Patents

Literature

1197results about How to "Achieving stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

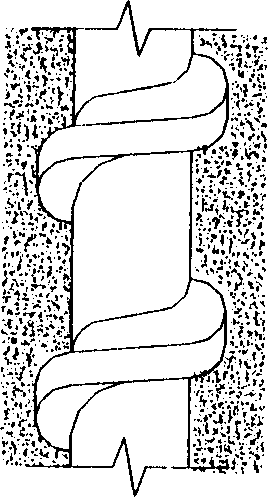

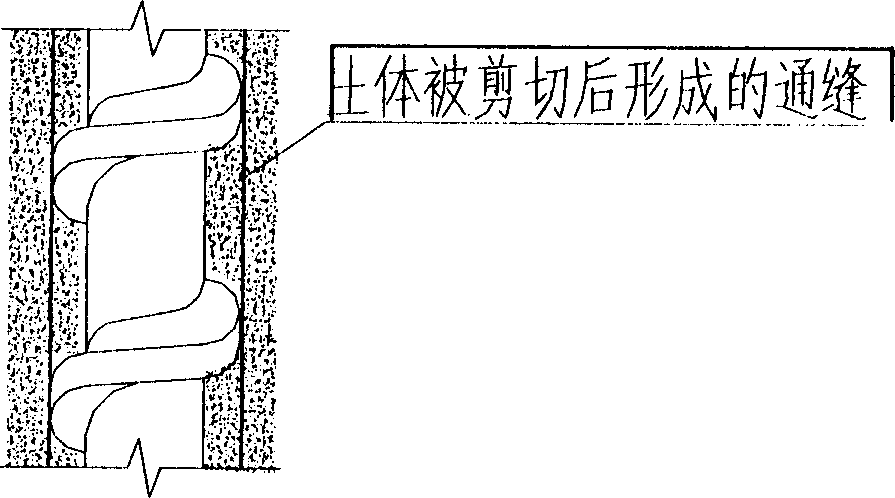

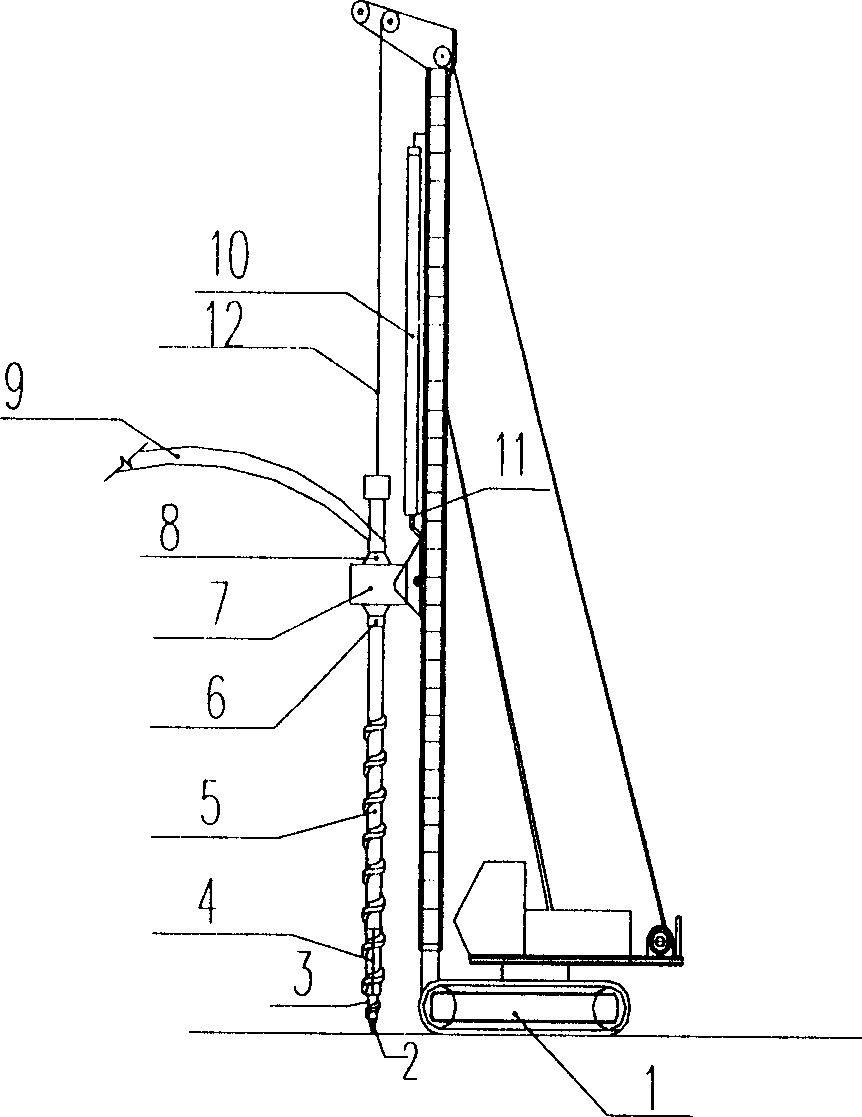

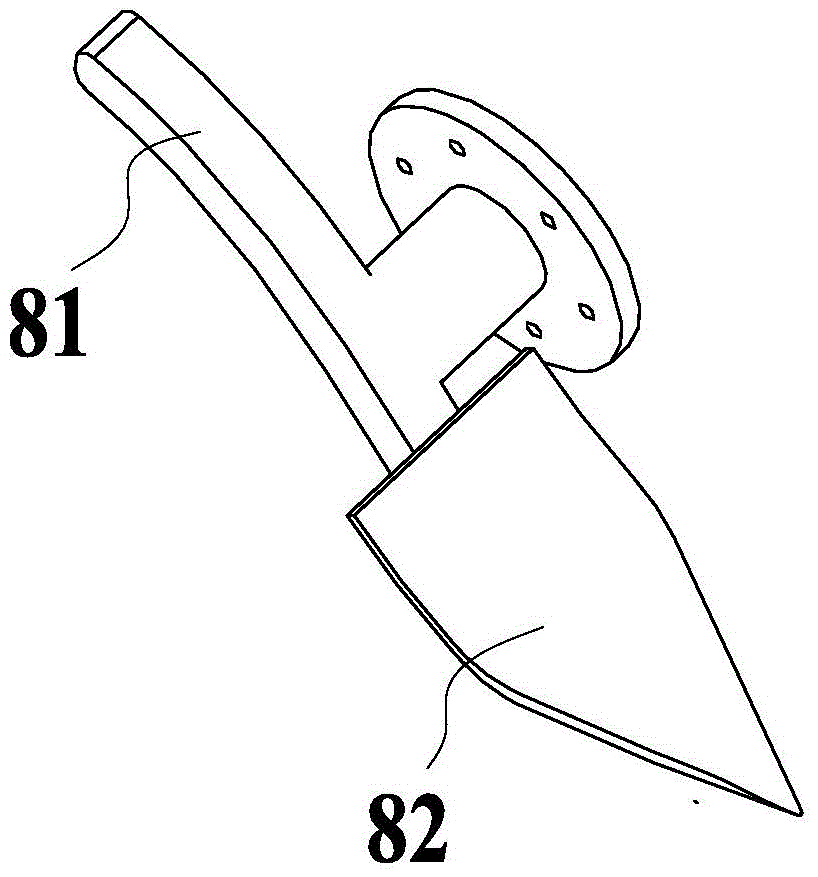

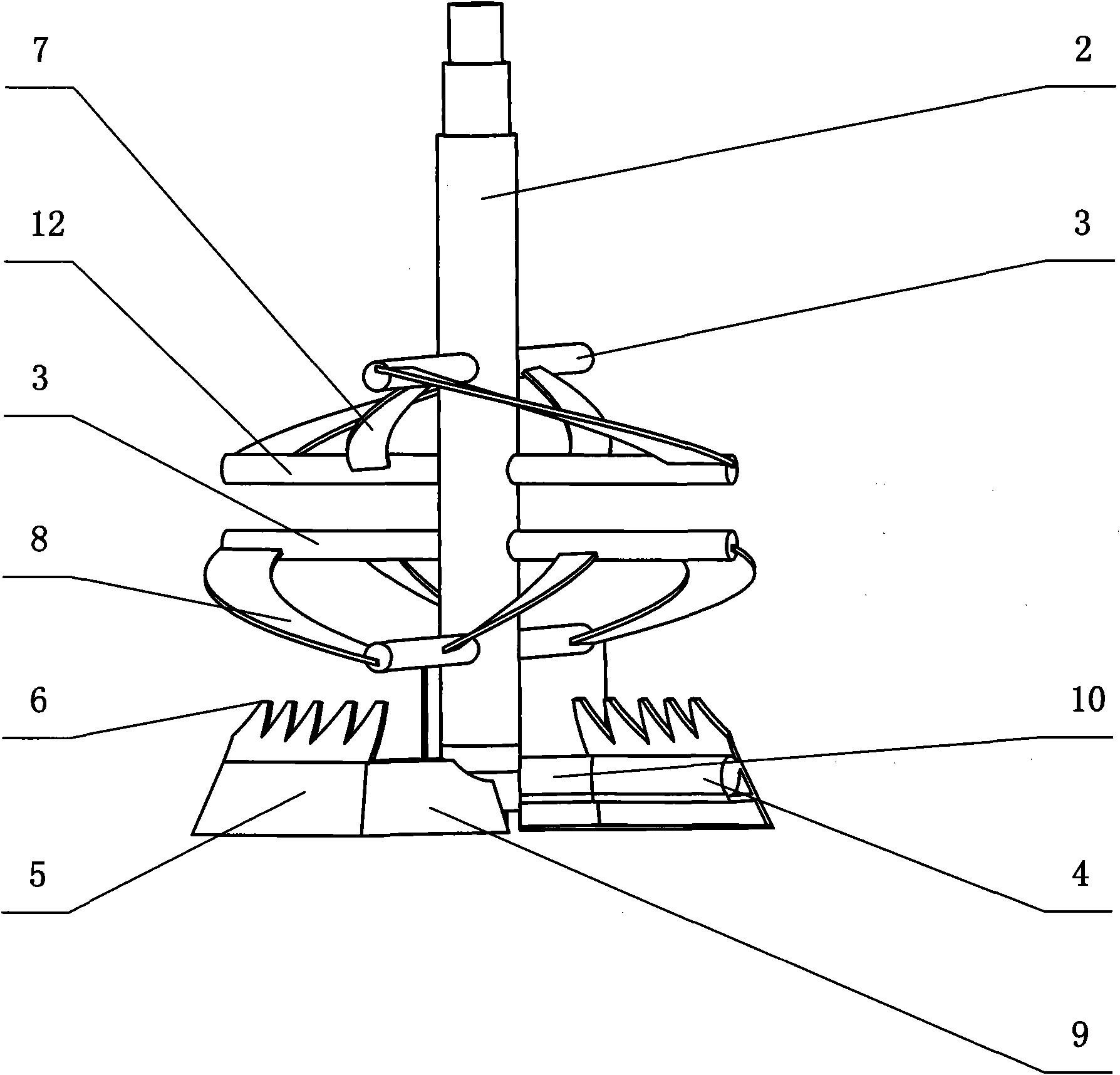

Screw pile, thread pile piling equipment and piling method

InactiveCN1904225AIncreased drilling depthImprove homogeneityBulkheads/pilesElectricityAutomatic control

This invention relates to screw stake, making screw stake equipment and the making method. The making screw stake equipment is mainly composed of the engine body, the oil cylinder, the hydraulic electric engine, the automation equipment and the transfer piping. The power head is installed on the engine body base's stand support. The hydraulic electric engine is installed on the engine body's base. The hydraulic electric engine connects with the power head through the power head. The drill pipe's clamp apparatus connects with the power's removable clamp apparatus. The transfer piping connects with the inner drill pipe. The automation equipment separately connects with the hydraulic electric engine and the oil cylinder. This invention has the following advantages: the power output saves electricity and time, it enlarges the equipment's application range and the construction speed excels other similar inventions evidently; the equipment adopts the extensible drill pipe, the drill's drilling depth largely improves; the three independent drill heads' structure has the unique ability of thrice enlarging aperture; it realizes the revolution and the raising to keep synchronous and non- synchronous; it adopts low gravity center pile frame, the equipment's weight is reduced evidently, the safety improves; it realizes the stake's stirring and evidently improves the stake's uniformity

Owner:卓典设计(海南)有限公司

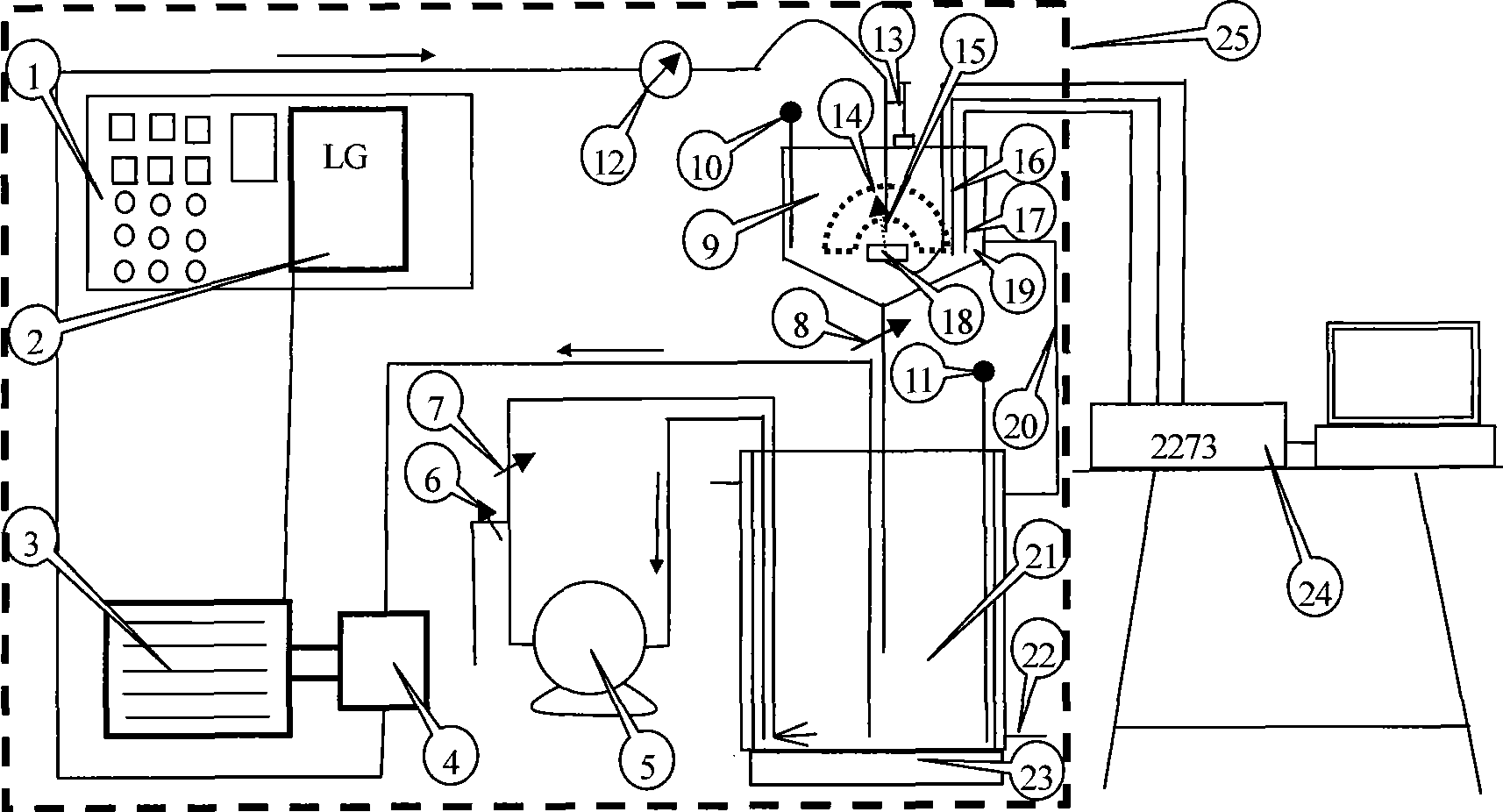

Jetting type liquid-solid double-phase scouring corrosion experiment apparatus

InactiveCN101382477AReduce pulsationWith angle of attackWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFrequency changerDouble phase

The invention relates to an erosion-corrosion device, in particular to a jet type liquid-solid dual-phase fluid erosion-corrosion experimental device which solves the problems in the prior art that the adjustment of an attack angle is relatively difficult and the experimental period is long as well as the problem of real-time measurement of electrochemical parameters and the like. The experimental apparatus is provided with an ejector pump, a nozzle, a nozzle chamber and an electrochemical test system, and adopts the cam pump of a motor drive provided with a transducer as the ejector pump, wherein, an attack angle adjustment device used for adjusting the attack angle of samples is arranged in the nozzle chamber, the pipeline where the nozzle locates is connected with a jet distance adjustment device. The device adopts the cam pump as the ejector pump to realize the smooth conveying of media containing bigger solid phase particles, utilizes the cam pump of the motor drive provided with the transducer to control the flow speed; and the nozzle chamber is provided with the samples which can control the attack angle and the jet distance, the samples can fulfill the electrochemical measurement. The device can control the flow speed, attack angle and the temperature of the media, and fulfill the electrochemical measurement.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

