Stainless-steel band special apparatus for steel-aluminum composite contact rail

A stainless steel strip and steel-aluminum composite technology, which is applied in metal processing equipment, other manufacturing equipment/tools, and driving devices for metal rolling mills, can solve the problem that general equipment cannot meet the requirements of mass production of steel-aluminum composite contact rails and stainless steel strips There are no mature special equipment for processing, bending technology and high drilling precision requirements, etc., to achieve the effect of novel structure, reasonable design and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

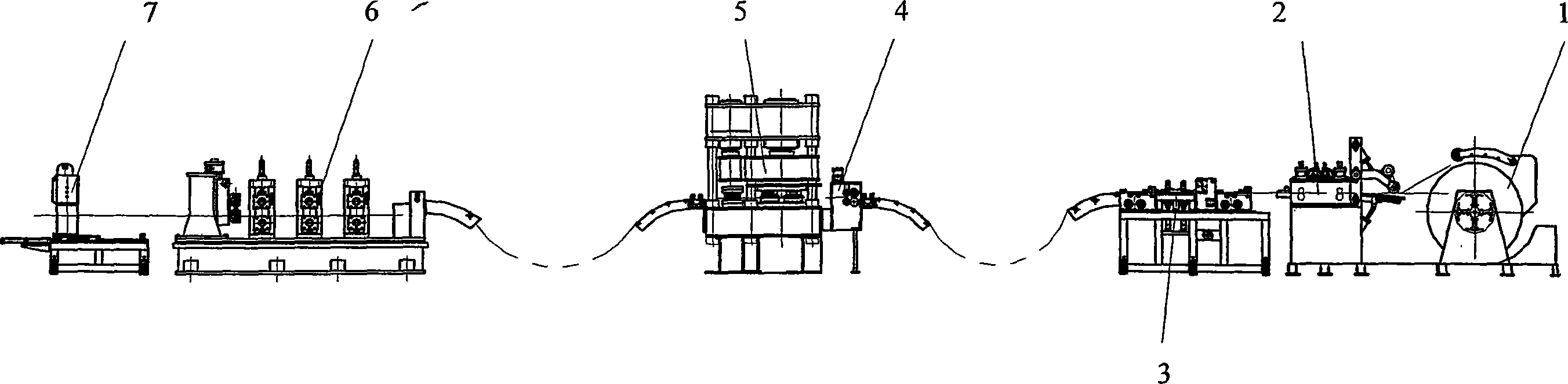

[0018] A special equipment for forming stainless steel strips for steel-aluminum composite contact rails according to the present invention, including an uncoiler 1, a material leveling machine 2, a shearing butt welding platform 3, a servo feeder 4, a hydraulic punching machine 5, a rolling press Forming unit 6, cut-to-length machine 7.

[0019] The uncoiler 1 is used to support the unwinding of the stainless steel coil, and the uncoiler 1 is arranged on the front side of the leading material leveling machine 2 . The uncoiler is composed of a welding frame, a tensioning shaft system, a motor reducer drive, a binder head and a brake.

[0020] The material leveling machine 2 makes the stainless steel coil unroll smoothly and flattens the unfolded steel coil; the feeding rollers are set before and after the material leveling machine 2, the motor is decelerated and driven by frequency conversion, and the front roller guides the plate. The head of the sheet is released and the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com