Patents

Literature

41 results about "Steel company" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The top iron & steel companies are Arcelor Mittal, VALE, Nippon Steel & Sumitomo Metal, POSCO & JFE Steel along with brands like Baosteel, TATA Steel, Hyundai Steel, Kobe Steel and NUCOR. It continues to contribute to the major industries like Manufacturing, Construction, Automobiles, Defense and Transportation etc.

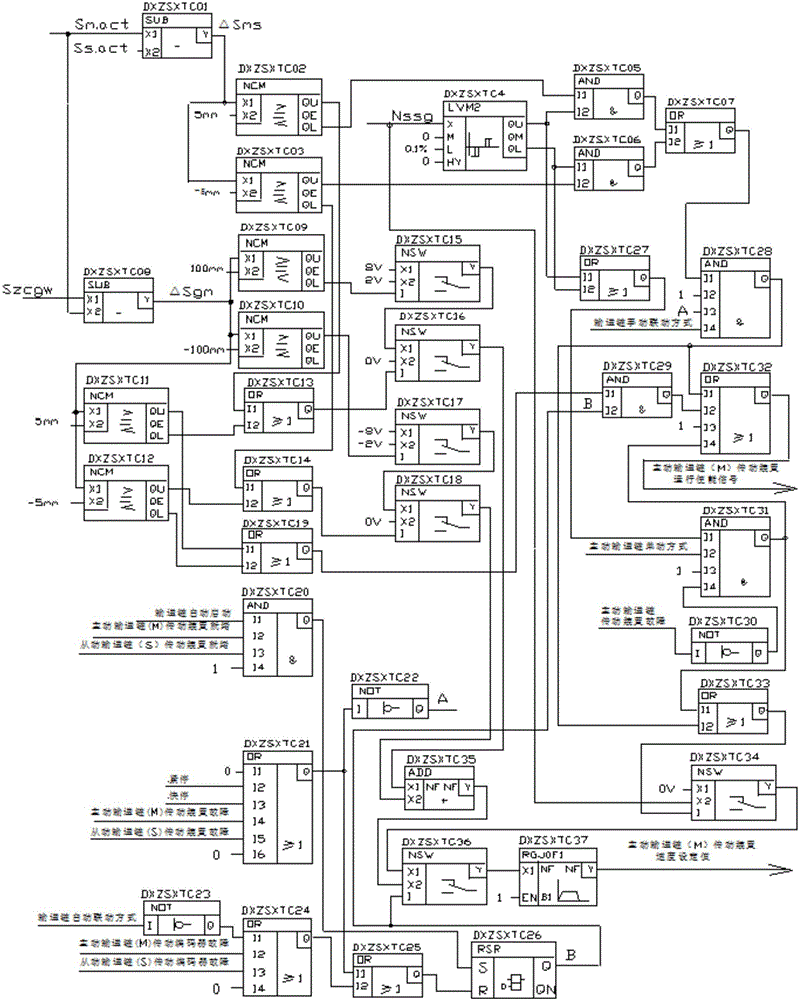

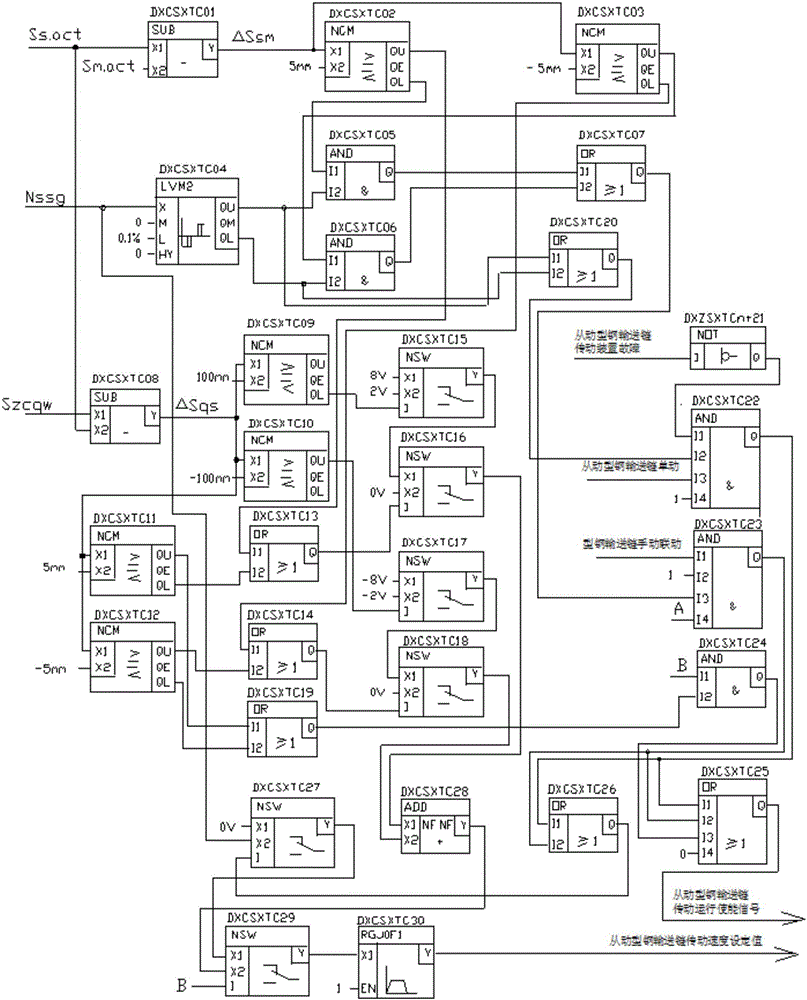

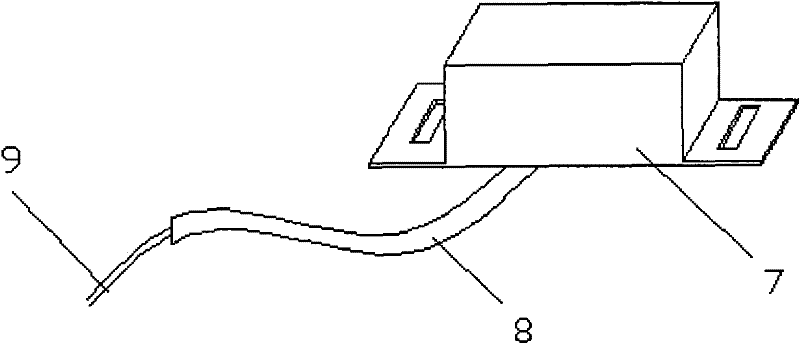

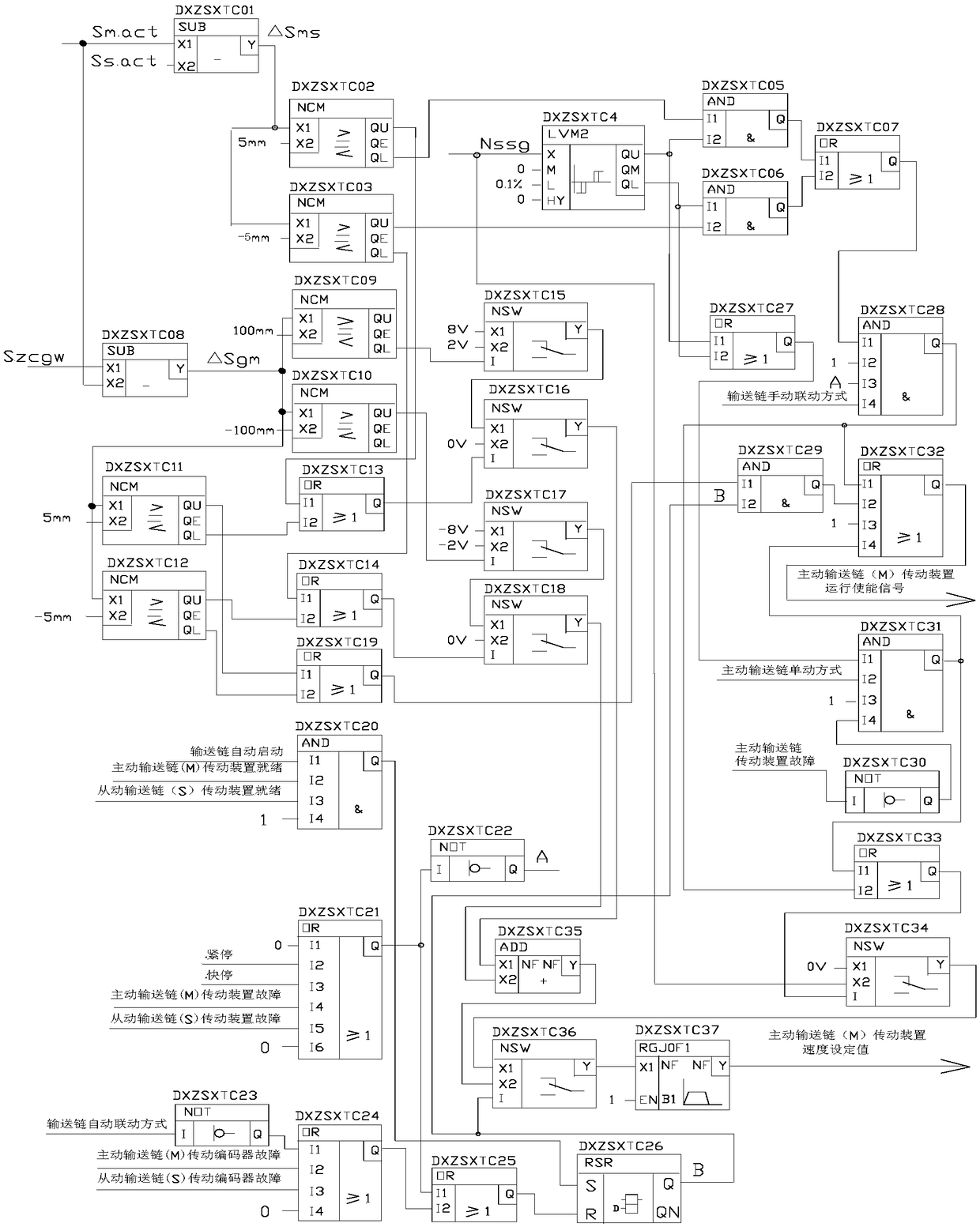

Synchronous control method for two independent motor drive type steel conveying chains

The invention discloses a synchronous control method for two independent motor drive type steel conveying chains. The method comprises driving type steel conveying chain synchronous control and driven type steel conveying chain synchronous control, according to the driving type steel conveying chain synchronous control and the driven type steel conveying chain synchronous control, retreating terminal position values of a main conveying chain and a slave conveying chain are 0 mm, and given position values and actual position values of the main conveying chain and the slave conveying chain are positive values or zero. The driving type steel conveying chain synchronous control comprises a driving type steel conveying chain synchronous position over-tolerance judging unit, a driving type steel conveying chain automatic linkage transmission enabling control unit, a driving type steel conveying chain automatic linkage speed given control unit, a driving type steel conveying chain manual linkage transmission enabling and speed given control unit and a driving type steel conveying chain single-action transmission enabling and speed given control unit. The control method is used in two-section conveying chains of a large H-shaped steel CP9 stacking machine tool of the Maanshan Iron and Steel Company, and has good effect.