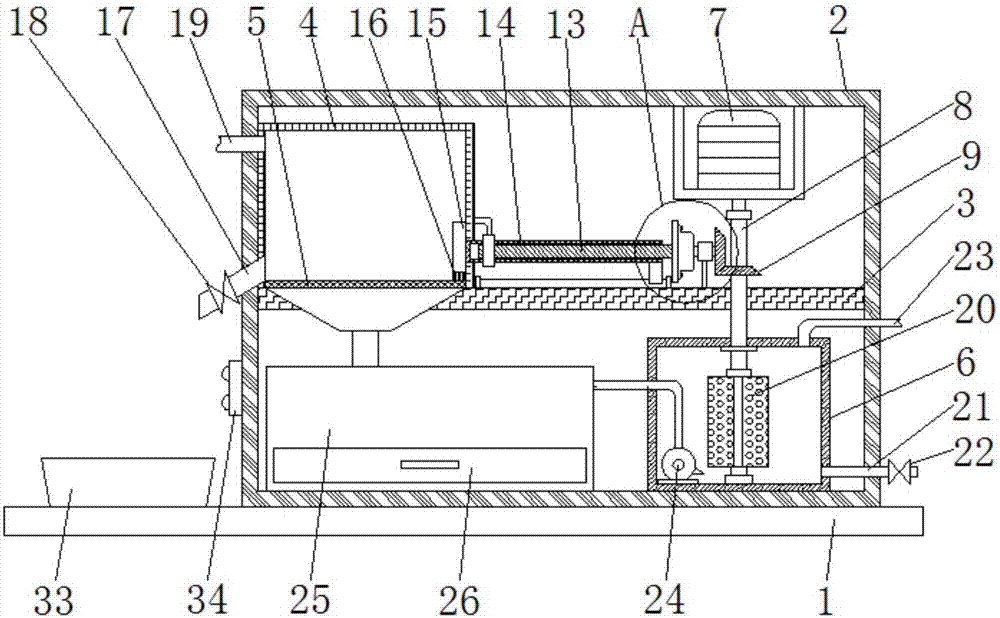

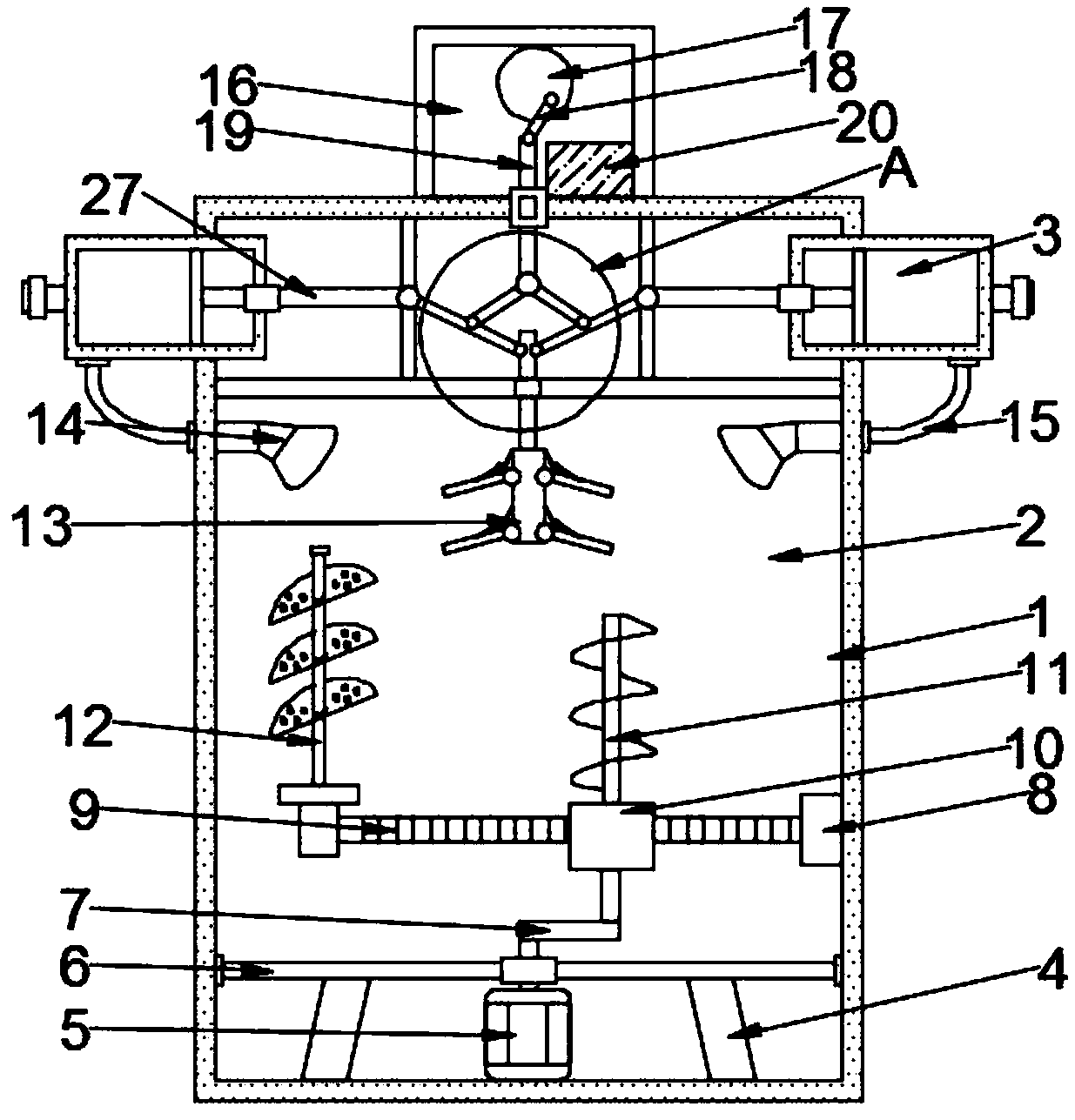

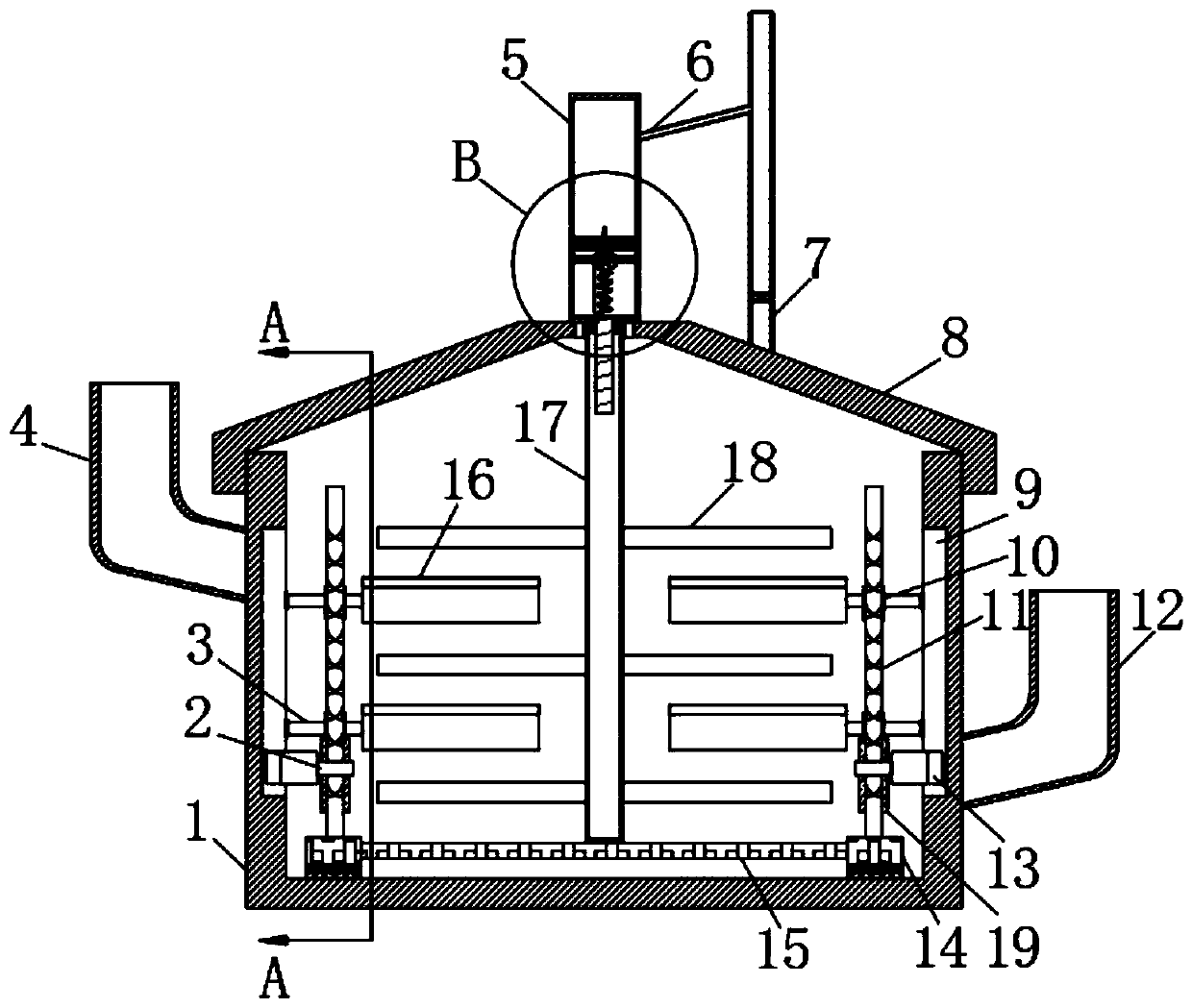

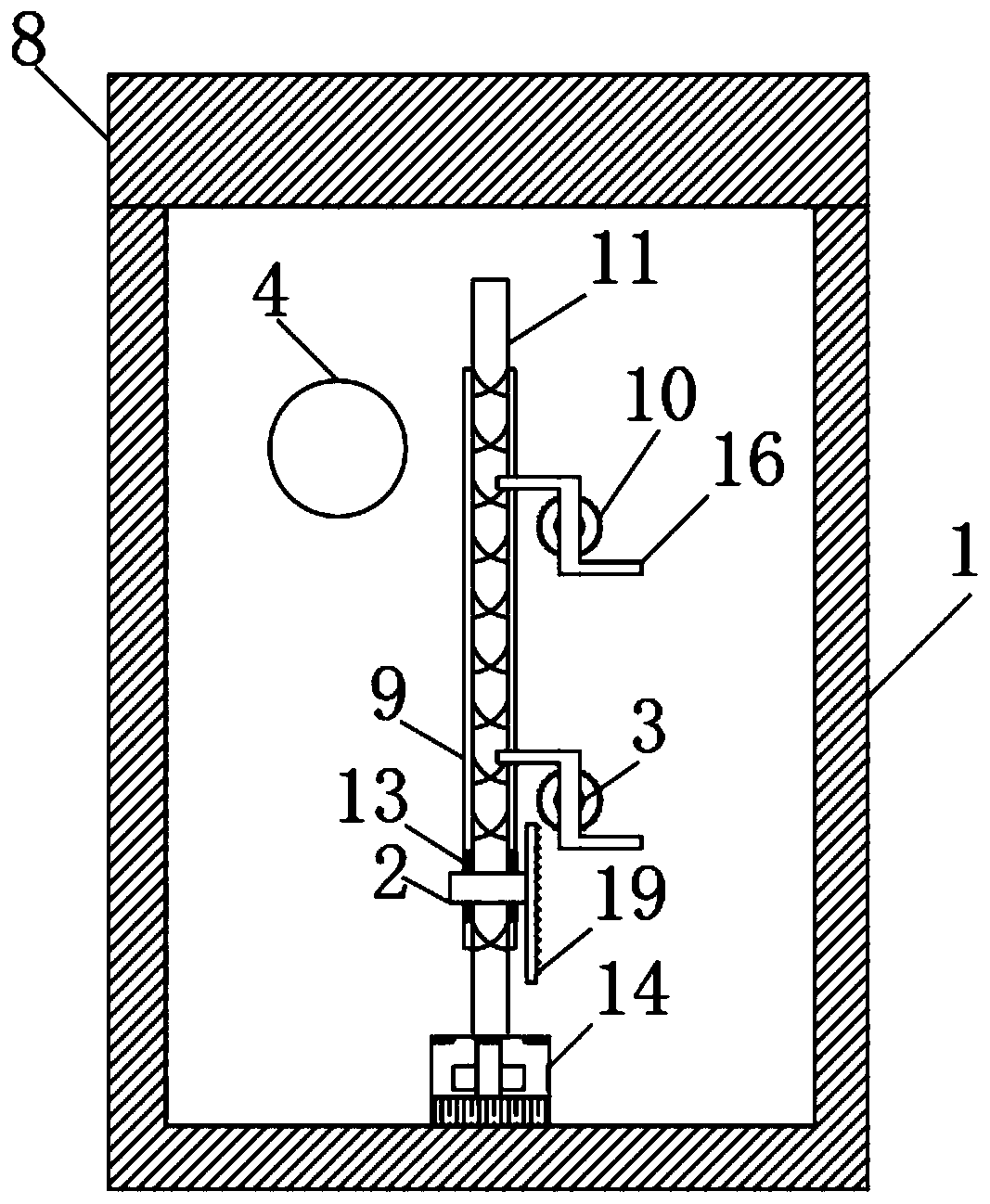

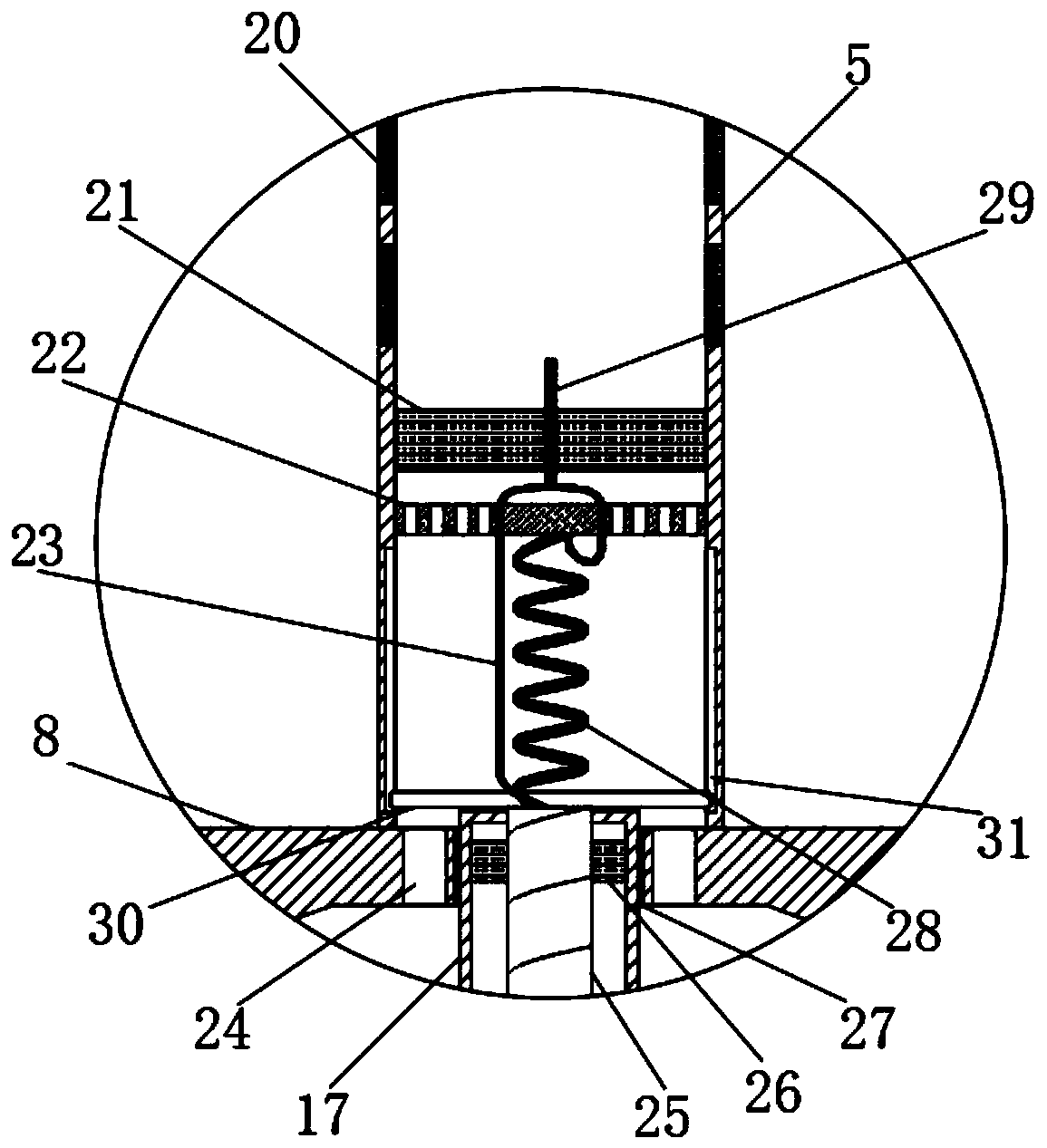

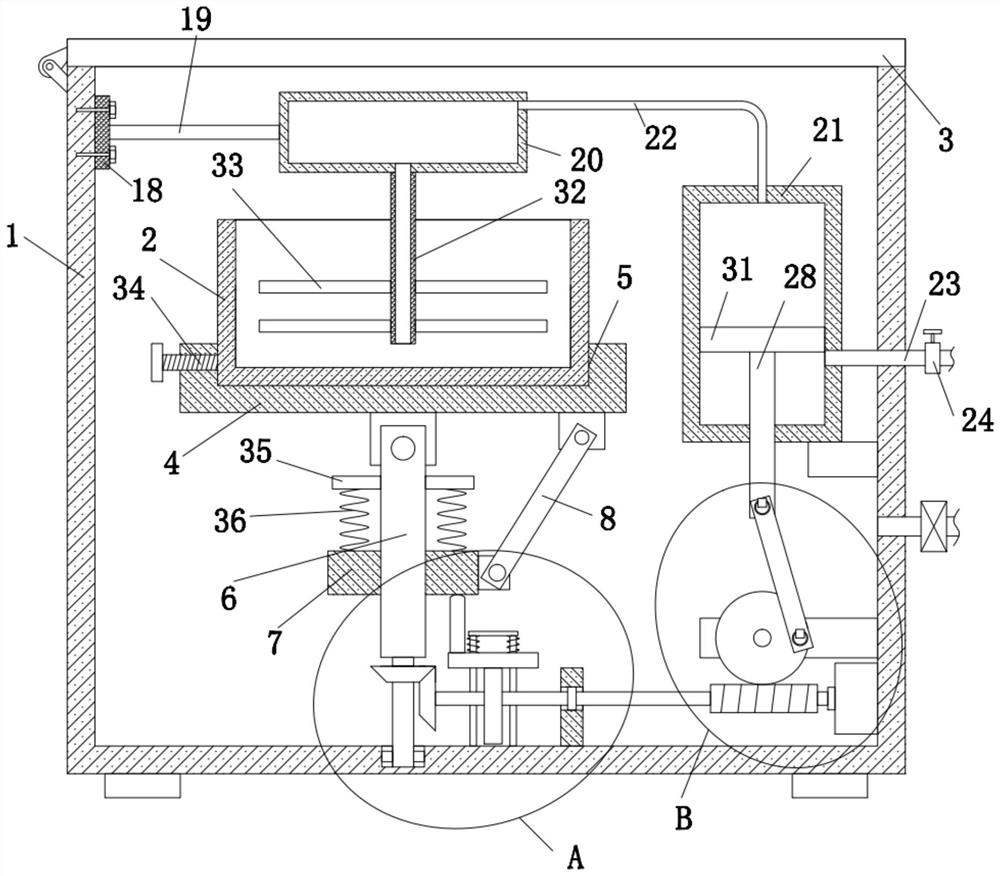

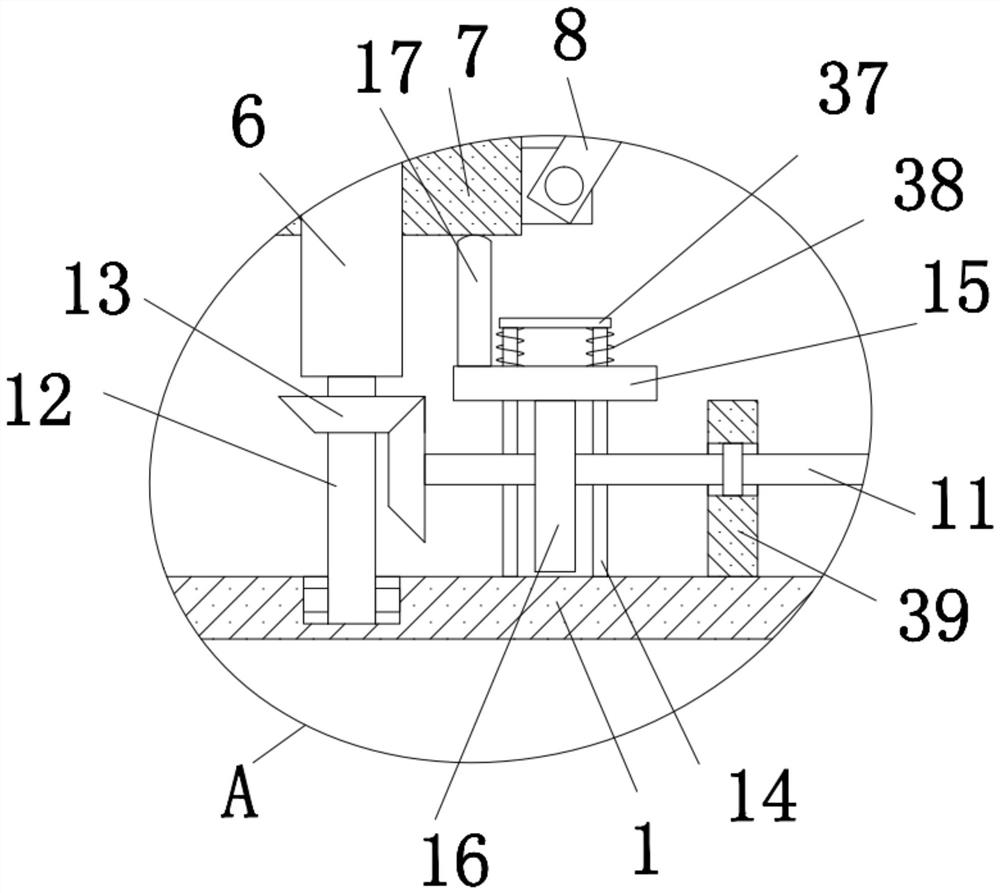

Culturing farm sewage treatment device with environmental protection function

ActiveCN107381938ASave time at workReduce workloadSpecific water treatment objectivesWaste water treatment from animal husbandryWork periodEngineering

The invention discloses a culturing farm sewage treatment device with environmental protection function. The device includes a pedestal, the top of the pedestal is fixedly connected to a case, a partition plate is fixedly connected between two sides of the case inner wall, one side at the top of the partition plate is fixedly connected to a filter tank, the bottom of the filter tank inner wall is fixedly connected to a filter net, one side at the bottom of the case inner wall is fixedly connected to a disinfection tank, and one side at the top of the case inner wall is fixedly connected to a motor through a mounting rack. The invention relates to the technical field of culturing farm sewage treatment equipment. The culturing farm sewage treatment device with environmental protection function provided by the invention has no need for manual cleaning of the filtered filter residue and precipitated sludge by culture staff, saves a lot of working time for the culture staff, alleviates the workload of culture staff, and realizes fast and thorough automatic cleaning of filter residue and precipitated sludge, thus greatly facilitating the sewage treatment work of the culture staff.

Owner:阳信亿利源清真肉类有限公司

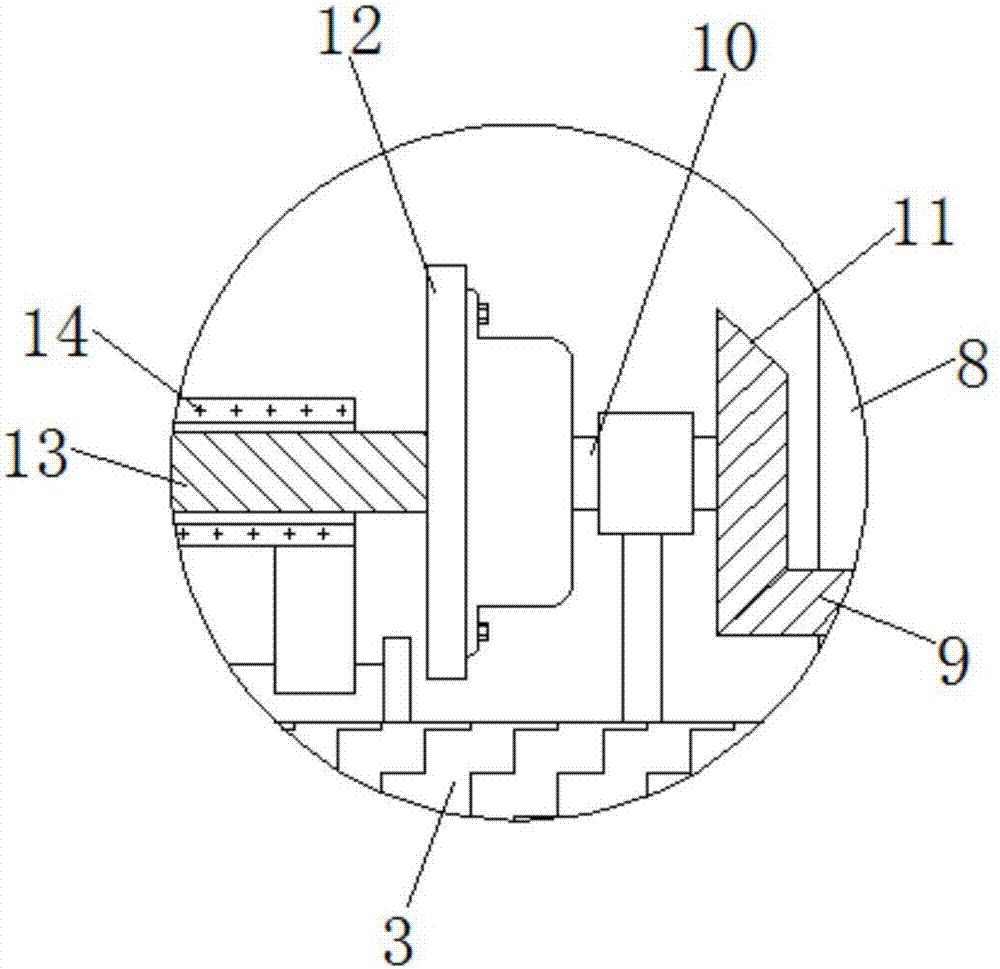

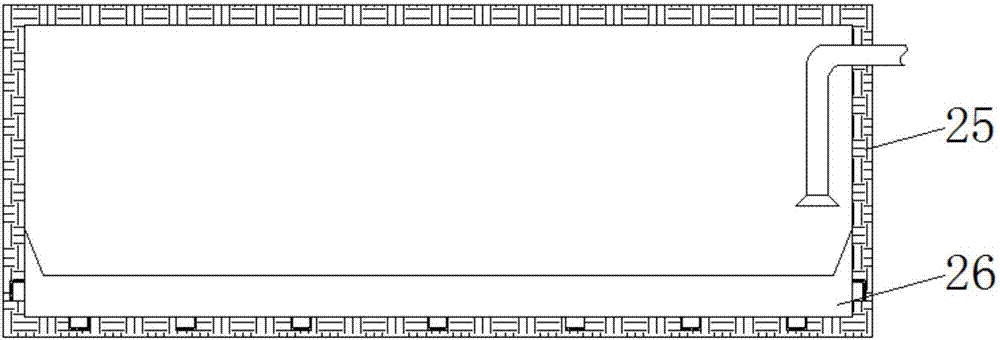

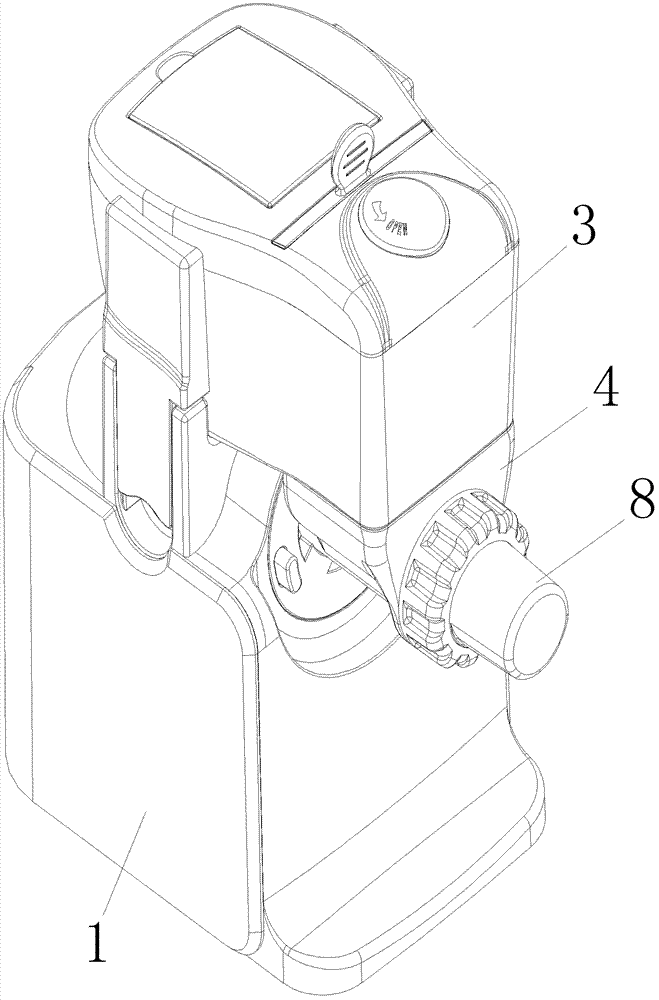

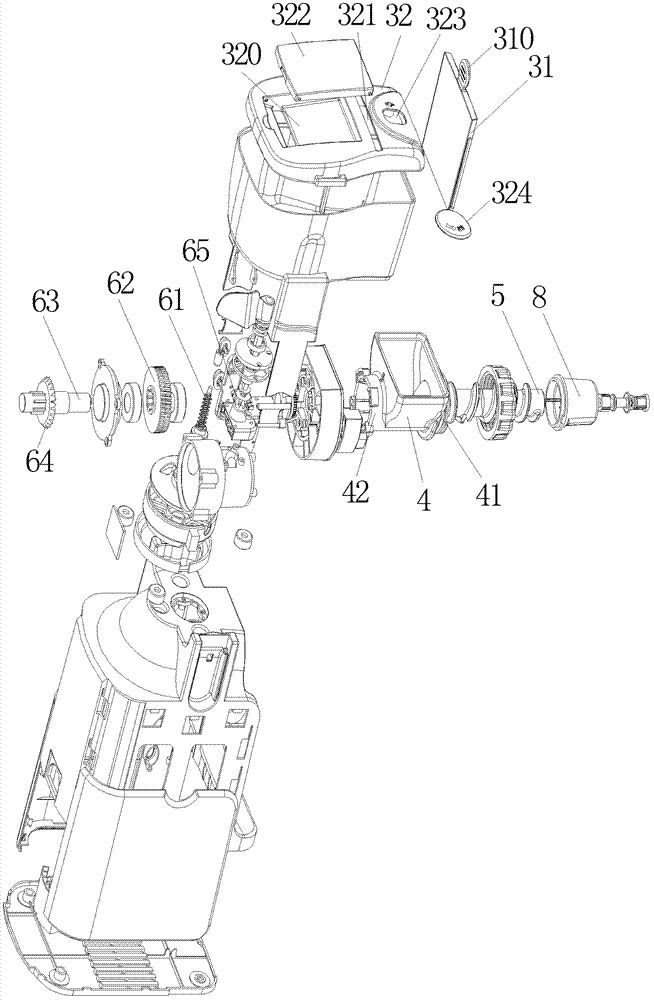

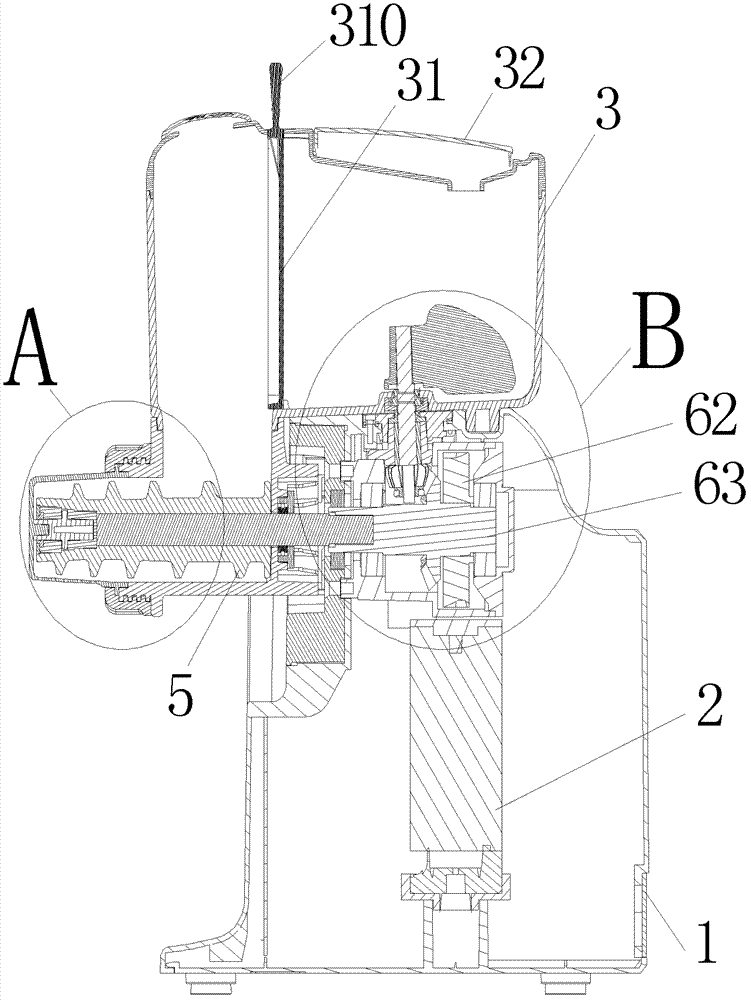

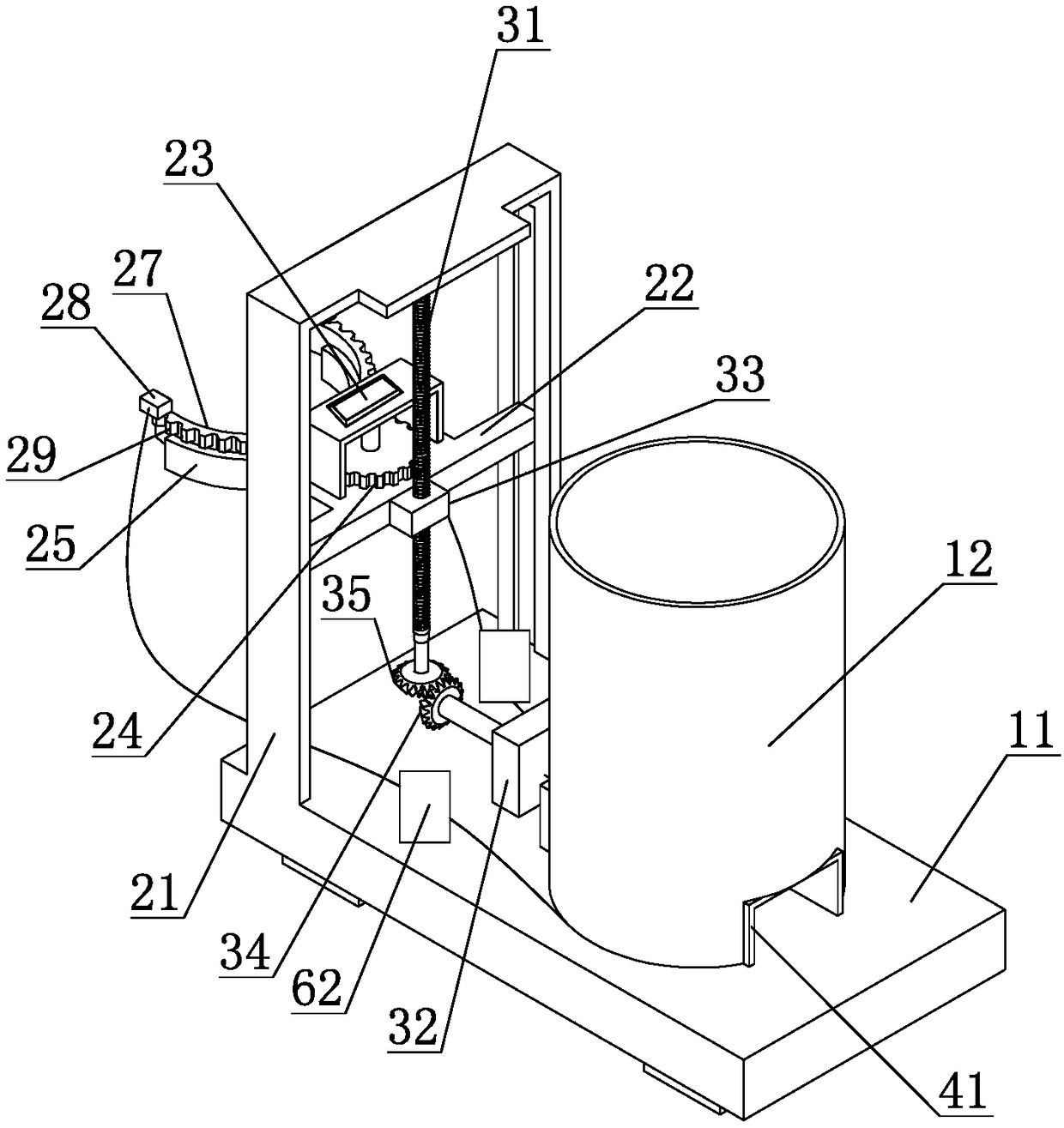

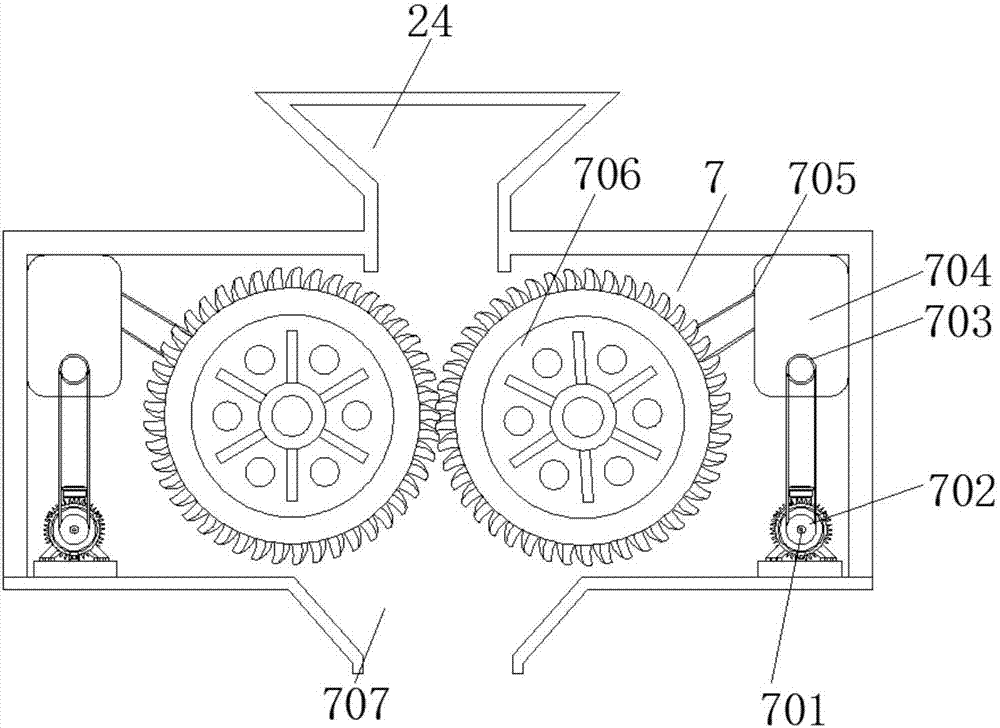

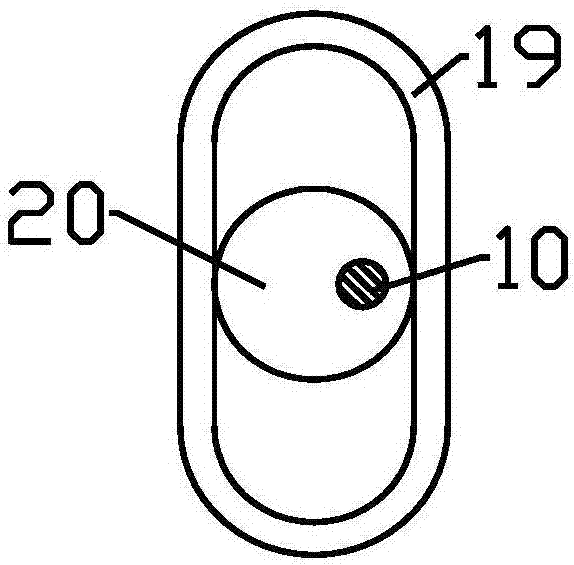

Multifunctional noodle machine

ActiveCN103190566AAchieving stirringReduce noiseDough extruding machinesFood preparationGear driveGear wheel

The invention relates to a multifunctional noodle machine comprising a machine body and a motor arranged in the machine body. A dough-making tank is arranged on the machine body. Stirring blades and a stirring rotation shaft are arranged in the dough-making tank. A dough-pressing tank is arranged on the front side of the machine body. A dough-pressing screw is arranged in the dough-pressing tank. A replaceable noodle shaping module is sleeved on the front end of the dough-pressing screw. A movable door with which the dough-pressing tank can communicate with the dough-making tank is provided on the upper end of the dough-pressing tank. When the movable door is opened, the dough in the dough-making tank can be thrown into the dough-pressing tank under a centrifugal force effect of the stirring device. Gear transmission devices are arranged between the motor and the double-pressing screw and the stirring rotation shaft. The invention aims at providing the multifunctional noodle machine with simpler structure.

