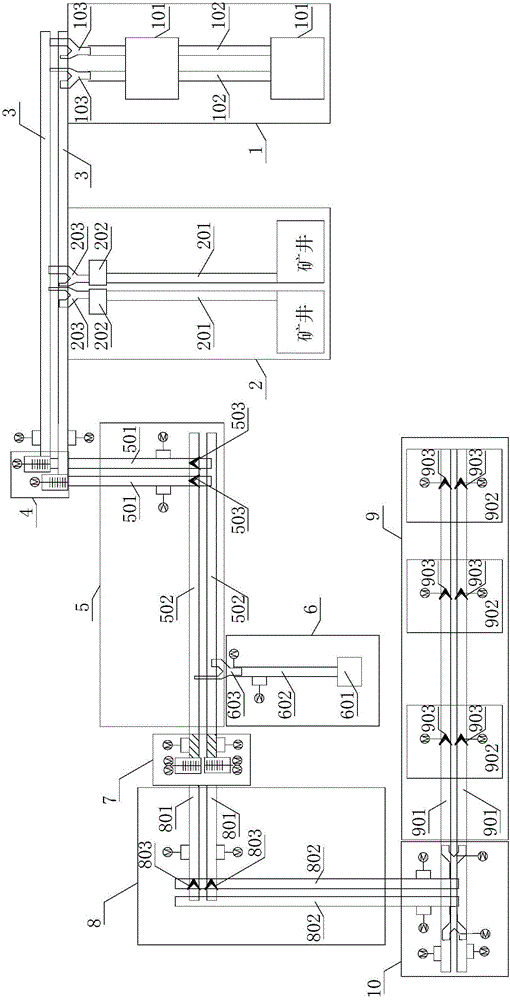

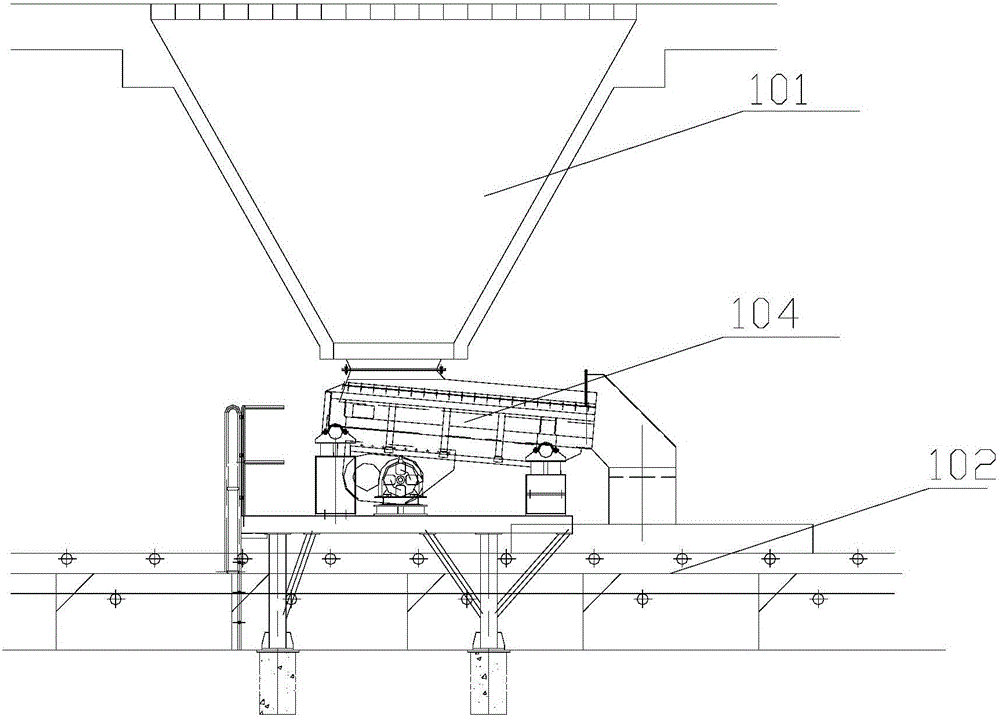

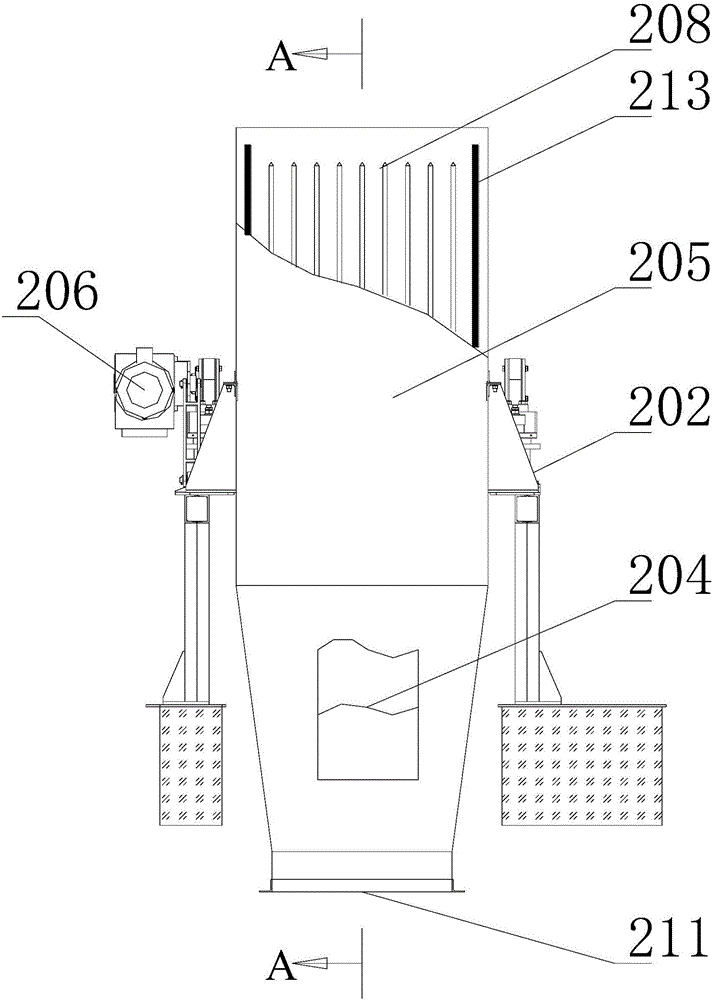

Method of large-proportion coal slime blending combustion of circulating fluidized bedboiler

ActiveCN105953257AIncrease the amount of blendingImprove efficiencyLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationFluidized bedProcess engineering

The invention discloses a method of large-proportion coal slime blending combustion of a circulating fluidized bedboiler. The method comprises the steps of (1) coal slime screening; (2) coarse slime unloading; (3) coarse slime airing and drying; (4) conveying of humidity-qualified coarse slime to a coal handling system; (5) coal conveying of the coal handling system; (6) coal feeding of the circulating fluidized bedboiler; and (7) combustion of fuel coal in the circulating fluidized bedboiler. The method of large-proportion coal slime blending combustion of the circulating fluidized bedboiler has the advantages that after low bed pressure operational optimization is implemented, the boiler efficiency reaches up to 91.9% and is increased by 1.9% when compared with a design value, the vibration of a material return device is effectively controlled, and the abrasion of a boiler heating surface is reduced; by means of implementation of low oxygen combustion optimization, the cost can be reduced by 4,800,000 RMB annually, and the standard coal can be saved by approximately 5,120 tons annually; and the generation of part of nitric oxide can be inhibited from the angle of combustion, and the urea usage amount of an SNCR system can be reduced.

