Patents

Literature

108results about How to "Achieve heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

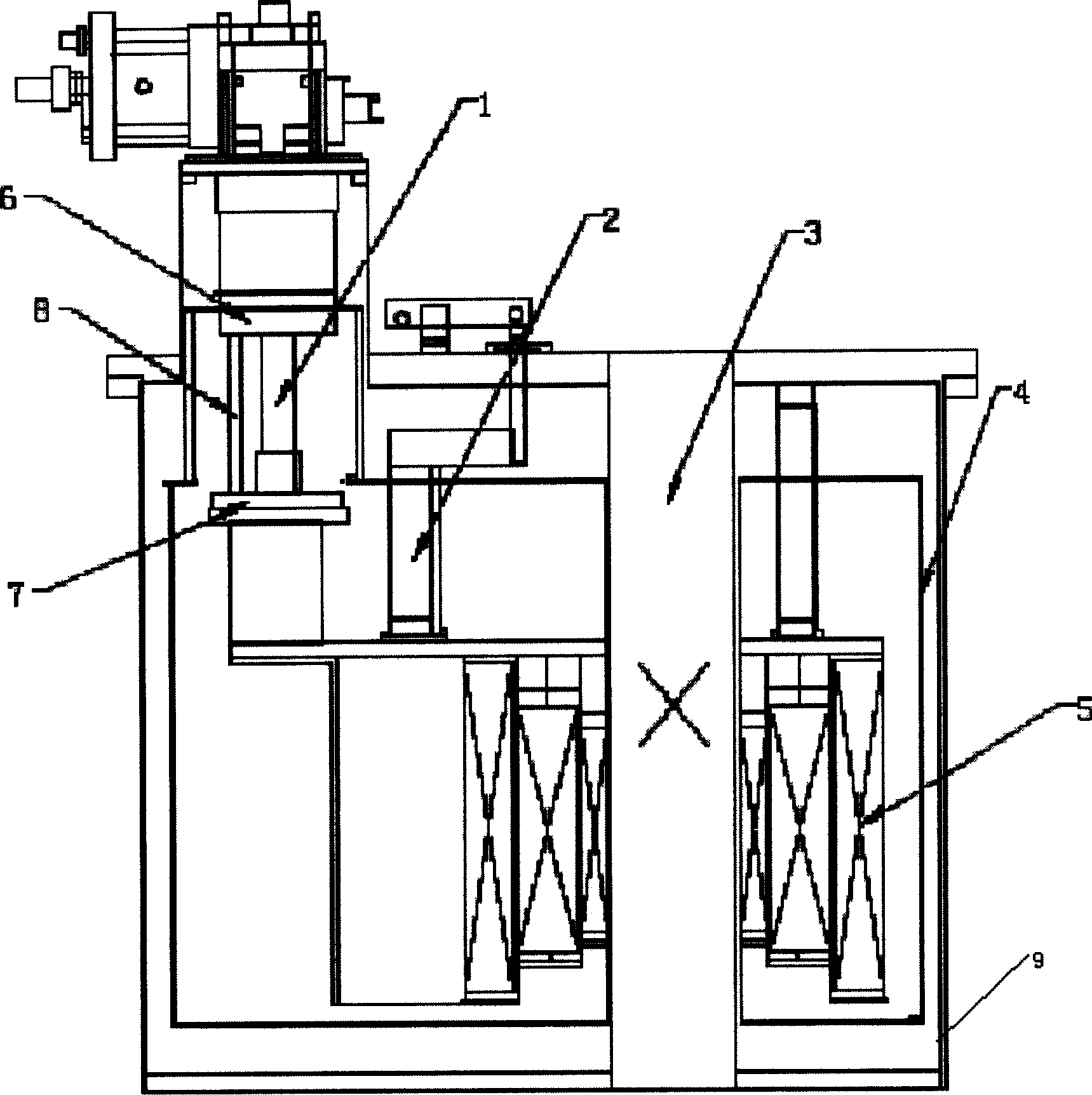

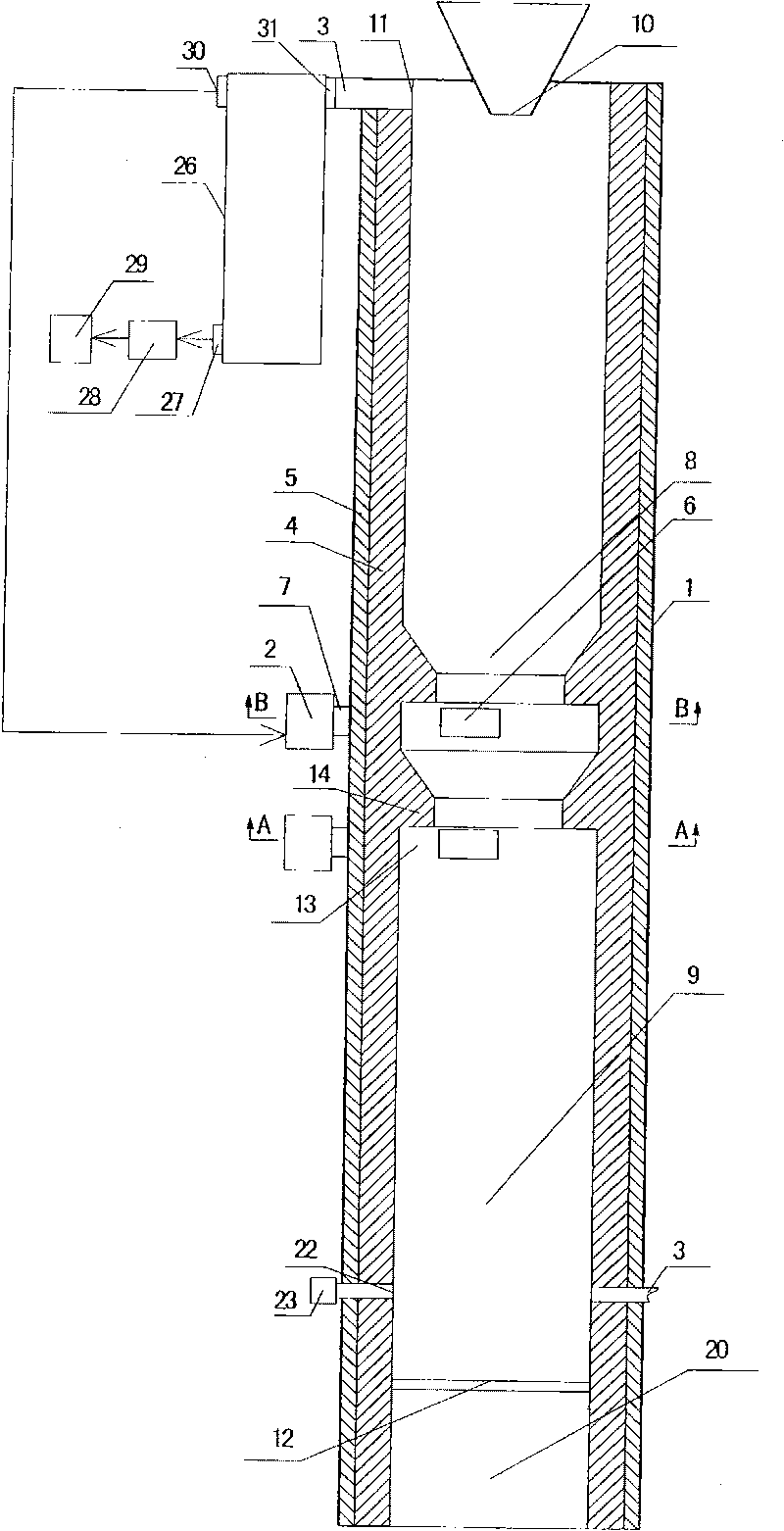

Device and process method for continuously producing carbon nanotubes

ActiveCN102120570ASuitable for productionImprove standardizationNanotechnologyNanoparticleFluidized bed

The invention discloses a device for continuously producing carbon nanotubes, which consists of a feeder, a reduction reactor, a synthesis reactor and a product collector which are connected in series in turn, wherein the reduction reactor is a fluidized bed reactor; and the synthesis reactor is a spouted bed reactor. The invention also discloses a process method for continuously producing carbonnanotubes based on the device. The catalyst reduction and deposition preparation of the carbon nanotubes are respectively realized by the fluidized bed and the spouted bed, so that the process conditions can be regulated in a wider range, the fluidized state of agglomerated nanoparticles in the beds is ensured, and the high-quality carbon nanotubes are continuously produced.

Owner:GUANGZHOU BAIYUN CHEM IND

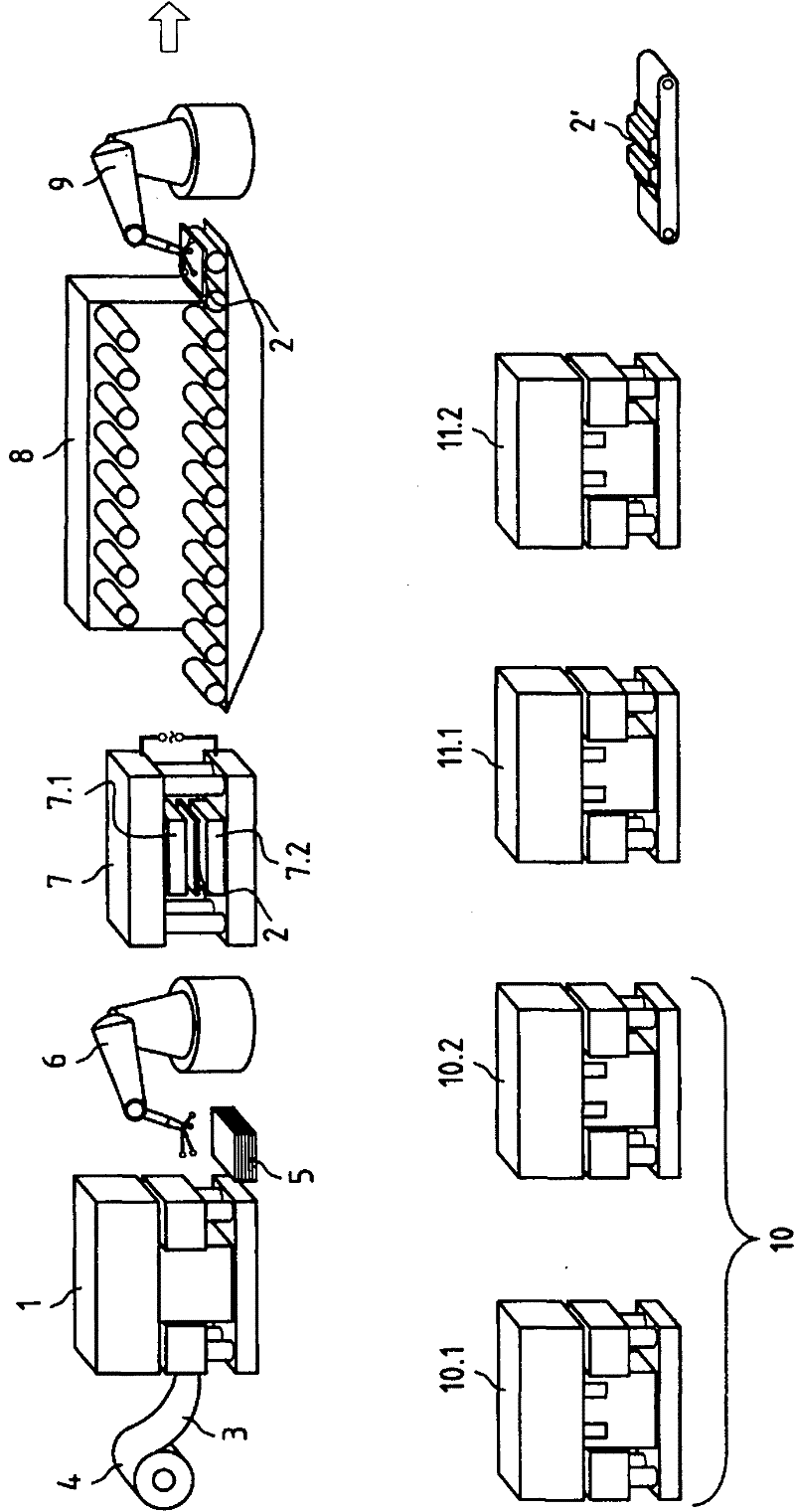

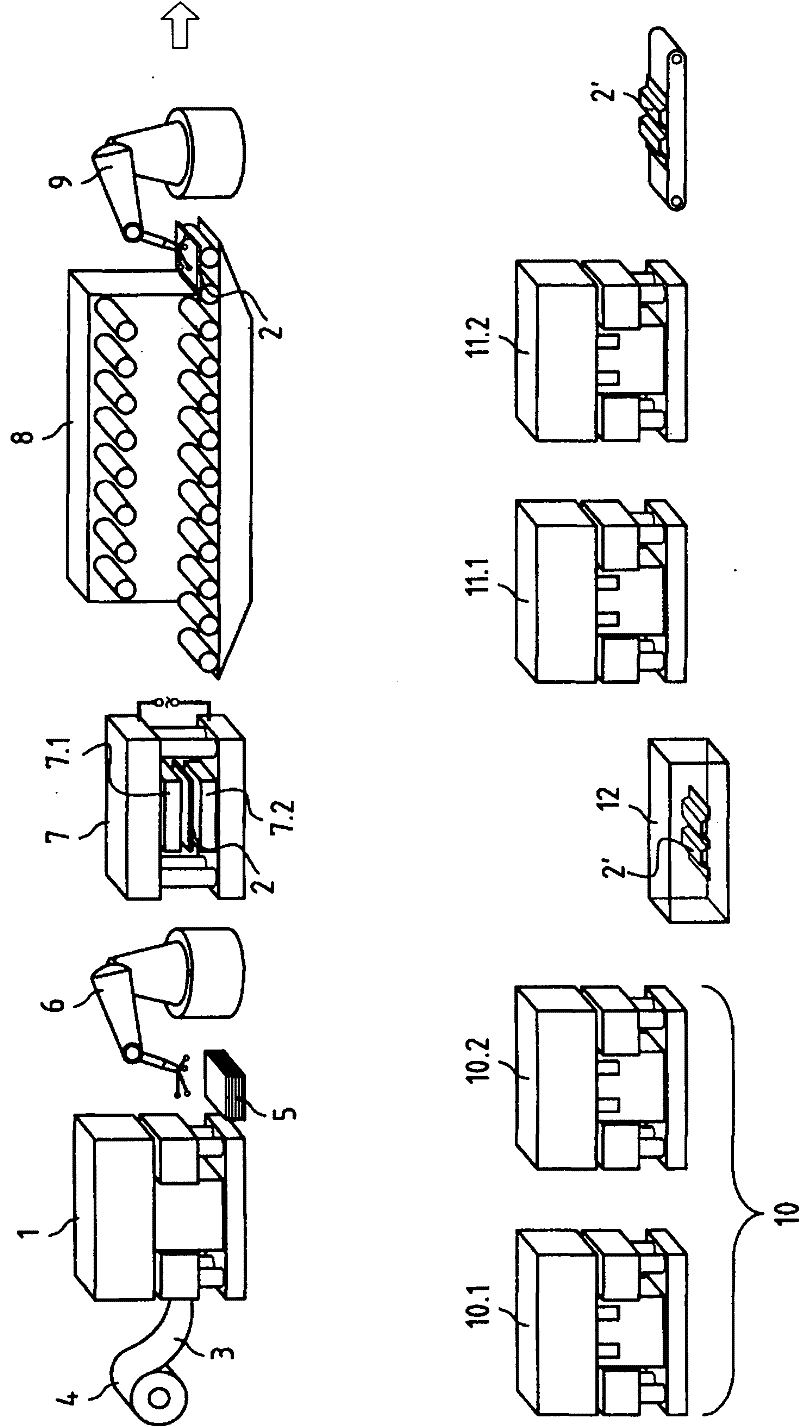

Method and thermoforming apparatus for producing forged steel sheet forming components

The invention relates to a method and a thermoforming device for producing forged steel sheet shaped components, the thermoforming device comprising a furnace (8) by means of which the steel sheet to be hot formed is at least partially heated to an austenitizing temperature, the heat The forming device also includes a forging device (10) for hot forming and forging of steel sheets heated in a furnace. In order to realize the utilization of the capacity of the current rolling mill and realize a higher number of strokes and thereby realize a higher production capacity, it can be seen from the present invention that a heating device (7) is arranged in front of the melting furnace (8), and the steel plate (2) is heated by the heating device. ) is at least partially heated to a temperature below the austenitizing temperature, preferably to a temperature in the range of 500°C to 700°C, and the forge (10) is arranged in a multi-stage form, wherein the first part (10.1) of the forge has at least A first tool for hot forming and cooling of the steel sheet heated in the furnace (8), while the next part (10.2) of the forging plant (10) has at least one second tool for further cooling of the hot formed steel sheet and wherein the second tool further forms, shears and / or perforates the hot-formed steel sheet.

Owner:蒂森克虏伯金属成型技术有限公司 +1

Low temperature heat tube for thermal switch

This is a low temperature heat pipe used to the thermal switch. The body of this heat pipe is double layers stainless steel ripple pipes, inside two layers there are high pressure strong neon gas. On the two ends of this ripple pipe is installed wih high conduct qure copper block, between two blocks are connected with high pure copper electric cable. This heat pipe can be stretched out and drawn back by its working state. The lower end of this heat pipe is fixed with the secondary grade cooling head of refrigerator. The upper end of it is free state. The free end can connect with the first grade cooling head of refrigerator or separate it according to the temperature of magnetic body and refrigerator's first grade cooling head.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Ultra-supercritical strengthening fluid heat-transferring method and heat-transferring medium

InactiveCN101284984AImprove heat transfer performanceAchieve heat transferHeat-exchange elementsBulk chemical productionEnhanced heat transferWorking temperature

The invention discloses a supercritical multiphase enhanced heat transfer method and a heat transfer medium. The method is to add an auxiliary phase change heat transfer material to a basic heat transfer medium, so as to ensure that: when no phase change heat transfer is carried out in the working temperature range of the basic heat transfer medium, the auxiliary phase change heat transfer material carries out phase change heat transfer; when the basic heat transfer medium carries out phase change heat transfer, the auxiliary phase change heat transfer material carries out phase change heat transfer at the phase change temperature lower than a basic phase change heat transfer medium. The method and the medium can realize the integral thermal control and thermal management on heat transfer.

