Patents

Literature

46results about How to "Achieve rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

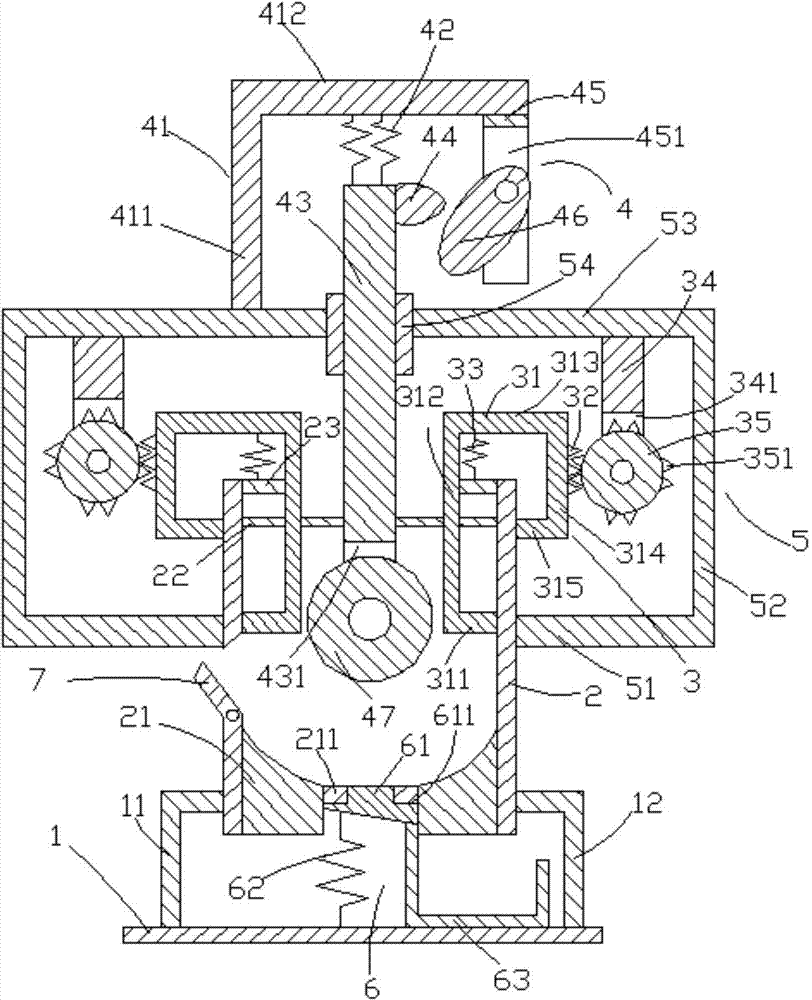

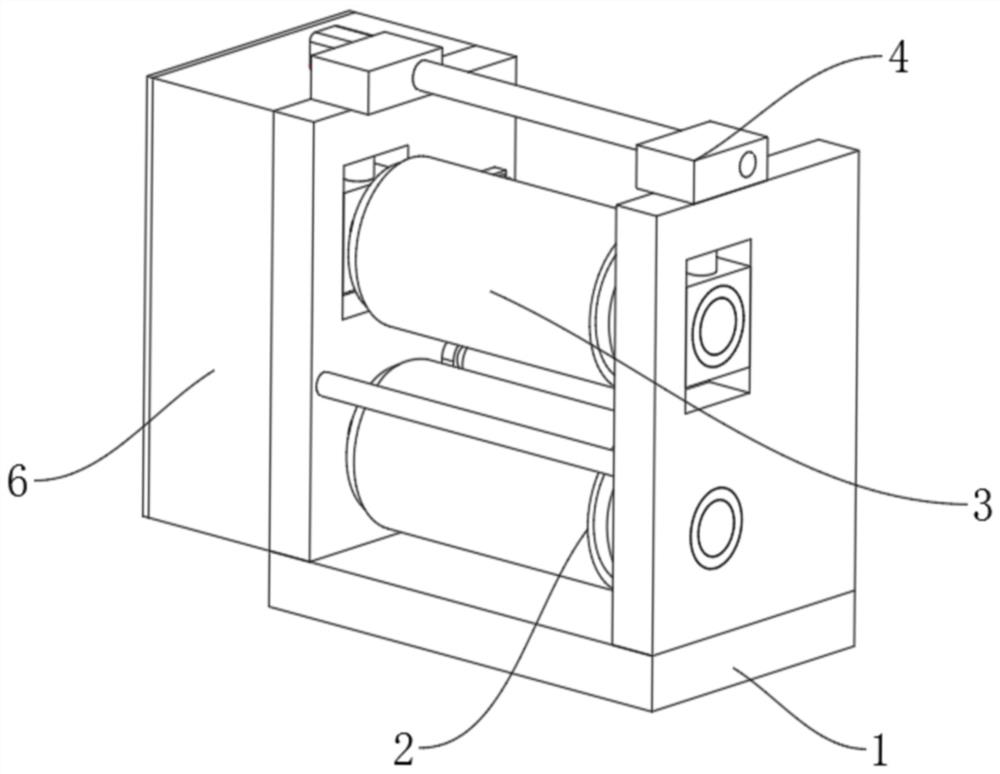

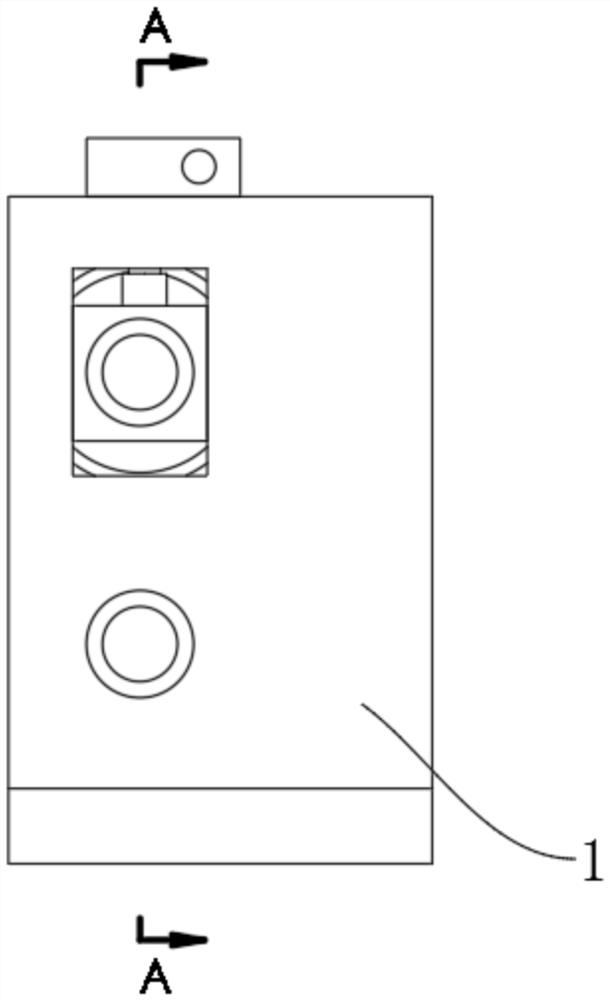

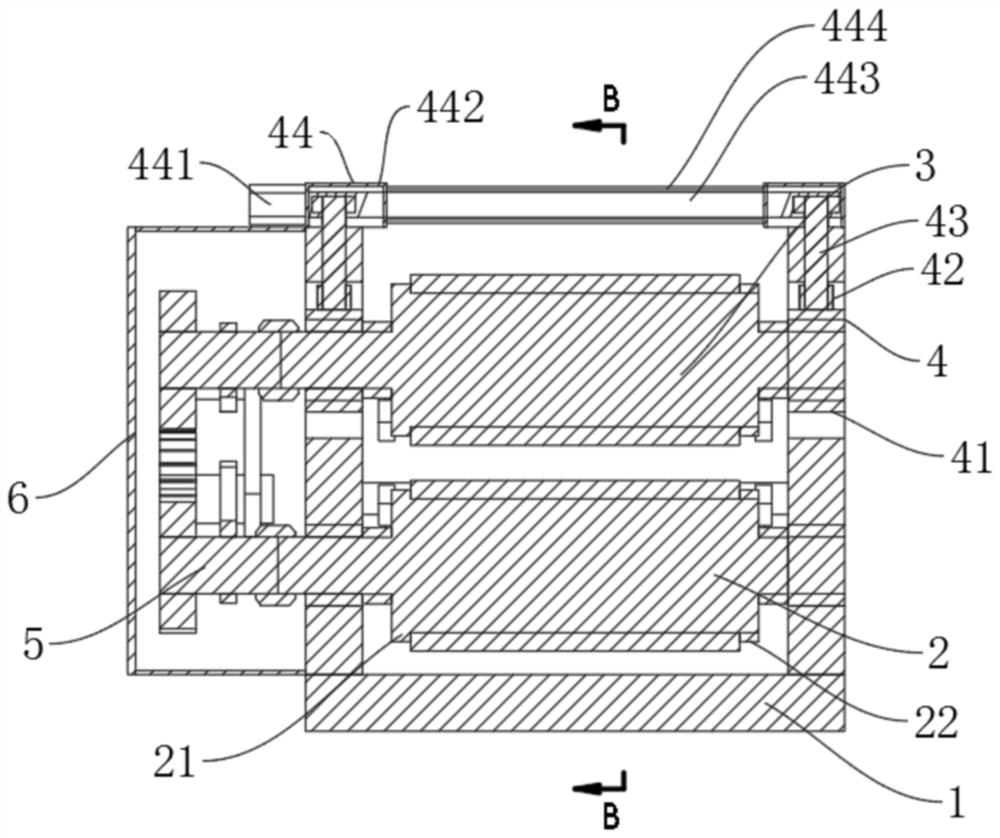

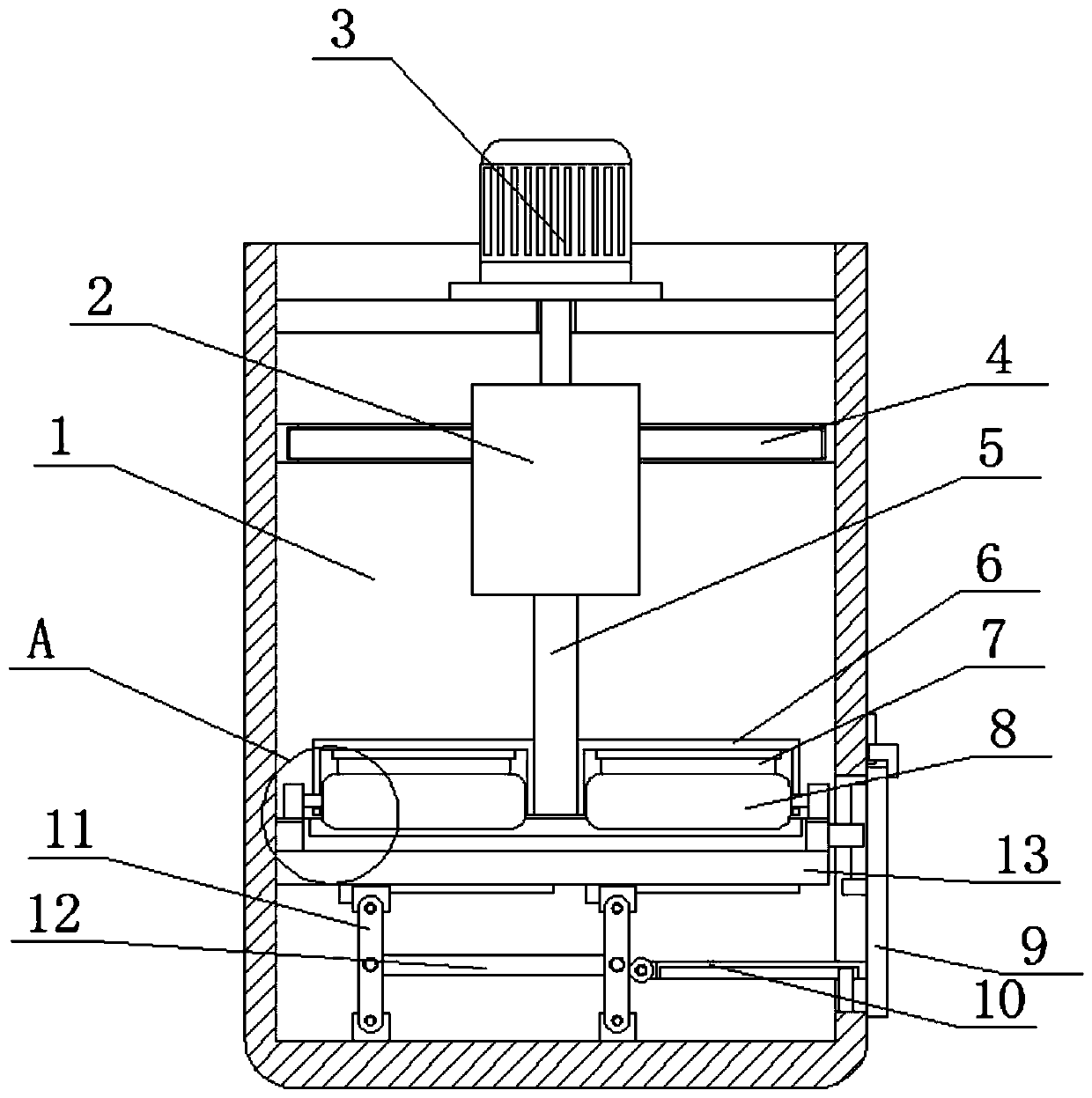

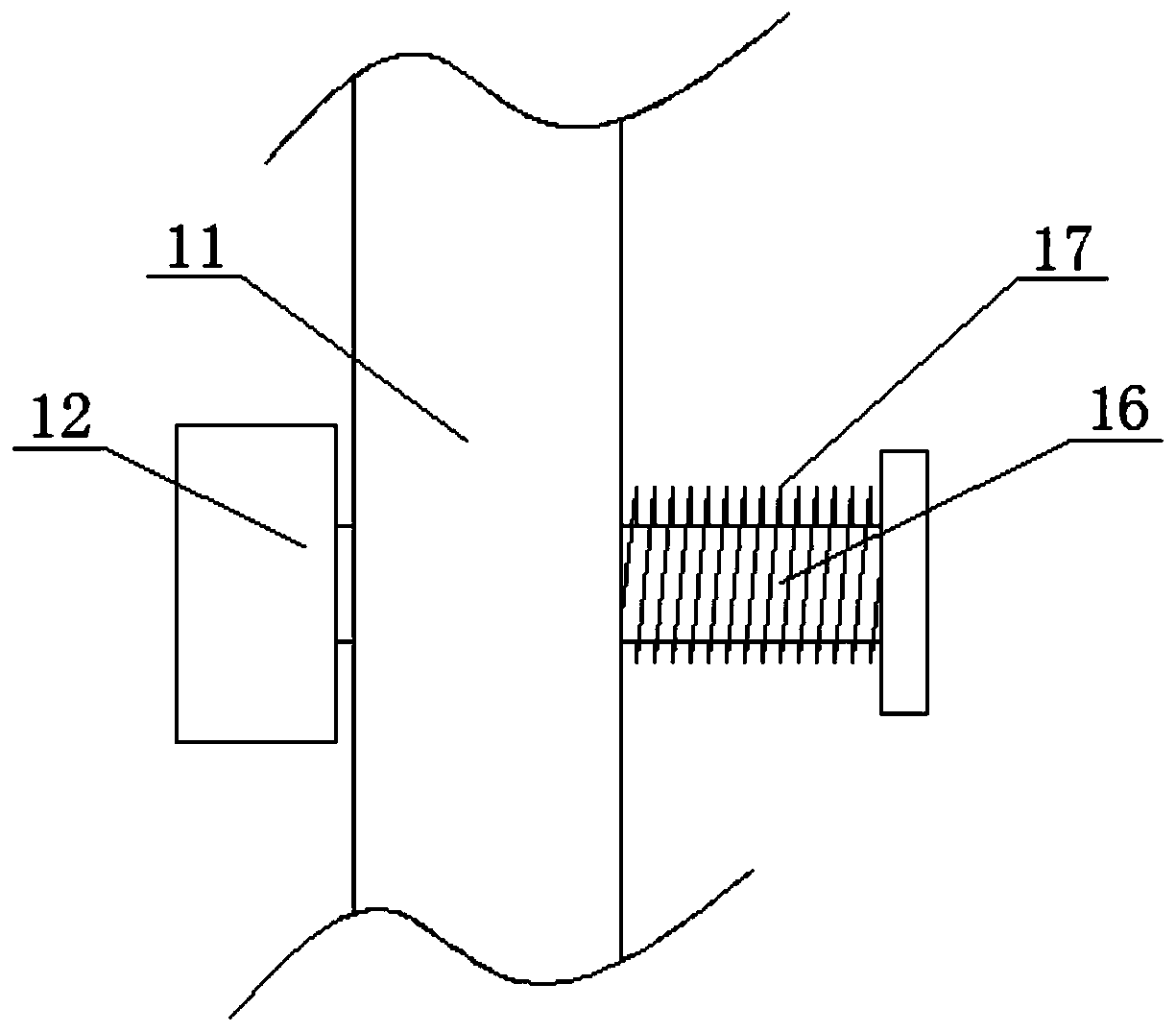

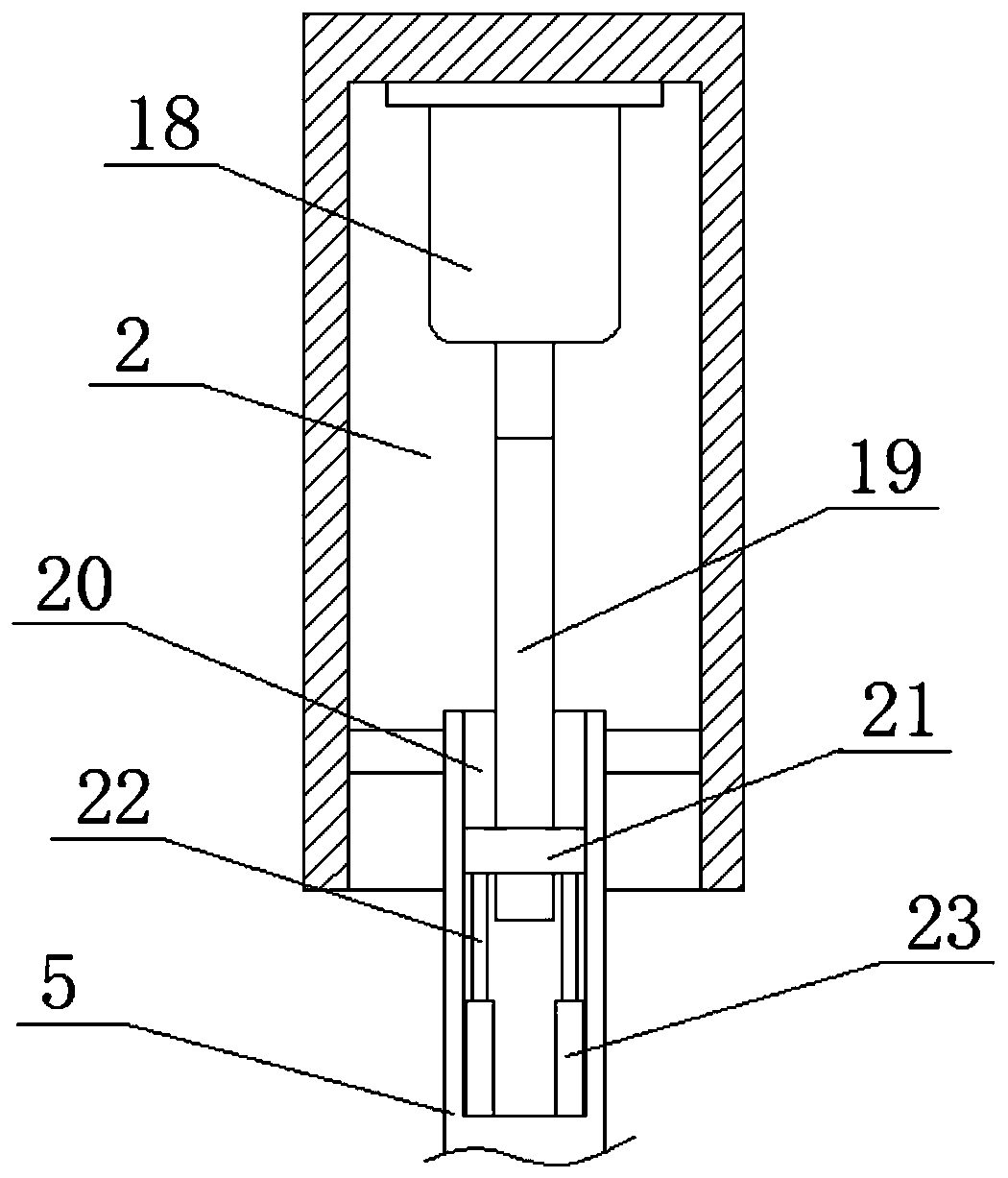

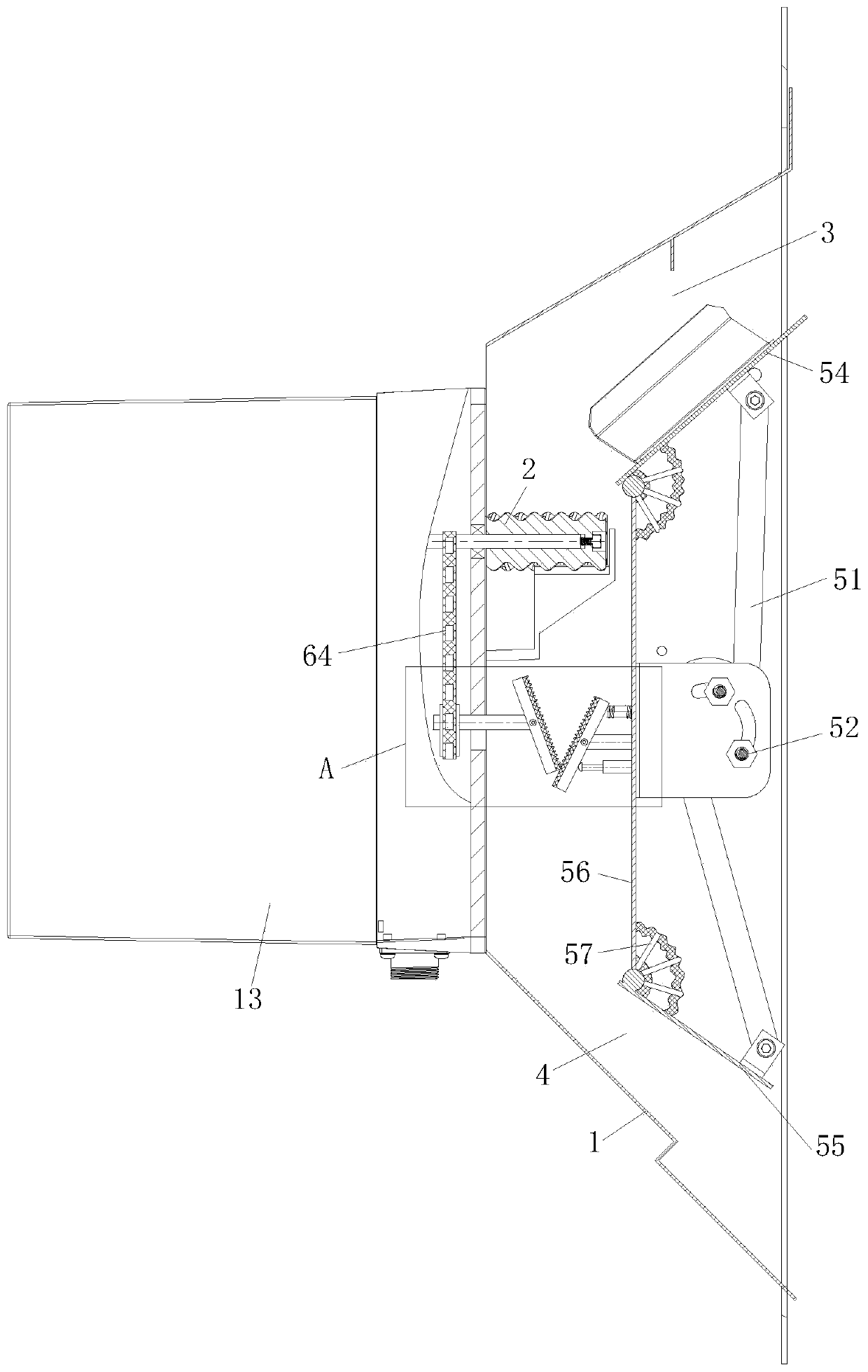

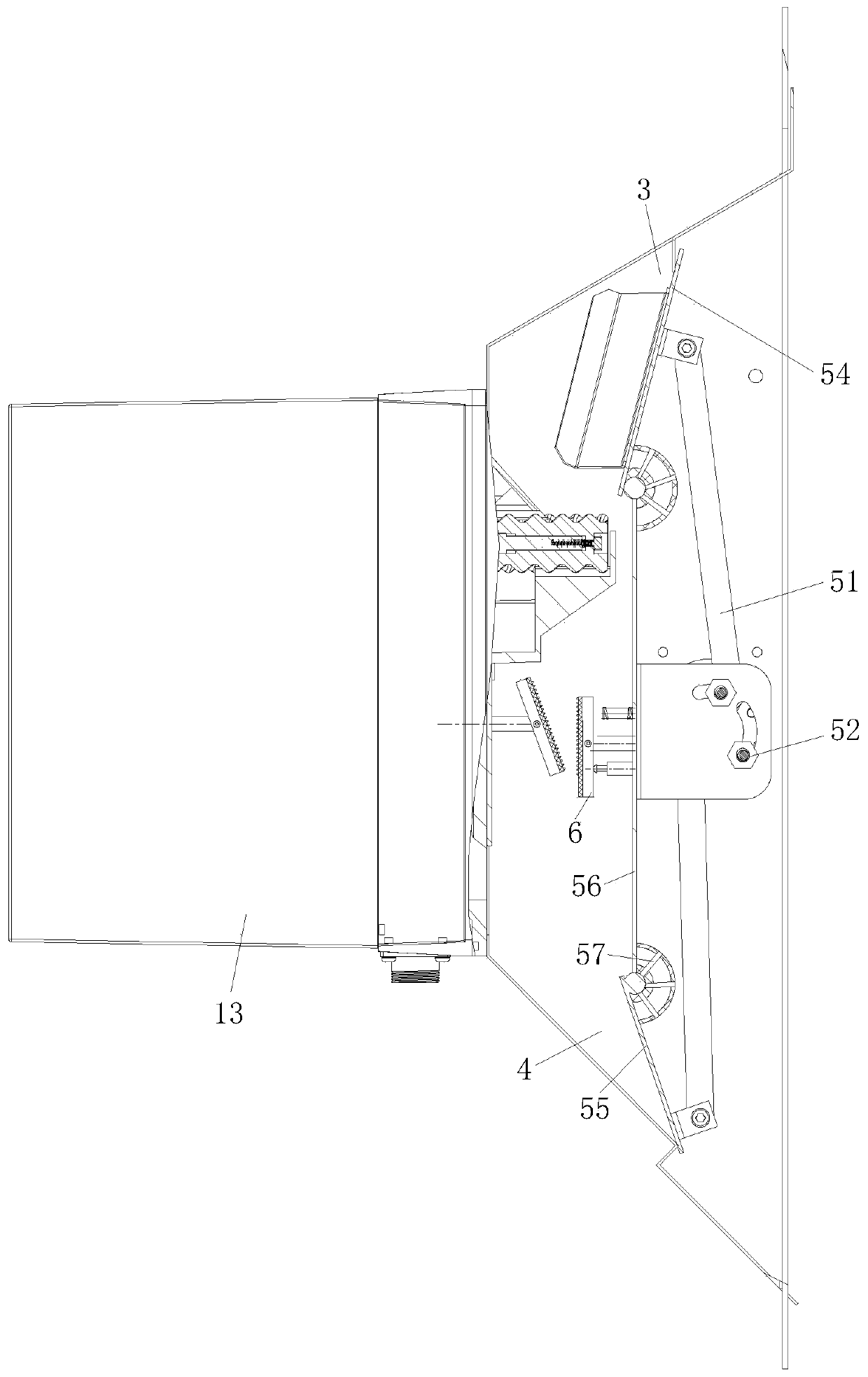

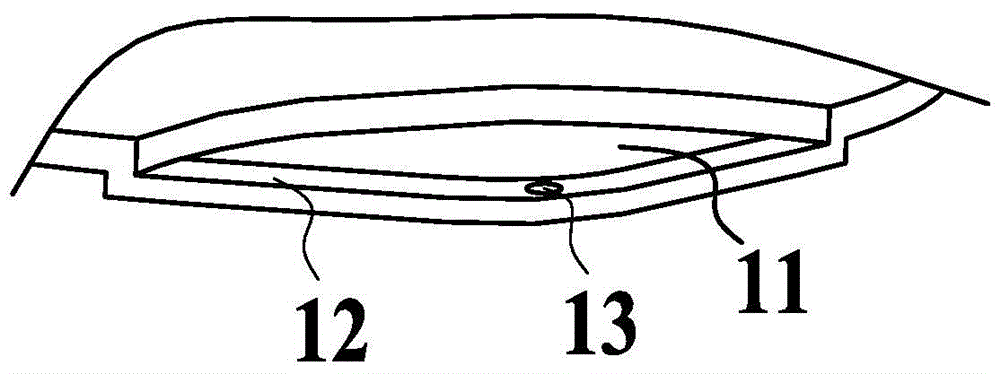

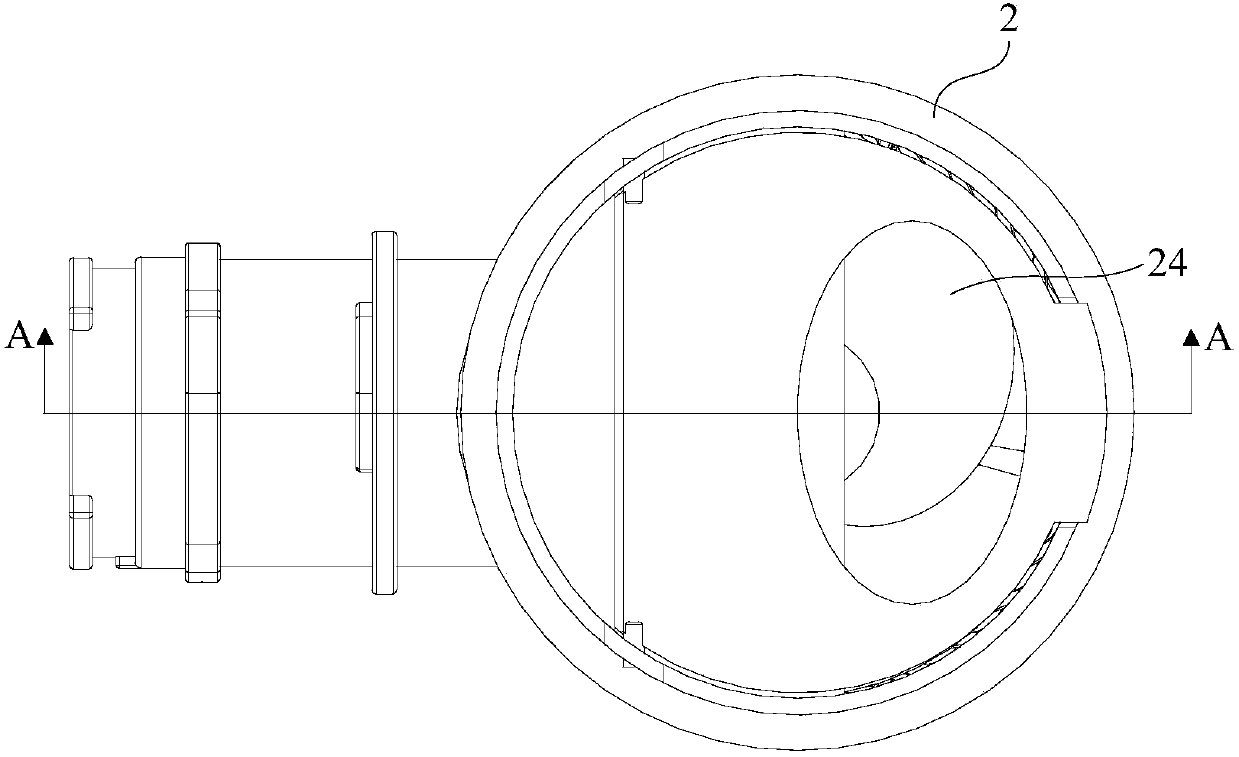

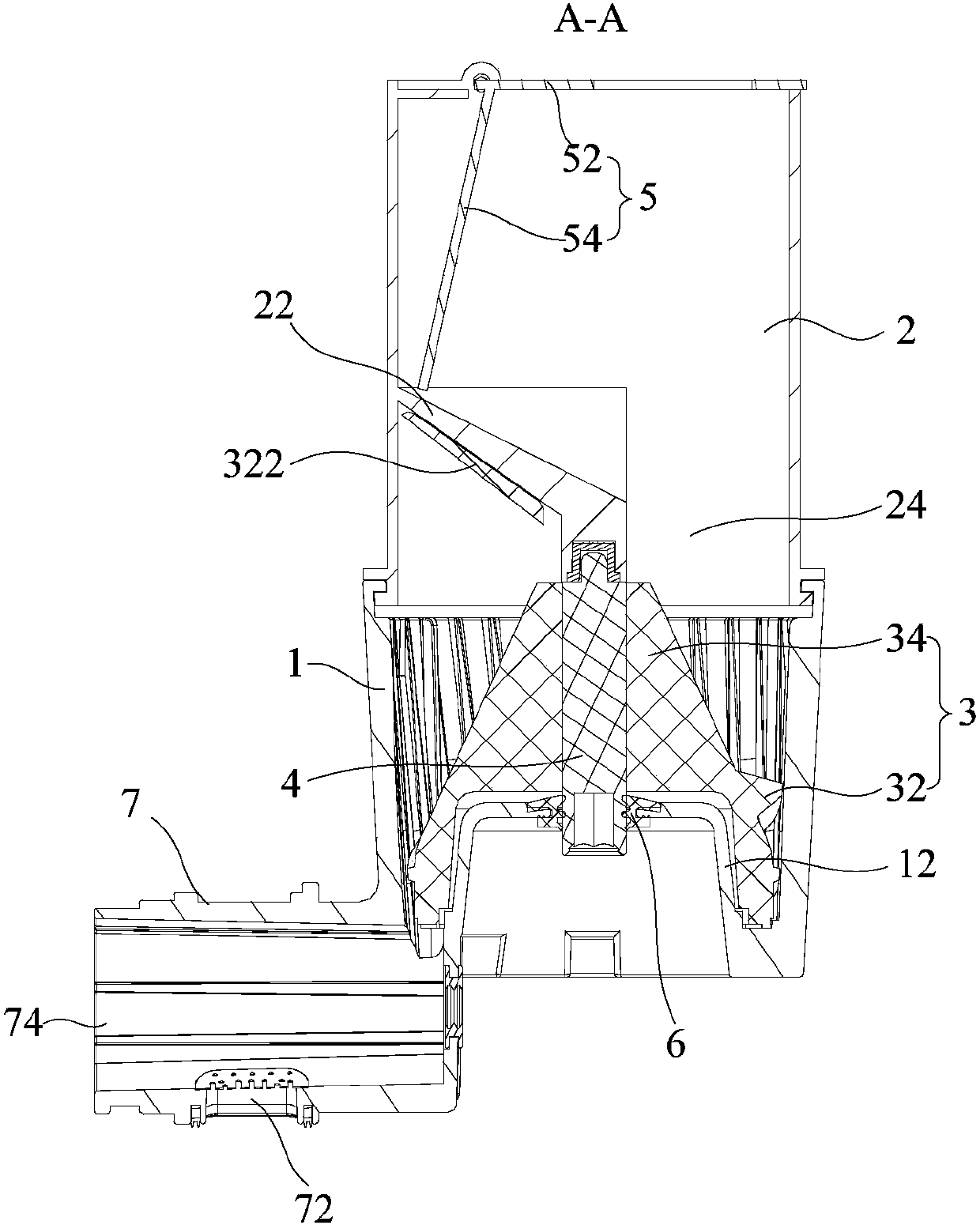

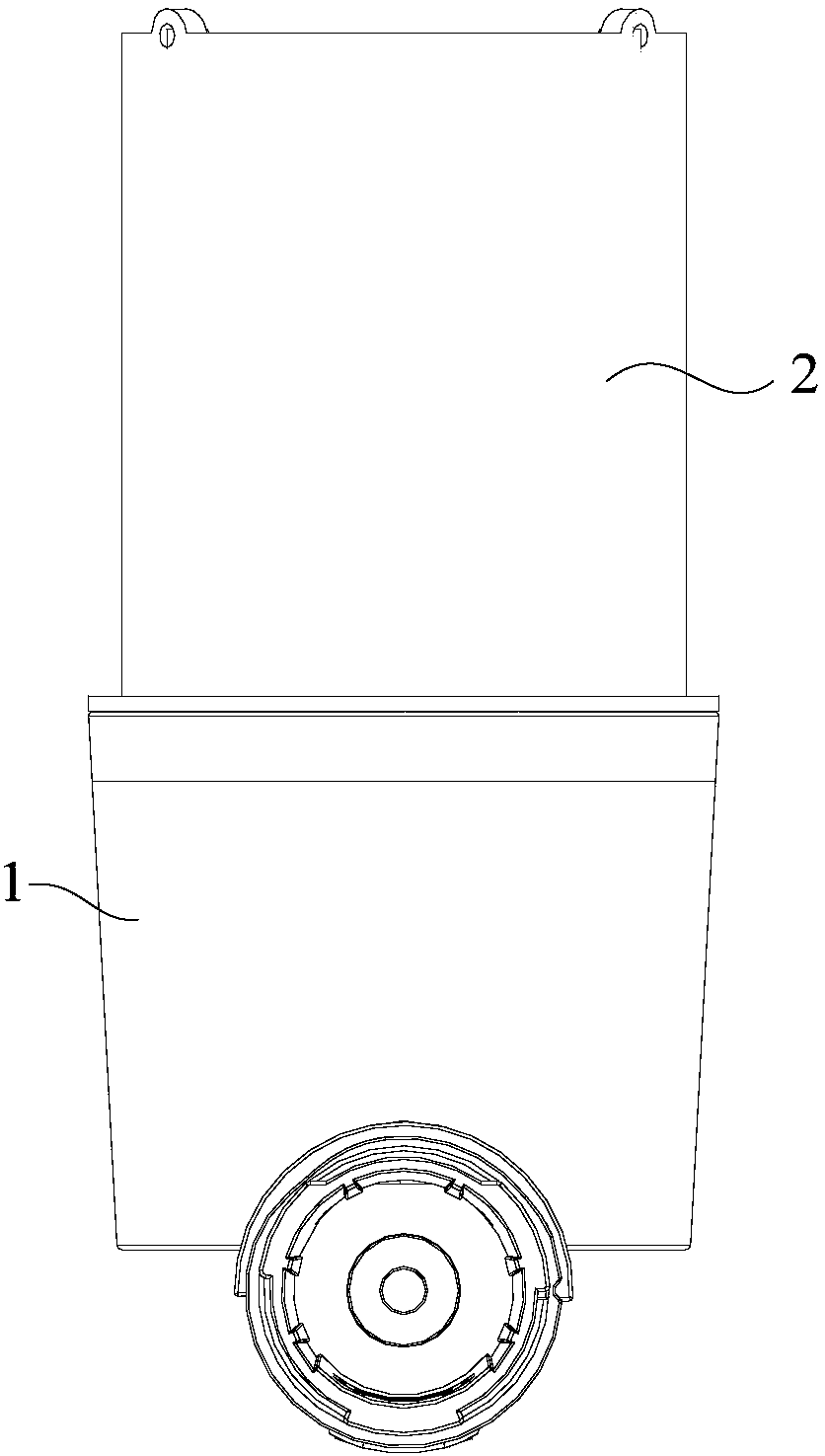

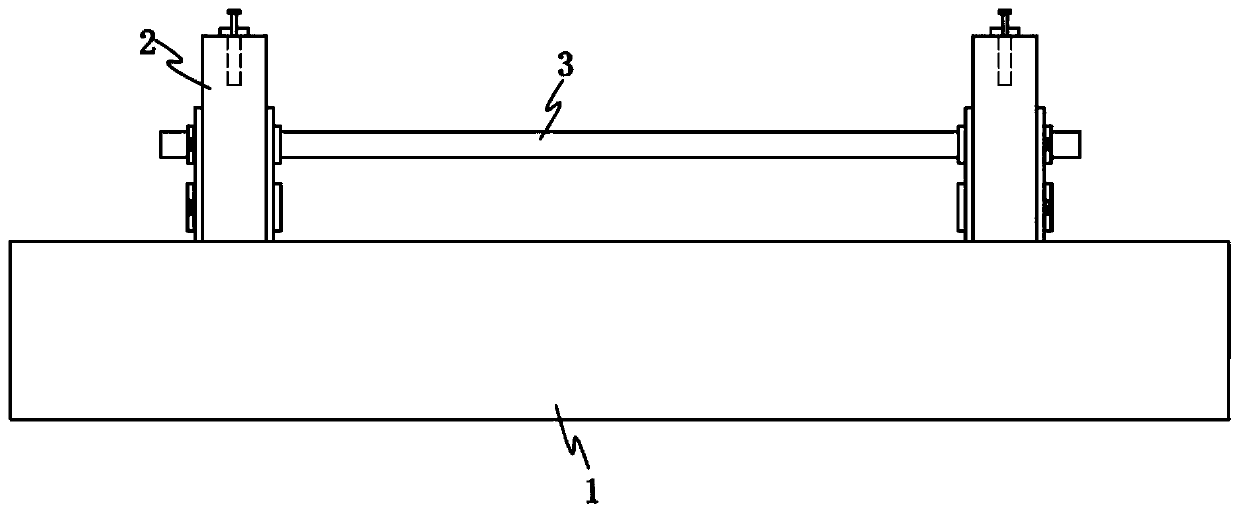

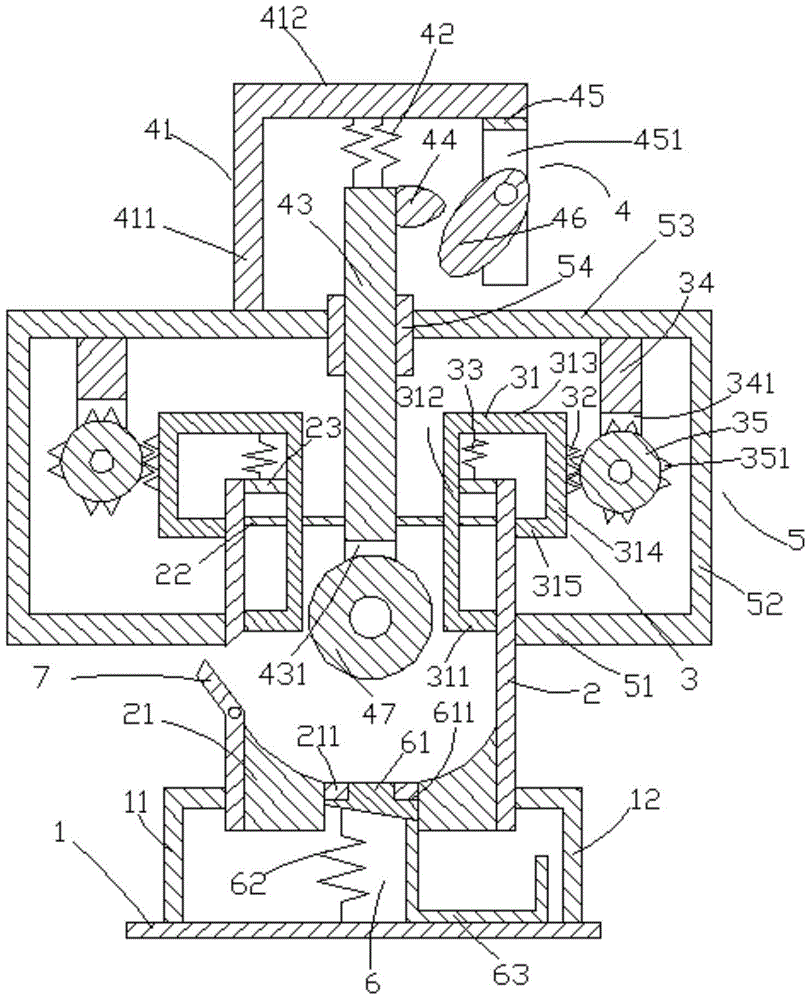

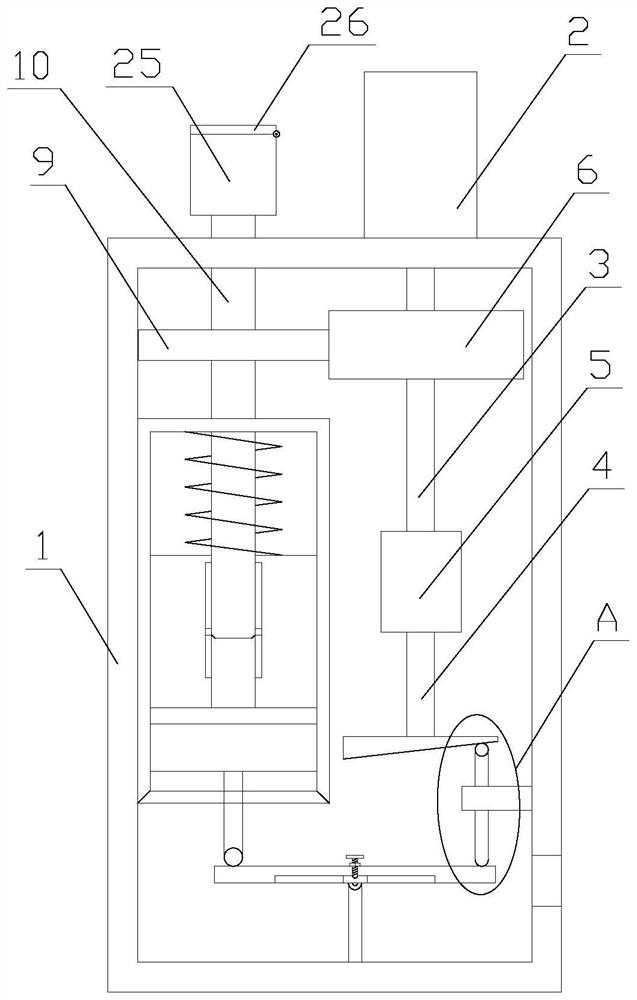

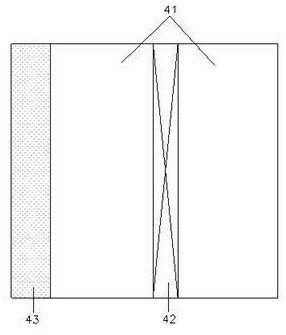

Masher for traditional Chinese medicinal materials

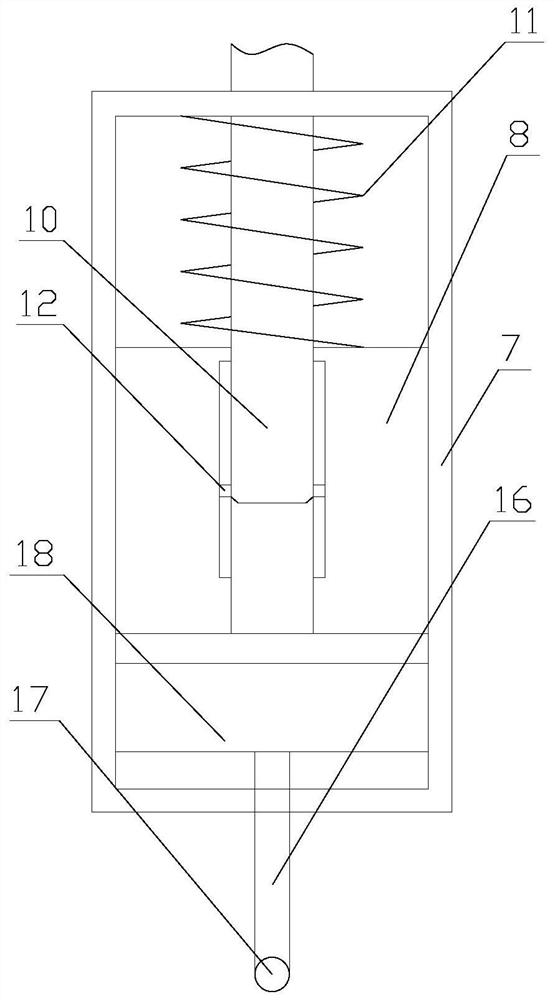

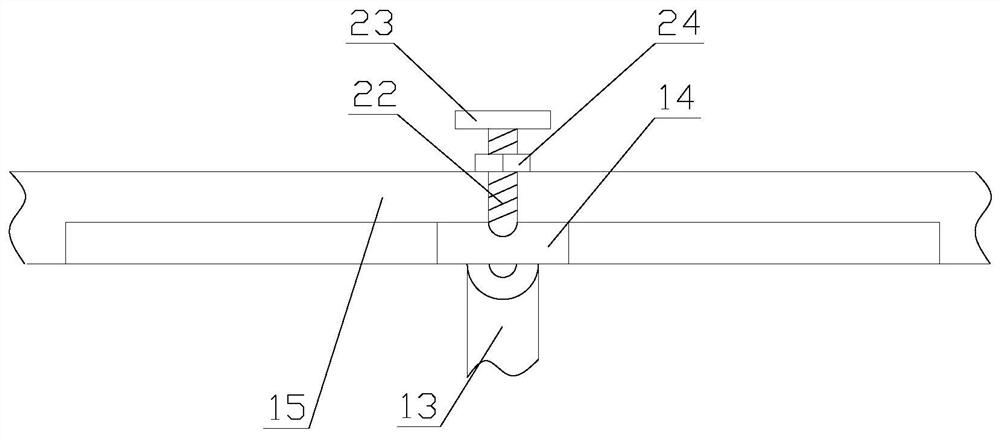

The invention provides a masher for traditional Chinese medicinal materials. The masher comprises a base (1), a frame (2), an squeezing unit (3), a positioning frame (5), a medicine material mashing unit (4) and a recovery unit (6), wherein the interior of the frame (2) is provided with a support block (21), a horizontal plate (22) and a positioning rod (23); the squeezing unit (3) comprises a squeezing frame (31), a first sawtooth (32), a first spring (33), a vertical rod (34) and a rolling wheel (35); the medicine material mashing unit (4) comprises a fixed frame (41), a second spring (42), a medicine material mashing rod (43), a sliding block (44), a support rod (45), an elliptic wheel (46) and a grinding wheel (47); the positioning frame (5) comprises a fourth horizontal part (51), a third vertical part and a rectangular block (54); and the recovery unit (6) comprises a base plate (61) and a material-collecting box (63). The masher for the traditional Chinese medicinal materials provided by the invention reduces manual workload, improves working efficiency and gives full play to pharmacological effects of traditional Chinese medicines.