Owner:INNER MONGOLIA JINGTAI POWER GENERATION

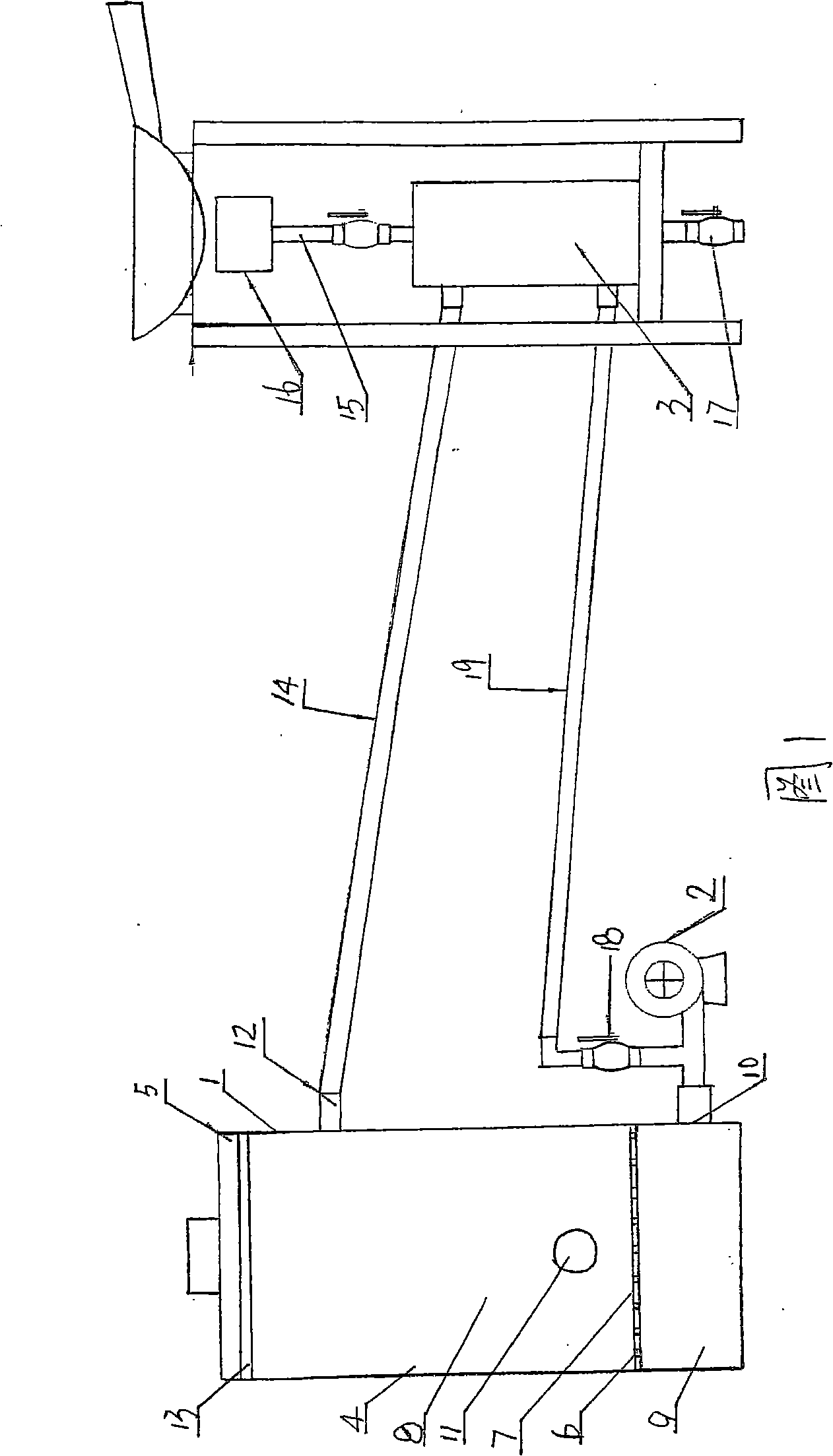

Biomass gasification stoves

InactiveCN101275752AZero costSuitable for gas demandDomestic stoves or rangesLighting and heating apparatusCarbonizationEngineering

