Patents

Literature

1201results about "Rolling mill drives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

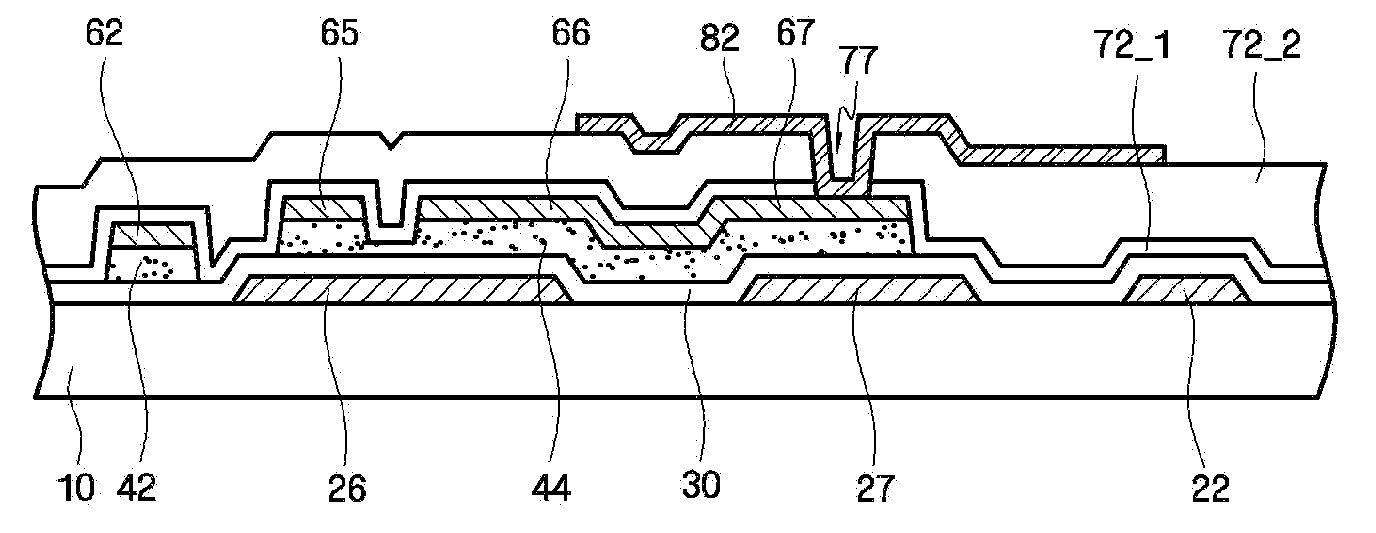

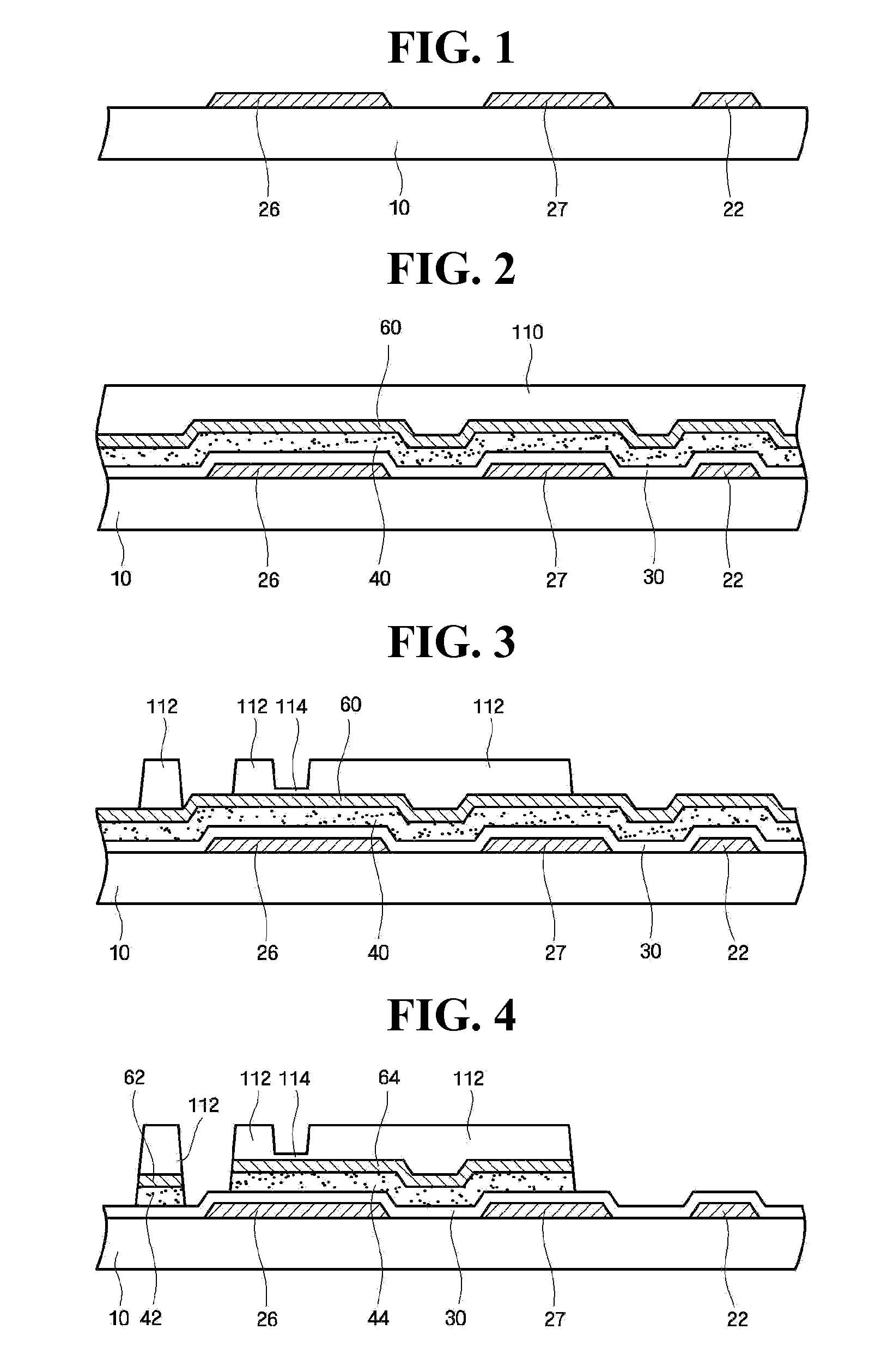

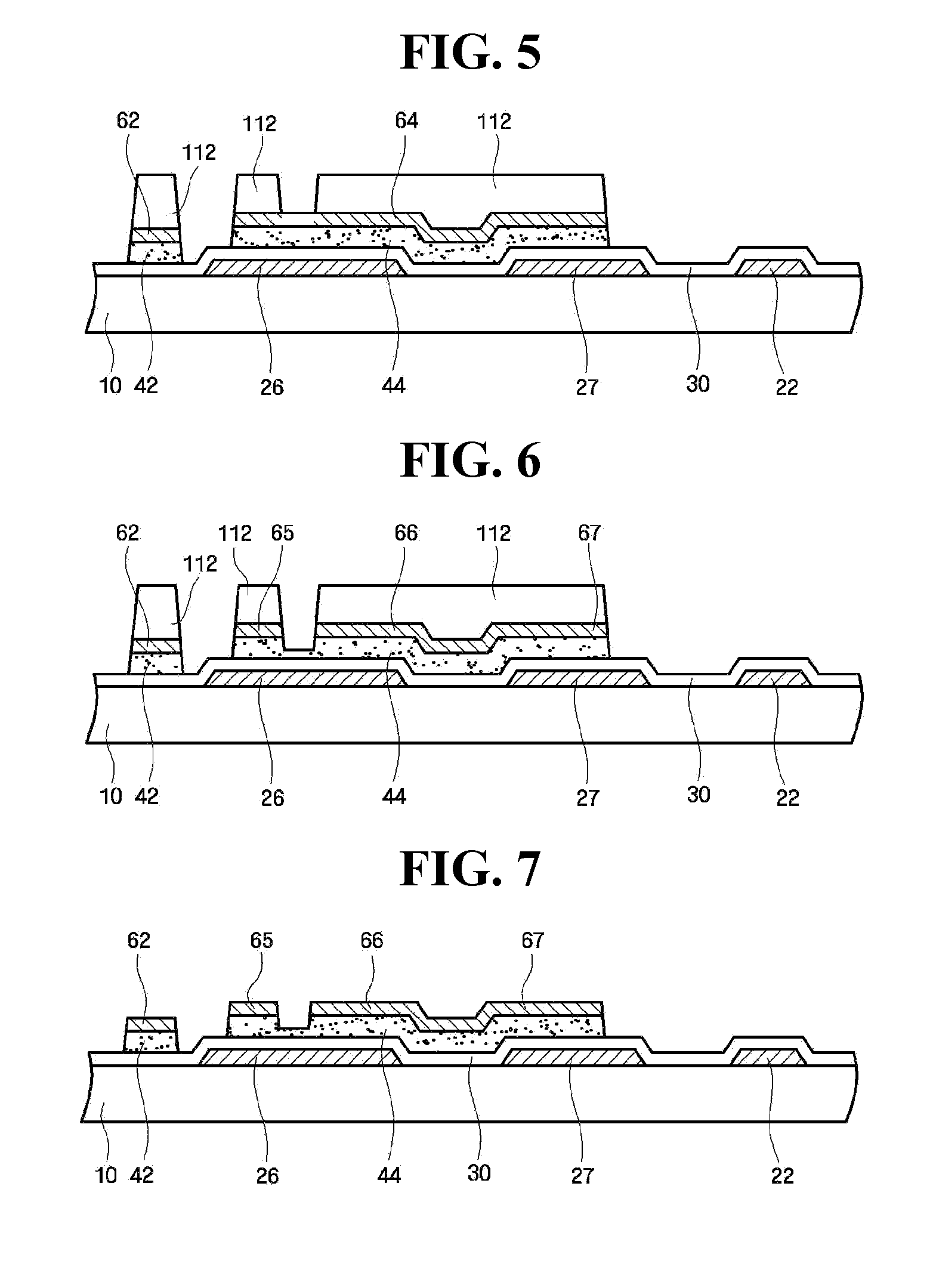

Method of manufacturing thin film transistor substrate

InactiveUS20080176364A1Enhance layeringImprove featuresTransistorSolid-state devicesActive layerPellicle membrane

The present invention provides a method for manufacturing a thin film transistor substrate including forming gate wires on an insulation substrate, forming oxide active layer patterns on the gate wires, forming data wires on the oxide active layer patterns so that the data wires cross the gate wires, forming a passivation film on the oxide active layer patterns and the data wires using a non-reductive reaction gas and SiH4, and forming pixel electrodes on the passivation film

Owner:SAMSUNG DISPLAY CO LTD

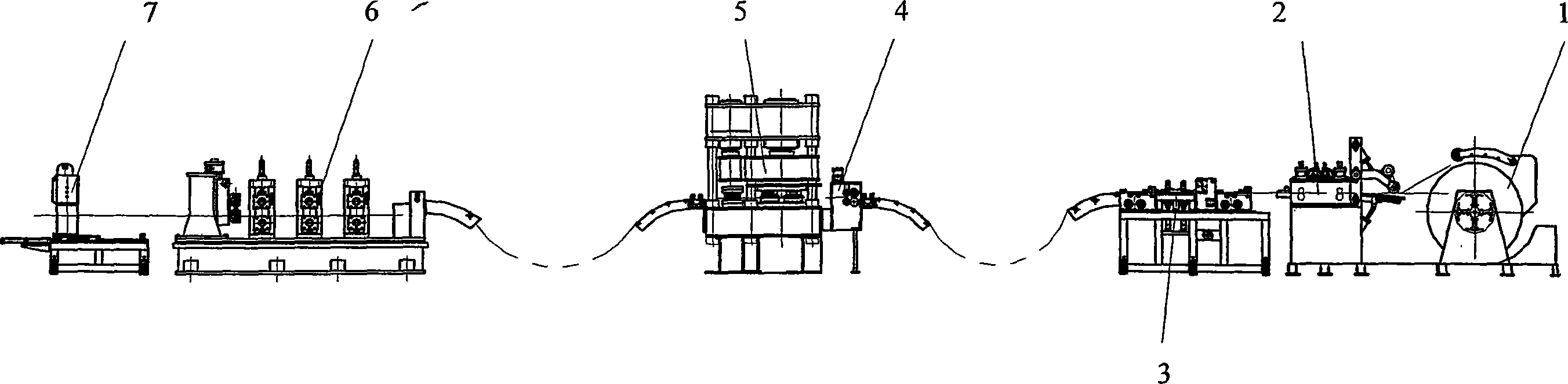

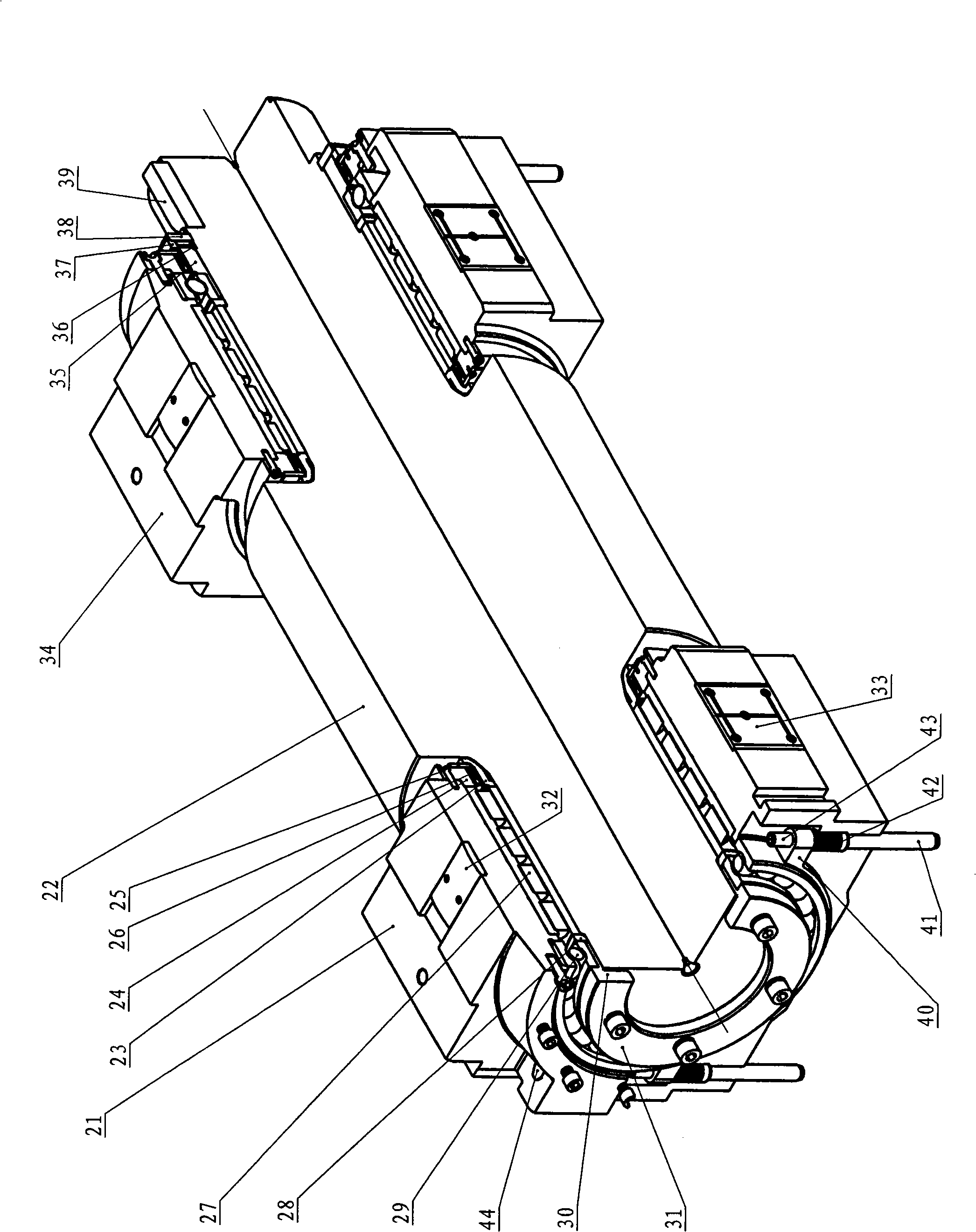

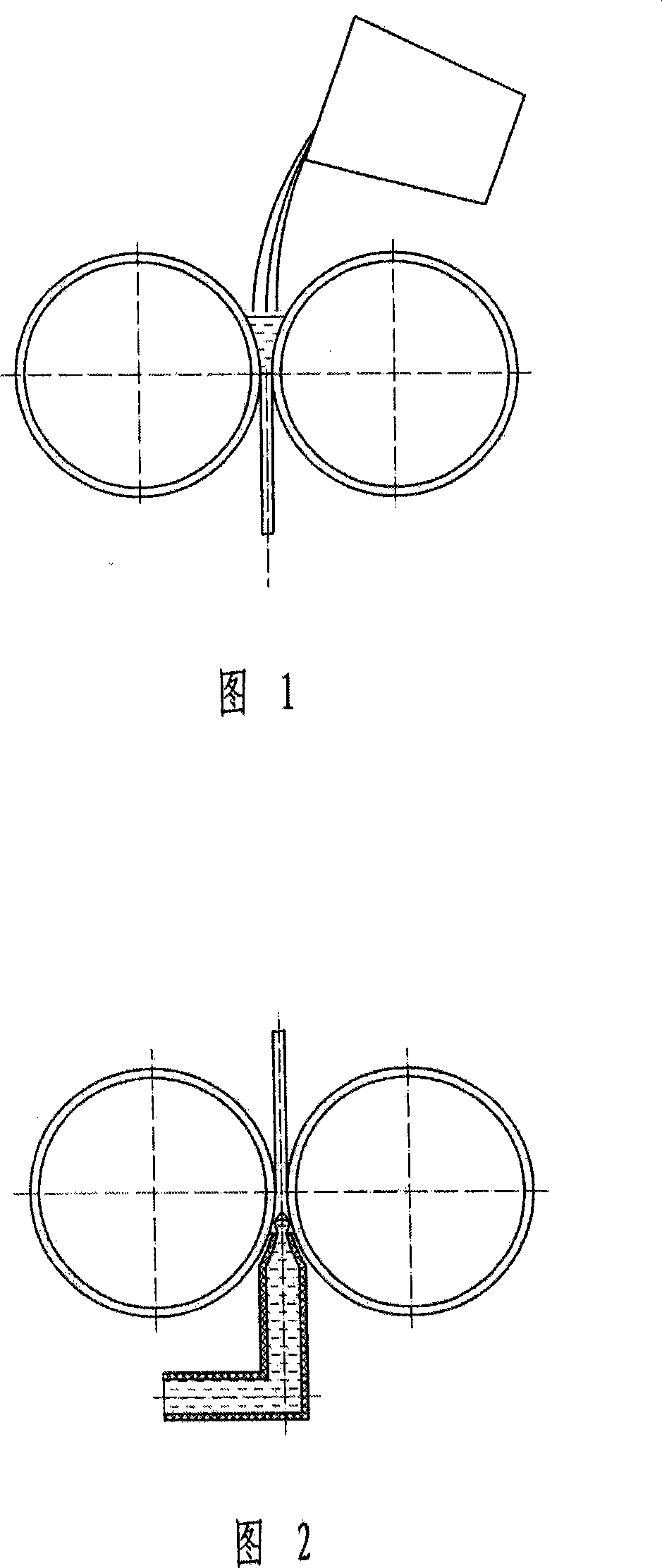

Stainless-steel band special apparatus for steel-aluminum composite contact rail

InactiveCN101028685AImprove performanceQuality improvementMetal-working feeding devicesOther manufacturing equipments/toolsButt weldingControl theory

Owner:南京赛彤铁路电气化有限公司

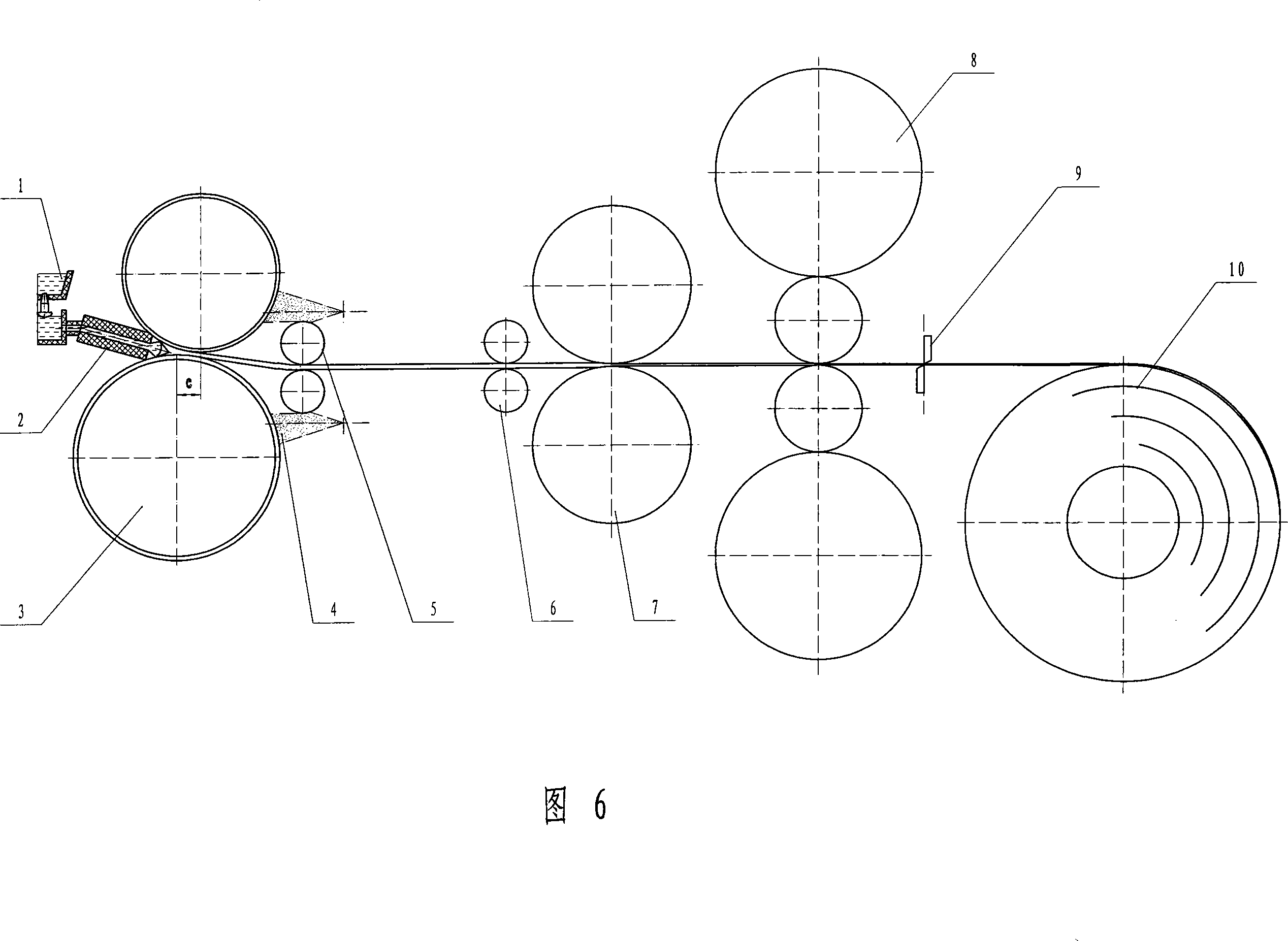

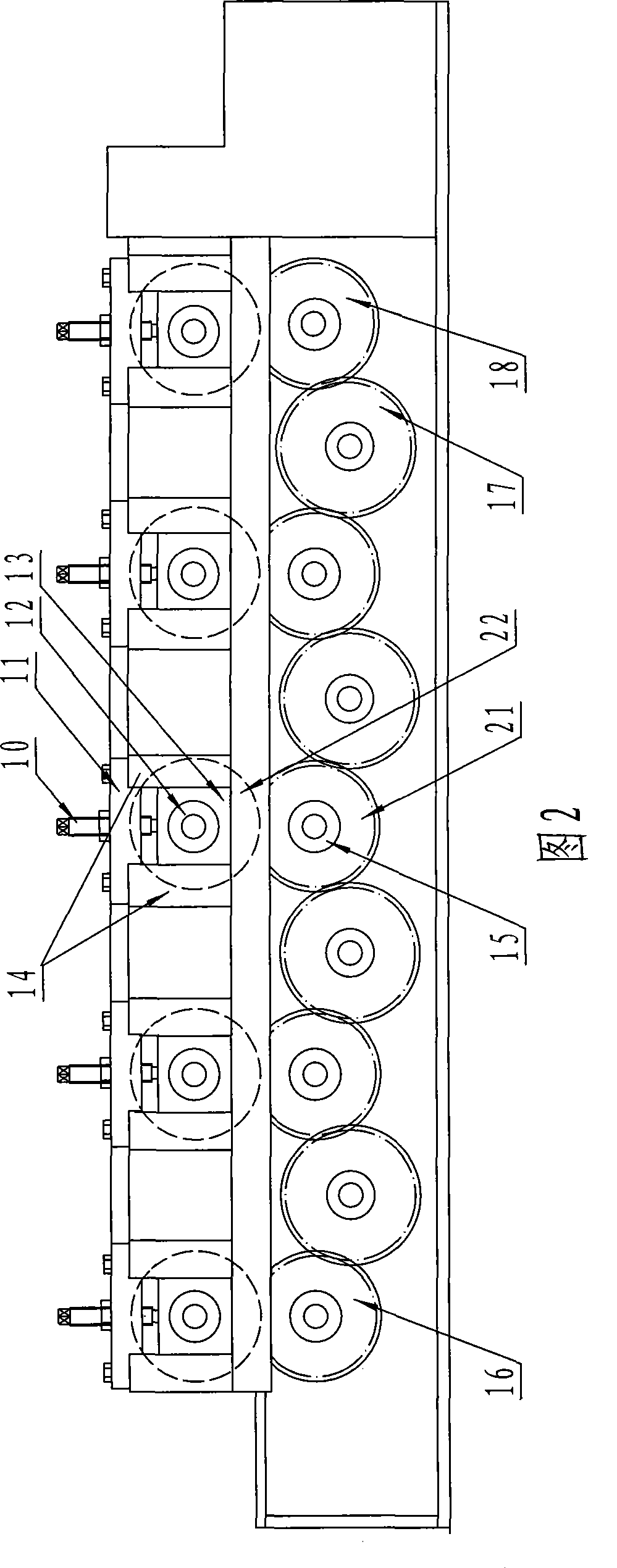

Strip mill of thin film

InactiveCN101347791AEfficient and stable productionEasy to change rollsMetal rolling stand detailsRolling mill drivesAutomatic controlEngineering

The invention provides a film band and strip rolling mill, consisting of a motor-reducer device, an elastic pin coupling device, a balance symmetric gear transmission device, a front stander device and a rear stander device, a lower roller system device, an upper roller system device, a roller system bearing radial windage eliminating device, a left baffle device of a roller, a right baffle device of the roller, an electro-hydraulic servo press-down device, a roller changing device and a base; the film band and strip rolling mill is characterized in that the size of the roller seam can be automatically controlled by adopting an electro-hydraulic servo control technology, thus stably producing battery electrodes which meet the quality standard without compressing air source from external part; meanwhile, the developed balance symmetric transmission device, the roller system bearing radial windage eliminating device, the roller left baffle device, the roller right baffle device and the roller changing device lead the adjustment and maintenance of the rolling mill to be simple and convenient, The invention is an ideal film band and strip rolling mill which has the advantages of improving the precision of battery electrodes, improving the productivity of the rolling mill and overcoming the shortages of the prior art.

