Patents

Literature

69results about How to "Easy to smelt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

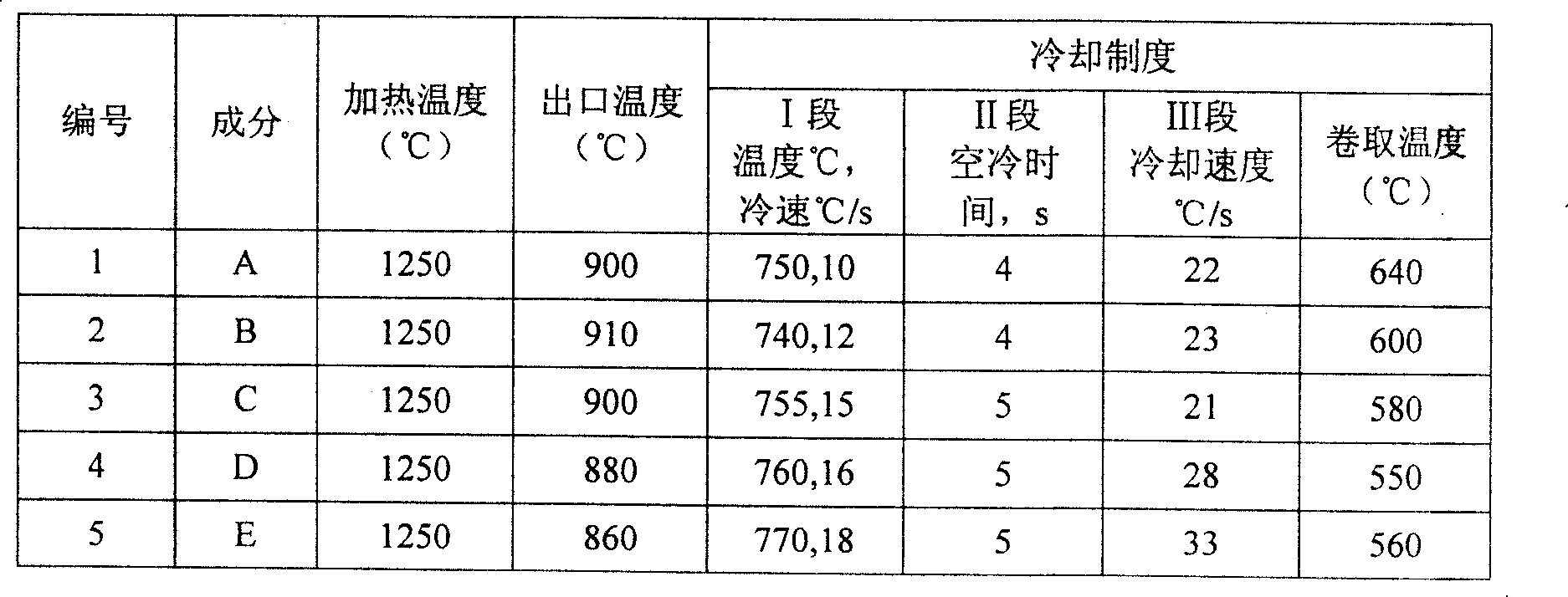

Diphasic steel plate by continuous casting and rolling middle bar strip and manufacturing method thereof

ActiveCN101130847ASimple chemical compositionHigh tensile strengthMetal rolling arrangementsChemical compositionSheet steel

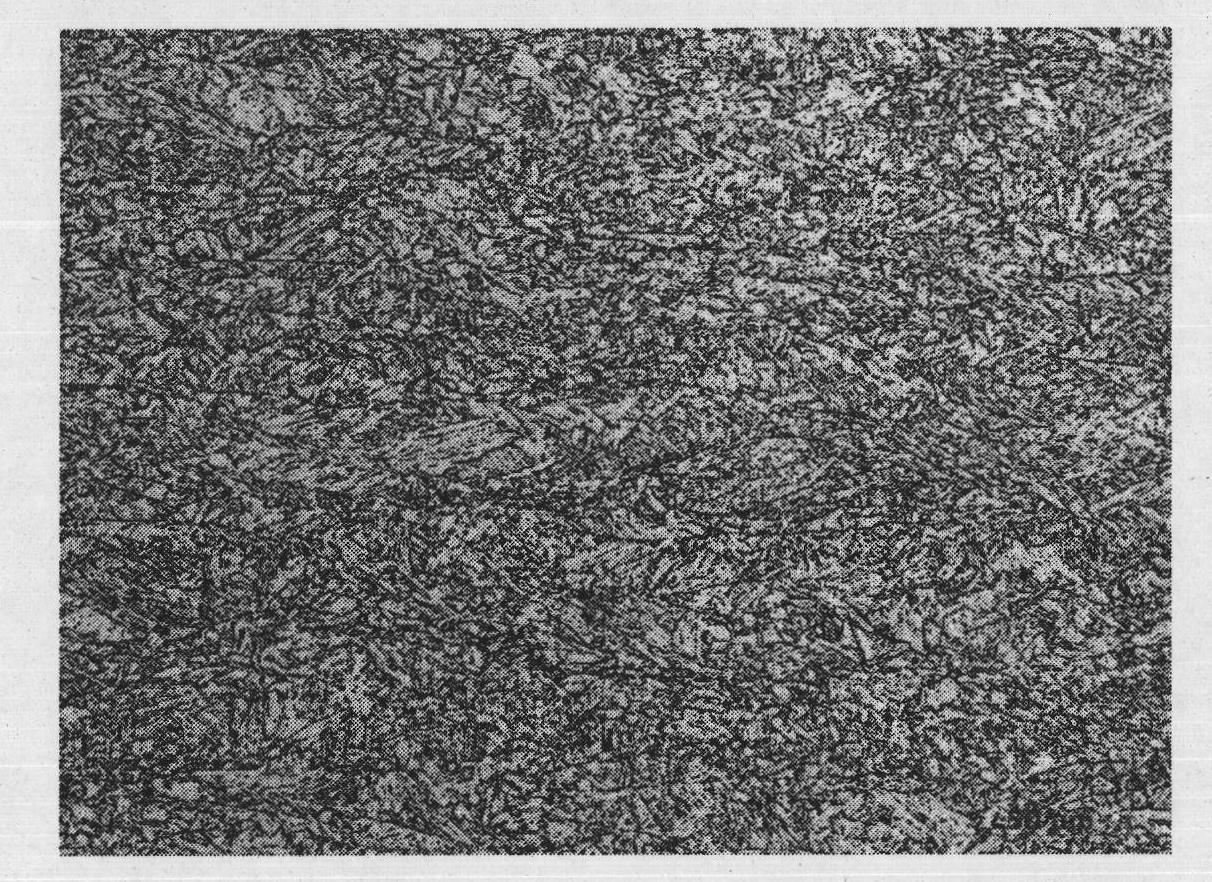

The present invention provides a dual phase steel sheet made up by using medium-thin sheet billet through a certain continuous-casting and continuous-rolling process. The component composition of said steel sheet includes (by wt%) 0.04%-0.11% of C, 0.02%-1.5% of Si, 0.6%-2.50% of Mn, 0.02%-2.0% of Cr, also can contain Mo or Ti, the rest is Fe and unavoidable impurity. The microscopic structure of said steel sheet includes: matrix phase is ferrite and second phase mainly is martensite. Besides, said invention also provides the concrete operation steps of its production method.

