Hot rolled strip steel finishing rolling temperature control method based on speed adjustment

A technology for adjusting the temperature and speed of finishing rolling, which is applied in the field of hot rolling, can solve the problems of poor control effect and low efficiency of finishing temperature control of hot-rolled strip steel, and improve the precision of rolling temperature control, timely response to temperature deviation, and control accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

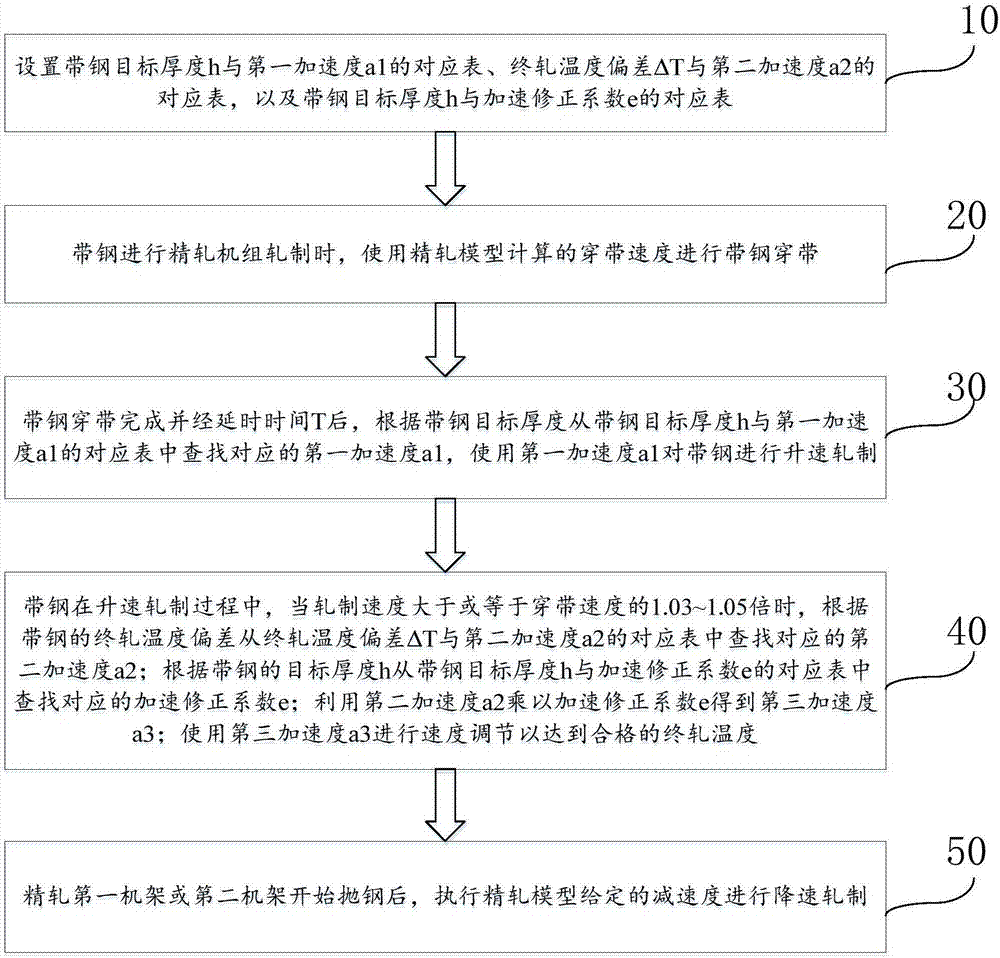

[0025] The embodiment of the present invention solves the technical problems of low efficiency and poor control effect of the finishing temperature control of hot-rolled strip in the prior art by providing a method for controlling the finish-rolling temperature of hot-rolled strip steel based on speed adjustment, and improves the temperature of hot-rolled strip steel. The control efficiency of the finish rolling temperature of the strip steel ensures the control effect of the finish rolling temperature of the strip steel. see figure 1 , the embodiment of the present invention provides a speed regulation-based method for controlling the finishing temperature of hot-rolled strip steel, comprising the following steps:

[0026] Step 10: Set up a correspondence table between the target strip thickness h and the first acceleration a1, a correspondence table between the finishing temperature deviation ΔT and the second acceleration a2, and a correspondence table between the strip tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com