Owner:MAANSHAN IRON & STEEL CO LTD

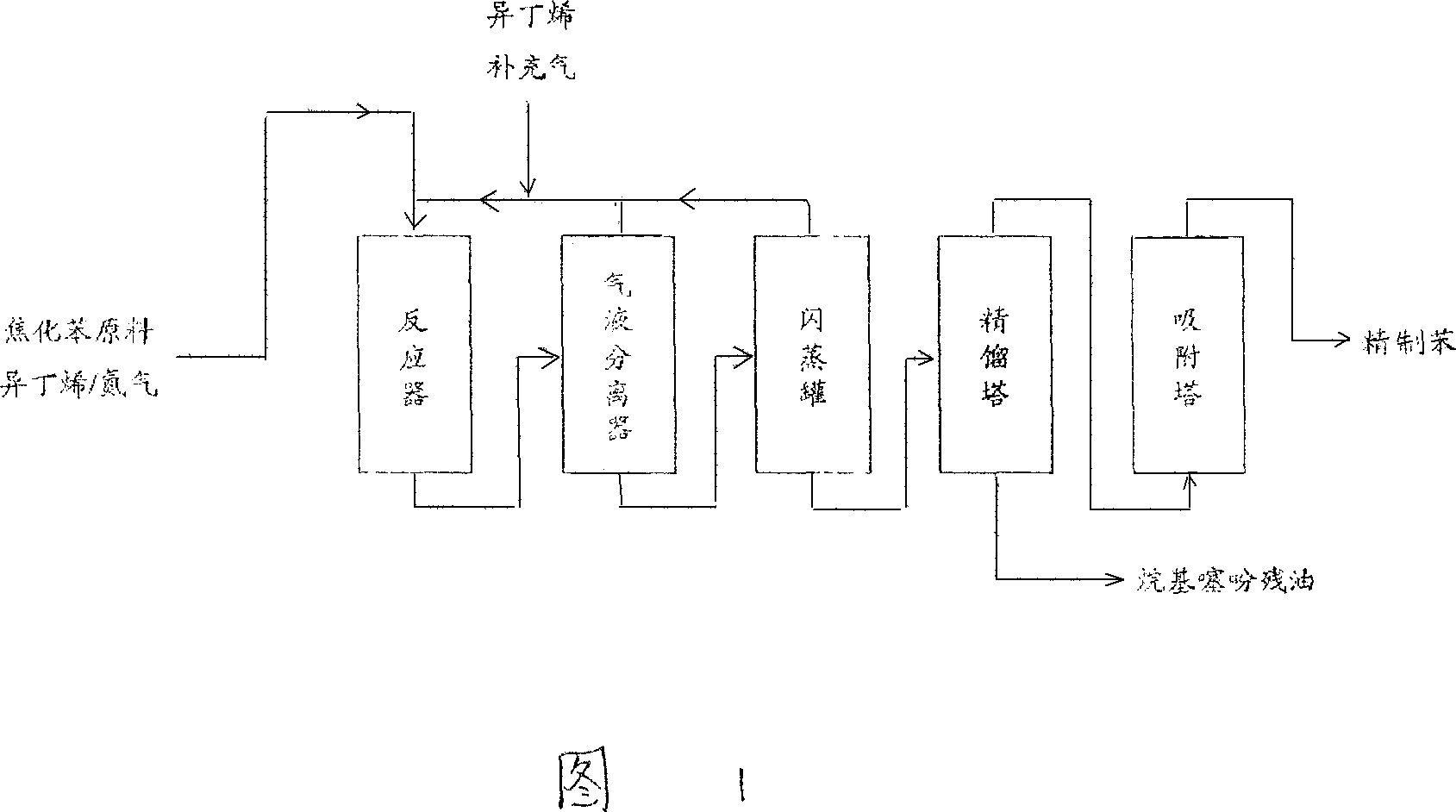

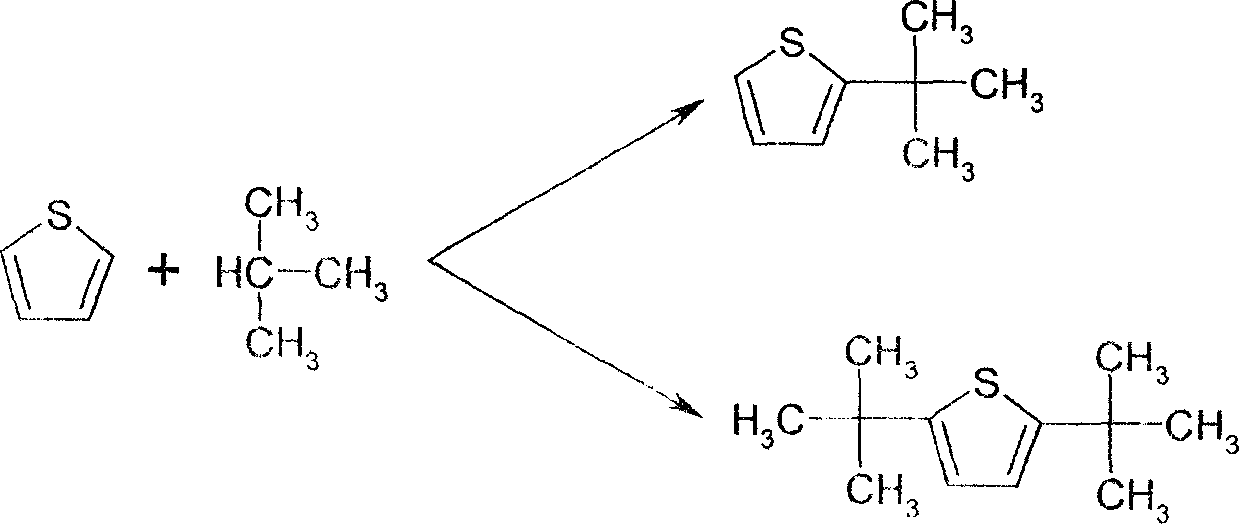

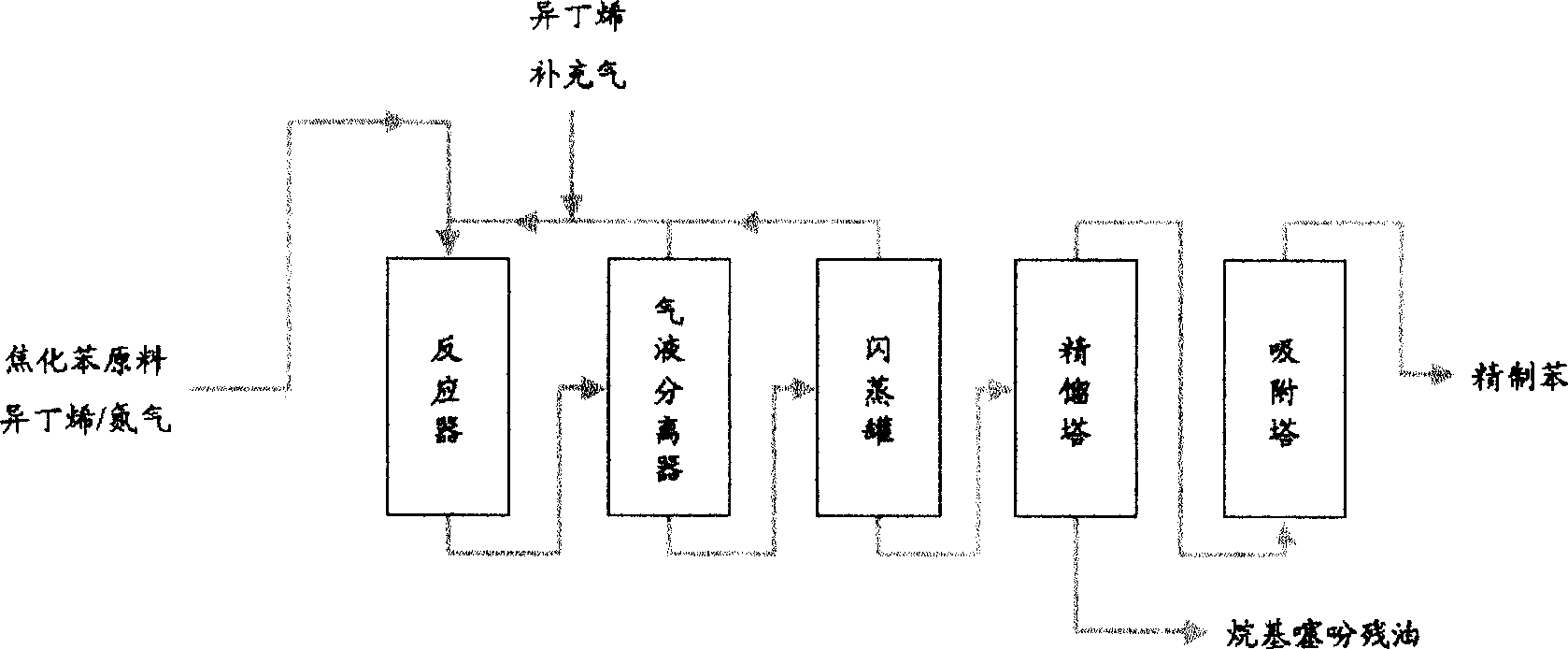

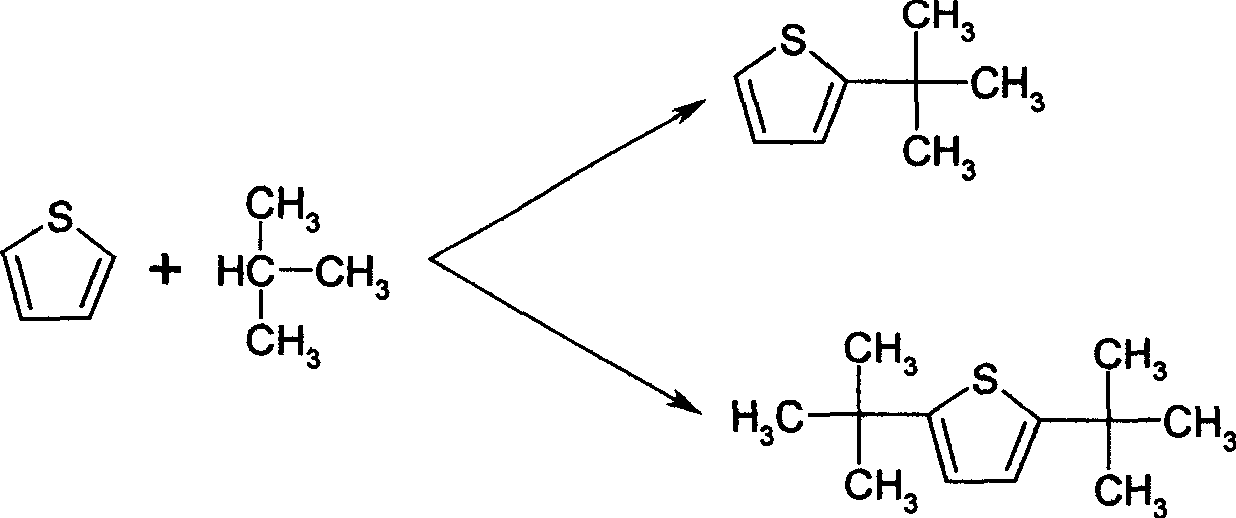

Coking benzene deep desulfuration purification method

InactiveCN101062879AHigh base conversion rateImprove adsorption capacityHydrocarbon purification/separationHydrocarbonsPurification methodsCoking plant

The invention discloses a method of coking benzene deep desulfurizing refined method, which comprises the following steps: adopting catalytic alkylthiophene desulfuration and selective adsorption desulfurizing associated craft; generating alkylthiophene with higher boiling point; rebuilding alkylthiophene through rectifying abscission; selective-adsorbing with desulfurizer; stripping excess un-reaction thiophene; reaching the demand of deep purifying harmful sulfur impurities in coking benzene. This invention possesses small corrosion, low cost and high earning rate, which is a better method for deep processing by-product of steel company and coking plant.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Method for calcination of chamotte in rotary cement kiln with coal gas as fuel

InactiveCN101195522AThoroughly mix and evenly calcinedCalcined evenlyMechanical apparatusRotary drum furnacesCement kilnMixed gas

The invention belongs to a manufacture technique of calcining cement clinker, in particular to a process of calcining cement clinker using coal gas as the heat source in rotary kiln. The manufacture technique includes a process of voltage stabilization and transformation of the coal gas, and a process of burning and heat calcinations of the coal gas in the rotary kiln. The invention is characterized in that the coal gas enters a burner through the coal gas pipe after the voltage is stabilized by a voltage stabilization cabinet and the flow capacity is adjusted by a control valve, then the coal gas is lit by the coal burner and sprayed in the rotary kiln. The coke-oven gas, blast furnace gas, converter gas and high coke mixed gas left in the process of metallurgy production can take place coal powder as fuel to calcine the cement clinker. The invention has the advantages that the manufacture technique can reduce environmental pollution caused by burning coal, increase the utilization ratio of the surplus gas in iron and steel companies, and reduce the exhaust of coal gas, thereby having good economic benefit and social benefit.

Owner:LAIWU IRON & STEEL GRP

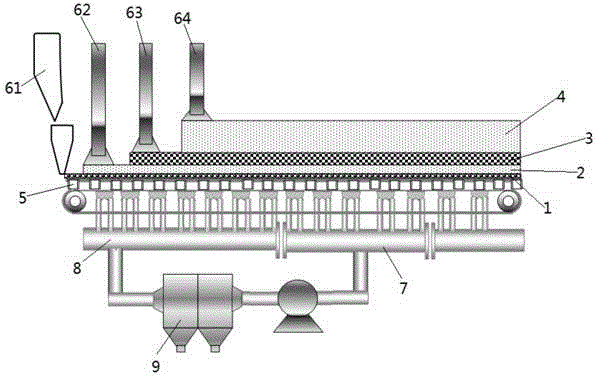

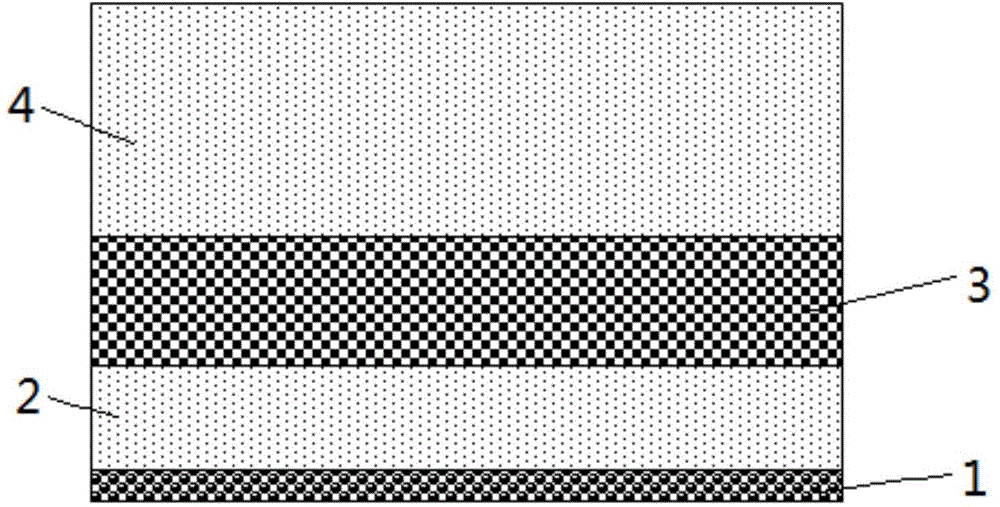

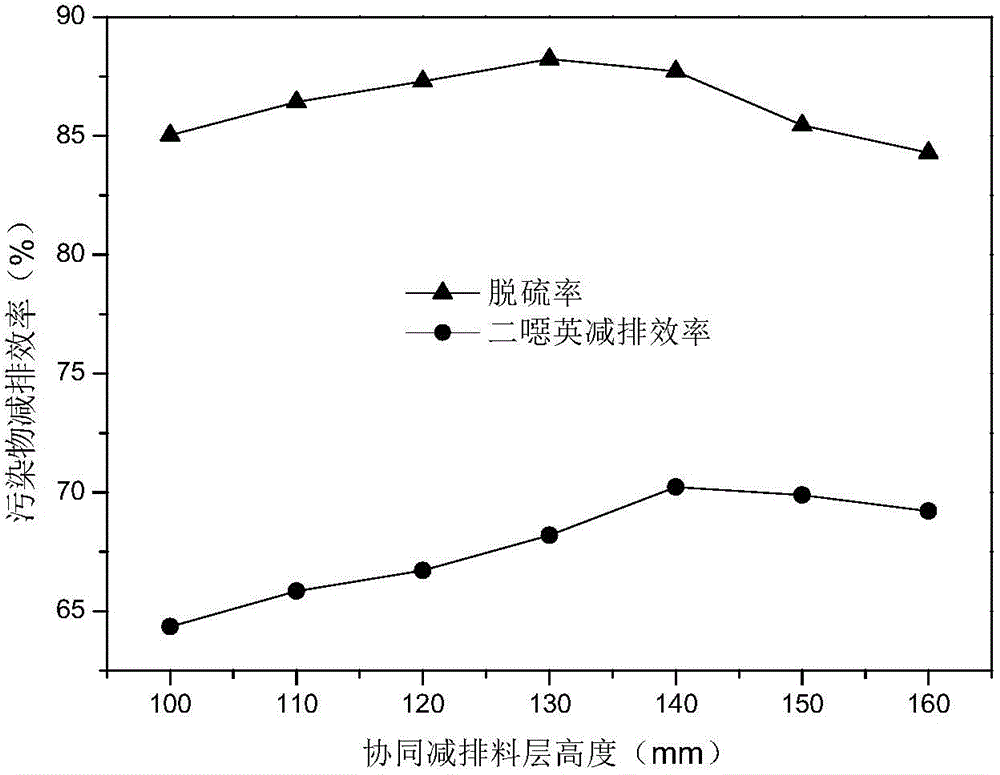

Solid inhibitor addition based method for collaborative emission reduction of SO2 and dioxins in sintering process

ActiveCN105861816AAir volume balanceStable productionDispersed particle filtrationBaghouseCertified Emission Reduction

The present invention discloses a solid inhibitor addition based method for collaborative emission reduction of SO2 and dioxins in sintering process, and belongs to the technical field emissions of pollutants reduction in the sintering process. The present invention comprises the steps of: step 1, sintering cloth (A) paving a pavement material layer on the upper part of a sintering trolley, (B) paving a first mixture layer on the top of the pavement material layer, (C) mixing solid ammonia inhibitor granules with a sinter mixture, and paving a collaborative emission reduction material layer over the first mixture layer, and (D) paving a second mixture layer over the collaborative emission reduction material layer; and step 2, flue concentrated collection and treatment: emerging the flue gas in a bellows at the middle rear part of the sintering trolley into a bag dust remover by a booster pump, and introducing the flue gas after dust removal into a main flue collector by a pipe. Through addition of urea granules in the collaborative emission reduction material layer, the method achieves collaborative emission reduction of SO2 and dioxins in the sintering process on the premise of unchanged sinter quality, and greatly reduces the emission reduction burden of steel companies.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

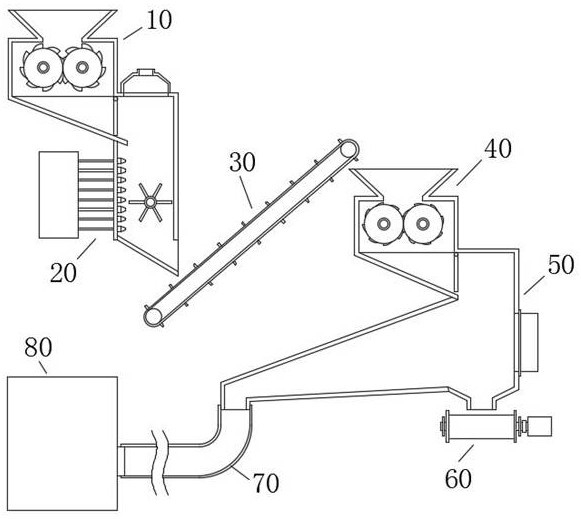

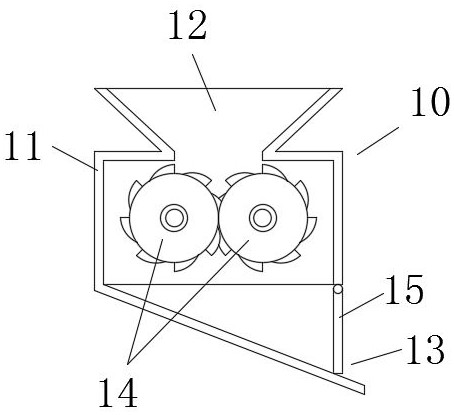

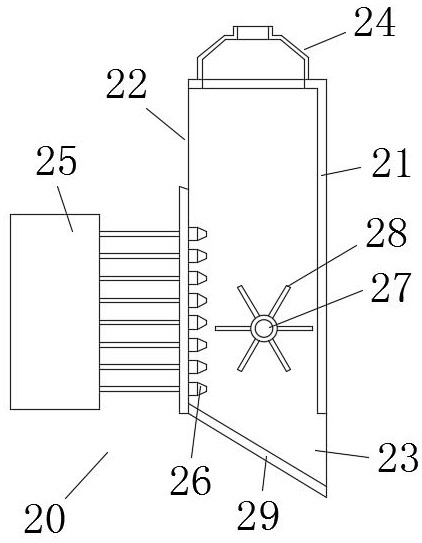

Scrap steel breaking and impurity removing machine

PendingCN111822479AAchieve removalEasy to smeltSolid waste disposalGrain treatmentsThermodynamicsCombustor

The invention relates to a scrap steel breaking and impurity removing machine. The scrap steel breaking and impurity removing machine comprises a primary breaker, a combustor, a secondary breaker, a lifting machine and a winnowing machine. The scrap steel breaking and impurity removing machine has the beneficial effects that scrap steel blocks are broken to form scrap steel sheets with the diameter smaller than 4 centimeters through the primary breaker, then combustible impurity objects on the surfaces of the scrap steel sheets which enter the combustor can be burnt through the combustor, thescrap steel sheets which are discharged from the combustor are conveyed to the secondary breaker through the lifting machine, then the scrap steel sheets which are burnt by the combustor are broken toform scrap steel particles with the diameter smaller than 1 centimeter through the secondary breaker, combustion ash can be separated from the scrap steel sheets at the same time, finally the scrap steel particles entering the winnowing machine and the combustion ash entering the winnowing machine are separated through the winnowing machine, and therefore the purpose that the combustible impurityobjects which adhere to the surface of scrap steel are moved is achieved, and the iron and steel scrap which is recovered from the society is conveniently smelted by an iron and steel company.