Owner:ANGANG STEEL CO LTD

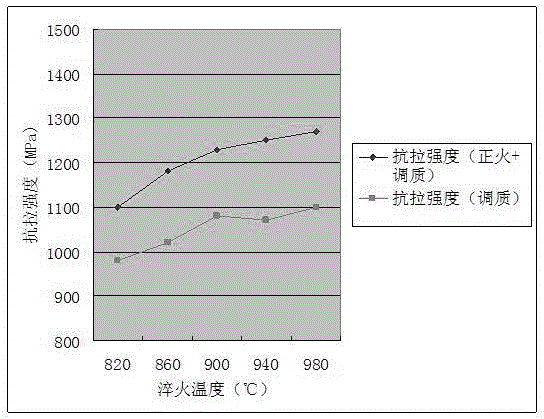

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

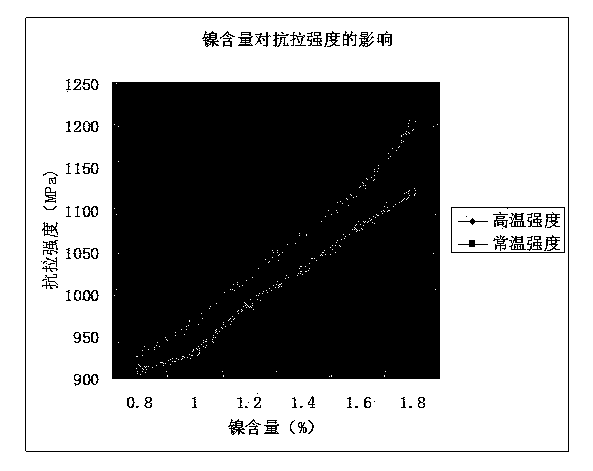

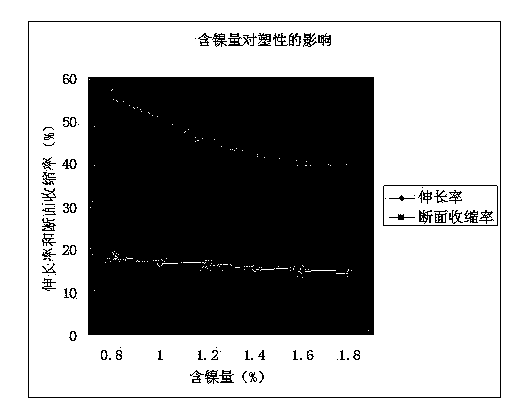

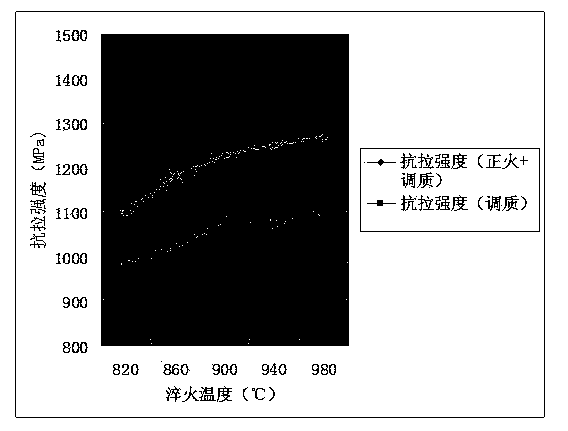

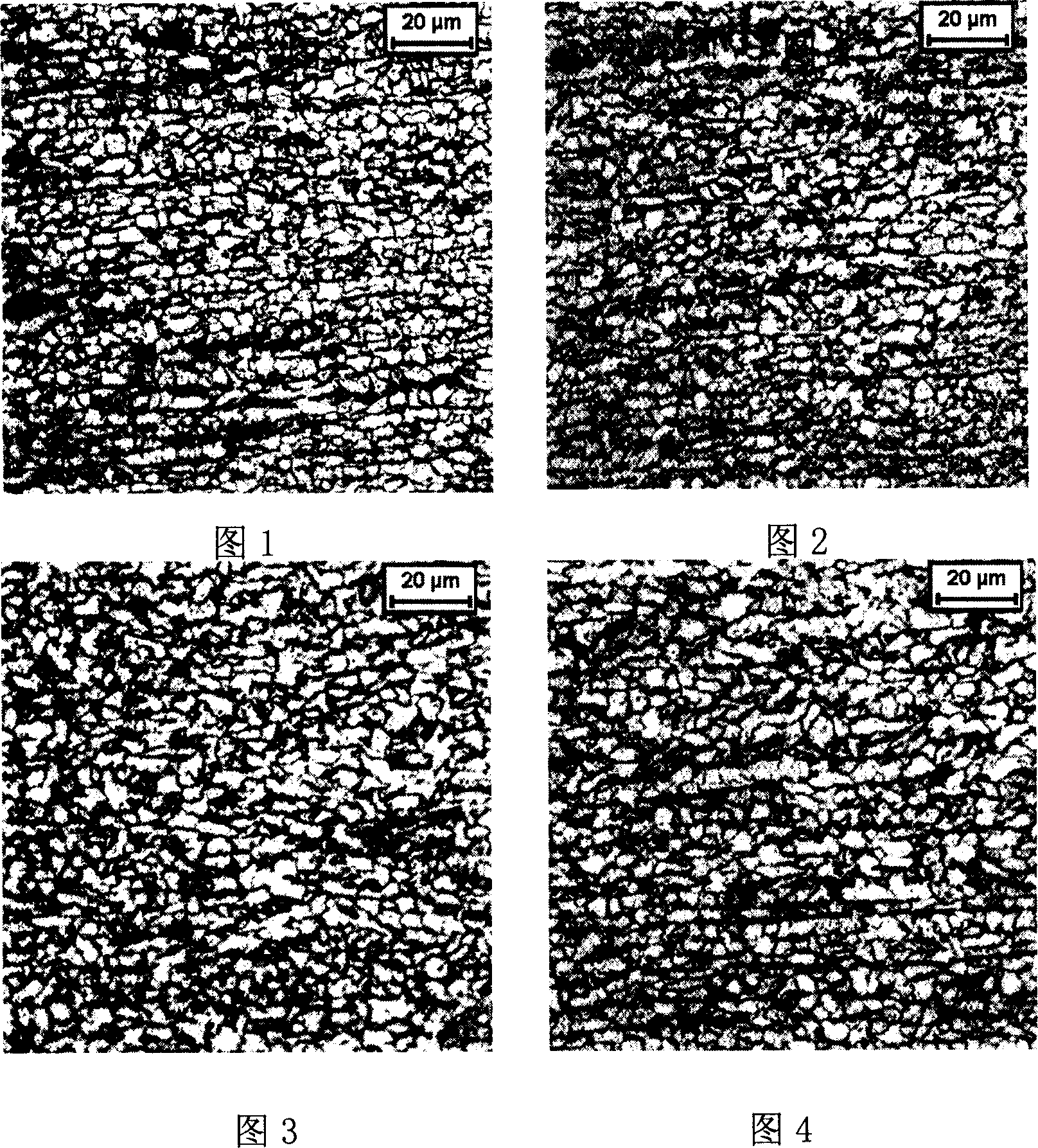

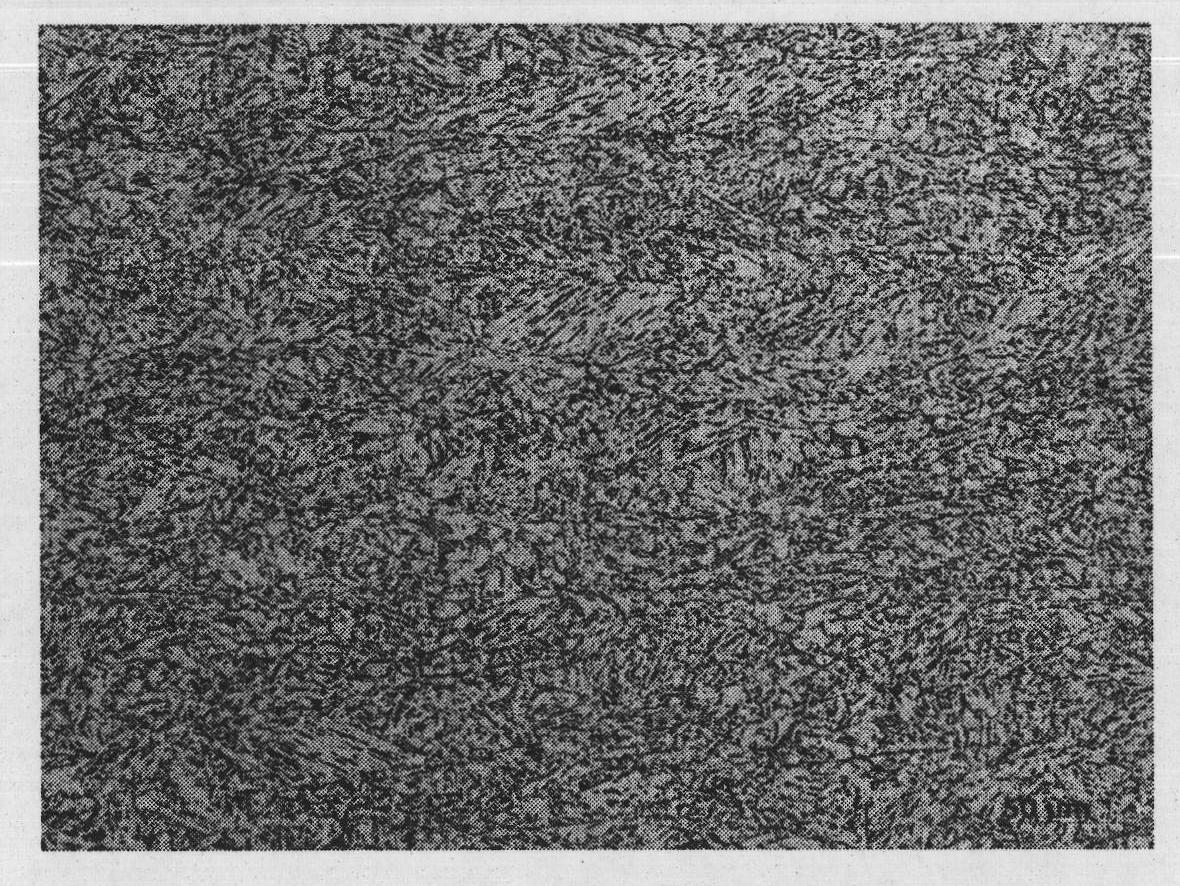

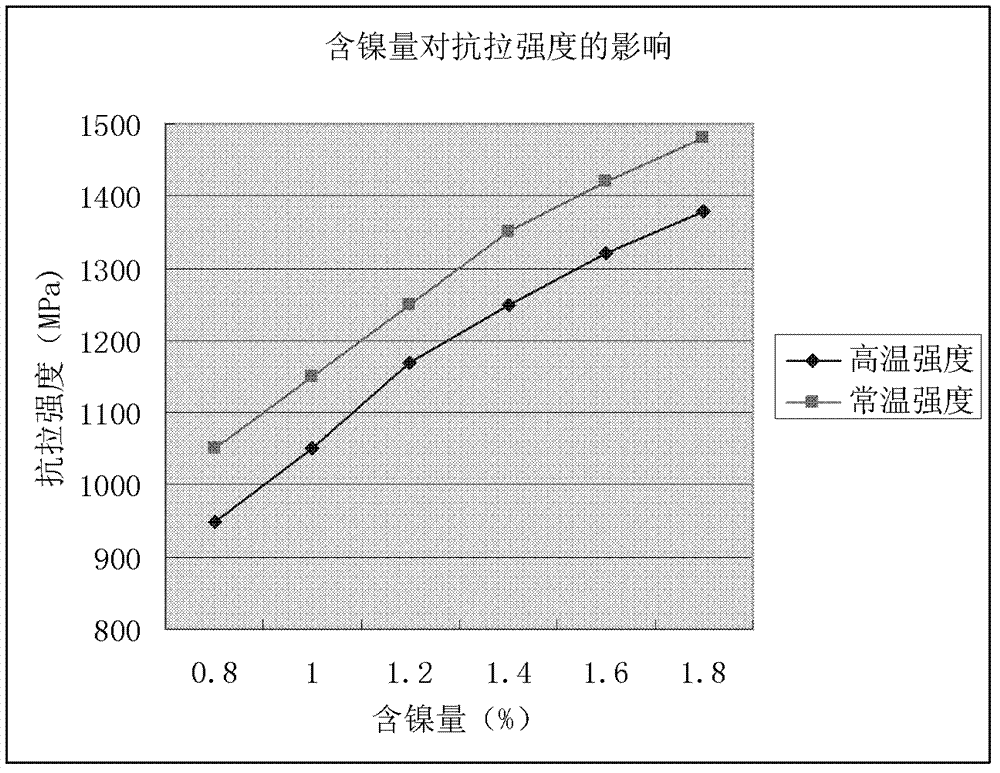

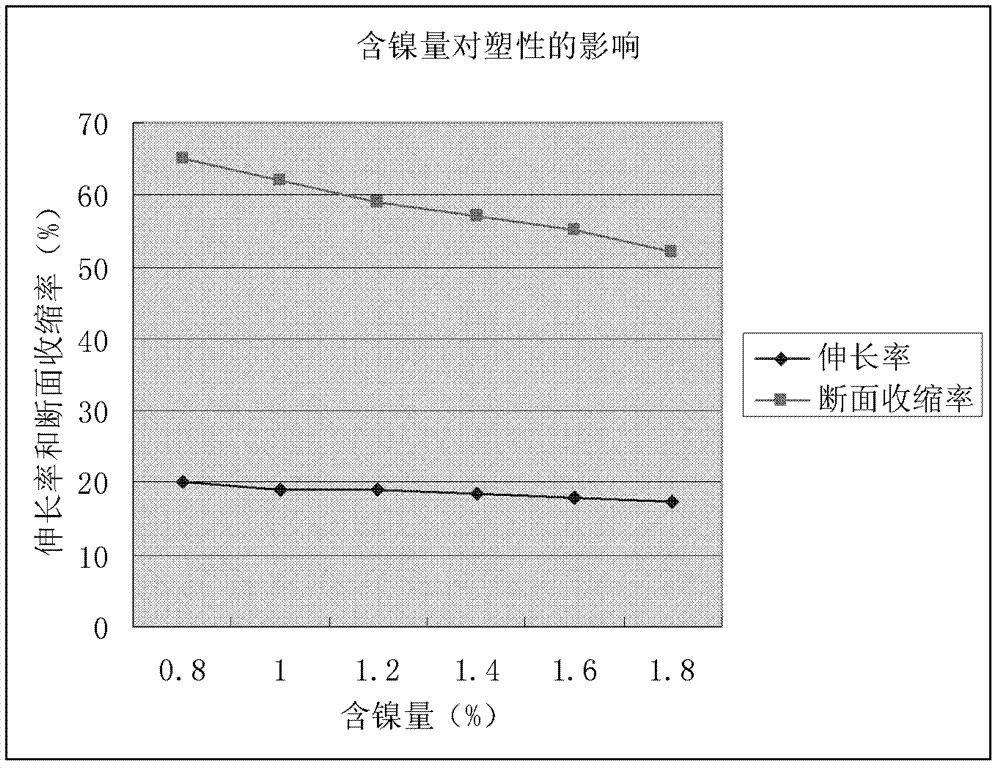

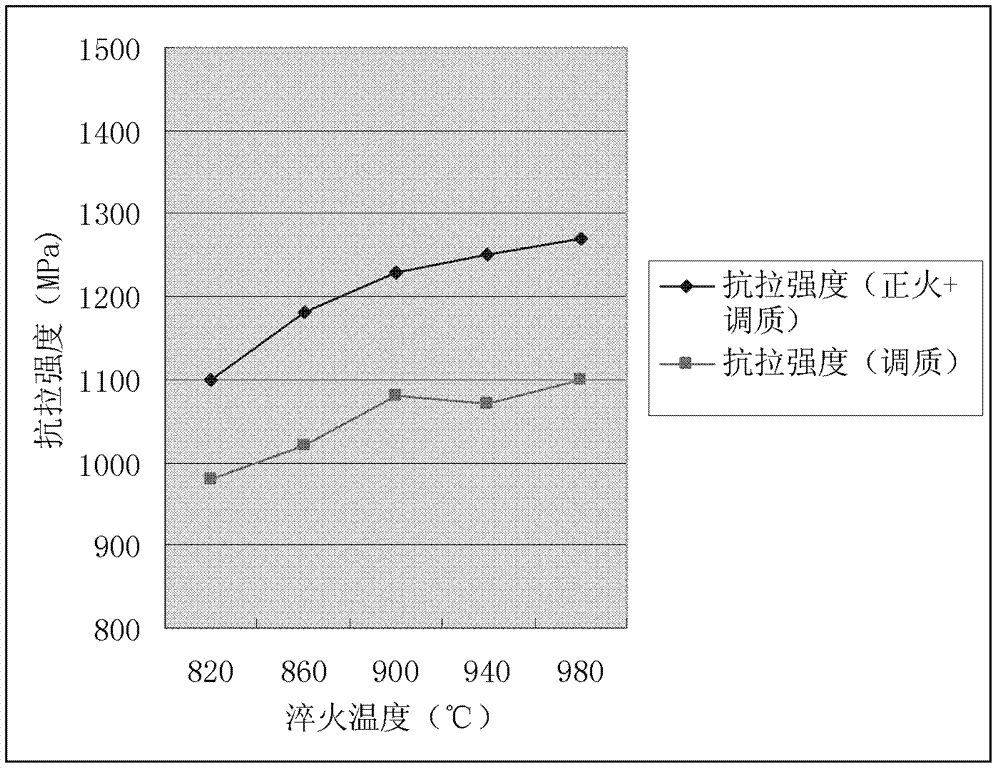

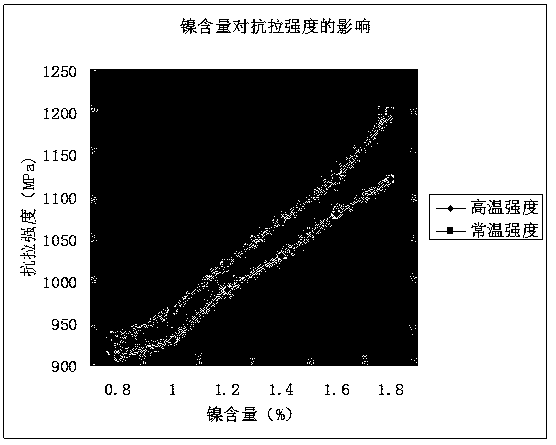

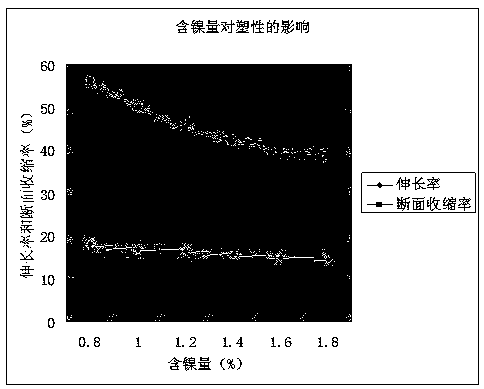

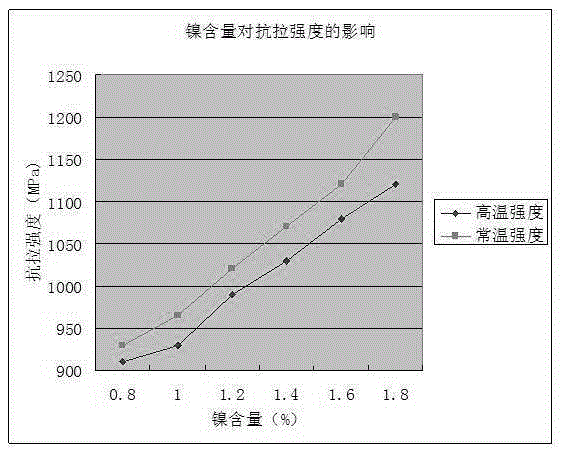

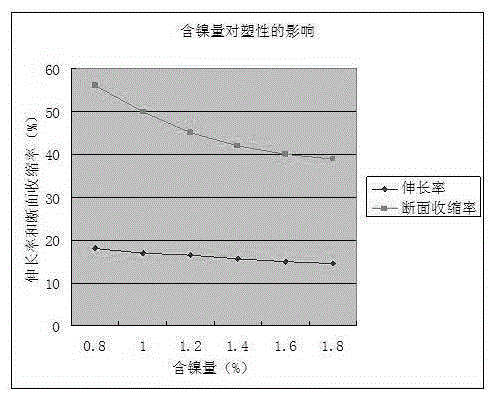

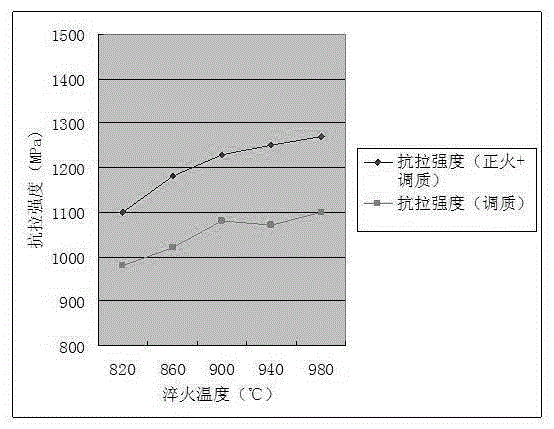

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

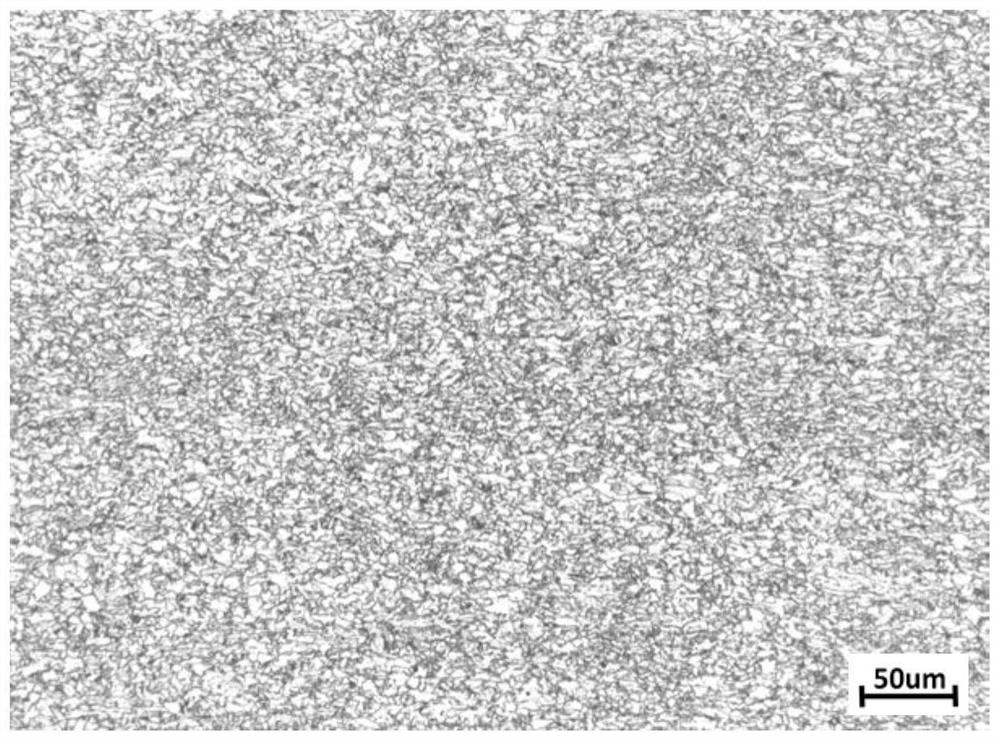

Method for medium sized or thin plate blank continuous casting and continuous rolling for producing superfine crystal grain steel plate and the steel plate

InactiveCN1995431ASimple chemical compositionImprove plastic toughnessTemperature control deviceFurnace typesSheet steelChemical composition

The invention discloses a manufacturing method of hyperfine crystal steel board through continuous rolling thin board, which comprises the following steps: allocating raw material with 0.12-0.18% C, 0.15- 0.35% Si, 0.65-1. 20% Mn, not more than 0.02% P, not more than 0.015% S and Fe; casting in the 100-200mm*1000-2000mm blank; setting the loading temperature over 800 deg. c; heating to 1100-1280 deg. c; reducing rough rolling of blank to 30-60 mm; setting refining rolling temperature between 920 and 1050 deg. c; exerting multi-channel and large-deforming strain accumulation with even deforming velocity at 1-10 / s; setting the refining rolling outlet temperature at 750-900 deg. c; setting cooling speed of laminar flow at 10-45 deg. c / s; coiling at 400-620 deg. c; setting the norm of continuous heat rolling steel at 2-18mm with even crystal size at 3-7um and yielding strength over 400Mpa; making the extending proof strength between 510 and 580 Mpa and extending rate over 26%.

