20 DEG C-gasification vacuum superconductive radiator

A heat sink and superconducting technology, applied in the field of 20-degree gasification vacuum superconducting heat sink, can solve the problems of large water demand, long warm-up time, and scaling of the heat sink, so as to improve the utilization rate of heat energy and heat transfer The effect of fast start-up speed and less circulating hot water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

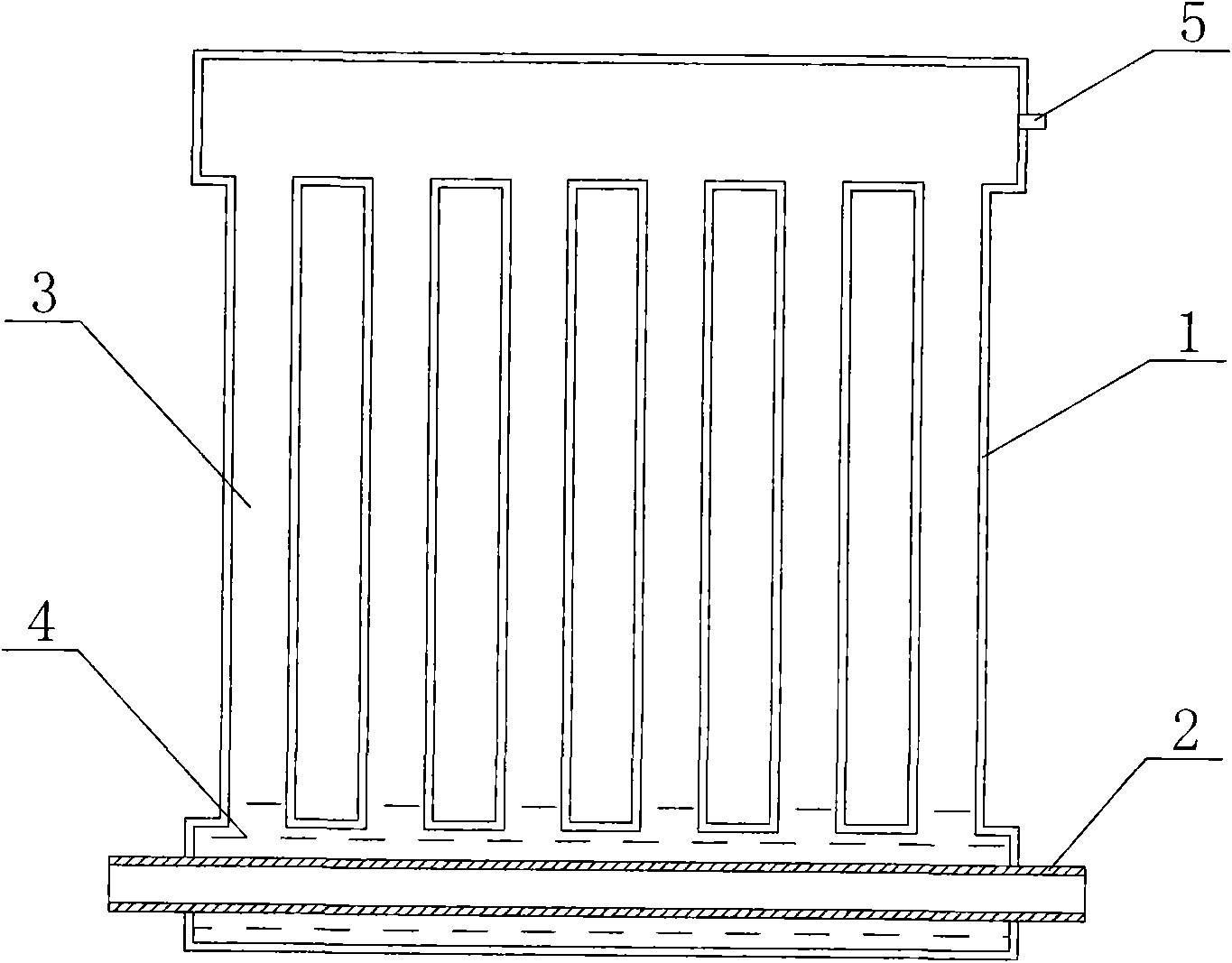

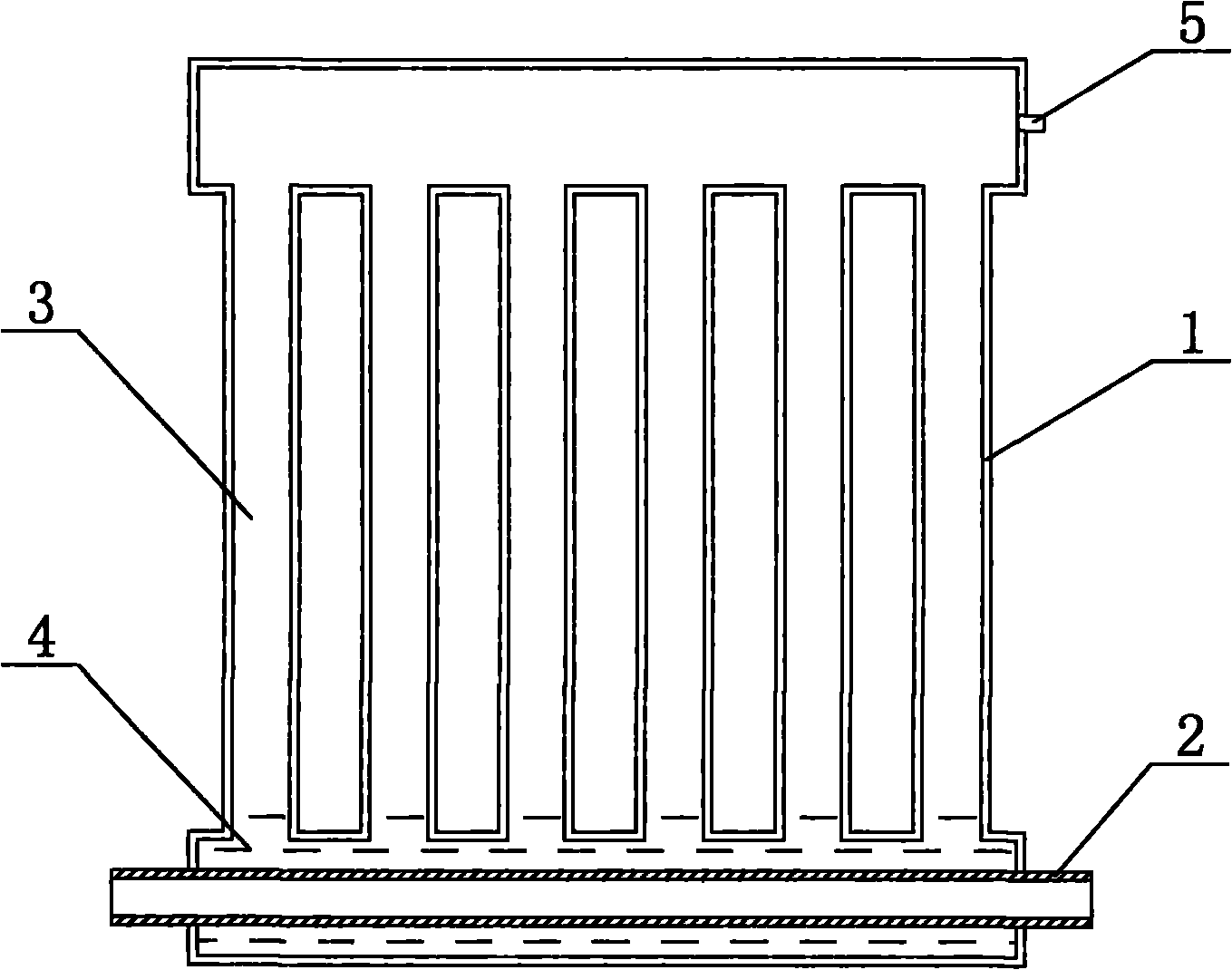

[0015] Such as figure 1 As shown, the vacuum superconducting heat sink of the present invention communicates with the inside of the heat sink 1 to form a completely airtight vacuum cavity 3, and the bottom of the vacuum cavity 3 is pierced with a steel pipe as the heating tube 2, and is used to To pass through the heating medium used in the heating system, such as commonly used hot water, the cavity 3 is filled with a part of the superconducting liquid 4 that is vaporized at 20 degrees.

[0016] The superconducting liquid 4 is prepared from the following ingredients in the following percentages by weight: 98.6% of dichloromethane, 0.05% of red color paste, 0.05% of sodium metasilicate, 0.5% of sodium benzoate, and 0.8% of triethanolamine; 1 It is welded by argon arc welding with automatic seamless welding equipment, which can form a good sealing effect. The heat sink 1 is provided with a vacuum port blocked by a plug 5, through which the superconducting liquid can be injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com