Owner:徐州信莱德电子科技有限公司

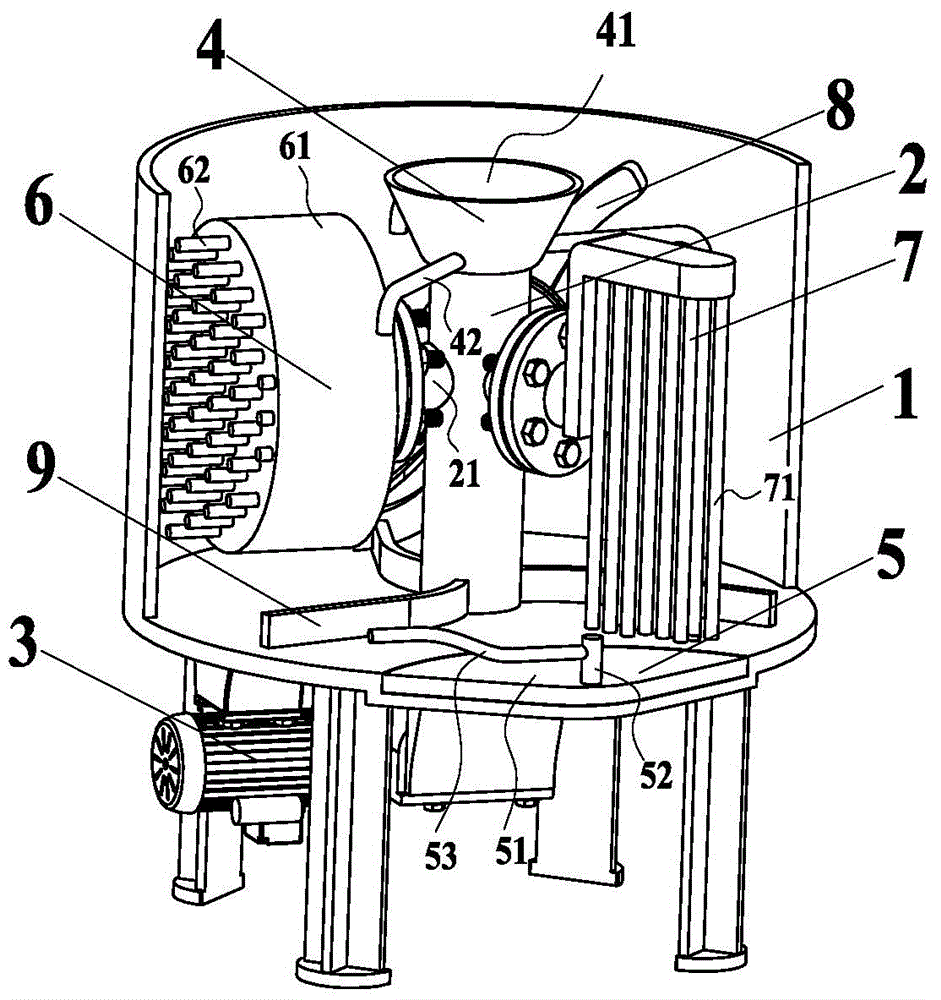

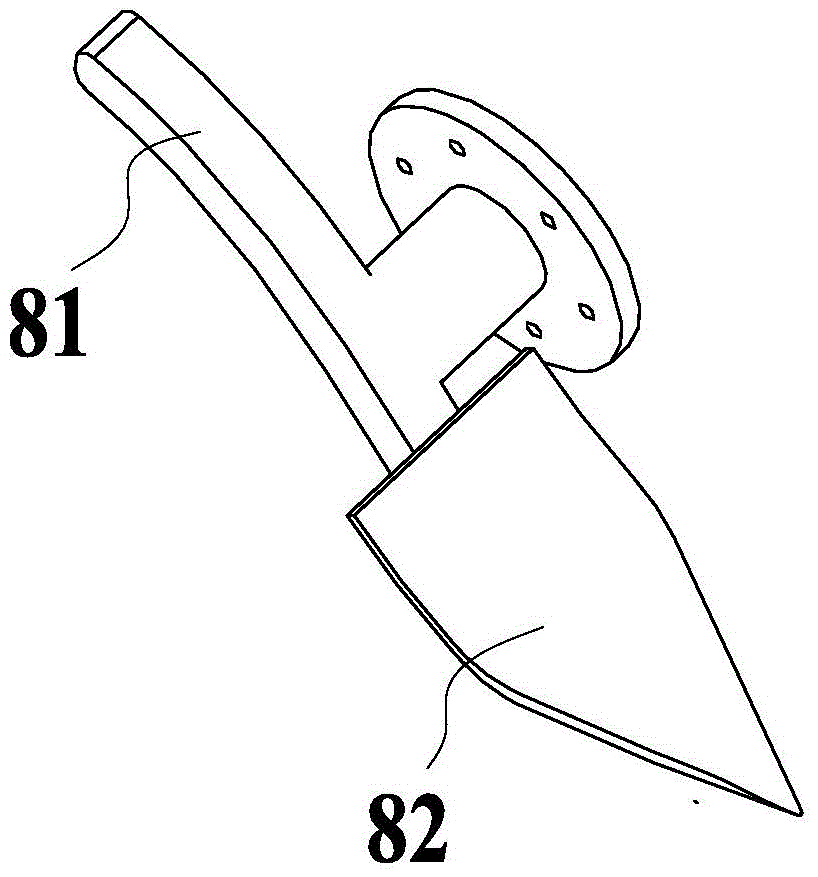

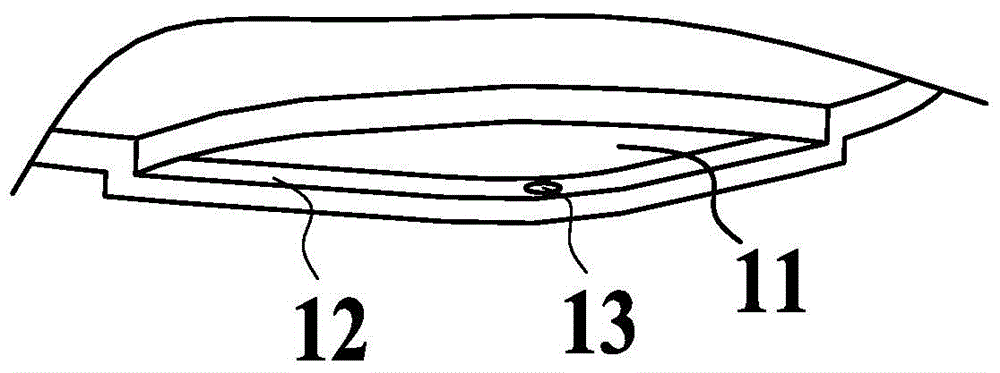

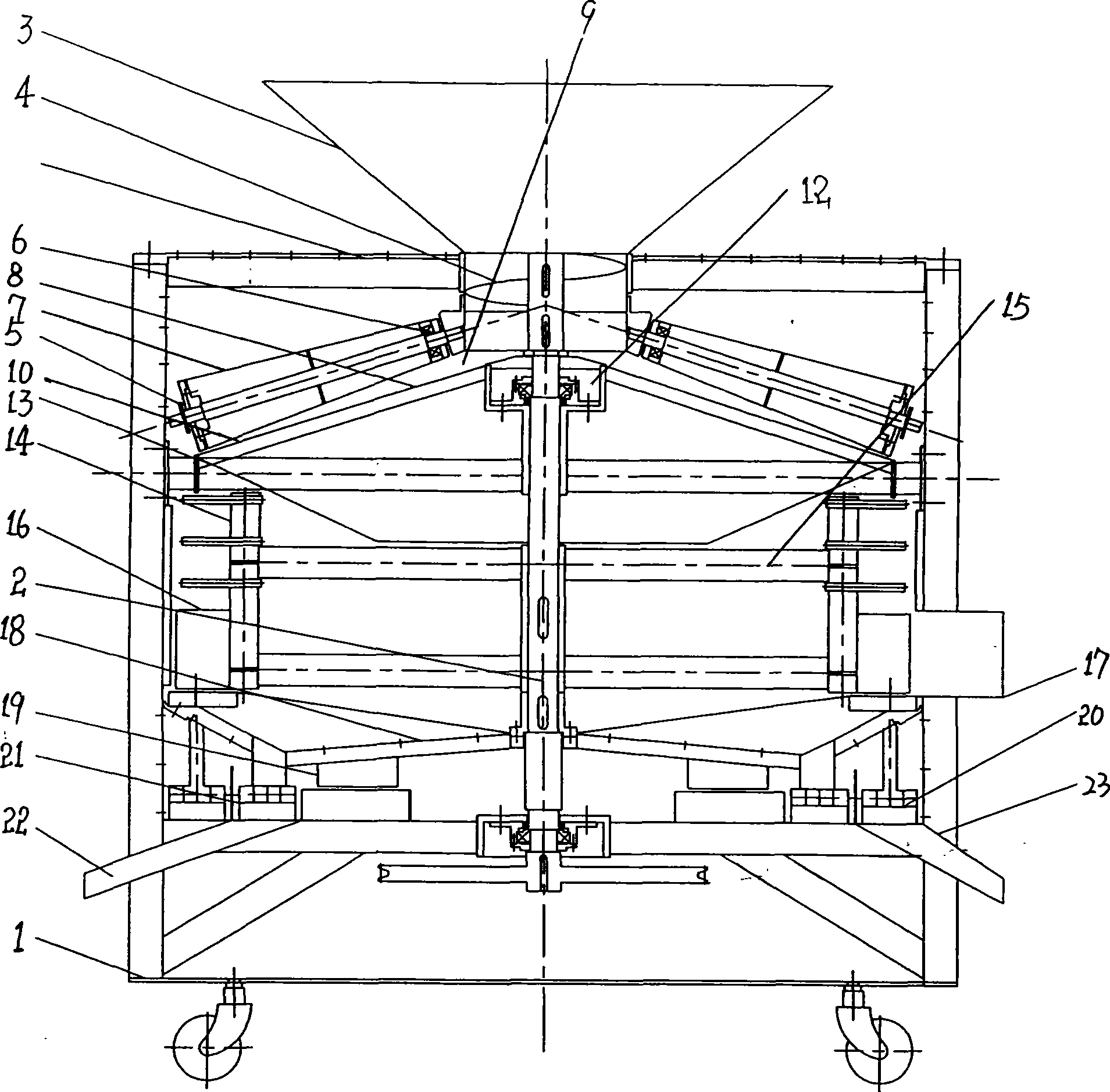

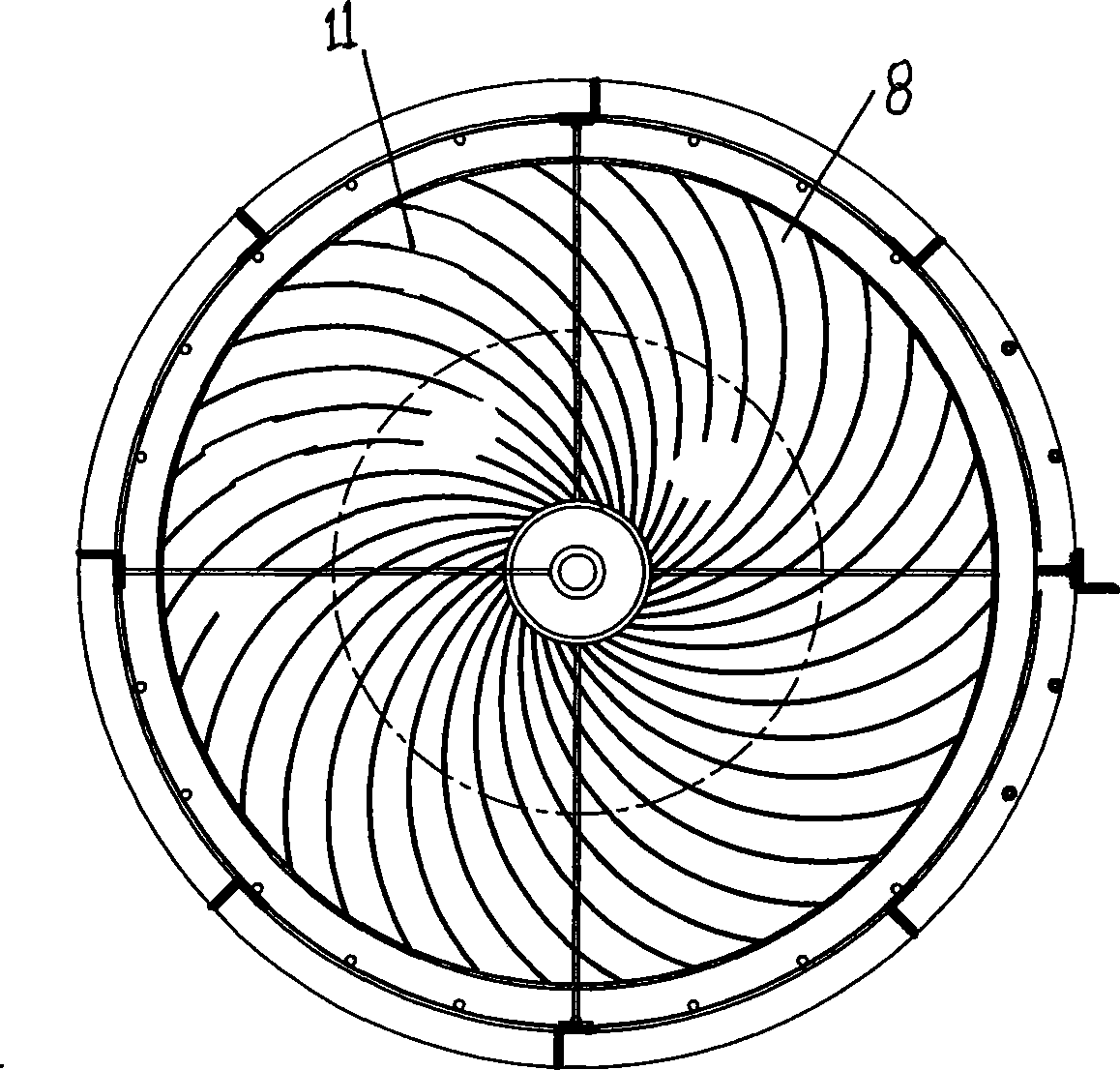

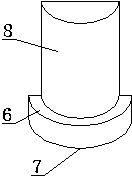

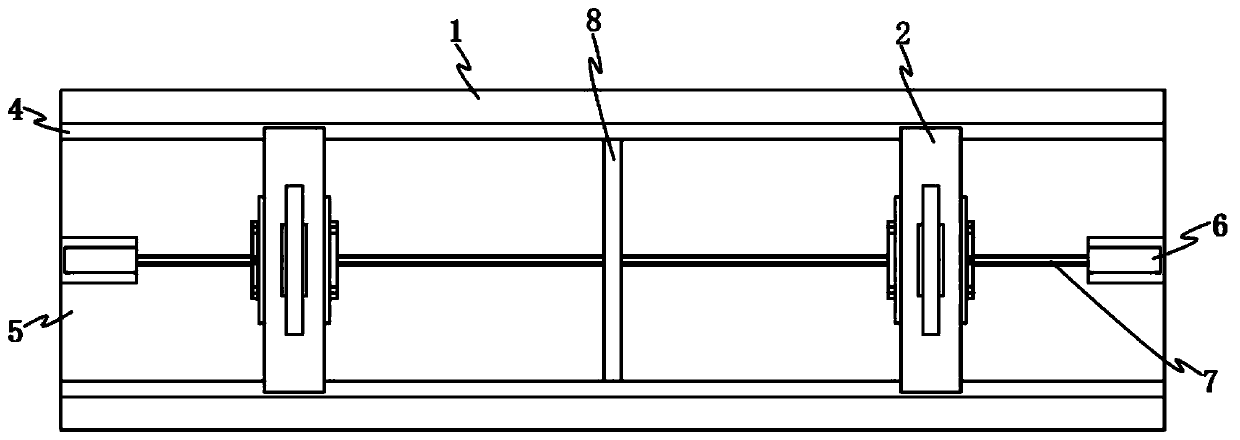

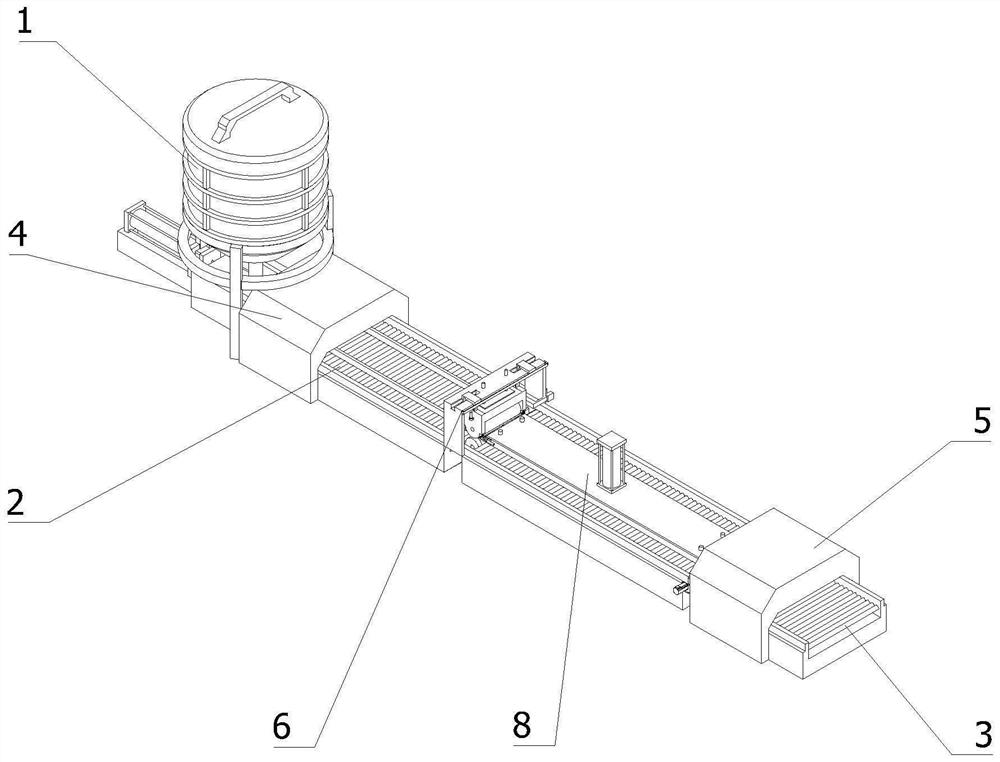

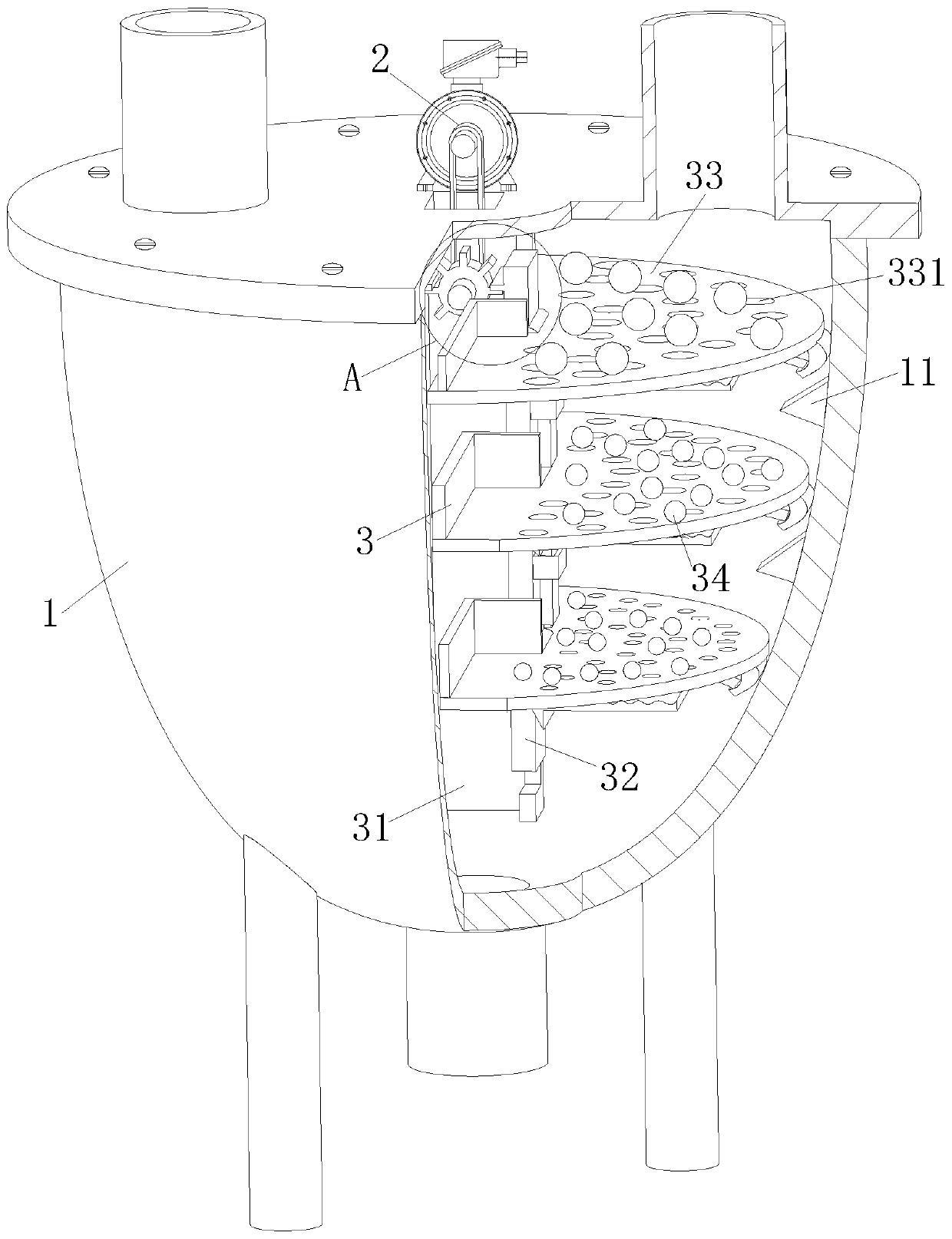

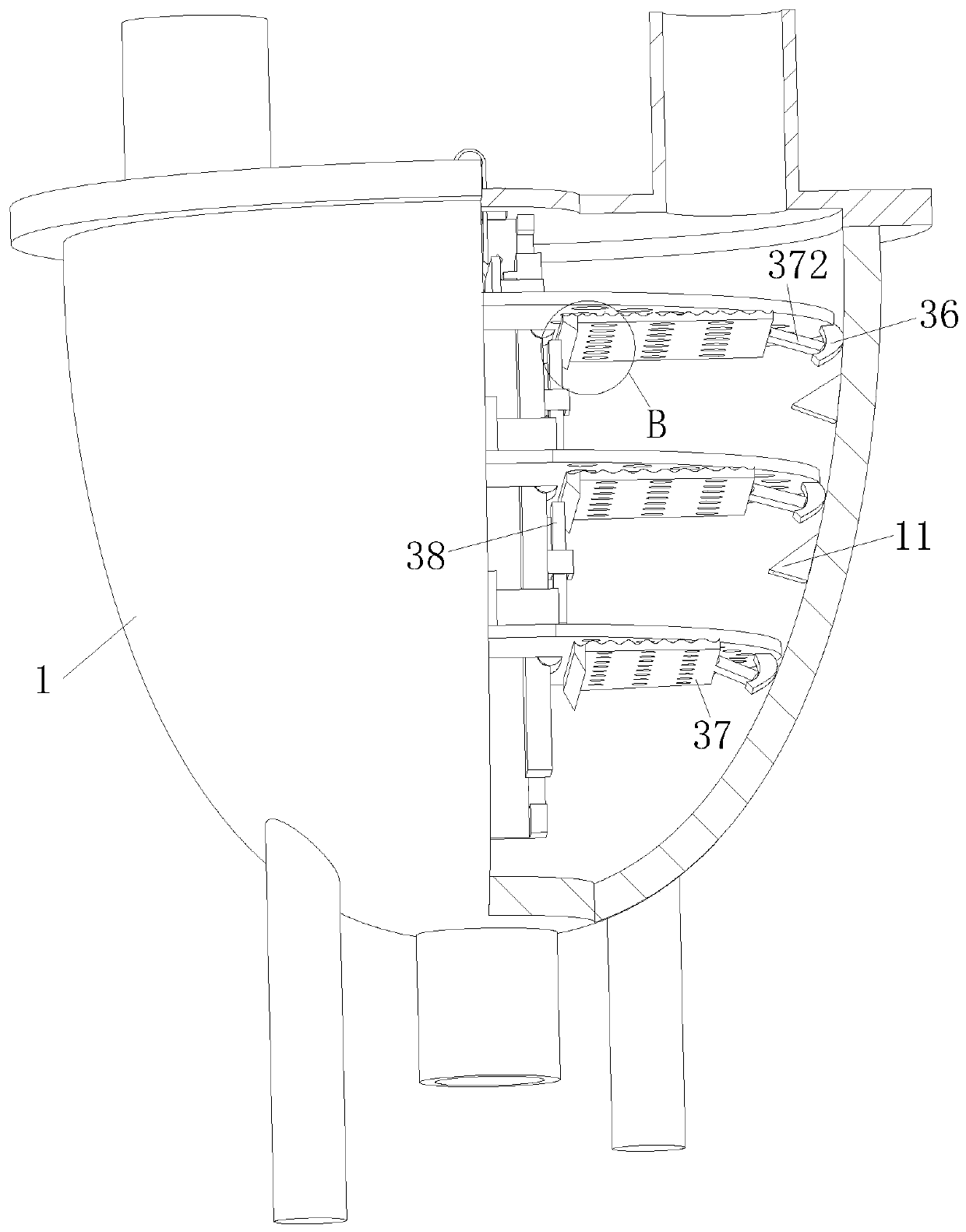

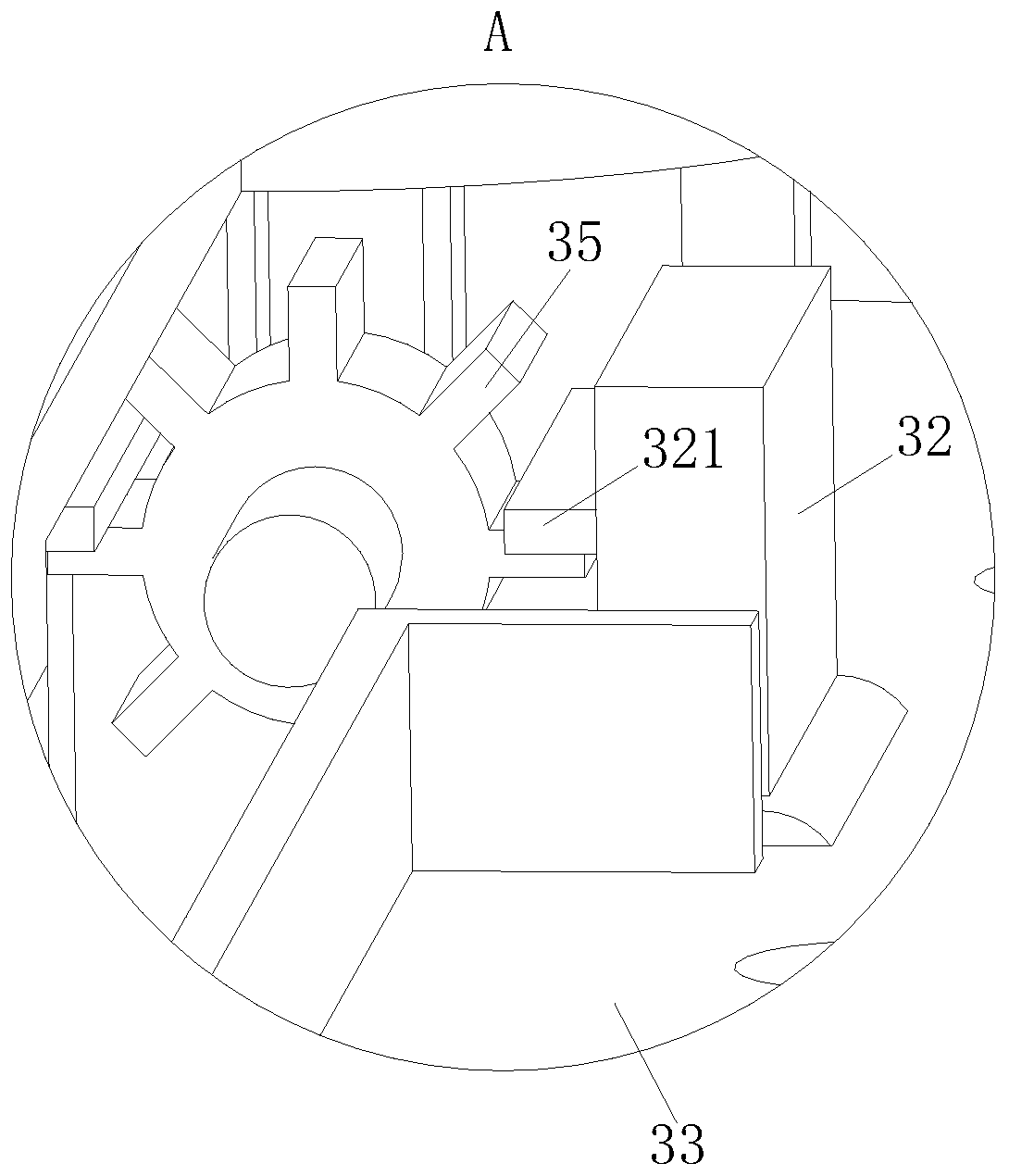

Sand mixing equipment

ActiveCN104815950AAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorEngineering

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

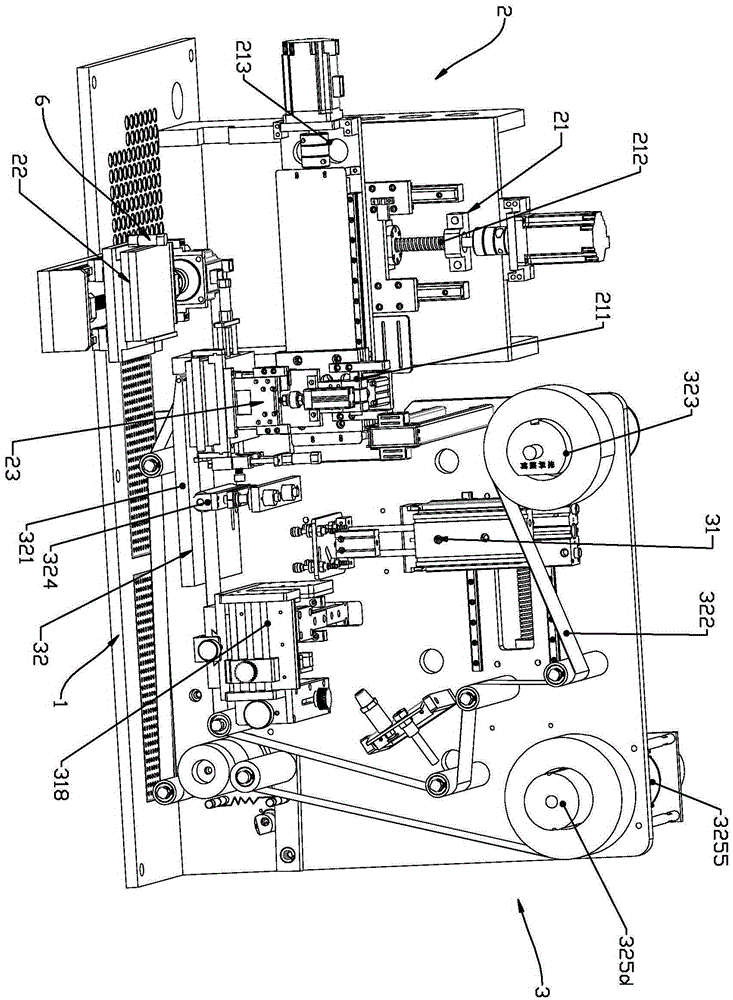

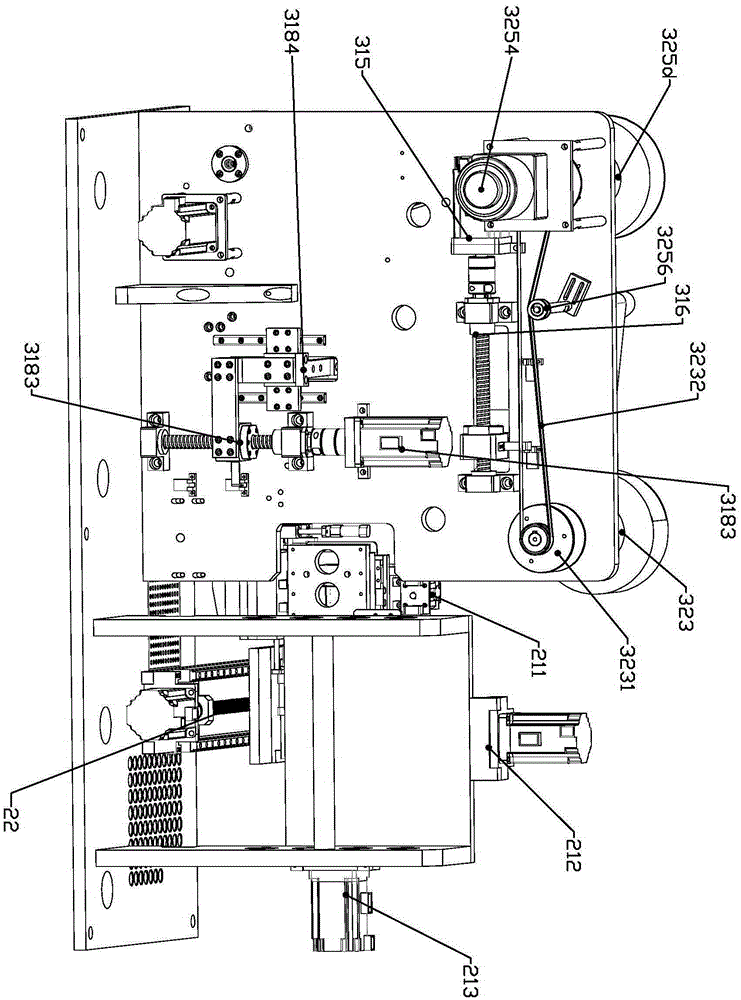

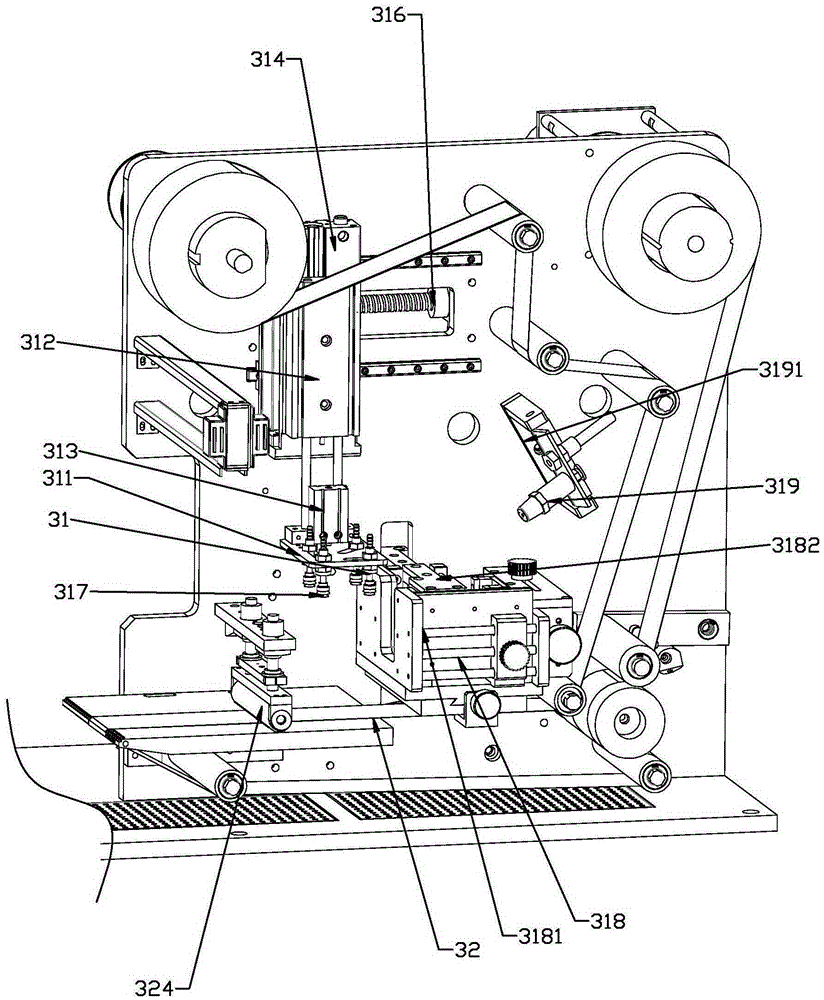

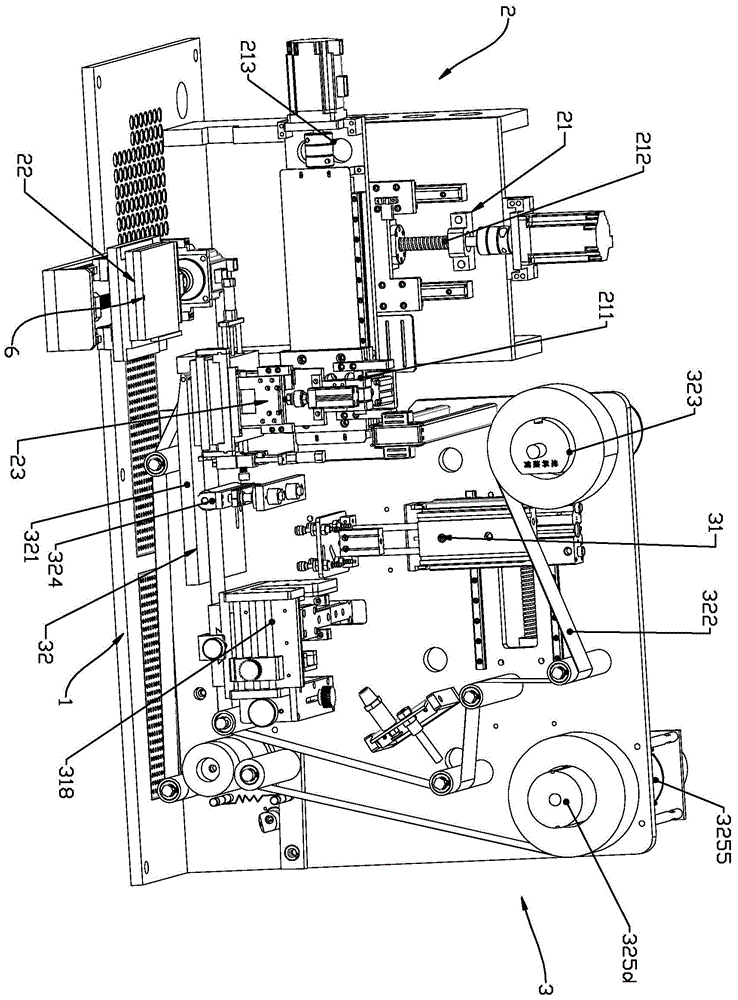

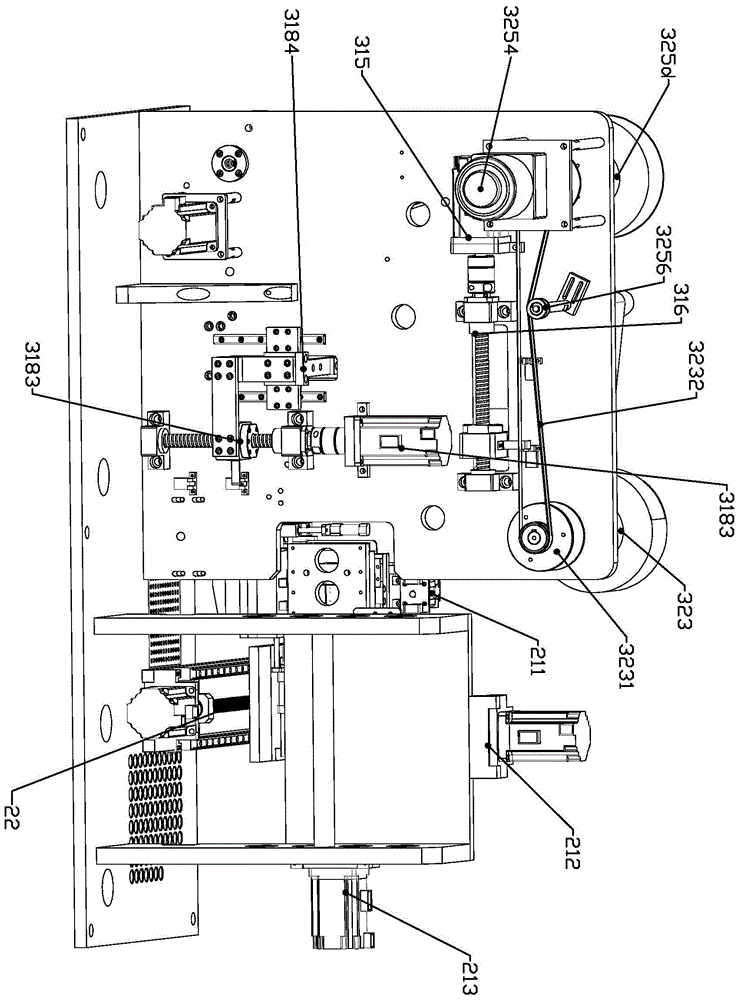

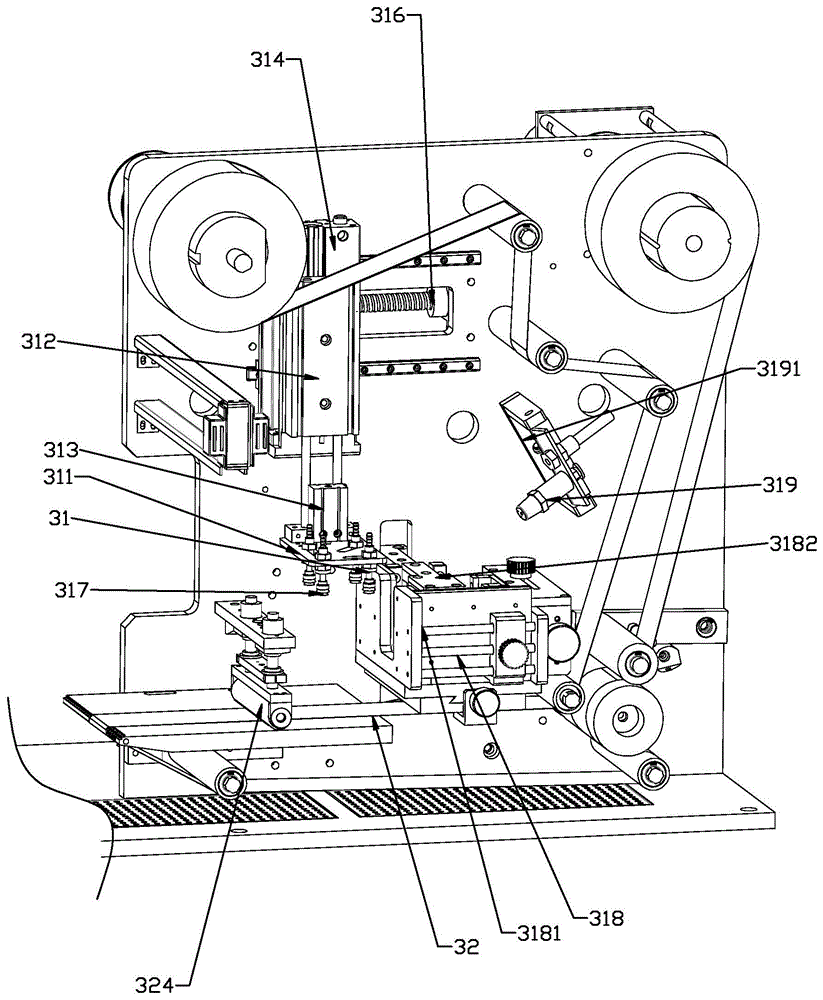

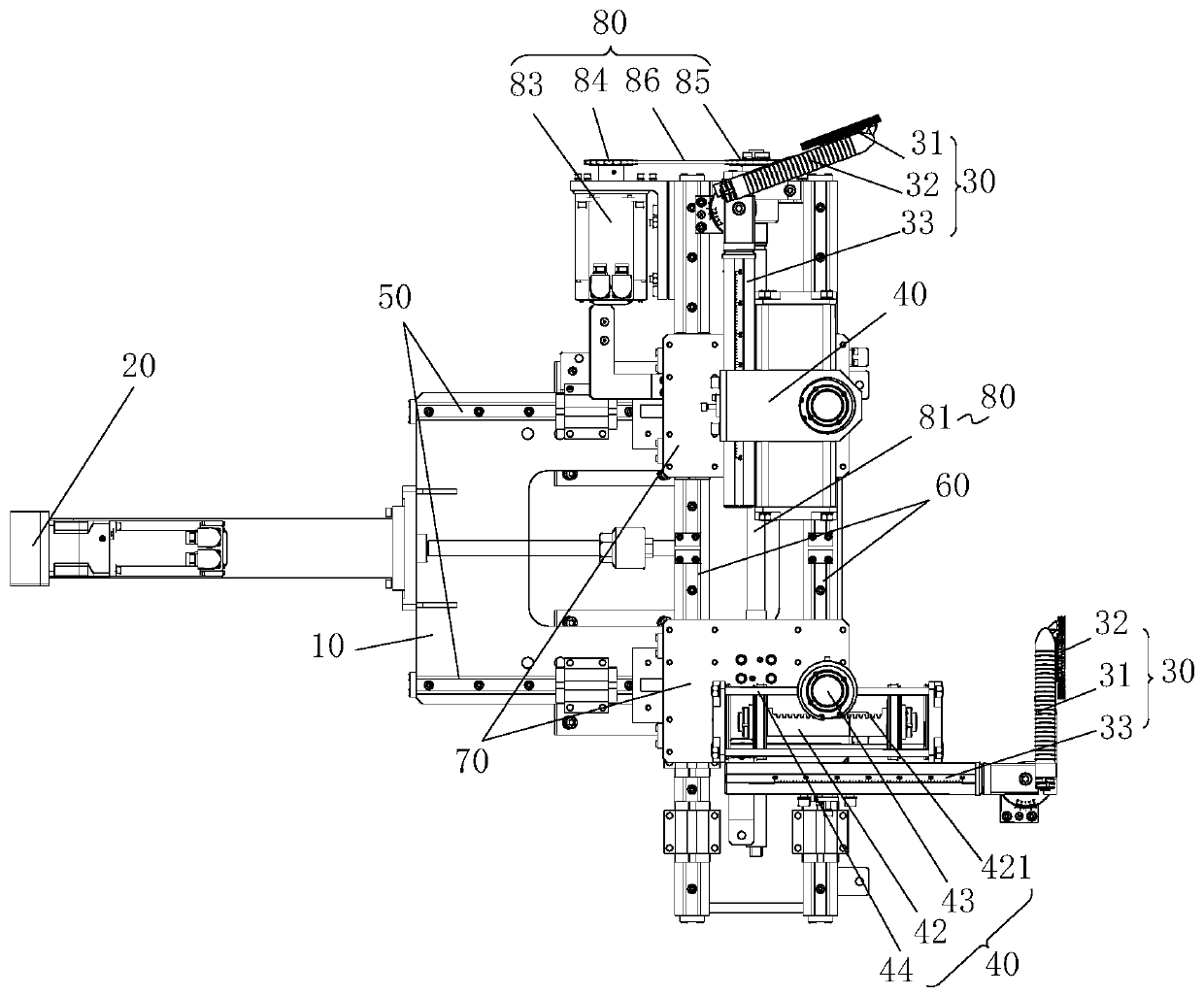

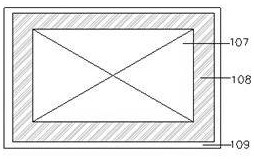

Mobile phone polaroid laminating machine capable of reliably laminating polaroid

InactiveCN105242419AGood for extrusionEasy to operateNon-linear opticsEngineeringMechanical engineering

The invention relates to a mobile phone polaroid laminating machine capable of reliably laminating a polaroid. A polaroid loading mechanism comprises a loading platform longitudinally lifting mechanism, a loading platform station switching mechanism installed on the loading platform longitudinally lifting mechanism and a polaroid loading platform installed on the loading platform station switching mechanism; the polaroid loading platform comprises a laminated polaroid transferring substrate and a laminated polaroid transferring hinged side panel which is installed on the loading platform station switching mechanism, the laminated polaroid transferring substrate is hinged to the bottom end of the laminated polaroid transferring hinged side panel, the side, opposite to the hinged point, of the laminated polaroid transferring substrate can longitudinally rotate around the laminated polaroid transferring hinged side panel, the laminated polaroid transferring substrate is connected with a laminated polaroid transferring cylinder which drives one side edge of the laminated polaroid transferring substrate to rotate, a polaroid aligning mechanism is installed on the laminated polaroid transferring substrate, a vacuum adsorption plate which can absorb and fix the polaroid is installed at the bottom of the laminated polaroid transferring substrate in an attached mode, and a high-speed camera is arranged on the side edge of a vacuum adsorption seat which is fixed through a glass substrate. The mobile phone polaroid laminating machine capable of reliably laminating the polaroid has the advantages of being reasonable in polaroid laminating action and good in polaroid laminating quality.