Owner:何剑波

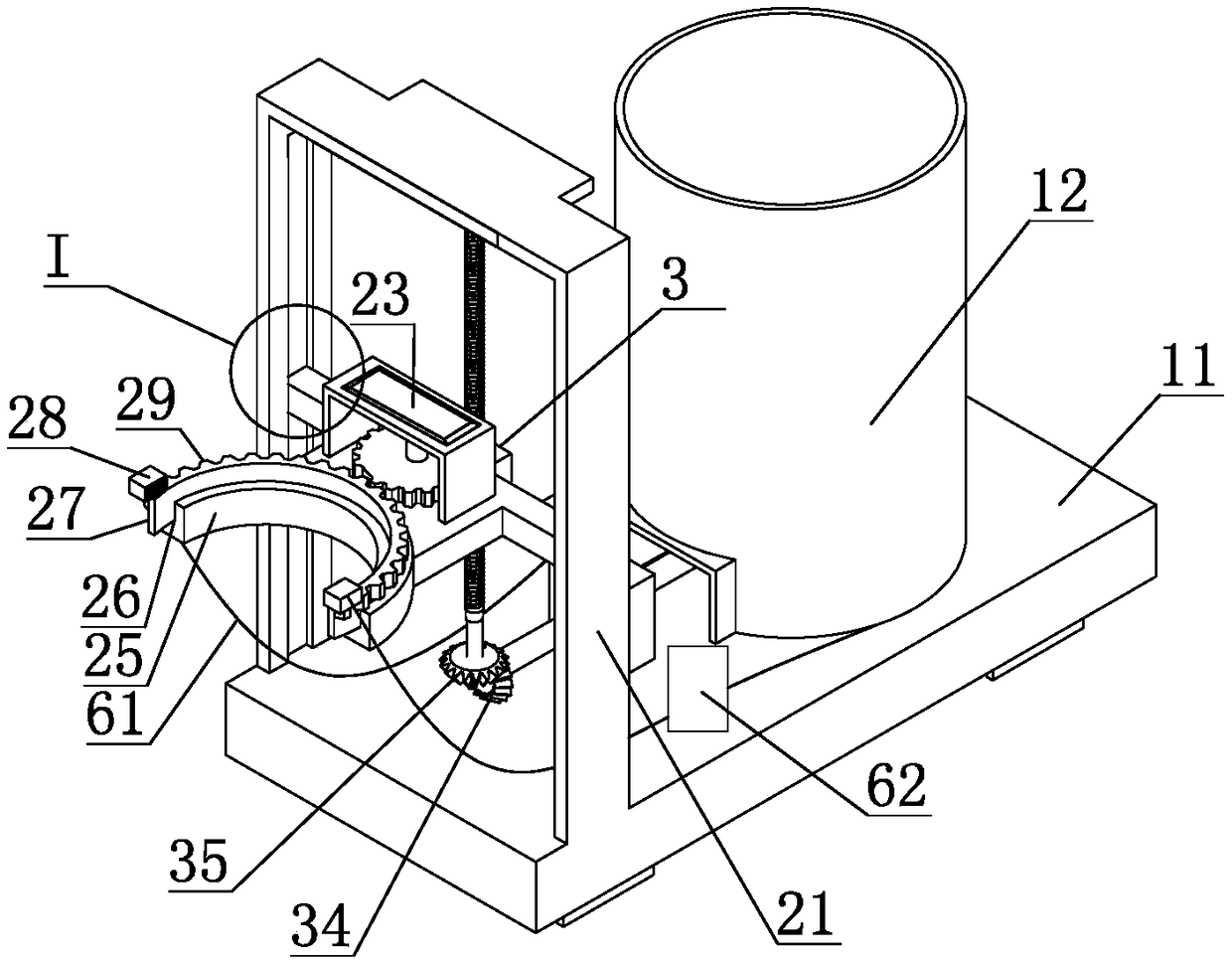

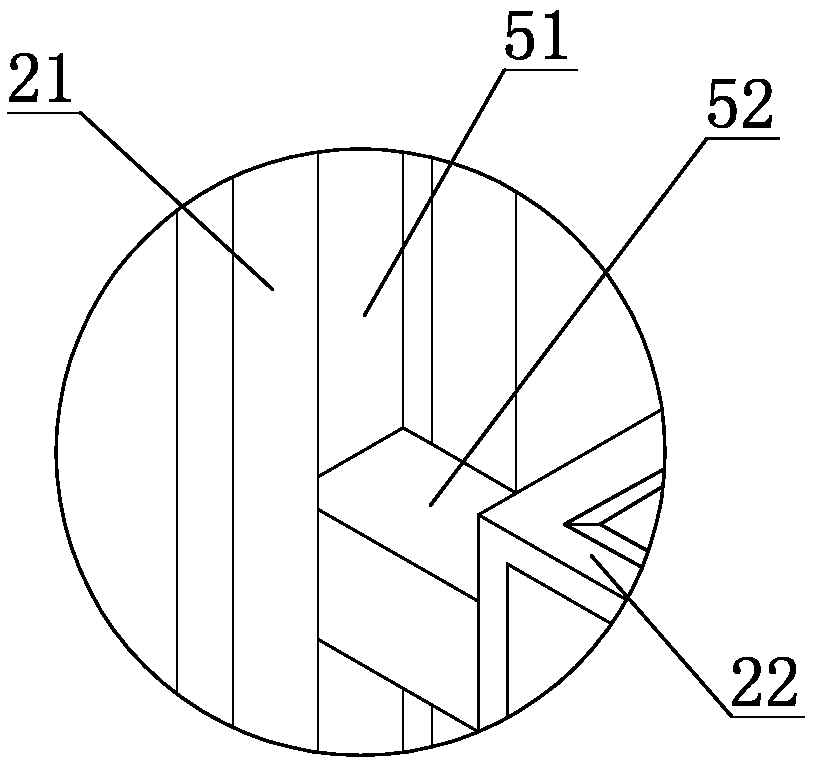

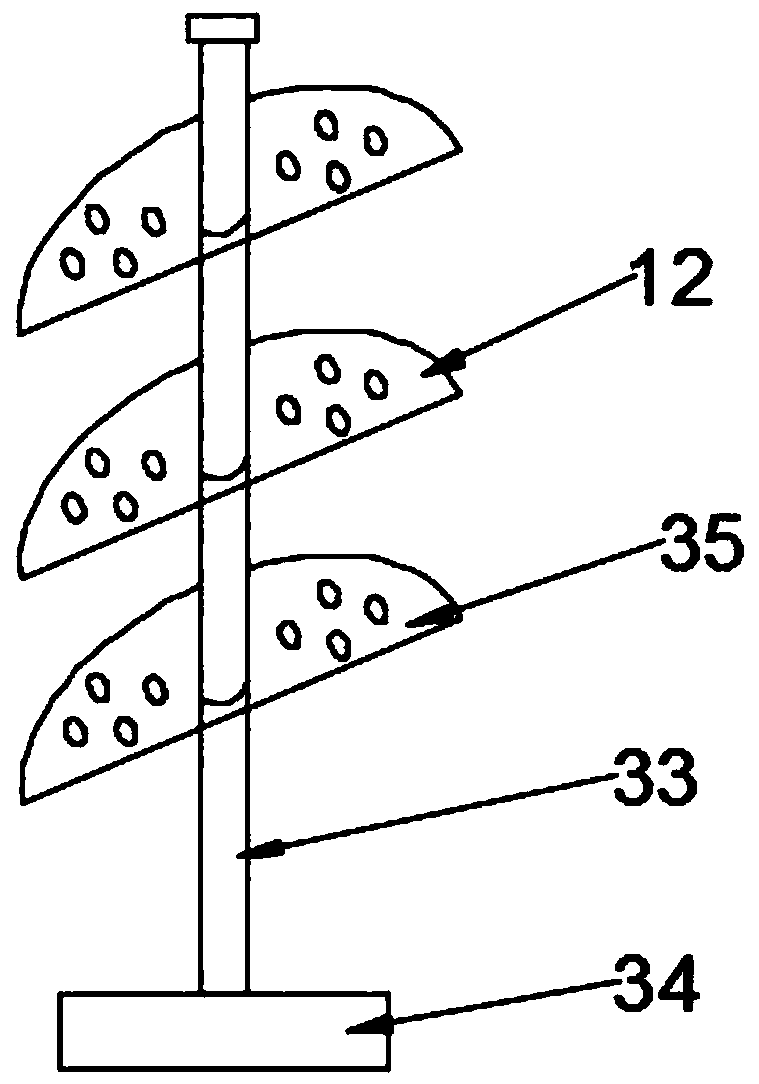

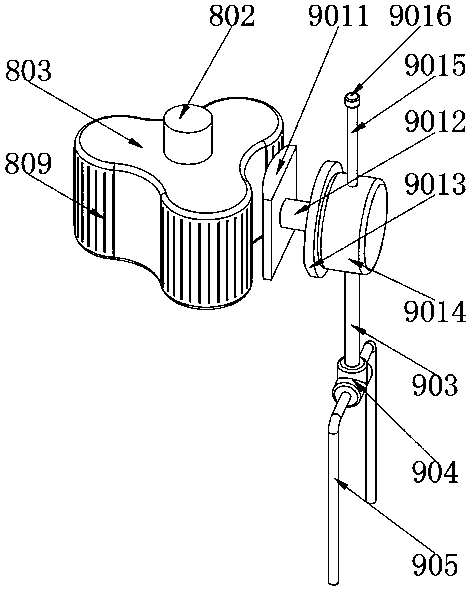

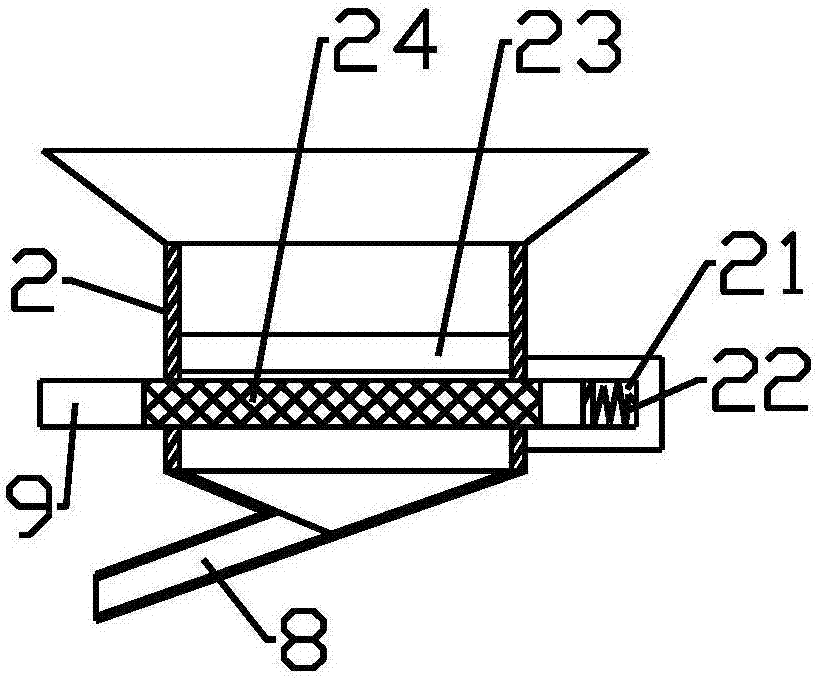

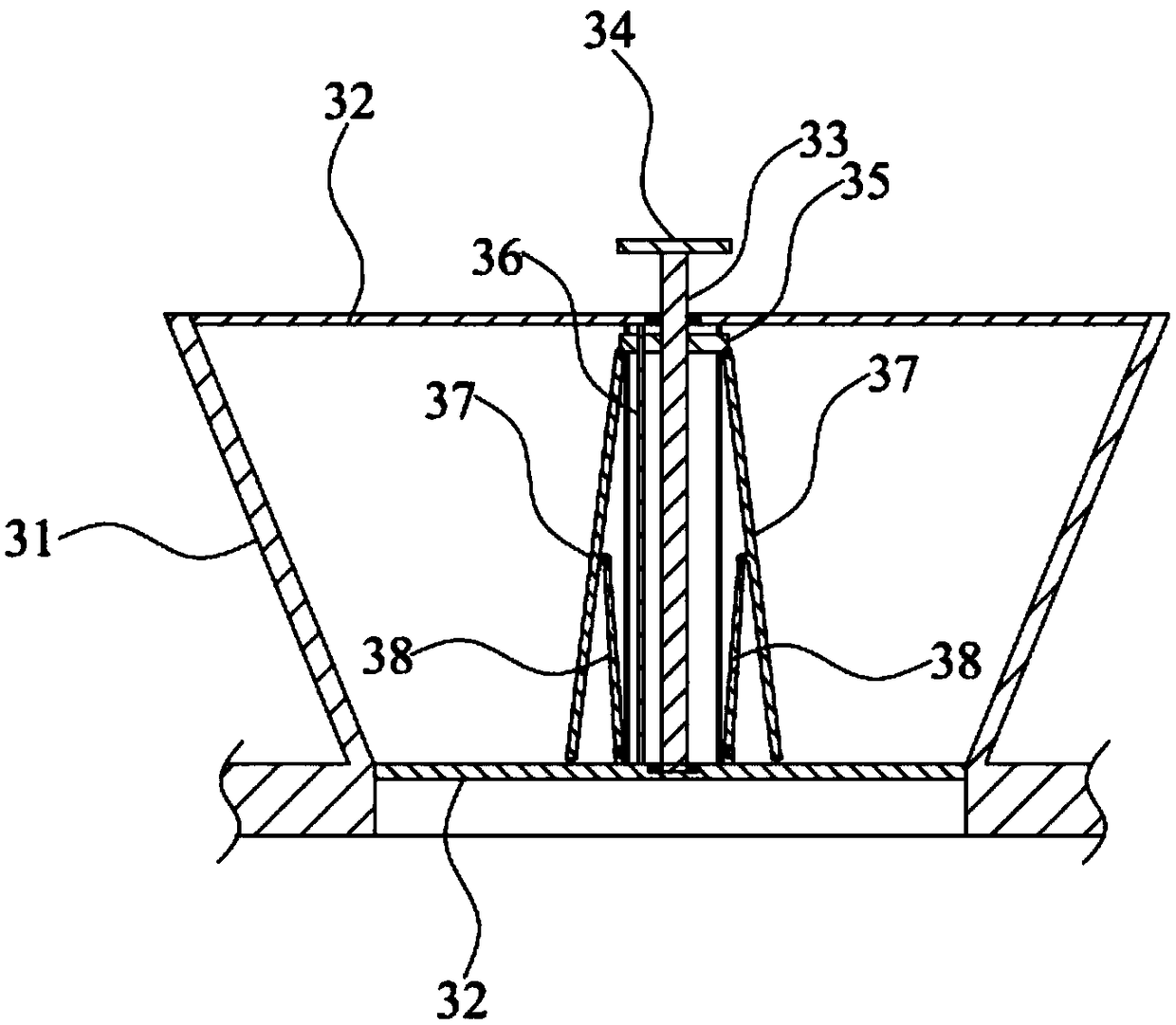

Lime slurry smearing device for trees

PendingCN109395943AAchieving Circumferential CoverageRealize smearing workSpraying apparatusPlant protectionEngineeringSlurry

The invention discloses a lime slurry smearing device for trees, and relates to the technical field of tree maintenance. The lime slurry smearing device for trees includes a base, wherein a lime slurry containing bucket is arranged on the base; a support frame is arranged at the front portion of the base; a support plate is slidably connected with the support frame; a first motor is arranged on the support plate; the output end of the first motor is provided with a gear; the front end of the support plate is provided with a curved plate; the curved plate is provided with a curved sliding rail;the inside of the curved sliding rail is slidably connected with a curved slider; the ends of the curved slider are provided with two spaying heads; the spray heads are connected with the lime slurrycontaining bucket; a rack is arranged on the upper portion of the outer wall of the curved slider; and the rack meshes with the gear. The lime slurry smearing device for trees has the beneficial effect that the lime slurry can be quickly smeared on the trees without dead angle.

Owner:韩东峻

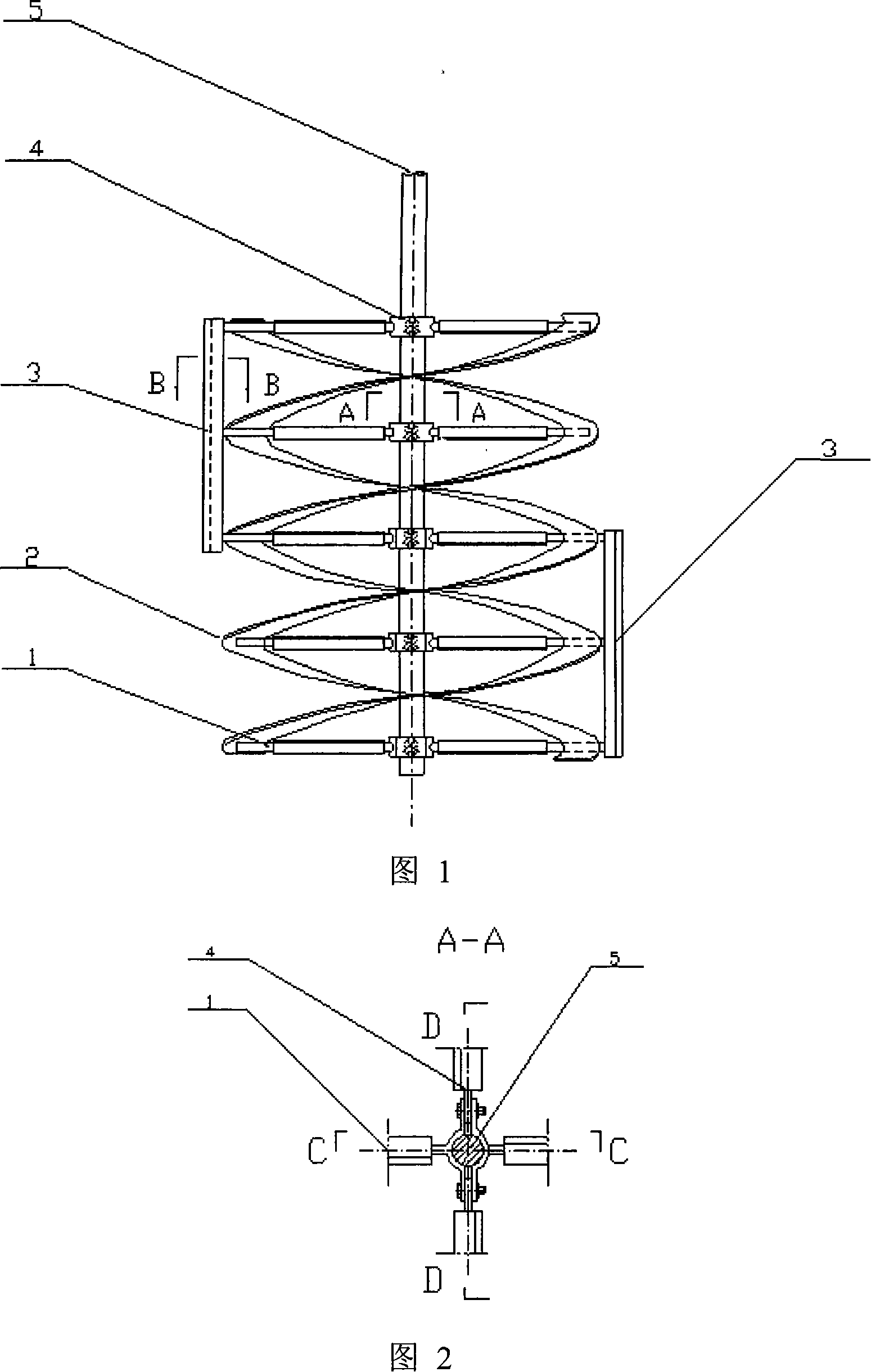

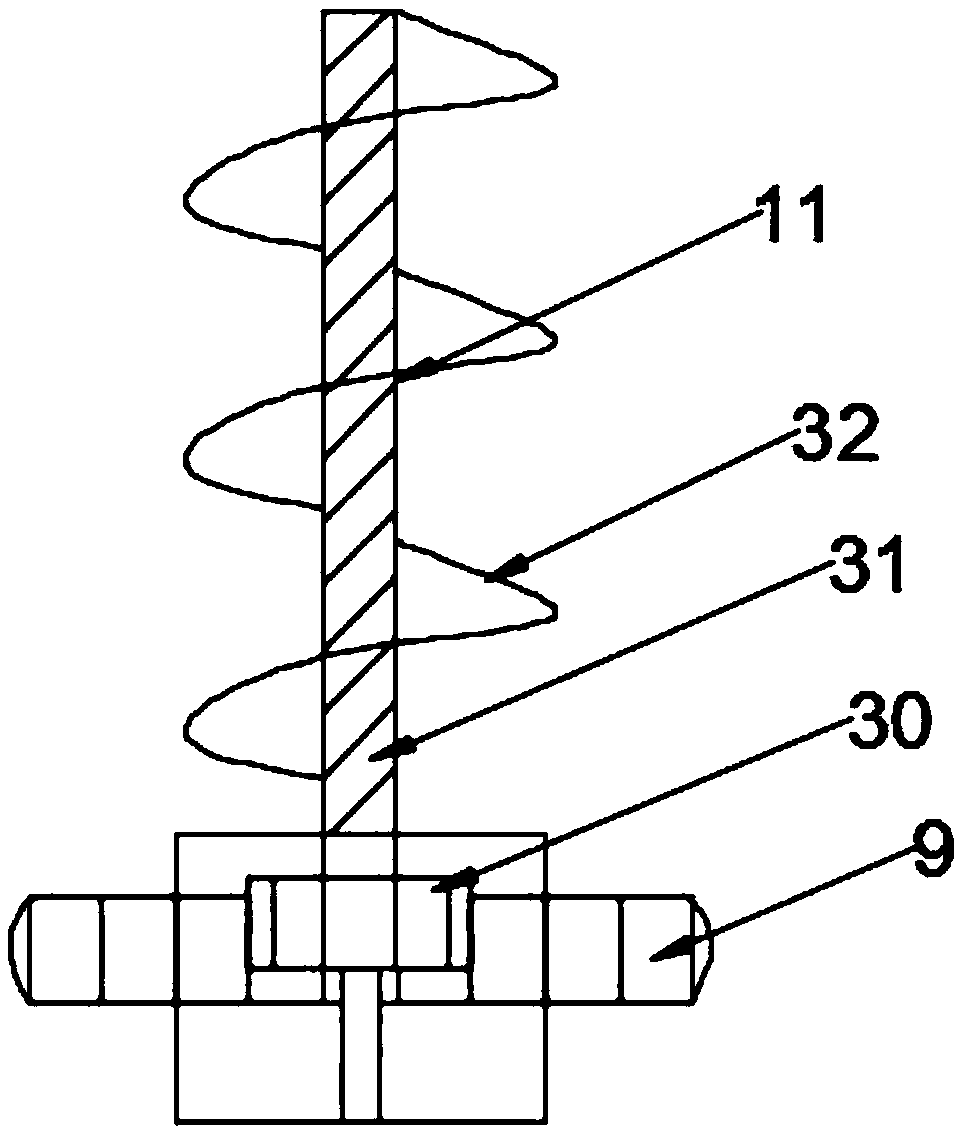

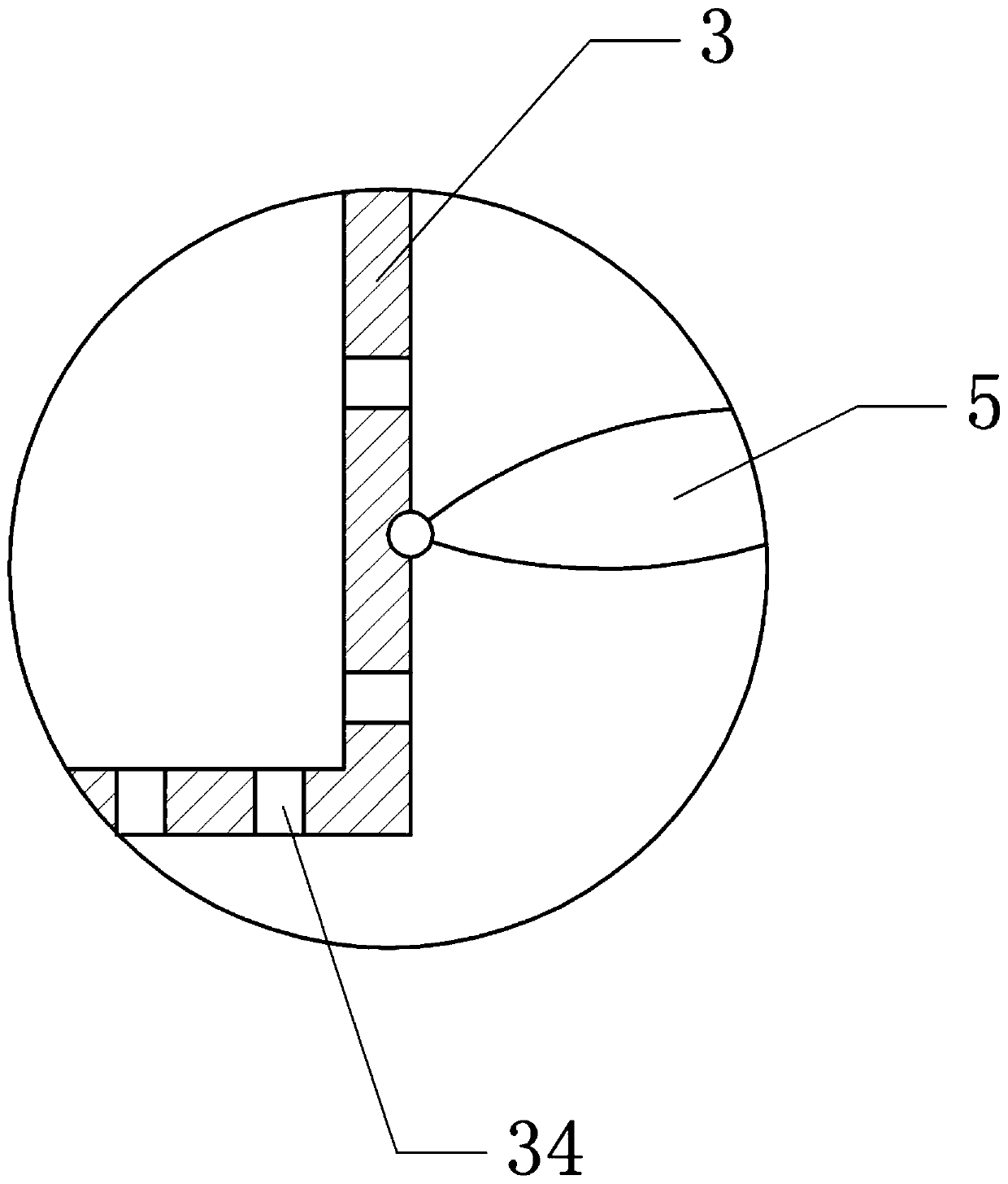

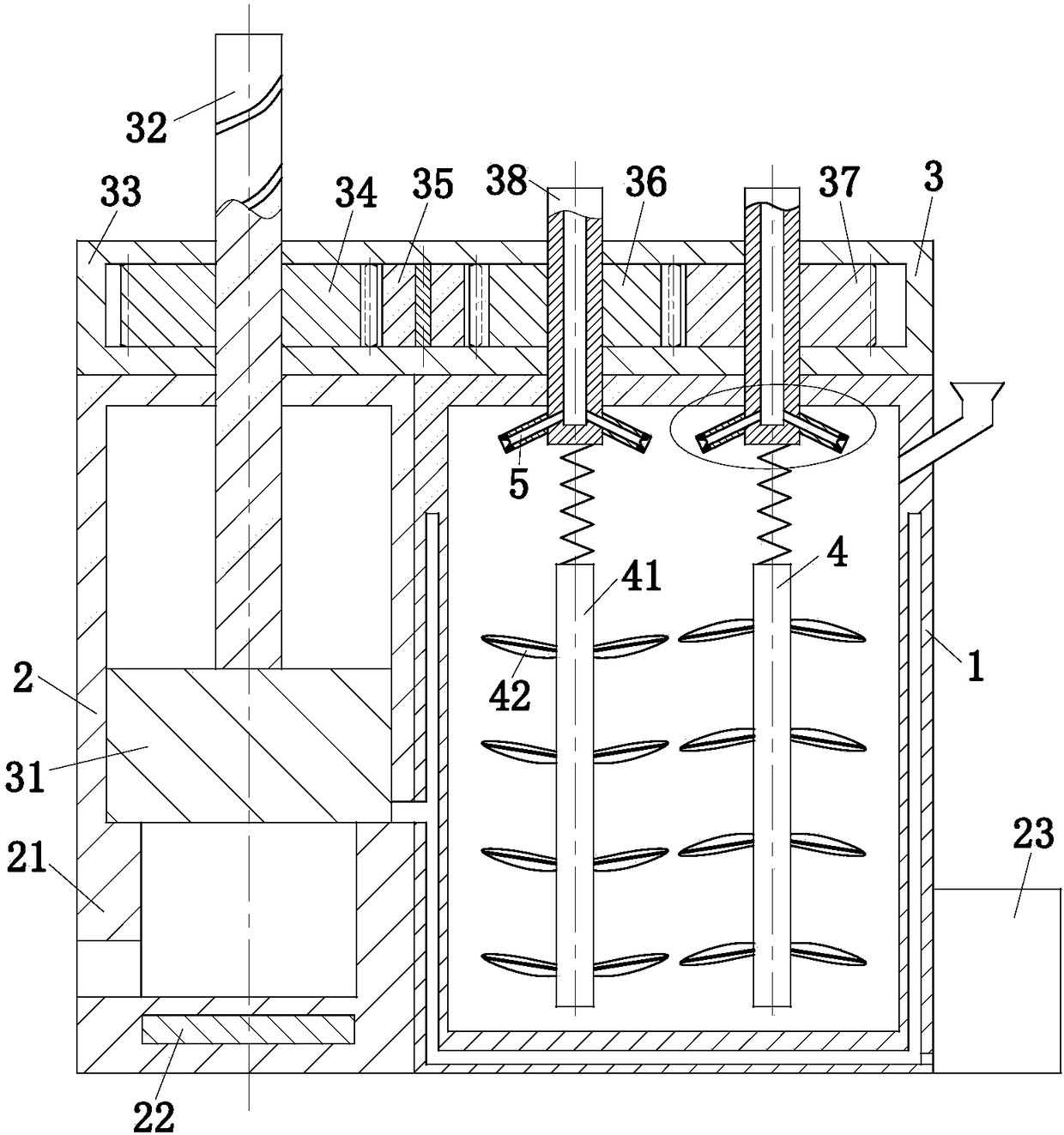

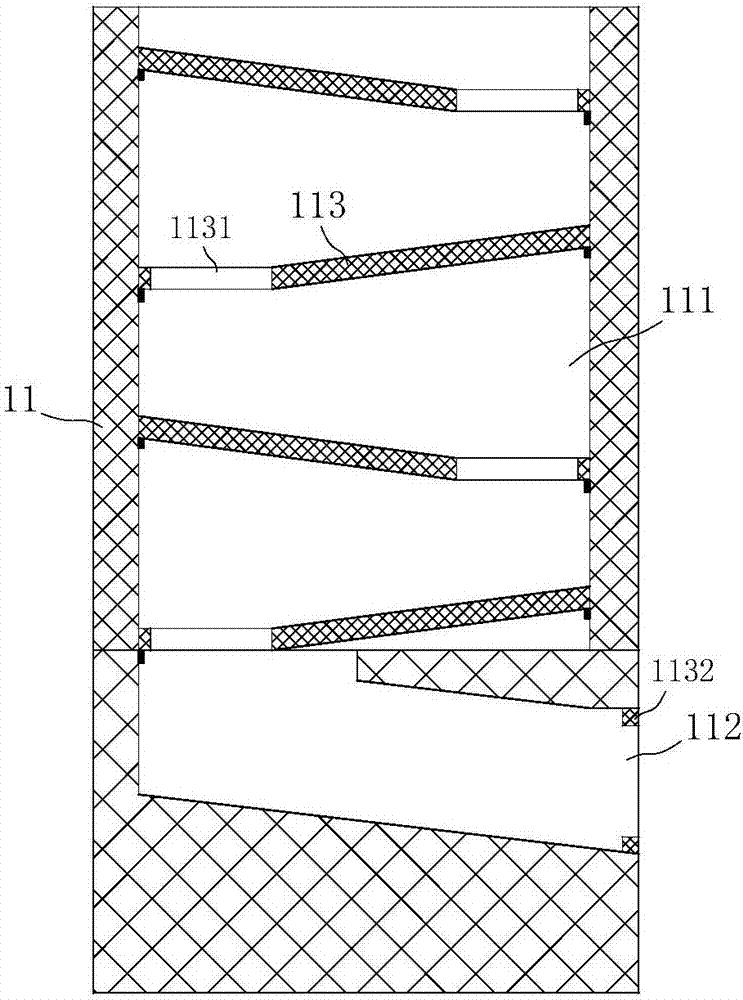

Double helical ribbon multi-layer oar blade scraping cutter type stirrer

InactiveCN101234309AAvoid liquid-liquid separationUniform temperatureRotary stirring mixersTransportation and packagingIncomplete mixingMaterial system

A double helical ribbon stirrer with multiple layers of blade scrapers comprises a stirring shaft (5), helical ribbons (2), support blades (1), separate blades (4) and a soft scraper (3). The support blades (1) and the separate blades (4) are layered and arranged on the stirring shaft (5), and the support blade and the separate blade of each layer are arranged on the stirring shaft (5) symmetrically, and the support blade (1) and the separate blade (4) keep a dip beta of 10 degrees to 45 degrees with the radical level section, and smaller dip can reduce the loss of useful work effectively. The helical ribbons (2) are connected with the stirring shaft (5) through the support blades (1) which have the functions of connecting ribs and strengthening ribs, thus causing reasonable structure design of the whole stirrer. The soft scraper (3) is divided into two sections which are fixed on the top of the helical ribbons (2) symmetrically, and an angle alpha between the soft scraper (3) and a still wall is 20 degrees to 60 degrees. The soft scraper (3) can scrape sticky material on the stirring still wall in time, thus solving the problem of incomplete mixing on the surface of the still wall and avoiding the damage to the still wall. The stirrer of the invention provides a material system that can adapt to different viscosities, in particular to the material system which has large viscosity variation range in a short time.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