Owner:ZHOUKOU NORMAL UNIV

Method for producing margin coal gas by using steel in rotary cement kiln predecomposition furnace

InactiveCN101195521AEmission reductionReduce pollutionMechanical apparatusRotary drum furnacesCement kilnCalcination

Provided is a method of using surplus gas of iron and steel production to produce cement in a predecomposition furnace of a rotary kiln, belonging to the technical field of calcining cement clinker and including a process of voltage stabilization and transformation of coal gas, a process of burnt and heat calcinations of the coal gas in the predecomposition furnace. The coal gas is burnt sufficiently and used in the predecomposition process of the cement raw meal. The coke-oven gas, blast furnace gas, converter gas and high coke mixed gas left in the process of metallurgy production can take place coal powder as fuel to decompose carbonate in the cement raw meal. The invention has the advantages that the manufacture technique can reduce environmental pollution caused by burning coal, increase the utilization ratio of the surplus gas in iron and steel companies, and reduce the exhaust of coal gas, thereby having good economic benefit and social benefit.

Owner:LAIWU IRON & STEEL GRP

Method for preparing Sialon material inside blast furnace

The invention discloses a method for preparing a Sialon material inside a blast furnace. The method comprises the following steps: when performing fireproofing material machining inside the blast furnace, pre-burying a fire waste tube inside a construction body, wherein a fire waste tube inlet and a fire waste tube outlet are formed in a furnace wall; when the blast furnace is used, burning the fire waste tube to form a channel, introducing nitrogen into the channel, sealing up the channel outlet when the amounts at the inlet and outlet of the channel are identical, stopping introducing the nitrogen, pressing a filling material into the channel and pressing tightly, and subsequently normally operating the blast furnace. When the Sialon material is prepared inside the blast furnace by using the method, the method is simple and reasonable, and application and preparation of Sialon are integrated, so that the production cost is greatly saved, and redundant nitrogen of steel companies is sufficiently utilized. The method is applicable to large and small blast furnaces, the service life of the blast furnace is prolonged, and great economic and social benefits are brought to the companies.

Owner:巩义市时创新材料孵化器有限公司

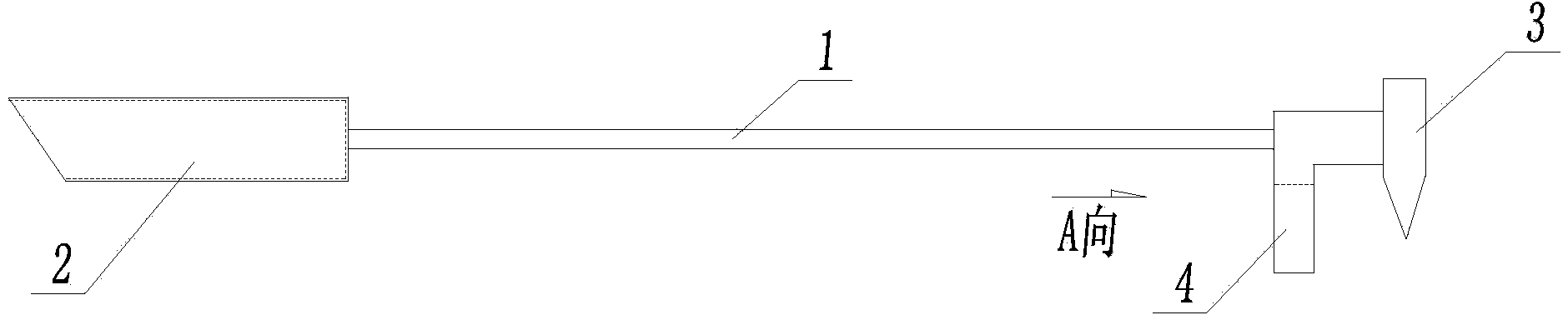

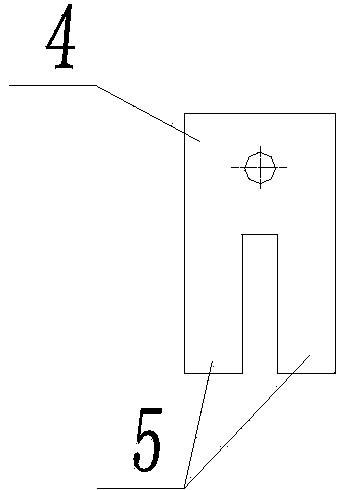

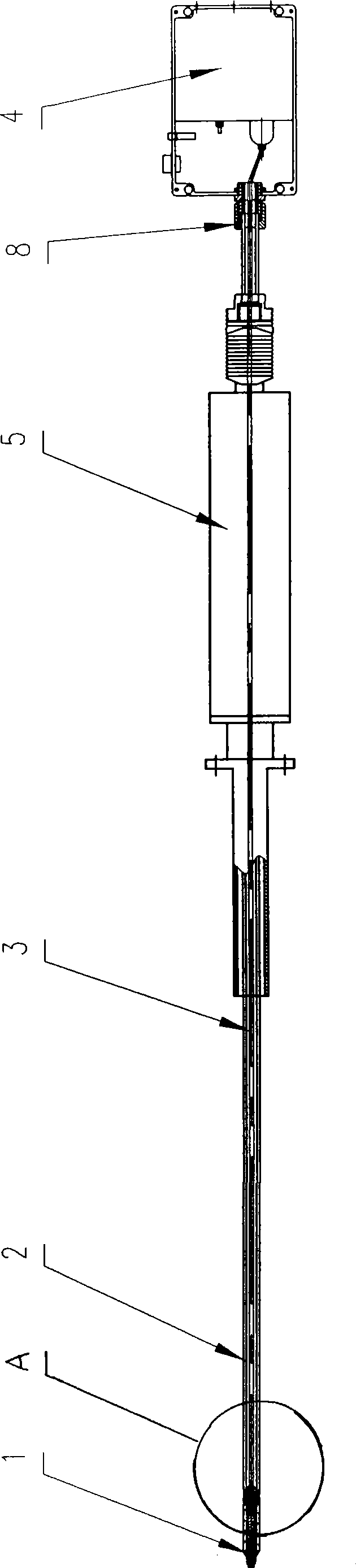

Multi-purpose coal sampler

The invention relates to the field of sampling inspection, and in particular relates to a multi-purpose coal sampler. The multi-purpose coal sampler is characterized by comprising a rod piece, a sampling cylinder, a hammerhead and a clamp fork, wherein the hammerhead is arranged at one end of the rod piece; the sampling cylinder is arranged at the other end of the rod piece; the clamp fork is arranged below the hammerhead; two finger tips parallel to each other are arranged on the clamp fork; a gap of which the width is 5-8mm and the depth is 25-35mm is formed in the middle of the clamp fork; the inner diameter of the sampling cylinder is 70-80mm; a pointed end formed by inclined cutting is arranged at the end part of the sampling cylinder; the hammerhead is a pointed hammer. Compared with the prior art, the multi-purpose coal sampler has the beneficial effects that the multi-purpose coal sampler can be used for opening a door of a train and can also be used for sampling; the quality of coal supplied to the Anshan steel company by a supplier can be truly reflected; the true content of the coal is objectively reflected; the multi-purpose coal sampler is small in size; collapse of a coal layer can be avoided to the greatest extent; the slide quantity of the coal is decreased; high-quality strategy goals of the company are achieved.

Owner:ANGANG STEEL CO LTD

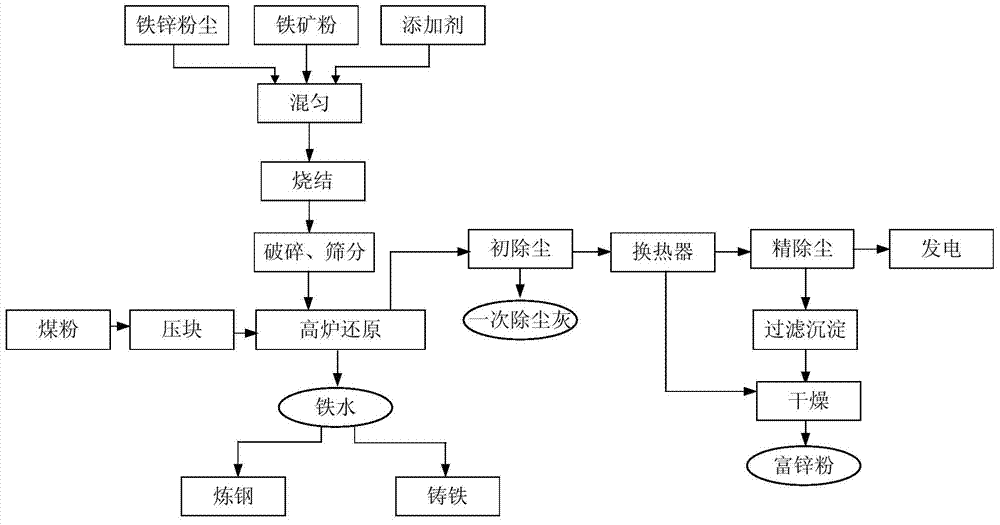

Process for recycling zinc and producing molten iron by using iron-containing zinc dust

ActiveCN103695665ASolve the hazardImprove resource utilizationBlast furnace detailsProcess efficiency improvementAdhesiveBriquette

The invention relates to a process for recycling zinc and producing molten iron by using iron-containing zinc dust. The process is characterized by comprising the following steps: S1, uniformly mixing iron-zinc dust, iron ore powder and additives in a mixing machine, feeding the mixture into a sintering machine to be sintered, crushing and screening the sintered ore, and subsequently feeding into a furnace; S2, uniformly mixing grinded powder coal with an adhesive, and pressing into shaped coal; S3, feeding the sintered ore and the shaped coal into a blast furnace so as to react the sintered ore and the shaped coal in the blast furnace to generate molten iron and zinc vapor, and discharging out the zinc vapor along with dust and coal gas from the blast furnace; S4, primarily removing the dust of the coal gas with the zinc vapor, and subsequently feeding into a heat exchanger to exchange the heat; S5, feeding the coal gas after heat exchange into a fine dust remover to remove the dust so as to obtain gas mud, and feeding the gas mud into a settling pond to be filtered, settled and thickened; and S6, drying the thickened gas mud so as to obtain powder rich in zinc. By adopting the process, the problem that the blast furnace production is not smooth because of zinc circulation enrichment in steel companies can be solved, zinc and iron in dust can be economically recycled, carbon can be efficiently utilized, and comprehensive utilization of resources is achieved.

Owner:WISDRI ENG & RES INC LTD

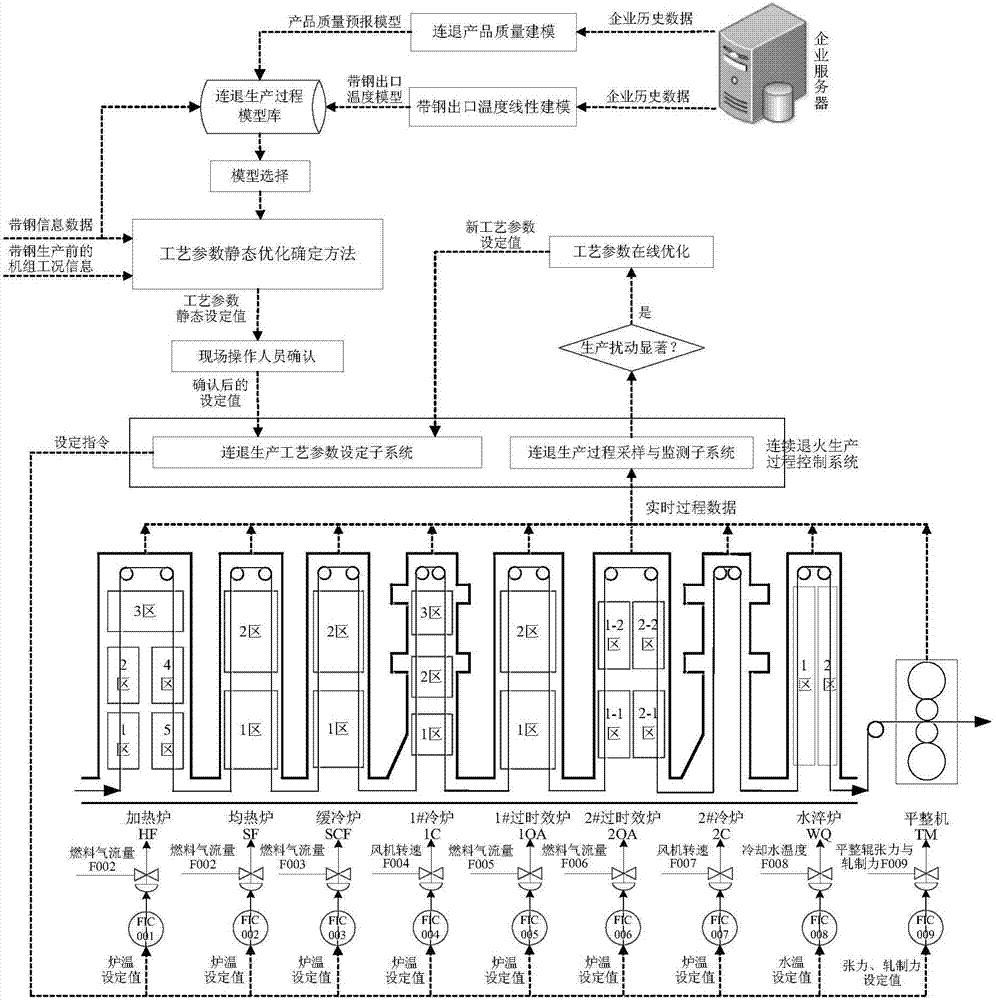

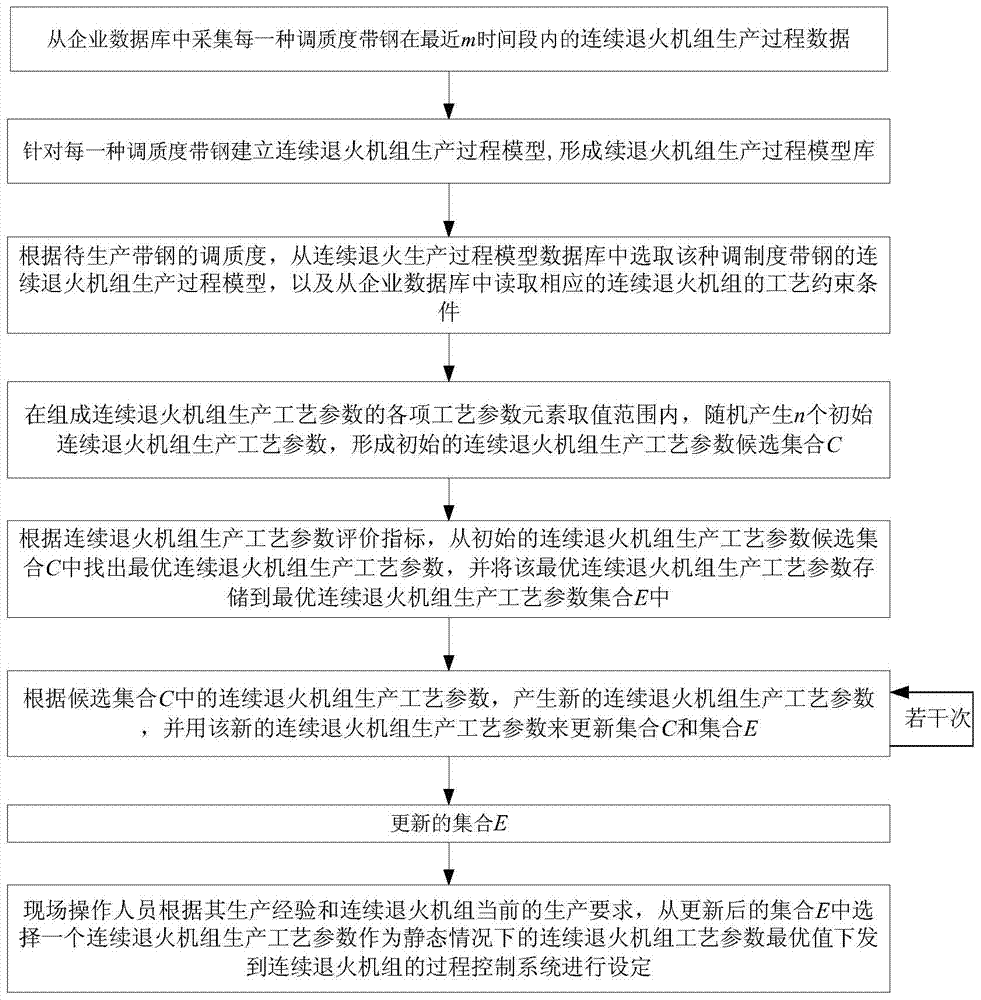

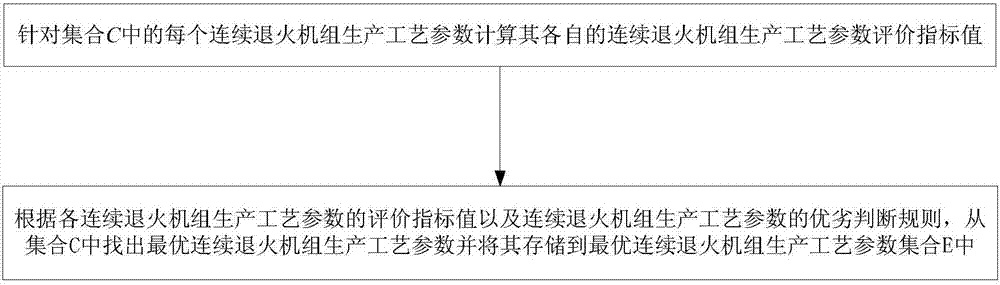

A Method for Setting and Online Optimization of Process Parameters in Production Process of Continuous Annealing Unit

ActiveCN104714519BIncrease productivityReduce consumptionTotal factory controlProgramme total factory controlStatic optimizationAutomatic control

A production process parameter setting and online optimization method of a continuous annealing unit belongs to the technical field of automatic control of continuous annealing units in iron and steel enterprises, including the main task of the static optimization stage of the production process parameters of the continuous annealing unit is to determine the continuous annealing process before strip production. The optimal value of the process parameters of the unit; the main task of the online dynamic optimization stage of the production process parameters of the continuous annealing unit is to monitor the production and operation status, and quickly obtain the optimal setting value of the new process parameters when the status changes. The present invention simultaneously considers the four evaluation indexes of product quality, energy consumption, production efficiency of the unit, and execution degree of annealing process regulations, and can ensure that the continuous annealing unit always operates under the optimal process parameters of the continuous annealing unit during the dynamic production process, thereby Make up for the lack of manual experience, help continuous annealing units to improve product quality, reduce energy consumption, and improve unit production efficiency.