Owner:WENZHOU ZHIXIN ELECTROMECHANICAL TECH

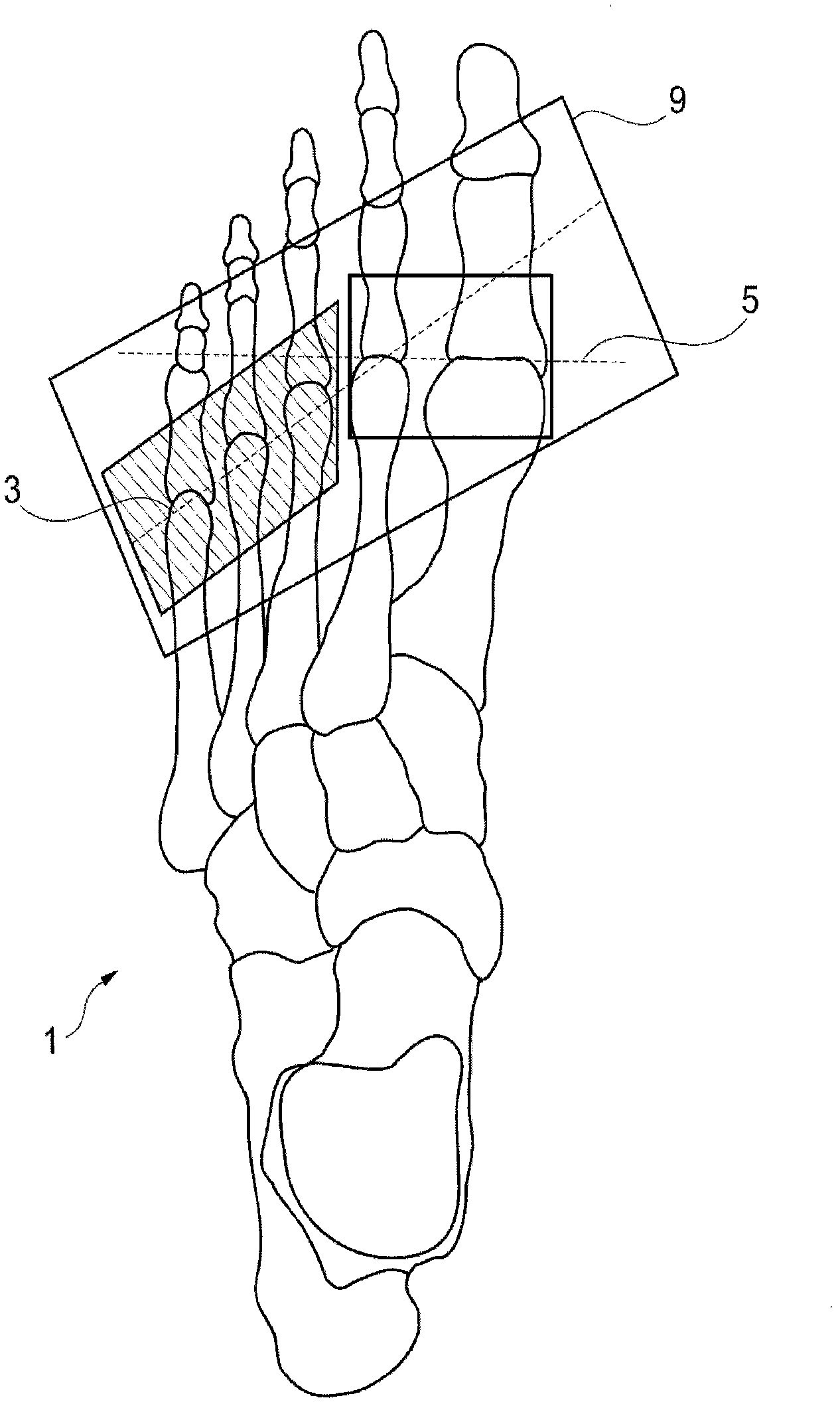

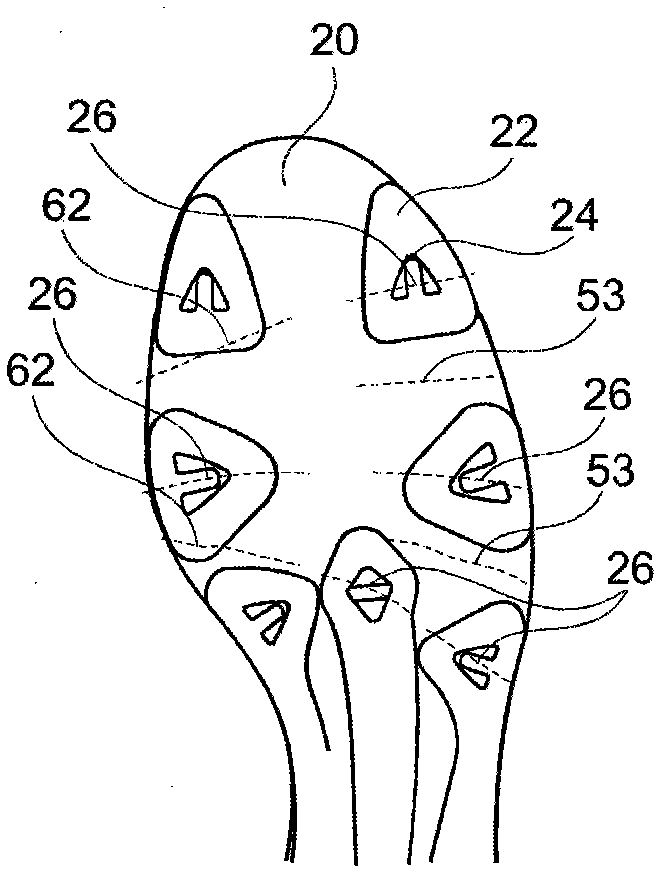

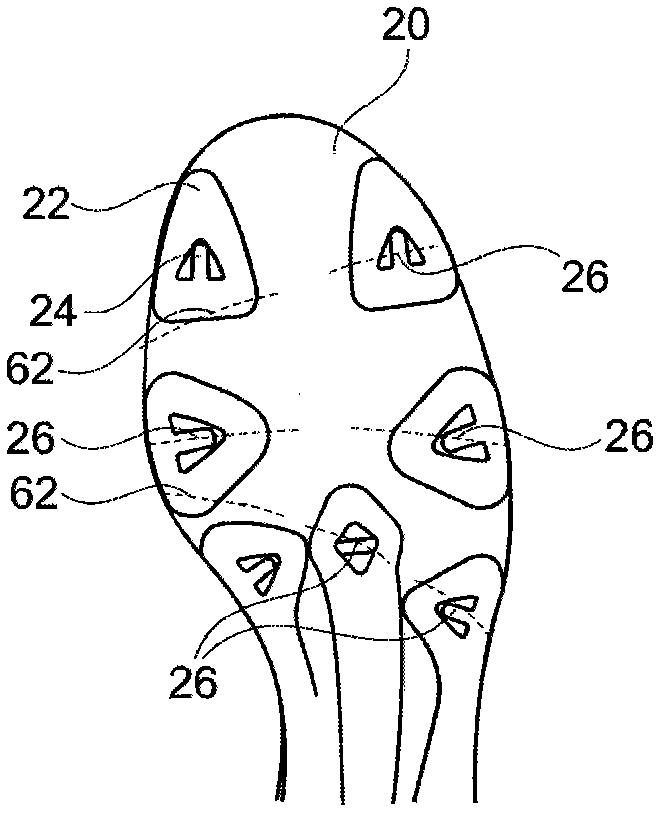

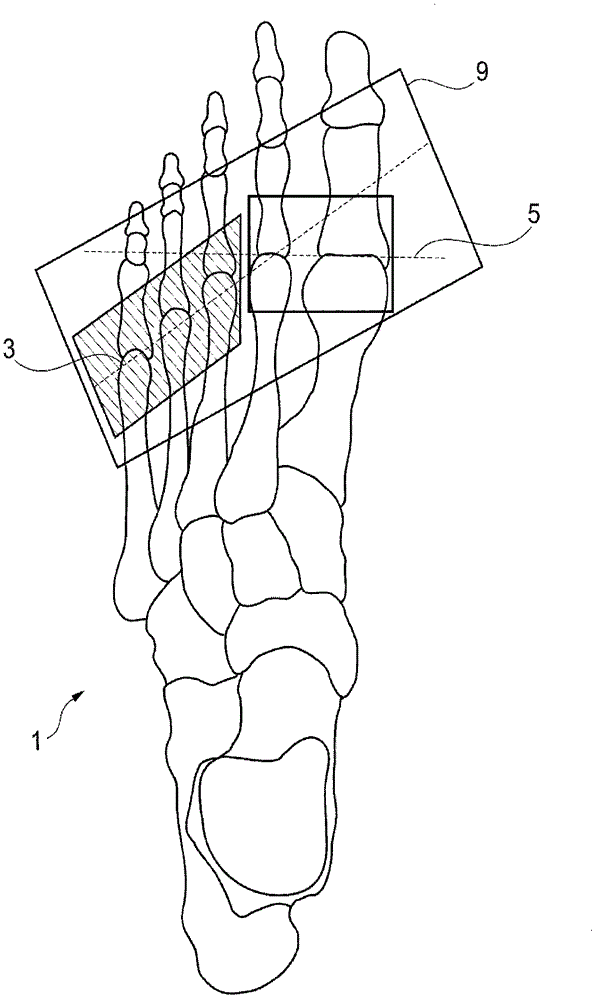

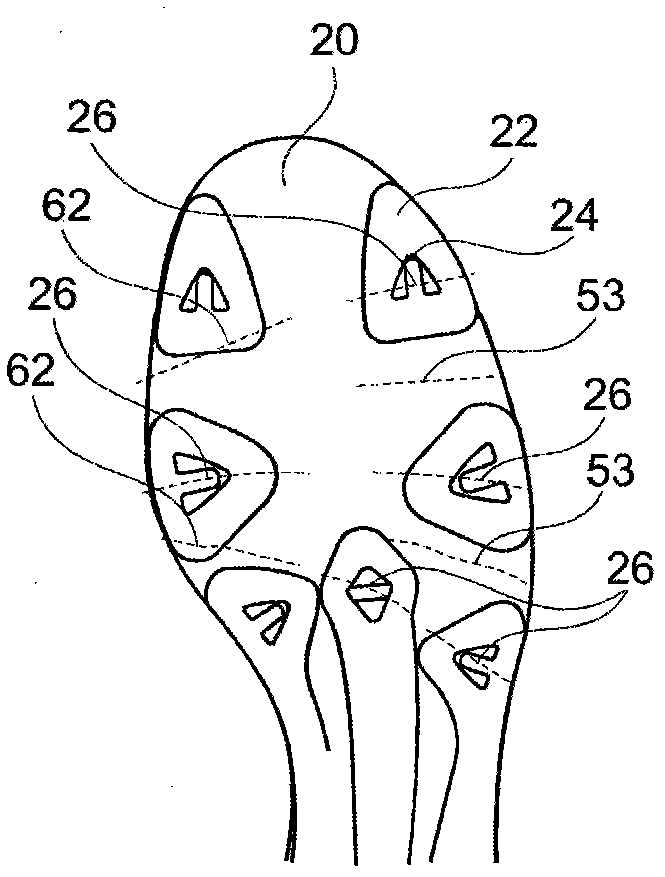

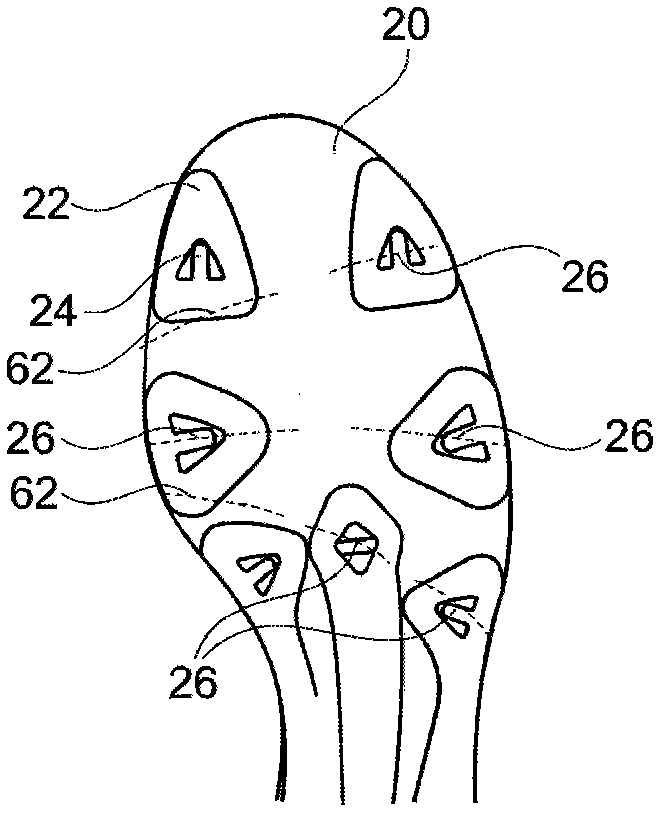

Flexible stud-football boot with elastic flexibility area passing through stud body

InactiveCN102406276AReduce in quantityGood flexibilitySolesFasteningsEngineeringMechanical engineering

Owner:ADIDAS

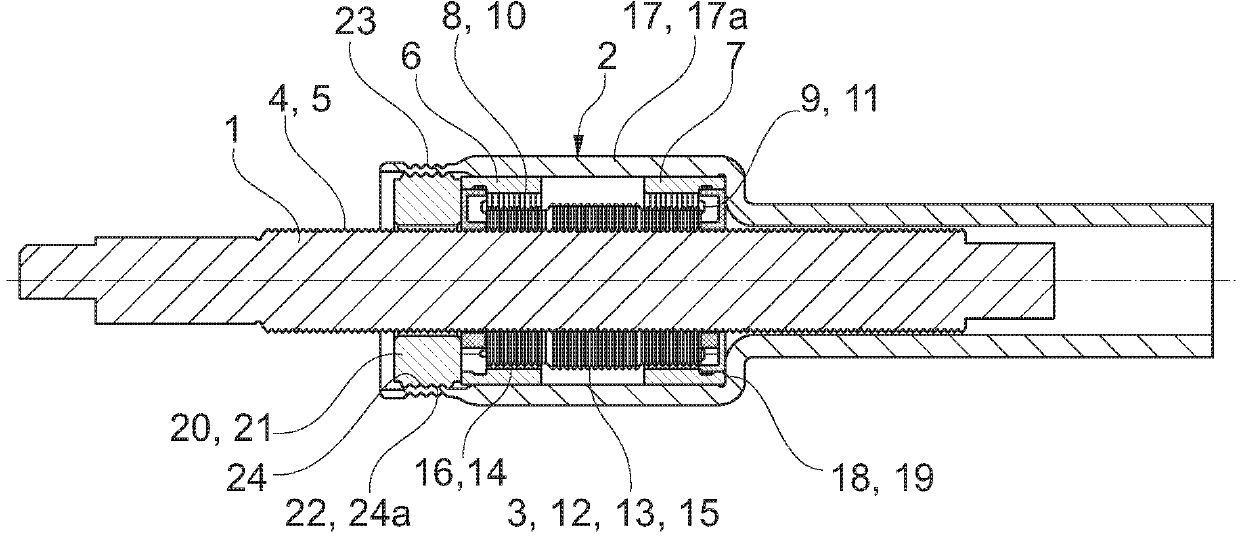

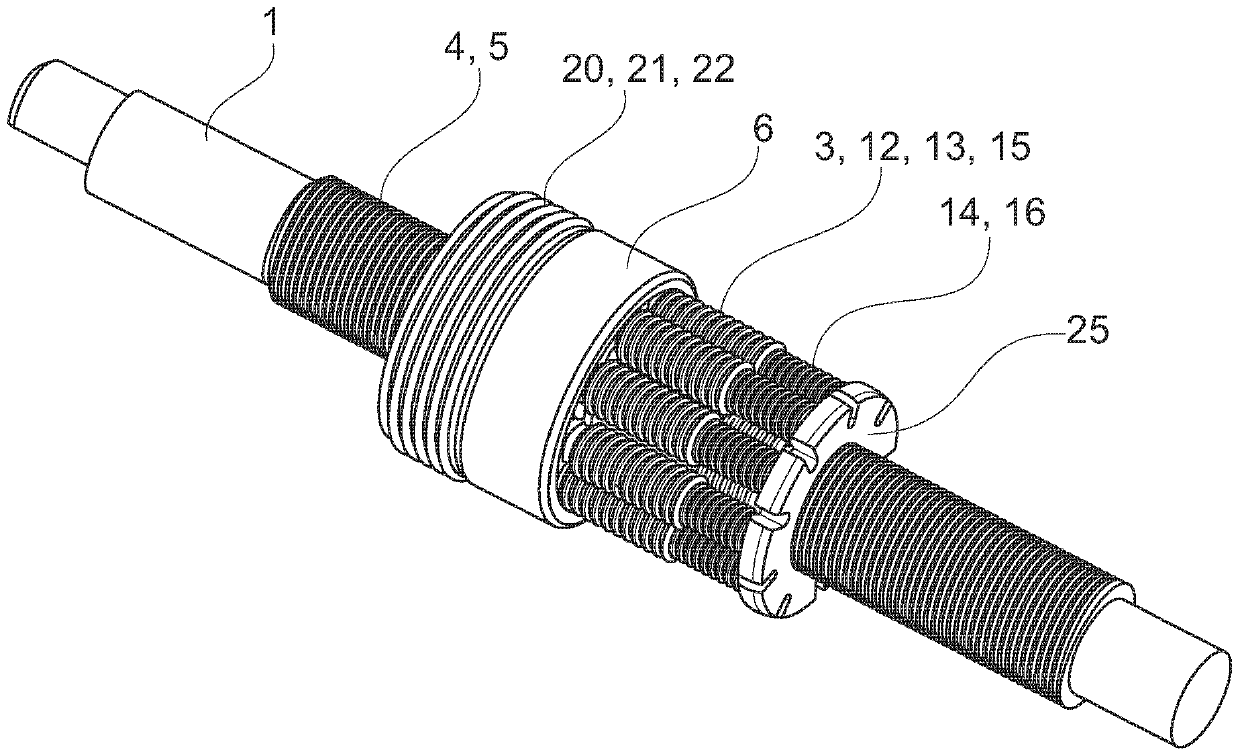

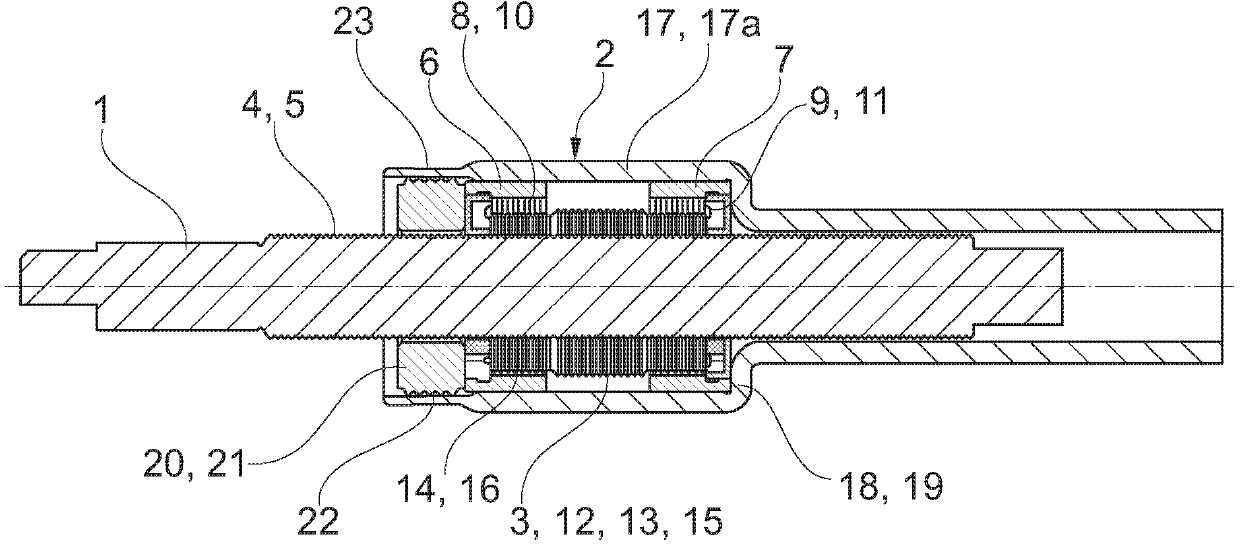

Planetary rolled thread drive

ActiveCN103133619AAchieve rollingPrevent reverse adjustment movementToothed gearingsCouplings for rigid shaftsGear driveEngineering

The invention relates to a planetary rolled thread drive. Planetary roller gear drive with a spindle nut (2) that is arranged on a threaded spindle (1) and is divided into nut parts (6, 7) that can be adjusted relative to each other in the axial direction, and with a plurality of planets (3) that are arranged distributed around a periphery and are in roller engagement with the spindle nut (2) and the threaded spindle (1). An adjustment part (20) set in the axial direction against the one nut part (6) that can be adjusted in the axial direction is provided and the one nut part (6) that can be adjusted in the axial direction is arranged between this adjustment part and the other nut part (7).

Owner:SCHAEFFLER TECH AG & CO KG

Rolling system with efficient cleaning function

PendingCN113385538ANo bendingAchieve rollingMetal rolling stand detailsRolling equipment maintainenceStructural engineeringMechanical engineering

The invention relates to a rolling system with an efficient cleaning function, and relates to the technical field of aluminium plate rolling. The rolling system comprises a machine frame, a lower roller and an upper roller, the horizontally-arranged lower roller is fixedly installed on the inner side of the machine frame, auxiliary supporting rollers parallel to the lower roller are arranged in front of and behind the lower roller, the auxiliary supporting rollers are flush with the top of the lower roller, the upper roller parallel to the lower roller and adjustable in height is arranged above the lower roller, the upper roller and the lower roller are the same in diameter, and one end of the lower roller and one end of the upper roller extend into a transmission box. Materials with different thicknesses can be rolled by adjusting the up-down position of the upper roller, the function of sweeping impurities on the upper and lower surfaces of the lower roller, the upper roller and materials in a rolling brush mode can be achieved through a cleaning mechanism, a horizontal sliding rail pair can drive a first cleaning roller to move, and position adjusting equipment can drive a second driving box to further move a second cleaning roller, so that the condition that the cleaning effect is affected after the first cleaning roller and the second cleaning roller are used and abraded is avoided.

Owner:LUOYANG WANJI ALUMINUM PROCESSING CO LTD

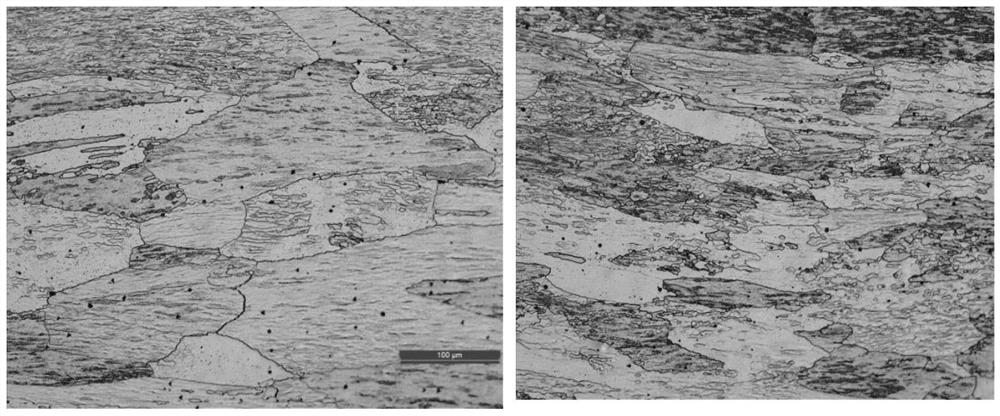

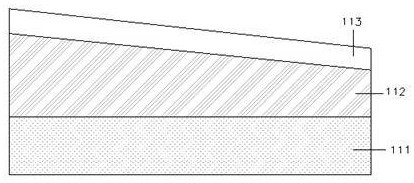

Cerium-containing high-strength non-oriented silicon steel thin strip and preparing method thereof

The invention relates to a cerium-containing high-strength non-oriented silicon steel thin strip and a preparing method thereof. According to the technical scheme, the cerium-containing high-strengthnon-oriented silicon steel thin strip comprises chemical components including, by weight, 3.0%-3.5% of Si, 0.5%-1.0% of Al, 0.1%-1.0% of Mn, 0.01%-0.03% of Ce and the balance Fe and inevitable impurities. Smelting is conducted according to the chemical components of the cerium-containing high-strength non-oriented silicon steel thin strip, a slab is formed in a casting manner under the condition of 1400 DEG C to 1550 DEG C, the slab is subjected to hot rolling under the condition of 1200 DEG C to 1300 DEG C, and a hot-rolled plate with the thickness being 0.8 mm to 1.5 mm is obtained; then thehot-rolled plate is subjected to cold rolling under the condition of the room temperature to reach the thickness being 0.1 mm to 0.3 mm, and the cerium-containing non-oriented silicon steel thin strip is obtained; and then the cerium-containing non-oriented silicon steel thin strip is subjected to recrystallization annealing, and the cerium-containing high-strength non-oriented silicon steel thinstrip is obtained. The cerium-containing high-strength non-oriented silicon steel thin strip and the preparing method thereof have the beneficial effects that the technology is simple, the productioncycle is short, and the preparing cost is low, and the prepared cerium-containing high-strength non-oriented silicon steel thin strip has high strength, low iron losses and high magnetic induction.

Owner:WUHAN UNIV OF SCI & TECH

Lining machine for mobile phone polarizer with reliable alignment

The invention relates to a lining machine for a mobile phone polarizer with reliable alignment. A polarizer loading mechanism comprises a loading platform longitudinal lifting mechanism, a loading platform station switching mechanism and a polarizer loading platform, wherein the loading platform station switching mechanism is mounted on the loading platform longitudinal lifting mechanism; the polarizer loading platform is mounted on the loading platform station switching mechanism; the polarizer loading platform comprises a lining transferring base plate and a lining transferring hinge lateral plate; the lining transferring hinge lateral plate is mounted on the loading platform station switching mechanism; the lining transferring base plate is hinged with the bottom end of the lining transferring hinge lateral plate; a lateral edge of the lining transferring base plate opposite to a hinge point can be rotated along the longitudinal direction of the lining transferring hinge lateral plate; a lining transferring cylinder which is used for driving the lateral edge of the lining transferring base plate to rotate is connected with the lining transferring base plate; a polarizer aligning mechanism is mounted on the lining transferring base plate; a vacuum absorbing plate which is used for absorbing and fixing a polarizer is lined at the bottom of the lining transferring base plate; a high-speed camera is arranged on the lateral side of a vacuum absorbing base fixed by the lining transferring base plate. The lining machine for the mobile phone polarizer with reliable alignment has the advantages of reasonable lining action and high lining quality.

Owner:WENZHOU ZHIXIN ELECTROMECHANICAL TECH

Smashing device with smashed fine powder collecting mechanism for biomass particle production

The invention belongs to the field of smashing devices, and particularly relates to a smashing device with a smashed fine powder collecting mechanism for biomass particle production. The smashing device aims at solving the problem that after existing biomass particles are smashed, no collecting device is arranged, and therefore the particles cannot be conveniently moved out of the smashing deviceafter processing. According to the scheme, the smashing device comprises a smashing box, wherein a mounting cover is rotationally connected to the inner wall of the smashing box; a drive motor positioned above the mounting cover is fixedly mounted in the smashing box; and an output shaft of the drive motor is fixedly connected with the top of the mounting cover. According to the smashing device, arotation motor is started to apply pressure to a pressing wheel, then the drive motor is started to drive the pressing wheel to annularly move, meanwhile, autorotation happens, and therefore the biomass particles can be ground and smashed; and after smashing is finished, a pressing plate can be conveniently taken out, and therefore the biomass particles can be conveniently collected. Therefore, during usage, the smashing device is convenient to use, and very high market popularization prospects are achieved.