Owner:张清

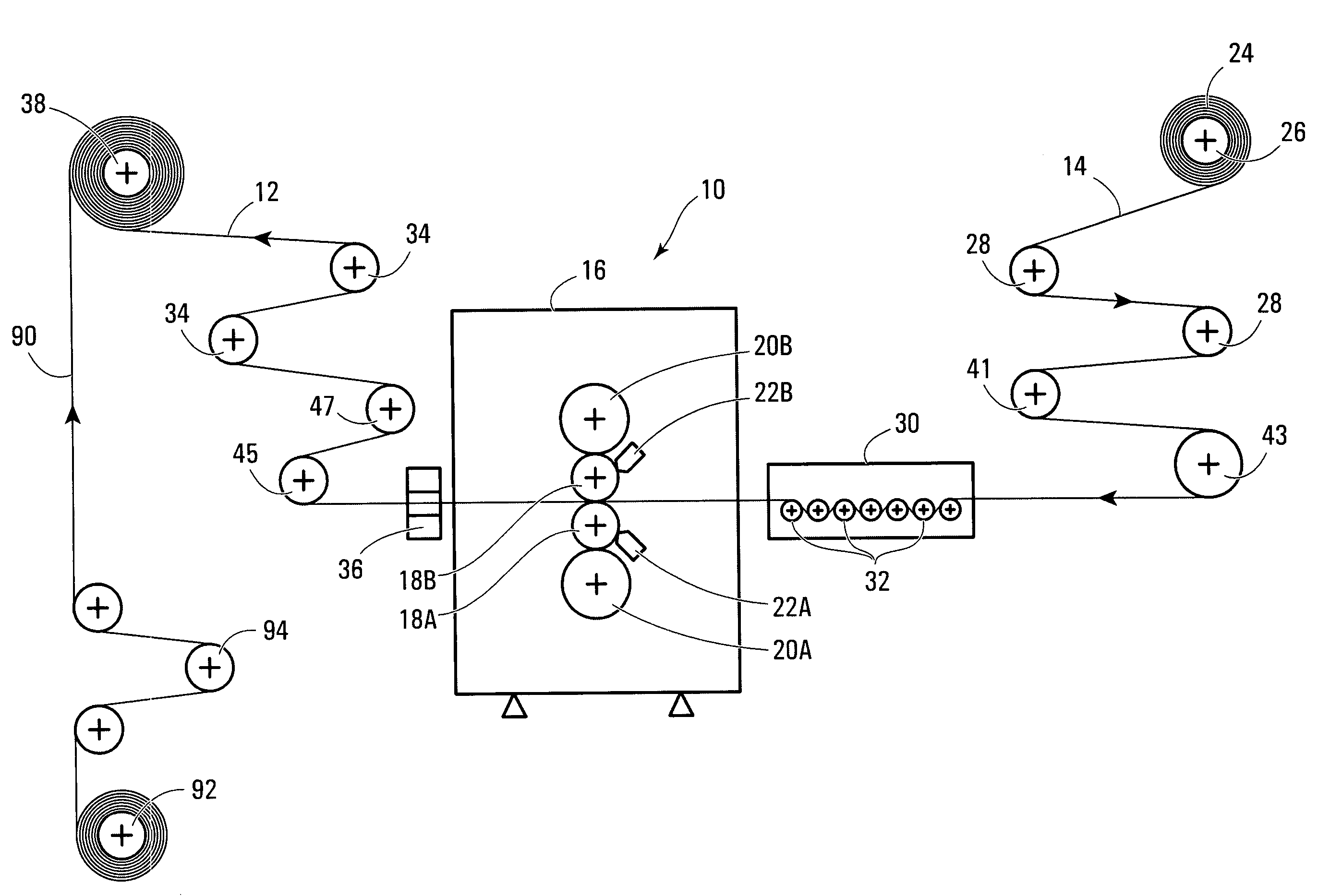

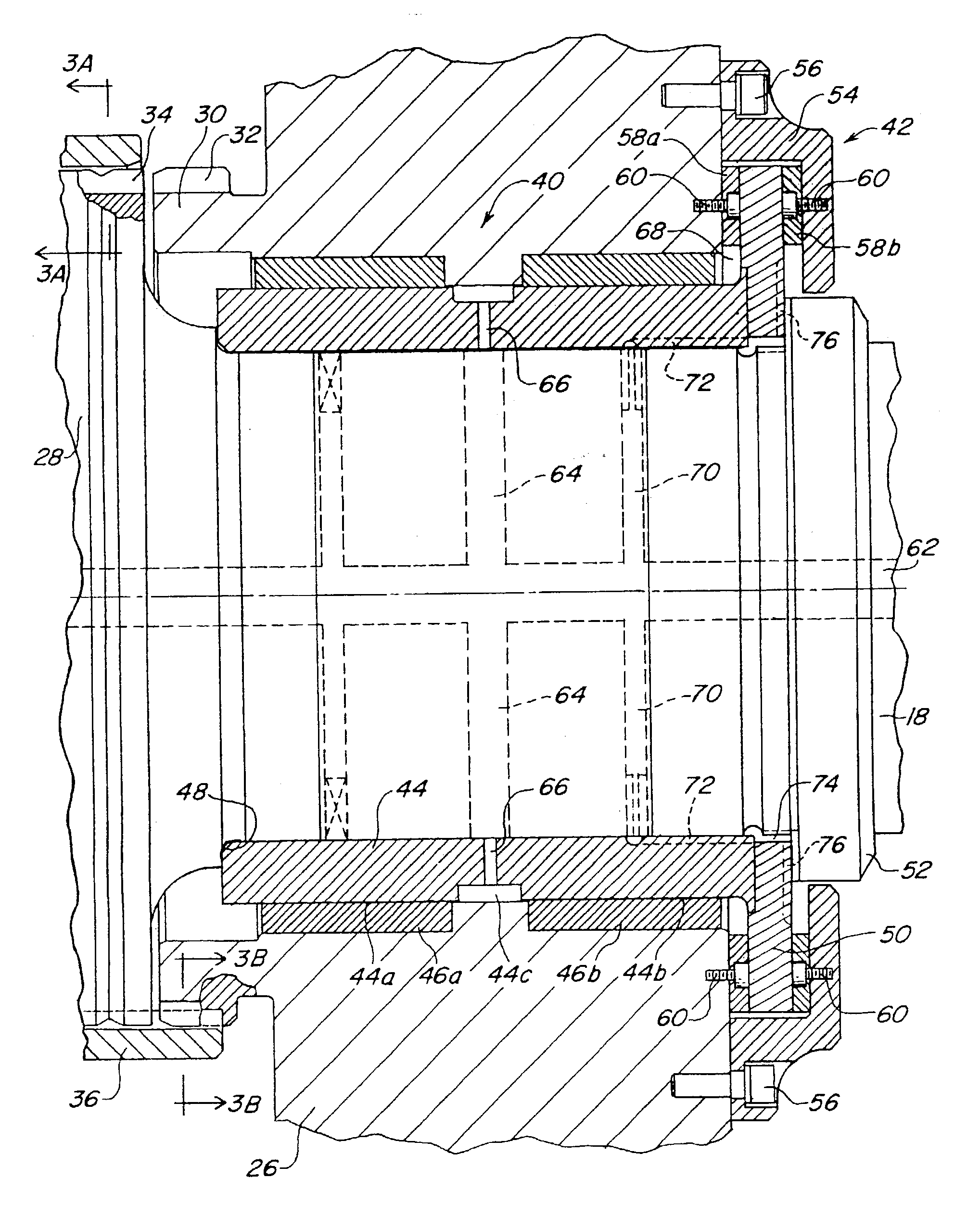

Lamination process and apparatus for alkali metals or alloys thereof

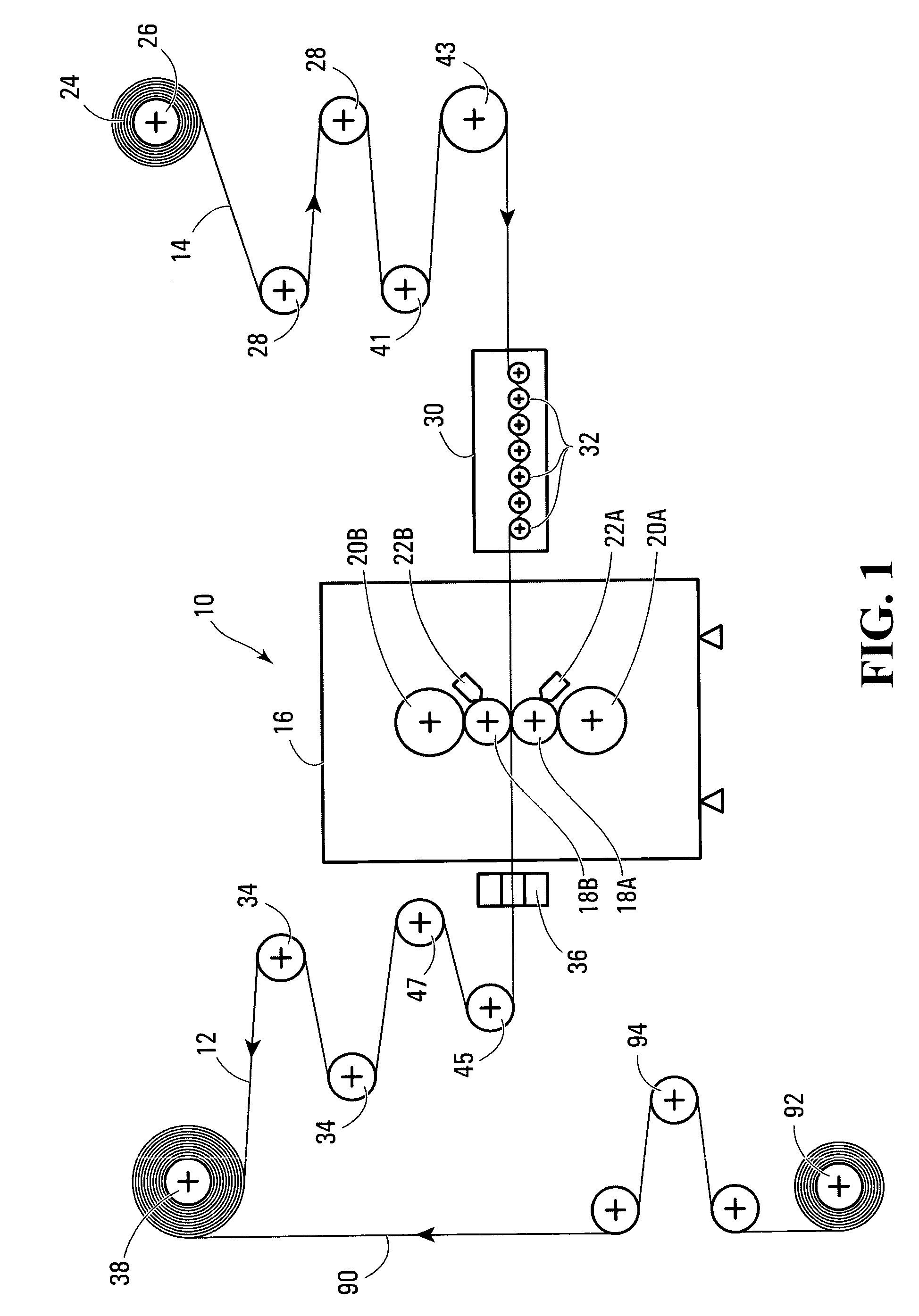

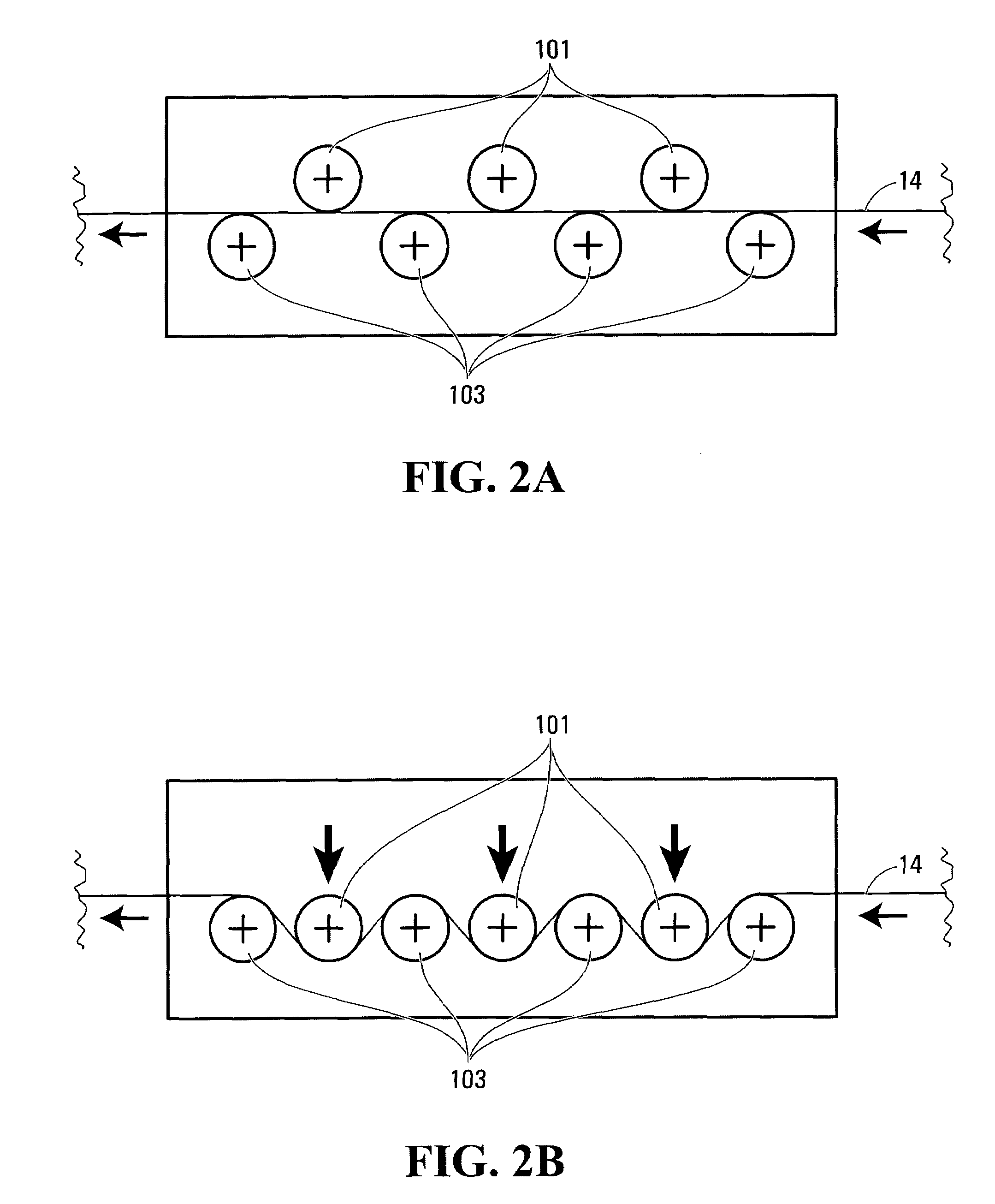

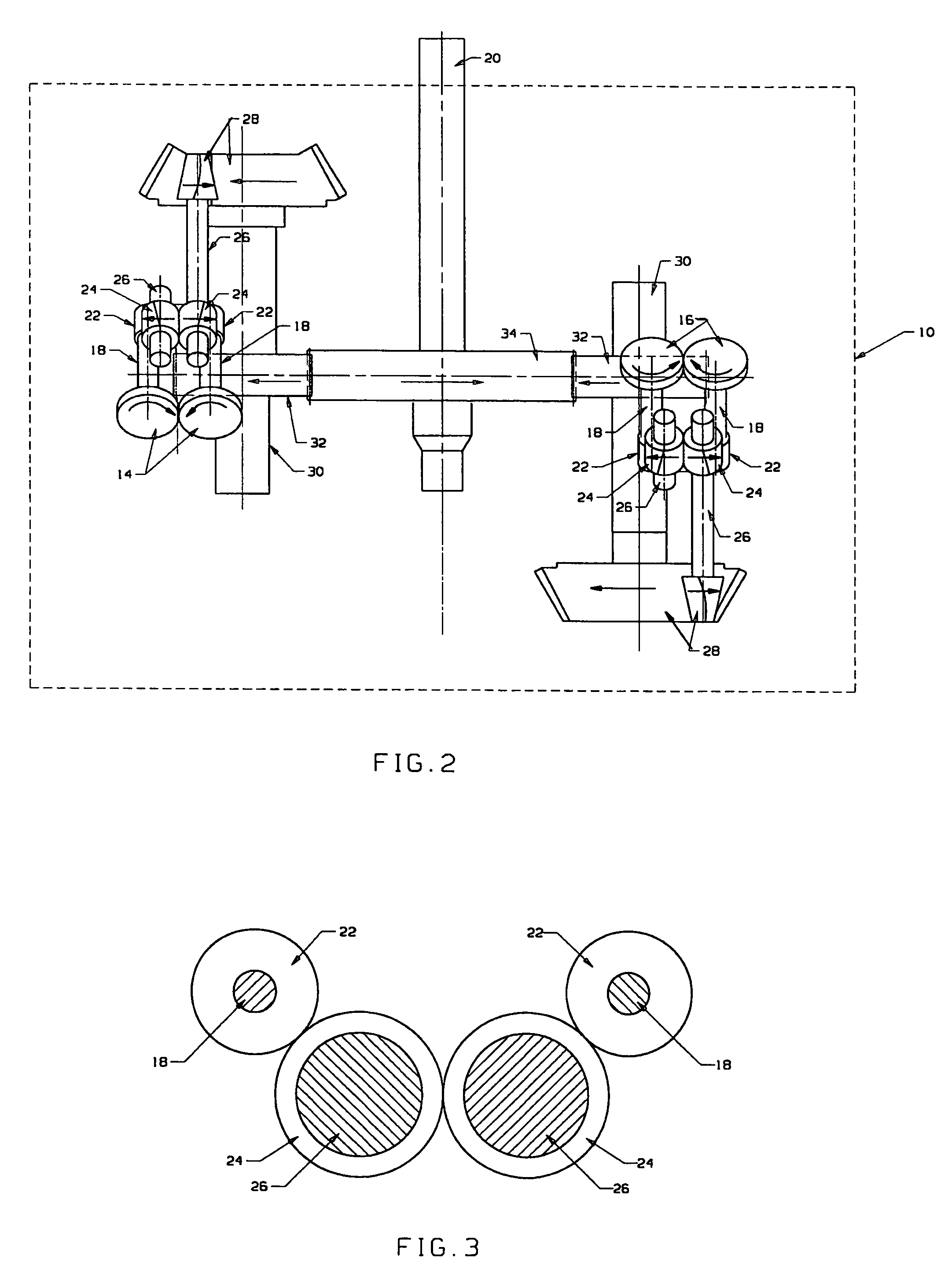

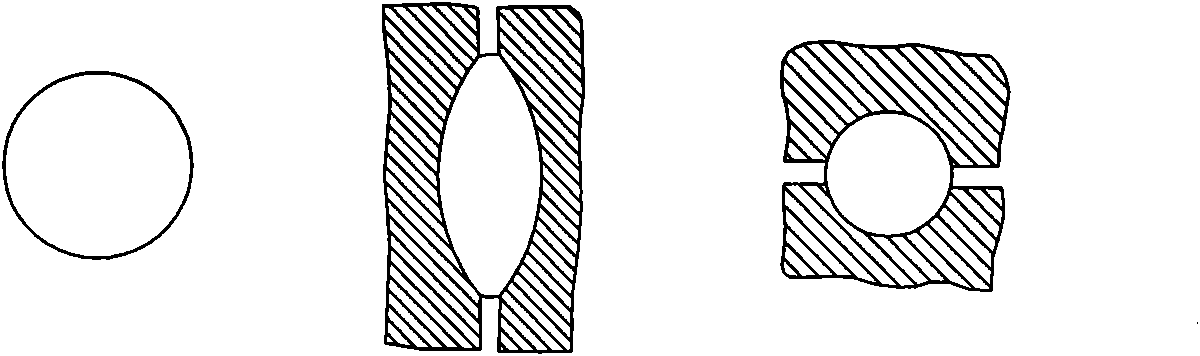

ActiveUS7513136B2Reduce thicknessElectrode rolling/calenderingRoll force/gap control deviceLithiumElectrical battery

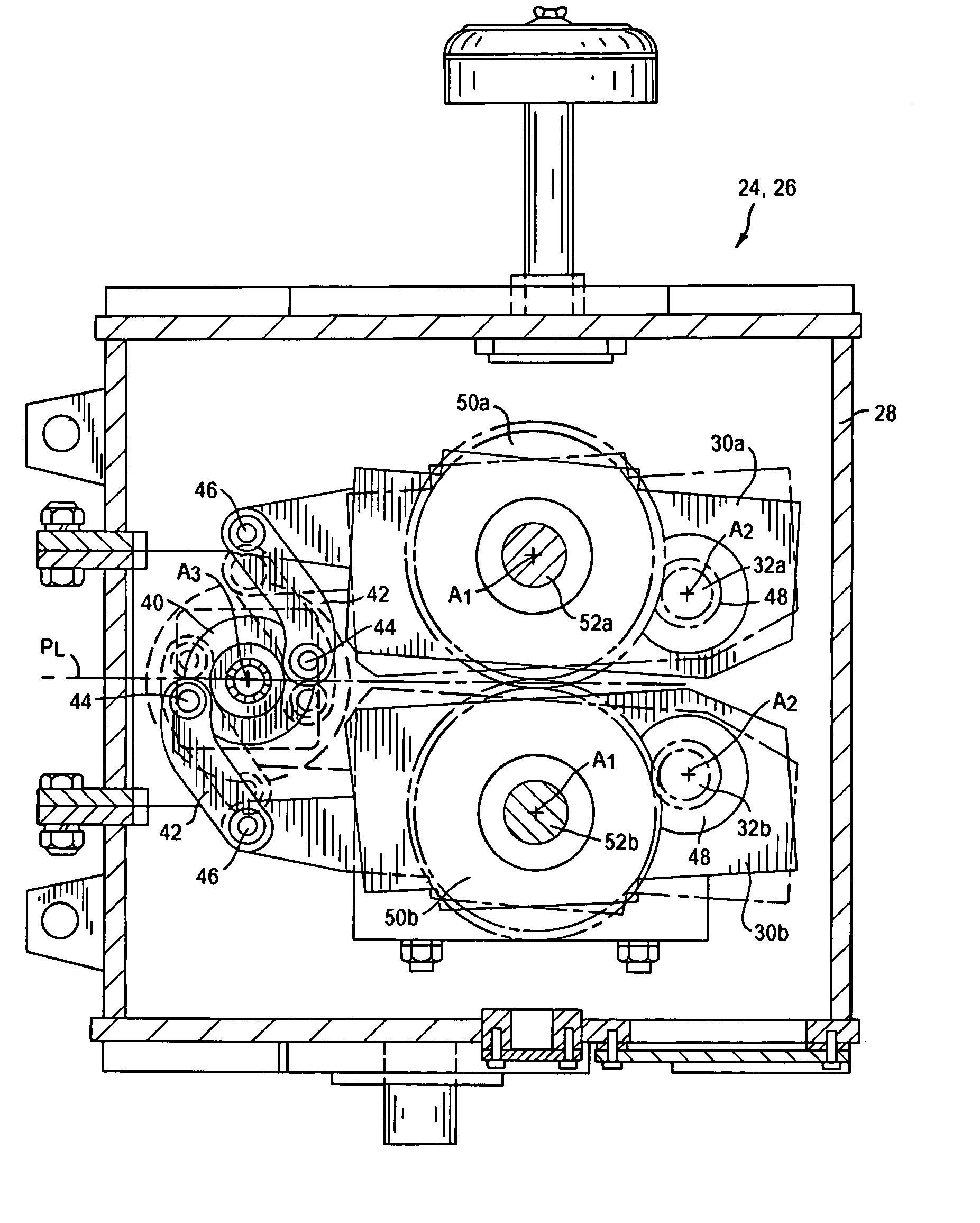

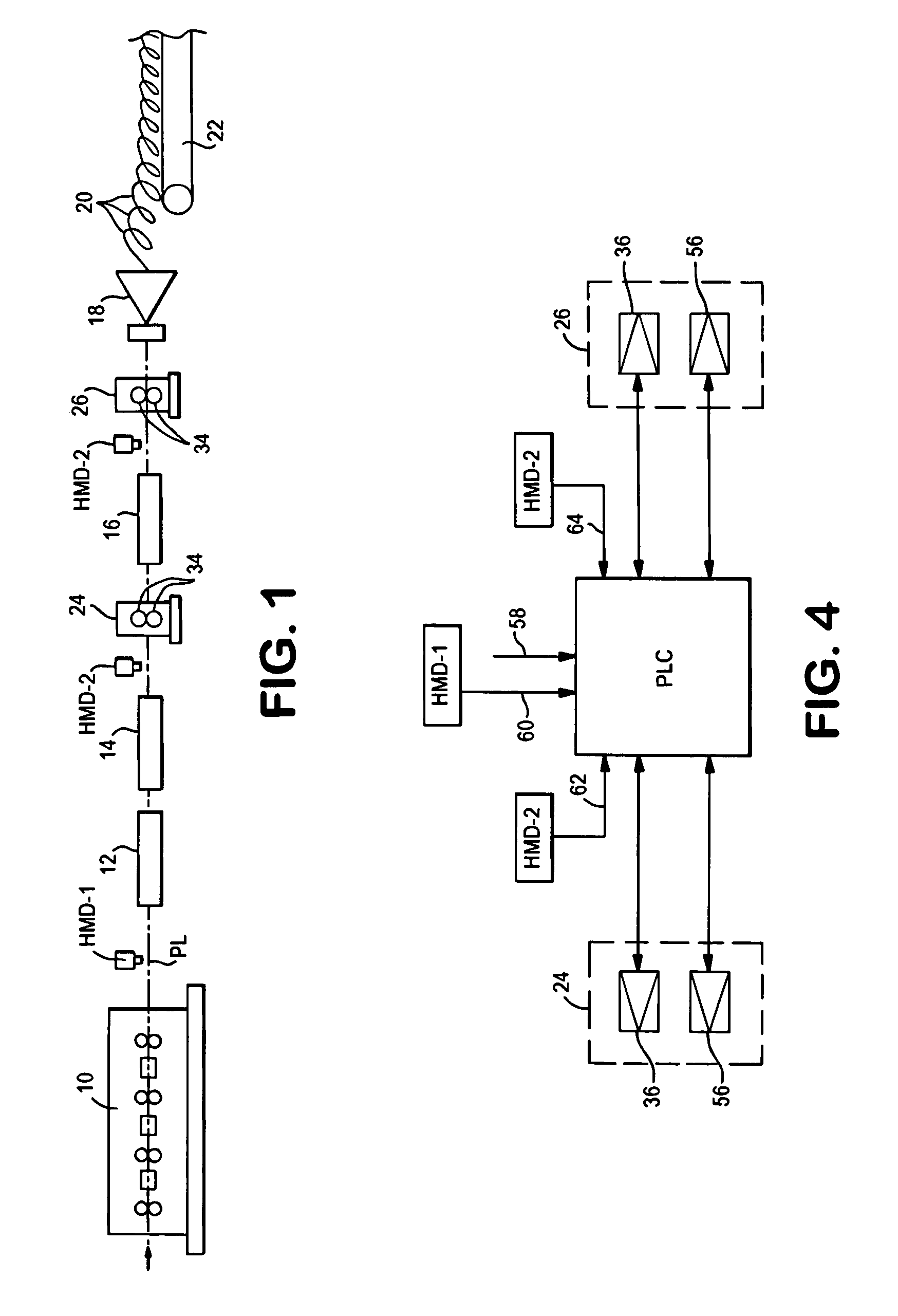

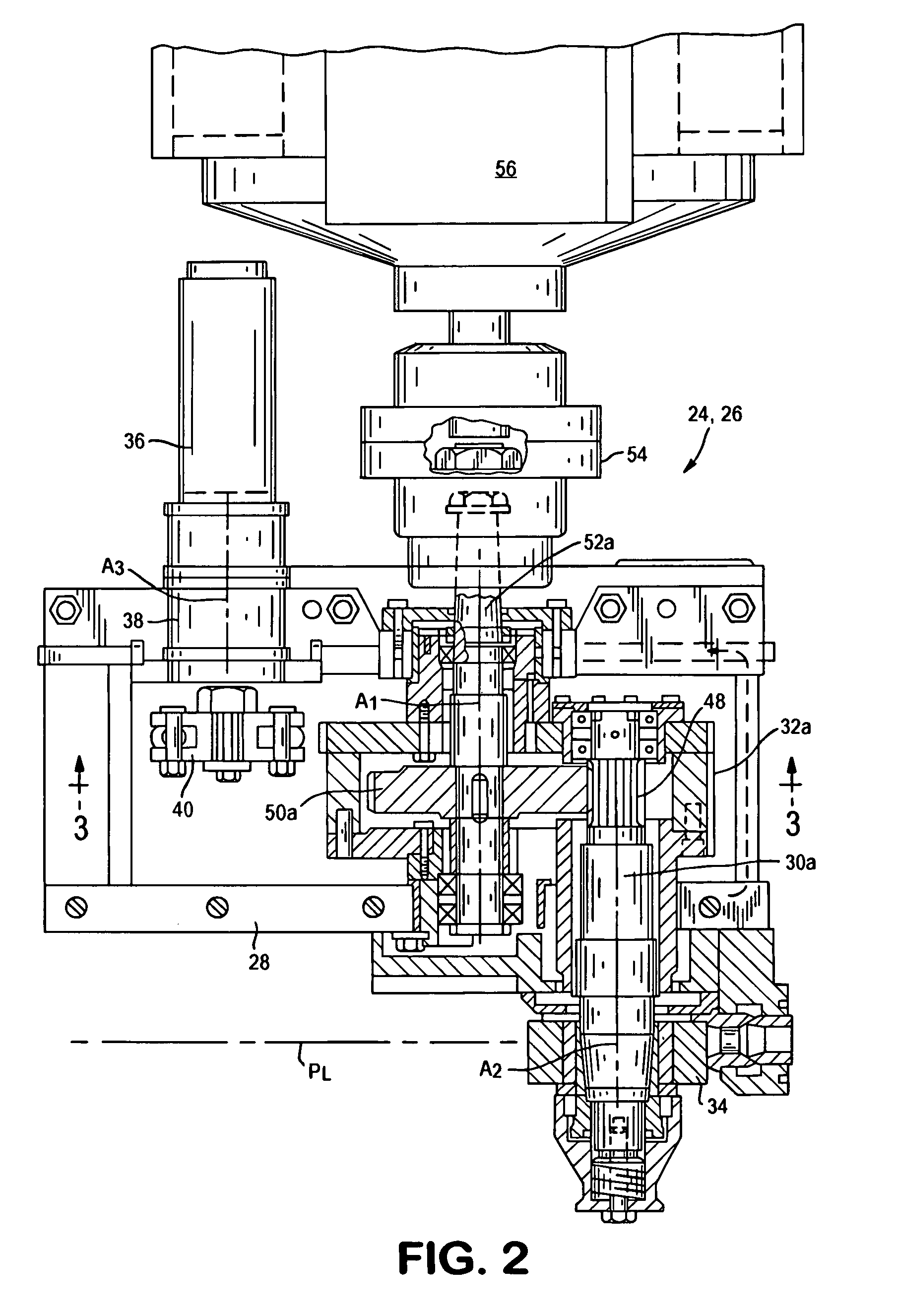

An apparatus for and method of manufacturing lithium or lithium alloy anodes for electrochemical cells by a lamination process wherein a lithium or lithium alloy sheet is reduced into a thin lithium or lithium alloy film. The method and apparatus provide adjustments of the profile defined by the meeting surfaces of a pair of working rollers to compensate for thermal dilation of the working rollers or to compensate for irregular thickness of the lithium or lithium alloy sheet to control the shape and profile of the lithium or lithium alloy film being laminated.

Owner:BATHIUM CANADA

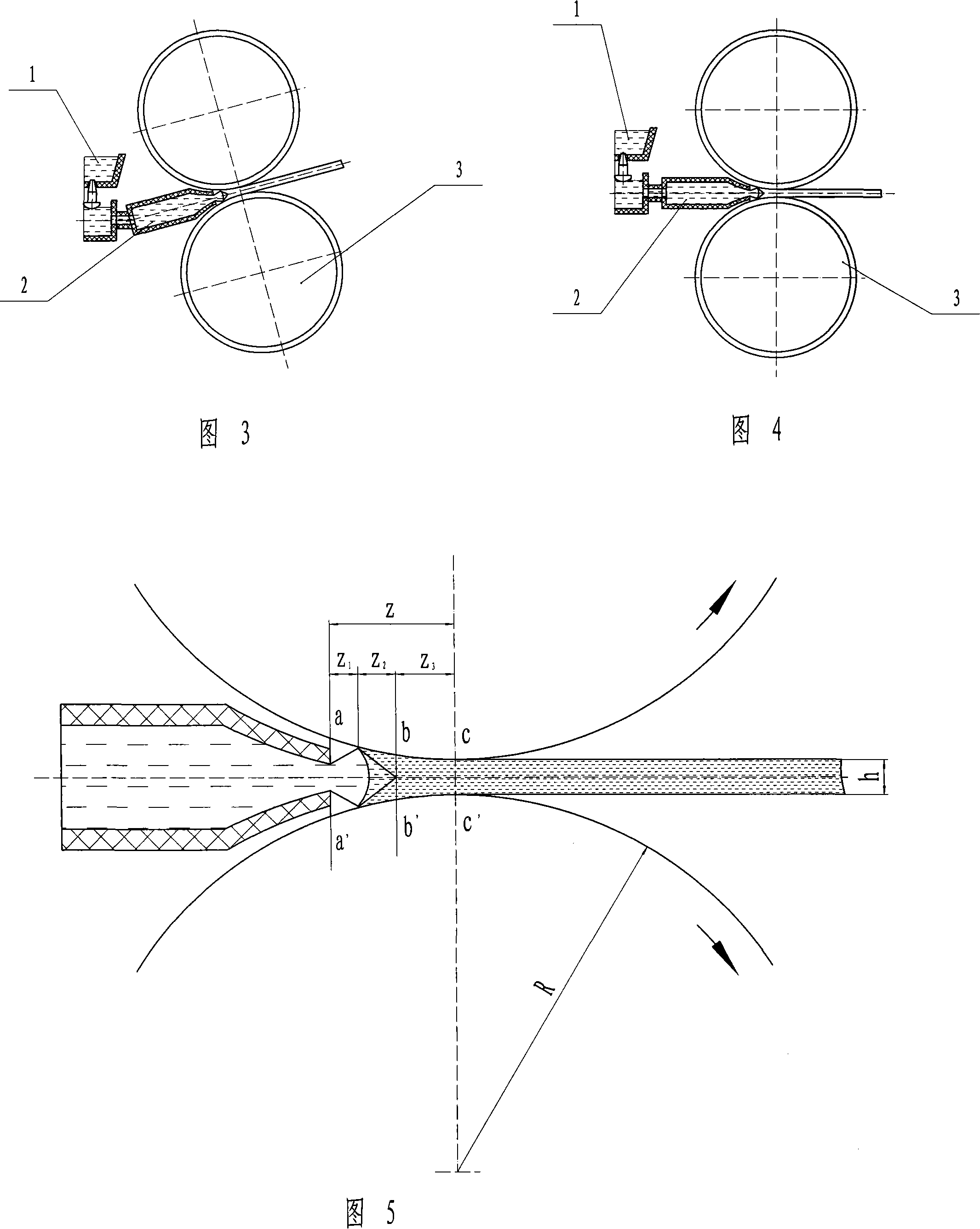

Double-roller casting rolling-hot continuous rolling method and equipment

ActiveCN101239358AIncrease productionHigh dimensional accuracyTemperature control deviceMetal rolling stand detailsProduction lineUltimate tensile strength

The invention provides a method and device for double-roller cast rolling-thermal tandem rolling, which are a method and device for producing aluminum and aluminum alloy plate blank. By using the method, thick cast rolling plate blank can be produced, and coiled material with quality corresponding to that of thermal rolling plate is produced by large rolling amount of thermal rolling, transmitting and coiling. The invention provides a method and device for producing aluminum and aluminum alloy coiled material with high efficiency and greatly improved property by modification aiming at shortcoming of limited cooling space and cooling intensity of the double-roller cast rolling mill in prior art. The invented device enlarges the cast rolling space of the cast rolling mill in prior art with 1.8-4.0 times, enlarges the roller gap thereof with 1.5-2.5 times, enhances the cast rolling speed thereof with 1.5-3.0 times, cast rolls the casting blank continuously with a temperature ranging from 310 DEC C to 510 DEG C, and the integral processing amount is controlled in the range of 40-85, thereby the yield, size accuracy and mechanical property are greatly improved, and the product range is enlarged. The invented device is: inclination angle adjustable off-centering reducing double-roller cast rolling-thermal tandem rolling- cutting-coiling production line.