Owner:ANGANG STEEL CO LTD

Low-yield-ratio and high strength thick plate and preparation process thereof

ActiveCN101775561AEasy to smeltReduce manufacturing costFurnace typesHeat treatment furnacesLower yieldHigh intensity

The invention provides a low-yield-ratio and high strength thick plate and a preparation process thereof. The thick plate comprises the following components in percentage by weight: 0.05-0.10 percent of C, 0.20-0.30 percent of Si, 1.60-1.80 percent of Mn, 0.05-0.07 percent of Nb, 0.30-0.40 percent of Ni, 0.30-0.40 percent of Cu, 0.15-0.30 percent of Cr, 0.20-0.40 percent of Mo, not more than 0.02 percent of Ti, not more than 0.045 percent of Al and the balance of iron and impurities. The preparation process adopts a rolling and cooling control process on the basis of the component design. The invention successfully solves the problems of contradiction and difficult accordancy of high strength and low yield ratio of a building thick plate, has simple process and wide application prospect, can effectively improve the yield and reduce the production cost and is suitable for industrialized large production and the fields of high-rise buildings, bridges, pipelines, and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

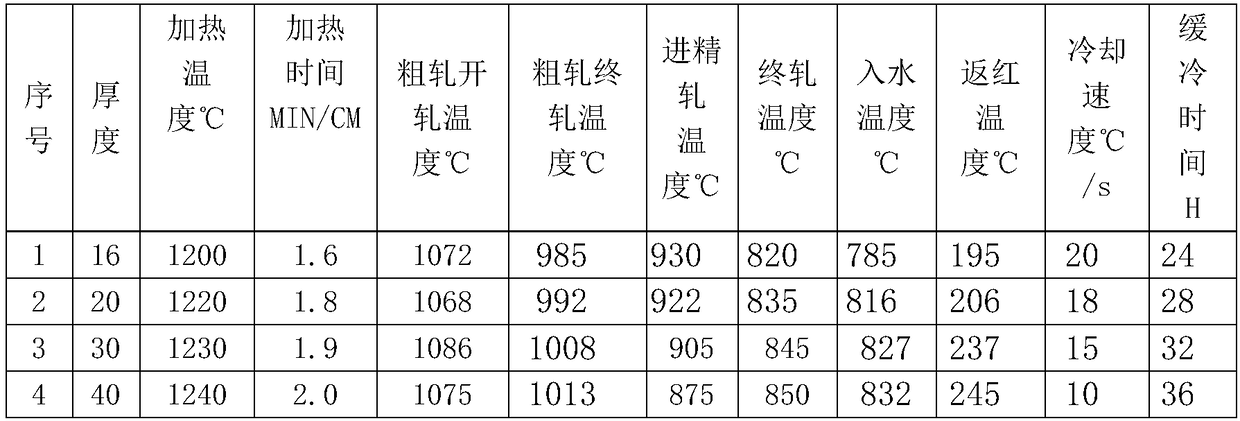

Method for rolling thick specification low-alloy structure steel plate by using middle and thin plate blank

InactiveCN101148735AIncreasing the thicknessIncrease reduction rateRoll mill control devicesMetal rolling arrangementsChemical compositionMaterials science

The present invention relates to production of structural low alloy steel plate, and is especially process of producing high strength hot rolled coiled sheet of 16-20 mm thickness with continuous cast billet of 150-170 mm thickness. The steel has chemical composition comprising C 0.15-0.20 wt%, Si 0.20-0.40 wt%, Mn 1.40-1.60 wt%, S not more than 0.030 wt%, P not more than 0.030 wt%, and Fe and impurity for the rest. The production process includes the steps of controlled heating, rough rolling, finish rolling, cooling, etc. and the produced hot rolled coiled sheet has simple composition, low cost, high tensile strength, high yield strength, high elongation, high impact toughness, high cold bending performance, good welding performance and other features.

Owner:LAIWU IRON & STEEL GRP

Zinc-plated double-phase steel and production method thereof

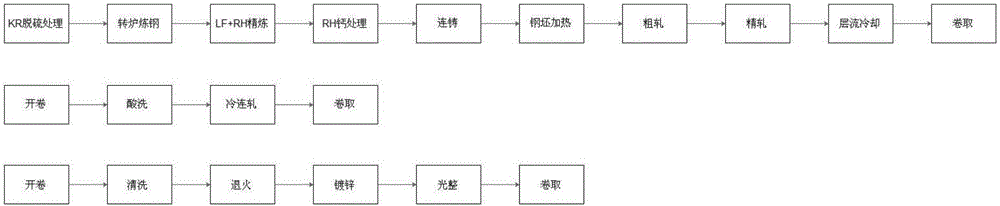

The invention belongs to the technical field of cold rolled steel and discloses zinc-plated double-phase steel and a production method of the zinc-plated double-phase steel. The zinc-plated double-phase steel comprises, by weight percentage, 0.085%-0.115% of C, 0.15%-0.24% of Si, 1.45%-1.55% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.025%-0.065% of Alt, 0.14%-0.24% of Cr, 0.24%-0.29% of Mo, not larger than 0.006% of N and the balance Fe and other inevitable impurities. The production method includes the steps of KR desulfuration, converter steelmaking, LF+RH refining treatment, RH calcium treatment, continuous steel casing, billet heating, rough rolling, finish rolling, laminar cooling and winding; unwinding, acid pickling, cold continuous rolling and winding; and unwinding, cleaning, annealing, zinc plating, finishing and winding. Through composition design and process control, the zinc-plated double-phase steel is suitable for annealing production lines having the rapid cooling segment or not.

Owner:SHOUGANG CORPORATION

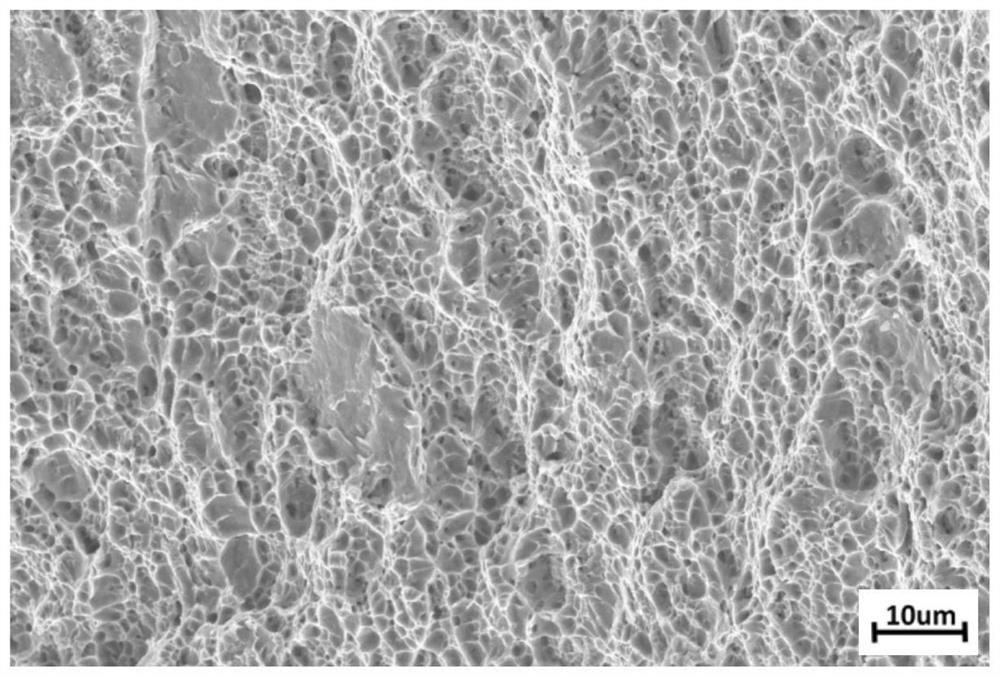

Alloy forged steel and its heat treatment method and use

ActiveCN102953008AGood comprehensive mechanical propertiesImprove hardenability and heat strength propertiesBraking membersAlloy elementCompound (substance)

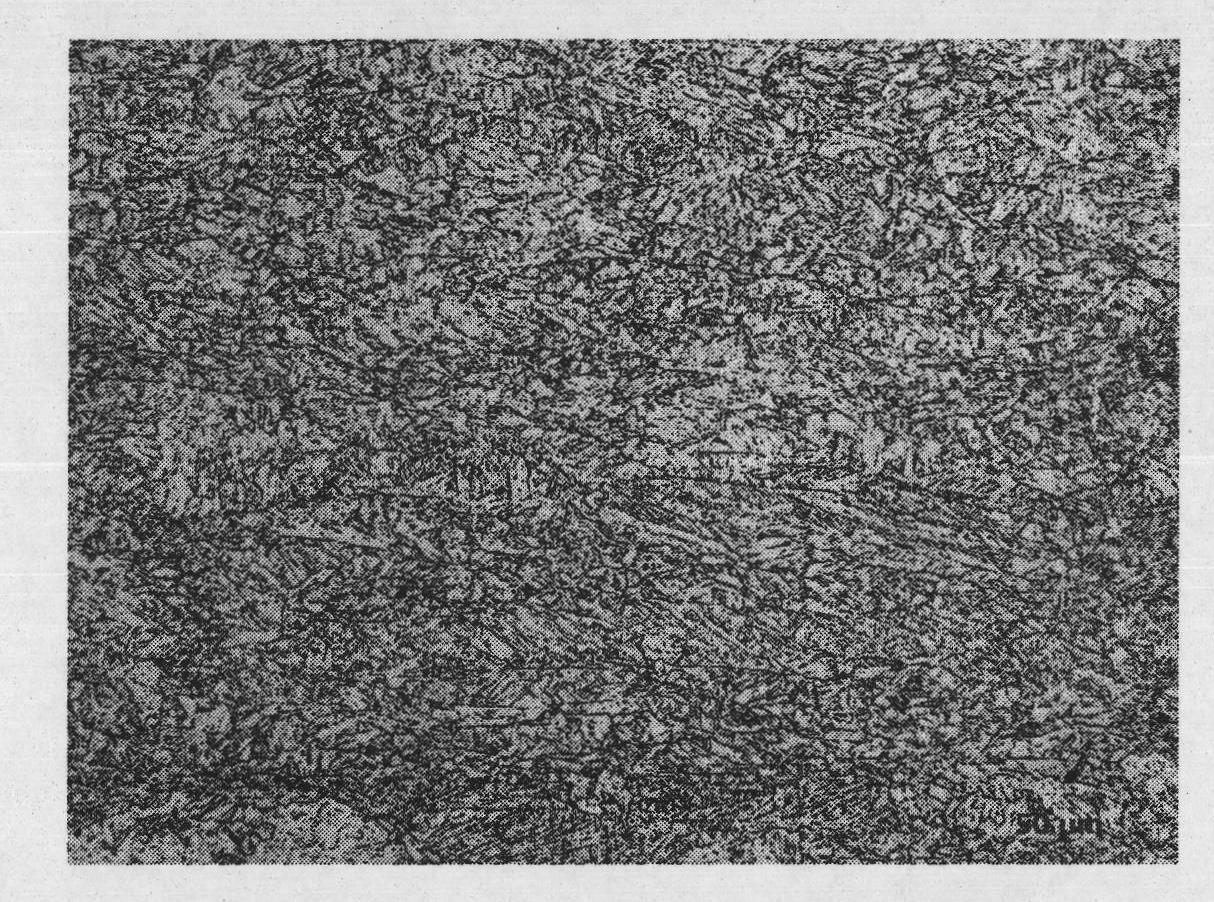

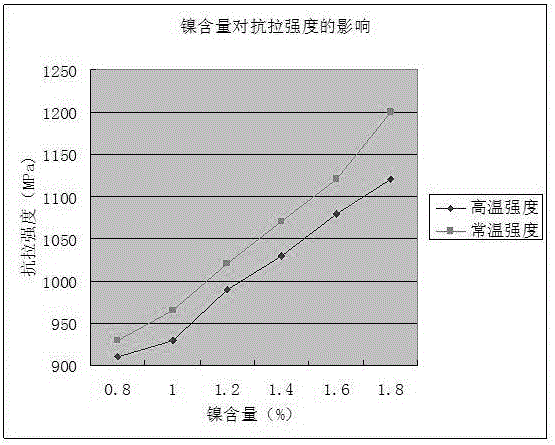

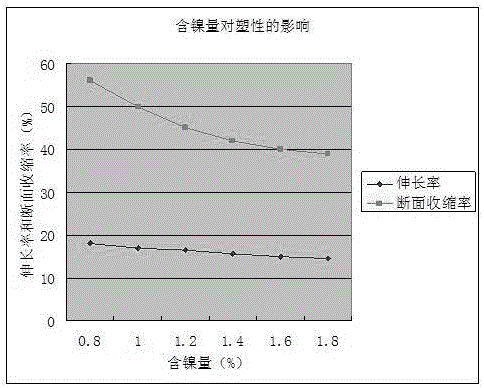

The invention provides an alloy forged steel and its heat treatment method and use. The alloy forged steel comprises: by mass, 0.26 to 0.35% of C, 0.15 to 0.39% of Si, 0.85 to 1.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.80 to 2.00% of Cr, 0.70 to 2.00% of Ni, 0.35 to 1.00% of Mo, and the balance Fe and other elements. Through reasonable proportioning of alloy elements such as Mn, Ni, Cr and Mo, and main chemical components such as C and Si in forged steel materials, through appropriate heat treatment processes, grains are refined; hardenability and heat intensity properties of the alloy forged steel are improved; normal temperature strength and high temperature strength of the alloy forged steel are greatly improved; and excellent comprehensive mechanical properties of the alloy forged steel are obtained.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

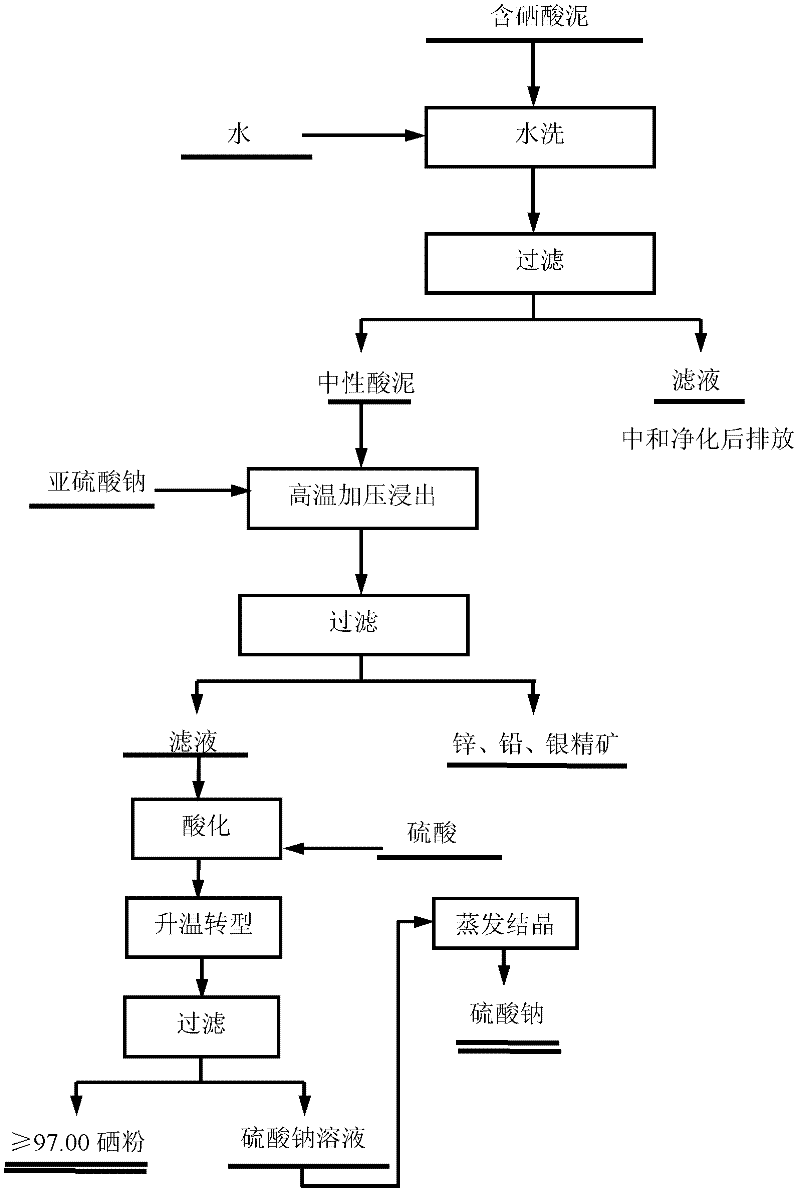

Method for leaching selenium in acid mud by using sodium sulfite

ActiveCN102583264AHigh extraction rateEasy to smeltElemental selenium/telluriumSulfite saltDistillation

The invention discloses a method for leaching selenium in acid mud by using sodium sulfite. The method comprises the following steps: selenium-containing acid mud and industrial water are mixed into pulp, and the pulp is put into a stirring groove for water washing till the acid mud is neutral; the neutral acid mud is mixed with the sodium sulfite and the industrial water into pulp, the pulp is put into a high-pressure reactor, nitrogen is introduced for reaction, the pressure and the temperature are reduced after the reaction is finished, the material is taken out and filtered, and the filtrate is sodium selenate solution; the sodium selenate solution is put into an acidizing groove, and sulfuric acid is added under the stirring condition; after the acidification is finished, temperature rise is started, the mixture is continuously stirred and then filtered, and the filter residue is selenium powder with the content of more than or equal to 97.0%; the selenium is leached by using the industrial sodium sulfite in the process of extracting the selenium in the acid mud, and the leached selenium is acidized to obtain the selenium powder with the content of more than or equal to 97.0%; and sodium sulfate produced in the technical process is effectively recycled by a distillation and crystallization method. The method has the characteristics of low cost, easiness in industrialization and low-carbon environmental protection.

