Vertical kiln

A technology of vertical kiln and kiln chamber, applied in the field of vertical kiln, which can solve the problems of excessive dust and harmful gas emissions, insufficient fuel combustion, uneven temperature in the furnace, etc. The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

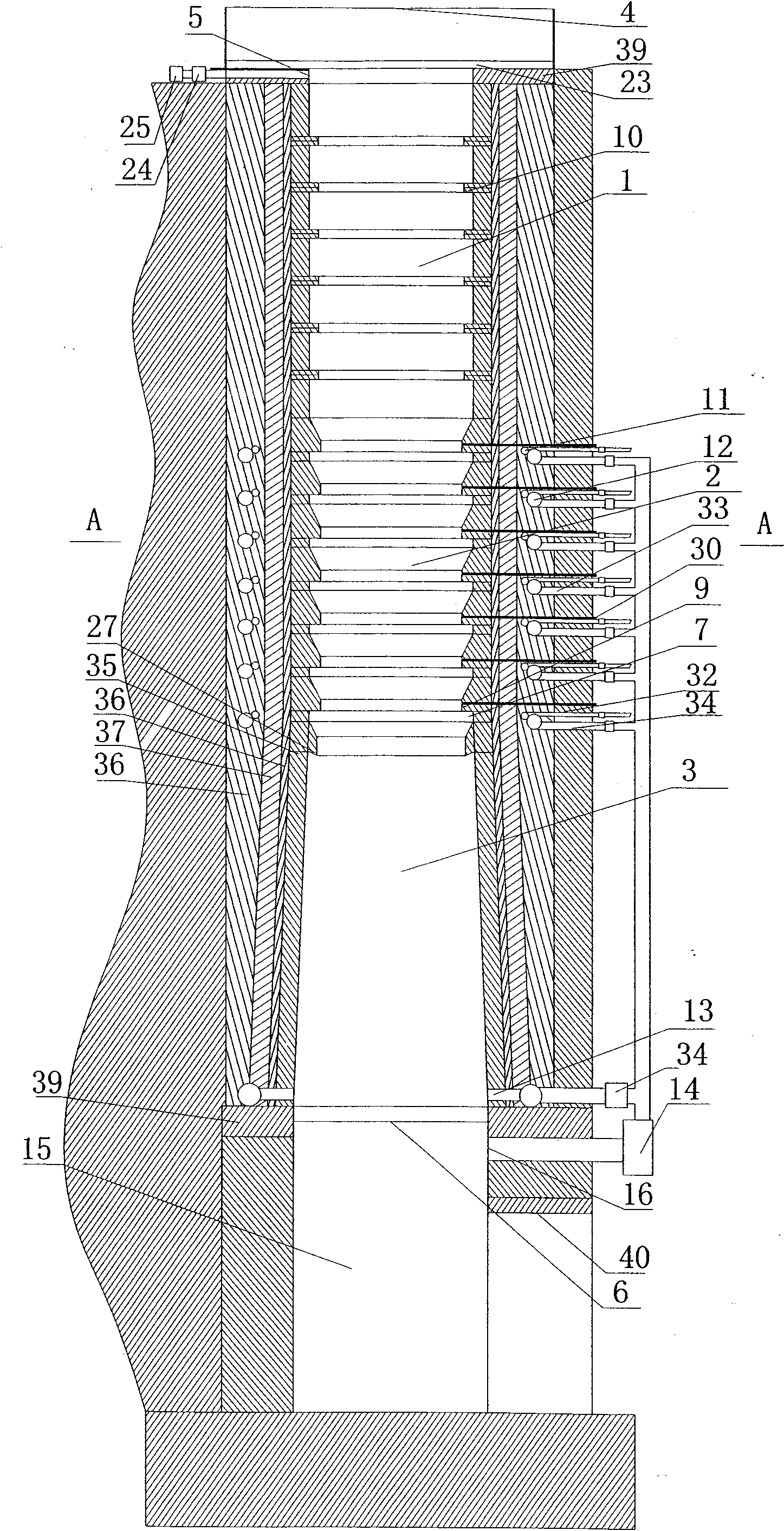

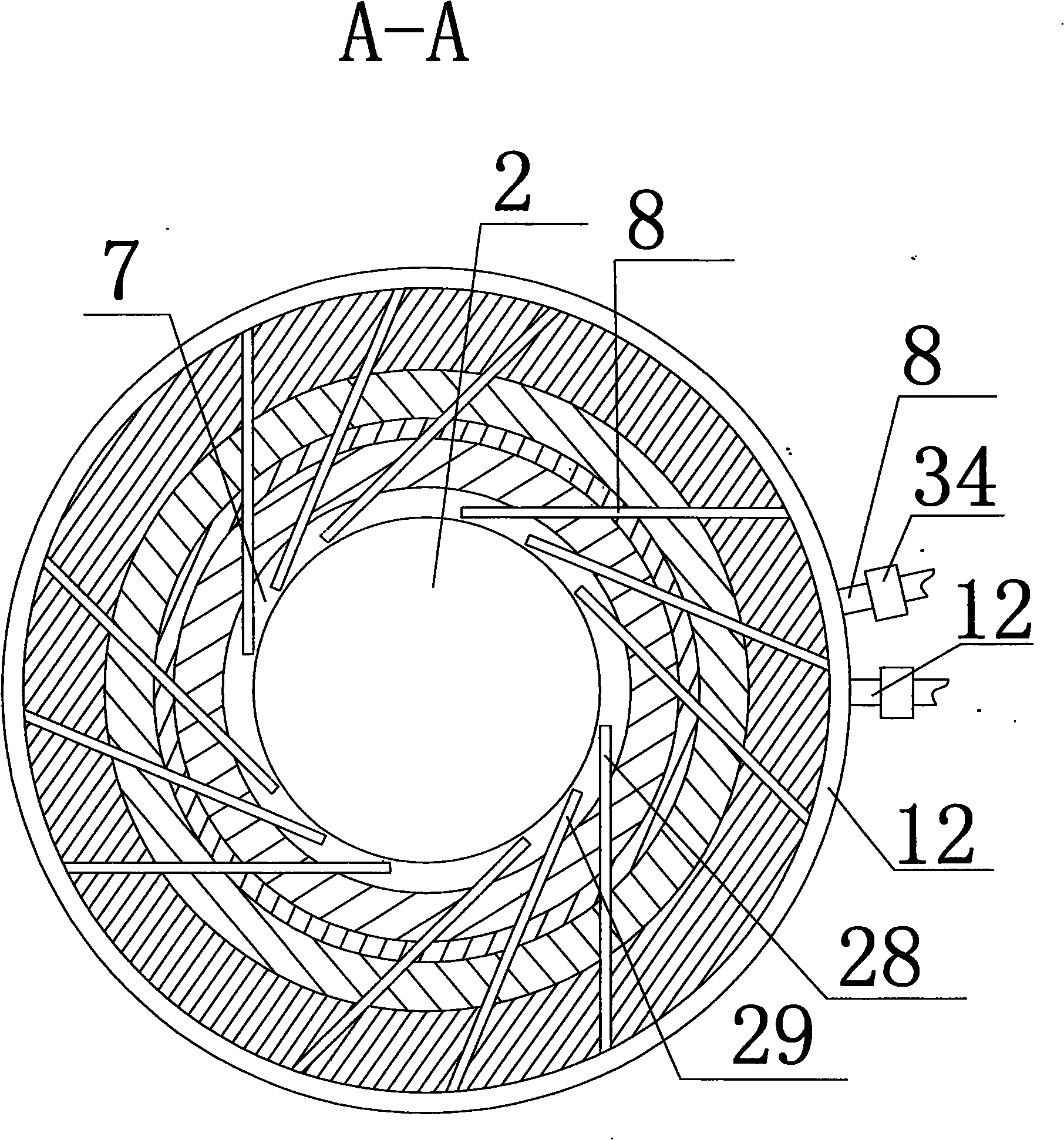

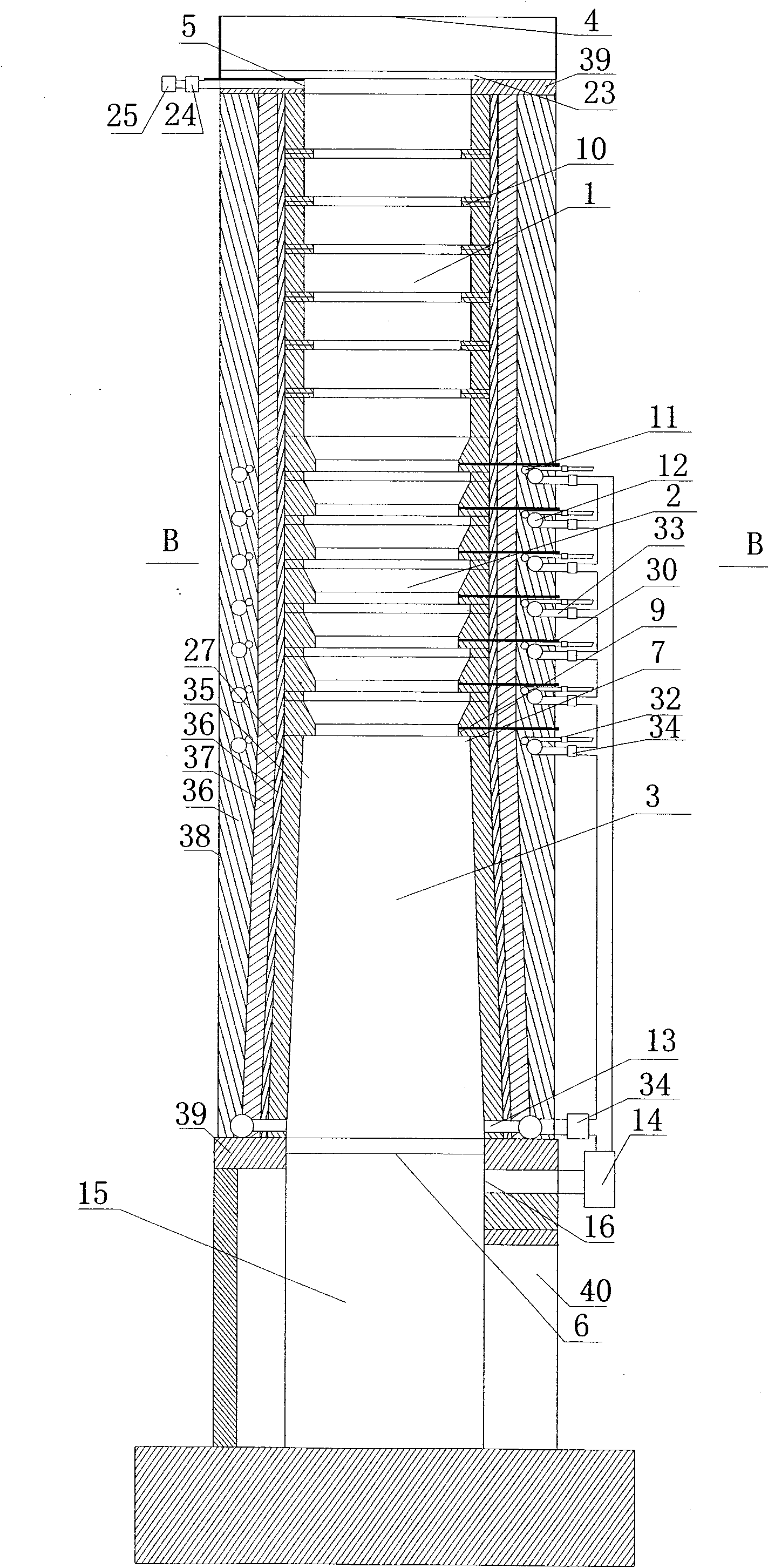

[0021] The main structure of the present invention is: a shaft kiln, comprising: a fuel supply device 32, an ignition device, a temperature measuring device 30, a discharge device 22, a kiln chamber, a fan 14, a pipeline 33, a valve 34, a refractory material 35, and a refractory fiber Material 36, thermal insulation and reinforcement material 37, iron plate 38, reinforced concrete material 39, brick-concrete material 40, tail gas treatment device 25 and waste heat collection device 26, the kiln chamber is equipped with a preheating chamber 1, a heating chamber 2 and a cooling chamber 3, and a heating chamber 2 The upper part is connected to the preheating chamber 1, the lower part of the heating chamber 2 is connected to the cooling chamber 3, the upper part of the preheating chamber 1 is provided with a feed inlet 4, the upper part of the preheating chamber 1 is provided with a preheating chamber outlet 5, and the side wall of the heating chamber 2 is provided with multiple Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com