Patents

Literature

341results about How to "High separation factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

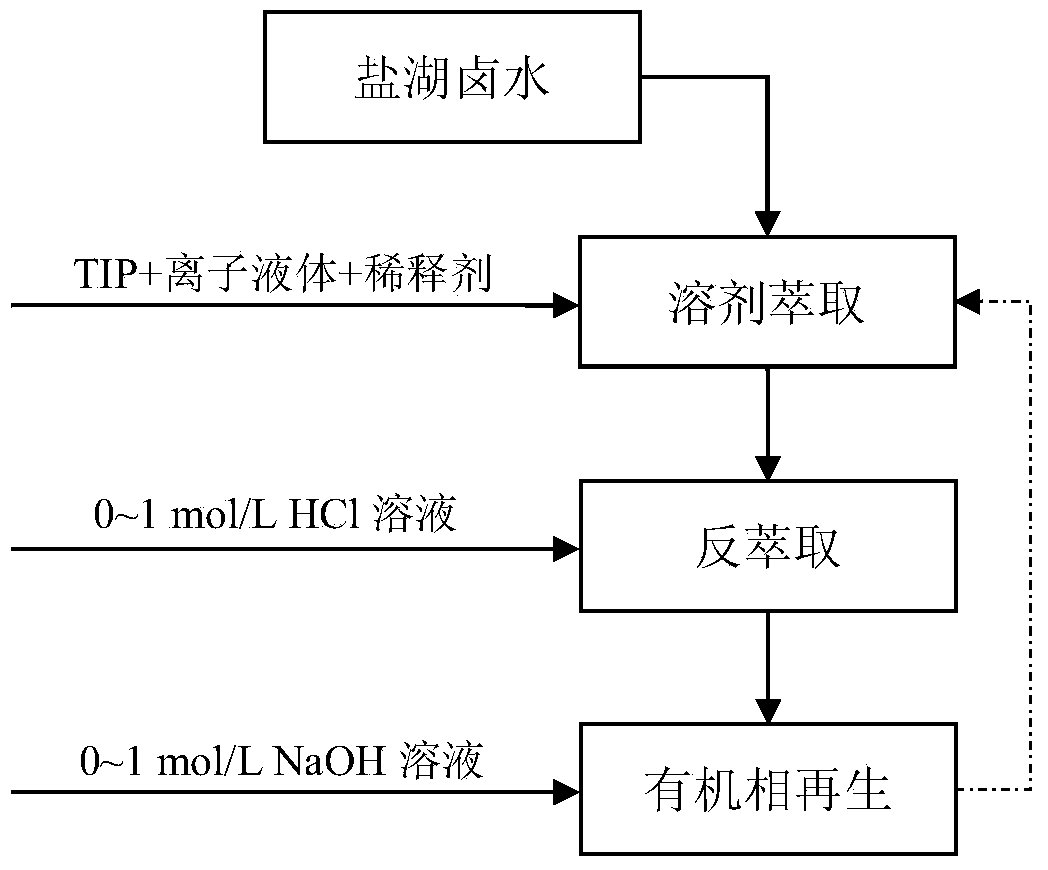

Method for efficiently extracting lithium from salt lake brine

ActiveCN103710549AAvoid interferenceHigh separation factorProcess efficiency improvementSeparation factorIonic liquid

The invention relates to a method for efficiently extracting lithium from salt lake brine. The method comprises the following steps: (1) forming an extraction organic phase by an extraction agent, a co-extraction agent and a diluent, and then mixing the extraction organic phase with salt lake brine according to the volume ratio of (3-4):2 for three-stage extraction with single extraction time being 2-10 minutes to obtain an organic phase; and (2) mixing the organic phase obtained in step (1) with a reverse extraction acid solution (0-1 mol / L) for three-stage reverse extraction with single reverse extraction time being 2-10 minutes, and collecting an aqueous phase which is an aqueous solution containing lithium ions. The co-extraction agent of an extraction system of the method is hydrophobic ionic liquid, compared with conventional synergist ferric trichloride, the interference caused by iron ions is avoided, the reverse extraction acidity is greatly reduced, more importantly the lithium-magnesium separation factor is significantly improved, and the elution step of magnesium ions is reduced; in addition, the method provided by the invention is easy in process, easy to control, high in operation reliability, and good in recyclability of the organic phase, and greatly reduces the production cost for extracting the lithium from the salt lake brine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

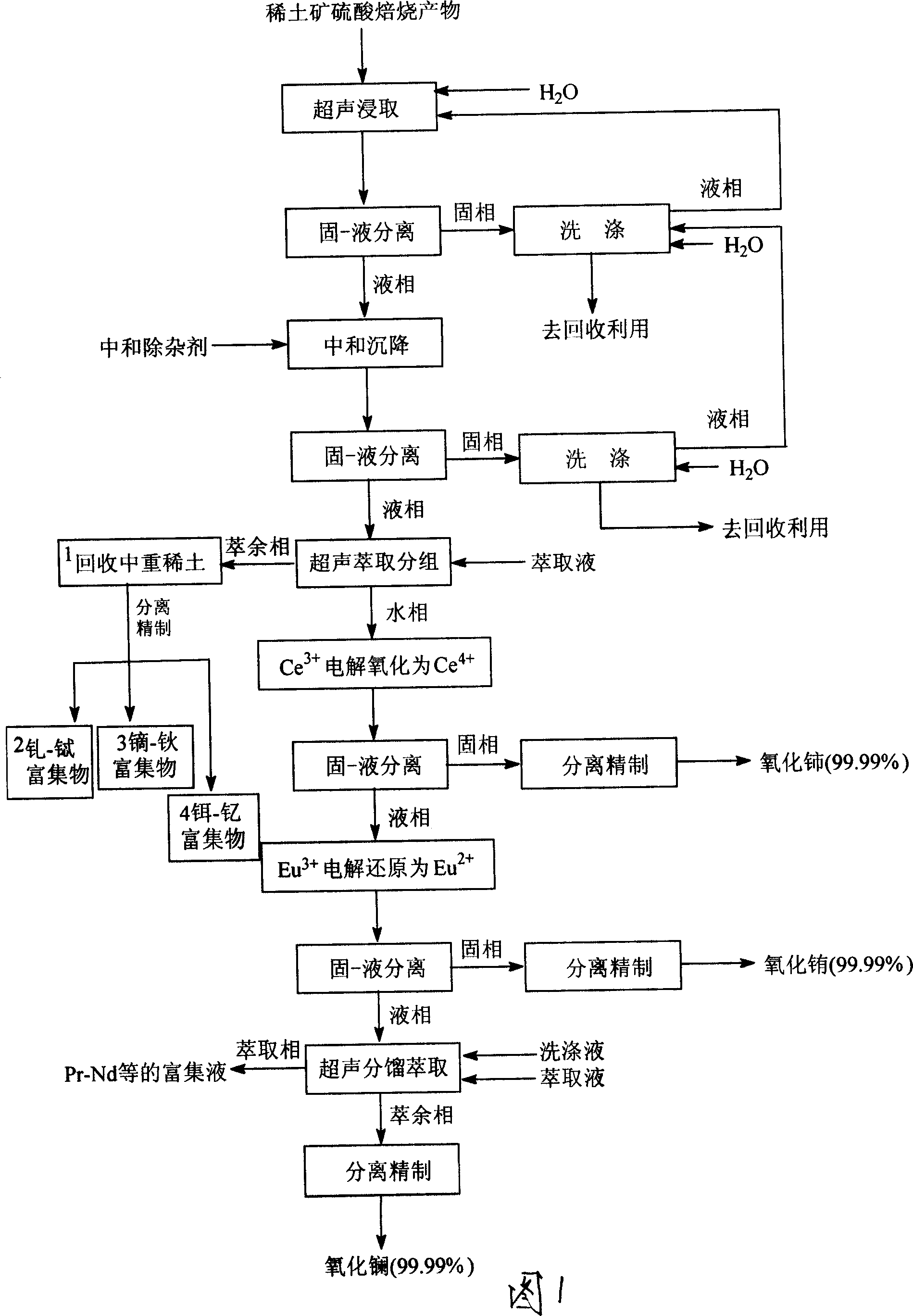

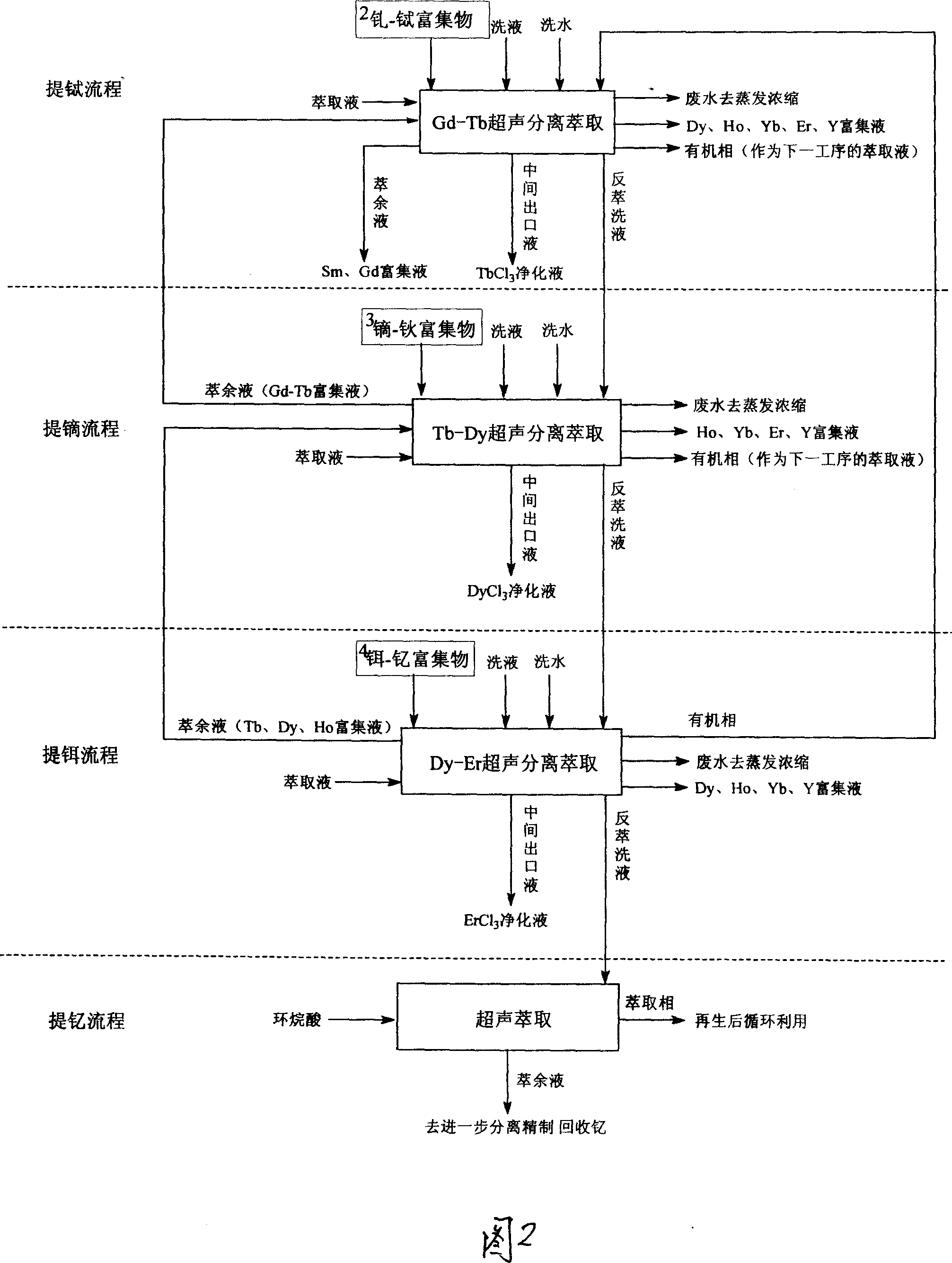

Method for separating highly-pure rare-earth oxide from sulphating roasting rare earth mine

InactiveCN101012499AHigh recovery rateAvoid generatingProcess efficiency improvementElectrochemical responseChemical treatment

The invention discloses a full-separating method of high-purity rare earth oxide from rare earth rare earth ore reinforced and sintered by sulfuric acid, which is characterized by the following: producing La2O3, Ce2O3, Pr5O11, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb4O7, Dy2O3 and Y2O3 through ultrasonic extracting-electrochemical quantivalence-changing synthetic separating technique; oxidizing Ce3+ into Ce4+; reducing Eu3+ into Eu2+ t oseparate from other tervalent rare earths.

Owner:YANGZHOU UNIV +2

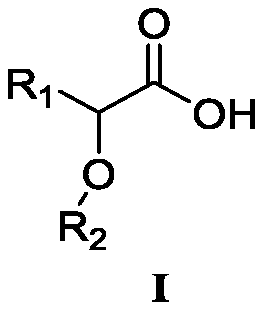

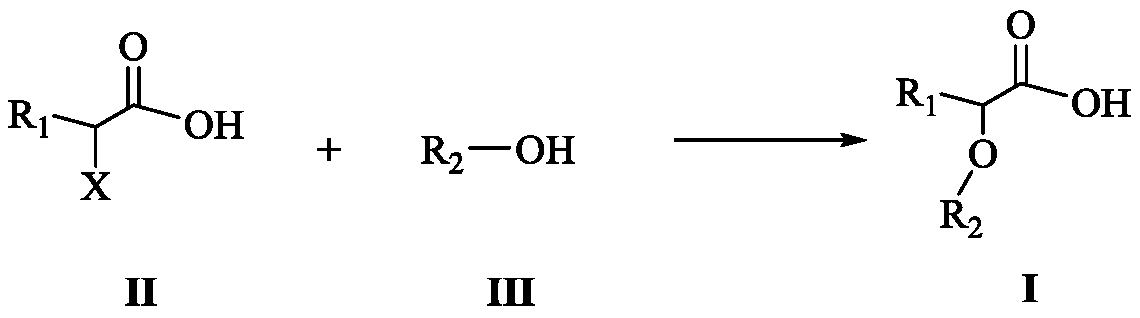

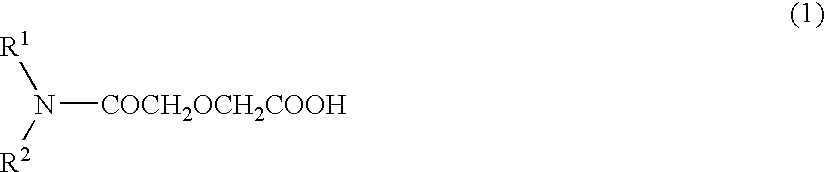

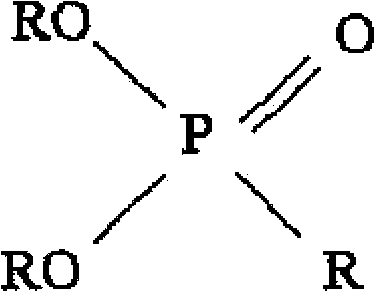

Carboxylic acid compound as well as preparation method and application thereof

ActiveCN111592459AHigh separation factorHigh load rateOrganic compound preparationCarboxylic compound preparationCarboxylic acidAqueous solubility

The invention discloses a carboxylic acid compound as well as a preparation method and application thereof. When the carboxylic acid compound is applied to extraction separation of metal ions, the separation coefficient is high, the reverse extraction acidity is low, the load rate is high, and the reverse extraction rate is high. The carboxylic acid compound serving as an extraction agent is highin stability and low in water solubility, so that the extraction process is stable, the environmental pollution can be reduced, and the cost is reduced. The carboxylic acid compound disclosed by the invention is low in cost, has a great application prospect and can be used for various systems such as ternary battery recovery and battery-grade nickel sulfate preparation.

Owner:BOTREE CYCLING SCI & TECH CO LTD

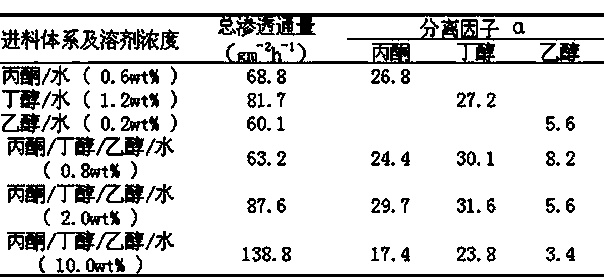

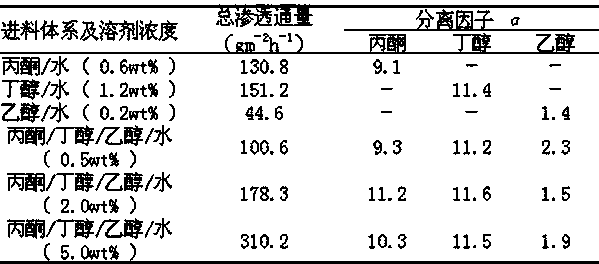

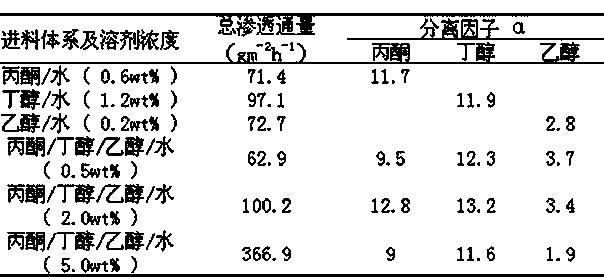

Porous granule MCM-41-ZIF-8/PDMS pervaporation hybrid membrane, preparation and application

The invention relates to a porous granule MCM-41-ZIF-8 / PDMS pervaporation hybrid membrane, preparation and application, and belongs to the technical field of membrane separation. According to the invention, silicon hydroxyl enriched on the surface of a mesoporous molecular sieve MCM-41 is used, and a vacuum in-situ growth method is adopted to synthesize metal-organic framework material namely micropore ZIF-8 on the surface of the mesoporous molecular sieve MCM-41, so that porous granules containing mesoporous-micropore passages are prepared; silazane is adopted to further improve the hydrophobic modification of the porous granule MCM-41-ZIF-8, and the porous granule MCM-41-ZIF-8 is mixed with PDMS, then a membrane scraping method is adopted to prepare the pervaporation hybrid composite membrane on a polysulfone base membrane, the holes of which are blocked by deionized water, and the pervaporation hybrid composite membrane is used for the separation of ethyl alcohol / water system. The large aperture of MCM-41 and adsorbability of the ZIF-8 are used to promote alcohol molecules to adsorb on the surface of the membrane and to diffuse in the porous granule pore passages, and the defect of Trade-off phenomenon between separation factors and permeation flux is overcome, therefore, the separation performance of the hybrid membrane is improved. The porous granule MCM-41-ZIF-8 / PDMS pervaporation hybrid membrane has the advantages that the synthesis method of the porous granules is simple, the membrane preparation technology is simple and feasible, and a better industrial application prospect is achieved.