Owner:NORTHEASTERN UNIV LIAONING

Molybdenum-iron-boron ternary alloy metal and ceramic drill bit

InactiveCN101613773AImprove performanceReduce weightDrill bitsBlast furnace componentsPrice ratioBoron

The invention relates to a molybdenum-iron-boron ternary alloy metal and ceramic drill bit, which is a novel drilling tool manufactured by refining molybdenum, iron and boron in a certain proportion and sintering the refined molybdenum, iron and boron with other metal materials to produce metal ceramic, processing the metal ceramic into a ball or sheet to be welded with a drill bit skirt body. A molybdenum-iron-boron ternary alloy metal and ceramic drilling tool is jointly developed by Hubei Jiayu Pipe (Group) Co., Ltd., China University of Geosciences and Xi'an Technological University, and is widely used in steel companies for blast furnace iron notch opening and mine rock drilling. The molybdenum-iron-boron ternary alloy metal and ceramic drill bit is light, low in price and high in performance to price ratio and saves a large amount of valuable tungsten metal resource.

Owner:湖北嘉裕钎具股份有限公司 +1

Production method for reducing grade A inclusion rating of titanium-containing steel

The invention relates to a production method for reducing grade A inclusion rating of titanium-containing steel, and belongs to the technical field of steel smelting. The production method for reducing the grade A inclusion rating of the titanium-containing steel comprises the following steps of: during a smelting process, feeding a core-spun yarn containing titanium dioxide powder to molten steelin 2-5 batches, wherein a feeding speed is 1-4 m / s, the total amount of the fed titanium dioxide is controlled to be 40-120 ppm, the core-spun yarn is composed of two parts: an outer skin and a corelayer, and the core layer is composed of the titanium dioxide powder with a particle size of 5-300 nm. The application of the production method can solve the situation of sulfide inclusion and exceeding the standard of most steel companies at present, and meet the production requirements of the steel with higher requirements on the grade A inclusion, such as sulfur-containing alloy structural steel, sulfur-containing free-cutting steel, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

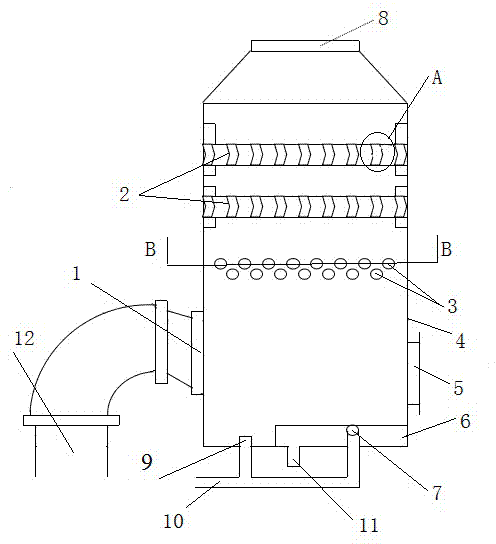

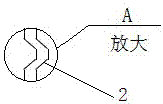

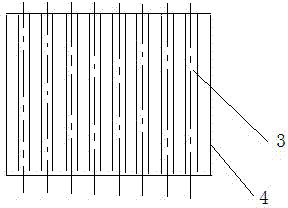

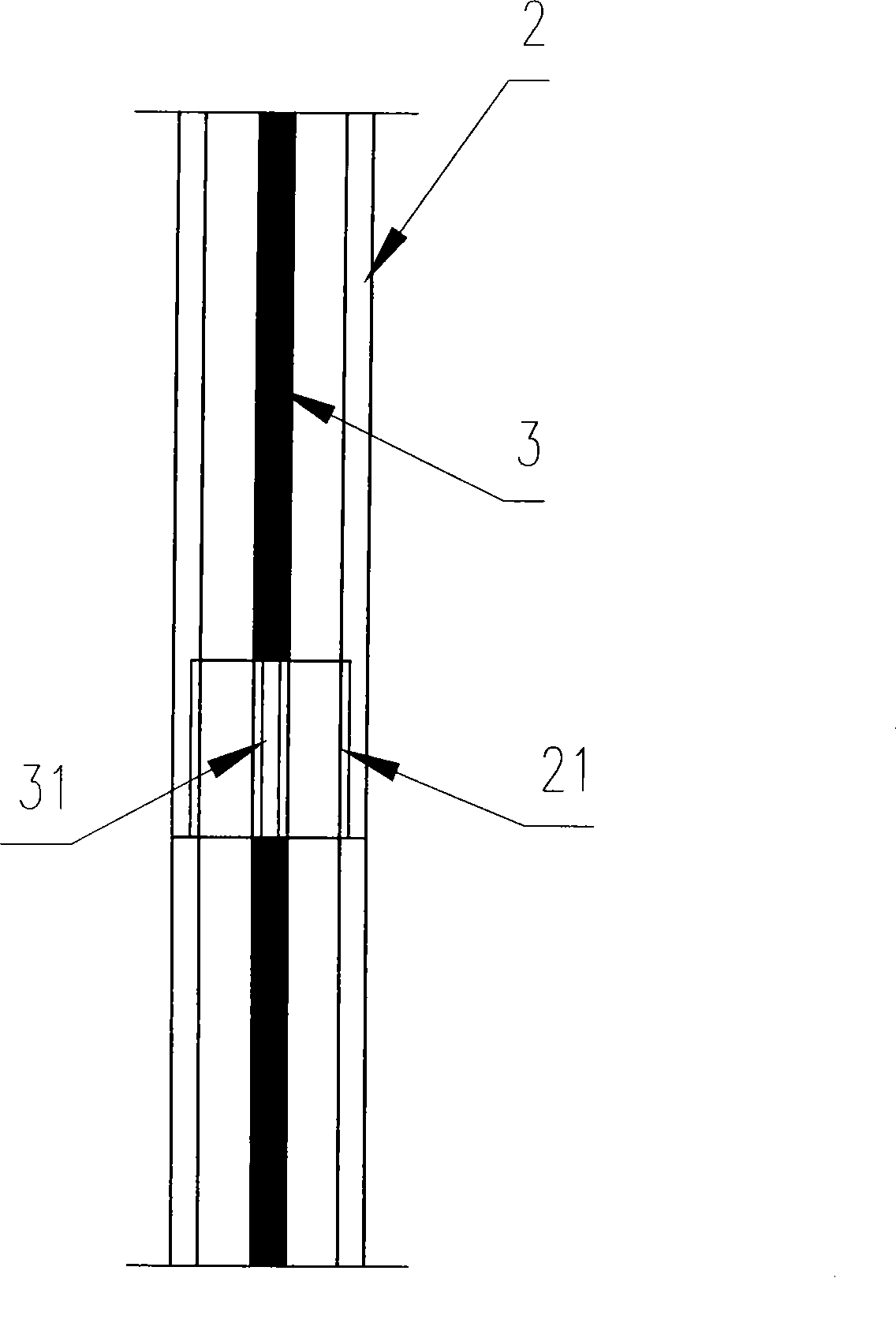

Separation and recovery device for low pressure and high air volume condensation water containing steam

InactiveCN103480225AAchieve recyclingSolve the problem of direct discharge into the atmosphereCombination devicesAir volumeAtmospheric air

The invention discloses a separation and recovery device for low pressure and high air volume condensation water containing steam. The separation and recovery device is characterized by comprising a casing; a mist inlet, a drainage opening and a dry air exhaust outlet are formed in the casing; the mist inlet is communicated with an original air duct mist outlet; the drainage opening is communicated with a drainage main pipe; a water collection tank is arranged at the bottom inside the casing; an overflow water opening for limiting the water level and formed in the water collection tank is communicated with the drainage main pipe; calandria water condensers are arranged in the casing and located above the mist inlet; baffling mist eliminators are arranged above the calandria water condensers. The calandria water condensers are formed by one or more calandria pipes transversely arranged in the casing. The baffling mist eliminators are formed by one or more rows of baffling plates longitudinally arranged in the casing. The area of the dry air exhaust outlet is less than the cross-sectional area of the casing and is greater than the area of the mist inlet. The separation and recovery device can effectively solve the problem of steel companies, namely low-pressure and high air volume contained steam and the condensation water are directly discharged into the atmosphere, as a result, the separation of water and mist and the recovery and utilization are realized.

Owner:王向阳

Ignition device for vacuum refining furnace

InactiveCN101520184AIncrease contactInhibit sheddingElectric spark ignitersTransformerContact failure

The invention discloses an ignition device for vacuum refining furnace with smart structure and stable quality. The ignition device is formed by the combination of an ignition head, a duct, a high-voltage ignition cable, an ignition transformer, and a lifting cylinder; the ignition head is firstly connected with the high-voltage ignition cable and then linked with the duct; the duct is an integrated seamless steel pipe; the ignition transformer is firstly connected with the high-voltage ignition cable and then linked with the duct. The device has the advantages that due to the integrated design of the ignition device, the clever structure is characterized by not needing centration, and successfully solves the problems of poor contact due to unideal centration when the imported similar equipment is installed on the steel-making site and the falling of an ignition pipe due to the jitter of equipment in the running process, thereby avoiding a series of losses; simultaneously, the installation process is simplified and product qualification rate and quality are greatly improved; the ignition device is widely applied to Tangshan Iron and Steel Company, Handan Steel, Baoshan Iron & Steel Co., Ltd., and Xinyu Steel.

Owner:SUZHOU BAOLIAN HEAVY IND

Energy-saving production method of mineral wool insulation boards in iron and steel companies

InactiveCN102787185AIncrease productionAvoid reheating and meltingGlass making apparatusRecycling and recovery technologiesSteel companyMutual influence

The invention discloses an energy-saving production method of mineral wool insulation boards in iron and steel companies. The energy-saving production method comprises steps as follows: directly conveying high-temperature slag into a mineral wool production system from a metallurgical blast furnace, conveying the produced mineral wool and the heat recycled by the process into a mineral wool board production system to manufacture the mineral wool insulation boards. With the adoption of the method provided by the invention, the mineral wool insulation boards in an iron-making or steelmaking process can be synchronously produced, secondary heating and melting of the slag of the blast furnace is avoided, and the heat released by producing the mineral wool is effectively recycled to serve as the heat for thermally shaping the mineral wool insulation boards. With the adoption of the method, a heat insulating tank is arranged, so that the production of the steel and the insulation boards is effectively regulated, and mutual influence in an inconsistent production process is avoided; and a centrifugal sedimentation structure is arranged in the heat insulating tank, so that molten iron and molten steel from the slag can be effectively collected, the metal content in the slag is reduced, the damage on centrifugal rollers of a mineral wool manufacturing device is relieved and the steel output is increased at the same time; and recycling utilization of the waste in the iron and steel companies is realized, the cost of additional products is reduced while energy saving and consumption reduction are realized, and the competitiveness of the products is improved.

Owner:周学义

Molybdenum iron boron ternary metal-ceramic alloy vacuum sintered friction welding boring bit

InactiveCN102039415AImprove performanceReduce weightDrill bitsBlast furnace componentsCermetSteel company

The invention relates to a molybdenum iron boron ternary alloy metal-ceramic boring bit. According to the molybdenum iron boron ternary alloy metal-ceramic boring bit, molybdenum, iron, boron and other nonmetallic substances are matched on an iron-based matrix in a certain ratio, and a ternary alloy metal-ceramic iron-based matrix with good toughness and abrasion resistance is obtained by superfine treatment and vacuum sintering; and the ternary alloy metal-ceramic iron-based matrix and the molded alloy structure steel form a boring bit for a blast furnace tapping machine or a spherical sheet tooth boring bit for mines by friction welding, namely forming a novel boring tool. The molybdenum iron boron ternary alloy metal-ceramic boring tool is the novel boring tool researched by Hubei Jiayu Pipe Industry Co., Ltd. and Wuhan University of Technology together, and is widely applied to blast furnace tapping holes of steel companies and rock advancement of mines. The boring bit has light weight, low price and high cost performance, and saves a large amount of precious tungsten metal resources.

Owner:湖北嘉裕钎具股份有限公司 +1

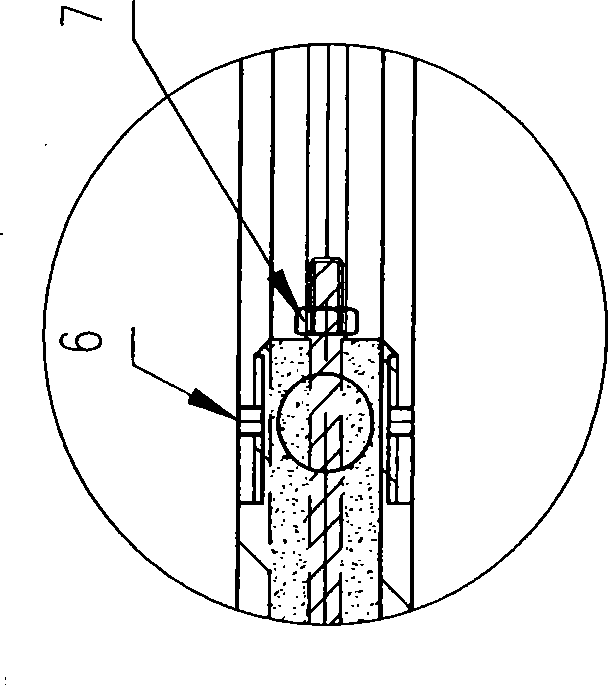

Method for preparing ordinary Portland cement from vanadium-titanium slag partially instead of mineral slag

The invention discloses a method for preparing ordinary Portland cement from vanadium-titanium slag partially instead of mineral slag, and particularly relates to the technical field of construction material preparation. The method is provided mainly aiming at the ordinary Portland cement, and the ordinary Portland cement comprises the following main materials: clinker, gypsum, limestone, mineralslag, fire coal furnace slag and the vanadium-titanium slag. According to the method, the low-chlorine gypsum is used to replace partial desulfurization gypsum to balance chloride ions in the cement,the vanadium-titanium slag is used to partially replace the mineral slag, so that the vanadium-titanium slag can be used reasonably, the ingredient costs of the cement are reduced and the waste discharge pressure in a Chengde iron and steel company is alleviated while the quality of the cement is guaranteed; and through dozens of laboratory ball mill tests and three months of industrial ball millproduction, production of the ordinary Portland cement by using 50% of vanadium-titanium slag instead of the mineral slag can be realized, the strength of the produced cement is qualified, the chloride ion content meet a national standard in China, the cement performance is not changed, and the ingredient costs are greatly reduced.