Owner:MENGCHENG SHENGYAN STRAW

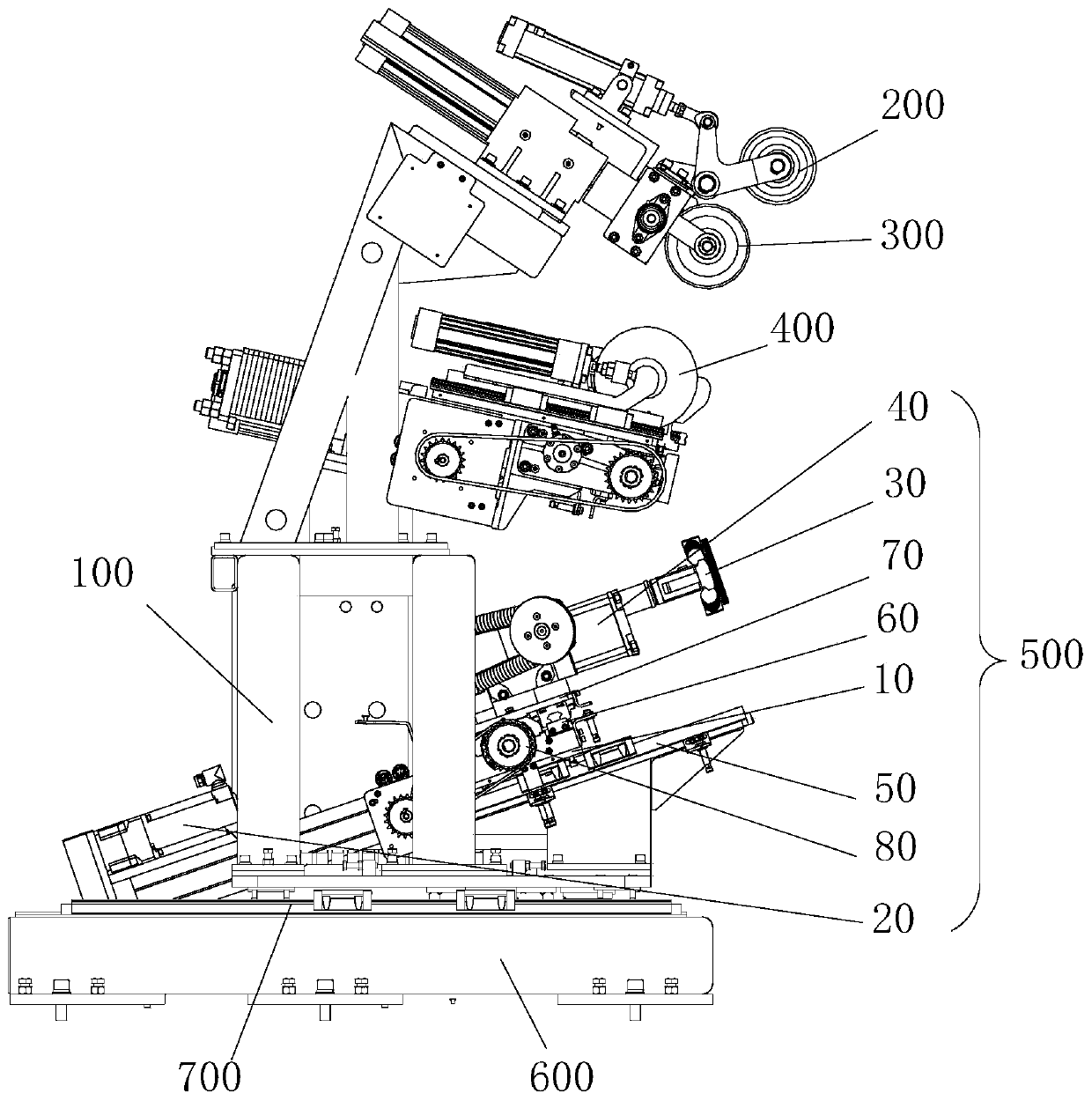

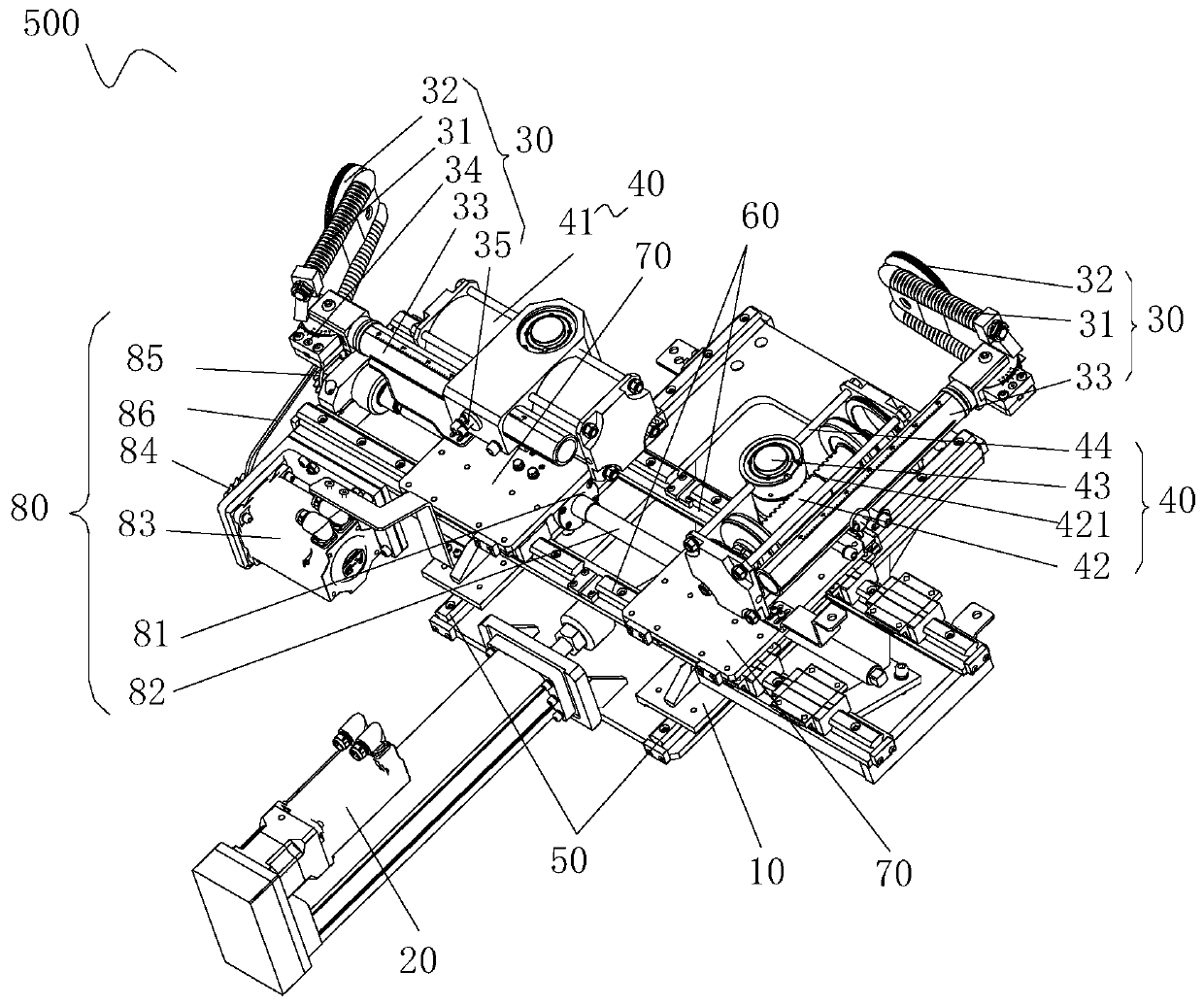

Three-drum forming machine, control method thereof and combined type compression roller equipment

PendingCN110341223AAchieve rollingSuspension turn-down implementationTyresPulp and paper industryTread

The invention provides combined type compression roller equipment, a three-drum forming machine and a control method of the three-drum forming machine. The combined type compression roller device comprises a mounting frame, a central compression roller device, a tire shoulder compression roller device, a tread separating and combining compression roller device and a suspension reverse wrapping compression roller device. The central compression roller device, the tire shoulder compression roller device, the tread separating and combining compression roller device and the suspension reverse wrapping compression roller device are arranged on the mounting frame at intervals in a vertical direction. By means of the technical scheme, the problem that a combined type compression roller in the prior art cannot achieve suspension reverse wrapping of a tire side is solved.

Owner:MESNAC +1

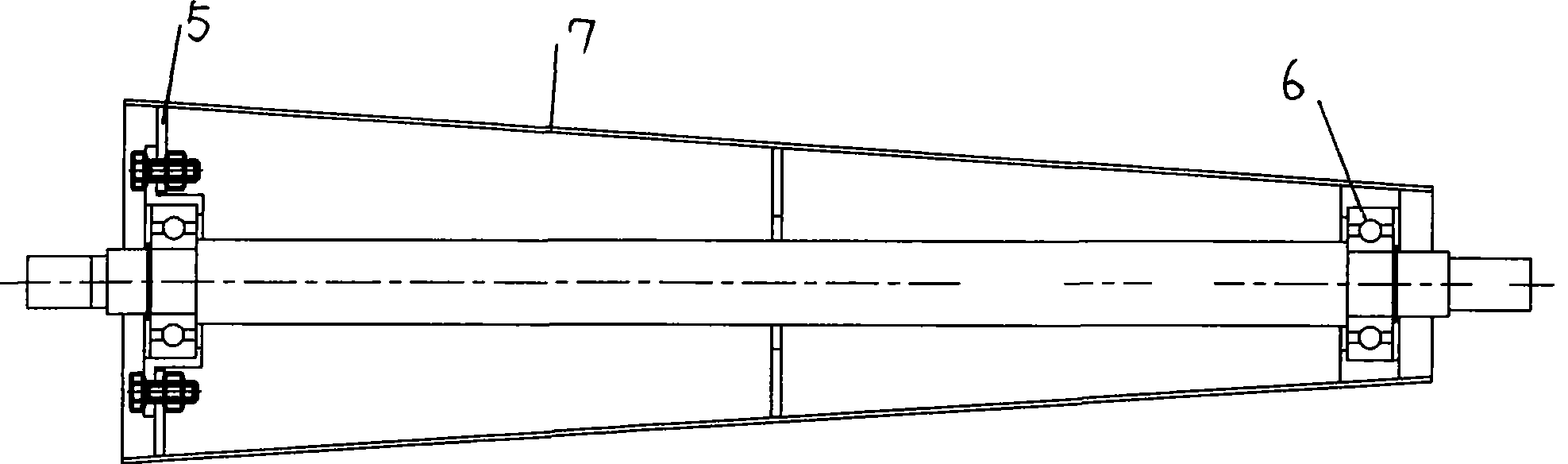

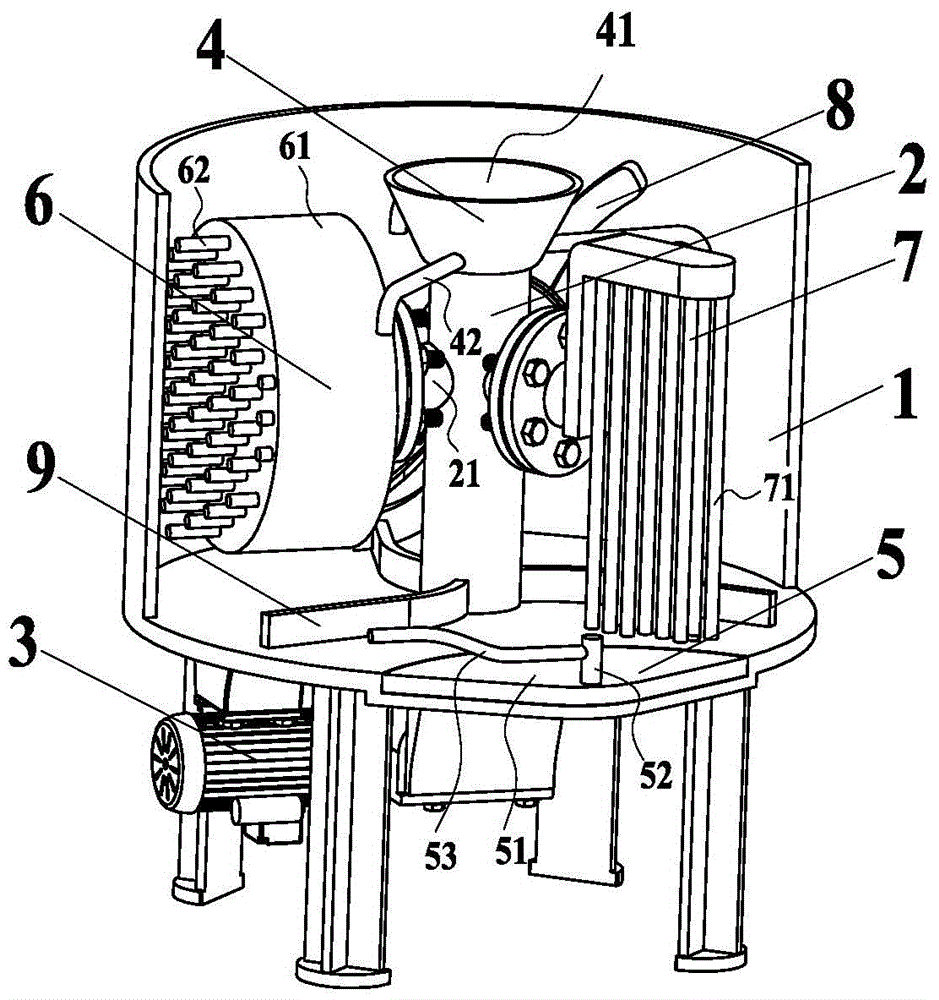

Grinding-rubbing type millet threshing mechanism

The invention relates to the field of agricultural machinery, in particular to a grinding and rubbing type grain threshing device, and solves the problems the prior grain threshing machine such as high grinding rate, high loss rate, low threshing performance and complicated operation. The grinding and rubbing type grain threshing device comprises a machine frame and a main shaft, wherein a feeding hopper is fixed above the machine frame. A feeding device is arranged under the feeding hopper. A cone-shaped grinding roller is arranged under the feeding device. A cone-shaped grinder-vein grid plate fixed with the main shaft is arranged under the grinding roller. An outlet of the feeding device is positioned between an inlet of the grinding roller and an inlet of the grinder-vein grid plate. Through the fit of the grinding roller and the grid plate, the grains between the grinding roller and the grid plate are ground and gradually conveyed around, thereby realizing grinding and rubbing of the grains. Meanwhile, with a cleaning device, the grinding and rubbing type grain threshing device can separate grains from husks and husks from grain ears at one time, avoids 'grinding grains', 'twisting braids' due to high water content and so on during grain threshing, improves threshing performance, reduces loss rate and grinding rate and improves the threshing quality.

Owner:SHANXI AGRI UNIV

Flexible studs - football boots with elastic flexible zones passing through the stud body

Owner:ADIDAS

Deep deoxidation process for fire refining of copper

The invention relates to a deep deoxidation process for fire refining of copper. After the deoxidation impurity removal of fire refining of copper in a reactor reaches a predetermined indicator, two forms of oxygen exists in the reactor actually, namely oxygen [O] in liquid copper containing saturated Cu2O and oxygen (O) in Cu-saturated liquid cuprous oxide, and at the moment, by using compressed air or nitrogen as a carrier, a reducing agent NFA is sprayed into the reactor to perform reduction for 10-90 minutes, wherein the unit consumption is 2-11kg of the reducing agent NFA per ton of copper; the reducing agent NFA reacts with oxygen in a melt in a furnace to generate a gas product; the gas product overflows from the furnace, or generates a slag phase to float on the surface of Cu liquid and is discharged from the furnace, thus realizing the deep deoxidation. The application range comprises a reduction process in the later stage of fire refining of copper in the field of non-ferrous metallurgy, or a melting impurity removal process in early-stage preparation of copper material production. By adopting the process, the remaining oxygen content of copper can be less than 30-1500ppm.

Owner:昆明理工精诚科技有限责任公司

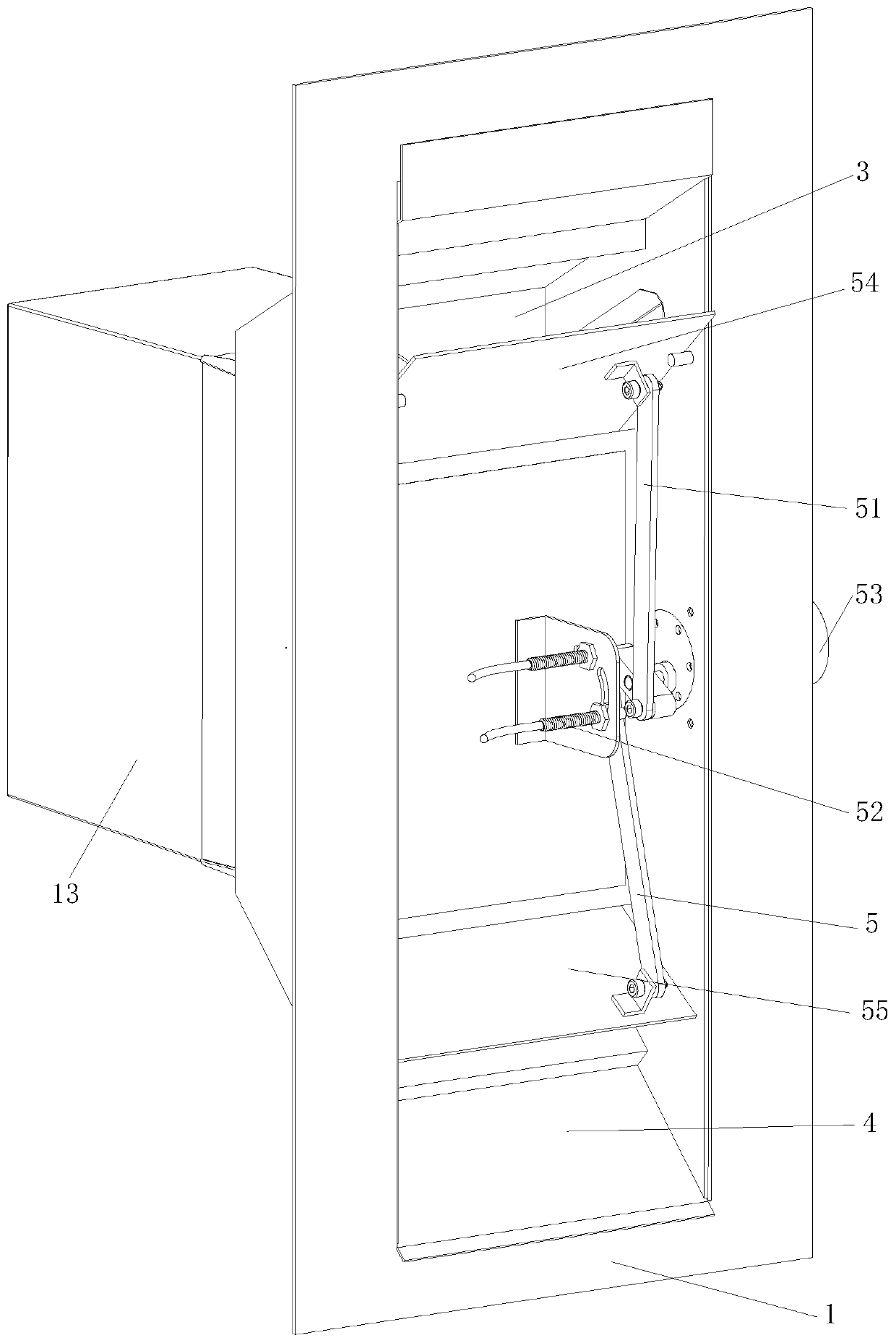

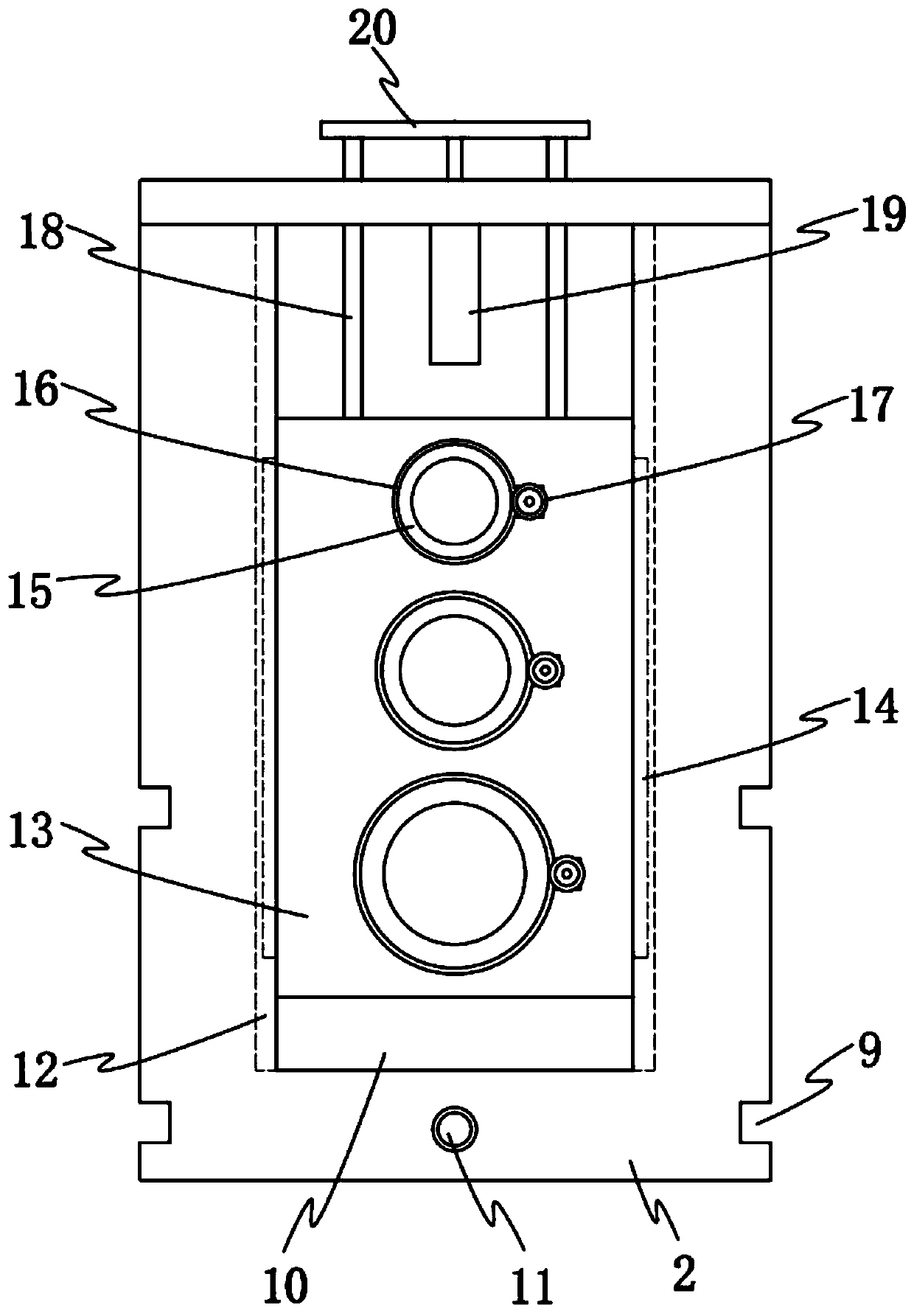

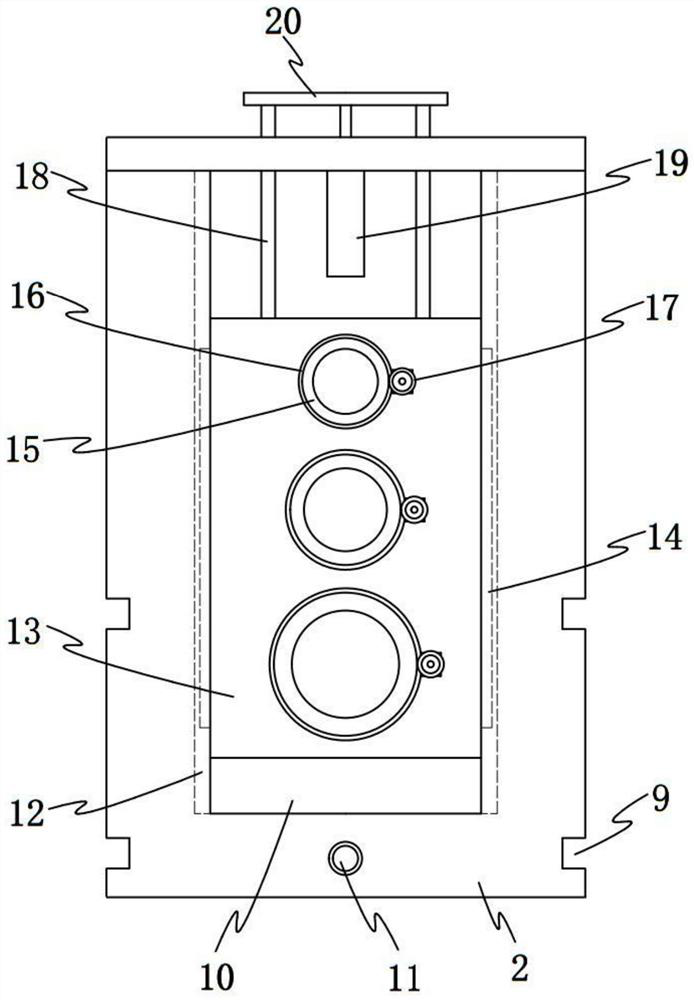

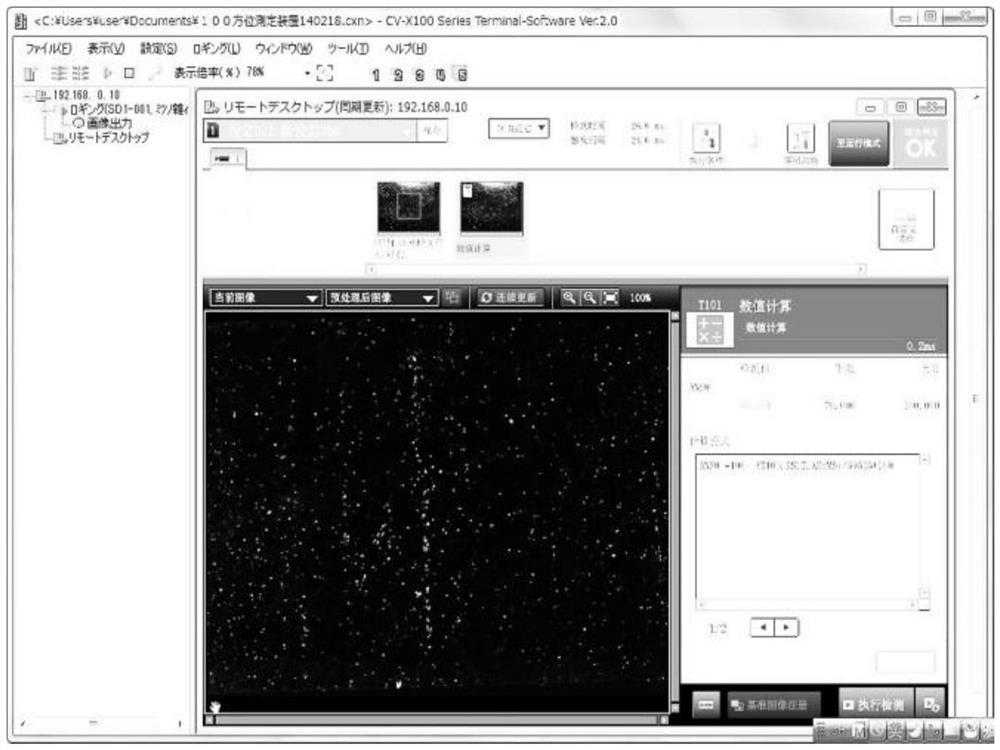

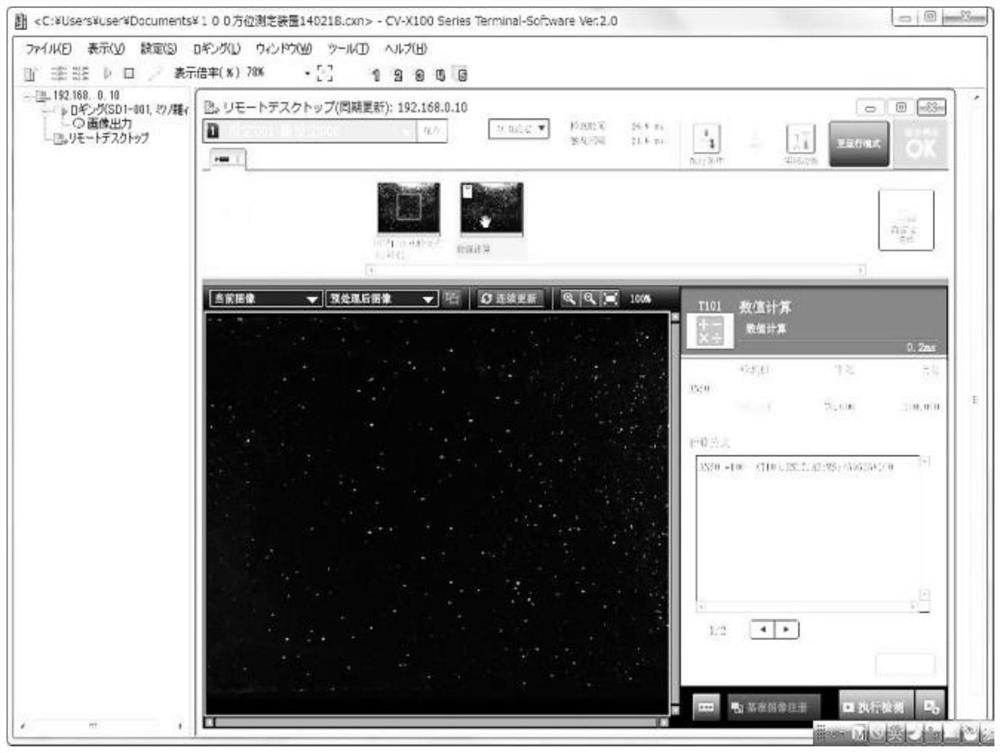

Linkage type closed door structure and grain moisture detector

ActiveCN110376339AAchieve rollingAchieve contactPreparing sample for investigationTesting foodAgricultural engineeringGrain moisture

The invention belongs to the technical field of grain moisture detection, in particular to a linkage type closed door structure and grain moisture detector. The linkage type closed door structure andgrain moisture detector comprises a shell body, a motor No.1 and a controller, wherein the shell body is internally provided with rolling wheels by means of a rotating shaft, a feeding port is arranged above the shell body, a discharging port is arranged below the shell body, and a controller is fixedly mounted on the outer side of the shell body; the controller is used for controlling the automatic operation of the device; two of the rolling wheels are set; and the rotating shaft is driven by means of the motor No.1. The linkage type closed door structure and grain moisture detector further comprises a closed door module and a rolling module, wherein the closed door module is used for closing or opening the feeding port and the discharging port in a linked manner, and comprises a connecting rod, a proximity switch, a motor No.2, a rotating base, an upper sealing plate and a lower sealing plate. The linkage type closed door structure and grain moisture detector improves the precision of grain moisture detection through fully rolling the grain by means of the rolling module and the rolling wheels in cooperation, realizes the linkage between the upper sealing plate and the lower sealing plate by means of the closed door module, and enables the feeding port and the discharging port to be kept in a synchronized open or closed state.