Owner:BEIJING UNIV OF TECH

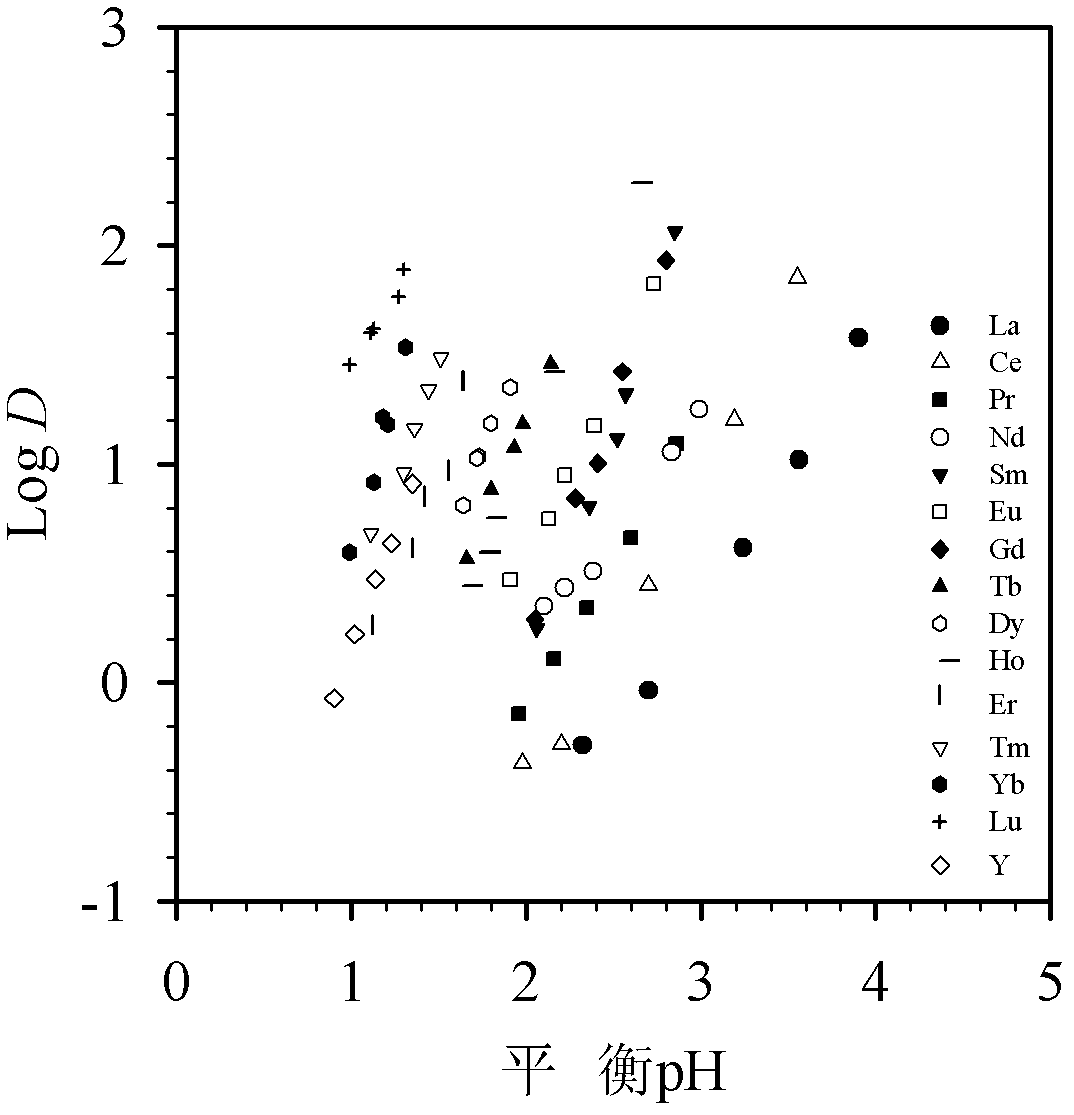

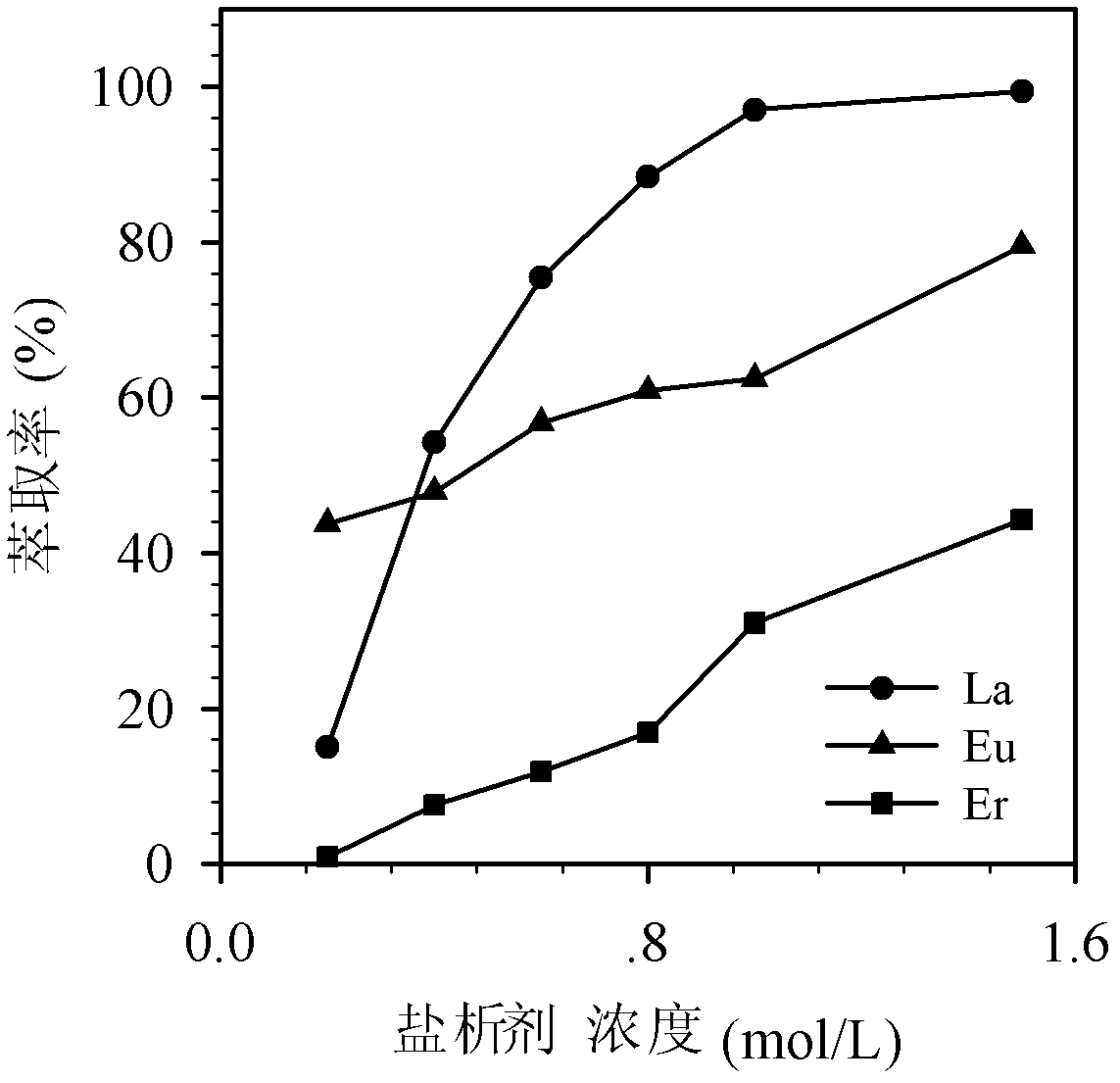

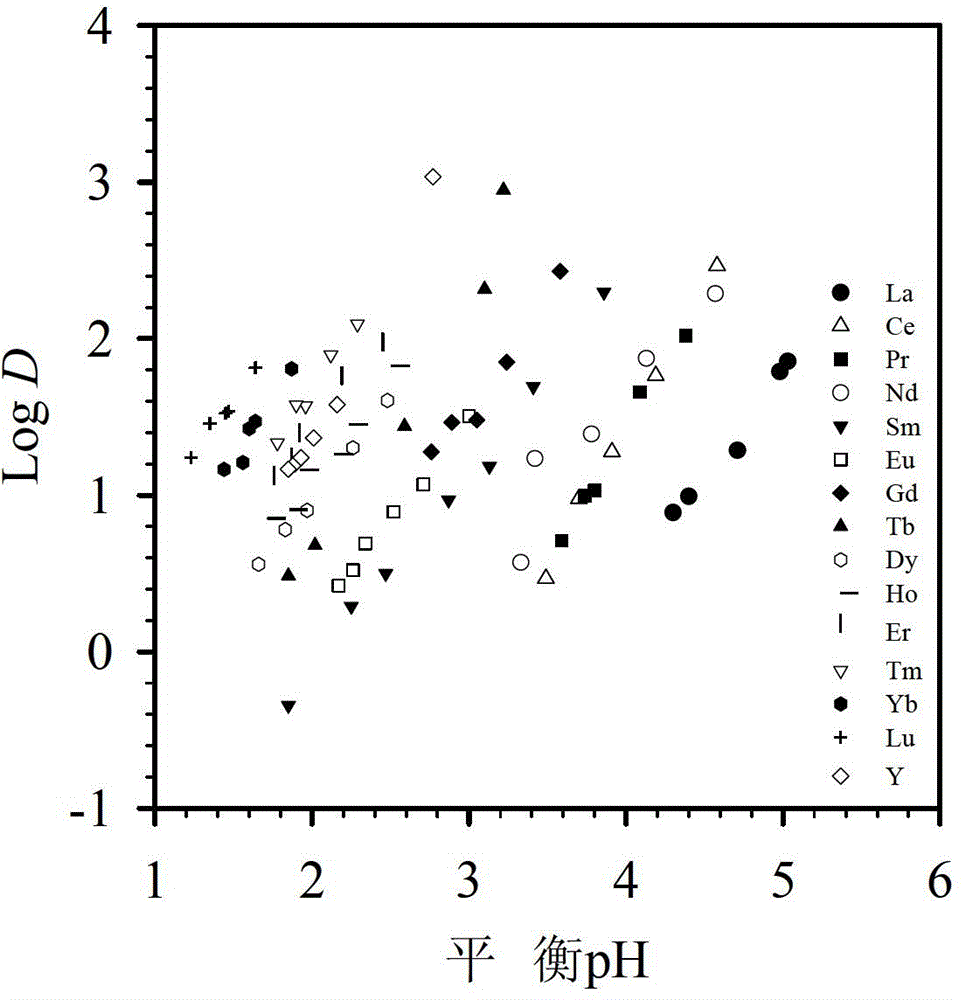

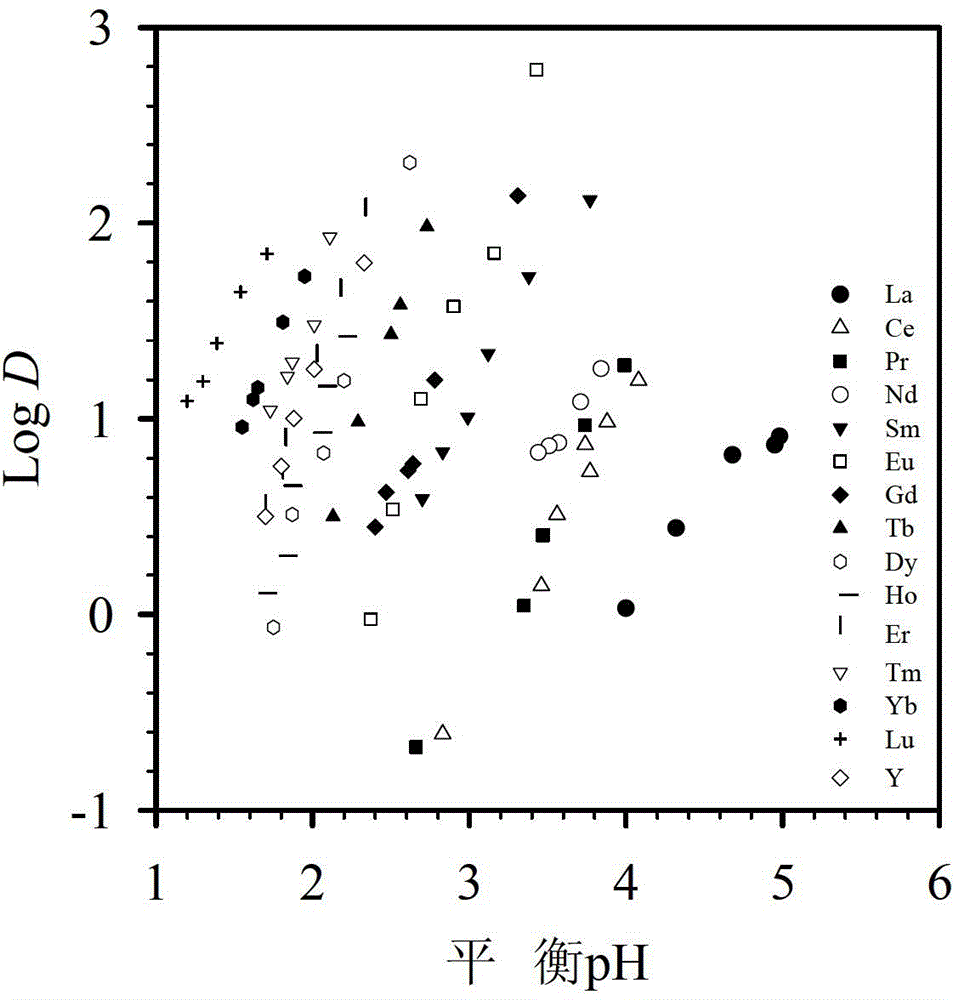

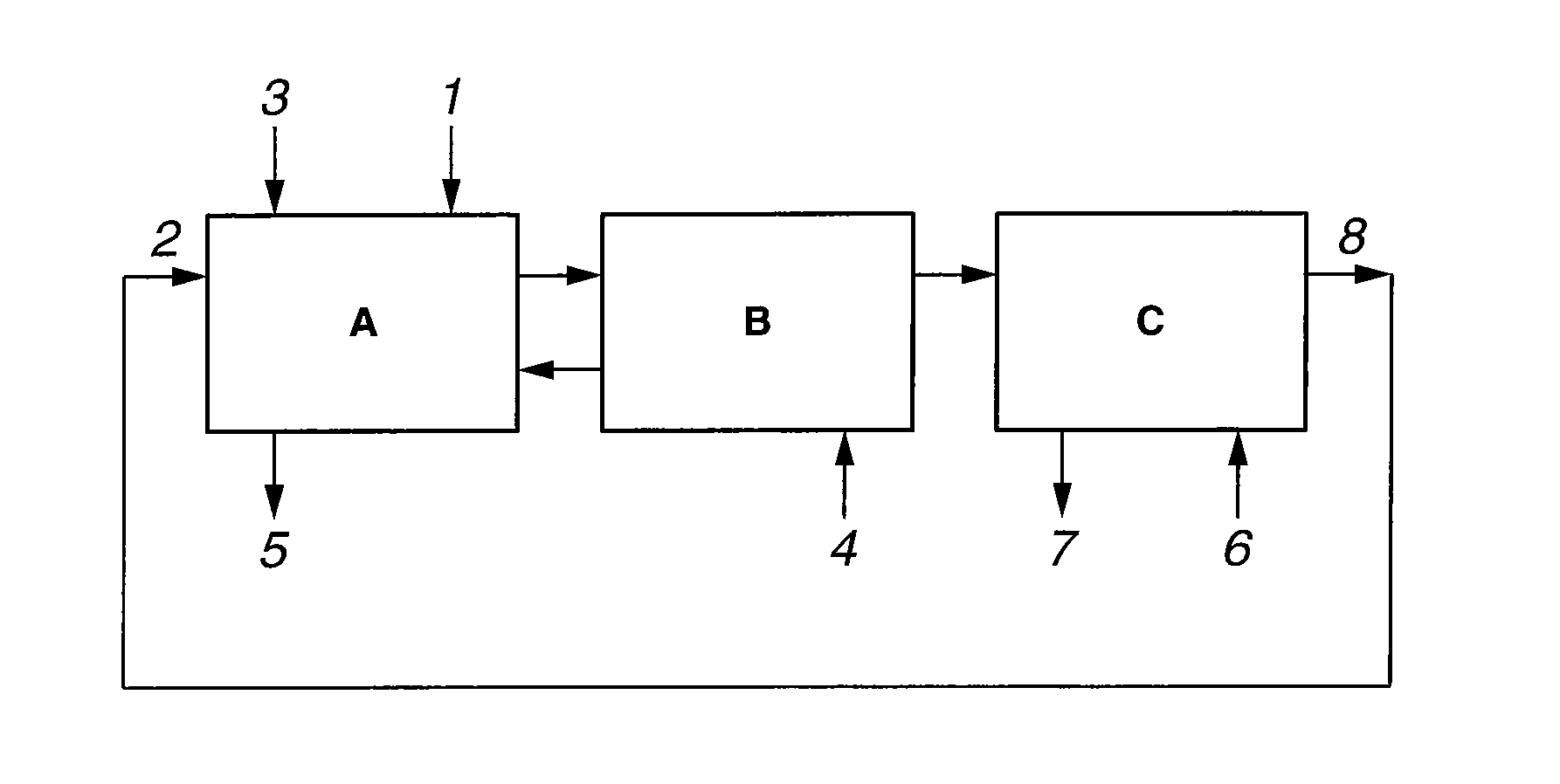

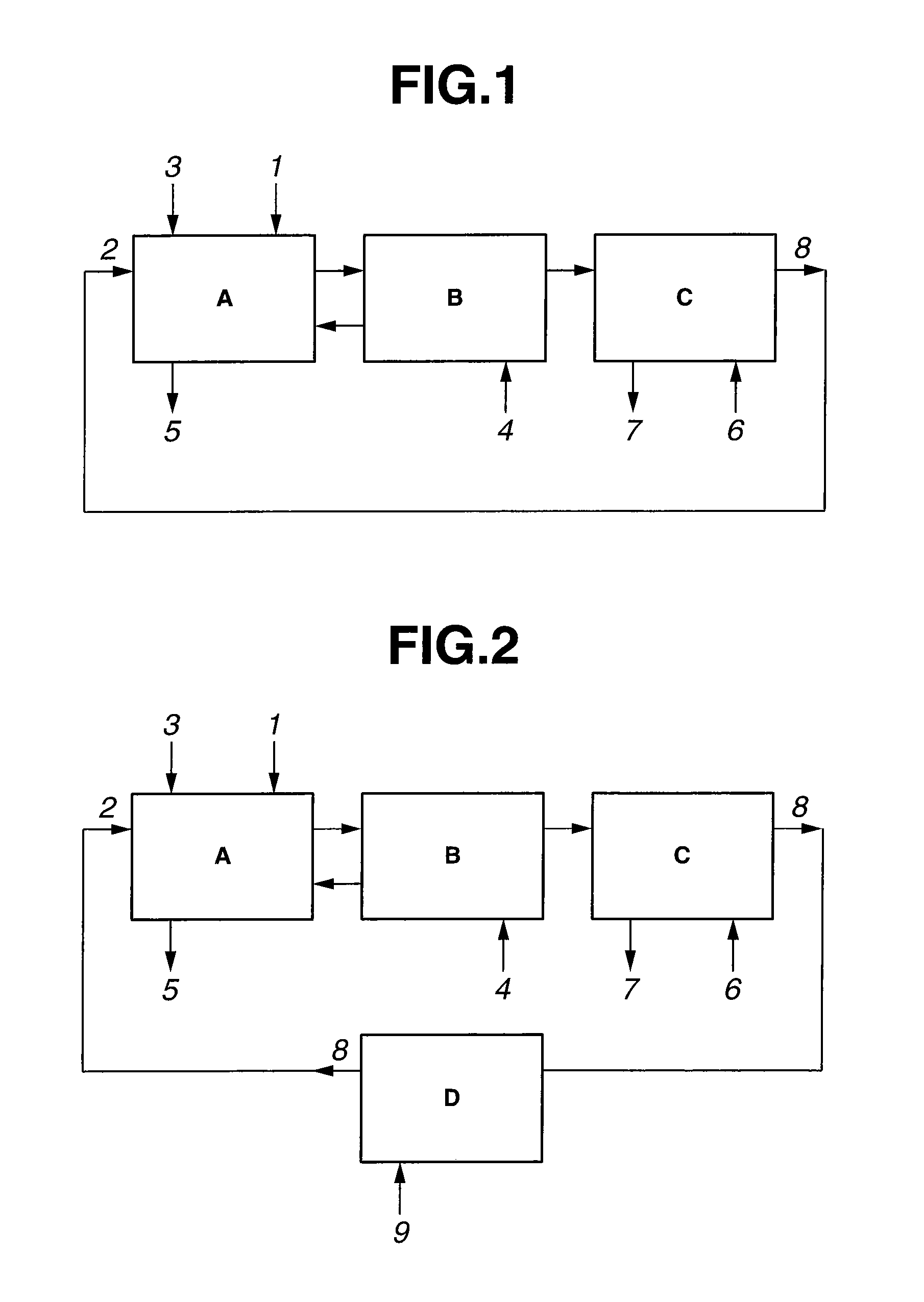

Method for extracting and separating rare earth elements

ActiveUS20100319491A1High separation factorReduce investmentRare earth metal compoundsProcess efficiency improvementRare-earth elementSolvent

Solvent extraction from an aqueous phase containing first and second rare earth elements is carried out by contacting an organic phase containing a diglycolamic acid as an extractant and a hydrocarbon or a low-polar alcohol as a solvent, with the aqueous phase below pH 3 for extracting the first rare earth element into the organic phase, back-extracting from the organic phase with an aqueous acid solution for recovering the first rare earth element, and recovering the second rare earth element which has not been extracted into the organic phase and has remained in the aqueous phase.

Owner:SHIN ETSU CHEM CO LTD +1

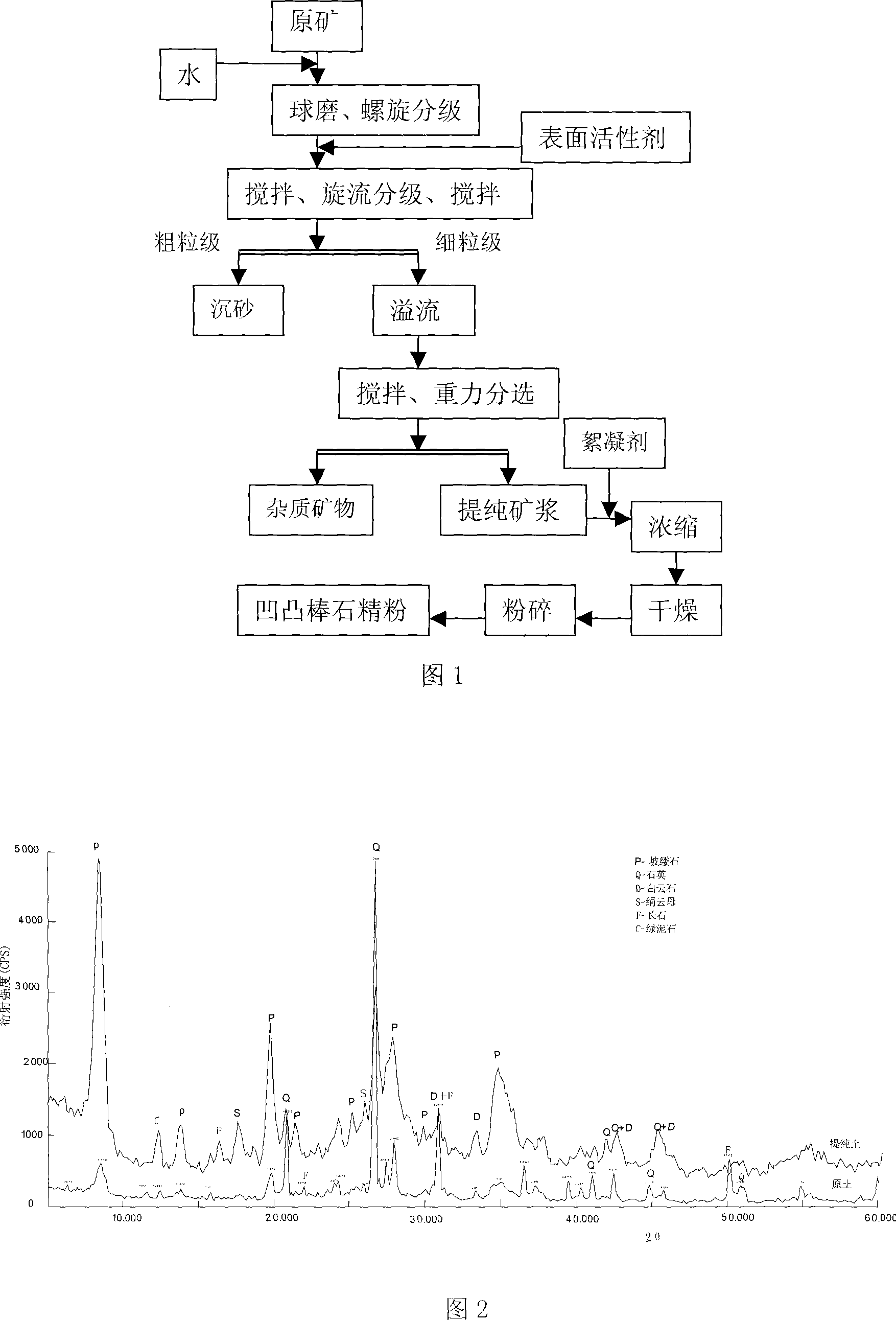

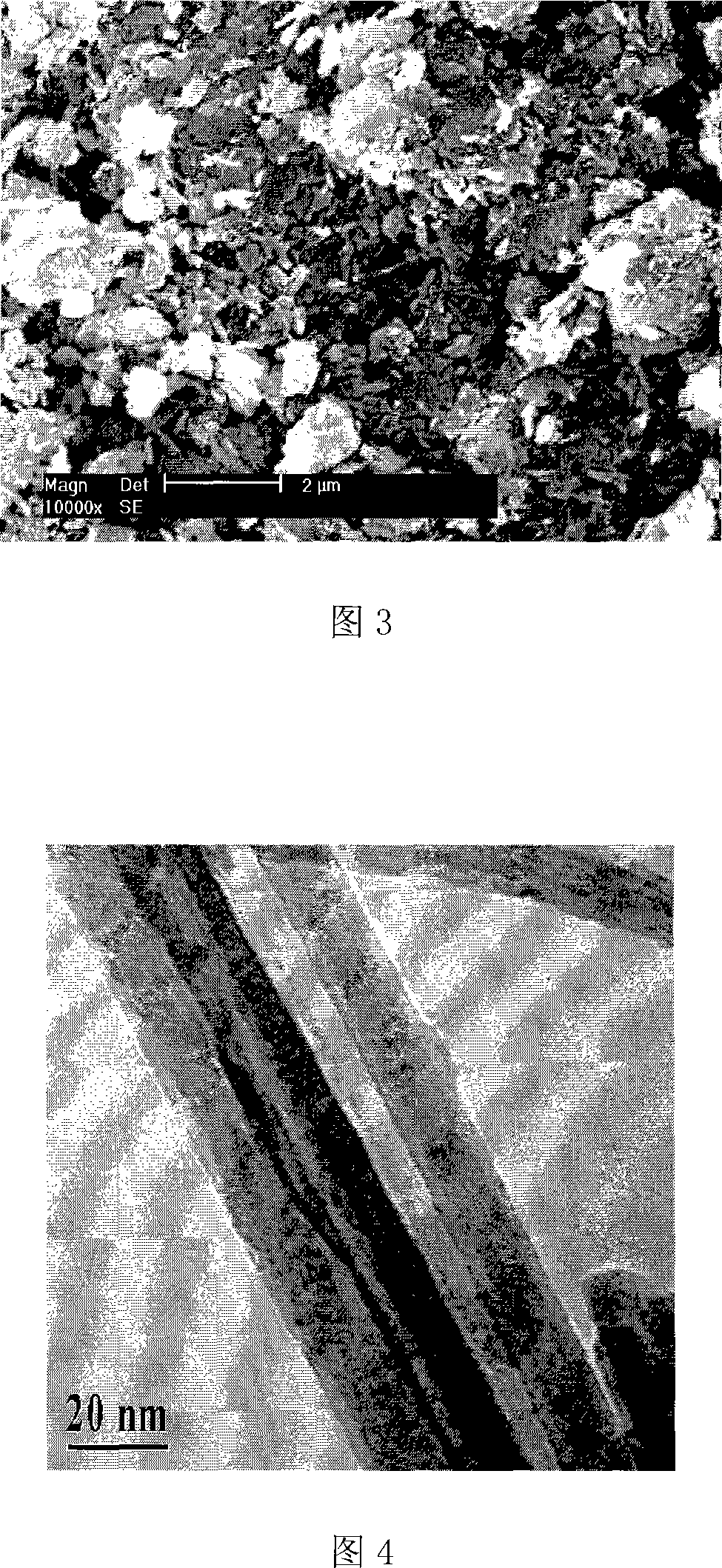

Method for purifying and processing attapulgite clay mineral

InactiveCN101214968AMeet the needs of industrial mineral processing and purificationEase of industrial productionEnergy inputSilicon compoundsSeparation factorClay minerals

The invention relates to a purifying and processing method of attapulgite clay minerals, which belongs to the technical field of the wet separating technique of minerals. The specific steps comprise utilizing spiral classifier for primary purification, utilizing cyclone classifier for secondary purification, employing gravity separation equipment for three-stage purification, concentration, drying and disintegration, thereby preparing ultrafine powders of the purified attapulgite clay minerals with the average particle size of 0.93-2.0 micron, and particle size of the largest particle is 3.5-5.0 micron. The method employs spiral classifier to remove the partly impure minerals with bigger particles in raw ores in advance, reinforcing the dispersion effect and the difference of suspension property of the attapulgites and impure minerals by means of surfactants, increasing separation factor, utilizing gravity separation equipment to separate the impure minerals and the attapulgite clay minerals efficiently, thereby overcoming the shortcomings that the prior art is difficult to achieve industrial production and obtain qualified purification products.