Owner:承德金隅水泥有限责任公司

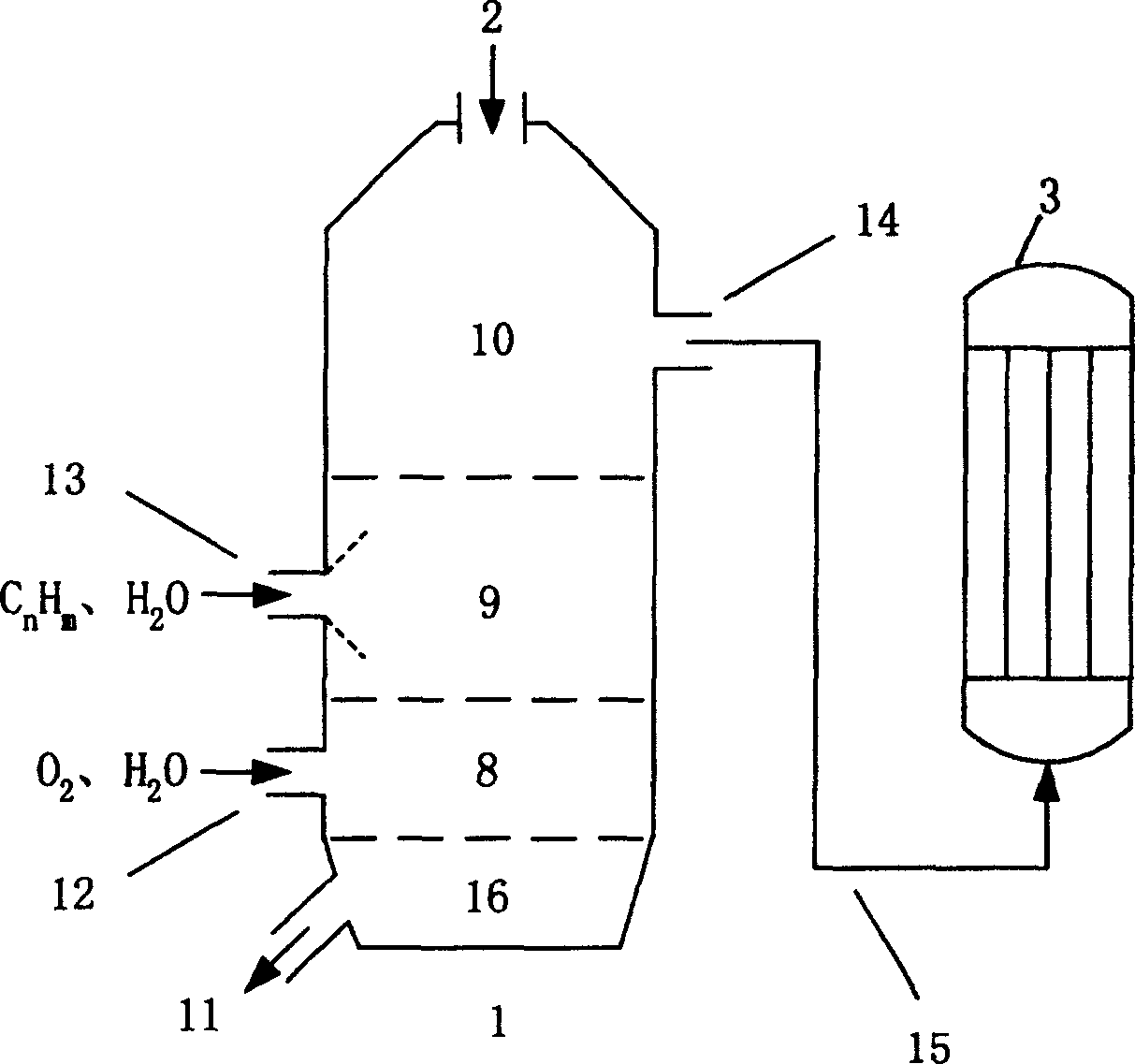

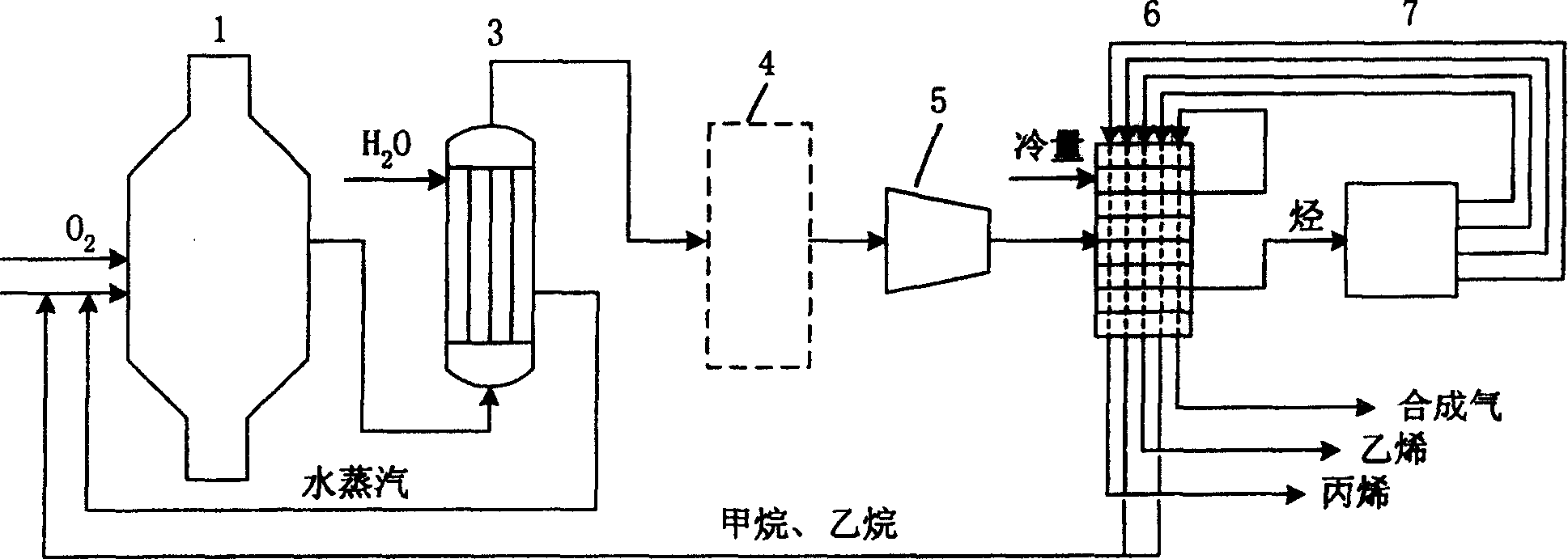

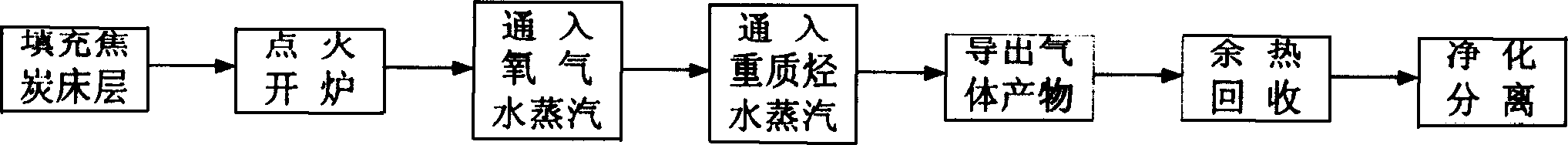

Method of cracking heavy hydrocarbon to prepare low-carbon olefin and the cracking gasifier system

InactiveCN1259391CImprove thermal efficiencyMeet the technical requirements of heatingThermal non-catalytic crackingAlkanePresent method

The invention relates to a method and system for producing light olefins by cracking heavy hydrocarbons. The system takes the decommissioned blast furnace of the iron and steel enterprise as the main body, increases the inlet and outlet of raw materials and products on the blast furnace, and transforms it into a cracking gasifier; the method includes: integrating cracking and heat supply in the same reactor; filling the reactor The coke is used as the heat source and heat carrier, the lower combustion zone is charged with oxygen, the cracking raw material and water vapor are sprayed into the middle cracking gasification zone, hydrocarbon cracking and coke gasification reactions occur, and the gas products are exported out of the upper gasification completion zone. The exported gas can also be cooled and purified, then compressed and sent to the cold box for separation to obtain synthesis gas and light olefins, etc., and the alkane components in it are returned to the reactor for cracking again. The coke consumed by the reaction is supplemented by the coke from the cracking of heavy hydrocarbons. Compared with the conventional heavy hydrocarbon cracking process, this method can use heavier hydrocarbon raw materials without worrying about the problem of coking, and the ethylene content in the composition of the outlet gas is more than 10%, and the synthesis gas is co-produced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

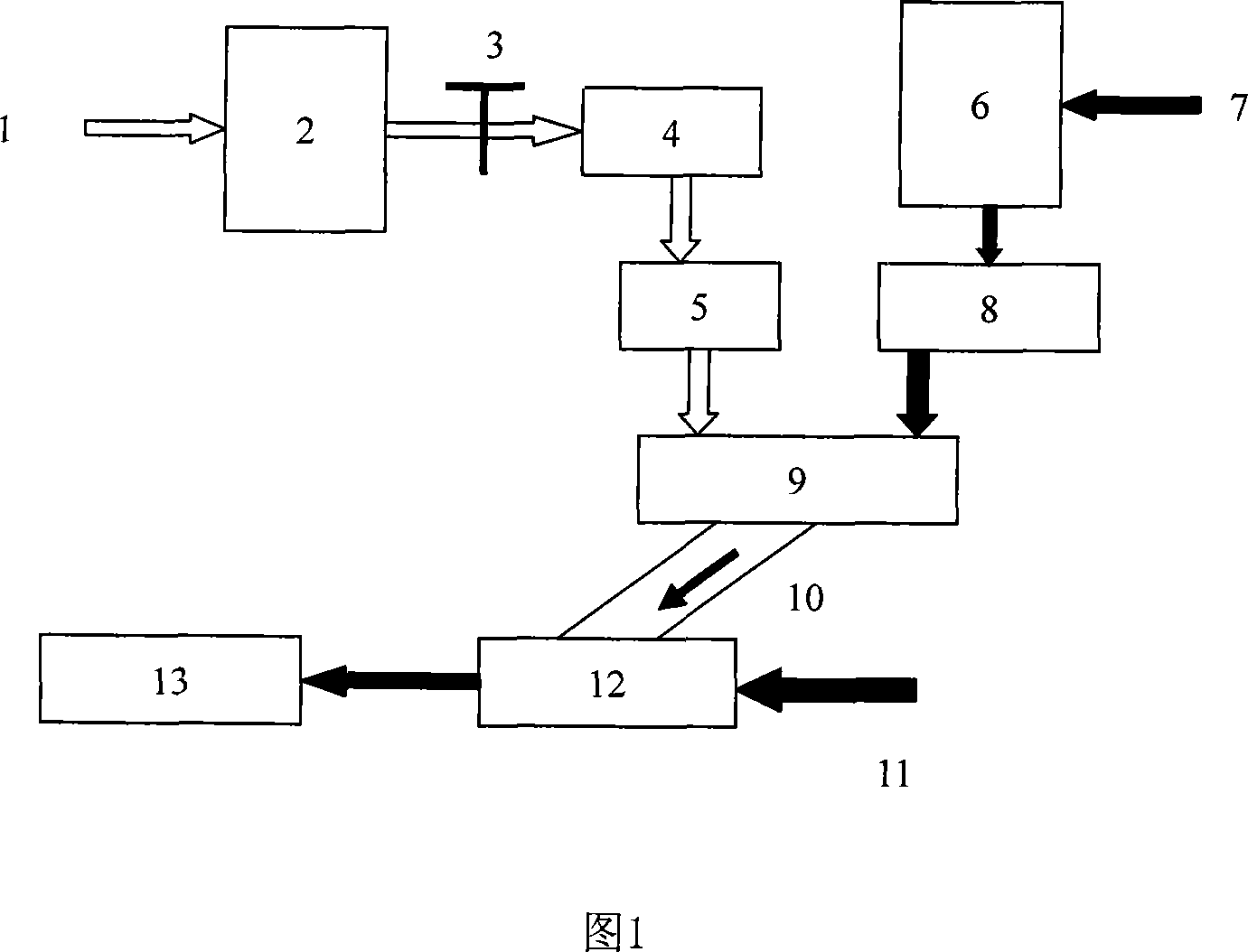

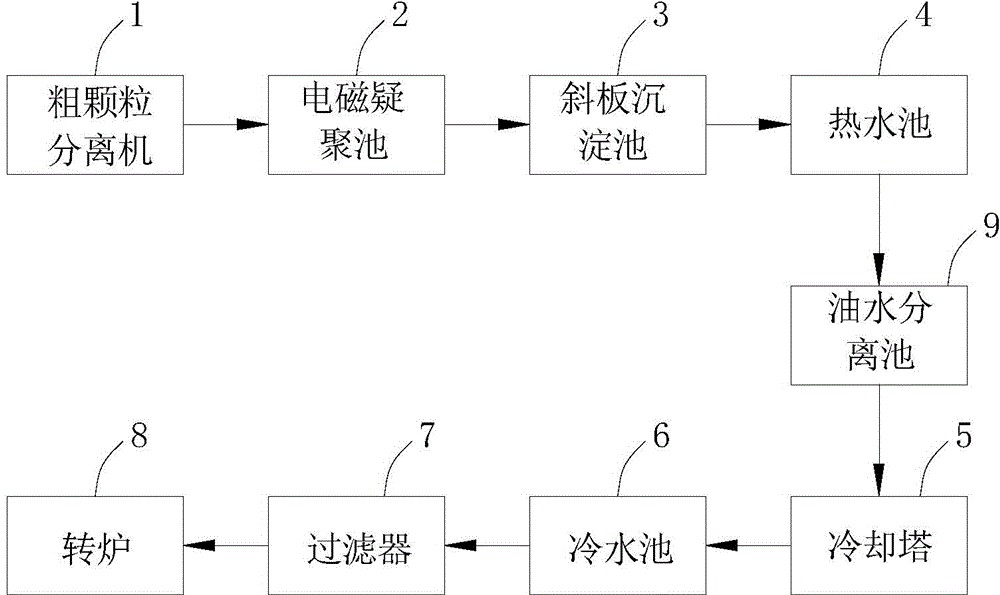

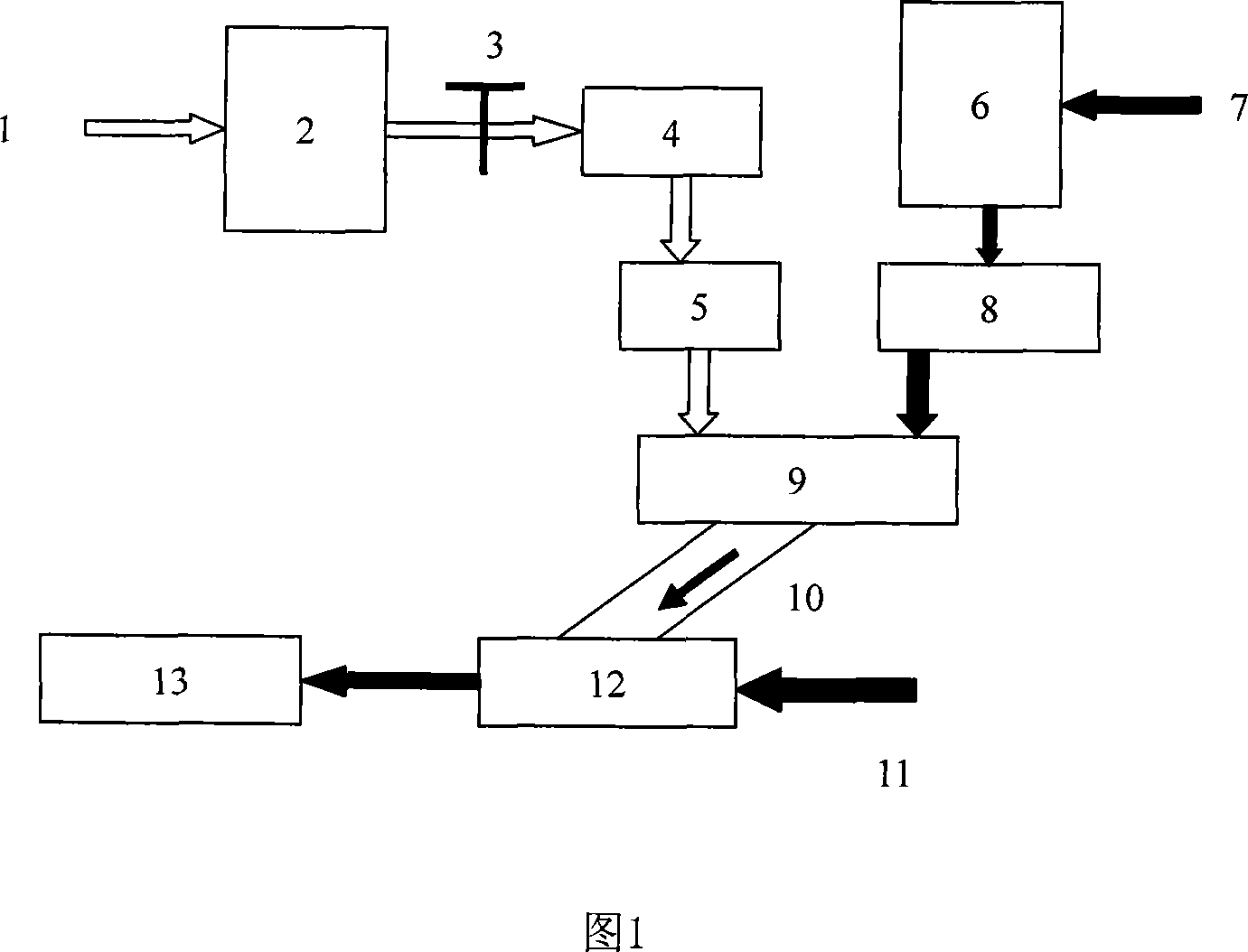

Steel wastewater treatment system

InactiveCN104649501ASolve pollutionConserve waterWaste water treatment from metallurgical processMultistage water/sewage treatmentWater savingCooling tower

The invention relates to a steel wastewater treatment system. According to the steel wastewater treatment system, the output end of a rough grain separator is connected with the input end of an electromagnetic coagulator, the output end of the electromagnetic coagulator is connected with the input end of an inclined plate deposition tank, the output end of the inclined plate deposition tank is connected with the input end of a hot water tank, the output end of the hot water tank is connected with the input end of a cooling tower, the output end of the cooling tower is connected with the input end of a cold water tank, the output end of the cold water tank is connected with the input end of a filter, and the output end of the filter is connected with the input end of a rotary furnace. By adopting the steel wastewater treatment system, the problem of wastewater pollution of steel companies can be solved, and the water can be saved.