Owner:KUNMING METALLURGY INST

High-strength anti-seismic steel bar and rolling process thereof

The invention discloses a high-strength anti-seismic steel bar. The steel bar comprises, by weight, 0.24-0.28% of C, 0.50-0.80% of Si, 1.40-1.60% of Mn, less than or equal to 0.040% of S, less than orequal to 0.040% of P, 0.120-0.160% of V, 0.010-0.030% of Nb, 0.0140-0.0220% of N, and the balance being Fe and inevitable impurities. The rolling process comprises the following steps: (1) preparingmaterials according to the components by weight; (2) preparing a steel billet of suitable size; (3) rolling, wherein heating temperature of the steel billet is 1000-1200 DEG C, soaking temperature is1150-1230 DEG C, and rolling temperature is 1100-1200 DEG C; and (4) treating on a cold bed for natural cooling after heating and rolling, and then carrying bundling and stacking. A steel bar alloy system is simple and is easy for blank smelting and continuous casting efficient production; precious alloys such as nickel and molybdenum are not adopted, the content of niobium and vanadium is low, and the product alloy cost is low; and the developed high-strength steel bar has excellent comprehensive performance and safety performance, the durability and the safety of key engineering buildings can be ensured, and the application and popularization prospects are good.

Owner:NANJING IRON & STEEL CO LTD

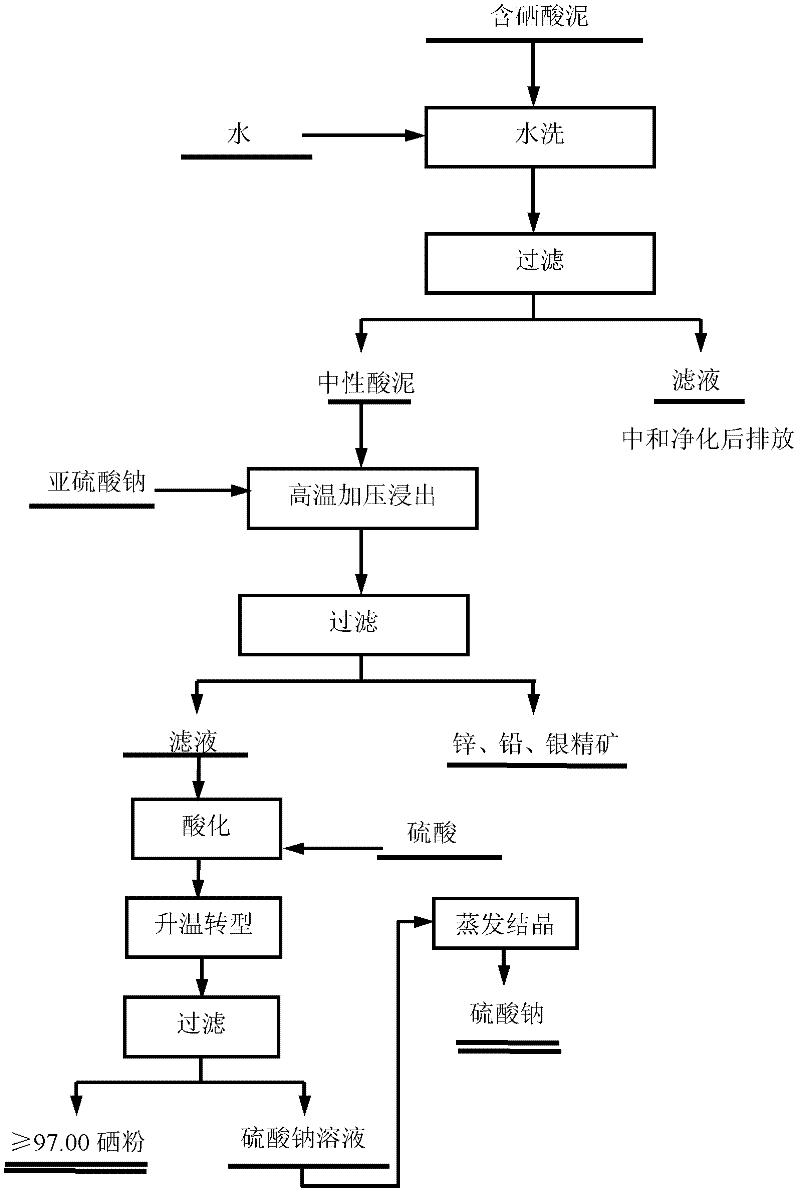

Production technology of high purity silicon carbide

The invention provides a production technology of high purity silicon carbide, comprising the following steps of: mixing silicon dioxide and carbon black with the weight ratio of 1:1.2; preparing pulp from the mixture and sulfuric acid solution with the concentration of 60-80g / l according to the solid-liquid ratio of 1:4; putting the pulp in a pressurizing reactor; controlling the pressure in the reactor; stirring for 1-3h,and filtering to obtain mixing slag; washing the mixing slag to neutral; pelletizing the mixing slag, putting particles into an electric furnace; roasting the particles with the temperature of 1600 DEG C to 1800 DEG C; separating liquid and solid; cooling; crushing obtained silicon carbide; washing the crushed silicon carbide by sulfuric acid with the concentration of 80-120g / L; filtering, and drying to obtain the high purity silicon carbide with the impurity content less than 0.001 percent. The invention belongs to a smelting method for preparing the high purity silicon carbide by the silicon dioxide and the carbon black. After carrying out pressurization and acid leaching on the silicon dioxide and graphite, the electric furnace is utilized to roast, and the silicon dioxide and the graphite are separated, then the sulfuric acid is used to wash the silicon dioxide and the graphite to obtain the high purity silicon carbide. The invention has the advantages of simple equipment, short technological process, low production cost and environment protection.

Owner:杨大锦

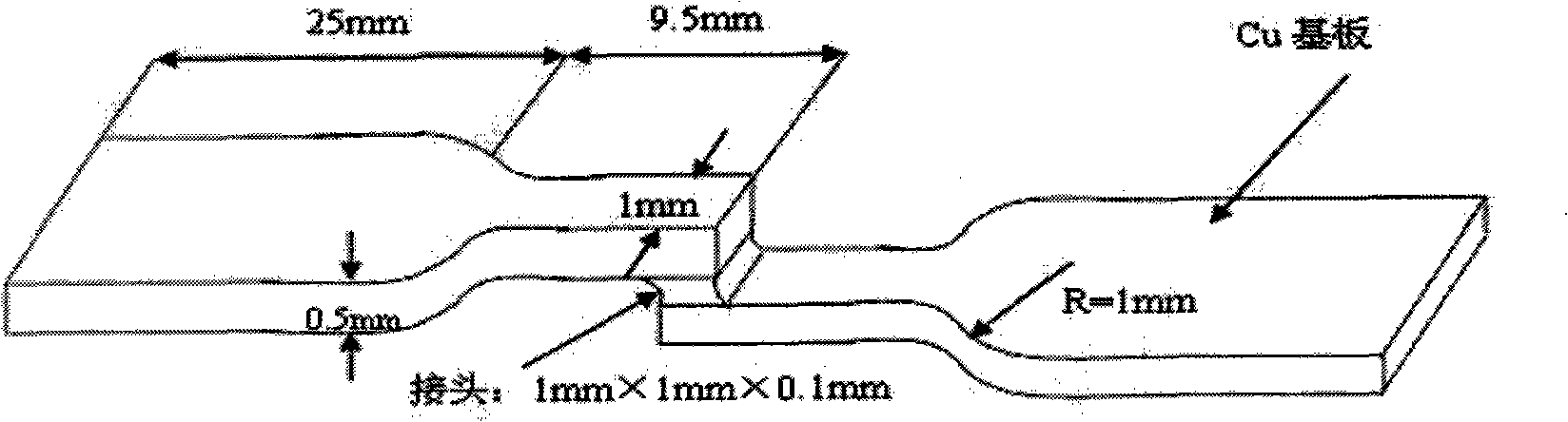

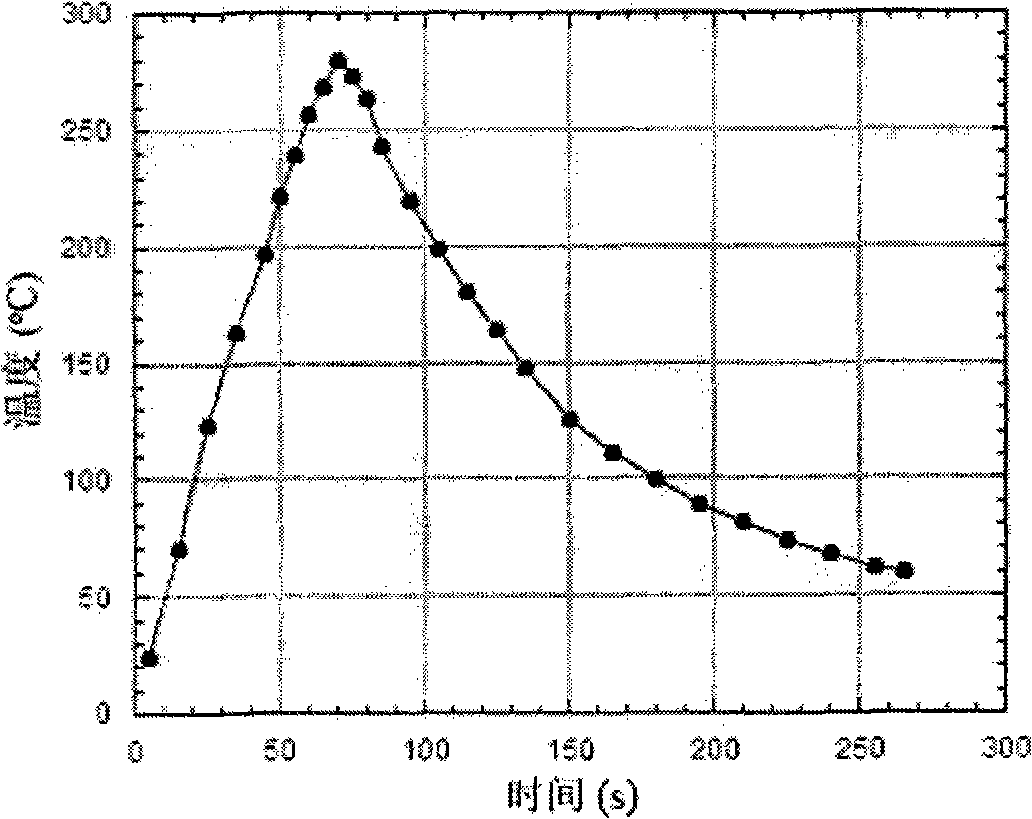

SnAgCu leadless brazing filler metal with antioxygenic performance

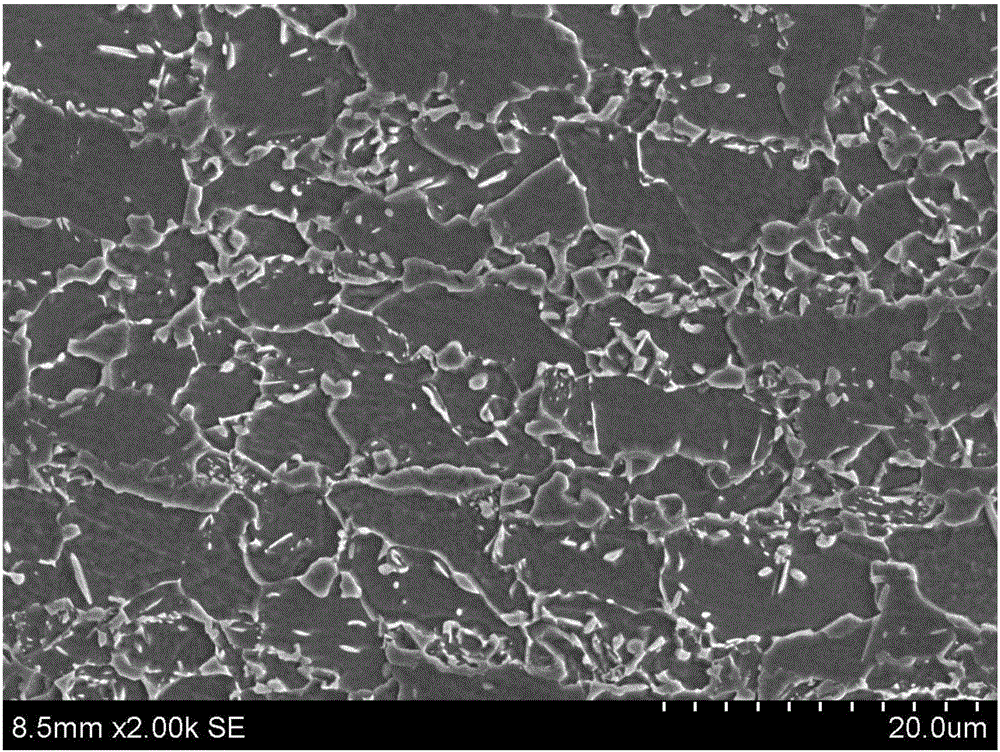

InactiveCN101157162APromote nucleationUniform microstructureWelding/cutting media/materialsSoldering mediaRare-earth elementManufacturing technology

The invention relates to Sn-Ag-Cu lead-free solder with oxidation resisting performance, and belongs to the manufacture technical field of lead-free solder for electronic assembly in microelectronics. The solder comprises the following components (mass percent): 0.1 percent to 5 percent is Ag, 0.1 percent to 1.5 percent is Cu, 0.01 percent to 1 percent is Ce, 0.01 percent to 0.5 percent is Ni, 0.0001 percent to 0.2 percent is P, or at the same time, 0.001 percent to 0.5 percent of Ge is added and the rest comprises Sn. The invention provides a method that microelements such as Ni, rare earth element CE, P, or at the same time Ge are added into the Sn-Ag-Cu solder alloy, the wet ability and the mechanical property of the alloy solder are further improved, and especially the oxidation resisting performance is greatly improved. The organism of the alloy solder of the invention is refined and uniform, no toxic element such as PB is included, the pollution to environment does not exist, the smelting is convenient, the invention can be processed into a great variety of production forms, the WEEE and RoHS instruction issued can be met, and the invention is the good low temperature lead-free solder.