The invention discloses a biomass gasifier, wherein the propellant bottle is composed of a barrel (4) and a barrel cover (5), the berrel is divided into an upper carbonization gas making chamber (8) and a lower air chamber (9) through a clapboard (7) with ventholes (6), the turnnel wall of an air chamber (10) is provided with an air inlet (10), a fan (2) is arranged on the air inlet (10), the upper turnnel wall of the carbonization gas making chamber (8) is provided with an air supply opening (12), the top of the barrel (4) is equipped with the barrel cover (5) through a water seal trough (13), an air supply tube (14) on the air supply opening (12) is connected with a fuel gas filtering pot (3), which is connected with an oven (16) through a hose (15). The invention performs the deep exploitation and use on the agricultural resources, changes wastes into valuables, which can increase the utilance of the agricultural resources.

Owner:曾明友

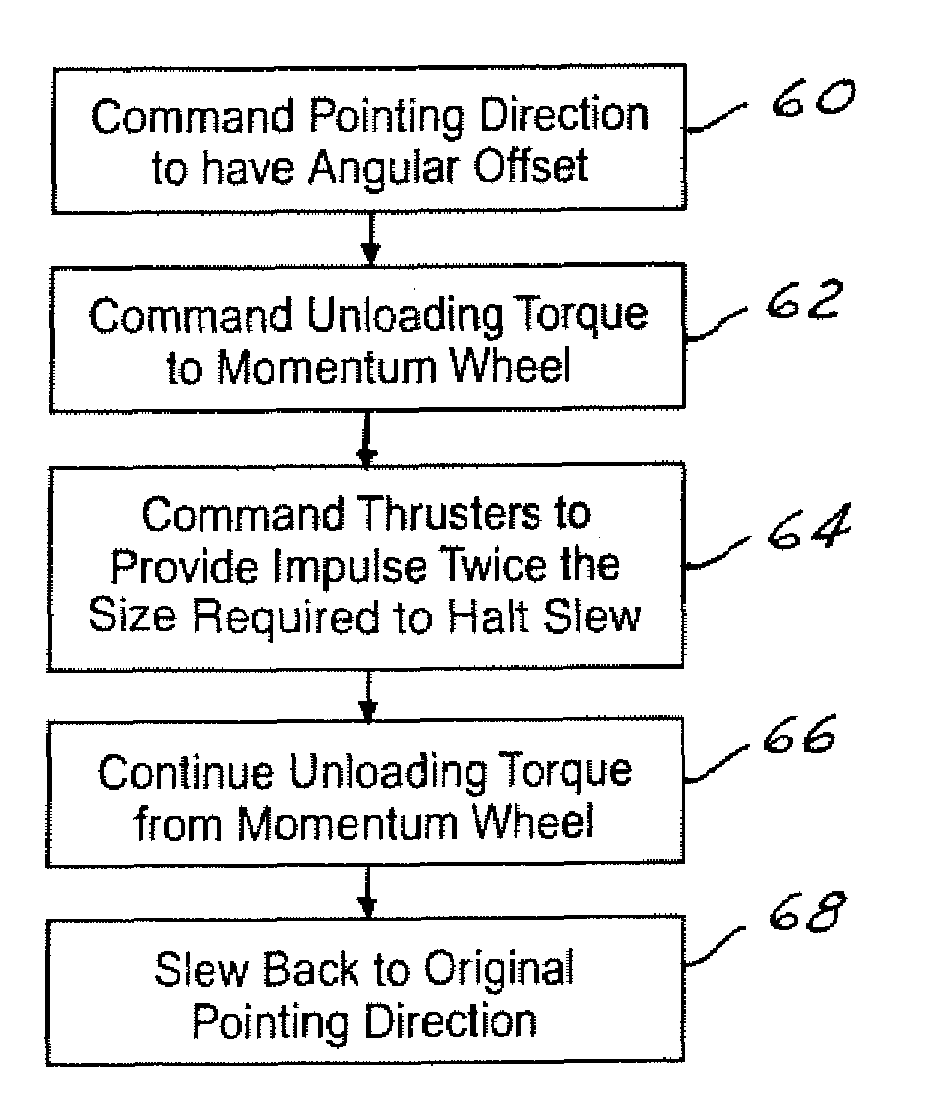

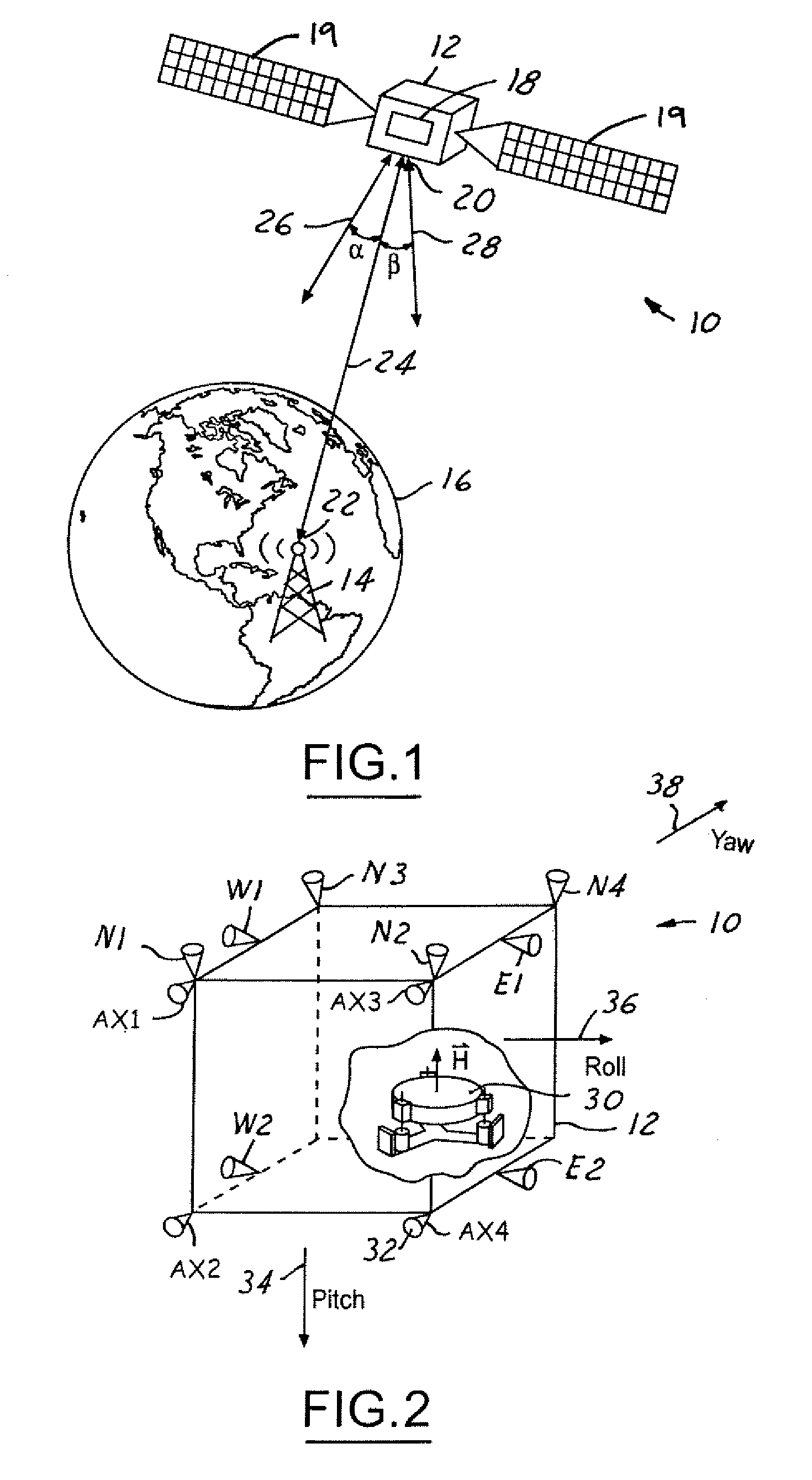

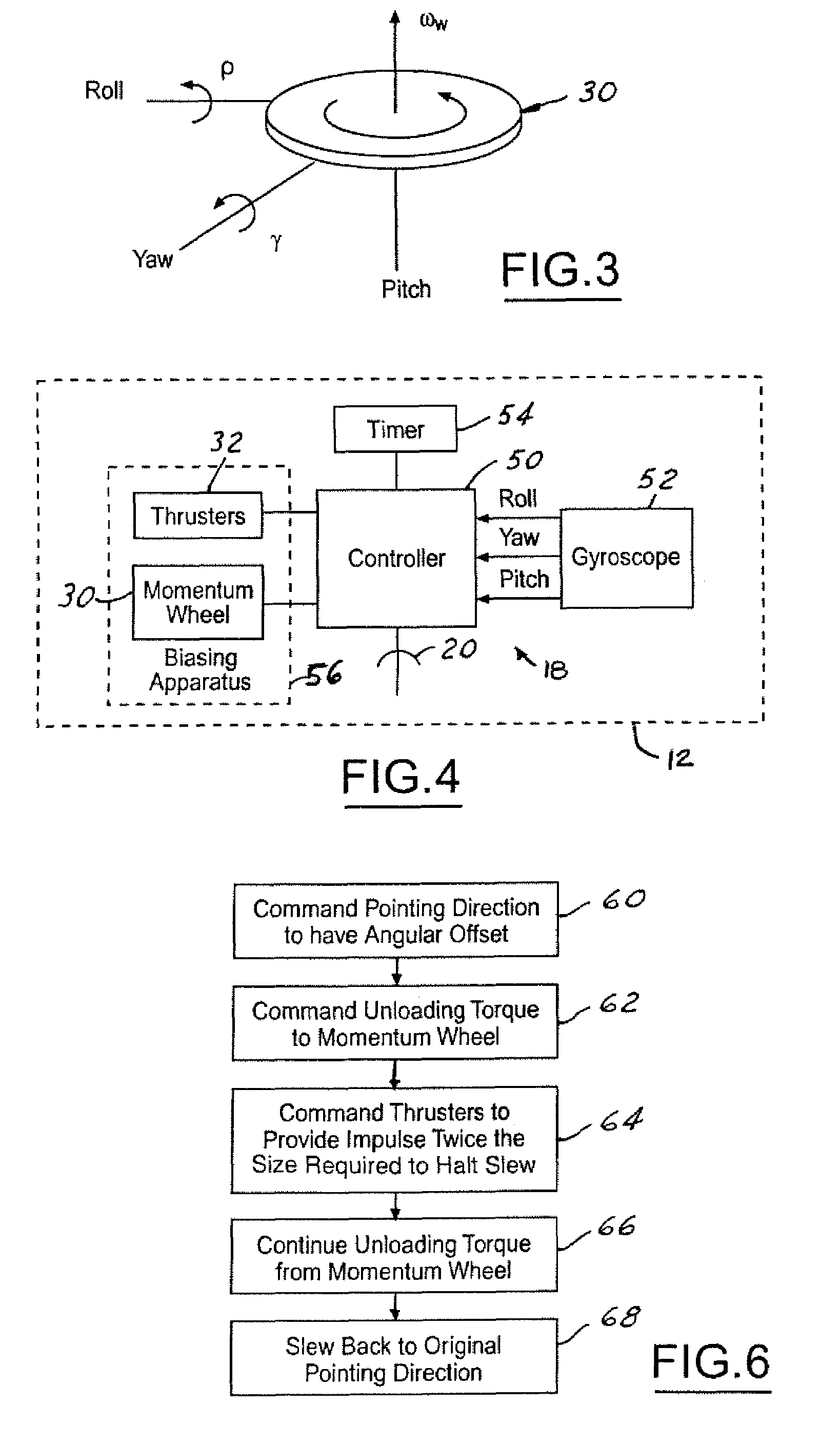

System for counteracting a disturbance in a spacecraft

ActiveUS6921049B2Extended burn timeReduce the number of timesCosmonautic vehiclesDigital data processing detailsMomentumSpace vehicle control