Owner:李建民

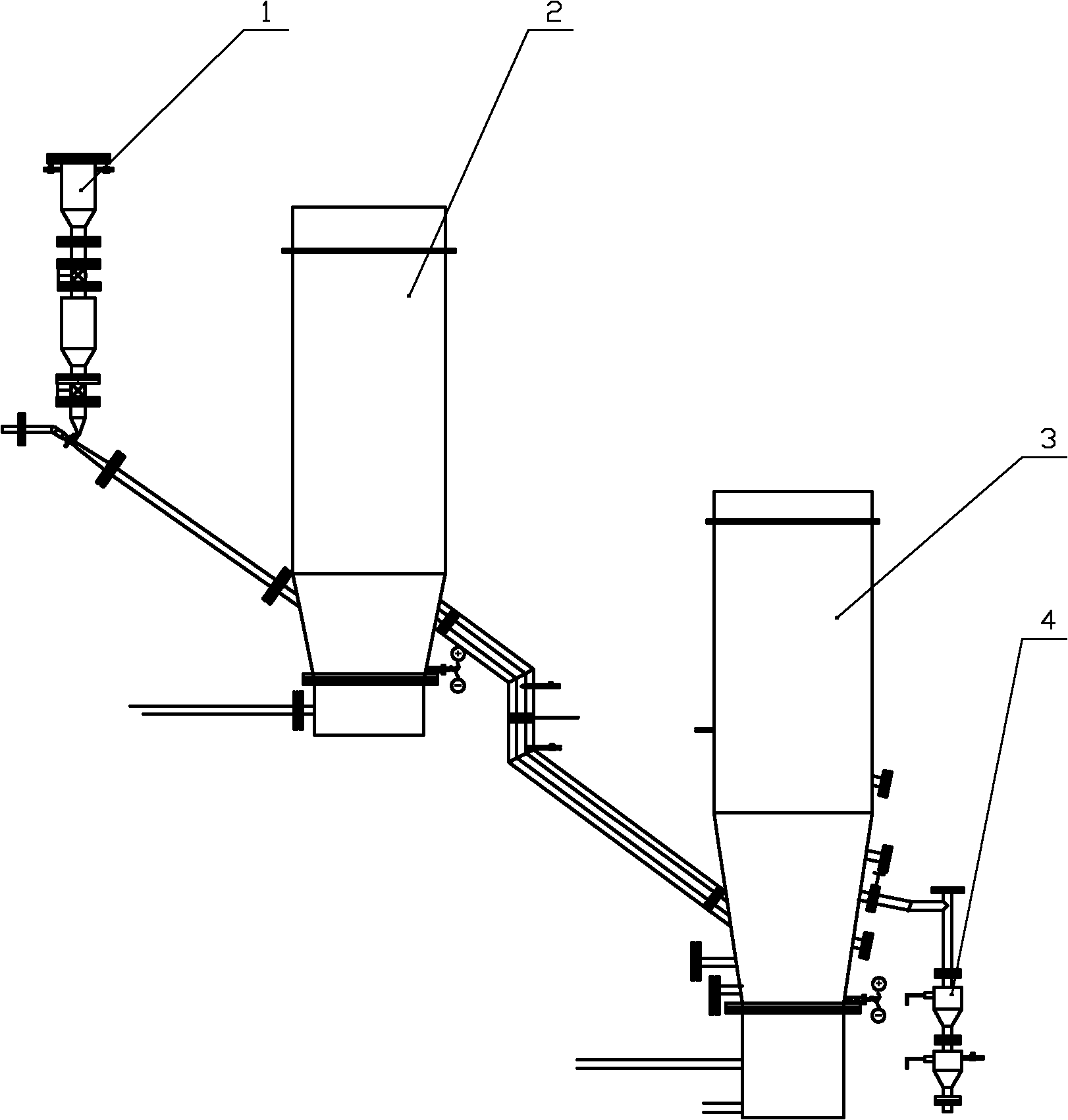

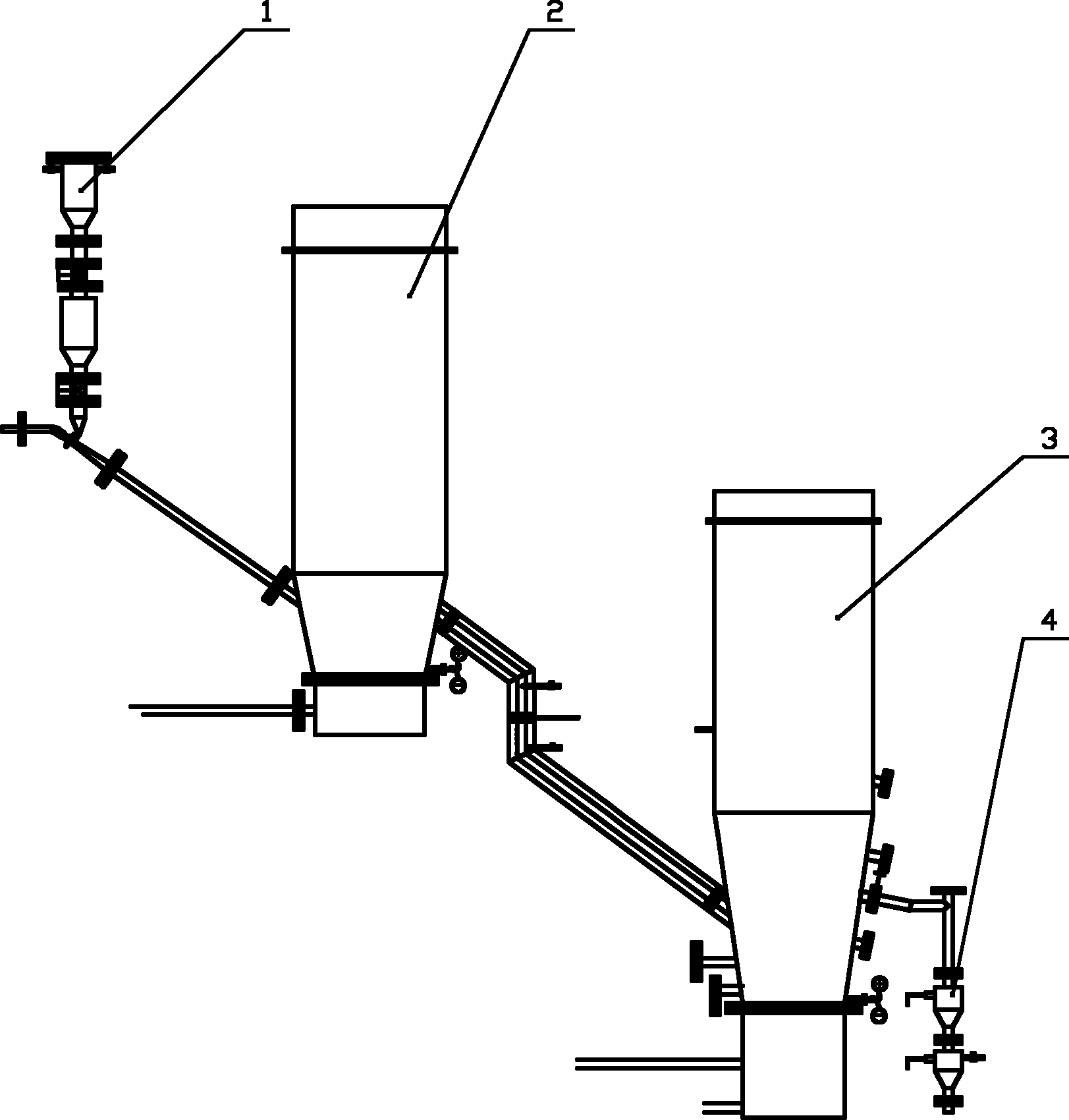

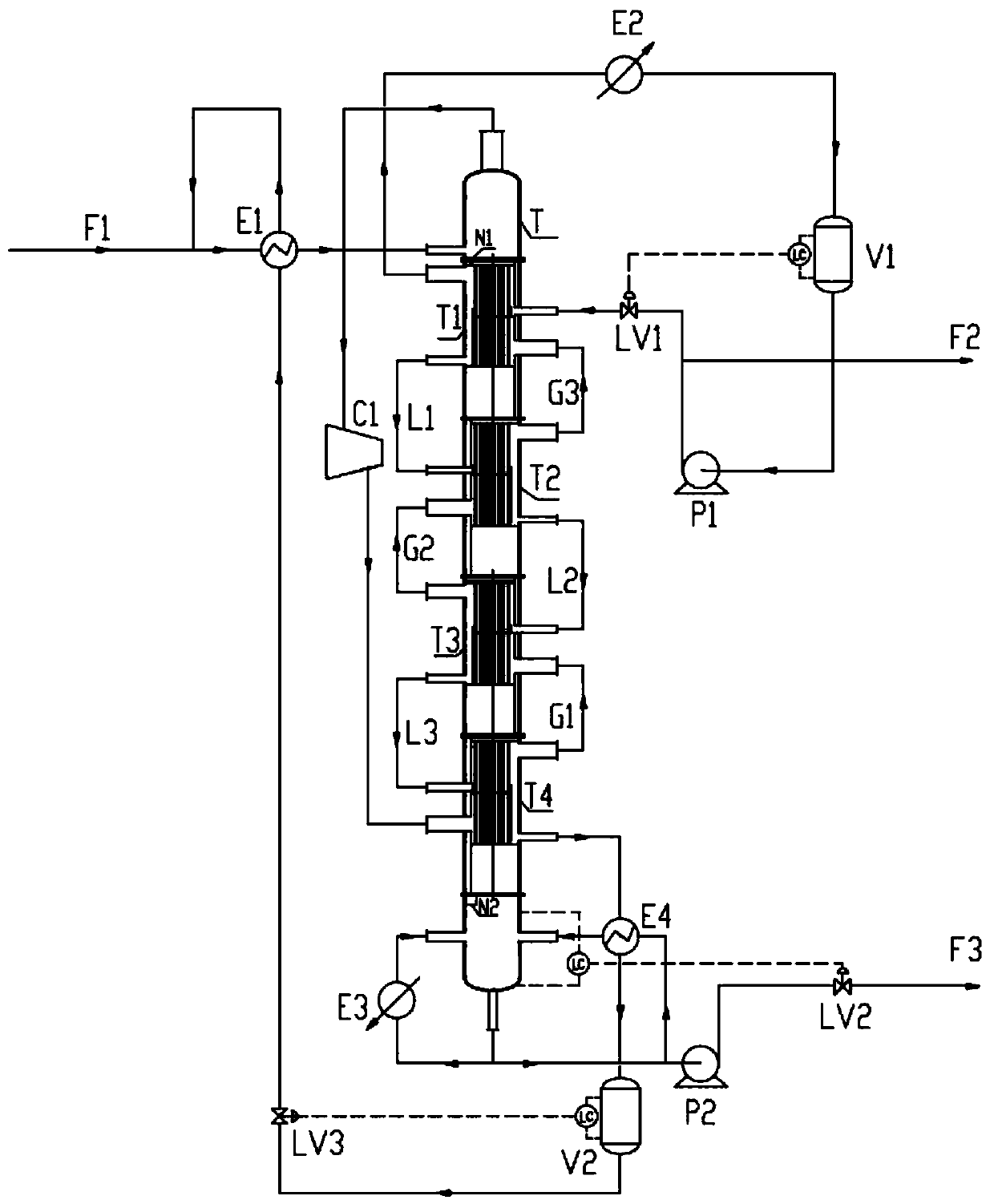

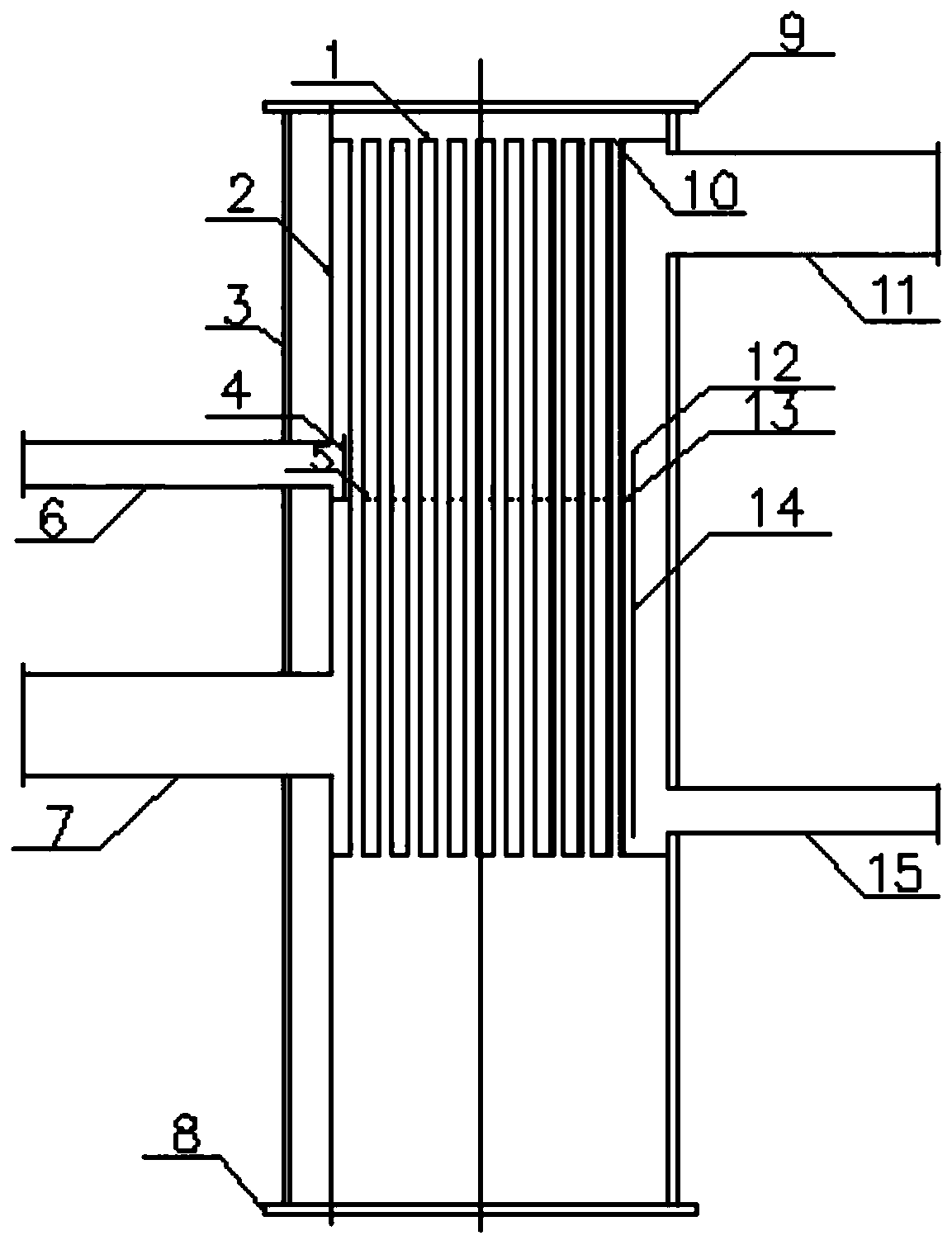

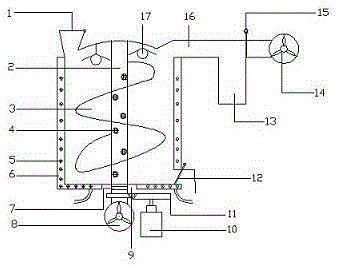

Matching device and method of novel rectifying tower system with internal energy integration

ActiveCN110180205AImprove mass and heat transferLower the altitudeDistillation regulation/controlChemical industryInternal energyMass transfer

The invention relates to a novel rectifying tower system with internal energy integration. The rectifying tower system comprises a raw material preheater, a tower top condenser, a starting heater, a tower bottom heat exchanger, a rectifying tower, a compressor, a tower top reflux tank, a tower bottom buffer tank, a reflux pump, a tower bottom extraction pump and a tower bottom throttling valve; the energy integration rectifying tower is formed by coaxially connecting N tower sections in a sealing mode, wherein N is larger than or equal to 1; and a stripping section and a rectifying section which are in airtight separation with each other are formed in each tower section. The rectifying tower device is of a composite coupling structure, and then the rectifying sections and the stripping sections are coupled together, so that the effects of mass transfer and heat transfer are enhanced, the theoretically designed rectifying tower height is reduced, and cost is saved. The heat exchange area of the rectifying sections and the stripping sections is increased between a liquid descending pipe and a pipe bundle, the heat exchange effect is enhanced, energy consumption is saved, operation issimple, and safety and reliability are achieved.

Owner:TIANJIN UNIV

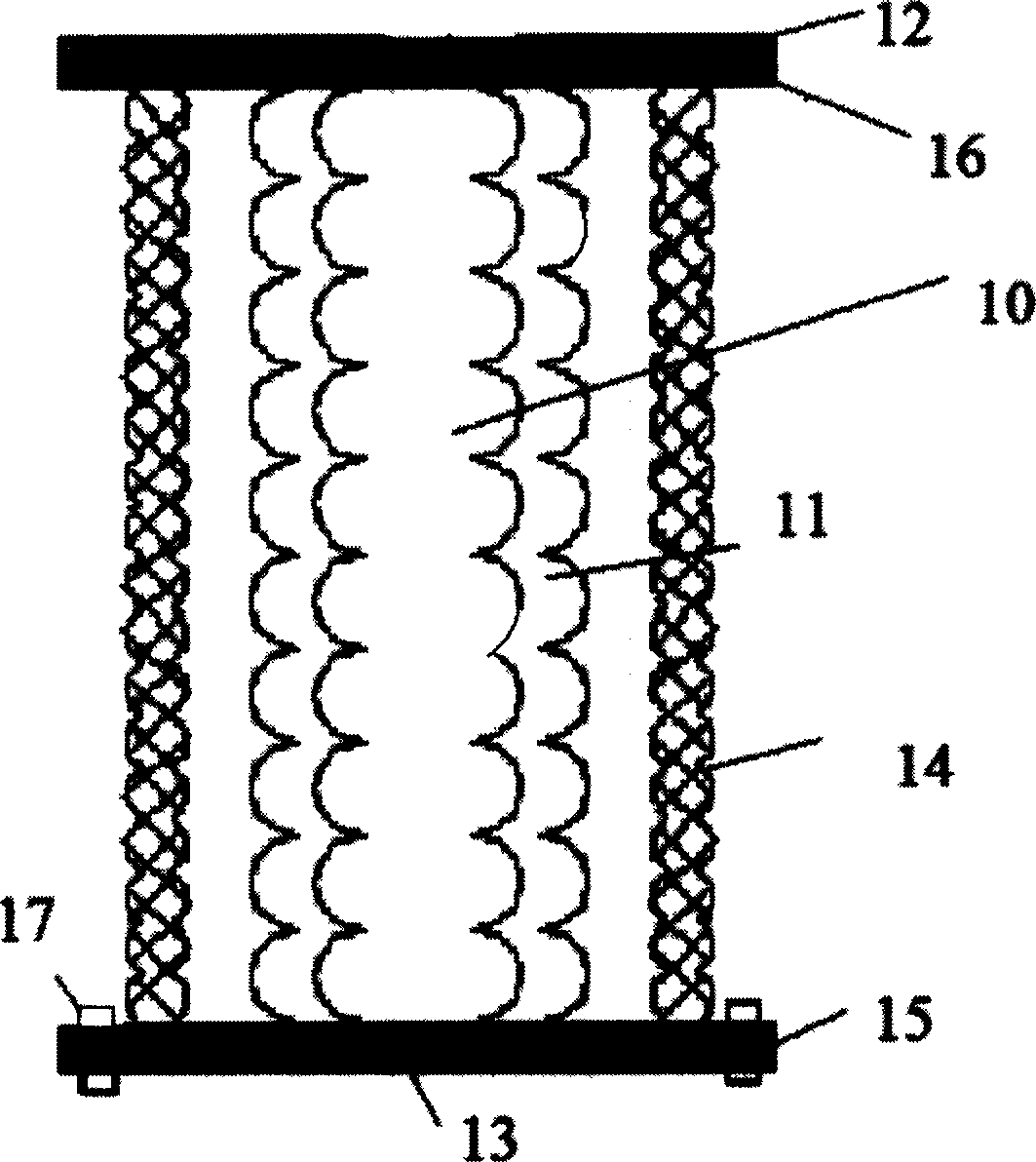

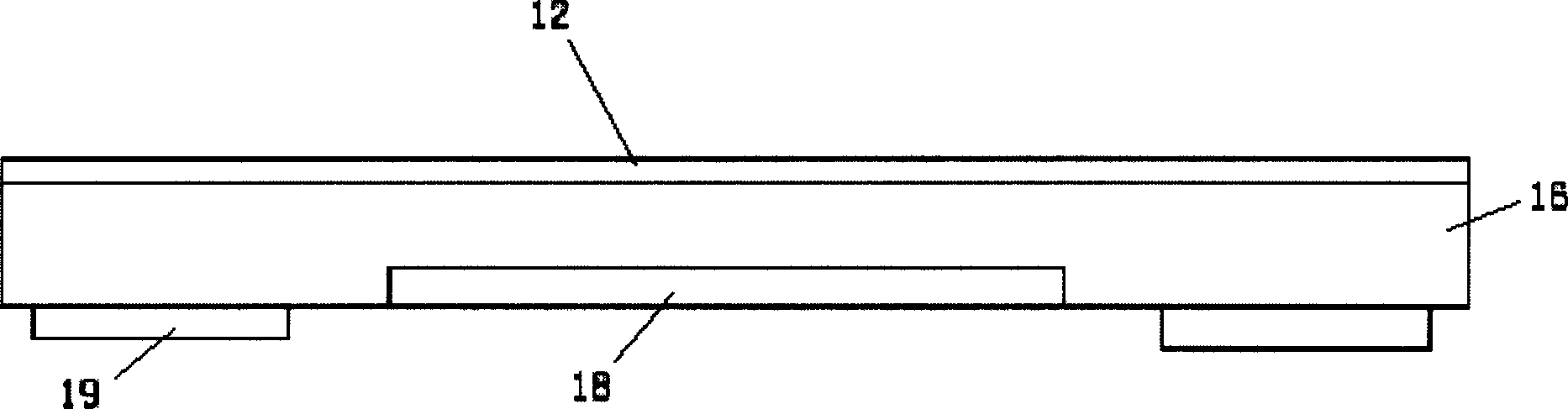

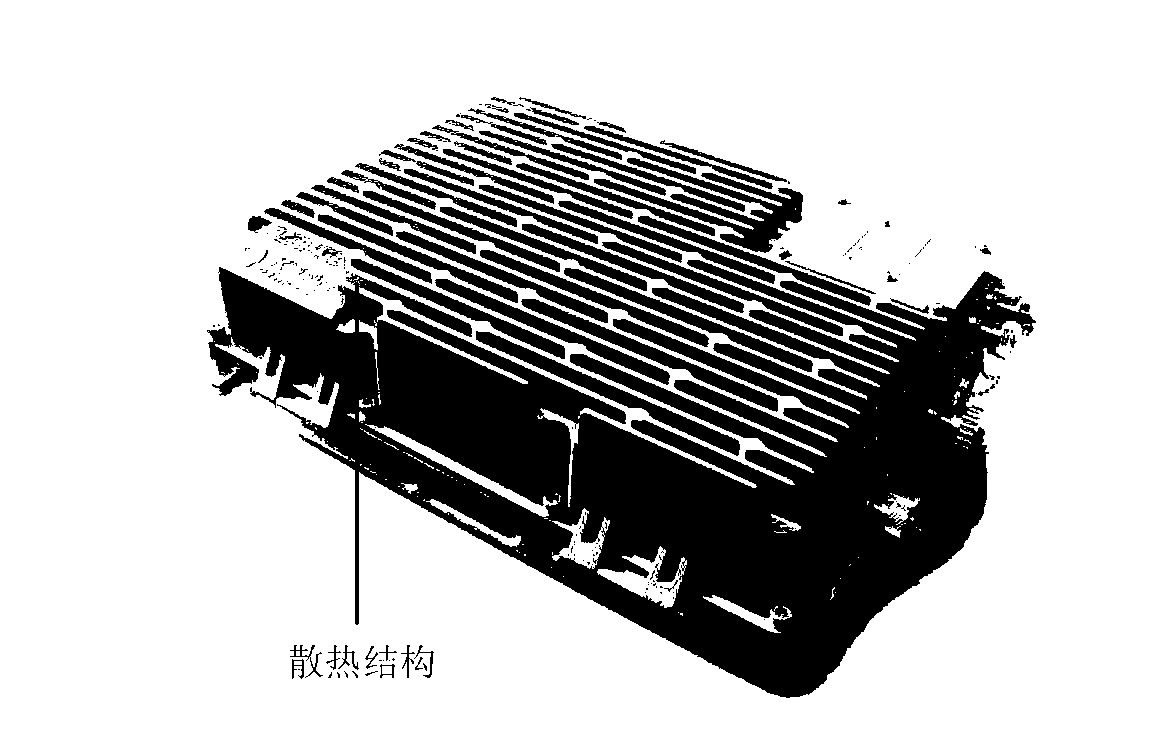

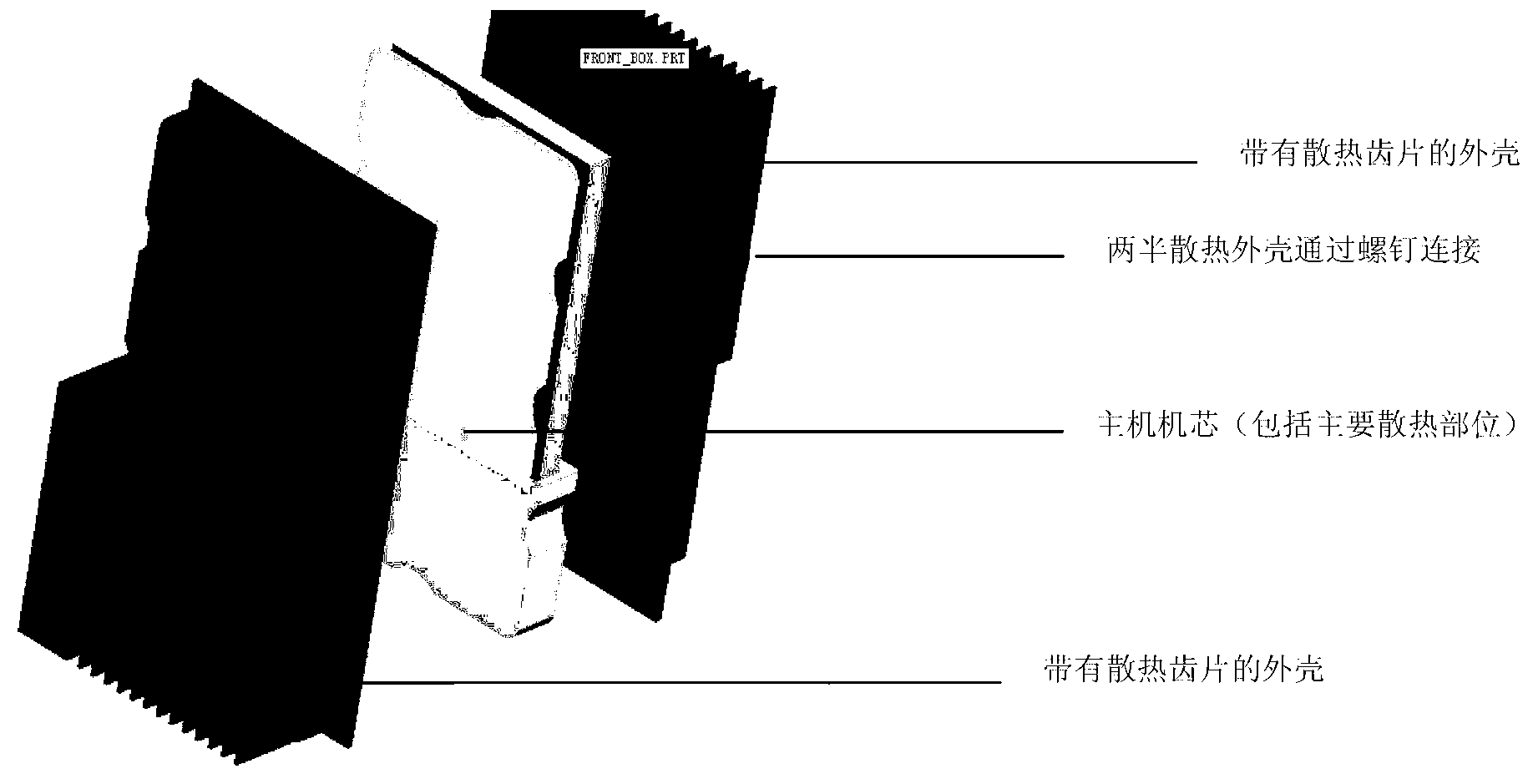

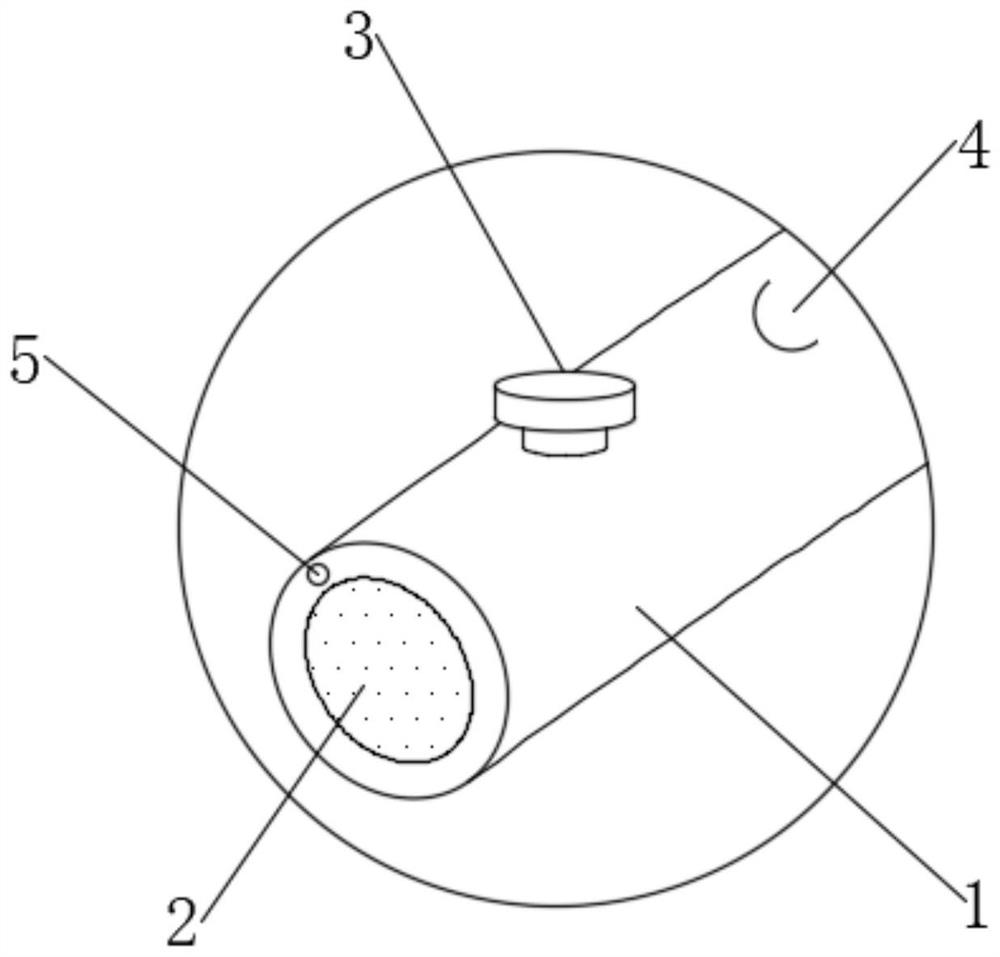

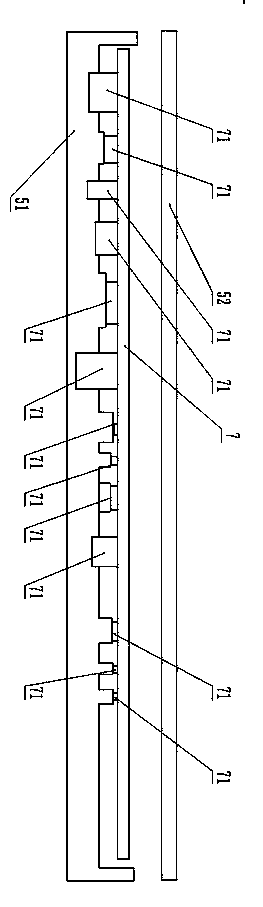

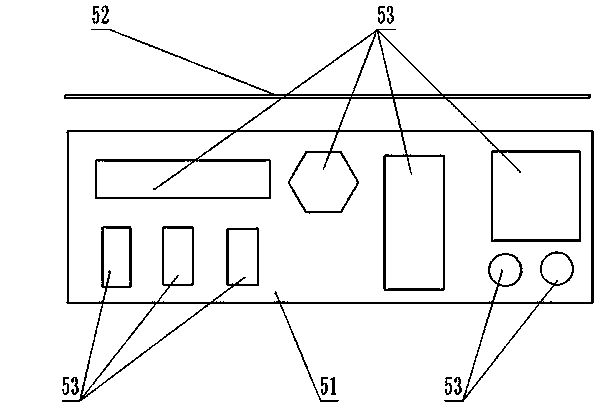

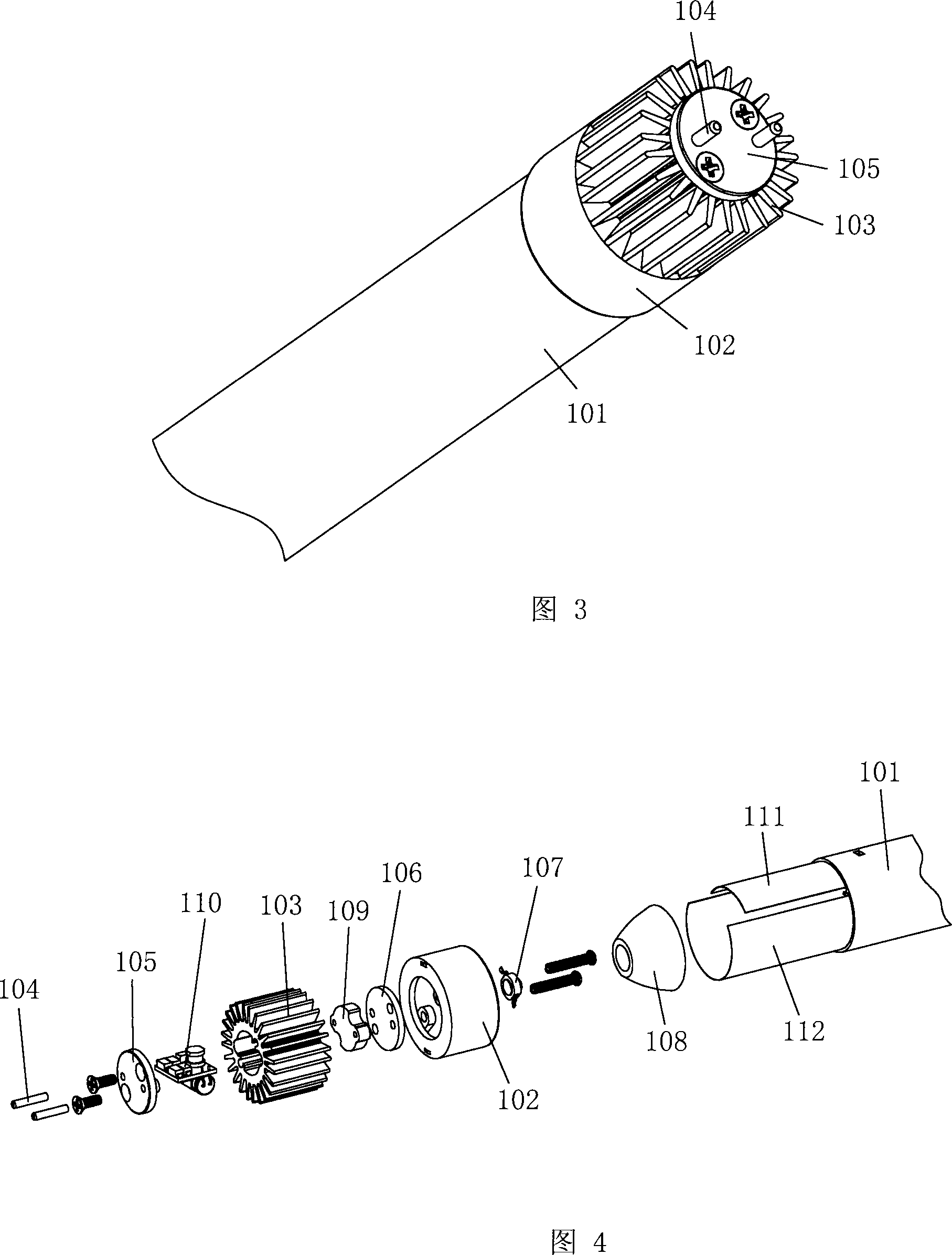

Radio remote unit and standard connecting component

InactiveCN102984831AImprove maintenance efficiencyImprove upgrade efficiencyWireless communicationMultiplexingComputer module

The invention discloses a remote radio unit (RRU) and a standard connecting component and relates to the field of wireless communication. The remote radio unit and standard connecting component is used for solving a multiplexing problem of products, improving maintenance and upgrade efficiency of the RRU and saving resources. The RRU comprises a heat dissipation module and a main engine module which are connected through the standard connecting component. Heat produced by the main engine module is transmitted to the heat dissipation module through the standard connecting component to dissipate heat. By adopting the remote radio unit and standard connecting component, the heat dissipation module can be flexibly assembled according to heat dissipation requirements of the main engine module of the RRU, and therefore the multiplexing problem of the products with different property can be solved, maintenance and upgrade efficiency of the RRU can be improved and the resources are saved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Vertical kiln

The invention discloses a vertical kiln, comprising a fuel supply device, an ignitor, a temperature measuring device, an unloading and discharging device, a kiln chamber, a blower, a pipeline, a valve, refractory materials, refractory fibre materials, heat preserving and reinforcement materials, an iron panel, reinforced concrete materials, brick-concrete materials, a tail gas treating device, a kiln preheating chamber, a heating chamber and a cooling chamber, wherein, a preheating chamber is communicated with the heating chamber; the cooling chamber is communicated with the heating chamber; a feed inlet is arranged at the upper part of the preheating chamber; an air outlet of the preheating chamber is arranged at the upper part of the preheating chamber; a plurality of flame paths are arranged at the side wall of the preheating chamber; a plurality of air inlet channels are arranged at the side wall of the flame paths; the air inlet channel is communicated with the flame paths; a discharge hole is arranged at the lower part of the cooling chamber and is communicated with a discharge chamber which is provided with an unloading device. The vertical kiln utilizes hot convection, and vortex for combustion, saves more energy and protects environment, and can use various fuels, such as coal powder, gas and liquid and the like; the materials are heated evenly by utilizing vortex; the materials can naturally move to a preheating zone, a heating zone and a cooling zone by utilizing natural settlement; the vertical kiln of the invention can be used for firing various lump materials, such as cement, lime, alumina and flint clay and the like.