Owner:BEIJING UNIV OF TECH

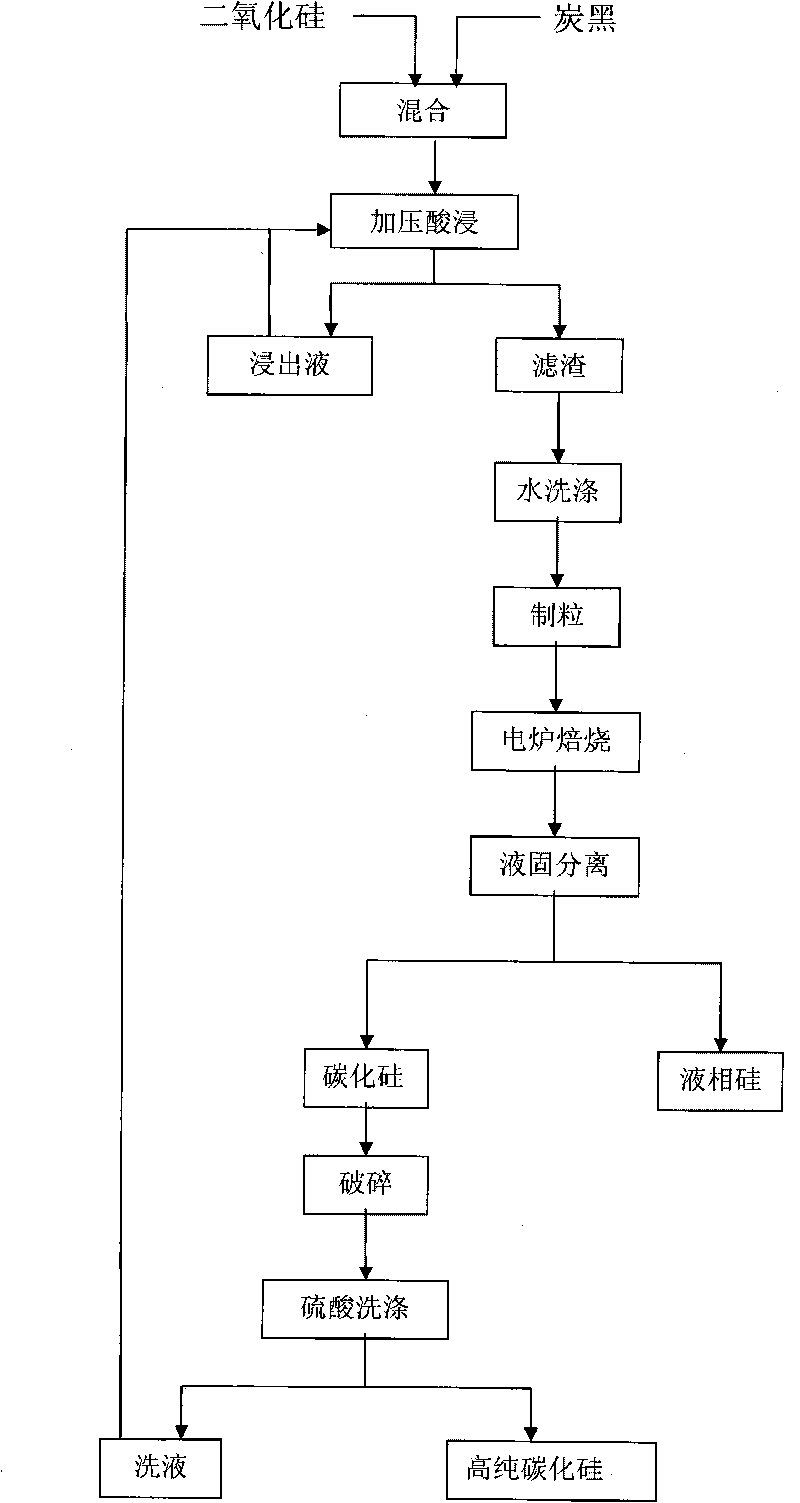

Heat-resistant wear-resistant steel plate and production method thereof

The invention discloses a heat-resistant wear-resistant steel plate and a production method thereof. The heat-resistant wear-resistant steel plate consists of the following components in percentage byweight: 0.33%-0.40% of C, 0.2%-0.4% of Si, 0.80%-1.00% of Mn, 0.5-0.7% of Cr, 0.2-0.4% of Mo, 0.015%-0.03% of Nb, 0.0005-0.0022% of B, 0.10%-0.20% of Ti, 0.015%-0.045% of Als and the balance of Fe and inevitable impurities; and impurity elements in steel are controlled as follows: less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.0040% of [N] and less than or equal to 0.0020% of [O]. According to the heat-resistant wear-resistant steel plate and the production method thereof provided by the invention, the steel plate has surface hardness greater than HB400 after being tempered at a temperature lower than 500 DEG C; the production method is simple, and does not need special compound equipment; and residual stress is low, cracks are not liable togenerate, components are simple and common, and the cost is low.

Owner:ANGANG STEEL CO LTD

Low-cost yield strength 400MPa-grade steel strip and production method thereof

The invention discloses a low-cost yield strength 400MPa-grade steel strip and a production method thereof. The steel strip contains the following components in percentage by weight: 0.18-0.22% of C, 0.20-0.40% of Mn, less than or equal to 0.020% of S, less than or equal to 0.025% of P, less than or equal to 0.03% of Si, 0.015-0.035% of Als, 0.0009-0.0030% of B and the balance being Fe and inevitable impurities. The steel strip, on the basis of low-silicon manganese and boron microalloying thinking, can reduce raw material cost, and can be produced through a thin slab casting and rolling process; thickness specification is 1.0-3.5mm; the steel strip has the characteristics of being simple to smelt, relatively low in cost, stable in physical performance and applicable to industrial mass production. The steel strip, by controlling smelting through low-silicon manganese and boron microalloying, reduces cost, improves utilization rate of lower equipment through continuous casting high pulling speed, reduces cost by directly charging a continuous casting slab, guarantees surface quality of product by controlling temperature of a heating furnace, and meets physical performance of the product by optimizing a hot rolling process; the steel strip has the characteristics of being simple in process, low in cost and applicable to industrial mass production.

Owner:HEBEI IRON AND STEEL

Alloy cast steel used for high-speed train brake disc and high-speed train brake disc manufactured through alloy cast steel

The invention discloses alloy cast steel used for a high-speed train brake disc and the high-speed train brake disc manufactured through the alloy cast steel. The alloy cast steel in the claim 1 comprises, by weight percent, 0.18%-0.26% of carbon, 0.30%-0.50% of silicon, 0.68%-1.40% of manganese, smaller than or equal to 0.025% of phosphorus, smaller than or equal to 0.013% of sulfur, 1.10%-1.82% of chromium, 0.90%-1.50% of nickel, 0.65%-1.02% of molybdenum, 0.22%-0.34% of vanadium, smaller than or equal to 0.30% of the sum of the content of other components and the balance iron, wherein tungsten is smaller than 0.1%. The alloy cast steel has the main beneficial effects that grains are refined through reasonable matching and heat treatment of alloy elements such as manganese, nickel, chromium, molybdenum and vanadium and main components such as carbon and silicon in a cast steel material, hardenability and the thermal strength performance of the alloy cast steel material are improved, the constant-temperature strength and the high-temperature strength are greatly improved, and the good comprehensive mechanical property is achieved. The brake disc manufactured through the alloy cast steel can completely meet the technical requirement for use of high-speed trains under the working condition.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

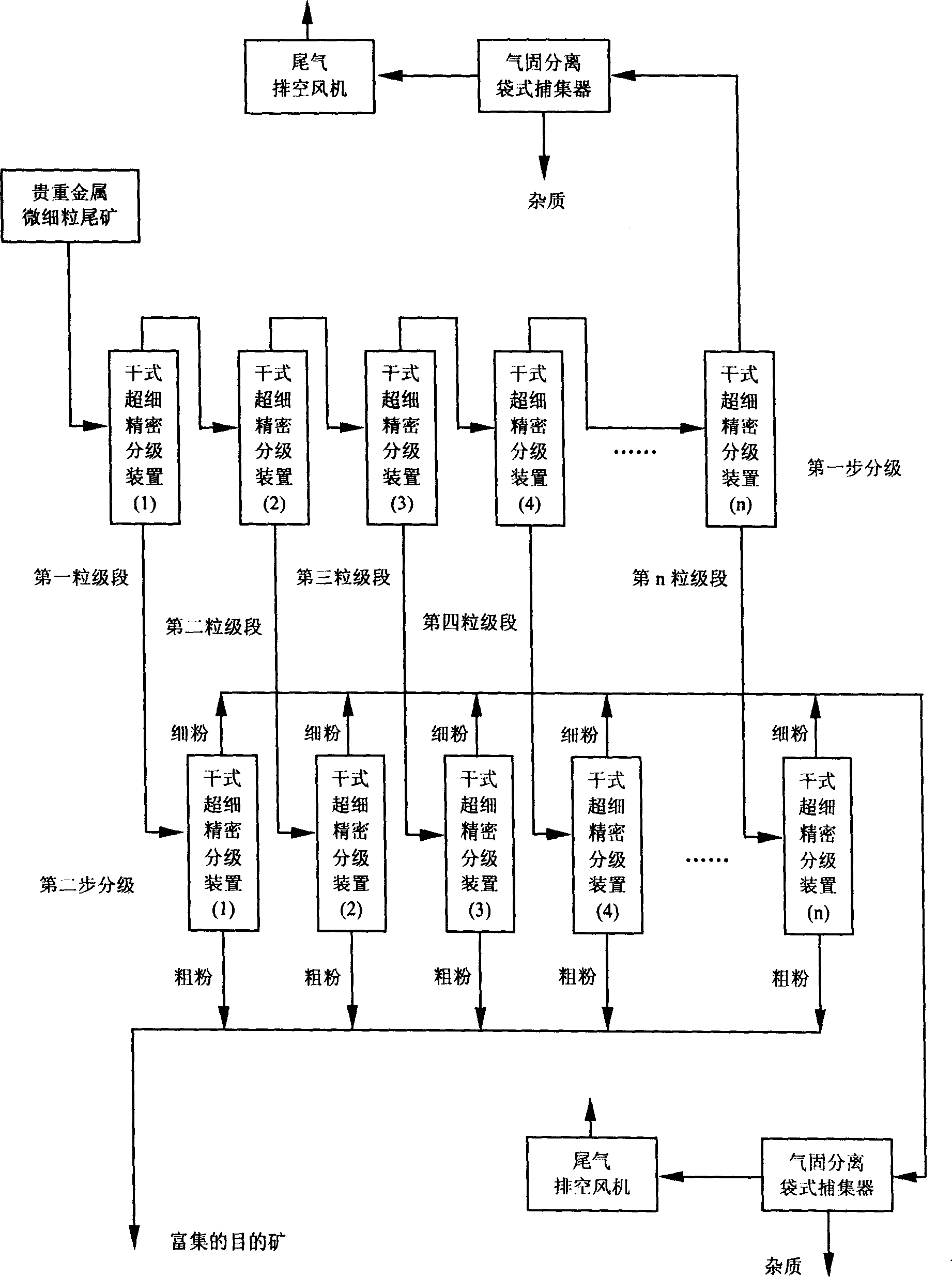

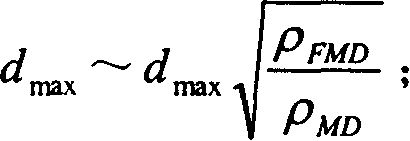

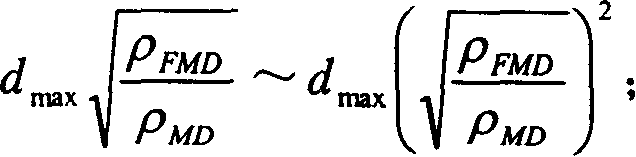

Dry-type graded concentration method for precious metal tenuousness grainy tailings

The present invention relates to mineral separation technology, and is dry graded enriching process of fine noble heavy metal tailings. The fine noble heavy metal tailings separating process includes the first step of dry grading, in which fine noble heavy metal tailings powder is graded into n grades according to grain size in a dry superfine precise grading unit and each grain size grade is measured and analyzed in destination mineral content before discarding the grades with lower destination mineral content; and the second step of dry grading, in which each grade of tailings powder is further divided into two parts, i. e., coarse powder as the heavier destination mineral of noble heavy metal and fine powder of lighter non-destination mineral impurity. Thus, the enrichment of fine noble heavy metal ore powder is realized. The present invention has the features of high efficiency and environment friendship.

Owner:WUHAN UNIV OF TECH

Rare earth Er contained SnZn based leadless solder and its preparation method

InactiveCN1621195AEasy to smeltLow priceWelding/cutting media/materialsSoldering mediaMolten saltRare earth

The RE containing SnZn-base lead-free brazing alloy for assembling in microelectronics contains Zn 5-9 wt%, Ag 0-1.5 wt%, Bi 3-5 wt% and marketable Er 0.05-1.0 wt% except Sn. The preparation process includes melting mixed salt of KCl and LiCl in the ratio of 1-1.6 to 0.8-1.2 and pouring the molten salt to Sn, melting Sn, adding Zn, Ag and Bi into Sn liquid to melt, pressing Er with holed bell jar into the mixed salt and SnZn-base alloy, rotating the bell jar, maintaining for 1-2 hr, stirring, letting stand and eliminating mixed salt in the surface after solidification. The brazing alloy has fined microscopic structure, low cost, no pollution, convenient smelting, and improved moistening technological performance and metallurgical quality.