Owner:张明

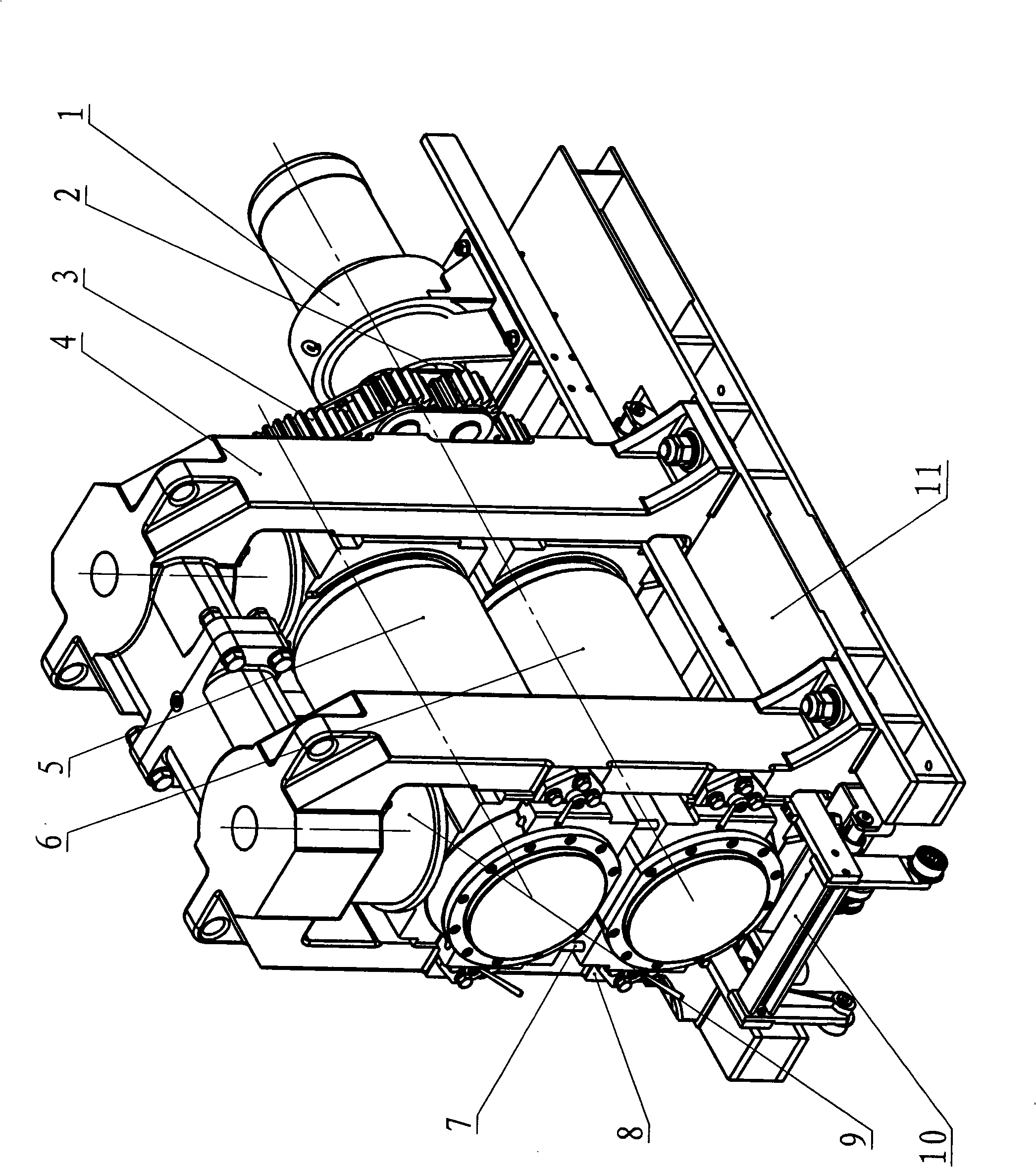

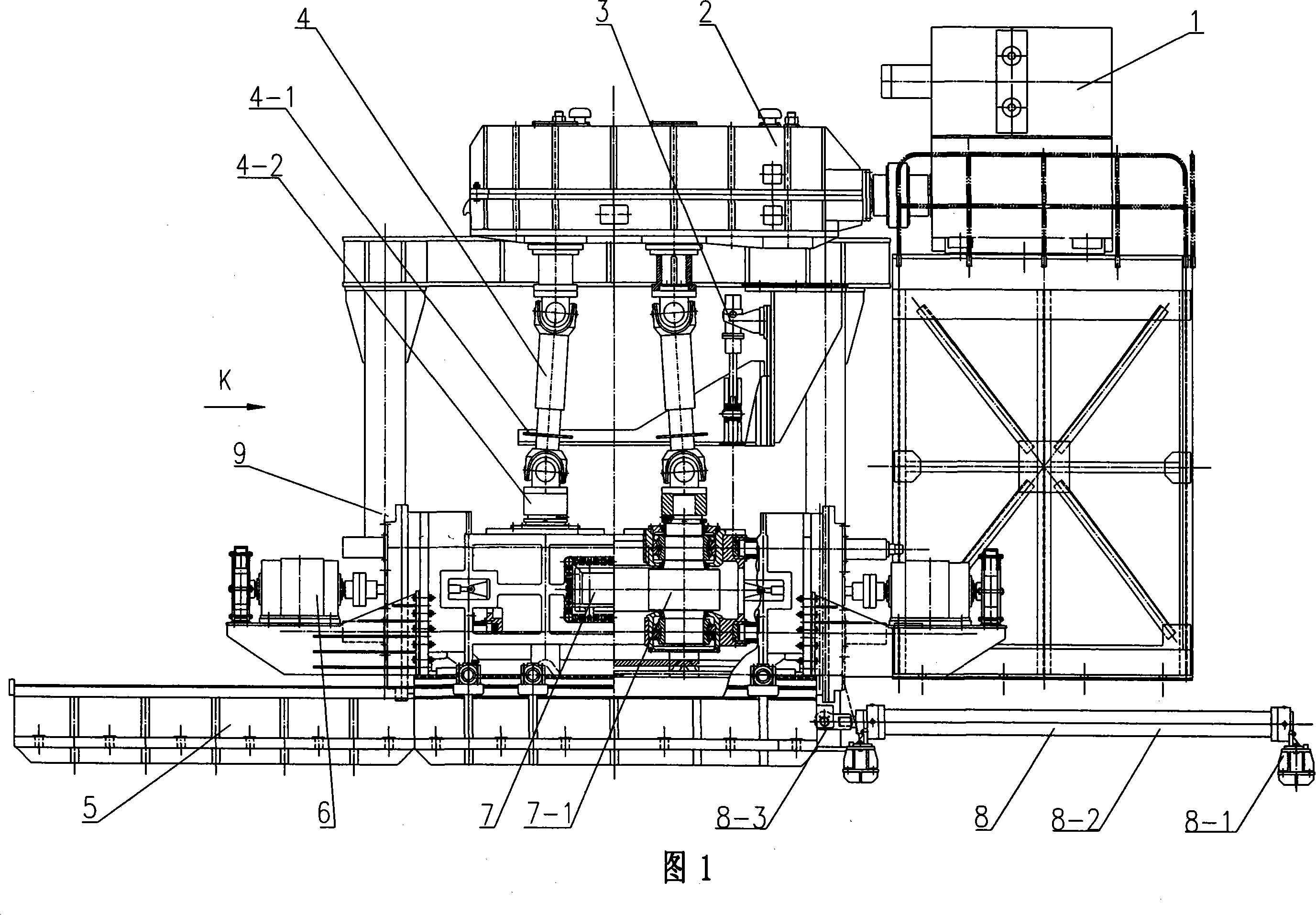

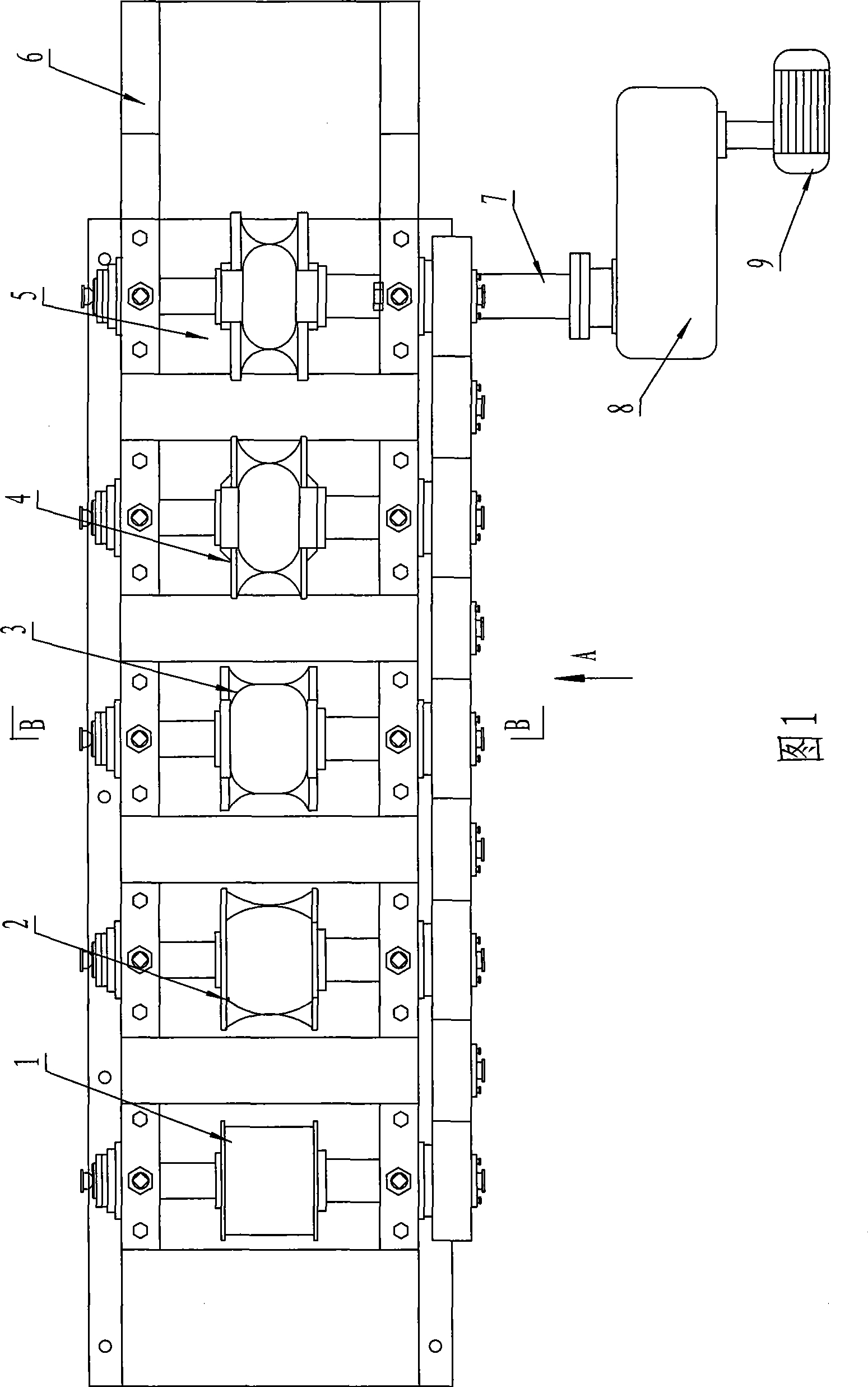

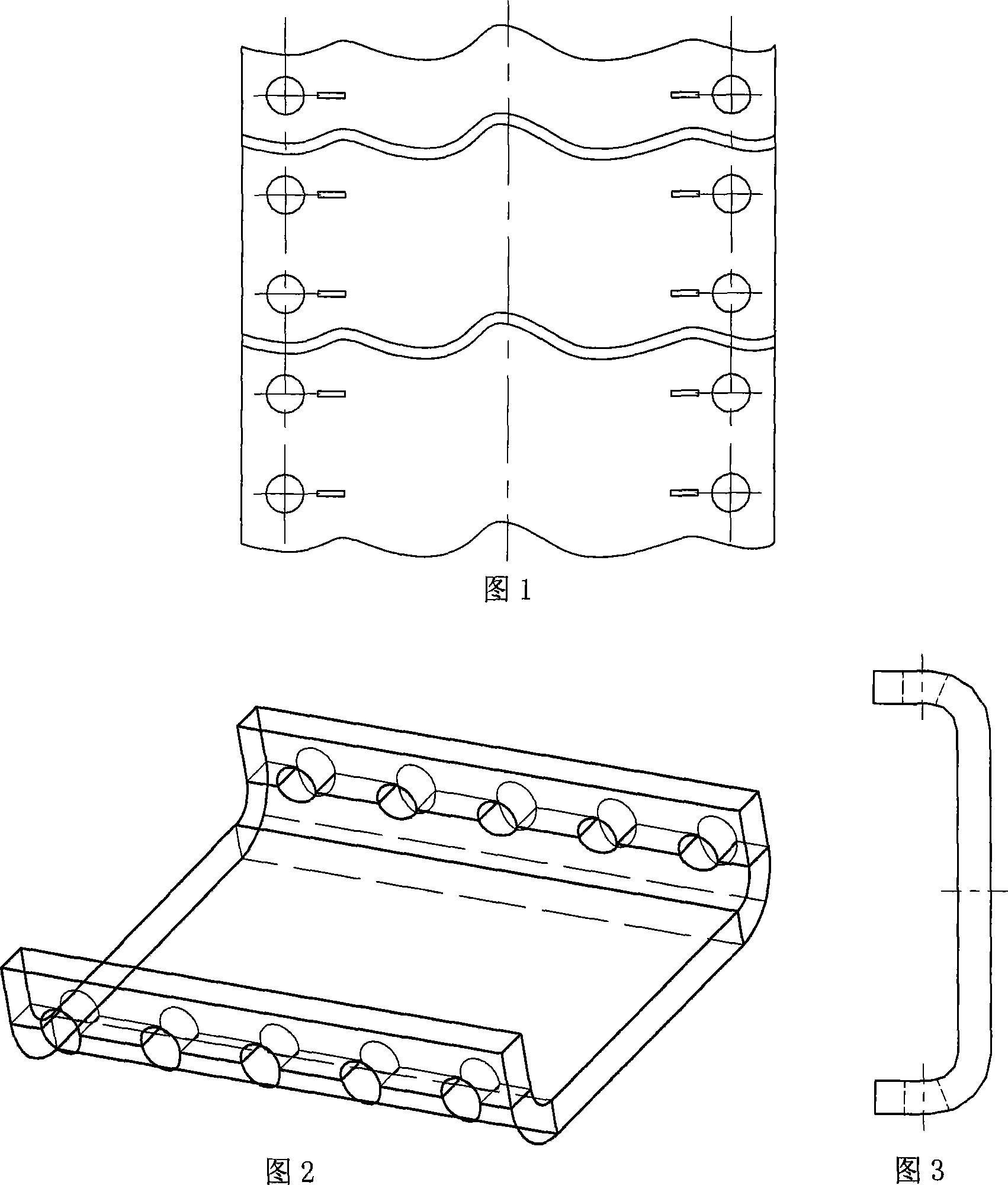

Rough rolling vertical roller mill

InactiveCN101108395AEasy to adjustQuick roll changeMetal rolling stand detailsRolling mill drivesMotor driveGear wheel

The invention relates to a rough rolling vertical milling caster is provided, wherein, the main transmission combination speed reducer is a whole structure, the output axle is two output gear axles arranged vertically, a main transmission motor is connected with the main transmission combine speed reducer by a shaft joint, the two output gear axles extending vertically under the main transmission combination speed reducer are connected with a cross universal spiale, a sleeve at the low end of the cross universal spiale is arranged on the roller platycephaly of a roller structure on a lead rail equipment, the two sides of the roller structure is connected with a side pressure screwdown equipment of a transmission bolt structure with direct current motor driving gear, a hydraulic pressure roll changing lifting device is arranged on a frame under the main transmission combination speed reducer, a side of the lead rail base equipment is arranged with a roll changing structure. The advantage of the invention is that: the invention improves the transmission rigidity and service life, which can meet the requirements of large torsion distance; the invention can realize quick roll changing, which shortens the online roll changing time greatly and improves work efficiency; the invention cooperates with a plain-barrel rolling machine, which can produce blank with different standard and lowers the process cost.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