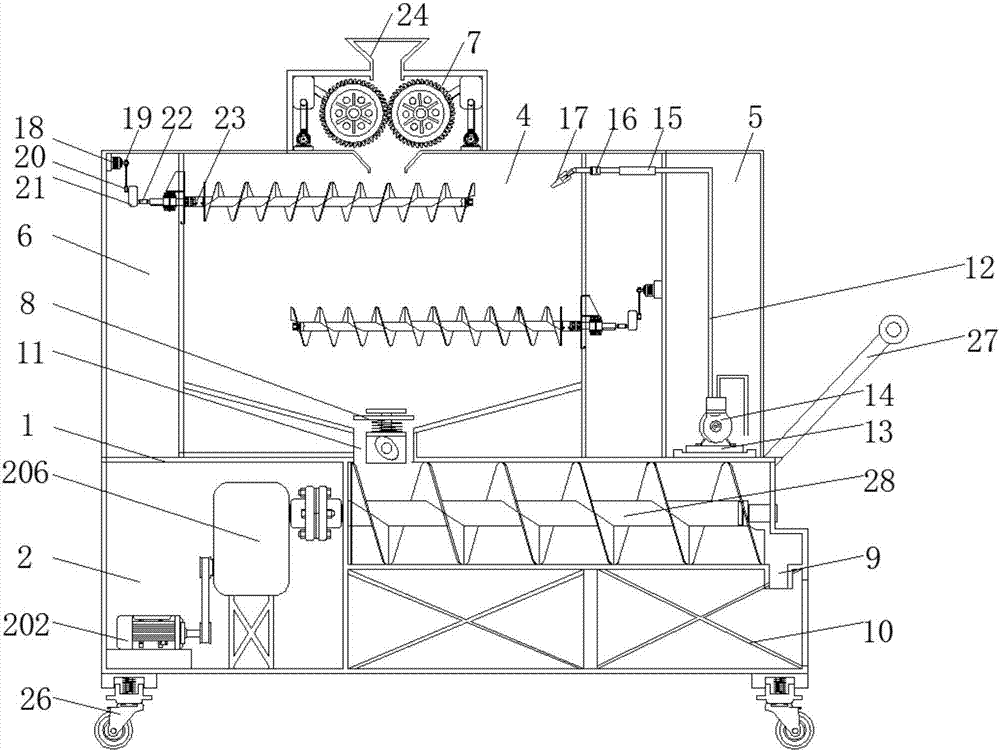

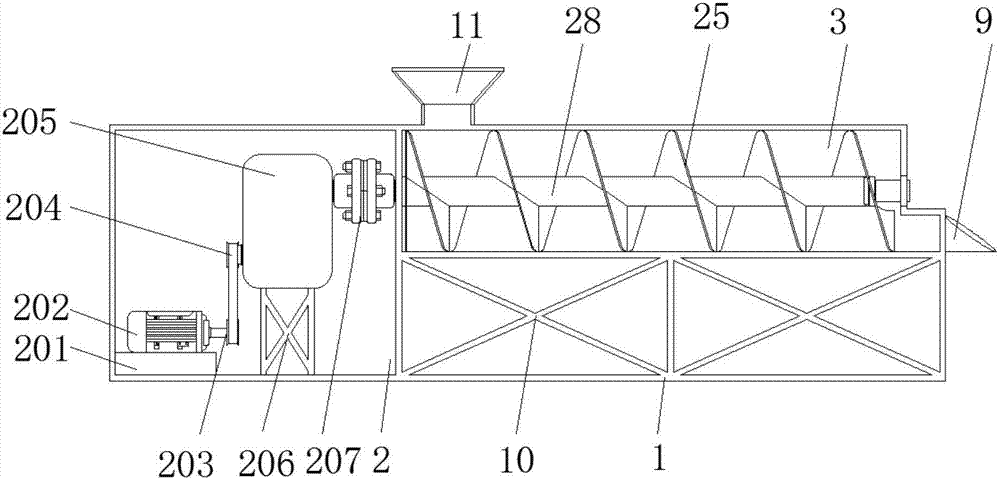

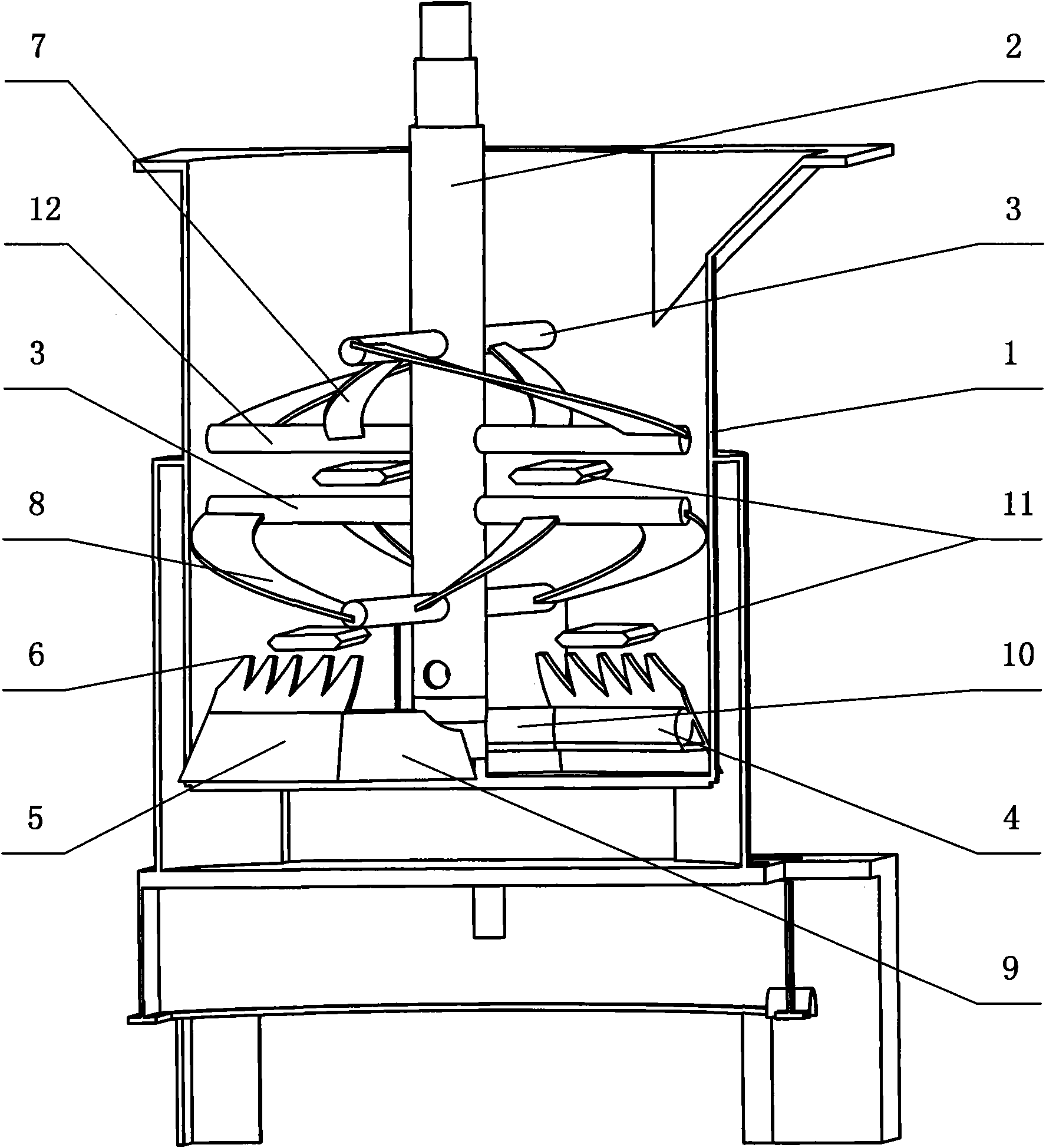

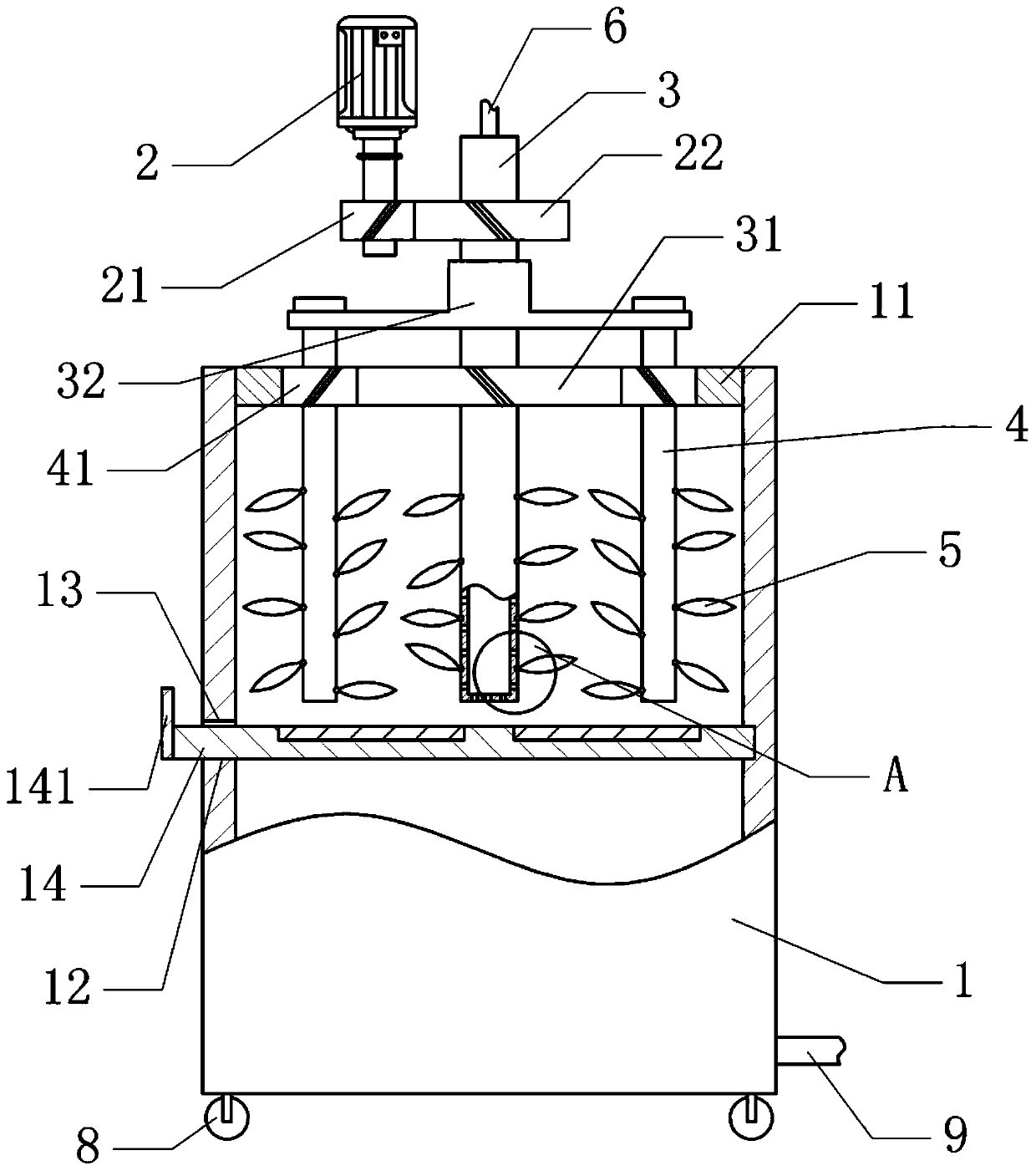

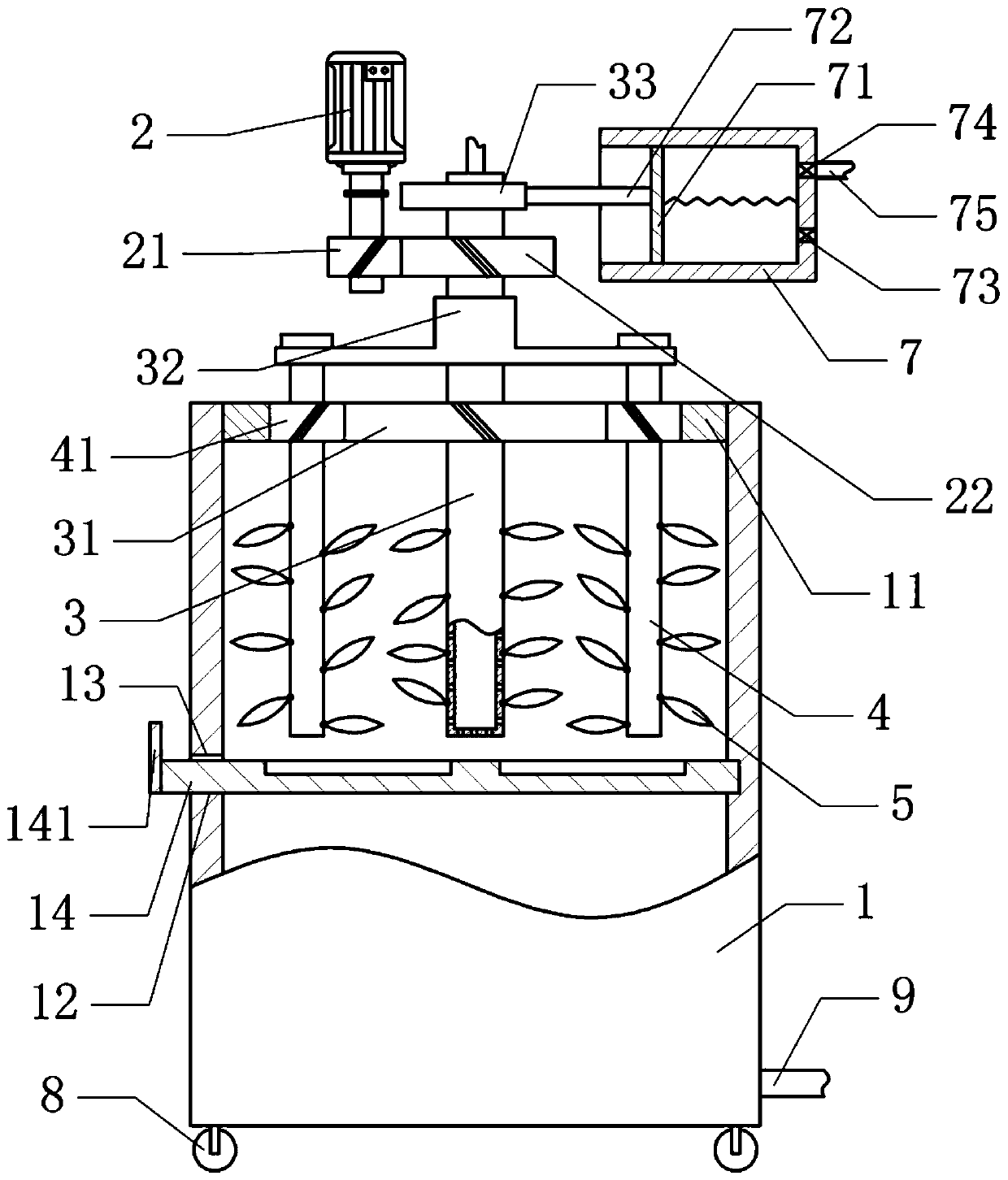

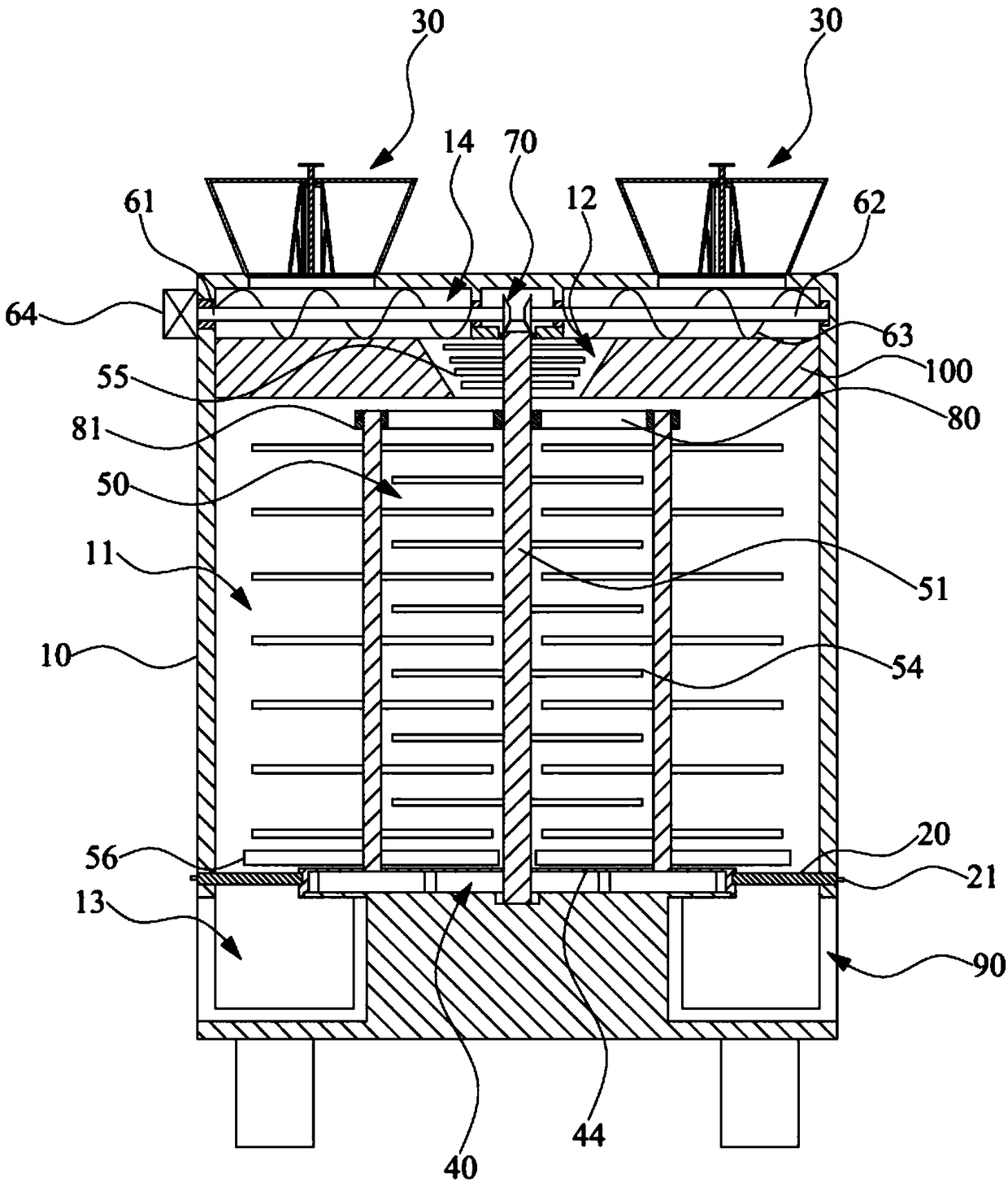

Movable efficient stirring machine used for civil engineering

InactiveCN107225680AQuality assuranceEnsure safetyDischarging apparatusMixing operation control apparatusLeather beltReduction drive

The invention discloses a movable efficient stirring machine used for civil engineering. The movable efficient stirring machine comprises a box body. A transmission device is fixedly connected to one side of an inner cavity of the box body. The top of the outer wall of the box body is fixedly connected with a stirring box. Stirring power boxes are arranged on the two sides of the inner cavity of the stirring box. Stirring motors are fixedly connected to the inner walls of the stirring power boxes and are connected with first belt wheels through output shafts in a rotating manner. The first belt wheels are connected with second belt wheels through belts in a rotating manner. The stirring motors are connected with first speed reducers through the first belt wheels and the second belt wheels in a rotating manner. The invention relates to the technical field of civil engineering machines. The movable efficient stirring machine used for the civil engineering achieves the aim of making concrete more uniform by conducting smashing and then conducting stirring on the to-be-stirred concrete, stable and controllable water addition of the stirring box and stable discharge of a discharge port are achieved, quality of the concrete is ensured, and the aim of moving the stirring machine is achieved.

Owner:中鸿瑞达(厦门)科技有限公司

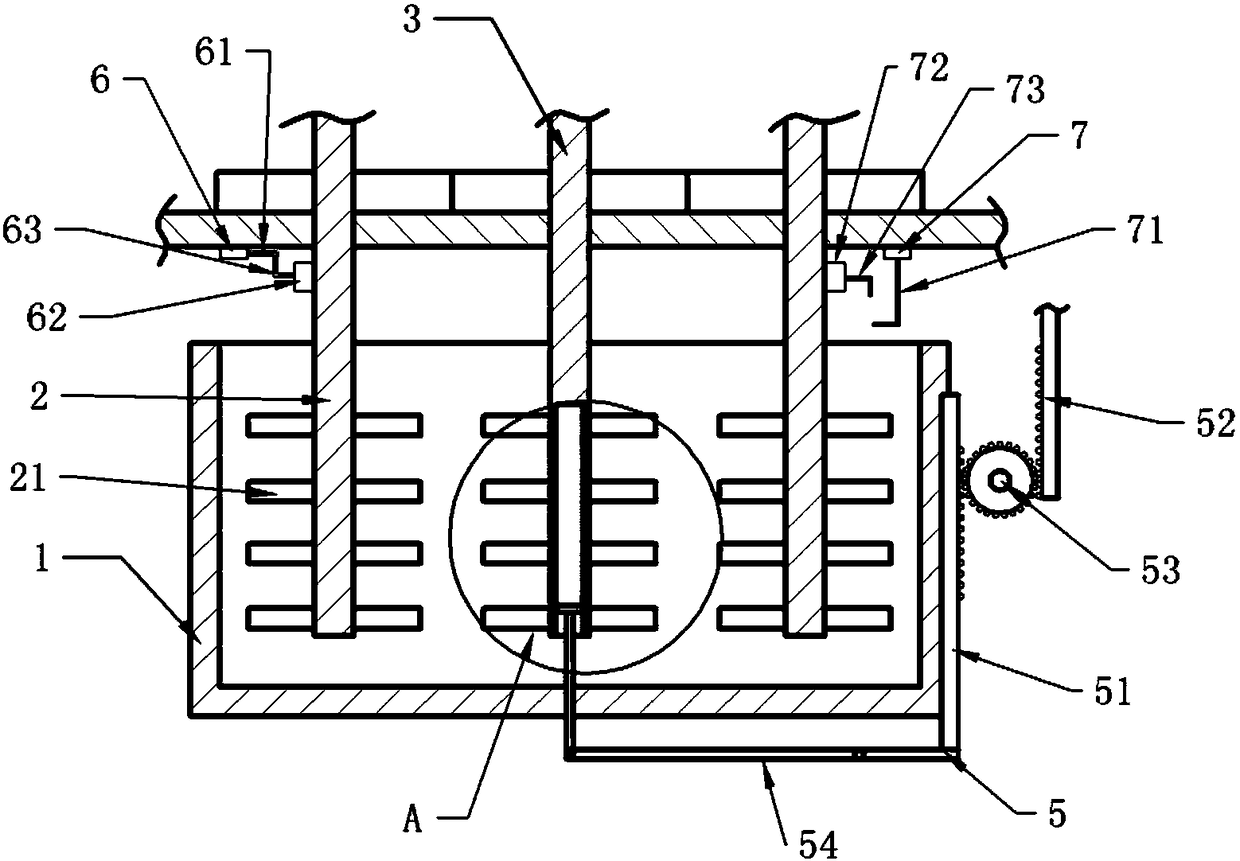

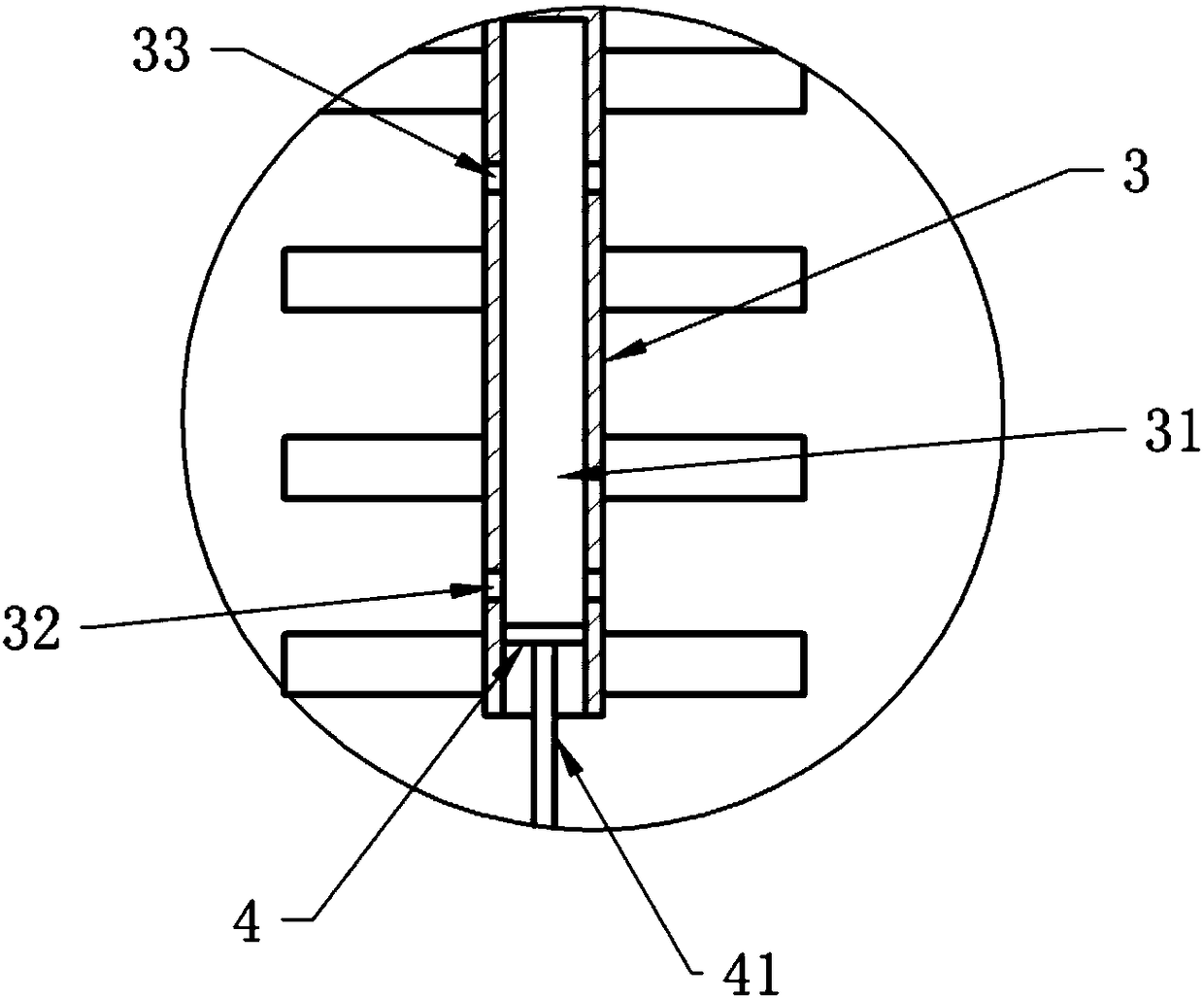

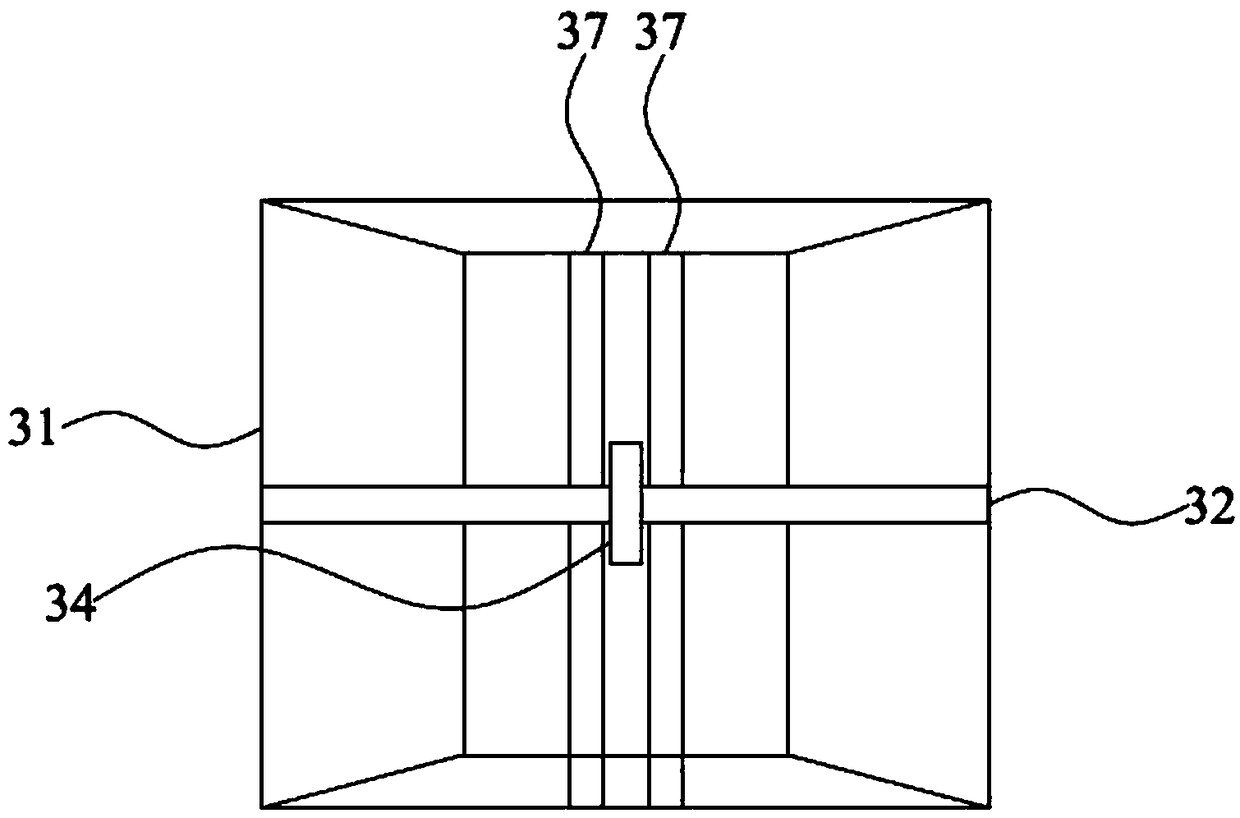

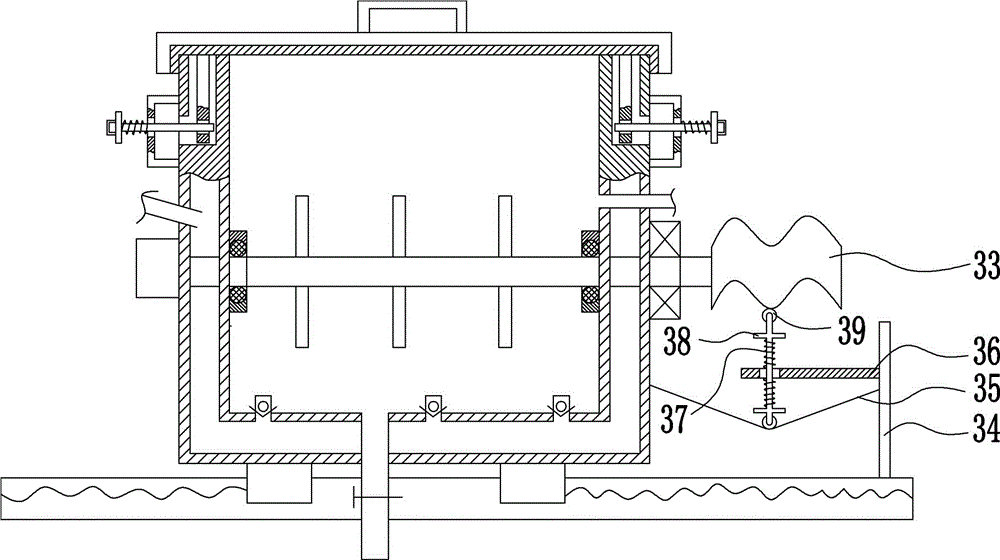

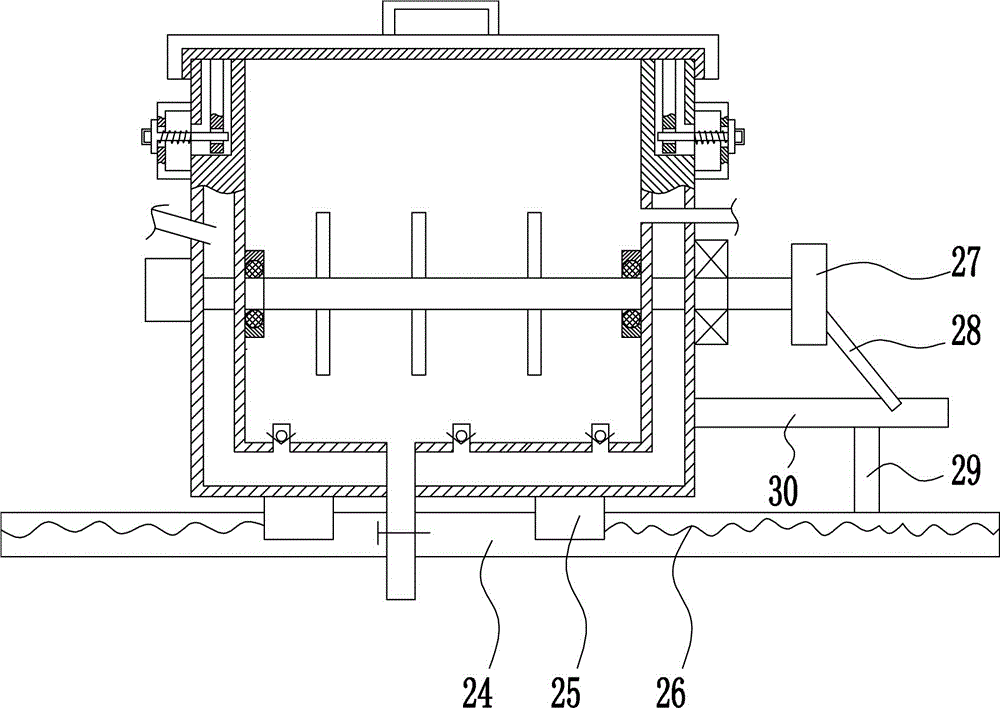

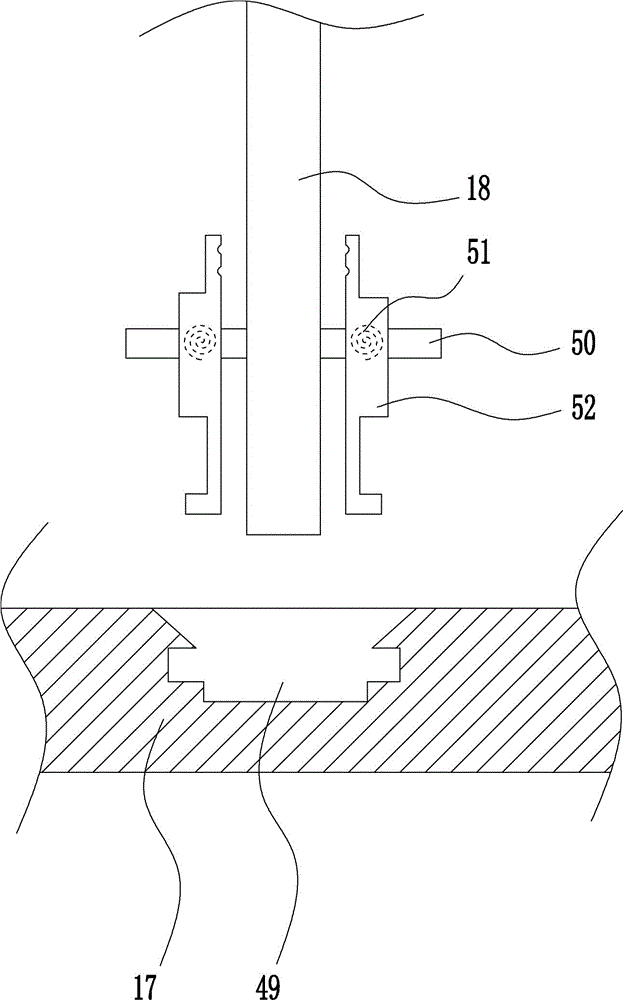

Sand mixing equipment

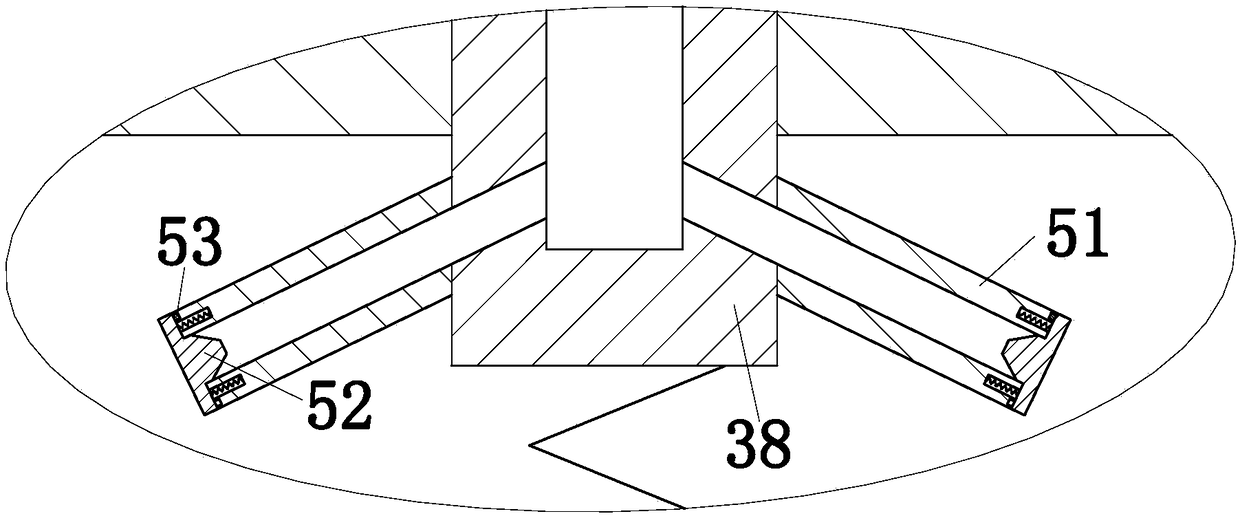

ActiveCN104815950AAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorEngineering

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

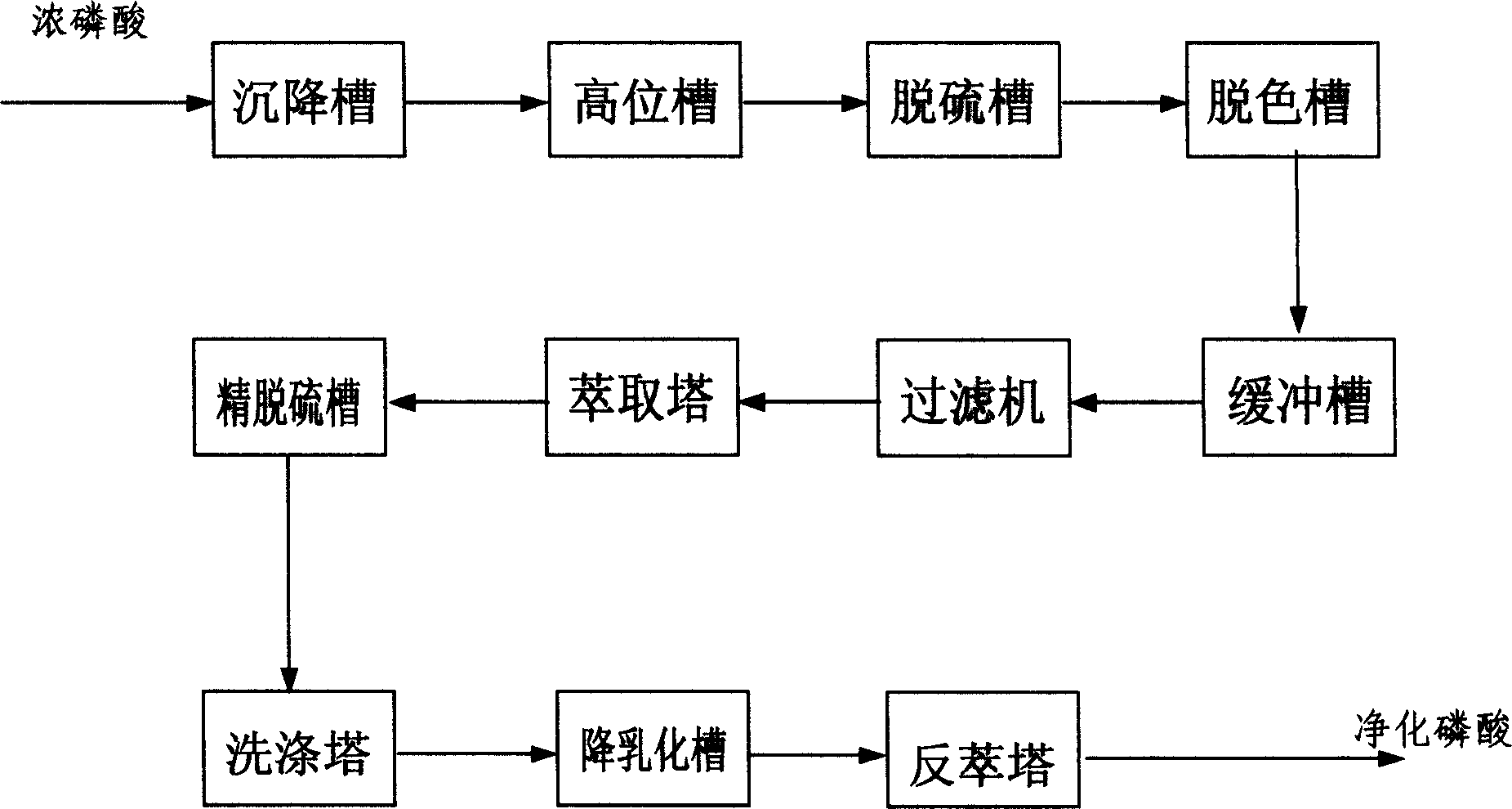

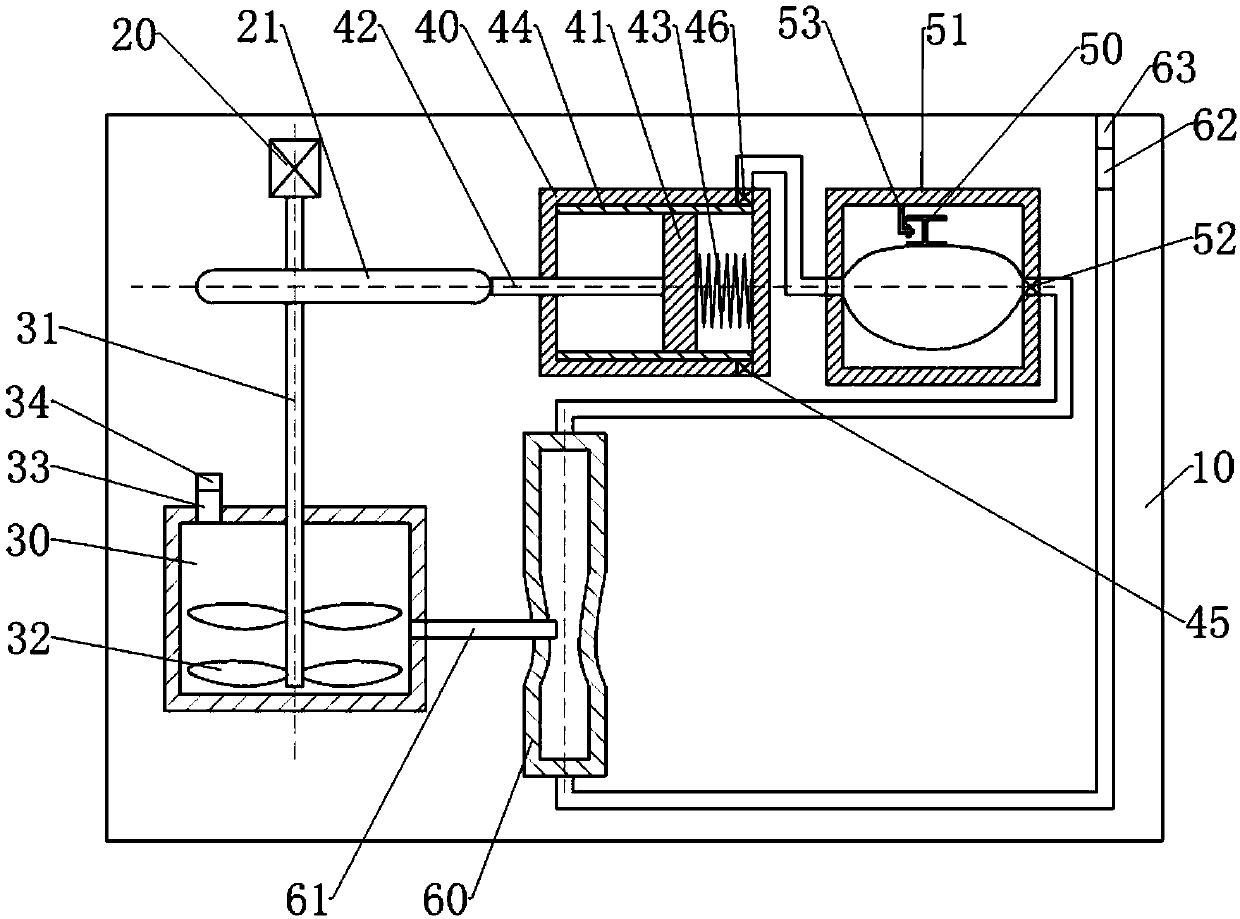

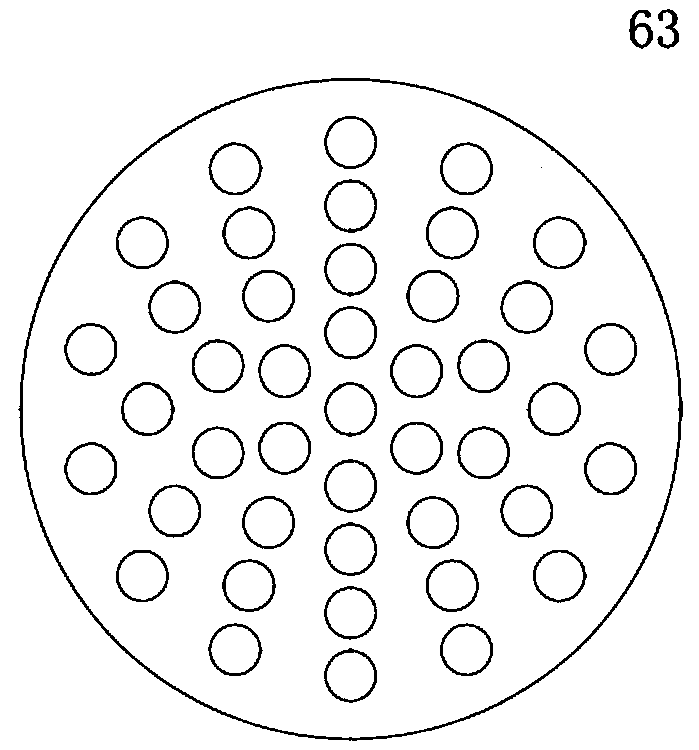

Purified wet-process technique for producing phosphoric acid and equipment thereof

InactiveCN1654317AAchieving stirringRealize reciprocating motionPhosphorus compoundsPhosphoric acidTower

The present invention relates to solvent extracting process as industrial wet process phosphoric acid purifying process. On the basis of technological process of preparing industrial phosphoric acid with wet process phosphoric acid, the present invention has the measures of: 1) setting desulfurizing and defluorinating buffer in the pre-treating section and setting one re-desulfurizing and deferrizing tank between the extracting tank and the washing tank for reinforced desulfurizing, defluorinating and deferrizing; 2) performing extraction, washing and reverse extraction in the rotary vibrating sieve-plate tower; and 3) setting one demulsifying tank between the washing tower and the reverse extracting tower. The present invention has one special rotary vibrating sieve-plate tower developed as the key apparatus. The present invention is used in the industrial production of purifying wet process phosphoric acid and has greatly reduced loss and low cost.

Owner:WENGFU (GRP) CO LTD

Production and processing device for liquid disinfectant

PendingCN108816086AAchieving stirringIncrease contact areaTransportation and packagingRotary stirring mixersDisinfectantEngineering

The invention discloses a production and processing device for a liquid disinfectant. The production and processing device comprises a casing, a stirring cavity, solution releasing cavities and drainports, wherein the stirring cavity is formed in the casing; the solution releasing cavities are formed in the upper parts of two side walls of the casing; a partition board is arranged at the bottom of the stirring cavity; the drain ports are symmetrically formed in two sides of the bottom surface of the partition board, arranged obliquely and communicated with the stirring cavity. The productionand processing device is characterized in that a servo motor is mounted between the drain ports, an output shaft of the servo motor penetrates the partition board and extends into the stirring cavity,a motor case is arranged in the middle of the upper surface of the casing, and a lifting motor is mounted in the motor case. Disinfectant raw materials and aromatic can be mixed sufficiently, the operation is simple, the mixing effect is good, pungent scent of the disinfectant can be removed effectively, and comfort is brought to a user.

Owner:安徽广志药业有限公司

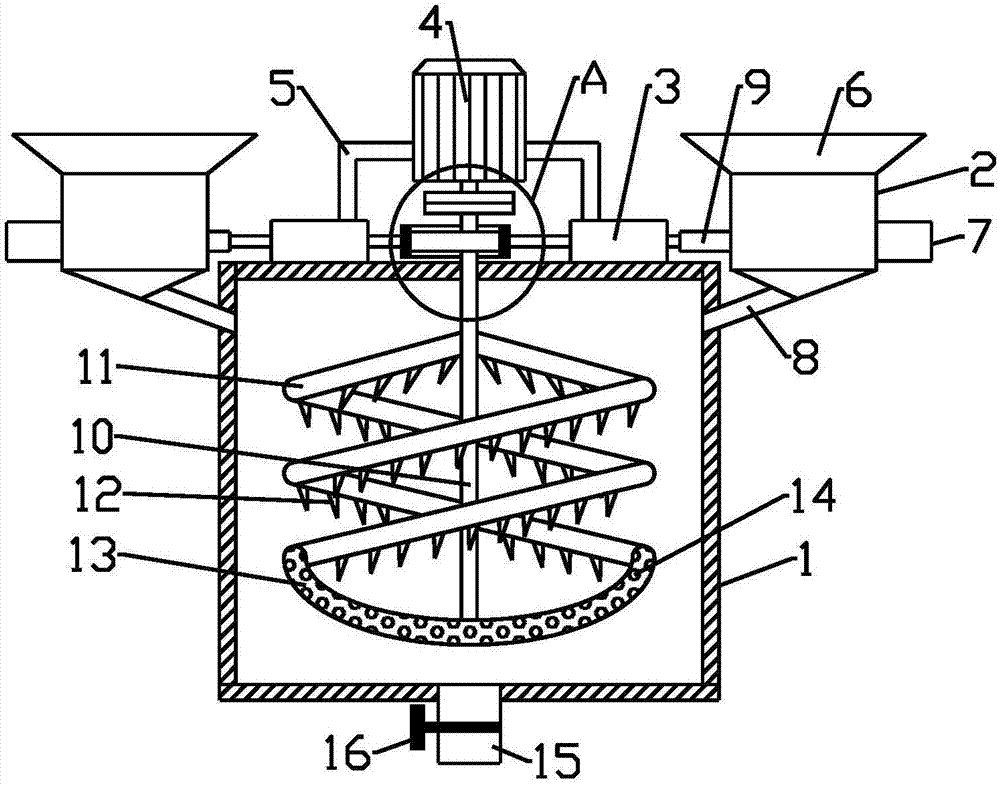

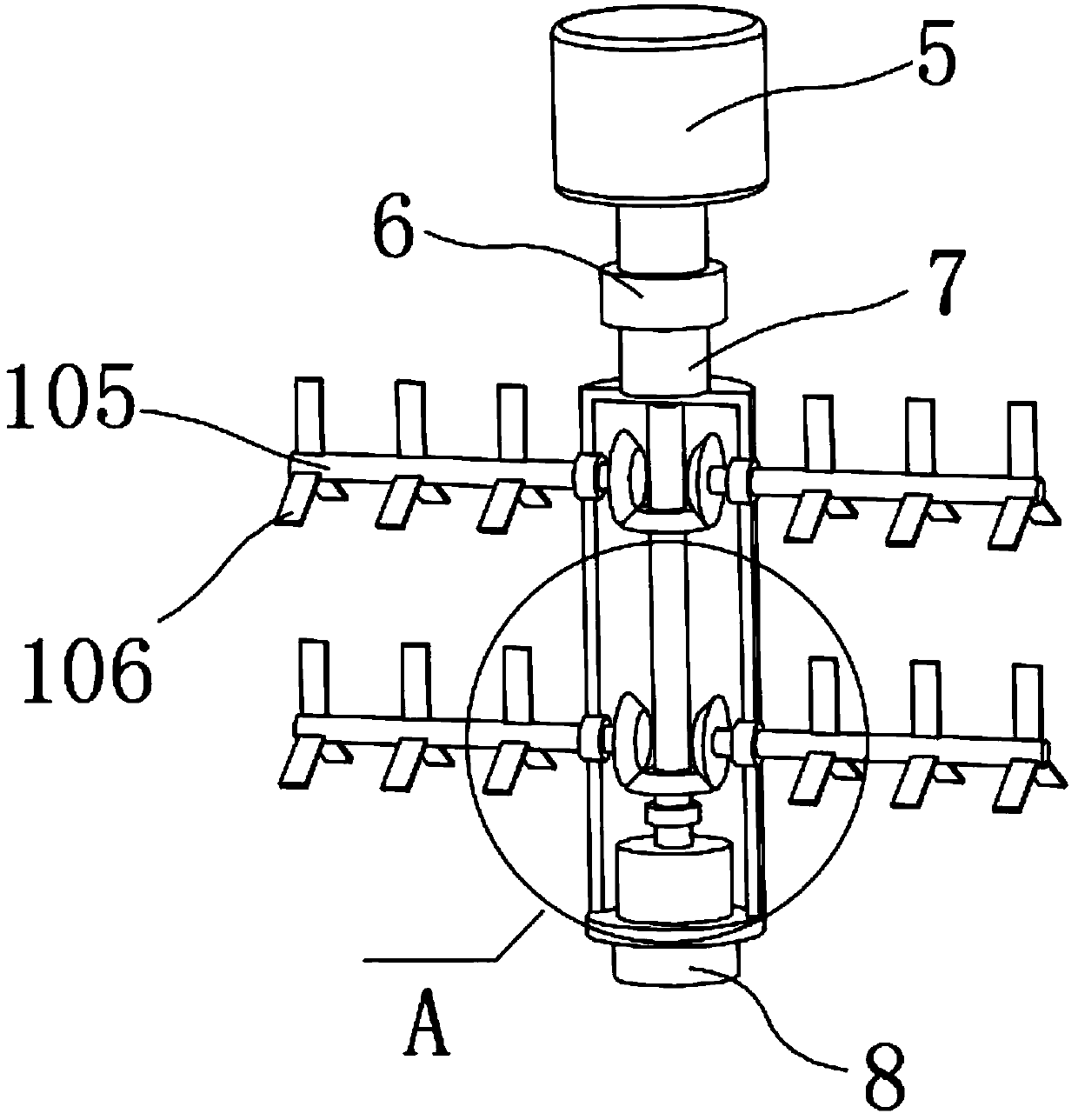

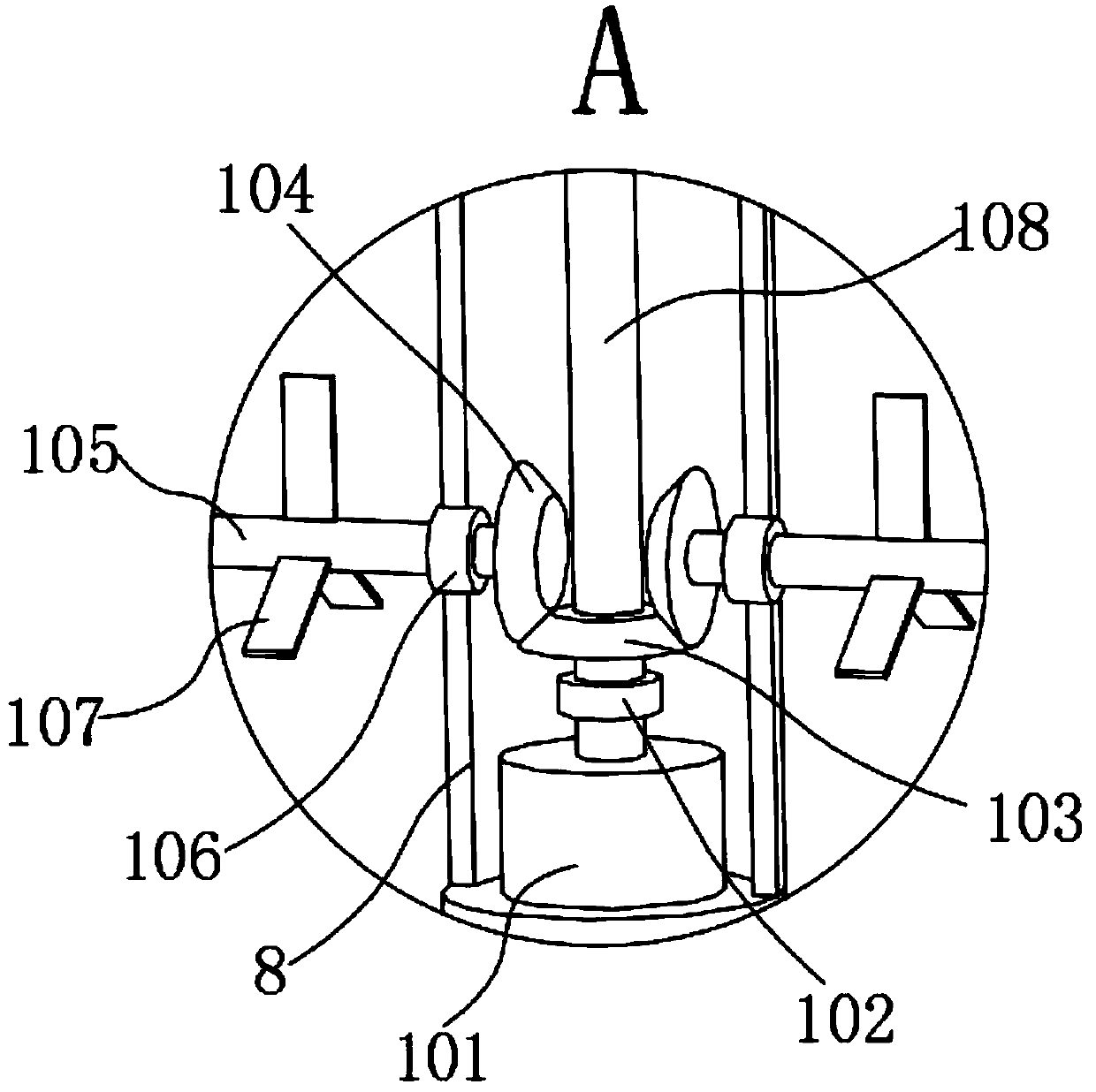

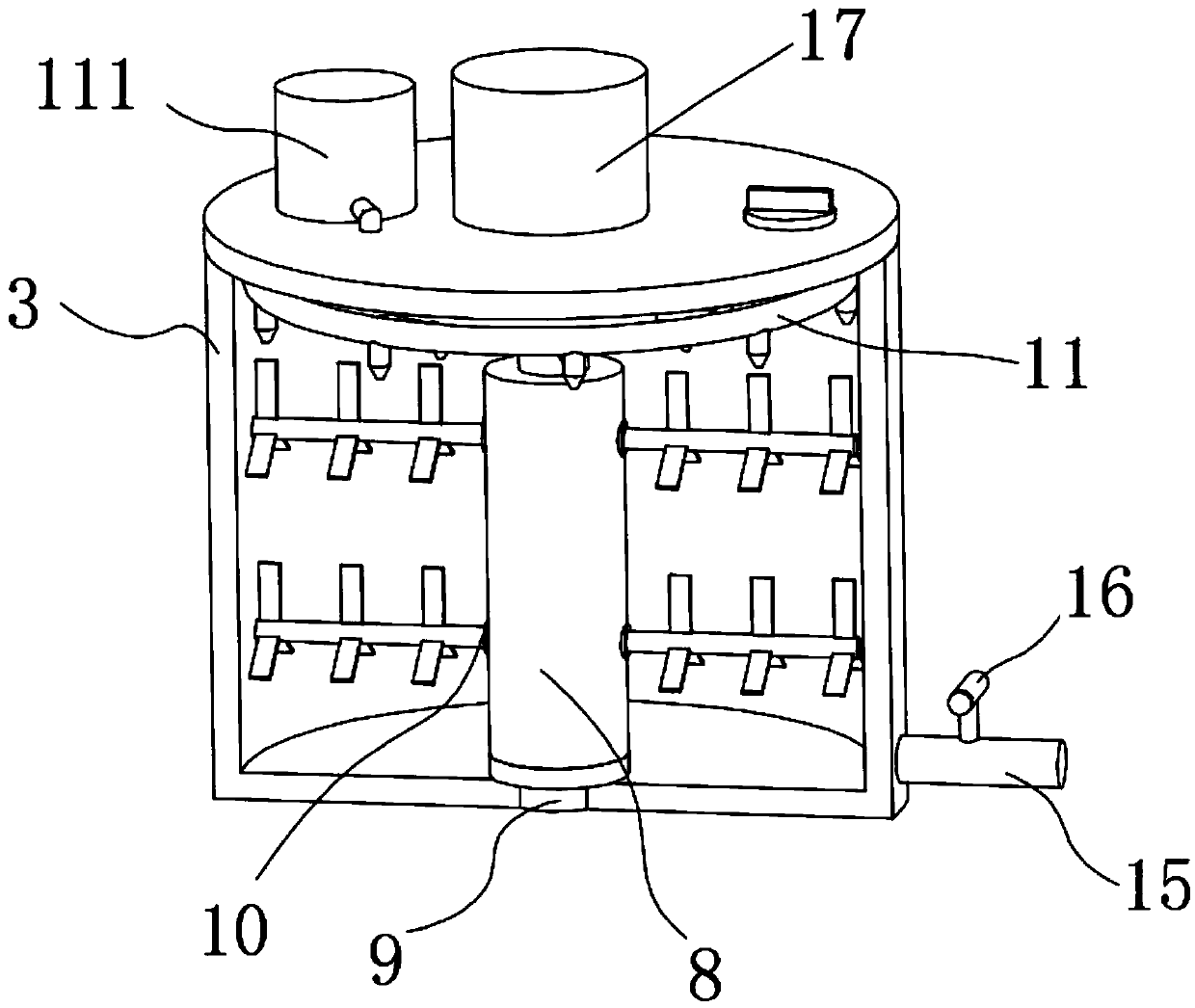

Disposed substance mixing plant

InactiveCN101579606ASave energyAchieving stirringRotary stirring mixersGrain treatmentsCross connectionEngineering

The invention discloses a disposed substance mixing plant used for a food garbage disposer, which comprises a disposal barrel and a mixer placed in the disposal barrel. The mixer comprises a mixing shaft with a transmission mechanism and mixing rods, and is characterized in that the mixing rods are crossly and radially fixed on the mixing shaft at intervals; the lower end of the mixing shaft is radially provided with a pushing shaft which is provided with a push pedal; the end of the pushing shaft is provided with a stirring bar which is crossly connected with the pushing shaft; the stirring bar is provided with a plow-shaped mixing blade; the push pedal is connected with the plow-shaped mixing blade which is provided with plow teeth at the upper end; the mixing rods are provided with spiral mixing strips and spiral sickle strips; the spiral mixing strips encircle the mixing shaft and are connected with the mixing rods; the spiral sickle strips are connected with the end of the adjacent mixing rods in a reverse way relative to the spiral mixing strip; a separating mixing rod is arranged above the mixing rod at the middle of the mixing shaft and is parallel to the mixing rod; the spiral sickle strips are connected intermittently; and smashing teeth are arranged on the side wall of the disposal barrel and positioned between the separating mixing rod and the mixing rod. The disposed substance mixing plant has the advantages of novel structure, high mixing efficiency, even mixing, reduced energy consumption and the like.

Owner:山东名流实业集团有限公司

Robot with sterilizing device

ActiveCN109646964AAvoid bacterial infectionProtect your healthSelf-moving toy figuresChemicalsPiston cylinderEngineering

The invention relates to the technical field of educational toys, and particularly discloses a robot with a sterilizing device. The robot with the sterilizing device comprises a robot cavity and a motor, wherein a sterilizing device is arranged in the robot cavity and comprises a disinfectant storage chamber; a motor is rotatably connected with a stirring column; the stirring column is provided with stirring blades and a cam; a piston cylinder is arranged on the right side of the cam; a piston and a piston rod is arranged in the piston cylinder; the other end of the piston rod is attached to the outline of the cam; the piston cylinder is further provided with a one-way air inlet valve and a one-way air outlet valve; the one-way air outlet valve is connected with an air bag; a box body is arranged on the outside of the air bag; an automatic valve is arranged at an outlet of the air bag; a control mechanism for the automatic valve is arranged on the inner wall of the box body; the automatic valve is connected with a venturi tube; a throat portion of the venturi tube communicates with the disinfectant storage chamber through a suction tube; and an outlet of the venturi tube is connected with a sprayer through a pipe. The invention aims to solve the problem that bacteria on the surface of the robot can infect a user.