Owner:BEIJING UNIV OF TECH

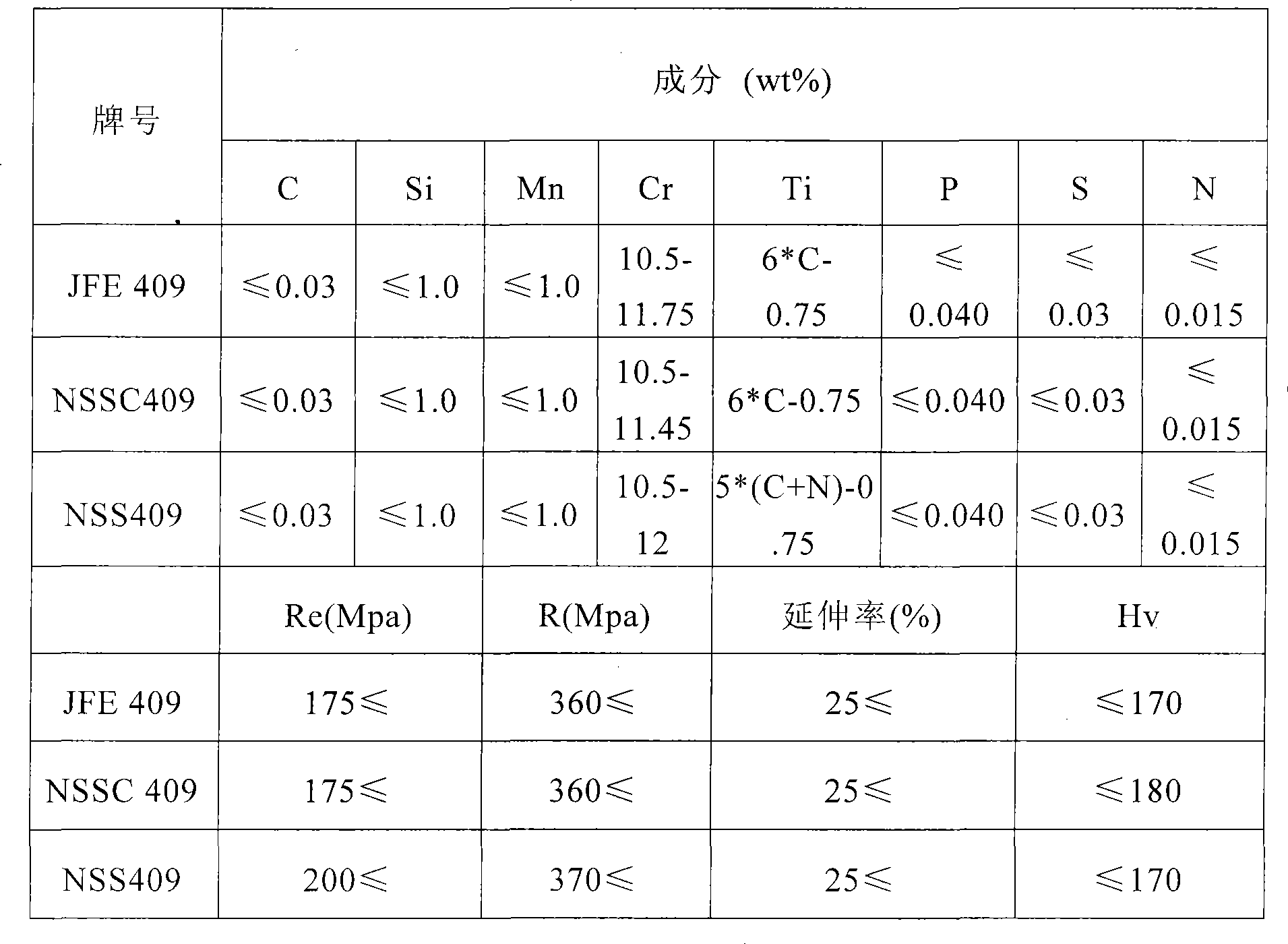

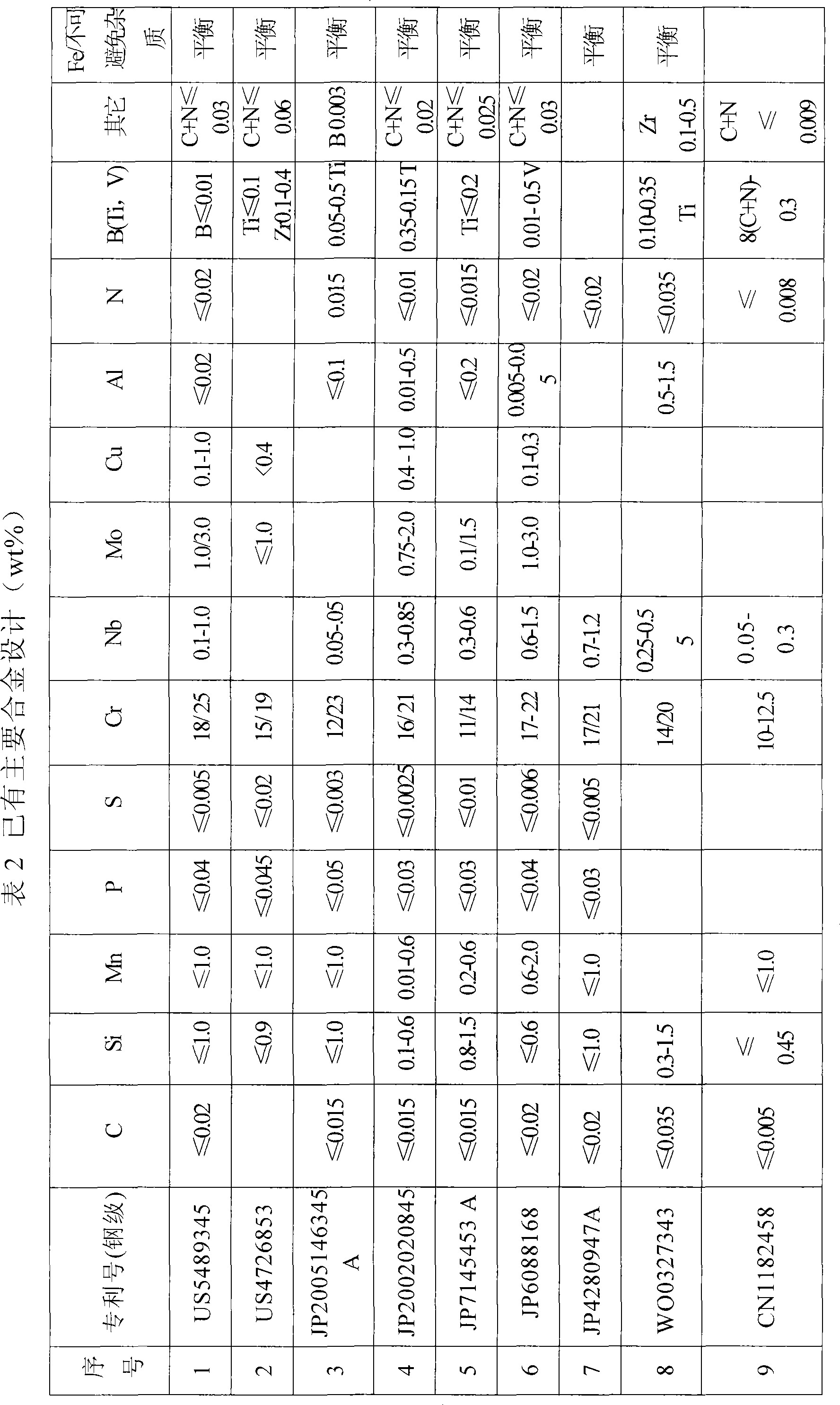

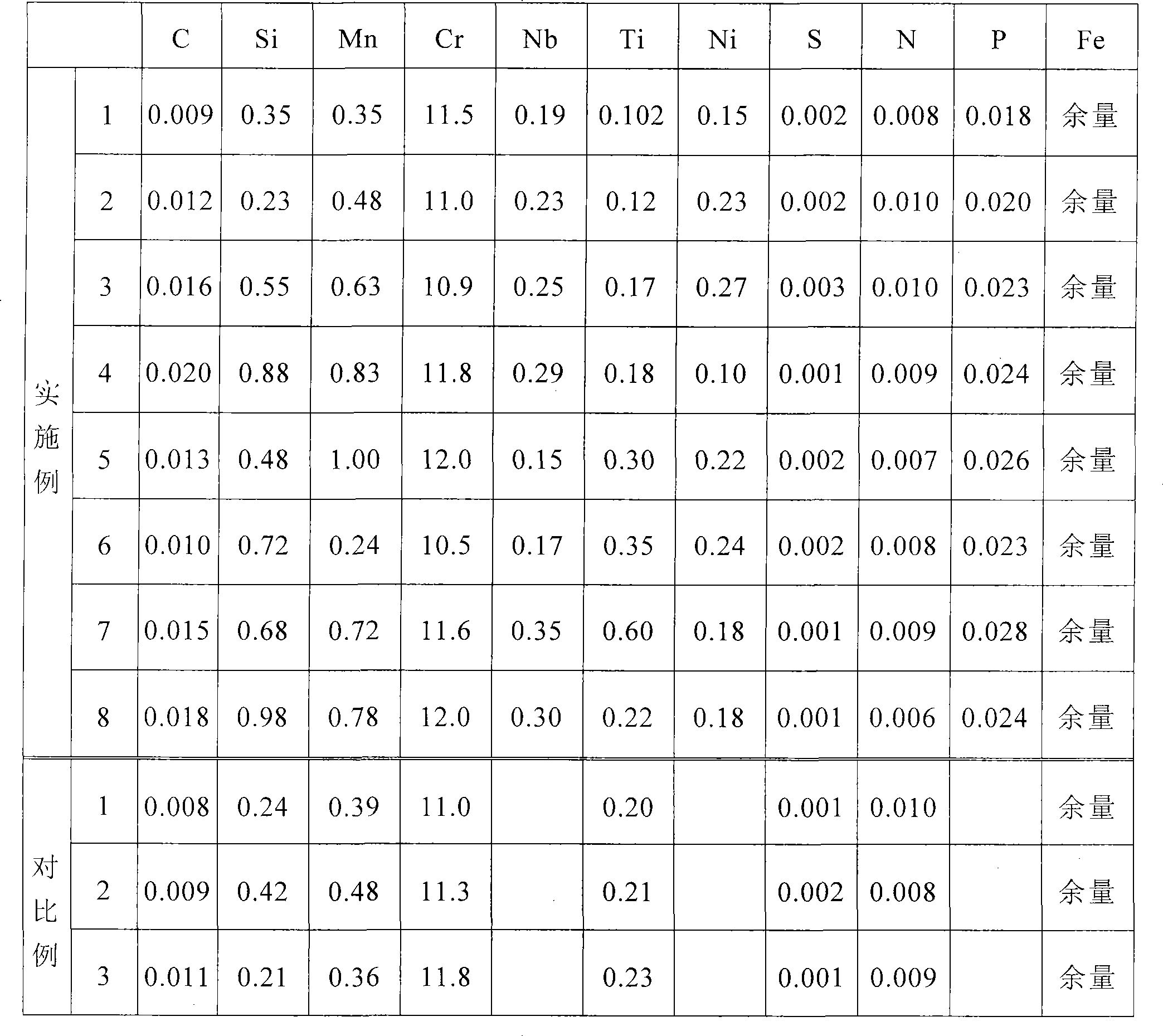

Ferritic stainless steel for automobile exhaust emission system

The invention discloses a ferritic stainless steel used for an automobile exhaust discharging system, wherein, the elements quality ratio is as follows: C is less than or equal to 0.02, Si is less than or equal to 1.0, Mn is less than or equal to 1.0, Cr is between 10.5 and 12.0, P is less than or equal to 0.03, S is less than or equal to 0.003, Ni is less than or equal to 0.3, Ti is less than or equal to 0.60 and larger than or equal to 6 multiplied by C+N, Nb 0.15 to 0.35, N is less than or equal to 0.01, C+N is less than or equal to 0.03, Fe and inevitable impurity as the rest. The invention adopts low carbon-nitrogen design route, and the ferritic stainless steel is added with Ti and Nb. Therefore, double stability not only improves corrosion-resistance, surface quality of the continuous casting billets, but also improves the comprehensive mechanical properties of the materials simultaneously. Smelting is much easier to achieve in the existing production line, the success rate is greatly increased, and the production cost is effectively reduced. By mechanical and corrosion testing of the steel product, the properties of the invention are better than single-stable low-chromium ferritic stainless steel .

Owner:BAOSHAN IRON & STEEL CO LTD

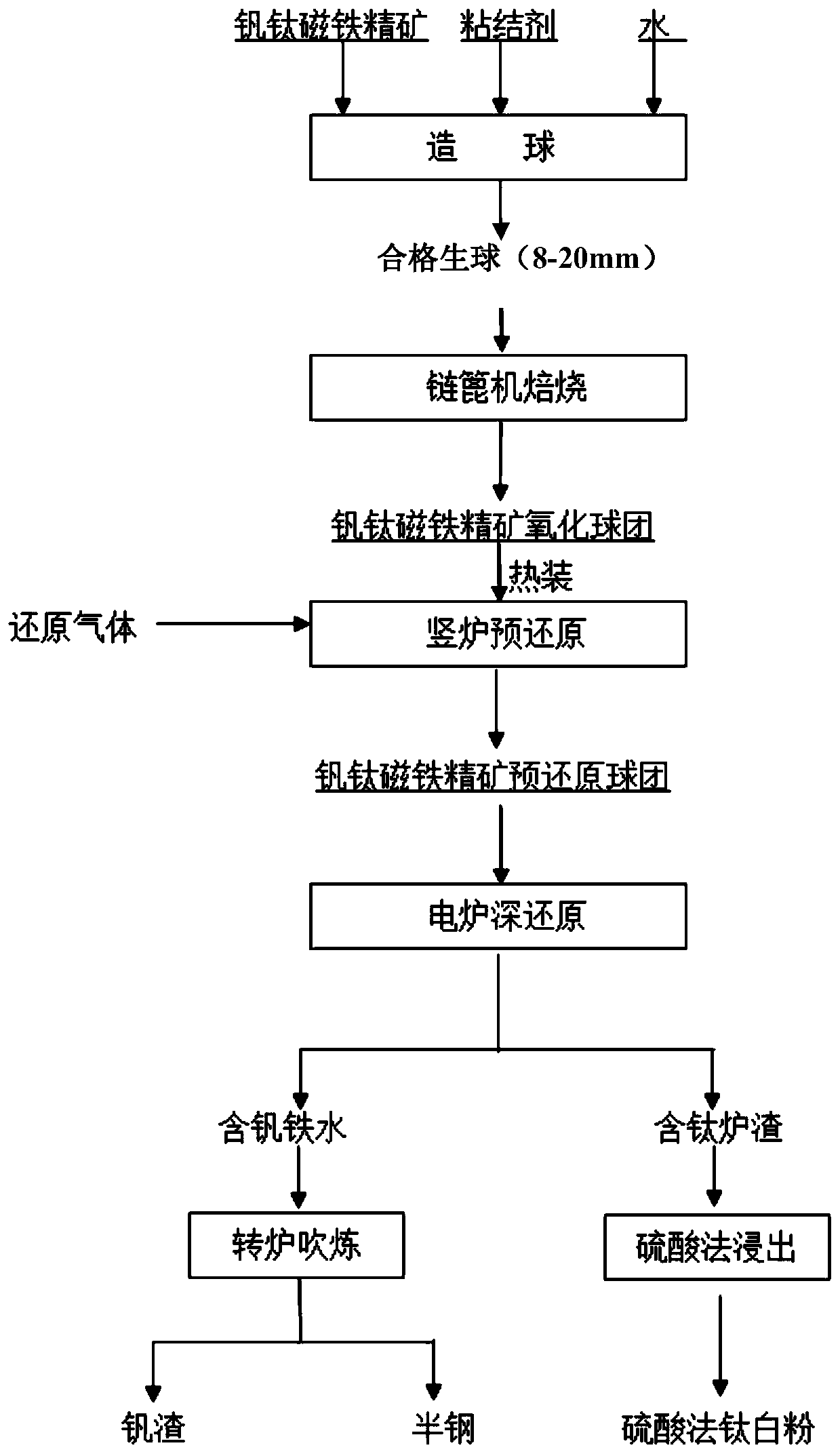

Process for comprehensively utilizing vanadium-titanium magnetite through chain grate roasting, gas-based shaft furnace prereduction, and electric furnace deep reduction

The invention discloses a process for comprehensively utilizing vanadium-titanium magnetite through chain grate roasting, gas-based shaft furnace prereduction, and electric furnace deep reduction. Theprocess comprises the following steps: (1) oxidized pellet preparation: uniformly mixing vanadium-titanium magnetite concentrate, a binder and water in a ratio, pelletizing to obtain vanadium-titanium magnetite green pellets with qualified particle sizes, conveying the green pellets into a chain grate, and carrying out drying and oxidation roasting to obtain vanadium-titanium magnetite oxidized pellets; (2) gas-based shaft furnace prereduction; (3) electric furnace deep reduction: filing the vanadium-titanium magnetite prereduction pellets into an electric furnace and carrying out deep reduction, adding a flux and proportioned carbon, controlling a melting temperature to be 1550-1650 DEG C, and separating to obtain vanadium-containing molten iron and titanium-containing slag; and (4) using the obtained vanadium-containing molten iron for vanadium extraction in a converter, and carrying out titanium extraction on the titanium-containing slag through a sulfuric acid method. According tothe process, the reduction degradation rate for the oxidized pellets is greatly reduced, so that the requirement of the subsequent shaft furnace reduction can be met; and efficient and clean utilization for iron, vanadium and titanium is realized, and meanwhile, the cost is reduced, and the production efficiency is increased.

Owner:CENT SOUTH UNIV

Gray cast iron and production technology thereof

The invention relates to gray cast iron which is prepared by the following ingredients according to mass percent: 2.7 to 3.0 percent of C, 0.9 to 1.2 percent of Mn, 1 to 1.5 percent of Ni, 0.3 to 0.5 percent of Cr, 0.3 to 0.5 percent of Sn, 1.6 to 2.0 percent of core-spun yarns, not higher than 0.1 percent of P, not higher than 0.1 percent of S, and the balance ofiron and inevitable impurities. Powdery inner cores of the core-spun yarns contain light rare earth. Through the reasonable regulation of the proportioning of raw materials of the gray cast iron and the addition of inoculation, the strength and hardness of the gray cast iron are obviously improved. The gray cast iron is convenient in smelting and outstanding in casting property. After inoculation, the cast iron piece cannot be easily fractured. The gray cast iron casting smelted by the current materials has obviously-improved pressure resistant strength and hardness, lowers the production cost of the enterprise, increases the qualification rate of the product, enlarges the application scope of the casting, and has obvious economic benefits.

