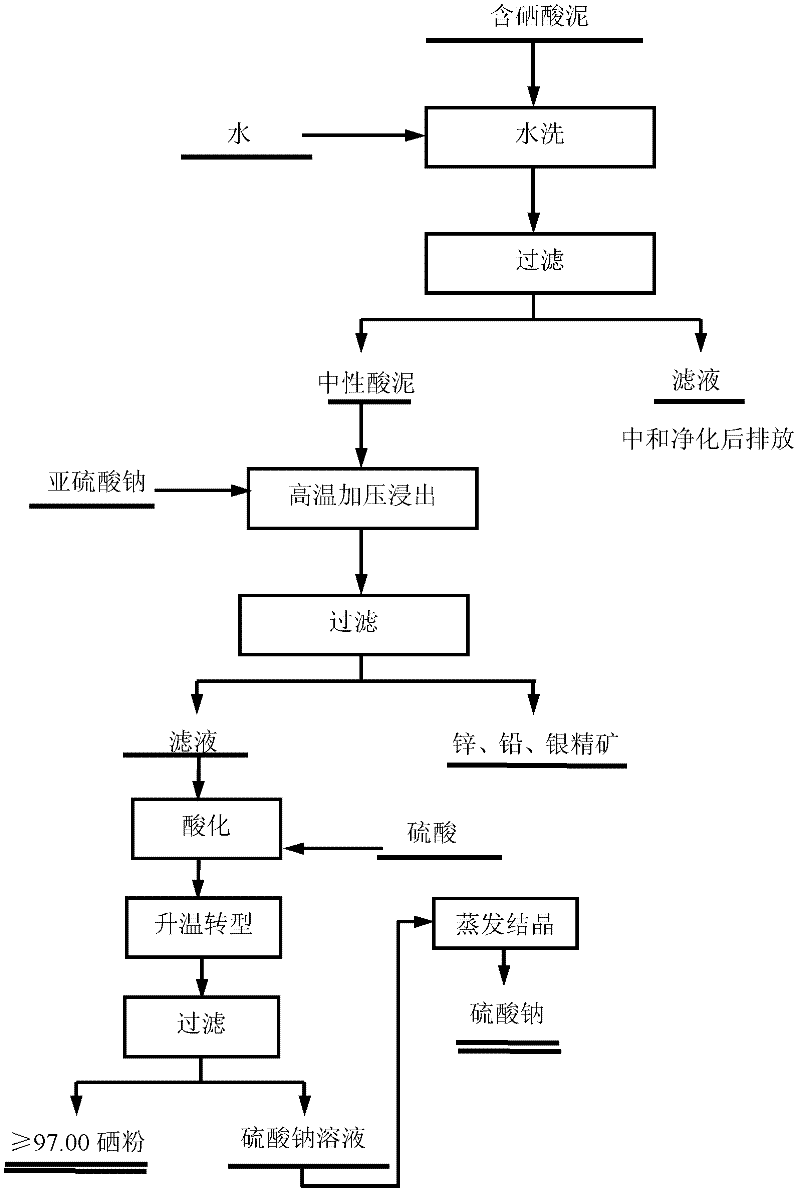

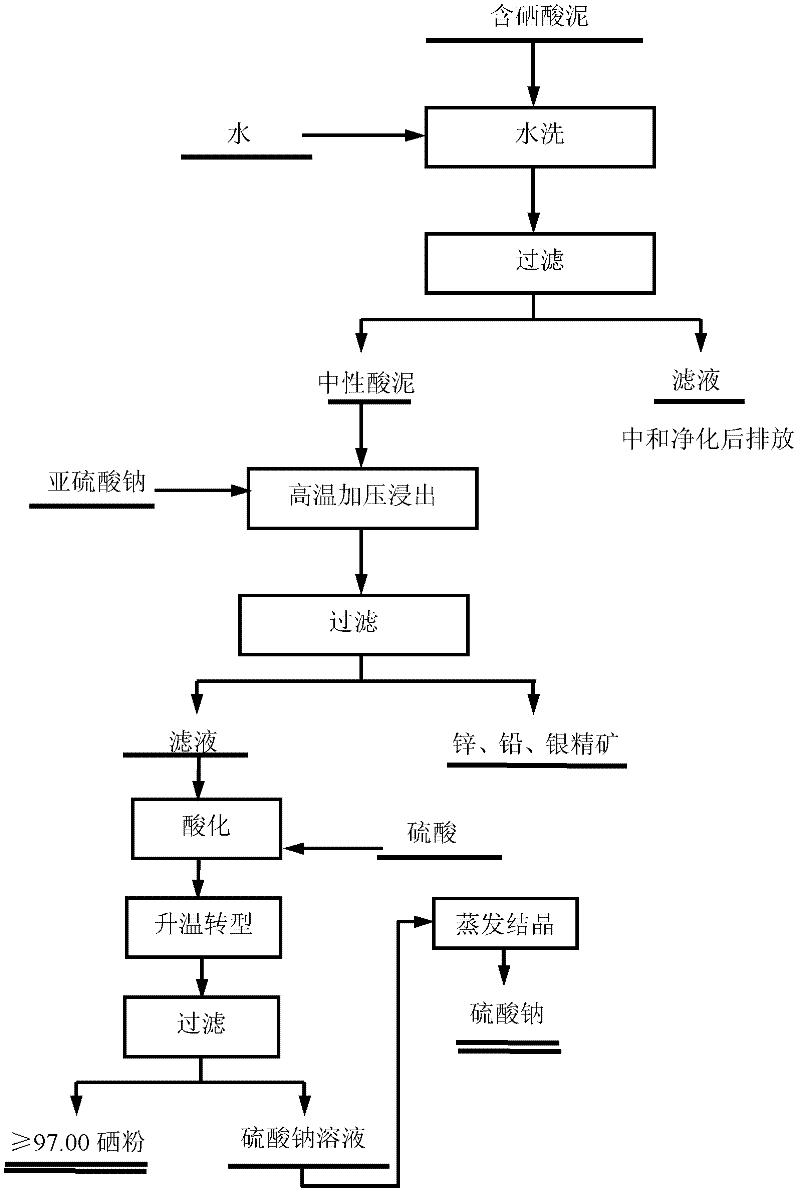

Method for leaching selenium in acid mud by using sodium sulfite

A technology of sodium sulfite and acid sludge, applied in the direction of element selenium/tellurium, can solve the problems of long process flow, high cost, difficult recovery of waste acid and waste liquid, etc., and achieve the effect of short process flow, low cost and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1. The selenium content in the acid mud is 13.50%, the iron content is 5.40%, the zinc content is 28.45%, the lead content is 18.42%, and the silver content is 2.50%. This acid mud is used as a raw material for high temperature and pressure leaching.

[0013] Mix the acid mud with industrial water and put it into the mixing tank for water washing. Control the liquid-solid ratio to 5:1, the temperature is 50-55°C, the reaction time is 0.5h and then filtered, repeat this process 3 times until the acid mud reaches neutrality. The filtrate is discharged after neutralization and purification, and the neutral acid mud enters the high temperature and pressure leaching process. Mix the obtained neutral acid mud with sodium sulfite and industrial water, put it into an autoclave, and blow nitrogen into it. The liquid-solid ratio is controlled at 3:1, the concentration of sodium sulfite is 180g / L, the temperature is 120-125°C, the reaction time is 1.5h, and the pressure i...

Embodiment 2

[0014] Example 2. The selenium content in the acid mud is 14.70%, 4.40% iron, 30.45% zinc, 19.40% lead, and 3.20% silver. This acid mud is used as raw material for high temperature and pressure leaching.

