Novel high-efficient reaction still

A kind of reaction kettle, high-efficiency technology, applied in chemical/physical/physical-chemical process, chemical instrument and method, chemical/physical process, etc., can solve the problem of not being able to have anti-corrosion lining and stirring, internal heat transfer at the same time, and achieve low cost , easy to replace and maintain, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

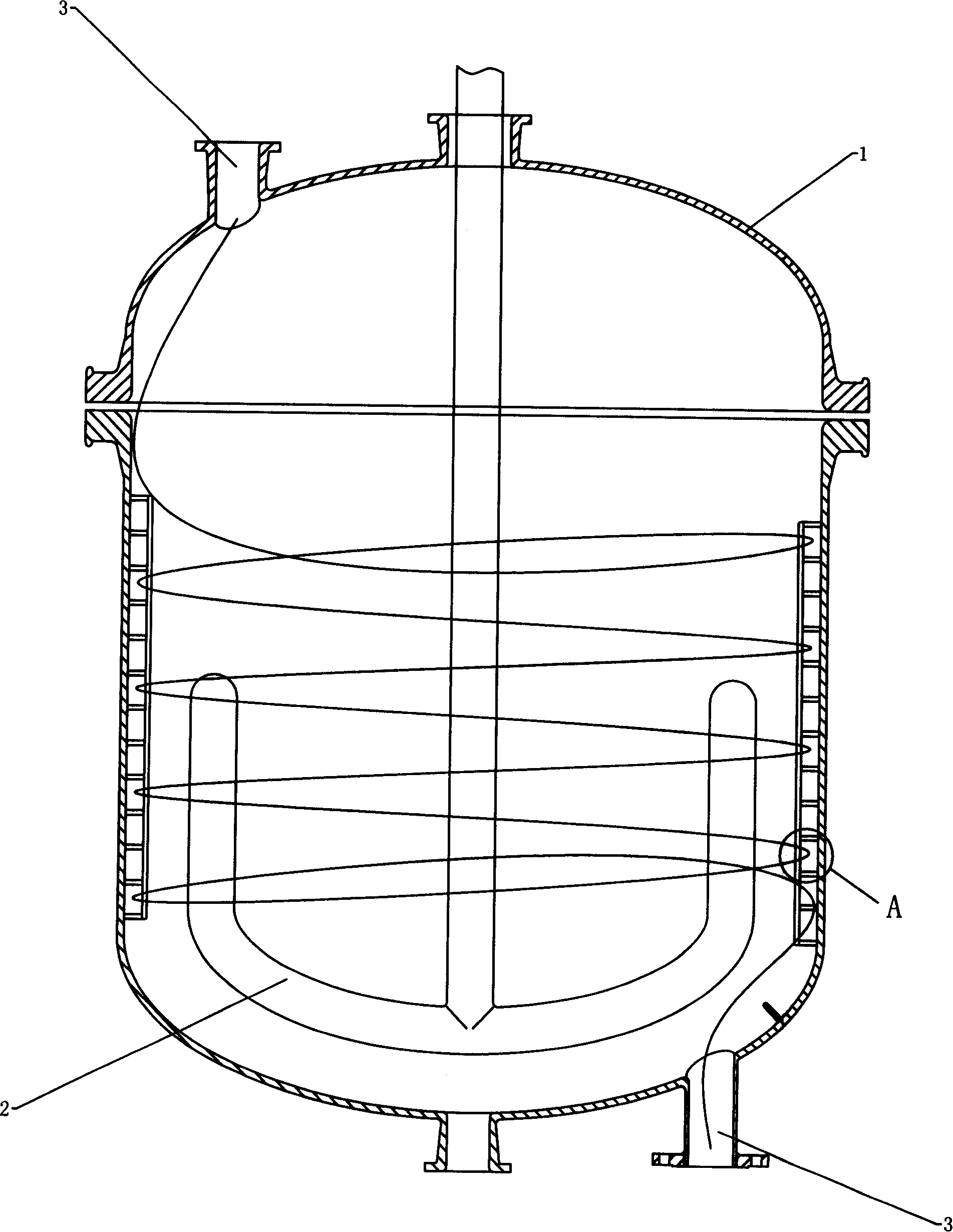

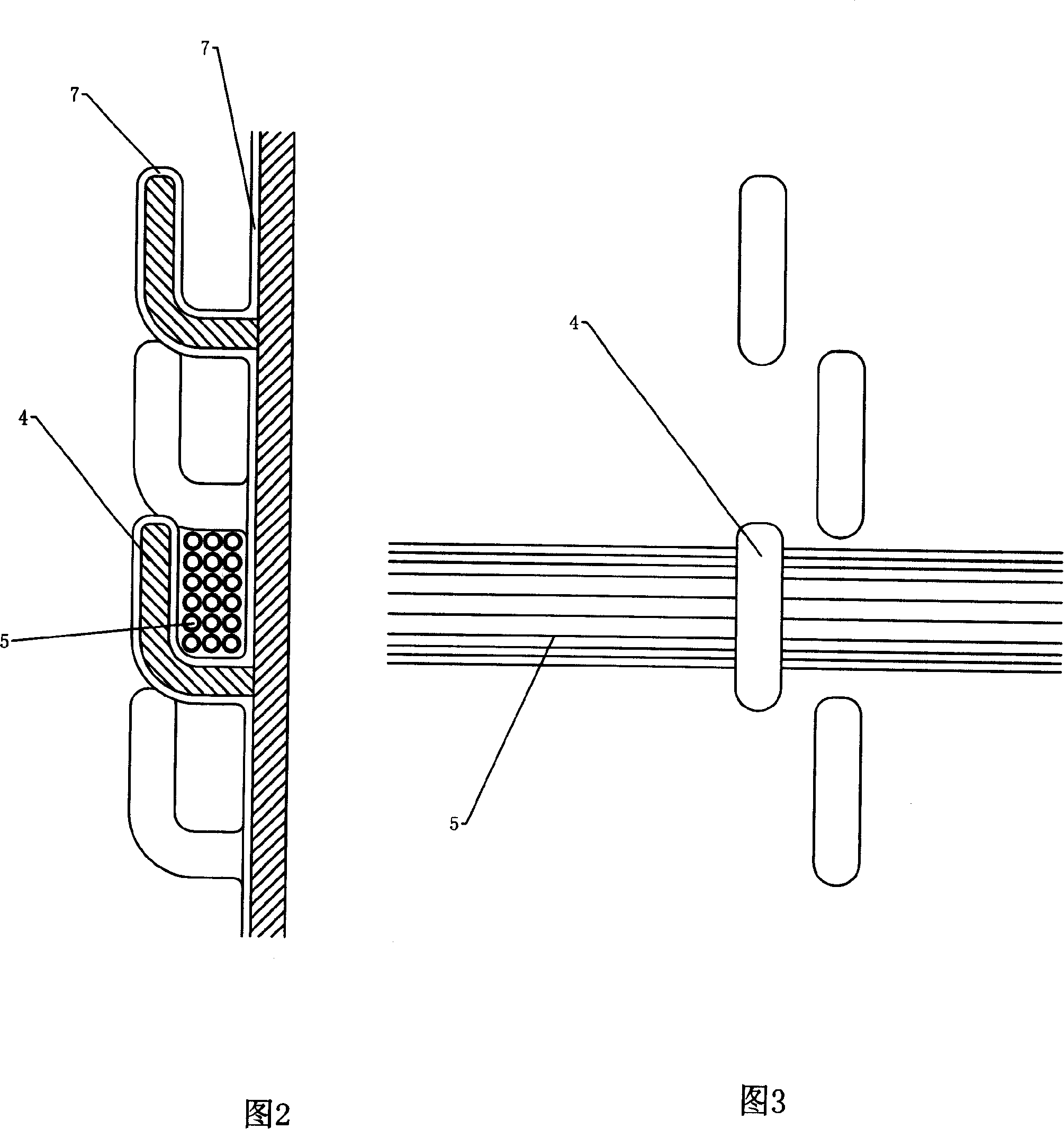

[0022] Embodiment 1: the present invention comprises kettle body 1, is located at the agitator 2 in kettle body and is located at the inlet and outlet 3 of heat exchange tube at both ends of kettle body, as shown in Figure 1, the kettle inner wall is provided with some fixed bodies, in In this embodiment, the fixed body is 12 rows of hook bodies 4, and 18 heat exchange tubes 5 are arranged in the hook bodies. The diameter of the heat exchange tubes is 6 millimeters, and the heat exchange tubes are arranged in the hook body in a rectangular shape. There are 3 layers of heat exchange tubes, and the height is 6 layers of heat exchange tubes. The inner wall of the kettle body, the hook body, and the outer surface of the agitator are covered with a layer of anti-corrosion lining 7, which can protect the inner wall and hook body from being damaged by the kettle body. Corrosion of reactants in the body, as shown in Figure 2, the heat exchange tube first enters the interior of the kett...