Owner:HUBEI JIANGHAN HEAVY IND

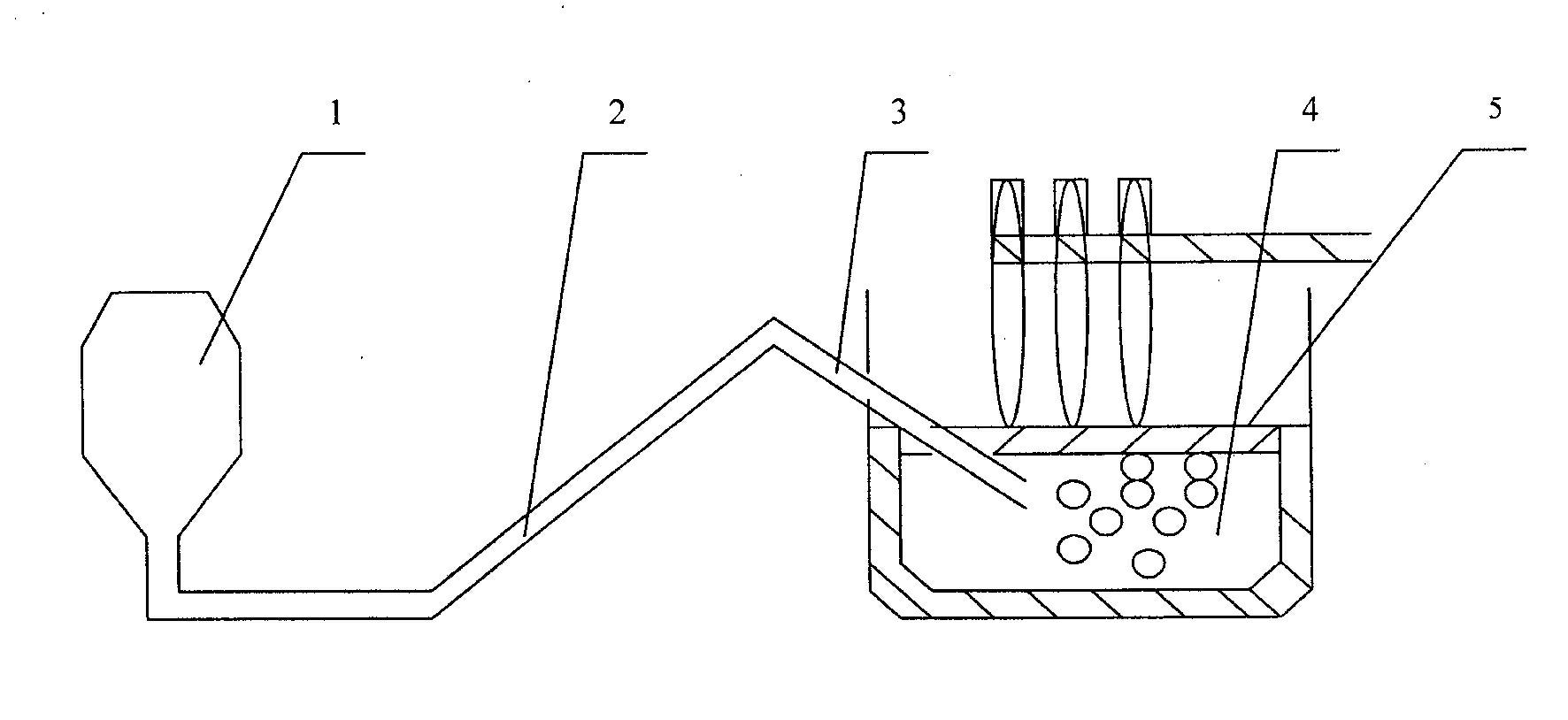

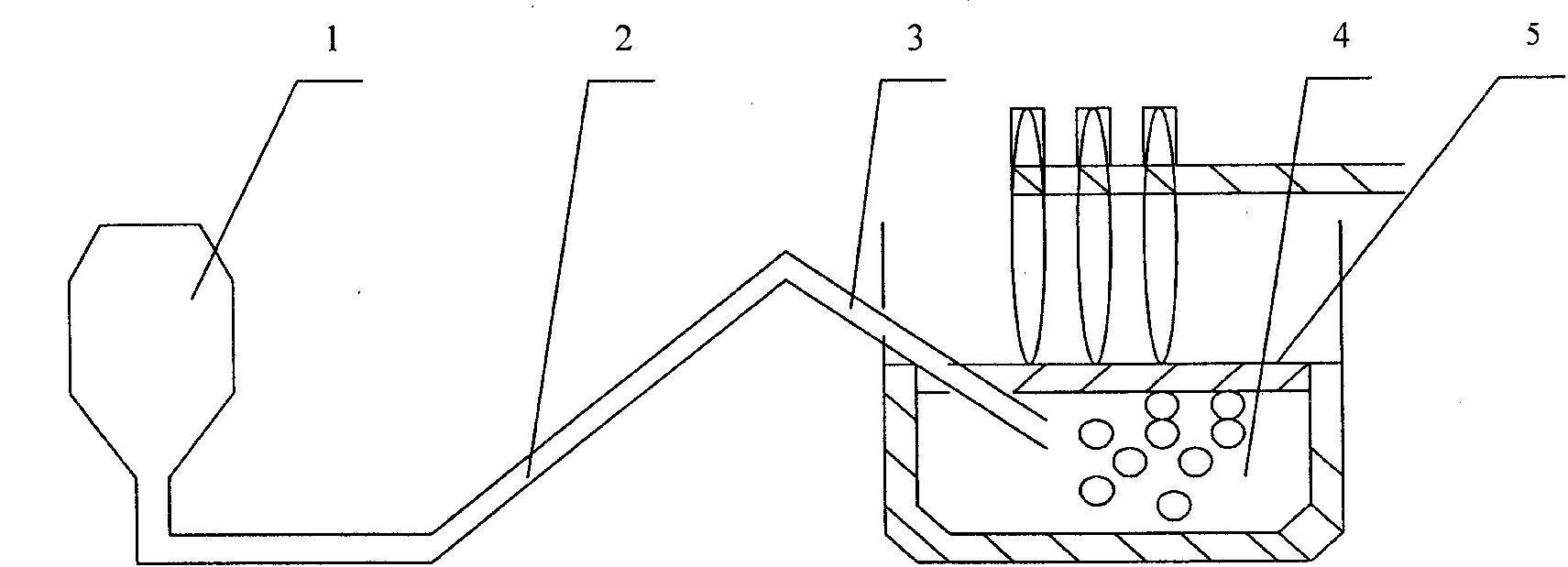

Carbon blowing technique for electric furnace smelting

InactiveCN102212646AReduce consumptionIncrease oxygen contentProcess efficiency improvementElectric furnaceSelf consumptionElectric arc furnace

The invention relates to a carbon blowing technique for electric furnace smelting. The method comprises the following steps: a. filling carbon powder: screening carbon powder to obtain carbon powder of which the granularity phi is at most 3mm, the water content is at most 3% and the sulfur content is at most 2.5%, and filling the screened carbon powder in a supplementary blowing machine (1); b. adjusting pressure of compressed air: respectively adjusting the pressure of the supplementary blowing machine (1) and the pressure of the self-consumption carbon blowing gun (3) to 0.2-0.3 MPa; c. opening a carbon powder baiting valve of the supplementary blowing machine; d. inserting the self-consumption carbon blowing gun (3) into molten steel of an electric arc furnace melting bath (4) via a furnace slag layer (5); and e. electric arc furnace smelting by charging three times: when the temperature of the melting bath is increased, melting down scrap steel, starting the supplementary blowing machine to blow the carbon powder into the melting bath three minutes a time, and tapping after the steel meets the chemical composition requirement for steel grade Q235 and achieve the tapping conditions. The invention can save electric energy, increases the steel scrap recovery rate, is simple to operate, and has the advantages of simple equipment and strong feasibility. By adopting the carbon blowing technique, the electricity can be saved by 30 KWH per ton of steel, and the steel scrap recovery rate can be increased by more than 1%, the comprehensive economic benefit per ton of steel is more than 50 Yuan. If the technique is used for electric furnace smelting all over China, 10 billion Yuan can be saved every year.

Owner:兰州兴元铸锻有限公司 +1

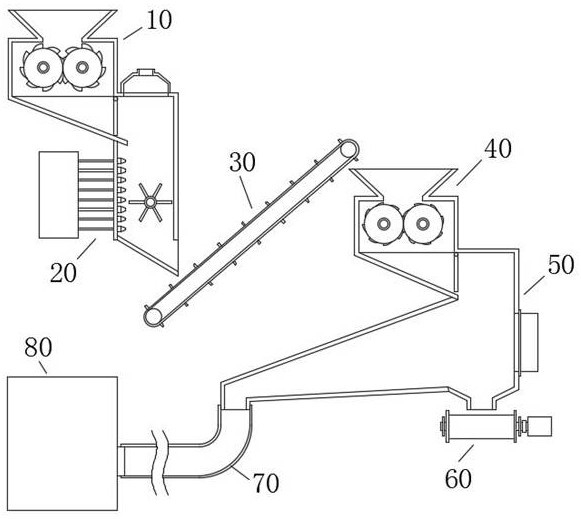

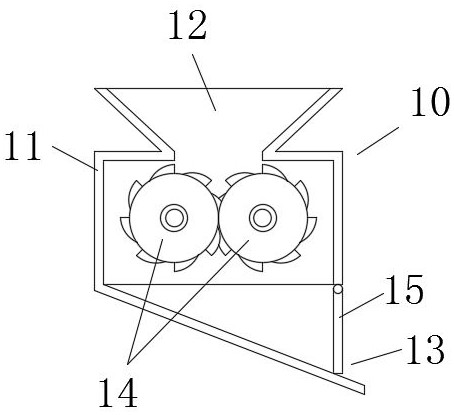

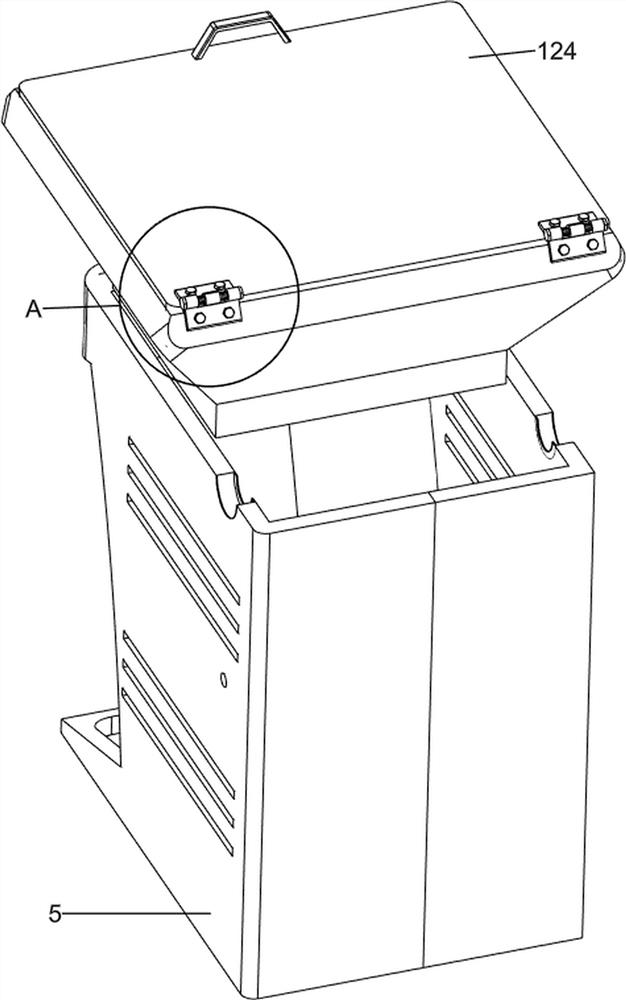

Scrap steel breaking and impurity removing machine

PendingCN111822479AAchieve removalEasy to smeltSolid waste disposalGrain treatmentsThermodynamicsCombustor

The invention relates to a scrap steel breaking and impurity removing machine. The scrap steel breaking and impurity removing machine comprises a primary breaker, a combustor, a secondary breaker, a lifting machine and a winnowing machine. The scrap steel breaking and impurity removing machine has the beneficial effects that scrap steel blocks are broken to form scrap steel sheets with the diameter smaller than 4 centimeters through the primary breaker, then combustible impurity objects on the surfaces of the scrap steel sheets which enter the combustor can be burnt through the combustor, thescrap steel sheets which are discharged from the combustor are conveyed to the secondary breaker through the lifting machine, then the scrap steel sheets which are burnt by the combustor are broken toform scrap steel particles with the diameter smaller than 1 centimeter through the secondary breaker, combustion ash can be separated from the scrap steel sheets at the same time, finally the scrap steel particles entering the winnowing machine and the combustion ash entering the winnowing machine are separated through the winnowing machine, and therefore the purpose that the combustible impurityobjects which adhere to the surface of scrap steel are moved is achieved, and the iron and steel scrap which is recovered from the society is conveniently smelted by an iron and steel company.

Owner:ZHOUKOU NORMAL UNIV

X70 pipeline rolling plate for microalloyed resistance weld pipe and production method of X70 pipeline rolling plate

InactiveCN111996461AReduce design costEasy to smeltMetal rolling arrangementsElectrical resistance and conductanceLine tubing

The invention discloses an X70 pipeline rolling plate for a microalloyed resistance weld pipe and a production method of the X70 pipeline rolling plate. Steel is prepared from 0.05%-0.09% of C, 0.15%-0.35% of Si, 1.45%-1.70% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.006% of S, 0.040%-0.070% of Nb, 0.005%-0.025% of Ti and the balance iron and inevitable impurities, wherein Al / N is larger than or equal to 4, Mn / C is larger than or equal to 16, Ceq is smaller than or equal to 0.40, and Pcm is smaller than or equal to 0.20. The heating temperature of a casting blank is 1,150-1,250 DEG C, and the holding time is longer than or equal to 150 min; the rough rolling starting temperature is higher than or equal to 1,000 DEG C, and the accumulative reduction of top threepasses is larger than or equal to 50%; the finish rolling starting rolling temperature is 950-1,050 DEG C, the final rolling temperature is 800-900 DEG C, and the accumulative reduction rate of finish rolling top three passes reaches 65% or above; and header centralized cooling is adopted for a laminar flow cooling section, the cooling rate is 15-25 DEG C / s, the coiling temperature is 500-600 DEGC, and then the temperature is air-cooled to room temperature. The toughness is good at the low temperature of -40 DEG C.

Owner:ANGANG STEEL CO LTD

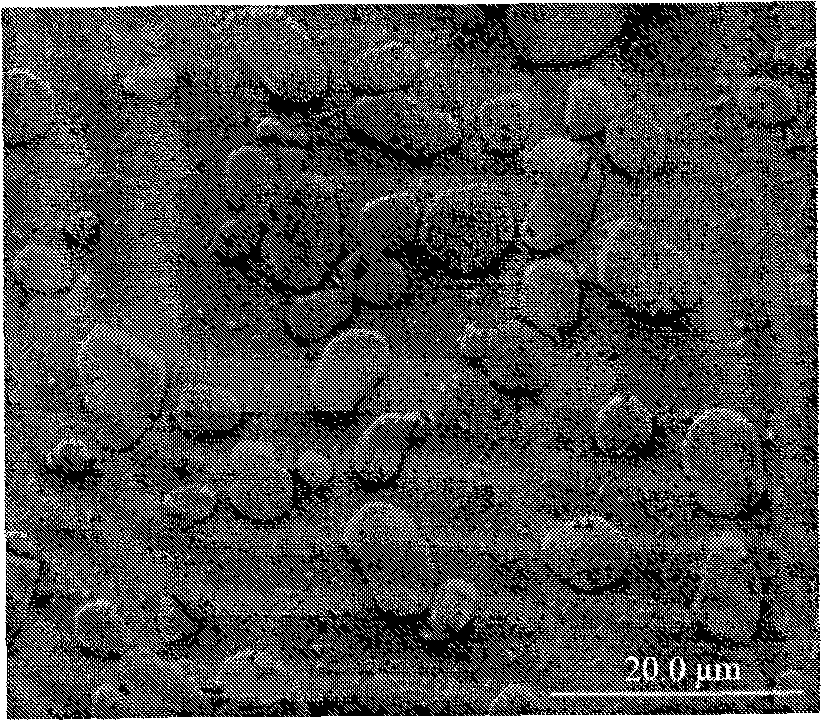

Endogenetic Cu6Sn5 granule reinforced leadless compound solder alloy and manufacture method thereof

InactiveCN101323059AEvenly distributedImprove ball effectWelding/cutting media/materialsSoldering mediaParticulatesLithium chloride

The invention relates to an endogenous Cu6Sn5 particulate reinforced tin and silver based lead-free composite solder alloy and the preparation method, belonging to the technical field of manufacturing lead-free solder for electronic assembly in the microelectronic industry. The composite solder prepared by a traditional endogenous method has uneven distribution of the endogenous particles, and the technology and mechanical property of solder are influenced. The composite solder of the invention is composed of Cu6Sn5 reinforced particles and the eutectic alloy of Sn-3.5Ag; the volume percentages of the two components are respectively 20 percent and 80 percent. The invention is characterized in that potassium chloride and lithium chloride are mixed and melted according to the weight percentage of 1.3:1, and then poured on the eutectic alloy of Sn-3.5Ag; when the eutectic alloy of Sn-3.5Ag is melted, Cu and Sn particles are added; the mixture is preserved at the temperature of 450 DEG C, stirred and staying silently; then the mixture is rapidly cooled to room temperature at a rate of 20, 2, 0.6 or 0.1 DEG C / sec; the complex solder of the invention is obtained by removing mixed salt. The complex solder of the invention has the advantages of low cost, convenient smelting, and good mechanical property and creep resistance.

Owner:BEIJING UNIV OF TECH

Permeable dry stamp mass for furnace bottom of intermediate frequency furnace

The invention discloses a permeable dry stamp mass for the furnace bottom of an intermediate frequency furnace. The permeable dry stamp mass is a uniform mixture of 89 percent by weight of refractory aggregate and 11 percent by weight of additive. The permeable dry stamp mass disclosed by the invention is stamped in an area with a diameter being 300-400mm and with an air brick as the center at a top of the air brick, wherein a stamping thickness is 100-250mm; and the whole furnace bottom can be stamped according to the size of the furnace body and a stamping thickness is 100-250mm. Compared with the prior art, a permeable stamp mass is stamped at the top of the air brick, so that the air brick is prevented from directly bearing the corrosion of liquid steel and the service life of the air brick is prolonged. The permeable dry stamp mass disclosed by the invention has the advantages of stable permeable performance, no blockage of an electric furnace subjected to stamping, easy operation, safe smelting and freeness of breakout accidents.