Owner:陈久斌

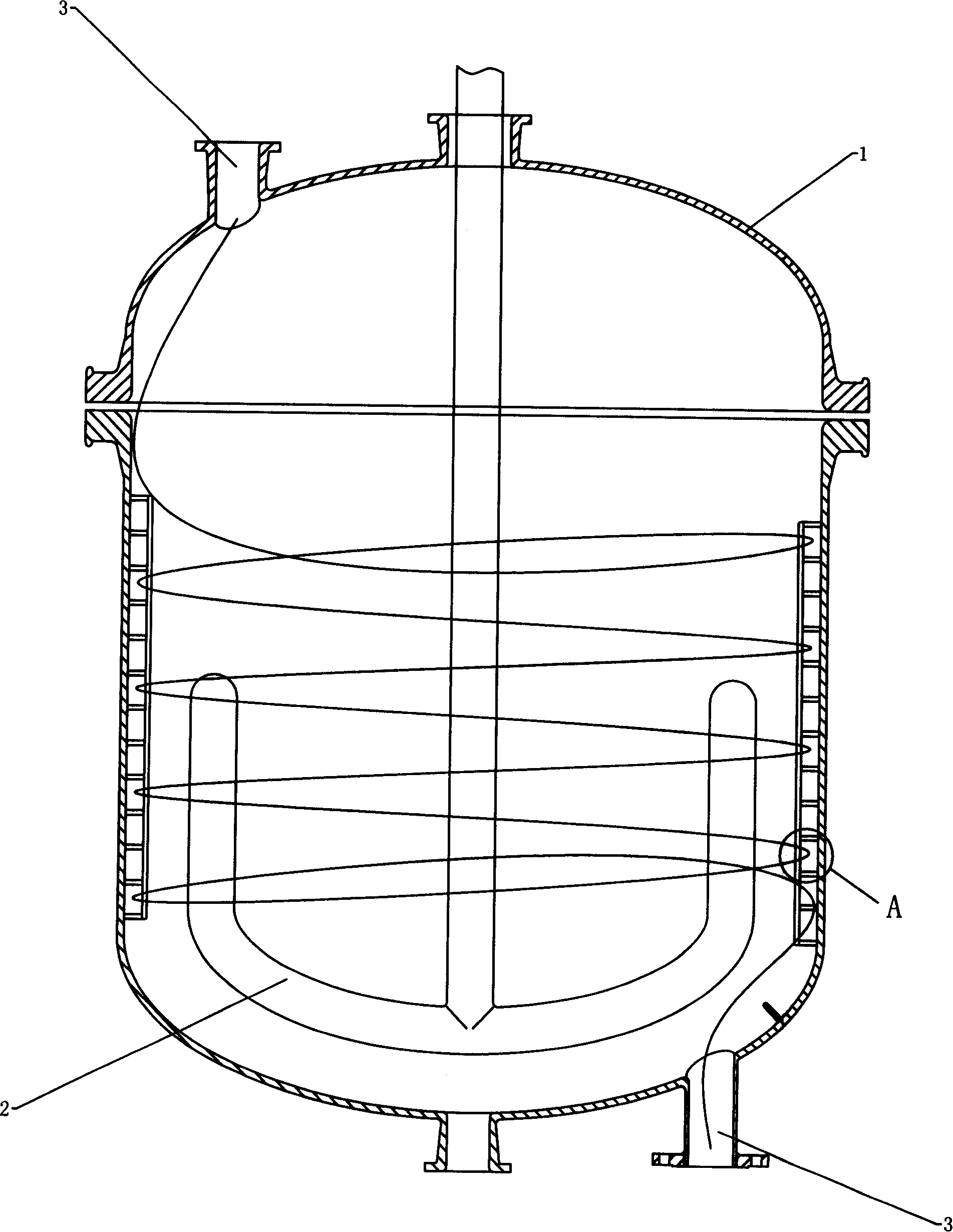

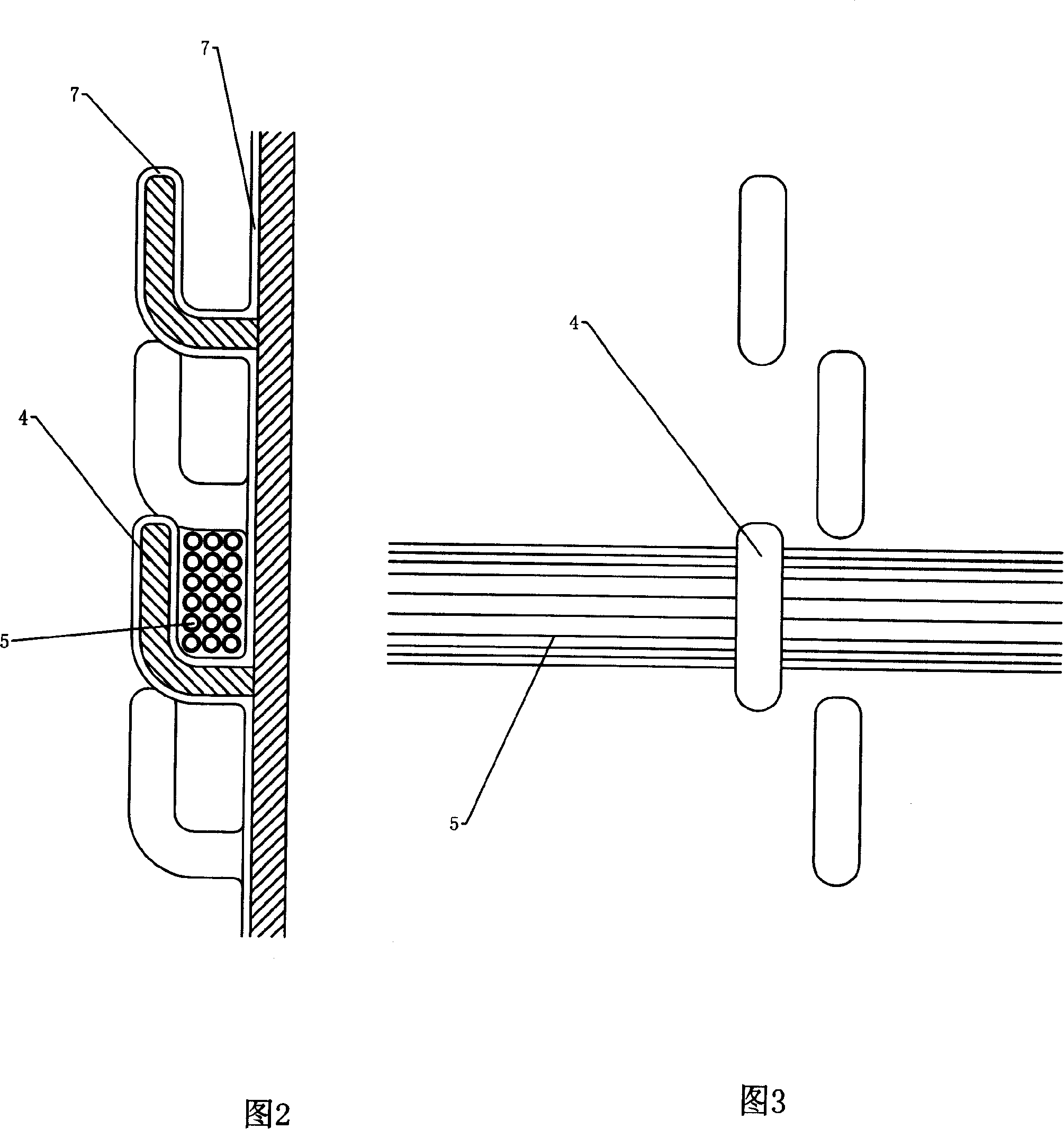

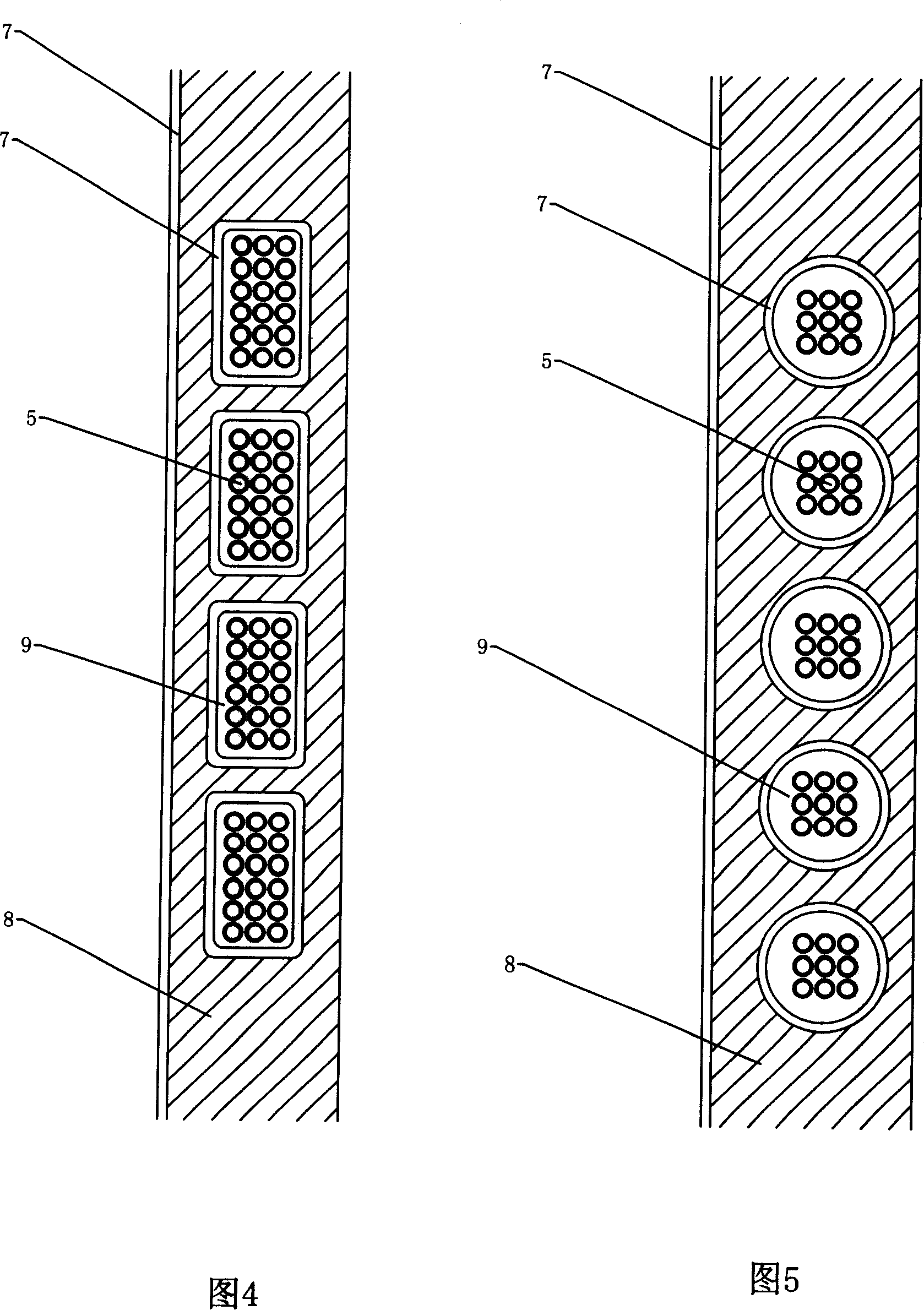

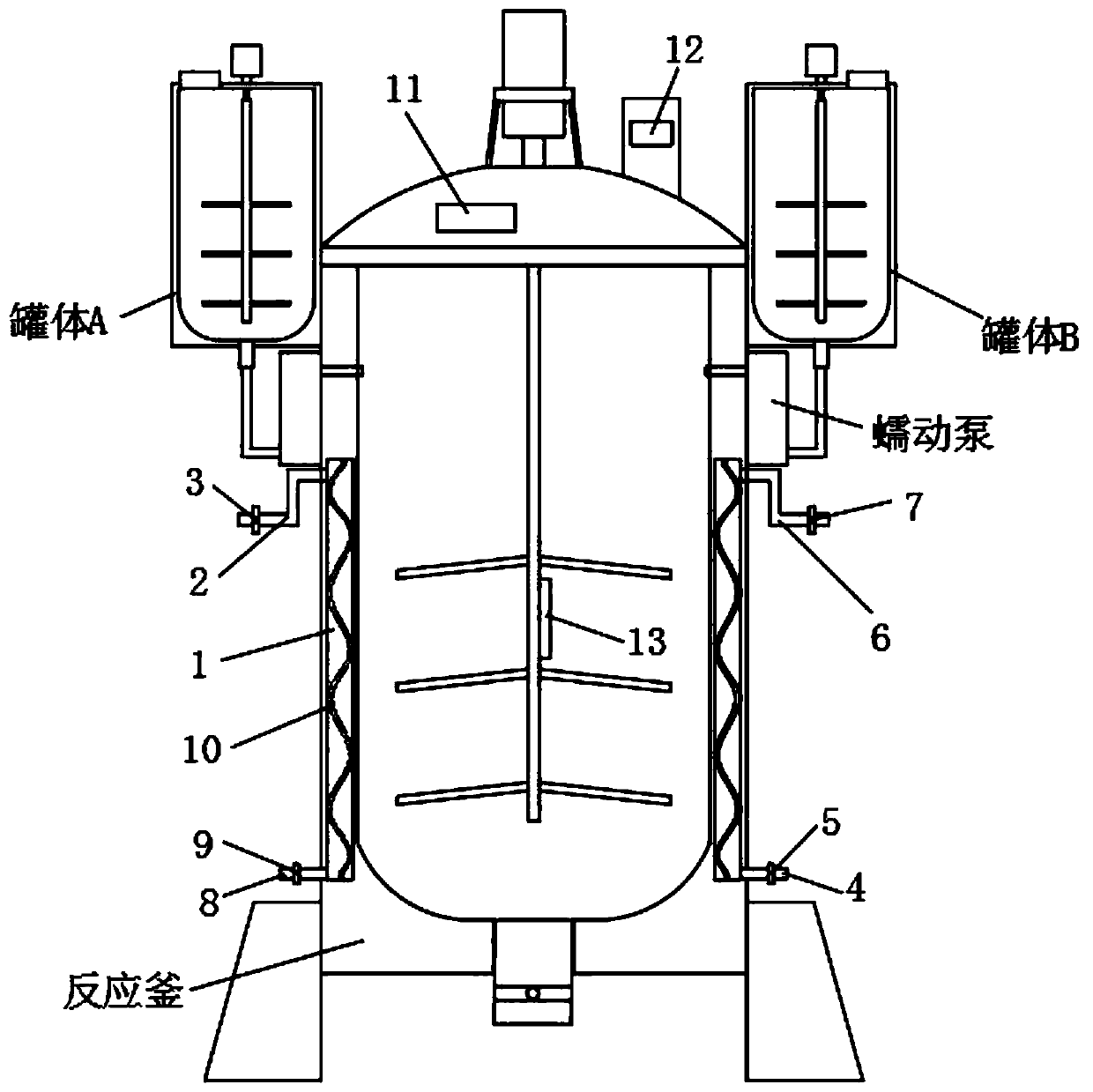

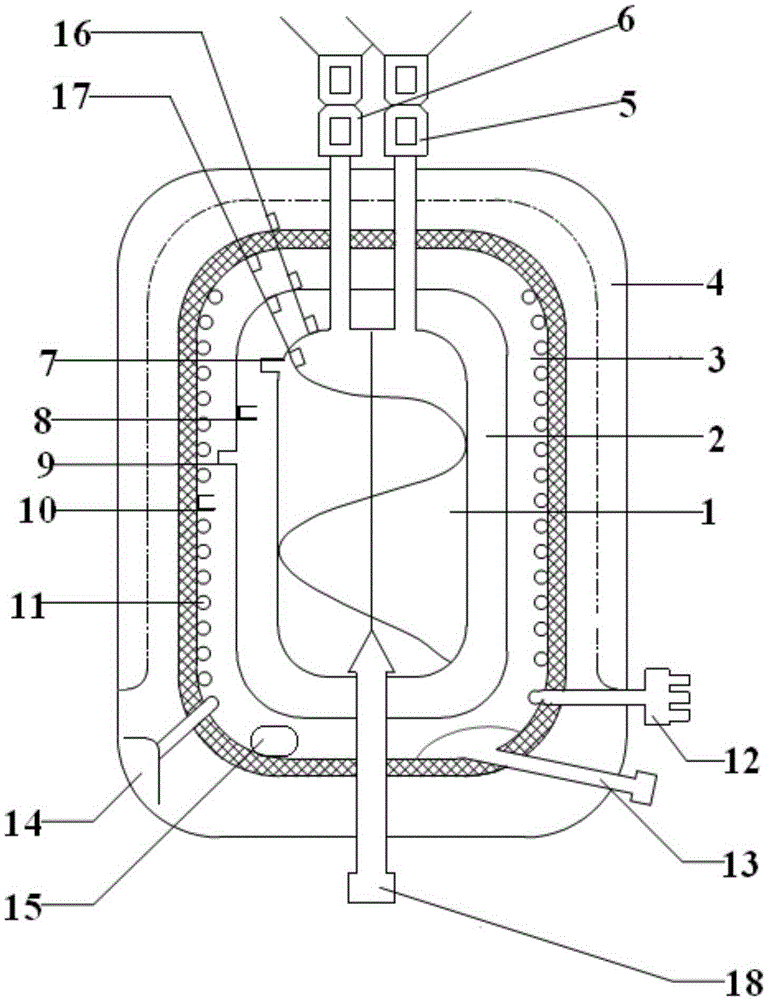

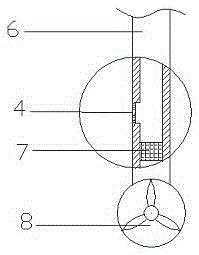

Novel high-efficient reaction still

InactiveCN101130156AEasy to replaceEasy maintenanceChemical/physical/physico-chemical processesBiochemical engineeringEngineering

The invention discloses a new-typed high-effective autoclave, which comprises the following parts: autoclave body, stirrer in the autoclave body, heater on the autoclave body and inlet and outlet of heat exchange pipe at two ends of the autoclave body, wherein the heat exchange pipe contains several fixing bodies on the inner wall of the autoclave body and several heat exchange pipes on the inner wall of the autoclave body fixed by fixing bodies; the fixing body can be hook with one end assembled on the inner wall of the autoclave body, which can also be several rows of frames. The invention adopts inner heat exchange pattern of built-in fixing bodies to improve the working efficiency and production to provide convenient assemblage and maintenance for the autoclave, which has antiseptic lining on the fixing body, outer surface of the stirrer and inner wall of the autoclave body, which ensures the safety of the autoclave body and lengthens the life of the autoclave body.

Owner:四达氟塑股份有限公司

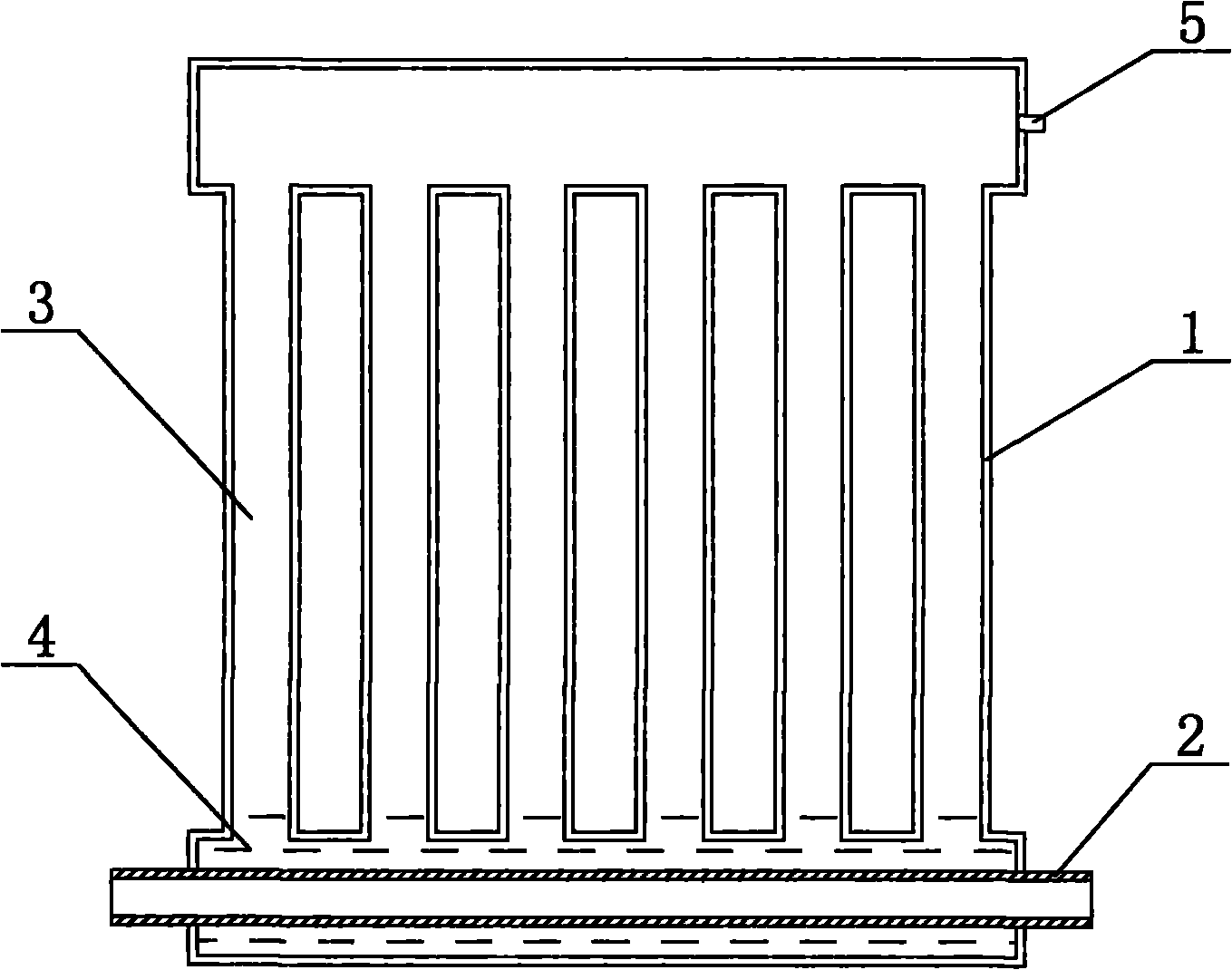

20 DEG C-gasification vacuum superconductive radiator

InactiveCN101832725AEffective indication range of activitiesMonitor the sealIndirect heat exchangersThermal energyBoiling point

The invention discloses a 20 DEG C-gasification vacuum superconductive radiator which comprises radiating fins, wherein the interiors of the radiating fins are communicated to form a completely closed vacuum cavity; the bottom of the cavity is penetrated with a heating pipe; and the cavity is filled with partial superconductive liquid gasified at 20 DEG C. Hot water is led into the heating pipe, then the superconductive liquid absorbs heat to gasify and rises to the upper parts of the radiating fins to condense, and a large quantity of phase change heat is released and diffused to surroundings so as to achieve the purpose of heating; and the condensed superconductive liquid flows back to the lower parts along the inner wall of the cavity and continues to be heated to form a heat-transfer cycle. The device adopts the low-boiling-point 20 DEG C-gasification superconductive liquid, and gasification can be realized at 20 DEG C. The heat transfer starting speed is high, and the vacuum superconductive radiator is particularly suitable for an independent heating system taking a family as a unit. The system needs less cycling hot water, thus water resources are saved, meanwhile, the utilization rate of heat energy is improved, and the purpose of saving energy is also achieved. Scale depositions are not generated in the process of use, and the heat transfer efficiency cannot be reduced after long-term use; and the structure is firm, the tightness is good, thus the service life is effectively prolonged.

Owner:CHUZHOU YANGZI THERMAL ENERGY EQUIP

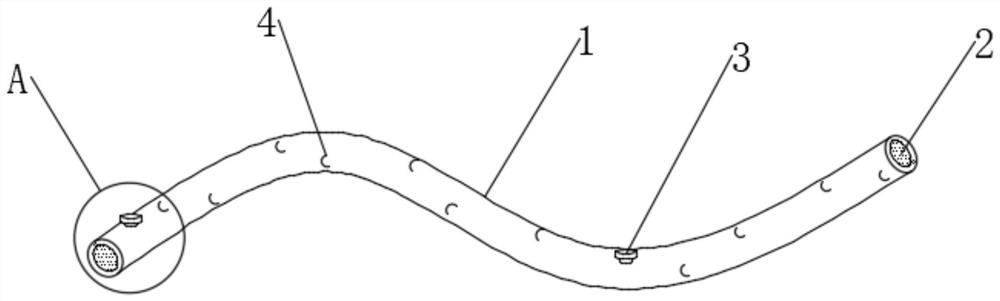

Internal heating type anti-freezing cable for severe cold regions and anti-freezing method thereof

ActiveCN112071487AFully contactedAvoid burningInsulated cablesInsulated conductorsCold areaEngineering

The invention discloses an internal heating type anti-freezing cable for a severe cold area and an anti-freezing method thereof, belongs to the technical field of cables, and can realize that a contraction action is triggered after external cold is sensed by arranging cold sensing outer coating scales outside the cable, so that the cable can be prevented from being frozen. Pre-filled magnetic heat-generating microspheres are subjected to powder scraping and adsorption by virtue of shrinkage action, and then an external gap is opened to be communicated with the outside after the magnetic heat-generating microspheres are shrunk to a certain extent, so that a small amount of external air enters the cable and is subjected to an oxidation reaction of releasing heat with the scraped powdery magnetic heat-generating microspheres, a gentle heating environment can be formed in the cable, on one hand, the cable can be assisted to resist external cold, on the other hand, burnout caused by excessive heat release can be avoided, technicians can regularly supplement the magnetic heat generation microspheres to realize autonomous low-temperature protection action of the cable, the use safety of the cable in severe cold areas is effectively improved and the service life is greatly prolonged.

