Planetary rolled thread drive

A technology of planetary rollers and transmission mechanisms, which is applied to transmission devices, gear transmission devices, mechanical equipment, etc., and can solve problems such as the cost of intermediate rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

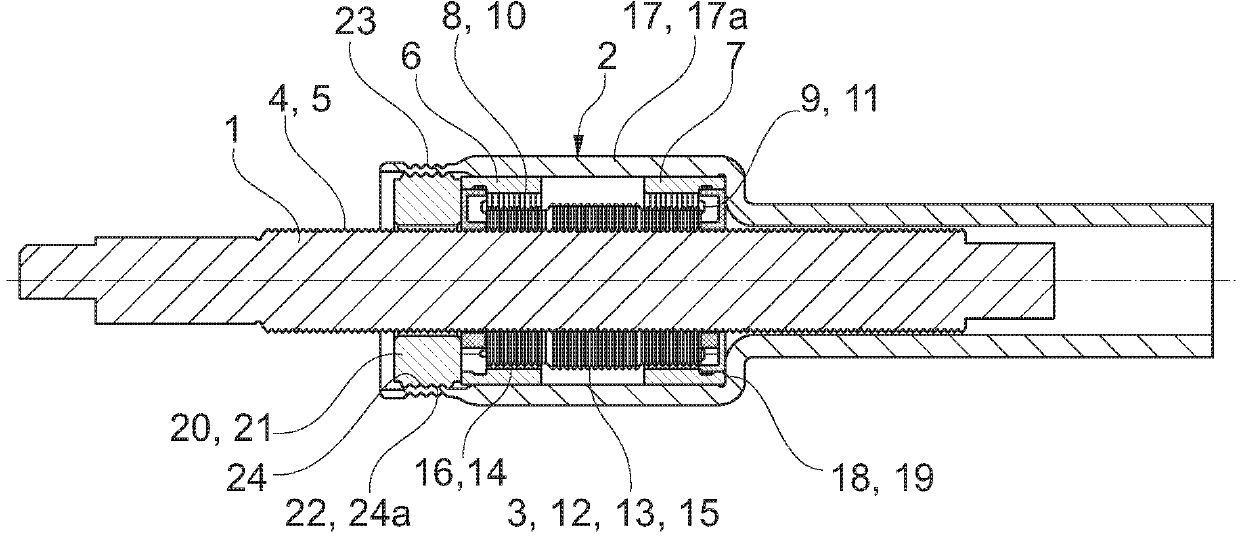

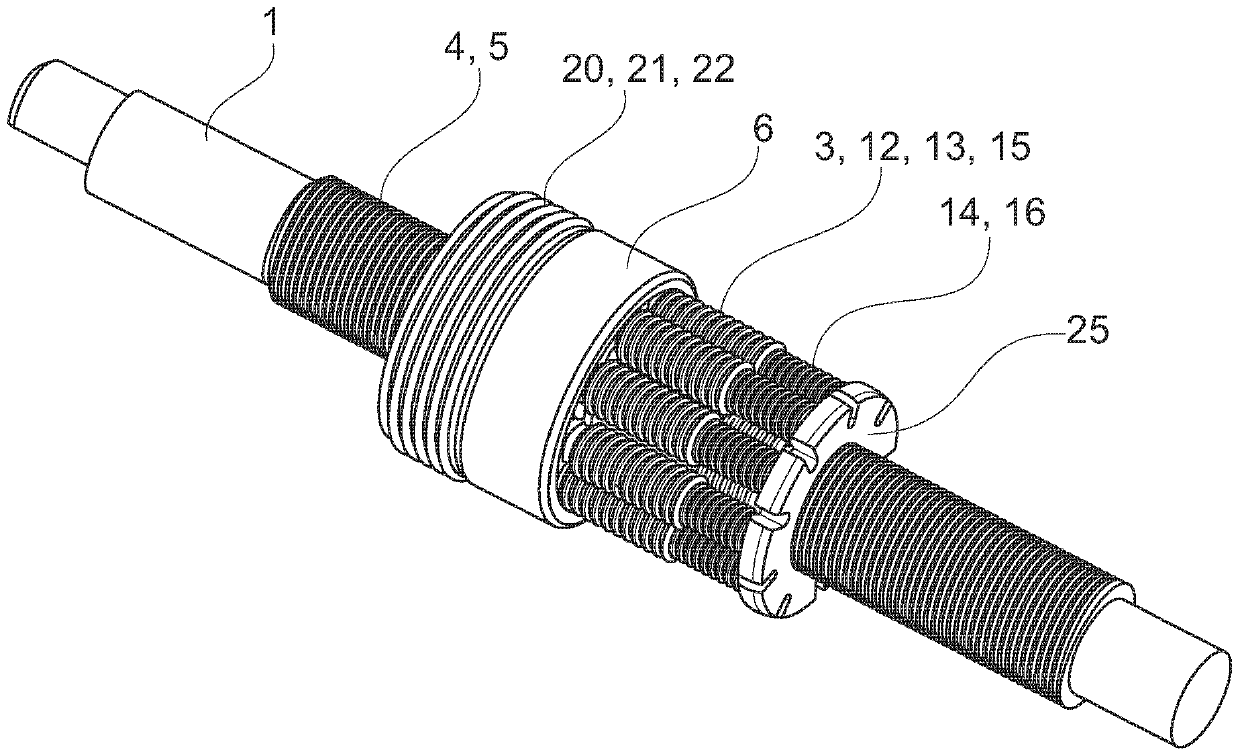

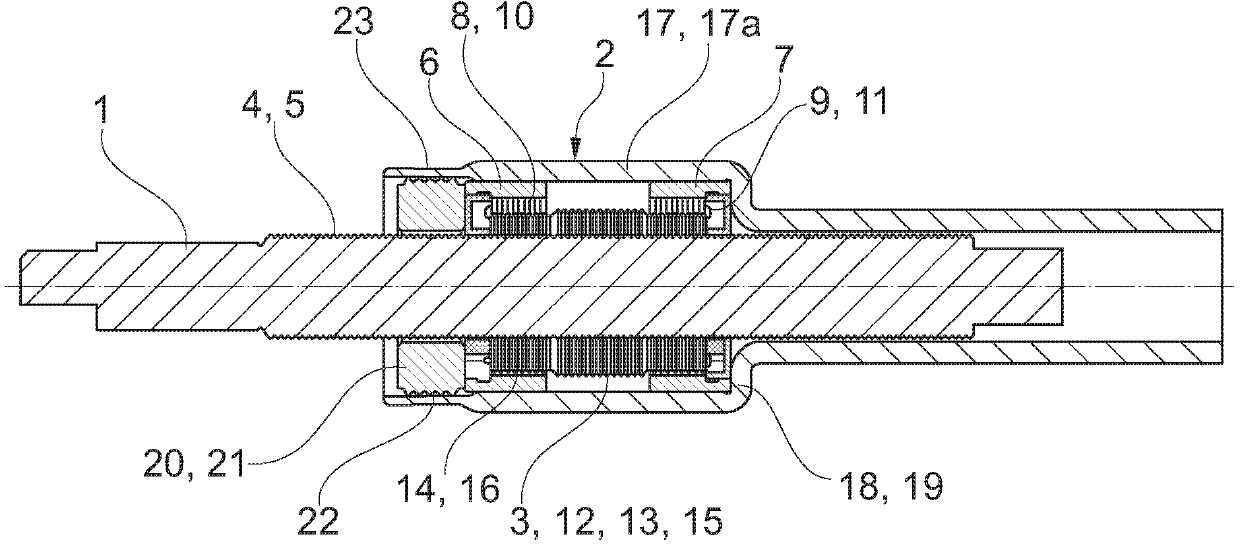

[0028] figure 1 A planetary roller screw drive according to the invention is shown with a spindle nut 2 arranged on a threaded spindle 1 . The planets 3 are arranged distributed over the circumference between the spindle nut 2 and the threaded spindle 1 and are in rolling engagement with the spindle nut 2 and the threaded spindle 1 . Under the relative rotation between the threaded screw 1 and the screw nut 2, the planets 3 roll both on the inner circumference of the screw nut 2 and on the outer circumference of the screw nut 1 and around their own planet axis and Rotate around the screw axis. The planets 3 run along planetary orbits arranged perpendicular to the axis of the screw.

[0029] The threaded spindle 1 is provided with a thread 4 wound helically around the spindle axis, which thread is formed by a plurality of turns of thread grooves 5 . Instead of a single thread groove 5 , it is also possible to provide a multi-threaded thread with a large number of thread groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com