A system for counteracting a disturbance in a spacecraft includes a biasing apparatus that is coupled to the spacecraft and a spacecraft controller within the spacecraft. The disturbance has a known sign, magnitude and time. The biasing apparatus controls the biasing apparatus to place the spacecraft in a first dynamic state or position as a function of the sign, magnitude, and time of the disturbance. The controller also controls the spacecraft to a second dynamic state as a function of the known sign, magnitude, and time so that the spacecraft is oriented in a position other than the desired orientation so that after the disturbance the spacecraft is oriented in the desired orientation in response to the disturbance. The biasing apparatus may comprise a momentum wheel and the disturbance may comprise thrusting firing used for controlling momentum dumping.

Owner:THE BOEING CO

Biomass wood sawdust pellet fuel and preparation method thereof

ActiveCN103992835AExtended burn timeImproved thermal efficiency and combustion rateBiofuelsSolid fuelsThermal efficiencySawdust

The invention discloses a biomass wood sawdust pellet fuel and a preparation method thereof. The biomass wood sawdust pellet fuel contains the ingredients in parts by weight: 5-15 parts of pine wood sawdust and 60-100 parts of hard miscellaneous wood sawdust, wherein the hard miscellaneous wood sawdust contains two or more of toothed oak wood sawdust, olive ash wood sawdust, ash wood sawdust, birch wood sawdust, elm wood sawdust, jujube wood sawdust and oak wood sawdust. The biomass wood sawdust pellet fuel has the advantages that the combustion time is prolonged and the calorific value of combustion, combustion rate and thermal efficiency are remarkably increased while the requirements on energy saving and environmental friendliness are met.

Owner:联合优发生物质能源徐州有限公司

High-capacity quartz combustion tube for oil product analysis

InactiveCN103604904AFull combustion reactionBurn completelyChemical analysis using combustionPreparing sample for investigationCombustion chamberEngineering

The invention relates to a high-capacity quartz combustion tube for oil product analysis. The high-capacity quartz combustion tube is characterized by being provided with two combustion chambers, wherein a spiral carrier gas preheating tube and an oxygen preheating tube are arranged inside the first combustion chamber; a spiral combustion-supporting tube is arranged inside the second combustion chamber; the two adjacent combustion chambers are spaced by a partition plate with a through hole; a blowback oxygen inlet is formed at the outlet end of the combustion tube. The quartz combustion tube is mainly used for measuring the contents of total sulfur, total nitrogen and total chlorine in petrochemical products; conventional sample amount of 10-20 microlitres in oil product analysis is prominently improved by 5-10 times so as to be up to 100 microlitres, and carbon deposition is not caused, so that a measurement signal is relatively enhanced, and the low-content total sulfur, total nitrogen total sulfur and total chlorine detection sensitivity is prominently improved; the lower limit of detection is 0.05mg / L, and the detection limit is as low as 0.01mg / L.

Owner:江苏东华分析仪器有限公司

Water-resistant fireproof coating

The invention discloses a water-resistant fireproof coating. The coating comprises the following raw materials by weight: 20 to 50 parts of self-crosslinking elastic acrylic emulsion, 5 to 10 parts of copolymer emulsion of vinyl acetate and ethylene, 10 to 25 parts of a flame retardant, 10 to 25 parts of a pigment filler, 2 to 10 parts of propylene glycol, 0.2 to 1 part of 2-ethyl-4-methylimidazole, 0.5 to 1 part of polyvinylpyrrolidone, 0.2 to 1 part of sodium carboxymethylcellulose, 0.2 to 1.5 parts of 1,2-benzisothiazol-3-one, 0.3 to 1.2 parts of dodecyl mercaptan, 0.1 to 0.8 part of dodecyl dimethyl benzyl ammonium chloride, 0.5 to 1.5 parts of a defoaming agent, 0.5 to 2 parts of aluminium triphosphate and 25 to 40 parts of water. The water-resistant fireproof coating provided by the invention has the advantages of high strength, excellent fireproof property and water resistantce, strong adhesive force with a substrate, high bonding strength and long service life.