Owner:HEBEI UNIV OF TECH

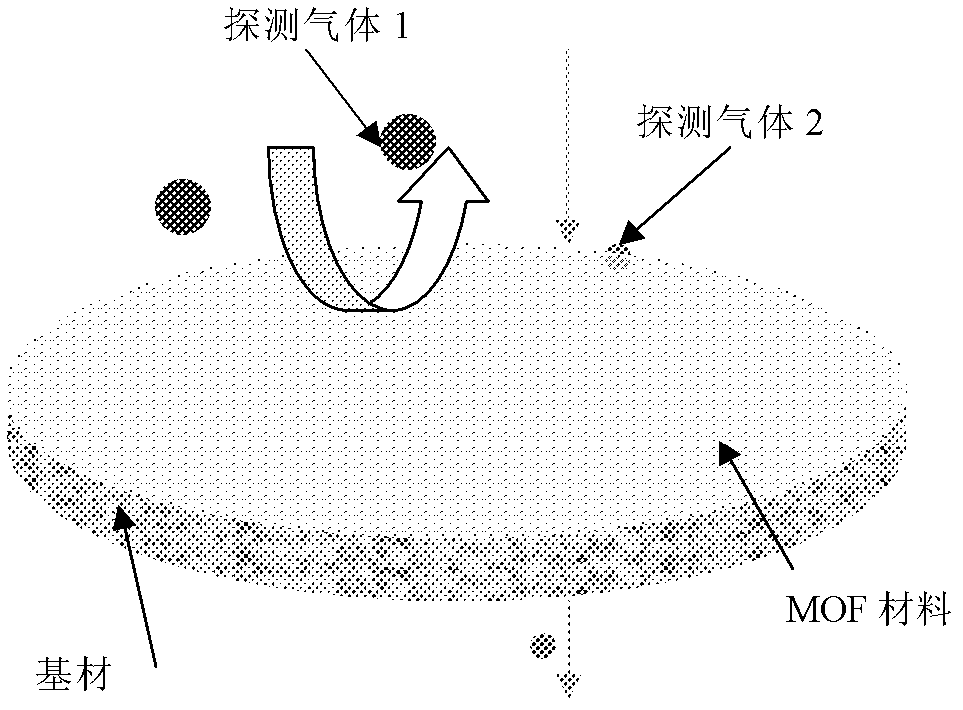

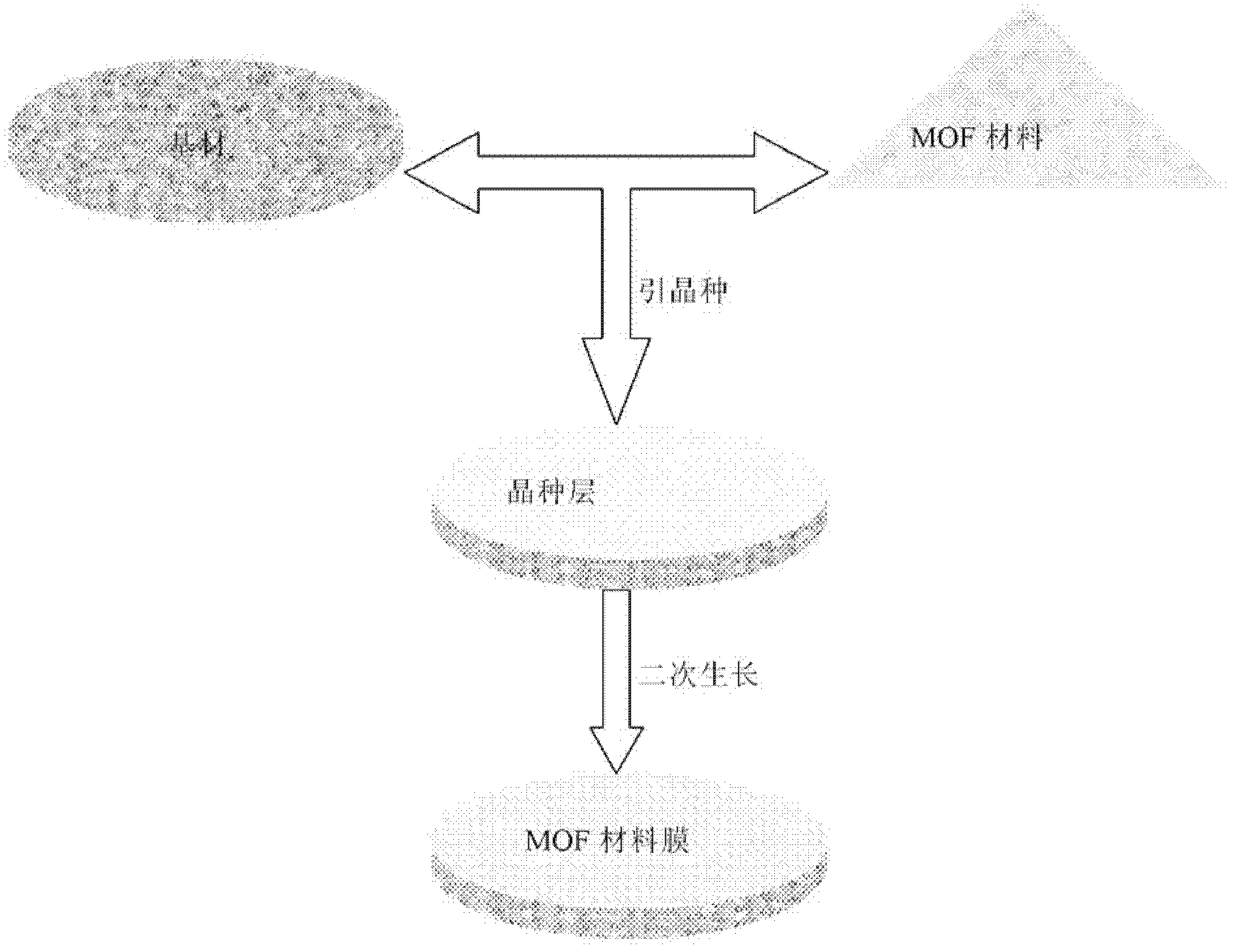

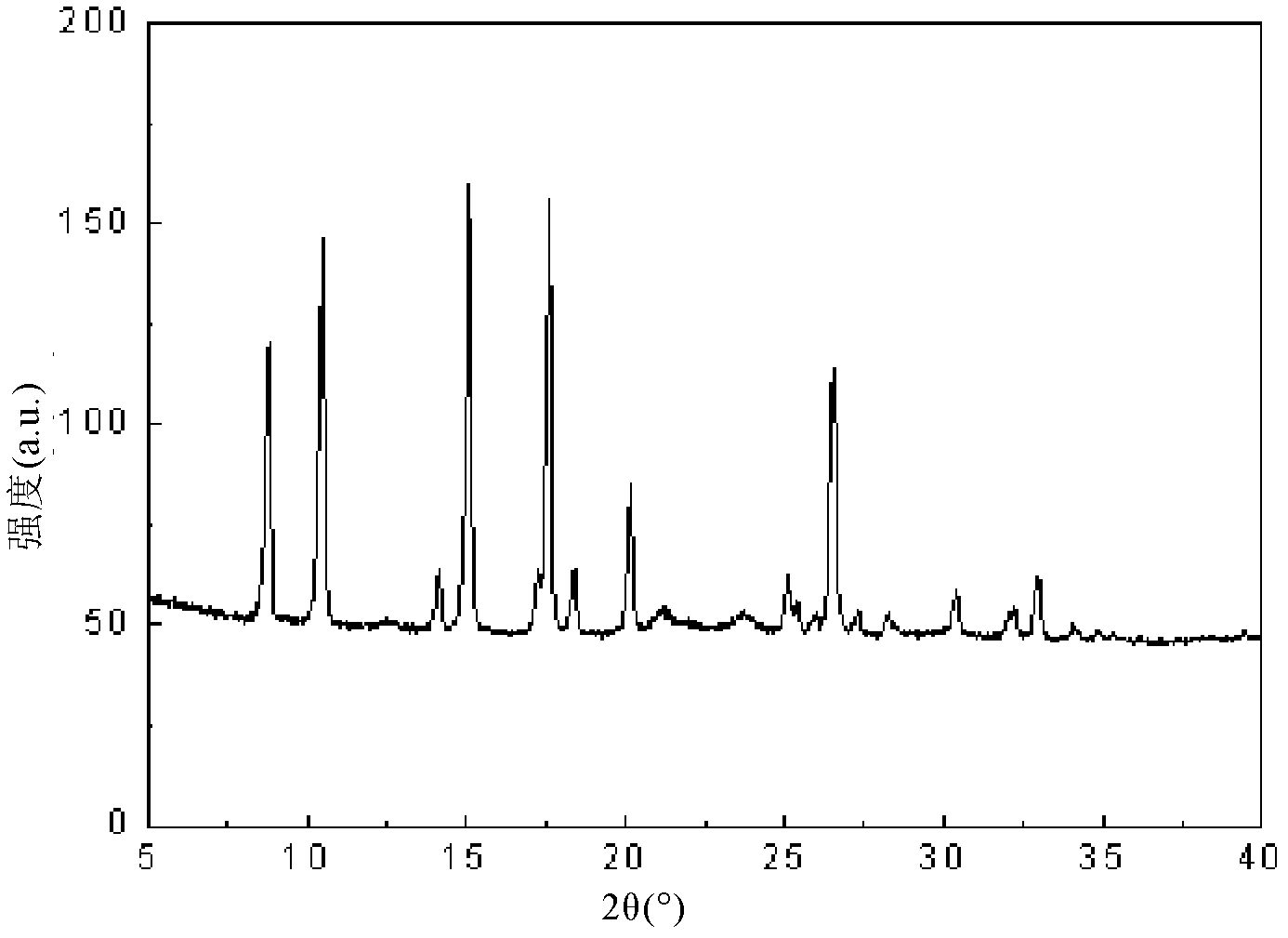

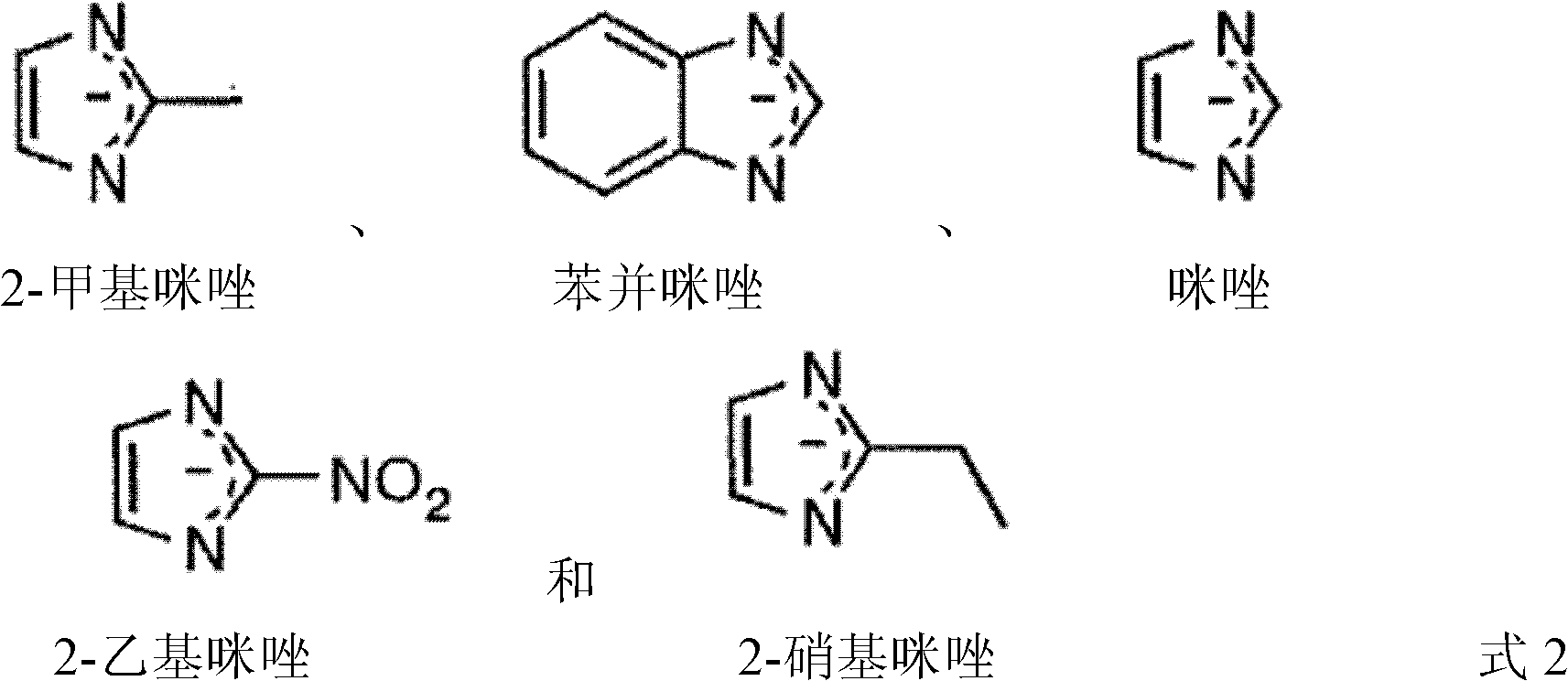

Metal-organic framework (MOF) material for permeating and separating gases and preparation method thereof

ActiveCN102489183AEasy to manufactureWell formedSemi-permeable membranesDispersed particle separationMetal-organic frameworkPermeation

The invention discloses a metal-organic framework (MOF) material for permeating and separating gases and a preparation method thereof. Specifically, an MOF film disclosed by the invention is provided with a functional group, which contributes to nucleating on a substrate, increase the nucleating density on the substrate and contributes to the growth of a dense film; and the functional group can coact with certain specific gases, so that selective permeation of gases is facilitated. Due to the adoption of a film preparation method disclosed by the invention, the growing process of the film is simplified, the structure and shape of the film are optimized simultaneously, and film permeating and separating performance is enhanced. The MOF film prepared with the method has the advantages of high permeation amount, high separating coefficient, low energy consumption and avoidance of secondary pollution, and is particularly suitable for permeating and separating gases such as H2, CO2, CH4 and the like.

Owner:宁波大膜科技有限公司

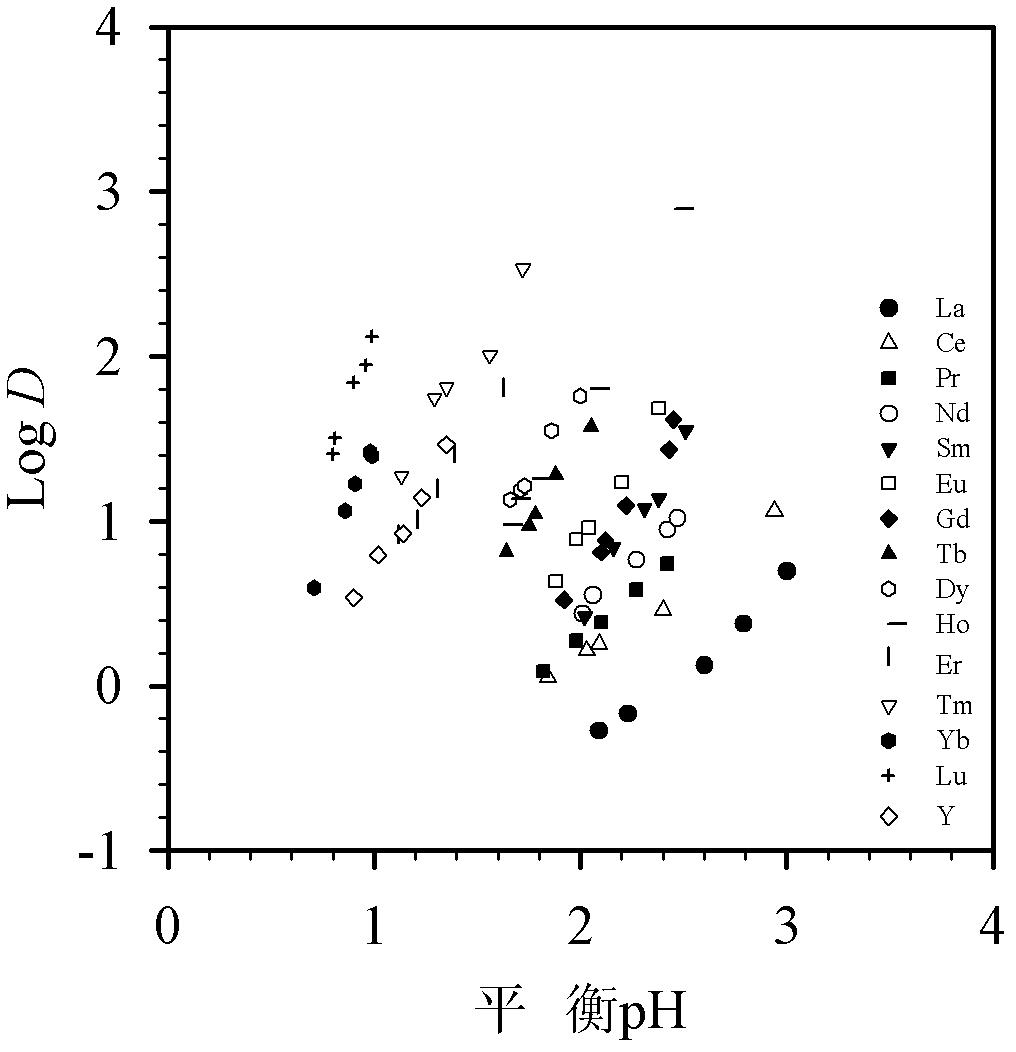

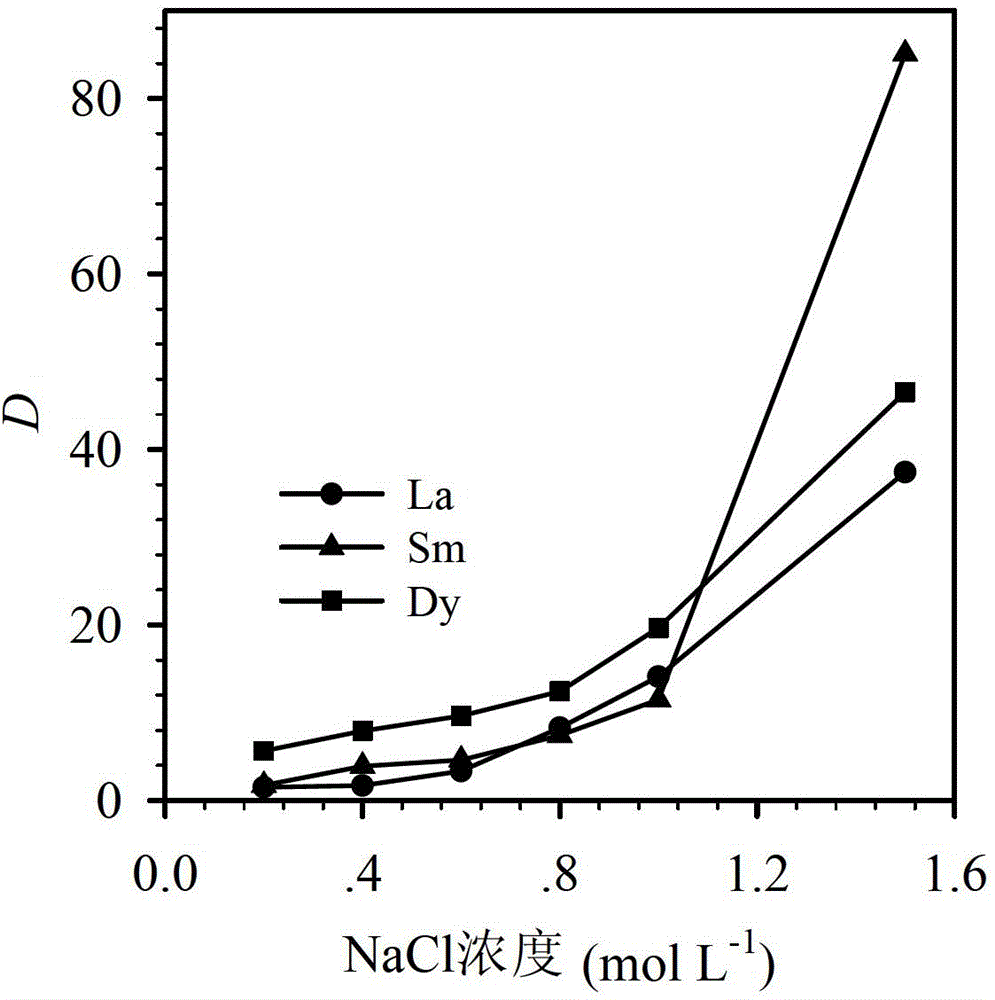

Extraction seperation method of rare-earth element

ActiveCN102618736AHigh separation factorLow extraction acidityProcess efficiency improvementRare-earth elementRare earth ions

The invention discloses an extraction seperation method of a rare-earth element. According to extraction seperation method, positive ions and negative ions in a quaternary ammonium salt ionic liquid extracting agent, i.e. 2-ethylhexyl phosphonic acid mono 2-ethylhexyl ester trialkyl methyl ammonium and phosphonic acid binary (2-ethylhexyl) ester trialkyl methyl ammonium react with rare earth ions to form neutral complex molecules, and the positive ions and negative ions in the quaternary ammonium salt ionic liquid extracting agent have inner synergistic effect and competitive effect in the process of extracting the rare-earth element, thereby the seperation factor of the rare-earth element is increased. Therefore, the extraction seperation method provided by the invention has the advantages that an interfacial phenomenon is good in the extraction process, no emulsification is generated, and an extracting solvent does not need to be saponified, the extraction seperation method has higher seperation factor of the rare-earth element and particularly high extraction seperation effect on heavy rare earth. In addition, the extraction seperation method of the rare-earth element, which is provided by the invention, has low extraction acidity and back extraction acidity and consumes little acid.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