Owner:深圳深华新电缆实业有限公司

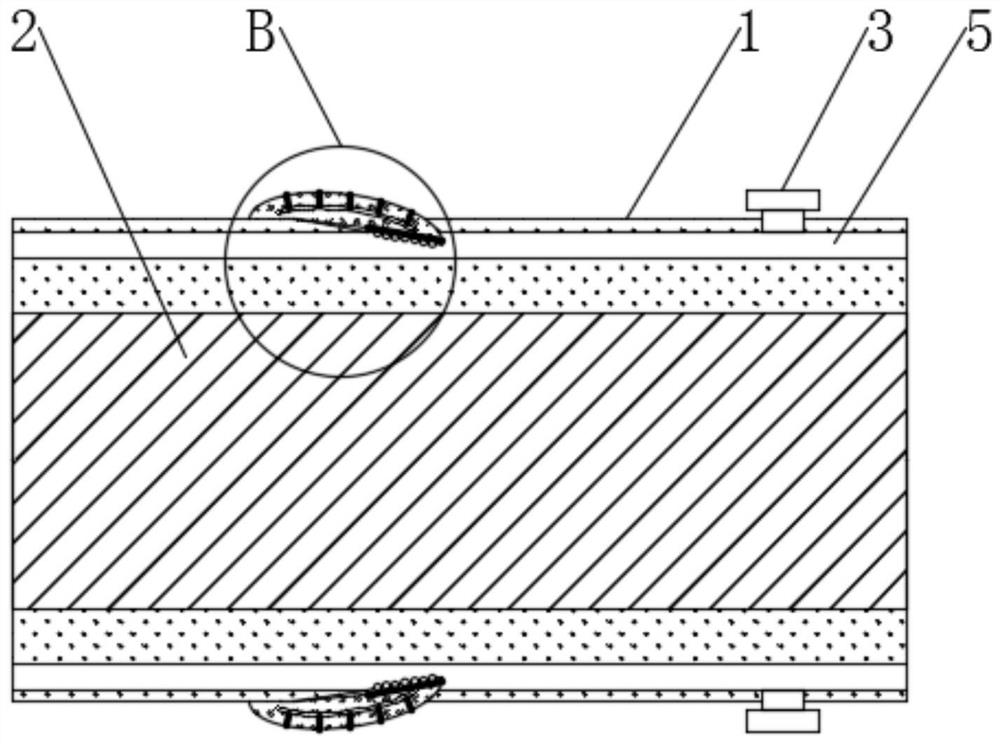

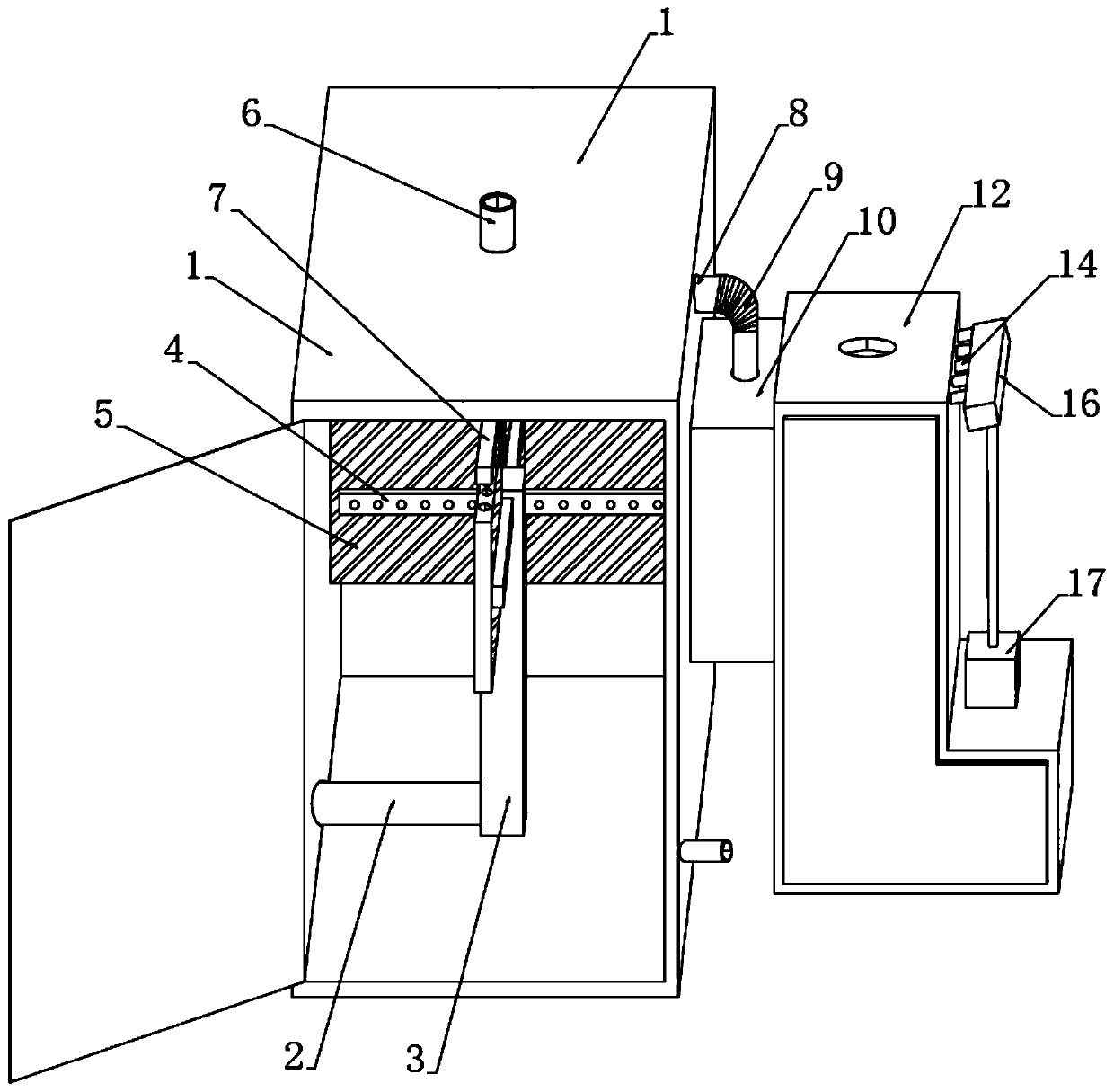

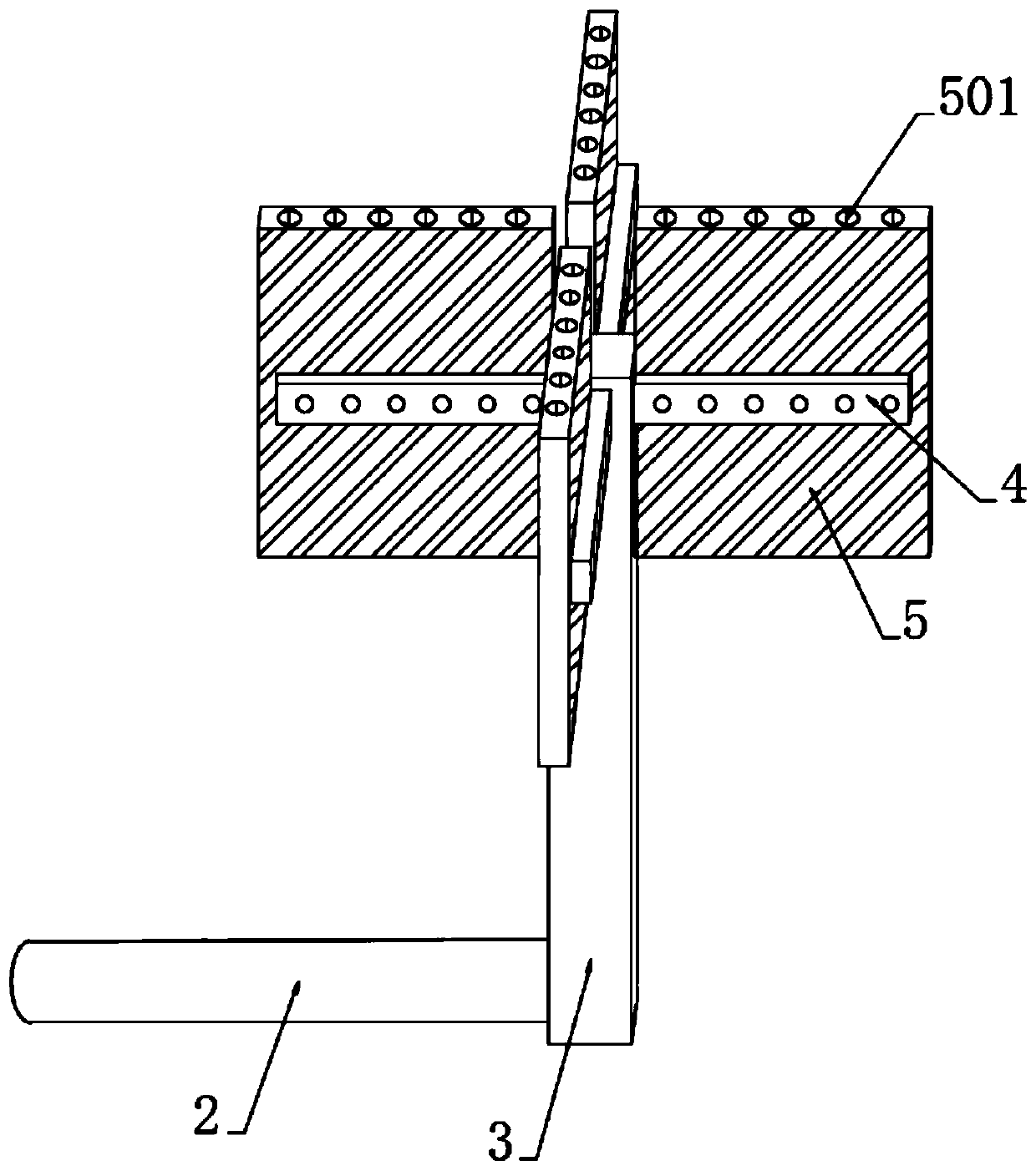

Data center server cooling equipment cabinet

ActiveCN103838337AContact heat transferExtended service lifePower supply for data processingHeat transmissionEngineering

The invention discloses a data center server cooling equipment cabinet which comprises a server equipment cabinet, a phase change heat transmission system, server machine shells and spring pieces for fixing the server machine shells. The phase change heat transmission system comprises a plurality of heat exchangers arranged in the server equipment cabinet, an outdoor cooling device and connecting pipelines. The heat exchangers are arranged on support layers for placing of servers in the server equipment cabinet respectively. The server machine shells are placed on the upper portions of the heat exchangers, the servers are sealed in the server machine shells, air cooling does not exist in the whole data center server cooling equipment cabinet, server heating units are in direct contact with the server machine shells, the server machine shells are in direct contact with the heat exchangers placed in the server machine cabinet, contact heat transmission is achieved, and heat transmission efficiency is improved. According to the data center server cooling equipment cabinet, server placing density can be increased, building cost is low, a building cycle is short, and the running cost of a whole data center is greatly lowered.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

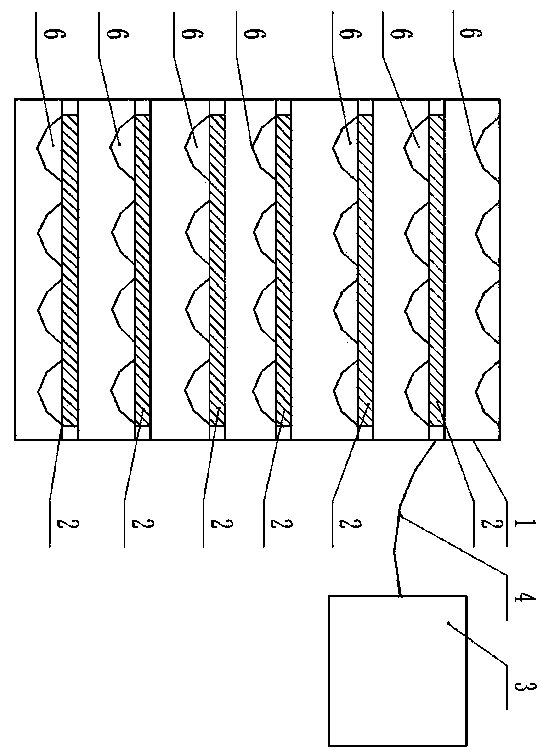

Gas heat and mass transfer method based on self-microcirculation of caloric infinitesimal liquid

InactiveCN1558175AReduce thermal resistanceAvoid liquid entrainmentDirect contact heat exchangersChemistryProduct gas

The present invention discloses one kind of gas heat and mass transferring method based on the self micro circulation of the heat and mass micro element liquid. The heat and / or mass transfer between two or more kinds of gas is completed via the liquid circulation in the heat and / or mass transfer wall and realized based on the heat and / or mass transfer of innumerous heat and / or mass transfer micro elements. The heat and / or mass transfer micro element consists of gas micro element, heat and / or mass transfer wall micro element and liquid micro element; and the heat and / or mass transfer of heat and / or mass transfer micro element includes the acceptance of heat and / or mass of the liquid micro element on one side of the heat and / or mass transfer wall, self micro circulation of the liquid micro element, and the release of heat and / or mass of the liquid micro element on the other side. The present invention has high heat and mass transfer efficiency and other advantages.

Owner:袁一军

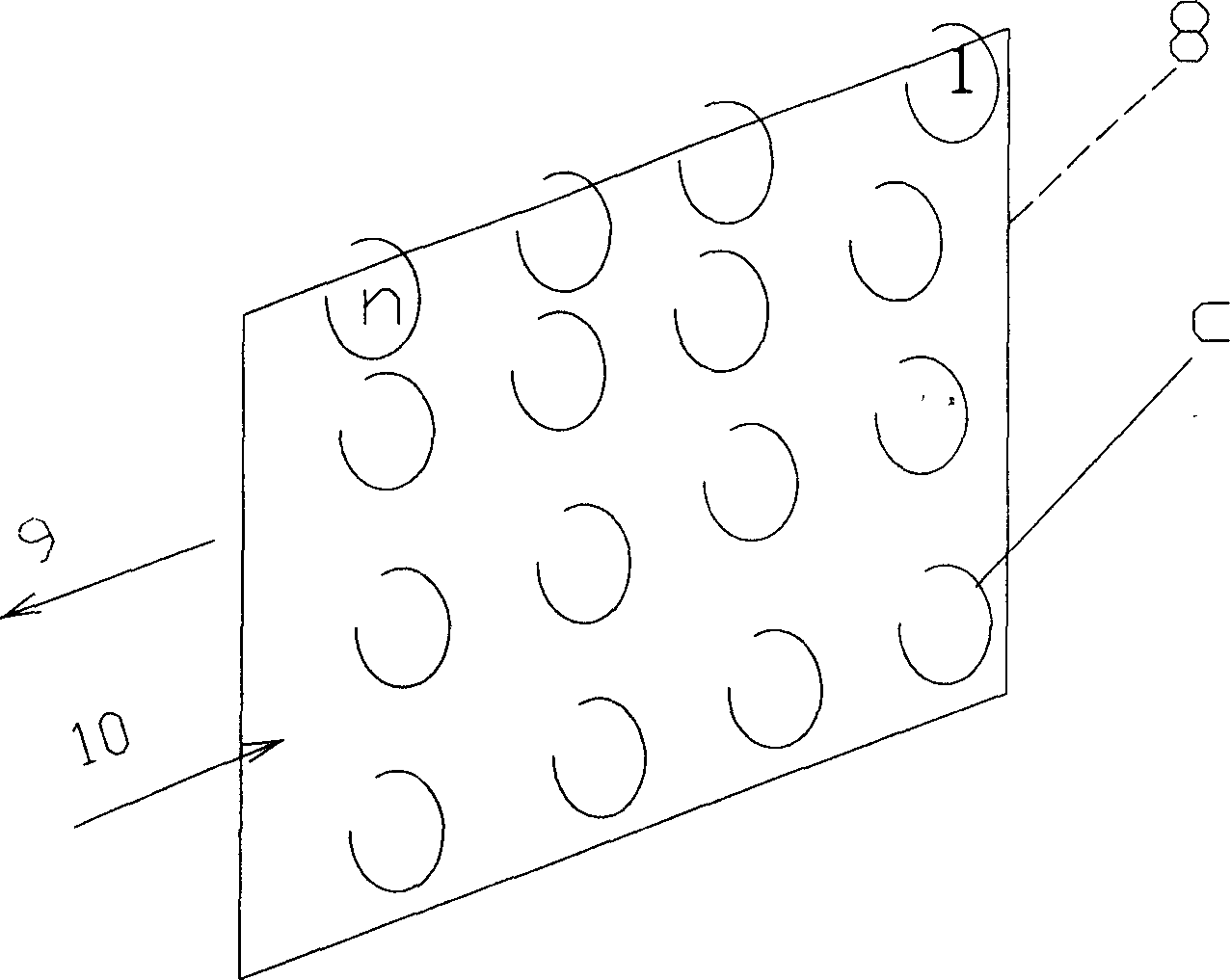

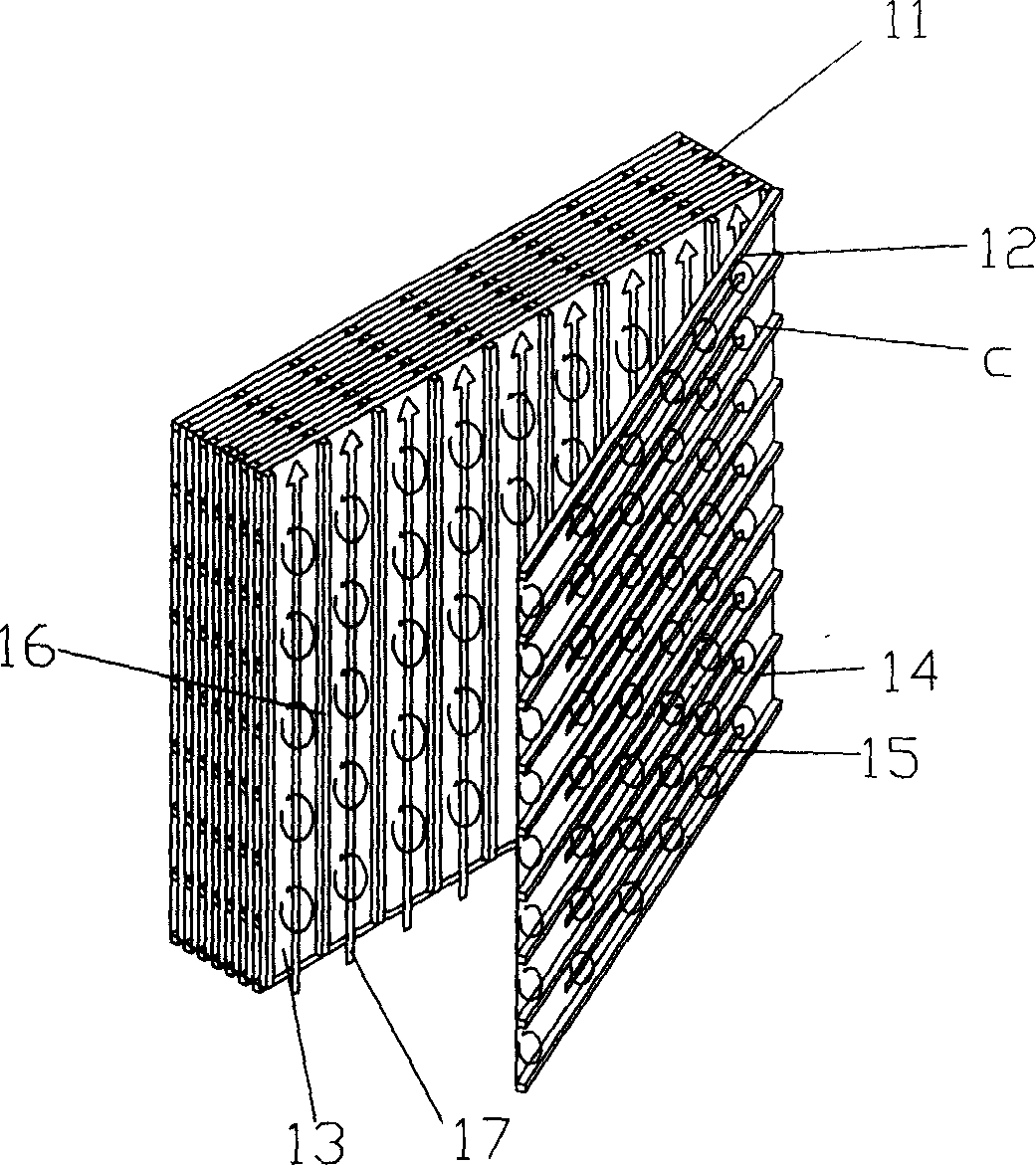

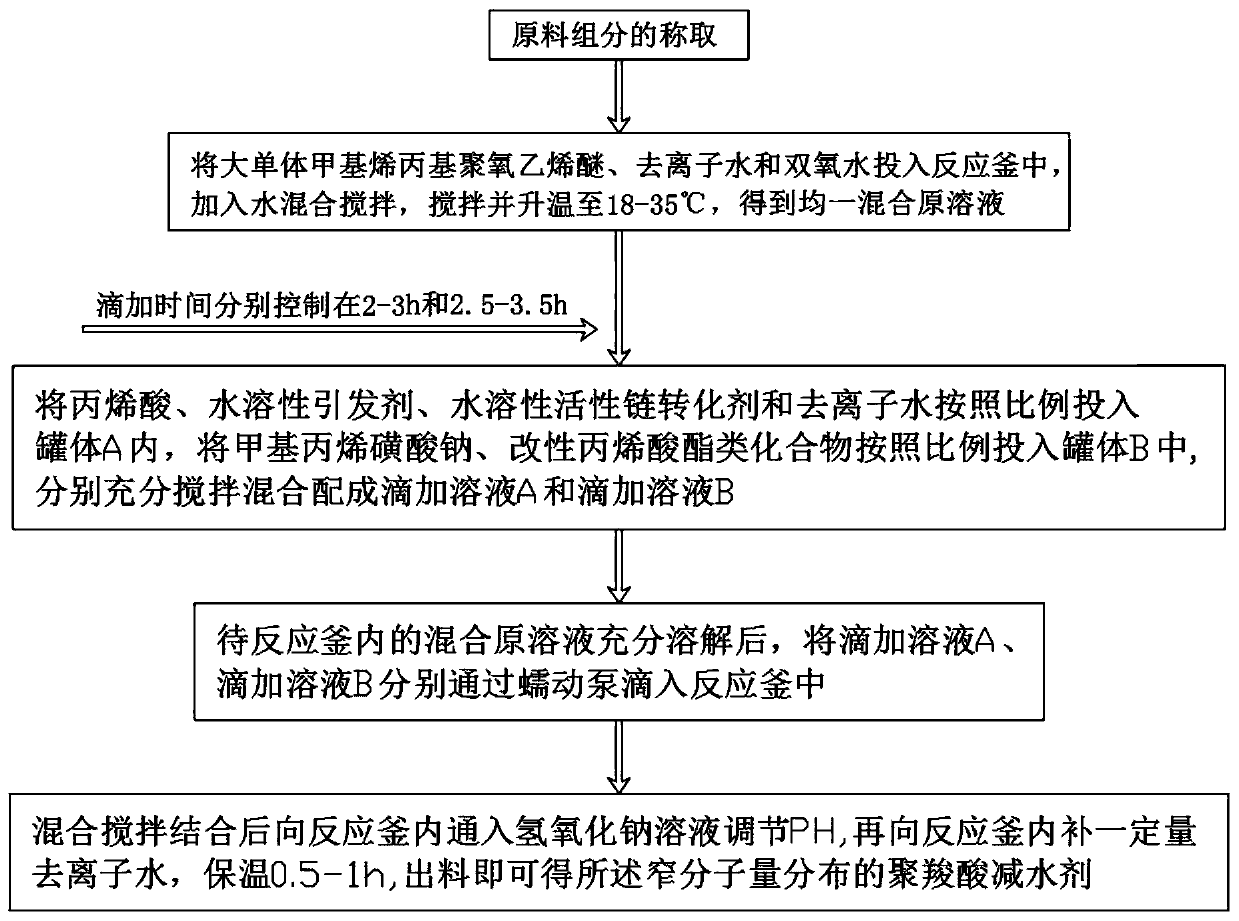

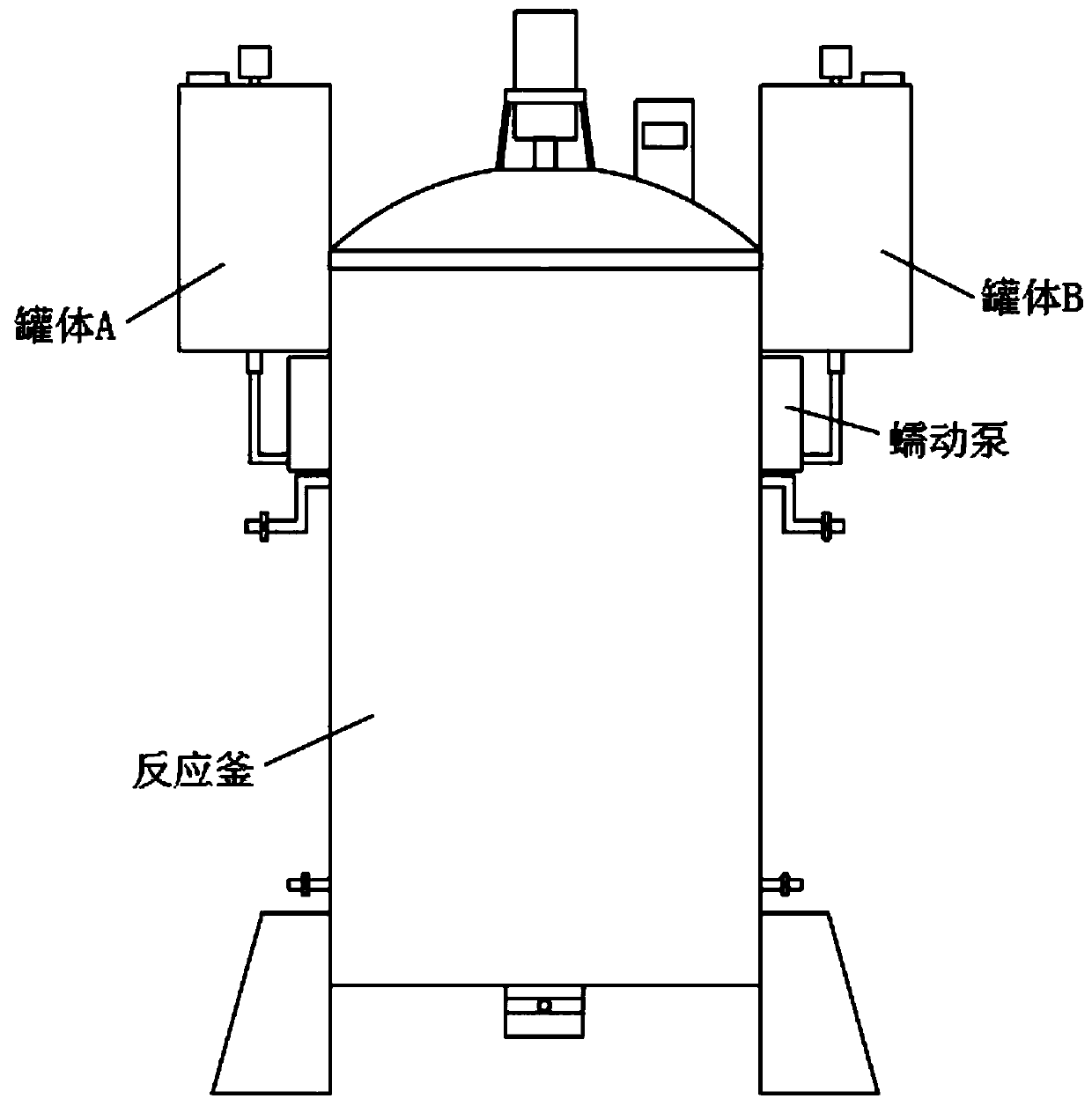

Polycarboxylic acid water reducing agent with narrow molecular weight distribution and preparation method thereof

PendingCN110407985APromote circulationSpeed up heat transferChemical/physical/physico-chemical stationary reactorsPolymer scienceControllability

The invention discloses a polycarboxylic acid water reducing agent with narrow molecular weight distribution and a preparation method thereof, belonging to the technical field of slump retaining agentpreparation. The polycarboxylic acid water reducing agent with narrow molecular weight distribution and the preparation method thereof realize that the molecular weight distribution and controllability of the obtained polycarboxylic acid high-efficiency water reducing agent are greatly improved. After propyl polyoxyethylene ether is mixed with a water-soluble initiator and a water-soluble activechain transfer agent, the obtained molecular weight distribution is narrower, and the dispersibility of the product is better. At the same time, sodium methacrylate sulfonate and modified acrylate compounds are added to facilitate improving of the early strength, slump retention, reinforcement and other properties of the prepared polycarboxylic acid water reducing agent; moreover, a heat preservation interlayer with an automatic regulation function is arranged in a reaction kettle, is beneficial to realizing the conversion of heat transfer and cold transfer in the heat preservation interlayer,improving the lifting sensitivity of the temperature in the reaction kettle, eliminating the need for manual temperature regulation, and effectively avoiding the influence on the preparation of the polycarboxylic acid water reducing agent caused by large temperature control difficulty.