Owner:邯郸市鑫福冶金科技有限公司

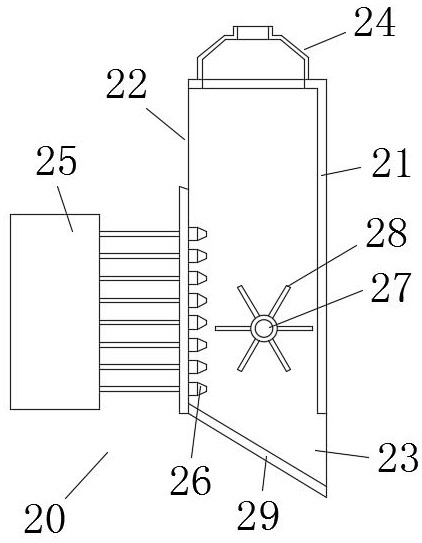

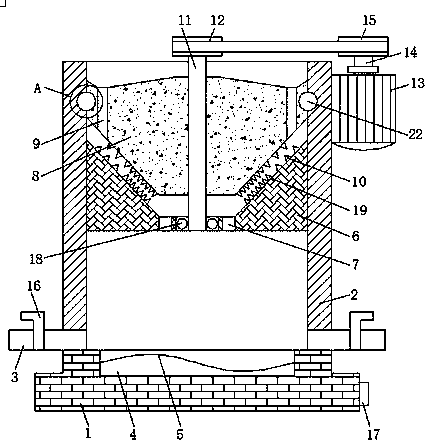

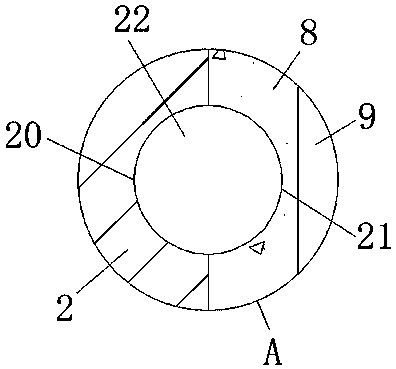

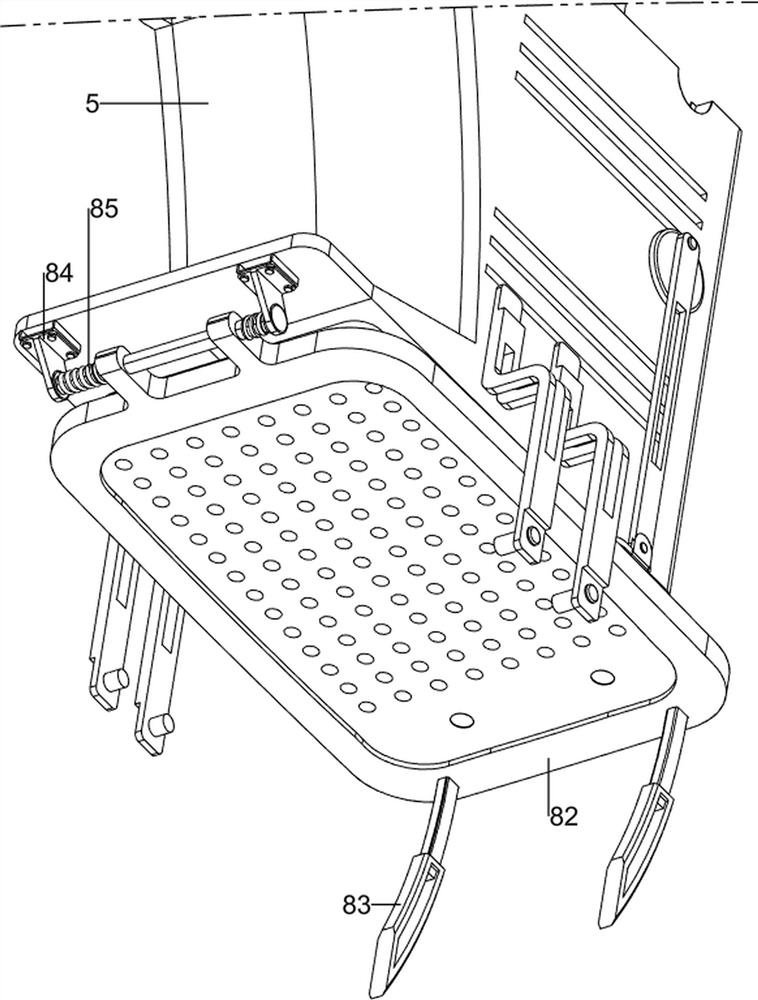

Solid smelting pretreatment equipment

InactiveCN109746076ATo achieve the effect of primary crushingEasy to smeltGrain treatmentsEngineeringPre treatment

The invention discloses solid smelting pretreatment equipment comprising an installing base. A smelting box is fixedly connected to the upper surface of the installing base. The inner bottom wall of the smelting box is provided with a discharge outlet. The upper surface of the installing base is provided with a heating cavity. An electric heating wire is fixedly installed on the inner wall of theheating cavity. Through the solid smelting pretreatment equipment, the effect of primary crushing of solid smelting materials is achieved, the smelting materials are crushed into small shapes and small sizes after crushed by primary crushing teeth, smelting is convenient, the shapes and sizes of the smelting materials are further limited, and smelting is convenient. The smelting materials can be effectively crushed by the rectangular-pyramid-shaped primary crushing teeth and advanced crushing teeth, a crushing rotor can be located rotationally, the shake problem caused by too large stress on the crushing rotor during rotary crushing is avoided, and thus the problems that smelting efficiency is liable to be lowered due to different shapes and sizes of solid smelting objects are solved effectively.

Owner:扬州市江都区正谊研磨工具厂

Alloy cast steel for high-speed train brake discs and high-speed train brake discs made of the alloy cast steel

The invention discloses an alloy cast steel used for a high-speed train brake disc and a high-speed train brake disc made of the alloy cast steel, its components and the weight percentage of each component are: according to claim 1 The alloy cast steel is characterized in that its components and the weight percentage of each component are: carbon 0.18-0.26%; silicon 0.30-0.50%; manganese 0.68-1.40%; phosphorus ≤ 0.025%; sulfur ≤0.013%; chromium 1.10~1.82%; nickel 0.90~1.50%; molybdenum 0.65~1.02%; The beneficial effects of the present invention are mainly reflected in: through the reasonable proportioning and heat treatment of alloying elements such as manganese, nickel, chromium, molybdenum, vanadium and the main components such as carbon and silicon in the cast steel material, the crystal grains are refined and the alloy casting is improved. The hardenability and thermal strength of the steel material, and the normal temperature strength and high temperature strength have been greatly improved, and it has excellent comprehensive mechanical properties. The brake disc manufactured by it can fully meet the technical requirements for the use of high-speed trains under working conditions.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Alloy cast steel for high-speed train brake disc and its heat treatment method, and high-speed train brake disc manufactured from the alloy cast steel

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Diphasic steel plate by continuous casting and rolling middle bar strip and manufacturing method thereof

ActiveCN101130847BSimple chemical compositionHigh tensile strengthMetal rolling arrangementsChemical compositionSheet steel

The present invention provides a dual phase steel sheet made up by using medium-thin sheet billet through a certain continuous-casting and continuous-rolling process. The component composition of said steel sheet includes (by wt%) 0.04%-0.11% of C, 0.02%-1.5% of Si, 0.6%-2.50% of Mn, 0.02%-2.0% of Cr, also can contain Mo or Ti, the rest is Fe and unavoidable impurity. The microscopic structure ofsaid steel sheet includes: matrix phase is ferrite and second phase mainly is martensite. Besides, said invention also provides the concrete operation steps of its production method.

Owner:ANGANG STEEL CO LTD

Extraction device for arsenic in copper smelting waste residues

PendingCN114570457AEasy to smeltImprove the extraction effectProcess efficiency improvementGrain treatmentsSlagMaterial distribution

The invention relates to an extraction device, in particular to an extraction device for arsenic in copper smelting waste residues. The technical problem to be solved is to provide an extraction device for arsenic in copper smelting waste slag, which can crush the waste slag so as to improve the extraction effect. According to the technical scheme, the extraction device for arsenic in the copper smelting waste residues comprises a containing box, a hot melting furnace, a material distribution box, a gas outlet frame, a material passing frame, a gas barreling mechanism and an explosion mechanism, the hot melting furnace is arranged on the upper side of the interior of the containing box, the material distribution box is arranged on the upper side of the containing box, a rotary disc is rotationally connected to the middle of the front side of the material distribution box, and the gas outlet frame is arranged on the left side of the material distribution box; a material passing frame is arranged between the upper portions of the front side and the rear side of the material distributing box, the front side and the rear side of the upper portion of the air outlet frame are each provided with two air barrel filling mechanisms in a threaded mode, and an explosion mechanism is arranged in the material passing frame. According to the arsenic extraction device, large-size waste residues can be extruded through the exploder, so that the crushed waste residues are smelted more easily, and the arsenic extraction effect is improved.

Owner:丁喜英

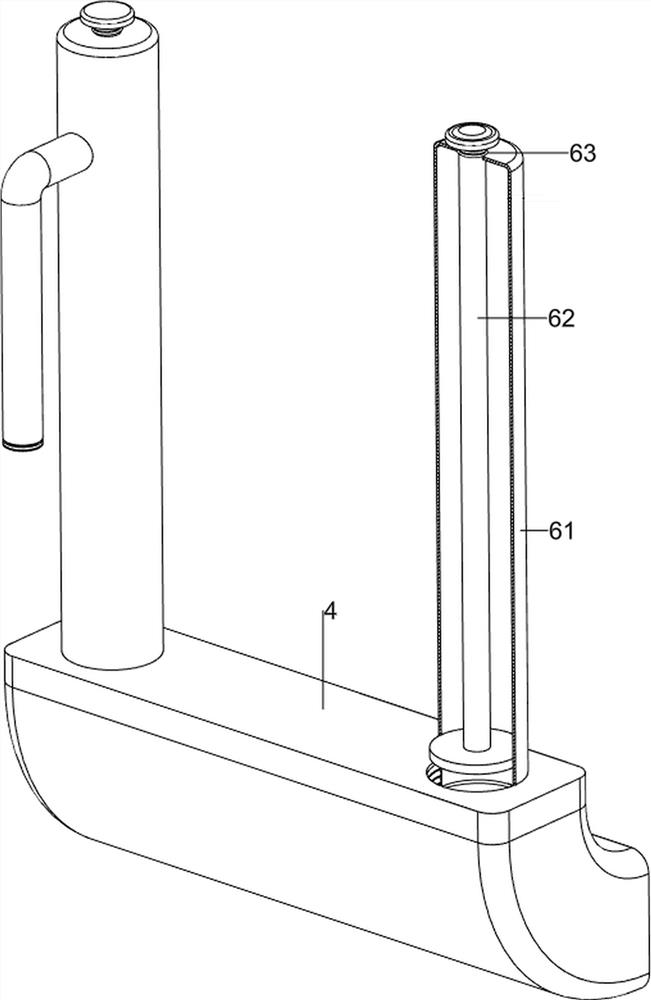

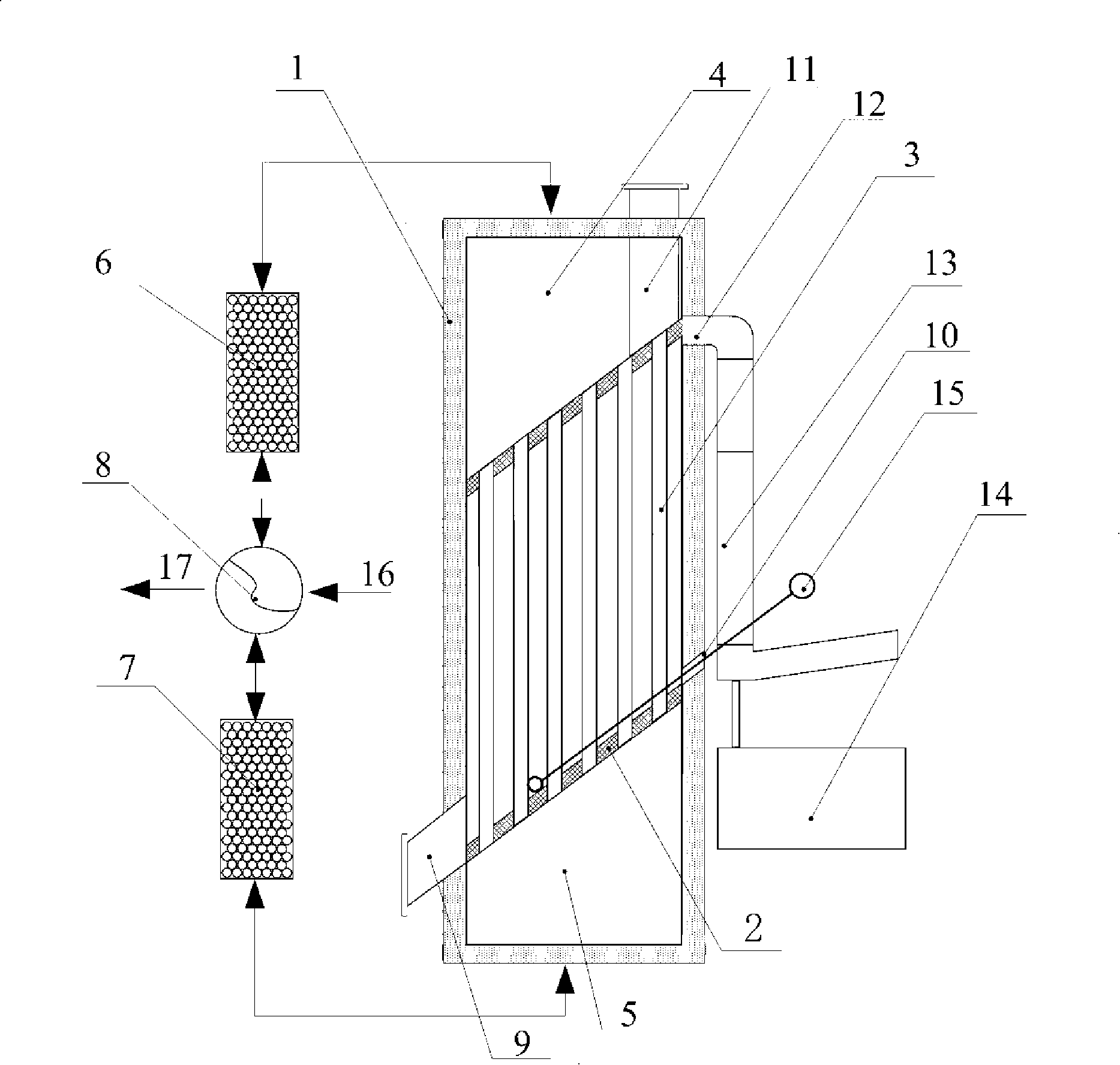

Vacuum metal smelting heat accumulation reducing furnace system

The invention discloses a vacuum regenerative and reduction furnace system for metal smelting, which comprises a reduction furnace (1), a reduction kettle (2), a regenerative burning system and a liquid-state metal collection system. The reduction kettle with a bevel bottom structure is provided with a radiation pipe (3) penetrating in the reduction kettle and is arranged at the middle section of the reduction furnace to divide the reduction furnace into an upper or a left combustion chamber (4) and a lower or a right combustion chamber (5), and the two combustion chambers are communicated with each other through the radiation pipe (3), so that the hot smoke in the combustion chambers can pass through the radiation pipe (3). The two combustion chambers are respectively connected with each other a regenerative combustion system, which is used for storing the heat of smoke discharged from the reduction furnace after heating materials through the radiation pipe and for controlling the alternate combustion of the combustion chambers and the flow direction of the high-temperature gas in the radiation pipe. A reduction material in the reduction kettle produces a metal vapor after reduction reaction, and the metal vapor is collected by the liquid-state metal collection system and is directly cast or conveyed to a refining furnace. The invention has the advantages of high heat utilization rate, good power saving effect, complete combustion and short reduction reaction time.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com