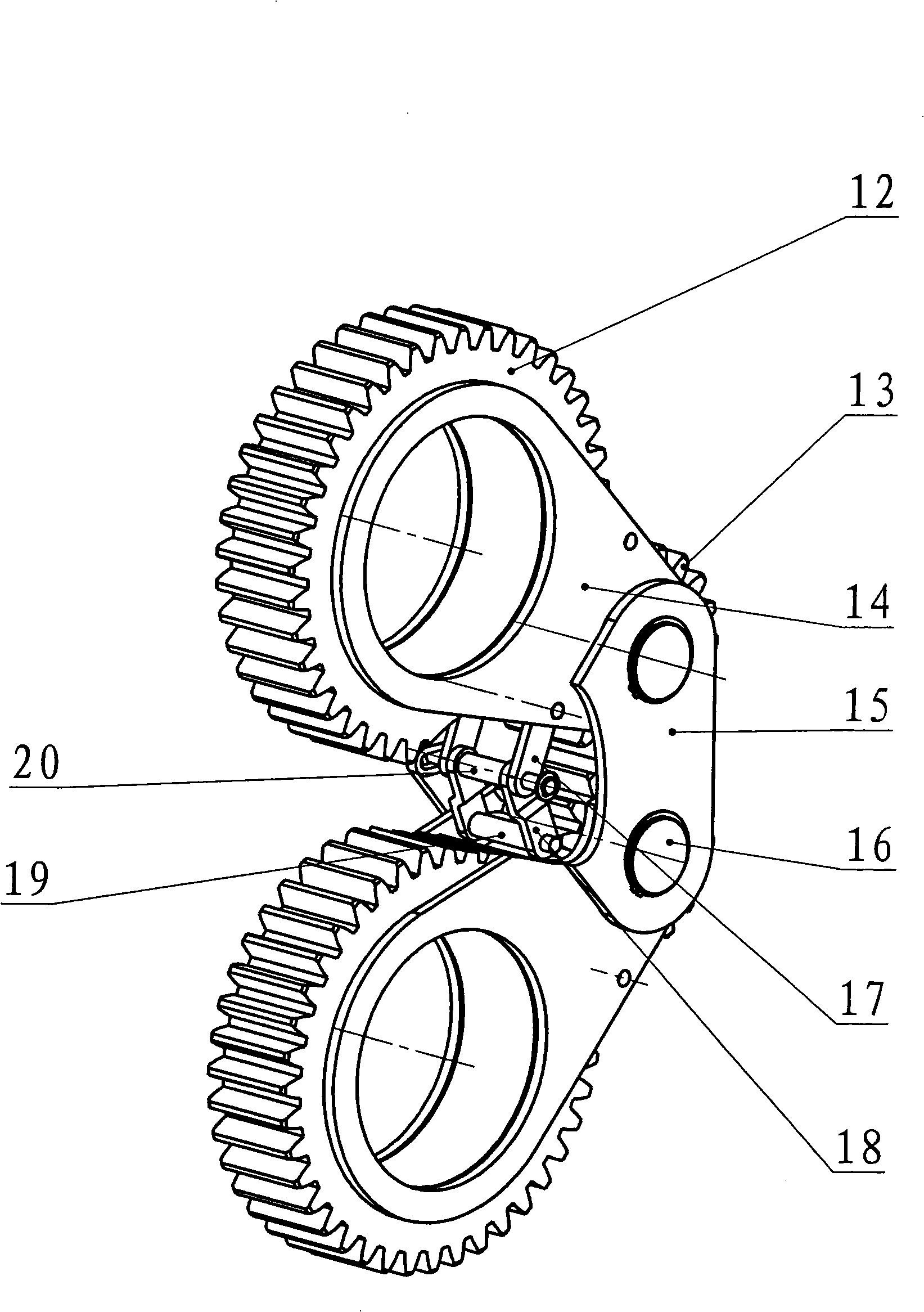

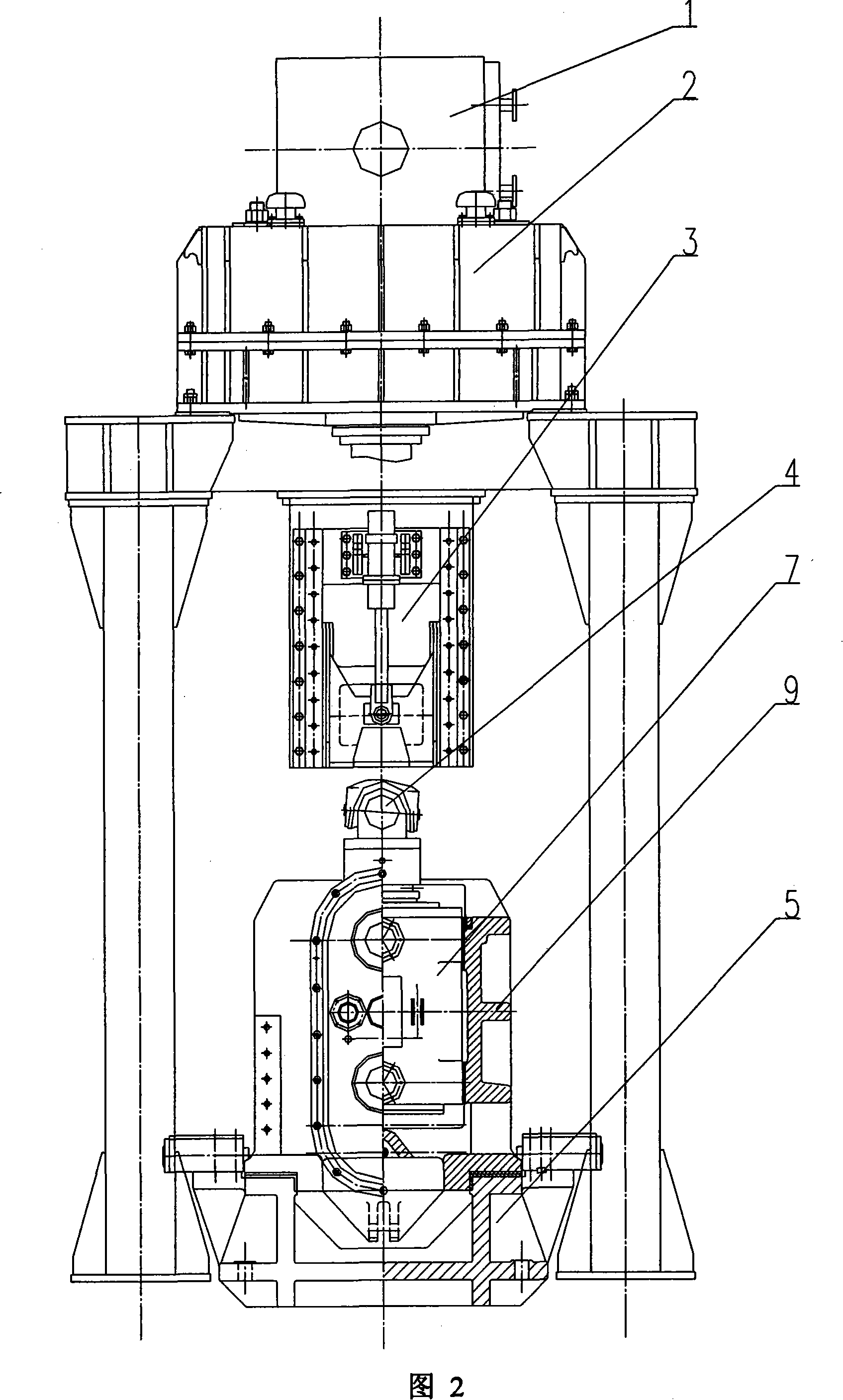

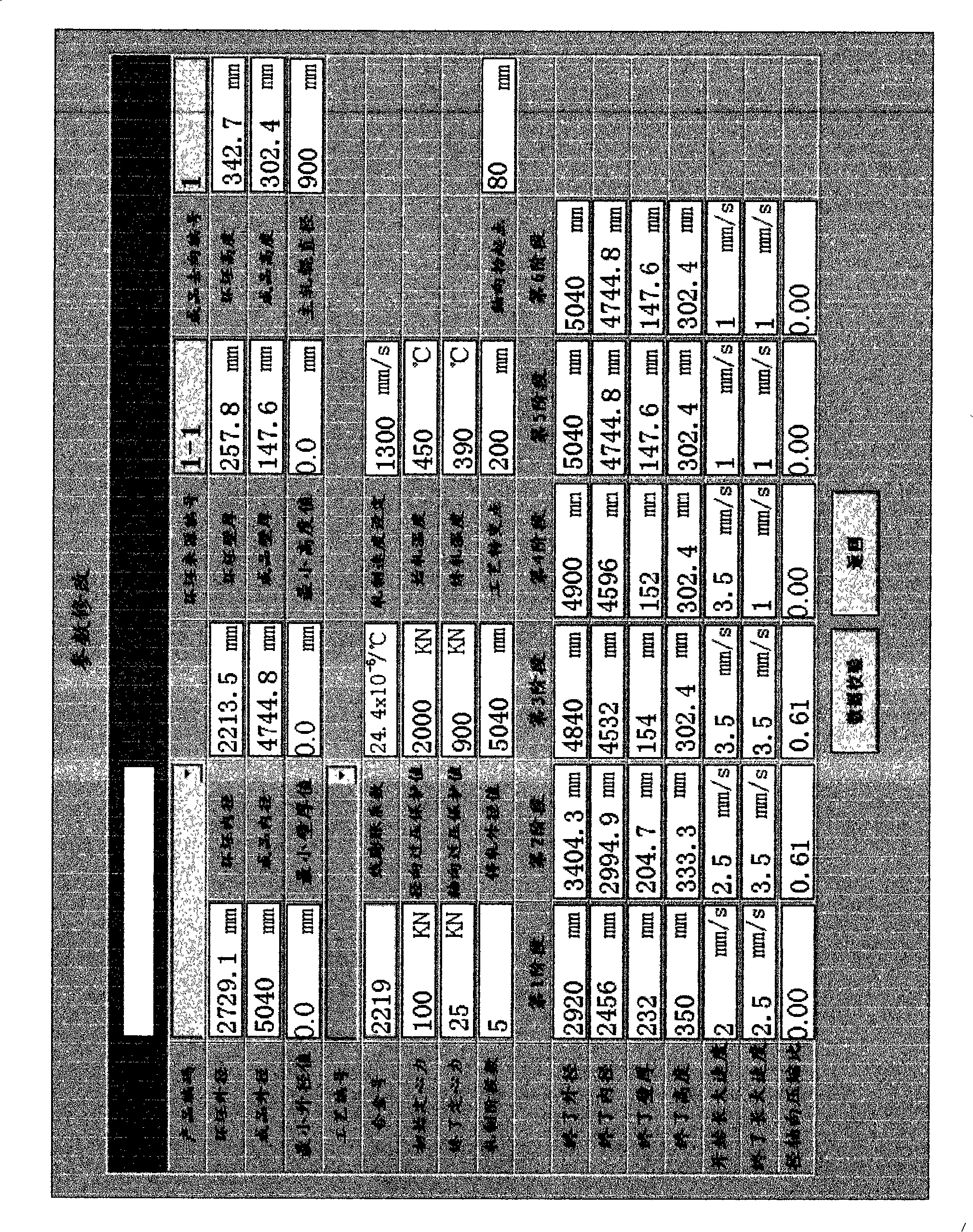

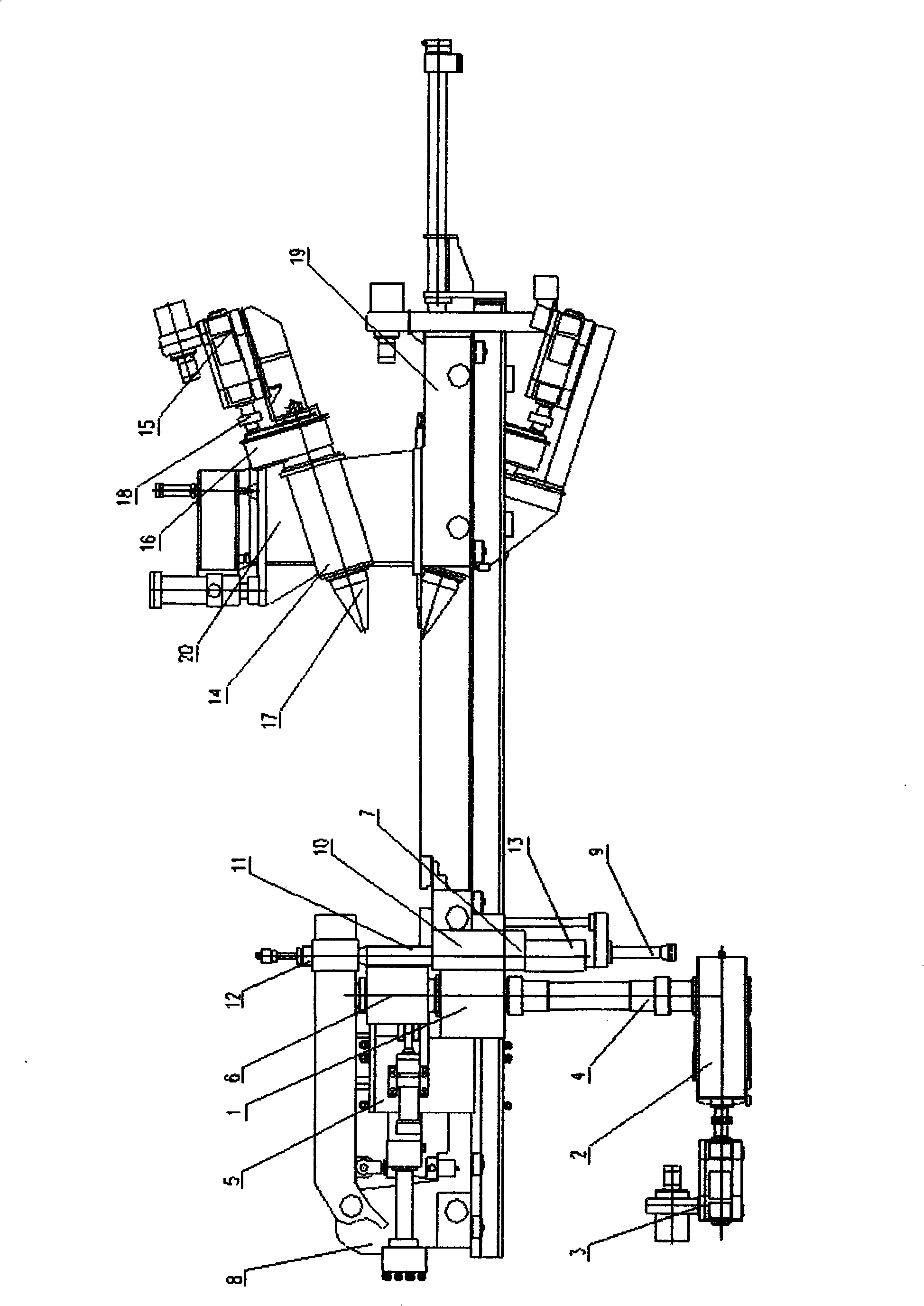

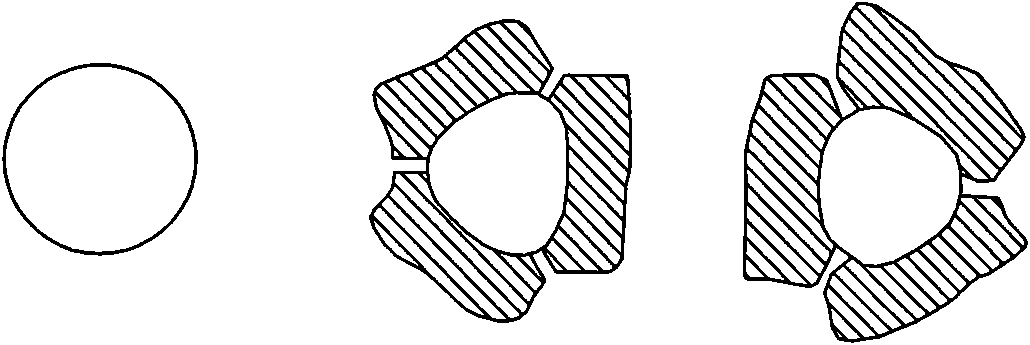

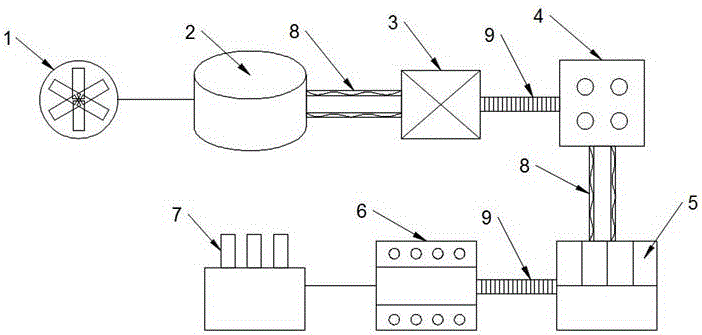

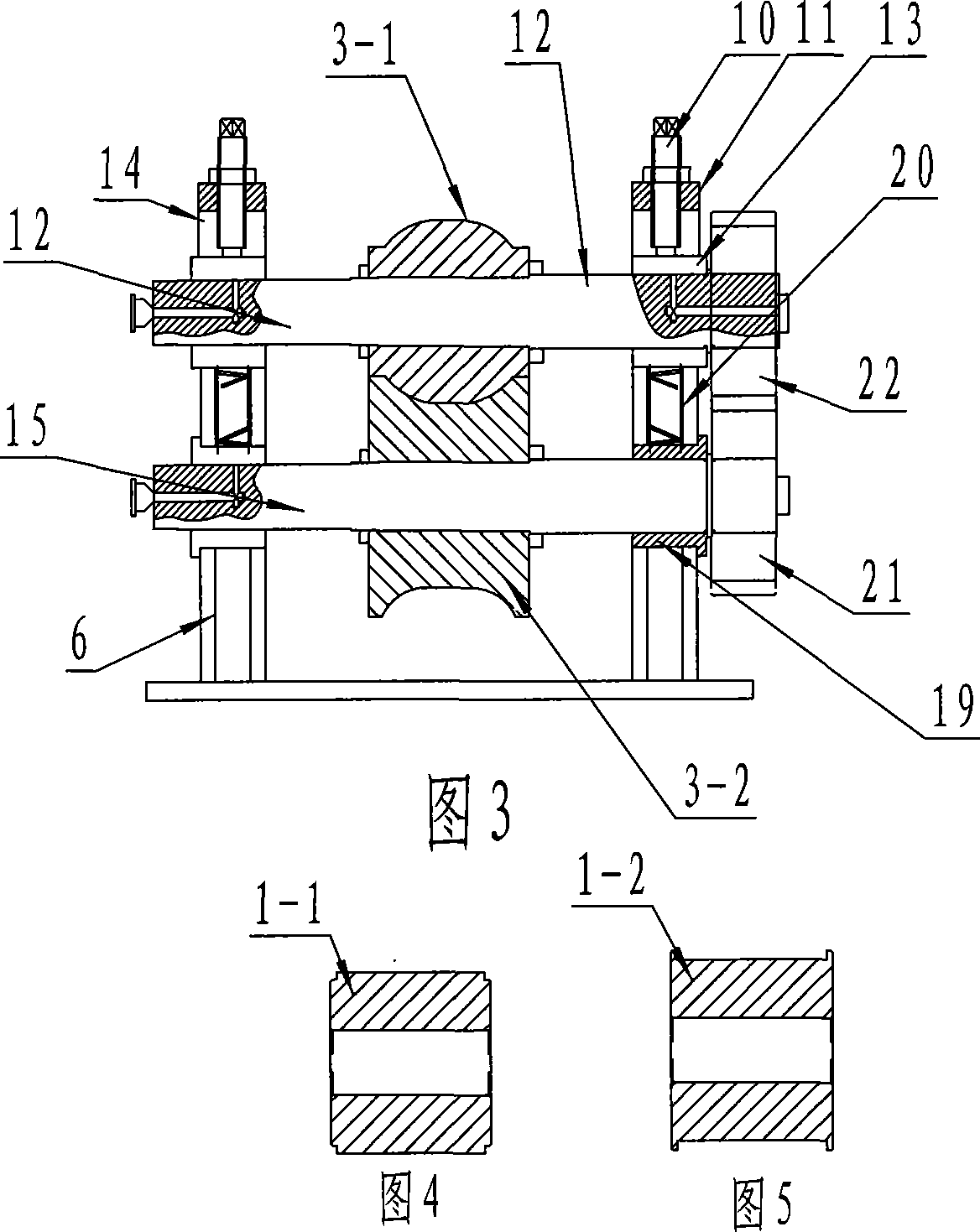

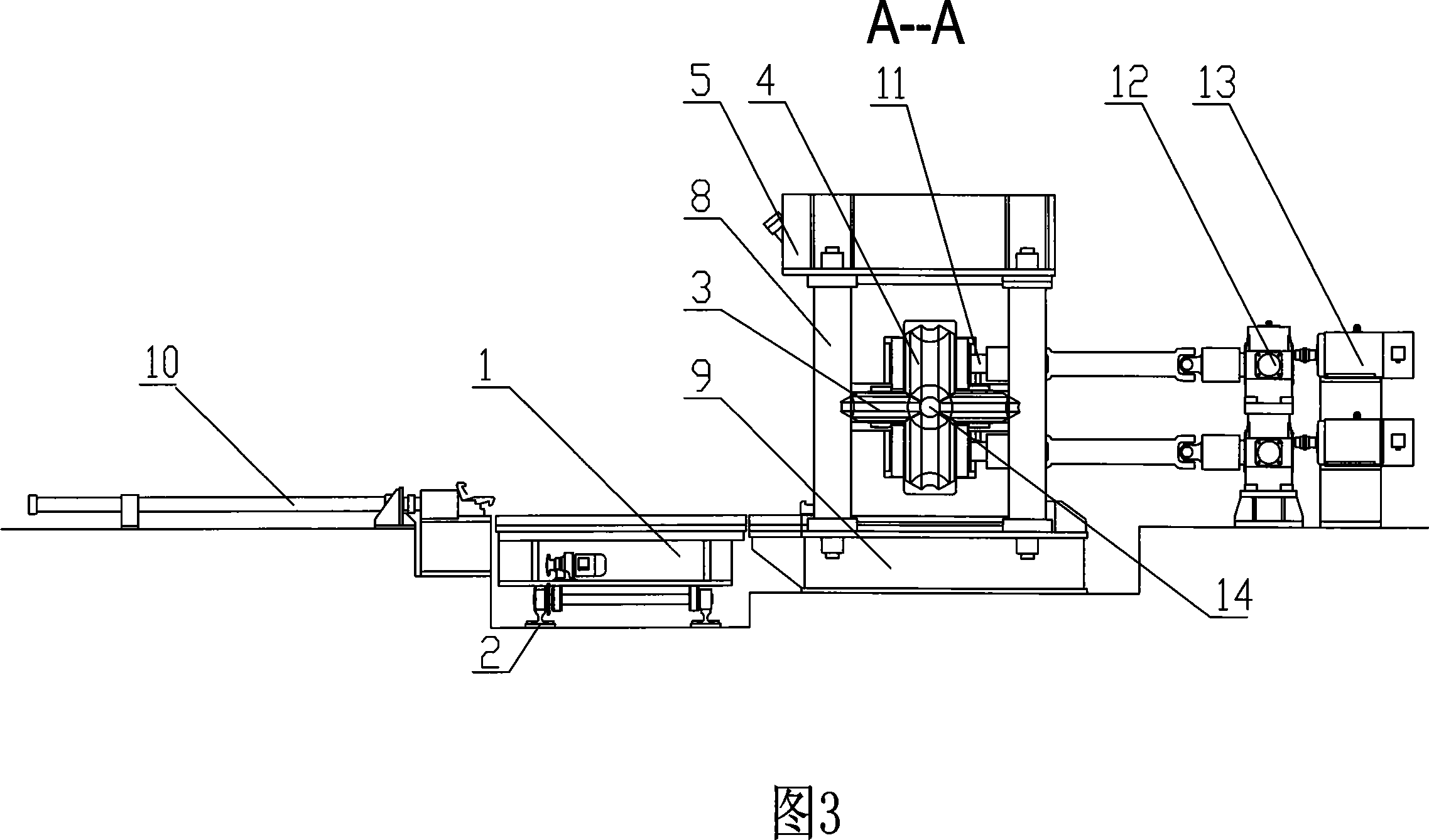

Aluminum alloy ring piece rolling technique and device

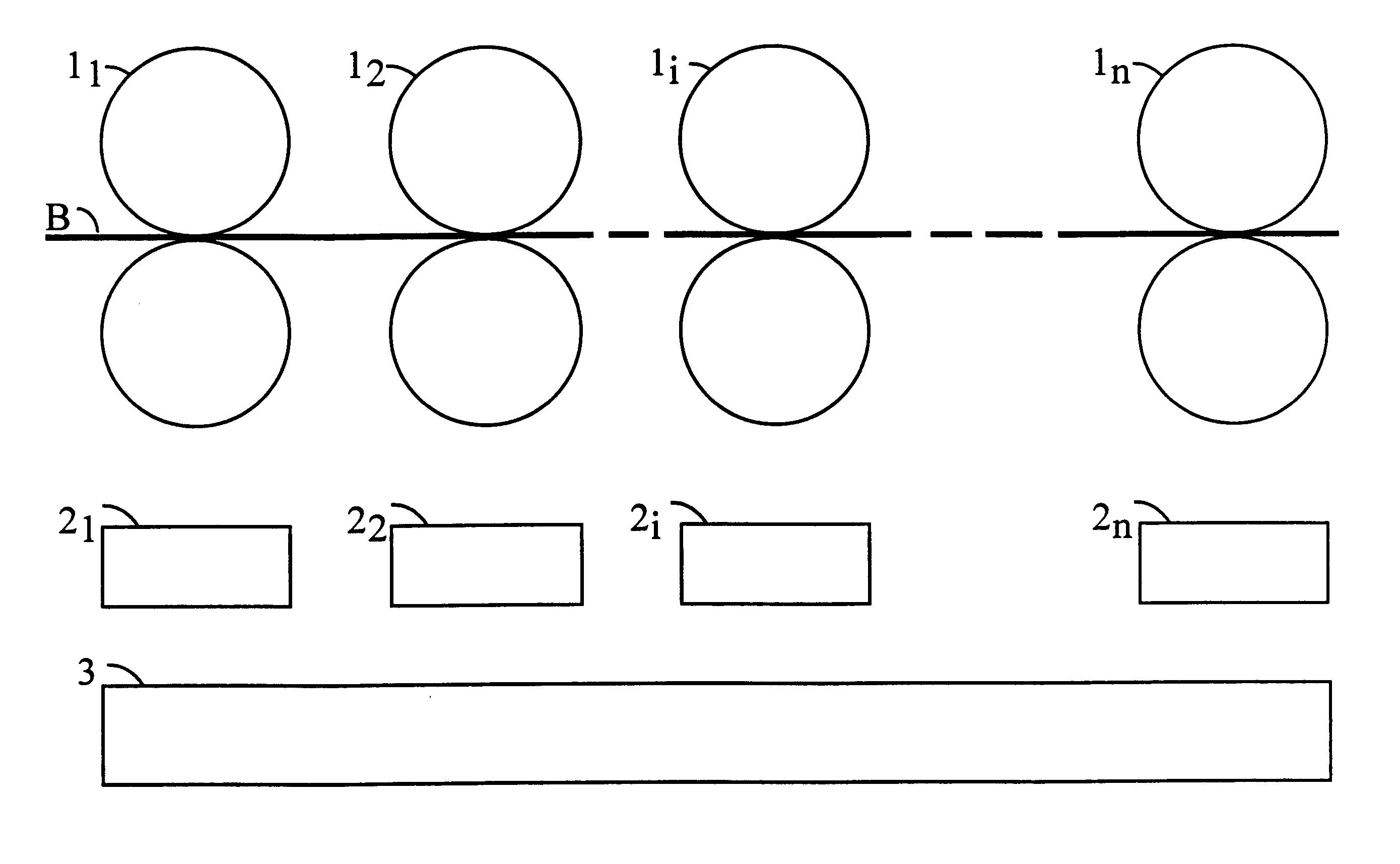

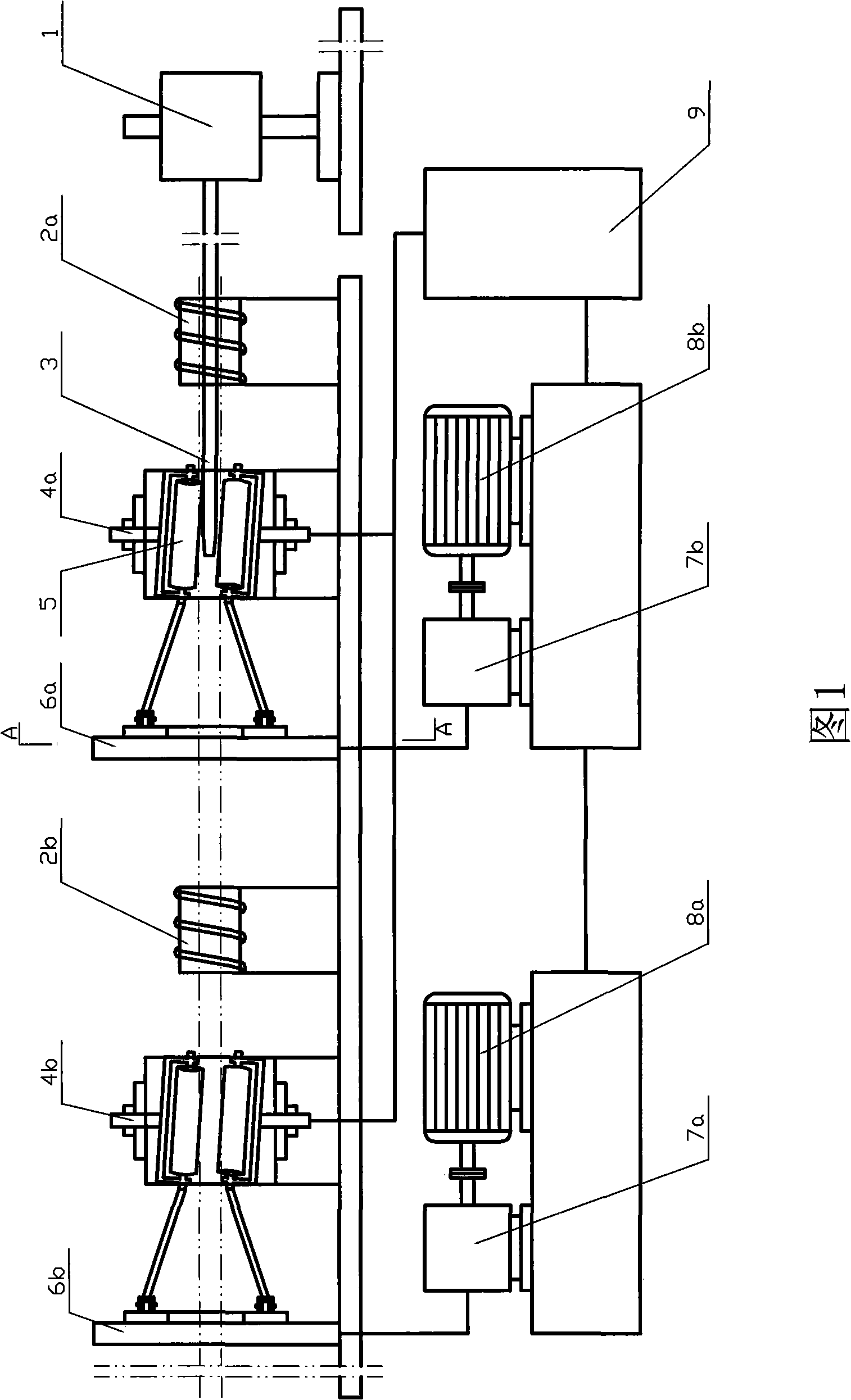

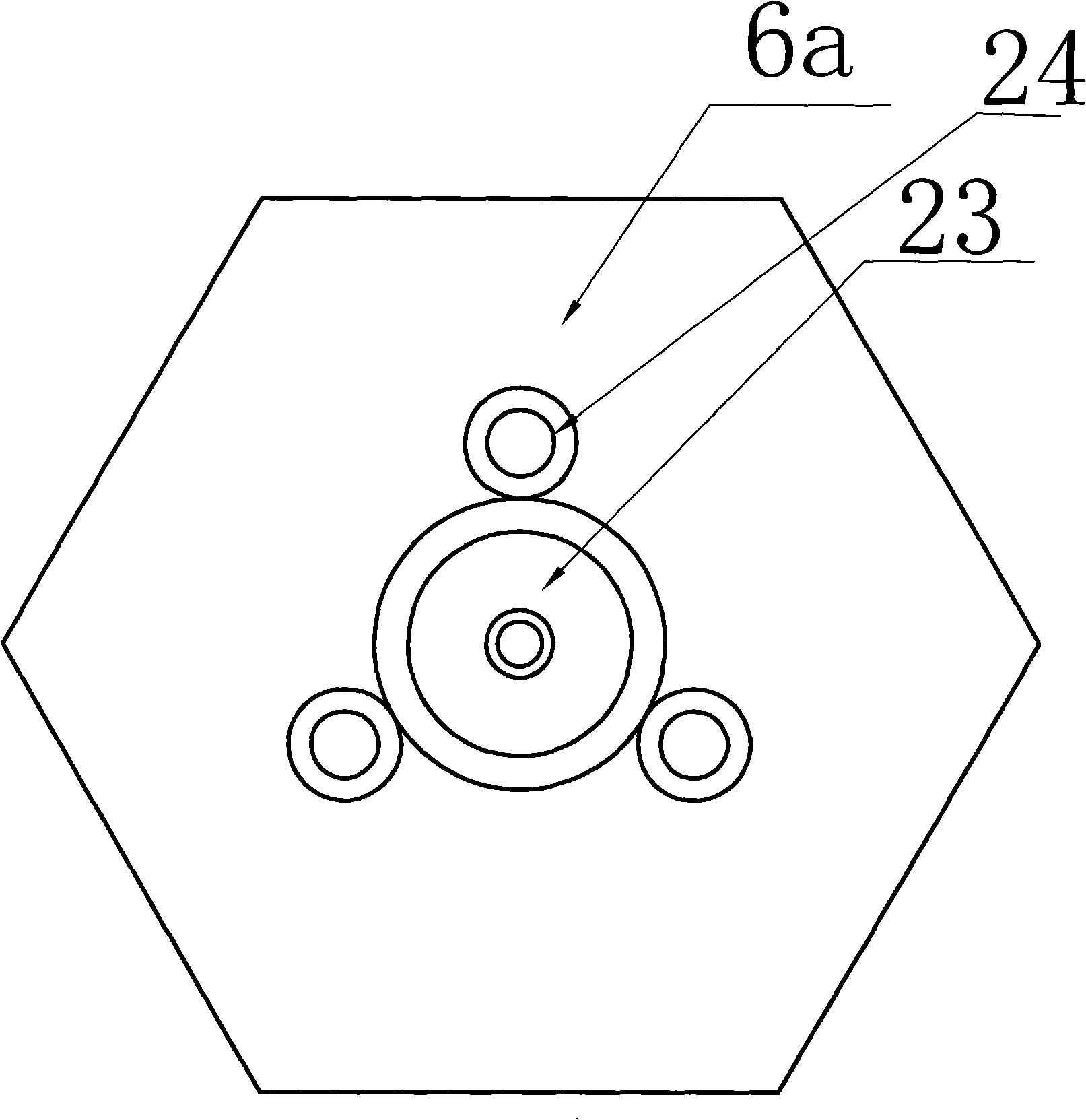

InactiveCN101337256AStepless adjustable speedMeet speed requirementsRoll mill control devicesRolling mill drivesNumerical controlMaterials processing

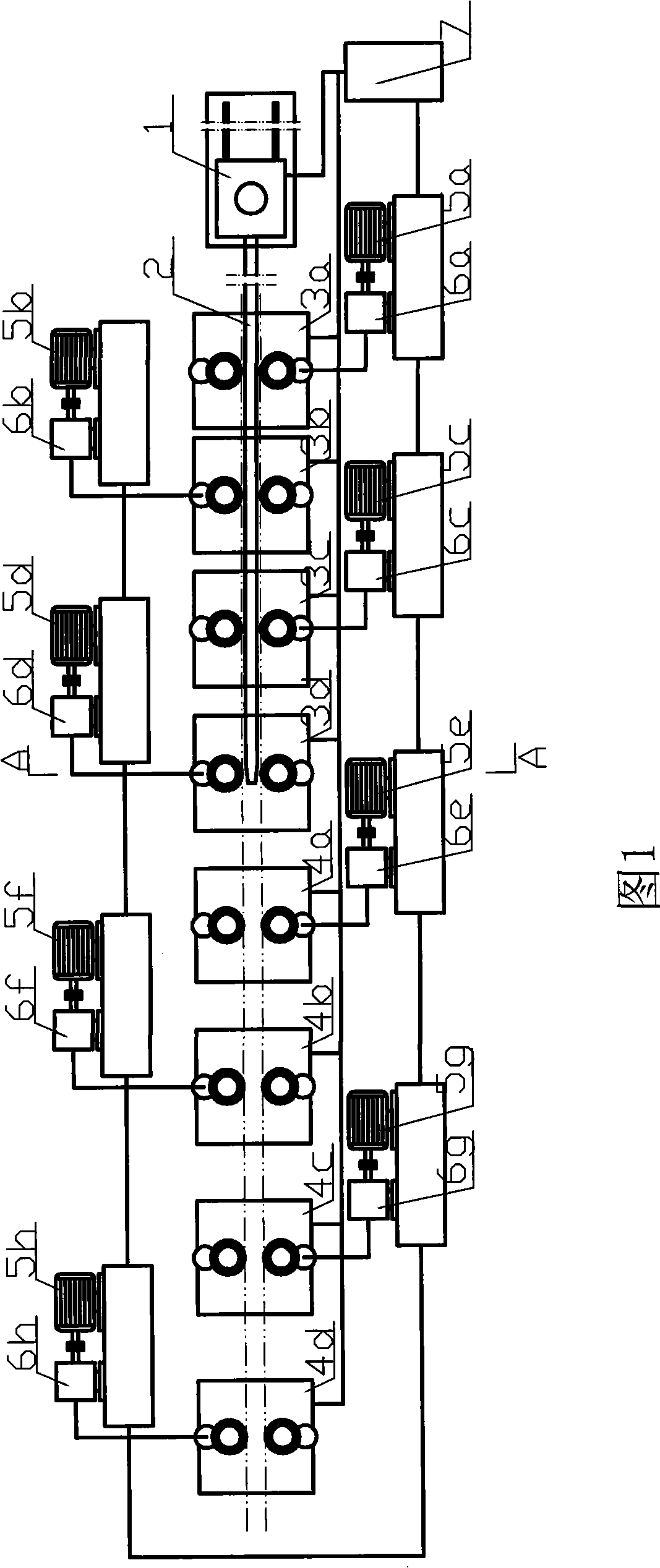

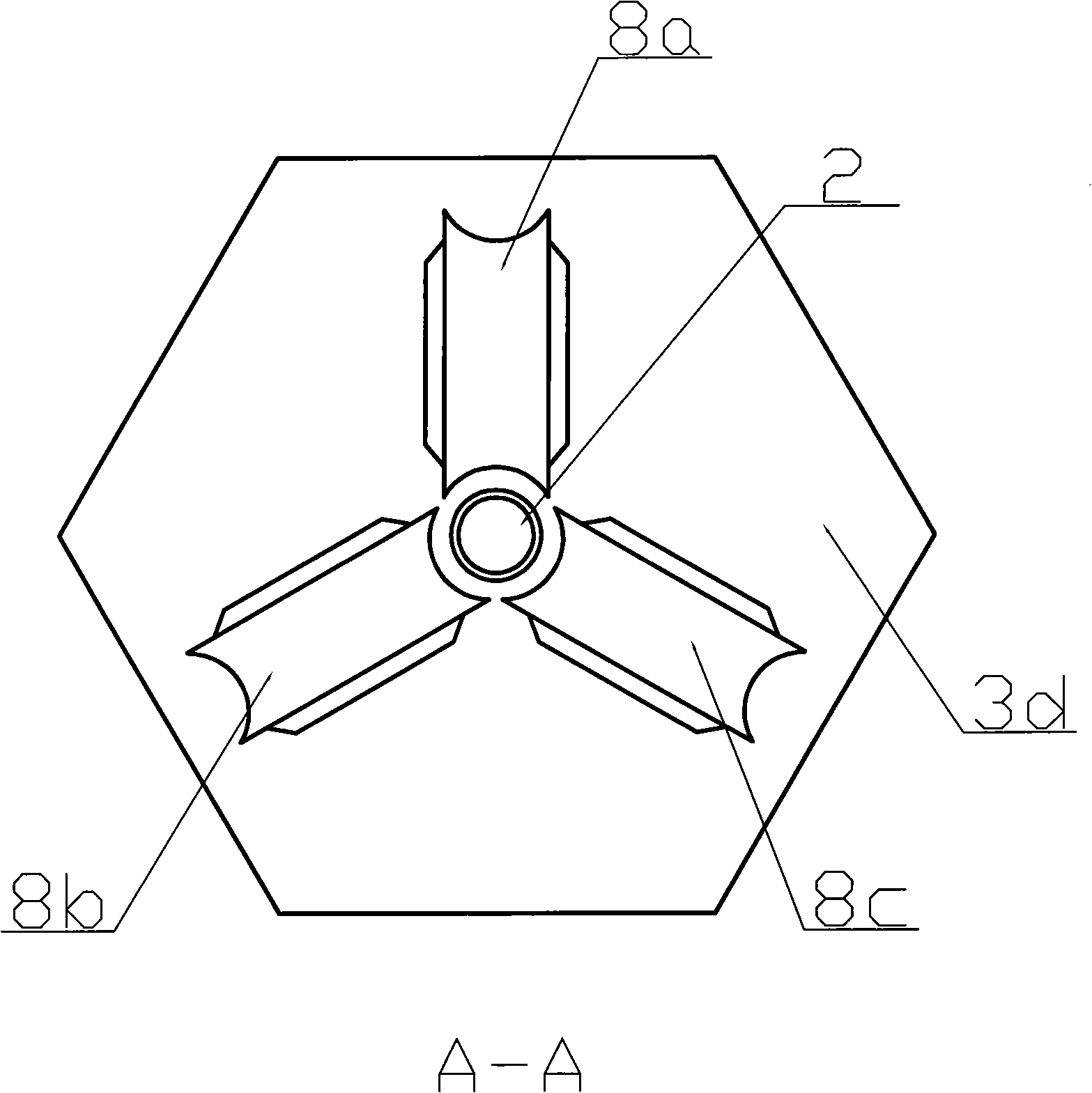

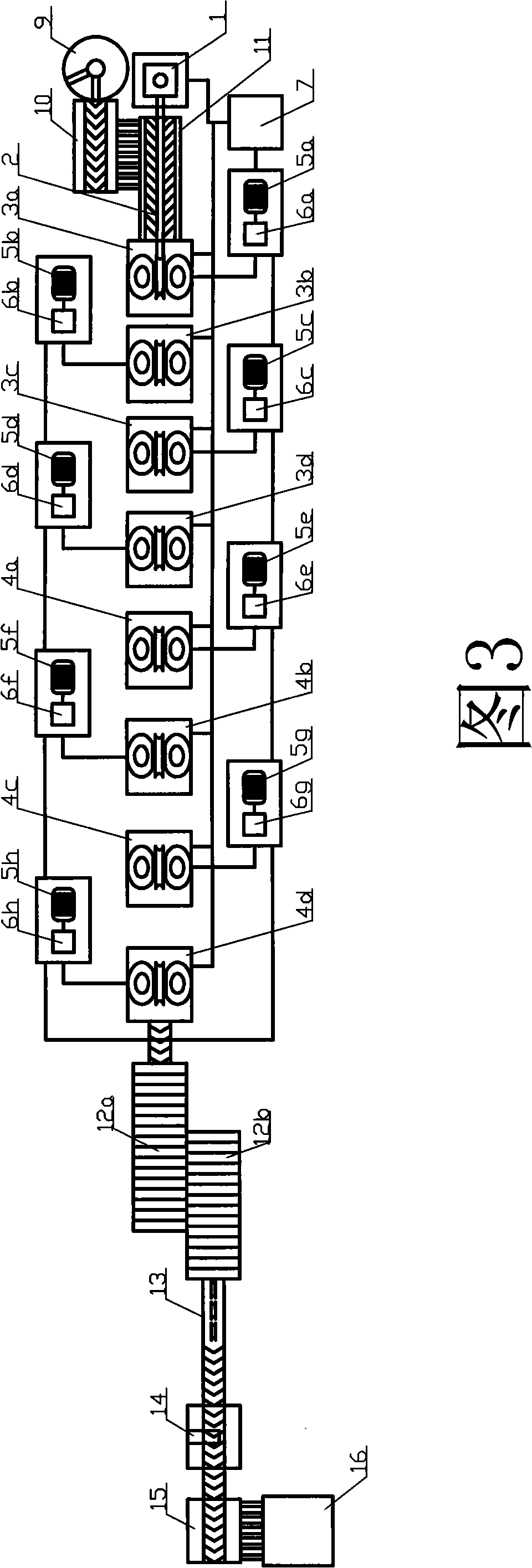

The invention relates to a method and equipment for processing metal material, particularly to a technology and equipment for rolling superlarge-diameter aluminium alloy ring pieces. The method and the equipment are characterized in that the rolling technology comprises the following steps: A. calculating parameters: calculating technical control parameters including the dimensions of a roughcast, the rolling linear speed, the radial-axial rolling force during various stages, the enlargement rate of the ring pieces, the radial-axial feed speed, the external diameter of the ring pieces, the height of the ring pieces and the wall thickness of the ring pieces according to the dimensions of a product ring; B. inputting parameters: inputting the various technical control parameters into a numerical control ring rolling mill computer according to the calculation results; C. numerically controlled rolling: fully automatic control is adopted during the rolling process. A radial rolling mechanism and an axial rolling mechanism are connected on the chassis of the equipment; and the radial rolling mechanism is connected with a king roller drive mechanism (1) and a core roller mechanism (7). The axial rolling mechanism is connected with an axial roller drive mechanism (14). The technology and the equipment for rolling superlarge-diameter aluminium alloy ring pieces lead to smooth rolling process and high-precision of the dimensions of product rings.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Journal bearing and thrust pad assembly

An apparatus for rotatably mounting and axially fixing a gear on a shaft comprises a bushing fixed within a bore of the gear. A sleeve is received on and fixed relative to the shaft. The sleeve is surrounded by and journalled for rotation within the bushing. A thrust ring is fixed relative to and projects radially from the shaft on one side of the gear. A retainer on the one side of the gear defines a circular channel within which the annular thrust ring is axially confined.

Owner:PRIMETALS TECH USA

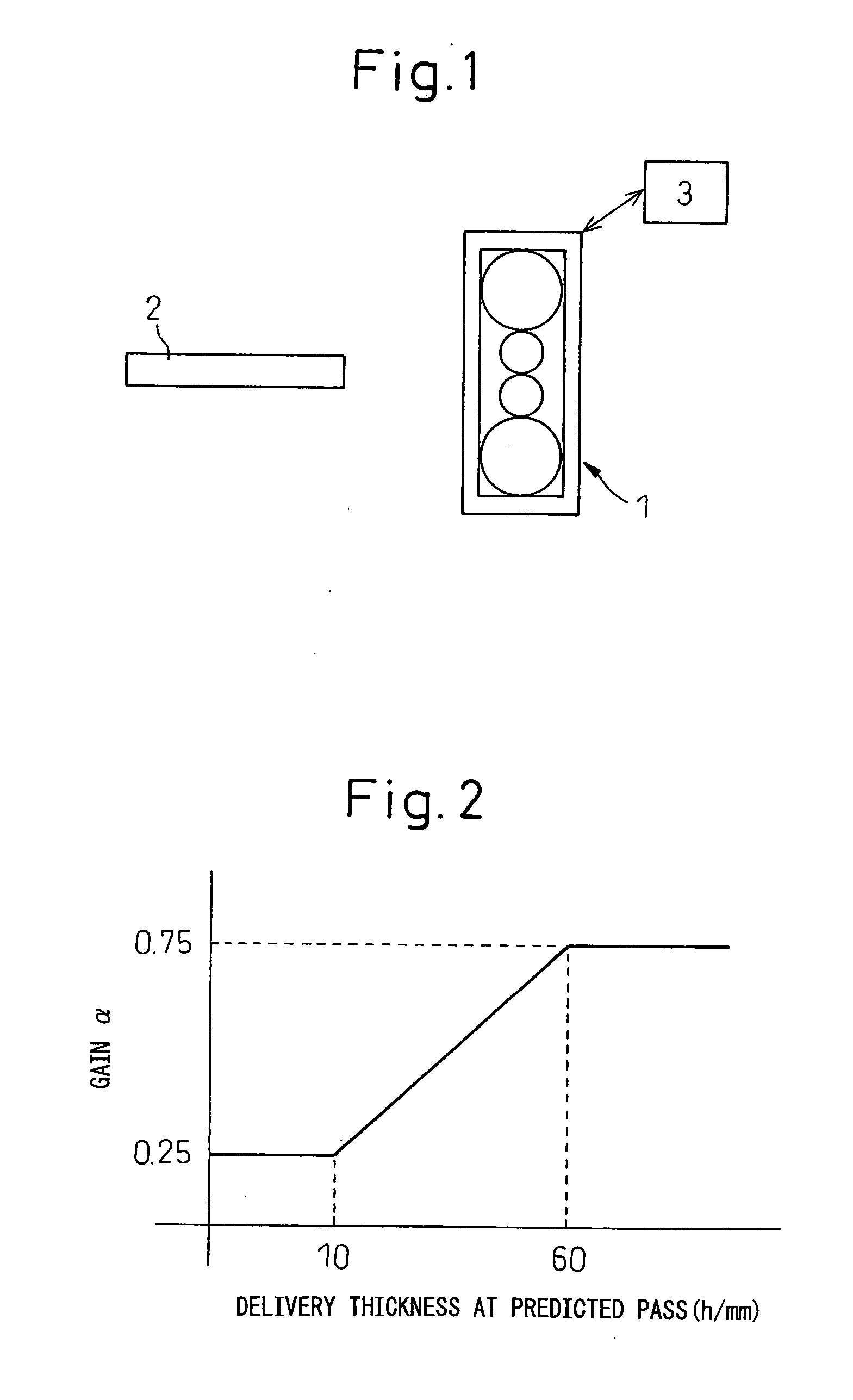

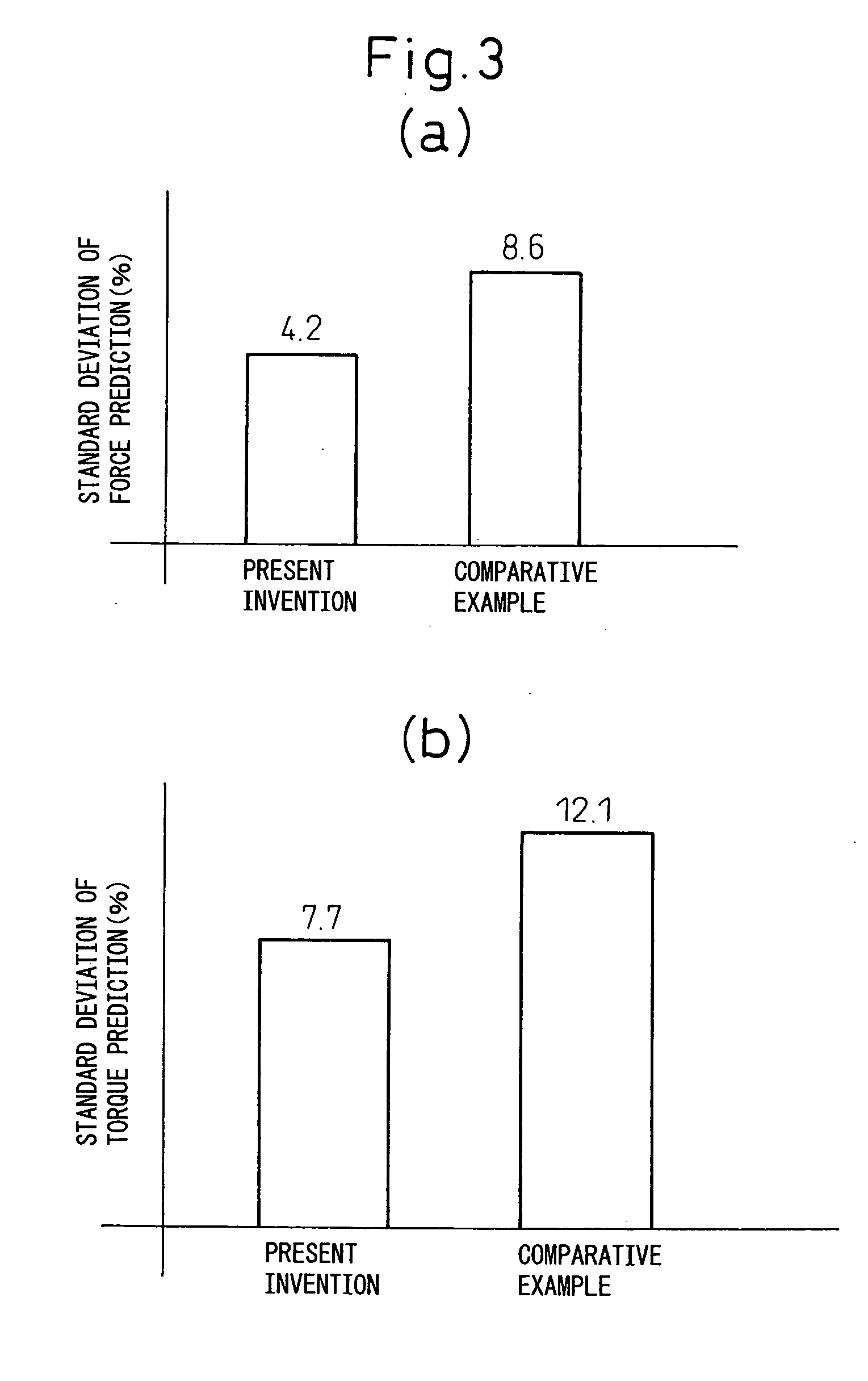

Learing method of rolling load prediction for hot rolling

ActiveUS20100121471A1High precisionStable improvement of precisionRoll force/gap control deviceShaping safety devicesTime changesError factor

In the learning method of rolling load prediction in hot rolling, in the past the prediction error of the rolling load was corrected based on envisioned error factors, but in the complicated rolling phenomenon, there are many influential factors and therefore logical extraction and estimation had been difficult.Therefore, the learning method of rolling load prediction according to the present invention refers to prediction error of a rolling load at an actual pass of a stock in hot rolling to correct a predicted value of rolling load at a rolling pass to be performed from then on, at which time changing a gain multiplied with the prediction error of the rolling load at said actual pass in accordance with a thickness of said stock to thereby set the learning coefficient of the rolling load prediction and improve the precision of the prediction.