Owner:GUANGZHOU JIANSHENG BUILDING MATERIALS CO LTD

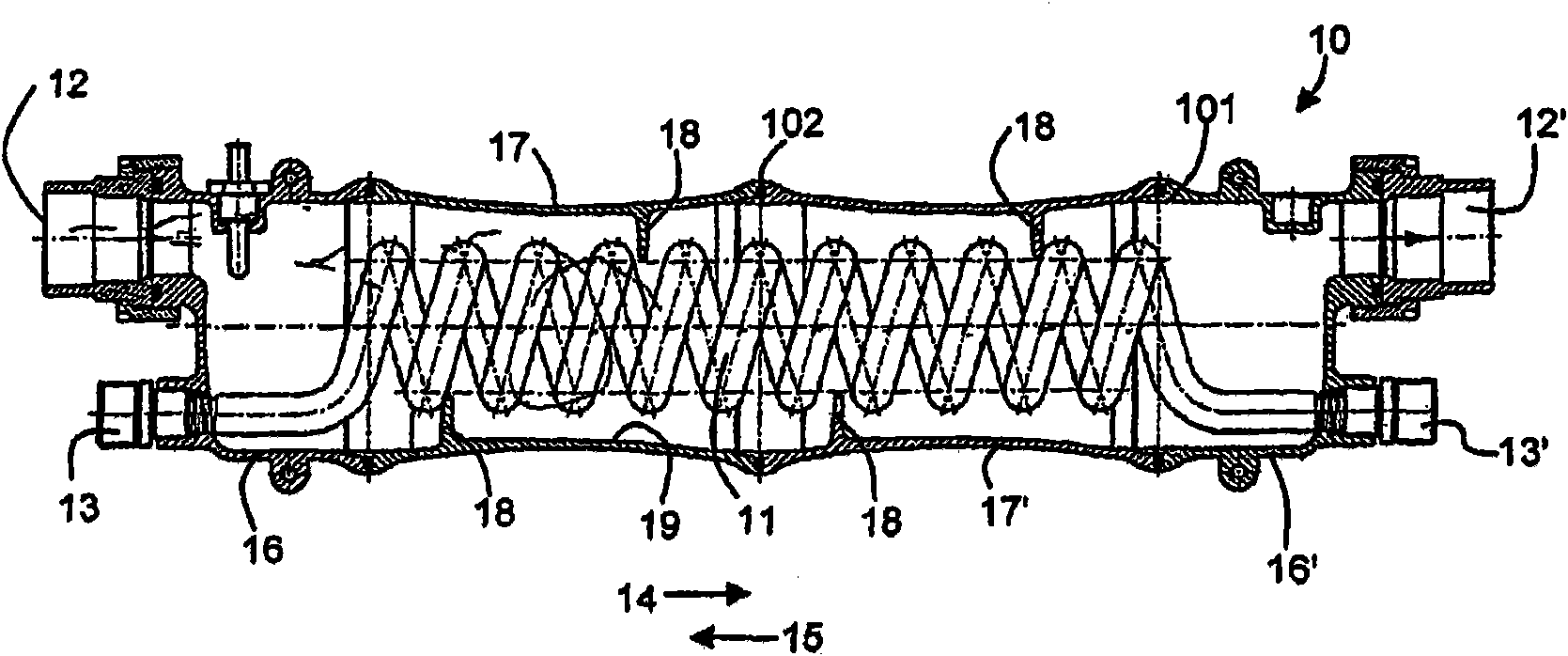

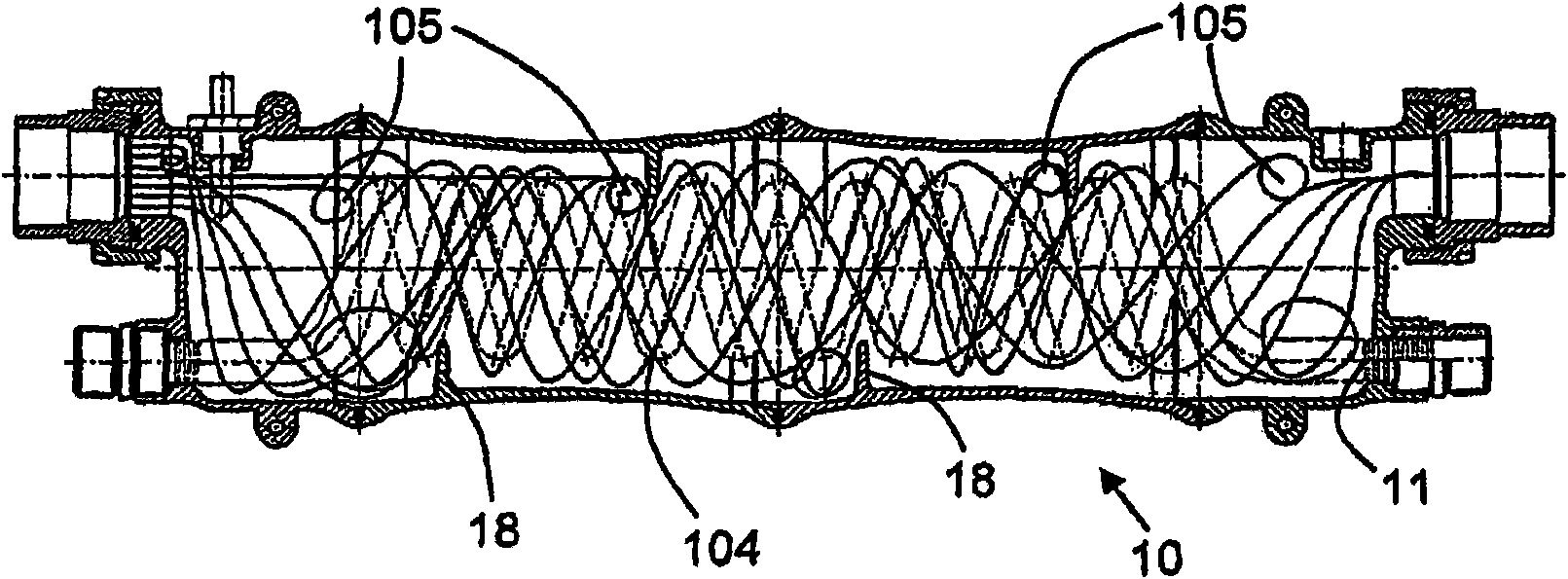

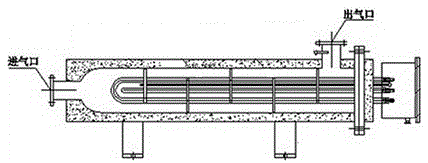

Heat exchanger

InactiveCN101796364AOptimize dwell timeImprove stabilityHeat exchanger casingsStationary tubular conduit assembliesEngineeringMechanical engineering

The invention relates to a heat exchanger (10) having an elongate hollow body with connections (12, 12', 13, 13') for the supply and discharge of a first and of a second medium, in which the first medium is guided through the elongate hollow body in a counterflow with respect to a second medium, and the second medium flows through a spiral tube (11) which extends longitudinally axially between the end sides of the hollow body, and wherein a plurality of deflecting elements (18) projects into the hollow body interior from the hollow body inner casing, which deflecting elements deflect the flow of the first medium. To improve efficiency, it is provided that the deflecting elements project in an alternating sequence from in each case opposite hollow body sides into the hollow body interior and into the region of the spiral tube, in such a way that said deflecting elements end between two spirals, and that the hollow body inner casing has, in sections, a plurality of concavely-shaped constrictions.

Owner:WTS KERESKEDELMI & SZOLGALTATO

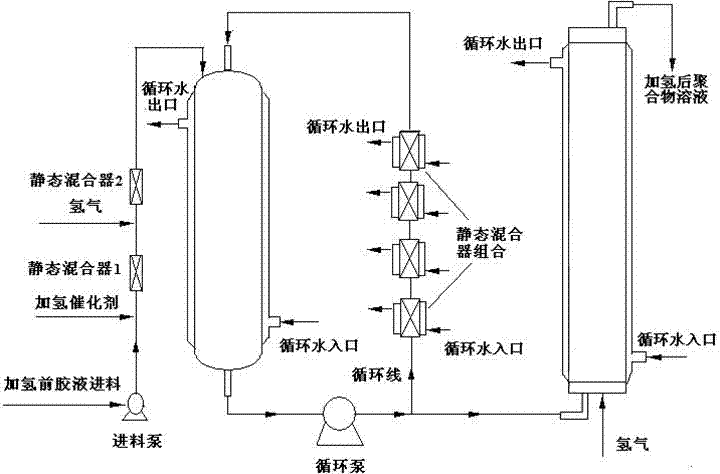

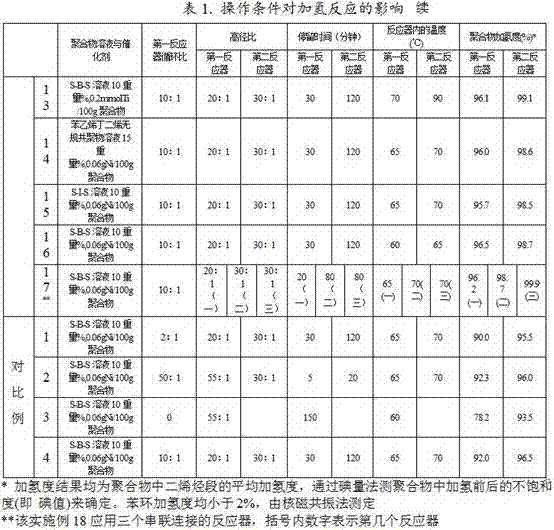

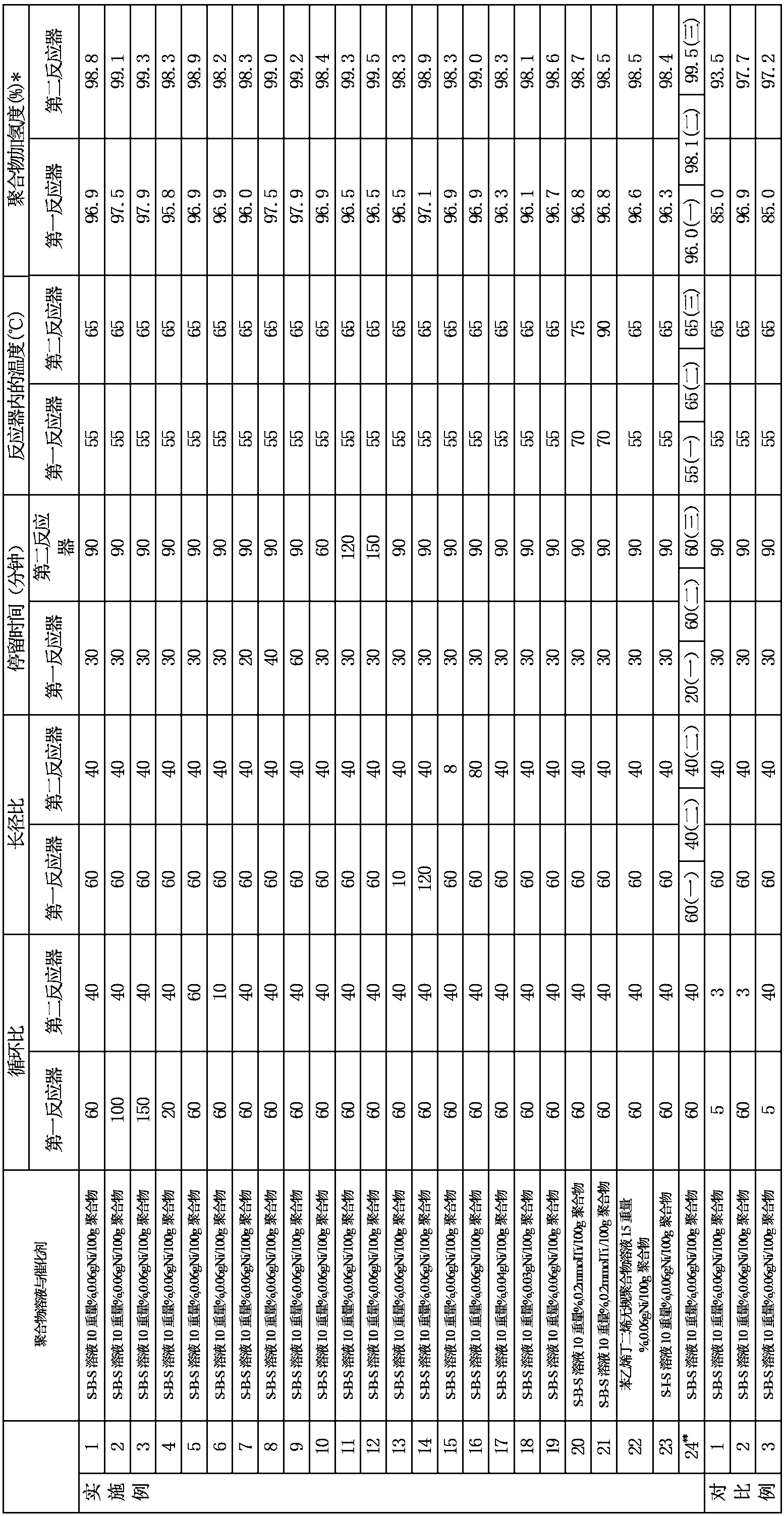

A hydrogenation method for a polymer comprising an olefin unsaturated bond

A hydrogenation method for a polymer comprising an olefin unsaturated bond is disclosed. The method includes bringing a solution of the polymer comprising the olefin unsaturated bond into contact with hydrogen in reactors under a hydrogenation condition and with the existence of a hydrogenation catalyst. The method is characterized in that the reactors are at least two reactors in series connection, the first reactor is formed by combining a tower reactor or a stirring reactor with a static mixer, materials in the reactors are allowed to be in a near complete mixing state through controlling the recycle ratio of the first reactor, the recycle ratio of the first reactor is 1-40:1, the second and latter reactors are tower reactors, and materials in the second and latter reactors are in a near plug-flow state. The method can allow the hydrogenation degree of the polymer to reach an ideal value stably.

Owner:苏州双湖化工技术有限公司

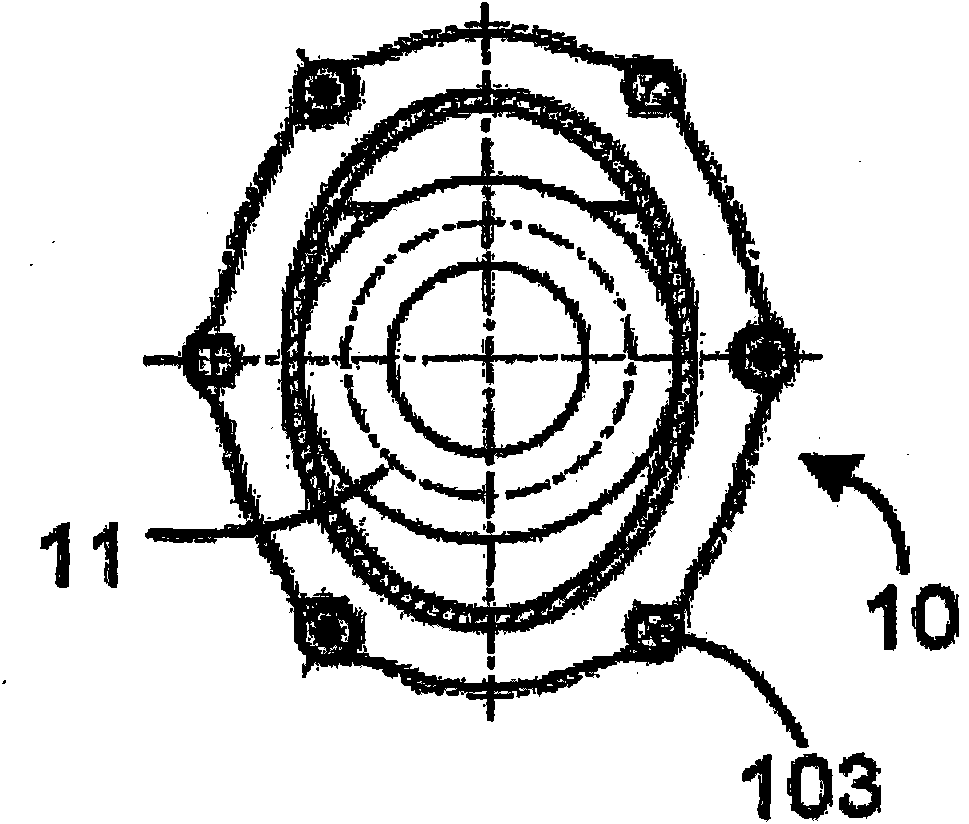

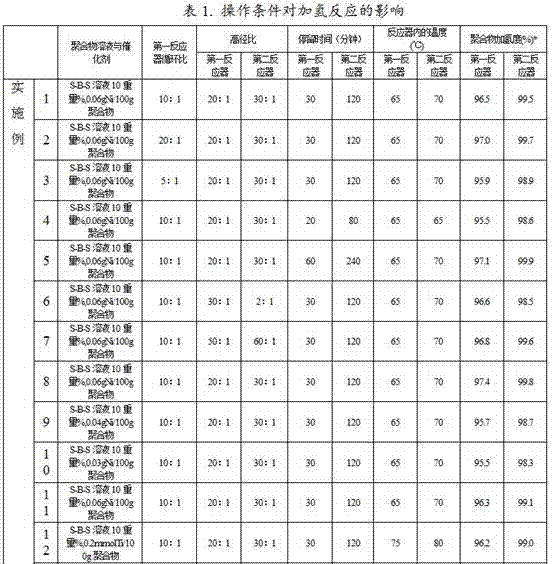

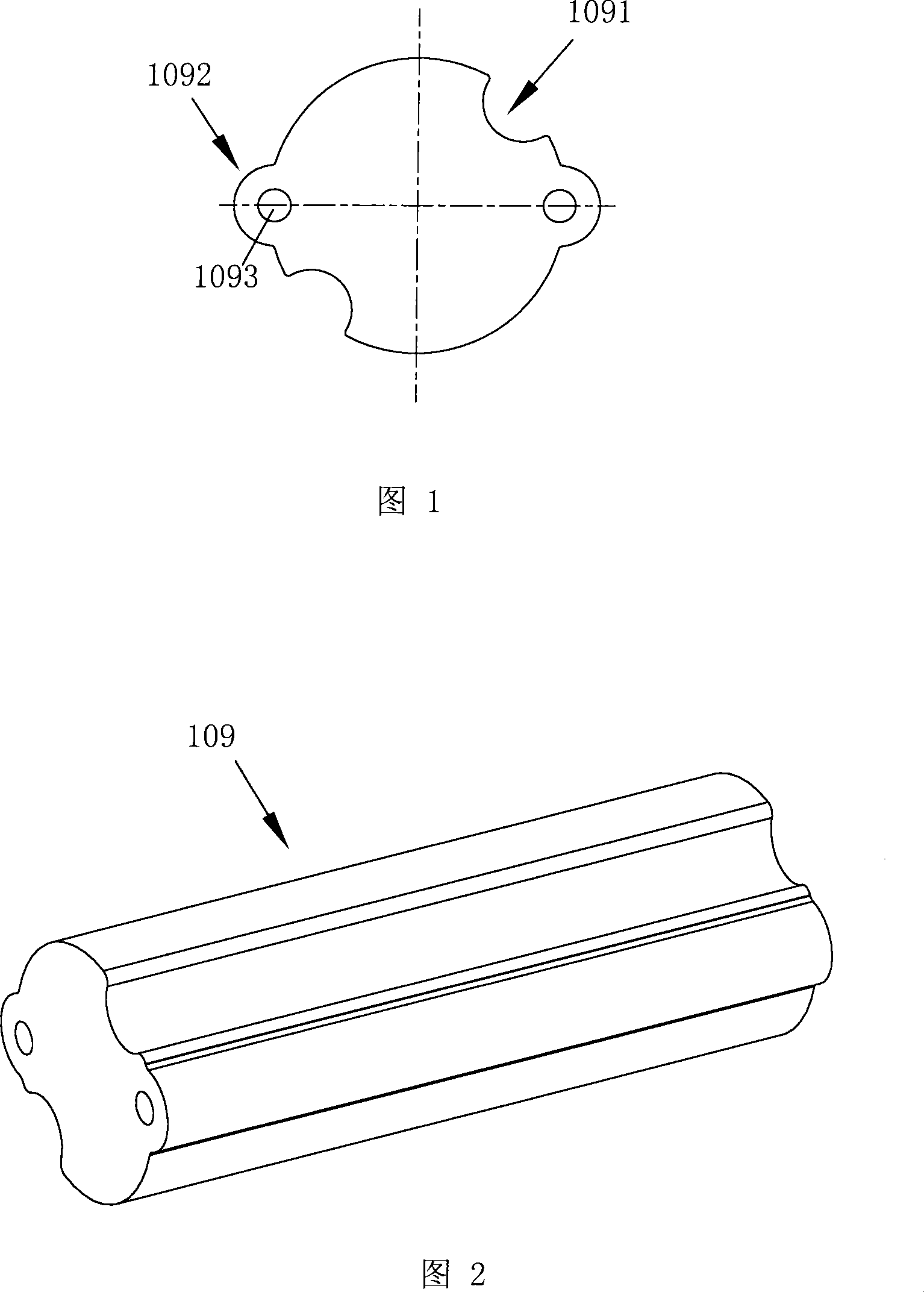

Section bar

InactiveCN101144605AImprove thermal conductivityAchieve heat transferPoint-like light sourceSemiconductor/solid-state device detailsHeat conductingHeat transmission

The invention relates to the LED illumination technology, in particular to a special heat radiation section material used for an LED illumination device. Different positions have the same cross section along the length direction of the section material. The invention is characterized in that the cross section of the section material consists of a circle, and two concave positions and two convex positions which are arranged on the circumference; the two concave positions are arranged symmetrically along a diameter of the circle, and extend along the length direction of the section material, in order to form two grooves; the two convex positions are arranged symmetrically along a diameter of the circle, and extend along the length direction of the section material, to form two convex ribs; the two concave positions and the two convex positions are arranged in a staggered way in the circumferential direction of the heat conducting wall; the two convex positions also have a thread bottom hole which is arranged in the length direction of the section material. The invention provides an LED daylight lamp special heat radiation section material with good heat conduction effect, and realizes the heat transmission between an LED illuminator as well as a heat radiation element outside a pipe body.

Owner:DONGGUAN KINGSUN OPTOELECTRONIC CO LTD

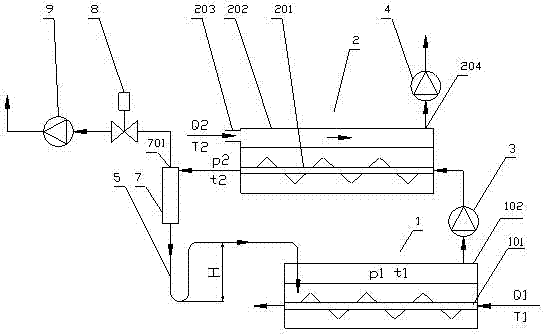

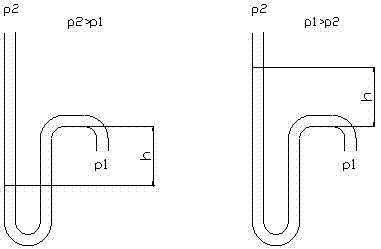

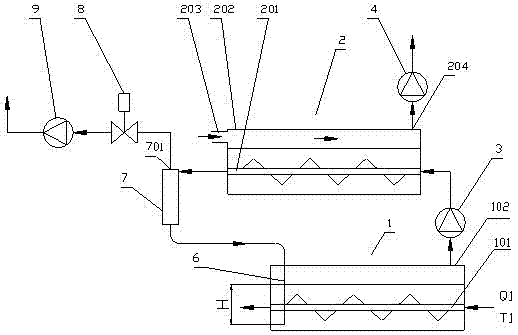

Refrigeration system with low energy consumption and using method thereof

ActiveCN102353169AActs as an expansion valveNo energy consumptionEvaporators/condensersCompression machines with reversible cycleCarnot cycleEngineering

The invention relates to a refrigeration system. The refrigeration system comprises an evaporator, a condenser, a compressor and a U-shaped tube or a straight tube, wherein the mounting position of the condenser is higher than that of the evaporator; and the height H of the U-shaped tube or the depth H that the straight tube is inserted below the liquid level of a refrigerant in the evaporator accords with a formula of rho gH>p2-p1, wherein rho is the density of the refrigerant. For a condition that indoor temperature T1 is lower than outdoor temperature T2, the refrigeration system adopts Carnot reverse cycle; and for a condition that the indoor temperature T1 is higher than the outdoor temperature T2, the refrigeration system adopts Carnot cycle, p2<p1, at the moment, refrigerant steam pushes the compressor to idle, and the refrigerant in the U-shaped tube or the straight pipe completes constant entropy compression by means of self gravity without energy consumption, so that the energy consumption of the system is extremely low. The refrigeration system can use other liquid with the boiling point between 20 and 100 DEG C, such as methanol, ethanol and the like as the refrigerant.