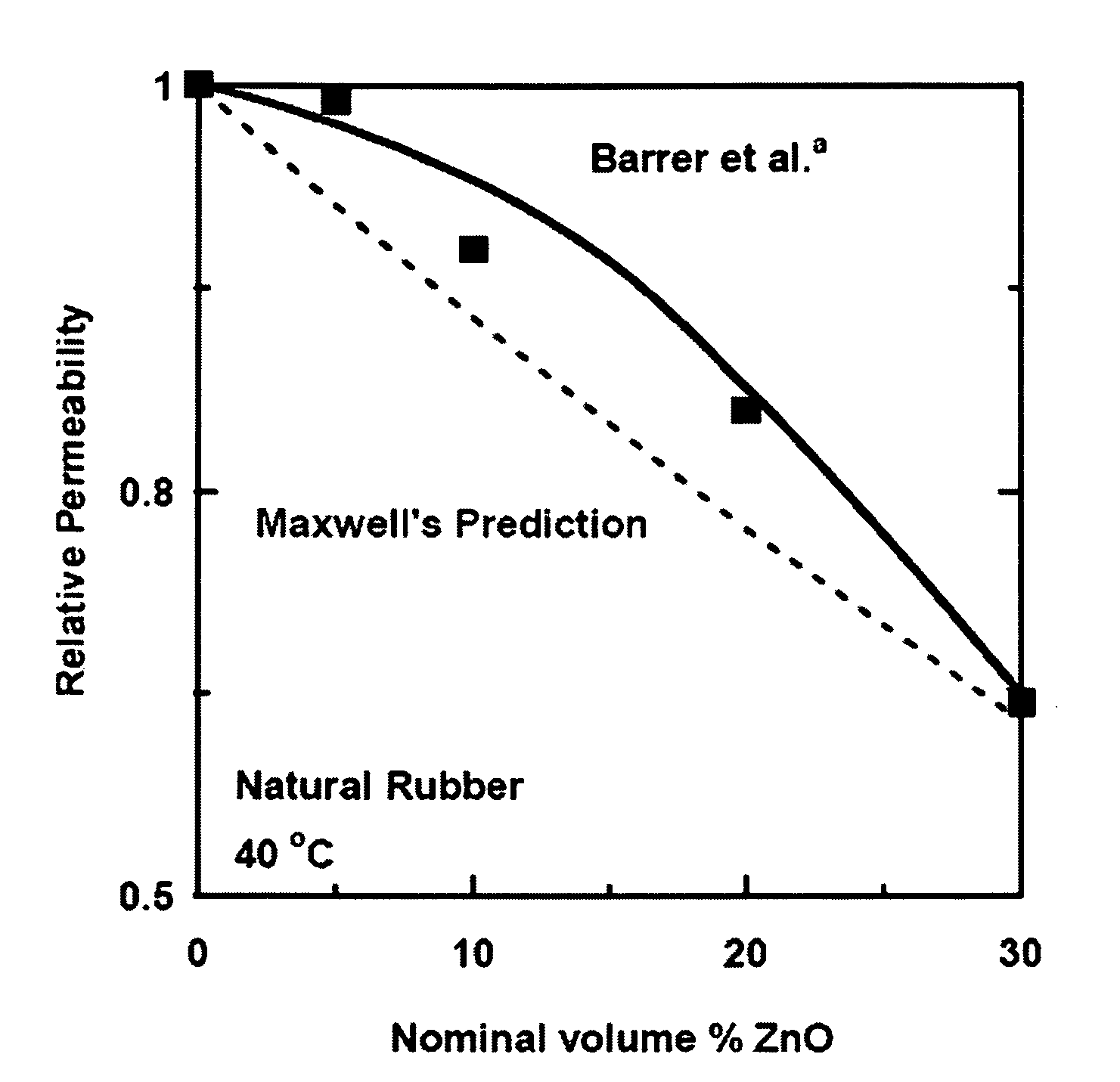

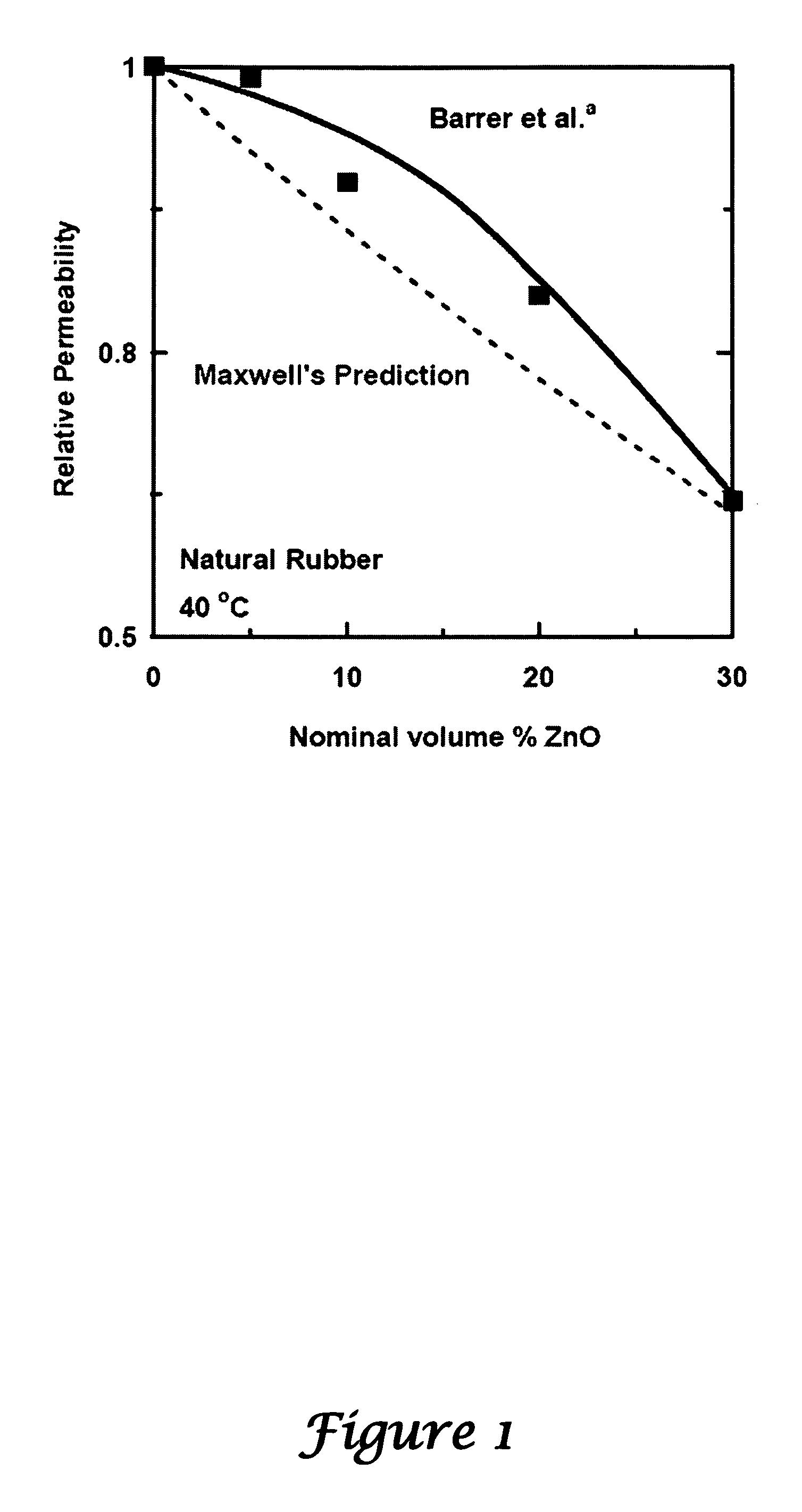

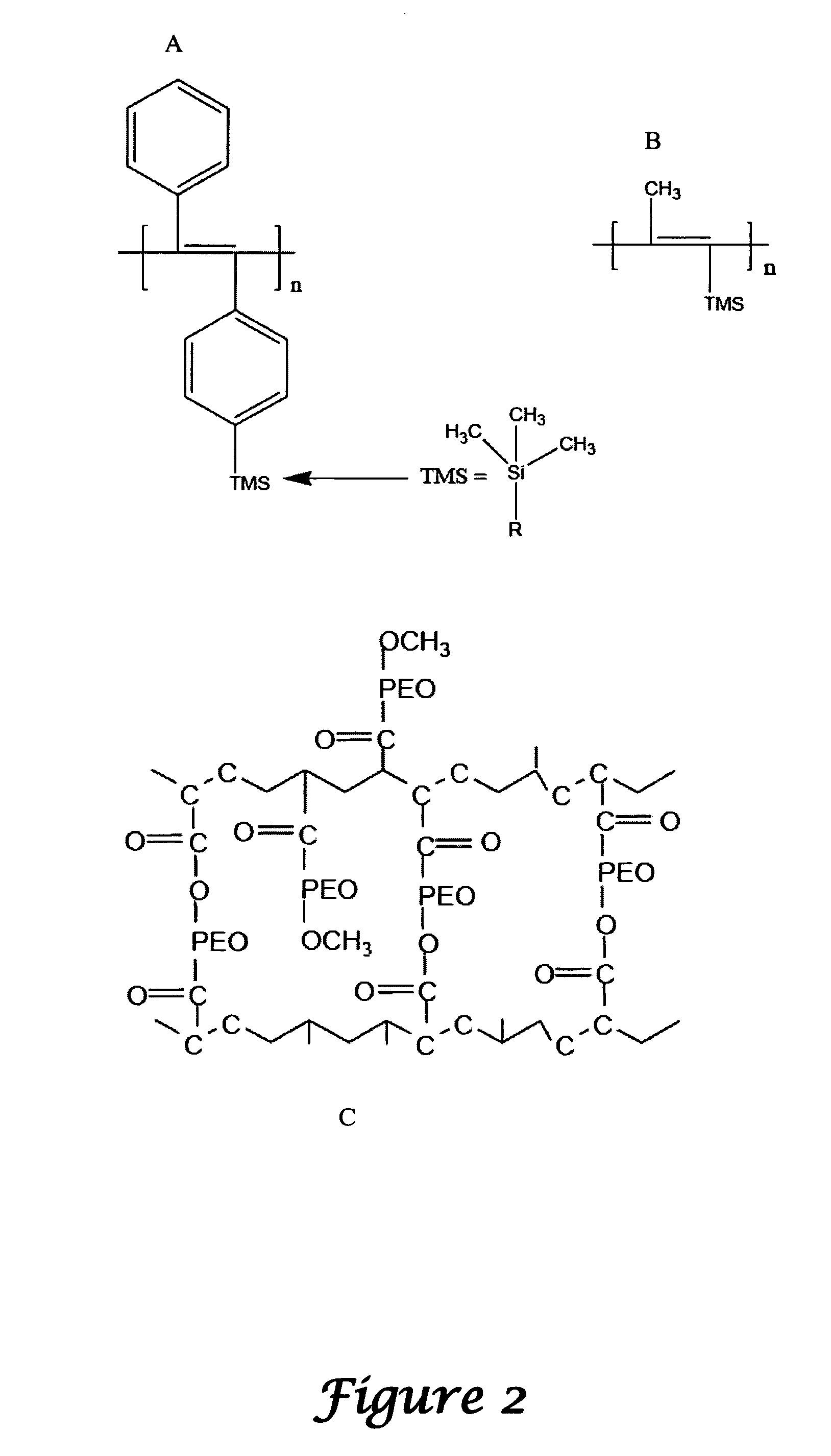

Metal oxide nanoparticle filled polymers

InactiveUS7510595B2Easy to separateImprove gas separation performanceMembranesSemi-permeable membranesMetal oxide nanoparticlesProduct gas

The present invention includes a method, composition and apparatus for forming a nanoparticle filled polymer having similar gas selectivity and greater gas permeability than the native polymer. The nanoparticle filled polymer includes one or more polymeric materials and one or more nanoparticles dispersed within the one or more polymeric materials that increasing the permeability of the nanoparticle filled polymers relative to the permeability of the native polymer membrane.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method for separating zirconium hafnium by tributyl phosphate extraction chromatography method

ActiveCN101209858AHigh separation factorReduce consumptionLiquid solutions solvent extractionZirconium oxidesHafniumChromatographic column

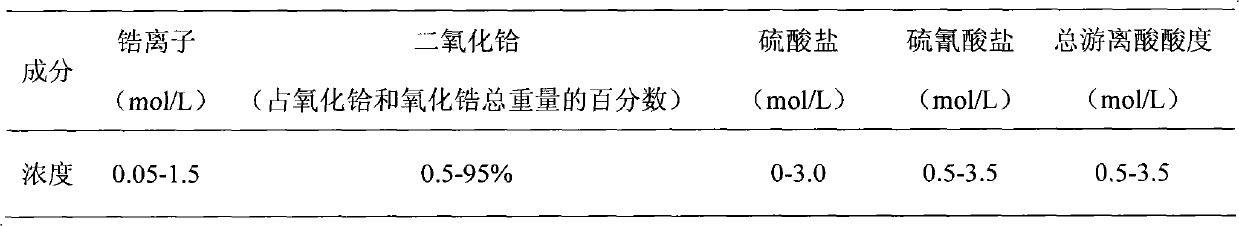

The invention relates to a separation method of zirconium and hafnium by adopting extraction chromatography, in particular to extraction chromatography of zirconium and hafnium by employing tributylphosphate. The method comprises the following steps that: extractant-containing resin TBP is adopted to load the extraction chromatographic column; mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 3.5-7.5 mol / l is adopted for eluting the extraction chromatographic column; then the obtained material is added with material liquid which is the mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 3.5-7.5 mol / l; the total concentration of zirconium and hafnium is 0.05-1.5 mol / l; next, the mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 4-8 mol / l is used for eluting the obtained material, until the concentration of overflowed hafnium solution is less than 0.01 g / l; then the mixed solution containing 0-1.5mol / l chlorhydric acid and nitric acid or 0-1.5mol / l chlorhydric acid solution is used for eluting, so as to get the zirconium solution containing no hafnium.

Owner:有研资源环境技术研究院(北京)有限公司

Carbon nanotube filling composite membrane with alcohol penetration priority and preparation method thereof

InactiveCN103223309AEvenly dispersedHigh mechanical strengthDistillationPolyesterSeparation technology

The invention discloses a carbon nanotube filling composite membrane with alcohol penetration priority in the field of penetration vaporization membrane separation technology and preparation method thereof. The preparation method of the composite membrane comprises the following steps: casting polyvinylidene fluoride on a polyester non-woven fabric, scraping membrane by an immersion phase inversion method for obtaining a supporting layer; And then stirring the carbon nanotube and the polydimethylsiloxane by ultrasound for uniform dispersion, adding cross-linking agent and catalyst for reacting and forming a membrane casting solution, casting onto the bottom membrane and obtaining a separating layer. The membrane obtained by the method has the advantages of improved mechanical strength, penetration throughtput and selectivity, especially substantially increased hydroxylate multi-wall carbon nanotube hydrophobicity after trichlorosilane modification, improved polydimethylsiloxane compatibility and separating factor. The invention has the advantages of reliable and stable method, simple preparation technology, enhanced mechanical performance of pure polydimethylsiloxane membrane, improved penetration throughput and separating factor, and good industrial application prospect.

Owner:TSINGHUA UNIV +1

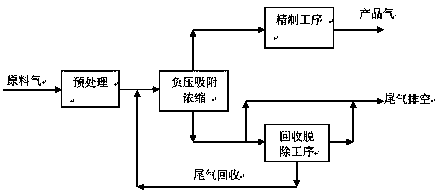

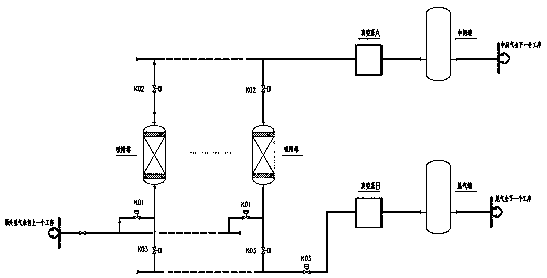

Gas separation method using sub-pressure swing adsorption

ActiveCN107789949AAchieve balanced cycle operationGood for desorption and regenerationDispersed particle separationAdsorption purification/separationDesorptionProduct gas

The invention discloses a gas separation method using sub-pressure swing adsorption, wherein the method comprises pretreatment, negative pressure adsorption concentration, refinement, and recovery removal. According to the present invention, based on pressure swing adsorption, different material components have different adsorption separation coefficients and different physicochemical properties under a negative pressure, adsorption is performed under the negative pressure, evacuation or rinsing desorption is performed, and various separation methods are coupled, such that various mixed gasesare separated and purified through the circulation operation of the pressure swing adsorption process, and particularly the relatively easily adsorbed (and relatively difficultly desorbed) component is separated and purified, wherein the adsorption and the desorption in the circulation are easily matched and balanced; the generated non-adsorbed gas is the intermediate gas, or is the product gas and the qualified discharge gas, or enters the subsequent refining process so as to be refined to obtain the product gas or the qualified discharge gas; and the generated desorbed gas is the condensed gas, and sequentially enters the subsequent recovery removal process so as to further recover or remove the adsorbate component.

Owner:SICHUAN TECHAIRS

Method for extracting and separating rare earth elements in hydrochloric acid system

InactiveCN102876894AHigh separation factorLow extraction acidityProcess efficiency improvementRare-earth elementSeparation coefficient

The invention provides a method for extracting and separating rare earth elements in a hydrochloric acid system. The method includes the steps: taking mono (2-ethylhexyl) phosphonate 2-ethylhexyl methoxy cinnamate trialkyl methyl ammonium or phosphonate (2-ethylhexyl) diester trialkyl methyl ammonium as an extracting agent; taking normal heptane as diluent; and extracting the rare earth elements in rare earth chloride water solution into the normal heptane. The extracting agent used in the method does not need to be saponified, extraction and reverse extraction acidity is low, and separation coefficient for the rare earth elements is high.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Technique for separating boron isotope with boron specific resin ion-exchange chromatography

ActiveCN101274217AEasy to separateHigh separation factorCation exchanger materialsOrganic anion exchangersIon exchangeIsotope

The invention provides a process for separating boron isotope with a boron special-effect resin ion exchange chromatography. The process adopts chelate-typed ion exchanging resin-boron special-effect resin, separates <10>B from boric acid solution, and uses hydrochloric acid or nitric acid as eluent to separate the boron isotope in the boric acid solution by the adsorption of the boric acid on resin columns and the washing of the eluent on the boric acid adsorbed on the resin. According to the process of the invention, the enrichment ratio of the <10>B can be enriched from natural 20 percent or so to 91 percent or so, with fast enrichment speed. The process of the invention is a simple and high-efficiency process which separates the boron isotope from the boric acid solution.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

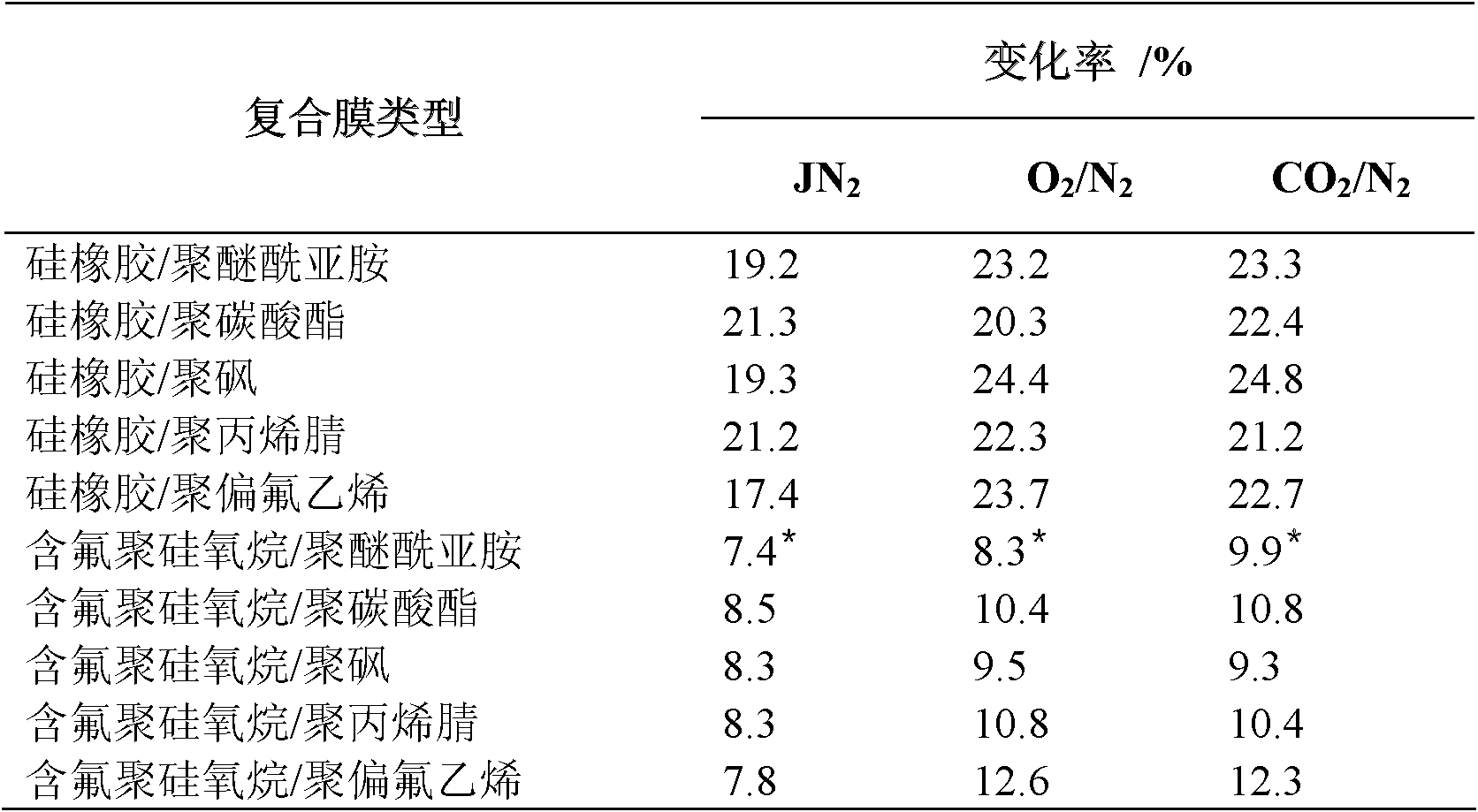

Fluorine-containing polysiloxane rubber state composite gas separation membrane, preparation method and application thereof

ActiveCN102327747AMild preparation conditionsResistant to swellingSemi-permeable membranesDispersed particle separationCross-linkProduct gas

The invention discloses a fluorine-containing polysiloxane rubber state composite gas separation membrane, a preparation method and an application thereof. A porous polymer material is used as a support membrane, and a fluorine-containing polysiloxane material is coated on the surface of the support membrane. The preparation method of the fluorine-containing polysiloxane rubber state composite gas separation membrane comprises the following steps of: dissolving fluorine-containing polysiloxane into a solvent to prepare coating liquid; adding a cross-linking agent and a catalyst into the obtained solution; uniformly stirring, standing and de-foaming; coating the coating liquid on the porous support membrane; and heating, curing and cross-linking until the porous support membrane is dried to obtain the fluorine-containing polysiloxane rubber state composite gas separation membrane. The composite gas separation membrane provided by the invention can be applied to separations of oxygen gas from nitrogen gas, carbon dioxide from nitrogen gas, and organic vapors, and has the characteristics of swelling resistance, resistance to pressure, weather fastness, and the like.