Owner:绍兴津源午马机械股份有限公司

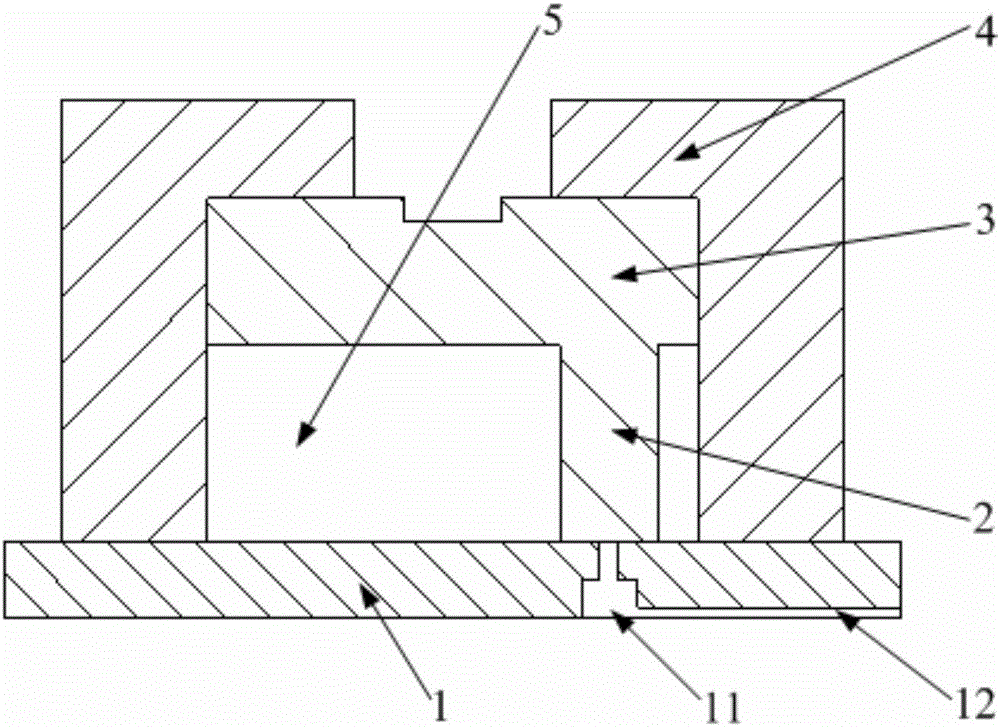

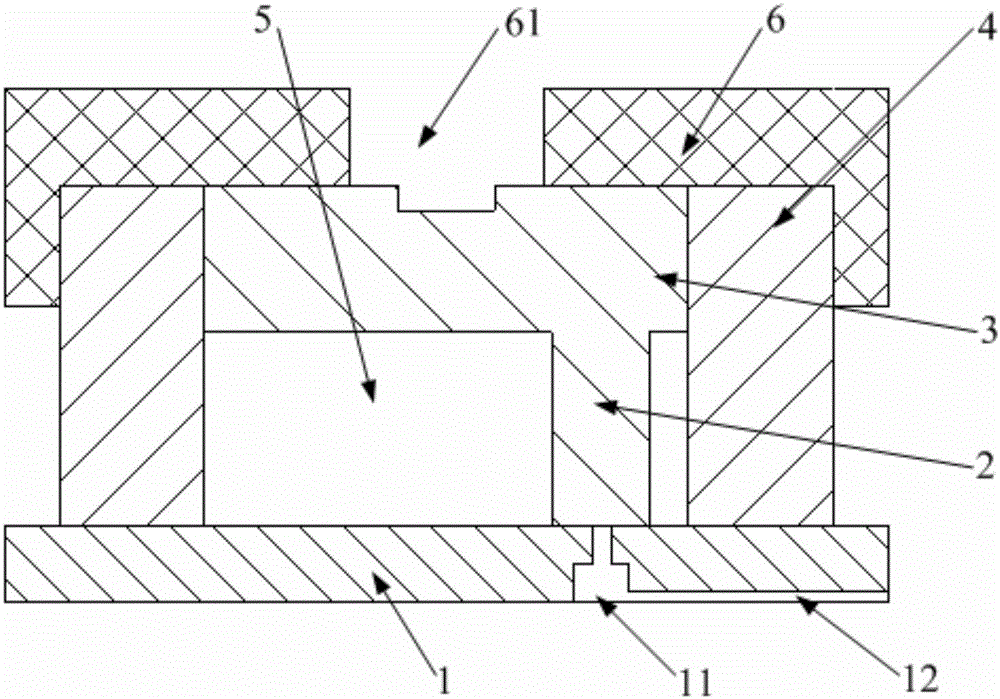

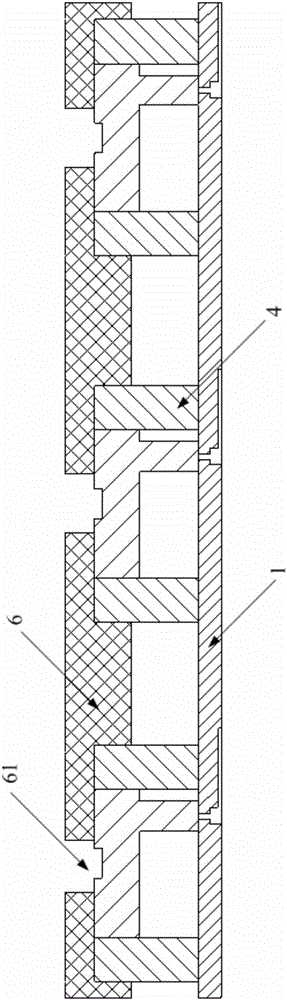

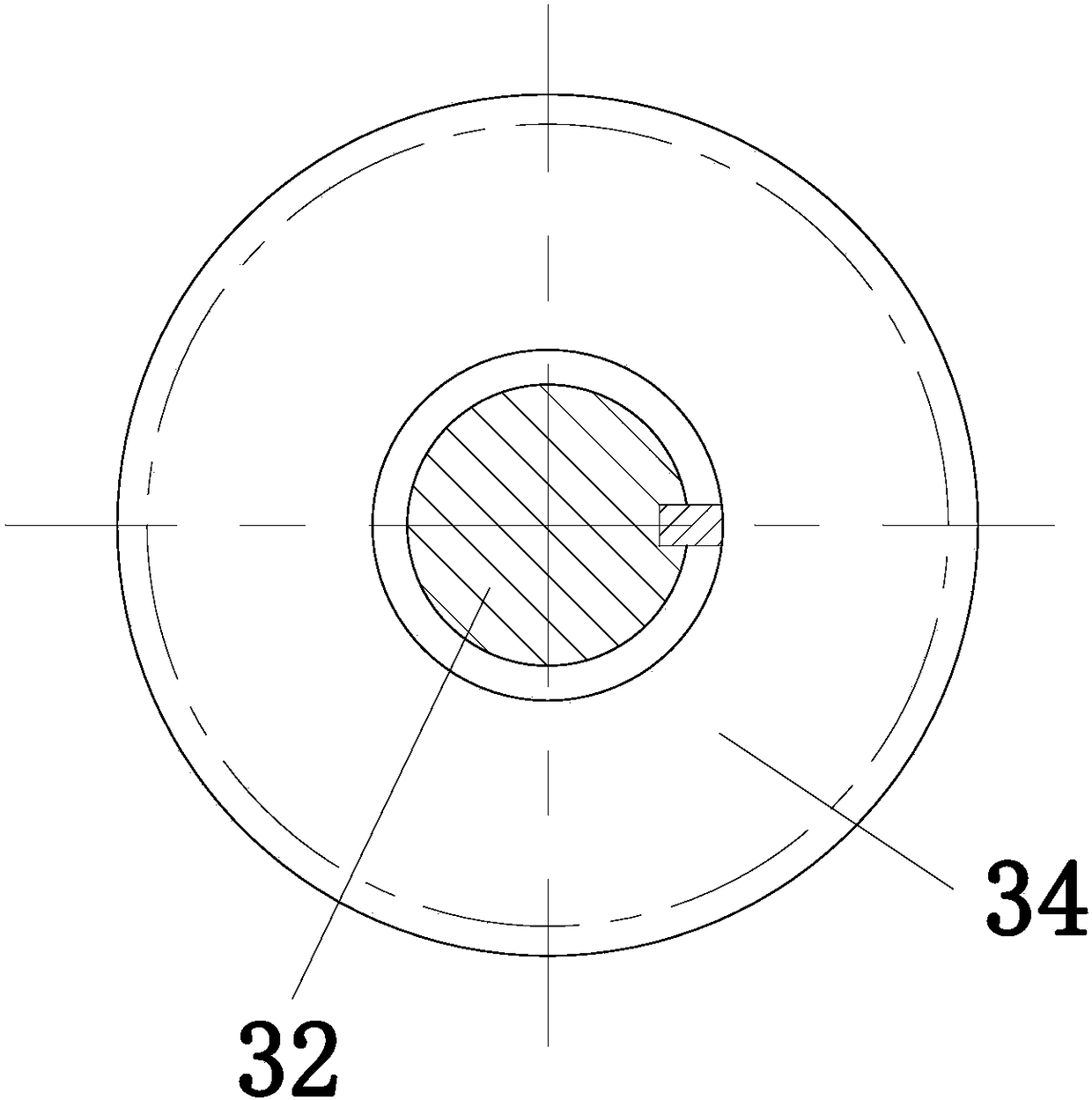

Microfluidic valve and microfluidic chip

ActiveCN105135051ARealize on-offAchieving stirringValve arrangementsFlow mixersMicro columnEngineering

The invention provides a microfluidic valve and a microfluidic chip. The microfluidic valve comprises a base, a sleeve, a rotor and micro-columns, wherein the base is provided with micropores; the sleeve is arranged on the base; the rotor is rotatablely sheathed on one end of the sleeve away from the base; the rotor, sleeve and base are matched to form a stirring cavity; the micropores can be communicated with the stirring cavity; and the micro-columns are arranged on the rotor and positioned in the stirring cavity, and can seal the micropores. The microfluidic valve provided by the invention can implement the on-off state of the micropores on the base through the rotation of the rotor, and can also implement stirring and mixing on the liquid in the stirring cavity; and therefore, the microfluidic valve has the functions of flow path on-off and fluid stirring, thereby reducing the number of components installed on the microfluidic chip and further being convenient for assembly.

Owner:CAPITALBIO CORP

Solvent-free glue liquid feeding device for packaging bag compounding

InactiveCN110860239AStir wellAchieving stirringTransportation and packagingRotary stirring mixersBLENDER/MIXERDrive shaft

Belonging to the technical field of liquid material mixing devices, the invention discloses a solvent-free glue liquid feeding device for packaging bag compounding. The device comprises a stirring barrel, a stirring mechanism driven by a motor is arranged in the stirring barrel, a discharge pipe is communicated with the stirring barrel, and a liquid outlet spray head is arranged at a discharge endof the discharge pipe, the stirring mechanism comprises a bracket arranged above the stirring barrel, a rotating shaft driven by the motor is rotatably connected on the bracket, a central gear is fixed on the rotating shaft, a rotating frame is also fixed on the rotating shaft, a plurality of driven shafts are rotatably connected to the rotating frame and are uniformly distributed at the periphery of the rotating shaft, and driven gears engaged with the central gear are fixed on the driven shafts; an inner gear ring engaged with the driven gears are fixed to an inner ring at the upper part ofthe stirring barrel; and the lower parts of the rotating shaft and the driven shafts all extend into the stirring barrel, and stirring blades are arranged on the rotating shaft and the driven shaftsin the stirring barrel. The device provided by the invention solves the problem that existing apparatuses cannot realize uniform mixing of pure glue liquid.

Owner:重庆富美包装印务有限公司

Mixing equipment for processing and producing health-care food

ActiveCN111001340AWell mixedReduce energy consumptionTransportation and packagingMixer accessoriesRotational axisElectric machinery

The invention discloses mixing equipment for health food processing and production, and belongs to the technical field of mixing equipment. The mixing equipment comprises a mixing tank; a protective cover is arranged at the top end of the mixing tank. A pneumatic stirring assembly for realizing gas stirring of raw materials and a pneumatic vibration assembly for realizing vibration of a gas-drivenmixing tank are mounted in the protective cover. The mixing equipment is scientific and reasonable, is safe and convenient to use, and is provided with pneumatic stirring assemblies. A driving motoris used to drive a rotating shaft to rotate. A stirring and extruding airbag is extruded by utilizing a rotary extruding convex block. Gas extruded by the stirring and extruding airbag is sprayed intoraw materials in the mixing tank by utilizing the pneumatic nozzle; the raw materials are stirred, mechanical stirring and pneumatic stirring are conducted on the raw materials at the same time through one driving motor, the health food raw materials are mixed more evenly, meanwhile, energy consumption is reduced, and the production cost is reduced.

Owner:广州赛太特生物医学科技有限公司

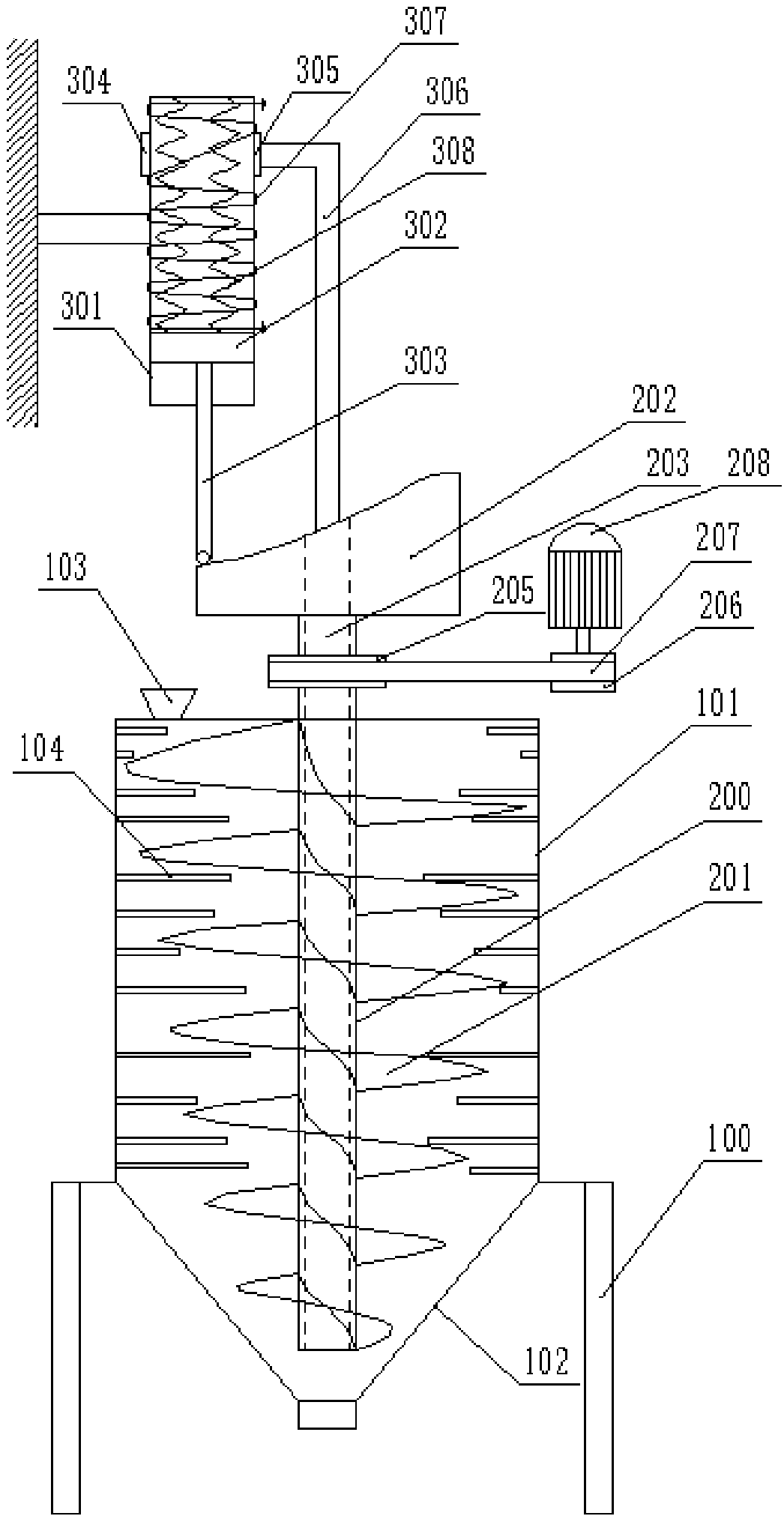

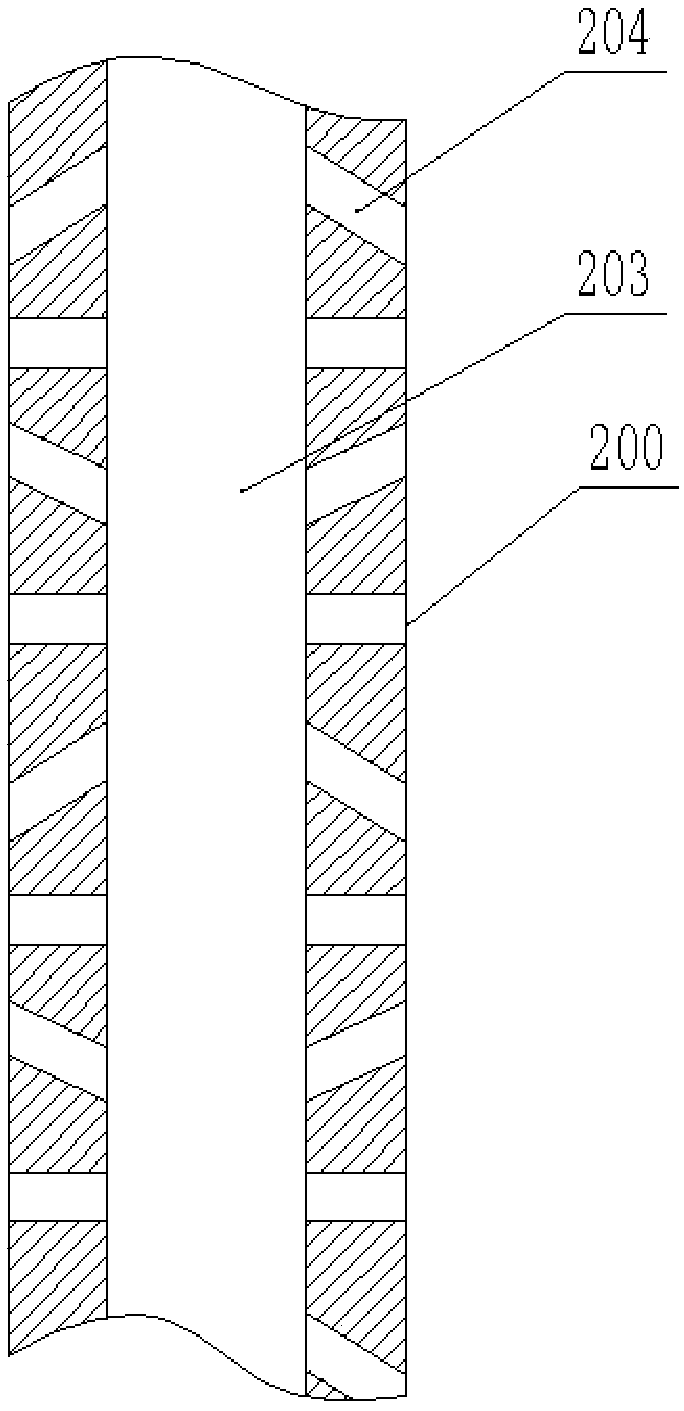

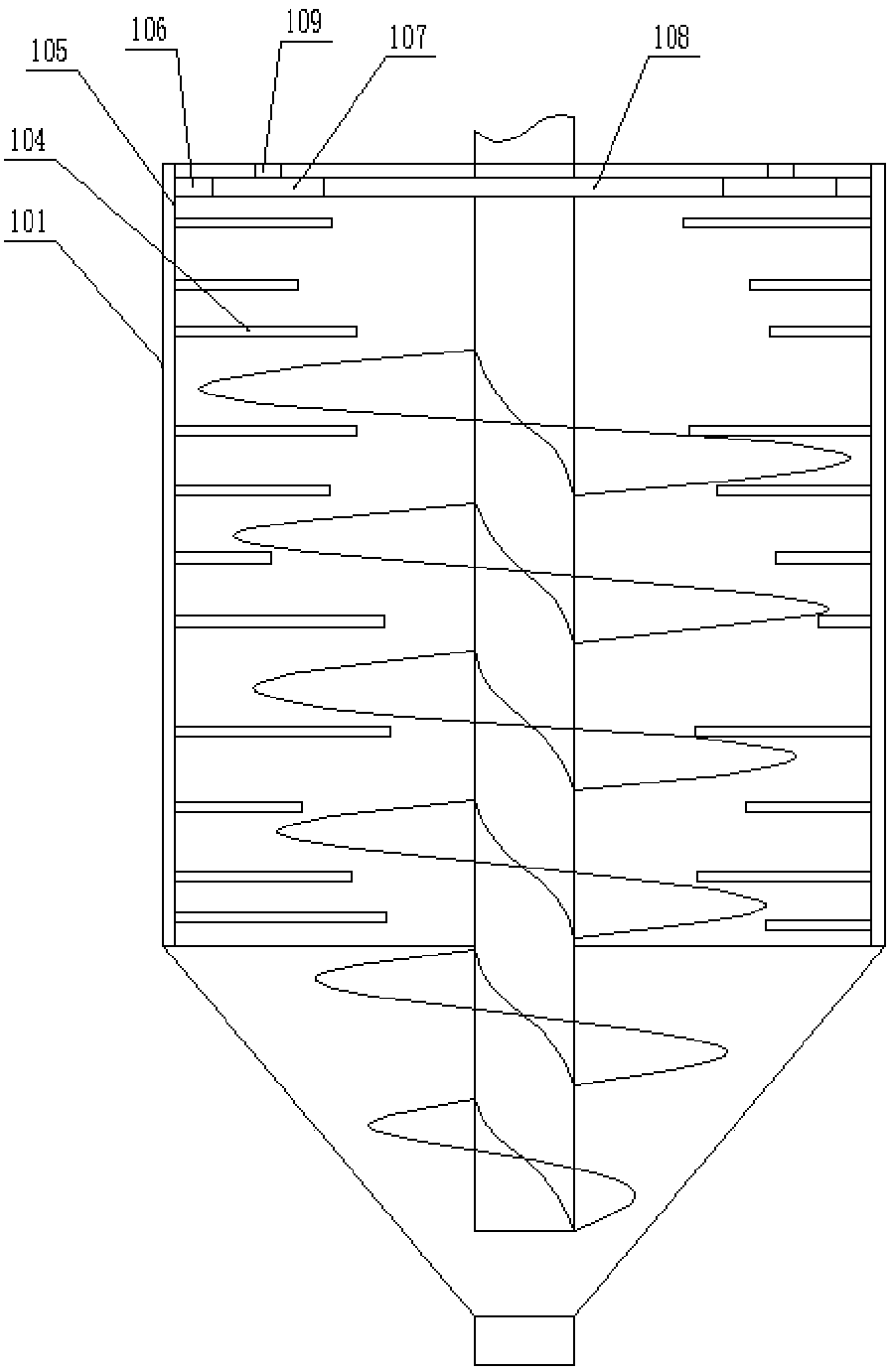

Self-stirring type biogas digester based on electro-magnetic induction

InactiveCN110468034AStir wellNo manual operationBioreactor/fermenter combinationsBiological substance pretreatmentsCopperAtmospheric pressure

The invention discloses a self-stirring type biogas digester based on electro-magnetic induction. The self-stirring type biogas digester based on the electro-magnetic induction comprises a digester body and a head cover, the head cover is located at the upper end of the digester body, a feeding pipe is arranged on the side wall, close to the upper end, of the digester body in a communicating mode,a discharging pipe is arranged on the side wall, close to the lower end, of the digester body, a stirring mechanism is arranged in the digester body, an exhaust pipe is arranged on the side wall, close to the upper end, of the head cover, an installation barrel is arranged on the upper wall of the head cover, the head cover communicates with the installation barrel through two air holes, a drivemechanism capable of driving the stirring mechanism is arranged in the installation barrel, the drive mechanism comprises a sliding plug, the sliding plug is slidably connected to the inner wall of the installation barrel in a sleeving mode, a copper bar is fixedly inserted and connected to the side wall of the sliding plug, and the copper bar is in a U shape. According to the self-stirring type biogas digester based on the electro-magnetic induction, time of people is shortened, vigor of the people is saved, and the stirring cost is reduced; and the self-stirring type biogas digester based onthe electro-magnetic induction stirs biogas slurry only when air pressure is lower according to the air pressure of the interior of the biogas digester, and danger cannot occur due to excessive air pressure in the biogas digester.

Owner:李朝瑞

Coating processing device

InactiveCN108079842AAchieving stirringStir wellRotary stirring mixersTransportation and packagingAgricultural engineeringMaterials processing

The invention belongs to the technical field of decorative material processing, and discloses a coating processing device. Screw thread pairs are formed between stirring shafts and a rack; a rotatingshaft is arranged between the two stirring shaft on the rack, and stirring blades are also arranged at the lower part of the rotating shaft; the coating processing device also comprises a first gear,a second gear and a third gear which are meshed with one another; a guide chute is arranged at the bottom of the rotating shaft and is internally provided with a piston, and the bottom of the piston is connected with a pull rod; feeding holes and discharge holes are respectively formed in the lower part and the upper part of the rotating shaft; the coating processing device also comprises a traveling mechanism, and the traveling mechanism comprises a first rack, a second rack, and a rotating gear which is separately meshed with the first rack and the second rack; the top of the second rack isprovided with a connecting rod, and one end of the connecting rod is hinged with the stirring shaft; the bottom of the first rack is connected with a support rod hinged on the rack. The coating processing device solves the problem that in the prior art, a material can not be enabled to move along the vertical direction, so that the material can not be evenly mixed, and a prepared coating is poor in quality.

Owner:重庆市长寿区分素装饰工程有限责任公司

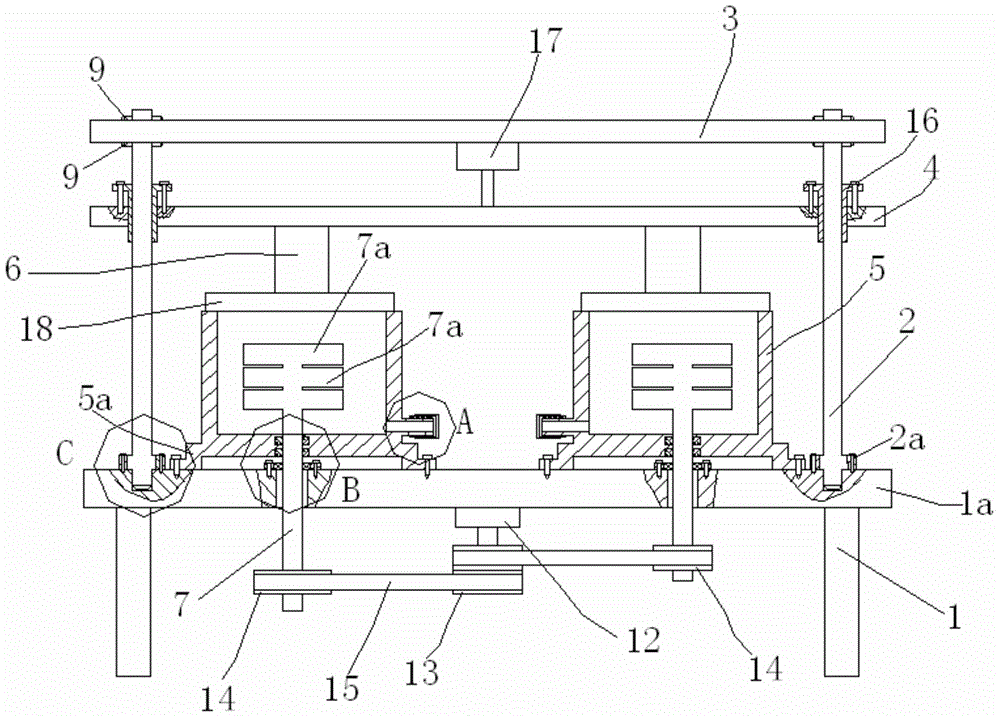

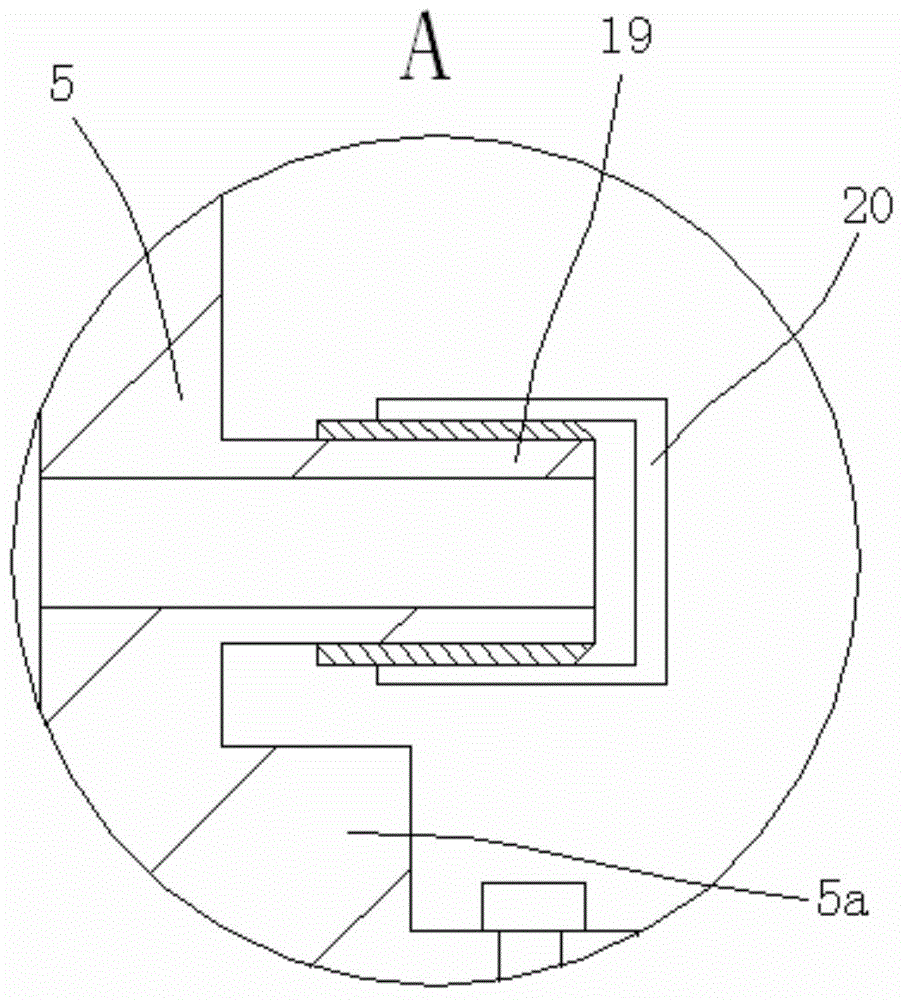

Agitator

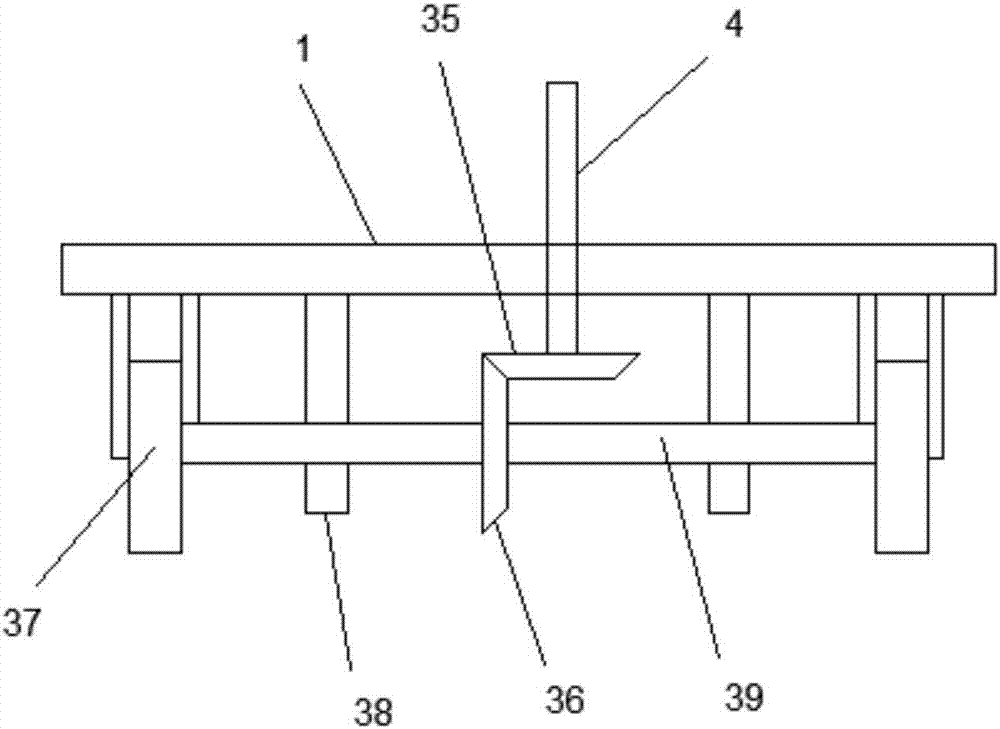

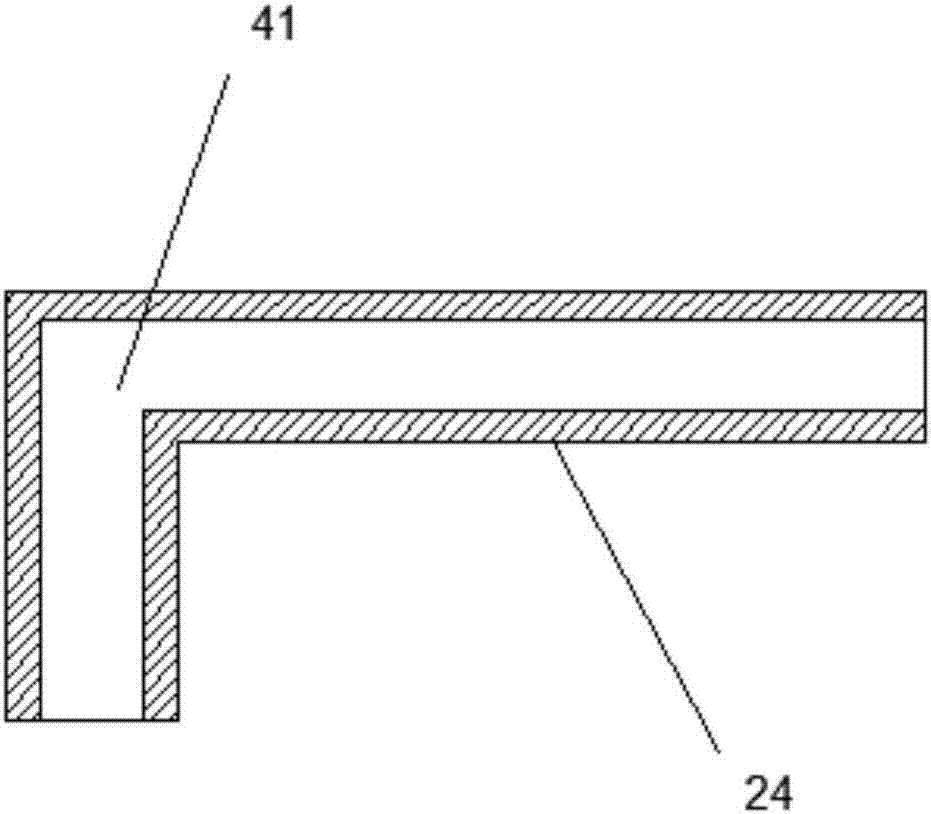

InactiveCN104437179AWell mixedReduce the chance of leaksRotary stirring mixersMixer accessoriesMotor drivePulp and paper industry

The invention discloses an agitator having high efficiency and a good stirring effect. The agitator comprises a rack provided with a working platform, wherein two guide columns are arranged on the working platform, fixing plates are arranged on the two guide columns, a guide plate is arranged between the fixing plates and the working platform, the guide plate is connected to the two guide columns in a sliding manner, a cylinder is connected to the inner side of each fixing plate, the end part of a piston rod of the cylinder is connected with the middle of the guide plate, two stirring boxes are further fixed on the working platform, a lower rotating shaft is arranged in each stirring box, the outer end of the lower rotating shaft stretches out from the stirring box and is fixedly connected with the working platform in the axial direction, a convex stirring paddle is arranged on the outer side wall at the inner end of the lower rotating shaft, a sealing plate is propped on the upper end face of each stirring box, the sealing plate is fixedly connected with the guide plate through a connecting shaft, a motor is arranged in the rack, the motor drives the two lower rotating shafts to simultaneously rotate through a transmission mechanism, and the stirring device has the advantages of high working efficiency and good stirring effect.