Owner:NIPPON STEEL CORP

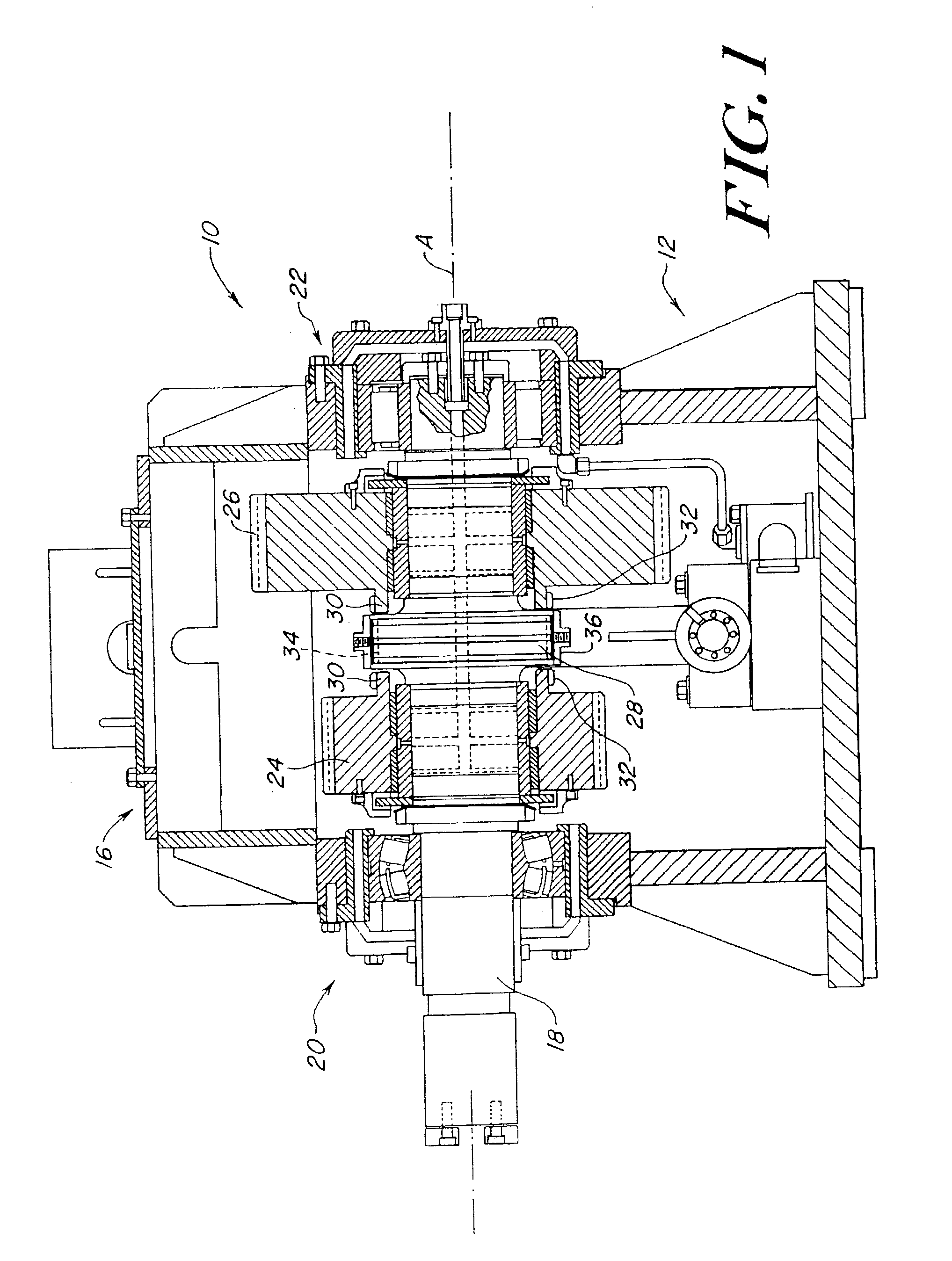

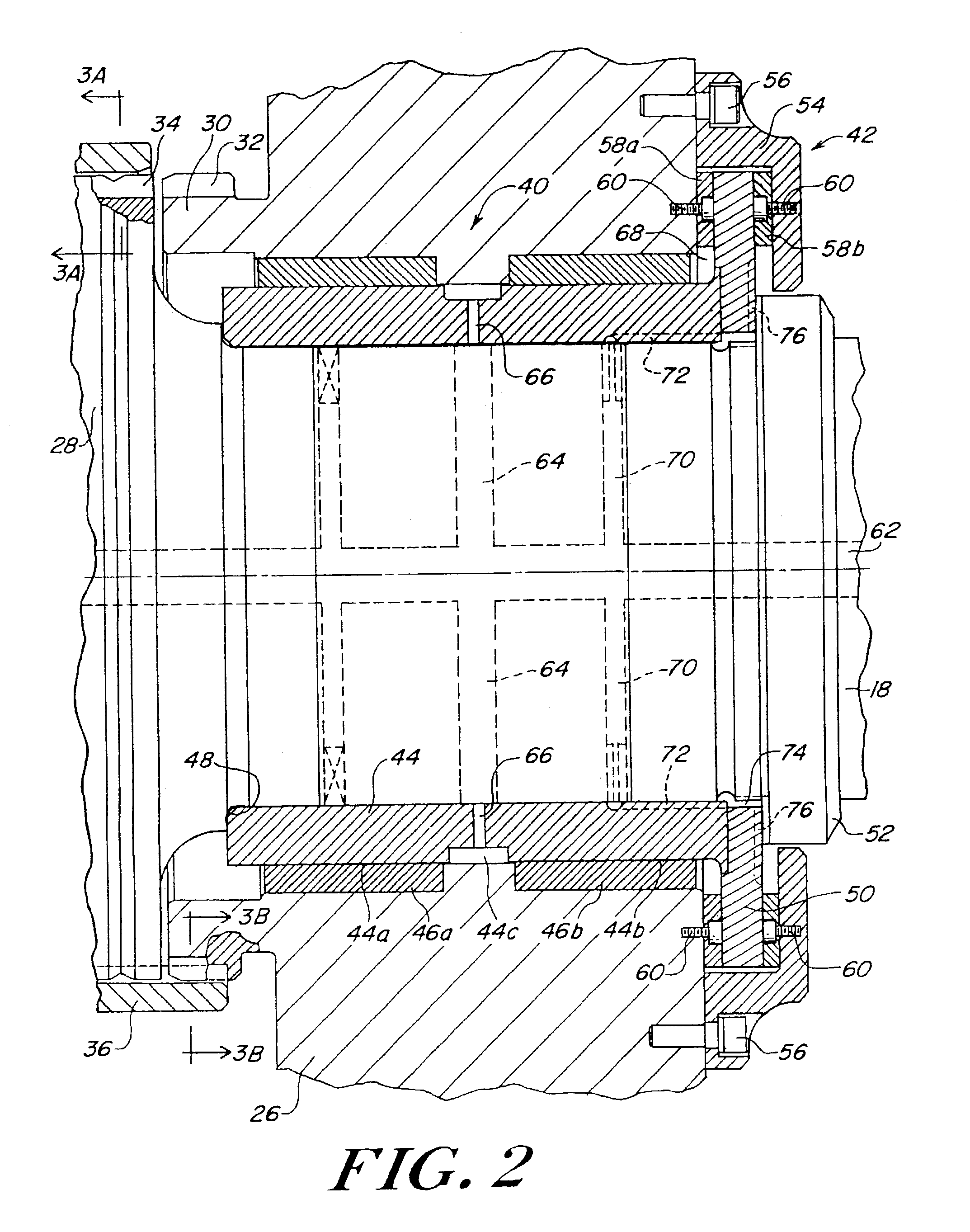

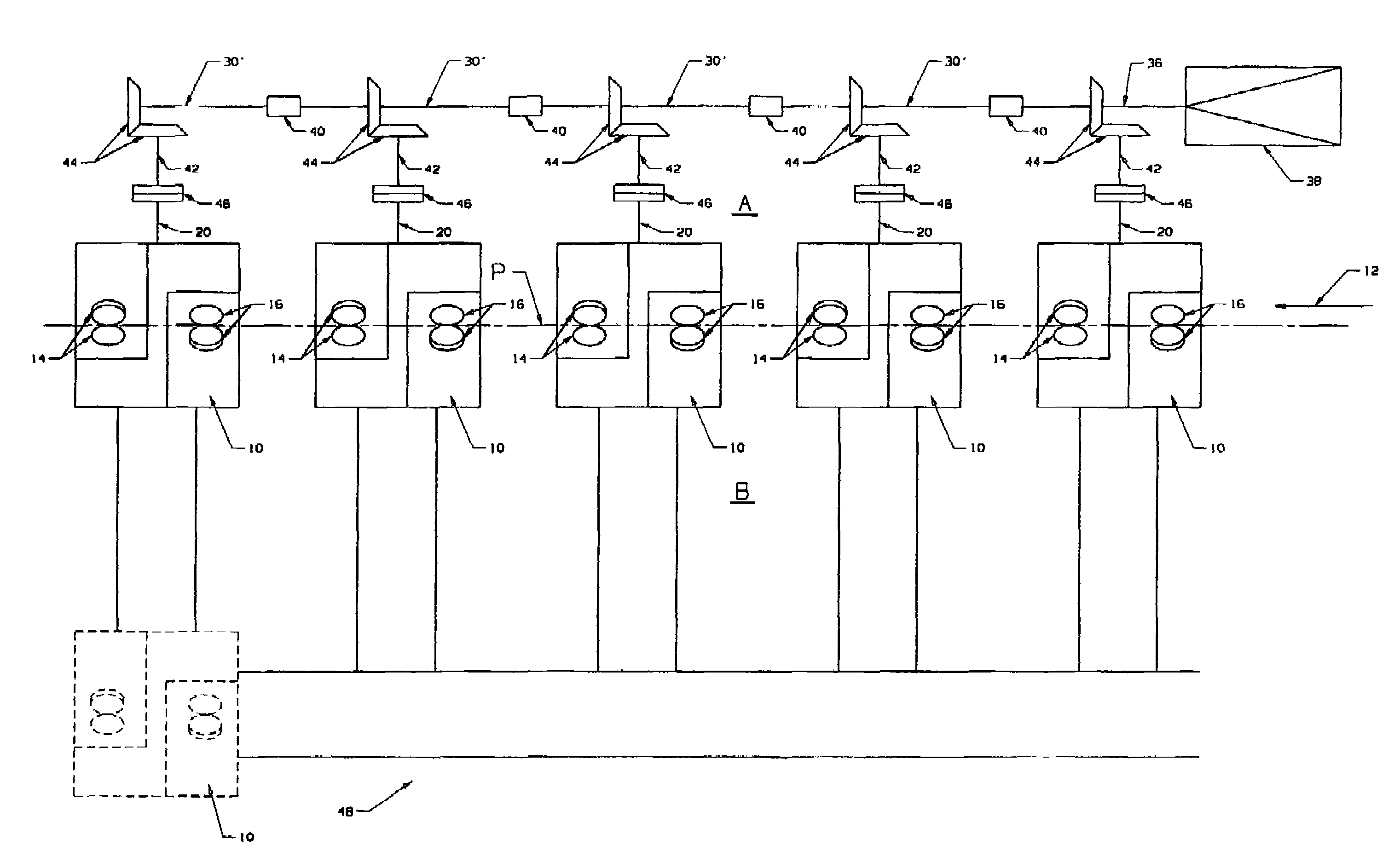

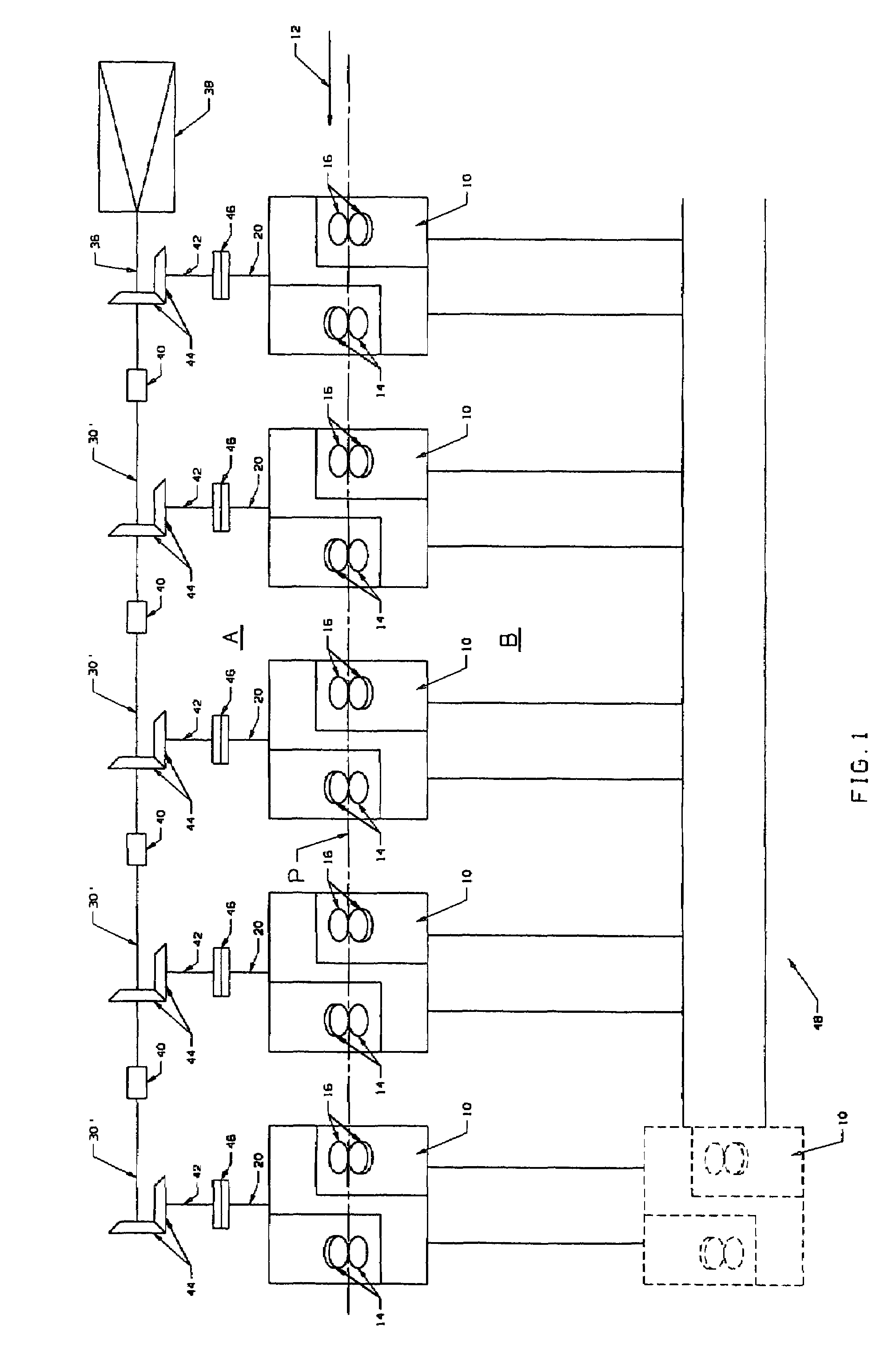

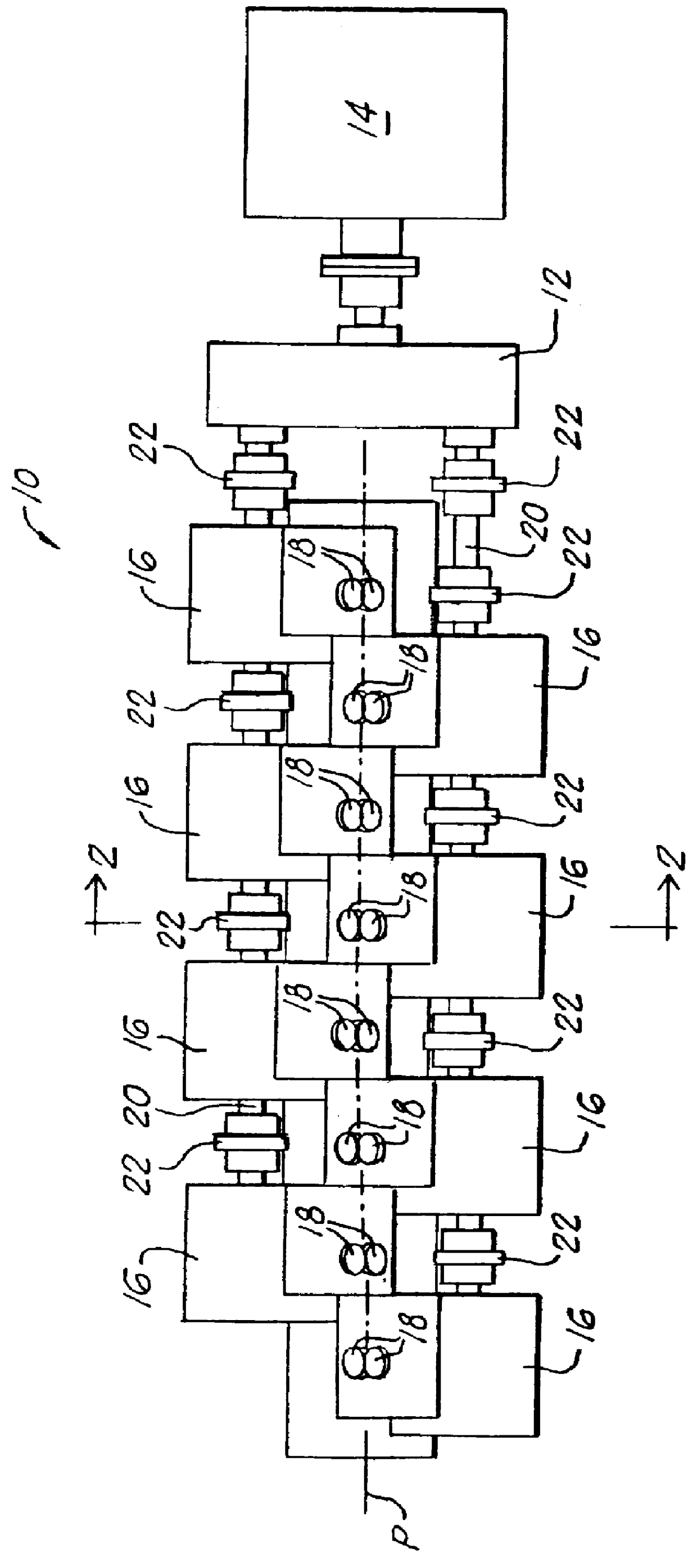

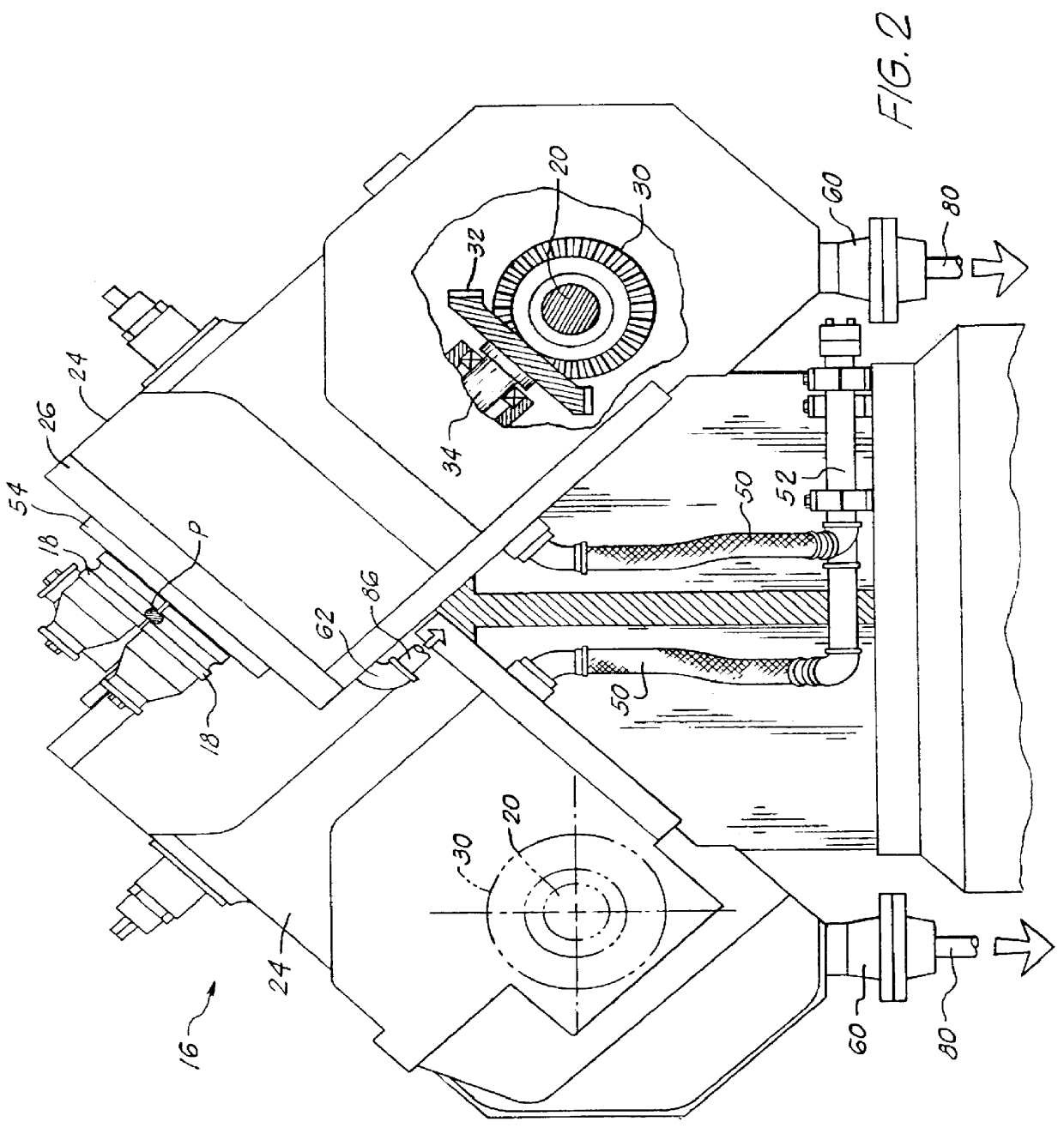

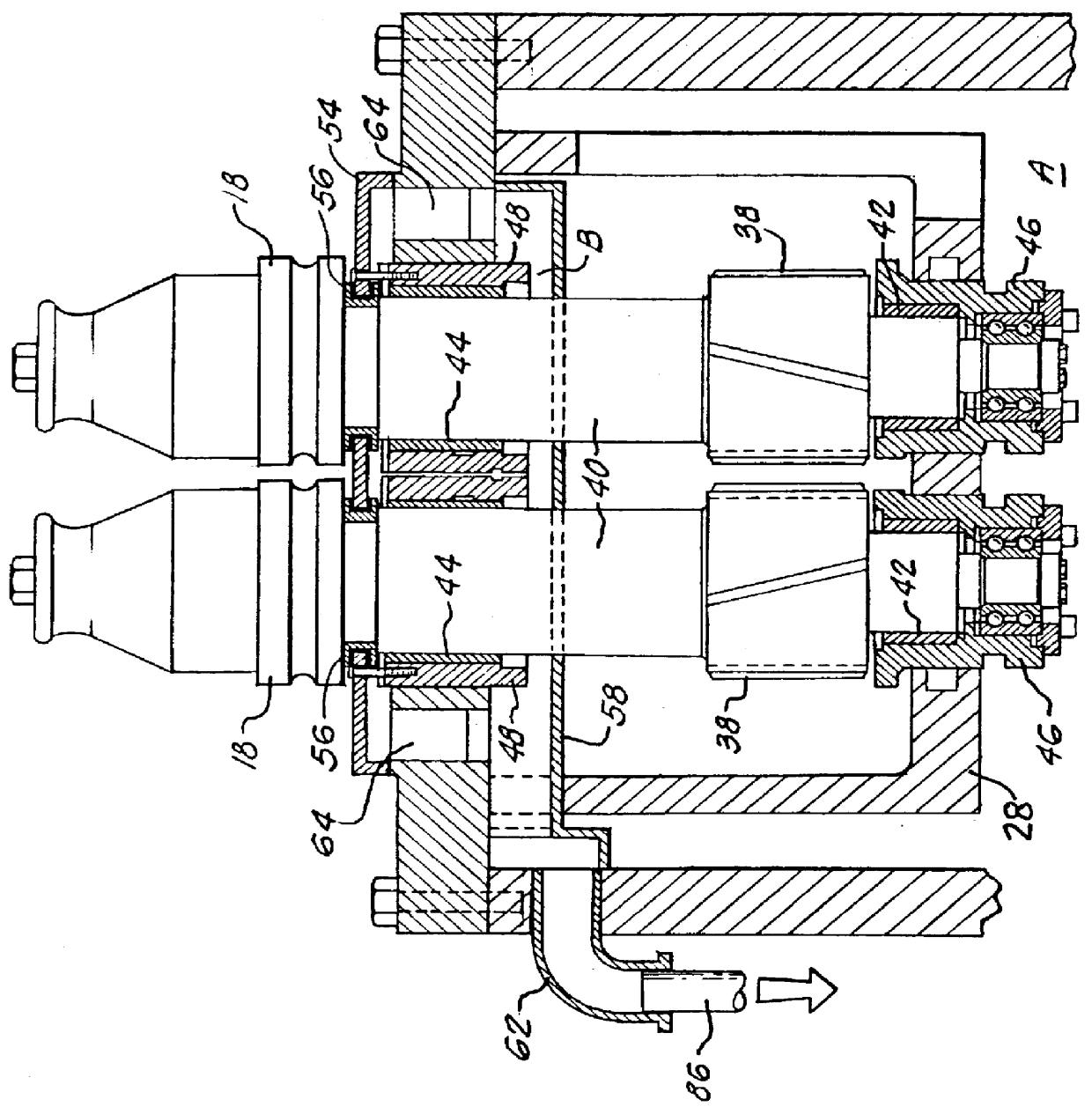

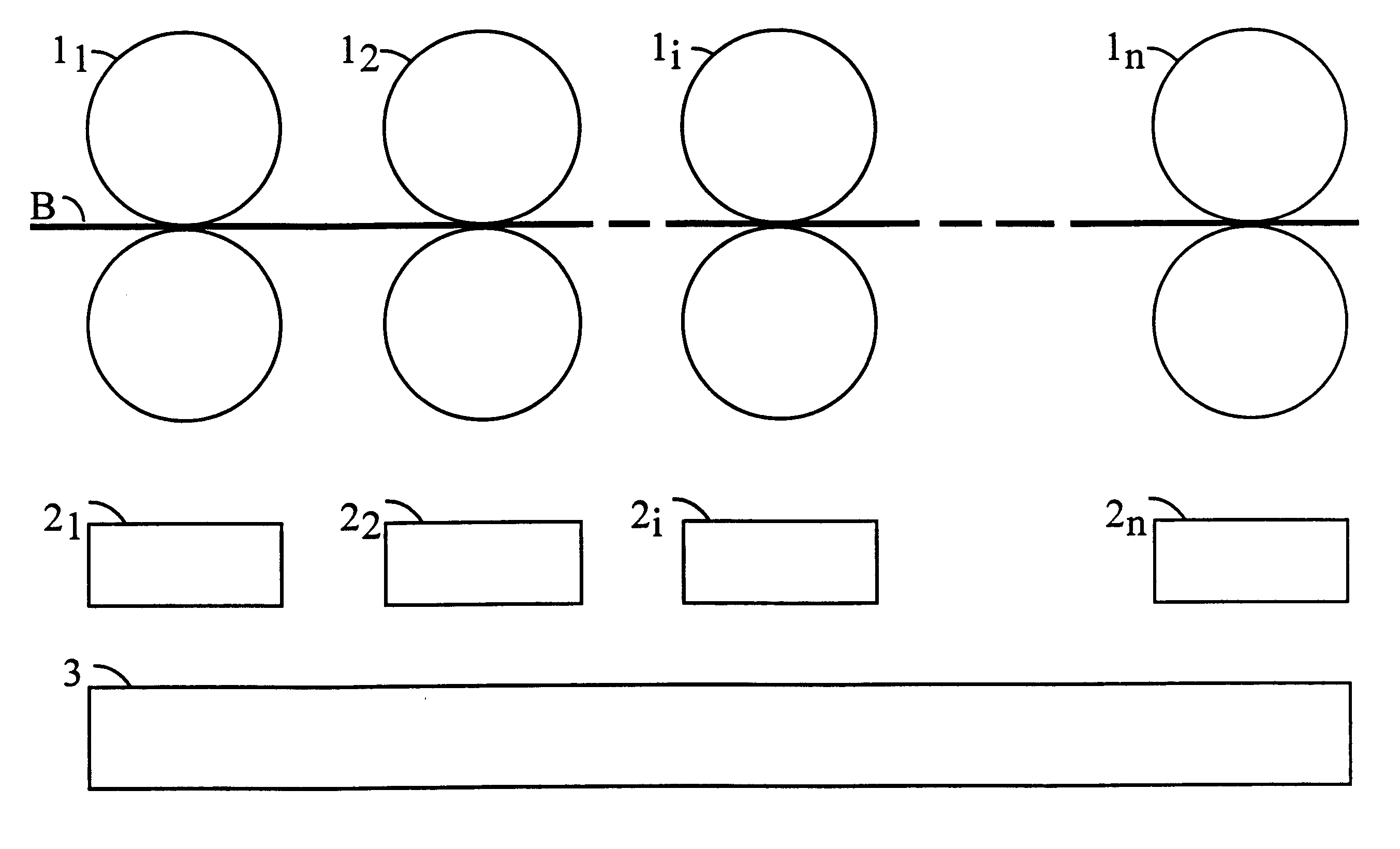

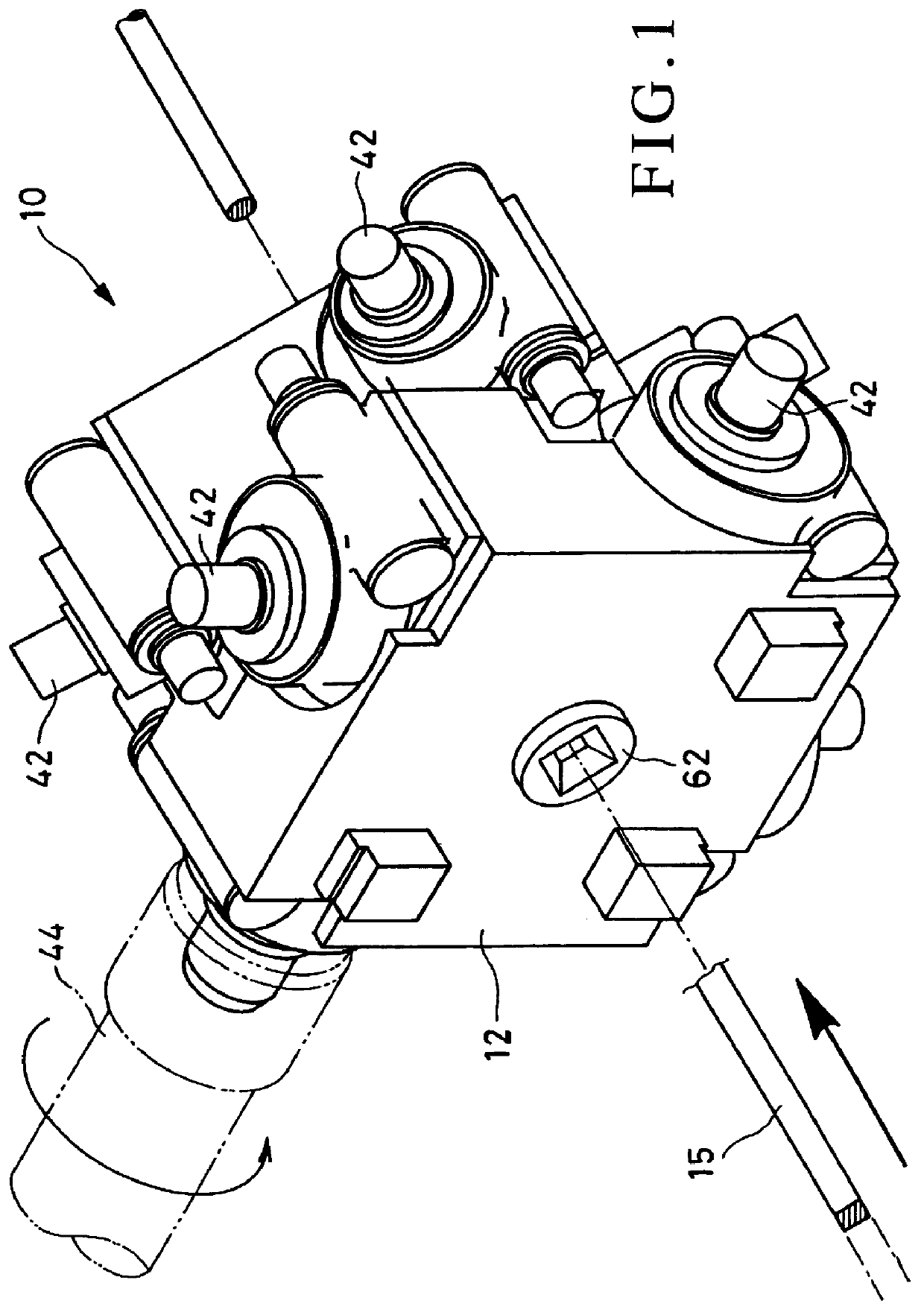

Modular rolling mill

InactiveUS7191629B1Metal rolling stand detailsGuiding/positioning/aligning arrangementsLine shaftWork roll

A modular rolling mill comprises a plurality of separate rolling units arranged along a mill pass line. Each rolling unit includes at least two pairs of work rolls defining oval and round roll passes and carried on roll shafts that are staggered 90° with respect to each other. The rolling units contain intermediate drive trains configured to connect the roll shafts to parallel input shafts projecting to a first side of the pass line from the respective rolling units. A single driven line shaft is parallel to and on the first side of the pass line. Output shafts are mechanically coupled to the line shaft by bevel gear sets. The output shafts project laterally from the line shaft towards the pass line and are connected by separable couplings to the input shafts of the rolling units.

Owner:PRIMETALS TECH USA

Lubrication system

A system is disclosed for applying a liquid lubricant to first and second components enclosed in a housing, with the lubricant applied to the second components being exposed to contamination by a liquid coolant applied to the exterior of the housing, and with the lubricant applied to the first components being substantially isolated from the liquid coolant. The system includes a partition internally subdividing the housing into a first chamber containing the first components and a second chamber containing the second components. Lubricant is delivered from a storage tank to the housing for application to the first and second components. A first conduit network communicates with the first chamber for returning the lubricant applied to the first components to the storage tank, and a second conduit network communicates with the second chamber for returning lubricant applied to the second components to the storage tank. A liquid coolant removal unit in the second conduit network removes liquid coolant from the lubricant being returned to the storage tank.

Owner:SIEMENS IND INC

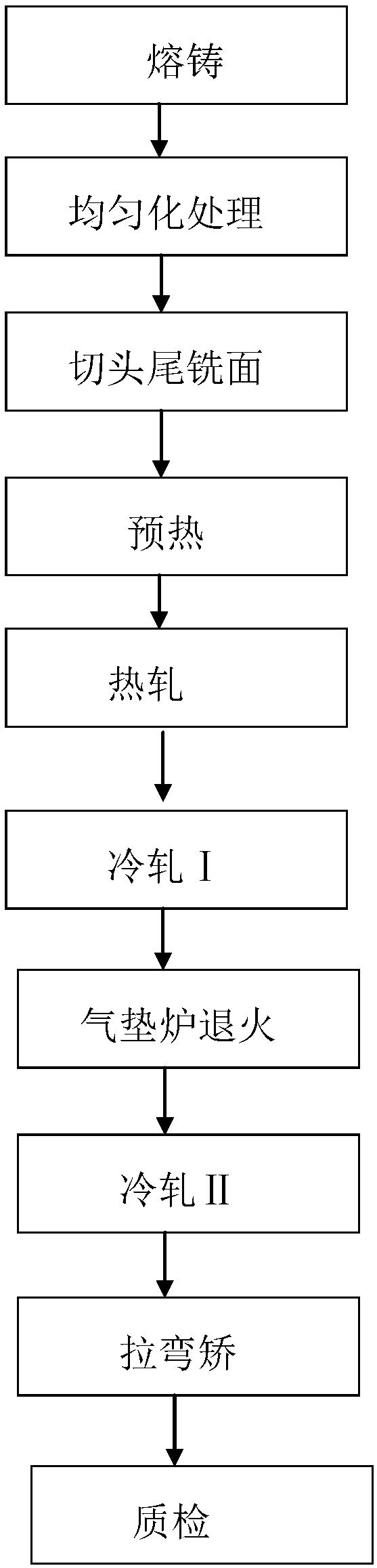

5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

ActiveCN106834825AHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

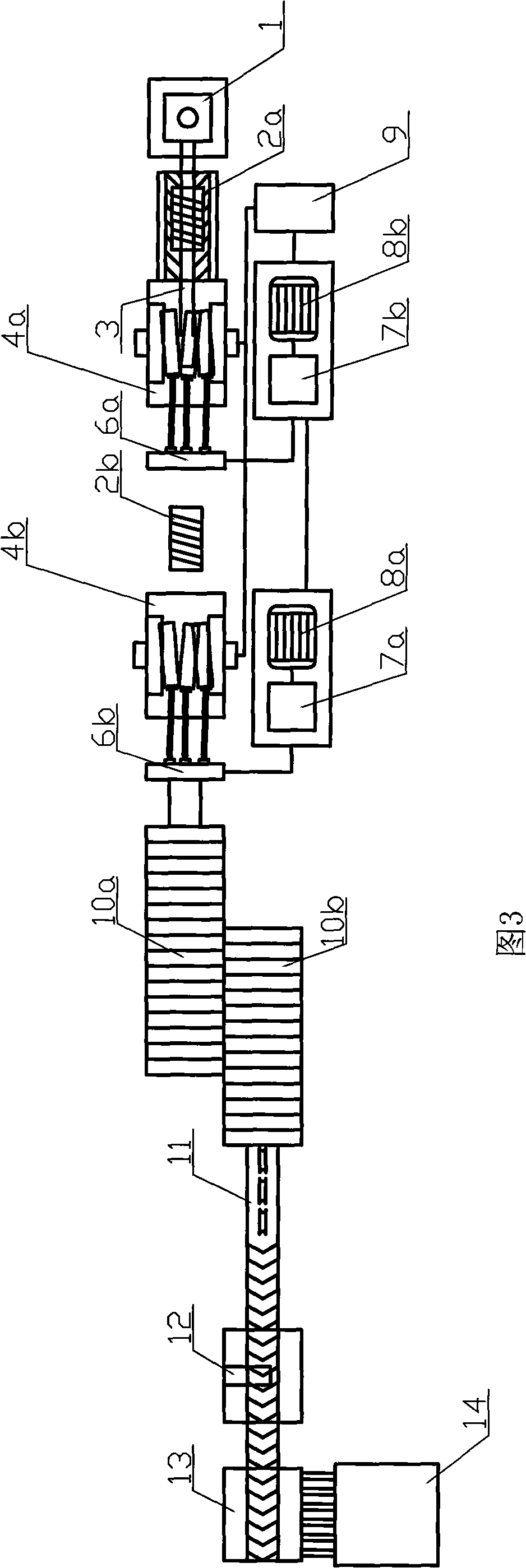

Fewer stands longitudinal hot rolling minor diameter thin wall seamless steel tube rolling technique and equipment thereof

InactiveCN101259588AEnsure implementationIncrease speedTemperature control deviceMandrelsHeating furnace% diameter reduction

The invention discloses the rolling technology of a fewer stander longitudinal hot rolling small diameter thin wall seamless steel tube which uses a heating furnace to heat a pierced billet to 950 DEG C to 1150 DEG C, a mandrel trolley pushes a mandrel into the heating pierced billet and is pushed to move forward, and the pierced billet is pushed into a wall reduction rolling unit that is formed by a plurality of wall reduction rolling mills to lead the pierced billet to be carried out longitudinal wall reduction rolling; the pierced billet that breaks away from the mandrel continues to be pushed into a stretch reducing rolling unit that is formed by a plurality of stretch reducing rolling mills to lead the pierced billet to be carried out longitudinal stretch reducing rolling until the rolling is finished; the pierced billet is put into a cold bed to cool; a straightening machine is used for straightening; a finished product is used for delivering and cutting; a flat head machine is used and a detecting machine is used for inspecting; a hydrostatic testing machine is used for detecting; the finished product is bundled and is put in storage. The invention uses the combination of the three-roll longitudinal rolling technology and a retained mandrel to adjust the straight roller longitudinal rolling with umbrella-shaped gears hydraulically and preciously to carries out diameter reduction and wall reduction rolling, and a rolled tube pipeline main control cabinet is used for operating stepless speed regulation of various stands so as to guarantee implementation of the technology, thus rolling the small diameter thin wall seamless steel tube with the diameter of Phi 12mm to Phi 76mm and wall thickness of 1mm to 6mm.