Owner:DALIAN UNIV OF TECH

Metal organic compound filled cross-linked polysiloxane pervaporation membrane and preparation method thereof

InactiveCN102489190AIncrease the degree of cross-linkingGood film formingSemi-permeable membranesPrepolymerSolvent

The invention relates to a metal organic compound filled cross-linked polysiloxane pervaporation membrane and a preparation method thereof, and belongs to the field of membrane separation. The method comprises the following steps of: mixing a cross-linking agent, a catalyst, linear polysiloxane and a solvent, reacting to generate prepolymer, adding a metal organic compound, and performing cross-linking reaction to obtain a membrane casting solution; and coating the membrane casting solution on a macromolecular porous bottom membrane, drying, and heating to obtain a product, namely the metal organic compound filled cross-linked polysiloxane pervaporation membrane. The metal organic compound filled cross-linked polysiloxane pervaporation membrane prepared by the method has the characteristics of high permeation flux, good separation effect, high strength, stable structure and the like, is suitable for removing low-concentration organic compounds from water, and is particularly suitable for separating low molecular alcohol from a fermentation solution.

Owner:JIANGNAN UNIV

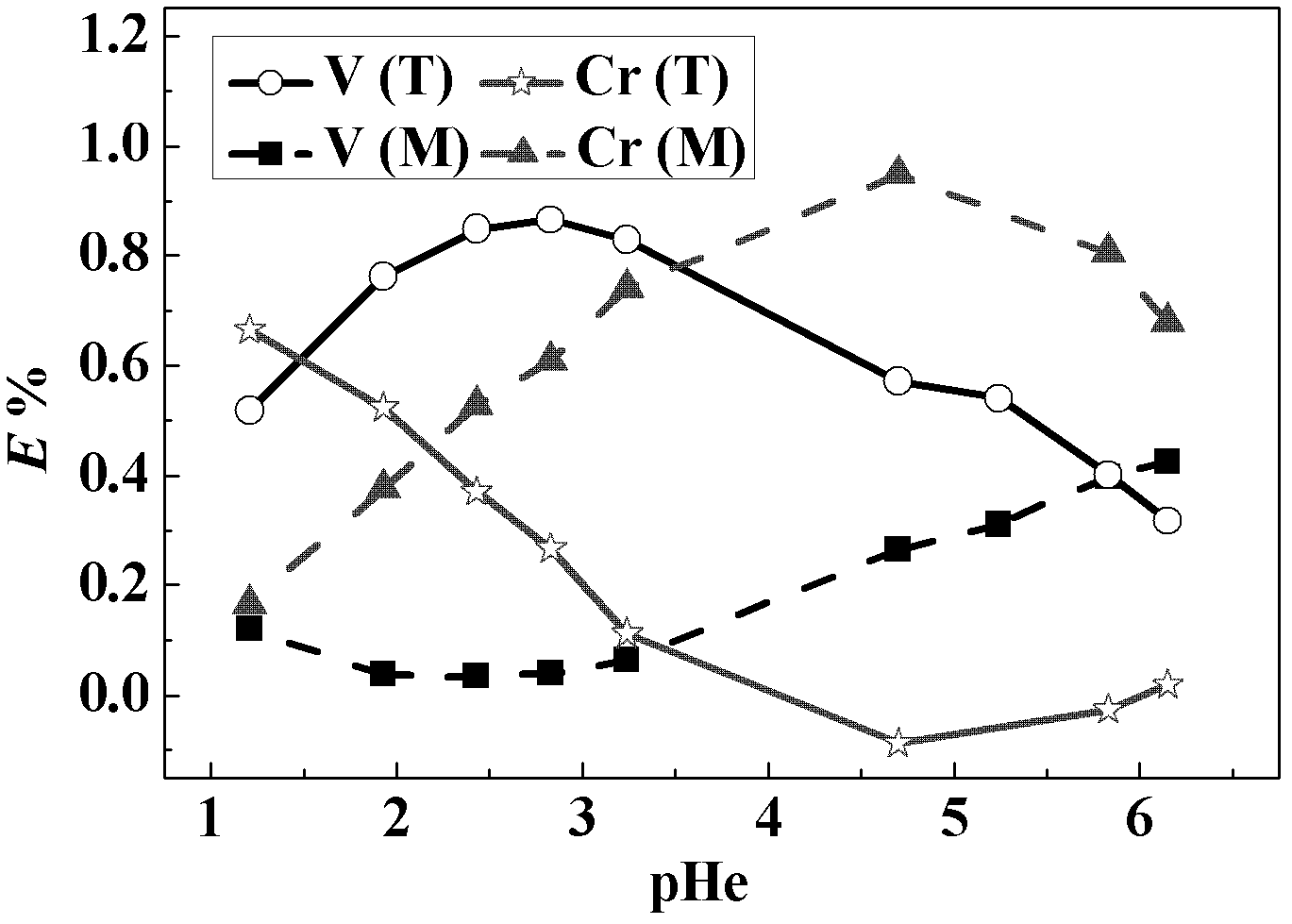

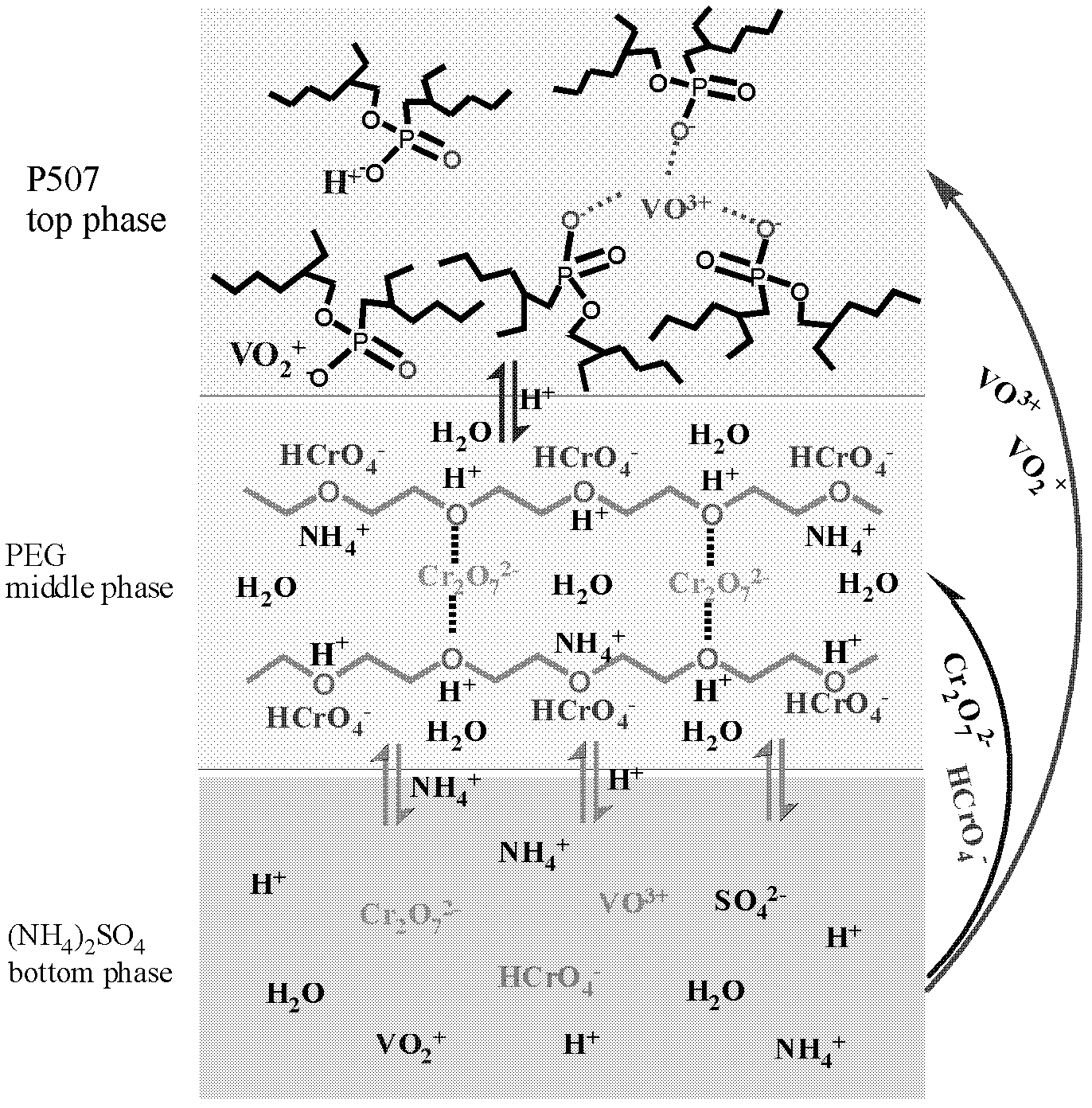

Method for extracting and separating vanadium from chromium by using three-phase system

InactiveCN102534266AHigh separation factorEfficient separationProcess efficiency improvementPolymer dissolutionSeparation coefficient

The invention relates to a method for extracting and separating vanadium from chromium by using liquid-liquid-liquid three-phase system, which comprises the following steps of: adding phase forming salt and a polymer in vanadium and chromium solution and forming an aqueous two-phase system after the phase forming salt and the polymer are dissolved; and then adding an organic phase in the formed aqueous two-phase system, vibrating and carrying out phase separation to obtain the three-phase system. Compared with the prior art, the method has the advantages that: (1) the separation coefficient of vanadium from chromium is large, so that the effective separation of vanadium from chromium can be realized in one step; (2) the utilization rate of vanadium and chromium is high, so that the resource waste is effectively reduced; (3) the method is good in physical phenomenon, short in process flow, simple and convenient in operation, low in cost, less in energy consumption and good in control, and as long as the effective separation of vanadium from the chromium can be realized, the production process for further recovering vanadium and chromium is mature.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Technique for separating high purity yttrium oxide through solvent extraction

InactiveCN1563442AImprove extraction capacityLow liquid requirementProcess efficiency improvementAcetic acidPhosphoric acid

This invention relates to a technology for extracting and separating pure Y oxide applying HAB as the extractant, TBP as the additive, among which, HAB is composed of HA+HB, HA is secondary hepayl phenoxy instead of acetic acid, secondary octyl phenoxy instead of acetic acid etc. HB is a salt base phosphoric acid P204, P507, Cyanax 272, Cyanex 302.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Process for screening and refining wheat starch

The invention discloses a process for screening and refining wheat starch. The process comprises the following steps: screening starch slurry material by a 250-mesh primary centrifugal screen at the rotation speed of 900r / min, screening oversize materials by a 200-mesh secondary centrifugal screen at a rotation speed of 900r / min, collecting the undersized materials screened out by the primary and the secondary centrifugal screen and feeding into a primary horizontal-spiral decanter centrifuge for separation treatment, wherein obtained light-phase substances such as soluble proteins and sugar can be treated in other ways, the obtained starch phase is concentrated by a secondary horizontal-spiral decanter centrifuge to obtain the finished starch slurry; and drying the finished starch slurry to obtain the standard finished starch product. Compared with the prior art, the process has the advantages of simple technology and reduction of energy consumption due to the use of the horizontal-spiral decanter centrifuge instead of the cyclone separator unit used in the conventional processes.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for extracting and separating rare earth elements

ActiveUS8177881B2High separation factorImprove efficiencyRare earth metal compoundsProcess efficiency improvementRare-earth elementSolvent

Solvent extraction from an aqueous phase containing first and second rare earth elements is carried out by contacting an organic phase containing a diglycolamic acid as an extractant and a hydrocarbon or a low-polar alcohol as a solvent, with the aqueous phase below pH 3 for extracting the first rare earth element into the organic phase, back-extracting from the organic phase with an aqueous acid solution for recovering the first rare earth element, and recovering the second rare earth element which has not been extracted into the organic phase and has remained in the aqueous phase.

Owner:SHIN ETSU CHEM IND CO LTD

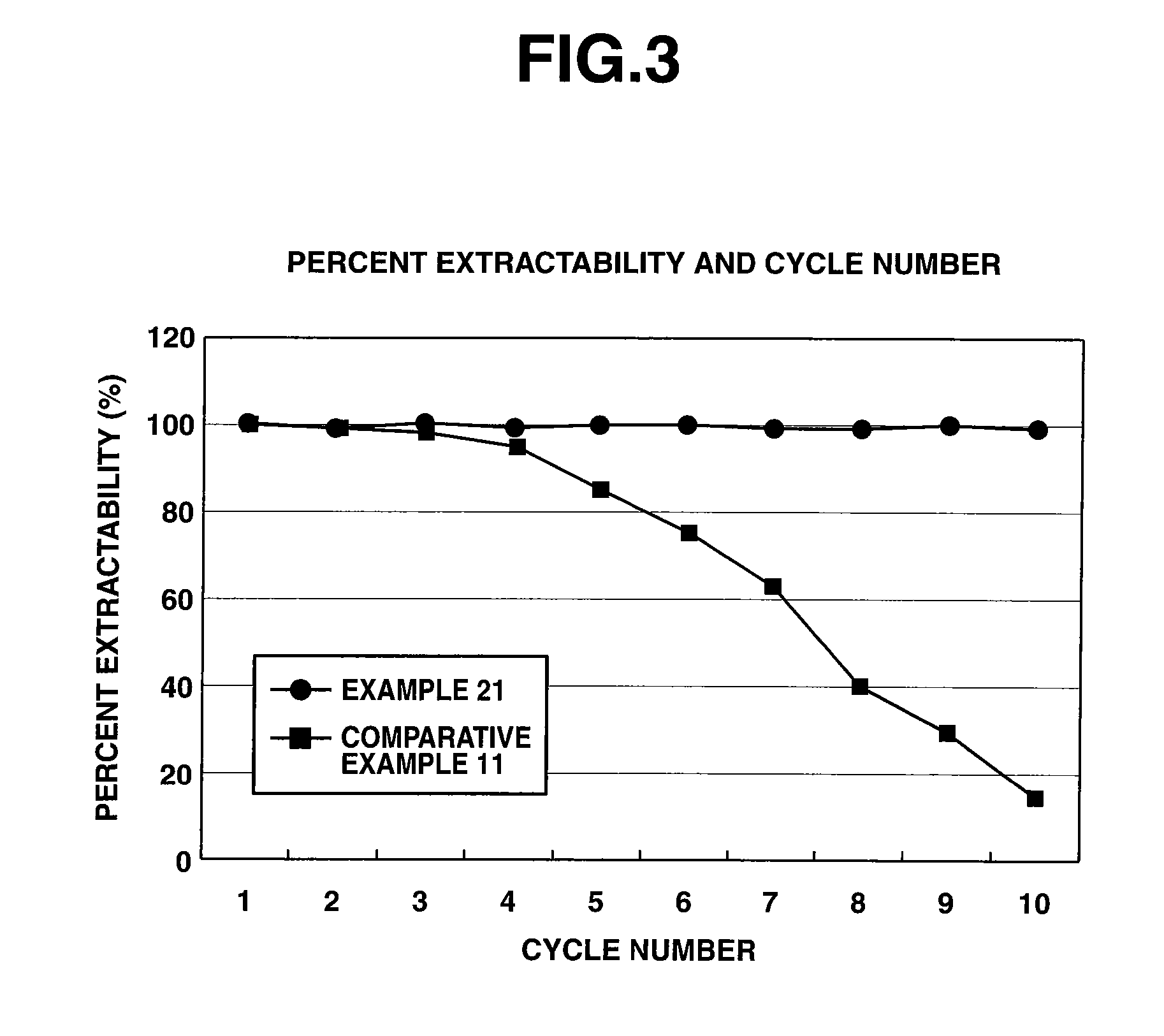

Method for extraction separating of lithium isotope by virtue of sol-gel material

InactiveCN103768945AHigh separation factorSignificant separation factorIsotope separationMesoporous materialAqueous solution

The invention provides a solid-liquid extraction method for extraction separating of a lithium isotope by virtue of a sol-gel material. The method comprises the following steps: forming a mesoporous material through sol-gel by adopting hydrophobic ion liquid, loading benzo-crown ether on the mesoporous material as an extraction agent, carrying out extraction separating on the lithium isotope, extracting a solid-liquid mixture formed by different lithium saline solutions and the solid-phase sol-gel material, collecting water and solid phases, mixing the solid phase after extracting and a hydrochloric acid solution, carrying out reextraction, and collecting a water phase to obtain an aqueous solution of lithium ions, wherein a synergist is the hydrophobic ion liquid, and the extraction agent is benzo15-crown-5. At present, a lithium amalgam method is used for separating the lithium isotope, however, serious environmental safety problem is brought caused by large amount of mercury used in the production process; with the adoption of the method, as the environment-friendly ion liquid and the benzo15-crown-5 are used as the synergist and the extraction agent, respectively, the lithium salt extraction efficiency is improved, and the separation efficacy of the isotope is also high; the used sol-gel phase can be reextracted by hydrochloride, the purpose of recycling is reached, and the production cost is reduced.