Embodiment 2

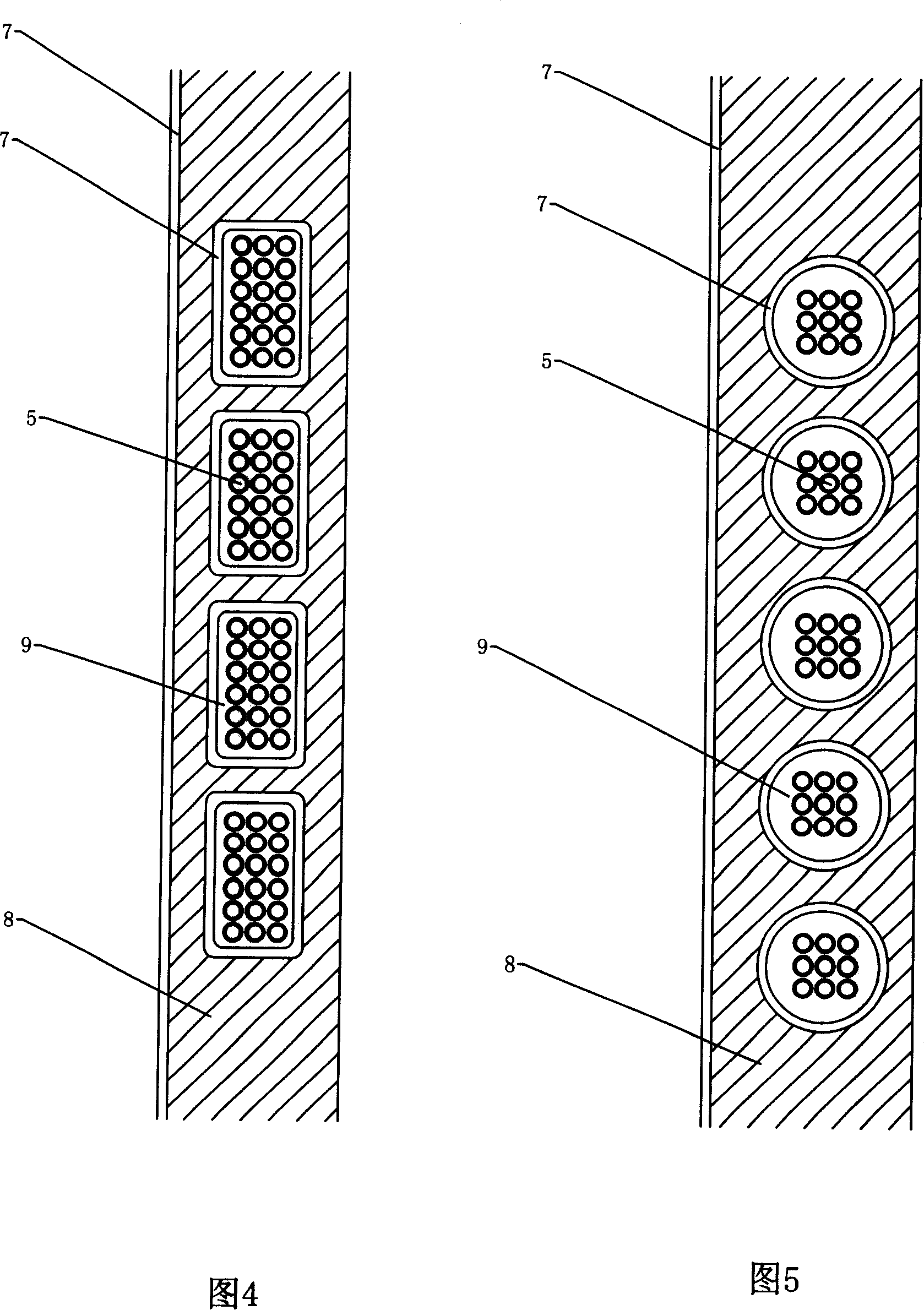

[0023]Embodiment 2: the present invention comprises kettle body 1, is located at the agitator 2 in kettle body and is located at the inlet and outlet 3 of heat exchange pipe at both ends of kettle body, as shown in Figure 1, the kettle inner wall is provided with some fixed bodies, in In this embodiment, the fixed body is a series of frame bodies 8 arranged on the inner wall of the kettle, and several frame holes 9 are evenly distributed on the frame body. The frame holes are of the same size and can be rectangular, as shown in Figure 4 , can also be circular, as shown in Figure 5. The end of the frame connected to the inner wall of the kettle is provided with rounded corners, and the edges and corners of the frame are also provided with rounded corners. The rounded corners are conducive to increasing the strength of the frame and making the anti-corrosion lining more It is easy to cover the outer surface of the frame. For a rectangular frame, 18 heat exchange tubes are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com