Owner:ANHUI OCEAN AUTOMATION EQUIP

A thin strip of cerium-containing high-strength non-oriented silicon steel and its preparation method

The invention relates to a cerium-containing high-strength non-oriented silicon steel strip and a preparation method thereof. The technical solution is: the chemical composition of the cerium-containing high-strength non-oriented silicon steel strip is: Si is 3.0-3.5wt%, Al is 0.5-1.0wt%, Mn is 0.1-1.0wt%, Ce is 0.01-0.03 wt%, the rest is Fe and unavoidable impurities; it is smelted according to the chemical composition of the cerium-containing high-strength non-oriented silicon steel strip, and cast into slabs at 1400-1550 °C, and the slabs are heated at 1200-1300 hot-rolled at ℃ to a hot-rolled sheet with a thickness of 0.8-1.5mm; then cold-rolled the hot-rolled sheet at room temperature to 0.1-0.3mm to obtain a cerium-containing non-oriented silicon steel strip; and then The cerium-containing non-oriented silicon steel thin strip is subjected to recrystallization annealing, and the cerium-containing high-strength non-oriented silicon steel thin strip is obtained. The invention has the characteristics of simple process, short production cycle and low preparation cost, and the prepared cerium-containing high-strength non-oriented silicon steel strip has high strength, low iron loss and high magnetic induction.

Owner:WUHAN UNIV OF SCI & TECH

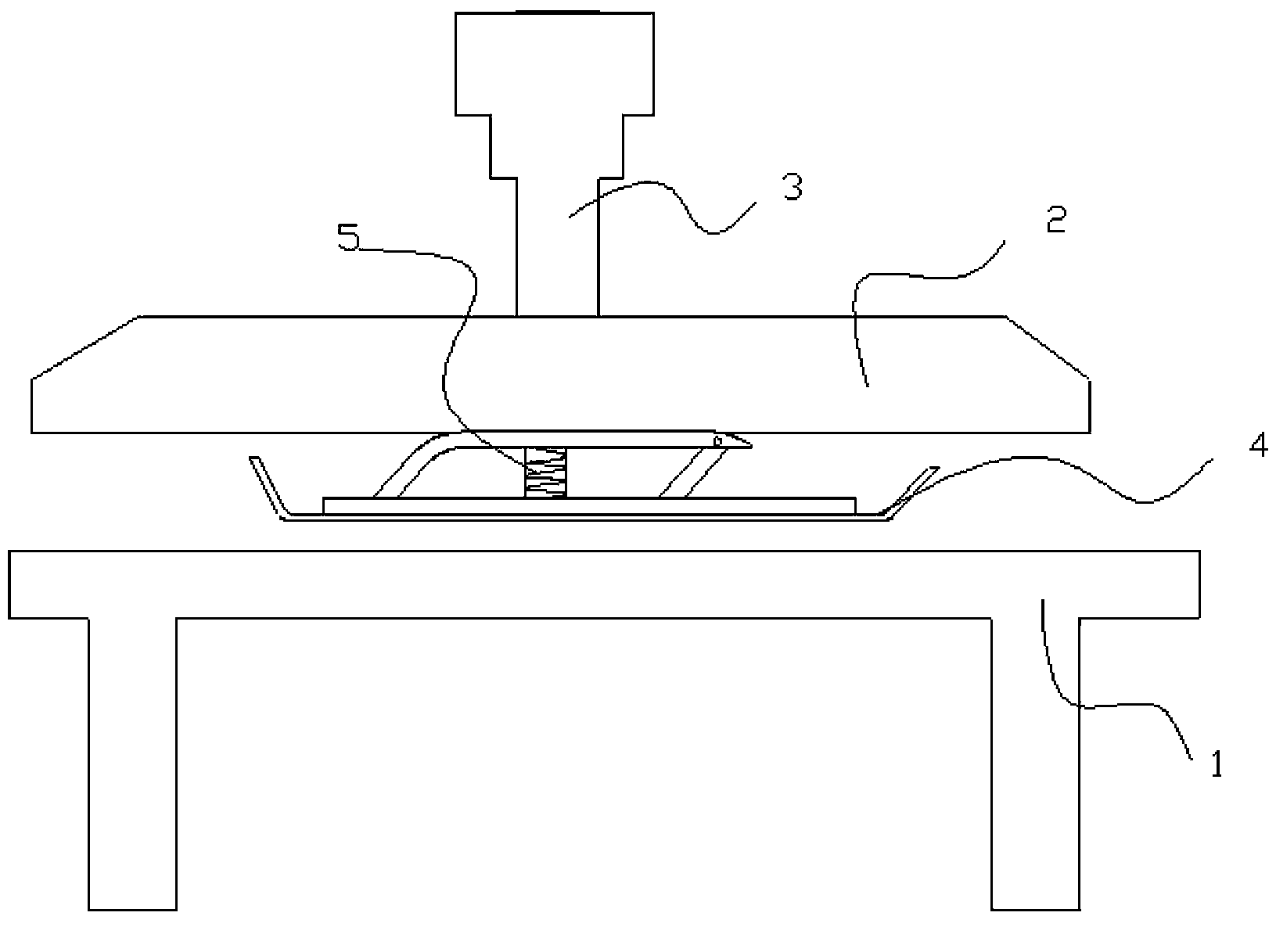

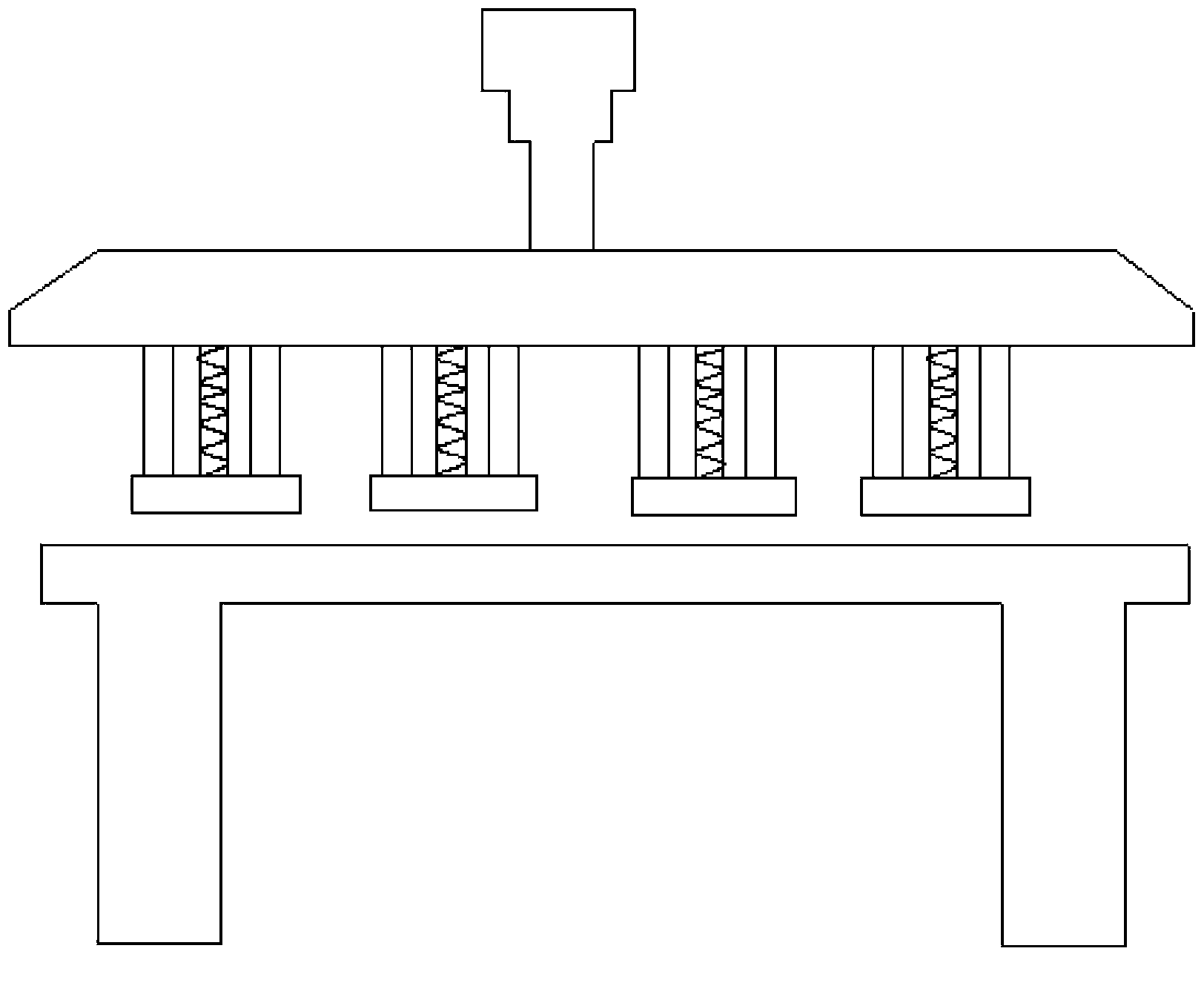

Paper board forming grinding device

InactiveCN103407622APrevent uneven rollingSimple structureMechanical working/deformationPackagingCardboardPulp and paper industry

The invention provides a paper board forming grinding device, and relates to the field of paper product packaging machines. The body of the paper board forming grinding device is a base, a pressing board is arranged above the base and suspended above the base through the connection with an air pump, a plurality of iron boards are evenly arranged between the pressing board and the base, and the iron boards are fixed to the pressing board. The paper board forming grinding device has the advantages that the structure is simple, the design is novel, a paper board can be effectively prevented from being unevenly grinded in the grinding process, the appropriate pressure can be adjusted according to the requirement of the paper board, and working efficiency is improved.

Owner:BENGBU SHENHUI COLOR PRINTING & PACKAGING LIMITED

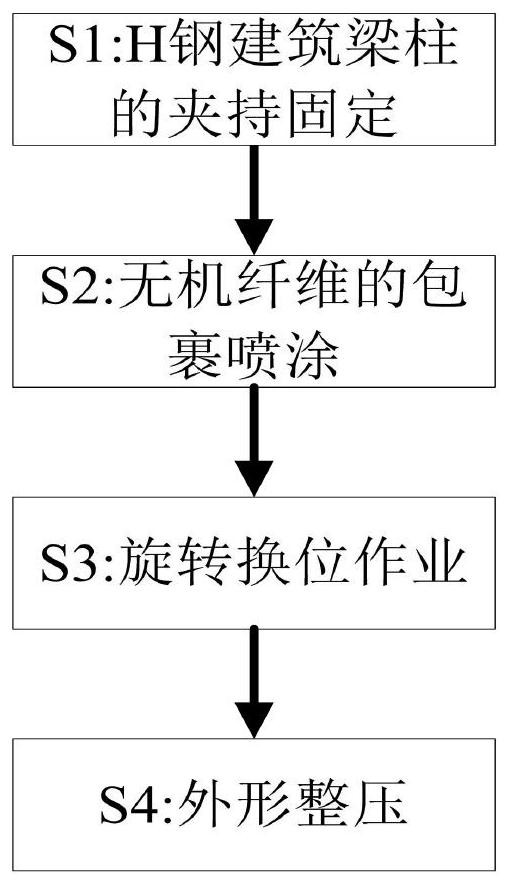

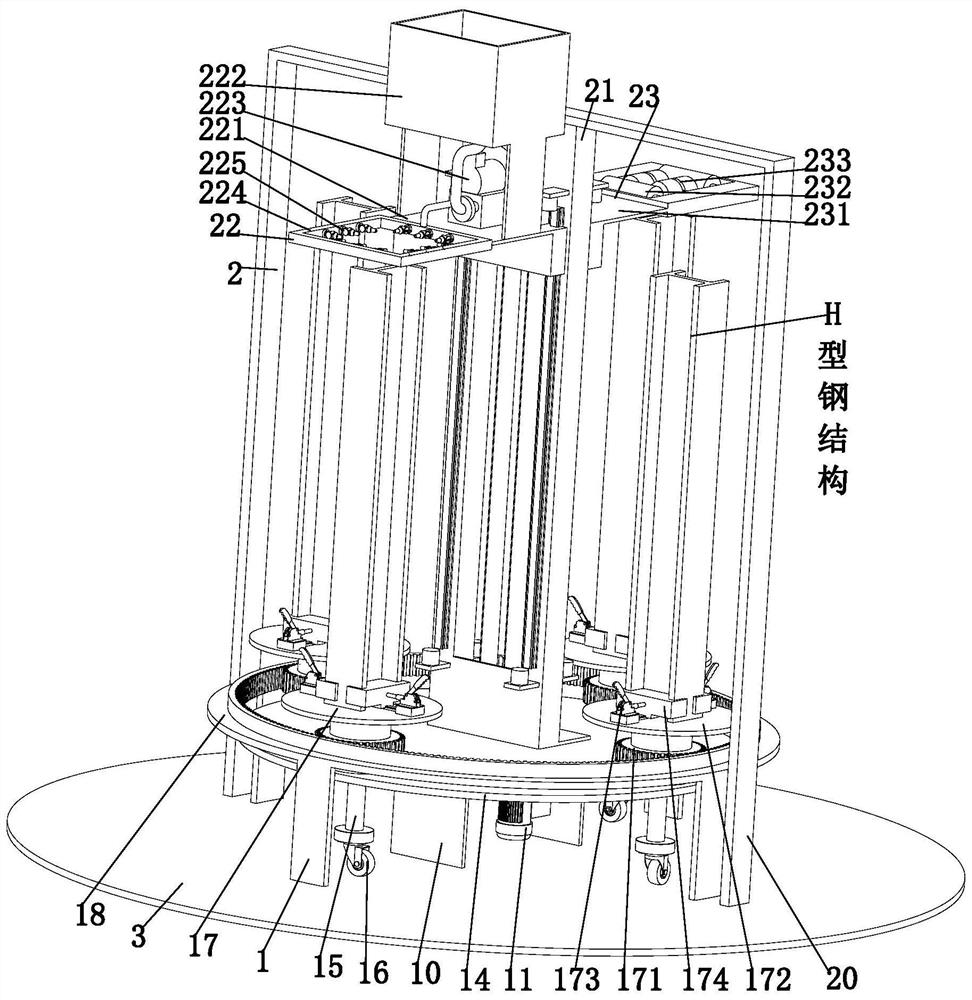

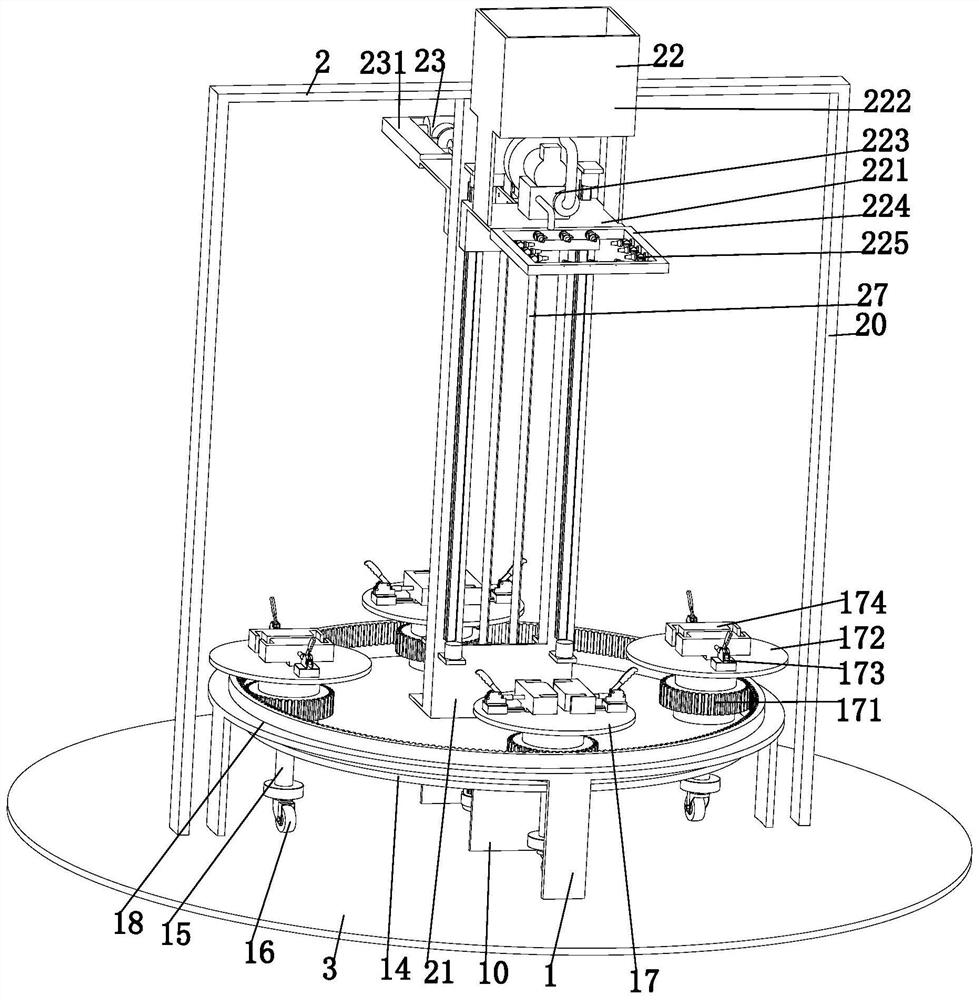

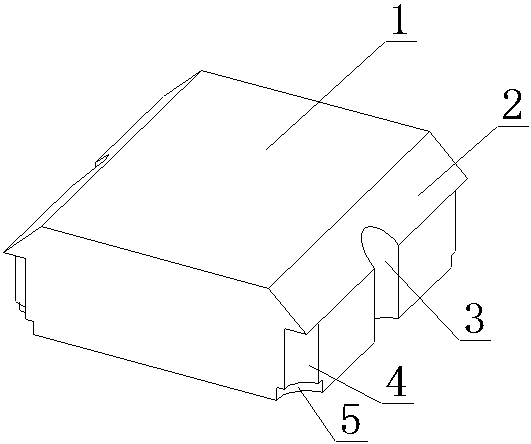

Method for establishing fabricated building steel structure beam column heat preservation system

ActiveCN112523350AQuality improvementStable position transferPassive housesHeat proofingFiberClassical mechanics

The invention provides a method for establishing a fabricated building steel structure beam column heat preservation system. The fabricated building steel structure beam column heat preservation system comprises a rotating mechanism, a lifting type spraying mechanism and a circular plate, the rotating mechanism is installed on the circular plate, the lifting type spraying mechanism is arranged inthe center of the rotating mechanism, and the lifting type spraying mechanism is installed on the circular plate. The problems that at present, inorganic fiber spraying for a steel structure adopts manual spraying, the working intensity is high, the surface of the H-shaped steel structure cannot be uniformly sprayed, the spraying thickness of an inorganic fiber spraying layer cannot be ensured, acoating cannot be rolled and shaped to enable a flat appearance to be formed on the surface of the coating, and a better use effect cannot be achieved are solved.

Owner:山东东珠新型房屋科技有限公司

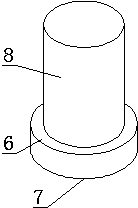

Ecological water-accumulation-proof parking lot and laying method

InactiveCN107663821AFirmly connectedEasy outflowSingle unit pavingsPaving gutters/kerbsEngineeringDrainage ditch

The invention relates to an ecological water-accumulation-proof parking lot and a laying method. The ecological water-accumulation-proof parking lot comprises a parking lot, wherein the parking lot comprises ground tiles, connecting parts and base plates; the bottom surface of each ground tile is square and an inclined edge is arranged at the upper part of each ground tile; a semicircular hole isformed in the middle part of each inclined edge; grooves A are formed in the lower middle parts of four corners of each ground tile respectively; grooves B are formed in the lower sides of the groovesA; each connecting part comprises a base and a column body is arranged at the upper side of each base; the parking lot is formed by laying the ground tiles and the connecting parts; the connecting parts are arranged on the grooves A and the grooves B of the adjacent ground tiles; a V-shaped groove is formed by the inclined edges of the adjacent ground tiles; the base plates are arranged at the edges of the parking lot; water drainage grooves are formed in the inner sides of the base plates; flow guide holes are formed between the V-shaped grooves and the base plates; roads are arranged at theouter sides of the base plates; water drainage ditches are arranged below the roads and water drainage ditch covers are arranged above the water drainage ditches; openings are formed in side faces ofthe base plates. The ecological water-accumulation-proof parking lot provided by the invention has the advantages of reasonable structure, convenience for utilization, good ecological benefits and uneasiness of accumulating water.

Owner:河南净润环境科技有限公司

A kind of sand mixing equipment

ActiveCN104815950BAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorSand casting

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

Food processor

The invention provides a food processor which comprises a first cup body, a rolling device and a second cup body. The rolling device embedded in the first cup body comprises a main body and a first cutting rib, and the first cutting rib extends spirally from top to bottom along the outer wall of the main body; the second cup body is buckled on the first cup body, and is in clamp connection with the first cup body; and the bottom wall of the second cup body adapts the top wall of the first cutting rib, and the top wall of the first cutting rib is arranged in an inclined way. The bottom wall ofthe second cup body adapts the top wall of the first cutting rib, and thus food is cut by cooperation between the first cutting rib and the bottom wall of the second cup body, the first cutting rib approaches the bottom wall of the second cup body more, the height of the first cutting rib is increased, and further the rolling device can drive more fruits and vegetables into the first cup body in asingle time, and the juicing speed is improved; and the top wall of the first cutting rib is arranged in the inclined way, the peripheral height of the cutting rib is further improved, and the juicing speed is further improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

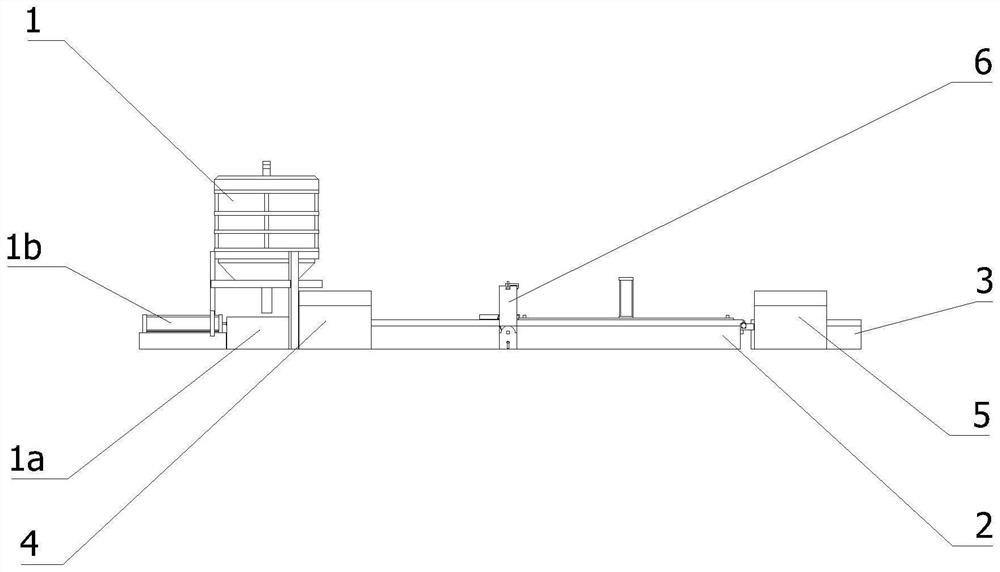

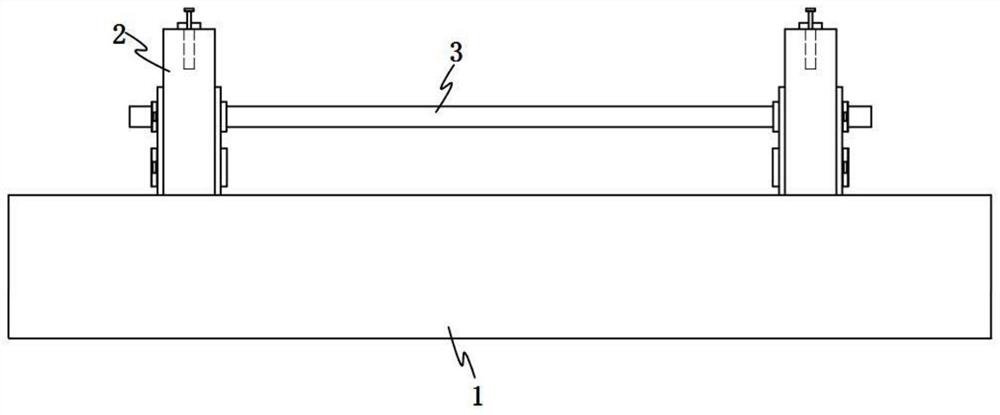

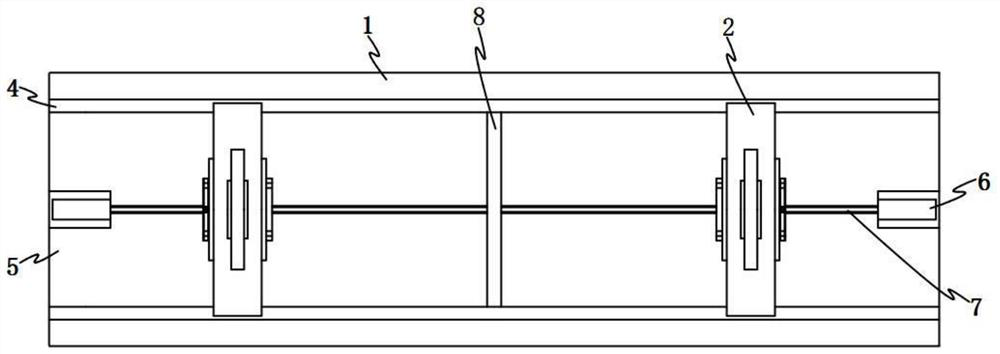

High-precision seamless steel tube cold rolling equipment and machining method thereof

ActiveCN111420993AGood surface cold rolling effectImprove rolling efficiencyMetal rolling stand detailsRolling mill drivesLap jointElectric machinery

The invention relates to high-precision seamless steel tube cold rolling equipment and a machining method thereof. The equipment comprises a rolling mill base, a cold rolling guide groove is formed inthe rolling mill base, guide sliding rails are arranged on the groove wall faces of the two sides of the cold rolling guide groove, a connection and partition plate is arranged in the middle of the interior of the cold rolling guide groove, operation driving motors are arranged at the groove ends of the two ends of the cold rolling guide groove, sliding rolling frames are slidably connected to the guide sliding rails, the operation driving motors are in transmission connection with driving screw rods, the driving screw rods are movably connected with the sliding rolling frames in a penetrating mode, the other ends of the driving screw rods are in lap joint with the connection and partition plate, and the two sliding rolling frames are arranged on the guide sliding rails. According to thehigh-precision seamless steel tube cold rolling equipment and the machining method thereof, cold rolling can be performed for a plurality of seamless steel tubes with different tube diameters at the same time, the cold rolling process is achieved through back-and-forth movement and self-rotation of rollers on the surfaces of tube bodies, the production mode that a rolling mill is manually operatedfor rolling is replaced, rolling of the multiple steel tubes with the different tube diameters can be completed simultaneously at a time, the rolling efficiency is high, and the surface cold rollingeffect of seamless steel tubes is good.