Owner:LUOYANG BANGQIANG MACHINERY

Pinch roll unit

A pinch roll unit for either propelling or retarding a product moving along the pass line of a rolling mill comprises a pair of levers mounted for rotation about parallel first axes. Roll shafts are carried by the levers with each roll shaft being journalled for rotation about a second axis parallel to the first axis of its respective lever. Pinch rolls are carried by the roll shafts and are positioned to define a gap therebetween for receiving the product. An electrically powered first motor operates via a linkage to rotate the levers about the first axes and to move the pinch rolls between open positions spaced from the product, and closed positions contacting and gripping the product therebetween. An electrically powered second motor rotatably drives the pinch rolls.

Owner:PRIMETALS TECH USA

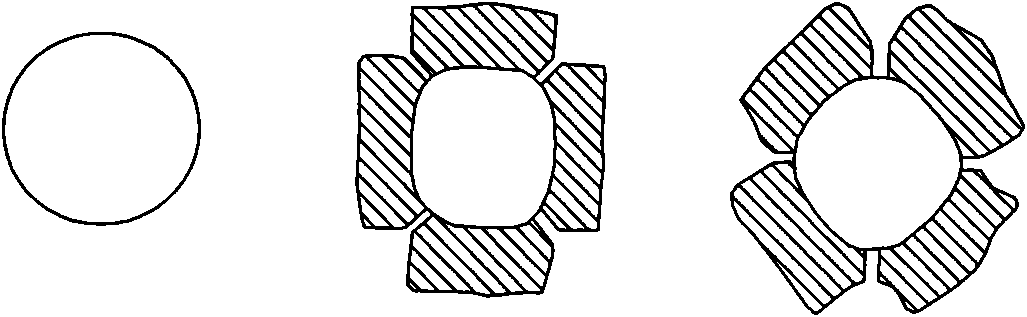

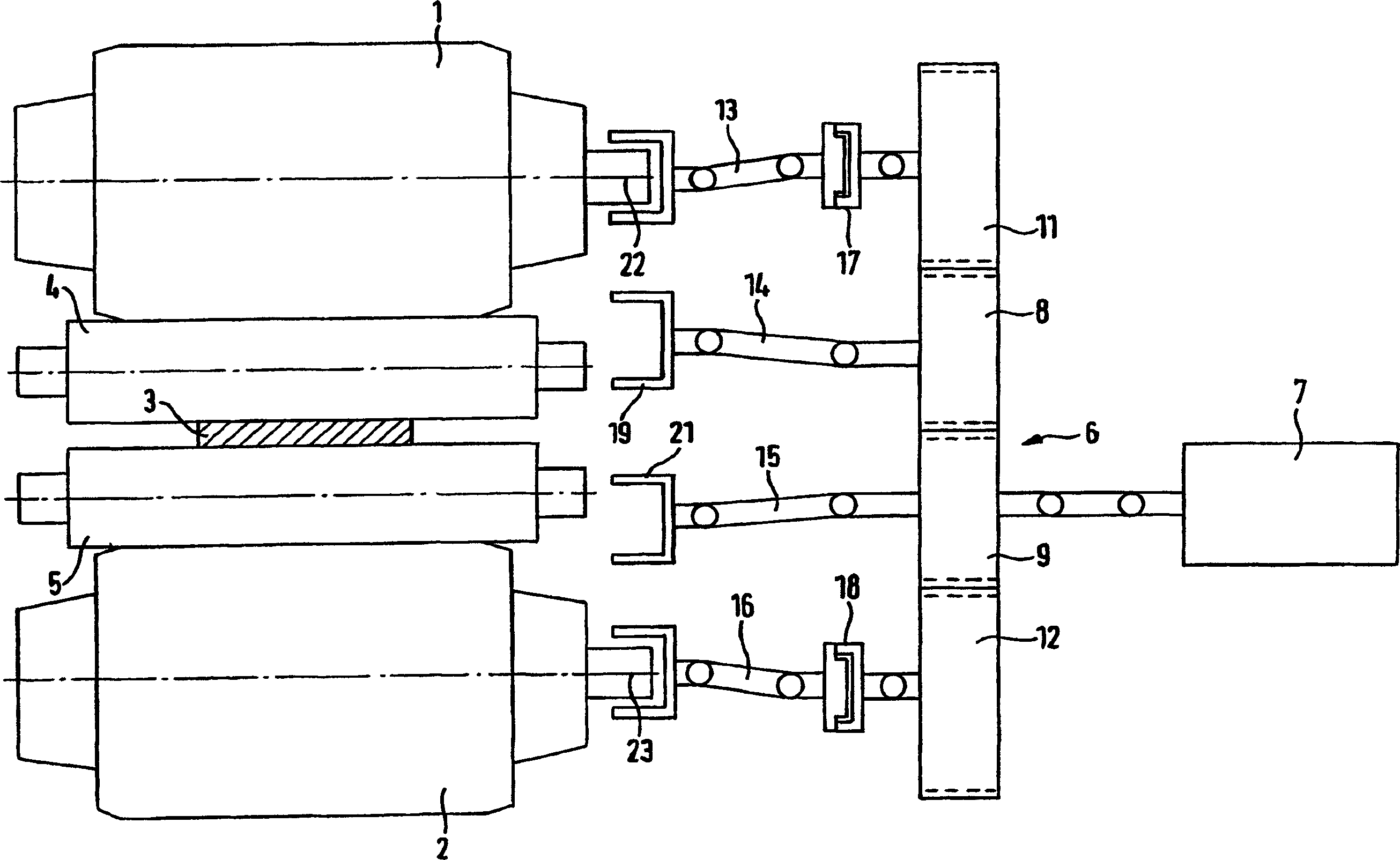

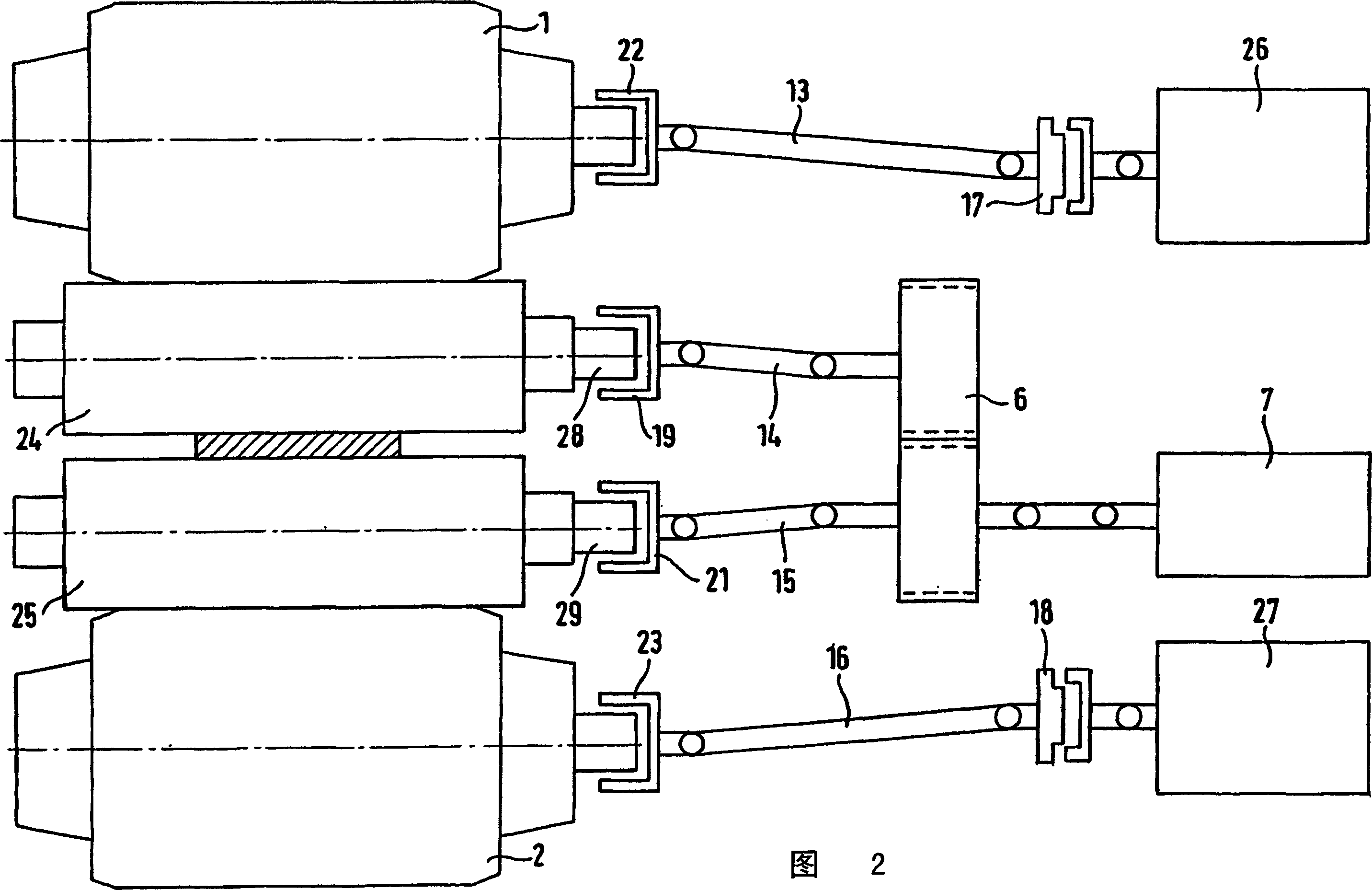

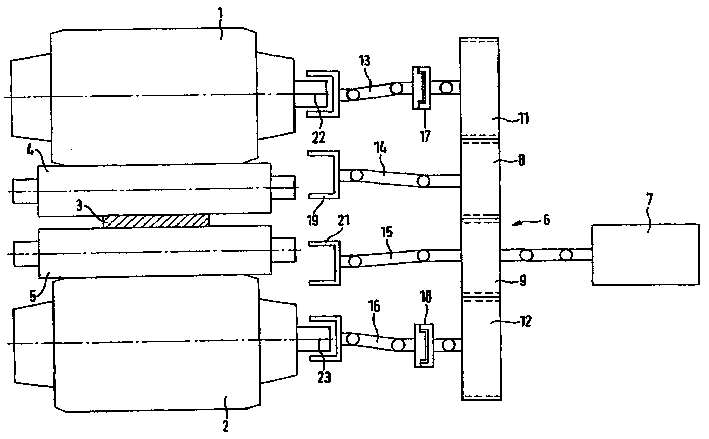

Two transmission shaft and four roller cross adjustable universal rolling mill and universal continuous rolling mill set formed by same

ActiveCN101574705AChange roll gapStable structureMetal rolling stand detailsRolling mill drivesWire rodProduction line

The invention provides a two transmission shaft and four roller cross adjustable universal rolling mill comprising a stand and also comprising an upper transmission shaft, a lower transmission shaft, a left vertical roller shaft, a right vertical roller shat, an inclined angle adjusting device and a stepping motor which are arranged in the stand. The invention also provides a universal continuous rolling mill set formed by the two transmission shaft and four roller cross adjustable universal rolling mill. The invention has reliable, practical and compact structure; the seams of four rollers can be rapidly changed automatically or manually on the production line, and the position of the cross section by which the four rollers contact and metal rolled pieces are rolled can be changed; in addition, the invention has low power consumption, high workpiece rolling precision, free size of workpiece rolling, no broadening and no traditional guiding, is applicable to the cold-hot continuous rolling, the reducing and the sizing of tubes, rods and wires, the cold-hot continuous rolling of a special-shape workpiece, the tension reducing of tubes, and the like, can replace the cold drawing of the workpieces and has various other functions.

Owner:福州金泉冶金机械设备有限公司 +1

Method of regulating tension/compression in a multi-frame hot rolling mill, and a corresponding control system

InactiveUS6205829B1Minimal levelRoll force/gap control deviceRolling mill drivesMultiple frameControl system

The value of the rolling torque is measured at each frame through which a metal product passes, and the measurement is performed at the moment when said product reaches the following frame, at which point the frame at which the measurement is performed is switched over to torque regulation. The last frame reached by the product remains in speed regulation and it acts as a controlling frame for all other frames situated upstream therefrom so as to enable them to conserve torque equal to their respective reference torques by adapting their speeds. Once the reference torque measurements have been stored in the control system, regulation is obtained by making use of a distribution key for the stresses between the frames.

Owner:ALSTOM SA

Two-stand angularly hot rolling minor diameter seamless steel tube rolling technique and equipment thereof

InactiveCN101259589AGuaranteed wall thicknessGuaranteed ovalityTemperature control deviceMandrelsIntermediate frequencyHeating furnace

The invention discloses the rolling technology of a double-stander oblique hot rolling small diameter seamless steel tube, and the rolling technology of the invention is that a mandrel trolley pushes a mandrel into a pierced billet and is pushed to move forward, the mandrel is heated to 950 DEG C to 1150 DEG C by an intermediate frequency induction heating electric furnace, the mandrel trolley continues to pushes the heating pierced billet into a rolling mill to carry out wall increasing and diameter reducing rolling, only the mandrel and a roller are cooled during rolling process; the pierced billet that breaks away from the mandrel is placed into a reheating electric furnace for heating to 950 DEG C to 1150 DEG C and is sent into a stretch reducing and wall increasing rolling mill to carries out the diameter reducing rolling, the heating while rolling can be realized, and only the roller is cooled during the rolling process; the invention is finished by cooling, straightening, cutting and online detecting after rolling. The invention realizes the technology of heating the mandrel and the roller while rolling and cooling by improving the heating method of a heating furnace, structure and the cooling method of the mandrel and the roller. The rolling technology of a double-stander oblique hot rolling small diameter seamless steel tub improves efficiency, simplifies the technology, reduces cost, saves energy and reduces pollution, thus the rolled steel tube is high in precision.

Owner:LUOYANG DINGRUI MATERIAL TECH

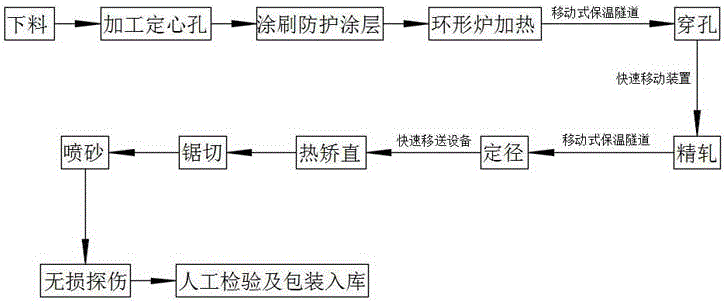

Hot-processing production system for titanium and titanium alloy seamless tube, product prepared on basis of system and manufacture method for product

The invention relates to a hot-processing production system for a titanium and titanium alloy seamless tube, a seamless tube prepared by using the hot-processing production system and a hot-processing production method for the seamless tube, and belongs to the technical field of titanium and titanium alloy seamless tube production. By improving various units and all kinds of auxiliary equipment, particularly, reselecting materials of parts and heating and rolling working modes thereof, thus the equipment precision is improved and the stability of the system is controlled, and a rolling process is enabled to be more stable, thereby ensuring that the quality and size of the inner and outer surfaces of the seamless tube are stable. On such basis, according to the hot-processing production method, various working procedures are arranged reasonably and efficiently, and a tube blank is coated with a protective layer before heating, so that the problem that the tube blank reacts with oxygen and nitrogen and absorbs hydrogen is well solved, the defect of exceeding standards does not occur in the tube blank and a foundation is laid for subsequent rolling.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

Semicanal formation rolling machine

ActiveCN101386023AReduce stiffnessImprove flexibilityMetal rolling stand detailsRollsSteel beltHelix

A rolling mill for forming a semi-tube belongs to the technical field of rolling, and is used for solving the problem of one-time forming of steel strips. The technical proposal is that the rolling mill comprises a frame, a rolling part, a transmission part and a cogging adjusting mechanism. The rolling part consists of a guide roller, a pre-forming roller, a semi-forming roller, a forming roller and a rolling roller which are arranged in sequence. The upper roller and the lower roller of the guide roller are cylindrical rollers, while the other four rollers respectively consist of upper rollers and lower rollers which are provided with mutually matched arc roll surfaces. The rolling mill can roll the steel strip with the thickness of 2-3mm into semi-tubes in different diameters. The thickness of the wall of the semi-tube rolled by the rolling mill is evenly changed with the curvature thereof, and the semi-tube shows no folding. The finished product semi-tube has the advantages of low rigidity and good flexibility, and can be smoothly and spirally wound or directly laid on a cylindrical shell of a device while arranging the device.

Owner:HEBEI INSTALLATION ENG

Making process of stainless steel belt for composite aluminium-steel contact rail

InactiveCN101020283AQuality improvementImprove performanceShearing machinesOther manufacturing equipments/toolsPunchingSteel belt

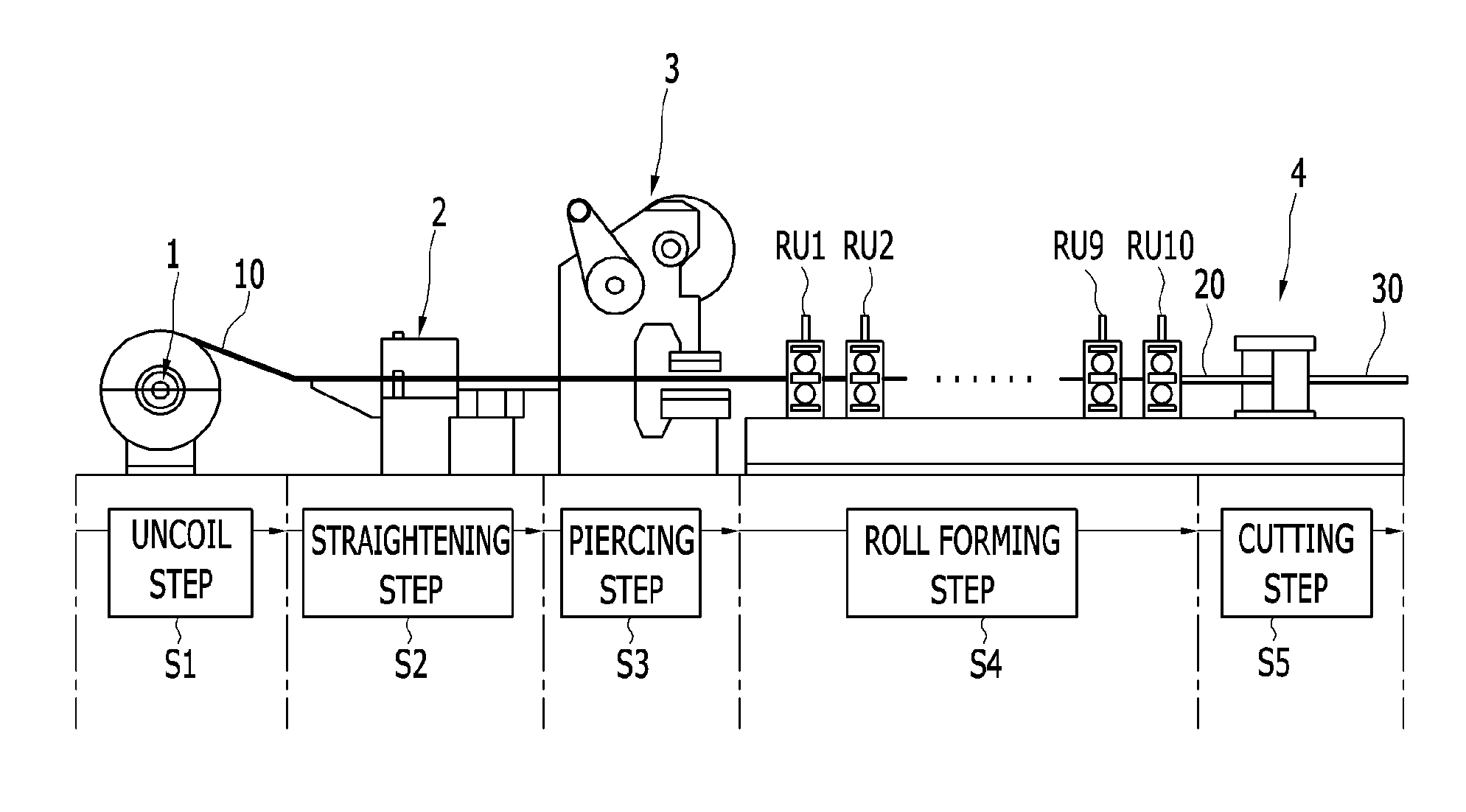

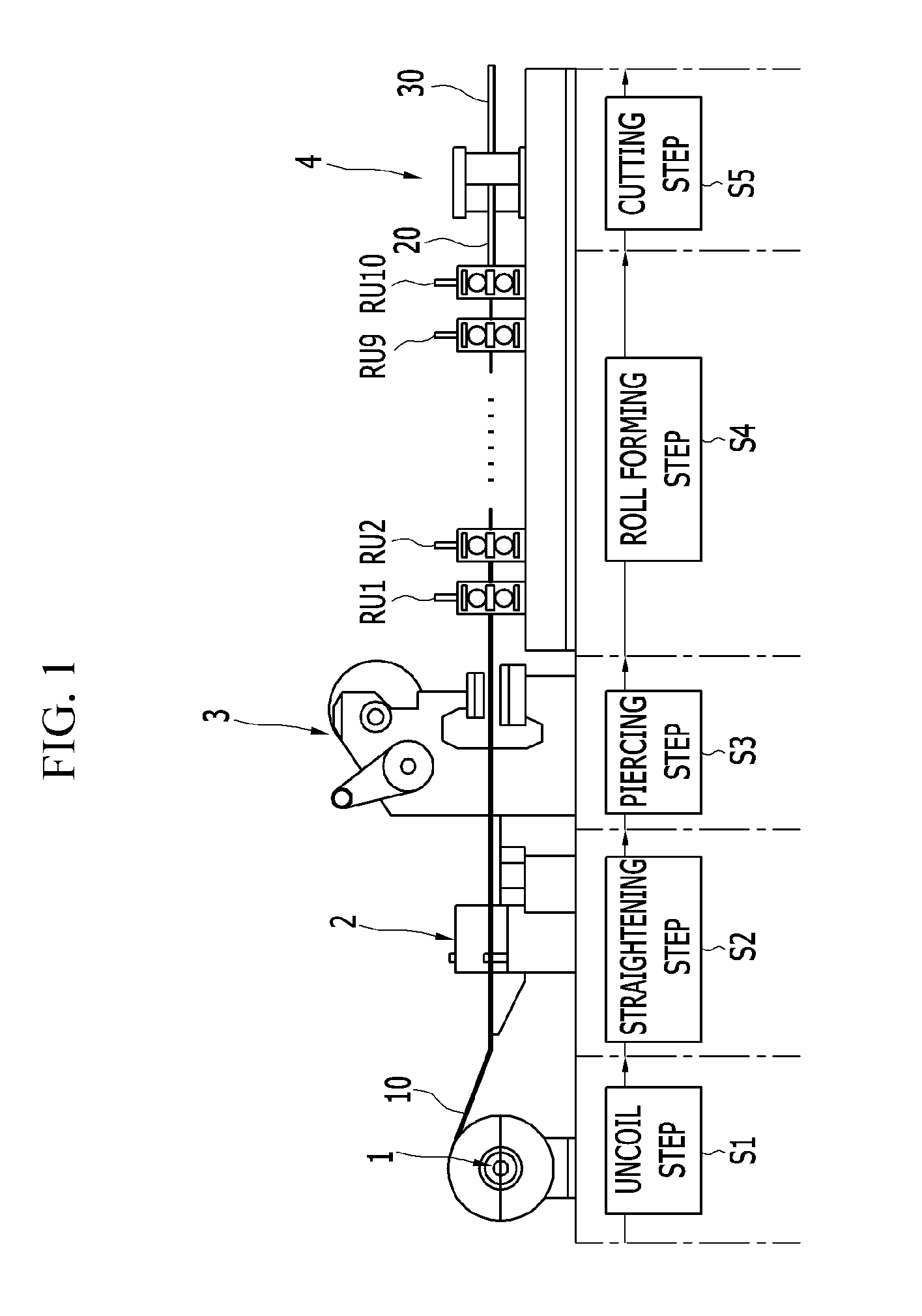

The present invention discloses the making process of stainless steel belt for composite aluminum-steel contact rail. The making process includes the following steps: uncoiling stainless steel belt, flattening, punching surface holes, gradual cold bending to form in a special cold bending apparatus and cutting to required size. The present invention has reasonable technological process, continuous production, high product quality, high production efficiency and other advantages.

Owner:南京赛彤铁路电气化有限公司

Eight-roller type rolling mill and method of rolling using the mill

A final finish-rolling stand of a rolling machine for producing round bar material is constructed as an eight-roller type rolling machine comprising: front four rollers of "+" distribution and back four rollers of "X" distribution which are contained in one housing block. Only one driving source is used for the rolling machine, and the driving force from the driving source is transmitted to one roller of the front four rollers to forcibly drive this roller. The remaining rollers are freely rotatable and rotate synchronously with transfer of the material being rolled so as to carry out rolling down of the material. Structure of the rolling machine is simple and adjustable range of sizes of the product is wide.