Owner:卓卫民

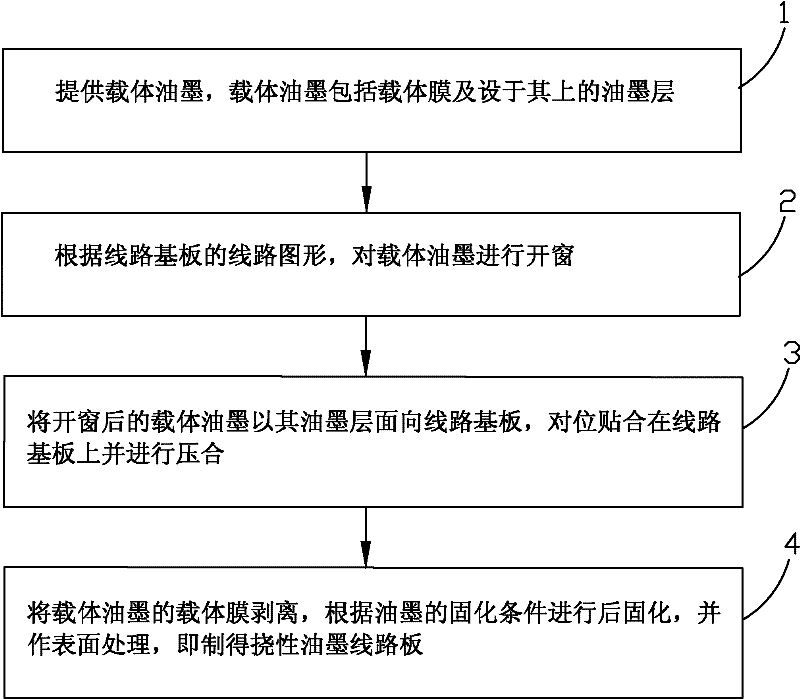

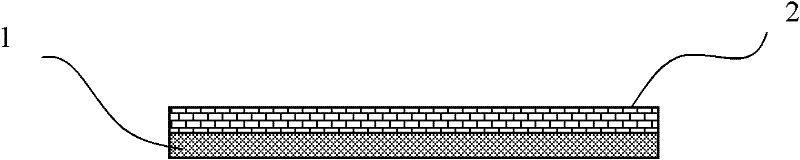

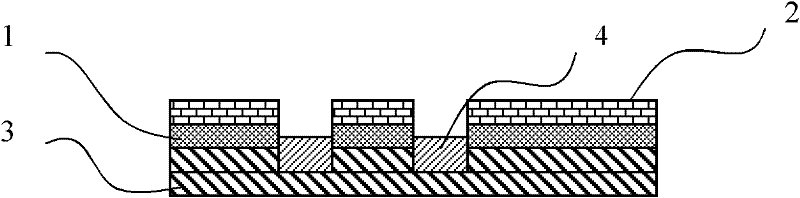

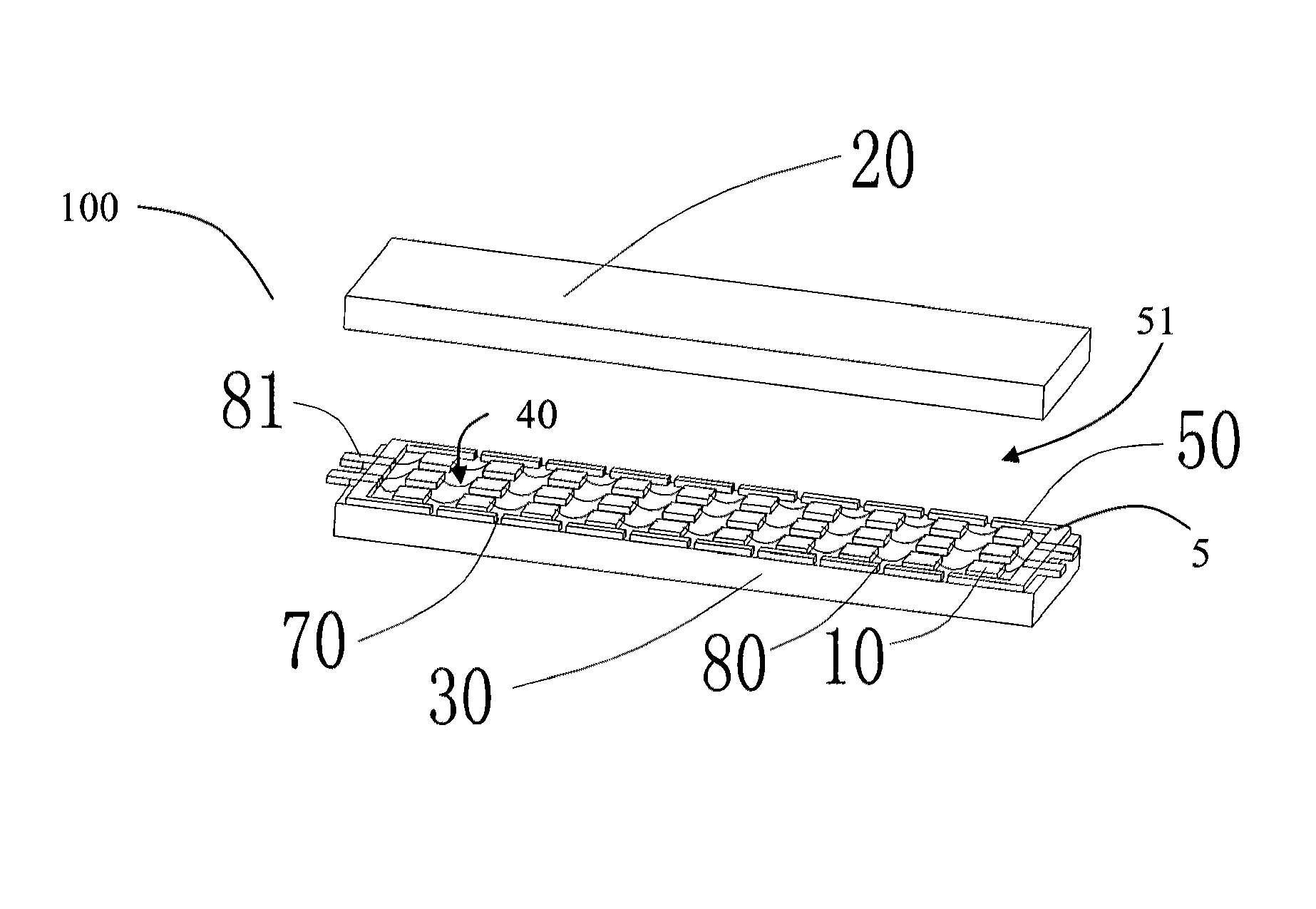

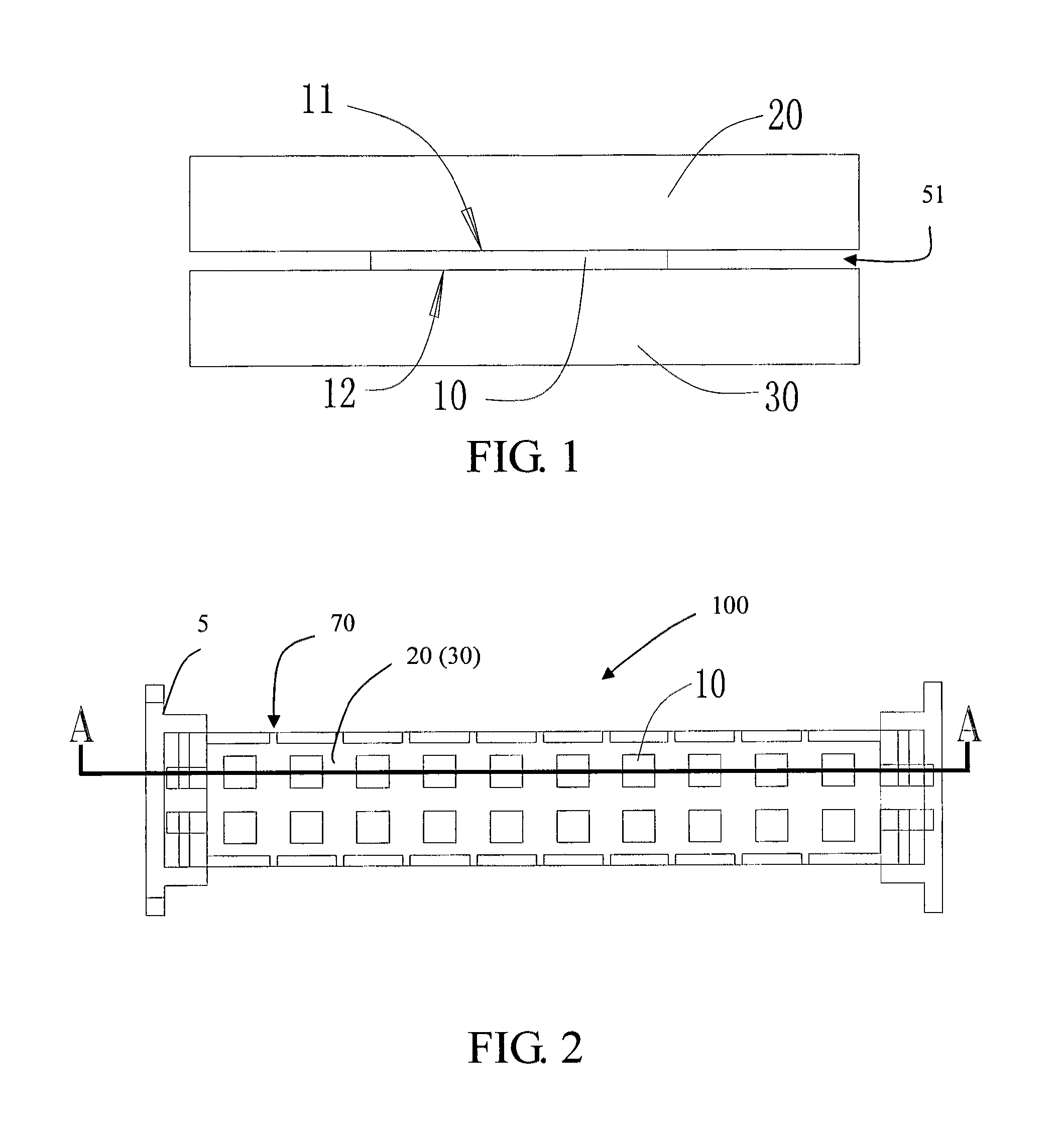

Method for manufacturing flexible printed circuit board

InactiveCN102307436ASkip the silk screen processAchieve heat transferNon-metallic protective coating applicationEngineeringPrinted circuit board

The invention provides a method for manufacturing a flexible printed circuit board. The method comprises the following steps of: 1, providing carrier ink, wherein the carrier ink comprises a carrier membrane and an ink layer thereon; 2, windowing the carrier ink according to a circuit pattern of a circuit substrate; 3, aligning and adhering the windowed carrier ink to the circuit substrate in the way of making an ink layer face the circuit substrate, and pressing; 4, stripping the carrier membrane of the carrier ink, post-curing according to the curing condition of the ink, and performing surface treatment to obtain the flexible printed circuit board. Compared with the conventional method for manufacturing the flexible printed circuit board, the method provided by the invention has the advantages that: a silk screening process is eliminated, heat transfer of the ink can be realized by common quick pressing, and thus the thickness of the ink can be reduced; meanwhile, a good covering effect can be achieved, the utilization rate of the ink is improved, the cost is reduced, product yield is increased greatly, labor is saved, the production cycle is shortened, and environmental pollution is reduced.

Owner:GUANGDONG SHENGYI SCI TECH

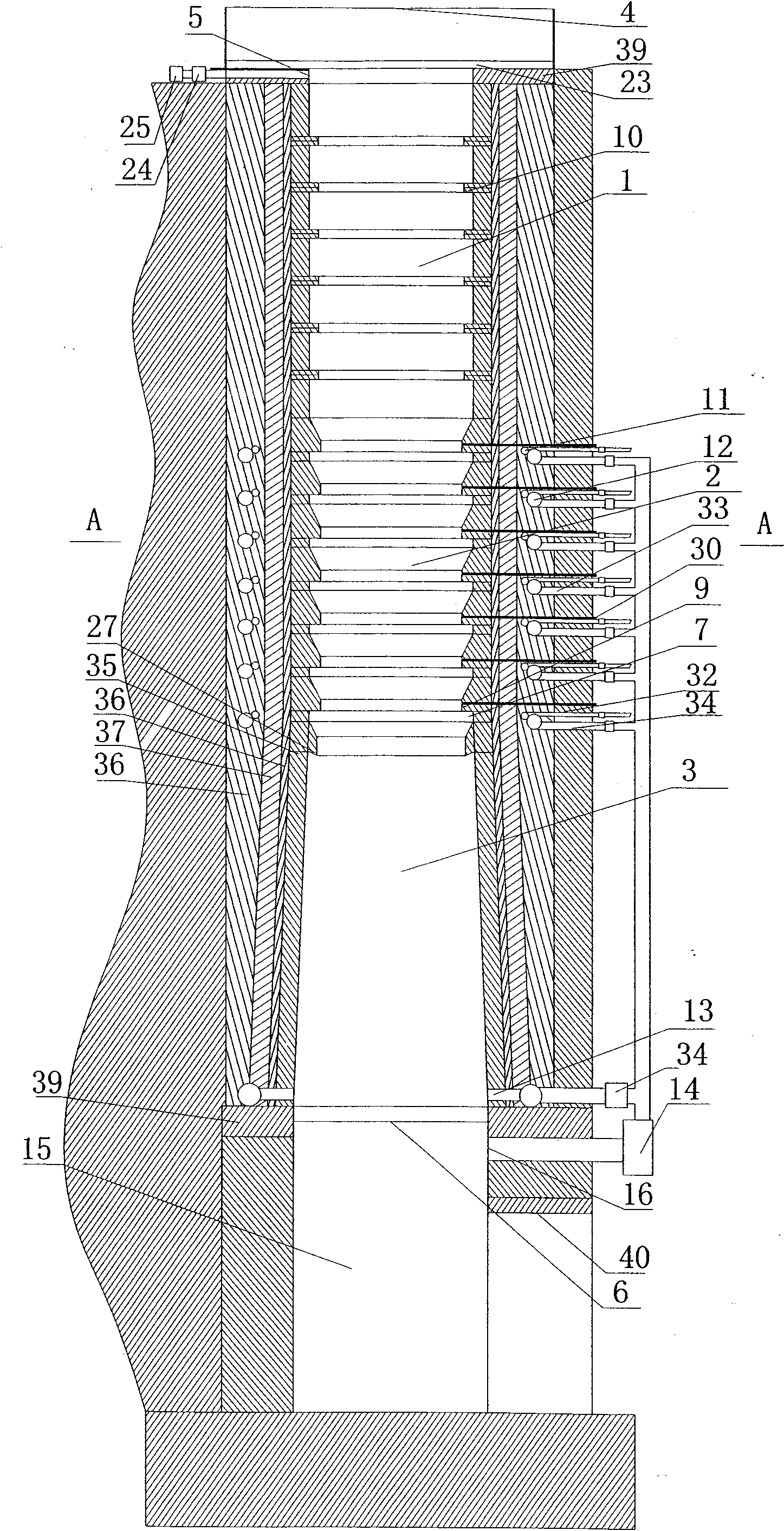

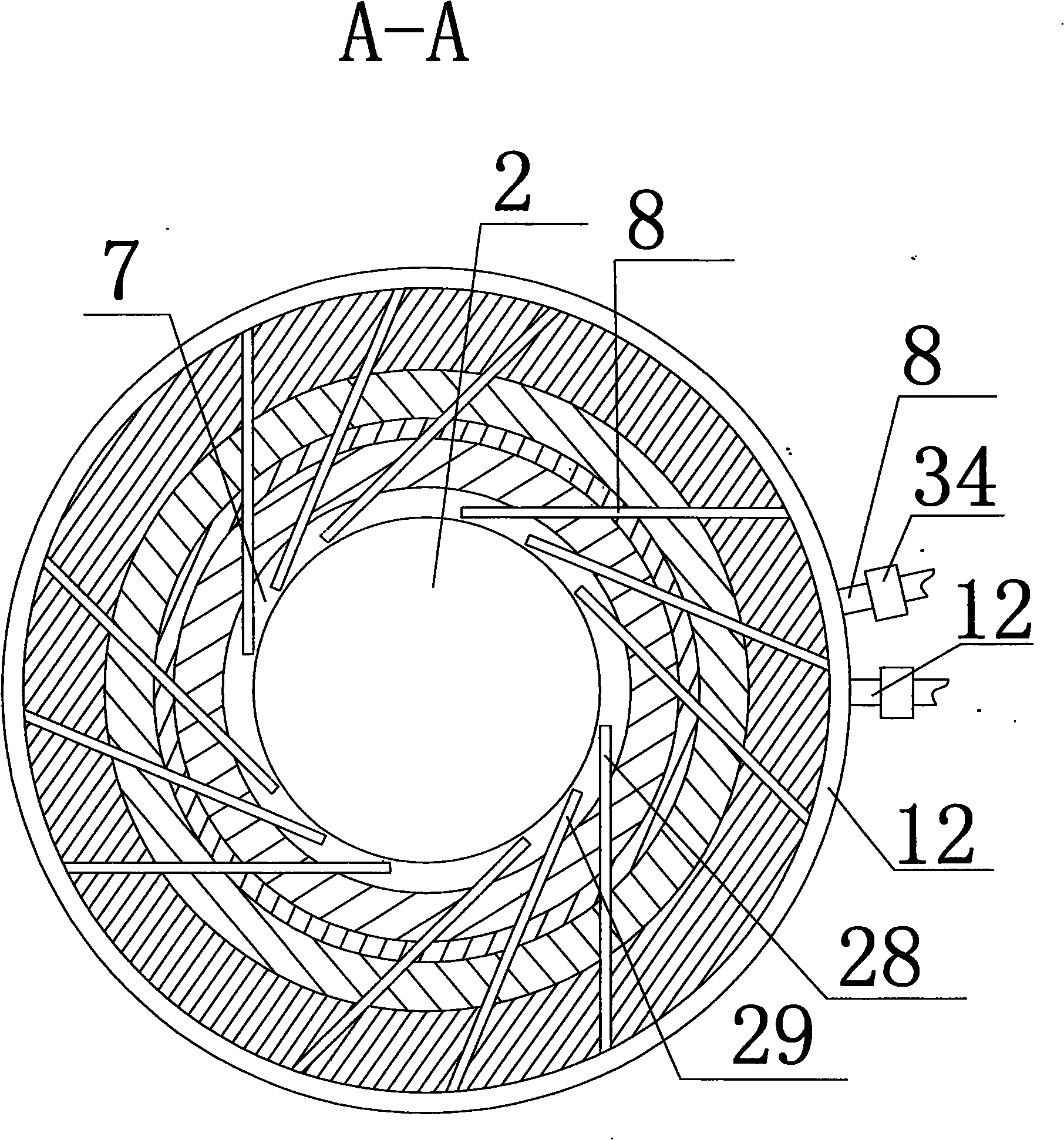

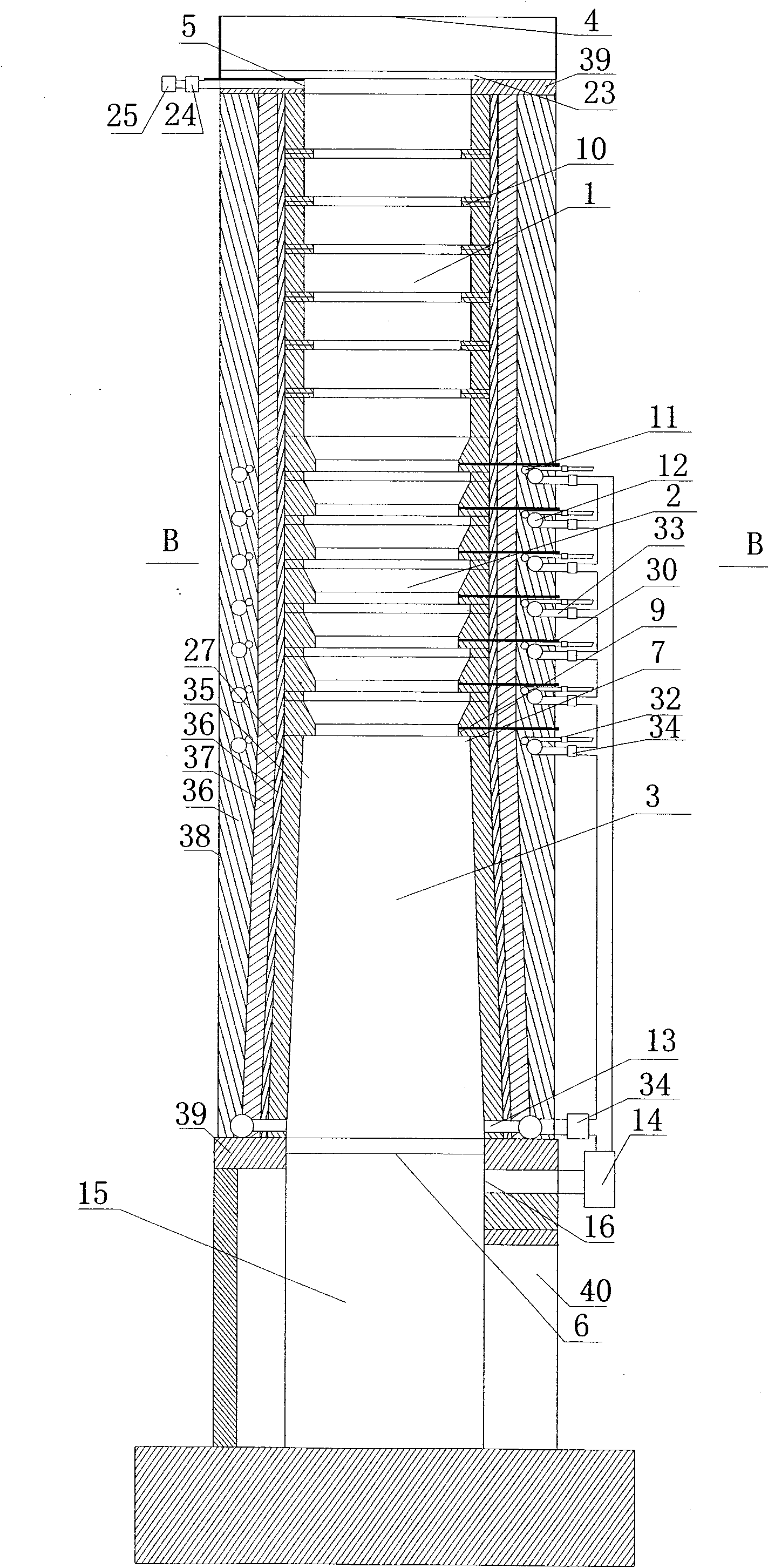

Shaft kiln

The invention discloses a shaft kiln, which comprises a fuel supply device, an ignition device, a discharge device, a kiln chamber, a refractory material, an insulating material, a fan and a pipeline. The side wall of the kiln chamber is provided with at least one air inlet which is at least connected with an air inlet passage. The fan is arranged on the air inlet passage. The kiln chamber is provided with a heating chamber and a cooling chamber, wherein the lower part of the heating chamber is communicated with the cooling chamber; the upper part of the heating chamber is provided with a feed inlet and an air outlet for the heating chamber; and the lower part of the cooling chamber is provided with a discharge outlet. The discharge outlet is provided with the discharge device; and at least one flame path is arranged on the side wall of the kiln chamber between the heating chamber and the cooling chamber, and is communicated with the air inlet. Due to the use of heat convection and vortexes for combustion, the shaft kiln is more energy-saving and environment-friendly. The vortexes are formed in the kiln chamber by using forced air, so that the material is uniformly heated. The movement of hot air around the material replaces a heating mode of rolling the material, and the material naturally moves to a preheating zone, a heating zone, and a cooling zone by using natural sedimentation. The shaft kiln can be applied to burning cement, lime, alumina and other blocked materials.

Owner:陈久斌

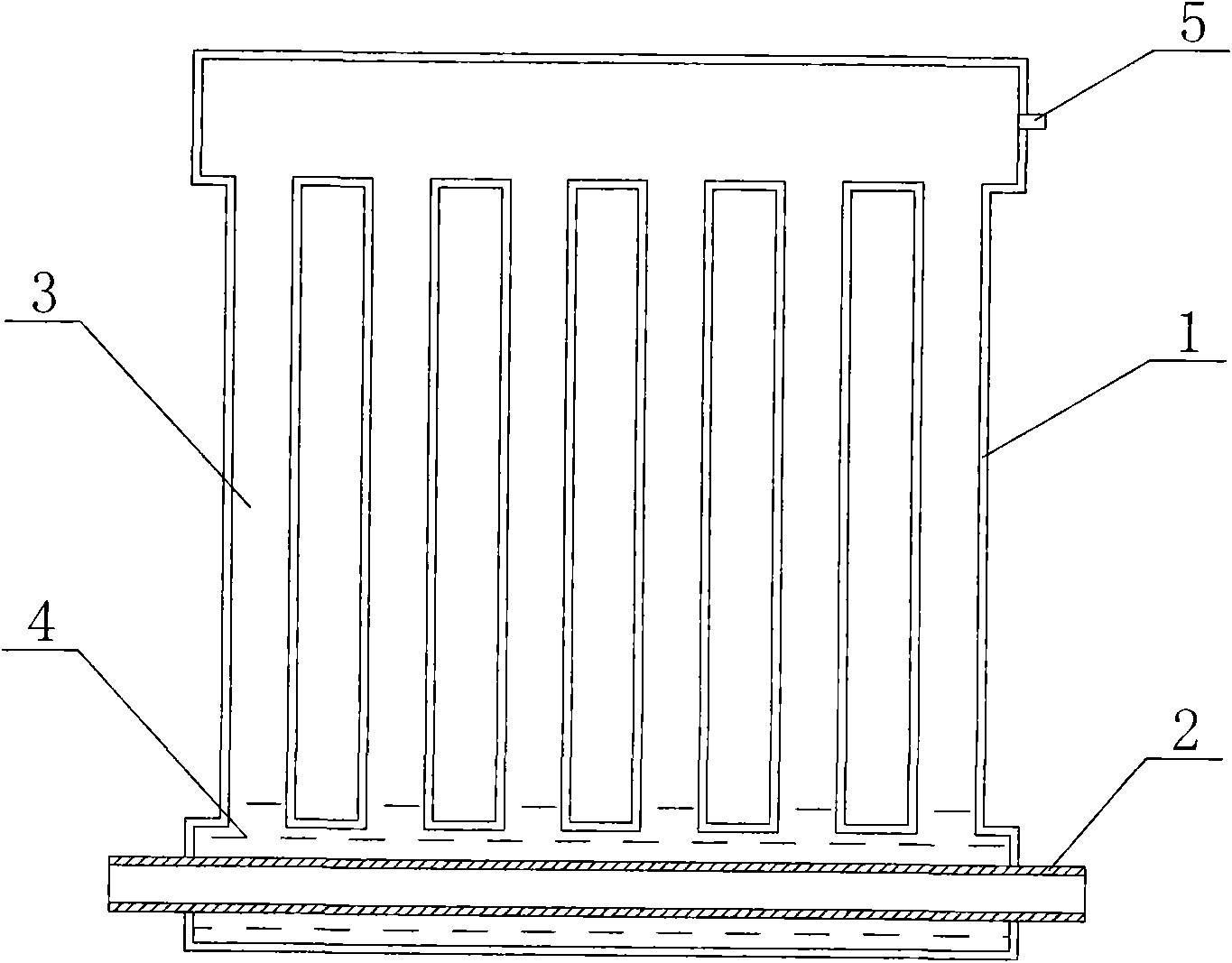

Split solar water heater

InactiveCN101329111AEasy and flexible installationLow costSolar heating energySolar heat devicesSolar waterEngineering

The invention relates to a split solar energy water heater, belonging to the solar energy water heating technical field and comprising a pressure-bearing water tank, a heat tube and a solar energy heat collecting device, a heat exchanging tank and an in-out connecting tube in which an anti-freezing heat-exchanging medium is respectively filled; wherein, an inlet and an outlet of the solar energy heat collecting device are respectively communicated with the heat-exchanging tank through the in-out connecting tube to form a circulation loop. An upper radiation section of the heat tube is positioned in the pressure-bearing water tank and a lower heat absorbing section is positioned in the heat exchanging tank. The invention realizes the heat transmission between the solar energy heat collecting device and the pressure-bearing water tank which is provided with strong water transmission power to meet the requirement of users well; the heat collecting device, the heat exchanging tank and the in-out connecting tube are not directly communicated with the pressure-bearing tank so as to fill the anti-freezing heat-exchanging medium and to lead the external parts to obtain the required anti-freezing effect; the organic combination between the circulation loop and a second-level heat exchanging of the heat tube just needs a less quantity of heat tube, so as to realize both the high-effective heat exchanging and the distinct manufacturing-cost reduction.