Owner:佛山市迅力机械有限公司

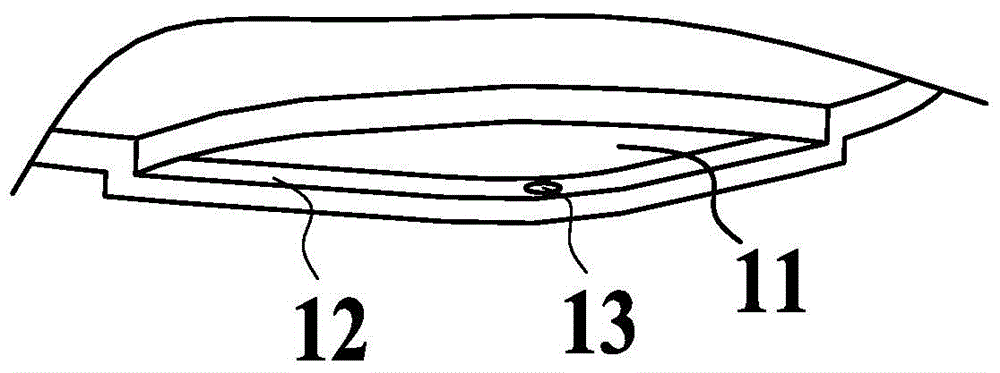

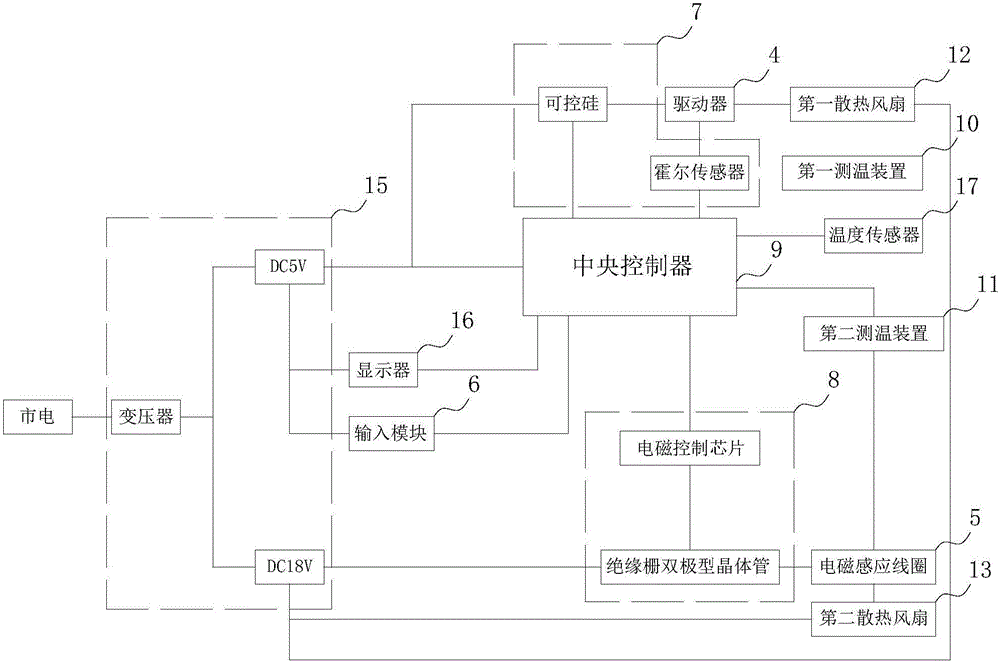

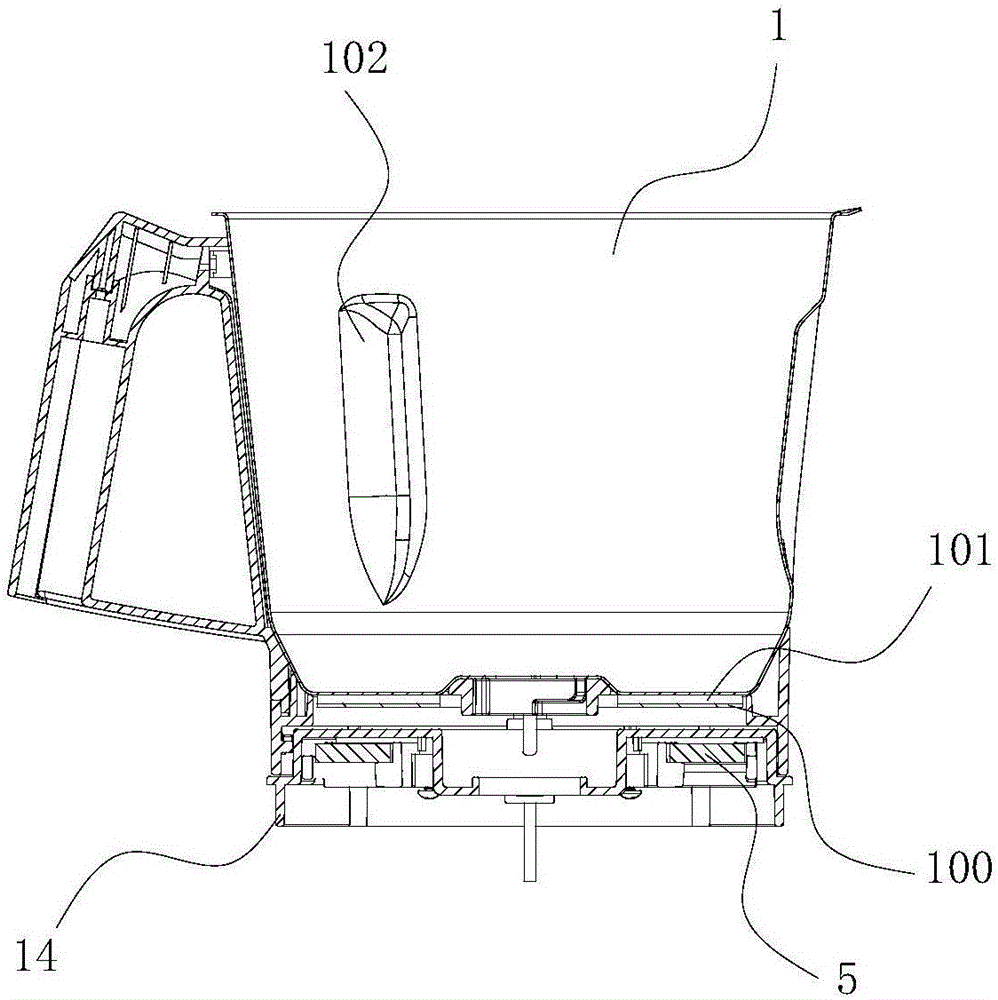

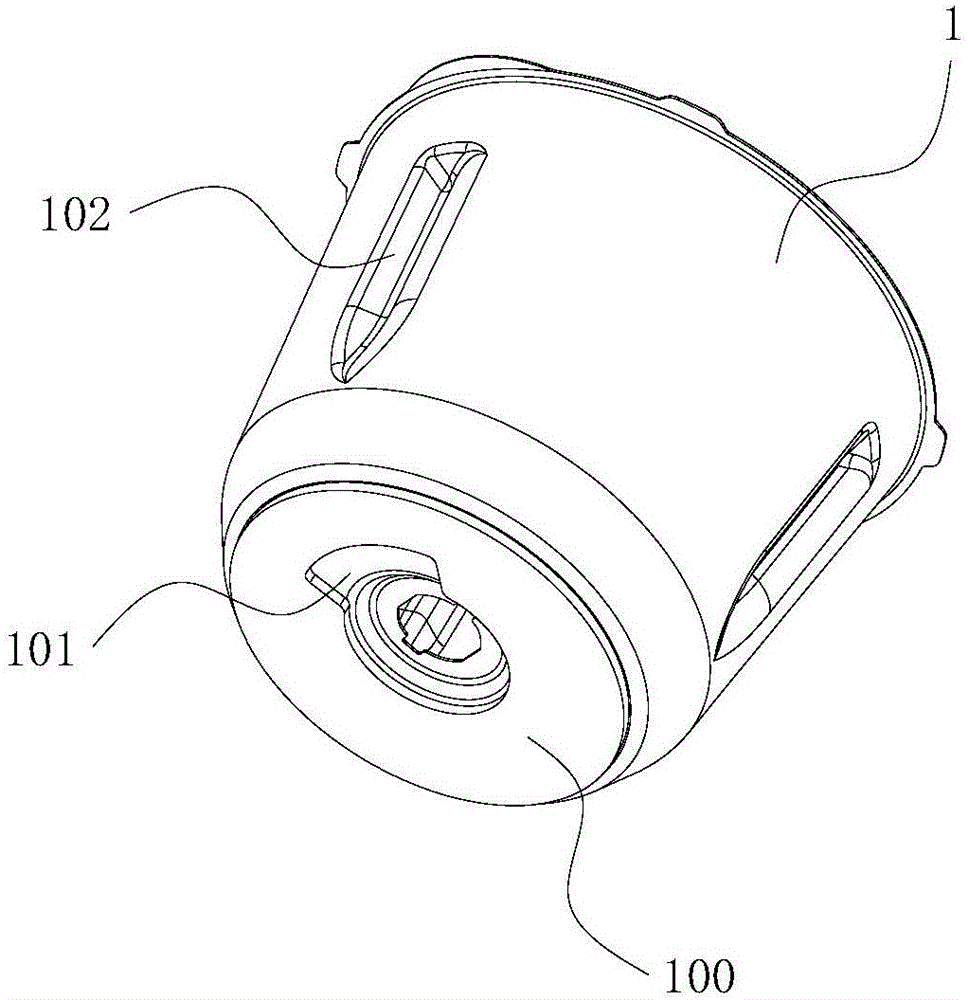

Food processor

InactiveCN105725732AReduces the possibility of burnt bottomsAchieving stirringWarming devicesCooking vessel constructionsElectromagnetic inductionEngineering

The invention discloses a food cooking machine, which is composed of a pot body, a knife seat, a driver, an electromagnetic induction coil, an input module, a driver control module, an electromagnetic control module, a central controller and other components. In the above-mentioned food cooking machine, after the user adds ingredients to the cooking cavity, the input module is controlled and operated according to the cooking requirements, and the central controller receives and processes the operation signal from the input module, and then sends the control signal to the driver control module and the electromagnetic control module. The running state of the driver and the electromagnetic induction coil are controlled simultaneously, the driver realizes the stirring of the stirring tool, and the electromagnetic induction coil realizes the heating of the pot body, and the food is stirred while heating, which can reduce the possibility of burning the bottom of the food paste. Moreover, different cooking methods can be realized under the cooperation of different degrees of stirring and heating, so as to meet people's different cooking needs.