Owner:TIANCHANG YINHU PAINT

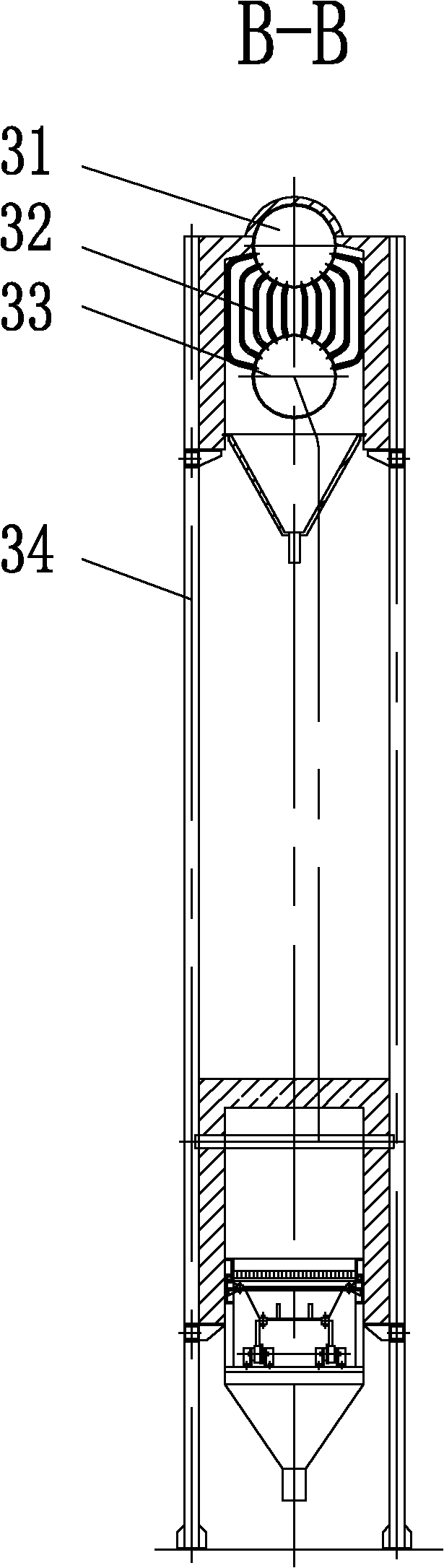

Vertical kiln

The invention discloses a vertical kiln, comprising a fuel supply device, an ignitor, a temperature measuring device, an unloading and discharging device, a kiln chamber, a blower, a pipeline, a valve, refractory materials, refractory fibre materials, heat preserving and reinforcement materials, an iron panel, reinforced concrete materials, brick-concrete materials, a tail gas treating device, a kiln preheating chamber, a heating chamber and a cooling chamber, wherein, a preheating chamber is communicated with the heating chamber; the cooling chamber is communicated with the heating chamber; a feed inlet is arranged at the upper part of the preheating chamber; an air outlet of the preheating chamber is arranged at the upper part of the preheating chamber; a plurality of flame paths are arranged at the side wall of the preheating chamber; a plurality of air inlet channels are arranged at the side wall of the flame paths; the air inlet channel is communicated with the flame paths; a discharge hole is arranged at the lower part of the cooling chamber and is communicated with a discharge chamber which is provided with an unloading device. The vertical kiln utilizes hot convection, and vortex for combustion, saves more energy and protects environment, and can use various fuels, such as coal powder, gas and liquid and the like; the materials are heated evenly by utilizing vortex; the materials can naturally move to a preheating zone, a heating zone and a cooling zone by utilizing natural settlement; the vertical kiln of the invention can be used for firing various lump materials, such as cement, lime, alumina and flint clay and the like.

Owner:陈久斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com