Owner:A O SMITH CHINA WATER HEATER CO LTD

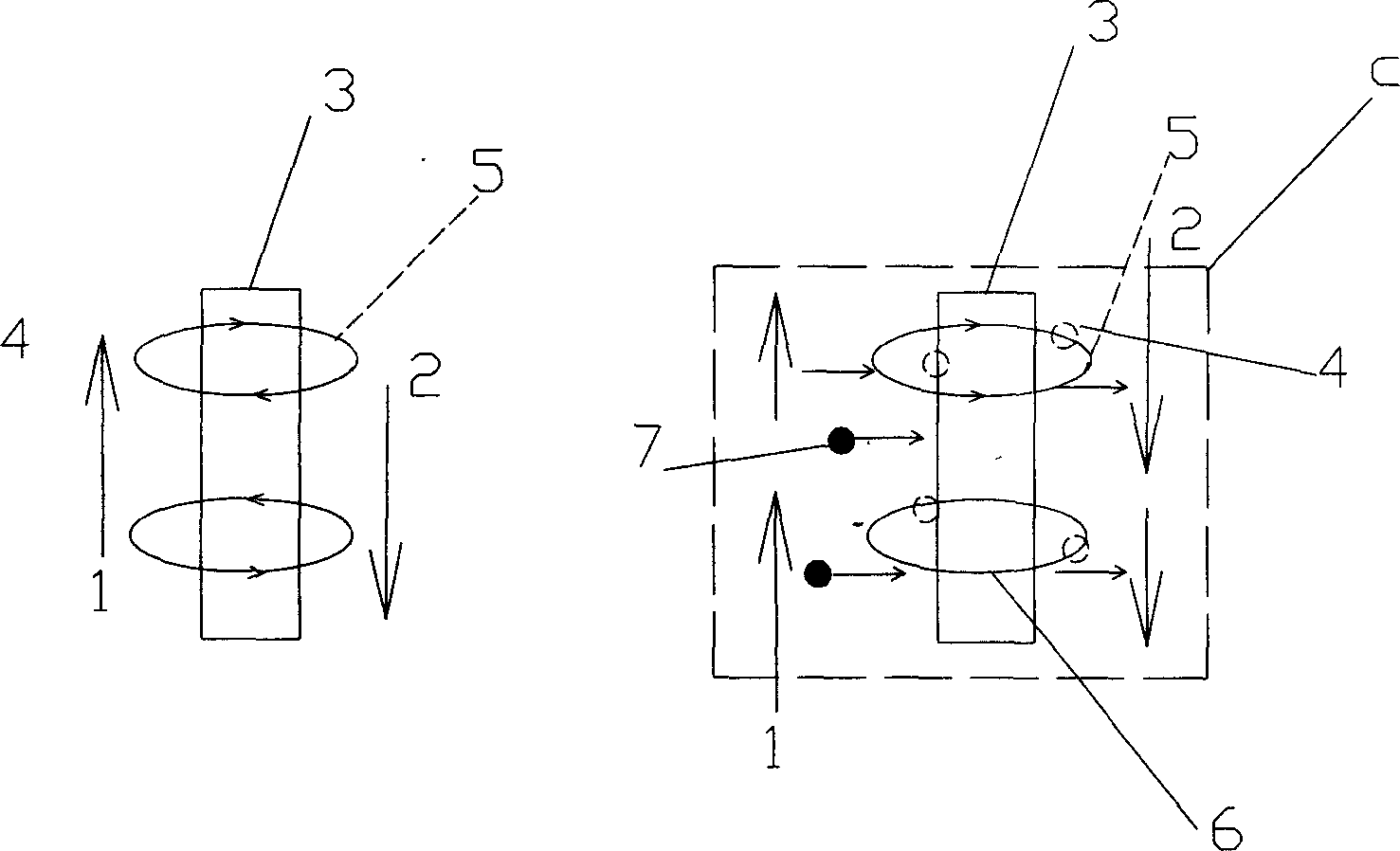

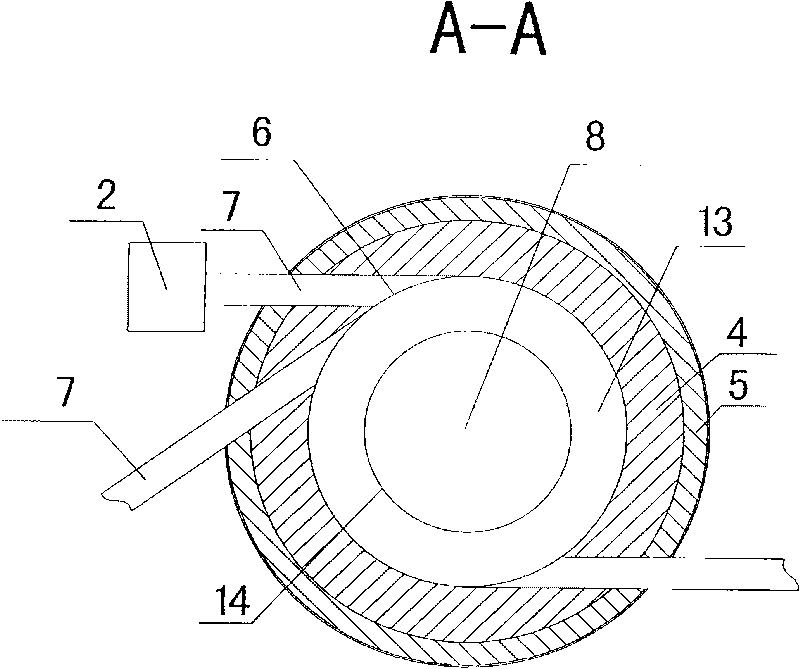

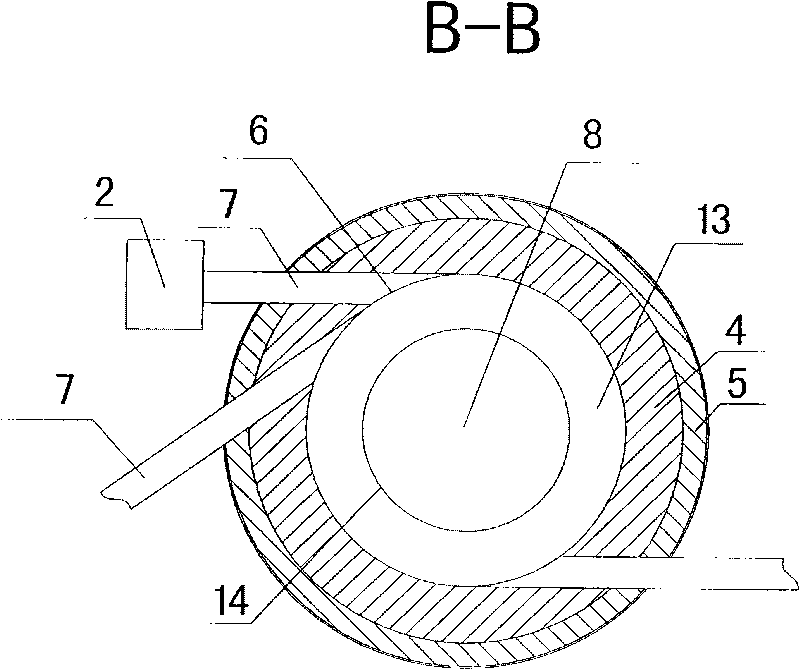

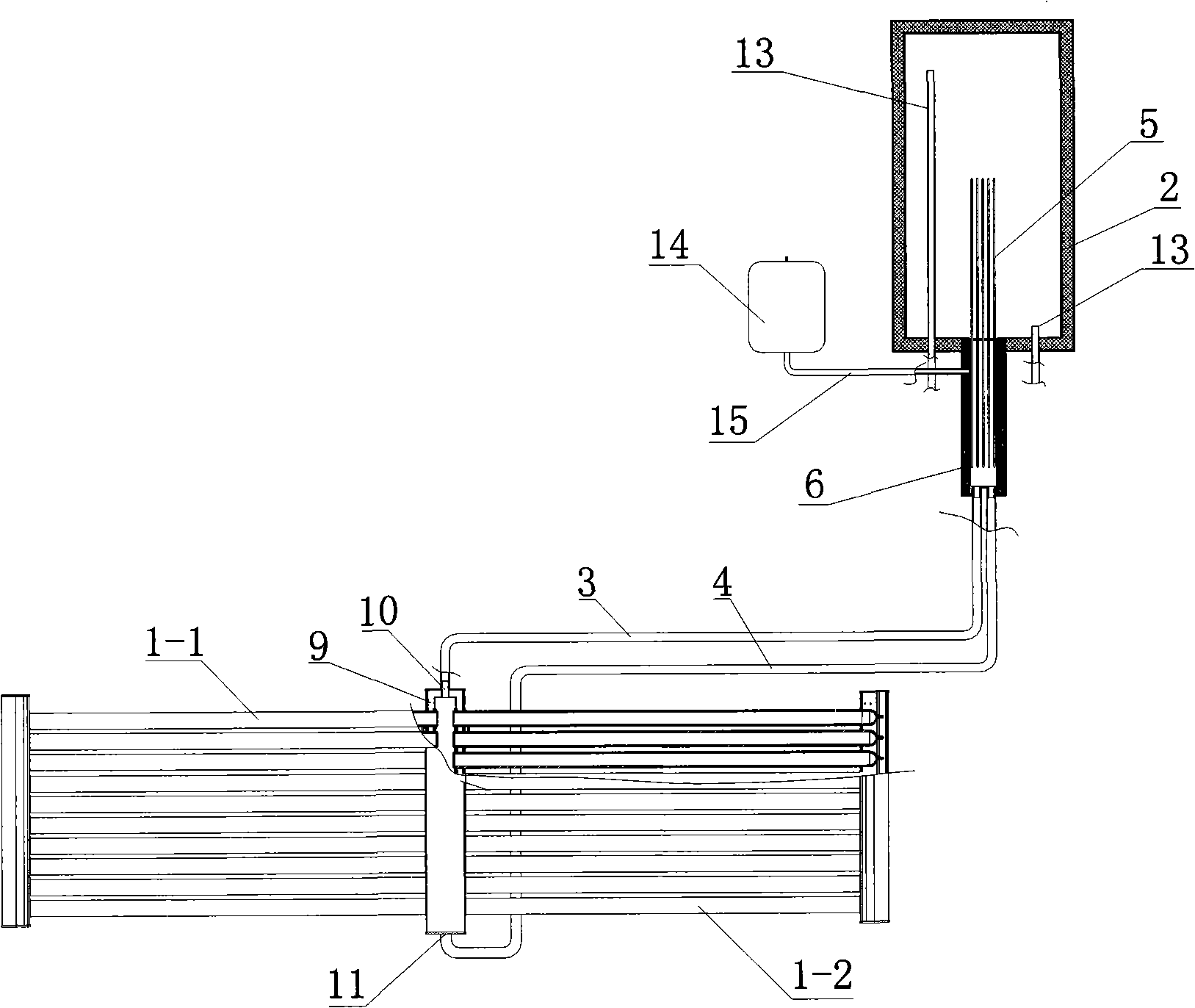

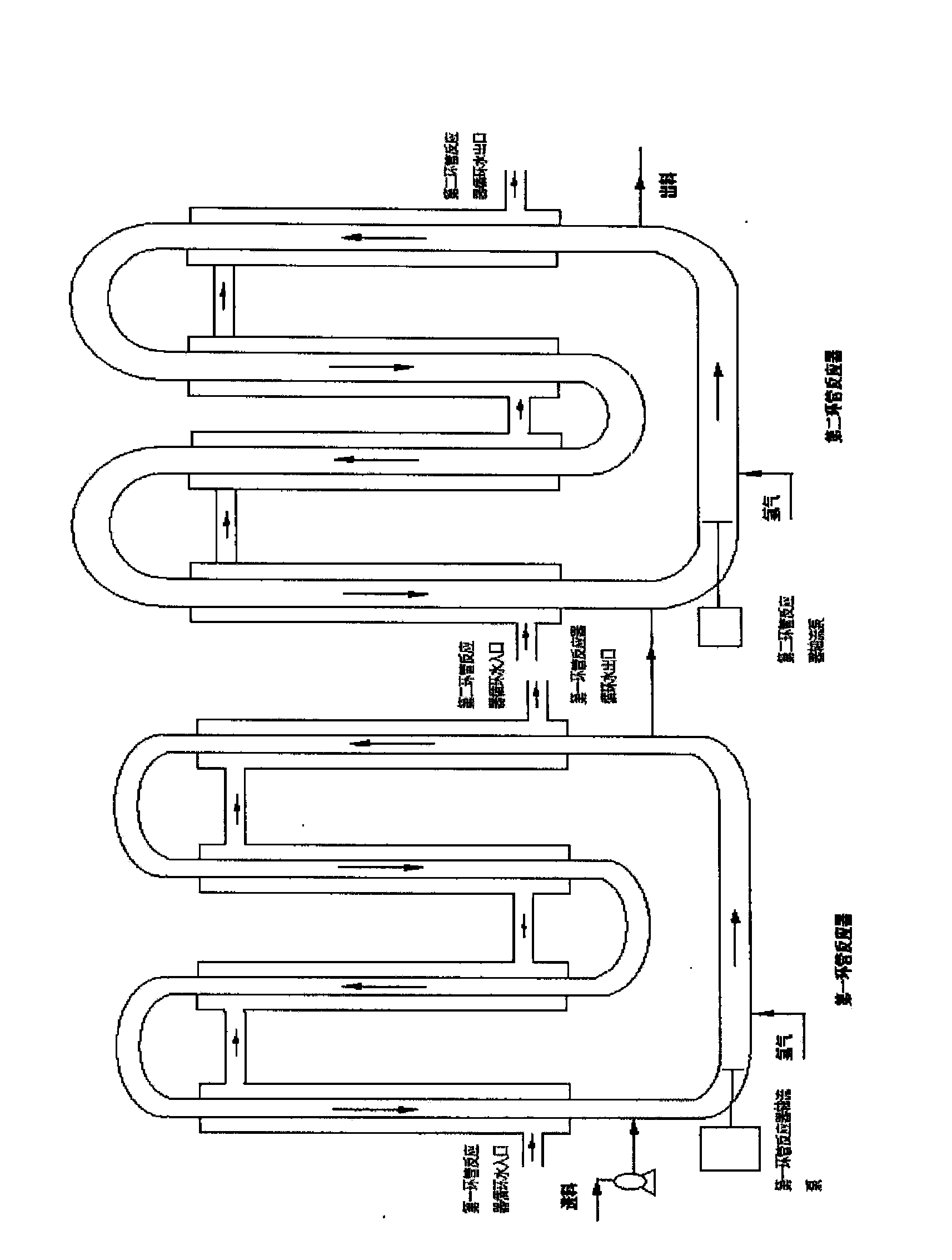

Olefines unsaturated bond-containing polymer hydrogenation reaction method

ActiveCN103788317AGood heat transferImprove hydrogenation reaction efficiencyChemistryUnsaturated bonds

The invention discloses an olefines unsaturated bond-containing polymer hydrogenation reaction method. The method comprises the following steps: under a hydrogenation reaction condition and existence of a hydrogenation catalyst, an olefines unsaturated bond-containing polymer solution and hydrogen are contacted in a reactor, wherein the reactors are two or more loop reactors connected in series, the cycle ratio of the loop reactors can be controlled so that the material in the reactor is close to a complete mixing flow state, wherein the cycle ratio of a first reactor is 10-200, and the cycle ratio of a second reactor and other reactor is 10-100. The method can better control the reaction temperature, the catalyst activity can be kept in a long operation period, hydrogenation efficiency is increased, and ideal hydrogenation degree can reached.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aluminium-water reaction high-energy system apparatus

InactiveCN105244522ASimple structureEasy to operateFinal product manufactureAqueous electrolyte fuel cellsCombustion chamberExhaust valve

The invention provides an aluminium-water reaction high-energy system apparatus, and the apparatus at least comprises a vortex reaction chamber. The exterior of the vortex reaction chamber is successively provided with a first combustion chamber, a second combustion chamber and a heat-energy power generation system; the vortex reaction chamber, the first combustion chamber, the second combustion chamber and the heat-energy power generation system together form a four-layer concentric jacket kettle; the vortex reaction chamber, the first combustion chamber, the second combustion chamber and the heat-energy power generation system are inside provided with a cleaning pipe, a charge pipe, a water-supplementing pipe, a first-order automatic igniter, a second-order automatic igniter, a first-order automatic exhaust valve, a second-order automatic exhaust valve, a spiral cooling water pipe and a nano-material outlet; and the exterior of the vortex reaction chamber is also provided with a comprehensive regulation and control chamber, and the comprehensive regulation and control chamber comprises a water pump, an oxygen-increasing valve, a multistage temp measurer and a multistage pressure gauge. The apparatus solves deficiencies in the prior art, by using the apparatus, a nano-material is efficiently produced when the aluminium-water reaction generates high energy, and the apparatus guarantees product friendliness, reduces production cost and possesses industrialization universality.

Owner:龚光波 +1

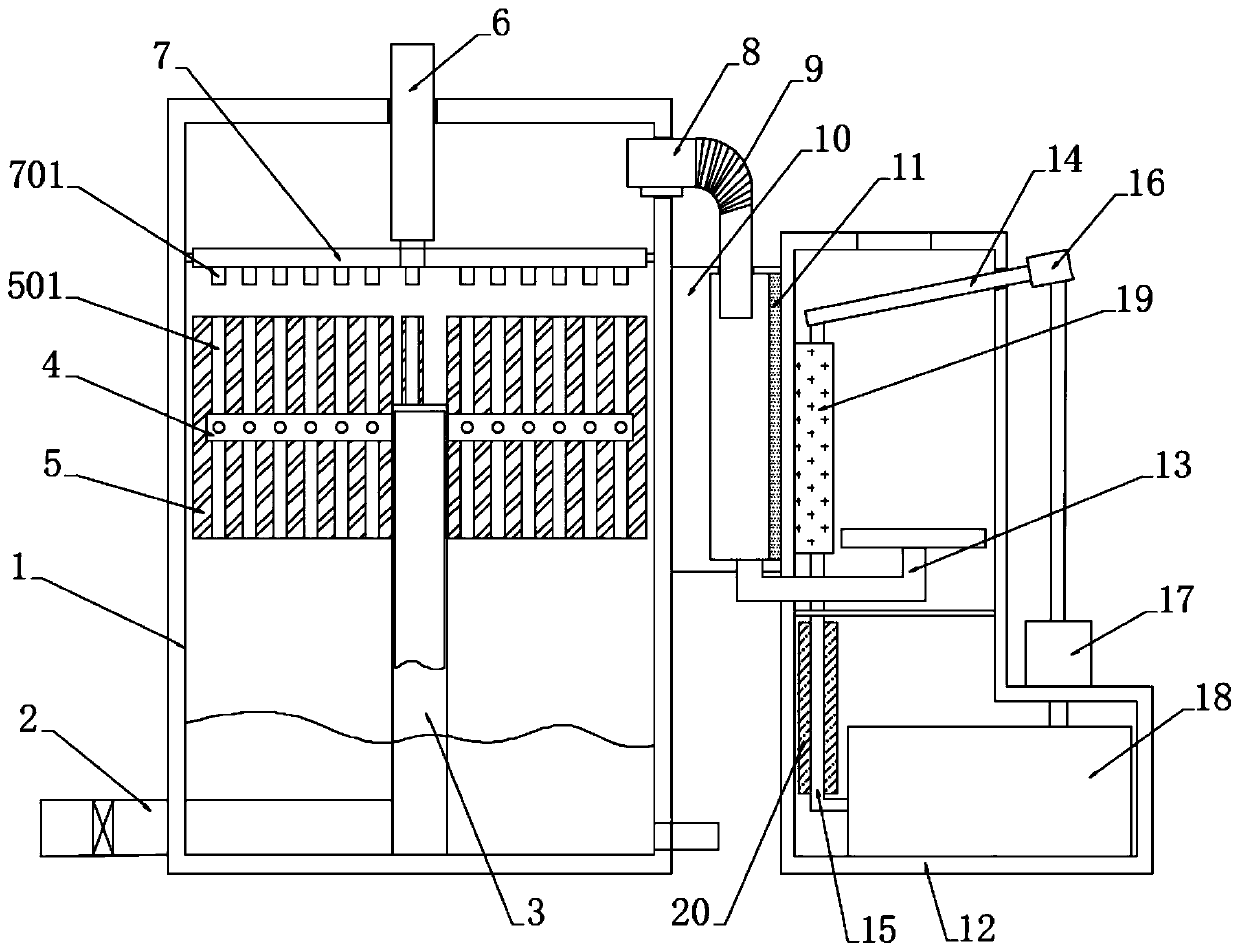

Cereal dryer

InactiveCN105230777ASimple structure setupLow input costSeed preservation by dryingAgricultural engineeringLand occupation

The invention discloses a cereal dryer. The cereal dryer comprises a drying barrel. The upper part of the drying barrel is provided with a feed inlet and an air outlet. The lower part of the drying barrel is provided with a discharge outlet and an air inlet. An exhaust fan is arranged at the air outlet. An air inlet fan is arranged at the air inlet. A hollow mixer shaft is arranged in the drying barrel. The upper end of the mixer shaft is connected to the top plate of the drying barrel. The lower end of the mixer shaft goes through the air inlet, extends out of the drying barrel and is connected to a driving device. The mixer shaft is provided with a spiral stirring piece and multiple air outlets arranged from up to down. The air inlet fan is arranged under the lower end of the mixer shaft. The cereal dryer has a simple structure, a small land occupation area and high drying efficiency.

Owner:GUANGXI POLYTECHNIC

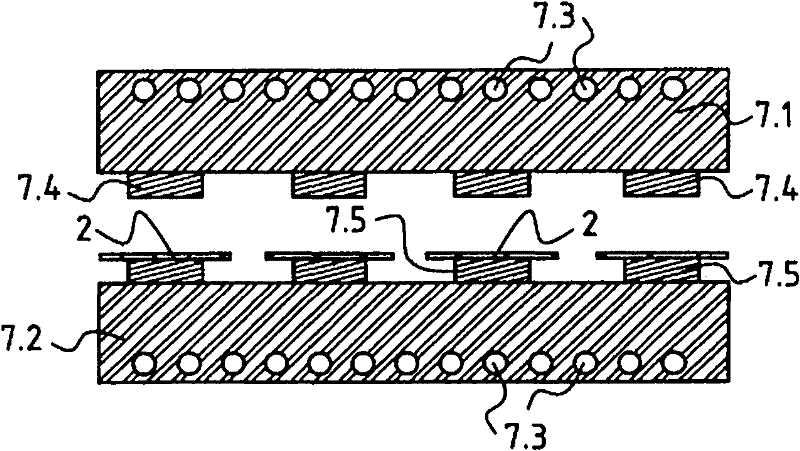

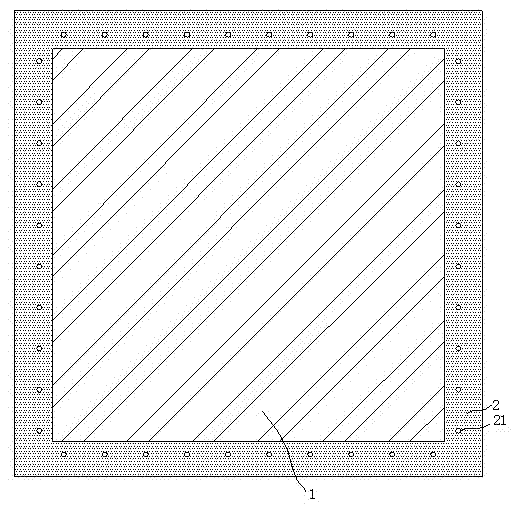

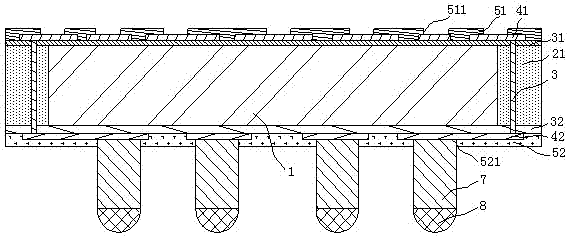

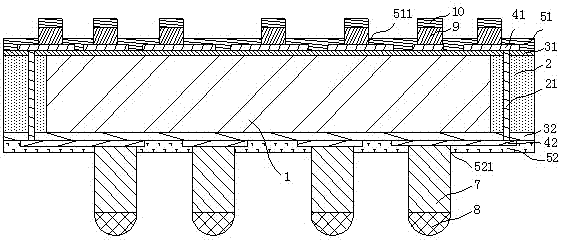

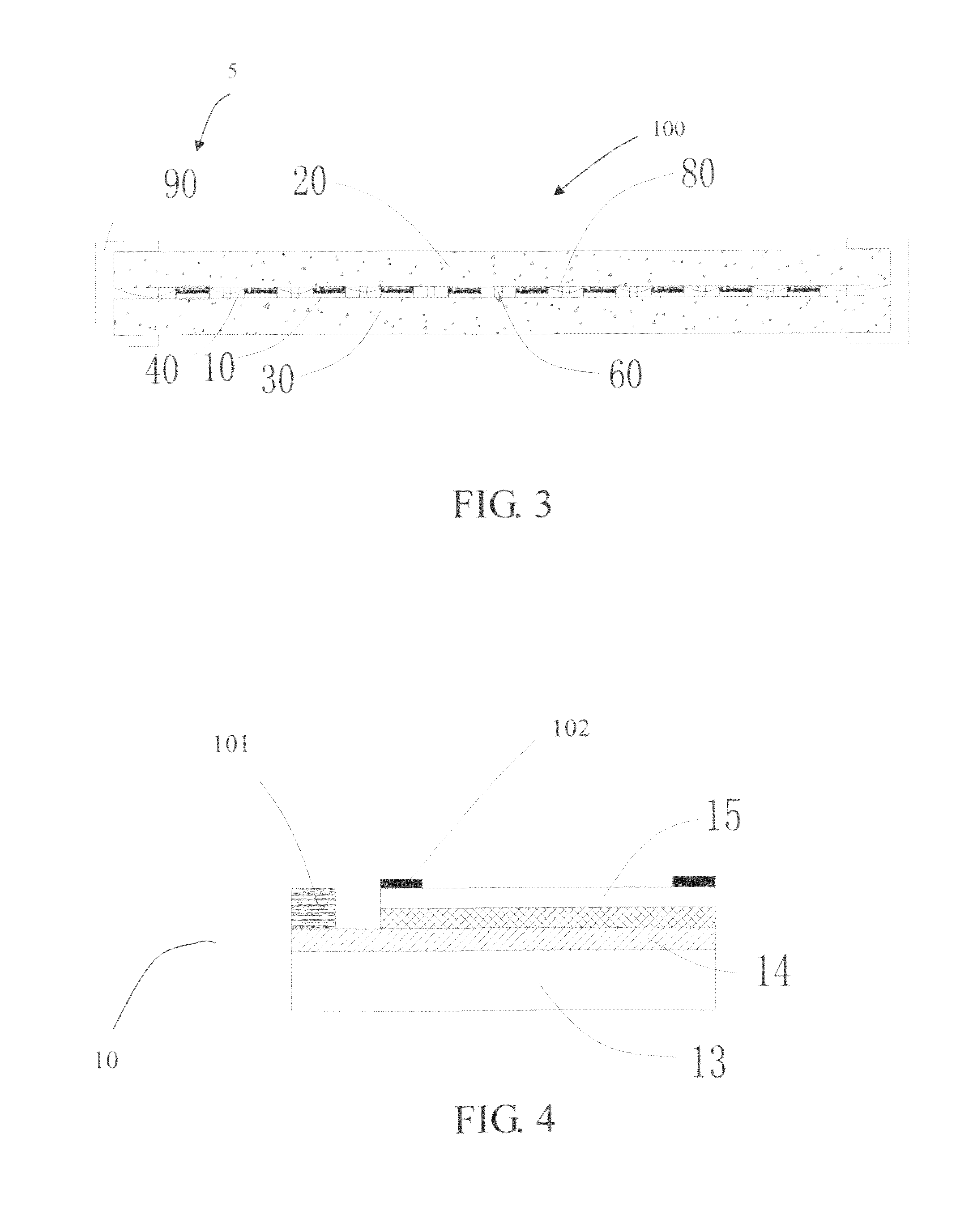

Encapsulation structure of silicon substrate pinboard

ActiveCN103165561ASolve process problemsSolve the costSemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

The invention relates to an encapsulation structure of a silicon substrate pinboard and belongs to the technical field of semiconductor encapsulation. The encapsulation structure of the silicon substrate pinboard comprises a silicon substrate carrier (1), an encapsulation region (2), a front insulation layer (31), a back insulation layer (32), a front re-wiring metal layer (41), a back re-wiring metal layer (42), a front protective layer (51) and a back protective layer (52). The encapsulation region (2), the front insulation layer (31), the back insulation layer (32), the front re-wiring metal layer (41), the back re-wiring metal layer (42), the front protective layer (51) and the back protective layer (52) are arranged on the periphery of the silicon substrate carrier (1) and are respectively and sequentially arranged on the front and the back of the silicon substrate carrier (1) and the front and the back of the encapsulation region (2). A through hole (21) for filling metal is formed in the encapsulation region (2), and the front re-wiring metal layer (41) is connected with the back re-wiring metal layer (42) through metal in the through hole (21). The encapsulation structure of the silicon substrate pinboard is simple in encapsulation structure, low in encapsulation cost and high in product yield.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

Coal-based natural gas flue gas multi-point replacement desulfurization device and use method thereof

InactiveCN111359395AImprove desulfurization effectEven contactGas treatmentDispersed particle separationCoalFlue gas

The invention discloses a coal-based natural gas flue gas multi-point replacement desulfurization device and a use method thereof, and belongs to the technical field of flue gas desulfurization. A flue gas distribution mechanism is distributed on the pipe wall of a rectangular pipe; therefore, flue gas introduced into a desulfurization box is effectively subjected to a multi-point distribution treatment; when a liquid desulfurization alkaline medicine is sprayed downwards; the liquid medicine can be in full and uniform contact with the flue gas subjected to multi-point diffusion; after sufficient neutralization, the sulfur element in the flue gas is replaced; multi-point desulfurization operation is realized, the low desulfurization efficiency caused by non-uniform local desulfurization iseffectively avoided; besides, desulfurized gas is introduced into a circulating cooling pipe, high-temperature water vapor in the gas is cooled and liquefied, a gas cooling treatment is effectively achieved, water drops formed by liquefaction are guided downwards and adsorbed and dried by adsorption cotton, water mist is easy to remove, and the effect is good.