Owner:常州市江南环保设备有限公司

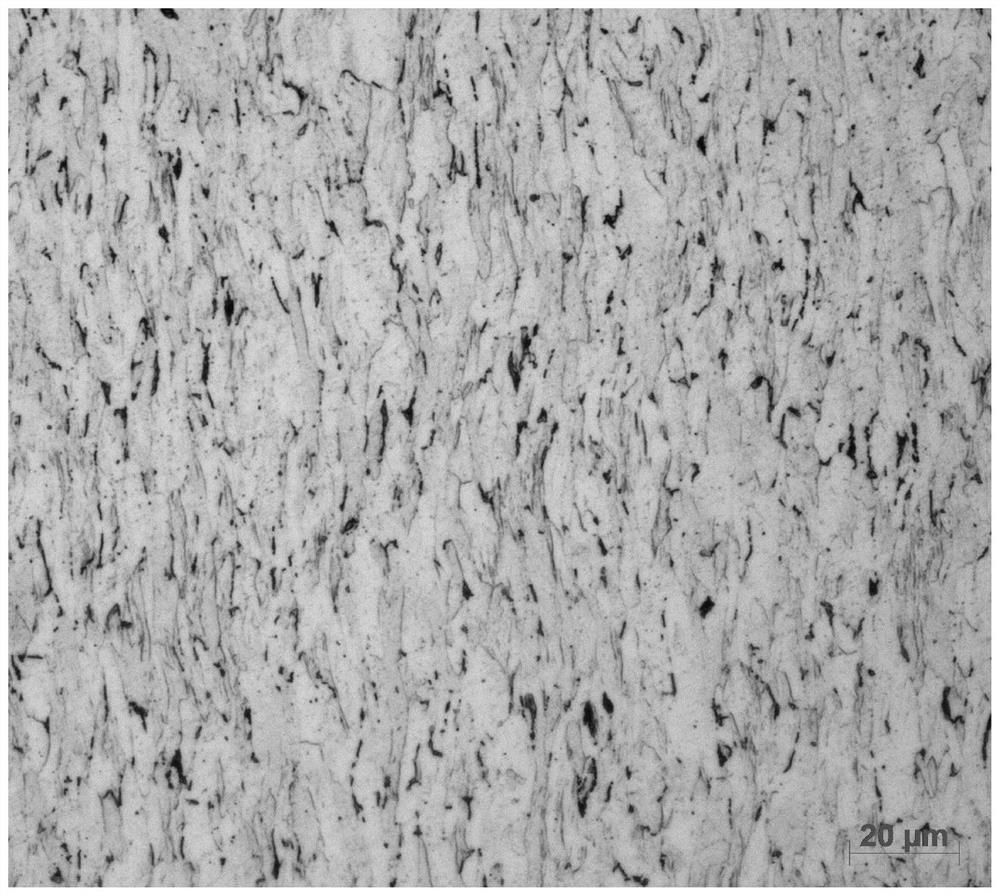

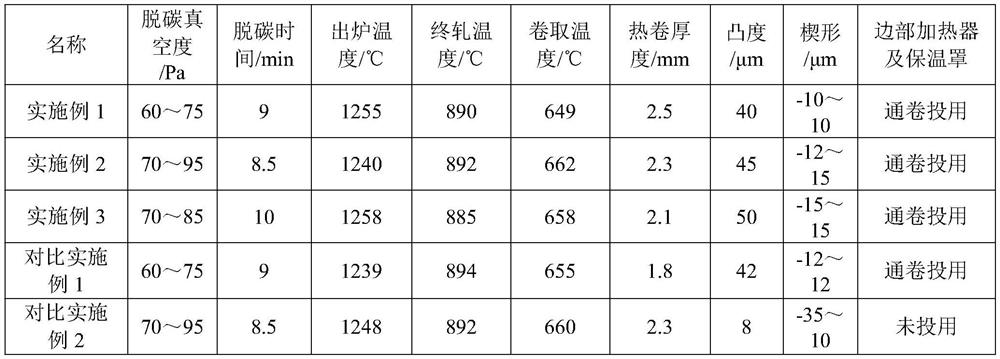

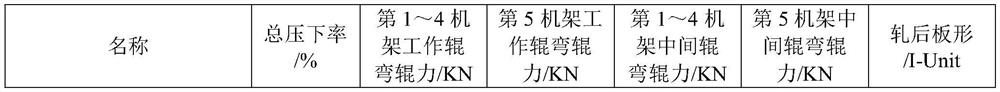

A production method of economical cold-rolled steel plate for water heater water tank outer plate

ActiveCN112157135BReasonable design of ingredientsShort processMetal rolling arrangementsEngineeringMechanical engineering

The invention relates to a production method of an economical cold-rolled steel plate for the outer plate of a water heater water tank. After being smelted in a converter and refined by RH, the molten iron in a blast furnace is continuously cast into a slab with a thickness of 230 mm and sent directly to red, and then rolled in a completely austenite zone, After laminar flow cooling and medium temperature coiling, natural air cooling to below 60 °C obtains a hot-rolled steel coil with uniform ferrite structure and full analysis of AlN particles, and then re-uncoiled, continuously pickled and trimmed, and directly after special cold continuous rolling. A finished rolled hard steel sheet is obtained. The thickness of the finished cold-rolled steel plate is 0.30-0.40mm, the yield strength is 800-900MPa, the height of the edge wave is less than or equal to 1mm, and the sharpness is less than or equal to 1.0%, which can fully meet the all-round application requirements of the cold-rolled steel plate for the outer plate of the water heater tank, and can greatly Reduce the cost of material procurement for customers. The invention has remarkable economic benefits and brand benefits, and is very suitable for popularization and application in domestic mainstream iron and steel enterprises.

Owner:SD STEEL RIZHAO CO LTD

A method for preparing activated carbon from dedusting ash emitted by iron and steel enterprises

ActiveCN108557818BGood flat dispersion functionImprove adsorption capacityCarbon compoundsActivated carbonSocial benefits

The invention provides a method for preparing activated carbon from dedusting ash discharged by iron and steel enterprises, which relates to the field of environmental protection technology and comprises the following steps: adding water to the dedusting ash to make slurry, and performing primary flotation to obtain carbon powder with relatively high carbon content; The carbon powder with high carbon content is slurried with water and subjected to secondary flotation to obtain carbon powder with high carbon content; the dried carbon powder is mixed with petroleum coke, ground into powder and sieved, then added to the reaction kettle and heated to Stir at 80-90°C for 4-6 hours, filter, dry the solid and add it to the reaction kettle; add the obtained solution dropwise to the above reaction kettle, after the dropwise addition, filter, and exhaust the air in the furnace with nitrogen , heat up, and after calcining, water vapor can be introduced to obtain activated carbon. The invention can prevent secondary pollution of dust, protect the environment, and make full use of resources. The activated carbon produced is of good quality and has good economic and social benefits.

Owner:MAANSHAN SHUNDA ENVIRONMENTAL PROTECTION EQUIP

Method for reducing sulfur in iron ore concentrate through flotation

The invention discloses a floating sulfur collecting agent and a method for reducing the sulfur in iron ore concentrate through flotation. The floating sulfur collecting agent consists of amyl potassium xanthate and N,N-diethyl sulfo-amino sodium formate in a mass ratio of 1-3:1. The method for reducing the sulfur in the iron ore concentrate through flotation by using the floating sulfur collecting agent comprises the following steps of: adding regulators into low intensity magnetic separation iron ore concentrate pulp so as to adjust the pH value, further adding the floating sulfur collecting agent provided by the invention, and carrying out the primary rough separation and the primary fine separation, wherein pyrrhotite with better dissociation can be floated in the rough separation, pyrrhotite coenobium can be further floated in the fine separation, the sulfur content in the iron ore concentrate obtained after the fine separation can be less than 0.1%, and the iron loss can be less than 5%. The method for reducing the sulfur in the iron ore concentrate through flotation is simple in steps and is strong in operability as only the floatation working needs to be added, and the sulfur can be reduced to 0.1% under the condition that the sulfur content in feeding is as high as 1%, so that the requirements of large steel companies for the raw materials are met, and the overall quality of steel materials is improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for producing margin coal gas by using steel in rotary cement kiln predecomposition furnace

InactiveCN101195521BBurn fullyEmission reductionMechanical apparatusRotary drum furnacesCement kilnCalcination

Provided is a method of using surplus gas of iron and steel production to produce cement in a predecomposition furnace of a rotary kiln, belonging to the technical field of calcining cement clinker and including a process of voltage stabilization and transformation of coal gas, a process of burnt and heat calcinations of the coal gas in the predecomposition furnace. The coal gas is burnt sufficiently and used in the predecomposition process of the cement raw meal. The coke-oven gas, blast furnace gas, converter gas and high coke mixed gas left in the process of metallurgy production can take place coal powder as fuel to decompose carbonate in the cement raw meal. The invention has the advantages that the manufacture technique can reduce environmental pollution caused by burning coal, increase the utilization ratio of the surplus gas in iron and steel companies, and reduce the exhaust of coal gas, thereby having good economic benefit and social benefit.