Owner:DAIDO STEEL CO LTD

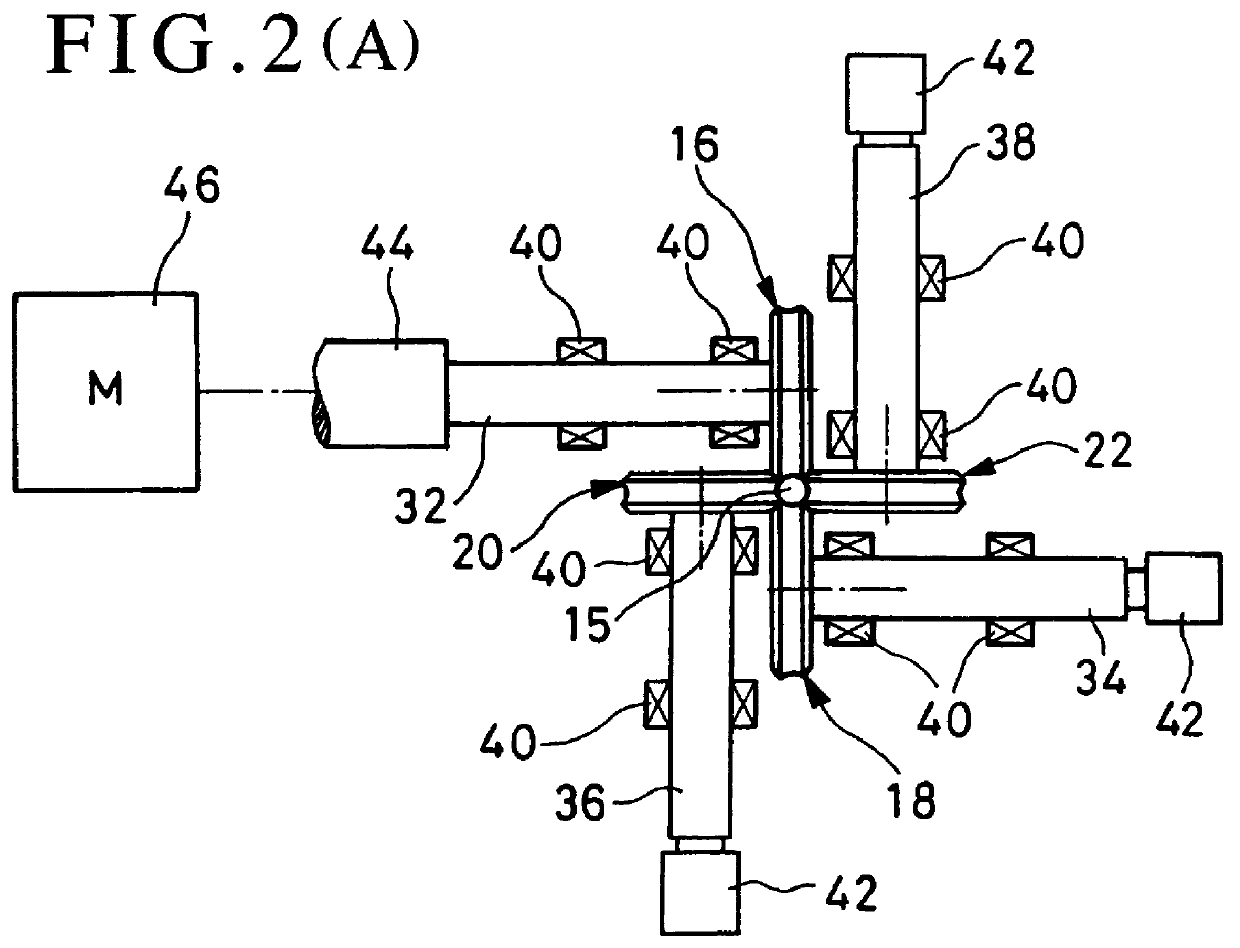

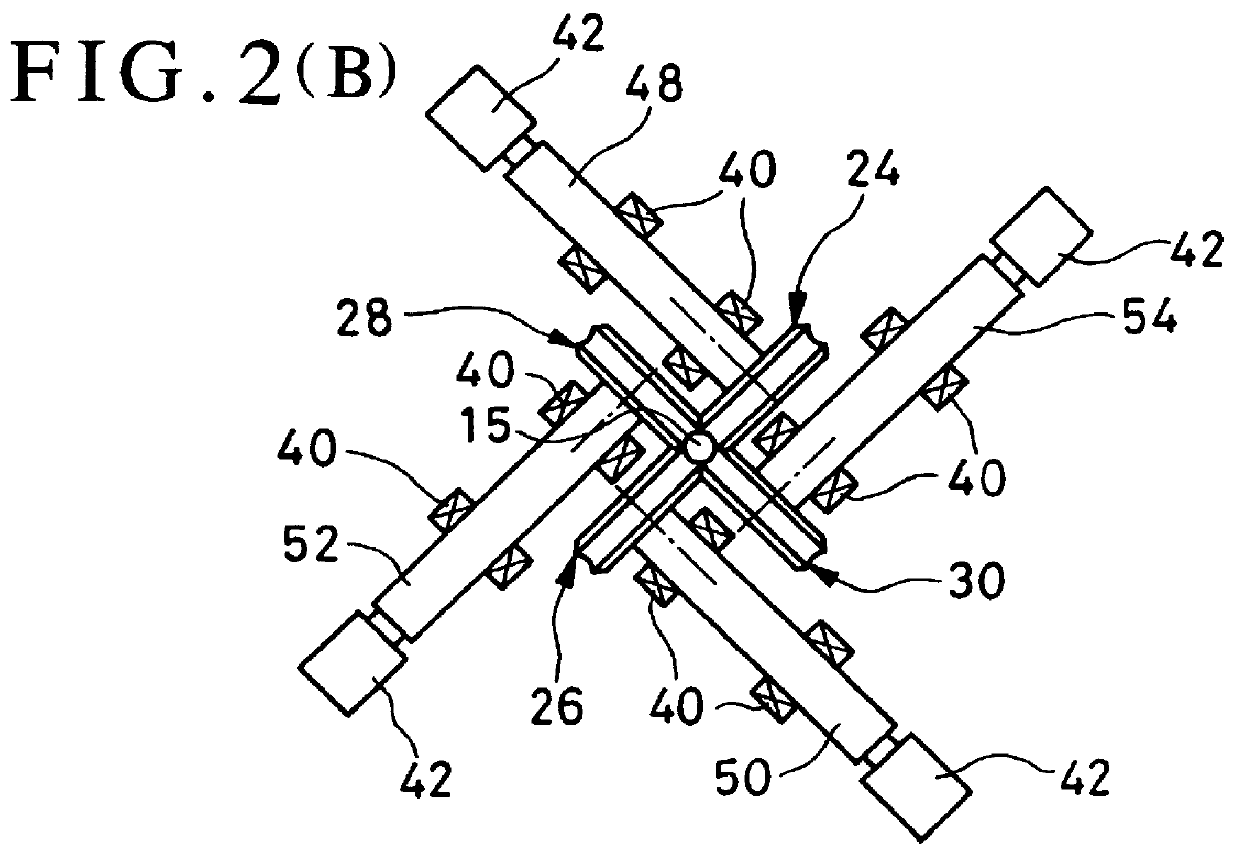

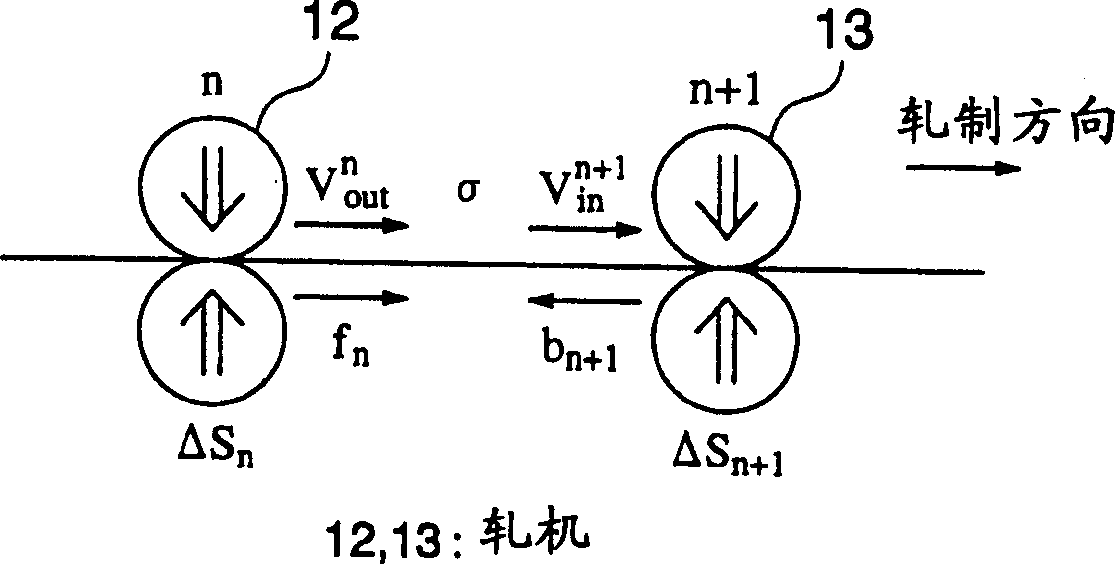

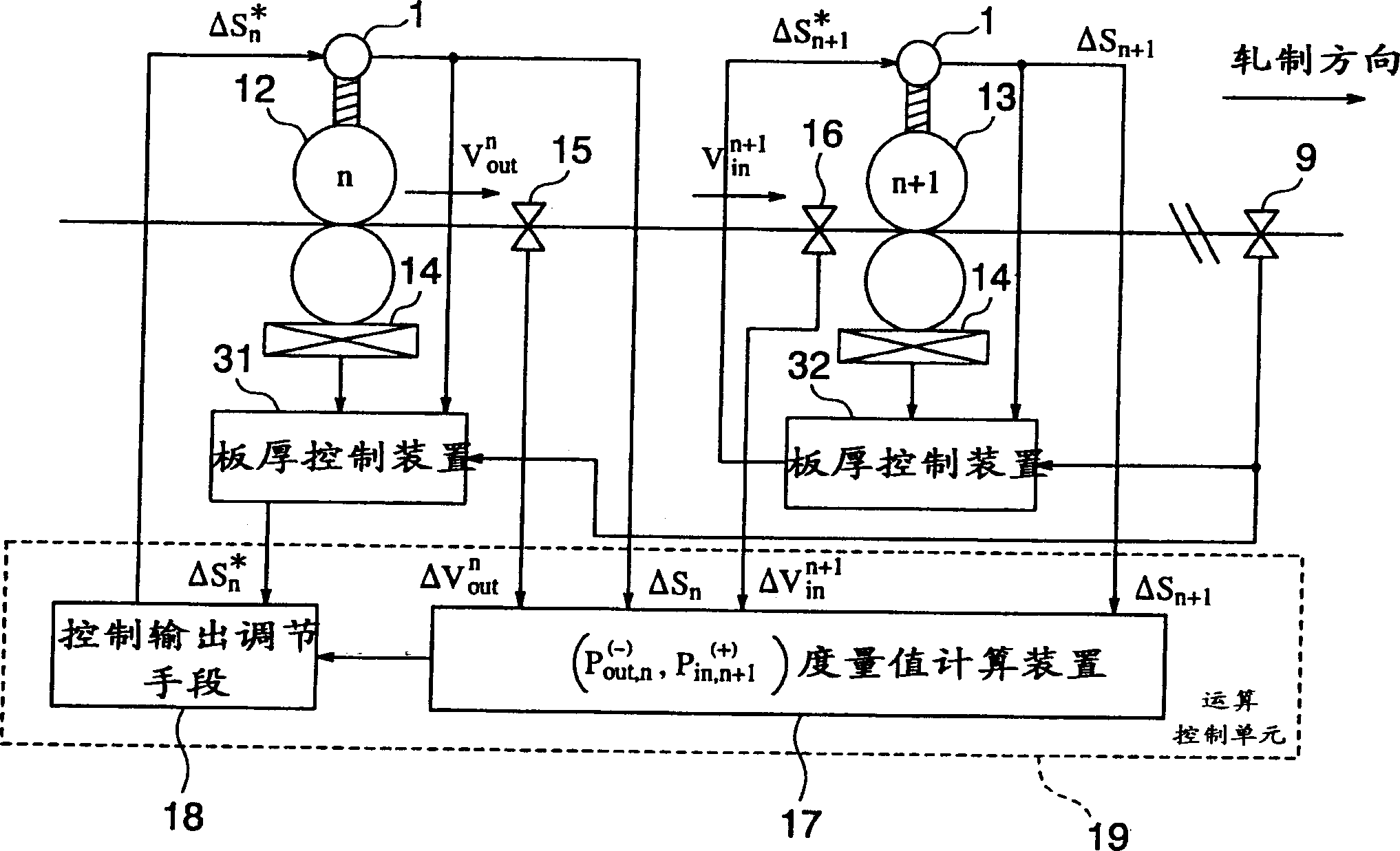

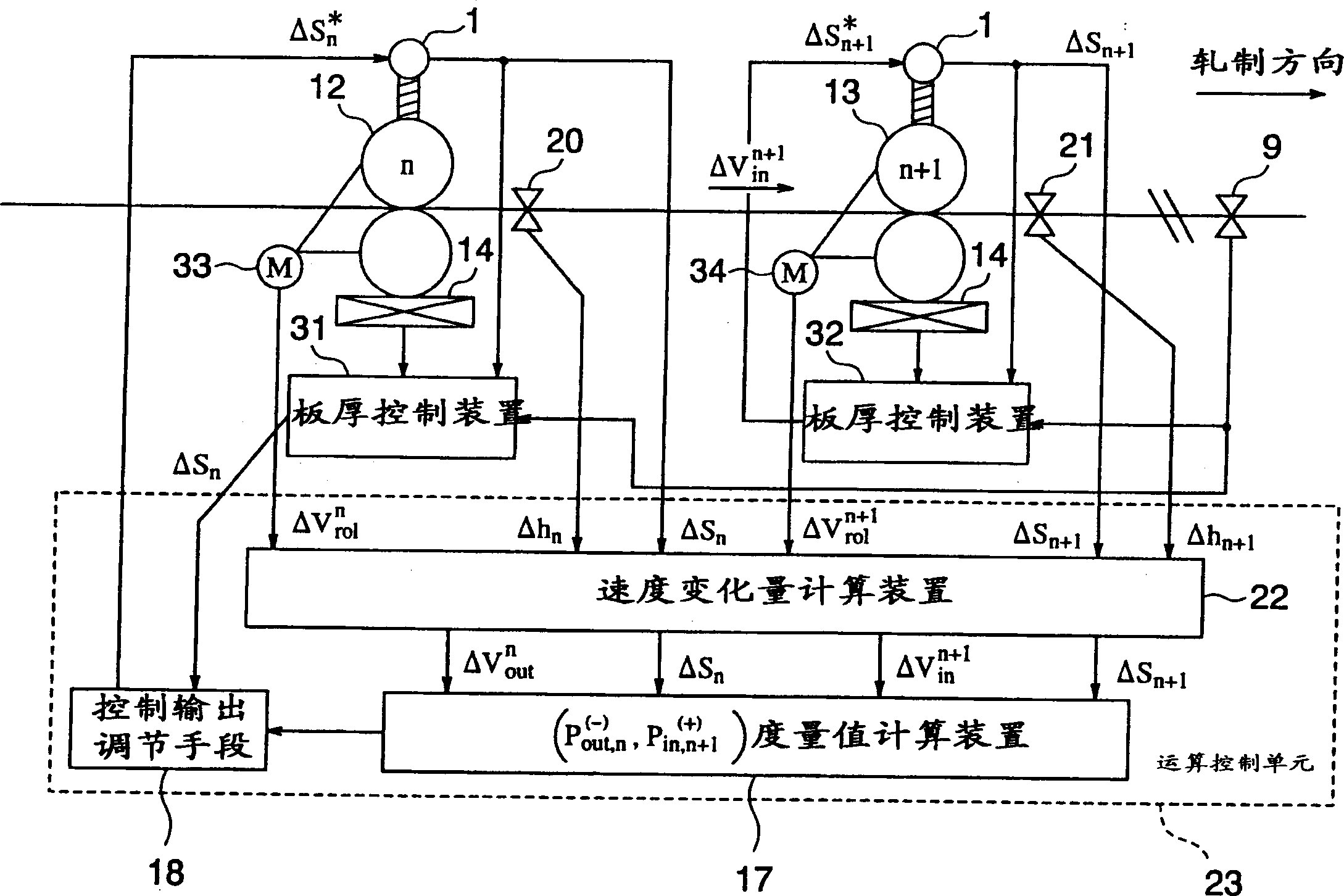

Plate thickness controller for continuous roll mill

To provide a plate thickness control system for a continuous rolling mill which improves accuracy on plate thickness control by formulating and regulating the influence which the correction amount of screw down position gives to the tensile force between rolling mills, and by making it easy to set up an output threshold value. This system comprises a measurement means to measure a plate speed variation Delta Vout at the exit of a rolling mill 12, a measurement means to measure a plate speed variation Delta Vin at the entrance of a rolling mill 13, a measurement means to measure a correction amount of screw down position Delta V Sn at the rolling mill 12 and the correction amount or screw down position Delta V Sn+1 at the rolling mill 13, a measured quantity calculation means 17 to calculate a measured quantity Pout ,n <(-)> , Pin ,n+1 <(+)> which affects accuracy on the plate width of the workpiece based on the plate speed variation Delta Vout , Delta Vin and the correction amount of screw down position Delta V Sn , Delta V Sn+1 , and a control output adjustment means 18 to adjust a plate control output during rolling the workpiece, using a measured quantity.

Owner:MITSUBISHI ELECTRIC CORP

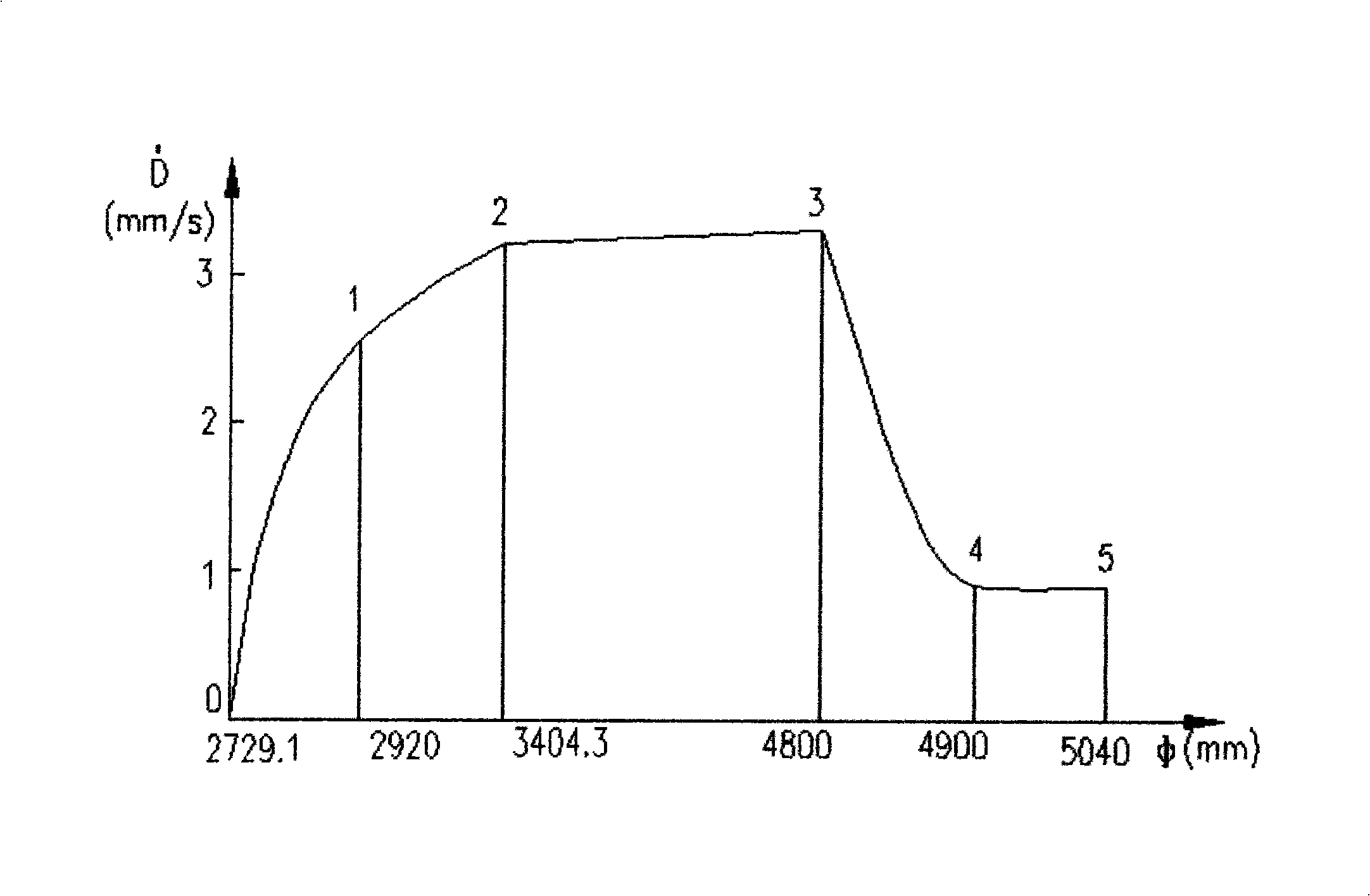

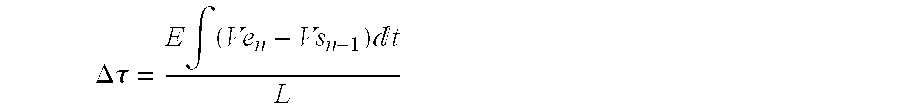

Annular rolling speed control method of huge aluminum alloy annular forging

InactiveCN106111709AStable direct growth rateGuaranteed ring rolling speedRolling mill drivesMetal rolling arrangementsThree-phaseRolling speed

The invention relates to an annular rolling speed control method of a huge aluminum alloy annular forging. Three phases in a traditional annular rolling method are changed to four phases, and the rolling is performed by two times, so that the annular rolling speed in each phase is guaranteed, the direct growing speed of an annular blank is stable, and the purpose of once molding is achieved; and the numerical value simulation and the theoretic analysis are combined in each phase, so that the product scrape rate is largely reduced, and the success rate is guaranteed.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

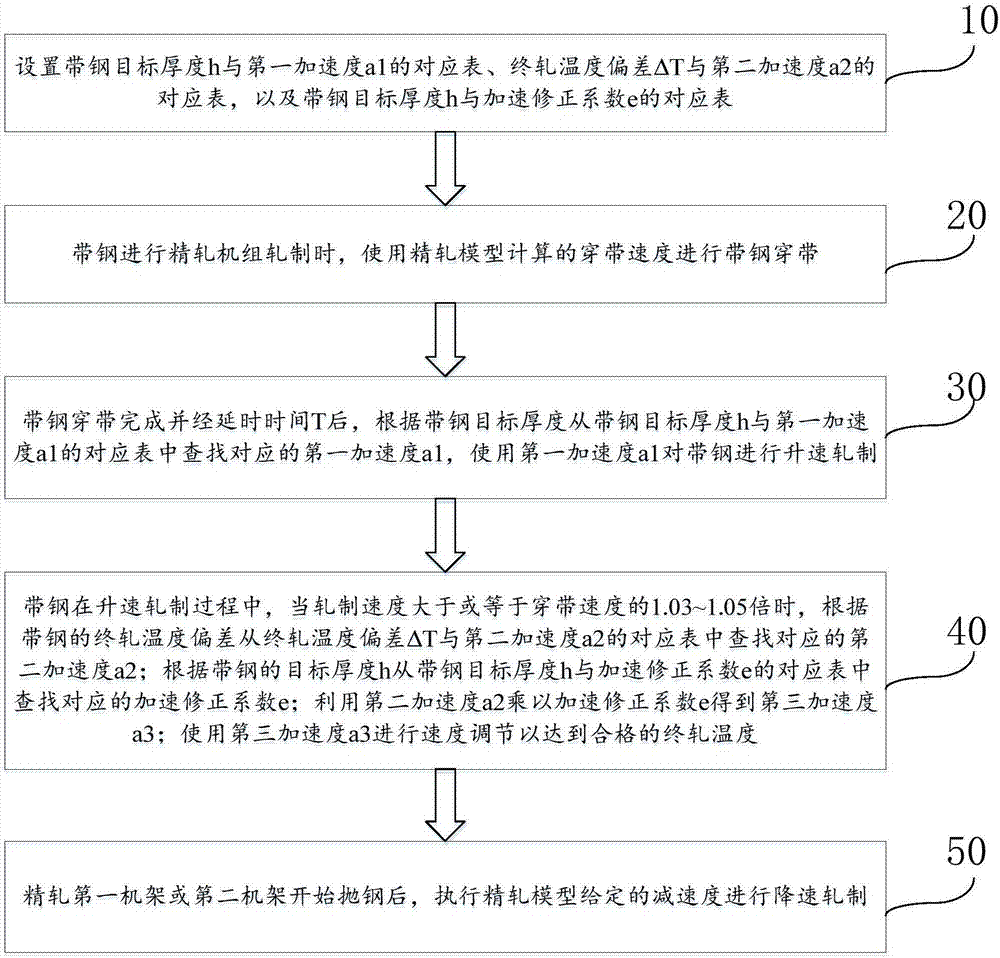

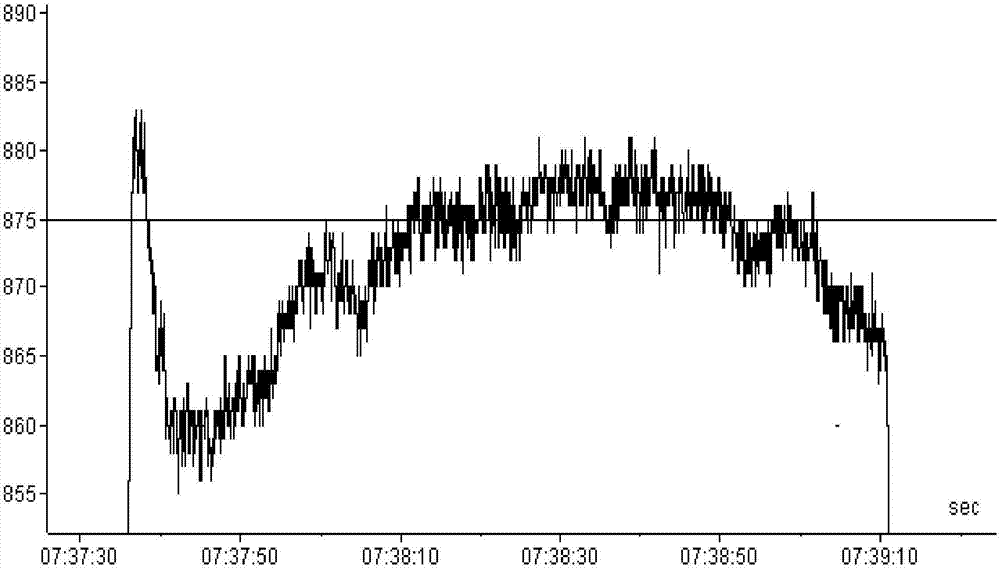

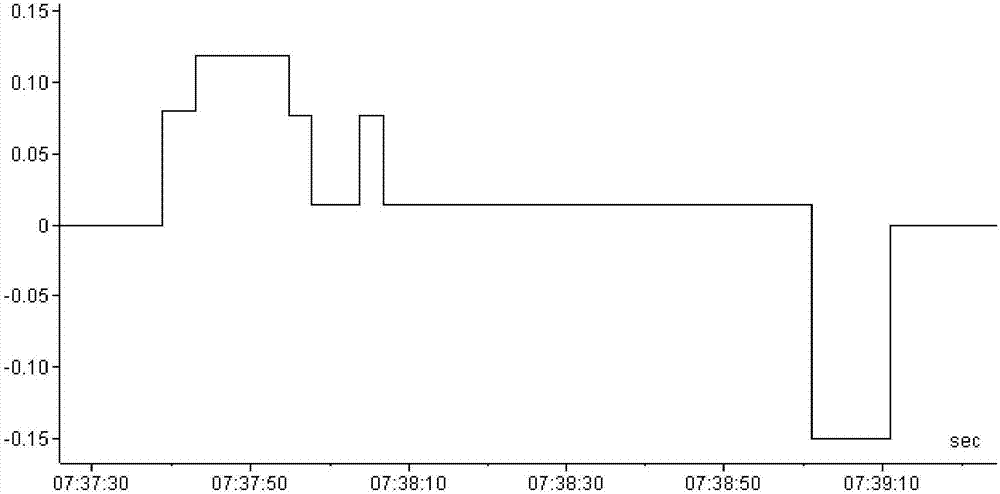

Hot rolled strip steel finishing rolling temperature control method based on speed adjustment

ActiveCN106925614ATimely responseEasy to controlTemperature control deviceRolling mill drivesTemperature controlStrip steel

The invention relates to a hot rolled strip steel finishing rolling temperature control method based on speed adjustment. The method comprises the steps that a corresponding table of the strip steel target thicknesses and first accelerated speeds, a corresponding table of the finishing rolling temperature deviations and second accelerated speeds, and a corresponding table of the strip steel target thicknesses and acceleration revision coefficients are set; strip steel threading is conducted at a threading speed; the corresponding first accelerated speeds are searched according to the strip steel target thicknesses and used for conducting accelerated rolling on strip steel; the corresponding second accelerated speeds are searched according to the finishing rolling temperature deviations of the strip steel; the corresponding acceleration revision coefficients are searched according to the strip steel target thicknesses; a third accelerated speed is obtained by multiplying the second accelerated speeds by the acceleration revision coefficients; the third accelerated speed is used for adjusting the speed; and after a first finish rolling rack or a second finish rolling rack starts to tailing-out, a deceleration speed given by a finish rolling model is used for deceleration rolling. The hot rolled strip steel finishing rolling temperature control method based on speed adjustment can effectively improve the rolling temperature control precision.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Combined drive for flur-or six-high rolling mill and operating method for the same

InactiveCN1461246ASimple structureConsistent driveMetal rolling stand detailsRollsHardnessRolling mill

The invention relates to a four- or six-high rolling stand for a rolling train and to a method for operating the same. The aim of the invention is to provide rolling stands that can adapt rapidly to rolling products of different thicknesses and / or hardnesses. To achieve this, rolling stands are provided with minimum expenditure that can be selectively operated with both thin and thick working rolls. The inventive combined drive in the four- or six-high rolling stand allows thick working rolls to be directly connected to a motor, whereas thin working rolls are merely carried along by neighbouring back-up rolls or intermediate rolls by means of friction.