[0015] Mix the acid mud with industrial water and put it into the mixing tank for water washing. Control the liquid-solid ratio to 5:1, the temperature is 55-60°C, the reaction time is 1.0h, and then filter, repeat this process 3 times until the acid mud reaches neutrality. The filtrate is discharged after neutralization and purification, and the neutral acid mud enters the high temperature and pressure leaching process. Mix the obtained neutral acid mud with sodium sulfite and industrial water, put it into an autoclave, and blow nitrogen into it. The liquid-solid ratio is controlled at 4:1, the concentration of sodium sulfite is 190g / L, the temperature is 130-135°C, the reaction time is 2.0h, and the pressure is 0.6MPa. After the reaction is finished, the pressure is lowe...

Embodiment 3

[0016] Embodiment 3, the content of selenium in acid mud is 15.20%, iron 4.60%, zinc 31.40%, lead 19.48%, silver 3.60%. This acid mud is used as raw material for high temperature and pressure leaching.

[0017] Mix the acid mud with industrial water and put it into the mixing tank for water washing. Control the liquid-solid ratio to 5:1, the temperature is 60-65°C, the reaction time is 1.5h, and then filter. Repeat this process 3 times until the acid mud reaches neutrality. The filtrate is discharged after neutralization and purification, and the neutral acid mud enters the high temperature and pressure leaching process. Mix the obtained neutral acid mud with sodium sulfite and industrial water, put it into an autoclave, and blow nitrogen into it. The liquid-solid ratio is controlled at 5:1, the concentration of sodium sulfite is 210g / L, the temperature is 135-140°C, the reaction time is 2.0h, and the pressure is 0.7MPa. After the reaction is finished, the pressure is lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com