Owner:GUANGZHOU FULIDA ELECTRICAL APPLIANCE

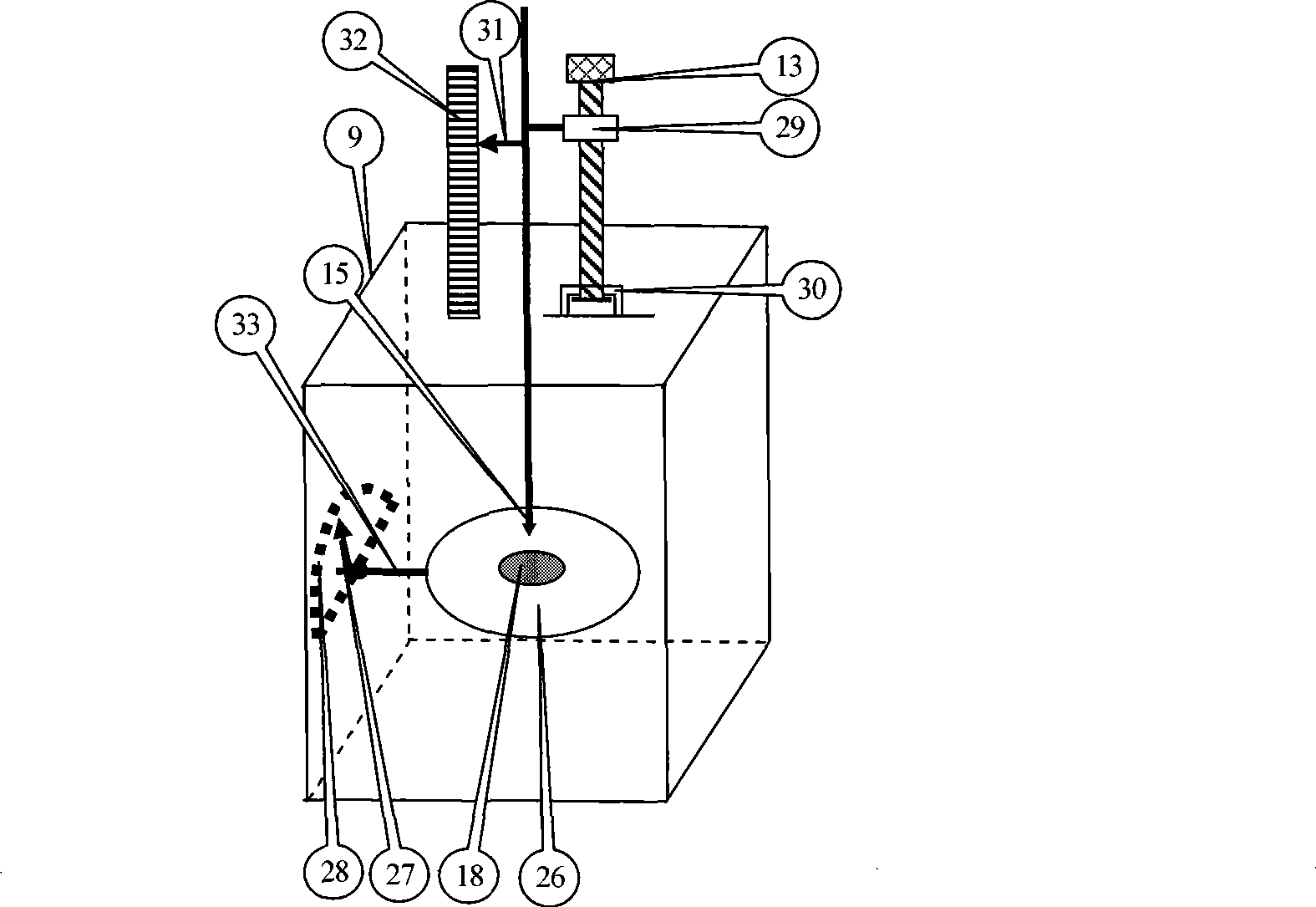

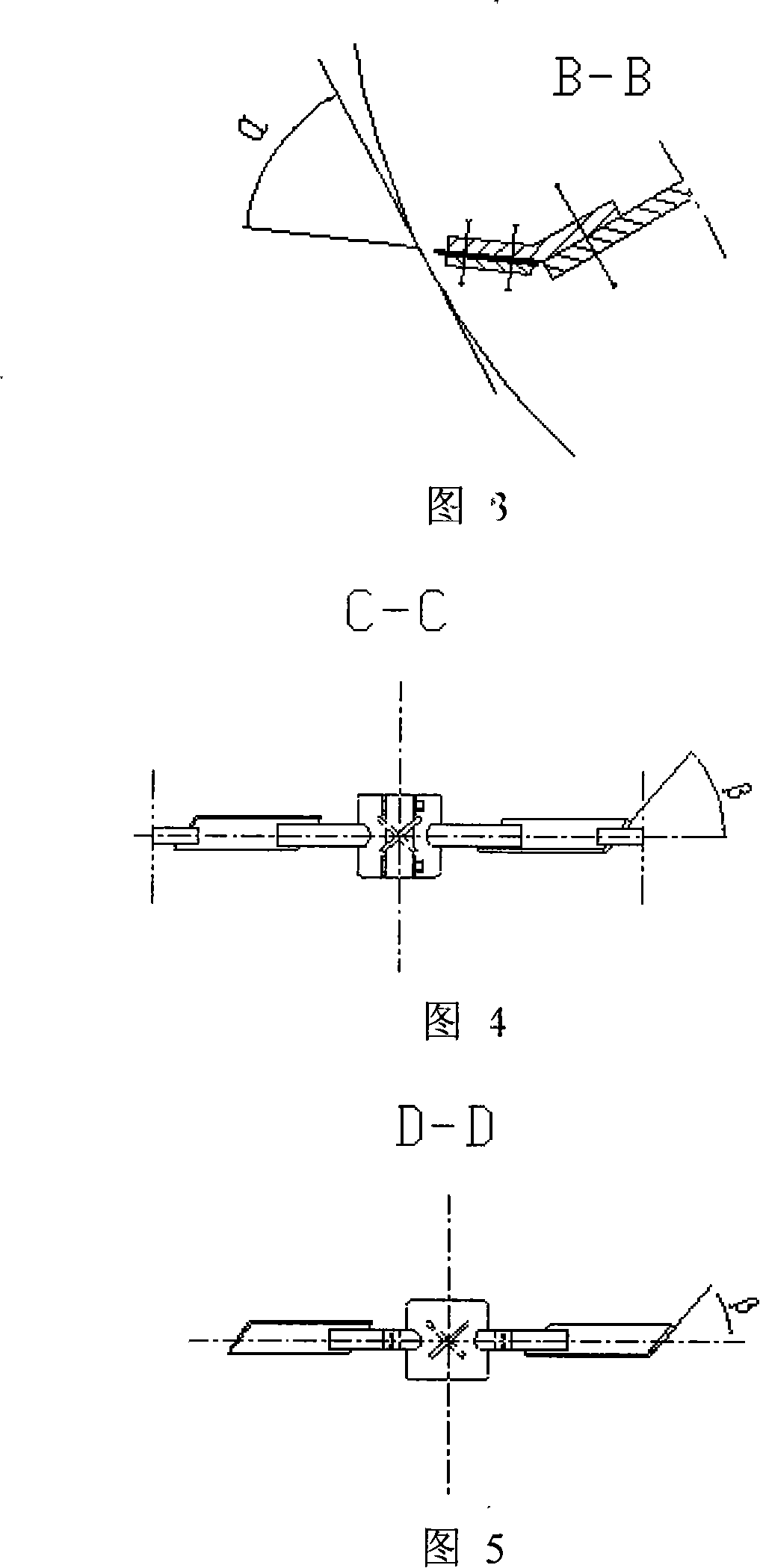

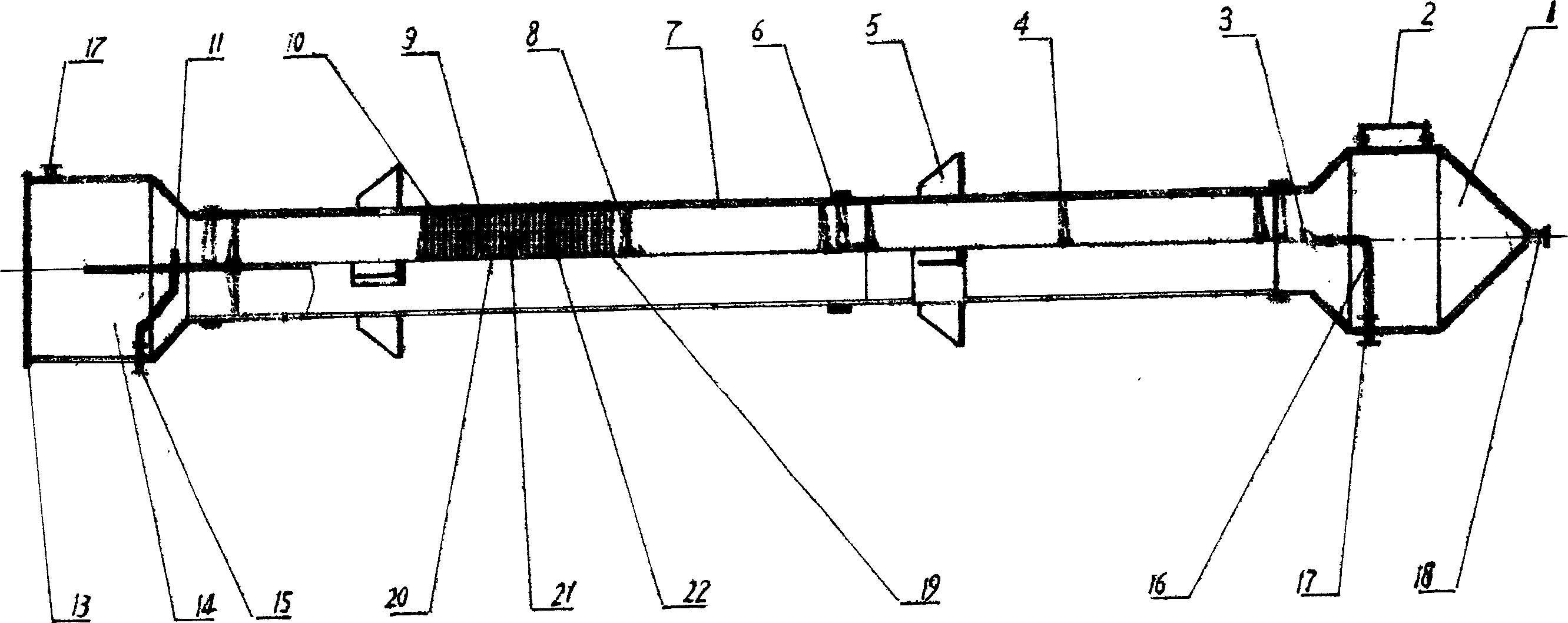

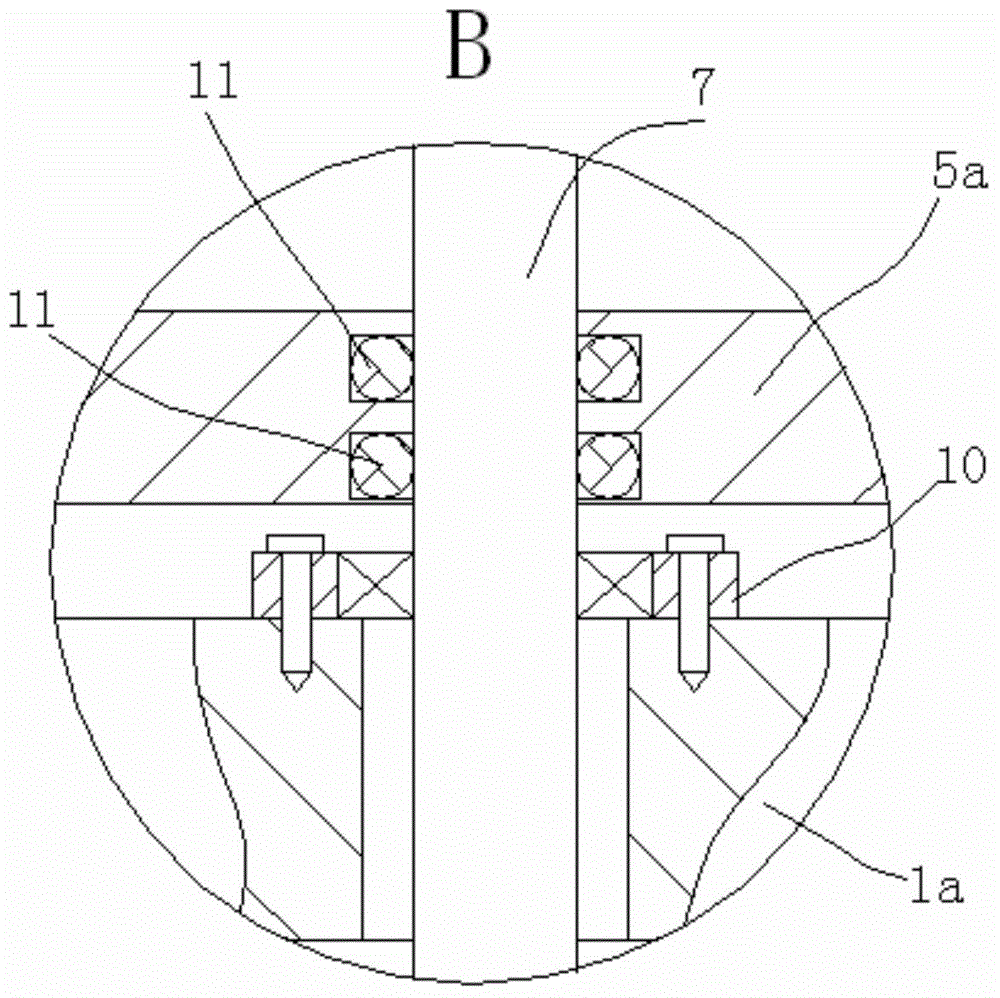

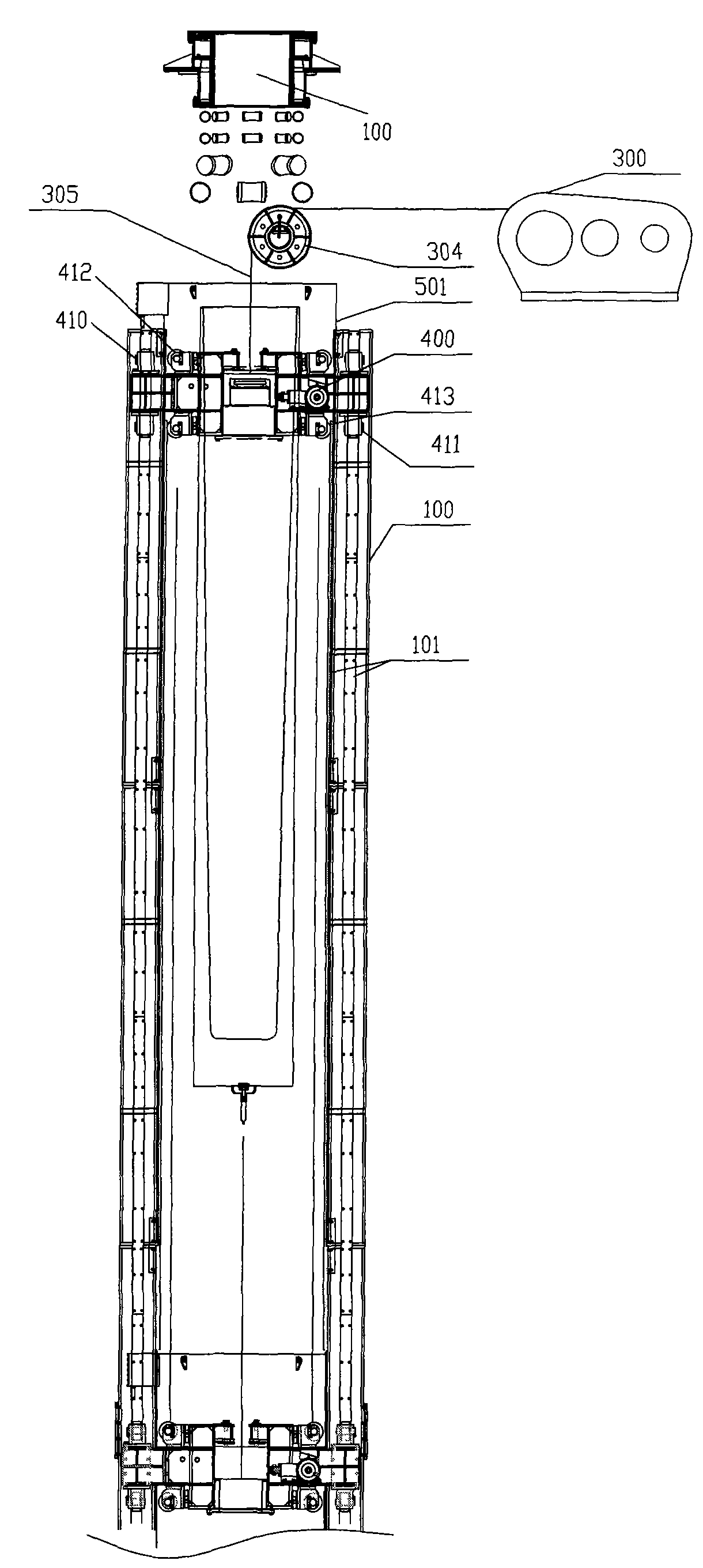

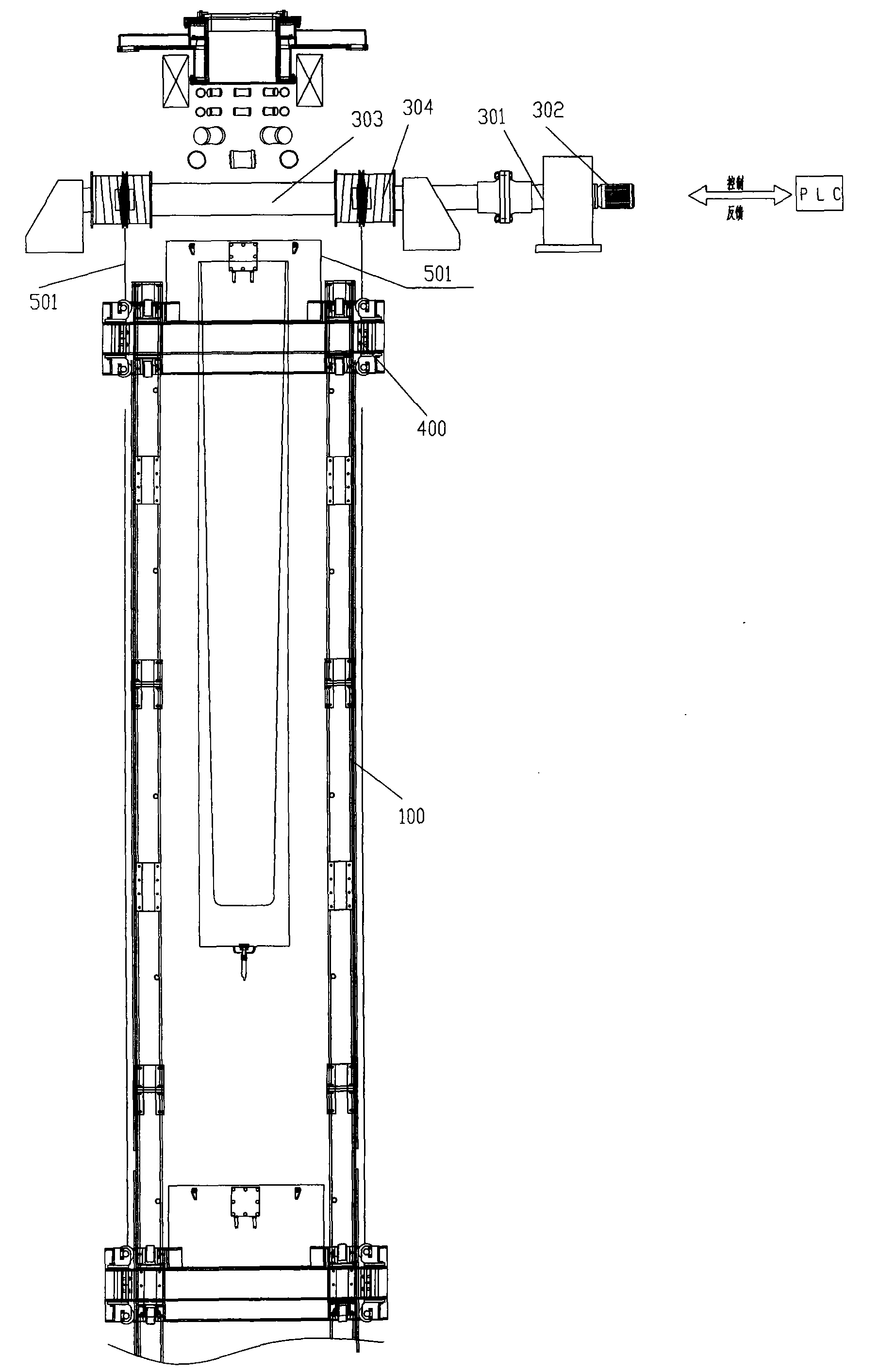

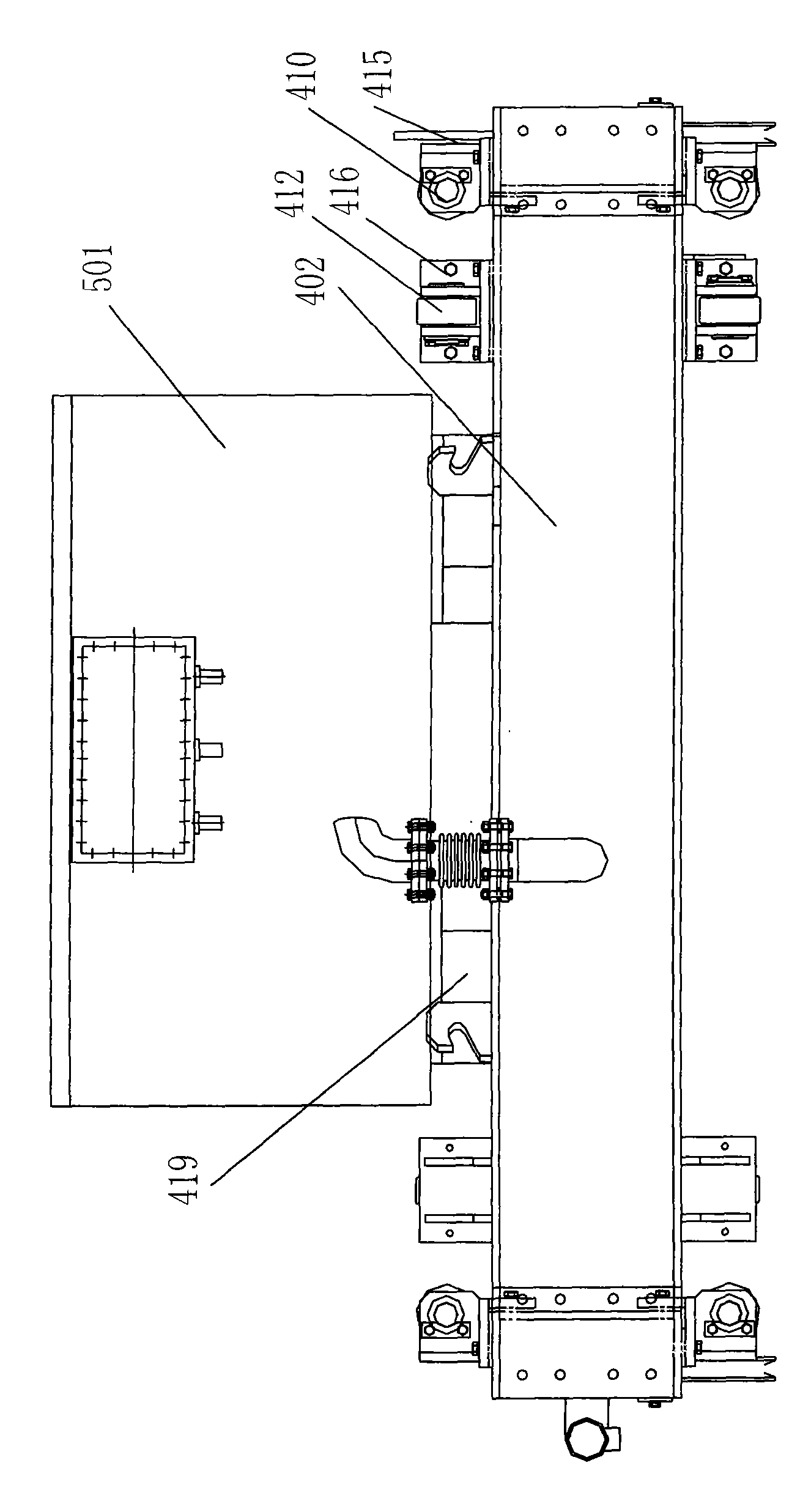

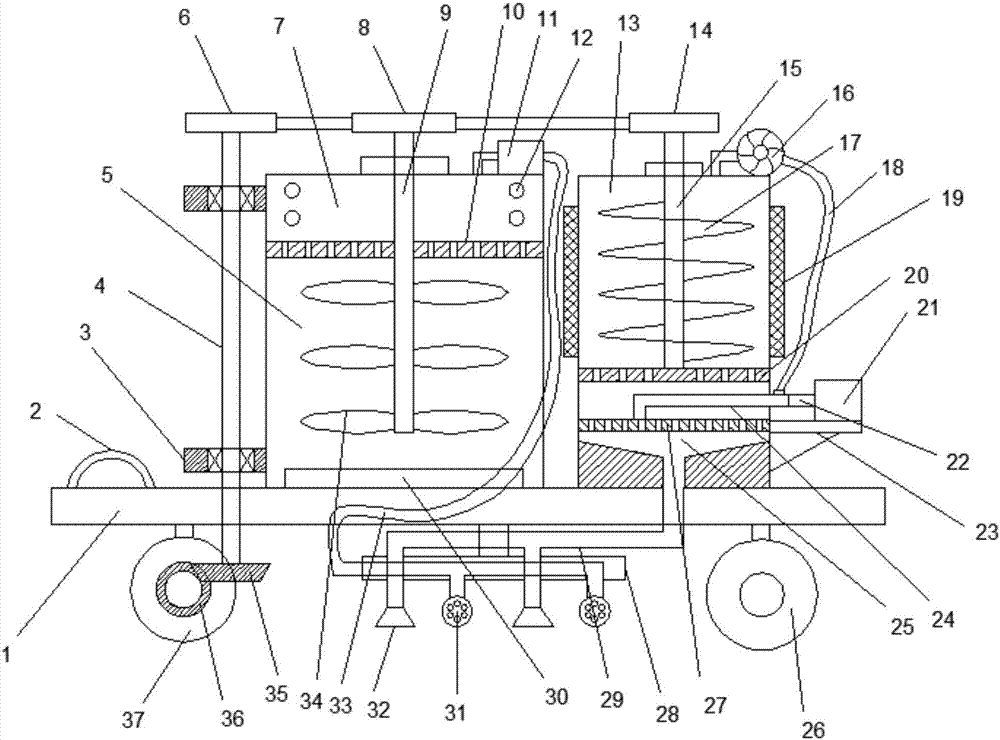

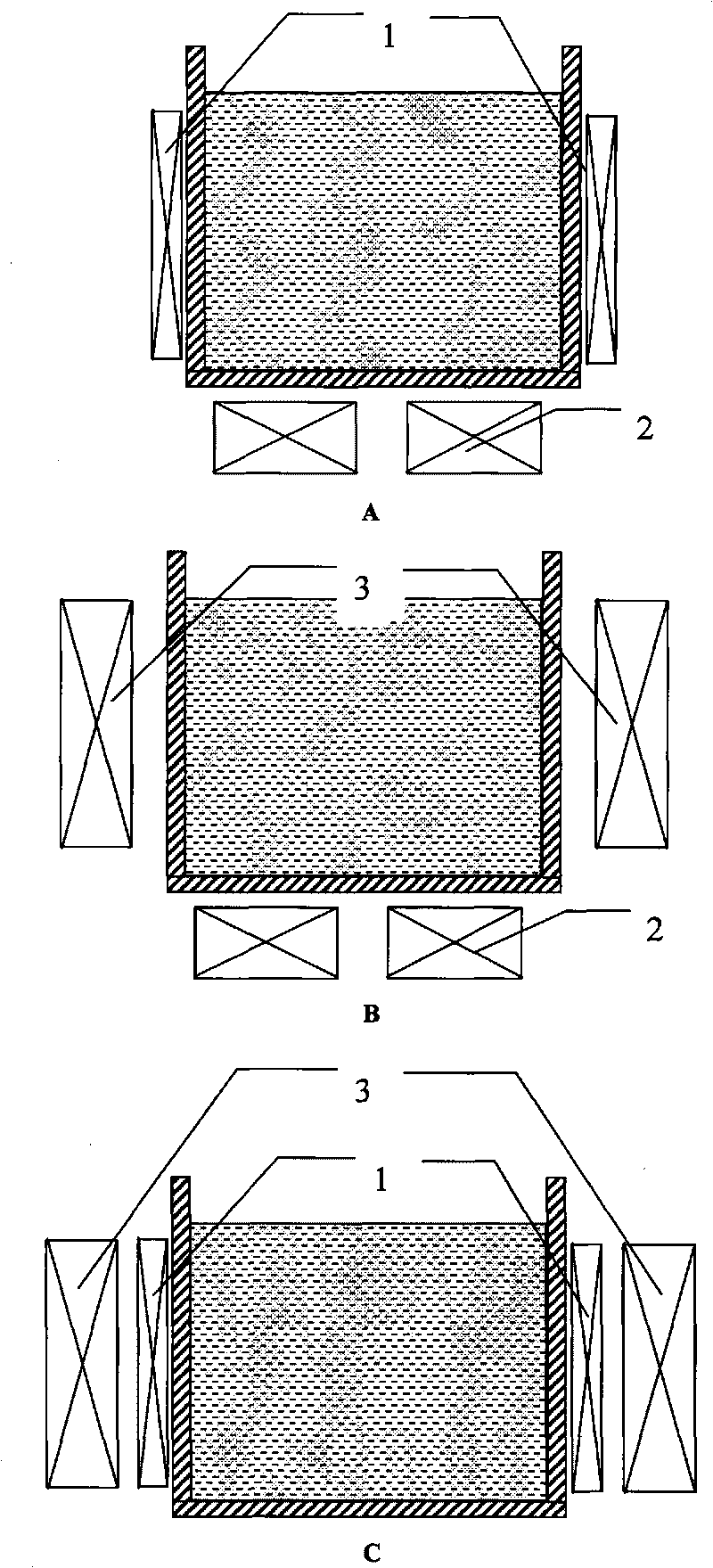

Moveable casting blank solidification end electromagnetic stirring device

The invention discloses a moveable casting blank solidification end electromagnetic stirring device, comprising a solidification end electromagnetic stirring device, wherein the solidification end electromagnetic stirring device is connected and fixed on an installation and positioning trolley for an electromagnetic stirrer, the middle of the installation and positioning trolley for the electromagnetic stirrer is provided with a steel blank sleeve, the periphery of the movable trolley is provided with horizontal guide rolling wheels, and the installation and positioning trolley for the electromagnetic stirrer is connected with a lifting drive device. The horizontal guide rolling wheels on the periphery of the trolley of the device are arranged on four upright posts of a vertical casting machine, the four upright posts are used as guide ways, the lifting drive device is used for realizing the up and down movement of the installation and positioning trolley for the electromagnetic stirrer and the electromagnetic stirrer in the solidification end electromagnetic stirring device so as to regulate the position of the electromagnetic stirrer corresponding to the casting blank solidification end, and therefore, the casting blank solidification end can be electromagnetically stirred. The invention can accurately position the working position of the electromagnetic stirrer according to technological requirements, and can meet the demand of variation of technological conditions.

Owner:武汉大西洋连铸设备工程有限责任公司

Liquid-state cosmetic mixed process treatment system

ActiveCN108187540AReduce procurement costsExpand the scope of useRotary stirring mixersTransportation and packagingThermal insulationDistillation

The invention belongs to the technical field of production of cosmetics and particularly relates to a liquid-state cosmetic mixed process treatment system which comprises a tank body, a distillation module, a rotating module, a stirring module and an auxiliary material adding module, wherein the tank body is used for containing a liquid raw material to be stirred, stirring of a liquid cosmetic isrealized in the tank body, and the side wall of the tank body is provided with a feed port; the distillation module is used for producing distilled water required for the cosmetic and performing heating and thermal insulation on the tank body by utilizing hot steam; the rotating module is used for driving the stirring module to rotate by utilizing the high-pressure steam generated in production ofthe distilled water as power; the stirring module is positioned inside the tank body and is used for realizing stirring of the liquid cosmetic; and the auxiliary material adding module is mounted onthe stirring module and is used for adding auxiliary materials into the tank body by utilizing rotation of the stirring module. The system provided by the invention can utilize the high-pressure steamgenerated during distillation to realize stirring of the liquid cosmetic, so that the arrangement of a power source is omitted, and furthermore, self-supply of the distilled water is realized.

Owner:GUANGZHOU OPSEVE COSMETICS

Efficient mixing device for water-soluble fertilizer processing

InactiveCN107224909AAchieving stirringAchieve sievingSievingTransportation and packagingPush pullEngineering

The invention discloses an efficient mixing device for water-soluble fertilizer processing. The efficient mixing device comprises a mixing box, feeding boxes and guide sliding sleeves, wherein a rotating rod is rotationally arranged in an inner cavity of the mixing box; a spiral stirring rod is fixedly arranged at the outer ring of the rotating rod; a stirring blade is arranged and erected on the bottom end of the rotating rod; two guide sliding sleeves are symmetrically and fixedly welded and erected on the upper surface of a top plate of the mixing box; guide sliding holes are formed in the guide sliding sleeves; the guide sliding holes are internally connected with push-pull rods in a left-right sliding way; an eccentric wheel is fixedly arranged on the outer ring of the top end of the rotating rod in a sleeving way; an annular guiding sleeve is arranged on the outer ring of the eccentric wheel in a sliding and sleeving way; two mutually-parallel side plates on the annular guiding sleeve are respectively and fixedly arranged on the end parts of the two push-pull rods; the other ends of sieve plates are fixedly connected with the end parts of the push-pull rods. The efficient mixing device disclosed by the invention is simple in structure, convenient in operation, good in dissolution effect of fertilizer granules, fast in dissolution speed and high in transmission efficiency, is energy-saving and environment-friendly and is suitable for being popularized and used.

Owner:汪辉

Pretreatment apparatus with stirring function for liquid food detection

InactiveCN109569365AAchieving stirringStir wellTransportation and packagingRotary stirring mixersCouplingLiquid state

The invention discloses a pretreatment apparatus with stirring function for liquid food detection, which comprises a frame. A mounting plate is fixed to the upper end of the frame; a stirring barrel is fixed to the middle of the upper end of the mounting plate; a barrel cover is fixed to the upper end of the stirring barrel; a first motor is fixed to the middle of the upper end of the barrel cover; the end of an output shaft of the first motor is fixedly provided with a first connection shaft through a first coupling; a mounting barrel is fixed to the lower end of the first connection shaft; the mounting barrel is positioned in the center of the stirring barrel; a second connection shaft is fixed to the lower end of the mounting barrel and is rotationally connected with the bottom end of the stirring barrel; a stirring mechanism is arranged inside the stirring barrel; a washing mechanism is arranged at the lower end of the barrel cover and is positioned at the inner upper end of the stirring barrel. The pretreatment apparatus provides multidirectional stirring for food, so that working efficiency is improved, stirring quality is high, automatic washing is achieved, and workload isreduced.

Owner:黎庆佳

Plastic particle mixing dryer

InactiveCN108204732AStir wellAchieving stirringGranular material dryingDrying gas arrangementsHelical bladeReciprocating motion

The invention belongs to the technical field of plastic manufacturing, and specifically discloses a plastic particle mixing dryer comprising a material barrel and a discharging hopper. The inner wallof the material barrel is provided with a plurality of columnar bulges, and a rotating shaft is provided with helical blades; the top of the rotating shaft is provided with an end cam, and the rotating shaft and the end cam are internally provided with through holes which communicate with each other; the side wall of the rotating shaft in the material barrel is provided with air outlets which communicate with the through holes; a support frame is provided with a cylinder, and the lower end face of an ejector rod in the cylinder abuts against the concave side of the end cam; a coil is wound onthe outer wall of the cylinder, and connected to an AC motor; and the outer wall of the cylinder is provided with a one-way air inlet valve and a one-way air outlet valve, and a hot air pipe communicating with the through holes is installed between the one-way air outlet valve and the end cam. According to the technical scheme, hot air is intermittently discharged into a drying oven through the quick reciprocating motion of a cylinder piston, so that plastic particles are switched between two motion states, namely irregular movement and falling-down, and the plastic particles are mixed thoroughly.

Owner:重庆市中塑新材料有限公司

Trailed high efficiency road surface snow removing device for municipal engineering

The invention discloses a trailed high efficiency road surface snow removing device for municipal engineering. The trailed high efficiency road surface snow removing device includes a traction seat; a hot water box is arranged on the left side of an upper end of the traction seat; an air outlet plate is arranged in the hot water box; a steam chamber is formed in an upper end of the air outlet plate; a stirring shaft is arranged in the hot water box; a stirring belt wheel is connected to a top end of the stirring shaft; a left end of the stirring belt wheel is connected to a transmission belt wheel; the center of a lower end of the transmission belt wheel is connected to a transmission shaft; a bottom end of the transmission shaft is connected to a transmission gear; a lower end of the transmission gear is engaged with a travelling gear; a salt storage box is connected to a right side of the upper end of the traction seat; a rotation shaft is arranged in the salt storage box; an upper end of the rotation shaft is connected to a rotation belt wheel; a lower end of the rotation shaft is connected to a dispensing plate; a discharging plate is arranged on an inner bottom end of the salt storage box; a fixing plate is arranged on the center of a lower end of the supporting seat; and a lower end of the fixing plate is connected to salt outlet nozzles and steam outlet nozzles evenly. Traction type motion of the whole trailed high efficiency road surface snow removing device can be achieved, a dual snow removing function for removing snow covering a road surface is achieved, and the snow removing efficiency and the snow removing quality can be improved.

Owner:王淑兰

Energy-saving graphene blending stirrer

InactiveCN108355565AAchieving stirringStir wellRotary stirring mixersTransportation and packagingHelical bladeSlurry

The invention discloses an energy-saving graphene blending stirrer. The energy-saving graphene blending stirrer comprises a shell body, two feeding assemblies, a planetary gear assembly, a stirring assembly, a left rotary shaft and a right rotary shaft, spiral blades and a motor, wherein the shell body is provided with a main stirring cavity, an auxiliary stirring cavity, a discharging cavity anda feeding cavity; the two feeding assemblies are arranged at left and right sides of the feeding cavity; the planetary gear assembly is mounted at the bottom of the main stirring cavity; the stirringassembly penetrates through the planetary gear assembly; a stirring main shaft of the stirring assembly penetrates through the auxiliary stirring cavity into the feeding cavity from the main stirringcavity; the left rotary shaft and the right rotary shaft are arranged in the feeding cavity and are located at two sides of the stirring main shaft respectively; the spiral blades are arranged on theleft rotary shaft and the right rotary shaft; the motor is mounted on the shell body and is used for driving the left rotary shaft; the left rotary shaft and the right rotary shaft are engaged with the stirring main shaft through tapered teeth. According to the energy-saving graphene blending stirrer disclosed by the invention, the rotary shafts are driven through the motor and graphene slurry isspirally conveyed into the stirring cavities; meanwhile, the rotary shafts drive the main shaft and further drive the stirring assembly through the planetary gear assembly, so that the graphene slurryis stirred; finally, the graphene slurry is discharged from the discharging cavity; the energy-saving graphene blending stirrer has the advantages of energy saving and convenience, and uniformity instirring.

Owner:NINGBO FEICHAI ROBOT TECH CO LTD

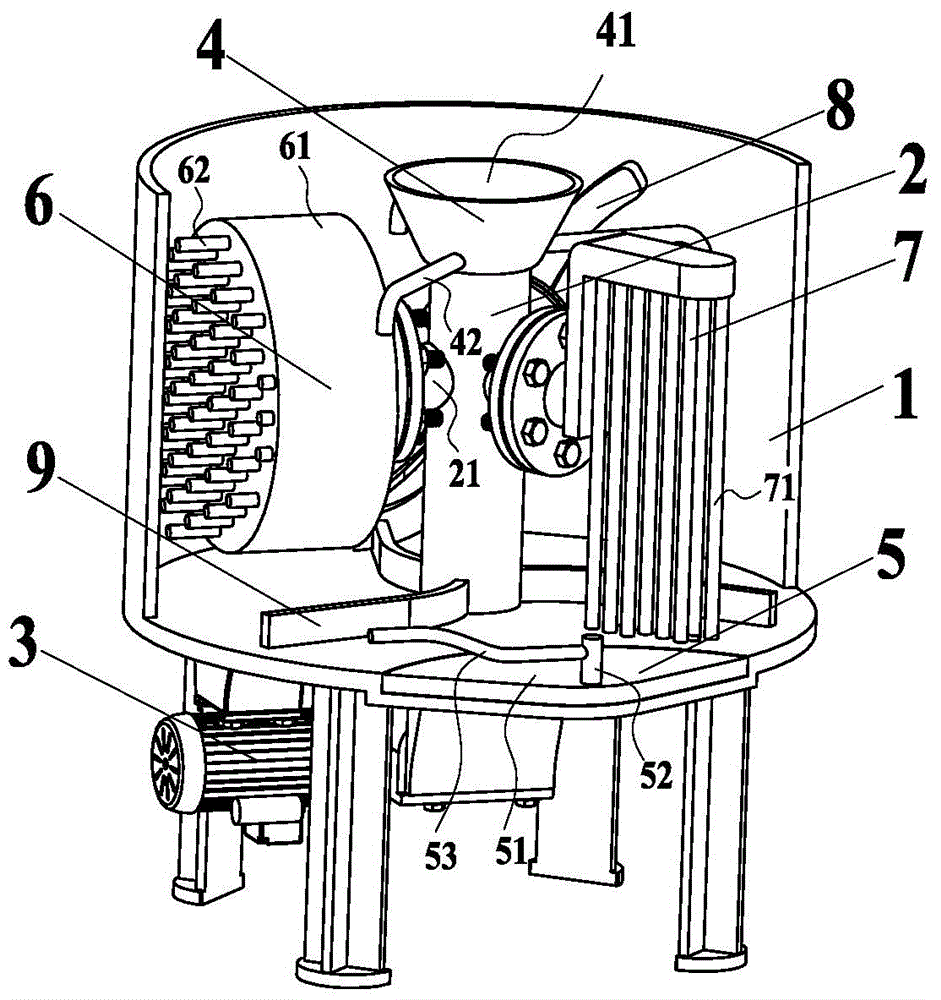

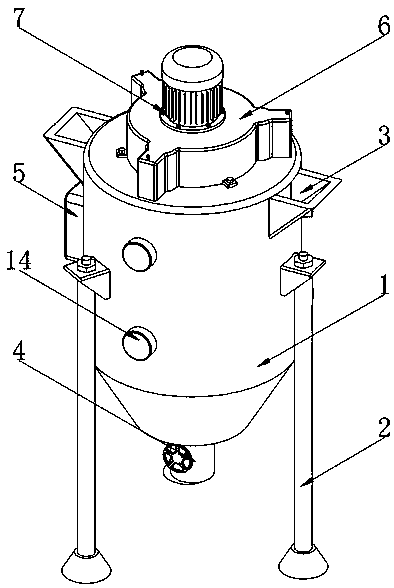

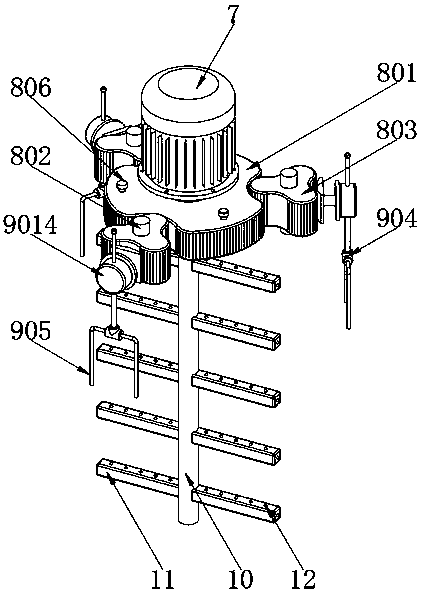

Separation and extraction equipment for streptomyces fermentation metabolite Xinaomycin

ActiveCN106479861AEasy to disassembleSafe and convenientBioreactor/fermenter combinationsBiological substance pretreatmentsMotor driveMetabolite

The invention relates to separation and extraction equipment and particularly relates to separation and extraction equipment for a streptomyces fermentation metabolite Xinaomycin. The invention aims at providing separation and extraction equipment for a streptomyces fermentation metabolite Xinaomycin, which realizes a good grinding effect and a good stirring effect. To solve the technical problem, the invention provides separation and extraction equipment for a streptomyces fermentation metabolite Xinaomycin, which comprises a fermentation box, a box cover, a rubber pad, a first handle, an insertion rod, a first through hole, a guide rod, a first spring, a moving rod, a second handle, a gas inlet pipe, a first gas outlet pipe and the like; the box cover is arranged above the fermentation box; the rubber pad is pasted at the bottom of the box cover; and the top middle of the box cover is connected with the first handle through screws. In the invention, a rotating motor drives a rotation rod to rotate so as to realize the stirring and fermentation treatment of seed liquid; and moreover, the rotation rod is also provided with a stirring device capable of improving the stirring effect.

Owner:广西乾坤活酒生物技术有限公司

Anti-pollution bacterium culture device and method for clinical lab

InactiveCN112342122APromote growthEvenly distributedBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyPetri dish

The invention relates to the technical field of bacterial culture, and discloses an anti-pollution bacterium culture device and method for a clinical lab. The anti-pollution bacterium culture device for the clinical lab comprises a box body, a culture dish and a placement table, wherein the inner wall of one side of the box body is vertically provided with a vertical plate through bolts; one sideof the vertical plate is fixedly provided with a horizontal plate; one side of the horizontal plate is fixedly provided with an empty box; the bottom of the empty box communicates with one end of a straight pipe; the other end of the straight pipe extends into the culture dish; the outer side of the straight pipe is fixedly provided with a plurality of stirring rods; and the top of the placement table is provided with a placement groove. The anti-pollution bacterium culture device is reasonable in design, while the culture dish is driven to rotate, the culture dish vertically shakes, through acooperation function with the stirring rods, culture liquid is stirred, so that the culture liquid forms circulation, bacteria suspend, an illumination effect is guaranteed, and oxygen can be introduced into the culture dish to supplement oxygen required by aerobic bacteria growth so as to guarantee a bacteria culture effect.

Owner:何伟

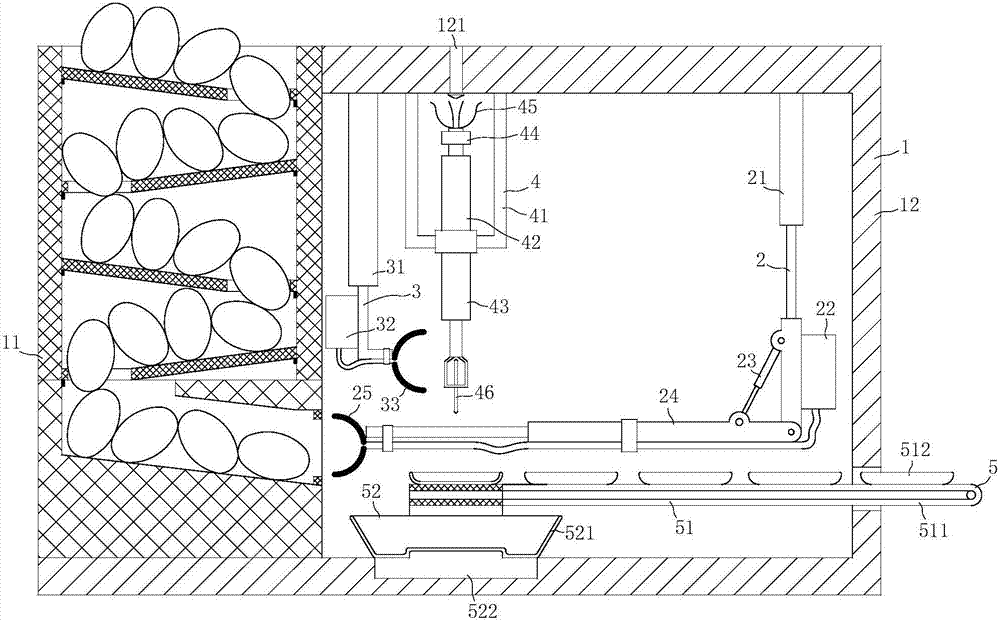

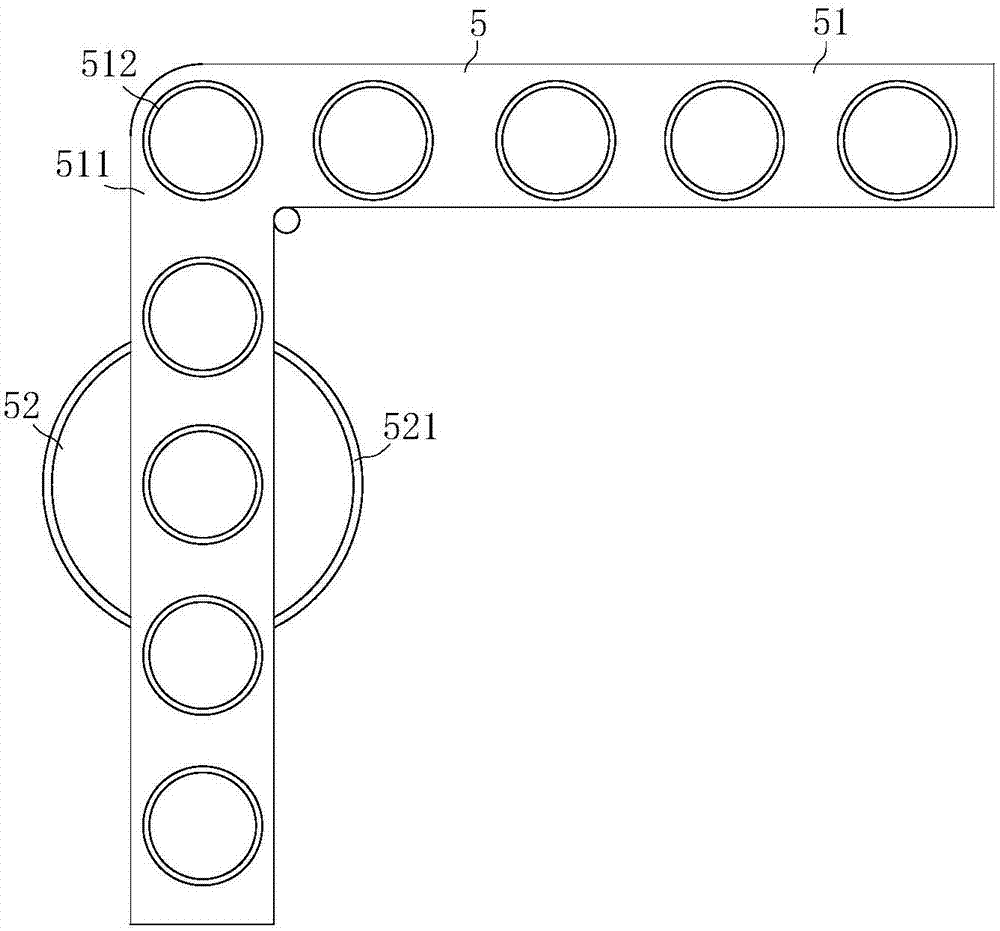

Domestic intelligent egg whisking robot

ActiveCN107411594ARealize the egg breaking operationAchieving stirringKitchen equipmentYolkAnimal science

The invention relates to the field of intelligent kitchen ware, in particular to a domestic intelligent egg whisking robot. The domestic intelligent egg whisking robot is mainly used in the process that a batch of eggs need to be used when a banquet is held. The domestic intelligent egg whisking robot comprises a rack, an egg taking unit, an egg stabilizing unit, an egg whisking unit and a receiving unit; the rack comprises an egg conveying unit and a main bin, and the egg taking unit is used for placing eggs at the receiving unit; the egg stabilizing unit is used for fixing the eggs which are not broken and throwing shells; the egg whisking unit is used for breaking the shells of the eggs, whisking egg white and yolk and throwing the shells; and the receiving unit is used for receiving the egg white, the yolk and the shells. According to the domestic intelligent egg whisking robot, whisking operation of batch of eggs is achieved, normal shell breaking is achieved, the egg white and the yolk can further be whisked, moreover, the whisked egg white and the yolk can be loaded in dinner plates and conveyed out automatically and successively, and the time for whisking batch of eggs when the banquet is held is reduced greatly.

Owner:南京溪苏机器人有限公司

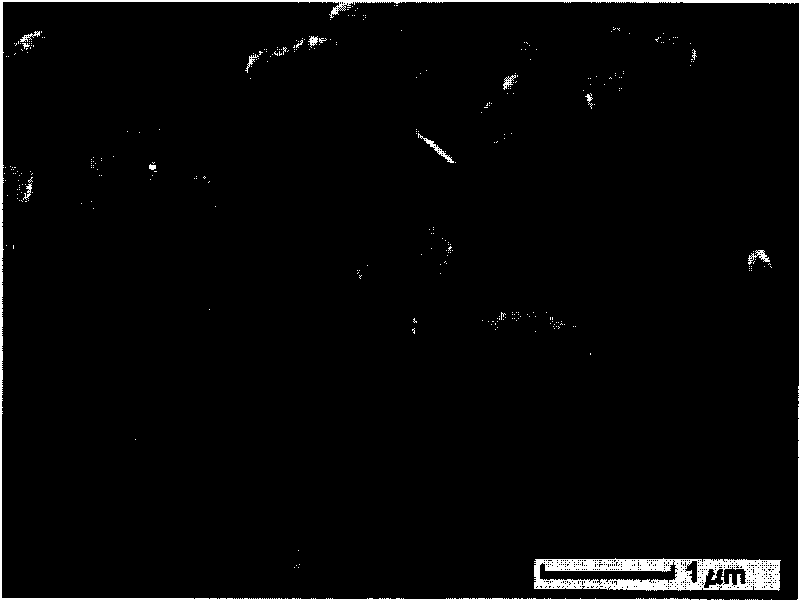

Method for synthesizing aluminum-based composite material by multielement magnetic field combined fusant reaction

ActiveCN101704075AThe combined magnetic field is effectiveIncrease dispersion speedChemical reactionMaterials science

The invention relates to a method for synthesizing an aluminum-based composite material by multielement magnetic field combined fusant reaction, which belongs to the technical field of preparation of materials. In the method, the fusant reaction synthesizing process is divided into three phases of reactant dispersion, contact chemical reaction and reaction product dispersion and by-product separation according to the characteristic that the fusant synthesizing reaction is solid-liquid phase reaction; and a corresponding combined magnetic field is applied according to different characteristics of all phases to carry out control. A high-frequency magnetic field and a low-frequency traveling wave magnetic field are applied in the reactant dispersion phase to improve the dispersing effect and the dispersing rate of a reactant; a pulse magnetic field and the low-frequency traveling wave magnetic field are applied in the contact reaction phase to accelerate the in-situ reaction course in a fusant; and the high-frequency magnetic field and the pulse magnetic field are applied in the reaction product dispersion and by-product discharge phase to control the clustering of particles and be beneficial to separating slag phases. The method can realize accurate control on the reaction synthesizing process of the fusant, improves the synthesizing efficiency and is beneficial to improving the quality of the composite material fusant.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com