Owner:SMS DEMAG AG

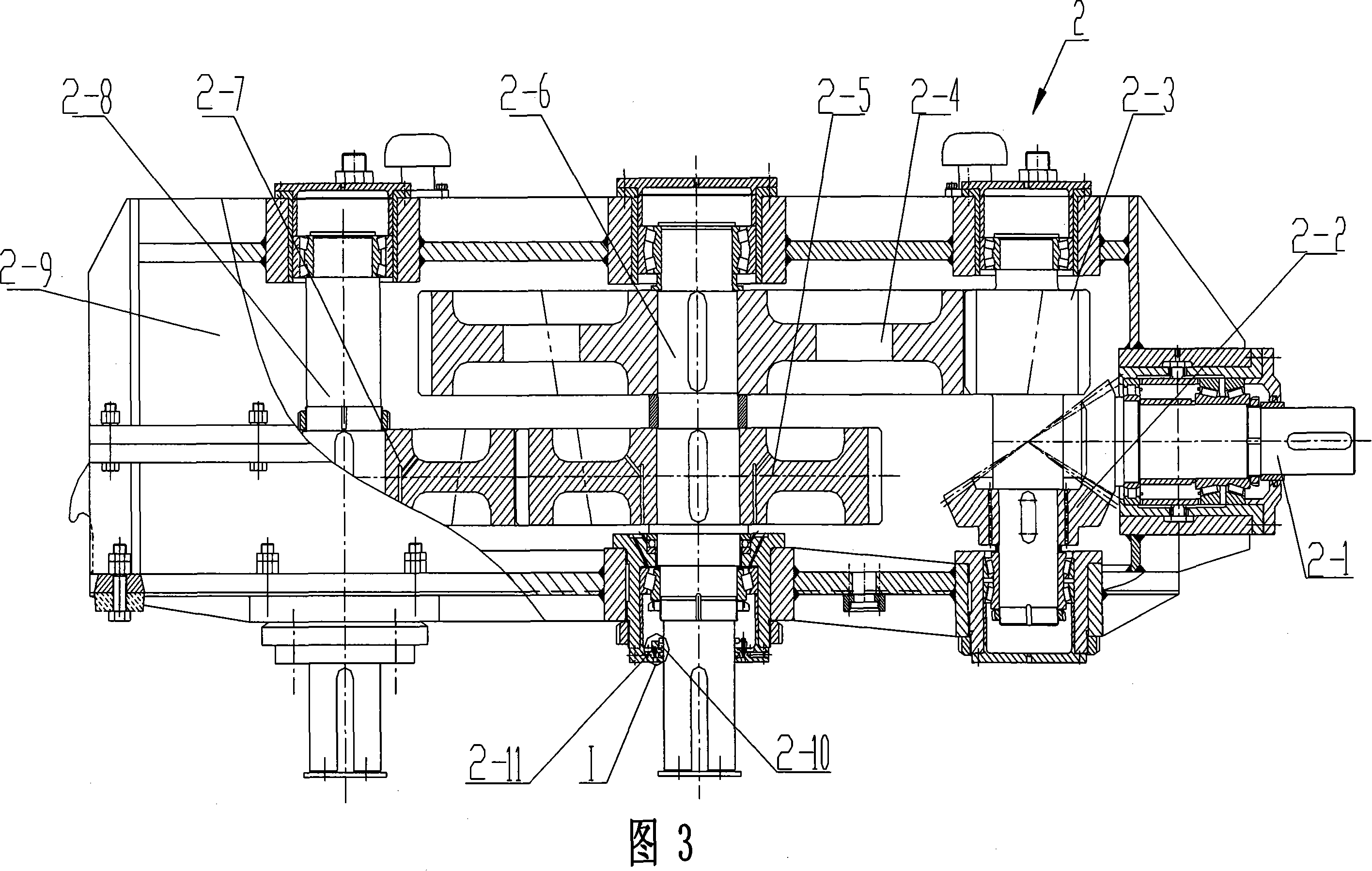

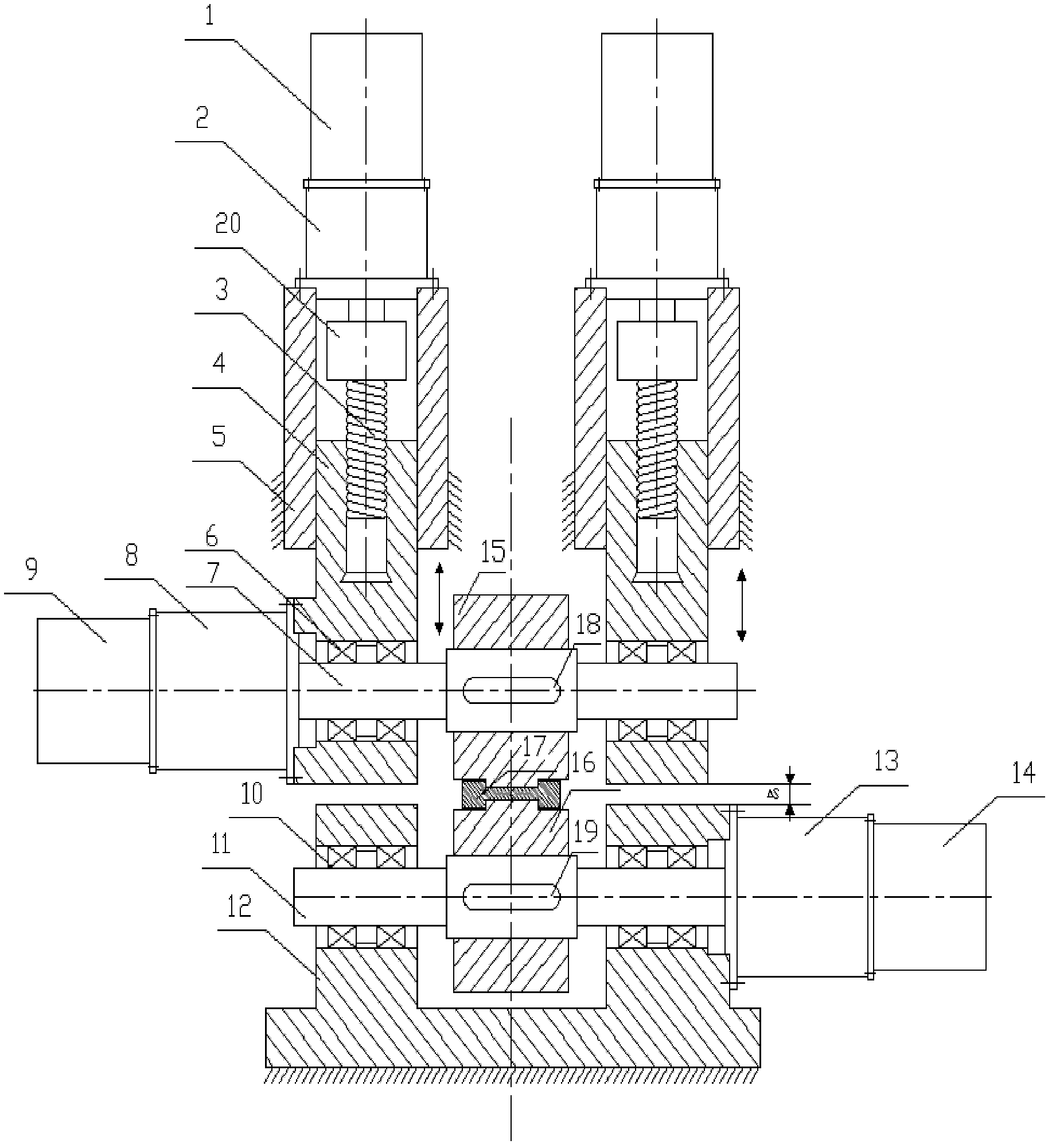

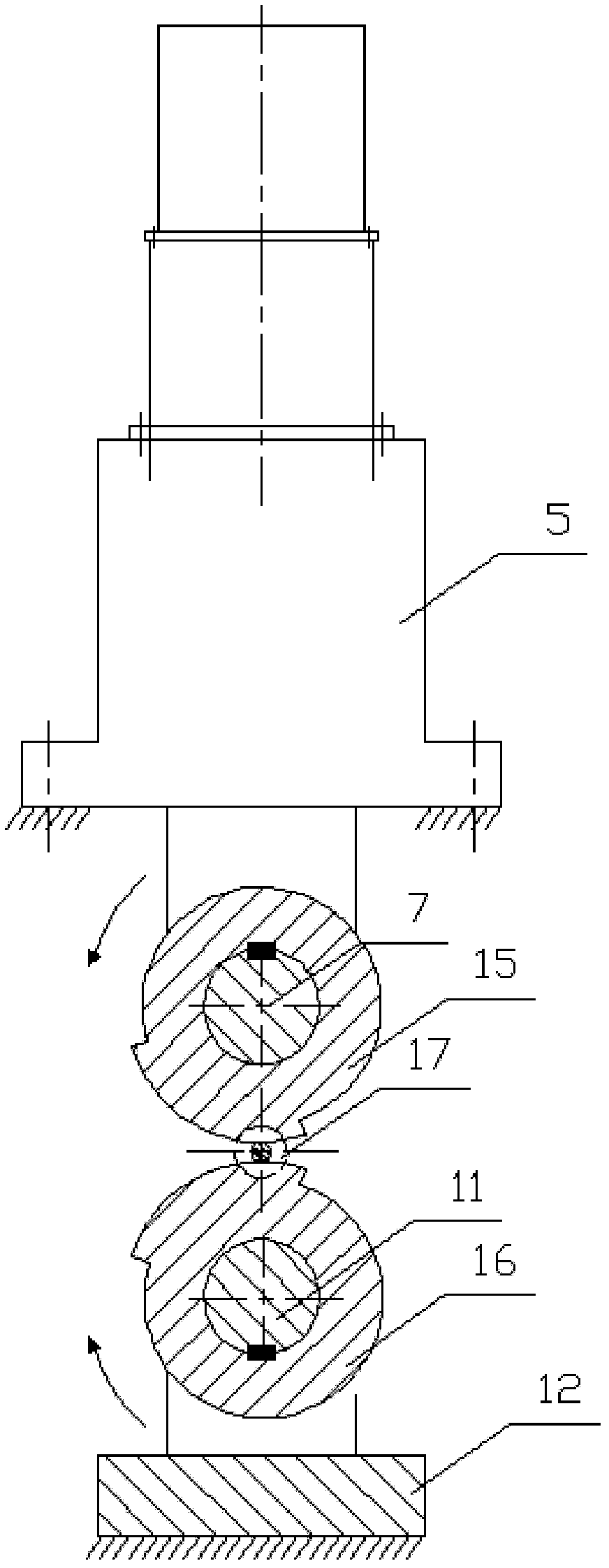

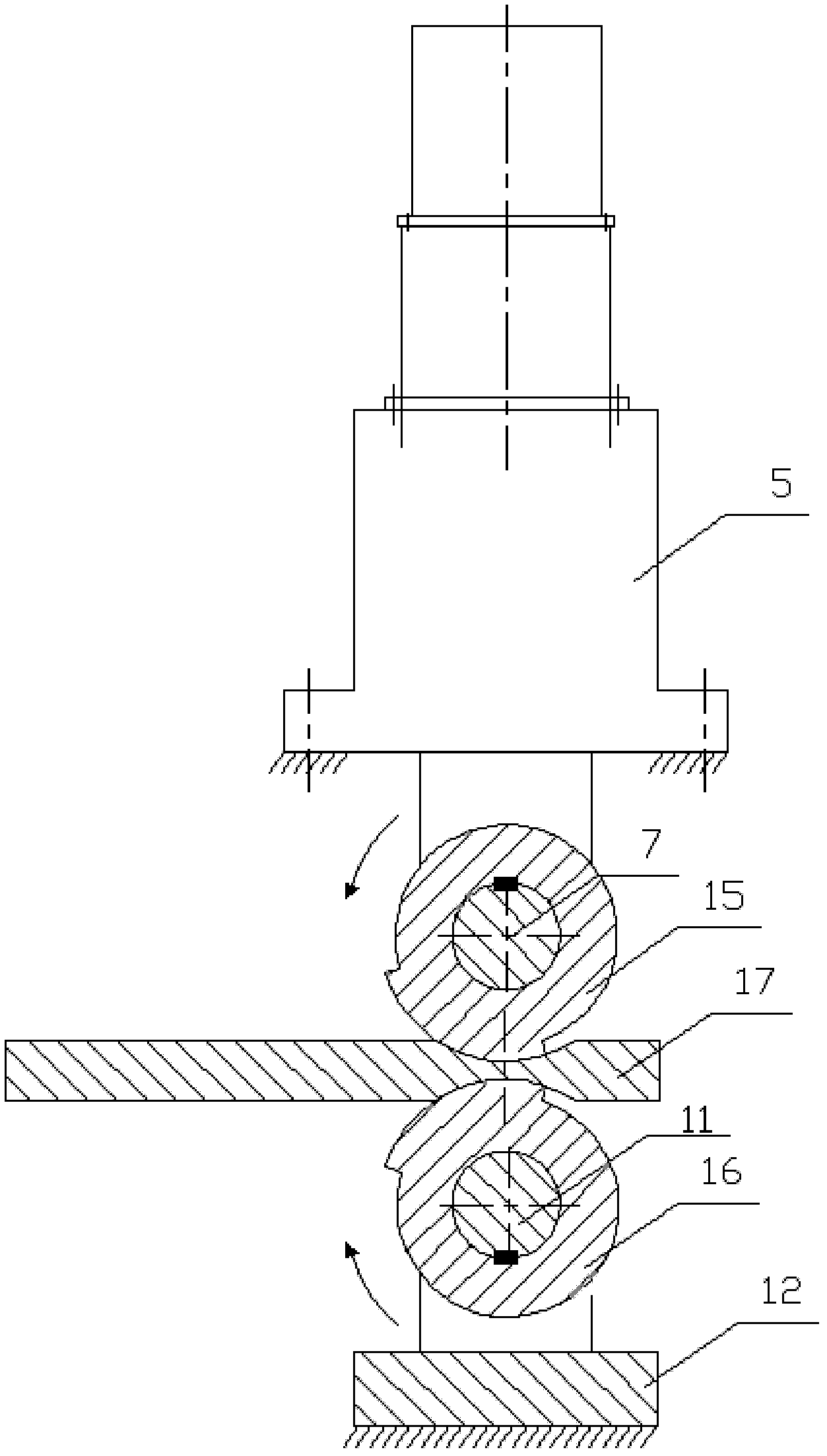

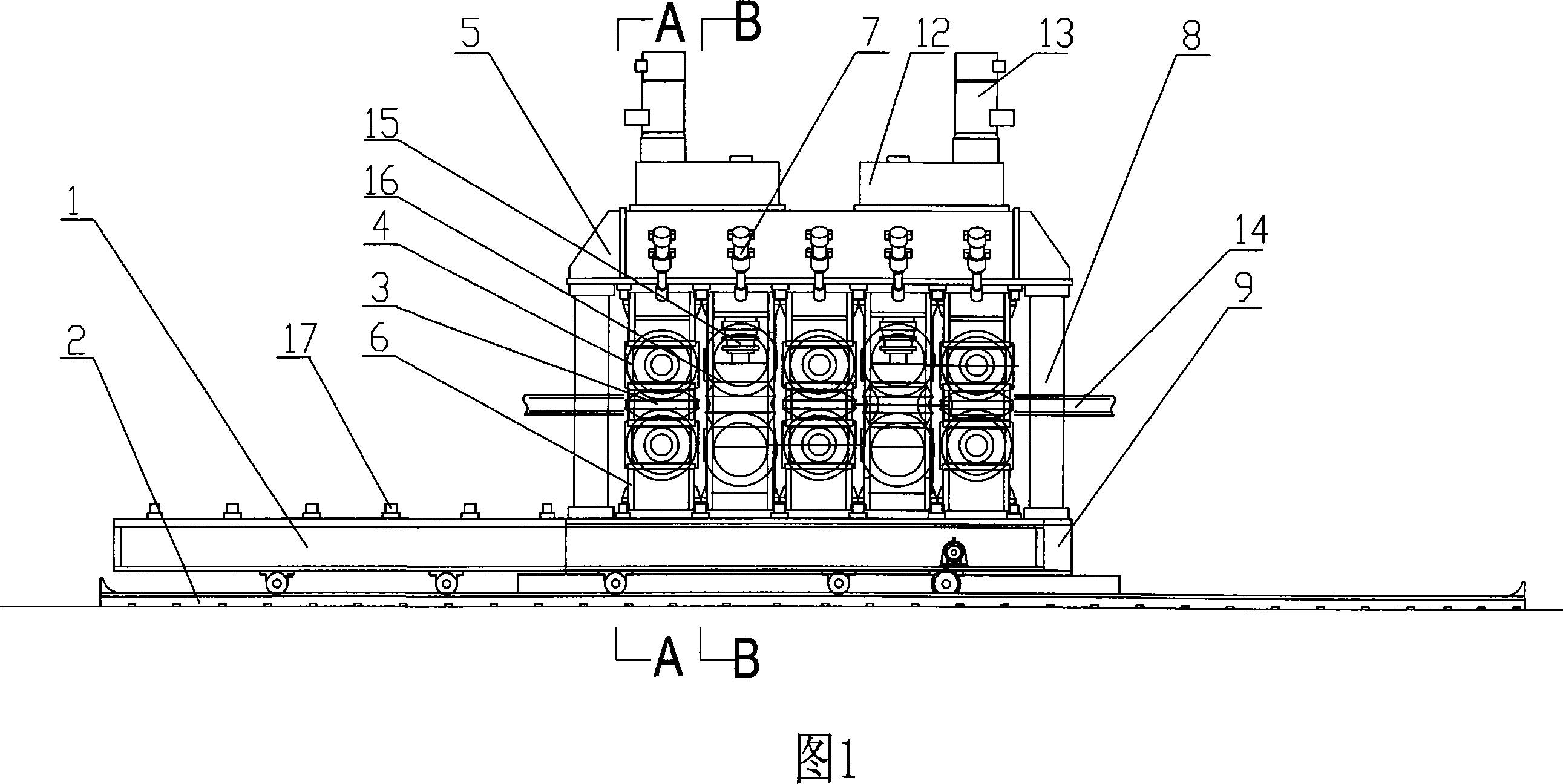

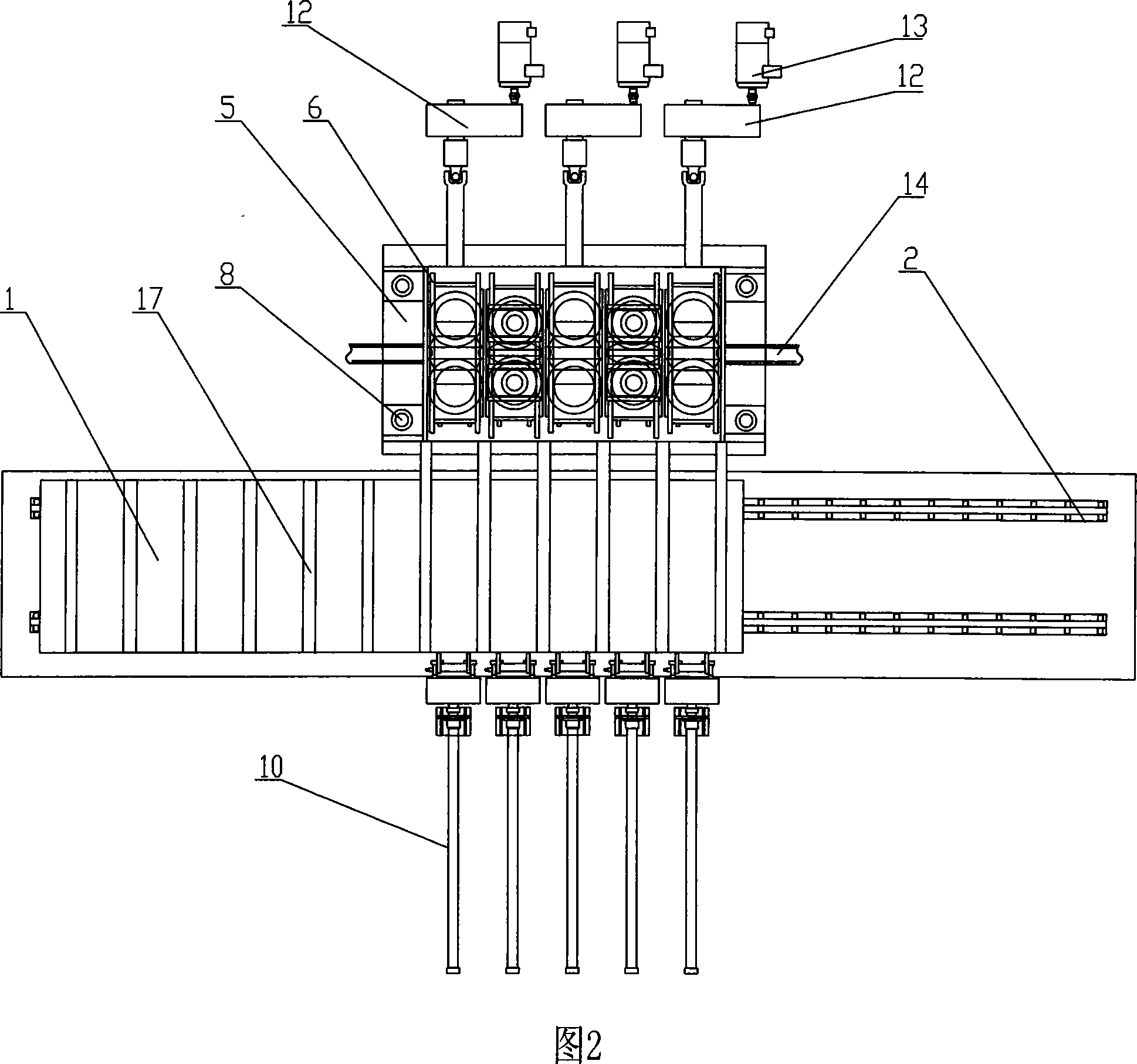

Alternating-current direct-drive servo device for main transmission and two-roller radial spacing adjustment

InactiveCN102601122AGuaranteed parallelismGuaranteed accuracyMetal rolling stand detailsRolling mill drivesReduction driveReducer

Disclosed is an alternating-current direct-drive servo device for main transmission and two-roller radial spacing adjustment. A roller radial spacing adjustment device of the servo device comprises a bilaterally symmetric radial adjusting mechanism. An alternating-current servo motor of the mechanism is connected with a lead screw through a speed reducer and the like, a nut is mounted on the lead screw, a left main drive alternating-current servo motor on the upper portion of a main transmission device is connected with an upper roller shaft mounted on the nut, an upper mould is mounted on the upper roller shaft, a right main drive alternating-current servo motor on the lower portion of the main transmission device is connected with a lower roller shaft mounted on a base, a lower mould is mounted on the lower roller shaft, the alternating-current servo motors are controlled to rotate and to drive the upper roller shaft to move, the upper mould is further driven to move, the distance between the upper roller shaft and the lower roller shaft is adjusted, the left main drive alternating-current servo motor and the right left main drive alternating-current servo motor are controlled to drive the upper roller shaft and the lower roller shaft to rotate, and the upper mould and the lower mould are matched with each other so that a workpiece is processed. The alternating-current direct-drive servo device has the advantages of high efficiency, high precision and the like, and is convenient in operation and easy in use.

Owner:XI AN JIAOTONG UNIV

Seamless pipe four-roller type hot sizing stand

InactiveCN101032724AReasonable structural designCompact structureMetal rolling stand detailsRolling mill drivesHydraulic cylinderPulp and paper industry

The present invention relates to one kind of four roller type hot sizing machine for seamless steel pipe. The hot sizing machine includes one main sizing mechanism on one side of the rail and comprising one frame, one horizontal sizing roller set and one side vertical sizing roller set; one roller changing carriage with roller changing hydraulic cylinder for pushing the horizontal sizing roller set and the side vertical sizing roller set into the square frame or drawing out; and horizontal sizing roller set and side vertical sizing roller set locking hydraulic cylinder. The present invention has reasonable design, compact structure, closed pass structure resulting in increased sizing reduction and raised sizing quality, high production efficiency and other advantages.

Owner:DALIAN SAGE GROUP

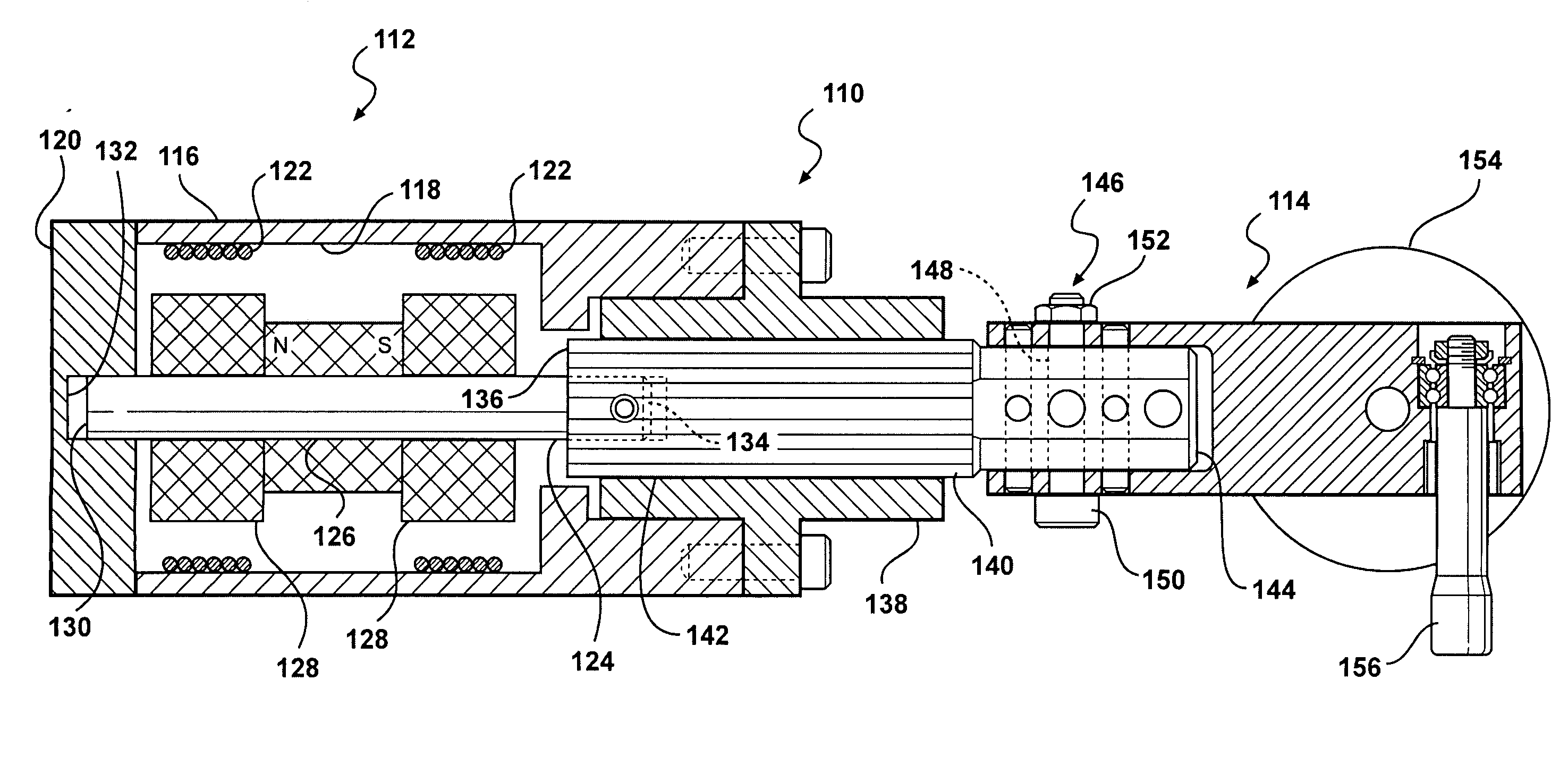

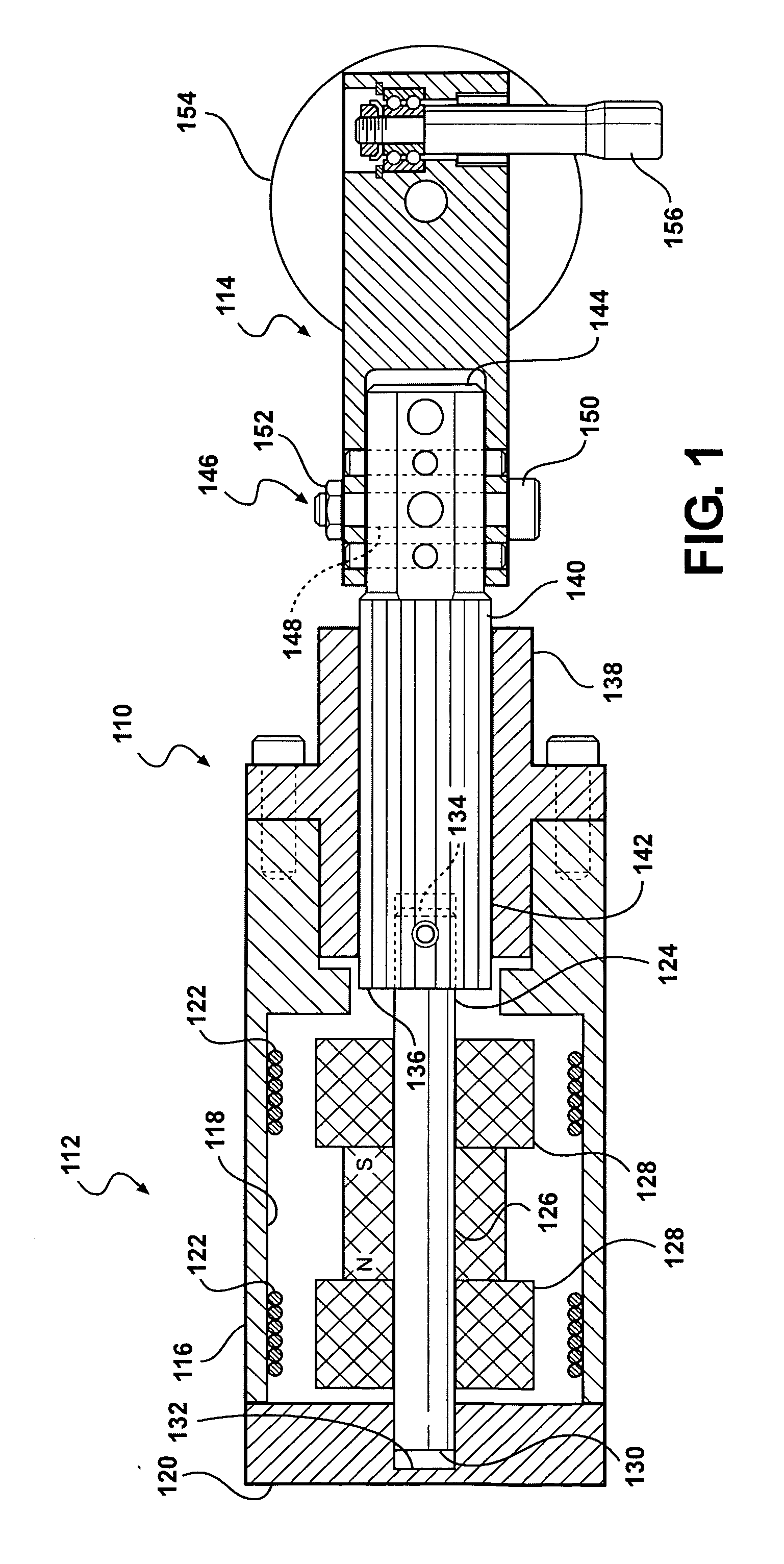

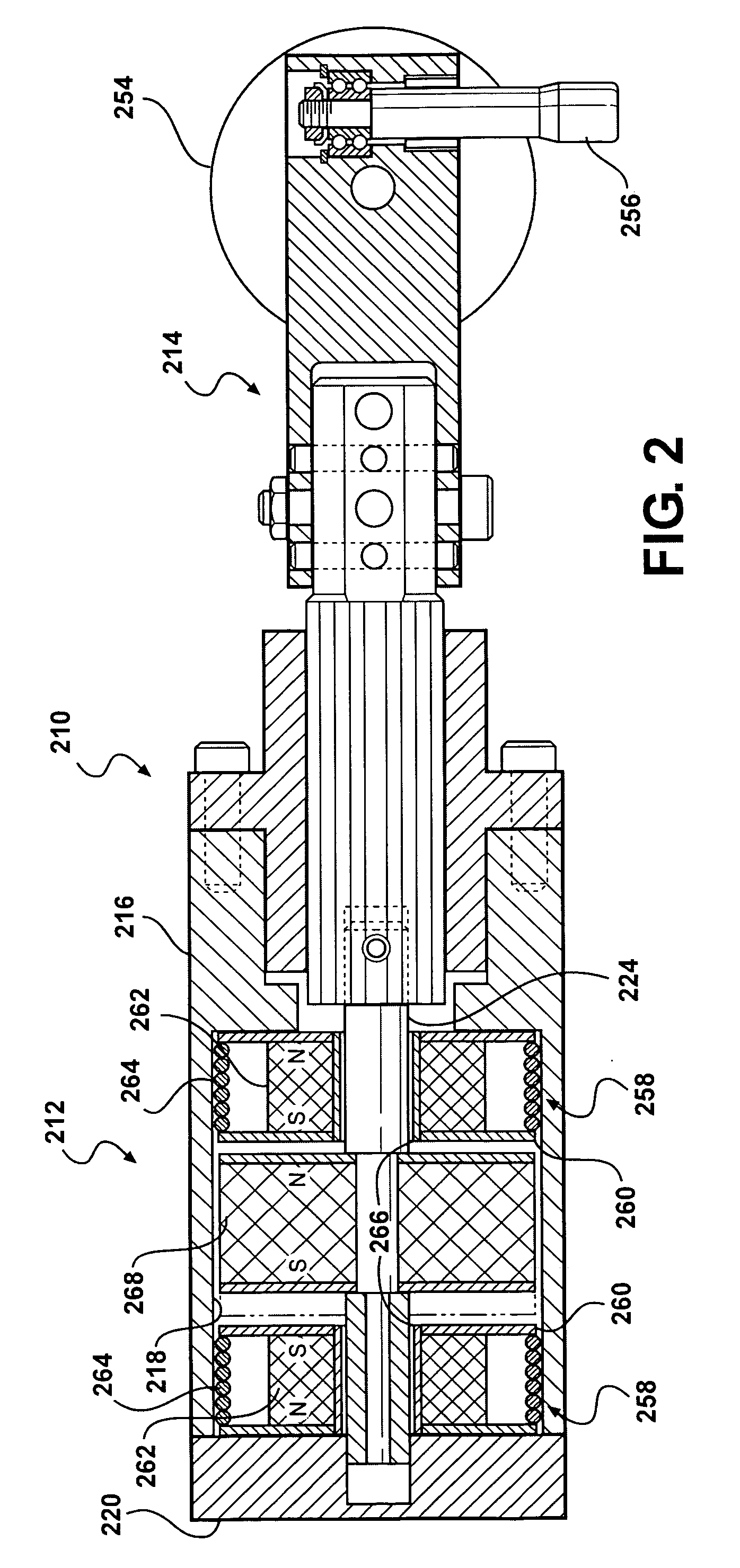

Magnetically actuated roller head

InactiveUS20090235713A1Eliminate needMetal rolling stand detailsLarge fixed membersRobotic armMulti axis

A magnetically actuated roller head includes a linear actuator mountable on an end of a multi-axis robotic arm. The linear actuator includes a slide, a magnet operably connected to the slide and operable to urge the slide in a linear direction, and a connector disposed on a distal end of the slide. A roller hemming head is mounted on the linear actuator by the connector. The roller hemming head includes at least one hem roller.

Owner:HIROTEC AMERICA

Flexible roll forming device, blank guide device, blank feeding device, and flexible roll forming system having the same

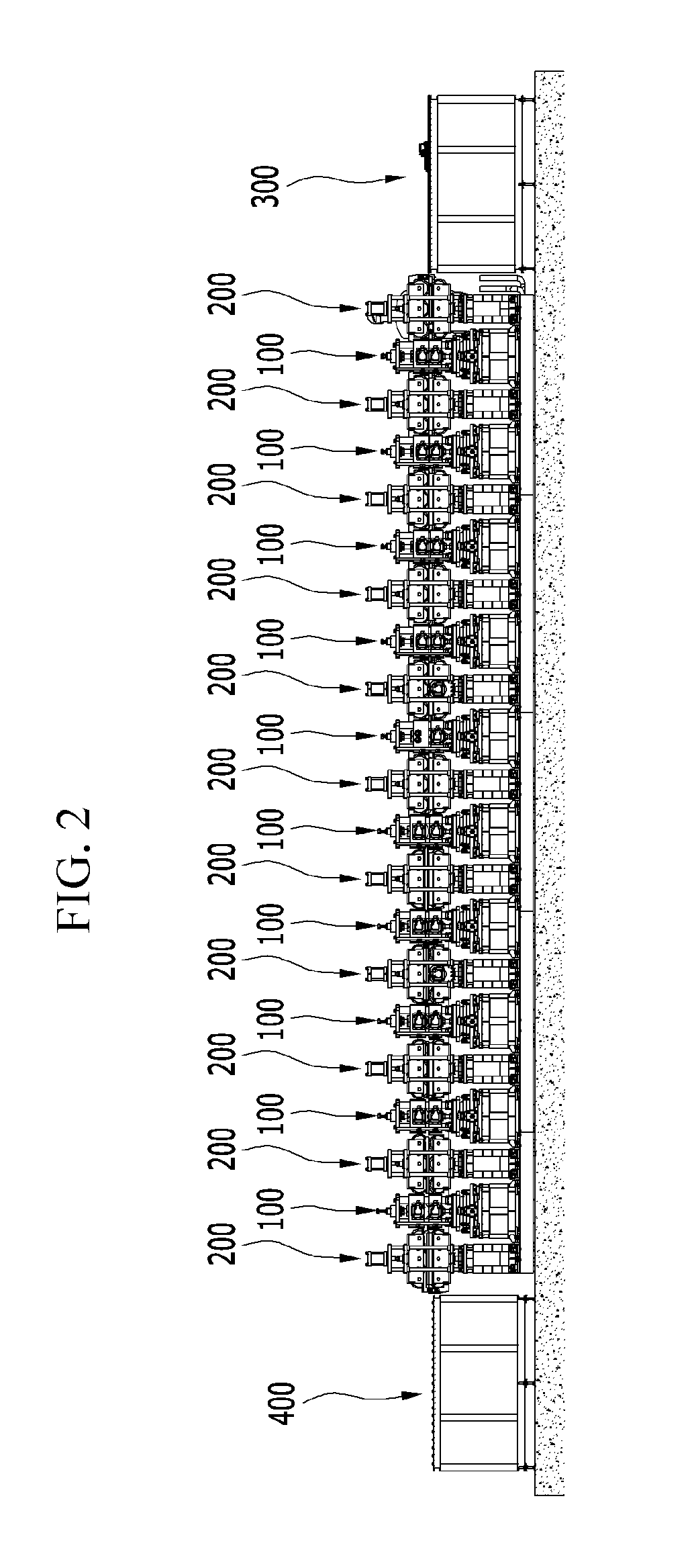

Disclosed is a flexible roll forming device including: bases respectively disposed on opposite sides with respect to a process direction center line in a left / right direction, each having an opening formed in an upper side thereof connected to an inside thereof, and rails configured thereon on opposite sides of the opening in a lateral direction of the process; forward / backward moving means having a slide plate provided to be movable along the rails on the base; turning means rotatably provided to the slide plate; and roll forming means provided on the turning means to include upper and lower forming rolls for subjecting a material fed thereto to flexible roll forming by using the upper and lower forming rolls while varying positions in the lateral direction of processing with the forward / backward moving means, and angles from a process direction with the turning means.

Owner:SUNG WOO HITECH

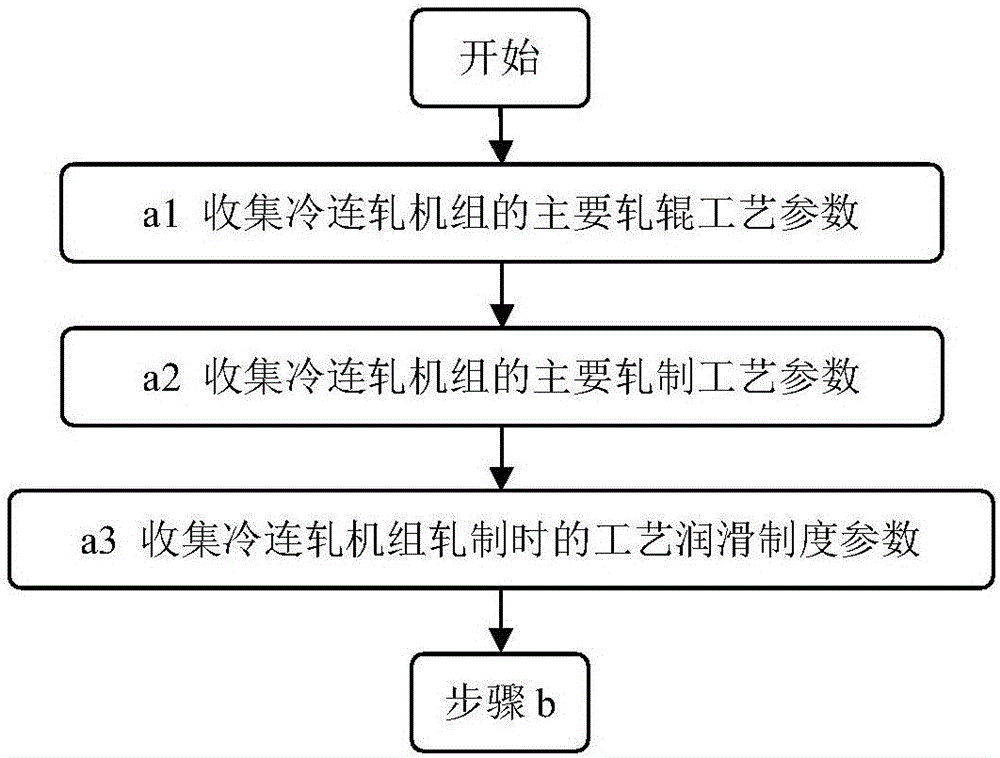

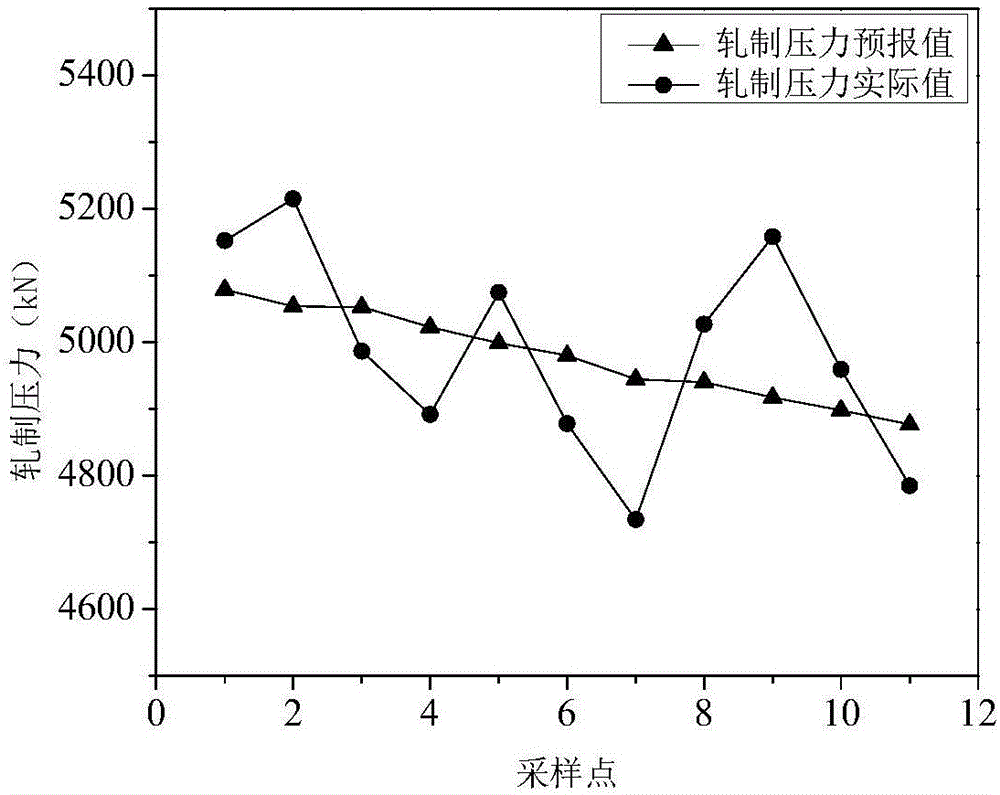

Method for predicting changes of rolling pressure with change of rolling speed in cold rolling process

ActiveCN106391725AQuality assuranceGuaranteed accuracyRoll force/gap control deviceRollsEmulsionStrip steel

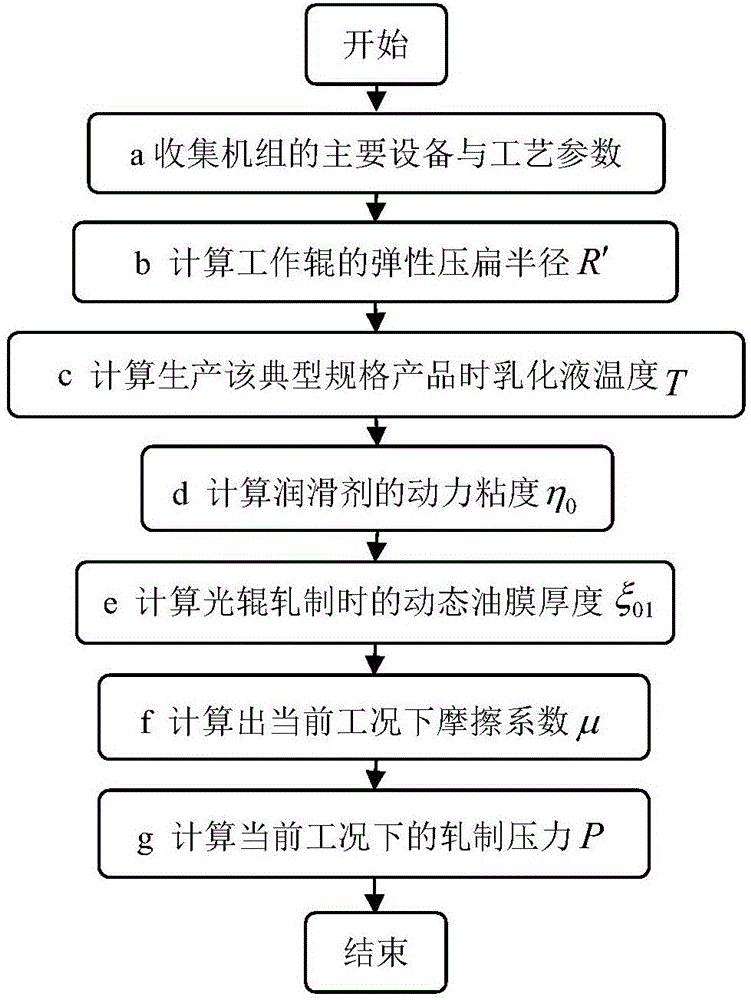

The invention discloses a method for predicting the changes of a rolling pressure with the changes of a rolling speed in a cold rolling process. The method comprises the following computer executed steps: (1) collecting main equipment and technological parameters of a cold continuous rolling unit; (2) calculating an elastic flattening radius of a working roller; (3) calculating the temperature of emulsion in the rolling process for producing products of the typical specification under the current working condition; (4) calculating power viscosity of a lubricant; (5) calculating dynamic oil film thickness in rolling of a smooth roller; (6) calculating the friction coefficient in the rolling process under the current working condition; and (7) calculating the rolling pressure under the current working condition. The method disclosed by the invention can realize on-line prediction of changes of the rolling pressure in a speed increasing and reducing process and can be used for monitoring the change condition of the rolling pressure in the speed increasing and reducing process in real time so as to provide a control strategy in time, so the rolling pressure fluctuation degree is greatly alleviated, on-site workers can be provided with an on-line rapid early warning mechanism, and the surface quality and strip shape accuracy of strip steel are guaranteed.

Owner:唐山市榕泽钢材加工有限公司

Popular searches

Semiconductor/solid-state device manufacturing Load-engaging elements Positioning devices Metal-working storage devices Final product manufacture Counter-pressure devices Active material electrodes Non-aqueous electrolyte accumulator electrodes Tension/compression control device Profile control device

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com