Owner:吴晓毛

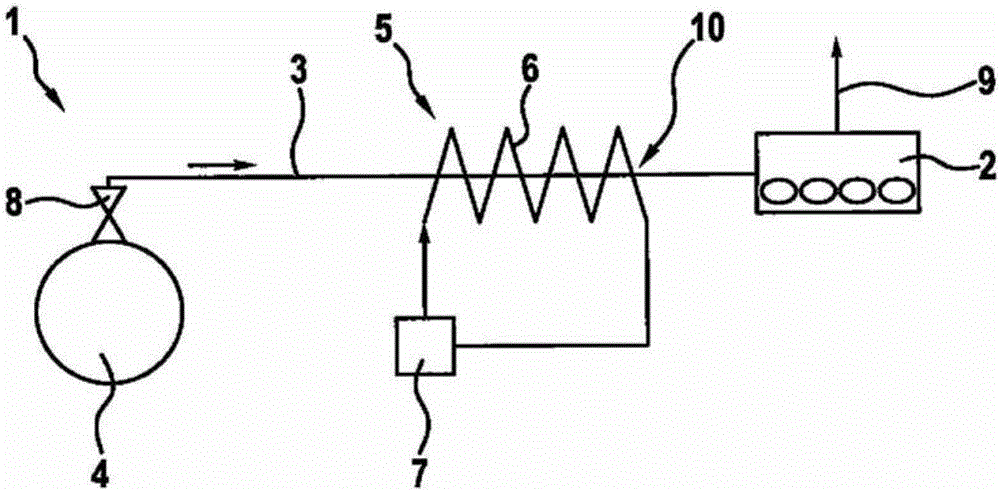

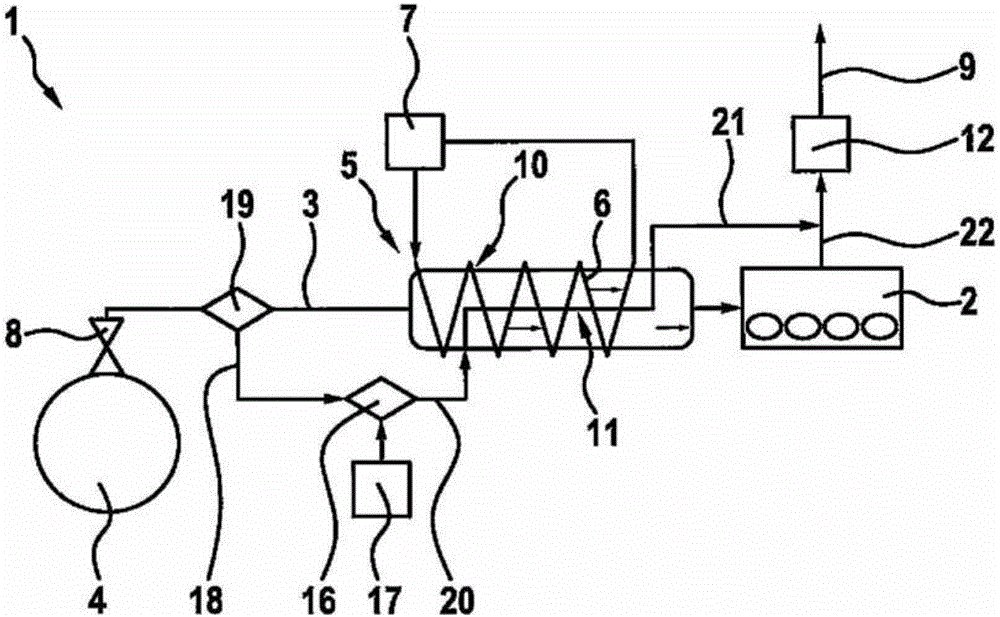

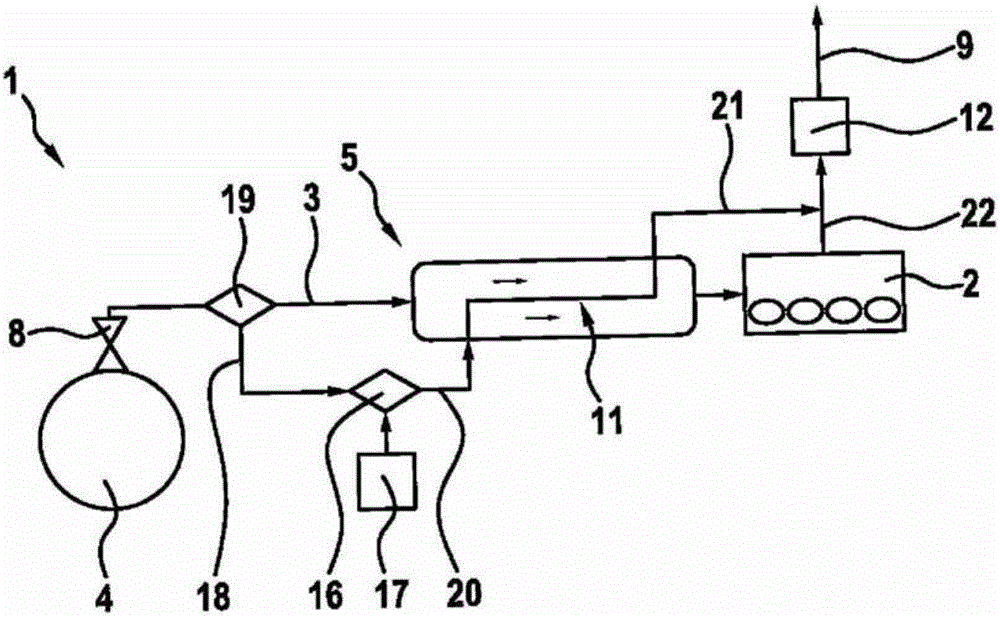

Gas-powered device, in particular gas-powered vehicle

InactiveCN105275669AIncrease temperatureImprove operational safetyLiquid coolingInternal combustion piston enginesProcess engineeringInternal combustion engine

The present invention relates to a gas powered device comprising an internal combustion engine (2), a gas tank (4) for storage of a gas as fuel for the internal combustion engine, a feed line (3) from the gas tank (4) to the internal combustion engine (2) and a heater (5 ) which heats the gas from the tank (4) discharged gas in the area of the feed line (3).

Owner:ROBERT BOSCH GMBH

LED light source and manufacturing method thereof

ActiveUS8714762B2Achieve heat transferPlanar light sourcesPoint-like light sourceFluorescenceOptoelectronics

Owner:CAI ZOU

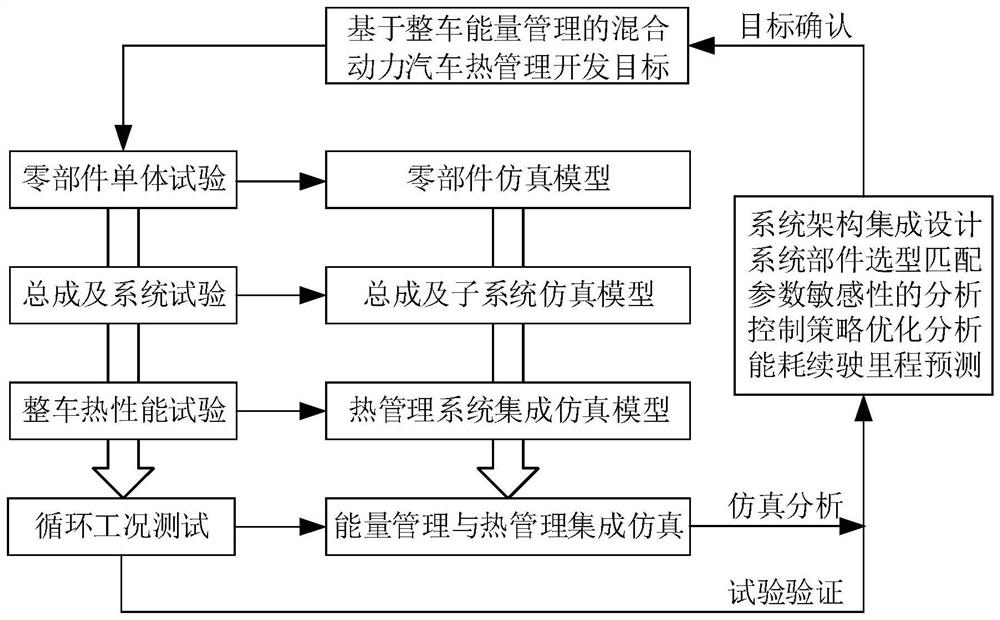

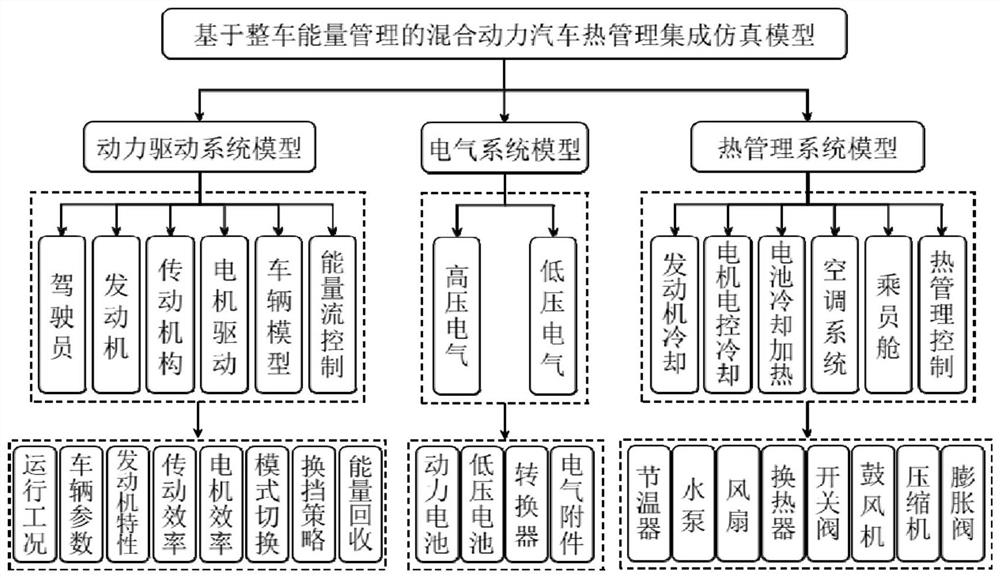

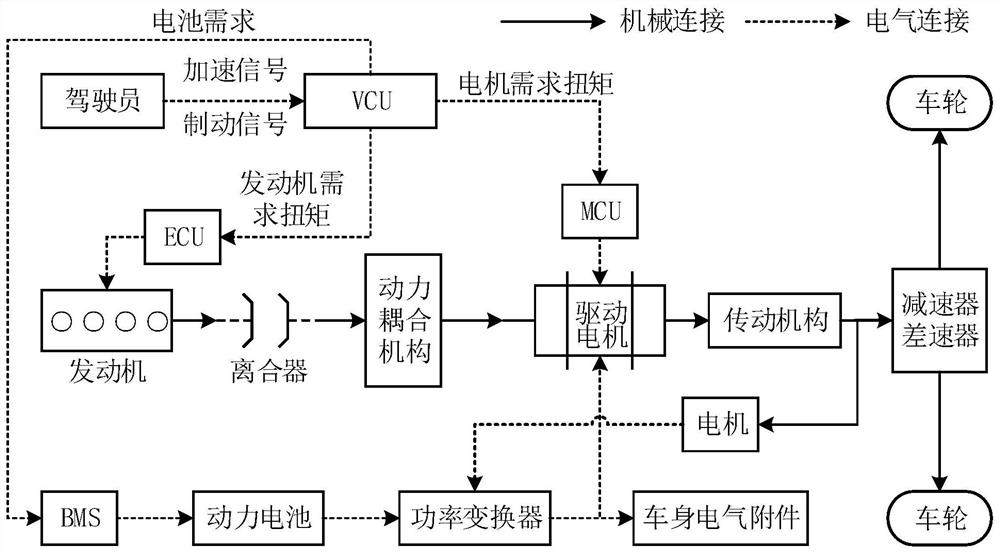

One-dimensional joint simulation modeling method for thermal management system of hybrid electric vehicle

PendingCN114239133AAchieve couplingRealize what-if analysisGeometric CADSpecial data processing applicationsElectric machineryAutomotive engineering

The invention provides a hybrid electric vehicle thermal management system one-dimensional simulation modeling method. Comprising a power driving system model, an electrical system model, an engine cooling system model, a power battery thermal management system model, a motor electric control cooling system model, an air conditioning system model, a passenger compartment model, a vehicle energy management control model, a thermal management system control model and the like. According to the coupling relation of energy management and heat management of the whole vehicle, the simulation models of all the systems and the simulation models of the control modules are integrated by combining the transmission paths of energy flow and heat flow of the whole vehicle, control logic and the like, and a one-dimensional joint simulation model of the whole vehicle heat management system of the hybrid electric vehicle is constructed; a simulation platform is provided for integrated design, system component model selection matching, comprehensive performance analysis, control strategy optimization, energy consumption and driving range analysis and prediction and the like of a hybrid electric vehicle thermal management system.

Owner:中汽研(常州)汽车工程研究院有限公司

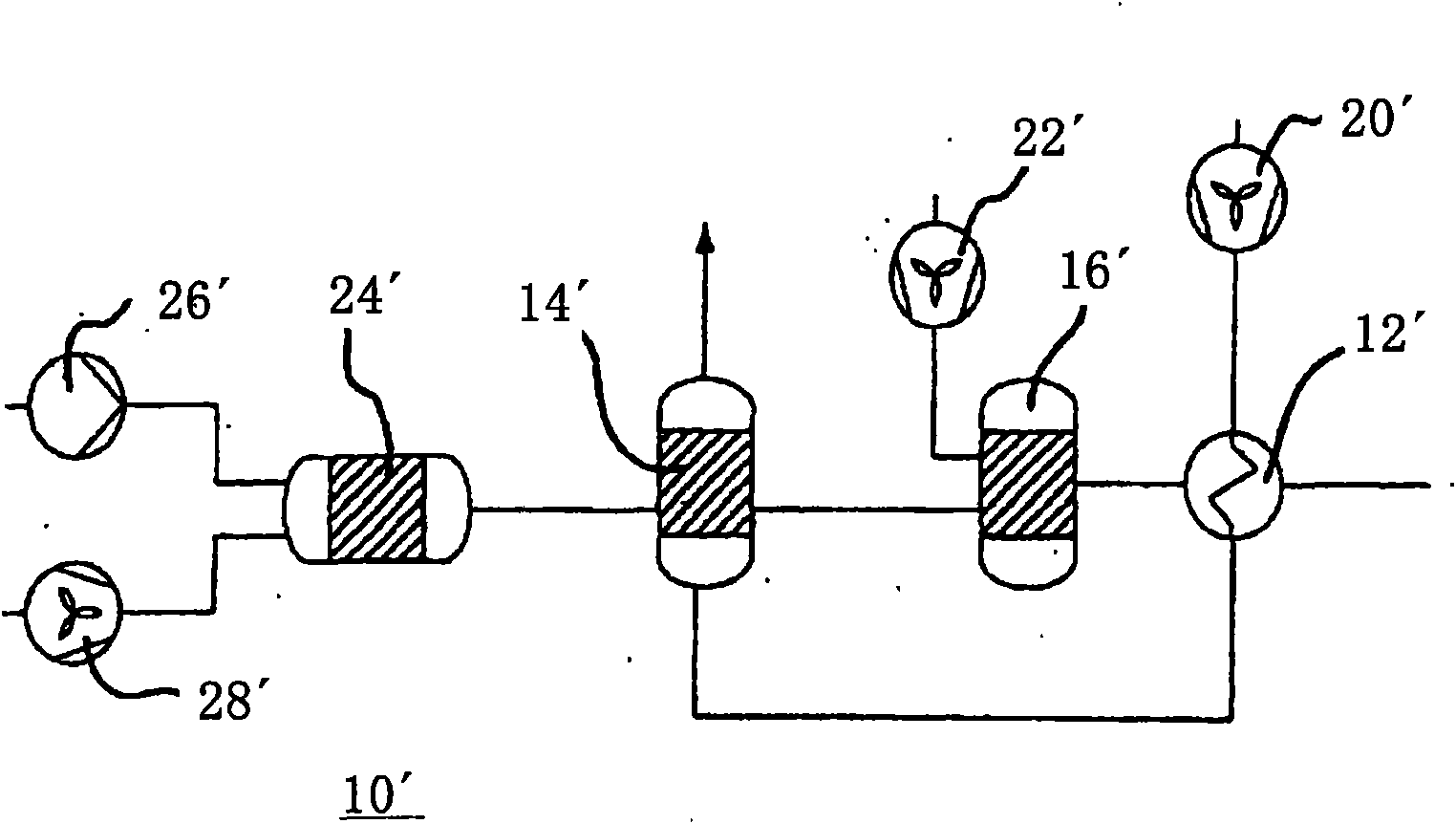

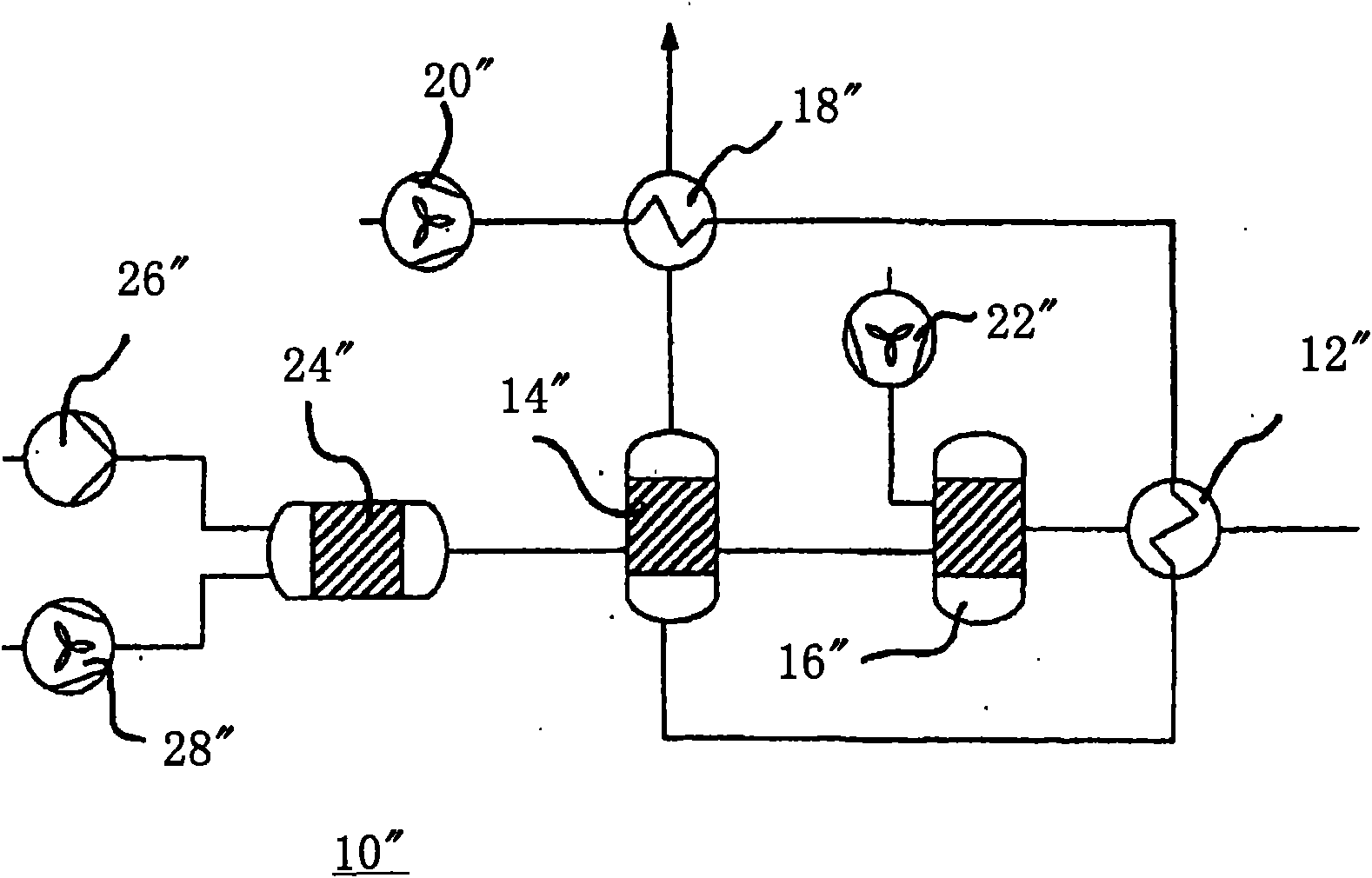

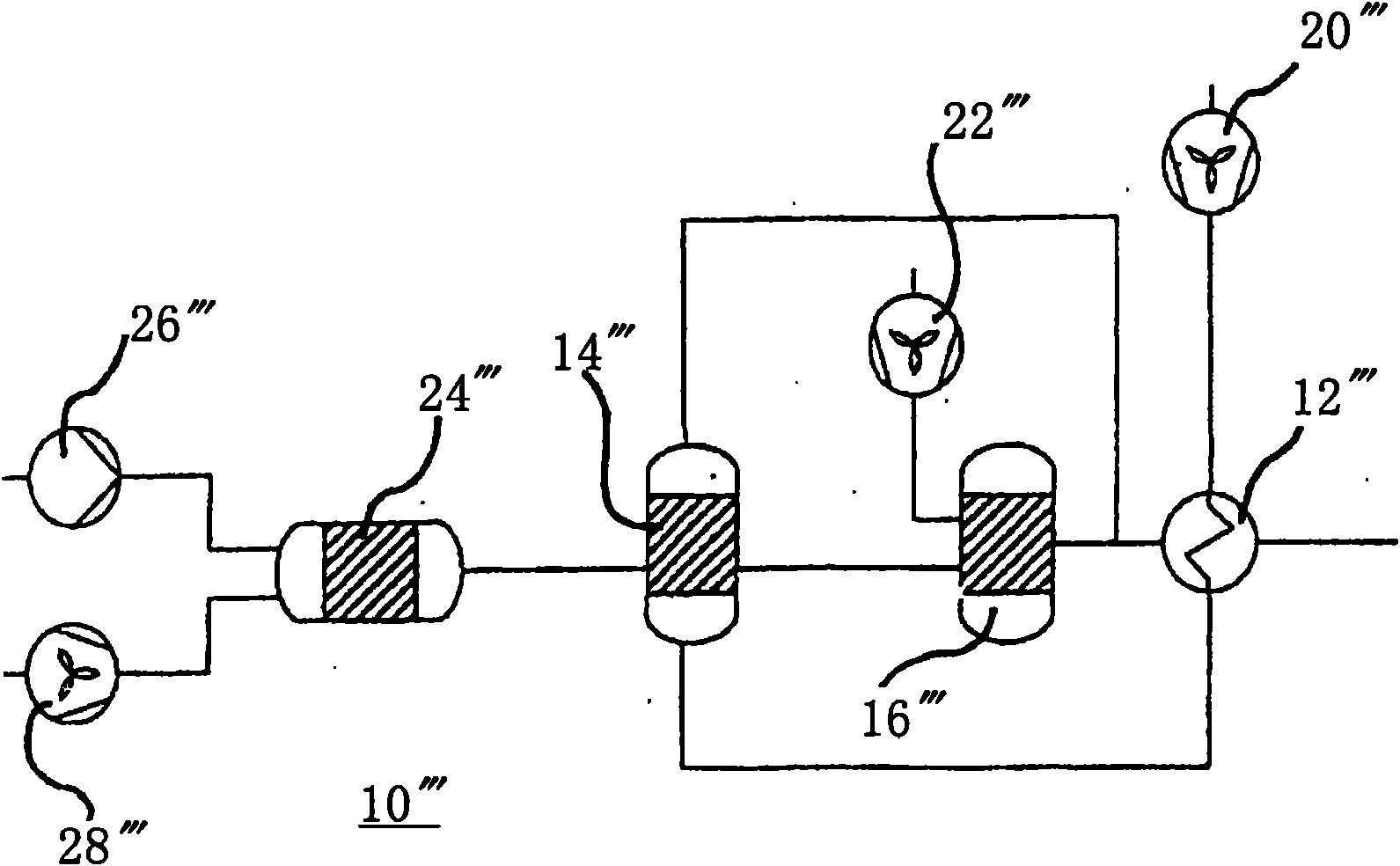

Fuel cell system with device for cathode inlet air preheating

InactiveCN101601157AEffective warm-upSuppresses heat lossFuel cell auxillariesFused electrolyte fuel cellsExhaust gasEngineering

The invention relates to a fuel cell system (10) with a first heat exchanger (12), via which cathode inlet air can be supplied to a fuel cell or a fuel cell stack (14) and to which a mixture of afterburner exhaust gas from an afterburner (16) and cathode exhaust air produced in the fuel cell or the fuel cell stack (14) can be supplied in order to enable heat exchange between the cathode inlet air and the mixture by means of the first heat exchanger (12). The invention provides that a second heat exchanger (18) is provided, via which the cathode inlet air can be supplied by the first heat exchanger to the fuel cell or the fuel cell stack (14) and via which the afterburner exhaust gas can be supplied to the first heat exchanger (12) so as to form the mixture, in order to enable heat exchange between the afterburner exhaust gas and the cathode inlet air by means of the second heat exchanger (18).

Owner:圣火有限责任公司

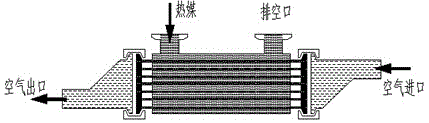

Health-level air heater structure

ActiveCN105627562AAvoid cross contaminationHigh thermal efficiencyStorage heatersEngineeringAir heater

The invention discloses a health-level air heater structure. The health-level air heater structure comprises a heating container. The heating container is provided with an air inlet, an air outlet, a heating medium inlet, a heating medium outlet and a condensate water outlet. A middle sleeve and an inner sleeve are arranged in the heating container. An outer heating medium cavity is defined by the middle sleeve and the side wall of the heating container and communicates with the heating medium inlet, the heating medium outlet and the condensate water outlet. The inner sleeve is arranged in the middle sleeve and communicates with the outer heating medium cavity. A space is defined by the inner sleeve and the middle sleeve. A ventilation cavity is composed of an air inlet segment, a space segment and an air outlet segment. A heating medium enters from the heating medium inlet, a part of the heating medium enters the outer heating medium cavity between the middle sleeve and the side wall of the heating container, the other part of the heating medium enters the inner sleeve, and finally the heating medium is discharged from the heating medium outlet and the condensate water outlet; and air enters from the air inlet, passes through the space segment and flows out from the air outlet.

Owner:NA SHENG CLEAN TECH SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com