Owner:浙江巨龙钢业有限公司

Hot rolling production process of aluminum foil for electrolytic capacitor

ActiveCN111014295AAchieve rollingMetal rolling stand detailsProfile control deviceThick plateMetallurgy

The invention relates to a hot rolling production process of an aluminum foil for an electrolytic capacitor. According to the hot rolling production process for the aluminum foil for the electrolyticcapacitor, a single-machine frame four-roll reversible hot-rolling unit is adopted to carry out hot rolling on a thick plate ingot, and the plate ingot biting speed, the rolling method and the speed and the bending roll control are controlled, wherein during the initial rolling stage, the plate ingot biting speed is 60 m / min; during rolling, the heavy reduction rate is adopted, and the single passreduction rate reaches 50%-70%; and the rolling speed during rolling is 60-120 m / min. The bending roll control during rolling is characterized in that when the hot rolling machining deformation rateis 0-90%, balanced rolling is adopted by a bending roll; when the hot rolling machining deformation rate is 90%-95%, the bending roll is rolled by adopting the negative bending of 10%-20%; and when the hot rolling processing deformation rate is 95%-97%, the bending roll is rolled by adopting the negative bending of 20%-30%, and when the hot rolling machining deformation rate is 97% or above, the bending roll is rolled by adopting the negative bending of 30%-50%. According to the hot rolling production process of the aluminum foil for the electrolytic capacitor, stable production of the thick plate ingot is realized by adopting the single-machine frame four-roll reversible hot rolling unit.

Owner:XINJIANG JOINWORLD CO LTD

A kind of Chinese herbal medicine masher

ActiveCN104841538BAchieve rollingEasy to recycleGrain treatmentsTraditional medicineMechanical engineering

A traditional Chinese medicinal material smasher, comprising a base (1), a frame body (2), an extruding device (3), a positioning frame (5), a pounding device (4) and a recovery device (6), the frame body (2 ) includes an internal support block (21), a horizontal plate (22) and a positioning rod (23), and the extrusion device (3) includes an extrusion frame (31), a first sawtooth (32), a first spring (33) , vertical rod (34) and roller (35), and medicine pounding device (4) comprises fixed frame (41), second spring (42), medicine stamping lever (43), slide block (44), support rod (45 ), oval wheel (46) and rolling wheel (47), positioning frame (5) comprises the 4th horizontal part (51), the 3rd vertical part and rectangular block (54), recovery device (6) comprises base plate (61 ) and the receiving box (63). The invention reduces the manual workload, improves the work efficiency, and enables the efficacy of the traditional Chinese medicine to be fully brought into play.

Owner:陕西妙应扶民堂药业有限公司

Intelligent continuous casting and rolling equipment

PendingCN114433629AImprove processing qualityLow costRoll force/gap control deviceGuiding/positioning/aligning arrangementsPhysicsSteel plates

The invention relates to the field of continuous casting and rolling, in particular to intelligent continuous casting and rolling equipment which comprises a continuous casting machine, a cold mold, a first roller conveyor and a second roller conveyor, a pusher is arranged at the cold mold, a heating chamber and a cooling chamber are arranged on the first roller conveyor, and a rolling device is further arranged at the middle end of the first roller conveyor. The rolling device comprises a supporting frame, a fixed pressing roller and a movable pressing roller, the fixed pressing roller is rotationally arranged on a fixed seat, the movable pressing roller is rotationally arranged on a movable seat, a thickness adjusting mechanism is further arranged on the supporting frame, a synchronous driving device is further arranged on the supporting frame, and an anti-curling device is further arranged between the movable pressing roller and the cooling chamber. The distance between the movable pressing roller and the fixed pressing roller is adjusted through the thickness adjusting mechanism, a steel plate is flattened through the edge curling preventing device, rolling of the steel plate is achieved, flattening of the steel plate is guaranteed, the machining quality of the steel plate is improved, and cost is saved.

Owner:芜湖旭能自动化设备设计有限公司

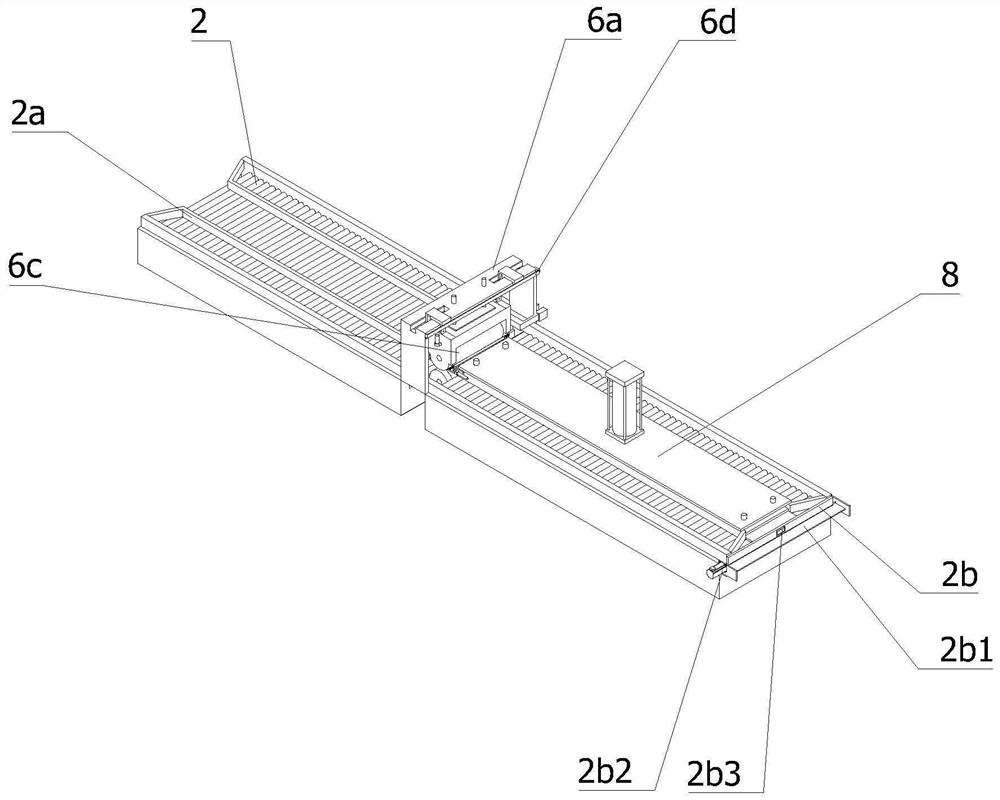

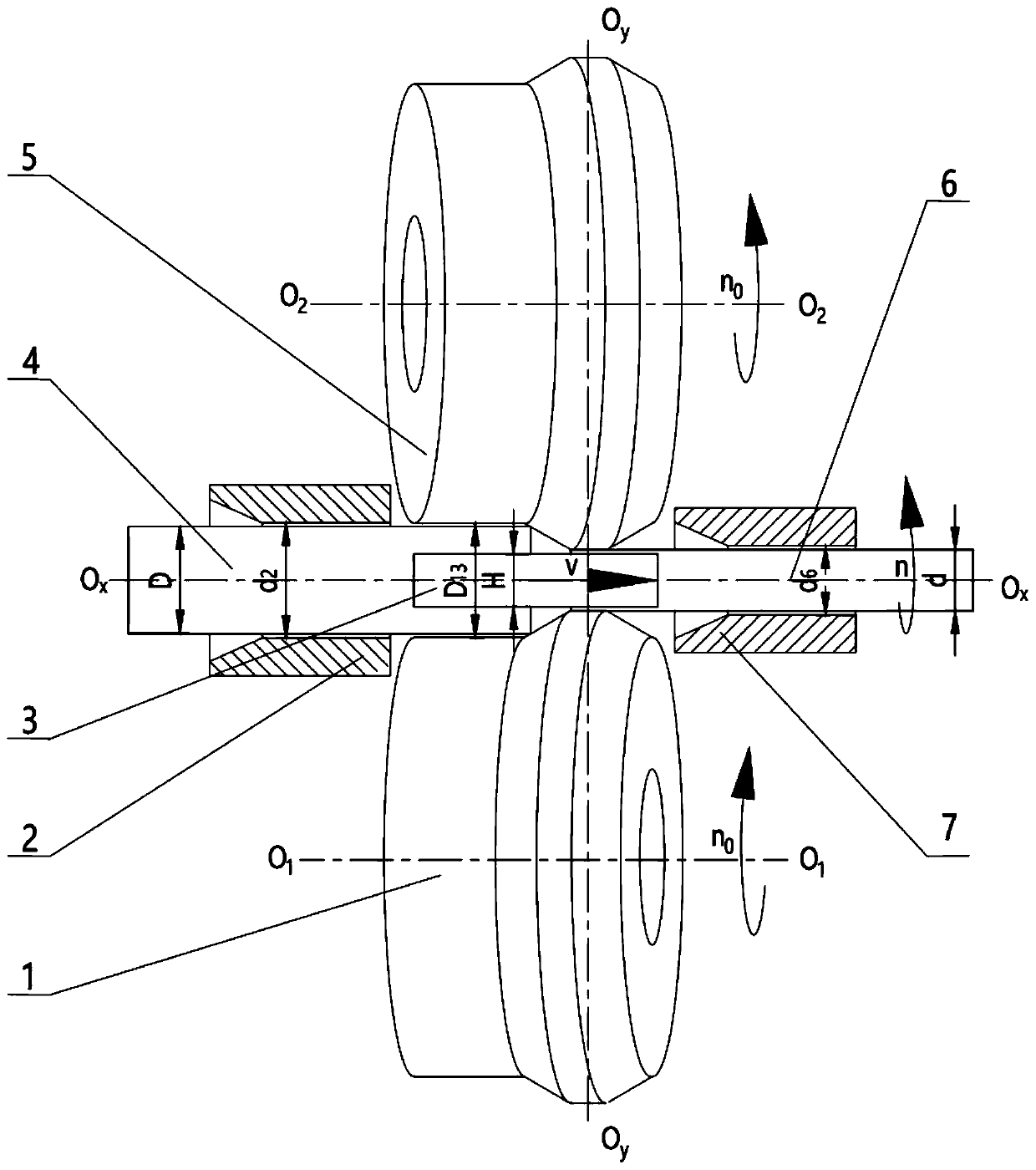

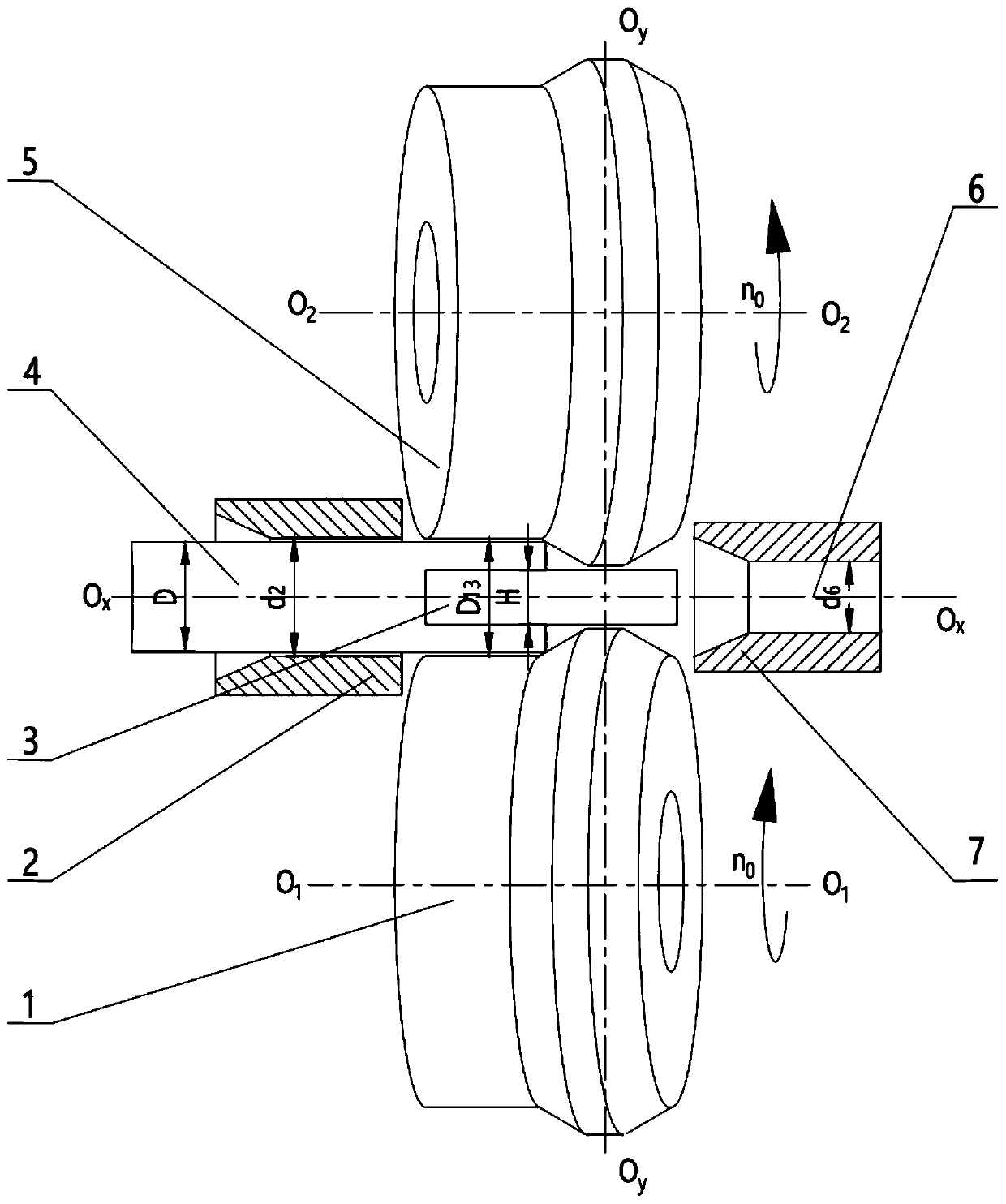

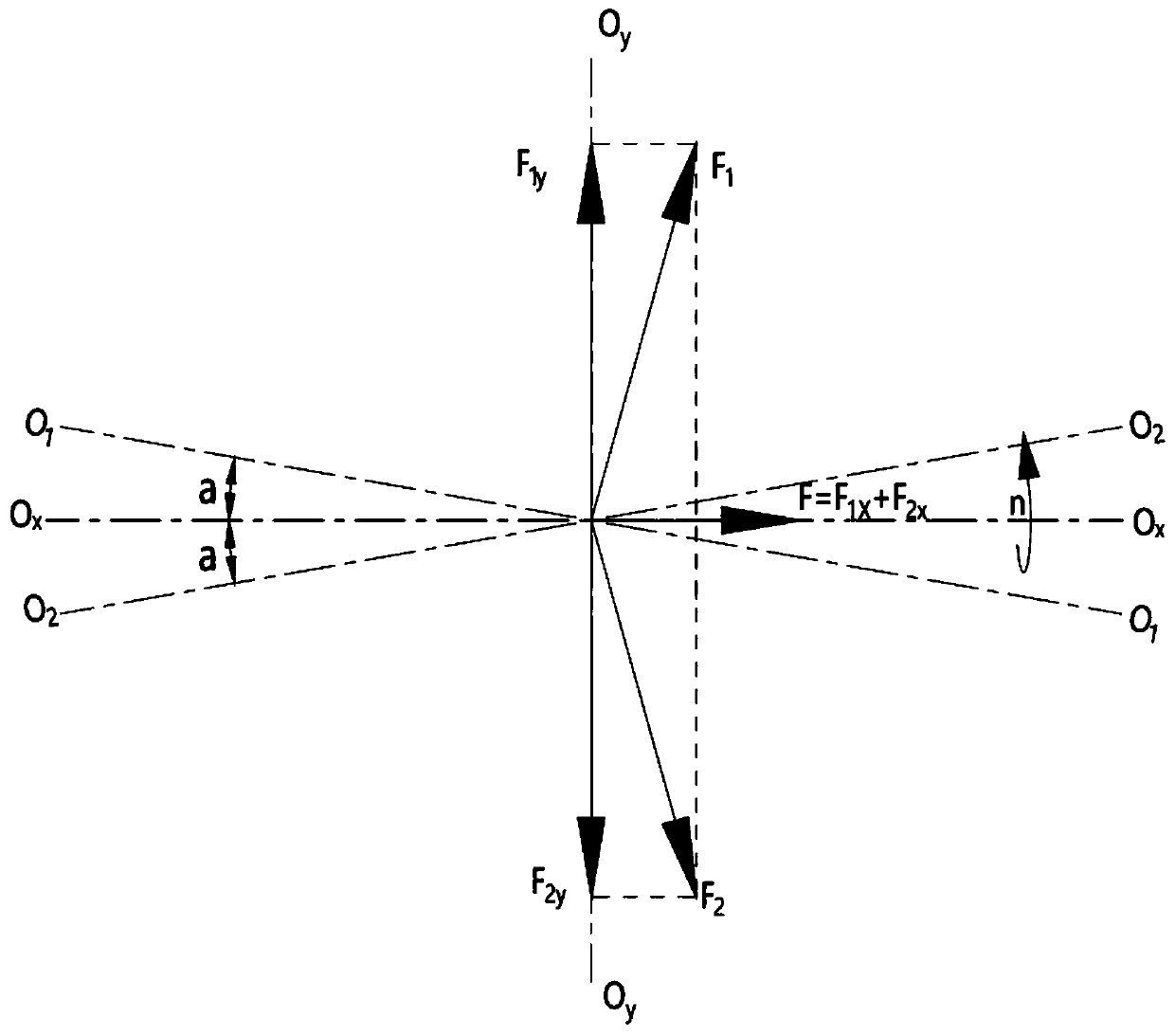

Apparatus and method for two-roll skew rolling forming of round bar

ActiveCN110076198BSimple structureAchieve rollingMetal rolling stand detailsMetal rolling arrangementsRound barFriction force

The invention relates to the technical field of metal plastic forming processes and equipment, and provides a two-roller skew rolling forming device and method for round bar. The device comprises twoinclined rollers, a guide plate, a feeding end guide cylinder and a discharge end guide cylinder; the two inclined rollers are arranged in a staggered and inclined manner, the axes of the two inclinedrollers are in the same included angle with the axis of the round bar; the guide plate is fixedly arranged between the two inclined rollers, the round bar rotates between the two inclined rollers; the feeding end guide cylinder is arranged on the feeding side and is used for limiting swinging of to-be-rolled round bar, the discharging end guide cylinder is arranged on the discharging side and isused for limiting swinging of the rolled round bar. The two inclined rollers do same-direction constant-speed rotation motion, the round bar do rotation around an axis and axial feed movement in the space formed by the two inclined rollers and the guide plate under the action of the friction force of the rollers / round bar, and the large-diameter round bar is skew rolled into a small-diameter roundbar. The device and method has the advantages of being simple in forming equipment, high in forming precision, short in technological process and low in production cost, and is suitable for rolling process of medium and small batch round bars.

Owner:UNIV OF SCI & TECH BEIJING

A high-precision seamless steel pipe cold rolling equipment and processing method thereof

ActiveCN111420993BGood surface cold rolling effectImprove rolling efficiencyMetal rolling stand detailsRolling mill drivesElectric machineryEngineering

The invention relates to a high-precision seamless steel pipe cold-rolling equipment and a processing method thereof, comprising a rolling mill base, on which a cold-rolling guide groove is arranged, and guide slide rails are arranged on the groove wall surfaces on both sides of the cold-rolling guide groove, so that The middle part of the cold-rolled guide groove is provided with a connecting partition, and the ends of the two ends of the cold-rolled guide groove are provided with running drive motors. Screw, the driving screw is connected with the sliding rolling stand, and the other end of the driving screw is overlapped with the connecting partition, and there are two sliding rolling stands on the guide rail. The present invention can cold-roll multiple seamless steel pipes with different diameters at the same time, and the cold-rolling process is realized by the rolling back and forth on the surface of the pipe body and its own rotation, replacing the production mode of manual rolling with a rolling mill, and can simultaneously Complete the rolling of multiple steel pipes with different diameters, the rolling efficiency is high, and the surface cold rolling effect of the seamless steel pipe is good.

Owner:浙江巨龙钢业有限公司

A hot rolling production process of aluminum foil for electrolytic capacitors

ActiveCN111014295BAchieve rollingMetal rolling stand detailsMetal rolling arrangementsThick plateMetallurgy

The invention relates to a hot rolling production process of an aluminum foil for an electrolytic capacitor. According to the hot rolling production process for the aluminum foil for the electrolyticcapacitor, a single-machine frame four-roll reversible hot-rolling unit is adopted to carry out hot rolling on a thick plate ingot, and the plate ingot biting speed, the rolling method and the speed and the bending roll control are controlled, wherein during the initial rolling stage, the plate ingot biting speed is 60 m / min; during rolling, the heavy reduction rate is adopted, and the single passreduction rate reaches 50%-70%; and the rolling speed during rolling is 60-120 m / min. The bending roll control during rolling is characterized in that when the hot rolling machining deformation rateis 0-90%, balanced rolling is adopted by a bending roll; when the hot rolling machining deformation rate is 90%-95%, the bending roll is rolled by adopting the negative bending of 10%-20%; and when the hot rolling processing deformation rate is 95%-97%, the bending roll is rolled by adopting the negative bending of 20%-30%, and when the hot rolling machining deformation rate is 97% or above, the bending roll is rolled by adopting the negative bending of 30%-50%. According to the hot rolling production process of the aluminum foil for the electrolytic capacitor, stable production of the thick plate ingot is realized by adopting the single-machine frame four-roll reversible hot rolling unit.

Owner:XINJIANG JOINWORLD CO LTD

Corn grinding device

The invention relates to a corn grinding device. The corn grinding device comprises a fixing box, a grinding mechanism and a driving mechanism, wherein the driving mechanism comprises a motor, a rotating rod, a connecting rod, a gearbox and a first gear, wherein the grinding mechanism comprises a grinding box, a grinding block, a second gear, a feeding pipe, a spring and a limiting block. According to the corn grinding device, grinding of the main body is achieved through cooperation of the driving mechanism and the grinding mechanism, smashing and grinding of the main body are achieved through cooperation of the grinding block and a pushing block, grinding of the main body is achieved through pushing of the pushing block, therefore a gap between the grinding block and the pushing block is reduced, and the grinding efficiency is improved; and linkage of a plurality of mechanisms is achieved through the same driving source, the use practicability is improved, meanwhile, through a movable transverse rod, collection of the main bodies is conveniently achieved, the main bodies remaining in the grinding box are reduced, and the main body grinding yield is increased.

Owner:陈嘉玲

A special pressing device for waste pop cans

The invention relates to a special pressing device for waste pop cans, comprising a base, the base is provided with a shell, the shell is provided with an inner cavity connected by a shock-absorbing layer, and the top of the inner cavity is provided with a feeding port. The feed port extends to the outer side of the shell, and drumstick devices are provided on the left and right sides of the inner wall of the inner cavity, and the drum hammer device is connected to a fixed plate. Valve, the outlet is connected to the rolling device at the bottom, the rolling device is connected to the pressure-resistant layer at the bottom of the inner cavity, the bottom of the inner cavity is provided with a discharge port, the discharge port extends to the outside of the shell, the base There is a motor on it. The invention is simple in structure, firm and stable, and the working efficiency and precision are improved through the combined use of the drumstick device and the rolling device, and the use of the pressure-resistant layer and the fixing plate improves the stability of the structure, strengthens the connection of the structure, and prolongs the service life.

Owner:山东微腾信息科技有限公司

Distiller's grains treatment device for production of baijiu

PendingCN110699205ACrushed and enlargedImprove crushing effectAlcoholic beverage preparationElectric machineryProcess engineering

The invention belongs to the technical field of production of baijiu, and particularly relates to a distiller's grains treatment device for production of baijiu. The distiller's grains treatment device for production of baijiu comprises a shell, a motor and a crushing unit; the motor is arranged at the top end of the shell; the crushing unit comprises a chute plate, a sliding plate, a first filterplate, a rolling ball and a gear; the first filter plate is hinged to a side wall of the sliding plate, the side wall of the first filter plate is in contact with the inner side wall of the shell, and a plurality of first filter holes are formed in the first filter plate; distiller's grains are crushed through cooperation of the chute plate, the sliding plate, the first filter plate, the rollingball and the gear, preparation is carried out for subsequent fermentation, the crushed distiller's grains fall through the first filter holes for next grinding until the size of the distiller's grainsmeets the processing requirement, the trouble and inconvenience of manually crushing the distiller's grains are greatly avoided, the working efficiency of baijiu brewing is improved, and the time cost of a user is reduced.

Owner:周杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com