Owner:JIANGNAN UNIV

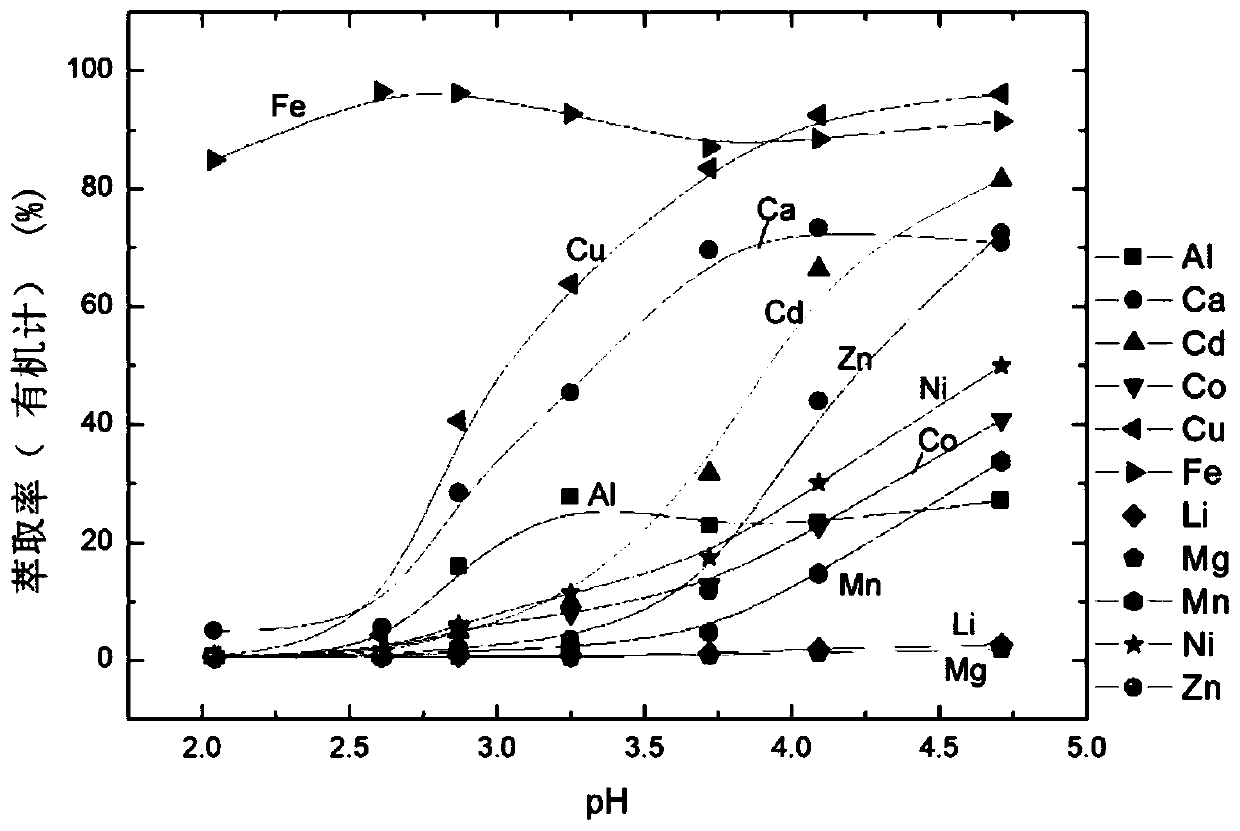

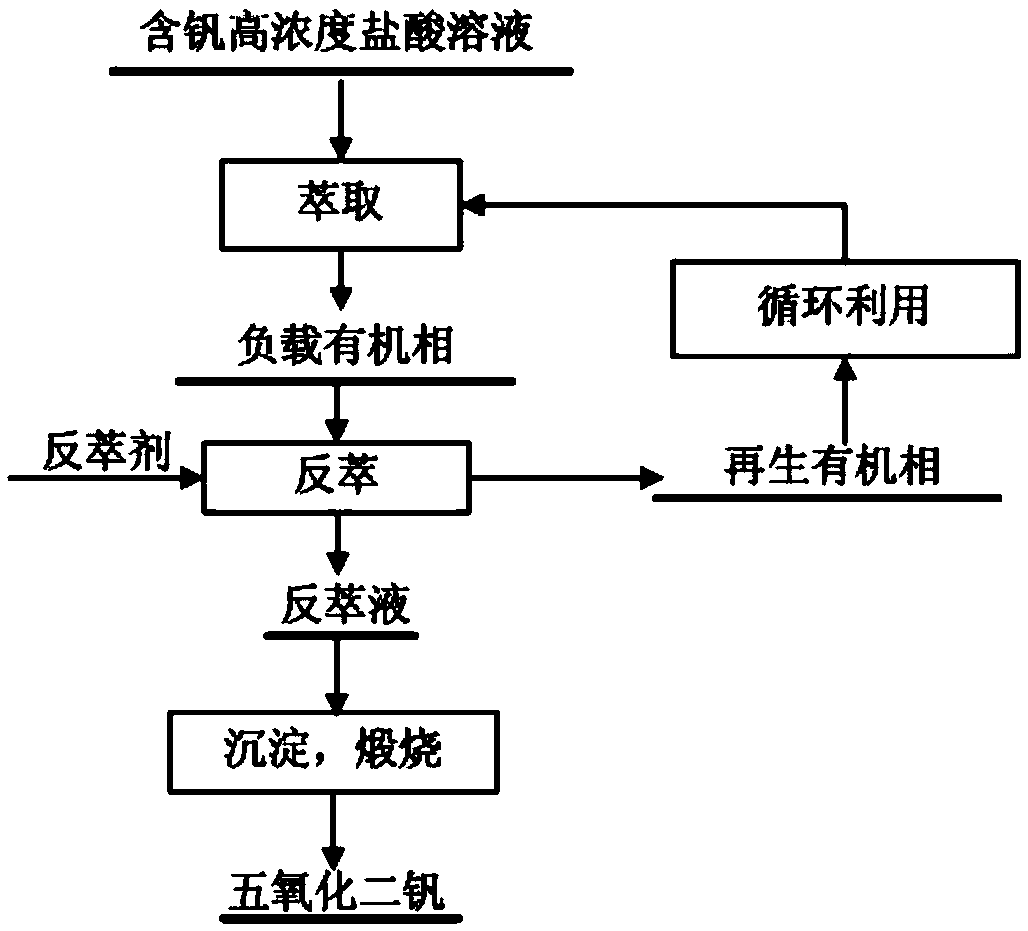

Method for extracting vanadium from vanadium-containing high-concentration hydrochloric acid solution

ActiveCN105369036AEfficient use ofMild reaction conditionsProcess efficiency improvementHigh concentrationManganese

The invention belongs to the field of hydrometallurgy and particularly relates to a method for extracting vanadium from a vanadium-containing high-concentration hydrochloric acid solution. The method mainly includes the steps of extraction, reverse extraction, strip liquor sedimentation and calcination, and the like, that is, an amine extraction agent and a neutral extraction agent are utilized for selectively extracting vanadium in the vanadium-containing high-concentration hydrochloric acid solution instead of impurities such as calcium, aluminum, magnesium, chromium, titanium, manganese and silicon in the solution; an organic phase loaded with vanadium is subjected to reverse extraction with a sulfuric acid solution or the hydrochloric acid solution or a sodium chloride solution or an ammonia water solution or water, and the organic phase subjected to reverse extraction can be returned to the extraction procedure for use; and a vanadium pentoxide product can be obtained by conducting edimentation and calcination on strip liquor. By means of the method, vanadium can be extracted from the solution with the hydrochloric acid concentration larger than 2.5 mol / L, the coefficient of separation of vanadium from the impurities such as calcium, aluminum, magnesium, chromium, titanium, manganese and silicon is large, the technological process is simple, and the extraction agents can be recycled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Nitrogen adsorbent and use thereof

InactiveUS6423121B1Improve performanceImprove adsorption capacityNitrogen purification/separationGas treatmentHeat resistanceSorbent

A nitrogen adsorbent comprising a crystalline X zeolite having a faujasite structure with an SiO2 / Al2O3 ratio of less than 3.0, wherein the crystal contains at least one trivalent element of the group consisting of Fe, B and Ga and (AlO4)5- tetrahedral units thereof associated with cations. Although the adsorbent contains a designated trivalent element in the zeolite, it maintains the number of cation sites contributing to adsorption, has an excellent separation performance of nitrogen and oxygen, and exhibits excellent heat resistance. Further, when the nitrogen adsorbent of the present invention is used in such a particular manner that it adsorbs nitrogen after being heated under a vacuum, adsorption performance is improved.

Owner:AIR WATER INC

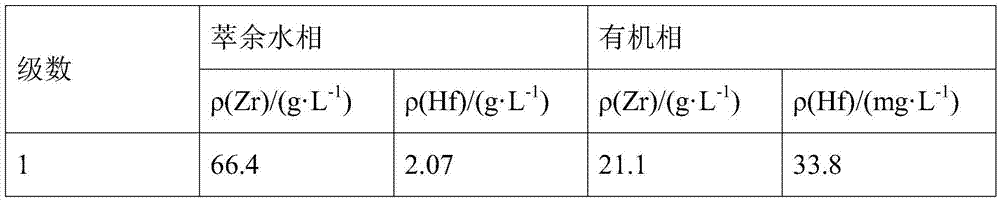

Method for fractionating, extracting and separating zirconium and hafnium

The invention relates to a method for fractionating, extracting and separating zirconium and hafnium, in particular to a method for fractionating, extracting and separating zirconium and hafnium by using di(2-ethylhexyl)phosphorous acid as an extracting agent. The method comprises the following steps of: (1) extraction, using 50-300 parts by weight of di(2-ethylhexyl)phosphorous acid, 25-150 parts by weight of mixing alcohol with the carbon number of 7-9, and 550-925 parts by weight of sulfonated kerosene to prepare a di(2-ethylhexyl)phosphorous acid organic phase to extract; (2) washing, adding oxalic acid into a sulphuric acid solution to prepare a washing solution to wash; and (3) stripping, using a mixing solution of ammonia and carbonate as a strip liquor, stripping to obtain a strip liquor containing hafnium, slowly adding concentrated hydrochloric acid to adjust the solution into acidity, adding concentrated ammonia to obtain hafnium hydroxide precipitate, washing, filtering, calcining, and then obtaining hafnium oxide. The used chemical agents are difficult to volatilize, the toxicity is low, the corrosion is weak, the disposition is easy, and the discharged waste water can not cause the environments to be polluted. The technology has the advantages of quick phase separation, convenient operation, and high and stable product quality.

Owner:有研资源环境技术研究院(北京)有限公司

Earthworm protein polypeptide preparation

InactiveCN101584853AHigh activityTo lower blood pressureAnthropod material medical ingredientsPeptide/protein ingredientsAngiotensin-converting enzymeAdditive ingredient

The invention discloses an earthworm protein polypeptide preparation, its preparation method and application. The protein polypeptide preparation is prepared by hydrolyzing the earthworm homogenate coarse extract or hydrolyzing the earthworm homogenate coarse extract to obtain the hydrolyzed protein polypeptide, separating by a hyperfiltration membrane with different hole diameter to obtain the protein polypeptide ingredients with different hole diameter. Test proves that the earthworm protein polypeptide preparation has good angiotensin converting enzyme after enzyme hydrolysis and can effectively prevent the high blood pressure. The invention provides a preparation method for the earthworm protein polypeptide preparation with strong operability, high efficiency and realizes an industrialization big production.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Method for separating zirconium from hafnium by using elution extraction method

ActiveCN102021335AHigh separation factorReduce consumptionProcess efficiency improvementLiquid waterSolvent

The invention discloses a method for separating zirconium from hafnium by using an elution extraction method, belonging to the technical field of zirconium and hafnium separation. The method comprises the following steps of: preparing liquid MIBK (Methyl Iso Butyl Ketone) into MIBK elution extraction resin; extracting hafnium with an extraction agent of MIBK; reserving hafnium in a material liquid water phase and precipitating water ammonia water; eluting the elution extraction resin with hydrochloric acid and desorbing the elution extraction resin with sulfuric acid solution to obtain a solution containing hafnium; precipitating with ammonia water; and respectively washing and roasting the precipitation to obtain zirconium oxide and hafnium oxide in atomic energy level. The process method has the advantages of less mass transfer, high extraction capacity, large zirconium and hafnium separation coefficient, simple process flow and less investment and is easy for operation; two qualified products can be obtained by one-time extraction; the equipment has high yield and the consumption of chemical materials is low. According to the invention, the concentration of the used thiocyanic acid is lower than that used by a liquid-liquid solvent extraction method; the equipment is easy to close; and the pollution of H2S, HCN and methyl mercaptan generated by decomposing the volatilized MIMK and HSCN to the environment can be greatly reduced.

Owner:有研资源环境技术研究院(北京)有限公司

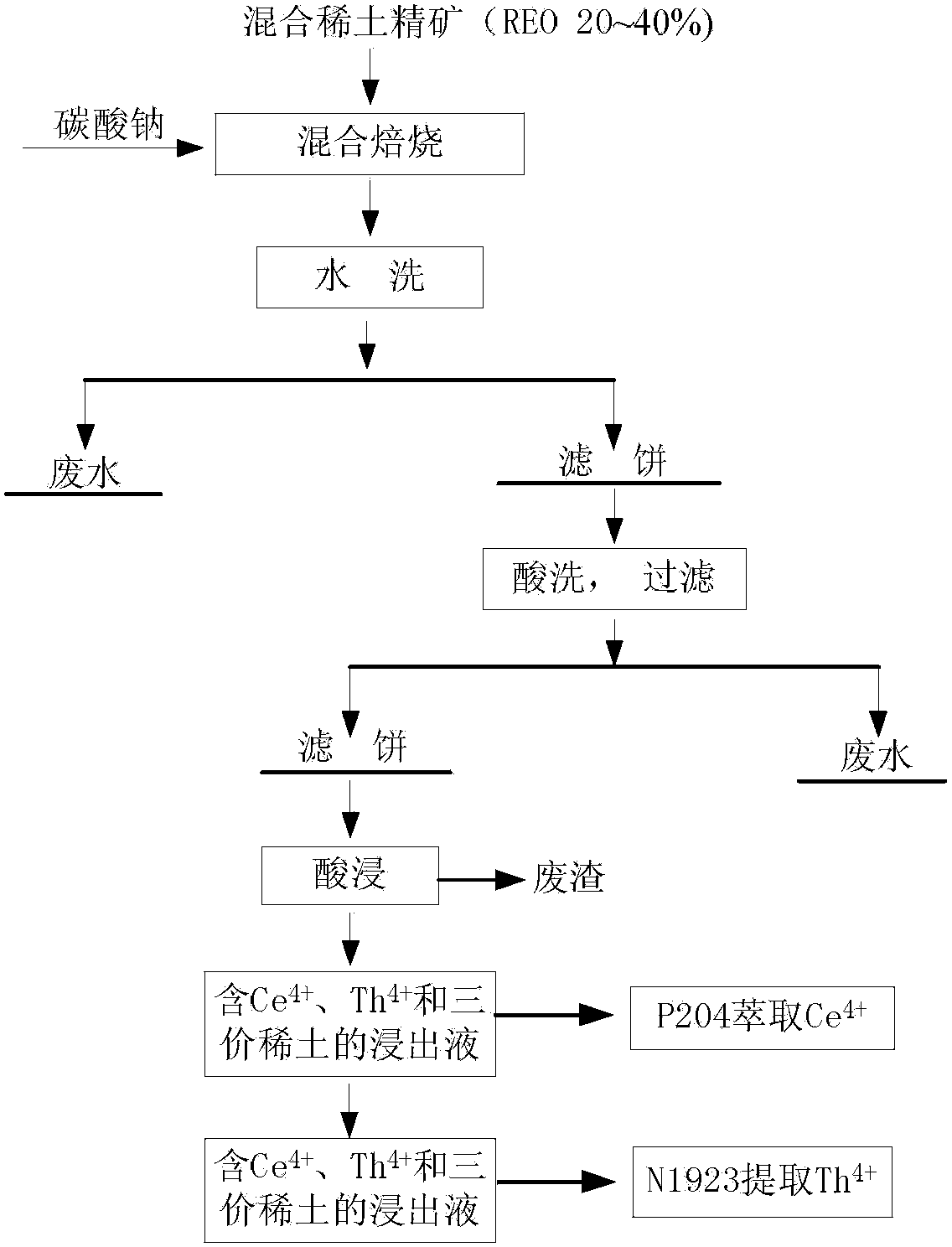

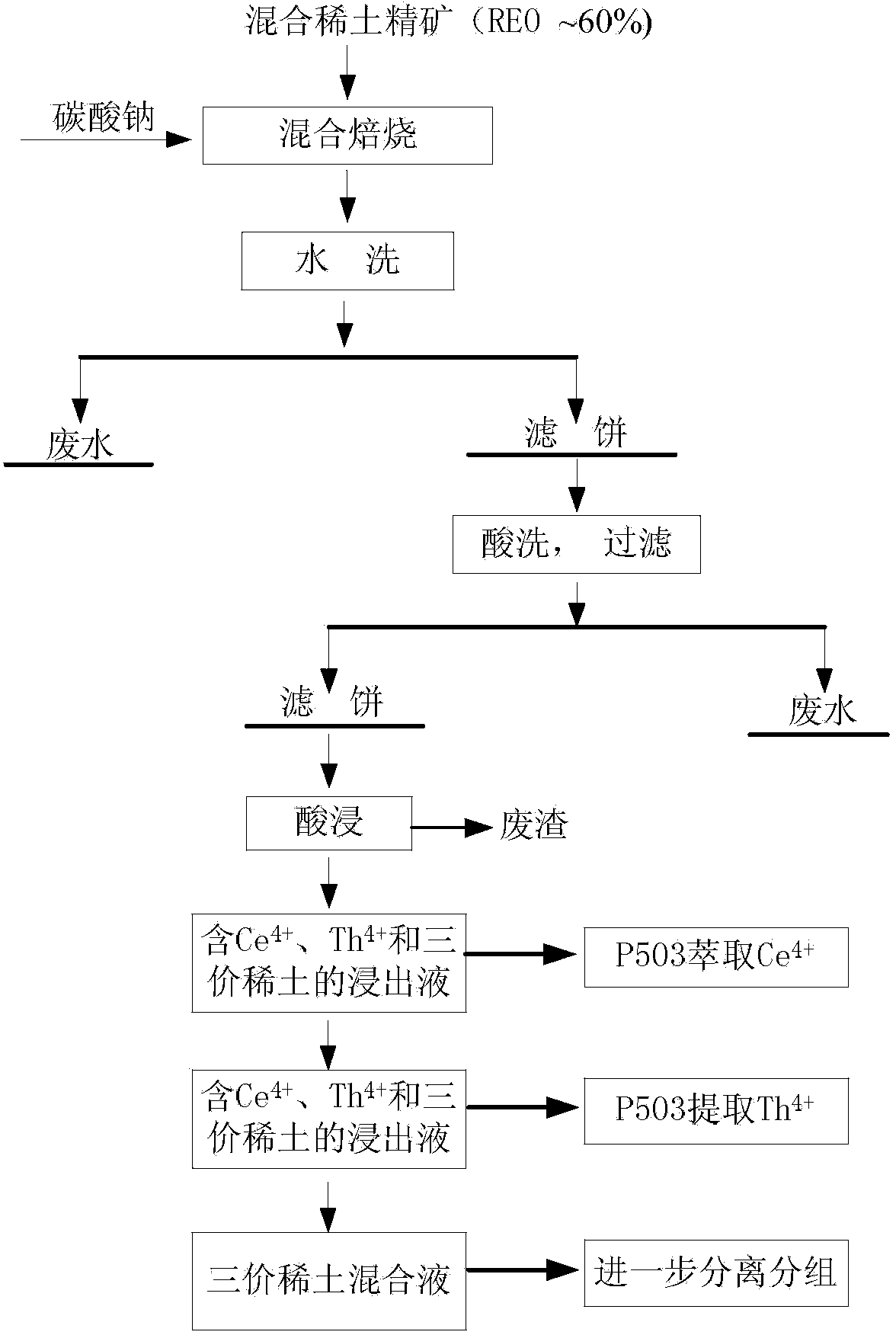

Clean separating method of Baotou rare-earth ore concentrate

InactiveCN103540740AReduce pollutionReduce contentProcess efficiency improvementRare-earth elementSeparation coefficient