Owner:LAIWU IRON & STEEL GRP

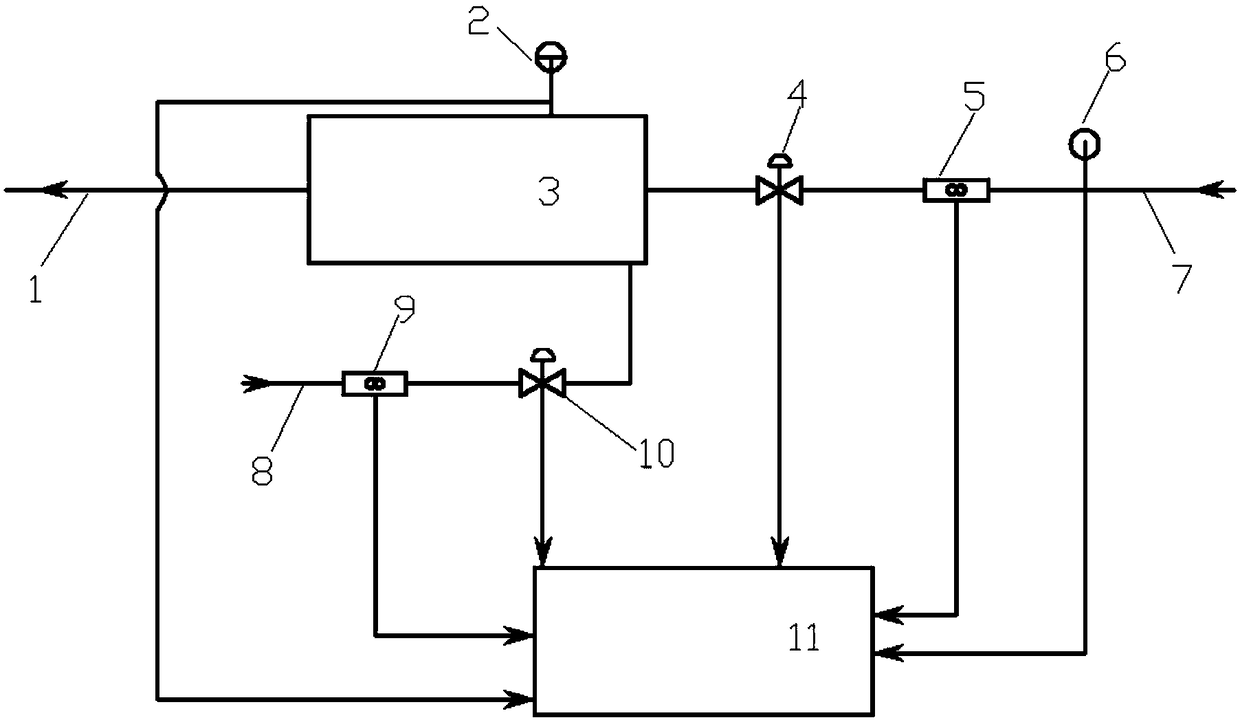

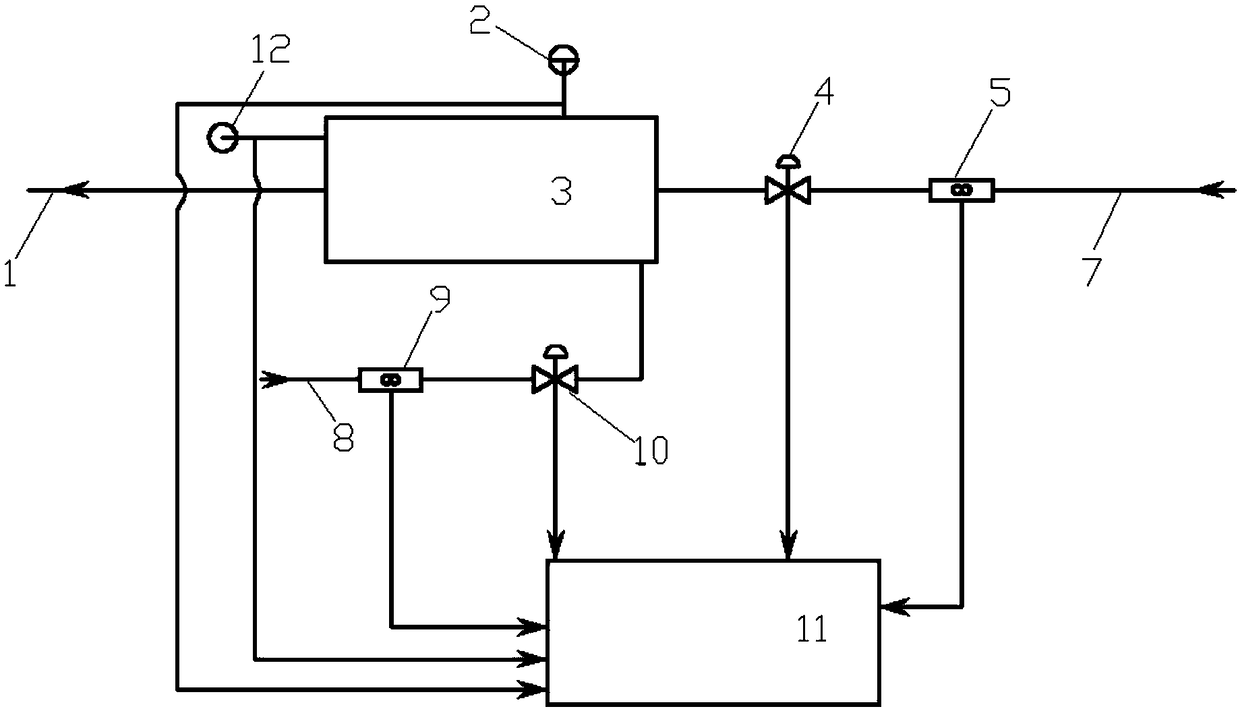

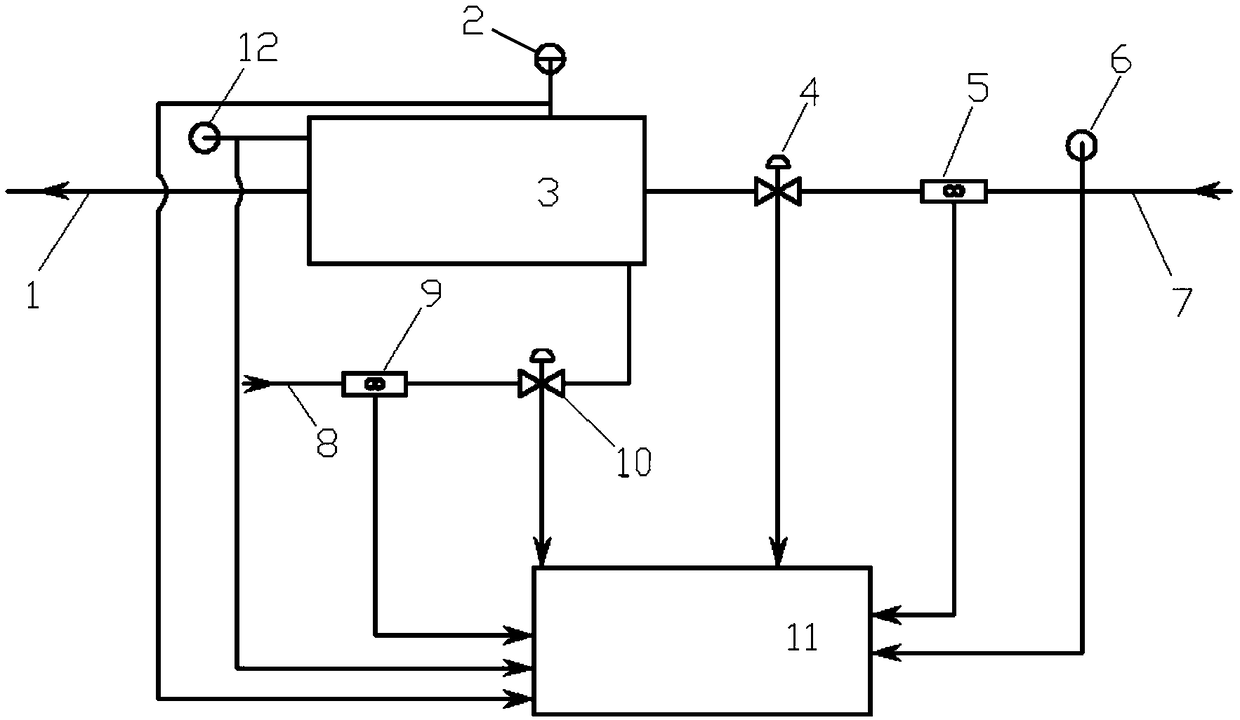

Regenerated water making system and method

InactiveCN108996561AReduce manufacturing costImprove reuse rateWater treatment parameter controlWater/sewage treatment apparatusSaline waterWater quality

The invention relates to a regenerated water making system and method. The system comprises a regenerated water sucking well, a reclaimed water supply tube, a desalted water supply tube, a reclaimed water pressure difference flowmeter, a reclaimed water adjusting valve, a desalted water pressure different flowmeter and a desalted water adjusting valve, wherein the reclaimed water supply tube and the desalted water supply tube are connected with the input end of the regenerated water sucking well; the reclaimed water pressure difference flowmeter and the reclaimed water adjusting valve are arranged on the reclaimed water supply tube; the desalted water pressure different flowmeter and the desalted water adjusting valve are arranged on the desalted water supply tube. The method comprises thefollowing steps: treating sewage generated in a steel company into reclaimed water in a sewage treatment station; feeding the reclaimed water into the regenerated water sucking well; feeding desaltedwater into the regenerated water sucking well; mixing the reclaimed water with desalted water according to a set ratio, thereby obtaining regenerated water. The regenerated water made by using the regenerated water making system and method is capable of meeting requirements on quality of industrial purified circulated water and turbid recycled water, reducing the making cost of regenerated water,increasing the recycling rate of reclaimed water, reducing emission of reclaimed water, and increasing economic and environment protection benefits.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

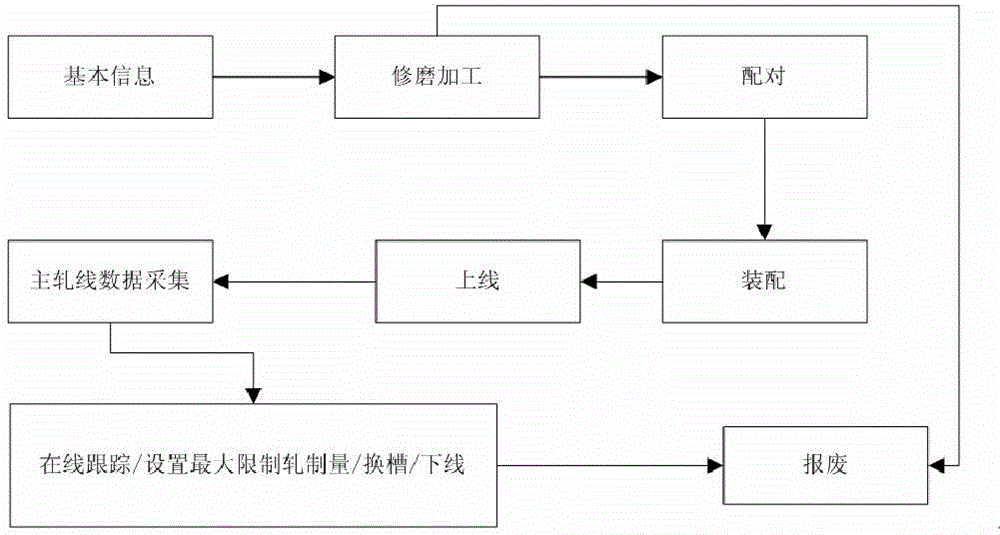

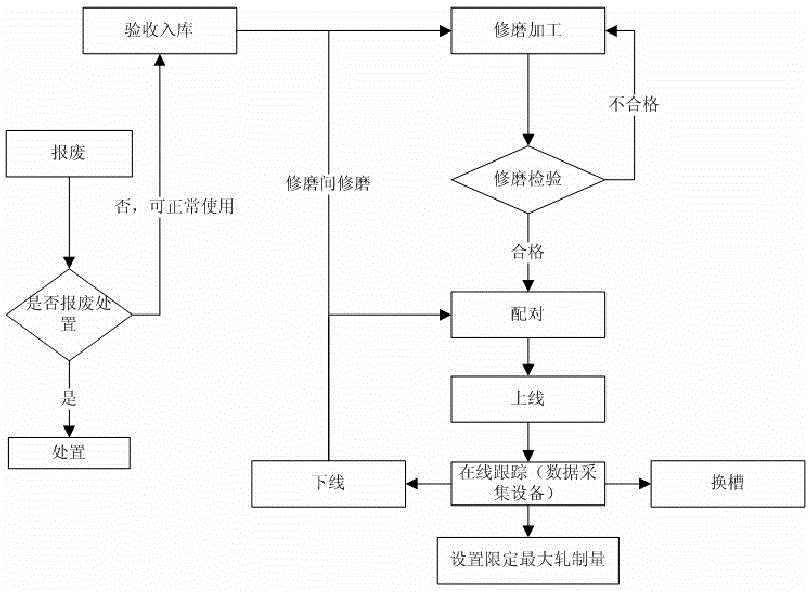

Roll management system and method for bar rolling in iron and steel enterprises

ActiveCN103817153BReduce wearRoll mill control devicesMetal rolling arrangementsEngineeringMechanical engineering

The invention discloses an iron and steel enterprise bar rolling roller management system and method. The iron and steel enterprise bar rolling roller management system comprises a basic information module, a machining module, a matching module, an assembling module, a rolling line feeding module, a main rolling line data acquiring module, a tracking module and a discarding module. The method includes allowing rollers to be in storage in a factory, repairing dies, matching, assembling, feeding on or discharging from a rolling line, changing grooves, setting a maximum rolling quantity, discharging from the rolling line, tracking, discarding and issuing statements. The rollers are managed through a roller chamber or a production preparation team in a centralized manner, rolling grooves or the rollers are changed according to alarms, rollers are pre-matched according to rolling specifications, a frame can be assembled more quickly according to roll gaps during changing, operating situations of all the rollers on the rolling line can be tracked after the rollers are fed onto the rolling line, and the rolling quantity from the initial use to present can be recorded; when the rollers are discarded, discarding reasons can be issued, turning and rolling data can be further provided.

Owner:YUNNAN KUNGANG ELECTRONICS INFORMATION TECH CO LTD

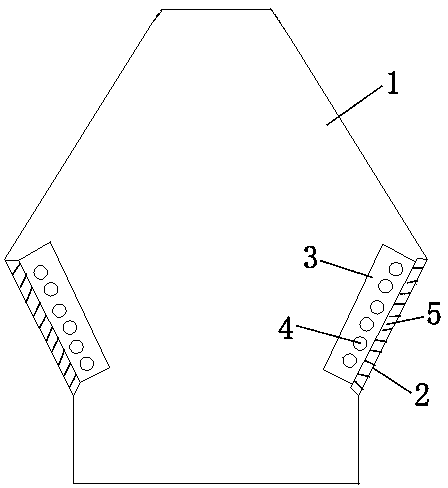

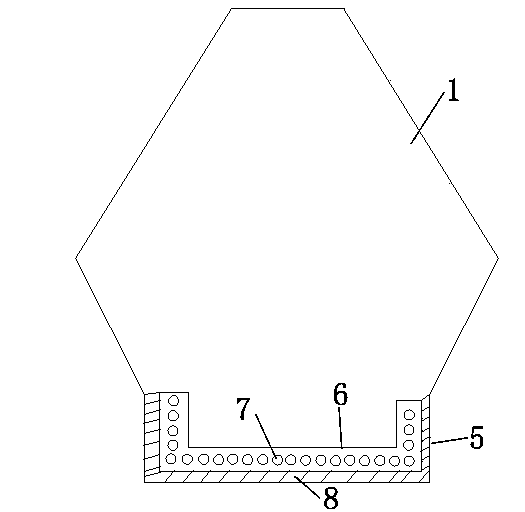

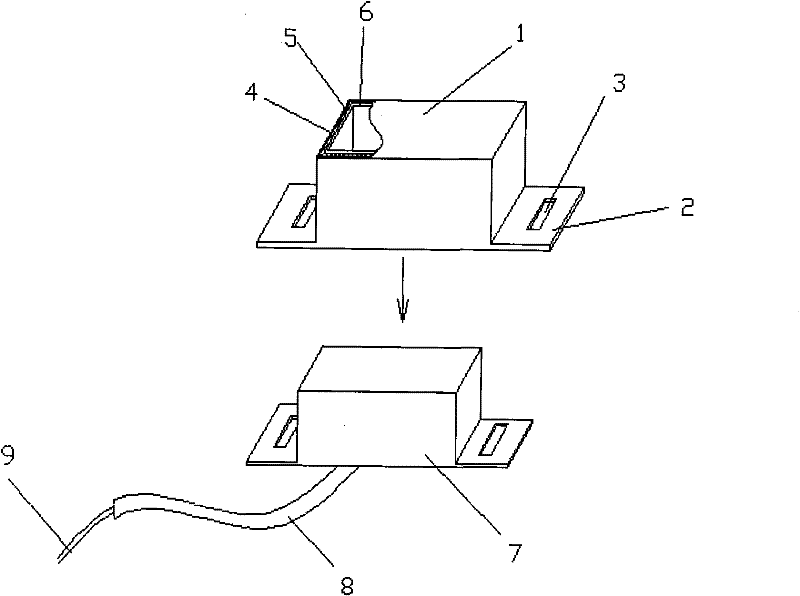

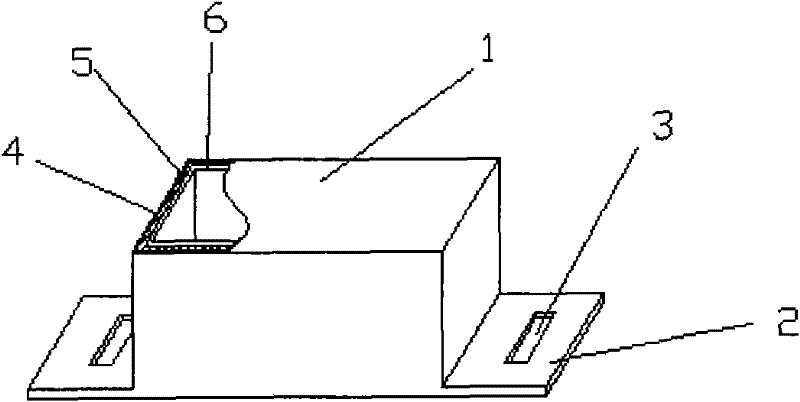

Magnetic steel heat-insulating shield and manufacturing method thereof

The invention relates to a magnetic steel heat-insulating shield and a manufacturing method thereof, belonging to the technical field of magnetic steel protection. The shield comprises an upper shield (1) and a mounting bottom plate (2), wherein the mounting bottom plate (2) is provided with two mounting holes (3), and the upper shield (1) comprises three heat-insulating layers including an aviatic heat-insulating dope layer (4), a glass reinforced plastic heat-insulating layer (5) and an asbestos heat-insulating layer (6). In the manufacturing method, a mold for the magnetic steel heat-insulating shield is manufactured according to the volume and the contour of magnetic steel, asbestos casing is packed at the outer layer of the mold, and resin, talcum powder and spun yarn which are mixedby the ratio of 3:2:1 are evenly coated to the surface of the asbestos for 3-5mm, and are naturally dried or died by an oven; and finally, the aviatic heat-insulating dope is evenly coated at the outermost layer for 1-2 mm. The invention has the advantage that the working temperature of the magnetic steel is controlled to be below 65 DEG C, and completely reaches the working temperature required by the magnetic steel, thereby the microwave radio-frequency recognition technology can be used in an iron cased following system of a steel company.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Synchronous control method of two independent motor-driven steel conveyor chains

The invention discloses a synchronous control method for two independent motor drive type steel conveying chains. The method comprises driving type steel conveying chain synchronous control and driven type steel conveying chain synchronous control, according to the driving type steel conveying chain synchronous control and the driven type steel conveying chain synchronous control, retreating terminal position values of a main conveying chain and a slave conveying chain are 0 mm, and given position values and actual position values of the main conveying chain and the slave conveying chain are positive values or zero. The driving type steel conveying chain synchronous control comprises a driving type steel conveying chain synchronous position over-tolerance judging unit, a driving type steel conveying chain automatic linkage transmission enabling control unit, a driving type steel conveying chain automatic linkage speed given control unit, a driving type steel conveying chain manual linkage transmission enabling and speed given control unit and a driving type steel conveying chain single-action transmission enabling and speed given control unit. The control method is used in two-section conveying chains of a large H-shaped steel CP9 stacking machine tool of the Maanshan Iron and Steel Company, and has good effect.