The invention relates to a clean separating method of Baotou rare-earth ore concentrate. The method comprises the following steps: roasting the rare-earth ore concentrate by using sodium carbonate; carrying out acid leaching by adopting a nitric acid after washing and pickling by a dilute acid, so as to obtain a leach liquor containing Ce4<+>, Th4<+> and trivalent rare-earth elements; respectively extracting the Ce4<+> and Th4<+> by adopting a P503 extracting agent, and then carrying out separation of light rare earth. By adopting the same extracting agent, selective separation of cerium, thorium and other trivalent rare earth can be achieved; the clean separating method is economical to a factory, small in equipment pressure, and easy to operate; only separation of lanthanum, praseodymium and neodymium exists in separation of the trivalent rare earth; the extraction technology is mature. Interference of an adjacent element trivalent cerium is not generated, so that the separation coefficient of lanthanum, praseodymium and neodymium is large; corresponding extraction and separation flows are greatly simplified and shortened.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for PDMS (polydimethylsiloxane)/PTFE polytetrafluoroethylene pervaporation hollow-fiber membrane

InactiveCN104069751ASimple processEasy to operateSemi-permeable membranesCross-linkDimethyl siloxane

The invention discloses a preparation method for a PDMS (polydimethylsiloxane) / PTFE polytetrafluoroethylene pervaporation hollow-fiber membrane. The method comprises the following steps: dissolving 1 weight part of PDMS into n-hexane, adding 0.04 to 0.15 part of a cross-linking agent TEOS, carrying out mixing and stirring for 0.5 to 4 hours, adding 0.01 to 0.1 part of a catalyst dibutyltin dilaurate, supplementing n-hexane till the mass concentration percentage of PDMS in the mixed liquor is 5 to 35 percent, carrying out stirring at the room temperature for 4 to 24 hours, and carrying out centrifugation and defoaming to obtain a membrane preparation liquid; cleaning a PTFE hollow-fiber membrane with distilled water till the hollow-fiber membrane is neutral, airing the neutral hollow-fiber membrane, dipping the aired hollow-fiber membrane in the membrane preparation liquid for 1 to 3 seconds, taking out the hollow-fiber membrane for airing at the room temperature, carrying out membrane dipping and airing repeatedly for 1 to 4 times, placing the aired hollow-fiber membrane into a vacuum oven for 35 to 115 DEG C' vacuum drying till crosslinking is complete, so as to obtain the PDMS / PTFE compound hollow-fiber membrane. The method is simple in technology; the hollow-fiber membrane has better separation effect for an acetone / butanol / ethyl alcohol solution in a fermentation liquid.

Owner:陈雄

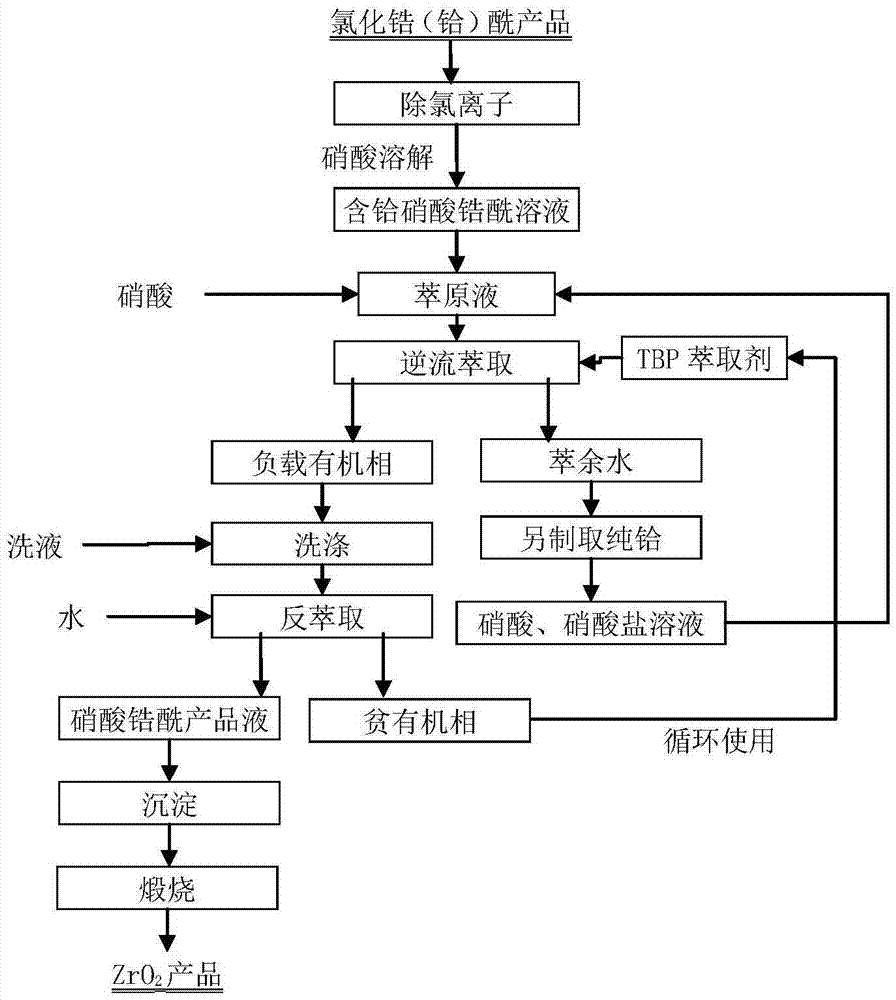

Process for separating zirconium and hafnium by solvent extracting method

ActiveCN106929695AFulfil requirementsImprove product qualityProcess efficiency improvementZirconium oxidesKeroseneHydrometallurgy

The invention belongs to the field of wet metallurgy and the technical field of zirconium and hafnium separation, and in particular, relates to a process for separating zirconium and hafnium by a solvent extracting method. Industrial products containing hafnium zirconium chloride acetyl are used as raw materials for such procedures as water solution, alkali sinking, washing and nitric acid dissolving to prepare zirconium (hafnium) nitrate acetyl solution; TBP kerosene solution of adding phase modifying agent octanol is used as an extracting agent; most zirconium and less hafnium are extracted into an organic phase through multistage counter-current extraction by using the characteristic of TBP priority extraction of zirconium; the loaded organic phase is washed by nitric acid solution with a certain concentration to further remove most hafnium in the organic phase; the acid-washed loaded organic phase is reversely extracted by water to obtain zirconium nitrate acetyl solution; the solution is precipitated in ammonia, dried and calcined to obtain zirconium dioxide powder, and the mass of the zirconium dioxide powder accords with the atomic energy-level zirconium dioxide standard; less zirconium and most hafnium only remained in residual water phase of zirconium after reverse extraction are extracted; the content of zirconium in hafnium meets the requirements on impurity zirconium by atomic energy-level hafnium; and atomic energy-level hafnium can be directly prepared by enrichment.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

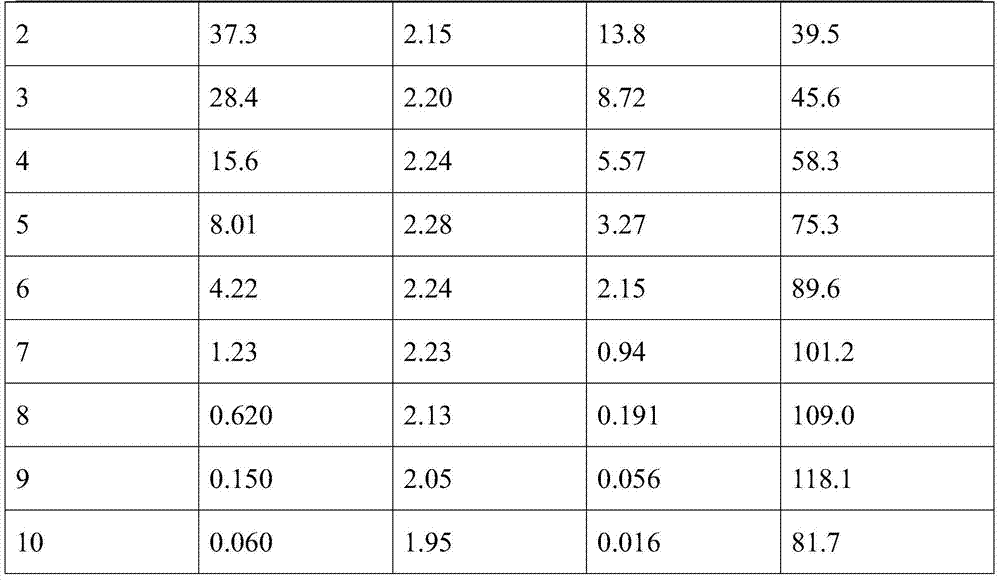

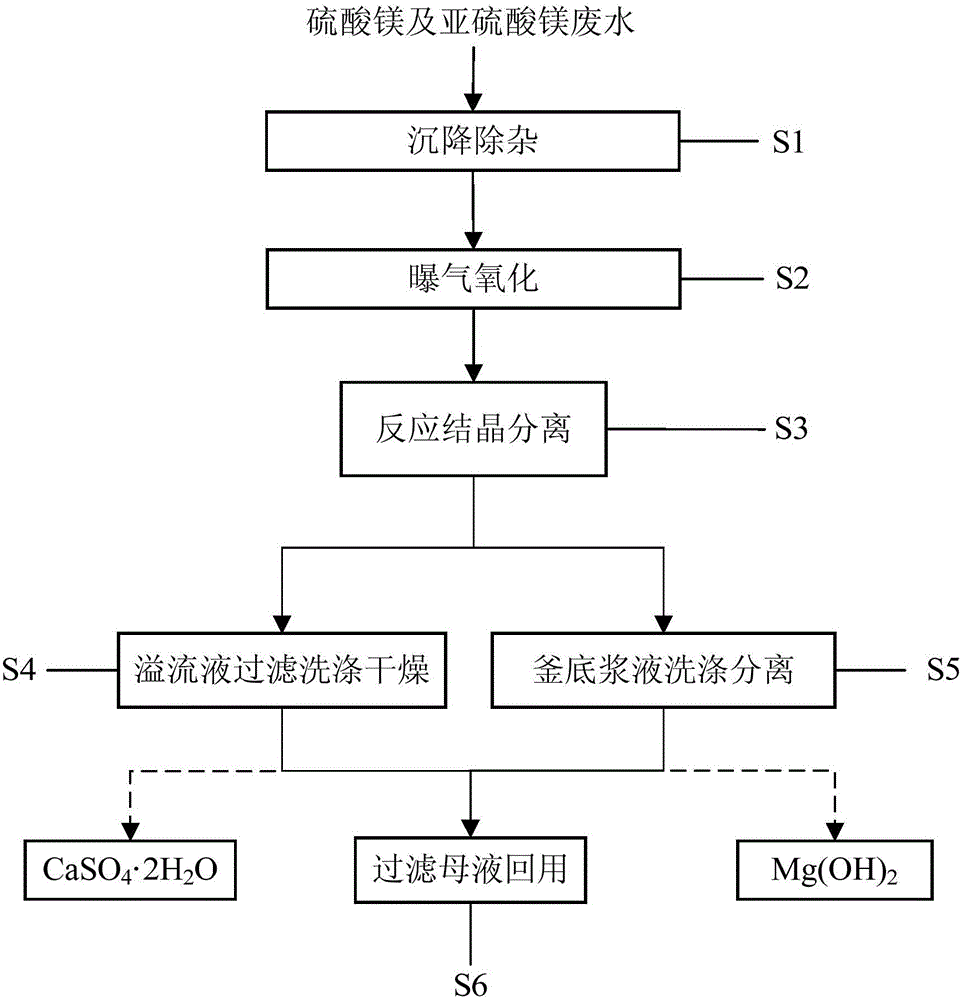

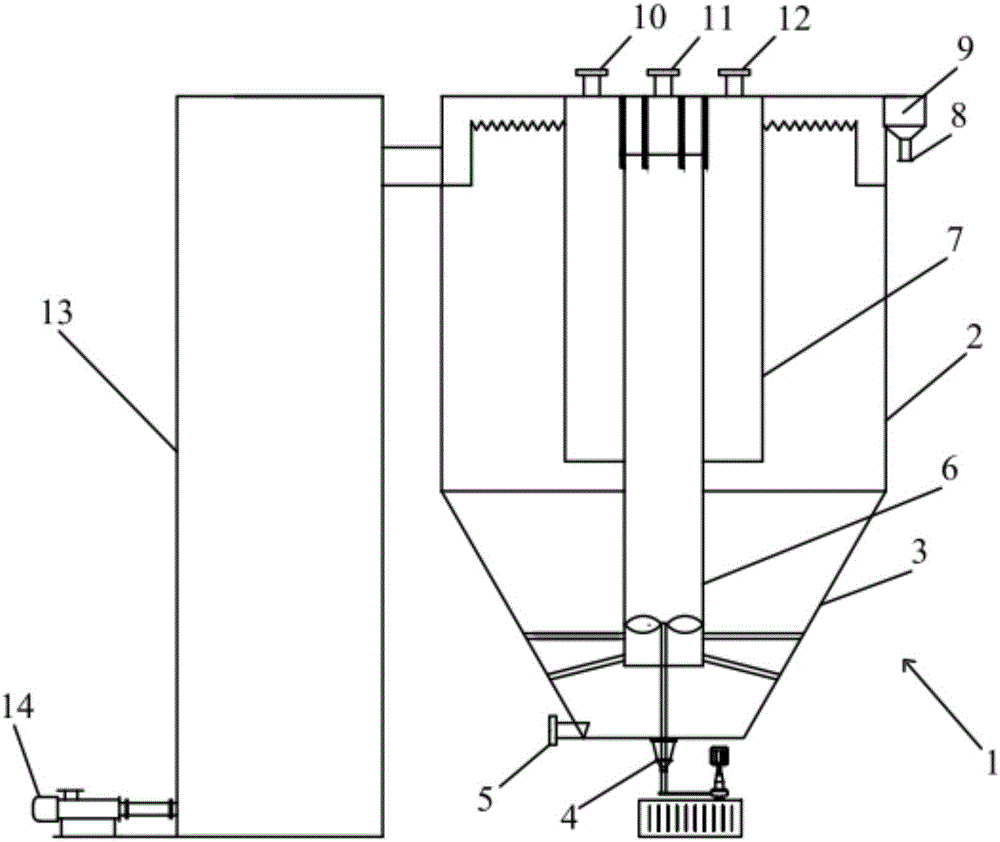

Method for treating magnesium sulfate and magnesium sulfite wastewater by virtue of lime method

ActiveCN105858692AHigh calcium and magnesium separation coefficientHigh product purityCalcium/strontium/barium sulfatesSolution crystallizationMagnesium carbonate hydroxideChemistry

The invention discloses a method for treating magnesium sulfate and magnesium sulfite wastewater by virtue of a lime method. Technical steps comprise settling purification, aeration oxidization, reactive crystallization separation, overflow liquid filtering, washing and drying, kettle-bottom slurry washing and separation and filtered stock recycling. Purified and oxidized wastewater and lime slurry are continuously added into a reaction crystallizer respectively, and a reactive crystallization condition is controlled to bond sulfate ions and calcium ions to form and settle calcium sulfate dihydrate crystals with larger particle sizes at the bottom of the reactive crystallizer and bond magnesium ions and hydroxide ions to form magnesium hydroxide with smaller particle sizes to continuously overflow from an overflow opening of the reactive crystallizer. The method has the characteristics of simple procedures, high separation efficiency, low equipment investment and running cost and the like, and can be used for treating magnesium sulfate and magnesium sulfite wastewater in large batches. Reaction products can be used for preparing high-quality magnesium hydroxide and calcium sulfate dihydrate for selling as chemical products; reaction mother liquor can be used as process water instead of fresh water, so that zero emission of magnesium sulfate and magnesium sulfite wastewater can be implemented.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com