Owner:MAANSHAN IRON & STEEL CO LTD

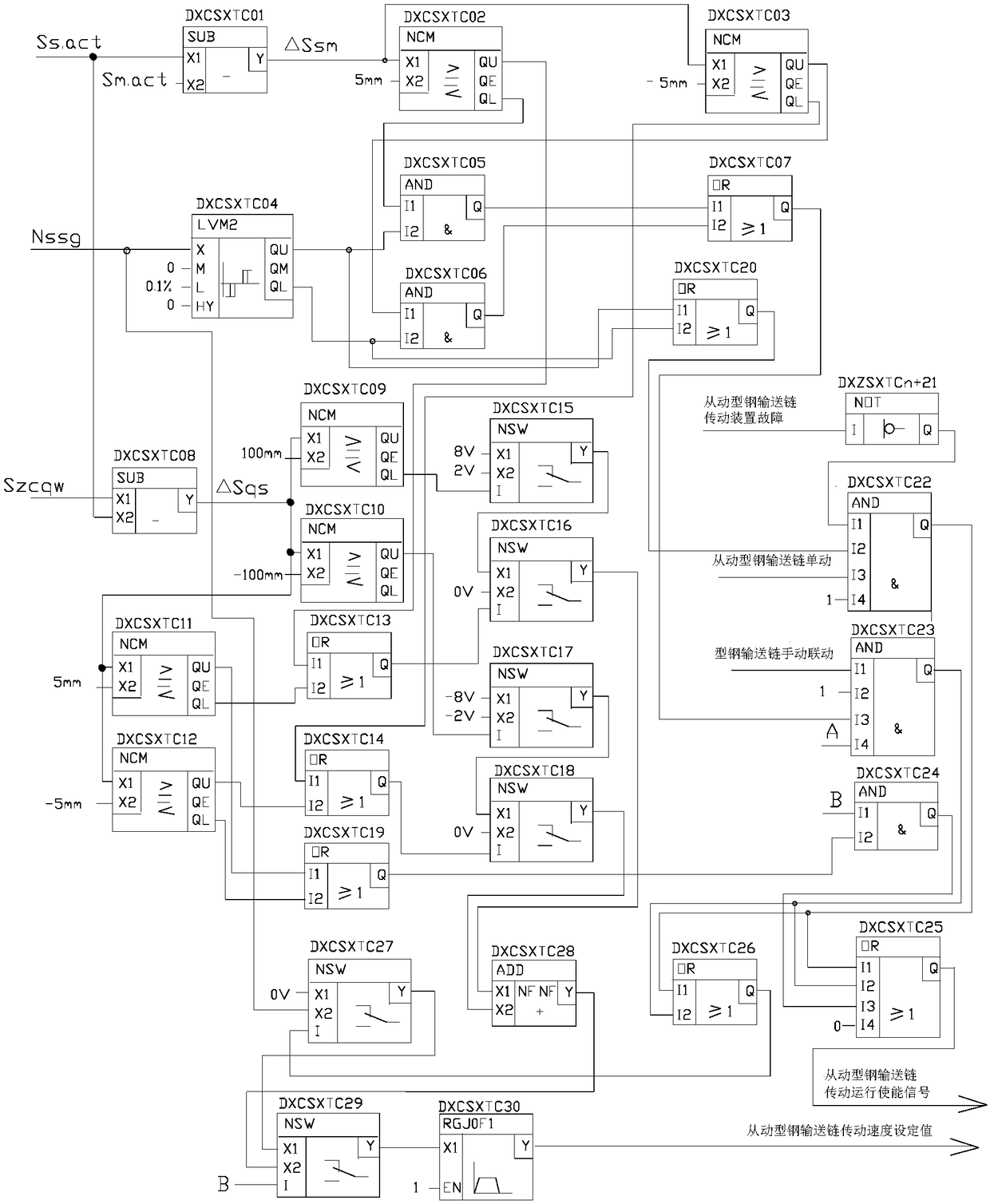

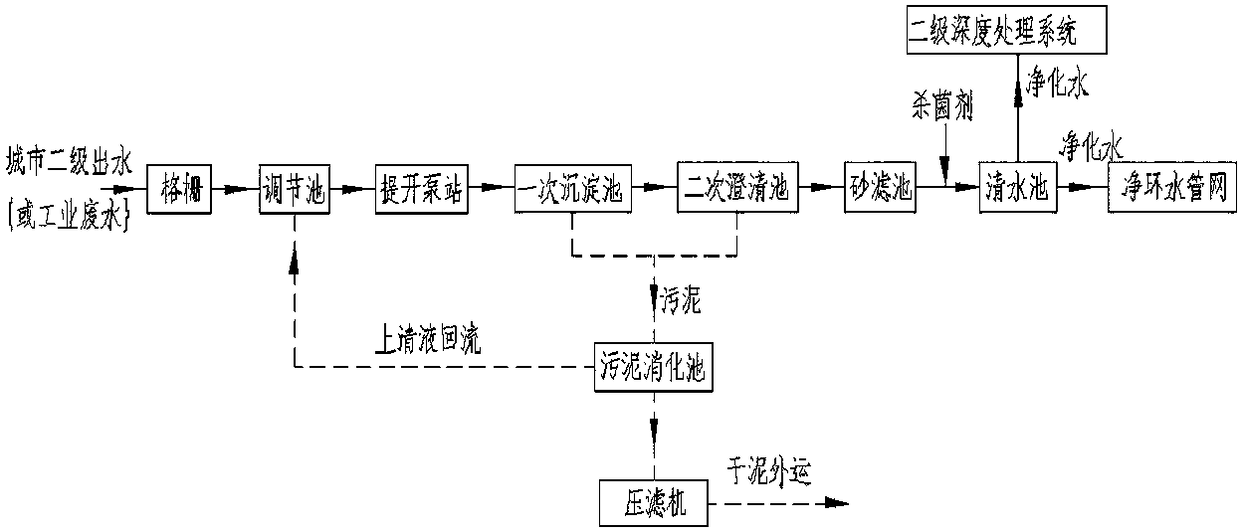

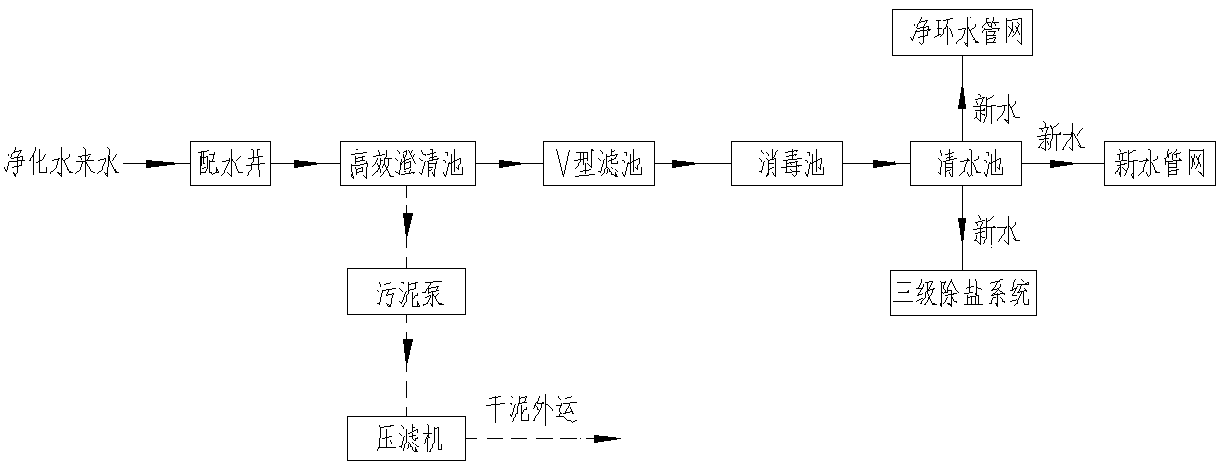

Combined graded reuse of urban reclaimed water and steel wastewater for steel enterprise systems and processes

ActiveCN105271623BMeet various water needsImplement joint processingWaste water treatment from metallurgical processMultistage water/sewage treatmentWater dischargeMaterials science

The invention relates to a system and process for combined and graded recycling of urban gray water and steel wastewater for use in iron and steel enterprises, and belongs to the technical field of recycling and utilization of urban gray water and steel production wastewater. This invention uses the urban gray water discharged from the urban sewage treatment plant to be recycled into the clean water pipe network and new water pipe network of the iron and steel enterprise after two-stage treatment of the first-level gray water treatment system and the second-level deep treatment system. At the same time, the iron and steel production wastewater After the first-level wastewater treatment system, the second-level deep treatment system, and the third-level desalination system, it is graded and recycled for use in the steel enterprise itself. The use of hierarchical joint treatment methods and different reuse plans enables the sharing of water treatment equipment, solves the problem of water shortage in steel companies, reduces the operating costs of steel companies, achieves sustainable development of water resources, and avoids serious environmental pollution problems and has important economic and social environmental benefits.

Owner:NORTHEASTERN UNIV

Coking benzene deep desulfuration purification method

InactiveCN101062879BHigh base conversion rateImprove adsorption capacityHydrocarbon purification/separationHydrocarbonsPurification methodsCoking plant

The invention discloses a method of coking benzene deep desulfurizing refined method, which comprises the following steps: adopting catalytic alkylthiophene desulfuration and selective adsorption desulfurizing associated craft; generating alkylthiophene with higher boiling point; rebuilding alkylthiophene through rectifying abscission; selective-adsorbing with desulfurizer; stripping excess un-reaction thiophene; reaching the demand of deep purifying harmful sulfur impurities in coking benzene. This invention possesses small corrosion, low cost and high earning rate, which is a better method for deep processing by-product of steel company and coking plant.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

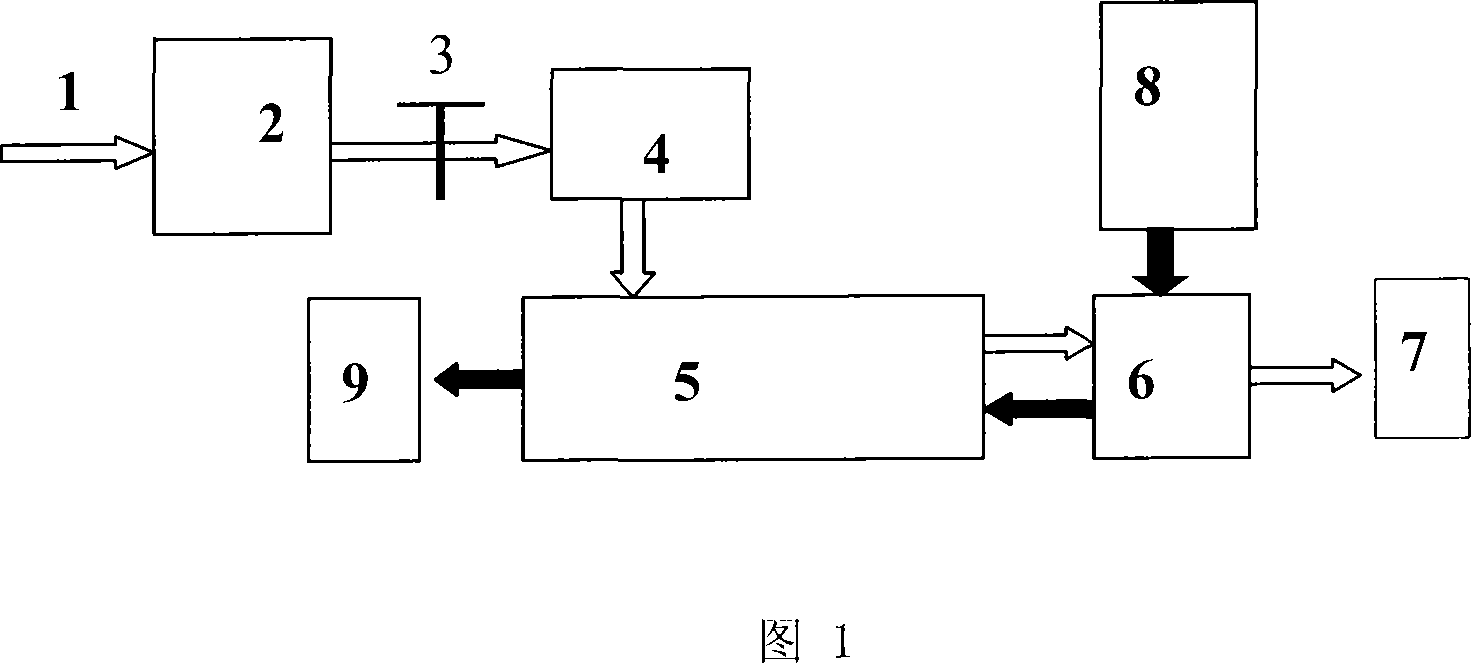

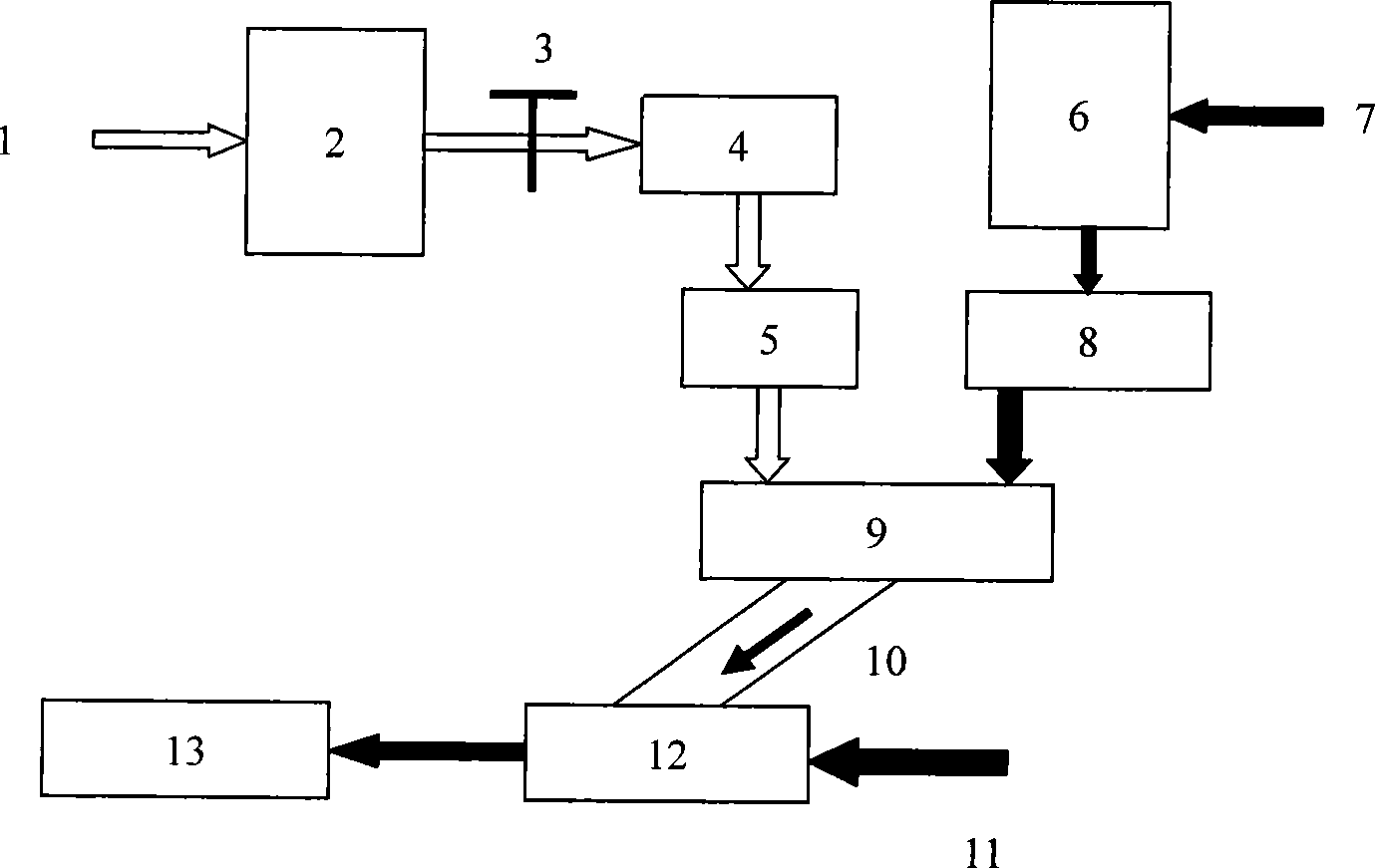

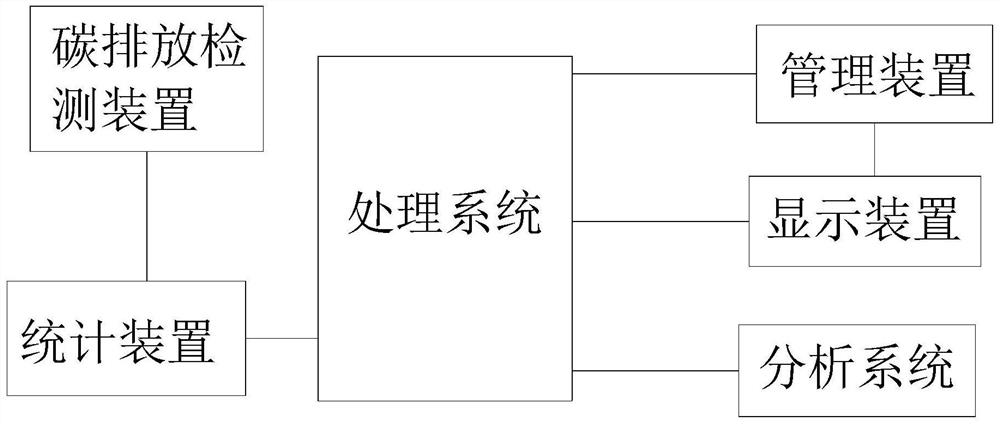

Carbon emission cost control system for small and medium-sized iron and steel companies

InactiveCN111948956AImprove accuracyQuick collectionTechnology managementResourcesControl systemDisplay device

The invention discloses a carbon emission cost control system for small and medium-sized iron and steel companies, and relates to the technical field of iron and steel tools. The carbon emission detection device is connected with the statistics device, the statistics device is connected with the analysis system, the analysis system is connected with the processing system, and the processing systemis connected with the analysis system, the display device and the management device. The management device is connected with the display device, the carbon emission detection device is used for detecting carbon emission and transmitting carbon detection data to the statistical device, the statistical device is used for counting the data and transmitting the counted data to the processing system,and the processing system is used for processing the data and transmitting the data to the analysis device. The analysis device transmits the analyzed data to the processing system, and the processingsystem displays the information on the display device; according to the invention, the efficiency is improved, rapid data acquisition and control can be realized, the stability is high, and the dataaccuracy is high; the time is saved, the control is convenient, the use is convenient, and the data processing and marking can be realized.

Owner:LIAONING TECHNICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com